Page 1

IMPORTANT MANUAL

Do Not Throw AwaY

g' _/ARS

operator's

manual

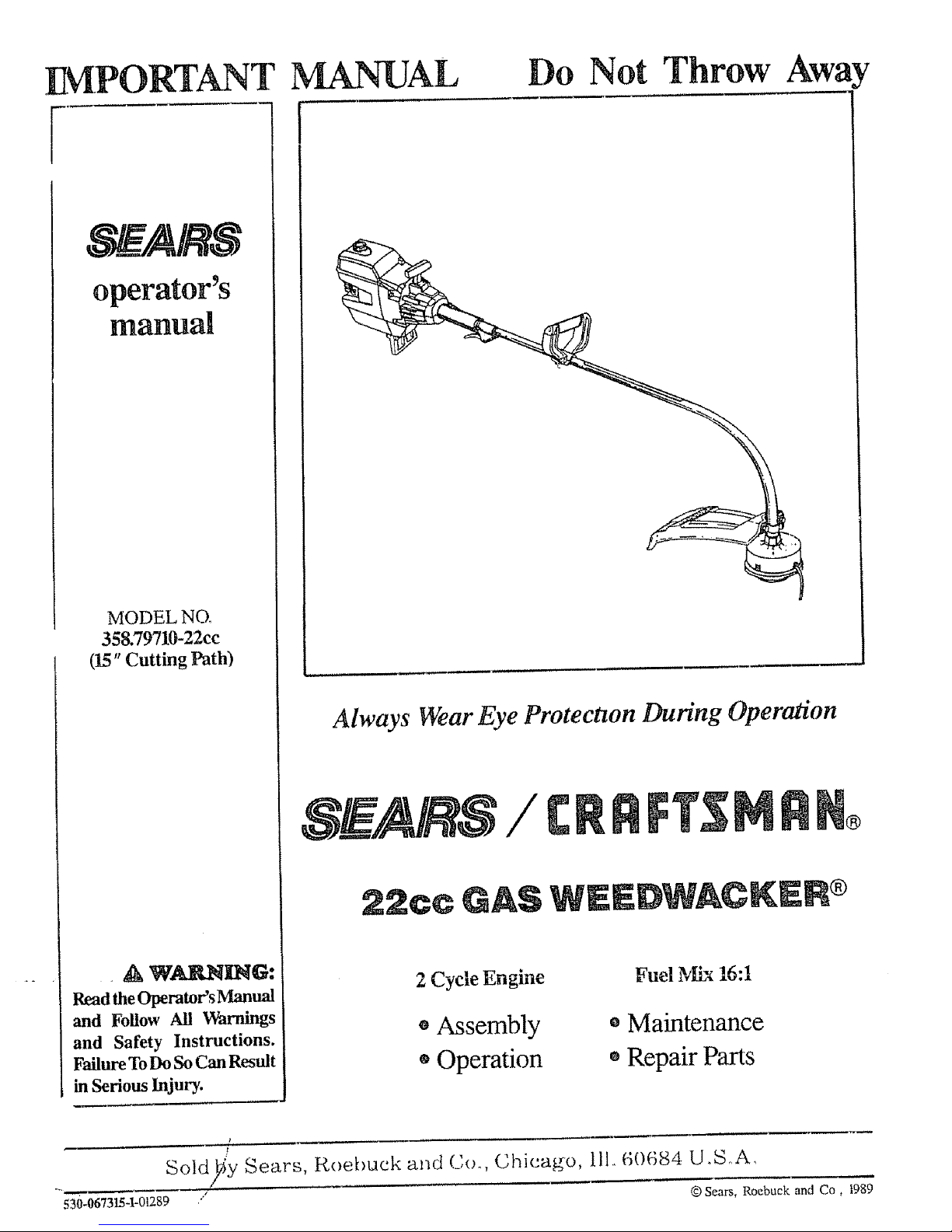

MODEL NO.

358.79710-22cc

(15" Cutting Path)

. A WAR_ING:

Read theOperators _hnual

and Follow All V_hrnings

and Safety Instructions.

FailureToDoSoCan Result

inSerious Injury.

Always Wear Eye Protection During Operation

C

22cc

2 Cycle Engine

• Assembly

®Operation

Fuel Mix 16:1

o Maintenance

e Repair Parts

Sold _y Sears, koebuck and Co. Chicago, ill., 60684 U_S..A,

"4 ff_ I

530-067315-1-0!289 / © Sears, Roebuck and Co, I989

Page 2

ONE YE.__RLIMITED WA_qRANTY ON CRAFTSMAN WEEDWACKER ®

ForOneYearfromdateofpurchase, whenthisWeedwacker ® ismalntained,lubricated,andtunedupaccordingtotheoperating

and maintenance instructions in the operator's manuat. Sears will repair fl'ee of charge any defect in material or workmanship "'_<:_

This warranty excludes nylon line. spark plug. and air cleaner; which are expendable parts and become worn during normal

use

If'this Weedwacker _ isused forcommercial or rentalpurposes, this warranty applies foronly 30 daysfrom the date of purchase,

WARRANTY SERVICE IS AVAILABLE BYCONTAC_ING IHE NEAREST SEARS SERV1CECENTERJDEPARTMEN 1

IN THE UNITED STATES This warranty applies onty while this product is in use in the United States ,--,_=,

This warranty gives you specific legal rights, and you may also have other rights which vary from state to state

SEARS ROEBUCK AND CO DEP"f 698173[ASEARSTOWERCHtCAGO. Ik 60684

TABLE @F

WARNINGS AND SAFETY INSTRUCTIONS

KNOW' YOUR TRIMMER

ASSEMBLY .

ACCESSORIES

ENGINE INFORMATION

A Fueling Your Engine

B Pre-Operation Checks

C Starting Instructions

D, Operating Instructions

USING YOUR TRIMMER

A Trimmer Safety

B Trimmer Line Advance

C Cutting Methods

D Line Replacement

3

6

7

I0

I1

11

12

12

13

13

14

14

I5

16

GENERAL MAINTENANCE 17

17

A Maintenance Safety

B Air Filter 17

C Starter Rope 18

D Flexible Drive Shaft Lubrication 19

E Carburetor Adjustments 20

F Storage 22

GA'frouble Shooting Chart 22

REPAIR PARTS LIS'I- 23

INDEX 26

QUICK REFERENCE PAGE 27

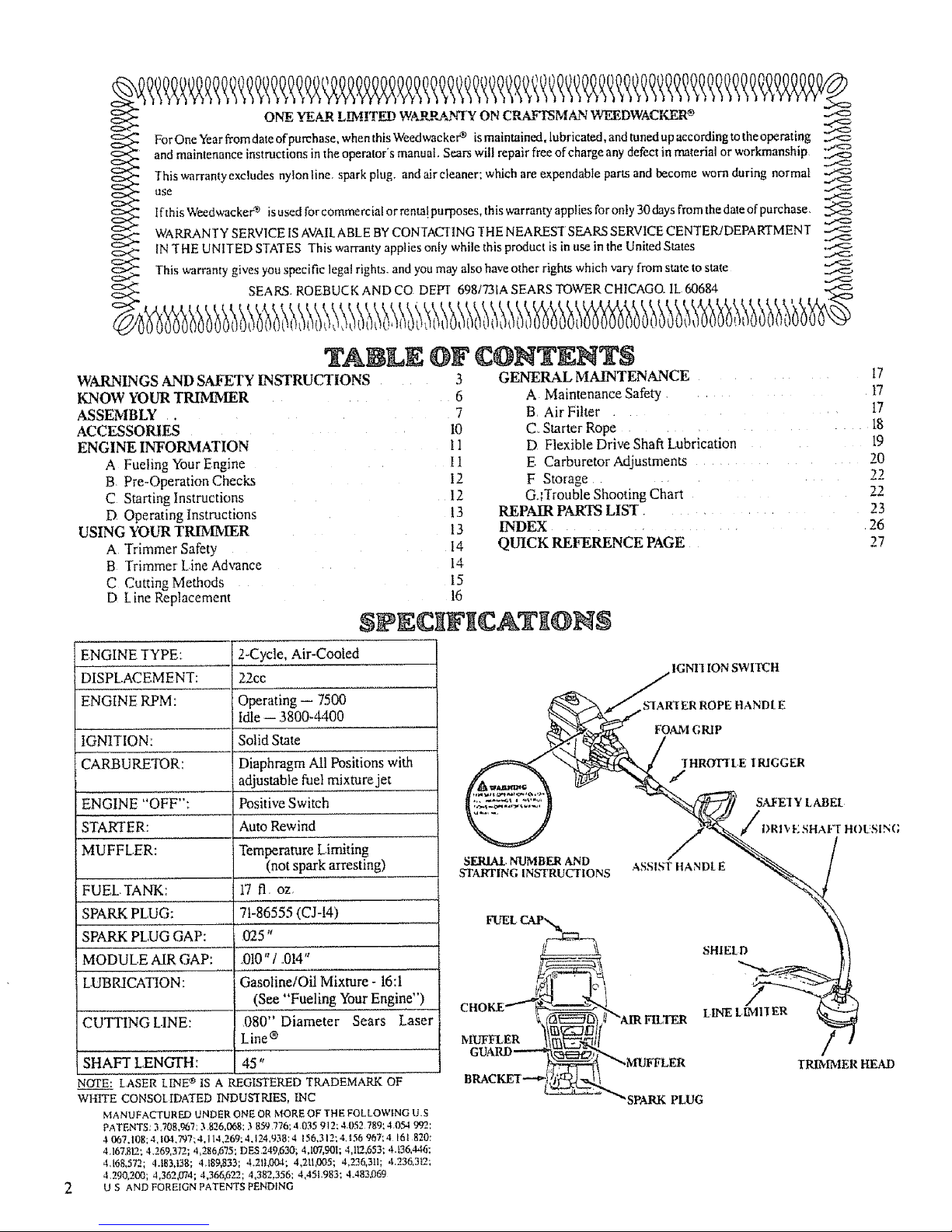

ENGINE TYPE:

DISPLACEMENT:

ENGINE RPM:

IGNITION:

CARBURETOR:

ZNGIN -0@:::

STARTER.:

MUFFLER:

FUEL, TANK:

SPARK PLUG:

SPARK PLUG GAP:

MODULE AIR GAP:

LUBRICATION:

CUTTING LINE:

$tPN ;gNgCAT [@NN

2-Cycle, Air-Cooled

22cc

Operating- 7500

Idle -- 13800-4400

Solid State

Diaphragm All Positions with

i adjustable fuel mixture jet

Positive Switch

Auto Rewind

Temperature Limiting

(not spark arresting)

t7 fl, oz,

7t-86555 (CJ-I4)

025"

_010" / ,014"

Gasoline/Oil Mixture- 16:i

(,See "Fueling You[Engine")__

080" Diameter Sears Laser

Line ®

SHAFT LENGTH: 45"

NOTE: LASER LINt_ IS A REGISTERED TRADEMARKOF

WHITE CONSOLIDAfED INDUS'IRJES, INC

MANUFACTURED UNDER ONE OR MORE OF THE FOLLOWING U.S

PATENTS: 3,708,967:3 826,068; 3 859 776:4035 912: 4,052789; 4054 992:

.I 007.108;4,104.797:4,11.t,269:4,124,938:4 156.312;4,156967;4 16t 820:

4,167,812; 4,269,372; 4,286,6"/5; DES 249,630; 4A07,901; 4,112,653: 4A36,446;

4,168,572.; 4.t83,138; 4,!89,833; 4.21|,004; 4,211,005; 4,236,311; 4,236,3L2;

