Page 1

Instruction Manual

25cc/1.5 cu.in. 2-Cycle

17 Inch Cutting Path / 0.080 In. Line

GASOLINE WEEDWAOKER ®

Model No.

358.791010

• Safety

• Assembly

• Operation

• Maintenance

• Parts List

• Espar_ol

For Occasional Use Only

WARNING:

Read and follow all Safety Rules and Operating

Instructions before first use of this product.

For answers to your questions about this product:

Call 7 am-7 pm, Mon.-Sat., or 10 am-7 pm, Sun.

1-800-235-5878 (Hours listed are Central Time)

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

545082939 1/20/06

Page 2

Warranty Statement 2 Storage 11

Safety Rules 2 Troubleshooting Chart 12

Assembly 4 Emissions Statement 13

Operation 5 Parts List 15

Maintenance 9 Spanish 17

Service & Adjustments 10 Parts and Ordering Back

FULL ONE YEAR WARRANTY ON CRAFTSMAN ® GAS POWERED

WEEDWACKER ® LINE TRIMMER.

For one year from the date of purchase, when this Craftsman DGas Powered

Weedwacker Line Trimmer is maintained, lubricated, and tuned up according to

the operating and maintenance instructions in this manual, Sears will repair, free

of charge, any defect in materials or workmanship.

This warranty excludes nylon line, spark plug, and air filter, which are expendable

parts and become worn during normal use.

If this Weedwacker line trimmer is used for commercial purposes, this warranty ap-

plies for only 90 days from the date of purchase. If this Weedwacker line trimmer is

used for rental purposes, this warranty applies for only 30 days from the date of pur-

chase. This warranty applies only while this product is in use in the United States.

WARRANTY SERVICE ISAVAILABLEBY RETURNING THE WEEDWACKER LINE TRIMMER

TO THE NEAREST SEARS STORE OR SERVICE CENTER INTHE UNITED STATES.

This warranty gives you specific legal rights, and you may also have other rights

which vary from state to state.

Sears, Roebuck and Co., D/817 WA, Hoffman Estates, IL 60179

4tSWARNING: When using gar-

dening appliances, basic safety pre-

cautions must always be followed to

reduce the risk of fire and serious

injury. Read and follow all instructions=

This power unit can be dangerous! Op-

erator is responsible for following

instructions and warnings on unit and in

manual. Read entire instruction manual

before using unit! Be thoroughly familiar

with the controls and the proper use of

the unit. Restrict the use of this unit to

persons who have read, understand,

and will follow the instructions and

warnings on the unit and in the manual.

Never allow children to operate this unit.

INSTRUCTION SAFETY INFORMATION

MANUAL ON THE UNIT

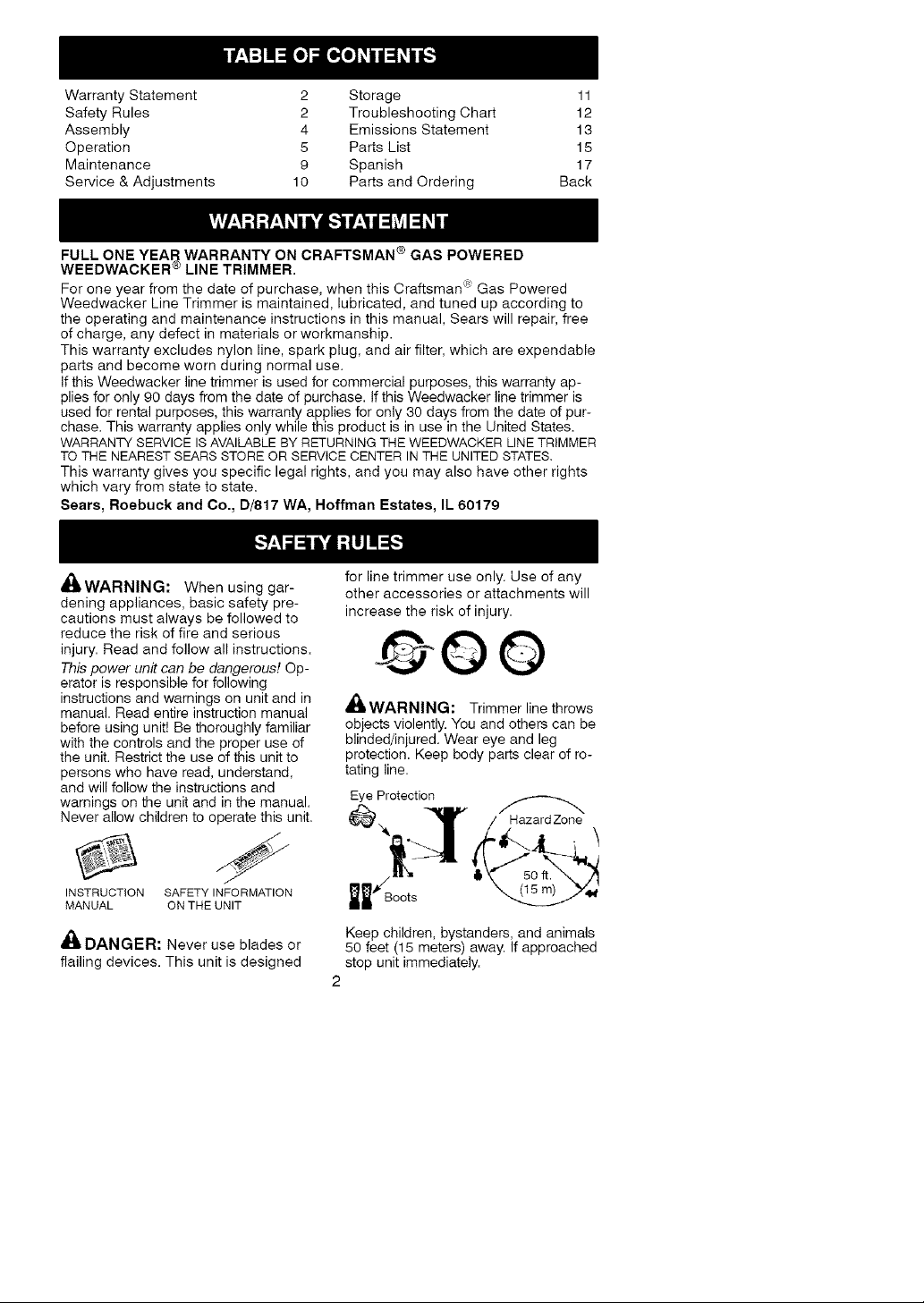

_k DANGER: Never use blades or

flailing devices. This unit is designed

for line trimmer use only. Use of any

other accessories or attachments will

increase the risk of injury.

@QO

_WARNING: Trimmer line throws

objects violently. You and others can be

blinded/injured. Wear eye and leg

protection. Keep body parts clear of ro-

tating line.

Eye Protection

/ Hazard Zone

::4oo,s

Keep children, bystanders, and animals

50 feet (15 meters) away. If approached

stop unit immediately.

2

Page 3

Ifsituationsoccurwhicharenotcov-

eredinthismanual,usecareand

goodjudgment.Ifyouneedassis-

tance,contactyourSearsService

Centerorcall1-800-235-5878.

OPERATORSAFETY

• Dress properly. Always wear safety

glasses or similar eye protection when

operating, or performing maintenance,

on your unit (safety glasses are avail-

able). Eye protection should be

marked Z87.

• Always wear face or dust mask if op-

eration is dusty.

• Always wear heaW, long pants, long

sleeves, boots, and gloves. Wearing

safety leg guards is recommended.

• Always wear foot protection. Do not

go barefoot or wear sandals. Stay

clear of spinning line.

• Secure hair above shoulder length.

Secure or remove loose clothing or

clothing with loosely hanging ties,

straps, tassels, etc. They can be

caught in moving parts.

• Being fully covered also helps protect

you from debris and pieces of toxic

plants thrown by spinning line.

• Stay Alert. Do not operate this unit

when you are tired, ill, upset or under

the influence of alcohol, drugs, or

medication. Watch what you are do-

ing; use common sense.

• Wear hearing protection.

• Never start or run inside a closed

room or building. Breathing exhaust

fumes can kill.

• Keep handles free of oil and fuel.

UNIT / MAINTENANCE SAFETY

• Disconnect tile spark plug before per-

forming maintenance except carbure-

tor adjustments.

• Look for and replace damaged or

loose parts before each use. Look for

and repair fuel leaks before use. Keep

in good working condition.

• Replace trimmer head parts that are

chipped, cracked, broken, or dam-

aged in any other way before using

the unit.

• Maintain unit according to recom-

mended procedures. Keep cutting line

at proper length.

• Use only 0.080 inch (2 mm) diameter

Craftsman(R_ brand line. Never use

wire, rope, string, etc.

• Install required shield properly before

using the unit. Use only specified trim-

mer head; make sure it is properly

installed and securely fastened.

• Make sure unit is assembled correctly

as shown in this manual.

• Make carburetor adjustments with

lower end supported to prevent line

from contacting any object.

• Keep others away when making car-

buretor adjustments.

• Use only recommended Craftsman®

accessories and replacement parts.

• Have all maintenance and service not

explained in this manual performed by

a Sears Service Center.

FUEL SAFETY

• Mix and pour fuel outdoors.

• Keep away from sparks or flames.

• Do not smoke or allow smoking near

fuel or the unit.

• Avoid spilling fuel or oil. Wipe up all

fuel spills.

• Move at least 10 feet (3 meters) away

from fueling site before starting en-

gine.

• Stop engine and allow to cool before

removing fuel cap.

• Always store gasoline in a container

approved for flammable liquids.

CUTTING SAFETY

_'WARNING: Inspect the area be-

fore each use. Remove objects

(rocks, broken glass, nails, wire, etc.)

which can be thrown by or become

entangled in line. Hard objects can

damage the trimmer head and be

thrown causing serious injury.

• Use only for trimming, scalping, mow-

ing and sweeping. Do not use for edg-

ing, pruning or hedge trimming.

• Keep firm footing and balance. Do not

overreach.

• Keep all parts of your body away from

muffler and spinning line. Keep engine

below waist level. A hot muffler can

cause serious burns.

• Cut from your left to your right. Cutting

on right side of the shield will throw

debris away from the operator.

• Use only in daylight or good artificial

light.

• Use only for jobs explained in this

manual.

TRANSPORTING AND STORAGE

• Allow engine to cool; secure unit be-

fore storing or transporting in vehicle.

• Empty the fuel tank before storing or

transporting the unit. Use up fuel left

in the carburetor by starting the en-

gine and letting it run until it stops.

• Store unit and fuel in area where fuel

vapors cannot reach sparks or open

Page 4

flamesfromwaterheaters,electric

motorsorswitches,furnaces,etc.

• Storeunitsolinelimiterbladecannot

accidentallycauseinjury.Theunit

canbehungbythetube.

• Storeunitoutofreachofchildren.

SAFETYNOTICE:Exposuretovibra-

tionsthroughprolongeduseofgaso-

linepoweredhandtoolscouldcause

bloodvesselornervedamageinthe

fingers,hands,andjointsofpeople

pronetocirculationdisordersorab-

normalswellings.Prolongedusein

coldweatherhasbeenlinkedtoblood

vesseldamageinotherwisehealthy

people.Ifsymptomsoccursuchas

numbness,pain,lossofstrength,

changeinskincolorortexture,orloss

offeelinginthefingers,hands,or

joints,discontinuetheuseofthistool

andseekmedicalattention.Ananti-

vibrationsystemdoesnotguarantee

theavoidanceoftheseproblems.Us-

erswhooperatepowertoolsonacon-

tinualandregularbasismustmonitor

closelytheirphysicalconditionand

theconditionofthistool.

SPECIALNOTICE:Thisunitis

equippedwithatemperaturelimiting

mufflerandsparkarrestingscreen

whichmeetstherequirementsofCali-

forniaCodes4442and4443.AllU.S.

forestlandandthestatesofCalifornia,

Idaho,Maine,Minnesota,NewJersey,

Oregon,andWashingtonrequireby

lawthatmanyinternalcombustionen-

ginesbeequippedwithasparkarrest-

ingscreen.Ifyouoperateinalocale

wheresuchregulationsexist,youare

legallyresponsibleformaintainingthe

operatingconditionoftheseparts.

