Page 1

OWNERS

MANUAL

MODEL NO.

315.23/43

Serial

Number

Model and serial number

may be found on plate at

motor end cap,

CRAFTSMAN_

You should record both

model and serial number in

a safe place for future use.

CAUTION:

Read Rulesfor

Safe Operation

and Instructions

Carefully

SAVE THIS

MANUALFOR

FUTURE REFERENCE

q,-,J,4h,, q_'&_S, ROEBUCK AND CO., Dept. 698/731A, Sears Tower, Chicago, IL 60684

612547-228

71/2 INCH RADIAL

ARM MITER SAW

DOUBLE INSULATED

WITH MECHANICAL BRAKE

Introduction

Assembly

Operation

Maintenance

Repair Parts

PP,INTEO IN U,S,A

Page 2

FULL ONE YEAR WARRANTY ON CRAFTSMAN RADIAL ARM MITER SAW"

If within one year from the date of purchase, this Craftsman Radial Arm Miter Saw falls due to a

defect In matedal or workmanship, Sears will repair It, free of charge,

WARRANTY SERVICE IS AVAILABLE BY SIMPLY CONTACTING THE NEAREST SEARS STORE OR

SERVICE CENTER THROUGHOUT THE UNITED STATES,

This warranty gives you specific legal dghts, end you may also have other rights which vary from

state to state.

SEARS ROEBUCK AND CO.

698/731A

SEARS TOWER

CHICAGO, IL 60684

i! l !! !

INTRODUCTION

DOUBLE INSULATION Is a concept in safety, In elec-

tric power tools, which eliminates the need for the

usual three wlregrounded power cord and grounded

supply system, Wherever there is electric current in

the tool there are two complete sets of insulation to

protect the user. All exposed metal parts are Isolated

from the Internal metal motor components with pro-

tatting insulation.

RULES FOR SAFE OPERATION

WARNING -- DO NOT ATTEMPT TO OPERATE UNTIL YOU HAVE READ THOROUGHLY AND UNDERSTAND

COMPLETELY ALL INSTRUCTIONS, RULES, ETC. CONTAINED IN THIS MANUAL. FAILURE TO COMPLY CAN

RESULT IN ACCIDENTS INVOLVING FIRE, ELECTRIC SHOCK, OR SERIOUS PERSONAL INJURY. SAVE

OWNERS MANUAL AND REVIEW FREQUENTLY FOR CONTINUING SAFE OPERATION, AND INSTRUCTING

POSSIBLE THIRD.PARTY USER.

IMPORTANT -- Servicing of a tool with double in-

sulation requires extreme care and knowledge of the

system and should be performed only by a qualified

service technician, For service we suggest you

return the tool to your nearest Sears Store for repair.

Always use original factory replacement parts when

servicing.

READ ALL INSTRUCTIONS

1. KNOW YOUR POWER TOOL -- Read owner's manual carefully. Learn its ap-

plications and limitations as well as the specific potential hazards peculiar to

this tool.

2. GUARD AGAINST ELECTRICAL SHOCK BY PREVENTING BODY CONTACT

WITH GROUNDED SURFACES. For example: Pipes, radiators, ranges, refrig-

erator enclosures.

.

KEEP GUARDS IN PLACE and in working order.

4.

REMOVE ADJUSTING KEYS AND WRENCHES. Form habit of checking to see

that keys and adjusting wrenches are removed from tool before turning it on.

5. KEEP WORK AREA CLEAN. Cluttered areas and benches invite accidents.

J

DON'T USE IN DANGEROUS ENVIRONMENT. Don't use power tool in damp

or wet locations or expose to rain. Keep work area well lit. Never use in explo-

sive atmosphere. Normal sparking of motor could ignite fumes.

.

KEEP CHILDREN AWAY. All visitors should be kept safe distance from work

area.

8. MAKE WORKSHOP KID.PROOF with padlocks, master switches, or by re-

moving starter keys.

Page 3

RULES FoR SAFE OPERATION (Continued)

9. DON'T FORCE TOOL. It will do the job better and safer for which it was design-

ed.

10.

USE RIGHT TOOL. Don't force tool or attachment to do a job it was not design-

ed for.

11.

WEAR PROPER APPAREL. No loose clothing, gloves, neckties, rings, bracelets,

or other jewelry to get caught in moving parts. Non-slip footwear is recommend-

ed. Wear protective hair covering to contain long hair. Roll long sleeves above

elbow.

12.

ALWAYS USE SAFETY GLASSES. Also use face or dust mask if cutting oper.

ation is dusty. Everyday glasses only have impact resistant lenses, they are

NOT safety glasses.

i3.

SECURE WORK, Use clamps or a vise to hold work. It's safer than using your

hand and it frees both hands to operate tool,

DON'T OVERREACH -.- Keep proper footing and balance at all times.

MAINTAIN TOOLS WITH CARE -- Keep tools sharp and clean for best and

safest performance. Follow instructions for lubricating and changing access-

ories. Always use a clean cloth when cleaning. Never use brake fluid, gasoline,

or any strong solvents to clean your tool.

16.

DISCONNECT TOOLS -- Before servicing and when changing accessories

such as blades, bits, cutters, etc., all tools should be disconnected.

17.

AVOID UNINTENTIONAL STARTING -. Make sure switch is in off position

before plugging in cord.

18.

USE RECOMMENDED ACCESSORIES -- Consult the owners manual for re-

commended accessories. The use of improper accessories may cause hazards.

19.

NEVER STAND ON TOOL -- Serious injury could occur if the tool is tipped or if

the cutting tool is accidentally contacted.

20.

CHECK DAMAGED PARTS -- Before further use of the tool, a guard or other

part that is damaged should be carefully checked to ensure that it will operate

properly and perform its intended function -- check for alignment of moving

parts, binding of moving parts, breakage of parts, mounting, and any other con-

ditions that may affect its operation. A guard or other part that is damaged

should be properly repaired or replaced.

21.

DIRECTION OF FEED .-. When cutting, always pull blade into material from rear

to front of saw. Never push blade into material from front to rear. Wrong feed

direction could result in material kick.back causing serious personal injury.

NEVER LEAVE TOOL RUNNING UNATTENDED. TURN POWER OFF. Don't

22.

leave tool until it comes to a complete stop.

23.

DRUGS, ALCOHOL, MEDICATION. Do not operate tool under the Influence of

drugs, alcohol or any medication.

Page 3

Page 4

RULES FOR SAFE OPERATION (Continued)

24. OUTDOOR USE EXTENSION CORDS -- When tool is used 6u_do____, use only

extension cords suitable for use outdoors, Outdoor approved cords are marked

with the suffix W-A, for example -- SJTW-A or SJOW.A.

25. DON'T-- Place either hand in the cutting area when the saw is connected to the

electrical power supply, Accidental starting could result in serious personal in-

jury.

26. DON'T -- FORCE CUTTING ACTION. Stalling or partial stalling of motor can

cause major damage, Allow motor to reach full speed before cutting.

27, DON'T -- Use blades recommended for operation at less than 5500 RPM or of a

diameter not recommended. The use of improper blades may cause hazardous

operating conditions,

28. DON'T -- Attempt to cut small pieces, Injury could result from improper control

or clamping of such material,

29. DON'T -- Wedge anything against fan to hold motor shaft, This action will

cause serious damage to the saw motor,

30. DO -- Make certain the blade rotates in the correct direction, Incorrect rotation

will cause material "Kickback" and possible serious injury to operator,

31, DO -- Keep saw blade sharp and properly set to avoid blade cracking and grab-

bing, possibly resulting in a serious accident,

32. DANGER: A coasting cutting tool can be dangerous, To avoid possible serious

injury, apply brake immediately after completion of cut,

33. ALWAYS use identical replacement parts when servicing,

34. WEAR EYE PROTECTION.

35. KEEP HANDS OUT OF PATH OF SAW BLADE.

36, DO NOT OPERATE SAW WITHOUT GUARDS IN PLACE.

37. DO NOT PERFORM ANY OPERATION FREEHAND.

38. NEVER REACH AROUND SAW BLADE.

39, SHUT OFF POWER AND WAIT FOR SAW BLADE TO STOP BEFORE SERViC.

ING OR ADJUSTING TOOL.

40, WARNING: TO REDUCE THE RISK OF INJURY, RETURN SAW HEAD TO THE

FULL REAR POSITION AFTER EACH CROSSCUT OPERATION,

41, This tool is intended for residential use only,

42, SAVE THESE INSTRUCTIONS.

