Page 1

Operator’s Manual

32cc/1.9 cu.in. 2-Cycle

GASOLINE BRUSHWACKER®

DANGER:

Read and follow all Safety Rules and Operating

A

9

Instructions before first use of this product.

For answers to your questions about this product:

Call 7 am-7 pm, Mon.-Sat., or 10 am-7 pm, Sun.

1 -800-235-5878 (Hours listed are Central Time)

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

530164363 9/12/06

Page 2

TABLE OF CONTENTS

Warranty Statement 2 Storage 16

Safety Rules 2 Troubleshooting Table 17

Assembly 5 Emissions Statement 18

Operation 9 Parts List 20

Maintenance 13 Spanish 22

Service & Adjustments 15 Parts and Ordering Back Cover

WARRANTY STATEMENT

TWO YEAR FULL WARRANTY ON CRAFTSMAN® GAS BRUSHWACKER®

When used and maintained according to the operator's manual, if this product fails

due to a defect in material or workmanship within two years from the date of pur

chase, return it to any Sears store, Sears Service Center, or other Craftsman outlet in

the United States for free repair (or replacement if repair proves impossible).

This warranty excludes cutting line, blade, spark plug and air filter, which are ex

pendable parts that can wear out from normal use in less than one year.

This warranty applies for only 30 days from purchase date if this product is used

for commercial or rental purposes.

This warranty gives you specific legal rights, and you may also have other rights

which vary from state to state.

Sears, Roebuck and Co., Hoffman Estates, IL 60179

SAFETY RULES

a WARNING: When using gar

dening appliances, basic safety pre

cautions must always be followed to

reduce the risk of fire and serious

injury.

A DANGER: This power tool can

be dangerous! This unit can cause se

rious injury including amputation or

blindness to the operator and others.

The warnings and safety instructions

in this manual must be followed to pro

vide reasonable safety and efficiency

in using the unit. The operator is re

sponsible for following the warnings

and instructions in this manual and on

the unit. Read the entire operator’s

manual before assembling and using

the unit! Restrict the use of this unit to

persons who read, understand, and

follow the warnings and instructions in

this manual and on the unit. Never al

low children to operate this unit.

INSTRUCTION

MANUAL

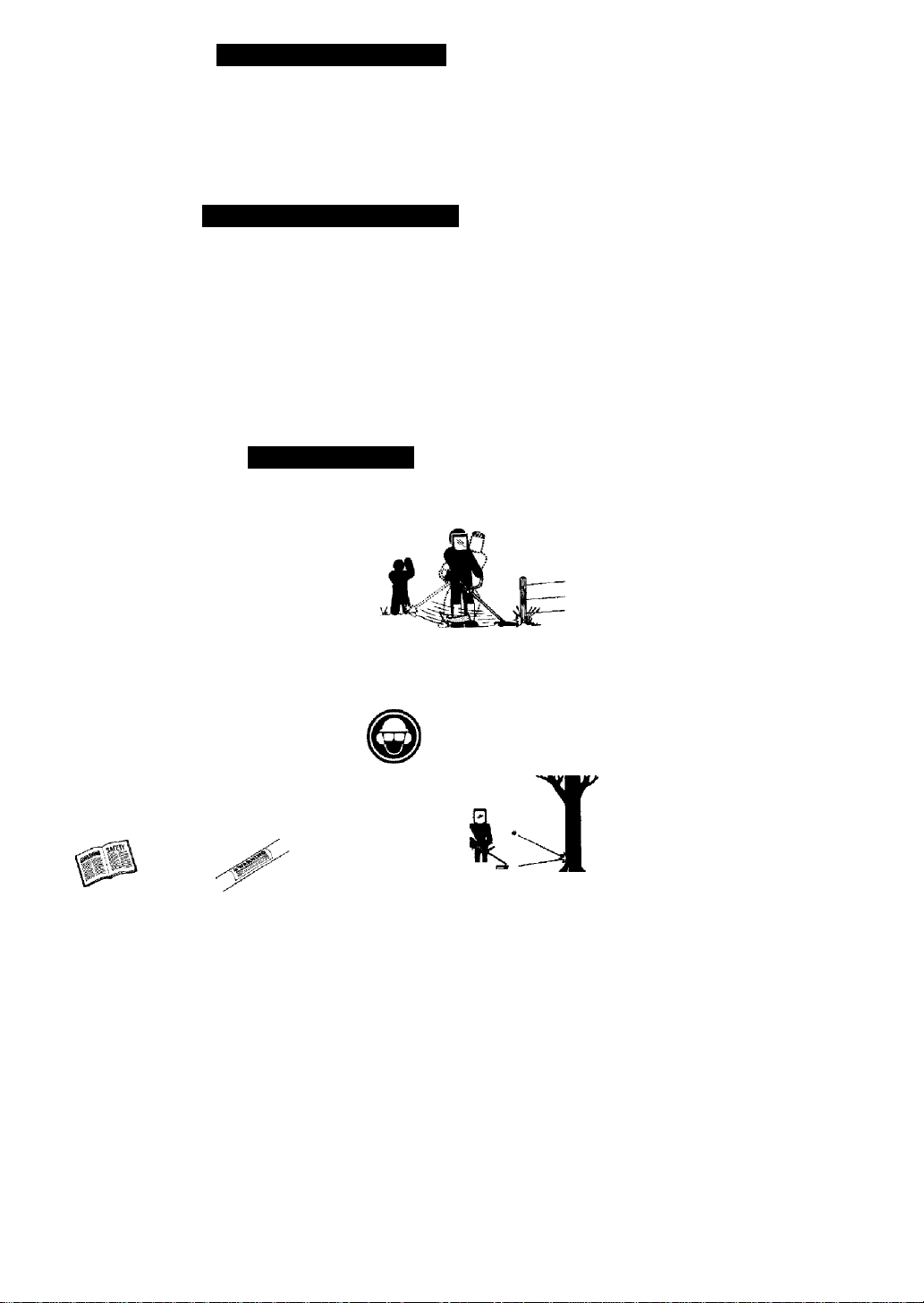

MM DANGER: Blade can thrust vio

lently away from material it does not

SAFETY INFORMATION

ON THE UNIT

cut. Blade thrust can cause amputa

tion of arms or legs. Keep people and

animals 50 feet (15 meters) away.

^WARNING: Trimmer line can

throw objects violently. You and others

can be blinded or injured. Wear safety

glasses and leg protection.

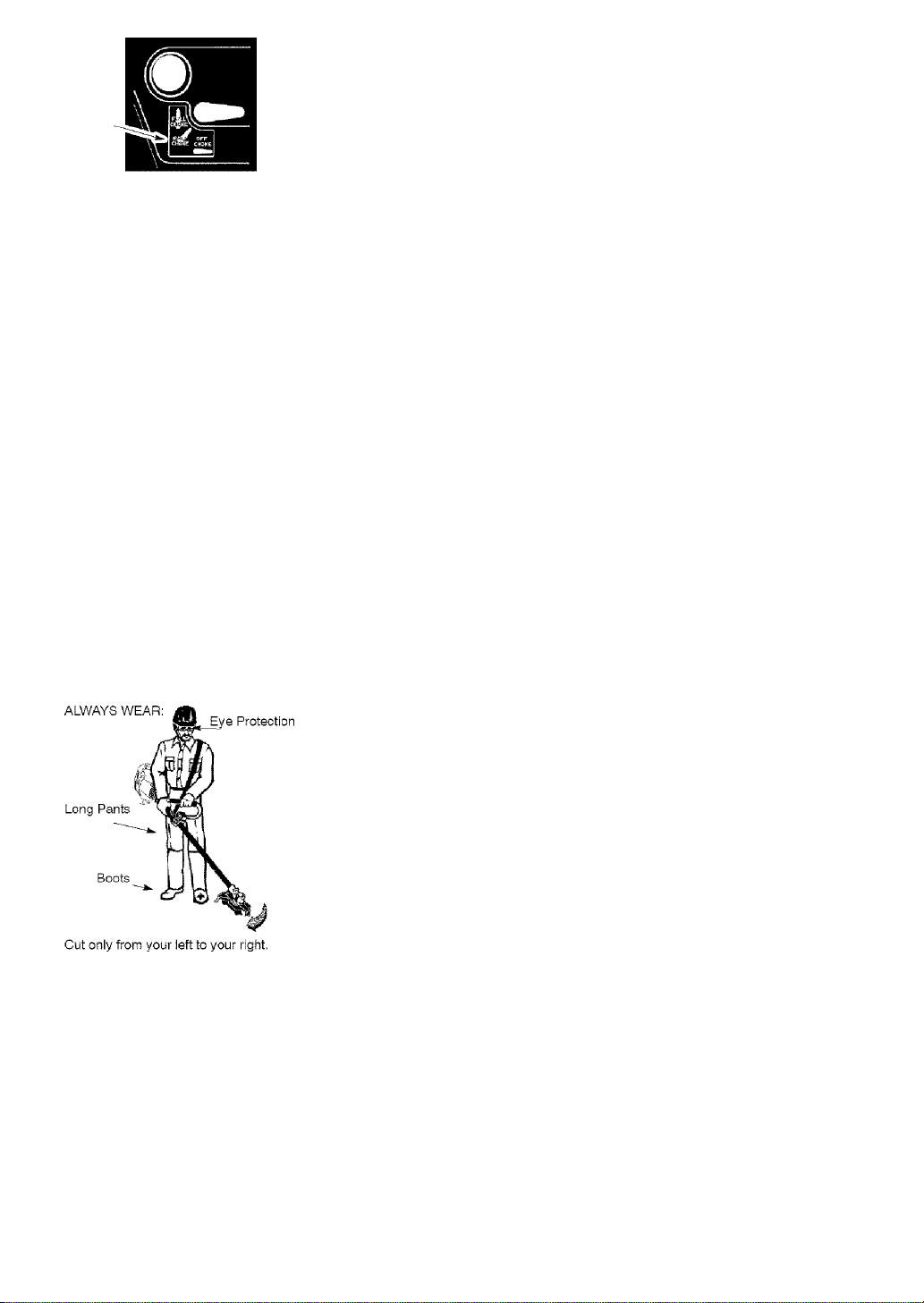

ALWAYS WEAR:

p g Leg Guards

^WARNING: Hazard zone for

thrown objects. Blade/Trimmer line

Eye^^

Protection

Boots

Always use;

• Hearing protection

• Eye protection

• Head protection

Thrown

Objects

S!

can throw objects violently. Others can

be blinded or injured. Keep people

and animals 50 feet (15 meters) away.

Page 3

mm WAR NIN G: Do not usg trim mer

head as a fastening device for the

blade.

^WARNING; The blade continues

to spin after the throttle is released or,

engine is turned off. The coasting blade

can throw objects or seriously cut if ac

cidentally touched. Stop the blade by

contacting the right hand side of the

coasting blade with material already cut.

OPERATOR SAFETY

• Dress properly. Always wear safety

glasses or similar eye protection when

operating, or performing maintenance

on your unit. (Safety glasses are

available.) Eye protection should be

marked Z87.

• Always wear face or dust mask if op

eration is dusty.

• Aiways wear heavy, long pants, long

sleeves, boots, and gloves. Wearing

safety ieg guards is recommended.

