Craftsman 247889990 Owner’s Manual

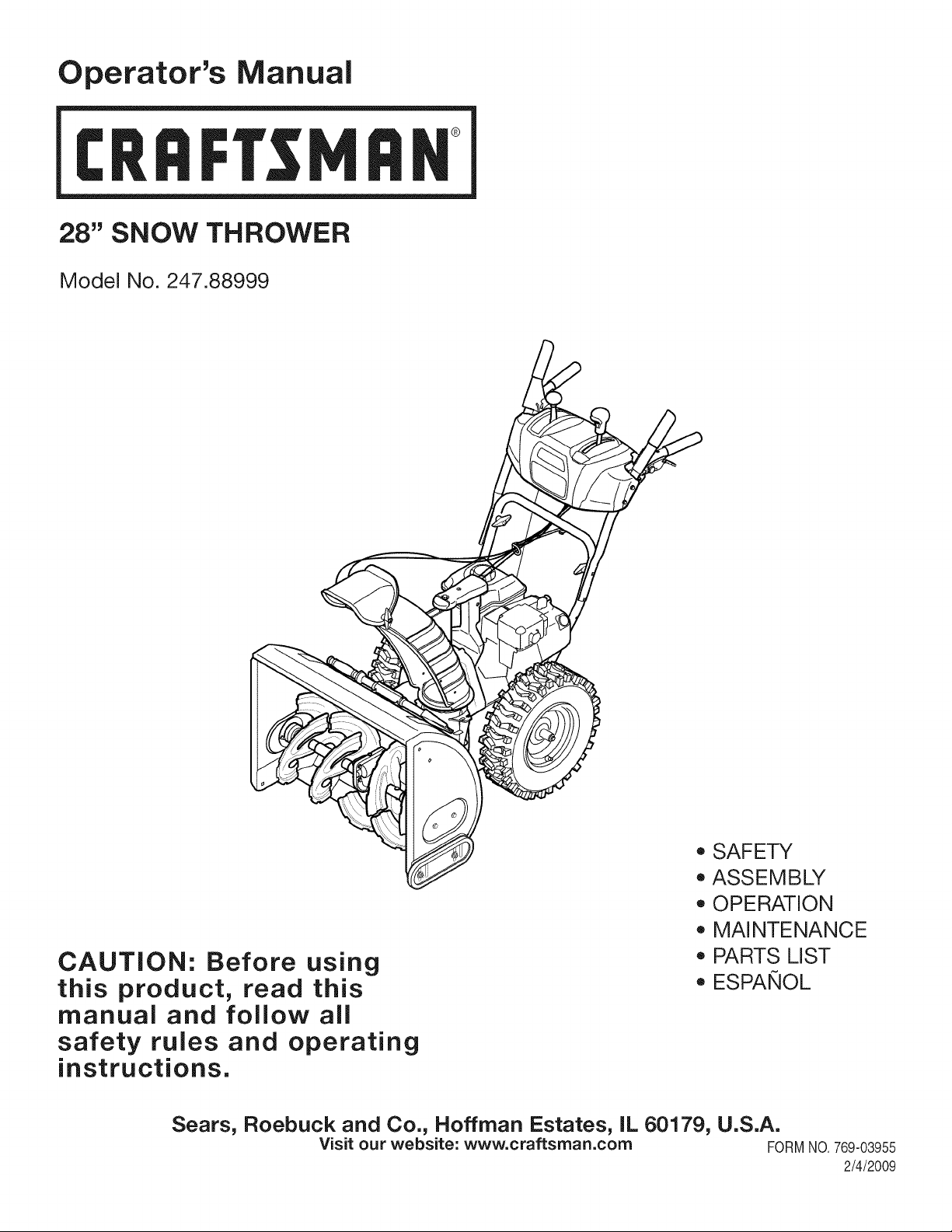

Operator's Manual

CRRFr MRN

28" SNOW THROWER

Model No. 247.88999

CAUTION: Before using

this product, read this

manual and follow all

safety rules and operating

instructions.

Sears, Roebuck and Co., Hoffman Estates, IL 60179, U.S.A.

Visit our website: www.craftsman.com FORMNO.769-03955

o SAFETY

ASSEMBLY

OPERATION

MAINTENANCE

PARTS LIST

o ESPArqOL

2/4/2009

WarrantyStatement.................... Page2

SafeOperationPractices.............. Pages3-6

SafetyLabels......................... Page7

Assembly......................... Pages8-11

Operation........................ Pages12-15

Service&Maintenance.............. Pages16-21

CRAFTSMAN LiMiTED WARRANTY

Two Years on Snow Thrower

Whenoperatedandmaintainedaccordingtoall suppliedinstructions,if thissnowthrowerfailsdueto adefectin materialor workmanshipwithin

two yearsfromthedateorpurchase,call1-800-4-MY-HOME®toarrangefor freerepair.

Thiswarrantyappliesforonly90daysfromthedateof purchaseif thissnowthroweriseverusedforcommercialorrentalpurposes.

Duringthefirstyearof purchase,therewillbeno chargeforwarrantyservicein yourhome.Foryourconvenience,in-homewarrantyservicewill

still beavailableafterthefirstyearof purchase,buta tripchargewillapply.Thischargewillbewaivedif youtransportthesnowthrowertoan

authorizedCraftsmandrop-offlocation.Forthe nearestauthorizedlocation,call1-800-4-MY-HOME®.

Thiswarranty coversONLYdefects inmaterial andworkmanship. SearswillNOTpay for:

• Expendableitemsthat becomewornduringnormaluse,includingbutnot limitedtoskidshoes,shaveplate,shearpins,sparkplug,air

cleaner,belts,andoilfilter.

• Standardmaintenanceservicing,oil changes,ortune-ups.

• Tirereplacementor repaircausedbypuncturesfromoutsideobjects,suchas nails,thorns,stumps,orglass.

• Tireorwheel replacementorrepairresultingfromnormalwear,accident,orimproperoperationor maintenance.

• Repairsnecessarybecauseofoperatorabuse,includingbutnotlimitedtodamagecausedbyimpactingobjectsthatbendtheframeor

crankshaft,or over-speedingtheengine.

• Repairsnecessarybecauseofoperatornegligence,includingbutnotlimitedto,electricalandmechanicaldamagecausedbyimproper

storage,failuretouse thepropergradeandamountofengineoil,orfailuretomaintaintheequipmentaccordingto theinstructionscontained

intheoperator'smanual.

• Engine(fuelsystem)cleaningor repairscausedbyfueldeterminedtobe contaminatedor oxidized(stale).Ingeneral,fuelshouldbe used

within30daysofitspurchasedate.

• Normaldeteriorationandwearoftheexteriorfinishes,or productlabelreplacement.

Off-SeasonStorage................... Page22

Troubleshooting...................... Page23

PartsList......................... Pages24-36

RepairProtectionAgreement............ Page40

Espa_ol............................. Page41

ServiceNumbers................... BackPage

Thiswarrantyappliesonlywhilethis productisusedinthe UnitedStates.

Thiswarrantygivesyouspecificlegalrights,andyoumayalsohaveotherrightswhichvaryfromstateto state.

Sears,Roebuckand Co.,NoffmanEstates, IL60179

EngineOilType: SAE5W-30

EngineOilCapacity: 20ounces

FuelCapacity: 3 Quarts

SparkPlug: Champion®RC12YC

SparkPlugGap: .030"

©SearsBrands,LLC

ModelNumber.................................................................

Serial Number.................................................................

Dateof Purchase.............................................................

Recordthemodelnumber,serialnumber

anddateof purchaseabove

2

Thissymbolpointsout importantsafetyinstructionswhich,if not

followed,couldendangerthepersonalsafetyand/orpropertyof

yourselfandothers. Readandfollowallinstructionsin thismanual

beforeattemptingto operatethismachine.Failuretocomplywith

theseinstructionsmayresultin personalinjury.Whenyouseethis

symbol,HEEDITSWARNING!

Thismachinewasbuiltto beoperatedaccordingtothe safeopera-

tionpracticesinthismanual.Aswithanytypeofpowerequipment,

carelessnessor erroronthepartofthe operatorcanresultinserious

injury.Thismachineiscapableofamputatingfingers,hands,toes

andfeetandthrowingdebris.Failuretoobservethefollowingsafety

instructionscould resultinseriousinjuryordeath.

CALIFORNIA PROPOSiTiON 65

EngineExhaust,someof itsconstituents,andcertainvehicle

componentscontainoremitchemicalsknowntoStateof California

tocausecancerandbirthdefectsorotherreproductiveharm,

TRAiNiNG

• Read,understand,andfollowall instructionson themachineand

in themanual(s)beforeattemptingtoassembleandoperate.

Keepthis manualinasafeplacefor futureand regularreference

andfororderingreplacementparts.

• Readthe Operator'sManualand followallwarningsandsafety

instructions.Failuretodosocan resultin seriousinjurytothe

operatorand/orbystanders.Forquestionscall, 1-800-659-5917.

Befamiliarwithall controlsandtheirproperoperation.Knowhow

tostopthe machineanddisengagethemquickly.

• Neverallowchildrenunder14yearsofageto operatethis

machine.Children14andovershouldreadandunderstandthe

instructionsandsafeoperationpracticesin thismanualandon

themachineandbe trainedandsupervisedbyanadult.

Neverallowadultsto operatethismachinewithoutproper

instruction.

• Thrownobjectscan causeseriouspersonalinjury.Planyour

snow-throwingpatterntoavoiddischargeof materialtoward

roads,bystandersandthelike.

Keepbystanders,petsandchildrenat least75feetfromthe

machinewhileit isin operation.Stopmachineifanyoneenters

thearea.

• Exercisecautiontoavoidslippingor falling,especiallywhen

operatinginreverse.

Your Responsibility--Restrict the useofthis powermachineto

personswhoread,understandandfollowthewarningsandinstruc-

tionsin thismanualandonthemachine,

SAVE THESE INSTRUCTIONS!

PREPARATION

Thoroughlyinspecttheareawherethe equipmentistobeused.

Removeall doormats,newspapers,sleds,boards,wiresandother

foreignobjects,whichcouldbe trippedoverorthrownbytheauger/

impeller.

• Alwayswearsafetyglassesoreyeshieldsduringoperationand

whileperformingan adjustmentor repairto protectyoureyes.

Thrownobjectswhichricochetcancauseseriousinjurytothe

eyes.

Donot operatewithoutwearingadequatewinteroutergarments.

Donot wearjewelry,longscarvesorotherlooseclothing,which

couldbecomeentangledin movingparts.Wearfootwearwhich

willimprovefootingonslipperysurfaces.

Usea groundedthree-wireextensioncordand receptacleforall

machineswithelectricstartengines.

Adjustcollectorhousingheightto cleargravelorcrushedrock

surfaces.

Disengageall controlleversbeforestartingtheengine.

• Neverattempttomakeanyadjustmentswhileengineis running,

exceptwherespecificallyrecommendedintheoperator'smanual.

Letengineandmachineadjustto outdoortemperaturebefore

startingtoclearsnow.

3

SafeHandling of Gasoline

Toavoidpersonalinjuryor propertydamageuseextremecarein

handlinggasoline.Gasolineisextremelyflammableandthe vaporsare

explosive.Seriouspersonalinjurycan occurwhengasolineisspilled

onyourselforyourclotheswhichcan ignite.Washyourskinand

changeclothesimmediately.

• Useonlyanapprovedgasolinecontainer.

• Extinguishallcigarettes,cigars,pipesandother sources

ofignition.

• Neverfuelmachineindoors.

• Neverremovegascapor addfuelwhiletheengineis hot

or running.

• Allowenginetocoolat leasttwo minutesbeforerefueling.

• Neveroverfillfueltank.Filltanktono morethan1/2inch

belowbottomoffiller neckto providespaceforfuel

expansion.

• Replacegasolinecapandtightensecurely.

• Ifgasolineisspilled,wipeit offthe engineandequipment.

Movemachinetoanotherarea.Wait5 minutesbefore

startingtheengine.

• Neverstorethemachineor fuelcontainerinsidewhere

thereis anopenflame,sparkorpilotlight(e.g.furnace,

waterheater,spaceheater,clothesdryeretc.).

• Allowmachinetocoolatleast5 minutesbeforestoring.

• Neverfillcontainersinsidea vehicleor ona truckor trailer

bedwitha plasticliner.Alwaysplacecontainersonthe

groundawayfromyourvehiclebeforefilling.

• If possible,removegas-poweredequipmentfromthetruck

ortrailerand refueliton theground.Ifthisis not possible,

thenrefuelsuchequipmentona trailerwitha portable

container,ratherthanfromagasolinedispensernozzle.

• Keepthenozzleincontactwiththe rimof thefueltankor

containeropeningatalltimesuntilfuelingiscomplete.Do

notuse a nozzlelock-opendevice.

OPERATION

• Donot puthandsorfeetnear rotatingparts,in the auger/impeller

housingorchuteassembly.Contactwiththerotatingpartscan

amputatehandsandfeet.

• Theauger/impellercontrolleverisa safetydevice.Neverbypass

itsoperation.Doingsomakesthe machineunsafeandmaycause

personalinjury.

• Thecontrolleversmustoperateeasilyinbothdirectionsand

automaticallyreturntothe disengagedpositionwhenreleased.

• Neveroperatewitha missingordamagedchuteassembly.Keep

all safetydevicesinplaceandworking.

• Neverrunanengineindoorsorina poorlyventilatedarea.Engine

exhaustcontainscarbonmonoxide,anodorlessanddeadlygas.

• Donotoperatemachinewhileundertheinfluenceofalcoholor

drugs.

• Mufflerandenginebecomehotandcancausea burn.Do not

touch.Keepchildrenaway.

• Exerciseextremecautionwhenoperatingon orcrossinggravel

surfaces.Stayalertforhiddenhazardsortraffic.

• Exercisecautionwhenchangingdirectionandwhileoperatingon

slopes.

• Planyoursnow-throwingpatternto avoiddischargetowards

windows,walls,carsetc. Thus,avoidingpossibleproperty

damageorpersonalinjurycausedby a ricochet.

