Craftsman 247888520 Owner’s Manual

Owner's Manual

CRRFTSMRN

9 Horse Power

|

26" Two-Stage Wheel Drive

Snow Thrower

Model No.

247.888520

MR

CAUTION: Before using this product,

read this manual and follow all Safety

Rules and Operating Instructions.

Sears, Roebuck And Co., Hoffman Estates, IL 60179, U.S.A.

770-10057B

Printed in USA. (10/98)

Content Page

Warranty Information ......................................... 2

Safe Operation Practices ................................... 3

Assembly ........................................................... 6

Operation ........................................................... 12

Maintenance ...................................................... 17

Two -Year Warranty on Craftsman Snow Thrower

For two years from the date of purchase, when this Craftsman Snow Thrower is maintained, lubricated and tuned

up according to the instructions in the owner's manual, Sears will repair, free of charge, any defect in material

and workmanship.

If this Craftsman snow thrower is used for commercial or rental purposes, this warranty applies for only 30 days

from the date of purchase.

This warranty does not cover:

Expendable items which become worn during normal use, such as skid shoes, shave plate and spark

plugs.

Repairs necessary because of operator abuse or negligence, including bent crankshafts and the failure to

maintain the equipment according to the instructions contained in the owner's manual.

WARRANTY SERVICE IS AVAILABLEBYRETURNING THE CRAFTSMAN SNOW THROWER TOTHE NEAREST

SEARS SERVICE CENTER/DEPARTMENT INTHE UNITED STATES.

This warranty applies only while this product is in use in the United States.

This warrantygives you specific legal rights and you may also have other rightswhich may varyfrom statetostate.

SEARS, ROEBUCKAND CO., D/817WA, HOFFMAN ESTATES,IL60179

Content Page

Service & Adjustment ......................................... 20

Off-Season Storage ........................................... 25

Trouble-Shooting ............................................... 26

Accessories ....................................................... 27

Horsepower: ......................... 9

Engine Oil ............................. SAE 5W30 oil

Fuel Capacity: ....................... 1 gallon

Spark Plug: ........................... RJ-19LM

Engine:.................................. 143.999005

Model Number 247.888520

Serial Number ...........................................................

Date of Purchase ......................................................

Record both serial number and date ofpurchase and

keep in a safe place for future reference.

This symbol points out important safety instructions which,ifnotfollowed, couldendangerthe

personalsafety and/or propertyofyourselfand others. Read and followall instructionsinthis manual

beforeattemptingtooperate yoursnowthrower. Failure tocomplywiththese instructionsmay result in

personalinjury.When you see thissymbol--heed its warning.

Your snow throwerwasbuilt to be operated according to the rules for safe operation in this

DANGER: operator can result in serious injury. Ifyou violate any of these rules,you may cause serious

,_ manual. As withany type of power equipment, carelessness orerror on the part of the

injury to yourself or others.

This unit is equipped with an internal combustion engine and should not be used on or near any unimproved

forest-covered, brush-covered or grass-covered land unless the engine's exhaust system is equipped with a

spark arrester meeting applicable local or state laws (ifany). If a spark arrester is used, it should be

maintained in effective working order by the operator.

In the State of California the above is required by law (Section 4442 of the California Public Resources

Code). Other states may have similar laws. Federal laws apply on federal lands. A spark arrester for the

muffler is available through your nearest Sears Authorized Service Center (See the REPAIR PARTS section

of this manuaL.)

The engine exhaust from this product contains chemicals known to the state of California to cause cancer,

birth defects or other reproductive harm,

TRAINING

Read this owner's guide carefully in itsentirety before

attempting to assemble or operate this machine. Be

completely familiar with the controls and the proper

use of this machine before operating it. Keep this

manual in a safe place for future and regular

reference and for ordering replacement parts.

Never allow children under 14 years old to operate a

snow thrower. Children 14 years old and over should

only operate a snow thrower under close parental

supervision. Only persons well acquainted with these

rules of safe operation should be allowed to use your

snow thrower.

No one should operate this unit while intoxicated or

while taking medication that impairs the senses or

reactions.

Keep the area of operation clear of all persons,

especially small children and pets.

Exercise caution to avoid slipping orfalling, especially

when operating in reverse.

PREPARATION

Thoroughly inspect the area where the equipment is

to be used and remove all door mats, sleds, boards,

wires and other foreign objects.

Do not operate equipment without wearing adequate

outer garments for winter. Do not wear jewelry, long

scarfs or other loose clothing which could become

entangled in moving parts. Wear tootwear which will

improve footing on slippery surfaces.

Before working with gasoline, extinguish all cigarettes

and other sources of ignition. Check the fuel before

starting the engine. Gasoline is an extremely

flammable fuel. Do not fill the gasoline tank indoors,

while the engine is running, or until engine has been

allowed to cool at least two minutes. Replace

gasoline cap securely and wipeoff any spilled

gasoline before starting the engine as it may cause a

fire or explosion.

Use a grounded three wire plug-in for all units with

electric drive motors or electric starting motors.

Adjust collector housing height to clear gravel or

crushed rock surface.

Never attempt to make any adjustments while engine

is running (except where specifically recommended

by manufacturer).

Let engine and machine adjust to outdoor

temperature before starting to clear snow.

Always wear safety glasses or eye shields during

operation or while performing an adjustment or repair,

to protect eyes from foreign objects that may be

thrown from the machine inany direction.

OPERATION

Do not put hands or feet near or under rotatingparts.

Keep clear of discharge opening and auger at all

times.

Exercise extreme caution when operating on or

crossing gravel drives, walks, or roads. Stay alert for

hidden hazards or traffic.

Do not carry passengers.

After striking a foreign object, stop the engine, remove

wire from the spark plug and thoroughly inspect the

snow thrower for any damage. Repair the damage

before restarting and operating the snow thrower.

Itthe snow thrower starts to vibrate abnormally, stop

the engine and check immediately for the cause.

Vibration is generally a warning of trouble.

Stop the engine whenever you leave the operating

position, before unclogging the collector/impeller

housing or discharge guide and before making any

repairs, adjustments, or inspections. Never place your

I

3

handin the discharge or collectoropenings. Use a

stickor wooden broom handle to unclog the

discharge opening.

Take all possible precautions when leaving the unit

unattended. Disengage thecollector/impeller, stop

the engine and remove the key.

When cleaning, repairing, or inspecting, make certain

collector/impeller and alJmoving parts have stopped.

Disconnectspark plugwire and keep away from plug

to prevent accidental starting.

Do not run the engine indoors, except when starting it

and/or transporting the snow thrower inor out of

building. Open doors before starting the engine inthat

case. Exhaust fumes are dangerous.

Do not clear snow across the face of slopes. Exercise

extreme caution when changing directionon slopes.

Do not attempt toclear steep slopes.

Never operate the snow thrower without guards,

pJatesor other safety protection devices inplace.

Never operate the snow thrower near glass

enclosure, automobiles, window wells, drop off, etc.,

without proper adjustments of snow thrower

discharge angle. Keep children and pets away.

