Page 1

Operator’s Manual

CRAFTSMAN

25CC/1.5 cu.in. 2-Cycle

200 MPH/430 CFM

GASOLINE POWERED

BLOWERA^AC

Model No.

358.794740

• Safety

• Assembly

• Operation

• Maintenance

• Parts List

• Español, p. 20

WARNING:

Read and follow all Safety Rules and Operating

Instructions before first use of this product.

For answers to your questions about this product;

9

Call 7 am-7 pm, Mon.-Sat., or 10 am-7 pm. Sun.

1 ^00-235-5878 (Hours listed are Centra! Time)

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

545146930 Rgv. 3 8/22/07 BRW

Page 2

TABLE OF CONTENTS

Warranty Statement 2 Storage 14

Identification of Safety Symbols 2 Troubleshooting Table 15

Safety Rules 3 Emissions Statement 16

Assembly 6 Parts List 18

Operation 9 Spanish 21

Maintenance 11 Parts and Ordering Back Cover

WARRANTY STATEMENT

TWO YEAR FULL WARRANTY ON CRAFTSMANcB GAS BLOWER

When used and maintained according to the operator’s manual, if this product fails

due to a defect in material or workmanship within two (2) years from the date of pur

chase, return it to any Sears store, Sears Service Center, or other Craftsman outlet

in the United States for free repair {or replacement If repair proves impossible).

This warranty excludes spark plug and air cleaner, which are expendable parts that

can wear out from normal use in less than two years.

This warranty applies for only 30 days from the date of purchase if this product is

used for commercial or rental purposes.

This warranty gives you specific legal rights, and you may also have other rights

which vary from state to state.

Sears, Roebuck and Co., Hoffman Estates, IL 60179

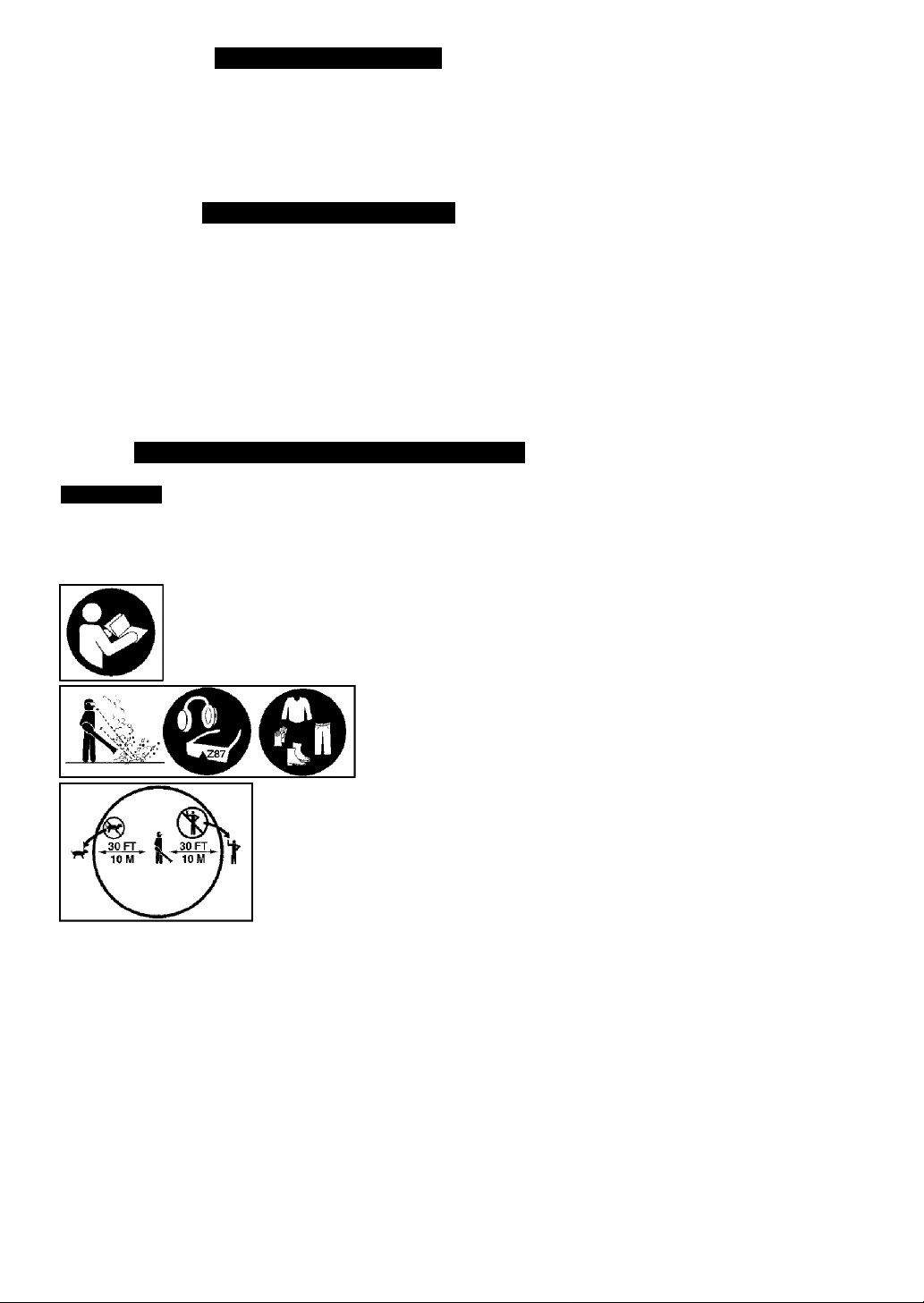

IDENTIFICATION OF SAFETY SYMBOLS

AwARNING: This unit can be dangerous! Careless or

improper use can cause serious injury.

Read your operator’s manual carefully until you completely un

derstand and can follow all warnings and safety rules before

operating the unit. Failure to do so can result in serious injury.

Save operator's manual.

The blower can throw objects

violently. You can be blinded or

injured. Always wear hearing

protection and safety glasses

marked Z87. Always wear

heavy, long pants, long sleeves,

boots and gloves.

Hazard zone for thrown objects. Keep children,

bystanders, and animals away from work area a

minimum of 30 feet (10 meters) when starting or

operating unit. Do not point blower nozzle in the

direction of people or pets.

Page 3

IDENTIFICATION OF SAFETY SYMBOLS

Secure hair above shoulder length.

Do not wear jewelry, loose clothing,

or clothing with loosing hanging

straps, ties, tassels, etc. They can

be caught in moving parts.

Always stop unit and disconnect spark plug

before cleaning or servicing.

WARNING: Stop the engine before opening the vacuum inlet door. The

engine must be stopped and the impeller blades no longer turning to avoid serious

injury from the rotating blades. Gently tilt the handle of the screwdriver toward the

back of the unit to release the latch while pulling up on the vacuum inlet cover with

your other hand.

When using the vacuum attachment, the unit is designed to

pick up dry material such as leaves, grass, small twigs, and bits

of paper. Do not vacuum stones, gravel, metal, broken glass,

etc., to avoid severe damage to the impeller.

A WARNING: Fire hazard. Never mix, pour, or store gasoline

or use the unit near a flame or sparks {including smoking, open

flames, or work that can cause sparks).

SAFETY RULES

a WARNING: Failure to follow all

Safety Rules and Precautions can re

sult in serious injury.

KNOW YOUR UNIT

• Read your instruction manual care

fully until you completely understand

and can follow all warnings and

safety rules before operating the unit.

• Restrict unit to users who under

stand and will follow all warnings and

safety rules in this manual.

A WARNING; Inspect area before

starting unit. Remove ail debris and

hard objects such as rocks, glass.

wire, etc. that can ricochet, be thrown,

or otherwise cause injury or damage

during operation.

Use your unit as a blower for:

• Sweeping debris or grass clippings

from driveways, sidewalks, patios, etc.

• Blowing grass clippings, straw, or

leaves into piles, around joints, or be

tween bricks.

Use your unit as a vacuum for:

• Picking up dry material such as

leaves, grass, small twigs, and bits of

paper.

• For best results during vacuum use,

operate your unit at high speed.

Page 4

• Move slowly back and forth over the

material as you vacuum. Avoid forc

ing the unit into a pile of debris as

this can clog the unit.

• Keep the vacuum tube about an inch

above the ground for best results.

PLAN AHEAD

• Always wear eye protection when op

erating, servicing, or performing main

tenance on unit. Wearing eye protec

tion wiil help to prevent rocks or debris

from being blown or ricocheting into

eyes and face which can result in

blindness and/or serious injury. Eye

protection should be marked Z87.

• Always wear foot protection. Do not

go barefoot or wear sandals.

• Always wear respirator or face mask

when working with unit in dusty envi

ronments.

• Secure hair above shoulder length.

Secure or remove jewelry, loose

clothing, or clothing with loosely

hanging straps, ties, tassels, etc.

They can be caught in moving parts.

• Do not operate unit when you are

tired. Hi, upset, or if you are under the

influence of alcohol, drugs, or medi

cation.

• Keep children, bystanders, and ani

mals away from work area a mini

mum of 30 feet {f 0 meters) when

starting or operating unit. Do not

point blower nozzle in the direction of

people or pets.

HANDLE FUEL WITH CAUTION, iT IS

HIGHLY FLAMMABLE

• Eliminate all sources of sparks or

flame {including smoking, open

flames, or work that can cause

sparks) in the areas where fuel is

mixed, poured, or stored.

• Mix and pour fuel in an outdoor area;

store fuel in a cool, dry, well ventilated

place; use an approved, marked con

tainer for all fuel purposes.

• Do not smoke while handling fuel or

while operating the unit.

• Make sure the unit is properly as

sembled and in good operating con

dition.

• Do not fill fuel tank while engine is

running.

• Avoid spilling fuel or oil. Wipe up fuel

spills before starting engine.

• Move at least 10 feet (3 meters)

away from fuel and fueling site be

fore starting engine.

• Always store gasoline in a container

approved for flammable liquids.

OPERATE YOUR UNIT SAFELY

A WARNING: Stop the engine be

fore opening the vacuum inlet door.

The engine must be stopped and the

impeller blades no longer turning to

avoid serious injury from the rotating

blades.

• Inspect unit before each use for

worn, loose, missing, or damaged

parts. Do not use until unit is in

proper working order.

• Keep outside surfaces free from oil

and fuel.

• Never start or run engine inside a

closed room, building or other un

ventilated area. Breathing exhaust

fumes can kill.

• To avoid static electricity shock, do

not wear rubber gloves or any other

insulated gloves while operating unit.

• Do not set unit on any surface except

a clean, hard area while engine is run

ning. Debris such as gravel, sand,

dust, grass, etc. could be picked up by

the air intake and thrown out through

discharge opening, damaging unit,

property, or causing serious injury to

bystanders or operator.

• Avoid dangerous environments. Do

not use in unventilated areas or

where explosive vapors or carbon

monoxide build up could be present.

• Do not overreach or use from unsta

ble surfaces such as ladders, trees,

steep slopes, rooftops, etc. Keep firm

footing and balance at all times.