• Always wear foot protection. Do not

go barefoot or wear sandals.

• Secure hair above shoulder length.

Secure or remove loose clothing and

jewelry or clothing with loosely hang

ing ties, straps, tassels, etc. They can

be caught in moving parts.

• Being fully covered also helps protect

you from debris and pieces of toxic

plants thrown by spinning line/blade.

• Stay Alert. Do not operate unit when

you are tired, ill, upset or under influ

ence of alcohol, drugs, or medication.

Watch what you are doing; use com

mon sense.

• Wear hearing protection.

• Never start or run the engine inside

a closed room or building. Breathing

exhaust fumes can kill,

• Keep handles free of oil and fuel,

• Always use the handlebar and a

properly adjusted shoulder strap

with a blade (see ASSEMBLY).

UNIT/MAINTENANCE SAFETY

^WARNING: Stop unit and dis

connect the spark plug before per

forming maintenance (except carbure

tor adjustments).

• Look for and replace damaged or

loose parts before each use. Look

for and repair fuel leaks before use.

Keep unit in good working condition.

• Throw away blades that are bent,

warped, cracked, broken, or dam

aged in any other way. Replace trim

mer head parts that are cracked,

chipped, broken, or damaged in any

other way before using the unit.

• Maintain unit according to recom

mended procedures. Keep blade

sharp. Keep cutting line at the prop

er length. ^

• Use only Craftsman®' brand replace

ment line. Never use wire, rope,

string, etc.

• Install required shield properly before

using the unit. Use the metal shield

for all metal blade use. Use the plastic

shield for all line trimmer use.

• Use only specified blade or trimmer

head; make sure it is properly in

stalled and securely fastened.

Page 4

• NGVGr Start GnginG with clutch

shroud rGmoved. The dutch can fly

off and cause SGrious injury.

• Be sure blade or trimmer head stops

turning when engine idles.

• Make carburetor adjustments with

the lower end supported to prevent

blade or trimmer line from contacting

any object. Hold unit by hand; do not

use the shoulder strap for support.

• Keep others away when making car

buretor adjustments. _

• Use only recommended Craftsman'"'

accessories and replacement parts.

• Have all maintenance and service not

explained in this manual performed by

your Sears Service Center.

FUEL SAFETY

• Mix and pour fuel outdoors.

• Keep away from sparks or flames.

• Use a container approved for fuel.

• Do not smoke or allow smoking near

fuel or the unit or while using the unit.

• Avoid spilling fuel or oil. Wipe up all

fuel spills before starting engine.

• Move at least 10 feet {3 meters)

away from fueling site before start

ing engine.

• Stop engine and allow it to cool be

fore removing fuel cap.

• Empty the fuel tank before storing or

transporting the unit. Use up fuel left

in the carburetor by starting the en

gine and letting it run until it stops.

• Store unit and fuel in area where fue!

vapors cannot reach sparks or open

flames from water heaters, electric

motors or switches, furnaces, etc.

• Always store gasoline in a container

approved for flammable liquids.

CUTTING SAFETY

^WARNING; Inspect the area to

be cut before each use. Remove ob

jects (rocks, broken glass, nails, wire,

string, etc.) which can be thrown or

become entangled in the blade or

trimmer head.

• Keep others including children, ani

mals, bystanders, and helpers at least

50 feet (15 meters) away. Stop engine

immediately if you are approached.

• Always keep engine on the righthand side of your body.

• Hold the unit firmly with both hands.

• Keep firm footing and balance. Do

not overreach.

• Keep blade or trimmer head below

waist level. Do not raise engine

above your waist.

• Keep all parts of your body away

from blade, trimmer head, and muf

fler when engine is running. A hot

muffler can cause serious burns.

• Cut from your left to your right.

Cutting on right side of the shield will

throw debris away from the operator.

• Use only in daylight or good artificial

light.

• Use only for jobs explained in this

manual.

TRANSPORTING AND STORAGE

• Stop the unit before carrying.

• Keep muffler away from your body.

• Allow the engine to cool and secure

the unit before storing or transport

ing it in a vehicle.

• Empty the fuel tank before storing or

transporting the unit. Use up fuel left

in the carburetor by starting the en

gine and letting it run until it stops.

• Store unit so the blade or line limiter

blade cannot accidentally cause in

jury. The unit can be hung by the

shaft.

• Store unit out of reach of children.

This unit is not equipped with an anti

vibration system and is intended for

occasional use only.

SAFETY NOTICE: Exposure to vibra

tions through prolonged use of gasoline

powered hand tools could cause blood

vessel or nerve damage in the fingers,

hands, and joints of people prone to cir

culation disorders or abnormal swell

ings. Prolonged use in cold weather

has been linted to blood vessel dam

age in otherwise healthy people. If

symptoms occur such as numbness,

pain, loss of strength, change in skin

color or texture, or loss of feeling in the

fingers, hands, or joints, discontinue the

use of this tool and seek medical atten

tion. An anti-vibration system does not

guarantee the avoidance of these prob

lems. Users who operate power tools

on a continual and regular basis must

monitor closely their physical condition

and the condition of this tool.

SPECIAL NCTiCE: This unit is

equipped with a temperature limiting

muffler and spark arresting screen

which meets the requirements of Cali

fornia Codes 4442 and 4443. All U.S.

forest land and the states of California,

Idaho, Maine, Minnesota, New Jersey,

Oregon, and Washington require by law

that many internal combustion engines

be equipped with a spark arresting

screen. If you operate in a locale where

such regulations exist, you are legally

Page 5

responsible for maintaining the operat

ing condition of these parts. Failure to

do so is a violation of the law. For nor

mal homeowner use, the muffler and

spark arresting screen will not require

ASSEMBLY

CARTON CONTENTS

Check carton contents against the fol

lowing list.

Model 358.795800

• Brushcutter

• Cupped washer

• Large nut for installing blades

• Hex wrench

• Handlebar

• Bracket cover

• Bracket cover screws (2)

• Metal blade shield

• Blade shield screws (4)

• 4-Point weed blade

• 8-Point weed blade

• Plastic shield

• Wing nut (screwed onto shield)

• Trimmer head (assembled on unit)

• Shoulder strap with warning

• Container of line

• Container of oil

Examine parts for damage. Do not

use damaged parts.

NOTE: If you need assistance or find

parts missing or damaged, call

1-800-235-5878.

It is normal for the fuel filter to rattle in

the empty fuel tank.

Finding fuel or oil residue on muffler is

normal due to carburetor adjustments

and testing done by the manufacturer.

ASSEMBLY

^WARNING: Always stop unit

and disconnect spark plug before per

forming any assembly procedures.

^ WARNING: if received as

sembled, repeat all steps to ensure

your unit is properly assembled and all

fasteners are secure.

TOOLS REQUIRED

• Hex Wrench (provided)

• Adjustable Wrench

• Phillips Screwdriver

ATTACHING THE HANDLEBAR

A DANGER: To avoid serious inju

ry, the barrier portion of the handlebar

must be installed as shown to provide a

barrier between operator and the spin

any service. After 50 hours of use, we

recommend that your muffler be ser

viced or replaced by your Sears Service

Center.

ning blade.

1. Locate the decal on the handlebar.

This decal includes an arrow. Posi

tion the handlebar with the mount

ing bracket at the end of the arrow.

2. Position the bracket cover over the

handlebar. Again make sure the

handlebar is at the end of the arrow.

3. insert screws and hand tighten

only. Be sure the handlebar is

installed correctly; then, tighten

each screw securely with the hex

wrench.

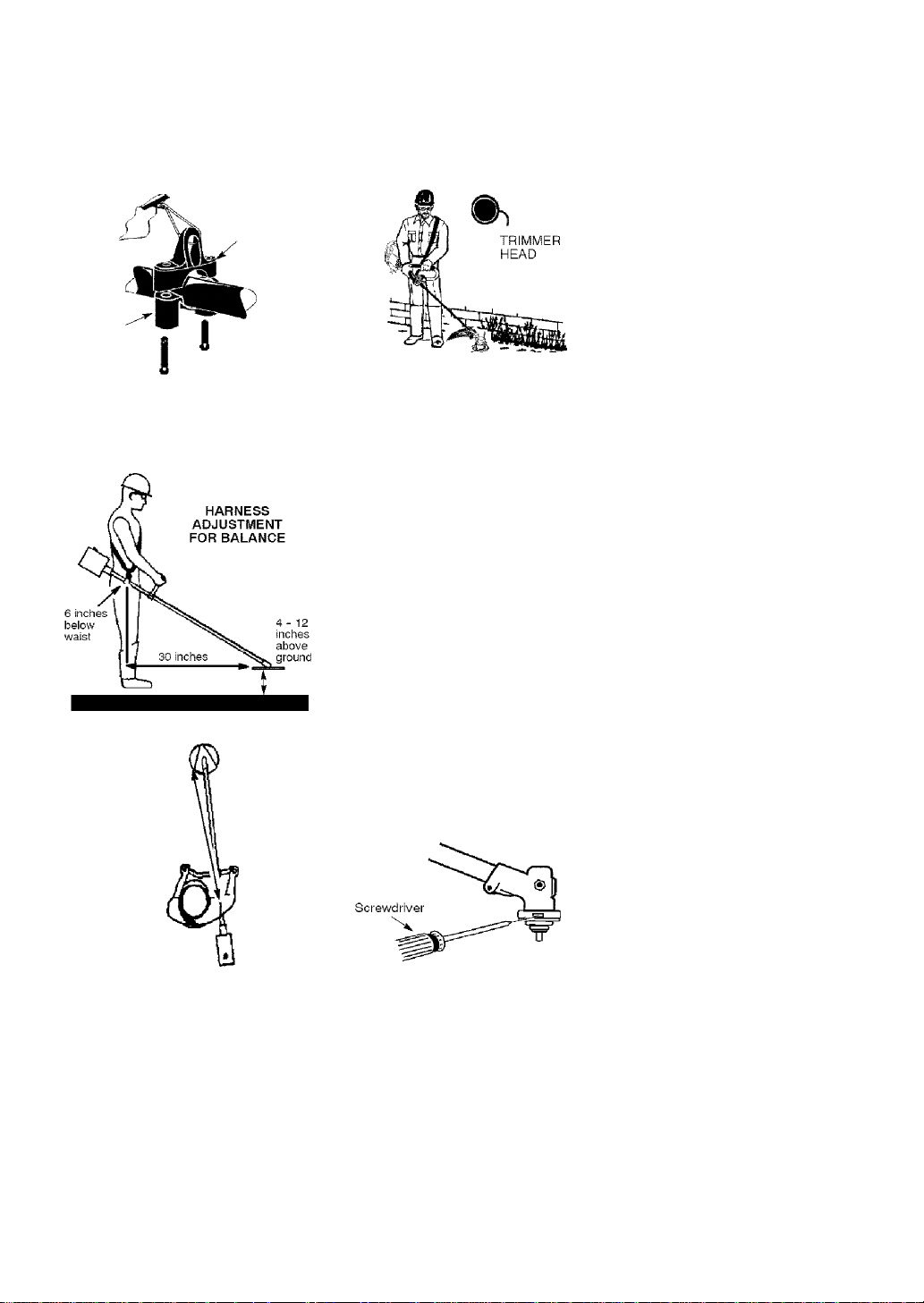

liWARNING: Proper shoulder

strap and handlebar adjustments must

be made with the engine completely

stopped before using unit.

