Page 1

Instruction Manual

CRRFTSMHN

BRUSHCUTTER ATTACHMENT

Model No.

358.792430

NOT DESIGNED FOR USE

WITH ELECTRIC POWERHEADS

Safety

Assembly

Operation

Maintenance

Parts List

Español

DANGER:

Read and follow all Safety Rules and Operating

A

9

Instructions before first use of this product.

For answers to your questions about this product: Call 7

am-7 pm, Mon.-Sat., or 10 am-7 pm. Sun.

1 -800-235-5878

Sears, Roebuck and Co., Hoffman Estates, !L 60179 U.S.A.

530163558 8/26/02

Page 2

TABLE OF CONTENTS

Warranty Statement 2 Service & Adjustments

10

Safety Rules 2 Storage 11

Assembly 5 Parts List 12

Operation 7 Spanish 13

Maintenance Э Parts and Ordering Back Cover

WARRANTY STATEMENT

FULL ONE YEAR WARRANTY ON CRAFTSMAN® BRUSHCUTTER ATTACH

MENT

For one year from the date of purchase, when this Craftsman Brushcutter Attach

ment is maintained and lubricated according to the operating and maintenance

instructions in this manual, Sears will repair, free of charge, any defect in materi

als or workmanship.

This warranty excludes expendable parts that become worn during normal use.

if this Craftsman Brushcutter Attachment is used for commercial purposes, this war

ranty applies for only 90 days from the date of purchase. If this Craftsman Brushcut

ter Attachment is used for rental purposes, this warranty applies for only 30 days from

the date of purchase.

This warranty applies only while this product is In use In the United States.

WARRANTY SERVICE IS AVAILABLE BY RETURNING THE CRAFTSMAN BRUSHCUT

TER ATTACHMENT TO THE NEAREST SEARS STORE OR SERVICE CENTER IN THE

UNITED STATES.

This warranty gives you specific legal rights, and you may also have other rights

which vary from state to state.

Sears, Roebuck and Co., D/817 WA, Hoffman Estates, iL 60179

SAFETY RULES

ÂWARNING : When using garden

ing appliances, basic safety precau

tions should always be followed to re

duce the risk of fire and serious injury.

Read and follow all instructions. Fail

ure to do so can result in serious injury.

A DANGER: This power tool can be

dangerous! This unit can cause seri

ous injury including amputation or

blindness to the operator and others.

The warnings and safety instructions

in this manual must be followed to pro

vide reasonable safety and efficiency

in using the unit. The operator is re

sponsible for following the warnings

and instructions in this manual and on

the unit. Read the entire instruction

manual before assembling and using

the unit! Restrict the use of this unit to

persons who read, understand, and

follow the warnings and instructions in

this manual and on the unit. Never al

low children to operate this unit.

INSTRUCTION

MANUAL

SAFETY INFORMATION

ON THE UNIT

A DANGER: Never use flailing de-

Page 3

A DANGER: Blade can thrust vio

lently away from material it does not

cut. Blade thrust can cause amputa

tion of arms or legs. Keep people and

animals 50 feet (15 meters) away.

A WARNING; Blade can throw ob

jects violently. You can be blinded or

injured. Wear eye and leg protection.

ALWAYS WEAR

Eye

Protection

F

Leg

ft

Guards

■■

Boots

11

^WARNING: Hazard zone for

thrown objects. Blade can throw ob

jects violently. Others can be blinded

or injured. Keep people and animals

50 feet (15 meters) away.

OPERATOR SAFETY

• Dress properly. Always wear safety

glasses or similar eye protection

when operating, or performing main

tenance on your unit (safety glasses

are available). Eye protection should

be marked Z87.

• Always wear face or dust mask if op

eration is dusty.

• Always wear heavy, long pants, long

sleeves, boots, and gloves. Wearing

safety leg guards is recommended.

• Always wear foot protection. Do not

go barefoot or wear sandals.

• Secure hair above shoulder length.

Secure or remove loose clothing and

jewelry or clothing with loosely hang

ing ties, straps, tassels, etc. They

can be caught in moving parts.

• Being fully covered also helps pro

tect you from debris and pieces of

toxic plants thrown by spinning

blade.

• Stay Alert. Do not operate unit when

you are tired, ill, upset or under influ

ence of alcohol, drugs, or medica

tion. Watch what you are doing; use

common sense.

• Wear hearing protection.

• Never start or run the engine inside a

closed room or building. Breathing

exhaust fumes can kill.

• Keep handles free of oil and fuel.

• Always use the handlebar and a

properly adjusted shoulder strap

when using brushcutter attachment

(see ASSEMBLY).

UNIT/MAINTENANCE SAFETY

A WARNING: The blade continues

to spin after throttle is released or en

gine is turned off. The coasting blade

can throw objects or seriously cut you

if accidentally touched. Stop the blade

by contacting the left hand side of

coasting blade with material already

cut.

^WARNING: Disconnect power-

head spark plug (or disconnect powerhead from power source) before per

forming maintenance.

• Look for and replace damaged or

loose parts before each use. Look

for and repair fuel leaks before use.

Keep unit in good working condition.

• Throw away blades that are bent,

warped, cracked, broken, or dam

aged in any other way. Replace trim

mer head parts that are cracked,

chipped, broken, or damaged in any

other way before using the unit.

• Maintain the unit according to recom

mended procedures. Keep the blade

sharp. Never use flailing devices,

wire, rope, string, etc.

• Use only specified blade; make sure

it is properly installed and securely

fastened.

Page 4

• Never start engine with clutch shroud

removed. The clutch can fly off and

cause serious injury.

• Be sure blade stops turning when

engine idles.

• Make carburetor adjustments with

the lower end supported to prevent

the blade from contacting any object.

Hold the unit by hand; do not use the

shoulder strap for support.

• Keep others away when making car

buretor adjustments.

• Use only recommended Craftsman

accessories and replacement parts.

• Have all maintenance and service

not explained in this manual per

formed by a Sears Service Center.

FUEL SAFETY

• Mix and pour fuel outdoors.

• Keep away from sparks or flames.

• Use a container approved for fuel.

• Do not smoke or allow smoking near

fuel or the unit or while using the unit.

• Avoid spilling fuel or oil. Wipe up all

fuel spills before starting engine.

• Move at least 10 feet (3 meters) away

from fueling site before starting engine.

• Stop engine and allow it to cool be

fore removing fuel cap.

• Remove fuel cap slowly.

CUTTING SAFETY

^filf WARNING: Inspect the area to

be cut before each use. Remove ob

jects (rocks, broken glass, nails, wire,

string, etc.) which can be thrown or be

come entangled in the blade.

• Keep others including children, ani

mals, bystanders, and helpers at

least 50 feet (15 meters) away. Stop

the engine immediately if you are ap

proached.

• Always keep engine on the right-

hand side of your body.

• Hold the unit firmly with both hands.

• Keep firm footing and balance. Do

not overreach.

• Keep blade below waist level.

• Do not raise powerhead engine above

your waist.

• Keep all parts of your body away

from blade and muffler.

• Cut from your right to your left.

• Use only in daylight or good artificial

light.

• Use only for jobs explained in this

manual.

TRANSPORTING AND STORAGE

• Stop the powerhead engine before

carrying unit.

• Keep muffler away from your body.

• Allow engine to cool and secure unit

before storing or transporting it in a

vehicle.

• Empty the fuel tank before storing or

transporting the unit. Use up fuel left

in the carburetor by starting the en

gine and letting it run until it stops.

• Store unit and fuel in an area where

fuel vapors cannot reach sparks or

open flames from water heaters,

electric motors or switches, furnaces,

etc.

• Store unit so the blade cannot acci

dentally cause injury.

• Store unit indoors, out of reach of

children.

SPECIAL NOTICE: Exposure to vibra

tions through prolonged use of gaso

line powered hand tools could cause

blood vessel or nerve damage in the

fingers, hands, and joints of people

prone to circulation disorders or abnor

mal swellings. Prolonged use in cold

weather has been linked to blood ves

sel damage in otherwise healthy

people, if symptoms occur such as

numbness, pain, loss of strength,

change in skin color or texture, or loss

of feeling in the fingers, hands, or

joints, discontinue the use of this tool

and seek medical attention. An anti

vibration system does not guarantee

the avoidance of these problems. Us

ers who operate power tools on a con

tinual and regular basis must monitor

closely their physical condition and the

condition of this tool.

SAVE THESE INSTRUCTIONS

Page 5

ASSEMBLY

CARTON CONTENTS

Check carton contents against the fol

lowing iist.

