Page 1

IMPORTANT MANUAL

Operator's

Manual

MODEL NO.

358.797161.32cc

A WAR__ING:

ReadtheOperato_sManua_

and FoUmv All

and Safety Instructions,

FailureToDo So CanResult

inSeriousInjury.

Do Not Throw Away

Always Wear Eye Protection During Operation

L

WEEDWACKER ®

2 Cycle Engine

• Assembly

• Operation

b-_uelMix 40:1

• Maintenance

• Repair Parts

Sold.by Sears, Roebuck and Co., Chicago, IL 60684 U.S.A.

5304167877-6-03/31/93 © 1993, Sears, Roebuck and Co.

Page 2

_ o_ Y_ r_o_d_,__W_. _, ,+,isw_k_e- i__,,_i_.m_,_.o_ ,u_,,p_.d,.g__

operatingandmaimenanceiastruaionsintheoi_':atgr_manual.Searswdl repatr_reeoicna$fieany acmct inmatena_

or Workmanship.

This w'arcatuyexcludes nylon fine. sparkplu_ and ali" cleaner which amexpendable partsand become v,Oraduringnor-

mat use. " "'<::"

<_" = If the Wcedwacker"_ is used for commercial or-reataI purposes, this warrantydoes not apply.

*_>.t

C>.t

WARRANTY SERVICE IS AVAILABLEBY CONTAC'I'IIqG THE NEAREST SEARS SERVICECENTER/DEPART-

MENT IN THE UNflED STATES. This warrantyapplies only while this product is in use ia the United States.

This warrant3' gives you specific legal rightS,and you may also have other rights which vary from state to state. _

SEA_RS,ROEBUCK AND CO. DEPT. DISITWA HOFFMAN ESTATES, EL _0IY9 , o "_

TABLE OF CONTENTS

WARNINGS AND SAFETY INSIRUCrIONS ......... 3

KNOW X,DUR TRIMMER

ASSEMBLY ..................................... 6

ACCESSOR!_ ................................ .. 9

S'IX)RAGE ....................................... 9

ENGINE INFORMATION ... .................... :. 10

A .Furling Your E_gine. ......................... l0

B. Pre_tion Che_ ...................... ... 11

C, Starting h-_ons ........... ; ......... ..... 11

D. Op_rati_ Imstr_ctions ......................... 12

USING YOI_ TI_MVIMF_ ......................... 12

A. LineTrimmer Safety .......................... 13

B, Automatic Line ASvanee ....................... 13

....C. Cutting M_ods ............................. 14

D. Line Replaeemeat ................... : .... I5

GENERAL MAINTENANCE ....................... 16

A. Maintenance Safety ........................... 16

B, Air Filter ................................... 16

C. StarterRo_ ................................ _7

D. Flexible Dfim Shaft La_brication ................. 18

E. Carburetor Adjttsanents....................... 19

E Gear Box Lubrication . : ....................... 20

G. Trouble Shooting Omrt ......................... 21

REPMR PAEIS LIST..-_ .......................... 22

INDEX ............................................ 25

QUICK REFERENCI_, PAGE ........................26

ENGINE "OFP;i

MUFFLER:

CLUTCH:

FL1ELTANK:

SPARKPLUG:

SPECIFICATIONS

[2-Cycle, Air-Cooled

o_- 75oo

Idle- 2500 - 3200

Sald State

Diaphragm All Positions with

............... adjustable fuel mixmrejets

Positive Switch

i Auto Rewind

[Tempetmure I.,hmtiag(not spark

arre_g; see Notice, V6)

17ft. oz.

71-858_ (O-14)

FOAMGRW

Page 3

WARNINGS ................. ....

AND SAFETY INSTRUCTIONS

• _ i ,,.............. i ....,

This tool can cause serious injury or blindness to the operator and others.The wamings and safety instructions in this manual

must be followed toprovide reasonable safety and efficiency in using this tool, The operator is responsible for following the

warnings and instructions in this manual and on thetool. Read theentireOperator,s Manual befnreassemblingand using

this tool! Restrict the use of this power tool to persons who read, understand, and follow the warnings and instructions

in this manual and on the tool.

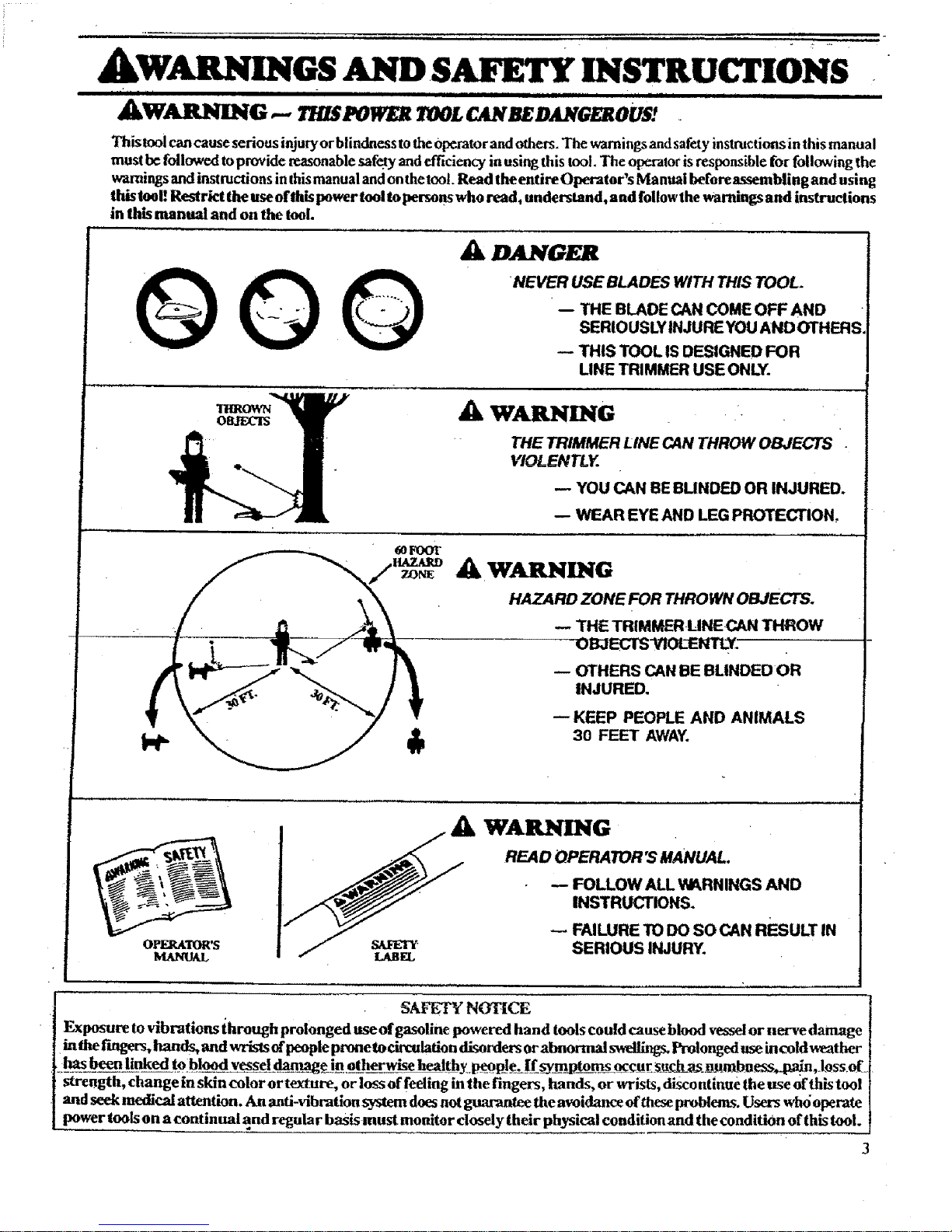

A DANGER

NEVER USE BLADES WITH THIS TOOL.

-- THE BLADE CAN COME OFF AND

SERIO USLYINJURE YOU AND OTHERS

-- THIS TOOL IS DESIGNED FOR

UNE TRIMMER USE ONLY.

A WARNING

THE TRIMMER LINE CAN THROW OBJECTS .

ViOLENTLE

-- YOU CAN BE BLINDF..DOR INJURED.

-- WEAR EYE AND LEG PROTECTION.

HAZARD ZONE FOR THROWN OBJECTS.

THE TRIMMERLINECAN THROW

OBJECTSVlOL_ENTL Y.

-- OTHERS CAN BE BUNDED OR

INJURED.

KEEP PEOPLE AND ANIMALS

30 FEET AWAY.

OPERATOR'S

MANUAL

A WARNING

READ OPERATOR'S MANUAL.

-- FOLLOW ALL Wa,RNINGS AND

INSTRUCTIONS.

-- FAILURE TO DO SO CAN RESULT IN

SERIOUS INJURY.

SAFETY NOTICE

Exposure to vibrations ihrough prolonged useofgasoline powered hand tools could cause blood vessel or nerve damage

in the fingers, hands, and wrists of people prone to ¢irctdation disorders or abnormal smdlings. Prolonged use in cold weather

has been linked to blood vessel damageZm otherwise healthy. _ pJe.J(_3,mpt_o ms occur_is¢£h_!_mbncss._i_i'n,oloss o[

strength, change in skin color or texture, or loss of feeling in the fingers, hands, or wrists, discontlnue the use of this tool

and seek medical attention. An anti-vibration system does not guarantee the avoidatg'e of these problems.Users who operate

power tools on a continual and regular basis must monitor closely their physical condition and the condition of this tool.

3

Page 4

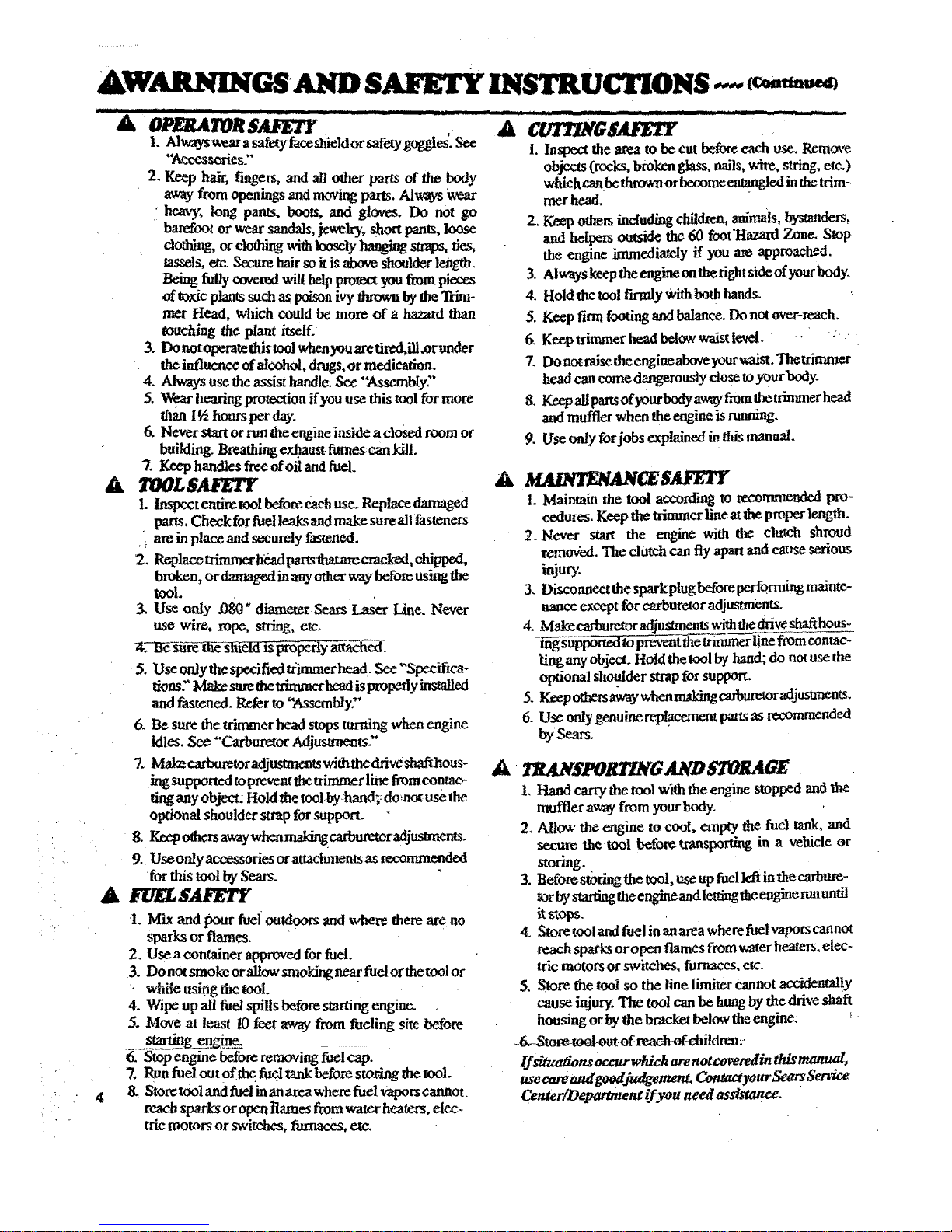

• +

AWARNINGS AND SAFETY INSTRUCTIONS

.........A ___- II __I iiiiL _ I ii IIIL. _.Jl

.M

L ways wear a safety face shield or safety goggtes. See

_'Aecessories;"

2. Keep hair, fiagees, and all other parts of the body

away from openings and moving parts. Air,rays wear

+ heavy, long pants, boots, and gloves. Do not go

barefoot or wear sandals, jewelry, short pants, loose

dottfing, or clothing with loosely hanging straps, ties,

tassels, el_. Secure hair so it is above slao_Aderlength.