Do not overload machine capacity by attempting to

clear snow at too fast a rate. Never operate the

machine at high transport speeds on slippery

surfaces. Look behind and use care when backing.

Never direct discharge at bystanders or allow anyone

in front of unit while throwing snow.

Disengage power tocollector/impeller ofthe snow

throwerwhen transporting itor when the unitis not in use.

Use only attachments and accessories (such as

wheel weights, counter weights, cabs, etc.) approved

by the snow thrower manufacturer.

Never operate the snow thrower without good visibility

or right.Always be sure of your footing and keep a firm

hold on the handles. Walk, never run,

Muffler and engine become hot and can cause severe

burn injury. DOnot touch the muffler or the engine

while starting or operating the snow thrower.

MAINTENANCE AND STORAGE

Check shear bolts, engine mounting bolts, etc., at

frequent intervals for proper tightness, thusensuring

that the equipment is in safe working condition.

Never store the machine with fuel in the fuel tank

inside a building where ignitionsources are present,

such as hot water heaters, space heaters, clothes

dryers and the like.Allow engine to cool before storing

in any enclosure,

Always refer to owner's guide instructions for

importantdetails if the snow thrower is to be stored for

an extended period.

Run machine a few minutes after throwing snow to

prevent freeze-up of the collector/impeller.

Check clutch controls periodicallyto verify that these

engage and disengage properly and readjust if

necessary. Refer to Service and Adjustments section

page of this owner's guide.

YOUR RESPONSIBILITY

Restrict the use of thispower machine to persons who

read, understand and follow the warnings and

instructions in this manual and on the machine.

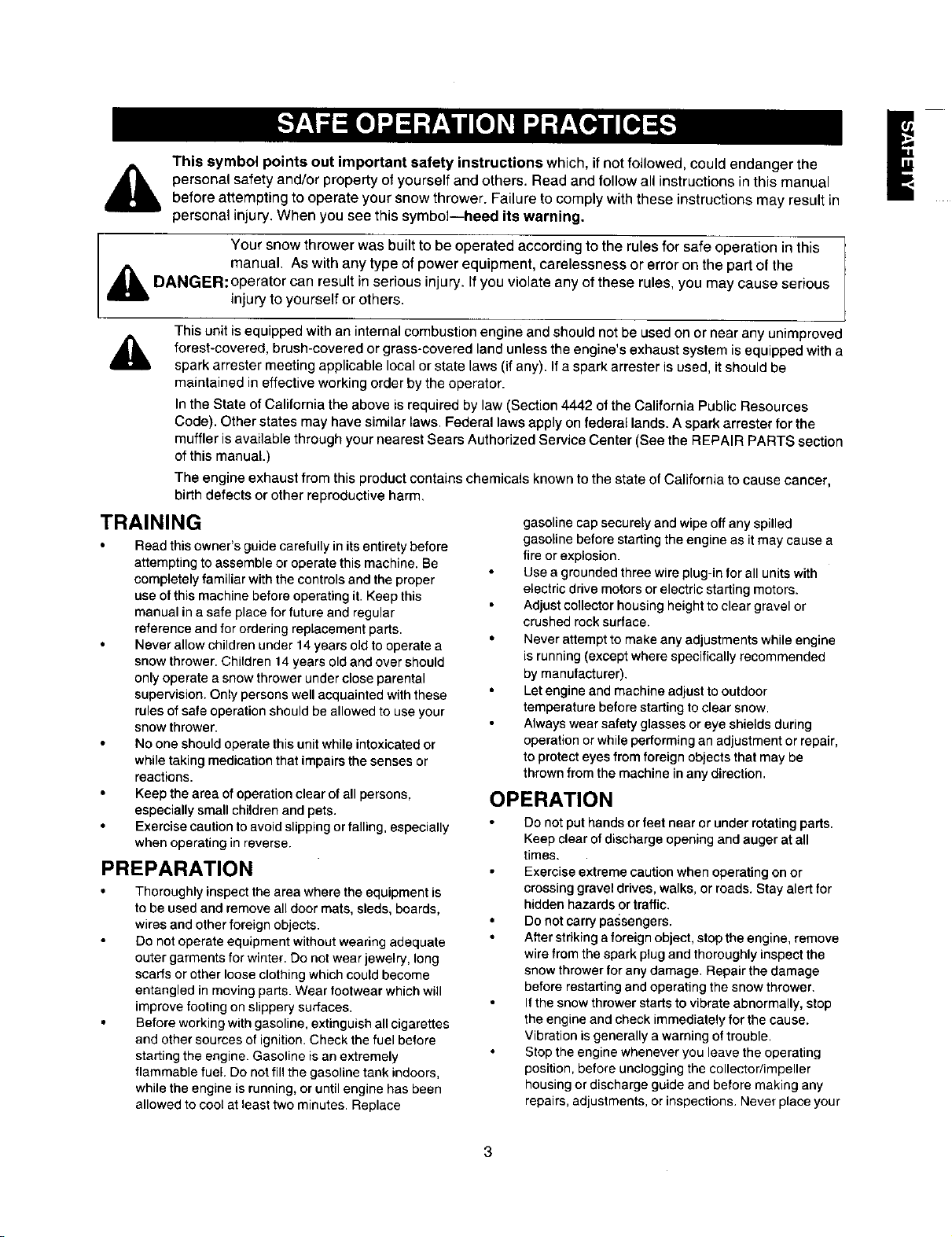

Following are representations of some of the safety labelson your Craftsman snowtbrower. Please follow the

instruction on these labels and maintain safety while using or servicing the equipment.

DAHGER

WARNING ]

4

Lay the hardware pieces from the hardware pack on the figure here and you will have automatically sorted these

according to the steps of the assembly procedure described later. (Only one unit of each hardware has been shown per group.

The number in parenthesis indicates the total number of the hardware needed in that group.)

A Lock Wa,_her (4)

Hex B_ (6) (_ j Flutng(6_

Hex Bolt (2)

5/16-16 x 1.75

m

L

__ 5/16-18 x .75

__ 5/16-18 x .75 _ ,

B Cupped Washer (4)

/____ 5116-18 Hex Nut (4)

Cupped Washer (4)

5/16-16 x 1.50 ¢ irrlage Bolt (4)

5/16-18 x 1.50 Carriage Bolt (4)

.a,rp_/

c,p(1) _

Chute Flange Keeper (3) --I

'_-It

I_ Hex Bolt (2) _ --_1

Bellevile Washer ( ) _ _[

1/4-20 _1

:._ Chute _l

:_ _._ j Flange -_

_L "" %. ,,/ Bracket -_1

InOtcth°lWn _1

size) ''_1

G Hairpin Clip (1) Flat ---II

\ _ Washer(2)At

D _. Hairpin Clip (21 _

12 ©

Wat'a_WaehS/__2) C) Fe(rlr) e

Replacement Part

,,a,em,

'_ Shear Bolt (2) 5/16-18x 1,5

0,,F, i

_// Flat Weld Nut (2)