Model 358.792430

• Brushcutter Attachment

• Handlebar (with Clamp and Knob)

• Handlebar Clamp Base (with Spacer

Tabs)

• Shoulder Strap

• Upper Shoulder Strap Clamp

• Lower Shoulder Strap Clamp (with

Spacer Tabs)

• Handlebar Clamp Screws (4)

• Shoulder Strap Clamp Screws (2)

• Attachment Hanger

• Hex Wrench

Examine parts for damage. Do not use

damaged parts.

NOTE: If you need assistance or find

that parts are missing or damaged, call

1-800-235-5878.

ASSEMBLY

WARNING: If received assembled,

repeat all steps to ensure your unit is

properly assembled and all fasteners

are secure.

• A hex wrench (provided) is required

for assembly.

INSTALLING BRUSHCUTTER AT

TACHMENT

CAUTION: When removing or instal

ling attachments, place the unit on a

flat surface for stability.

1. Loosen the coupler by turning the

knob counterclockwise.

Coupler

LOOSEN

Coupler Primary Hole

Guide Recess

Upper Locking/

Tube attachment

Button

A WARNING: Make sure the lock

ing/release button is locked in the pri

mary hole and the knob is securely

tightened before operating the unit.

HANDLEBAR ASSEMBLY

A DANGER: RISK OF CUT. To

avoid serious injury, the barrier portion of

the handlebar must be installed as

shown on the upper tube of the power-

head to provide a barrier between op

erator and the spinning blade. Attach

tube clamp above arrow on safety warn

ing decal on the upper tube (powerhead

end of unit). Ensure handieter is posi

tioned on handlebar clamp between the

arrovi/s on the handlebar decal.

NOTE: The tube clamp base has four

spacer tabs attached. These tabs are

provided to adapt this attachment for

use with powerheads that have a 1" di

ameter upper tube (the tube clamp will

not tighten down securely on the 1" di

ameter upper tube without using these

spacer tabs). The tabs must be broken

off completely before use and placed

over the screw holes on the clamp base.

These tabs are not needed for power-

heads with a 7/8" upper tube.

HANDLEBAR CLAMP BASE

Spacer Tabs

TIGHTEN Knob

Remove the tube cap from the

brushcutter attachment (if present).

Position locking/release button of

3.

attachment into guide recess of

coupler.

4.

Push the attachment into the cou

pler until the locking/release button

snaps into the primary hole.

Before using the unit, tighten the

knob securely by turning clock

wise.

111“

Spacer Tabs

positioned for use

on 1" diameter

upper tube

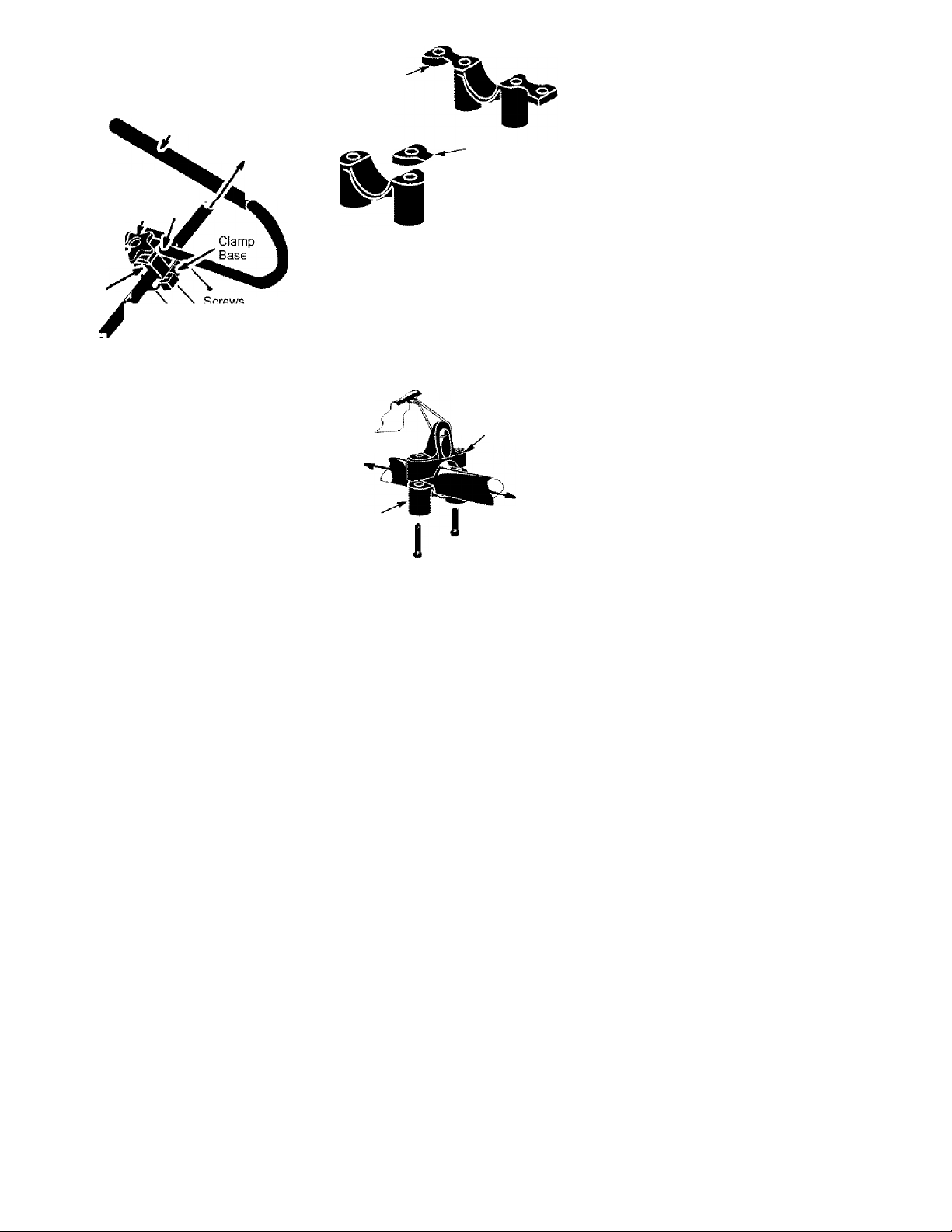

1. Place the tube clamp over the up

per tube above the arrow on the

safety decal.

2. Position the clamp base under the

upper tube and align the tube

Page 6

damp and clamp base screw

holes (use spacer tabs between

tube clamp and clamp base if nec

essary to secure clamp, i.e. for 1"

diameter upper tube).

Handlebar

POWERHEAD

END

Handlebar Clamp

between arrows on

handlebar decal

LOWER SHOULDER STRAP

CLAMP

Spacer Tabs

Spacer Tabs

positioned for use

on 1" diameter

upper tube

Clamp,

Knob

Tube ■

Clamp

Arrow on

Safety Decal

ATTACHMENT END

3. Insert four screws into the screw

holes.

4. Secure tube clamp by tightening

screws with the hex wrench.

5. Position the handlebar as shown,

ensuring the handlebar is posi

tioned on the handlebar clamp be

tween the two arrows on the han

dlebar decal.

6. Retighten handlebar by turning

clamp knob clockwise until handle

bar is secure and stationary in

damp (clamp knob cannot be

overtightened).

SHOULDER STRAP ASSEMBLY

4^^ WARNING: Proper shoulder

strap and handlebar adjustments must

be made with the engine completely

stopped before using unit. The shoul

der strap clamp must be installed as

shown above the handlebar on the up

per tube (powerhead end of unit).

NOTE: The lower shoulder strap clamp

has two spacer tabs attached. These

tabs are provided to adapt this attach

ment for use with powerheads that have

a 1" diameter upper tube (the shoulder

strap clamp will not tighten down se

curely on the 1" diameter upper tube

without using these spacer tabs). The

tabs must be broken off completely be

fore use and placed over the screw

holes on the lower shoulder strap damp.

These tabs are not needed for power-

heads with a 7/8" upper tube.

1. Place the upper shoulder strap

damp over the upper tube above

the handlebar.

2. Position the lower shoulder strap

damp under the upper tube and

align the upper and lower damp

screw holes (use spacer tabs be

tween upper and lower clamps if

necessary to secure clamp, i.e. for

1" diameter upper tube).

Upper Shoulder

Strap Clamp

POWERHEAD

END

Lower Shoulder

Strap Clamp

3. Insert two screws into the screw

holes.

