Craftsman 247889360 Owner’s Manual

Operator's Manual

12.5 Horse Power

36-inch Wide Cut Mower

Model No. 247.889360

CAUTION: Before using

this product, read this

manual and follow all

Safety Rules and

Operating Instructions.

Safety

Assembly

Operation

Maintenance

For answers to your questions

about this product, call:

1-800-659-5917

Sears Craftsman Help Line

5 a.m. - 5 p.m., Mon - Sat

Parts

Espahol, p.60

Sears, Roebuck and Co., Hoffman Estates, IL 60179, U.S.A.

Visit our Sears website: www.sears.com/craftsman

Printed in U.S.A. FORM NO. 02005404 Rev 09_0

(4/2009)

WarrantyStatement 2 Maintenance 17

SafetyInstructions 3 ServiceandAdjustments 21

SlopeGuide 6 Off-SeasonStorage 24

RepairProtectionAgreement 7 AccessoriesandAttachments 24

SafetyLabels 8 Troubleshooting 25

ProductSpecification 10 PartsList 26

Assembly 11 Espanol 60

Operation 12

Craftsman Two Year Limited Warranty on 36-inch Wide Cut Mower

When used and maintained according to all supplied instructions, if this Craftsman product fails due to a defect in

material within two years from the date of purchase, return it to any Sears store, Parts & Repair Service Center, or

other Craftsman outlet in the United States for free repair. In-home warranty service is available, but you will have

to pay a trip charge.

This Warranty does not cover:

• Expendable items which become worn during normal use, such as rotary mower blades, blade adaptors,

spark plugs, air cleaners, belts, and oil filters.

• Tire replacement or repair caused by punctures from outside objects, such as nails, thorns, stumps, or glass.

• Repairs necessary because of operator abuse, including but not limited to, damage caused by objects, such

as stones, metal debris or oversized pieces of wood, or impacting objects that bend the frame or crankshaft,

or over-speeding the engine.

• Repairs necessary because of operator negligence, including but not limited to, electrical and mechanical

damage caused by improper storage, failure to use the proper grade and amount of engine oil, or failure to

maintain the equipment according to the instructions contained in the operator's manual.

• Engine (fuel system) cleaning or repairs caused by fuel determined to be contaminated or oxidized (stale). In

general, fuel should be used within 30 days of its purchase date.

This warranty applies for only 90 days if this product is ever used for commercial or rental purposes.

This warranty applies only while this product is used inthe United States.

This warranty gives you specific legal rights and you may also have other rights, which vary from state to state.

Sears, Roebuck and Co., Hoffman Estates, IL 60179

MODEL NUMBER

Model Number .........................................................

Serial Number ...........................................................

Date of Purchase ......................................................

Record the model number, serial number and date of

purchase above.

WARNING: This symbol points out important safety instructions which, if not followed, could

endanger the personal safety and/or property of yourself and others. Read and follow all

instructions in this manual before attempting to operate this machine. Failure to comply with these

instructions may result in personal injury. When you see this symbol - heed its warning.

WARNING: Engine Exhaust, some of its constituents, and certain vehicle

components contain or emit chemicals known to State of California to cause cancer

and birth defects or other reproductive harm.

DANGER: This machine was built to be operated according to the rules for safe operation inthis

manual. As with any type of power equipment, carelessness or error on the part of the operator can

result in serious injury. This machine is capable of amputating hands and feet and throwing objects.

Failure to observe the following safety instructions could result in serious injury or death.

GENERAL

1. Read this Operator's Manual completely before

starting the mower. Study the controls and learn

the proper sequence of operation. Retain

Operator's Manual in a safe place for future

reference.

operator English

Spanish, the owner is responsible for explaining the

IMPORTANT: Ifthe cannot read

information inthis manual.

2. Do not allow anyone to operate or maintain this

machine who has not read the manual. Never

permit children under the age of 16 to operate

this machine.

3. Always have your feet and hands clear of the

cutter deck when starting the engine.

4. Do not remove any shields, guards, decals or

safety devices. If a shield, guard, decal or safety

device is damaged or does not function, repair or

replace it before operating the mower.

5. Always wear safety glasses, long pants and

safety shoes when operating or maintaining this

mower. Do not wear loose-fitting clothing, or have

loose long hair or jewelry.

6. Never run the engine indoors without adequate

ventilation. Exhaust fumes are deadly.

7. To avoid serious burns, do not touch the engine

or muffler while the engine is running or until it

has cooled for at least 30 minutes after it has

been shut off.

8. Do not allow anyone to ride on this mower. No

passengers.

9. Do not operate this mower under the influence of

alcohol and or drugs.

10. Do not operate or store the machine or fuel

container inside where there is an open flame,

spark or pilot light such as a water heater,

furnace, clothes dryer, etc.

11. The owner is responsible for training the users,

and is responsible for accidents or injuries

occuring to themselves or others.

or

OPERATION

WARNING: Never mow in fifth gear I

(transport speed).

I

Keep adults, children and pets away from the

area to be mowed. (75 feet reccommended)

2. Never use this mower without the discharge

chute installed and set in the down position

(except when material collection system is used.)

3. Mow only in daylight or proper artificial light.

4. Always remove debris and other objects from the

area to be mowed.

5. Watch for holes, sprinkler heads and other

hidden hazards.

6. Reduce speed when making sharp turns.

7. Always have proper footing on slopes and hill

sides and never operate when conditions are

slippery.

8. Always keep both hands on the handles when

mowing. Always walk, never run.

9. Never engage the blade clutch when the engine

is running unless you are on grass that you intend

to mow.

10. Be careful when crossing gravel paths or road-

ways. Always disengage the blade clutch and

wait until the blades stop rotating.

11. Never leave the mower unattended without

disengaging the blade clutch, shifting the

transmission into neutral, placing the neutral latch

levers in the neutral lock position, shutting off the

engine, removing the key from the ignition switch

and closing the fuel shutoff valve.

12. Always park the mower and start the engine on a

level surface with the transmission in neutral, the

blade clutch disengaged and the neutral latch

levers in the neutral lock position.

13. Shut off the engine and wait for the blades to stop

rotating before removing the grass catcher.

14. If you hit a solid object while mowing, disengage

the blade clutch, shift the transmission into

neutral,placetheneutrallatchleversintheneutral

lockpositionandstoptheengine.Disconnectthe

sparkplugwire(s)andinspectfordamage.Repair

anydamageandmakesurethebladesareingood

conditionandthebladeboltsaretightbefore

restartingtheengine.

15.Donotmowexcessivelysteepslopes(Nomore

than15degreesora26.8%grade).Mowacross

theslope.

the slope. You could slip and slide into the

_ ARNING: Do not mow up and down

16. Never raise the mower deck while the blades are

17. Never walk or stand on the discharge side of a

18. Always disconnect the spark plug wire to prevent

19. Keep the mower and especially the engine clean

20. The operator presence control levers located at

mower, or the mower could loose traction

and steering control.

rotating.

mower with the engine running. Disengage the

blade clutch if another person approaches while

you are operating a mower.

the engine from accidentally starting before

performing any maintenance on this mower.

and free of grease, grass and leaves to reduce the

chance of fire and to permit proper cooling.

each handle are designed for your safety. Do not

try to defeat their operation. If the blade clutch is

engaged or the transmission is in gear, releasing

both handles will shut off the mower's engine.

MAINTENANCEANDSTORAGE

WARNING: Never let children or

untrained people operate or service this

mower.

1. Never tamper with safety devices. Check their

proper operation regularly.

2. Check bolts and screws for proper tightness at

frequent intervals to keep the machine in safe

working condition. Also, visually inspect machine

for any damage and repair, if needed.

3. Before cleaning, repairing, or inspecting, stop the

engine and make certain all moving parts have

stopped. Disconnect the spark plug wire and

ground it against the engine to prevent unintended

starting.

4. Do not change the engine governor settings or

overspeed the engine. The governor controls the

maximum safe operating speed of the engine.

5. Maintain or replace safety and instruction labels, as

necessary.

6. Follow this manual for safe loading, unloading,

transporting, and storage of this machine. (See

page 16 and page 24)

7. Never store the machine or fuel container inside

where there is an open flame, spark or pilot light

such as a water heater, furnace, clothes dryer, etc.

8. Always refer to the operator's manual for proper

instructions on off-season storage. (See page 24)

9. Ifthe fuel tank has to be drained, do this outdoors.

Observe proper disposal laws and regulations for gas,

oil, etc. to protect the environment.

RELATEDTOFUEL

1. Fuel is highly flammable and its vapors can explode

if ignited. Please respect it.

2. Do not smoke or permit others to smoke while han-

dling fuel.

3. Always use approved containers for fuel and fill

slowly to decrease the chance of static electricity

buildup and spillage.

4. Store fuel in well ventilated and unoccupied build-

ings away from sparks and flames.

5. When dispensing gasoline into approved contain-

ers, place the container on the ground when refuel-

ing to avoid a possible static electricity ignition of

fuel vapors.

6. Do not fill containers while it is inside a vehicle,

trunk, the bed of a pickup or floor of a trailer.

7. Always shut off the engine and permit it to cool

before removing the fuel tank cap.

8. Always fill the fuel tank outdoors.

9. If the fuel container spout will not fit inside the fuel

tank opening, use a funnel.

10. When filling the fuel tank, stop when the fuel reaches

one inch from the top. This space is necessary fortank

expansion. Do not overfill.

11. Wipe up any spilled fuel.

12. Do not operate or store the machine or fuel

container inside where there is an open flame,

spark or pilot light such as a water heater, furnace,

clothes dryer, etc.

SLOPEOPERATION

DO:

• Mow across slopes, and exercise caution when

turning or changing direction.

• Watch for holes, ruts or bumps and hidden objects.

• Be sure of your footing. A slip could cause personal

injury.

• Check the area thoroughly before mowing.

• Slow down and use extra care.

DO NOT:

• Do not mow up and down slopes.

• Do not mow near drop offs, ditches, embankments,

etc. The mower could suddenly turn over if a wheel is

over the edge of a cliff or ditch, or if an edge caves in.

• Do not mow on wet or slippery grass. Reduced

traction could cause sliding.

• Do not mow on slopes greeater than 15 degrees as

shown on the slope gauge.

FIRSTTIME OPERATORS

• Start off in a flat, open, area.

• Keep bystanders away.

• Set the throttle to low speed.

• Practice maneuvering (forward, turn left, turn right,

reverse), without the mower deck engaged.

5

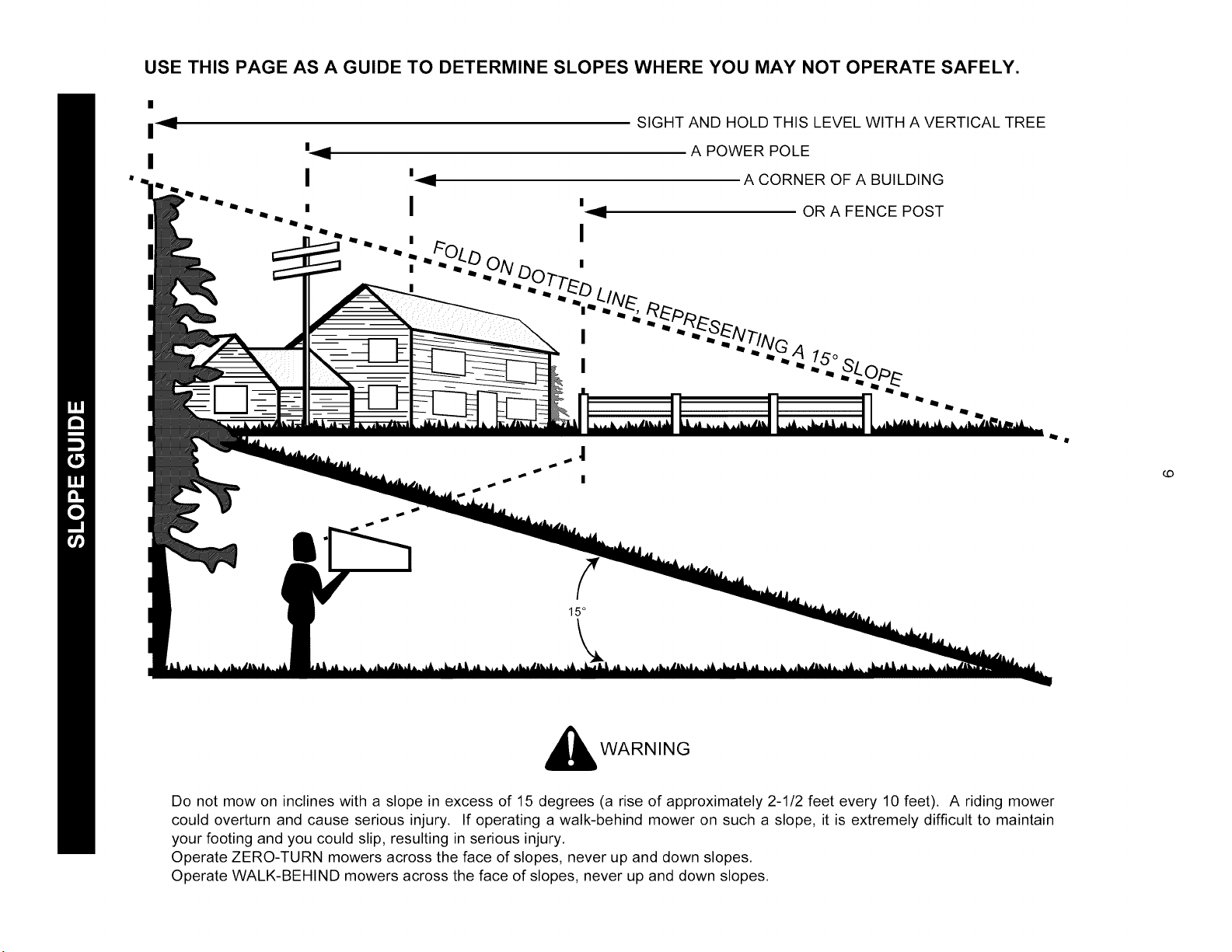

USE THIS PAGE AS A GUIDE TO DETERMINE SLOPES WHERE YOU MAY NOT OPERATE SAFELY.