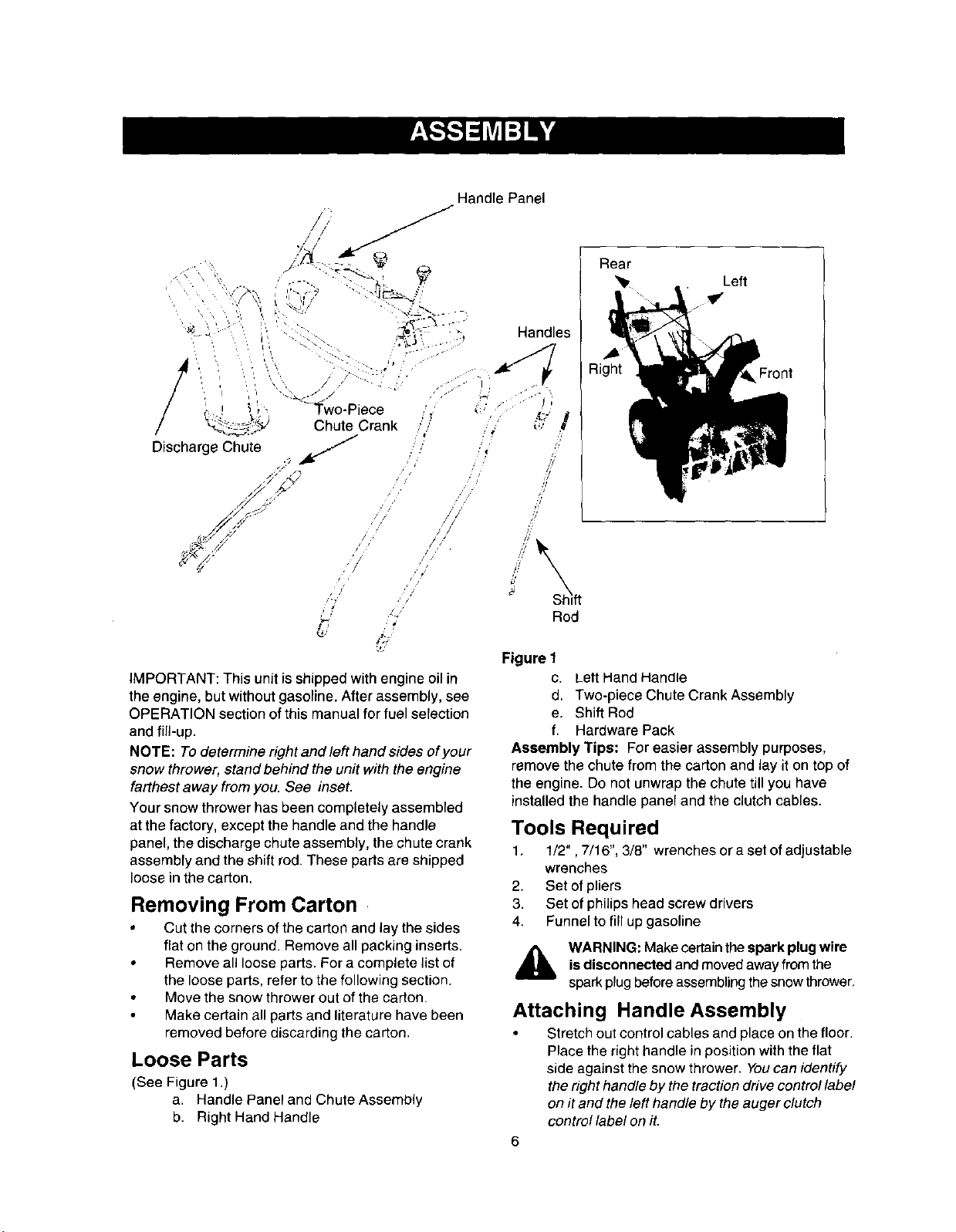

Handle Panel

Rear

• Left

• _L,J

"_i"wo-Piece

Chute Crank _,? ._

Discharge Chute

/

/

IMPORTANT: This unit is shipped with engine oil in

the engine, but without gasoline. After assembly, see

OPERATION section of this manual for fuel selection

and fill-up.

NOTE: To determine right and left hand sides of your

snow thrower, stand behind the unit with the engine

farthest away from you. See inset•

Your snow thrower has been completely assembled

at the factory, except the handle and the handle

panel, the discharge chute assembly, the chute crank

assembly and the shift rod• These parts are shipped

loose in the carton.

Removing From Carton

• Cut the corners of the carton and lay the sides

flat on the ground• Remove all packing inserts.

• Remove all loose parts. For a complete list of

the loose parts, refer to the following section•

• Move the snow thrower out of the carton.

Make certain all parts and literature have been

removed before discarding the carton.

Loose Parts

(See Figure 1.)

a. Handle Panel and Chute Assembly

b. Right Hand Handle

Handles

R i Front

4"

,i/

W

//

Rod

Figure 1

c. Lett HandHandle

d, Two-piece Chute Crank Assembly

e. Shift Rod

f. Hardware Pack

Assembly Tips: Foreasier assembly purposes,

remove the chute from the cartonand layit on topof

the engine. Do not unwrapthe chute tillyou have

installedthe handle panel and the clutch cables.

Tools Required

1, 1/2", 7/16", 3/8" wrenches or a set ofadjustable

wrenches

2, Set ofpliers

3. Set of philipshead screw drivers

4. Funnelto fill up gasoline

i_ WARNING:Make certain the spark plug wire

isdisconnectedand movedaway from the

sparkplugbefore assemblingthesnowthrower.

Attaching Handle Assembly

• Stretch out control cables and place on the floor•

Place the right handle in position with the flat

side against the snow thrower• Youcan identify

the right handle bythe traction drive control label

on it and the left handle by the auger clutch

control label on it.

Secure bottom hole in the handle to the snow

thrower using 5/16 x0.75" hex bolt and lock

washer from the hardware pack (group A on

page 5 ).Do nottighten at this time. See Figure 2.

Lock Washer &

Hex Bolt (1-3/4")

Right Handle

Handle _[Washer &

Tab Hex Bolt (3/4")

Figure 2

Place a handle tab, included inthe hardware

pack (group Aonpage 5),over the upper hole in

handle so that the contour of the handle tab

matches that of the handle. See Figure 2.

Secure handle tab to the snow thrower using

hex bolt (5/16 x 1.75" long) and lock washer

from the same group inthe hardware pack. Do

not tighten at this time.

Attach the left handle in the same manner. Do

not tighten at this time.

Place the handle panel in position between the

handles so the ends of the curved part of the

handles go through the slots in the handle panel.

While placing the handle panel, make sure to

route chute and chute cable between the

handles underneath the panel keeping the cable

on top of the engine. Align the holes in the

handle with theholes on two sides of the handle

panel. See Figure 3.

