Craftsman 247887821 Owner’s Manual

Operator's Manual

I:RRFrSMRN°

21" SNOW THROWER

Model No. 247.887821

• SAFETY

• ASSEMBLY

• OPERATION

• MAINTENANCE

CAUTION: Before using this product,

read this manual and follow all safety

rules and operating instructions.

Sears Brands Management Corporation, Hoffman Estates, IL 60179, U.S.A.

Visit our website: www.craftsman.com

• PARTS LIST

• ESPANOL

FormNo.769-07096C

(JuLy9,2013)

Warranty Statement ................................... 2

Safety Instructions .................................... 3

Assembly ............................................. 7

Operation ........................................... 11

Service and Maintenance ............................ 14

Off-Season Storage ................................... 19

Parts List............................................. 24

Engine Parts List ..................................... 28

Labels ............................................... 36

Repair Protection Agreement ......................... 37

Espa_ol .............................................. 40

Service Numbers ............................ Back Cover

Troubleshooting ..................................... 20

CRAFTSMANTWOYEARFULLWARRANTY

FORTWOYEARSfromthedateofpurchase,thisproductiswarrantedagainstanydefectsinmaterialorworkmanship.Adefectiveproductwillreceivefree

repairorreplacementif repairisunavailable.

Forwarrantycoveragedetailsto obtainfreerepairorreplacement,visitthewebsite:www.craftsman.com

ThiswarrantycoversONLYdefectsinmaterialandworkmanship.WarrantycoveragedoesNOTinclude:

• Expendableitemsthatcanwearoutfromnormalusewithinthewarrantyperiod,includingbutnotlimitedtoaugers,augerpaddles,drift cutters,skid

shoes,shaveplate,shearpins,sparkplug,aircleaner,belts,andoilfilter.

• Standardmaintenanceservicing,oilchanges,ortune-ups.

• Tirereplacementorrepaircausedbypuncturesfromoutsideobjects,suchasnails,thorns,stumps,orglass.

• Tireorwheelreplacementorrepairresultingfromnormalwear,accident,orimproperoperationormaintenance.

• Repairsnecessarybecauseofoperatorabuse,includingbutnot limitedtodamagecausedbyover-speedingtheengine,orfromimpactingobjectsthat

bendtheframe,augershaft,etc.

• Repairsnecessarybecauseofoperatornegligence,includingbutnotlimitedto,electricalandmechanicaldamagecausedbyimproperstorage,failureto

usethepropergradeandamountofengineoil,orfailuretomaintaintheequipmentaccordingtotheinstructionscontainedintheoperator'smanual.

• Engine(fuelsystem)cleaningorrepairscausedbyfueldeterminedtobecontaminatedoroxidized(stale).ingeneral,fuelshouldbeusedwithin30days

ofitspurchasedate.

• Normaldeteriorationandwearoftheexteriorfinishes,orproductlabelreplacement.

Thiswarrantyisvoidifthisproductiseverusedwhileprovidingcommercialservicesorif rentedtoanotherperson.

Thiswarrantygivesyouspecificlegalrights,andyoumayalsohaveotherrightswhichvaryfromstateto state.

SearsBrandsManagementCorporation,NoffmanEstates,IL60179

Engine Oil: SAE 5W-30

Engine Oil Capacity: 20 ounces

Fuel: Unleaded Gasoline

Fuel Capacity: 2 quarts

Spark Plug: F6RTC

Model Number

Serial Number

Date of Purchase

Record the model number, serial number,

and date of purchase above.

Spark Plug Gap: .020-.030"

© Sears Brands, LLC

2

Thissymbolpointsout importantsafetyinstructionswhich,if not

followed,couldendangerthe personalsafetyand/orproperty of

yourselfand others.Readandfollow all instructions inthismanual

beforeattempting to operatethis machine.Failureto complywith these

instructionsmayresultinpersonalinjury.Whenyou seethis symbol, HEED

ITSWARNING!

Thismachinewasbuilt to beoperatedaccordingtothesafeoperation

practicesinthis manual.Aswith anytype of powerequipment,

carelessnessorerroronthe part of the operatorcanresultinseriousinjury.

Thismachineiscapableof amputatingfingers, hands,toesandfeet and

throwingdebris.Failuretoobservethefollowing safetyinstructionscould

resultinseriousinjuryor death.

CALIFORNIA PROPOSITION 65

EngineExhaust,someof its constituents,andcertainvehiclecomponents

containor emit chemicalsknowntoStateof Californiatocausecancerand

birth defectsorother reproductiveharm.

TRAINING

Read,understand,andfollowallinstructionsonthemachineandinthe

manual(s)beforeattemptingtoassembleandoperate.Failuretodosocan

resultinseriousinjurytotheoperatorand/orbystanders.Keepthismanualina

safeplaceforfutureandregularreferenceandfororderingreplacementparts.

Befamiliarwith allcontrolsandtheirproperoperation.Knowhowtostop

themachineanddisengagethemquickly.

Neverallowchildrenunder14yearsofagetooperatethismachine.Children

14andovershouldreadandunderstandtheinstructionsandsafeoperation

practicesinthismanualandonthemachineandbetrainedandsupervised

byanadult.

Neverallowadultsto operatethismachinewithoutproperinstruction.

Thrownobjectscancauseseriouspersonalinjury.Planyoursnow-throwing

patterntoavoiddischargeofmaterialtowardroads,bystandersandthelike.

Keepbystanders,petsandchildrenat least75feetfromthemachinewhileit

isin operation.Stopmachineif anyoneentersthearea.

Exercisecautiontoavoidslippingorfalling,especiallywhenoperatinginreverse.

PREPARATION

Thoroughlyinspecttheareawheretheequipmentistobeused.Removeall

doormats,newspapers,sleds,boards,wiresandotherforeignobjects,which

couldbetrippedoverorthrownbytheauger/impeller.

Alwayswearsafetyglassesoreyeshieldsduringoperationandwhile

performinganadjustmentorrepairtoprotectyoureyes.Thrownobjects

whichricochetcancauseseriousinjuryto theeyes.

Donotoperatewithoutwearingadequatewinteroutergarments.Donotwear

jewelry,longscarvesorotherlooseclothing,whichcouldbecomeentangledin

movingparts.Wearfootwearwhichwill improvefootingonslipperysurfaces.

Useagroundedthree-wkeextensioncordandreceptacleforallmachines

with electricstartengines.

Disengageallcontrolleversbeforestartingtheengine.

Neverattempttomakeanyadjustmentswhileengineisrunning,except

wherespecificallyrecommendedintheoperator'smanual.

Letengineandmachineadjusttooutdoortemperaturebeforestartingto

clearsnow.

Your Responsibility--Restrict theuseof this powermachineto

personswhoread,understandandfollow thewarningsand instructionsin

thismanualandonthe machine.

