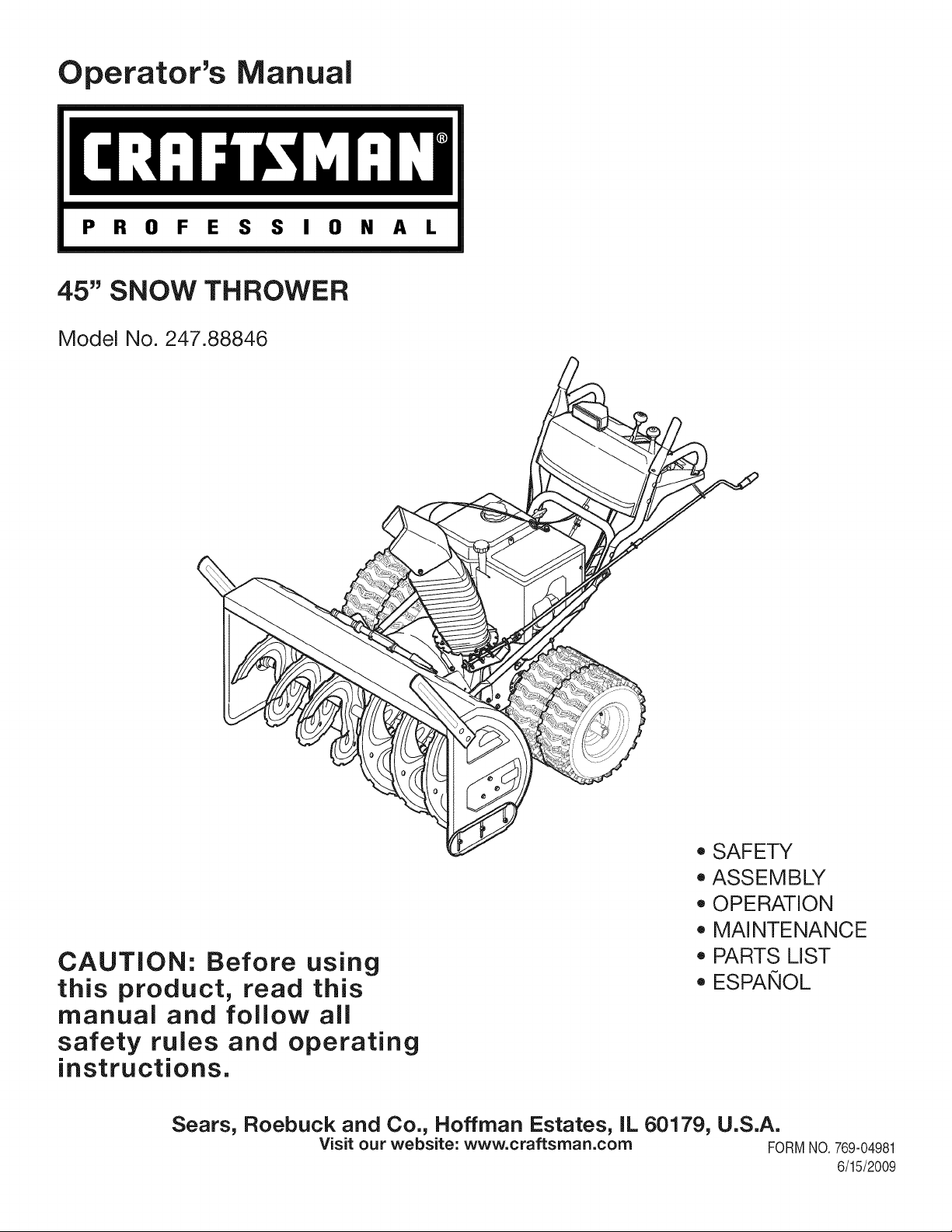

Craftsman 247888460 Owner’s Manual

Operator's Manual

P R 0 F E S S I 0 N A L

45" SNOW THROWER

Model No. 247.88846

CAUTION: Before using

this product, read this

manual and follow all

safety rules and operating

instructions.

Sears, Roebuck and Co., Hoffman Estates, IL 60179, U.S.A.

Visit our website: www.craftsman.com FORMNO.769-04981

, SAFETY

, ASSEMBLY

, OPERATION

, MAINTENANCE

, PARTS LIST

o ESPArqOL

6/15/2009

WarrantyStatement..................................Page2

SafeOperation Practices .......................... Pages 3-6

Safety Labels ............................................ Page 7

Assembly .................................................. Pages 8-12

Operation .................................................. Pages 13-16

Service and Maintenance ......................... Pages 17-24

Off-Season Storage .................................. Page 25

Troubleshooting ........................................ Page 26

Parts List ................................................... Page 28-40

Repair Protection Agreement ................... Page 45

Espa_ol ..................................................... Page 46

Service Numbers ...................................... Back Cover

CRAFTSMAN PROFESSIONALFULL WARRANTY

Whenoperatedand maintainedaccordingtoallsuppliedinstructions,ifthis CraftsmanProfessionalsnowthrowerfailsduetoa defectinmaterial

orworkmanshipwithintwoyearsfromthedateofpurchase,call1-800-4-MY-HOME(1-800-469-4663)toarrangeforfreein-homerepair(or

replacementifrepairprovesimpossible).

Thiswarrantyappliesforonlyone yearfromthedateof purchaseifthis productiseverusedforcommercialor rentalpurposes.

ThiswarrantycoversONLYdefectsinmaterialandworkmanship.SearswillNOTpayfor:

• Expendableitemsthatbecomewornduringnormaluse,includingbutnotlimitedtoaugerbladesorpaddles,driftcutters,skidshoes,

shaveplate,shearpins,sparkplug,air cleaner,belts,andoilfilter.

• Standardmaintenanceservicing,oilchanges,ortune-ups.

• Tirereplacementorrepaircausedbypuncturesfromoutsideobjects,suchasnails,thorns,stumps,orglass.

• Tireor wheelreplacementor repairresultingfromnormalwear,accident,orimproperoperationormaintenance.

• Repairsnecessarybecauseof operatorabuse,includingbutnotlimitedtodamagecausedbyover-speedingtheengine,or from

impactingobjectsthatbendtheframe,augershaft,etc.

• Repairsnecessarybecauseof operatornegligence,includingbutnotlimitedto,electricalandmechanical

damagecausedbyimproperstorage,failureto usethepropergradeandamountofengineoil, or failureto maintaintheequipment

accordingtothe instructionscontainedintheoperator'smanual.

• Engine(fuelsystem)cleaningorrepairscausedbyfuel determinedto becontaminatedoroxidized(stale).In

general,fuelshouldbeusedwithin30 daysof itspurchasedate.

• Normaldeteriorationandwearoftheexteriorfinishes,orproductlabelreplacement.

Thiswarrantyappliesonlywhilethisproductiswithinthe UnitedStates.

Thiswarrantygivesyouspecificlegalrights,andyou mayalsohaveotherrightswhichvaryfromstatetostate.

Sears, Roebuckand Co., Hoffman Estates,IL 60179

EngineOilCapacity: 37ounces

FuelCapacity: Approx.5 Quarts

SparkPlug: TorchF6RTC(951-10292)

SparkPlugGap: .020"to.030"

©SearsBrands,LLC

Serial Number .................................................................

Dateof Purchase.............................................................

Recordthemodelnumber,serialnumber

anddateof purchaseabove

2

Thissymbolpointsout importantsafetyinstructionswhich,if not

followed,couldendangerthepersonalsafetyand/orpropertyof

yourselfandothers. Readandfollowallinstructionsin thismanual

beforeattemptingtooperatethismachine.Failuretocomplywith

theseinstructionsmayresultin personalinjury.Whenyou seethis

symbol,HEEDITSWARNING!

Thismachinewasbuiltto beoperatedaccordingtothesafeopera-

tionpracticesinthis manual.As withanytypeof powerequipment,

carelessnessorerroron the partofthe operatorcanresultin serious

injury.Thismachineiscapableofamputatingfingers,hands,toes

andfeetandthrowingdebris.Failuretoobservethefollowingsafety

instructionscouldresultin seriousinjuryordeath.

CALIFORNIA PROPOSITION 65

EngineExhaust,someof itsconstituents,andcertainvehicle

componentscontainoremitchemicalsknowntoStateof California

tocausecancerandbirthdefectsorotherreproductiveharm,

TRAiNiNG

• Read,understand,andfollowall instructionsonthe machineand

in themanual(s)beforeattemptingtoassembleandoperate.

Failuretodo socan resultinseriousinjurytotheoperatorand/

orbystanders.Keepthismanualin a safeplaceforfutureand

regularreferenceandfororderingreplacementparts.Forques-

tionscall,1-800-4MY-HOME.

• Befamiliarwithall controlsandtheir properoperation.Knowhow

tostopthe machineanddisengagethemquickly.

Neverallowchildrenunder14yearsofageto operatethis

machine.Children14andovershouldreadandunderstandthe

instructionsandsafeoperationpracticesin thismanualandon

themachineandbe trainedandsupervisedbyanadult.

Neverallowadultsto operatethismachinewithoutproper

instruction.

• Thrownobjectscancauseseriouspersonalinjury.Planyour

snow-throwingpatterntoavoiddischargeof materialtoward

roads,bystandersandthe like.

Keepbystanders,petsandchildrenat least75feetfromthe

machinewhileitisinoperation.Stopmachineifanyoneenters

thearea.

Exercisecautiontoavoidslippingor falling,especiallywhen

operatinginreverse.

Your Responsibility--Restrict the useofthis powermachineto

personswhoread,understandandfollowthewarningsandinstruc-

tionsin thismanualandonthemachine,

SAVE THESE INSTRUCTIONS!

PREPARATION

Thoroughlyinspecttheareawheretheequipmentisto beused.

Removeall doormats,newspapers,sleds,boards,wiresandother

foreignobjects,whichcouldbe trippedoverorthrownbytheauger/

impeller.

Alwayswearsafetyglassesoreyeshieldsduringoperationand

whileperformingan adjustmentor repairto protectyoureyes.

Thrownobjectswhichricochetcancauseseriousinjurytothe

eyes.

Donot operatewithoutwearingadequatewinteroutergarments.

Donot wearjewelry,longscarvesorotherlooseclothing,which

couldbecomeentangledinmovingparts.Wearfootwearwhich

willimprovefootingonslipperysurfaces.

Usea groundedthree-wireextensioncordand receptacleforall

machineswithelectricstartengines.

Disengageallcontrolleversbeforestartingtheengine.

Adjustcollectorhousingheightto cleargravelorcrushedrock

surfaces.

Neverattempttomakeanyadjustmentswhileengineis running,

exceptwherespecificallyrecommendedintheoperator'smanual.

Letengineandmachineadjustto outdoortemperaturebefore

startingtoclearsnow.

3

SafeHandling of Gasoline

Toavoidpersonalinjuryor propertydamageuseextremecarein

handlinggasoline.Gasolineisextremelyflammableandthevaporsare

explosive.Seriouspersonalinjurycanoccurwhengasolineisspilled

onyourselforyourclotheswhichcan ignite.Washyourskinand

changeclothesimmediately.

• Useonlyanapprovedgasolinecontainer.

• Extinguishall cigarettes,cigars,pipesandothersources

ofignition.

• Neverfuelmachineindoors.

• Neverremovegascapor addfuelwhiletheengineishot

or running.

• Allowengineto coolat leasttwominutesbeforerefueling.

• Neveroverfill fueltank.Filltanktono morethan1/2inch

belowbottomoffiller neckto providespaceforfuel

expansion.

• Replacegasolinecapandtightensecurely.

• Ifgasolineis spilled,wipeit offtheengineandequipment.

Movemachinetoanotherarea.Wait5 minutesbefore

startingtheengine.

• Neverstorethemachineorfuel containerinsidewhere

thereis anopenflame,sparkorpilotlight(e.g.furnace,

waterheater,spaceheater,clothesdryeretc.).

• Allowmachinetocoolat least5 minutesbeforestoring.

• Neverfillcontainersinsidea vehicleorona truckor trailer

bedwitha plasticliner.Alwaysplacecontainersonthe

groundawayfromyourvehiclebeforefilling.

• If possible,removegas-poweredequipmentfromthetruck

ortrailerand refuelitontheground.Ifthisis not possible,

thenrefuelsuchequipmentona trailerwithaportable

container,ratherthanfromagasolinedispensernozzle.

• Keepthenozzleincontactwiththe rimofthefueltankor

containeropeningatalltimesuntilfuelingiscomplete.Do

notuse a nozzlelock-opendevice.

OPERATION

• Do notputhandsorfeetnear rotatingparts,in the auger/impeller

housingorchuteassembly.Contactwiththerotatingpartscan

amputatehandsandfeet.

• Theauger/impellercontrolleverisa safetydevice.Neverbypass

itsoperation.Doingsomakesthe machineunsafeandmaycause

personalinjury.

• Thecontrolleversmustoperateeasilyin bothdirectionsand

automaticallyreturntothedisengagedpositionwhenreleased.

• Neveroperatewitha missingor damagedchuteassembly.Keep

all safetydevicesinplaceandworking.

• Neverrunanengineindoorsor ina poorlyventilatedarea.Engine

exhaustcontainscarbonmonoxide,anodorlessanddeadlygas.

• Do notoperatemachinewhileundertheinfluenceofalcoholor

drugs.

• Mufflerandenginebecomehotandcan causea burn.Donot

touch.Keepchildrenaway.

• Exerciseextremecautionwhenoperatingonorcrossinggravel

surfaces.Stayalertforhiddenhazardsortraffic.

• Exercisecautionwhenchangingdirectionandwhileoperatingon

slopes.

• Planyoursnow-throwingpatternto avoiddischargetowards

windows,walls,carsetc. Thus,avoidingpossibleproperty

damageorpersonalinjurycausedby a ricochet.

• Neverdirectdischargeatchildren,bystandersand petsor allow

anyoneinfrontof themachine.

• Donot overloadmachinecapacityby attemptingtoclearsnowat

toofastof arate.

• Neveroperatethismachinewithoutgoodvisibilityorlight.Always

be sureofyourfootingandkeepafirmholdon the handles.Walk,

neverrun.

• Disengagepowertotheauger/impellerwhentransportingor not

in use.

• Neveroperatemachineathightransportspeedsonslippery

surfaces.Lookdownand behindand usecarewhenbackingup.

• Ifthemachineshouldstartto vibrateabnormally,stopthe engine,

disconnectthe sparkplugwire andgrounditagainsttheengine.

Inspectthoroughlyfor damage.Repairanydamagebefore

startingandoperating.

• Disengageallcontrolleversandstopenginebeforeyouleave

theoperatingposition(behindthehandles).Waituntiltheauger/

impellercomestoa completestopbeforeuncloggingthechute

assembly,makinganyadjustments,orinspections.

• Neverputyourhandinthedischargeorcollectoropenings.Do

notunclogchuteassemblywhileengineis running.Shutoff

engineand remainbehindhandlesuntilallmovingpartshave

stoppedbeforeunclogging.

• Useonlyattachmentsandaccessoriesapprovedbythemanufac-

turer(e.g.wheelweights,tirechains,cabsetc.).

• Whenstartingengine,pullcordslowlyuntilresistanceisfelt,then

pull rapidly.Rapidretractionofstartercord(kickback)willpull

handandarmtowardenginefasterthanyoucanlet go.Broken

bones,fractures,bruisesorsprainscouldresult.

• Ifsituationsoccurwhichare notcoveredinthismanual,usecare

andgoodjudgment.ContactCustomerSupportforassistance

andthenameofyour nearestservicingdealer.

CLEARING A CLOGGED DISCHARGE CHUTE

Handcontactwiththe rotatingimpellerinsidethedischargechute

is themostcommoncauseofinjuryassociatedwithsnowthrowers.

Neveruseyourhandtocleanoutthedischargechute.

Toclear thechute:

1. SHUTTHEENGINEOFF!

2. Wait 10secondstobe suretheimpellerbladeshavestopped

rotating.

3. Alwaysusea clean-outtool,not yourhands.

4

MAINTENANCE & STORAGE

• Nevertamperwithsafetydevices.Checktheirproperoperation

regularly.Refertothe maintenanceandadjustmentsectionsof

thismanual.

• Beforecleaning,repairing,or inspectingmachinedisengageall

controlleversandstoptheengine.Waituntilthe auger/impeller

cometoa completestop.Disconnectthe sparkplugwireand

groundagainsttheengineto preventunintendedstarting.

Checkboltsand screwsfor propertightnessatfrequentintervals

tokeepthemachineinsafeworkingcondition.Also,visually

inspectmachineforanydamage.