4290,200; 4,362,074; 4,366.622; 4,382,356; 4,45t.983; 4.483,069

O S AND FOREIGN PATENTS PENDING

STARTING INSTRUCTIONS '*........... * ...... _/

"%,

SHIEtD 11

TRIMMER HEAD

B

'SPARK PLUG

Page 3

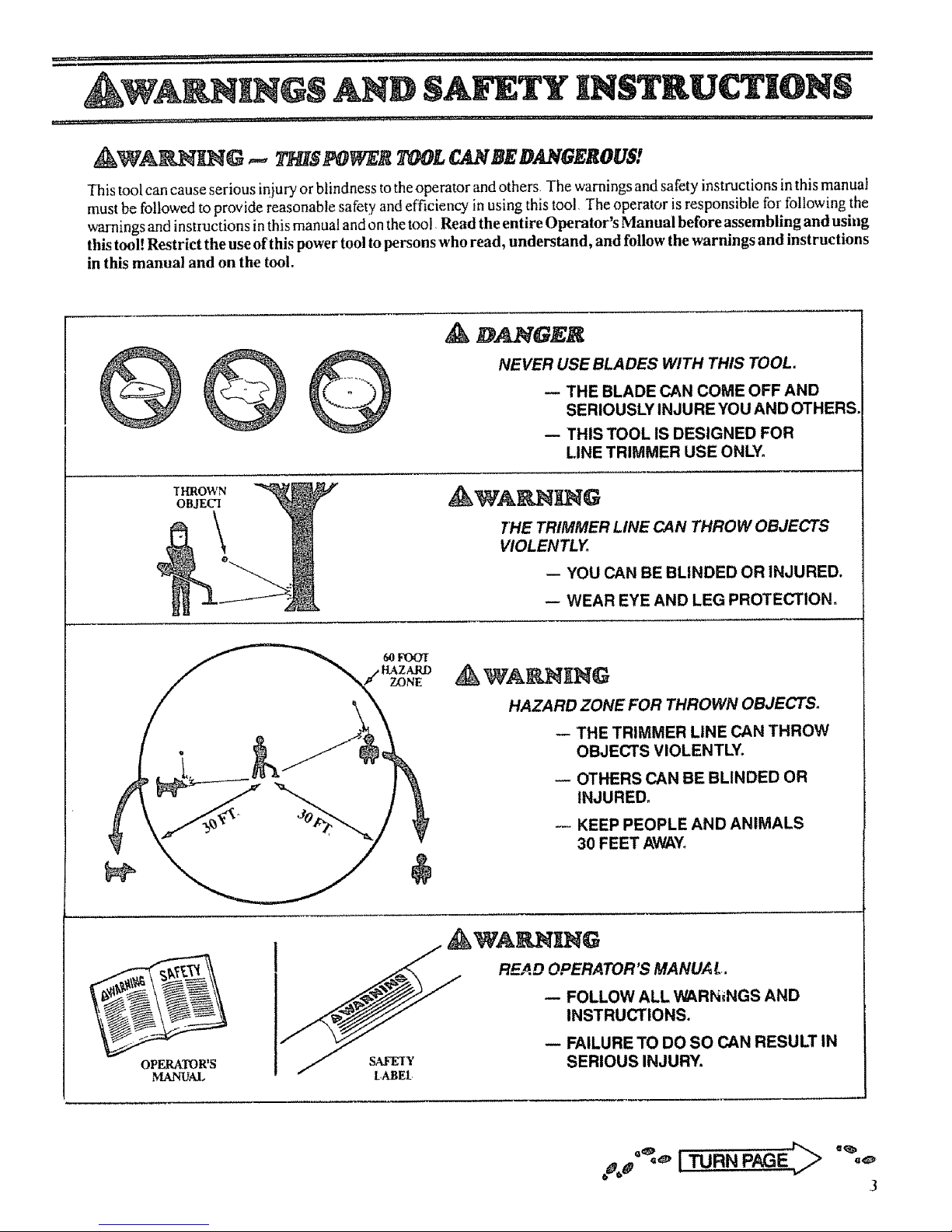

WA INGS AND SAFETY

This tool can cause serious injury or blindness to the operator and others, The warnings and safety instructions in this manual

must be followed to provide reasonable safety and efficiency in using this tool, The operator is responsible for following the

warnings and instructions in this manual and on the tool. Read the entire Operator's Manual before assembling and using

this tool! Restrict the use of this power tool to persons who read, understand, and follow the warnings and instructions

in this manual and on the tool.

A DANGER

NEVER USE BLADES WITH THIS TOOL.

-- THE BLADE CAN COME OFF AND

SERIOUSLY INJURE YOU AND OTHERS.

-- THIS TOOL IS DESIGNED FOR

LINE TRIMMER USE ONLY,

THROWN

OBJECI

THE TRIMMER LINE CAN THROW OBJECTS

VIOLENTLY.

-- YOU CAN BE BLINDED OR INJURED.

-- WEAR EYE AND LEG PROTECTION,

HAZARD ZONE FOR THROWN OBJECTS.

-- THE TRIMMER LINE CAN THROW

OBJECTS VIOLENTLY.

-- OTHERS CAN BE BLINDED OR

INJURED_

KEEP PEOPLE AND ANIMALS

30 FEET AWAY_

OPERATOR'S

MANUAL

READ OPERATOR S MANUAl,.

-- FOLLOW ALL WARNINGS AND

INSTRUCTIONS.

- FAILURETODOSOCANRESULTIn

/ LA_E_ SERIOUS INJURY.

oaoa°*,*"I TURN PAGE,:"> "%_

3

Page 4

(this page intentionally left blank)

Page 5

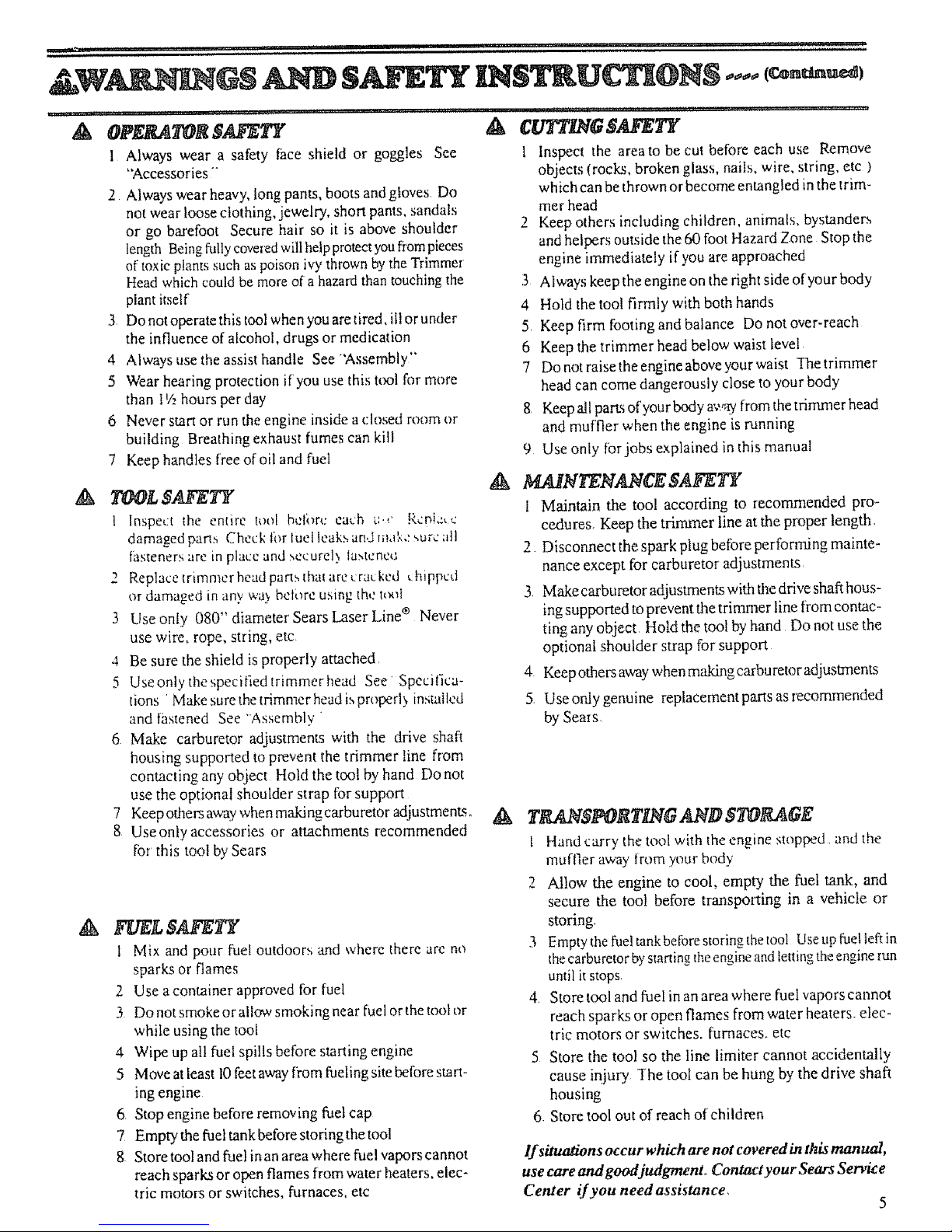

,1: ,.

tL ii

i i ii1,1,,11111......................... , .......

,,, ,,_,.., • ,,

1 Always wear a safety face shield or goggles See

"Accessories ""

2 Always wear heavy, long pants, boots and gloves Do

not wear loose clothing, jewelry, short pants, sandals

or go barefoot Secure hair so it is above shoulder

length Being fully coveled will help protect you from pieces

of toxic plants such as poison ivy thrown by the Trimmer

Head which could be more of a hazard than touching the

plant itself

3 Do not operate this tool when you are tired, illor under

the influence of alcohol, drugs or medication

4 Always use the assist handle See "'Assembly"

5 Wear hearing protection if'you use this tcx:,lfar more

than II/2hours per day

6 Never san' or run theengine inside aclosed room or

building Breathing exhaust fumes can kill

7 Keep handles f'ree of oil and fuel

TOOLSAFETY

1 Inspect the entire tool bclorc each u._' Rcn!.=,,:

damaged parts Check tbr rue[ leaks and n_a!.,,_,,urcall

fiasteners are in place and _ccurel) taxtcncu

2 Replace trimmer head parts that arc cracked _:hippcd

or damaged in any wa,, beli_rc using the ux_l

3 Use only 080" diameter' Sears Laser Line ® Never

use wire, rope, string, etc.

4 Be sure the shield is properly attached.

5 Use only thespecified Irimmerhead See' Specifica-

tions ' Make sure the tfimnrer head L',properh installed

and fastened See "Assembly

6 Make carburetor adjustments with the drive shaft

housing supported to prevent the trimmer line from

contacting any object Hold the tool by hand Donor

use the optional shoulder strap for support

7 Keep others away when matdng carburetor adjustments°

8 Use only accessories or attachments recommended

fbr this tool by Sears

& FOg/., SA!_gT1"

1 Mix and pour fuel outdoors and where there arc no

sparks or flames

2 Use acontainer approved for fuel

3 Do not smoke or allow smoking near fuel or the tool or

while using the toot

4 Wipe up all fuel spills before starting engine

5 Move at least 10feet away fi'om fueling site before start-

ing engine

6 Stop engine before removing fuel cap

7 Empty the fuel tank before storing the tool

8 Store tool and fuel in an area where fuel vapors cannot

reach sparks or open flames from water heaters, elec-

tric motors or switches, furnaces, etc

.............. =, ,L,,,,.,,,1,,,

&

1 Inspect the area to be cu! before each use Remove

objects frocks, broken glass, nails, wire, string, etc )

which can be thrown or become entangled in the Irim-

mer head

2 Keep others including children, animals, bystanders

and helpers outside the 60 foot Hazard Zone Stop the

engine immediately if you are approached

3 Always keep the engine on the fight side of your body

4 Hold the tool firmly with both hands

5, Keep firm footing and balance Do not over-reach

6 Keep the trimmer head below waist level

7 Donotraisetheengineaboveyourwaist "[hetrimmer

head can come dangerously close to your body

g Keep all parts d'your body awa3i,from the trimmer head

and muffler when the engine is running

9 Use only forjobs explained in this manual

J_/dNTEN_NCE SA_T

I Maintain the tool according to recommended pro-

cedures. Keep the trimmer line at the proper length,

2 Disconnect the spark plug before performing mainte-

nance except for carburetor' adjustments

3 Make carburetor adjustments with thedrive shafxhous-

ing supported to prevent the trimmer line fiom contac-

ting any object Hold thetool byhand Do not use the

optional shoulder strap for support

Keep others awaywhenmaking carburetor adjustments

5,

Use only genuine replacement parts asrecommended

by Sears

l Hand carry the tool with the engine stopped, and the

muffler away from your body

2 A_low the engine to cool, empty the fuel tank, and

secure the tool before transporting in a vehicle or

storing,

3 Empty the fuel tank betbre storing the tool Use up fuel tef_in

the carburetor bystarting the engine and letting the engine mn

until it stops

4 Store tool and fuel in an area where fuel vapors cannot

reach sparks or open flames from water heaters, elec-

tric motors or switches, furnaces, etc

5 Store the too! so the tine limiter cannot accidentally

cause injury The tool can be hung by the drive shaft

housing

6. Store tool out of reach of children

If situations occur which are not covered in this manual,

use care and goodjudgmento Contact.your Sears Service

Center if you need assistance,

5

Page 6

.................................................... i ,HIq,UM U,I ,ll,,,,,I,,lll*U I, H NI