SAVETHESEINSTRUCTIONS!

Safe Handling of Gasoline:

Toavoidpersonalinjuryorproperty damageuseextremecareinhandling

gasoline.Gasolineisextremelyflammable andthe vaporsareexplosive.

Seriouspersonalinjurycanoccurwhen gasolineis spilledon yourselforyour

clotheswhich canignite.Washyourskinandchangeclothesimmediately.

Useonlyanapprovedgasolinecontainer.

Extinguishallcigarettes,cigars,pipesandothersourcesofignition.

Neverfuel machineindoors.

Neverremovegascaporaddfuelwhiletheengineishotorrunning.

Allowenginetocoolatleasttwominutesbeforerefueling.

Neveroverfillfueltank.Filltankto nomorethan1/2inchbelowbottomof

fillernecktoprovidespaceforfuelexpansion.

Replacegasolinecapandtightensecurely.

Ifgasolineisspilled,wipeit offtheengineandequipment.Movemachineto

anotherarea.Wait5 minutesbeforestartingtheengine.

Neverstorethemachineorfuelcontainerinsidewherethereisanopen

flame,sparkorpilotlight (e.g.furnace,waterheater,spaceheater,clothes

dryeretc.).

Allowmachinetocoolatleast5minutesbeforestoring.

Neverfill containersinsideavehicleoronatruckortrailerbedwitha plastic

liner.Alwaysplacecontainersonthegroundawayfromyourvehiclebefore

filling.

Ifpossible,removegas-poweredequipmentfromthetruckortrailerand

refuelit ontheground.Ifthis isnotpossible,then refuelsuchequipment

onatrailerwith a portablecontainer,ratherthanfromagasolinedispenser

nozzle.

Keepthenozzleincontactwiththerimofthefueltankorcontaineropening

atalltimesuntilfuelingiscomplete.Donotuseanozzlelock-opendevice.

OPERATION

Donotputhandsorfeetnearrotatingparts,intheauger/impellerhousing

orchuteassembly.Contactwiththerotatingpartscanamputatehandsand

feet.

Theauger/impellercontrolleverisasafetydevice.Neverbypassitsoperation.

Doingsomakesthemachineunsafeandmaycausepersonalinjury.

Thecontrolleversmustoperateeasilyin bothdirectionsandautomatically

returntothedisengagedpositionwhenreleased.

Neveroperatewithamissingordamagedchuteassembly.Keepallsafety

devicesinplaceandworking.

Neverrunanengineindoorsor inapoorlyventilatedarea.Engineexhaust

containscarbonmonoxide,anodorlessanddeadlygas.

Donotoperatemachinewhileundertheinfluenceof alcoholordrugs.

Mufflerandenginebecomehotandcancauseaburn.Donottouch.Keep

childrenaway.

Exerciseextremecautionwhenoperatingonorcrossinggravelsurfaces.Stay

alertforhiddenhazardsortraffic.

Exercisecautionwhenchangingdirectionandwhileoperatingonslopes.

Planyoursnow-throwingpatterntoavoiddischargetowardswindows,

walls,carsetc.Thus,avoidingpossiblepropertydamageorpersonalinjury

causedbyaricochet.

Preventpossiblepropertydamageorpersonalinjuryfromobjectricochetby

planningyoursnowthrowingpatternto avoiddischargetowardswindows,

walls,cars,etc.

Donotoverloadmachinecapacitybyattemptingtoclearsnowattoofastof

arate.

Neveroperatethismachinewithoutgoodvisibilityorlight.Alwaysbesureof

yourfootingandkeepafirm holdonthehandles.Walk,neverrun.

Disengagepowertotheauger/impellerwhentransportingornotinuse.

Neveroperatemachineathightransportspeedsonslipperysurfaces.Look

downandbehindandusecarewhenbackingup.

Ifthemachineshouldstarttovibrateabnormally,stoptheengine,

disconnectthesparkplugwireandgrounditagainsttheengine.Inspect

thoroughlyfordamage.Repairanydamagebeforestartingandoperating.

Disengageallcontrolleversandstopenginebeforeyouleavetheoperating

position(behindthehandles).Waituntiltheauger/impellercomesto

acompletestopbeforeuncloggingthechuteassembly,makingany

adjustments,orinspections.

Neverputyourhandinthedischargeorcollectoropenings.Donotunclog

chuteassemblywhileengineisrunning.Shutoff engineandremainbehind

handlesuntilallmovingpartshavestoppedbeforeunclogging.

Useonlyattachmentsandaccessoriesapprovedbythemanufacturer(e.g.

wheelweights,tirechains,cabsetc.).

Whenstartingengine,pullcordslowlyuntilresistanceisfelt,thenpull

rapidly.Rapidretractionofstartercord(kickback)will pullhandandarm

towardenginefasterthanyoucanletgo.Brokenbones,fractures,bruisesor

sprainscouldresult.

CLEARING A CLOGGED DISCHARGE CHUTE

Handcontactwith therotatingimpellerinsidethedischargechuteisthemost

commoncauseofinjuryassociatedwith snowthrowers.Neveruseyourhandto

cleanoutthedischargechute.

Toclearthechute:

a. SHUTTHEENGINEOFF!

b. Wait10secondsto besuretheimpellerbladeshavestopped

rotating.

c. Alwaysuseaclean-outtool,notyourhands.

MAINTENANCE & STORAGE

Nevertamperwithsafetydevices.Checktheirproperoperationregularly.

Referto themaintenanceandadjustmentsectionsofthismanual.

Beforecleaning,repairing,orinspectingmachinedisengageallcontrol

leversandstoptheengine.Waituntiltheauger/impellercometoacomplete

stop.Disconnectthesparkplugwireandgroundagainsttheengineto

preventunintendedstarting.

Checkboltsandscrewsforpropertightnessatfrequentintervalstokeepthe

machineinsafeworkingcondition.Also,visuallyinspectmachineforanydamage.

Donotchangetheenginegovernorsettingorover-speedtheengine.The

governorcontrolsthemaximumsafeoperatingspeedof theengine.

Snowthrowershaveplatesandskidshoesaresubjecttowearanddamage.

Foryoursafetyprotection,frequentlycheckallcomponentsandreplace

with originalequipmentmanufacturer's(OEM)partsonlyaslistedinthe

PartspagesofthisOperator'sManual.Useof partswhichdonotmeetthe

originalequipmentspecificationsmayleadto improperperformanceand

compromisesafety!

Checkcontrolleversperiodicallytoverifytheyengageanddisengage

properlyandadjust,ifnecessary.Refertotheadjustmentsectioninthis

operator'smanualfor instructions.

Maintainorreplacesafetyandinstructionlabels,asnecessary.