• Never place objects inside the

blower tubes; always direct the blow

ing debris away from people, ani

mals, glass, and solid objects such

as trees, automobiles, walls, etc. The

force of air can cause rocks, dirt, or

sticks to be thrown or to ricochet

which can hurt people or animals,

break glass, or cause other damage.

• Never run unit without the proper

equipment attached. When using

your unit as a blower, always install

blower tubes. When using the op

tional vacuum kit, always install vac

uum tubes and vacuum bag assem

bly. Make sure vacuum bag assem

bly is completely zipped.

• Check air intake opening, blower

tubes, and vacuum tubes frequently,

always with engine stopped and

spark plug disconnected. Keep vents

and discharge tubes free of debris

Page 5

which can accumulate and restrict

proper air flow.

• Never place any object in air intake

opening as this could restrict proper air

flow and cause damage to the unit.

• Never use for spreading chemicals,

fertilizers, or other substances which

may contain toxic materials.

• To avoid spreading fire, do not use

near leaf or brush fires, fireplaces,

barbecue pits, ashtrays, etc.

• Use only for jobs explained in this

manual.

MAINTAIN YOUR UNIT PROPERLY

WARNING; Disconnect spark

plug before performing maintenance

except for carburetor adjustments.

• Have all maintenance other than the

recommended procedures described

in the instruction manual performed

by a Sears Service Center.

• Use only recommended Craftsman

replacement parts; use of any other

parts may void your warranty and

cause damage to your unit.

• Empty fuel tank before storing the

unit. Use up fuel left in carburetor by

starting engine and letting it run until

it stops.

• Do not use any accessory or attach

ment other than those recommended

by manufacturer for use with your unit,

• Do not store the unit or fuel in a closed

area where fuel vapors can reach

sparks or an open flame from hot

water heaters, electric motors or

switches, furnaces, etc.

• Store in a dry area out of reach of

children.

SAFETY NOTICE: Exposure to vibra

tions through prolonged use of gaso

line powered hand tools could cause

blood vessel or nerve damage in the

fingers, hands, and joints of people

prone to circulation disorders or abnor

mal swelling. Prolonged use in cold

weather has been linked to blood ves

sel damage in otherwise healthy

people. If symptoms occur such as

numbness, pain, loss of strength,

change in skin color or texture, or loss

of feeling in the fingers, hands, or

joints, discontinue the use of this tool

and seek medical attention. An

antivibration system does not guaran

tee the avoidance of these problems.

Users who operate power tools on a

continual and regular basis must moni

tor closely their physical condition and

the condition of this tool.

SPECIAL NOTICE: This unit is

equipped with a temperature limiting

muffler and spark arresting screen

which meets the requirements of Cali

fornia Codes 4442 and 4443. All U.S.

forest land and the states of California,

Idaho, Maine, Minnesota, New Jersey,

Oregon, and Washington require by

law that many internal combustion en

gines be equipped with a spark arrest

ing screen. If you operate in a locale

where such regulations exist, you are

legally responsible for maintaining the

operating condition of these parts. Fail

ure to do so is a violation of the law.

Refer to the MAINTENANCE section

for information on maintenance of the

muffler and spark arresting screen.

Page 6

ASSEMBLY

CARTON CONTENTS

Check carton contents against the fol

lowing list.

Model 358.794740

• Blower

• Upper blower tube

• Lower blower tube

• High velocity nozzle

• Elbow tube

• Vacuum bag

• Upper vacuum tube

• Lower vacuum tube

• 2-Cycle engine oil

NOTE: It is norma! for the fuel filter to

rattle in the empty fuel tank.

ASSEMBLY

^WARNING: Stop engine and be

sure the impeller blades have stopped

turning before opening the vacuum in

let door or attempting to Insert or re

move the vacuum tubes. The rotating

blades can cause serious injury.

A WARNING: If you receive your

unit assembled, repeat all steps to en

sure your unit is properly assembled

and all fasteners are secure.

• A standard screwdriver Is required

for assembly.

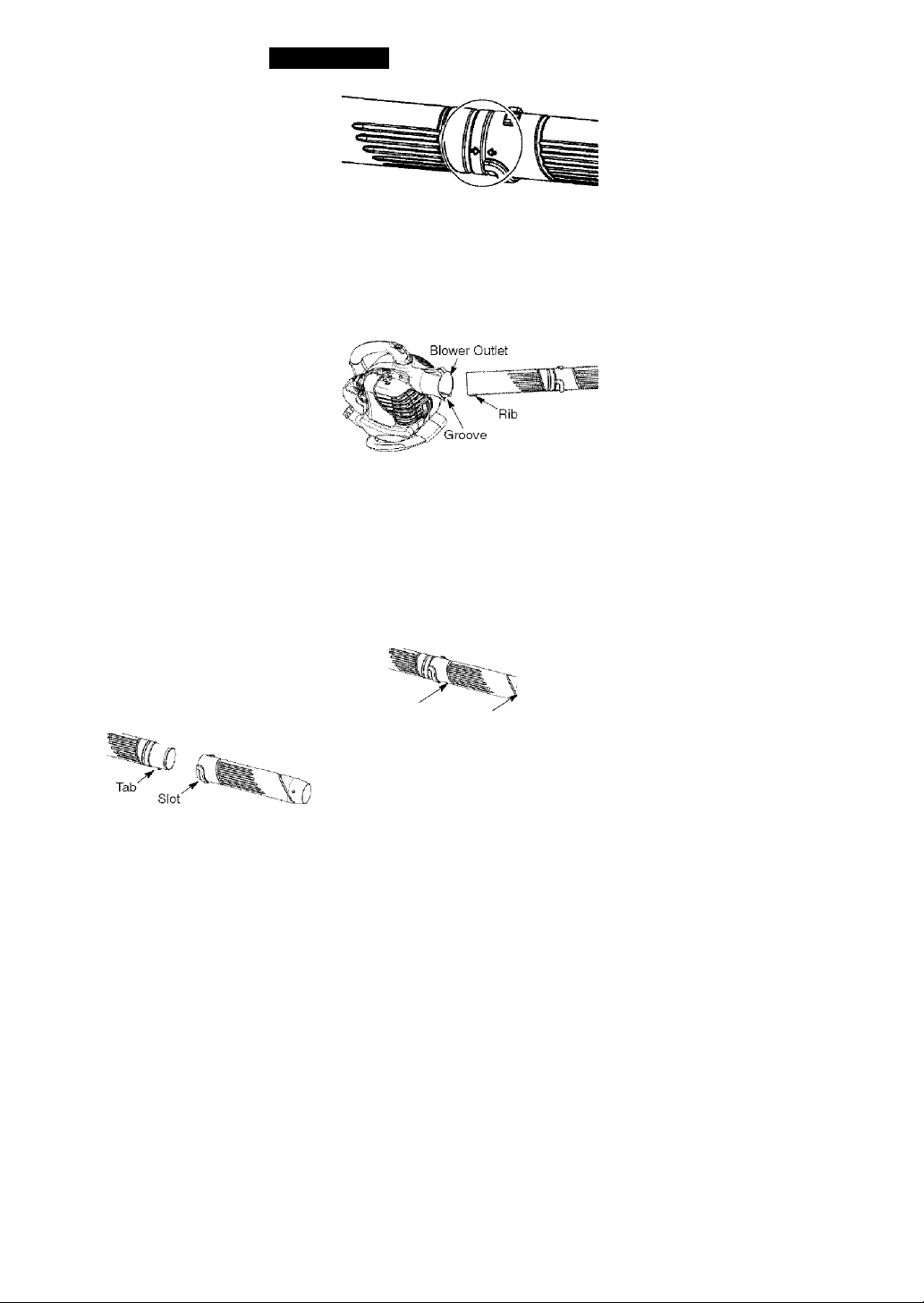

BLOWER ASSEMBLY

BLOWER TUBE ASSEMBLY

if you have already assembled your

unit for use as a vacuum, remove the

vacuum tubes and collection bag.

1. Align the slots on the lower blower

tube with the tabs on the upper

blower tube.

Upper Blower Tube

Lower Blower Tube

2. Slide the lower blower tube onto

the upper blower tube.

3. Turn the lower blower tube clock

wise until a click is felt to secure

the lower blower tube to the upper

blower tube.

NOTE: When the upper and lower

blower tubes are assembled together

properly, the arrows on both tubes will

be aligned.

4. Align the rib on the upper blower

tube with the groove in the blower

outlet; slide the tube into place.

NOTE: Knob must be loose enough to

allow blower tubes to be inserted in

blower outlet. Loosen knob by turning

counterclockwise.

5. Secure the tubes by turning the

knob clockwise.

6. To remove the tubes, turn the knob

counterclockwise to loosen the

tubes; remove the tubes.

HIGH-SPEED NOZZLE ASSEMBLY

When greater air speed is desired, use

the high-speed nozzle.

1. Align the slots on the nozzle with

the tabs on the lower blower tube.

High-Speed

Nozzle

Lower Blower

Tube

Tab

2. Slide the nozzle onto the lower

blower tube.

3. Turn the nozzle clockwise until a

click is felt to secure the nozzle to

the lower blower tube.

