Craftsman 247888550 Owner’s Manual

Owner's Manual

9 Horse Power

28" Two-Stage Track Drive

Snow Thrower

Model No.

247.888550

CAUTION: Before

usingthis product,

read this manual and

follow all safety rules

and operating

instructions.

Sears, Roebuck And Co., Hoffman Estates, IL 60179, U.S.A.

Visit ourSears website: www.sears.condcraftsman

PdntedJnU.S.A. (6/99)

• Safety

• Assembly

• Operation

• Service

• Maintenance

• Espafiol

FormNo.770-10051C

Content Page

Warranty Information......................................... 2

Safe OperationPractices................................... 3

Hardware Pack .................................................. 5

Assembly........................................................... 6

Operation............... ............................................ 12

Content Page

Service & Adjustment......................................... 20

Off*Season Storage ........................................... 24

Trouble-Shooting............................................... 25

PartsList............................................................ 26

Espanbl.............................................................. 40

Maintenance ...................................................... 17

Two -Year Warranty on Craftsman Snow Thrower

Fortwoyearsfrom the date ofpurchase, when this CraftsmanSnow Thrower ismaintained,lubricatedand tuned

up accordingto the instructionsinthe owner'smanual, Sears will repair,free ofcharge, any defect in material

and workmanship.

Ifthis Craftsman snow throwerisused for commercialor rental purposes, thiswarrantyapplies for only30 days

from the date of purchase.

This warranty does not cover:

Expendable items which become worn duringnormal use, suchas skidshoes, shave plate and spark

plugs.

Repairs nec•ssary because of operatorabuse or negligence, includingbent crankshaftsand the failure to

maintainthe equipment accordingto the instructionscontainedin theowner's manual.

WARRANTY SERVICE ISAVAILABLEBYRETURNING THECRAFTSMAN SNOWTHROWER TOTHE NEAREST

SEARS SERVICE CENTER/DEPARTMENT INTHE UNITED STATES.

This warranty applies only while this product Is In use in the United States.

Thiswarrantygivesyouspecificlegal rightsandyou mayalsohaveotherdghtswhichmayvary fromstatetostate.

SEARS,ROEBUCK AND CO., D/817WA, HOFFMAN ESTATES,IL60179

Horsepower: 9

EngineOil SAE 5W30 oil

FuelCapacity: 1 gallon

Spark Plug: RJ-19LM

Engine: 143.999005

Model Number 247.888550

Serial Number ...........................................................

Date of Purchase ......................................................

Record both serial number and date of purchase and

keep in a safe place for future reference.

This symbol points out important safety instructions which, ifnotfollowed, could endanger the

personalsafetyand/or propertyofyourselfand others. Read and followall instructions in this manual

beforeattemptingto operate your snow thrower. Failure to complywiththese instructionsmay resultin

personal injury.When yousee thissymbol--heed its warning.

,_ Your snowthrower was builttobe operated accordingtothe rulesfor safe operation inthis manual. As

DANGER" withany type of power equipment carelessness or erroron the partofthe operator canresultin serious

in ury. f you vo ate anyofthese rules, you may cause serious njuryto yourselfor others.

forest-covered, brush-coveredorgrass-coveredlandunlessthe engine'sexhaustsystemis equippedwitha

Thisunitisequippedwithan internalcombustionengineandshouldnotbe usedonornearany unimproved

sparkarrestermeetingapplicablelocalorstate laws(ifany). Ifa sparkarresterisused,itshouldbe

maintainedineffectiveworkingorderbytheoperator.

In theStateofCaliforniathe aboveisrequiredby law(Section4442 ofthe CaliforniaPublicResources

Code).Otherstatesmayhavesimilarlaws.Federallawsapplyonfederal lands.Asparkarresterfor the

mufflerisavailablethroughyournearestSearsAuthorizedServiceCenter(See theREPAIR PARTS section

ofthismanual.)

TRAINING

Read thisowner'sguide carefullyin itsentirety before

attemptingtoassemble oroperate this machine. Be

completelyfamiliar withthe controlsand the proper

useof this machine before operating it. Keep this

manual ina safe place for future and regular

reference and for orderingreplacement parts.

Never allowchildrenunder 14 years old to operate a

snowthrower. Children 14 years oldandover should

onlyoperate a snow throwerunderclose parental

supervision.Onlypersonswell acquainted with these

rulesof safe operationshould be allowed to use your

snowthrower.

No one should operate thisunitwhileintoxicated or

whiletaking medicationthat impairsthe senses or

reactions.

Keepthe area ofoperationclear ofall persons,

especially smallchildrenand pets.

Exercise caution to avoid slippingor falling,especially

when operatinginreverse.

PREPARATION

Thoroughlyinspectthe area where the equipment is

to be usedand remove alldoor mats, sleds,boards,

wiresand other foreign objects.

Donot operate equipmentwithoutwearing adequate

outergarments for winter. Do not wear jewelry, long

scarfsor otherlooseclothingwhich couldbecome

entangled inmoving parts. Wear footwear which will

improvefootingon slipperysurfaces.

Before workingwithgasoline,extinguishalt cigarettes

and othersourcesofignition.Check the fuel before

startingthe engine. Gasolineis an extremely

flammable fuel. Do not fillthe gasolinetank indoors,

while the engine is running,or untilengine has been

allowed to cool at least twominutes. Replace

gasolinecap securelyand wipe off any spilled

gasolinebefore startingthe engine as itmay cause a

fireor explosion.

Use a grounded threewire plug-in for all unitswith

electricdrive motors or electricstarting motors.

Adjustcollector housingheightto clear gravel or

crushed rocksurface.

Never attempttomake any adjustmentswhile engine

is running(except where specificallyrecommended

by manufacturer).

Letengine and machineadjust tooutdoor

temperature beforestartingto clear snow.

Always wear safety glasses oreye shields during

operationor whileperformingan adjustmentor repair,

to protecteyes from foreign objectsthat may be

thrownfrom the machine in any direction.

OPERATION

Do not puthands orfeet near or underrotatingparts.

Keep clear ofdischargeopening and auger at all

times.

Exercise extremecaution when operatingon or

crossinggravel drives, walks,or roads. Stay alert for

hidden hazardsor traffic.

Do not carry passengers.

Afterstrikinga foreign object, stopthe engine, remove

wire from the sparkplug and thoroughlyinspect the

snowthrower for any damage. Repair the damage

before restartingand operating the snowthrower.

Ifthe snow thrower startsto vibrate abnormally,stop

the engineand check immediatelyfor the cause.

Vibrationis generallya warningof trouble.

Stopthe engine whenever you leave the operating

position,before uncloggingthe collector/impeller

housingor dischargeguide andbefore making any

repairs,adjustments,or inspections.Never placeyour

hand inthe discharge or collectoropenings. Use a

stickor woodenbroom handle to unclogthe

discharge opening.

Take allpossibleprecautionswhen leaving the unit

unattended. Disengage the collector/impeller,stop

the engine and removethe key.

When cleaning, repairing,or inspecting,makecertain

collector/impellerand all moving parts have stopped.

Disconnectsparkplug wire and keep away from plug

to prevent accidentalstarting.

• Do notrunthe engine indoors,except when startingit

and/ortransportingthe snowthrower in orout of

building.Open doors beforestartingtheengine inthat

case. Exhaust fumes are dangerous.

Do not clearsnow across theface ofslopes.Exercise

extreme caution whenchanging directionon slopes.

Do not attemptto clear steep slopes.

Never operate the snowthrower withoutguards,

plates or othersafetyprotectiondevices in place,

• Never operate the snow throwernear glass

enclosure, automobiles,window wells, drop off,etc.,

withoutproper adjustmentsofsnow thrower

dischargeangle. Keep childrenand pets away.

Do notoverload machine capacity by attemptingto

clear snow at toofast a rate. Never operate the

machine at hightransportspeeds onslippery

surfaces. Lookbehindand use care when backing.

Never direct dischargeat bystanders or allow anyone

in front of unitwhilethrowing snow.

• Disengagepower to collector/impellerofthe srx)w

throwerwhentransportingitorwhenthe unitisnotin use.

Use only attachments andaccessories (suchas

wheel weights,counterweights, cabs, etc.)approved

by the snow thrower manufacturer.

Never operatethe snowthrowerwithoutgood visibility

or light.Alwaysbe sure ofyourfooting and keep afirm

holdonthe handles. Walk, never run.

Mufflerand engine become hotandcan cause severe

bum injury.Do not touchthe mufflerorthe engine

whilestarting or operatingthe snowthrower.

MAINTENANCE AND STORAGE

Check shear bolts, enginemountingbolts,etc., at

frequent intervalsfor propertightness,thusensuring

thatthe equipment isinsafe workingcondition.

Never storethe machine withfuel in the fuel tank

insidea buildingwhere ignitionscumes are present,

suchas hot water heaters,space heaters, clothes

dryersand the like. Allowengine to cool beforestoring

in anyenclosure.

Alwaysrefer to owner'sguide instructionsfor

importantdetails ifthesnowthrower isto be storedfor

an extended period.