I

I

I

B

r.D

15 °

_ WARNING

Do not mow on inclines with a slope in excess of 15 degrees (a rise of approximately 2-1/2 feet every 10 feet). A riding mower

could overturn and cause serious injury. If operating a walk-behind mower on such a slope, it is extremely difficult to maintain

your footing and you could slip, resulting in serious injury.

Operate ZERO-TURN mowers across the face of slopes, never up and down slopes.

Operate WALK-BEHIND mowers across the face of slopes, never up and down slopes.

Congratulations on making a smart purchase. Your new

Craftsman® Professional product is designed and

manufactured for years of dependable operation. But like all

products, it may require repair from time to time. That's when

having a Repair Protection Agreement can save you money and

aggravation.

Here's what the Repair Protection Agreement* includes:

Expert service by our 10,000 professional repair

specialists

Unlimited service and no charge for parts and labor

on all covered repairs

Product replacement up to $1500 if your covered

product cannot be fixed

,_ Discount of 10% from regular price of service and

related installed parts not covered by the agreement;

also, 10% off regular price of preventive maintenance

check

Fast help by phone- we call it Rapid Resolution- phone

support from a Sears representative. Think of us as a

'_talking owner's manual."

Once you purchase the Repair Protection Agreement, a simple

phone call is all that it takes for you to schedule service. You can

call anytime day or night, or schedule a service appointment

online.

The Repair Protection Agreement isa risk-free purchase. If you

cancel for any reason during the product warranty period, we will

provide a full refund. Or, a prorated refund anytime after the

product warranty period expires. Purchase your Repair

Protection Agreement today!

Some limitations and exclusions apply. For prices and

additional information in the U.S.A. call 1-800-827-6655.

*Coverage in Canada varies on some items. For full details

call Sears Canada at 1-800-361-6665.

Sears Installation Service

For Sears professional installation of home appliances, garage

door openers, water heaters, and other major home items, inthe

U.S.A. or Canada call 1-800-4-MY-HOME®

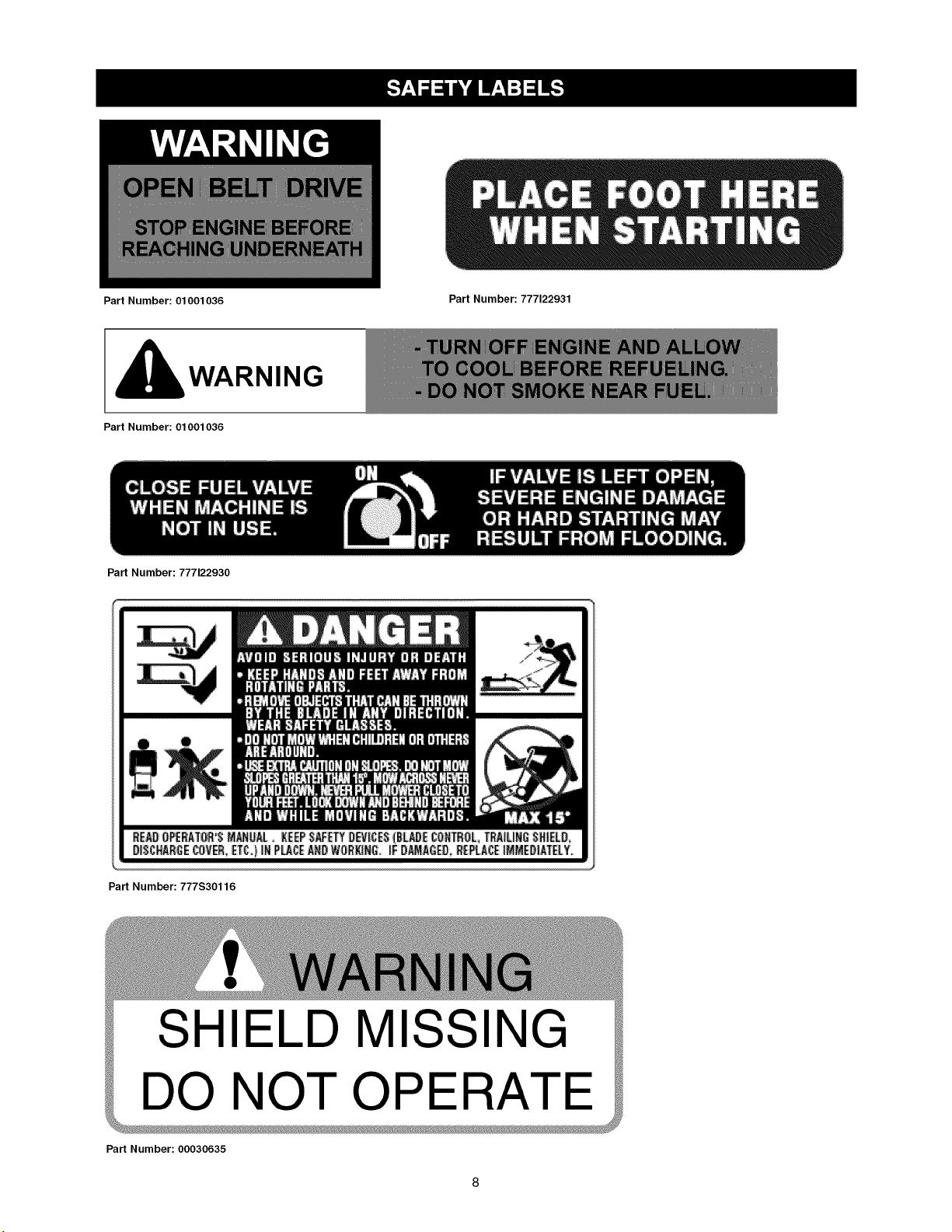

Part Number: 01001036

I_WARNING

Part Number: 01001036

Part Number: 777122930

Part Number: 777122931

Part Number: 777S30116

SHIELD MISSING

DO NOT OPERAT

Part Number: 00030635

PartNumber:777122919

PartNumber:777S33036

PartNumber:777S30503

Part Number: 01002166

5TRANSPORT

|

Part Number: 777122929

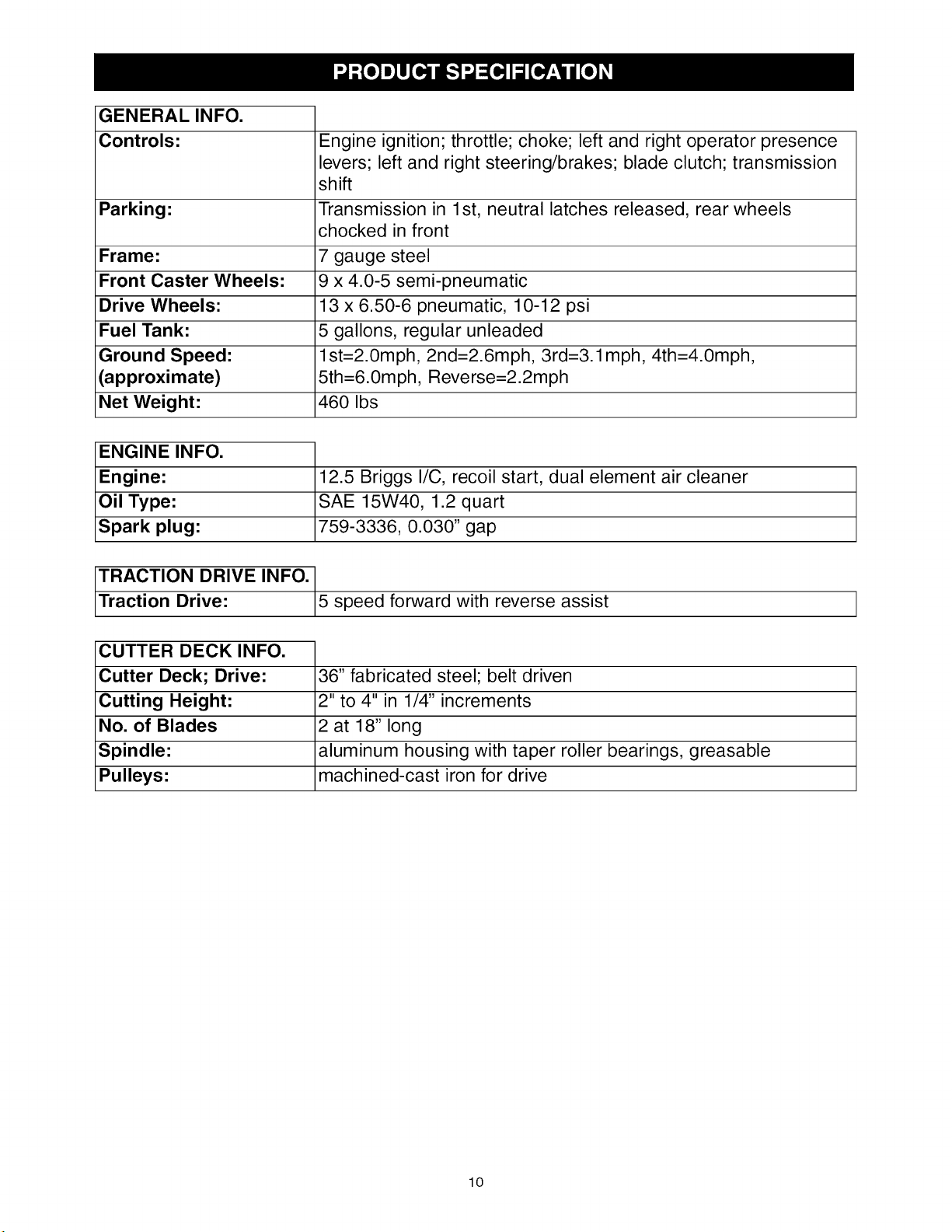

GENERAL INFO.

Controls: Engine ignition; throttle; choke; left and right operator presence

levers; left and right steering/brakes; blade clutch; transmission

shift

Parking: Transmission in 1st, neutral latches released, rear wheels

chocked in front

Frame: 7 gauge steel

Front Caster Wheels: 9 x 4.0-5 semi-pneumatic

Drive Wheels: 13 x 6.50-6 pneumatic, 10-12 psi

Fuel Tank: 5 gallons, regular unleaded

Ground Speed: l st=2.0mph, 2nd=2.6mph, 3rd=3.1mph, 4th=4.0mph,

(approximate) 5th=6.0mph, Reverse=2.2mph

Net Weight: 460 Ibs

ENGINE INFO.

Engine:

Oil Type:

Spark plug:

TRACTION DRIVE INFO. 1

Traction Drive: 5 speed forward with reverse assist

12.5 Briggs I/C, recoil start, dual element air cleaner

SAE 15W40, 1.2 quart

759-3336, 0.030" gap

CUTTER DECK INFO.

Cutter Deck; Drive:

Cutting Height:

No. of Blades

Spindle:

Pulleys:

36" fabricated steel; belt driven

2" to 4" in 1/4" increments

2 at 18" long

aluminum housing with taper roller bearings, greasable

machined-cast iron for drive

lO

IMPORTANT:This unit is shipped with oil in the engine.

After assembly, see OPERATION section of this

manual for fuel and engine oil details.

NOTE: Reference to right and left hand side of the

mower is observed from the operating position.

This pedestrian controlled wide area mower has been

completely assembled at the factory.

LOOSEPARTSIN CARTON

The following items are packaged in a bag:

Operator's Manual and Engine Manual

TOOLSNEEDEDFORASSEMBLY

A tire Gauge

REMOVINGTHEUNITFROMTHECRATE

1. Cut straps securing unit to pallet.

2. Remove any protective packaging and plastic tie

straps.

REMOVINGTHECHUTESTRAP

1. Locate the chute strap which secures the discharge

chute in a vertical position.

2. Pull chute back towards the engine. While holding

the chute with one hand, cut the strap with the other

hand.

FINALADJUSTMENTS

Tire Pressure

The recommended operating rear tire pressure is 10-

12 psi. The caster wheels are semi-pneumatic and do

not require air pressure. Check the tire pressure

periodically and maintain equal pressure in both rear

tires at all times.

IMPORTANT: Refer to the tire sidewall for exact tire I

manufacturer;s recommended or maximum psi. Do not

overinflate. Uneven tire pressure could cause the

cutt ng deck to mow uneven y.

11

Know Your Mower

Read this operator's manual and safety rules before operating your Mower. Compare the illustrations below

with your equipment to familiarize yourself with the location of various controls, safety signs and adjustments.

Save this manual for future reference.

The operation of any lawn mower can result in foreign objects being thrown into the eyes, which can damage

your eye severely. Always wear safety glasses, while operating the mower or while performing any

adjustments or repairs on it. Check local regulations, hard hats and hearing protection may be required! Use

only approved accessories and attachments.