Donotchangetheenginegovernorsettingor over-speedthe

engine.Thegovernorcontrolsthe maximumsafeoperatingspeed

ofthe engine.

Snowthrowershaveplatesandskidshoesaresubjecttowear

anddamage.Foryoursafetyprotection,frequentlycheckall

componentsandreplacewithoriginalequipmentmanufacturer's

(OEM)partsonly."Useofpartswhichdo not meettheoriginal

equipmentspecificationsmayleadto improperperformanceand

compromisesafety!"

Checkcontrolleversperiodicallytoverifytheyengageanddisen-

gageproperlyandadjust,ifnecessary.Refertothe adjustment

sectioninthisoperator'smanualforinstructions.

Maintainor replacesafetyandinstructionlabels,as necessary.

• Observeproperdisposallawsand regulationsforgas,oil,etc. to

protecttheenvironment.

Priorto storing,runmachinea few minutestoclearsnowfrom

machineand preventfreezeupofauger/impeller.

Neverstorethemachineorfuel containerinsidewherethereisan

openflame,sparkorpilot lightsuchasa waterheater,furnace,

clothesdryeretc.

Alwaysrefertothe operator'smanualforproperinstructionson

off-seasonstorage.

Checkfuelline,tank, cap,andfittingsfrequentlyfor cracksor

leaks.Replaceif necessary.

Donotcrankenginewithsparkplugremoved.

Accordingtothe ConsumerProductsSafetyCommission(CPSC)

andtheU.S.EnvironmentalProtectionAgency(EPA),thisproduct

hasan AverageUsefulLifeof seven(7)years,or60 hoursof

operation.At the endoftheAverageUsefulLifehavethemachine

inspectedannuallybyan authorizedservicedealertoensurethat

allmechanicalandsafetysystemsareworkingproperlyand not

wornexcessively.Failuretodo socanresultinaccidents,injuries

ordeath.

DO NOT MODIFY ENGINE

Toavoidseriousinjuryor death,donotmodifyengineinany way.

Tamperingwiththegovernorsettingcanleadtoa runawayengineand

causeitto operateat unsafespeeds.Nevertamperwithfactorysetting

ofenginegovernor.

NOTICE REGARDING EMiSSiONS

EngineswhicharecertifiedtocomplywithCaliforniaandfederal

EPAemissionregulationsforSORE(SmallOff RoadEquipment)are

certifiedto operateonregularunleadedgasoline,and mayinclude

thefollowingemissioncontrolsystems:EngineModification(EM),

OxidizingCatalyst(OC),SecondaryAirInjection(SAI)and ThreeWay

Catalyst(TWO)if soequipped.

SPARK ARRESTOR

Thismachineisequippedwithaninternalcombustionengineand

shouldnotbe usedonornearanyunimprovedforest-covered,

brush-coveredorgrass-coveredlandunlesstheengine'sexhaust

systemisequippedwitha sparkarrestermeetingapplicablelocalor

statelaws(if any)

Ifa sparkattesterisused,itshouldbemaintainedineffectiveworking

orderbytheoperator.Inthe StateofCaliforniatheaboveis required

bylaw (Section4442oftheCaliforniaPublicResourcesCode).Other

statesmayhavesimilarlaws. Federallawsapplyonfederallands.

A sparkarresterforthemufflerisavailablethroughyournearestSears

PartsandRepairServiceCenter.

SAFETY SYMBOLS

Thispagedepictsanddescribessafetysymbolsthatmayappearonthisproduct. Read,understand,andfollowall instructionson themachine

beforeattemptingtoassembleandoperate.

READ THE OPERATOR'S MANUAL(S)

i

i

Read, understand, and follow all instructions in the manual(s) before attempting to assemble and

operate

WARNING-- ROTATING BLADES

Keep hands out of inlet and discharge openings while machine is running. There are rotating blades

inside

WARNING-- ROTATING BLADES

Keep hands out of inlet and discharge openings while machine is running. There are rotating blades

inside

WARNING-- ROTATING AUGER

Do not put hands or feet near rotating parts, in the auger/impeller housing or chute assembly.

Contact with the rotating parts can amputate hands and feet.

WARNING--THROWN OBJECTS

This machine may pick up and throw objects which can cause serious personal injury.

WARNING--GASOLINE IS FLAMMABLE

Allow the engine to cool at least two minutes before refueling.

WARNING-- CARBON MONOXIDE

Never run an engine indoors or in a poorly ventilated area. Engine exhaust contains carbon

monoxide, an odorless and deadly gas.

WARNING-- ELECTRICAL SHOCK

Do not use the engine's electric starter in the rain

6

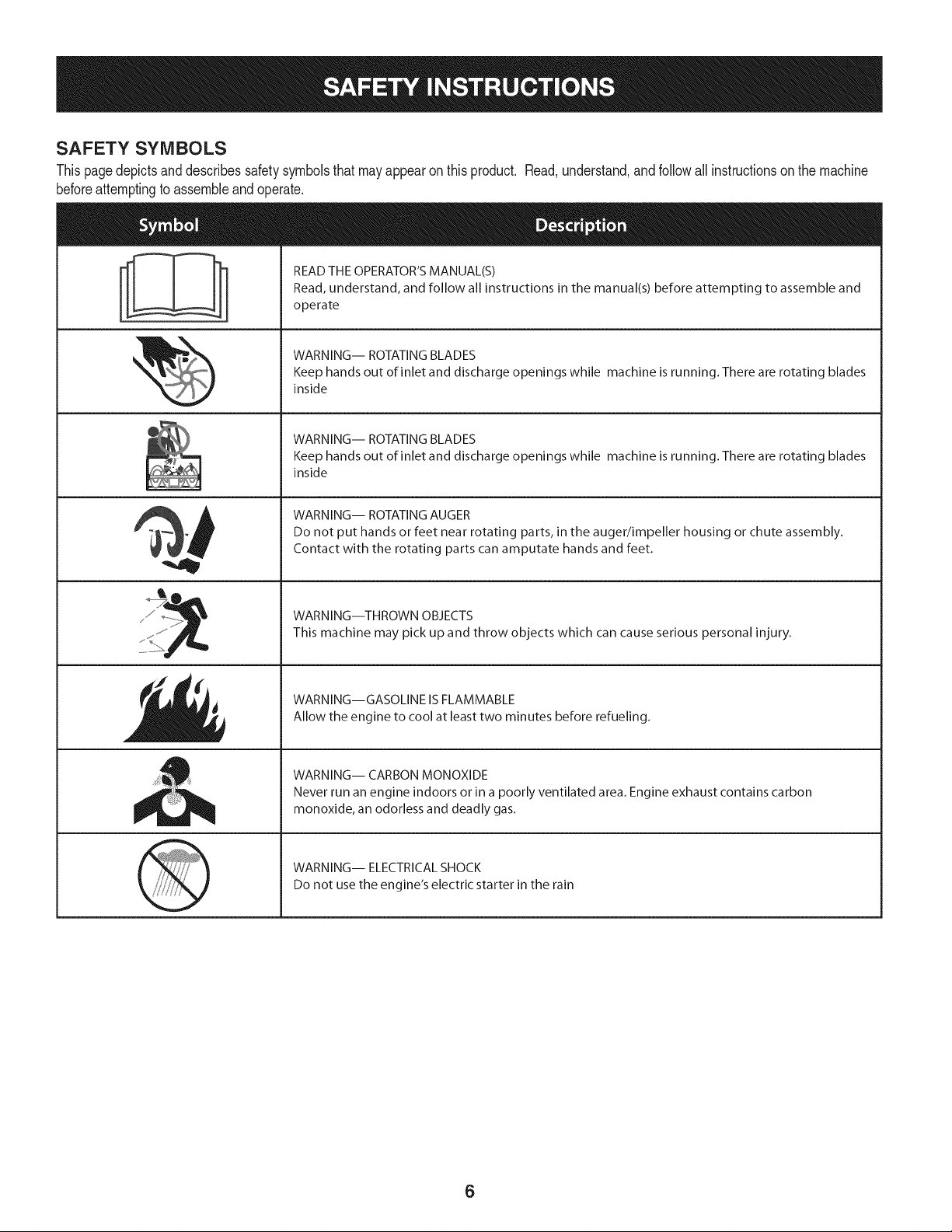

100JL J,IIO-NV=IlO

"'IVI1NVIAIS,EIOIVEI:IdOQV3EI"_

"S:IOV:IEI(1S"IqAVEI9NO9NIlVEIqdO

N]HMNOIII1VOVBIX]]SI1"SEI3ONVISA8IV]gEIVHOSIO

10qBI0BLAIN'S:IIEIIlrNI$103r80 NMOEIHLQIOAV01 "17

"3NIHOVW9NIOIAB:ISBO9NIOOOlON[I

qElO-1:18O]ddOlS:IAVHSIEIVa£)NIAO_llP lllNI1 S:IIONVH

ONIH]8NIVW]BONV']NION]d01S'SB]A31H011110qOVgN]SIO"_

":llrlHO39EIVHOSIO9010NI101 10011[10-NV31038rl"z

•133JQNV8QNVH]lPllldBJP NVOEI3_)I1VBOB:lll:kl_l HIlM

IOVINO0"EI:IO[1VONVB::lll:ld_JIONIIVIOB_OB:IAVMVdq:lH•L

7

NOTE:Referencesto rightorleft sideofthesnowthrowerare

determinedfromthe operatingpositionlookingforwardtothefrontof

themachine.

REMOVING FROM CRATE

1. Removescrewsfromthebottomof thecratesecuringthesides,

andendsof theshippingcrate.

2. Liftoff the topoffofthecrateandsetoutof thewayof the

assemblyarea.

3. Removeanddiscardplasticbagthatcoversunit.

4. Removeanyloosepartsincludedwithunit(e.g.,Operator's

Manual,etc.).

5. Pushdownonthelowerhandleandpullunit backoutofcrate.

6. Makecertainthecratehasbeencompletelyemptiedbefore

discardingit.

ASSEMBLY

1. Makecertainthe springsatthe lowerendoftheaugeranddrive

cablesaresecurelyhookedintotheir respectiveactuator

bracketsbeforepivotingthehandleupward.Referto Fig. 10.

a. Placethe speedselectorshiftleverin theF6position.

b. Cutthecabletie securingthetwopiecechutecranktothe

lowerhandle.Thecable tieisusedfor shippingpurposes.

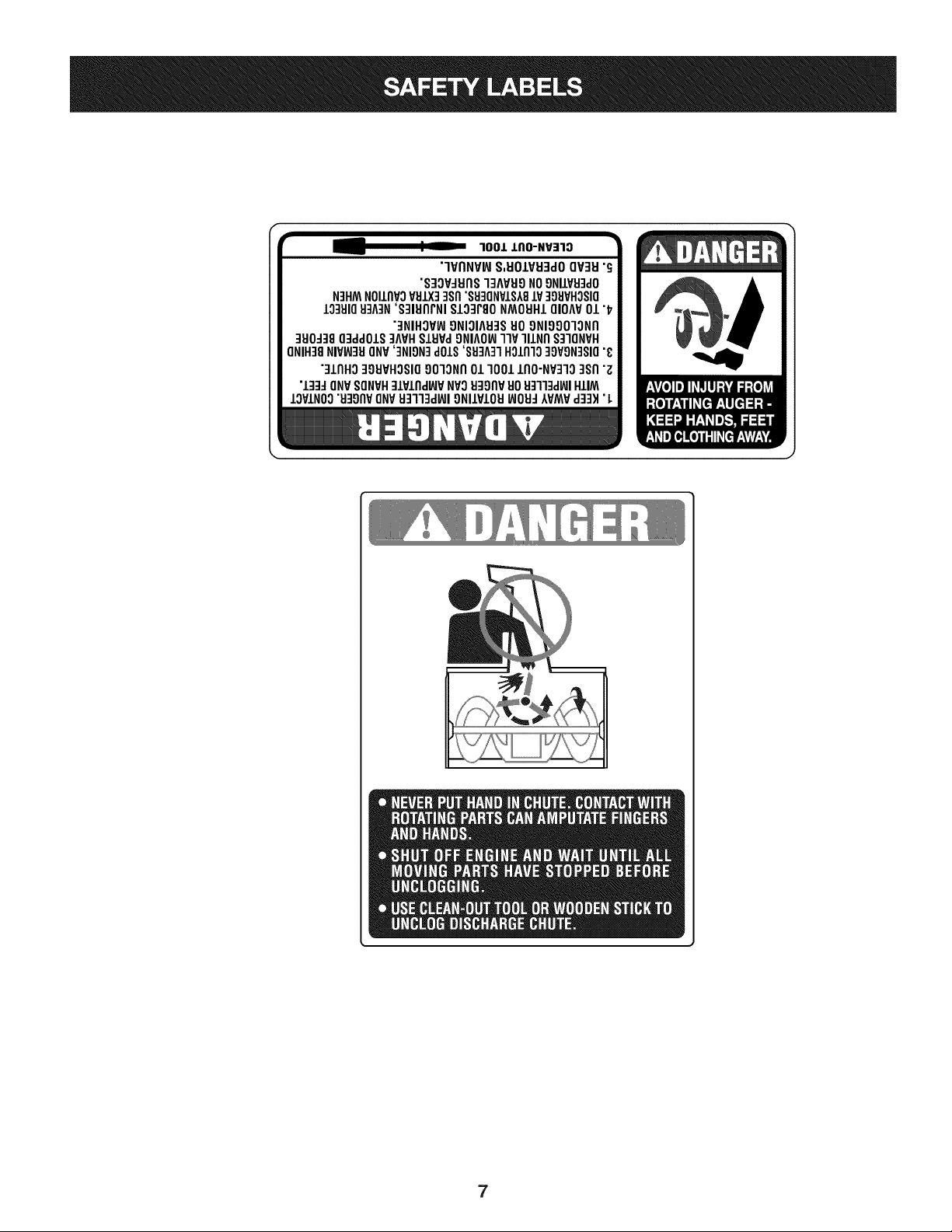

c. Removethe upperwingknobandcarriageboltfromeach

sideof thelowerhandle.Pulluponupperhandleasshown

in Fig.1.Alignupperhandlewiththe lowerhandle.Again,

makecertainthespringsat thelowerendoftheaugerand

drivecablesaresecurelyhookedintotheirrespective

actuatorbrackets.Also,removeanyrubberbandssecuring

thecablesto thewingnuts.

2. a. Securetheupperhandleandlowerhandlewiththetwo wing

knobsandcarriageboltsremovedearlier.

b. Tightenthetwo wingknobsalreadyinstalledin theupper

holesto firmlysecuretheupperhandleand supporttubes.

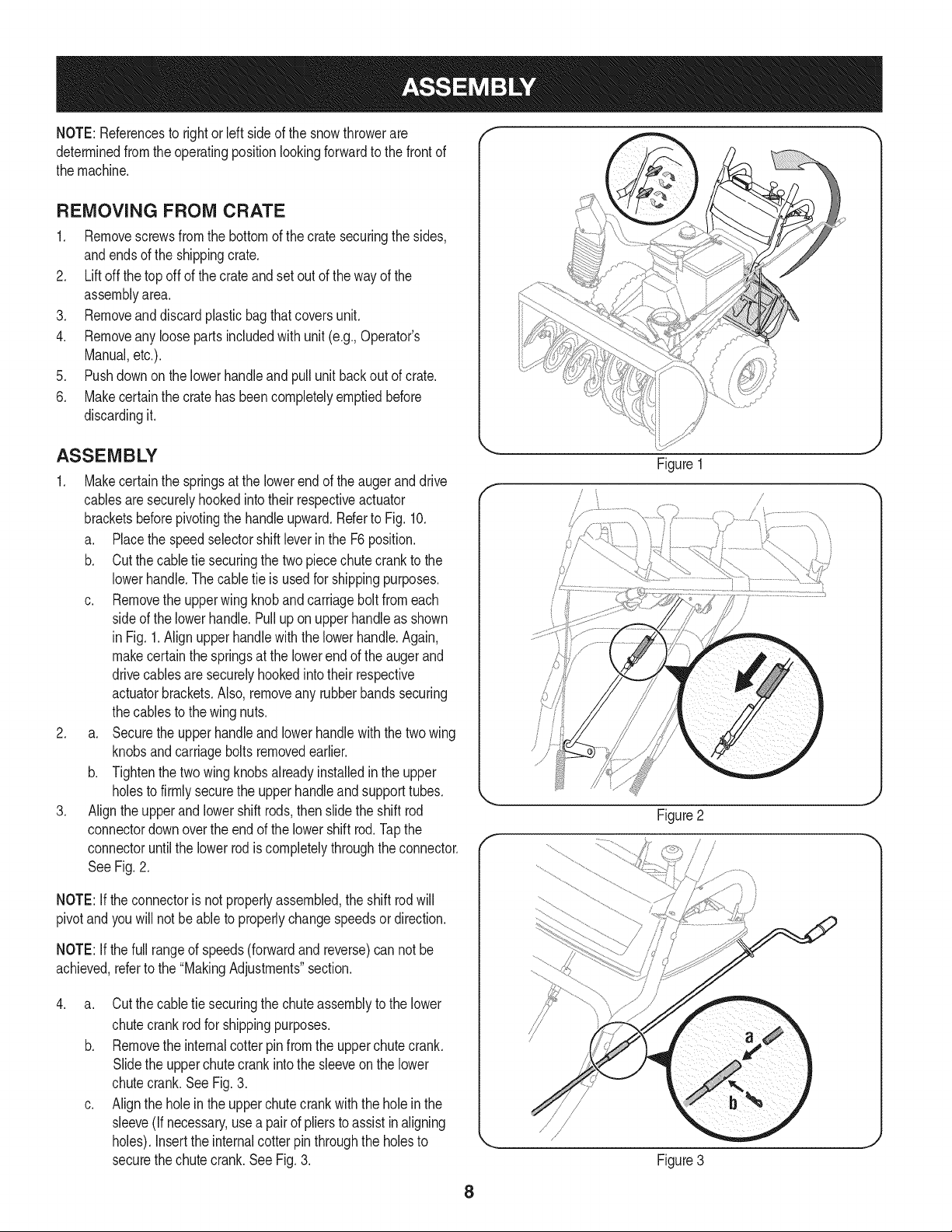

3. Alignthe upperand lowershiftrods,thenslidetheshift rod

connectordownoverthe endofthelowershift rod.Tapthe

connectoruntilthelower rodiscompletelythroughtheconnector.

