Page 1

operator's

manual

MODEL NO.

358.796131-26.2cc

___WARNING:

Carefully read and follow

Safety Rules, Precautions

and Operating Instructions.

Failure to do sO-can result in

serious personal injury.

Sold by Sears, Roebuck and Co., Chicago, Ill. 60684 U.S.A.

RnFT,SMn

GAS WEEDWACKER ®

Fuel Mix 16:1 2 Cycle Engine

• Assembly • Maintenance

• Operation • Repair Parts

Always Wear Eye Protection During Operation

66706-1-34385-1-34485 PRINTED IN U.S.A.

Page 2

FULL ONE YEAR WARRANTY ON SEARS CRAFTSMAN GAS WEEDWACKER

Ifthis CRAFTSMAN GAS WEEDWACKER trimmer fails toperform properlydue to adefect inmateria! or workmanshipwithin

one year ofpurchase, Sears will repair it, free of charge.

_fthis _RAFTS"_AN GAS _EE _A_KER_ trimmer is usedf_r c_mmercia_ _rrentaI purp_ses thiswarranty c_v`erage app_ies

for only g0 days from the date of pumhase. , -, --" "-

WARRANTY SERVICE IS AVAILABLE BY CONTACTING THE NEAREST SEARS SERVICE CENTER/DEPARTMENT

THROUGHOUT THE UNITED STATES.THIS WARRANTYAPPLIES ONLY WH ENTHIS PRODUCTtS IN USE INTHE UNITED

STATES.

This warranty gives you specific legal rights, and you mayalso have other rights which vary from state to state.

/ , - • , ..... • t t , , • / , i ,

®

SEARS, ROEBUCK AND CO. / DEPT. 698/731A / SEARS TOWER / CHICAGO, IL 60684

TABLE OF CONTENTS

Safety Rules and Precautions ................... 3

Know Your WEEDWACKER ® Trimmer ............. 4

Assembly - 5

Engine Information ............................ 6

A. FuelingYourUnit .......................... 6

B. Pre-operation Checks ....................... 7

C. StartingInstructions ........................ 7

D.Operating Instructions ...................... 9

E. Engine Adjustments ........................ 9

Using YourUnit .............................. 10

A. OperatingInstructions ..................... 10

B.AdvancingThe Cutting Line ................. 10

C. Cutting Methods .......................... 11

D.Cutting Head Maintenance .................. 12

General Maintenance ......................... 14

A. Drive Shaft Lubrication ..................... 14

B.Air Filter Care ............................ 14

C. Fuel Tank Upkeep ......................... 14

D.Starter Rope Repair ....................... 15

E. Trouble Shooting Chart ..................... 16

Accessories ................................ 17

Parts List ................................ !8-24

Quick Reference Page ........................ 27

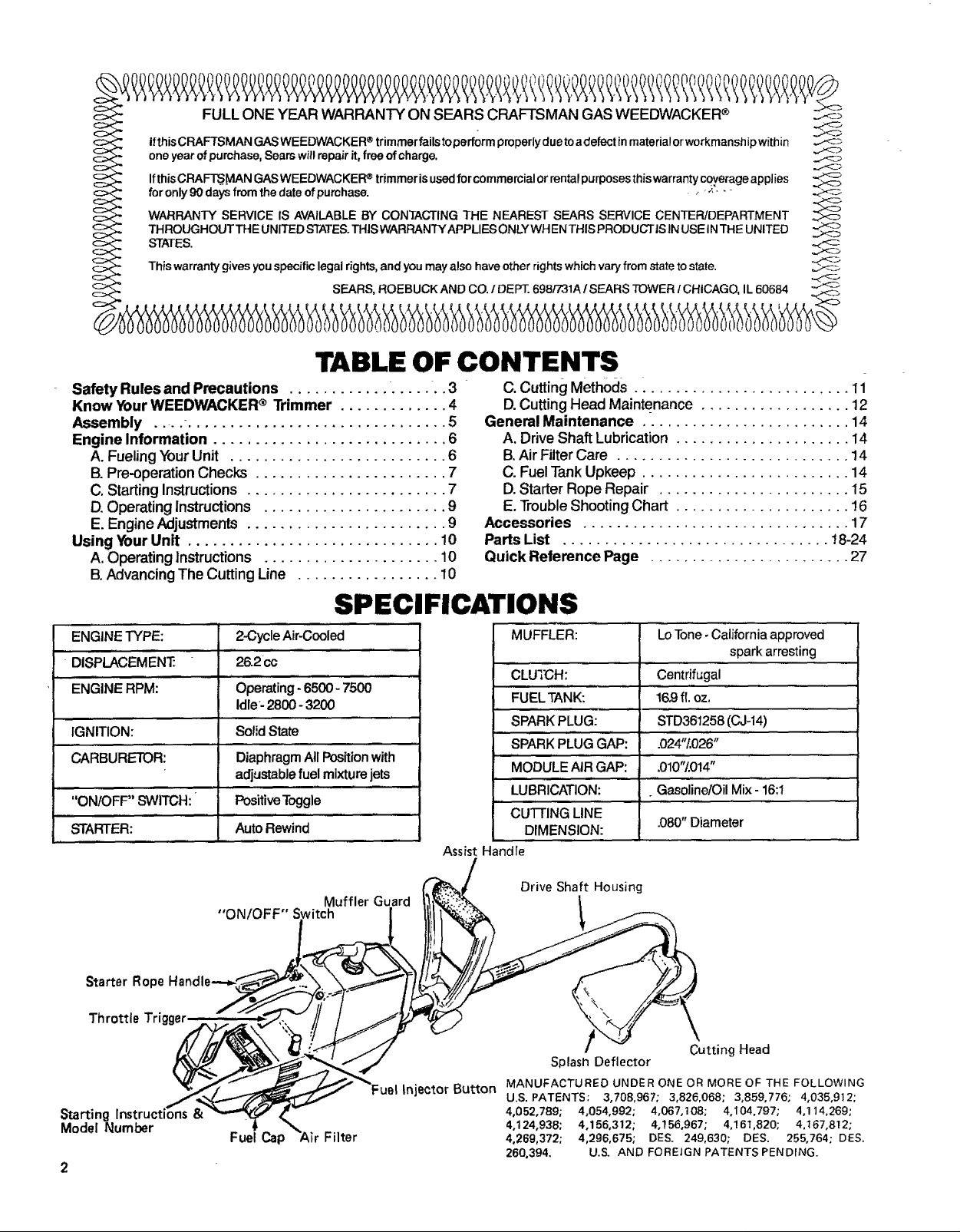

SPECIFICATIONS

ENGINE"I_PE: 2-CycleAir-Cooled

DISPLACEMEN'£ 26.2cc

ENGINERPM: Operatingo6500- 7500

Idle-2800- 3200

IGNITION: SolidState

CARBURETOR: DiaphragmAllPositionwith

adjustablefuelmixturejets

"ON/OFF' SWITCH: PositiveToggle

STARTER: Auto Rewind

Muffler Guard

Starter Rope

Throttle Trigger

Starting Inst

Model Number

"ON/OFF" Switch

Fuel Cap Filter

Assist Handle

Injector Button

MUFFLER: LoTone-Californiaapproved

spark arresting

CLUTCH: Centrifugal

FUELTANK: 16.9fl. oz.

SPARKPI"UG: STD3"6i258((_J-14)

SPARKPLUGGAP: .024"/.02t_"

MODULEAIRGAP: ,010't/,014 "

LUBRICATION: . Gasoline/OilMix-16:1

cUTrlNG LINE

DIMENSION:

Drive Shaft Housing

Splash Deflector

MANUFACTURED UNDER ONE OR MORE OF THE FOLLOWING

U.S. PATENTS: 3,708,967; 3,826,068; 3,859,776; 4,035,912;

4,052,789; 4,054,992; 4,067,!08; 4,I04,797; 4,114,269;

4,124,938; 4,156,312; 4,156,967; 4,161,820; 4.167,812;

4,269,372; 4,296,675; DES. 249,630; DES. 255,764; DES.

260.394, U.S. AND FOREIGN PATENTS PENDING.

.080"Diameter

Cutting Head

Page 3

SAFETY RULES AND PRECAUTIONS

Failure to follow safety rules and precautions could result in serious personal injury.

AI

KNOW YOUR UNIT

1. Read your Operator's Manual carefully until

you completely understand and can follow

all safety rules, precautions and operating

instructions before operating the unit.

2 Restrict your unit to users who understand

and follow all safety rules, precautions, and

operating instructions found in this manual.

B. PLAN AHEAD

Always wear eye protection. The

1. splash deflector/line iimiter willnot

prevent rocksand debris frombeing

--and face which can result In loss of vision or

serious personal injury.

2. Dress safely in long pants and wear boots or

safety shoes. Do not wear loose clothing,

jewelry, short pants or sandals; or go barefoot.

3. Do not operate the unit when you are tired,

ill, or upset; or if you have taken alcohol or

drugs/medication.

4. Inspect the area to be cut before starting the

unit. Remove all debris and objects that can

ricochet,be thrown,become entangledinthecutting

head, or cause injuryor damage duringcutting.

5. Keep children, bystanders and animals a safe

distance away from the work area -- a minimum

of 30 feet (10 meters).

C. HANDLE FUEL WITH CAUTION

1. Eliminate all sources of sparks or flame (in-

eluding smoking, open flames, or work that

could cause sparks) in the areas where fuel

is mixed, poured, or stored.

2. Mix and pour fuel in an outdoor area; store fuel in

a cool, dry, well-ventilated place; and use an

approved, marked container for allfuel purposes.

3. DO .n_oLsmoke while handling fuel or while

operating the unit.

4. Wipe up all spills before starting the eng'ine.

5. Move at least 10 feet (3 meters) away from

fuel and fueling site before starting the

engine.

thrown or ricocheting into the eyes

De

OPERATE YOUR UNIT SAFELY

1. Inspect the entire unit before each use for loose,

missing or damaged parl_Do not useuntil the unit

isin properworkingorder.

2. Use only flexible, non-metalic, monofilament

cutting line. Do notuseothermaterialssuchas rope,

wire,etc. Wirecan break offduring cutting and be -

come a dangerous missile.

3. Make sure the cutting head stops turning

when the throttle trigger is released and the

engine runs at idle speed. For correction,

refer to "Carburetor Adjustments," page 9.

4. Keep the handles free of oil and fuel.

5. Never start or run the engine inside a closed

room or building. Exhaus[ _LJmes contain

dangerous carbon monoxide.

.

Keep your body clear of the cutting head

while the unit is in use.

7.

Do not operate in a position over waist high.

8.

Do not overreach. Keep firm footing and

balance at att times.

9.

Run the engine at full throttle only when

cutting.

10.