Being fully coveted will help protect you from pieces

of toxic plantssuch as peison ivy thrown by the Trim-

mer Head, which could be more of a hazard than

touching the plant itself.

3. Do not operate this tool whenyou are tired,iU .or under

the influence of alcohol, drags, or medication.

4. Always use the assist handle. See "_.rnbly:'

5. Wearhearingprotectionifyouusethistoolformore

than I_ hoursper day.

6. Never start or run the engine inside a dosed room or

building. Breathing exlk.a,ast fumes can kill.

7. Keep handles free of oil and fuel.

A TOOLSAFETY

1. Inspect endretool before each use. Replace damaged

parts. Check forfuel leaks and make sure all fasteners

.... are in place and securely fa.qened.

2. Replacetdmmerhihdpartsdaatareemcked,ehipped,

broken,ordamagedinanyotherway beforeusingthe

tool.

3. Use only .080" diameter Sears Laser Line. Never

use wire, rope, string, etc.

7tTBi_gffre--i]a-es_eld is pmperiy_.

5. Useordythespecifiedtfimmerhead. See"Specifica-

tions7 Makesare Ihetriramerhead is pmpeflyinstalled

and fastened. Refer to "Assembly:'

6. Be sure the trimmer head stops turning when engine

idles. See "'Carburetor Adjustments.'"

7. Make cattxwetor adjustments with the drive shaft hous-

ingsupported top,vent thetrimmerline fromcontac-

ting any object: Hold the toolby:hand;_do,not use the

optional shoulder strap for support.

8. Keep odg_ away when rnaldng carburetor adjusanents.

9. Useonly accessories or attachments as recommended

for this toot by Sears.

& EiT/m

L Mix and pour fuel outdoors and where them ar e no

sparks or flames.

2. Usea container approved for fuel.

3. Donot smoke or allow smoking near fuelor thetooi or

while using the tool.

4. Wipe up all fuel spills before starting engine.

5- Move at least 10 feet away from fueling site before

....... e.

6. Stop engine be[ore removing fuei _.

7, Run fuel out of the fuel tank before storing the tool.

4 K Storetoot and fuel in an ;uea where fuel vapors cannot.

reach sparks or open iiame, from water heaters, elec-

tric motors or switches, furnaces, etc.

im II

&

1. Inspect the area to be cut before each use. Remove

objects (rocks, broken glass, nails, wire, string, etc.)

which cart bethrown or become ent,aagled in the trim-

mer head.

2. Keep others including children, animals, _ers,

and hellxrs outside the 60 fcot'_ Zone. Stop

the engine immediately if you are approached.

3. Always keep the engine ou tim right side of your body-

4. Hold the tool firmly with both hands.

5. Keep firm footing ard balance. Do not over-reach.

6. Keep trimmer head below waist level. -" ' "

Z DOnot raise the engine above yourwaist. The trimmer

head can come dangerously close toyour body.

8. Keep all parts ofyourbody awayfrom thetrimmer head

and muffler when the engine is running.

9. Use only for jobs explained inthismanual.

A MMrO' A/ $Agg/T

1. Maintain the tool according to recommended pro-

cedures. Keep the trimmer line at the proper length.

2. Never start the engine with the clutch shroud

removed. The dutch can fly apart and cause serious

injury.

3. Disconnect the spark plug before performing mainte-

nance except for carburetor adjustments.

4. Make_retor adj__h9 us"

mg sup_tled top_ithe trimmer line from contac-

Ling any object. Hold the tool by hand; do not use the

optional shotflder strap for support.

5. Keep ot,hersaway when maki.ng carbtaetor adjustments,

6. Use only genuinereplacement partsas recommended

bySears.

,A TR.4NSPORTI_G AND STOgAGE

L Hand carry the tool with the engine mopped and the

muffler away from y_ur Ixxly.

2. Allow the engine to cool, empty the fuel tank, and

secure the tool before transporting in a vehicle or

storing.

3. Before stodng th_ tool, us_ up fuel left in the carbure-

torby starting the engine and letting the engine runtmdl

it s_ops.

4. Store tool and fttel in an area where fuel vapors cannot

reach sparks oropen flames from water heaters, elec-

tric motors or switches, furnaces, etc.

5. Store the tool so the line iimiter cannot accidentally

cause injury. The tool can be hung by the drive shaft

housing or bythe bracket below the engine.

..6+..Store-tooloat of+reac4aofchildren =_

[f si_a/ions occur which are not covered in thls rnanual,

use_ and goodjudgement. Contact your Sears Serdce

Center/Depar_ent if you need ass_tance.

Page 5

.,llL,i i I [ " " r Illl II I IIII II I II Illll II roll ,,,.,

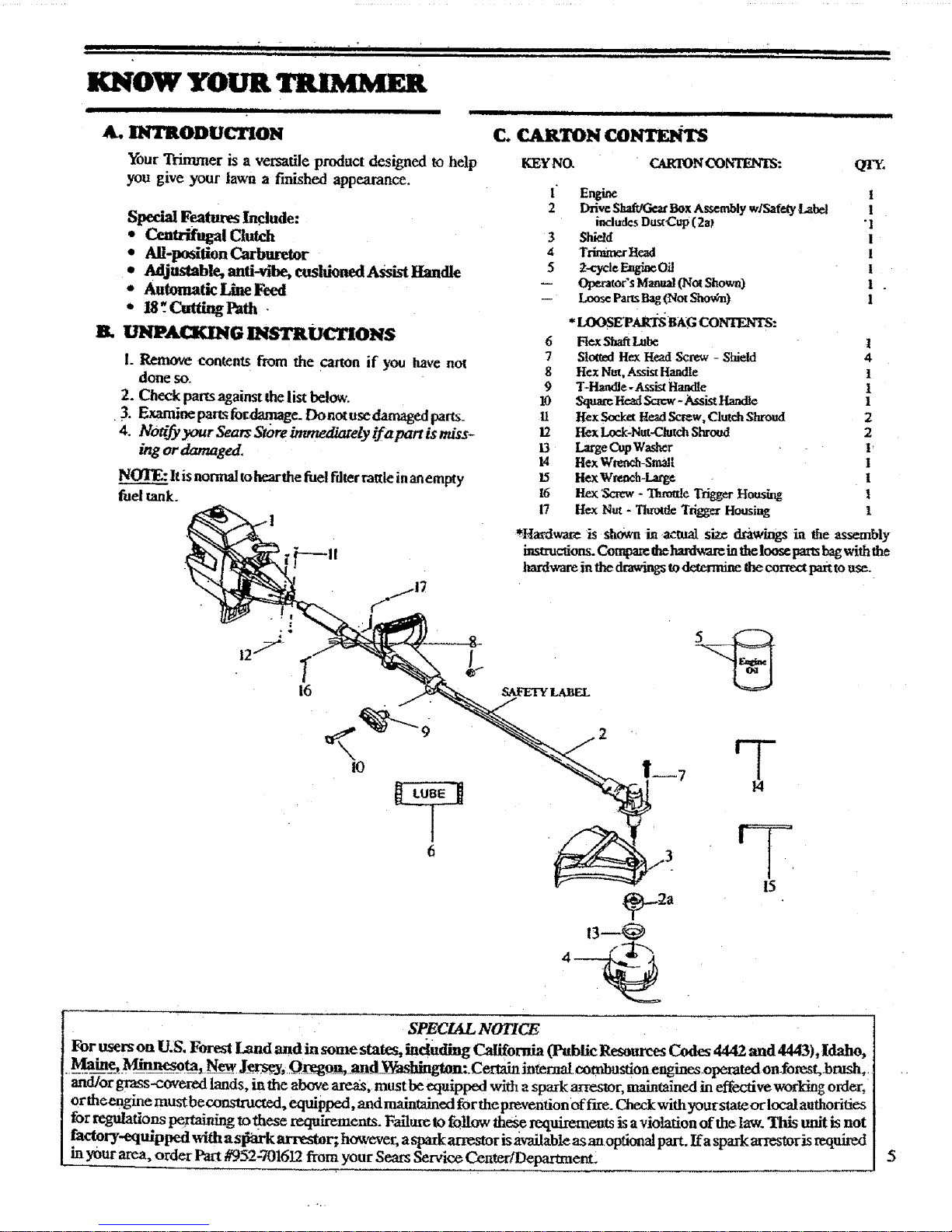

KNOW YOUR TRIMMER

ii m i nl. ,.,., , ,,,,,.,, ,, ,.,

A. INTRODU_ON

Your Trimmer is a versatile product designed to help

you give your lawn a finished appearance.

Special Features Include:

* CentrifugalClutch

" AU-posifion Carburetor

* Adjllslable, anli-vibe, cushioned Assist Handle

- Automatic Line Feed

" 18."Cutang Path .

B. UNPACKING INSTRUCTIONS

I. Remove contents from the carton if you love not

done so.

2. Check parts against the list below.

.3. Examine parts fotdamage. Donotusedamagedparts_

4. NOtify your Sears Store immediately ffapart is miss-

ing or damaged.

NOTE: Itis normaltohearthe fuel fdter rattle in anempty

fuel tank.

16

10

6

i iii ii i I I i I ii

c. TON

KEY NO.

CARXONCONIXN'IS: Q]_y.

I Engine I

2 DriveS_ Box Assembly w/SafetyLabel I

includes Dus(Cup (2a9 "l

3 Shle!d I

4 Trlrmner Head 1

5 -2-cycle F.atghaeOil !

-- Operator's Mmual ('NotShowa) 1 .

-- Loo_ PartsBag (Not ShovM) I

*LOOSE'PAR_ _G CONTE_S:

6 FlexShaftLu_ I

7 Slotted Hex Head Screw - Shield 4

8 He.,x Nm, Assist Handle 1

9 T-Hardle - AssistHandle I

I0 _qu_ I._ad SCleW - A._i_ }_mdte 1

U HexSocket HeadScrew, ClutchShroud 2

12 Hex Lock-Nut-ClutchShroud 2

13 Large Oap Washer 1,

14 Hex Wrench-Small I

15 Hex Wreneh-Lavg_ I

16 Hex'Screw - Throttle Trigger Housing 1

17 Hex Nut - Tlnut_ Trigger Housing 1

*Hardware'is shown in actual size drawings in the assembly

imtm_ons. Comparethehardwareintheloose partsbagwith the

hardwareinthedrawingsto dctermim fl_€correctlint to us_.

SAFETY LABE3L

_-2a

13--@

15

SPECIAL NOTICE

For users on U.S. Forest Land andin some states, including California (Public Resources Codes 4442 and 4443),Idaho,

. _in_%Minnesota, New_J_ O_on,__d...Washington:.Certain internal combustion.engines.operatedon-for,.st,bmsh,

and/or grass-covered lands, in the above area_, must be equipped with a spark arrestor, maintained in effective working order,

or theengine must be constructed, equipped, and maintained for the prevention of fh-e.Check with your state or l_al authorities

for regulationspertainingto tI-_se requirements. Failure to follow these requirements is a violation of the taw. This unit is not

.fact0ry-equlp pod with a _ arrestor; however, asparkanes_r is _ able as an optiooal part. If aspark arrestor is required

m your area, order Part #952-701612 from your Sears Service Center/Department:

Page 6

.............. 72

iiiiiiiii i

i1111111|1| i I I i i IIII I1_ II IIIII I IIIIIIIIIIIIIIIIHIII

A. PMJ_ALATION

This Oix:rator's Manual has been developed to help you

assemble thetool and to provide its safe operation. It is

important that you read the entire manual to become

familiar with the tool before youbegin assembly.

L _ I'OU[ OP_T01"S MANNUAL

Tookyuwm

Hex Wrenches provided withtool

........ iiiiiiillt I ........ "....