The operation of any miter saw can result in

foreign objects being thrown into the eyes, which

can result in severe eye damage. Always wear

safety goggles complying with ANSI Z87,1 (shown

on Package) before commencing power tool

or_eration. Safety Goggles are available at Sears

Catalog Order or Retail Stores,

TABLE OF CONTENTS

Unpacking ................................... 5

Mounting of Miter Saw ........................ 6

Assembly ................................... 6

Adjustments ............................... 7-9

Operating Instructions ..................... 10-11

Table Extension and

Securing Workpiece ....................... 11.12

Typical Operations ........................ 12-16

Maintenance ............................. 18-21

Trouble Shooting ............................ 22

illustration and Parts List ................... 25-31

How to Order Repair Parts .................... 32

p,,._ _ i_ 4

Page 5

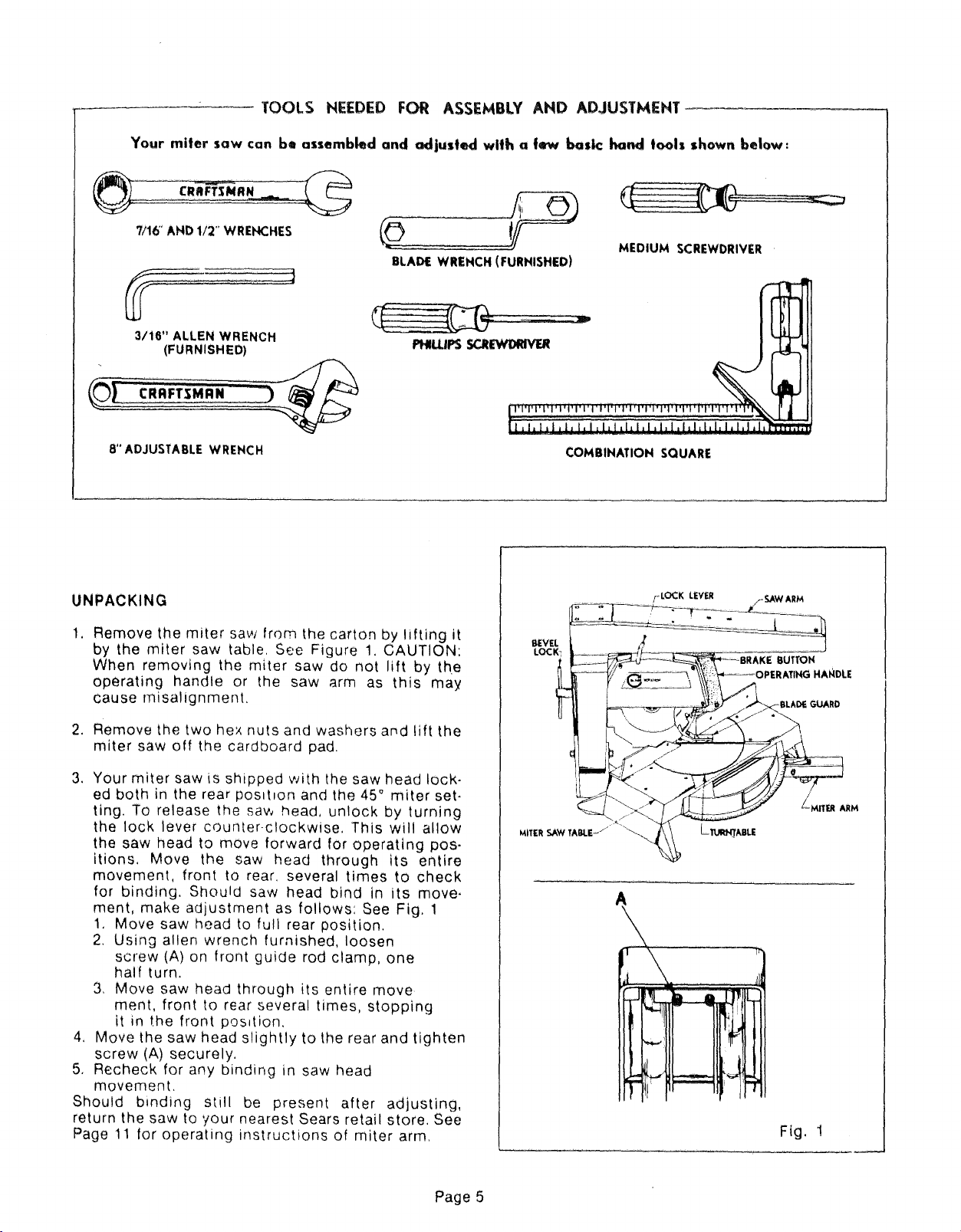

TOOLS HEEDED FOR ASSEMBLY AND ADJUSTMEHT

Your miter saw can be assembled and adjusted with a tow be$1c hand tools shown below:

?/16" AND 1/2" WRENCHES

BLADE WRENCH (FURNISHED)

MEDIUM SCREWDRIVER :

3/i6" ALLEN WRENCH

(FURNISHED)

PHILLIPSSCREWI:_VER

CRRFTSMRN

8" ADJUSTABLE WRENCH

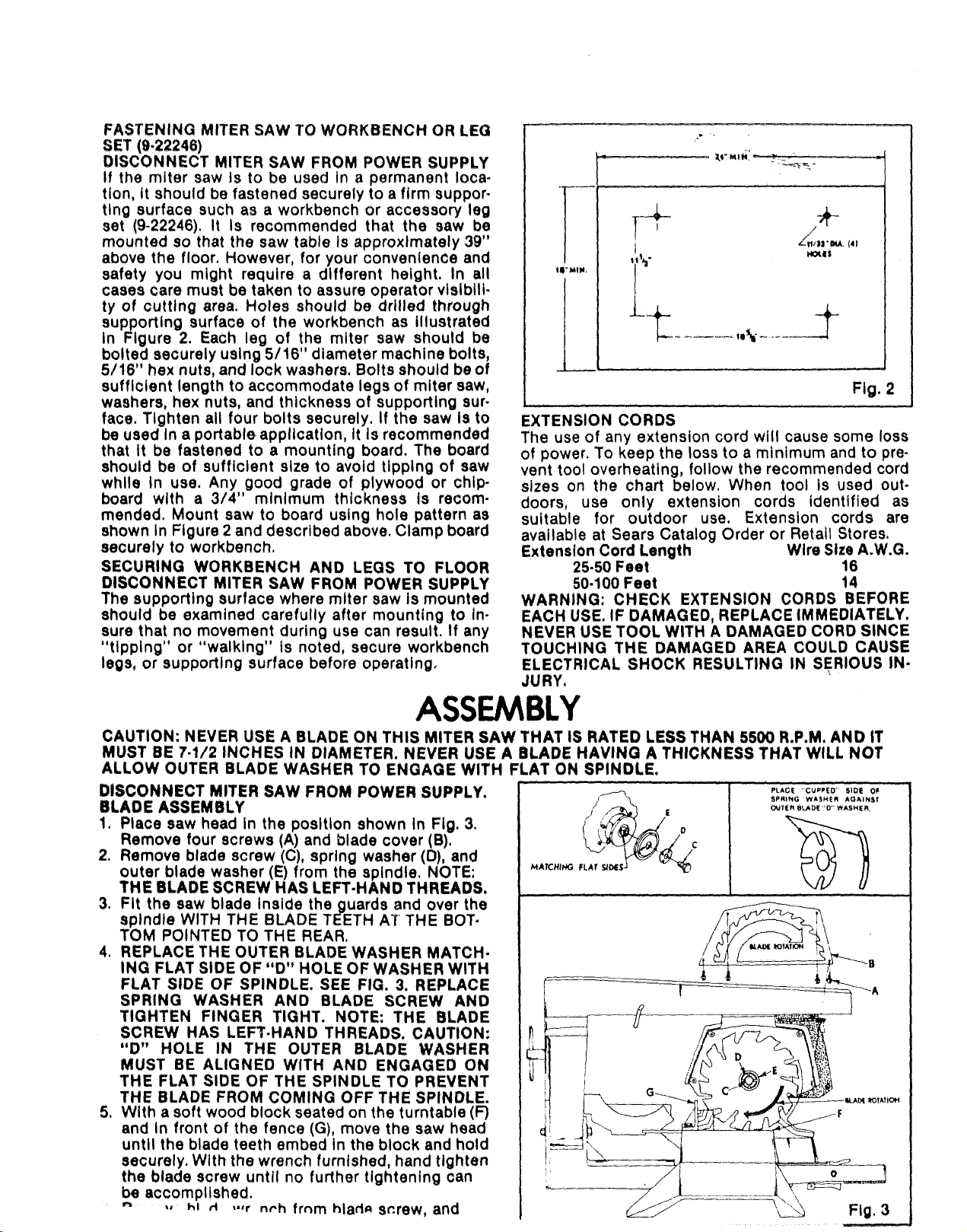

UNPACKING

,

Remove the miter saw from the carton by lifting it

by the miter saw table. See Figure 1. CAUTION:

When removing the miter saw do not lift by the

operating handle or the saw arm as this may

Cause misalignment.

2. Remove the two hex nuts and washers and lift the

miter saw off the cardboard pad.

3, Your miter saw is shipped with the saw head lock-

ed both in the rear positron and the 45 ° miter set.

ting. To release the saw head, unlock by turning

the lock lever counter-clockwise, This will allow

the saw head to move forward for operating pos.

itions, Move the saw head through its entire

movement, front to rear. several times to check

for binding, Should saw head bind in its move.

merit, make adjustment as follows: See Fig. 1

1, Move saw head to futl rear position.

2. Using allen wrench furnished, loosen

screw (A) on front guide rod clamp, one

half turn.

3. Move saw head through its entire move

ment, front to rear several times, stopping

it in the front position,

4, Move the saw head slightly to the rear and tighten

screw (A) securely,

5. Recheck for any binding in saw head

movement.

Should binding Still be present after adjusting,

return the saw to your nearest Sears retail store. See

Page 11 for operating instructions of miter arm,

E1',1i I, I'_i, i ,1i i,'1 ' I, i,i,l'q_ ,I,ili, I,iii,i,i i i'i,l'l_

|l,/i,l,,_iii, i_,l_/,lli,l'l,i'ili,l,hl,],l'l

COMBINATION SQUARE

,-LOCK LEVER

BEVEL

LOCK_

\

BurToN

ATING HAHDLE

Fig, 1

Page 5

Page 6

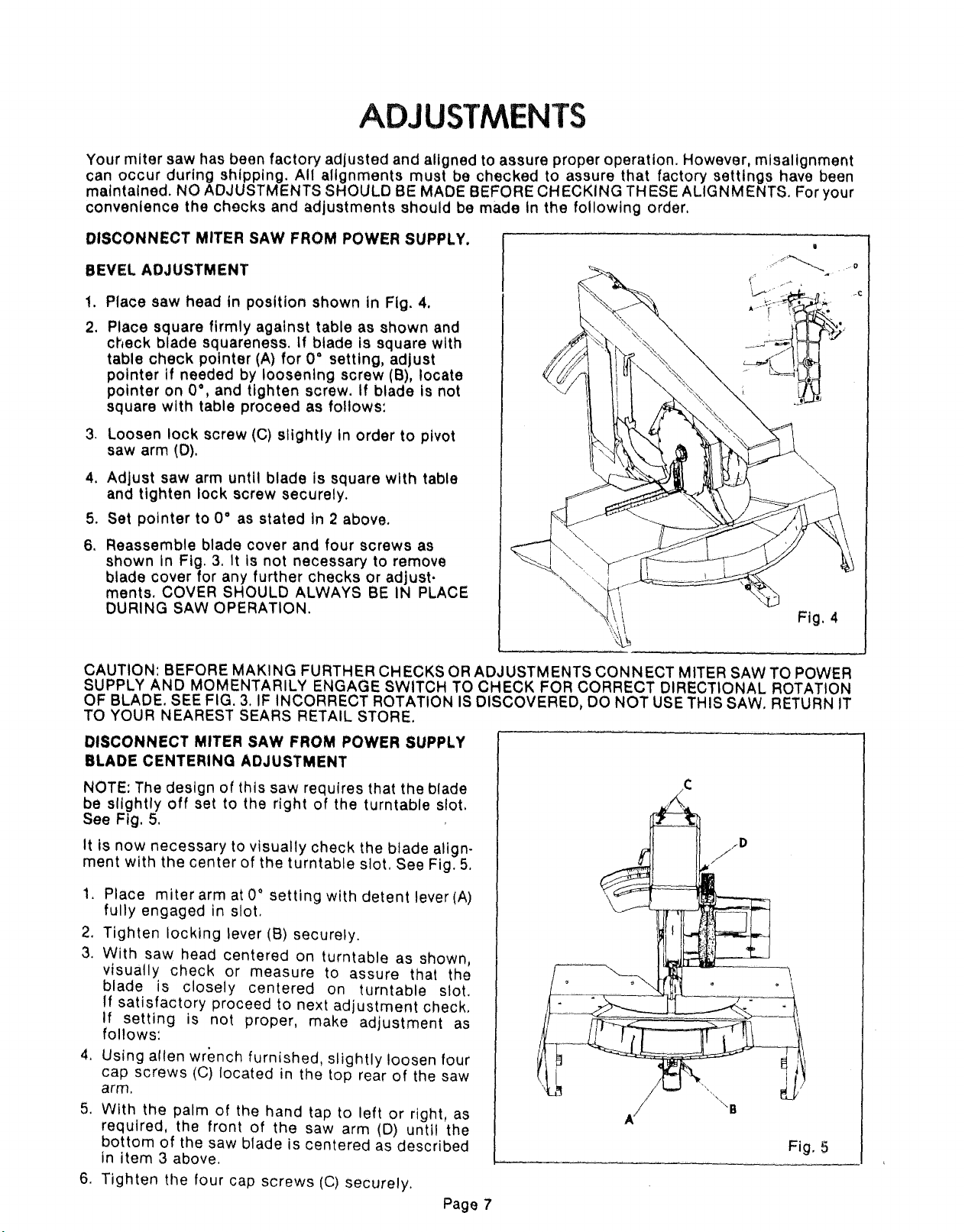

FASTENING MITER SAW TO WORKBENCH OR LEG

SET (9.22246)

DISCONNECT MITER SAW FROM POWER SUPPLY

if the miter saw Is to be used in a permanent loca-

tion, it should be fastened securely to a firm suppor-

ting surface such as a workbench or accessory leg

set (9-22246). It Is recommended that the saw be

mounted so that the saw table Is approximately 39"

above the floor, However, for your convenience and

safety you might require a different height, in all

cases care must be taken to assure operator vislblll-

ty of cutting area. Holes should be drilled through

supporting surface of the workbench as illustrated

in Figure 2. Each leg of the miter saw should be

bolted securely using 5/16' diameter machine bolts,

5/16" hex nuts, and lock washers. Bolts should be of

sufficient length to accommodate legs of miter saw,

washers, hex nuts, and thickness of supporting sur-

face. Tighten all four bolts securely, if the saw Is to

be used in a portable application, It is recommended

that It be fastened to a mounting board. The board

should be of sufficient size to avoid tipping of saw

while in use. Any good grade of plywood or chip.

board with a 3/4" minimum thickness Is recom.

mended, Mount saw to board using hole pattern as

shown in Figure 2 and described above. Clamp board

securely to workbench.