Runmachine a few minutesafterthrowingsnow to

preventfreeze-up ofthe collector/impeller.

Check clutchcontrolsperiodicallytoverifythat these

engage and disengageproperlyand readjust if

necessary. Refer to Service and Adjustmentssection

page ofthis owner'sguide.

YOUR RESPONSIBILITY

Restrictthe useof this powermachine to personswho

read, understandand follow the warnings and

instructionsinthis manualand on the machine.

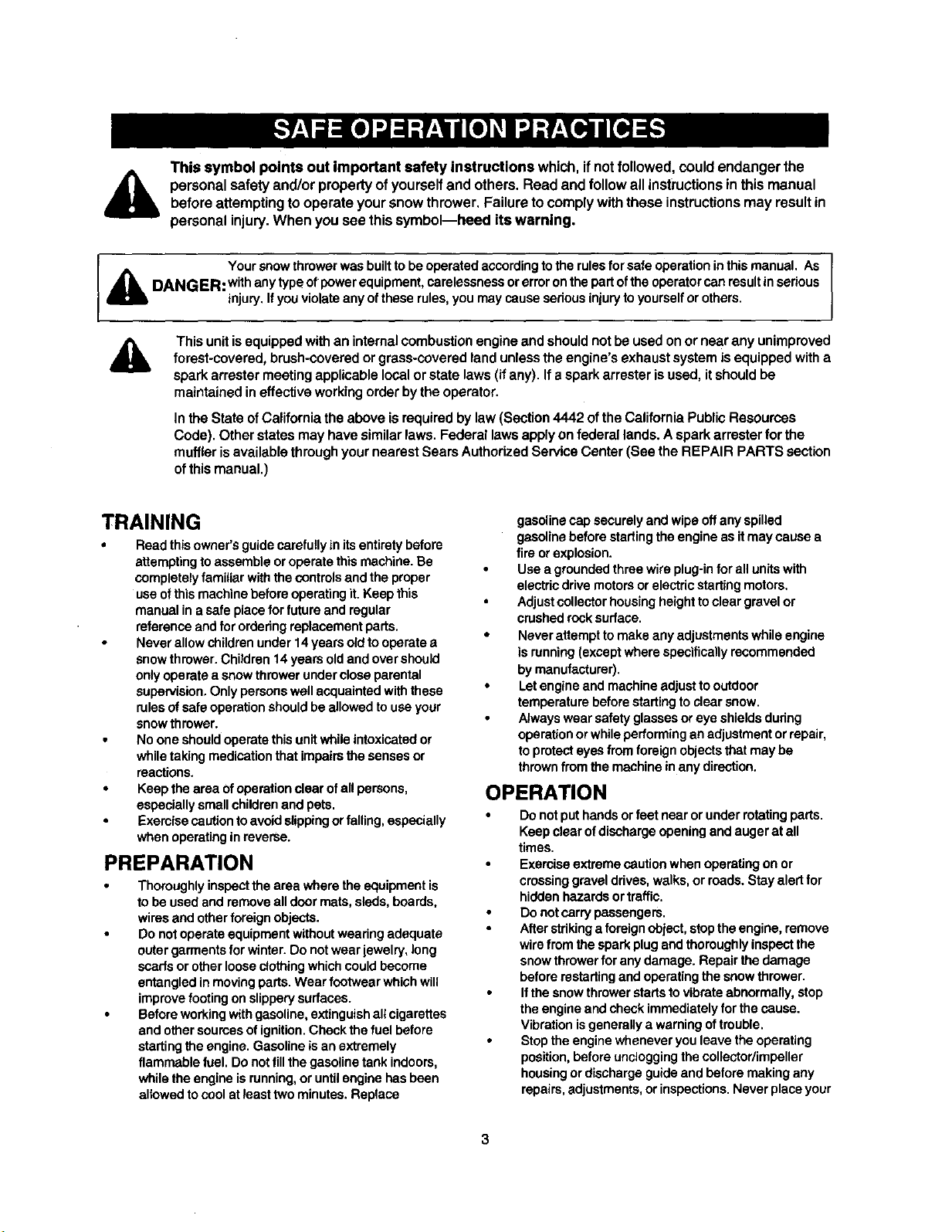

Following are representationsof some of thesafety labels on yourCraftsman snowthrower.Please follow the

instructiononthese labels and maintain safety while usingor servicingthe equipment.

ADANGER

I ,A WARNING

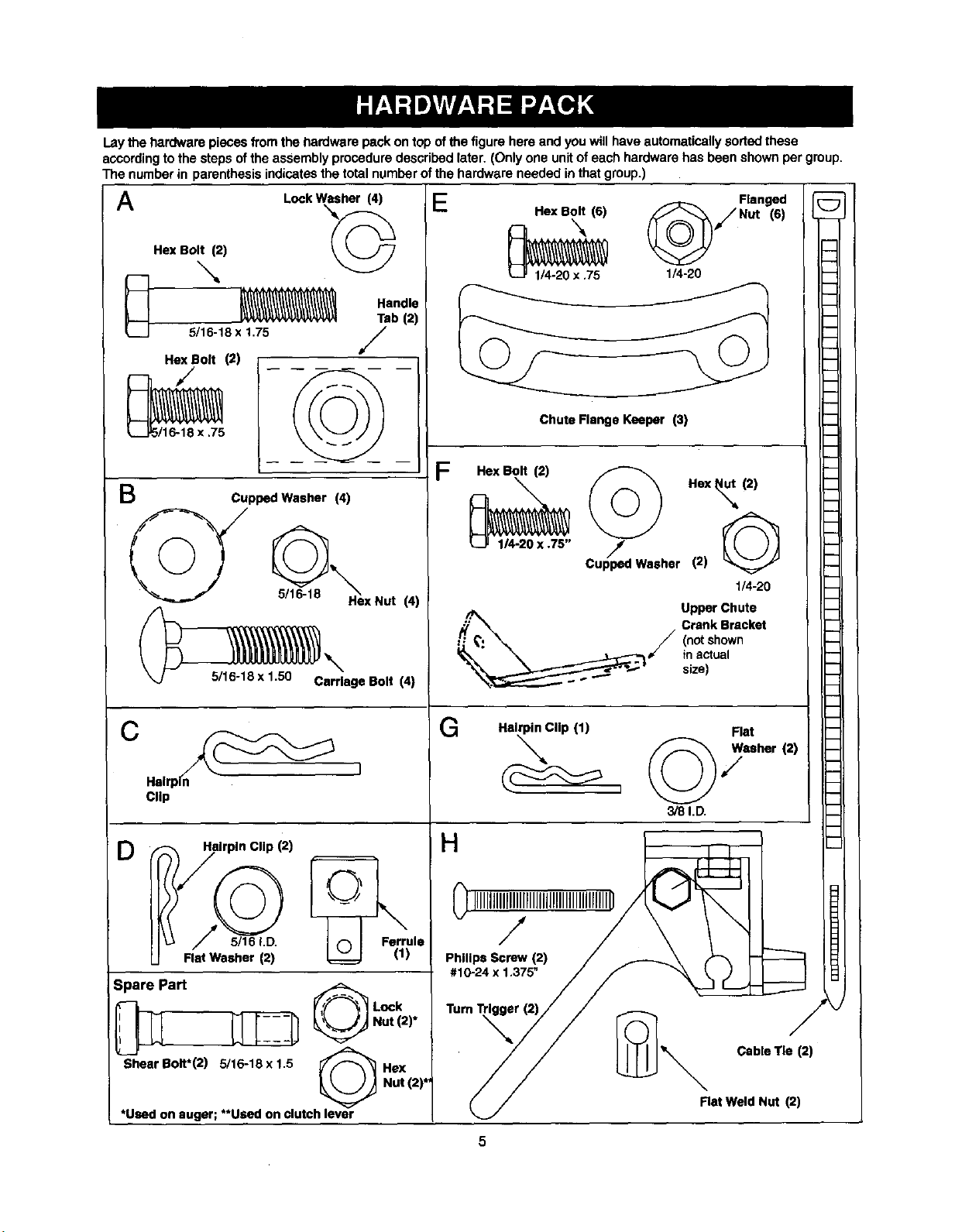

Lay the hardware pieces from the hardware pack on top of the figure here and youwill haveautomatically soded these

aCCordingtothe steps of the assembly procedure described later. (Only one unit ofeach hardware has been shown per group.

The numberin parenthesis indicatesthe total number of the hardware needed in that group.)

A

Hex Bolt (2) /_

q

m

h

5/16-18 x 1.75

Hex Bolt (2)

LockWasher (4)

/

Handle

Tab (2)

E_ Hex Bolt (6) Nut (6)

- 'N "--"

_/Flanged _;

1/4-20 x .75 1/4-20

,/t

NN

5/16-18 x .75

B

_5/16-18 x 1,50 Carriage Bolt

(_ Helrp_ ]

Clip

D

-_fi_ilrpln Clip (2)

Cupped Washer (4)

_\ (4)

HexNut (4)

Chute Flange Keeper (3)

F

:-_"exBolt(2) _) Hex_, (2)

1/4-20 X .75" Cup_ped Washer (2) G

Upper Chute

(notshown

'_/ Crank Bracket

G

Hairpin Clip (1) Flat

inactual

size)

©7

3/8 I.D.