• Neverdirectdischargeatchildren,bystandersand petsor allow

anyoneinfrontof themachine.

• Donotoverloadmachinecapacitybyattemptingtoclearsnowat

toofastof a rate.

• Neveroperatethismachinewithoutgoodvisibilityorlight.Always

be sureofyourfootingandkeepafirmholdon thehandles.Walk,

neverrun.

• Disengagepowertotheauger/impellerwhentransportingornot

in use.

• Neveroperatemachineathightransportspeedsonslippery

surfaces.Lookdownand behindandusecarewhenbackingup.

• Ifthemachineshouldstarttovibrateabnormally,stoptheengine,

disconnectthesparkplugwire andgrounditagainsttheengine.

Inspectthoroughlyfordamage.Repairanydamagebefore

startingandoperating.

• Disengageall controlleversandstopenginebeforeyouleave

theoperatingposition(behindthehandles).Waituntiltheauger/

impellercomestoa completestopbeforeuncloggingthechute

assembly,makingany adjustments,or inspections.

• Neverputyourhandinthe dischargeor collectoropenings.

Alwaysusetheclean-outtoolprovidedtounclogthedischarge

opening.Donotunclogchuteassemblywhileengineis running.

Shutoff engineand remainbehindhandlesuntilallmovingparts

havestoppedbeforeunclogging.

• Useonlyattachmentsandaccessoriesapprovedbythe manufac-

turer(e.g.wheelweights,tirechains,cabsetc.).

• Whenstartingengine,pullcord slowlyuntilresistanceisfelt,then

pull rapidly.Rapidretractionofstartercord(kickback)willpull

handandarmtowardenginefasterthanyoucanlet go. Broken

bones,fractures,bruisesorsprainscouldresult.

• Ifsituationsoccurwhichare notcoveredinthis manual,usecare

andgoodjudgment.ContactCustomerSupportforassistance

andthenameofyour nearestservicingdealer.

4

MAINTENANCE & STORAGE

• Nevertamperwithsafetydevices.Checktheirproperoperation

regularly.Refertothe maintenanceandadjustmentsectionsof

thismanual.

• Beforecleaning,repairing,or inspectingmachinedisengageall

controlleversandstoptheengine.Waituntilthe auger/impeller

cometoa completestop.Disconnectthe sparkplugwireand

groundagainsttheengineto preventunintendedstarting.

Checkboltsand screwsforpropertightnessat frequentintervals

tokeepthemachineinsafeworkingcondition.Also,visually

inspectmachineforanydamage.

Donotchangetheenginegovernorsettingor over-speedthe

engine.Thegovernorcontrolsthe maximumsafeoperatingspeed

ofthe engine.

Snowthrowershaveplatesandskidshoesaresubjecttowear

anddamage.Foryoursafetyprotection,frequentlycheckall

componentsand replacewithoriginalequipmentmanufacturer's

(OEM)partsonly."Useofpartswhichdo not meettheoriginal

equipmentspecificationsmayleadto improperperformanceand

compromisesafety!"

Checkcontrolleversperiodicallytoverifytheyengageanddisen-

gageproperlyandadjust,ifnecessary.Refertothe adjustment

sectioninthisoperator'smanualforinstructions.

Maintainor replacesafetyandinstructionlabels,asnecessary.

• Observeproperdisposallawsand regulationsforgas,oil,etc. to

protecttheenvironment.

Priorto storing,runmachineafew minutestoclearsnowfrom

machineand preventfreezeupofauger/impeller.

Neverstorethemachineorfuel containerinsidewherethereisan

openflame,sparkorpilot lightsuchasa waterheater,furnace,

clothesdryeretc.

Alwaysrefertothe operator'smanualforproperinstructionson

off-seasonstorage.

Checkfuelline,tank, cap,andfittingsfrequentlyforcracksor

leaks.Replaceif necessary.

Donotcrankenginewithsparkplugremoved.

Accordingtothe ConsumerProductsSafetyCommission(CPSC)

andtheU.S.EnvironmentalProtectionAgency(EPA),thisproduct

hasan AverageUsefulLifeof seven(7)years,or 60 hoursof

operation.Atthe endoftheAverageUsefulLifehavethe machine

inspectedannuallybyan authorizedservicedealerto ensurethat

allmechanicalandsafetysystemsareworkingproperlyand not

wornexcessively.Failureto do so canresultinaccidents,injuries

ordeath.

DO NOT MODIFY ENGINE

Toavoidseriousinjuryor death,do notmodifyengineinany way.

Tamperingwiththegovernorsettingcanleadtoa runawayengineand

causeitto operateat unsafespeeds.Nevertamperwithfactorysetting

ofenginegovernor.

NOTICE REGARDING EMISSIONS

EngineswhicharecertifiedtocomplywithCaliforniaandfederal

EPAemissionregulationsfor SORE(SmallOffRoadEquipment)are

certifiedto operateonregularunleadedgasoline,and mayinclude

thefollowingemissioncontrolsystems:EngineModification(EM),

OxidizingCatalyst(OC),SecondaryAirInjection(SAI)and ThreeWay

Catalyst(TWO)if so equipped.

SPARK ARRESTOR

Thismachineisequippedwithaninternalcombustionengineand

shouldnotbe usedonornearanyunimprovedforest-covered,

brush-coveredorgrass-coveredlandunlessthe engine'sexhaust

systemisequippedwitha sparkarrestermeetingapplicablelocalor

statelaws(if any)

Ifa sparkattesterisused,itshouldbemaintainedineffectiveworking

orderbytheoperator.Inthe StateofCaliforniatheaboveis required

bylaw (Section4442oftheCaliforniaPublicResourcesCode).Other

statesmayhavesimilarlaws. Federallawsapplyonfederallands.

A sparkarresterforthemuffleris availablethroughyournearestSears

PartsandRepairServiceCenter.

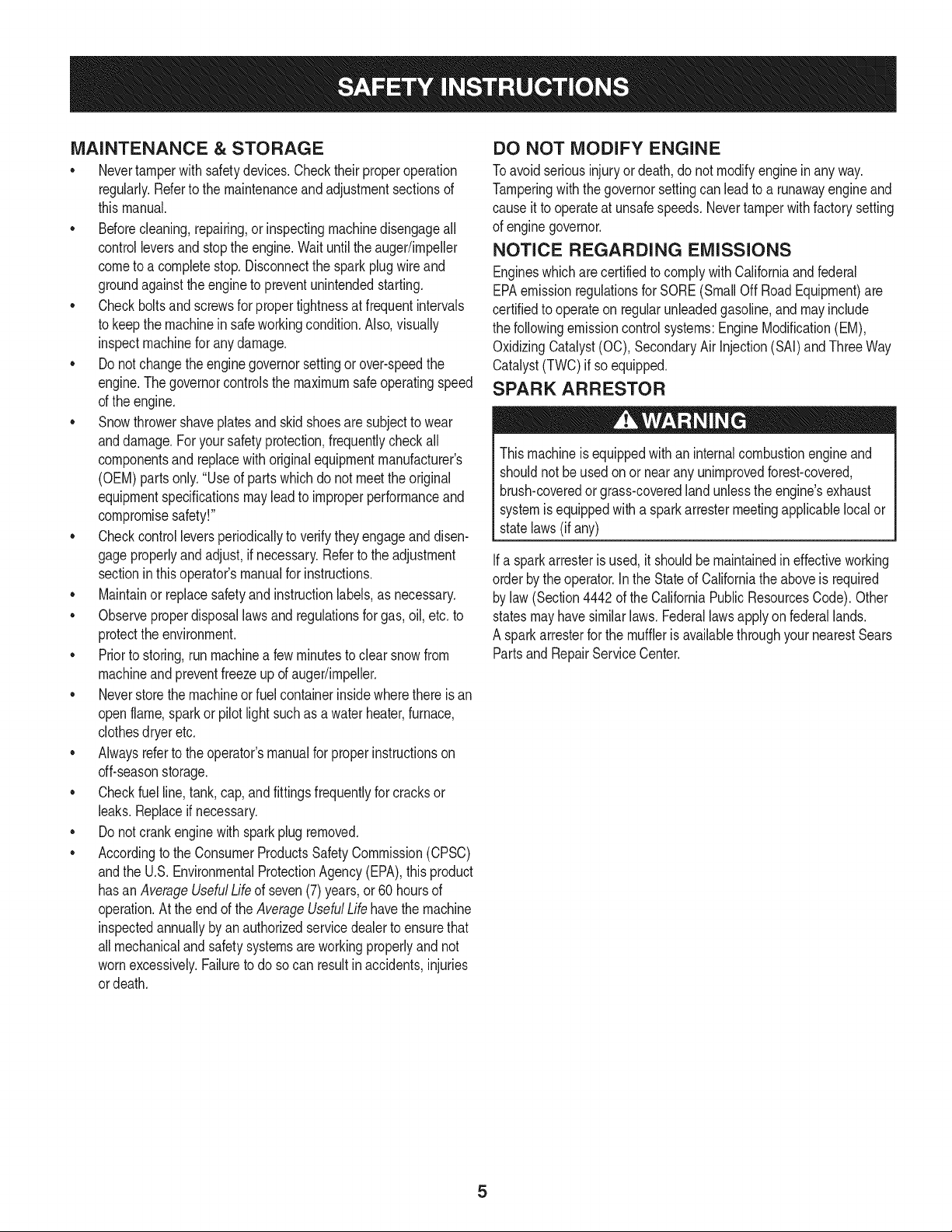

SAFETY SYMBOLS

Thispagedepictsanddescribessafetysymbolsthatmayappearonthisproduct. Read,understand,andfollowall instructionson themachine

beforeattemptingto assembleandoperate.

READ THE OPERATOR'S MANUAL(S)

i

i

Read, understand, and follow all instructions in the manual(s) before attempting to assemble and

operate

WARNING-- ROTATING BLADES

Keep hands out of inlet and discharge openings while machine is running. There are rotating blades

inside

WARNING-- ROTATING BLADES

Keep hands out of inlet and discharge openings while machine is running. There are rotating blades

inside

WARNING-- ROTATING AUGER

Do not put hands or feet near rotating parts, in the auger/impeller housing or chute assembly.

Contact with the rotating parts can amputate hands and feet.

WARNING--THROWN OBJECTS

This machine may pick up and throw and objects which can cause serious personal injury.

WARNING--GASOLINE ISFLAMMABLE

Allow the engine to cool at least two minutes before refueling.

WARNING-- CARBON MONOXIDE

Never run an engine indoors or in a poorly ventilated area. Engine exhaust contains carbon

monoxide, an odorless and deadly gas.

WARNING-- ELECTRICAL SHOCK

Do not use the engine's electric starter in the rain

6

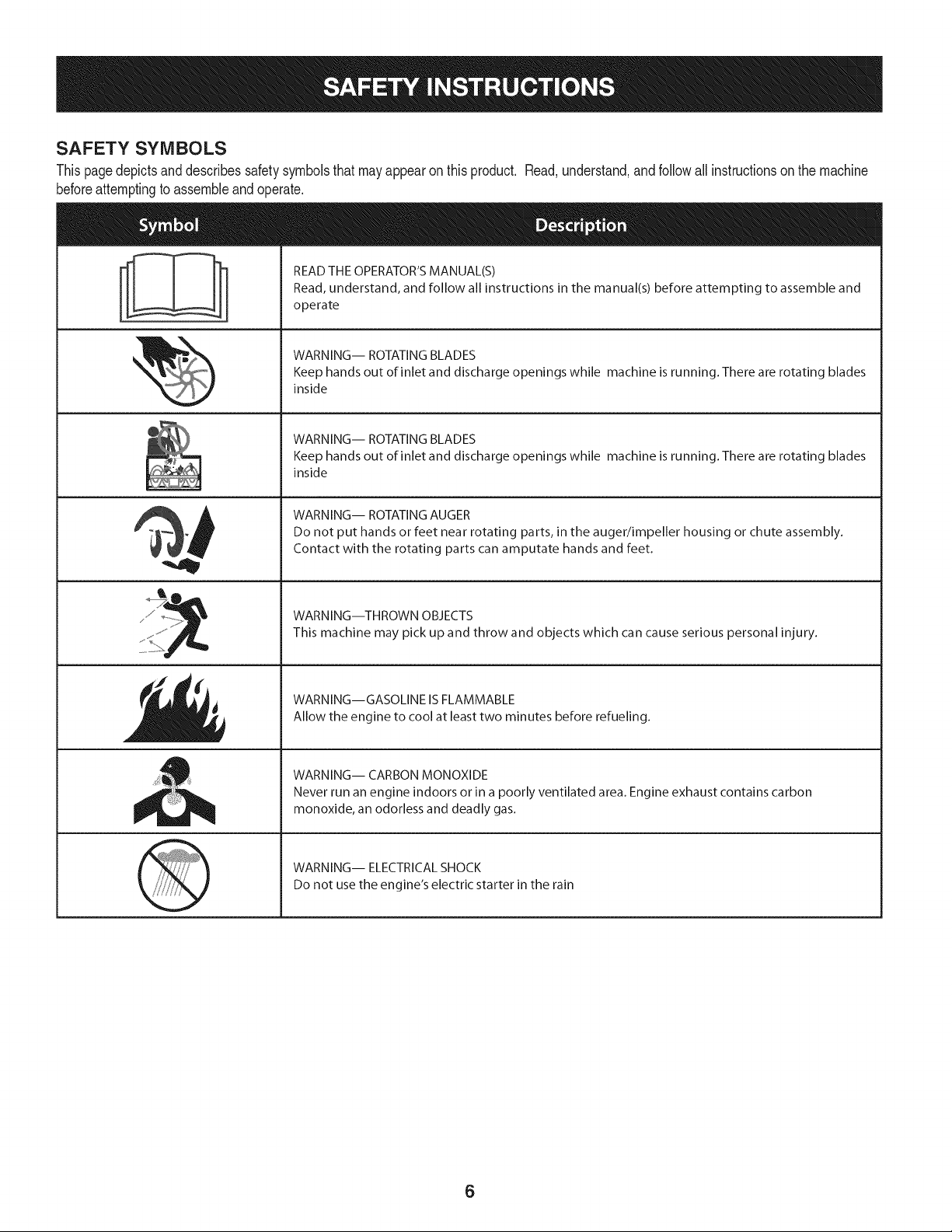

1.KEEPAWAYFROMROTATINGiMPELLER

ANDAUGER,CONTACTWiTHiMPELLEROR

AUGERCANAMPUTATEHANDSANDFEET.

