Craftsman 358.797150 Owner's Manual

IMPORTANT MANUAL

Operator's

Manual

MODEL NO.

358.797150-32cc.

_7_ CuU_ _t_)

& WARNING:

Readtl__sManml

_ FonowAnWam_

and Saf_y Instructions.

Fa_TO Do So Can R¢_

Do-.Not Throw Away

Always Wear Eye Protection During Operation

,_,gJ i-CRR FTSMR

32CC GAS WEEDWACKER ®

2 Cycle Engine

"Assembly

• Operation

Fuel Mix 40:1

"Maintenance

• Repair Parts

Sears, Roebuck and Co., Hoffman Estate, IL 60179

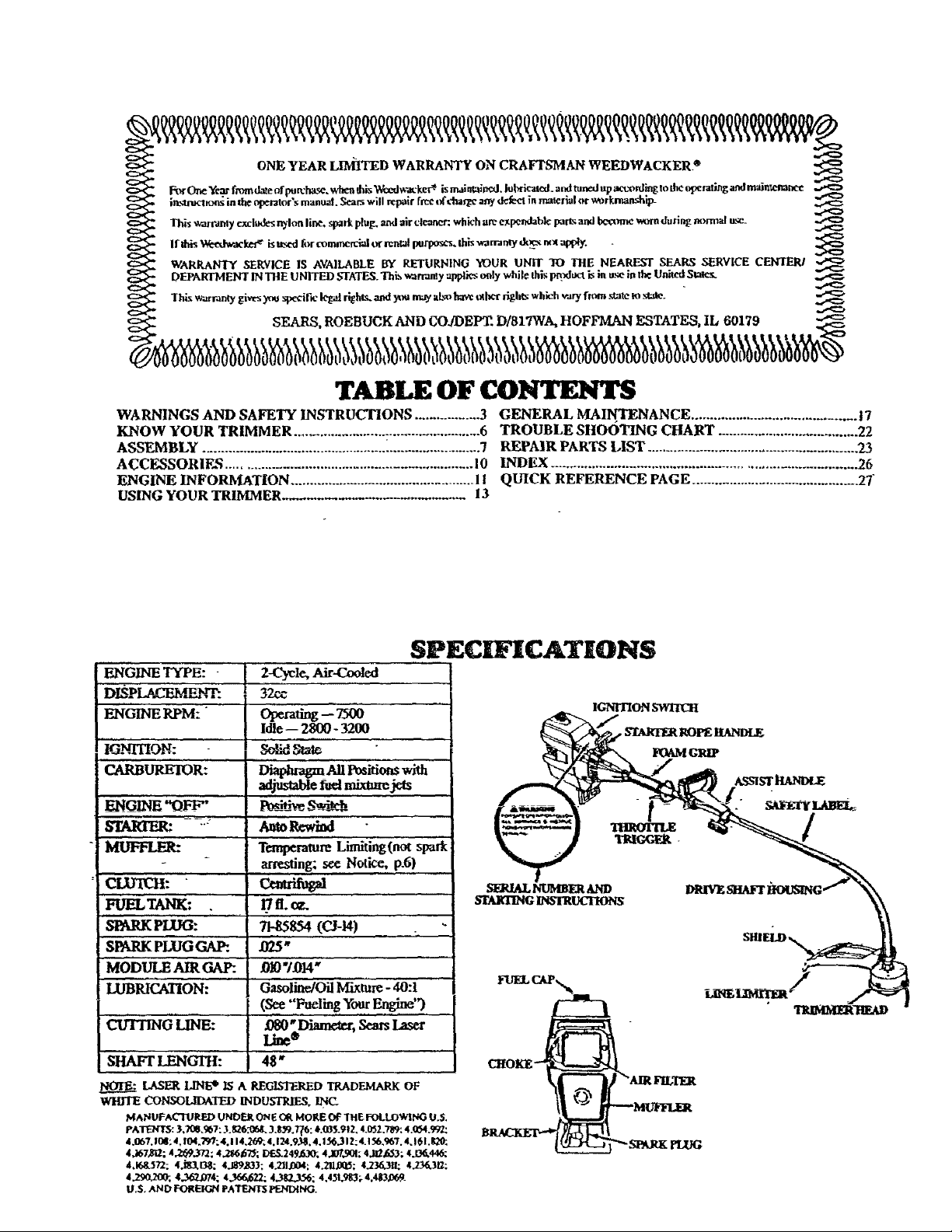

TABLE OF CONTENTS

WARNINGS AND SAFETY INSTRUCTIONS .................. 3 GENERAL MAINTENANCE .......................................... 17

KNOW YOUR TRIMMER .................................................. 6 TROUBLE SHOOTING CHART ..................................... 22

ASSEMBLY .................................................. :......................... 7 REPAIR PARTS LIST ........................................................ 23

ACCESSORIF_; ................................................................ I0 INDEX ................................................................................. 26

ENGINE [NFORRLATION .................................................. II QUICK REFERENCE PAGE ............................................. 27-