B. ASSEMBLY STEPS

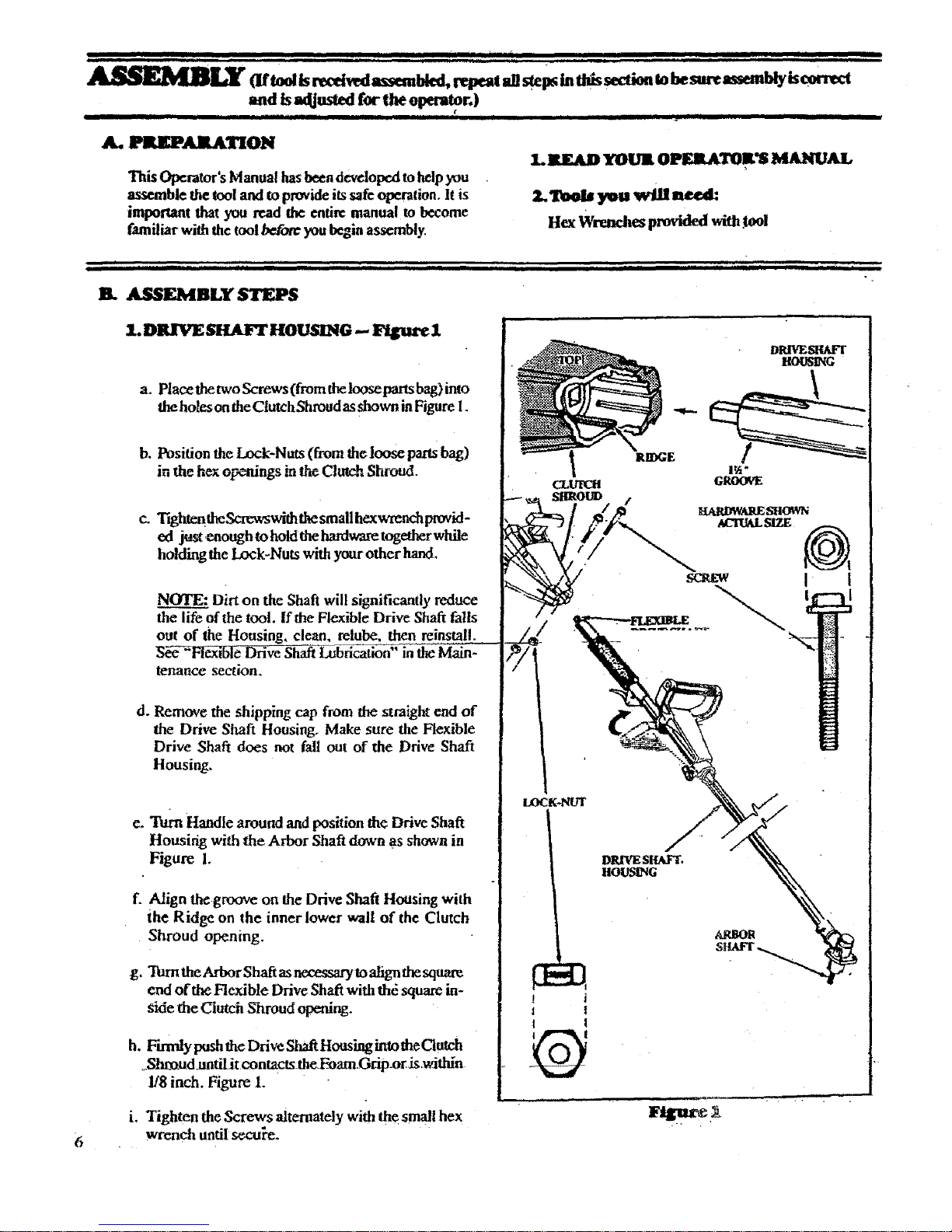

1. DRIVESHAFF HOUSING -- Figure 1

a_

b,

Place the two Screws (from the loose parts bag) into

the holes on the Clutch Shroud asshown in Figure I.

Posifon the Lock-Nuts (from the loose parts bag)

in the hex openings in_e Clm_ Shroud.

c. "I_ghtenthescrewswith thesmall hexwrench provid-

ed just enough to hold the hardware togetherwhile

holding the Lock-Nuts with your other hand.

NOTE: Dirt on the Shaft will significantly reduce

the life of the tool. If the Flexible Drive Shaft falls

out of the Housing, clean, relube, then reinstall.

See-_Flexible Drive S_ Lubrication" inthe Main-

tenance sectiom

d. Remove the shipping cap from the straight end of

the Drive Shaft Housing, Make sure the Flexible

Drive Shaft does not fall out of the Drive Shaft

Housing.

e, Turn Handle around and position the Drive Shaft

Housirig with the Arbor Shaft down _ shown in

Figure 1,

L Align the groove on the Drive Shaft Housing with

ihe Ridge on the inner lower wall of the Clutch

Shroud opening.

g. Turn theArbor Shaft asnecessmTto align the square

end of the Flexible Drive Shaft with th_ square in-

side the Clutch Shroud opening.

h. Ftrmly push the Drive Shatt Housing imo lheClntch

...Shred untilit contacts theEoamGtip_ar is ,within

118inch. Figure L

i. Tighten the Screws alternately with the. small hex

wrench undl secu_'e.

r

! i

l t

! I

@

DRIVESITAF'r

HOC_ING

GROOVE

DRIVESHA_.

HOUSING

Ftgu_ _

Page 7

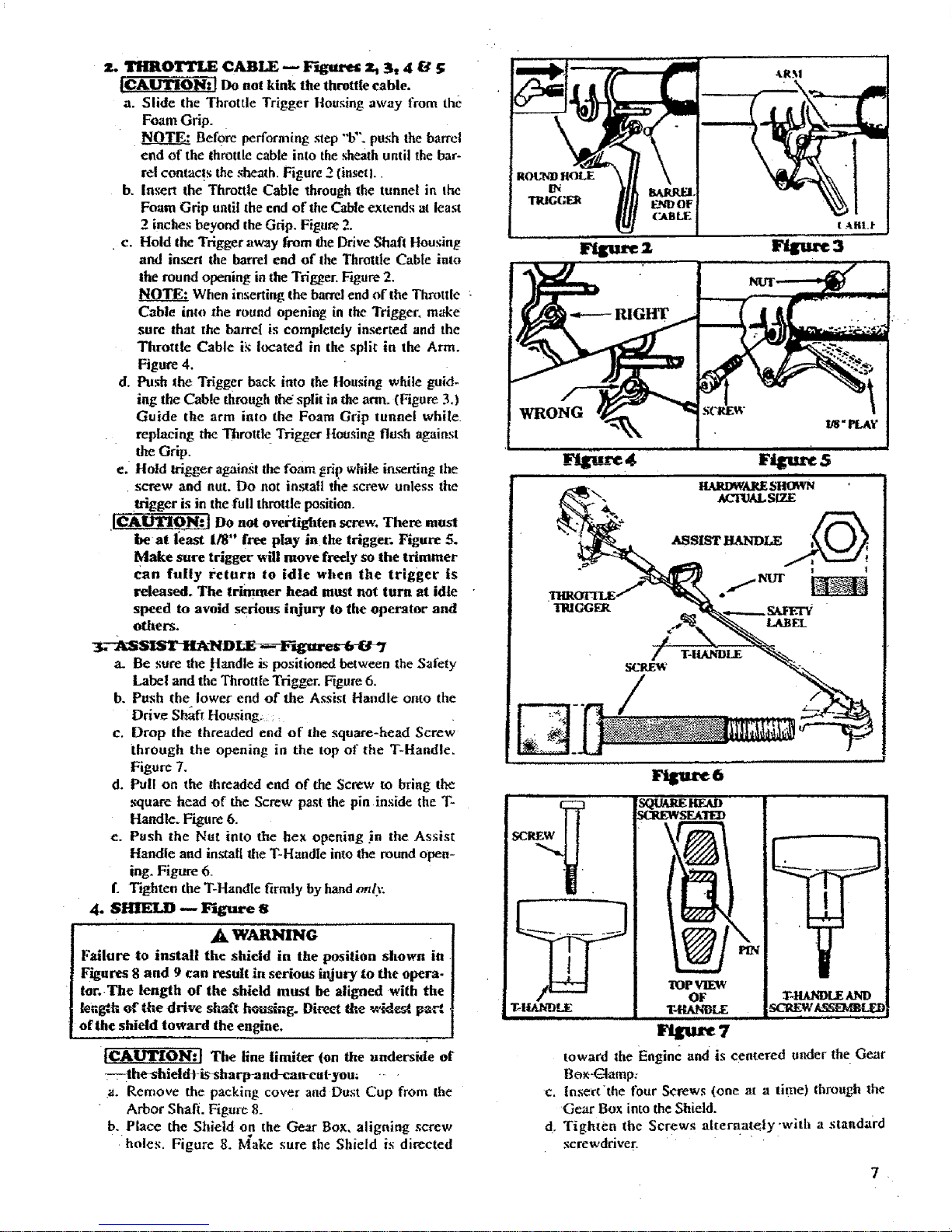

2. THROTTLE CABI._. _ F_u¢_ 21 3, 4 & 5

|CAUTION: [ Do out kink the throttle cable.

a. Slide the Throttle Trigger Housing away from the

Foam Grip.

NOTE: Before performing step "b'\ push the barrel

end of the throttle cable into the sheath until the bar-

rel contacts the sheath. Figure 2 (in_t L

b. insert the Throttle Cable through the tunnel in the

Foam Grip until the end of the Cable extends at least

2 inches beyond the Grip. Figure 2.

• e. Hold the Trigger away from the Drive Shaft Housing

and inscrl the barrel end of the Throttle Cable into

the round opening in the Trigger. Figure 2.

When inserting the barrelend of the Throttle

Cable into the round opening in the Trigger, make

sure that the barrel is completely inserted and the

Throttle Cable ik located in the split in the Arm.

Figure 4.

d. Push the Trigger back into the Housing while guid-

ing the Cable through the split in the arm. (Figure 33

Guide the arm into the Foam Grip tunnel while

re#acing the Throttle Trigger Housing flu_ against

the Grip.

€. Hold trigger agaimit the foam grip while in.fling the

, screw and nut. Do not install the screw unless the

.trigger is in the full throttle position.

]CAUTION:t DO not overtighten screw. There must

be at [east 1/8" free play inthe trigger. Figure 5.

Make sure trigger will move freely so the trimmer

can fully return to idle when the trigger is

released. The trimmer head must not turn at idle

speed to avoid serious injury to the operator and

others.

3.--AS_'D LE_--Figures-6-&7

a. Be sure the Handle is positioned between the Safety

Label and the Throttle Trigger. Figure 6.

b. Push the lower end of the Assist Handle onto the

Drive Shaft Housing.:

c. Drop the threaded end of the square-head Screw

through the opening in the mp of the T-Handle.

Figure 7.

d. Pull on the threaded end of the Screw to bring the

square head of the Screw pest the pin inside the T-

Handle. Figure 6.

e. Push the Nut into the hex opening .in the Assist

Handle and install the T-Handle into the round open-

ing. Figure 6.