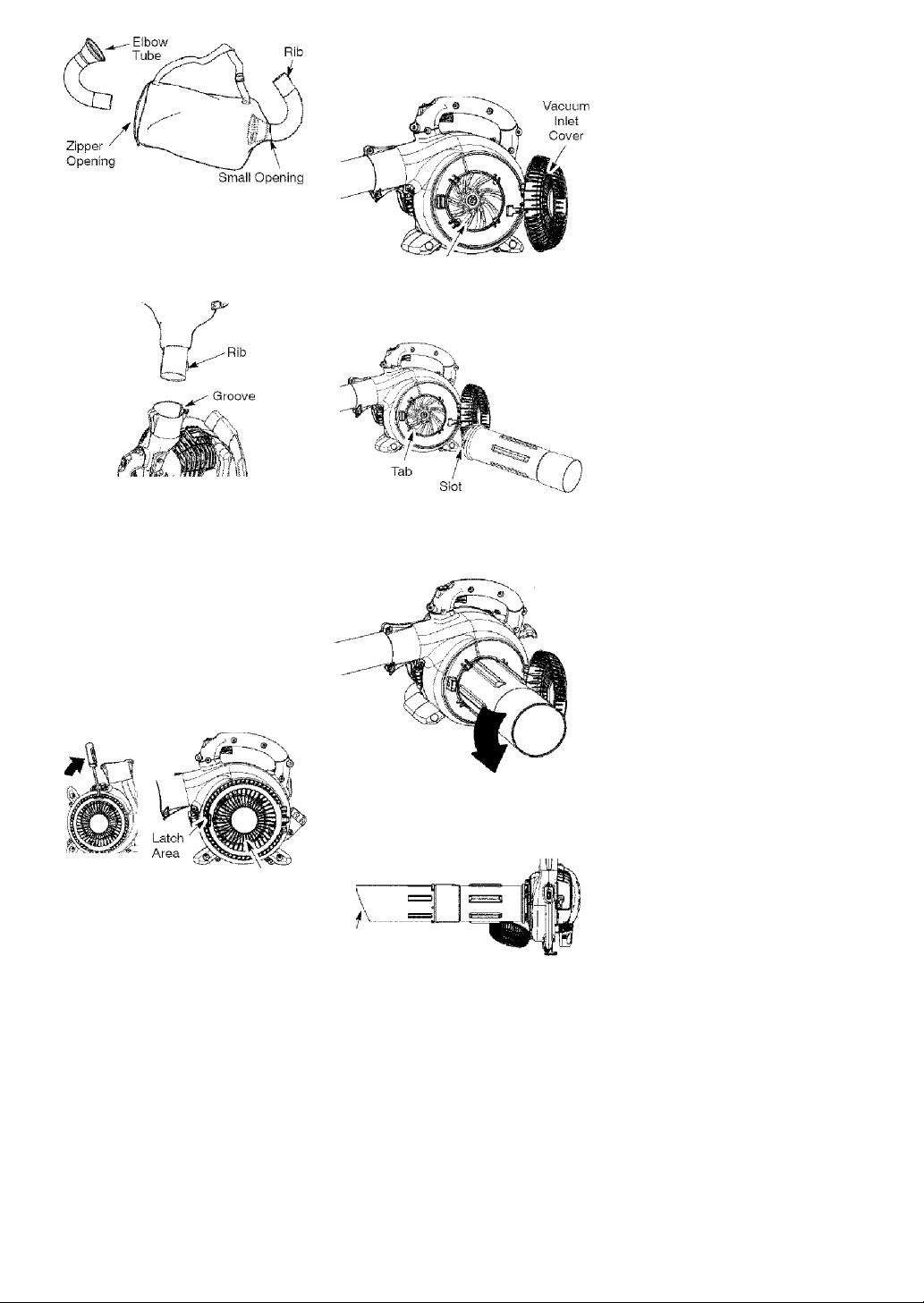

VACUUM ASSEMBLY

VACUUM BAG ASSEMBLY

1.

Open the zipper on the vacuum

bag and insert the elbow tube.

Push the small end of the elbow

2.

tube through the small opening in

the bag.

Page 7

NOTE: Make sure edge of the small

opening is flush against the flared area

of the elbow tube, and the rib on the

elbow tube is on the bottom.

3. Close the zipper on the bag. Make

sure the zipper is closed completely.

4. Remove blower tubes from engine.

5. insert the elbow tube into the blow

er outlet. Make sure elbow tube rib

is aligned with the blower outlet

groove.

6. Turn knob clockwise to secure el

bow tube.

VACUUM TUBE ASSEMBLY

A WARNING: Stop engine and be

sure the impeller blades have stopped

turning before opening the vacuum inlet

door or attempting to insert or remove

the vacuum or blower tubes. The rotat

ing blades can cause serious injury,

1. insert the tip of a screwdriver into

the latch area of the vacuum inlet.

Blower

Outlet

3. Hold the vacuum inlet cover open

until upper vacuum tube is

installed.

Vacuum Inlet

4. Align the tabs on the inside of the

vacuum inlet with the slots in the

upper vacuum tube.

Push the upper vacuum tube into

the vacuum inlet. Turn the tube

counterclockwise until a click is felt

to secure the tube to the blower unit.

Vacuum Inlet Cover

Gently tilt the handle of the screw

driver toward the front of the unit to

release the latch while pulling up

on the vacuum inlet cover with your

other hand.

6. Align slanted end of lower vacuum

tube as shown. Firmly push lower

vacuum tube into upper vacuum

tube.

Slanted end of

lower vacuum tube

Page 8

HOW TO CONVERT UNIT FROM

VACUUM USE TO BLOWER USE

1. Remove the elbow tube and vacu

um bag by turning the knob coun

terclockwise to loosen the elbow

tube.

2. Remove the vacuum tubes by turn

ing the tubes clockwise.

3. Close the vacuum inlet cover and

make sure it is latched closed.

4. Reinstall the blower tubes (see

BLOWER TUBE ASSEMBLY).

VACUUM BAG SHOULDER STRAP

ADJUSTMENT

1. Hold the unit as shown with the muf

fler side facing away from your body

and clothes.

2. Pass the shoulder strap over your

head and onto your right shoulder.

3. Extend your left arm toward the

rear of the vacuum bag.

4. Adjust shoulder strap until the

vacuum bag/shoulder strap seam

lies between your thumb and index

finger.

5. Make sure air flows freely from the

elbow tube into bag. If bag is

kinked, the unit will not operate

properly.

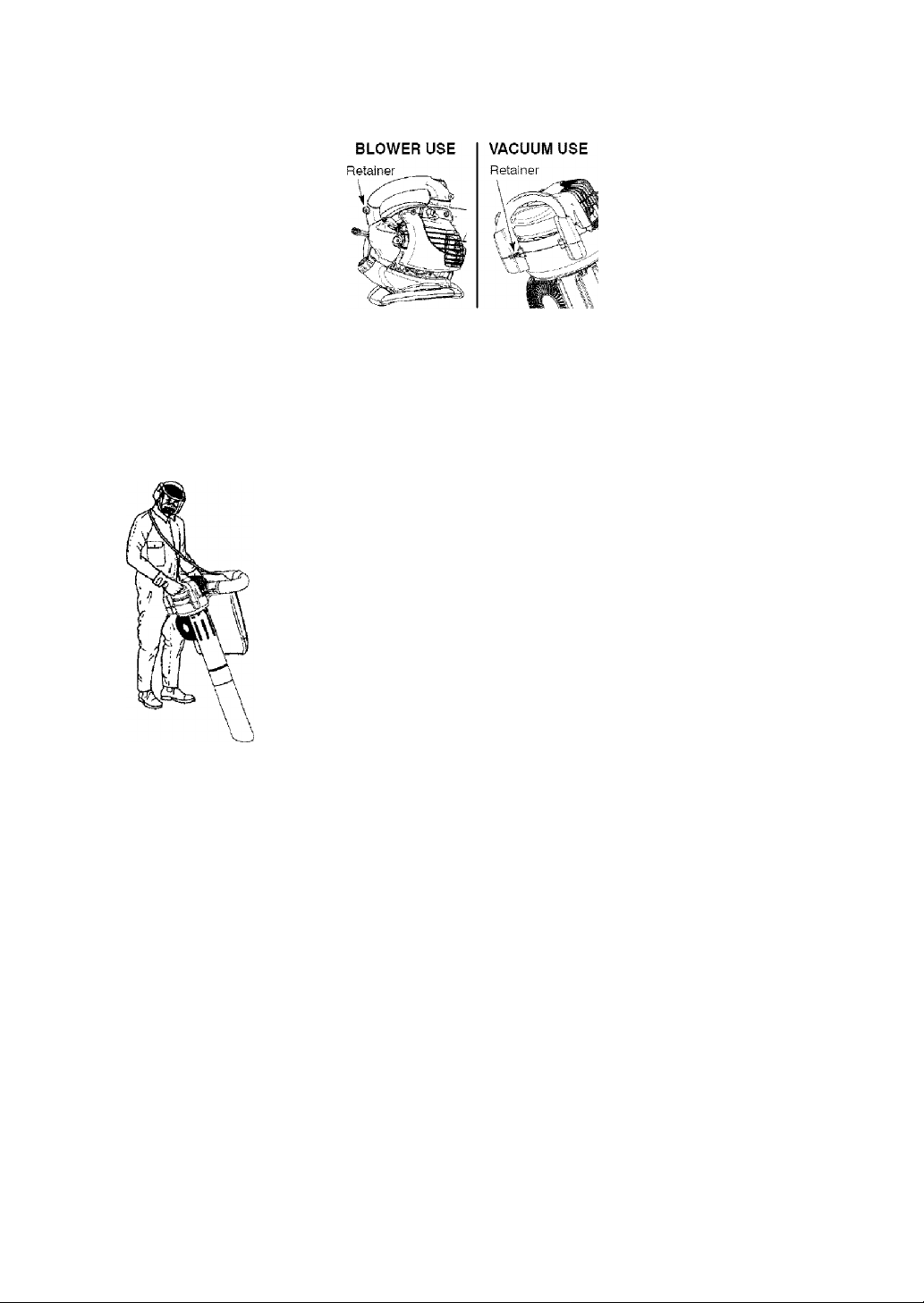

SHOULDER STRAP ATTACHMENT

(optional accessory #71-85783)

1. Pass the shoulder strap over your

head and onto your left shoulder.

2. Snap the hook onto the retainer

(see following illustration).

Page 9

OPERATION

KNOW YOUR BLOWER

READ THIS INSTRUCTION MANUAL AND SAFETY RULES BEFORE OPERATING YOUR

UNIT Compare the illustrations with your unit to familiarize yourself with the location

of the various controls and adjustments. Save this manual for future reference.

Upper Vacuum Tube

Starter

Rope^

Fuel Mix

Fill Cap \

Lower Vacuum Tube

, STOP ''A.-

Throttle Switch

Trigger \ Spark

' Plug

Choke Lever

Vacuum Handle

Elbow Tube

Upper Blower Tube

Lower Blower Tube

High-Speed

Nozzle ,

STOP SWITCH

The STOP switch is used to stop the

engine. To stop the engine, push and

hold the STOP switch in the STOP posi

tion until the engine stops.

THROTTLE TRIGGER

The THROTTLE TRIGGER is used to se

lect the desired engine speed.

