Page 1

Operator’s Manual

25cc/1.5 cu.in. 2-Cycle

215 MPH/470 CFM

GASOLINE POWERED

BLOWER/VAC

Model No.

358.794772

• Safety

• Assembly

• Operation

• Maintenance

• Parts List

• Español, p. 20

WARNING:

Read and follow ail Safety Rules and Operating

A

Instructions before first use of this product.

For answers to your questions about this product:

Call 7 am-7 pm, Mon.-Sat., or 10 am-7 pm. Sun.

1 -800-235^878 (Hours lisied are Central Time)

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

545167641 Rev. 4 4/16/08 BRW

Page 2

TABLE OF CONTENTS

Warranty Statement 2 Storage 13

Identification of Safety Symbols 2 Troubleshooting Table 14

Safety Rules 3 Emissions Statement 15

Assembly 5 Parts List 17

Operation 8 Spanish 20

Maintenance 11 Parts and Ordering Back Cover

WARRANTY STATEMENT

TWO YEAR FULL WARRANTY ON CRAFTSMAN® GAS BLOWER

When used and maintained according to the operator’s manual, if this product fails

due to a defect in material or workmanship within two (2) years from the date of pur

chase, return it to any Sears store, Sears Service Center, or other Craftsman outlet

in the United States for free repair (or replacement If repair proves Impossible).

This warranty excludes spark plug and air cleaner, which are expendable parts that

can wear out from normal use in less than two years.

This warranty applies for only 30 days from the date of purchase If this product is

used for commercial or rental purposes.

This warranty gives you specific legal rights, and you may also have other rights

which vary from state to state.

Sears, Roebuck and Co., Hoffman Estates, IL 60179

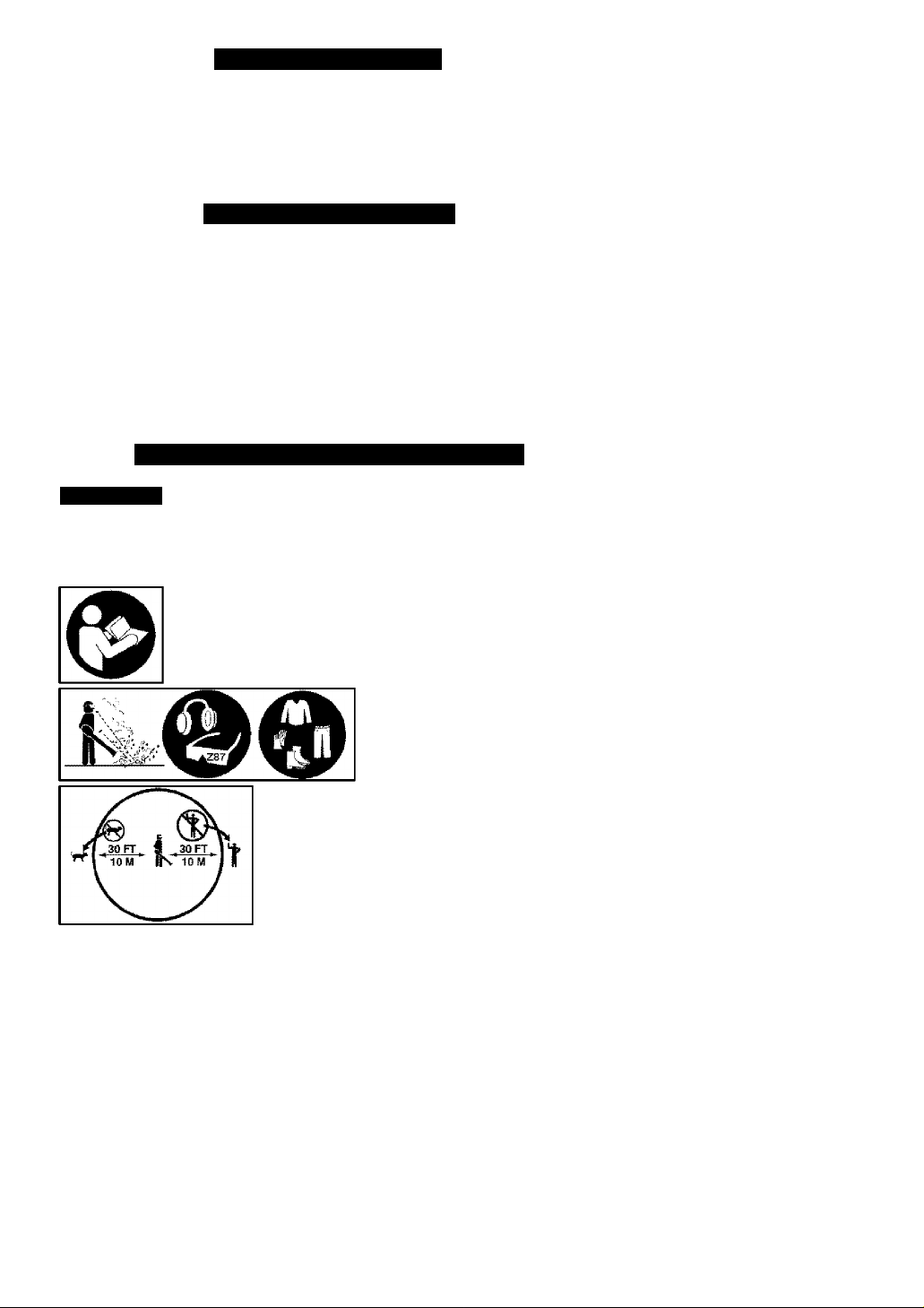

IDENTIFICATION OF SAFETY SYMBOLS

AwARNiNG: This unit can be dangerous! Careless or

improper use can cause serious injury.

Read your operator's manual carefully until you completely un

derstand and can follow all warnings and safety rules before

operating the unit. Failure to do so can result in serious injury.

Save operator's manual.

The blower can throw objects

violently. You can be blinded or

injured. Always wear hearing

protection and safety glasses

marked Z87. Always wear

heavy, long pants, long sleeves,

boots and gloves.

Hazard zone for thrown objects. Keep children,

bystanders, and animals away from work area a

minimum of 30 feet (10 meters) when starting or

operating unit. Do not point blower nozzle in the

direction of people or pets.