USING YOUR TRIMMER_ 13

,,, i iiiiiii i i imllll iiiiiiii i iiii iii i iiiii IIIIHIII I II I I IIIIII

L .m

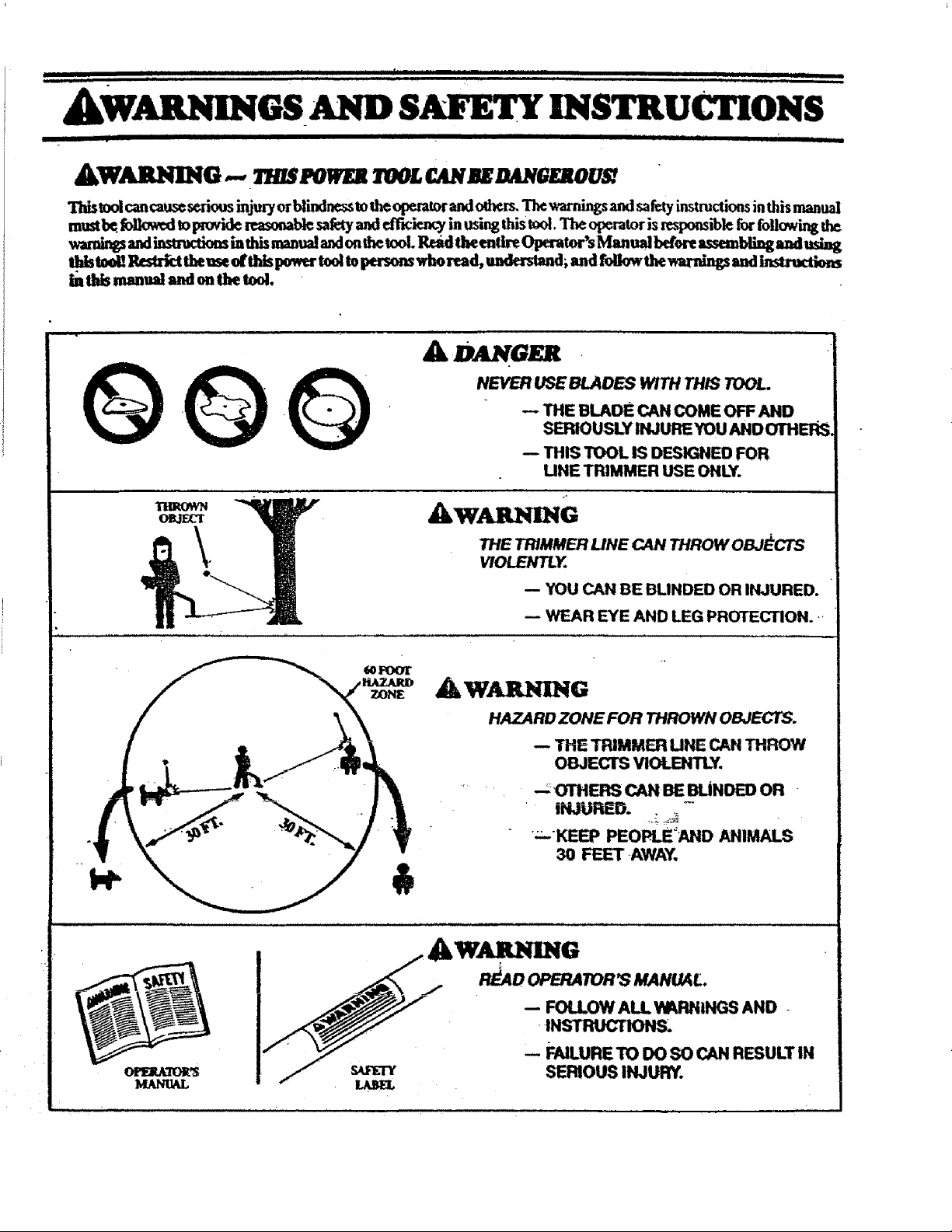

kWARNINGS AND SAFETY INSTRUCTIONS

_I I I IIWJll I ._

AWARNING -- _ PO_ TOOL__LNG/ZO/_

Thlstooi cancau_ seriousinjuryorblindncsstoth_opemtorandolh¢_ Thevmrn_ _ _ __ in_is _

musfl_ followed Ioprovide_asona_ saf_ andefficiency in usingthis u_ol.The ol_ra_r is _ _ foll_ _

wamin_ and_ inthis manu_andontl-ae_ool.Readtheenflre Operator'sMan_ _ __ _

lhislooU l_r_ theuse oftl_s powertooltopersons whoread, undersland;and follow _ _ _ _

Infl_rsmanual and on the tool

A DANGER

NEVER U_'BLAD_ _ _ TOOL.

-- THE BLADE CAN COME OFF AND

SERIOUSLY INJURE YOU AND OTHER_

-- THIS TOOL IS DESIGNEO FOR,

LINE TRIMMER USE ONLY.

Aw (;

THE TRIMMER LINE CAN THROW OBJ_'CTS

VIOLENTLY.

-- YOU CAN BE BUNDED OR INJURED.

-- WEAR EYE AND LEG PROTECTION..

ZONE

AW_G

HAZARD ZONE FOR THROWN OBJECTS.

-- THE TRIMMER LINE CAN THROW

OBJECTS VIOLENTLY.

--_OTHERS CAN BIEBUNOED OR -

iNJURED.

_-KEEP PEOPLEAND ANIMALS

3O FEET-AWAY,

RF-AD OPERATOR "SMANUAL.

--+-!I_WRUCTIONs.FOLLOWALL PI_FINIHGS AND +

,- _/ -- FAILURETODOSOCANRESULTIN

/ smouslmu .

................................................. ,,,,, ,,,,,HH ,|,, I , ,,,,, , , ,,I --

& WARNINGSANDSAFE INSTRUCTIONS- .

