Craftsman 247888330 Owner’s Manual

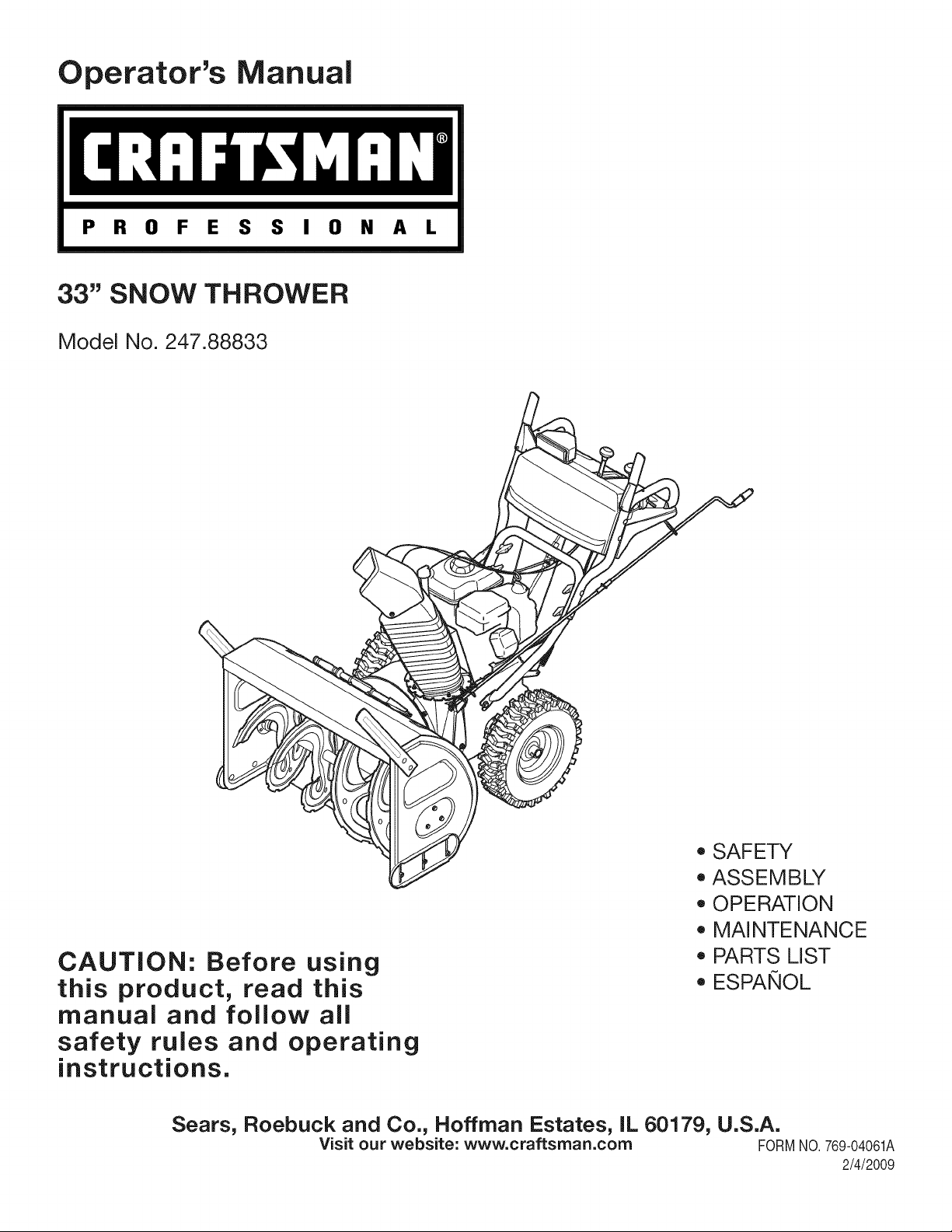

Operator's Manual

P R 0 F E S S I 0 N A L

33" SNOW THROWER

Model No. 247.88833

CAUTION: Before using

this product, read this

manual and follow all

safety rules and operating

instructions.

Sears, Roebuck and Co., Hoffman Estates, IL 60179, U.S.A.

Visit our website: www.craftsman.com FORMNO.769-04061A

, SAFETY

, ASSEMBLY

, OPERATION

, MAINTENANCE

, PARTS LIST

o ESPANOL

2/4/2009

WarrantyStatement..................................Page2

SafeOperationPractices..........................Pages3-6

SafetyLabels............................................Page7

Assembly..................................................Pages8-11

Operation..................................................Pages12-15

ServiceandMaintenance.........................Pages16-23

Off-SeasonStorage..................................Page24

Troubleshooting........................................Page25

PartsList...................................................Page26-41

RepairProtectionAgreement...................Page46

Espa_ol.....................................................Page47

ServiceNumbers......................................BackCover

CRAFTSMAN PROFESSIONALLiMiTED WARRANTY

Two Years on Snow Thrower

Whenoperatedand maintainedaccordingtoall suppliedinstructions,ifthis snowthrowerfailsdue toadefectin materialor workmanshipwithintwoyearsfrom

thedateorpurchase,call 1-800-4-MY-HOME®toarrangeforfreerepair.

Thiswarrantyappliesfor onlyone yearfromthe dateof purchaseif this snowthroweris everusedforcommercialorrentalpurposes.

Duringthefirst yearofpurchase,therewillbenochargefor warrantyservicein your home.Foryour convenience,in-homewarrantyservicewill stillbeavailable

afterthefirstyear of purchase,but atrip chargewill apply.Thischargewillbe waivedifyoutransportthe snowthrowerto anauthorizedCraftsmandrop-off

location.Forthe nearestauthorizedlocation,call1-800-4-MY-HOME®.

ThiswarrantycoversONLYdefectsinmaterialandworkmanship.SearswillNOTpayfor:

• Expendableitemsthatbecomewornduringnormaluse,includingbutnotlimitedto skidshoes,shaveplate,shearpins,sparkplug, air

cleaner,belts,and oilfilter.

• Standardmaintenanceservicing,oil changes,ortune-ups.

• Tirereplacementor repaircausedby puncturesfromoutsideobjects,suchasnails,thorns,stumps,or glass.

• Tireorwheelreplacementorrepairresultingfrom normalwear,accident,orimproperoperationormaintenance.

• Repairsnecessarybecauseofoperatorabuse,includingbut notlimitedto damagecausedby impactingobjectsthatbendthe frameor

crankshaft,orover-speedingtheengine.

• Repairsnecessarybecauseofoperatornegligence,includingbut notlimitedto,electricaland mechanicaldamagecausedbyimproper

storage,failureto usethe propergradeandamountofengineoil,orfailureto maintainthe equipmentaccordingtothe instructions

containedintheoperator'smanual.

• Engine(fuelsystem)cleaningor repairscausedbyfueldeterminedto becontaminatedor oxidized(stale).Ingeneral,fuelshouldbe

usedwithin30 daysof itspurchasedate.

• Normaldeteriorationandwearoftheexteriorfinishes,or productlabelreplacement.

Thiswarrantyappliesonly whilethisproductis withintheUnitedStates.

Thiswarrantygivesyouspecificlegalrights,andyoumayalsohaveother rightswhichvaryfromstateto state.

Sears, Roebuck andCo., Hoffman Estates,IL 60179

EngineOilType: SAE5W-30

EngineOilCapacity: 28ounces

FuelCapacity: 4 Quarts

SparkPlug: Champion®RC12YC

SparkPlugGap: .030"

©SearsBrands,LLC

Model Number.................................................................

Serial Number .................................................................

Dateof Purchase.............................................................

Recordthemodelnumber,serialnumber

anddateof purchaseabove

2

Thissymbolpointsoutimportantsafetyinstructionswhich,if not

followed,couldendangerthepersonalsafetyand/orpropertyof

yourselfandothers. Readandfollowallinstructionsin thismanual

beforeattemptingto operatethismachine.Failuretocomplywith

theseinstructionsmayresultinpersonalinjury.Whenyou seethis

symbol,HEEDITSWARNING!

Thismachinewasbuilttobeoperatedaccordingtothe safeopera-

tionpracticesinthismanual.Aswithanytypeof powerequipment,

carelessnessorerroronthe partoftheoperatorcanresultinserious

injury.Thismachineiscapableof amputatingfingers,hands,toes

andfeetandthrowingdebris.Failuretoobservethefollowingsafety

instructionscouldresultin seriousinjuryordeath.

CALIFORNIA PROPOSITION 65

EngineExhaust,someof itsconstituents,andcertainvehicle

componentscontainoremitchemicalsknowntoStateofCalifornia

tocausecancerandbirthdefectsorotherreproductiveharm,

TRAiNiNG

• Read,understand,andfollowall instructionsonthe machineand

in themanual(s)beforeattemptingtoassembleandoperate.

Failuretodosocan resultinseriousinjurytotheoperatorand/

orbystanders.Keepthismanualina safeplaceforfutureand

regularreferenceandfororderingreplacementparts. Forques-

tionscall,1-800-659-5917.

• Befamiliarwithallcontrolsandtheirproperoperation.Knowhow

tostopthemachineanddisengagethemquickly.

• Neverallowchildrenunder14yearsofagetooperatethis

machine.Children14andovershouldreadandunderstandthe

instructionsandsafeoperationpracticesinthismanualandon

themachineandbe trainedandsupervisedbyanadult.

• Neverallowadultstooperatethismachinewithoutproper

instruction.

• Thrownobjectscancauseseriouspersonalinjury.Planyour

snow-throwingpatterntoavoiddischargeof materialtoward

roads,bystandersandthelike.

• Keepbystanders,petsandchildrenat least75feetfromthe

machinewhileitisinoperation.Stopmachineifanyoneenters

thearea.

• Exercisecautiontoavoidslippingor falling,especiallywhen

operatinginreverse.

Your Responsibility--Restrict theuseofthis powermachineto

personswhoread,understandandfollowthewarningsandinstruc-

tionsinthismanualandon themachine,

SAVE THESE INSTRUCTIONS!

PREPARATION

Thoroughlyinspecttheareawheretheequipmentis to beused.

Removeall doormats,newspapers,sleds,boards,wiresandother

foreignobjects,whichcouldbetrippedoverorthrownbytheauger/

impeller.

Alwayswearsafetyglassesor eyeshieldsduringoperationand

whileperformingan adjustmentor repairto protectyoureyes.

Thrownobjectswhichricochetcancauseseriousinjurytothe

eyes.

Donot operatewithoutwearingadequatewinteroutergarments.

Donot wearjewelry,longscarvesorotherlooseclothing,which

couldbecomeentangledinmovingparts.Wearfootwearwhich

willimprovefootingonslipperysurfaces.

Usea groundedthree-wireextensioncordand receptacleforall

machineswithelectricstartengines.

Disengageall controlleversbeforestartingtheengine.

Adjustcollectorhousingheighttocleargravelorcrushedrock

surfaces.

Neverattempttomakeanyadjustmentswhileengineis running,

exceptwherespecificallyrecommendedinthe operator'smanual.

Letengineandmachineadjusttooutdoortemperaturebefore

startingtoclearsnow.

3

SafeHandlingof Gasoline

Toavoidpersonalinjuryorpropertydamageuseextremecarein

handlinggasoline.Gasolineisextremelyflammableandthevaporsare

explosive.Seriouspersonalinjurycanoccurwhengasolineisspilled

onyourselfor yourclotheswhichcanignite.Washyourskinand

changeclothesimmediately.

• Useonlyanapprovedgasolinecontainer.

• Extinguishall cigarettes,cigars,pipesandother sources

ofignition.

• Neverfuelmachineindoors.

• Neverremovegascaporaddfuelwhilethe engineishot

or running.

• Allowengineto coolat leasttwo minutesbeforerefueling.

• Neveroverfill fueltank.Filltanktono morethan1/2inch

belowbottomoffillerneckto providespaceforfuel

expansion.

• Replacegasolinecapandtightensecurely.

• Ifgasolineisspilled,wipeit offtheengineandequipment.

Movemachinetoanotherarea.Wait5 minutesbefore

startingtheengine.

• Neverstorethemachineor fuelcontainerinsidewhere

thereis anopenflame,sparkor pilotlight (e.g.furnace,

waterheater,spaceheater,clothesdryeretc.).

• Allowmachinetocoolatleast5 minutesbeforestoring.

• Neverfillcontainersinsidea vehicleor onatruckor trailer

bedwitha plasticliner.Alwaysplacecontainersonthe

groundawayfromyourvehiclebeforefilling.

• If possible,removegas-poweredequipmentfromthetruck

ortrailerand refuelit onthe ground.If thisisnotpossible,

thenrefuelsuchequipmentona trailerwitha portable

container,ratherthanfromagasolinedispensernozzle.

• Keepthenozzleincontactwiththe rimofthefueltankor

containeropeningatalltimesuntil fuelingiscomplete.Do

notuse a nozzlelock-opendevice.

OPERATION

• Do notputhandsorfeetnear rotatingparts,in theauger/impeller

housingorchuteassembly.Contactwiththerotatingpartscan

amputatehandsandfeet.

• Theauger/impellercontrolleverisa safetydevice.Neverbypass

itsoperation.Doingsomakesthemachineunsafeandmaycause

personalinjury.

• Thecontrolleversmustoperateeasilyinbothdirectionsand

automaticallyreturntothedisengagedpositionwhenreleased.

• Neveroperatewithamissingordamagedchuteassembly.Keep

all safetydevicesin placeandworking.

• Neverrunanengineindoorsor ina poorlyventilatedarea.Engine

exhaustcontainscarbonmonoxide,anodorlessanddeadlygas.

• Do notoperatemachinewhileunderthe influenceofalcoholor

drugs.

• Mufflerandenginebecomehotandcancauseaburn.Donot

touch.Keepchildrenaway.

• Exerciseextremecautionwhenoperatingon orcrossinggravel

surfaces.Stayalertforhiddenhazardsor traffic.

• Exercisecautionwhenchangingdirectionandwhileoperatingon

slopes.

• Planyoursnow-throwingpatternto avoiddischargetowards

windows,walls,carsetc. Thus,avoidingpossibleproperty

damageorpersonalinjurycausedbya ricochet.

• Neverdirectdischargeatchildren,bystandersand petsor allow

anyoneinfrontofthemachine.

• Donot overloadmachinecapacitybyattemptingtoclearsnowat

toofastof arate.

• Neveroperatethismachinewithoutgoodvisibilityorlight.Always

be sureofyourfootingand keepafirmholdonthehandles.Walk,

neverrun.

• Disengagepowerto theauger/impellerwhentransportingor not

in use.

• Neveroperatemachineat hightransportspeedsonslippery

surfaces.Lookdownand behindand usecare whenbackingup.

• Ifthemachineshouldstart tovibrateabnormally,stoptheengine,

disconnectthesparkplugwireandgrounditagainsttheengine.

Inspectthoroughlyfor damage.Repairanydamagebefore

startingandoperating.

• Disengageall controlleversandstopenginebeforeyouleave

theoperatingposition(behindthehandles).Waituntiltheauger/

impellercomestoa completestopbeforeuncloggingthechute

assembly,makingany adjustments,or inspections.

• Neverputyourhandinthedischargeorcollectoropenings.Do

notunclogchuteassemblywhileengineisrunning.Shutoff

engineand remainbehindhandlesuntilallmovingpartshave

stoppedbeforeunclogging.

• Useonlyattachmentsandaccessoriesapprovedbythemanufac-

turer(e.g.wheelweights,tirechains,cabsetc.).

• Whenstartingengine,pullcordslowlyuntilresistanceisfelt,then

pull rapidly.Rapidretractionofstartercord(kickback)willpull

handandarmtowardenginefasterthanyoucanletgo.Broken

bones,fractures,bruisesorsprainscouldresult.

• Ifsituationsoccurwhicharenotcoveredinthis manual,usecare

andgoodjudgment.ContactCustomerSupportforassistance

andthenameofyour nearestservicingdealer.