Failuretodosoisaviolationofthe

law.Fornormalhomeowneruse,the

mufflerandsparkarrestingscreenwill

notrequireanyservice.After50hours

ofuse,werecommendthatyourmuf-

flerbeservicedorreplacedbyyour

SearsServiceCenter.

CARTONCONTENTS

Checkcartoncontentsagainstthefol-

lowinglist.

Model 358.791010

• Trimmer

• Shield

• Container of Oil

Examine parts for damage. Do not

use damaged parts.

NOTE: If you need assistance or find

parts missing or damaged, call

1-800-235-5878.

It is normal for the fuel filter to rattle in

the empty fuel tank.

Finding fuel or oil residue on muffler is

normal due to carburetor adjustments

and testing done by the manufacturer.

ASSEMBLY

,_WARNING: If received as-

sembled, repeat all steps to ensure

your unit is properly assembled and all

fasteners are secure.

ADJUSTING THE HANDLE

'_WARNING: When adjusting tile

assist handle, be sure it remains above

the safety label and below the mark or

arrow on the shaft.

1. Loosen wing nut on handle.

2. Rotate the handle on the shaft to an

upright position; retighten wing nut.

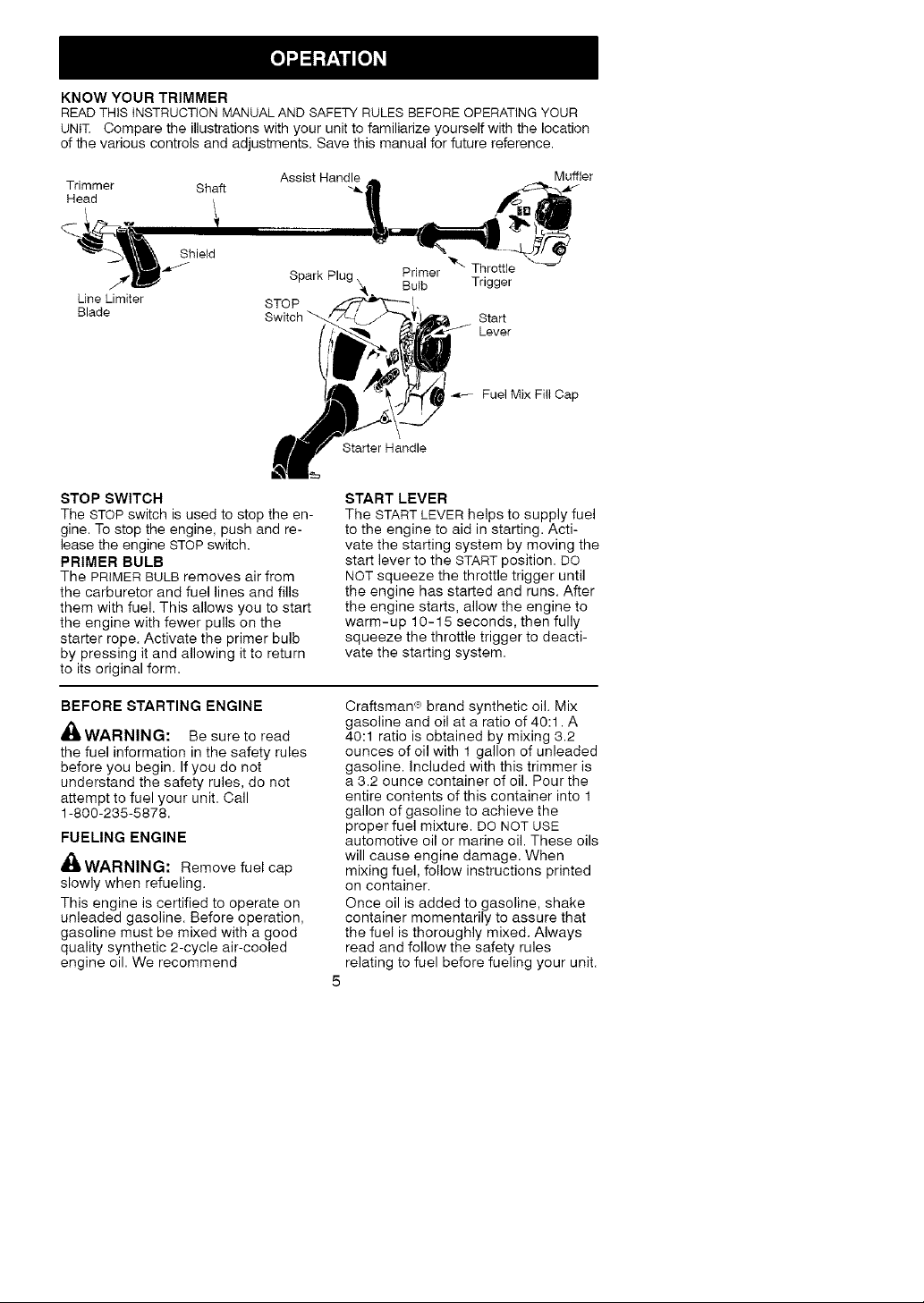

ATTACHING SHIELD

_WARNING: The shield must be

properly installed. The shield provides

partial protection from the risk of thrown

objects to the operator and others and

is equipped with a line limiter blade

which cuts excess line to the proper

length. The line limiter blade (on under-

side of shield) is sharp and can cut you.

For proper orientation of shield, see

KNOW YOUR TRIMMER illustration in OP-

ERATION section.

1. Remove wing nut from shield.

2. Insert bracket into slot as shown.

3. Pivot shield until bolt passes

through hole in bracket.

4. Securely tighten wing nut onto

bolt.

Bracket

Slot

Wing Nut

PIVOT

Shield

Page 5

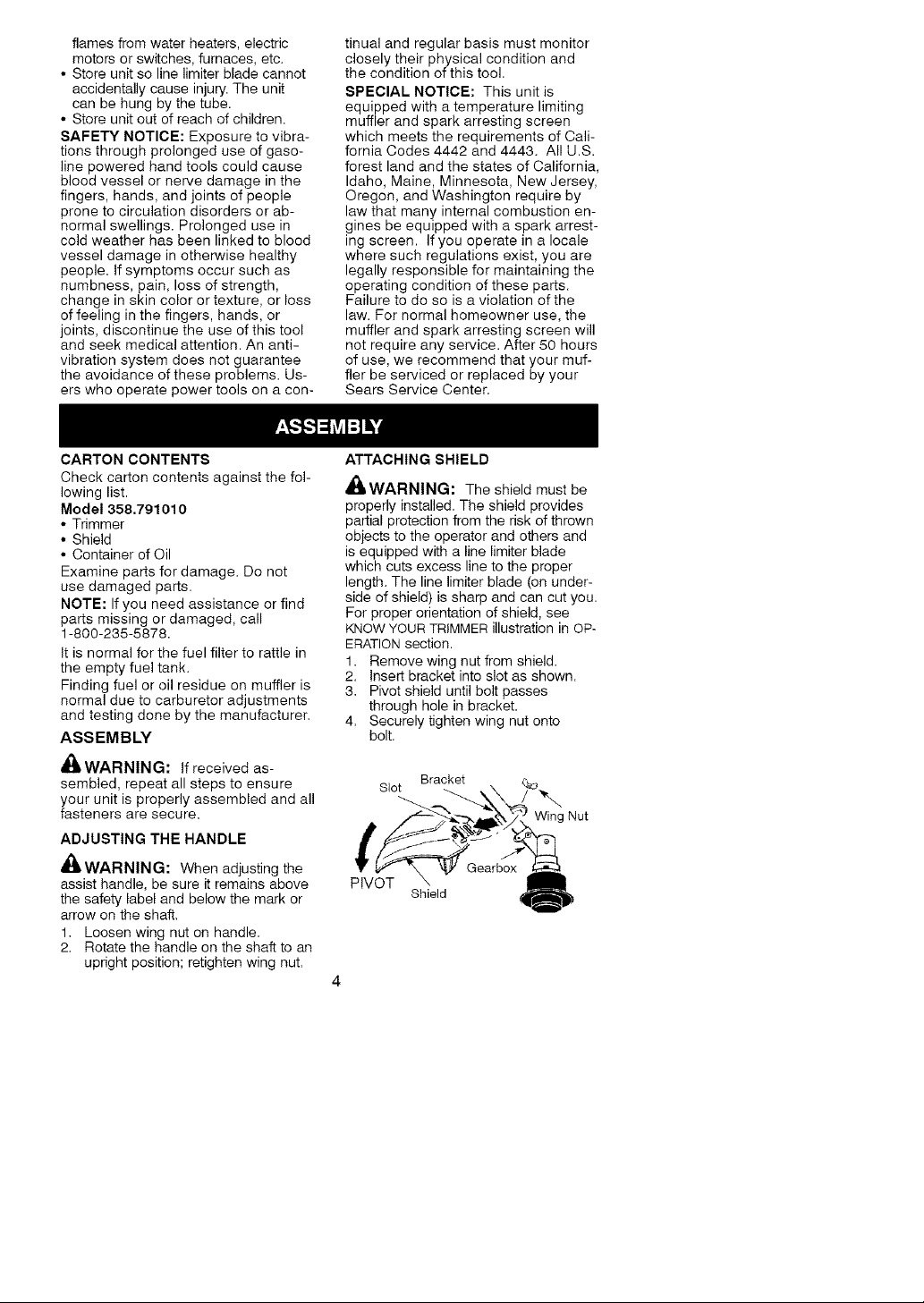

KNOWYOURTRIMMER

READ THiS iNSTRUCTiON MANUAL AND SAFETY RULES BEFORE OPERATING YOUR

UNIT. Compare the illustrations with your unit to familiarize yourself with the location

of the various controls and adjustments. Save this manual for future reference.

Trier_e r Assist Handle -- Muffler

_ -_11 _ Shaft ___

_._hield Spark Plu '

Line Limiter STOP

Blade Start

Starter Handle

Lever

Fuel Mix Fill Cap

STOP SWITCH

The STOP switch isused to stop the en-

gine. To stop the engine, push and re-

lease the engine STOP switch.

PRIMER BULB

The PRIMER BULB removes air from

the carburetor and fuel lines and fills

them with fuel. This allows you to start

the engine with fewer pulls on the

starter rope. Activate the primer bulb

by pressing it and allowing it to return

to its original form.

BEFORE STARTING ENGINE

_WARNING: Be sure to read

the fuel information in the safety rules

before you begin. If you do not

understand the safety rules, do not

attempt to fuel your unit. Call

1-800-235-5878.

FUELING ENGINE

_WARNING: Remove fuel cap

slowly when refueling.

This engine is certified to operate on

unleaded gasoline. Before operation,

gasoline must be mixed with a good

quality synthetic 2-cycle air-cooled

engine oil. We recommend

START LEVER

The START LEVER helps to supply fuel

to the engine to aid in starting. Acti-

vate the starting system by moving the

start lever to the START position. DO

NOT squeeze the throttle trigger until

the engine has started and runs. After

the engine starts, allow the engine to

warm-up 10-15 seconds, then fully

squeeze the throttle trigger to deacti-

vate the starting system.

Craftsman <_brand synthetic oil. Mix

gasoline and oil at a ratio of 40:1. A

40:1 ratio is obtained by mixing 3.2

ounces of oil with 1 gallon of unleaded

gasoline. Included with this trimmer is

a 3.2 ounce container of oil. Pour the

entire contents of this container into 1

gallon of gasoline to achieve the

proper fuel mixture. DO NOT USE

automotive oil or marine oil. These oils

will cause engine damage. When

mixing fuel, follow instructions printed

on container.

Once oil is added to gasoline, shake

container momentarily to assure that

the fuel is thoroughly mixed. Always

read and follow the safety rules

relating to fuel before fueling your unit.

5

Page 6

IMPORTANT

Experience indicates that alcohol

blended fuels (called gasohol or using

ethanol or methanol) can attract mois-

ture which leads to separation and

formation of acids during storage.

Acidic gas can damage the fuel sys-

tem of an engine while in storage.

To avoid engine problems, empty the

fuel system before storage for 30 days

or longer. Drain the gas tank, start the

engine and let it run until the fuel lines

and carburetor are empty. Use fresh

fuel next season.

Never use engine or carburetor clean-

er products in the fuel tank or perma-

nent damage may occur.

See the STORAGE section for addition-

al information.

HOW TO STOP YOUR UNIT

• To stop the engine, push and re-

lease the engine STOP switch. The

switch will automatically return to the

ON position. Wait 5 seconds before

attempting to restart unit to allow

switch to reset.