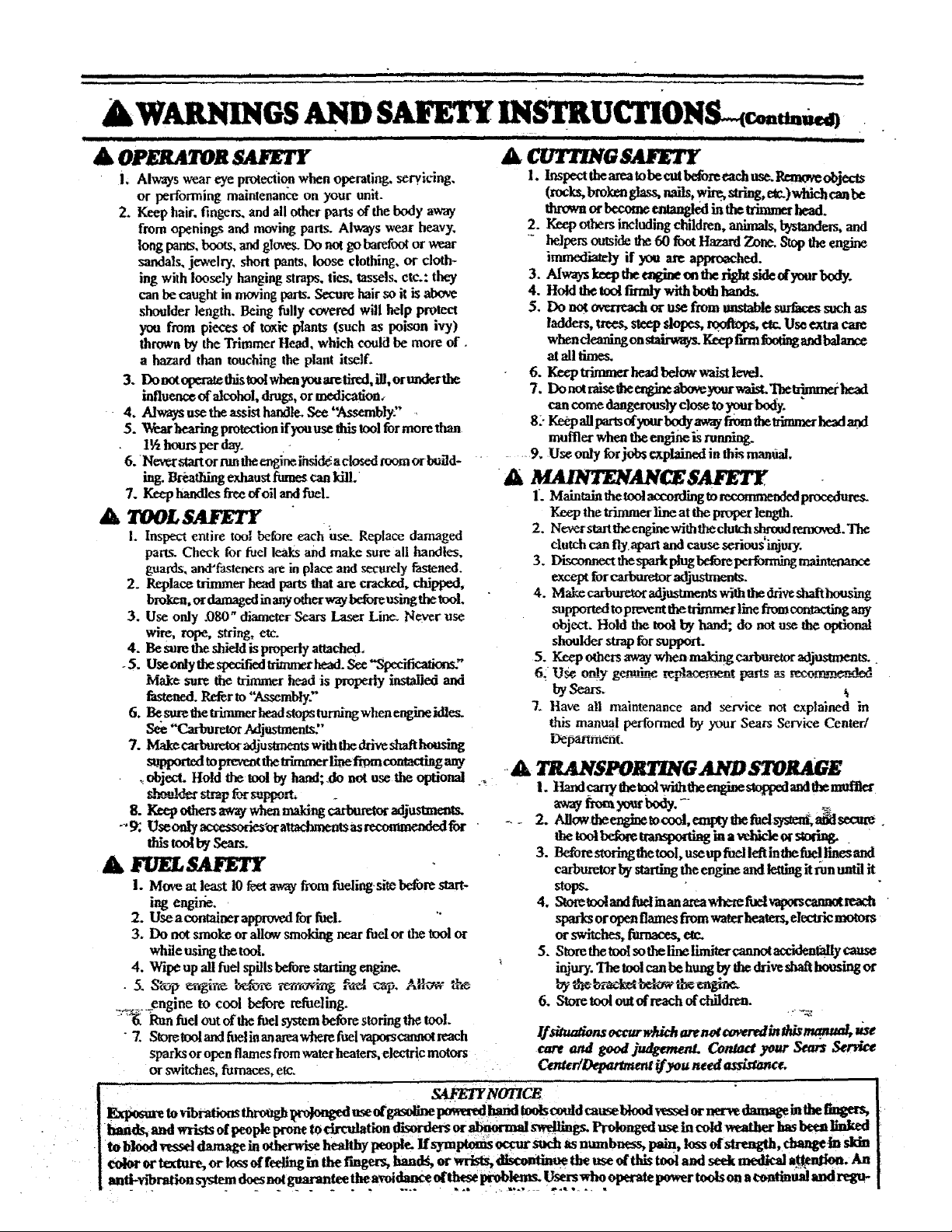

A OPERATOR SAFETY

I. Always wear eye protectionwhen operating, se_icing.

or performing maimenance on your unit.

2. Keep hair. fingers, and all otherparts of thebody av,W

from openings aM moving parts. AIv,-ayswear heavy,

longpants, boots,and gloves.Do not go barefootorwear

sandals, jewelry, short pants, loose clothing, or cloth-

ing with loosely hanging straps, ties. tassels, etc.: they

can be caught in movingparts. Secure hair so it is above

shoulder length. Being fully _red will help protect

you from pieces of toxic plants (such as poison ivy)

thrown by the TrimmerHead, which could be more of.

a hazard than touching the plant itself.

3. Donot_a-at_ thistoolwhea_a areti_, in, ortraderthe

influenc_ of alcohol, drugs,or uxxlication,

- 4. Alwa_ use the assist han01e.See 'l_ssembly?'

5. Wearhearing protoctionifyouuse thistoolfor more than

A ¢U'/T/NG_

1, hspect thearea tobe cut hefore eachuse. 1_ _]ects

(rocks,brokenghss. nails,wir_ string,e_)whichcanbe

• rowa or b_om_ entaaglddia the trimmer head.

2. Keepothers including children, animals, bys_gters, and

hejpersoutsidethe60 footHazardZone.Stoptheengine

immediately if y0u are ap_oached.

3. Alwayslmepthe¢r,gineontherlghtskleofyourhedy.

4. Holdthetoolfirmlywithboth_

5. Do not _ or use from unsm_ surfaces such as

ladders,trees, steep slopcg _ etc. Use exwacare

whendeaning onstairwa_ Keepfirm_andbalance

at alltimes,

6. Keeptrimawa"headbdowwaistl_vel.

7. Do not raise _',,€engimabovcyour _ist, Theuimn_ head

cancorr_ 0aagenmsty close toy0ur body. "

muffler whentheen#ne isrunning.

1½ hoursper day,

6.Nevtrstartornmtheergir_ihsid_$aclosedmomorbu_d- " ...... 9. Use only forjob_ cxplained in thismamiaL

ing. Bri_athiagexhaustfumescanldll. A _AL_S_L.Ik"Jg_,

7. Keep handles freeofoil and fuel.

I. Inspect entire tool beforeeach use. Replace damaged

parts. Check for fitelleaks and make sure all handles.

guaM.s,and'fasteners ace in place and securely Fastened.

2. Replace trimmer head parts that are cracked, chipped,

brola.m,ordamaged inanyotherwaybeforeusingthe tool

3. Use only .080" diameterSears Laser Line.. Never use

wire, rope, string, etc.