f. Tighten the T-Handle firmly by hand truly

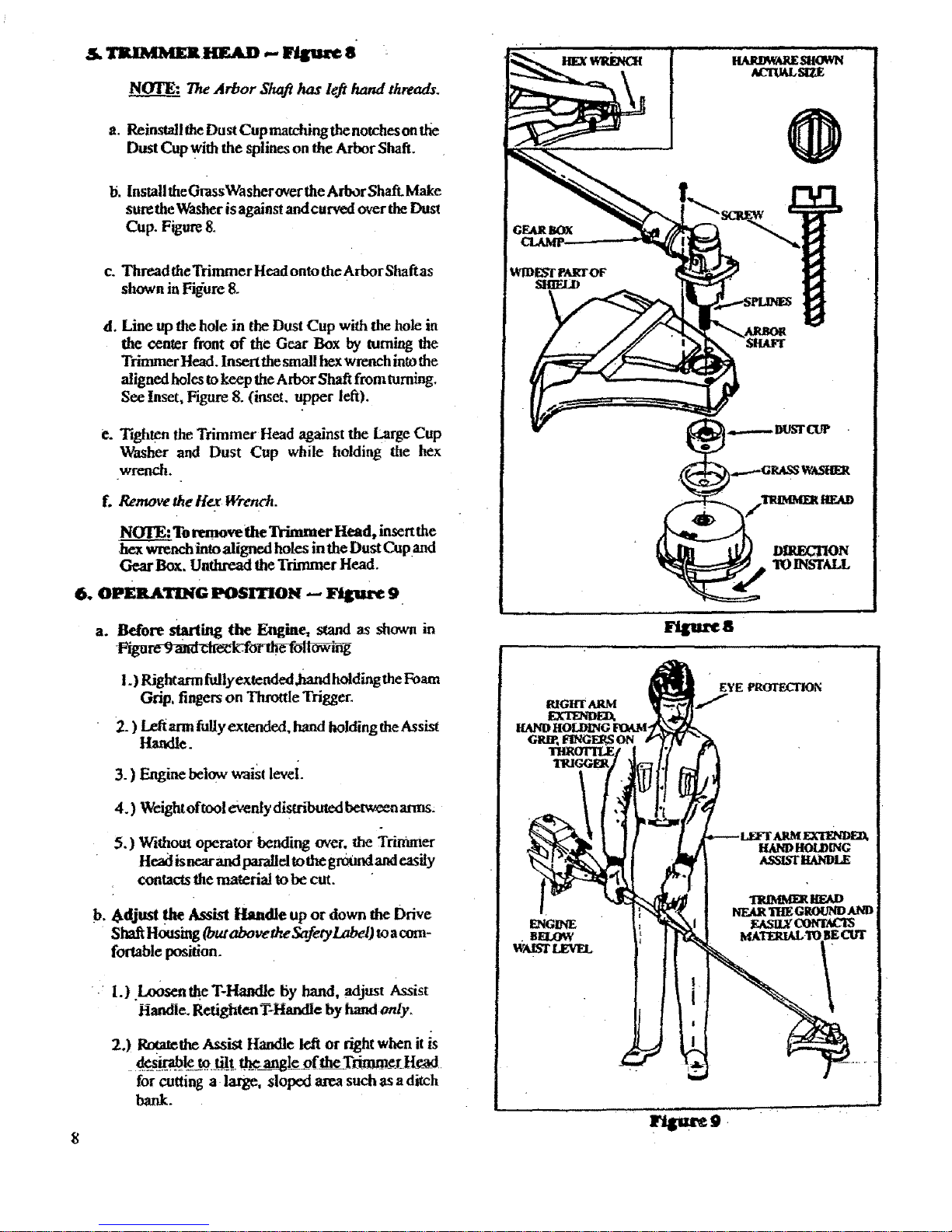

4. SHIELD _ Figure 8

_k WARNING

Failure to install the shield in the position shown in

Figures 8 and 9 can result in serious injury to the opera-

tot. The length of the shield must be aligned with the

lee.gth of the drive shaft h_h'_g. Direct the widest part

of the shield toward the engine,

C[CAUT][ON:] The Hoe limiter {on the underside of

7:- lhe_shieldt-is-sharpa nd can-eat-you; ....

a. Remove the packing cover and Dust Cup from the

Arbor Shaft. Figure 8.

b. Place the Shield on the Gear Box, aligning screw

• holes. Figure 8. lVlake sure the Shield is directed

Ftguge 2

Figu_ 3

LABEL

T-flANDLE

t

Flgure 7

toward the Engine and is

centered

under the Gear

Bo_<-C--lamp:

c, insertthe Ibur Screws (one at a time) through the

Gear Box into the Shield.

d. Tighten the Screws alternately'with a standard

screwdriver.

•

Page 8

S. HZAn -- S

NOTE: _ Arbor Shaft has left hand threads.

a. Reinstall ate Dust Cupmatching the notcheson the

Dust Cupwith the splines on the Arbor Shah.

b. Install theGrassWasherover the Arbor Shaft Malce

sure theWasher is against and curved over the Dust

Cup. Figure 8.

c. Thread theTrimmerHeadontothe Arbor Shaftas

shown inFigure 8.

d,

Line up ate hole in the Dust Cup with the hole in

the center front of the Gear Box by turningate

Trimmer Head. Insert the small hex wrench into the

aligned holes tokeep the Arbor Shaft from turning.

See Inset, Figure 8. (inset. upper left).

e. Tighten the Trimmer Head against the Large Cup

Washer and Dust Cup while holding the hex

wrell_.

f. Remove the Her Wrench.

NOTE: Toremove the Trimmer Head, insert the

hex wrenchinto aligned holes in the Dust Cupand

Gear Box. Unthread the Trimmer Head.

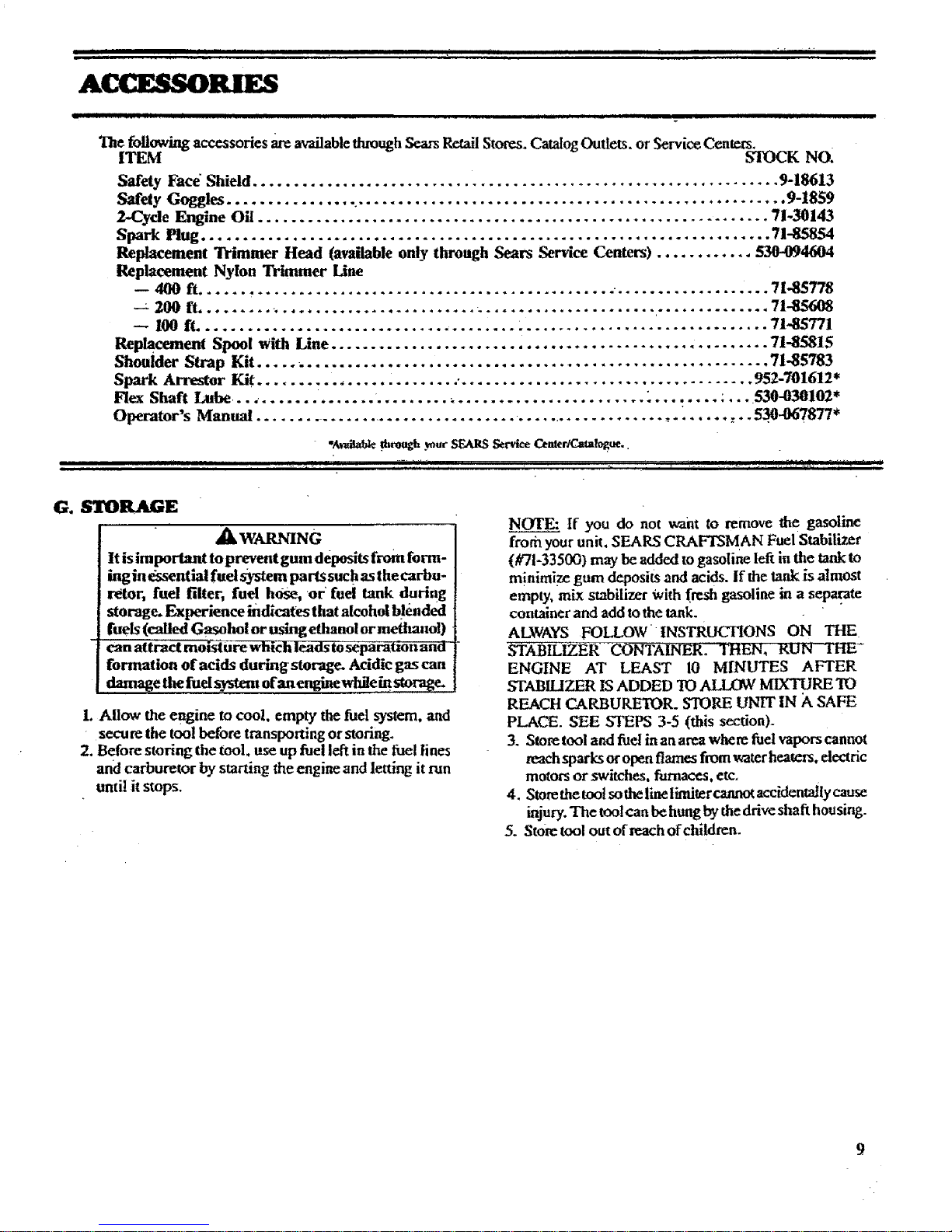

6.OPE TmGtmsmos - 9

a.

Before starting the Engine, stand as shown in

Figure9and_treek_-f_ng

1.) Rightarm fullyexlended ,hand holdingthe Foam

Grip, fingers on Throttle Trigger.

2. ) Leh_ fullyextended, hand holding the Assist

3. ) Engine below waist level.

4.) Weight of tool evenly distributed between arms;

5.) Without operator heading over, the Trimmer

Head isaearand parTdlel to the ground and easily

contacts the material to be cut.

b. bdjth"t the Assist Handle up or down the Drive

Sha_ H o_sing (but above the Safety Label) toacom-

fortable position.

L

• • 1.).LoosentheT-Handle By hand, adjust Assist

Handle. RetightenT-HaixUe by hand ordy.

2.) Rotateate Assist Handle left or right when itis

for cutting a large, sloped area such as a ditch

bank.

IPlgU_ 9

@

Page 9

I i .. • i I I Ill . Ulll n " II ....

A RIF

tllll I ...... IUlllll ]l

The following accessories _re available through Sears Retail Stores. Catalog O_aflets.or Service Cenu_rs.

ITEM S'IOCK NO.

Safety Face" Shield ................................................................. 9-18613

Safely Goggles 9-1859

2-Cycle Engine Oil ............................................................... 71-30143

Spark Plug ...................................................................... ?1-85854

Replacement Trimmer Head (available only through Sears Service Centers) ............ 530-094604

Replacement Nylon Trimmer Line

-- 400 ft ...... , ............................................ ................... 71-85778

--= 200 ft ......... _ ........................ _ ................................... 71-85608

-- 100 f{...................................................................... 71-85771

Replacement Spool with Line .... 71-85815

Shoulder Strap Kit ............................................................... 71-85783

Spark Arrestor Kit ......................... •.................................... 952-701612*

Flex Shaft Iad_ .., ............. ............................ "........ ; .... 530-030102*

Operator's Manual ............................................................ ...530-067877*

•Awilable _magh your SEARS Service Cenler/Galalegue..

G. STORAGE

It is important to prevent gum deposits from form-

ing in e_sential fuel system parts such as the carbu-

retor, fuel filter, fuel hose, or" fuel tank during

storage. Experience indicates that alcohol b lP.nded

fuelS (called Gasohol or using ethanol ormethanol)

can attl-act moisture which leads tOse-i_a-t_t_ona--n-ffK_

formation of acids durlngstot-age. Acidic gas can

damage the fuel system of an englr_wh_e_ storage.

I. Allow the engine to cool, empty the fuel system, and

secure the tool before transporting or storing.

2. Before storing the tool. use up fuel left in Ihe fi_el lines

and carburetor by starting the engine and letting it run

until h stops.

NOTE: If you do not wa_nt to remove the gasoline

from your uniL SEARS CRAFTSMAN Fuel Stabilizer

(#71-33500) may be added to gasoline left in the tankto

minimize gum deposits and acids, if the tank is almost

empty, mix stabilizer With fresh gasoline in a separate

container and add to the tank.

ALWAYS FOLLOW INSTRUCTIONS ON THE

S_ABILIZER CONTAINER. TH_HE-

ENGINE AT LEAST 10 MINUTES AFTER

STABILIZER IS ADDED TO ALLOW MIXTURE TO

REACH CARBURETOR. STORE UNIT IN A SAFE

PLACE. SEE STEPS 3-5 (this section).

3. Store tool and fuel in an area whe re fuel vapors canno_

teach sparks or open flames from waterheaters, electric

motors or switches, furnaces, etc.

4. Store the tool so the line timidercannot accidentally cause

injury. The toolcan be hung by the drive shaft housing.

5. Storctool out ofreachofchildren.

9

Page 10

ENGINE INFORMATION

A. FUELING YOUR ENGINE

,, ,, , i ii i |1 I .__

1. FUEL SAFETY

a. Use only recommended fuel mixtures.

b. Mix and pour fuel outdoors and where

there are no spark8 or flames.

¢_ Use a conteiner approved for fuel.

d. Do not smoke or allow smoking near fuel

or tle unit or while using the unit_

_. Wipe up all fuel spills before starting the

engine.

K Move at least 10 feet (3 meters) away

from fueling site before starting engine.

g. Step engine before removing fuel cap.

Allow engine to cool before refueling.

h. Beforestoring the unit, use up i_ae!left in

the fuellinesand carburetorby startingthe

engine and letting it run until it stops.

i. Store unit and fuel in an area where fuel

vapors cannot reach sparks or open

flames from water heaters, electric motors or

switches,furnaces,eta.

2. FUEL MIXTURE

a. Your unit is powered by a2-cycle engine

which requires a fuel mL_ture of regular

unleaded gasoline and a high quality en-

-b_i_e-eiF_lyomade._or_2--cyele_-air .......

cooled engines, The internaldesignofthe

2--cycle enginerequireslubricationofmoving

parts.Lubricationisprovidedwhen thetee-

•ommended mixtureofgesollneand oilisused.

b. Genitlne Sears 40.1,2-cyole engine oilis

strongly recommended for the protection

ofyourunit.Extensiveenglneeringtestshave

proven thatSears.2-cycleengine oilresists

break-down atoperatingtemperaturescom-

mon to 2-cycle engines; resulting in depend-

able performance and 10nger engine life.

e. Gasoline must be clean and not over two

months old. After a short period of time,

gasolinewillchemicallybreakdown and form

compounds thatcausehardstartingand dam-

age in 2-cycle engines.

d. The correct measure of gasoIine to oil is

very important. Too much oil in the mixture

willfoulthespark plug.