Observeproperdisposallawsandregulationsforgas,oil,etc.toprotectthe

environment.

Priortostoring,runmachineafewminutestoclearsnowfrommachineand

preventfreezeupofauger/impeller.

Neverstorethemachineorfuelcontainerinsidewherethereisanopen

flame,sparkorpilotlight suchasawaterheater,furnace,clothesdryeretc.

Alwaysrefertotheoperator'smanualforproperinstructionsonoff-season

storage.

Checkfuelline,tank,cap,andfittingsfrequentlyforcracksorleaks.Replace

ifnecessary.

Donotcrankenginewithsparkplugremoved.

AccordingtotheConsumerProductsSafetyCommission(CPSC)andtheU.S.

EnvironmentalProtectionAgency(EPA),thisproducthasanAverageUsefulLife

ofseven(7)years,or60hoursofoperation.AttheendoftheAverageUseful

Lifehavethemachineinspectedannuallybyanauthorizedservicedealerto

ensurethatallmechanicalandsafetysystemsareworkingproperlyandnot

wornexcessively.Failureto dosocanresultinaccidents,injuriesordeath.

4

DO NOT MODIFY ENGINE

Toavoidseriousinjuryordeath,donot modify engineinanyway.Tampering

with thegovernorsettingcanleadto arunawayengineandcauseitto operate

atunsafespeeds.Nevertamperwith factorysettingofenginegovernor.

NOTICE REGARDING EMiSSiONS

Engineswhicharecertifiedto complywith CaliforniaandfederalEPA

emissionregulationsfor SORE(SmallOffRoadEquipment)arecertified

tooperateonregularunleadedgasoline,and mayincludethefollowing

emissioncontrolsystems:EngineModification (EM),OxidizingCatalyst(0C),

SecondaryAirinjection(SAI)andThreeWayCatalyst(TWC)if soequipped.

SPARK ARRESTOR

Thismachineisequippedwith aninternalcombustionengineandshould

not beusedon ornearanyunimprovedforest-covered,brushcoveredor

grass-coveredland unlesstheengine'sexhaustsystemisequippedwith a

sparkarrestormeetingapplicablelocalorstate laws(ifany).

Ira sparkarrestorisused,it shouldbemaintainedineffective working order

bytheoperator,intheState ofCaliforniathe aboveisrequiredbylaw (Section

4442oftheCaliforniaPublicResourcesCode).Otherstatesmayhavesimilar

laws.Federallawsapplyonfederallands.

Asparkarrestorfor the muffler isavailablethroughyour nearestSearsParts

andRepairServiceCenter.

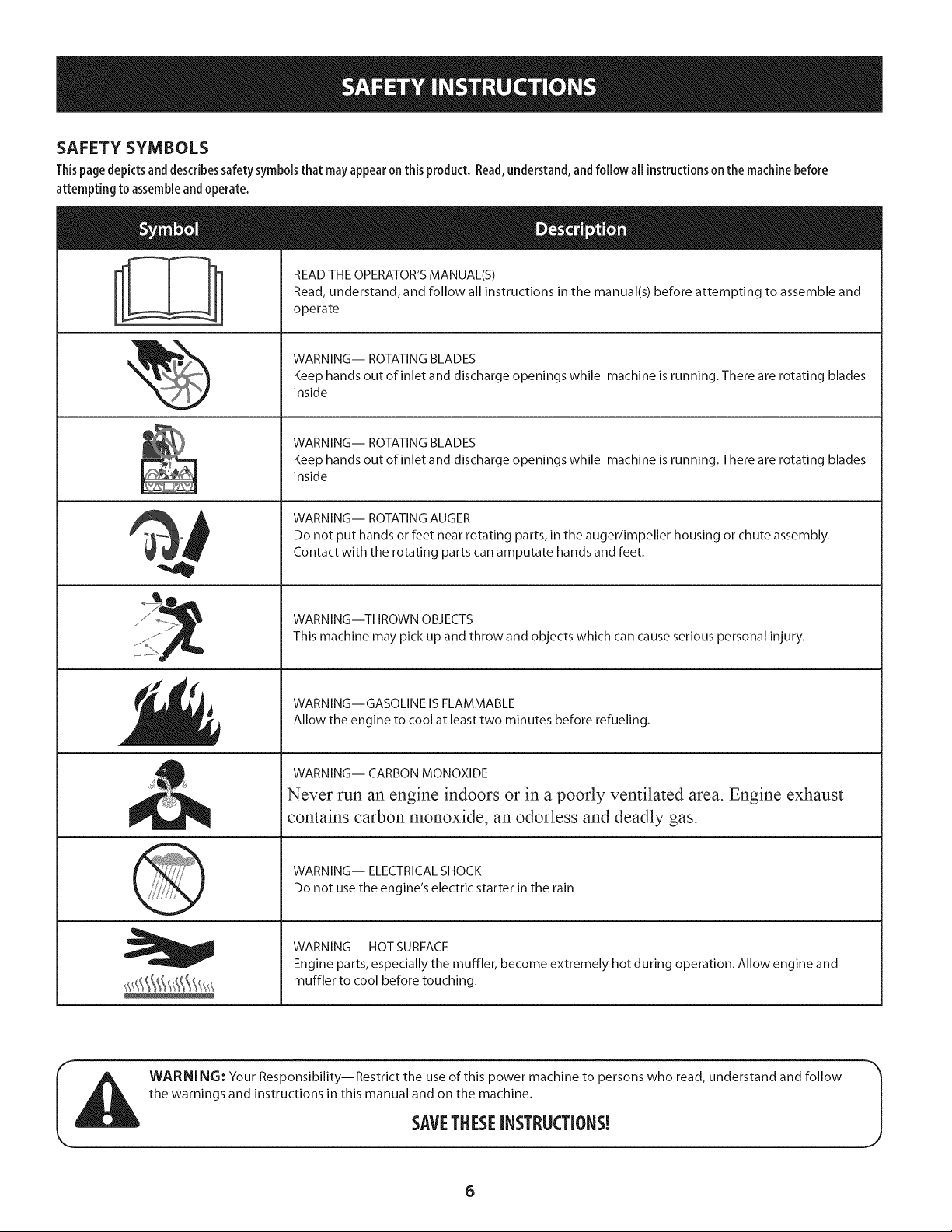

SAFETY SYMBOLS

Thispage depicts and describes safety symbols that may appear on this product. Read,understand, and follow all instructions on the machine before

attempting to assemble and operate.

READ THE OPERATOR'S MANUAL(S)

Read, understand, and follow all instructions in the manual(s) before attempting to assemble and

operate

WARNING-- ROTATING BLADES

Keep hands out of inlet and discharge openings while machine is running. There are rotating blades

inside

WARNING-- ROTATING BLADES

Keep hands out of inlet and discharge openings while machine is running. There are rotating blades

inside

WARNING-- ROTATING AUGER

Do not put hands or feet near rotating parts, in the auger/impeller housing or chute assembly.