Stop the engine before removing the fuel

cap.

11.

Use only for jobs explained in this manual.

El

MAINTAIN YOUR UNIT PROPERLY

1. Maintain the unit according to recommend.

ed procedures.

2. Disconnect spark plug before performing

maintenance except for carburetor adjustment.

3. Use only recommended replacement •parts.

The use of any part, or accessory not specifically

designed forthis unit couldcreate ahazardand/or void

your warranty.

4. Drain fuel from the fuel tank before storing

for 30 or more days.

5. Do not store theunit or fuel in a closed area

where fuelvaporsocan reach sparks or an

open flame from hot water heaters, furnaces,etc.

6. Store in a dry ar.ea out of the reach of

children.

i_WAR NI NG

The lower unit of this machine is designed as a line

trimmer only, andmust not be equipped with any type

blade. Serious injury can occur to the user or

bystanders because:

The necessary protective devices for blade useare

not part of-the lower unit.

-- Some blades are not designed for the high speed

this engine produces. This can cause Injury due to

blade failure.

Do not use any attachment with this engine other than

those supplied by the manufacturer and specifically

recommended for this power head. Serious injury to

the user or damage to the engine can resultotherwise,

STATE AN D LOCAL

ORDINANCE REQUIREMENTS

Your engine is equipped with a temperature limiting

muffler and spark arresting screen which meets the

requirements of California Codes 4442 and 4443. All

U.S. Forest Land and the states of California, Maine,

Oregon,and Washingtonrequire bylaw thatcertaininter-

nal combustion engines operated on forest, brush, and

grass covered areas be equipped with a temperature

limiting muffler and/or spark .arresting screen. If you

operate an internal combustion engine in a state or

locale where such regulations exist, you are legally

responsible for maintaining the operating condition of

these parts. Failure to do so can subject you to

liability or to a fine.

Page 4

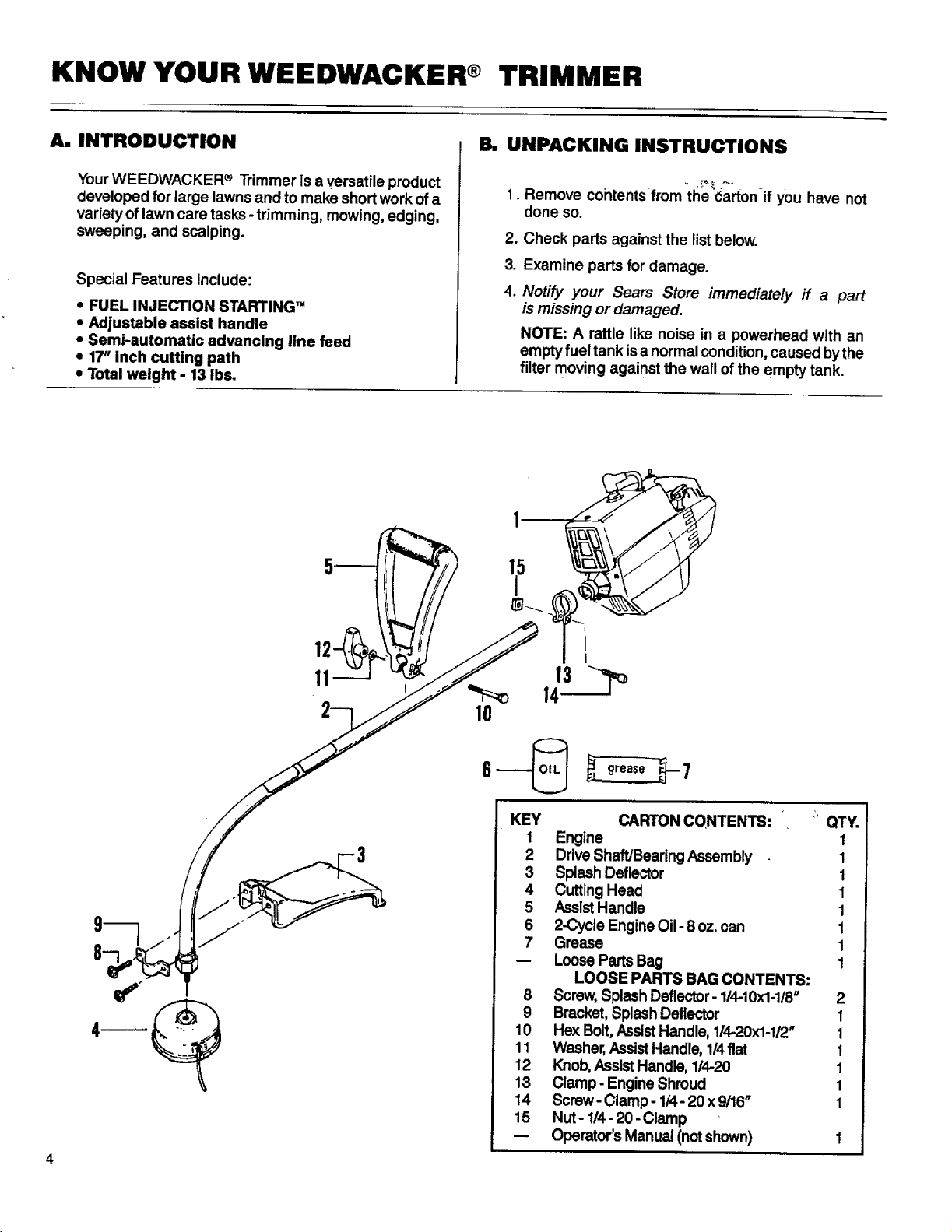

KNOW YOUR WEEDWACKER ® TRIMMER

A. INTRODUCTION

Your WEEDWACKER ® Trimmer is a versatile product

developed for large lawns and to make short work ofa

variety of lawn care tasks -trimming, mowing, edging,

sweeping, and scalping.

Special Features include:

• FUEL INJECTION STARTING"

• Adjustable assist handle

• Semi-automatic advancing line feed

• 17" inch cutting path

• Total weight -13 ibs. -

B. UNPACKING INSTRUCTIONS

°

Remove contentsfrom the Carton if you have not

done so.

,

Check parts against the listbelow.

3

Examine parts for damage.

4

Notify your Sears Store immediately ff a part

is missing or damaged.

NOTE: A rattle like noise in a powerhead with an

emptyfuet tank isanormal condition,caused by the

filter moving against the wall of the empty tank.

..

10

,,'L__m

KEY

1

Engine 1

2

DriveShaft/Bearing Assembly 1

3

SplashDeflector 1

4

CuttingHead 1

5

AssistHandle 1

6

2-Cycle Engine Oil - 8 oz. can 1

7

Grease 1

LooseParts Bag 1

8

Screw, SplashDeflector- 114-10x1-1/8" 2

9

Bracket,Splash Deflector 1

10

Hex Bolt,AssistHandle, 114-20x1-1/2" 1

11

Washer,AssistHandle, 1/4fiat 1

12

Knob, AssistHandle, 114-20 1

13

Clamp - Engine Shroud 1

14

Screw- Clamp - 1/4- 20 x 9/16" 1

15

Nut - 1/4- 20 -Clamp

Operator's Manual (not shown) 1

CARTON CONTENTS: '" QTY.

LOOSE PARTS BAG CONTENTS:

Page 5

ASSEMBLY

A. PREPARATION

Your Operator's Manual has been developed to help

you assemble the unit and to understand its safe opera-

tion. It is important that you read your manual com-

pletely to become familiar with the unit before you begin

assembly.

I. READ YOUR OPERATOR'S MANUAL.

2. Tools you will need:

a:

/

Z" 1-1/4inch Wrench

7116inch Wrench "

3/8 inch Wrench

or

Z

Adjustable Wrench

b. _ _

_ Slotted Screwdriver

CLAMP ___J ._

ASSEMBLYSTEPS

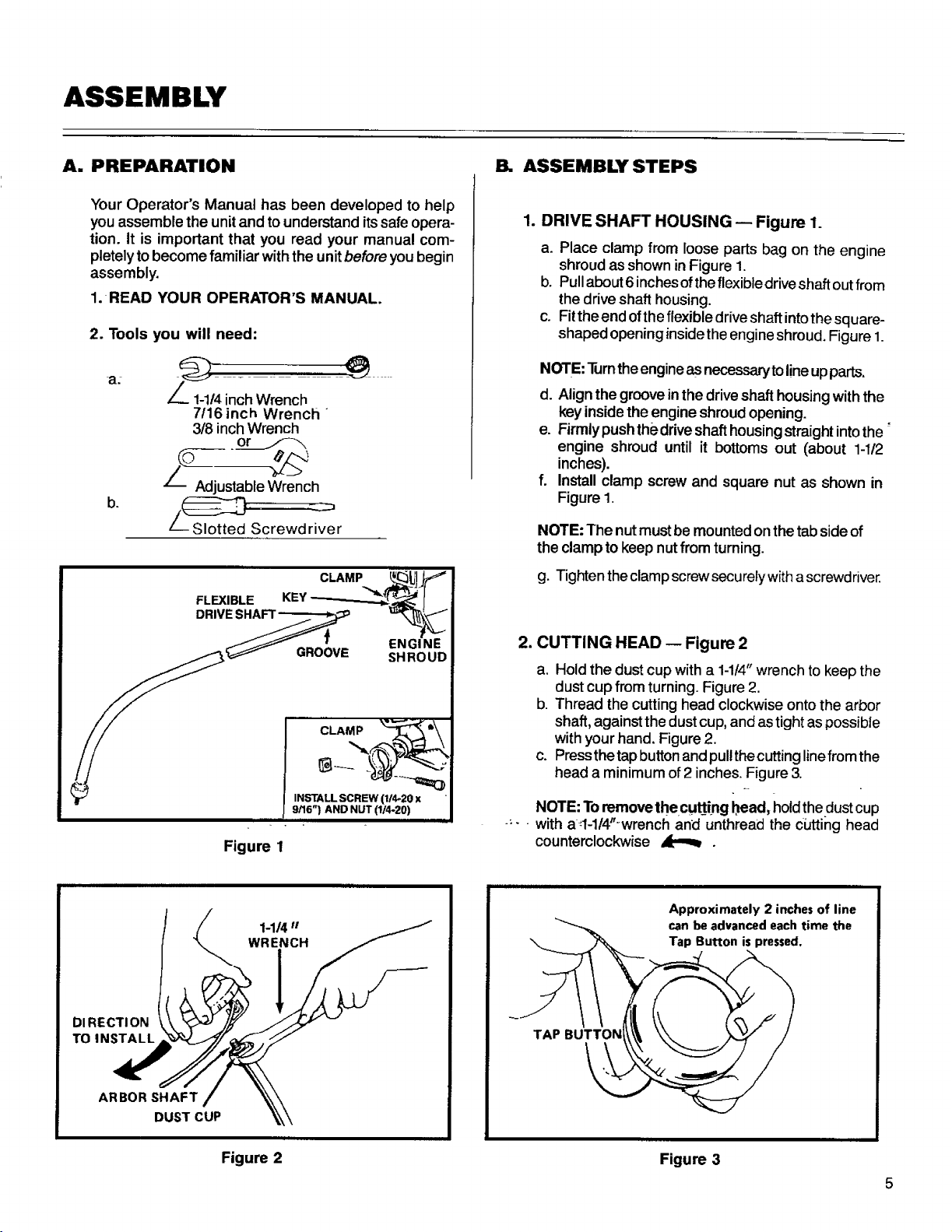

1. DRIVE SHAFT HOUSING -- Figure 1.

a. Place clamp from loose parts bag on the engine

shroud as shown inFigure 1.

b. Pull about 6inches ofthe flexible drive shaft out from

the drive shaft housing.

c. Fitthe end of the flexible drive shaft intothesquare-

shaped opening insidethe engine shroud. Figure 1.