1. Insert your right arm and head

through the shoulder strap and al

low it to rest on your left shoulder.

Make sure the danger sign is on

your back and the hook is to the

right side of your waist.

NOTE: A one-half twist is built in the

shoulder strap to allow the strap to rest

flat on the shoulder.

2. Adjust the strap, allowing the hook

to be about 6 inches below the

waist.

3. Fasten the strap hook to the clamp

located between the trigger handle

and the handlebar clamp base and

lift the tool to the operating position.

4. Try on shoulder strap and adjust

for fit and balance before starting

the engine or beginning a cutting

operation.

NOTE: It may be necessary to relo

cate the shoulder strap clamp on the

shaft for proper balancing of unit.

Page 6

TO RELOCATE SHOULDER STRAP

CLAMP:

1. Loosen and remove both clamp

screws.

2. Place the upper shoulder strap

clamp over the shaft.

3. Position the lower shoulder strap

clamp under the shaft and align

the upper and lower clamp screw

holes.

Upper Shoulder

Strap Clamp

Lower Shoulder

Strap Clamp

Screws

4. Insert two screws into the screw

holes.

5. Secure shoulder strap clamp by

tightening screws with a hex

wrench.

30 inches

CONFIGURING YOUR UNIT

You can configure your unit using a cut

ting head for grass and light weeds, or

a weed blade for cutting grass, weeds,

and brush up to 1/2 inch In diameter. To

assemble your unit, go to the section for

the desired configuration and follow the

instructions.

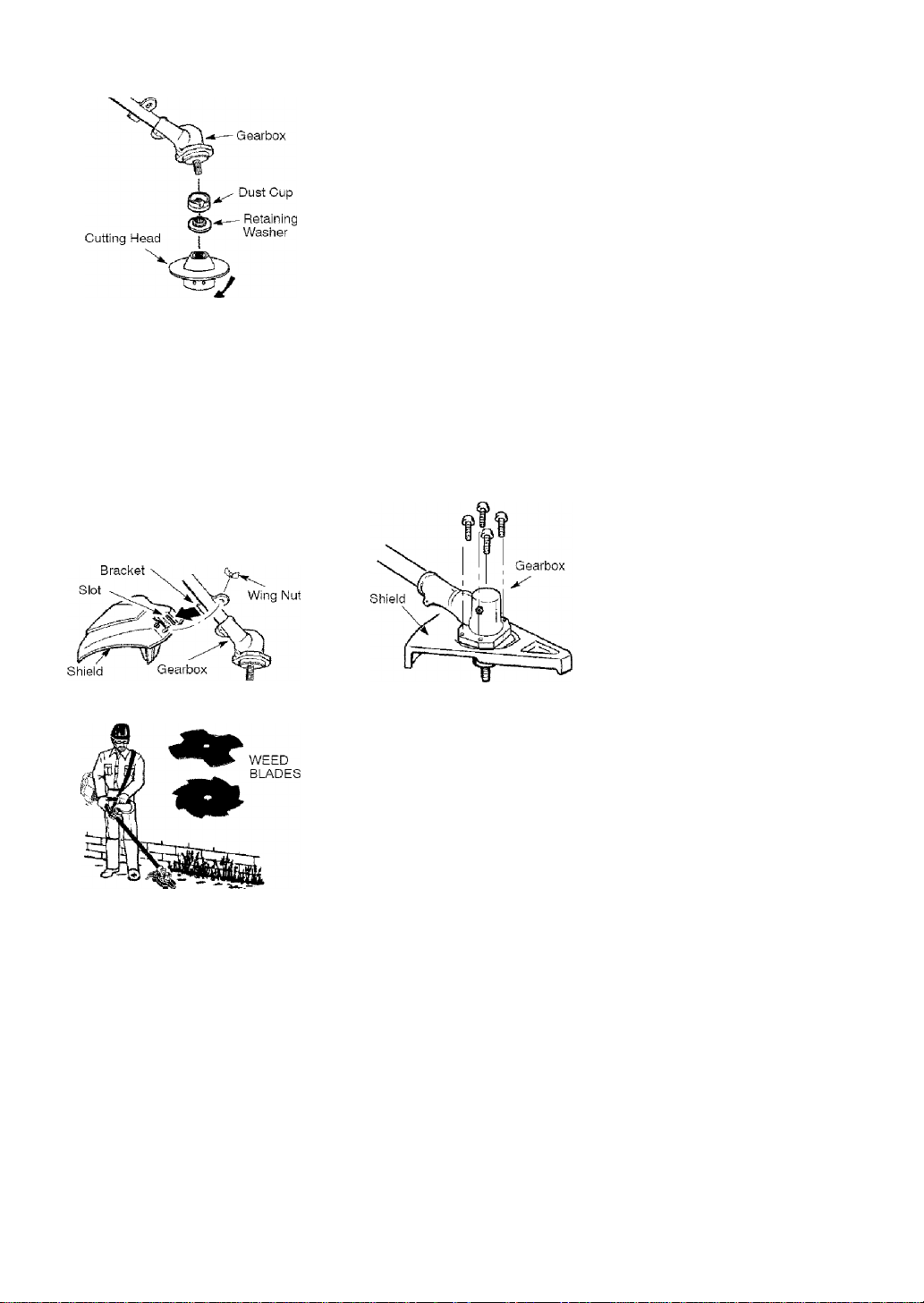

ASSEMBLY INFORMATION TRIMMER HEAD

NOTE: Remove the blade and metal

shield before attaching the plastic shield

and trimmer head. To remove blade,

align hole in the dust cup with the hole

in the side of the gearbox by rotating

the dust cup. Insert a small screwdriv

er into aligned holes. This will keep the

shaft from turning while loosening the

blade nut. Remove blade nut by turning

clockwise. Remove the screwdriver.

Remove both washers and blade. To

remove metal shield, loosen and re

move the four mounting screws. See

ATTACHING THE METAL SHIELD and

INSTALLATION OF THE METAL BLADE for

illustrations. Be sure to store ali parts

and instructions for future use.

INSTALLATION OF THE CUTTING

HEAD (if not already installed)

NOTE: Before installing the trimmer

head, make sure the dust cup and re

taining washer are positioned on the

shaft of the gearbox. The retaining

washer must be positioned with the

raised section toward the gearbox.

1. Align hole in the dust cup with the

hole in the side of the gearbox by

rotating the dust cup.

2. Insert a small screwdriver into

aligned holes. This will keep the

shaft from turning while tightening

trimmer head.

Page 7

While holding the screwdriver in

position, thread trimmer head onto

the shaft by turning counterclock

wise. Only tighten hand tight!

4. Remove the screwdriver.

ATTACHING THE PLASTIC SHIELD

A WARNING: The shield must be

properly installed. The shield provides

partial protection from the risk of

thrown objects to the operator and

others and is equipped with a line lim

iter blade which cuts excess line to the

proper length. The line limiter blade

(on underside of shield) is sharp and

can cut you.

1. Remove wing nut from shield.

2. insert bracket into slot on shield.

3. Pivot shield until bolt passes

through hole in bracket.

4. Tighten the wing nut securely.

in the side of the gearbox by rotating

the dust cup. Insert a small screwdriver

into aligned holes. This will keep the

shaft from turning while loosening the

trimmer head. Remove the trimmer

head by turning clockwise. Remove the

screwdriver. To remove the plastic

shield, loosen and remove wing nut.

Pivot shield to release bracket from slot.

See INSTALLATION OF THE CUTTING

HEAD and ATTACHING THE PLASTIC

SHIELD for illustrations. Be sure to store

all parts and instructions for future use.

Never use the trimmer head with the

metal blade installed.

ATTACHING THE METAL SHIELD

^WARNING: The metal shield

must be properly installed on the tool

anytime the too! is used with a blade.

The forward tip of the metal shield

helps to reduce the occurrence of

blade thrust which can cause serious

injury such as amputation to the oper

ator or bystanders. Failure to install

the shield in the position shown can

result in serious injury to the operator.

The length of the shield must be

aligned with the length of the shaft.

1. Place the metal shield under the

gearbox, and align the screw holes.

ASSEMBLY INFORMATION - WEED

BLADES

NOTE: Remove the trimmer head and

plastic shield before attaching the metal

shield and installing one of the weed

blades. To remove the trimmer head,

align hole in the dust cup with the hole

2. Insert and thread the 4 mounting

screws through the holes of the

gearbox and the metal shield.

Tighten evenly and securely with

the hex wrench provided,

INSTALLATION OF THE METAL

BLADE

^ WARN IN G: Wear protective

gloves when handling or performing

maintenance on the blade to avoid inju

ry. The blade is sharp and can cut you

even when it is not moving,

A WARNING : Do not use any

blades, or fastening hardware other

than the washers and nuts shown in the

following illustrations. These parts must

be provided by Sears, and installed as

Page 8

shown below. Failure to use proper

parts can cause the blade to fly off and

seriously hurt you or others.

NOTE: The dust cup and retaining

washer are located on the gearbox

shaft and not in the parts bag. All other

fasteners mentioned in the following as

sembly steps are in the parts bag.

1. Remove the retaining washer from

the threaded shaft of the gearbox.

Leave the dust cup on the shaft,

2. install the blade and the retaining

washer over the threaded shaft.

3. Make sure the raised part of the

retaining washer is facing the

gearbox and the raised area fits

into the hole in the center of the

biade.

4. Slide the blade and retaining wash

er onto the shaft of the gearbox.

NOTE; When installing 8-point

weed blade, ensure side of blade

with decal is facing gearbox and

points of blade will rotate counter

clockwise (see illustration).

8-POINTBLADE

DECAL SIDE OF

BLADE MUST

FACE GEARBOX

Place the cupped washer onto the

shaft. Make sure the cupped side

of the washer is toward the biade,

install the blade nut by threading

onto the shaft counterclockwise.

NOTE: Make sure all parts are in piace

as illustrated, and the blade is sand

wiched between the dust cup and the

retaining washer. There should be no

space between the blade and the dust

cup or the retaining washer.

7. Aiign hole in dust cup with hole in

side of gearbox by rotating the

blade.

8. insert a small screwdriver into

aligned holes. This will keep the

shaft from turning while tightening

the blade nut.

9,

Tighten blade nut firmly with a

wrench while holding screwdriver in

position.

10.

Remove the screwdriver.

11.

Turn blade by hand. If the blade

binds against the shield, or appears

to be uneven, the blade is not cen

tered, and you must reinstali,

NOTE: To remove blade, insert screw

driver into aligned holes. Unthread the

nut and remove parts. Be sure to store

parts and instructions for future use.