• If engine does not stop, move choke

to the FULL CHOKE position.

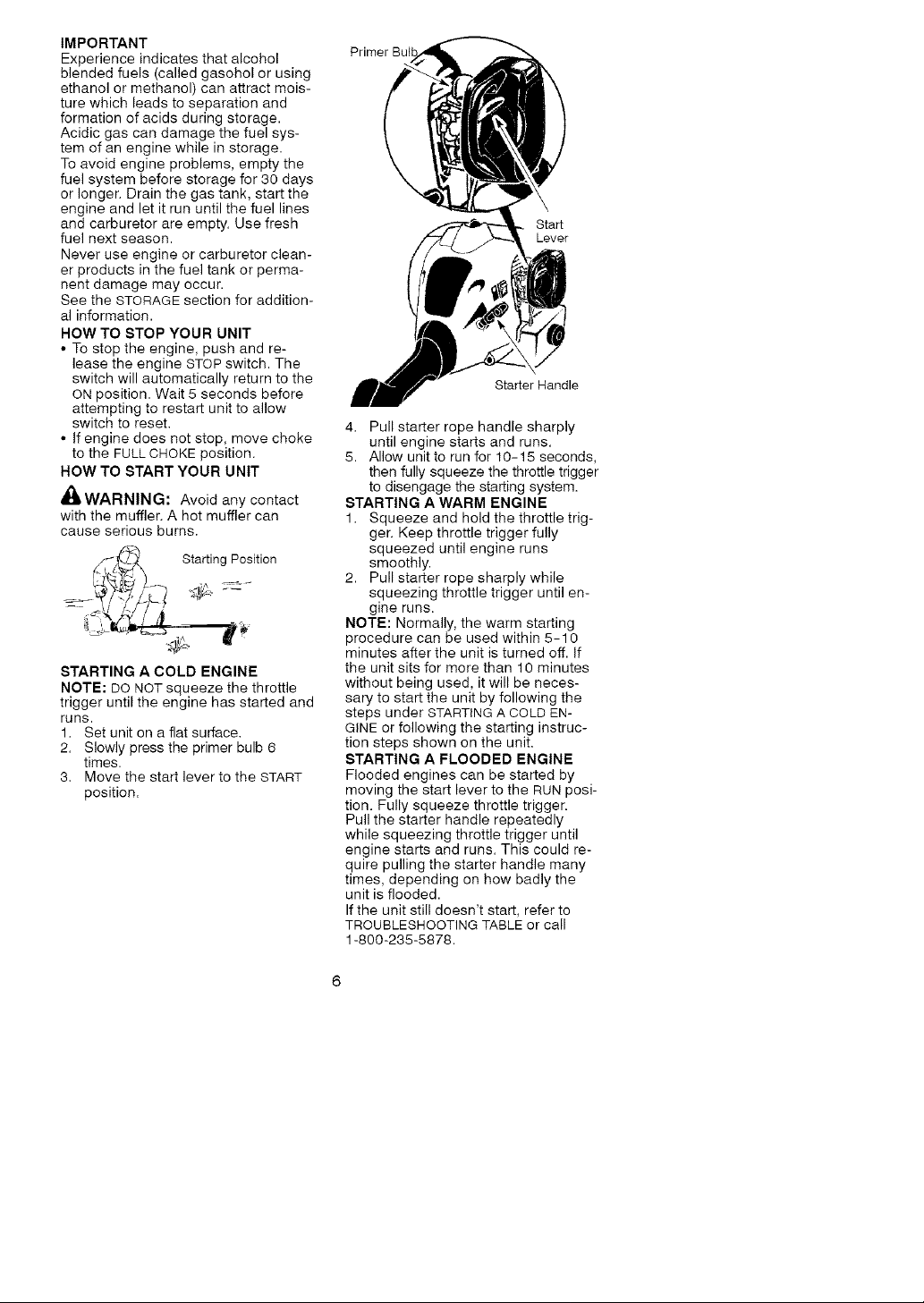

HOW TO START YOUR UNIT

_WARNING: Avoid any contact

with the muffler. A hot muffler can

cause serious burns.

¢_,_{% Starting Position

STARTING A COLD ENGINE

NOTE: DO NOT squeeze the throttle

trigger until tile engine has started and

runs.

1. Set unit on a flat surface.

2. Slowly press the primer bulb 6

times.

3. Move the start lever to the START

position.

Primer

Start

Lever

Starter Handle

4. Pull starter rope handle sharply

until engine starts and runs.

5. Allow unit to run for 10-15 seconds,

then fully squeeze the throttle trigger

to disengage the starting system.

STARTING A WARM ENGINE

1= Squeeze and hold tile throttle trig-

ger. Keep throttle trigger fully

squeezed until engine runs

smoothly.

2. Pull starter rope sharply while

squeezing throttle trigger until en-

gine runs.

NOTE: Normally, the warm starting

procedure can be used within 5-10

minutes after the unit is turned off. If

the unit sits for more than 10 minutes

without being used, it will be neces-

sary to start the unit by following the

steps under STARTING A COLD EN-

GINE or following the starting instruc-

tion steps shown on the unit.

STARTING A FLOODED ENGINE

Flooded engines can be started by

moving the start lever to the RUN posi-

tion. Fully squeeze throttle trigger.

Pull the starter handle repeatedly

while squeezing throttle trigger until

engine starts and runs. This could re-

quire pulling the starter handle many

times, depending on how badly the

unit is flooded.

If the unit still doesn't start, refer to

TROUBLESHOOTING TABLE or call

1-800-235-5878.

Page 7

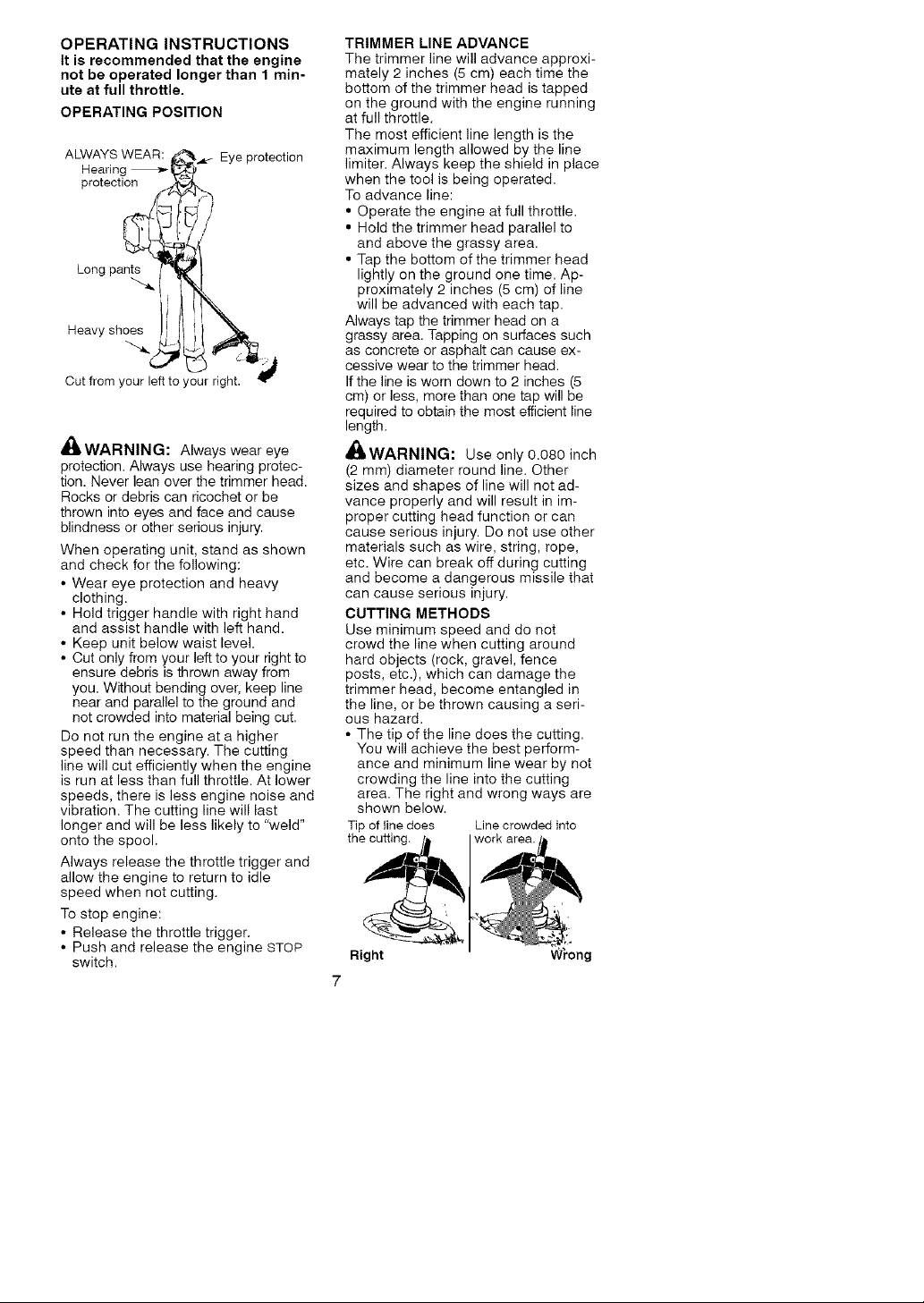

OPERATING INSTRUCTIONS

It is recommended that the engine

not be operated longer than 1 min-

ute at full throttle.

OPERATING POSITION

ALWAYS WEAR: _ _r- Eye protection

Hearing _{L_

protection _. "_

/

Cut from your left to your right _

A ________

,I_,WARNING: Always wear eye

protection, Always use hearing protec-

tion, Never lean over the trimmer head.

Rocks or debris can ricochet or be

thrown into eyes and face and cause

blindness or other serious injury.

When operating unit, stand as shown

and check for the following:

• Wear eye protection and heavy

clothing.

• Hold trigger handle with right hand

and assist handle with left hand.

• Keep unit below waist level.

• Out only from your left to your right to

ensure debris is thrown away from

you. Without bending over, keep line

near and parallel to the ground and

not crowded into material being cut.

Do not run the engine at a higher

speed than necessary. The cutting

line will cut efficiently when the engine

is run at less than full throttle. At lower

speeds, there is less engine noise and

vibration. The cutting line will last

longer and will be less likely to "weld"

onto the spool.

Always release the throttle trigger and

allow the engine to return to idle

speed when not cutting.

To stop engine:

• Release the throttle trigger.

• Push and release the engine STOP

switch.

TRIMMER LINE ADVANCE

The trimmer line will advance approxi-

mately 2 inches (5 cm) each time the

bottom of the trimmer head is tapped

on the ground with the engine running

at full throttle.

The most efficient line length is the

maximum length allowed by the line

limiter. Always keep the shield in place

when the tool is being operated.

To advance line:

• Operate the engine at full throttle.

• Hold the trimmer head parallel to

and above the grassy area.

• Tap the bottom of the trimmer head

lightly on the ground one time. Ap-

proximately 2 inches (5 cm) of line

will be advanced with each tap.

Always tap the trimmer head on a

grassy area. Tapping on surfaces such

as concrete or asphalt can cause ex-

cessive wear to the trimmer head.

If the line is worn down to 2 inches (5

cm) or less, more than one tap will be

required to obtain the most efficient line

length.

Ag&WARNING: Use only 0.080 inch

(2 ram) diameter round line. Other

sizes and shapes of line will not ad-

vance properly and will result in im-

proper cutting head function or can

cause serious injury. Do not use other

materials such as wire, string, rope,

etc. Wire can break off during cutting

and become a dangerous missile that

can cause serious injury.

