Craftsman 247889701 Owner’s Manual

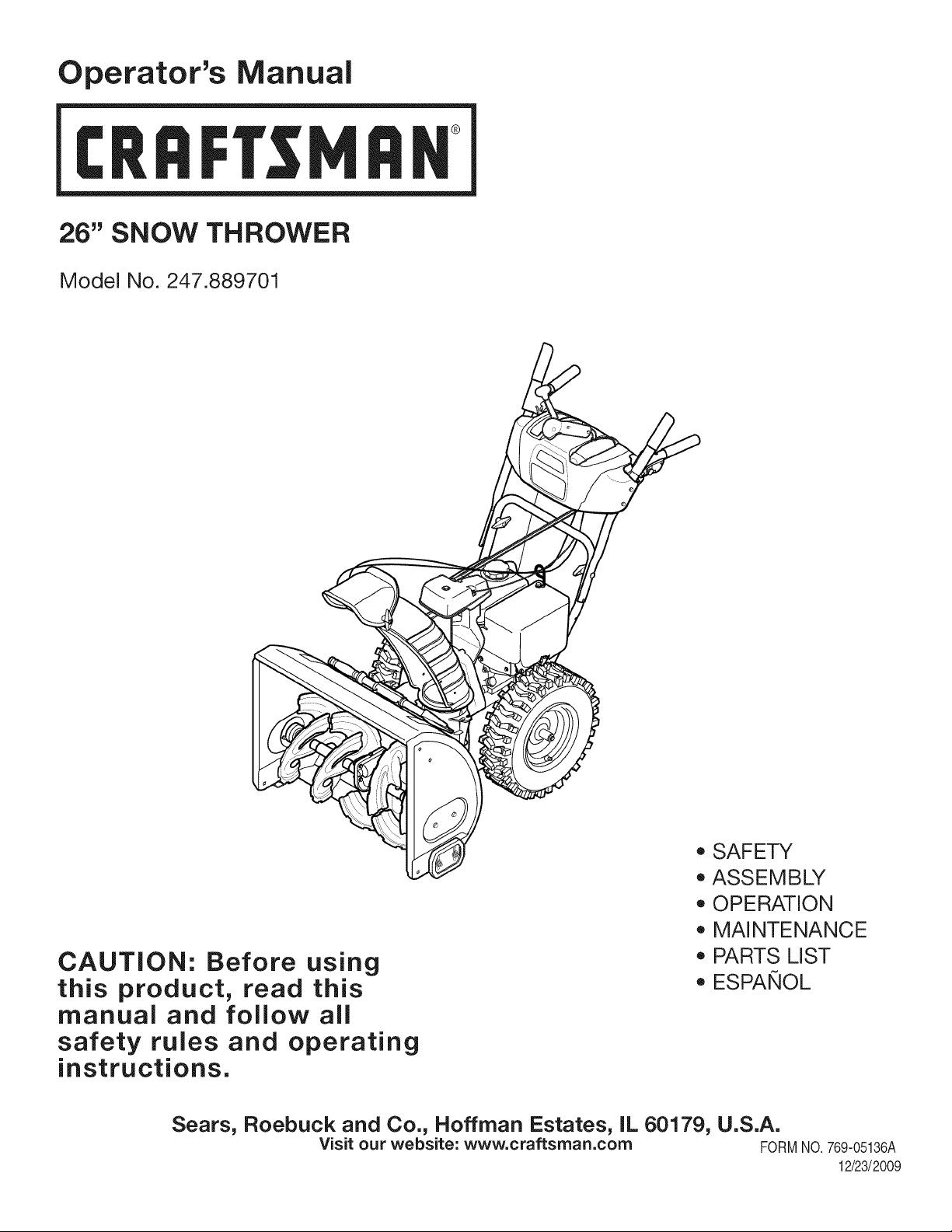

Operator's Manual

CRRFTSMRH

26" SNOW THROWER

Model No. 247.889701

CAUTION: Before using

this product, read this

manual and follow all

safety rules and operating

instructions.

Sears, Roebuck and Co., Hoffman Estates, IL 60179, U.S.A.

Visit our website: www.craftsman.com FORMNO.769-05136A

o SAFETY

ASSEMBLY

OPERATION

MAINTENANCE

PARTS LIST

o ESPANOL

12/23/2009

Warranty Statement .................... Page 2

Safe Operation Practices .............. Pages 3-6

Safety Labels ......................... Page 7

Assembly ......................... Pages 8-13

Operation ........................ Pages 14-17

Service &Maintenance .............. Pages 18-25

CRAFTSMAN FULL WARRANTY

Whenoperatedand maintainedaccordingtoallsuppliedinstructions,ifthis Craftsmansnowthrowerfailsduetoa defectin materialor workman-

shipwithintwoyearsfromthe dateof purchase,returnitto anySearsstore,SearsParts&RepairServiceCenter,orotherCraftsmanoutletin the

UnitedStatesforfreerepair(or replacementif repairprovesimpossible).

Thiswarrantyappliesforonly90 daysfromthedateof purchaseifthissnowthroweriseverusedforcommercialor rentalpurposes.

Thiswarranty coversONLYdefects in materialandworkmanship. Sears will NOTpay for:

• Expendableitemsthatbecomewornduringnormaluse,includingbutnotlimitedto augers,augerpaddles,skidshoes,shaveplate,shear

pins,sparkplug,air cleaner,belts,andoil filter.

• Standardmaintenanceservicing,oilchanges,ortune-ups.

• Tirereplacementor repaircausedbypuncturesfromoutsideobjects,suchasnails,thorns,stumps,orglass.

• Tireor wheelreplacementor repairresultingfromnormalwear,accident,orimproperoperationor maintenance.

• Repairsnecessarybecauseof operatorabuse,includingbutnotlimitedto damagecausedbyover-speedingtheengine,or fromimpacting

objectsthatbendthe frame,augershaft,etc.

• Repairsnecessarybecauseof operatornegligence,includingbutnotlimitedto,electricalandmechanicaldamagecausedbyimproper

storage,failureto usethepropergradeandamountof engineoil,or failureto maintaintheequipmentaccordingtothe instructionscontained

intheoperator'smanual.

• Engine(fuelsystem)cleaningorrepairscausedbyfuel determinedto becontaminatedoroxidized(stale).Ingeneral,fuelshouldbeused

within30 daysof itspurchasedate.

• Normaldeteriorationandwearof theexteriorfinishes,orproductlabelreplacement.

Off-Season Storage ................... Page 26

Troubleshooting ...................... Page 27

Parts List ......................... Pages 28-38

Repair Protection Agreement ............ Page 43

Espa_ol ............................. Page 45

Thiswarrantyappliesonlywhilethisproductis usedinthe UnitedStates.

Thiswarrantygivesyouspecificlegalrights,andyou mayalsohaveotherrightswhichvaryfromstatetostate.

EngineOilType: 5W-30

EngineOilCapacity: 20ounces

FuelCapacity: 2.3Quarts

SparkPlug: TorchF6RTC

SparkPlugGap: .020"to.030"

©SearsBrands,LLC

Sears, Roebuckand Co., Hoffman Estates,IL 60179

ModelNumber.................................................................

Serial Number .................................................................

Dateof Purchase.............................................................

Recordthemodelnumber,serialnumber

anddateof purchaseabove

2

Thissymbolpointsout importantsafetyinstructionswhich,if not

followed,couldendangerthepersonalsafetyand/orpropertyof

yourselfandothers. Readandfollowall instructionsin thismanual

beforeattemptingto operatethismachine.Failuretocomplywith

theseinstructionsmayresultin personalinjury.Whenyou seethis

symbol,HEEDITSWARNING!

Thismachinewasbuiltto beoperatedaccordingtothesafeopera-

tionpracticesinthis manual.Aswithanytypeof powerequipment,

carelessnessorerroron the partof theoperatorcanresultin serious

injury.Thismachineiscapableofamputatingfingers,hands,toes

andfeetandthrowingdebris.Failuretoobservethefollowingsafety

instructionscouldresultin seriousinjuryor death.

CALIFORNIA PROPOSITION 65

EngineExhaust,someof itsconstituents,andcertainvehicle

componentscontainoremitchemicalsknowntoStateof California

tocausecancerandbirthdefectsorotherreproductiveharm,

TRAiNiNG

• Read,understand,andfollowall instructionson themachineand

in themanual(s)beforeattemptingtoassembleandoperate.

Failuretodo socan resultinseriousinjurytotheoperatorand/

orbystanders.Keepthismanualin a safeplaceforfutureand

regularreferenceandfororderingreplacementparts.Forques-

tionscall,1-800-4MY-HOME.

• Befamiliarwithall controlsandtheir properoperation.Knowhow

tostopthe machineanddisengagethemquickly.

Neverallowchildrenunder14yearsofageto operatethis

machine.Children14andovershouldreadandunderstandthe

instructionsandsafeoperationpracticesin thismanualandon

themachineandbe trainedandsupervisedbyanadult.

Neverallowadultsto operatethismachinewithoutproper

instruction.

• Thrownobjectscan causeseriouspersonalinjury.Planyour

snow-throwingpatterntoavoiddischargeof materialtoward

roads,bystandersandthelike.

Keepbystanders,petsandchildrenat least75feetfromthe

machinewhileitisinoperation.Stopmachineifanyoneenters

thearea.

Exercisecautiontoavoidslippingor falling,especiallywhen

operatinginreverse.

Your Responsibility--Restrict the useof this powermachineto

personswhoread,understandandfollowthewarningsandinstruc-

tionsin thismanualandon the machine,

SAVE THESE INSTRUCTIONS!

PREPARATION

Thoroughlyinspecttheareawherethe equipmentisto beused.

Removeall doormats,newspapers,sleds,boards,wiresandother

foreignobjects,whichcouldbe trippedoverorthrownbythe auger/

impeller.

Alwayswearsafetyglassesoreyeshieldsduringoperationand

whileperformingan adjustmentor repairto protectyoureyes.

Thrownobjectswhichricochetcancauseseriousinjurytothe

eyes.

Donot operatewithoutwearingadequatewinteroutergarments.

Donot wearjewelry,longscarvesorotherlooseclothing,which

couldbecomeentangledinmovingparts.Wearfootwearwhich

willimprovefootingonslipperysurfaces.

Usea groundedthree-wireextensioncordand receptaclefor all

machineswithelectricstartengines.

Disengageall controlleversbeforestartingtheengine.

Adjustcollectorhousingheightto cleargravelorcrushedrock

surfaces.

Neverattempttomakeanyadjustmentswhileengineis running,

exceptwherespecificallyrecommendedintheoperator'smanual.

Letengineandmachineadjustto outdoortemperaturebefore

startingtoclearsnow.

3

SafeHandling of Gasoline

Toavoidpersonalinjuryor propertydamageuseextremecarein

handlinggasoline.Gasolineisextremelyflammableandthe vaporsare

explosive.Seriouspersonalinjurycan occurwhengasolineisspilled

onyourselforyourclotheswhichcan ignite.Washyourskinand

changeclothesimmediately.

• Useonlyanapprovedgasolinecontainer.

• Extinguishallcigarettes,cigars,pipesandothersources

ofignition.

• Neverfuelmachineindoors.

• Neverremovegascapor addfuelwhiletheengineishot

or running.

• Allowenginetocoolat leasttwo minutesbeforerefueling.

• Neveroverfillfueltank.Filltanktono morethan1/2inch

belowbottomoffiller neckto providespaceforfuel

expansion.

• Replacegasolinecapandtightensecurely.

• Ifgasolineisspilled,wipeit offtheengineandequipment.

Movemachinetoanotherarea.Wait5 minutesbefore

startingtheengine.

• Neverstorethemachineorfuelcontainerinsidewhere

thereis anopenflame,sparkor pilotlight(e.g.furnace,

waterheater,spaceheater,clothesdryeretc.).

• Allowmachinetocoolatleast5 minutesbeforestoring.

• Neverfillcontainersinsideavehicleoronatruckor trailer

bedwitha plasticliner.Alwaysplacecontainersonthe

groundawayfromyourvehiclebeforefilling.

• If possible,removegas-poweredequipmentfromthetruck

ortrailerand refueliton the ground.Ifthisis notpossible,

thenrefuelsuchequipmentona trailerwitha portable

container,ratherthanfromagasolinedispensernozzle.

• Keepthenozzleincontactwiththe rimofthefueltankor

containeropeningatalltimesuntilfuelingiscomplete.Do

notuse a nozzlelock-opendevice.

OPERATION

• Donot puthandsorfeetnear rotatingparts,in the auger/impeller

housingorchuteassembly.Contactwiththerotatingpartscan

amputatehandsandfeet.

• Theauger/impellercontrolleverisa safetydevice.Neverbypass

itsoperation.Doingsomakesthe machineunsafeandmaycause

personalinjury.

• Thecontrolleversmustoperateeasilyinbothdirectionsand

automaticallyreturntothe disengagedpositionwhenreleased.

• Neveroperatewitha missingor damagedchuteassembly.Keep

all safetydevicesinplaceandworking.

• Neverrunanengineindoorsorina poorlyventilatedarea. Engine

exhaustcontainscarbonmonoxide,anodorlessanddeadlygas.

• Donotoperatemachinewhileundertheinfluenceofalcoholor

drugs.

• Mufflerandenginebecomehotandcancausea burn.Donot

touch.Keepchildrenaway.

• Exerciseextremecautionwhenoperatingon orcrossinggravel

surfaces.Stayalertforhiddenhazardsortraffic.

• Exercisecautionwhenchangingdirectionandwhileoperatingon

slopes.

• Planyoursnow-throwingpatternto avoiddischargetowards

windows,walls,carsetc. Thus,avoidingpossibleproperty

damageorpersonalinjurycausedby a ricochet.

• Neverdirectdischargeatchildren,bystandersandpetsorallow

anyoneinfrontof themachine.

• Donotoverloadmachinecapacitybyattemptingtoclearsnowat

toofastof a rate.

• Neveroperatethismachinewithoutgoodvisibilityorlight.Always

be sureof yourfootingand keepa firmholdon thehandles.Walk,

neverrun.

• Disengagepowertotheauger/impellerwhentransportingornot

in use.

• Neveroperatemachineathightransportspeedsonslippery

surfaces.Lookdownand behindandusecarewhenbackingup.

• Ifthemachineshouldstarttovibrateabnormally,stoptheengine,

disconnectthesparkplugwire andgrounditagainstthe engine.

Inspectthoroughlyfordamage.Repairanydamagebefore

startingandoperating.

• Disengageall controlleversandstopenginebeforeyouleave

theoperatingposition(behindthehandles).Waituntiltheauger/

impellercomestoa completestopbeforeuncloggingthechute

assembly,makingany adjustments,or inspections.