CLEARING A CLOGGED DISCHARGE CHUTE

Handcontactwiththe rotatingimpellerinsidethedischargechute

is themostcommoncauseofinjuryassociatedwithsnowthrowers.

Neveruseyourhandto cleanoutthedischargechute.

Toclear thechute:

1. SHUTTHEENGINEOFF!

2. Wait 10secondsto besuretheimpellerbladeshavestopped

rotating.

3. Alwaysuseaclean-outtool,not yourhands.

4

MAINTENANCE & STORAGE

• Nevertamperwithsafetydevices.Checktheirproperoperation

regularly.Refertothemaintenanceandadjustmentsectionsof

thismanual.

• Beforecleaning,repairing,or inspectingmachinedisengageall

controlleversandstopthe engine.Waituntiltheauger/impeller

cometoa completestop.Disconnectthe sparkplugwireand

groundagainsttheenginetopreventunintendedstarting.

Checkboltsand screwsfor propertightnessat frequentintervals

tokeepthe machineinsafeworkingcondition.Also,visually

inspectmachineforanydamage.

Donotchangetheenginegovernorsettingor over-speedthe

engine.Thegovernorcontrolsthe maximumsafeoperatingspeed

oftheengine.

Snowthrowershaveplatesandskidshoesaresubjecttowear

anddamage.Foryoursafetyprotection,frequentlycheckall

componentsand replacewithoriginalequipmentmanufacturer's

(OEM)partsonly."Useofpartswhichdonotmeettheoriginal

equipmentspecificationsmayleadto improperperformanceand

compromisesafety!"

Checkcontrolleversperiodicallytoverifytheyengageanddisen-

gageproperlyandadjust,if necessary.Refertotheadjustment

sectioninthisoperator'smanualforinstructions.

Maintainor replacesafetyandinstructionlabels,asnecessary.

• Observeproperdisposallawsand regulationsforgas,oil,etc. to

protecttheenvironment.

Priorto storing,runmachineafew minutestoclearsnowfrom

machineand preventfreezeupofauger/impeller.

Neverstorethemachineorfuelcontainerinsidewherethereisan

openflame,sparkorpilotlightsuchasa waterheater,furnace,

clothesdryeretc.

Alwaysrefertotheoperator'smanualforproperinstructionson

off-seasonstorage.

Checkfuelline,tank,cap,andfittingsfrequentlyforcracksor

leaks.Replaceif necessary.

Donotcrankenginewithsparkplugremoved.

AccordingtotheConsumerProductsSafetyCommission(CPSC)

andtheU.S.EnvironmentalProtectionAgency(EPA),thisproduct

hasan AverageUsefulLifeof seven(7)years,or 60hoursof

operation.AttheendoftheAverageUsefulLifehavethe machine

inspectedannuallybyanauthorizedservicedealertoensurethat

allmechanicalandsafetysystemsareworkingproperlyandnot

wornexcessively.Failuretodo socanresultinaccidents,injuries

ordeath.

DO NOT MODIFY ENGINE

Toavoidseriousinjuryor death,donot modifyengineinanyway.

Tamperingwiththegovernorsettingcanleadtoa runawayengineand

causeittooperateat unsafespeeds.Nevertamperwithfactorysetting

ofenginegovernor.

NOTICE REGARDING EMiSSiONS

EngineswhicharecertifiedtocomplywithCaliforniaandfederal

EPAemissionregulationsfor SORE(SmallOff RoadEquipment)are

certifiedto operateon regularunleadedgasoline,and mayinclude

thefollowingemissioncontrolsystems:EngineModification(EM),

OxidizingCatalyst(OC),SecondaryAirInjection(SAI)and ThreeWay

Catalyst(TWO)if soequipped.

SPARK ARRESTOR

Thismachineisequippedwithaninternalcombustionengineand

shouldnotbeusedonor nearanyunimprovedforest-covered,

brush-coveredorgrass-coveredlandunlesstheengine'sexhaust

systemisequippedwithasparkarrestermeetingapplicablelocalor

statelaws(ifany)

Ifasparkattesterisused,itshouldbemaintainedin effectiveworking

orderbytheoperator.IntheStateof Californiatheaboveis required

bylaw (Section4442ofthe CaliforniaPublicResourcesCode).Other

statesmayhavesimilarlaws. Federallawsapplyonfederallands.

A sparkarresterfor themuffleris availablethroughyournearestSears

PartsandRepairServiceCenter.

SAFETY SYMBOLS

Thispagedepictsanddescribessafetysymbolsthatmayappearonthisproduct. Read,understand,andfollowall instructionson themachine

beforeattemptingto assembleandoperate.

READ THE OPERATOR'S MANUAL(S)

i

i

Read, understand, and follow all instructions in the manual(s) before attempting to assemble and

operate

WARNING-- ROTATING BLADES

Keep hands out of inlet and discharge openings while machine is running. There are rotating blades

inside

WARNING-- ROTATING BLADES

Keep hands out of inlet and discharge openings while machine is running. There are rotating blades

inside

WARNING-- ROTATING AUGER

Do not put hands or feet near rotating parts, in the auger/impeller housing or chute assembly.

Contact with the rotating parts can amputate hands and feet.

WARNING--THROWN OBJECTS

This machine may pick up and throw and objects which can cause serious personal injury.

WARNING--GASOLINE IS FLAMMABLE

Allow the engine to cool at least two minutes before refueling.

WARNING-- CARBON MONOXIDE

Never run an engine indoors or in a poorly ventilated area. Engine exhaust contains carbon

monoxide, an odorless and deadly gas.

WARNING-- ELECTRICAL SHOCK

Do not use the engine's electric starter in the rain

6

1.KEEPAWAYFROMROTATINGiMPELLER

ANDAUGER,CONTACTWiTHiMPELLEROR

AUGERCANAMPUTATEHANDSANDFEET.

2. USECLEAN-OUTTOOLTOUNCLOG

DISCHARGECHUTE.

3.DISENGAGECLUTCHLEVERS,STOPENGINE,

AND REMAINBEHINDHANDLESUNTILALL

MOVING PARTSHAVE STOPPEDBEFORE

UNCLOGGING OR SERViCiNGMACHINE.

TO AVOIDTHROWN OBJECTSiNJURiES,

NEVERDIRECTDISCHARGEATBYSTANDERS.

USEEXTRACAUTIONWHEN OPERATINGON

GRAVELSURFACES.

5.BEAD OPERATOR'S MANUAL.

CLEAN-OUT TOOL

7

NOTE:Referencesto rightorleftsideofthesnowthrowerare

determinedfrombehindtheunitintheoperatingposition(standing

directlybehindthesnowthrower,facingthe handlepanel).

REMOVING FROM CRATE

1. Removescrewsfromthebottomof thecratesecuringthesides,

andendsoftheshippingcrate.

2. Liftoffthe topoffof the crateandsetoutof thewayofthe

assemblyarea.

3. Removeanddiscardplasticbagthatcoversunit.

4. Removeanyloosepartsincludedwithunit(e.g.,Operator's

Manual,etc.).

5. Pushdownonthelowerhandleandpullunitbackoutofcrate.

6. Makecertainthecratehasbeencompletelyemptiedbefore

discardingit.

ASSEMBLY

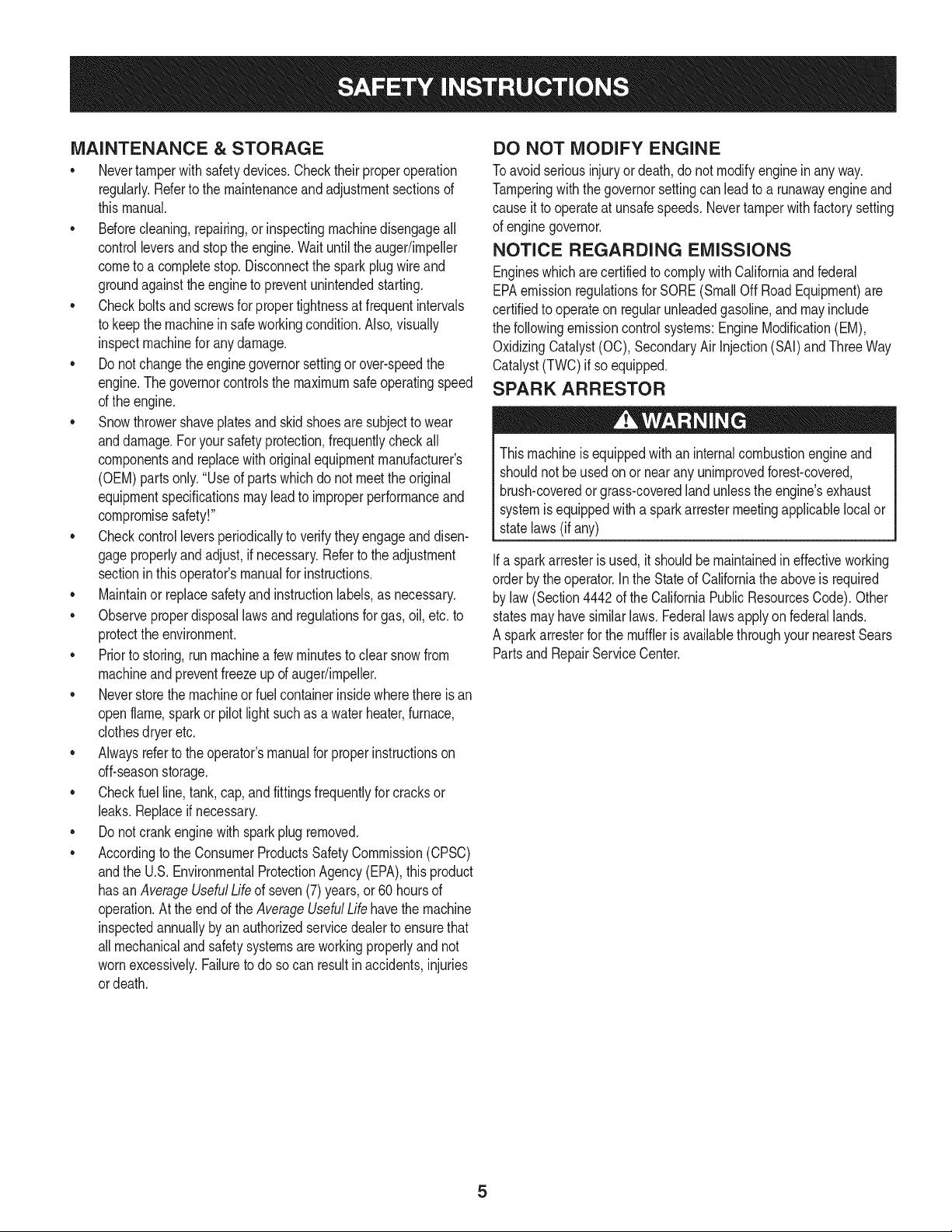

1. Makecertainthe springsat thelowerendoftheaugeranddrive

cablesaresecurelyhookedintotheirrespectiveactuator

bracketbeforepivotingthehandleupward.RefertoFig. 10.

a. Placethe shiftleverintheF6position.

b. Removethe lowerwingknobandcarriageboltfromeach

sideof the upperhandle.Pulluponupperhandleas shown

in Fig.1.Alignupperhandlewiththelowerhandle.Again,

makecertainthespringsatthelowerendof theaugerand

drivecablesaresecurelyhookedintotheir respective

actuatorbracket.Also,removeanyrubberbandssecuring

thecablestothewingnuts.

2. a. Securetheupperhandleandlowerhandlewiththetwo wing

knobsandcarriageboltsremovedearlier.

b. Tightenthetwo wingknobsalreadyinstalledin the upper

holesto firmlysecuretheupperhandleand supporttubes.

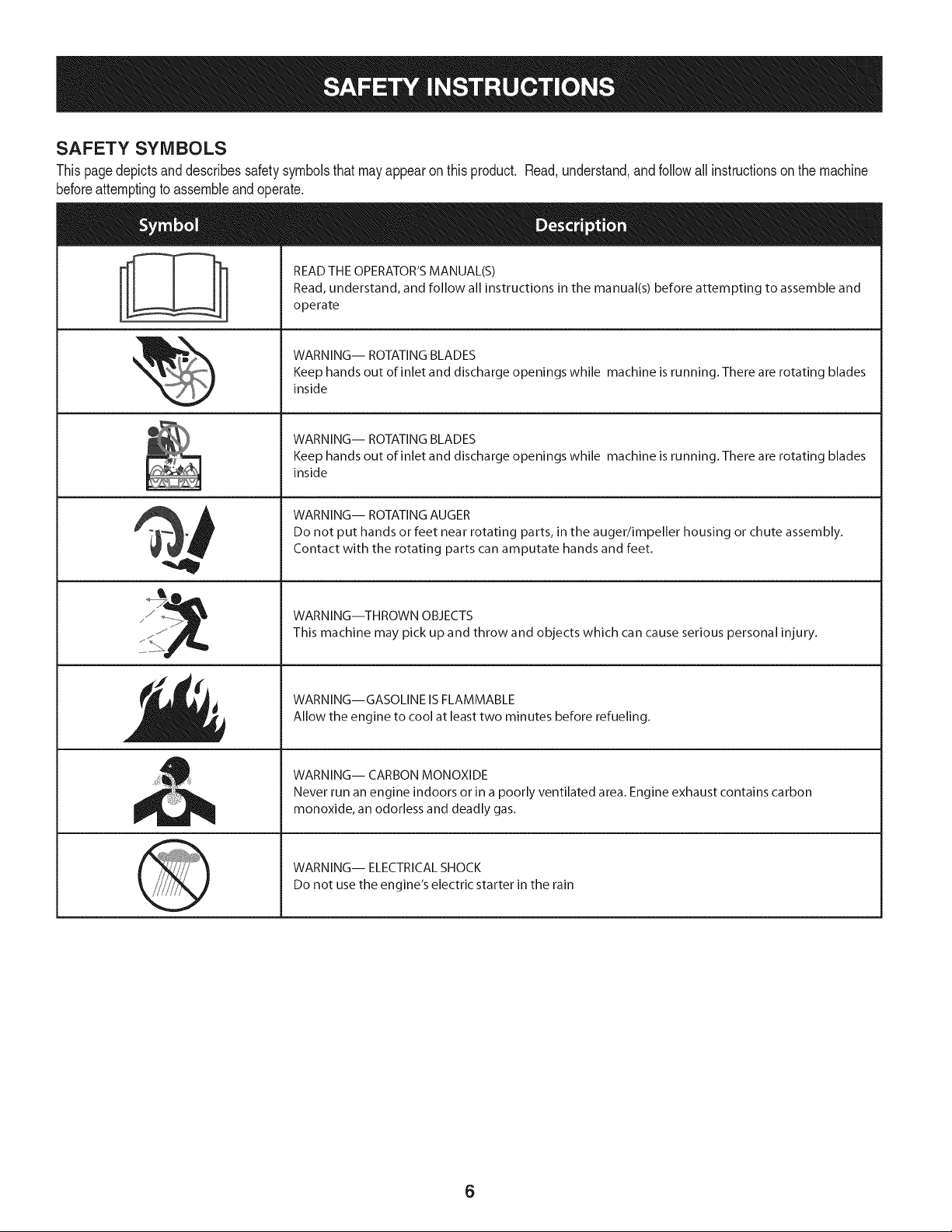

3. Aligntheupperand lowershiftrods,thenslidetheshift rod

connectordownoverthe endofthe lowershiftrod.Tapthe

connectoruntilthelowerrodiscompletelythroughtheconnector.

See Fig.2.

NOTE:If theconnectoris notproperlyassembled,the shift rodwill

pivotand youwillnotbe abletoproperlychangespeedsordirection.

Figure 1

/

Figure2

f

NOTE:If thefull rangeof speeds(forwardandreverse)can notbe

achieved,refertothe"MakingAdjustments"section.

