Craftsman 247888300 Owner’s Manual

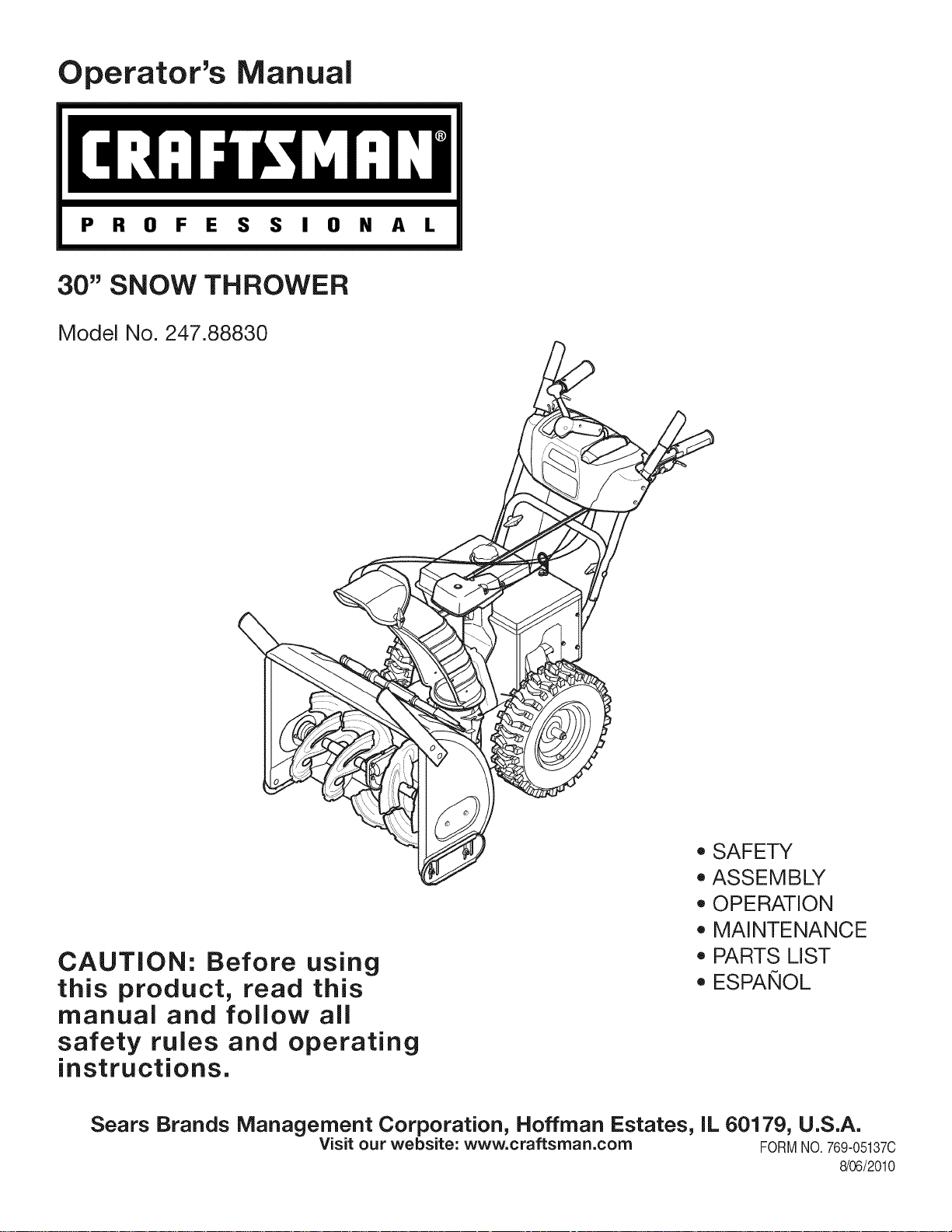

Operator's Manual

P R 0 F E S S I 0 N A

30" SNOW THROWER

Model No. 247.88830

o SAFETY

ASSEMBLY

OPERATION

MAINTENANCE

CAUTION: Before using

this product, read this

PARTS LIST

o ESPANOL

manual and follow all

safety rules and operating

instructions.

Sears Brands Management Corporation, Hoffman Estates, IL 60179, U.S.A.

Visit our website: www.craftsman.com FORM1/0.769-05137C

8/06/2010

WarrantyStatement.................... Page2

SafeOperationPractices.............. Pages3-6

SafetyLabels......................... Page7

Assembly......................... Pages8-13

Operation........................ Pages14-17

Service&Maintenance.............. Pages18-23

Off-SeasonStorage................... Page24

Troubleshooting...................... Page25

PartsList......................... Pages26-36

RepairProtectionAgreement............ Page41

Espa_ol............................. Page42

ServiceNumbers................... BackPage

CRAFTSMANPROFESSIONAL TWO YEAR FULL WARRANTY

FORTWOYEARSfromthedateofpurchase,this productis warrantedagainstanydefectsin materialorworkmanship.Defectiveproductwill

receivefreerepairor freereplacementif repairis unavailable.

Thiswarrantyappliesforonlyone yearfromthe dateof purchaseifthisproductiseverusedwhileprovidingcommercialservicesorif rentedto

anotherperson.

Forwarranty coverage details to obtain repairor replacement,visit the web site: www.craftsman.com

This warranty covers ONLYdefects in materialandworkmanship. Warrantycoverage does not include:

• Expendableitemsthatcanwearoutfromnormalusewithinthewarrantyperiod,includingbutnotlimitedtoaugers,augerpaddies,drift

cutters,skidshoes,shaveplate,shearpins,sparkplug,aircleaner,belts,andoil filter.

• Standardmaintenanceservicing,oilchanges,ortune-ups.

Tirereplacementor repaircausedbypuncturesfromoutsideobjects,suchasnails,thorns,stumps,orglass.

Tireor wheelreplacementor repairresultingfromnormalwear,accident,orimproperoperationor maintenance.

Repairsnecessarybecauseof operatorabuse,includingbutnotlimitedtodamagecausedbyover-speedingthe engine,or fromimpacting

objectsthatbendthe frame,augershaft,etc.

• Repairsnecessarybecauseof operatornegligence,includingbutnot limitedto,electricalandmechanicaldamagecausedbyimproper

storage,failureto usethepropergradeandamountofengineoil,or failureto maintaintheequipmentaccordingtotheinstructionscontained

intheoperator'smanual.

• Engine(fuelsystem)cleaningor repairscausedbyfueldeterminedto becontaminatedoroxidized(stale).in general,fuelshouldbeused

within30 daysof itspurchasedate.

Normaldeteriorationandwearof the exteriorfinishes,orproductlabelreplacement.

Thiswarrantygivesyouspecificlegalrights,andyoumayalsohaveotherrightswhichvaryfromstateto state.

Sears BrandsManagementCorporation, Hoffman Estates, IL 60179

EngineOilType: SAE5W-30

EngineOilCapacity: 37ounces

FuelCapacity: Approx.5Quarts

SparkPlug: TorchF6RTC

SparkPlugGap: .020"to .030"

©SearsBrands,LLC

ModelNumber.................................................................

Serial Number.................................................................

Dateof Purchase .............................................................

Recordthemodelnumber,serialnumber

anddateof purchaseabove

2

Thissymbolpointsoutimportantsafetyinstructionswhich,if not

followed,couldendangerthepersonalsafetyand/orpropertyof

yourselfandothers. Readandfollowall instructionsin thismanual

beforeattemptingto operatethismachine.Failuretocomplywith

theseinstructionsmayresultin personalinjury.Whenyou seethis

symbol,HEEDITSWARNING!

Thismachinewasbuilttobeoperatedaccordingtothesafeopera-

tionpracticesinthis manual.Aswithanytypeof powerequipment,

carelessnessorerroron thepartoftheoperatorcanresultin serious

injury.Thismachineiscapableofamputatingfingers,hands,toes

andfeetandthrowingdebris.Failuretoobservethe followingsafety

instructionscouldresultin seriousinjuryor death.

CALIFORNIA PROPOSITION 65

EngineExhaust,someof itsconstituents,andcertainvehicle

componentscontainoremitchemicalsknownto Stateof California

tocausecancerandbirthdefectsorotherreproductiveharm,

TRAiNiNG

• Read,understand,andfollowall instructionsonthe machineand

in themanual(s)beforeattemptingto assembleandoperate.

Failuretodo socan resultinseriousinjurytothe operatorand/

orbystanders.Keepthismanualin a safeplaceforfutureand

regularreferenceandfor orderingreplacementparts.Forques-

tionscall,1-800-4MY-HOME.

• Befamiliarwithall controlsandtheir properoperation.Knowhow

tostopthemachineanddisengagethemquickly.

Neverallowchildrenunder14yearsofageto operatethis

machine.Children14andover shouldreadandunderstandthe

instructionsandsafeoperationpracticesin thismanualandon

themachineandbe trainedandsupervisedbyanadult.

Neverallowadultsto operatethis machinewithoutproper

instruction.

• Thrownobjectscancauseseriouspersonalinjury.Planyour

snow-throwingpatterntoavoiddischargeof materialtoward

roads,bystandersandthe like.

Keepbystanders,petsandchildrenat least75feetfromthe

machinewhileitisinoperation.Stopmachineifanyoneenters

thearea.

Exercisecautiontoavoidslippingor falling,especiallywhen

operatinginreverse.

Your Responsibility--Restrict theuseof this powermachineto

personswhoread,understandandfollowthewarningsand instruc-

tionsin thismanualandon themachine,

SAVE THESE INSTRUCTIONS!

PREPARATION

Thoroughlyinspecttheareawheretheequipmentis to beused.

Removeall doormats,newspapers,sleds,boards,wiresandother

foreignobjects,whichcouldbe trippedoverorthrownbytheauger/

impeller.

Alwayswearsafetyglassesoreyeshieldsduringoperationand

whileperformingan adjustmentor repairto protectyoureyes.

Thrownobjectswhichricochetcancauseseriousinjuryto the

eyes.

Donot operatewithoutwearingadequatewinteroutergarments.

Donot wearjewelry,longscarvesorotherlooseclothing,which

couldbecomeentangledinmovingparts.Wearfootwearwhich

willimprovefootingonslipperysurfaces.

Usea groundedthree-wireextensioncordand receptacleforall

machineswithelectricstartengines.

Disengageall controlleversbeforestartingtheengine.

Adjustcollectorhousingheighttocleargravelorcrushedrock

surfaces.

Neverattempttomakeanyadjustmentswhileengineis running,

exceptwherespecificallyrecommendedinthe operator'smanual.

Letengineandmachineadjustto outdoortemperaturebefore

startingtoclearsnow.

3

SafeHandling of Gasoline

Toavoidpersonalinjuryor propertydamageuseextremecarein

handlinggasoline.Gasolineisextremelyflammableandthevaporsare

explosive.Seriouspersonalinjurycanoccurwhengasolineisspilled

onyourselforyourclotheswhichcanignite.Washyourskinand

changeclothesimmediately.

• Useonlyanapprovedgasolinecontainer.

• Extinguishall cigarettes,cigars,pipesandothersources

ofignition.

• Neverfuelmachineindoors.

• Neverremovegascapor addfuel whiletheengineishot

or running.

• Allowengineto coolat leasttwo minutesbeforerefueling.

• Neveroverfill fueltank.Filltanktono morethan1/2inch

belowbottomoffiller neckto providespacefor fuel

expansion.

• Replacegasolinecapandtightensecurely.

• Ifgasolineis spilled,wipeit offtheengineandequipment.

Movemachinetoanotherarea.Wait5 minutesbefore

startingtheengine.

• Neverstorethemachineorfuelcontainerinsidewhere

thereis anopenflame,sparkor pilotlight(e.g.furnace,

waterheater,spaceheater,clothesdryeretc.).

• Allowmachinetocoolatleast5 minutesbeforestoring.

• Neverfillcontainersinsidea vehicleorona truckor trailer

bedwitha plasticliner.Alwaysplacecontainersonthe

groundawayfromyourvehiclebeforefilling.

• If possible,removegas-poweredequipmentfromthetruck

ortrailerandrefueliton theground.Ifthisisnotpossible,

thenrefuelsuchequipmentona trailerwitha portable

container,ratherthanfromagasolinedispensernozzle.

• Keepthenozzleincontactwiththe rimofthefueltankor

containeropeningatalltimesuntilfuelingis complete.Do

notuse a nozzlelock-opendevice.

OPERATION

• Do not puthandsorfeetnear rotatingparts,intheauger/impeller

housingorchuteassembly.Contactwiththe rotatingpartscan

amputatehandsandfeet.

• Theauger/impellercontrolleverisa safetydevice.Neverbypass

itsoperation.Doingsomakesthemachineunsafeandmaycause

personalinjury.

• Thecontrolleversmustoperateeasilyinbothdirectionsand

automaticallyreturntothedisengagedpositionwhenreleased.

• Neveroperatewitha missingordamagedchuteassembly.Keep

all safetydevicesin placeandworking.

• Neverrunanengineindoorsorina poorlyventilatedarea.Engine

exhaustcontainscarbonmonoxide,anodorlessanddeadlygas.

• Do notoperatemachinewhileundertheinfluenceofalcoholor

drugs.

• Mufflerandenginebecomehotandcancausea burn.Do not

touch.Keepchildrenaway.

• Exerciseextremecautionwhenoperatingon orcrossinggravel

surfaces.Stayalertforhiddenhazardsor traffic.

• Exercisecautionwhenchangingdirectionandwhileoperatingon

slopes.

