Page 1

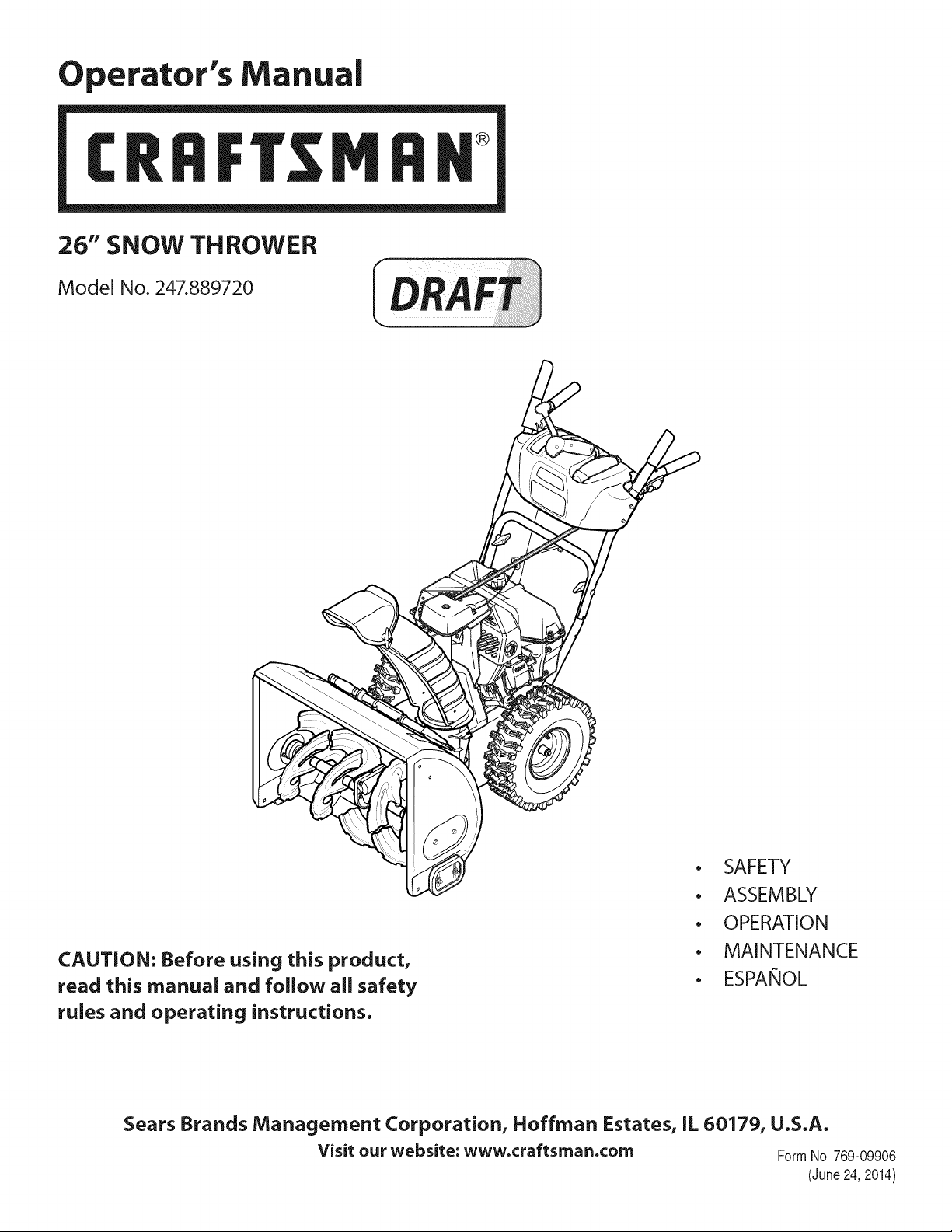

Operator's Manual

CRRFTSMFIN

26" SNOW THROWER

Model No. 247.889720

CAUTION: Before using this product,

read this manual and follow all safety

rules and operating instructions.

Sears Brands Management Corporation, Hoffman Estates, IL 60179, U.S.A.

Visit our website: www.craftsman.com FormNo.769-09906

• SAFETY

• ASSEMBLY

• OPERATION

• MAINTENANCE

• ESPANOL

(,June24,2014)

Page 2

Warranty Statement .............................. Page 2

Safe Operation Practices ...................... Pages 3-6

Assembly .................................... Pages 8-13

Operation .................................. Pages 14-17

Off-Season Storage ............................. Page 25

Troubleshooting ............................... Page 26

Repair Protection Agreement ................... Page 30

Espa_ol ......................................... Page 31

Service & Maintenance ...................... Pages 18-24

CRAFTSMANLIMITEDWARRANTY

FORTWOYEARSfromthedateofpurchase,thisproductiswarrantedagainstanydefectsinmaterialorworkmanship.

WITHPROOFOFSALE,adefectiveproductwill receivefreerepairorreplacementatoptionofseller.

ADDITIONALLIFETIMELIMITEDWARRANTYonUPPERand LOWERCHUTE

FORASLONGASITISUSEDbytheoriginalownerafterthe secondyearfromthedateofpurchase,theupperandlowerchuteofthissnowthrowerare

warrantedagainstanydefectsinmaterialorworkmanshipasverifiedbyaSearsauthorizedserviceprovider.Withproofofpurchase,youwill receiveanew

chutefreeofcharge.Youareresponsiblefor thelaborcostofinstallationandanycostincurredtoverifythedefect.

Forwarrantycoveragedetailstoobtainfreerepairorreplacement,visitthewebpage:www.craftsman.com/warranty

ThiswarrantycoversONLYdefectsinmaterialandworkmanship.WarrantycoveragedoesNOTinclude:

• Expendableitemsthatcanwearoutfromnormalusewithinthewarrantyperiod,includingbutnotlimitedtoaugers,augerpaddles,driftcutters,skid

shoes,shaveplate,shearpins,sparkplug,aircleaner,belts,andoilfilter.

• Standardmaintenanceservicing,oilchanges,ortune-ups.

• Tirereplacementorrepaircausedbypuncturesfromoutsideobjects,suchasnails,thorns,stumps,orglass.

• Tireorwheelreplacementorrepairresultingfromnormalwear,accident,orimproperoperationormaintenance.

• Repairsnecessarybecauseofoperatorabuse,includingbutnot limitedtodamagecausedbyover-speedingtheengine,orfromimpactingobjectsthat

bendtheframe,augershaft,etc.

• Repairsnecessarybecauseofoperatornegligence,includingbutnotlimitedto,electricalandmechanicaldamagecausedbyimproperstorage,failureto

usethepropergradeandamountofengineoil,orfailuretomaintaintheequipmentaccordingtotheinstructionscontainedintheoperator'smanual.

• Engine(fuelsystem)cleaningorrepairscausedbyfueldeterminedtobecontaminatedoroxidized(stale).Ingeneral,fuelshouldbeusedwithin30days

ofitspurchasedate.

• Normaldeteriorationandwearoftheexteriorfinishes,orproductlabelreplacement.

Thiswarrantyisvoidifthisproductiseverusedwhileprovidingcommercialservicesorif rentedtoanotherperson.

Thiswarrantygivesyouspecificlegalrights,andyoumayalsohaveotherrightswhichvaryfromstateto state.

SearsBrandsManagementCorporation,HoffmanEstates,IL60179

Engine Oil: 5W-30

Fuel: Unleaded Gasoline

Engine: Craftsman

Model Number

Serial Number

Date of Purchase

Record the model number, serial number,

and date of purchase above.

© Sears Brands, LLC 2

Page 3

Thissymbolpointsout importantsafetyinstructionswhich,ifnot

followed,couldendangerthe personalsafetyand/or propertyof

yourselfandothers.Readandfollow all instructions inthismanual

beforeattempting to operatethis machine.Failureto complywith these

instructionsmayresultinpersonalinjury.Whenyou seethis symbol,HEED

ITSWARNING!

Thismachinewasbuilt tobeoperatedaccordingtothesafeoperation

practicesinthis manual.Aswith anytype of powerequipment,

carelessnessorerroronthe part oftheoperatorcanresultinseriousinjury.

Thismachineiscapableof amputatingfingers, hands,toesand feetand

throwingdebris.Failuretoobservethefollowing safety instructionscould

resultinseriousinjuryor death.

CALIFORNIA PROPOSITION 65

EngineExhaust,someofitsconstituents,andcertainvehiclecomponents

containor emit chemicalsknowntoStateof Californiatocausecancerand

birth defectsorother reproductiveharm.

TRAINING

Read,understand,andfollowall instructionsonthemachineandinthe

manual(s)beforeattemptingtoassembleandoperate.Failuretodosocan

resultinseriousinjurytotheoperatorand/orbystanders.Keepthis manual

inasafeplaceforfutureandregularreferenceandfororderingreplacement

parts.

Befamiliarwith allcontrolsandtheirproperoperation.Knowhowtostop

themachineanddisengagethemquickly.

Neverallowchildrenunder14yearsofagetooperatethismachine.Children

14andovershouldreadandunderstandtheinstructionsandsafeoperation

practicesinthis manualandonthemachineandbetrainedandsupervised

byanadult.

Neverallowadultstooperatethismachinewithout properinstruction.

Thrownobjectscancauseseriouspersonalinjury.Planyoursnow-throwing

patterntoavoiddischargeofmaterialtowardroads,bystandersandthelike.

Keepbystanders,petsandchildrenatleast75feetfromthemachinewhileit

isin operation.Stopmachineif anyoneentersthearea.

Exercisecautionto avoidslippingorfalling,especiallywhenoperatingin

reverse.

PREPARATION

Thoroughlyinspecttheareawheretheequipmentistobeused.Removeall

doormats,newspapers,sleds,boards,wiresandotherforeignobjects,which

couldbetrippedoverorthrownbytheauger/impeller.

Alwayswearsafetyglassesoreyeshieldsduringoperationandwhile

performinganadjustmentor repairtoprotectyoureyes.Thrownobjects

whichricochetcancauseseriousinjurytotheeyes.

Donotoperatewithout wearingadequatewinteroutergarments.Donot

wearjewelry,longscarvesorotherlooseclothing,whichcouldbecome

entangledinmovingparts.Wearfootwearwhichwill improvefootingon

slipperysurfaces.

Usea groundedthree-wireextensioncordandreceptacleforall machines

with electricstartengines.

Your Responsibility--Restrict theuseof this power machineto

personswhoread,understandandfollow thewarningsand instructionsin

thismanualandonthe machine.

SAVETHESEINSTRUCTIONS!

Disengageallcontrolleversbeforestartingtheengine.

Adjustcollectorhousingheighttocleargravelorcrushedrocksurfaces.

Neverattemptto makeanyadjustmentswhileengineisrunning,except

wherespecificallyrecommendedin theoperator'smanual.

Letengineandmachineadjusttooutdoortemperaturebeforestartingto

clearsnow.

Safe Handling of Gasoline:

Toavoidpersonalinjuryor propertydamageuseextremecareinhandling

gasoline.Gasolineisextremelyflammableandthe vaporsareexplosive.