See Fig.2.

Y

Figure 1

/

J

NOTE:If theconnectoris notproperlyassembled,theshiftrodwill

pivotand youwillnotbeabletoproperlychangespeedsordirection.

NOTE:If thefullrangeof speeds(forwardandreverse)cannot be

achieved,referto the "MakingAdjustments"section.

.

a. Cutthecabletie securingthechuteassemblyto thelower

chutecrankrodforshippingpurposes.

b. Removethe internalcotterpinfromtheupperchutecrank.

Slidetheupperchutecrankinto thesleeveon the lower

chutecrank.See Fig.3.

c. Alignthe holein theupperchutecrankwiththe holeinthe

sleeve(Ifnecessary,useapairof plierstoassistinaligning

holes).Inserttheinternalcotterpinthroughtheholesto

securethechutecrank.SeeFig.3.

Figure3

8

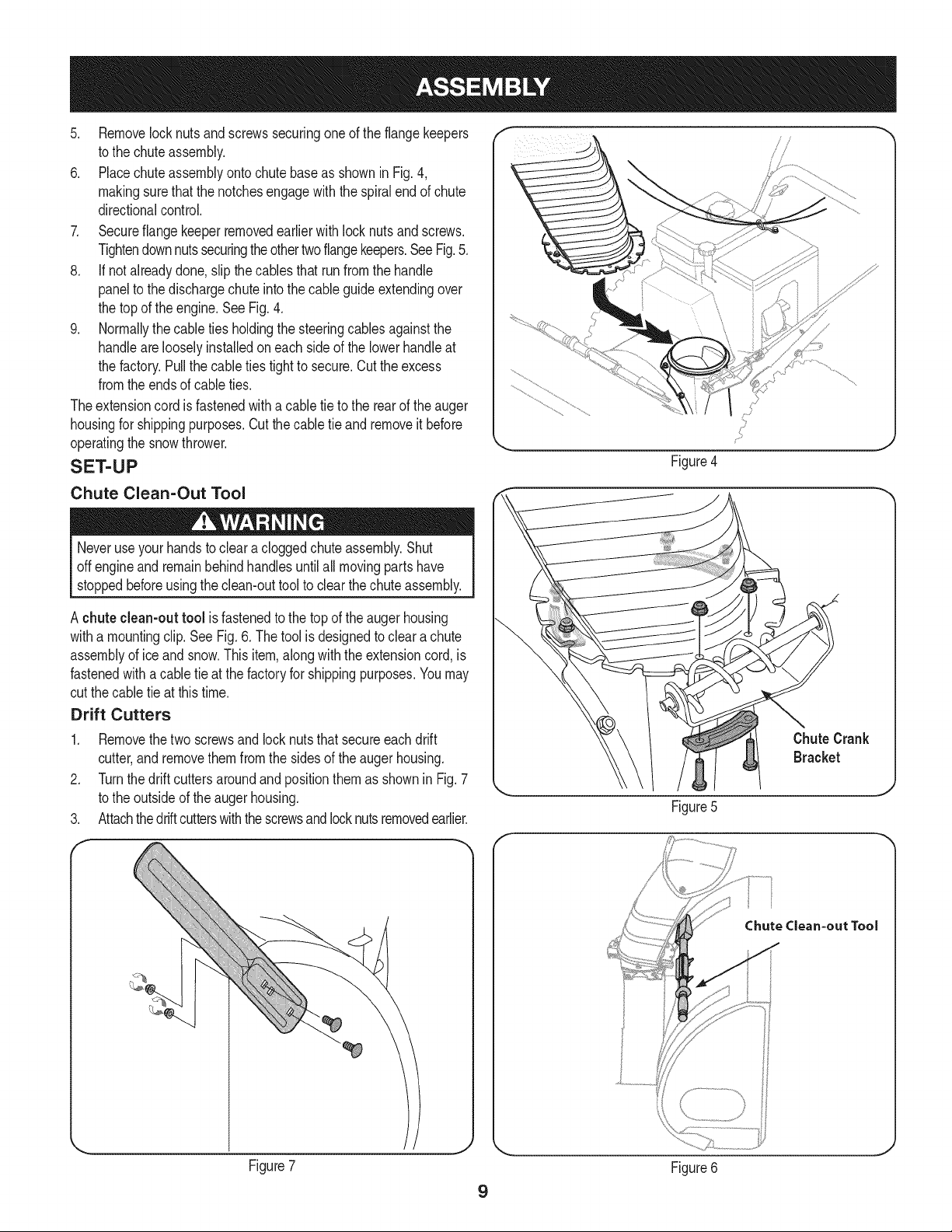

5. Removelocknutsandscrewssecuringoneofthe flangekeepers

tothe chuteassembly.

6. Placechuteassemblyontochutebaseas showninFig.4,

makingsurethatthe notchesengagewiththespiralendofchute

directionalcontrol.

7. Secureflangekeeperremovedearlierwithlocknutsandscrews.

Tightendownnutssecuringtheothertwoflangekeepers.SeeFig.5.

8. If notalreadydone,slipthe cablesthat runfromthehandle

paneltothe dischargechuteintothecableguideextendingover

thetopofthe engine.SeeFig.4.

9. Normallythecabletiesholdingthesteeringcablesagainstthe

handlearelooselyinstalledoneachsideofthe lowerhandleat

thefactory.Pullthecableties tighttosecure.Cuttheexcess

fromtheendsof cableties.

Theextensioncordis fastenedwithacabletie to therearoftheauger

housingforshippingpurposes.Cutthecabletie andremoveit before

operatingthesnowthrower.

SET-UP

Chute Clean=Out Tool

Neveruseyourhandsto clearacloggedchuteassembly.Shut

off engineandremainbehindhandlesuntilallmovingpartshave

stoppedbeforeusingtheclean-outtoolto clearthechuteassembly.

J

Figure4

A chuteclean-outtool isfastenedtothetop oftheaugerhousing

witha mountingclip.SeeFig.6.Thetoolisdesignedtoclearachute

assemblyofice andsnow.Thisitem,alongwiththeextensioncord,is

fastenedwithacable tieatthefactoryfor shippingpurposes.Youmay

cutthecabletieat thistime.

Drift Cutters

1. Removethetwo screwsand locknutsthat secureeach drift

cutter,andremovethemfromthesidesof theaugerhousing.

2. Turnthedriftcuttersaroundandpositionthemas shownin Fig.7

tothe outsideoftheaugerhousing.

3. Attachthedriftcutterswiththescrewsandlocknutsremovedearlier.

F-

ChuteCrank

Bracket

J

Figure5

f

Chute Clean=out Tool

Figure7

J

Figure6

9

Tire Pressure (Pneumatic Tires)

Underanycircumstancedonotexceedmanufacturer'srecom-

mendedpsi.Equaltire pressureshouldbemaintainedat alltimes.

Excessivepressurewhenseatingbeadsmaycausetire/rim

assemblytoburstwithforcesufficienttocauseseriousinjury.Refer

to sidewallof tireforrecommendedpressure.

Thetirescan beover-inflatedforshippingpurposes.Checkthetire

pressurebeforeoperatingthe snowthrower. Refertothetire sidewall

for rnanufactures'srecommendedpsianddeflate(or inflate)thetires

as necessary.

NOTE:Equaltirepressureisto bemaintainedatalltimesforperfor-

mancepurposes.

Fuel Recommendations

Useautomotivegasoline(unleadedor low leadedto minimizecombus-

tionchamberdeposits)witha minimumof 87 octane.Gasolinewith

upto 10%ethanolor15%MTBE(MethylTertiaryButylEther)canbe

used.Neverusean oil/gasolinemixtureordirty gasoline.Avoidgetting

dirt, dust,orwaterinthefueltank.DONOTuse E85gasoline.

• Refuelina well-ventilatedareawiththeenginestopped.Donot

smokeorallowflamesor sparksintheareawheretheengineis

refueledor wheregasolineisstored.

• Donot overfillthefueltank. Afterrefueling,makesurethetank

capis closedproperlyandsecurely.

• Becarefulnotto spillfuelwhenrefueling.Spilledfuel orfuel vapor

mayignite.Ifany fuelis spilled,makesuretheareaisdry before

startingtheengine.

• Avoidrepeatedor prolongedcontactwithskinor breathingofvapor.

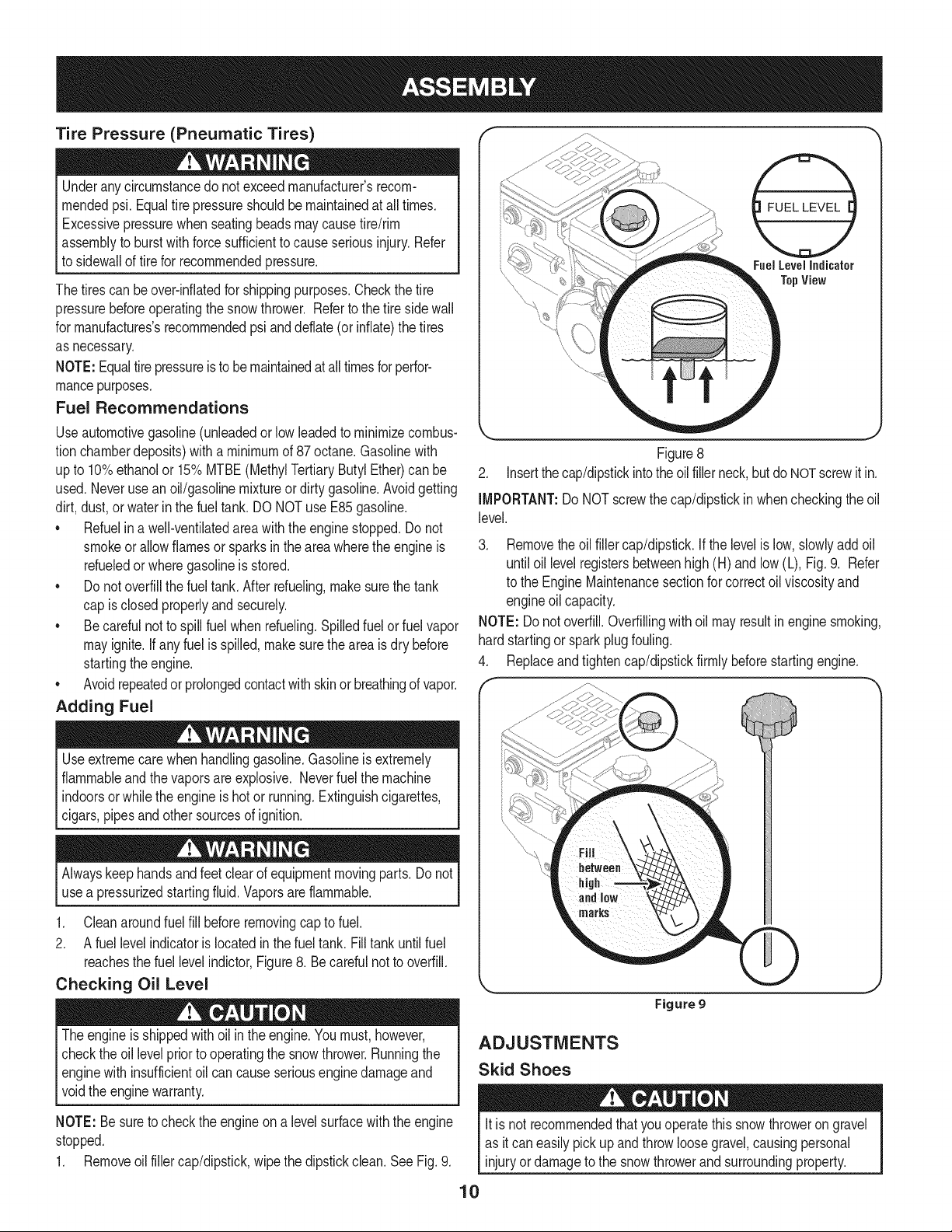

Adding Fuel

Fuel Level Indicator

TopView

Figure8

2. Insertthecap/dipstickintotheoilfillerneck,butdoNOTscrewit in.

IMPORTANT:DoNOTscrewthecap/dipstickinwhencheckingtheoil

level.

3. Removethe oilfillercap/dipstick.Ifthelevelis low,slowlyaddoil

untiloil levelregistersbetweenhigh(H) andlow (L),Fig.9. Refer

tothe EngineMaintenancesectionforcorrectoilviscosityand

engineoil capacity.

NOTE:Do notoverfill.Overfillingwithoilmayresultinenginesmoking,

hardstartingor sparkplugfouling.

4. Replaceandtightencap/dipstickfirmlybeforestartingengine.

Useextremecarewhenhandlinggasoline.Gasolineisextremely

flammableandthe vaporsareexplosive.Neverfuelthemachine

indoorsorwhile theengineishotor running.Extinguishcigarettes,

cigars,pipesandothersourcesofignition.

usea pressurizedstartingfluid.Vaporsareflammable.

1. Cleanaroundfuelfillbeforeremovingcaptofuel.

2. A fuel levelindicatorislocatedinthefueltank.Filltankuntilfuel

reachesthefuel levelindictor,Figure8. Becarefulnottooverfill.

Checking Oil Level

Theengineis shippedwithoilintheengine.Youmust,however,

checkthe oil levelpriortooperatingthe snowthrower.Runningthe

enginewith insufficientoil cancauseseriousenginedamageand

[vo d theengne warranty.

NOTE:Be suretochecktheengineon a levelsurfacewiththeengine

stopped.

1. Removeoil fillercap/dipstick,wipethedipstickclean.SeeFig.9.

Figure g

ADJUSTMENTS

Skid Shoes

itis notrecommendedthatyouoperatethissnowthrowerongravel

asit caneasilypickupand throwloosegravel,causingpersonal

injuryordamagetothe snowthrowerandsurroundingproperty.

10

Thesnowthrowerskidshoesareadjustedupwardatthefactoryforship-

pingpurposes.Adjustthemdownwardpriortooperatingthe machine.

• Forclosesnowremovalona smoothsurface,raiseskidshoes

higherontheaugerhousing.

• Useamiddleorlowerpositionwhentheareatobeclearedisuneven.

NOTE:Ifyou choosetooperatethesnowthroweron agravelsurface,

keepthe skidshoesin positionformaximumclearancebetweenthe

groundandtheshaveplate.

Toadjusttheskidshoes:

1. Loosenthesixhexnuts(threeoneachside)andcarriagebolts.Move

skidshoestodesiredposition.SeeFig.10.

NOTE:Whenengagingtheauger,youmayheara "chirp"sound.

Thisisnormal,itisthe beltengagingthepulley.Asthebeltwears,

this soundwillnotbeheardwhenengagingtheauger.