• Planyoursnow-throwingpatternto avoiddischargetowards

windows,walls,carsetc.Thus,avoidingpossibleproperty

damageorpersonalinjurycausedby a ricochet.

• Neverdirectdischargeatchildren,bystandersand petsor allow

anyoneinfrontofthemachine.

• Donot overloadmachinecapacitybyattemptingto clearsnowat

toofastof arate.

• Neveroperatethismachinewithoutgoodvisibilityorlight.Always

be sureofyourfootingandkeepafirmholdon the handles.Walk,

neverrun.

• Disengagepowerto theauger/impellerwhentransportingor not

in use.

• Neveroperatemachineathightransportspeedsonslippery

surfaces.Lookdownand behindand usecare whenbackingup.

• Ifthemachineshouldstarttovibrateabnormally,stoptheengine,

disconnectthesparkplugwire andgroundit againstthe engine.

Inspectthoroughlyfor damage.Repairanydamagebefore

startingandoperating.

• Disengageall controlleversandstopenginebeforeyouleave

theoperatingposition(behindthehandles).Waituntiltheauger/

impellercomestoa completestopbeforeuncloggingthechute

assembly,makingany adjustments,or inspections.

• Neverputyourhandinthedischargeor collectoropenings.Do

notunclogchuteassemblywhileengineisrunning.Shutoff

engineand remainbehindhandlesuntilall movingpartshave

stoppedbeforeunclogging.

• Useonlyattachmentsandaccessoriesapprovedbythemanufac-

turer(e.g.wheelweights,tirechains,cabsetc.).

• Whenstartingengine,pullcordslowlyuntilresistanceisfelt,then

pull rapidly.Rapidretractionofstartercord(kickback)willpull

handandarmtowardenginefasterthan youcanletgo.Broken

bones,fractures,bruisesorsprainscouldresult.

• Ifsituationsoccurwhichare notcoveredinthis manual,usecare

andgoodjudgment.ContactCustomerSupportforassistance

andthenameof your nearestservicingdealer.

CLEARING A CLOGGED DISCHARGE CHUTE

Handcontactwiththe rotatingimpellerinsidethe dischargechute

is themostcommoncauseofinjuryassociatedwithsnowthrowers.

Neveruseyourhandtocleanout thedischargechute.

Toclear thechute:

1. SHUTTHEENGINEOFF!

2. Wait 10secondstobe suretheimpellerbladeshavestopped

rotating.

3. Alwaysusea clean-outtool,not yourhands.

4

MAINTENANCE & STORAGE

• Nevertamperwithsafetydevices.Checktheirproperoperation

regularly.Refertothemaintenanceandadjustmentsectionsof

thismanual.

• Beforecleaning,repairing,or inspectingmachinedisengageall

controlleversandstoptheengine.Waituntilthe auger/impeller

cometoa completestop.Disconnectthe sparkplugwireand

groundagainsttheengineto preventunintendedstarting.

Checkboltsand screwsfor propertightnessat frequentintervals

tokeepthe machineinsafeworkingcondition.Also,visually

inspectmachineforanydamage.

Donotchangetheenginegovernorsettingor over-speedthe

engine.Thegovernorcontrolsthe maximumsafeoperatingspeed

oftheengine.

Snowthrowershaveplatesandskidshoesaresubjecttowear

anddamage.Foryoursafetyprotection,frequentlycheckall

componentsand replacewithoriginalequipmentmanufacturer's

(OEM)partsonly."Useofpartswhichdo not meetthe original

equipmentspecificationsmayleadto improperperformanceand

compromisesafety!"

Checkcontrolleversperiodicallytoverifytheyengageanddisen-

gageproperlyandadjust,ifnecessary.Refertotheadjustment

sectioninthisoperator'smanualforinstructions.

Maintainor replacesafetyandinstructionlabels,asnecessary.

• Observeproperdisposallawsand regulationsforgas,oil,etc.to

protecttheenvironment.

Priorto storing,runmachinea few minutestoclearsnowfrom

machineand preventfreezeupof auger/impeller.

Neverstorethemachineorfuelcontainerinsidewherethereisan

openflame,sparkorpilotlightsuchasa waterheater,furnace,

clothesdryeretc.

Alwaysrefertothe operator'smanualforproperinstructionson

off-seasonstorage.

Checkfuelline,tank, cap,andfittingsfrequentlyforcracksor

leaks.Replaceif necessary.

Donotcrankenginewithsparkplugremoved.

AccordingtotheConsumerProductsSafetyCommission(CPSC)

andtheU.S.EnvironmentalProtectionAgency(EPA),thisproduct

hasan AverageUsefulLifeof seven(7)years,or 60 hoursof

operation.Attheendof theAverageUsefulLifehavethemachine

inspectedannuallybyan authorizedservicedealertoensurethat

allmechanicalandsafetysystemsareworkingproperlyand not

wornexcessively.Failuretodo so can resultinaccidents,injuries

ordeath.

DO NOT MODIFY ENGINE

Toavoidseriousinjuryor death,do notmodifyengineinanyway.

Tamperingwiththegovernorsettingcanleadtoa runawayengineand

causeittooperateat unsafespeeds.Nevertamperwithfactorysetting

ofenginegovernor.

NOTICE REGARDING EMiSSiONS

EngineswhicharecertifiedtocomplywithCaliforniaandfederal

EPAemissionregulationsforSORE(SmallOffRoadEquipment)are

certifiedto operateon regularunleadedgasoline,and mayinclude

thefollowingemissioncontrolsystems:EngineModification(EM),

OxidizingCatalyst(OC),SecondaryAirInjection(SAI)and ThreeWay

Catalyst(TWO)if soequipped.

SPARK ARRESTOR

Thismachineisequippedwithaninternalcombustionengineand

shouldnotbe usedonor nearanyunimprovedforest-covered,

brush-coveredorgrass-coveredlandunlesstheengine'sexhaust

systemisequippedwitha sparkarrestermeetingapplicablelocalor

statelaws(if any)

Ifa sparkattesterisused,itshouldbemaintainedin effectiveworking

orderbytheoperator.IntheStateof Californiatheaboveis required

bylaw (Section4442of the CaliforniaPublicResourcesCode).Other

statesmayhavesimilarlaws. Federallawsapplyonfederallands.

A sparkarresterforthemufflerisavailablethroughyournearestSears

PartsandRepairServiceCenter.

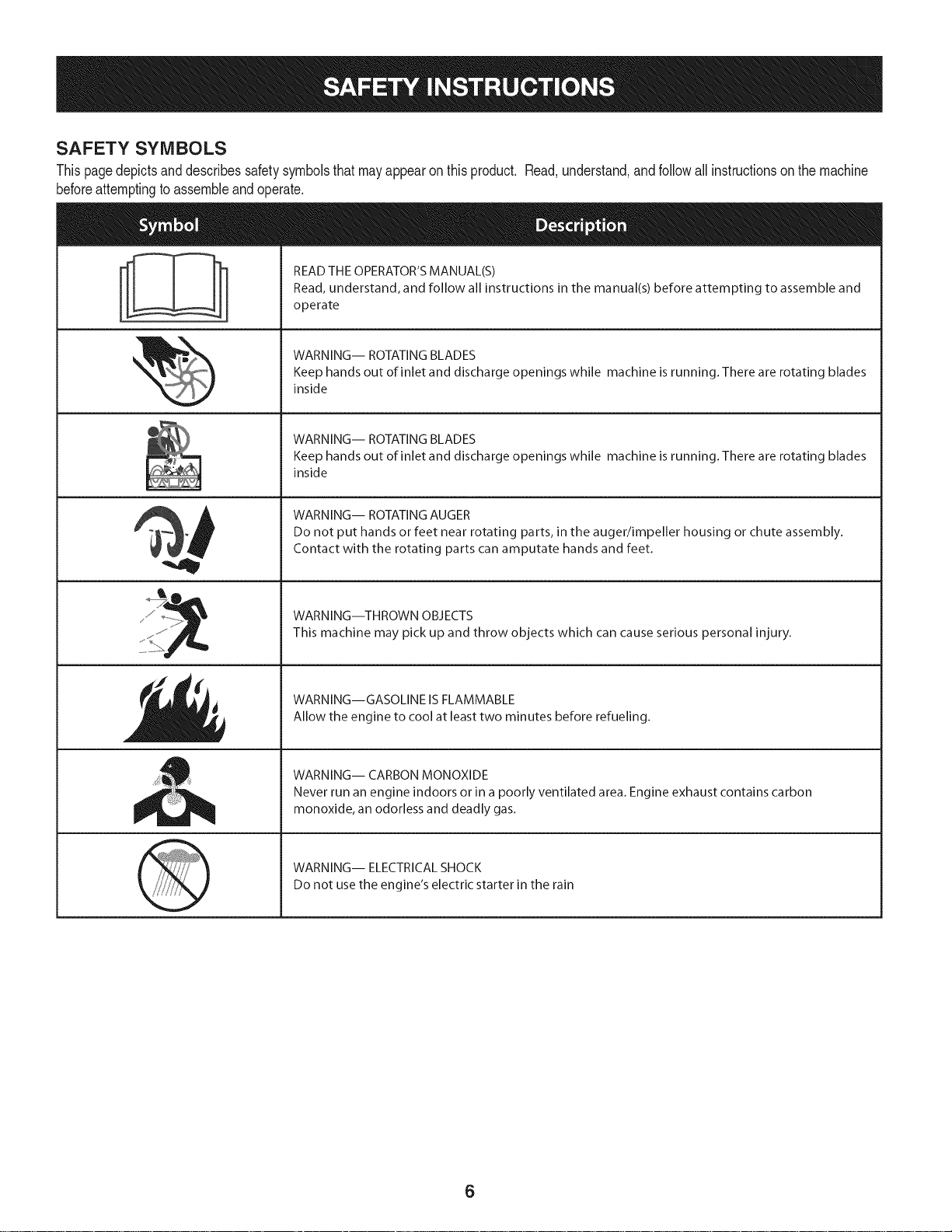

SAFETY SYMBOLS

Thispagedepictsanddescribessafetysymbolsthatmayappearonthisproduct. Read,understand,andfollowall instructionson the machine

beforeattemptingto assembleandoperate.

READ THE OPERATOR'S MANUAL(S)

i

. +

i

Read, understand, and follow all instructions in the manual(s) before attempting to assemble and

operate

WARNING-- ROTATING BLADES

Keep hands out of inlet and discharge openings while machine is running. There are rotating blades

inside

WARNING-- ROTATING BLADES

Keep hands out of inlet and discharge openings while machine is running. There are rotating blades

inside

WARNING-- ROTATING AUGER

Do not put hands or feet near rotating parts, in the auger/impeller housing or chute assembly.

Contact with the rotating parts can amputate hands and feet.

'JIp

WARNING--THROWN OBJECTS

This machine may pick up and throw objects which can cause serious personal injury.

WARNING--GASOLINE IS FLAMMABLE

Allow the engine to cool at least two minutes before refueling.

WARNING-- CARBON MONOXIDE

Never run an engine indoors or in a poorly ventilated area. Engine exhaust contains carbon

monoxide, an odorless and deadly gas+

WARNING-- ELECTRICAL SHOCK

Do not use the engine's electric starter in the rain

6

lOOJ.,J.IlO=NV]10

"lVflNV_ S,UOJLVU3dOQV3H"_

N3HMNOIJ,RVOVtdJ,X33Sll"SU3QNVIS18IV30UVH3SBQ

13:lUiOH:IA:IN'S3iURrNIS13]F80NMOUHIQIOAV01 "t_

:IUO:J3gQ3dd01S3MH S.LUVd9HJAOI_1WlJlHn S31QNVH

QNIH38NiV_:t_lQNV'::lNiON::ldOlS'SH3A:rlH31R133OVON:lSl(]"_

":11AH33OSVHOSiQ90"13NI301 1001 lflO=NV:rl3:lSfl"_

"1:13dQNV8QHVH:11vlrld_VHVOU39flV}JO_13l13dL_lHJ,IM

IOVlN03"U3911VQNV1:131"13dlAIJ9NllVlOldINO_J:J)_VMVd:13)t"L

"S33VdUnS13AVU9NOgNilVU:ldO

"_]NiHOV_9Ni31Atd_SUO9NI99013NI'I

7

NOTE:Referencesto rightorleft sideof the snowthrowerare

determinedfrombehindtheunitintheoperatingposition(standing

directlybehindthesnowthrower,facingthe handlepanel).

REMOVING FROM CARTON

1. Cutthecornersofthecartonandlaythesidesflaton theground.

Removeanddiscardallpackinginserts.

2. Movethesnowthroweroutofthecarton.

3. Makecertainthecartonhasbeencompletelyemptiedbefore

discardingit.