2. USECLEAN-OUTTOOLTOUNCLOG

DISCHARGECHUTE.

3.DISENGAGECLUTCHLEVERS,STOPENGINE,

AND REMAINBEHINDHANDLESUNTILALL

MOVING PARTSHAVESTOPPEDBEFORE

UNCLOGGING OR SERViCiNGMACHINE.

TO AVOIDTHROWN OBJECTSiNJURiES,

NEVERDIRECTDISCHARGEATBYSTANDERS.

USEEXTRACAUTIONWHEN OPERATINGON

GRAVELSURFACES.

5.BEAD OPERATOR'S MANUAL.

CLEAN-OUT TOOL

7

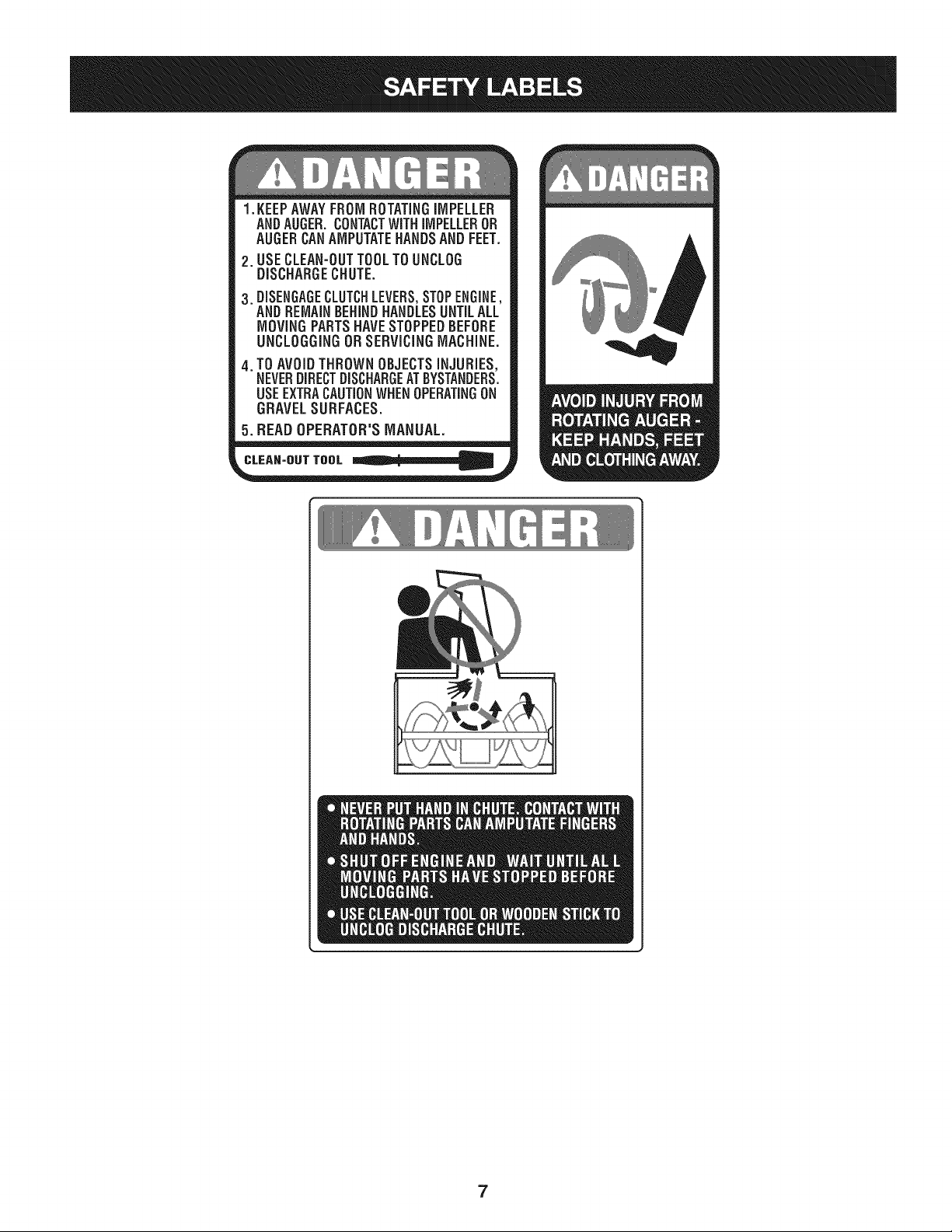

NOTE:Referencesto rightorleft sideofthesnowthrowerare

determinedfrombehindtheunit intheoperatingposition(standing

directlybehindthesnowthrower,facingthe handlepanel).

REMOVING FROM CARTON

1. Cutthecornersofthecartonandlaythe sidesflaton theground.

Removeanddiscardallpackinginserts.

2. Movethesnowthroweroutof thecarton.

3. Makecertainthecartonhasbeencompletelyemptiedbefore

discardingit.

ASSEMBLY

1. Observethe lowerrearareaof the snowthrowertobesureboth

cablesarealignedwith rollerguidesbeforepivotingthehandle

upward.

a. Placethe shiftleverin theF6position.

b. Pullupandbackon upperhandleas shownin Figure1.As

youare raisingthehandleupward,makesurethatbothends

ofthe centercablearepositionedproperlyinthebrackets.

Alignupperhandlewiththelowerhandle.

c. Tightenhandknobssecuringupperhandletolowerhandle.

Removeanddiscardany rubberbands,ifpresent.Theyare

forpackagingpurposesonly.

2. Removewingnutandhexscrewfromchutecontrolassembly

andclevispinandcotter pinfromchutesupportbracket.See

Figure2. Positionthechuteassembly(forward-facing)overthe

chutebase.

3. Placechutecontrolleverinthe centeredposition.SeeFigure1.

4. Placechuteassemblyontochutebaseand securechutecontrol

assemblytochutesupportbracketwithclevispinand cotterpin

removedearlier.SeeFigure3.

f

Figure2

Figure1

Figure3

8

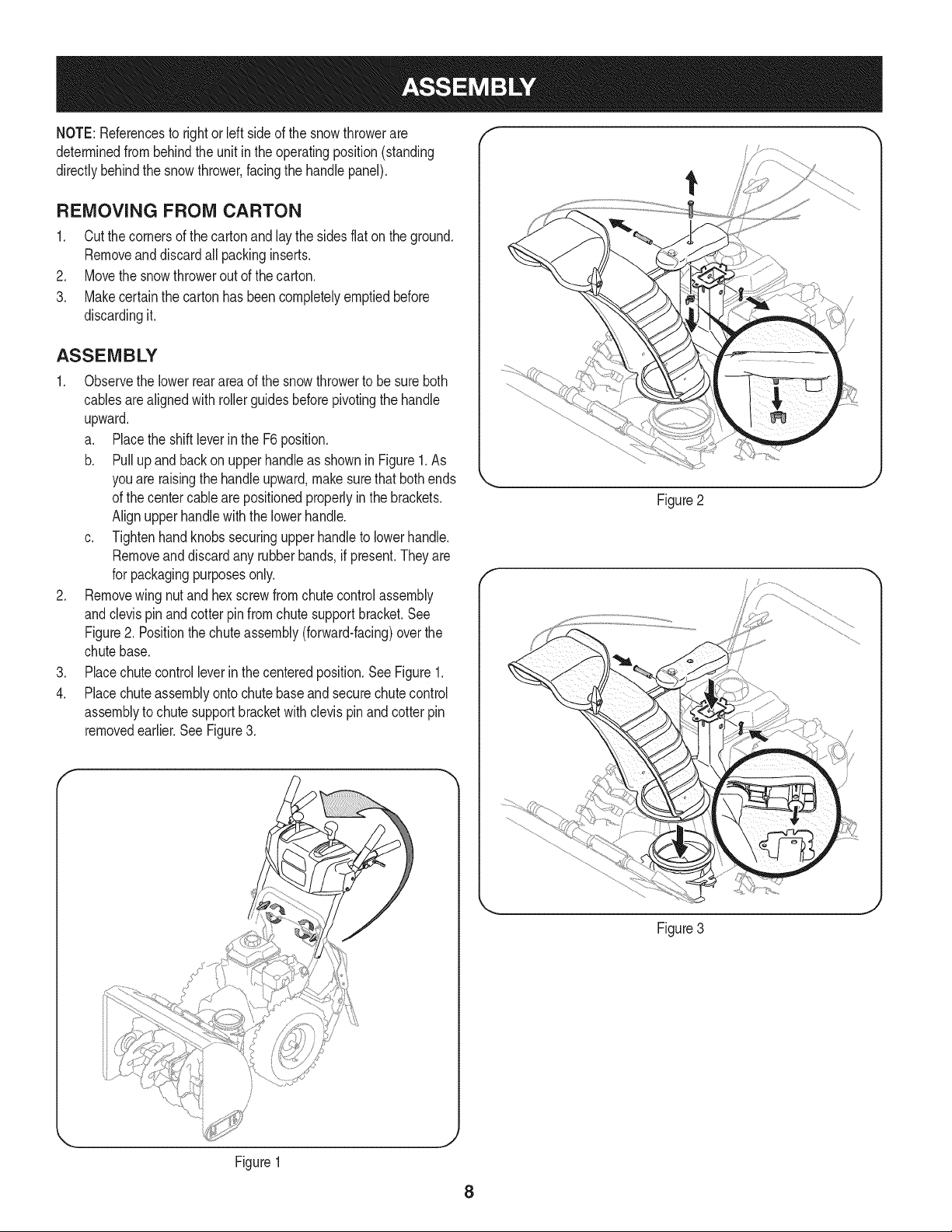

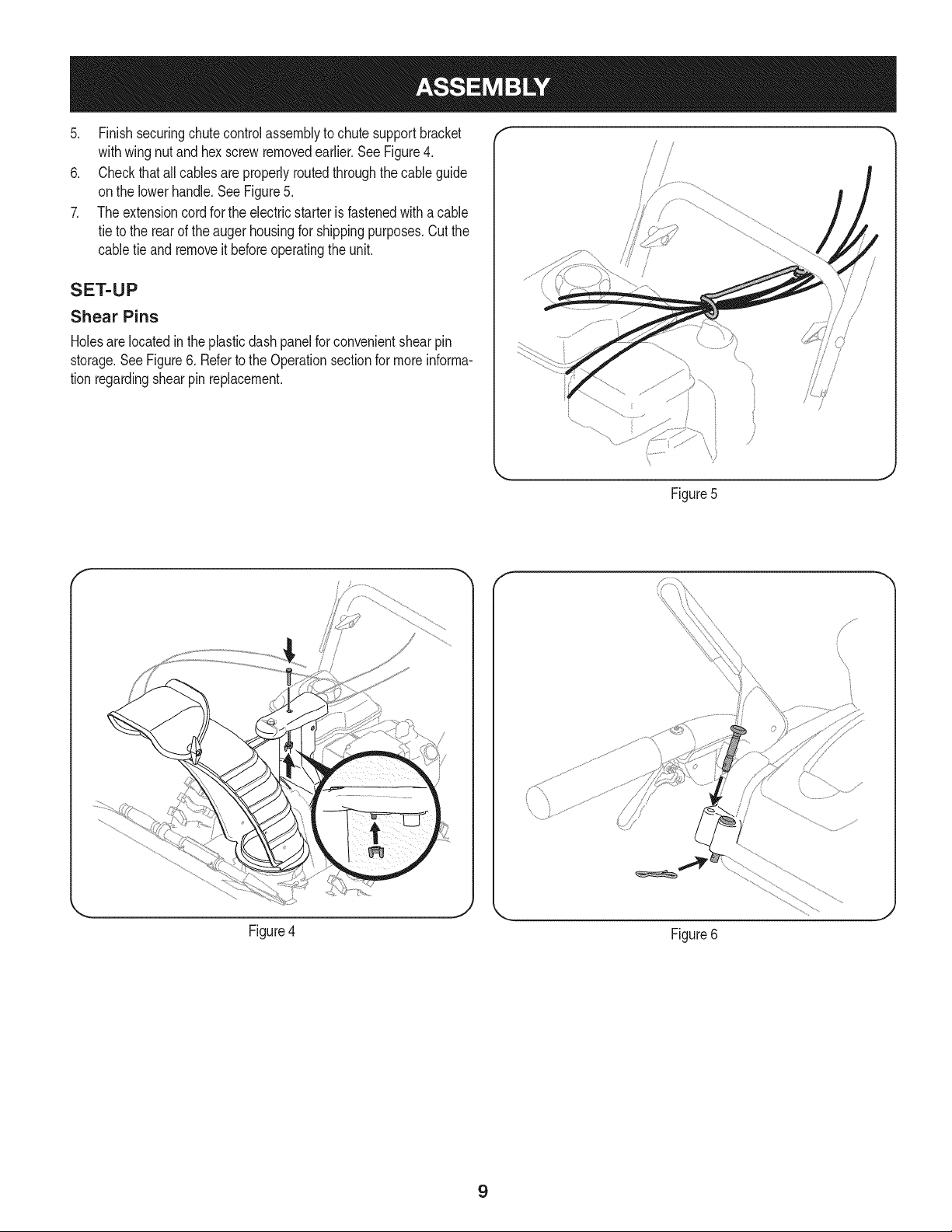

5. Finishsecuringchutecontrolassemblytochutesupportbracket

withwingnutandhexscrewremovedearlier.SeeFigure4.

6. Checkthatallcablesareproperlyroutedthroughthecableguide

onthelowerhandle.SeeFigure5.