3. Withtheenginerunningandtheaugercontrolin thedisengaged

"up"position,walktothe frontof themachine.Confirmthatthe

augerhascompletelystoppedrotatingandshowsno signsof

motion.

4. Iftheaugershowsany signsof rotating,immediatelyreturntothe

operator'spositionandshutoff theengine.Waitfor all moving

partsto stopbeforereadjustingtheaugercontrolcable.

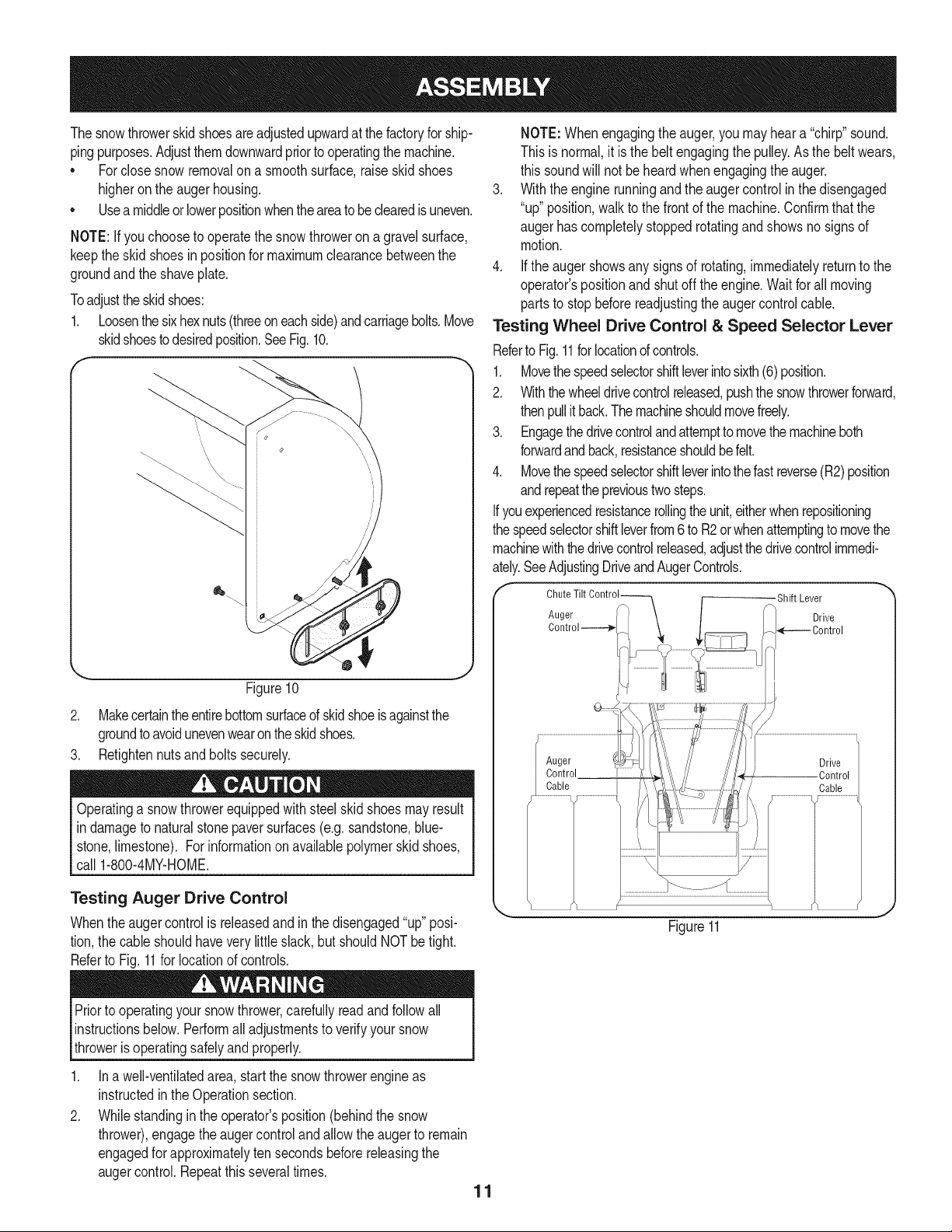

Testing Wheel Drive Control & Speed Selector Lever

RefertoFig.11forlocationofcontrols.

1. Movethespeedselectorshiftleverintosixth(6)position.

2. Withthewheeldrivecontrolreleased,pushthesnowthrowerforward,

thenpullit back.Themachineshouldmovefreely.

3. Engagethedrivecontrolandattemptto movethemachineboth

forwardandback,resistanceshouldbefelt.

4. Movethespeedselectorshiftleverintothefastreverse(R2)position

andrepeattheprevioustwosteps.

Ifyouexperiencedresistancerollingtheunit,eitherwhenrepositioning

thespeedselectorshiftleverfrom6 to R2orwhenattemptingto movethe

machinewiththedrivecontrolreleased,adjustthedrivecontrolimmedi-

ately.SeeAdjustingDriveandAugerControls.

Figure10

2. Makecertaintheentirebottomsurfaceofskidshoeisagainstthe

groundtoavoidunevenwearontheskidshoes.

3. Retightennutsandboltssecurely.

Operatinga snowthrowerequippedwithsteelskidshoesmayresult

in damagetonaturalstonepaversurfaces(e.g.sandstone,blue-

stone,limestone).Forinformationon availablepolymerskidshoes,

call1-800-4MY-HOME.

Testing Auger Drive Control

Whentheaugercontrolis releasedandin thedisengaged"up"posi-

tion,thecableshouldhaveverylittleslack,butshouldNOTbetight.

Referto Fig.11forlocationofcontrols.

Priortooperatingyoursnowthrower,carefullyreadandfollowall

instructionsbelow.Performall adjustmentsto verifyyoursnow

throwerisoperatingsafelyandproperly.

.

Ina well-ventilatedarea,startthesnowthrowerengineas

instructedin theOperationsection.

2.

Whilestandinginthe operator'sposition(behindthe snow

thrower),engagetheaugercontrolandallowtheaugertoremain

engagedfor approximatelyten secondsbeforereleasingthe

augercontrol.Repeatthisseveraltimes.

11

Auger

Control

Cable

Shift Lever

Drive

_(--.---- Control

Drive

Control

Cable

Figure11

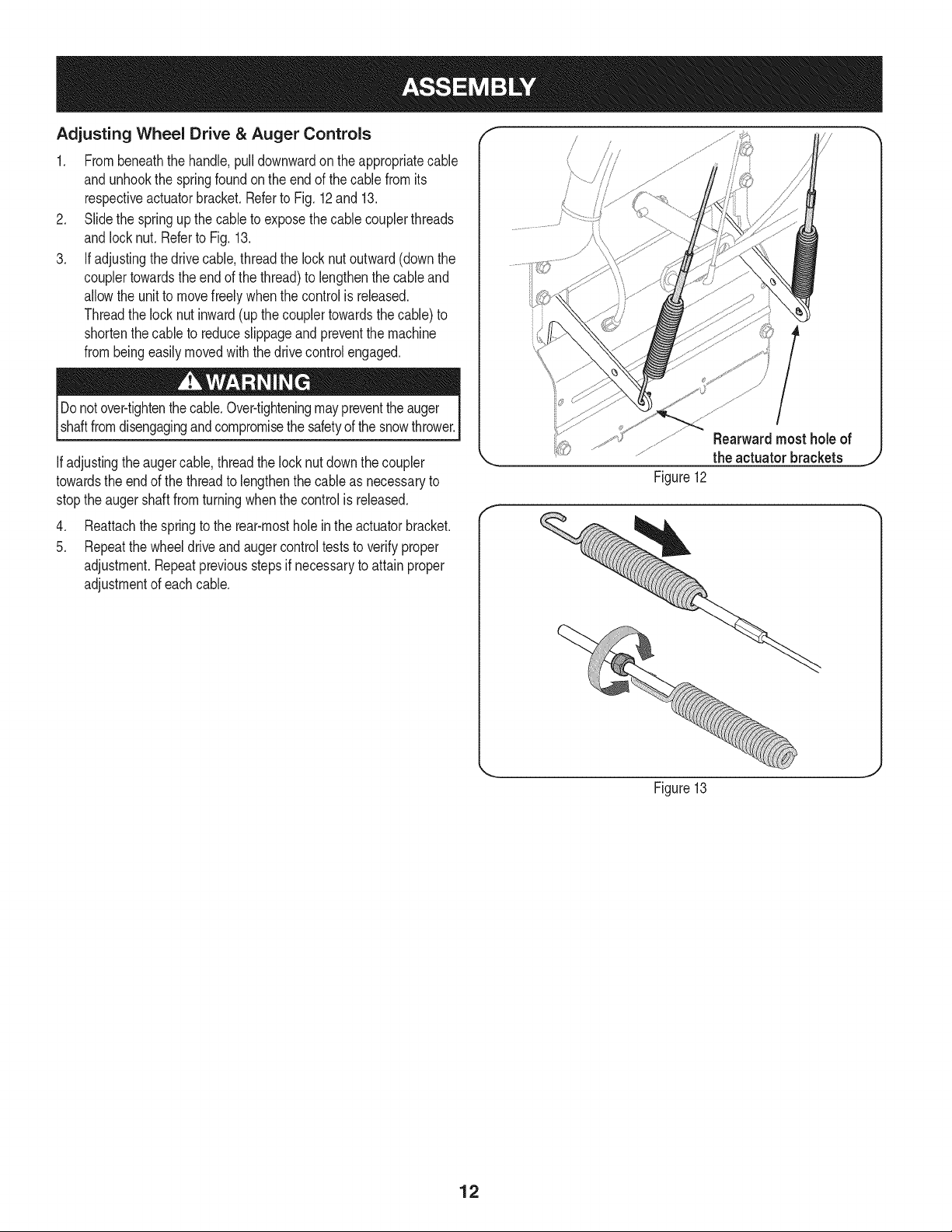

Adjusting Wheel Drive & Auger Controls

1. Frombeneaththehandle,pulldownwardonthe appropriatecable

andunhookthespringfoundontheendof thecablefromits

respectiveactuatorbracket.RefertoFig.12and13.

2. Slidethe springupthecableto exposethecablecouplerthreads

andlocknut.Referto Fig.13.

3. Ifadjustingthedrivecable,threadthelocknutoutward(downthe

couplertowardsthe endof thethread)tolengthenthecableand

allowthe unitto movefreelywhenthecontrolis released.

Threadthelocknutinward(up thecouplertowardsthecable)to

shortenthecable toreduceslippageandpreventthemachine

frombeingeasilymovedwiththedrivecontrolengaged.

Donotover-tightenthecable.Over-tighteningmaypreventtheauger

shaftfromdisengagingandcompromisethesafetyofthesnowthrower.

Ifadjustingtheaugercable,threadthelocknut downthecoupler

towardstheendof thethreadtolengthenthecableasnecessaryto

stoptheaugershaftfromturningwhenthecontrolis released.

4. Reattachthespringtotherear-mostholein theactuatorbracket.

5. Repeatthewheeldriveandaugercontrolteststoverifyproper

adjustment.Repeatpreviousstepsif necessarytoattainproper

adjustmentof eachcable.

Rearwardmost holeof

the actuator brackets

Figure12

12

J

Figure13

f

DriftCutters

Drive Two-wayChuteControlTM

Headli<

ChuteAssembly

SpeedSelector

ShiftLever

_._-=-==AugerControl

Steering

Wheel Control

Clean-out Tool_

_!r'_Auger

Housing

SkidShoes

Figure

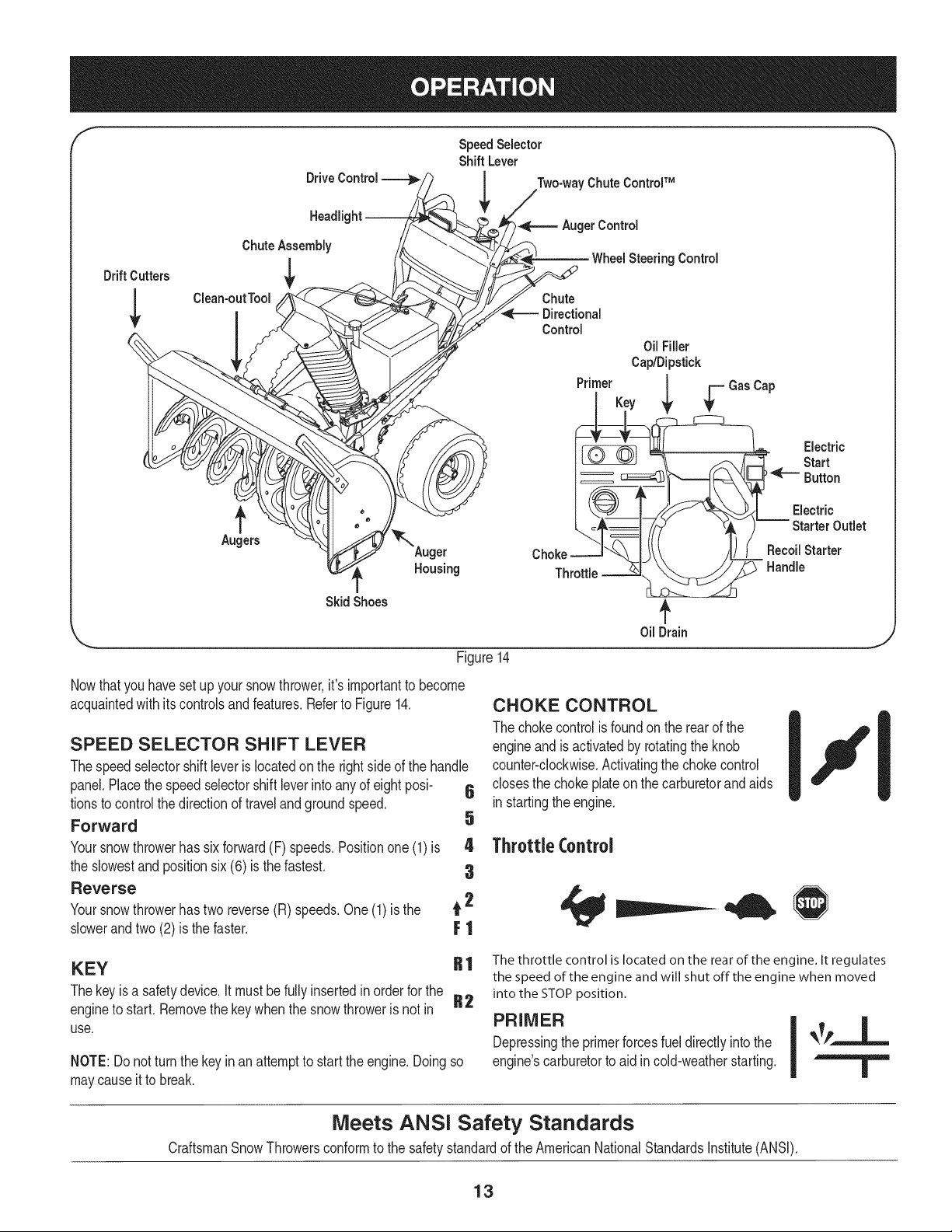

Nowthatyouhavesetupyoursnowthrower,it'simportanttobecome

acquaintedwithitscontrolsandfeatures.Referto Figure14.

SPEED SELECTOR SHIFT LEVER

Thespeedselectorshiftleveris locatedon therightsideofthehandle

panel.Placethespeedselectorshiftleverintoanyof eightposi- 6

tionstocontrolthedirectionoftravelandgroundspeed.