KNOW Y@UI IUbtK ER

&, IlCI_@Duc'rloN

C. CAR_N C@N_NTS

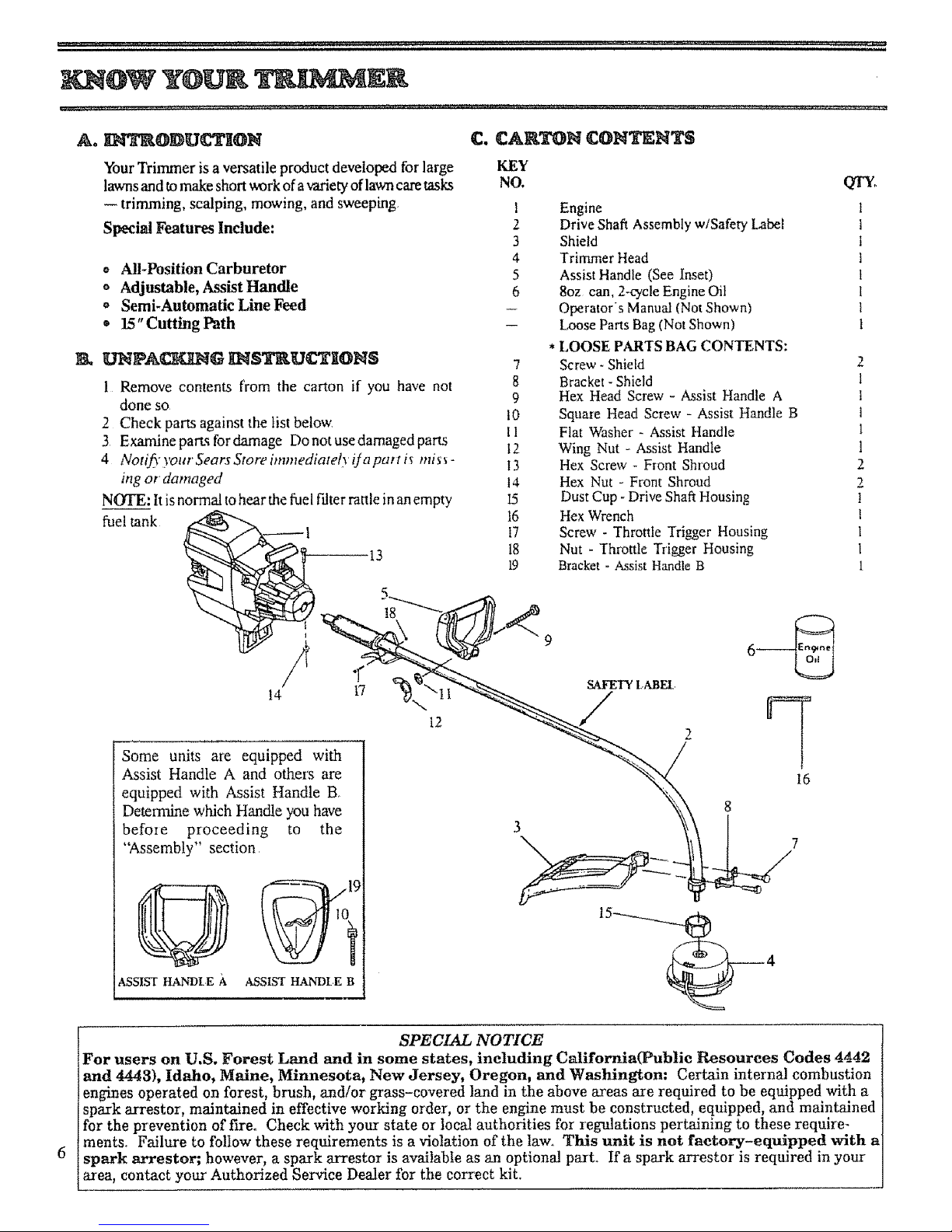

"four Trimmer isa versatile product developed for large KEY

lawns and to make short work of a variety of lawn care tasks NO,

-- trimming, scalping, mowing, and sweeping,

Special Features Include:

o All-Position Carburetor

o Adjustable, Assist Handle

o Semi-Automatic Line Feed

o 15" Cutting Path

• k UNPA_G _$_U_I@N$

1 Remove contents from the carton if you have not

done so

2 Check parts against the list below

3 Examine parts for damage Do not use damaged parts

4 NotifyyourSearsStoreimmediatel)iJapart i_ mis_-

ing or' damaged

NOTE: It is normal to hear the fuel filter rattle in an empty

fuel tank

13

1 Engine

2 Drive Shaft Assembly w/Safety Label

3 Shield

4 Trimmer Head

5 Assist Handle (See Inset)

6 8oz can, 2-cycle Engine Oil

-- Operators Manual (Not Shown)

-- L,ooseParts Bag (Not Shown)

*LOOSE PARTS BAG CONTENTS:

7 Screw - Shield

8 Bracket - Shield

9 Hex Head Screw - Assist Handle A

t0 Square Head Screw - Assist Handle B

11 Flat Washer - Assist Handle

12 Wing Nut - Assist Handle

13 Hex Screw _ Front Shroud

14 Hex Nut - Front Shroud

I5 Dust Cup -Drive Shaft Housing

16 Hex Wrench

17 Screw - Throttle Trigger Housing

18 Nut - Throttle Trigger Housing

19 Bracket - Assist Handle B

QT_

2

1

1

t

1

1

2

2

!

I

1

I

1

18

Some units are equipped with

Assist Handle A and others are

equipped with Assist Handle B,

Determine which Handle you have

before proceeding to the

"Assembly" section

ASSIST HANDLE B

G

ASSIST HANDt E

12

3

\

SPECIAL NOTICE

For users on U.S. Forest Land and in some states, including California(Public Resources Codes 4442

and 4443), Idaho, Maine, Minnesota, New Jersey, Oregon, and Washington: Certain internal combustion

engines operated on forest, brush, and/or grass-covered land in the above areas are required to be equipped with a

spark arrestor, maintained in effective working order, or the engine must be constructed, equipped, and maintained

for the prevention of fire. Check with your state or local authorities for regulations pertaining to these require-

ments. Failure to follow these requirements is a violation of the law. This unit is not factory-equipped with a

spark arrestor; however, a spark arrestor is available as an optional part. If a spark arrestor is required in your

area, contact your Authorized Service Dealer for the correct kit.

Page 7

_,,m ................. ,i,, ,,,,, ,,

__L_ tr (If to!!! is received assembled, repeat all steps in this section to be sure assembly is correct

and is adjusted for the operator.)

Ao PRF._A_A_ON

This Operator's Manual has been developed to help you

assemble the tool and to provide its safe operation It is

important that you read the entire manual to become

familiar with the tool before you begin assembly

2,. _ yOU will ne_tlh

a, Flathead Screwdriver.

b. i-1/4 inch wrench or adjustable wrench

co Hex Wrench provided with tool

X. READ YOUR OPE_kTOR°S I_&NUAL

A,_EMBLY STEPS

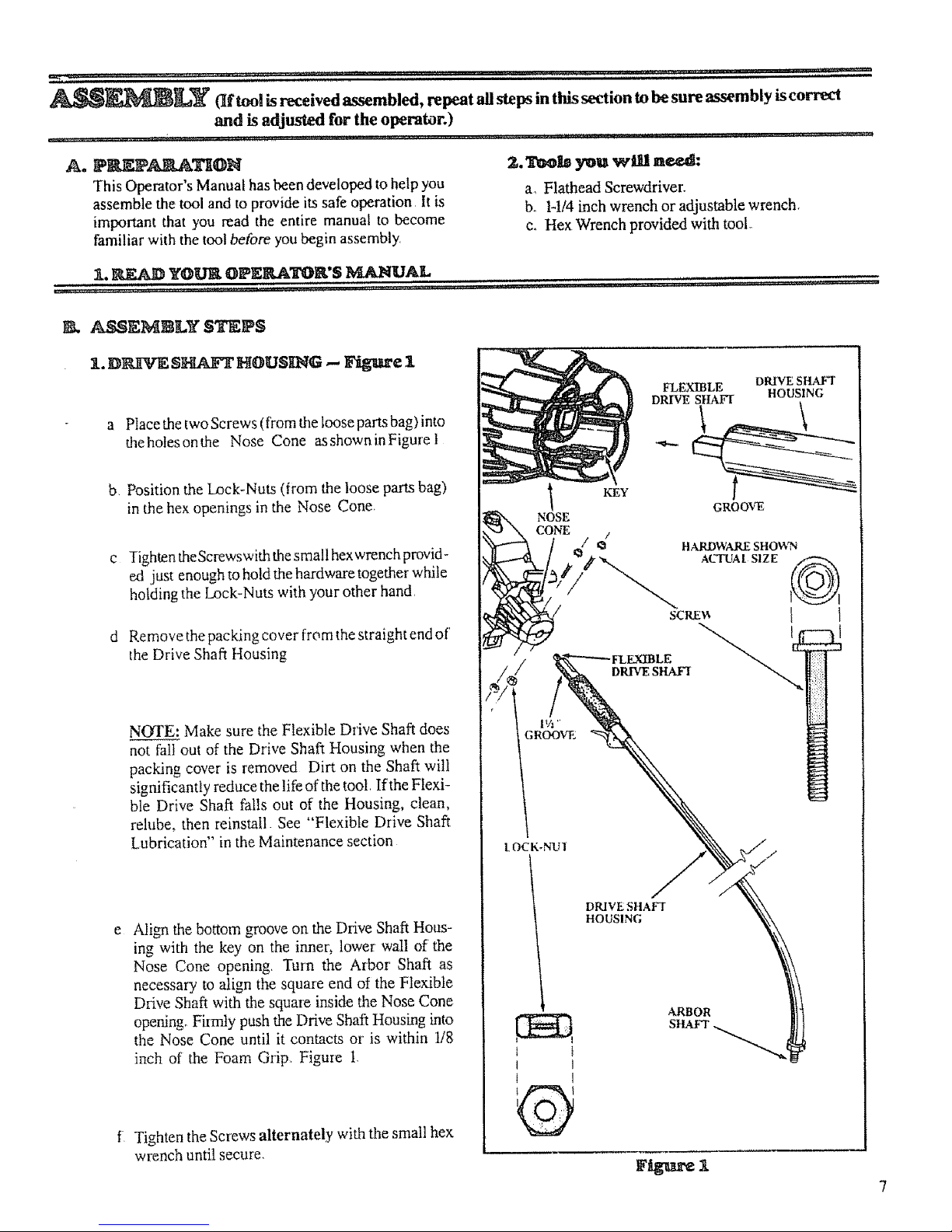

I. D_rE S_ HOUSING -- Figure 1

a Ptace the two Screws (from the loose parts bag) into

the holes on the Nose Cone as shown in Figure t

b Position the Lock-Nuts (from the loose parts bag)

in the hex openings in the Nose Cone.

Tighten theScrewswith the small hexwrench provid-

ed just enough to hold the hardware together while

holding the Lock-Nuts with your other hand.

Remove the packing cover from the straight end of'

the Drive Shaft Housing

NOTE: Make sure the Flexible Drive Shaft does

not fall out of the Drive Shaft Housing when the

packing cover is removed Dirt on the Shaft will

significantly reduce the life of the toot If the Ffexi-

ble Drive Shaft falls out of the Housing, clean,

relube, then reinstall See "Flexible Drive Shaft

Lubrication" in the Maintenance section

e

Align the bottom groove on the Drive Shaft Hous-

ing with the key on the inner, lower wail of the

Nose Cone opening. Turn the Arbor Shaft as

necessary to align the square end of the Flexible

Drive Shaft with the square inside the Nose Cone

opening_ Firmly push the Drive Shaft Housing into

the Nose Cone until it contacts or is within 1/8

inch of the Foam Grip. Figure t.

f Tighten the Screws alternately with the small hex

wrench until secure.