7. Theextensioncordfortheelectricstarterisfastenedwithacable

tietotherearoftheaugerhousingforshippingpurposes.Cutthe

cabletieandremoveitbeforeoperatingtheunit.

SET-UP

Shear Pins

Holesare locatedintheplasticdashpanelforconvenientshearpin

storage.SeeFigure6. Refertothe Operationsectionformoreinforma-

tionregardingshearpinreplacement.

f

Figure5

Figure4

/

\

J

Figure6

9

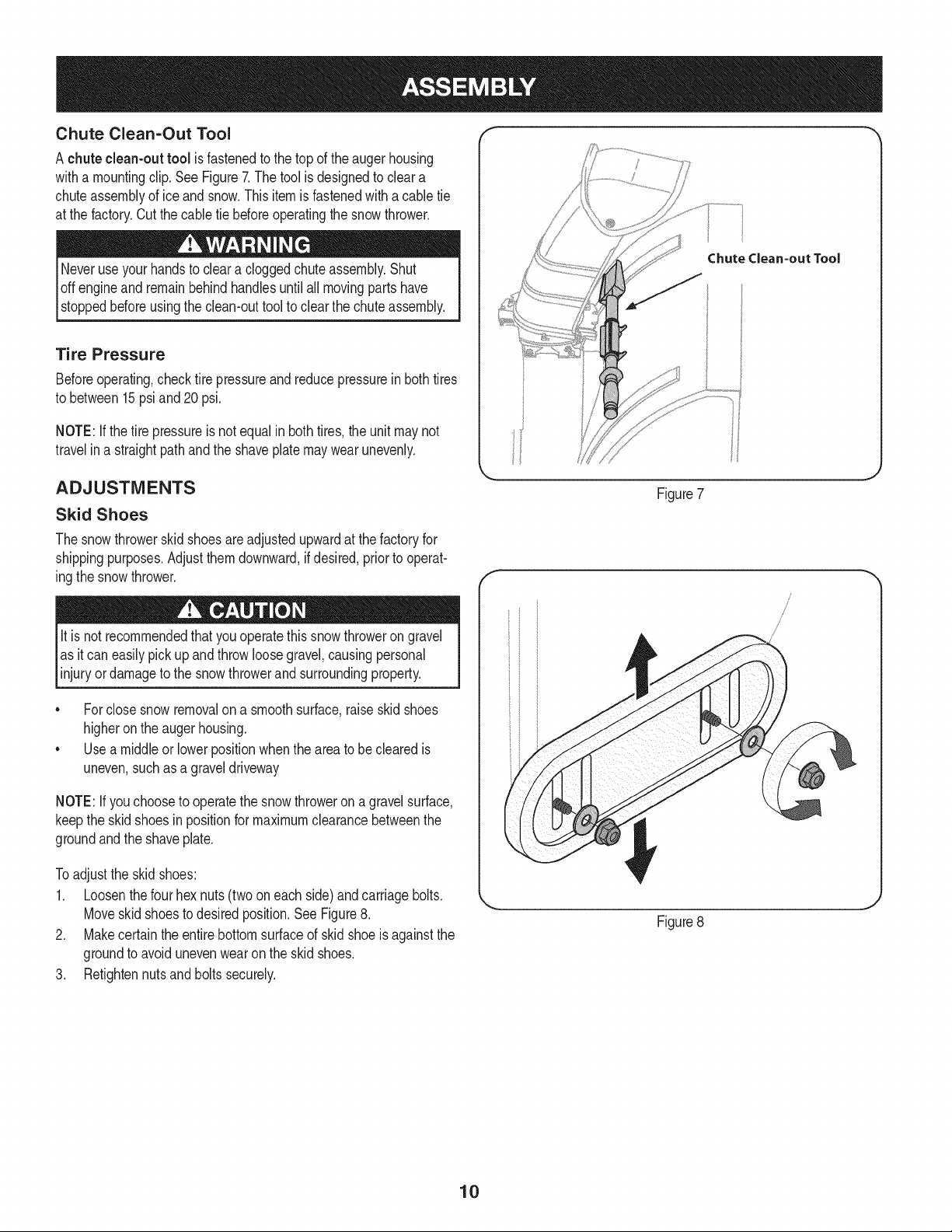

Chute Clean-Out Tool

A chute clean-out tool isfastenedtothe topoftheaugerhousing

witha mountingclip.SeeFigure7.The toolisdesignedtocleara

chuteassemblyofice andsnow.Thisitemis fastenedwith acabletie

atthe factory.Cutthecabletie beforeoperatingthesnowthrower.

Neveruseyour handstoclearacloggedchuteassembly.Shut

loft engineand remainbehindhandlesuntilall movingpartshave

[stoppedbeforeusingthe clean-outtooltoclearthechuteassembly.

Tire Pressure

Beforeoperating,checktirepressureandreducepressurein bothtires

to between15psiand20 psi.

NOTE:Ifthe tirepressureisnotequalinboth tires,theunitmaynot

travelina straightpathandthe shaveplatemaywearunevenly.

Chute Clean=out Tool

ADJUSTMENTS

Skid Shoes

Thesnowthrowerskidshoesareadjustedupwardatthe factoryfor

shippingpurposes.Adjustthemdownward,if desired,priortooperat-

ingthesnowthrower.

youoperate

as itcan easilypickupandthrowloosegravel,causingpersonal

lit is notrecommendedthat this thrower

injuryordamagetothe snowthrowerandsurroundingproperty.

snow on

• Forclosesnowremovalona smoothsurface,raiseskidshoes

higherontheaugerhousing.

• Useamiddleor lowerpositionwhentheareato beclearedis

uneven,suchasa graveldriveway

NOTE:Ifyouchooseto operatethesnowthrowerona gravelsurface,

keeptheskidshoesin positionformaximumclearancebetweenthe

groundandtheshaveplate.

Toadjustthe skidshoes:

1. Loosenthefourhexnuts(twoon eachside)andcarriagebolts.

Moveskidshoestodesiredposition.SeeFigure8.

2. Makecertaintheentirebottomsurfaceofskidshoeis againstthe

groundtoavoid unevenwearon the skidshoes.

3. Retightennutsandboltssecurely.

gravel

Figure7

Figure8

/

/

/

10

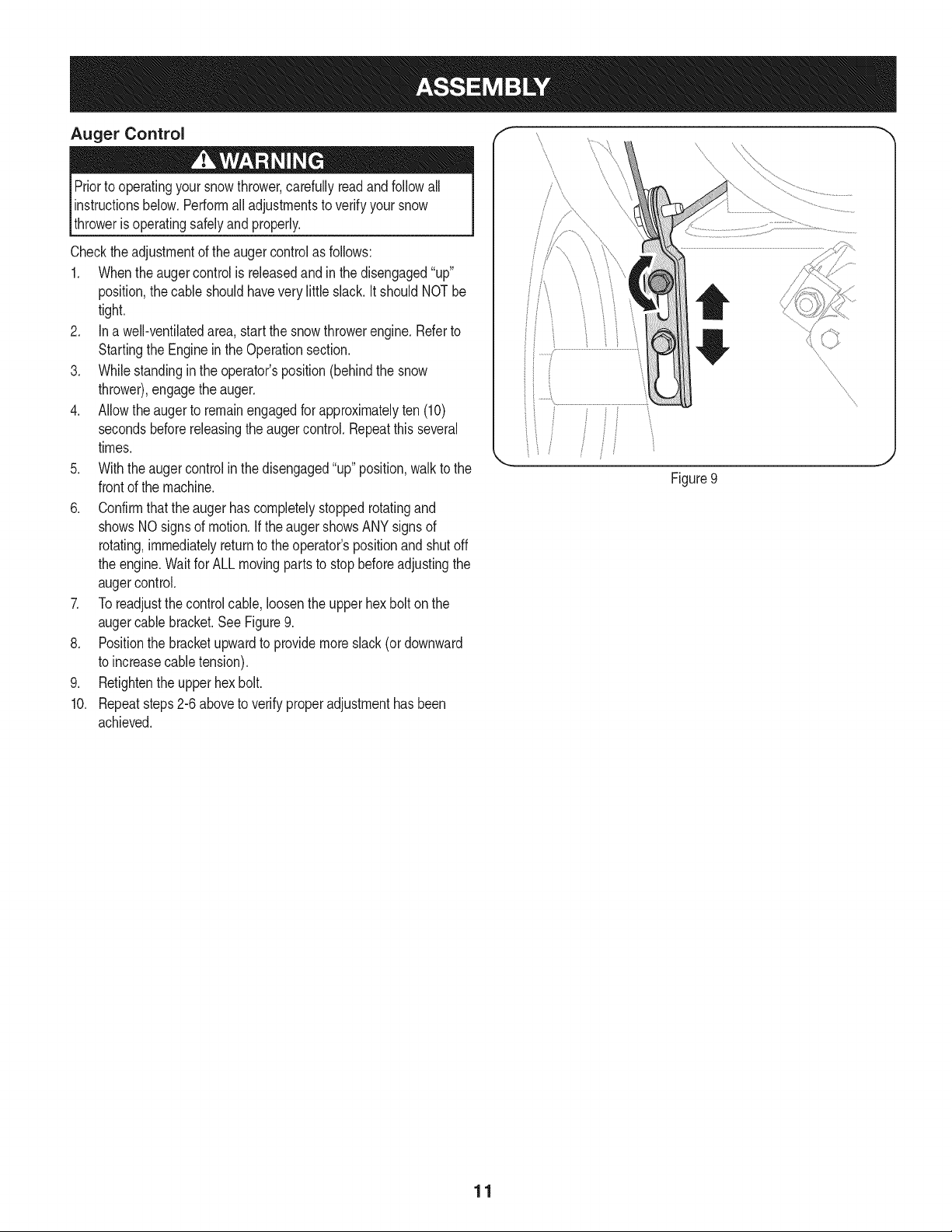

Auger Control

Priortooperatingyoursnowthrower,carefullyreadandfollowall

instructionsbelow.Performalladjustmentstoverifyyoursnow

throwerisoperatingsafelyandproperly.

Checktheadjustmentofthe augercontrolasfollows:

1. Whentheaugercontrolis releasedandin thedisengaged"up"

position,thecableshouldhaveverylittleslack.ItshouldNOTbe

tight.

2. Ina well-ventilatedarea,startthesnowthrowerengine.Referto

StartingtheEngineinthe Operationsection.

3. Whilestandingintheoperator'sposition(behindthe snow

thrower),engagethe auger.

4. Allowtheaugertoremainengagedforapproximatelyten(10)

secondsbeforereleasingthe augercontrol.Repeatthisseveral

times.

5. Withtheaugercontrolinthedisengaged"up"position,walktothe

frontofthe machine.

6. Confirmthatthe augerhas completelystoppedrotatingand

showsNOsignsofmotion.If theaugershowsANYsignsof

rotating,immediatelyreturntothe operator'spositionandshutoff

theengine.WaitforALLmovingpartsto stopbeforeadjustingthe

augercontrol.

7. Toreadjustthecontrolcable,loosentheupperhexboltonthe

augercablebracket.SeeFigure9.

8. Positionthebracketupwardtoprovidemoreslack(or downward

toincreasecabletension).

9. Retightentheupperhexbolt.

10. Repeatsteps2-6abovetoverifyproperadjustmenthasbeen

achieved.

f

Figure9

11

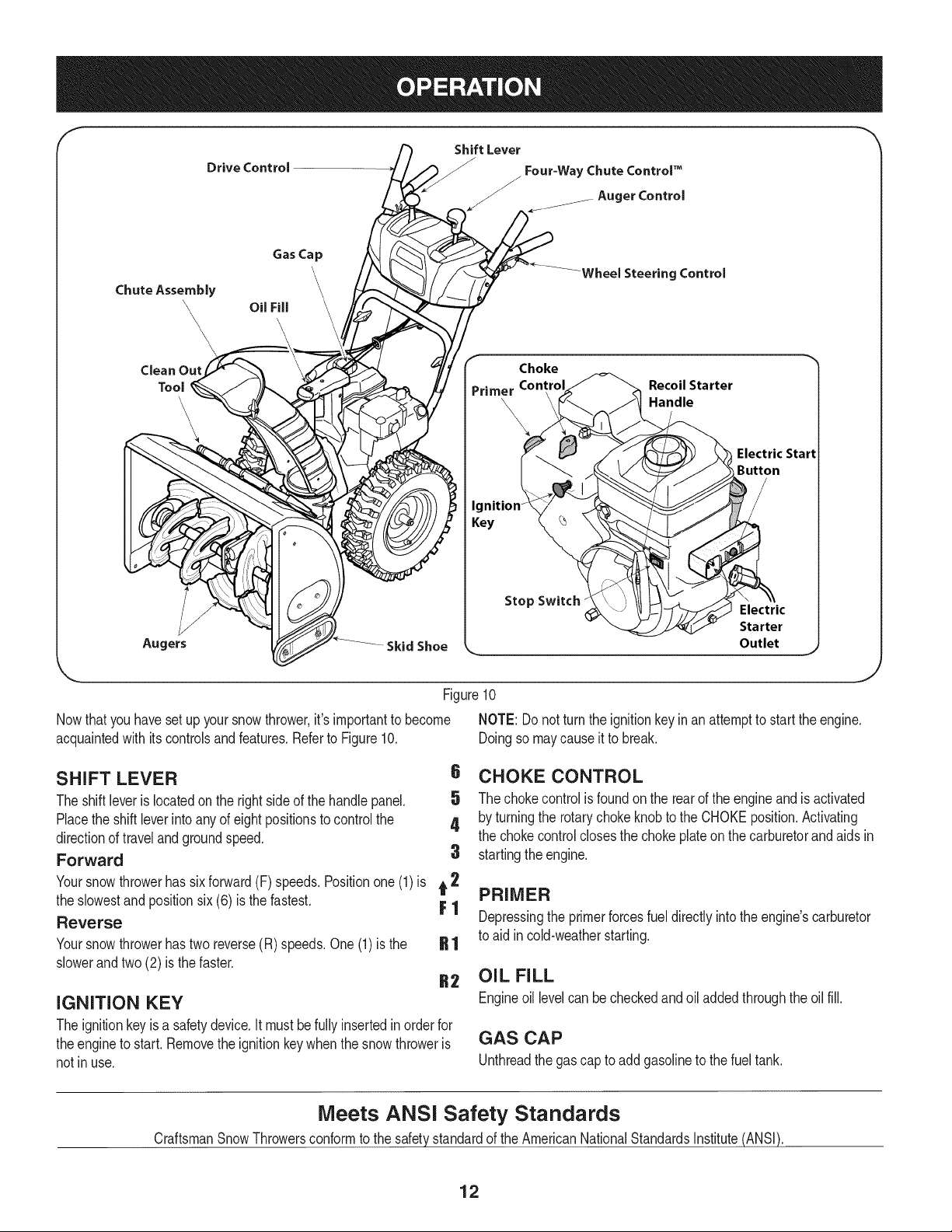

f

Shift Lever

Drive Control

/

Four=WayChuteControP

/_ AugerControl

Gas Cap

Wheel Steering Control

Chute Assembly

\

\

'\

OU Fill

\

Key

Choke

Stop Switch

Recoil Starter

Handle

Electric Star

Button

Electric

Starter

Outlet

Clean Out

Tool

\

Augers Skid Shoe

Figure10

Nowthat youhavesetup yoursnowthrower,it'simportanttobecome NOTE:Donot turntheignitionkeyinanattemptto startthe engine.

acquaintedwith itscontrolsandfeatures.RefertoFigure10. Doingsomaycauseit to break.