Contact with the rotating parts can amputate hands and feet.

WARNING--THROWN OBJECTS

This machine may pick up and throw and objects which can causeserious personal injury.

WARNING--GASOLINE IS FLAMMABLE

Allow the engine to cool at least two minutes before refueling.

WARNING-- CARBON MONOXIDE

Never run an engine indoors or in a poorly ventilated area. Engine exhaust

contains carbon monoxide, an odorless and deadly gas.

WARNING-- ELECTRICAL SHOCK

Do not use the engine's electric starter in the rain

WARNING-- HOT SURFACE

Engine parts, especially the muffler, become extremely hot during operation. Allow engine and

muffler to cool before touching.

WARNING: Your Responsibility--Restrict the use of this power machine to persons who read, understand and follow

the warnings and instructions in this manual and on the machine.

SAVETHESEiNSTRUCTIONS!

6

NOTE"Allreferencestothe[eftorrightsideofthesnowthrowerarefromthe

operator'sposition.Anyexceptionswi[[benoted.

Unpackingthe SnowThrower

1.

Openthetopofthecarton.

2.

Cutdownthecornerson thefrontof thecartonandfolddownthefrontside.

3.

Pullthesnowthroweroutofthecarton.Besurenotto damagethechute,

chuterotationcontrolassemblyoranycablesattachedto thechute.Some

ofthesepartsareshippedundertheshroudonthebacksideofthecarton.

Checkfor anycabletiessecuringthechuteandremoveifnecessary.

Assembly

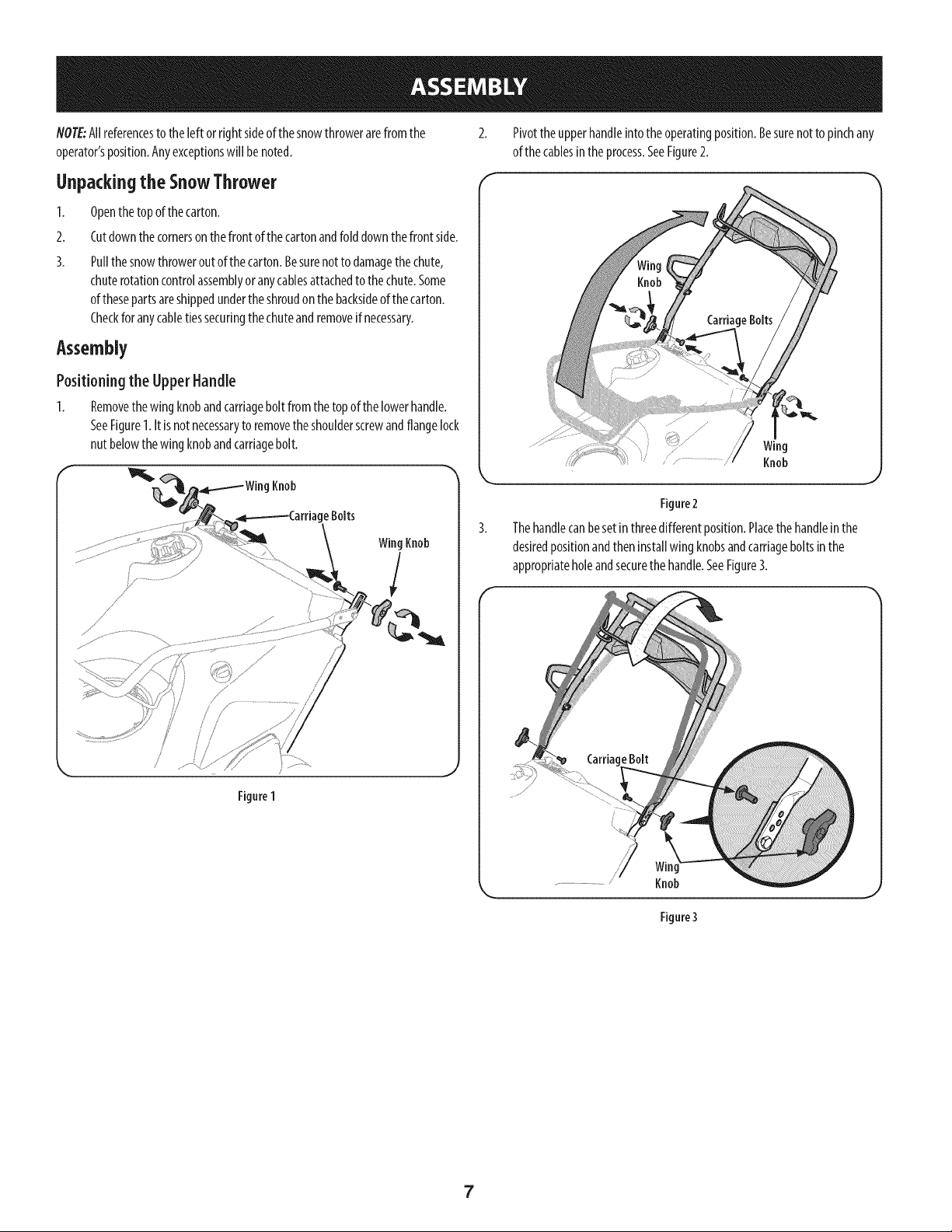

Positioningthe UpperHandle

I. Removethewing knobandcarriageboltfromthetopof thelowerhandle.

SeeFigureI. It isnotnecessarytoremovetheshoulderscrewandflangelock

nutbelowthewing knobandcarriagebolt.

Knob

geBolts

Pivottheupperhandleintotheoperatingposition.Besurenottopinchany

ofthecablesinthe process.SeeFigure2.

Wing

" ................. Knob

J

Figure2

Thehandlecanbesetinthreedifferentposition.Placethe handleinthe

desiredpositionandtheninstallwing knobsandcarriageboltsinthe

appropriateholeandsecurethehandle.SeeFigure3.