4. Secure shoulder strap damp by

tightening screws with the hex

wrench.

5. insert your right arm and head

through the shoulder strap and al

low it to rest on your left shoulder.

Make sure the danger sign is on

your back and the hook is to the

right side of your waist.

ATTACHMENT

END

Screws

NOTE: A one-half twist is built in the

shoulder strap to allow the strap to rest

flat on the shoulder.

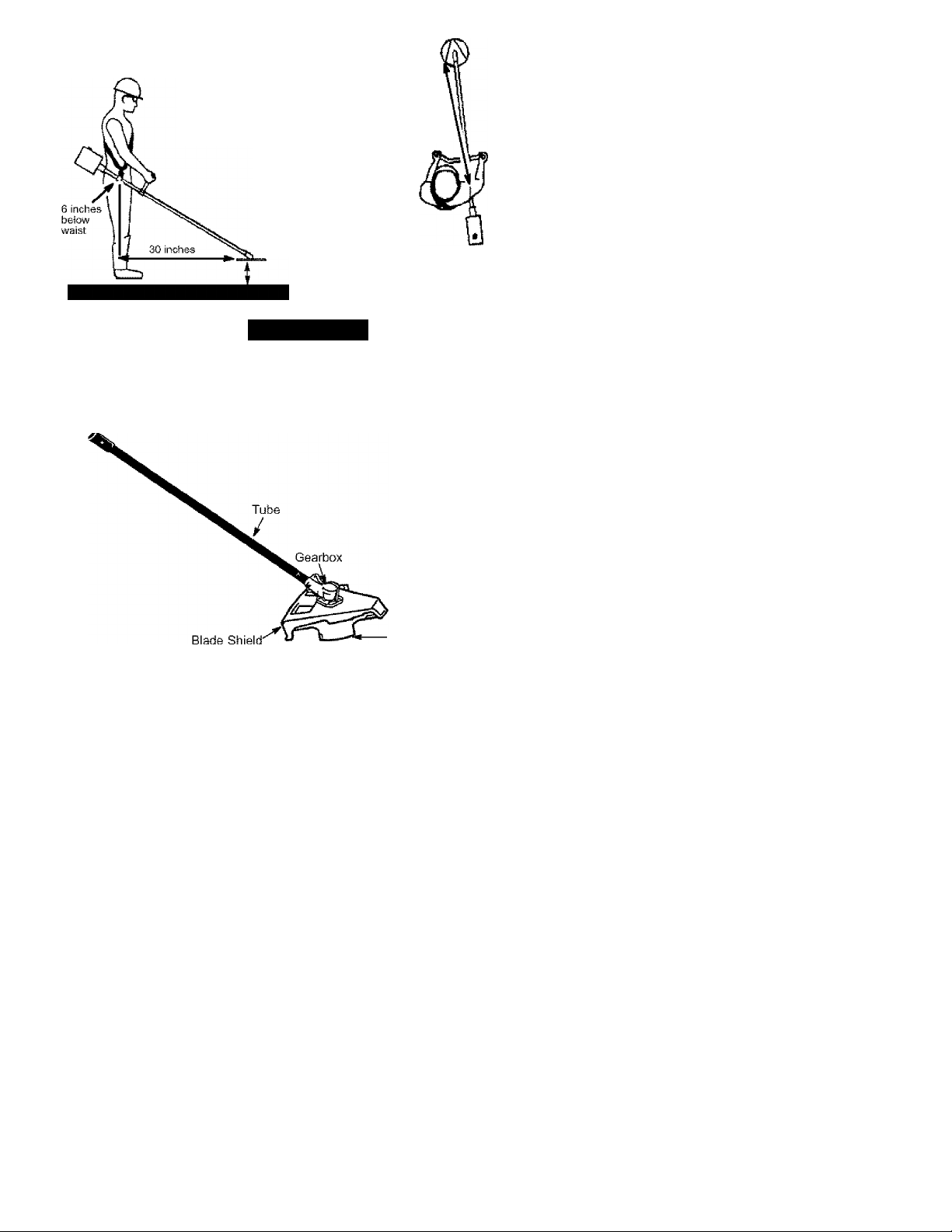

6. Adjust the strap, allowing the hook

to be about 6 inches below the

waist.

7. Fasten the strap hook to the clamp

and lift the tool to the operating

position.

8. Try on shoulder strap and adjust

for fit and balance before starting

the engine or beginning a cutting

operation.

Page 7

NOTE: It may be necessary to relo

cate the shoulder strap clamp on the

shaft for proper balancing of unit.

HARNESS

ADJUSTMENT

FOR BALANCE

4-12

inches

above

ground

30 inches

OPERATION

KNOW YOUR BRUSHCUTTER ATTACHMENT

READ THIS INSTRUCTION MANUAL AND SAFETY RULES BEFORE OPERATING YOUR

BRUSHCUTTER ATTACHMENT. Compare the Illustrations with your unit to familiarize

yourself with the location of various controls and adjustments. Save this manual for

future reference.

Hanger

BLADE

The BLADE Is designed for cutting

grass, weeds, and brush up to 1/2 inch

in diameter.

OPERATING THE COUPLER

Your powerhead is equipped with a

coupler which enables optional attach

ments to be installed. The optional at

tachments are:

Edger

..........................

Cultivator

Blower

.........................

.....................

358.792400

358.792410

358.792420

Blade

BLADE SHIELD

The BLADE SHIELD provides protection

from the spinning blade.

WARNING: Always disconnect

powerhead spark plug before remov

ing or installing attachments.

REMOVING BRUSHCUTTER AT

TACHMENT {OR OTHER OPTIONAL

ATTACHMENTS)

CAUTION: When removing or instal

ling attachments, place the powerhead

and attachment on a flat surface for

stability.

Page 8

Loosen the coupler by turning the

knob counterclockwise.

Upper Tube

Coupler

Lower

Attachment

TIGHTEN

LOOSEN

OPERATING POSITION

2. Press and hold the locking/release

button.

Locking/Release

Button

/ Coupler.

Lower Attachment

3. While securely holding the upper

tube, puli the attachment straight

out of the coupler.

INSTALLING OPTIONAL ATTACH

MENT

1. Remove the tube cap from the at

tachment (if present) and discard.

2. Position locking/release button of

attachment into guide recess of

upper tube coupler.

Coupler Primary Hole

■ Guide Recess

Upper Locking/ Attachment

Tube Release

Button

3. Push the attachment into the cou

pler until the locking/release button

snaps into the primary hole.

4. Before using the unit, tighten the

knob securely by turning clock

wise.

INSTALLING ATTACHMENT

HANGER

An attachment hanger is provided for

storage when attachment is not in use.

To install hanger on attachment:

1. Remove the tube cap from the at

tachment (if present) and discard.

2. Press and hold the locking/release

button.

3. Push hanger onto the attachment

until the locking/release button

snaps into the hole.

NOTE: This brushcutter attachment is

not designed for use with electric pow-

erheads.

When operating unit with brushcutter

attachment, clip shoulder strap onto

upper shoulder strap clamp, stand as

shown and check for the following:

• Wear eye protection and heavy

clothing.

• Keep arms extended with right hand

holding the trigger handle of powerhead.

• Keep left arm extended with left hand

holding the handlebar.

• Keep unit below waist level.

• Shoulder strap pad should be cen

tered on your left shoulder and dan

ger sign centered on your back.

• Maintain full weight of tool on left

shoulder.

• Without bending over, keep the blade

near and parallel to the ground and

not crowded into material being cut.

OPERATING INSTRUCTIONS FOR

BRUSHCUTTER ATTACHMENT

• Blade Thrust is a reaction that only

occurs when using a bladed unit. This

reaction can cause serious injury such

as amputation. Carefully study this

section. It is important that you under

stand what causes blade thrust, how

you can reduce the chance of its oc

curring, and how you can remain in

control of unit if blade thrust occurs.

• WHAT CAUSES BLADE THRUST Blade Thrust can occur when spin

ning blade contacts an object that it

does not cut. This contact causes

blade to stop for an instant and then

suddenly move or “thrust" away from

object that was hit. The “thrusting” re

action can be violent enough to cause

operator to be propelled in any direc

tion and lose control of unit. The un

controlled unit can cause serious injury

if blade contacts operator or others.

8

Page 9

WHEN BLADE THRUST OCCURS

- Blade Thrust can occur without

warning if the blade snags, stalls, or

binds. This is more likely to occur in

areas where it is difficult to see the

material being cut. By using the unit

properly, the occurrence of blade

thrust will be reduced and the opera

tor wiil be less likely to lose control.