Page 9

OPERATION

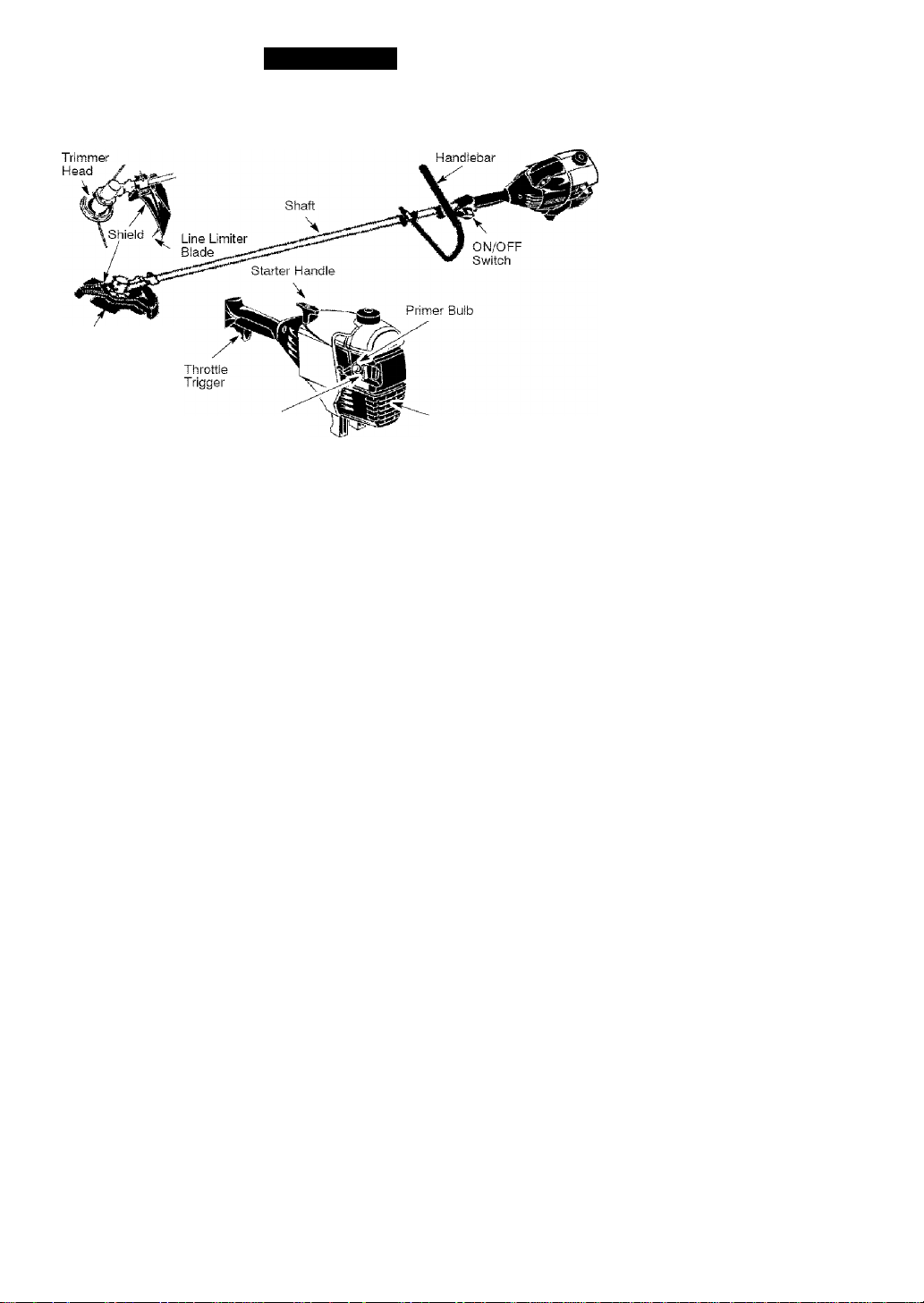

KNOW YOUR BRUSHWACKER

READ THIS OPERATOR’S MANUAL AND SAFETY RULES BEFORE OPERATING YOUR

UNIT. Compare the illustrations with your unit to familiarize yourself with the location of

the various controls and adjustments. Save this manual for future reference.

Blade

Choke Lever

ON/OFF SWITCH

The ON/OFF SWITCH is used to stop the

engine. Move the switch to the OFF

position to stop the engine.

PRIMER BULB

The PRIMER BULB removes air from

the carburetor and fuel lines and fills

them with fuel. This allows you to start

the engine with fewer pulls on the

starter rope. Activate the primer bulb

by pressing it and allowing it to return

to its original form.

BEFORE STARTING ENGINE

ik WARNING; Be sure to read

the fuel information in the safety rules

before you begin. If you do not under

stand the safety rules, do not attempt

to fuel your unit. Call 1 -800-235-5878.

FUELING ENGINE

A WARNING: Remove fuel cap

slowly when refueling.

This engine is certified to operate on

unleaded gasoline. Before operation,

gasoline must be mixed with a good

quality synthetic 2-cycle air-cooled en

gine oil. We recommend Craftsman

brand synthetic oil. Mix gasoline and

oil at a ratio of 40:1, A 40:1 ratio is ob

tained by mixing 3.2 ounces of oil with

1 gallon of unleaded gasoline. In

cluded with this brushcutter is a 3.2

ounce container of oil. Pour the entire

Muffler

CHOKE

The CHOKE helps to supply fuel to the

engine to aid in cold starting. Activate

the choke by moving the choke lever to

the FULL CHOKE position. After the en

gine attempts to start, move the choke

lever to the HALF CHOKE position. Once

engine has started, move the choke le

ver to the OFF CHOKE position.

contents of this container into 1 gallon

of gasoline to achieve the proper fuel

mixture. DO NOT USE automotive oil or

marine oil. These oils will cause en

gine damage. When mixing fuel, fol

low instructions printed on container.

Once oil is added to gasoline, shake

container momentarily to assure that the

fuel is thoroughly mixed. Always read

and follow the safety rules relating to

fuel before fueling your unit.

IMPORTANT

Experience indicates that alcohol

blended fuels (called gasohol or using

ethanol or methanol) can attract mois

ture which leads to separation and

formation of acids during storage.

Acidic gas can damage the fuel sys

tem of an engine while in storage.

To avoid engine problems, empty the

fuel system before storage for 30 days

Page 10

or longer. Drain the gas tank, start the

engine and let it run until the fuel lines

and carburetor are empty. Use fresh

fuel next season.

Never use engine or carburetor clean

er products in the fuel tank or perma

nent damage may occur.

See the STORAGE section for addition

al information.

HOW TO STOP YOUR UNIT

• To stop the engine, move the ON/

OFF switch to the off position.

• if engine does not stop, move choke

lever to FULL CHOKE position.

Throttle Trigger

HOW TO START YOUR UNIT

WARNING; The trimmer head

will turn while starting the engine.

Avoid any contact with the muffler. A

hot muffler can cause serious burns.

STARTING A COLD ENGINE (or a

warm engine after running out of

fuel)

.§1 <№

,e-iitjA' Ll Starting Position

Starter Handle

Primer Bulb

Muffler

1. Set unit on a flat surface.

2. Move ON/OFF switch to the ON

position.

3. Slowly press the primer bulb 6

times,

4. Move choke lever to FULL CHOKE

by aligning lever with position

shown on decal {see following

illustration).

Choke

position

decal

Squeeze the throttle trigger ftjlly and

hold through all remaining steps.

Pull starter rope handle sharply

until engine sounds as if it is trying

to start, but do not pull rope more

than 6 times.

As soon as engine sounds as if it

is trying to start, move choke lever

to HALF CHOKE by aligning lever

with position shown on decal (see

illustration below).

Choke

position

decal

________

Pull starter rope sharply until engine

runs, but no more than 6 pulls. If the

engine doesn’t start after 6 pulls (at

the HALF CHOKE position), move the

choke lever to the FULL CHOKE

position and press the primer bulb 6

times. Squeeze and hold the throttle

trigger and pull the starter rope 2

more times. Move the choke lever

to the HALF CHOKE position and pull

the starter rope until the engine

runs, but no more than 6 pulls. It the

engine doesn’t start, repeat proce

dure 2 additional times,

NOTE: If engine still doesn’t start, it

is probably flooded. Proceed to

STARTING A FLOODED ENGINE.

Once the engine starts, allow it to

run 10 seconds, then move the

choke lever to OFF CHOKE by align

ing lever with position shown on de

cal (see illustration below). Allow the

unit to run for 30 more seconds at

OFF CHOKE before releasing the

throttle trigger. NOTE: if engine dies

with the choke lever in the OFF

CHOKE position, move the choke le

ver to the HALF CHOKE position and

pull the rope until engine runs, but

no more than 6 pulls.

10

Page 11

Choke

position

decal

STARTING A WARM ENGINE

1. Move ON/OFF switch to the ON

position.

2. Move the choke lever to the HALF

CHOKE position.

3. Squeeze and hold the throttle trig

ger. Keep throttle trigger fully

squeezed until the engine runs

smoothly.

4. Pull starter rope sharply until engine

runs, but no more than 5 pulls.

5. Allow engine to run 15 seconds,

then move the choke lever to the

OFF CHOKE position.

NOTE: If engine has not started, pull

starter rope 5 more pulls. If engine still

does not run, it is probably flooded.

STARTING A FLOODED ENGINE

Flooded engines can be started by

placing the choke lever in the OFF

CHOKE position; then, pull the rope to

clear the engine of excess fuel. This

could require pulling the starter handle

many times depending on how badly

the unit is flooded. If the unit still

doesn’t start, refer to TROUBLESHOOT

ING TABLE or call 1 -800-235-5878.

OPERATING INSTRUCTIONS

To maximize operating efficiency, do

not run the engine for longer than 1

minute at a time at full throttle.

OPERATING POSITION

When operating unit, clip shoulder

strap onto clamp, stand as shown and

check for the following:

• Wear hearing protection, eye protec

tion, head protection and heavy clo

thing.

• Extend your left arm and hold han

dlebar grip with your left hand.

• Field throttle grip with your right hand

with finger on throttle trigger.

• Keep unit below waist level.

• Keep shoulder strap pad centered

on your left shoulder and danger

sign centered on your back.

• Maintain full weight of tool on your

left shoulder.

• Cut only from your left to your right to

ensure debris is thrown away from

you. Without bending over, keep the

blade or trimmer head near and par

allel to the ground and not crowded

into material being cut.

OPERATING INSTRUCTIONS FOR

USE WITH TRIMMER HEAD

^WARNING: Always wear eye

protection. Never lean over the trimmer

head, flocks or debris can ricochet or

be thrown into eyes and face and

cause blindness or other serious injury.

Before trimming, bring engine to a

speed sufficient to cut material to be

trimmed.

Do not run the engine at a higher speed

than necessary. The cutting line will cut

efficiently when the engine is run at less

than full throttle. At lower speeds, there

is less engine noise and vibration. The

cutting line will last longer and will be

less likely to “weld” onto the spool.

Always release the throttle trigger and

allow the engine to return to idle

speed when not cutting.

To stop engine:

• Release the throttle trigger.

• Move ON/OFF switch to the OFF

position.

^WARNING: Use minimum

speed and do not crowd the line when

cutting around hard objects (rock,

gravel, fence posts, etc.), which can

damage the trimmer head, become

entangled in the line, or be thrown

causing a serious hazard.