• Neverputyourhandinthedischargeorcollectoropenings.Do

notunclogchuteassemblywhileengineis running.Shutoff

engineand remainbehindhandlesuntilall movingpartshave

stoppedbeforeunclogging.

• Useonlyattachmentsandaccessoriesapprovedbythemanufac-

turer(e.g.wheelweights,tirechains,cabsetc.).

• Whenstartingengine,pullcord slowlyuntilresistanceisfelt, then

pull rapidly.Rapidretractionofstartercord(kickback)willpull

handandarmtowardenginefasterthanyoucanlet go.Broken

bones,fractures,bruisesorsprainscouldresult.

• Ifsituationsoccurwhichare notcoveredinthismanual,usecare

andgoodjudgment.ContactCustomerSupportforassistance

andthenameofyour nearestservicingdealer.

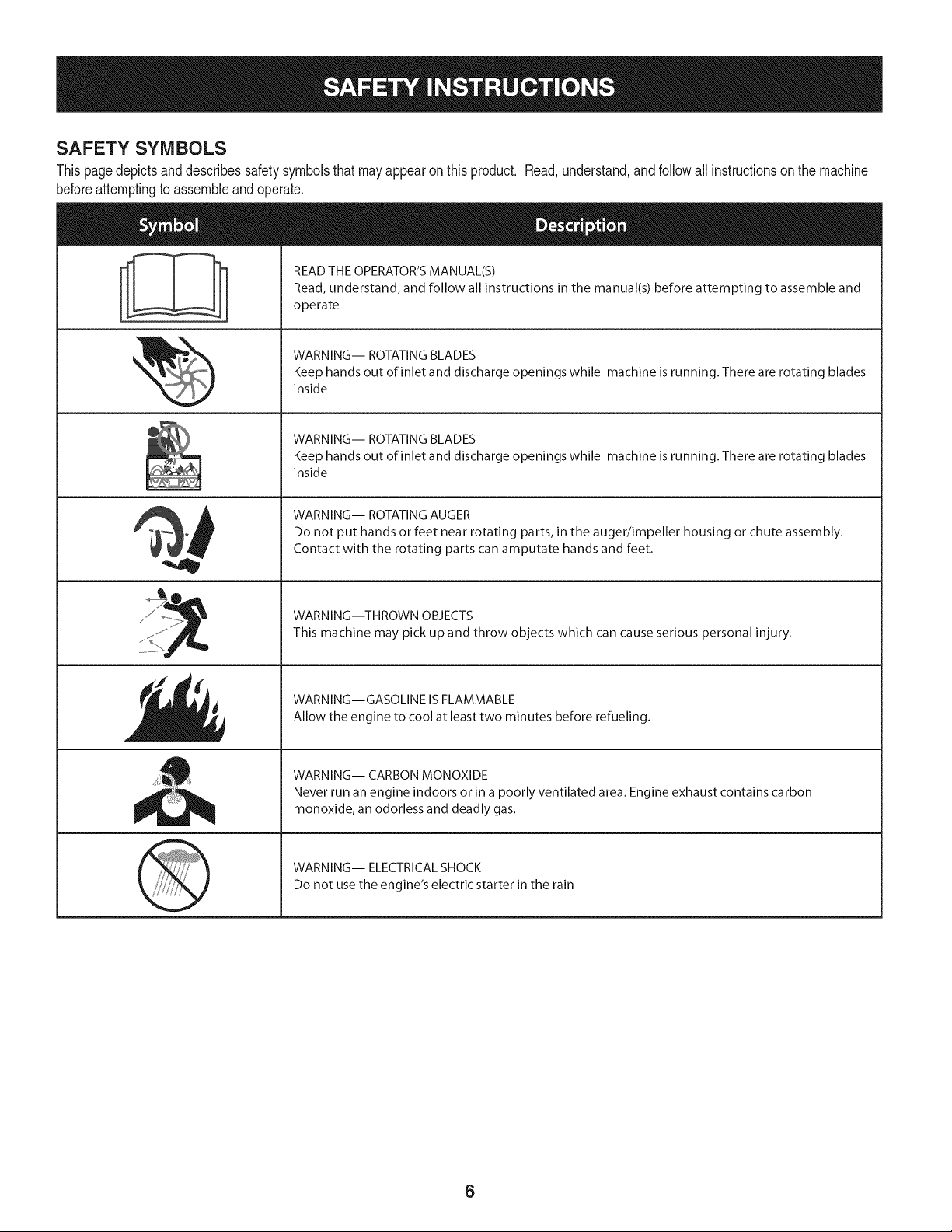

CLEARING A CLOGGED DISCHARGE CHUTE

Handcontactwiththe rotatingimpellerinsidethedischargechute

is the mostcommoncauseofinjuryassociatedwithsnowthrowers.

Neveruseyourhandtocleanoutthedischargechute.

Toclear thechute:

1. SHUTTHEENGINEOFF!

2. Wait 10secondstobe suretheimpellerbladeshavestopped

rotating.

3. Alwaysusea clean-outtool,notyourhands.

4

MAINTENANCE & STORAGE

• Nevertamperwithsafetydevices.Checktheirproperoperation

regularly.Refertothe maintenanceandadjustmentsectionsof

thismanual.

• Beforecleaning,repairing,or inspectingmachinedisengageall

controlleversandstoptheengine.Waituntilthe auger/impeller

cometoa completestop.Disconnectthe sparkplugwireand

groundagainsttheengineto preventunintendedstarting.

Checkboltsand screwsforpropertightnessatfrequentintervals

tokeepthemachineinsafeworkingcondition.Also,visually

inspectmachineforanydamage.

Donotchangetheenginegovernorsettingor over-speedthe

engine.Thegovernorcontrolsthe maximumsafeoperatingspeed

ofthe engine.

Snowthrowershaveplatesandskidshoesaresubjecttowear

anddamage.Foryoursafetyprotection,frequentlycheckall

componentsand replacewithoriginalequipmentmanufacturer's

(OEM)partsonly."Useofpartswhichdonotmeettheoriginal

equipmentspecificationsmayleadto improperperformanceand

compromisesafety!"

Checkcontrolleversperiodicallytoverifytheyengageanddisen-

gageproperlyandadjust,ifnecessary.Refertothe adjustment

sectioninthisoperator'smanualforinstructions.

Maintainor replacesafetyandinstructionlabels,asnecessary.

• Observeproperdisposallawsand regulationsforgas,oil,etc.to

protecttheenvironment.

Priorto storing,runmachinea few minutestoclearsnowfrom

machineand preventfreezeupofauger/impeller.

Neverstorethemachineorfuel containerinsidewherethereisan

openflame,sparkorpilot lightsuchas a waterheater,furnace,

clothesdryeretc.

Alwaysrefertothe operator'smanualforproperinstructionson

off-seasonstorage.

Checkfuelline,tank, cap,andfittingsfrequentlyfor cracksor

leaks.Replaceif necessary.

Donotcrankenginewithsparkplugremoved.

Accordingtothe ConsumerProductsSafetyCommission(CPSC)

andtheU.S.EnvironmentalProtectionAgency(EPA),thisproduct

hasan AverageUsefulLifeof seven(7)years,or 60 hoursof

operation.Atthe endoftheAverageUsefulLifehavethemachine

inspectedannuallybyan authorizedservicedealertoensurethat

allmechanicalandsafetysystemsareworkingproperlyand not

wornexcessively.Failureto do socan resultinaccidents,injuries

ordeath.

DO NOT MODIFY ENGINE

Toavoidseriousinjuryor death,do not modifyengineinany way.

Tamperingwiththegovernorsettingcanleadtoa runawayengineand

causeitto operateat unsafespeeds.Nevertamperwithfactorysetting

ofenginegovernor.

NOTICE REGARDING EMiSSiONS

EngineswhicharecertifiedtocomplywithCaliforniaandfederal

EPAemissionregulationsfor SORE(SmallOff RoadEquipment)are

certifiedto operateonregularunleadedgasoline,and mayinclude

thefollowingemissioncontrolsystems:EngineModification(EM),

OxidizingCatalyst(OC),SecondaryAirInjection(SAI)and ThreeWay

Catalyst(TWO)if soequipped.

SPARK ARRESTOR

Thismachineisequippedwithaninternalcombustionengineand

shouldnotbe usedonor nearany unimprovedforest-covered,

brush-coveredorgrass-coveredlandunlessthe engine'sexhaust

systemisequippedwitha sparkarrestermeetingapplicablelocalor

statelaws(if any)

Ifa sparkattesterisused,it shouldbemaintainedineffectiveworking

orderbytheoperator.Inthe StateofCaliforniatheaboveis required

bylaw (Section4442ofthe CaliforniaPublicResourcesCode).Other

statesmayhavesimilarlaws. Federallawsapplyonfederallands.

A sparkarresterforthe muffleris availablethroughyournearestSears

PartsandRepairServiceCenter.

SAFETY SYMBOLS

Thispagedepictsanddescribessafetysymbolsthatmayappearonthisproduct. Read,understand,andfollowall instructionson the machine

beforeattemptingto assembleandoperate.

READ THE OPERATOR'S MANUAL(S)

i

i

Read, understand, and follow all instructions in the manual(s) before attempting to assemble and

operate

WARNING-- ROTATING BLADES

Keep hands out of inlet and discharge openings while machine is running. There are rotating blades

inside

WARNING-- ROTATING BLADES

Keep hands out of inlet and discharge openings while machine is running. There are rotating blades

inside

WARNING-- ROTATING AUGER

Do not put hands or feet near rotating parts, in the auger/impeller housing or chute assembly.

Contact with the rotating parts can amputate hands and feet.

WARNING--THROWN OBJECTS

This machine may pick up and throw objects which can cause serious personal injury.

WARNING--GASOLINE IS FLAMMABLE

Allow the engine to cool at least two minutes before refueling.

WARNING-- CARBON MONOXIDE

Never run an engine indoors or in a poorly ventilated area. Engine exhaust contains carbon

monoxide, an odorless and deadly gas.

WARNING-- ELECTRICAL SHOCK

Do not use the engine's electric starter in the rain

6

r

100/.LIIO-NV:IIO

"lVflNV_ S,UOIVU3dOQV3H"G

"S3OV_IJflS]3AVUONO9NIIV_J3dO

N3HMNOIIflVOVSIX]qsfl"S9]ONVIS181V]98VHOSIO

10381083A3N'S]IUflrNI SI03PgoNMOUHIQIOAV01 "_

"3NIHOV_ONIOIA83SUOONIOOO]ONfl

]UO_38O3ddOIS]AVHSlHPd9NIAOW11VlllNfl S]IQNVH

ONIH]8NIVW3UONV']NION]dOlS'88]A]1HOlnlo]9VON]SIO"8

"]lnHg ]gHVHOSIO9010Nfl01 1001lflO-NP]lO ]Sfl "Z

"l]]d ONVSONVH]lPlnd_P NVOH3onvuoHq]l]d_JIHIIM

IOVINO0"u39npONV_J3113dWI9NllVIOU_JOH_IVMV d]3H"L

7

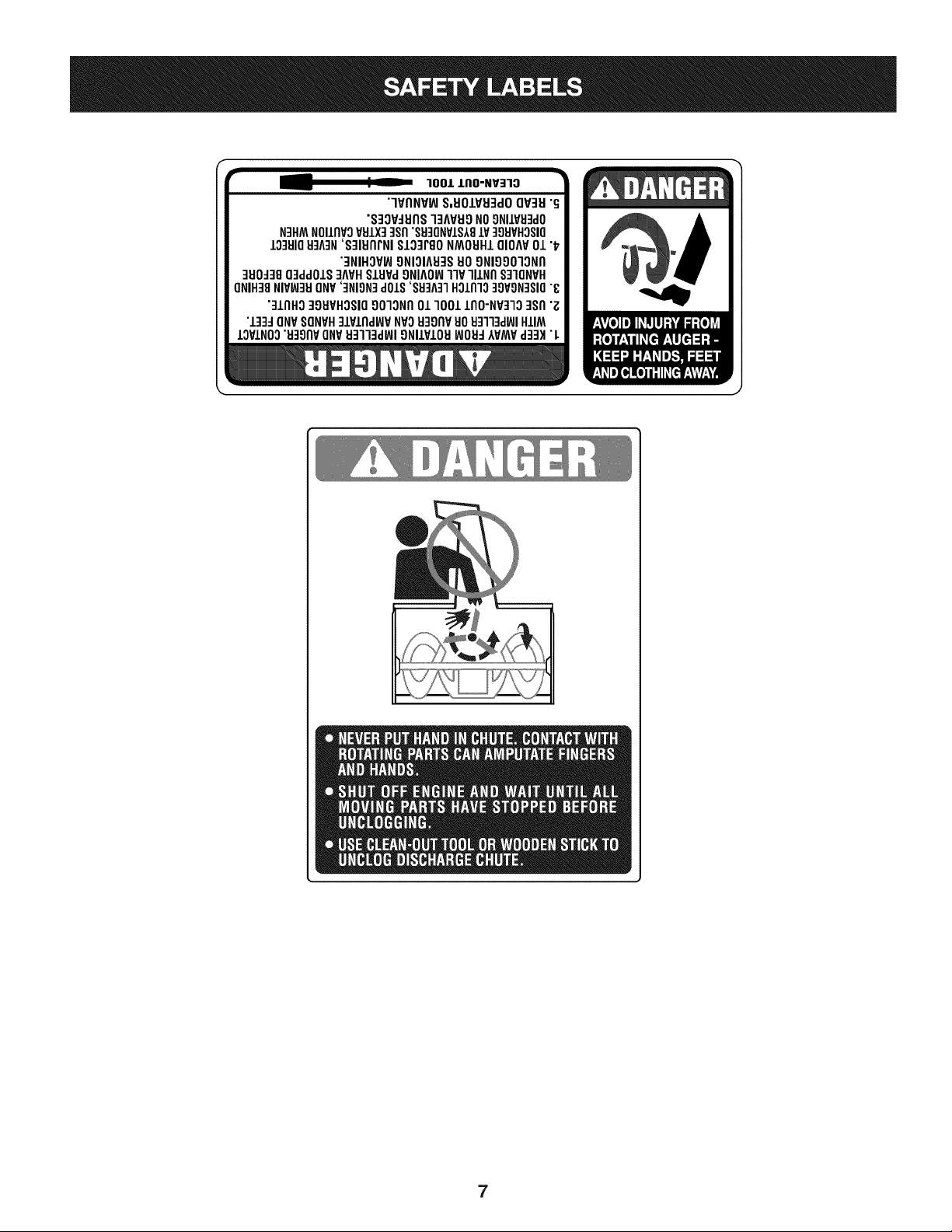

NOTE:Referencesto rightorleft sideofthe snowthrowerare

determinedfrombehindtheunit intheoperatingposition(standing

directlybehindthesnowthrower,facingthe handlepanel).