SHIFT LEVER

Theshiftleveris locatedonthe rightsideofthehandlepanel.

Placethe shiftleverintoanyof eightpositionstocontrolthe

directionoftravelandgroundspeed.

Forward

Yoursnowthrowerhassixforward(F) speeds.Positionone(1)is t 2

6 CHOKE CONTROL

5 Thechokecontrolisfoundon therearof theengineand isactivated

4 byturningtherotarychokeknobtotheCHOKEposition.Activating

thechokecontrolclosesthechokeplateon thecarburetorandaidsin

3 startingthe engine.

PRIMER

theslowestandpositionsix(6) isthe fastest. F 1

Reverse

Yoursnowthrowerhastwo reverse(R)speeds.One(1)isthe

Depressingthe primerforcesfueldirectlyintotheengine'scarburetor

toaid incold-weatherstarting.

slowerandtwo(2) isthefaster.

OIL FILL

IGNITION KEY

Theignitionkeyis a safetydevice.It mustbefullyinsertedinorderfor

theengineto start.Removetheignitionkeywhenthe snowthroweris

notinuse.

Engineoil levelcanbecheckedandoiladdedthroughtheoil fill.

GAS CAP

Unthreadthegas captoadd gasolinetothefuel tank.

Meets ANSi Safety Standards

CraftsmanSnowThrowersconformtothe safetystandardoftheAmericanNationalStandardsInstitute(ANSI).

12

STOP SWITCH

PressintotheONpositionwhenstartingtheengineand willshutoff

theenginewhenmovedintothe OFFposition.

RECOIL STARTER HANDLE

Thishandleisusedto manuallystartthe engine.

ELECTRIC STARTER BUTTON

Pressingtheelectricstarterbuttonengagestheengine'selectric

starterwhenpluggedintoa 120Vpowersource.

ELECTRIC STARTER OUTLET

Requirestheuseof athree-prongoutdoorextensioncord(included)

anda 120Vpowersource/walloutlet.

AUGERS

Whenengaged,theaugersrotateanddrawsnowintotheauger

housing.

SKID SHOES

Positiontheskid shoesbasedonsurfaceconditions.Adjustupward

forhard-packedsnow.Adjustdownwardwhenoperatingon gravelor

crushedrocksurfaces.

CHUTE ASSEMBLY

Snowdrawnintotheaugerhousingisdischargedoutthe chute

assembly.

WHEEL STEERING CONTROLS

Theleft andrightwheelsteeringcontrolsarelocatedon theunderside

ofthe handles.Squeezetherightcontroltoturnright;squeezetheleft

controltoturn left.

NOTE:Operatethesnowthrowerinopenareasuntilyou arefamiliar

withthesecontrols.

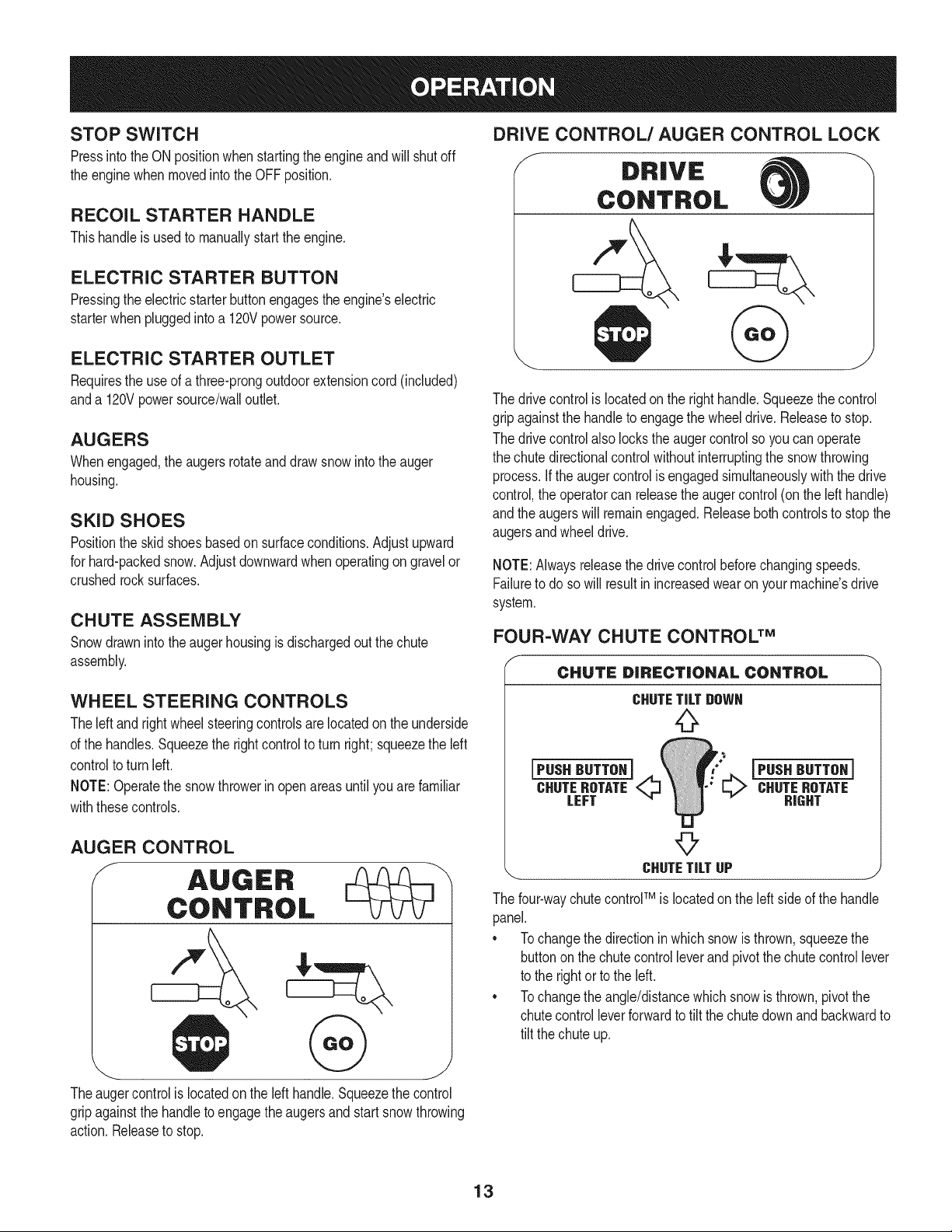

DRIVE CONTROL/AUGER CONTROL LOCK

Thedrivecontrolis locatedon therighthandle.Squeezethecontrol

gripagainstthehandleto engagethewheeldrive.Releasetostop.

Thedrivecontrolalsolockstheaugercontrolso youcanoperate

thechutedirectionalcontrolwithoutinterruptingthesnowthrowing

process.If theaugercontrolisengagedsimultaneouslywiththedrive

control,the operatorcanreleasetheaugercontrol(onthelefthandle)

andtheaugerswillremainengaged.Releaseboth controlstostopthe

augersandwheeldrive.

NOTE:Alwaysreleasethedrivecontrolbeforechangingspeeds.

Failureto doso willresultinincreasedwearonyourmachine'sdrive

system.

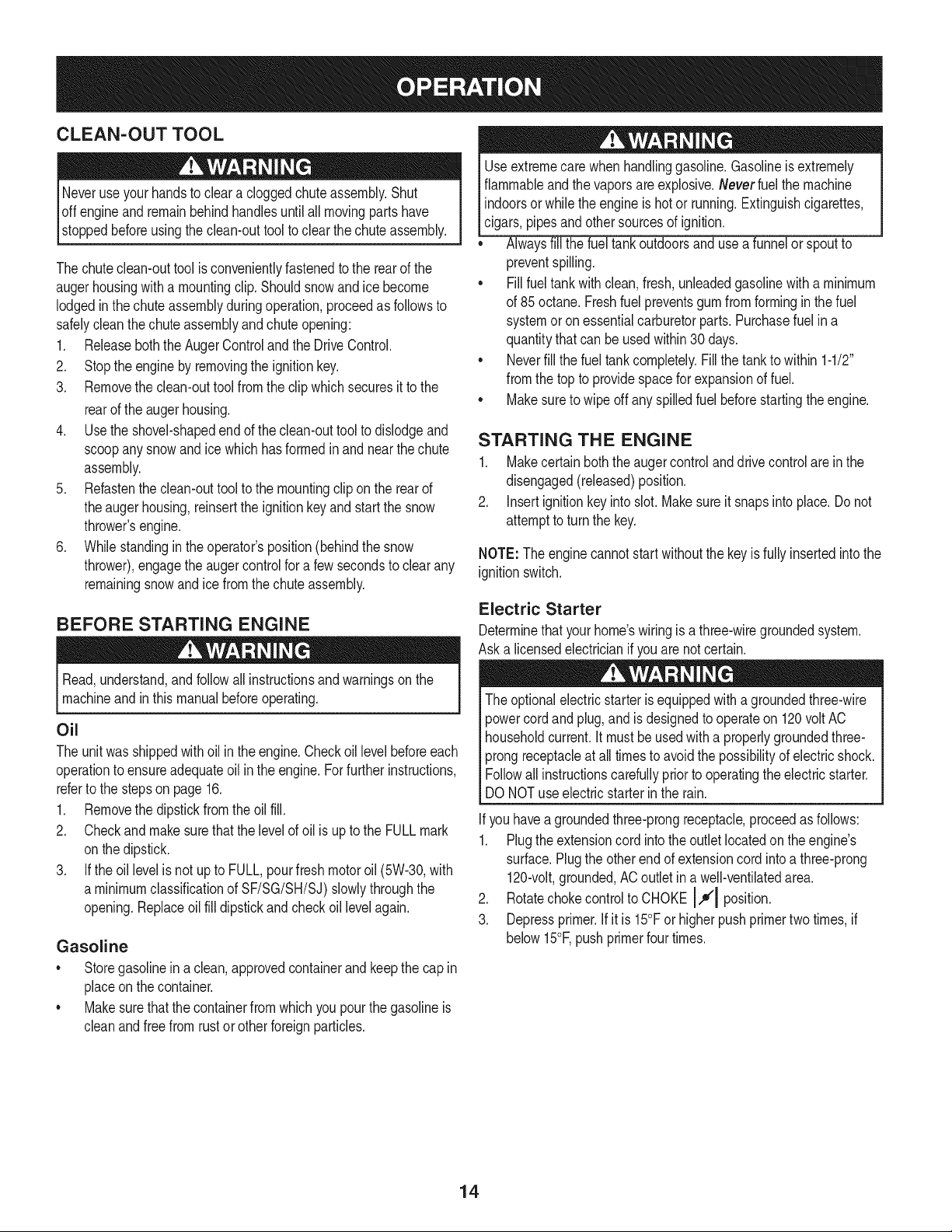

FOUR-WAY CHUTE CONTROL TM

f

CHUTE DiRECTiONAL CONTROL

CHUTETiLTgOWN

jPUSHHUTTOHi

CHUTEROTATE_

LEFT

jPUSHHUTTOHi

_ CHUTENOTATE

HIGHT

AUGER CONTROL

J AUGER

Theaugercontrolis locatedontheleft handle.Squeezethecontrol

gripagainstthehandleto engagetheaugersandstartsnowthrowing

action.Releasetostop.

CONTROL

©

_.. CHUTETiLTUP j

Thefour-waychutecontrolTM iSlocatedontheleft sideof thehandle

panel.

* Tochangethe directioninwhichsnowis thrown,squeezethe

buttononthechutecontrolleverand pivotthechutecontrollever

tothe rightortothe left.

* Tochangethe angle/distancewhichsnowisthrown,pivotthe

chutecontrolleverforwardto tiltthechutedownandbackwardto

tilt thechuteup.

13

CLEAN-OUT TOOL

Neveruseyourhandsto clearacloggedchuteassembly.Shut

loft engineand remainbehindhandlesuntilallmovingpartshave

lstoppedbeforeusingtheclean-outtool toclearthe chuteassembly.

Thechuteclean-outtoolisconvenientlyfastenedtothe rearof the

augerhousingwitha mountingclip. Shouldsnowandicebecome

lodgedin thechuteassemblyduringoperation,proceedasfollowsto

safelycleanthechuteassemblyandchuteopening:

1. Releaseboththe AugerControlandthe DriveControl.

2. Stopthe engineby removingtheignitionkey.

3. Removetheclean-outtoolfromtheclipwhichsecuresit tothe

rearofthe augerhousing.