Seriouspersonalinjurycan occurwhengasolineisspilledonyourselforyour

clotheswhich canignite. Washyourskinandchangeclothesimmediately.

Useonlyanapprovedgasolinecontainer.

Neverfill containersinsideavehicleorona truckortrailerbedwithaplastic

liner.Alwaysplacecontainersonthegroundawayfromyourvehiclebefore

filling.

Whenpractical,removegas-poweredequipmentfromthetruckor

trailerandrefuelitontheground.Ifthisis notpossible,thenrefuelsuch

equipmentonatrailerwithaportablecontainer,ratherthanfromagasoline

dispensernozzle.

Keepthenozzleincontactwith therimofthefueltankorcontaineropening

atalltimesuntilfuelingiscomplete.Donotuseanozzlelock-opendevice.

Extinguishallcigarettes,cigars,pipesandothersourcesofignition.

Neverfuelmachineindoors.

Neverremovegascaporaddfuelwhiletheengineishotorrunning.Allow

engineto coolatleasttwominutesbeforerefueling.

Neveroverfill fueltank.Filltankto nomorethan1/2inchbelowbottomof

fillernecktoallowspaceforfuelexpansion.

Replacegasolinecapandtightensecurely.

Ifgasolineisspilled,wipeit offtheengineandequipment.Moveunitto

anotherarea.Wait5minutesbeforestartingtheengine.

Page 4

Toreducefirehazards,keepmachinefreeofgrass,leaves,orotherdebris

build-up.Cleanupoilorfuelspillageandremoveanyfuelsoakeddebris.

Neverstorethemachineorfuelcontainerinsidewherethereisanopen

flame,sparkorpilotlightasonawaterheater,spaceheater,furnace,clothes

dryerorothergasappliances.

OPERATION

Donotputhandsorfeetnearrotatingparts,intheauger/impellerhousing

orchuteassembly.Contactwith therotatingpartscanamputatehandsand

feet.

Theauger/impellercontrolleverisasafetydevice.Neverbypassits

operation.Doingsomakesthemachineunsafeandmaycausepersonal

injury.

Thecontrolleversmustoperateeasilyin bothdirectionsandautomatically

returntothedisengagedpositionwhenreleased.

Neveroperatewith amissingordamagedchuteassembly.Keepallsafety

devicesinplaceandworking.

Neverrunanengineindoorsor inapoorlyventilatedarea.Engineexhaust

containscarbonmonoxide,anodorlessanddeadlygas.

Donotoperatemachinewhileundertheinfluenceofalcoholordrugs.

Mufflerandenginebecomehotandcancauseaburn.Donottouch.Keep

childrenaway.

Exerciseextremecautionwhenoperatingonorcrossinggravelsurfaces.Stay

alertforhiddenhazardsortraffic.

Exercisecautionwhenchangingdirectionandwhileoperatingonslopes.Do

notoperateonsteepslopes.

Planyoursnow-throwingpatterntoavoiddischargetowardswindows,

walls,carsetc.Thus,avoidingpossiblepropertydamageorpersonalinjury

causedbyaricochet.

Neverdirectdischargeat children,bystandersandpetsorallowanyonein

frontofthemachine.

Donotoverloadmachinecapacitybyattemptingtoclearsnowattoofastof

arate.

Neveroperatethismachinewithoutgoodvisibilityorlight.Alwaysbesureof

yourfootingandkeepafirmholdonthehandles.Walk,neverrun.

Disengagepowertotheauger/impellerwhentransportingornotin use.

Neveroperatemachineathightransportspeedsonslipperysurfaces.Look

downandbehindandusecarewhenbackingup.

Ifthemachineshouldstarttovibrateabnormally,stoptheengine,

disconnectthesparkplugwireandgrounditagainsttheengine.Inspect

thoroughlyfordamage.Repairanydamagebeforestartingandoperating.

Disengageallcontrolleversandstopenginebeforeyouleavetheoperating

position(behindthehandles).Waituntiltheauger/impellercomesto

acompletestopbeforeuncloggingthechuteassembly,makingany

adjustments,orinspections.

Neverputyourhandin thedischargeorcollectoropenings.Donotunclog

chuteassemblywhileengineis running.Shutoff engineandremainbehind

handlesuntil allmovingpartshavestoppedbeforeunclogging.

Useonlyattachmentsandaccessoriesapprovedbythemanufacturer(e.g.

wheelweights,tirechains,cabsetc.).

Whenstartingengine,pullcordslowlyuntilresistanceisfelt,thenpull

rapidly.Rapidretractionofstartercord(kickback)will pullhandandarm

towardenginefasterthanyoucanletgo.Brokenbones,fractures,bruisesor

sprainscouldresult.

Ifsituationsoccurwhicharenotcoveredinthismanual,usecareandgood

judgment.

CLEARING A CLOGGED DISCHARGE CHUTE

Handcontactwiththerotatingimpellerinsidethedischargechuteisthemost

commoncauseofinjuryassociatedwith snowthrowers.Neveruseyourhandto

cleanoutthedischargechute.

Toclearthechute:

a. SHUTTHEENGINEOFF!

b. Wait10secondsto besuretheimpellerbladeshavestopped

rotating.

c. Alwaysuseaclean-outtool,notyourhands.

MAINTENANCE & STORAGE

Nevertamperwith safetydevices.Checktheir properoperationregularly.

Refertothemaintenanceandadjustmentsectionsofthismanual.

Beforecleaning,repairing,orinspectingmachinedisengageallcontrol

leversandstoptheengine.Waituntiltheauger/impellercometo acomplete

stop.Disconnectthesparkplugwire andgroundagainsttheengineto

preventunintendedstarting.

Checkboltsandscrewsforpropertightnessatfrequentintervalsto keepthe

machineinsafeworkingcondition.Also,visuallyinspectmachineforany

damage.

Donotchangetheenginegovernorsettingorover-speedtheengine.The

governorcontrolsthemaximumsafeoperatingspeedoftheengine.

Snowthrowershaveplatesandskidshoesaresubjectto wearanddamage.

Foryoursafetyprotection,frequentlycheckallcomponentsandreplace

with originalequipmentmanufacturer's(OEM)partsonlyaslistedinthe

Partspagesofthisoperator'smanual.Useof partswhichdonotmeetthe

originalequipmentspecificationsmayleadtoimproperperformanceand

compromisesafety!

Checkcontrolleversperiodicallyto verifytheyengageanddisengage

properlyandadjust,ifnecessary.Refertotheadjustmentsectioninthis

operator'smanualfor instructions.

Maintainorreplacesafetyandinstructionlabels,asnecessary.

Observeproperdisposallawsandregulationsforgas,oil,etc.toprotectthe

environment.

Priortostoring,runmachineafewminutestoclearsnowfrommachineand

preventfreezeupof auger/impeller.

Neverstorethemachineorfuelcontainerinsidewherethereisanopen

flame,sparkorpilotlight suchasawaterheater,furnace,clothesdryeretc.

Alwaysrefertotheoperator'smanualforproperinstructionsonoff-season

storage.

4

Page 5

Checkfuelline,tank,cap,andfittingsfrequentlyfor cracksor leaks.Replace

if necessary.

Donotcrankenginewith sparkplugremoved.

AccordingtotheConsumerProductsSafetyCommission(CPSC)andthe

U.S.EnvironmentalProtectionAgency(EPA),thisproducthasanAverage

Useful Lifeof seven(7)years,or60hoursofoperation.Attheendof

theAverage Useful Lifehavethemachineinspectedannuallybyan

authorizedservicedealertoensurethat allmechanicalandsafetysystems

areworkingproperlyandnotwornexcessively.Failureto dosocanresultin

accidents,injuriesordeath.

DO NOT MODIFY ENGINE

Toavoidseriousinjuryordeath,donot modifyengineinanyway.Tampering

with thegovernorsetting canleadto arunawayengineandcauseitto

operateat unsafespeeds.Nevertamperwith factorysetting ofengine

governor.

NOTICE REGARDING EMiSSiONS

Engineswhich arecertifiedto complywith Californiaandfederal EPA

emissionregulationsfor SORE(Sinai[OffRoadEquipment)arecertified

tooperateonregularunleadedgasoline,and mayincludethe following

emissioncontrolsystems:EngineModification (EM),OxidizingCatalyst(0C),

SecondaryAirinjection(SAI)andThreeWayCatalyst(TWC)ifsoequipped.

SPARK ARRESTOR

®

Thismachineisequippedwith aninternalcombustionengineandshould

not beusedonornearanyunimprovedforest-covered,brusbcoveredor

grass-covered[andunlessthe engine'sexhaustsystemisequippedwith a

sparkarrestormeetingapplicablelocalorstatelaws(if any).

Ifa sparkarrestorisused,it shouldbemaintainedineffectiveworking order

bythe operator,in the Stateof Californiathe aboveisrequiredbylaw (Section

4442ofthe CaliforniaPublicResourcesCode).Otherstates mayhavesimilar

laws.Federallawsapplyonfederal lands.

Asparkarrestorfor the muffler isavailablethrough yournearestSearsParts

andRepairServiceCenter.