ASSEMBLY

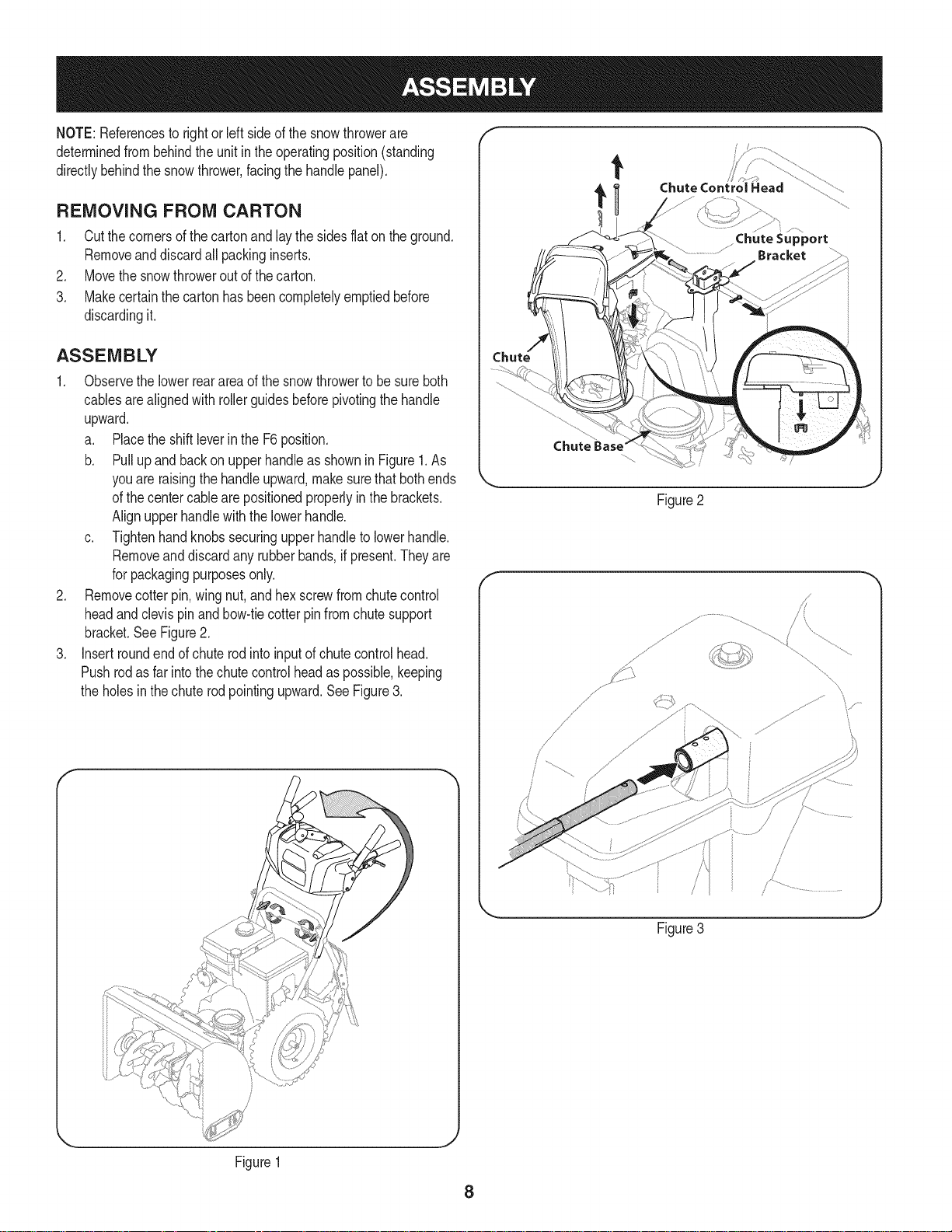

1. Observethe lowerrearareaof the snowthrowerto besure both

cablesarealignedwith rollerguidesbeforepivotingthehandle

upward.

a. Placethe shiftleverin the F6position.

b. Pullupandbackon upperhandleasshownin Figure1.As

youare raisingthehandleupward,makesurethatbothends

ofthecentercablearepositionedproperlyinthebrackets.

Alignupperhandlewiththelowerhandle.

c. Tightenhandknobssecuringupperhandleto lowerhandle.

Removeanddiscardanyrubberbands,ifpresent.Theyare

forpackagingpurposesonly.

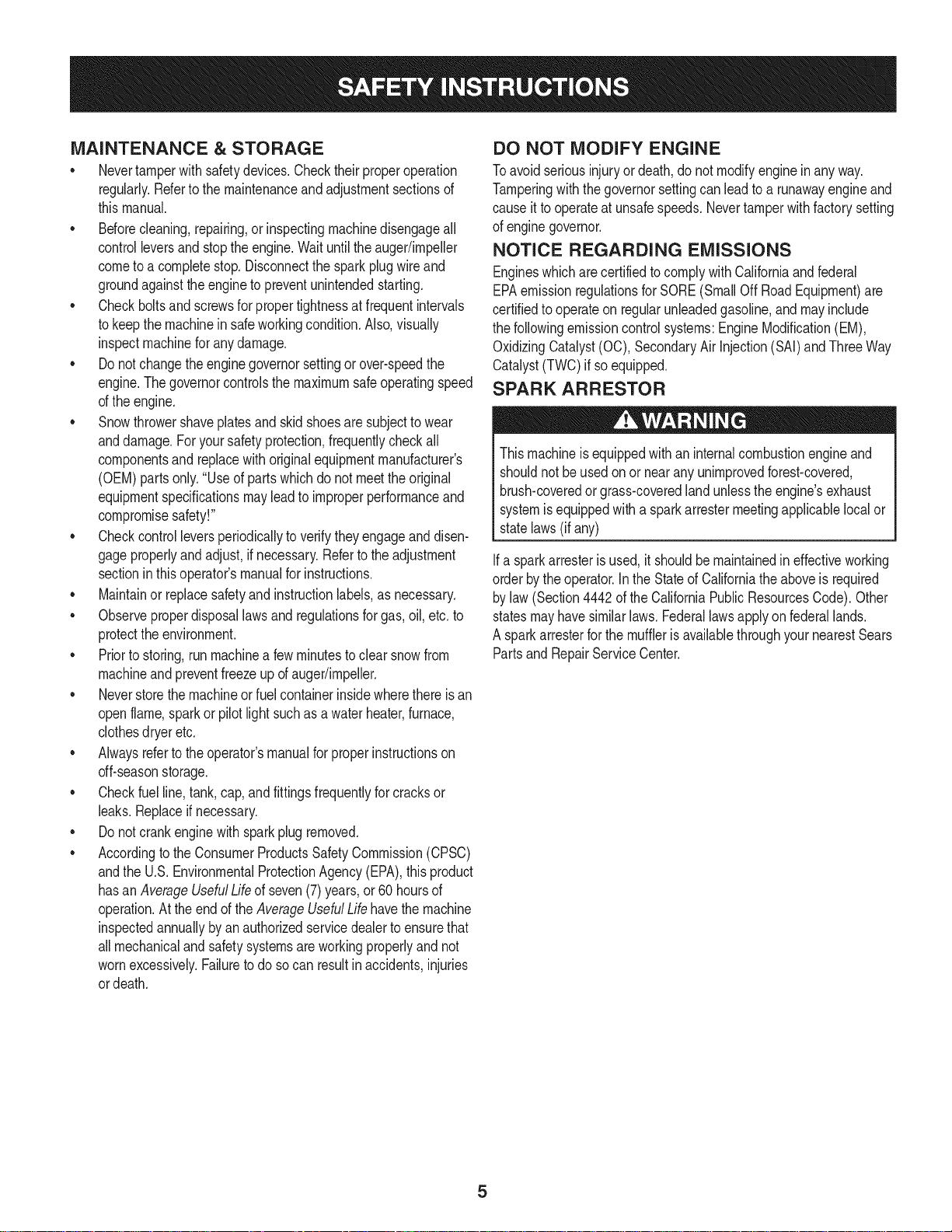

2. Removecotterpin,wing nut,andhexscrewfromchutecontrol

headandclevispinandbow-tiecotterpinfromchutesupport

bracket.SeeFigure2.

3. Insertroundendofchuterodinto inputofchutecontrolhead.

Pushrodas far intothechutecontrolheadas possible,keeping

theholesinthe chuterodpointingupward.SeeFigure3.

t

Chute Control Head

Chute

Figure2

f

// .....

%

Figure1

Figure3

8

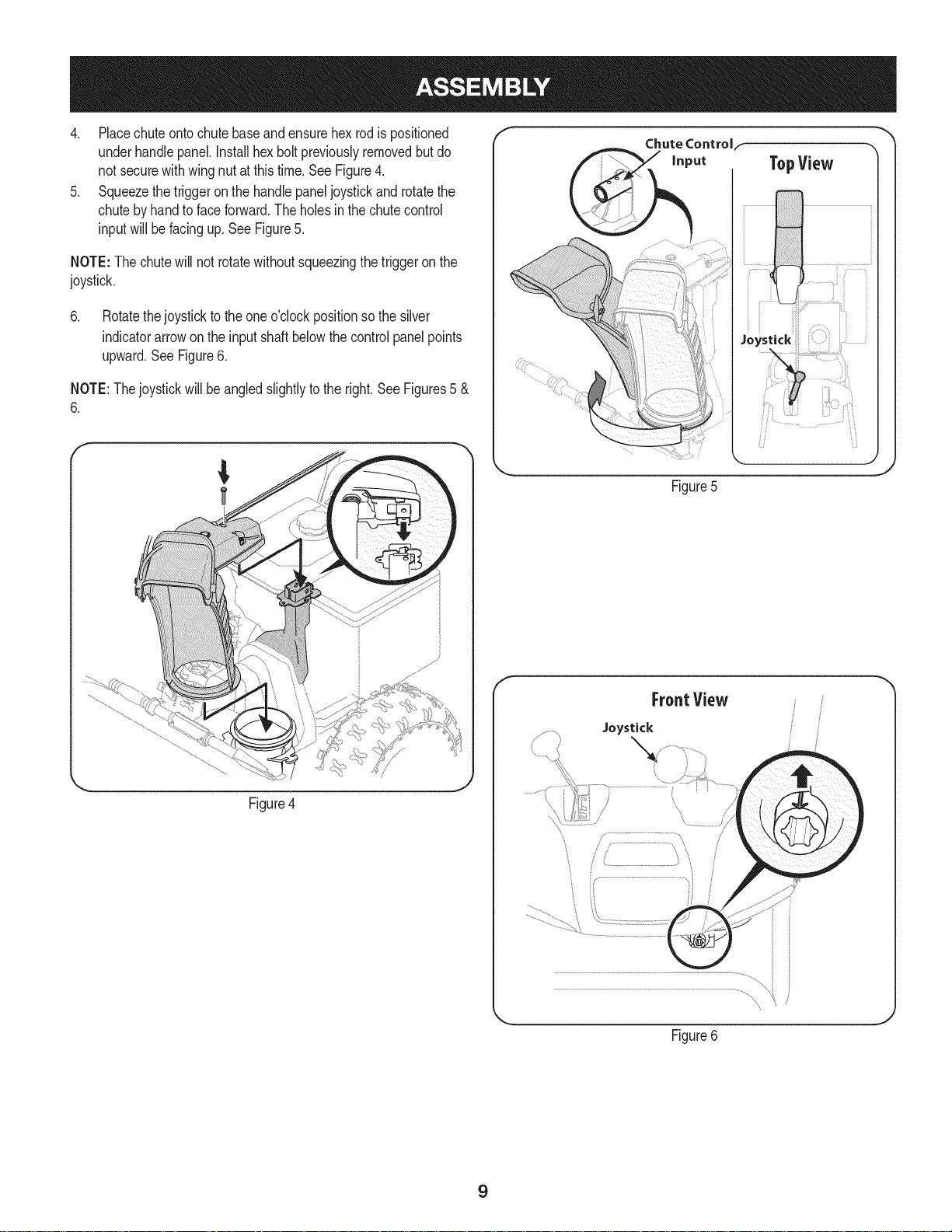

4. Placechuteontochutebaseandensurehexrodis positioned

underhandlepanel.Installhexboltpreviouslyremovedbutdo

notsecurewithwingnut at thistime.See Figure4.

5. Squeezethetriggeron thehandlepaneljoystickandrotatethe

chutebyhandtofaceforward.Theholesinthechutecontrol

inputwill befacingup.SeeFigure5.

NOTE:The chutewill not rotatewithoutsqueezingthetriggeronthe

joystick.

6. Rotatethejoystickto the oneo'clockpositionsothesilver

indicatorarrowontheinputshaft belowthecontrolpanelpoints

upward.SeeFigure6.