4. Be sure the shield is properly attached.

_5.Useo_ thespech_uimmerhead.S_ _"

Make sure ff_ _immer headis properly instal|edand

fastened. Referto "Assembly"

6. Be.surethe trimmerheadstopsturningwhen engineidles.

See "CarburetorAdjustments."

7.Mal_ carhuct_adjusanentswiththedriveshaRhousing

supported topreventthe trimmerline flora contacting any

objecLHold thetoolbyhand;.do notusetheoptional

8. Xeq,othmmwywhenma_ c_-bum__justm_as.

-9; Use onty accessor_r a_achmeatsas recom_aded for

this toot bySear_

& FI,'I SAggrl"

!. Move at least 10feetawayfrom fueliegsit_ before smrt-

iag engifie.

2. Useacontainer_ forfuel.

3. Do notsmok_orallowsmokiagnearfuelor thetool or

whileusingthetoot.

4.Wipeup allfuelspillsbeforestartingeagine.

.......enginetocoolbeforerefueling.

•"-6_Run fuelout of thefiwJsystem before storing the tool.

"7. Storetoolandfuelinanmeawherefuelvaixxscannotreach

sparksor open flamesfromwater heaters, electric motors

or switches, furnaces, etc.

l. Maintaia thetoolaccordingto_ procedures.

Keep the trimmerline at the proper length.

2. Neverstarttheenginewith theclutch shrtod remove. The

clutchcan fly.apartandcause serious'injury.

3. _ thesparkplugheforeperfom_ maht_mnce

exceptfor _r adj_ts.

4. Make carburetor adjustments with the driveshaftho_ing

supported toprevent the trimmerline fromcotaacting any

object. Hold the tool by hand; do not use the optional

shoulder strap for support.

5. Keep others away when making carburv,or adjumnents.

6_ L]_ o_ly genuine tep!___t rm_q__ recom_men.'!,_o5

bySears.

7. Have all maintenance and service not explained in

this manual performed by your Sears Service Center/

D_partment.

•&, TRANSPORTING AND STORAGE

L _____m_k_

_f__.-

t_ _<,It_r_ _ ina_el_deor_a_

3. Beforestming thetool, useup fitelleft inthefuel lines and

carbu_ by starting theengine and lettiagitrununtil it

stops.

4. _ofe rodand furlinanarea _ fuetwapotscannommch

sparksoropenflamesfromwater heaters,electric motors

orswitches,farnac_ etc.

5. Store the tooIsu theline limitercannotaccidentallycaase

injury. The toolcan be huagby the drivesha_ h_ing or

6. Storetool out ofreach ofchildren.

lf si_at_ns ocrurw_,ch are not co_eredln_ts _mml, _se

care and good _¢men_ Contaa your Sea_ _er_ce

C.ntedt_ i_youneedasslstimce.

I _ to,'bratlonsthr_agh_,o!on_ useor__,hand _ .c_.dcau_bloodvessdornervedamagem_ _

I ott t ,

IIIIII I 1111 _ l ill i i iiiiiiiii i ii L ii + iiiiiiiiiiiiiiil l i ulm,,1111ul f " IL,I111'II 11 11 1 111 . ......................