Page 3

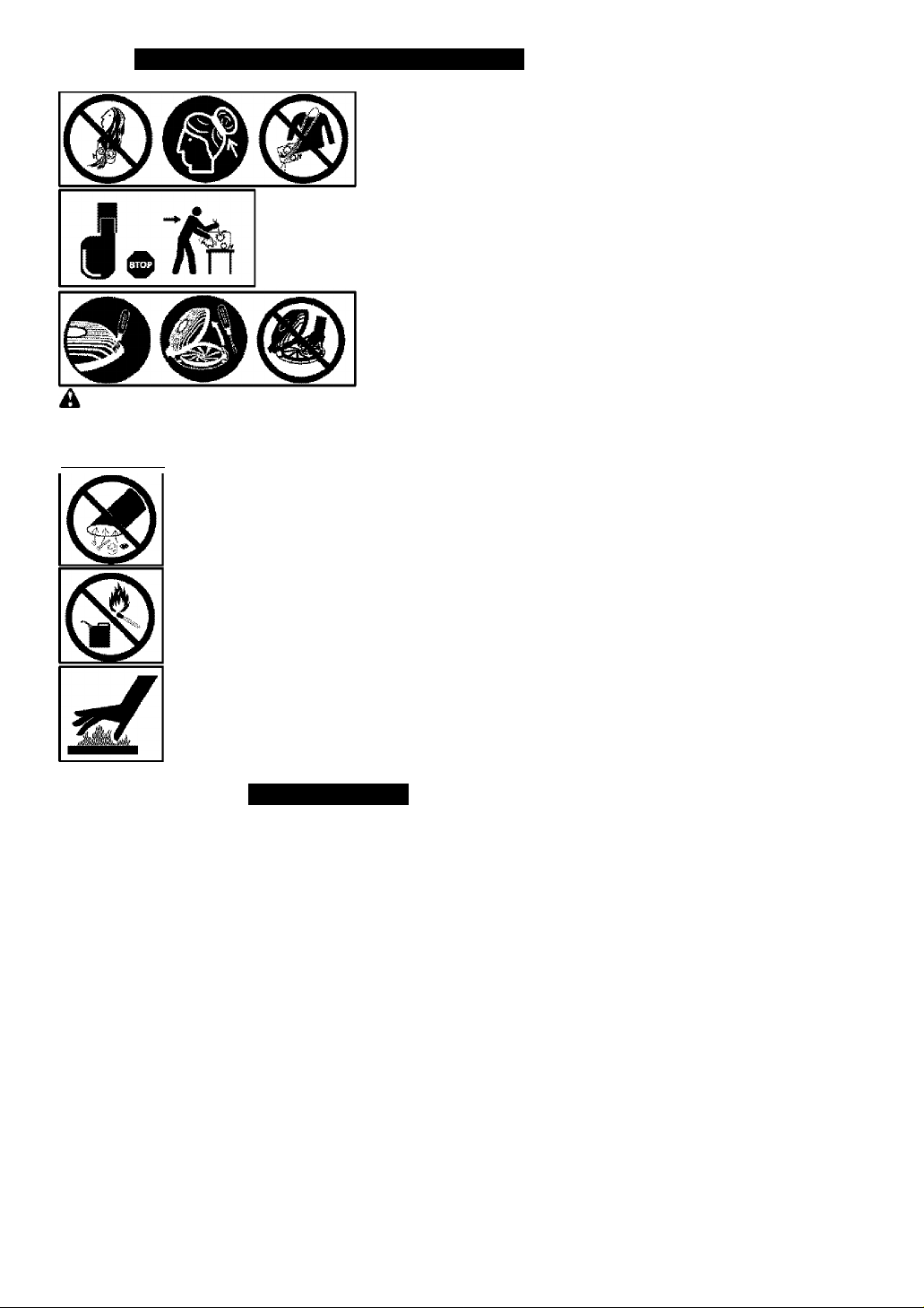

IDENTIFICATION OF SAFETY SYMBOLS

Secure hair above shoulder length.

Do not wear jewelry, loose olothing,

or clothing with loosing hanging

straps, ties, tassels, etc. They can

be caught In moving parts.

Always stop unit and disconnect spark plug

before cleaning or servicing.

WARNING; Stop the engine before opening the vacuum inlet door. The

engine must be stopped and the impeller blades no longer turning to avoid serious

injury from the rotating blades. Gently tilt the handle of the screwdriver toward the

back of the unit to release the iatch while pulling up on the vacuum inlet cover with

your other hand.

When using the vacuum attachment, the unit is designed to

pick up dry material such as leaves, grass, small twigs, and bits

of paper. Do not vacuum stones, gravel, metal, broken glass,

etc., to avoid severe damage to the impeller.

A WARNING: Fire hazard. Never mix, pour, or store gasoline

or use the unit near a flame or sparks (including smoking, open

flames, or work that can cause sparks).

A WARNING: The muffler is very hot during and after use.

Do not touch the muffler, muffler guard, or surrounding surfaces,

or allow combustible material such as dry grass or fuel to do so.

SAFETY RULES

A

WARNING; Failure to follow ail

Safety Rules and Precautions can re

sult in serious injury.

KNOW YOUR UNIT

• Read your operator’s manual care

fully until you completely understand

and can follow all warnings and

safety rules before operating the unit.

• Restrict unit to users who under

stand and will follow all warnings and

safety rules in this manual.

A WARNING: Inspect area before

starting unit. Remove all debris and

hard objects such as rocks, glass,

wire, etc. that can ricochet, be thrown,

or otherwise cause injury or damage

during operation.

Page 4

Use your unit as a bbwer for:

• Sweeping debris or grass clippings

from driveways, sidewalks, patios, etc.

• Blowing grass clippings, straw, or

leaves into piles, around joints, or be

tween bricks.

Use your unit as a vacuum for;

• Picking up dry material such as

leaves, grass, small twigs, and bits of

paper.

• For best results during vacuum use,

operate your unit at high speed.

• Move slowly back and forth over the

material as you vacuum. Avoid forc

ing the unit into a pile of debris as

this can clog the unit,

• Keep the vacuum tube about an inch

above the ground for best results.

PLAN AHEAD

• Always wear eye protection when op

erating, servicing, or performing main

tenance on unit. Wearing eye protec

tion will help to prevent rocks or debris

from being blown or ricocheting into

eyes and face which can result in

blindness and/or serious injury. Eye

protection should be marked Z87.

• Always wear foot protection. Do not

go barefoot or wear sandals.

• Always wear respirator or face mask

when working with unit in dusty envi

ronments,

• Secure hair above shoulder length.

Secure or remove jewelry, loose

clothing, or clothing with loosely

hanging straps, ties, tassels, etc.

They can be caught in moving parts,

• Do not operate unit when you are

tired, ill, upset, or if you are under the

influence of alcohol, drugs, or medi

cation.

• Keep children, bystanders, and ani

mals away from work area a mini

mum of 30 feet (10 meters) when

starting or operating unit. Do not

point blower nozzle in the direction of

people or pets.

HANDLE FUEL WITH CAUTION, IT IS

HIGHLY FLAMMABLE

• Eliminate all sources of sparks or

flame (including smoking, open

flames, or work that can cause

sparks) in the areas where fuel Is

mixed, poured, or stored,

• Mix and pour fuel in an outdoor area;

store fuel in a cool, dry, well ventilated

place; use an approved, marked con

tainer for ali fuel purposes.

• Do not smoke while handling fuel or

while operating the unit.