Cut only grass, weeds, and woody

brush up to 1/2 inch in diameter with

weed blade. Do not let blade contact

material it cannot cut such as stumps,

rocks, fences, metai, etc., or clusters

of hard, woody brush with a diameter

greater than 1/2 inch.

Use a sharp blade. A dull blade is

more likely to snag and thrust.

Cut only at full throttle. The blade will

have maximum cutting power and is

less likely to bind or stali.

“Feed” the blade deliberately and not

too rapidly. The blade can thrust

away if it is fed too rapidly.

Cut only from your right to your left.

Swinging unit in the same direction as

blade spin increases cutting action.

Use the shoulder strap and keep a

firm grip on the unit with both hands.

A properly adjusted shoulder strap

will support the weight of the unit,

freeing your arms and hands to con

trol and guide the cutting motion.

Keep feet comfortably spread apart

and braced for a possible sudden,

rapid thrust of unit. Do not overreach.

Keep firm footing and balance.

Keep blade below waist level. It will

be easier to maintain control of unit.

• Do not raise the engine above your

waist as the blade can come danger

ously close to your body.

• Do not swing the unit with such force

that you are in danger of losing your

balance.

Bring the powerhead engine to cutting

speed before entering the materia! to

be cut.

If the blade does not turn when you

squeeze the throttle trigger of the pow

erhead, make sure the attachment is

fully inserted into the coupler.

Always release the throttle trigger and

allow powerhead engine to return to

idle speed when not cutting. The blade

should not turn while the engine is run

ning at idle. If the blade turns at idle,

do not use your unit. Refer to the CAR

BURETOR ADJUSTMENT section of the

powerhead manual or contact your

Sears Service Center.

• Maintain good firm footing while us

ing the unit. Do this by planting feet

firmly in a comfortable apart position.

• Cut while swinging the upper part of

your body from right to left.

• As you move forward to the next

area to cut, be sure to maintain your

balance, and footing.

RECOMMENDED CUTTING POSITION

10 o’clock x>

Cut using the 8 o’clock f

to 10 o'clock position ofV’

the blade „ , , ,'

* if A

8 o dock

^WARNING; The operator or oth

ers must not try to clear away cut ma

terial with the engine running or the

blade turning to avoid serious injury.

Stop engine and blade before remov

ing materials wrapped around blade or

tube.

Page 10

MAINTENANCE

MAINTENANCE SCHEDULE

^WARNING: Always stop unit and disconnect spark plug wire before

performing maintenance.

CARE AND MAINTENANCE TASK

Check for loose fasteners and parts Before each use

Check for damaged or worn parts Before each use

Inspect and clean unit and decals After each use

Check or replace blade Every 5 hours of operation

GENERAL RECOMMENDATIONS

The warranty on this attachment does

not cover items that have been sub

jected to operator abuse or negli

gence. To receive full value from the

warranty, the operator must maintain

the brushcutter attachment as instruct

ed in this manual.

CHECK FOR DAMAGED OR

WORN PARTS

Contact Sears Service Center for re

placement of damaged or worn parts.

• Blade Shield - Discontinue use of

brushcutter attachment if shield is

damaged.

• CHECK FOR LOOSE

FASTENERS AND PARTS

• Blade nut

INSPECT AND CLEAN UNIT

AND DECALS

• After each use, inspect complete unit

for loose or damaged parts. Clean

the unit and decals using a damp

cloth with a mild detergent.

WHEN TO PERFORM

• Wipe off unit with a clean dry cloth.

BLADE MAINTENANCE

WARNING: The blade will contin

ue to spin after the engine stops or af

ter the throttle trigger has been re

leased. To avoid serious injury, make

sure the blade has stopped coasting

and disconnect the spark plug before

performing work on the blade.

WARNING: Always replace a

blade that is bent, warped, cracked,

broken, or damaged in any other way.

Never attempt to straighten and reuse

a damaged blade. Use only specified

replacement blade. Wear protective

gloves when handling or performing

maintenance on the blade to help

avoid injury.

• Check blade for flatness periodically.

Lay the blade on a flat surface to in

spect for flatness. Throw away a

blade that is not flat.

SERVICE AND ADJUSTMENTS

BLADE REPLACEMENT

WARNING: The blade will contin

ue to spin after the engine stops or af

ter the throttle trigger has been re

leased. To avoid serious injury, make

sure the blade has stopped coasting

and disconnect the spark plug before

performing work on the blade.

^WARNING: Wear protective

gloves when handling or performing

maintenance on the blade to avoid

injury. The blade is sharp and can cut

you even when it is not moving.

1. To remove the blade, align hole In

the dust cup with the hole in the

side of the gearbox by rotating the

blade.

2. Insert a small screwdriver into

aligned holes. This will keep the

shaft from turning while loosening

the blade nut.

Screwdriver

While holding the screwdriver in

position, remove blade nut by turn

ing clockwise as you are facing the

nut.

Remove both washers and the

blade from the blade shaft. Leave

the dust cup on the gearbox.

10

Page 11

Install new blade and retaining

washer onto the threaded shaft ex

tending from the gearbox (blade

must be between the dust cup and

the retaining washer). Make sure

the raised part of the retaining

washer is facing the gearbox, and

the raised area fits into the hole in

the center of the blade.

STORAGE

6. Place the cupped washer onto the

shaft. Make sure the cupped side

of the washer is toward the blade.

7. install blade nut by threading onto

the shaft counterclockwise as you

are facing the nut.

NOTE: Make sure all parts are in place

as illustrated, and the blade is sand

wiched between the dust cup and the

retaining washer. There should be no

space between the blade and the dust

cup or the retaining washer.

8. Tighten blade nut firmly with a

wrench while holding screwdriver

in position.

9. Remove the screwdriver.

10. Turn blade by hand. If the blade

binds against the shield, or ap

pears to be uneven, the blade is

not centered, and you must rein

stall.

^WARNING: Perform the following

steps after each use:

• Allow attachment and gearbox to

cool before storing or transporting.

• Store attachment with blade shield in

place. Position attachment so that

any sharp object cannot accidentally

cause injury.

• Store the attachment in a dry, well

ventilated area out of the reach of

children.

SEASONAL STORAGE

Prepare attachment for storage at end

of season or if it will not be used for 30

days or more.

!f your brushcutter attachment is to be

stored for a period of time:

Clean the entire attachment.

Inspect the blade shield area and

clean any dirt, grass, leaves, or de

bris that has collected. Inspect the

blade and blade shield; replace a

blade that is bent, warped, cracked,

broken or damaged in any other way.

Lightly oil external meta! surfaces.

Apply a coating of oil to the entire

surface of the blade; wrap it in heavy

paper or cloth.

Check entire attachment for loose

screws or nuts. Replace any dam

aged, worn or broken parts.

At the beginning of the next season,

use only fresh fuel having the proper

gasoline to oil ratio.

11

Page 12

TABLA DE CONTENIDO

Declaración de Garantía 13 Servicio y Ajustes 22

Reglas de Seguridad 13

Montaje 16

Uso 18

Almacenaje 23

Lista de Piezas 12

Repuesto y Encargos Contrata pa

Mantenimiento 21

DECLARACION DE GARANTIA

GARANTIA COMPLETO DE UN AÑO PARA LA CORTADORA DE MALEZAS

ACCESORIO CRAFTSMAN®

Durante un año completo, a partir de la fecha de compra, siempre que se haga el

mantenimiento, la lubricación y los ajustes a esta Cortadora de Malezas Acceso

rio Craftsman según las instrucciones de uso y mantenimiento en el manual,

Sears reparará cualquier defecto de materiales o de mano de obra gratuitamente.

Esta garantía excluye las partes que se gastan durante el uso normal.

Si se usa esta Cortadora de Malezas Accesorio Craftsman con fines comerciales,

esta garantía tendrá validez por sola 90 días a partir de la fecha de compra. Si se

usa esta Cortadora de Malezas Accesorio Craftsman con fines de alquiler, esta

garantía tendrá validez solamente por 30 días a partir de la fecha de compra.

Esta garantía tendrá validez únicamente mientras se use este producto dentro de

los Estados Unidos.

SE OBTENDRA SERVICIO BAJO GARANTIA DEVOLVIENDO LA CORTADORA DE MAL

EZAS ACCESORIO CRAFTSMAN AL TIENDA CE SEARS O CENTRO DE SERVICIO

SEARS MAS CERCANO EN LOS ESTADOS UNIDOS.