Right Handle

Hex Bolt

and Flange

Nut

Handle Panel

\

CarriageBolt,

andHexNut

Figure 3

nHoles

Attach the handle panelto the handle with two

carriage bolts, cupped washers (cupped side

against the handle panel) and hex nuts on each

side. See Figure 3. You will find these fasteners

in the hardware pack (group Bon page 5). Align

the contour of the carriage bolt head with the

handle.

Attaching Chute

Place the chute assemblyoverthe chute

opening withthe chute facingfrontof the unit.

NOTE: Make sure that the chute cables are

straightened while assembling the chute.

• Place the chute flange keeper (flat side down)

beneath lip of chute assembly as shown in

Figure 4.You will find the chute flange keepers in

group E of the hardware pack.

• Insert 1/4-20 hex bolt and flange nutfrom group

E up through chute flange keeper and chute

assembly as shown in Figure 4. Do nottighten at

this time. Rotate chute to install all the flange

keepers.

Chute

Hex

Nut

\

Chute

'_e Flange

x Keeper

Bolt

Figure 4

After assembling all three chute flange keepers,

tighten, then back off 1/4 turn to allow easier

movement of the chute. Use (2) 7/16" wrenches.

Attaching Chute Crank

On the leftside of the handle panel, place the

upperchute crankbracket on tothe insideofthe

handle panelsupport. See Figure5. You willfind

thisbracket and associated hardware in group F

of hardware pack

• Insert hex bolt through the upper chute crank

bracket, handle panel support, and upper left

handle. Secure the bracket using cupped

washer and hex nut. Make sure that the cupped

side ofthe washer is set against the handle.

ook

Supped

Chute Crank ;

Bracket

Figure 5

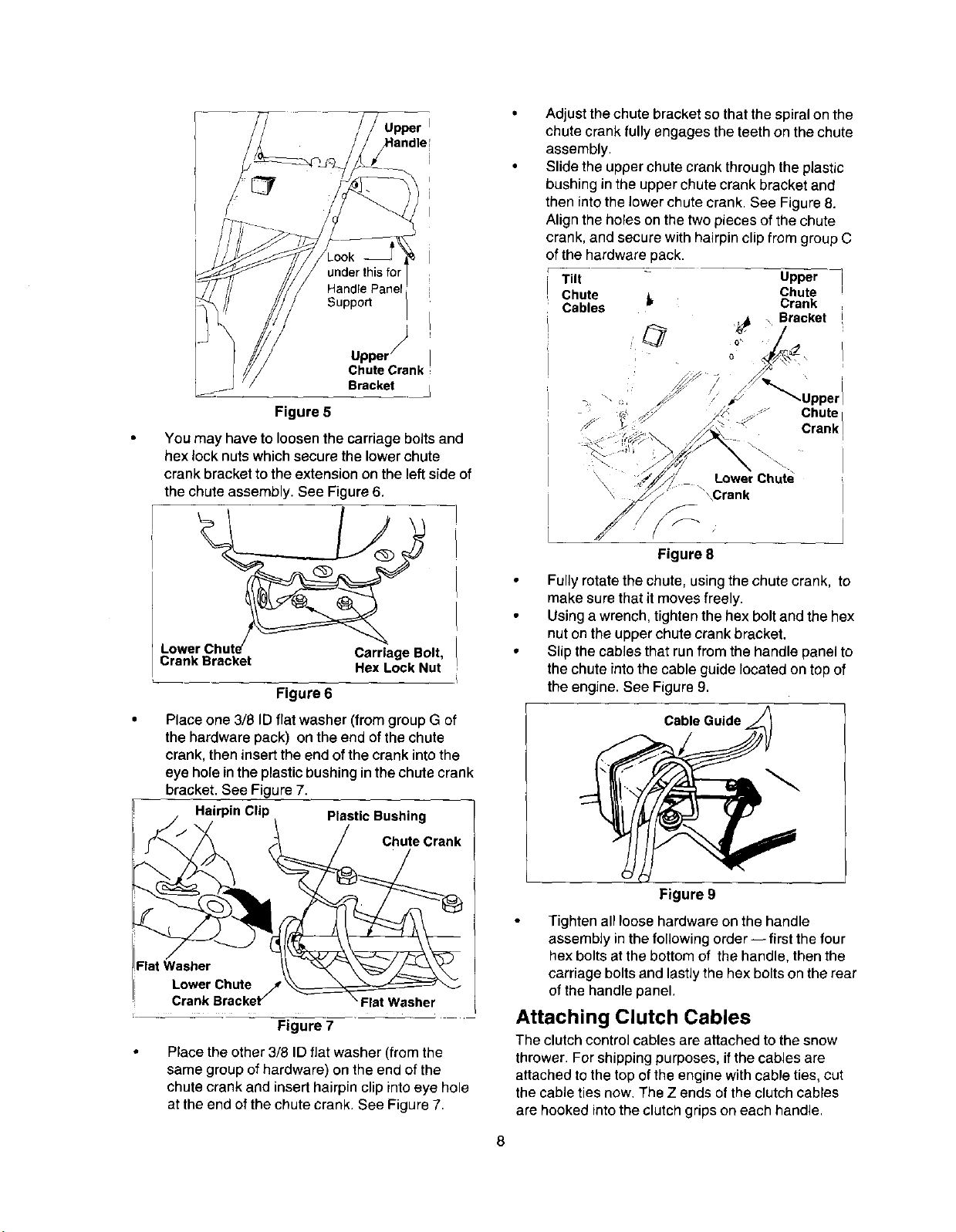

You may have to loosenthe carriage boltsand

hex lock nutswhichsecure the lower chute

crank bracket to the extension on the left side of

the chute assembly. See Figure 6.

Adjust the chute bracket so that the spiral on the

chute crank fully engages the teeth on the chute

assembly.

Slide the upper chute crank through the plastic

bushing in the upper chute crank bracket and

then into the lower chute crank. See Figure 8.

Align the holes on the two pieces of the chute

crank, and secure with hairpin clip from group C

of the hardware pack.

Tilt Upper

Chute _, Crank

Cables

Chute

j_ _ Bracket

_ \\ ::,

.Upperl

Chute

Crank

\

LowerChute

"_\_Crank

Figure 8

Crank Bracket Hex L_cEkNut'

Figure 6

Placeone 3/8 ID flat washer(fromgroupG of

the hardwarepack) on the end of thechute

crank,then insert the end of the crank intothe

eye hole inthe plasticbushing inthe chute crank

bracket. See Figure 7.

HairpinClip PlasticBushing

Chute Crank

LowerChute J

CrankBracket_ "FlatWasher

=

Figure 7

Placethe other3/8 ID flat washer (fromthe

same group of hardware) onthe end ofthe

chutecrank and insert hairpinclipintoeye hole

at the end ofthe chutecrank. See Figure7.

• Fullyrotate the chute, using the chute crank, to

make sure that it moves freely.

Using a wrench, tighten the hex bolt and the hex

nut on the upper chute crank bracket.

• Slip the cables that run from the handle panel to

the chute into the cable guide located on top of

the engine. See Figure 9.