Forward 5

Yoursnowthrowerhassixforward(F) speeds.Positionone(1)is 4

theslowestandpositionsix(6) isthefastest. 3

Reverse

Yoursnowthrowerhastwo reverse(R) speeds.One(1)isthe t 2

slowerandtwo(2) isthefaster. F ]

Control

Oil Filler

Cap/Dipstick

Primer

Key

Throttle

_L=-GasCap

OilDrain

14

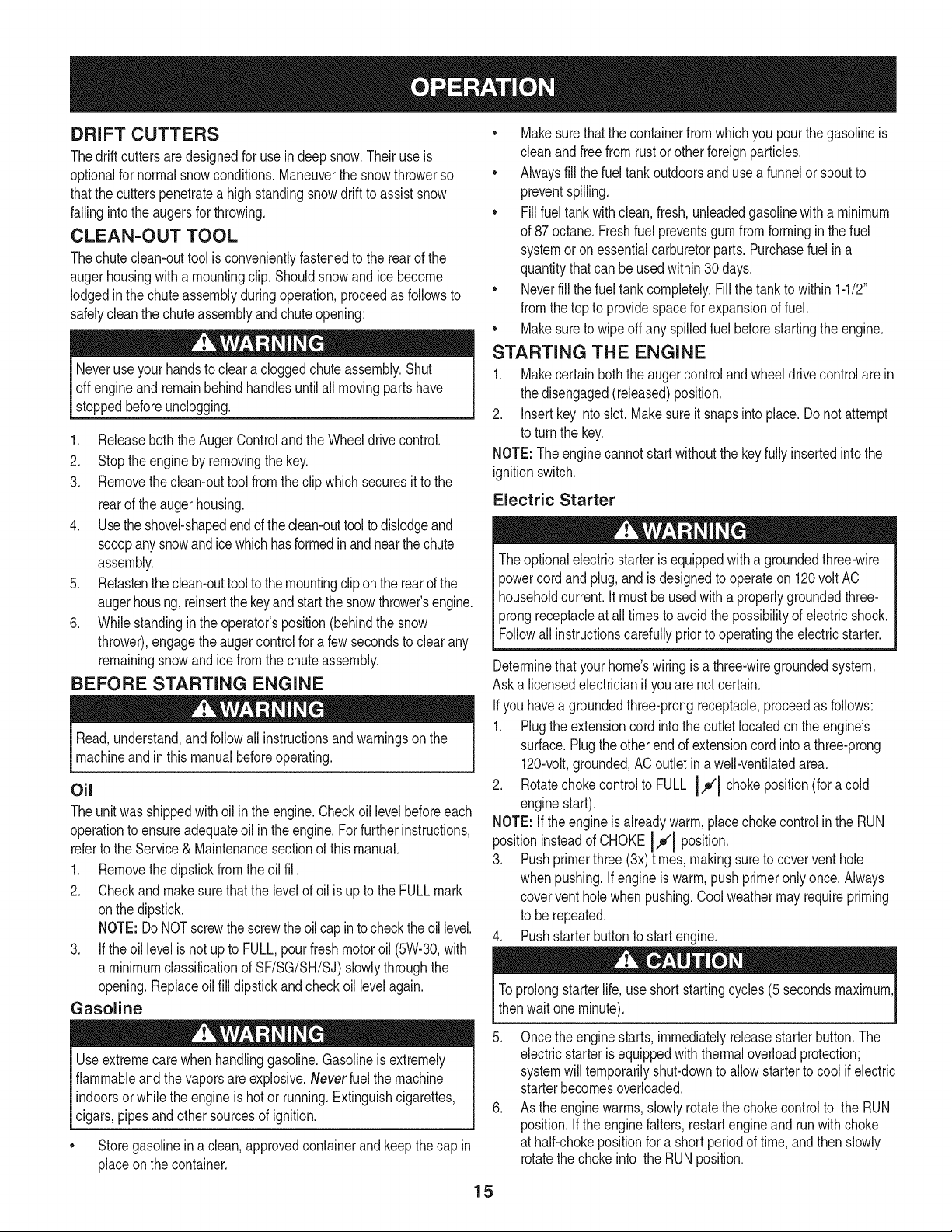

CHOKE CONTROL

Thechokecontrolis foundontherearof the

engineand isactivatedbyrotatingtheknob

counter-clockwise.Activatingthechokecontrol

closesthe chokeplateonthecarburetorandaids

instartingtheengine.

ThrottleControl

Electric

Start

Button

Electric

Outlet

RecoilStarter

Handle

KEY

Thekeyisa safetydevice.Itmustbefullyinsertedin orderforthe

enginetostart.Removethekeywhenthesnowthrowerisnotin

use.

NOTE:Do notturnthekeyin anattemptto starttheengine.Doingso

maycauseitto break.

Meets ANSI Safety Standards

CraftsmanSnowThrowersconformtothesafetystandardofthe AmericanNationalStandardsInstitute(ANSI).

R 1 The throttle control is located on the rear of the engine. It regulates

the speed of the engine and will shut off the engine when moved

into the STOP position.

R2

PRIMER

Depressingthe primerforcesfueldirectlyintothe

engine'scarburetorto aidin cold-weatherstarting.

13

OIL FILL

Engineoillevelcan becheckedandoiladdedthroughtheoil fill.

RECOIL STARTER HANDLE

Thishandleisusedto manuallystarttheengine.

ELECTRIC STARTER BUTTON

Pressingtheelectricstarterbuttonengagestheengine'selectric

starterwhenpluggedintoa 120Vpowersource.

ELECTRIC STARTER OUTLET

Requirestheuseofa three-prongoutdoorextensioncord(included)

anda 120Vpowersource/walloutlet.

AUGERS

Whenengaged,the augersrotateanddrawsnowintotheauger

housing.

CHUTE ASSEMBLY

Snowdrawnintotheaugerhousingisdischargedoutthe chute

assembly.

GAS CAP

Unthreadthegascapto addgasolinetothefueltank.

f

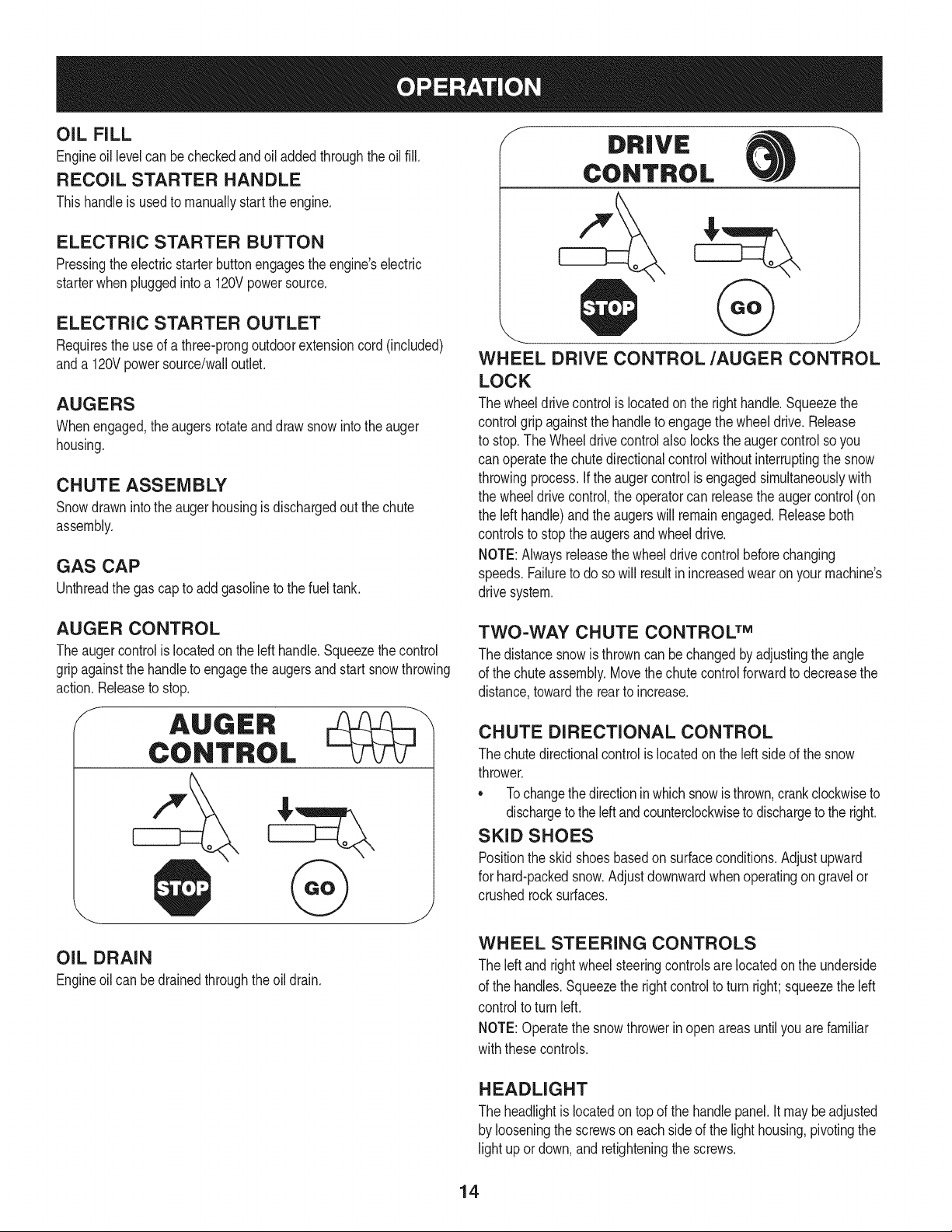

DRIVE

CONTROL

WHEEL DRIVE CONTROL/AUGER CONTROL

LOCK

Thewheeldrivecontrolis locatedon therighthandle.Squeezethe

controlgrip againstthehandletoengagethe wheeldrive.Release

to stop.TheWheeldrivecontrolalsolockstheaugercontrolsoyou

canoperatethechutedirectionalcontrolwithoutinterruptingthe snow

throwingprocess.Ifthe augercontrolisengagedsimultaneouslywith

thewheeldrivecontrol,theoperatorcanreleasetheaugercontrol(on

theleft handle)andtheaugerswillremainengaged.Releaseboth

controlsto stoptheaugersandwheeldrive.

NOTE:Alwaysreleasethewheeldrivecontrolbeforechanging

speeds.Failuretodo sowill resultinincreasedwearonyourmachine's

drivesystem.

AUGER CONTROL

Theaugercontrolis locatedontheleft handle.Squeezethecontrol

gripagainstthehandleto engagetheaugersandstartsnowthrowing

action.Releasetostop.

f

OIL DRAIN

Engineoilcanbedrainedthroughtheoil drain.

TWO-WAY CHUTE CONTROL TM

Thedistancesnowisthrowncan bechangedbyadjustingtheangle

ofthe chuteassembly.Movethe chutecontrolforwardtodecreasethe

distance,towardtherearto increase.

CHUTE DIRECTIONAL CONTROL

Thechutedirectionalcontrolis locatedontheleft sideofthe snow

thrower.

• Tochangethedirectioninwhichsnowisthrown,crankclockwiseto

dischargetothe leftandcounterclockwisetodischargetotheright.

SKID SHOES

Positiontheskidshoesbasedon surfaceconditions.Adjustupward

forhard-packedsnow.Adjustdownwardwhenoperatingongravelor

crushedrocksurfaces.

WHEEL STEERING CONTROLS

Theleftand rightwheelsteeringcontrolsare locatedontheunderside

ofthe handles.Squeezethe rightcontroltoturnright;squeezetheleft

controltoturn left.

NOTE:Operatethesnowthrowerin openareasuntilyouarefamiliar

withthesecontrols.

HEADLIGHT

Theheadlightislocatedontop ofthehandlepanel.It maybeadjusted

bylooseningthescrewsoneachsideof thelighthousing,pivotingthe

lightupor down,andretighteningthescrews.

14

DRIFT CUTTERS

Thedrift cuttersaredesignedforuseindeepsnow.Theiruseis

optionalfornormalsnowconditions.Maneuverthesnowthrowerso

thatthecutterspenetrateahighstandingsnowdriftto assistsnow

fallingintotheaugersforthrowing.

CLEAN-OUT TOOL

Thechuteclean-outtoolisconvenientlyfastenedtotherearofthe

augerhousingwitha mountingclip. Shouldsnowandice become

lodgedin thechuteassemblyduringoperation,proceedasfollowsto

safelycleanthechuteassemblyandchuteopening:

Neveruseyour handstoclearacloggedchuteassembly.Shut

off engineand remainbehindhandlesuntilallmovingpartshave

stoppedbeforeunclogging.

1. ReleaseboththeAugerControland theWheeldrivecontrol.

2. Stopthe engineby removingthekey.

3. Removetheclean-outtoolfromthe clip whichsecuresittothe

rearoftheaugerhousing.

4. Usetheshovel-shapedendoftheclean-outtooltodislodgeand

scoopanysnowandice whichhasformedin andnearthechute

assembly.

5. Refastentheclean-outtooltothemountingclipontherearofthe

augerhousing,reinsertthekeyandstartthesnowthrower'sengine.

6. Whilestandingintheoperator'sposition(behindthe snow

thrower),engagetheaugercontrolforafewsecondsto clearany

remainingsnowandice fromthechuteassembly.

BEFORE STARTING ENGINE

Read,understand,andfollowall instructionsandwarningson the

machineandin thismanualbeforeoperating.

Oil

Theunit wasshippedwithoilintheengine.Checkoil levelbeforeeach

operationtoensureadequateoilin theengine.Forfurtherinstructions,

referto theService& Maintenancesectionofthismanual.

1. Removethedipstickfromtheoilfill.

2. Checkandmakesurethatthe levelofoil isuptothe FULLmark

onthedipstick.

NOTE:Do NOTscrewthe screwtheoilcapintochecktheoillevel.

3. If theoil levelisnot upto FULL,pourfreshmotoroil (5W-30,with

a minimumclassificationofSF/SG/SH/SJ)slowlythroughthe

opening.Replaceoil fill dipstickandcheckoillevelagain.

Gasoline

• Makesurethatthe containerfromwhichyoupourthegasolineis

cleanandfree fromrustorotherforeignparticles.

• Alwaysfillthe fuel tankoutdoorsandusea funnelor spoutto

preventspilling.

• Fillfuel tankwithclean,fresh,unleadedgasolinewitha minimum

of87 octane.Freshfuelpreventsgumfromformingin thefuel

systemor on essentialcarburetorparts.Purchasefuelin a

quantitythatcanbe usedwithin30days.

• Neverfillthe fueltankcompletely.Fillthetankto within1-1/2"

fromthetopto providespaceforexpansiond fuel.

• Makesureto wipeoffanyspilledfuelbeforestartingtheengine.

STARTING THE ENGINE

1. Makecertainboththe augercontrolandwheeldrivecontrolarein

thedisengaged(released)position.

2. Insertkeyintoslot.Makesureit snapsintoplace.Donot attempt

toturn thekey.

NOTE:Theenginecannotstartwithoutthe keyfullyinsertedintothe

ignitionswitch.

Electric Starter

Theoptionalelectricstarterisequippedwitha groundedthree-wire

powercordandplug,and isdesignedtooperateon120voltAC

householdcurrent.It mustbe usedwitha properlygroundedthree-

prongreceptacleatall timestoavoidthe possibilityof electricshock.

Followall instructionscarefullypriortooperatingtheelectricstarter.

Determinethatyour home'swiringisa three-wiregroundedsystem.

Aska licensedelectricianifyouarenotcertain.

Ifyouhavea groundedthree-prongreceptacle,proceedas follows:

1. Plugtheextensioncordintothe outletlocatedontheengine's

surface.Plugtheother endofextensioncordintoathree-prong

120-volt,grounded,ACoutletina well-ventilatedarea.

2. Rotatechokecontrolto FULL I,,"1chokeposition(fora cold

enginestart).

NOTE:If theengineisalreadywarm,placechokecontrolintheRUN

positioninsteadof CHOKEIJl position.

3. Pushprimerthree(3x)times,makingsuretocoverventhole

whenpushing.If engineiswarm,pushprimeronlyonce.Always

coverventholewhenpushing.Coolweathermayrequirepriming

to berepeated.

4. Pushstarterbuttontostartengine.

Toprolongstarterlife,useshortstartingcycles(5 secondsmaximum

thenwaitone minute).

Useextremecarewhenhandlinggasoline.Gasolineisextremely

flammableandthe vaporsareexplosive.Neverfuelthemachine

indoorsorwhiletheengineis hotor running.Extinguishcigarettes,

cigars,pipesand othersourcesofignition.

Storegasolineina clean,approvedcontainerandkeepthecap in

placeonthe container.

5. Oncetheenginestarts,immediatelyreleasestarterbutton.The

electricstarterisequippedwiththermaloverloadprotection;

systemwilltemporarilyshut-downtoallowstartertocoolif electric

starterbecomesoverloaded.

6. Astheenginewarms,slowlyrotatethechokecontrolto the RUN

position.Ifthe enginefalters,restartengineandrunwithchoke

athalf-chokepositionfora shortperiodoftime,andthenslowly

rotatethechokeinto theRUNposition.

15

7. Whendisconnectingtheextensioncord,alwaysunplugtheend

atthe three-prongwalloutletbeforeunpluggingtheoppositeend

fromthesnowthrower.

Recoil Starter

1. Rotatechokecontrolto CHOKE IJl position.Ifengineis

alreadyhot,do notusetheCHOKE.

2. Pushprimerthreeto five(3-5)times,makingsuretocovervent

holewhenpushing.Ifengineiswarm,pushprimeronlyonce.