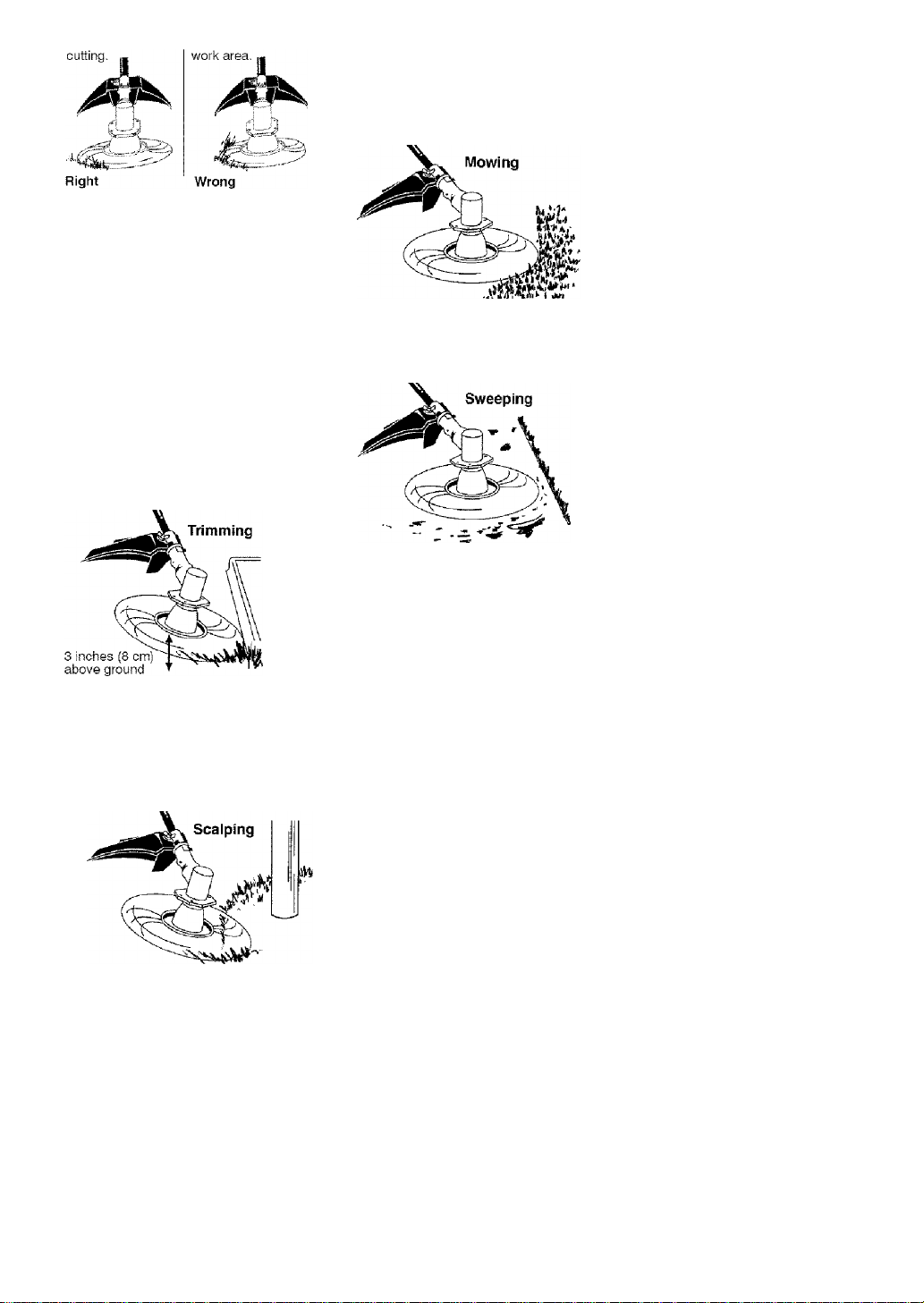

• The tip of the line does the cutting.

You wiil achieve the best perform

ance and minimum line wear by not

crowding the line into the cutting

area. The right and wrong ways are

shown below.

11

Page 12

Tip of line does the Line crowded into

• The line will easily remove grass

and weeds from around walls,

fences, trees and flower beds, but it

also can cut the tender bark of trees

or shrubs and scar fences.

• For trimming or scalping, use less

than full throttle to increase line life

and decrease head wear, especially:

• During light duty cutting.

• Near objects around which the line

can wrap such as small posts,

trees or fence wire.

• For mowing or sweeping, use full

throttle for a good clean job.

TRIMMING - Hold the bottom of the

trimmer head about 3 inches {8 cm)

above the ground and at an angle. Al

low only the tip of the line to make

contact with vegetation. Do not force

trimmer line into work area.

SCALPING - The scalping technique

removes unwanted vegetation down to

the ground. Hold the bottom of the trim

mer head about 3 inches (8 cm) above

the ground and at an angle. Allow the

tip of the line to strike the ground

around trees, posts, monuments, etc.

This technique increases line wear.

MOWING - Your trimmer is ideal for

mowing in places conventional lawn

mowers cannot reach. In the mowing

position, keep the iine parallel to the

ground. Avoid pressing the head into

the ground as this can scalp the

ground and damage the tool.

SWEEPING - The fanning action of the

rotating line can be used to blow away

loose debris from an area. Keep the line

parallel to and above the area surface

and swing the tool from side to side.

OPERATING INSTRUCTIONS FOR

USE WITH WEED BLADES

• Blade Thrust is a reaction that only

occurs when using a bladed unit. This

reaction can cause serious injury

such as amputation. Carefully study

this section. It is important that you

understand what causes blade thrust,

how you can reduce the chance of its

occurring, and how you can remain in

control of unit if blade thrust occurs.

• WHAT CAUSES BLADE THRUST -

Blade Thrust can occur when the

spinning blade contacts an object that

it does not cut. This contact causes

the blade to stop for an instant and

then suddenly move or “thrust” away

from the object that was hit. The

“thrusting” reaction can be violent

enough to cause the operator to be

propelled in any direction and lose

control of the unit. The uncontrolled

unit can cause serious injury if the

blade contacts the operator or others.

• WHEN BLADE THRUST OCCURS

- Blade Thrust can occur without

warning if the blade snags, stalls, or

binds. This is more likely to occur in

12

Page 13

areas where it is difficult to see the

material being cut. By using the unit

properfy, the occurrence of blade

thrust will be reduced and the opera

tor will be less likely to lose control.

Cut only grass, weeds, and woody

brush up to 1/2 inch in diameter with

the weed blade. Do not let the blade

contact material it cannot cut such as

stumps, rocks, fences, metal, etc., or

clusters of hard, woody brush having

a diameter greater than 1/2 inch.

Keep the blade sharp. A dull blade

is more likely to snag and thrust.

Cut only at full throttle. The blade will

have maximum cutting power and is

less likely to bind or stall.

“Feed” the blade deliberately and

not too rapidly. The blade can thrust

away if it is fed too rapidly.

Cut only from your left to your right.

Cutting on right side of the shield will

throw debris away from the operator.

Use the shoulder strap and keep a

firm grip on the unit with both hands.

A properly adjusted shoulder strap

will support the weight of the unit,

freeing your arms and hands to con

trol and guide the cutting motion.

Keep feet comfortably spread apart

and braced for a possible sudden,

rapid thrust of unit. Do not overreach.

Keep firm footing and balance.

Keep blade below waist level; it will

be easier to maintain control of unit.

• Do not raise the engine above your

waist as the blade can come dan

gerously close to your body.

• Do not swing unit with such force

that you are in danger of losing your

balance.

Bring the engine to cutting speed be

fore entering the material to be cut.If

the blade does not turn when you

squeeze the throttle trigger, make sure

shaft is fully inserted into the engine.

Always release the throttle trigger and

allow engine to return to idle speed

when not cutting. The blade should

not turn while the engine is running at

idle. If the blade turns at idle, do not

use your unit. Refer to the

TOR ADJUSTMENT section or contact

your Sears Service Center,

• Maintain good firm footing while using

the unit. Do this by planting feet firmly

in a comfortable apart position.

• Cut while swinging the upper part of

your body from left to right.

• As you move forward to the next

area to cut, be sure to maintain your

balance and footing.

RECOMMENDED CUTTING POSITION

Cut using the 2 ■

o'clock to 4 o'clock

position of the

blade

Ci WARNING: The operator or oth

ers must not try to clear away cut mate

rial with the engine running or the blade

turning to avoid serious injury. Stop en

gine and blade before removing materi

als wrapped around blade or shaft.

CARBURE

2 o’clock

I't

4 o'clock

MAINTENANCE

MAINTENANCE SCHEDULE

A

WARNING: Disconnect the spark plug before performing maintenance

except for carburetor adjustments.

CARE & MAINTENANCE TASK WHEN TO PERFORM

Check for loose fasteners and parts Before each use

Check for damaged or worn parts Before each use

Inspect and clean unit and decals After each use

Clean air filter Every 5 hours of operation

Inspect muffler and spark arresting screen Every 50 hours of operation

Replace spark plug Yearly

13

Page 14

GENERALRECOMMENDATIONS

The warranty on this unit does not

cover items that have been subjected

to operator abuse or negligence. To

receive full value from the warranty,

the operator must maintain unit as

instructed in this manual. Various ad

justments wiil need to be made peri

odically to properly maintain your unit.

CHECK FOR LOOSE

FASTENERS AND PARTS

• Spark Plug Boot

• Air Filter

• Housing Screws

• Assist Handle Screw

• Debris Shield

CHECK FOR DAMAGED OR

WORN PARTS

Contact Sears Service Center for re

placement of damaged or worn parts.

• ON/OFF Switch - Ensure ON/OFF

switch functions properly by moving

the switch to the OFF position. Make

sure engine stops; then restart en

gine and continue.

• Fuel Tank - Discontinue use of unit

if fuel tank shows signs of damage

or leaks.

• Debris Shield - Discontinue use of

unit if debris shield is damaged.

INSPECT AND CLEAN UNIT AND

DECALS

• After each use, inspect complete

unit for loose or damaged parts.

Clean the unit and decals using a

damp cloth with a mild detergent.

• Wipe off unit with a clean dry cloth.

CLEAN AIR FILTER

A dirty air filter decreases engine per

formance and increases fuel con

sumption and harmful emissions. Al

ways clean after every 5 hours of

operation.

1. Clean the cover and the area

around it to keep dirt from falling

into the carburetor chamber when

the cover is removed.

2. Remove parts by pressing button

to release air filter cover.

NOTE: To avoid creating a fire hazard

or producing harmful evaporative

emissions, do not clean filter in gaso

line or other flammable solvent.

3. Wash the filter in soap and water.

4. Allow filter to dry.

5. Replace parts.

INSPECT MUFFLER AND SPARK

ARRESTING SCREEN

^WARNING: The muffler on this

product contains chemicals known to

the State of California to cause cancer.

As your unit is used, carbon deposits

build up on the muffler and spark ar

resting screen.

For normal homeowner use, however,

the muffler and spark arresting screen

will not require any service. After 50

hours of use, we recommend that your

muffler be serviced or replaced by your

Sears Service Center.

REPLACE SPARK PLUG

Replace the spark plug each year to

ensure the engine starts easier and

runs better. Set spark plug gap at

0. 025.inch, ignition timing is fixed and

nonadjustable.

1. Twist, then pull off spark plug boot.

2. Remove spark plug from cylinder

and discard.