• Make sure the unit is properly as

sembled and in good operating con

dition.

• Do not fill fuel tank while engine is

running.

• Avoid spilling fuel or oil. Wipe up fuel

spills before starting engine.

• Move at least 10 feet (3 meters)

away from fuel and fueling site be

fore starting engine,

• Always store gasoline in a container

approved for flammable liquids,

OPERATE YOUR UNIT SAFELY

WARNING: Stop the engine be

fore opening the vacuum Inlet door. The

engine must be stopped and the impel

ler blades no longer turning to avoid se

rious injury from ffie rotating blades.

• Inspect unit before each use for

worn, loose, missing, or damaged

parts. Do not use until unit is In

proper working order,

• Keep outside surfaces free from oil

and fuel.

• Never start or run engine inside a

closed room, building or other unventllated area. Breathing exhaust

fumes can kill.

• To avoid static electricity shock, do

not wear rubber gloves or any other

Insulated gloves while operating unit.

• Do not set unit on any surface except

a clean, hard area while engine is run

ning. Debris such as gravel, sand,

dust, grass, etc, could be picked up by

the air intake and thrown out through

discharge opening, damaging unit,

property, or causing serious Injury to

bystanders or operator.

• Avoid dangerous environments. Do

not use in unventilated areas or

where explosive vapors or carbon

monoxide build up could be present.

• Do not overreach or use from unsta

ble surfaces such as ladders, trees,

steep slopes, rooftops, etc. Keep firm

footing and balance at all times,

• Never place objects inside the

blower tubes; always direct the blow

ing debris away from people, ani

mals, glass, and solid objects such

as trees, automobiles, walls, etc. The

force of air can cause rocks, dirt, or

sticks to be thrown or to ricochet

which can hurt people or animals,

break glass, or cause other damage.

• Never run unit without the proper

equipment attached. When using

your unit as a blower, always install

Page 5

blower tubes. When using the op

tional vacuum kit, always install vac

uum tubes and vacuum bag assem

bly. Make sure vacuum bag assem

bly is completely zipped,

• Check air intake opening, blower

lubes, and vacuum tubes frequently,

always with engine stopped and

spark plug disconnected. Keep vents

and discharge tubes free of debris

which can accumulate and restrict

proper air flow.

• Never place any object in air intake

opening as this could restrict proper air

flow and cause damage to the unit.

• Never use for spreading chemicals,

fertilizers, or other substances which

may contain toxic materials.

• To avoid spreading fire, do not use

near leaf or brush fires, fireplaces,

barbecue pits, ashtrays, etc.

• Use only for jobs explained in this

manual,

MAINTAIN YOUR UNIT PROPERLY

^WARNING: Disconnect spark

piug before performing maintenance

except for carburetor adjustments.

• Have all maintenance other than the

recommended procedures described

in the operator’s manuai performed

by a Sears Service Center.

• Use only recommended Craftsman

replacement parts; use of any other

parts may void your warranty and

cause damage to your unit.

• Empty fuel tank before storing the

unit. Use up fuel left in carburetor by

starting engine and ietting it run until

it stops.

• Do not use any accessory or attach

ment other than those recommended

by manufacturer for use with your unit,

• Do not store the unit or fuel in a closed

area where fuel vapors can reach

____

sparks or an open flame from hot

water heaters, electric motors or

switches, furnaces, etc,

• Store in a dry area out of reach of

children.

SAFETY NOTICE: Exposure to vibra

tions through prolonged use of gaso

line powered hand tools could cause

blood vessel or nerve damage in the

fingers, hands, and joints of people

prone to circulation disorders or abnor

mal swelling. Prolonged use in cold

weather has been linked to blood ves

sel damage in otherwise healthy

people, if symptoms occur such as

numbness, pain, loss of strength,

change in skin color or texture, or loss

of feeling in the fingers, hands, or

joints, discontinue the use of this tool

and seek medical attention. An

anti vibration system does not guaran

tee the avoidance of these problems.

Users who operate power tools on a

continual and regular basis must moni

tor closely their physicai condition and

the condition of this tool.

SPECIAL NOTICE; This unit is

equipped with a temperature limiting

muffler and spark arresting screen

which meets the requirements of Cali

fornia Codes 4442 and 4443. All U.S.

forest land and the states of California,

Idaho, Maine, Minnesota, New Jersey,

Oregon, and Washington require by

law that many internal combustion en

gines be equipped with a spark arrest

ing screen. If you operate in a locale

where such regulations exist, you are

legally responsible for maintaining the

operating condition of these parts. Fail

ure to do so is a violation of the law.

Refer to the MAINTENANCE section for

information on maintenance of the

muffler and spark arresting screen.

ASSEMBLY

CARTON CONTENTS

Check carton contents against the fol

lowing list.

Model 358.794772

• Blower

• Upper blower tube

• Lower blower tube

• High velocity nozzle

• Elbow tube

• Vacuum bag

• Upper vacuum tube

• Lower vacuum tube

• 2-Cycle engine oil

NOTE: It is normal for the fuel filter to

rattle in the empty fuel lank.

ASSEMBLY

^WARNING: Stop engine and be

sure the impeller blades have stopped

turning before opening the vacuum in

let door or attempting to insert or re

move the vacuum tubes. The rotating

blades can cause serious injury.

Page 6

A WARNING: !f you receive your

unit assembled, repeat all steps to en

sure your unit is properly assembled

and all fasteners are secure.

• A standard screwdriver Is required

for assembly.