NOSE

CONE

1½'

3 ROOVE

KEY

FLLVO_BLE DRIVE SHAFT

DRIVE SHAFT HOUSING

GROOVE

/

I.OCK.NUI"

DRIVE SIIAFI

HOUSING

ARBOR

SttAFr

a

Page 8

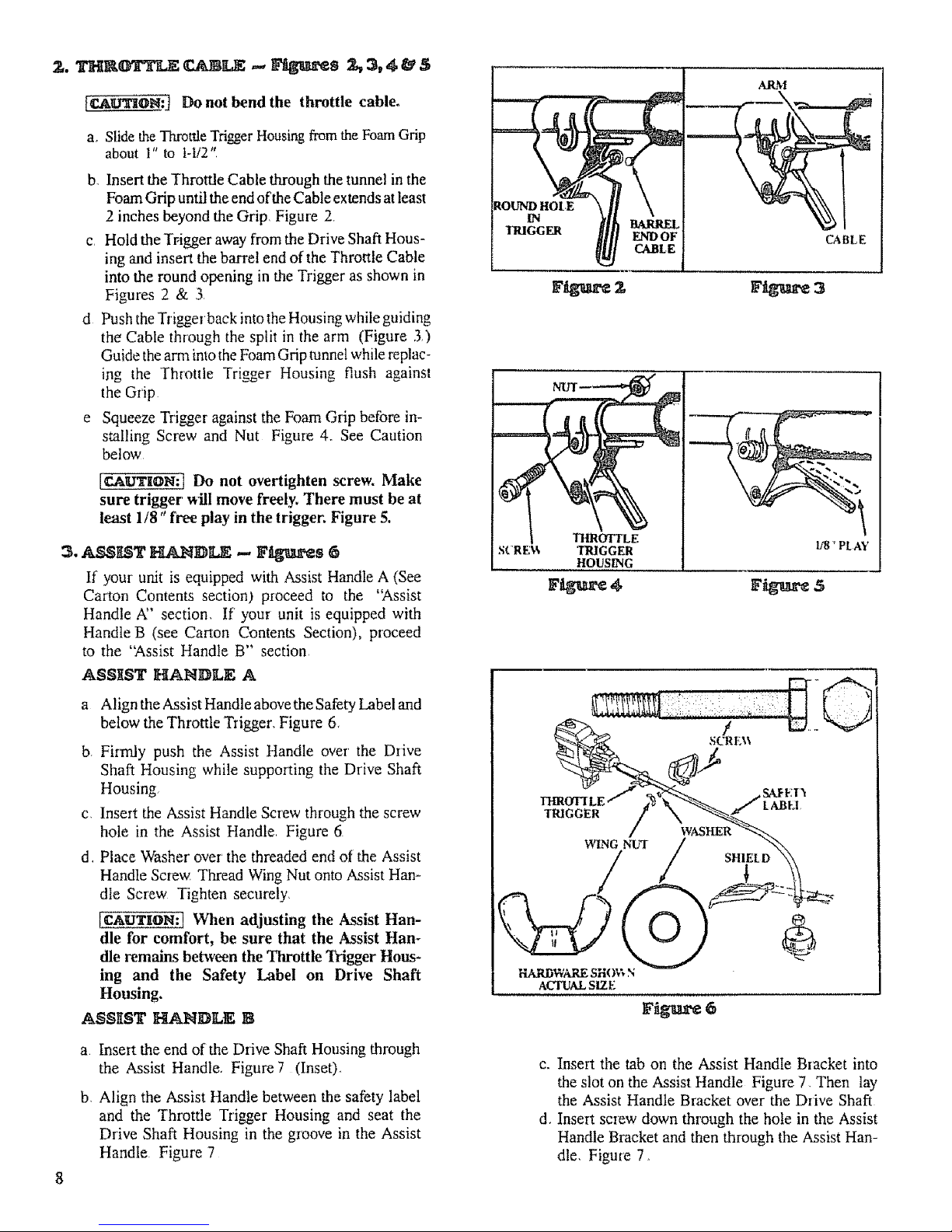

[_u'rloN:] Do not bend the throttle cable°

a, Slide the Throttle TriggerHousing from the Foam Grip

about 1" to 1-t/2"

bo Insert the Throttle Cable through the tunnel in the

Foam Grip until the end of the Cable extends at least

2 inches beyond the Grip, Figure 2

c Hold the Tl,igger away from the Drive Shaft Hous-

ing and insert the barrel end of the Throttle Cable

into the round opening in the Trigger as shown in

Figures 2 & 3

d Push the Trigge_ back into the Housing while guiding

the Cable through the split in the arm (Figure 3)

Guide the arm into the Foam Grip tunnel while replac-

ing the Throttle Trigger Housing flush against

the Grip

e Squeeze Trigger against the Foam Grip before in-

stalling Screw and Nut Figure 4_ See Caution

below

[CAU'rlON:I Do not overtighten screw. Make

sure trigger vdll move freely, There must be at

least 1/8" free play in the trigger. Figure 5.

3. A_I_T HANDI_ -- F_s 6

If your unit is equipped with Assist Handle A (See

Carton Contents section) proceed to the 'Assist

Handle A" section, If your unit is equipped with

Handle B (see Carton Contents Section), proceed

to the "Assist Handle B" section

ASSIST HANDLE A

a Align the Assist Handle above the Safety Label and

below the Throttle Trigger, Figure 6,

b Firmly push the Assist Handle over the Drive

Shaft Housing while supporting the Drive Shaft

Housing

c Insert the Assist Handle Screw through the screw

hole in the Assist Handle Figure 6

d Place Washer over the threaded end of the Assist

Handle Screw Thread Wing Nut onto Assist Han-

dle Screw Tighten securely,

[CAu'IrloN:] When adjusting the Assist Han-

dle for comfort, be sure that the Assist Han*

die remains between the Throttle 'lYigger Hous-

ing and the Safety Label on Drive Shaft

Housing.

ASSKST _--_NDLE B

a Insert the end of the Drive Shaft Housing through

the Assist Handle Figure 7 (Inset)

b. Align the Assist Handle between the safety label

and the Throttle Trigger Housing and seat the

Drive Shaft Housing in the groove in the Assist

Handle Figure 7

ROUND HOLE

IN

TRIGGER

BARREL

ENDOF

CABLE

ARM

:c

CABLE

THROTTLE

TRIGGER U8 "PLAY

HOUSING

F gure 5

TRIGGER

SHIEL D

ACq_AL SiZE

6

c. Insert the tab on the Assist Handle Bracket into

the slot on the Assist Handle Figure 7, Then lay

the Assist Handle Bracket over the Drive Shaft

d. Insert screw down through the hole in the Assist

Handle Biacket and then through the Assist Han-

dle, Figure 7_

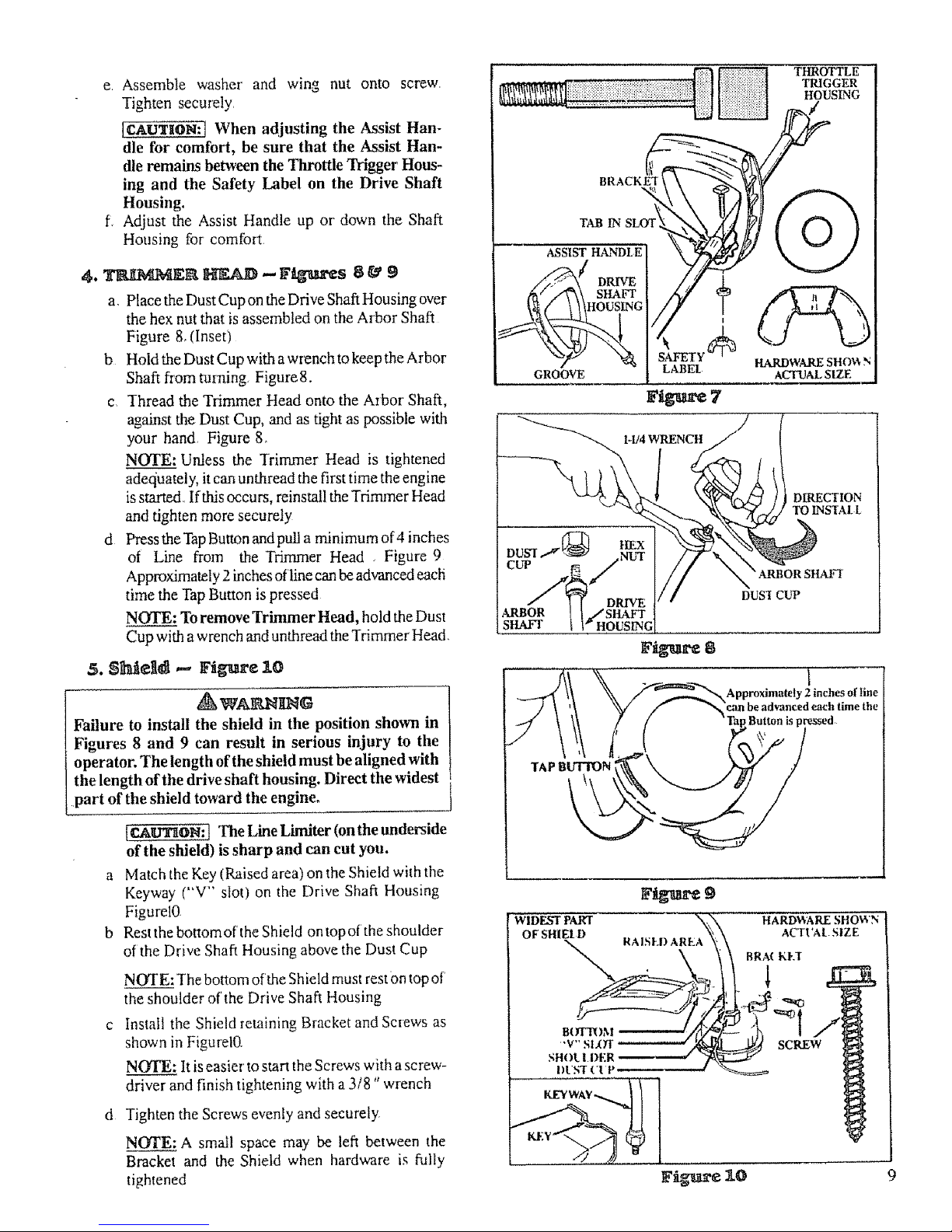

Page 9

e Assemble washer and wing nut onto screw,

Tighten securely,

lCAUTION:I When adjusting the Assist Han-

dle for comfort, be sure that the Assist Han-

dle remains between the Throttle Trigger Hous-

ing and the Safety Label on the Drive Shaft

Housing.

f_ Adjust the Assist Handle up or down the Shaft

Housing for' comtbrt

a, Place the Dust Cup on the Drive Shaft Housing over

the hex nut that is assembled on the Arbor Shaft

Figure 8, (Inset)

b Hold the Dust Cup with a wrench to keep the Arbor

Shaft from mining Figure 8.

c Thread the Trimmer Head onto the Arbor Shaft,

against the Dust Cup, and as tight as possible with

your hand, Figure 8,

NOTE: Urdess the Trimmer Head is tightened

adec_uately, it can unthread the first time the engine

is s_, If this occurs, reinstal! the Trimmer Head

and tighten more securely

d Press the Tap Button and pull a minimum of 4 inches

of Line from the Trimmer Head , Figure 9

Approximately 2 inches of line can be advanced each

time the Tap Button is pressed

NOTE: To remove Trimmer Head, hold the Dust

Cup with a wrench and unthread the Trimmer Head_

5. SlMeltd _ Figure 10

_WANNgN_

Failure to install the shield in the position shown in

Figures 8 and 9 can result in serious injury to the

operator. The length of the shield must be aligned with

the length of the drive shaft housing. Direct the widest

part of the shield toward the engine.

[CAU'riON: ] The Line Limiter (on the underside

of the shield) is sharp and can cut you.