H

1/4-20

m

i

m

m

b

b

m

Flat Washer (2) _ ! (1)

3pare Part

"ShearBolt*(2) 5/16-18 x 1.5

*Used on auger; **Used on clutch lever

I Ferrule

Lock

Nut (2)*

Hex

Hot (2)*

HIIIIIIIIIIIIIIII_,@_ -

,1024x,375"/F "__

TurnTr_r_//// _" Cable Tie (2)_

//

_,/ Rat Weld Nut (2)

Chute

Chute

Crank

iMPORTANT: This unitisshippedwithengine oil, but

without gasoline, in the engine.Afterassembly, see

OPERATION sectionof thismanLJalfor fuel selection

and fill-up.

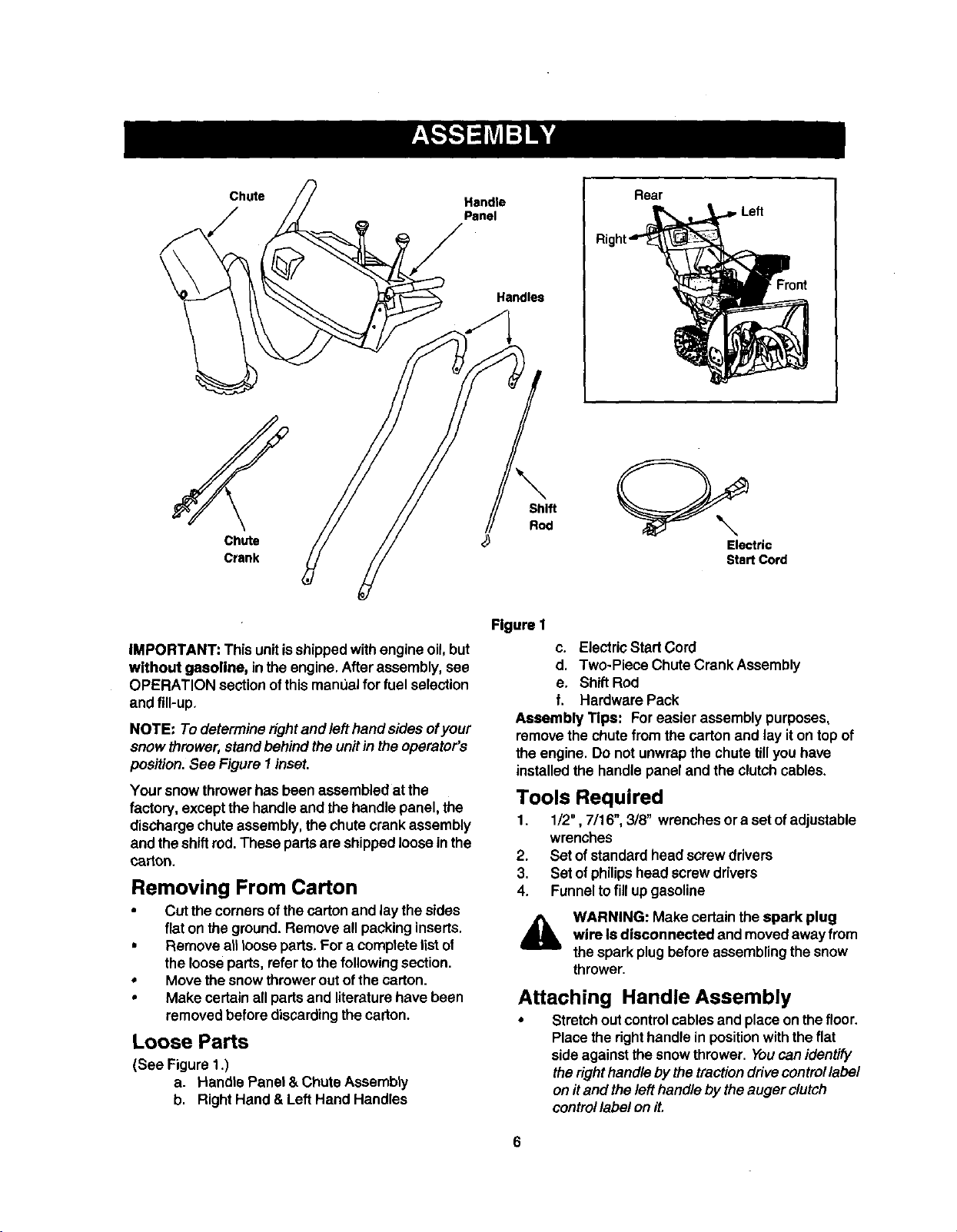

NOTE: Todetermineright andlefthand sidesofyour

snow thrower,standbehind the unitin the operator's

position.See Figure I inset,

Your snowthrowerhas been assembledat the

factory, exceptthe handle and thehandle panel, the

dischargechute assembly,the chute crank assembly

and the shiftrod.These partsare shippedloose inthe

carton.

Removing From Carton

• Cut the comersof thecarton and lay the sides

fiaton the ground.Remove all packinginserts.

• Remove all looseparts, For a complete listof

the looseparts, referto the following section.

• Move thesnow throweroutof the carton.

• Make certain all partsand literaturehave been

removedbefore discardingthe carton.

Loose Parts

(See Figure 1.)

a. Handle Panel & ChuteAssembly

b. Right Hand & Left Hand Handles

Handte

Panel

Figure I

Rear

, Left

Handles

Shift

Rod

Electric

Start Cord

c. Electric StartCord

d. Two-Piece Chute Crank Assembly

e. Shift Rod

f. Hardware Pack

Assembly Tips: For easier assembly purposes,

remove thechute from the carton and lay iton top of

the engine. Do not unwrapthe chute tillyou have

installedthe handlepanel and the clutchcables.

Tools Required

1. 1/2", 7/16",3/8" wrenchesor a set of adjustable

wrenches

2. Set ofstandardhead screw drivers

3. Set ofphilipshead screw drivers

4. Funnelto fill up gasoline

wire Is disconnected and movedaway from

WARNING: Make certainthe spark plug

the spark plugbefore assemblingthe snow

thrower.

Attaching Handle Assembly

• Stretchout controlcables and place on the floor.

Placethe righthandle in positionwiththeflat

side againstthe snow thrower. Youcan identify

the right handleby the traction drive control label

on it and the left handle by the auger clutch

control label on it.