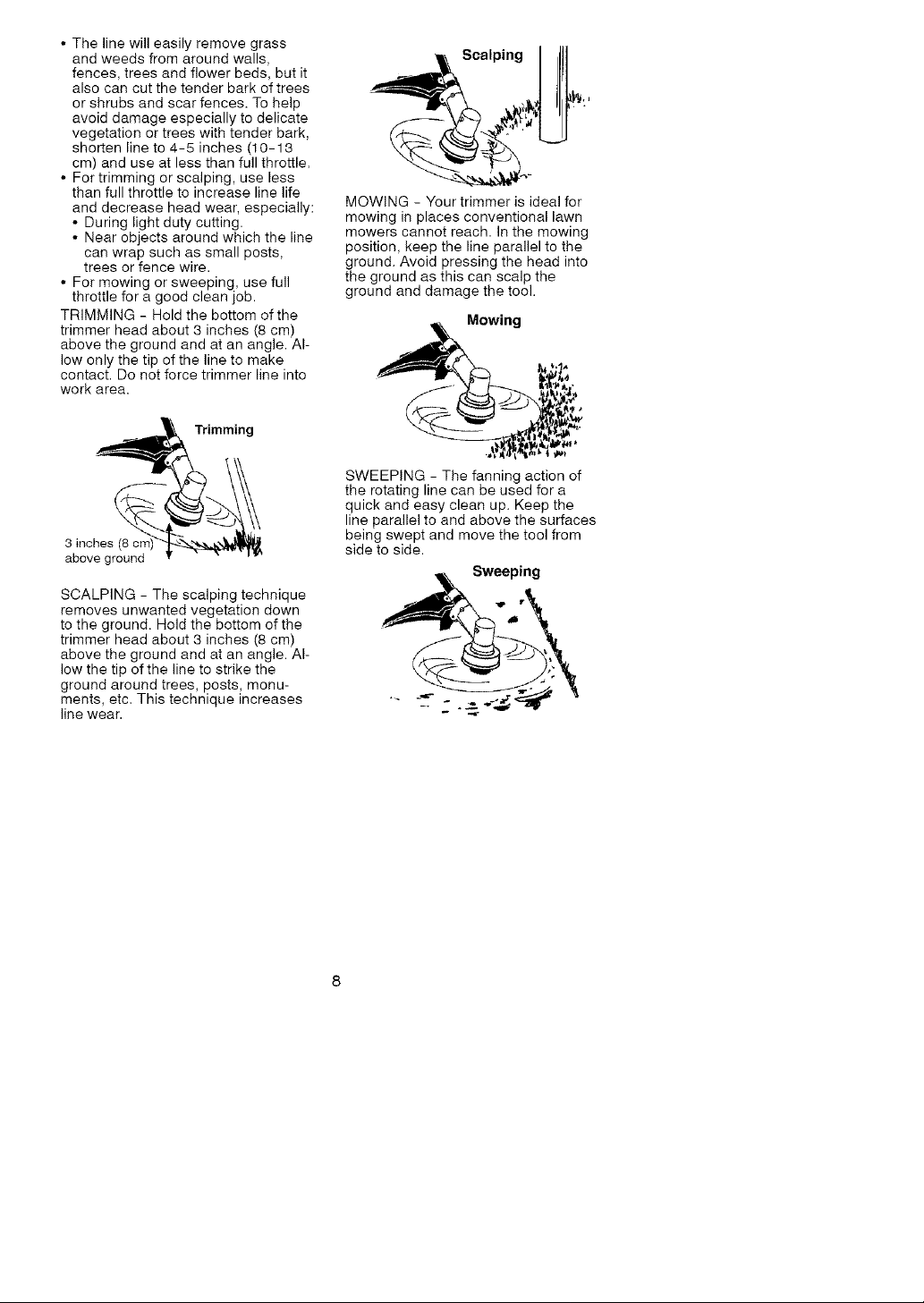

CUTTING METHODS

Use minimum speed and do not

crowd the line when cutting around

hard objects (rock, gravel, fence

posts, etc.), which can damage the

trimmer head, become entangled in

the line, or be thrown causing a seri-

ous hazard.

• The tip of the line does the cutting.

You will achieve the best perform-

ance and minimum line wear by not

crowding the line into the cutting

area. The right and wrong ways are

shown below.

Tip of line does Line crowded into

the cutting.

Right W_'ong

7

Page 8

• Thelinewilleasilyremovegrass

andweedsfromaroundwalls,

fences,treesandflowerbeds,butit

alsocancutthetenderbarkoftrees

orshrubsandscarfences.Tohelp

avoiddamageespeciallytodelicate

vegetationortreeswithtenderbark,

shortenlineto4-5inches(10-13

cm)anduseatlessthanfullthrottle.

• Fortrimmingorscalping,useless

thanfullthrottletoincreaselinelife

anddecreaseheadwear,especially:

• Duringlightdutycutting.

• Nearobjectsaroundwhichtheline

canwrapsuchassmallposts,

treesorfencewire.

• Formowingorsweeping,usefull

throttleforagoodcleanjob.

TRIMMING- Holdthebottomofthe

trimmerheadabout3inches(8cm)

abovethegroundandatanangle.Al-

lowonlythetipofthelinetomake

contact.Donotforcetrimmerlineinto

workarea.

Trimming

3 inches (8 cm

above ground

SCALPING - The scalping technique

removes unwanted vegetation down

to the ground. Hold the bottom of the

trimmer head about 3 inches (8 cm)

above the ground and at an angle. Al-

low the tip of the line to strike the

ground around trees, posts, monu-

ments, etc. This technique increases

line wear.

Scalping

MOWING - Your trimmer is ideal for

mowing in places conventional lawn

mowers cannot reach. In the mowing

position, keep the line parallel to the

ground. Avoid pressing the head into

the ground as this can scalp the

ground and damage the tool.

Mowing

SWEEPING - The fanning action of

the rotating line can be used for a

quick and easy clean up. Keep the

line parallel to and above the surfaces

being swept and move the tool from

side to side.

Sweeping

Page 9

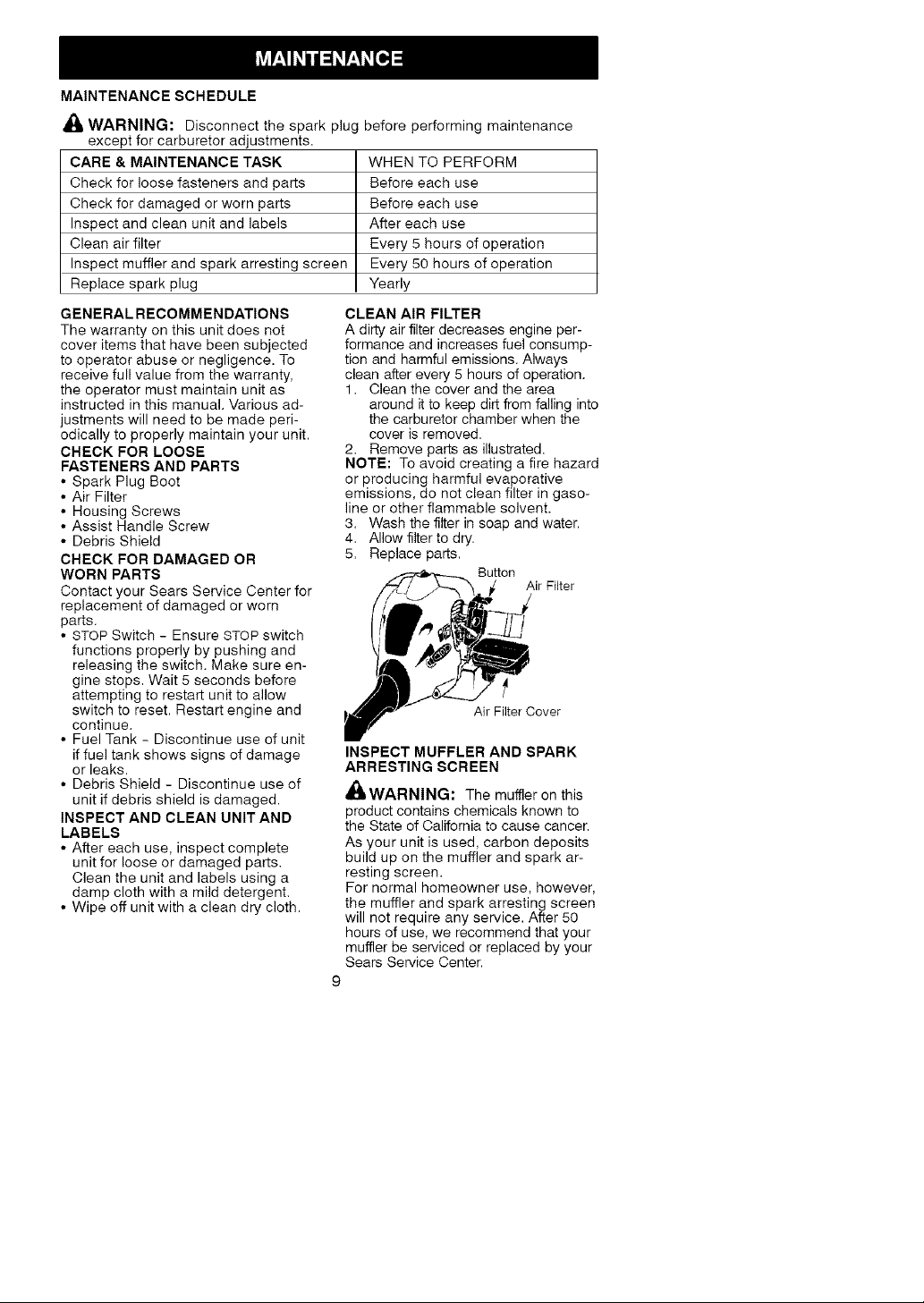

MAINTENANCE SCHEDULE

_, WARNING: Disconnect the spark plug

except for carburetor adjustments.

CARE & MAINTENANCE TASK

Check for loose fasteners and parts

Check for damaged or worn parts

Inspect and clean unit and labels

Clean air filter

Inspect muffler and spark arresting screen

Replace spark plug

GENERAL RECOMMEN DATIONS

The warranty on this unit does not

cover items that have been subjected

to operator abuse or negligence. To

receive full value from the warranty,

the operator must maintain unit as

instructed in this manual. Various ad-

justments will need to be made peri-

odically to properly maintain your unit.

CHECK FOR LOOSE

FASTENERS AND PARTS

• Spark Plug Boot

• Air Filter

• Housing Screws

• Assist Handle Screw

• Debris Shield

CHECK FOR DAMAGED OR

WORN PARTS

Contact your Sears Service Center for

replacement of damaged or worn

parts.

• STOP Switch - Ensure STOP switch

functions properly by pushing and

releasing the switch. Make sure en-

gine stops. Wait 5 seconds before

attempting to restart unit to allow

switch to reset. Restart engine and

continue.

• Fuel Tank - Discontinue use of unit

if fuel tank shows signs of damage

or leaks.

• Debris Shield - Discontinue use of

unit if debris shield is damaged.

INSPECT AND CLEAN UNIT AND

LABELS

• After each use, inspect complete

unit for loose or damaged parts.

Clean the unit and labels using a

damp cloth with a mild detergent.

• Wipe off unit with a clean dry cloth.

9

before performing maintenance

WHEN TO PERFORM

Before each use

Before each use

After each use

Every 5 hours of operation

Every 50 hours of operation

Yearly

CLEAN AIR FILTER

A dirty air filter decreases engine per-

formance and increases fuel consump-

tion and harmful emissions. Always

clean after every 5 hours of operation.

1. Clean the cover and the area

around it to keep dirt from falling into

the carburetor chamber when the

cover is removed.

2. Remove parts as illustrated.

NOTE: To avoid creating a fire hazard

or producing harmful evaporative

emissions, do not clean filter in gaso-

line or other flammable solvent.

3. Wash the filter in soap and water.

4. Allow filter to dry.

5. Replace parts.

INSPECT MUFFLER AND SPARK

ARRESTING SCREEN

_WARNING: The muffler on this

product contains chemicals known to

the State of California to cause cancer.

As your unit is used, carbon deposits

build up on the muffler and spark ar-

resting screen.

For normal homeowner use, however,

the muffler and spark arresting screen

will not require any service. After 50

hours of use, we recommend that your

muffler be serviced or replaced by your

Sears Service Center.

Button

Air Filter

Air Filter Cover

Page 10

REPLACE SPARK PLUG

Replace the spark plug each year to

ensure the engine starts easier and

runs better. Set spark plug gap at

0.025 inch. Ignition timing is fixed and

nonadjustable.

1. Twist, then pull off spark plug boot.

2. Remove spark plug from cylinder

and discard.

3. Replace with Champion RCJ-6Y

spark plug and tighten securely with

a 3/4 inch socket wrench.

4. Reinstall the spark plug boot.

LINE REPLACEMENT

1= Push and release the engine

STOP switch.

2. Disconnect the spark plug wire.

3. Remove spool by firmly pulling on

tap button.