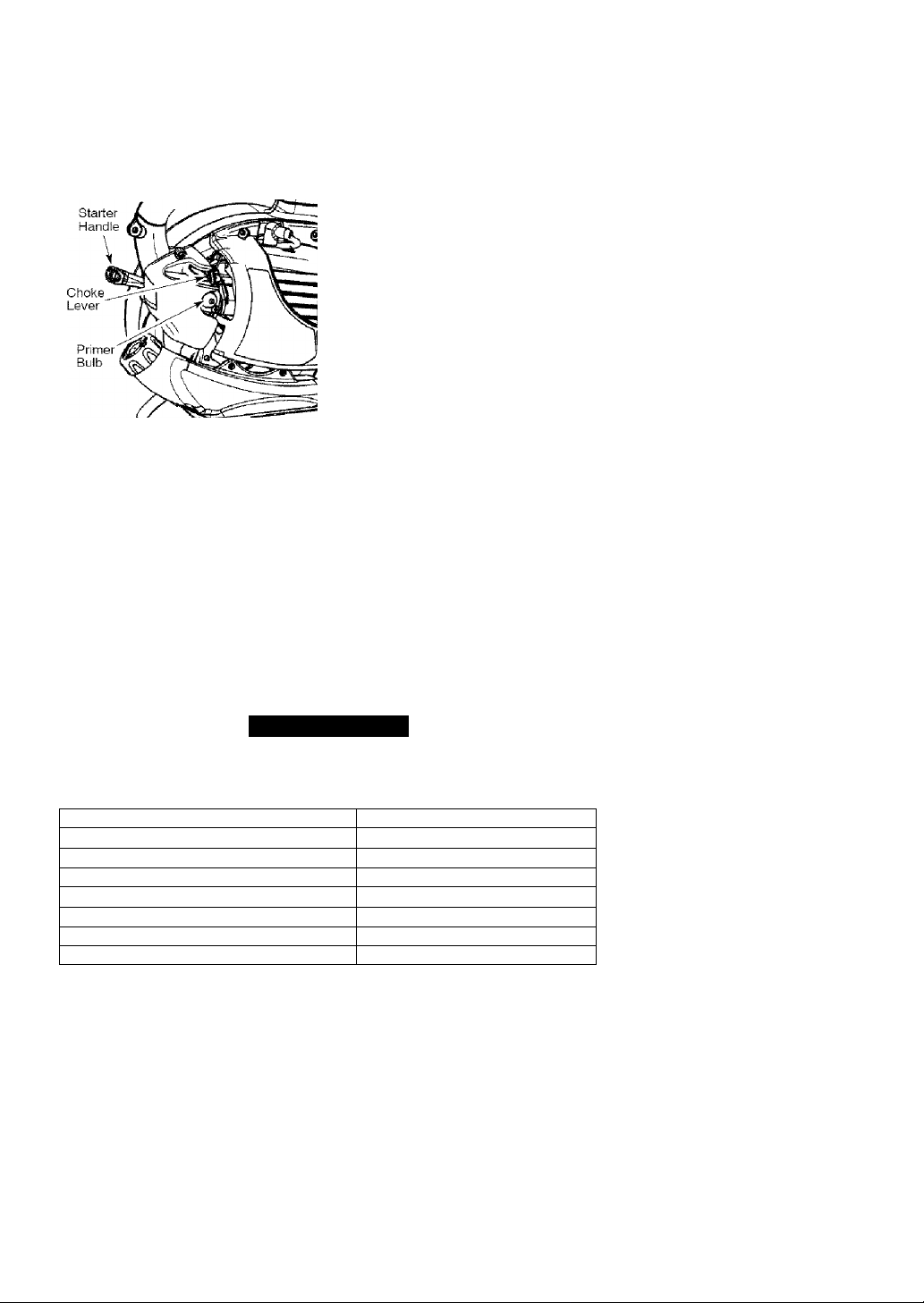

PRIMER BULB

The PRIMER BULB removes air from

the carburetor and fuel lines and fills

them with fuel. This allows you to start

OPERATING TIPS

• While vacuuming or blowing debris,

hold the unit with the muffler side fac

ing away from your body and clothes

{see OPERATING POSITION below).

• To reduce the risk of hearing loss

associated with sound levei(s), hear

ing protection is required.

• To reduce the risk of injury associated

with contacting rotating parts, stop the

engine before installing or removing

attachments. Do not operate without

guard(s) in place.

• Operate power equipment only at rea

sonable hours-not early in the morn

ing or late at night when people might

be disturbed. Comply with times listed

in local ordinances. Usual recommen

the engine with fewer pulls on the

starter rope. Activate primer bulb by

pressing it and allowing it to return to

its original position.

CHOKE LEVER

The CHOKE helps to supply fuel to the

engine to aid in cold starting. Activate

the choke by moving the choke lever to

the FULL CHOKE position. After engine

attempts to start, move the choke lever

to the HALF CHOKE position. Once en

gine starts, move choke lever to the

RUN position.

dations are 9:00 a.m. to 5:00 p.m.,

Monday though Saturday.

To reduce noise levels, limit the num

ber of pieces of equipment used at

any one time.

To reduce noise levels, operate pow

er blowers at the lowest possible

throttle speed to do the job.

Use rakes and brooms to loosen

debris before blowing.

In dusty conditions, slightly dampen

surfaces or use a mister attachment

when water is available.

Conserve water by using power blow

ers instead of hoses for many lawn

and garden applications, including

areas such as gutters, screens, patios,

grills, porches, and gardens.

Page 10

• Watch out for children, pets, open

windows, or freshly washed cars.

Blow debris away safely.

• Use the full blower nozzle extension

so the air stream can work close to

the ground.

• After using blowers and other equip

ment, CLEAN UP! Dispose of debris

in trash receptacles.

OPERATING POSITION

Blower

BEFORE STARTING ENGINE

A WARNING: Be sure to read the

fuel information in the safety rules

before you begin. If you do not

understand the safety rules, do not

attempt to fuel your unit. Call

1-800-235-5878.

FUELING ENGINE

A WARNING: Remove fuel cap

slowly when refueling.

This engine Is certified to operate on un

leaded gasoline. Before operation, gaso

line must be mixed with a good quality

synthetic 2-cycle air-cooled engine oil.

We recommend Craftsman brand syn

thetic oil. Mix gasoline and oil at a ratio

of 40:1. A 40:1 ratio is obtained by mix

ing 3.2 ounces of oil with 1 gallon of un

leaded gasoline. Included with this blow

er is a 3.2 ounce container of oil. Pour

the entire contents of this container into

1 gallon of gasoline to achieve the prop

er fuel mixture. DO NOT USE automotive

oil or boat oil. These oils will cause en

gine damage. When mixing fuel, follow

instructions printed on container. Once

oil is added to gasoline, shake container

momentarily to assure that the fuel is

thoroughly mixed. Always read and fol

low the safety rules relating to fuel be

fore fueling your unit.

IMPORTANT

Experience indicates that alcohol

blended fuels (called gasohol or using

ethano! or methanol) can attract mois

ture which leads to separation and

formation of acids during storage.

Acidic gas can damage the fuel sys

tem of an engine while in storage.

To avoid engine problems, empty the

fuel system before storage for 30 days

or longer. Drain the gas tank, start the

engine and let it run until the fuel lines

and carburetor are empty. Use fresh

fuel next season. Never use engine or

carburetor cleaner products in the fuel

tank or permanent damage may occur.

Fuel stabilizer is an acceptable alter

native in minimizing the formation of

fuel gum deposits during storage.

Craftsman brand oil is already blended

with fuel stabilizer. See the STORAGE

section for additional information.

HOW TO STOP YOUR ENGINE

• Release the throttle trigger.

• Push and hold the STOP switch in

the STOP position until the engine

stops.

HOW TO START YOUR ENGINE

A WARNING: You MUST make sure

the tubes are secure before using the

unit.

• Fuel engine. Move at least 10 feet (3

meters) away from the fueling site.

• Hold the unit in the starting position

as shown. Make sure the blower end

is directed away from people, ani

mals, glass, and solid objects.

a WARNING; When starting engine,

hold the unit as illustrated. Do not set

unit on any surface except a ciean, hard

area when starting engine or while en

gine is running. Debris such as gravel,

sand, dust, grass, etc. could be picked

- 10 ■

Page 11

up by the air intake and thrown out

through the discharge opening, damag

ing the unit or property, or causing seri

ous injury to bystanders or the operator.

STARTING A COLD ENGINE

1. Slowly press the primer buib 6 times,

2. Move choke lever to the FULL

CFIOKE position.

3. Squeeze the throttle trigger fully and

hold through all remaining steps.

This unit has the Sim-pul " starting

system. You do not have to pull the

starter rope handle sharply or briskly.

Pull starter rope handle with a con

trolled and steady motion until en

gine sounds as if it is trying to start,

but do not pull rope more than 6

times.

As soon as engine sounds as if it is

trying to start, move choke lever to

HALF CHOKE position.

Pull Starter rope until engine runs,

but no more than 6 pulls. NOTE: If

the engine doesn’t start after 6

pulls (at the HALF CHOKE position),

move the choke lever to the FULL

CHOKE position and press the

primer bulb 6 times. Squeeze and

hold the throttle trigger and pull the

starter rope 2 more times. Move

the choke lever to the HALF CHOKE

position and pull the starter rope

until the engine runs, but no more

than 6 pulls. If the engine still

doesn’t start, it is probably flooded.

Proceed to STARTING A FLOODED

ENGINE,

7. Once the engine starts, allow it to

run 10 seconds, then move the

choke lever to the RUN position. Al

low the unit to run for 30 more se

conds at RUN before releasing the

throttle trigger. NOTE: If engine dies

with the choke lever in the RUN

position, move the choke lever to

the HALF CHOKE position and pull

the rope until engine runs, but no

more than 6 pulls.

STARTING A WARM ENGINE

1. Move the choke lever to the HALF

CHOKE position.

2. Squeeze the throttle trigger fully and

hold through all remaining steps.

3. Pull starter rope with a controlled

and steady motion until engine

runs, but no more than 6 pulls.

4. Allow engine to run 15 seconds,

then move the choke lever to RUN.

NOTE: If engine has not started, pull

starter rope 5 more pulls. If engine still

does not run, it is probably flooded.

STARTING A FLOODED ENGINE

Flooded engines can be started by plac

ing the choke lever in the RUN position;

then, pull the rope to clear the engine of

excess fuel. This could require pulling

the starter handle many times depend

ing on how badly the unit is flooded. If

the unit still doesn’t start, refer to

TROUBLESHOOTING TABLE or call

1 -800-235-5878.

MAINTENANCE

CUSTOMER RESPONSIBILITIES

A WARNING: Disconnect the spark plug before performing maintenance,

service, or adjustments.

CARE & MAINTENANCE TASK WHEN TO PERFORM

Check for loose fasteners and parts Before each use

Check for damaged or worn parts Before each use

Inspect and clean unit and labels After each use

Clean air filter Every 5 hours of operation

Replace spark plug Yearly

Replace fuel filter Yearly

Check muffler mounting screws Yearly

- 11 -

Page 12

a WARNING: Avoid touching muf

fler unless engine and muffler are cold.

A hot muffler can cause serious burns.

^WARNING; Stop engine and be

sure the impeller blades have stopped

turning before opening the vacuum in

let door or attempting to insert or re

move the vacuum or blower tubes.

The rotating blades can cause serious

injury. Always disconnect the spark

plug before performing maintenance or

accessing movable parts.

GENERALRECOMMENDATIONS

The warranty on this unit does not cov

er items that have been subjected to

operator abuse or negligence. To re

ceive full value from the warranty, the

operator must maintain unit as instruct

ed in this manual. Various adjustments

will need to be made periodically to

properly maintain your unit.

CHECK FOR LOOSE FASTENERS AND PARTS

• Muffler

• Spark Plug Boot

• Air Filter

• Housing Screws

CHECK FOR DAMAGED OR

WORN PARTS

Contact Sears Service Center for re

placement of damaged or worn parts.

• Throttle Lever - Ensure throttle lever

functions properly by moving the

throttle lever to the

STOP position.

Make sure engine stops; then restart

engine and continue.

• Fuel Tank - Do not use unit if fuel tank

shows signs of damage or leaks.

• Vacuum Bag - Do not use vacuum

bag if it is torn or damaged.

INSPECT AND CLEAN UNIT

AND LABELS

• After each use, inspect complete unit

for loose or damaged parts. Clean

the unit using a damp cloth with a

mild detergent.

• Wipe off unit with a clean dry cloth.

CLEAN AIR FILTER

A dirty air filter decreases engine per

formance and increases fuel consump

tion and harmful emissions. Always

clean after every 5 hours of operation.

Cleaning the air filter;

1. Clean the cover and the area

around it to keep debris from falling

into the carburetor chamber when

the cover is removed.

NOTE: Move choke lever to RUN posi

tion before opening air filter cover.

2. Open air filter cover by pushing

button {see illustration). Remove

air filter.