Too little oil or incorrect oil

will cause e_ne to overheat and seize.

e. Always mix the fuel thoroughly in a con-

tainer since gasoline and oil do not readily

combine. Do not mix gasoline and oil directly

: in the ftii_:ii_. ................

3. USE THE FOLLOWING:

SEARS CRAFTSMAN 2-cycle engine oil mixed

at 40:1 is strongly recommended. Consult the

instructions on oil container for proper mixing.

IPART OIL TO 40 PARTS GASOLINE=

3.2ft.oz,oiltoI gallongasoline

8.0 ft. oz, oil to 2.5 gallon gasoline

Not all air cooled 2~cycle engine oils have the

same qualifies. If SEARS CRAFTSMAN

2-cy.de engine oil is not available, use a good

quality, 2-cycle engine oil recommended for

air -cooled engines. _JLx at a ratio of 16:1 (8 oz,

oil to 1 gallon gasoline). A 16:1 fuel mixture with

theseoil.willassureadequate lubricationfor

yourengine.

4. DO NOT USE:

• NMMA Oil--National Marine Manufac-

turers Association (formerly BIA oil)--

I)oes not have prover additives for ah'-ccoted,

2-cycle engines and can cause engine damage.

• AIYrOMOTIVE OIL--

Does not have proper additives for air-cooled,

2 -cycle engines and c_mcause engine ddmage.

Ak "CAUTION

Exverience in_e__A_hLt _c_o__

(called gasohol or using ethanol or methanol)

can attract momture which leads to separation

and formation ofaclds during storage. Acidic

g_.. can damage the fuel system of an engine

while in storag e . To avoid engine problems, do

not leave fuel in the unit when storing for 30

days or longer. Start the engine and let lt run

mttil the fuel lines and carhuretor are empty,;

Use fresh fuel next season. See the "Storage'

section for additional information. Never use

engi'ne or carburetor el e-aner products in the

fuel tank or permanent damage can occur. .

5. HOWTO MIX FUELAND FILLTANK

Pour the proper measure of engine oil into an

approved, marked container. Then, fdl the

container with regtday unleaded gasoline.

Iffuelisalready in the container, add the

propermeasure of engine oil. Then, dose the

container tightly and shake it momentarily.

Do not mL_ ga_o!ir_ and o_ dir_t!y in th_

fuel tank.

b. Using a spout or funnel, fill the fuel tank with

fuel mix.

,I0

Page 11

B. PRE_PERATION CHECKS

AWA/LNmG t

_dew sU Wm_s and Sd_ _ _ _:

Betore operat_ your tool, _wa_:

I. Inspect the entire tool before each use. Replace

dsm_ed parts. Check forfuel leaks and make sureall

f_lr_rs arc in place and securely fastened.

2. Replace trimmer head parts that are crocked,

chipped, broken, or damaged in any other way

before using this tool.

3. Useonly ,080"diameterSears Laser Line. Neverues

wire, rope, string, etc.

4. Use only with the shield properly attached.

Nil I , II, I,,I Jl I I ,, J , I

I I l Ill IN I i illllll

fions." Make sure the trimmer head Is properly

Iilsmlled mid tmcu_ fastmed, Rffcr to "Assembly7

6. se sure trfnmmrimd aOl_ turntngwSenmOm

Idles, See "Carlmretor Adjumnea_:'

7. Make_xb_r a@tstments with the drive shaft

houangml_Oaed to_t thetrimm_ linefrmn

omdacting tmyobjoct, Holdthe tool by band; do not

use theoptional shoulder strap fOrsupport.

8. Keep others away when making carbuggtor

aajustment_

9. Use-only accessories or attachments as re_m-';

mended by Sears for this tool.

10. Cteantbeair£dterifd_rtybeforeoperatingthetool,

Ref_ to" " .....

Specificauons, for air filter location.

J t; roll, i .G.tlI . ! i . .,ll

C_ STARTING INSTRUCTIONS (For location of controls, refer to"Specifications._

LSdorc, r me e.

a. Fuel engine. Move 10feet away.from fueling site.

Figure XO

b. Extend 4-6 inches of Line from Trimmer Head to

pro.ride adequate load on the engine.

I & WAnNInG

"lhetrhm_r hess!lwl/t turn _ s_n_ ti_ engh_ st_t_.

e. Rest Engit_ art Shield _n ground, supportirtgTrim-

mer Head off the ground away from trees, bushes,

-or__Figure-10:

d. If usingoptional Shoulder Strap, place Shoulder

Strap on }_urshoulder. Start engine b_re clipping

Shoulder Strap to the tool.

2. For a Cold Engin¢_

a. Move OrdOffSwitch to ,on:' Figure IL

b. Move Choke to "'full" position, Figure 12.

c. Grasp Foam Grip and squeeze Thro(tle Trigger fully

I_ep Throttle Trigger fully squeezed until engine

runs smoothly (through step "g").

d; Pull Starter Rope sharply anal engine attempt_ to run.

bttr no more than 8 pulls at full choke toavoid flood*

ing the engine./'he engine "attempt to run" may be

hard to hear. The operator must listen earefuUy.

After 8 pulls, proceed to step "e.'" even if engine has

not _ttempted to run.

€. Move Choke to "'half' position, Figure 12+

f. Pull Starter Rope sharply until engine attemps tonm,

but no mo,m than 5 pulis.

NOtrE: Ifen$ineha_ nois_a_ctaft*rSpulis, repeat

s,_ps-_" through"f:'

g. Allow engineto run 5seconds,then move Choke to

• squeezed untilengine runs smoothly

NOIX: Ifengir, e dies with C_okeat "off" position,

rq,eatsteps"e"thto_ "'g:"

AW_t.m_G [

Avold anybodily contact with the m_when starting

awarm engine. A hot muffler can cause serious burns..

:3. For aWagtn Engtne:

a. Move OrdOffSwitch to "on." Figure 11.

b. Move Choke to "'half" position. Figure 12.

c. Gt-asp Foam Grip andsqueeze TarotdeTrigger fully.

Keep lhrottle Trigger fully squeezed untilengine

t_nff.

d. Pull Starter Rope _harply until engine rum, but

nomore than 5 pulls.

NOTE: Ifenginedoes n0t run afterSimlls, idspro-

cedurewith Choke at "oW' position. Figure 12.

e. MoveChoketo"otT'position. Figure_..KeepTrfg,

get fully squeezed until engine runs smoothly.

I1

Page 12

efl'ud}:

a. Rdaelengine. Mdve lOfeaaway from fudingsite.

b. Move On/Off Switch to "on:' Figure I1.,

c. Move Choke to "full" position. Figme 12.'

d.G_ FoamGrtpa__ Thro_eT,igg_rmy.

Keep Throttle Trigger f#lly squeezed._l engine

€. Pull StarterRope sharply untilengine attemptsto

run, but no more than 5 pulls.

D. OPERATINGINS'gRUCTIONS

I. Before entering the material to be cut, bring the

engine to cutting speed by squeezing the throttle

tl"iggeK

a. Do not run the engine at a higher speed than

necessary. The cutting line will cut efficiently

when the engine is van atless than full _x_ttle,

At lower speeds there is less engine noise and

vibration. The trimmer line _ last longer and

will be less likely to "weld" onto the spool.

b. If theTrimmer Headdoesnot turn aben the

i

L Move 0_ to "off" po_don, Figure 1.2..

5pulls./_o rd_er_ys_e_dunti/en_ r_

smoo_.

NOTE:Xfe_aehasnocsma_, paUSta_P, ope

5 more palls. Ifengi_ still does not run, itis pro-

bably flo0ded. Wait a few minutes and n_at in_

cedurewithChokeat"off"po_on. Fgur¢ 12.

m,,,,,,,,,,, m, P ,,,,.,,,,,, ' ,,

mm III II I Jill I

2. Always rel_se theThrottleTiigger and allowthe

enginet0retaratoidtespeedwhennotcat6ng.

3. MakesuretheTrtmm_Headsto_ mn_'_ea

the Thro_ liigger is rdeased and the eagiae

runs at idle speed. For correction refer to "_.at_-

w.lor Adjustments:"

4. To stop the engine:

engine is accelerated, make sure the Drive Shaft a. Relea_ the Throttle Trigger.

Housing is propedy seztcdin the Clutch Shroud. b. Move On!Off Switch to the "OiT' position.

.Refer to '_.ss_mbly-Driv¢ Shaft Housing7 Figure 11.

,,,,,m , ,,, i , mmmm,m,, m, I ,H , J,,' '

USING YOUR TRIMMER

IIIIIIIIIIIUIIIJ I II lllll l l l l III llll

l.e ,,1,

AW amsG.- ows

The rapidlymovinglin_causesobjectstobcthrownviotcutty.

The shield will not pt'ovidc complete pr0tcction to the opera-

mr or others. The operator must were"a safety face shield

or goggks, Always wear heavy, long pants and boot_ Keep

others at least 30 feet away.

.£t WARNING ,- _ZONE

This tool will throw objects aad cut. Keep others including

children, animals, bystanders, and hdpers at least 30 feet

away from the operator and tool. Stop rite ehgine ifyou are

approached.

Trimmer Head

,Use Oaly Genalne Rephcements Parts

WARNTNG --

.... T_+_+E._.p_..+++ .._+.+_, _._._:g1,.+b+m_+m.+or

damagedtaanyo_r.rw_ycaaflyaparta_lcaus_s_ri_tsinjaryo

Do notuse.Throw damaged partsaway.Replace damaged

partsbeforeusingthet_ L

Page 13

i i !ll :iL_, _ I i i

A. LINlg TlglMMEIg $_

L OP .TOI

J

a. Always wear a safety face shield or goggte_, See

"Accessories;"

b. Keep hair, fingers, and allether parts of the body

away' from openings and moving parts. Always

wear heavy, long pants, beets, and gloves. Do not

go barefoot or wearsandals, jewdry, short pants,

loose clothing, or clothing with loosely hanging

straps, ties, tassels, etc. Secure hair so it is above

shoulder length. Being fullycg_;et_l will help pro-

tect you from pieces of toxic plants(such as poison

ivy) thrown by the.Trimmer Head; which could be

more of a hazard than touching theplant itself.

c. Do not operate this to01 when you are tired,

ill, or under the influence of alcohol, drugs,

or medication.

d. Do hot swlng the ualt withstw_hforce that you are

in dangeroflosing your balance.

c. Never _xt or run theeaglne insidea dosed room

or buildin_ Breathing exha,,_ fum_ can kill.

f. Keep handles free of oH and fuel.

2. TO0/.

a. Inspect the entire tool before each use. Replace

damaged pants. Check forfuel leaks and make rare

all fastcmrs are in place and securely fastened.

b. Use only.080" diameter Sears Inset Line. Never

use wire, string, rope, etc.

c. _he s--au-'_Idis properly-_t_:

.......... ! ! ' !'!, '',,,I'I'I'.,,, ,

d. Make sure the trimmer head isproperly imtalled

and securely fastened. Refer to "Assembly."

e. Be sure the trimmer headstops tm-ning when the

engine idles, See "'CarburetorAdjustments.*'

f. Make carburetor adjustments with the drive

shaft housing supported to prevent the trim-

mer linefrom contactingany objecLHold the

tool with 3_mJrharfl; do not use the optional shoul-

der strap for support.

g. Keep others away when making carburetor

adjnslmen_

h. Use only accessories or attachments as recom-

mended for this tool by Sears.

3. tr[rr//NG

a. rInSp_'t [he ar_ _o he cm b_ _ usP_ _[[love

objects(Rxks,hx_m g_;s, mi_, wir_s_,g, _)

whie.hcanbe th,'v_ or beco,-m_ entangled in the

trimmerhead.

b. Always keep the englne on the right side ofyour

body.

c. Hold the tool t'wndy with both hands.

d. Keepffu-m foo_and balan_ Do notover-teach.

e.. Keep the trimmer head below waist level.

L Do not raise the engine above your waist.

g. Keep all parts of your body away from tl_ trim-

mer lhteand m_ when thee_is rmmlng.

_-Useo_fo_jobs_xplain_naL

18. AU1X_I_4tATIC LINE ADVANCE

• The trimmer line advancesautomatically a._d_iir_

wears and reduces the cutting path.

o The line will wear f_ and will advance more fre-

quently when cuttiagagaiust hard surfaces such as

rocks, bricks, concrete, metal fences, etc., than when

cutting against woody objects such as trees or wooden

fences.

• Ifiine does not advance properly:

-- Operate the engine at full throttle and allow the line

to strike a hard sdrface such as concrete or the

ground.

Hl_aeis 4"or less, stop theeagine and cheek for _ae

binding or tangling on the spool. See "Trimmer

Head"inthe MaimenanceSection for rewinding

insmlctions.

a Ah_ayskeeptheshidd in ptaeewhenthetonisbeing

operab_LFigure13.

iii i iii i ii i ]l itt _ ii ii i ii

_kWARNING

Use only DSO" diameter laser Line. Other sizes of

line _ill not advance properly and can cause serious

injury.Do notme other materials inch as wire,strin_

rope, etc. Wire can break off during cutting and

become a dangerous missile.