BLOWER ASSEMBLY

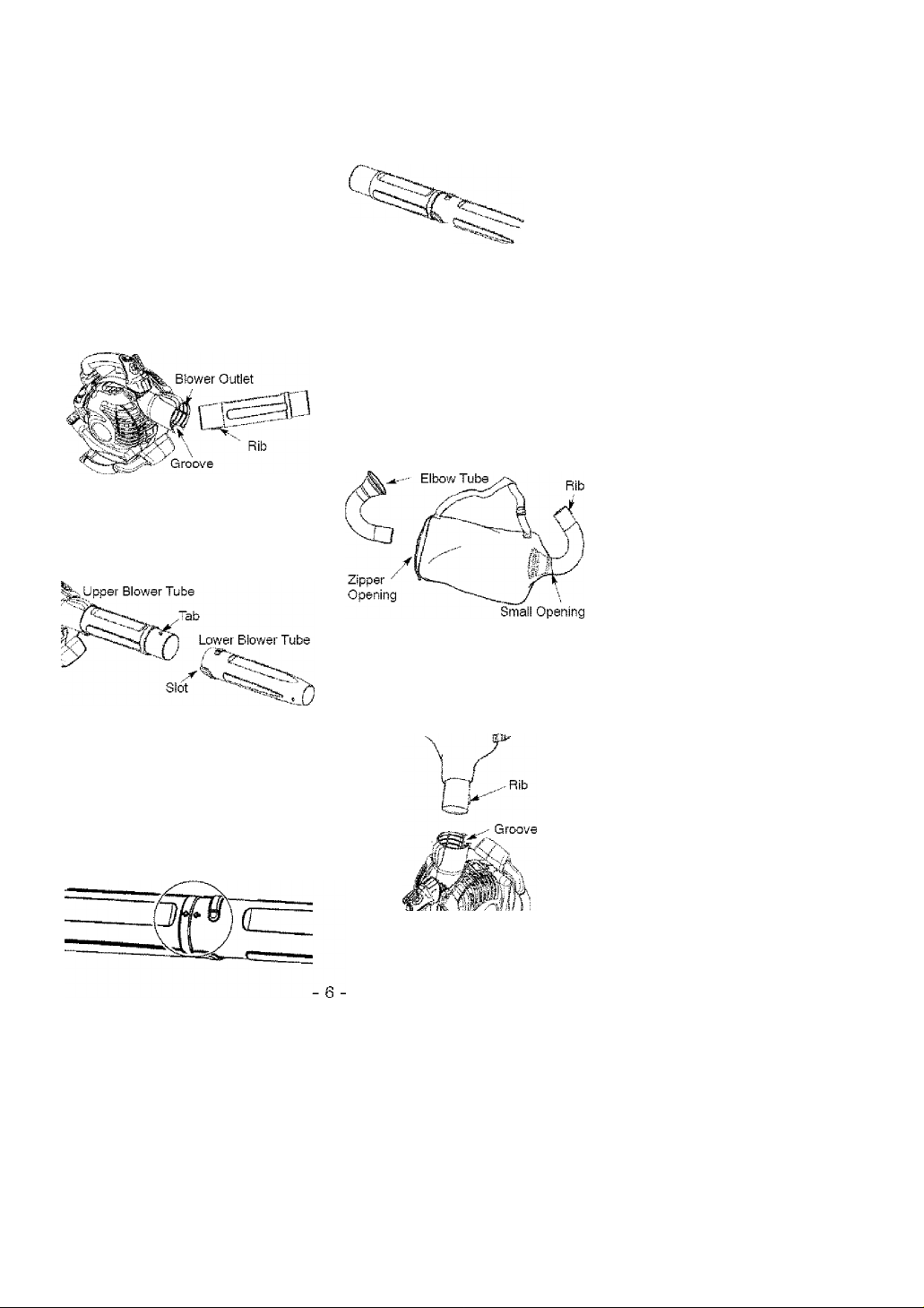

BLOWER TUBE ASSEMBLY

If you have already assembled your

unit for use as a vacuum, remove the

vacuum tubes and collection bag,

1. Align the rib on the upper blower

tube with the groove in the blower

outlet; slide the tube into place.

NOTE; Knob must be loose enough to

allow blower tube to be Inserted in

blower outlet. Loosen knob by turning

counterclockwise.

2.

Secure the tube by turning the

knob clockwise.

3.

Align the slots on the lower blower

tube with the tabs on the upper

blower tube.

6, To remove the tubes, turn the knob

counterclockwise to loosen the

tubes; remove the tubes.

HIGH-SPEED NOZZLE ASSEMBLY

When greater air speed is desired, use

the high-speed nozzle.

1, Align the slots on the nozzle with

the tabs on the lower blower tube.

High-Speed

Nozzle

Lower Blower

Tube

2.

Slide the nozzle onto the lower

blower tube.

3.

Turn the nozzle clockwise until a

click is felt to secure the nozzle to

the lower blower tube.

i)i\

VACUUM ASSEMBLY

VACUUM BAG ASSEMBLY

1, Open the zipper on the vacuum

bag and insert the elbow tube.

2, Push the small end of the elbow

tube through the small opening in

the bag.

4.5.Slide the lower blower tube onto

the upper blower tube.

Turn the lower blower tube clock

wise until a click is felt to secure

the lower blower tube to the upper

blower tube.

NOTE; When the upper and lower

blower tubes are assembled together

properly, the arrows on both tubes will

be aligned.

NOTE: Make sure edge of the small

opening is flush against the flared area

of the elbow tube, and the rib on the

elbow tube is on the bottom.

3, Close the zipper on the bag. Make

sure the zipper is closed completely.

4, Remove blower tubes from engine.

Insert the elbow tube into the blow

er outlet. Make sure elbow tube rib

is aligned with the blower outlet

groove.

Page 7

6. Turn knob clockwise to secure el

bow tube.

VACUUM TUBE ASSEMBLY

A WARNING; Stop engine and be

sure the impeller blades have stopped

turning before opening the vacuum inlet

door or attempting to insert or remove

the vacuum or blower tubes. The rotat

ing blades can cause serious injury.

1. insert the tip of a screwdriver into

the latch area of the vacuum inlet.

5, Push the upper vacuum tube into

the vacuum inlet. Turn the tube

counterclockwise until a click is felt

to secure the tube to the blower unit.

6, Align slanted end of lower vacuum

tube as shown. Firmly push lower

vacuum tube into upper vacuum

tube.

2. Gently tilt the handle of the screw

driver toward the front of the unit to

release the latch while pulling up

on the vacuum inlet cover with your

other hand.

3. Hold the vacuum inlet cover open

until upper vacuum tube is installed,

Vacuum

Inlet

4. Align the tabs on the inside of the

vacuum inlet with the slots in the

upper vacuum tube.

“ Vacuum

Slanted end of

lower vacuum tube

HOW TO CONVERT UNIT FROM

VACUUM USE TO BLOWER USE

1, Remove the elbow tube and vacu

um bag by turning the knob coun

terclockwise to loosen the elbow

tube.

2, Remove the vacuum tubes by turn

ing the tubes clockwise.

3, Close the vacuum inlet cover and

make sure it is latched closed,

4, Reinstall the blower tubes (see

BLOWER TUBE ASSEMBLY).

VACUUM BAG SHOULDER STRAP

ADJUSTMENT

1, Hold the unit as shown with the

muffler side facing away from your

body and clothes.

2, Pass the shoulder strap over your

head and onto your right shoulder.

3, Extend your left arm toward the

rear of the vacuum bag,

4, Adjust shoulder strap until the vacu

um bag/shoulder strap seam lies be

tween your thumb and index finger.

5, Make sure air flows freely from the

elbow tube into bag. If bag is

kinked, the unit will not operate

properly.

Page 8

SHOULDER STRAP ATTACHMENT

(optional accessory #71-85783)

1, Pass the shoulder strap over your

head and onto your left shoulder,

2, Snap the hook onto the retainer

(see following Illustration).

BLOWER USE

Retainer

VACUUM USE

Retainer

OPERATION

KNOW YOUR BLOWER

READ THIS OPERATOR’S MANUAL AND SAFETY RULES BEFORE OPERATING YOUR

UNIT, Compare the illustrations with your unit to familiarize yourself with the location

of the various controls and adjustments. Save this manual for future reference,

MULCHING BLADES

Your blower is equipped with mulching blades as a standard feature. When using

the vacuum attachment, the mulching blades automatically reduce debris at a

ratio of up to 16:1.