-mow mum'rammvma¸

I II lllllJ J I I II IIII IIII I I I L lllllltllll_ _

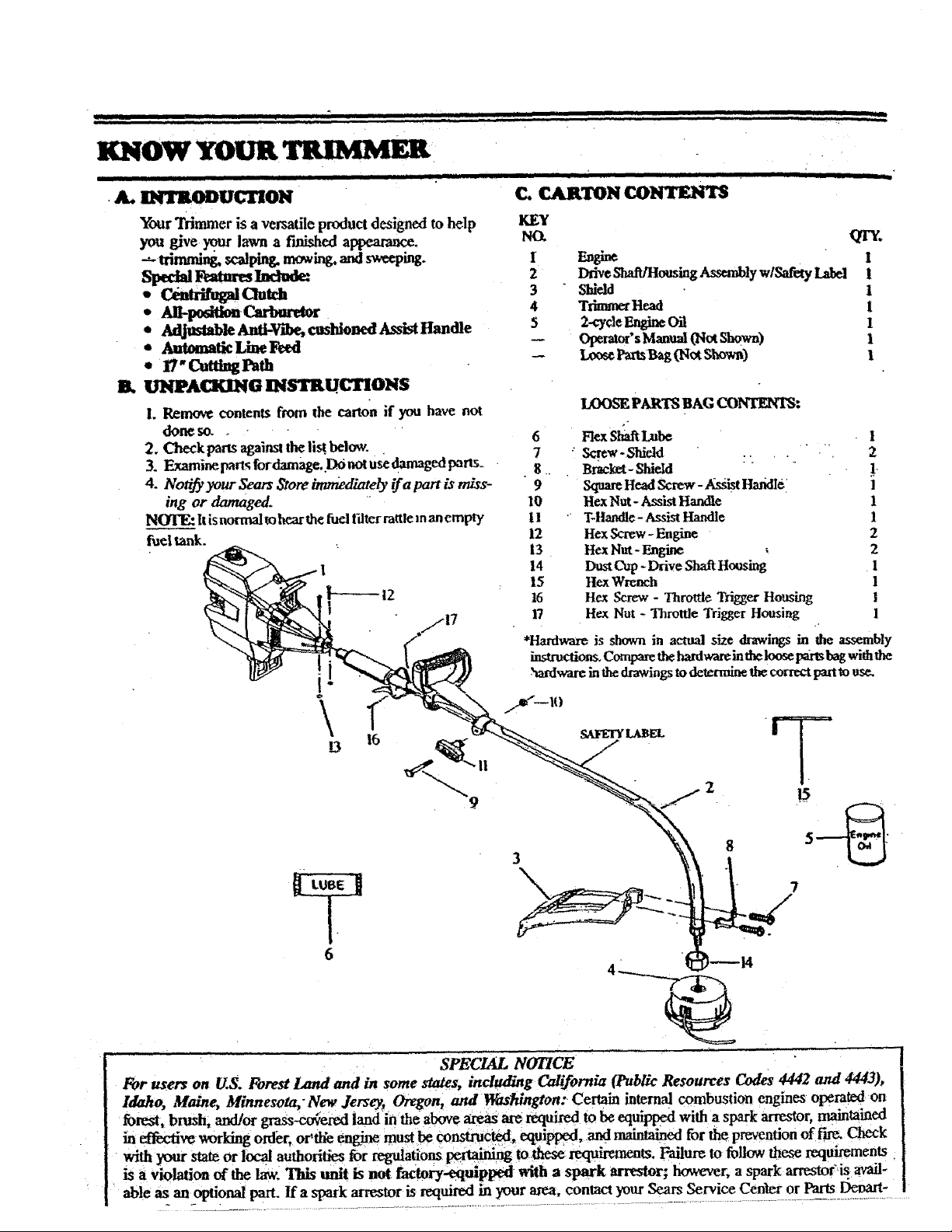

•L INTRODUCTION

YourTrimmeris a versatile product designed to help

you give .yma-lawna finishedappearance.

trimmingscalping, sweeping.

spec veat.r=s

• _ O.tch

• Albp0sitimCartmr=_

• AdjustableAnfl-Vibe,cushiemaedAssistltandle

• Autmnatic Line Feed

• 17-C.tangl"ath

II. UNPACKING INSTRUCTIONS

1. Remove contents from the carton if you have not

doneso. + •

2. Check vans againstthe li_ bekr,,v. •

3. Examineparts fordamage..D6 notuse damagedpans_

4. Notify your Seam Store immediately if a part is miss-

ing or damaged.

NOI'E: Itisnormal to hearthe fuel l'dterrattlem anempty

fuel tank.

J / _ i i ii iiiiiii I IIllllllllll Illllll

C. CA1L'rON C.O_

KEY

No+ fir,,,.

I Eag_ 1

2 Ihive Shafl/llousing Assembly wlSafety Label 1

3 Shield 1

4 Ts_r_ Head I

5 2-.cydeF__ Oil 1

-- Opemor'sManual_ Shown) 1

-- LoosePamBag _ot Show_) t

_ PARTS BAG G3_:

6 ' FIexShaflL.bc

7 : Screw-Shield :. _ .

8 .. Bracket+Shidd

9 SquareHeadScrew- Ks._istHafi_el

10 Hex Nut- Asslst Handle

11 + T-Handle- Assist Ha.,_e

12 HexScrew - Engine

13 HexNut - Engine +

14 DustCup +IMiveShaR Housing

15 Rex Wrench

16 Hex Screw - ThrottJ¢ Tdgger Housing

17 Hex Nut + Throttle Trigger Housing

1

2

1

1

1

2

2

I

1

I

1

!

\

D

6

16

*Hardware is shown in actual size drawings in the assembly

insUuctions_Compare the hatdwar_ imhe 1oo_ pare hag wi6__e

-hardwarein thedrawingsto determine6_ecorrect Fartto use.

7

=

SPECIAL NOTICE

For users on U.$. Forest Land and in some states, including California (Public Resources Codes 4442 and 4443),

Idaho, Maine, Minnesota,'Ne_ Jersey, Oregon, and Was_ngtom Certain internal combustion engines operated on

forest, brush, and/or grass-coqered land in the above areas ar_ required to be equipped with a spark me__or, maintained

in effective vmrking order, or'th% engh'm:must be construct_, equipped, and maintained for the pr_eation of fire. Check

your state or local authorities for tegu!ations pe_ toLt_ requirements+ Failur_ to follow these requirements

is a violation of the law. This unit is not factory-equipped with a spark arrestor; however, a spark arrestor'+isavail+

able as an optional part+ If a spark arrestor is required in your area, contact your Sears Service Center or Parts _-

......................................................................

II Illl!lllllllllllllll II Ull Illllll Ill I II Ill Illll - I I

I

_tslmltm_ forthe_)

i I I I JllllllIItllltIItIllll I Ill I I I I

L itqlglP_

_ _'s°M_ z_s_ d_.Zof_dtohctp_u

.asScm_€the toolandio provideitssafeoperation, it is

_ dm _ readtl_ endremanual_ I_omc

familiar_iththetooli_.foleyoubeginassembly.