Page 6

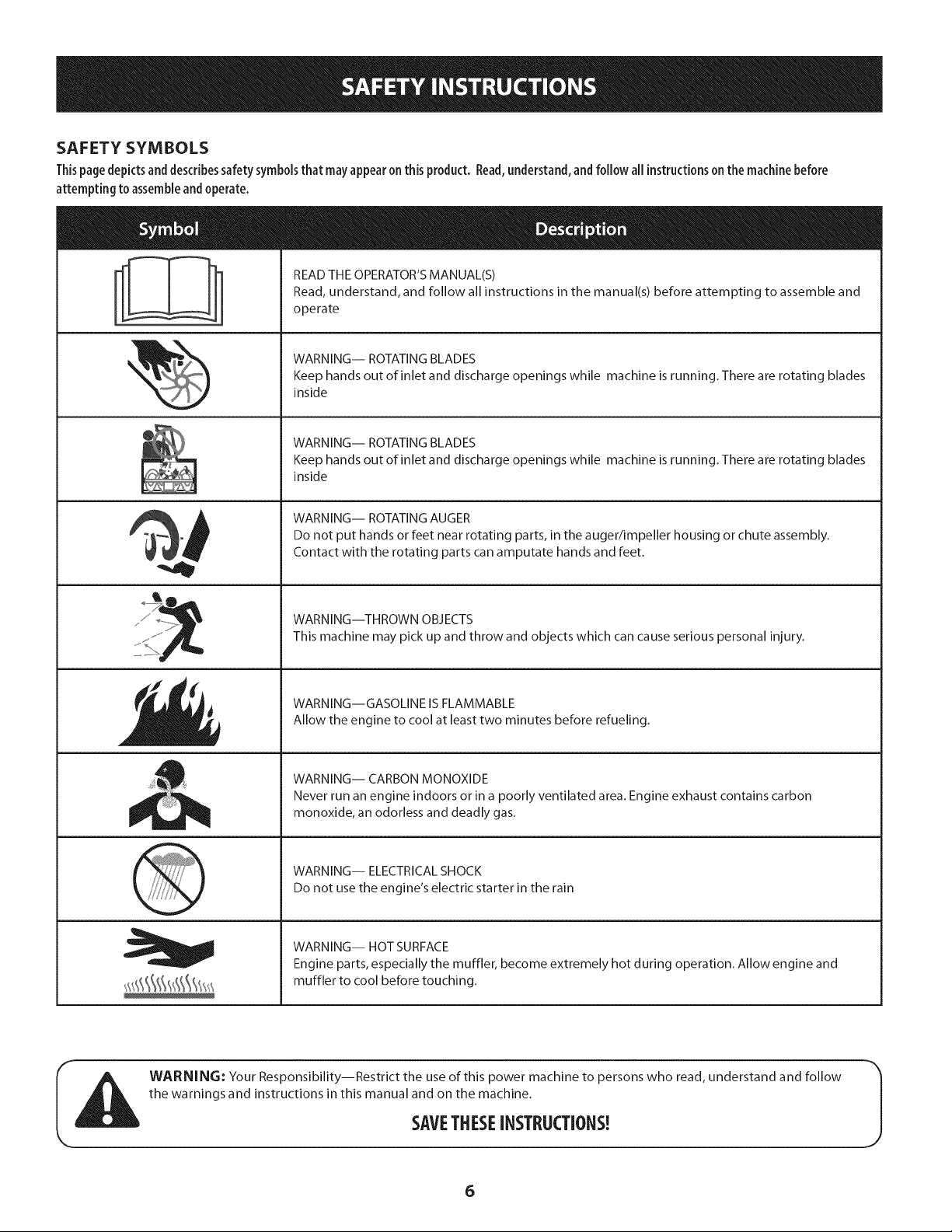

SAFETY SYMBOLS

Thispage depicts and describes safety symbols that may appear on this product. Read,understand, and follow all instructionson the machine before

attempting to assemble and operate.

READ THE OPERATOR'S MANUAL(S)

Read, understand, and follow all instructions in the manual(s) before attempting to assemble and

operate

WARNING-- ROTATING BLADES

Keep hands out of inlet and discharge openings while machine is running. There are rotating blades

inside

WARNING-- ROTATING BLADES

Keep hands out of inlet and discharge openings while machine is running. There are rotating blades

inside

WARNING-- ROTATING AUGER

Do not put hands or feet near rotating parts, in the auger/impeller housing or chute assembly.

Contact with the rotating parts can amputate hands and feet.

WARNING--THROWN OBJECTS

This machine may pick up and throw and objects which cancause serious personal injury.

WARNING--GASOLINE IS FLAMMABLE

Allow the engine to cool at least two minutes before refueling.

WARNING-- CARBON MONOXIDE

Never run an engine indoors or in a poorly ventilated area. Engine exhaust contains carbon

monoxide, an odorless and deadly gas.

WARNING-- ELECTRICAL SHOCK

Do not use the engine's electric starter in the rain

WARNING-- HOT SURFACE

Engine parts, especially the muffler, become extremely hot during operation. Allow engine and

muffler to cool before touching.

WARNING: Your Responsibility--Restrict the use of this power machine to persons who read, understand and follow

the warnings and instructions in this manual and on the machine.

SAVETHESEiNSTRUCTIONS!

6

Page 7

This pageleft intentionallyblank.

7

Page 8

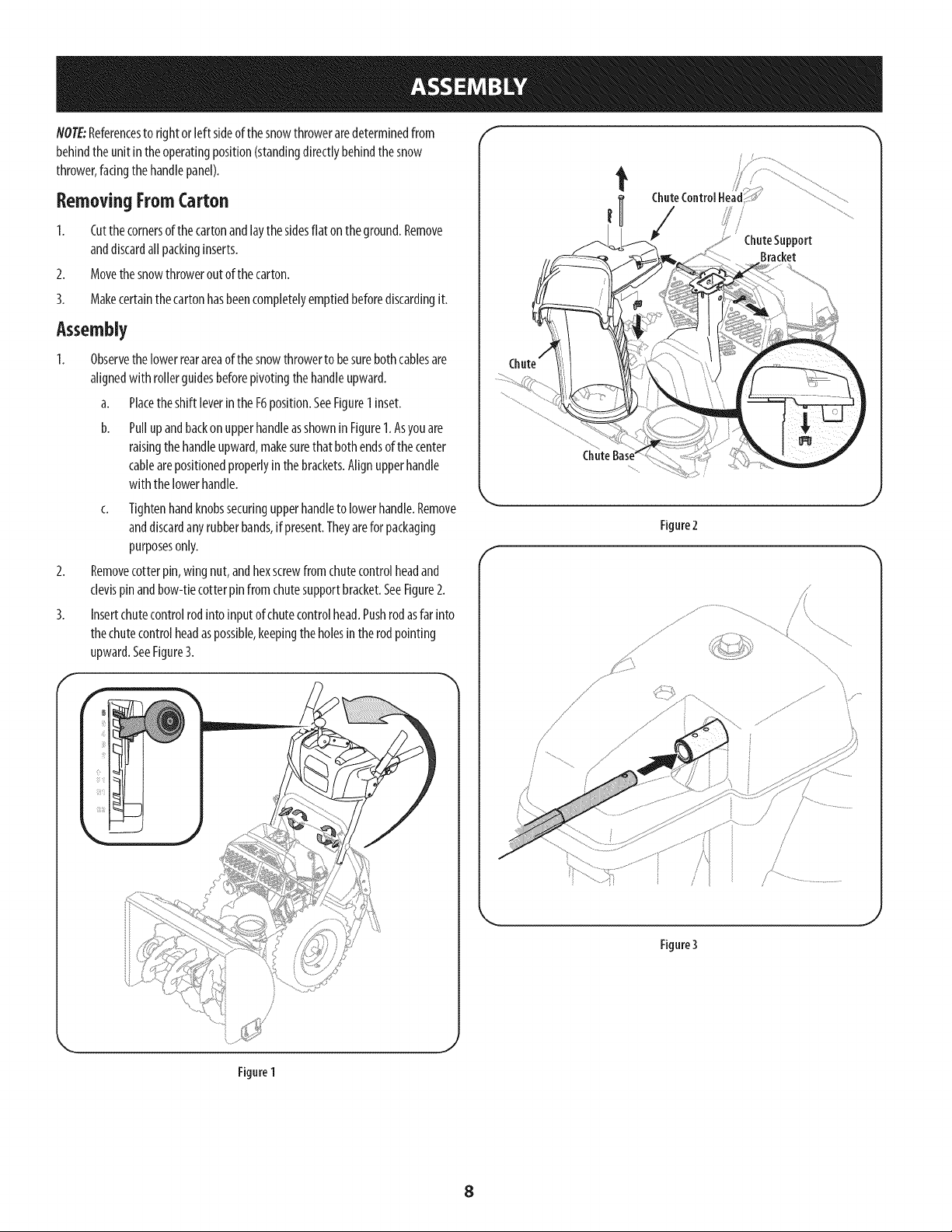

flOTE:Referencestorightorleft sideofthesnowthroweraredeterminedfrom

behindtheunitin theoperatingposition(standingdirectlybehindthesnow

thrower,facingthehandlepanel).

Removing FromCarton

1. Cutthecornersofthecartonandlaythesidesflat ontheground.Remove

anddiscardallpackinginserts.

2. Movethesnowthroweroutofthecarton.

3. Makecertainthecartonhasbeencompletelyemptiedbeforediscardingit.

Assembly

Observethelowerrearareaofthesnowthrowertobesurebothcablesare

alignedwith rollerguidesbeforepivotingthehandleupward.

a. Placetheshift[everintheF6position.SeeFigure1inset.

b. Puffupandbackonupperhandleasshownin Figure1.Asyouare

raisingthehandleupward,makesurethat bothendsof thecenter

cablearepositionedproperlyinthebrackets.Alignupperhandle

withthelowerhandle.

c. Tightenhandknobssecuringupperhandletolowerhandle.Remove

anddiscardanyrubberbands,if present.Theyareforpackaging

purposesonly.

Removecotterpin,wingnut,andhexscrewfromchutecontrolheadand

clevispinandbow-tiecotterpinfromchutesupportbracket.SeeFigure2.

Insertchutecontrolrodintoinputofchutecontrolhead.Pushrodasfarinto

thechutecontrolheadaspossible,keepingtheholesin therodpointing

upward.SeeFigure3.

/ /

ChuteSupport

Bracket

.J

Figure2

f

/ .....

f

j

Rgure3

J

Figure1

8

Page 9

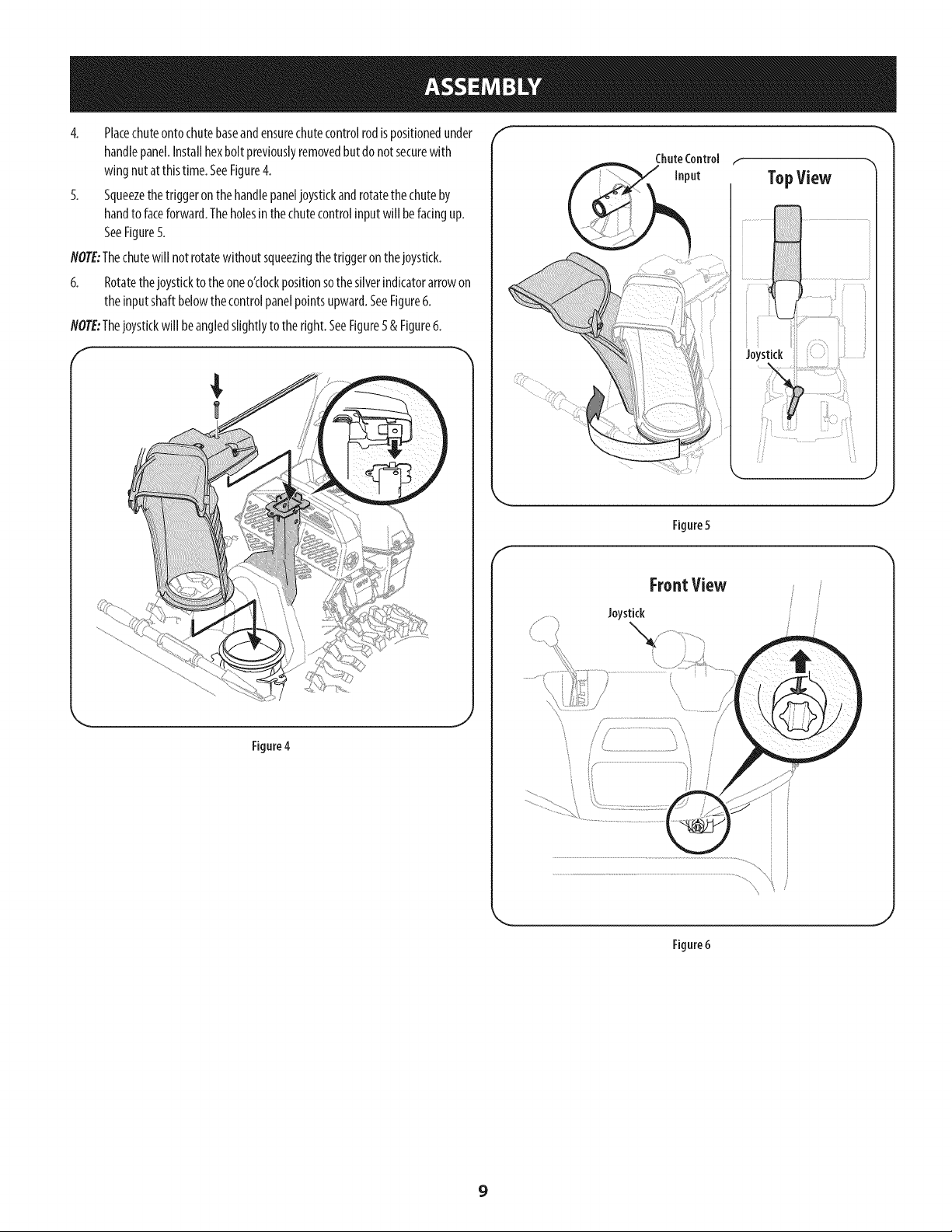

4. Placechuteontochutebaseandensurechutecontrolrodispositionedunder

handlepanel.Installhexbolt previouslyremovedbutdonotsecurewith

wingnutat thistime.SeeFigure4.