/

Figure1

Knob

Figure3

7

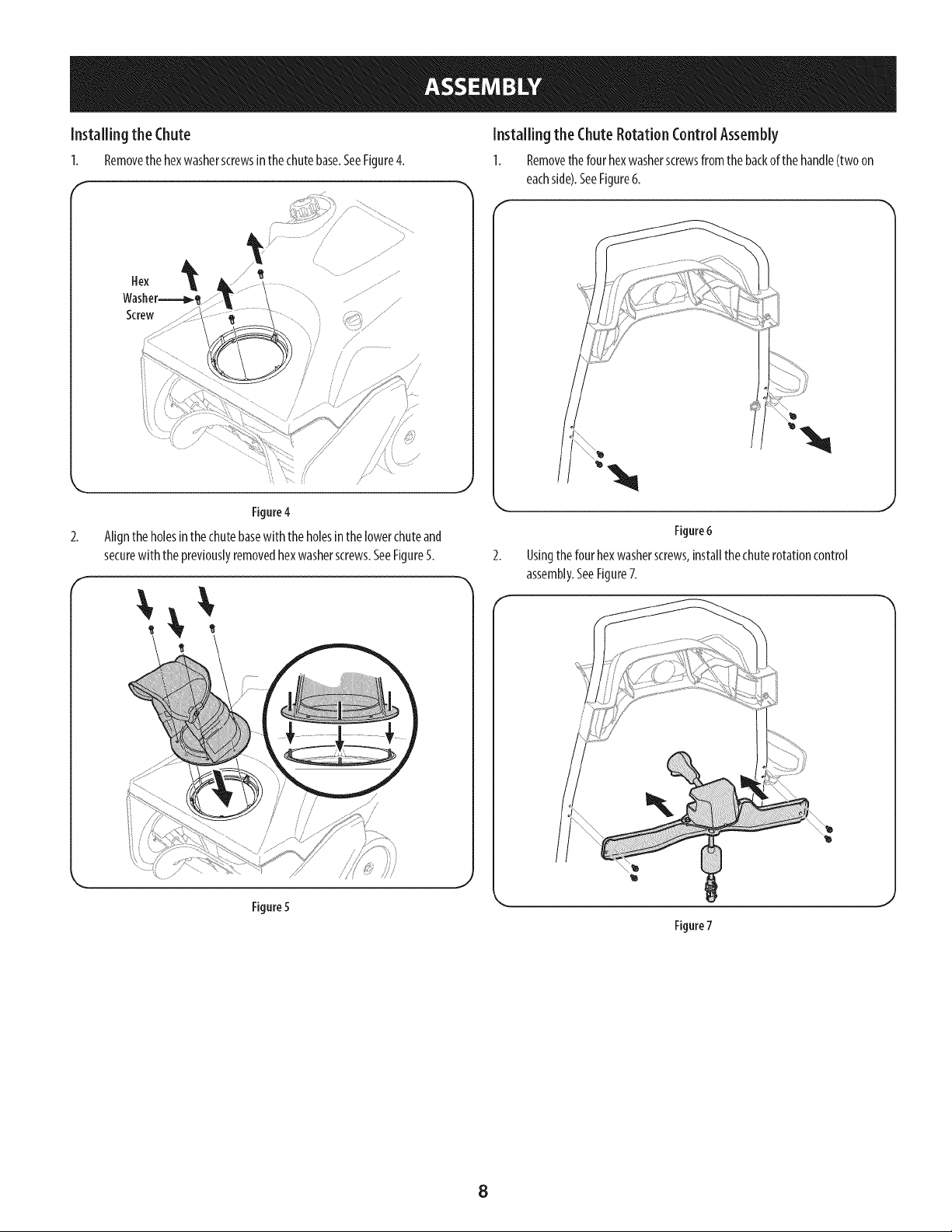

Installing the Chute

1. Removethehexwasherscrewsinthechutebase.SeeFigure4.

f

Hex

Screw

/ /

Figure4

2.

Alignthe holesinthechutebasewith theholesinthelowerchuteand

securewith thepreviouslyremovedhexwasherscrews.SeeFigure5.

f

Installing the ChuteRotation ControlAssembly

1. Removethefourhexwasherscrewsfromthebackofthehandle(twoon

eachside).SeeFigure6.

Figure6

Usingthefourhexwasherscrews,installthechuterotationcontrol

assembly.SeeFigure7.

Figure5

Figure7

8

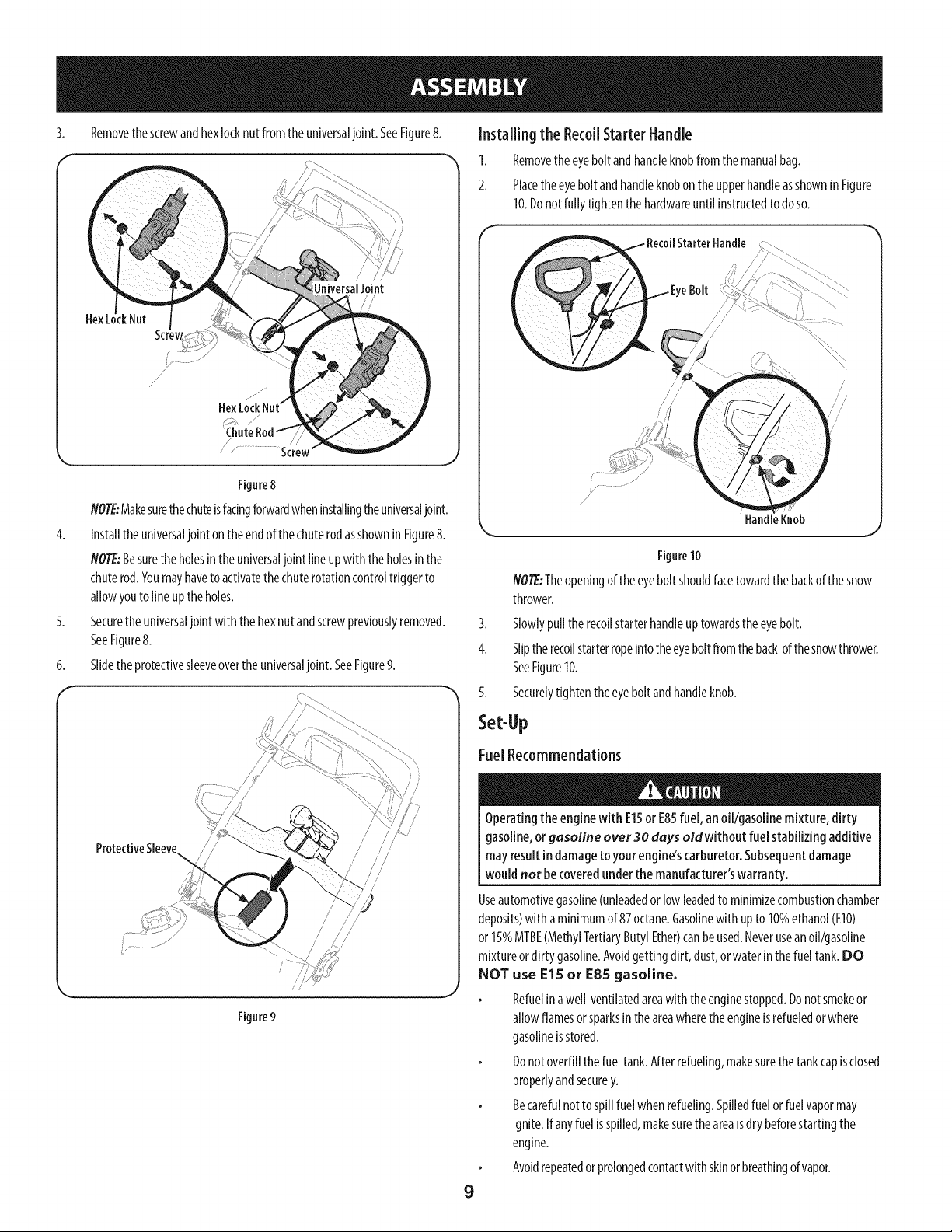

3. Removethescrewandhexlocknutfromtheuniversaljoint.SeeFigure8.

OniversaIJoini

/

/

...................Screw

Installing the RecoilStarter Handle

I. Removetheeyeboltandhandleknobfromthemanualbag.

2. Placetheeyeboltandhandleknobontheupperhandleasshownin Figure

10.Donotfully tightenthehardwareuntilinstructedtodoso.