CableGuide_/_

Figure 9

Tightenall loose hardware on the handle

assembly inthe following order-- first the four

hex bolts at the bottom of the handle, then the

carriage bolts and lastly the hex bolts on the rear

of the handle panel.

Attaching Clutch Cables

The clutchcontrol cablesare attached tothe snow

thrower.For shippingpurposes, ifthecables are

attachedto the top of theengine withcable ties, cut

thecable ties now.The Z ends ofthe clutchcables

are hooked into the clutch grips on each handle.

8

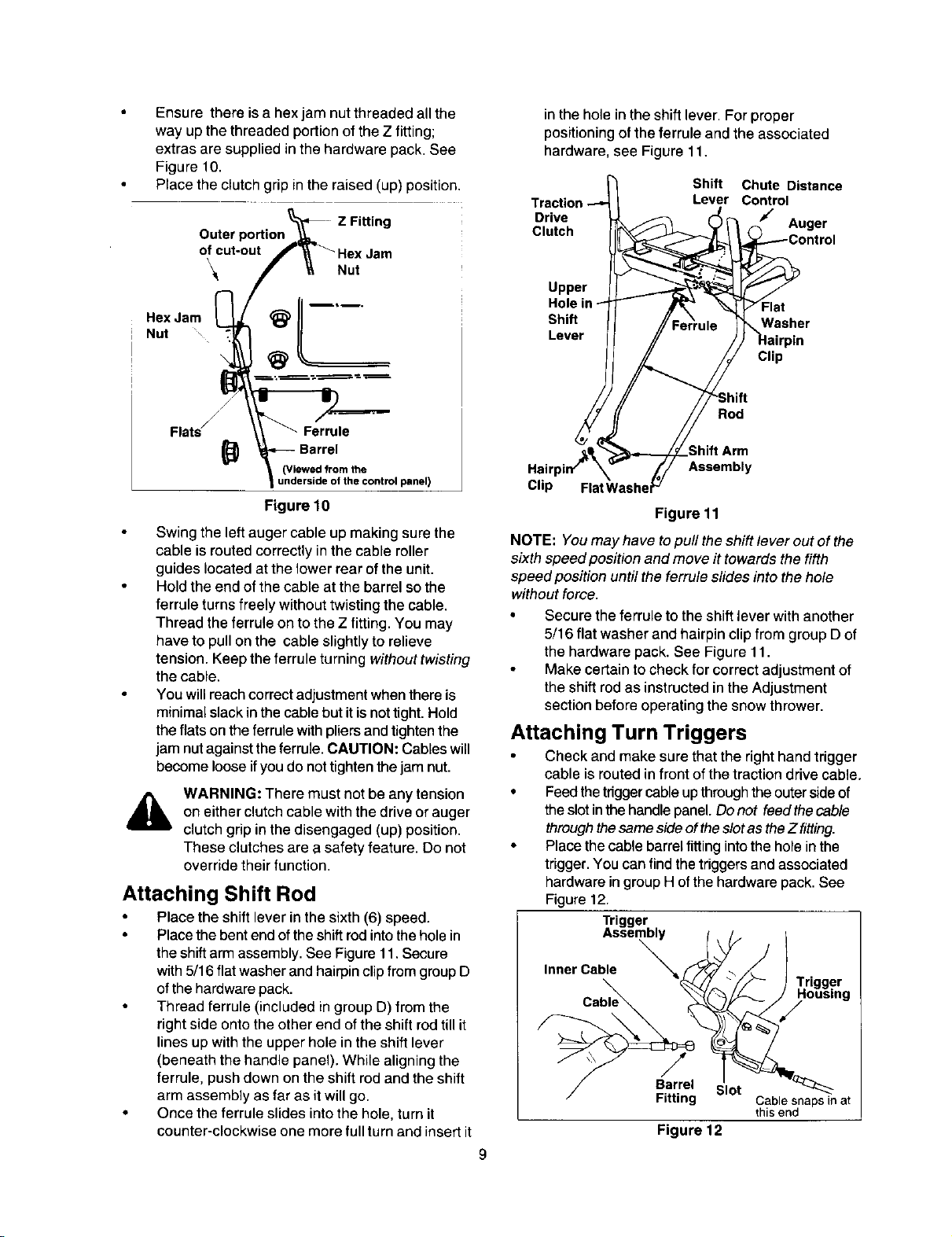

Ensurethereisahexjamnutthreadedallthe

way up the threaded portion of the Z fitting;

extras are supplied inthe hardware pack. See

Figure 10.

Place the clutch grip inthe raised (up) position.

Outer

of cut-out

\

Hex Jam

Nut "_ '

Z Fitting

Nut

in the hole in the shift lever. For proper

positioning of the ferrule and the associated

hardware, see Figure 11.

Shift Chute Distance

Lever Control

Drive Auger

Clutch

Upper

Shift Washer

Lever

Flat

Clip

Rod

_(Vi_ii_i_theont rol panel)

Figure 10

Swing the left auger cable up making sure the

cable is routed correctly in the cable roller

guides located at the lower rear of the unit.

Hold the end of the cable at the barrel so the

ferrule turns freely without twisting the cable.

Thread the ferrule on to the Z fitting. You may

have to pull on the cable slightly to relieve

tension. Keepthe ferrule turning without twisting

the cable.

You will reach correct adjustment when there is

minimal slack in the cable but it is nottight. Hold

the flats on the ferrule with pliers and tighten the

jam nut against the ferrule. CAUTION: Cables will

become loose ifyou do not tighten the jam nut.

WARNING: There must not be any tension

A

on either clutch cable with the drive or auger

clutch grip in the disengaged (up) position.

These clutches are a safety feature. Do not

override their function.

Attaching Shift Rod

Placethe shiftlever inthe sixth(6) speed.

Placethe bent end of the shift rod into thehole in

the shift arm assembly. See Figure 11. Secure

with 5/16flat washer and hairpin clip from group D

of the hardware pack.

Thread ferrule (included in group D) from the

right side onto the other end of the shift rod till it

lines up with the upper hole in the shift lever

(beneath the handle panel). While aligning the

ferrule, push down on the shift rod and the shift

arm assembly as far as it will go.

• Once the ferrule slides into the hole, turn it

counter-clockwise one more full turn and insert it

Hair Assembly

Clip

Figure 11

NOTE: You may have topull theshift lever out of the

sixth speed position and move it towards the fifth

speed position until the ferrule slides into the hole

without force.

Secure theferrule to the shift lever with another

5/16 flat washer and hairpin clip from group D of

the hardware pack. See Figure 11.

Make certain tocheck for correct adjustment of

the shift rod as instructed inthe Adjustment

section before operating the snow thrower.

Attaching Turn Triggers

Check and make sure that the right hand trigger

cable is routed in front of the traction drive cable.

• Feedthe triggercableup through the outer sideof

theslot inthe handle panel. Donot feedthe cable

throughthesame side of the slotas theZ fitting.