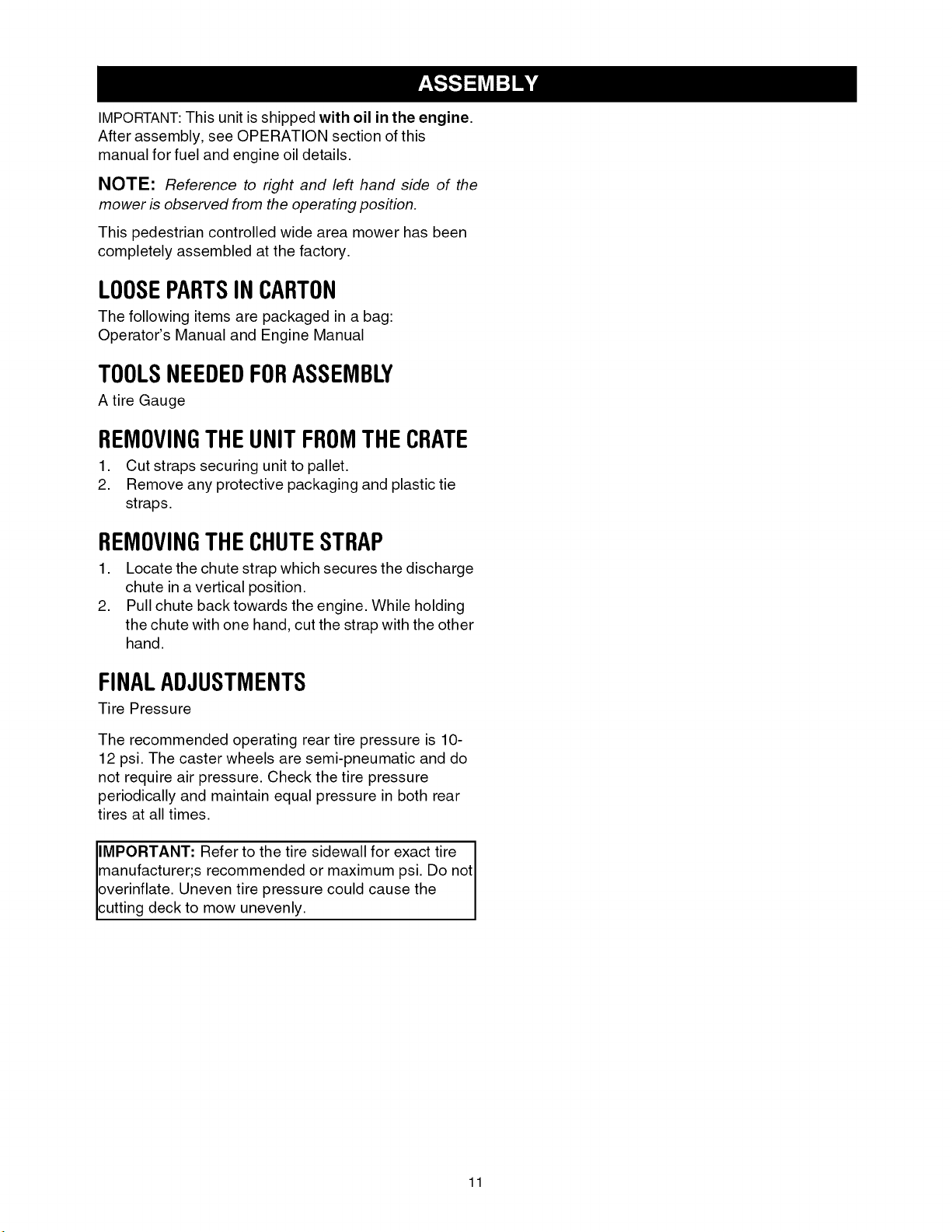

Figure 1 The Control Panel

1. Ignition Switch 2. Choke

3. Engine Throttle 4. Blade Clutch lever

5. Right Steering Brake Lever 6. Neutral Latch Levers

7. Operator Presence Lever 8. Fuel Shutoff Valve

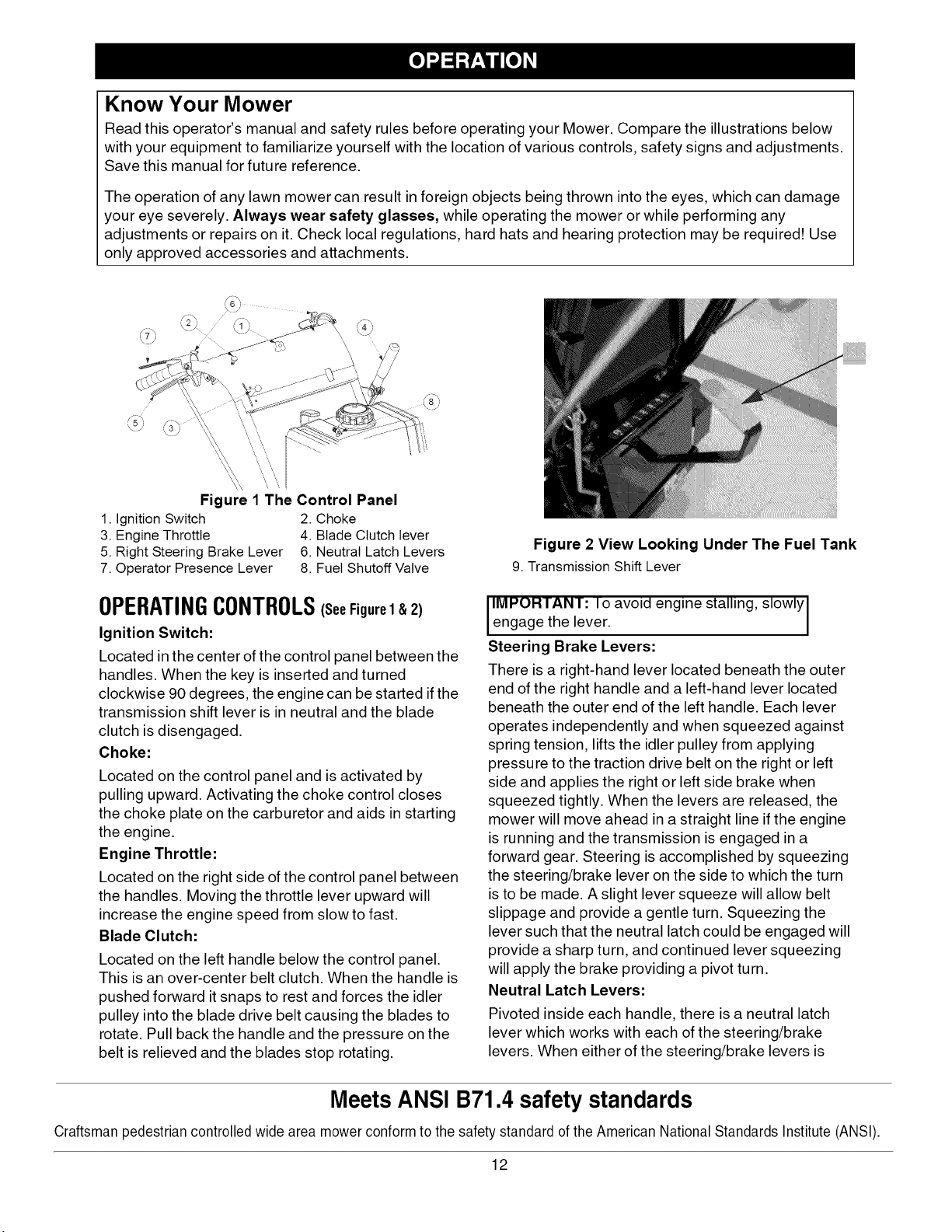

Figure 2 View Looking Under The Fuel Tank

9. Transmission Shift Lever

OPERATINGCONTROLS(seeFigurel& 2)

Ignition Switch:

Located in the center of the control panel between the

handles. When the key is inserted and turned

clockwise 90 degrees, the engine can be started if the

transmission shift lever is in neutral and the blade

clutch is disengaged.

Choke:

Located on the control panel and is activated by

pulling upward. Activating the choke control closes

the choke plate on the carburetor and aids in starting

the engine.

Engine Throttle:

Located on the right side of the control panel between

the handles. Moving the throttle lever upward will

increase the engine speed from slow to fast.

Blade Clutch:

Located on the left handle below the control panel.

This is an over-center belt clutch. When the handle is

pushed forward it snaps to rest and forces the idler

pulley into the blade drive belt causing the blades to

rotate. Pull back the handle and the pressure on the

belt is relieved and the blades stop rotating.

IMPORTANT: Io avoid engine stalling, slowly I

engage the lever. I

Steering Brake Levers:

There is a right-hand lever located beneath the outer

end of the right handle and a left-hand lever located

beneath the outer end of the left handle. Each lever

operates independently and when squeezed against

spring tension, lifts the idler pulley from applying

pressure to the traction drive belt on the right or left

side and applies the right or left side brake when

squeezed tightly. When the levers are released, the

mower will move ahead in a straight line if the engine

is running and the transmission is engaged in a

forward gear. Steering is accomplished by squeezing

the steering/brake lever on the side to which the turn

is to be made. A slight lever squeeze will allow belt

slippage and provide a gentle turn. Squeezing the

lever such that the neutral latch could be engaged will

provide a sharp turn, and continued lever squeezing

will apply the brake providing a pivot turn.

Neutral Latch Levers:

Pivoted inside each handle, there is a neutral latch

lever which works with each of the steering/brake

levers. When either of the steering/brake levers is

Meets ANSI B71.4 safety standards

Craftsmanpedestriancontrolled wide area mower conformto the safety standard ofthe American National Standards Institute (ANSI).

12

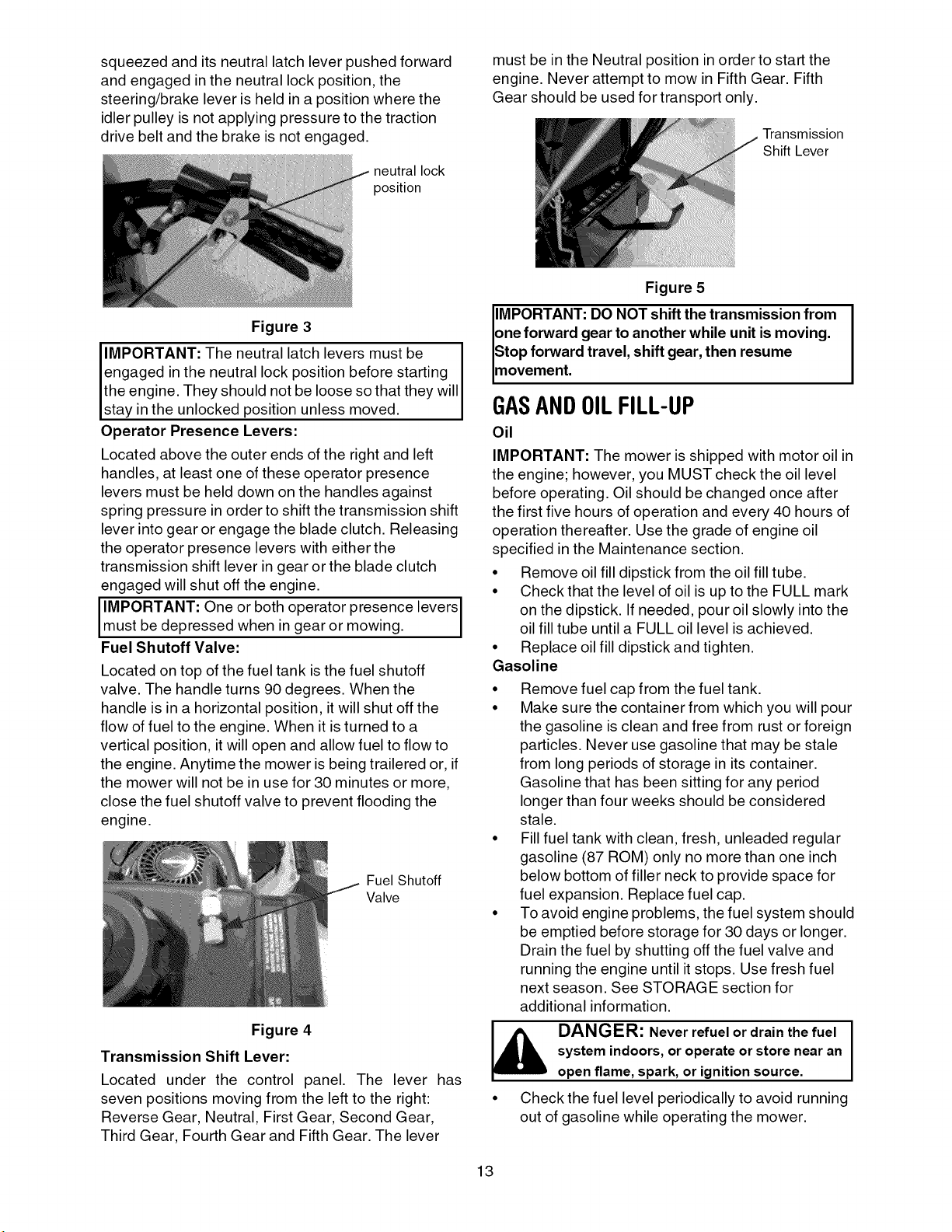

squeezedanditsneutrallatchleverpushedforward

andengagedintheneutrallockposition,the

steering/brakeleverisheldinapositionwherethe

idlerpulleyisnotapplyingpressuretothetraction

drivebeltandthebrakeisnotengaged.

neutral lock

position

must be in the Neutral position in order to start the

engine. Never attempt to mow in Fifth Gear. Fifth

Gear should be used for transport only.

Transmission

Shift Lever

Figure 5

Figure 3

IMPORTANT: The neutral latch levers must be I

engaged in the neutral lock position before starting I

the engine. They should not be loose so that they will

stay n the un ocked post on un ess moved.

Operator Presence Levers:

Located above the outer ends of the right and left

handles, at least one of these operator presence

levers must be held down on the handles against

spring pressure in order to shift the transmission shift

lever into gear or engage the blade clutch. Releasing

the operator presence levers with either the

transmission shift lever in gear or the blade clutch

engaged will shut off the engine.

IMPORTANT: One or both operator presence levers

must be depressed when n gear or mow ng.