NOTE: Do not clean filter in gasoline

or other flammable solvent. Doing so

can create a fire hazard or produce

harmful evaporative emissions.

3. Wash the filter in soap and water.

4. Allow filter to dry.

5. Apply a few drops of oi! to the filter;

squeeze filter to distribute oil.

6. Replace parts.

REPLACE SPARK PLUG

Replace spark plug each year to ensure

the engine starts easier and runs better.

Set spark plug gap at 0.025 inch. Igni

tion timing is fixed, nonadjustable.

1. Twist, then pull off spark plug boot.

2. Remove spark plug from cylinder

and discard.

3. Replace with Champion RCJ-6Y

spark plug and tighten securely

with a 3/4 inch socket wrench.

4. Reinstall the spark plug boot.

REPLACE FUEL FILTER

To replace fuel filter, drain unit by run

ning it dry of fuel, then remove fuel

cap/retainer assembly from tank. Pul!

filter from tank and remove it from the

fuel line. Install new fuel filter on fuel

line; reinstall parts.

- 12

Page 13

CHECK MUFFLER MOUNTING

SCREWS

Once each year, ensure muffler

mounting screws are secure and tight

ened properly to prevent damage.

INSPECT MUFFLER AND SPARK

ARRESTING SCREEN

^ WARNING: The muffler on this

product contains chemicals known to

the State of California to cause cancer.

As the unit is used, carbon deposits

build up on the muffler and spark ar

resting screen, and must be removed

to avoid creating a fire hazard or af

fecting engine performance.

NOTE: Do not attempt to clean the

spark arresting screen.

1. Remove 3 screws from muffler cov

er. Remove muffler cover.

2. Loosen and remove 4 screws from

the muffler hood.

3. Remove the muffler hood and spark

arresting screen.

4. Install new spark arresting screen.

5. Reinstall muffler hood and 4

screws. Tighten screws securely.

6. Reinstall muffler cover and 3

screws. Tighten securely.

NOTE: If any part of the muffler is

cracked, broken or damaged, we rec

ommend that the muffler be replaced.

CARBURETOR ADJUSTMENT

The carburetor has been carefully set

at the factory. Adjustments may be

necessary if you notice any of the fol

lowing conditions:

• Engine will not idle when the throttle is

released.

idle Speed Adjustment

Allow engine to idle. Adjust speed until

engine runs without stalling (idle speed

too slow).

• Turn idle speed screw clockwise to

increase engine speed if engine

stalls or dies.

• Turn idle speed screw counterclock

wise to decrease engine speed.

Spark

Arresting

.Screen

Screws

Replace the spark arresting screen ev

ery 50 hours of operation or if any

damage or breaks in the screen are

noted.

if you require further assistance or are

unsure about performing this proce

dure, contact your Sears Service Cen

ter or calí our customer assistance

help line at 1-800-235-5878.

- 13

Page 14

STORAGE

WARNING: Perform the following

steps after each use:

• Allow engine to cool, and secure the

unit before storing or transporting.

• Store unit and fuel in a well venti

lated area where fuel vapors cannot

reach sparks or open flames from

water heaters, electric motors or

switches, furnaces, etc.

• Store unit with all guards in place.

Position unit so that any sharp object

cannot accidentally cause injury.

• Store unit and fuel well out of the

reach of children.

SEASONAL STORAGE

Prepare unit for storage at end of sea

son or if it will not be used for 30 days

or more.

If your unit is to be stored for a period

of time:

• Clean the entire unit before lengthy

storage.

• Store in a clean dry area.

• Lightly oil external metal surfaces.

FUEL SYSTEM

Empty the fuel system before storage for

30 days or longer. Drain the gas tank,

start the engine and let it run until the

fuel lines and carburetor are empty. Use

fresh fuel next season. Under FUELING

ENGINE in the OPERATION section of this

manual, see message labeled

IMPORTANT regarding the use of gaso-

hol in your engine.

Fuel stabilizer is an acceptable alterna

tive in minimizing the formation of fuel

gum deposits during storage. Add stabi

lizer to gasoline in fuel tank or fuel stor

age container. Follow the mix instruc

tions found on stabilizer container. Run

engine at least 3 minutes after adding

stabilizer.

Craftsman 40:1,2-cycle engine oil {air

cooled) is already blended with fuel

stabilizer, if you do not use this Sears

oil, you can add a fuel stabilizer to your

fuel tank.

ENGINE

• Remove spark plug and pour 1 tea

spoon of 40:1, 2-cycle engine oil (air

cooled) through the spark plug open

ing. Slowly pull the starter rope 8 to

10 times to distribute oil.

• Replace spark plug with new one of

recommended type and heat range.

• Clean air filter.

• Check entire unit for loose screws,

nuts, and bolts. Replace any dam

aged, broken, or worn parts.

• At the beginning of the next season,

use only fresh fuel having the proper

gasoline to oil ratio.

OTHER

• Do not store gasoline from one sea

son to another.

• Replace your gasoline can if it starts

to rust.

- 14 ■

Page 15

TROUBLESHOOTING TABLE

A WARNING: Always stop unit and disconnect spark plug before perform

ing any of the recommended remedies below other than remedies that re

quire operation of the unit.

TROUBLE CAUSE REMEDY

Engine will not

start.

Engine will not

idle properly.

Engine will not

accelerate,

lacks power, or

dies under a

load.

Engine smokes

excessively.

Engine runs hot.

1, Engine flooded.

2, Fuel tank empty.

3, Spark plug not firing.

4, Fuel not reaching

carburetor.

5, Compression low.

1. Fuel not reaching

carburetor.

2. Carburetor requires

adjustment.

3. Crankshaft seals worn.

4. Compression low.

1. Air filter dirty.

2. Fuel not reaching

carburetor,

3. Spark plug fouled.

4. Carburetor requires

adjustment.

5. Carbon build up.

6. Compression tow.

1. Choke partially on.

2. Fuel mixture incorrect.

3. Air filter dirty.

4. Carburetor requires

adjustment.

1. Fuel mixture incorrect.

2. Spark plug incorrect.

3. Carburetor requires

adjustment.

4. Carbon build up.

1. See “Starting a Flooded Engine”

in Operation section.

2. Fill tank with correct fuel mixture.

3. Install new spark plug.

4. Check for dirty fuel filter; replace.

Check for kinked or spilt fuel line;

repair or replace.

5. Contact Sears Service (see back cover).

1. Check for dirty fuel filter; replace.

Check for kinked or spilt fuel line;

repair or replace.

2. Contact Sears Service (see back cover).

3. Contact Sears Service (see back cover).

4. Contact Sears Service (see back cover).

1. Clean or replace air filter.

2. Check for dirty fuel filter; replace.

Check for kinked or split fuel line;

repair or replace.

3. Clean or replace spark plug

and re-gap.

4. Contact Sears Service (see back cover),

5. Contact Sears Service (see back cover).

6. Contact Sears Service (see back cover).

1. Adjust choke.

2. Empty fuel tank and refill with

correct fuel mixture.

3. Clean or replace air filter.

4. Contact Sears Service (see back cover).

1. See “Fueling Engine” in Operation

section.

2. Replace with correct spark plug.

3. Contact Sears Service (see back cover) .

4. Contact Sears Service (see back cover).

- 15 ■

Page 16

U.S. EPA/CALIFORNIA

EMISSION CONTROL WARRANTY STATEMENT

YOUR WARRANTY RIGHTS AND OB

LIGATIONS: The U.S. Environmentaf

Protection Agency/California Air Re

sources Board and Sears, Roebuck and

Co., U.S.A., are pleased to explain the

emissions control system warranty on

your year 2007 and later small off-road

engine. In California, all small off-road

engines must be designed, built, and

equipped to meet the State’s stringent

anti-smog standards. Sears must war

rant the emission control system on your

small off-road engine for the periods of

time listed below provided there has

been no abuse, neglect, or improper

maintenance of your small off-road en

gine. Your emission control system in

cludes parts such as the carburetor, the

ignition system and the fuel tank (Califor

nia only). Where a warrantable condition

exists. Sears will repair your small off

road engine engine at no cost to you.

Expenses covered under warranty in

clude diagnosis, parts and labor.

MANUFACTURER'S WARRANTY

COVERAGE: If any emissions related

part on your engine (as listed under

Emissions Control Warranty Parts List) is

defective or a defect in the materials or

workmanship of the engine causes the

failure of such an emission related part,

the part will be repaired or replaced by

Sears.

OWNER’S WARRANTY RESPONSIBI

LITIES: As the small off-road engine

engine owner, you are responsible for

the performance of the required mainte

nance listed in your instruction manual.

Sears recommends that you retain all

receipts covering maintenance on your

small off-road engine, but Sears cannot

deny warranty solely for the lack of re

ceipts or for your failure to ensure the

performance of all scheduled mainte

nance. As the small off-road engine en

gine owner, you should be aware that

Sears may deny you warranty coverage

if your small off-road engine engine or a

part of it has failed due to abuse, ne

glect, improper maintenance, unap

proved modifications, or the use of parts

not made or approved by the original

equipment manufacturer. You are re

sponsible for presenting your small off

road engine to a Sears authorized repair

center as soon as a problem exists.

- 16 ■

Warranty repairs should be completed in

a reasonable amount of time, not to ex

ceed 30 days. If you have any ques

tions regarding your warranty rights and

responsibilities, you should contact your

nearest authorized service center or call

Sears at 1-800-469-4663. WARRANTY

COMMENCEMENT DATE: The warran

ty period begins on the date the small

off-road engine is purchased. LENGTH

OF COVERAGE: This warranty shall be

for a period of two years from the initial

date of purchase. WHAT !S COV

ERED: REPAIR OR REPLACEMENT

OF PARTS. Repair or replacement of

any warranted part will be performed at

no charge to the owner at an approved

Sears Service Center. If you have any

questions regarding your warranty rights

and responsibilities, you should contact

your nearest authorized service center

or call Sears at 1-800-469-4663. WAR

RANTY PERIOD: Any warranted part

which is not scheduled for replacement

as required maintenance, or which is

scheduled only for regular inspection to

the effect of “repair or replace as neces

sary” shall be warranted for 2 years. Any

warranted part which is scheduled for

replacement as required maintenance

shall be warranted for the period of time

up to the first scheduled replacement

point for that part. DIAGNOSIS: The

owner shall not be charged for diagnos

tic labor which leads to the determina

tion that a warranted part is defective if

the diagnostic work is performed at an

approved Sears Service Center. CON

SEQUENTIAL DAMAGES: Sears may

be liable for damages to other engine

components caused by the failure of a

warranted part still under warranty.

WHAT IS NOT COVERED: All failures

caused by abuse, neglect, or improper

maintenance are not covered. ADD-ON

OR MODIFIED PARTS: The use of

add-on or modified parts can be

grounds for disallowing a warranty claim.

Sears is not liable to cover failures of

warranted parts caused by the use of

add-on or modified parts. HOW TO

FILE A CLAIM: If you have any ques

tions regarding your warranty rights and

responsibilities, you should contact your

nearest authorized service center or call

Sears at 1-800-469-4663.