6

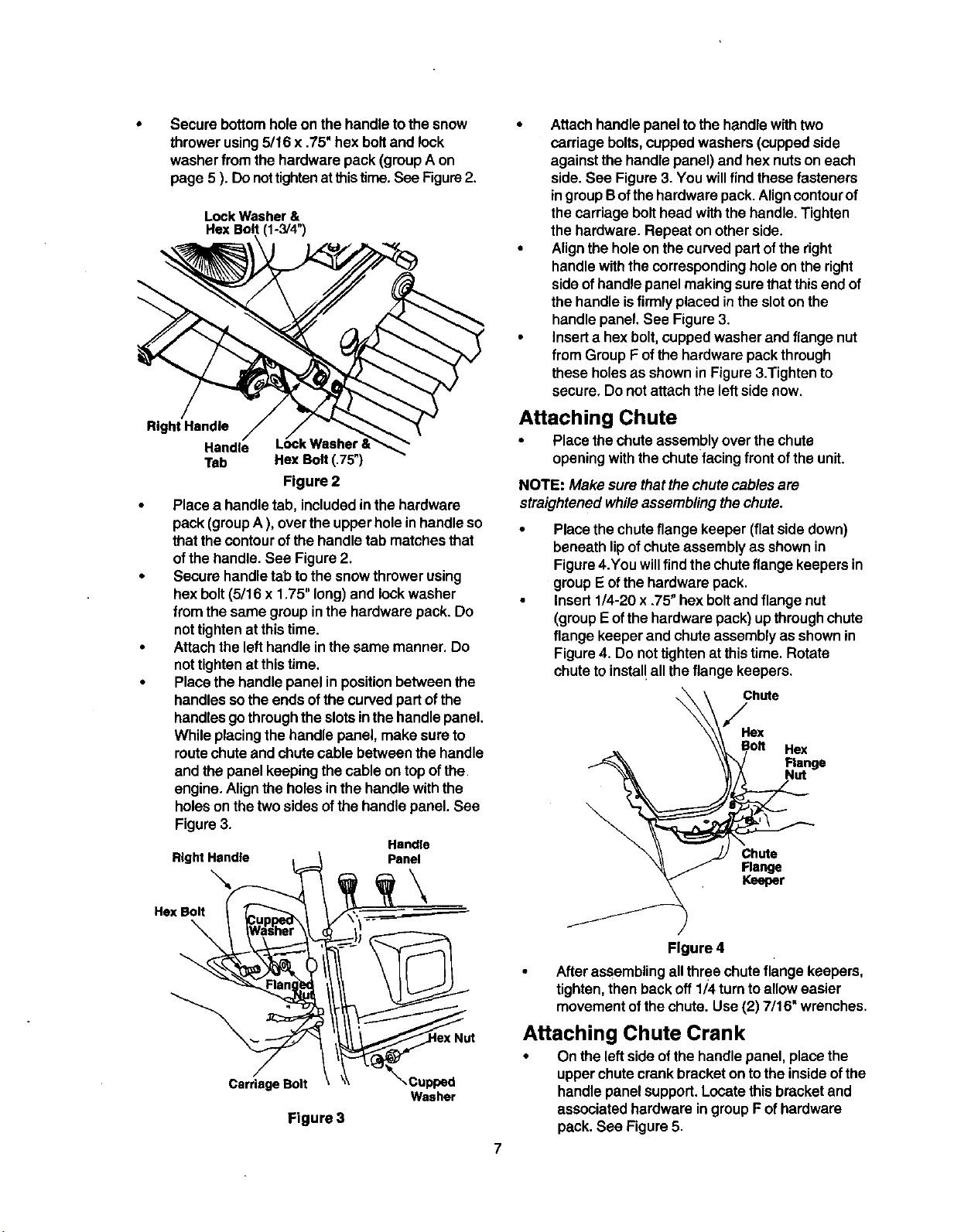

Securebottomholeonthehandletothesnow

throwerusing5/16x.75"hexboltandlock

washerfrom the hardware pack (groupA on

page 5 ). Donottightenatthistime.See Figure2.

Lock Washer &

He]( Bolt (1-3/4")

• Attachhandle panelto the handle withtwo

carriagebolts,cupped washers (cuppedside

againstthe handle panel) and hex nutson each

side.See Figure3. You willfind these fasteners

ingroupB ofthe hardware pack.Aligncontourof

thecarriage bolt head withthe handle. Tighten

thehardware. Repeat on otherside.

• Align the hole on thecurved partofthe right

handle withthecorrespondinghole on the right

side ofhandlepanel makingsure thatthisend of

the handle isfirmly placedinthe sloton the

handlepanel. See Figure3.

• Inserta hex bolt, cuppedwasherandflange nut

from Group F of the hardware pack through

these holes as shown in Figure 3.Tighten to

secure, Do notattach the left side now.

Right Handle

Handle

Tab Hex Bolt (.75")

Figure 2

• Place a handle tab, includedinthe hardware

pack (groupA ), overthe upperhole inhandle so

thatthe contourof the handle tab matchesthat

of the handle. See Figure2.

• Secure handletab to the snow throwerusing

hexbolt (5/16 x 1.75" long)and lockwasher

from the same groupinthe hardware pack. Do

nottightenat thistime.

• Attachthe left handle inthe same manner. Do

nottightenat this time.

• Placethe handle panelin positionbetween the

handles sothe ends ofthe curvedpart of the

handlesgo throughtheslotsinthe handlepanel.

While placingthe handle panel, make sure to

routechute andchute cable between the handle

and thepanel keepingthe cable on top of the

engine. Align the holesinthe handlewiththe

holesonthe two sides ofthe handlepanel. See

Figure3.

Handle

RightHandle 1

Panel

Attaching Chute

• Place the chute assemblyover thechute

openingwiththe chutefacing front ofthe unit.

NOTE: Make sure that thechute cables are

straightened while assembling thechute.

Placethe chuteflange keeper (flat side down)

beneath lipof chute assembly asshownin

Figure 4.You will find the chute flange keepers in

group E of the hardware pack.

Insert 1/4-20 x .75" hex bolt and flange nut

(group Eof the hardware pack) up through chute

flange keeper and chute assembly asshown in

Figure 4. Do not tighten at this time. Rotate

chute to instal! all the flange keepers.

..xoo,t

Carriage Bolt

/

Figure 3

Washer

Figure 4

Afterassembling allthree chuteflange keepers,

tighten,then back off 1/4 turnto alloweasier

movementofthe chute.Use (2) 7/16" wrenches.

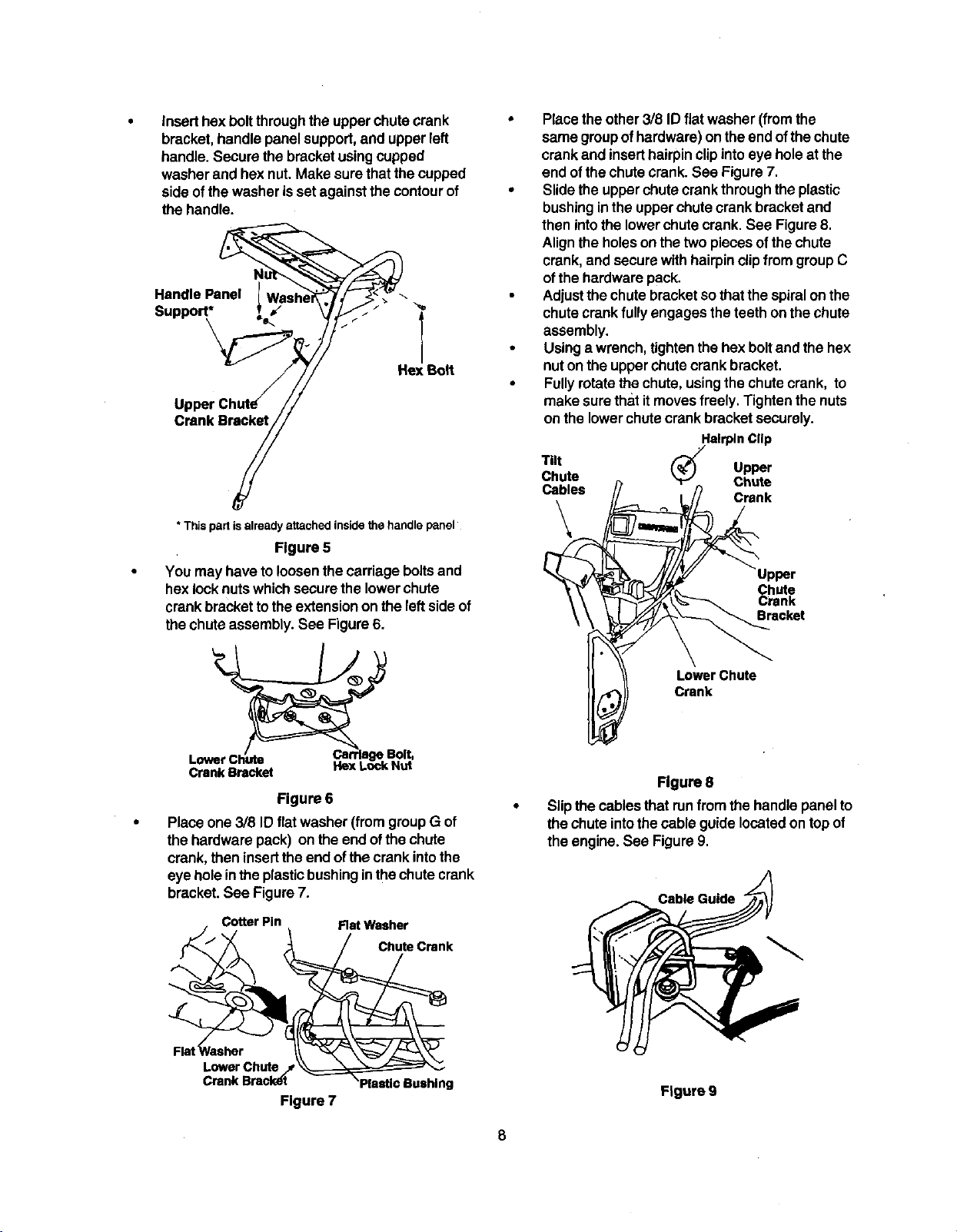

Attaching Chute Crank

• Onthe leftside of the handle panel, placethe

upperchute crankbracket ontothe insideofthe

handle panelsupport.Locate thisbracketand

associatedhardware ingroup F of hardware

pack. See Figure 5.

7

Inserthexboltthroughthe upper chutecrank

bracket,handle panel support,and upper left

handle.Secure the bracketusingcupped

washer and hex nut. Make surethat thecupped

side ofthe washer isset against the contourof

the handle.

Handle Panel l

Support*

\ "<

Hex Bolt

Crank Bracket

Placethe other3/8 ID flat washer (fromthe

same groupof hardware)on theend of thechute

crank and inserthairpinclip intoeye hole at the

end ofthe chutecrank. See Figure 7.

Slidethe upperchute crank throughtheplastic

bushinginthe upperchute crank bracketand

then intothe lowerchutecrank. See Figure8.

Alignthe holeson the two piecesof the chute

crank,and securewith hairpinclip from groupC

ofthe hardwarepack.

Adjustthe chutebracketso thatthe spiralon the

chutecrankfully engages the teeth onthe chute

assembly.

Using a wrench, tightenthe hex boltand the hex

nut onthe upperchutecrank bracket.