SECURING WORKBENCH AND LEGS TO FLOOR

DISCONNECT MITER SAW FROM POWER SUPPLY

The supporting surface where miter saw is mounted

should be examined carefully after mounting to in-

sure that no movement during use can result. If any

"tipping" or "walking" is noted, secure workbench

legs, or supporting surface before operating.

t|'MtN,

2

Fig. 2

EXTENSION CORDS

The use of any extension cord will cause some loss

of power, To keep the loss to a minimum and to pre.

vent tool overheating, follow the recommended cord

sizes on the chart below, When tool is used out-

doors, use only extension cords identified as

suitable for outdoor use. Extension cords are

available at Sears Catalog Order or Retail Stores,

Extension Cord Length Wire Size A.W.G.

25-50 Feet 16

50-100 Feet 14

WARNING: CHECK EXTENSION CORDS BEFORE

EACH USE. IF DAMAGED, REPLACE IMMEDIATELY.

NEVER USE TOOL WITH A DAMAGED CORD SINCE

TOUCHING THE DAMAGED AREA COULD CAUSE

ELECTRICAL SHOCK RESULTING IN SERIOUS IN-

JURY,

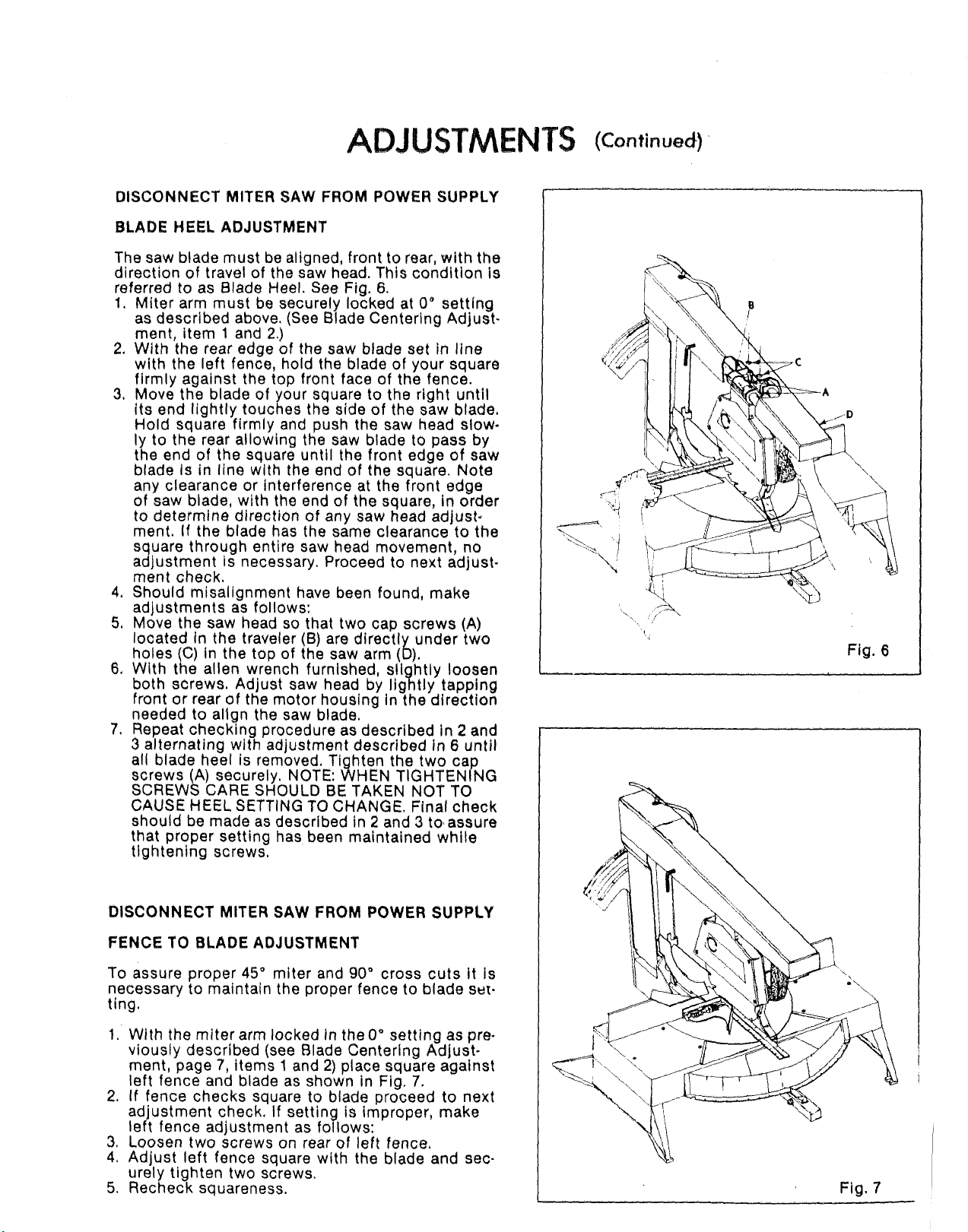

ASSEMBLY

CAUTION: NEVER USE A BLADE ON THIS MITER SAW THAT IS RATED LESS THAN 5500 R.P.M. AND IT

MUST BE 7.1/2 INCHES IN DIAMETER. NEVER USE A BLADE HAVING A THICKNESS THAT WILL NOT

ALLOW OUTER BLADE WASHER TO ENGAGE WITH FLAT ON SPINDLE.

DISCONNECT MITER SAW FROM POWER SUPPLY.

BLADE ASSEMBLY

1. Place saw head in the position shown in Fig. 3.

Remove four screws (A) and blade cover (B).

2. Remove blade screw (C), spring washer (D), and

outer blade washer (E) from the spindle, NOTE:

THE BLADE SCREW HAS LEFT.HAND THREADS.

3. Fit the saw blade inside the guards and over the

spindle WITH THE BLADE TEETH AT THE BOT-

TOM POINTED TO THE REAR.

4, REPLACE THE OUTER BLADE WASHER MATCH.

ING FLAT SIDE OF "D" HOLE OF WASHER WITH

FLAT SIDE OF SPINDLE. SEE FIG. 3. REPLACE

SPRING WASHER AND BLADE SCREW AND

TIGHTEN FINGER TIGHT. NOTE: THE BLADE

SCREW HAS LEFT.HAND THREADS. CAUTION:

"D" HOLE IN THE OUTER BLADE WASHER

MUST BE ALIGNED WiTH AND ENGAGED ON

THE FLAT SIDE OF THE SPINDLE TO PREVENT

THE BLADE FROM COMING OFF THE SPINDLE.

5. With a soft wood block seated on the turntable (F')

and In front of the fence (G), move the saw head

until the blade teeth embed in the block and hold

securely, With the wrench furnished, hand tighten

the blade screw until no further tightening can

be accomplished.

........ hi ,-t ,,,r nr'h frnm blade, shrew, and

D

C

, ,,,, , ,,i,,, , , , i ,

PLAGI_ "¢UP_'_O" SlOt O!=

SPRING WASHE_ AGAINST

O_T_R _J_D_ "O" WA_HER_

A

Page 7

ADJUSTMENTS

Your miter saw has been factory adjusted and altgned to assure proper operation. However, misallgnment

can occur during shipping, All alignments must be checked to assure that factory settings have been

maintained, NO ADJUSTMENTS SHOULD BE MADE BEFORE CHECKING THESE ALIGNMENTS. For your

convenience the checks and adjustments should be made In the following order,

DISCONNECT MITER SAW FROM POWER SUPPLY.

BEVEL ADJUSTMENT

1. Place saw head in position shown in Fig. 4,

2. Place square firmly against table as shown and

check blade squareness, If blade is square with

table check pointer (A) for 0 ° setting, adjust

pointer if needed by loosening screw (B), locate

pointer on 0 °, and tighten screw, If blade is not

square with table proceed as follows:

3, Loosen lock screw (C) slightly in order to pivot

saw arm (D).

4. Adjust saw arm until blade is square with table

and tighten lock screw securely.

5, Set pointer to 0 ° as stated in 2 above.

6. Reassemble blade cover and four screws as

shown in Fig. 3, it is not necessary to remove

blade cover for any further checks or adjust.

merits. COVER SHOULD ALWAYS BE IN PLACE

DURING SAW OPERATION,

CAUTION: BEFORE MAKING FURTHER CHECKS OR ADJUSTMENTS CONNECT MITER SAW TO POWER

SUPPLY AND MOMENTARILY ENGAGE SWITCH TO CHECK FOR CORRECT DIRECTIONAL ROTATION

OF BLADE, SEE FIG, 3, IF INCORRECT ROTATION IS DISCOVERED, DO NOT USE THIS SAW. RETURN IT

TO YOUR NEAREST SEARS RETAIL STORE,

DISCONNECT MITER SAW FROM POWER SUPPLY

BLADE CENTERING ADJUSTMENT

II

\\

NOTE: The design of this saw requires that the blade

be slightly off set to the right of the turntable slot,

See Fig. 5.

it is now necessary to visually check the blade align-

ment with the center of the turntable slot, See Fig. 5,

1. Place miter arm at0 ° setting with detent lever(A)

fully engaged in slot,

2. Tighten locking lever (B) securely.

3. With saw head centered on turntable as shown,

visually check or measure to assure that the

blade is closely centered on turntable slot.

if satisfactory proceed to next adjustment check.

if setting is not proper, make adjustment as

follows:

4, Using allen wrench furnished, slightly loosen four

cap screws (C) located in the top rear of the saw

arm.

5. With the palm of the hand tap to left or right, as

required, the front of the saw arm (D) until the

bottom of the saw blade is centered as described

in item 3 above,

6. Tighten the four cap screws (C) securely.

Page 7

5,

Fig. 5

Page 8

ADJUSTMENTS (Con'" ued)

DISCONNECT MITER SAW FROM POWER SUPPLY

BLADE HEEL ADJUSTMENT

The saw blade must be aligned, front to rear, with the

direction of travel of the saw head. This condition is

referred to as Blade Heel. See Fig. 6.