NOTE:Thejoystickwillbe angledslightlyto the right.SeeFigures5 &

6.

f

Chute Controlf

TopView

_i¸ ............... t_i

Figure5

Figure4

f

FrontView

Joystick

J

Figure6

9

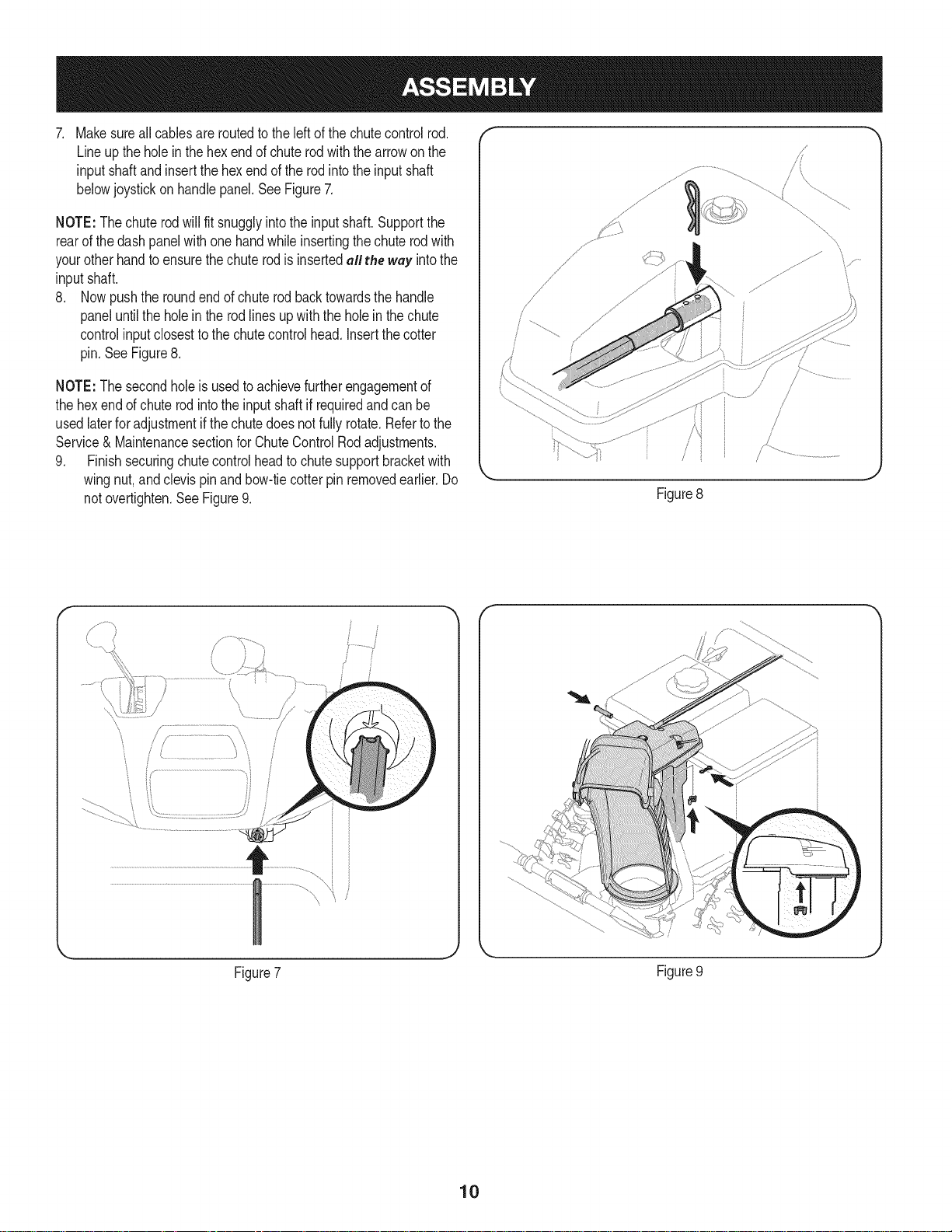

. Makesureallcablesareroutedtotheleft ofthe chutecontrolrod.

Lineuptheholein thehexendofchuterodwiththe arrowonthe

inputshaftandinsertthe hex endof the rodintothe input shaft

belowjoystickon handlepanel.SeeFigure7.

NOTE:Thechuterodwill fit snugglyintotheinputshaft.Supportthe

rearofthedashpanelwithonehandwhileinsertingthechuterodwith

yourotherhandto ensurethechuterodis insertedall the way intothe

inputshaft.

8. Nowpushthe roundend ofchuterod backtowardsthehandle

paneluntilthe holein therodlinesupwiththe holeinthechute

controlinputclosestto the chutecontrolhead. Insertthecotter

pin.SeeFigure8.

NOTE:The secondholeis usedtoachievefurtherengagementof

thehexendofchuterodintotheinputshaft if requiredandcan be

usedlaterforadjustmentif thechutedoesnotfullyrotate.Refertothe

Service& Maintenancesectionfor ChuteControlRodadjustments.

9. Finishsecuringchutecontrolheadtochutesupportbracketwith

wingnut,andclevispinandbow-tiecotterpinremovedearlier.Do

notovertighten.SeeFigure9.

/i _

.J

Figure8

y..................

\,

\

Figure7

Figure9

10

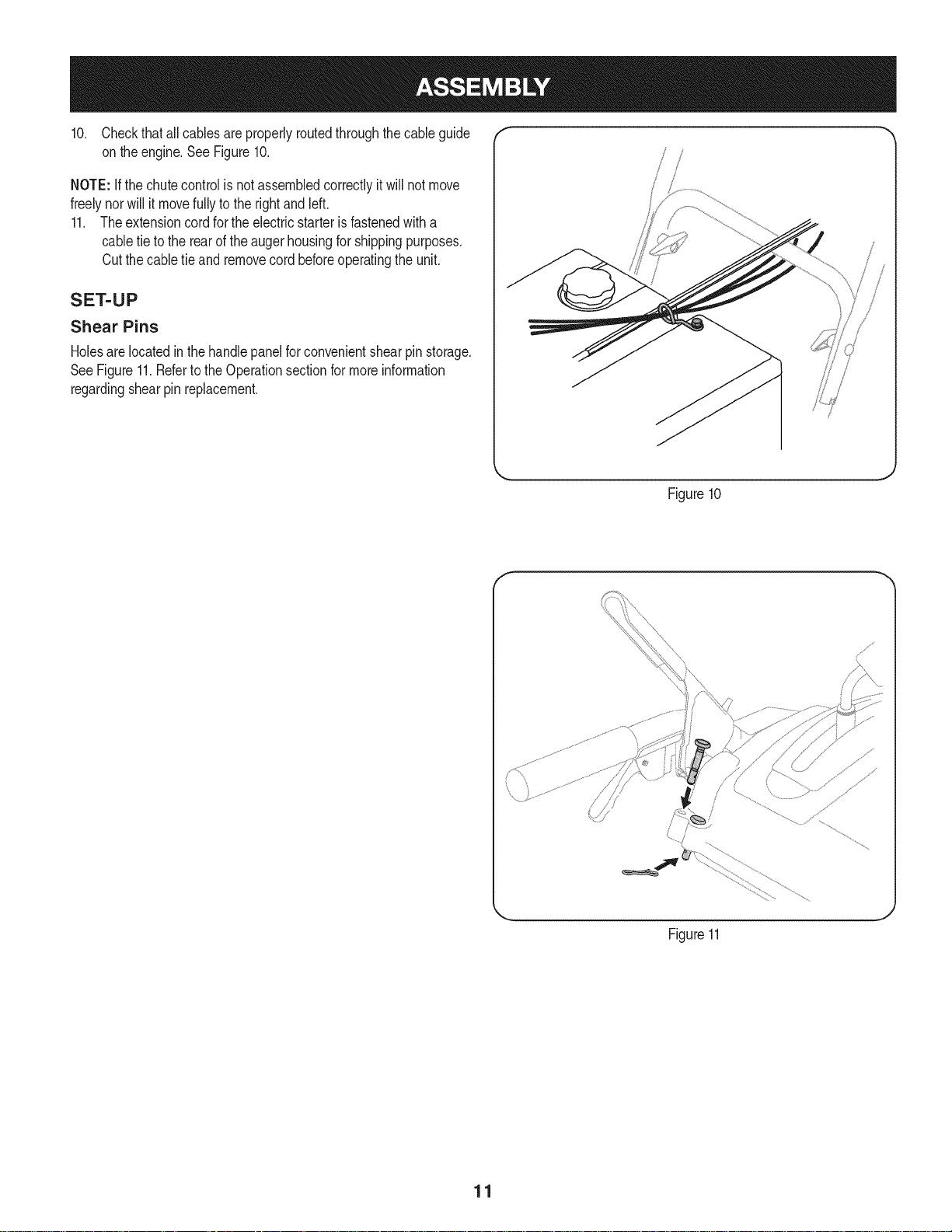

10. Checkthatallcablesareproperlyroutedthroughthecableguide "_

on theengine.SeeFigure10.

NOTE:ifthechutecontrolisnotassembledcorrectlyitwillnotmove

freelynorwillit movefullyto the rightandleft.

11. Theextensioncordforthe electricstarterisfastenedwitha

cabletie to therearoftheaugerhousingforshippingpurposes.

Cutthecabletieand removecordbeforeoperatingthe unit.

SET-UP

Shear Pins

Holesare locatedinthe handlepanelfor convenientshearpin storage.

SeeFigure11.RefertotheOperationsectionformoreinformation

regardingshearpin replacement.

f

Figure10

11

J

Figure11

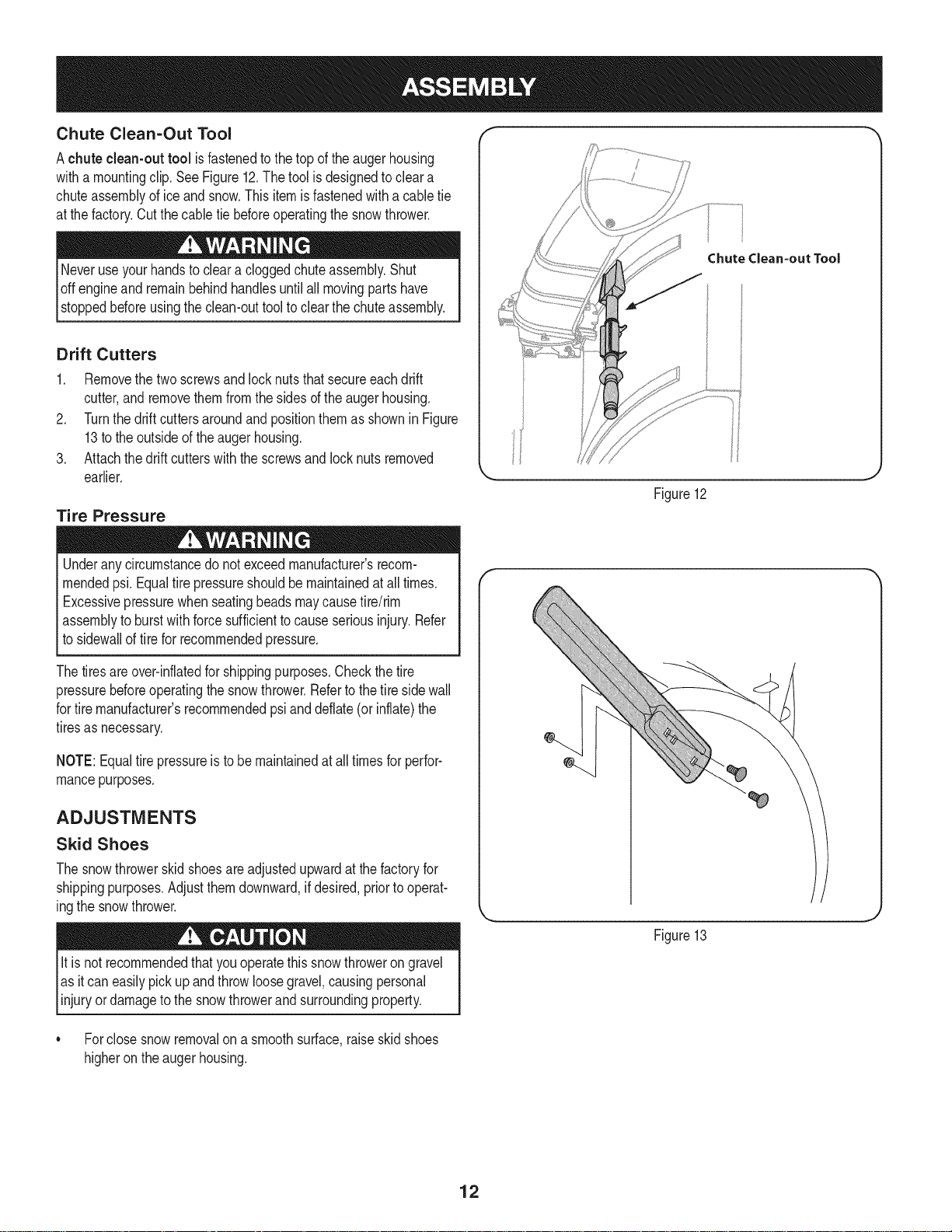

Chute Clean-Out Tool

Achute clean-out tool isfastenedtothe top of the augerhousing

witha mountingclip.SeeFigure12.Thetoolisdesignedtocleara

chuteassemblyofice andsnow.Thisitemisfastenedwitha cabletie

atthefactory.Cutthecabletiebeforeoperatingthesnowthrower.

loft _1 .allmovingpartshave

stoppedbeforeusingtheclean-outtooltoclearthechuteassembly.

Drift Cutters

1. Removethetwo screwsandlocknutsthatsecureeachdrift

cutter,andremovethemfromthesidesoftheaugerhousing.

2. Turnthedriftcuttersaroundandpositionthemas showninFigure

13totheoutsideoftheaugerhousing.

3. Attachthedrift cutterswiththescrewsandlocknutsremoved

earlier.

Tire Pressure

Underanycircumstancedo notexceedmanufacturer'srecom-

mendedpsi.Equaltirepressureshouldbemaintainedatall times.

Excessivepressurewhenseatingbeadsmaycausetire/rim

assemblytoburstwithforcesufficienttocauseseriousinjury.Refer

tosidewallof tirefor recommendedpressure.

Chutedean-out Tool

Figure12

Thetiresareover-inflatedforshippingpurposes.Checkthetire

pressurebeforeoperatingthe snowthrower.Refertothetiresidewall

fortiremanufacturer'srecommendedpsianddeflate(or inflate)the

tiresasnecessary.

NOTE:Equaltire pressureistobe maintainedat alltimesfor perfor-

mancepurposes.

ADJUSTMENTS

Skid Shoes

Thesnowthrowerskidshoesareadjustedupwardatthefactoryfor

shippingpurposes.Adjustthemdownward,ifdesired,priortooperat-

ingthesnowthrower.

It isnotrecommendedthatyouoperatethissnowthrowerongravel

asitcan easilypickup andthrowloosegravel,causingpersonal

njuryordamageto the snowthrowerandsurroundng property.