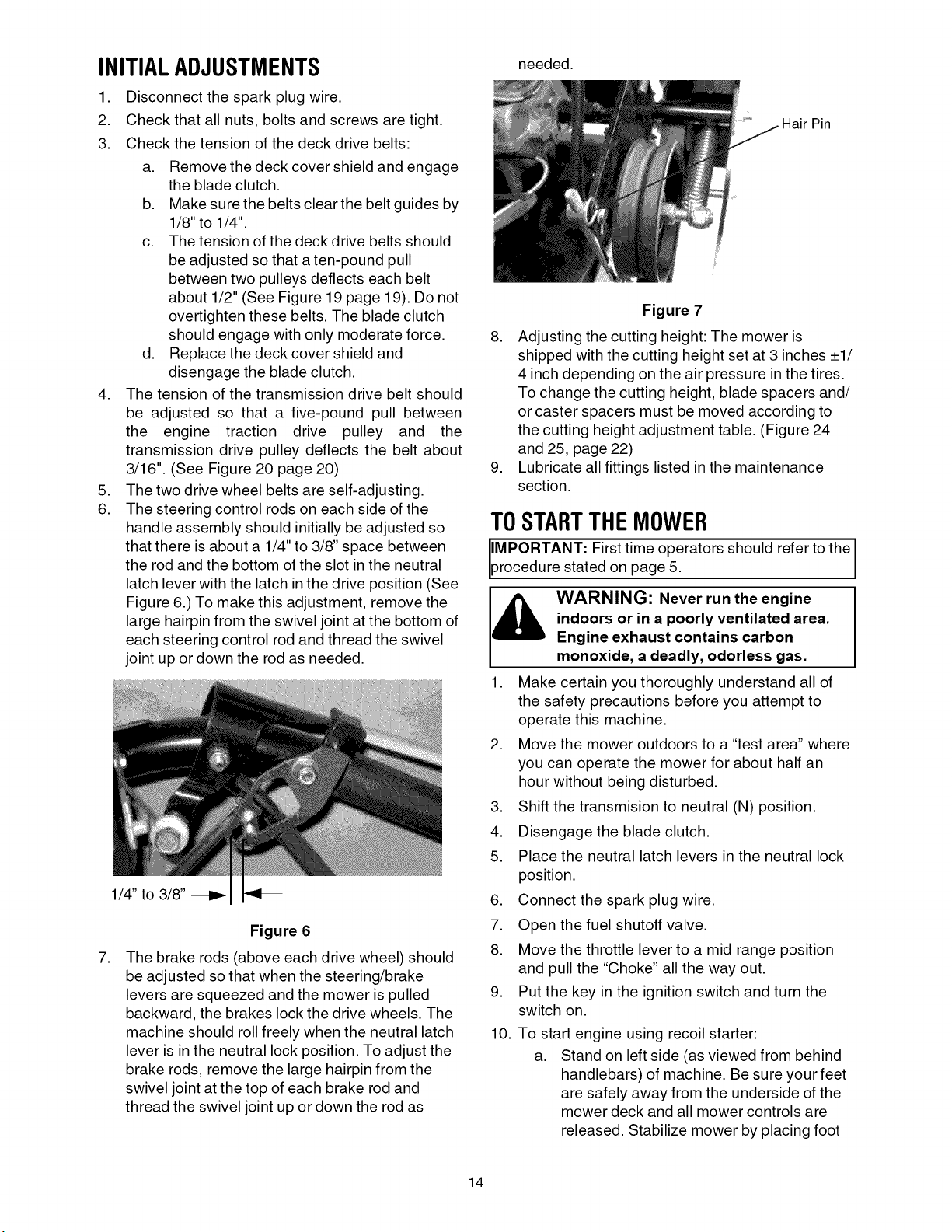

Fuel Shutoff Valve:

Located on top of the fuel tank is the fuel shutoff

valve. The handle turns 90 degrees. When the

handle is ina horizontal position, it will shut off the

flow of fuel to the engine. When it is turned to a

vertical position, it will open and allow fuel to flow to

the engine. Anytime the mower is being trailered or, if

the mower will not be in use for 30 minutes or more,

close the fuel shutoff valve to prevent flooding the

engine.

Fuel Shutoff

Valve

Figure 4

Transmission Shift Lever:

Located under the control panel. The lever has

seven positions moving from the left to the right:

Reverse Gear, Neutral, First Gear, Second Gear,

Third Gear, Fourth Gear and Fifth Gear. The lever

IMPORTANT: DO NOT shift the transmission from

one forward gear to another while unit is moving.

Stop forward travel, shift gear, then resume

movement.

GASANDOILFILL-UP

Oil

IMPORTANT: The mower is shipped with motor oil in

the engine; however, you MUST check the oil level

before operating. Oil should be changed once after

the first five hours of operation and every 40 hours of

operation thereafter. Use the grade of engine oil

specified in the Maintenance section.

• Remove oil fill dipstick from the oil fill tube.

• Check that the level of oil is up to the FULL mark

on the dipstick. If needed, pour oil slowly into the

oil fill tube until a FULL oil level is achieved.

• Replace oil fill dipstick and tighten.

Gasoline

• Remove fuel cap from the fuel tank.

• Make sure the container from which you will pour

the gasoline is clean and free from rust or foreign

particles. Never use gasoline that may be stale

from long periods of storage in its container.

Gasoline that has been sitting for any period

longer than four weeks should be considered

stale.

• Fill fuel tank with clean, fresh, unleaded regular

gasoline (87 ROM) only no more than one inch

below bottom of filler neck to provide space for

fuel expansion. Replace fuel cap.

• To avoid engine problems, the fuel system should

be emptied before storage for 30 days or longer.

Drain the fuel by shutting off the fuel valve and

running the engine until it stops. Use fresh fuel

next season. See STORAGE section for

additional information.

_lb DANGER: Never refuel or drain the fuel I

• Check the fuel level periodically to avoid running

system indoors, or operate or store nearan

open flame, spark, or ignition source.

out of gasoline while operating the mower.

I

13

INITIALADJUSTMENTS

1. Disconnect the spark plug wire.

2. Check that all nuts, bolts and screws are tight.

3. Check the tension of the deck drive belts:

a. Remove the deck cover shield and engage

the blade clutch.

b. Make surethe belts clearthe belt guides by

1/8" to 1/4".

c. The tension of the deck drive belts should

be adjusted so that a ten-pound pull

between two pulleys deflects each belt

about 1/2" (See Figure 19 page 19). Do not

overtighten these belts. The blade clutch

should engage with only moderate force.

d. Replace the deck cover shield and

disengage the blade clutch.

,

The tension of the transmission drive belt should

be adjusted so that a five-pound pull between

the engine traction drive pulley and the

transmission drive pulley deflects the belt about

3/16". (See Figure 20 page 20)

,

The two drive wheel belts are self-adjusting.

6.

The steering control rods on each side of the

handle assembly should initially be adjusted so

that there is about a 1/4" to 3/8" space between

the rod and the bottom of the slot inthe neutral

latch lever with the latch in the drive position (See

Figure 6.) To make this adjustment, remove the

large hairpin from the swivel joint at the bottom of

each steering control rod and thread the swivel

joint up or down the rod as needed.

Figure 6

,

The brake rods (above each drive wheel) should

be adjusted so that when the steering/brake

levers are squeezed and the mower is pulled

backward, the brakes lock the drive wheels. The

machine should roll freely when the neutral latch

lever is in the neutral lock position. To adjust the

brake rods, remove the large hairpin from the

swivel joint at the top of each brake rod and

thread the swivel joint up or down the rod as

needed.

Hair Pin

Figure 7

8. Adjusting the cutting height: The mower is

shipped with the cutting height set at 3 inches _+1/

4 inch depending on the air pressure in the tires.

To change the cutting height, blade spacers and/

or caster spacers must be moved according to

the cutting height adjustment table. (Figure 24

and 25, page 22)

9. Lubricate all fittings listed in the maintenance

section.

TOSTARTTHEMOWER

IMPORTANT: First time operators should refer to the

procedure stated on page 5.

indoors or in a poorly ventilated area.

[_ ARNING: Never run the engine

1. Make certain you thoroughly understand all of

2. Move the mower outdoors to a "test area" where

3. Shift the transmision to neutral (N) position.

4. Disengage the blade clutch.

5. Place the neutral latch levers in the neutral lock

6. Connect the spark plug wire.

7. Open the fuel shutoff valve.

8. Move the throttle lever to a mid range position

9. Put the key in the ignition switch and turn the

10. To start engine using recoil starter:

Engine exhaust contains carbon

monoxide, a deadly, odorless gas.

the safety precautions before you attempt to

operate this machine.

you can operate the mower for about half an

hour without being disturbed.

position.

and pull the "Choke" all the way out.

switch on.

a. Stand on left side (as viewed from behind

handlebars) of machine. Be sure your feet

are safely away from the underside of the

mower deck and all mower controls are

released. Stabilize mower by placing foot

14

as indicated below in Figure 8.

Figure 8

b. Grasp starter rope handle and pull slowly

until rope pulls slightly harder. Let rope

rewind slowly. Then pull rope with a rapid,

full arm stroke. Let rope return slowly. If

engine fails to start after three pulls, repeat

instructions (try setting throttle at fast

setting).

c. When engine starts, operate in fast throttle

setting (move choke control to off).

KNOWYOURMOWER

,

After the engine has warmed up, shut off the

ignition and check the operation of the safety

switches. Make certain that the engine will not

start unless the ignition switch is turned on, the

transmission is in neutral and the blade clutch is

disengaged. Place the neutral latch levers in the

neutral lock position. If the engine will start with

the transmission in any gear (not neutral),

immediately shut off the engine and contact

customer service at 1-800-659-5917 or log on to

managemyhome.com. If the engine will start with

the blade clutch engaged, immediately shut off

the engine and contact customer service at 1-

800-659-5917 or log on to managemyhome.com.

To check operator presence controls:

a. Start the engine and hold the left operator

presence control lever down against the left

handle and move the transmission shift

lever into first gear. Now take your hand off

the operator presence control lever and the

engine should die. If itdoes not, immediately

shut off the engine and contact customer

service at 1-800-659-5917 or log on to

managemyhome.com.

b. Repeat this procedure using the right

operator presence control lever.

c. Shift the transmission into neutral, restart

the engine, hold one of the operator

presence controls down against the handle

and engage the blade clutch. Now take your

hand off of the operator presence lever and

the engine should die. If it does not,

immediately shut off the engine and

disengage the blade clutch and contact

customer service at 1-800-659-5917 or log

on to managemyhome.com.

2. With the neutral latch levers engaged restart the

engine.

3. Push the blade clutch lever forward until it

engages and the cutter blades start rotating.

4. Shift the transmission into first gear. (It is

suggested that you practice mowing in first gear.)

5. Squeeze both steering/brake levers with both

hands and release the neutral latch levers from the

neutral lock position.

6. Slowly release the steering/brake levers and the

mower will move ahead in a straight line. To turn

the mower, squeeze the steering/brake lever on

the side to which you want to turn.

7. To stop the mower's forward motion, squeeze both

steering/brake levers until the mower stops and

place the neutral latch levers into the neutral lock

position.

IMPORTANT: Squeezing the control levers from the

released position to the Neutral lock position releases

traction-drive belt tension. Additional squeezing of

these levers applies the service brakes. Applying the

left brake will create a counter clockwise pivot or u-

turn and applying the right brake will create a

clockwise pivot or u-turn. Applying both brakes will

stop the machine without turning.

8. Before shifting into reverse gear, the mower's

forward motion must be completely stopped. For

maximum traction in reverse, the steering/brake

levers should be pushed downward.

and during Reverse operation.Stopthe mower

DANGER: Look behind the mower before

bladesbefore operating in Reverse.

and to prevent damageto the transmission,

the mower must be completely stopped before

I_, ARNING: Toavoid possible bodily injury

attempting to shift from forward to reverse or

reverseto forward.

9. Practice operating the mower and as you gain

confidence, shift the transmission from first to

second and mow for a while and then shift from

second to third. Mow for at least one-half hour

and then return the mower to the shop.

shifted-on-the-go as transmission damage

_lb WARNING: The machine should not be I

could occur, causing the machineto suddenly

stop Stopthe mach ne, then sh ft.

10. To stop and shut off the mower, squeeze both

steering/brake levers and place the neutral latch

levers into the neutral lock position, disengage the

blade clutch, shift the transmission into neutral,

turn off the ignition to stop the engine, close the

I

15

fuel shutoff valve and disconnect the spark plug

wire.

11. Check that all nuts, bolts and screws are still

tight.

12. Check, and adjust if necessary, the tension of the

deck drive belts and the transmission drive belt

as described in items 3 and 4 of the Initial

Adjustment section.

13. Readjust the steering control rods and the brake

rods. They may require frequent adjustment until

the belts and brake bands have properly seated.

These adjustments are described in items 6 and

7 of the Initial Adjustment section.

14. After the first full day of mowing, all nuts, bolt and

screws should be rechecked for proper tightness

and the belts should be rechecked for proper

tension.

USINGTHEMOWER

MPORTANT: First time operators should refer to the I

rocedure stated on page 5. I

1. Be sure area is clear of rocks, sticks, toys, wire,

or other objects that could be thrown by the

mower. Survey the entire area to be mowed.

Make sure that the accessories and attachments

would be suitable for use on the terrain.

2. With the neutral latches locked and the operator

presence levers depressed, select a mowing

speed. (a slower speed is suggested during first

time use.)

3. Engage the mower by pushing the blade clutch

lever forward until it locks.

4. Squeeze the steering control levers and release

the neutral latches.

5. Slowly release the steering control levers and the

mower should go straight ahead.

6. To operate in Reverse, look behind and down

before backing up to be sure the path is clear.

7. Be aware of the mower discharge and do not

point it at anyone, or onto sidewalks and streets.

8. Use care when approaching blind corners,

shrubs, trees or other objects that could obstruct

vision.

9. To mow grass and produce a striped pattern:

a. Pick a point on the opposite side of the

area to be mowed (post, tree, shrub, etc).

b. Ifon a hillside, start at the bottom so that

the turns are uphill rather than downhill.

c. Align the mower so as to head directly

toward the object on the far side.

d. Slowly increase the speed of the machine

to match cutting conditions, terrain, and

operator familiarity with the controls and

keep the machine headed directly toward

the alignment object. Do not go fast as to

reduce cut quality or to be uncomfortable in

controlling the speed and direction of the

machine.

e. When approaching the other end of a strip,

slow down or stop before turning. A U-turn

is recommended.

f. To prevent rutting or grooving of the turf,

change the direction that the strips are

mowed by approximately 45 degrees the

next and each subsequent time that the

area is mowed.

g. Ifthe grass is repeatedly mowed in the

same direction, it will be "trained" so that

the Striped appearance is more

pronounced and longer lasting. Grooving

of the turf from the tires will occur.

10.

For empting material collection systems or for

any other operation involving the mower deck,

before leaving the operator station:

• shut off the mower deck.

• place the transmission in neutral.

• latch the neutral locks.

• shut off the engine.

• apply wheel chocks.

TRANSPORTINGMOWER

1. If ramps are used, be sure they are secured to

the trailer, truck bed, etc. and are designed for

the application.

2. The mower should be pushed or pulled onto or off

the trailer, truck bed, etc., never try to drive iton.

3. Turn the fuel valve off.

4. Secure mower with chocks, straps, etc.

5. Make sure accessories and attachments are

secured or removed.

16

GENERALRECOMMENDATIONS

people operate or servicethe mower.

WARNING: Never let children or untrained

• Always observe safety rules when performing any

type of maintenance on the mower.

• The warranty on this lawn mower does not cover

items that have been subjected to operator abuse

or negligence. To receive full value from the

warranty, operator must maintain the equipment as

instructed in this manual.

• Changing of engine-governed speed will void

engine warranty.

• Periodically check all fasteners and make sure they

are tight.