Alwayscoverventholewhenpushing.Coolweathermayrequire

primingtobe repeated.

3. Graspthe recoilstarterhandleandslowlypullthe ropeout.At

thepointwhereit becomesslightlyhardertopulltherope,slowly

allowthe ropetorecoil.

4. Pullthestarterhandlewitha firm,rapidstroke.Engineshould

start.Donot releasethehandleandallowitto snapback.Keepa

firmholdonthestarterhandleandallowit to slowlyrecoil.

5. Astheenginewarms,slowlyrotatethechokecontrolto theRUN

position.Ifthe enginefalters,restartengineandrunwithchoke

athalf-chokepositionfora shortperiodoftime,andthenslowly

rotatethechokeinto the RUNposition.

STOPPING THE ENGINE

Runenginefor a fewminutesbeforestoppingto helpdry off any

moistureonthe engine.

1. Movethrottlecontrolto STOPposition.

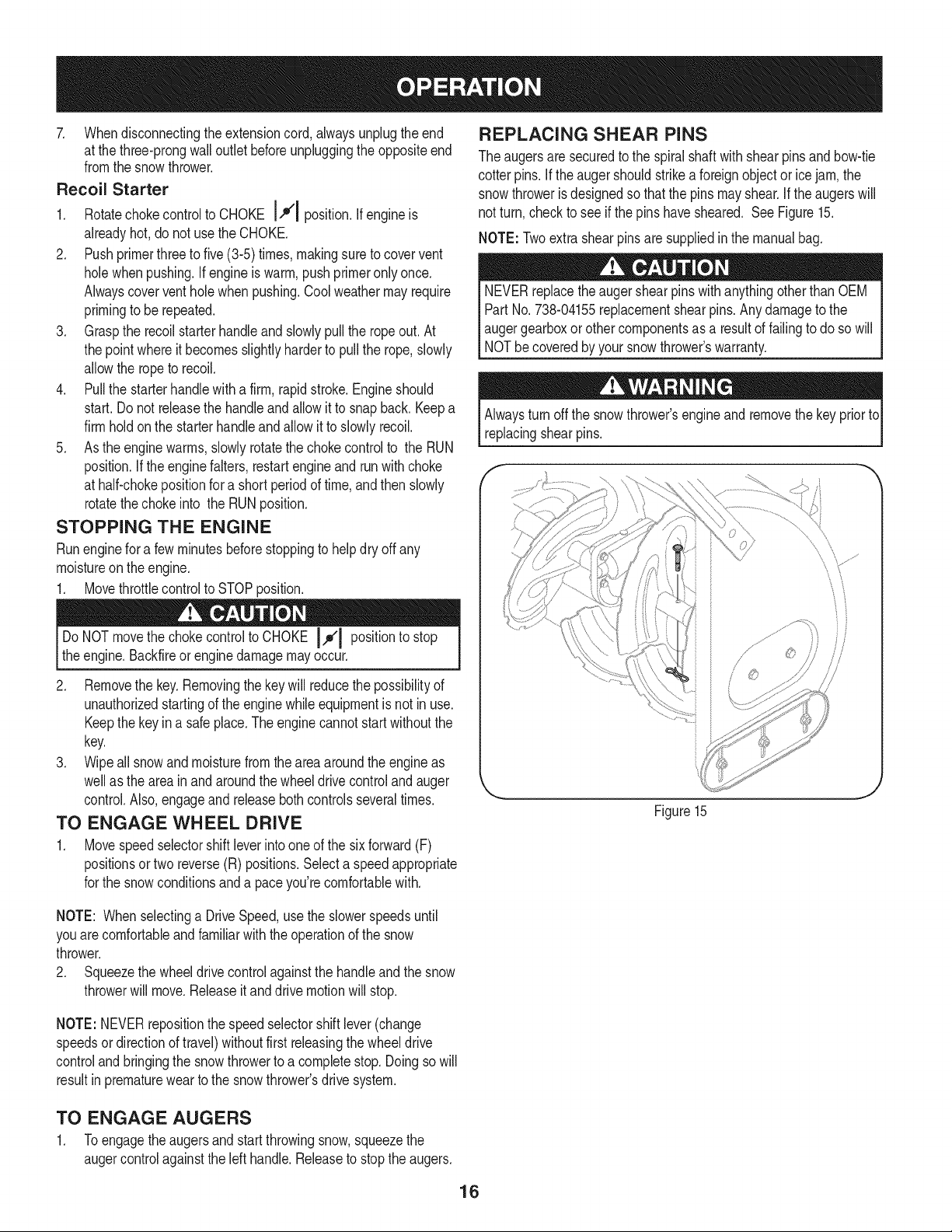

REPLACING SHEAR PINS

Theaugersare securedtothespiralshaftwith shearpinsandbow-tie

cotterpins.If theaugershouldstrikeaforeignobjectoricejam,the

snowthrowerisdesignedsothatthe pinsmayshear.Iftheaugerswill

notturn,checktosee ifthepinshavesheared. SeeFigure15.

NOTE:Twoextrashearpinsaresuppliedin themanualbag.

NEVERreplacetheaugershearpins withanythingotherthanOEM

PartNo.738-04155replacementshearpins.Anydamagetothe

augergearboxorothercomponentsas a resultoffailingtodo sowill

NOTbecoveredbyyour snowthrower'swarranty.

Alwaysturnoffthesnowthrower'sengineand removethekeypriorto

replacingshearpins.

DoNOTmovethe chokecontroltoCHOKE 14¢1positionto stop

theengine.Backfireorenginedamagemayoccur.

2. Removethe key.Removingthekeywillreducethepossibilityof

unauthorizedstartingofthe enginewhileequipmentisnot inuse.

Keepthekeyina safeplace.Theenginecannotstart withoutthe

key.

3. Wipeallsnowandmoisturefromtheareaaroundtheengineas

wellas theareainandaroundthewheeldrivecontrolandauger

control.Also,engageandreleasebothcontrolsseveraltimes.

TO ENGAGE WHEEL DRIVE

1. Movespeedselectorshiftleverintooneofthesixforward(F)

positionsortwo reverse(R)positions.Selectaspeedappropriate

forthe snowconditionsanda paceyou'recomfortablewith.

NOTE: WhenselectingaDriveSpeed,usetheslowerspeedsuntil

youarecomfortableandfamiliarwiththe operationof thesnow

thrower.

2. Squeezethewheeldrivecontrolagainstthehandleandthesnow

throwerwillmove.Releaseitanddrive motionwillstop.

NOTE:NEVERrepositionthespeedselectorshiftlever(change

speedsordirectionoftravel)withoutfirstreleasingthewheeldrive

controlandbringingthesnowthrowerto a completestop.Doingsowill

resultinprematurewearto thesnowthrower'sdrive system.

Figure15

TO ENGAGE AUGERS

1. Toengagetheaugersandstart throwingsnow,squeezethe

augercontrolagainsttheleft handle.Releaseto stoptheaugers.

16

MAINTENANCE SCHEDULE

Beforeperforminganytypeofmaintenance/service,disengageall

controlsandstoptheengine.Waituntilallmovingpartshavecometo a

completestop.Removethekeytopreventunintendedstarting.Always

wearsafetyglassesduringoperationorwhileperforminganyadjustments

orrepairs.

EachUse

1. Engineoillevel

2. Looseormissinghardware

3. Unitandengine.

1st5 - 8hours

25 hours

1. Engineoil

1. Engineoi11-

2. Controllinkagesand pivots

50 hours

Annuallyor100hours

1. Engineoil

1. Sparkplug

BeforeStorage 1. Fuelsystem

1. Check

2. Tightenor replace

3. Clean

1. Change

1. Change

2. Lubewithlightoil

1. Change

1. Cleanand re-gap,orelse replace

1. Runengineuntilit stopsfromlackof

Underheavyloador inhightemperatures

Followthemaintenanceschedulegivenbelow.Thischartdescribes

serviceguidelinesonly.UsetheServiceLogcolumnto keeptrackof

completedmaintenancetasks.To locate the nearest SearsService

Centeror toscheduleservice,simplycontactSearsat

1-800-4-MY-HOME®.

= =

withnewplug.

fueloradda gasolineadditivetothe

gasin thetank.

ENGINE MAINTENANCE

Checking Engine Oil

Beforelubricating,repairing,or inspecting,disengageallcontrolsand

stopengine.Waituntilallmovingpartshavecometoa completestop.

Removethekeytopreventunintendedfiringoftheengine.

NOTE: Checktheoillevelbeforeeachuseto besurecorrectoil level

ismaintained.

Whenaddingoilto theengine,referto viscositychart below.Engineoil

capacityisapproximately37 ounces.Donotover-fill.Usea4-stroke,

oran equivalenthighdetergent,premiumqualitymotoroilcertified

tomeetorexceedU.S.automobilemanufacturer'srequirementsfor

serviceclassificationSG,SRMotoroilsclassifiedSG,SFwillshow

thisdesignationonthecontainer.

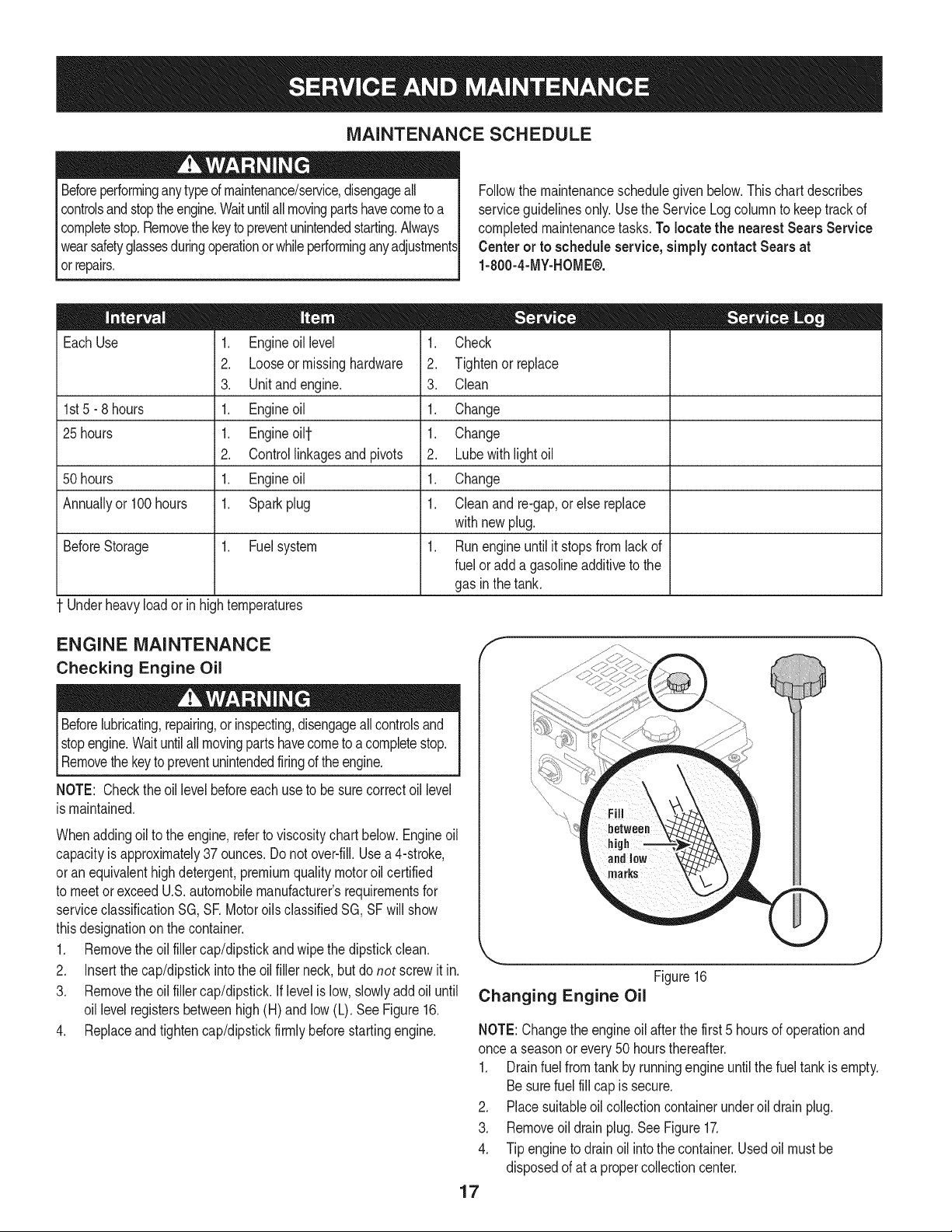

1. Removetheoil fillercap/dipstickandwipethe dipstickclean.

2. Insertthe cap/dipstickintotheoilfiller neck,butdo not screwit in.

3. Removetheoil fillercap/dipstick.Iflevelislow,slowlyadd oiluntil

oil levelregistersbetweenhigh(H)andlow (L). SeeFigure16.

4. Replaceandtightencap/dipstickfirmlybeforestartingengine.

J

Figure16

Changing Engine Oil

NOTE:Changetheengineoil afterthefirst5 hoursofoperationand

oncea seasonor every50hoursthereafter.

1. Drainfuelfromtankbyrunningengineuntilthefueltankis empty.

Besurefuel fillcapis secure.

2. Placesuitableoilcollectioncontainerunderoil drainplug.

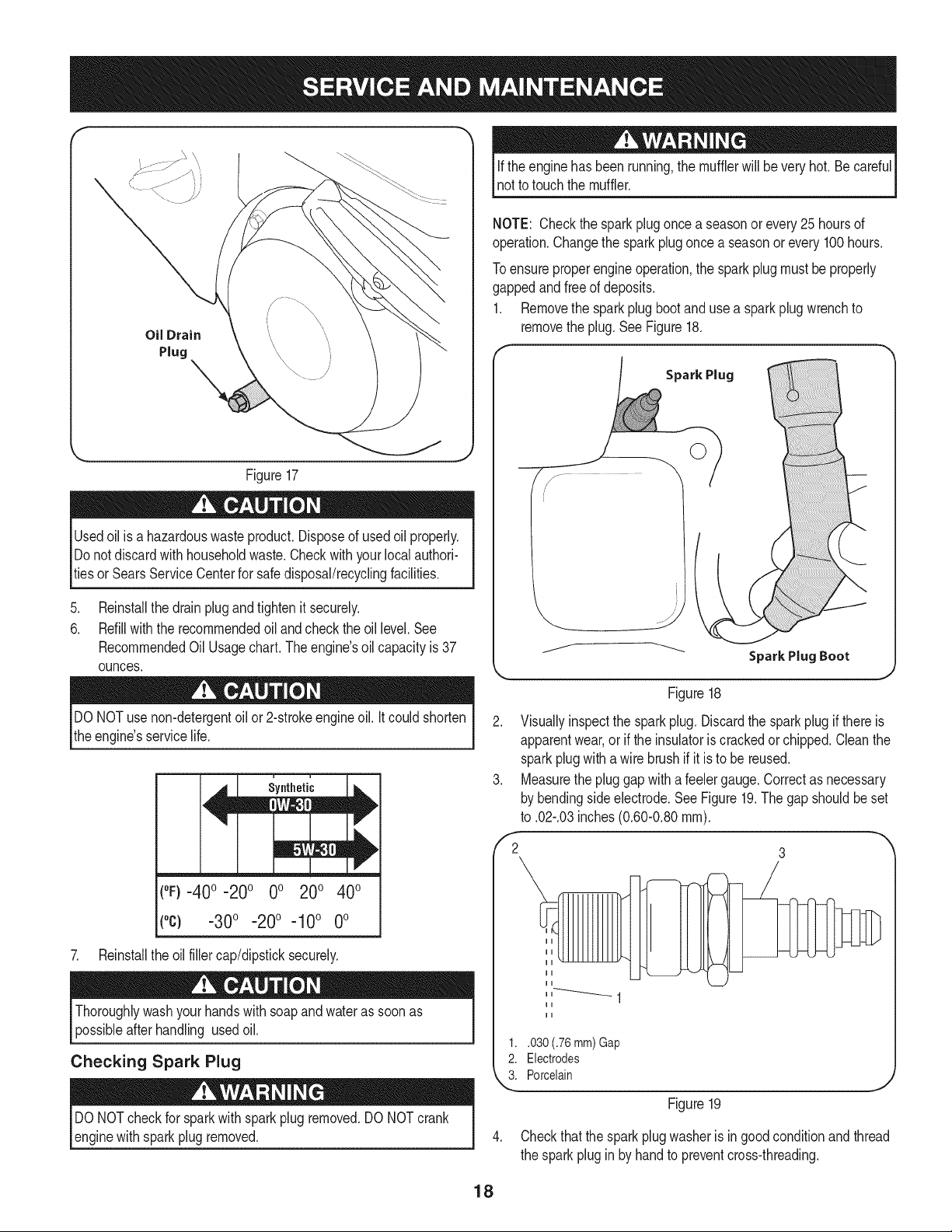

3. Removeoil drainplug.SeeFigure17.

4. Tipenginetodrainoil intothecontainer.Usedoil mustbe

disposedofat a propercollectioncenter.