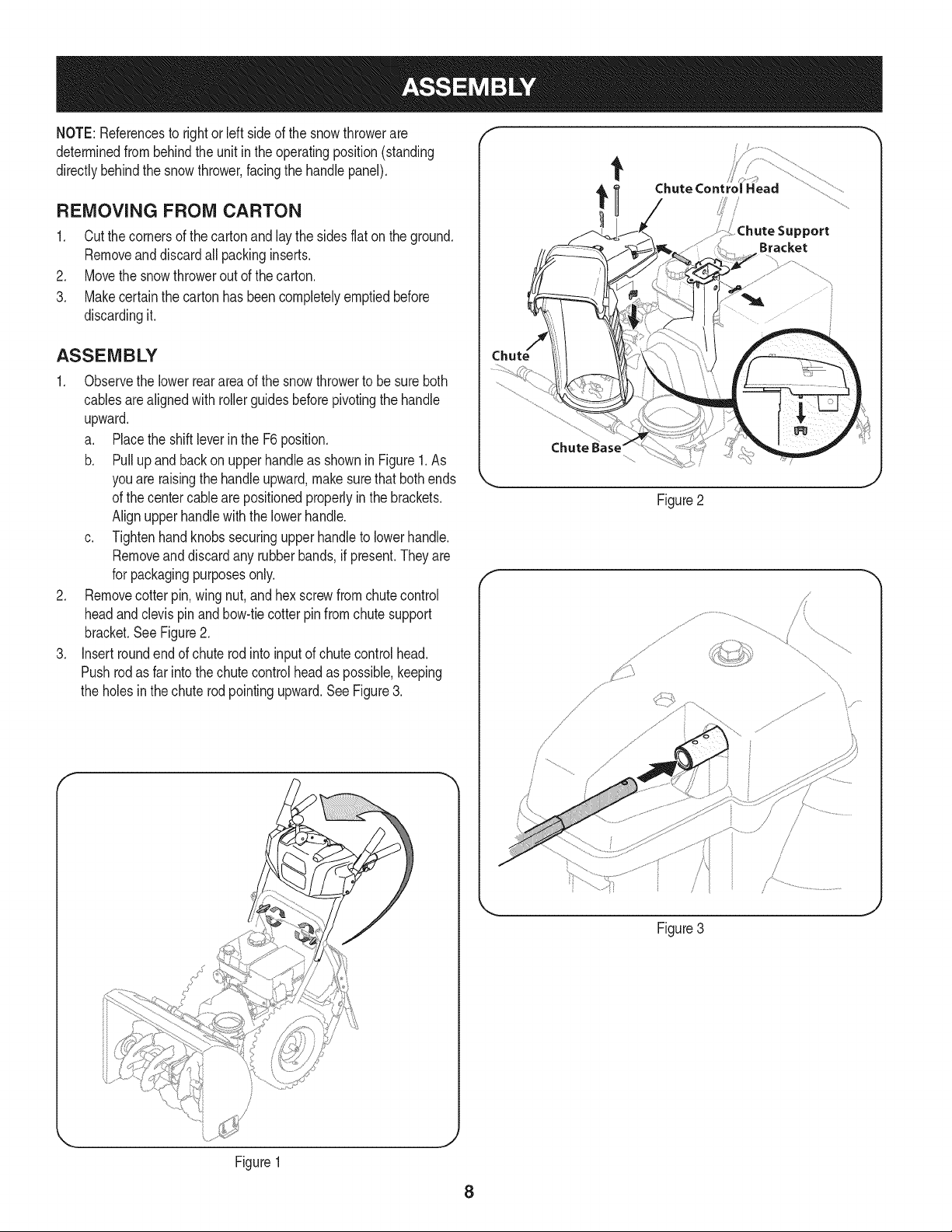

REMOVING FROM CARTON

1. Cutthecornersofthecartonandlaythesidesflatontheground.

Removeanddiscardallpackinginserts.

2. Movethesnowthroweroutofthecarton.

3. Makecertainthecartonhas beencompletelyemptiedbefore

discardingit.

ASSEMBLY

1. Observethe lowerrearareaofthesnowthrowertobesureboth

cablesarealignedwith rollerguidesbeforepivotingthehandle

upward.

a. Placethe shiftleverin theF6position.

b. Pullupandbackon upperhandleasshowninFigure1.As

youare raisingthehandleupward,makesurethat bothends

ofthe centercablearepositionedproperlyinthebrackets.

Alignupperhandlewiththelowerhandle.

c. Tightenhandknobssecuringupperhandletolowerhandle.

Removeanddiscardany rubberbands,ifpresent.Theyare

forpackagingpurposesonly.

2. Removecotterpin,wing nut,andhexscrewfromchutecontrol

headandclevispinandbow-tiecotterpinfromchutesupport

bracket.SeeFigure2.

3. Insertroundendof chuterodintoinputofchutecontrolhead.

Pushrodas farintothechutecontrolheadas possible,keeping

theholesinthechuterodpointingupward.SeeFigure3.

ChuteControlHead

.........ChuteSupport

Bracket

Chute Base"

Figure2

f

I

Figure1

/

/

!

J

Figure3

J

8

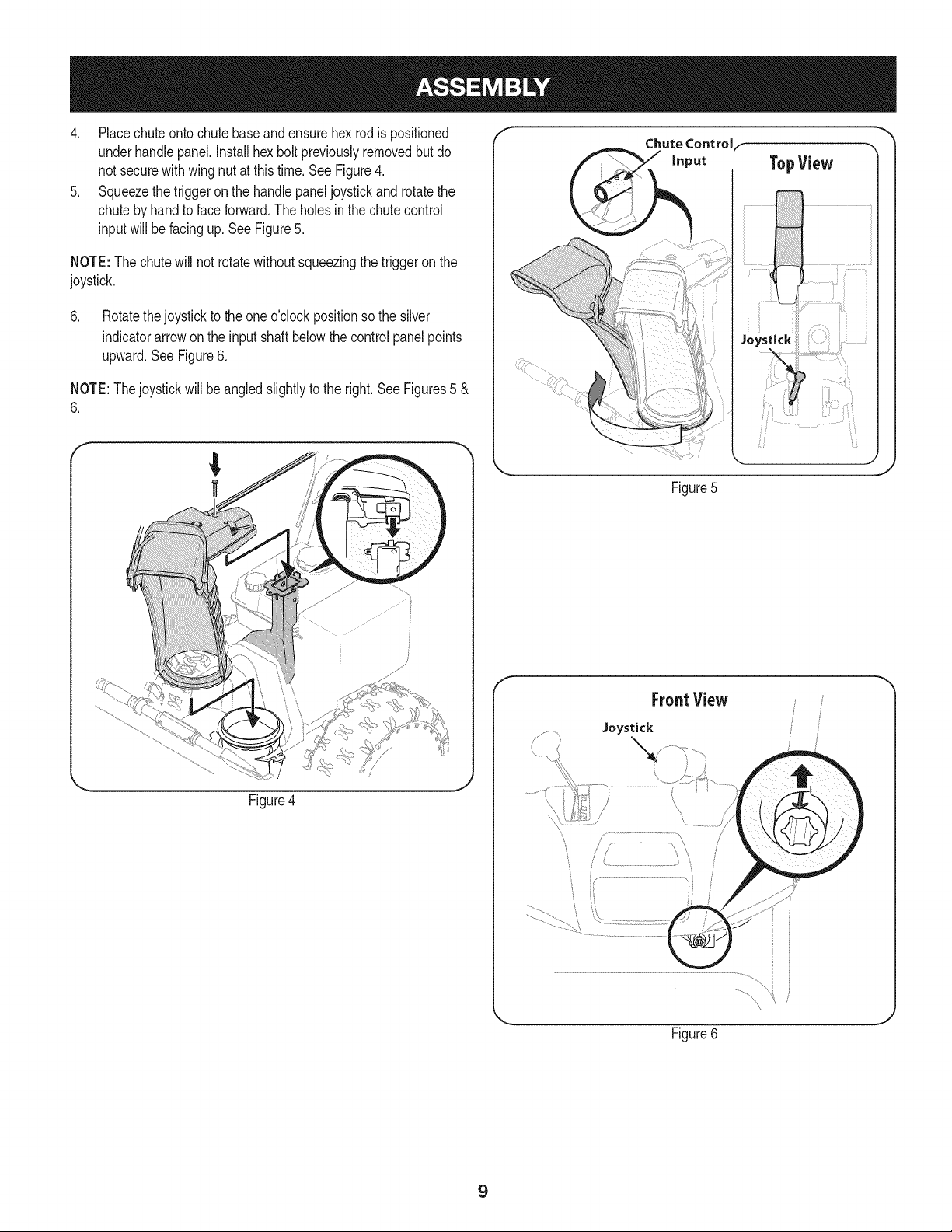

4. Placechuteontochutebaseandensurehexrodis positioned

underhandlepanel.Installhexboltpreviouslyremovedbut do

notsecurewithwingnutat thistime.See Figure4.

5. Squeezethetriggeron the handlepaneljoystickandrotatethe

chutebyhandto faceforward.Theholesinthe chutecontrol

inputwill befacingup.SeeFigure5.

NOTE:The chutewillnot rotatewithoutsqueezingthe triggeronthe

joystick.

6. Rotatethejoystickto theoneo'clockpositionsothesilver

indicatorarrowonthe inputshaft belowthecontrolpanelpoints

upward.SeeFigure6.

NOTE:Thejoystickwillbe angledslightlyto theright.SeeFigures5 &

6.

f

Chute Controlf

TopView

_i¸• ............... t_i

Figure5

Figure4

f

FrontView

Joystick

J

Figure6

9

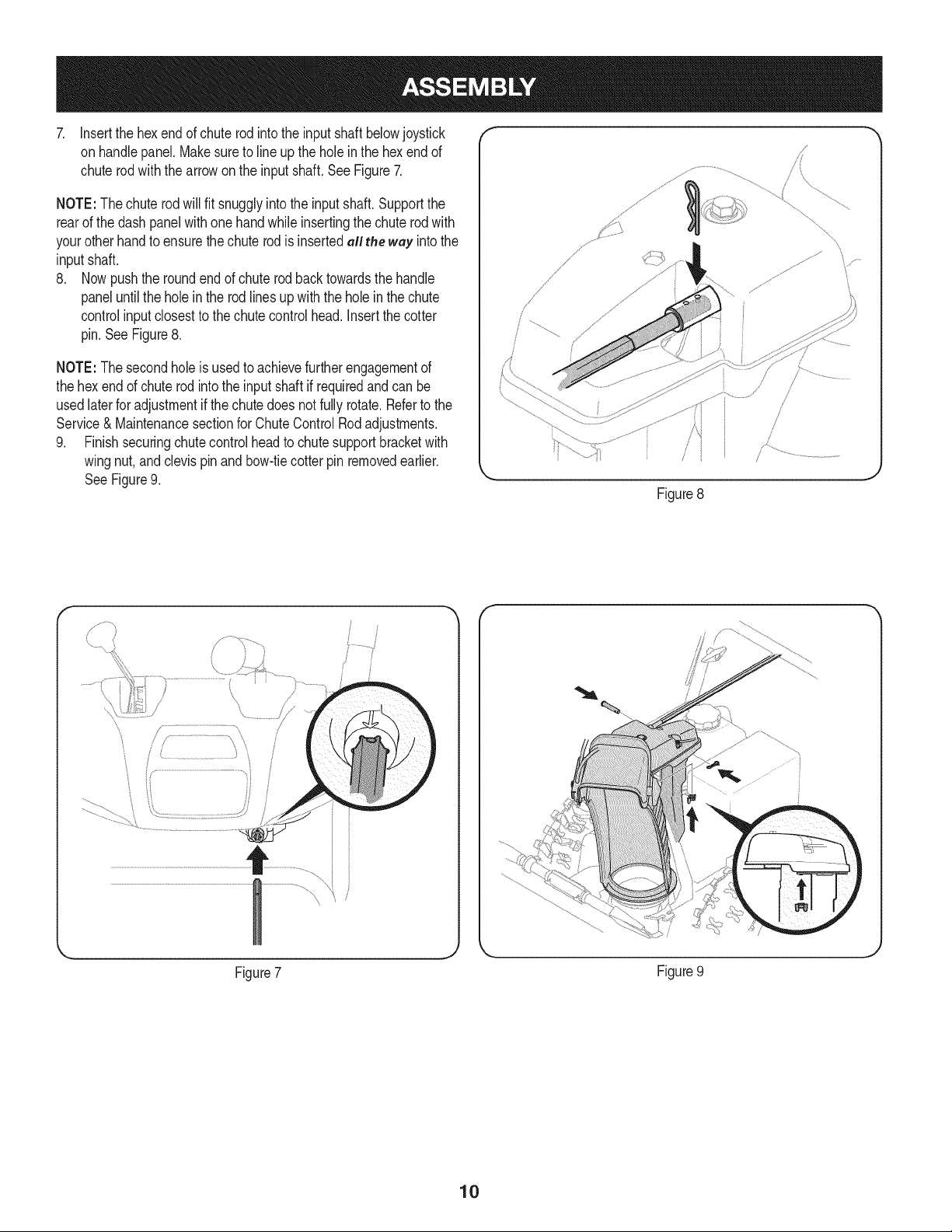

7, Insertthehexendofchuterodintothe inputshaftbelowjoystick

onhandlepanel,Makesuretolineupthe holein thehexendof

chuterodwiththearrowonthe inputshaft.See Figure7.

NOTE:The chuterodwillfit snugglyintotheinputshaft.Supportthe

rearofthe dashpanelwithonehandwhileinsertingthechuterodwith

yourotherhandtoensurethechuterodis insertedall theway intothe

inputshaft.

8. Nowpushthe roundendofchuterodbacktowardsthehandle

paneluntilthe holeintherodlines upwiththeholeinthechute

controlinputclosestto thechutecontrolhead.Insertthecotter

pin.See Figure8.

NOTE:The secondholeisusedtoachievefurtherengagementof

thehexendofchuterodintotheinput shaftif requiredandcanbe

usedlaterforadjustmentifthechutedoes notfully rotate.Refertothe

Service& MaintenancesectionforChuteControlRodadjustments.

9. Finishsecuringchutecontrolheadtochutesupportbracketwith

wingnut,andclevis pinandbow-tiecotterpinremovedearlier.

See Figure9.