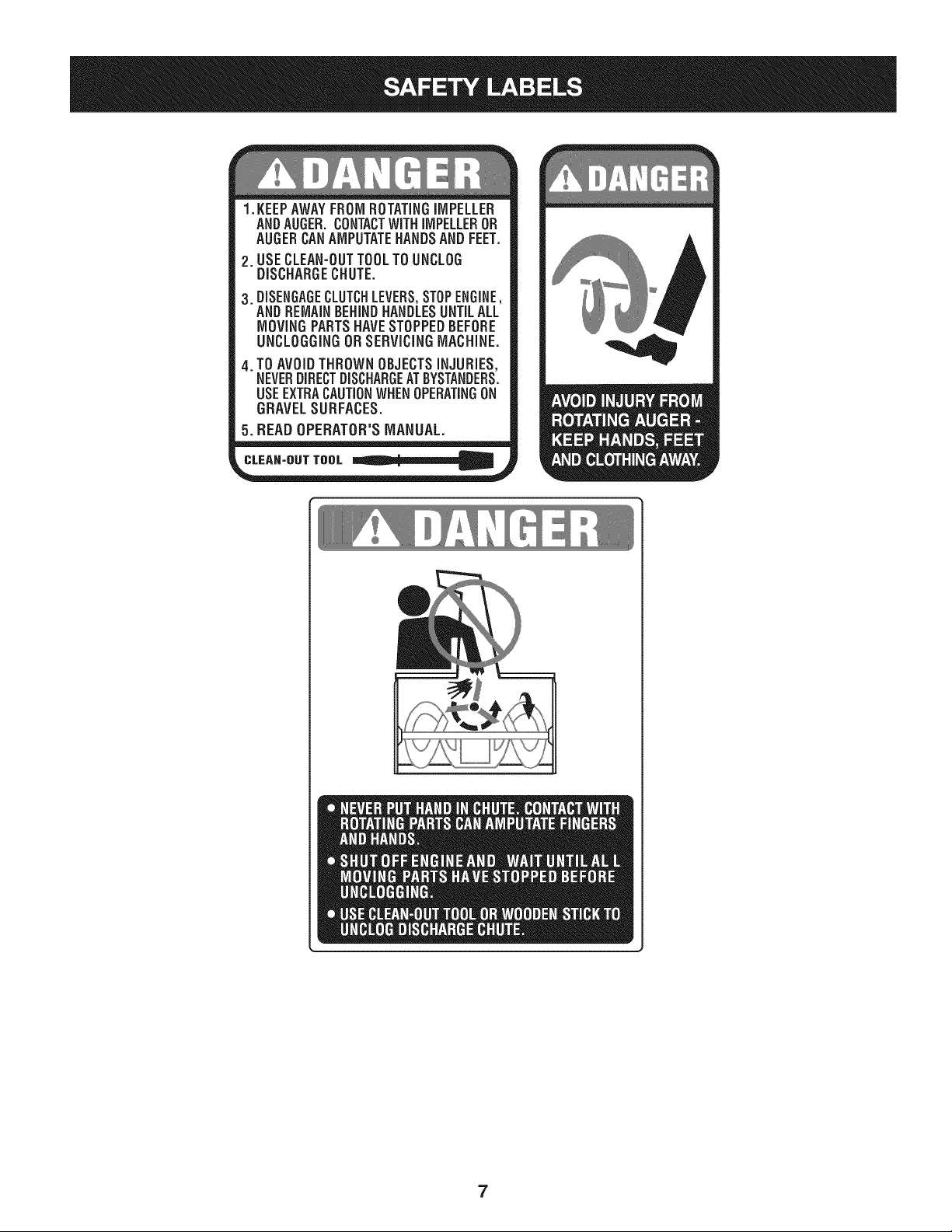

4. a. Cutthecabletie securingthechuteassemblytothelower

chutecrankrodfor shippingpurposes.

b. Removethe internalcotterpinfromtheupperchutecrank.

Slidetheupperchutecrankintothesleeveon thelower

chutecrank.See Fig.3.

c. Alignthe holeinthe upperchutecrankwiththeholeinthe

sleeve(ifnecessary,useapairof plierstoassistinaligning

holes).Inserttheinternalcotterpinthroughtheholesto

securethechutecrank.SeeFig.3.

5. Removelocknutsand screwssecuringoneoftheflangekeepers

tothechuteassembly.

Figure3

8

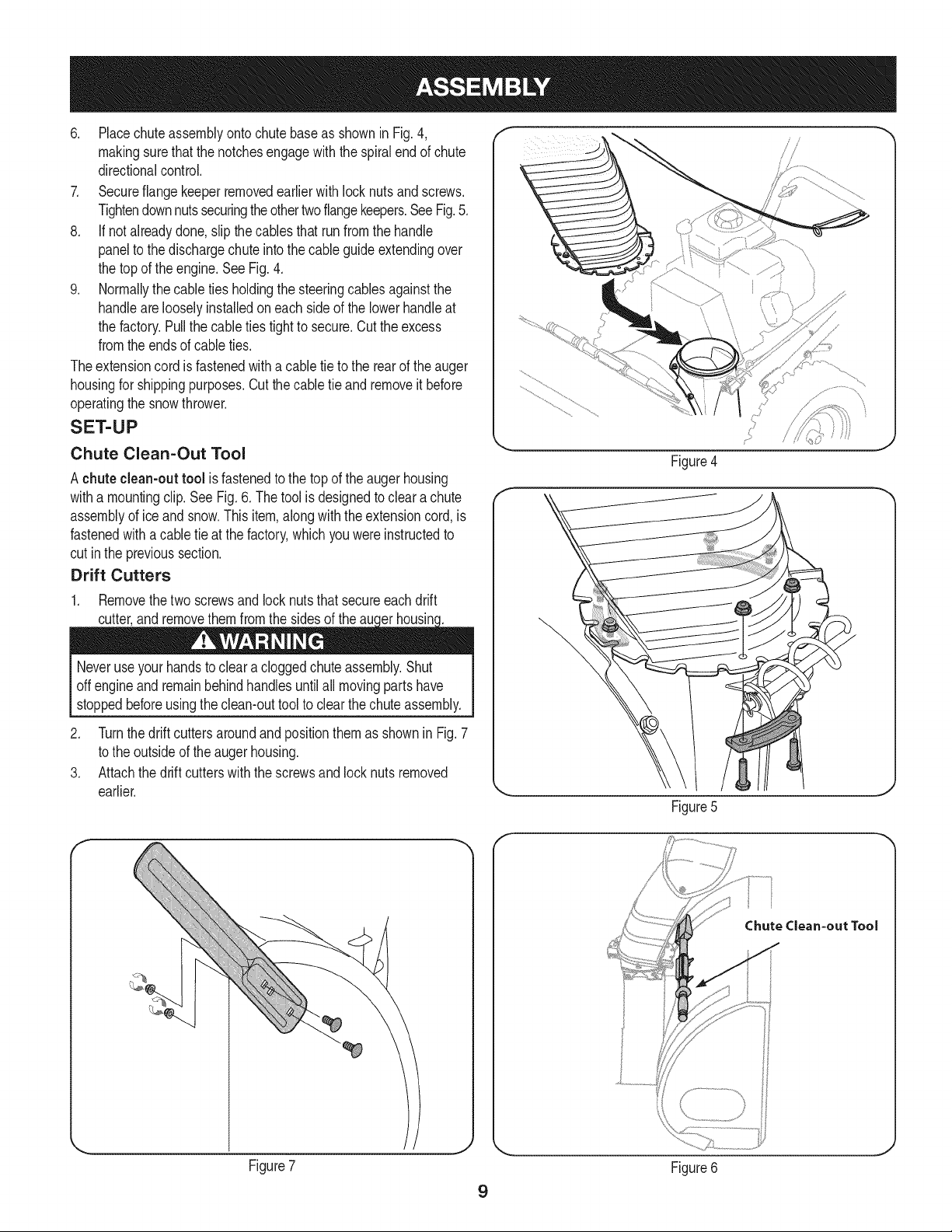

6. PlacechuteassemblyontochutebaseasshowninFig.4,

makingsurethatthenotchesengagewiththespiralendofchute

directionalcontrol.

7. Secureflangekeeperremovedearlierwithlocknutsandscrews.

Tightendownnutssecuringtheothertwoflangekeepers.SeeFig.5.

8. If notalreadydone,slipthe cablesthat runfromthehandle

paneltothedischargechuteintothecableguideextendingover

thetopof theengine.SeeFig.4.

9. Normallythecabletiesholdingthesteeringcablesagainstthe

handlearelooselyinstalledoneach sideofthe lowerhandleat

thefactory.Pullthecableties tighttosecure.Cuttheexcess

fromtheendsof cableties.

Theextensioncordisfastenedwithacabletieto therearoftheauger

housingforshippingpurposes.Cutthecabletie andremoveit before

operatingthesnowthrower.

SET-UP

Chute Clean=Out Tool

A chuteclean-outtool isfastenedtothetopoftheaugerhousing

withamountingclip.SeeFig.6.Thetoolisdesignedtoclearachute

assemblyofice andsnow.Thisitem,alongwiththe extensioncord,is

fastenedwithacabletieat the factory,whichyou wereinstructedto

cutintheprevioussection.

Drift Cutters

1. Removethetwo screwsand locknutsthatsecureeach drift

?

J

Figure4

Neveruseyour handstocleara cloggedchuteassembly.Shut

offengineandremainbehindhandlesuntilallmovingpartshave

stoppedbeforeusingtheclean-outtoolto clearthechuteassembly.

2. Turnthedriftcuttersaroundandpositionthemas shownin Fig.7

totheoutsideofthe augerhousing.

3. Attachthedriftcutterswiththescrewsand locknutsremoved

earlier.

F-

J

Figure5

f

Chute Clean=out Tool

Figure7

J

Figure6

9

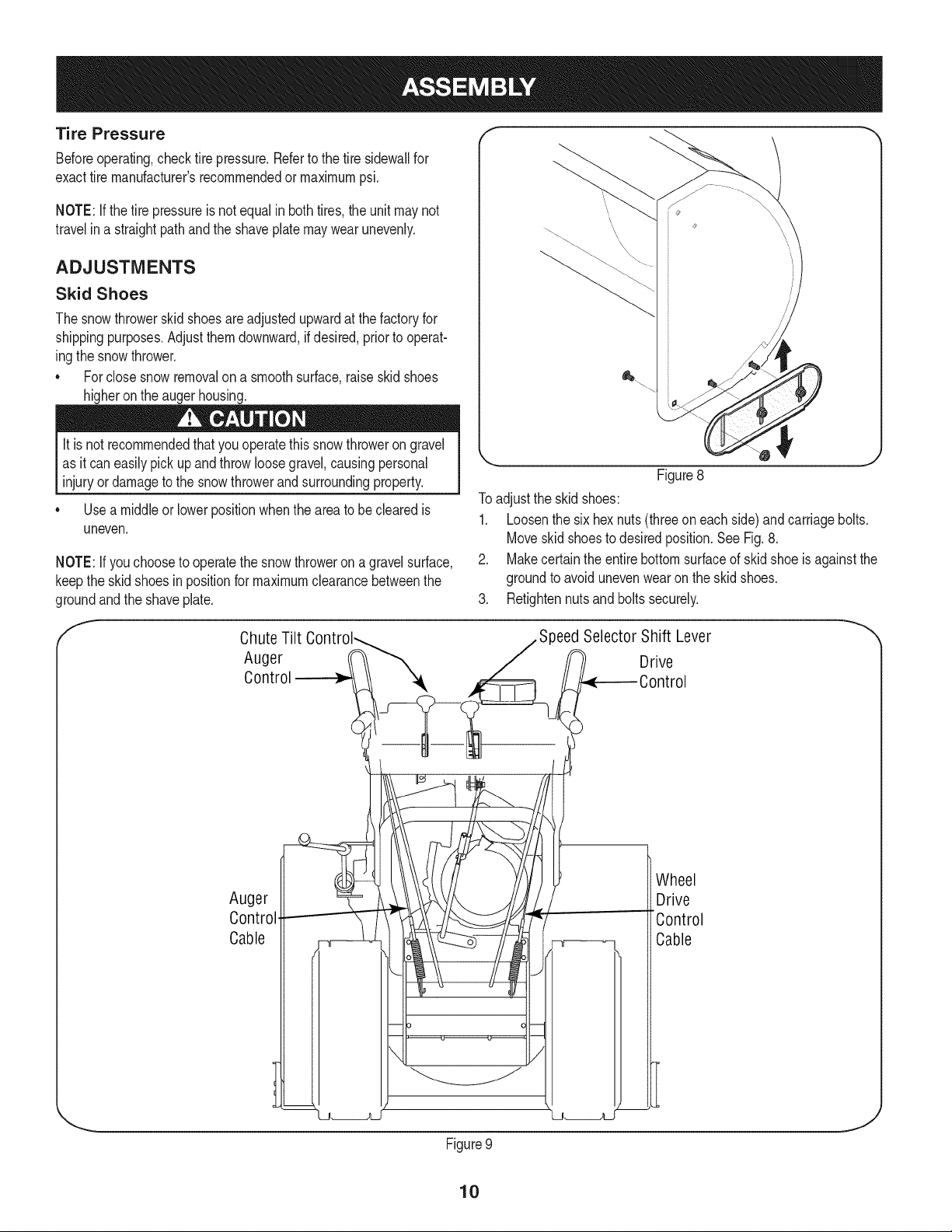

Tire Pressure f

Beforeoperating,checktirepressure.Refertothetiresidewallfor

exacttire manufacturer'srecommendedor maximumpsi.

NOTE:Ifthetirepressureisnotequalinbothtires,theunitmaynot

travelina straightpathandtheshaveplatemaywearunevenly.

ADJUSTMENTS

Skid Shoes

Thesnowthrowerskidshoesareadjustedupwardatthefactoryfor

shippingpurposes.Adjustthemdownward,ifdesired,priortooperat-

ingthesnowthrower.

• Forclosesnowremovalona smoothsurface,raiseskidshoes

higherontheaugerhousing.

It is notrecommendedthatyouoperatethissnowthrowerongravel

asitcan easilypickupandthrowloosegravel,causingpersonal

injuryor damagetothesnowthrowerandsurroundingproperty.

Usea middleorlowerpositionwhentheareatobeclearedis

uneven.

NOTE:Ifyouchooseto operatethe snowthrowerona gravelsurface,

keeptheskidshoesin positionformaximumclearancebetweenthe

groundandtheshaveplate.

Figure8

Toadjusttheskidshoes:

1. Loosenthesixhexnuts(threeon eachside)andcarriagebolts.

Moveskidshoestodesiredposition.SeeFig.8.

2. Makecertaintheentirebottomsurfaceofskidshoe isagainstthe

groundtoavoidunevenwearon theskidshoes.