1. Miter arm must be securely locked at 0° setting

as described above, (See Blade Centering Adjust-

ment, item 1 and 2.)

2. With the rear edge of the saw blade set in line

with the left fence, hold the blade of your square

firmly against the top front face of the fence.

3, Move the blade of your square to the right until

its end lightly touches the side of the saw blade,

Hold square firmly and push the saw head slow-

ly to the rear allowing the saw blade to pass by

the end of the square until the front edge of saw

blade is in line with the end of the square. Note

any clearance or interference at the front edge

of saw blade, with the end of the square, in order

to determine direction of any saw head adjust,

ment, if the blade has the same clearance to the

square through entire saw head movement, no

adjustment is necessary. Proceed to next adjust-

ment check.

4, Should misalignment have been found, make

adjustments as follows:

5, Move the saw head so that two cap screws (A)

located in the traveler (B) are directly under two

holes (C) in the top of the saw arm (D).

6, With the allen wrench furnished, slightly loosen

both screws, Adjust saw head by lightly tapping

front or rear of the motor housing in the direction

needed to align the saw blade.

7. Repeat checking procedure as described in 2 and

3 alternating with adjustment described in 6 until

all blade heel is removed. Tighten the two cap

screws (A) securely, NOTE: WHEN TIGHTENING

SCREWS CARE SHOULD BE TAKEN NOT TO

CAUSE HEEL SETTING TO CHANGE. Fina! check

should be made as described in 2 and 3 toassure

that proper setting has been maintained while

tightening screws,

\

Fig, 6

DISCONNECT MITER SAW FROM POWER SUPPLY

FENCE TO BLADE ADJUSTMENT

To assure proper 45 ° miter and 90 ° cross cuts it is

necessary to maintain the proper fence to blade sut-

ting,

1. With the miter arm locked in the0 ° setting as pre-

viously described (see Blade Centering Adjust-

ment, page 7, items 1 and 2) place square against

left fence and blade as shown in Fig. 7.

2. if fence checks square to blade proceed to next

adjustment check, If setting is improper, make

left fence adjustment as follows:

3. Loosen two screws on rear of left fence,

4. Adjust left fence square with the blade and sec-

urely tighten two screws,

5. Recheck squareness.

Fig. 7

Page 9

ADJUSTMENTS Continued)

DISCONNECT MITER SAW FROM POWER SUPPLY

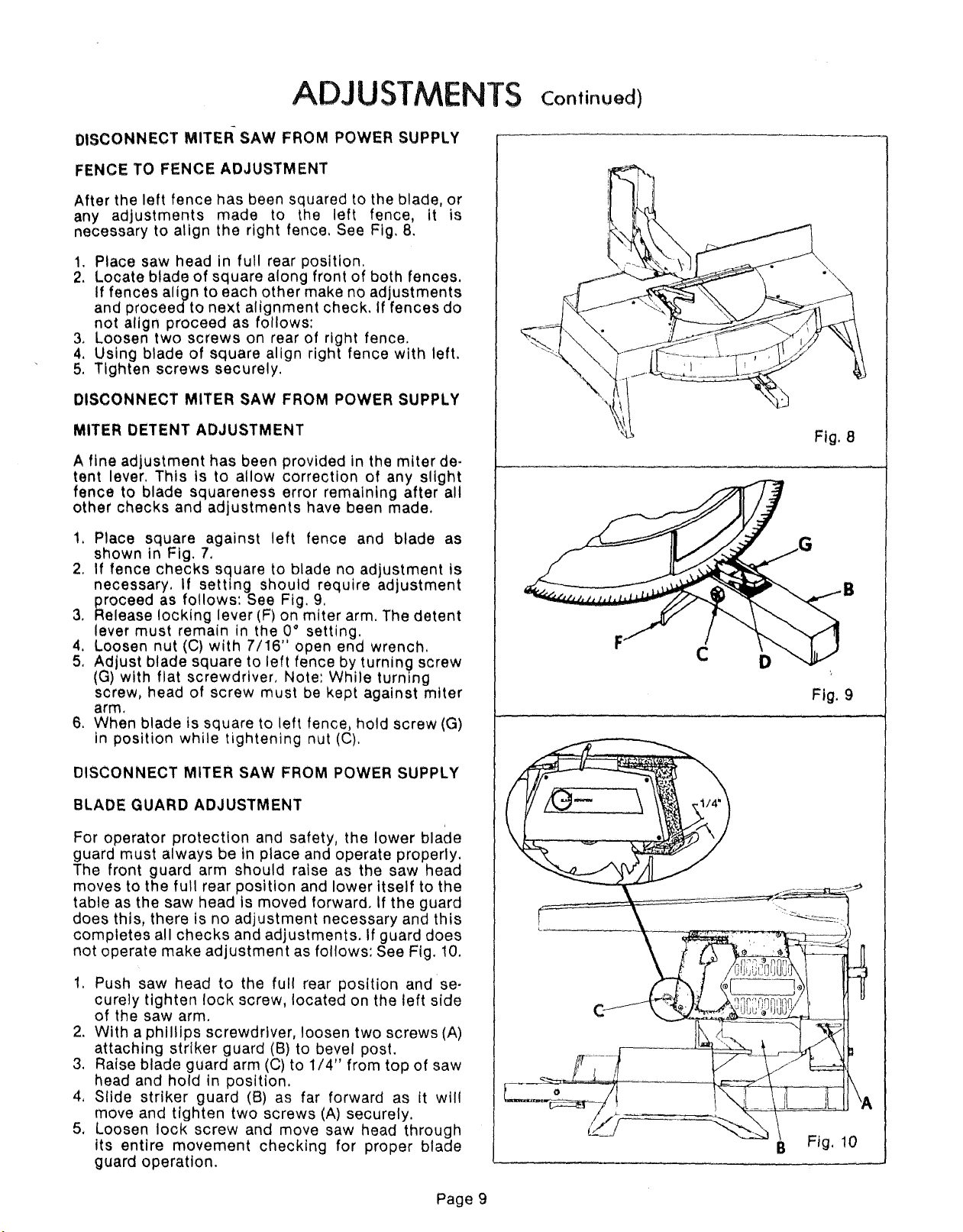

FENCE TO FENCE ADJUSTMENT

After the left fence has been squared to the blade, or

any adjustments made to the left fence, it is

necessary to align the right fence, See Fig. 8.

1. Place saw head in full rear position.

2. Locate blade of square along front of both fences.

if fences align to each other make no adjustments

and proceed to next alignment check. If fences do

not align proceed as follows:

3. Loosen two screws on rear of right fence,

4, Using blade of square align right fence with left,

5, Tighten screws securely.

DISCONNECT MITER SAW FROM POWER SUPPLY

MITER DETENT ADJUSTMENT

A fine adjustment has been provided in the miter de-

tent lever, This is to allow correction of any slight

fence to blade squareness error remaining after all

other checks and adjustments have been made,

1, Place square against left fence and blade as

shown in Fig. 7,

2. If fence checks square to blade no adjustment is

necessary, If setting should require adjustment

proceed as follows: See Fig. 9,

3. Release locking lever (F) on miter arm, The detent

lever must remain in the 0 ° setting,

4, Loosen nut(C) with 7/16' open end wrench,

5, Adjust blade square to left fence by turning screw

(G) with flat screwdriver, Note: While turning

screw, head of screw must be kept against miter

arm.

6. When blade is square to left fence, hold screw (G)

in position while tightening nut (C),

DISCONNECT MITER SAW FROM POWER SUPPLY

BLADE GUARD ADJUSTMENT

For operator protection and safety, the lower blade

guard must always be in place and operate properly.

The front guard arm should raise as the saw head

moves to the full rear position and lower itself to the

table as the saw head is moved forward. If the guard

does this, there is no adjustment necessary and this

completes all checks and adjustments. If guard does

not operate make adjustment as follows: See Fig. 10,

Fig. 8

G

B

1, Push saw head to the full rear position and se-

curely tighten lock screw, located on the left side

of the saw arm.

2. With a phillips screwdriver, loosen two screws (A)

attaching striker guard (B) to bevel post.

3, Raise blade guard arm (C) to 1/4" from top of saw

head and hold in position,

4, Slide striker guard (B) as far forward as it will

move and tighten two screws (A) securely.

5, Loosen lock screw and move saw head through

its entire movement checking for proper blade

guard operation.

Page 9

Page 10

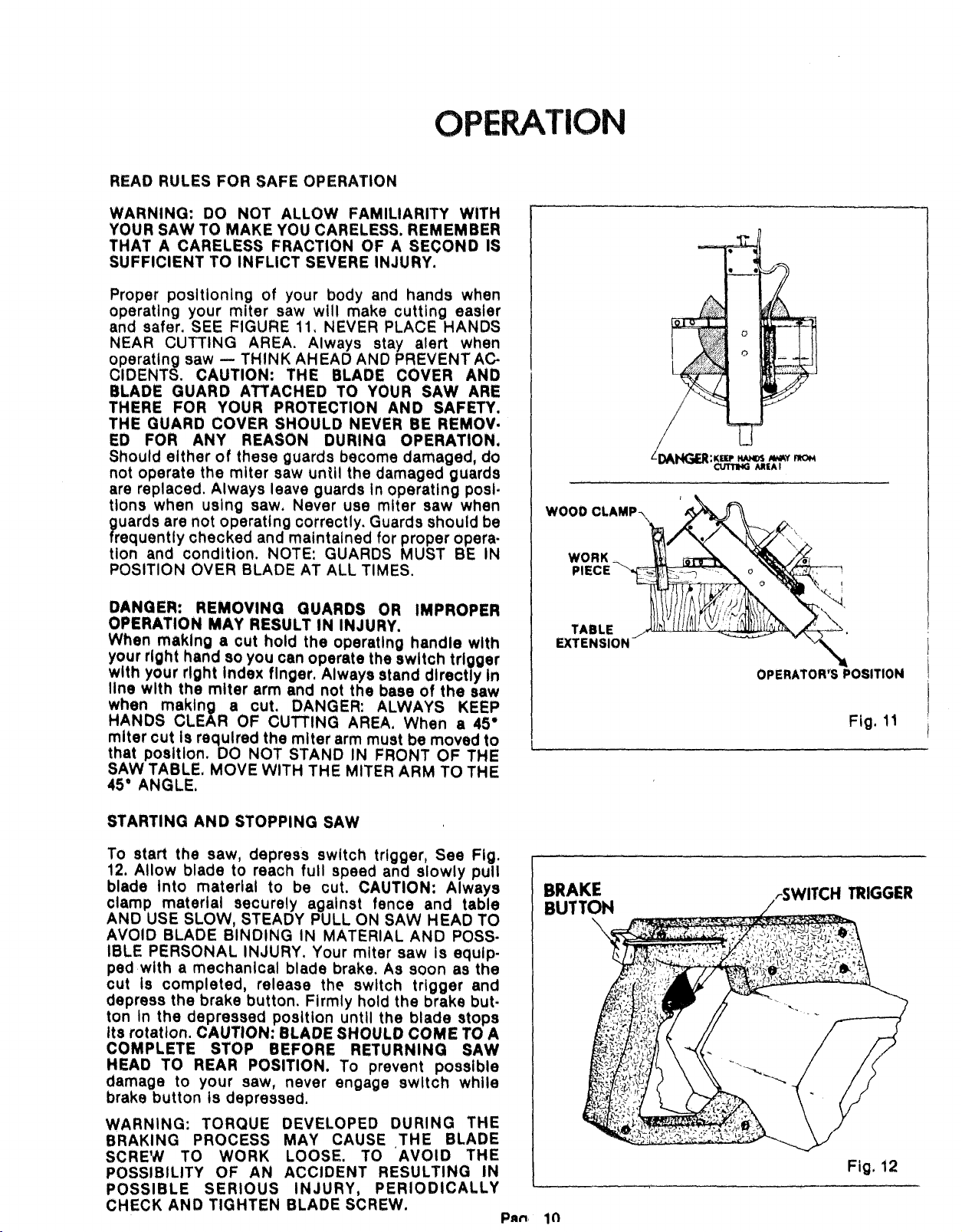

OPERATION

READ RULES FOR SAFE OPERATION

WARNING: DO NOT ALLOW FAMILIARITY WITH

YOUR SAW TO MAKE YOU CARELESS. REMEMBER

THAT A CARELESS FRACTION OF A SECOND IS

SUFFICIENT TO INFLICT SEVERE INJURY.