H .......... i!,.i

H

ii i i

B. ASSEMBLY STEPS

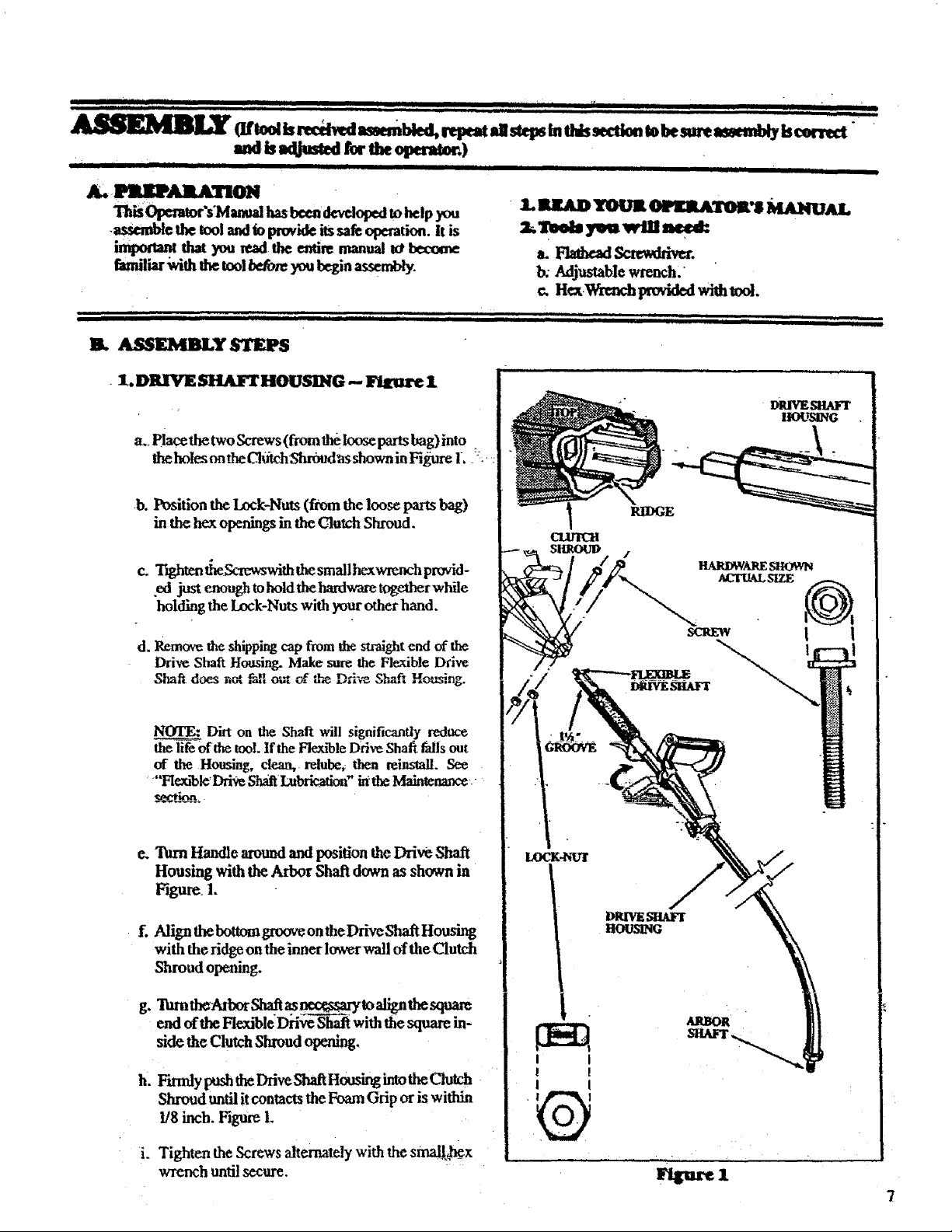

• 1. DR/VE SHAI_ HOUSING .-- Figure 1

a.. Piacethe two Screws (from the loose parts bag) into .

theholesontheClmchShr6udasshowninFi_e 1. L

.b.

Position the Ix_k:Nuts (from the loose parts bag)

in the hex openings in the Clutch Shroud.

c. T_hten tim_wwswith thesmall hexwrench provid-

ed just enough to hold thehardware together while

holding the Lock-Nuts with your other hand.

d. Remove the shipping cap from the straight end of the

Drive Sha_ Housing. Make sure the Flexible Dri'_x:

Shaft d,_ not f_l out r_,_-_ _

NOTE: Dirt on the Shaft will significantly reduce

_of the tool. If the Flenu'bleDrive Shaft fails out

of the Housing, clean,, relube_ then reinstall. See

Ftexa'bleDri_?eShaft Lubricalicm" ia the Maintenance .-

r_-t.ion.

e.

g_

h_

i.

"lMmHandle around and position the Drive Shaft

Housing with the Arbor Shaft down as shown in

Figure. 1.

Align the bottom glXXWeon the Drive Shaft Housing

with the ridge on the inner lower wall of the Clutch

Shroud opening.

_theAex,rS_. _ _to ati_thesqua_

end of the FlexibleDriveShaft with the square in-

side theClutch Shroud opening.

Shroud until it contacts the Foam Grip or is within

1/8 inch. Figure 1.

Tighten the Screws alternately with the smal[kcx

wrench until secure.

II iii II IIII II

I. luta_ l'OOIt _'g Ma.tetlal.

=,a'=a, my.

b. Adjustable wrench."

c. Hot,Wrtnch provided with tool.

,Ill I I ,,I, I ,,ll II I

II IIIII Illll_

I I

! !