Match the Key (Raised area) on the Shield with the

Keyway ("V" slot) on the Drive Shaft Housing

FigurelO

Rest the bottom of the Shield on topof the shoulder

of the Drive Shaft Housing above the Dust Cup

NOTE: The bottom of the Shield must rest Ontop of

the shoulder of the Drive Shaft Housing

Install the Shield retaining Bracket and Screws as

shown in FigurelO

N(YrE; It iseasier' to start the Screws with a screw-

driver and finish tightening with a 3/8" wrench

d Tighten the Screws evenly and securely

NOTE: A small space may be left between the

Bracket and the Shield when hardware is fully

tightened

THRffFTLE

TRIGGER

HOUSING

SHAFF

HARDWARE SHO_ N

ACTUAL SIZE

F_g_ s

1

Approximately 2 inches of line

°1

9

I WIDEST PART

OF SHIEr D

RAISEI) A

HARD_ARE SHOWN

8RA_ KI-T

/

SCREW

ACTVAI SIZE

Page 10

¢_.@I_I_A'_I_G _lfnOtq -- F_m'e 11

a. Before s_ng the Engine, stand as shown in

Figure [0 and check for the following:

1) Left arm fully extended, hand holding Assist

Handle.

2). Right arm slightly bent, hand holding the Foam

Grip, fingers on Throttle Trigger

,3). Engine below waist level

4) Weight of tool evenly distributed between arms

5) Without operator bending over, the Trimmer

Head is near and parallel to the ground and easily

contacts the material to be cut

b Adjust the Assist HMndle up or down the Drive

Shaft Housing (but above the Safety Label) to a

comfortable position

I) Loosen the Wing Nutby hand, adjust AssistHan-

dle, Retighten Wing Nut by hand only

2)_ Rotate the Assist Handle from left to right if it is

necessary, to tilt the angle of the Trimmer Head

such as when cutting a large, sloped area such as

a ditch bank.

RIGHTARM

SLIGHTLY BENT,

HAND HOLDING

FOAM GRIP.

FINGERS ON

THROTTLE !

TRIGGER

\

"-.._

ENGINE

IS BELOW

VvAlSq- [ EVEr

FACESHIELD

tEl:q" ARM EXTENDED

HAND HOLDING

ASSIST HANDI E

I RIMMER HEAD tS

NEAR THE GROUND AND

EASILY CONTACTS

Figure 11

ACC g F

The following accessories are available through Sears Retail Stores, Catalog, Outlets or Service Centers

ITEM SqOC K NO.

Safety Face Shield ................................................................ 9-I86L3

Safety Goggles ................................................................... 9-1859

2-Cycle Engine Oil .............................................................. 71-36555

Spark Plug ..................................................................... 71-86555

Fuel Cap ...................................................................... 71-79705

Replacement Trimmer Head (available only through Sears Service Centers) ............... 71-85860

Replacement Nylon Trimmer Line

-- 400 ft ..................................................................... 71-85778

-- 200 ft ..................................................................... 71-85608

Replacement Spool with Line ..................................................... 71-85810

Flex Shaft Lube .............................................................. 530-030102

Shoulder Strap Kit ............................................................... 71-85783

Spark Arrestor Kit ............................................................ 952-701612

Operator's Manual ........................................................... 530-067315

10

Page 11

......_7 ;_,,7 ......................................... i .......2, ...................

A. _G YOUR EN_E

i. FUEL SAFETY

a Use only recommended fuel mixtures.

b MLxand pour fue! outdoors and where there are

no sparks or flames.

c Use a container approved for fuel,

d, Do not smoke or allow smoking near fuel or the

tool or while using the tool,

e Wipeupallfuelspillsbeforestartingengine,

f Moveatleas_ 10feetawayfromfuelingsitebefore

starting engine.

g Stop engine before removing fuel cap.

h Emptythefueltankbeforestoringthetoo[. Useup

fuel left in the carburetor bYstarting the engine and

letting the engine run until it stops.

Store tool and fuel in an area where fuel vapors

cannot reach sparks or open flames from water

heaters, electric motors or switches, furnaces,

etc.

3. USE THE _'_LLOWINtG :

(16 parts gasoline to I part oil)

WARNING: Alcohol blended fuels, called gasohot

(using ethanol or methanol), can attract moisture

which teads to separation and formation of acids

during storage. Acidic gas can damage the fuel

system of an engine while in storage, To avoid

engine problems, empty the fuel tank before stor-

ing for' :30 days or' longer. Use up fuel teft in the

carburetor by star_:ing the engine and letting it run

until it stops, Use flesh fuel after taldng your unit

out of storage_ Never use engine or' carburetor

cteane_ products in the fuel tank or permanent

engine damage may occm_ See the Storage section

for additional information

_,. FUEL MXXTU_E

Your tool is powered by a two-cycle engine which

requires a fuel mixture of regular unleaded

gasoline and a high quality engine oil specially

made for 2-cycle, air cooled engines. The internal

design of the 2-cycle engine requires lubrication of

moving parts Lubrication is provided when the

recommended mixture of gasoline and oil is used

Gasoline must be clean and fresh.After a short

period of time, gasoline wilt chemically break

down and form compounds that cause hard

starling and damage in 2-cycle engines,

o The correct measure of gasoline to oil is very

important. Too much oi! in the mixture wilt fnul the

spark plug

IcA_ Too little oil or incorrect oil will

cause the engine to overheat and seize.

o Always mix the fuel thoroughly in a container

since gasoline and oil do not readily combine Do not

mix gasoline and oil directly in the fuel tank

4. DO NOT riSE:

o BIA OIL (Boating Institute of America) --

-- Does not have proper additives for aii-cooled

2-cycle engines and can cause engine damage

o AIYrOMO'I IVE OIL --

-- Does not have proper additives for2-cycle engines

and can cause damage

5. HOW TO MLX FUEL AND FNLIL T_K

a Pour 1/2 of the regular unleaded gasoline to be used

into an approved, marked container'. Do not mi_:

gasoline and oil directly in the fuel tank

b Add entire measure of engine oil

c Cover container tightly and shake for one minute

d Slowly remove fuel container cover

e Add remainderofgasoline

fl Cover container tightly and shake again

g Slowly remove fuel container cover

h Slowly remove fuel cap See "Specifications"

for location

i Fill the tank using a spout or funnel

j Reinstall the fuel cap securely

Page 12

PRE_PE_TION CHECKS

all Warnings and Safety Instructions in this

manual.

Before operating your tool, always:

1 Inspect the entire tool before each use_ Replace

damaged parts. Check for fuel leaks and make sure all

fasteners are in place and securely fastened

2. Replace trimmer head parts that are cracked,

chipped or damaged before using this tool.

3o Use only ,080" diameter Sears Laser Line ®, Never

use wire, rope, string, etc

4

Use only with the shield properly attached,

5. Useonlytl_ _ trimmer _d. See"Spmtica-

t.ions?' Make same the trimmer head is propei'ly

installed and securely fastened. Refer to '_kssembly"

6 Make carburetor adjustments with the drive shaft

housing supported to prevent the trimmer line from

contacting any object. Hold the tool by hand; do not

use the optional shoulder strap for support

7, Keep others away when making carburetor

adjustments.

8 Use only accessories or attachments as recom-

mended by Sears for tNs tool.

9 CleantheairFdterifdirtybeforeoperatingtheto, ol.

Refer to "Specifications;' for air filter location

C. STARTI_IqG H_STRUCTIOI_S (For location of controls, refer to "Sg_cifications. '')

1. I_fo_ a_ _e engine.

a Fuel engine. Move 10 feet away from fueling site

b. Extend 4-6 inches of Line from Trimmer Head

,_ WAgN_G

Thetrimmerhead will turn while starting the engine.

c, Rest Engine and Shield on ground, supportingTrim-

mer Head off the ground away from trees, bushes,

onlookers, etc, Figure 12

d If using optional Shoulder Strap, place Shoulder

Strap on your shoulder, Start engine before dipping

Shoulder Strap to the tool

_. For a _.old Engine:

ao Move Ignition Switch to "on 7 Figure 13

b Move Choke to "full" position Figure 14

c Grasp Foam Grip and squeeze Throttle Trigger fidly

Keep Throttle Trigger fully squeezed until engine

runs smoothly (through step "g")

d. Pu!t Starter Rope sharply until engine pops or attempts

to run, but no more than 8pulls at full choke to avoid

flooding the engine The engine '_pops" or 't_ttempts

to run" may be hard to hear.. The operator must listen

carefully, After 8 pulis, proceed to step "e." even if

engine has not attempted to run.

eo Move Choke to "half' position. Figure 14

f. Pull Starter Rope sharply until engine pops or attempts

to run, but no more than 5 pu!Is.

NOTE: If engine has not started after 5 pails, repeat

steps "a" through "fo"

g. Allow engine to run 5 seconds, then move Choke to

"off" position, Figure 9. Keep Throttle Triggerfu!ly

squeezed until engine runs smoothly_

NCtYE: If engine dies with Choke at "off" position,

repeat steps "e" through "gY

" [ S*IAR'I/NG POSII1ON

ON/OF1;

SWITCH

Figure 13 F_e

Avoid any bodily contact with the muffler when starting

a warm engine. A hot muffler can cause serious burns.

_. _r _ W_ Igng_e:

a, Move Ignition Switch to "on." Figure 13

b Move Choke to "half" position, Figure 14

c Grasp Foam Grip and squeeze Throttle Trigger fiflly

Keep Throttle Trigger fully squeezed until engine

ru_L

d Pull Starter Rope sharply until engine runs, but

nomore than 5 pulls.

e. Move Choke to "off"position Figure 14,Keep Trig

ger fulty squeezed until engine runs smoothly.

NOTE: If engine does not ran after 5 pulls, it is pro-

bably flooded. Wait a few minutes and repeat pro-

cedure with Choke at "off" position. Figure 14

12

Page 13

4. _r aW_E_e(_er R__t

a. Refuel engine. Move 10 feet away from fueling site_

b.

C_

d

e.

Move Ignition Switch to "on" Figure 13,

Move Choke to "full" position. Figure 14

Grasp Foam Grip and squeeze Throttle Trigger fully.

Keep Throttle THgger fully squeezed until engine

runs_

Pull Starter Rope sharply until engine pops, but no

more than 5 pulls,

_""''"_ ............... i ...i...,11 i_ i'I .i.i1......11.1.............._.._...._

D. OPE_G _S_U_IONS

f Move Choke to "off" position. Figure t4.

g. Pull Starter Rope until engine runs, but no more than

5pulls. Keep Triggerfiallysqueezeduntilengine runs

smoothly

NOTE: If engine has not started, pull Starter Rope

5 more pulls. If engine still does not run, it is pro-

bably flooded. Wait a few minutes and repeat pro-

cedure with Choke at "off" position. Figure 14,

1, Bring the engine to cutting speed beforeentering the

material to be cut°

a Do not run the engine at a higher speed than

necessary. The cuaing line will cut efficiently when

the engine is run at less than flail throttle, At lower

speeds, there is less engine noise and vibration. The

trimmer line will last longer and will be less likely

to "weld" on the spool.

b, If the Trimmer Head does not turn when the

engine is running, make sure the Drive Shaft

Housing is properly seated in the Engine Shloud

Refer' to "Assembly-Drive Shaft Housing."

,il t, 100101.p011t i ......... i iiiiiiql01 ItlI"H

2, Always release the Throttle Trigger and allow the

engine to return to idle speed when not cutting.

3, To stop the engine:

a. Release the Throttle Trigger,

b, Move Ignition Switch to the "OFF" position Figure t3_

........ .... t., .,,..., ..

USING T KMME

WlklI I gMG ttOWS OB 6"TS

The rapidly moving line causes objects tobe thrown violently

The shield will not provide complete protection tothe operator

or others The operator must wear a safety face shield or

goggles. Always wear heavy, long pants and boots. Keep

others at least 30 feet away.

NE

This tool will throw objects and cut Keep others including

children, animals, bystanders and helpers at least 30 feet

away from the operator and toolo Stop the engine ifyou are

approached.

Trimmer Head

#71-85800

Use Only Genuine Replacement Parts

Trinuner head parts that are chipped, cracked or damaged in

any way, can fly apart and cause serious injury, Do not use.

Throw damaged paris away. Replace damaged parts before

using the tool.