NOTE: Turntheengine as necessarytolineupparts.

d. Alignthe groove in the drive shaft housing with the

key inside the engine shroud opening.

e. Firmly push the drive shaft housing straight into the"

engine shroud until it bottoms out (about 1-1/2

inches).

f. Install clamp screw and square nut as shown in

Figure 1.

NOTE: The nutmust be mountedon thetabside of

the clamp to keepnut from turning.

g. Tighten the clamp screw securerywith ascrewdriver.

DRIVE SHAFT _ _

.o'ovo

DI RECTI ON

TO INSTALL

Figure 1

1-1/4"

WRENCH

2. CUTTING HEAD -- Figure 2

a. Holdthe dust cup with a 1-1/4"wrench tokeep the

dust cup fromturning. Figure 2.

b. Thread the cutting head clockwise onto the arbor

shaft, against the dust cup, and as tight aspossible

with your hand. Figure 2.

c. Press the tapbutton and pullthe cutting linefrom the

head a minimum of 2 inches. Figure 3.

NOTE: Toremove the cu_ing bead, hold thedust cup

.... with at-l/4"-wrench and unthread the cutting head

counterclockwise &[_,_ .

Approximately2inchesof line

canbeadvanced each timethe

L.

ARBOR SHAFT

DUST CUP

Figure 2

Figure 3

Page 6

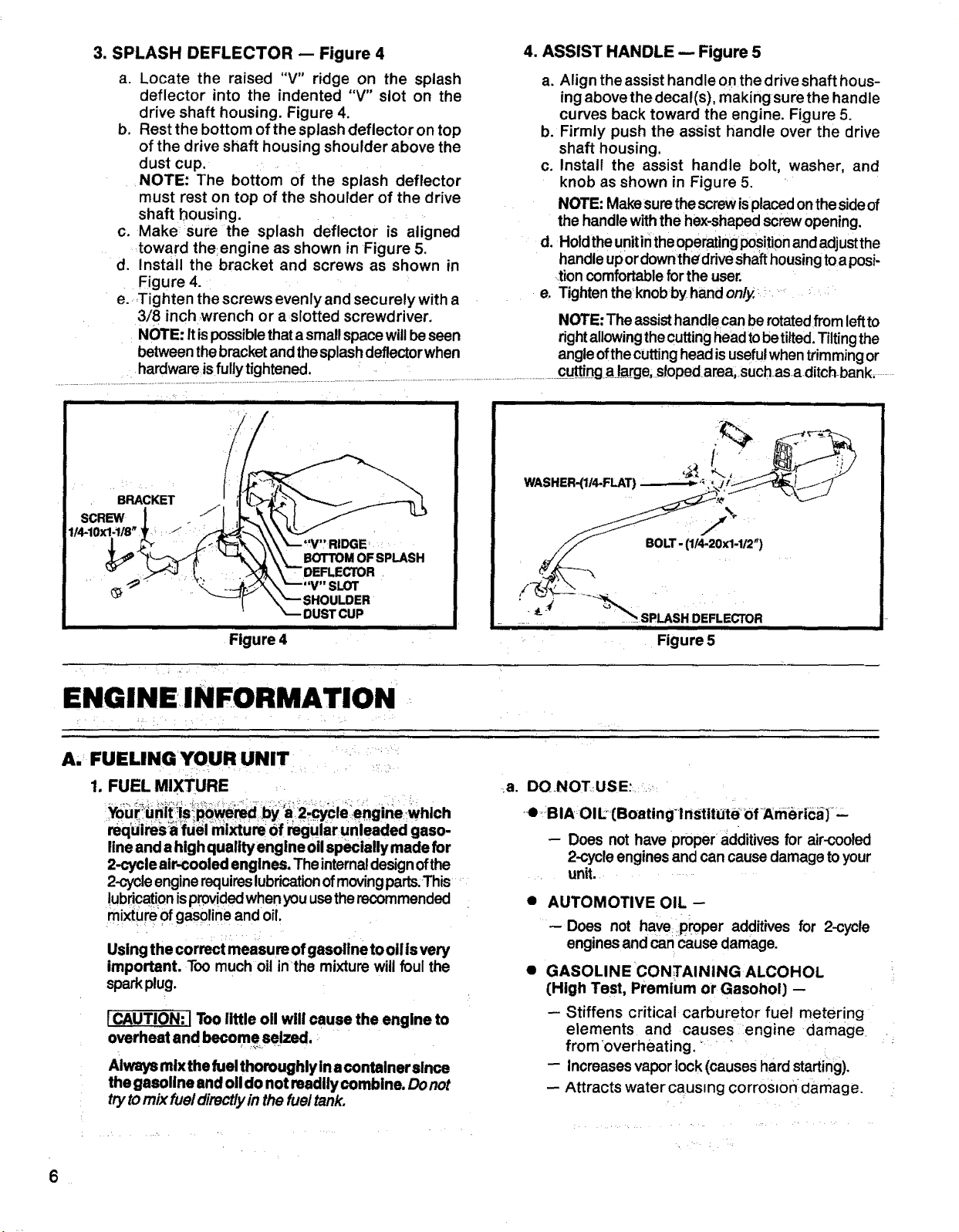

3. SPLASH DEFLECTOR -- Figure 4

a. Locate the raised "V" ridge on the splash

deflector into the indented "V" slot on the

drive shaft housing. Figure 4.

b. Rest the bottom of the splash deflector on top

of the drive shaft housing shoulder above the

dust cup.

NOTE: The bottom of the splash deflector

must rest on top of the shoulder of the drive

shaft housing.

c. Make sure the splash deflector is aligned

toward the:engine as shown in Figure 5.

d. Install the bracket and screws as shown in

Figure 4.

e. _Tighten the screws evenly and secu rely with a

3/8 inch wrench or a slotted screwdriver.

NOTE: It ispossible that a smallspacewill beseen

between the bracket and the splashdeflector when

4. ASSIST HANDLE -- Figure 5

a. Align the assist handle onthe drive shaft hous-

ing above the decal(s), making surethe handle

curves back toward the engine. Figure 5.

b. Firmly push the assist handle over the drive

shaft housing.

c. Install the assist handle bolt, washer, and

knob as shown in Figure 5.

NOTE: Makesurethescrewisplacedonthe sideof

the handle withthe hex-shapedscrewopening,

d. Holdthe unitinthe operatingPositionand adjustthe

handleupor downthe'driveShafthousingtoa posi-

,tion comfortableforthe user.

e, Tightentheknobby handonly,+.;+. .....

NOTE: The assist handle canbe rotated from leftto

rightallowingthecuttinghead tobe tilted.Tilting the

angle ofthecuttinghead is usefulwhentrimmingor

iii iiiiililli ¸

I14-10X1-I18" ,++ :-_ " +

.... • • iiiiiiiiii ii i ii iiii

l R=O

+ '_.__._.S_,.-,,"---v SLOT

-. s.ouLoE.

ii iiii

..... DUST CUP ,, ......

Figure 4

ENGINEINFORMATION

A,: FUELINGYOUR UNIT ...._:_ _ :+

1. FUEL MIXTURE

require_;:_ifuel mixture Ofregularunleaded gaso-

lineand ahigh qualltyengine oil specially made for

2-cycleair-cooled engines. The internaldesignofthe

2-cycleenginerequireslubricationofmoving parts,This.....

!ubric=i0 nisp[0videdwhenyouusethe recommended

mixture of gasol ineand oil.

Using the correct measure of gasoitne to oll isvery

important. Too much oit in'the mixture will foul the

sparkplug.

ICAUTION: I Too little oll will cause the engine to

overheat and become seized. _

Always mix the fuel thoroughly in acontainer since

the gasoline and oil do not readily combine. Donot

tryto mix fueldirectlyinthe fuel tank.

' + i '' .... ;: "

, . _ . :

"""I=IIHIIII I + ""111 I L

WASHER-(1/4-FLAT)

BOLT -(1/4-20x1-1/2")

_ SPLASH DEFLECTOR

III

Figure 5

a. DONOTUSE:_ _..._'

.

•,e•BIAOIi.:[Boating-lnStitUte _of+Amei+ic_)+

- Does not have proper additives for air-cooled

2-cycleengines and can causedamage to your

• unit. ..............

• AUTOMOTIVE OIL --

--Does not haveproper additives for 2-cycle

. .' ;

engines and can cause damage.

• GASOLINE CON;rAINING ALCOHOL

(High Test, Premium or Gasohol) --

-- Stiffens critical carburetor fuel metering

elements and causes engine damage

from _overheating. +'

-- Increasesvapor lock(causes hardstarting).

-- Attracts watercausmg corros=on_damage

6

Page 7

b. USE THE

FOLLOWING:

3. IMPORTANT POINTS TO REMEMBER

M

1GALLON

REGULAR

UNLEADED

GASOLINE

+ --OR-- =

2. HOW TO MIX FUEL AND FILL TANK

-a. Pour 112gallongasoline into an approved marked

container.Do not try tomix fueldirectly in the fuel

tank.

b. Add entiremeasure of2-cycleengine oil.

c. Cover containertightlyand shake forone minute.

d. Add remainder ofgasoline.

e. Cover containertightlyand shake again.

f. Remove thefuel cap. Referto "Specifications", page

2, for fuel cap location.

g. Fill the tank using a spout or funnel.

h. Reinstall the fuel cap securely.

B. PRE-OPERATION CHECKS

Before operating your unit, always:

1. v, CHECK OVER SAFETY RULESAND PRECAU-

TIONS inthisOperator's Manual. Make certain you

completely understandand follow e&chone.