• Placethe cable barrel fitting into the hole inthe

trigger. You can find the triggers and associated

hardware in group Hof the hardware pack. See

Figure 12.

Trigger

Assembly /

Inner Cable _'N_

Slot

Cable snaps in at

this end

Figure 12

9

Trigger

Housing

/

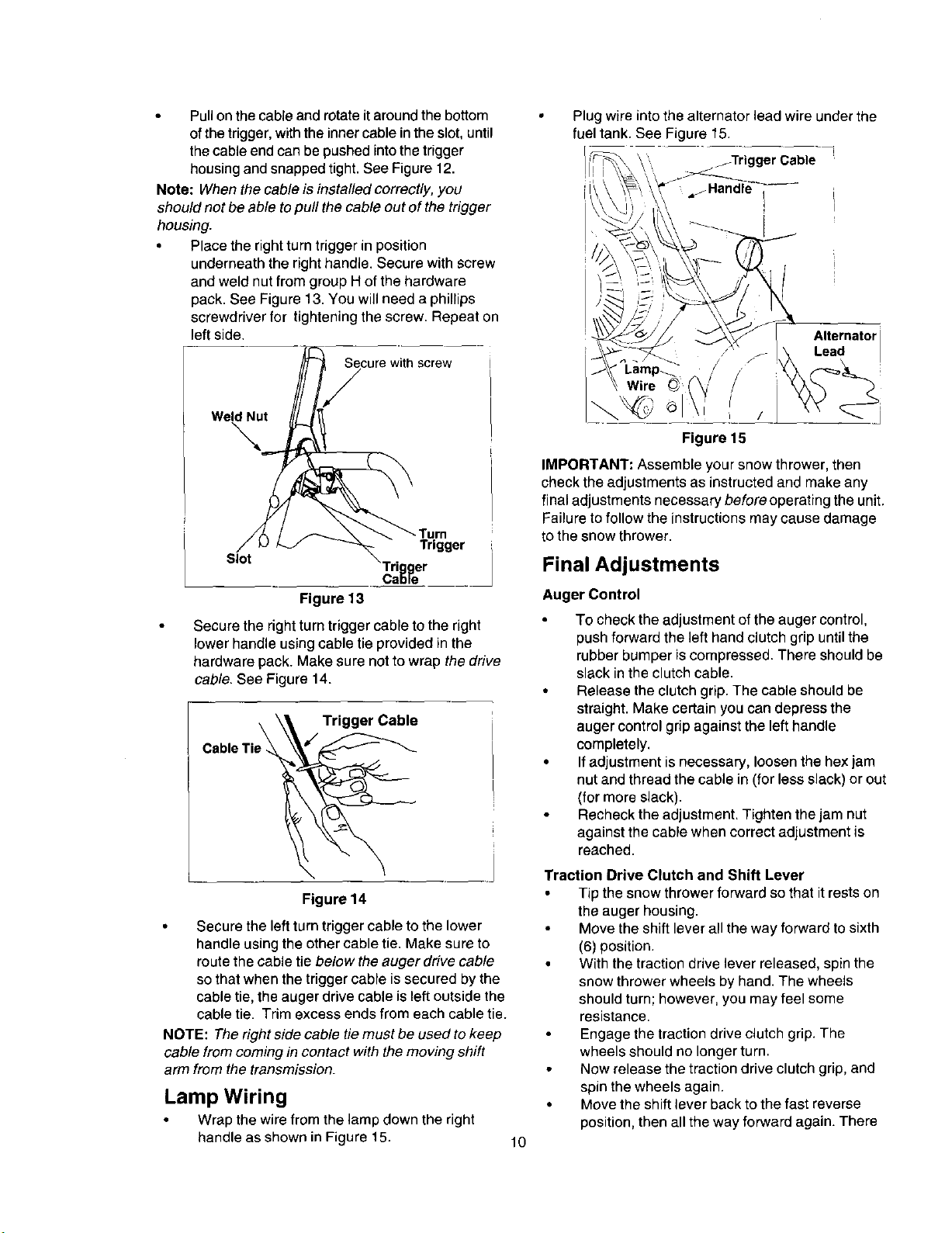

Pull on the cable and rotate itaround the bottom

of the trigger, with the inner cable inthe slot, until

the cable end can be pushed intothe trigger

housing and snapped tight. See Figure 12.

Note: When the cable is installed correctly, you

should not beable topull the cable out of the trigger

housing.

• Place the right turn trigger in position

underneath the right handle. Secure with screw

and weld nut from group H of the hardware

pack. See Figure 13. You will need a phillips

screwdriver for tightening the screw. Repeat on

left side.

Secure with screw

WeldNut

Slot

i rl er

Ca_le

Trigger

Figure 13

Secure the right turn trigger cable to the right

lower handle using cable tie provided in the

hardware pack. Make sure not to wrap the drive

cable. See Figure 14.

CableTie_ Trigger Cable

Figure 14

Secure the left turn trigger cable to the lower

handle using the other cable tie. Make sure to

route the cable tie below the auger drive cable

so that when the trigger cable is secured by the

cable tie, the auger drive cable is left outside the

cable tie. Trim excess ends from each cable tie.

NOTE: The right side cable tie must be used to keep

cable from coming in contact with the moving shift

arm from the transmission.

Lamp Wiring

• Wrap the wire from the lamp down the right

handle as shown in Figure 15.

• Plugwireinto the alternator lead wire under the

fuel tank. See Figure 15.

jTrigger Cable

" ,,_Handle" I

Alternatori

Lead

Figure 15

IMPORTANT: Assemble your snow thrower, then

check the adjustments as instructed and make any

final adjustments necessary before operating the unit.

Failure to follow the instructions may cause damage

to the snow thrower.

Final Adjustments

Auger Control

To check the adjustment of the auger control,

push forward the left hand clutch grip until the

rubber bumper is compressed. There should be

slack inthe clutch cable.

Release the clutch grip. The cable should be

straight. Make certain you can depress the

auger control gnp against the left handle

completely.

If adjustment is necessary, loosen the hex jam

nut and thread the cable in (for less slack) or out

(for more slack).

Recheck the adjustment. Tighten the jam nut

against the cable when correct adjustment is

reached.

Traction Drive Clutch and Shift Lever

Tip the snow throwerforward so that it rests on

the auger housing.

Move the shift leverall the way forward to sixth

(6) position.

• Withthe tractiondrive lever released, spin the

snow throwerwheels by hand.The wheels

should turn;however, you may feel some

resistance.

Engagethe tractiondrive clutchgrip. The

wheelsshould nolongerturn.

Now release the tractiondrive clutch grip,and

spin the wheels again.

• Move the shift lever back to thefast reverse

position,thenall the way forward again. There

10

should beno resistance inthe shift lever, and the

wheels should turn.

Ifyou face resistance when moving the shift

lever or the snow thrower wheels stop when they

should not, loosen the lock nut on the traction

drive cable and unthread the cable one turn.