//

Figure8

y..................

x

\

\

Figure7

Figure9

10

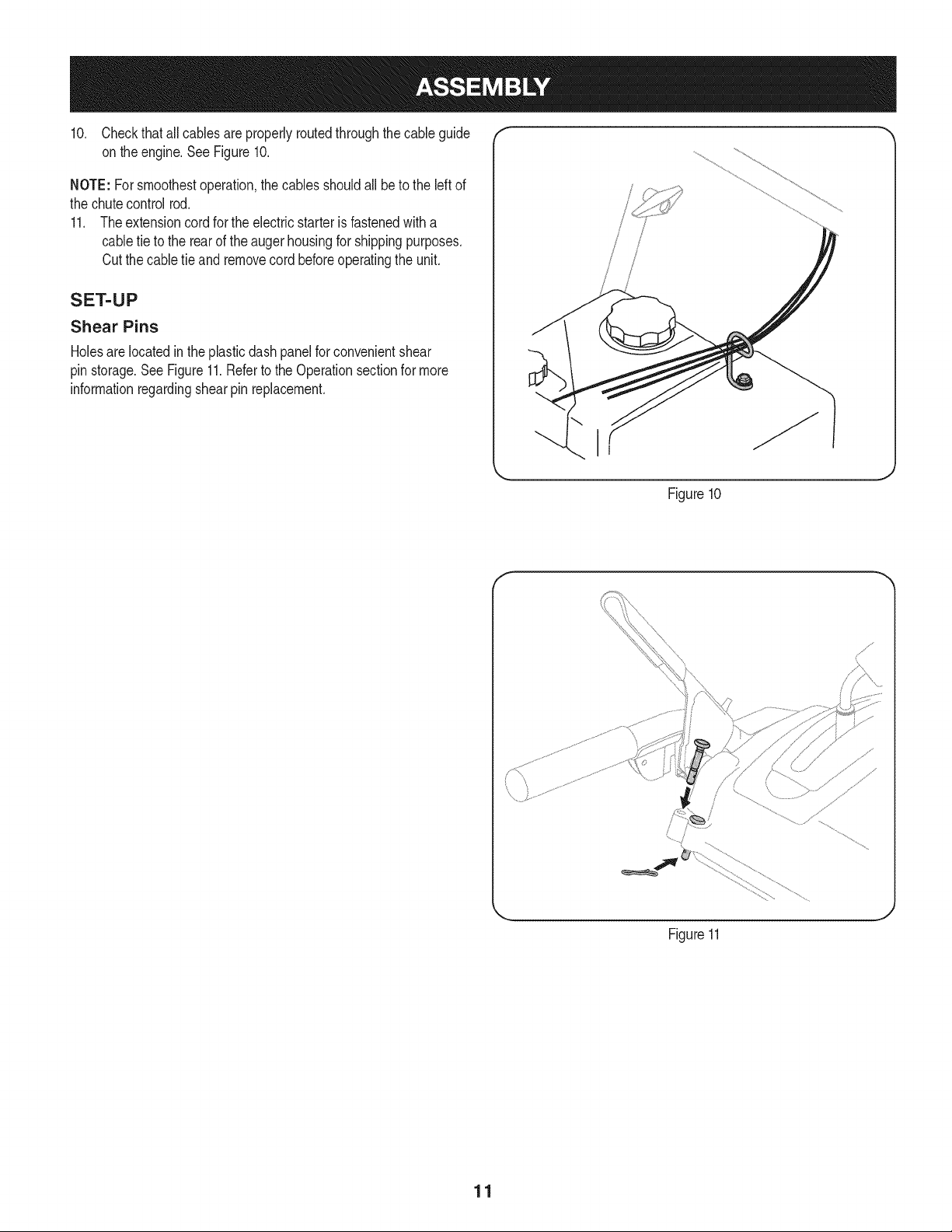

10. Checkthatallcablesareproperlyroutedthroughthecableguide

on theengine.SeeFigure10.

NOTE:Forsmoothestoperation,thecablesshouldallbeto theleftof

thechutecontrolrod.

11. Theextensioncordfortheelectricstarterisfastenedwitha

cabletie to the rearofthe augerhousingforshippingpurposes.

Cutthecabletieand removecordbeforeoperatingthe unit.

SET-UP

Shear Pins

Holesare locatedintheplasticdashpanelfor convenientshear

pinstorage.SeeFigure11.RefertotheOperationsectionformore

informationregardingshearpin replacement.

....ill /ii

IIIhll iillii!

Figure10

11

J

Figure11

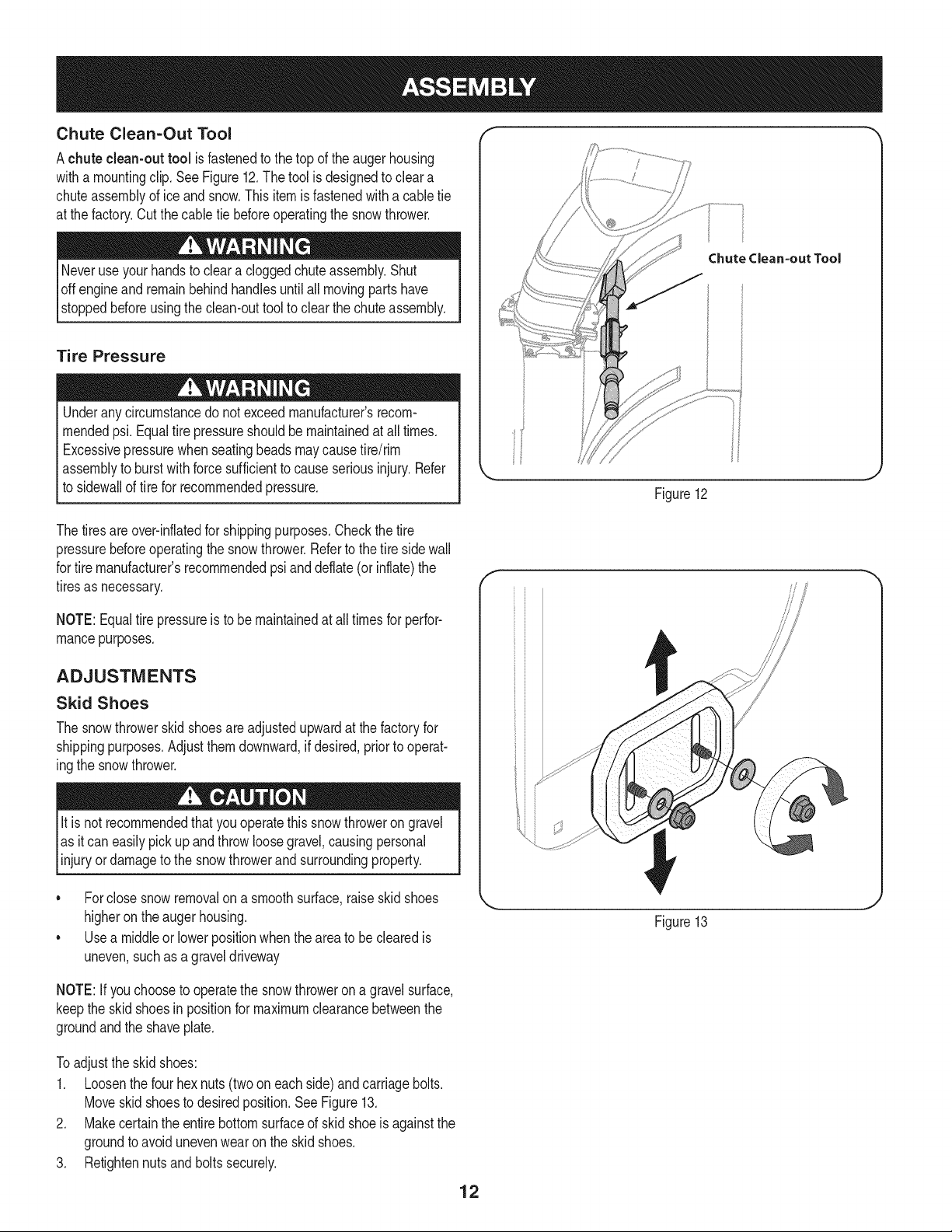

Chute Clean-Out Tool

Achute clean-out tool is fastenedtothetop ofthe augerhousing

witha mountingclip.SeeFigure12.Thetool isdesignedtocleara

chuteassemblyofice andsnow.Thisitemis fastenedwitha cabletie

atthe factory.Cutthecabletie beforeoperatingthesnowthrower.

loft _1 .allm?vingpartshave.

stoppedbeforeusingtheclean-outtooltoclear thechuteassembly.

Tire Pressure

Underanycircumstancedo notexceedmanufacturer'srecom-

mendedpsi.Equaltirepressureshouldbemaintainedat all times.

Excessivepressurewhenseatingbeadsmaycausetire/rim

assemblytoburstwithforcesufficienttocauseseriousinjury.Refer

tosidewallof tirefor recommendedpressure.

Thetiresareover-inflatedforshippingpurposes.Checkthetire

pressurebeforeoperatingthesnowthrower.Refertothe tiresidewall

fortiremanufacturer'srecommendedpsianddeflate(orinflate)the

tiresasnecessary.

Chute Clean-out Tool

Figure12

NOTE:Equaltire pressureisto be maintainedat alltimesforperfor-

mancepurposes.

ADJUSTMENTS

Skid Shoes

Thesnowthrowerskidshoesareadjustedupwardatthefactoryfor

shippingpurposes.Adjustthemdownward,ifdesired,priortooperat-

ingthesnowthrower.

It isnot recommendedthatyouoperatethissnowthrowerongravel

asit caneasilypickup andthrowloosegravel,causingpersonal

njuryordamageto the snowthrowerand surroundng property.

• Forclosesnowremovalona smoothsurface,raiseskidshoes

higherontheaugerhousing.

• Usea middleorlowerpositionwhentheareatobe clearedis

uneven,suchasa graveldriveway

NOTE:If youchoosetooperatethesnowthrowerona gravelsurface,

keepthe skidshoesin positionformaximumclearancebetweenthe

groundandtheshaveplate.

Toadjustthe skidshoes:

1. Loosenthefourhexnuts(twooneachside)andcarriagebolts.

Moveskidshoestodesiredposition.SeeFigure13.

2. Makecertaintheentirebottomsurfaceof skidshoeisagainstthe

groundtoavoidunevenwearontheskidshoes.

3. Retightennutsandboltssecurely.

Figure13

12

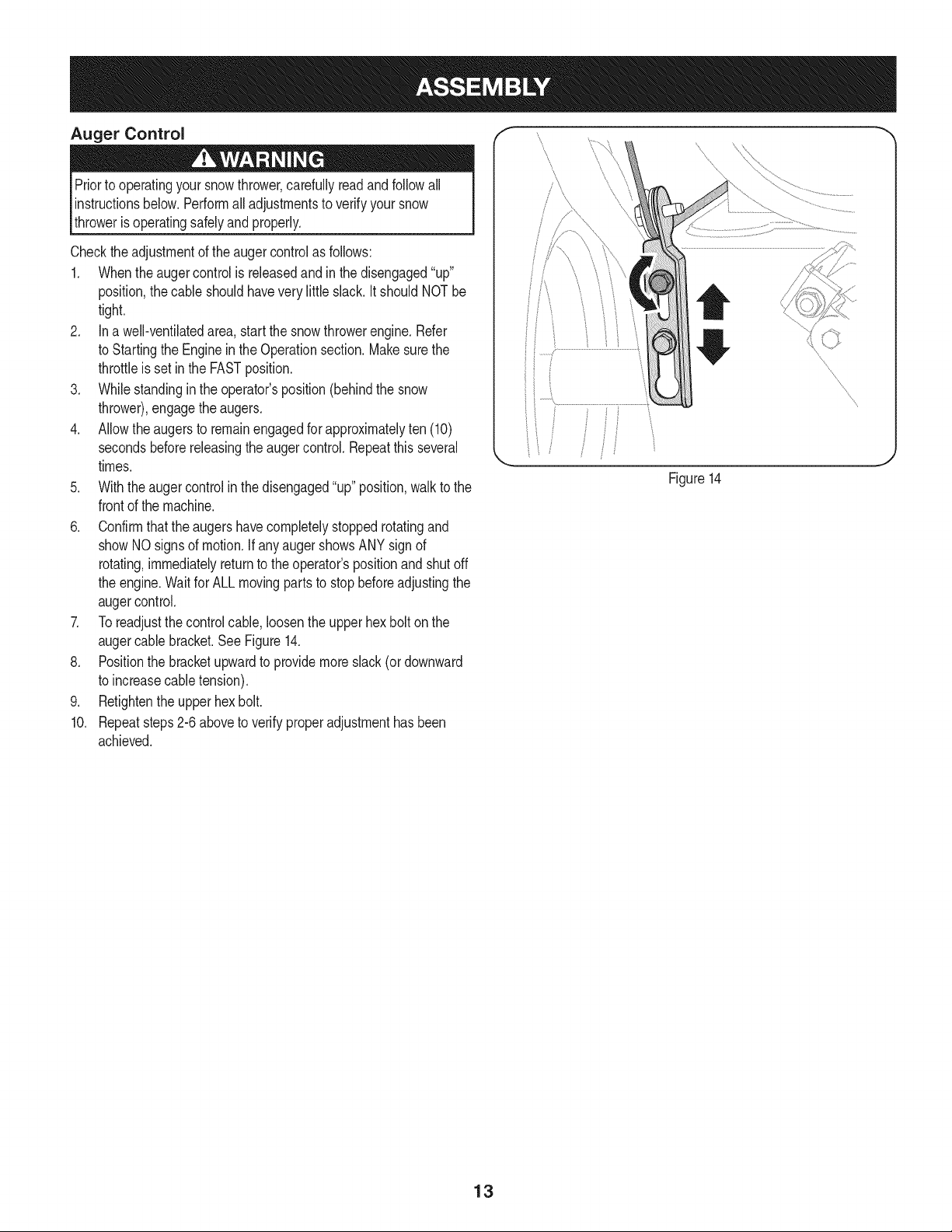

Auger Control

Priortooperatingyoursnowthrower,carefullyreadandfollowall

instructionsbelow.Performalladjustmentsto verifyyoursnow

throwerisoperatingsafelyandproperly.

Checktheadjustmentofthe augercontrolasfollows:

1. Whentheaugercontrolis releasedandin thedisengaged"up"

position,thecableshouldhaveverylittleslack.ItshouldNOTbe

tight.

2. Inawell-ventilatedarea,startthesnowthrowerengine.Refer

toStartingthe EngineintheOperationsection.Makesurethe

throttleis setin theFASTposition.

3. Whilestandingintheoperator'sposition(behindthe snow

thrower),engagethe augers.

4. Allowtheaugersto remainengagedforapproximatelyten(10)

secondsbeforereleasingthe augercontrol.Repeatthisseveral

times.

5. Withtheaugercontrolinthedisengaged"up"position,walktothe

frontofthe machine.

6. Confirmthatthe augershavecompletelystoppedrotatingand

showNOsignsof motion.IfanyaugershowsANYsignof

rotating,immediatelyreturntothe operator'spositionandshutoff

theengine.WaitforALLmovingpartsto stopbeforeadjustingthe

augercontrol.