3. Replace with Champion RCJ-6Y

spark plug and tighten securely

with a 3/4 inch socket wrench.

4. Reinstall the spark plug boot.

14

Page 15

SERVICE AND ADJUSTMENTS

LINE REPLACEMENT

• Always use Craftsman replacement

line.

Choose the line size best suited for

the job at hand. Red line is designed

for cutting grass and small weeds.

The black colored line is designed for

cutting larger weeds and light brush.

NOTE: Before inserting new line into

the holes in the cutting head, identify

the proper holes. Follow directions as

shown on the line glide plate.

1. Remove the old line and line glide

plate from the cutting head.

2. Clean entire surface of cutting head.

3. Reinstall line glide plate (see il

lustration). Align arrow with:

when using medium (red) or

©

large (black) line

when using lines with diameter

(§) smaller than medium (red) line

(optional)

Arrow

/

Cutting head

NOTE: Line glide plate must be rein

stalled in cutting head before inserting

new line.

4. insert both ends of your line

through the proper holes in the

side of the cutting head.

Pull the line and make sure the

line is against the hub and ex

tended full through the positioning

tunnels.

6. Correctly installed line will be the

same length on both ends

Line against

the hub

BLADE REPLACEMENT

Refer to the ASSEMBLY section for

blade replacement instructions and

illustrations.

CARBURETOR ADJUSTMENT

^WARNING: Keep others away

when making idle speed adjustments.

The trimmer head or blade will be

spinning during most of this proce

dure. Wear your protective equipment

and observe all safety precautions.

After making adjustments, the trimmer

head or blade must not move/spin at

idle speed.

The carburetor has been carefully set

at the factory. Adjustments may be

necessary if you notice any of the fol

lowing conditions:

• Engine will not idle when the throttle is

released.

• The trimmer head or blade moves/

spins at idle.

Make adjustments with the unit sup

ported so the cutting attachment is off

the ground and will not make contact

with any object. Hold the unit by hand

while running and making adjust

ments. Keep all parts of your body

away from the cutting attachment and

muffler.

Idle Speed Adjustment

Allow engine to idle. Adjust speed until

engine runs without trimmer head or

blade moving or spinning (idle too

fast) or engine stalling (idle speed too

slow).

• Turn idle speed screw clockwise to

increase engine speed if engine

stalls or dies.

• Turn idle speed screw counterclock

wise to decrease engine speed if

trimmer head or blade moves or

spins at idle.

15

Page 16

a WARNING: Recheck the idle

speed after each adjustment. The

trimmer head or blade must not move

or spin at idle speed to avoid serious

injury to the operator or others.

Idle Speed

Screw

STORAGE

a WARNING: Perform the follow

ing steps after each use:

• Allow engine to cool before storing

or transporting.

• Store unit and fuel in a well venti

lated area where fuel vapors cannot

reach sparks or open flames from

water heaters, electric motors or

switches, furnaces, etc.

• Store unit with all guards in place.

Position unit so that any sharp ob

ject cannot accidentally cause injury.

• Store unit and fuel well out of the

reach of children.

SEASONAL STORAGE

Prepare unit for storage at end of sea

son or if it will not be used for 30 days

or more.

If your unit is to be stored for a period

of time:

• Clean the entire unit before lengthy

storage.

• Store in a clean dry area.

• Lightly oil external metal surfaces.

FUEL SYSTEM

Empty the fuel system before storage

for 30 days or longer. Drain the gas

tank, start the engine and let it run un

til the fuel lines and carburetor are

empty. Use fresh fuel next season.

Under FUELING ENGINE in the OPERA

TION section of this manual, see mes

sage labeled IMPORTANT regarding

the use of gasohol in your engine.

If you require further assistance or are

unsure about performing this proce

dure, contact your Sears Service Cen

ter or call our customer assistance

help line at 1 -800-235-5878.

Fuel stabilizer is an acceptable alter

native in minimizing the formation of

fuel gum deposits during storage. Add

stabilizer to the gasoline in the fuel

tank or fuel storage container. Follow

the mix instructions found on stabilizer

container. Run engine at least 5 min

utes after adding stabilizer.

Craftsman 40:1,2-cycle engine oil {air

cooled) is already blended with fuel

stabilizer. If you do not use this Sears

oil, you can add a fuel stabilizer to

your fuel tank.

ENGINE

• Remove spark plug and pour 1 tea

spoon of 40:1, 2-cycle engine oil (air

cooled) through the spark plug

opening. Slowly pul! the starter rope

8 to 10 times to distribute oil.

• Replace spark plug with new one of

recommended type and heat range.

• Clean air filter.

• Check entire unit for loose screws,

nuts, and bolts. Replace any dam

aged, broken, or worn parts.

• At the beginning of the next season,

use only fresh fuel having the proper

gasoline to oil ratio.

OTHER

• Do not store gasoline from one sea

son to another.

• Replace your gasoline can if it starts

to rust.

16

Page 17

TROUBLESHOOTING TABLE

^WARNING: Always stop unit and disconnect spark plug before perform

ing all of the recommended remedies below except remedies that require

operation of the unit.

TROUBLE CAUSE REMEDY

Engine wilt not

start.

Engine wilt

not idle

properly.

Engine wilt not

accelerate,

lacks power,

or dies under

a load.

1. ON/OFF switch in

OFF position.

2. Engine flooded.

3. Fuel tank empty.

4. Spark plug not firing.

5. Fuel not reaching

carburetor.

e. Carburetor requires

adjustment.

1. Carburetor requires

adjustment.

2. Crankshaft seals worn.

3. Compression low.

1. Air filter dirty.

2. Spark plug fouled.

3. Carburetor requires

adjustment.

4. Carbon build-up on

muffler outlet screen.

5. Compression low.

1. Move ON/OFF switch to the ON

position.

2. See “Starting a Flooded Engine” in

Operation Section.

3. Fill tank with correct fuel mixture.

4. Install new spark plug.

5. Check for dirty fuel filter; replace.

Check for kinked or split fuel line;

repair or replace.

6. Contact Sears Service (see back cover).

1. See “Carburetor Adjustment” in

Service and Adjustments Section.

2. Contact Sears Service (see back cover).

3. Contact Sears Service (see back cover).

1. Clean or replace air filter.

2. Clean or replace plug and regap.

3. Contact Sears Service (see back cover).

4. Contact Sears Service (see back cover).

5. Contact Sears Service (see back cover).

Engine

smokes

excessively.

Engine runs

hot.

1. Choke partially on.

2. Fuel mixture incorrect.

3. Air filter dirty.

4. Carburetor requires

adjustment.

1. Fuel mixture incorrect.

2. Spark plug incorrect,

3, Carburetor requires

adjustment.

4, Carbon build-up on

muffler outlet screen.

1. Adjust choke.

2. Empty fuel tank and refill with

correct fuel mixture.

3. Clean or replace air filter.

4. Contact Sears Service (see back cover).

1. See “Fueling Engine” in Cperation

section.

2. Replace with correct spark plug.

3. Contact Sears Service (see back cover).

4. Contact Sears Service (see back cover).

17

Page 18

U.S. EPA / CALIFORNIA

EMISSION CONTROL WARRANTY STATEMENT

YOUR WARRANTY RIGHTS AND OB

LIGATIONS: The U.S. Environmental

Protection Agency/Caiifornia Air Re

sources Board and Sears, Roebuck

and Co., U.S.A., are pleased to explain

the emissions control system warranty

on your year 2005 and later small off

road engine. In California, all small off

road engines must be designed, built,

and equipped to meet the State’s strin

gent anti-smog standards. Sears must

warrant the emission control system on

your small off-road engine for the peri

ods of time listed below provided there

has been no abuse, neglect, or improp

er maintenance of your small off-road

engine. Your emission control system

includes parts such as the carburetor

and the ignition system. Where a war

rantable condition exists. Sears will re

pair your small off-road engine engine

at no cost to you. Expenses covered

under warranty include diagnosis, parts

and labor.

RANTY COVERAGE; if any emissions

related part on your engine {as listed

under Emissions Control Warranty Parts

List) is defective or a defect in the mate

rials or workmanship of the engine

causes the failure of such an emission

related part, the part will be repaired or

replaced by Sears. OWNER’S WAR

RANTY RESPONSIBILITIES: As the

small off-road engine engine owner,

you are responsible for the performance

of the required maintenance listed in

your operator’s manual. Sears recom

mends that you retain all receipts cover

ing maintenance on your small off-road

engine, but Sears cannot deny warranty

solely for the lack of receipts or for your

failure to ensure the performance of all

scheduled maintenance. As the small

off-road engine engine owner, you

should be aware that Sears may deny

you warranty coverage if your small off

road engine engine or a part of it has

failed due to abuse, neglect, improper

maintenance, unapproved modifica

tions, or the use of parts not made or

approved by the original equipment

manufacturer. You are responsible for

presenting your small off-road engine to

a Sears authorized repair center as

soon as a problem exists. Warranty re

pairs should be completed in a reason

able amount of time, not to exceed 30

days. If you have any questions re

garding your warranty rights and re

MANUFACTURER’S WAR

sponsibilities, you should contact your

nearest authorized service center or call

Sears at 1-800-469-4663.

WARRAN

TY COMMENCEMENT DATE: The

warranty period begins on the date the

small off-road engine is purchased.

LENGTH OF COVERAGE: This war

ranty shall be for a period of two years

from the initial date of purchase. WHAT

IS COVERED; REPAIR OR REPLACE

MENT OF PARTS. Repair or replace

ment of any warranted part will be per

formed at no charge to the owner at an

approved Sears Service Center. If you

have any questions regarding your war

ranty rights and responsibilities, you

should contact your nearest authorized

service center or call Sears at

1-800-469-4663. WARRANTY PE

RIOD: Any warranted part which is not

scheduled for replacement as required

maintenance, or which Is scheduled

only for regular inspection to the effect

of “repair or replace as necessary” shall

be warranted for 2 years. Any war

ranted part which is scheduled for re

placement as required maintenance

shall be warranted for the period of time

up to the first scheduled replacement

point for that part. DIAGNOSIS: The

owner shall not be charged for diagnos

tic labor which leads to the determina

tion that a warranted part is defective if

the diagnostic work is performed at an

approved Sears Service Center. CON

SEQUENTIAL DAMAGES: Sears may

be liable for damages to other engine

components caused by the failure of a

warranted part still under warranty.

WHAT IS NOT COVERED: All failures

caused by abuse, neglect, or improper

maintenance are not covered. ADD-ON

OR MODIFIED PARTS: The use of

add-on or modified parts can be

grounds for disallowing a warranty

claim. Sears is not liable to cover fail

ures of warranted parts caused by the

use of add-on or modified parts. HOW

TO FILE A CLAIM; If you have any

questions regarding your warranty rights

and responsibilities, you should contact

your nearest authorized service center

or call Sears at 1 -800-469-4663.

WHERE TO GET WARRANTY SER

VICE: Warranty services or repairs shall

be provided at all Sears Service Cen

ters. Call 1-800-469-4663.

18

Page 19

MAINTENANCE, REPLACEMENT

AND REPAIR OF EMISSION RE

LATED PARTS: Any Sears approved

replacement part used in the perfor

mance of any warranty maintenance or

repair on emission related parts will be

provided without charge to the owner if

the part is under warranty.