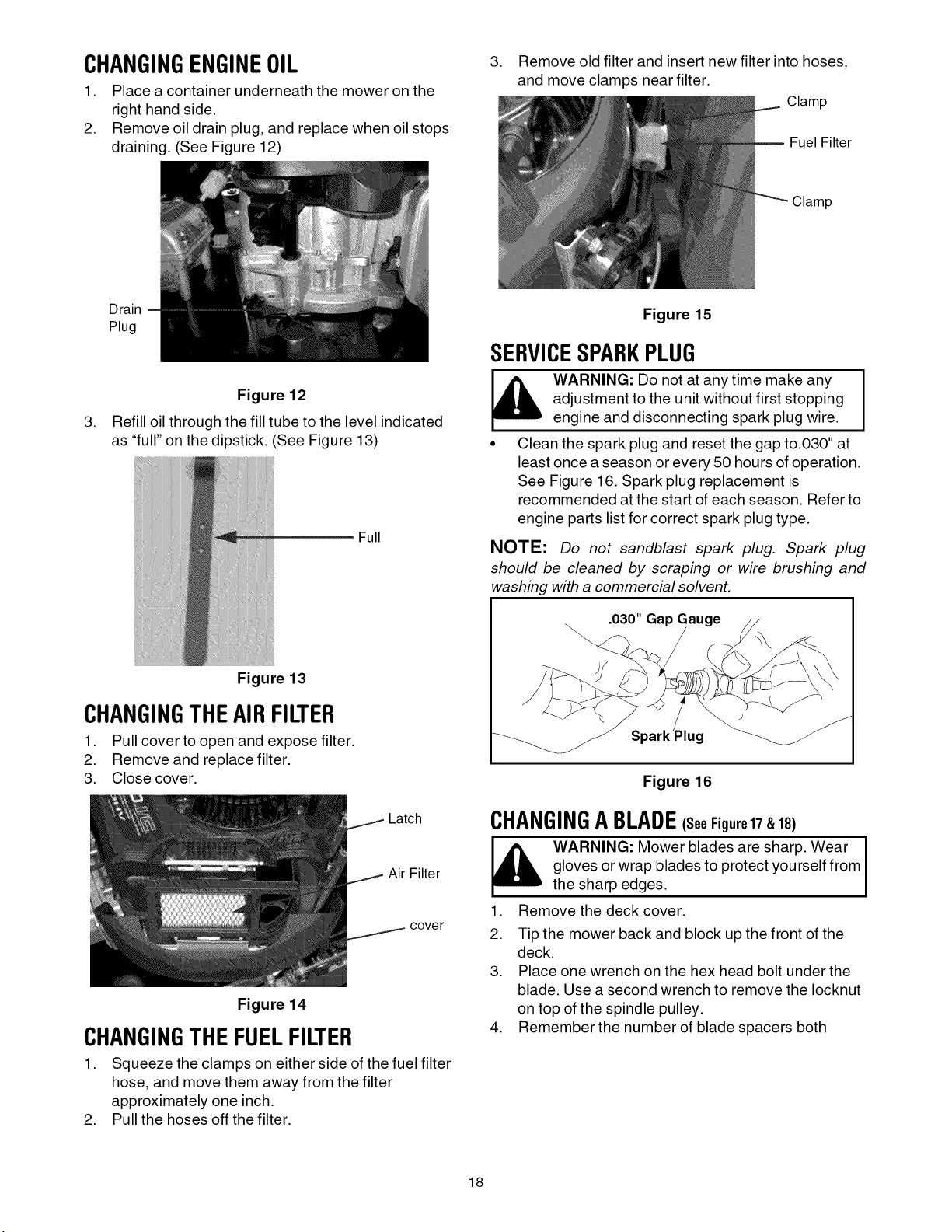

Transmission-Jackshaft Couplers- There are

two grease positions. See Figure 11 item H

disconnect and ground the spark plug wire

J& ARNING: Always stop the engine and I

Engine Oil: Use Shell Rimula 15W40 oil or any 10W30

or 15W40 oil rated SJ or higher.

Spindle Lubricant: Use only Shell Alvania RL 2

grease. This grease is an amber-colored grease

designed for high speed bearing applications. It has a

base oil viscosity that reduces running losses, has

been formulated for low noise, has excellent corrosion

_rotection, and has excellent bearing lubrication.

3eneral Purpose Lubrication: Use any NLGI grade 2

multi-purpose grease. Shell Albida EP2 is recom-

mended. Shell Albida EP 2 is a red-colored multi-pur-

pose grease designed for heavy-duty bearing

_pplications. It has high base oil viscosity for mechani-

;al stability, has been formulated for high load, low-

speed applications, and has excellent lubrication and

;orrosion protection.

before performing any maintenance oradjustments.

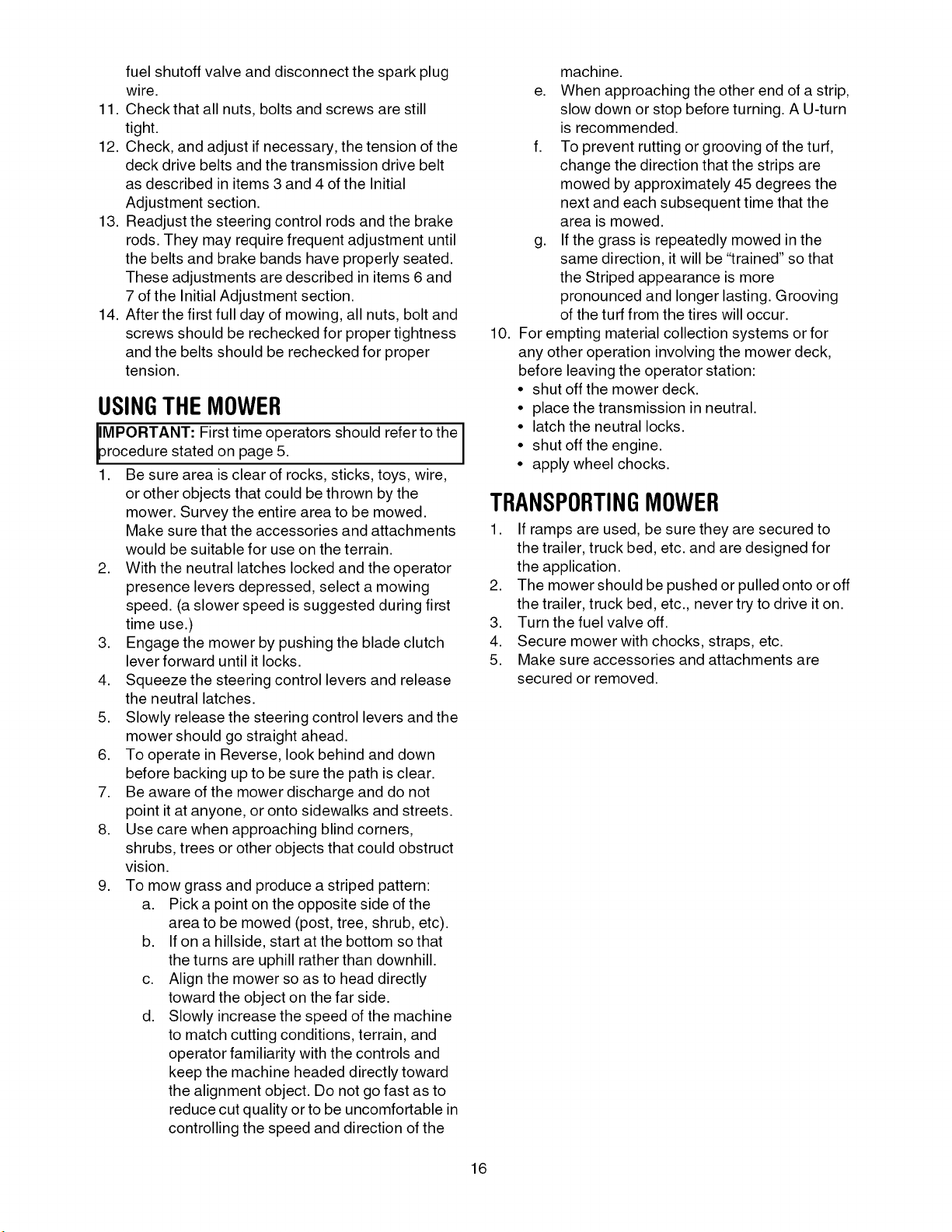

LUBRICATION(seeFigures9,10 & 11)

Daily

• Cutter Blade Spindle Bearings- There are two

grease positions. See Figure 9 item A.

• Caster Wheel Bearing- There are two grease

positions. See Figure 9 item B.

• Caster Wheel Pivot Shafts- There are two grease

positions. See Figure 9 item C.

• Deck Idler Pulley Pivot Arms- There is one

grease position. See Figure 9 item D.

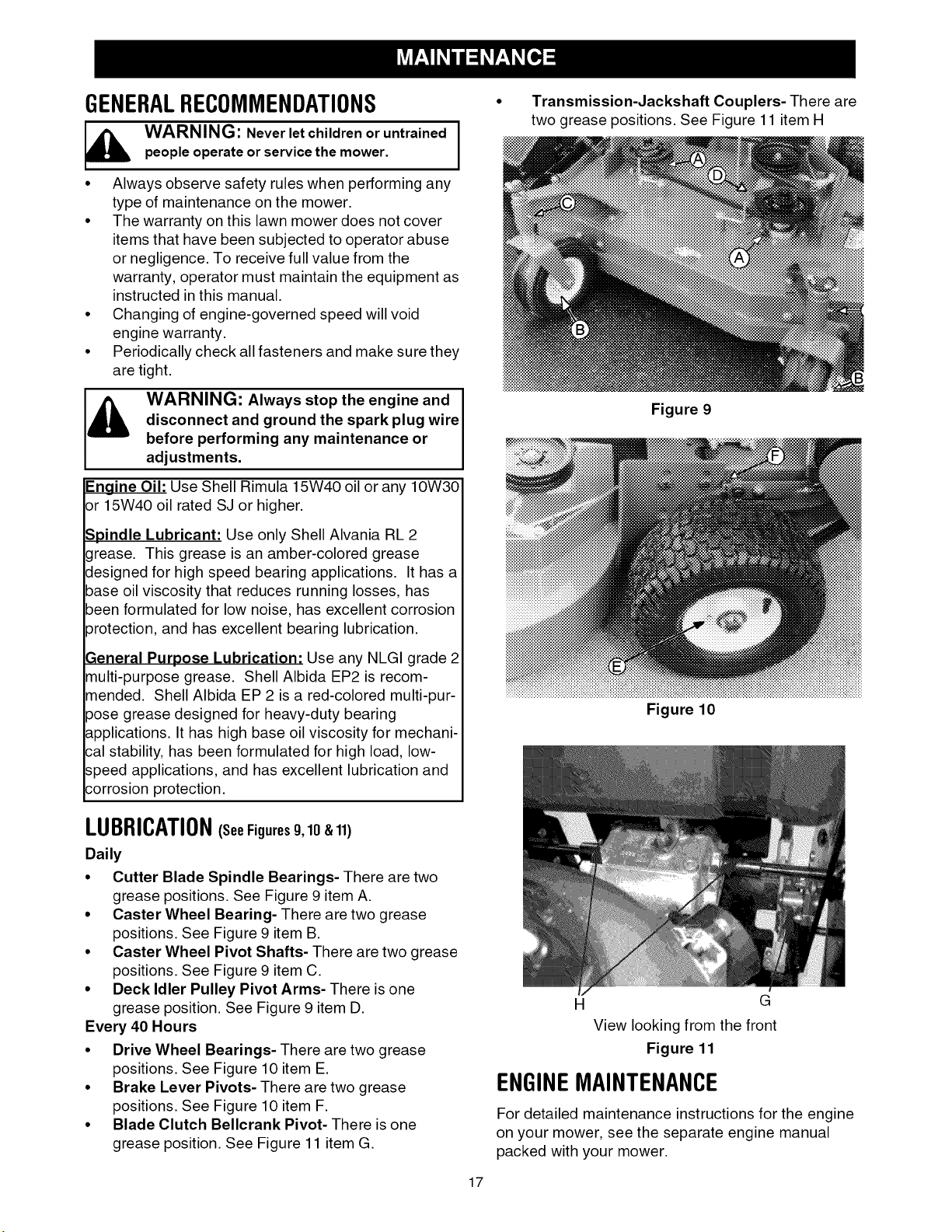

Every 40 Hours

• Drive Wheel Bearings- There are two grease

positions. See Figure 10 item E.

• Brake Lever Pivots- There are two grease

positions. See Figure 10 item F.

• Blade Clutch Bellcrank Pivot- There is one

grease position. See Figure 11 item G.

Figure 9

Figure 10

H G

View looking from the front

Figure 11

ENGINEMAINTENANCE

For detailed maintenance instructions for the engine

on your mower, see the separate engine manual

packed with your mower.

17

CHANGINGENGINEOIL

1. Place a container underneath the mower on the

right hand side.

2. Remove oil drain plug, and replace when oil stops

draining. (See Figure 12)

, Remove old filter and insert new filter into hoses,

and move clamps near filter.

Clamp

Fuel Filter

Clamp

Drain

Plug

Figure 12

,

Refill oil through the fill tube to the level indicated

as "full" on the dipstick. (See Figure 13)

Full

Figure 13

CHANGINGTHEAIRFILTER

1. Pull cover to open and expose filter.

2. Remove and replace filter.

3. Close cover.

Figure 15

SERVICESPARKPLUG

adjustment to the unit without first stopping

WARNING: Do not at any time make any

engine and disconnecting spark plug wire.

• Clean the spark plug and reset the gap to.030" at

least once a season or every 50 hours of operation.

See Figure 16. Spark plug replacement is

recommended at the start of each season. Refer to

engine parts list for correct spark plug type.

NOTE: Do not sandblast spark plug. Spark plug

should be cleaned by scraping or wire brushing and

washing with a commercial solvent.

.030" Ga

Plug

Figure 16

Latch

Air Filter

cover

Figure 14

CHANGINGTHEFUELFILTER

1. Squeeze the clamps on either side of the fuel filter

hose, and move them away from the filter

approximately one inch.

2. Pull the hoses off the filter.

CHANGINGABLADE€seeFigure17&18)

gloves or wrap blades to protect yourself from

WARNING: Mower blades are sharp. Wear I

the sharp edges.

1. Remove the deck cover.

2. Tip the mower back and block up the front of the

deck.

3. Place one wrench on the hex head bolt under the

blade. Use a second wrench to remove the Iocknut

on top of the spindle pulley.