7. Toreadjustthecontrolcable,loosentheupperhexboltonthe

augercablebracket.SeeFigure14.

8. Positionthebracketupwardtoprovidemoreslack(ordownward

toincreasecabletension).

9. Retightentheupperhexbolt.

10. Repeatsteps2-6aboveto verifyproperadjustmenthasbeen

achieved.

\

\

\

\

\

J

i

i

Figure14

13

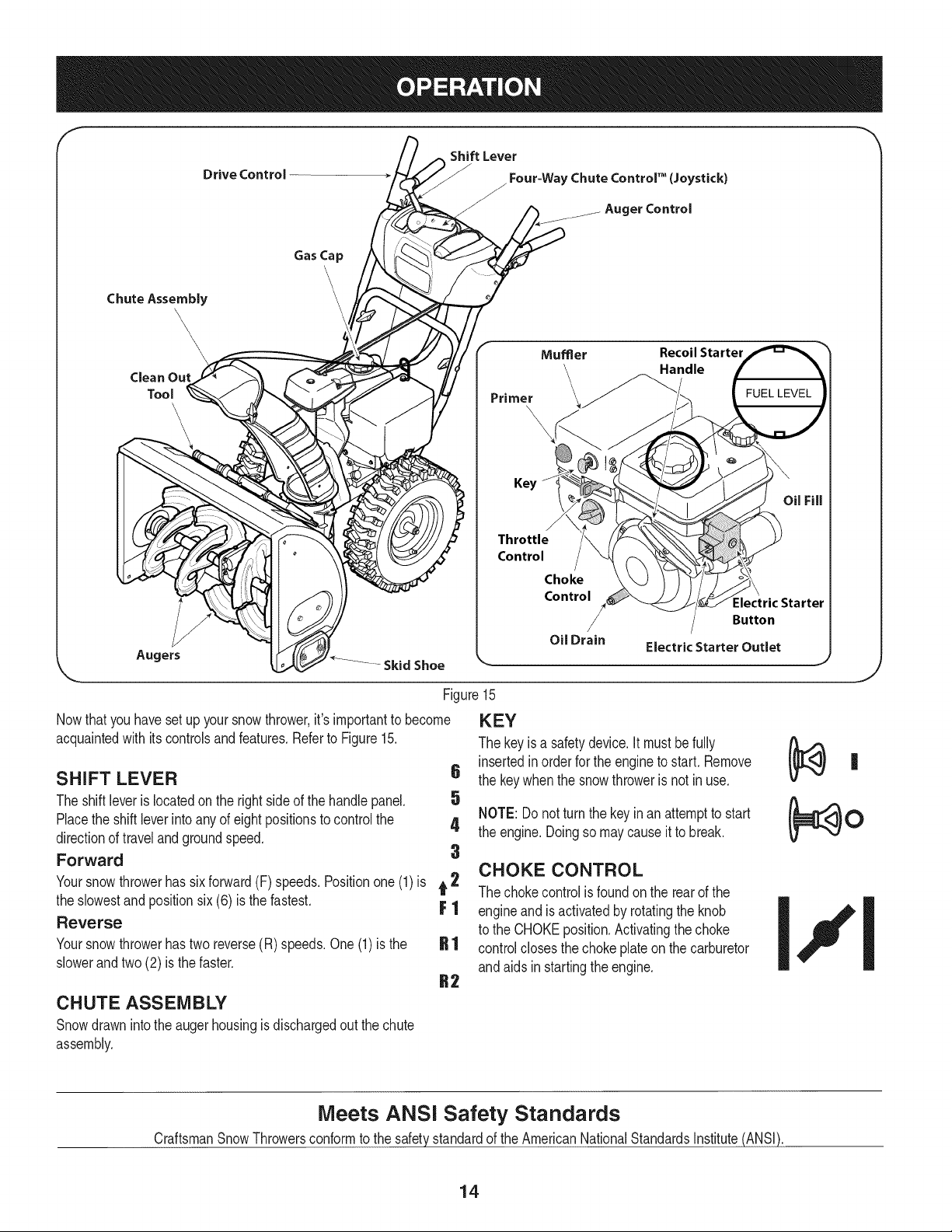

f

Drive Control

Gas Cap

Chute Assembly

CleanOut

Tool

\

\

Augers

Skid Shoe

Figure15

Nowthat youhavesetup yoursnowthrower,it'simportanttobecome

acquaintedwith itscontrolsandfeatures.Referto Figure15.

SHIFT LEVER 6

Theshiftleveris locatedonthe rightsideof thehandlepanel. 5

Placethe shiftleverintoanyofeightpositionstocontrolthe 4

directionoftravelandgroundspeed.

Forward 3

Yoursnowthrowerhassixforward(F) speeds.Positionone(1)is t 2

theslowestandpositionsix(6) is thefastest. F 1

Reverse

Yoursnowthrowerhastwo reverse(R)speeds.One(1)is the

slowerandtwo(2) isthe faster.

ShiftLever

z Four-WayChuteControP (Joystick)

J

AugerControl

Mumer Recoil Starter

\ Handle

Primer ___ FUEL LEVEL

\

\

Key

Throttle

Control

Choke

Control

/

Oil Drain

KEY

Thekeyis a safetydevice.It mustbefully

insertedin orderforthe enginetostart. Remove

thekeywhenthesnowthroweris notin use.

NOTE:Donotturnthekeyinan attemptto start

theengine.Doingsomaycauseit to break.

CHOKE CONTROL

Thechokecontrolis foundon the rearofthe

engineand isactivatedbyrotatingtheknob

tothe CHOKEposition.Activatingthe choke

controlclosesthe chokeplateon the carburetor

andaidsin startingtheengine.

Electric Starter Outlet

Electric Starter

Button

,J

CHUTE ASSEMBLY

Snowdrawnintothe augerhousingisdischargedoutthe chute

assembly.

Meets ANSi Safety Standards

CraftsmanSnowThrowersconformtothe safetystandardofthe AmericanNationalStandardsInstitute(ANSi).

14

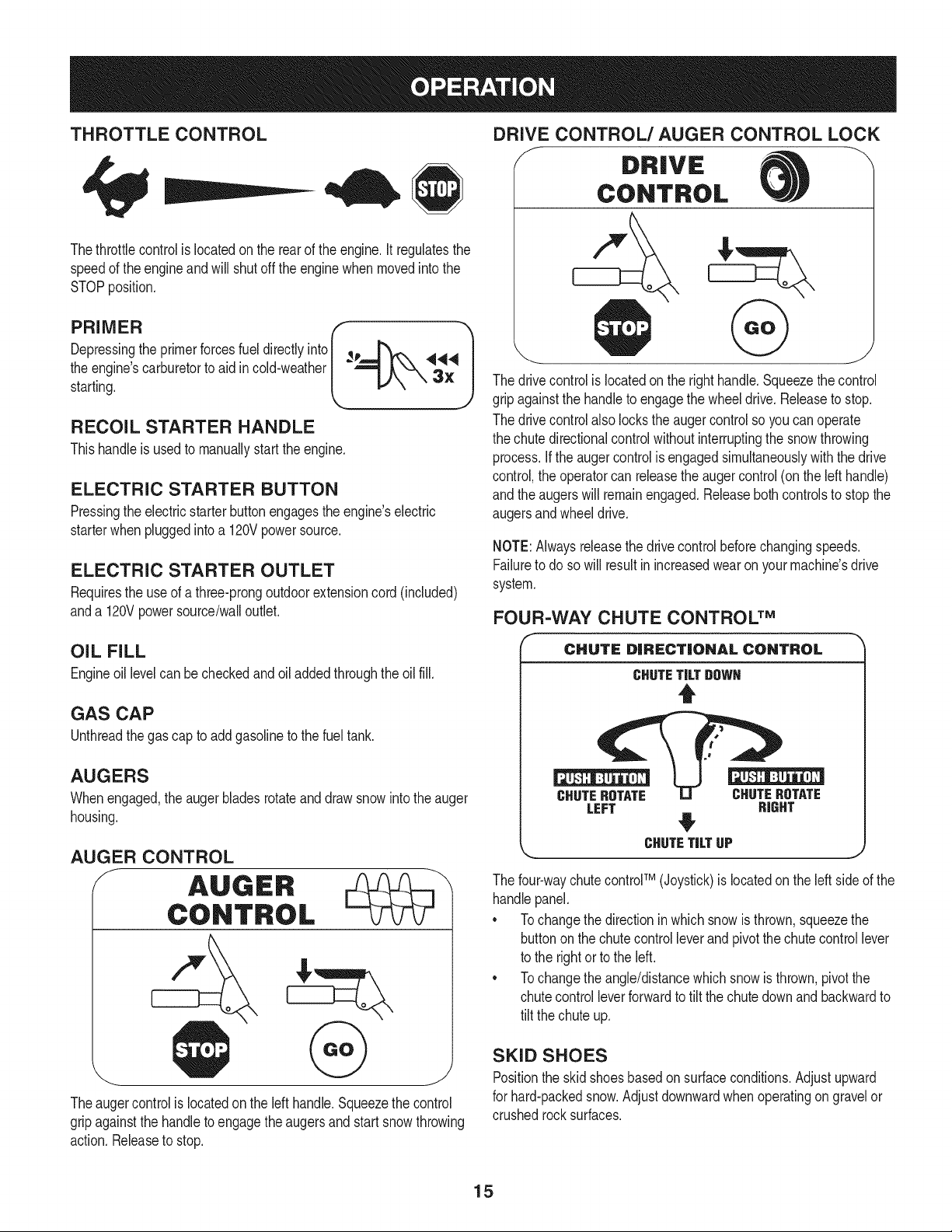

THROTTLE CONTROL

Thethrottlecontrolis locatedonthe rearofthe engine.It regulatesthe

speedof theengineandwill shutoff theenginewhenmovedintothe

STOPposition.

DRIVE CONTROL/AUGER CONTROL LOCK

f DRIVE

CONTROL

Depressingthe primerforcesfueldirectlyinto _p

theengine'scarburetortoaidincold-weather

starting.

RECOIL STARTER HANDLE

Thishandleisusedto manuallystarttheengine.

ELECTRIC STARTER BUTTON

Pressingtheelectricstarterbuttonengagestheengine'selectric

starterwhenpluggedintoa 120Vpowersource.

ELECTRIC STARTER OUTLET

Requirestheuseof athree-prongoutdoorextensioncord(included)

anda 120Vpowersource/walloutlet.

OIL FILL

Engineoil levelcanbecheckedandoiladdedthroughtheoil fill.

GAS CAP

Unthreadthegascapto addgasolinetothefuel tank.

AUGERS

Whenengaged,theaugerbladesrotateand drawsnowintotheauger

housing.

AUGER CONTROL

f AUGER

CONTROL

@

Thedrivecontrolis locatedonthe righthandle.Squeezethecontrol

gripagainstthehandleto engagethewheeldrive.Releasetostop.

Thedrivecontrolalsolockstheaugercontrolso youcan operate

thechutedirectionalcontrolwithoutinterruptingthesnowthrowing

process.If theaugercontrolis engagedsimultaneouslywiththe drive

control,the operatorcan releasetheaugercontrol(onthelefthandle)

andtheaugerswillremainengaged.Releaseboth controlstostopthe

augersandwheeldrive.

NOTE:Alwaysreleasethedrivecontrolbeforechangingspeeds.

Failureto dosowill resultinincreasedwearon yourmachine'sdrive

system.

FOUR-WAY CHUTE CONTROL TM

f

CHUTE DiRECTiONAL CONTROL

CHUTETiLTDOWH

t

CHUTEROTATE CHUTEROTATE

LEFT RIGHT

CHUTETiLTUP

Thefour-waychutecontroFM(Joystick)islocatedon theleft sideof the

handlepanel.

* Tochangethe directioninwhichsnowisthrown,squeezethe

buttononthechutecontrolleverand pivotthechutecontrollever

tothe rightorto theleft.

* Tochangethe angle/distancewhichsnowisthrown,pivotthe

chutecontrolleverforwardto tiltthechutedownand backwardto

tilt thechuteup.

Theaugercontrolis locatedontheleft handle.Squeezethecontrol

gripagainstthehandleto engagetheaugersandstartsnowthrowing

action.Releasetostop.

SKID SHOES

Positiontheskidshoesbasedonsurfaceconditions.Adjustupward

forhard-packedsnow.Adjustdownwardwhenoperatingon gravelor

crushedrocksurfaces.

15

CLEAN-OUT TOOL

Neveruseyourhandsto cleara cloggedchuteassembly.Shut

off engineandremainbehindhandlesuntilall movingpartshave

stoppedbeforeusingtheclean-outtooltoclear thechuteassembly.

Thechuteclean-outtoolisconvenientlyfastenedtothe rearofthe

augerhousingwitha mountingclip.Shouldsnowandice become

lodgedin thechuteassemblyduringoperation,proceedasfollowsto

safelycleanthechuteassemblyandchuteopening:

1. Releaseboththe AugerControlandtheDriveControl.

2. Stopthe enginebyremovingtheignitionkey.

3. Removetheclean-outtoolfromtheclipwhichsecuresittothe

rearofthe augerhousing.

4. Usetheshovel-shapedendof theclean-outtoolto dislodgeand

scoopanysnowand icewhichhasformedin andnearthechute

assembly.

5. Refastentheclean-outtooltothemountingclipontherearof

theaugerhousing,reinserttheignitionkeyandstartthesnow

thrower'sengine.

6. Whilestandingintheoperator'sposition(behindthesnow

thrower),engagethe augercontrolfora fewsecondstoclear any

remainingsnowandice fromthechuteassembly.

BEFORE STARTING ENGINE

Read,understand,andfollowall instructionsandwarningson the

machineand inthismanualbeforeoperating.

Oil

Theunit wasshippedwith oil inthe engine.Checkoillevelbefore

eachoperationtoensureadequateoilinthe engine.Forfurther

instructions,refertothe stepson page18.

NOTE:Besuretochecktheengineon a levelsurfacewiththeengine

stopped.

1. Removetheoil fillercap/dipstickandwipethedipstickclean.

2. insertthecap/dipstickintotheoilfillerneck,butdoNOTscrewit

in.

3. Removetheoil fillercap/dipstick,ifthelevelislow,slowlyadd

oil (5%30, witha minimumclassificationof SF/SG)untiloil level

registersbetweenhigh(H) andlow(L).

NOTE:Do notoverfill.Overfillingwithoil mayresultinenginesmoking,

hardstartingorsparkplugfouling.

4. Replaceandtightencap/dipstickfirmlybeforestartingengine.

Gasoline

Useautomotivegasoline(unleadedor low leadedtominimizecombus-

tionchamberdeposits)witha minimumof87octane.Gasolinewith

upto 10%ethanolor 15%MTBE(MethylTertiaryButylEther)canbe

used.Neveruseanoil/gasolinemixtureor dirtygasoline.Avoidgetting

dirt,dust,or waterinthefueltank. DONOTuse E85gasoline.