5. Squeezethetriggeronthehandlepaneljoystickandrotatethechuteby

handtofaceforward.Theholesinthechutecontrolinputwill befacingup.

SeeFigure5.

NOTE:Thechutewill notrotatewithoutsqueezingthetriggeronthejoystick.

6. Rotatethejoysticktotheoneo'clockpositionsothesliverindicatorarrowon

theinputshaftbelowthecontrolpanelpointsupward.SeeFigure6.

NOTE:Thejoystickwill beangledslightlytotheright.SeeFigure5&Figure6.

f

TopView

Figure5

FrontView

Figure4

//f "_

Joystick

\

Figure6

9

Page 10

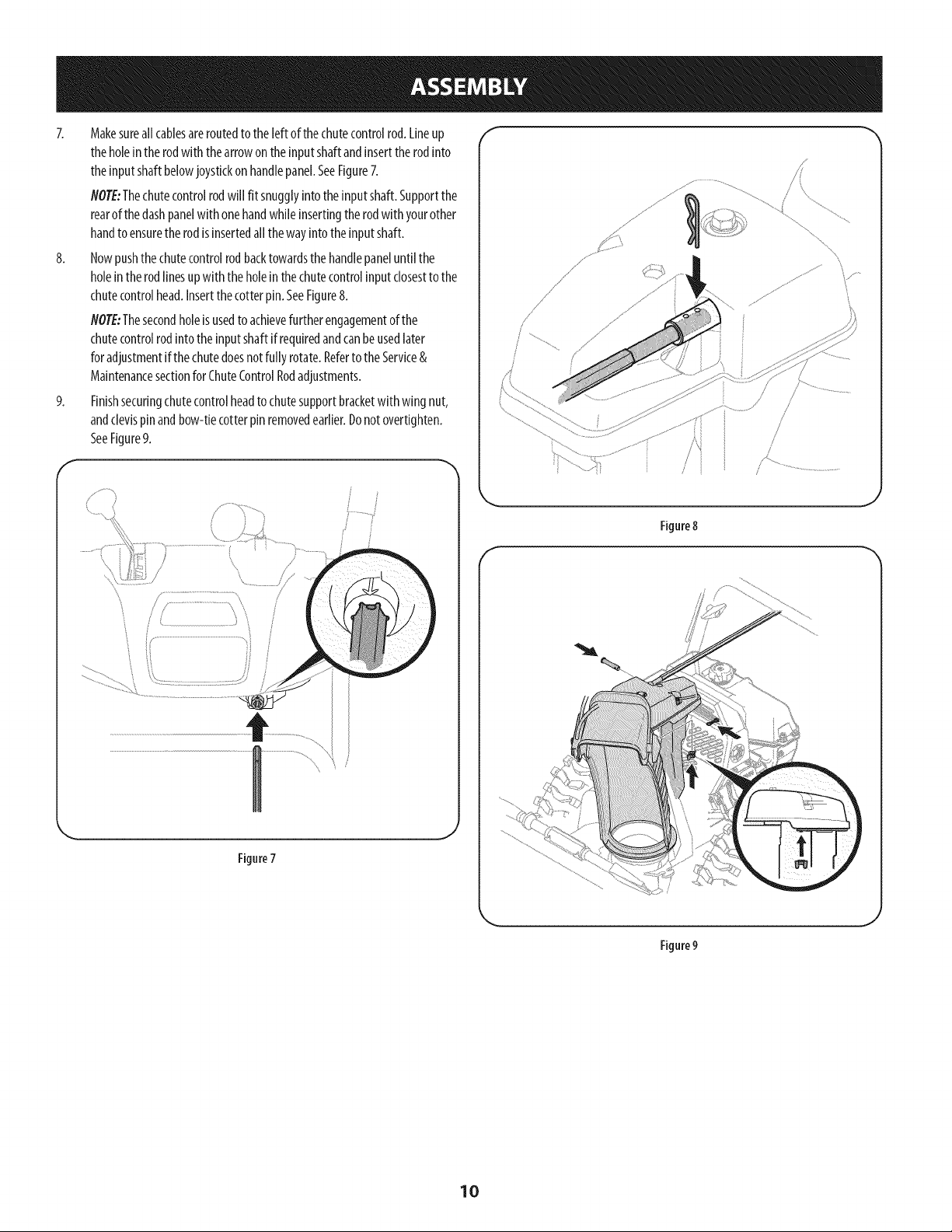

7. Makesureallcablesareroutedtotheleftofthechutecontrolrod.Lineup

theholeintherodwiththearrowontheinputshaftandinserttherodinto

theinputshaftbelowjoystickonhandlepanel.SeeFigure7.

NOTE:Thechutecontrolrodwill fit snugglyintotheinputshaft.Supportthe

rearofthedashpanelwith onehandwhileinsertingtherodwith yourother

handtoensurethe rodisinsertedallthewayintotheinputshaft.

8. Nowpushthechutecontrolrodbacktowardsthehandlepaneluntilthe

holeintherodlinesupwith theholeinthechutecontrolinputclosestto the

chutecontrolhead.Insertthecotterpin.SeeFigure8.

NOTE:Thesecondholeisusedtoachievefurtherengagementof the

chutecontrolrodintotheinputshaftifrequiredandcanbeusedlater

foradjustmentifthechutedoesnotfully rotate.RefertotheService&

MaintenancesectionforChuteControlRodadjustments.

9. Finishsecuringchutecontrolheadto chutesupportbracketwithwing nut,

andclevispinandbow-tiecotterpinremovedearlier.Donotovertighten.

SeeFigure9.

f

f

/ /

Figure8

f

Figure7

\

Figure9

10

Page 11

Checkthatallcablesareproperlyroutedthroughthecableguideonthe

engine.SeeFigure10.

NOTE:Ifthechutecontrolisnotassembledcorrectlyitwill notmovefreely

norwill it movefully totherightandleft.

Set-Up

ShearPins

Holesarelocatedintheplasticdashpanelfor convenientshearpinstorage.See

Figure11.RefertotheOperationsectionfor moreinformationregardingshearpin

replacement.

J

Figure10

f

11

J

Figure11

Page 12

ChuteClean-OutTool /"

Achuteclean-outtoolisfastenedtothetopoftheaugerhousingwith amounting

clip.SeeFigure12.Thetoolisdesignedto clearachuteassemblyoficeand

snow.Thisitemisfastenedwith acabletie atthefactory.Cutthecabletiebefore

operatingthesnowthrower.

Neveruseyour handstoclearacloggedchuteassembly.Shutoff engine

andremainbehindhandlesuntil all movingparts havestoppedbefore

usingthe clean-outtool to clearthe chuteassembly.

TirePressure

Underanycircumstancedo notexceedmanufacturer'srecommendedpsi.

Equaltire pressureshouldbemaintainedat alltimes. Excessivepressure

when seatingbeadsmaycausetirelfim assemblyto burst with force

sufficient to causeseriousinjury. Refertosidewalloftirefor recommended

pressure.

Thetiresareover-inflatedforshippingpurposes.Checkthetire pressurebefore

operatingthesnowthrower.Refertothetiresidewallfor tiremanufacturer's

recommendedpsianddeflate(orinflate)thetiresasnecessary.

NO?E:Equaltire pressureisto bemaintainedatalltimesforperformancepurposes.

Adjustments

SkidShoes

Thesnowthrowerskidshoesareadjustedupwardatthefactoryforshipping

purposes.Adjustthemdownward,ifdesired,priortooperatingthesnowthrower.

ChuteClean-outTool

.J

Figure12

f

Itis notrecommendedthat youoperatethis snowthrower on gravelas

it caneasilypickupandthrow loosegravel,causingpersonalinjury or

damageto thesnowthrower andsurroundingproperty.

Forclosesnowremovalonasmoothsurface,raiseskidshoeshigheronthe

augerhousing.Referto Figure13.

Useamiddleorlowerpositionwhentheareatobeclearedisuneven,suchas

agraveldriveway.

NOTE:Ifyouchooseto operatethesnowthroweronagravelsurface,keep

theskidshoesinpositionformaximumclearancebetweenthegroundand

theshaveplate.

Toadjusttheskidshoes:

1. Loosenthefourhexnuts(twooneachside)andcarriagebolts.Moveskid

shoestodesiredposition.SeeFigure13.

2. Makecertaintheentirebottomsurfaceofskidshoeisagainstthegroundto

avoidunevenwearontheskidshoes.

3. Retlghtennutsandboltssecurely.

UnevenSurface

\

Figure13

12

Page 13

Thedistancesnowisthrowncanbeadjustedbychangingtheangleoftheupper

chute.Todoso:

Stoptheenginebyremovingtheignitionkeyandloosenthe plasticwing

knobfoundontheleft sideofthechuteassembly.

2.

Pivotthechuteupwardordownwardbeforeretighteningthewingknob.

SeeFigure14.

AugerControl

Priorto operatingyoursnowthrower,carefullyreadandfollow all

instructionsbelow.Performall adjustmentsto verifyyoursnowthrower is

operatingsafelyandproperly.

Checktheadjustmentoftheaugercontrolasfollows:

1. Theaugercontrolislocatedonthelefthandle.SeeFigure15inset.When

theaugercontrolisreleasedandinthedisengaged"up"position,thecable

shouldhaveverylittle slack.ItshouldNOTbetight.

2. Inawell-ventilatedarea,startthesnowthrowerengine.Referto Starting

theEngineintheOperationsection.

3. Whilestandingintheoperator'sposition(behindthesnowthrower),engage

theauger.

4. Allowtheaugerto remainengagedfor approximatelyten(10)seconds

beforereleasingtheaugercontrol.Repeatthisseveraltimes.

5. Withtheaugercontrolin thedisengaged"up" position,walkto thefrontof

themachine.