Proper positioning of your body and hands when

operating your miter saw will make cutting easier

and safer. SEE FIGURE 11. NEVER PLACE HANDS

NEAR CUTTING AREA, Always stay alert when

operating saw -- THINK AHEAD AND PREVENT AC-

CIDENTS. CAUTION: THE BLADE COVER AND

BLADE GUARD ATTACHED TO YOUR SAW ARE

THERE FOR YOUR PROTECTION AND SAFETY.

THE GUARD COVER SHOULD NEVER BE REMOV.

ED FOR ANY REASON DURING OPERATION.

Should either of these guards become damaged, do

not operate the miter saw until the damaged guards

are replaced. Always leave guards tn operating posl.

tlons when using saw, Never use miter saw when

uards are not operating correctly. Guards should be

equently checked and maintained for proper opera.

tlon and condition. NOTE: GUARDS MUST BE IN

POSITION OVER BLADE AT ALL TIMES.

DANGER: REMOVING GUARDS OR IMPROPER

OPERATION MAY RESULT IN INJURY.

When making a cut hold the operating handle with

your right hand so you can operate the switch trigger

with your right Index finger. Always stand directly tn

line with the miter arm and not the base of the saw

when making a cut. DANGER: ALWAYS KEEP

HANDS CLEAR OF CUTTING AREA. When a 45"

mlter cut is required the miter arm must be moved to

that position, DO NOT STAND IN FRONT OF THE

SAW TABLE, MOVE WITH THE MITER ARM TO THE

45 ° ANGLE,

STARTING AND STOPPING SAW

To start the saw, depress switch trigger, See Fig.

!2. Allow blade to reach full speed and slowly pull

blade Into material to be cut. CAUTION: Always

clamp material securely against fence and table

AND USE SLOW, STEADY PULL ON SAW HEAD TO

AVOID BLADE BINDING IN MATERIAL AND POSS-

IBLE PERSONAL INJURY. Your miter saw is equip-

ped with a mechanical blade brake. As soon as the

cut Is completed, release the switch trigger and

depress the brake button. Firmly hold the brake but-

ton In the depressed position until the blade stops

Its rotation. CAUTION: BLADE SHOULD COME TO A

COMPLETE STOP BEFORE RETURNING SAW

HEAD TO REAR POSITION. To prevent possible

damage to your saw, never engage switch while

brake button is depressed.

WARNING: TORQUE DEVELOPED DURING THE

BRAKING PROCESS MAY CAUSE THE BLADE

SCREW TO WORK LOOSE. TO AVOID THE

POSSIBILITY OF AN ACCIDENT RESULTING IN

POSSIBLE SERIOUS INJURY, PERIODICALLY

CHECK AND TIGHTEN BLADE SCREW.

BRAKE

BUTTOH

pin in

Fig, 11

--SWITCH TRIGGER

Fig, 12

Page 11

OPERATION

OPERATION OF MITER ARM

Your miter saw will cut any angle from 0 ° to 47.1/2"

left and right. To operate miter arm release lock lever

(A) on underside of miter arm (B) by turning

counterclockwise. See Figure 13, Depress detent

lever (C), move miter arm to desired angle, and

tighten lock lever (A). Your miter saw also has

positive stops at 0 ° and 45 ° left and right. When any

of these cuts are desired release lock lever (A) on

underside of miter arm (B). Release detent lever (C)

and move miter arm to desired angle, The spring

loaded positive stop engages In the Indent

automatically,

OPERATION OF BEVEL POST

Your miter saw Is also capable of making bevel cuts

from 45' to 90 °. To operate bevel post, loosen lock

screw (A) as shown in Fig, 14 and pivot saw arm until

the pointer (B) is on desired bevel ang_e. Tighten lock

screw securely. Note: While adjusting bevel post,

care should be taken to hold saw arm and saw head

securely to prevent sudden fall to the 45° position

and possibly damaging your saw,

4J A

____ Fig. "14

TABLE EXTENSION AND SECURING WORKPIECE

Caution: Due to Inherent dangers from using this type of saw, especially during miter and compound

angle cutting, It Is strongly recommended that table extensions and material clamps be used to avoid

possible serious injury to operator.

To construct a, table extension it Is suggested that a

1/2" thick x 9 wide x 48' long straight, solid board

be used, See Fig. 15. The bottom surface of the

board must be relieved 118" in the area of the turn.

table to permit rotation of the miter arm. Attach the

board to the miter saw table, according to the I1-

tustration shown, using six (6) 1/4.20 x 1" long

counter-sunk flat head machine screws, All screw

heads must be recessed below the top surface of the

board. After assembly of the board to the table, make

a clearance cut into the board with the miter arm

and/or bevel post at the setting to be used. NOTE:

The usable height of the fence as well as the

thickness cutting capacity of saw will be reduced by

the thickness of the table extension board, CAU-

TION: Screw heads must clear blade in all cutting

positions of miter arm and bevel post.

_ COUNTERSUNK FLAT

HEAD MACHINE SCREW. 1/8' CLEARANCE BETWEEN

| .... L_ i/8-FROM TURNTABLE I

L

I_I _-RELIEVEBOARD

Materials should always be positioned with their

widest side against the table extension.

Page 11

Fig. 15

Page 12

TABLE EXTENSION AND SECURING WORKPIECE (Continued)

Because of the possibility of the material being cut

causing the saw blade to jam or feed itself into the

material, and possibly causing serious personal in.

jury to the operator, CLAMPS SHOULD ALWAYS BE

USED TO SECURE MATERIALS TO THE TABLE EX.

TENSION DURING CUTTING. This eliminates any

need for the operators hands to be used in, the cut.

ting area of the saw, Wooden glue clamps or metal

'C' clamps are recommended for this purpose and

are available at your nearest Sears store or catalog

center. These clamps must be of sufficient size to

securely hold the material during cutting. After the

desired saw settings are made for the required cut,

the material should be placed on the table exten-

sion, properly located in relation to the blade, and

pushed firmly against the fences, See Fig. 16. When

the material has been properly positioned the clamp

must be located and tightened to securely hold the

material to the table extension,

CAUTION: BECAUSE OF POSSIBLE SERIOUS PER-

SONAL INJURY TO THE OPERATOR, MATERIAL

NOT LONG ENOUGH TO BE SECURELY CLAMPED

TO TABLE EXTENSION SHOULD NOT BE CUT WITH

THiS SAW.

EXTENSION -"

OPERATOR'S POSITION

Fig, 16

To prevent material bow and possible saw blade jam-

ming in the material, long lengths of material must

be supported at some distance from the saw, See

Fig. 17, The support should be strong enough to pro-

perly hold the material being cut and located at the

same height as the table or extension,

Fig. 17

TYPICAL OPERATIONS

Your Craftsman Radial Arm miter saw was designed to cut wood and plastics. It is not recommended for cu

ting ferrous metals or hard non.ferrous alloys, Shown below are just some of the many operations that may b

performed with your miter saw. As you become mere familiar with the operation of your saw you will find man

more uses, Always use proper blade for material being cut, The blade packed with your miter saw was desigr

ed to cut wood,

The cutting capacity of your saw depends upon the setting at which the cut is being made, The saw will cu!

material 9-7/8" wide at 0 ° miter setting and 7.3/8" wide at 45 ° miter setting, Your miter saw will also cu_

material 2-3/8" thick at 0° bevel setting and 1-5/8" thick at 45° bevel setting. Care should be taken prior to cut

ring of any material to :_ssure that it is not too wide or thick for the angle being cut.

CAUTION: To prevent possible personal injury, you should read and understand all items shown under"Tabl,

Extension and Securing Workpiece" before attempting any cutting with this saw.

Securely tighten both the bevel and miter arm locking screws before making any cut and return the saw head t(

the full rear position when cuts are complete, and after the blade has stopped rotating.

P,n 19

Page 13

CUTTING MOULDINGS

TYPICAL OPERATIONS (Co,-,t,-,uod)

You can cut 45 ° miter cuts on material and moldings

up to 2.3/8" thick, See Fig, 18. Instead of making

right and left hand 45 ° cuts for matching miters, or

cornering, simply make the 45 ° cut and for the mat.

ching face turn the work completely over and make

your cut with the saw at the same setting, Your miter

saw is also capable of cutting angles up to 47.1/20

to allow the operator to compensate for existing out

of square corners, Miters on material such as

baseboards that are wider than 2-3/8" should be cut

with the material lying flat on the saw table, The

miter cut can be made with the bevel post at 45 ° set,

ting and the miter arm at 0°, Refer to page 21 for pro-

per blades to be used with your materials.

CUTTING FRAMING MATERIALS

2 x 4 and 2 x 6 framing material as well as moldings

can be cut at all angle settings of the miter arm. it is

an ideal saw for squaring ends of framing material

where random lengths are being used, See Fig, 19.

NOTE: Care must be taken to properly support long

lengths of material during cutting to avoid possible

damage to the miter saw and/or serious injury to

operator. See page 21 for proper blade for your cut-

ting requirement.

WOOD CLAMP

WORK

OPERATOR'S POSITION

Fig. 18

CUTTING ROOF RAFTERS

With this saw it is possible to make compound angle

cuts using required settings cf both the miter arm

and the bevel post, See Fig, 20, Ends of roof rafters,

for joining with hip roof ridge and valley rafters, can

be readily cut to proper angles. With the material lay-

ing flat on the saw table and firmly against fences,

set the miter arm for the correct pitch angle and the

bevel post for the correct intersect angle, The

resulting cut will give an excellent fitting rafter end,

NOTE: After cut is completed, release the switch

trigger, depress the brake button to stop rotation of

blade, Then remove the material from the saw table

before returning saw head to rear position. This

prevents the blade guard from binding on the

material when returning saw head to rear position,

Again care should be used to properly support long

lengths of material, See Fig, 17, NOTE: Table exten.

sion and clamp are not used when making this cut,

WARNING: Keep hands clear of cutting area.