The information on the product label indicates to which standard your engine is certified.

Example: (Year) EPA Phase I or Phase II and/or CALIFORNIA.

This engine is certified to be emissions compliant for the following use:

68 Moderate (50 hours)

EMISSION CONTROL WARRANTY

PARTS LIST: Carburetor, Ignition Sys

tem: Spark Plug (covered up to mainte

nance schedule), Ignition Module, Muf

fler including catalyst. MAINTENANCE

STATEMENT: The owner is responsible

for the performance of all required main

tenance as defined in the operator’s

manuai.

I I Intermediate (f 25 hours)

□ Extended (300 hours)

19

Page 20

TABLA DE CONTENIDO

Declaración de Garantía 22 Almacenaje 38

Reglas de Seguridad 22

Montaje

Uso

Mantenimiento 35

Servicio y Ajustes 36 Repuesto y Encargos Contratapa

25

30

Tabla Diagnóstica 39

Declaración de Emisión 40

Lista de Piezas 20

DECLARACION DE GARANTIA

DOS AÑOS COMPLETO DE GARANTÍA PARA CORTADORA DE MALEZAS

CON CUCHILLA A GASOLINA BRUSHWACKER® DE CRAFTSMAN®

Si este producto falla por un defecto en el material o de mano de obra dentro de

dos años a partir de la fecha de compra y este se ha utilizado y mantenido de

acuerdo al manual del usuario, envíelo a cualquier tienda Sears, Centro de Servi

cios Sears u otra tienda Craftsman en los Estados Unidos para su reparación gra

tuita (o reempiazo si no es posible repararlo).

Esta garantía excluye la línea y la cuchilla de corte, las bujías y el filtro de aire,

que son partes desechadles y pueden desgastarse ai usarlas normalmente en

menos de un año.

Esta garantía es aplicable por sólo 30 días desde la fecha de compra si este pro

ducto se usa con fines comerciales o se usa para arriendo.

Esta garantía le otorga derechos legales específicos, y usted también puede

tener otros derechos que varían de estado a estado.

Sears, Roebuck and Co., Hoffman Estafes, IL 60179

REGLAS DE SEGURIDAD

A ADVERTENCIA: Al usar cualqui

er herramienta de fuerza de jardinería,

deberán observarse precauciones bási

cas de seguirdad en todo momento para

reducir el riesgo de incendio y graves heri

das.

Apeligro: ¡Esta herramienta

motorizada puede ser peligrosa!

Puede ocasionar lesiones graves, inclu

so la amputación o la ceguera, tanto al

operador como a otras personas. Las

advertencias e instrucciones de seguri

dad contenidas en este manual deben

cumplirse en todo momento para garan

tizar un nivel de seguridad y efectividad

razonable durante la utilización del apa

rato. El operador es responsable del

cumplimiento de las advertencias e

instrucciones indicadas en este manual

y en el aparato. Antes de ensamblar y

utilizar el aparato, lea íntegramente el

manual del usuario. Limite el uso de

este aparato a personas que previa

mente hayan leído y comprendido, y

posteriormente cumplan, las adverten

cias e instrucciones indicadas en este

manual y en el aparato. Nunca permita

que este aparato sea utilizado por niños.

MANUAL DE

INSTRUCCIONES

O PELIGRO: La cuchilla puede re

botar violentamente en materiales que

no puede cortar. Los rebotes de fa

cuchilla pueden causar la amputación

de brazos o piernas. Mantenga a perso

nas y animales a una distancia mínima

de 15 metros (50 pies).

INFORMACION DE

SEGURIDAD DEL

APARATO

ADVERTENCIA: La línea de

corte arroja objetos violentamente.

Usted, al igual que otras personas,

puede quedar ciego o herido. Use

anteojos de seguridad y protección en

las piernas.

22

Page 21

Siempre utilice:

• Protección de oídos

• Anteojos de seguridad

• Casco de seguridad

UTILICE SIEMPRE:

Protección

ocular

Perneras

■ ■

Botas

Objetos

despedidos ’

«ADVERTENCIA: Zona de peli

gro de objetos despedidos. La cuchilla

y la línea de corte arroja objetos

violentamente. Esto puede ocasionar

ceguera o lesiones a otros. Mantenga

a personas y animales a una distancia

mínima de 15 metros (50 pies).

A ADVERTENCIA: No utilice el

cabezal de corte como dispositivo de

sujeción de la cuchilla.

A ADVERTENCIA: La cuchilla

sigue girando incluso después de sol

tar el acelerador o de apagar el motor.

Incluso cuando está girando libremen

te, la cuchilla puede despedir objetos

o causar cortes profundos si se toca

accidentalmente. Detenga la cuchilla

poniendo en contacto el lado derecho

de la misma con material ya cortado.

Para detener la

cuchilla cuando gire

libremente, póngala

en contacto con ma

terial previamente ^

cortado.

SEGURIDAD DEL OPERADOR

• Vístase apropiadamente. Siempre

use anteojos de seguridad o similar

protección para los ojos cuando use

o dé mantenimiento a este aparato

(anteojos de seguridad están dispo

nibles). La protección para los ojos

debe ser marcada con Z87.

• Siempre utilize mascarilla para la

cara o mascarilla a prueba de polvo

si se va a trabajar en condiciones

donde hay polvo.

• Siempre utilize pantalones pesados

y largos, mangas largas, botas y

guantes. Se recomienda el uso de

pantorrilleras de seguridad.

• Siempre utilize protección para los

pies. No trabaje descalzo ni en

sandalias. Evite la línea/cuchilla gi

rante.

• Mantenga el cabello por encima de

los hombros, atándolo para tal efecto

si es necesario. No use ropa suelta

ni ropa con corbatas, tiras, borlas,

etc. que cuelgan libremente. Pueden

enredarse en las piezas en movi

miento.

• Si está completament tapado, estará

más protegido de los escombros y

pedazos de plantas tóxicos arroja

dos por la línea girante.

• Manténgase alerta. No haga uso del

aparato estando cansado, enfermo o

bajo la influencia del alcohol, de dro

gas o de remedios. Vigile bien lo que

está haciendo; use del sentido

común.

• Use protección de oídos.

• Nunca ponga el aparato en marcha

ni lo deje en marcha dentro de un

recinto cerrado. Respirar los vapores

del combustible lo puede matar,

• Mantenga las manijas libres de

aceite y de combustible.

• Siempre que trabaje con cuchillas,

utilice el mango y una correa al hom

bro correctamente ajustada (vea

MONTAJE).

SEGURIDAD DEL APARATO Y EN

EL IVIANTENIMIENTO

A ADVERTENCIA: Apague el

aparato y desconecte la bujía antes de

hacer cualquier mantenimiento menos

los ajustes al carburador.

• Inspeccione el aparato y cambie las

piezas dañadas o flojas antes de

cada uso. Repare toda fuga de com

bustible antes de usar el aparato.

Mantenga el aparato en buenas con

diciones de uso.

23

Page 22

• Deseche la cuchillas dobladas, den

tadas, partidas, rotas o deterioradas

de algún modo. Antes de utilizar el

aparato, sustituya las piezas del ca

beza! de corte que estén partidas,

rotas o deterioradas de algún modo.

• Haga el mantenimiento del aparato

de acuerdo a los procedimientos re

comendados. Mantenga la línea de

corte el largo aprodiado.

• Use solamente línea de la marcha

CrattsmanCg). Nunca use alambre,

soga, hilo, etc.

• instale la protector requerida antes

de usar su aparato. Use la protector

de metal para todo el uso con cuchil

las de metal. Use la protector de

plástico para todo el uso con línea

de corte.

• Use solamente la cuchilla o el cabe

za! de corte que aquí se especifica

da. Asegúrese queestén instalados

apropiadamente y ajustados con se

guridad.

• Nunca ponga en marcha el motor

con el cobertor del embrague des

montado. El embrague podría des

prenderse y causar graves lesiones.

• Asegúrese que el cuchilla o el

cabezal de corte paren de girar

cuando el motor se encuentra en

marcha lenta.

• Realice los ajustes del carburador con

la parte inferior apoyada en alto para

impedir que la cuchilla o el hilo podador entren en contacto con algún ob

jeto. Sujete el aparato con ías manos,

sin utilizar ía correa hombrera.

• Cuando realice ajustes en el carbu

rador, mantenga alejadas del lugar a

otras personas.

• Utilice exclusivamente los acceso

rios y recambios recomendados por

Craftsman®.

• Todo servicio y mantinimiento no ex

plicado en este manual deberá ser

efectuado por un Centro de Servicio

Sears.

SEGURIDAD CON EL

COMBUSTIBLE

• Mezcle y vierta el combustible al aire

libre.

• Manténgalo alejado de las chispas y

de las llamas.

• Use recipiente aprobado para el

combustible.

• No fume ni permita que se fume cer

ca del combustible ni del aparato ni

mientras éste esté en uso.

• Evite derramar el combustible o el

aceite. Limpie todo el combustible

derramado.

• Aléjese a por lo menos 3 metros (10

pies) del lugar de abastecimiento

antes de poner en marcha el motor.

• Antes de guarder el aparato, vacíe el

depósito de combustible. Arranque

el motor y déjelo en marcha hasta

que se detenga con el fin de agotar

el combustible que pueda quedar en

el carburador.

• Pare el motor y permita que se enfríe

el aparato antes de retirar la tapa del

tanque.

• Almacéne siempre combustible en

un recipiente aprobado para los

líquidos inflamables.

SEGURIDAD AL CORTAR

A ADVERTENCIA: Antes de cada

uso, inspeccione la zona de trabajo.

Retire todos los objetos (rocas, cris

tales rotos, clavos, cables, hilos, etc.)

que puedan ser despedidos o quedar

enredados en la cuchilla o en el cabe

zal de corte.

• Mantenga alejados del lugar de traba

jo 15 metros (50 pies) a otras perso

nas, ya sean niños, acompañantes o

ayudantes, y a animales. Detenga el

motor tan pronto como aíguien se le

aproxime.

• Mantenga siempre el motor junto al

lado derecho de su cuerpo.

• Sujete firmemente el aparato con

ambas manos.

• Pise con seguridad y mantenga el

equilibrio en todo momento. No esti

re el cuerpo en exceso.

• Mantenga la cuchilla o cabeza! de

corte por debajo de la cintura. No le

vante el motor por encima de su cin

tura.

• Mientras el motor esté en marcha,

mantenga todas las partes de su

cuerpo alejadas de ía cuchilla o del

cabezal de corte, y del silenciador.

Un silenciador caliente podría provo

car quemaduras de qravedad si se

toca.

• Corte siempre de izquierda a dere

cha. Si se corta con la línea del lado

derecho del protector, los escombros

volarán en sentido opuesto al usuario.

• Use el aparato únicamente de día o

en luz artificial fuerte.

• Utilice el aparato solamente para las

tareas explicadas en este manual.

TRANSPORTE Y ALMACENAMIENTO

• Antes de proceder a su transporte,

detenga el aparato.

• Mantenga el silenciador alejado del

cuerpo.

24

Page 23

• Antes de almacenar o transportar el

aparato en un vehículo, deje enfriar

el motor y sujete bien el aparato.