• Forclosesnowremovalona smoothsurface,raiseskidshoes

higherontheaugerhousing.

Figure13

12

Usea middleorlowerpositionwhentheareato be clearedis

uneven,suchas a graveldriveway.

NOTE:Ifyouchoosetooperatethesnowthroweron agravelsurface,

keepthe skidshoesin positionformaximumclearancebetweenthe

groundandtheshaveplate.

Operatinga snowthrowerequippedwith steelskidshoesmayresult

indamageto naturalstonepaversurfaces(e.g.sandstone,blue-

stone,limestone).Forinformationonavailablepolymerskidshoes,

call1-800-4MY-HOME.

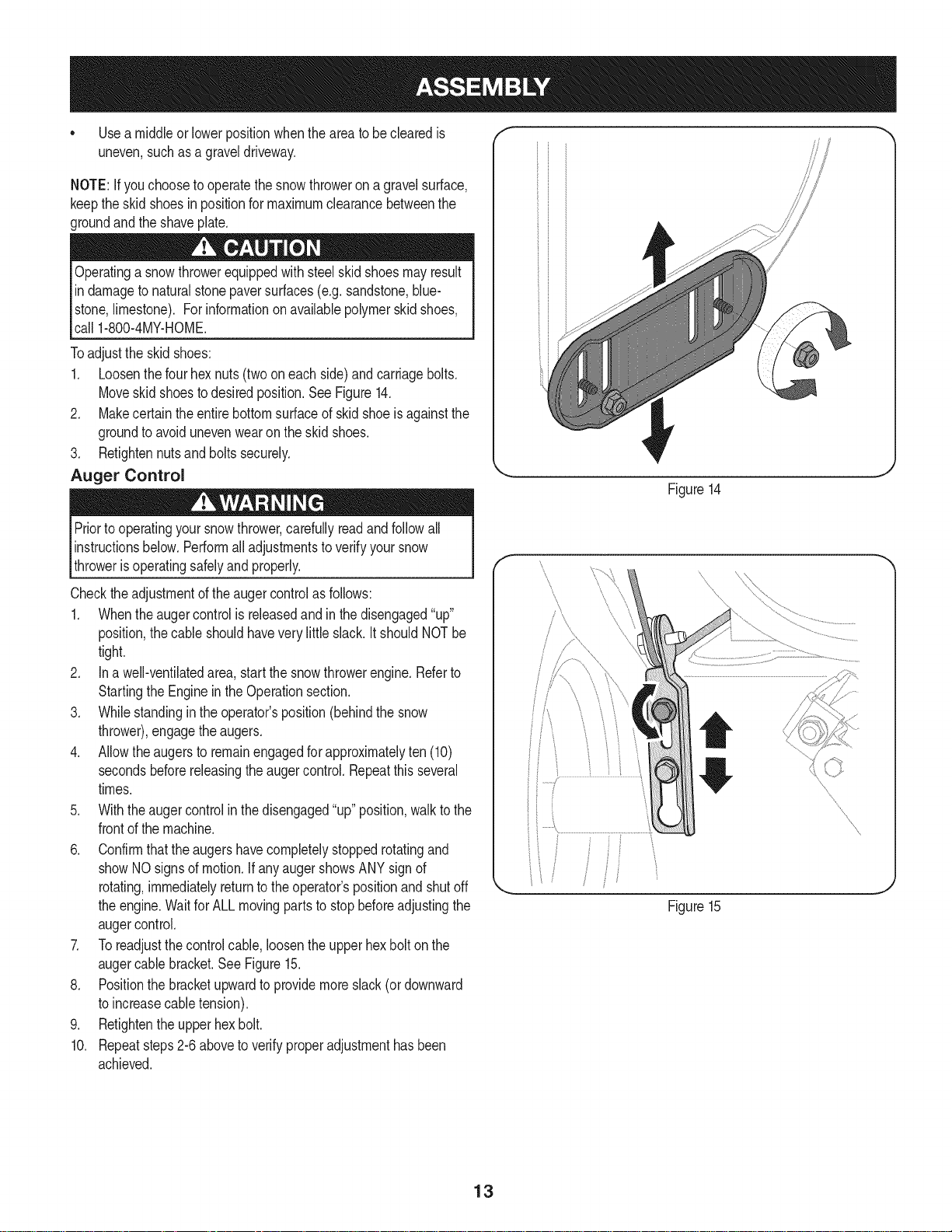

Toadjustthe skidshoes:

1. Loosenthefourhexnuts(twooneach side)andcarriagebolts.

Moveskidshoestodesiredposition.See Figure14.

2. Makecertaintheentirebottomsurfaceof skidshoeis againstthe

groundtoavoidunevenwearonthe skidshoes.

3. Retightennutsandboltssecurely.

Auger Control

Priortooperatingyoursnowthrower,carefullyreadand followall

instructionsbelow.Performalladjustmentstoverifyyoursnow

throwerisoperatingsafelyand properly.

J

Figure14

f

Checktheadjustmentof the augercontrolasfollows:

1. Whentheaugercontrolis releasedandin thedisengaged"up"

position,thecableshouldhaveverylittleslack.ItshouldNOTbe

tight.

2. Ina well-ventilatedarea,startthesnowthrowerengine.Referto

StartingtheEngineintheOperationsection.

3. Whilestandingintheoperator'sposition(behindthe snow

thrower),engagethe augers.

4. Allowtheaugersto remainengagedforapproximatelyten (10)

secondsbeforereleasingthe augercontrol.Repeatthisseveral

times.

5. Withtheaugercontrolin thedisengaged"up"position,walktothe

frontofthemachine.

6. Confirmthatthe augershavecompletelystoppedrotatingand

showNOsignsof motion.IfanyaugershowsANYsignof

rotating,immediatelyreturntothe operator'spositionandshutoff

theengine.WaitforALLmovingpartsto stopbeforeadjustingthe

augercontrol.

7. Toreadjustthecontrolcable,loosentheupperhexbolt onthe

augercablebracket.SeeFigure15.

8. Positionthe bracketupwardtoprovidemoreslack(or downward

toincreasecabletension).

9. Retightentheupperhex bolt.

10. Repeatsteps2-6aboveto verifyproperadjustmenthasbeen

achieved.

f

/

J

Figure15

13

f

Drive Control

Headlight

GasCap

Shift Lever

F Four-Way Chute ControP (Joystick)

F

F

Auger Control

Heated Grip

Chute Assembly

Drift Cutter

Augers

\

\

\

Skid Shoe

Figure15

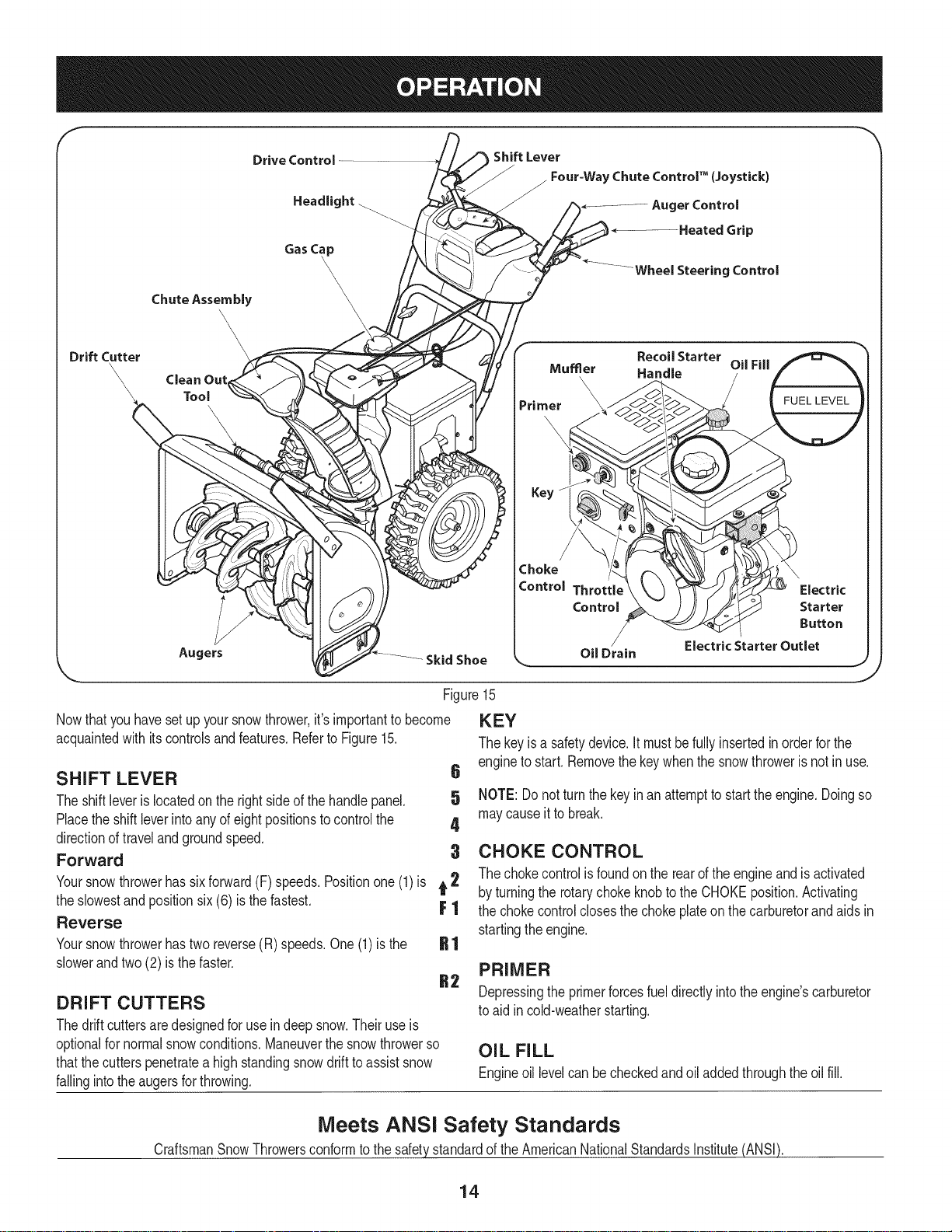

Nowthat youhavesetup yoursnowthrower,it'simportanttobecome

acquaintedwith itscontrolsandfeatures.Referto Figure15.

SHIFT LEVER 6

Theshiftleverislocatedonthe rightsideofthe handlepanel. 5

Placethe shiftleverinto anyofeightpositionstocontrolthe 4

directionoftravelandgroundspeed.

Forward 3

Yoursnowthrowerhassixforward(F)speeds.Positionone(1)is t 2

theslowestand positionsix (6) is the fastest. F 1

Reverse

Yoursnowthrowerhastwo reverse(R) speeds.One(1)is the

slowerandtwo(2) isthefaster.

DRIFT CUTTERS

Thedrift cuttersaredesignedforuse indeepsnow.Theiruseis

optionalfornormalsnowconditions.Maneuverthe snowthrowerso

thatthecutterspenetratea highstandingsnowdrifttoassistsnow

fallingintotheaugersforthrowing.

Mumer

Primer

Recoil Starter

\

\

Handle

Oil Fill

FUEL LEVEL

\

Key

Choke

Control Throttle

Control

/

OilDrain

Electric StarterOutlet

KEY

Thekeyisa safetydevice.It mustbefullyinsertedinorderfor the

engineto start.Removethekeywhenthesnowthroweris not inuse.

NOTE:Donot turnthekeyinan attempttostarttheengine.Doingso

maycauseit tobreak.

CHOKE CONTROL

Thechokecontrolisfoundon therearoftheengineand is activated

byturningthe rotarychokeknobtotheCHOKEposition.Activating

thechokecontrolclosesthe chokeplateon thecarburetorandaidsin

startingthe engine.

PRIMER

Depressingthe primerforcesfueldirectlyintotheengine'scarburetor

toaid incold-weatherstarting.

OIL FILL

Engineoil levelcan becheckedandoiladdedthroughtheoil fill.

\

Electric

Starter

Button

Meets ANSI Safety Standards

CraftsmanSnowThrowersconformto the safetystandardoftheAmericanNationalStandardsInstitute(ANSI).

14

THROTTLE CONTROL

Thethrottlecontrolis locatedonthe rearof the engine.It regulatesthe

speedof theengineandwill shutoff theenginewhenmovedintothe

STOPposition.

ELECTRIC STARTER BUTTON

Pressingtheelectricstarterbuttonengagestheengine'selectric

starterwhenpluggedintoa 120Vpowersource.

ELECTRIC STARTER OUTLET

Requirestheuseof athree-prongoutdoorextensioncord(included)

anda 120Vpowersource/walloutlet.

AUGERS

Whenengaged,theaugerbladesrotateand drawsnowintotheauger

housing.

SKID SHOES

Positiontheskid shoesbasedonsurfaceconditions.Adjustupward

forhard-packedsnow.Adjustdownwardwhenoperatingongravelor

crushedrocksurfaces.

HEADLIGHT

Theheadlightison whenevertheengineisrunning.

HEATED GRIPS

Toactivatethe heatedgrips,movetheswitchfoundon therearof the

dashpanelintotheONposition.

WHEEL STEERING CONTROLS

Theleft andrightwheelsteeringcontrolsarelocatedon theunderside

ofthehandles.Squeezethe rightcontroltoturnright;squeezethe left

controltoturn left.

NOTE:Operatethesnowthrowerinopenareasuntilyou arefamiliar

withthesecontrols.

Theaugercontrolislocatedon thelefthandle.Squeezethe control

gripagainstthehandletoengagetheaugerand startsnowthrowing

action.Releaseto stop.