• Refuelina well-ventilatedareawiththeenginestopped.Donot

smokeorallowflamesor sparksin theareawheretheengineis

refueledor wheregasolineisstored.

• Donotoverfillthefueltank.Afterrefueling,makesurethetank

capis closedproperlyandsecurely.

• Becarefulnotto spillfuelwhenrefueling.Spilledfuelorfuelvapor

mayignite,ifanyfuelisspilled,makesuretheareaisdrybefore

startingthe engine.

• Avoidrepeatedorprolongedcontactwithskinor breathingof

)or.

Useextremecarewhenhandlinggasoline.Gasolineisextremely

flammableandthevaporsare explosive.Neverfuelthe machine

indoorsorwhilethe engineishotor running.Extinguishcigarettes,

cigars,pipesandothersourcesof ignition.

1. Cleanaroundfuel fillbeforeremovingcapto fuel.

2. A fuellevelindicatorislocatedinthe fueltank. SeeFigure15

inset.Becarefulnottooverfill.Filltank untilfuelreachesthefuel

levelindicatorto allowspacefor fuelexpansion.

STARTING THE ENGINE

Alwayskeephandsandfeetclearof movingparts.Donot usea

pressurizedstartingfluid.Vaporsareflammable.

NOTE:Allowtheengineto warmupfora fewminutesafter starting.

Theenginewill notdevelopfullpoweruntilit reachesoperating

temperatures.

1. Makecertainboththe augercontrolanddrivecontrolareinthe

disengaged(released)position.

2. insertignitionkeyintoslot.Makesureitsnapsintoplace.Donot

attempttoturn thekey.

NOTE:Theenginecannotstartwithoutthekeyisfully insertedintothe

ignitionswitch.

Electric Starter

Theoptionalelectricstarterisequippedwitha groundedthree-wire

powercordand plug,andis designedtooperateon120voltAC

householdcurrent.Itmustbe usedwitha properlygroundedthree-

prongreceptacleat all timesto avoidthe possibilityofelectricshock.

Followall instructionscarefullypriortooperatingtheelectricstarter.

DONOTuseelectricstarterinthe rain.

Determinethatyourhome'swiringisa three-wiregroundedsystem.

Aska licensedelectricianifyouarenotcertain.

Ifyou haveagroundedthree-prongreceptacle,proceedasfollows.

Ifyou donothavetheproperhousewiring,DONOTusetheelectric

starterunderanyconditions.

1. Plugtheextensioncordintotheoutletlocatedon theengine's

surface.Plugtheotherendof extensioncordintoa three-prong

120-volt,grounded,ACoutletina well-ventilatedarea.

16

2. MovethrottlecontroltoFAST(rabbit)_ position.

3. MovechoketotheCHOKEI,"1pos t /co denginestart).If

engineiswarm,placechokein RUNposition.

4. Pushprimerthree(3)times,makingsuretocoverventholewhen

pushing.Ifengineiswarm,pushprimeronlyonce.Alwayscover

ventholewhenpushing.Coolweathermayrequireprimingtobe

repeated.

5. Pushstarterbuttontostartengine.Oncetheenginestarts,im-

mediatelyreleasestarterbutton.Electricstarterisequippedwith

thermaloverloadprotection;systemwilltemporarilyshut-downto

allowstartertocool ifelectricstarterbecomesoverloaded.

6. Astheenginewarms,slowlyrotatethe chokecontroltoRUN

position.Ifthe enginefalters,restartengineandrunwithchoke

athalf-chokepositionfora shortperiodof time,andthen slowly

rotatethechokeinto RUNposition.

7. Afterengineisrunning,disconnectpowercordfromelectric

starter.Whendisconnecting,alwaysunplugtheendatthe wall

outletbeforeunpluggingtheoppositeendfromtheengine.

Recoil Starter

Donotpullthestarterhandlewhilethe enginerunning.

1. Movethrottlecontrolto FAST(rabbit)_ position.

2. MovechoketotheCHOKEJ..#Jposition(coldenginestart).If

engineiswarm,placechokein RUNposition.

3. Pushprimerthree(3)times,makingsuretocoverventholewhen

pushing.Ifengineiswarm,pushprimeronlyonce.Alwayscover

ventholewhenpushing.Coolweathermayrequireprimingtobe

repeated.

4. Pullgentlyonthe starterhandleuntilitbeginstoresist,then

pullquicklyandforcefullytoovercomethe compression.Engine

shouldstart.Donotreleasethehandleandallow itto snapback.

ReturnropeSLOWLYto originalposition.If required,repeatthis

step.

5. Astheenginewarms,slowlyrotatethe chokecontroltoRUN

position.Ifthe enginefalters,restartengineandrunwithchoke

athalf-chokepositionfora shortperiodof time,andthen slowly

rotatethechokeinto RUNposition.

TO ENGAGE DRIVE

1. Withthethrottlecontrolinthe Fast(rabbit)'_ position,move

shiftleverintooneof thesix forward(F) positionsortwo reverse

(R)positions.Selectaspeedappropriatefor thesnowconditions

anda paceyou'recomfortablewith.

NOTE:When selectinga DriveSpeed,usethe slowerspeedsuntil

youarecomfortableandfamiliarwiththe operationofthesnow

thrower.

2. Squeezethedrivecontrolagainstthehandleandthesnow

throwerwillmove.Releaseitanddrive motionwillstop.

NOTE:NEVERrepositionthe shiftlever(changespeedsordirection

oftravel)withoutfirstreleasingthedrivecontrolandbringingthesnow

throwertoa completestop.Doingsowill resultin prematurewearto

thesnowthrower'sdrivesystem.

TO ENGAGE AUGERS

1. Toengagethe augersandstartthrowingsnow,squeezethe

augercontrolagainstthelefthandle.Releasetostoptheaugers.

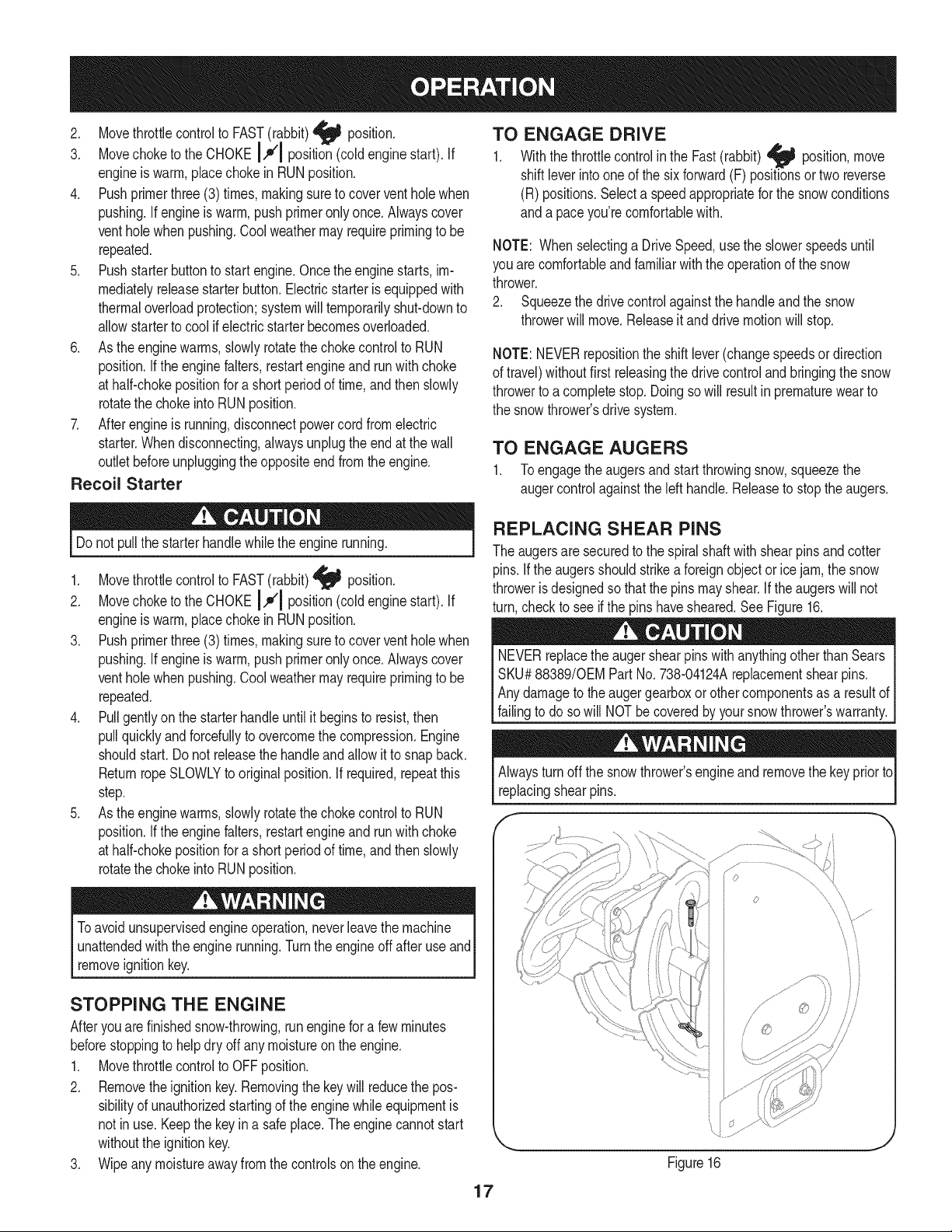

REPLACING SHEAR PINS

Theaugersare securedtothe spiralshaftwith shearpinsandcotter

pins.If theaugersshouldstrikeaforeignobjectorice jam,thesnow

throwerisdesignedsothatthe pinsmayshear.If theaugerswill not

turn,checkto seeif thepins havesheared.SeeFigure16.

NEVERreplacethe augershearpinswithanythingotherthanSears

SKU#88389/0EMPart No.738-04124Areplacementshearpins.

Anydamagetothe augergearboxorothercomponentsasa resultof

[fang to dosow NOTbe coveredbyyoursnowthrowerswarranty.

Alwaysturnoff thesnowthrower'sengineandremovethekeypriorto

replacingshearpins.

o

Toavoid unsupervisedengineoperation,neverleavethemachine

unattendedwiththeenginerunning.Turnthe engineoffafteruseand

removeignitionkey.

STOPPING THE ENGINE

Afteryouarefinishedsnow-throwing,runenginefora fewminutes

beforestoppingtohelpdryoffany moistureonthe engine.

1. Movethrottlecontrolto OFFposition.

2. Removetheignitionkey.Removingthekeywill reducethepos-

sibilityof unauthorizedstartingof theenginewhileequipmentis

notinuse.Keepthe keyin a safeplace.Theenginecannotstart

withouttheignitionkey.

3. Wipeanymoistureawayfromthecontrolsontheengine.

iJ

Figure16

17

MAINTENANCE SCHEDULE

Beforeperforminganytypeofmaintenance/service,disengageall

controlsandstoptheengine.Waituntilallmovingpartshavecometo

acompletestop.Disconnectsparkplugwireandgrounditagainstthe

enginetopreventunintendedstarting.Alwayswearsafetyglassesduring

operationor whileperforminganyadjustmentsorrepairs.

EachUseandevery5

hours

1st5 hours

Annuallyor25hours

Annuallyor50hours

Annuallyor100hours

BeforeStorage

1. Engineoillevel

2. Looseormissinghardware

3. Unitandengine.

1. Engineoil

1. Sparkplug

2. Controllinkagesand pivots

3. Wheels

4. GearshaftandAugershaft

5. 4-WayChuteControlTM

1. Engineoil

1. Sparkplug

1. Fuelsystem

1. Check

2. Tightenor replace

3. Clean

1. Change

1. Check

2. Lubewithlightoil

3. Lubewithmultipurposeautogrease

4. Lubewithlightoil

5. Checkfor cableslackness

1. Change

1. Change

1. Runengineuntilit stopsfromlack

Followthemaintenanceschedulegivenbelow.Thischartdescribes

serviceguidelinesonly.UsetheServiceLogcolumnto keeptrackof

completedmaintenancetasks.To locate the nearest Sears Service

Centeror to scheduleservice,simplycontactSearsat

1-800-4-MY-HOME®.

offuel

ENGINE MAINTENANCE

Beforelubricating,repairing,or inspecting,disengageall controls

Iandstopengine.Waituntilall movingpartshavecometo a complete

_stop.

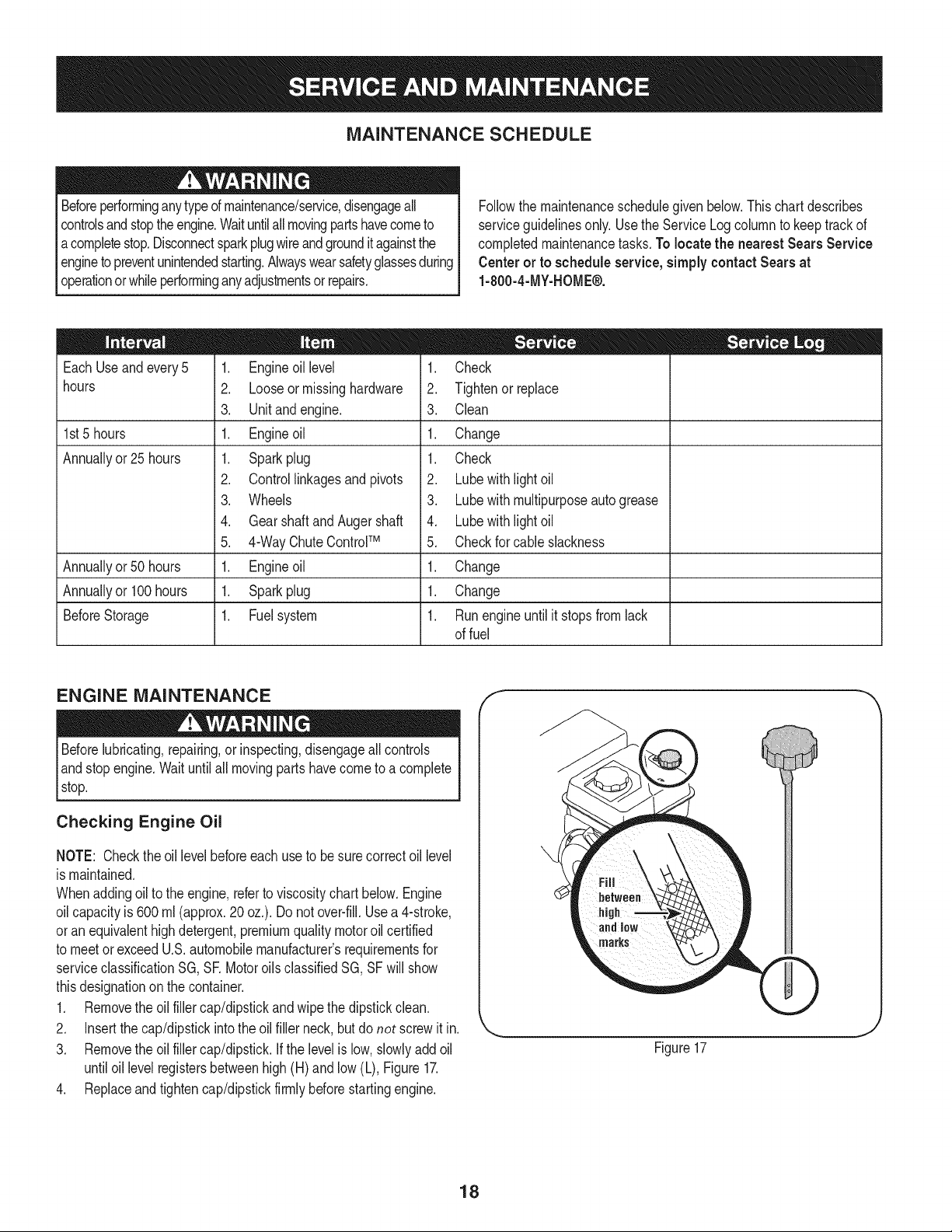

Checking Engine Oil

NOTE: Checktheoil levelbeforeeachuseto besurecorrectoil level

ismaintained.