Throttle Position Lever

Upper Vacuum Tube

Elbow Tube

Throttle Trigger ^

starter

Rope

STOP Switch

Spark Plug

Upper Blower Tube

X

Fuel Mix

Fill Cap

Primer

Bulb

STOP SWITCH

The STOP switch is used to stop the

engine. To stop the engine, push and

hold the STOP switch in the STOP posi

tion until the engine stops.

Vacuum Handie

Lower Vacuum Tube

Lower Blower Tu

THROTTLE TRIGGER

The THROTTLE TRIGGER is used to se

lect the desired engine speed.

High

Speed

Nozzle

Page 9

THROTTLE POSITION LEVER

The THROTTLE POSITION LEVER is de

signed to allow setting engine speed

during blower use only. To avoid caus

ing damage to the unit, DO NOT at

tempt to use the throttle position lever

during vacuum use.

PRIMER BULB

The PRIMER BULB removes air from

the carburetor and fuel lines and fills

them with fuel. This allows you to start

the engine with fewer pulls on the

starter rope. Activate primer bulb by

pressing it and allowing it to return to

its original position.

START LEVER

The START LEVER helps to supply fuel

to the engine to aid in starting. Activate

the starting system by moving the start

lever to the START position. DO NOT

squeeze the throttle trigger until the

engine has started and runs. After the

engine starts, allow the engine to

warm-up 10-15 seconds, then fully

squeeze the throttle trigger to deacti

vate the starting system (start lever re

turns to RUN position).

OPERATING TIPS

• While vacuuming or blowing debris,

hold the unit with the muffler side fac

ing away from your body and clothes

(see OPERATING POSITION below).

• To reduce the risk of hearing loss

associated with sound level(s), hear

ing protection is required,

• To reduce the risk of injury associated

with contacting rotating parts, stop the

engine before installing or removing

attachments. Do not operate without

guard(s) in place.

• Operate power equipment only at rea

sonable hours-not early in the morn

ing or iate at night when people might

be disturbed. Comply with times listed

in local ordinances. Usual recommen

dations are 9:00 a.m. to 5:00 p.m.,

Monday though Saturday,

• To reduce noise levels, limit the num

ber of pieces of equipment used at

any one time,

• To reduce noise levels, operate pow

er blowers at the lowest possible

throttle speed to do the job.

• Use rakes and brooms to loosen

debris before blowing.

• In dusty conditions, slightly dampen

surfaces or use a mister attachment

when water is available.

• Conserve water by using power blow

ers instead of hoses for many lawn

and garden applications, including

areas such as gutters, screens, patios,

grills, porches, and gardens.

• Watch out for children, pets, open

windows, or freshly washed cars.

Blow debris away safely,

• Use the full blower nozzle extension

so the air stream can work close to

the ground.

• After using blowers and other equip

ment, CLEAN UPl Dispose of debris

in trash receptacles.

OPERATING POSITION

BEFORE STARTING ENGINE

^WARNING: Be sure to read the

fuel information in the safety rules

before you begin. If you do not

understand the safety rules, do not

attempt to fuel your unit. Cali

1 -800-235-5878.

FUELING ENGINE

^WARNING: Remove fuel cap

slowly when refueling.

This engine is certified to operate on un

leaded gasoline. Before operation, gaso

line must be mixed with a good quality

synthetic 2-cycle air-cooled engine oil.

Vife recommend Craftsman brand syn

thetic oil. Mix gasoline and oil at a ratio

of 40:1. A 40:1 ratio is obtained by mix

ing 3.2 ounces of oil with 1 gallon of un

Page 10

leaded gasoline, included with this blow

er is a 3.2 ounce container of oil. Pour

the entire contents of this container into

1 gallon of gasoline to achieve the prop

er fuel mixture. DO NOT USE automotive

oil or boat oil. These oils will cause en

gine damage. When mixing fuel, follow

instructions printed on container. Once

oil is added to gasoline, shake container

momentarily to assure that the fuel is

thoroughly mixed. Always read and fol

low the safety rules relating to fuel be

fore fueling your unit.

IMPORTANT

Experience indicates that alcohol

blended fuels (called gasohol or using

ethanol or methanol) can attract mois

ture which ieads to separation and

formation of acids during storage.

Acidic gas can damage the fuel sys

tem of an engine while in storage.

To avoid engine problems, empty the

fuel system before storage for 30 days

or longer. Drain the gas tank, start the

engine and let it run until the fuel lines

and carburetor are empty. Use fresh

fuel next season. Never use engine or

carburetor cleaner products in the fuel

tank or permanent damage may occur.

Fuel stabilizer is an acceptable alter

native in minimizing the formation of

fuel gum deposits during storage.

Craftsman brand oil is already blended

with fuel stabilizer. See the STORAGE

section for additional information.

HOW TO STOP YOUR ENGINE

• Release the throttle trigger.

• Push and hold the STOP switch in the

STOP position until the engine stops,

HOW TO START YOUR ENGINE

A WARNING: You MUST make sure

the tubes are secure before using the

unit.

• Fuel engine. Move at least 10 feet (3

meters) away from the fueling site,

• Hold the unit in the starting position

as shown. Make sure the blower end

Is directed away from people, ani

mals, glass, and solid objects.

^WARNING: When starting engine,

hold the unit as illustrated. Do not set

unit on any surface except a clean, hard

area when starting engine or while en

gine is running. Debris such as gravel,

sand, dust, grass, etc. could be picked

up by the air intake and thrown out

through the discharge opening, damag

ing the unit or property, or causing seri

ous injury to bystanders or the operator.

STARTING A COLD ENGINE (or

warm engine after running out of fuel)

1, Move the throttle position lever

(cruise control) to the idle position.

Throttle

Position

Lever

(Cruise

Control)

2, Slowiy press the primer bulb 6 times.

3. Move the start lever to the START

position.

10

Page 11

system. You do not have to pull the

starter rope handle sharply or

briskly. Pull starter rope handle 5

times with a controlled and steady

motion (no more than 3 times

above 90°F). If engine starts and

runs prior to 5 pulls, allow engine to

run for 5 seconds; then, fully

squeeze the throttle trigger to dis

engage the starting system (start

lever returns to RUN position).

Steps 5 and 6 are not necessary.

Fully squeeze the throttle trigger to

5.

disengage the starting system (start

lever returns to RUN position).

6, Puli starter rope handle with a con

trolled and steady motion while

squeezing throttle trigger until

engine starts and runs.

STARTING A WARM ENGINE

1. Squeeze and hold the throttfe trigger.

2, Pull starter rope handle with a con

trolled and steady motion while

squeezing throttle trigger until en

gine starts and runs.