2. _, CHECK THE AtR FILTER

Clean the filter ifdirty beforeoperating the unit.For

location, seepage 14.

a. Use only recommended fuel mixtures.

b.

Eliminate all sources of sparks or flame in

the areas where fuel is mixed, poured, or

stored. There should be no smoking, open

flames or work that could cause sparks.

C.

Use anapproved, marked container for all fuel

purposes.

d,

Mix and pour fuel in an outdoor area. Store fuel

in a cool, dry, well-ventilated place. Gasoline

vaporsare harmful to your health and can cause

serioushazards,such as explosionandfire.

e,

Wipe up all fuel spills before starting the

engine.

f.

Move at least 10 feet (3 meters) away from fuel

and fueling site before starting the engine.

,

v-CHECK THE UNIT FOR LOOSE BOLTS, NUTS,

OR FITTINGS.

Tighten, repairor replace parts as necessary.Tools

required are shown on page 5. Use only recom-

mended, genuine Sears/Craftsman replacement

parts.

4

_-CHECK THE FUEL TANK.

Fill with a clean, fresh fuel mixture according to

instructionsinfuel mixturesection.

C. STARTING INSTRUCTIONS

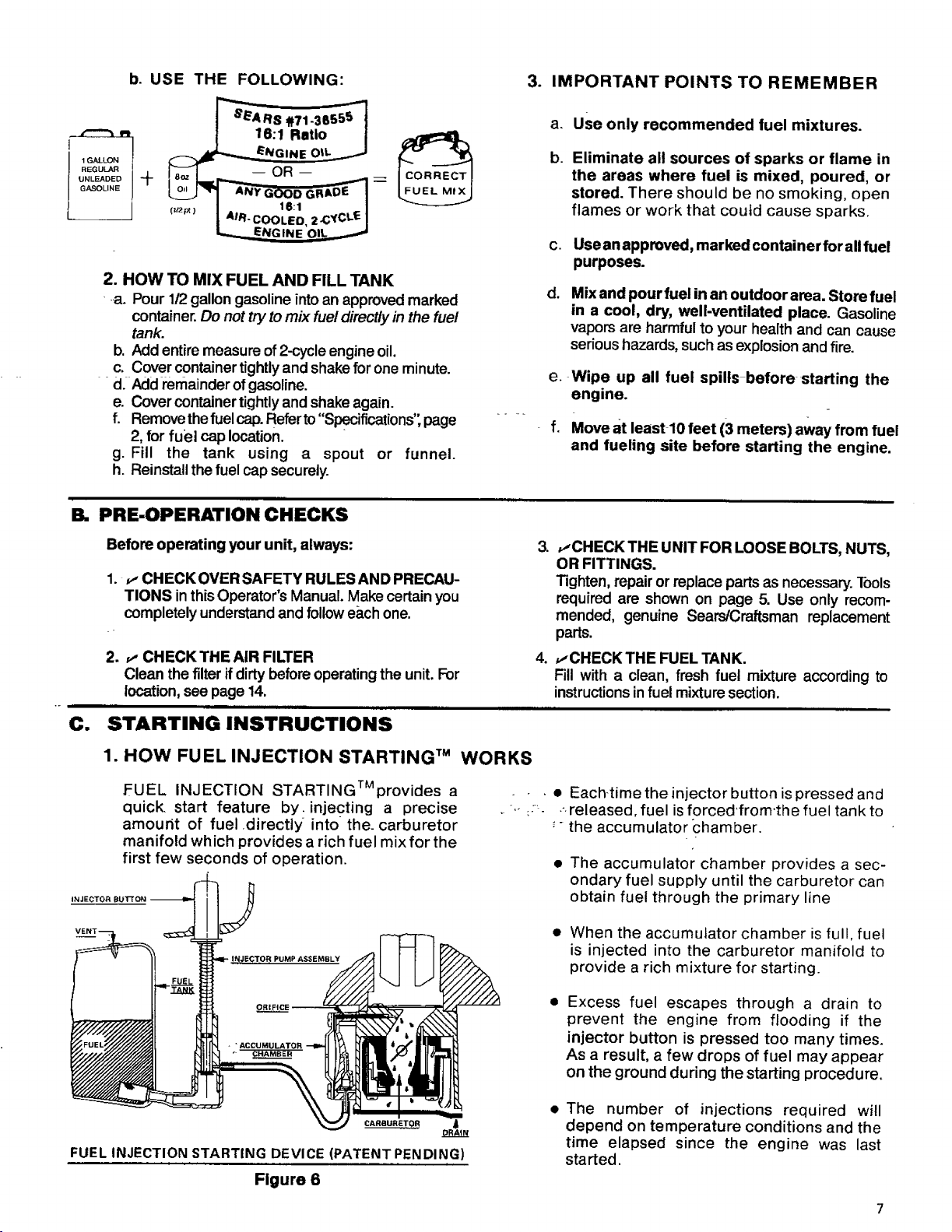

1. HOW FUEL INJECTION STARTING TM WORKS

FUEL INJECTION STARTINGTMprovides a

quick, start feature by. injecting a precise

amount of fuel .directly into the. carburetor

manifold which provides a rich fuel mix for the

first few seconds of operation.

INJECTOR BuI-r ON

CARBURETOR

FUEL INJECTIONSTARTING DEVICE (PATENT PENDING)

Figure 6

DRAIN

- . • Each-time the injector button is pressed and

-.+.:_- ---released, fuel is forced'from'the fuel tank to

'- the accumulator c:hamber.

• The accumulator chamber provides a sec-

ondary fuel supply until the carburetor can

obtain fuel through the primary line

• When the accumulator chamber isfull, fuel

is injected into the carburetor manifold to

provide a rich mixture for starting.

Excess fuel escapes through a drain to

prevent the engine from flooding if the

injector button is pressed too many times.

As a result, a few drops of fuel may appear

on the ground during the starting procedure.

The number of injections required will

depend on temperature conditions and the

time elapsed since the engine was last

started.

Page 8

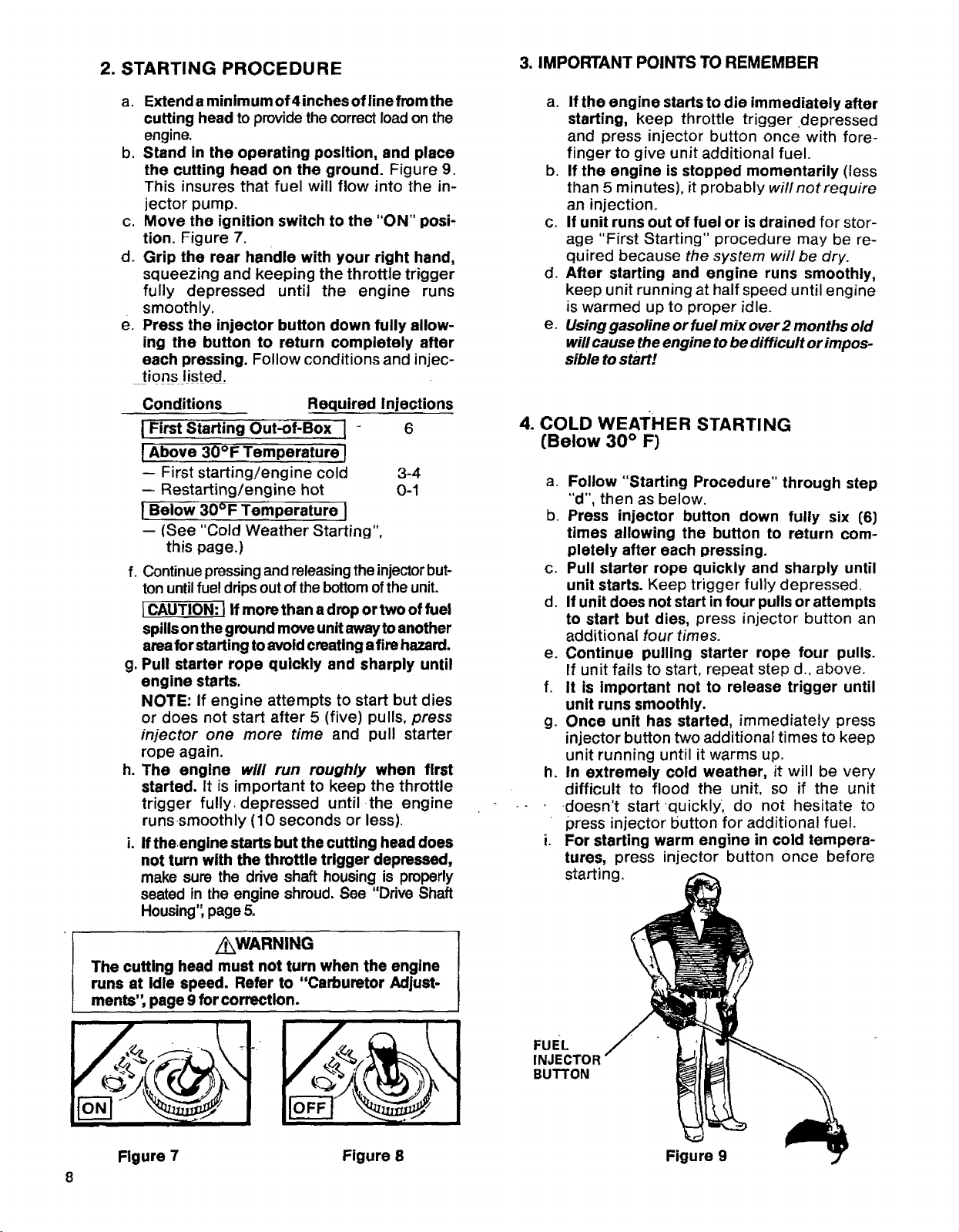

2. STARTING PROCEDURE

3. IMPORTANT POINTS TO REMEMBER

a. Extenda minimumof4inchesoflinefromthe

cutting head to providethe correctload on the

engine.

b. Stand in the operating position, and place

the cutting head on the ground. Figure 9.

This insures that fuel will flow into the in-

jector pump.

c. Move the ignition switch to the "ON" posi-

tion. Figure 7.

d. Grip the rear handle with your right hand,

squeezing and keeping the throttle trigger

fully depressed until the engine runs

smoothly.

e. Press the injector button down fully allow-

ing the button to return completely after

each pressing. Follow conditions and injec-

tions listed.

Conditions

I First Starting Out-of-Box [ -

[ Above 30°F Temperature_

-- First starting/engine cold

-- Restarting/engine hot

{Below 30°F Temperature ]

-- (See "Cold Weather Starting",

this page.)

f. Continue pressing and releasing the injector but-

ton untilfuel drips out of the bottom of the unit.

[CAUTION: ] If more than a drop ortwo of fuel

spills onthe ground moveunit away toanother

area for starting to avoid creating a fire hazard.

g. Pull starter rope quickly and sharply until

engine starts.