3. Retightennutsandboltssecurely.

f

Chute Tilt

Auger

Auger

Control

Cable

)eed Selector Shift Lever _'

Drive

Wheel

Drive

"Control

Cable

Figure9

10

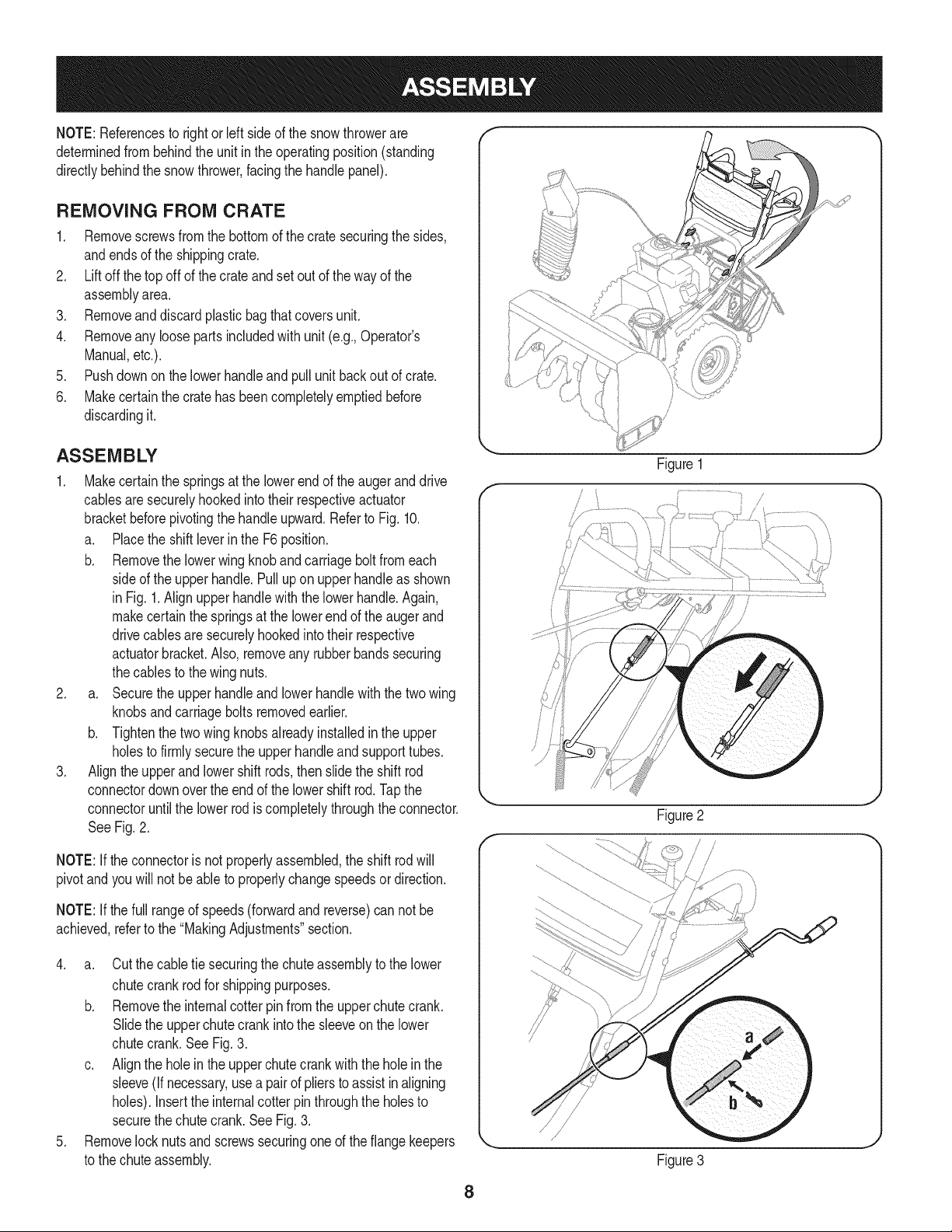

J

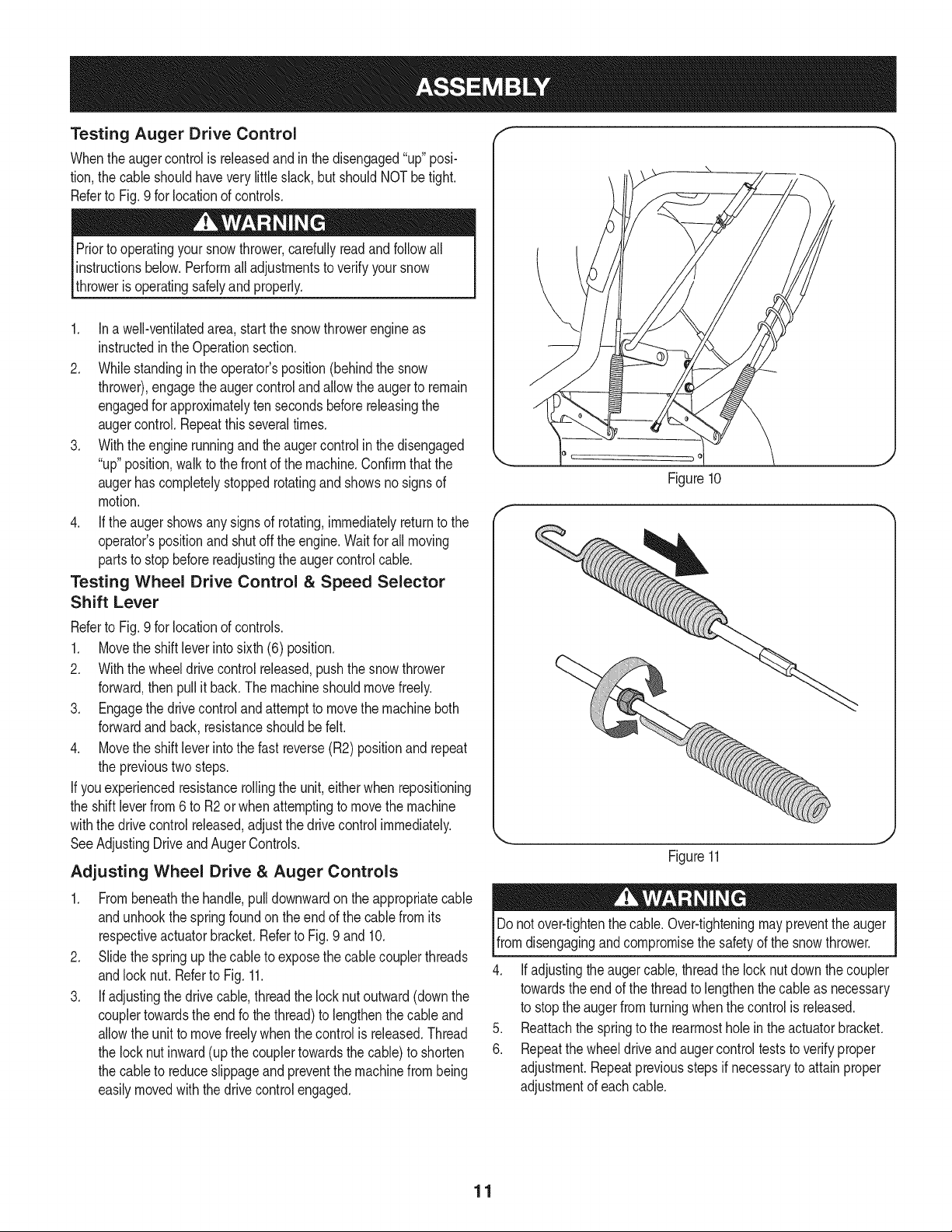

Testing Auger Drive Control

Whentheaugercontrolis releasedandin the disengaged"up"posi-

tion,thecableshouldhaveverylittleslack,but shouldNOTbetight.

Referto Fig.9 forlocationofcontrols.

Priortooperatingyoursnowthrower,carefullyreadandfollowall

instructionsbelow.Performall adjustmentstoverifyyoursnow

throwerisoperatingsafelyandproperly.

1. Ina well-ventilatedarea,start thesnowthrowerengineas

instructedin theOperationsection.

2. Whilestandingintheoperator'sposition(behindthe snow

thrower),engagethe augercontrolandallowtheaugerto remain

engagedforapproximatelytensecondsbeforereleasingthe

augercontrol.Repeatthisseveraltimes.

3. Withtheenginerunningandtheaugercontrolinthedisengaged

"up"position,walktothefrontofthemachine.Confirmthatthe

augerhascompletelystoppedrotatingandshowsnosignsof

motion.

4. If theaugershowsanysignsof rotating,immediatelyreturntothe

operator'spositionandshutoff theengine.Waitfor allmoving

partstostopbeforereadjustingtheaugercontrolcable.

Testing Wheel Drive Control & Speed Selector

Shift Lever

Referto Fig.9 forlocationofcontrols.

1. Movetheshift leverintosixth(6) position.

2. Withthewheeldrivecontrolreleased,pushthesnowthrower

forward,thenpullit back.Themachineshouldmovefreely.

3. Engagethedrivecontrolandattempttomovethe machineboth

forwardandback,resistanceshouldbefelt.

4. Movetheshiftleverintothefastreverse(R2)positionand repeat

theprevioustwosteps.

If youexperiencedresistancerollingtheunit,either whenrepositioning

theshiftleverfrom6toR2orwhenattemptingtomovethemachine

withthedrivecontrolreleased,adjustthe drivecontrolimmediately.

SeeAdjustingDriveandAugerControls.

Adjusting Wheel Drive & Auger Controls

1. Frombeneaththehandle,pulldownwardontheappropriatecable

andunhookthespringfoundontheendofthecablefromits

respectiveactuatorbracket.RefertoFig.9and10.

2. Slidethespringupthecableto exposethecablecouplerthreads

andlocknut. Referto Fig.11.

3. If adjustingthedrivecable,threadthelocknutoutward(downthe

couplertowardstheendfothethread)to lengthenthecableand

allowthe unittomovefreelywhenthecontrolis released.Thread

thelocknutinward(upthecouplertowardsthecable)toshorten

thecableto reduceslippageand preventthemachinefrombeing

easilymovedwiththedrivecontrolengaged.

_o

Figure10

J

Figure11

Donotover-tightenthecable.Over-tighteningmaypreventtheauger

fromdisengagingandcompromisethesafetyofthesnowthrower.

4. Ifadjustingtheaugercable,threadthe locknutdownthecoupler

towardstheendof thethreadto lengthenthecable asnecessary

to stoptheaugerfromturningwhenthecontrolisreleased.

5. Reattachthe springtothe rearmostholeintheactuatorbracket.

6. Repeatthe wheeldriveandaugercontrolteststoverifyproper

adjustment.Repeatpreviousstepsifnecessarytoattainproper

adjustmentofeachcable.

11

f

Headlk

GasCa

Drift

Cutters

Chute

Assembl

WheelDriveControl

SpeedSelector

_......_Shift LeverTwo-Way

WheelSteering

Control

ChuteDirectional

Control

Primer

Ignition

Key

ChuteControlTM

erControl

Muffler

On/ Off Switch

OilFill

Angers

SkidShoe

Figure11

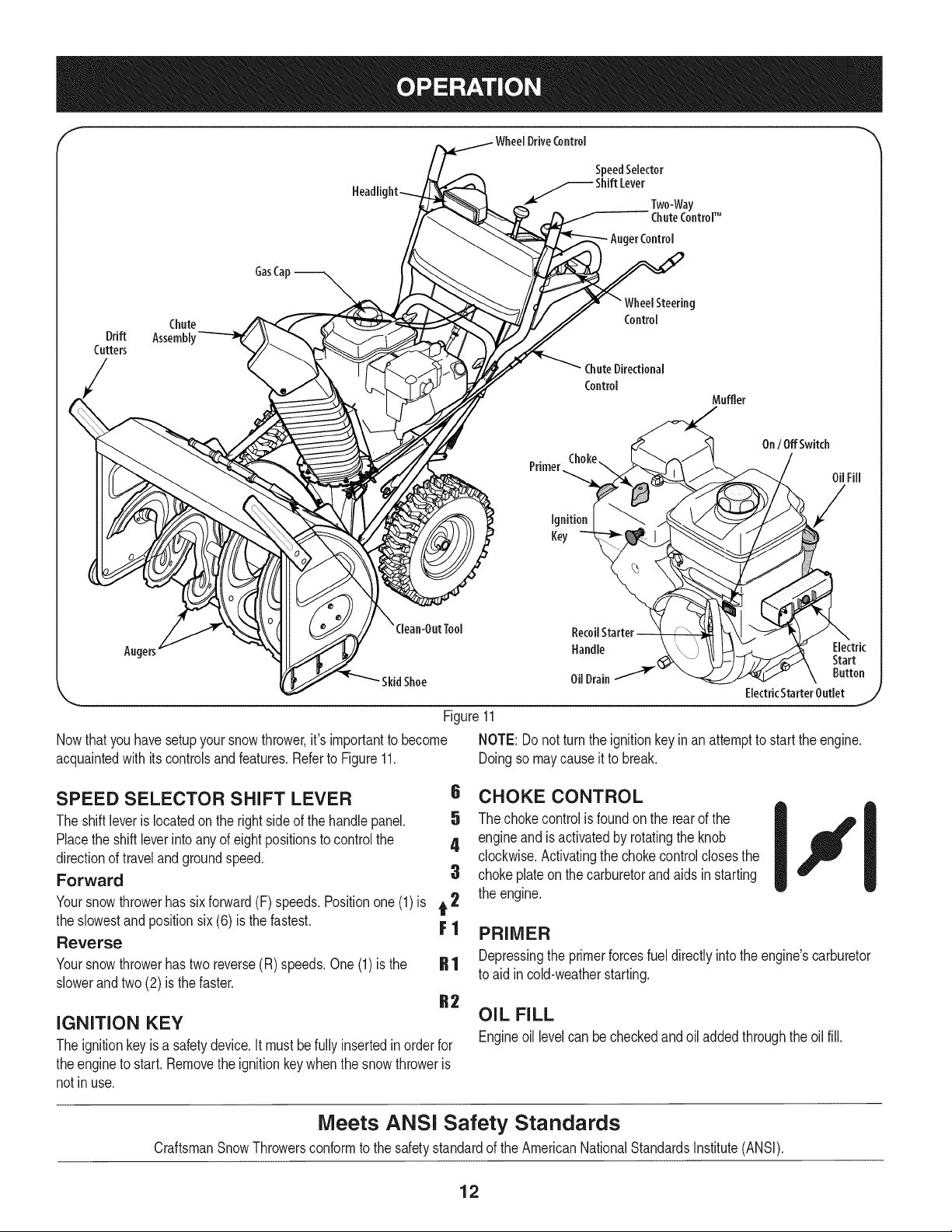

Nowthat youhavesetupyoursnowthrower,it's importanttobecome

acquaintedwith itscontrolsandfeatures.RefertoFigure11.

SPEED SELECTOR SHIFT LEVER

Theshiftleverislocatedonthe rightsideofthehandlepanel.

Placethe shiftleverintoanyofeightpositionstocontrolthe

directionoftravelandgroundspeed.

Forward

Yoursnowthrowerhassixforward(F)speeds.Positionone(1)is t 2

theslowestand positionsix (6) isthefastest. F 1

Reverse

Yoursnowthrowerhastwo reverse(R) speeds.One(1)isthe

slowerandtwo(2) isthe faster.

IGNITION KEY

Theignitionkeyis asafetydevice.Itmustbefullyinsertedinorderfor

theenginetostart.Removethe ignitionkeywhenthesnowthroweris

notinuse.

Handle Electric

OilDrain -'_( Button

ElectricStarterOutlet

NOTE:Donot turntheignitionkeyinan attemptto starttheengine.

Doingsomaycauseit to break.

6 CHOKE CONTROL

5 Thechokecontrolis foundonthe rearof the

4 engineand isactivatedbyrotatingthe knob

clockwise.Activatingthechokecontrolclosesthe

3 chokeplateonthecarburetorandaidsinstarting

theengine.

PRIMER

Depressingthe primerforcesfueldirectlyintotheengine'scarburetor

toaid incold-weatherstarting.

OIL FILL

Engineoil levelcan becheckedandoiladdedthroughtheoilfill.

Start

J

Meets ANSI Safety Standards

CraftsmanSnowThrowersconformtothesafetystandardof theAmericanNationalStandardsInstitute(ANSI).

12

ON / OFF SWITCH

PressintotheON positionwhenstartingtheengineand willshutoff

theenginewhenmovedintotheOFFposition.

RECOIL STARTER HANDLE

Thishandleisusedto manuallystarttheengine.

ELECTRIC STARTER BUTTON

Pressingtheelectricstarterbuttonengagestheengine'selectric

starterwhenpluggedintoa 120Vpowersource.

f

ELECTRIC STARTER OUTLET

Requirestheuseof athree-prongoutdoorextensioncord(included)

anda120Vpowersource/walloutlet.

AUGERS

Whenengaged,theaugersrotateanddrawsnowintotheauger

housing.

CHUTE ASSEMBLY

Snowdrawnintotheaugerhousingisdischargedoutthechute

assembly.

GAS CAP

Unthreadthegascaptoaddgasolinetothe fuel tank.