Page 17

WHERE TO GET WARRANTY SER

VICE: Warranty services or repairs shall

be provided at all Sears Service Cen

ters. Call 1-800-469-4663.

MAINTENANCE, REPLACEMENT

AND REPAIR OF EMISSION RE

LATED PARTS: Any Sears approved

replacement part used in the perfor

mance of any warranty maintenance or

EMISSION CONTROL WARRANTY

PARTS LIST: Carburetor, Ignition Sys

tem: Spark Plug (covered up to mainte

nance schedule), Ignition Module, Muf

fler including Catalyst, Fuel Tank (Cali

fornia only). MAINTENANCE STATE

MENT: The owner is responsible for the

performance of all required maintenance

as defined in the instruction manual.

repair on emission related parts will be

provided without charge to the owner if

the part is under warranty.

The information on the product label indicates which standard your engine is certified.

Example: (Year) ERA Phase 1 or Phase 2 and/or CALIFORNIA.

___________

WPORTART EMISSION INFORMATION

THIS ENGINE CONFORMS TO EXH, AND EVAP.

EMISSIONS REGULATIONS FOR SMALL OFF

FAMILVfflSP.

SERIAL#

MODEL#

ROAD ENGINES

Fi!l!lliTHE AIR INDEX OF THIS ENGINE IS 3

This engine is certified to be emissions compliant for the following use:

63 Moderate (50 hours)

I I Intermediate (125 hours)

□ Extended (300 hours)

- 17 ■

Page 18

REPAIR PARTS

SEARS GAS BLOWER MODEL 358.794740

A WARNING

All repairs, adjustments and

maintenance not described in

the Operator’s Manual must be

performed by Qualified Service

Personnel.

Ref. Part No. Description Ref. Part No.

1. 530015814 Screw

2. 545135806 Assy - Engine Cover

3, 530015880 Screw

4, 545134001 Shield - Baffle

5. 545099101 Baffle

6. 545052401 Hub

7. 545052501 Spring - Pulley

8. 545050407 Kit -Starter Pulley (IncI, 6,7)

9. 545054901 Spring - Starter

10, 530054834 Handle - Starter

11, 545081833 Kit - Rope

12, 545107101 Tube - Starter rope

13, 545081830 Kit - Switch (inci. 14)

14, 545128201 Protector - Switch

15, 545116201 Nut - Lock

16, 545113804 Trigger - Throttle

17, 545134105 Assy - Scroll LH {Inci, 19,20)

18, 530015814

19, 545100801 Door - Vac

20, 545115601 Spring - Vac door

21, 545144501 Knob - Blower tube

22, 530016406 Screw - Handle vac

23, 545109901 Washer - Impeller

24, 545113601 Assy - impeller

25, 545113701 spacer - Flywheel

26, 530015197 Nut - Blower Knob

27, 530016386 Screw

28, 545161605 Assy - Scroll RH

29, 545101201 Handle - Vac

30, 545100401 Assy - Fuel tank

(Inci. 31,32,33,34)

31. 530095646

32. 530069247

33. 530069216

34. 530057973

35. 530016445

545146930

545136304

Not

Description

Assy ■ Fuel Pickup

Kit ■ Fuel line (carb/purge)

Kit ■ Fuel line (tank/purgej

Assy - Fue! Cap with retainer

Screw - Fuel tank retainer

Operator Manual

Decal - Warning

Decal - Start instruction

Page 19

REPAIR PARTS

SEARS GAS BLOWER MODEL 358.794740

WARNING

All repairs, adjustments and

maintenance not described in

the Operator’s Manual must be

performed by Qualified Service

Personnel.

Ref. Part No. Description

1. 545090001 Assy - Muffler (Inol. 2,3,4,5)

2, 530015241 Screw

3, 545081845 Kit - Spark Screen (Incl. 2)

4, 530058982 Bolt - Muffler

5, 545081832 Gasket - Muffler (gasket kit)

6, 545115301 Cylinder

7, 530015953 Bolt

8, 952030249 Accy - Spark plug (RCJ-6Y)

9, 545084901 Adapter - Garb.

10. 545115501 Linkage - Throttle

11. 545081855 Kit - Garb. Assy (WT-875)

12. 545157103 Lever - Choke

13. 545112603 Base - Airbox

14. 530016429 Screw

15. 545116801 Filter

16. 545112702 Cover - Air box filter

17. 530035497 Bulb - Purge (Walbro 188-16)

18. 545081832 O-ring (Carb/Adapter) (gasket kit)

19. 530016441 Screw

20. 545081832 0-Ring (Adapter/Cyl.){gasket kit)

21. 545081864 Kit - Piston/Connecting Rod

22. 530012472 Ring - Piston

23. 530015162 Retainer - Wrist Pin

24. 545081865 Kit - Assy Connecting Rod

25. 545158001 Module - Ignition

26. 530016357 Screw

27. 545127601 Assy - Wire Harness

28. 545081832 O-ring sea! - Crankcase {kit)

29. 530015828 Washer

30. 530054115 Assy - Flywheel

31. 530015941 Retainer -Crankshaft

32. 530055728 Bearing - Outer

33. 530019264 Seal

(Incl. 13,18)

(Inol. 22,23,24)

Ref. Part No. Description

34, 530032125 Bearing - Inner

35, 530012582 Assy - Crankcase

36, 545102102 Assy - Crankcase/Crankshaft

37, 545081832 O - Ring (Rear p!ug)(gasket kit)

38, 530057954 Assy - Rear Plug (incl. 37)

39, 530016386 Screw

40, 545081832 Kit - Gasket (Inol. 5,18,20,28,37)

19

(Inci. 32,33,34)

(Inc!. 31,35)

Page 20

a

REPAIR PARTS

SEARS GAS BLOWER MODEL 358.794740

Ref. Part No. Description

1. 545099401 Tube - Upper vac

2. 530095589 Tube - Lower vac

3. 545116601 Tube - J

4. 530095564 Assy - Vao bag

5. 545100501 Tube - Upper Blower

6, 545100601 Tube - Lower Blower

7, 545151201 Nozzle - High Speed

20

Page 21

TABLA DE CONTENIDO

Declaración de Garantía 21 Mantenimiento 31

Identificación de los Símbolos

de Seguridad 21

Reglas de Seguridad 22

Montaje 25

Almacenaje 34

Tabla Diagnóstica 35

Declaración de Emisión 36

Lista de Piezas 18

Uso 28 Repuestos y Encargos Contratapa

DECLARACION DE GARANTIA

DOS ANOS COMPLETO DE GARANTIA PARA CORTADORA DE LINEA A GASOLINA WEEDWACKER® DE CRAFTSMAN®

Si este producto falla por un defecto en el material o de mano de obra dentro dos

años a partir de la fecha de compra y este se ha utilizado y mantenido de acuerdo

al manual de! usuario, envíelo a cualquier tienda Sears, Centro de Servicios Sears

u otra tienda Craftsman en los Estados Unidos para su reparación gratuita {o reem

plazo si no es posible repararlo).

Esta garantía excluye la bujía y el filtro de aire, que son partes desechadles y pue

den desgastarse al usarlas normalmente en menos de dos años.

Esta garantía es aplicable por sólo 30 días desde la fecha de compra si este produc

to se usa con fines comerciales o se usa para arriendo.

Esta garantía le otorga derechos legales específicos, y usted también puede tener

otros derechos que varían de estado a estado.

Sears, Roebuck and Co., Hoffman Estafes, IL 60179

IDENTIFICACION DE LOS SIMBOLOS DE SEGURIDAD

AaDVERTENCIA: ¡Este aparato puede ser peligrosa! El

uso descuidado o indebido de esta herramienta puede causar

graves heridas.

Lea el manual del usuario cuidadosamente hasta que comprenda

perfectamente todas las advertencias e instrucciones de seguri

dad y las pueda cumplir, antes de poner el aparato en

funcionamiento. De no cumplir con todas las advertencias e

instrucciones de seguridad, correrá el riesgo de accidentes muy

graves. Guarde el manual de usuario.

El aparato arroja objetos violenta

mente. Los objetos arrojados

pueden cegarlo o herirlo a usted y

a terceros. Use protección de

oídos y anteojos de seguridad mar

car con Z87. Use siempre panta

lones pesados y largos, mangas

largas, botas y guantes.

Zona de peligro por objetos arrojados al aire.

Mantenga a niños, espectadores y animales a

una distancia mínima de 10 metros (30 pies) al

poner en marcha o al usar el aparato. No

señale la boquilla en la dirección de la personas

o de animales domésticos.

- 21

Page 22

IDENTIFICACION DE LOS SIMBOLOS DE SEGURIDAD

Asegúrese de tener el cabello re

cogido por encima de los hombros.

No use joyería, ropa suelta ni ropa

con corbatas, tiras, borlas, etc. que

cuelgan libremente. Pueden enre

darse en las piezas en movimiento.

Siempre apague el aparato y desconecte la

bujía antes de dar mantenimiento.

AaDVERTENCIA: Detenga el motor antes de abrir la compuerta de entrada

de aire del aspirador. El motor deberá encontrarse detenido y las cuchillas de la

impulsor no deberán estar girando para evitar serios accidentes provocados por

las cuchillas girantes. Suavemente, gire el mango del destornillador hacia la

parte trasera del aparato para abrir la cerradura, mientras jala hacia arriba de la

cubierta de la entrada de aire del aspirador con su otra mano.

Cuando esté usando el accesorio de la aspirador, el aparato

está diseñado para recoger material seco como son hojas,

hierba, ramas pequeñas y pedazos pequeños de papel. No

aspire piedras, gravilla, metal, vidrio roto, etc., para evitar

daños severos al impulsor.

AaDVERTENCIA: Riesgo de incendios. Nunca mezcle,

vierta, o almacene el combustible o utilice el aparato cerca de

llamas o fuentes de chispas (inclusive los cigarrillos, las llamas

abiertas, y cualquier trabajo que cause chispas).

REGLAS DE SEGURIDAD

ém ADVERTENCIA: De no cumplir

con todas las Reglas y Precauciones

de Seguridad, correrá el riesgo de ac

cidentes muy graves.

CONOZCA SU APARATO

• Lea el manual del usuario cuidado

samente hasta que comprenda per

fectamente todas las advertencias e

instrucciones de seguridad y las

pueda cumplir, antes de poner el

aparato en funcionamiento.

• Limite el uso del aparato a aquellas

personas que comprendan todas las

advertencias e instrucciones de se

guridad en este manual y vayan a

cumplir con ellas.

A ADVERTENCIA: Inspeccione el

área antes de poner en matodos los es

combros y objetos sólidos tales como

piedras, vidrio, alambre, etc., que el apa

rato pueda arrojar al aire o hacer rebotar

causando heridas de este o cualquier

otro modo durante el uso del mismo.

Utilice su aparato como soplador de

aire para;

• Barrer escombros o recortes de

hierba de caminos de entrada,

aceras, patios, etc.

- 22

Page 23

• Soplar recortes de hierba, para u

hojas en montones, o para remover

escombros de esquinas, alrededor

de uniones o entre ladrillos.

Utilice su aparato como aspiradora para:

• Recoger material seco como hojas,

hierba, ramas pequeñas y pedazos

pequeños de papel.