Page 13

Fig, 19

Fig. 20

Page 14

CUTTING THIN MATERIALS

TYPICAL OPERATIONS (Continued)

Your miter saw can be used for cutting thin materials

such as laminated plastics and composition board,

See Fig, 21. To avoid Jammlng under the fences all

thin materials should only be cut when the saw Is

equipped wtth a table extension and material Is

securely clamped, See "Table Extension and Secur-

ing Workplece" as shown on page 11 . For proper

blade requirements, see page 21,

CUTTING PLASTIC PIPE

You can use your miter saw on plastic pipe, it makes

clean, square ends for butt joining and mitered ends

for cornering, Care must be taken to properly clamp

pipe during cut to prevent its rotation, See Fig, 22,

Long material should also be supported at saw table

height for ease of cutting and to avoid possible In-

jury to the operator, See "Table Extension and

Securing Workplece", page 1i , See page 21 for the

correct blade to use on the material to be cut.

\,\

\

Fig. 21

Fig. 22

WARNING: DUE TO THE POSSIBILITY OF CAUSING PERSONAL INJURY TO THE OPERATOR AND DAMAG.

iNG YOUR SAW, ONLY THOSE BLADES AND ACCESSORIES LISTED ON PAGE 21 SHOULD BE USED WITH

THIS SAW. THiS SAW WAS NOT DESIGNED FOR USE WiTH DADOES, MOLDING HEADS, SANDING DISCS

OR CUT,OFF WHEELS, AND THESE MUST NEVER BE USED WITH IT. REMEMBER, READ AND UNDERSTANI;

ALL INSTRUCTIONS, USE YOUR SAW CAREFULLY, AND PREVENT INJURIES.

CUTTING BOWED MATERIAL

When cutting any material, check to make sure it is

not bowed, if it is bowed the material must be posi-

tioned and cut in the proper manner. Material posi-

tioned lrfcorrectly will cause pinching of the blade

near the end of the cut. See Fig. 23 for correct posi-

tioning of material on miter saw, It also shows incor-

rect positioning of material which will cause pin-

ching of the blade,

Page 14

CORRECT

INCORRECT

Fig. 23

Page 15

TYPICAL OPERATIONS (Continued)

CUTTING POLYGON MITERS

Any closed construction has a number of sides

which must be joined together at the proper angles.

This can be done with either a miter or bevel setting

of the correct angle and the material lying with the

flat side against the saw table. See Fig, 24. Fiat

miters, as shown, can be cut with a miter arm set-

tlng, but miters to be used with the material on edge

must be cut with the bevel post at the proper setting.

See table In Fig, 25 for proper angle setting of either

the miter arm or bevel post to create your desired

cuts. For an object requtrl,lg a number of sides not

shown In the table, a simple formula of 180' dtvlded

by the number of sides in the object results In the

miter arm degree setting for each cut. See Page 12

for cutting capacity of your saw for this type of cut.

CUTTING CROWN MOULDING

The majority of crown mouldings have contact sur.

faces of 52" and 38 ° on the top and bottom rear cur.

faces, and in some instances are wider than the cut.

ttng capacity of the saw. Because of this, it ts much

easier to cut crown moulds for square corners with

the material lying flat on its back surface and a com.

pound setting on the saw. See Fig, 26. in all cases

the bevel post should be set at 33.85' and the miter

arm set at 31.62' either right or left, depending on

the desired cut. Your saw angle quadrants are

graduated In 1/2 ° (.50°). Care should be taken In

making set-ups to properly adjust saw settings to

decimal degrees. Excellent corner fits should be ob-

tained with these settings, However, angle settings

cannot be relied upon to be precise. Always test

angle setting accuracy on scrap and plan each cut

before you begin.

Fig. 24

EXAMPLES

NO,

SIDES

4

5

6

?

8

9

10

Fig, 25

OUTSIDE CORNER

FLAT

ON_EOG_

POLYGON MITERS

ANGLE

MITER OR BEVEL

45°

36°

30°

22,5°

20°

18°

CUTTING COMPOUND MITERS

A compound miter, sometimes called a hopper or

bevel miter, is a cut utilizing both a miter and bevel

setting on the same cut. It is used for making frames

or boxes with sloping sides (see Fig. 27) and for cer-

tain roof framing cuts (see "Cutting Roof Rafters").

To make this type cut, the miter arm must be ad-

justed to the correct angle and the bevel post tilted

the correct amount, Care should always be taken

when making compound miter set,ups due to the in-

teraction of the two angle settings. After the first

setting is made, miter or bevel post, adjusting the se-

cond setting will change the first. Because of this,

angles previously set should always be checked

after a setting of the second angle, Repeat as re-

quired until the two correct settings for your par-

ticular cut are obtained, See Page 12 for cutting

capacity of your saw for this type of cut. NOTE: After

cut is completed release the switch trigger, depress

the brake button to stop rotation of blade, Then

remove the material from the saw table before retur-

ning saw head to rear position, This prevents ttle

blade guard from binding on the material when retur-

ning saw head to rear position.

Page 15

i_.l_T E R ANGL_

INSIDE CORNER

Fig. 26

PITCH ,_,NG LE

COMPOUND MITER

Fig, 27

Page 16

TYPICAL OPERATIONS (Continued)

CUTTING COMPOUND MITERS (Cont'd)

To aid In making the correct settings, the compound angle setting chart shown in Fig 28 has been provided.

Since compound cuts are the most difficult to accurately obtain, trial cuts should be made in scrap material,

and much thought and planning made, prior to making your required cut,

NUMBER OF SIDES

PITCH

OF SIDE 4

0 o

5o

i 0°

15°

20°

25 ° 8.17.39 °

,_o M,40,89 ° M-32,18 ° M.26,57 M'22.64 d M.19.73°iM.iT'500iM.15.72°

.... •_u ....... 8- 20,70 ° B- 17.09 ° B- 14.48°! B" 12,53 ° B'il, .03 °[ B".... 9. .....850 I B " 8,89 °.......

35 ° B.23.93 o B.19.70 ° B.16,67°!B.14.41 ° B.12,68°IB.11,31 ° B.10.21 °

40o M'37.450 M-29'10 ° 1_.23'860'M'20.250'M:i7.60°'M.iS'SB0"M.13.980

45°

50°

55°

.... , , , , ,,

60o !

65o

70°

75°

....... J

80o

85°

90o

M.45.00 °

B" 0,0 °

M,44.89 °

B" 3,53 °

M-44.56 °

B" 7,05 °

M,44,01 °

B. 10,55 °

M .43.22 °

B" 14.00 °

M-42.19 °

M.39,32°IM.30,76 ° M.18,74 ° M.16,60 ° M.14,90 °

B.27,03 ° B.22,20 ° B-18.75 °!B'16.19°!B-14,24 ° B-12.70 ° B-11.46 °

M.35.26 °

B "30.00 °

M-32.73 °

B -32.80 °

M.29.84 °

B - 35.40 °

M2657_

B- 37.760

M-22,91 o

8-39.86

B-41,64 °

M.14.51 °

B-43.08 °

M- 9.85 0

B.44,14 °

M- 4,98 °

B-44.78 °

M- 0.00 °

8 -4,5.00 °

Each B (Bevel)

5

M.36.00 °

LB:°,00

M-35.90 °

8" 2.94 °

M-35.58 °

B- 5.86 °

M-35.06 °

B- 8.75 °

M.34.32 °

8- 11.60 °

M-33.36 °

B - 14,38 °

M.27.19 °

IB -24.56 °

M.25.03 °

B.26.76 °

iM-22.62 °

B.28.78 °

6

M.30.O0 o

B.00.0 °

M.29.91 °

M.29.62 °

M-29.15°1 M.24.95 °

8- 7.440 8 • 6.45 O

M.28.48 °] M.24.35°1

B" 9.85 ° B" 8.53°I

M.27.62 °! M.23.58 °1

B-12.20°1 B- 10.57 °

M.22.21°I

B.20.70 °

j M.20.36 °

B "22.52 °

M-18.32 °

B.24.18 °

M16,1o°

8- 30.60 °

M 17o7O

B.32,19 °

M.13.95 °

=8.33.53,°.

M-10.65 °

8- 34.59 °

M. 7.19 °

B. 35.37 °

M- 3.62 °

8-35 84 °

M- 0.00 °

B- 36.00 °

and M (Miter) Setting I$ Given to the Closest 0.OOS °.

B-25.66 °

M.13.71 °

B.26.95 °

M-11.17 °

B.28.02 °

M- 8.50 °

B.28.88 °

M. 5.73 _

B- 29.50 °

M. 2.88 °

¢1.29.87°.B-25.61 ° B.22.4!° B.19.92 °

M- 0.00 ° M- 0.00 ° M- 0.00 ° M- 0.00 °

B.30.00 ° 8-25.71 ° B-22.50 ° B-20.00 °

........ i .....

7

M_25.71 °

B- 0.0 °

M.25.63 °

B- 2.17 °

M.25.37 °

M-18.80°i M-16.32°;

B. 17.87 ° B. 15.70 °

8 9

IM.22.50 ° M.20.O0 °

B* 0.0 ° B- 0,0 °

M.22.42 ° M-19.93 °

B. 1,91°lB - 1,71 °

M.22.19°i M.19.72 °

B- 3.810 B- 3.40 °

M-21,81° M-Z937° M:1742

B" 5.68° B - 5.08°_ 4.59 °

M.21.27 ° M.18.88 ° M.16.98 °

B" 7.52 ° B- 6.72° 8 , 6.07 °

M-20.58 ° M-18.26 °IM:16.41 °,

B- 9.31 ° B- 8.31 ° B" 7.50 °

M.i7200;M'1491o

B-19.41 ° B'17,O5 °

M.lS440M.1336o'

B.20.82 ° B.18.27 °

M:13.54 ° M'1i.70 °

B-22.07 ° B. 19.35 °

M.11,5o° M. 9.93°

B.23,16 ° B.20,29 °

M- 9.35 ° M- 8.06 °

B.24,06 ° 8.21.08 °

M- 7,10 ° M- 6,12 °

B.24.78 ° B.21,69 °

M- 4.78 ° M- 4.110

B-25.30 ° B-22.14 °

M- 2.40 ° M- 2,O7 °

M-18.O0

M.14.43 °

B- 14.000

13.170

:15,i9 °

M111796

B.16,27 °

....... 6!

M-10,31

B-17,23 °

M- 8.1714OI

B " 18,06 °

M. 7.1o_'

B.18.75 °

M- 5.38 °

B-19.29 °

M- 3.62 °

8-!9.68 °

M- 1,82 °

10

B" 0.O °

M.1 7.94 °

B" 1.54 °

M-17,74 °

B-3.08 °

M.12.94 °

B. i2.62 °

M.11.80 °

B" 13.69 °

M.i0.56 °

B-1,4,66 °

M- 9.23 o

B-15.52

M:7.82o'

B-16.26

M- 6.34 b

B-Z6.a8°

M- 4.81 °

B. 17.37 °

M- 3.23 °

B- 17.72 °

M- 1.62 °

B- 17.93 °

M- 0.00 °

B - 18.00 °

COMPOUND-ANGLE SETTINGS FOR POPULAR STRUCTURES

Fig. 2B

Page 16

Page 17

NOTES

Page 17

Page 18

MAINTENANCE

WHEN SERVICING USE ONLY IDENTICAL REPLACEMENT_RARTS

BRUSH REPLACEMENT

DISCONNECT MITER SAW FROM POWER SUPPLY.