4. Usetheshovel-shapedendof theclean-outtool todislodgeand

scoopanysnowand icewhichhasformedin andnearthechute

assembly.

5. Refastentheclean-outtoolto themountingcliponthe rearof

theaugerhousing,reinserttheignitionkeyandstartthesnow

thrower'sengine.

6. Whilestandingintheoperator'sposition(behindthesnow

thrower),engagethe augercontrolforafewsecondstoclearany

remainingsnowandice fromthechuteassembly.

BEFORE STARTING ENGINE

Useextremecarewhenhandlinggasoline.Gasolineisextremely

flammableandthevaporsare explosive.Neverfuelthemachine

indoorsorwhiletheengineis hotor running.Extinguishcigarettes,

cigars,pipesandothersourcesof ignition.

Alwaysfillthefuel tankoutdoorsandusea funnelorspoutto

preventspilling.

• Fillfueltankwithclean,fresh,unleadedgasolinewitha minimum

of85 octane.Freshfuelpreventsgumfromforminginthefuel

systemoronessentialcarburetorparts.Purchasefuelin a

quantitythatcan beusedwithin30days.

• Neverfillthefuel tankcompletely.Fillthetanktowithin1-1/2"

fromthetop toprovidespaceforexpansionoffuel.

• Makesuretowipeoffanyspilledfuelbeforestartingthe engine.

STARTING THE ENGINE

1. Makecertainboththe augercontrolanddrivecontrolarein the

disengaged(released)position.

2. Insertignitionkeyintoslot.Makesure it snapsintoplace.Donot

attempttoturn thekey.

NOTE:Theenginecannotstartwithoutthekeyis fully insertedintothe

ignitionswitch.

Electric Starter

Determinethatyourhome'swiringisa three-wiregroundedsystem.

Aska licensedelectricianifyouarenotcertain.

Read,understand,andfollowall instructionsandwarningsonthe

machineand inthismanualbeforeoperating.

Oil

Theunitwasshippedwithoil intheengine.Checkoillevelbeforeeach

operationto ensureadequateoilin theengine.Forfurtherinstructions,

referto thestepsonpage16.

1. Removethedipstickfromtheoil fill.

2. Checkandmakesurethatthe levelofoil is upto the FULLmark

onthedipstick.

3. Iftheoil levelisnotupto FULL,pourfreshmotoroil (5W-30,with

a minimumclassificationofSF/SG/SH/SJ)slowlythroughthe

opening.Replaceoil filldipstickandcheckoil levelagain.

Gasoline

o Storegasolineinaclean,approvedcontainerandkeepthecap in

placeonthe container.

• Makesurethatthe containerfromwhichyoupourthegasolineis

cleanandfreefromrustor otherforeignparticles.

Theoptionalelectricstarterisequippedwithagroundedthree-wire

powercordand plug,andisdesignedtooperateon 120voltAC

householdcurrent.It mustbeusedwitha properlygroundedthree-

prongreceptacleat alltimestoavoidthepossibilityof electricshock.

Followall instructionscarefullypriortooperatingtheelectricstarter.

DONOTuseelectricstarterin therain.

Ifyouhavea groundedthree-prongreceptacle,proceedasfollows:

1. Plugtheextensioncord intotheoutletlocatedon the engine's

surface.Plugtheotherendof extensioncord intoathree-prong

120-volt,grounded,ACoutletina well-ventilatedarea.

2. RotatechokecontroltoCHOKEI,._¢1position.

3. Depressprimer.Ifitis 15°Forhigherpushprimertwotimes,if

below15°F,pushprimerfourtimes.

14

4. PushStopswitchto ONposition.

5. Pushstarterbuttontostartengine.

Toprolongstarterlife,useshortstartingcycles(5 secondsmaximum

thenwaitoneminute).

2. Squeezethedrivecontrolagainstthehandleandthesnow

throwerwillmove.Releaseitanddrivemotionwillstop.

NOTE:NEVERrepositiontheshiftlever(changespeedsordirection

oftravel)withoutfirstreleasingthedrivecontrolandbringingthesnow

throwertoa completestop.Doingsowill resultin prematurewearto

thesnowthrower'sdrivesystem.

6. Oncethe enginestarts,releasestarterbutton.

7. Allowtheenginetowarmup severalminutes,adjustingchoke

towardRUNposition.Waituntilengineruns smoothlybeforeeach

chokeadjustment.

8. Whendisconnectingthe extensioncord,alwaysunplugtheend

atthe three-prongwalloutletbeforeunpluggingtheoppositeend

fromthesnowthrower.

Recoil Starter

1. Rotatechokecontrolto CHOKE IJl position.

2. Depressprimer.Ifit is 15°Forhigherpushprimertwotimes,if

below15°F,pushprimerfourtimes.

3. PushStopswitchto ONposition.

4. Graspthe recoilstarterhandleandslowlypullthe ropeout.At

thepointwhereit becomesslightlyhardertopulltherope,slowly

allowthe ropeto recoil.

5. Pullthestarterhandlewitha firm,rapidstroke.Donotrelease

thehandleandallowitto snap back.Keepafirmholdonthe

starterhandleandallowitto slowlyrecoil.

6. Allowtheenginetowarmup severalminutes,adjustingchoke

towardRUNposition.Waituntilengineruns smoothlybeforeeach

chokeadjustment.

STOPPING THE ENGINE

Afteryouarefinishedsnow-throwing,runenginefora fewminutes

beforestoppingtohelpdryoffany moistureontheengine.

1. PushStopswitchto OFFposition.

2. Removetheignitionkeyandstoreina safeplace.

3. Wipeallsnowandmoisturefromtheareaaroundtheengineas

wellas theareainandaroundthedrivecontrolandaugercontrol.

Also,engageand releasebothcontrolsseveraltimes.

TO ENGAGE AUGERS

1. Toengagethe augersandstartthrowingsnow,squeezethe

augercontrolagainstthelefthandle.Releasetostoptheaugers.

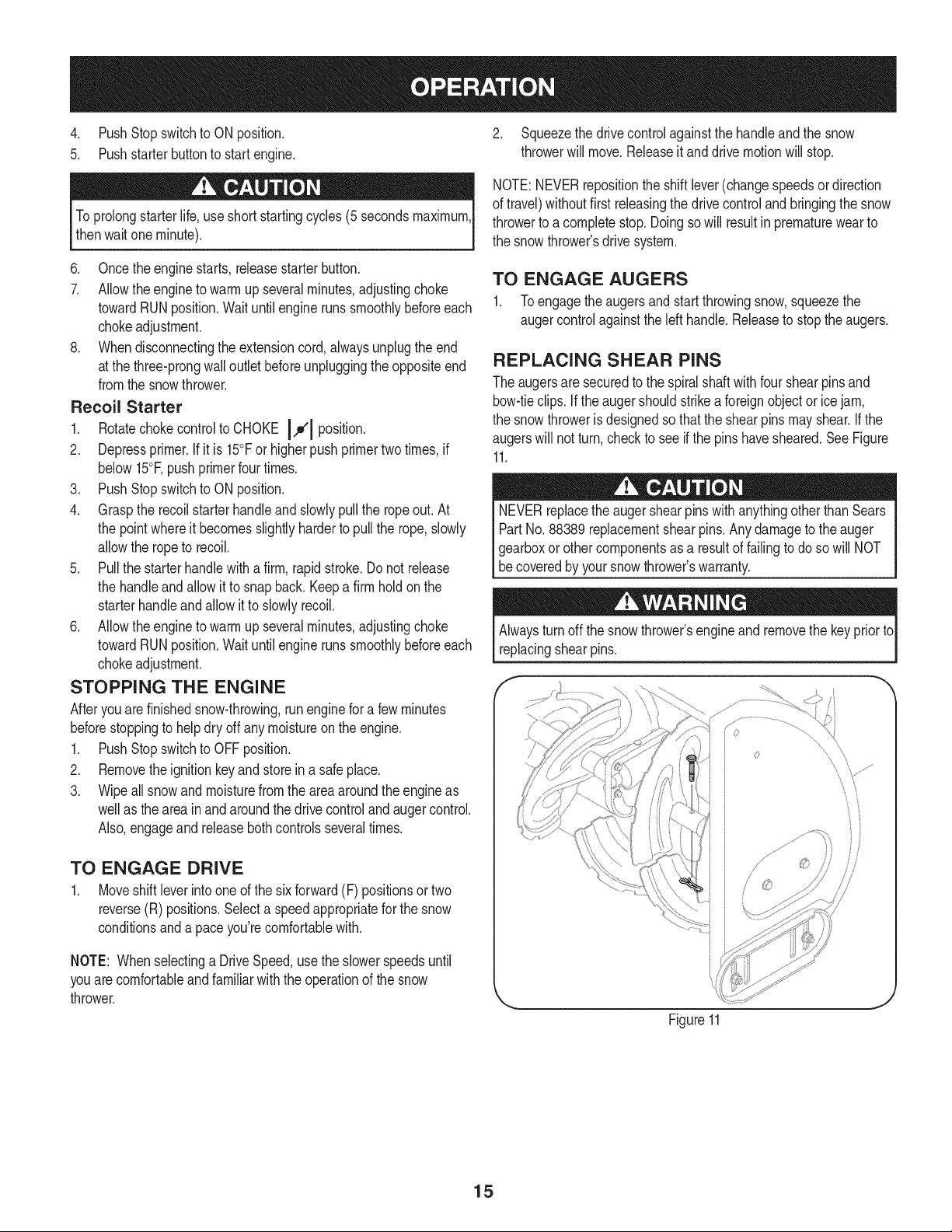

REPLACING SHEAR PINS

Theaugersare securedtothespiralshaftwithfourshearpinsand

bow-tieclips.Ifthe augershouldstrikea foreignobjector icejam,

thesnowthrowerisdesignedsothattheshearpins mayshear.If the

augerswill notturn,checktoseeifthe pinshavesheared.SeeFigure

11.

NEVERreplacetheaugershearpinswithanythingotherthan Sears

PartNo.88389replacementshearpins.Any damagetotheauger

gearboxorothercomponentsasa resultoffailingtodoso will NOT

becoveredbyyoursnowthrower'swarranty.

Alwaysturnoff thesnowthrower'sengineandremovethekeypriorto

replacingshearpins.

\\

TO ENGAGE DRIVE

1. Moveshiftleverintooneofthesixforward(F) positionsor two

reverse(R)positions.Selectaspeedappropriatefor thesnow

conditionsand a paceyou'recomfortablewith.

NOTE: Whenselectinga DriveSpeed,usetheslowerspeedsuntil

youarecomfortableandfamiliarwiththe operationofthesnow

thrower.

15

Figure11

/

/ ©

J

MAINTENANCE SCHEDULE

Beforeperforminganytypeofmaintenance/service,disengageall

controlsandstoptheengine.Waituntilallmovingpartshavecometo

acompletestop.Disconnectsparkplugwireandgrounditagainstthe

enginetopreventunintendedstarting.Alwayswearsafetyglassesduring

operationor whileperforminganyadjustmentsor repairs.

EachUseandevery5

hours

1st5 hours

Annuallyor25 hours

Annuallyor50 hours

Annuallyor100hours

BeforeStorage

1 Underheavyloadorin hightemperatures

1. Engineoil level

2. Looseormissinghardware

3. Unitandengine.

1. Engineoil

1. Engine0i11-

2. Controllinkagesandpivots

3. Wheels

4. GearshaftandAugershaft

5. 4-WayChuteControlTM

1. Engineoil

1. Sparkplug

1. Fuelsystem

1. Check

2. Tightenor replace

3. Clean

1. Change

1. Change

2. Lubewith lightoil

3. Lubewith multipurposeautogrease

4. Lubewith lightoil

5. Checkfor cableslackness

1. Change

1. Change

1. Runengineuntilitstopsfromlack

Followthemaintenanceschedulegivenbelow.Thischartdescribes

serviceguidelinesonly.UsetheServiceLogcolumnto keeptrackof

completedmaintenancetasks.Tolocate the nearest Sears Service

Centeror toscheduleservice,simplycontactSearsat

1-800-4-MY-HOME®.

offuel

ENGINE MAINTENANCE

all controls

and stopengine.Waituntilall movingpartshavecometoa complete

lBeforelubricating,repairing,or inspecting,disengage

stop.