6.

Toreadjustthecontrolcable,loosenthe upperhexboltontheaugercable

bracket.SeeFigure15.

Positionthebracketupwardtoprovidemoreslack(ordownwardto increase

cabletension).

8. Retightentheupperhexbolt.

9. Repeatsteps2-6aboveto verifyproperadjustmenthasbeenachieved.

10. Confirmthat theaugerhascompletelystoppedrotatingandshowsNOsigns

ofmotion.IftheaugershowsANYsignsofrotating,immediatelyreturnto

theoperator'spositionandshutoff theengine.WaitforALLmovingpartsto

stopbeforeadjustingtheaugercontrol.

.J

Figure14

f

I \, \\

1!5

J

Figure15

Page 14

Chute Assembly

Drive Control

Shift Lever

J

J

Two=WayChute Control (Joystick)

_.. Auger Control

CI

Auger Housing

Augers

Nowthatyouhavesetupyoursnowthrower,it'simportantto becomeacquainted

with itscontrolsandfeatures.Referto Figure16.

__Oil _ilid Shoe

Figure16

Shift [ever

Theshift leverislocatedontherightsideofthehandlepanel.Placetheshift

leverintoanyofeightpositionstocontrolthedirectionoftravelandground

speed.Forward

Yoursnowthrowerhassixforward(F)speeds.Positionone(1)istheslowest

andpositionsix(6)isthefastest.

Reverse

Yoursnowthrowerhastworeverse(R)speeds.One(1)istheslowerandtwo(2)R1

isthefaster. [I 2

t 2 ChokeControl

Gas

Recoil Starter

Handle

:lectric Start

Button

Oil Drain

\

Electric Starter Outlet

,ey6 Thekeyisasafetydevice.It mustbefullyinsertedin Ii

5 orderfortheenginetostart.Removethekeywhenthe

4 NOTE:Donotturntheignitionkeyinanattempttostart

snowthrowerisnotinuse. (_ O

3 theengine.Doingsomaycauseittobreak.

activated byturning the rotarychoke knob to the CHOKE

position.Activatingthechokecontrolclosesthechoke

plateon the carburetorandaids instarting the engine.

RecoUStarter Handle

Thishandleisusedtomanuallystarttheengine.

MeetsANSiSafetyStandards

CraftsmanSnowThrowersconformto thesafetystandardoftheAmericanNationalStandardsInstitute(ANSI).

14

Page 15

Throttlecontrol

Thethrottlecontrolislocatedontherearoftheengine.It regulatesthespeedofthe

engineandwill shutoffthe enginewhenmovedintotheSTOPposition.

Primer

Depressingtheprimerforcesfueldirectlyintothe

engine'scarburetortoaidincold-weatherstarting.

ElectricStarter Button

DriveControl/Auger ControlLock

f DRIVE

CONTROL

Pressingtheelectricstarterbuttonengagestheengine'selectricstarterwhen

pluggedintoa 120Vpowersource.

ElectricStarter Outlet

Requirestheuseofathree-prongoutdoorextensioncordanda120Vpowersource/

walloutlet.

OilFill

Engineoil levelcanbecheckedandoiladdedthroughtheoil fill.

GasCap

Unthreadthegascaptoaddgasolinetothefueltank.

Auger

Whenengaged,theaugerbladesrotateanddrawsnowintotheaugerhousing.

ChuteAssembly

Snowdrawnintotheaugerhousingisdischargedoutthechuteassembly.

SkidShoes

Positiontheskidshoesbasedonsurfaceconditions.Adjustupwardforhard-packed

snow.Adjustdownwardwhenoperatingongravelorcrushedrocksurfaces.

AugerControl

f

Thedrivecontrolislocatedontherighthandle.Squeezethecontrolgripagainstthe

handleto engagethewheeldrive.Releasetostop.

Thedrivecontrolalsolockstheaugercontrolsoyoucanoperatethechute

directionalcontrolwithoutinterruptingthesnowthrowingprocess.Iftheauger

controlisengagedsimultaneouslywiththedrivecontrol,theoperatorcanrelease

theaugercontrol(onthelefthandle)andtheaugerswill remainengaged.Release

bothcontrolstostoptheaugersandwheeldrive.

NOTE:Alwaysreleasethedrivecontrolbeforechangingspeeds.Failuretodosowill

resultinincreasedwearonyourmachine'sdrivesystem.

Two-WayChuteControl

Thetwo-waychutecontrol(Joystick)islocatedontheleftsideofthehandlepanel.

CHUTE DIRECTIONAL CONTROL

CHUTEROTATE CHUTEROTATE

LEFT RIGHT

J

Theaugercontrolislocatedonthelefthandle.Squeezethecontrolgripagainstthe

handleto engagetheaugerandstartsnowthrowingaction.Releaseto stop.

Tochangethedirectioninwhichsnowisthrown,squeezethebuttononthe

chutecontrolleverandpivotthechutecontrollevertotherightorto the

left.

15

Page 16

Clean-OutTool

Neveruseyour handstodear acloggedchuteassembly.Shutoffengine

andremainbehindhandlesuntil all movingparts havestoppedbefore

usingthe clean-outtool to clearthe chuteassembly.

Thechuteclean-outtoolisconvenientlyfastenedto therearoftheaugerhousing

with amountingclip.Shouldsnowandicebecomelodgedinthechuteassembly

duringoperation,proceedasfollowstosafelycleanthechuteassemblyandchute

opening:

1. ReleaseboththeAugerControlandtheDriveControl.

2. Stoptheenginebyremovingthe ignitionkey.

3. Removetheclean-outtoolfromtheclipwhichsecuresittotherearofthe

augerhousing.

4. Usetheshovel-shapedendoftheclean-outtooltodislodgeandscoopany

snowandicewhichhasformedinandnearthechuteassembly.

5. Refastentheclean-outtooltothemountingclipontherearoftheauger

housing,reinserttheignitionkeyandstartthesnowthrower'sengine.

6. Whilestandingintheoperator'sposition(behindthesnowthrower),engage

theaugercontrolforafewsecondstoclearanyremainingsnowandicefrom

thechuteassembly.

BeforeStarting Engine

Read,understand,andfollow all instructionsandwarningson the

machineandin this manualbeforeoperating.

Oil

Theunitwasshippedwith oilintheengine.Checkoillevelbeforeeachoperationto

ensureadequateoilin theengine.

NOTE:Besuretochecktheengineonalevelsurfacewiththeenginestopped.

1. Removetheoilfillercap/dipstickandwipethedipstickclean.

2. Insertthecap/dipstickintotheoilfillerneck,butdoNOTscrewit in.

3. Removetheoilfillercap/dipstick.Ifthelevelislow,slowlyaddoil(5W-30,

with aminimumclassificationofSF/SG)untiloillevelregistersbetweenhigh

(N)andlow(L).

NOTE:Donotoverfill.Overfillingwith oil mayresultinenginesmoking,hard

startingorsparkplugfouling.

4.

Replaceandtightencap/dipstickfirmlybeforestartingengine.

Gasoline

Useautomotivegasoline(unleadedorlowleadedtominimizecombustionchamber

deposits)with aminimumof87octane.Gasolinewith upto10%ethanolor15%

MTBE(MethylTertiaryButylEther)canbeused.Neveruseanoil/gasolinemixture

ordirtygasoline.Avoidgettingdirt,dust,orwaterinthefueltank.DONOTuseE85

gasoline.

Refuelin awell-ventilatedareawiththeenginestopped.Donotsmokeor

allowflamesorsparksin theareawheretheengineisrefueledorwhere

gasolineisstored.

Donotoverfillthefueltank.Afterrefueling,makesurethetankcapisclosed

properlyandsecurely.

Becarefulnottospillfuelwhenrefueling.Spilledfuelorfuelvapormay

ignite.Ifanyfuelisspilled,makesuretheareaisdrybeforestartingthe

engine.

Avoidrepeatedorprolongedcontactwithskinorbreathingofvapor.

Useextremecarewhenhandlinggasoline.Gasolineisextremely

flammableandthevaporsare explosive.Neverfuel the machineindoorsor

while the engineishotorrunning.Extinguishcigarettes,cigars,pipesand

othersourcesofignition.

I.

Cleanaroundfuelfill beforeremovingcaptofuel.

2.

Afuel levelindicatoris locatedinthefueltank.SeeFigure16inset.Be

carefulnottooverfill.Filltankuntil fuelreachesthefuellevelindicatorto

allowspaceforfuelexpansion.

Starting The Engine

Alwayskeephandsandfeet clearof movingparts.Donot useapressurized

starting fluid. Vaporsareflammable.

flOrE:Allowtheenginetowarmupfor afewminutesafterstarting.Theenginewill

notdevelopfull poweruntilit reachesoperatingtemperatures.

1. Makecertainboththeaugercontrolanddrivecontrolareinthedisengaged

(released)position.

2. Insertkeyintoslot.Makesureit snapsintoplace.Donotattemptto turnthe

key.

NOTE:Theenginecannotstartwithoutthekeyfully insertedintothe

ignitionswitch.

ElectricStarter

Theelectric starterisdesignedto operateon 120volt AChousehold

current. Itmust beusedwith aproperlygroundedextensioncordand

three-prongreceptacleat alltimes to avoidthe possibilityof electrk

shock.Followall instructionscarefullypriorto operatingthe electric

starter.DONOTuseelectricstarter inthe rain.

Determinethatyourhome'swiringisathree-wiregroundedsystem.Askalicensed

electricianif youarenotcertain.

Ifyouhavea groundedthree-prongreceptacle,proceedasfollows.Ifyoudonot

havetheproperhousewiring,DONOTusetheelectricstarterunderanyconditions.

1. Pluganextensioncordintotheoutletlocatedontheengine'ssurface.Plug

theotherendofextensioncordintoathree-prong120-volt,grounded,AC

outletinawell-ventilatedarea.

Theextensioncordcanbeanylength, but must beratedfor 15ampsat 125

volts,groundedandratedfor outdooruse.

16

Page 17

2. Movethrottlecontrolto FAST(rabbit)_l[r position.

3 MovechoketotheCHOKEI-"Ipos t on(co,deng nestart),lengthens

warm,placechokein RUNposition.

4. Pushprimerthree(3)times,makingsuretocoverventholeinprimerbulb

whenpushing.Ifengineiswarm,pushprimeronlyonce.AIwayscovervent

holewhenpushing.Coolweathermayrequireprimingto berepeated.

5. Pushstarterbuttontostartengine.Oncetheenginestarts,immediately

releasestarterbutton.Electricstarterisequippedwith thermaloverload

protection;systemwill temporarilyshut-downtoallowstarterto coolif

electricstarterbecomesoverloaded.

6.

Astheenginewarms,slowlyrotatethechokecontroltoRUNposition.Ifthe

enginefalters,restartengineandrunwith chokeat half-chokepositionfor a

shortperiodof time,andthenslowlyrotatethechokeinto RUNposition.

Afterengineisrunning,disconnectpowercordfromelectricstarter.When

disconnecting,alwaysunplugtheendatthewalloutletbeforeunplugging

theoppositeendfromtheengine.