DRIVE CONTROL/AUGER CONTROL LOCK

DRIVE

CONTROL

Thedrivecontrolis locatedon the righthandle.Squeezethecontrol

gripagainstthehandletoengagethewheeldrive.Releasetostop.

Thedrivecontrolalso lockstheaugercontrolsoyoucan operate

thechutedirectionalcontrolwithoutinterruptingthesnowthrowing

process.If theaugercontrolis engagedsimultaneouslywiththedrive

control,the operatorcanreleasetheaugercontrol(onthelefthandle)

andtheaugerswill remainengaged.Releasebothcontrolstostopthe

augersandwheeldrive.

NOTE:Alwaysreleasethedrivecontrolbeforechangingspeeds.

Failureto dosowill resultinincreasedwearon yourmachine'sdrive

system.

FOUR=WAY CHUTE CONTROL TM

CHUTE DiRECTiONAL CONTROL

CHUTETiLTDOWN

t

CHUTEROTATE CHUTEROTATE

LEFT RIGHT

AUGER CONTROL

CHUTETiLTUP

Thefour-waychutecontrolTM (Joystick)islocatedon theleft sideof the

handlepanel.

* Tochangethedirectioninwhichsnowisthrown,squeezethe

buttononthechutecontrolleverandpivotthechutecontrollever

tothe rightortotheleft.

* Tochangetheangle/distancewhichsnowisthrown,pivotthe

chutecontrolleverforwardto tiltthechutedownandbackwardto

tilt the chuteup.

15

j,

CLEAN-OUT TOOL

Neveruseyourhandsto cleara cloggedchuteassembly.Shut

loft engineandremainbehindhandlesuntilallmovingpartshave

lstoppedbeforeusingtheclean-outtoolto clearthechuteassembly.

Thechuteclean-outtoolisconvenientlyfastenedtothe rearof the

augerhousingwitha mountingclip. Shouldsnowandicebecome

lodgedin thechuteassemblyduringoperation,proceedasfollowsto

safelycleanthechuteassemblyandchuteopening:

1. Releaseboththe AugerControlandtheDriveControl.

2. Stopthe engineby removingtheignitionkey.

3. Removetheclean-outtoolfromthe clip whichsecuresittothe

rearoftheaugerhousing.

4. Usetheshovel-shapedendof theclean-outtoolto dislodgeand

scoopanysnowand icewhichhasformedinandnearthechute

assembly.

5. Refastenthe clean-outtooltothemountingcliponthe rearof

theaugerhousing,reinserttheignitionkeyandstartthesnow

thrower'sengine.

6. Whilestandingintheoperator'sposition(behindthesnow

thrower),engagethe augercontrolfora fewsecondstoclearany

remainingsnowandice fromthechuteassembly.

BEFORE STARTING ENGINE

Read,understand,andfollowall instructionsandwarningson the

machineand inthismanualbeforeoperating.

Oil

Theunit wasshippedwith oil inthe engine.Checkoillevelbefore

eachoperationtoensureadequateoilintheengine.Forfurther

instructions,refertothe stepson page18.

NOTE:Besureto checktheengineon a levelsurfacewiththeengine

stopped.

1. Removetheoil fillercap/dipstickandwipethedipstickclean.

2. insertthecap/dipstickintotheoilfiller neck,andtightenthecap

untilseated.

3. Removetheoil fillercap/dipstick,ifthelevelislow,slowlyadd

oil (5%30, witha minimumclassificationof SF/SG)untiloil level

registersbetweenhigh(H) andlow(L).

NOTE:Do notoverfill.Overfillingwithoil mayresultinenginesmoking,

hardstartingorsparkplugfouling.

4. Replaceandtightencap/dipstickfirmlybeforestartingengine.

Gasoline

Useautomotivegasoline(unleadedor lowleadedtominimizecombus-

tionchamberdeposits)witha minimumof87octane.Gasolinewith

upto 10%ethanolor 15%MTBE(MethylTertiaryButylEther)canbe

used.Neveruseanoil/gasolinemixtureordirtygasoline.Avoidgetting

dirt,dust,or waterinthefueltank.DONOTuseE85gasoline.

• Refuelina well-ventilatedareawiththeenginestopped.Donot

smokeorallowflamesor sparksinthe areawheretheengineis

refueledor wheregasolineisstored.

• Donot overfillthe fueltank.After refueling,makesurethetank

capisclosedproperlyandsecurely.

• Becarefulnotto spillfuelwhenrefueling.Spilledfuelorfuel vapor

mayignite,ifany fuelisspilled,makesurethe areaisdry before

startingthe engine.

• Avoidrepeatedorprolongedcontactwithskinor breathingof

)or.

Useextremecarewhenhandlinggasoline.Gasolineisextremely

flammableandthevaporsare explosive.Neverfuelthemachine

indoorsorwhiletheengineis hotor running.Extinguishcigarettes,

cigars,pipesandothersourcesof ignition.

1. Cleanaroundfuelfill beforeremovingcaptofuel.

2. A fuellevelindicatorislocatedin thefueltank.SeeFigure15

inset.Becarefulnotto overfill.Filltank untilfuelreachesthe fuel

levelindicatortoallowspaceforfuel expansion.

STARTING THE ENGINE

Alwayskeephandsandfeetclearof movingparts.Donot usea

pressurizedstartingfluid.Vaporsareflammable.

NOTE:Allowtheenginetowarmupfor a fewminutesafter starting.

Theenginewillnotdevelopfullpoweruntilit reachesoperating

temperatures.

1. Makecertainboththe augercontrolanddrivecontrolarein the

disengaged(released)position.

2. insertkeyintoslot.Makesureit snapsintoplace.Donotattempt

toturnthekey.

NOTE:Theenginecannotstartwithoutthekeyfullyinsertedintothe

ignitionswitch.

Electric Starter

Theoptionalelectricstarteris equippedwitha groundedthree-wire

powercordandplug,and is designedto operateon 120voltAC

householdcurrent.It mustbeusedwitha properlygroundedthree-

prongreceptacleatall timestoavoidthe possibilityofelectricshock.

Followall instructionscarefullypriortooperatingtheelectricstarter.

DONOTuse electricstarterintherain.

Determinethatyourhome'swiringisa three-wiregroundedsystem.

Aska licensedelectricianifyouarenotcertain.

Ifyouhaveagroundedthree-prongreceptacle,proceedasfollows.

Ifyoudonothavetheproperhousewiring,DONOTusetheelectric

starterunderanyconditions.

1. Plugtheextensioncord intotheoutletlocatedonthe engine's

surface.Plugtheotherendof extensioncordintoa three-prong

120-volt,grounded,ACoutletina well-ventilatedarea.

16

2. Movethrottlecontrolto FAST(rabbit)'_ position.

3. MovechoketotheCHOKEIJl position(coldenginestart).If

engineiswarm,placechokein RUNposition.

4. Pushprimerthree(3)times,makingsuretocoverventholein

primerbulbwhen pushing.Ifengineis warm,pushprimeronly

once.Alwayscoverventholewhenpushing.Coolweathermay

requireprimingtobe repeated.

5. Pushstarterbuttontostartengine.Oncetheenginestarts,im-

mediatelyreleasestarterbutton.Electricstarteris equippedwith

thermaloverloadprotection;systemwilltemporarilyshut-downto

allowstartertocoolifelectricstarterbecomesoverloaded.

6. Astheenginewarms,slowlyrotatethechokecontrolto RUN

position.Ifthe enginefalters,restartengineandrunwithchoke

athalf-chokepositionfor a shortperiodoftime,andthenslowly

rotatethechokeinto RUNposition.

7. Afterengineisrunning,disconnectpowercordfromelectric

starter.Whendisconnecting,alwaysunplugtheendatthewall

outletbeforeunpluggingtheoppositeendfromtheengine.

Recoil Starter

Donotpullthestarterhandlewhiletheenginerunning.

1. Movethrottlecontrolto FAST(rabbit)'_ position.

2. MovechoketotheCHOKEI,'_1 position(coldenginestart).If

engineiswarm,placechokein RUNposition.

3. Pushprimerthree(3)times,makingsuretocoverventholewhen

pushing.Ifengineiswarm,push primeronlyonce.Alwayscover

ventholewhenpushing.Coolweathermayrequireprimingtobe

repeated.

4. Pullgentlyonthe starterhandleuntil it beginstoresist,then

pullquicklyandforcefullytoovercomethecompression.Engine

shouldstart.Donotreleasethehandleandallow it to snapback.

ReturnropeSLOWLYtooriginalposition.If required,repeatthis

step.

5. Astheenginewarms,slowlyrotatethechokecontrolto RUN

position.Ifthe enginefalters,restartengineandrunwithchoke

athalf-chokepositionfor a shortperiodoftime,andthenslowly

rotatethechokeinto RUNposition.

TO ENGAGE DRIVE

1. Withthe throttlecontrolinthe Fast(rabbit)position,moveshift

leverintooneofthesixforward(F) positionsor tworeverse(R)

positions.Selecta speedappropriateforthesnowconditionsand

a paceyou'recomfortablewith.

NOTE:Whenselectinga DriveSpeed,usetheslowerspeedsuntil

youarecomfortableandfamiliarwiththe operationofthesnow

thrower.

2. Squeezethedrivecontrolagainstthehandleandthesnow

throwerwillmove.Releaseitanddrive motionwillstop.

NOTE:NEVERrepositionthe shiftlever(changespeedsordirection

oftravel)withoutfirst releasingthedrivecontrolandbringingthe snow

throwertoa completestop.Doingsowill resultinprematurewearto

thesnowthrower'sdrivesystem.

TO ENGAGE AUGER

1. Toengagetheaugerand startthrowingsnow,squeezethe auger

controlagainsttheleft handle.Releasetostopthe auger.

REPLACING SHEAR PiNS

Theaugersaresecuredtothespiralshaftwith shearpinsandcotter

pins.If the augersshouldstrikeaforeignobjectoricejam,the snow

throwerisdesignedsothatthepinsmayshear.If theaugerswillnot

turn,checkto see if thepins havesheared.SeeFigure16.

NEVERreplacetheaugershearpinswithanythingotherthan Sears

SKU#88389/0EM PartNo.738-04124Areplacementshearpins.

Anydamagetotheaugergearboxorother componentsas a resultof

failingto do sowill NOTbecoveredbyyoursnowthrower'swarranty.

Alwaysturnoff thesnowthrower'sengineand removethe keypriorto

replacingshearpins.

if -,

Toavoidunsupervisedengineoperation,neverleavethemachine

unattendedwiththeenginerunning.Turnthe engineoffafter useand

removekey.

STOPPING THE ENGINE

Afteryouhavefinishedsnow-throwing,runenginefora few minutes

beforestoppingtohelpdryoffany moistureontheengine.

1. MovethrottlecontroltoOFFposition.

2. Removethekey.Removingthe keywill reducethepossibilityof

unauthorizedstartingoftheenginewhileequipmentis notin use.

Keepthekeyina safeplace.Theenginecannotstartwithoutthe

key.

3. Wipeanymoistureawayfromthe controlson theengine.

Figure16

17

MAINTENANCE SCHEDULE

Beforeperforminganytypeofmaintenance/service,disengageall

controlsandstoptheengine.Waituntilallmovingpartshavecometo

acompletestop.Disconnectsparkplugwireandgrounditagainstthe

enginetopreventunintendedstarting.Alwayswearsafetyglassesduring

operationorwhileperforminganyadjustmentsorrepairs.

EachUseandevery5

hours

1st5 hours

Annuallyor25 hours

Annuallyor50 hours

Annuallyor100hours

BeforeStorage

1. Engineoil level

2. Looseormissinghardware

3. Unitandengine.

1. Engineoil

1. Sparkplug

2. Controllinkagesandpivots

3. Wheels

4. GearshaftandAugershaft

1. Engineoil

1. Sparkplug

1. Fuelsystem

1. Check

2. Tightenor replace

3. Clean

1. Change

1. Check

2. Lubewithlightoil

3. Lubewithmultipurposeautogrease

4. Lubewithlightoil

1. Change

1. Change

1. Runengineuntilit stopsfromlack

ENGINE MAINTENANCE

Checking Engine Oil

Followthemaintenanceschedulegivenbelow.Thischartdescribes

serviceguidelinesonly.Usethe ServiceLogcolumnto keeptrackof

completedmaintenancetasks.Tolocate the nearest SearsService

Centeror to scheduleservice,simplycontactSearsat

1-800-4-MY-HOME®.

d fuel

Beforelubricating,repairing,or inspecting,disengageall controls

Iandstopengine.Waituntilall movingpartshavecometo acomplete

_stop.

NOTE: Checktheoil levelbeforeeachuseto besurecorrectoil level

ismaintained.