NOTE: If engine attempts to start but dies

or does not start after 5 (five) pulls, press

injector one more time and pull starter

rope again.

h. The engine will run roughly when first

started. It is important to keep the throttle

trigger fully depressed until the engine

runs smoothly (10 seconds or less)

i. If theengine starts but the cutting head does

not tum with the throttle trigger depressed,

make sure the drive shaft housing is properly

seated in the engine shroud. See "Ddve Shaft

Housing",page 5.

Required Injections

6

3-4

0-1

a. If the engine starts to die immediately after

starting, keep throttle trigger depressed

and press injector button once with fore-

finger to give unit additional fuel.

b. If the engine is stopped momentarily (less

than 5 minutes), it probably will not require

an injection.

c. If unit runs out of fuel or is drained for stor-

age "First Starting" procedure may be re-

quired because the system will be dry.

d. After starting and engine runs smoothly,

keep unit running at half speed until engine

is warmed up to proper idle.

e Usinggasoline orfuelmix over2 months old

will cause the engine to bedifficult or impos-

sible to start!

4. COLD WEATHER STARTING

(Below 30 ° F)

a. Follow "Starting Procedure" through step

"d", then as below.

b. Press injector button down fully six (6}

times allowing the button to return com-

pletely after each pressing.

c. Pull starter rope quickly and sharply until

unit starts. Keep trigger fully depressed.

d. If unit does not start in four pulls or attempts

to start but dies, press injector button an

additional four times.

e. Continue pulling starter rope four pulls.

If unit fails to start, repeat step d., above.

f. It is important not to release trigger until

unit runs smoothly.

g. Once unit has started, immediately press

injector button two additional times to keep

unit running until it warms up.

h. in extremely cold weather, it will be very

difficult to flood the unit, so if the unit

doesn't start-quickly, do not hesitate to

press injector button for additional fuel.

i. For starting warm engine in cold tempera-

tures, press injector button once before

starting.

/_WARNING

The cutting head must not turn when the engine

runs at idle speed. Refer to "Carburetor Adjust-

merits", page 9 for correction.

FuEL

INJECTOR

BUTTON

Figure 7 Figure 8 Figure 9

Page 9

D=

OPERATING INSTRUCTIONS

For maximum performance and efficiency:

1. Always accelerate the engine to the desired

speed before cutting.

2, Never operate the engine at a higher speed

than necessary.

3. Always release the trigger and allow the en-

gine to return to idle speed when not cutting.

Sm

ENGINE ADJUSTMENTS

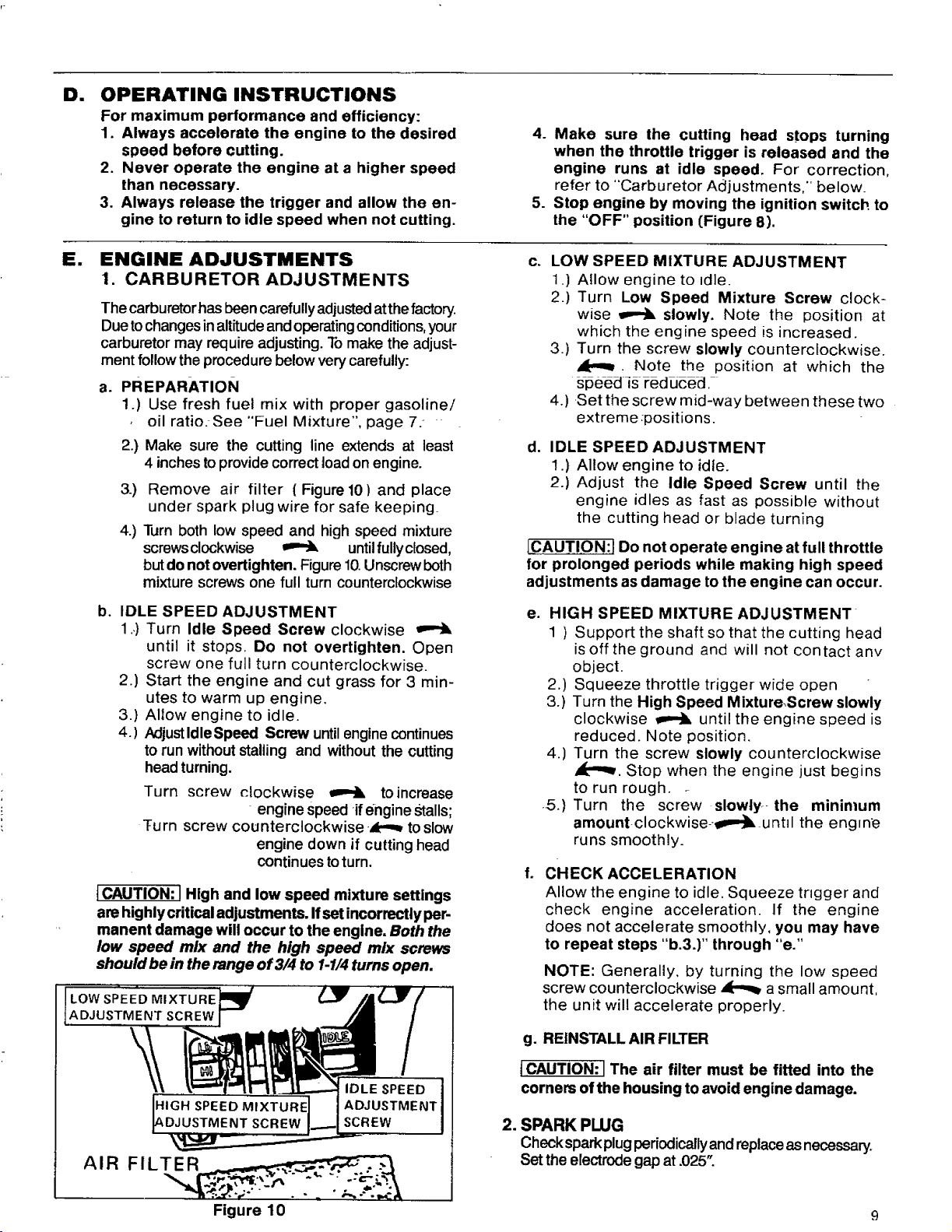

1. CARBURETOR ADJUSTMENTS

The carburetorhasbeen carefully adjusted atthe factory.

Dueto changesin altitude and operating conditions, your

carburetor may require adjusting. To make the adjust-

ment follow the procedure below very carefully:

a. PREPARATION

1.) Use fresh fuel mix with proper gasoline/

oil ratio. See "Fuel Mixture", page 7.

2.)

Make sure the cutting line extends at least

4 inches toprovide correct load on engine.

3.)

Remove air filter ( Figure 10) and place

under spark plug wire for safe keeping_

4.)

Turn both tow speed and high speed mixture

screws clockwise _ untilfullyclosed,

but do not overtighten. Figure 10.Unscrew beth

mixture screws one full turn counterclockwise

b.

IDLE SPEED ADJUSTMENT

1 .,)Turn Idle Speed Screw clockwise

until it stops. Do not overtighten. Open

screw one full turn counterclockwise.

2.) Start the engine and cut grass for 3 min-

utes to warm up engine.

3.) Allow engine to idle.

4. ) AdjustIdleSpeed Screw untilengine continues

to run withoutstalling and without the cutting

head turning.

Turn screw clockwise _ to increase

Turn screw counterclockwise -_k'.,_to slow

l CAUTION: JHigh and low speed mixture settings

are highly critical adjustments. If setincorrectly per-

manent damage will occur to the engine, Both the

low speed mix and the high speed mix screws

should be in the range of 3/4 to 1-1/4turns open.

- engine speed if engine Stalls;

engine down if cutting head

continues toturn.

4. Make sure the cutting head stops turning

when the throttle trigger is released and the

engine runs at idle speed, For correction,

refer to "Carburetor Adjustments," below_

5. Stop engine by moving the ignition switch to

the "OFF" position (Figure 8).

C. LOW SPEED MIXTURE ADJUSTMENT

1.) Allow engine to =die.

2.) Turn Low Speed Mixture Screw clock-

wise _ slowly. Note the position at

which the engine speed is increased.

3.) Turn the screw slowly countercfockwise.

JP.,_. Note the position at which the

speed is reduced.

4.) Set the screw mid-way between these two

extreme :positions.

d. IDLE SPEED ADJUSTMENT

1.) Allow engine to idle.

2.) Adjust the Idle Speed Screw until the

engine idles as fast as possible without

the cutting head or blade turning

E-CAUTION:] Do not operate engine at full throttle

for prolonged periods while making high speed

adjustments as damage to the engine can occur.

e. HIGH SPEED MIXTURE ADJUSTMENT

1 ) Support the shaft so that the cutting head

is off the ground and will not contact anv

object.

2.) Squeeze throttle trigger wide open

3.) Turn the High Speed MixtureScrew slowly

clockwise _ until the engine speed is

reduced. Note position.

4.) Turn the screw slowly counterclockwise

_'"_. Stop when the engine just begins

to run rough.

,.5.) Turn the screw slowly.-the minimum

amount-clockwise--_p--']l= until the engvne

runs smoothly.

f.

CHECK ACCELERATION

Allow the engine to idle. Squeeze trigger and

check engine acceleration. If the engine

does not accelerate smoothly, you may have

to repeat steps "b.3.)" through "e."

NOTE: Generally, by turning the low speed

screw counterclockwise _ a small amount,

the unit will accelerate properly.

g. REINSTALL AIR FILTER

tCAUTION: I The air filter must be fitted into the

corners of the housing to avoid engine damage.

2. SPARK PLUG

Check sparkplugperiodically and replaceasnecessary.

Set the electrodegap at .025".

Figure 10 9

Page 10

USING YOUR UNIT

Your Trimmer is equipped with a semi-automatic advancing

cutting head that cuts with the tipof amonofilament nylon line.

The nylon cutting line will easily remove grass and

weeds from around walls, fences, trees, and flower

beds, but it also can cut the tender bark of trees or

shrubs and scar fences. For this reason, it is very

important to learn the proper techniques of cutting

around and near objects.

The nylon cutting line will wear faster and will

require being advanced more frequently when you

are cuttingagainst rocks, bricks,concrete, metalfences,

etc., than against trees or wooden fences.

The cuttinghead will wear prematurely:

--if allowed to continuously contact the ground

during normal cutting.

--if the line limiter is not kept sharp.

WARNING

Use only flexible, non-metalic, monofllament cutting

line. Do not use other materials such as rope, wire, etc.

Wire can break off during cutting and become a

dangerous missile.