f

RecoilStarter Handle, i

EyeBolt

/

Figure8

NOTE:Makesurethechuteisfacingforwardwheninstallingtheuniversaljoint.

4. Installthe universaljointontheendofthechuterodasshownin Figure8.

NOTE:Besuretheholesintheuniversaljoint lineupwith theholesinthe

chuterod.Youmayhavetoactivatethechuterotationcontroltriggerto

allowyoutolineuptheholes.

5. Securetheuniversaljoint with thehexnutandscrewpreviouslyremoved.

SeeFigure8.

6. Slidetheprotectivesleeveovertheuniversaljoint. SeeFigure9.

ProtectiveSleeve

Figure9

/ .........

//J

HandleKnob

Figure10

NOTE:Theopeningof theeyeboltshouldfacetowardthe backof thesnow

thrower.

3. Slowlypulltherecoilstarterhandleuptowardstheeyebolt.

4. Sliptherecoilstarterropeintotheeyeboltfromthebackofthesnowthrower.

SeeFigure10.

5. Securelytightentheeyeboltandhandleknob.

Set-Up

FuelRecommendations

Operatingthe enginewith E15or E85fuel,anoil/gasolinemixture,dirty

gasoline,orgasoline over30 days oldwithout fuel stabilizing additive

mayresultindamagetoyourengine'scarburetor.Subsequentdamage

wouldnot becoveredunderthe manufacturer'swarranty.

Useautomotivegasoline(unleadedorlowleadedtominimizecombustionchamber

deposits)with aminimumof87octane.Gasolinewith upto 10%ethanol(EIO)

or 15%MTBE(MethylTertiaryButylEther)canbeused.Neveruseanoil/gasoline

mixtureordirty gasoline.Avoidgettingdirt, dust,orwaterinthefueltank.DO

NOT use E15 or E85 gasoline.

Refuelinawell-ventilatedareawiththeenginestopped.Donotsmokeor

allowflamesorsparksintheareawheretheengineisrefueledorwhere

gasolineisstored.

Donotoverfillthefueltank.Afterrefueling,makesurethetankcapisclosed

properlyandsecurely.

Becarefulnottospillfuelwhenrefueling.Spilledfuelorfuelvapormay

ignite.Ifanyfuelisspilled,makesuretheareaisdry beforestartingthe

engine.

Avoidrepeatedorprolongedcontactwith skinorbreathingofvapor.

9

Adding Fuel

Useextremecarewhen handlinggasoline.Gasolineisextremelyflammable

andthevaporsareexplosive.Neverfuelthe machineindoorsorwhile the

engineishotor running.Extinguishcigarettes,cigars,pipesandother

sourcesofignition.

Alwayskeephandsandfeet dear ofequipmentmovingparts.Donot usea

pressurizedstarting fluid. Vaporsareflammable.

Removethegascap,checkthefuel levelandaddfuelifnecessary.Fillthe

tankuntilthefuel reaches1/2"belowthebottomofthefillernecktoallow

forfuel expansion.Becarefulnottooverfill.

CheckingandAdding Oil

Theengineisshippedwithout oil inthe engine.Youmustfill the engine

with oil beforeoperating. Runningtheenginewith insufficientoil can

causeseriousenginedamageandvoidthe productwarranty.