1, Remove brush caps (A) from motor housing (B)

with screwdriver. See Figure 29,

2, Remove brushes (C).

3, Assemble new brushes into motor housing,

making sure that the brushes move freely in the

brush tube,

4, Replace the brush caps,

5, After brush replacement is completed saw should

be run at no load 3 to 5 minutes to properly seat

the brushes,

SWITCH REPLACEMENT

DISCONNECT MITER SAW FROM POWER SUPPLY.

1, Remove the six screws (A) that secure the handle

cover and carefully llft it from the tool. Note the

locations of all wiring in the handle and how each

connection is made to the switch. Connections

and wiring position must be identical when in-

stalling the new switch.

2, Remove the screw (B) securing the switch (C) and

lift the switch away from the handle.

3, Remove the leads from the switch and attach

them to the new switch making sure they are at.

tached in proper location as shown In Fig, 30.

4. Arrange the wiring in the handle so that it will not

be pinched when the handle cover is replaced and

secure switch In place with screw (B).

5. Place the cord and bend relief in their correct lo-

cations.

6, Properly locate and seat brake linkage in its

proper place making sure linkage does not bind

or interfere with wiring.

7, Replace handle cover and tighten all screws,

C

Fig. 29

B

CORD REPLACEMENT

DISCONNECT MITER SAW FROM POWER SUPPLY.

1, Remove handle cover as described above.

2. Remove switch from handle and disconnect the

supply cord leads from the switch,

3. Attach each lead of the new supply cord to the

switch in the proper location making sure red lead

from motor is attached at this time, See Figure

30,

4, Arrange the wiring in the handle so that it will not

be pinched when handle cover is replaced and

secure the switch in place, CAUTION: DO NOT

PINCH WIRING WITH SCREW BOSSES.

5, Place the bend relief and cord in their correct

locations,

6. Properly locate and seat brake linkage in its

proper place making nure linkage does not bind

or interfere with wiring.

7, Replace handle cover and tighten all screws.

BLACK

(POWER CORD)

/

(POWER CORD) ':._

.....

Fig, 30

Page 18

Page 19

MAINTENANCE ¢Coot nued)

REMOVING THE BLADE

DISCONNECT MITER SAW FROM POWER SUPPLY.

1, Place saw head in the position shown in Fig. 31.

Remove four screws (A) and blade cover (B).

2, Place a soft wood block on the turntable (F) seat-

ed against the front of the fence (G). See Fig. 31.

Move the saw head until the blade teeth embed in

the block and hold securely,

3. With the wrench furnished loosen the blade

screw (C) until it can be removed byhand, NOTE:

THE BLADE SCREW HAS LEFT.HAND THREADS.

4, Remove the screw (C), spring washer (D), and

outer blade washer (E),

5, Remove saw blade from spindle.

6, To assemble blade see Fig, 3, Page 6. Note: Blade

cover must always be in place when blade is

mounted on unit.

i

Fig, 31

WHEN NOT IN USE LOCK SWITCH IN THE "OFF"

POSITION

IMPORTANT: We suggest that when the miter saw is

not in use it should be disconnected from the power

supply. The switch should be locked in the "off"

position using a padlock, as shown in Figure 32. A

lock with a shackle up to 3/16" diameter may be us-

ed,

FOR ADDED SAFETY the saw head should be locked

in the rear position when the miter saw is not in use

or is being moved. To lock the saw head in the rear

position,

DISCONNECT MITER SAW FROM POWER SUPPLY.

1, Push saw head to rear as shown in Fig, 33.

Fig, 32

LOCK LEVER 7

2, Lock saw head in this position by tightening lock

lever,

Page 19

Fig, 33

Page 20

MAINTENANCE

TO CLEAN SAWDUST FROM TURNTABLE

Periodically sawdust will accumulate between the

turntable and miter saw table, This will cause dif-

ficulty in the movement of the turntable when mak-

tng different angle cuts, To clean sawdust from bet-

ween turntable and miter saw table,

DISCONNECT MITER SAW FROM POWER SUPPLY.

1, Remove the blade,

2, Place saw head in the rear position.

(Continued)

3, Clean between miter saw table and turntable,

See Fig. 34,

4, Replace blade.

PROPER TENSION OF TURNTABLE

DISCONNECT MITER SAW FROM POWER SUPPLY

Proper tension on turntable should be maintained to

help prevent "wobble" in saw arm, To make the ad-

justment simply loosen or tighten lock nut (A) on pin.

tie bolt (B) located on underside of miter arm, See

Fig, 35,

LUBRICATION

in order to malntatn proper bearing lubrication, your

saw arm assembly has an oil reservoir that should be

refilled from time to time. SEE FIGURE 36, To refill:

Slide saw head along guide rods until the oil reser-

voir on one end of the traveler lines up with one of

the oll holes on top of the saw arm assembly. Add

several drops of machine oil, Next, slide saw head

along guide rods until the oil reservoir on the other

end of the traveler lines up with one of the oil holes

on top of the saw arm assembly, Add several drops

of machine oil to this side of your traveler also,

MOTOR PLAY ADJUSTMENT

As mentioned earlier, your miter saw has been fac-

tory adjusted and aligned to assure proper operation,

After use, however, the bearings in the traveler of

your saw arm assembly may begin to wear creating

motor play, To remove this motor play make the

following adjustments,

1, See Figure 37, Move the saw head so that two

screw heads (A & B) can be seen thru the 3/8"

diameter holes in top of the saw arm assembly,

UNDERSIDE OF MITER SAW

SAWARM

ASSEMBLY

OIL

RESERVOIR

SAW ARM

/.j_'_,._ ._" ASSEMBLY

OIL

HOLES

/ ,

/

//

GUIDE

RODS

Fig. 34

i

Fig. 35

AVELER

/I

j_

Fig, 36

2, Tighten screw (A) so that the motor will not slide

back or forth, Loosen screw (A) just enough so

that motor will slide,

3, Adjust screw (B) by the same procedure.

4. Move the saw head forward about 2-1/2" until you

see the third screw (C). This screw can be seen

thru the right hand 3/8" diameter hole.

5. Adjust screw (C) the same as screws (A) & (B)

above.

Fig, 37

,'_t'l

Page 21

MAINTENANCE (Continued)

SAW BLADES

The best of saw blades will not cut efficiently if they are not kept clean and sharp. Using a dull blade will

do nothing more than place a heavy load on your saw, Keep extra blades on hand, so that sharp blades are

always available, Gum and wood pitch hardened on blade will slow it down, Use Craftsman Gum and Pitch

Remover No, 9.49191 to remove these accumulations, DO NOT USE GASOLINE, ALWAYS REMOVE

BLADE FROM MITER SAW WHEN CLEANING.

GENERAL

Only the parts shown on parts lists, pages 27, 29 and 31 are intended to be repaired or replaced by the

customer. All other parts represent an important part of the double insulation system and should be ser-

viced only by a qualified technician.

Avoid using solvents when cleaning plastic parts. Most plastics are susceptible to various types of com-

mercial solvents and may be damaged by their use, Use clean cloths to remove dirt, carbon dust, etc.

WARNING: DO NOT AT ANY TIME LET BRAKE FLUIDS, GASOLINE, PENETRATING OILS, ETC., COME IN

CONTACT WITH PLASTIC PARTS. THEY CONTAIN CHEMICALS THAT CAN DAMAGE AND/OR

DESTROY PLASTIC.

When electric tools are used on fiberglass, it has been found that they are subject to accelerated wear and

possible premature failure, as the fiberglass chips and grindings are highly abrasive to bearings, brushes,

commutators, etc, Consequently tt is not recommended that this tool be used for extended work on any

fiberglass material, During any use on fiberglass it is extremely important that the tool is cleaned fre-

quently by blowing with an air jet. ALWAYS WEAR SAFETY GLASSES OR EYE SHIELDS BEFORE BEGIN.

NING THIS OPERATION,

RECOMMENDED ACCESSORIES

THE FOLLOWING RECOMMENDED ACCESSORIES ARE CURRENT AND WERE AVAILABLE AT

THE TIME THIS MANUAL WAS PRINTED.

iTEM USAGE CAT. NO.

Leg Set

Blade (Master Combination)

Blade (Chisel.Tooth Combination)

Blade (Crosscut Plywood)

WARNING: CARBIDE TIPPED BLADES ARE NOT RECOMMENDED FOR USE ON THIS SAW. THE USE OF

ATTACHMENTS OR ACCESSORIES NOT LISTED ABOVE MIGHT BE HAZARDOUS,

• Always clamp workpiece securely for cutting,

• A safe operator is one who thinks ahead.

• Always wear eye protection when sawing,

• Make set-up adjustments carefully. Then double

check.

• Don't let familiarity make you careless.

Mounting Miter Saw

Large Hard and Soft Wood

All Purpose Hard and Soft Wood

Plywood, Fiberboard, Plastics

HELPFUL HINTS

• NEVER place your hands in jeopardy.

• Make certain clamps can't loosen while in use,

• Test difficult set-ups on scrap - Don't waste

lumber,

• Plan each operation before you begin,

• Remember- Guards must always be used.

22246

32495

32665

32449

• Study all safety rules and do the job safely.

• THINK SAFETY BY THINKING AHEAD.

Page 21

Page 22

TROUBLE SHOOTING

PROBLEM

Saw will not run,

Mechanical brake not

functioning.

Blade does not reach full

speed,

Saw vibrates excessively.

Saw makes rough cuts.

POSSIBLE CAUSE

1, Saw not plugged in to power

supply.

2, Fuse blown or circuit breaker

tripped.

3, Damaged cord.

4, Motor brushes worn.

5, Faulty switch,

1, Faulty brake linkage.

2, Worn brake lining,

1, Extension cord too light _

or too long,

2, Low house voltage.

3, Sticking motor brush.

4, Blade improperly tightened,

1, Saw not mounted to bench or

supporting suface securely,

2. Bench or support on uneven

floor or surface,

3, Damaged saw blade.

1, Dull blade,

2, Blade mounted backwards.

3. Gum or pitch on blade.

4, Incorrect blade for job.

5, Heel setting incorrect.

W_HAT=TODO

1, Connect saw to

power supply.

2. Replace fuse or reset circuit

breaker, Check for circuit

overload,

3, Replace cord. See Page 18

4, Replace brushes, See Page 18

5, Replace switch. See Page 18,

Contact your nearest Sears

Service Center or Sears Store.

1, Replace with proper size cord,

See Page 6

2, Contact your power company,

3, Remove brush and check for

uniform surfaces or binding.

4, See Blade Assembly, Page 6.

1, Tighten all mounting screws.

See Page 6.

2, Reposition on flat level surface,

Fasten securely.

3, Replace blade, See Page 19,

1, Replace blade, See Page 19

2, Turn blade around.

3, Remove and clean blade.

4, Change the blade, See Page 21,

5. Check heel adjustment, See

Page 8,

Materlal pinches blade,

Saw does not make ac.

curate cross cuts or miter

cuts.

Saw does not make

accurate bevel cuts.

.

Cutting bowed material in

wrong position,

2.

Fences not aligned.

3,

Heel Setting incorrect,

.

Detent lever not adjusted

correctly,

2,

Blade is "heeling."

3,

Mtsaligned fences.