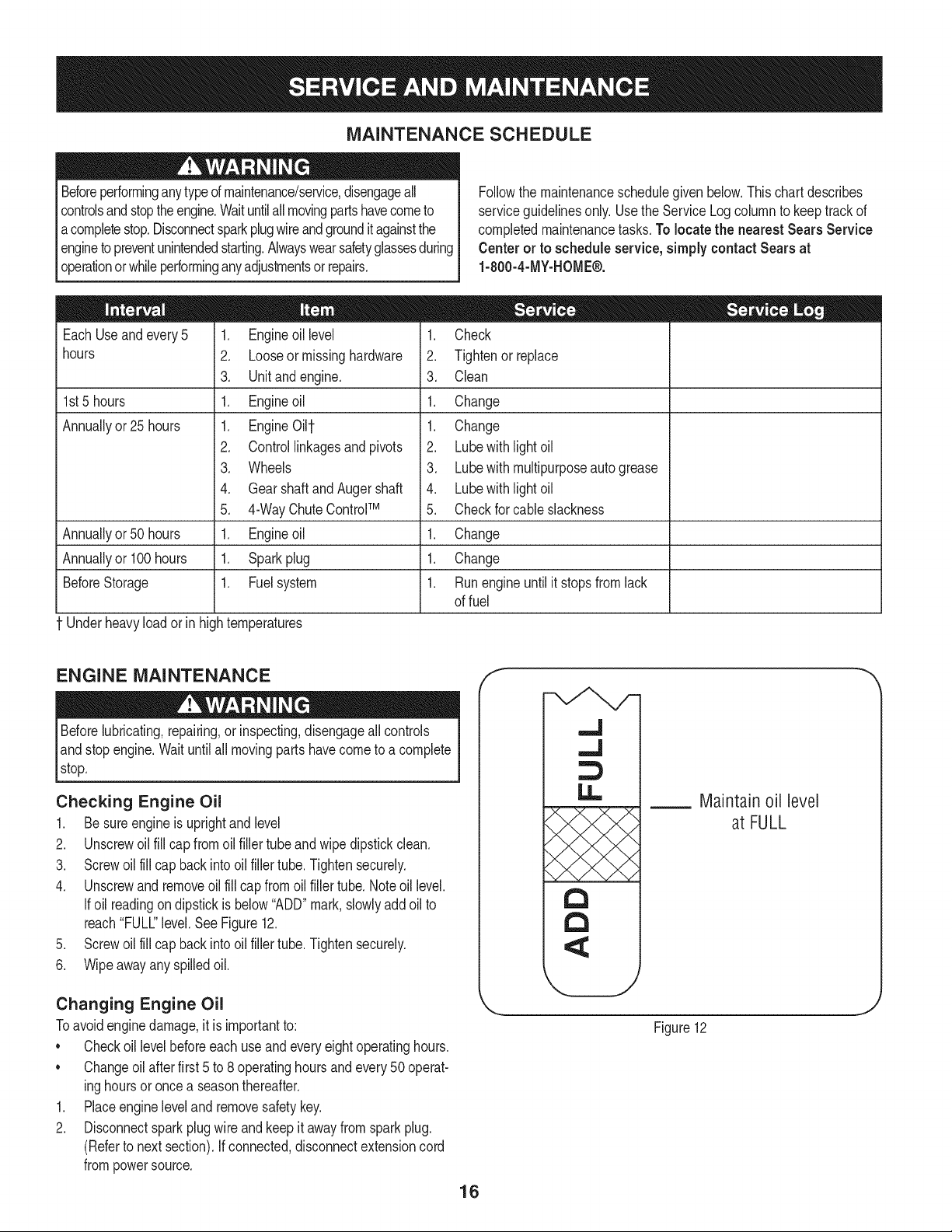

Checking Engine Oil

1. Besureengineisuprightandlevel

2. Unscrewoilfillcapfromoilfiller tubeandwipedipstickclean.

3. Screwoilfillcapbackintooil fillertube.Tightensecurely.

4. Unscrewandremoveoil fill capfromoil fillertube.Noteoillevel.

Ifoil readingondipstickisbelow"ADD"mark,slowlyaddoilto

reach"FULL"level.SeeFigure12.

5. Screwoilfillcapbackintooil fillertube.Tightensecurely.

6. Wipeawayanyspilledoil.

Changing Engine Oil

Toavoidenginedamage,it isimportantto:

• Checkoillevelbeforeeachuseandeveryeightoperatinghours.

• Changeoilafterfirst5 to 8operatinghoursandevery50operat-

inghoursoronce a seasonthereafter.

1. Placeengineleveland removesafetykey.

2. Disconnectsparkplugwireandkeepitawayfromsparkplug.

(Refertonextsection).If connected,disconnectextensioncord

frompowersource.

f

,,.J

,,,,J

Maintain oil level

at FULL

13

13

J

Figure12

16

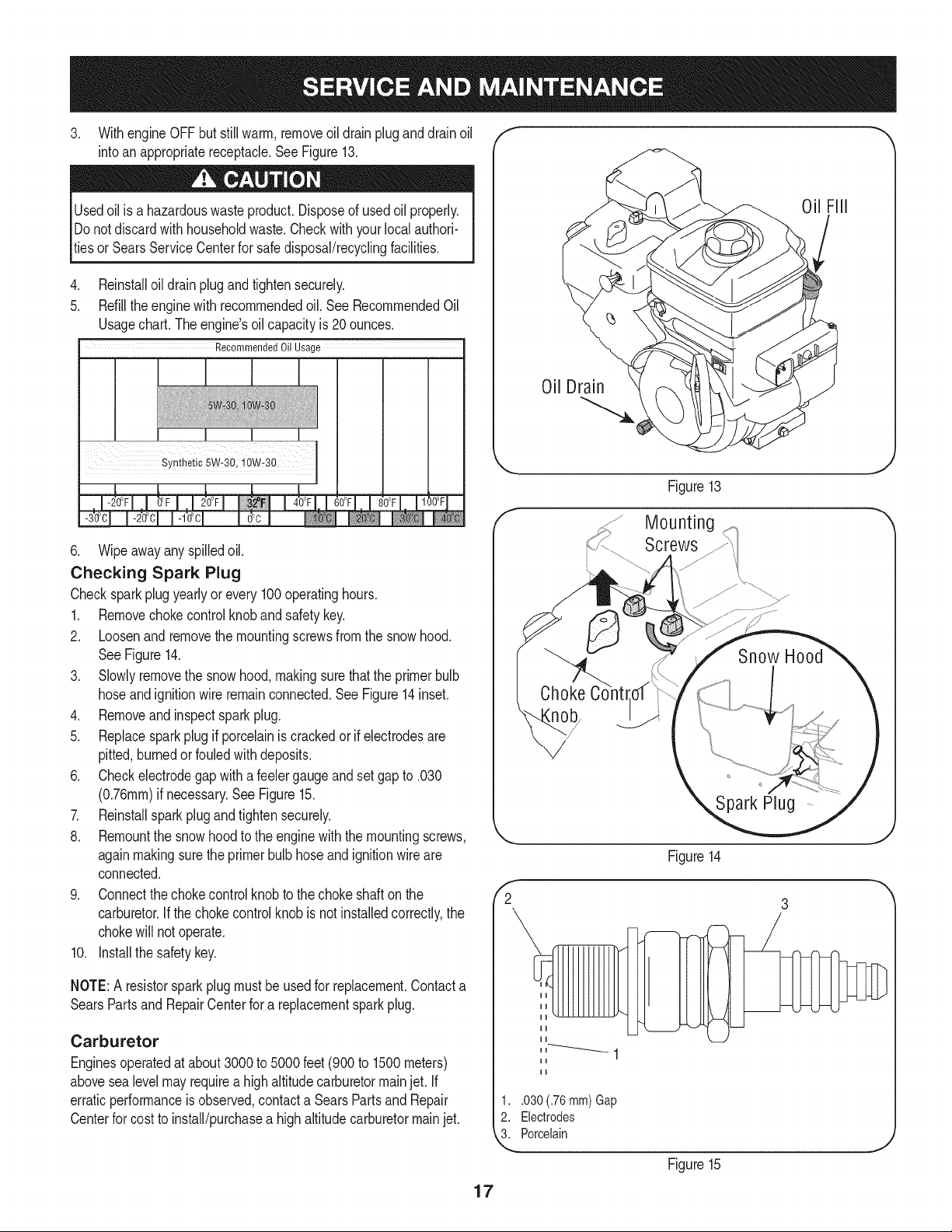

3. WithengineOFFbutstillwarm,removeoildrainpluganddrainoil

intoanappropriatereceptacle.SeeFigure13.

Usedoilisahazardouswasteproduct.Disposeofusedoilproperly.

Donotdiscardwithhouseholdwaste.Checkwithyourlocalauthori-

tiesorSearsServiceCenterforsafedisposal/recyclingfacilities.

.

Reinstalloildrainplugandtightensecurely.

5.

Refilltheenginewith recommendedoil. SeeRecommendedOil

Usagechart.The engine'soil capacityis20ounces.

Recommended Oil Usage

I

SiUiheiic 5W 3Q:i O_io

6. Wipeawayanyspilledoil.

Checking Spark Plug

Checksparkplugyearlyor every100operatinghours.

1. Removechokecontrolknobandsafetykey.

2. Loosenandremovethemountingscrewsfromthesnowhood.

SeeFigure14.

3. Slowlyremovethesnowhood,makingsurethattheprimerbulb

hoseandignitionwireremainconnected.SeeFigure14inset.

4. Removeandinspectsparkplug.

5. Replacesparkplugifporcelainiscrackedorif electrodesare

pitted,burnedorfouledwithdeposits.

6. Checkelectrodegapwitha feelergaugeandsetgapto .030

(0.76ram)ifnecessary.SeeFigure15.

7. Reinstallsparkplugandtightensecurely.

8. Remountthe snowhoodto theenginewith themountingscrews,

againmakingsurethe primerbulbhoseandignitionwireare

connected.

9. Connectthechokecontrolknobto thechokeshaftonthe

carburetor.Ifthe chokecontrolknobisnotinstalledcorrectly,the

chokewillnotoperate.

10. Installthe safetykey.

Oil Drain

Figure13

g

Screws

Figure14

f

2

NOTE:A resistorsparkplugmustbe usedforreplacement.Contacta

SearsPartsand RepairCenterfora replacementsparkplug.

Carburetor

Enginesoperatedatabout3000to5000feet(900to 1500meters)

abovesealevelmayrequireahighaltitudecarburetormainjet. If

erraticperformanceis observed,contactaSearsPartsand Repair

Centerforcosttoinstall/purchasea highaltitudecarburetormainjet.

1..030 (.76mm)Gap

2. Electrodes

3. Porcelain

Figure15

17

Engine Speed

Toavoidseriousinjuryordeath,DO NOTmodifyengineinany

way.Tamperingwiththe governorsettingcancausetheengineand

equipmentto operateatunsafespeeds.NEVERtamperwithfactory

settingofenginegovernor.Runningthe enginefasterthanthespeed

setatthe factoryisdangerous.

LUBRICATION

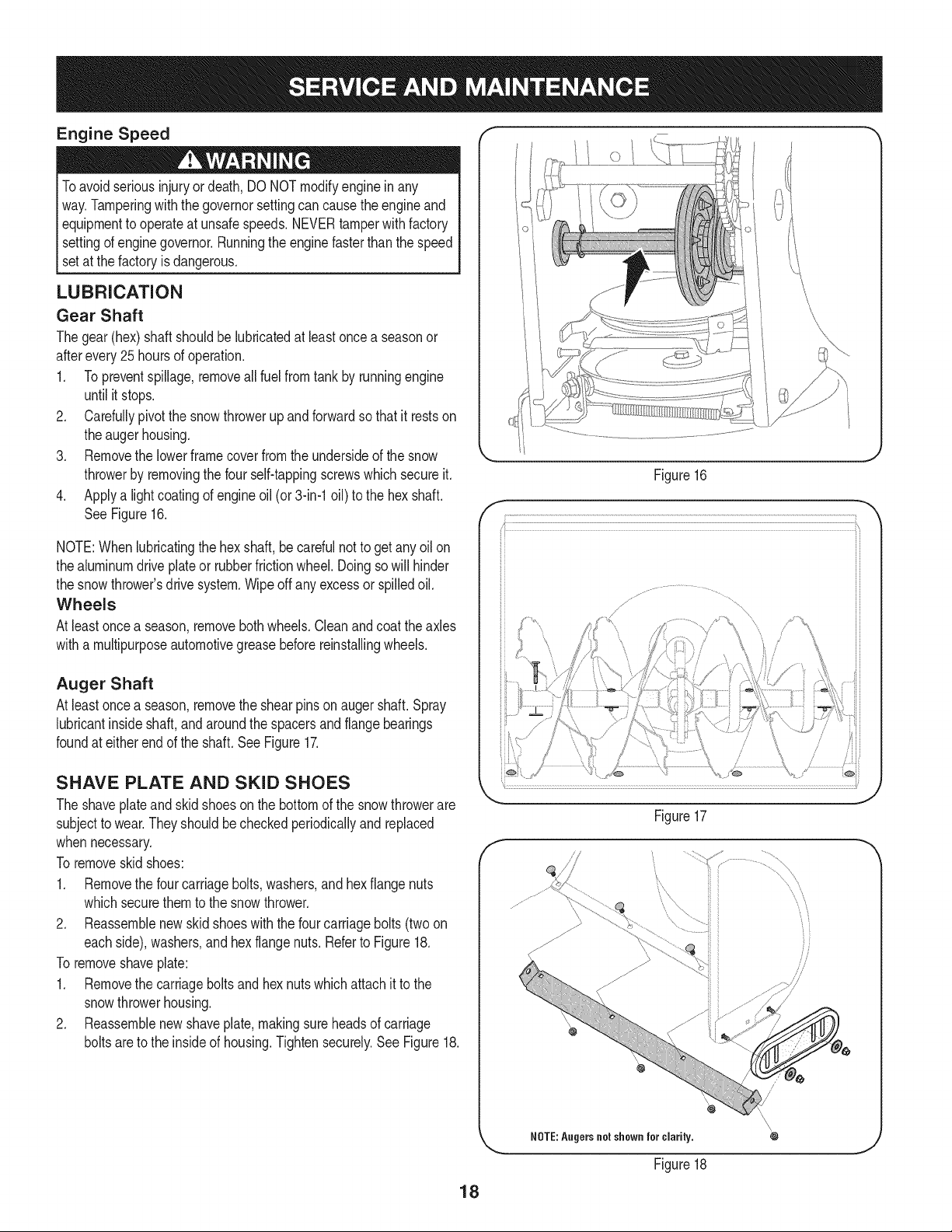

Gear Shaft

Thegear(hex)shaftshouldbe lubricatedatleastoncea seasonor

afterevery25 hoursofoperation.

1. Topreventspillage,removeallfuelfromtank byrunningengine

untilit stops.

2. Carefullypivotthesnowthrowerupandforwardsothat itrestson

theaugerhousing.

3. Removethe lowerframecoverfromtheundersideofthe snow

throwerbyremovingthe fourself-tappingscrewswhichsecureit.

4. Applya lightcoatingof engineoil (or3-in-1oil) tothehexshaft.

SeeFigure16.

NOTE:Whenlubricatingthehexshaft,be carefulnottoget anyoilon

thealuminumdriveplateor rubberfrictionwheel.Doingsowill hinder

thesnowthrower'sdrivesystem.Wipeoff anyexcessor spilledoil.

Wheels

Atleastoncea season,removebothwheels.Cleanandcoattheaxles

witha multipurposeautomotivegreasebeforereinstallingwheels.

Figure16

Auger Shaft

Atleastoncea season,removetheshearpinson augershaft.Spray

lubricantinsideshaft,andaroundthe spacersandflangebearings

foundat eitherendoftheshaft.SeeFigure17.