If the wheels can still be turned when you

engage the traction drive clutch grip, loosen the

lock nut on the traction drive cable and thread

the cable in one turn.

Recheck the adjustment and repeat adjustment

as necessary. Tighten the lock nut to secure the

cable when correct adjustment is reached.

NOTE: If you are not sure that you have reached

correct adjustment, referto theAdjustment section on

page 20.

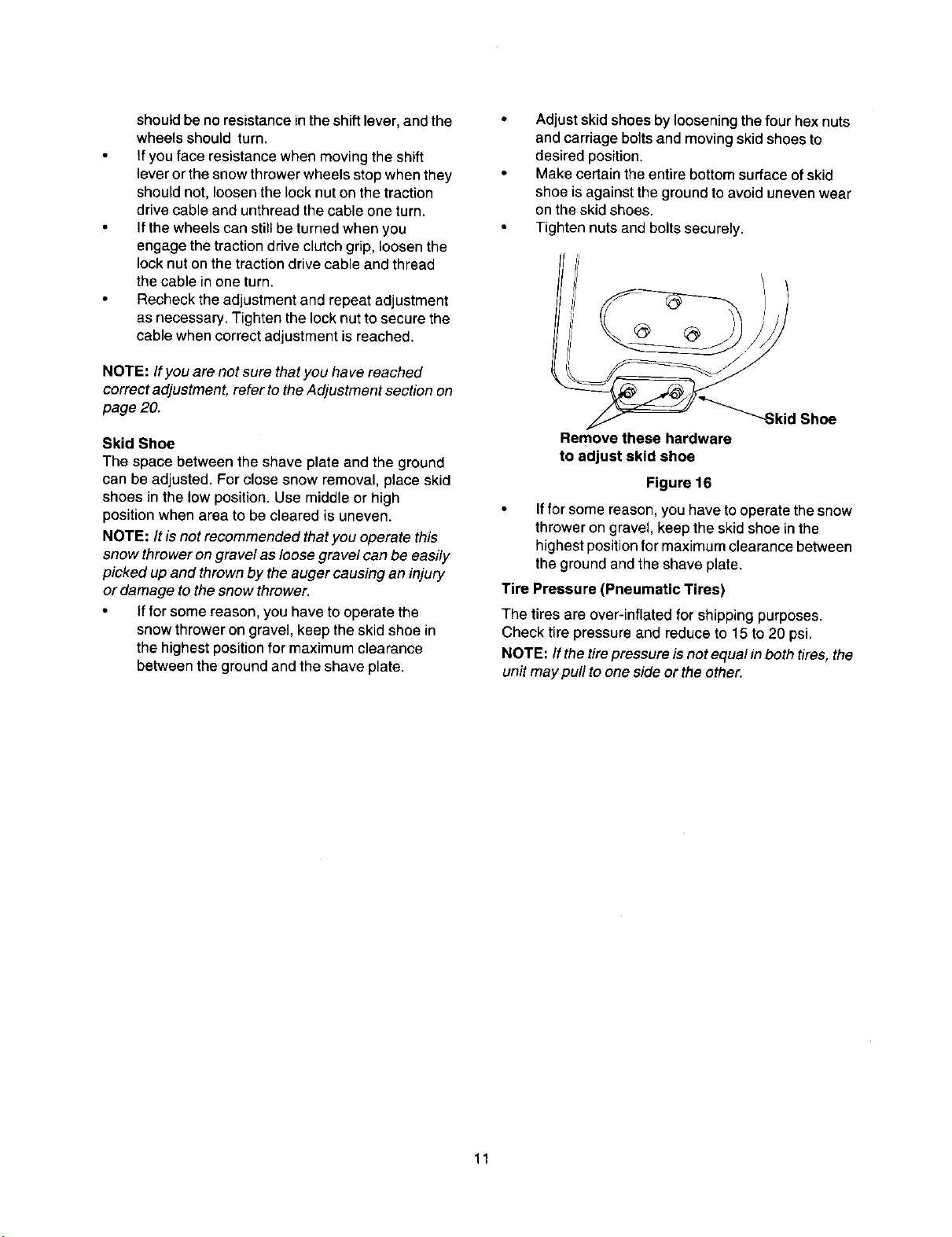

Skid Shoe

The space between the shave plate and the ground

can be adjusted. For close snow removal, place skid

shoes in the low position. Use middle or high

position when area to be cleared is uneven.

NOTE: It is not recommended that you operate this

snow thrower ongravel as loose gravel can be easily

picked up and thrown by the auger causing an injury

or damage to the snow thrower.

If for some reason, you have to operate the

snow thrower on gravel, keep the skid shoe in

the highest position for maximum clearance

between the ground and the shave plate.

Adjustskid shoes by loosening the four hex nuts

and carriage bolts and moving skid shoes to

desired position.

Make certain the entire bottom surface of skid

shoe is against the ground to avoid uneven wear

on the skid shoes.

Tighten nuts and bolts securely.

--Skid Shoe

Remove these hardware

to adjust skid shoe

Figure 16

If for some reason, you have to operate the snow

thrower on gravel, keep the skid shoe inthe

highest position for maximum clearance between

the ground and the shave plate.

Tire Pressure (Pneumatic Tires)

The tires are over-inflated for shipping purposes.

Check tire pressure and reduce to 15 to 20 psi.

NOTE: Ifthe tire pressure is not equal inboth tires, the

unit may pull to one side or the other.