4, Excessive looseness in turn-

table,

5. Excessive looseness in saw

arm,

6. Excessive Looseness in Saw

Head,

1. Bevel setting incorrect

2, Heel setting incorrect,

3. Excessive looseness in saw arm,

1, Position material as shown, See

Page 14,

2, Check fence to fence alignment.

See Page 9.

3, Check heel adjustment, See

Page 8,

1, Readjust Detent Lever. See

Page 9,

2, Check blade heel adjustment,

See Page 8,

3. Check fence to blade and fence

to fence adjustment, See

Pages 8 and 9.

4, Check turntable adjustment. See

Page 20,

5, Check blade centering ad-

justment. See Page 7,

6, Check Motor Play Adjust-

ment. See Page 20.

1, Check bevel adjustment,

See Page 1,

2, Check heel adjustment,

See Page 8,

3, Check blade centering adjust-

ment, See Page 7.

Miter arm difficult to rotate

1, Sawdust or wood chips binding

turntable.

Page 22

1, Clean out turntable. See Page 20.

Page 23

NOTES

'l Page 23

Page 24

NOTES

Page 24

Page 25

-------- CRAFTSMAN RADIAL ARM MITER SAW -- MODEL NUMBER 315.23743

SEEFIGURE'_' FOR

D VIEW

SEEFIGURE"C"FOR

EXPLODED VIEW

SEEFIGURE"B"FORj

EXPLODED VIEW

Page 25

Page 26

/

\

\

'\

\

'\

\,

\

\

\

II! I ! ! ! I I I!11 II I III I .... _ _-- _ I I I I! _ --L I _[_ ! ! L _ i I _.__

Page 27

Key Part

No. Number

1 611638-004

2 622180.001

3 989001-001

4 621644-006

5 612465-002

6 941401-023

7 989959-001

8 621644-002

9 931744-811

10 989960-001

11 989048-001

12 614658-010

13 989165-004

14 989645-001

15 623547-002

16 989630-003

17 611897-001

18 989963-001

21 718602-805

22 990454-001

CRAFTSMAN RADIAL ARM MITER SAW -- MODEL NUMBER 315.23743

Always mention the Model Number in all correspondence regarding your

The Model Number will be found on a plate attached to the Motor End Cap. !

RADIAL ARM MITER SAW or when ordering repair parts.

' ' • ,, , I I =, i i •

SEE BACK PAGE FOR PARTS ORDERING INSTRUCTIONS

FIGURE _, PARTS LIST

Key Part

Description Quantity

Cord Assembly ........... 1

*Screw (#8-32 x 1/2 Pan Hd.). 1

Clamp .................. 1

*Socket Head Cap Screw

(1/4-20 x 2) ............. 4

Locking Lever ............ 1

Roll Pin ................. 1

Saw Arm Logo (Left) ....... 1

*Socket Head Cap Screw

(1/4-20 x 1).............. 2

Washer ................. 2

Saw Arm Logo (Right) ..... 1

Saw Arm Assembly ....... 1

*Screw (8-32 x 3/8 Pan Hd.)

* *STD510803 .......... 4

Blade Cover .............. 1

Blade Screw .............. 1

Spring Washer ........... 1

Outer Blade Washer ....... 1

***Saw Blade- 7-1/2 Inch

For 5/8" Arbor ......... 1

Warning Plate ............. 1

Retaining Ring ........... 1

*Screw ................... 1

No. Number

23 611807-002

24 611806-002

25 611815-001

26 795247-037

27 617550-001

28 611114-001

29 989680-001

31 941401-825

32 617020-001

33 612219-001

34 990549-001

36 706404-007

37 989116-000

38 703428-025

39 989116-000

40 614658-005

41 614658-024

42 617966-006

43 989447-001

44 61710_001

45 612458-002

Description Quantity

Lever ................... 1

Connector ............... 1

Lower Blade Guard ........ 1

Drive Screw .............. 1

Spring .................. 1

*Screw (8-32 x 1/2 Flat Hd.)..4

Blade Spindle Assembly... 1

Roll Pin ................. 1

Brush Cap ................ 2

Brush ................... 2

Data Plate ............... 1

*Hex Nut (#8-32)

** STD541008 .......... 3

Handle (Includes Key #39).. 1

*Screw (#8-32 x 1/2 Ftat Hd.). 1

Handle Cover

(Includes Key #37) ....... 1

*Screw (8-32 x 7/8 Pan Hd.).. 3

*Screw (8-32 x 1-1/2 Pan Hd.)3

Screw ................... 1

Switch (Includes Key #44).. 1

*Screw (#6-32 x 3/16 Pan Hd.)

**STD510602 .......... 4

Wrench ................. 1

I

SECTION "'A" -- The assembly shown represents an important part of the Double Insulated System. To avoid the possibility of

alteration or damage to the System, service should be performed by your nearest Sears Repair Center. Contact your nearest

Catalog Order or Retail Store.

"Standard Hardware Item -- May Be Purchased Locali_f

**Available From Div. 98 -- Source 980.00

***Refer to Page 21 of Owners Manual for Recommended Saw Blades

Page 27

Page 28

CRAFTSMAN RADIAL ARM MITER SAW-- MODEL NUMBER 315.23743

9

SEE

NOTE

10

12

13

t

15

17

14

2O

NOTE 1: COAT WITH LIGHT

FILM OF HIGH PRESSURE GREASE

FIGURE"B"

Page 28

Page 29

CRAFTSMAN RADIAL ARM MITER SAW -- MODEL NUMBER 315.23743

The Model Number will be found on a plate attached to the Motor End Cap.

Always mention the Model Number in all correspondence regarding your

RADIAL ARM MITER SAW or when ordering repair parts,

SEE BACK PAGE FOR PARTS ORDERING INSTRUCTIONS

FIGURE B PARTS LIST

Key No, Number

Part

1 703428.010

2 989229.002

3 989227.003

5 703427-035

6 703473.032

7 931744-006

8 930687.008

9 610490.003

10 98996i-001

11 612875.003

12 611783.003

13 610393.009

14 610510.002

15 989956.001

16 610494.003

17 703473.042

18 622439.005

19 610493.003

Description Quantity

*Screw (//8-32 x 3/8 Flat Head) ........ 7

Pintle Bolt ........................ 1

Turntable ......................... 1

*Screw (1/4-20 x 1-1/4 Hex Head) ...... 4

* Lockwasher (1/4) * *STD551125 ...... 4

Washer ** STD551225 .............. 4

*Set Screw ........................ 1

Fence -- Right .................... 1

Logo Plate ........................ 1

Washer .......................... 1

Fence -- Left ..................... 1

Table (Includes Key No. 14) .......... 1

Sleeve Bearing .................... 1

Logo Plate ........................ 1

Foot -- Right ..................... 1

* Lockwasher (5/16) * *STD551 i31 ..... 4

*Screw (5/16.18 x 3/4 Hex Head) ...... 4

Foot -- Left ....................... 1

20 610489.003

"Stanclard Hardware item _ May Be Purchased Locally

"*Available From DIv. 98 _ Source 980,00

Quadrant ......................... 1

Page 29

Page 30

SEE

NOTE 3

CRAFTSMAN RADIAL ARM MITER SAW -- MODEL NUMBER 315.23743

.1

6

10

._,:'

TORQUE TO 100 INCH

LBS. MIH; /

,/

/

NOTE 1: COAT WITH LIGHT FILM OF

HIGH PRESSURE GREASE.

NOTE 2: TIGHTEN UNTIL ARM SWINGS

FREELY WITHOUT LOST MOTION.

NOTE 3: TIGHTEN UNTIL POST

SWINGS FREELY WITHOUT LOST

MOTION.

15

/

t

FIGURE"C"

Page30

Page 31

CRAFTSMAN RADIAL ARM MITER SAW -- MODEL NUMBER 315.23743

The Model Number will be found on a plate attached to the Motor End Cap.

Always mention the Model Number in all correspondence regarding your

RADIAL ARM MITER SAW or when ordering repair parts.

SEE BACK PAGE FOR PARTS ORDERING INSTRUCTIONS

FIGURE C PARTS LIST

Key Part

No. Number

1 989006-002

2 703776-098

3 617966-003

5 621377-004

6 612681-001

614658-010

8 611767-002

9 611800-004

10 621359-000

11 990542-002

12 622180-001

13 989229-002

14 612875-002

15 621433-009

16 610541-005

17 617802-001

18 612361-001

Description Quantity

Lock Screw Assembly ....... 1

Washer (3/8") .............. 2

Screw .................... 4

*Nut (3/8-16) ................ 2

Quadrant Insert ............ 1

*Screw (#8-32 x 3/8 Pan Hd.)

**STD510803 ............ 1

Pointer ..................... 1

Post (Includes Key #10) ...... 1

Sleeve Bearing ............. 2

Striker Guard .............. 1

*Screw (#8-32 x 1/2 Pan Hal.)...3

Pintle Bolt ................. 1

Washer ................... 1

Carriage Bolt .............. 1

Locking Lever .............. 1

Spring .................... 1

*Screw (1/4-28 x 1-7/8 Fil. Hd.). 1

Key Part

No. Number

19 612271-001

20 930687-002

21 617483-004

22 611642-003

23 931744-006

24 703473-032

25 621377-003

26 703477-047

27 610019-003

29 611772-003

30 611825-003

31 611790-003

32 621644-004

612547-228

Description Quantity

*,,:.

Handle Cover .............. 1

*Set Screw (#8-32 × 3/16i

* *ST D500802 ............ !

Locking Lever .............. 1

Locking Nut ............... !

Washer (1/4") * * STD551225.. 1

* Lockwasher (1/4")

* *STD551125 ............ 1

* Hex Nut (1/4-28)

* *STD541125 ............ 1

*Hex Lock Nut (1/2-13)

**STD541450 ............ 1

Disk Spring ................ 2

Trunnion Shaft ............. 1

Miter Arm ................. !

Quadrant .................. 1

*Hex Socket Cap Screw

(1/4-20 x 3/4") ............ 3

Owners Manual

"Standard Hardware Item -- May Be Purchased Locally

"*Available From Div. 98 -- Source 980.00

Page 31

Page 32

S_ A/RS

OWNERS

MANUAL

SERVICE

CRAFTSMAN

7½ INCH RADIAL

ARM MITER SAW

DOUBLE INSULATED

WITH MECHANICAL BRAK

Now that you have purchased your Radial Arm Miter

Saw, should a need ever exist for repair parts or ser-

vice, simply contact any Sears Service Center and

most Sears, Roebuck and Co. stores. Be sure to pro-

vide all pertinent facts when you call or visit.

MODEL NO.

315.23743

HOW TO ORDER

REPAIR PARTS

The model number of your Radial Arm Miter Saw will

be found on the plate attached to the motor end cap.

WHEN ORDERING REPAIR PARTS, ALWAYS GIVE

THE FOLLOWING INFORMATION'

• PART NUMBER • PART DESCRIPTION

• MODEL NUMBER •

315.23743

All parts listed may be ordered from any Sears Ser-

vice Center and most Sears stores.

If the parts you need are not stocked locally, your

order will be electronically transmitted to a Sears

Repair Parts Distribution Center for handling,

NAME OF ITEM

7-1/2 INCH RADIAL

ARM MITER SAW

Sold by SEARS, ROEBUCK AND CO., Dept. 698/731A, Sears Tower, Chicago, IL 60684

Loading...

Loading...