RecoilStarter

ToEngageDrive

1. Withthethrottlecontrolinthe Fast(rabbit)_ 1t position,moveshift lever

intooneofthesixforward(F)positionsortworeverse(R)positions.Selecta

speedappropriateforthesnowconditionsandapaceyou'recomfortable

with.

NOTE:WhenselectingaDriveSpeed,usetheslowerspeedsuntilyouare

comfortableandfamiliarwiththeoperationof thesnowthrower.

2. Squeezethedrivecontrolagainstthehandleandthesnowthrowerwill

move.Releaseit anddrivemotionwillstop.

NOTE:NEVERrepositiontheshift lever(changespeedsordirectionoftravel)

withoutfirst releasingthedrivecontrolandbringingthesnowthrowerto a

completestop.Doingsowill resultinprematureweartothesnowthrower'sdrive

system.

ToEngageAuger

Toengagetheaugerandstartthrowingsnow,squeezetheaugercontrol

againstthelefthandle.Releasetostoptheauger.

ReplacingShearPins

Eachaugerbladeissecuredto thespiralshaftwith ashearpinandbow-tieclip.If

Donotpull the starter handlewhile the enginerunning.

1. Movethrottlecontrolto FAST(rabbit)_J_11position.

2. MovechoketotheCHOKEI,,'1position(coldenginestart).If engineis

warm,placechokein RUNposition.

3. Pushprimerthree(3)times,makingsuretocoverventholewhenpushing.

Ifengineiswarm,pushprimeronlyonce.Alwayscoverventholewhen

pushing.Coolweathermayrequireprimingtoberepeated.

4. Pullgentlyonthestarterhandleuntilit beginsto resist,thenpullquickly

andforcefullytoovercomethecompression.Donotreleasethehandleand

allowit tosnapback.ReturnropeSLOWLYtooriginalposition.Ifrequired,

repeatthisstep.

5. Astheenginewarms,slowlyrotatethechokecontroltoRUNposition.Ifthe

enginefalters,restartengineandrunwith chokeat half-chokepositionfor a

shortperiodof time,andthenslowlyrotatethechokeinto RUNposition.

anaugerbladestrikesa foreignobjectoricejam,thepinwill shearoff toprevent

damageto theblade.Ifanaugerbladedoesnotturn,checktoseeif itspinhas

shearedoff. SeeFigure17.

NEVERreplacethe augershearpinswith anythingother than SearsSKU#

8838910EMPartNo.738-04124Areplacementshearpins.Anydamageto

the augergearboxorother componentsasa resultoffailing to dosowill

NOTbe coveredby yoursnowthrower'swarranty.

Alwaysturn off the snowthrower'sengineand removethe keypriorto

replacingshearpins.

E

Toavoidunsupervisedengineoperation,neverleavethe machine

unattendedwith theenginerunning. Turntheengineoff after useand

removekey.

Stopping TheEngine

Afteryouhavefinishedsnow-throwing,runenginefor afewminutesbefore

stoppingtohelpdryoffany moistureon theengine.

1. Movethrottlecontrolto OFFposition.

2. Removethekey.Removingthe keywillreducethepossibilityof

unauthorizedstartingoftheenginewhileequipmentisnotinuse.Keepthe

keyina safeplace.Theenginecannotstartwithoutthekey.

3. Wipeanymoistureawayfromthecontrolsontheengine.

17

J

Figure17

Page 18

MAINTENANCESCHEDULE

Beforeperforminganytype ofmaintenance/service,disengageallcontrols

andstopthe engine.Wait until all movingpartshavecometoa complete

stop.Disconnectsparkplugwireand grounditagainstthe engineto

preventunintendedstarting.

Followthemaintenanceschedulegivenbelow.Thischartdescribesservice

guidelinesonly.UsetheServiceLogcolumntokeeptrackofcompleted

maintenancetasks.TolocatethenearestSearsServiceCenterortoscheduleservice,

callthefollowingtollfreenumber:l-888-331-4569.

EachUseandevery5hours

Ist5hours

Annuallyor25hours

Annuallyor50hours

Annuallyor100hours

BeforeStorage

1. Engineoil level

2. Looseormissinghardware

3. Unitandengine.

1. Engineoil

1. Sparkplug

2. Controllinkagesandpivots

3. Wheels

4. GearshaftandAugershaft

1. Engineoil

1. Sparkplug

1. Fuelsystem

GENERALEECOMMENDATIONS

CheckingEngineOil

Beforelubricating, repairing,or inspecting,disengageall controlsandstop

engine.Waituntil all movingparts havecometo acompletestop.

NOTE:Checktheoillevelbeforeeachusetobesurecorrectoillevelismaintained.

Whenaddingoilto theengine,refertoviscositychartbelow.Engineoilcapacity

is600ml(approx.20oz.).Donotover-fill.Usea4-stroke,oranequivalenthigh

detergent,premiumqualitymotoroilcertifiedtomeetorexceedU.S.automobile

manufacturer'srequirementsforserviceclassificationSG,SEMotoroilsclassified

SG,SFwill showthisdesignationonthecontainer.

1. Removetheoilfillercap/dipstickandwipethedipstickclean.

2. Insertthecap/dipstickintotheoilfillerneck,butdoNOTscrewitin.

3. Removetheoilfillercap/dipstick.Iflevelislow,slowlyaddoiluntiloillevel

registersbetweenhigh(H)andlow(L).SeeFigure18.

4. Replaceandtightencap/dipstickfirmlybeforestartingengine.

ChangingEngineOil

NOTE:Changetheengineoilafterthefirst5 hoursof operationandonceaseason

orevery50hoursthereafter.

1. Drainfuelfromtankbyrunningengineuntilthefueltankisempty.Besure

fuelfill capissecure.

2. Placesuitableoilcollectioncontainerunderoil drainplug.

3. Removeoildrainplugandwasher.SeeFigure19onnextpage.

4. Tipunittodrainoil intothecontainer.Usedoilmustbedisposedofata

propercollectioncenter.

1. Check

2. Tightenorreplace

3. Clean

1. Change

1. Check

2. Lubewith lightoil

3. Lubewith multipurposeautogrease

4. Lubewith lightoil

1. Change

1. Change

1. Runengineuntilitstopsfromlackoffuel

J

Figure18

Usedoil isa hazardouswasteproduct.Disposeof usedoil properly.Donot

discardwith householdwaste.Checkwithyour localauthorities orSears

ServiceCenterforsafedisposal/recyclingfacilities.

Reinstallthedrainplugandwasherandtightenit securely.

18

Page 19

Refillwith therecommendedoilandchecktheoil level.SeeRecommended

OilUsagechart.Theengine'soilcapacityis20ounces.

(oF)-40o-20 o 0o 20o 40o

(oc) -30° -20° -10° 0°

DONOTusenondetergentoil or 2-strokeengineoil. it couldshortenthe

engine'sservicelife.

7. Reinstalltheoilfiller cap/dipsticksecurely.

Thoroughlywashyour handswith soapandwaterassoonaspossibleafter

handlingusedoil.

CheckingSparkPlug

OilDrain

Washer

PLug

Figure19

SparkPlugBoot

DONOTcheckfor sparkwith sparkplugremoved.DONOTcrankenginewith

sparkplug removed.

Ifthe enginehasbeenrunning,the muffler will beveryhot. Becarefulnot

to touchthe muffler.

NOTE:Checkthe sparkplugonceaseasonorevery25 hoursofoperation.Change

thesparkplugonceaseasonorevery100hours.Toensureproperengineoperation,

thesparkplugmustbeproperlygappedandfreeofdeposits.

1. Removethesparkplugbootandusea sparkplugwrenchtoremovethe

plug.SeeFigure20.

2. Visuallyinspectthesparkplug.Discardthesparkplugifthereisapparent

wear,orif theinsulatoriscrackedorchipped.Cleanthesparkplugwitha

wirebrushifit isto bereused.

3.

Measurethepluggapwithafeelergauge.Correctasnecessarybybending

sideelectrode.SeeFigure21.Thegapshouldbesetto.02-.03inches(0.60-

0.80mm).

4. Checkthatthesparkplugwasherisin goodconditionandthreadthespark

pluginbyhandtopreventcross-threading.

5. Afterthesparkplugisseated,tightenwith asparkplugwrenchto compress

thewasher.

NOTE:Wheninstallinganewsparkplug,tighten1/2-turnafterthesparkplug

seatsto compressthewasher.Whenreinstallinga usedsparkplug,tighten1/8-to

1/4-turnafterthesparkplugseatsto compressthewasher.

Figure20

Electrode

Thesparkplug mustbetightened securely.Aloosesparkplugcanbecome

very hotandcandamagetheengine.

Figure21

19

Page 20

Lubrication "I

GearShaft

Thegear(hex)shaftshouldbelubricatedat leastonceaseasonorafterevery25

hoursof operation.

I. Topreventspillage,removeallfuelfromtankbyrunningengineuntilit

stops.

2. Carefullypivotthesnowthrowerupandforwardsothatit restsontheauger

housing.

3. Removethelowerframecoverfromtheundersideofthesnowthrowerby

removingtheself-tappingscrewswhichsecureit.

4. Applya lightcoatingofanti-seizetothehexshaft.SeeFigure22.

NOTE:Whenlubricatingthehexshaft,becarefulnottogetanyanti-seizeon

thealuminumdriveplateorrubberfrictionwheel.Doingsowill hinderthesnow

thrower'sdrivesystem.Wipeoffanyexcessorspilledanti-seize.

Wheels

Atleastonceaseason,removebothwheels.Cleanandcoattheaxleswitha

multipurposeautomotivegreasebeforereinstallingwheels.

AugerShaft

Atleastonceaseason,removetheshearpinsonaugershaft.Spraylubricantinside

shaft,andaroundthespacersandflangebearingsfoundateitherendoftheshaft.

SeeFigure23.

ShavePlateand SkidShoes

Theshaveplateandskidshoesonthebottomofthesnowthroweraresubjectto

wear.Theyshouldbecheckedperiodkallyandreplacedwhennecessary.

NOTE:Theskidshoesonthismachinehavetwowearedges.Whenonesidewears

out,theycanberotated180°tousetheotheredge.

Toremoveskidshoes:

Removethetwo carriagebolts,washers,andhexflangenutsthatsecure

eachskidshoetothesnowthrower.

2. Reassemblenewskidshoeswith thefourcarriagebolts(twooneachside),

washers,andhexflangenuts.Referto Figure24.

Toremoveshaveplate:

1. Removethecarriageboltsandhexnutswhichattachitto thesnowthrower

housing.

2. Reassemblenewshaveplate,makingsureheadsof carriageboltsaretothe

insideof housing.Tightensecurely.SeeFigure24.

F

J

Figure22

f

f_S /

Figure23

2O

NOTE:Angers not shown lor clarity.