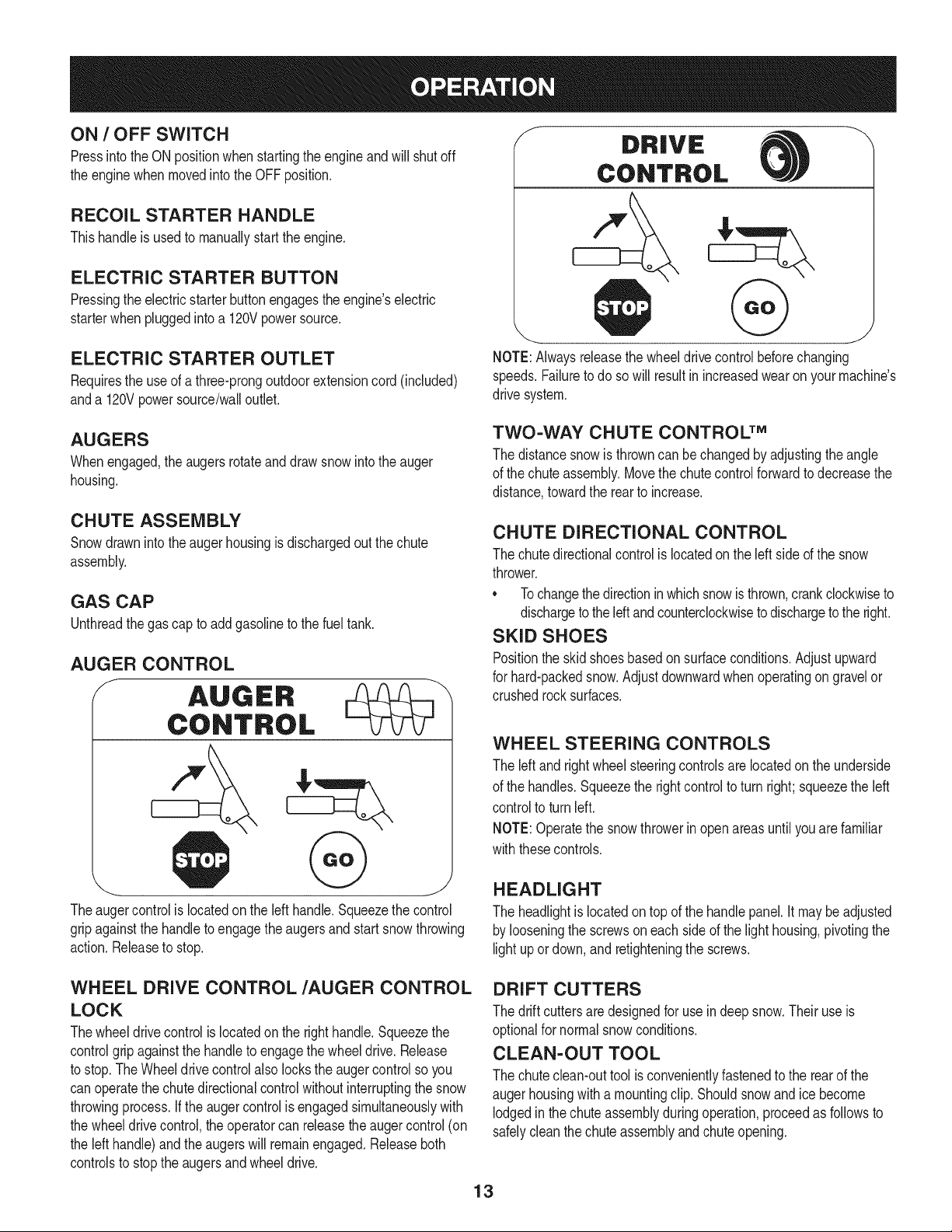

AUGER CONTROL

S

NOTE:Alwaysreleasethewheeldrivecontrolbeforechanging

speeds.Failuretodo sowill resultinincreasedwearonyourmachine's

drivesystem.

TWO-WAY CHUTE CONTROL TM

Thedistancesnowis throwncanbe changedbyadjustingthe angle

ofthechuteassembly.Movethe chutecontrolforwardto decreasethe

distance,towardthe rearto increase.

CHUTE DIRECTIONAL CONTROL

Thechutedirectionalcontrolislocatedontheleftsideofthesnow

thrower.

• Tochangethedirectioninwhichsnowisthrown,crankclockwiseto

dischargetotheleftandcounterclockwisetodischargeto theright.

SKID SHOES

Positiontheskidshoesbasedonsurfaceconditions.Adjustupward

forhard-packedsnow.Adjustdownwardwhenoperatingon gravelor

crushedrocksurfaces.

WHEEL STEERING CONTROLS

Theleftandrightwheelsteeringcontrolsarelocatedontheunderside

ofthehandles.Squeezethe rightcontroltoturnright;squeezethe left

controlto turnleft.

NOTE:Operatethesnowthrowerin openareasuntil youarefamiliar

withthesecontrols.

J

Theaugercontrolislocatedontheleft handle.Squeezethecontrol

gripagainstthehandletoengagetheaugersandstart snowthrowing

action.Releasetostop.

WHEEL DRIVE CONTROL/AUGER CONTROL

LOCK

Thewheeldrivecontrolislocatedon therighthandle.Squeezethe

controlgripagainstthehandletoengagethewheeldrive.Release

tostop.TheWheeldrivecontrolalsolockstheaugercontrolsoyou

canoperatethechutedirectionalcontrolwithoutinterruptingthe snow

throwingprocess.If theaugercontrolisengagedsimultaneouslywith

thewheeldrivecontrol,the operatorcan releasetheaugercontrol(on

thelefthandle)andtheaugerswill remainengaged.Releaseboth

controlstostopthe augersandwheeldrive.

HEADLIGHT

Theheadlightislocatedontopofthehandlepanel.It maybe adjusted

bylooseningthescrewsoneachsideof the lighthousing,pivotingthe

lightupor down,andretighteningthe screws.

DRIFT CUTTERS

Thedriftcuttersaredesignedforuseindeepsnow.Theiruseis

optionalfor normalsnowconditions.

CLEAN-OUT TOOL

Thechuteclean-outtoolisconvenientlyfastenedtotherearofthe

augerhousingwitha mountingclip.Shouldsnowandicebecome

lodgedinthechuteassemblyduringoperation,proceedasfollowsto

safelycleanthechuteassemblyandchuteopening.

13

CLEAN-OUT TOOL

Neveruseyourhandstoclearacloggedchuteassembly.Shut

off engineand remainbehindhandlesuntil allmovingpartshave

stoppedbeforeunclogging.

Thechuteclean-outtoolis convenientlyfastenedto the rearofthe

augerhousingwitha mountingclip. Shouldsnowandicebecome

lodgedin thechuteassemblyduringoperation,proceedasfollowsto

safelycleanthechuteassemblyandchuteopening:

1. Releaseboththe AugerControlandtheWheeldrivecontrol.

2. Stopthe enginebyremovingtheignitionkey.

3. Removetheclean-outtoolfromtheclipwhichsecuresittothe

rearoftheaugerhousing.

4. Usetheshovel-shapedendof theclean-outtooltodislodgeand

scoopanysnowand icewhichhasformedin andnearthechute

assembly.

5. Refastentheclean-outtooltothemountingclipontherearof

theaugerhousing,reinserttheignitionkeyandstartthesnow

thrower'sengine.

6. Whilestandingintheoperator'sposition(behindthesnow

thrower),engagethe augercontrolforafewsecondsto clearany

remainingsnowandice fromthechuteassembly.

BEFORE STARTING ENGINE

Read,understand,andfollowall instructionsandwarningson the

machineand inthismanualbeforeoperating.

Oil

Theunitwasshippedwithoilintheengine.Checkoil levelbeforeeach

operationto ensureadequateoilintheengine.Forfurtherinstructions,

referto the Service&Maintenancesectionof thismanual.

1. Removethedipstickfromtheoilfill.

2. Checkandmakesurethatthe levelofoil is uptothe FULLmark

onthedipstick.

3. Iftheoil levelisnotupto FULL,pourfreshmotoroil (5W-30,with

a minimumclassificationofSF/SG/SH/SJ)slowlythroughthe

opening.Replaceoil filldipstickandcheckoil levelagain.

Gasoline

• Storegasolineinaclean,approvedcontainerandkeepthecap in

placeonthecontainer.

• Makesurethatthecontainerfromwhichyoupourthegasolineis

cleanandfreefromrustor otherforeignparticles.

• Alwaysfillthefueltankoutdoorsand usea funnelorspoutto

preventspilling.

• Fillfuel tankwithclean,fresh,unleadedgasolinewithaminimum

of85 octane.Freshfuel preventsgumfromforminginthefuel

systemoronessentialcarburetorparts.Purchasefuelin a

quantitythatcanbeusedwithin30 days.

• Neverfillthe fuel tankcompletely.Fillthe tanktowithin1-1/2"

fromthetoptoprovidespaceforexpansionoffuel.

• Makesureto wipeoffanyspilledfuelbeforestartingtheengine.

STARTING THE ENGINE

1. Makecertainboththe augercontrolandwheeldrivecontrolarein

thedisengaged(released)position.

2. Insertignitionkeyintoslot.Makesureit snapsintoplace.Donot

attempttoturnthekey.

NOTE:Theenginecannotstartwithoutthekeyisfully insertedintothe

ignitionswitch.

Electric Starter

Determinethatyourhome'swiringis a three-wiregroundedsystem.

Askalicensedelectricianifyouarenotcertain.

Theoptionalelectricstarteris equippedwithagroundedthree-wire

powercordandplug,andis designedto operateon 120voltAC

householdcurrent.It mustbeusedwitha properlygroundedthree-

prongreceptacleatall timesto avoidthepossibilityofelectricshock.

Followall instructionscarefullypriortooperatingtheelectricstarter.

Ifyouhavea groundedthree-prongreceptacle,proceedasfollows:

1. Plugtheextensioncordintotheoutletlocatedontheengine's

surface.Plugtheotherendof extensioncordintoathree-prong

120-volt,grounded,ACoutletinawell-ventilatedarea.

2. Rotatechokecontrolto FULL I,,q¢lchokeposition(fora cold

enginestart).

NOTE:Iftheengineisalreadywarm,placechokecontrolin theOFF

I _ I positioninsteadof FULLIJl'

3. Depressprimer.If it is 15°For higherpushprimertwotimes,if

below15°F,pushprimerfour times.

4. PushrockerswitchtoONposition.

5. Pushstarterbuttonto startengine.

Toprolongstarterlife,use shortstartingcycles(5secondsmaximum

thenwaitone minute).

Useextremecarewhenhandlinggasoline.Gasolineisextremely

flammableandthevaporsareexplosive.Neverfuel themachine

indoorsorwhilethe engineishotor running.Extinguishcigarettes,

cigars,pipesandothersourcesof ignition.

NOTE:A plasticdustcap maybefoundinsidethefuelfillopening.

Removeanddiscard,if present.

6. Oncetheenginestarts,releasestarterbutton.

7. Allowtheenginetowarmupseveralminutes,adjustingchoke

towardRUNposition.Waituntilenginerunssmoothlybeforeeach

chokeadjustment.

8. Whendisconnectingthe extensioncord,alwaysunplugtheend

atthethree-prongwalloutletbeforeunpluggingtheoppositeend

fromthesnowthrower.

14

Recoil Starter

1. RotatechokecontroltoCHOKE Ill position.

2. Depressprimer.Ifit is 15°For higherpushprimertwotimes,if

below15°F,pushprimerfourtimes.

3. Pushrockerswitchto ONposition.

4. Graspthe recoilstarterhandleand slowlypullthe ropeout.At

thepointwhereitbecomesslightlyhardertopulltherope,slowly

allowthe ropeto recoil.

5. Pullthestarterhandlewitha firm,rapidstroke.Donot release

thehandleandallowitto snap back.Keepa firmholdonthe

starterhandleandallowit toslowlyrecoil.

6. Allowtheenginetowarmupseveralminutes,adjustingchoke

towardRUNposition.Waituntilenginerunssmoothlybeforeeach

chokeadjustment.

STOPPING THE ENGINE

Runenginefor a fewminutesbeforestoppingtohelpdryoff any

moistureonthe engine.

1. PushtheOn/ Offswitchto theOFFposition.

DoNOTmovethechokecontrolto CHOKE IJl positionto stop

theengine.Backfireor enginedamagemayoccur.

.

Removetheignitionkeyandstoreina safeplace.

3.

Wipeall snowandmoisturefromtheareaaroundtheengineas

wellas the areainandaroundthewheeldrivecontrolandauger

control.Also,engageandreleasebothcontrolsseveraltimes.

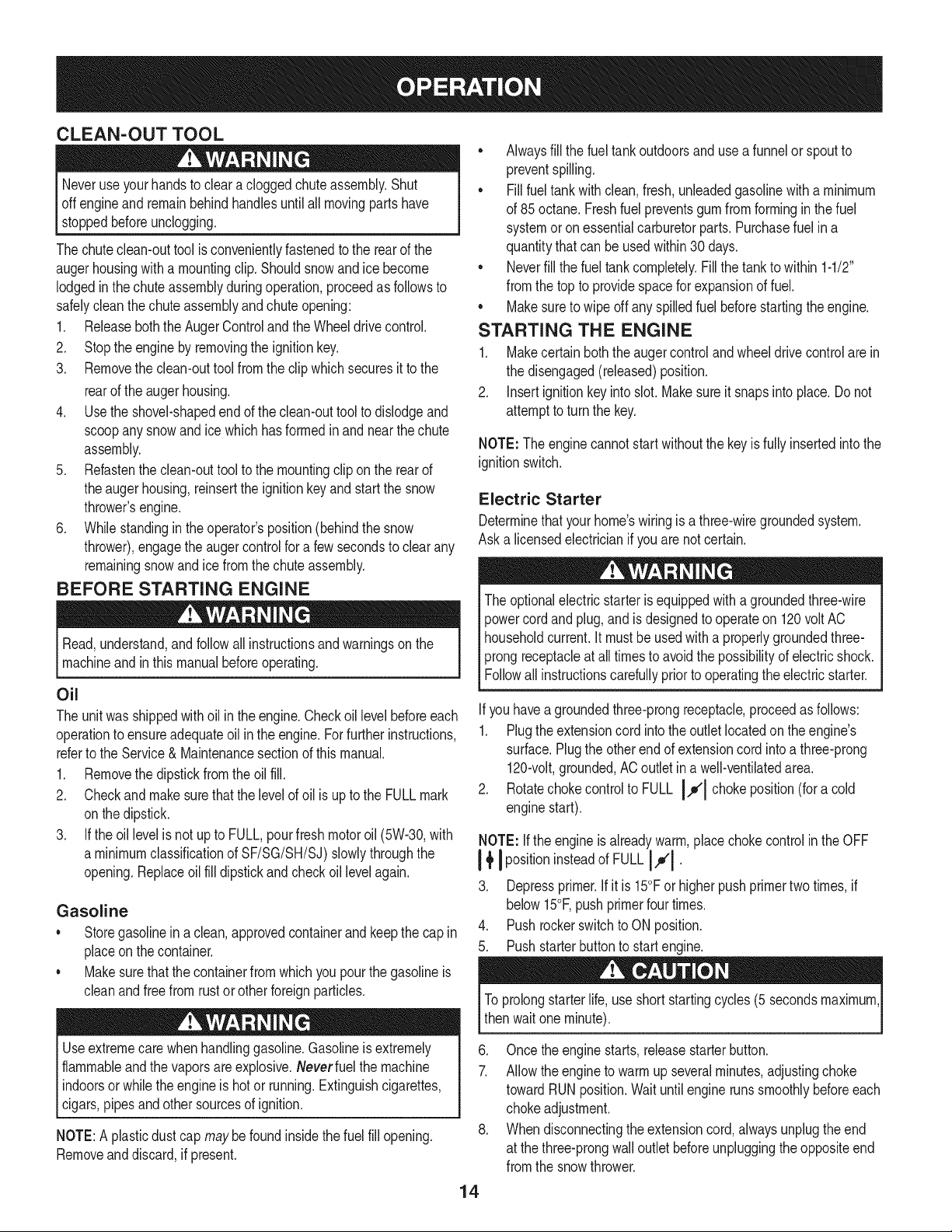

REPLACING SHEAR PINS

Theaugersaresecuredto thespiralshaftwithtwo shearpinsandcot-

terpins.Iftheaugershouldstrikea foreignobjectoricejam, thesnow

throwerisdesignedsothattheshearpinsmayshear.Iftheaugerswill

notturn,checkto seeifthepinshavesheared.SeeFigure12.