4. Remember the number of blade spacers both

18

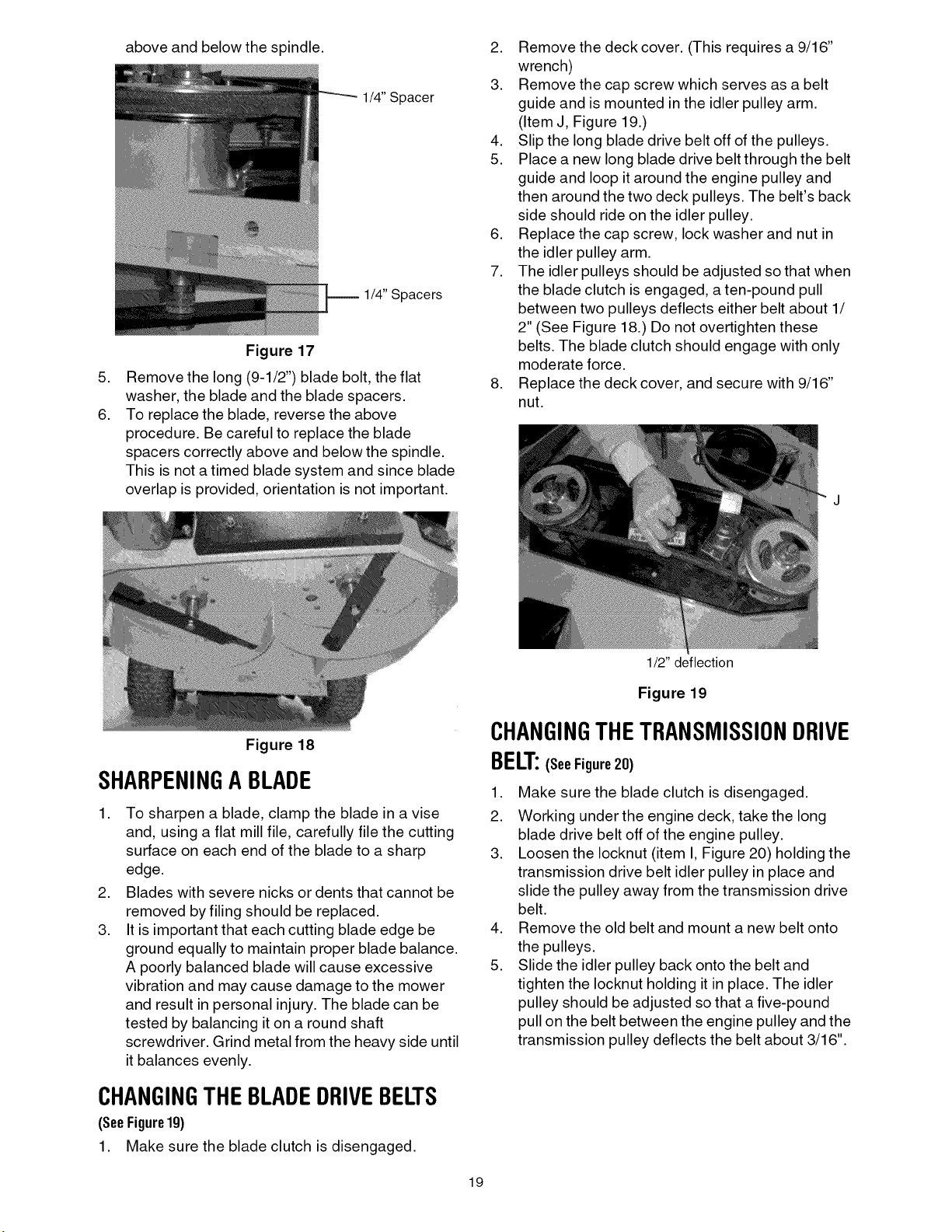

I

above and below the spindle.

1/4" Spacer

1/4" Spacers

Figure 17

,

Remove the long (9-1/2") blade bolt, the flat

washer, the blade and the blade spacers.

6.

To replace the blade, reverse the above

procedure. Be careful to replace the blade

spacers correctly above and below the spindle.

This is not a timed blade system and since blade

overlap is provided, orientation is not important.

2. Remove the deck cover. (This requires a 9/16"

wrench)

3. Remove the cap screw which serves as a belt

guide and is mounted in the idler pulley arm.

(Item J, Figure 19.)

4. Slip the long blade drive belt off of the pulleys.

5. Place a new long blade drive belt through the belt

guide and loop it around the engine pulley and

then around the two deck pulleys. The belt's back

side should ride on the idler pulley.

6. Replace the cap screw, lock washer and nut in

the idler pulley arm.

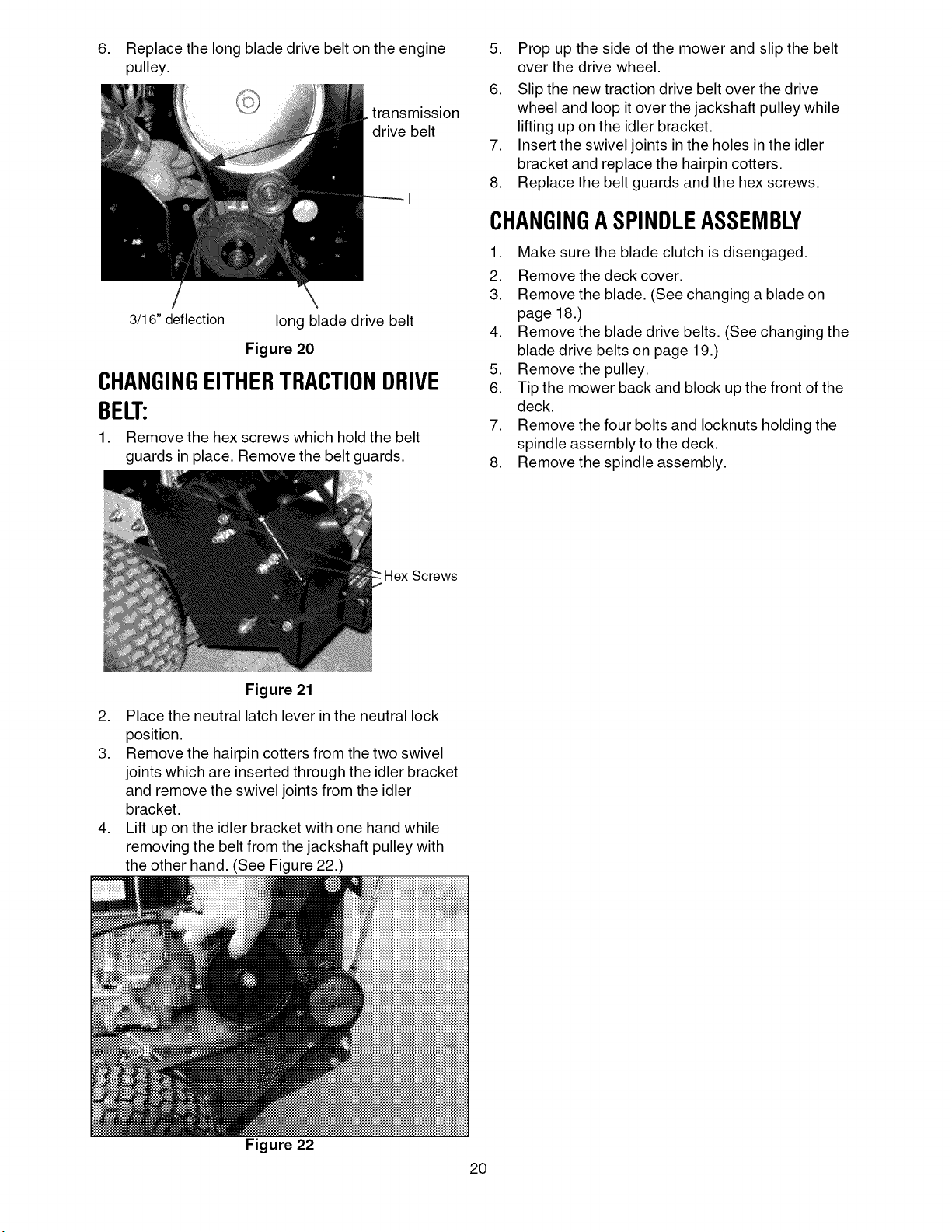

7. The idler pulleys should be adjusted so that when

the blade clutch is engaged, a ten-pound pull

between two pulleys deflects either belt about 1/

2" (See Figure 18.) Do not overtighten these

belts. The blade clutch should engage with only

moderate force.

8. Replace the deck cover, and secure with 9/16"

nut.

Figure 18

SHARPENINGA BLADE

,

To sharpen a blade, clamp the blade in a vise

and, using a flat mill file, carefully file the cutting

surface on each end of the blade to a sharp

edge.

,

Blades with severe nicks or dents that cannot be

removed by filing should be replaced.

3.

It is important that each cutting blade edge be

ground equally to maintain proper blade balance.

A poorly balanced blade will cause excessive

vibration and may cause damage to the mower

and result in personal injury. The blade can be

tested by balancing it on a round shaft

screwdriver. Grind metal from the heavy side until

it balances evenly.

CHANGINGTHEBLADEDRIVEBELTS

(SeeFigurelg)

1. Make sure the blade clutch is disengaged.

1/2" deflection

Figure 19

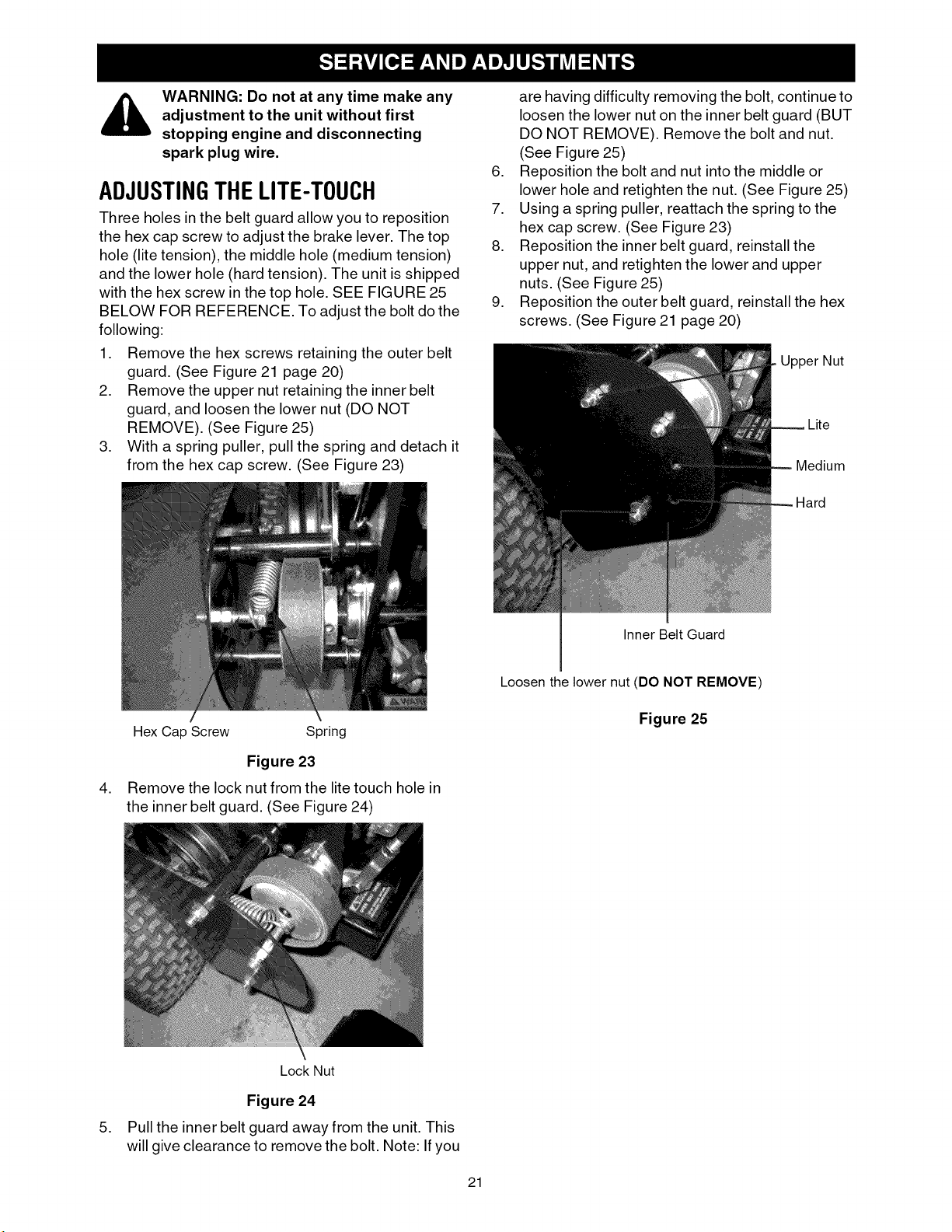

CHANGINGTHETRANSMISSIONDRIVE

BELT:(SeeFigure20)

1. Make sure the blade clutch is disengaged.

2. Working under the engine deck, take the long

blade drive belt off of the engine pulley.

3. Loosen the Iocknut (item I, Figure 20) holding the

transmission drive belt idler pulley in place and

slide the pulley away from the transmission drive

belt.

4. Remove the old belt and mount a new belt onto

the pulleys.

5. Slide the idler pulley back onto the belt and

tighten the Iocknut holding it in place. The idler

pulley should be adjusted so that a five-pound

pull on the belt between the engine pulley and the

transmission pulley deflects the belt about 3/16".

19

,

Replace the long blade drive belt on the engine

pulley.

. transmission

drive belt

3/16" deflection

long blade drive belt

Figure 20

CHANGINGEITHERTRACTIONDRIVE

BELT:

1. Remove the hex screws which hold the belt

guards in place. Remove the belt guards.

5. Prop up the side of the mower and slip the belt

over the drive wheel.

6. Slip the new traction drive belt over the drive

wheel and loop it over the jackshaft pulley while

lifting up on the idler bracket.

7. Insert the swivel joints in the holes in the idler

bracket and replace the hairpin cotters.

8. Replace the belt guards and the hex screws.

CHANGINGASPINDLEASSEMBLY

1. Make sure the blade clutch is disengaged.

2. Remove the deck cover.

3. Remove the blade. (See changing a blade on

page 18.)