SHAVE PLATE AND SKID SHOES

Theshaveplateand skidshoesonthebottomof the snowthrowerare

subjecttowear.Theyshouldbecheckedperiodicallyandreplaced

whennecessary.

Toremoveskidshoes:

1. Removethefourcarriagebolts,washers,andhexflangenuts

whichsecurethemtothe snowthrower.

2. Reassemblenewskidshoeswiththefourcarriagebolts(twoon

eachside),washers,andhex flangenuts.RefertoFigure18.

Toremoveshaveplate:

1. Removethecarriageboltsandhexnutswhichattachit tothe

snowthrowerhousing.

2. Reassemblenewshaveplate,makingsureheadsofcarriage

boltsaretothe insideof housing.Tightensecurely.SeeFigure18.

/

J

Figure17

f

\\

\\

\\

18

Figure18

ADJUSTMENTS

Shift Cable

If thefull rangeof speeds(forwardandreverse)cannotbeachieved,

referto thefigureto therightandadjustthe shift cableasfollows:

1. Placethe shiftleverin thefastest forwardspeedposition(F6).

2. Loosenthehex nuton theshiftcableindexbracket.SeeFigure

19.

3. Pivotthebracketdownwardto takeupslackinthecable.

4. Retightenthehexnut.

Drive Control

Whenthedrivecontrolis releasedandinthedisengaged"up"position,

thecableshouldhaveverylittle slack.It shouldNOTbetight.Also,

ifthereisexcessiveslackin thedrive cableoriftheunitexperiences

intermittentdrivewhileusing,the cablemayneedtobeadjusted.

Checktheadjustmentofthe drivecontrolasfollows:

1. Withthedrivecontrolreleased,pushthesnowthrowergently

forward.Theunitshouldrollfreely.

2. Engagethedrivecontrolandgentlyattemptto pushthesnow

throwerforward.Thewheelsshouldnotturn.Theunitshouldnot

rollfreely.

3. Withthedrivecontrolreleased,movetheshiftleverbackand

forthbetweenthe R2positionandthe F6positionseveraltimes.

Thereshouldbeno resistancein the shiftlever.

4. If anyofthe abovetestsfailed,thedrivecableis in needof adjust-

ment.Proceedasfollows:

5. Loosenthelowerhexboltonthedrivecablebracket.SeeFigure

20.

6. Positionthebracketupwardtoprovidemoreslack(or downward

toincreasecabletension).

7. Retightenthelowerhexbolt.

J

f

Chute Control

Oncea seasonorevery25hoursof operation,whicheverisearlier,

checkwhetherthefour-waychutecontrolTM cableshaveslackened.If

thechutedoes notrotatefully,thechutecontrolcableswillhavetobe

adjusted.RefertoFigure21.

J

Figure20

f

Figure21

19

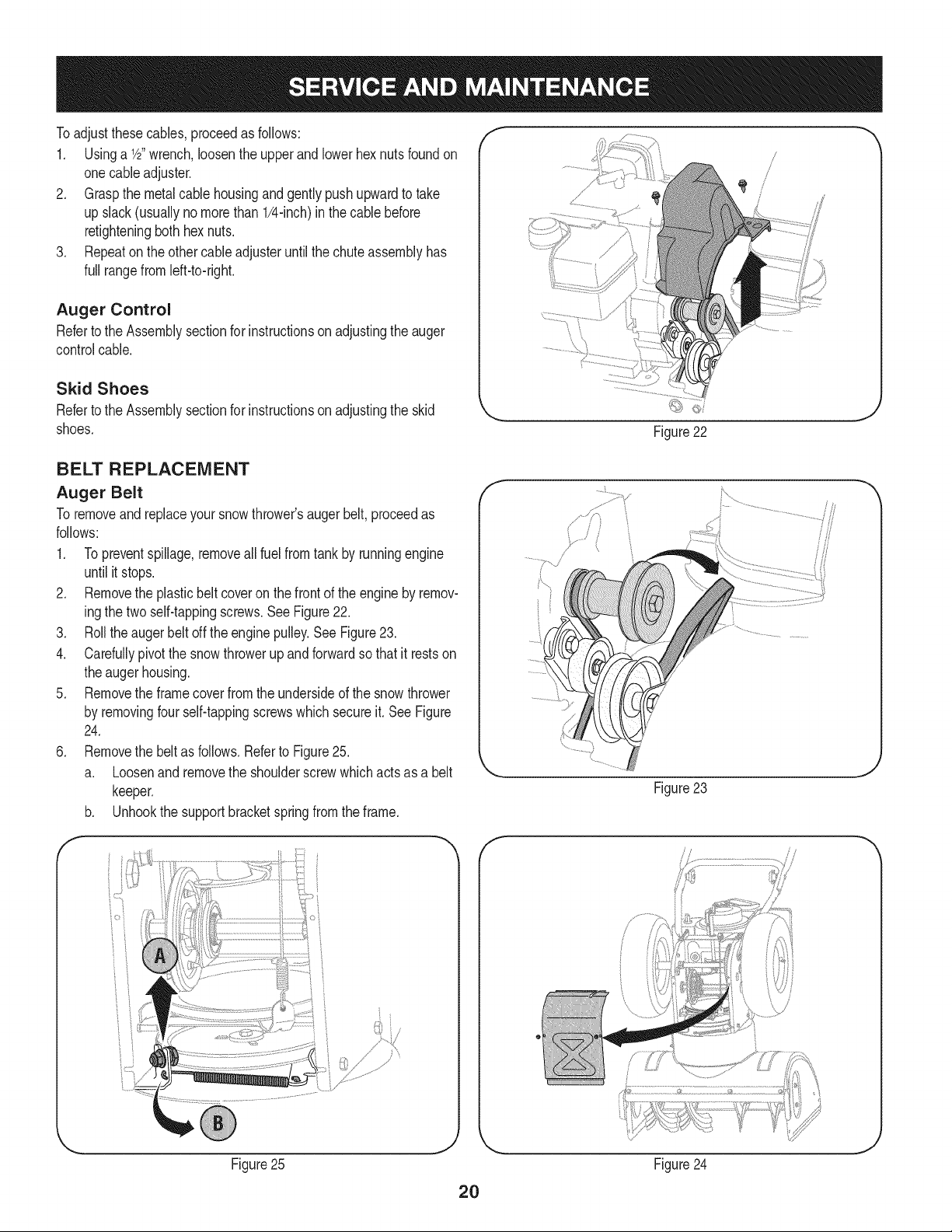

Toadjustthesecables,proceedasfollows:

1. Usinga 1/2"wrench,loosentheupperandlowerhexnutsfoundon

onecableadjuster.

2. Graspthe metalcablehousingandgentlypushupwardtotake

up slack(usuallynomorethan1/4-inch)inthecablebefore

retighteningbothhexnuts.

3. Repeatontheothercableadjusteruntilthe chuteassemblyhas

fullrangefromleft-to-right.

Auger Control

Refertothe Assemblysectionforinstructionsonadjustingtheauger

controlcable.

Skid Shoes

Refertothe Assemblysectionforinstructionsonadjustingthe skid

shoes.

/

BELT REPLACEMENT

Auger Belt

Toremoveandreplaceyoursnowthrower'saugerbelt,proceedas

follows:

1. Topreventspillage,removeallfuelfromtank byrunningengine

untilitstops.

2. Removethe plasticbeltcoveronthe frontoftheenginebyremov-

ingthetwoself-tappingscrews.SeeFigure22.

3. Rolltheaugerbeltofftheenginepulley.SeeFigure23.

4. Carefullypivotthesnowthrowerupandforwardsothat itrestson

theaugerhousing.

5. Removetheframecoverfromtheundersideof thesnowthrower

byremovingfourself-tappingscrewswhichsecureit.SeeFigure

24.

6. Removethe beltasfollows.Referto Figure25.

a. Loosenandremovetheshoulderscrewwhichactsasa belt

keeper.

b. Unhookthe supportbracketspringfromtheframe.

f _ f

f

J

Figure23

Figure25 Figure24

J

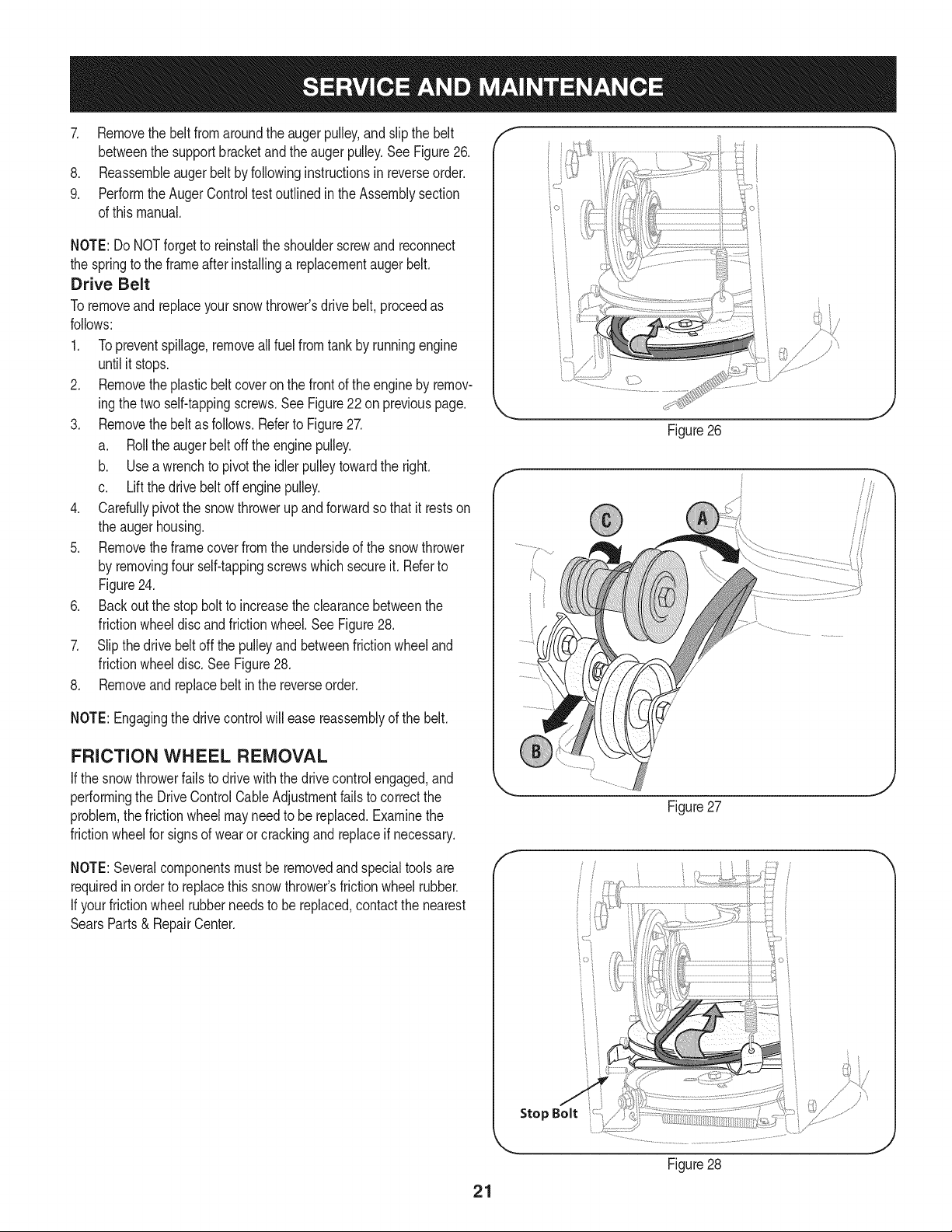

7. Removethebeltfromaroundtheaugerpulley,andslipthebelt

betweenthesupportbracketandtheaugerpulley.SeeFigure26.

8. Reassembleaugerbeltbyfollowinginstructionsinreverseorder.

9. PerformtheAugerControltestoutlinedintheAssemblysection

ofthismanual.

NOTE:DoNOTforgettoreinstalltheshoulderscrewandreconnect

thespringtotheframeafterinstallingareplacementaugerbelt.

Drive Belt

Toremoveandreplaceyoursnowthrower'sdrivebelt,proceedas

follows:

1. Topreventspillage,removeallfuel fromtankby runningengine

untilit stops.

2. Removetheplasticbelt coveronthe frontoftheengineby remov-

ingthetwoself-tappingscrews.SeeFigure22on previouspage.

3. Removethebeltasfollows.Referto Figure27.

a. Rolltheaugerbeltofftheenginepulley.

b. Useawrenchto pivottheidlerpulleytowardthe right.

c. Liftthedrivebeltoff enginepulley.

4. Carefullypivotthesnowthrowerupand forwardsothat itrestson

theaugerhousing.

5. Removetheframecoverfromtheundersideof the snowthrower

byremovingfourself-tappingscrewswhichsecureit.Referto

Figure24.

6. Backoutthestopbolttoincreasetheclearancebetweenthe

frictionwheeldiscandfrictionwheel.SeeFigure28.

7. Slipthedrivebelt offthepulleyandbetweenfrictionwheeland

frictionwheeldisc.SeeFigure28.

8. Removeandreplacebeltinthereverseorder.

ioi

Figure26

NOTE:Engagingthedrivecontrolwill easereassemblyofthebelt.

FRICTION WHEEL REMOVAL

If thesnowthrowerfailsto drivewiththedrivecontrolengaged,and

performingtheDriveControlCableAdjustmentfailstocorrectthe

problem,thefrictionwheelmayneedto be replaced.Examinethe

frictionwheelforsignsof wearorcrackingandreplaceifnecessary.

NOTE:Severalcomponentsmustbe removedandspecialtoolsare

requiredinordertoreplacethis snowthrower'sfrictionwheelrubber.

If yourfrictionwheelrubberneedsto bereplaced,contactthenearest

SearsParts& RepairCenter.

.J

Figure27

f

io i

i

Figure28

21

Loading...

Loading...