Figure24

Page 21

Adjustments

Shift Cable

Ifthefull rangeof speeds(forwardandreverse)cannotbeachieved,refertothe

figuretothefight andadjusttheshiftcableasfollows:

I. Placetheshiftleverinthefastestforwardspeedposition(F6).

2. Loosenthehex nutontheshiftcableindexbracket.SeeFigure25.

3. Pivotthebracketdownwardtotakeupslackinthecable.

4. Retightenthehexnut.

DriveControl

Whenthedrivecontrolisreleasedandinthedisengaged"up"position,thecable

shouldhaveverylittle slack.ItshouldNOTbetight. Also,ifthereisexcessiveslack

inthedrivecableor iftheunitexperiencesintermittentdrivewhileusing,thecable

mayneedtobeadjusted.Checktheadjustmentof thedrivecontrolasfollows:

I. Withthedrivecontrolreleased,pushthesnowthrowergentlyforward.The

unitshouldrollfreely.

2. Engagethedrivecontrolandgentlyattemptto pushthesnowthrower

forward.Thewheelsshouldnotturn.Theunitshouldnotrollfreely.

3. Withthedrivecontrolreleased,movetheshiftleverbackandforthbetween

theR2positionandthe F6positionseveraltimes.Thereshouldbeno

resistanceintheshiftlever.

f

Figure25

4. Ifanyoftheabovetestsfailed,thedrivecableisinneedofadjustment.

Proceedasfollows:

a. Shutoff theengineasinstructedintheOperationsection.

b. Loosenthelowerhexbolt onthedrivecablebracket.SeeFigure26.

c. Positionthebracketupwardtoprovidemoreslack(ordownwardto

increasecabletension).

d. Retightenthelowerhexbolt.

ChuteControlRod

Toachievemorechutecontrolrodengagementintheinputshaftunderthe handle

panel,thechutecontrolrodwill haveto beadjusted.RefertoFigure27.

Toadjustthisrod,proceedasfollows:

I. Removethecotterpinfromtheholeclosesttothechutecontrolheadonthe

chutecontrolinput.

2. Pulloutthechutecontrolroduntilthe holeinit linesupwith theotherhole

inthechutecontrolinput.

3. Reinsertthecotterpinthroughthisholeandthechutecontrolrod.

Figure26

21

Figure27

Page 22

AugerControl

RefertotheAssemblysectionforinstructionsonadjustingtheaugercontrolcable.

SkidShoes

RefertotheAssemblysectionforinstructionsonadjustingtheskidshoes.

Belt Replacement

Auger Belt

Toremoveandreplaceyoursnowthrower'saugerbelt,proceedasfollows:

I. Topreventspillage,removeallfuelfromtankbyrunningengineuntilit

stops.

2. Removetheplasticbeltcoveronthefrontoftheenginebyremovingthetwo

self-tappingscrews.SeeFigure28.

3. Loosenandremovethetwo boltsandflat washerssecuringthebeltguide.

SeeFigure29. Removebeltguide.

4. Rolltheaugerbeltoffthe enginepulley.SeeFigure30.

5. Carefullypivotthesnowthrowerupandforwardsothatit restsontheauger

housing.

6. Removetheframecoverfromtheundersideofthesnowthrowerby

removingfourself-tappingscrewswhichsecureit. SeeFigure31.

22

f

......

J

Figure30

Page 23

Loosenandremovetheshoulderscrewwhichactsasabeltkeeper.Referto

Figure32.

8.

Removethebelt fromaroundtheaugerpulley,andslipthebeltbetweenthe

supportbracketandtheaugerpulley.SeeFigure33.

NOTE:Engagingtheaugercontrolwill easeremovalandreinstallationofthe

belt.

Reassembleaugerbeltbyfollowinginstructionsinreverseorder.

NOTE:DoNOTforgettoreinstalltheshoulderscrewandreconnectthespring

totheframeafterinstallingareplacementaugerbelt.

10.

PerformtheAugerControltestoutlinedintheAssemblysectionofthis

manual.

Drive Belt

flOTE:Severalcomponentsmustberemovedandspecialtoolsarerequiredin order

toreplacethesnowthrower'sdrivebelt.ContactthenearestSearsParts& Repair

Centerto havethedrivebeltreplaced.

f

FrictionWheelRemoval

Ifthesnowthrowerfailstodrivewiththedrivecontrolengaged,andperforming

thedrivecontrolcablead ustmentfailstocorrecttheproblem,thefrictionwheel

mayneedtobereplaced.Followtheinstructionsbelow.Examinethefrictionwheel

rubberfor signsofwearorcrackingandreplacewheelif necessary.

1. Topreventspillage,removeailfuelfromtankbyrunningengineuntil it

stops.

2. Placetheshiftleverinfirst Forward(F1)position.

3. Carefullypivotthesnowthrowerupandforwardsothatit restsontheauger

housing.

4. Removetheframecoverfromtheundersideofthesnowthrowerby

removingtheself-tappingscrewswhichsecureit.

5. Removetheright-handwheelbyremovingthescrewandbellwasherwhich

secureitto theaxle.SeeFigure34.

Figure32

Figure33

0

/

//

Figure34

J

23

Page 24

6. Carefullyremovethehexnutandwasherwhichsecuresthehexshaftto

thesnowthrowerframeandNghtlytaptheshaft'sendto dislodgetheban

bearingfromthe rightsideoftheframe.SeeFigure35.

NOTE:Becarefulnottodamagethethreadsontheshaft.

7. Carefullypositionthehexshaftdownwardandtothe[eft beforecarefuNy

slidingthefrictionwheelassemblyofftheshaft.SeeFigure36.

NOTE:Ifyou'rerep[adngthefrictionwheelassemblyasawhole,discardthe

wornpartandslidethenewpartontothehexshaft.

8. FoNowthestepsaboveinreverseordertoreassemblecomponents.

9. PerformthetestpreviouslydescribedintheDriveControlsection.

Ifyou'redisassemblingthefrictionwheelandreplacingonlytherubberring,

proceedasfoNows:

NOTE:Notallfrictionwheelsareserviceable.Ifthisisthecase,simplyreplacethe

frictionwheelassembly.

1. Removethefourscrewswhichsecurethefrictionwheel'ssideplates

together.SeeFigure37.

2. Removetherubberringfrombetweentheplates.

3. Reassemblethesideplateswith anewrubberring.

NOTE:Whenreassemblingthefrictionwheelassembly,makesurethat the

rubberringiscenteredandseatedproperlybetweenthesideplates.Tighten

eachscrewonlyonerotationbeforeturningthewheelclockwiseand

proceedingwith thenextscrew.Repeatthisprocessseveraltimestoensure

theplatesaresecuredwith equalforce(between6ft-[bsand9ft-[bs).

4. SlidethefrictionwheelassemblybackontothehexshaftandfoNowthe

stepsabovein reverseordertoreassemblecomponents.

5. PerformthetestpreviouslydescribedintheDriveControlsection.

f

J

Figure35

f

Figure37

J

Figure76

,J

24

Page 25

Ifthesnowthrowerwill notbeusedfor 30daysorlonger,orifit istheendofthesnowseasonwhenthelastpossibilityofsnowisgone,theequipmentneedstobestored

properly.Followstorageinstructionsbelowtoensuretopperformancefromthesnowthrowerformanymoreyears.

PreparingEngine

Enginesstoredover30daysneedtobedrainedoffuelto preventdeteriorationand

gumfromforminginfuelsystemoronessentialcarburetorparts.Ifthegasolinein

yourenginedeterioratesduringstorage,youmayneedto havethecarburetor,and

otherfuelsystemcomponents,servicedorreplaced.

1. Removeallfuelfromtankbyrunningengineuntilit stops.Donotattemptto

pourfuelfromtheengine.

2. Changetheengineoil.

3. Removesparkplugandpourapproximately1oz.(30ml)ofcleanengineoil

intothecylinder.Pulltherecoilstarterseveraltimestodistributetheoil,and

reinstallthesparkplug.

4. Cleandebrisfromaroundengine,andunder,around,andbehindmuffler.

Applya lightfilm ofoilonanyareasthat aresusceptibletorust.

Storeinaclean,dryandwellventilatedareaawayfromanyappliancethat

operateswith aflameorpilotlight,suchasafurnace,waterheater,or

clothesdryer.Avoidanyareawithasparkproducingelectricmotor,orwhere

powertoolsareoperated.

Neverstoresnowthrowerwith fuel intank indoorsor inpoorlyventilated

areas,wherefuelfumesmayreachanopenflame,sparkor pilotlight ason

afurnace,water heater,clothesdryeror gasappliance.

PreparingSnowThrower

Whenstoringthe snowthrowerin anunventilatedormetalstorageshed,

careshouldbetakentorustprooftheequipment.Usinga lightoil orsilicone,

coattheequipment,especiallyanychains,springs,bearingsandcables.

Removealldirtfromexteriorofengineandequipment.

Followlubricationrecommendations.

Storeequipmentinaclean,dryarea.

InflatethetirestothemaximumPSI.Refertotire sidewall.

Ifpossible,avoidstorageareaswithhighhumidity.

Keeptheenginelevelinstorage.Tiltingcancausefueloroil leakage.

25

Page 26

Disconnectthesparkplugwireandgrounditagainsttheengineto prevent

unintendedstarting.Beforeperforminganytypeofmaintenance/service,

disengageallcontrolsandstoptheengine.Waituntilallmovingparts

havecometoacompletestop.Alwayswearsafetyglassesduringoperation

orwhileperforminganyadjustmentsorrepairs.

Thissectionaddressesminorserviceissues.TolocatethenearestSearsServiceCenterortoscheduleservice,callthefollowingtollfreenumber:1-888-

331-4%9.

Enginefailstostart

Enginerunningerratically/

inconsistentRPM(huntingor

surging)

Excessivevibration

Lossofpower

1. ChokecontrolnotinCHOKEposition.

2. Sparkplugwiredisconnected.

3. Faultysparkplug.

4. Fueltankemptyorstalefuel.

5. Enginenotprimed.

6. Keynotinserted.

7. Extensioncordnotconnected(whenusingelectricstart

button,onmodelssoequipped).

1. EnginerunningonCHOKE.

2. Stalefuel.

3. Waterordirtinfuelsystem.

4. Carburetoroutofadjustment.

S. Over-governedengine.

1. Loosepartsordamagedauger.

1. Sparkplugwireloose.

2. Gascapventholeplugged.

1. Movechokecontrolto CHOKEposition.

2. Connectwiretosparkplug.

3. Clean,adjustgap,orreplace.

4. Filltankwithclean,freshgasoline.

S. PrimeengineasinstructedintheOperationSection.

6. Insertkeyfullyintotheswitch.

7. Connectoneendoftheextensioncordtotheelectricstarter

outletandtheotherendtoathree-prong120-volt,grounded,

ACoutlet.

1. Movechokecontrolto RUNposition.

2. Filltankwithclean,freshgasoline.

3. Drainfueltankbyrunningengineuntilitstops.Refillwithfresh

fuel.

4. ContactyourSearsParts&RepairCenter.

5. ContactyourSearsParts&RepairCenter.

1. Stopengineimmediatelyanddisconnectsparkplugwire.

Tightenallboltsandnuts.Ifvibrationcontinues,haveunit

servicedbyaSearsParts& RepairCenter.