Esta garantía confiere derechos legales específicos al propietario, que tal vez

tenga asimismo otros derechos que varían entre estados.

Sears, Roebuck and Co., D/817 WA Hoffman Estafes, IL 60179

REGLAS DE SEGURIDAD

A ADVERTENCIA: Al usar cualqui

er herramienta de fuerza de jardinería,

deberán observarse precauciones bási

cas de seguirdad en todo momento

para reducir el riesgo de incendio y

graves heridas. Lea y cumpla con todas

las instrucciones. Su incumplimiento

puede ocasionar lesiones graves.

Apeligro: yEstaberram/enta mo

torizada puede ser peligrosa! Puede

ocasionar lesiones graves, incluso la

amputación o la ceguera, tanto al opera

dor como a otras personas. Las adver

tencias e instrucciones de seguridad

contenidas en este manual deben cum

plirse en todo momento para garantizar

un nivel de seguridad y efectividad ra

zonable durante la utilización del apara

to. El operador es responsable del

cumplimiento de las advertencias e

instrucciones indicadas en este manual

y en el aparato. Antes de ensamblar y

utilizar el aparato, lea íntegramente el

manual de instrucciones. Limite el uso

de este aparato a personas que previa

mente hayan leído y comprendido, y

posteriormente cumplan, las adverten

cias e instrucciones indicadas en este

manual y en el aparato. Nunca permita

que este aparato sea utilizado por niños.

MANUAL DE

INSTRUCCIONES

INFORMACION DE

SEGURIDAD DEL

APARATO

Apeligro: Nuncausedisposltivos

desgranadoras.

13

Page 13

À PELIGRO: La cuchilla puede rebo

tar violentamente en materiales que no

puede cortar. Los rebotes de la cuchilla

pueden causar la amputación de brazos

o piernas. Mantenga a personas y anima

les lejos de la herramienta (15 metros).

mn

A ADVERTENCIA: La cuchilla

puede despedir objetos violentamente.

Esto puede ocasionarle ceguera o le

siones. Protéjase los ojos y las pier

nas.

UTILICE SIEMBRE:

Protección

ocular

Perneras

Botas

A ADVERTENCIA: Zona de peli

gro de objetos despedidos. La cuchilla

puede despedir objetos violentamente.

Esto puede ocasionar ceguera o lesio

nes a otros. Mantenga a personas y

animales lejos de la herramienta 15

metros (50 pies).

^ADVERTENCIA: La cuchilla si

gue girando incluso después de soltar

el acelerador o de apagar el motor. In

cluso cuando está girando libremente,

la cuchilla puede despedir objetos o

causar cortes profundos si se toca ac

cidentalmente. Detenga la cuchilla po

niendo en contacto el lado izquierdo

de la misma con material ya cortado.

Para detener la cuchi

Na cuando gire libre

mente, póngala en

contacto con material

previamente cortado.

SEGURIDAD DEL OPERADOR

• Vístase apropiadamente. Siempre

use anteojos de seguridad o similar

protección para los ojos cuando use

o dé mantenimiento a este aparato

(anteojos de seguridad están dispo

nibles). La protección para los ojos

debe ser marcada con Z87.

• Siempre utilize mascarilla para la

cara o mascarilla a prueba de polvo

si se va a trabajar en condiciones

donde hay polvo.

• Siempre utilize pantalones pesados

y largos, mangas largas, botas y

guantes. Se recomienda el uso de

pantorrilleras de seguridad.

• Siempre utilize protección para los

pies. No trabaje descalzo ni en

sandalias. Evite la cuchilla girante.

• Mantenga el cabello por encima de

los hombros, atándolo para tal efecto

si es necesario. No use ropa suelta

ni ropa con corbatas, tiras, borlas,

etc. que cuelgan libremente. Pueden

enredarse en las piezas en movi

miento.

• Si está completament tapado, estará

más protegido de los escombros y

pedazos de plantas tóxicos arroja

dos por la cuchilla girante.

• Manténgase alerta. No haga uso del

aparato estando cansado, enfermo,

trastornado o bajo la influencia del

alcohol, de drogas o de remedios.

Vigile bien lo que está haciendo; use

del sentido común.

• Use protección de oidos.

• Nunca ponga el aparato en marcha

ni lo deje en marcha dentro de un

recinto cerrado. Respirar los vapores

del combustible lo puede matar.

• Mantenga las manijas libres de

aceite y de combustible.

• Utilice siempre el mango y una

correa para hombro correctamente

ajustada al usar la cortadora de

malezas accesorio (vea MONTAJE).

14

Page 14

MANTENIMIENTO Y SEGURIDAD

DEL APARATO

ál^ ADVERTENCIA: Desconecte la

bujía (o desconecte aparato de la cor

riente eléctrica) antes de hacer cualqu

ier mantenimienío.

• Antes de cada uso, busque las piezas

dañadas o sueltas y sustituyalas. An

tes de cada uso, busque posibles fu

gas de combustible y, en su caso, re

párelas. Mantenga el aparato en buen

estado de funcionamiento.

• Deseche la cuchillas dobladas, den

tadas, partidas, rotas o deterioradas

de algún modo. Antes de utilizar la

unidad, sustituya las piezas del ca

beza! podador que estén partidas,

rotas o deterioradas de algún modo.

• Realice ei mantenimiento del aparato

siguiendo los procedimientos recx)mendados. Mantenga la cuchilla afila

da. Nunca utilice dispositivos desgranadores, cable, cuerda, alambre, etc.

• Utilice exclusivamente la cuchilla es

pecificado y asegúrese de que esté

correctamente instalado y firmemen

te sujeto.

• Nunca ponga en marcha el motor

con el cubierta del embrague des

montado. El embrague podría des

prenderse y causar graves lesiones.

• Asegúrese de que el cuchilla se de

tiene al pasar el motor a! ralenti.

• Realice los ajustes del carburador

con la parte inferior apoyada en alto

para impedir que la cuchilla entren

en contacto con algún objeto. Sujete

el aparato con las manos, sin utilizar

la correa al hombro.

• Cuando realice ajustes en el carbu

rador, mantenga alejadas del lugar a

otras personas.

• Utilice exclusivamente los acceso

rios y recambios recomendados por

Craftsman.

• Confíe todas las tareas de manteni

miento y reparación no explicadas

en este manual a su Centro de

Servicio de Sears.

SEGURIDAD CON EL COMBUS

TIBLE

• Mezcle y vierta el combustible en

exteriores.

• Mantenga el combustible alejado de

chispas y llamas.

• Utilice recipientes homologados para

el uso de combustibles.

• Impida que se fume cerca del com

bustible o del aparato, tanto si éste

se encuentra parado o se está utili

zando.

• Antes de poner en marcha el motor,

limpie todo posible resto de combus

tible derramado.

• Antes de poner en marcha el motor,

aléjese como mínimo 3 metros del lu

gar de repostaje.

• Antes de quitar el tapón de combusti

ble, detenga el motor y déjelo enfriar.

• Remueva la tapa del tanque de com

bustible lentamente.

SEGURIDAD AL CORTAR

A ADVERTENCIA: Antes de cada

uso, inspeccione la zona de trabajo.

Retire todos los objetos (rocas, cris

tales rotos, clavos, cables, hilos, etc.)

que puedan ser despedidos o quedar

enredados en la cuchilla.

• Mantenga alejados del lugar de tra

bajo (15 metros) a otras personas,

ya sean niños, acompañantes o ayu

dantes, y a animales. Detenga el

motor tan pronto como alguien se le

aproxime.

• Mantenga siempre el motor junto al

lado derecho de su cuerpo.

• Sujete firmemente la unidad con am

bas manos.

• Pise con seguridad y mantenga el

equilibrio en todo momento. No esti

re el cuerpo en exceso.

• Mantenga la cuchilla por debajo de

la cintura.

• No levante el cabeza de motor por en

cima de su cintura.

• Mantenga todas las partes de su

cuerpo alejadas de la cuchilla y del

silenciador.

• Corte siempre de derecha a izquierda.

• Use el aparato únicamente de día o

en luz artificial fuerte.

• Utilice el aparato solamente para las

tareas explicadas en este manual.

TRANSPORTE Y ALMACENAMIENTO

• Antes de proceder a su transporte,

detenga el cabeza de motor.

• Mantenga el silenciador alejado del

cuerpo.

• Antes de almacenar o transportar el

aparato en un vehículo, deje enfriar

el motor y sujete bien el aparato.