11

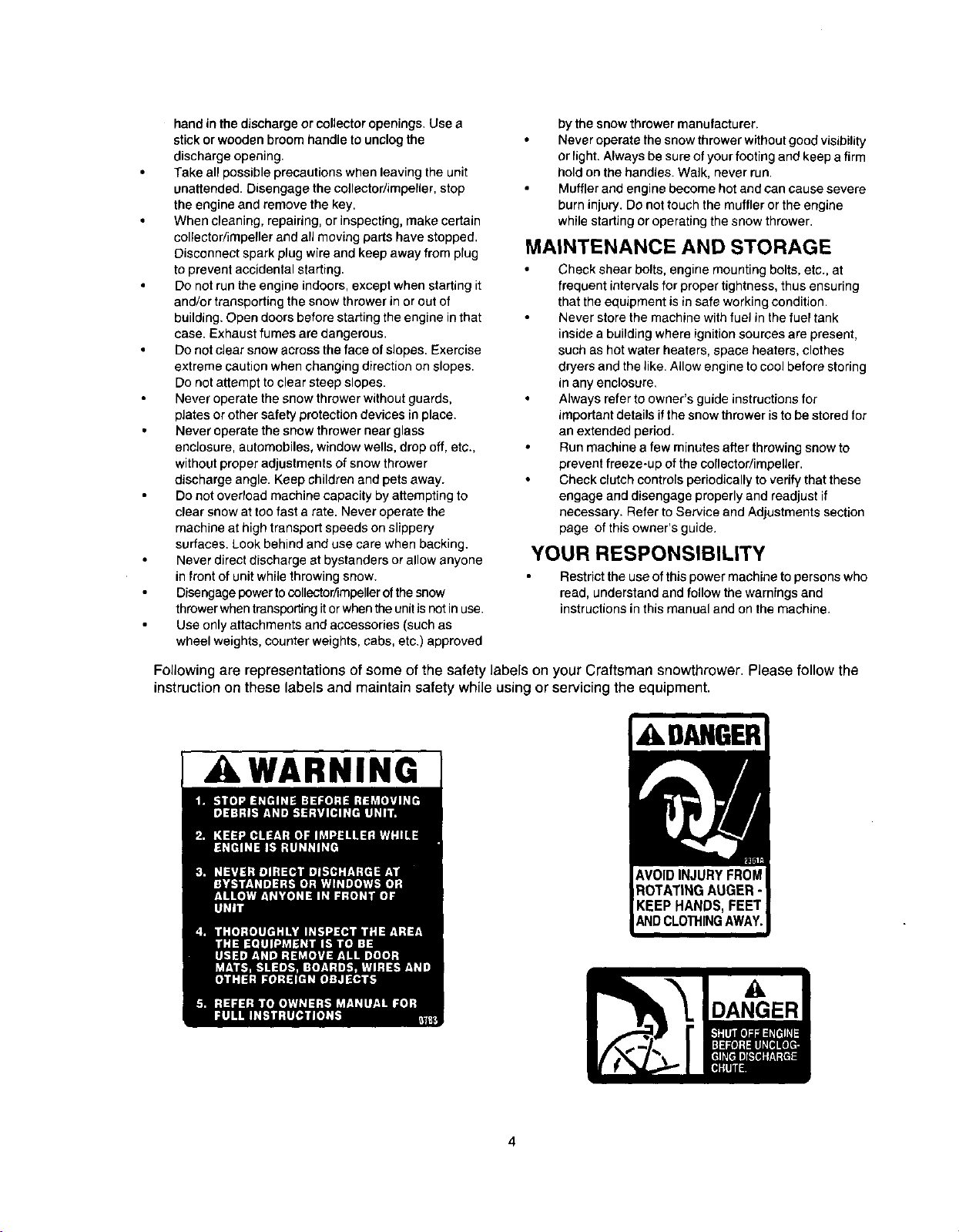

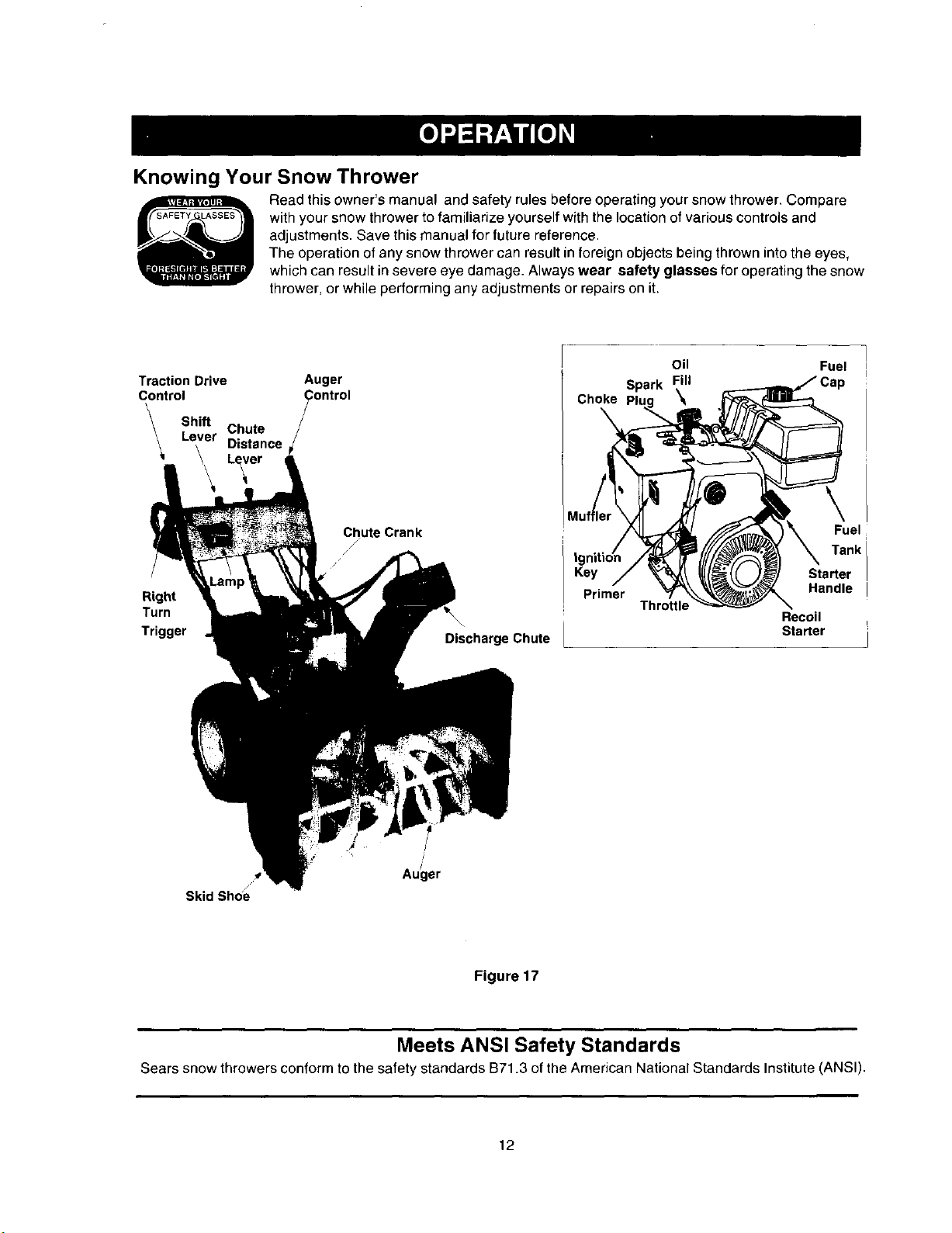

Knowing Your Snow Thrower

Read this owner's manual and safety rules before operating your snow thrower. Compare

with your snow thrower to familiarize yourself with the location of various controls and

adjustments. Save this manual for future reference.

The operation of any snow thrower can result in foreign objects being thrown into the eyes,

which can result in severe eye damage. Always wear safety glasses for operating the snow

thrower, or while performing any adjustments or repairs on it.

Traction Drive Auger

Control_ Control

Shift

Chute

Lever

Distance

Lever

Right

Turn

Trigger

ChuteCrank

/

/

/

\,

DischargeChute

Choke

Key

Primer

Oil

Spark Fill

\

Throttle

Starter

Handle

Recoil

Starter

Fuel

Tankl

Fuel

i

/

/

Au_]er

Skid Shoe

Figure 17

Meets ANSI Safety Standards

Sears snow throwers conform to the safety standards B71.3 of the American National Standards Institute (ANSI).

12

Loading...

Loading...