4. Clean entire surface of hub and

spool.

5. Replace with a pre-wound spool, or

cut two lengths of 12-1/2 feet (3.8

meters) of 0.080" (2 mm) diameter

Craftsman'> brand line.

_tlWARNING: Never use wire,

rope, string, etc., which can break off

and become a dangerous missile.

6. Insert ends of line about 1/2 inch

(1 cm) into the small holes on the

inside of the spool.

Spool _ />_/7 _

ZqWJ_/sma,,

if St/ Ho,es

7. Wind line evenly and tightly onto

spool. Wind in the direction of the

arrow on the spool.

8. Push the line into the notches, leav-

ing 3 to 5 inches (7 - 12 cm) un-

wound.

9. Insert the line into the exit holes in

the hub as shown in the illustration.

Line exit holes Line in Notch

\ x

Line in Notch

10. Align the notches with the line exit

holes.

11. Push spool into hub until it snaps

into place.

12. Pull the lines extending outside of

the hub to release them from the

notches.

REPLACING THE CUTTING HEAD

1. Align hole in the dust cup with the

hole inthe side of the gearbox by

rotating the dust cup.

2. Insert a small screwdriver into

aligned holes. This will keep the

shaft from turning while removing

and installing trimmer head.

Screwdriv_

3. While holding the screwdriver in

position, remove trimmer head by

turning clockwise.

4. Thread replacement trimmer head

onto the shaft by turning counter-

clockwise. Tighten until secure.

5. Remove the screwdriver.

CARBURETOR ADJUSTMENT

,_WARNING: Keep others away

when making idle speed adjustments.

The trimmer head will be spinning dur-

ing this procedure. Wear your protec-

tive equipment and observe all safety

precautions.

The carburetor has been carefully set

at the factory. Adjustments may be

necessary if you notice any of the fol-

lowing conditions:

• Engine will not idle when the throttle is

released.

Make adjustments with the unit sup-

ported so the cutting attachment is off

the ground and will not make contact

with any object. Hold the unit by hand

while running and making adjust-

ments. Keep all parts of your body

away from the cutting attachment and

muffler.

lO

Page 11

Idle Speed Adjustment

Allow engine to idle. Adjust speed until

engine runs without stalling (idle

speed too slow).

• Turn idle speed screw clockwise to

increase engine speed if engine

stalls or dies.

• Turn idle speed screw counterclock-

wise to decrease engine speed.

idle Speed Screw

Air Filter Cover

If you require further assistance or are

unsure about performing this proce-

dure, contact your Sears Service Cen-

ter or call our customer assistance

help line at 1-800-235-5878.

4t_WARNING: Perform the follow-

ing steps after each use:

• Allow engine to cool, and secure the

unit before storing or transporting.

• Store unit and fuel in a well venti-

lated area where fuel vapors cannot

reach sparks or open flames from

water heaters, electric motors or

switches, furnaces, etc.

• Store unit with all guards in place.

Position unit so that any sharp ob-

ject cannot accidentally cause injury.

• Store unit and fuel well out of the

reach of children.

SEASONAL STORAGE

Prepare unit for storage at end of sea-

son or if it will not be used for 30 days

or more.

If your unit is to be stored for a period

of time:

• Clean the entire unit before lengthy

storage.

• Store in a clean dry area.

• Lightly oil external metal surfaces.

FUEL SYSTEM

Under FUELING ENGINE in the OPERA-

TION section of this manual, see mes-

sage labeled IMPORTANT regarding

the use of gasohol in your engine.

Fuel stabilizer is an acceptable alter-

native in minimizing the formation of

fuel gum deposits during storage. Add

stabilizer to the gasoline in the fuel

tank or fuel storage container. Follow

the mix instructions found on stabilizer

container. Run engine at least 5 min-

utes after adding stabilizer.

Craftsman ® 40:1,2-cycle engine oil

(air cooled) is already blended with

fuel stabilizer. If you do not use this

Sears oil, you can add a fuel stabilizer

to your fuel tank.

INTERNAL ENGINE

• Remove spark plug and pour 1 tea-

spoon of 40:1,2-cycle engine oil (air

cooled) through the spark plug

opening. Slowly pull the starter rope

8 to 10 times to distribute oil.

• Replace spark plug with new one of

recommended type and heat range.

• Clean air filter.

• Check entire unit for loose screws,

nuts, and bolts. Replace any dam-

aged, broken, or worn parts.

• At the beginning of the next season,

use only fresh fuel having the proper

gasoline to oil ratio.

OTHER

• Do not store gasoline from one sea-

son to another.

• Replace your gasoline can if it starts

to rust.

11

Page 12

TROUBLESHOOTING TABLE

_, WARNING: Always stop unit and disconnect spark plug before perform-

ing all of the recommended remedies below except remedies that require

operation of the unit.

TROUBLE

Engine will not

start.

Engine will

not idle

properly.

Engine will not

accelerate,

lacks power.

or dies under

a load.

CAUSE

1. Engine flooded.

2. Fuel tank empty.

3. Spark plug not firing.

4. Fuel not reaching 4.

carburetor.

5. Carburetor requires 5.

adjustment.

1. Carburetor requires 1.

adjustment.

2. Crankshaft seals worn. 2.

3. Compression low. 3.

1. Air filter dirty. 1.

2. Spark plug fouled. 2.

3. Carburetor requires 3.

adjustment.

4. Carbon build-up on 4.

muffler outlet screen.

5. Compression low. 5.

REMEDY

1,

See "Starting a Flooded Engine" in

Operation Section.

2.

Fill tank with correct fuel mixture.

3.

Install new spark plug.

Check for dirty fuel filter; replace.

Check for kinked or split fuel line;

repair or replace.

Contact Sears Service (see back cover).

See "Carburetor Adjustment" in

Service and Adjustments Section.

Contact Sears Service (see back cover).

Contact Sears Service (see back cover).

Clean or replace air filter.

Clean or replace plug and regap.

Contact Sears Service (see back cover).

Contact Sears Service (see back cover).

Contact Sears Service (see back cover).

Engine

smokes

excessively.

Engine runs

hot.

1. Choke partially on. 1.

2. Fuel mixture incorrect. 2.

3. Air filter dirty. 3.

4. Carburetor requires 4.

adjustment.

1. Fuel mixture incorrect. 1.

2. Spark plug incorrect. 2.

3. Carburetor requires 3.

adjustment.

4. Carbon build-up on 4.

muffler outlet screen.

Adjust choke.

Empty fuel tank and refill with

correct fuel mixture.

Clean or replace air filter.

Contact Sears Service (see back cover).

See "Fueling Engine" in Operation

section.

Replace with correct spark plug.

Contact Sears Service (see back cover).

Contact Sears Service (see back cover).

12

Page 13

YOUR WARRANTY RIGHTS AND OB-

LIGATIONS: The U.S. Environmental

Protection Agency/California Air Re-

sources Board and Sears, Roebuck

and Co., U.S.A., are pleased to explain

the emissions control system warranty

on your year 2005 and later small off-

road engine. In California, all small off-

road engines must be designed, built,

and equipped to meet the State's strin-

gent anti-smog standards. Sears must

warrant the emission control system on

your small off-road engine for the peri-

ods of time listed below provided there

has been no abuse, neglect, or improp-

er maintenance of your small off-road

engine. Your emission control system

includes parts such as the carburetor

and the ignition system. Where a war-

rantable condition exists, Sears will re-

pair your small off-road engine at no

cost to you. Expenses covered under

warranty include diagnosis, parts and

labor. MANUFACTURER'S WARRAN-

TY COVERAGE: If any emissions re-

lated part on your engine (as listed un-

der Emissions Control Warranty Parts

List) is defective or a defect in the mate-

rials or workmanship of the engine

causes the failure of such an emission

related part, the part will be repaired or

replaced by Sears. OWNER'S WAR-

RANTY RESPONSIBILITIES: As the

small off-road engine owner, you are

responsible for the performance of the

required maintenance listed in your in-

struction manual. Sears recommends

that you retain all receipts covering

maintenance on your small off-road en-

gine, but Sears cannot deny warranty

solely for the lack of receipts or for your

failure to ensure the performance of all

scheduled maintenance. As the small

off-road engine owner, you should be

aware that Sears may deny you war-

ranty coverage if your small off-road

engine or a part of it has failed due to

abuse, neglect, improper maintenance,

unapproved modifications, or the use of

parts not made or approved by the orig-

inal equipment manufacturer. You are

responsible for presenting your small

off-road engine to a Sears authorized

repair center as soon as a problem ex-

ists. Warranty repairs should be com-

pleted in a reasonable amount of time,

not to exceed 30 days. If you have any

questions regarding your warranty rights

and responsibilities, you should contact

your nearest authorized service center

or call Sears at 1-800-469-4663.

WARRANTY COMMENCEMENT

DATE: The warranty period begins on

the date the small off-road engine is

purchased. LENGTH OF COVERAGE:

This warranty shall be for a period of

two years from the initial date of pur-

chase. WHAT IS COVERED: REPAIR

OR REPLACEMENT OF PARTS. Re-

pair or replacement of any warranted

part will be performed at no charge to

the owner at an approved Sears Servi-

ce Center. Ifyou have any questions

regarding your warranty rights and re-

sponsibilities, you should contact your

nearest authorized service center or call

Sears at 1-800-469-4663. WARRAN-

TY PERIOD: Any warranted part which

is not scheduled for replacement as re-

quired maintenance, or which is sched-

uled only for regular inspection to the

effect of "repair or replace as neces-

sary" shall be warranted for 2 years.

Any warranted part which is scheduled

for replacement as required mainte-

nance shall be warranted for the period

of time up to the first scheduled replace-

ment point for that part. DIAGNOSIS:

The owner shall not be charged for

diagnostic labor which leads to the de-

termination that a warranted part is de-

fective if the diagnostic work is per-

formed at an approved Sears Service

Center. CONSEQUENTIAL DAM-

AGES: Sears may be liable for dam-

ages to other engine components

caused by the failure of a warranted

part still under warranty. WHAT IS NOT

COVERED: All failures caused by

abuse, neglect, or improper mainte-

nance are not covered. ADD-ON OR

MODIFIED PARTS: The use of add-on

or modified parts can be grounds for

disallowing a warranty claim. Sears is

not liable to cover failures of warranted

parts caused by the use of add-on or

modified parts. HOW TO FILE A

CLAIM: If you have any questions re-

garding your warranty rights and re-

sponsibilities, you should contact your

nearest authorized service center or call

Sears at 1-800-469-4663.

13

Page 14

WHERE TO GET WARRANTY SER-

VICE: Warranty services or repairs shall

be provided at all Sears Service Cen-

ters. Call 1-800-469-4663. MAINTE-

NANCE, REPLACEMENT AND RE-

PAIR OF EMISSION RELATED

PARTS: Any Sears approved replace-

ment part used in the performance of

any warranty maintenance or repair on

emission related parts will be provided

The information on the product label indicates to which standard your engine is certified,

Example: (Year) EPA Phase Ior Phase II and/or CALIFORNIA.

without charge to the owner if the part is

under warranty. EMISSION CONTROL

WARRANTY PARTS LIST: Carburetor,

Ignition System: Spark Plug (covered

up to maintenance schedule), Ignition

Module, Muffler including catalyst.

MAINTENANCE STATEMENT: The

owner is responsible for the perfor-

mance of all required maintenance as

defined in the instruction manual.

This engine is certified to be emissions compliant for the following use:

[] Moderate (50 hours)

[] Intermediate (125 hours)

[] Extended (300 hours)

14

Page 15

Declaraci6n de Garantia 17 Almacenaje 28

Reglas de Seguridad 17 Tabla Diagn6stica 29

Montaje 20 Declaraci6n de Emision 30

Uso 21

Mantenimiento 25 Lista de Piezas 15

Servicio y Ajustes 26 Repuesto y Encargos Contratapa

GARANTIA DE UN AI_IO COI_PLETO PARA LA _;ORTADORA DE LINEA A

GASOLINA WEEDWACKER _ DE CRAFTSMAN _

Durante un a_o, a partir de la fecha de compra, siempre que se haga el mantenimi-

ento, la lubricaci6n y los ajustes a esta Cortadora de Linea a Gasolina Weedwacker

de Craftsman segQn las instrucciones de uso y mantenimiento en el manual, Sears

reparar& cualquier defecto de materiales o de mano de obra gratuitamente.