Fullyrotatethechute, usingthe chute crank, to

make surethat it movesfreely. Tightenthe nuts

on the lower chutecrank bracketsecurely.

Tilt Upper

Chute Chute

Cables

Crank

* This part isalready attached inside the handle panel

Figure 5

You may have to loosenthe carriage boltsand

hex locknutswhich securethe lower chute

crank brackettothe extensionon theleft side of

the chute assembly. See Figure6.

L rrlage Bolt,

CrankBracket Itex LockNut

Figure 6

Place one 3/8 ID flat washer (fromgroupG of

the hardware pack) on the end ofthe chute

crank,then insertthe end of thecrank intothe

eye holeinthe plasticbushinginthe chute crank

bracket.See Figure 7.

Cotter Pin

Flat Washer

Chute Crank

\

Upper

Chute

Crank

Bracket

LowerChute

Crank

Flgure 8

Slipthe cables thatrunfrom the handle panelto

thechute intothecable guidelocated on topof

theengine. See Figure9.

Cable Guide

Flat Rasher

Lower Chute /

Crank Bracl_t

Figure 7

Figure 9

8

Tightenallloose hardware on the handle

assemblyin thefollowingorder-- firstthe hex

boltsat the bottomof the handle, then the

carriagebolts and lastlythe hex boltsonthe rear

ofthe handle panel.

Attaching Clutch Cables

The clutchcontrolcables are attachedto the snow

thrower.If the cables ere attachedto the top ofthe

engine withcable ties, cutthe cable tiesnow. The Z

ends of the clutchcables are hooked intothe clutch

gripson each handle.

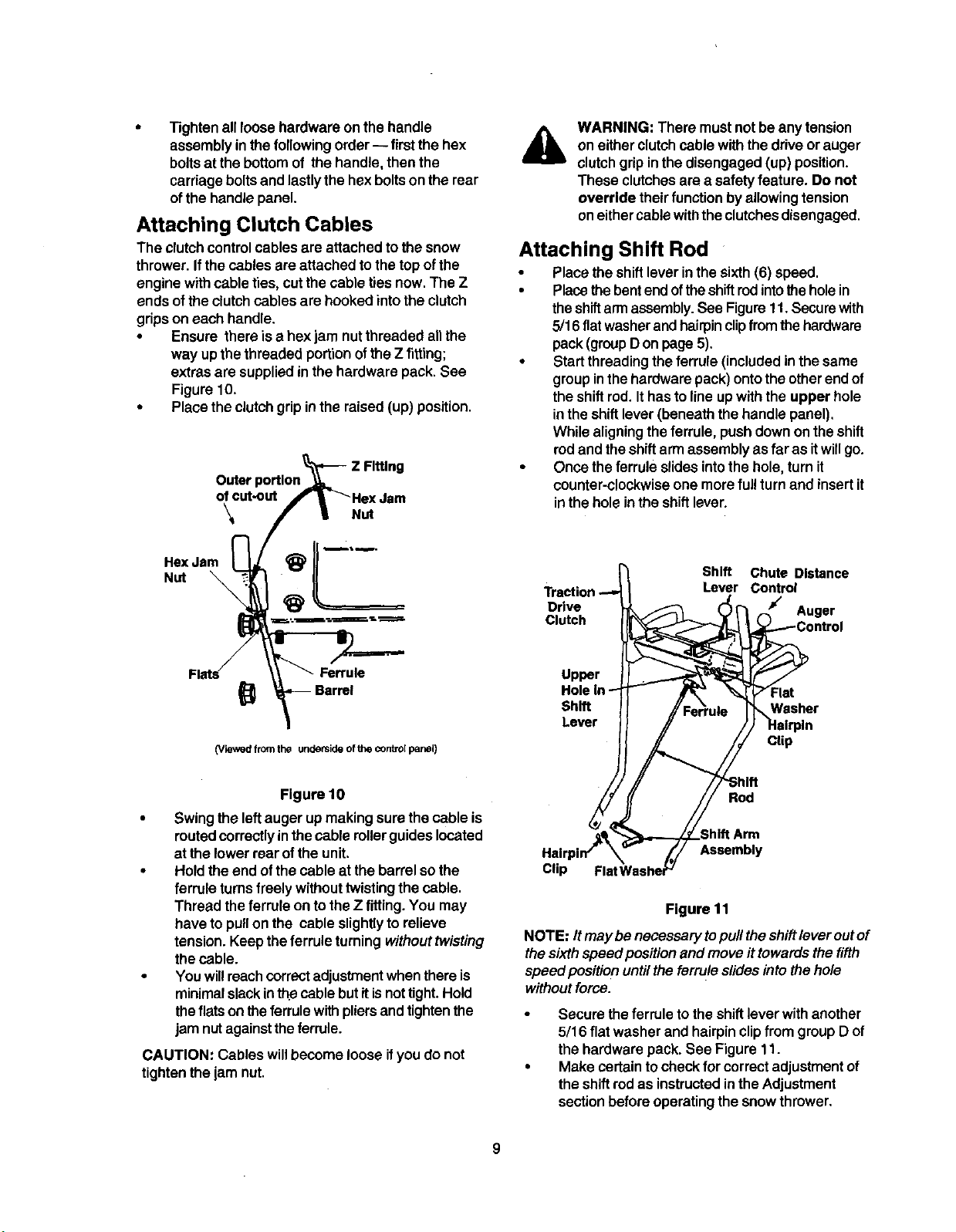

• Ensure there is a hexjam nutthreaded allthe

way upthe threaded portion ofthe Z fitting;

extras are supplied in the hardware pack. See

Figure 10.

• Place the clutch grip in the raised (up) position.

Z Fitting

Outer

ofcut-out

\ Nut

WARNING: There mustnotbe any tension

A

on eitherclutchcable withthe driveor auger

clutchgripinthe disengaged (up) position.

These clutchesare a safety feature. Do not

override theirfunction by allowingtension

on eithercablewiththe clutchesdisengaged.

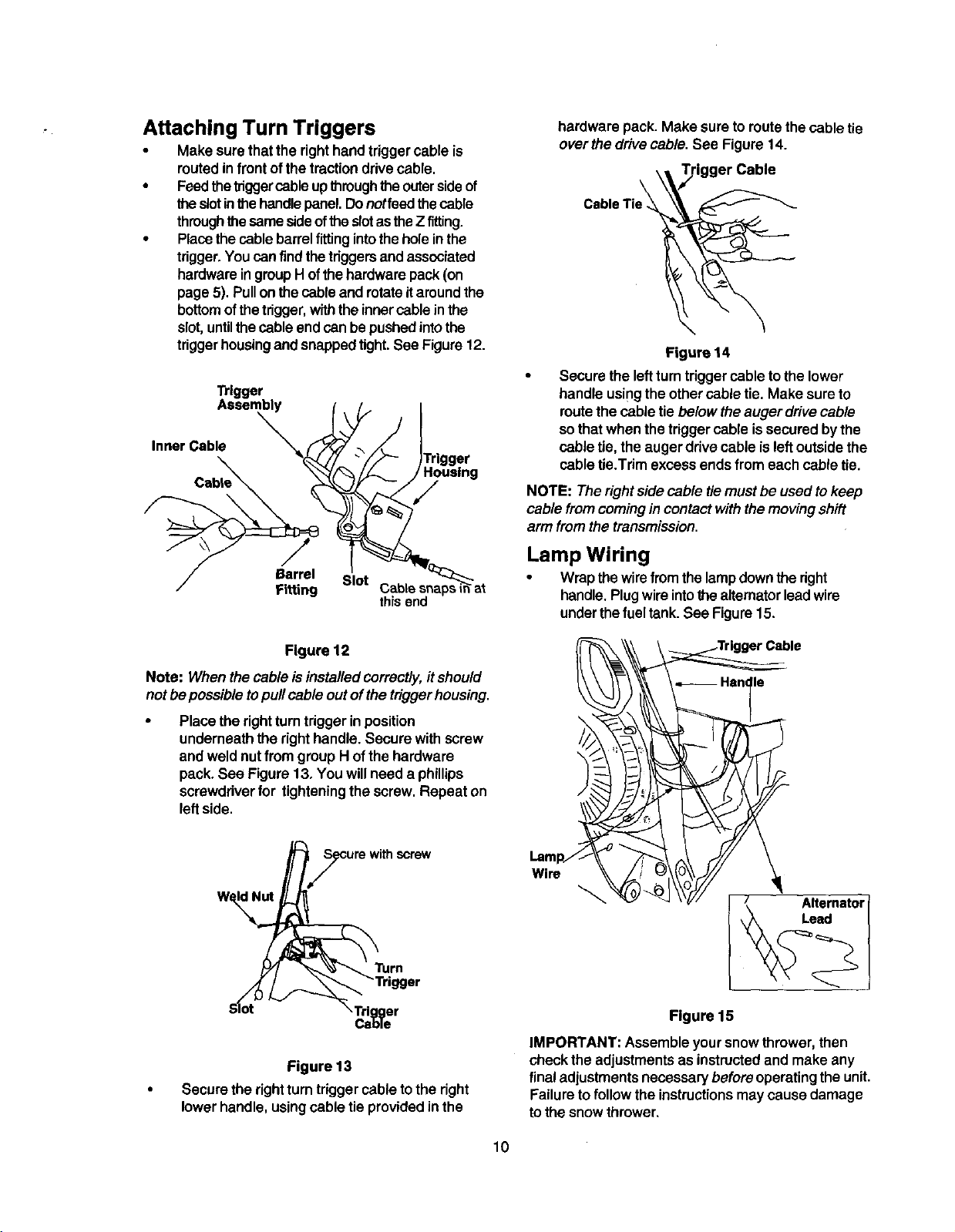

Attaching Shift Rod

• Placethe shiftlever inthesixth(6) speed.