• Antes de guardar o transportar el

aparato, vacíe el depósito de com

bustible. Arranque el motor y déjelo

en marcha hasta que se detenga

con el fin de agotar el combustible

que pueda quedar en el carburador.

• Guarde el aparato y el combustible

en un lugar donde los vapores ema

nados del combustible no puedan

entrar en contacto con chispas ni lla

mas procedentes de calentadores

de agua, motores o interruptores

eléctricos, hornos, etc.

• Guarde el aparato de modo que la

cuchilla o el limitador de hilo no pue

dan ocasionar lesiones accidental

mente. Este aparato puede colgarse

por la barra.

• Guarde el aparato fuera del alcance

de los niños.

Este aparato no esta eguipado con un

sistema de anti-vibración y se diseña si

es usado ocasionalmente.

AVISO DE SEGURIDAD: El estar ex

puesto a las vibraciones a través del

uso prolongado de herramientas de

fuerza a gasolina puede causar daños a

los vasos sanguíneos o a los nervios de

los dedos, las manos y las coyunturas

en aquellas personas que tienen propensidad a los trastornos de la circula

ción o a las hinchazones anormales. El

uso prolongado en tiempo frío ha sido

asociado con daños a los vasos san

guíneos de personas que por otra parte

se encuentran en perfecto estado de

salud. Si ocurren síntomas tales como el

entumecimiento, el dolor, la falta de fuer

za, los cambios en el color o la textura

de la piel o falta de sentido en los de

dos, las manos o las coyunturas, deje

de usar esta máquina inmediatamente y

procure atención médica. Los sistemas

de anti-vibración no garantizan que se

eviten tales problemas. Los usuarios

que hacen uso continuo y prolongando

de las herramientas de fuerza deben

fiscalizar atentamente su estado físico y

el estado del aparato.

AVISO ESPECIAL: Su aparato viene

equipada con silenciador limitador de

temperatura y con rejilla antichispa que

cumpla los requisitos de los Códigos de

California 4442 y 4443. Todas las tierras

forestadas federales, más los estados

de California, Idaho, Maine, Minnesota,

Nueva Jersey, Washington y Oregon,

requieren por ley que muchos motores

de combustión interna estén equipados

con rejilla antichispa. Si usted el aparato

en un estado y otra localidad donde ex

isten tales reglamentos, usted tiene la

responsabilidad jurídica de mantener

estas piezas en correcto estado de fun

cionamiento. De lo contrario, estará en

infracción de la ley. Para el uso normal

del dueño de la casa, el silenciador y la

rejilla antichispa no requerirán ningún

servicio. Después de 50 horas de uso,

recomendamos que al silenciador se le

de servicio o sea substituido por un

Centro de Servicio Sears.

MONTAJE

CONTENIDO DE LA CAJA

Use la siguiente lista para verificar que

todas la piezas hayan sido incluidas:

Modelo 358.795800

• Cortadora de malezas

• Arandela abombada

• Tuerca larga para instalar la cuchilla

• Llave hexagonal

• Mango

• Tapa del soporte

• Tornillos para la tapa de! soporte (2)

• Protector metálica del cuchilla

• Tornillos para el protector del cuchilla

(4)

• Cuchilla con 4 puntas para el corte

de malezas

• Cuchilla con 8 puntas para el corte

de malezas

• Protector plástica

• Tuerca mariposa (atornillada en la

protector)

• Cabezal de corte (ensamblado en el

aparato)

• Correa para el hombro con

advertencia

• Recipiente de línea

• Recipiente de aceite

Examine las piezas para verificar que

no haya daños. No use piezas daña

das.

AVISO: Si necesita ayuda, si faltan

piezas o si hay piezas dañadas, llame

al número 1-800-235-5876.

Es normal escuchar que el filtro de com

bustible golpetee en el tanque vacío.

Es normal encontrar residuos de aceite

o de gasolina en el silenciador, debido a

los ajustes al carburador y a las pruebas

efectuadas por el fabricante.

25

Page 24

MONTAJE

A ADVERTENCIA: Siempre apa

gue el aparato y desconecte la bujía

antes de hacer cualquiera de las pro

cedimientos de la montaje.

A ADVERTENCIA: Si recibió el

aparato ya armado, repita todos los

pasos para asegurar que el mismo se

encuentre correctamente armado y

que todos los fijadores se encuentren

bien ajustados.

HERRAMIENTAS NECESARIAS

• Llave hexagonale (incluidas)

• Llave ajustable

• Destornillador Phillips

INSTALACION DEL MANGO

A PELIGRO: Para evitar graves

heridas, la porción del mango en for

ma de barrera debe ser ajustada y se

guir instalada según se indica con el

fin de mantener la distancia entre el

operador y la cuchilla durante el giro

de ésta. La abrazadera del mango se

debe colocar entre las flechas en la

etiqueta del mango.

1. Localize la etiqueta adherida al

mango. Esta etiqueta contiene un

flecha. Coloque el mango en el

soporte del mango en el extremo

de esta flecha.

2. Coloque la tapa del soporte sobre

el mango. Asegúrese de que el

soporte quede situada en el

extremo de la flecha.

3. introduzca los tornillos y apriete a

mano. Asegúrese de que el mango

quede instalado correctamente,

después a continuación, apriete

firmemente cada uno de los torni

llos con la llave hexagonal,

Mannn n Tornillo

1. Introduzca el brazo derecho y ia

cabeza por el arco de la correa y

apoye ésta en el hombro izquierdo.

Asegúrese de que el signo de peli

gro se encuentre en su espalda y

de que el enganche se encuentre

en el lado derecho de su cintura,

AVISO: La correa puede girarse media

vuelta para garantizar que quede apo

yada en toda su anchura sobre el hom

bro.

2. Ajuste la correa para permitir que

el enganche quede a unos 15 cm

por debajo de la cintura.

3. Fije el enganche de la correa a la

abrazadera situada entre la empu

ñadura de espuma y el bloque de

montaje y levante la herramienta

hasta la posición de trabajo,

4. Antes de poner en marcha el motor

o iniciar cualquier tarea de corte,

póngase la correa en el hombro y

ajústela a su medida de modo que

le permita mantener el equilibrio.

AVISO: Puede ser necesario mover la

abrazadera de la correa para el hombro

en el eje para un equilibrio apropiado

del aparato.

PARA MOVER LA ABRAZADERA

DE LA CORREA AL HOMBRO:

1. Afloje y remueva ambos tornillos

de la abrazadera.

2. Coloque la abrazadera superior de

la correa para hombro sobre el eje.

3. Coloque la abrazadera inferior de la

correa para hombro debajo del eje y

alinee los huecos del tornillo de la

abrazadera superior y la abrazadera

inferior.

Abrazadera Superior

de la Correa para

Hombro

del soporte

Soporte

del mango

MONTAJE DE LA CORREA AL

HOMBRO

A ADVERTENCIA: Antes de hacer

algún ajuste de ia correa o el mango, es

imprescindible que el motor este

completamente detenido.

Abrazadera /^1

Inferior de

Correa para

Hombro

4.5.Inserte dos tornillos en los huecos

para tornillos.

Apriete la abrazadera de la correa

para el hombro apretando los tor

nillos con la llave hexagonal.

Tornillos

26

Page 25

AJUSTE DEL

CORREA AL HOMBRO

PARA EL BALANCE

15 cm

(6 pulga

das) de

bajo de la

cintura

CONFIGURACION DEL APARATO

Ei aparato puede configurarse con un

cabezal cortador para hierbas y plan

tas de pequeño tamaño, o bien con

una cuchilla para hierbas, plantas y

brozas con tallos de hasta 1 cm {1/2

de pulgada) de diámetro. Para ensam

blar el aparato, consulte la sección co

rrespondiente a la configuración des

eada y siga las instrucciones que allí

se indican.

INFORMACIÓN DE MONTAJE CABEZAL DE CORTE

taza para el polvo para hacer coincidir el

orificio con el otro orificio situado a un

lado del cajetín de engranajes.

Introduzca un destornillador pequeño

por los orificios confrontados. Esto

impedirá que el eje gire mientras afloja

la tuerca de la cuchilla. Remueva la

tuerca de la cuchilla girándola hacia la

derecha. Remueva el destornillador.

Remueva ambas arandelas y el cuchilla.

Para remover el protector metálica,

afloje Y remueva los 4 tornillos de

montaje. Vea las secciones

DE LA PROTECTOR METÁLICA y

MONTAJE DE LA CUCHILLA METÁLICA

MONTAJE

para las ilustraciones. Guarde las piezas

y las instrucciones para el uso futuro.

PARA INSTALAR EL CABEZAL DE

CORTE {si es que no está instalado)

AVISO; Antes de instalar el cabezal

de corte, asegúrese de que la taza

para el polvo y la arandela de retén

estén colocada en el eje de la caja de

engranajes. La arandela retén debe

colocarse con la sección elevada

orientada hacia el caja de engranajes.

Haga girar el taza para el polvo

1.

para hacer coincidir el orificio con

el otro orificio situado a un lado del

cajetín de engranajes.

Introduzca un destornillador peque

2.

ño por ios orificios confrontados. Es

to previene que el eje gire mientras

usted instale el cabezal de corte.

3. Sujete el destornillador en su posi

ción y enrosque el cabeza! de corte

en ei eje dando vuelta a la izquierda.

¡Ajuste el cabezal manualmente]

AVISO: Remueva el cuchilla y el

protector metálica antes de instalar el

protector plástica y cabezel de corte.

Para remover la cuchilla, haga girar el

27

Page 26

PARA INSTALAR EL PROTECTOR

PLÁSTICA

A ADVERTENCIA: El protector

deberá ser instalado correctamente. El

protector provee protección parcial

contra el riesgo de los objetos arroja

dos hacia el usuario y otras personas

y viene equipado con un cuchilla limi

tadora de línea que corta el exceso de

línea. El cuchilla limitadora de línea

{en la parte inferior del protector) es

filoso y puede cortar.

1. Remueva la tuerca mariposa del

protector.

2. inserte e! soporte dentro de la ra

nura del protector.

3. Gire el protector hasta que el tornil

lo pase a través del hueco en el

soporte.

4. Apriete firmemente la tuerca en for

ma de alas.

Soporte

Ranura

Protector

INFORMACION DE MONTAJE ■

CUCHILLAS PARA MALEZAS

INSTALAR EL CABEZAL DE CORTE y

PARA INSTALAR EL PROTECTOR

PLÁSTICA para las ilustraciones. Guarde

las piezas y las instrucciones para el

uso futuro. Nunca utilice el cabezal de

corte con la cuchilla metàllica instalada.

MONTAJE DE LA PROTECTOR

METÁLICA

A ADVERTENCIA: Siempre que

esta herramienta vaya a utilizarse con

la cuchilla, la protector metálica debe

rá estar correctamente instalada. El

extremidad frontal de la protector

metálica ayuda a reducir el número de

rebotes de la cuchilla que pueden oca

sionar lesiones graves, como la ampu

tación, tanto al operador como a las

personas cercanas. La omisión de ins

talar la protector en la posición mostra

da puede acarrear graves lesiones al

operador. La protector debe estar ali

neada longitudinalmente con la barra.