Esta garantia excluye la linea de nil6n, la bujia y el filtro de aire, que son piezas

fungibles que se gastan con el uso normal.

Si se usa esta Cortadora de linea Weedwacker de Craftsman para fines comer-

ciales, esta garantia tendr& validez pot s61a 90 dias a partir de la fecha de com-

pra. Si se usa esta Cortandor de linea Weedwacker de Craftsman para fines de

alquiler, esta garantia tendr& validez por s61a 30 dias a partir de la fecha de com-

pra. Esta garantia tendr& validez Qnicamente mientras se use este producto den-

tro de los Estados Unidos.

SE OBTENDRA SERVlCIO BAJO GARANTIA DEVOLVlENDO LACORTADORA DE LINEA

WEEDWACKER AL TIENDA DE SEARS O CENTRO DE SERVlCIO MAS CERCANO EN

LOS ESTADOS UNIDOS.

Esta garantia confiere derechos legales especificos al propietario, que tal vez

tenga asimismo otros derechos que varian entre estados.

Sears, Roebuck and Co., D/817 WA Hoffman Estates, IL 60179

_ADVERTENCIA: AI usar cualqui-

er herramienta de fuerza de jardinefia,

deber&n observarse precauciones b&si-

cas de seguirdad en todo momento para

reducir el riesgo de incendio y graves heri-

das. Lea y cumpla con todas las instruc-

ciones.

iEsta herramienta de fuerza puede ser

peligrosa! Cabe al usuario le responsa-

bilidad de cumplir con todas las adver-

tencias e instrucciones, iLea el manual

de instrucciones en su totalidad antes

de usar el aparato! Est6 completamente

familiarizado con los controles y con el

uso correcto de] aparato. Limite el uso

de este aparato a aquellas personas

que hayan leido y comprendido, y que

vayan a obedecer, todas las adverten-

cias e instrucciones tanto en el aparato

come en el manual. No permita nunca a

los ni_os que usen este aparato.

MANUAL DE INFORMACION

INSTRUCCIONES DE SEGURIDAD

A

A_, PELIGRO: Nunca use cuchillas ni

dispositivos desgranadores. El aparato

rue diseSado para ser usado exclusiva-

mente como cortador a linea. El uso de

cualquier otra pieza o accesorio incre-

mentar& el peligro de heridas. Este apara-

to ha sido diseSado exclusivamente

como cortador a linea.

DELAPARATO

17

Page 16

_ADVERTENClA: La lineadecorte

arroja objetos violentamente. Ustes, al

igual que otras personas, puede quedar

ciego o herido. Use anteojos de seguri-

dad y protecci6n en las piemas. Manten-

ga todas las partes del cuerpo alejadas

de la linea girante.

Use anteojos de seguridad

Mantenga a los niSos, los espectadores

y animales a una distancia minima de

15 metros (50 pies). Pare el motor

inmediatamente si alguien se le acerca.

Si acontece alguna situaci6n no prevista

en este manual, tenga cuidado y use

buen criterio. Si necesita ayuda, entre

en contacto con su Centro de Servicio

Sears o Ilame al 1-800-235-5878.

SEGURIDAD DEL USUARIO

• Vistase apropiadamente. Siempre

use anteojos de seguridad o similar

protecci6n para los ojos cuando use

o d6 mantenimiento a este aparato

(anteojos de seguridad est&n dispo-

nibles). La protecci6n para los ojos

debe ser marcada ANSI Z87.1.

• Siempre utilize mascarilla para la

cara o mascarilla a prueba de polvo

si se va a trabajar en condiciones

donde hay polvo.

• Siempre utilize pantalones pesados

y largos, mangas largas, botas y

guantes. Se recomienda el uso de

pantorrilleras de seguridad.

• Siempre utilize protecci6n para los

pies. No trabaje descalzo ni en

sandalias. Evite la linea girante.

• Mantenga el cabello por encima de

los hombros, at&ndolo para tal efecto

si es necesario. No use ropa suelta ni

ropa con corbatas, tiras, borlas, etc.

que cuelgan libremente. Pueden enre-

darse en las piezas en movimiento.

• Si est& completament tapado, estar&

m&s protegido de los escombros y

pedazos de plantas t6xicos arroja-

dos por la linea girante.

• Mant6ngase alerta. No haga uso del

aparato estando cansado, enfermo,

trastornado o bajo la influencia del

alcohol, de drogas o de remedios.

Vigile bien Io que est& haciendo; use

del sentido comQn.

• Use protecci6n de oidos.

• Nunca ponga el aparato en marcha

ni Io deje en marcha dentro de un

recinto cerrado. Respirar los vapores

del combustible Io puede matar.

• Mantenga las manijas fibres de

aceite y de combustible.

SEGURIDAD DEL APARATO Y EN

EL MANTENIMIENTO

• Desconecte la bujia antes de hacer

cualquier mantenimiento menos los

ajustes al carburador.

• Inspeccione el aparato y cambie las

piezas daSadas o flojas antes de

cada uso. Repare toda fuga de com-

bustible antes de usar el aparato.

Mantenga el aparato en buenas con-

diciones de uso.

• Cambie todas las piezas del cabezal

que est6n descantilladas, resquebra-

jadas, quebradas o daSadas de cu-

alquier otto modo, antes de usar el

aparato.

• Haga el mantenimiento del aparato

de acuerdo a los procedimientos re-

comendados. Mantenga la linea de

corte el largo aprodiado.

• Use solamente linea de di&metro 2

mm (0,080 de pulgada) de la marcha

Craftsman@. Nunca use alambre,

soga, hilo, etc.

• Instale la protector requerida antes

de usar su aparato. Use la bobina

especificada. AsegOrese que la bobi-

na est6 correctamente instalada y

este bien fijo.

• AsegOrese que el aparato est6 cor-

rectamente armado como se mues-

tra en el manual.

• Haga los ajustes al carburador con

el cabezal apoyado de mode que la

linea no pueda tocar nada.

• Mantenga alejadas alas dem&s per-

sonas siempre que haga ajustes al

carburador.

• Use exclusivamente los accesorios y

repuestos Craftsman® recomendados.

• Todo servicio y mantinimiento no ex-

plicado en este manual deber& set

efectuado per un Centro de Servicio

Sears.

SEGURIDAD CON EL COMBUSTIBLE

• Mezcle y vierta el combustible al aire

libre.

• Mant6ngalo alejado de las chispas y

de las llamas.

• No fume ni permita que se fume cer-

ca del combustible ni del aparato ni

mientras 6ste est6 en uso.

• Evite derramar el combustible o el

aceite. Limpie todo el combustible der-

ramado.

18

Page 17

• AI6jese a por Io menos 3 metros (10

pies) del lugar de abastecimiento

antes de poner en marcha el motor.

• Pare el motor y permita que se enfrie

el aparato antes de retirar la tapa del

tanque.

• AImac6ne siempre combustible en

un recipiente aprobado para los

liquidos inflamables.

SEGURIDAD AL CORTAR

ADVERTENCIA: Inspeccione el

&tea antes de cada use. Retire los obje-

tos (piedrae, vidrio roto, clavoe, alambre,

etc.) que se puedan enredar en la linea

o que _sta pueda arrojar. Los objetos

duros pueden daSar el cabezal y 6ete

los puede arrojar, causando graves heri-

dae.

• Use el aparato exclusivamente para

recortar, para cortar c6sped y para

barter. No Io use para cortar hordes,

para podar ni para recortar seto.

• Mantenga el equilibrio, con los pies

en una euperficie estable. No se ex-

tienda demasiado.

• Mantenga todas las partes del cuer-

po alejadas de la linea girante y del

silenciador. Mantenga el motor per

debajo del nivel de la cintura. El si-

lenciador puede causar graves que-

maduras cuando est& caliente.

• Corte siempre de izquierda a dere-

cha. Si se corta con la linea del lade

derecho del protector, los escombros

volar&n en sentido opuesto al usuario.

• Use el aparato Qnicamente de dia o

en luz artificial fuerte.

• Utilice el aparato solamente para las

tareas explicadas en este manual.

TRANSPORTE Y ALMACENAMIENTO

• Espere que el motor se enfrie y fije

bien el aparato antes de quardarlo o

de transportarlo en un vehiculo.

• Vacie el tanque de combustible antes

de guardar el aparato o de transpor-

tarlo. Consuma todo el combustible

restante en el carburador poniendo el

motor en marcha y dej&ndolo en mar-

cha hasta que le motor se pare solo.

• Guarde el aparato y el combustible

en un lugar donde los vapores del

combustible no puedan alcanzar

chispas ni llamas provenientes de

los termotanques, los motores o in-

terruptores el6ctricos, los calefac-

tores centrales, etc.

• Guarde el aparato de mode que el

limitador de linea no pueda causar

heridas accidentales. Se puede col-

gar el aparato por la caja el eje de

propulsi6n.

• Guarde el aparato fuera del alcance

de los niSos.

AVISO DE SEGURIDAD: El estar ex-

puesto alas vibraciones a trav6e del

uso prolongado de herramientae de

fuerza a gasolina puede causar dai]oe a

los vases eanguineos o a los nervios de

los dedos, lae manoe y lae coyunturas

en aquellae personas que tienen pro-

pensidad a los trastornos de la circula-

ci6n o a lae hinchazonee anormales. El

uso prolongado en tiempo frio ha side

asociado con daSoe a los vasos san-

guineos de personas que por otra parte

se encuentran en perfecto estado de

ealud. Si ocurren sintomas tales como el

entumecimiento, el dolor, la falta de fuer-

za, los cambios en el color o la textura

de la piel o falta de sentido en los de-

doe, las manoe o las coyunturas, deje

de usar esta m&quina inmediatamente y

procure atenci6n m6dica. Los sistemas

de anti-vibraci6n no garantizan que se

eviten tales problemae. Los usuarioe

que hacen use continuo y prolongando

de las herramientas de fuerza deben

fiscalizar atentamente su estado fieico y

el estado del aparato.

AVISO ESPECIAL: Su aparato viene

equipada con eilenciador limitador de

temperatura y con rejilla antichispa que

cumpla los requisitos de los C6digos de

California 4442 y 4443. Todas lae tierras

forestadae federalee, m&e los estadoe

de California, Idaho, Maine, Minnesota,

Nueva Jersey, Washington y Oreg6n,

requieren por ley que muchos motores

de combusti6n interna eeten equipados

con rejilla antichispa. Si usted el aparato

en un estado y otra Iocalidad donde ex-

isten tales reglamentoe, usted tiene la

reeponsabilidad juridica de mantener

estae piezas en correcto eetado de fun-

cionamiento. De Io contrario, estarb, en

infracci6n de la ley. Para el uso normal

del dueSo de la casa, el silenciador y la

rejilla antichiepa no requerir&n ningOn

servicio. Deepu6s de 50 horas de ueo,

recomendamos que al silenciador se le

de servicio o sea eubetituido per un

Centro de Servicio Sears.

19

Page 18

CONTENICO DE LA CAJA

Use la siguiente lista para verificar que

todas la piezas hayan side incluidas:

Modelo 358.791010

• Cortadora

• Protector

• Recipiente de Aceite

Examine las piezas para verificar que

no haya daSos. No use piezas daSa-

das.

AVlSO: Si necesita ayuda, si faltan

piezas o si hay piezas daSadas, Ilame

al n_mero 1-800-235-5878.

Es normal escuchar que el filtro de com-

bustible golpetee en el tanque vacio.

Es normal encontrar residuos de aceite

o de gasolina en el silenciador, debido a

los ajustes al carburador y alas pruebas

efectuadas por el fabricante.

MONTAJE

_ADVERTENCIA: Si recibi6 el

aparato ya armado, repita todos los

pasos para asegurar que el mismo se

encuentre correctamente armado y

que todos los fijadores se encuentren

bien ajustados.

AJUSTE DEL MANGO

_'ADVERTENCIA: AI ajustar la

mango auxiliar, asegOrese que _ste se

mantenga sobre la etiqueta de seguri-

dad y debajo la marca o la flecha en el

eje.

1. Afloje la tuerca mariposa en el

mango.

2. Gire el mango en posici6n vertical.

Vuelva a apretar la tuerca maripo-

sa firmemente.