13

Page 14

a Always wear a safety face shield or goggles. See

"Accessories:'

b Always wear heavy, long pants, boots and gloves°

Donor wear loose clothing, jewelry, short pants, san-

dais or go barefoot Secure hair so it is above

shoulder length Being fully covered will help protect

you from pieces of toxic plants such as poison ivy

thrown by the Tr'immet Head which could be more of

a hazard than touching the plant itself.

c Do not operate this tool when you are tired, ill or

under the influence of alcohol, drugs or

medication.

d Do not swing the tool with such force that you are

in danger of losing your balance.

e Never start or run the engine inside a closed room

or building. Breathing exhaust fumes can kill

f Keep handles free ofoil and fuel.

f,

g

Make carburetor adjustments with the drive

shaft housing supported to prevent the trimmer

line from contacting any object, Hold the tool with

your hand Do not use the optional shoulder strap for

support.

Keep others away when making carburetor

adjustments.

Use only accessories or attachments recom-

mended for this tool by Sears.

J. CUTTING

Inspect the area to be cut before each use. Remove

objects (rocks. broken glass, nails, wire. string, etc )

which can be thrown or become entangled in the

trimmer head

b Al_ays keep the engine on the right side of your

bod_,.

2._L

a Inspect the entire tool before each user Replace

damaged parts Check for fuel leaks and make sure

all fasteners are in place and securely fastened

b Use only .080" diameter Sears Laser Line ®.

Never use wire, rope, string, etc.

c Be sure the shield is properb attached.

d Make sure the trimmer head is properly installed

and securely fastened. Refer to "Assembly _

c Hold the tool l'trmly with both hands.

d Keep firm footing and balance. Do not over-reach

e Keep the trimmer head below waist level.

Do not raise the engine above your v,aist.

g Keepali partsofyourbody away from the trim-

mer line and muffler when the engine is runnhag,

h Use only for jobs explained in this manual.

_R _ ADVA__CE

o The line will advance approxhnately 2 inches each

time the bottom of the trimmer head is tapped on the

ground with the engine running at full throttle.

o The most eWmient line length is the maximum length

allowed by the line limiter,

o Airways keep the shield in place when the tool is being

operated.

To ad_ance line:

1 Operate the engine at full throttle

NOTE: Always tap the trimmer head on a grassy area Tapping

on surfaces such as concrete or asphaltcan cause excessive wear

to the trimmer head

d_WA_MD_G

Use only .080" diameter Sears Laser Line ®. Do not

use other materials such as rope, wire string, etc. Wwe

can break during cutting and become a dangerous

missile.

2 Hold trimmer head parallel to and above the grassy

area

14

3

Lightly tap the bottom of the trimmer head on the

ground one time, See Figure 15 Approximately

2 inches of line will be advanced with each tap°

NOTE: If the line is worn down to two inches or

less, more than one tap will be required toobtain the

most efficient line length

NOTE: Scalping can occur when tapping the bot-

tom of the trimmer head on the ground. To avoid

scalping in critical locations, tap the bottom of the

trinamer head in an inconspicuous area when

advancing the trimmer line.

LINE LIMI-fER

CLrIS OFF

EXCF.SS

fINE

TO ADVANCE LINE,

TAP BO'ITOM OF

TRIMMER LIGHTLY

ON GROUND

ONETIME

, &l,,t_€ _t

Page 15

The tip of the line does the cutting. Allow the line to

trim at its own pace, You will achieve better results by

not crowding the line into the cutting area, The right and

wrong way are shown in Figure 16.

The line will easily remove grass and weeds from

around walls, fences, trees and flower beds, but it

also can cut the tender bark of trees or shrubs and scar

fences. To help avoid damage to vegetation or trees with

tender bark, shorten line to 4-5 inches and use less than

full throttle

O

The li_ will wear fas_r and will need to be advanced

more frequently when you are cutting against rocks,

bricks, concrete, metal fences, etc., than when cut-

ting against trees or wooded fences.

Fortnmming or _calping, use less than full throttle

to increase line life and decrease head wear°

--during light duty cutting

-- next to rocks, bricks, concrete, metal fences, etc

Formowingorsweeping, use full throttle for a good

clean job.

o Avoid letting the trimmer head continuously contact

the ground during normal cutting. Constant contact

will cause trimmer head damage and premature wear

Always wear eye pro_ction. Never lean over the trim-

met head. Rocks or debris can rict_chet or be _ into

eyes and face and cause blindness or o_ber serious injury.

1. _@ -- F_g_axe 17

Hold the tap button about .3inches above the grot, nd and

tilt the trimmer head at an angle Altowthetipoftheline

to do the cutting Do not force the trimmer line into the

wolk area

2_

The scalping technique removes unwanted vegetation

Hold the tap button about 3 inches above the ground and

tilt the trimmer head at an angle Allow the tip of the line

to slrike the ground around trees, posts, monuments.

etc Thi_ technique mcrea_es line wear

I_@'WI._@ .- Fig_L_e 19

Yourrammer is ideal for mowing in places conventional

lawn mowers cannot reach In the mowing position.

keep the [ine parallel tothe ground Avoid pressing the

head into the ground as this can scalp the ground and

damage the too[

SWEEPlh_G -- Ftgume _0

The fanning action of the rotating line can be used for

a quick and easy clean up. Keep the line parallel to and

above the suHaces being swept and move the tool from

side to side

t

Fi_e 17

:TRIMMIN(;

F_g_e 19

15

Page 16

D. L_NE REPlaCEMENT

e For proper line feed:

-- Use only genuhae Sears pre-wound spools and

.080" diameter Sears Laser Line.® Use of other

spools or line can iesult inexcessive breakage, line

welding and improper line feed,

--Pre-wound spools offer the most convenient

method for replacing line as well as optimum per-

formance

o Always clean dirt and debris from thespool and hub

when performing any type maintenance

o To avoid line welding, keep trimmer line at a max-

imum length allowed by the line Ihniter.

--If line becomes too short it can weld onto the spool,

a, Hold the Trimmer Head as shown in Figure 2!, Press

the Imck Tab, and turn L_ck Ring as shown in

Figure 21'

b, Remove the Lock Ring and Spool Figure 22.

c, Clean dirt and debris from all parts, Inspect all

Tximmer Head paris for'damage Replace damaged

parts

d_ WA_NliNG

Trimmer head parts that are chipped, cracked or

danmged in any way can fly apart and cause serious

injury. Do not use, Replace damaged parts before

using the toolo

d. Insert the end of the Line in the Line Exit Hole as

shown in Figure 23, Place Spool in Hub, Make sure

the Trimmer Line is not caught between the rim of

the Spool and the Hub

e. Align the Lock Ring over the three Catches on the

Hub. Push the Lock Ring down on the Hub and turn

as shown in Figure 21

f, Check to make sure all thiee Catches (Figure22) and

the Lock Tab (Figure 23) are properly fastened as

shown in Figure24, Then test the Lock Ring

by trying to turn it counterclockwise

WA_tILNG

All three catches must be fastened and the lock tab

latched on to the lock ring. If installed incorrectly, the

lock ring can fly off and become a dangerous missile.

g, Pull on the Line to change the Spool from the locked

position to the operating positiom Figure 25

h, Obtain correct line length by pressing Tap Button(Fig-

ure 25) and pulling on the Line again _

NOTE: Each time the Tap Button is pressed, approx-

imately 2 inches of'Line can be pulled from the Trim-

mer Head Figure 25,

LINE EXIT

Fi_¢

Fig_a_e

APPROXIMATELY 2 INCHF_S OF LINE

CAN BE PULLED FROM TIIE "rR/MMER HEAD

EACH TIME THE TAP BUTION

IS PRESSEI_

16

Page 17

_1 Kns_zUing Line on Spool.

a To replace the Line on existing Spool:

L) Follow "Installing Spool w/Line," steps "a-cY and

remove any Line remaining on the Spool

2,) Use a 40 foot length of 080" diameter Sears Laser

Line ®

3,) Insert 1/16to 1/8inch of the end of the Line through

the hole in the inner rim of the Spool, Figure 26

Allow no more than I/8 inch of Line to extend beyond

the rim to avoid interference with the tapping action

4) Wrap the Line firmly and evenly onto Spool in a

clockwise direction as shown by arrow on Spool

Figure 26

NOTE: The Line must be wrapped firmly and

evenly for' proper line feed

5) Follow "Installing Spool w/Line," steps "d-h,'

b If the Line breaks off or backs up in the Trimmer

Head, follow "Installing Spool w/Line," steps "a-c?'

Pull slack in Line until the Line is tightly wound on

Spool, leaving 4-6 inches of extended Liner Continue

with steps "d-hY

WRAP MNE ON SPOOl_.

,, ASSHOWN BYARROW.

Figure 26

@@NAg 'IrNNANgE

A. ANClE SAFETg

1 Maintain the tool according to recommended pro- 6r

cedures. Keep the trimmer line at the proper length

2 Never start the engine with the Front Shroud

removed. The clutch can fly apart and cause serious 7,

injury

3 Disconnect the spark plug wire before perform-

ing maintenance except for carburetor 8,

adjustments.

4 Make carburetor adjustments with the drive shaft

housing supported to prevent the trimmer line 9

from contacting any object. Hold the tool with your

hand Do not use the optional shoulder strap for

support

5 Keep others away when making carburetor

adjustments.

Use only .080" diameter Sears Laser Line ®.

Never use wire, rope, string, etc

Replace trimmer head parts that are cracked,

chipped or damaged in any way before using the

toot.

Use only genuine replacement parts as recom-

mended by Sears.

Inspect entire tool. Replace damaged parts. Check

for' filet leaks, Make sure all fasteners are in place

and securely fastened,

]g Agg _"gg,_Ig

A dirty air filter decreases the lifeand performance oi the

engine and increases fuel consumption

Clean the Air Filter:

o Always after 5 tanks o[ fuel or 5 hours of operation,

whichever is less_

o More frequently in dusty conditions.

I Loosen the two screws on the Air Filter Cover

enough to remove the cover from the engine Fig-

ure ..-/7

2 Remove the Air Filter li'orn theCover Figure28.

3 Wash Filter in soap and water

4 Squeeze Filter dry and replace in Cover

[c,_,trrltoN:] Do not clean the air filter in

gasoline or other flammable solvent to avoid

creating a fire hazard.

5 Reinstall the AirFilterCover, making sure the Choke

exit slot (Figure 28) is placed over the Choke Lever,

[cAtrTION:] Fit air f'flter into thecorners ofthe

housing to keep dust from entering the engine and

causing engine damage.

CHOKE

CORNERS EXIT SIXYr

F_ _8

17

Page 18

!i¸ L2 ....... ,,_,_,,.......... _ ..........................

C, STA_ _@IPN

o Replace a starter rope that breaks.

_ WAIIg.M_IG

Do not remove the retaining tab and screw to remove

pulley. The spring beneath the pulley is under tension

and can fly out causing serious injury. If any part of the

pulley housing assembly is damaged other than the rope,

do not use the tool. Take it to your Sears Service Center.

1 Disconnect Spark Plug Wire_ Figure 29

.

Remove the Screw and Nut in the Thiottle Trigger

Housing as shown in Figure 4_ Hold the Throttle

Trigger away from Drive Shaft Housing and remove

Tbaottle Cable from Trigger° Pull Cable out of Foam

Grip tunnel,

3. Loosen the two Nose Cone Screws and remove Drive

Shat_ Housing from the Front Shroud Figure 29

4. Remove the six Front Shroud Screws as shown in

Figure 29 with the smatl hex wrench provided

5 Separate the Front Shroud fiom the Engine Figure

30,

R_gOVE SCR_

NOSE

CONE

SCILEWS

7

...--SPARK

PLUG

WIRE

Shown without

Drive Shaft Housing

for clarity

ii iii ii

z9

6 Untie Rope from around the Pulley Ratchet, loosen

screw and washer (Figure .3t), and pull the Rope out

of the Pulley Housing

Position Putley Housing as shown in Figure 31. Hand

turn the Pulley clockwise _ as far as it will go.

Then, turn the Pulley counterclockwise _ unti!

the Pulley Notch is aligned with the Housing Notch.

Figure .31. Next, turn the Pulley one complete turn

counterclockwise _ until the notches are align-

ed again

Insert the hex wrench into the hole formed by the

Notches to hold the Pulley in position. Figure 31.

9 Use a 42 "length of replacement Rope

PUI.,LEY HOUSING

1

I0.

Move away (10 feet) from the fuel tank with the replace-

ment Rope. Use a match and melt both ends of the Rope

to prevent fraying_

i, ,,i,,,u t ,,

F_tre 30

18

Page 19

11 Pull the melted ends through a thick, clean rag while

the Rope is still hot to obtain smooth, pointed ends.