4. Remove the blade drive belts. (See changing the

blade drive belts on page 19.)

5. Remove the pulley.

6. Tip the mower back and block up the front of the

deck.

7. Remove the four bolts and Iocknuts holding the

spindle assembly to the deck.

8. Remove the spindle assembly.

Screws

Figure 21

2. Place the neutral latch lever in the neutral lock

position.

3. Remove the hairpin cotters from the two swivel

joints which are inserted through the idler bracket

and remove the swivel joints from the idler

bracket.

4. Lift up on the idler bracket with one hand while

removing the belt from the jackshaft pulley with

the other hand. (See Figure 22.)

Figure 22

20

WARNING: Do not at any time make any

adjustment to the unit without first

stopping engine and disconnecting

spark plug wire.

ADJUSTINGTHELITE-TOUCH

Three holes in the belt guard allow you to reposition

the hex cap screw to adjust the brake lever. The top

hole (lite tension), the middle hole (medium tension)

and the lower hole (hard tension). The unit is shipped

with the hex screw in the top hole. SEE FIGURE 25

BELOW FOR REFERENCE. To adjust the bolt do the

following:

1. Remove the hex screws retaining the outer belt

guard. (See Figure 21 page 20)

2. Remove the upper nut retaining the inner belt

guard, and loosen the lower nut (DO NOT

REMOVE). (See Figure 25)

3. With a spring puller, pull the spring and detach it

from the hex cap screw. (See Figure 23)

are having difficulty removing the bolt, continue to

loosen the lower nut on the inner belt guard (BUT

DO NOT REMOVE). Remove the bolt and nut.

(See Figure 25)

6. Reposition the bolt and nut into the middle or

lower hole and retighten the nut. (See Figure 25)

7. Using a spring puller, reattach the spring to the

hex cap screw. (See Figure 23)

8. Reposition the inner belt guard, reinstall the

upper nut, and retighten the lower and upper

nuts. (See Figure 25)

9. Reposition the outer belt guard, reinstall the hex

screws. (See Figure 21 page 20)

Upper Nut

Medium

Hex Cap Screw Spring

Figure 23

,

Remove the lock nut from the lite touch hole in

the inner belt guard. (See Figure 24)

Lock Nut

Inner Belt Guard

Loosenthe lower nut (DO NOT REMOVE)

Figure 25

Figure 24

,

Pull the inner belt guard away from the unit. This

will give clearance to remove the bolt. Note: Ifyou

21

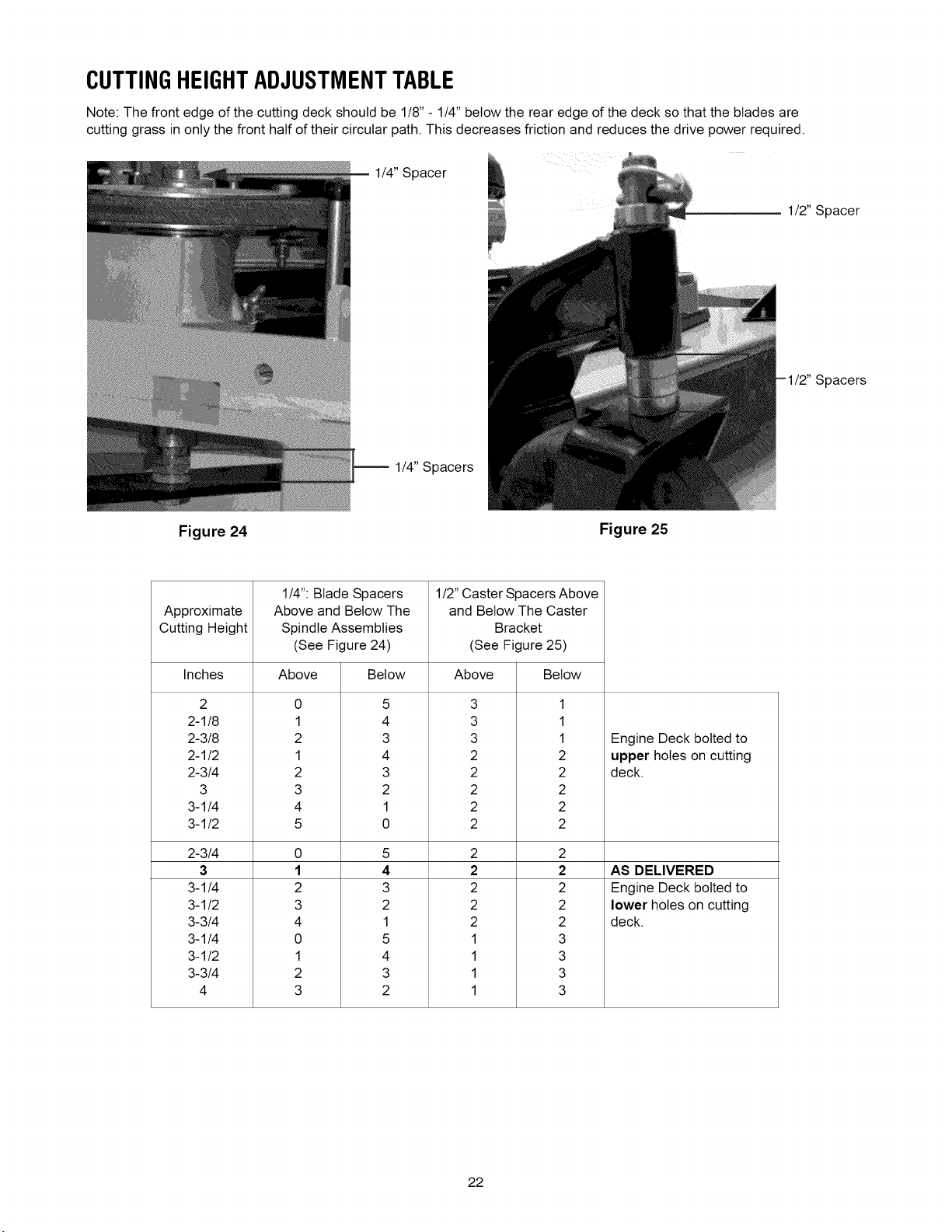

CUTTINGHEIGHTADJUSTMENTTABLE

Note: The front edge of the cutting deck should be 1/8" - 1/4" below the rear edge of the deck so that the blades are

cutting grass in only the front half of their circular path. This decreases friction and reduces the drive power required.

1/4" Spacer

1/4" Spacers

Figure 24 Figure 25

1/2" Spacer

1/2" Spacers

1/4": Blade Spacers

Approximate and Below The Caster

Cutting Height Bracket

Inches Above Below

2

2-1/8

2-3/8

2-1/2

2-3/4

3

3-1/4

3-1/2

2-3/4

3

3-1/4

3-1/2

3-3/4

3-1/4

3-1/2

3-3/4

4

Above and Below The

Spindle Assemblies

(See Figure 24)

Above Below

0 5

1 4

2 3

1 4

2 3

3 2

4 1

5 0

0 5

1 4

2 3

3 2

4 1

0 5

1 4

2 3

3 2

1/2" Caster Spacers Above

(See Figure 25)

3

3

3

2

2

2

2

2

2

2

2

2

2

1

1

1

1

1

1

1

2

2

2

2

2

2

2

2

2

2

3

3

3

3

Engine Deck bolted to

upper holes on cutting

deck.

AS DELIVERED

Engine Deck bolted to

lower holes on cutting

deck.

22

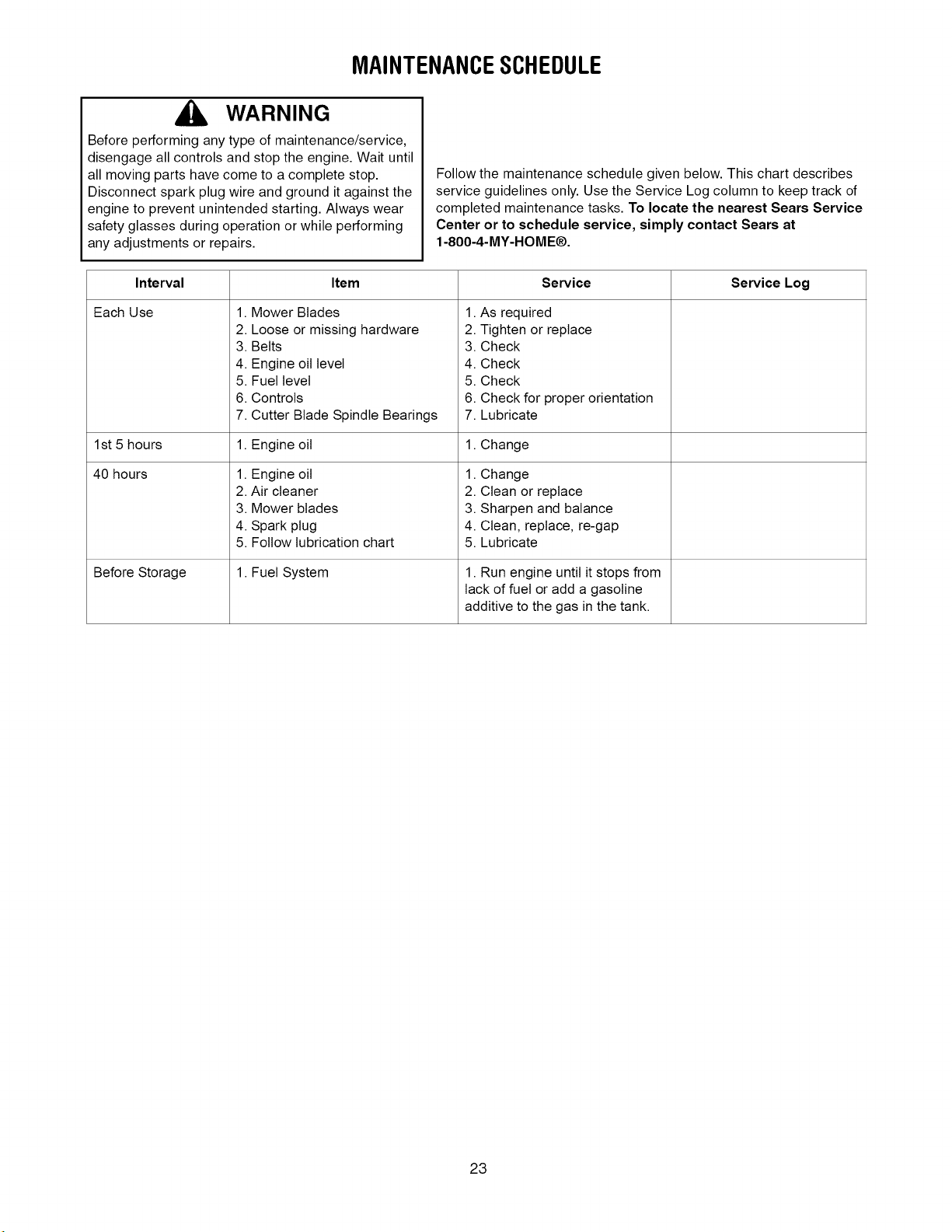

MAINTENANCESCHEDULE

WARNING

Before performing any type of maintenance/service,

disengage all controls and stop the engine. Wait until

all moving parts have come to a complete stop.

Disconnect spark plug wire and ground it against the

engine to prevent unintended starting. Always wear

safety glasses during operation or while performing

any adjustments or repairs.

Follow the maintenance schedule given below. This chart describes

service guidelines only. Use the Service Log column to keep track of

completed maintenance tasks. To locate the nearest Sears Service

Center or to schedule service, simply contact Sears at

1-800-4-MY-HOME®.

Interval Service Log

Each Use 1.

1st 5 hours 1.

40 hours

Before Storage

Mower Blades 1. As required

2.

Loose or missing hardware 2. Tighten or replace

3.

Belts 3. Check

4.

Engine oil level 4. Check

5.

Fuel level 5. Check

6.

Controls 6. Check for proper orientation

7.

Cutter Blade Spindle Bearings 7. Lubricate

Engine oil 1. Change

1.

Engine oil 1. Change

2.

Air cleaner 2. Clean or replace

3.

Mower blades 3. Sharpen and balance

4.

Spark plug 4. Clean, replace, re-gap

5.

Follow lubrication chart 5. Lubricate

• Fuel System 1. Run engine until it stops from

Item Service

lack of fuel or add a gasoline

additive to the gas in the tank.

23

WARNING

Never store lawn mowerwith fuel intank indoorsor in

poorly ventilated areas where fuelfumes may reach

an open flame, spark, or pilot light as on a furnace,

water heater,clothes dryer, or gas appliance. Never

refuel or drain thefuel system indoors.

PREPARING THE ENGINE

For engines stored over 30 days:

1. To prevent gum from forming infuel system or on

carburetor parts, turn off the fuel valve, run the

engine until it stops from lack of fuel or add a gaso-

line additive to the gas in the tank. If you use a gas

additive, run the engine for several minutes to circu-

late the additive through the carburetor, after which

the engine and fuel can be stored up to six months.

2. While engine is still warm, change the oil.

3. Remove spark plug and pour approximately 1 oz.

(30 ml) of clean engine oil into the cylinder. Pull the

recoil starter several times to distribute the oil, and

reinstall the spark plug.

4. Clean engine of surface debris.

PART NO. DESCRIPTION

33317 Bagger Grass Collector

33318 Mulch Kit

PREPARING THE LAWN MOWER

• When storing the mower in an unventilated or metal

storage shed, care should be taken to rustproof the

non-painted surfaces. Using a light oil or silicone,

coat the equipment, especially any springs, bear-

ings, and cables.

• Remove all dirt from exterior of engine and equip-

ment.

• Store equipment in a clean, dry area. Do not store

in an area where equipment is present that may use

a pilot light or has a component that can create a

spark, or open flame.