INSTALAClON DE LA PROTECTOR

,_ADVERTENCIA: El protector

deberf ser instalado correctamente. El

protector provee protecci6n parcial

contra el riesgo de los objetos arroja-

dos hacia el usuario y otras personas

y viene equipado con un cuchilla ]imi-

tadora de linea que corta el exceso de

]inea. El cuchilla limitadora de ]inea

(en ]a parte inferior del protector) es

filoso y puede cortar. Para conseguir ]a

orientaci6n apropiada para el protector,

vea la ilustraci6n CONOZCA SU APARATO

que se encuentra en la secci6n de USO.

1. Remueva la tuerca mariposa de la

protector.

2. Introduzca el soporte dentro de ]a

ranura como se muestra.

3. Haga girar ]a protector hasta que el

tornillo pase a trav6s del hueco en

el soporte.

4. Apriete firmemente la tuerca marl-

posa en el torni]lo.

Tuerca Mariposa

Ranura Soporte

PIVOTE engranajes

Protector

Caja de

20

Page 19

CONOZCA SU APARATO

LEA ESTE MANUAL DE INSTRUCCIONES Y LAS REGLAS DE SEGURIDAD ANTES DE

PONER EL APARATO EN MARCHA. Compare las ilustraciones con su aparato para

familiarizarse con la ubicaci6n de los diversos controles y ajustes. Guarde este

manual para uso futuro.

Cabezal

de Corte Eje

Mango Auxiiiar Silenciador

._otector

Cuchilla"

Limitadora

Interruptor

de Linea

INTERRUPTOR STOP

Se usa el interruptor STOP para detener

el motor. Para detener el motor, empuje

y suelte el interruptor STOP.

BOMBEADOR

El BOMBEADOR retira el aire de el car-

burador y de las lineae de combustible

y las Ilena de mezcla de combustible,

permiti6ndole poner el motor en mar-

cha con menos tironee de la cuerda de

arranque. Accione el bombeador opri-

mi6ndolo y luego dejando que eete re-

cobre su forma original.

ANTES DE PONER EN MARCHA EL

MOTOR

,_ ADVERTENCIA: Lea

atentamente la informaci6n sobre el

combustible en laas reglas de

seguridad antes de comenzar. Si no

comprende las reglas de seguridad,

no intente abastecer el aparato de

combustible. Llame al n_mero

1-800-235-5878.

ABASTECIMIENTO DEL MOTOR

_ADVERTENCIA: Flemueva la

tapa del tanque de combustible lenta-

mente al reabastecer combustible.

Este motor est& habilitado para

funcionar con gasolina sin plomo. Antes

de comenzar con el uso, se deber&

Bujia

Bombeador Acelerador

Palanca del

Arrancador

Tapa del Tanque

de Mezcla de

Combustible

Mango de la Cuerda

de Arranque

PALANCA DEL ARRANCADOR

La PALANCA DEL ARRANCADOR ayuda a

suministrar combustible al motor para

facilitar el arranque. Active el sistema

de arranque colocando la palanca en la

posici6n START.NO apriete el gatillo del

acelerador hasta que el motor arranque

y se ponga en marcha. Despu6s de que

el motor se haya puesto en marcha,

permita que el motor este en marcha

por 10-15 segundos; luego, apriete el

gatillo acelerador para desactivar el sis-

tema de arranque.

mezclar la gasolina con un aceite de

sintetico de buena calidad para motores

de 2 tiempos enfriados a aire.

Recomendamos el aceite de sint6tico

de la marca Craftsman _. Mezcle la

gasolina con el aceite en la proporci6n

40:1. Se obtiene una proporci6n de 40:1

mezclando 3,2 onzas de aceite con

cada gal6n de gasolina sin plomo. Se

incluye con esta aparato un recipiente

de 3,2 onzas de aceite. Adiera el

contenido entero de este recipiente en 1

gal6n de gasolina para alcanzar la

mezcla apropiada del combustible. NO

USE aceite para autom6viles ni para

barcas. Estos aceites daSar&n el motor.

AI mezclar el combustible, siga las

instrucciones impresas en el recipiente.

Una vez haya aSadido el aceite a la

21

Page 20

gasolina,agitealrecipientebrevemente

paraasegurarqueelcombustibleeste

completamentemezclado.Siemprelea

ysigalasinstruccionesdeseguridad

quetienenqueverconelcombustible

antesdeabastecerelaparato.

IMPORTANTE

Laexperienciaindicaqueloscombus-

tiblemezcladosconalcohol(losllama-

dosgasohololosquecontienenetanol

ometanol)puedenatraerlahumedad,

Ioquepuedecausarlaseparaci6nyla

formaci6nde&cidosduranteelalmace-

naje.Lagasolina&cidapuededailarel

sistemadecombustibledelmotordu-

ranteelalmacenaje.Paraevitarproble-

masconelmotor,deber_tvaciarseel

sistemadecombustibleantesdealma-

cenarelaparatopot30diasom&s.

Vacieeltanquedecombustible,ponga

elmotorenmarchayd6jeloenmarcha

hastaquelaslineasdecombustibleyel

carburadorquedenvacios.Usecom-

bustiblefrescoparalapr6ximatempora-

da.Nuncauseproductosdelimpiezade

motorocarburadoreneltanquede

combustibleyaquedehacerlapuede

provocarda_ospermanentes.

Vealasecci6ndeALMAOENAJEpara

informaci6nadicional.

PARA DETENER EL MOTOR

• Para detener el motor, empuje y suelte

el interruptor STOR El interruptor vol-

ver& autom&ticamente a la posici6n

ON. Espere 5 segundos antes de pon-

er en marcha el motor otra vez para

permitir que el interruptor se reajuste.

• Si el motor no se detiene, mueva el

cebador en la posici6n FULL CHOKE

(estrangulamiento total de aire).

PARA PONER EN MARCHA

EL MOTOR

_ADVERTENCIA: Evite el hacer

ningOn tipo de contacto con el silencia-

dor. Un silenciador caliente podria pro-

vocar quemaduras de gravedad si se

toca.

_.,_/_/_ Posici6n de Arranque

i / F_/

PARA ARRANCAR CON MOTOR

FRIO

AVISO: NO apriete el gatillo del aceler-

ador hasta que el motor arranque y se

ponga en marcha.

22

1. Ponga el aparato en una superficie

plana.

2. Oprima lentamente el bombeador

6 veces.

3. Mueva la palanca del arrancador a

la posici6n START.

Palanca del

Arrancador

Mango de la

Cuerda de Arranque

4. Tire firmemente del mango de la

cuerda de arranque hasta que el

motor arranque y se ponga en

marcha.

5. Permita que el motor este en mar-

cha por 10-15 segundos; luego,

apriete el gatillo acelerador para de-

sactivar el sistema del arranque.

PARA ARRANCAR CON EL MOTOR

CALIENTE

1. Oprima y sostenga el gatillo aceler-

ador. Mantenga el gatillo total-

mente oprimido hasta que el motor

marche sin problemas.

2. Tire firmemente del mango de la

cuerda de arranque hasta que el

motor se ponga en marcha.

AVlSO: Normalmente, el procedimiento

para arrancar con el motor caliente

puede ser utilizado dentro 5-10 minutos

despu6s que el motor se para. Si el

aparato esta sin funcionar por m&s de

10 minutos, ser& necesario arrancar el

aparato siguiendo los pasos abajo PARA

ARRANCAR CON MOTOR FRIO o des-

pues trate los pasos de las instruc-

ci6nes de como arrancar el aparato.

ARRANQUE DE MOTOR AHOGADO

Los motores ahogados pueden ponerse

en marcha moviendo la palanca del ar-

rancador a la posici6n RUN. Oprima y

Page 21

sostengaelgatilloacelerador.Tirando

delacuerdarepetidasvecesmientras

quepresionaelgatilloaceleradorhasta

elmotorarranqueysepongaenmar-

cha.Estopodr&requerirquesetirede

lacuerdadelmangorepetidasveces

dependiendoquetanahogadoseen-

cuentreelmotor.

Sielaparatosiguesinponerseen

marcha,vealaTABLADIAGNOSTtCAo

IlamealnOmero1-800-235-5878.

INSTRUCCIONESDE USO

Se reoomienda que no opere el mo-

tor pot rnas de un minuto a la velo-

cidad maxima.

POSIClON DE USO

USE SIEMPRE: _ _.Ar_ Protecci6n

anta,

Zapatos ] ', I "_.

Gru sosIp '1 "%.

Corte izauierda a deresha. _"

_'ADVERTENClA: Use siempre

protecci6n para los ojos y protecci6n

de oidos. Nunca se incline por encima

del cabezal. La linea puede arrojar o

hacer rebotar piedras o desechos ha-

cia los ojos y la cara, pudiendo causar

la perdida de la vista u otras graves

heridas.

Cuando aparato de funcionamiento,

p&rese como se vea en la figura y veri-

fique Io siguiente:

• Usando anteojos de seguridad y ropa

gruesa como protecci6n.

• Sostenga la manija del gatillo acelera-

dot con la mano derecha y manija

auxiliar con la mano izquierda.

• Mantenga el aparato debajo del nivel

de la cintura.

• Corte siempre desde la izquierda ha-

cia la derecha para que los escom-

bros sean arrojados en direcci6n

contraria a donde est& parado. Sin

tener que inclinarse, mantenga la

linea cerca del suelo y paralela al

mismo, sin meteda dentro del materi-

al que se est& cortando.

No haga marchar el motor a revolu-

clones m&s altas que las necesarias.

La linea de carte cortar& de una forma

m&s eficiente sin que el motor este acel-

erado a fondo. A revoluciones m&s ba-

jas, habrb, menos ruido y menor vibra-

ci6n del motor. La linea de corte durar&

m&s tiempo y tendr& menor probabilidad

de "fundirse" en la bobina.

Siempre que no se halle cortando,

suelte el gatillo acelerador y permita

que el motor vuelva a marcha lenta.

Para detener el motor:

• Suelte el gatillo acelerador.

• Empuje y suelte el interruptor STOP.

AVANCE DE LA LiNEA DE CORTE

La linea de corte avanza aproximada-

mente 5 cm (2 pulgadas) cada vez

que se toca el cabezal contra el suelo

con el motor acelerado a fondo.

El largo m&s eficiente de la linea es el

largo m&ximo permitido por el limitador

de finea.

Siempre mantenga la cubierta protec-

tara en su lugar siempre que el apara-

to est6 en uso.

Para avanzar la linea:

• Acelere el motor a fondo.

• Sostenga el cabezal paralelo al suelo,

por encima de un &rea con c6sped.

• Toque el cabeza] de corte contra el

suelo levemente una vez. Con cada

toque, la linea avanzar& aproxima-

damente 5 cm (2 pulgadas).

Toque el cabezal contra el suelo

siempre en un &rea con c6sped. Si se

hace tocar contra superficies como el

cemento o el asfalto, el cabezal podria

sufrir desgaste excesivo.

Si la linea se ha gastado y cuenta con

5 cm (2 pulgadas) o menos, har& falta

m&s de un toque para obtener el largo

de linea m&s eficiente.

ADVERTENCIA: Utilice exclusi-

vamente linea redonda de 2 mm (0,080

de pulgada) de di&metro. Otto tipo de

tamaflos y formas har&n que la linea no

gire de forma apropiada Io que resultar&

en el funcionamiento inadecuado del

cabezal de corte o en accidentes de

seria gravedad. No utilice otro tipo de

materiales tales coma alambre, hilo,

soga, etc. El alambre puede romperse

durante el corte y convertirse en un misil

peligroso Io que puede causar lesiones

de seria gravedad.

METODOS DE CORTE

Use la velocidad minima y no acerque

el aparato demasiado al cortar cerca

de objetos s61idos (piedra, gravilla,

postes, etc.): estos pueden daflar el

cabezal, pueden enredarse en la linea

23

Page 22

olalinealospuedearrojarviolenta-

mentealaire,causandoseriopeligro.

• Lapuntadelalineaeslaquecorta.

Seconseguir&mejorrendimientoy

elminimodesgastesinosemetela

lineadentrodelmaterialqueseest&

cortando.Lailustraci6nacontinua-

ci6nmuestralaformacorrectaein-

correctadecortar.

La punta de la linea La linea estA metida

es la que corta, dentro del material

Correcta Incorr_'cta

PARA ESCALPAR - La t6cnica del as-

calpado retira la vegetaci6n no desea-

da abajo a la tierra. Sostenga el cabe-

zal unos 8 cm (3 pulgadas) del suelo y

en &ngulo. Deje que la punta de la

linea golpee contra el suelo cerca de

los &rboles, los postes, los monumen-

tos, etc. Esta t6cnica incrementa el

desgaste de la linea.