12 Insert one end of the Rope through the Handle and

secure with a knot

134 Insert the other end of the Rope through the Rope Exit

Hole into the inside of the Housing, into the Pulley and

up through the Pulley Hole See Inset, Figure 31,

14. Wrap Rope counterclockwise _ around the

Pulley Ratchet and rock loose end tinder Rope where

it comes out of the Pulley Hole. Leave a 3/4 to 1

inch tail laying flat on top of the Pulley between the

Retainer Rib and Screw Post as shown in Figure 31

The Rope tail must not extend beyond the Raised Cir-

cle on the Pulley to prevent interference with the Re-

taining Tab Figure .31.

15 Secure the rope tait with the screw and washer

Tighten until washe_ contacts rope

NOTE: Do not over1:ighten screw. Plastic threads in

the screw post will strip out if the screw is

over'tightened

16 Hold Rope taut at Rope Exit Hole so it will not move

and remove hex wrench.

17 Slowly feed rope into pulley housing

18 Reverse steps I-5 to re-assemble,

IFig_re 3"I

ID. FILE_.UINg, E ID!N_VN Sg-XAF'Ir LLIBItLICATION

o Lubricate the Flexible Drive Shaft:

-- After each ten (1O)hours of operation.

-- Before operating i[ the unit has been stored for

90 days or longer.

o Use Flex Shaft Lube Part No. 530-030102.

NOTE: A tube of'_'Flex Shaft L_be' has been supplied

with your unit to be used after the first 10 hours of

operation

o Use the following procedure for best results:

It!engine has jth"tbeen operated, avoid touching the muf-

fler_ A hot muffler can cause serious burns.

[¢:Au'lraoN:] Lay the Flexible Drive Shaft on a clean

surface. Avoid laying the shaft on the tloor, ground or

on any surface that may have dirt or debris. Even after

wiping the shaft, grease residue can pick up dirt par-

ticles thai can cause damage or premature failure.

Fig_'c 3_ Fflg_re 33

AND SC RE_

ICAU"X_ION:t Take care to avoid injuring your hands

and fingers with broken wires when checking for

damage or wiping the flexible drive shall A cloth will

not prevent the broken wires from puncturingor tear-

ing your sldn_

1 Remove the Screw and Nut in the Throttle Trigger

Housing as shown in Figure 4

2 Hold the Trigger away from the Drive Shaft Housing and

remove the barrel end of the Cable from the Trigger' as

shown in Figure 2.

iCAU_ON: [ Do not bend the cable.

3 Pull the Cable from the tunnel in the Foam Grip.

4 Loosen (but do not _emove) the Hex Screws and

remove the Drive Shaft Housing from the Nose

Cone. Figure I

5 Remove the Flexible Drive Shaft from the Drive

Shaft Housing as shown in Figure 32

6 Check the Flexible Drive Shaft for broken wires, twists

or kinks and replace if damage is k)und

7 Using a clean cloth, wipe the surface of the Flexible

Drive Shaft thoroughly to remove any old grease

Figure34

8. Apply a uniform coat of lube to the entire surface of the

Flexible Drive Shaft

9. Inject the remaining contents ofthe tube into the top of

the Drive Shaft Housing

10 Replace Flexible Drive Shaft into the Drive Shaft

Housing. Turn the Flexible dIive shaft as necessary

to allow it to seat into the drive gear at the bottom

of the Drive Shaft Housing

1L Follow the instructions in "Assembly" to reinstall the

Throttle Cable and the Drive Shaft Housing

19

Page 20

o ]'his is a complicated task and it is iml_rtan! to

follow instructions in sequence as indica!ed.

AwA aN

Make carburetor adjustments with the drive shaft hous-

ing supported to prevent trimmer line from contacting

any object. Hold the tool with your hand; do not use the

optional shoulder strap for support.

2. _HC CA_E_ SE_GS

NOTE: In most cases, your engine can be made to

run properly with minor caiburetor adjustments.

Refer to "Trouble Shooting Suggestions" in the left

column for the condition you are experiencing and

follow the instructions The basic carburetor settings

are provided in the event they are required.

Keep others away when making carburetor adjust-

ments.

Serious injury to the operator and others can occur if the

carburetor is not properly adjusted.

a

Turn the Mixture Screw (Figure 34) clockwise

just until it stops. Do not turn the screw until

it i_ tight as damage to the needle seats can occur

b

Turn the Mixture Screw one full turn countetclock-

wise

Follow instructions "a, Preparation;' through "f

Mixture Adjustment _'

o Poor engine performance can be a result of other"

causes such as dirty air filter, carbon build-up

on muffler outlets, etc. See "Trouble Shooting

Chart" before proceeding with carburetor

adjustments.

o The carburetor has been carefully adjusted at the

factory. However, the operator must be sure that

adjustments are made when any of the conditions

occur as mentioned in "1'rouble Shooting Sugges-

tions" below.

@

Very small adjustments can affect engine perfor-

mance, It is important to turn the screw a red smalt

amount per adjustment and test pertbrmance betbre

making further adjustments Each adjustment should

be no more than the width of the slot in the adjusting

screws

1. T_OUBWE SHOOT_tG SU_ESTIIO]_$

-- Engine will not continue to run at idle position,

See "b, Idle Speed Adjustment" and "e. Mix-

ture Adjustment?'

3, P_OCEDUP_E

a. Pn_EPA__ATItO_[

1) Use a fresh fuel mix See "Fueling Your l_ngme"

2 )Make sure the line extends to the length allowed

by the line limiter to provide correct load on

engine

3 )Start the engine. Cut grass !br 3 minutes to warm

engine/Tw engine must beat operating temper_

amre bcfore carburetor adju_mwnts can be per-

formed correctly

4 )Stop engine and remove air' filter: Refe_ to "Air

Fi!ter" in Maintenance Section for location and

instructions

-- Engine diesor hesitates when it should accelerate.

See "c. Acceleration Check?'

-- Loss of cutting power which cannot be cor-

rected by cleaning the air filter, See "L Mix-

ture Adjustment?'

-- Engine does not return to idle from full throttle

within 2 seconds. See "d. Deceleration Check?'

--Engine will not run° See "Trouble Shooting

Chart?' Then, if the carburetor requires adjust-

ment, begin with"L Basic Carburetor Settings?'

The trimmer line wil! be spinning during this pro-

cedure. Wear your protective equipment and observe

all safety instructions.

b. I[I_LE $_EE_ AI)_TMENT

t )Aflow engine to idle

2,)Adjust Idle Speed Screw (Figure 34) until the

engine continues to run wihtout stalling and

without the trimmer head moving

-:- Turn _crew clockwise _ to increase

engine _peed lithe engine stall.s or die_

-- Turn _crew counterclockwise _ to How

engine do,vTqand/or to keep trinvner head from

turning

3 )Follow instructions in "c Acceleration Check"

and "d Deceleration Check"

4.) No further adjustments are necessary if per-

formance is satisfactory.

2O

Page 21

¢. ACCE_/kTION CHECK e. !_IXTUKE _JUSTMENT

!.)Allow engine to idle.

2 )Squeeze Trigger fully

a. If performance is satL,'factory, proceed to "d

Deceleration Check"

b. If the engine does not accelerate smoothly,

turn the Mixture Screw (Figure 34)

countetclocle, vise _ a small amount (no

more than the width of the slot in the ad-

justing seiew)

3 )Repeat step . ) untlJ smootla acceleration is

obtained

NOTE: It may be necessary to repeat % Idle

Speed Adjustment" through "c. Acceleration

Check," to obtain correct adjustments

4 ) Follow instructions in "d Deceleration Check"

d. DECELE_TION CHECK

1,)Mlow engine to idle, then squeeze Throttle Trig-

ger fully

2 )Allow engine to run at full speed for about 1

second

3 )Release the Throttle Trigger to the idle position

and listentothedeceleration ofthe engine It must

remm to idle smoothly and within 1to2 seconds

a If performance is satisfactory, proceed to

step "4)"

b If the engine slowly or erratically returns

to idle or idles erratically, repeat "b. Idle

Speed Adjustment" or' continue through

Mixture Adjustment to obtain proper

deceleration.

4. )Recheck idle speed

MIXTURE

ADJUSTMEN"I SCREW

[CAUTION:I Do not operate engine at full

throttle for prolonged periods while making high

speed adjustments as damage to the engine

can occur.

1 )Support the drive shaft housing so the trimmer

line is off the ground and will not make contact

with any object

2 )Allow engine to idle, then squeeze Throttle Trig-

ger fully

NOTE: Perform steps "3 )" through "5),"

at full throttle.

3)Turn Mixture Screw (Figure 34) very slowly

clockwise _ until engine speed is reduced

4)Turn Mixture Screw very slowly counter-

clockwise _ Stop when the engine just

begins to run roughly

5 )Turn the screw slowly the minimum amount

clockwise _ until the engine runs smoothly

6 )Follow instructions in "c Acceleration Check"

and "d. Deceleration Check"

[CA_J'rItON: I If the engine does not operate

according to these instructions after repeating

the adjusting steps, do not use the tool. Take

it to your Sears Service Center.

f. IgEITNSTALL _LI_ HLqi_

Be sure filter is clean See '_,Jr Filter" in the

Maintenance Section for instructions.

IDLE SPEED AIR

ADJUSTMENI FILTER

SCREW COVER

Figure 34

ICAUTION: [ Fit air Filter into the corners of the

housing to keep dirt from entering the engine and

causing engine damage.

2t

Page 22

_'. STORAGE

NOTE: It is important to prevent gum deposits flora

forming in essential fuel system parts such as the car-

buretor; fuel filter, fuel hose, or tank during storage.

Alcohol blended fuels, called Gasohol (using ethanol

or methanol), can attract moisture which leads to

separation and formation of acids during storage

Acidic gas can damage the fuel system of an engine

while in storage.

t Empty the fuel tank before storing the too!, Use up fuel

left in the carburetorby starting the engine and letting the

engine mn until it stops

2. AIIow the engine to cool before storing,

3, Store tooI and fuel in an area where fuel vapors cannot

teach sparks or open flames from water heater's, electric

motors or switches, furnaces, etc.

4 Stote the tool sothelinelimitercannotaccidentallycause

injury The toot can be hung by the drive shaft housing.

5 Store tool out of reach of children

_. _O_J_LE SI-__G C_T

SYM[q'OM CAUSE REMEDY

Engine will not start

or will run only for

a few seconds after

starting

Engine will not idle

properly

Engine will not

accelerate, lacks

power or dies

under a load

Engine smokes

excessively

Engine runs hot

Irimmer head

stops under a load or

does not turn when

engine is accelerated

Line does not advance

or breaks while cutting

Excessive line usage

1 Fuel tank empty

2. Engine flooded,

3 Spark plug not firing,

4 Fuel not reaching carburetor.

5, Carburetor requires adjustment,

6 None of the above

1 Idle speed set too fast or slow

2 Mixture requires adjustment

3 Throttle tzigger screw too tight

4 None of the above,

1 Air fdter dirty

2 Spark plug fouled

3 Carburetor requires adjustment

4 Muffler outlets plugged

5 None ofthe above

1 Air filter dirty

2 Fuel Mixture incorrect

3., lvlixture requires adjustment,

1 Fuel mixture incorrect

2 Mixture set too tow (lean)

3 Spark plug incorrect

4 None of the above

t Drive shaft broken or not engaged

2 Carburetor requires adjustments

I, Line caught between spool and hub

2 Line improperly wound onto spool

.3 Improper line size

t Improper line size,

2, Cutting at high speed around hard objects

3, Crowding line against material being cut.

t Fill tank with correct fuel mixture

2 See "Starting Instructions,"

3 Install new plug,

4 Clean fuel filter; inspect fuel line

5, See "CarburetorAdjustmentsY

6 Contact your Sears Service Center

1 See "Carburetor Adjustments !'

2 See "Carburetor Adjustments"

3 Loosen screw to free trigger

4. Contact your Sears Service Center,

1 Clean or replace air filter

2, Clean or replace spark plug and regap

3, See "Carburetor Adjustments"

4 Contact your Sears Service Center

5 Contact your Sears Service Center

1 Clean or replace air filter

2 Refuel with correct fuel mixture

3 See "Carburetor Adjustments"

1 See "Fueling Your Unit"

2 See "Carburetor Adjustments"

3 Replace with correct plug

4 Contact your Sears Service Center.

1, Replace or see "Assembly"

2 See "Carburetor Adjustments 7

1 Remove cover Check line routing

2 Rewind spoo! firmly and evenly

3 Replace spool

I_ Use only 080" Sears Laser Line®

2 Reduce cutting speed aroundhardobjects

3. Cut with tip,of line.

22

Page 23

SEARS WEEDWACKER® REPAIR PARTS LIST - 358.797100-22.0cc

Operator's

Manual

r

28

21

13

14

_t6

18

19

-- 20

Key

Noo

1

2

3

4

5

6

7

8

9

10

11

12

13

14

Part

No. Description

580-094672

530-010957

STD541025

530-027595

530-069252

530-069280

STD511005

580-094570

STD541410

530-094671

580-094543

530-092243

530-094562

580-094525

Drive Shaft Housing

Handle

Locknut 114-20

Drive Shaft Grip

"T" Handle Kit

Shield Kit Ass'y. (IncL

#7,8,9 & 12)

Screw #t0-24x5/8

Line Limiter

Nut

Flexible Drive Shaft.