• Antes de guardar o transportar ei

aparato, vacíe el depósito de com

bustible. Arranque el motor y déjelo

en marcha hasta que se detenga

con el fin de agotar el combustible

que pueda quedar en el carburador.

• Guarde el aparato y el combustible

en un lugar donde los vapores ema

nados del combustible no puedan

entrar en contacto con chispas ni lla

mas procedentes de calentadores

15

Page 15

de agua, motores o interruptores

eléctricos, hornos, etc.

• Guarde el aparato de modo que la

cuchilla no puedan ocasionar lesio

nes accidentalmente.

• Guarde el aparato dentro, fuera de!

alcance de los niños.

NOTA ESPECIAL: El estar expuesto

a las vibraciones a través del uso pro

longado de herramientas de fuerza a

gasolina puede cuasar daños a ios va

sos sanguíneos o a los nervios de los

dedos, las manos y las coyunturas en

aquellas personas que tienen propensidad a los trastornos de la circulación

o a las hinchazones anormales. El uso

prolongado en tiempo frío ha sido aso

ciado con daños a los vasos sna-

MONTAJE

CONTENIDO DE LA CAJA

Use la siguiente lista para verificar que

todas la piezas hayan sido incluido:

Modei 358.792430

• Cortadora de Malezas Accesorio

• Mango (con Abrazadara y Perilla)

• Base de Abrazadera (con Tabulaciones

del Espaciador)

• Correa al Hombro

• Abrazadera Superior del Correa de

Hombro

• Abrazadera Inferior del Correa de

Hombro (con Tabulaciones del Espa

ciador)

• Tornillos de Abrazadera del Mango (4)

• Tornillos de Abrazadera del Correa de

Hombro (2)

• Suspensor del Accesorio

• Llave Hexagonal

Asegúrese de que ninguna pieza esté

dañada. No utilice piezas dañadas.

NOTA: Si necesita ayuda o detecta que

alguna pieza falta o está dañada, llame

al 1-800-235-5878.

MONTAJE

A ADVERTENCIA: Si recibe el

aparato ya armado, repita todos los pa

sos para asegurarse de que el aparato

esté correctamente ensamblado y todas

las sujeciones firmes.

• Un llave hexagonale (incluidas) se

requiere para el montaje.

INSTALACION DE LA ACCESORIO

DEL CORTADORA DE MALEZAS

PRECAUCION: Al instalar las acceso

rio , ponga el aparato en una superfi

cie plana para estabilidad.

guíneos de personas que por otra

parte se encuentran en perfecto esta

do de salud. Si ocurren síntomas tales

como el entumecimiento, el dolor, la

falta de fuerza, los cambios en el color

o la textura de la piel o falta de sentido

en los dedos, las manos o las coyun

turas, deje de usar esta máquina in

mediatamente y procure atención

médica. Los sistemas de anti-vibración no garantizan que se eviten tales

problèmes. Los usuarios que hacen

uso continuo y prolongando de las

herramientas de fuerza deben fiscali

zar atentamente su estado físico y el

estado del aparato.

GUARDE ESTAS INSTRUCCIONES

1. Afloje el acoplador dando vuelta a

la perilla a la izquierda.

Acoplador

AFLOJE

APRIETAI Perilla

2.3.Retire la tapa de tubo de! acceso

rio del cortadora de malezas (si

presente).

oloque el botón de conexión/desconexión del accesorio en el aguj

ero de la guía del acoplador.

Empuje el accesorio en el acopla

dor hasta que el botón de conex-

ión/desconexión se encaje en el

primer agujero.

Antes de usar el aparato, apriete

la perilla firmemente dando vuelta

a la derecha.

Primer

Acoplador

Tubo Botón de Accesorio

Superior Conexión/ Inferior

Agujero Agujero de

’ la Guía

Desconexión

16

Page 16

A ADVERTENCIA; Antes de oper

ar esta aparato, asegúrese de que el

botón de conexión/desconexión esté

asegurado en e! primer agujero y la

perilla esté bien ajustada. Todos los

accesorios han sido diseñados para

ser utilizados en el primer agujero.

INSTALLATION DEL MANGO

Apeligro; riesgo de corta

dura. Para evitar graves heridas, la

parte del mango en forma de barrera

debe ser instalada en el tubo superior

de la cabeza del motor/tubo superior

con el fin de mantener la distancia

entre el operador y la cuchilla durante

el giro de ésta. Instale la abrazadera

del tubo sobre la flecha de la etiqueta

de seguridad de! tubo superior (extre

mo a la cabeza del motor de su apara

to). Asegure que el mango este en

posición con la abrazadera del mango

entre las flechas de la etiqueta del

mango.

AVISO: La base de la abrazadera del

tubo tiene cuatro (4) tabulaciones del

espaciador incluidas. Estas tabula

ciones se proporcionan para adaptar

esta accesorio para el uso con las ca

bezas de motor/tubo superior que tie

nen 1 pulgada del tubo superior de

diámetro (la abrazadera del tubo no

apretará abajo con seguridad en el

tubo superior de 1 pulgada de diáme

tro sin usar estas tabulaciones del es

paciador). Estas tabulaciones se de

ben remover antes del uso y ponerlos

sobre los huecos del tornillo en la

base de la abrazadera. Estas tabula

ciones no son necesarias para las ca

bezas de motor/ tubo con un 7/8 de

pulgada en el tubo superior.

BASE DE ABRAZADERA

Taíjuladones

del Espaciador

Coloque la base de la abrazadera

debajo del tubo superior y alinee

los huecos del tornillo de la abra

zadera con el tubo y la base de la

abrazadera (use las tabulaciones

del espaciador entre la abrazadera

del tubo y la base de la abrazadera

en caso de necesidad para asegu

rar la abrazadera, es decir para 1

pulgada de diámetro del tubo supe

rior).

Mango EXTREMO CON

Abrazadera del

Mango entre las

flechas de la etiqueta_^

del mango

Perilla

de la _

Flecha en la

Etiqueta de Seguridad

✓

EXTREMO CON

EL ACCESORIO

EL CABEZA DE

MOTOR

3. Inserte cuatro tornillos en los hue

cos del tornillo.

4. Asegure la abrazadera del tubo

apretando los tornillos con la llave

hexagonal.

5. Coloque el mango como se le a

mostrado, asegurado el mango se

coloca en !a abrazadera del man

go entre las dos flechas en la eti

queta del mango.

6. Vuelva a apretar el mango dando

vuelta a la perilla de la abrazadera

hacia la derecha hasta que el

mango es seguro e inmóvil en la

abrazadera (la perilla de la abra

zadera no se puede apretar dema

siado).

MONTAJE DE LA CORREA PARA

HOMBRO

Tabulaciones

del Espaciador

colocadas para el

uso en el 1 pulga

da de diámetro del

tubo superior

1. Coloque !a abrazadera del tubo en

la parte superior sobre la flecha en

la etiqueta de seguridad.

A ADVERTENCIA: Antes de hacer

algún ajuste de la correa o el mango, es

imprescindible que el motor este

completamente detenido. El abrazadera

del correa de hombro debe ser instalado

sobre el mango en el tubo superior

(extremo con el cabeza del motor).

AVISO: La abrazadera inferior del

correa para hombro tiene dos (2) tabu

laciones del espaciador incluidas. Es-

17

Page 17

tas tabulaciones se proporcionan para

adaptar esta accesorio para el uso con

las cabezas de motor/tubo superior

que tienen 1 pulgada del tubo superior

de diámetro (la abrazadera del correa

para hombro no apretará abajo con

seguridad en el tubo superior de 1 pul

gada de diámetro sin usar estas tabu

laciones del espaciador). Estas tabu

laciones se deben remover antes del

uso y ponerlos sobre los huecos del

tornillo en la abrazadera inferior de la

correa para el hombro. Estas tabula

ciones no son necesarias para las ca

bezas de motor/ tubo con un 7/8 de

pulgada en el tubo superior.

ABRAZADERA INFERIOR DEL

CORREA PARA HOMBRO

Tabulaciones

del Espaciador

Tabulaciones

del Espaciador

coiocadas para e!

uso en el 1 pulga

da de diámetro dei

tubo superior

1. Coloque la abrazadera superior de

la correa para hombro en la parte

superior sobre la mango.

2. Coloque la abrazadera inferior de la

correa para hombro debajo del tubo

superior y alinee los huecos del tor

nillo de la abrazadera superior y la

abrazadera inferior (use las tabula

ciones del espaciador entre la abra

zadera superior y abrazadera inferi

or en caso de necesidad para

asegurar la abrazadera, es decir

para tubos de 1 pulgada de diáme

tro del tubo superior).