NEVERreplacetheaugershearpinswithanythingotherthanOEM

PartNo.738-04155replacementshearpins.Anydamagetothe

augergearboxorothercomponentsasaresultof failingtodosowill

NOTbecoveredbyyoursnowthrower'swarranty.

Alwaysturnoffthesnowthrower'sengineand removethekeypriorto

replacingshearpins.

f

ii

TO ENGAGE WHEEL DRIVE

1. Moveshiftleverintooneofthesixforward(F) positionsor two

reverse(R)positions.Selecta speedappropriateforthe snow

conditionsand a paceyou'recomfortablewith.

NOTE: Whenselectinga DriveSpeed,usetheslowerspeedsuntil

youarecomfortableandfamiliarwiththeoperationofthesnow

thrower.

2. Squeezethewheeldrivecontrolagainstthehandlethesnow

throwerwillmove.Releaseit anddrivemotionwillstop.

NOTE:NEVERrepositiontheshiftlever(changespeedsordirection

oftravel)withoutfirst releasingthewheeldrivecontrolandbringing

thesnowthrowertoa completestop.Doingsowillresultinpremature

wearto the snowthrower'sdrive system.

TO ENGAGE AUGERS

1. Toengagetheaugersandstartthrowingsnow,squeezethe

augercontrolagainsttheleft handle.Releasetostoptheaugers.

J

Figure12

15

ENGINE MAINTENANCE

f

Beforelubricating,repairing,or inspecting,disengageallcontrolsand

stopengine.Waituntilallmovingpartshavecometoa completestop.

Removetheignitionkeytopreventunintendedfiringoftheengine.

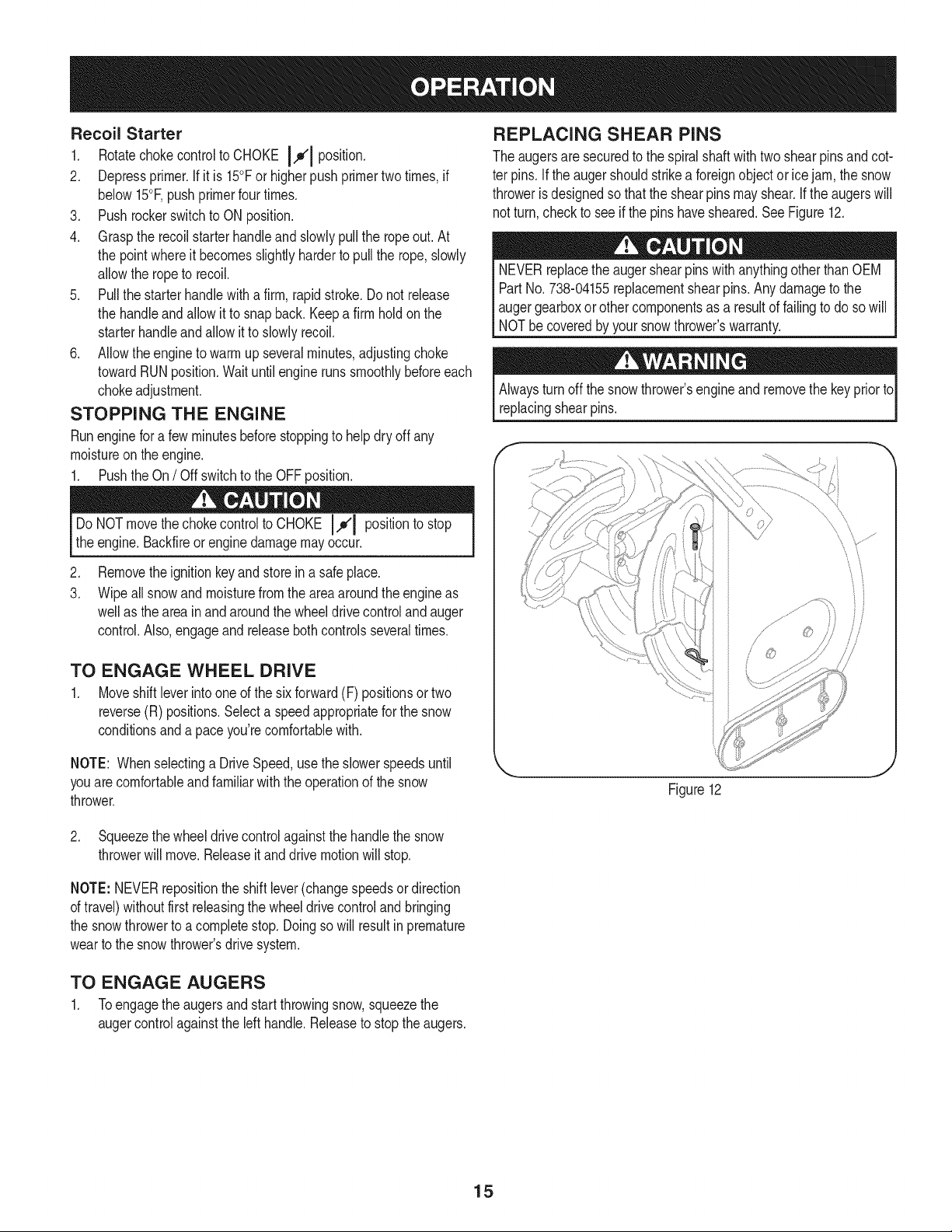

Checking Engine Oil

1. Besureengineisuprightand level

2. Unscrewoil fillcapfromoil fillertubeandwipedipstickclean.

3. Screwoil fillcapbackintooil fillertube.Tightensecurely.

4. Unscrewand removeoilfillcapfromoilfillertube.Noteoillevel.

Ifoil readingondipstickisbelow"ADD"mark,slowlyaddoil to

reach"FULL"level.SeeFigure13.

5. Screwoil fillcapbackintooil fillertube.Tightensecurely.

6. Wipeawayany spilledoil.

Changing Engine Oil

Toavoidenginedamage,it isimportantto:

• Checkoil levelbeforeeachuseandeveryeightoperatinghours.

• Changeoil afterfirst5to 8operatinghoursandevery50operat-

inghoursor oncea seasonthereafter.

1. Placeenginelevelandremovesafetykey.

2. WithengineOFFbutstillwarm,removeoil drainpluganddrainoil

intoan appropriatereceptacle.SeeFigure13.

,.J

..J

LI..

Maintain oil level

at FULL

a

a

X._j

J

Figure13

f

Usedoilisahazardouswasteproduct.Disposeofusedoil properly.

IDonotdiscardwithhouseholdwaste.Checkwithyourlocalauthori-

_tiesor SearsServiceCenterforsafedisposal/recyclingfacilities.

3. Reinstalloildrainplugandtightensecurely.

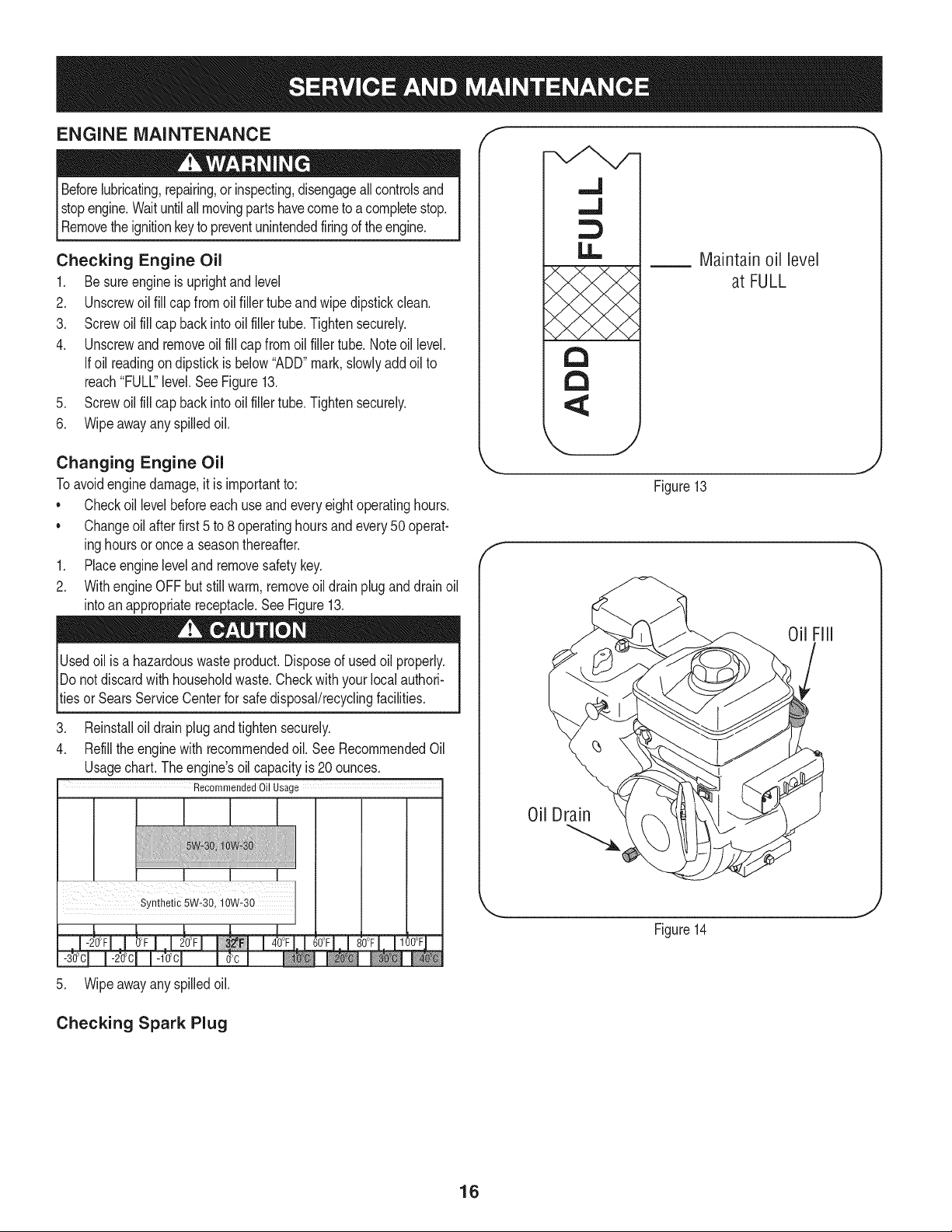

4. Refilltheenginewith recommendedoil.SeeRecommendedOil

Usagechart.The engine'soilcapacityis20 ounces.

Recommended Oil Usage

i¸ i!i!i¸iii¸,!i!i

5. Wipeawayany spilledoil.

Checking Spark Plug

Oil Drain

Figure14

16

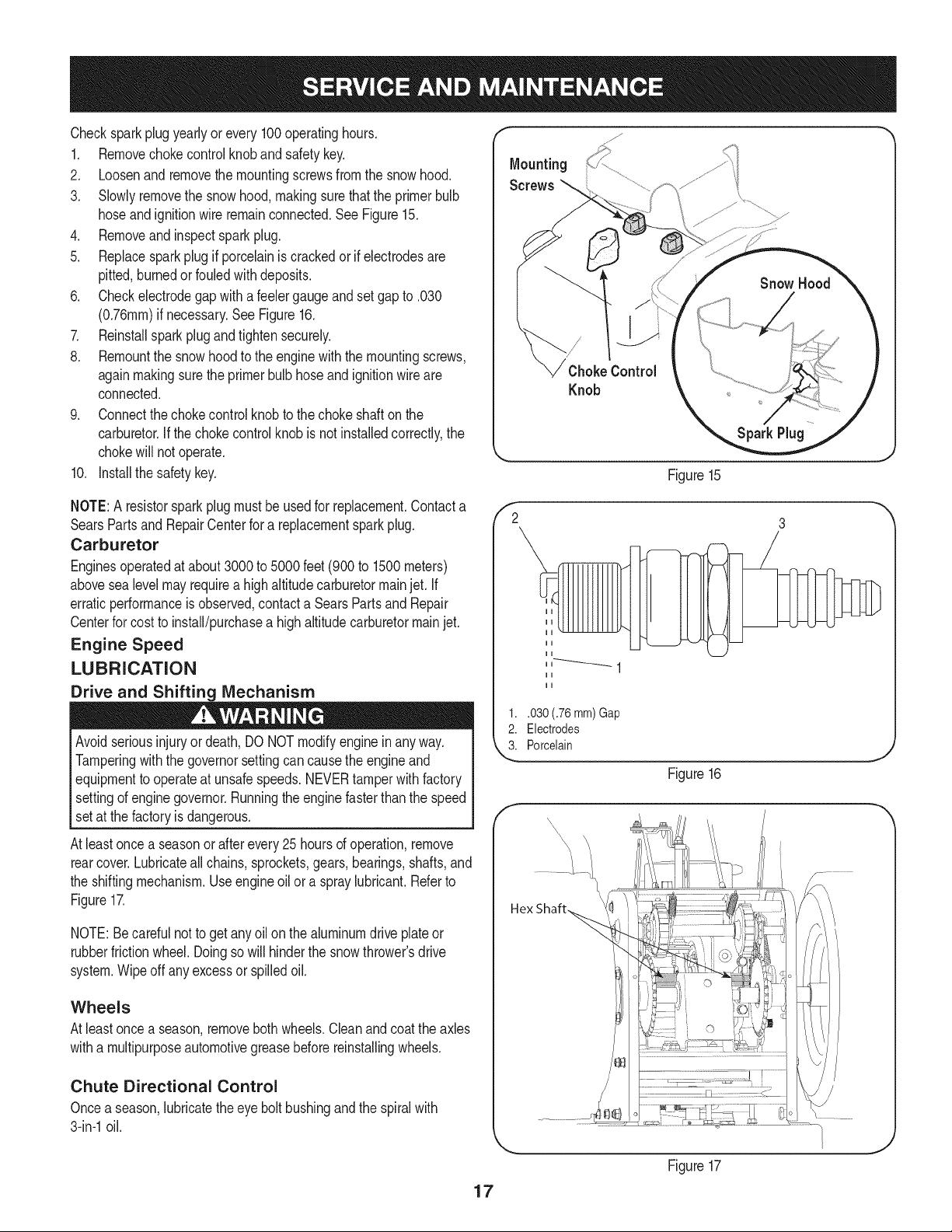

Checksparkplugyearlyor every100operatinghours.

1. Removechokecontrolknobandsafetykey.

2. Loosenandremovethe mountingscrewsfromthesnowhood.

3. Slowlyremovethe snowhood,makingsurethattheprimerbulb

hoseandignitionwireremainconnected.SeeFigure15.

4. Removeandinspectsparkplug.

5. Replacesparkplugif porcelainis crackedorif electrodesare

pitted,burnedorfouledwithdeposits.