17

f

Oil Drain

Plug

Figure17

Usedoil isa hazardouswasteproduct.Disposeof usedoil properly.

Donotdiscardwith householdwaste.Checkwithyourlocalauthori-

tiesor SearsServiceCenterforsafedisposal/recyclingfacilities.

Iftheenginehas beenrunning,themufflerwillbeveryhot.Becareful

notto touchthemuffler.

NOTE: Checkthesparkplugoncea seasonor every25hoursof

operation.Changethe sparkplugoncea seasonorevery100hours.

Toensureproperengineoperation,the sparkplugmustbeproperly

gappedandfreeof deposits.

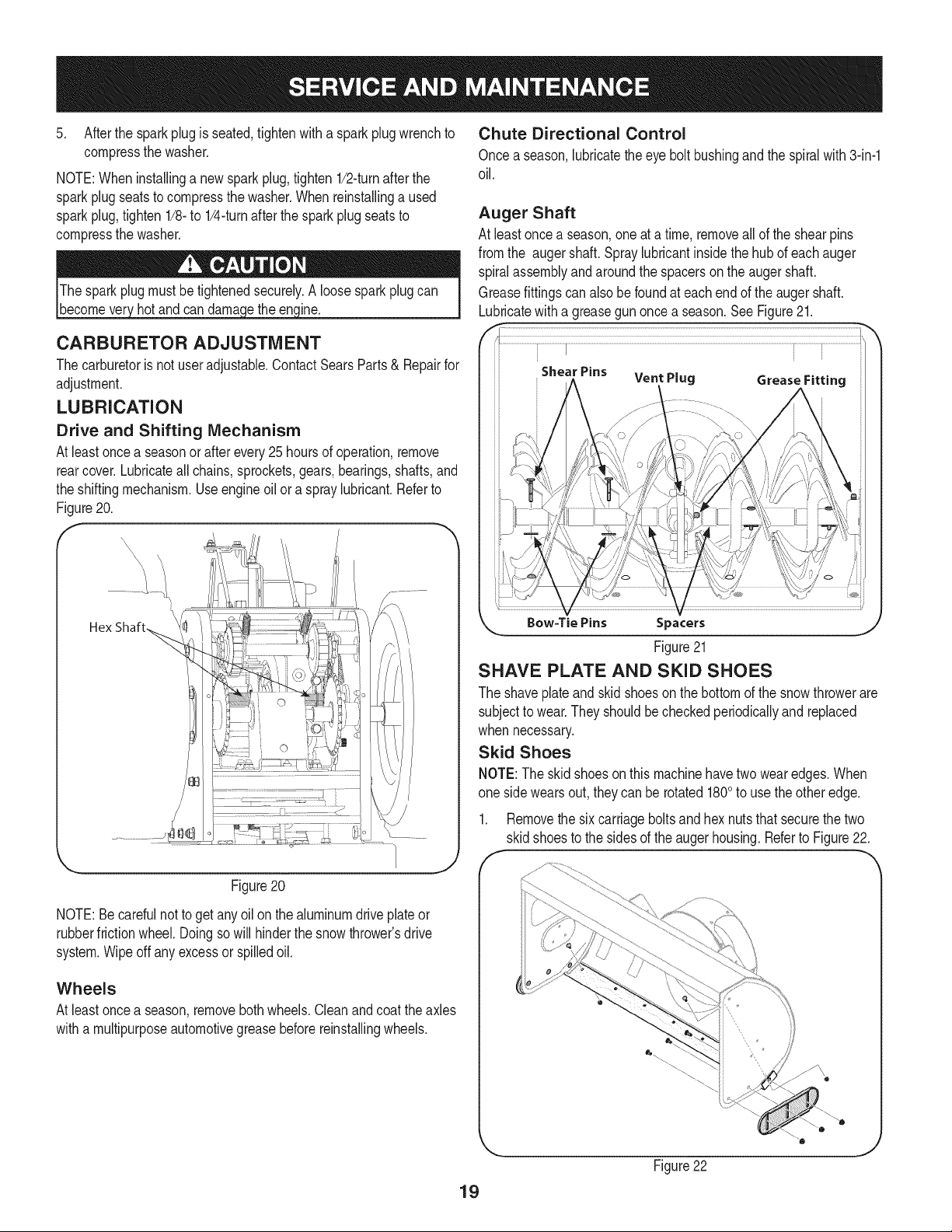

1. Removethesparkplugbootandusea sparkplugwrenchto

removetheplug.SeeFigure18.

Spark Plug

.

Reinstallthedrainplugandtightenit securely.

6.

Refillwiththerecommendedoilandcheckthe oil level.See

RecommendedOil Usage chart. The engine's oilcapacity is 37

ounces.

DONOTuse non-detergentoilor 2-strokeengineoil.Itcouldshorten

theengine'sservicelife.

(°F}=40o =20o 0o 200 400

(°c) -30° -20° -10° 0°

7. Reinstalltheoilfillercap/dipsticksecurely.

Thoroughlywashyour handswithsoapandwateras soonas

possibleafterhandling usedoil.

Checking Spark Plug

DONOTcheckforsparkwithsparkplugremoved.DONOTcrank

enginewithsparkplugremoved.

Figure18

2. Visuallyinspectthe sparkplug. Discardthe sparkplugifthereis

apparentwear,orif theinsulatoriscrackedorchipped.Cleanthe

sparkplugwithawirebrushifit is tobe reused.

3. Measurethepluggapwitha feelergauge.Correctasnecessary

bybendingsideelectrode.SeeFigure19.Thegap shouldbeset

to .02-.03inches(0.60-0.80ram).

,'2 3

1..030 (.76 mm) Gap

2. Electrodes

k"_i Porcelain

Figure19

4. Checkthatthesparkplugwasheris ingoodconditionandthread

thesparkpluginby handto preventcross-threading.

18

5. Afterthe sparkplugisseated,tightenwitha sparkplugwrenchto

compressthewasher.

NOTE:Wheninstallinga newsparkplug,tighten1/2-turnafterthe

sparkplugseatsto compressthewasher.Whenreinstallinga used

sparkplug,tighten1/8-to 1/4-turnafterthe sparkplugseatsto

compressthewasher.

hotandcan ine.

CARBURETOR ADJUSTMENT

Thecarburetoris notuseradjustable.ContactSearsParts& Repairfor

adjustment.

LUBRICATION

Drive and Shifting Mechanism

Atleastoncea seasonorafterevery25 hoursofoperation,remove

rearcover.Lubricateall chains,sprockets,gears,bearings,shafts,and

theshiftingmechanism.Useengineoilora spraylubricant.Referto

Figure20.

f

Chute Directional Control

Onceaseason,lubricatetheeyeboltbushingandthespiralwith3-in-1

oil.

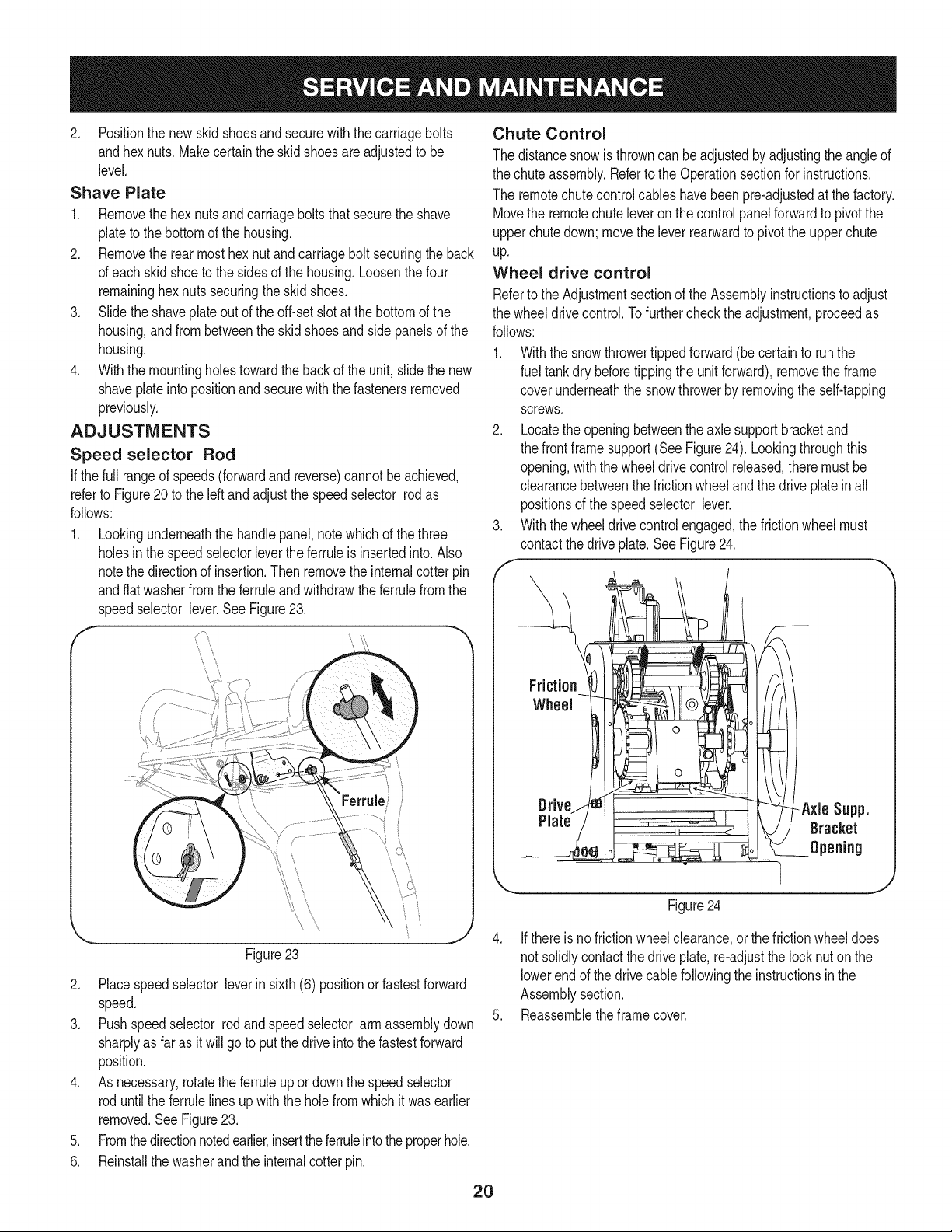

Auger Shaft

At leastoncea season,oneata time,removeallof theshearpins

fromthe augershaft.Spraylubricantinsidethehubof eachauger

spiralassemblyandaroundthe spacersontheaugershaft.

Greasefittingscan alsobefoundateachendofthe augershaft.

Lubricatewitha greasegunoncea season.SeeFigure21.

f ...............

Figure20

NOTE:Becarefulnottoget anyoilon thealuminumdriveplateor

rubberfrictionwheel.Doingsowill hinderthesnowthrower'sdrive

system.Wipeoff anyexcessor spilledoil.

Wheels

Atleastoncea season,removebothwheels.Cleanandcoattheaxles

witha multipurposeautomotivegreasebeforereinstallingwheels.

Bow=Tie Pins S pacers

Figure21

SHAVE PLATE AND SKID SHOES

Theshaveplateandskidshoeson thebottomofthesnowthrowerare

subjectto wear.Theyshouldbecheckedperiodicallyand replaced

whennecessary.

Skid Shoes

NOTE:The skidshoesonthis machinehavetwowearedges.When

one sidewearsout,theycanberotated1800touse theotheredge.

1. Removethesixcarriageboltsandhexnutsthatsecurethetwo

skidshoestothe sidesoftheaugerhousing.Referto Figure22.

19

J

Figure22

2. Positionthenew skidshoesandsecurewiththe carriagebolts

andhexnuts.Makecertaintheskidshoesare adjustedto be

level.

Shave Plate

1. Removethehexnutsandcarriageboltsthatsecuretheshave

plateto thebottomofthehousing.

2. Removetherearmosthexnutand carriageboltsecuringtheback

ofeachskidshoeto thesidesofthehousing.Loosenthefour

remaininghexnutssecuringtheskidshoes.

3. Slidetheshaveplateoutofthe off-setslotat thebottomofthe

housing,andfrombetweentheskidshoesandside panelsofthe

housing.

4. Withthemountingholestowardthebackofthe unit,slidethenew

shaveplateinto positionandsecurewiththefastenersremoved

previously.

ADJUSTMENTS

Speed selector Rod

If thefull rangeofspeeds(forwardandreverse)cannotbe achieved,

referto Figure20totheleftandadjustthe speedselector rodas

follows:

1. Lookingunderneaththehandlepanel,notewhichofthethree

holesin thespeedselectorlevertheferruleisinsertedinto.Also

notethe directionof insertion.Thenremovetheinternalcotterpin

andflatwasherfromtheferruleandwithdrawtheferrulefromthe

speedselector lever.SeeFigure23.

Chute Control

Thedistancesnowisthrowncanbe adjustedbyadjustingthe angleof

thechuteassembly.Refertothe Operationsectionforinstructions.

Theremotechutecontrolcableshavebeenpre-adjustedatthefactory.

Movethe remotechuteleveron thecontrolpanelforwardtopivotthe

upperchutedown;movetheleverrearwardtopivottheupperchute

up.

Wheel drive control

Referto theAdjustmentsectionof theAssemblyinstructionsto adjust

thewheeldrivecontrol.Tofurtherchecktheadjustment,proceedas

follows:

1. Withthesnowthrowertippedforward(becertaintorunthe

fueltankdry beforetippingtheunitforward),removetheframe

coverunderneaththesnowthrowerbyremovingthe self-tapping

screws.

2. Locatetheopeningbetweentheaxle supportbracketand

thefrontframesupport(See Figure24).Lookingthroughthis

opening,withthe wheeldrivecontrolreleased,theremustbe

clearancebetweenthe frictionwheelandthe driveplateinall

positionsofthespeedselector lever.

3. Withthewheeldrivecontrolengaged,thefrictionwheelmust

contactthedriveplate.SeeFigure24.

\ \

\

Ferrule

\ \

Figure23

2. Placespeedselectorleverin sixth(6) positionorfastestforward

speed.

3. Pushspeedselector rodand speedselectorarmassemblydown

sharplyasfaras itwillgoto putthe driveintothefastestforward

position.

4. Asnecessary,rotatetheferruleupordownthespeedselector

roduntilthe ferrulelinesup withtheholefromwhichitwasearlier

removed.See Figure23.

5. Fromthedirectionnotedearlier,inserttheferruleintotheproperhole.

6. Reinstallthewasherandtheinternalcotterpin.

Friction

Wheel

Figure24

4. Ifthereisnofrictionwheelclearance,or thefrictionwheeldoes

notsolidlycontactthe driveplate,re-adjustthelocknut onthe

lowerendof thedrivecablefollowingtheinstructionsinthe

Assemblysection.