AW_G

Use minimum speed and do not crowd the line when

cutting .a_mmi hard objects (rocks, gravel, loose object_

etc.), which can damage the trimmer head, become

entangled in the line, or be thrown causing a serious

hazard.

CU'ITINGUNE UNE LIMITER

rtt_ xa _3

Page 14

N.NI Hl l HII I I I I I I

IT,I

¢. ¢uTrmG Im_rHoiw

• Thetipofthe line does thecutting. Youwillachievethe

bestperformance andminimum linewear by notcrovd-

mgthelineintothecuttingarea.Therightand wrong ways

are shown in Figure 14.

• The line will easily remove grass and va_eds from

around wars, fences, trees, and flower beds, but it

also can cut the tender bark of trees or shrubs and

scar fences. To avoid damage, especially to delicate

vegetation or trees with tender bark, use less than full

throttle and keep a 3 inch distance away. Keep in mind

that the line will advance suddenly io a longer length

when it wears downto-4-Sinches.

e For wimming or scalpinguse less than full throttle

to prevent line breakage and excessive line usage:

•. during light duty cmIing.

-- near objects around which the line can wrap, such

as small posts, trees, or fence wire.

• For mowing orsweeplng, use full throttle for a good

dean job.

Irqm_ 14

&waaamo !

Always_ear ¢yt pmtecCon. Neverkan o_a-thetrin_

met head.Rocksordd_can rtmc_orbethnm, nimo

eyesand _ceand causebSndaessm-otherseriousl_u-y.

x. r a,e xs

Hold theIx_onlofthc tzimmerhead abo_3incl'esatx_

abovethegnmnd and at anangle. Allow onlythetipof

the lineto make contact. Donotforcethetrimmerline

intothe work area.

2. SCALPING -- Figure 16

The scalping techniquereraovesunwantedvegetation.

Holdthe_xtom ofthet_ner headabout3i_mhesabove

theground and at anangle.Allow the tipoftheline to

strike theground around trees, posts,monuments,etc_

Thistechniqueincreasesline wear.

3. MOw---iNG ,- Figure 17

Yourtrimmeris idealformowinginplaces ooaventiona!

lawnmowerscannot reach,la themowingposition,keep

thelineparallel(otheground.Avoidla-essingtheheadhRo

theground asthis canscalpthe ground anddamage the

tool.

4. SWE mG-- rg,urexa

........_fanaingaction_ea_g-linecanbeq_-for-a -

qttickand easy clean up. Keep the lirteparallel toand al:_e

the surfaces being sweptand move the toolfromside to

side.

•14

Page 15

ii

• Fer preper llne feed:

--Use only genuine Sears pre-wound spools and

.080" diameter Sears I_tser Line brand line.

Use of other types of spools or lines can result

in excessive breakage, line welding and improper

line feed.

-- Pre.wotmd spools offer the most convenient

method for replacing line as'well asoptimumpcr-

formance.

• Always ckan dirt and debris from the spool and hub

•when performing any type maintenance.

1..lln._fln_ NeW Spool with Line

a. HoldtheTtimmerHcadasshowninFigurel9. Press

the Lock Taband turn Cover cotmte_cloc_wis¢.

b. Remove the Cover and Spool. Figure 20.

c. Clean dirt and debris from all parts.

d. lnspectail TrimmerHeadpar_ fordamage, Replace

d_aged parts.

[Trimmer head parts that arecltipped, cracked, broken,[

[or _ in any ether way can fly ap_t and cause[

Iseriousinjm'y.Donotuse.Replacedamagedlna'tsberore/

]usitag the tool. [

e. Insert about 6 inches of-Line from the inside6f_he

Hub Ilwooghthe Line Exit Holeto theoutsideto_eep

--lhe--L__kF "glill-ffth'_head. Figure 21:

f. Route the Line behind the Balancing Pin (Figure2l)

while carefially p!acing the Spool in the Hub.

_g. Pull on theLine e.x/ending outsidethe Hub to make

sure the Line will not ad(ance. See Inset, Vlgur_21.

This indicates that the Line is routed properly.

h. Reinstall Cover:

L).Atign the four catches on the Hub with the cut-

outs in the Cover. Figure 20.

2.) Press the Cover onto the Hub.

3.) Turn Cover clockwise. Figure 19_-

i. Check to ma_ sure all four Catches and the Lock

Tab are properly _sw.aed as shown in Ftgure 22, lhen

test the Cover by trying to ann it counterclockwise.

j. Pull on the Lineagain from outside the Hub. It the Line

can be pulled from theassembled head, itis not properly

routed arotmd the Balancing Pin and willfeed con-

tinuously when the Tri0amer Head turns. Remove

Coverand re-rou_teLine_s shownin_Figure 21.

• _ iiiiiiiImllll'HII - IIII

vl_,ttt_ _

•A_ f_ar _l_sm_t bef_tmedan_l theto_ t_ _

onto th_x_r, ffh_dl_ hnpmi_rl_, _ _ver _m ll_

ell'and bevomea _ miss_

FlgUl_ 21

rlgu_

LOCK TAB

i5 •

Page 16

a. Follow "hstalling Spool wiI.iac;' st_ "a-d" and.i

remov¢ any Liac retaining o. the Spool

b. Use a 40 foot leagth_.080 "diamca_Sca_l.ascrLine.

c. Insert V16"to l/8"oftheend of the Linethrooghone

of the holes in the rimof the Spool. Allow no more

than 1/8" Line to extend beyoad the rim to avoid

interference with line release action. Figure 23.

d. Wind the Line onto the Spool in the direction shown

bythearrowontheSpoolandastightlyandevenly

as possible so the Linewill feed ptx_pedy.Figure23.

I¢adfflXOX: ITheTrinmaer Head willm_mcfion

properlyifthespoolisl'dled beyond thenmrA_

around the oaLside edgeoCthe spool

e. Follmv"InstallingSpoolw/Line"steps "€-j:"

NIgure 23

ilml

,Does not aa_mme, or breaks while eutting

-- Improperlymo_cdinhead.

-- Improperly vamadonto spool.

-- Linesize incorrect.

-- Too tittle line _tside head.

• Weldsonto spool

-- Linesize incorrect.

-- Incorrect spool.

-- Cromtiag lin_againstmaterial being ca.

-- Cuttha$at higher speeds thaanecessary.

-- Wound loosely on spool.

• Rd_ continuously

-- Woundbeyondn_hes on spool.

-- Improperly roc_l inhead.

-- Line size inconcct.

-- Shield installed improperly.

o Usage is excess_

-- Improl_ly ro_-_t in head.

-- Linesize incoming.

--Cutting at high gzeds around hard objects.

-- _ line agaimt material being cut.

• Pulisback _ _d

-- Too tittle lin_ c_._de of head.

omsma. . MAmr u cz

n . UIIIIIIII .

A. _ANOg SAFE'rY

I. Maintain the tool according torecommended pro-

eedures. Keep thetrimmer line atthe proper length.

_Ne_r-start-the-eaglae-wah-the_utch-shroud

tamaoved. The clutch can fly apart and cause serious

injury.

3. Disconnectthe spark plug beforeperfotmlag

maintenanee_cept for carburetor adjustments.

4. Make carburetor adjustmeats with the &iveshaft

housing supported toIa,evemthetrimater line from

cOntacting any object. Hold thctoOl with your hand;

.. do. notuse the optional shoulder strapforsupport.

5. Keep others away when making carburetor

adjuo-_anents.

B. AIg_

i Adiny air filterdecreasesthe lifeandperformance oflhe

engine and increases fuelconsumption.

Clean the Air Filter:

o .AJw_,safterStanksoffuelorS hours ofoperation.

ivhlcbever is less.

o More frequently in dusty conditions.

L _ _ two Screws _ the Air VL_r Cover

enough to remove the Cover from tim Engin_

F'gure24.

2. Remove the Air Filterfrom theCover. Figure25.

3.: W_li Filtc_iti S0ap_ _f.-

4. Squeeze Filter dry and replace in Coz:r.

[CA_JTtOIq: IDo not clean the air fdter in gasoline

16 or other flammable solvent to avoid c_ing a

fire hamrd.

nl

6.

Be sure trimmer hera stops turamg engm

idles. See "Carb_tor _djustmcnts7

Useoaly _0_0"dian_r Sears Laser Line . Never

use w_re_rope,smrg: _i

Replace trimmer _e_.d parts that are cracked,

chipped, broken; or damaged in any other way

beforeusing the to_L

9. Use only genuine, cp_xcement parts as recom-

mended bySears.

.10.IaspectretiretoolI_.epi_cedamagedpart_Checkfor

fuel.lea_. Make sure _._tfastenersare in place and

securely rasterS.

5. R_iasmll_'_AirFdt_C_r, makiagsat€theChol_

ExitSl(x(FgureLS),_sp_x_doverthe Chol_ Lever.

LcAunoml Make_.m_air f_ris _*i_

the_ ofthe c_ _ _pdust titan enter-

ingtheen_ andca_ _ dama_

Page 17

............ •.... _ _ 7:

ilUl i i iiiii i I i ii ii i I i i i i i i i i "-

...... i ill .H i " ,m_ ,,H ,i ,, i. , ,_,

C. STARTER ROPE

i F

Nevers_mm_eene_ _h _e c_ch sh_.td_' The

clutch l_t fly apa_ _ cause se_,ous _ju_.

Do not remove the retaining tab and screw to remove

pulley. The spring beneath the latlley is under tension

attd can fly out causiltg serious kOury. Ifany part of the

ptmeyhomlagassemblyisdmagedeaterthantherope,

do not use thetooL Take it toyour Sears Service Center.

1. Disconnect Spark Plug Wire_Figure26.

2. Remove the Screw and Nut in the Throttle Trigger

H_msingas ,J_m in Rgure 2. Holdthe"[h[_e Trigger

away from Drive Shaft Housing and remove Throttle

Cable from Trigger, Pull Cable out of Foam Grip

runnel.

3. Remove the four Ciutch Shroud Screws as shown in

Figure 261with thesmali, hex wrench provided,

4. Separate the Clutch Shroud from the Engine. Figure 27.

A. _NaJm

Uxe only a hand tool to remove the clutch. Do not use any

type of motmize_ tool or _ike _zeclu_ inm_yway. Other-

5i Hold the "Flats" of the Clutch (Figure 27) with an

atljustable wrench as shown in Figure 28 (inset) and

removethe Nut _ntea-clcckwise with_ ...................

wrench.

NOTE: Clutch will slideofftheclank_haR intact. Do

nat disassemble clutch.

6. Remove the Beveled Washer, Clutch, and Large Rat

Washer as shown in Figure 28.

7. RemovethePulIey Housing fromtheEngine. Figure28.

& Remove Rope Retention Screw. Remove any remain-

ing rope.

9.

Hold Pulley Housing and hand turnthe Pulley clock-

wiseas far as itwillgo. Then, turnthe Pulley counter-

clockwise until the Pulley Notch is aligned with the

Housing Notch nextto the Retaining Tab and Screw,

Figure 29, Next, turn the Pulley one complete turn

cotmtercloekwise until the notches are aligned again.

10. Insert the small hex w_nch into the hole formed by

. the Notches to hold the Pulley in position. Figure 29

(Inset).

11. Use a 42" length of replacement Rope.

,12., Movea_ray(10feet)fromthe,fueltank-withthe replace

'merit Rope. Use a match and melt both ends ofthe Ro_

to prevent fraying.

ttt_OVE _

!

, .11 i1,1

witho_

l)t'i_ Shaft

ford_u'Ity.

S_.

F_m_27

eULLEY l lOUSING

LARGE

FLAT

WASHI_

rtgure_

17

Page 18

13. Pull the melted ends th_ugha thick, cleantugwhile

the Rope is still hot to ob_n smooth, pointed ends.

B. Insert one end of the Rope through the Handle and

secure with a knot. .,

15. In--r( theother end of theRope through the Rope Exit

Hole, intotheinsideoftheHousing, intothePulley.

and up through the Pulley Hole. See Inset, Figure 29.

16• Wrap Ropecounterclockwise around thePulley Ratdaet

and tuck loose end under Rope where itcomes eUl of

the Pulley Hole• Leave a l-inch tail laying fiat on topof

the Pulleybetweea the _lainer Ribandthe RopeRe_.n-

tion $crew/Posk Figure 29.

IZ Reinstall the Rope Retention Screw into the reten-

tion post. Tighten until snug.

NOTE: Do not ovenighten the Screw. Overtighten-

ing the screw can cause the threads in the screw post

to strip out.

Hold Rope taut at Rope Exit Hole so it will not move

and remove hex wrench.

Slowly feed rope into the Pulley Housing.