Abrazadera Superior

EXTREMO CON

EL CABEZA DE

de ia Correa para

Hombro

MOTOR

4. Asegure la abrazadera de la cor

rea para el hombro apretando los

tornillos con ia llave hexagonal.

5. Introduzca el brazo derecho y la ca

beza por el arco de la correa y apo

ye ésta en el hombro izquierdo.

Asegúrese de que el signo de peli

gro se encuentre en su espalda y

de que el enganche se encuentre

en el lado derecho de su cintura.

AVISO: La correa puede girarse media

vuelta para garantizar que quede apo

yada en toda su anchura sobre el

hombro.

6. Ajuste la correa para permitir que

el enganche quede a unos 15 cm

por debajo de la cintura.

7. Fije el enganche de la correa a la

abrazadera y levante la herramien

ta hasta la posición de trabajo.

8. Antes de poner en marcha el motor

o iniciar cualquier tarea de corte,

póngase la correa en el hombro y

ajústela a su medida de modo que

le permita mantener el equilibrio.

AVISO: Puede ser necesario mover la

abrazadera de la correa para el hombro

en el eje para un equilibrio apropiado

del aparato.

AJUSTE DEL

CORREA AL HOMBRO

PARA EL BALANCE

15 cm

(6 pulga

das) de

bajo de la

cintura

10 - 30 cm

(4 - 12 pul

gadas) del

suelo

EXTREMO CON

EL ACCESORIO

Abrazadera | Tornillos

inferior de i a

Correa para Hombro

3. Inserte dos tornillos en los huecos

para tornillo.

18

Page 18

CONOZCA SU CORTADORA DE MALEZAS ACCESORIO

LEA ESTE MANUAL DE INSTRUCCIONES Y LAS REGLAS DE SEGURIDAD ANTES DE

COMENZAR A USAR ESTE CORTADORA DE MALEZAS ACCESORIO. Compare las

ilustraciones con su aparato para familiarizarse con la ubicación de los diversos

controles y ajustes. Guarde este manuai para uso futuro.

Suspensor I

Cuchilla

CUCHILLA

La CUCHILLA ha sido diseñada para

cortar hierba, plantas de pequeño ta

maño y brozas con tallos de madera

de hasta 13 mm de diámetro.

OPERACION DEL ACOPLADOR

Este modelo está equipado con un

acoplador, el cual permite la instala

ción de accesorios opcionales. Los

accesorios opcionales son:

Cortadora de Bordes .. 358.792400

Cultivador........................ 358.792410

Propulsor de Aire

...........

358.792420

A ADVERTENCIA: Siempre desco

necte la bujía de la cabeza de motor

antes de retirar o instalar los accesorios.

COMO REMOVER EL ACCESORIO

DEL CORTADORA DE MALEZAS (U

OTROS ACCESORIOS OPCIONAL)

PRECAUCION: Al retirar o instalar las

accesorios, ponga el cabeza de motor

y el accesorio en una superficie plana

para estabilidad.

1. Afloje el acoplador dando vuelta a

la perilla a la izquierda.

Tubo

Acoplador j Superior

Accesorio

Inferior

APRIETA!

PROTECTOR DE LA CUCHILLA

El PROTECTOR DE LA CUCHILLA protege

al operador de la cuchilla girante.

2. Oprima y sostenga el botón de

conexión/desconexión.

Botón de Conexión/

Desconexión

^^Acopladoi

Tubo Superior

Accesorio Inferior

3.

Mientras sostiene el tubo superior

con firmeza, retire el accesorio in

ferior del acoplador en forma recta.

INSTALACIÓN DEL ACCESORIOS

OPCIONAL

1.2.Retire la tapa de tubo del acceso

rio (si presente) y deseche.

Coloque el botón de conexión/des

conexión del accesorio inferior en

el agujero de la guía del acoplador

de la tubo superior.

Primer

Acoplador

Agujero Agujero de

' la Guía

Tubo

Superior

Botón de Accesorio

Conexión/ Inferior

Desconexión

19

Page 19

3. Empuje el accesorio inferior en el

acoplador hasta que el botón de

conexión/desconexlón se encaje

en el primer agujero.

4. Antes de usar el aparato, apriete

la perilla firmemente dando vuelta

a la derecha.

INSTACALIÓN DEL SUSPENSOR

Una suspensor de la accesorio se pro

porciona para el almacenaje cuando la

accesorio no se está utilizando.

Para instalar la suspensión en la acce

sorio:

1. Retire la tapa de tubo del acceso

rio (si presente) y deseche.

2. Presione y sostenga el botón de

conexión/desconexlón.

3. Empuje la suspensor sobre la ac

cesorio hasta que el botón de conexión/desconexión se encaja en el

hueco.

POSICIÓN DE USO

AVISO: Esta cortadora de malezas

accesorio no se diseña para el uso

con los cabezas del motor eléctricos.

Cuando aparato de funcionamiento

con el cortadora de malezas acceso

rio, enganche la correa para hombro

en el abrazadera de la correa para el

hombro, paróse como se vea en la fi

gura y verifique lo siguiente:

• Usando anteojos de seguridad y

ropa gruesa como protección.

• Mantenga brazos extendido con la

mano derecha sostiene el mango del

gatillo acelerador del cabeza de motor.

• Mantenga el brazo izquierdo extendi

do con la mano izquierda sostenga el

mango.

• Mantenga el aparato por debajo de

la cintura.

• Mantenga almohadilla de la correa al

hombro centrada en el hombro

izquierdo y señal de peligro centrada

en su espalda.

• Mantenga todo el peso de la herra

mienta en el hombro izquierdo.

• Sin tener que inclinarse, mantenga

la cuchilla debe permanecer paralelo

al suelo y entrar fácilmente en con

tacto con el material a cortar.

INSTRUCCIONES DE MANEJO CON

CORTADORA DE MALEZAS

ACCESORIO

• El Rebote de la Cuchilla es una

reacción que sólo se produce cuan

do el aparato está equipado con una

cuchilla. Esta reacción puede cau

sar graves lesiones, como la ampu

tación. Estudie detenidamente esta

sección. Es importante que el usua

rio comprenda por qué se producen

los rebotes, cómo reducir las proba

bilidades de que ocurran y cómo

mantener el control del aparato

cuando se producen.

• CAUSAS DEL REBOTE DE LA

CUCHILLA - El Rebote de la

Cuchilla puede producirse cuando

la cuchilla en rotación entra en con

tacto con un objeto que no puede

cortar. Este contacto detiene la

cuchilla durante un instante y la ale

ja súbitamente del objeto tocado. La

reacción de “rebote” puede ser lo su

ficientemente violenta para empujar

al operador en cualquier dirección y

hacer que pierda el control del apa

rato. Una vez fuera de control, el

aparato puede causar lesiones gra

ves si la cuchilla entra en contacto

con el operador u otras personas.

• CUÁNDO SE PRODUCE UN REBO

TE DE CUCHILLA - El Rebote de

la Cuchilla puede ocurrir sin previo

aviso si ésta se cala, engancha o

traba. La probabilidad de que esto

ocurra aumenta en las zonas donde

resulta difícil ver el material a cortar.

Utilizando el aparato adecuadamen

te se reduce el número de rebotes

de cuchilla y la probabilidad de que

el operador pierda el control.

Con la cuchilla para hierbas sólo

puede cortarse hierba, plantas de

pequeño tamaño y brozas con tallos

de madera de hasta 13 mm de diá

metro. No permita que la cuchilla

entre en contacto con material que

no puede cortar, como tocones, pie

dras, vallas, metales, etc. o grupos

de tallos de broza con diámetros su

periores a 13 mm.

20

Page 20

• Mantenga la cuchilla bien afilada.

Una cuchilla roma puede enganchar

se y rebotar con más facilidad.

• Corte solamente a plena potencia.

Así, la cuchilla dispondrá de la máxi

ma potencia de corte y tendrá menos

posibilidades de calarse o trabarse.

• “Alimente" la cuchilla con cuidado y no

demasiado rápidamente. La cuchilla

puede rebotar si se le obliga a cortar

demasiado material ai mismo tiempo.

• Corte solamente de derecha a iz

quierda. La acción de corte aumenta

si se desplaza el aparato en la mis

ma dirección que gira la cuchilla.

» Utilice la correa al hombro y manten

ga bien sujeto el aparato con ambas

manos. Una correa al hombro ajus

tada correctamente absorberá el pe

so del aparato, dejando libres sus

brazos y manos para controlar y

guiar el movimiento de corte.