A. OPERATING INSTRUCTIONS

1. Read your Operator's Manual.

Make certain you completely understand and follow

all safety rules, precautions, and operating instruc-

tions before operating the unit.

,

and face which can result in loss of vision or

serious personal injury.

3.

Dress safely in long pants-and wear boots or

safety shoes.

Do not wear Iooseclothing, jewelry, short pants or

sandals; or go barefoot.

4. Check the unit before operation.

Lookforworn,loose, missing,ordamaged parts.Donot

useuntilthe unit isinproperworkingorder.

,

Inspect the area to be cut.

Remove all debris and objects that can ricochet, be

thrown,becomeentangledinthe cuttingheadorother-

wisecause injuryor damage duringcutting.

6.

Keep observers, children, bystanders, and animals

safely away.

Beforestartingthe engineandduringoperation,make

certainchildren,animalsandbystandersare awayfrom

the workarea - a minimumof 30 feet(10meters).

Always wear eye protection. The

splash deflector/line limiter will not

prevent rocksand debris frombeing

thrown or ricocheting into the eyes

B. ADVANCING THE CUTTING LINE

• The cutting line is extended semi-automatically by

tapping thebottom ofthe head on the ground with

.the engine_running.

k.• Approximately 2 Inches oflinelsextended each

time the tap button istapped on the ground,

• The line,miter on the splash deflector cuts line to

a maximum allowable length.

• The most efficient cutting line length Is the max-

imum length allowed by the line Iimiter.

1. To advance line:

a. Operate the engine at fullthrottle.

b. Hold cutting head parallel to and above the

grassy area ofthe ground.

c. Tap the cutting head lightlyonthe ground one

time. See Figure 12. Approximately2 inches of

line will be advanced after each tap.

NOTE: Ifthe line isworn down totwo inches or

less, more than one tap may be required to

obtain the most efficient line cutting length.

10

2. Always keep the splash deflector in place when

the unit Is being operated.

-3. Keep the line Iimitersharpfor fast, easycut-off.

See page 13for sharpening instructions.

NOTE: Always tap the cutting head ona grassy

area of the ground. Tapping on surfaces such

as concrete or asphalt can cause excessive

wear to the cutting head.

LINE CUTTING LINE,

LIMITER TAP LIGHTLY

CUTSEXCESS ON GROUND

LINE ONE TIME

TO ADVANCE

-q

Page 11

C. CUTTING METHODS

• The tip of the line does the cutting. Allow the unit

to trim at its ownpace. YouwilJachieve better results

bynot crowding the line into the cutting area. The right

way and wrong way are shown in Figure 13.

• Always cut left to right,

ii

'- \

RIGHT

, I

_WRONG

iii i

Figure 13

_WARNING

Always wear eye protection. Never lean over the

cutting head. Rocks or debris can ricochet or be

thrown into eyes and face and cause loss of

vision or serious personal injury.

J p

\',,

TRIMMING

i i

Figure 14

.

TRIMMING -- Figure 14

Hold the cutting head at a 30 degree angle to the

cutting area for efficient trimming. Do not forcethe

cutting line intothe workarea. Allowt.hetipofthe line

todo the cutting.

2, EDGING -- Figure 15

Adjustyourtrimmer foredging byturningtheengine

upside down so the drive shaft housing angles out

rather than down. Rotate the assist handle on the

shaft, placing it in an up, usable position. Hold the

cutting head above the area to be edged as shown

and operate thethrottle trigger with your thumb,

3. MOWING -- Figure 16

Yourtrimmeris idealfor mowing inplaces conventional

fawnmowers cannot reach.Inthe mowingposition,the

cuttinglineisparalleltotheground.Avoidlettingthecut-

tinghead continuously contact the groundas this can

causedamage toyourunitaswell asscalpthe ground.

4. SCALPING -- Figure 17

Toremove unwanted vegetation around trees, posts,

monuments, etc., maintain a 30degree angle with the

cutting head and allow the tip of thecutting line to

strike the ground.

NOTE: Increased line wear is to be expected when

using scalping techniques.

,

SWEEPING -- Figure 18

Forquick and easy clean up extend the line to the

length allowed bythe line limiter and move the unit

from sidetoside, keeping the cutting headparallelto

the surfaces being swept•

Figure 15

Figure 16

Figure 18

11

Page 12

D. CUTTING HEAD MAINTENANCE

1. CUTTING LINE REPLACEMENT

a. Hold the cutting head as shown in Figure 18.

Press the lock tab, and turn lock ringcounter-

clockwise

b. Remove the lock ring, tap button, and

spool. Figure 19.

c. Clean dirt and debris from housing and

spool.

d. Inspect spool. Replace as necessary. See

instruction #3 this section.

i i i i i i

PressLock Tab.

Turn outer ring

counterclockwise,

\l

l

LOCK TAB

Figure 18

,=,,i ii ii

NOTE: The aluminum line saver is reversi-

ble. After a groove is worn into one side,

reverse the line saver (with the spool

removed) to provide a new wear surface.

Figure 21.

e°

Replace a worn spool with a new pre-wound

spoolfor quickeasy replacement.Or asan alter-

native, replace nylon line on existing, usable

spool.Toreplaceline,insert1/16to1/8 inchofthe

endofthe linethroughtheholeinthe spool.Wrap

the line evenly onto the spool in a clockwise

directionasshownby arrowonspool.

Figure20.

f. Insertthe endofthe linethrough the line saver as

showninFigure21.Pushspoolin housing.Force

spooldown. Turnandlockspoolunderthe drive

lugsonthe drive gear.

g. Replace the tal_button; press lock tab and

install the lock ring. Turn the lock ring

clockwise _ and fasten under the

catches on the housing. Figure 22. Check

to be certain all catches are properly se-

cured.

TAP BUTTON

Figure 19

U$1NG

Figure 21

! I I I[11 II I

Turn Lock Ring

clockwise to install,

\

12 Figure 20 Figure 22

Page 13

h.

Pull on the nylon line to change the spool from the

lockedposition tothe operating position. Figure 24.

in

Obtain correct line length bypressing tap button and

pulling on nylon line again.

NOTE: Approximately 2 inches of line can be

advanced each time the tap button is pressed.

Figure 24.

USE ONLY SEARS/CRAFTSMAN ®

REPLACEMENT PARTS

2. CUTTING LINE REPAIR

•If the cutting line breaks off or backs up in the

cutting head, follow "Cutting Line Replacement",

omittingstep "e".

3. SPOOL REPLACEMENT

Approximately2 inches

of linecanbeadvanced

eachtime the Tap Button

is pressed.

TAP BUTTON

Figure 24

a Replace the spool when: The square corners of

the drive lugs are rounded off, reduced in size, or

broken off. Figure25.

b. To replace the spool, follow "Cutting Line

Replacement" (page 12).

4. LINE LIMITER MAINTENANCE

• The line limiter is the metal blade found on the

splash deflector.

_-Theline-limiter must be kept sharp to:

-- allow fast, easy cut-off.

avoid excessive wear to the cutting head.

•• Tosharpen:

Use a fiat file and file from the outside towardthe

insideofthe line limiter,Figure 26.

NOTES

NORMAL SPOOL

WORN SPOOL

i ii

Figure 25

Figure 26

13

Page 14

GENERAL MAINTENANCE

A. DRIVE SHAFT LUBRICATION

• Lubricate the Flexible Drive Shaft:

-- After each ten (10) hours of operation:

-- Before operating if the unit has been stored

for 90 days or longer.

• Use gear grease stock #28-59071.

NOTE: Atube ofgrease has been suppliedwithyour

unit tobe used after the first 10 hoursofoperation.

NOTE: Check the Flexibie Drive Shaft for

wear or damage, Replace if broken wires,

twists or kinks are found.

ICAUTION:tLay the Flexible Drive Shaft on a

clean surface. Avoid laying the shaft on the

floor, ground or on any surface that may have

dirt or debris. Even after wiping the shaft,

grease residue can pick up dirt particles that

can cause damage or premature failure.

• Observe the following procedure for best

results:

CAUTION: IAvoid bodily contact with the muffler

area when the engine is warm. Always replace

the muffler guard if it becomes damaged or

broken.

1. Loosen the Pinch Clamp Bolt and remove the

Drive Shaft Housing from the Engine Shroud.

2. Remove the Flexible Drive Shaft as shown in

Figure 26.

3. Using a clean cloth, thoroughly wipe the sur-

face of the Flexible Drive Shaft to remove any

old grease that may be present/

4. Applya uniformcoatofgear greasetothe entire sur-

face ofthe Flexible Drive Shaft. Figure 27.

5. Inject the remaining contents of the tube sup-

plied with the unit into the top of the Drive

Shaft Housing.

6. Replace Flexible Drive Shaft in the Drive

Shaft Housing.

7. Follow the instructions on page 6 to replace

Drive Shaft Housing in the Engine Shroud.

Wipethe Flexible

14

Figure 26

El

AIR FILTER CARE

A dirty air filter decreases engine performance

and increases fuel consumption,

Clean the Air Filter:

• Frequently,

• Always after 5 tanks of fuel or 5 hours of opera-

tion, whichever is less,

Follow these steps:

1, Removetheairfilter(Iocatedatthebettom, rearofthe

Engine Shroud)see page 2.

2, Wash in soap and water.

ICAUTION:] Do not clean filter in gasoline

or other flammable solvent to avoid creating

a fire hazard.

3. Squeeze filter dry.

4, Replace the air filter.

ICAUTION: fThe air filter must be fitted into

the corners of the housing to avoid engine

damage.

iiii ]1 iii

Figure 27

Cll

FUEL TANK UPKEEP

Never use gasoline that ismore than 2 months

old in a fuel mixture. Gasoline begins to break

down after a period of time and will form com-

pounds that cause hard starting and damage in

2-cycle engines.

,

inspect the unit for fuel leaks each time it is

used. Repair or replace parts as necessary.

2.

Using gasoline or fuel mix over 2 months old will

cause the engine to be difficult or impossible to

startl

.

Drain the fuel tank or allow the unit to run out

of fuel before storing for 30 or more days.

NOTE: "First Starting" procedure may be

required fora unit that runs out of fuel or from

which fuel is drained, See "Starting Instruc-

tions", page 8.

Page 15

D. STARTER ROPE REPAIR

• Repair the starter rope If the rope breaks next

to the pulley.

• Replace the starter rope if the rope breaks 2-3

inches away from the pulley as the rope will be

too short to repair properly.

/_WARNING

Always wear eye protection when ser-

vicing the starter rope. The recoil spring,

located beneath the pulley, is under ten-

sion. Ifthe spring pops out, serious per-

sonal injury can result.

• To repair or replace:

NOT_ Use caution when separating the

fan housing from the shroud to avoid

breaking or damaging the fuel line fittings.