NOTE: Normally, the warm starting

prooedure can be used within 5-10

minutes after the unit is turned off. If

the unit sits for more than 10 minutes

without being used, it will be necessary

to start the unit by following the steps

under STARTING A COLD ENGINE or fol

lowing the starting instruction steps

shown on the unit.

STARTING A FLOODED ENGINE

Flooded engines can be started by mov

ing the start lever to the RUN position

and fully squeezing the throttle trigger.

Pull the starter handle repeatedly while

squeezing throttle trigger until engine

starts and runs. This could require pull

ing the starter handle many times, de

pending on how badly the unit is

flooded. If the unit still doesn't start, re

fer to the TROUBLESHOOTING TABLE or

call 1-800-235-5878,

MAINTENANCE

CUSTOMER RESPONSIBILITIES

A WARNING: Disconnect the spark plug before performing maintenance,

service, or adjustments.

CARE & MAINTENANCE TASK WHEN TO PERFORM

Check for loose fasteners and parts Before each use

Check for damaged or worn parts Before each use

Inspect and clean unit and labels After each use

Clean air filter Every 5 hours of operation

Replace spark plug Yearly

Replace fuel filter Yearly

Check muffler mounting screws Yearly

Ay

I WARNING; Avoid touching muf

fler unless engine and muffler are cold,

A hot muffler can cause serious burns.

Ay

I WARNING; Stop engine and be

sure the impeller blades have stopped

turning before opening the vacuum in

let door or attempting to insert or re

move the vacuum or blower tubes.

The rotating blades can cause serious

injury. Always disconnect the spark

plug before performing maintenance or

accessing movable parts.

GENERALRECOMMENDATIONS

The warranty on this unit does not cov

er items that have been subjected to

operator abuse or negligence. To re

ceive full value from the warranty, the

operator must maintain unit as instruct

ed in this manual. Various adjustments

will need to be made periodically to

properly maintain your unit.

11

Page 12

CHECK FOR LOOSE

FASTENERS AND PARTS

• Muffler

• Spark Plug Boot

• Air Filter

• Housing Screws

CHECK FOR DAMAGED OR

WORN PARTS

Contact Sears Service Center for re

placement of damaged or worn parts.

• Fuel Tank - Do not use unit if fuel tank

shows signs of damage or leaks.

• Vacuum Bag - Do not use vacuum

bag if it is tom or damaged,

INSPECT AND CLEAN UNIT

AND LABELS

• After each use, inspect complete unit

for loose or damaged parts. Clean

the unit using a damp doth with a

mild detergent.

• Wipe off unit with a clean dry cloth.

CLEAN AIR FILTER

A dirty air filter decreases engine per

formance and increases fuel consump

tion and harmful emissions. Always

clean after every 5 hours of operation.

REPLACE SPARK PLUG

Replace spark plug each year to ensure

the engine starts easier and runs better.

Set spark plug gap at 0.025 inch. Igni

tion timing is fixed, nonadjustable.

1, Twist, then pull off spark plug boot.

2, Remove spark plug from cylinder

and discard.

3, Replace with Champion RCJ-6Y

spark plug and tighten securely

with a 3/4 inch socket wrench.

4, Reinstall the spark plug boot,

REPLACE FUEL FILTER

To replace fuel filter, drain unit by run

ning it dry of fuel, then remove fuel

cap/retainer assembly from tank. Pull

filter from tank and remove it from the

fuel line. Install new fuel filter on fuel

line; reinstal! parts.

CHECK MUFFLER MOUNTING

SCREWS

Once each year, ensure muffler

mounting screws are secure and tight

ened properly to prevent damage.

Cleaning the air filter:

1. Clean the cover and the area

around it to keep debris from falling

into the carburetor chamber when

the cover is removed.

NOTE; Move start lever to RUN posi

tion before opening air filter cover.

2. Open air filter cover by pushing

button (see illustration). Remove

air filter.

NOTE; Do not clean filter in gasoline

or other fiammabie solvent. Doing so

can create a fire hazard or produce

harmful evaporative emissions.

3. Wash the filter in soap and water.

4. Allow filter to dry,

5. Apply a few drops of oil to the filter;

squeeze filter to distribute oil.

6. Replace parts.

INSPECT MUFFLER AND SPARK

ARRESTING SCREEN

^ WARNING; The muffler on this

product contains chemicals known to

the State of California to cause cancer.

As the unit is used, carbon deposits

build up on the muffler and spark ar

resting screen, and must be removed

to avoid creating a fire hazard or af

fecting engine performance.

12

Page 13

Replace the spark arresting screen ev

ery 50 hours of operation or if any dam

age or breaks in the screen are noted.

NOTE; Do not attempt to clean the

spark arresting screen.

1. Remove 3 screws from muffler cov

er. Remove muffler cover.

Loosen and remove 4 screws from

the muffler hood.

Remove the muffler hood and spark

arresting screen.

Install new spark arresting screen.

Reinstall muffler hood and 4

sorews. Tighten screws securely.

Reinstall muffler cover and 3

sorews. Tighten seourely.

NOTE; If any part of the muffler is

cracked, broken or damaged, we rec

ommend that the muffler be replaced.

CARBURETOR ADJUSTMENT

The carburetor has been carefully set

at the factory. Adjustments may be

necessary if you notice any of the fol

lowing conditions;

• Engine will not idle when the throttle is

released.

Idle Speed Adjustment

Allow engine to idle. Adjust speed until

engine runs without stalling (idle speed

too slow).

• Turn idle speed screw clockwise to

increase engine speed if engine

stalls or dies.

• Turn idle speed screw counterclock

wise to deorease engine speed.

If you require further assistance or are

unsure about performing this proce

dure, contact your Sears Service Cen

ter or call our customer assistance

help line at 1-800-235-5878.

STORAGE

A WARNING; Perform the following

steps after each use:

• Allow engine to cool, and secure the

unit before storing or transporting.

• Store unit and fuel in a well venti

lated area where fuel vapors cannot

reach sparks or open flames from

water heaters, electric motors or

switches, furnaces, etc.

• Store unit with all guards in place.

Position unit so that any sharp object

cannot accidentally cause injury.

• Store unit and fuel well out of the

reach of children.

SEASONAL STORAGE

Prepare unit for storage at end of sea

son or if it will not be used for 30 days

or more. If your unit is to be stored for

a period of time:

• Clean the entire unit before lengthy

storage.

• Store in a clean dry area,

• Lightly oil external metal surfaces.

FUEL SYSTEM

Empty the fuel system before storage for

30 days or longer. Drain the gas tank,

start the engine and let it run until the

tuel lines and carburetor are empty. Use

fresh fuel next season. Under FUELING

ENGINE in the OPERATION section of this

manual, see message labeled

IMPORTANT regarding the use of gasohoi in your engine.