I I

DmV_SnAlzr

HO_._ING

RIDGE

Igigtlre 1

7

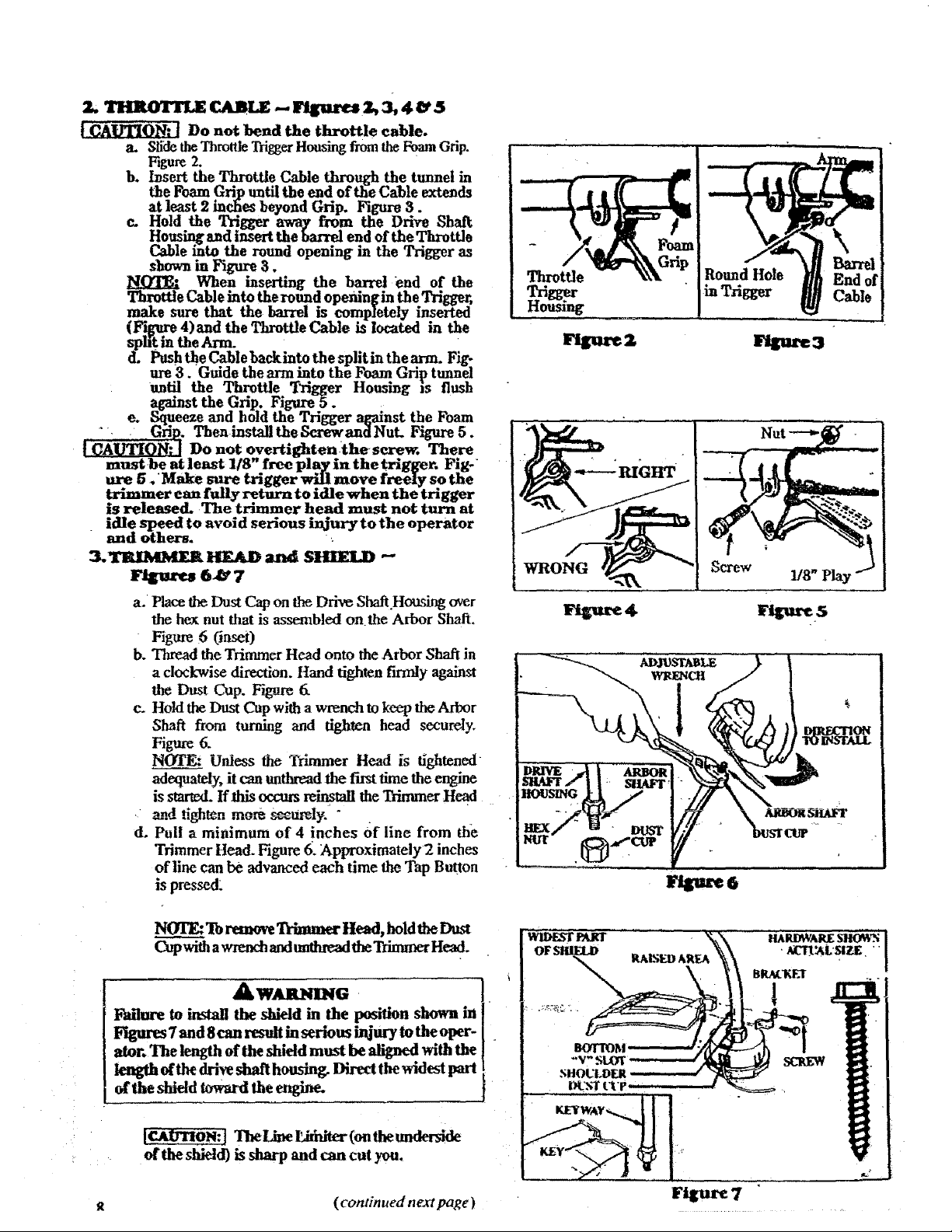

iCAUTION: | Do not bend the throttle cable.

a. Slid_ theThrottleTrigger Housing from the Foam Grip. "

Figure 2. . ,

b. Insext the Throttle Cable through the tunnel m

the Foam Grip until the end of the Cable extends

at least 2 indies beyond Grip. Figure 3.

c. Hold the Trigger away from the Drive Shaft

Hou_ing and insert the barrel end of the Throttle [

C_le into the round opening in the Trigger as - Foam

!

shown in l_ure 3..

When insexting the barrel end of the Throttle - \\X - Round Hole nd of

make sure that the barrel is completely inserted

(I_.._tre 4)and the Throttle Cable is located in the

split m the Arm. IPigu_ _ _'1L_3

d. Push the Cable backinto the splitin thearm. Fig-

ure 3. Guide the arm into the Foam Grip tunnel

until the Throttle Trigger Housing is flush

against the Grip. Figure 5.

e. Squeeze and hold the Trigger against the Foam

_ GHp. Then install .th.e_and Nut Figure 5. __

] CAUTION" ] Do not overtzghten the screw. There

must be at least 1/8" free pla_. in the tagger. Fig-

_er can fully return to idle when the trigger

xs released_ The trimmer head must not turn at __ _+--_.%_

idle speed to avoid serious injuryto the operator "::?_

and others.

_dfl_tEi: HE&

FJlDII"q_ 6-,_ 7 WRO Screw 1/8" Play "_

3,TRIMME_ HEAD mn_ SHIELD -"

a. PLacethe Dust Cap on the Drive Shaft.Housing over

the hex nut that is assembled onthe Arbor Shaft.

Figme 6 Onset)

b. Thread the Trimmer Head onto the Arbor Shaft in

a clockwise direction. Hand tighten firmly against

the Dust Cup. Figure 6_

c. Hold the Dust Cap with a wrvnch to keep th¢ Arbor

Shaft from turning and tighten head secuwly.

Figure 6.

NOTE: Unless the Trimmer Head is tightened

adequately, it can unthread the first time the engine

is started. If this occurs reinstall the Trimmer Head

• a.-A tighten more seeu,_Iy. "

d. Pull a minimum of 4 inches 0f line from the

Trimmer Head. Figure 6. Approximately 2 inches

of line can be advanced each time the Tap Button

is pressed_

Figure 4 Flgurt S

_6

NOI_ To remo_ Trimmer Head, holdthe Dust

Cupwithawrench aadtmthreadtheTfimmer Head.

_WARNING

Failure to imtali the shield in the position shown in

Figures 7 and 8 can result in serious injury to the oper-

ator. The length of the shield must be aligned with the

of the shield toward the engine.

L_o.:l TheL_e 'r_i_ (onthe_

otthe shietd) is sharp and vm cut you.

( continued next page )

€. Match the Key (Raised area)on the Shield with the

Keyway ("V" slot) on the Drive Shaft Housing.

l_gure 7.

f. Restthebotto'moftheShield ontopofthe shoulder

of the Drive Shaft Housingabove the Dust Cup.

NOTE:Ihe boaomofthe Shield must rest on topof

the shoulder of the Drive Shaft Housing.

g. lnstatlthe_ asshownin FIgure 7.