5. Reassembletheframecover.

2O

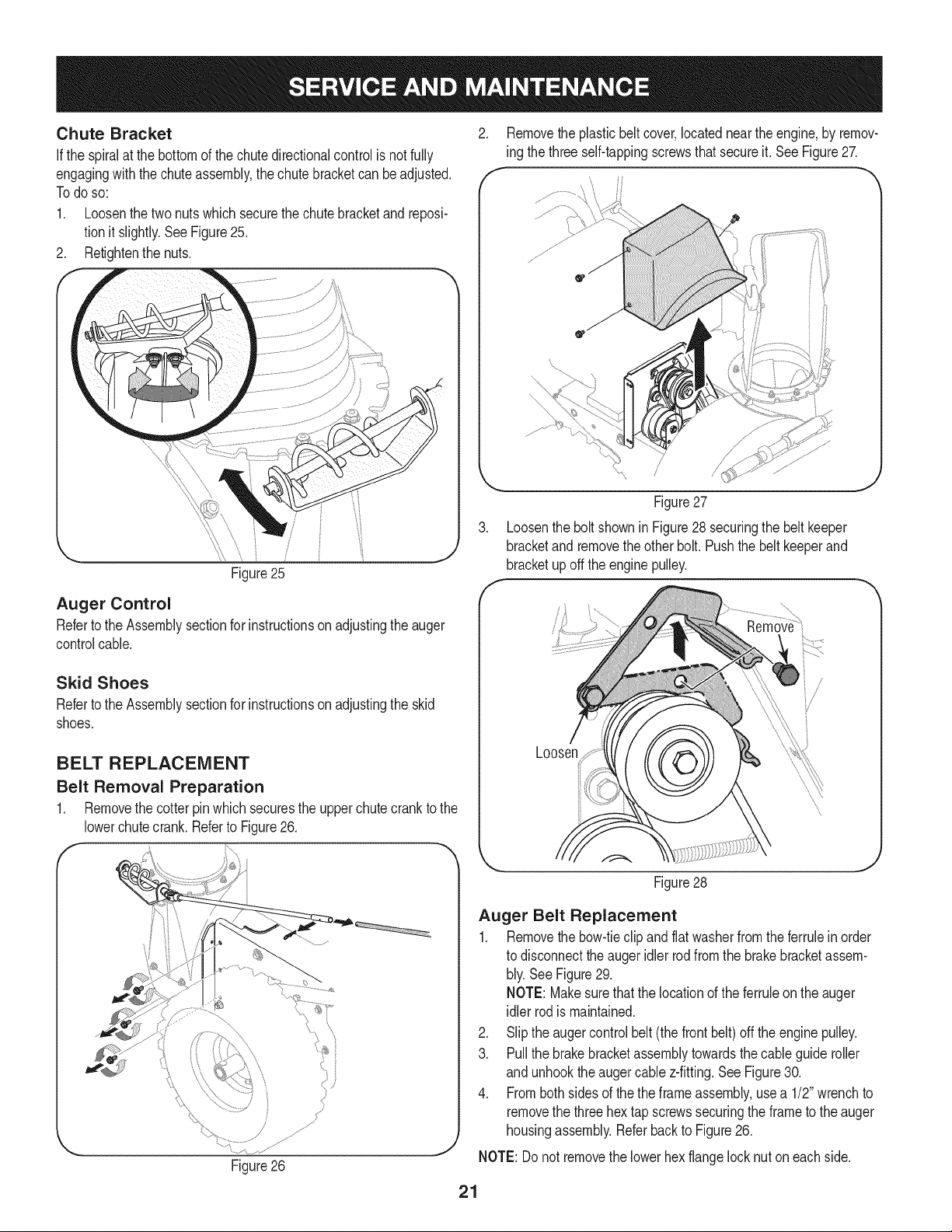

Chute Bracket

Ifthe spiralatthebottomofthechutedirectionalcontrolis notfully

engagingwiththechuteassembly,thechutebracketcanbeadjusted.

Todo so:

1. Loosenthetwonutswhichsecurethechutebracketandreposi-

tionit slightly.SeeFigure25.

2. Retightenthenuts.

/

Figure25

2. Removethe plasticbeltcover,locatedneartheengine,by remov-

ing thethreeself-tappingscrewsthatsecureit.See Figure27.

\

Figure27

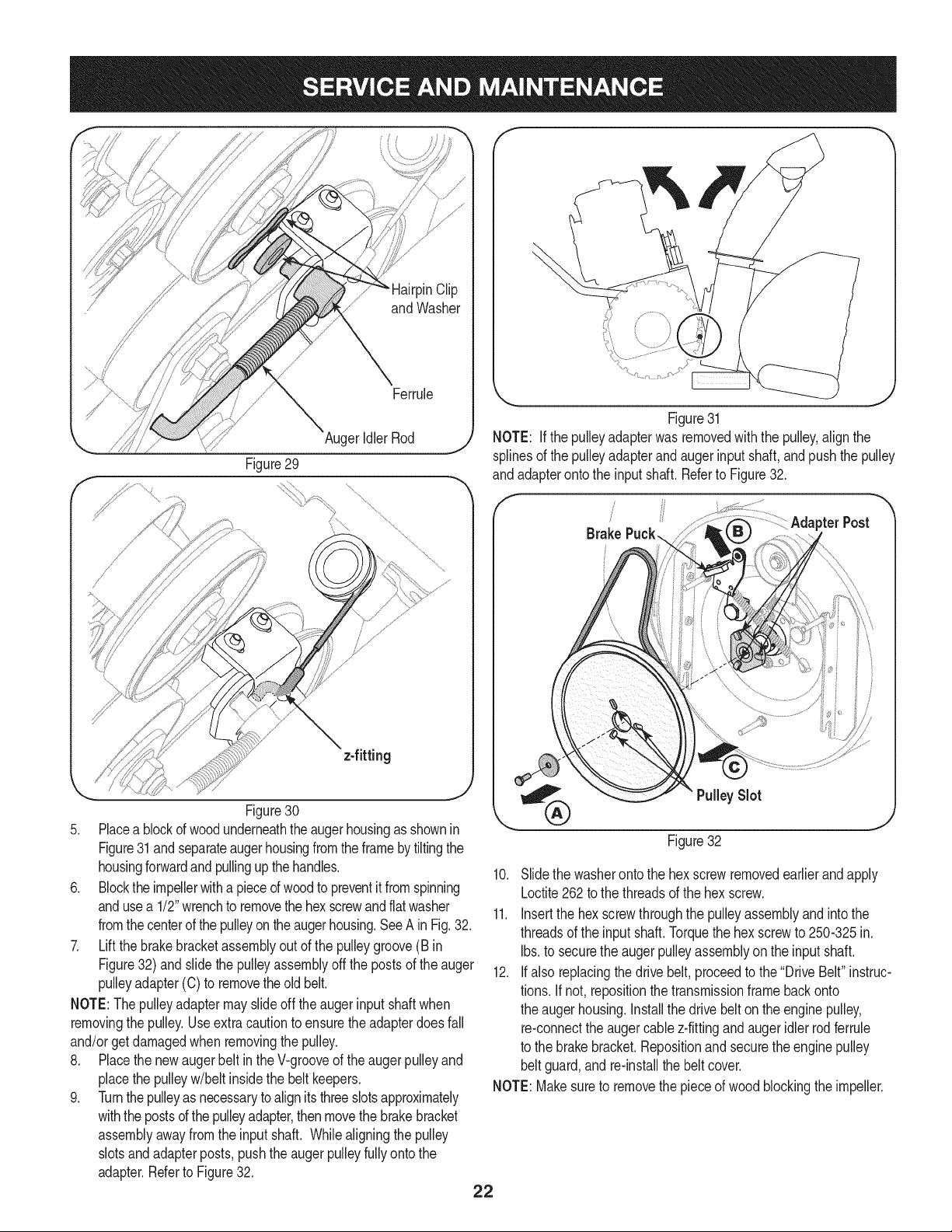

3. LoosentheboltshowninFigure28securingthe beltkeeper

bracketandremovetheotherbolt.Pushthebelt keeperand

bracketupoff theenginepulley.

Auger Control

Refertothe Assemblysectionforinstructionsonadjustingtheauger

controlcable.

Skid Shoes

Refertothe Assemblysectionforinstructionsonadjustingthe skid

shoes.

BELT REPLACEMENT

Belt Removal Preparation

1. Removethecotterpinwhichsecurestheupperchutecranktothe

lowerchutecrank.Referto Figure26.

Figure26

Figure28

Auger Belt Replacement

1. Removethebow-tieclipandflatwasherfromtheferruleinorder

todisconnecttheaugeridlerrodfromthe brakebracketassem-

bly.SeeFigure29.

NOTE:Makesurethatthelocationoftheferruleontheauger

idlerrodismaintained.

2. Sliptheaugercontrolbelt(the frontbelt)offtheenginepulley.

3. Pullthebrakebracketassemblytowardsthecableguideroller

and unhooktheaugercablez-fitting.SeeFigure30.

4. Frombothsidesofthetheframeassembly,usea 1/2"wrenchto

removethethreehextap screwssecuringtheframeto theauger

housingassembly.ReferbacktoFigure26.

NOTE:Donotremovethelowerhexflangelocknut oneach side.

21

Figure29

\

AugerIdlerRod

Figure31

NOTE: Ifthepulleyadapterwasremovedwiththepulley,alignthe

splinesof thepulleyadapterandaugerinputshaft,andpushthepulley

andadapterontotheinputshaft.RefertoFigure32.

/

/ pterPost

Brake

Figure30

5. Placeablockofwoodunderneaththeaugerhousingasshownin

Figure31andseparateaugerhousingfromtheframebytiltingthe

housingforwardandpullingupthehandles.

6. Blocktheimpellerwitha pieceofwoodtopreventitfromspinning

andusea 1/2"wrenchtoremovethehexscrewandflatwasher

fromthecenterof thepulleyontheaugerhousing.SeeA in Fig.32.

7. Liftthebrakebracketassemblyoutof thepulleygroove(B in

Figure32)andslidethepulleyassemblyoffthe postsof theauger

pulleyadapter(C)to removetheoldbelt.

NOTE:Thepulleyadaptermayslideoff theaugerinputshaftwhen

removingthepulley.Useextracautionto ensuretheadapterdoesfall

and/orget damagedwhenremovingthepulley.

8. Placethe newaugerbeltinthe V-grooveoftheaugerpulleyand

placethe pulleyw/beltinsidethebeltkeepers.

9. Turnthepulleyasnecessarytoalignitsthreeslotsapproximately

withthepostsofthe pulleyadapter,thenmovethe brakebracket

assemblyawayfromtheinputshaft. Whilealigningthepulley

slotsandadapterposts,pushthe augerpulleyfullyontothe

adapter.Referto Figure32.

PulleySlot

Figure32

10. Slidethewasherontothe hexscrewremovedearlierandapply

Loctite262to thethreadsofthe hexscrew.

11. Insertthe hexscrewthroughthepulleyassemblyandintothe

threadsofthe inputshaft.Torquethehexscrewto 250-325in.

Ibs.to securetheaugerpulleyassemblyonthe inputshaft.

12. Ifalsoreplacingthedrivebelt,proceedtothe"DriveBelt"instruc-

tions.Ifnot, repositionthetransmissionframebackonto

theaugerhousing.Installthedrivebelton theenginepulley,

re-connecttheaugercablez-fittingandaugeridlerrodferrule

tothe brakebracket.Repositionandsecuretheenginepulley

beltguard,andre-installthebelt cover.

NOTE:Makesuretoremovethepieceof woodblockingtheimpeller.

22

Checktheaugerdrivebeltadjustment.Withthe augerclutchlever

inthedisengagedposition,thetopsurfaceofthe newbeltshouldbe

evenwiththeoutsidediameterofthe pulley.

Toadjust,disconnectferrulefrombrakebracketassembly.Thread

ferrulein(towardsidler)toincreasetensiononbelt,orout to decrease

belttension.

NOTE:Thebrakepuckmustalwaysbefirmly seatedinthepulley

groovewhenaugercontrolisdisengaged.

IMPORTANT:Repeatthe"AugerDriveControlTest"fromtheAs-

semblysectionbeforeoperatingsnowthrower.

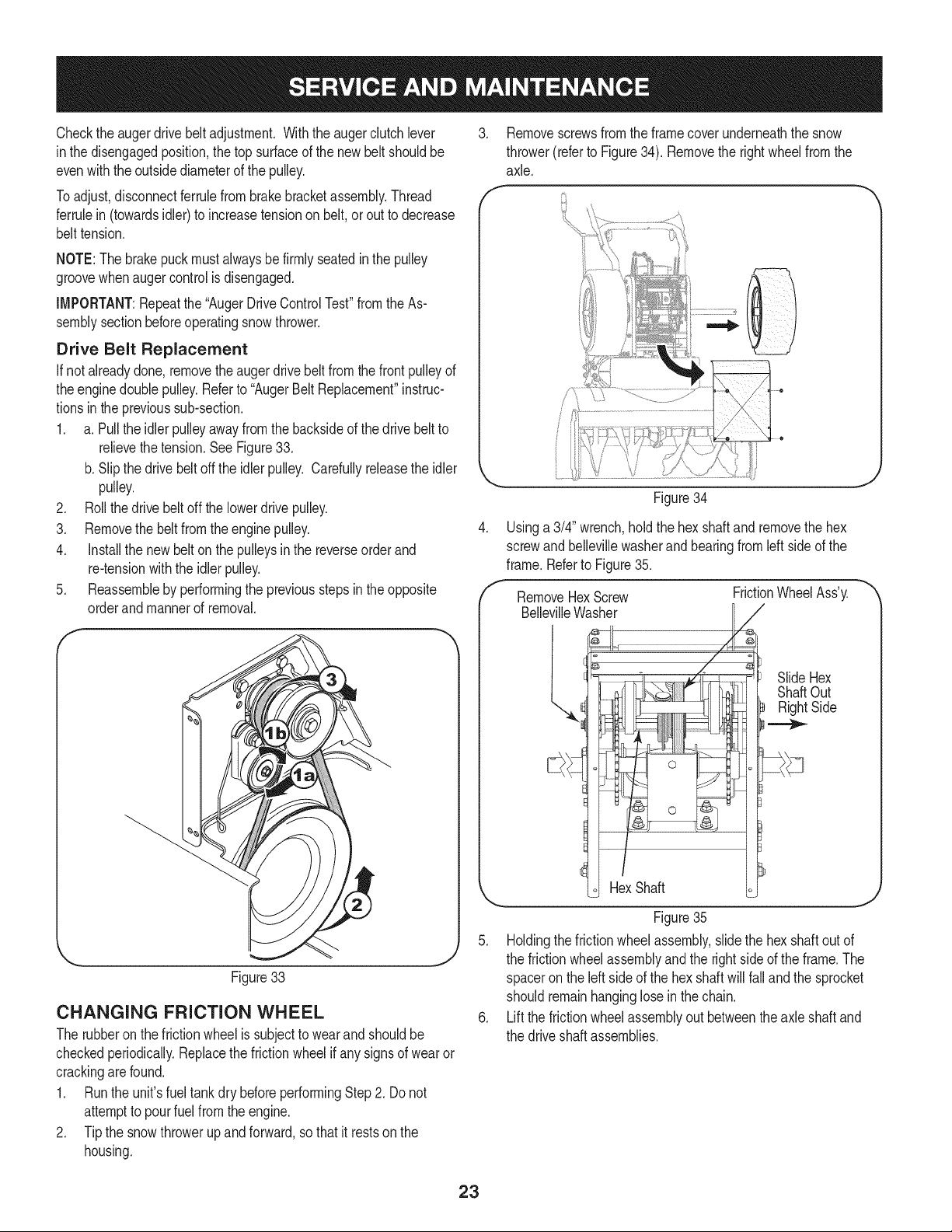

Drive Belt Replacement

If notalreadydone,removethe augerdrivebeltfromthefrontpulleyof

theenginedoublepulley.Referto "AugerBeltReplacement"instruc-

tionsintheprevioussub-section.

1. a.Pulltheidlerpulleyawayfromthebacksideofthe drivebeltto

relievethetension.SeeFigure33.

b.Slipthe drivebeltoffthe idlerpulley. Carefullyreleasetheidler

pulley.

2. Rollthedrive beltoffthelowerdrivepulley.

3. Removethebeltfromtheenginepulley.

4. Installthenewbelt onthepulleysinthe reverseorderand

re-tensionwiththeidlerpulley.

5. Reassemblebyperformingthepreviousstepsintheopposite

orderandmannerof removal.

f

3. Removescrewsfromtheframecoverunderneaththesnow

thrower(referto Figure34).Removethe rightwheelfromthe

axle.

f

e

Figure34

.

Usinga3/4"wrench,holdthehexshaftand removethehex

screwandbellevillewasherandbearingfromleftsideof the

frame.Referto Figure35.

f

RemoveHexScrew

FrictionWheelAss'y.

BellevilleWasher

J

J

Figure33

CHANGING FRICTION WHEEL

Therubberonthe frictionwheelissubjecttowearandshouldbe

checkedperiodically.Replacethefrictionwheelifanysignsof wearor

crackingarefound.

1. Runthe unit'sfueltankdrybeforeperformingStep2.Do not

attempttopourfuel fromtheengine.

2. Tipthe snowthrowerupandforward,sothatit restsonthe

housing.

SlideHex

ShaftOut

RightSide

.._

HexShaft

Figure35

5. Holdingthefrictionwheelassembly,slidethehexshaftoutof

thefrictionwheelassemblyandthe rightsideoftheframe.The

spaceron theleftsideof the hexshaftwillfallandthesprocket

shouldremainhangingloseinthe chain.

6. Liftthefrictionwheelassemblyoutbetweentheaxleshaft and

thedriveshaftassemblies.

23

Loading...

Loading...