1. Placethesnowthroweronaflat,levelsurface.

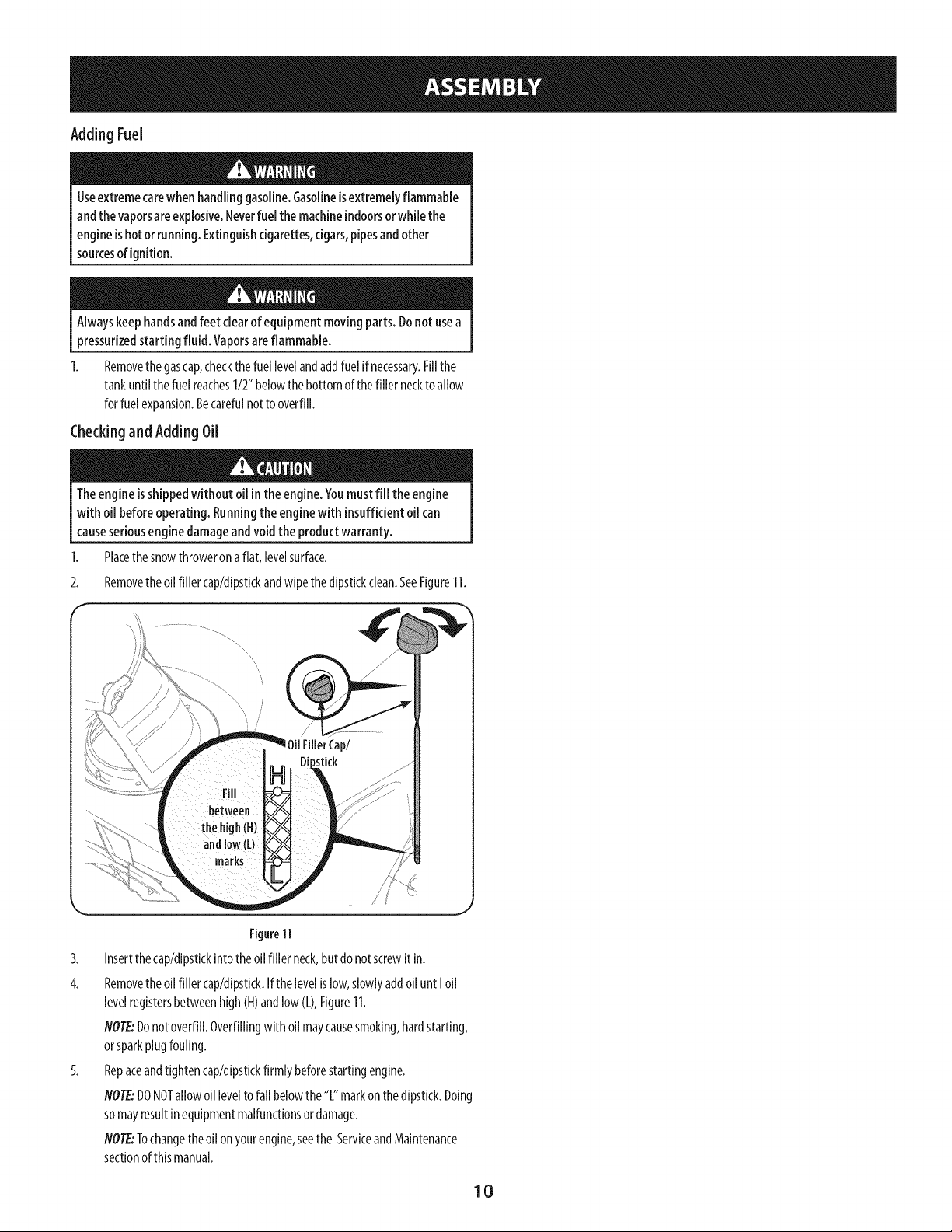

2. Removetheoilfiller cap/dipstickandwipethedipstickclean.SeeFigure11.

f

)il FillerCap/

bstick

Figure11

3. Insertthecap/dipstickintotheoilfillerneck,butdonotscrewitin.

4. Removetheoilfiller cap/dipstick.Ifthelevelislow,slowlyaddoiluntil oil

levelregistersbetweenhigh(H)andlow(L),Figure11.

NOTE:Donotoverfill.Overfillingwith oilmaycausesmoking,hardstarting,

orsparkplugfouling.

5. Replaceandtightencap/dipstickfirmlybeforestartingengine.

NOTE:DONOTallowoilleveltofall belowthe"L"markonthedipstick.Doing

somayresultinequipmentmalfunctionsordamage.

NOTE:Tochangetheoilonyourengine,seethe ServiceandMaintenance

sectionofthis manual.

J

10

f

Primer,

GasCa

ShavePlate'

OilDrain

Figure12

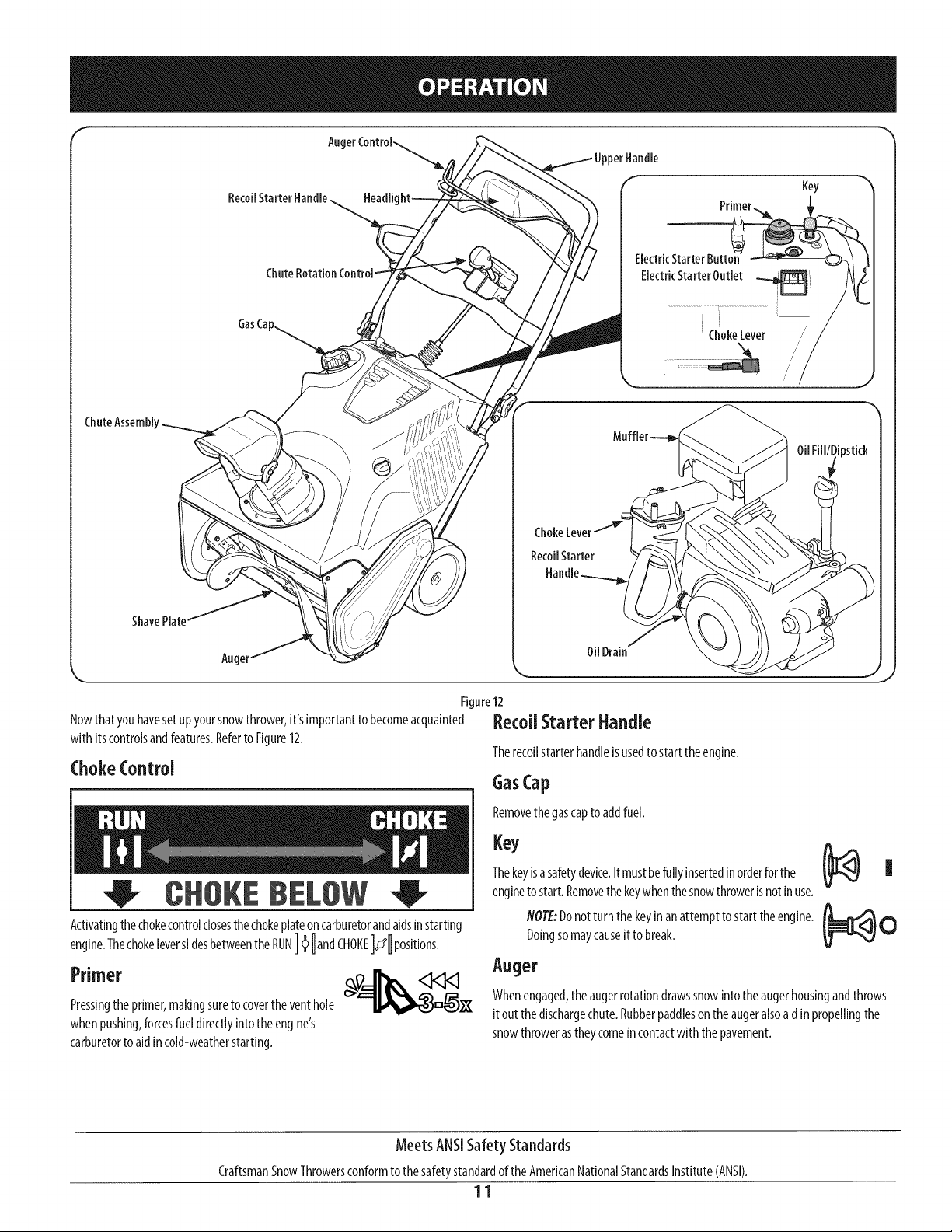

Nowthatyouhavesetupyoursnowthrower,it's importanttobecomeacquainted Re€OnStarter Handle

with itscontrolsandfeatures.Referto Figure12.

Therecoilstarterhandleisusedto starttheengine.

Choke Control GasCap

Removethegascaptoaddfuel.

"°YThekeyisasafetydevice.Itmustbefullyinsertedinorderforthe II

CHOKEBELOW

ActivatingthechokecontroJdosesthechokepJateoncarburetorandaidsJnstarting

engine.Thechokeleverslidesbetweenthe"UNI_andC,OKEMpositions.

Primer

Pressingtheprimer,makingsuretocovertheventhole

whenpushing,forcesfueldirectlyintotheengine's

carburetorto aidincold-weatherstarting.

enginetostart.Removethekeywhenthesnowthrowerisnotinuse.