• Placethe bentendofthe shiftrodintotheholein

theshiftarmassembly.See Figuret 1.Securewith

5/16 flatwasherandhairpinclipfromthe hardware

pack(groupDon page 5).

• Startthreadingthe ferrule(includedinthe same

groupinthe hardware pack)ontothe otherendof

the shiftrod. It has to lineup withthe upper hole

inthe shiftlever(beneath thehandle panel).

While aligningthe ferrule,push downon the shift

rodand the shiftarmassemblyas far as itwillgo.

• Once the ferrule slidesintothe hole, turn it

counter-clockwiseonemore ful!turn and insertit

inthe hole inthe shiftlever.

HexJam

Nut

Ferrule

Barrel

(Viewed from the underside of the controlpanel)

Figure 10

• Swingthe leftauger upmaking surethe cable is

routed correctlyin the cable rollerguideslocated

at thelower rear of the unit.

• Hold theend of the cable at the barrel sothe

ferrule turnsfreely withouttwistingthe cable.

Thread theferrule on to theZ fitting.You may

have to pullon the cable slightlyto relieve

tension.Keepthe ferrule turningwithout twisting

thecable.

• You willreachcorrectadjustmentwhenthere is

minimalslackinthe cable butit isnottight.Hold

theflats on theferrule withpliersandtightenthe

jam nutagainsttheferrule.

CAUTION: Cables willbecome looseifyoudo not

tighten thejam nut.

Shift Chute Distance

Lever Control

Drive Auger

Clutch

Upper

Shift

Lever

Clip

Rod

Assembly

Clip

Figure 11

NOTE: It may be necessary topull theshiftlever outof

thesixthspeed positionand move it towardsthe fifth

speedpositio n untiltheferruleslides intothe hole

withoutforce.

Secure theferrule to the shift leverwithanother

5/16 flat washer and hairpin clipfrom group D of

the hardware pack. See Figure 11.

Make certain tocheck for correctadjustmentof

the shiftrodas instructedinthe Adjustment

sectionbefore operatingthesnow thrower.

9

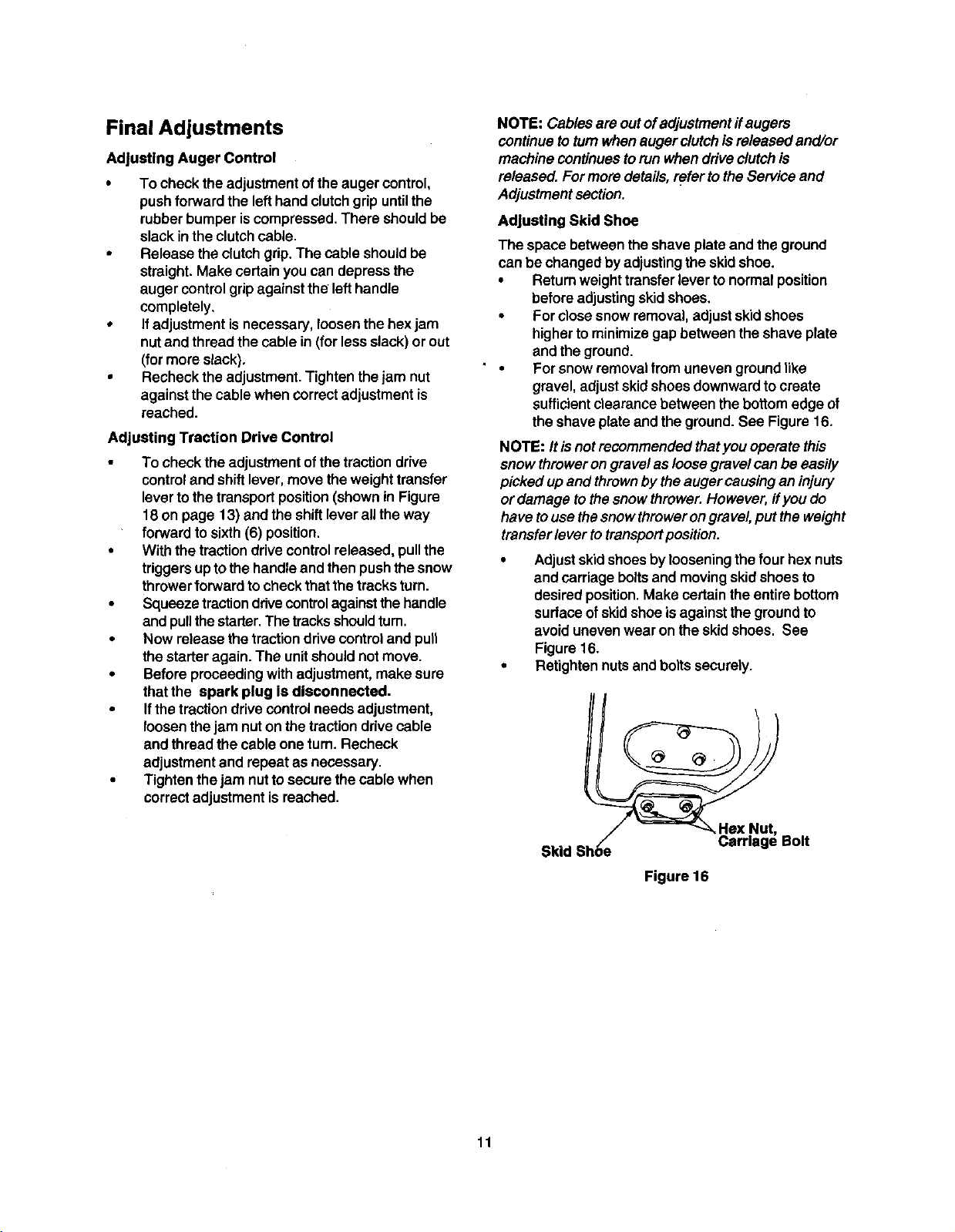

Attaching Turn Triggers

Make surethat the righthand triggercable is

routedinfrontof thetractiondrive cable.

• Feedthetriggercableupthroughthe outersideof

theslotinthe handlepanel.Donotfeedthe cable

throughthe samesideofthe slotastheZ fitting.

• Placethe cablebarrelfitting intothe holeinthe

trigger.You canfindthetriggersandassociated

hardwareingroupH ofthe hardwarepack(on

page5). Pullonthe cable and rotateitaroundthe

bottomofthetrigger,withthe innercable inthe

slot,untilthecable endcan be pushedintothe

triggerhousingandsnappedtight.See Figure 12.

Trigger

Assembly

Inner Cable

hardware pack. Make sure to routethe cable tie

over thedrive cable. See Figure 14.

Figure 14

Secure the leftturntriggercable to the lower

handle usingthe othercable tie. Make sureto

route the cable tie below the auger drive cable

sothat when the trigger cable is securedby the

cable tie, the auger drive cable is left outside the

cable tie.Trim excess ends from each cable tie.

NOTE: The right sidecable tiemust be used tokeep

cable from comingin contact withthe moving shift

armfromthe transmission.

Y

Barrel Slot

Fitting

Figure 12

Note: When the cable is installed correctly, it should

not be possibleto pullcable out ofthe trigger housing.

Place the rightturntrigger inposition

underneaththe righthandle. Secure withscrew

and weld nutfrom group H of the hardware

pack. See Figure 13. You willneed a phillips

screwdriverfor tighteningthe screw. Repeat on

leftside.

thisend

Turn

Lamp Wiring

• Wrapthe wirefrom thelampdownthe right

handle.Plugwireintothe aitemator leadwire

underthefuel tank. See Figure15.

I _ Hsn le

S_ot ,Trigger

Cable

Figure 13

• Secure therightturn triggercable to the right

lowerhandle, usingcable tieprovidedinthe

Figure 15

IMPORTANT: Assembleyour snowthrower, then

checkthe adjustmentsas instructedand make any

final adjustmentsnecessarybefore operatingthe unit.

Failureto follow the instructionsmaycause damage

tothe snowthrower.

10

Final Adjustments

Adjusting Auger Control

• To checkthe adjustment ofthe auger control,

pushforward the left handclutchgrip untilthe

rubberbumper is compressed,There shouldbe

slackinthe clutchcable.

• Release the clutchgrip.The cable should be

straight. Make certain you can depress the

auger controlgripagainst the lefthandle

completely.