1_ Drain all fuel from tank.

2. Remove the four (4) screws from fan

housing. Figure 28.

3. Carefully separate fan housing from shroud-

about one (1) inch.

4. Disconnect fuel lines from fittings.

5. Disconnect ignition module wires. Figure

28.

6. Slide high tension lead grommet from slot,

in fan housing.

7. Separate the fan housing completely from

the shroud.

8. If the starter rope is not broken, release

the spring tension by pulling about 12

inches of rope from the pulley and catch

the rope in the notch as shown. Figure 30.

NOTE: The tension on thestarter spring

will be released if the rope has broken.

9. Remove screw and pulley very carefully.

Figure 29. The recoil spring which lies

beneath the pulley must stay in the hous-

Ing, flat against t6e bottom. Itthe spring Is

disturbed, it will require oonsiderable time

and effort to reinstall. Twist the pulley

gently clockwise ,,,,-]& ' as you pull up to

release the spring.

10. Moveawayfromthefuel tankand melttheend0f

the newrope togo intothe pulley,

11. Allowthe meltedendtoddponce, thenwhilerope

isstillhotpullthe meltedend througha cleanrag

toobtain a smooth, pointedend.

12. Insert rope through the rope exit hole in

the fan housing.

13. Guide rope insidepulley,thenupthroughtopside

pulley holebypushing the rope fromthe under-

side hole with a small object such as a

screwdriver.

14. Wrap rope counterclockwise 4[--,, around

pulley ratchet and tuck loose end back

under-rope leaving a 1/4 to I/2 inch

tail laying in the rope groove. Figure 30.

15. Wind all but about 12 inches of the rope

counterclockwise _ around pulley.

16. Replace pulley in the housing. Be sure

the pulley is all the way down and the

spring is secured. Replace screw and

tighten. Figure 29.

17. Hold the 12 inch slack in the rope and

catch rope in pulley notch. Figure 30.

18. Hold the rope taut and make 2 complete

turns of the pulley counterclockwise

to place tension on the pulley.

Hold the pulley to retain tension.

19. Align pulley notc_ with rope exit hole,

pull starter handl_tothe full extent of the

rope and allow the rope to slowly wind

around the pulley.

NOTE: While the unit is disassembled, in-

spect the carburetor housing seal and

replace if worn. Figure 28.

20. Reverse procedure for re-assembly of fan

housing to shroud.

NOTE: Make sure the fuel line with the

black stripe or solid color is installed on

i.i i i

GROMMET

SHROU[

CARBURETOR

HOUSING

FUEL LINE FITTINGS

IIGNITION MODULE WIRES

LINES

i ii

Figure 28

,o., ,o.,

NOTCH

Figure 29

Figure 30

FAN

3USING

15

Page 16

TROUBLE SHOOTING CHART

TROUBLE CAUSE

Engine will not start 1. Ignitionswitch off.

2. Fuel tank empty,

3, Spark plug not firing.

4. Fuel not reaching carburetor,

5. Engine flooded.

6. Compression low.

Engine will not idle

1. Idlingspeed set toolow.

properly

2. idle speed set too high.

3. Low speed screw requiresadjustment.

I 4. Crankshaftseals worn.

5 Compression low.

Engine will not - 1.

accelerate, lacks 2.

power or dies 3.

under a load 4.

Carburetorrequires adjustment.

Air filter dirty.

Spark plugfouled.

Carbonbuild-up.

5. Lowcompression.

Engine smokes

excessively

1. Highspeed needle requiresadjustment. 1.

2. Air filter dirty. 2.

3. Oil richfuel mixture. 3`

Engine runs hot 1.

! Unit engages at 1.

idle speed 2,

Cutting head dobs not 1.

tum when engine is 2.

accelerated 3.

Cutting head stops

:under e load

Cutting line does

not advance.

Fuel Mixture Incorrect.

2.

Spark Plug Incorrect.

3.

Carbon build-up.

4.

High Speed Mixture set too low.

Carburetorrequires adjustment.

Clutch requiresrepair.

Driveshaft notengaged.

Carburetorre_:luiresadjustment.

Clutch slipping.

1.

Drive shaftnotengaged.

2.

Carburetorrequires adjustment.

&

Clutch slipping.

Line improperlywound'ontospool,

1.

2.

Drive.gear damaged orworn.

3.

Worn spool.

REMEDY

1. Move switch'to"Start", ....

2. Filltank withcorrectfuel mixture.

3` Installnewplug.

4. Check for dirtyfuelfilter; ctean.Check

forkinkedorsplit fuelline; repairor

replace.

5. See Starting Instructions.

6. Contact your SearsService Center.

,,,,,........

1. Adjust idle speed screw clockwise to

increase speed.

2. Adjust idle speed screw counter-

clockwiseto reduce speed.

3. See Carburetor Adjustments.

4. Contact your Sears Service Center.

5. Contact your Sears Service Center.

1. See Carburetor Adjustments.

2. Clean or replace air filter,

3. Clean or replace Spark Plug and regap.

4. Clean exhaust system includingspark

arrestor.

5. Contactyour SearsService center.

See Carburetor Adjustments.

Clean or replaceair filter.

Emptyfuel tankand refillwithcorrect

fuel mixture.

.

See FuelingYour Llnit.

2.

Replace with correct plug.

3.

Clean exhaustsystemincludingspark

arrestor.

4.

See CarburetorAdjustments.

1.

See Carburetor Adjustments.

2.

Contactyour Sears Service Center.

1.

See AssemblyInstructions.

2.

See Carburetor Adjustments.

3.

Contact your Sears Service Center.

1.

See Assembly Instructions.

.2,

See CarburetorAdjustments....

Contact .yourSears Se,rviceCenter.

1.

Rewindspool.

2,

Replace drive gear.

&

Replace spool.

16

Page 17

ACCESSORIES

A. ACCESSORIES

2-Cycle Engine Oil ............................................ Stock No.

Gear Grease (14-112oz.) ........................................ Stock No.

Spark Plug ................................................... Part No.

Replacement Cutting Head ..................................... Stock No.

Spool W/Line ................................................ Stock No.

Nylon Cutting Line ............................................ Stock No.

Shoulder Strap Kit ............................................ Stock No.

NOTES

71-36555

28-59071

STD361258

71-85764

71-85789

71-85778

71-85783

17

Page 18

SEARS WEEDWACKER ® PARTS LIST -- MODEL 358.796131 -26.2cc

Figure 1

25

101

26

28

27

29

30

f

I

31

18

19

2O

14

10

Page 19

SEARS WEEDWACKER ® PARTS LIST m MODEL 358.796131-26.2cc

Figure I

KEY

NO.

1

2 93896 1

3 93898 1

4 92067 1

5 92068 1

6 93897 1

7 706502 1

8....... 9338? ..... 1

9 92133 1

10 92243 2

11

12

14

15

19

2O

KeyNo's Excluded:#13,1618, 21.24.

PART

NO.

706515

"93653 1

93716 1

94440 1

15337 2

93853 1

STD 2

540410

QTY.

RECL

DESCRIPTION

1

Cutting Head Assembley

Stock#71-85764 (Incl. 2-9)

Hub wlLine Saver

Line Saver

Spring

Adaptor- Spring

Drive Gear

Spool w/Une-Stock #71-85789

....ReleaseButton_

COVer

Screw-l/4-10xl-l/8-Splash

Deflector

Bracket- Splash Deflector

DustCup

Splash Deflector

Screw- 10-24xl - Line Limiter

LineLimiter

Nut- 10 -24 - Locking

KEY

NO.

25

26

27

28

29

3O

_3_1_

32

Decals

-101

102

103

104

PAR'I:

NO.

10618

92059

STD

551025

STD

522517

94439

93936

3_0_1_02

66706

26593

27153

26674

26570

REQ.

1

1

I

1

1

i

1

1

1

DESCRIPTION

Assist Handle

Knob- 1/4- 20

Washer- 1/4- Flat

Hex Bolt-114-20x1-112

DriveShaft Housing

Rexible Drive Shaft

.....GeajG re_e_Sto__k#28-590"£1....

Operator's Manual

Warning Label -AssistHandle

Decal -Warning (Shaft)

Decal -Weedwacker

Decal -Splash Deflector

19

Page 20

SEARS WEEDWACKER ® PARTS LIST -- MODEL 358.796131-26.2cc

Figure 2

21

I

I

t

I

I

I

J

24

36

6 ] 11

!

!

(

43

20

-35

Page 21

SEARS WEEDWACKER ® PARTS LIST -- MODEL 358.796131-26.2cc

Figure 2

1

PART QTY.

NO. REQ,

24436 i: 1

26566 1

26567 1

KEY

NO.

2

3

24365 1

5 24371

6 23575

7 STD

6108O7

8 69182

9 15706

10 24569

11 15582

12 24461

13 15367

14 26109

15 21052

16 10729

18 22290

19 21053

20 26931

21. 69178

22 _ 42067

- 23 26035

24 15544*

25 26048

DESCRIPTION

Bumper Fuel Tank Housing

Handle & Fuel Tank Housing

KEY

NO.

26

27

Handle Cover

_igger- Throttle

1

Air Filter

1

Nut- Grounding Switch

1

Screw - 8 - 16 x3/4 Pan Head-

Handle Cover

K'rt-Grounding Switch

(Inc1.#6,10&39, this page

28

29

30

31

32

33

and #12from page 23)

Screw- 10- 24 x 1- 1/2- Sems

Fan Housing - Top

1

Washer- Ground Terminal

2

Screw- 10- 24 x 5/8- Seres

Fan Housing - Bottom

1

Trigger- Spring

5

Screw- 10-14 x 3/4- Fan

Housing to Handle & Fuel

Tank

1

Rlter- Fuel (InletLine)

1

Une- Fuel Inlet

1

FuelCap.Assembly

(Incl. O-Ring)

1

Rope (3.5ft)

1

Line- Pump toAccumulator

1

FuelPick-Up Assembly

1

Fan HousingI_t

1

Starter Recoil Spdng

1

AirBaffle

2

Screw- 1/10x 3/8 Pan Hd.-

34

35

36

37

38

39

4O

41

42

43

Decals

101

PART QTY.

NO. REQ.

15123

15479

26O32

10738

16563*

= -=

26119

21054

26178

26549

10773

15590

15669

26560

39122

15610

26792

STD

511010

15274

27153

26568

26569

DESCRIPTION

1

1

Washer#10StarterPulleyScrew

Screw -#10 x 3/4- Hex Washer

Head - Starter Pulley

1

1

1

InjectorButton

Pump Assembly(Inc1.#19)

•screw- #10x 1 - 3/16Plastite

AirBaffleI Pump Mounting

1

1

1

Check Valve- Duck Bill

Fuel Une - Tankto Accumulator

Clip- Retainer- Inlet Line-

FuelTank

1

1

Shroud

FuelTankAssembly(Incl. #14,

15,16,20,31,32&33)

2

1

1

1

1

1

Screw- 10- 2 x 5/8 Binder Head

Screw-Pinch Clamp-1/4-20x9/16

Clamp

Lead Wire - Ground

Nut #12-24Square

Ass'y.- Rope and Handle-

Starter(Incl.#18)

4

Screw- 10- 24 x 718- FiI.Hd.