Dust Cup

Screw 1/4-10x1-1/16

Hub Ass'y,

Spring

Keyt

No.

15

16

17

18

19

20

21

22

23

#24

25

26

27

28

Part

No. Description

530-094523

580-015542

71-85810

580-094522

530-094521

71-85800

530-093653

530-030102

530-015768

580-015774

530-010959

530-067315

530-031111

530-031098

530-027480

580-027975

Spool Post

Screw #i0-24x5/8

Spool w/Line

Release Button

Cover

Cutting Head Ass'y.

Bracket

Shaft Lubrication

Nut #10-24

Screw #10-24xl

Throttle Lever Ass'y

Operator's Manual

Hex Wrench (5/32) _

Hex Wrench (3/16)

Shaft Warning Decal

Shield Decal

23

Page 24

I

Page 25

SEARS WEEDWACKER® REPAIR PARTS LIST - 358.797100-22.0cc

Key

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

2O

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

_36

38

39

40

41

42

43

44

45

46

47

_'48

49

Pa_t

No, Description

530-015778

530-027529

530-027530

530-015766

530-027528

530-015254

530-027526

530-027527

530-069247

530-010897

530-035262

530-019156

530-010729

530-015775

530-027955

530-027606

530-019154

530-027593

530-027594

530-014005

530-010945

530-015126

530-015772

530-015780

530-027546

530-027547

530-015771

530-014016

530-027545

530-027543

530-027525

530-014004

STD610603

530-015162

530-026413

530-019161

530-069274

530-015788

530-032103

530-015787

530-019158

530-032102

530-015789

530-015717

530-027781

530-069257

530-024903

530-012244

530-030077

Screw

Air Filter Cover

Air Filter

Screw

Spacer

Wave Washer

Choke Shutter

Air Filtgr _late

Fuel Line Flit

Fuel Pick-up Ass'y.

Carburetor .-

Carburetor Gasket

Fuel Cap Ass'y.

Screw

Throttle Cable Assay,

Shroud & Tank Ass'y.

Gasket

Reed

Reed Stop

Connecting Rod Ass'y,

(IncL Bearings)

Crankshaft Ass'y,

Flywheel Key

Screw

Screw

Kill Switch Insulator

Lead Wire

Screw

Crankcase Ass'y (Incl.

#39-42)

Kill Switch Ramp

Switch Spring Ass'y,

Spacer

Crankcase & Crankshaft

Ass'y, (Incl, #21,28,

38 & 43)

Screw

Piston Pin Retainer

Piston Ring

Cylinder Gasket

Piston Kit (Incl. #34,35 &

pin)

Spacer

Inner Bearing

Retaining Ring

Crankshaft Seal

Outer Bearing

Crankshaft Retaining Ring

Screw

Muffler Guard

Muffler Kit

Muffler Spring

Cylinder

Spark Plug

Key

No,

50

51

52

53

55

56

_57

58

59

"_60

61

62

64

65

66

68

',69

_70

7t

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

9O

Not Shown

Part

No. Description

530-015239

530-039134

530-015776

530-039136

530-014047

530-069291

530-027531

530-027569

530-069232

530-015823

530-027953

530-015127

530-015767

530-015768

530-015770

530-015769

530-015496

530-027523

530-069276

952-701612

530-035014

530-035151

530-035211

530-035212

530-035214

530-035217

530-035218

530-035166

530-035164

530-035203

530-035208

530-035028

530-035031

530-035188

530-035106

530-035178

530-035264

530-035219

530-027956

Screw

Ignition Module Kit

Screw

Flywheel Ass'y

Fan Housing Ass'y,

Stazter Pulley Kit

(Incl #60)

Starter Spring

Starter Handle

Rope Kit

Screw

Drive Coupling

Washer

Screw

Locknut

Screw

Screw

Screw

Pulley Retainer

Engine Gasket Kit (Hndi-

cares Contents)

Spark Arrestor Kit

Metering Dmphragm

*+ Metering Diaphragm Gasket

*+ Circlfit Plate Gasket

Mixture Needle

Mixture Needle Spring

Mixture Needle Washer

*+ "O" Ring MLxture

* + Fuel Pump Diaphragm

* + Fuel Pump Gasket

Idle Speed Screw

Idle Speed Spring

* Metering Lever Pin

* Metering Lever

* Metering Lever Spring

* Inlet Needle Valve

* Fuel Inlet Screen

Carb, Kwik Repair Kit

(*Indicates Contents)

Carb, Gasket/Diaphragm

Kit (+ Indicates Contents)

Instruction Decal

25

Page 26

.... i

gNDglg

,, I"%¸ ................. ', ..... u,,, ...........

ACCESSORIES

ADJUSTMENTS

Assist Handle ........

Carburetor .......

Line Advance ....

Module Air' Gap

Spark Plug Gap

AIR FILTER

ASSElVIBLY

Assist Handle

Drive Shaft Housing

Preparation ..........

Shield .........

Throttle Cable .......

Trimmer Head ........

TRI/_DIER LINE FEED .........

CARBURE'IOR ADJUSTMENTS

CARTON CONTENTS ....

COLD ENGINE STARTING .....

CONTROLS .............

CUTTING METHODS ............

20

2O

14

2

2

17

8

7

7

8

9

14

20

6

I2

2

15

17

20

2

I1

28

t2

.5

22

lI

It

17

19

I1

I1

11

11

21

I1

Ii

20

14,22

17,22

27

16

I7

16

14

17

I6

22

DRIVE SHAFr HOUSING ASSEMBLY .......

ENGINE

Air Filter

Carburetor

Controls

Fue! Mixture ......

Starter Pulley

Starting Instructions

Storage .,

Trouble Shooting

ENGINE OIL

Ratio to Gasoline .....

Types to Use; not to Use

FILTER, AIR ...................

FLEXIBLE DRIVE SHAFT LUBRICATION

FUEL

Gasoline/Oil Mixture

Mixing Fuel

Pouring Fue!

Safety

Storage

GASOLINE

Patio to Oil

Types to Use; not to Use.

IDLE SPEED ADJUSTMENT

LINE

Advance

Breaking .......

Length to Cut as Replacement

Replacement ....

Rewinding on Spool

Routing in Head

Safety .......

Size to Use ....

Welding onto Spool .....

Trouble Shooting ....

LUBRICATION

Engine .... 11

Flexible Drive Shaft 29

MAINTENANCE

Air Filter 27

Carburetor 20

Flexible Drive Shaft 29

Safety _ 17

Starter Rope 18

Trimmer Head 16

Trouble Shooting Chart 22

MODULE AIR GAP 2

OIL, ENGINE

Ratio to Gasoline II

Types to Use: not to Use I!

OPERATION

Advancing the Line 14

Mowing . 15

Pre-Operation Checks 12

Position l0

Safety 14

Scalping. 15

Starting the Engine 12

Speed , 23

Stopping the Engine 13

Sweeping 15

Trimming 15

PARTS LIST ............. 23

PRE-OPERATION CHECKS t2

PREWOUND SPOOLS , ,. 16

QUICK REFERENCE PAGE

SHIELD ASSEMBLY .9

REPAIR PARTS LIST .............. 23

SAFETY INSTRUCTIONS, WARNINGS 3 & 5

SPARK PLUG GAP ............ 2

SPARK ARRESTOR- SPECIAL NCfI'ICF 6

SPECIFICATIONS

SPOOL

Installation 16

Maintenance 16

Prewound 16

Rewinding ............. 17

STARTER ROPE REPLACElVIENT I8

STARTING INSTRUCTIONS . 12

STORAGE ............. 5,22

THROTTLE CABLE ASSEMBLY g

TRIMMER HEAD

Assembly. 9

Line Routing , 16

Removal. 8

Maintenance ............. 16

TROUBLE SHOOTING CHART 22

WARM ENGINE STARTING .............. 1.2

WARM ENGINE STARTING AFTER RUNNING

OUT OF FUEL ...................... 1,3

WARNINGS AND SAFETY INSTRUCTIONS 3 & 5

WARRANTY ......... 2

26

Page 27

QUICK REd.NeE PAGE

Read and Follow All Warnings, Safety Instructions and Opera_g Instructions.

Failure to do so can result in serious injury_

Page No.

PREPANAT_ON ............................................ $ _ 5

1 Know all warnings and safety instructions in this manua[

2 Wear safety face shield or goggles for eye protection

3 Dress safely - boots or safety shoes and heavy, long pants

4 Check tool for worn, loose, missing or damaged parts; repair or replace as necessary before using the tool

5 Inspect and ensure the area to be cut is safe

6 Keep children, bystanders, and animals 30 feet away

$_JELglgG .................................................. 11

I Eliminate all sources o[ sparks or flame where fuel is mixed, poured or stored

2 Use !6 parts regular unleaded gasoline to 1 part air-cooled, 2- cycle engine oil

3 Use clean and fresh fuel not over 2 months old

4 Mix and store fuel in an approved, marked container

5 Mix and pour fuel in an outdoor area

6 Move a minimum of t0 feet away from the fuel and fueling site beIore starting engine

START_G THE ENGLN'E ....................................... L_

I Extend line 4-6 inches from the head

2 Rest the shietd on the ground supporting the trimmer head up offthe ground away fiomlobiects and on-lookers.

3 Keep throttle trigger squeezed fully until engine runs

4 Pull the starter rope sharply and quickly

OPENATgNG _ '_N_IL ........................................ 11.3

1 Do not operate the tool at a higher speed than necessary

2 Release the throttle trigger and allow the engine to idle when not cutting

3 Stop the engine by moving the ignition switch to the "Off" position

¢_ • • _t ,m • • t* *1 t_ tl t* ,t, ,_ _ e J t, _, ¢j • _t • s m e, *, _ _ • i, • • ¢0 _ ,i _ _ o i, u • • _ ,m

1 Drain fuel from the unit before storing

2 Disconnect spark plug before performing maintenance except for carburetor adjustments

3 Clean air filter frequently but always after 5 tanks of fuel

4 Store in a dry place out of the reach of children

27

Page 28

operator's

manual

MODEL NO,

353.797!00-22cc

(15" Cutting Path)

How to Order

Repair parts

SEARS SERVICE

IS AT YOUR SERVICE

The Model Number will be found on top of the engine with the Serial Number, Always

mention the Model Number when requesting service or repair for your unit,

All parts listed herein may be ordered from any Sears Service Center and most Sears

Stores

WHEN ORDERING REPAIR PARTS GIVE THE FOLLOWING INFORMA-

TION AS SHOWN IN THIS LIST,

I The PART NUMBER ' 3 The PART DESCRIPt7ON

2 The MODEL NUMBER

358.797100

4 The NAME OF ITEM --

22cc Gas Weedwacker _

If the parts you need are not stocked locally, your order will be electronically transmit-

ted to a Sears Repair Parts Distribution Center for handling.

When you buy merchandise from

Sears you get an extra something that

nobody else can offer Sears Service

Across town or across the country,

Sears Service follows you, providing

trustworthy, competent service techni-

cians using only Sears specified factory

parts

Your Sears Merchandise takes on added value when you discover that Sears has Ser-

vice Units throughout the country Each is staffed by Sears-Trained. professional

techniciatl5 using Sears approved methods

Sears, Roebuck and Co., Chicago, Ill. 60684 U.S.A.

530-067315-1-01289 PRINTED tN U S A

Loading...

Loading...