Fuel stabilizer is an acceptable alterna

tive in minimizing the formation of fuel

gum deposits during storage. Add stabi

lizer to gasoline in fuel tank or fuel stor

age container. Follow the mix instruc

tions found on stabilizer container. Run

engine at least 3 minutes after adding

stabilizer.

Craftsman 40:1,2-cycle engine oil (air

cooled) is already blended with fuel

stabilizer. If you do not use this Sears

oil, you can add a fuel stabilizer to your

fuel tank.

13

Page 14

ENGINE

• Remove spark plug and pour 1 tea

spoon of 40:1,2-cycle engine oil (air

cooled) through the spark plug open

ing. Slowly puli the starter rope 8 to

10 times to distribute oil,

• Replace spark plug with new one of

recommended type and heat range.

• Clean air filter.

TROUBLESHOOTING TABLE

• Check entire unit for loose screws,

nuts, and bolts. Replace any dam

aged, broken, or worn parts,

• At the beginning of the next season,

use only fresh fuel having the proper

gasoline to oil ratio.

OTHER

• Do not store gasoline from one sea

son to another.

• Replace your gasoline can if it starts

to rust.

A WARNING: Always stop unit and disconnect sparkplug before perform

ing any of the recommended remedies below otherthan remedies that re

quire operation of the unit.

TROUBLE CAUSE REMEDY

Engine will not

start.

Engine will not

idle properly.

Engine will not

accelerate,

lacks power, or

dies under a

load.

Engine smokes

excessively.

Engine runs hot.

1. Engine flooded.

2. Fuel tank empty,

3. Spark plug not firing.

4. Fuel not reaching

carburetor.

5. Compression low.

1. Fuel not reaching

carburetor.

2. Carburetor requires

adjustment.

3. Crankshaft seals worn.

4. Compression low.

1. Air filter dirty.

2. Fuel not reaching

carburetor.

3. Spark plug fouled.

4. Carburetor requires

adjustment.

5. Carbon build up.

6. Compression low.

1, Choke partially on.

2. Fuel mixture incorrect.

3. Air filter dirty.

4, Carburetor requires

adjustment.

1, Fuel mixture incorrect.

2, Spark plug incorrect.

3, Carburetor requires

adjustment.

4- Carbon build up.

1, See “Starting a Flooded Engine"

in Operation section.

2, Fill tank with correct fuel mixture.

3- Install new spark plug.

4, Check for dirty fuel filter; replace.

Check for kinked or spilt fuel line;

repair or replace.

5, Contact Sears Service (see back cover).

1, Check for dirty fuel filter; replace.

Check for kinked or spilt fuel line;

repair or replace.

2- Contact Sears Service (see back cover).

3, Contact Sears Service (see back cover).

4, Contact Sears Service (see back cover).

1. Clean or replace air filter.

2. Check for dirty fuel filter; replace.

Check for kinked or split fuel line;

repair or replace.

3. Clean or replace spark plug

and re-gap.

4. Contact Sears Service (see back cover).

5. Contact Sears Service (see back cover).

6. Contact Sears Service (see back cover).

1, Adjust choke.

2, Empty fuel tank and refill with

correct fuel mixture.

3, Clean or replace air filter.

4, Contact Sears Service (see back cover).

1. See “Fueling Engine” in Operation

section.

2. Replace with correct spark plug.

3. Contact Sears Service (see back cover).

4. Contact Sears Service (see back cover).

14

Page 15

U.S. EPA/CALIFORNIA

EMISSION CONTROL WARRANTY STATEMENT

YOUR WARRANTY RiGHTS AND OB

LiGATIONS; The U.S. Environmental

Protection Agency/California Air Re

sources Board and Sears, Roebuck and

Co., U.S.A., are pleased to explain the

emissions control system warranty on

your year 2007 and later small off-road

engine. In California, all small off-road

engines must be designed, built, and

equipped to meet the State's stringent

anti-smog standards. Sears must war

rant the emission control system on your

small off-road engine for the periods of

time listed below provided there has

been no abuse, neglect, or improper

maintenance of your small off-road en

gine. Your emission control system in

cludes parts such as the carburetor, the

ignition system and the fuel tank (Califor

nia only). Where a warrantable condition

exists. Sears will repair your small off

road engine engine at no cost to you.

Expenses covered under warranty in

clude diagnosis, parts and labor.

MANUFACTURER'S WARRANTY

COVERAGE: If any emissions related

part on your engine (as listed under

Emissions Control Warranty Parts List) is

defective or a defect in the materials or

workmanship of the engine causes the

failure of such an emission related part,

the part will be repaired or replaced by

OWNER’S WARRANTY RESPONSIBI

LITIES; As the small off-road engine

engine owner, you are responsible for

the performance of the required mainte

nance listed in your operator's manual.

Sears recommends that you retain all

receipts covering maintenance on your

small off-road engine, but Sears cannot

deny warranty solely for the lack of re

ceipts or for your failure to ensure the

performance of all scheduled mainte

nance. As the small off-road engine en

gine owner, you should be aware that

Sears may deny you warranty coverage

if your small off-road engine engine or a

part of it has failed due to abuse, ne

glect, improper maintenance, unap

proved modifications, or the use of parts

not made or approved by the original

equipment manufacturer. You are re

sponsible for presenting your small off

road engine to a Sears authorized repair

center as soon as a problem exists.

Warranty repairs should be completed in

a reasonable amount of time, not to ex

ceed 30 days, if you have any ques

tions regarding your warranty rights and

responsibilities, you should contact your

nearest authorized service center or call

Sears at 1-800-469-4663. WARRANTY

COMMENCEMENT DATE: The warran

ty period begins on the date the small

off-road engine is purchased. LENGTH

OF COVERAGE: This warranty shall be

for a period of two years from the initial

date of purchase. WHAT IS COV

ERED: REPAIR OR REPLACEMENT

OF PARTS. Repair or replacement of

any warranted part will be performed at

no charge to the owner at an approved

Sears Service Center, if you have any

questions regarding your warranty rights

and responsibilities, you should contact

your nearest authorized service center

or call Sears at 1-800-469-4663. WAR

RANTY PERIOD: Any warranted part

which is not scheduled for replacement

as required maintenance, or which is

scheduled only for regular inspection to

the effect of “repair or replace as neces

sary” shall be warranted for 2 years. Any

warranted part which is scheduled for

replacement as required maintenance

shall be warranted for the period of time

up to the first scheduled replacement

point for that part.

owner shall not be charged for diagnos

tic labor which leads to the determina

tion that a warranted part is defective if

the diagnostic work is performed at an

approved Sears Service Center. CON

SEQUENTIAL DAMAGES: Sears may

be liable for damages to other engine

components caused by the failure of a

warranted part sill under warranty.

WHAT IS NOT COVERED:

caused by abuse, neglect, or improper

maintenance are not covered. ADD-ON

OR MODIFIED PARTS: The use of

add-on or modified parts can be

grounds for disaiiowing a warranty claim.