Shroud

4

Washer- Flat,#10Narrow

Shroud

Decal- Instructions

1

DeCal- Shroud(Right)

-(not shown)

• Decal - Shroud(Left)

_;(notshown)

Air Baffle

Starter Pulley

*If yourunit has beenserviced withthe metal fan housing, use PartNo. 15373(Screw- #10 -24x 1/4- FiL Hd.), instead of15544

(KeyNo.24), and Part No. 15305 (Screw- #10 - 24x 1 - 3/1-6RI. Hd.), instead of15563 (KeyNo30).

Key No'sExcluded:#17

21

Page 22

4

SEARS WEEDWACKER ®PARTS LIST -- MODEL 358.796131-26.2cc

Figure 3

10-

11-

7

51

52

9

7

16

53

54

57

58

35

22

Page 23

SEARS WEEDWACKER ® PARTS LIST- MODEL 358.796131-26.2cc

Figure 3

KEY

NO.

:27

10

11

12

13

14

15

16

17

18

19

2O

21

22

23

24

25

26

26

29

3O

4

6

8

9

1

2

3

5

7

PART

NO.

42059

STD

54I 131

15127

39114

STD

551OO8

69181

19059

15168

1O316

39103

24435

25995

15235

1O677

19128

15565

39082

3934

3933

STD

361258

15126

23373

26177

10651

24302

15162

32058

15351

24438

QTY.

REQ.

2

I

1

1

2

1

2

4

1

1

1

1

2

1

2

1

1

1

1

1

1

1

1

1

2

2

2

1

DESCRIPTION

Spring - Starter Dog

Nut - Flywheel - (5/16x 26)

Washer- Flywheel

Rywheel Assembly (Incl. #1)

Screw - 8-32 x 3/4 - Fil. Hd.-

Ignition Module

Kit - Ignition Module

Seal - Crankcase

Screw - Crankcase

Crankcase Ass'y.(Incl.#7& 28)

High Tension- Lead Assembly

(Incl. #17,18& 19)

Grommet- Plug Wire

ElectricalTab

Screw- 8-18 x 9tl6

Cap Assembly- Accumulator

(Incl. Cap, Screen & "O"

Ring)

O-Ring-Accumulator

Chamber

Screw - 8-18x1'-'Accumulator

High TensionLead Wire

Boot- Spark Plug

Connector- Spark Plug Lead

Spark Plug (CJ-14)

Key- Rywheet

Boot-Throttle

ThrottleWire (Red)

AccumulatorAssembly

(Incl,#14,15 &34)

Gasket -Cylinder

Ring -Piston

Retainer-Wrist Pin .

Beadng- Crankcase

Washer- Thrust -Crankcase

Reed Valve

KEY

NO.

31

32

33

34

35

36

37

38

"39

40

41

42

43

44

45

46

47

48

49

5O

51

52

53

54

55

56

57

58

PART

NO.

19108

19105

21055

19131

26047

STD

610805

STD

610603

23367

15239,.

12070

26949

24903

22198

32057

26675

26O46

19115

35183

15566

24364

24361

24362

69196

69194

24932

24855

10797- -

3O054

QTY.

REQ.

1

1

1

1

4

1

1

2

1

1

2

1

1

1

1

1

1

1

1

1

1

1

2

1

1''

DESCRIPTION

Gasket- Carburetor Case to

Crankcase

Seal -Carburetor Case

Fuel Line- Carburetor

O- Ring (Orifice)

Cover- Carburetor Case

Screw- 8 - 18 x9/16 - Pan

Hd. - CarburetorCase Cover

Screw-6 - 19x 5/15- Pan Hal.-

Reed Valve

:Washer- Reed Valve Screw

,Screw- 114-20 x3/4 - Hex

SocketHd.- Cylinder

Cylinder

Diffuser- Muffler

Spring- Muffler Detachment

PistonKit (Inc1.#26,27& Pin)

Bearing - WristPin

Crankshaft & ROdAssembly

Carburetor Housing

Gasket- Carburetor

Carburetor- WA - 149 -

(See Page 24 for Assembly)

Screw - 10- 24 x 2-1/4"-

Fil. Hd. -Carburetor

Screen - Spark Arresting

Cover- Muffler

Body- Muffler

Kit- ClutchWasher

Kit- ClutchAssembly (Incl.

ClutchWasher)

Spring- Muffler Guard

Guard - Muffler

Coupling &Bearing Assembly

_Sealant- Crankcase

(Not SuppliedWith Unit)

23

Page 24

SEARS WEEDWACKER ® PARTS LIST -- MODEL 358.796131-26.2cc

CARBURETOR NUMBER 35183

Figure 4

KEY PART

NO. NO.

1 35017

2 35191

3 35164

4 35156

5_ 35178

6 35166

7 35133

8 35007

9 35138

10 35015

11 35132

12 35023

13 35141

14 35106

15 35031

16 35o31

Conteht_ of Gasket/Diaphragm Kit

+Contents of Kwik Repair Kit

QTY'. KEY

REQ. DESCRIPTION NO.

1 Screw -"Pump- Cover 17

1 Pump Cover Ass'y. (Incl. #4) 18

1 *+ Gasket- Pump 19

1 . Screw- Idle Adjustment 20

1_ + Screen - Inlet

1 *+ Diaphragm - Pump

1 Valve - Throttle

1 Clip - Throttle Shaft

1 Spring - Throttle Return

1 + Screw - Throttle Valve

1

1

1

1

1

1

Shaft Assembly - Throttle

Spring - Idle Needle

Needle - Idle

+

Spring - Metering Lever

+

Valve - Inlet Needle

+

Lever- Metering

PART QTY

NO, REQ.

35036 1

35142 1

35026 1'

35016 1

21

22

23

24

25

26

27 35149

35147

35042

35137

35151

35014

35153

35185

35186

DESCRIPTION

Spring- Hi Speed Needle

Needle - Hi Speed

+

Pin - Metering Lever

Screw - Metering Lever Pin

-1* *+ Gasket - Circuit Plate

1 •Plate - Circuit

1 + Screw - Circuit Plate

1 *+ Gasket-Metering Diaphragm

1 *+ Diaphragm Ass'y.- Metering

4 Screw Assembly - Metering

Cover & Throttle Shaft Clip

1

1

Cover- Metering Diaphragm

Kit - Kwik Repair Kit

(Not Shown)

Kit - Gasket / Diaphragm

(Not Shown)

Page 25

NOTES

25

Page 26

NOTES

26

Page 27

I I I IIII IIIIII

QUICK REFERENCE PAGE

Read and follow all Safety Rules, Precautions and Operating Instructions.

Failure to do so can cause in serious personal injury.

PAGE

PREPARATION ........................................................................... 3

1.Know all safety rulesand precautions inthismanual.

2. Wear safety glassesorgoggles for eye protection

3. Dress safely- bootsor safetyshoes, long pants.

4. Check for worn, loose, missing or damaged parts and repair.

5. Inspectand ensure the area to be cut issafe.

6. Keep children,bystanders,and animals a minimum of30feet (10 meters)away from the workarea.

FUELING ............................................................................... 6-7

1. Eliminate allsourcesofsparks orflame where fuel ismixed, poured orstored.

2. Use fuel notover2 months old.

3. Mix and pour fuel inan approved, marked container in anoutdoorarea.

4. Use 1 partair-cooled, 2-cycle,engine oil to 16partsregularunleaded gasoline.

5. Move a minimumof 10feet (3 meters) awayfromfuel and fueling sitebefore startingengine.

STARTING THE ENGINE ................................................................ 7- 8

1.Extend a minimum of4 inchesoflinefrom the cutting head.

2. Place unit ongroundaway from objects andon-lookers.

3. Keep thethrottletrigger depressed untilengine runs.

4. Press injectorbuttonas indicatedon page 8.

5. Pullthe starter rope sharplyandquickly.

OPERATING THE UNIT ....... .......................................................... 9- 11

1.Accelerate the enginetothe desired speed before cutting.

2. Release the triggerand allowthe engine to idle when notcutting.

& Make sure the cuttinghead stopstuming when the throttletriggeris released.

4. Stopthe engine bymovingthe ignitionswitchtothe "off" position,

ADVANCING THE CUTTING LINE ......................................................... 10

1.Operate the engine at full throttle.

2. Hold cutting head parallelto grassyarea ofground.

3. Tapcutting head lightlyon the ground once.

MAINTENANCE .......................................................................... 14

1.Drain all fuel fromthe unit before storingfor more than 30 days.

2. Disconnect sparkplug before performingany maintenance except for carburetor adjustment.

3. Clean air filterfrequently butalways after 5 hours ofoperationor 5 tanksofgas whichever isless.

4. Lubricatethe flexibledriveshaft after each 10 hoursofoperationand afterstoringformore than 90 days.

5. Store ina dry place outof the reach ofchildren.

I]11 II II]] I]1 I]]111 II

27

Page 28

The Model Number will be found under the handle with the Serial

Number. Always mention the Model Number when requesting service

or repair parts for your unit.

All parts listed herein may be ordered from any Sears Service Center

and most Sears Stores.

WHEN ORDERING REPAIR PARTS, ALWAYS GIVE THE

FOLLOWING INFORMATION AS SHOWN IN THIS LIST.

MODEL NO.

358.796131- 26.2cc

How to Order

Repair Parts

1. The PART NUMBER

2. The MODEL NUMBER

358.796131

If the parts you need are not stocked locally, your order will be

electronically transmitted to a Sears Repair Parts Distribution center

for expedited handling.

3. The PART DESCRIPTION

4. The NAME OF ITEM-

26.2cc Gas WEEDWACKE R®

When you buy merchandise

from Sears you get an extra

something that nobody else

can offer... Sears Service.

Across town or across the

country, Sears Service follows

you, providing trustworthy,

competent service technicians

using only Sears specified

factory parts.

Your Sears Merchandise takes on added value when you discover

that Sears has Service Units throughout the country. Each is staffed

by Sears-Trained, professional technicians using Sears approved

methods.

SEARS SERVICE

IS AT YOUR SERVICE

Sold by Sears, Roebuck and C()., Chicago, IlL 60684 U.S.A.

66706-1-34385-1-34485 PRINTED IN U.S.A.

Loading...

Loading...