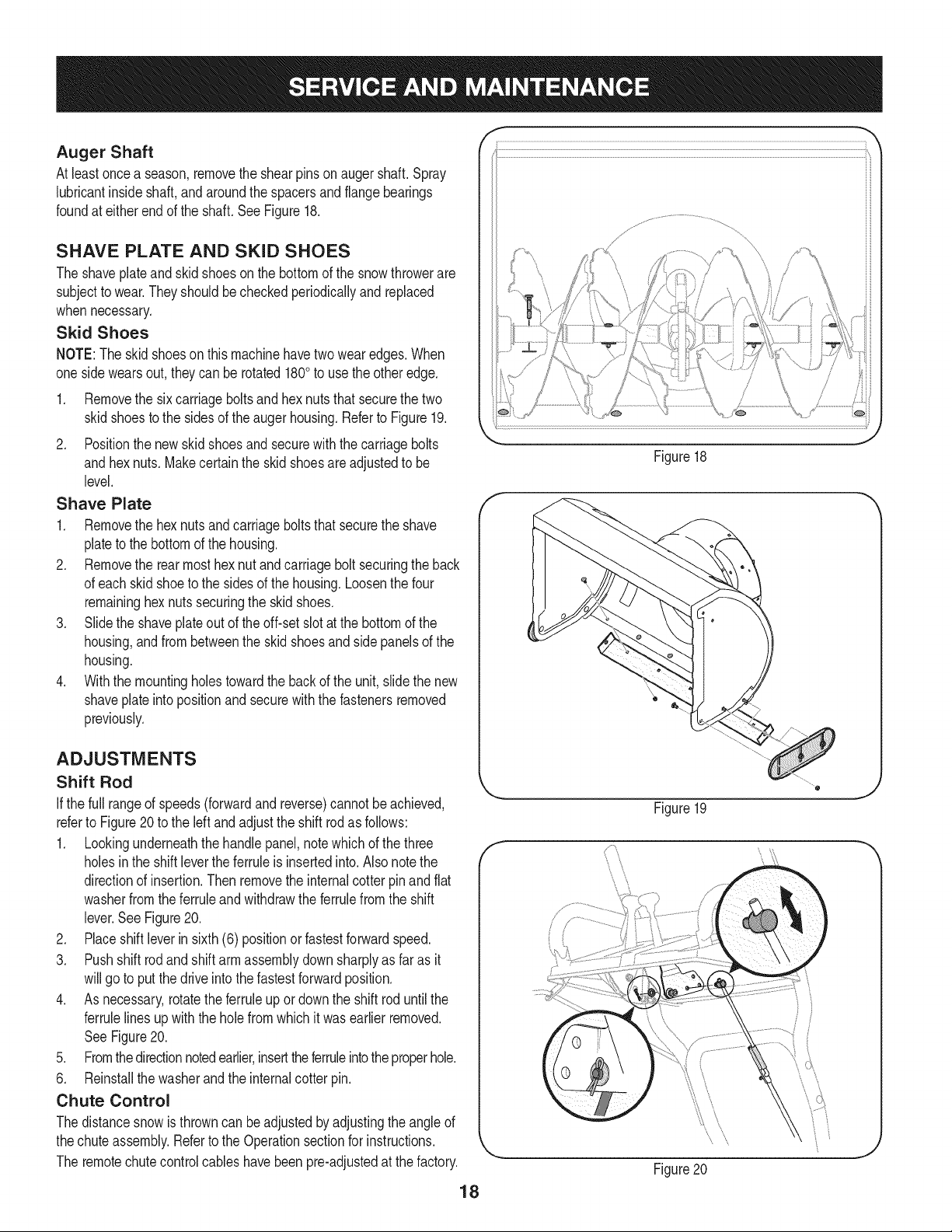

6. Checkelectrodegapwitha feelergaugeandsetgapto .030

(0.76ram)ifnecessary.SeeFigure16.

7. Reinstallsparkplugandtightensecurely.

8. Remountthe snowhoodtotheenginewith themountingscrews,

againmakingsurethe primerbulbhoseandignitionwireare

connected.

9. Connectthechokecontrolknobto thechokeshaftonthe

carburetor.Ifthechokecontrolknobis not installedcorrectly,the

chokewillnotoperate.

10. Installthe safetykey.

NOTE:A resistorsparkplugmustbeusedforreplacement.Contacta

SearsPartsand RepairCenterforareplacementsparkplug.

Carburetor

Enginesoperatedatabout3000to 5000feet(900to 1500meters)

abovesealevelmayrequireahighaltitudecarburetormainjet. If

erraticperformanceis observed,contacta SearsPartsand Repair

Centerforcostto install/purchasea highaltitudecarburetormainjet.

Engine Speed

LUBRICATION

Drive and Shifting Mechanism

Mounting

Screws

Knob

Figure15

Avoidseriousinjuryordeath,DONOTmodifyengineinanyway.

Tamperingwiththegovernorsettingcancausetheengineand

equipmenttooperateat unsafespeeds.NEVERtamperwithfactory

settingof enginegovernor.Runningtheenginefasterthanthespeed

setat thefactoryisdangerous.

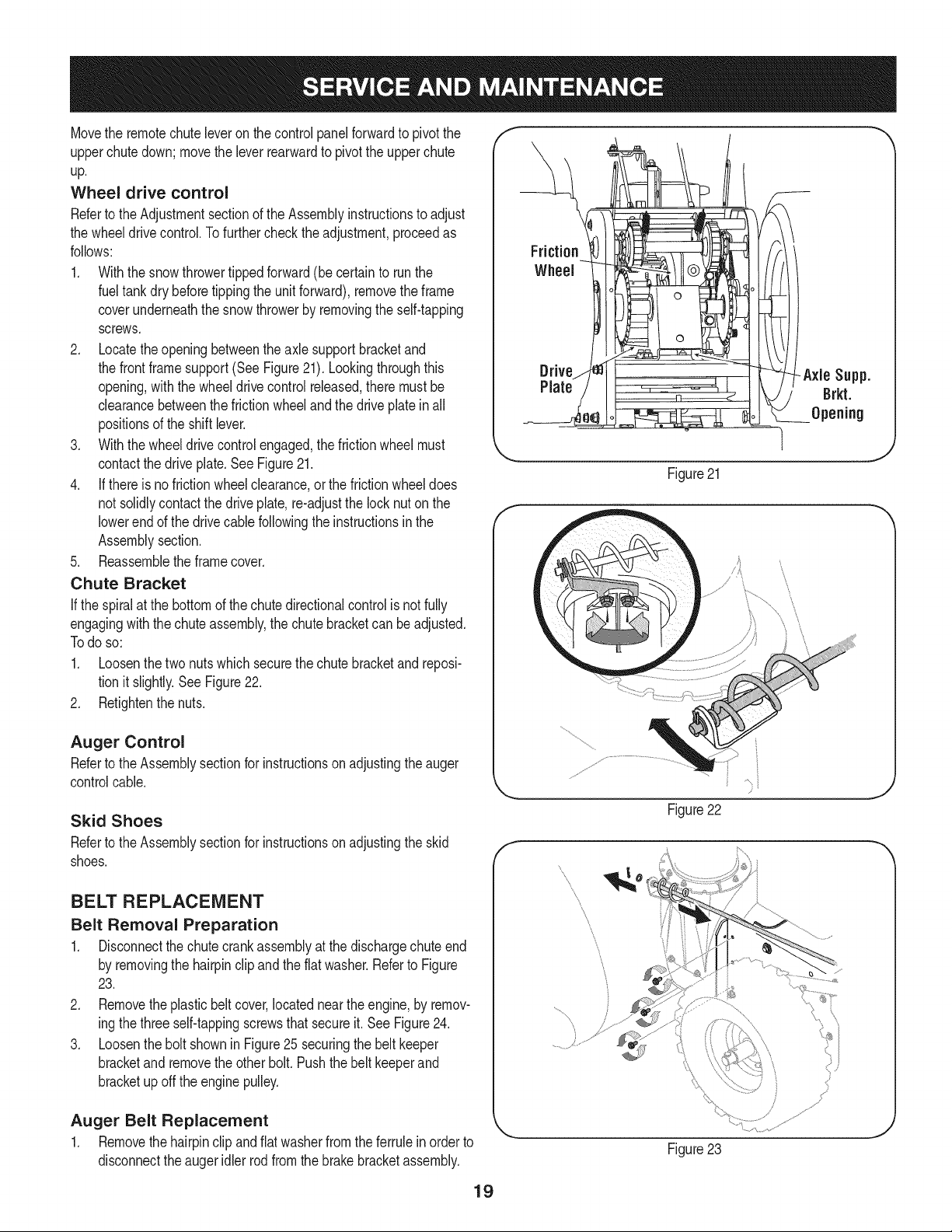

Atleastoncea seasonorafterevery25 hoursofoperation,remove

rearcover.Lubricateallchains,sprockets,gears,bearings,shafts,and

theshiftingmechanism.Useengineoil oraspraylubricant.Referto

Figure17.

NOTE:Becarefulnotto getanyoil on thealuminumdrive plateor

rubberfrictionwheel.Doingsowillhinderthesnowthrower'sdrive

system.Wipeoffanyexcessor spilledoil.

Wheels

Atleastoncea season,removeboth wheels.Cleanandcoattheaxles

withamultipurposeautomotivegreasebeforereinstallingwheels.

Chute Directional Control

Oncea season,lubricatethe eyeboltbushingandthe spiralwith

3-in-1oil.

Figure16

f

Figure17

17

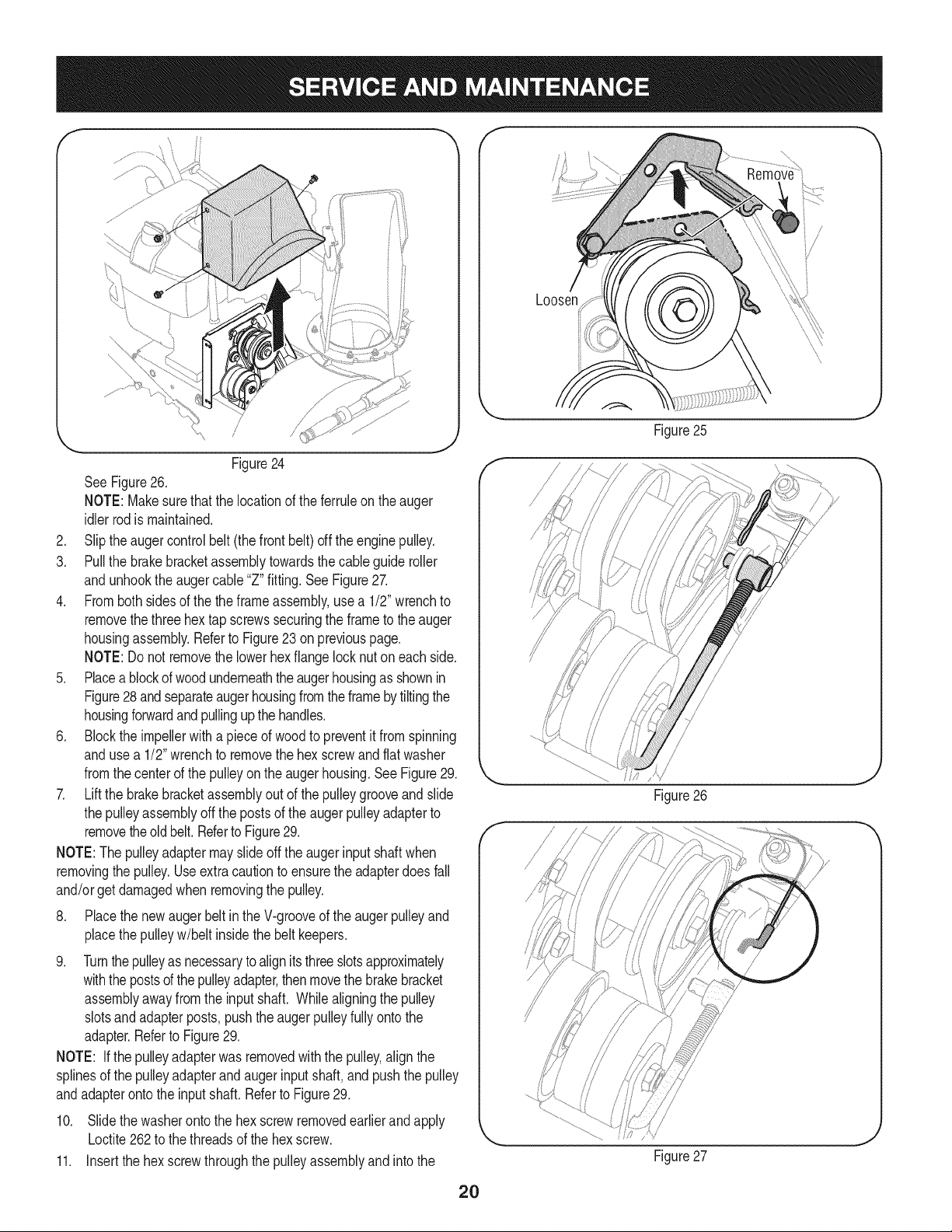

Auger Shaft

Atleastonceaseason,removetheshearpinsonaugershaft.Spray

lubricantinsideshaft,andaroundthespacersandflangebearings

foundateitherendoftheshaft.SeeFigure18.

SHAVE PLATE AND SKID SHOES

Theshaveplateandskidshoesonthebottomofthesnowthrowerare

subjecttowear.Theyshouldbecheckedperiodicallyandreplaced

whennecessary.

Skid Shoes

NOTE:Theskidshoeson thismachinehavetwowearedges.When

onesidewearsout,theycanberotated1800to usetheotheredge.

1. Removethe sixcarriageboltsandhexnutsthatsecurethetwo

skidshoestothesidesoftheaugerhousing.RefertoFigure19.

2. Positionthe new skidshoesandsecurewiththecarriagebolts

andhexnuts.Makecertaintheskidshoesareadjustedtobe

level.

Shave Plate

1. Removethe hexnutsandcarriageboltsthatsecuretheshave

plateto the bottomof thehousing.

2. Removethe rearmosthexnutandcarriageboltsecuringthe back

ofeachskidshoetothe sidesofthehousing.Loosenthefour

remaininghexnutssecuringthe skidshoes.

3. Slidethe shaveplateoutoftheoff-setslotatthe bottomofthe

housing,andfrombetweentheskidshoesandsidepanelsofthe

housing.

4. Withthe mountingholestowardthebackoftheunit,slidethenew

shaveplateinto positionandsecurewiththefastenersremoved

previously.

/ /7 "'! ......_, .....

.............. _':'f!'t, .......... }_\_. _,

i _ \ .....77',!.1< ' L _k;,..... +El'\t;......

k, -Jr 7 r'W'i / '

, , _ ' ...... 7

....................,'r......................................\ i ........ +>, F .............................

J

Figure18

f

ADJUSTMENTS

Shift Rod

Ifthefull rangeofspeeds(forwardandreverse)cannotbe achieved,

referto Figure20totheleftandadjusttheshiftrodas follows:

1. Lookingunderneaththehandlepanel,notewhichof thethree

holesinthe shiftlevertheferruleis insertedinto.Alsonotethe

directionof insertion.Thenremovetheinternalcotterpinandflat

washerfromtheferruleandwithdrawtheferrulefromthe shift

lever.SeeFigure20.

2. Placeshift leverin sixth(6) positionor fastestforwardspeed.

3. Pushshift rodandshiftarmassemblydownsharplyas farasit

willgo toputthe driveintothefastestforwardposition.

4. Asnecessary,rotatetheferruleupor downthe shiftroduntilthe

ferrulelinesupwiththeholefromwhichit wasearlierremoved.

SeeFigure20.

5. Fromthedirectionnotedearlier,inserttheferruleintotheproperhole.

6. Reinstallthewasherandtheinternalcotterpin.

Chute Control

Thedistancesnowisthrowncanbeadjustedbyadjustingtheangleof

thechuteassembly.Referto theOperationsectionforinstructions.

Theremotechutecontrolcableshavebeenpreladjustedat the factory.

18

Figure19

f

t,

'ii /

Figure20

Movetheremotechuteleveronthecontrolpanelforwardtopivotthe

upperchutedown;movetheleverrearwardtopivottheupperchute

up,

Wheeldrive control

RefertotheAdjustmentsectionoftheAssemblyinstructionstoadjust

thewheeldrivecontrol,Tofurtherchecktheadjustment,proceedas

follows:

1. Withthesnowthrowertippedforward(becertaintorunthe

fueltankdrybeforetippingtheunitforward),removetheframe

coverunderneaththesnowthrowerbyremovingtheself-tapping

screws.