• Mantenga los pies separados cómo

damente y bien apoyados en previ

sión de que el aparato rebote repenti

namente. No estire el cuerpo en

exceso. Manténgase firmemente en

postura erguida y equilibrada.

• Mantenga la cuchilla por debajo de

la cintura; asi le resultará más fácil

mantener el control del aparato.

• No levante el motor por encima de su

cintura, ya que la cuchilla podría acer

carse peligrosamente a su cuerpo.

• No balancee el aparato con tal fuer

za que pueda perder el equilibrio.

Antes de penetrar en el material a cor

tar, acelere el motor hasta la velocidad

de corte.

Si la cuchilla no gira al apretar el gatillo

del acelerador, asegúrese de que la

barra esté completamente insertada

en el motor.

Siempre que no esté cortando, suelte

el gatillo del acelerador y deje que el

motor regrese a la velocidacf de ra

lenti. La cuchilla no debe girar mien

tras el motor se encuentre al ralenti. Si

la cuchilla sigue girando con el motor

al ralenti, no utilice el aparato. Con

sulte la sección de ajustes del carbu

rador o póngase en contacto con el

Centro de Servicio Sears.

• Manténgase firmemente en pie y

pise con seguridad siempre que uti

lice el aparato. Para ello, mantenga

los pies cómodamente separados.

• Corte mientras balancea la parte

superior de su cuerpo de derecha a

izquierda.

• Mientras avanza a la siguiente zona

de corte, cerciórese de mantener el

equilibrio y de pisar firme.

POSICION

RECOMENDADA

PARA CORTAR

Corte utilizando la

sección de la cuchilla g q,.,

correspondiente

a la franja horaria

entre las 8 y las 10.

10 en pun'

X

. /''■

punto

^ADVERTENCIA: Para evitar

graves lesiones, ni el operador ni otras

personas deben intentar retirar el ma

terial de corte mientras el motor esté

en marcha o la cuchilla se encuentre

girando. Antes de retirar materiales en

rollados alrededor de la cuchilla o de

la barra, detenga el motor y la cuchilla.

MANTENIMIENTO

CRONOGRAMA DE MANTENIMIENTO

ADVERTENCIA: Siempre apague el aparato y desconecte la bujía

antes de hacer cualquier mantenimiento.

TAREA DE CUIDADO Y MANTENIMIENTO CUANDO HACER

Verificar que no haya piezas ni fijadores sueltos Antes de cada uso

Verificar que no haya piezas dañadas ni gastadas Antes de cada uso

Inspeccione v limpie el aparato v las placas Después de cada uso

Inspeccionar o cambiar la cuchilla Cada 5 horas de uso

21

Page 21

RECOMENDACiONES GENERALES

La garantía de este aparato no cubre

los artículos que han sido sometidos a!

abuso o a la negligencia por parte del

usuario. Para recibir el valor completo

de la garantía, el usuario deberá man

tener el cortadora de malezas accesorio

según las instrucciones en este manual.

VERIFIQUE QUE NO HAYA PIEZAS

DAÑADAS NI GASTADAS

Entre en contacto con el Centro de

Servicio Sears para el remplazo de

piezas dañadas o desgastadas.

• Protector para la cuchilla - Deje de

usar el accesorio si el protector para la

cuchilla está dañado.

VERIFIQUE QUE NO HAYA FIJA

DORES SUELTOS NI OTRAS PIE

ZAS SUELTAS

• Tuerca de la cuchilla

• Fijadores

INSPECCIONE Y LIMPIE EL

APARATO Y LAS PLACAS

• Después de que cada uso, Inspec

cione la aparato completa para

saber si hay piezas flojas o dañados.

Limpie el aparato y sus placas usando

u trapo húmedo con detergente

suave.

• Seque el aparato con un trapo limpio

y seco.

MANTENIMIENTO DE LA CUCHILLA

^ADVERTENCIA: La cuchilla si

gue girando después de que el motor

para y después de que se suelte el ga

tillo. Para evitar graves heridas,

asegúrese de que la cuchilla se haya

detenido completamente y desconecte

la bujía antes de hacer ningún tragajo

con la cuchilla.

^ADVERTENCIA: Cambio

siempre la cuchilla si está doblada,

otro forma. Nunca intente enderezar y

volver a usar una cuchilla dañada.

Use únicamente la cuchilla de repues

to especificada. Use guantes protec

tores al tocar u al hacer mantenimiento

a la cuchilla para evitar heridas.

• Periódicamente verifique que la cu

chilla esté perfectamente recta.

Apoye la cuchilla en una superficie

plana e inspecciónela. Descarte la

cuchilla si no está perfectamente

plana.

SERVICE Y AJUSTES

CAMBIO DE LA CUCHILLA

^ADVERTENCIA: La cuchilla si

gue girando después de que el motor

para y después de que se suelte el ga

tillo. Para evitar graves heridas,

asegúrese de que la cuchilla se haya

detenido completamente y desconecte

la bujía antes de hacer ningún tragajo

con la cuchilla.

AaDVERTENCIA: Use guantes

de protección al tocar o al hacer man

tenimiento a la cuchilla para evitar her

idas. La cuchilla es muy filosa y corta

aún no estando en movimiento.

1. Gire la cuchilla para hacer coinci

dir el orificio del taza para el polvo

con el orificio lateral del cajetín de

engranajes.

2. introduzca un destornillador pe

queño por los orificios confronta

dos. Esto previene que el eje gire

mientras usted afloje la tuerca de

la cuchilla.

Destornillador

3. Manteniendo el destornillador en su

posición, remueva la tuerca de la

cuchilla dando vuelta a la derecha

como usted está frente a la tuerca.

4. Remueva ambas arandelas y la

cuchilla de la eje. Deje el taza

para el polvo en el caja de engra

najes.

5. instale la cuchilla nueva y la

arandela de retén en el eje rosca

do que sobresale del caja de

engranajes (la cuchilla debe estar

entre el taza para el polvo y la

arandela de retén). Asegúrese de

que el lado elevado de la arandela

de retén esté orientado hacia el

caja de engranajes y de que el re

salte quepa en el hueco central de

la cuchilla.

22

Page 22

6. Coloque la arandela abombada en

el eje. Asegúrese de que el lado

más ancho de la arandela esté

orientado bada la cuchilla.

7. Instale la tuerca de la cuchilla

enroscándola en el eje dando

vuelta a la tuerca a la izquierda

como usted está frente a la tuerca.

AVISO: Asegúrese de que todas las

piezas estén colocadas en su sitio y

de que la cuchilla esté aprisionada en

tre el taza para el polvo y la arandela

de retén. No debe quedar ninguna hol

gura entre !a cuchilla y el taza para el

polvo o la arandela de retén.

8. Manteniendo el destornillador en su

posición, apriete la tuerca firme

mente usando una llave.

9. Remueva el destornillador.

10. Gire la cuchilla de mano. Si la

cuchilla se aproxima a la protector

o parece girar irregularmente,

significa que no está centrada y

será necesario reinstalarla.

ALMACENAJE

A ADVERTENCIA: Realice los si

guientes pasos después de cada uso:

• Deje enfriar el motor y el caja de en

granajes antes de guardarlo o de

transportarlo.

• Almacene el aparato con todos los

protector del cuchilla en su lugar cor

respondiente. Posicione al aparato

de modo que la cuchilla no pueda

herir accidentalmente.

• Almacene ei aparato en un área

seca, bien ventilada y fuera del al

cance de los niños.

ESTACIONAL ALMACENAJE

Prepare el aparato para almacenarlo

al final de la temporada o si no lo va a

usar por más de 30 días.

Si se almacene su accesorio por un

período del tiempo:

• Limpie el aparato en su totalidad.

Inspeccione el área del protector y

limpie toda la tierra, el hierba, las ho

jas y los escombros que ha acumu

lado. Inspeccione la cuchilla y el

protector; cambie la cuchilla si está

doblada, torcida, resquebrajada,

quebrada o dañada de cualquier otro

modo.

Aplique una leve capa de aceite a

las superficies metálicas exteriores.

Aplique una capa de aceite a la su

perficie entera de la cuchilla; envuél

valo en papel grueso o tela.

Examine el aparato en su totalidad

para verificar que no haya tornillos ni

tuercas sueltos. Cambie toda pieza

dañada, gastado o quebrada.

Al comienzo de la próxima tempora

da, utilice solamente combustible

fresco mezclado en proporción con

el aceite.

23

Loading...

Loading...