NOTE:ItiseasiertostarttheScrewswitha _-

driver and finish ti&htcningwith a 3/8" w_nch.

h. T_m:n the 5crows evenly and securely.

NOTE: A small space may be left between the "

Bracket and the Sl'deld when hardware is fully

Eigh ae .

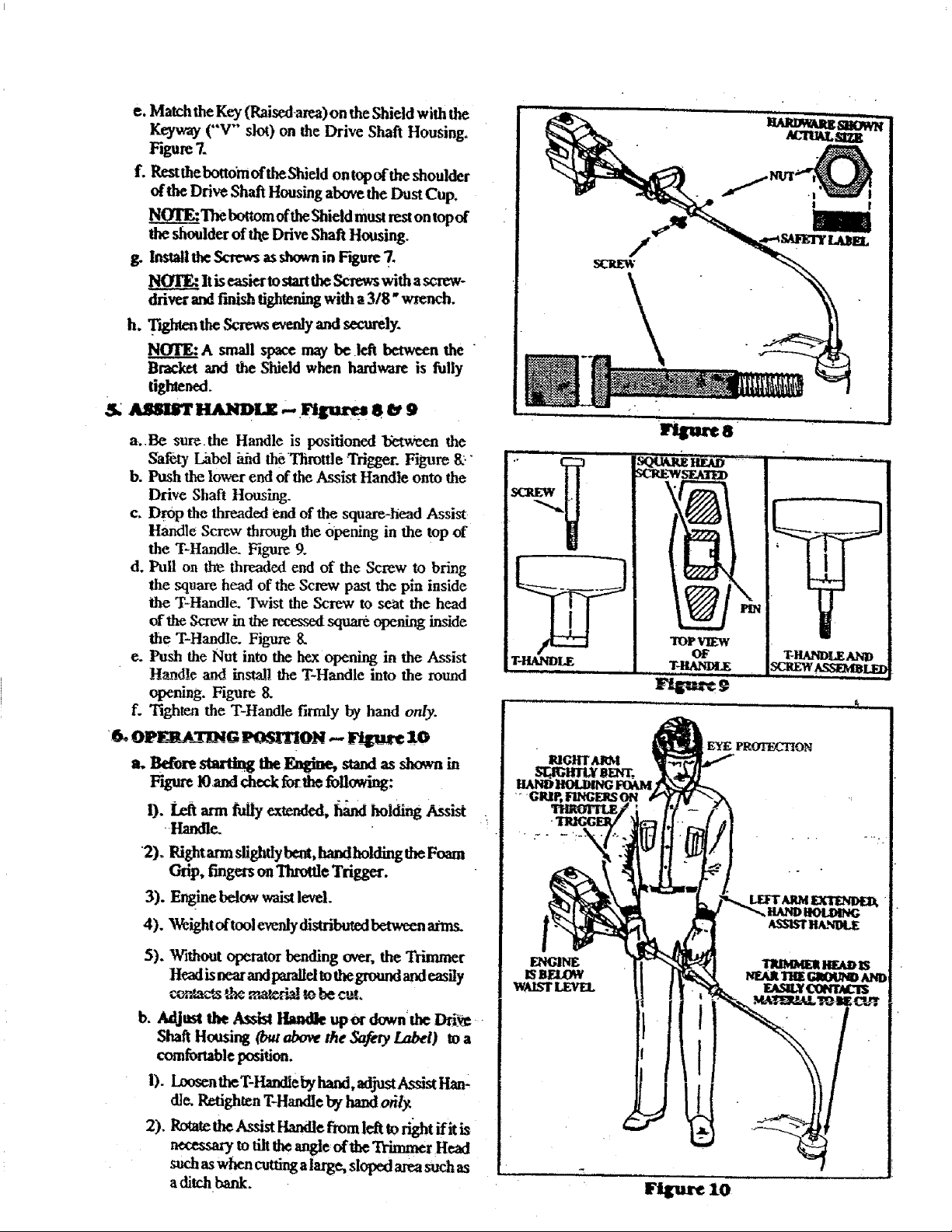

5. _swr_-,rtzu_ _ a e_9

a. Be sure.the Handle is positioned bi_ween the

Safety ISabel hind theTlirc_fleTrigger. Figure 8:."

b. Push the lower end of the Assist Handle onto the

Drive Shaft Housing.

c, Drop the threaded end of the square-head Assist

Handle Screw through the opening in the top of

the T-Handle. Figure 9.

d. Pull on tl_ threaded end of the Screw to bring

the square head of the Screw past the pin inside

the T-Handle. Twist the Screw to seat the head

of the Screw in the recessed square opening inside

the T-Handle. Figure 8.

e. Push the Nut into the hex opening in the Assist

H_n_dle and instal! the T-Handle into the round

opening. Figure 8.

f. Tighten the T-Handle firmly by hand only.

6. OPEKA_T_G POSITION .- _

a. Bd_ starting the Englne, stand as _ in

F_ 10and check for the follovdng:

l). t_ arm_ ex_ndea,_ hol_ Assist

•Handle.

2). Rightarm slighdybent, handholding the Foam

Grip, fingers onThrottleTrigger.

3). Enginebelo_vwaist level.

4). Weight oftool evenly distributed between _

5). Without operator bending over, the Trimmer

Headis near _axlparalId to theground and eas_y

b. Aaljest tl_ Asdst _ up er downtl_ D_

Shaft H_ng (but above the Salty Label) to a

comfortable position.

1). Inosen the T-Handleby hand, adjust Asdst Hart-

die. Retighten T-Handle by hand oth_

2). _ fl_eAssist HaMle from le& to right flit is

necess_ to tilt _heangle ofth_ Trimmer Head

such as when curling a large, sloped area such as

aditchbank.

lrllurcS

TOPVIEw

OF

T_

r_p,_r_zo

Loading...

Loading...