• Para obtener mejores resultados al

usar la aspiradora, ponga el motor a

alta velocidad.

• Muévase lentamente de un lado a

otro sobre el material que de sea

aspirar. Evite el forzar el aparato a

recoger montones de desechos

pues esto podría obstruir el aparato.

• Para obtener mejores resultados,

mantenga el tubo de aspiración unos

3 cm (uno pulgada) más arriba del

suelo.

PIENSE ANTES DE PROCEDER

• Use siempre protección para los ojos

al hacer uso, servicio o mantenimi

ento del aparato. El uso de proteción

de ojos ayudará a prevenir la pérdi

da de la vista y/u otras heridas

graves, provocadas por piedras o

escombros que reboten en los ojos y

en la cara al ser propulsados por el

aparato. La protección para los ojos

debe ser marcada Z87.

• Use siempre protección en los pies.

No use el aparato descalzo ni con

sandalias.

• Use siempre mascarilla de filtración

o de protección para la cara al traba

jar en ambientes polvorientos.

• Mantenga el cabello por encima de

los hombros, atándolo para tal efecto

si es necesario. No use joyas, ropa

suelta, ni ropa con tiras, corbatas, bor

las, etc. que cuelgen libremente, por

que podrían quedar enredadas en las

piezas en movimiento del aparato.

• No use el aparato estando cansado,

enfermo, ansioso, ni bajo la infuencia del alcohol, las drogas u otros

medicamentos.

• Mantenga a niños, espectadores y

animales a una distancia mínima de

10 metros (30 pies) al poner en mar

cha o al usar el aparato. No señale

la boquilla en la dirección de la per

sonas o de animales domésticos.

MANEJE EL COMBUSTIBLE CON

EXTREMO CUIDADO, ES ALTA

MENTE INFLAMABLE

• Elimine todas las posibles fuentes de

chispan o llamas (inclusive los cigar

rillos, las llamas abertas, y cualquier

trabajo que cause chispas) en las

áreas donde se mezcla, vierte o al

macena el combustible.

• Mezcle y vierta el combustible al aire

iibre, almacene el combustible en un

lugar fresco, seco y bien ventilado;

sue un recipiente aprobado para

combustible y marcado para todo

manejo de combustible.

• No fume mientras trabaja con el

combustible ni cuando esté hacien

do uso del aparato.

• Asegúrese que el aparato esté cor

rectamente armado y en buena con

dición de funcionamiento.

• No llene el tanque de combustible

mientras el motor se encuentre en

marcha.

• Evite derramar el combustible o el

aceite. Limpie todos los derrames de

combustible antes de poner el apa

rato en marcha.

• Aléjese por lo menos 3 metros (10

pies) del combustible y del lugar de

abastecimineto antes de poner el

motor en marcha.

• Almacéne siempre combustible en

un recipiente aprobado para los líqui

dos inflamables.

HAGA USO SEGURO DE SU

APARATO

Á ADVERTENCIA: Detenga el

motor antes de abrir la compuerta de

entrada de aire del aspirador. El motor

deberá encontrarse detenido y las cu

chillas del impulsor no deberán estar

girando para evitar serios accidentes

provocados por las cuchillas girantes.

• Verifique por inspección, antes de

cada uso, que no haya piezas gasta

das, sueltas, ni dañadas o piezas

que falten. No use el aparato hasta

que este se encuentre en perfectas

condiciones de funcionamiento.

• Mantenga las superficies externas

libres de aceite y de combustible.

• Nunca ponga el motor en marcha ni

lo deje en marcha dentro de un recintocerrado o en una área sin venti

lación. Respirar los vapores del com

bustible le podría causar ia muerte.

• Para evitar el choque por electrici

dad estática, no use guantes de

goma ni ningún otro guante aislado

al usar el aparato.

• No apoye el aparato con el motor en

marcha en ninguna superficie que no

esté limpia o que no sea sólida. El

aparato podría aspirar escombros

tales como gavilla, arena, polvo,

césped, etc, por la entrada de aspira

ción y arrojarlos por la salida de aire,

- 23

Page 24

dañando gI aparato y/u otros objetos,

o causando graves heridas a especta

dores o al usuario.

Evite ambientes peligrosos. No use

el aparato en lugares sin ventilación

ni donde puda haber vapores explo

sivos o monóxido de carbono.

No se extienda excesivamente ni use

el aparato en superficies inestables

tales como escaleras, árboles, de

clives acentuadas, techos, etc. Man

tenga el equilibrio, con ios pies en una

superficie estable en todo momento.

Nunca coloque objetos dentro de los

tubos del soplador; siempre dirija los

escombros en dirección contraria a

donde personas, animales, vidrierasu otros objetos sólidos tales como

árboles, automóviles, paredes, etc.

se encuentran. La fuerza del aire

puede arrojar o hacer rebotar pie

dras, tierra o ramas, hiriendo a per

sonas o animales, rompiendo vidrier

as o causando otros daños.

Nunca ponga el aparato en marcha

sin toner todo el equipo correspon

diente instalado. Al usar el aparato

como soplador, siempre instale los tu

bos del soplador. Al usar el equipo op

cional de aspirador, siempre instale los

tubos y la bolsa del aspirador.

Asegúrese que la cremallera de la bol

sa del aspirador se encuentre comple

tamente cerrada.

Inspeccione frecuentemente la aber

tura de entrada de aire, los tubos de

soplador, los tubos del aspirador y el

tubo en forma de codo siempre con

el motor detenido y la bujía desco

nectada. Mantenga las aberturas de

ventilación y los tubos de descarga

libres de escombros que se pueden

acumular y limitar la circulación debi

da de aire.

Nunca coloque objeto alguno dentro

de la entrada de aire ya que de hacer

lo podría limitar la circulación d’aire y

dañar el aparato.

Nunca use el aparato para esparcir

substancias químicas, fertilizantes u

otras substancias que puedan con

tener materiales tóxicos.

Para evitar la propagación de incen

dios, no use el aparato cerca de ho

gueras de hogassGcas o de mator

rales, de hogares de leña, de parril

las, barbacoas, ceniceros, etc.

Use e! aparato exclusivamente para

los fines descritos en este manual.

- 24 ■

HAGA EL MANTENIMIENTO DEL

APARATO EN LA FORMA DEBIDA

A ADVERTENCIA: Desconecte la

bujía antes de hacer cualquier man

tenimiento, con la excepción de los

ajustes ai carburador.

• Permita que todo mantenimiento

aparte de los procedimientos recom

endados descritos en este manual

del usuario, sean efectuados por un

Centro de Servicio Sears.

• Use exclusivamente los repuestos

recomendados de la marca

Craftsman; el uso de cualquier otro

repuesto podrá invalidar la garantía

o dañar el aparato.

• Vacía el tanque de combustible

antes de almacenar el aparato. Con

suma el combustible restante en el

carburador poniendo el motor en

marcha y dejándolo en marhca has

ta que se éste se detenga.

• No use ningún accesorio ni pieza adi

cional aparte de los recomendados

por el fabricante para usar con su

aparato.

• No almacene ei aparato ni el combus

tible en un recinto cerrado donde los

vapores el combustible puedan entrar

en contacto con chispas o llamas

abiertas procedentes de calentadores

de agua, motores o interruptores eléc

tricos, calefactores centrales, etc.

• Almacene el aparato en un lugar

seco, fuera del alcance de los niños.

AVISO DE SEGURIDAD: El estar ex

puesto a las vibraciones a través de!

uso prolongado de herramientas de

fuerza a gasolina, puede causar daños

a los vasos sanguíneos o a los nervios

de los dedos, las manos y las coyuntu

ras a aquellas persona! propensas a los

trastornos de la circulación o a las hin

chazones anormales. El uso prolongado

en climas fríos ha sido asociado con

daños a los vasos sanguíneos a perso

nas que por otra parte se encuentran en

perfecto estado de salud. Si ocurriera

síntomas tales como el entumecimiento,

el color, la falta de sentido en ios dedos,

las manos o en las coyunturas, pare de

usar esta máquina de inmediato y pro

cure atención médica. Los sistemas de

anti-vibración no garantizan que se evi

tan tales problemas. Los usuarios que

hacen uso continuo y prolongado de las

herramientas de fuerza deben fiscalizar

atnetamente su estado físico y el estado

del aparato.

Page 25

AVISO ESPECIAL: Su aparato viene

equipada con silenciador limitador de

temperatura y con rejilla aníichispa

que cumpla los requisitos de los Códi

gos de California 4442 y 4443. Todas

las tierras forestadas federales, más

los estados de California, Idaho,

Maine, Minnesota, Nueva Jersey,

Washington y Oregón, requieren por

ley que muchos motores de combus

tión interna estén equipados con rejilla

MONTAJE

antichispa. Si usted el aparato en un

estado y otra localidad donde existen

tales reglamentos, usted tiene la re

sponsabilidad jurídica de mantener es

tas piezas en correcto estado de fun

cionamiento. De lo contrario, estará en

infracción de la ley. Vea la sección

MANTENIMIENTO para informarse

acerca del mantenimiento de la rejilla

antichispa.

CONTENIDO DE LA CAJA

Verifique que todos los artículos de la

siguiente lista estén incluidos:

Modelo 358.794740

• Soplador

• Tubo Superior del Soplador

• Tubo Inferior del Soplador

• Boquilla de Alta Velocidad

• Tubo en Forma de Codo

• Bolsa del Aspirador

• Tubo Superior del Aspirador

• Tubo Inferior del Aspirador

• Aceite de Motor a 2 Tiempos

AVISO; Es normal que el filtro de com

bustible golpetee en el tanque vacío.

MONTAJE

Á ADVERTENCIA: Detenga el

motor y asegúrese de que las cuchil

las del impulsor no se encuentren gi

rando antes de abrir la compuerta de

entrada de aire del aspirador o de in

tentar introducir o remover los tubos

de aspiración o los tubos del soplador.

Las cuchillas girantes podrían causar

serios accidentes.

A ADVERTENCIA: Si recibió ei

aparato ya armado, repita todos los

pasos para asegurarse que el aparato

haya sido armado correctamente y

que todos los fíjafores se encuentren

bien fijos.

• Un destornillador se requiere para

el montaje.

MONTAJE DEL SOPLADOR DE

AIRE

MONTAJE DE LOS TUBOS DEL SOPLADOR

1. Alinee las ranuras en el tubo inferi

or del soplador con las lengüetas

en el tubo superior del soplador.

Tubo Superior del

. Soplador

"V Soplador

Lengüeta

Ranura

2. Empuje el tubo inferior del soplador

sobre e! tubo superior del soplador.

3. Gire el tubo inferior de! soplador a

la derecha hasta encajar en su lu

gar para asegurar el tubo inferior

del soplador al tubo superior del

soplador.

AVISO: Cuando el tubo superior del

soplador y el tubo inferior del soplador

están montados juntos correctamente,

las flechas en ambos tubos serán

alineadas.

4. Alinee la moldura saliente del tubo

superior del soplador con la ranura

en la salida de aire de la soplador;

gire hasta encajar en su lugar.