Sears is not liable to cover failures of

warranted parts caused by the use of

add-on or modified parts.

FILE A CLAIM: If you have any ques

tions regarding your warranty rights and

responsibilities, you should contact your

nearest authorized service center or call

Sears at 1 -800-469-4663,

DIAGNOSIS: The

Ail failures

HOW TO

15

Page 16

WHERE TO GET WARRANTY SER

VICE: Warranty services or repairs shaii

be provided at all Sears Service Cen

ters. Cai! 1-800-469-4663.

MAINTENANCE, REPLACEMENT

AND REPAIR OF EMISSION RE

LATED PARTS: Any Sears approved

replacement part used in tbe perfor

mance of any warranty maintenance or

EMISSION CONTROL WARRANTY

PARTS LIST: Carburetor, Ignition Sys

tem: Spark Plug (covered up to mainte

nance schedule), ignition Module, Muf

fler including Catalyst, Fuel Tank (Cali

fornia only). MAINTENANCE STATE

MENT: The owner is responsible for the

performance of all required maintenance

as defined in the operator’s manual.

repair on emission related parts will be

provided without charge to the owner if

the part is under warranty.

The information on the product iabei indicates which standard your engine is certified.

Exampfe: (Year) EPA Phase 1 or Phase 2 and/or CALIFORNIA.

___________

IMPORTANT EMISSIOti INFORMATIOH

THIS ENGINE CONFORMS TO EKH. AND EVAP.

EMISSIONS REGULATIONS POR SMALL OFF

F/MLÏ.fflSP.

SERIAL#

MODEL#

THE LOWER THE AIR INDEX, THE LESS POLLUTION

REFER TO OWNER'S MANUAL FOR MAINTENANCE

ROAD ENGINES

THE AIR INDEX OF THIS ENGINE IS3

4 I el i tel

SreCIFICATiONS AND ADJUSTMENTS.

This engine Is certified to be emissions compliant for the following use:

la Moderate (50 hours)

□ Intermediate (125 hours)

l~l Extended (300 hours)

16

Page 17

REPAIR PARTS

SEARS GAS BLOWER MODEL 358.794772

^WARNING

Af! repairs, adjustments and

maintenance not described in

the Operators Manual must be

performed by Qualified Service

Personnel,

Ref. Part No. Description R«f. Part No. Description

1. 530015814 Screw

2. 545150502 Assy - Engine Cover

3. 530015880 Screw

4. 545134001 Shield - Baffle

5. 545099101 Baffle

6. 545052401 Hub

7. 545052501

S. 545050407 Kit -Starter Pulley (Incl. 6.7)

9. 545054901 Spiing - Starter

10. 545152901 Handle - Starter

11. 545050416 Kit - Rope

12. 545107101 Tube - Staster l ope

13. 545138601 Handle - RH

14. 5450S1830 Kit - Switch (Incl. 15)

15. 54512S201 Pi'otectar - Switch

IS. 545137701 Grommet

17. 545099001 Bearing

IS. 545116201

19. 530015814 Screw

20. 545111501 Rächet - Cruise Control

21. 545173101 Washer - Wave

22. 5450S1867 Kit - Cruise cantro1(lncl.19.20.21)

23. 545144901 Trigger - Throltie

24. 545138801 Handle - LH

25.

530016406

26.

530015814

27. 545139001 Door - Vac

2S. 545115601 Spring - Vac door

545144501

29.

30. 530015940 Screw - Handle vac

31. 545152501 Assy - Scroll LH (Incl. 27.28)

32. 545120701 Blade - Mulch

33. 545113601 Assy - Impeller

34. 545113701 Spacer - Flywheel

35. 530015197 Nut - Blower Knob

Spring - Pulley

Screw

Knob - Blower tube

36, 530016386 Screw

37, 545161608 Assy -Scroll RH (Incl, 17)

38, 545138501 Handle - Vac

39, 545100401 Assy - Fuel tank

40, 530095646 Assy - Fuel Pickup

41, 530069247 Kit - Fuel line (carb/purge)

42, 530069216 Kit - Fuel line ftank/purqe)

43. 530057973 Assy - Fuel Cap with retainer

44, 530016445 Screw - Fuel tank retainer

ilncl. 40.41.42.43)

Not Shown

545167641

545001245 Decal - Warning

545042802 Decal - Start Instruction

Page 18

REPAIR PARTS

SEARS GAS BLOWER MODEL 358.794772

Rei. Part No. Description

1. 545090001 Assy - Muffler (ind. 2,3.4,5)

2. 530015241 Screw

3. 5450S1S45 Kit - Spark Screen

4. 53005S9S2 Boll - Muffier

5. 5450S1S32 Gasket - Muffler (gasket kit)

6. 545115301 Cylinder

7. 530015953 Bolt

8. Champion Spark plug iRCJ-5Y)

9. 545034901 Adapter - Carb.

10. 545115501 Linkage - Throttle

11. 545031357 Kit - Carb. Assy (C1U-W43B)

12. 545157104 Lever - Choke

13. 545139301 Base - Airbox

14. 530016429 Screw

15. 545146501 Filter

16. 545139201 Cover - Air box filter

17. 530053709 Bulb - Purge

18. 545031332 O-ring (Carb/Adapter)(gasket kit)

19. 530016441 Screw

20. 545031332 O-Ring (Adapter/Cyl.)(gasket kit)

21. 545031364 Kit - Piston/Connecting Rod

22. 530012472 Ring - Piston

23. 530015162 Retainer - Wrist Pin

24. 545031365 Kit - Assy Connecting Rod

25. 545153001 Module - Ignition

26. 530016357 Screw

27. 545127601 Assy - Wire Harness

28. 545031332 O-ring seal - Crankcase (kit)

29. 530015323 Washer

30. 530054115 Assy - Flywheel

31. 530015941 Retainer -Crankshaft

32. 530055723 Bearing - Outer

33. 530019264 Seal

(Ind. 12.17)

(Incl. 22.23.24)

Ret. Part No. Description

34. 530032125 Bearing - Inner

35. 530012582 Assy - Crankcase

36. 545102102 Assy - Crankcase/Crankshaft

37. 545081832 0 - Ring (Rear plug)(gasket kit)

33. 530057954 Assy - Rear Plug (Incl. 37)

39. 530016386 Sciew

40. 545081832 Kit - Gasket (Incl. 5.18.20.28.37)

iincl, 32,33,34)

iinci, 31,35)

Page 19

REPAIR PARTS

SEARS GAS BLOWER MODEL 358.794772

Ref. Part No. Description

1. 545099401 Tube - Upper vac

2. 530095539 Tube - Lower vac

3. 545139501 Tube - J

4. 530095564 Assy - Vac bag

5. 545138001 Tube - Upper Slower

6 . 545138101 Tube - Lower Slower

7. 545151201 Nozzle - High Speed

Loading...

Loading...