24

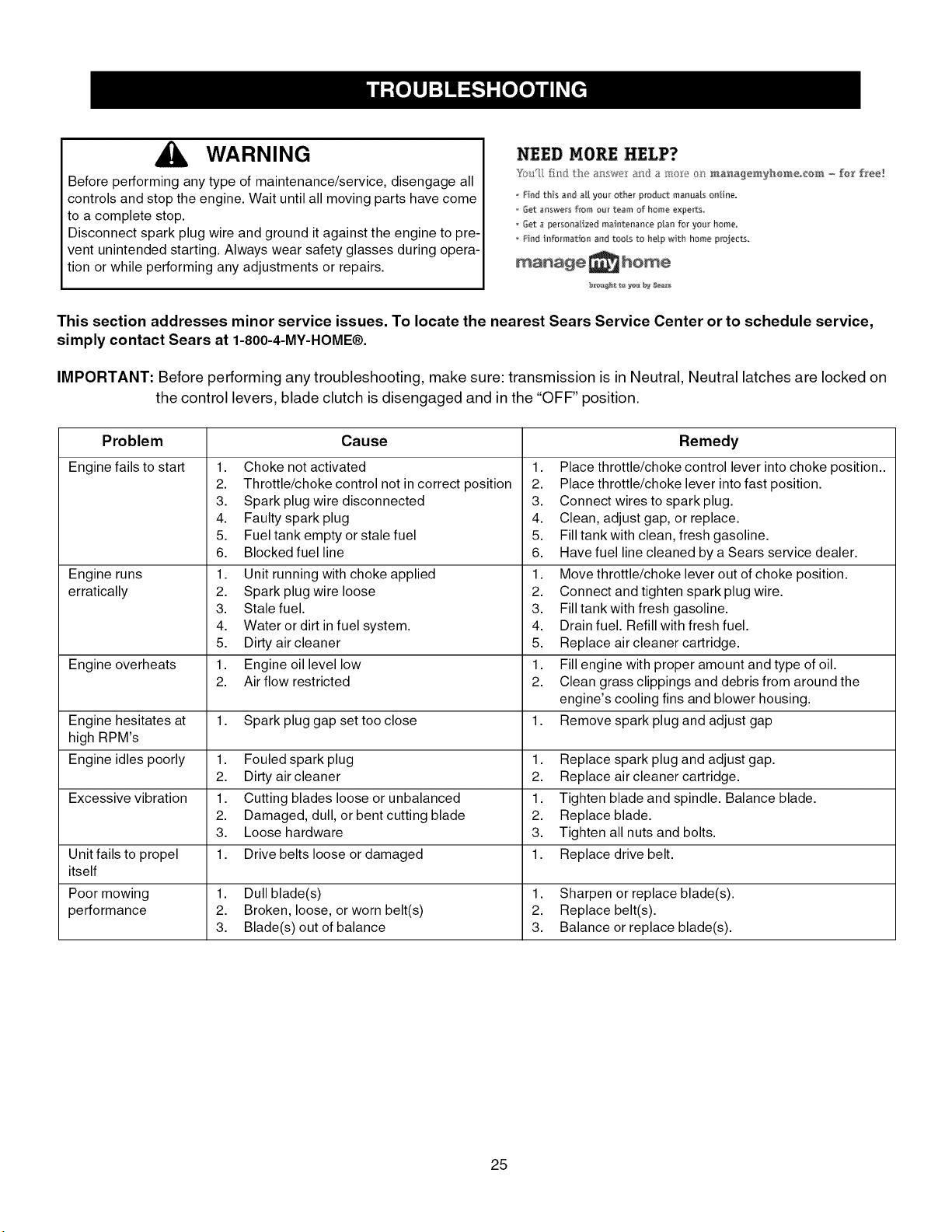

WARNING

Before performing any type of maintenance/service, disengage all

controls and stop the engine. Wait until all moving parts have come

to a complete stop.

Disconnect spark plug wire and ground it against the engine to pre-

NEED MORE HELP?

Y_ [ _h/d the _ we_ _t _ _oe o_ _a_agemyhomeocom _ _o_ f_ee_

o F_d tMs and a_.[you_ otl_e_ product manuals online.

- Get a_swers from our team of hol_le experts,

o Get a personalized maintenance plan for your home,

, F;I_ il_folmat_or_ and tools to help w_th home project,

vent unintended starting. Always wear safety glasses during opera-

tion or while performing any adjustments or repairs.

This section addresses minor service issues. To locate the nearest Sears Service Center or to schedule service,

simply contact Sears at 1-800-4-MY-HOME®.

IMPORTANT: Before performing any troubleshooting, make sure: transmission is in Neutral, Neutral latches are locked on

the control levers, blade clutch is disengaged and in the "OFF" position.

Problem Cause Remedy

Enginefails to start

Engine runs

erratically

Engine overheats

Engine hesitates at 1. Spark plug gap set too close 1.

high RPM's

Engine idles poorly 1. Fouled spark plug 1. Replace spark plug and adjust gap.

Excessive vibration 1. Cutting blades loose or unbalanced 1. Tighten blade and spindle. Balance blade.

Unit fails to propel 1. Drive belts loose or damaged 1. Replace drive belt.

itself

Poor mowing 1. Dull blade(s) 1. Sharpen or replace blade(s).

performance 2. Broken, loose, or worn belt(s) 2. Replace belt(s).

1. Choke not activated

2. Throttle/choke control not in correct position

3. Spark plug wire disconnected

4. Faulty spark plug

5. Fuel tank empty or stale fuel

6. Blocked fuel line

1. Unit running with choke applied

2. Spark plug wire loose

3. Stale fuel.

4. Water or dirt infuel system.

5. Dirty air cleaner

1. Engine oil level low

2. Air flow restricted

1. Place throttle/choke control lever into choke position..

2. Place throttle/choke lever into fast position.

3. Connect wires to spark plug.

4. Clean, adjust gap, or replace.

5. Fill tank with clean, fresh gasoline.

6. Have fuel line cleaned by a Sears service dealer.

1. Move throttle/choke lever out of choke position.

2. Connect and tighten spark plug wire.

3. Fill tank with fresh gasoline.

4. Drain fuel. Refill with fresh fuel.

5. Replace air cleaner cartridge.

1. Fill engine with proper amount and type of oil.

2. Clean grass clippings and debris from around the

engine's cooling fins and blower housing.

Remove spark plug and adjust gap

2. Dirty air cleaner 2. Replace air cleaner cartridge.

2. Damaged, dull, or bent cutting blade 2. Replace blade.

3. Loose hardware 3. Tighten all nuts and bolts.

3. Blade(s) out of balance 3. Balance or replace blade(s).

25

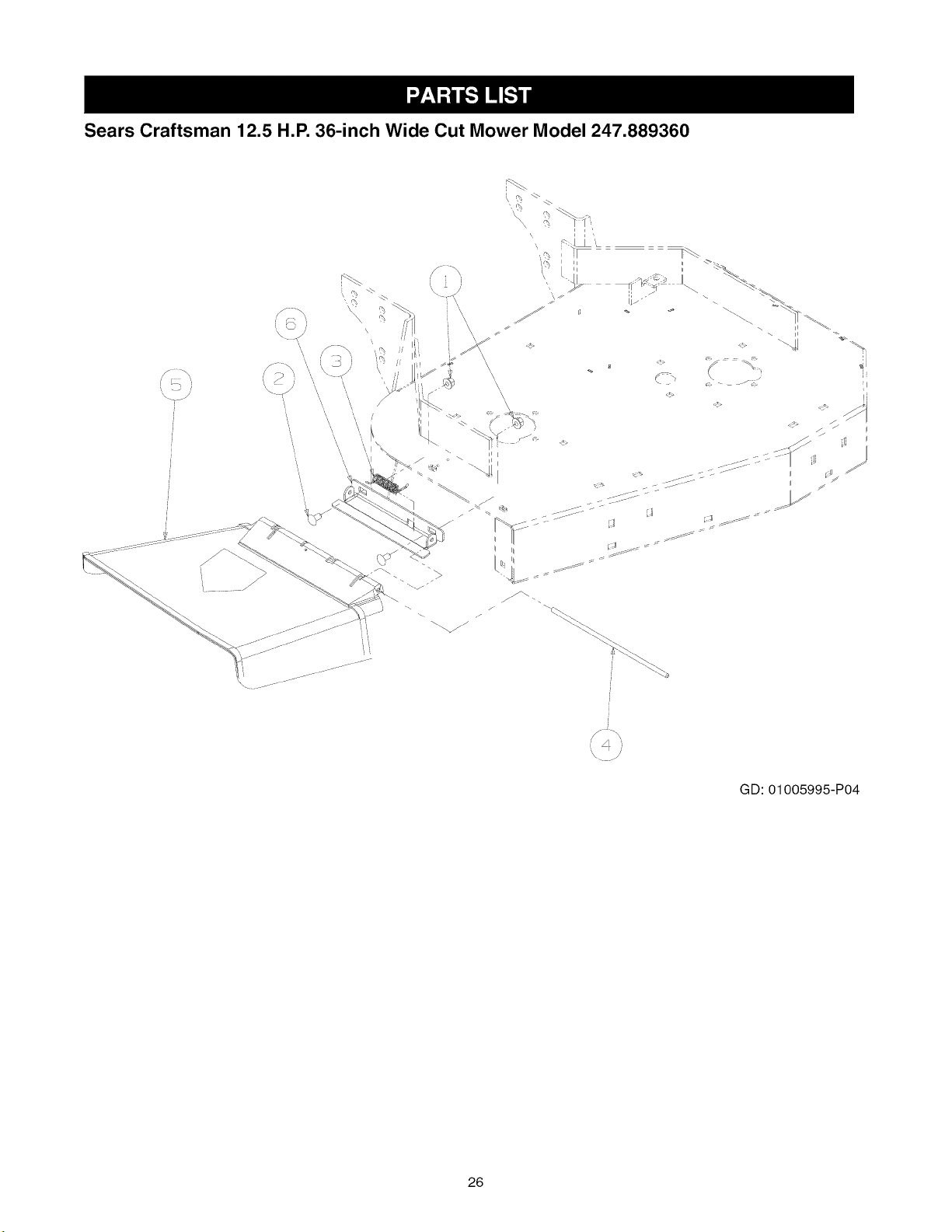

Sears Craftsman 12.5 H.P. 36-inch Wide Cut Mower Model 247.889360

\ •

26

GD: 01005995-P04

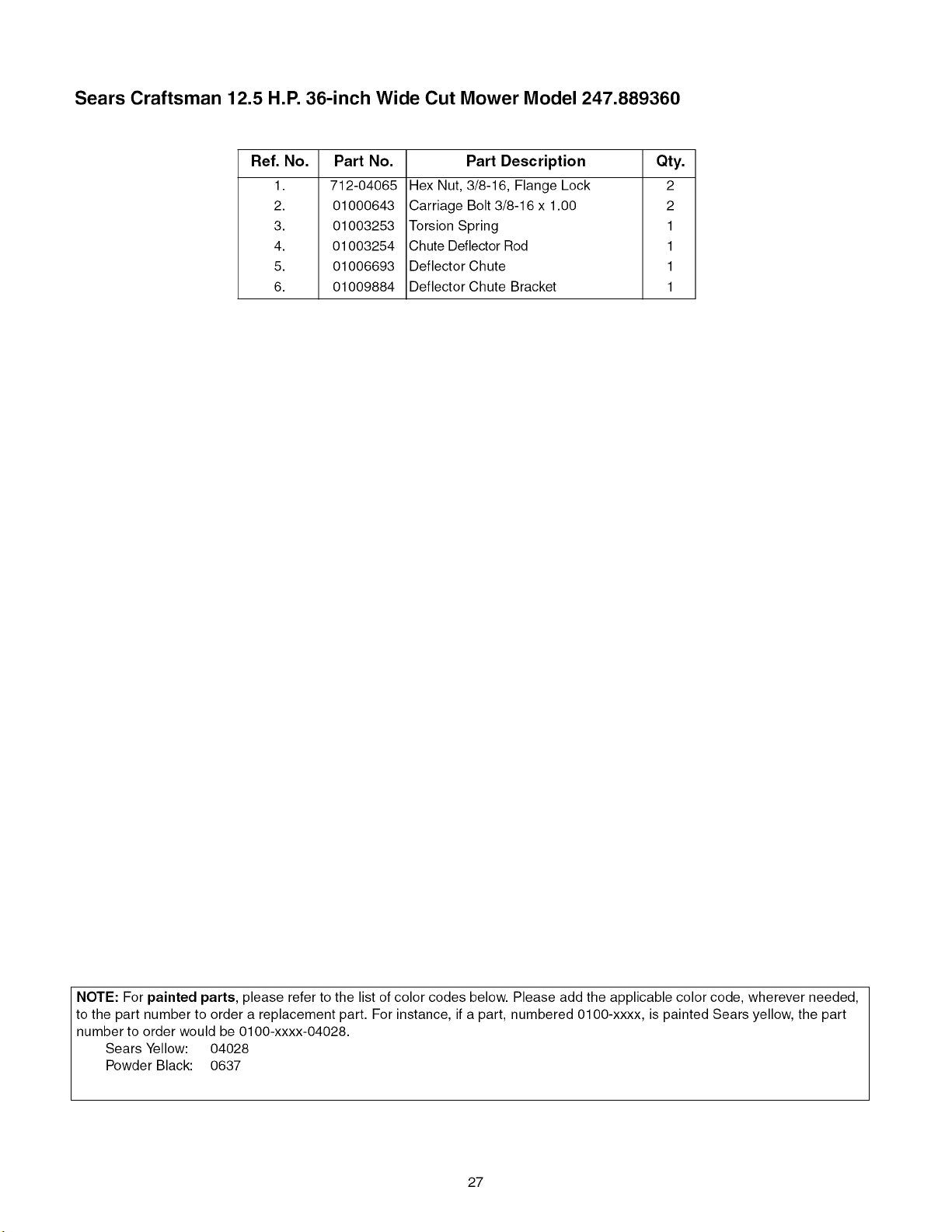

Sears Craftsman 12.5 H.P. 36-inch Wide Cut Mower Model 247.889360

Ref. No.

1.

2.

3.

4.

5.

6.

Part No.

712-04065

01000643

01003253

01003254

01006693

01009884

Part Description

Hex Nut, 3/8-16, Flange Lock

Carriage Bolt 3/8-16 x 1.00

Torsion Spring

Chute Deflector Rod

Deflector Chute

Deflector Chute Bracket

Qty.

2

2

1

1

1

1

NOTE: For painted parts, please refer to the list of color codes below. Please add the applicable color code, wherever needed,

to the part number to order a replacement part. For instance, if a part, numbered 0100-xxxx, is painted Sears yellow, the part

number to order would be 0100-xxxx-04028.

Sears Yellow: 04028

Powder Black: 0637

27

Loading...

Loading...