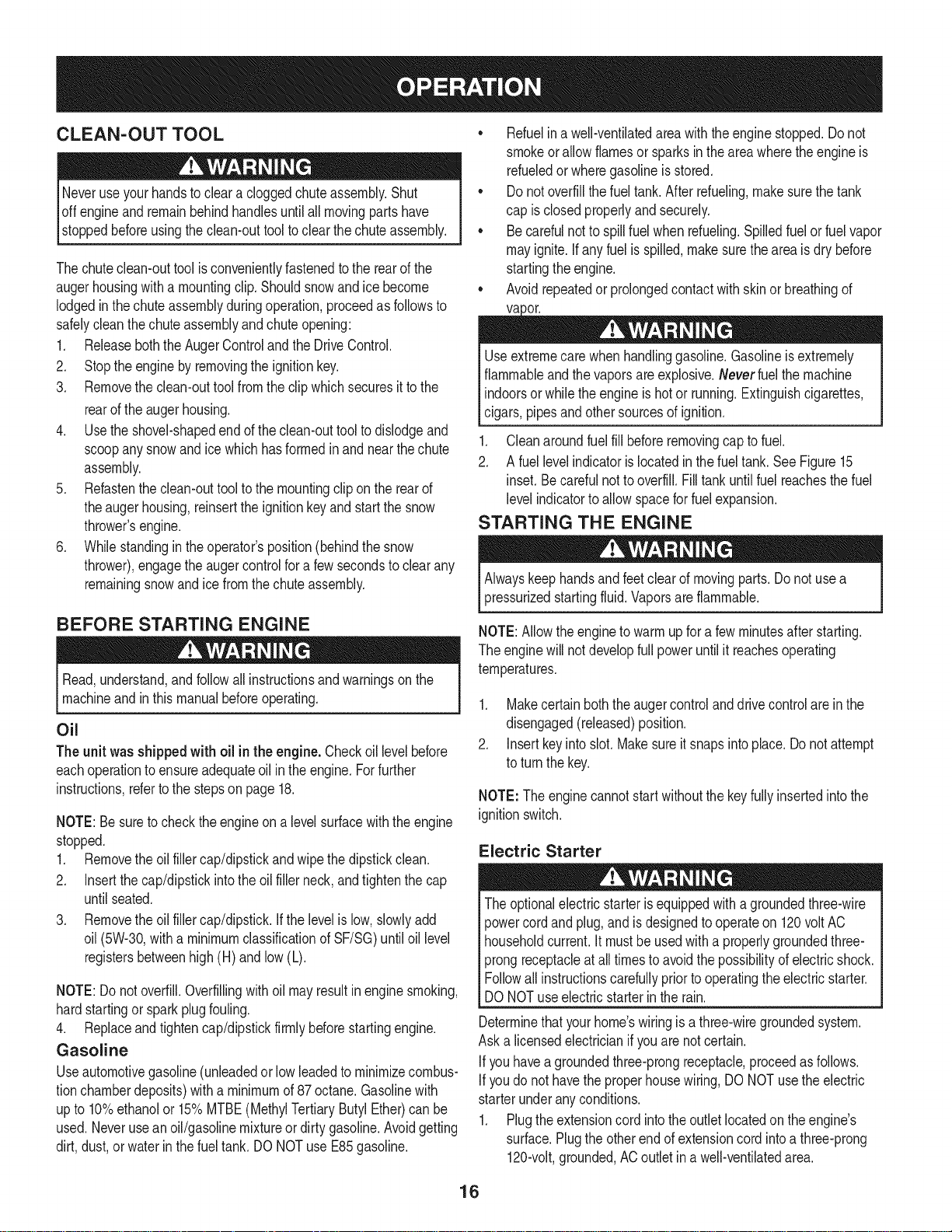

Whenaddingoilto the engine,referto viscositychart below.Engine

oilcapacityis 1100ml(approx.37oz.).Donotover-fill.Usea 4-stroke,

oran equivalenthighdetergent,premiumqualitymotoroilcertified

tomeetorexceedU.S.automobilemanufacturer'srequirementsfor

serviceclassificationSG, SR MotoroilsclassifiedSG,SFwillshow

thisdesignationonthe container.

1. Removetheoil fillercap/dipstickandwipethedipstickclean.

2. Insertthe cap/dipstickintothe oilfiller neck,andtightenthe cap

untilseated.

3. Removetheoil fillercap/dipstick.Iflevelislow,slowlyaddoiluntil

oil levelregistersbetweenhigh(H)andlow(L).SeeFigure17.

4. Replaceandtightencap/dipstickfirmlybeforestartingengine.

Changing Engine Oil

NOTE:Changetheengineoilafterthefirst5 hoursof operationand

oncea seasonorevery50 hoursthereafter.

1. Drainfuelfromtankbyrunningengineuntilthe fuel tankisempty.

Besurefuel fill capis secure.

J

Figure17

2. Placesuitableoil collectioncontainerunderoil drainplug.

3. Removeoil drainplug.SeeFigure18on nextpage.

4. Tipenginetodrainoil intothe container.Usedoil mustbe

disposedofat a propercollectioncenter.

Usedoil isa hazardouswasteproduct.Disposeofusedoil properly.

IDo notdiscardwithhouseholdwaste.Checkwithyourlocalauthori-

lties or SearsServiceCenterforsafedisposal/recyclingfacilities.

18

.

Reinstallthedrainplugandtightenit securely.

6.

Refillwiththerecommendedoilandchecktheoil level.See

RecommendedOil Usagechart.Theengine'soil capacityis37

ounces.

, ,

[

(%-40 °-20 o 0o 200 400

("c) -300 -200 -10° 0°

DONOTusenondetergentoilor 2-strokeengineoil.Itcouldshorten

theengine'sservicelife.

Oil Drain

Plug

7. Reinstalltheoilfillercap/dipsticksecurely.

Thoroughlywashyourhandswithsoapandwaterassoonas

possibleafterhandling usedoil.

Checking Spark Plug

DONOTcheckfor sparkwithsparkplugremoved.DONOTcrank

enginewithsparkplug removed.

Iftheenginehasbeenrunning,themufflerwillbevery hot.Becareful

notto touchthe muffler.

NOTE: Checkthesparkplugoncea seasonorevery25hoursof

operation.Changethesparkplugoncea seasonor every100hours.

Toensureproperengineoperation,thesparkplugmustbe properly

gappedandfreeof deposits.

1. Removethesparkplugbootanduse a sparkplugwrenchto

removetheplug.See Figure19.

2. Visuallyinspectthesparkplug.Discardthesparkplugifthereis

apparentwear,orif the insulatoris crackedor chipped.Cleanthe

sparkplugwitha wirebrush if it is to bereused.

3. Measurethe pluggapwitha feelergauge.Correctas necessary

bybendingsideelectrode.SeeFigure20.Thegap shouldbe set

to.02-.03inches(0.60-0.80ram).

4. Checkthatthe sparkplugwasherisingoodconditionandthread

thesparkplugin byhandto preventcross-threading.

5. Afterthesparkplugisseated,tightenwitha sparkplugwrenchto

compressthewasher.

NOTE:Wheninstallinga newsparkplug,tighten1/2-turnafterthe

sparkplugseatsto compressthewasher.Whenreinstallinga used

sparkplug,tighten1/8-to 1/4-turnafterthesparkplugseatsto

compressthewasher.

19

J

Electrode

Figure18

Spark Plug

O

SparkPlug Boot

Figure19

.02=.03 in.

(0.60-0.80 ram)

Figure20

hotandcan ine.

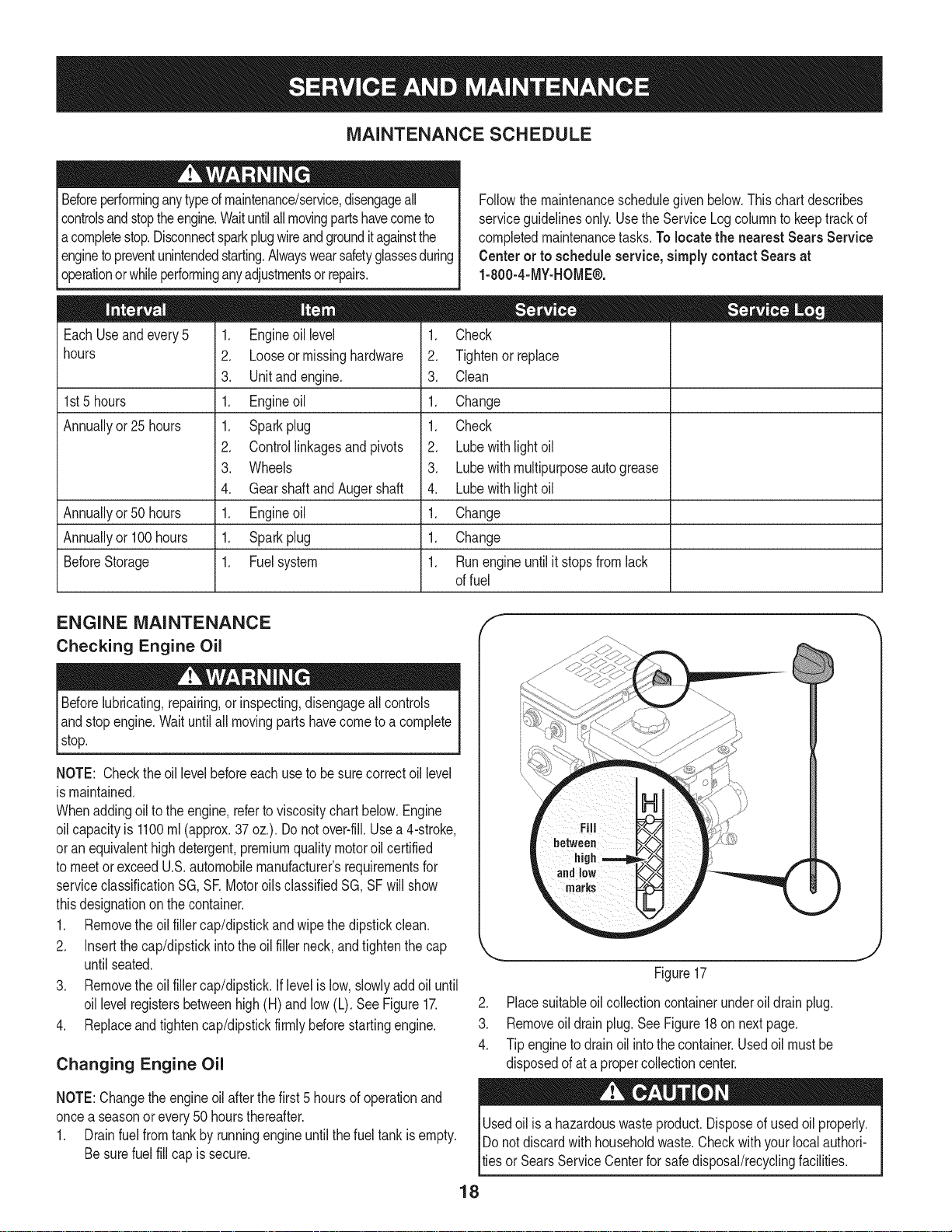

LUBRICATION

Gear Shaft

Thegear(hex)shaftshouldbelubricatedat leastoncea seasonor

afterevery25 hoursofoperation.

1. Topreventspillage,removeall fuelfromtank by runningengine

untilitstops.

2. Carefullypivotthesnowthrowerupandforwardso that itrestson

theaugerhousing.

3. Removethe lowerframecoverfromthe undersideofthesnow

throwerbyremovingtheself-tappingscrewswhichsecureit.

4. Applya lightcoatingofengineoil (or3-in-1oil) to the hexshaft.

SeeFigure21.

/ .... )

{;:7/

7/' ................

)

// "?X

NOTE:Whenlubricatingthehexshaft,be carefulnottogetanyoilon

thealuminumdriveplateor rubberfrictionwheel.Doingsowillhinder

thesnowthrower'sdrivesystem.Wipeoff anyexcessor spilledoil.

Wheels

Atleastoncea season,removebothwheels.Cleanandcoattheaxles

witha multipurposeautomotivegreasebeforereinstallingwheels.

Auger Shaft

Atleastoncea season,removetheshearpinson augershaft.Spray

lubricantinsideshaft,andaroundthe spacersandflangebearings

foundat eitherendoftheshaft.SeeFigure22.