Whenaddingoilto theengine,referto viscositychart below.Engine

oilcapacityis 600ml (approx.20 oz.).Donotover-fill.Usea 4-stroke,

oran equivalenthighdetergent,premiumqualitymotoroilcertified

tomeetorexceedU.S.automobilemanufacturer'srequirementsfor

serviceclassificationSG, SRMotoroilsclassifiedSG,SFwillshow

thisdesignationonthecontainer.

1. Removetheoil fillercap/dipstickandwipethedipstickclean.

2. Insertthe cap/dipstickintotheoil fillerneck,butdo not screwit in.

3. Removetheoil fillercap/dipstick.Ifthelevelislow,slowlyaddoil

untiloil levelregistersbetweenhigh(H) and low(L), Figure17.

4. Replaceandtightencap/dipstickfirmlybeforestartingengine.

f

Figure17

18

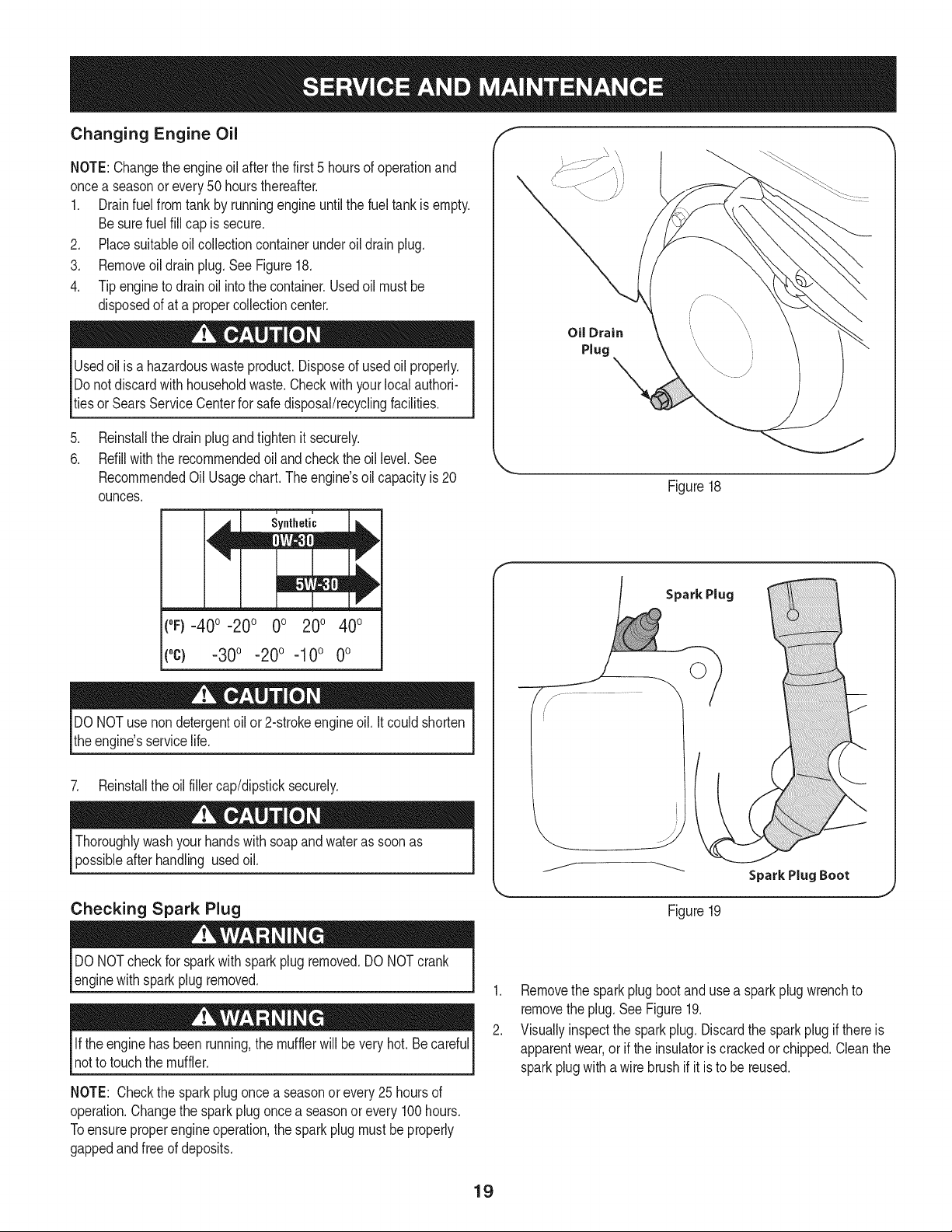

Changing Engine Oil

NOTE:Changetheengineoilafterthe first5 hoursofoperationand

oncea seasonorevery50hoursthereafter.

1. Drainfuelfromtankbyrunningengineuntilthefuel tankisempty.

Besurefuel fillcap issecure.

2. Placesuitableoilcollectioncontainerunderoildrainplug.

3. Removeoildrainplug.SeeFigure18.

4. Tipenginetodrainoil intothecontainer.Usedoilmustbe

disposedofat a propercollectioncenter.

Usedoil isa hazardouswasteproduct.Disposeof usedoil properly.

Donotdiscardwith householdwaste.Checkwithyourlocalauthori-

tiesor SearsServiceCenterfor safedisposal/recyclingfacilities.

.

Reinstallthedrainplugandtightenit securely.

6.

Refillwiththerecommendedoil andcheckthe oil level.See

RecommendedOil Usagechart.Theengine'soilcapacityis20

ounces.

u i

Synthetic

Oil Drain

Plug

Figure18

(0F)-40o-20 o 0o 200 400

("c) -30° -20° -10° 0°

DONOTuse nondetergentoilor 2-strokeengineoil.It couldshorten

theengine'sservicelife.

7. Reinstalltheoilfillercap/dipsticksecurely.

Thoroughlywashyourhandswithsoapandwateras soonas

possibleafterhandling usedoil.

Checking Spark Plug

DONOTcheckforsparkwithsparkplugremoved.DONOTcrank

enginewithsparkplugremoved.

Iftheenginehasbeenrunning,themufflerwillbevery hot.Becareful

notto touchthemuffler.

NOTE: Checkthesparkplugoncea seasonorevery25hoursof

operation.Changethesparkplugoncea seasonorevery100hours.

Toensureproperengineoperation,thesparkplugmustbe properly

gappedandfreeof deposits.

Spark Plug

©

SparkPlugBoot

J

Figure19

1. Removethesparkplugbootandusea sparkplugwrenchto

removetheplug.SeeFigure19.

2. Visuallyinspectthe sparkplug.Discardthe sparkplugifthereis

apparentwear,orif theinsulatoriscrackedorchipped.Cleanthe

sparkplugwithawirebrushifit isto be reused.

19

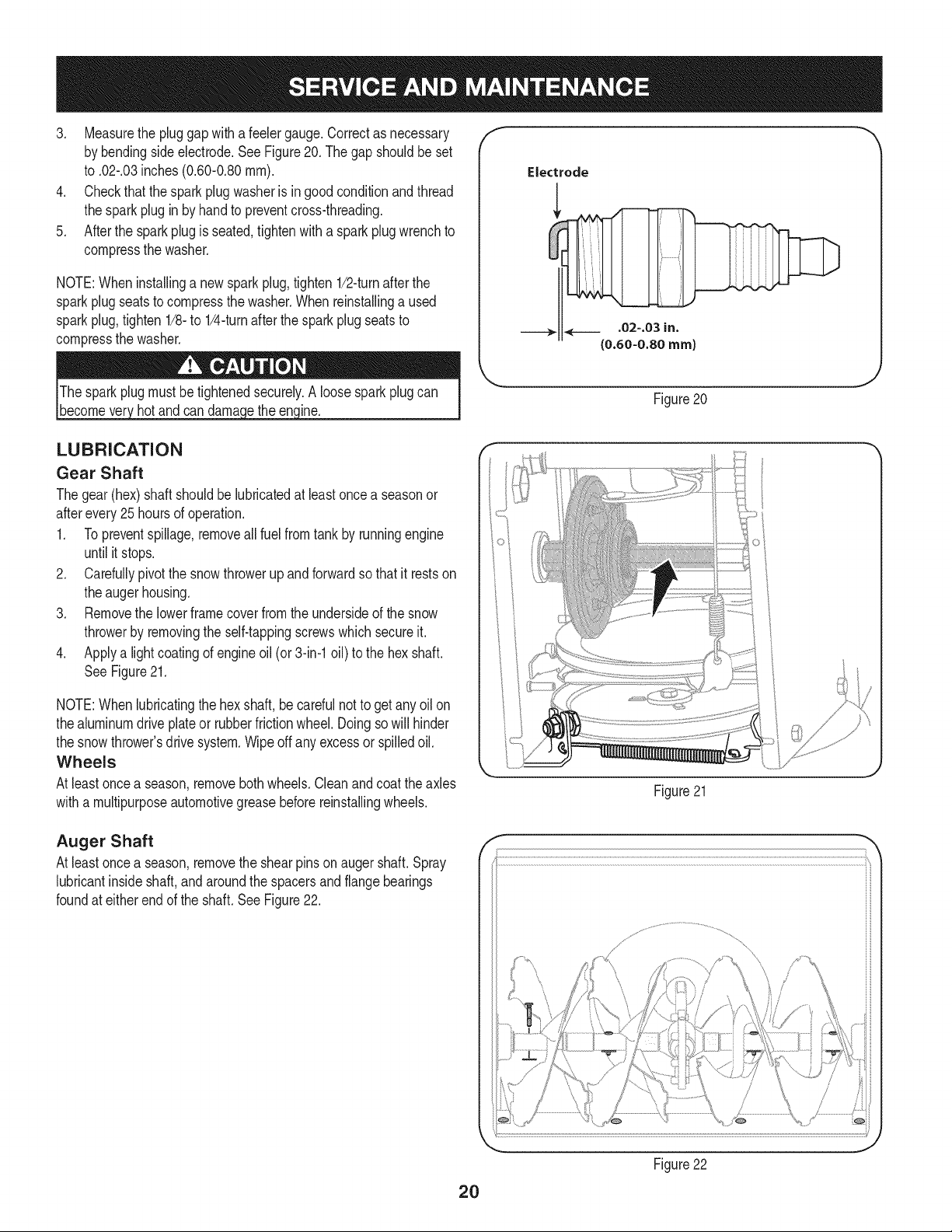

3. Measurethepluggapwithafeelergauge.Correctasnecessary

bybendingsideelectrode.SeeFigure20.Thegap shouldbeset

to.02-.03inches(0.60-0.80ram).

4. Checkthatthesparkplugwasherisingoodconditionandthread

thesparkplugin by handtopreventcross-threading.

5. Afterthe sparkplugisseated,tightenwitha sparkplugwrenchto

compressthewasher.

NOTE:Wheninstallinga newsparkplug,tighten1/2-turnafterthe

sparkplugseatsto compressthewasher.Whenreinstallinga used

sparkplug,tighten1/8-to 1/4-turnafterthe sparkplugseatsto

compressthewasher.

hotandcan ine.

LUBRICATION

Gear Shaft

Thegear(hex)shaftshouldbe lubricatedatleastoncea seasonor

afterevery25 hoursofoperation.

1. Topreventspillage,removeallfuelfromtank byrunningengine

untilit stops.

2. Carefullypivotthesnowthrowerupandforwardsothatitrestson

theaugerhousing.

3. Removethe lowerframecoverfromtheundersideofthesnow

throwerbyremovingthe self-tappingscrewswhichsecureit.

4. Applya lightcoatingofengineoil (or3-in-1oil)tothehexshaft.

SeeFigure21.

f

Electrode

.02=.03 in.

(0.60=0.80 rnrn)

J

Figure20

NOTE:Whenlubricatingthehexshaft,be carefulnotto getany oilon

thealuminumdriveplateor rubberfrictionwheel.Doingsowillhinder

thesnowthrower'sdrivesystem.Wipeoff anyexcessorspilledoil.

Wheels

Atleastoncea season,removebothwheels.Cleanandcoattheaxles

witha multipurposeautomotivegreasebeforereinstallingwheels.

Auger Shaft

Atleastoncea season,removethe shearpinson augershaft.Spray

lubricantinsideshaft,andaroundthe spacersandflangebearings

foundat eitherendof theshaft.SeeFigure22.