Make sure Spacer is in place as shown in Figure 28,

then reverse, steps to re-assemble.

IOttrrm_:! Whenramta!ting thedutch, tightea

the nut just until the beveled washer is flattened

agalnst thedutch. Over or under tightening the nnt

can cause engine damaage. •

...... 10111 ii " .l i

18.

19

20.

D. FI._'_t_tL_. DRIVE SHAFT LUBRICATION

@ l_bricate the Flexible Drive Shaft:

After each ten (10) hours of operation.

----l__e_et_ has_ forg0

: days or longer.

e Use the following procedure for best results:

e Use Flex Shaft Lube Part No. 530.030102,

NOTE: A tube of"Flex Shaft Lube •"hasbeen supplied

with your unit to be used after the first 10 hours of

operation.

lfenginebasjust beenope_ated , avoid touching the tour-

tier. A hot muffler can cause serious burns.

18

r x-€ 30 ms tre 31

Lay tl_ _ble dri_shaft on acleansur-

face. AvoidlaTing thesE_ on the floor, gronnd,oron

-any_t-nmy-h._eo dir t-er_ a f'_-

wiping the shaft, g_:_e _._._iduecan pick up dirt par-

tides that can caus_ ¢_,_¢ge or premature failure,

[caxrrto_ Take ca_ _, zvoid injuring your bands

and fingers with br_k_'_ wires when checking for

damageor w_pmg lh_ __c._._e drive shaft, Acloth will

not prevent the 1:4"oken_ from puncturing ortear-

ing 3our skin,

1. Remo_GearboxC[_ _crew and Locating Screw.

Figure 30.

2. Remove_theDriceSh_f_[_ousingfrom the Gear Box.

3, Remove the Flexible L_z_,eShaft from the Drive

Shaft H(msing. F_gur_ 3i.

4. Check the FlexiMe I_rSve Shaft for broken wires,

twists, or kinks aml _ep_ce if damage is found.

5. Using a clean cloth, wipe €he surface of the Flexible

Drive Shaft thorou#_y _<;remove any old grease.

6. Apply a uniform coat _f _t_betothe entire surfac_ ofthe

Fle_ble Drive Shall

7. inject the remainingco_t¢ n_ ofthe tube into the topof

the Drive Shaft Hca_s_ng.

& Replace Flexiblc _,_v¢ Shaft in the Drive Shaft

.............................................

9. Reassemble the Drive $_f-_ Housing and Gear Box.

T'ghten Screws s_y.

Page 19

i i Ill I II . ,,, , 2 "1 I " I II

E. __R AOJO_

• This isa complicated task. It is important to follow

instructions in sequence as indicated.

i Aw umCG

Makecarburetor adjustmentswi_ thedriveshaft

housing supported to prevent the trimmer line from

contacting any "ob_ Hold the tool with your hand;

do not use the optional shoulder strap for sapport.

A W.4d_NING

Keep others away when making carburetor

adjus_nents,

"- :-Ji

Serious injurytotheoperntorandothers can (_xurifthe

carburetorisnolproperlyadjusted, i

• Poor engine performance can be a result of other

causes such as dirty air=filter, carbon build-up

on muffler outlets, etc. See "Trouble Shooting

Chart" before proceeding with carburetor

adjustments.

o The carburetor has been _re.f_y adjusted at the

factory. However, the openttor must be sure that

adjustments are made when any of tbe conditions

: o_aw as mentioned in "lX,ouble Shooting Sugges-

tions" below.

0' _erv small adjustments can affect engine perfor-

mance. Itis important to turn the screw a verysmail

:-_-.amount per adjustment and tes_ performanc_ before

_g-fmther_ . o . "d

"be no more than the width ofthe slot in the adjusting

SCreWS.

1. TROUBLE SH(X)TING SUGGESTIONS

_ Engine will not tontine to runat idle [msitioa.

See "bY Idle Speed Adjustment" and "e. Low

Speed Mixture Adjustment:'

-- Trimmer Head continues to spin when the engine

idles. See "b. Idle Speed Adjustment" and "d.

Deceleration Check."

. Fatgine dies or besitates when it should accelerate.

See "c. Acceleration Check"

-- Loss of cutting power which cannot becorrected

bycleaningtheair lrdter.See"f. HighSpeed Mix-

lure Adjustment:'

Engine does not return to idle from full throttle

within 2 seconds. See"d. Deceleration Check."

Eng_ w_Jlnot run. See "Trouble Sh_.fing

Chat'L" Then, ifthecarburetor requires adj'ust-

ment, beginwith"2. Basic Carbu_tor Setti.gs."

I The trimmer line willbe spinning during most of this |

] procedure.Wearyourprotectiveequipmentandobserve /

Iall instrnc o.s. ]

2. lht_SlC CJkKBURETOK SETTINGS

NOTE: In most cases,your engine can be made to

run properly with minor carburetor adjustments.

Refer to "T[ouble Shooting Suggestions" in the left

column for the condition you are experiencing and

follow the instructions. The basic carburetor settings

are provided in case they are required.

a. Turn the Low Speed Mixture Screw and the High

Speed Mixture Screw (Figure 32) clockwise until

they stop. Do not turn thescrews until they.are tight,

as damage to the needle seats can occur.

b. Turn the Low Speed Mixture and High Speed Mix-

rare Screws one full turncounterclockwise.

c. Follow instructions "'a.Preparation:" through "f.

High Speed Mixture Adjustment:"

3. PROCEDURE

_. PF.EP.#.K&'rloN

!. )Osea fresh fuel mix. See "Fueling Your Engine:"

2. )Make sure the line extends tothe lengthallowed

by the line limiter to provide correct load on

engine.

3. )Startthe engine. Cut grass for3 minutes to warm

engine. The engine must be at operating temper-

amre before carburetor adjustments can beper-

__foxed_o,'_ab:

4. )Stop engine and remove air filter by puUingit out

with _ur fingers. Refer to "Specifications" for

location.

t_ roLE STEED ADJUSTMEST

I.)Allow engine to idle.

2.)Adjust Idle Speed Screw (Figure 32) until the

engine continues to run without stalling and

without the trimmer head moving.

-- Turnserewcloc_etoincreaseenginespeed

if the engine stalls or dies.

-- Turn screw counterclockwise to slow engine

down and/or to keep trimmer head from

mrning.

3.) Follow instructions in "c.Acceleration Check"

and "d. Deceleration Check:'

4.)No further a_ustments are necessary ffthe

trimmer head does not turn at idlespeed and

if performanceissatisfactory.

[-...... .Lk.WA_I[N G .......:....................

[ Recheck idle speed after each adjustment. The trimmer

] head must not turn atidlespeed to avoid seriousinjury

to the operator and othem

19

Page 20

A.'l,.qi,.l=,,_J'-ili,dlillitit_l I,,71"1II,,_idli_

l.}Altow engine to idli_.

2.)Squeeze Trigger hilly

a. If p_rformance issatisfactm_, proceedto "'d.

Deceleration Check:

b. If the enginedoes not accelerate smoothly,

turn the Low Speed Mixture Screw (Figure

32) .counterclockwise a small amount (no

more than the width of the slot in the adjust-

ing screw.

3,)Repeat step "2.1"" until smooth acceleration is

obtained.

NOTE: It may be necessary to repeat "b. Idle

Speed Adjustment" through "'c.Acceleration

Check," to obtain correctadjustments.

4. )Follow instructions in "d. Deceleration Check:"

i i

d. DECELERATION CHECK

l.)Allow engine to id!e,`then squeeze Throttle Trig-

ger fully.

2.)Allow engine to run at full speed for about 1

second.

3.)Release the Throttle Trigger to the idle position

and listen lothedeceleration oftheengine. Itmust

returnto idle smoothly and within I to2 seconds.

a. If performance is satisfactory, proceed to

step'_l.)"

b: If the engine slowlyor erratlcally retu!-ns to

idlleoridles ¢rratlcally, repeat "b. ldte Speed

Adjusxment" oreominue through Low Speed

Mixture and High SpeedMixture Adjustments

to obtain proper deceleration.

4. )Recheck idle speed.

rtl_mre32

r- Low i_'_;D MIXTUItJg ADJUSTMENT

i.)Ailow engine to idle.

2:)Trim the LowSpeed Mixture Screw (Figure 32)

slowly clockwise until the speed starts to drop.

" Notethis positio,.

3.)Turn the Low Speed Mixture Screw counter-

clockwise until the speed increases and then starts

to drop again. Note this position.

4.)Set the low Speed Mixture Screw at the mid-

point between the two positions.

5.)Follow instructions in "c, Acceleration Check"

and"d. Deceleration Cheeky

f. IlIGH SPEED MIXTURE ADJUSTMENT

Do not operate engine at full

th.q_e for prolonged periods while _ high

speed adjustments as damage'lo theengine

cau o_'Uro

l.)Suppon the drive shaft housing so the trimmer

line is offthe ground and will not make contact

with any object.

2. )Allow engine to idle, then squeeze Throttle Tl'ig-

get hilly.

NOTE: Perform steps "'3.)" through "5.):"

at ballthrottle.

3])TurnHigh Speed Mixture Screw _gure 32) very

slowly clockwise until engine speed is reduced.

4.)Turn High Speed Mixture Screw very slowly

counterclockwise. Stop when the engine begins

to mn roughly.

5.)Turn the screw slowly the minimum amount

clockwise until the engine runs smoothly.

6,) Follow instructions in "c; Acceleration Check"

ann '-d. _ie_i_ Check: _

!CAU_ON: ! If the engine does not operate

ac_dlng totiaseinswactlonsalter re_ting

the adjusting steps, do not use the t0ol. Take

Rto your Sears Service Center.

g. REINSTALL AIR FILTER

Be sure filter is--dean. See ".'Air Filter" for

instructions. "

_CAUTION: I Fitair f'dterinto lhecornet'softhe

hous to keepdlrtfromenteringtheeng and

causing engine damage.

iiii iii i i , i,ii1,1• i i,iii ,i ,i ,,,J,,, ,1111I i iiiiiii i i ¢11

• ii . i,

F. GEAR BOX I.IJBRICATION

20

• Lubricate the gear box airier evers 50 hour_ (if

operation.

II Use Lithium based gear gw.a.¢ea_iilable fnnn rr_st

automotive stores.

I. Remove the Screw and Washer on the Gear Box

......:.!_ing _t3vren_k._.Figure33_ ........

2 Fill Gear Box with gear lube.

3. Replace Washer and Screw. Tighten _rew securely.

r • •

Page 21

i lull/ i i i i ii iiiiii

Engine wiltnot sta_

or will runonly for

afewseconds after

starting

,,, ,, ,

Engine will not idle

properly

Engine will not

accdcrate, lacks

power,or dies

.undera load

•. ,,,,,,,,,,,,,,,,,

CAUSE

I. Fueltar&empty.

2. Engineflooded.

3. Sparkplug not firing.

,,_ u_

REMEDY

1. Fill ta_ withcorrect fuelmixture.

2, See "S_aing lnstrudious?"

3, Install new plug/check ignition system.

4. Ctean fuelfdter; inspectfuel line.

5. See "Csrburctor Adjusanents:"

6. Contact yourSears Service Center.

1..See"CarburetorAdjustments:"

2.See"C_oburetorhaljustmentsY

Engine smokes

excessively

Engine tans ho_

Trinaner headturns

at idlespeed

--Ttimme_ead__

stops undera loador

does not turn when

engine is accelerated

or breakswhile cutt!ag

,, ,,,,,,,, ,,, ,, ,,,,,, ,,,,,,, ,,,

Line welds oa spool

4. Fuelnotreaching carburetor.

5. Cadmretorrequiresadjustment.

6. Noneofthe above.

I. Idle speedset too fastor too slow.

2. Iz_ speed mixturerequiresadjustment.

3. Throtd¢triggerscrew toolight.

4. Noneof theabove.

,,,,, .... , ,,,

I- Air fiJter€lirty.

2,Sparkplug fouled.

3. Carburetcwrequiresadjustment.

4.Muffleroutletsp!ugged.

5.Noneoftheabov_

3.Loosenscrewto freetfigger.

4. C0mact yourSears Service Center.

1. Clean oi"replaceair Idler.

2, Cleanor replace spark plug and regap.

3. See "'CarburetorAdjustments:"

4. Contact),ourSears Service Center.

5. Contactyour Sears Service Center.

L Air fdterdirty. I.

2, Fuel mixture incorrect. 2.

3.

•,:_L __.., __ _.,-.lslguS_ mlxrdre requires aujustment. , .....

3.

I.Fuelmixtureincorrect. I.

2. Highspeedmixturese_tooIow(lean). 2.

3.Sparkplugineomxt. 3.

4_ Noneoftheabove. 4.

,,.......... ,, ,,,,,,

I.Carburetor requiresadjustment. L

2.Throtlle trigge_rscrew too tight.