• If adjustmentis necessary,loosen the hexjam

nutand thread the cable in(for lessslack) or out

(for more slack),

• Recheck theadjustment. Tightenthe jam nut

againstthe cablewhen correctadjustmentis

reached.

Adjusting Traction Drive Control

To checkthe adjustmentofthe tractiondrive

controland shiftlever, move the weighttransfer

levertothe transportposition(shownin Figure

18 on page 13) and theshiftlever allthe way

forward to sixth(6) position.

• Withthe tractiondrivecontrol released, pullthe

triggersupto the handleand then pushthesnow

throwerforward to checkthat the tracks turn.

• Squeeze tractiondrivecontrolagainstthe handle

and pullthestarter.The tracksshouldturn.

• Now release the tractiondrivecontroland pull

the starteragain. The unitshouldnot move.

• Beforeproceedingwith adjustment,make sure

thatthe spark plug is disconnected.

• Ifthe tractiondrivecontrolneeds adjustment,

loosen the jam nut on the tractiondrivecable

and threadthe cable one turn. Recheck

adjustmentand repeat as necessary.

• Tightenthe jam nutto secure thecable when

correctadjustment is reached.

NOTE: Cables are outof adjustmentifaugers

continueto turnwhenauger clutchis releasedand/or

machine continuestorun when driveclutchis

released. For more details,refer to theService and

Adjustmentsection.

Adjusting Skid Shoe

The space between the shave plate and theground

canbe changed byadjustingthe skidshoe.

• Returnweighttransferlever to normalposition

before adjustingskidshoes.

• For closesnow removal,adjust skidshoes

higher to minimizegap between the shaveplate

and the ground.

• For snow removalfrom uneven groundlike

gravel, adjustskidshoes downwardtocreate

sufficientclearancebetween the bottomedge of

the shave plate andthe ground. See Figure16.

NOTE: It isnot recommendedthat you operate this

snow throweron gravelas loose gravelcan be easily

pickedup and thrownby theauger causingan injury

or damage tothe snowthrower.However, if you do

have to usethe snow throwerongravel,put the weight

transfer lever to transport position.

• Adjustskidshoesby loosening the four hex nuts

and carriage bolts and moving skidshoes to

desired position. Make certain the entire bottom

surface of skidshoe is against the ground to

avoid uneven wear on the skid shoes. See

Figure 16.

• Retightennuts and bolts securely.

11

Skid Shoe_ _HeXNa_t" Bolt

Figure 16

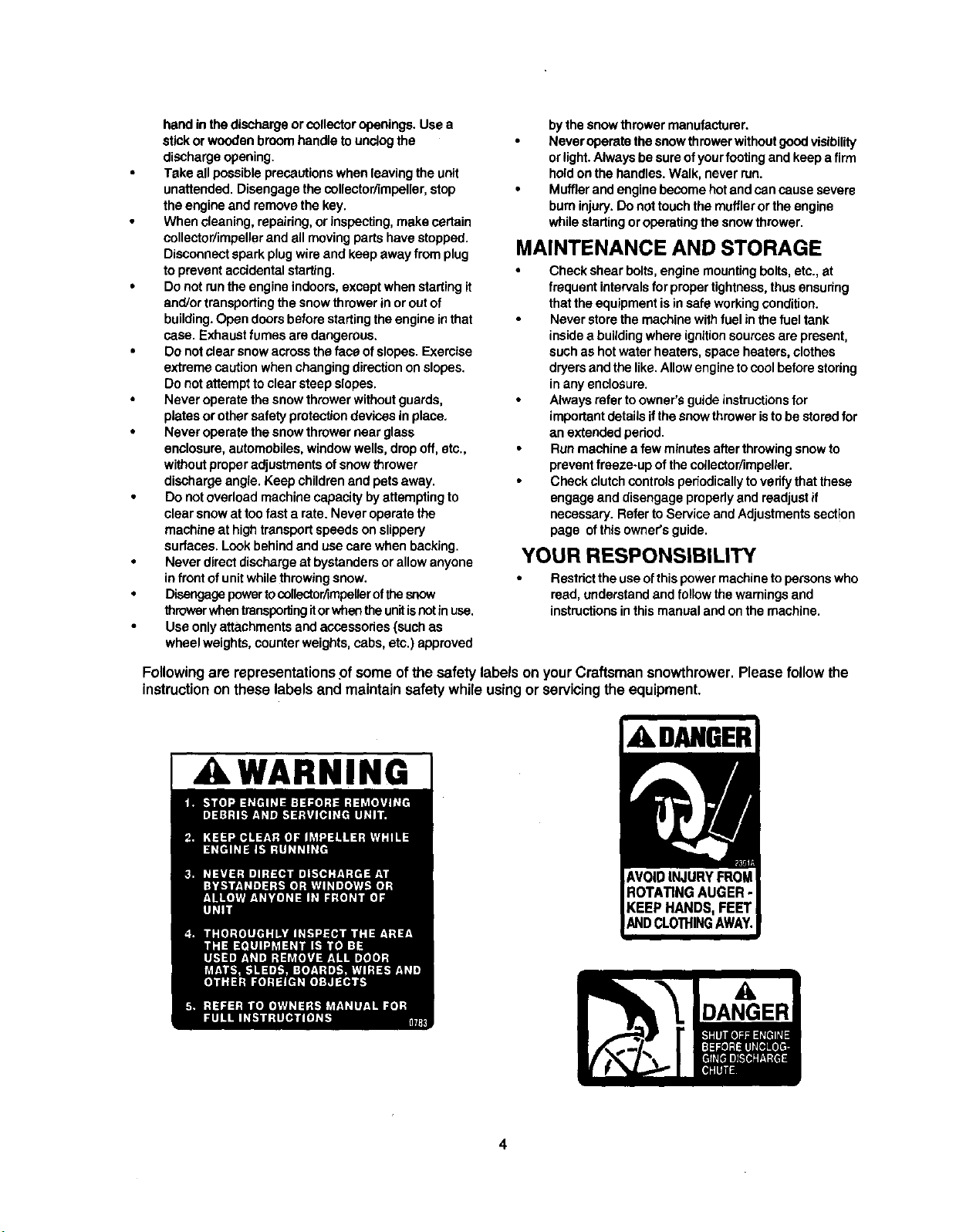

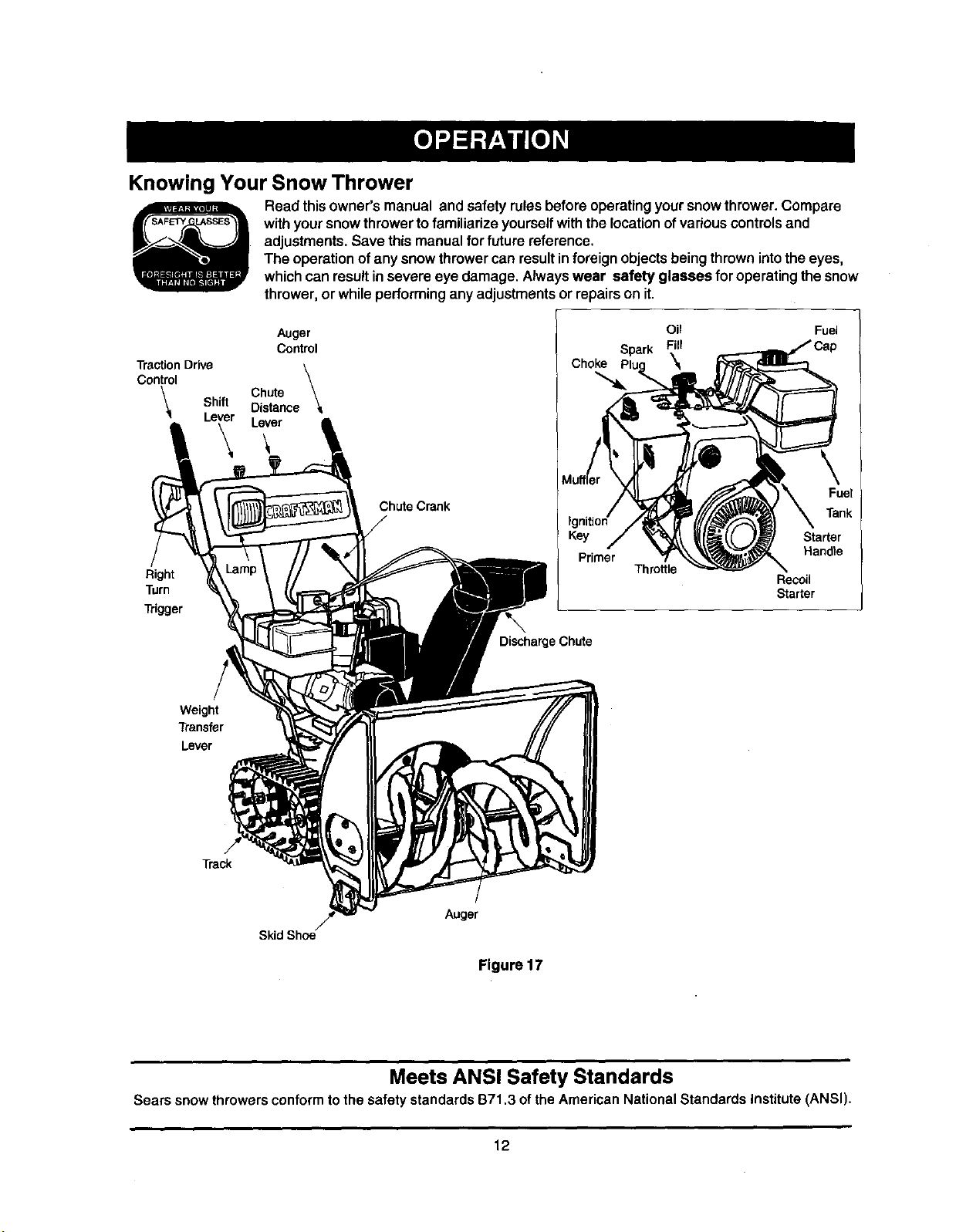

Knowing Your Snow Thrower

Read thisowner's manual and safety rules before operatingyoursnowthrower. Compare

withyoursnowthrowerto familiarize yourselfwiththe location of variouscontrols and

adjustments.Save this manual for future reference.