1.

Connectandtightensparkplugwire.

2.

Removeiceandsnowfromgascap.Becertainventholeisclear.

Unitfailstopropelitself

1. Drivecableinneedofadjustment.

2. Drivebeltlooseordamaged.

3. Wornfrictionwheel.

Find this and at[ your other product manuats online.

Get answers from our team of home experts.

Get a personatized maintenance plan for your home.

Find information and tools to hetp with home projects.

26

1.

Adjustdrivecontrolcable.RefertoServiceandMaintenance

section.

2.

Havedrivebeltreplaced.ContactyourSearsParts&Repair

Center.

3.

HavefrictionwheelreplacedataSearsParts&RepairCenter.

Page 27

Unitfailstodischargesnow

1. Chuteassemblyclogged.

2. Foreignobjectlodgedinauger.

3. Augercableinneedofadjustment.

4. Augerbeltlooseordamaged.

5. Shearpin(s)sheared.

1. Stopengineimmediatelyanddisconnectsparkplugwire.Clean

chuteassemblyandinsideofaugerhousingwithdean-outtool

orastick.

2. Stopengineimmediatelyanddisconnectsparkplugwire.

Removeobjectfromaugerwithclean-outtoolorastick.

3. Adjustaugercontrolcable.RefertoAssemblysection.

4. Replaceaugerbelt.Referto ServiceandMaintenancesection.

5. Replacewithnewshearpin(s).

Chutefailstoeasilyrotate180

degrees

1. Chuteassembledincorrectly.

1. Disassemblechutecontrolandreassembleasdirectedinthe

Assemblysection.

NEED MORE HELP?

o Firid this arid air your other product manuals online,

Get answers from our team of home experts,

o Get a personalized maintenance plan for your horae_

Find information and tools to help with home projects.

27

Page 28

FEDERALand/or CALiFORNiAEMiSSiONCONTROLWARRANTYSTATEMENT

YOURWARRANTYRIGHTSANDOBLiGATiONS

MTD Consumer Group Inc, the United States Environmental Protection Agency (EPA), and for those products certified for sale in the state

of California, the California Air Resources Board (CARB) are pleased to explain the emission control system (ECS) warranty on your 2013-

2014 small off-road spark-ignited engine and equipment (outdoor equipment). In California, new outdoor equipment must be designed,

built and equipped to meet the State's stringent anti-smog standards (in other states, outdoor equipment must be designed, built, and

equipped to meet the U.S. EPA small off-road spark ignition engine regulations). MTD Consumer Group Inc must warrant the ECSon your

outdoor equipment for the period of time listed below, provided there has been no abuse, neglect, or improper maintenance of the outdoor

equipment.

Your ECS may include parts such as the carburetor, fuel-injection system, ignition system, catalytic converter, fuel tanks, fuel lines, fuel caps,

valves, canisters, filters, vapor hoses, clamps, connectors, and other associated emission-related components.

Where a warrantable condition exists, MTD Consumer Group Inc will repair your outdoor equipment at no cost to you including diagnosis,

parts, and labor.

MANUFACTURER'SWARRANTYCOVERAGE:

This emission control system is warranted for two years. If any emission-related part on your outdoor equipment is defective, the part will be

repaired or replaced by MTD Consumer Group Inc.

OWNER'SWARRANTYRESPONSiBiLiTiES:

As the outdoor equipment owner, you are responsible for performance of the required maintenance listed in your owner's manual. MTD

Consumer Group Inc recommends that you retain all receipts covering maintenance on your outdoor equipment, but MTD Consumer Group Inc

cannot deny warranty solely for the lack of receipts.

As the outdoor equipment owner, you should however be aware that MTD Consumer Group Inc may deny you warranty coverage if your

outdoor equipment or a part has failed due to abuse, neglect, improper maintenance, or unapproved modifications.

You are responsible for presenting your outdoor equipment to MTD Consumer Group Inc's distribution center or service center assoon as

the problem exists. The warranty repairs should be completed in a reasonable amount of time, not to exceed 30 days. If you have a question

regarding your warranty coverage, you should contact the MTD Consumer Group Inc Service Department at 1-800-800-7310 or at

http://su pport.mtd prod ucts.com.

GENERALEMiSSiONSWARRANTYCOVERAGE:

MTD Consumer Group Inc warrants to the ultimate purchaser and each subsequent purchaser that the outdoor equipment is: (1) designed,

built, and equipped so asto conform with all applicable regulations; and (2) free from defects in materials and workmanship that cause the

failure of a warranted part for a period of two years.

The warranty period begins on the date the outdoor equipment is delivered to an ultimate purchaser or first placed into service.

Subject to certain conditions and exclusions as stated below, the warranty on emission-related parts is as follows:

1. Any warranted part that is not scheduled for replacement as required maintenance in the written instructions supplied is warranted for

the warranty period stated above. If the part fails during the period of warranty coverage, the part will be repaired or replaced by MTD

Consumer Group Inc according to subsection (4) below. Any such part repaired or replaced under warranty will be warranted for the

remainder of the period.

2. Any warranted part that is scheduled only for regular inspection in the written instructions supplied is warranted for the warranty period

stated above. Any such part repaired or replaced under warranty will be warranted for the remaining warranty period.

3. Any warranted part that is scheduled for replacement as required maintenance in the written instructions supplied is warranted for the

period of time before the first scheduled replacement date for that part. If the part fails before the first scheduled replacement, the part

will be repaired or replaced by MTD Consumer Group Inc according to subsection (4) below. Any such part repaired or replaced under

warranty will be warranted for the remainder of the period prior to the first scheduled replacement point for the part.

4.

Repair or replacement of any warranted part under the warranty provisions herein must be performed at a warranty station at no charge

to the owner.

5. Notwithstanding the provisions herein, warranty services or repairs will be provided at all of our distribution centers that are franchised to

service the subject engines or equipment.

6. The outdoor equipment owner will not be charged for diagnostic labor that is directly associated with diagnosis of a defective, emission-

related warranted part, provided that such diagnostic work is performed at a warranty station.

7. MTD Consumer Group Inc is liable for damages to other engine or equipment components proximately caused by a failure under

warranty of any warranted part.

8. Throughout the off-road engine and equipment warranty period stated above, MTD Consumer Group Inc will maintain a supply of

warranted parts sufficient to meet the expected demand for such parts.

9. Any replacement part may be used in the performance of any warranty maintenance or repairs and must be provided without charge to

the owner. Such use will not reduce the warranty obligations of MTD Consumer Group Inc.

Page 29

10. Add-onormodifiedpartsthatarenotexemptedbytheAirResourcesBoardmaynotbeused.Theuseofanynon-exemptedadd-onor

modifiedpartsbytheultimatepurchaserwillbegroundsfordisallowingawarrantyclaim.MTDConsumerGroupIncwillnotbeliableto

warrantfailuresofwarrantedpartscausedbytheuseofanon-exemptedadd-onormodifiedpart.

WARRANTEDPARTS:

The repair or replacement of any warranted part otherwise eligible for warranty coverage may be excluded from such warranty coverage if MTD

Consumer Group Inc demonstrates that the outdoor equipment has been abused, neglected, or improperly maintained, and that such abuse,

neglect, or improper maintenance was the direct cause of the need for repair or replacement of the part. That notwithstanding, any adjustment

of a component that has a factory installed, and properly operating, adjustment limiting device is still eligible for warranty coverage. Further,

the coverage under this warranty extends only to parts that were present on the off-road equipment purchased.

The following emission warranty parts are covered (if applicable):

1. Fuel Metering System

Cold start enrichment system (soft choke)

Carburetor and internal parts (or fuel injection system)

Fuel pump

Fuel tank

2. Air Induction System

Air cleaner

Intake manifold

3. Ignition System

Spark plug(s)

Magneto ignition system

4. Exhaust System

Catalytic converter

SAI (Reed valve)

5. Miscellaneous Items Used in Above System

Vacuum, temperature, position, time sensitive valves and switches

Connectors and assemblies

6. Evaporative Control

Fuel hose

Fuel hose clamps

Tethered fuel cap

Carbon canister

Vapor lines

050790Rev.B

Page 30

Congratulationsonmakingasmartpurchase.YournewCraftsman®productisdesignedandmanufacturedforyearsof

dependableoperation.Butlikeall products,it mayrequirerepairfromtimetotime.That'swhenhavingaRepairProtection

Agreementcansaveyoumoneyandaggravation.

Here'swhat the RepairProtectionAgreement*includes:

[] Expertservicebyour10,000professionalrepairspecialists

[] Unlimited serviceand nocharge forpartsandlaboronallcoveredrepairs

[] Productreplacementupto $1500ifyourcoveredproductcan'tbefixed

[] Discountof 25%fromregularpriceofserviceandrelatedinstalledpartsnotcoveredbytheagreement;also,25%off

regularpriceofpreventivemaintenancecheck

[] Fasthelpby phone - wecallitRapidResolution- phonesupportfromaSearsrepresentative.Thinkofusasa"talking

owner'smanual."

OnceyoupurchasetheRepairProtectionAgreement,asimplephonecallisallthatit takesforyoutoscheduleservice.You

cancallanytimedayornight,orscheduleaserviceappointmentonline.

TheRepairProtectionAgreementisa risk-freepurchase.Ifyoucancelforanyreasonduringtheproductwarrantyperiod,

wewill provideafull refund.Or,a proratedrefundanytimeaftertheproductwarrantyperiodexpires.PurchaseyourRepair

ProtectionAgreementtoday!

Somelimitations and exclusionsapply. Forpricesand additional informationinthe U.S.A.call 1-800-827-6655.

*Coveragein Canadavariesonsomeitems.Forfull detailscall SearsCanadaat 1-800-361-6665.

SearsInstallationService

ForSearsprofessionalinstallationofhomeappliances,garagedooropeners,waterheaters,andothermajorhomeitems,in

theU.S.A.orCanadacall1-800-4-MY-HOME®.

3O

Page 31

il/!it:_l ________;_W__;_j__________

I RFIFT$1qFIN°I

1-888 31 569

Customer Care Hot Line i_l

ustom Hot

Get answers to questions, troubleshoot problems,

order parts, or schedule repair service.

Para respu estas a preguntas o problemas, y ordenar

piezas o pedir servicio para la reparaci6n de su equipo.

To help us help you, register your product at www.craftsman.com/registration

Para poderte ayudar mejor, registra tu producto en www.craftsman.com/registration

Join the Craftsman Club today!

@

www.craftsman.com/signup

Receive exclusive member benefits including special pricing and offers,

project sharing, expert advice, and SHOP YOUR WAY REWARDS!

Como miembro exclusivo, recibe diversos beneficios como ofertas, precios especiales, proyectos

nuevos, consejos de expertos y nuestro programa de puntos SHOP YOUR WAY REWARDS!

® Registered Trademark / TMTrademark of KCD IP, LLC in the United States, or Sears Brands, LLC in other countries

® Marca Registrada / TMMarca de Fabrica de KCD IP, LLC en Estados Unidos, o Sears Brands, LLC in otros paises

Loading...

Loading...