2. Locatetheopeningbetweentheaxlesupportbracketand

thefrontframesupport(SeeFigure21).Lookingthroughthis

opening,withthewheeldrivecontrolreleased,theremustbe

clearancebetweenthefrictionwheelandthedriveplateinall

positionsoftheshiftlever.

3. Withthewheeldrivecontrolengaged,thefrictionwheelmust

contactthedriveplate.SeeFigure21.

4. Ifthereisnofrictionwheelclearance,orthefrictionwheeldoes

notsolidlycontactthedriveplate,re-adjustthelocknutonthe

lowerendofthedrivecablefollowingtheinstructionsinthe

Assemblysection.

5. Reassembletheframecover.

Chute Bracket

Ifthespiralatthebottomofthechutedirectionalcontrolisnotfully

engagingwiththechuteassembly,the chutebracketcanbeadjusted.

Todo so:

1. Loosenthetwonutswhichsecurethechutebracketandreposi-

tionitslightly.See Figure22.

2. Retightenthenuts.

Drive Axle Supp.

Plate Brkt.

Opening

Figure21

l

Auger Control

RefertotheAssemblysectionforinstructionsonadjustingtheauger

controlcable.

Skid Shoes

RefertotheAssemblysectionforinstructionsonadjustingtheskid

shoes.

BELT REPLACEMENT

Belt Removal Preparation

1. Disconnectthechutecrankassemblyatthedischargechuteend

byremovingthe hairpinclipandtheflatwasher.Referto Figure

23.

2. Removetheplasticbelt cover,locatednearthe engine,byremov-

ingthethreeself-tappingscrewsthatsecureit.SeeFigure24.

3. Loosentheboltshownin Figure25 securingthebeltkeeper

bracketandremovetheotherbolt.Pushthebeltkeeperand

bracketupoff theenginepulley.

Auger Belt Replacement

1. Removethehairpinclipandflatwasherfromtheferrulein orderto

disconnecttheaugeridlerrodfromthebrakebracketassembly.

j_

Figure22

f

Figure23

19

Figure24

SeeFigure26.

NOTE:Makesurethatthe locationoftheferruleontheauger

idlerrodis maintained.

2. Sliptheaugercontrolbelt(thefrontbelt)offtheenginepulley.

3. Pullthebrakebracketassemblytowardsthecableguideroller

andunhooktheaugercable"Z"fitting.See Figure27.

4. Frombothsidesofthe the frameassembly,usea 1/2"wrenchto

removethethreehextapscrewssecuringtheframetothe auger

housingassembly.Referto Figure23on previouspage.

NOTE:Do not removethelowerhexflangelocknuton eachside.

5. Placeablockofwoodunderneaththe augerhousingasshownin

Figure28andseparateaugerhousingfromtheframebytiltingthe

housingforwardandpullingupthe handles.

6. Blocktheimpellerwithapieceofwoodto preventit fromspinning

andusea 1/2"wrenchto removethe hexscrewandflatwasher

fromthecenterofthe pulleyontheaugerhousing.See Figure29.

7. Liftthebrakebracketassemblyoutofthe pulleygrooveandslide

thepulleyassemblyoffthe postsofthe augerpulleyadapterto

removetheoldbelt.RefertoFigure29.

NOTE:Thepulleyadaptermayslideoffthe augerinputshaftwhen

removingthepulley.Useextracautiontoensuretheadapterdoesfall

and/orget damagedwhenremovingthepulley.

8. Placethe newaugerbeltin theV-grooveoftheaugerpulleyand

placethe pulleyw/beltinsidethebeltkeepers.

9. Turnthepulleyasnecessarytoalignitsthreeslotsapproximately

withthepostsofthepulleyadapter,thenmovethebrakebracket

assemblyawayfromtheinputshaft. Whilealigningthe pulley

slotsandadapterposts,pushtheaugerpulleyfullyontothe

adapter.Referto Figure29.

NOTE: If thepulleyadapterwas removedwiththepulley,alignthe

splinesofthepulleyadapterandaugerinputshaft,andpushthepulley

andadapterontotheinputshaft.Referto Figure29.

10. Slidethewasherontothe hex screwremovedearlierandapply

Loctite262to the threadsofthehexscrew.

11. Insertthe hexscrewthroughthepulleyassemblyandintothe

Loosen

Figure25

//

Figure26

f

/

//

/

/

Figure27

20

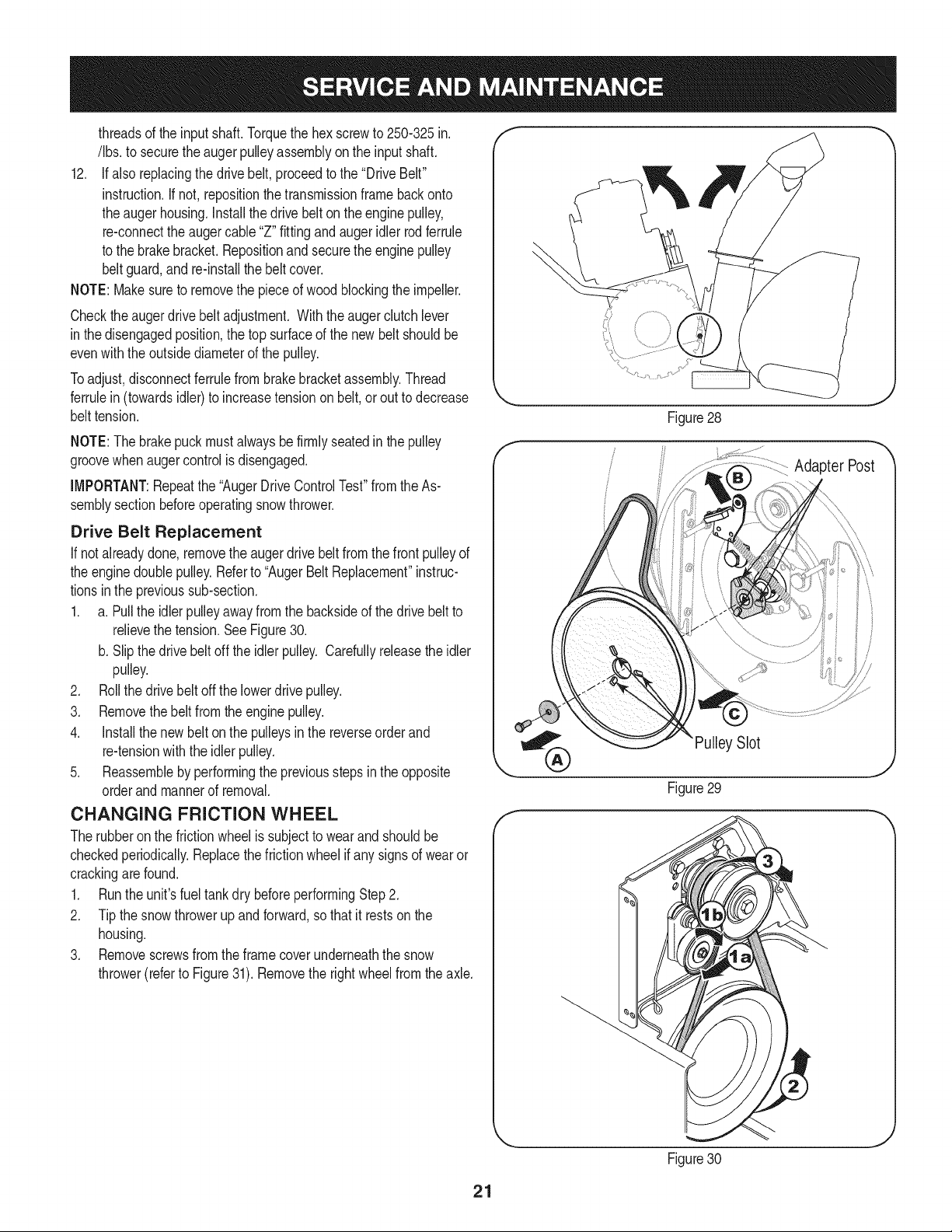

threadsoftheinputshaft.Torquethehexscrewto250-325in.

/Ibs.tosecuretheaugerpulleyassemblyonthe input shaft.

12. If alsoreplacingthe drivebelt,proceedtothe"DriveBelt"

instruction.If not,repositionthetransmissionframebackonto

theaugerhousing.Installthe drivebeltontheenginepulley,

re-connectthe augercable"Z" fittingandaugeridlerrodferrule

tothebrakebracket.Repositionandsecuretheenginepulley

beltguard,andre-installthebeltcover.

NOTE:Makesureto removethepieceofwoodblockingtheimpeller.

Checktheaugerdrivebeltadjustment.Withtheaugerclutch lever

in thedisengagedposition,thetop surfaceofthenewbelt shouldbe

evenwiththeoutsidediameterof thepulley.

Toadjust,disconnectferrulefrombrakebracketassembly.Thread

ferrulein(towardsidler)to increasetensionon belt,oroutto decrease

belttension.

NOTE:Thebrakepuckmustalwaysbefirmlyseatedinthe pulley

groovewhenaugercontrolisdisengaged.

IMPORTANT:Repeatthe "AugerDriveControlTest"fromtheAs-

semblysectionbeforeoperatingsnowthrower.

Drive Belt Replacement

If notalreadydone,removethe augerdrivebeltfromthefrontpulleyof

theenginedoublepulley.Referto"AugerBeltReplacement"instruc-

tionsintheprevioussub-section.

1. a.Pulltheidlerpulleyawayfromthebacksideof thedrivebeltto

relievethetension.SeeFigure30.

b.Slipthedrivebelt offtheidlerpulley.Carefullyreleasetheidler

pulley.

2. Rollthedrivebeltoff thelowerdrivepulley.

3. Removethebeltfromtheenginepulley.

4. Installthenewbeltonthepulleysinthereverseorderand

re-tensionwiththeidlerpulley.

5. Reassemblebyperformingthepreviousstepsintheopposite

orderandmannerof removal.

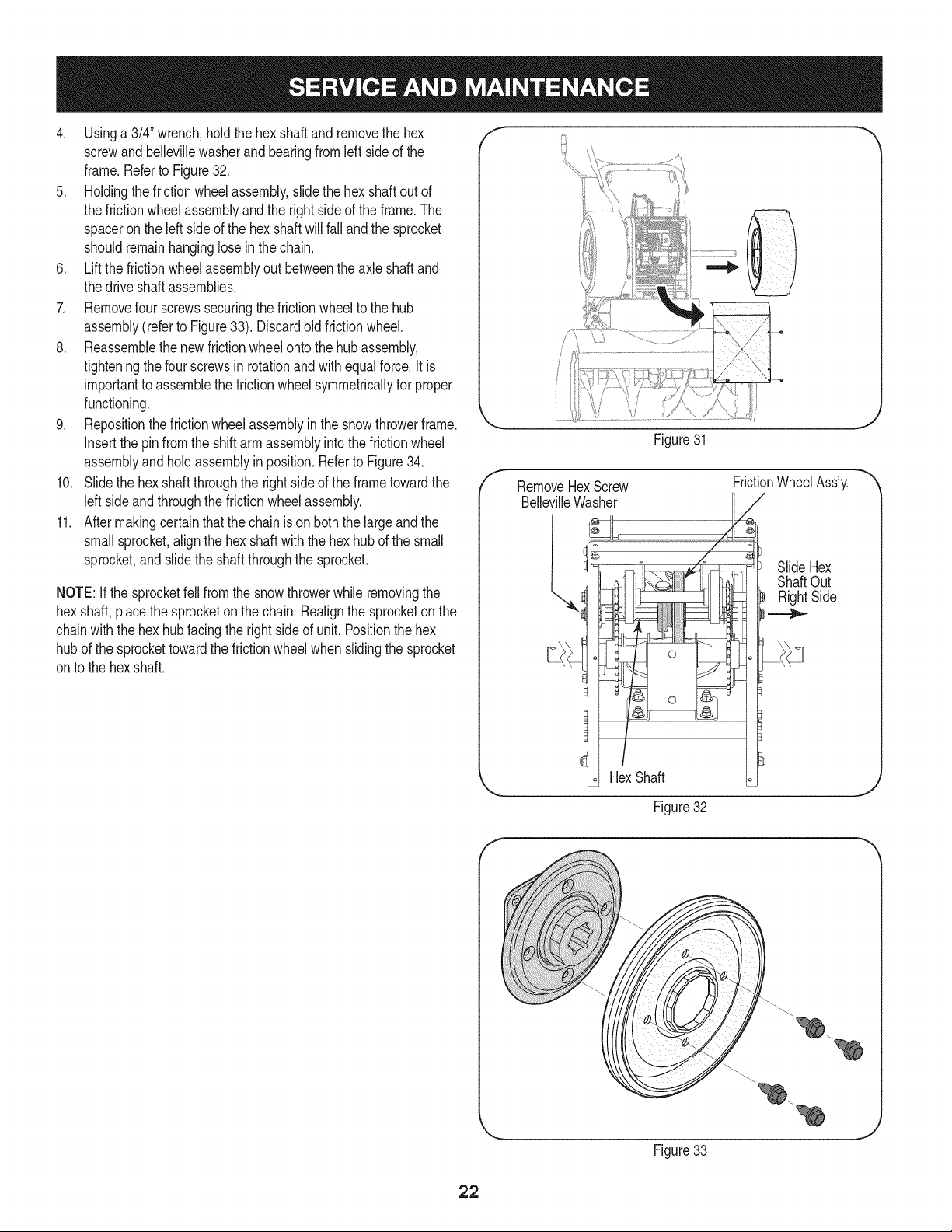

CHANGING FRICTION WHEEL

Therubberonthefrictionwheelissubjectto wearand shouldbe

checkedperiodically.Replacethefrictionwheelifany signsofwearor

crackingarefound.

1. Runtheunit'sfueltankdrybeforeperformingStep2.

2. Tipthesnowthrowerupandforward,so thatitrestsonthe

housing.

3. Removescrewsfromtheframecoverunderneaththesnow

thrower(referto Figure31).Removetherightwheelfromtheaxle.

Figure28

Adapter Post

Slot

Figure29

f

21

Figure30

4. Usinga 3/4"wrench,holdthehexshaftandremovethehex

screwandbellevillewasherandbearingfromleft sideofthe

frame.Referto Figure32.

5. Holdingthefrictionwheelassembly,slidethe hex shaftoutof

thefrictionwheelassemblyandtherightsideoftheframe.The

spacerontheleftsideofthehexshaftwill fallandthesprocket

shouldremainhanginglosein thechain.

6. Liftthefrictionwheelassemblyout betweentheaxleshaftand

thedrive shaftassemblies.

7. Removefourscrewssecuringthefrictionwheeltothehub

assembly(refertoFigure33).Discardoldfrictionwheel.

8. Reassemblethenewfrictionwheelontothehubassembly,

tighteningthefourscrewsinrotationandwith equalforce.It is

importanttoassemblethefrictionwheelsymmetricallyfor proper

functioning.

9. Repositionthefrictionwheelassemblyin the snowthrowerframe.

Insertthe pinfromtheshiftarm assemblyintothe frictionwheel

assemblyandholdassemblyin position.Referto Figure34.

10. Slidethe hexshaftthroughthe rightsideoftheframetowardthe

leftsideandthroughthefrictionwheelassembly.

11. Aftermakingcertainthatthechainison boththe largeandthe

smallsprocket,alignthehexshaftwiththehexhubof thesmall

sprocket,andslidetheshaftthroughthe sprocket.

NOTE:If thesprocketfellfromthesnowthrowerwhileremovingthe

hexshaft,placethe sprocketon thechain.Realignthesprocketon the

chainwiththehexhubfacingthe rightsideof unit.Positionthehex

hubofthesprockettowardthefrictionwheelwhenslidingthesprocket

ontothehexshaft.

RemoveHexScrew

BellevilleWasher

l°

Figure31

FrictionWheelAss'y.

/

SlideHex

ShaftOut

RightSide

22

HexShaft

J

Figure32

f

Figure33

Loading...

Loading...