Figure21

f

\

\

J

Figure22

2O

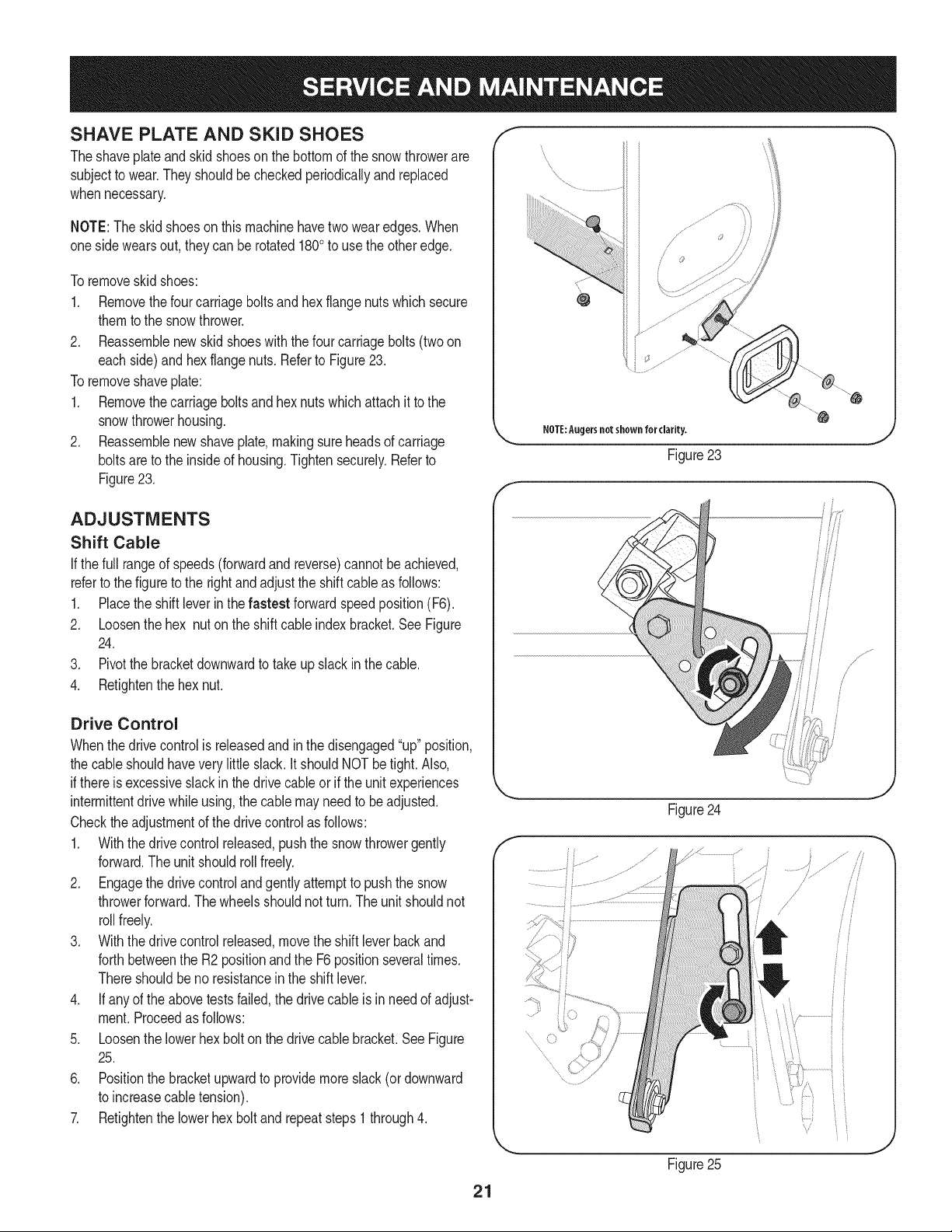

SHAVE PLATE AND SKiD SHOES

Theshaveplateand skidshoesonthebottomofthe snowthrowerare

subjectto wear.Theyshouldbecheckedperiodicallyandreplaced

whennecessary.

NOTE:Theskidshoesonthismachinehavetwowearedges.When

onesidewearsout, theycan be rotated1800to usetheotheredge.

Toremoveskidshoes:

1. Removethefourcarriageboltsandhexflangenutswhichsecure

themtothe snowthrower.

2. Reassemblenewskidshoeswiththefourcarriagebolts(twoon

eachside)and hexflangenuts.Referto Figure23.

Toremoveshaveplate:

1. Removethecarriageboltsand hexnutswhichattachit tothe

snowthrowerhousing.

2. Reassemblenewshaveplate,makingsureheadsof carriage

boltsaretothe insideof housing.Tightensecurely.Referto

Figure23.

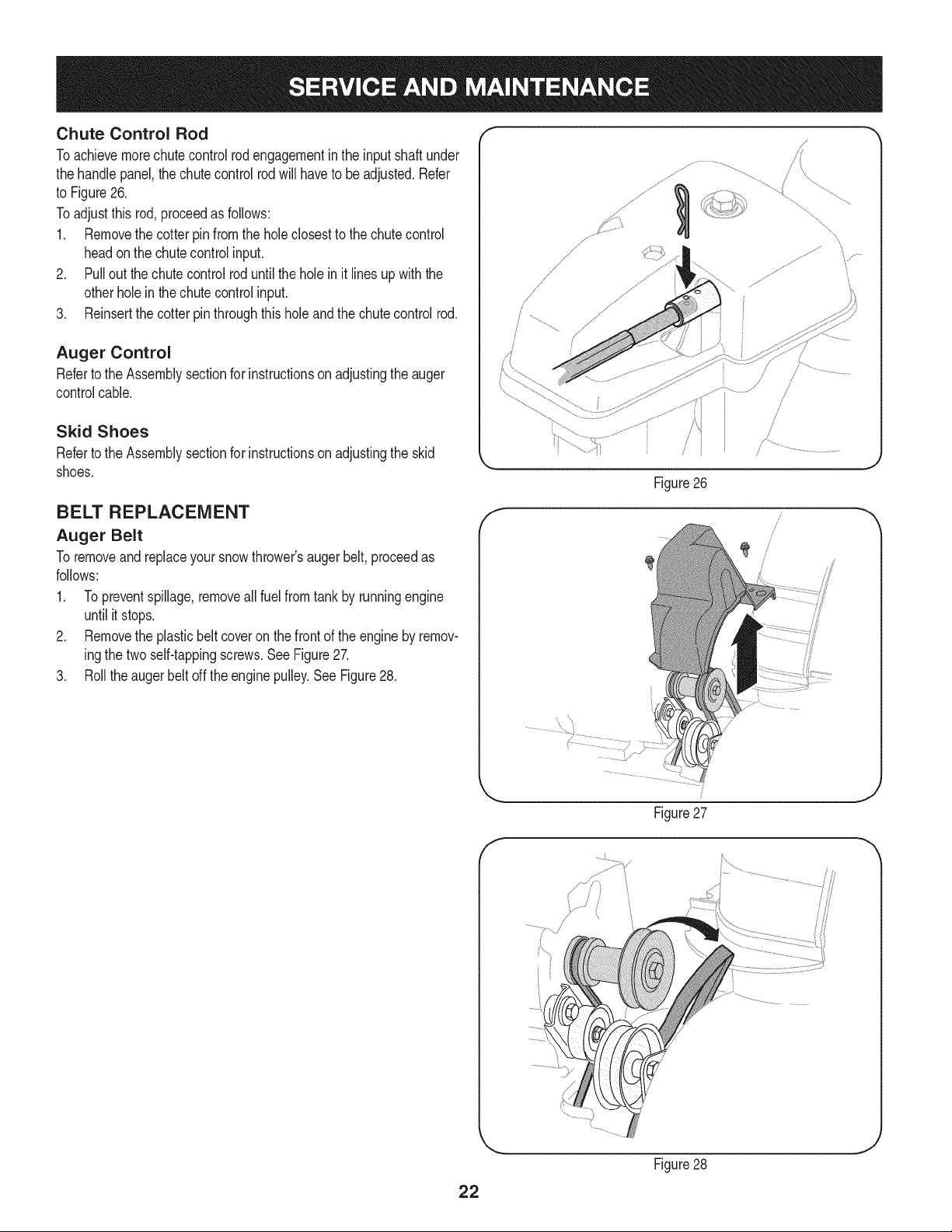

ADJUSTMENTS

Shift Cable

If thefull rangeofspeeds(forwardandreverse)cannotbeachieved,

referto thefiguretothe rightandadjustthe shiftcableasfollows:

1. Placethe shiftleverin thefastest forwardspeedposition(F6).

2. Loosenthehex nuton the shiftcable indexbracket.SeeFigure

24.

3. Pivotthebracketdownwardtotakeupslackinthecable.

4. Retightenthehexnut.

NOTE:Augersnotshown for clarity.

Figure23

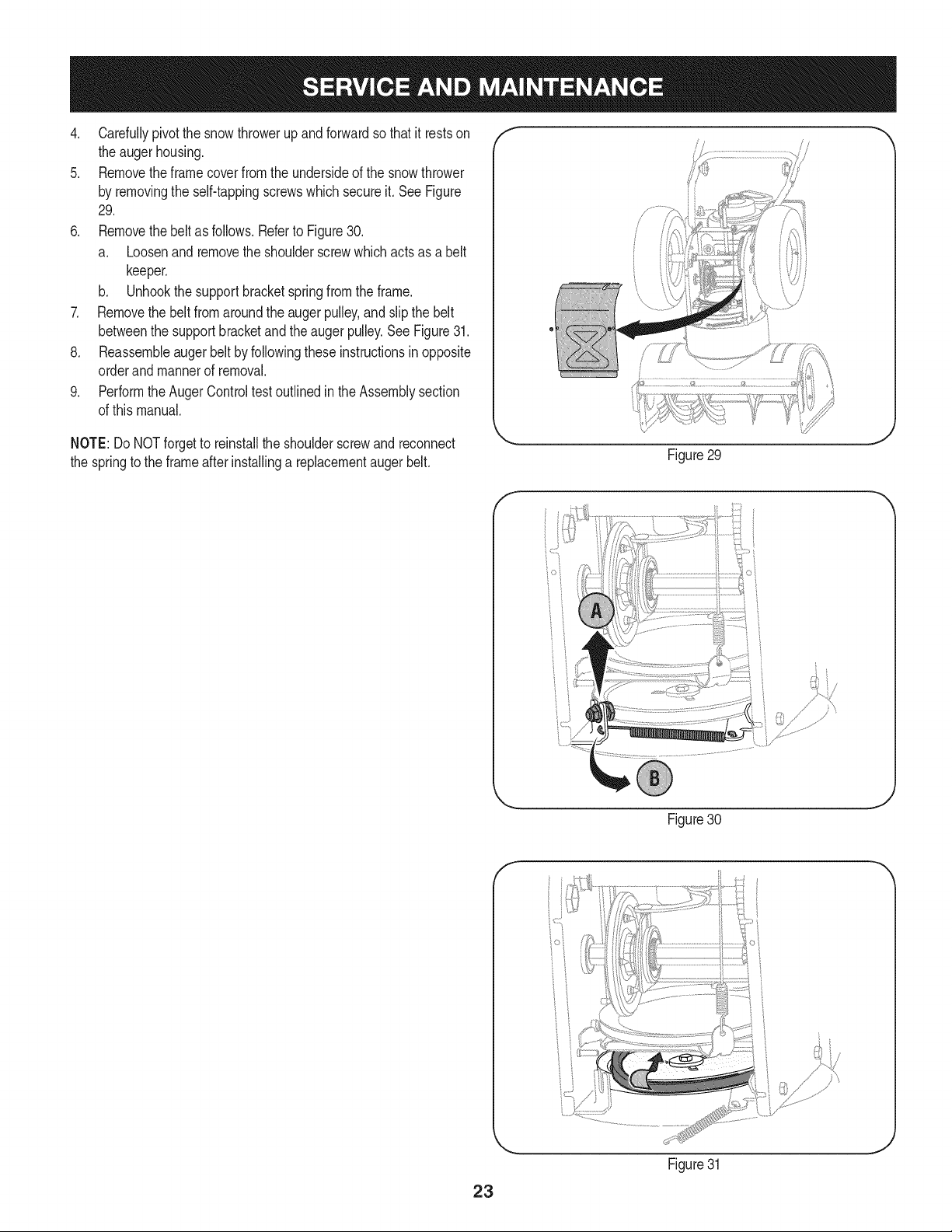

Drive Control

Whenthedrivecontrolis releasedandin thedisengaged"up"position,

thecableshouldhaveverylittle slack.It shouldNOTbetight. Also,

ifthereisexcessiveslackin thedrivecableor ifthe unitexperiences

intermittentdrivewhileusing,the cablemayneedto beadjusted.

Checktheadjustmentofthe drivecontrolas follows:

1. Withthedrivecontrolreleased,pushthe snowthrowergently

forward.Theunitshouldrollfreely.

2. Engagethedrivecontrolandgentlyattempttopushthesnow

throwerforward.Thewheelsshouldnotturn.Theunitshouldnot

rollfreely.

3. Withthedrivecontrolreleased,movetheshiftleverbackand

forthbetweenthe R2positionandtheF6 positionseveraltimes.

Thereshouldbeno resistancein theshiftlever.

4. If anyoftheabovetestsfailed,thedrivecableisin needofadjust-

ment.Proceedasfollows:

5. Loosenthelowerhexboltonthedrivecablebracket.SeeFigure

25.

6. Positionthebracketupwardtoprovidemoreslack(ordownward

toincreasecabletension).

7. Retightenthelowerhexboltandrepeatsteps1through4.

Figure24

f

/

........

Figure25

21

Chute Control Rod

Toachievemorechutecontrolrodengagementintheinputshaftunder

thehandlepanel,thechutecontrolrodwill haveto beadjusted.Refer

toFigure26.

Toadjustthis rod,proceedasfollows:

1. Removethecotterpinfromtheholeclosesttothechutecontrol

headon thechutecontrolinput.

2. Pulloutthechutecontrolroduntiltheholein it linesupwiththe

otherholein thechutecontrolinput.

3. Reinsertthecotterpinthroughthisholeandthechutecontrolrod.

Auger Control

Refertothe Assemblysectionfor instructionsonadjustingtheauger

controlcable.

Skid Shoes

Refertothe Assemblysectionfor instructionsonadjustingthe skid

shoes.

BELT REPLACEMENT

Auger Belt

Toremoveandreplaceyoursnowthrower'saugerbelt,proceedas

follows:

1. Topreventspillage,removeallfuelfromtank byrunningengine

untilit stops.

2. Removethe plasticbeltcoveronthefrontoftheenginebyremov-

ingthetwoself-tappingscrews.SeeFigure27.

3. Rolltheaugerbeltofftheenginepulley.See Figure28.

/

/

/

/

/

/

Figure26

f

22

J

Figure27

f

/

Figure28

4, Carefullypivotthesnowthrowerupandforwardsothatitrestson

theaugerhousing.

5, Removetheframecoverfromtheundersideofthesnowthrower

byremovingtheself-tappingscrewswhichsecureit,SeeFigure

29,

6, Removethebeltasfollows,RefertoFigure30,

a, Loosenandremovetheshoulderscrewwhichactsasabelt

keeper,

b, Unhookthesupportbracketspringfromtheframe.

7, Removethebeltfromaroundtheaugerpulley,andslipthebelt

betweenthesupportbracketandtheaugerpulley.SeeFigure31,

8, Reassembleaugerbeltbyfollowingtheseinstructionsinopposite

orderandmannerofremoval.

9, PerformtheAugerControltestoutlinedintheAssemblysection

ofthismanual,

NOTE:DoNOTforgettoreinstalltheshoulderscrewandreconnect

thespringtotheframeafterinstallingareplacementaugerbelt.

Figure29

f

Figure30

f

23

Figure31

Loading...

Loading...