The operationof any snow throwercan resultin foreign objectsbeing thrownintothe eyes,

whichcan resultinsevere eye damage. Alwayswear safety glasses for operating the snow

thrower,or while performingany adjustmentsor repairson it.

Control

Traction Drive

Right

Turn

Trigger

Weight

Transfer

Lever

Auger

Control

Shift Distance

Chute

Lever Lever

Chute Crank

Choke

DischargeChute

Oil

Spark Fill

Throttle

Fuel

\

Fuel

Tank

Starter

Handle

Recoil

Starter

Track

Auger

Skid Shoe

Figure 17

Meets ANSI Safety Standards

Sears snowthrowersconformto the safety standardsB71,3 of the AmericanNational StandardsInstitute(ANSI),

12

Operating Controls

(See Figure 17.)

Chute Crank

The chute crankis located on the left sideof the snow

thrower. To change the direction in which snow is

thrown, turn chute crank as follows:

turn clockwise to discharge to the left;

turn counterclockwiseto discharge to the right.

Chute Distance Control

The distance that snow is thrown can be adjusted by

adjusting the angle of the chute assembly. Push the

chute distance control lever forward to move the

upper chute down and decrease the distance. Pull the

lever back toward the rear to move the upper chute

up and increase the distance.

Left And Right Turn Trigger

The leftand rightturntriggers are located onthe

undersideofthe handles and are used toassist in

steeringyoursnow thrower. Squeeze the rightturn

triggerwhenturningright,squeeze the leftturntrigger

when turningleft. Operate yoursnowthrower inopen

areas untilyou become familiar withthesecontrols.

Shift Lever

The shift lever is located inthe center ofthe handle

panel. It may be moved into one of eight positions:

a. Forward--oneofsixspoeds;po,v_onone(1)

isthe slowest and position six (6) isthe

fastest.

b. Reverse--two reverse (R) speeds; R2is

faster.

Use the shift lever to determine ground speed. Do not

shiftto different speed while the unit is moving.

Auger Control

The auger controlis locatedon the left handle.

Squeeze the auger controlagainstthe handle to

engage the augers; release to disengagethe augers.

(Tractiondrive controlmust also be released.)

Traction Drive Control

The tractiondrive controlislocated onthe right

handle. Squeeze the tractiondrive controltoengage

thetrack drive;release to stop.

This same lever also locks the auger control so

thatyou can turn the chutecrank withoutinterrupting

the snowthrowingprocess.If the auger controlis

engaged withthetractiondrive controlengaged, you

can release the auger control(onthe lefthandle) and

the augers willremainengaged. Release the traction

drivecontrolto stopboth theaugers andthe track

drive. (Auger controlmust alsobe released).

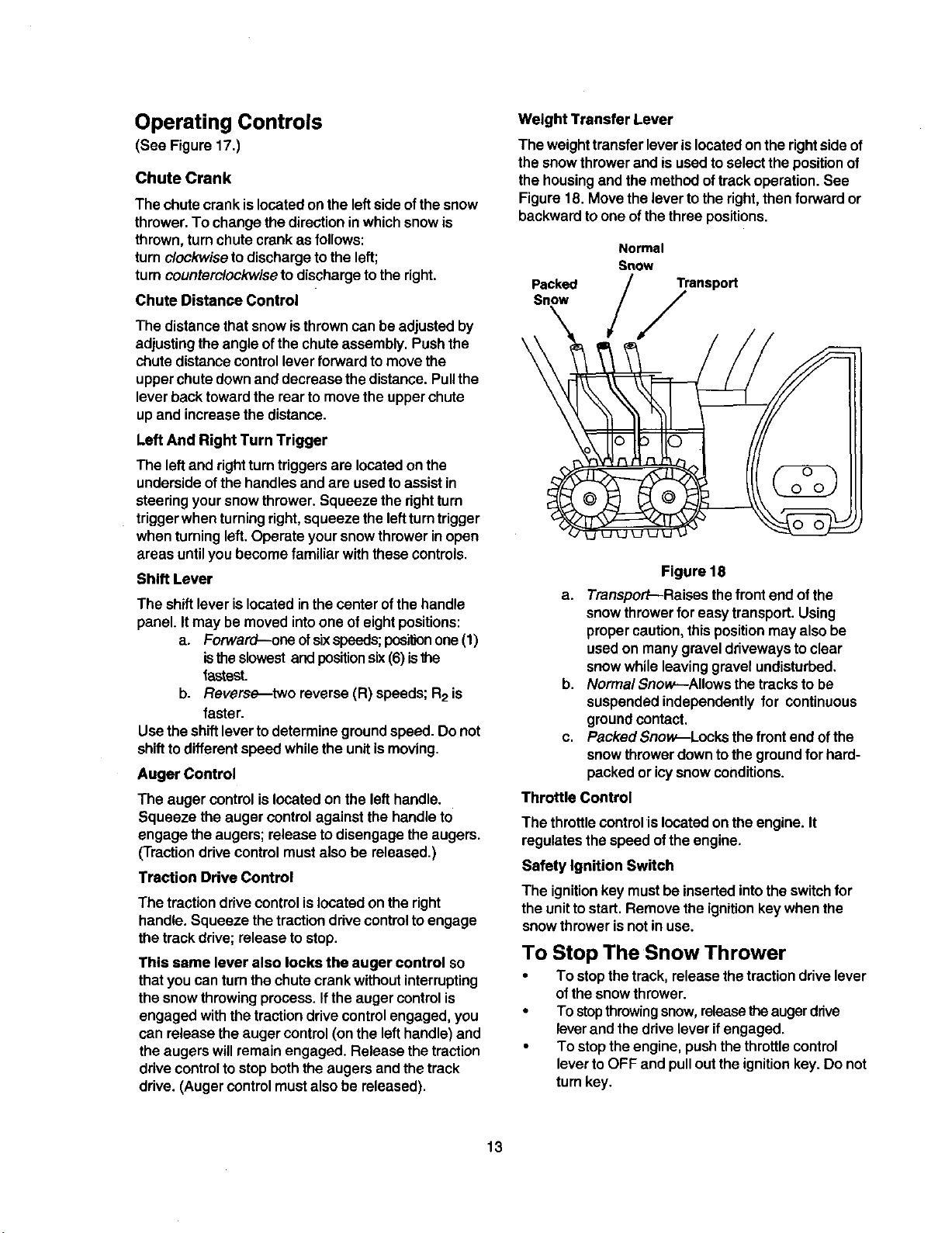

Weight Transfer Lever

The weighttransfer lever is locatedonthe rightside of

thesnow throwerand is used toselect the positionof

the housingand the methodoftrack operation. See

Figure 18. Move the lever tothe right,then forward or

backwardto one ofthe three positions.

Normal

Snow

Packed

Snow

Transport

,/

\

Figure 18

a. Transport--Raises the front end of the

snowthrowerfor easytransport. Using

propercaution, thispositionmay also be

used on manygravel drivewaysto clear

snowwhileleaving gravel undisturbed.

b. Normal Snow--Allows thetracks to be

suspendedindependently for continuous

groundcontact.

c. Packed Snow.--Locksthe frontend of the

snowthrowerdownto the groundforhard-

packed or icysnow conditions.

Throttle Control

The throttlecontrolis locatedonthe engine. It

regulatesthe speed of the engine.

Safety Ignition Switch

The ignitionkey must be insertedintothe switchfor

the unitto start. Remove the ignitionkeywhen the

snow thrower is not in use.

To Stop The Snow Thrower

• To stopthetrack, release the tractiondrivelever

ofthe snowthrower.

• To stopthrowingsnow,releasethe augerdrive

leverand the drive leverifengaged.

• To stopthe engine, pushthe throttlecontrol

leverto OFF and pulloutthe ignitionkey. Do not

turnkey.

13

Loading...

Loading...