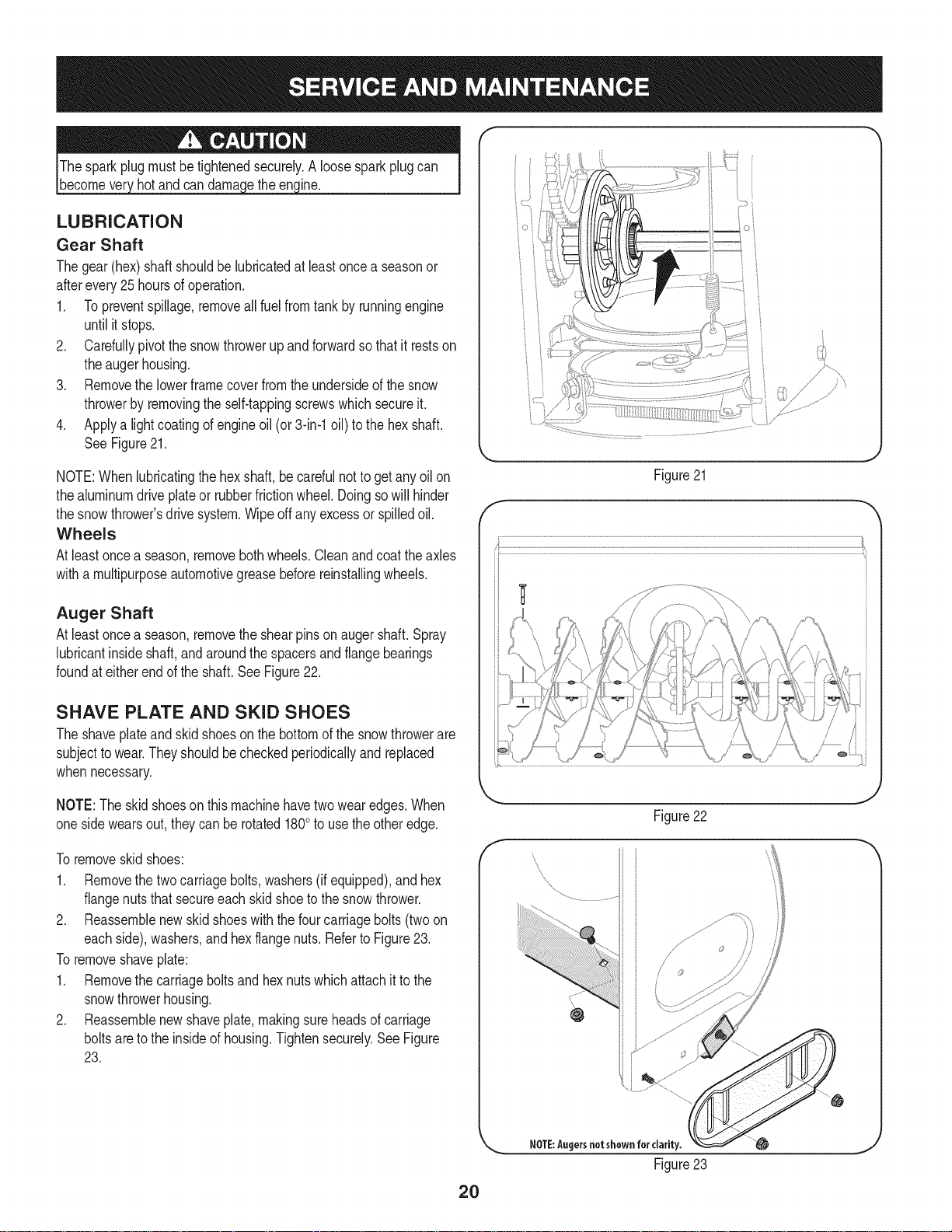

SHAVE PLATE AND SKID SHOES

Theshaveplateandskidshoesonthebottomofthe snowthrowerare

subjecttowear.Theyshouldbecheckedperiodicallyandreplaced

whennecessary.

NOTE:Theskidshoeson thismachinehavetwowearedges.When

onesidewearsout,theycanbe rotated1800to usetheotheredge.

Toremoveskidshoes:

1. Removethetwocarriagebolts,washers(ifequipped),andhex

flangenutsthat secureeach skidshoetothesnowthrower.

2. Reassemblenewskidshoeswiththe fourcarriagebolts(twoon

eachside),washers,andhex flangenuts.RefertoFigure23.

Toremoveshaveplate:

1. Removethecarriageboltsand hexnutswhichattachit to the

snowthrowerhousing.

2. Reassemblenewshaveplate,makingsureheadsofcarriage

boltsaretotheinsideofhousing.Tightensecurely.SeeFigure

23.

Figure21

f

J

Figure22

f

\

\

\

2O

NOTE:Augersnotshown for clarity.

Figure23

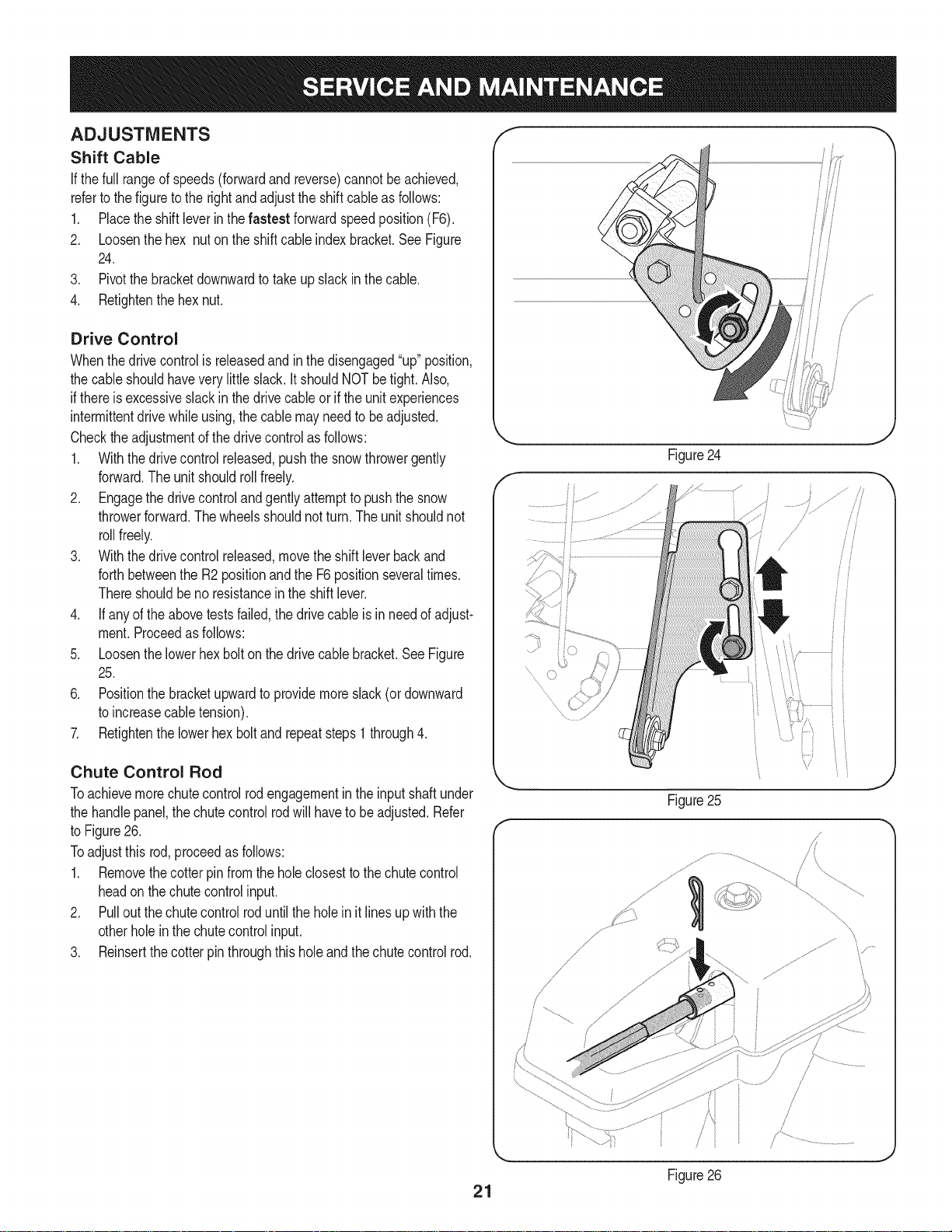

ADJUSTMENTS

Shift Cable

If thefull rangeofspeeds(forwardandreverse)cannotbeachieved,

referto the figuretotherightandadjusttheshiftcableas follows:

1. Placetheshiftleverin thefastest forwardspeedposition(F6).

2. Loosenthehex nuton the shiftcableindexbracket.SeeFigure

24.

3. Pivotthebracketdownwardto takeupslackinthe cable.

4. Retightenthehexnut.

Drive Control

Whenthedrivecontrolisreleasedandin thedisengaged"up"position,

thecableshouldhaveverylittle slack.It shouldNOTbetight.Also,

ifthereis excessiveslackin thedrivecableor ifthe unitexperiences

intermittentdrivewhileusing,thecable mayneedtobeadjusted.

Checktheadjustmentof the drivecontrolasfollows:

1. Withthedrivecontrolreleased,pushthesnowthrowergently

forward.Theunitshouldrollfreely.

2. Engagethe drivecontrolandgentlyattemptto pushthesnow

throwerforward.Thewheelsshouldnotturn.Theunitshouldnot

rollfreely.

3. Withthedrivecontrolreleased,movetheshiftleverbackand

forthbetweenthe R2positionandthe F6 positionseveraltimes.

Thereshouldbeno resistancein the shiftlever.

4. If anyoftheabovetestsfailed,thedrivecable is in needofadjust-

ment.Proceedasfollows:

5. Loosenthelowerhexbolt onthe drivecablebracket.SeeFigure

25.

6. Positionthe bracketupwardtoprovidemoreslack(or downward

toincreasecabletension).

7. Retightenthelowerhexboltand repeatsteps1 through4.

J

f

.........

Chute Control Rod

Toachievemorechutecontrolrodengagementintheinputshaftunder

thehandlepanel,thechutecontrolrodwill havetobeadjusted.Refer

toFigure26.

Toadjustthis rod,proceedasfollows:

1. Removethecotterpin fromthe holeclosestto the chutecontrol

headon thechutecontrolinput.

2. Pulloutthechutecontrolroduntilthe holein itlines upwiththe

otherholeinthechutecontrolinput.

3. Reinsertthecotterpinthroughthisholeandthechutecontrolrod.

21

Figure25

/

/ ,

Figure26

J

J

\

\

Auger Control f "_

RefertotheAssemblysectionforinstructionsonadjustingtheauger

controlcable. _'

Skid Shoes

RefertotheAssemblysectionforinstructionsonadjustingtheskid

shoes.

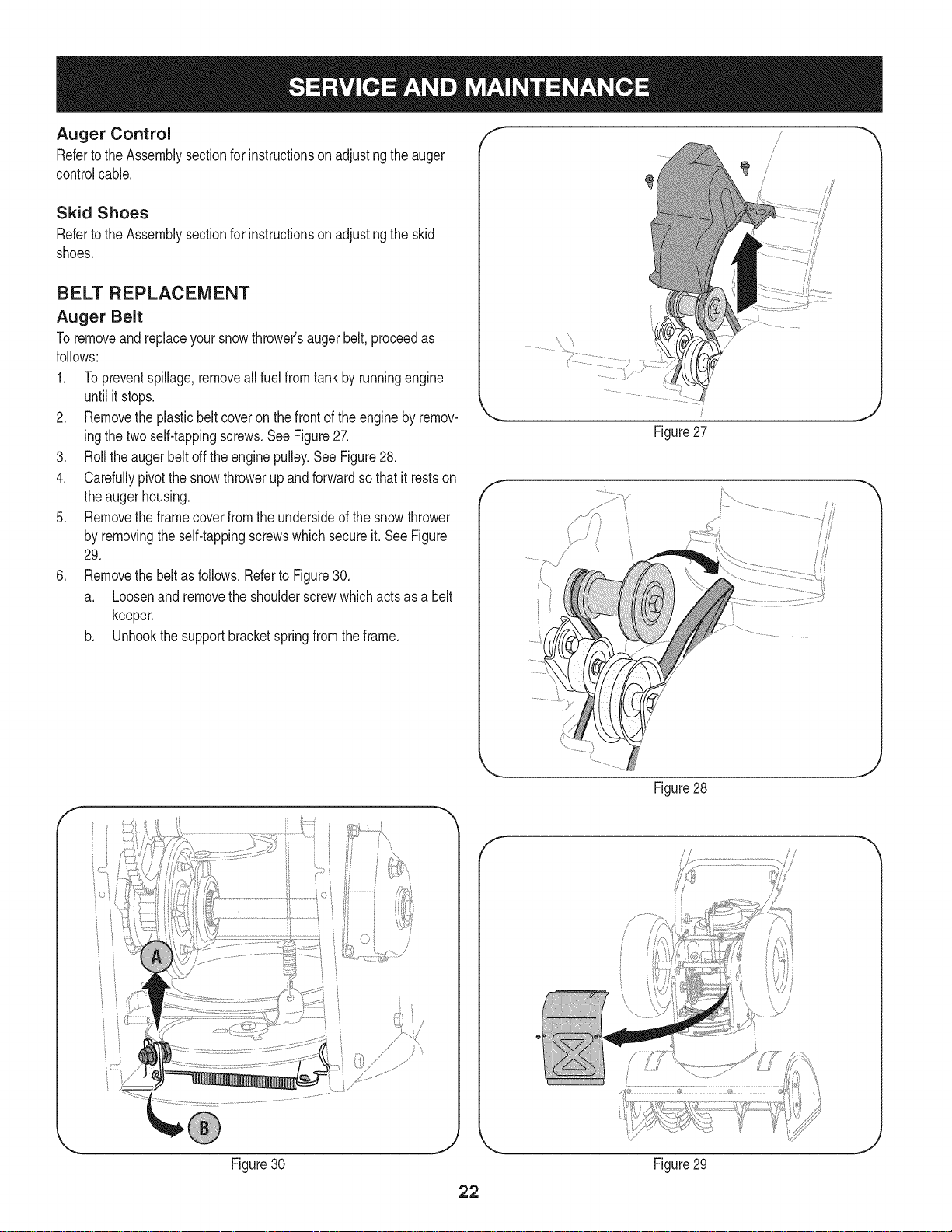

BELT REPLACEMENT

Auger Belt

Toremoveandreplaceyoursnowthrower'saugerbelt,proceedas

follows:

1. Topreventspillage,removeall fuelfromtank by runningengine

untilitstops.

2. Removethe plasticbeltcoveronthe frontof the engineby remov-

ingthetwoself-tappingscrews.SeeFigure27.

3. Rolltheaugerbeltoff theenginepulley.See Figure28.

4. Carefullypivotthesnowthrowerupandforwardso that itrestson

theaugerhousing.

5. Removetheframecoverfromtheundersideofthesnowthrower

byremovingtheself-tappingscrewswhichsecureit.SeeFigure

29.

6. Removethe beltas follows.Referto Figure30.

a. Loosenandremovethe shoulderscrewwhichactsasa belt

keeper.

b. Unhookthe supportbracketspringfromthe frame.

Figure27

f

J

Figure28

f

Figure30 Figure29

J

J

Loading...

Loading...