AVISO: La perilla debe ser aflojada lo

suficiente que permita al tubo se intro

duzca en la salida de aire del soplador.

Gire la perilla hacia la izquierda para

aflojar.

5. Asegúrese de apretar el tubo

girando la perilla hacia la derecha.

- 25 ■

Page 26

6. Para removar los tubos, gire la

perilla hacia la izquierda para

aflojar e! tubos del soplador;

remueva el tubos,

MONTAJE DE LA BOQUILLA DE

ALTA VELOCIDAD

Cuando se requiera una velocidad de!

aire más alta, utilice la boquilla de alta

velocidad.

1. Alinee las ranuras en la boquilla

con las lengüetas en el tubo inferior

de! soplador.

f ^Boquilla de

Tubo inferior de!

soplador

Alta Velocidad

Lengüeta

2. Empuje la boquilla sobre el tubo in

ferior del soplador.

3. Gire la boquilla a la derecha hasta

encajar en su lugar para asegurar

la boquilla al tubo inferior del sopla

dor.

MONTAJE DEL ASPIRADOR

MONTAJE DE LA BOLSA DEL

ASPIRADOR

1. Abra la cremallera en la bolsa del

aspirador e introduzca el tubo en

forma de codo.

2. Empuje la punta pequeña el tubo

en forma de codo por abertura pe

queña el la bolsa del aspirador.

Moldura

Ranura

5. Introduzca el tubo en forma de

codo en la salida de aire del

soplador. Asegúrese de que la

moldura del tubo en forma de codo

esté alineada con la ranura de

salida de aire del soplador.

6. Gire la perilla hacia la derecha para

apretar el tubo en forma de codo.

MONTAJE DE LOS TUBOS DE ASPIRADOR

Á ADVERTENCIA: Detenga e!

motor y asegúrese de que las cuchil

las del impulsor no se encuentren gi

rando antes de abrir la compuerta de

entrada de aire del aspirador o de in

tentar introducir o remover los tubos

de aspirador o los tubos del soplador.

Las cuchillas girantes podrían causar

serios accidentes,

1. Introduzca un destornillador dentro

del área del cerradura de la

entrada de aire del aspirador.

AVISO; Asegúrese de que el borde de

pequeña

la abertura pequeña de la bolsa de en

cuentre pegado a la parte en forma de

embudo del tubo en forma de codo, y la

moldura saliente del tobo en forma de

codo se encuentre al fondo.

3. Cierre la cremallera de la bolsa.

Asegúrese de que la cremallera se

encuentre completamente cerrada.

4. Retire el tubos de aspirador del

motor.

- 26 ■

Cubierta de

entrada de aire

Suavemente, gire el mango del

destornillador hacia la parte

delantera del aparato para abrir la

cerradura, mientras jala hacia arriba

de la cubierta de la entrada de aire

del aspirador con su otra mano.

Sostenga la cubierta de entrada de

3.

aire del aspirador abierta hasta que

el tubo del aspirador quede

instalado.

Page 27

Entrada de Aire del Aspirador

Alinee las lengüetas en el interior

de la entrada de aire del aspirador

con fas ranuras en el tubo superior

del aspirador.

5. Empuje el tubo superior del

aspirador en la entrada de aire del

aspirador. Gire el tubo a la izquierda

hasta encajar en su lugar para

asegurar los tubos a el aparato del

soplador.

COMO CONVERTIR EL APARATO

DE USO DE ASPIRADOR A USO DE

SOPLADOR

1. Remueva el tubo en forma de codo

y la bolsa del aspirador girando la

perilla a la izquierda para aflojar el

tubo en forma de codo.

2. Remueva los tubos del aspirador

girando ios tubos a la derecha.

3. Cierre la cubierta de entrada de

aire del aspirador y asegúrese que

este cerrada completamente.

4. Vuelva a instalar los tubos de

soplador (vea MONTAJE DE LOS

TUBOS DE SOPLADOR).

AJUSTE DE LA BANDA DEL

HOMBRO PARA LA BOLSA DEL

ASPIRADOR

1. Sujete el aparato como se ilustra

con el lado del silenciador alejado

de su cuerpo y de su ropa.

2. Pasando la banda del hombro

sobre su cabeza, colóquela en su

hombro derecho.

3. Extienda el brazo izquierdo hacia la

perte posterior de la bolsa del aspi

rador.

4. Ajuste la correa de hombro hasta

que la costura entre la bolsa del

aspirador y la correa quede entre el

pulgar y el índice.

5. Asegúrese de que el aire circule li

bremente desde el tubo en forma de

codo hasta la bolsa. Si la bolsa se

encuentra torcide, el aparato no fun

cionará apropiadamente.

Alinee la parte final inclinada del tubo

inferior del aspirador como se

muestra. Presione firmemente el

tubo inferior del aspirador dentro del

tubo superior del aspirador.

Parte final inclinada de!

tubo inferior del aspirador

- 27 ■

Page 28

MONTAJE DE LA BANDA DEL HOM

BRO (accesorio opcional #71 -85783)

1. Pasando la banda del hombro

sobre su cabeza, colóquela en su

hombro izquierdo.

2. Cierre el gancho en el retenedor

(vea la ilustración siguiente).

CONOZCA SU SOPLADOR

LEA EL MANUAL DEL USUARIO Y SUS REGLAS DE SEGURIDAD ANTES DE COMEN

ZAR A USAR ESTE APARATO. Compare las ilustraciones siguientes con su aparato

para familiarizarse con la localización de los controles y ajustes del mismo.

Guarde este manual para futuras referencias.

INTERRUPTOR STOP

Se usa el interruptor STOP para detener

el motor. Para detener el motor, empuje

y sostenga el interruptor en la posición

STOP hasta que el motor se haya dete

nido por completo.

GATILLO ACELERADOR

El GATILLO ACELERADOR regula la

velocidad del motor.

BOMBEADOR

El BOMBEADOR es usado para remover

aire de el carburador y de las líneas de

combustible y las llena de mezcla de

combustible. Esto le permite poner el

motor en marcha con menos tirones de

- 28 ■

la cuerda de arranque. Active el boton

del bombeador apretándolo y huego

dejando que retome su forma original.

PALANCA DEL CEBADOR

El CEBADOR ayuda a suiministrar com

bustible al motor para facilitar el arran

que cuando el motor está frió. Acione el

cebador colocando la palanca en la po

sición FULL CHOKE. Después que el mo

tor intente arrancar, mueva la palanca

del cebador a la posición HALE CHOKE.

Después que el motor se haya puesto

en marcha, ponga la palanca del ceba

dor en la posición RUN.

Page 29

SUGERENCIAS UTILES

• Al usar el aparato para soplar o

para aspirar los escombros, sujete

el aparato con el lado del silencia

dor alejado de su cuerpo y de su

ropa (vea POSICION DE USO en la

página siguiente).

• Se requiere que se use protección

de oídos para reducir el riesgo de

ia pérdida de la audición asociado

con los niveles de sonido.

• Detenga el motor antes de instalar

o remover accesorios para reducir

el riesgo asociado con el contacto

de las piezas girantes. No use este

aparato sin antes tener todos los

protectores en su lugar.

• Use el equipo de fuerza única

mente en horas razonables - no

muy temprano en la mañana o muy

tarde en la noche cuando otras

personas podrían ser perturbadas.

Cumpla con el horario enlistado por

los estatutos locales. Usualmente

se recomienda un horario normal

de 9:00 a.m. a 5:00 p.m., de lunes

a sábado.

• Limite el uso de número de piezas

de equipo al mismo tiempo para re

ducir los niveles de ruido.

• Para efectuar el trabajo, use los so

pladores de fuerza a la menor velo

cidad de aceleración posible para

reducir los niveles de sonido.

• Use rastrillos y escobas para aflojar

escombros antes de soplarlos con

el porpulsor de aire.

• En condiciones de mucho polvo,

moje ligeramente las superficies

de! suelo o use el accesorio “mis

ter” donde haya agua disponible.

• Conserve agua usando el soplador

en lugar de mangueras de agua

para las tantas aplicaciones del

césped y de jardinería, incluyendo

áreas como lo son canales de agua

en los techos, protección de tela

metálica en las ventanas y puertas,

patios, asadores a ia parrilla, bal

cones y jardines.

• Tenga cuidado con los niños, ani

males domésticos, ventanas abier

tas y carros recién lavados. Sople

los escombros con precaución.

• Use la extensión completa de la

boquilla del soplador para que la

corriente de aire pueda trabajar

cerca del suelo.

• Después de usar los sopladores de

aire y otro tipo de equipo, ¡LIMPIE!

Deseche los escombros en re

ceptáculos de basura.

POSICION DE USO

MARCHA

Á ADVERTENCIA: Asegúrese de

haber leído toda la información sobre el

combustible en las reglas de seguridad

antes de comenzar. Si no comprende

las reglas de seguridad, o intente

abastecer el aparato con combustible.

Llame al 1-800-235-5878.

ABASTECIMIENTO DEL MOTOR

A ADVERTENCIA: Remueva la

tapa del tanque de combustible lenta

mente al reabastecer combustible.

Este motor está habilitado para

funcionar con gasolina sin plomo. Antes

de comenzar con el uso, se deberá

mezclar la gasolina con un aceite de

sintético de buena calidad para motores

de 2 tiempos enfriados a aire.

Recomendamos el aceite de sintético

de la marca Craftsman. Mezcle la

gasolina con el aceite en la proporción

40:1. Se obtiene una proporción de 40:1

mezclando 3,2 onzas de aceite con

cada galón de gasolina sin plomo. Se

incluye con esta aparato un recipiente

de 3,2 onzas de aceite. Adiera el

contenido entero de este recipiente en 1

galón de gasolina para alcanzar la

mezcla apropiada del combustible. NO

USE aceite para automóviles ni para

barcas. Estos aceites dañarán el

motor.Ai mezclar el combustible, siga las

instrucciones impresas en el recipiente.

Una vez haya añadido el aceite a la

gasolina, agite al recipiente brevemente

para asegurar que el combustible esté

completamente mezclado. Siempre lea

y siga ias instrucciones de seguridad

que tienen que ver con el combustible

antes de abastecer el aparato.

- 29 ■

Page 30

IMPORTANTE

La GxpGriencia indie quG ios combus-

tiblGS mGzciados con alcohol, (los lla

mados gasohol o los que tienan etanoi

o metanol) pueden atraer humedad, lo

que puede causar la separación y la

formación de ácidos durante el alma

cenaje. La gasolina àcida puede dañar

el sistema de combustible del motor

durante el almacenaje. Para evitar pro

blemas con el motor, deberá vaciarse

gI sistema de combustible antes de

almacenar el aparato por 30 días o

más. Vacía el tanque de combustible,

ponga el motor en marcha y déjelo en

marcha hasta que las líneas de com

bustible y el carburador queden

vacíos. Use combustible fresco en la

próxima temporada. Nunca use pro

ductos de limpieza de motor o carbu

rador en el tanque de combustible ya

que de hacerlo puede provocar daños

permanentes. Un estabilizador de

combustible es una alternativa acept

able para minimizar la formación de

depósitos de goma en el combustible

durante el almacenaje. El aceite de la