Para Escalpar i J/

• La linea retira f&cilmente el c6sped y

las malas hierbas de alrededor de pa-

redes, cercados, &rboles y macizos de

flores; pero tambi6n es capaz de cor-

tar la corteza tierna de &rboles y ar-

bustos y de marcar las cercas. Para

evitar daflos, especialmente a la vege-

taci6n delicada o a los &rboles con

corteza fina, acorte la linea a unos 10

a 13 cm (4 a 5 pulgadas) y use el

aparato sin acelerar a fondo.

• Para recortar o escalpar, use el apa-

rato sin acelerar a fondo, para incre-

mentar la vida Otil de la linea y dismi-

nuir el desgaste del cabezal,

especialmente:

• AI hacer trabajos livianos.

• Cerca de objetos con los cuales la

linea se puede enredar, come son

los postes o &rboles de poco di&me-

troy el alambre de las cercas.

• Para cortar c6sped y barrer, acelere

el motor a fondo para Iograr un buen

trabajo de limpieza.

PARA RECORTAR - Sostenga el ca-

bezal unos 8 cm (3 pulgadas) del suelo

yen &ngulo. Unicamente la punta de la

linea deber& hacerel contacto con el

material a cortar. No meta la linea den-

tro del &rea que se est& cortando.

Para Recortar

PARA CORTAR CESPED - Este parato

es ideal para cortar c6sped en lugares

donde las cortadoras convencionales no

Ilegan. En posici6n de cortar c6sped,

mantenga la linea paralela al suelo.

Evite presionar el cabezal contra el sue-

Io, ya que de hacerlo podria escalpar la

vegetaci6n y daflar el aparato.

Para Cortar Cesped

PARA BARRER - Se puede usar la

acci6n ventiladora de la linea girante

para barter r&pida y f&cilmente un &tea

determinada. Mantenga la linea para-

lela al suelo directamente encima de

las superficies que se quiera barrer y

meuva el aparato de un lade al otro

r&pidamente.

Para Barrer

8 cm (3 pulga-

das) del suelo

24

Page 23

CRONOGRAMA DE MANTENIMIENTO

ADVERTENCIA: Desconecte la bujia antes de hacer cualquier manten-

imiento, con la excepci6n de los ajustes al carburador.

TAREA DE CUIDADO Y MANTENIMIENTO

Verificar que no haya piezas ni fijadores sueltos

Verificar que no haya piezas daSadas o gastadas

Inspeccione y limpie el aparato y sus placas

Limpiar el filtro de aire

Inspeccione el silenciador y la rejilla antichispa

Cambiar la bujia

RECOMENDAClONES GENERALES

La garantia de este aparato no cubre

los articulos que han sido sometidos al

abuso o a la negligencia por parte del

usuario. Para recibir el valor completo

de la garantia, el usuario deber& man-

tener el aparato segOn las instruc-

clones en este manual. Har& falta hac-

er varios ajustes peri6dicamente para

mantener el aparato de forma debida.

VERIFIQUE QUE NO HAYA FIJA-

DORES NI PIEZAS SUELTAS

• Cubierta de la Bujia

• Filtro de Aire

• Tornillos de la Caja

• Tornillo del Mango Auxiliar

• Protector

VERIFIQUE QUE NO HAY.& PIEZAS

DAI_IADAS O GASTADAS

Entre en contacto con el Centro de

Servicio Sears para el reemplazo de

piezas da_iadas o desgastadas.

• Interruptor STOP - AsegOrese de que

el interruptor STOP este funcionando

correctamente empujando y afloja-

miento el interrupter. Aseg_rese de

que el motor se haya detenido per

completo. Espere 5 segundos antes

de poner en marcha el motor otra

vez para permitir que el interruptor

se reajuste. Ponga el motor en mar-

cha nuevamente y contin0e.

• Tanque de Combustible - Deje de

usar el aparato si hay se_iales de

daSos o p6rididas en el tanque de

combustible.

• Protector - Deje de usar el aparato

si el protector est& daSado.

INSPECClONE Y LIMPIE EL APARA-

TO Y SUS PLACAS

• Despues de que cada uso, inspec-

clone la aparato completa para sa-

ber si hay piezas fiojas o daSadas.

Limpie el aparato y las placas usan-

do un trapo h0medo con un deter-

gente suave.

• Seque el aparato usando un trapo

seco y limpio.

LIMPIE EL FILTRO DEL AIRE

Los filtros de aire sucios disminuyen la

vida Otily el rendimiento del motor e

incrementan el consumo de combus-

tible y de emiciones nocivas. Limpie

siempre el filtro de aire despu6s de

cada 5 horas de uso.

1. Limpie la tapa y el &rea alrededor

2. Retire las piezas como se ilustra.

AVlSO: Para evitar peligro de incen-

dio y de emiciones evaporativas noci-

vas, no limpie el filtro de aire con gaso-

lina ni cualquier otro solvente inflam-

able.

3. Limpie el filtro con agua y jab6n.

4. Permita que el filtro se seque.

5. Reponga las piezas.

INSPECCIONE LA REJILLA ANTI-

CHISPA Y EL SILENCIADOR

_IbADVERTENCIA: El silenciador

en este producto contiene las substan-

cias quimicas que el estado de Califor-

nia reconoce como causantes de

c&ncer.

25

de la tapa para evitar que caiga su-

ciedad o desechos en el carbura-

dor cuando se saque la tapa.

CUANDO HACER

Antes de carla uso

Antes de carla uso

Despues de cada uso

Cada 5 horas de use

Carla 50 horas de uso

Anualmente

Bot6n

Tapadel Filtro de Aire

Filtro de Aire

Page 24

Amedidaqueseuseelaparato,elsi-

lenciadorylarejillaantichispassevan

carbonizando.

Paraelusonormaldelduet_odela

casa,sinembargo,elsilenciadoryla

rejillaantichispanorequerir&nningQn

servicio.Despu6sde50horasdeuso,

recomendamosquealsilenciadorsele

deserviciooseasubstituidoperundis-

tribuidorautorizadodelservicio.

CAMBIE LA BUJIA

Deber& cambiarse la bujia anualmente

para asegurar que el motor arranque

f&cilmente y tenga un mejor rendimein-

to. Ajuste la separaci6n de los electro-

dos a 0,6 mm (0,025 de pulgada). El

encendido es fijo e inalterable.

1. Gire y saque la cubierta de la bujia.

2. Retire la bujia del cilindro y des6-

chela.

3. C&mbiela per una bujia Champion

RCJ-6Y y ajuste firmemente la

bujia nueva con una Ilave de cube

de 19 mm (8/4 de pulgada).

4. Instale nuevamente la cubierta de

la bujia.

REEMPLAZO DE LA LINEA

1. Empuje y suelte el interrupter

STOP.

2. Desconecte la alambre del bujia.

3. Retire la bobina tirando del bot6n

de toque firmemente.

4. Limpie por entero la superficie del

cubo y de la bobina.

5. Reemplace la bobina por una pre-

viamente enrollada, o corte dos pe-

dazos de 3,8 metros (12-1/2 pies)

de largo de linea de 2 mm (0,080 de

pulgada) de la marca Craftsman_RL

_ADVERTENCIA: Nunca use

alambre, cuerda, hilo, etc., los cuales

pueden romperse y convertirse en pro-

yectiles pe]igrosos.

6. Introduzca las puntas de la linea, al-

rededor de 1 cm (1/2 pulgada), den-

tro del huecos pequefio que se en-

cuentra en la parte interior de la

bobina.

Bobina _ /;-.-./_,_, ,_

/_, _' pequei_os

"_[_'/_/L_ muecos

/j _iy

7. Enrolle la linea en la bobina de for-

ma pareja y ajustada. Enrolle la

linea en la direcci6n en que apunta

la flecha que se encuentra en la

bobina.

8. Introduzca la linea dentro de la

muescas, dejando de 7 a 12 cm (8

a 5 pulgadas) sin enrollar.

9. Introduzca la linea dentro de] hue-

cos de salida en el cube como se

muestra en la ilustraci6n.

Huecos de sa]ida Linea dentro

de la linea de la muesca

I,_Cubo Linea dentro de _amuesca

10. Alinee la muescas con el huecos

de salida de la linea.

11. Presione la bobina dentro del cube

hasta que 6sta encaje en su lugar.

12. Tire de la lineas que se extiende

fuera del cubo para soltarla de la

muescas.

REEMPLAZO DE LA CABEZAL DE

CORTE

1. Haga girar el taza para el polvo

para hacer coincidir el orificio con

el otro orificio situado a un lado de]

cajetin de engranajes.

2. Introduzca un destornillador pe-

quefio per los orificios confronta-

dos. Esto previene que el eje gire

mientras usted remueva y instale

el cabezal de carte.

Dest_llador

3. Sujete el destornillador en su posi-

ci6n y remueva el cabezal de corte

dando vuelta a la derecha.

4. Enrosque el cabezal de remplazo en

el eje dando vuelta a la izquierda.

Apriete firmemente.

5. Remueva el destornillador.

26

Page 25

AJUSTE AL CARBURADOR

,i_ADVERTENCIA: Mantenga a

otras personas alejadas de la zona en

donde se encuentre haciendo ajustes

de marcha lenta. El cabezal de corte

se mantendr_t girando durante este

procedimiento. Use su equipo protec-

tor y observe todas las precauciones

de seguridad.

El carburador ha sido ajustado cuida-

dosamente en la f_tbrica. Posible-

mente sea necesario hacer ajustes si

se nota cualquiera de las siguientes

condiciones:

• El motor no funciona en marcha len-

ta cuando se suelta el acelerador.

Haga los ajustes sosteniendo el equipo

de manera que el accesorio de corte se

encuentre alejado del suelo y no haga

contacto con ning0n objeto. Sostenga

el aparato manualmente mientras el mo-

tor se encuentre encendido y mientras

usted se encuentre haciendo los

ajustes. Mantenga todas las partes de

su cuerpo alejadas de los accesorios de

corte y del silenciador.

Marcha Lenta

Deje el motor en marcha lenta. Ajuste

las revoluciones hasta que el motor se

mantenga en marcha sin calarse (la

marcha lenta es demasiado lenta).

• Gire el tornillo de marcha lenta hacia

la derecha para aumentar las revolu-

ciones si el motor se ahoga o se para.

• Gire el tornillo de marcha lenta hacia

la izquierda para reducir las revolu-

ciones.

Si requiriera ayuda adicional o no se

sintiera seguro al desempeSar este

procedimiento, entre en contacto con

el Centro de Servicio Sears o Ilame al

n0mero de ayuda al consumidor

1-800-235-5878.

Tornillo de Ajuste de

la Marcha Lenta

Tapa del Filtro de Aire

27

Page 26

_IADVERTENClA: Realice los

siguientes pasos despu6s de cada

USO:

• Permita que el motor se enfrie y fije

bien el aparato antes de guardarlo o

transportarlo.

• Guarde el aparato y el combustible

en un lugar bien ventilado donde los

vapores del combustible no puedan

entrar en contacto con chispas ni lla-

mas abiertas provenientes de clenta-

dares de agua, motores o interrup-

tores electricos, calefactores

centrales, etc.

• Guarde el aparato con todos los pro-

tectores en su lugar y coloquelo de

modo que las piezas cortantes no

puedan causar heridas per acci-

dente.

• Guarde el aparato y el combustible

en un lugar completamente fuera del

alcance de los niSos.

ESTACIONAL ALMACENAJE

Prepare el aparato para almacenarlo

al final de la temporada o si no Io va a

usar par m&s de 30 dias.

Siva a almacenar el aparato durante

un periodo largo de tiempo:

• Limpie el aparato por completo antes

del almacenaje.

• Almacene en un &rea limpia y seca.

• Aplique una pequeSa cantidad de

aceite alas superficies extemas

met&licas.

SlSTEMA DE COMBUSTIBLE

Yea el mensaje marcado como

IMPORTANTE, que se refiere a] uso

de combustibles con mezcla de alco-

hol en su aparato, en la secci6n de

uso, bajo ABASTECIMIENTO DEL MO-

TOR. Los estabilizadores de combus-

tible son una alternativa aceptable

para minimizar la formaci6n de dep6si-

tos de goma durante el almacenaje.

ASada estabilizador a la gasolina en el