3. Clu_h requiresrepair.

I _fiv_ _hafihmk_.nnrnotenoagcgt .....

2. Carburetor requiregadjustments.

3. Clutchrequiresrepair, , r

L Line improperly'routedin head.

2. Line improperlywound onto spool,

3. Line size incorrect.

4. Toolittle lineoutside head.

, ,,,,,,,, ,, ,,

Linesize incorrecL

Incorrect spool.

Crowd_g line against materia! being cut.

Cutting at higher speed httannecessary. -

Linewoundbeyondnotcheson spool.

Line improperly routed in head.

Linesize incorrect.

Shield installedimproperly.

Lineimpropedy mutedin head.

Linesize incorrecl,

Clean orreplaceair fiher.

Refuelwithcorrect fuelmixture.

See "CarburetorAdjustments."

•..... , ,, ,j .............,,,,,,,,

See "Fueling YourUnit:"

See "Carburetor Adjustments:'

Replace with correct plug.

See "Carburetor Adjustments:"

2. Loosen screwto free trigger.

3. Contactyour Sears Service Ceqter.

_!_. _R_laceor see "_Assembl.y__._

2. See "Ca_uretor Adjustments?"

3. Contactyour Sears Service Center.

, ,,,,,

I, Removecover.Check linerouting.

2. Rewiadline 6ghtly and evenly. ®

3. Use onlyDSO"Sears LaserLine .

4. Removecover.Pull6" oflineto outside.

L Useonty Dg0" Sears LaserLine®.

2. Use properspool.

3. Cut wilhtipofline.

L Rewindline tightly and evenly•

2. Removecover.Check linerouting.

3. Use only.080_Sears LaserLine®."

4. Reinstalls,hieldproperly.

L Removecover.Check line routing.

2. UseonlyDS0"SearslaserLine®•

I.

2.

3.

Line releases continuously I.

2.

3.

4.

Line usage is excessive 1,

2.

3. Ctittingathighspeed aronndhard objeCts. 3. Re.Auees_aro_dhardo_jecls-

4. Crowding lineagainst material beingcut- 4• Cut withtip of line.

Line pulls back into head" 1, Toolittle line outside ofhead I. Removecover. Pull6" of line tooutside,

2I

Page 22

SEARS WEEDWACKER® REPAIR PARTS LIST - MODEL 358.797161-32cc

22 23

32 i

14

31

27

22

1

2

3

4

5

6

7

,.8

-9

10

1t

12

13

14

i5

16

]7

, ,,,,,,,

NO,

530-027549

530-094694

SrD5_1025

530-010958

530-09_.3

71-85805

530-027595

530 -069252

530-O69256

STD511005

530-094570

530-015653

530-094639

530-030139

.53O-094557

,..71-85815 .......:

530.09449¢

Description

24

25.

26

27

28

29

3O

31

32

33

101

102

103

Part

No, Description

530-094585 DrFce Shaft

_530-067877 Operator'v Manual

530-094568 _ Gear Bo_ Ass'_

530-015775 Screw

530-015774 Screw

530-010959 Throttle LeverAss'y. (Incl.

#22,& 24)

Se_

G_ Washer

Screw

_CT_W

Lackvcasher

H_ Wre_ch (5/32)

I-Ie_ W_:v_.cb (3[16)

D¢-:_---_haC_ Warning

-D,c_--Eh_dd

Da<_._--1_.¢:_- Vibe Handle

530-015768

530-094640

530-094571

530-094616

530-094612

530-015328

530-001642

530-001'711

530-031111

530-031098

530-029159 '

530-029763

530-029764

Throttle Cable Ass'y.

Drive Shaft Housing

Nut:

Handle

Screw

CUtting Head _A_s'y.

(Ind. # 15,16& 17)

Drive Shait Grip

_T" Handle" Ass'y.

Shield F.it Ass'y.

(Ind. #10,11 & 12)

Screw

Line Limiter

-Locknut

Dust Cup

Shaft Lubrication .

Hub Ass'y

....SpoolxvtLine

. Cover

18

19

2O

21

22

23

Page 23

i

\

_s

e

¢_j__ t/r

\

\

\

T

\

Page 24

SEARS WEEDWACKER ® REPAIR PARTS LIST - MODEL 358.797161-32cc

Key

No.

1

2

3

4

5

6

7

8

9

10

1I

12

I3

•14

15

16

17

18

19

2O

21

22

23

24

25

27

28

29

3O

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

Pail

No.

Description

• i , . ,,,,

530-015773 Screw

530 -027529

530-027530

530-015766

530-027528

530-015254

530-027526

530-027527

530-069247

530-010897

530 -035259

530-019156

530-010729

530-029675

530-019154

530-027593

530-027594

530.--014015

530-010960

530-015789

530-010934

530-015126

530-015772,

530 -015780

530-027546+

--530---0275-47-

530-015771

530-014016

530--027545

530--027543

STD610603

53O-015162

530-025875

530-.019178

530-069275

530 -032103

530--015787

530--019158

530-032102

530 -069232

530-015777

530-027523

530-069257

530-024903

530 -015823

530-039134

530-015128

530--012235

Key

tNo,

49

Air Filter Cover 50

Air Filter 51

Screw 52

Spacer 53

Wave Washer 54

Choke Shutter

Air Filter Plate 55

Fuel Line Kit . 56

Fuel Pick-up Ass'y. 57

Carburetor 58

_rCarburetor Gasket 59

Fuel Cap Ass'y. 60

Shroud & Tank Ass'),. 61

f (Incl. #9,10 & 13) 62

Crankcnse/Shroud Gasket 63

Reed 64

P_ Stop " 65

CrankcaselCrankshaft Ass'y. 66

(Incl. #20.21,28 & 66) 67

Connecting Rod Ass'y. 68

Bearings) 09

Crankshaft Retaining Ring 70

Crankshaft Ass'y. 71

Flywheel Key 72

Screw 73

Screw 74

Switch Insulator 75

.......Lead Wire - --76--

Screw 77

Crankcase Ass'y.

(Incl. #36-39) 78

Switch Ramp

Switch Spring Ass'y.

Screw 81

Piston Pin Retainer 82

Piston Ring 83

1 C'ylindetGasket ,,:- .84.

Piston Kit (Incl. #32,33, 85

& pin)

Inner Bearing 86

Retaining Ring

Crankshaft,Seal 87

Bearing Outer

Rope Kit 88

Screw 89

Retainer 90

Muffler Kit 91

Muffler Attachment Spring

Screw

Ignition Module Kit

Screw

Cylinder

Part

NO.

530-03OO77

530--015768

530-O39136

530-347987

• 530"027517

530-069291

530 -029395

530-027569

530-010961

530-094189

530-069254

• 530-010964

530-015767

530-027511

530--015770

530 -0/5769

530 -015496

530-015788

53O-015796

STD541137

530-035464

530 -035166

530-O35178

. 530.--035106

530-035188

530-035031

530 --035028

+_t4

530-035151

530-035147

530-035036

530 -035142

530 -035141

530--035023

530--035208

530--035203

53O-035260

530-035185

530 -069276

530-015239

530-015717

530-027781

952-701612

Not Shown

530-029734

530-061348

Description

Spark Plug

Locknut

Flywheel Ass'y.

Washer

Fan Housing

Starter Pulley Kit

(Ind. #45)

Starter Spring

Starter Handle

PulIey Housing A_'y.

Clutch Washer

ClutchAss'y Kit

ClutchHousing

Screw

+Spacer

Screw

Screw

Scr_

• Spacer

Washer

Nut

*÷ Pump Gasket

"+ Pump Diaphragm

+ Inlet Screen

+ Inlet Needle Valve

+ Metering l._a,er Spring

+ Metering Lever

.+ Metering Pin :

I-MeteringDiaphragm

*+ Metering Diaphragm

Gasket

*+ Circuit Plate Gasket

Hi Speed Needle Spring

Hi Speed Needle

Idle Needle

•Idle NeedleSpring

Idle Speed Spring

Idle Speed Screw •

Carb. Kwik Repair FAt

( +Indicates Contents)

Cm'b. Gasket/Diaphragm

Kit (*Indicates Contents)

Engine Gasket Kit

(tIndicates Contents)

Screw

Screw

MufflerGuard

Spark Arrestor Kit

Instruction Decal

Carton

24

Page 25

INDEX

AC_RIF_ .................................. 10

ADJU_

Assist Handle .................................. 9

Carburetor.: .................................. 20

Line Advan_ .................................14

Module Air Gap ........._.....................2

Spark Plug Gap ................................2

"Farotde Cable ..................................8

AIR FILTER .....................................17

ASSFaMIILY

.Assist Handle ..................................8

Drive Shaft Housing ............................. 7

Preparation......................•..............7

Shield ........................................8

Throttle. Cable .................................8

Trimn_r Head .................................9

AUTOMATIC LINE FEED ........................ 14

CARBURETOR ADJUSTMENTS.. _................20

CARTON CONTENIS .............................6

COLD ENGINE STARTING .......................12

•CONTROLS ...........: ..........................2

CUTTING METHODS. ....."...................... 15

DRIVE SHAFT HOUSINGASSEMBLY ............. 7

ENGINE

Air Filter .......................................17

Carburetor ................,....................20

Controls ...................................... 2

Fuel Mixture .................................. I1

Starer Rope ................................. 18

Starting Instructions ............................. 12

Storage ..................................... 5.1(3

Trouble Shooting ...._............."............22

ENGINE OIL

Rado to Gasoline .............................. II

_; ndtto Use ........ .........._....11

FILTER, AIR ................................ 17

FLEXIBLE DRIVE SHAFT LUBRICA_ON ..........19

FtmL

Gasoline/Oil Mixture ....................."....'...II

Mixing Fuel ...................... i ........... !!

PouringFuel ............................ ......11

Safety........................................ II

Storage.......... _.......................... 10Jl

GASOLINE

Ratio to Oil ................................... It

Types to Use; notto Use ........................ II

GEAR BOX LUBRICATION .........................21

IDLE SPEED ADJUSTME/'_£.... ......................20

Advance ...................................14,22

Breaking ..........-......................... 17. 22

LengthtO Cut as Rep[acera,n{........... .........17

Operationtengthi .............................. 13

Replacement ................................... 16

Rewinding on Spool ............................ 17

Routing in Head ............................... 16

Safety......... ................................ 14

Sizeto Use :........................ . .........17

Welding onto Spool ......... ................. 13,17,22

Trouble Shoo6ng ...., ..........................17,22

LUBRICATION

Engitm ....................................... II

Flexible Drive Shaft............................19

Gear Box .....................................21

MAINTENANCE

Air Filter.....................................17

Carburelor .....................:..............20

Flexible Drive Shaft ............................19

Gear Box ..................................... 19

Safety......................................... 1'7

Starter Rope ..................................IS

Trimmer Head ................................16

TroubleShooting Chart.........................22

MODULE &IR GAP ...............................2

OIL, ENGINE

Patio to Gasoline .............................. II

EI_T ONTYPeSlt°Us_; not toUse ........................II

OP

.Advancing the Line ............................14

Mowing ..................... ,.................. I5

Pre43tperation Checks .......................... 12

Position .................................... :.. 9

Safety .................................. 13,14

Scalping .................................... :.. 15

Slatling the Engine ............................. 12

Sp_d.., ..................................... t3

Stopping the Engine ............................13

Sweeping.....................................15

Trimming _...................................15

PAR'IS LIST .................."............... 23

PRE-OPERATION CHECKS .......................12

PREWOUI_ SPOOLS .....-................•.......16

QUICK REFERENCE PAGE :......................27

REPAIR PAR'IS LIST ............................23

XAFETY-INSI'R_ON , .......... -

•SHIEU), ASSEMBLY ..............................8

SPARK P[J3G GAP ..2

SPARK ARRF_R ...............................6

SPECIFICATIONS ............................... 2

SPOOL

•Installation ............................: .......16

Maiitte4"xance..................................16

Prewound.....................................16

Rewinding......... ...........................17

STARTER ROPE REPLACEMENT .................18

STARLING INSTRUCTIONS ......................12

STORAGE .....................................5,10

THROITLE CABLE ASSEMBLY ...................8

TRIMMER HEAD

Assembly ................. _...........-....:,.g

Line Routing .................................. 16

Removal ....................................... 8

Maintenance ........................ "........... 16

TROUBLE StIOOTING CHART ...................22

WARM ENGINE STARTING ...................... 12

WARM ENGINE STaG _ RUNNING

OUT OF FUEL _ .............................13

WARNINGS AND SAFETY INSTRUCTIONS .....3 & 5

W__ " ...... 2

25

Page 26

f

QUICK REFERENCE PAGE

Read and FolloW AU Warnings, Safety Ins_ctions, and Operating lnsWuaions.

Failure to do so can result in serious injury.

"k

'Page No_

PREPARAT/ON .................................................... 3 b' 5

L Know all warnings and safety instructions in this manual.