NOTE:Donotturnthekeyinanattemptto starttheengine.

Doingsomaycauseittobreak. _!_ 0

Auger

Whenengaged,theaugerrotationdrawssnowintotheaugerhousingandthrows

itoutthedischargechute.Rubberpaddlesontheaugeralsoaidin propellingthe

snowthrowerastheycomeincontactwiththe pavement.

MeetsANSISafetyStandards

CraftsmanSnowThrowersconformtothesafetystandardoftheAmericanNationalStandardsInstitute(ANSI).

11

AugerControl

Locatedontheupperhandle,theaugercontrolhandleisusedtoengageanddisengage

drivetotheauger.Squeezethecontrolhandleagainsttheupperhandletoengagethe

auger;releaseittodisengage.

Muffler

Engineexhaustexitstheengineviathemuffler.

ChuteRotation Control

Thechuterotatecontrolislocatedinthecenterofthecontrolpanelandcontrolsthe

directionsnowisthrown.Depressthebuttonandrotatethechuterotationcontroltothe

righttoturnthechutetotherightandrotatetothelefttoturnthechutetotheleft.

ChuteAssembly

Thepitchofthedischargechutecontrolstheangleatwhichthesnowisthrown.Loosen

thewingknobonthesideofthedischargechutebeforepivotingthedischargechute

upwardordownward.Retightentheknoboncethedesiredpositionhasbeenachieved.

ShavePlate

Theshaveplatemaintainscontactwith thepavementasthesnowthroweris

propelled,allowingsnowcloseto the pavement'ssurfacetobedischarged.

Oil Fill/Dipstick

Engineoillevelcanbecheckedandoiladdedthroughtheoilfill.

Oil Drain

Engineoilcanbedrainedthroughtheoildrain.

ffeadlight

Theheadlightislocatedontheuppercenterofthecontrolpanelandisonwhenthe

snowthrowerisrunning.

ElectricStarter Outlet

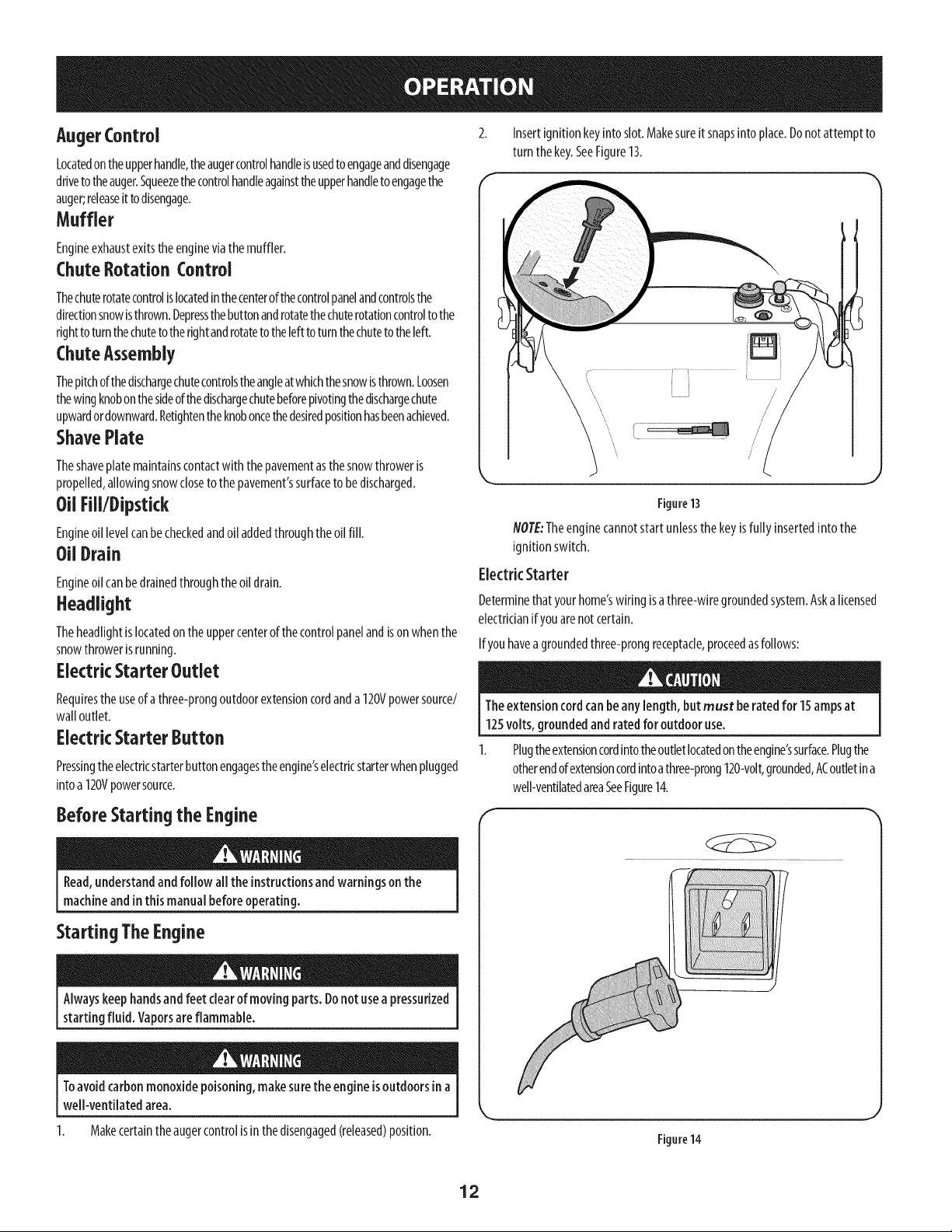

Insertignitionkeyintoslot.Makesureit snapsintoplace.Donotattemptto

turnthekey.SeeFigure13.

Figure13

NOTE:Theenginecannotstart unlessthekeyisfully insertedinto the

ignitionswitch.

ElectricStarter

Determinethatyourhome'swiringisathree-wiregroundedsystem.Askalicensed

electricianif youarenotcertain.

Ifyouhavea groundedthree-prongreceptacle,proceedasfollows:

Requirestheuseofathree-prongoutdoorextensioncordanda120Vpowersource/

walloutlet.

ElectricStarter Button

Pressingtheelectricstarterbuttonengagestheengine'selectricstarterwhenplugged

intoa120Vpowersource.

BeforeStarting the Engine

Read,understandandfollow all the instructionsandwarningsonthe

machineandin thismanualbeforeoperating.

Starting TheEngine

Alwayskeephandsandfeet clearof movingparts. Donot useapressurized

starting fluid. Vaporsareflammable.

Toavoidcarbonmonoxidepoisoning,makesurethe engineisoutdoorsin a

well-ventilated area.

1. Makecertaintheaugercontrolisinthedisengaged(released)position.

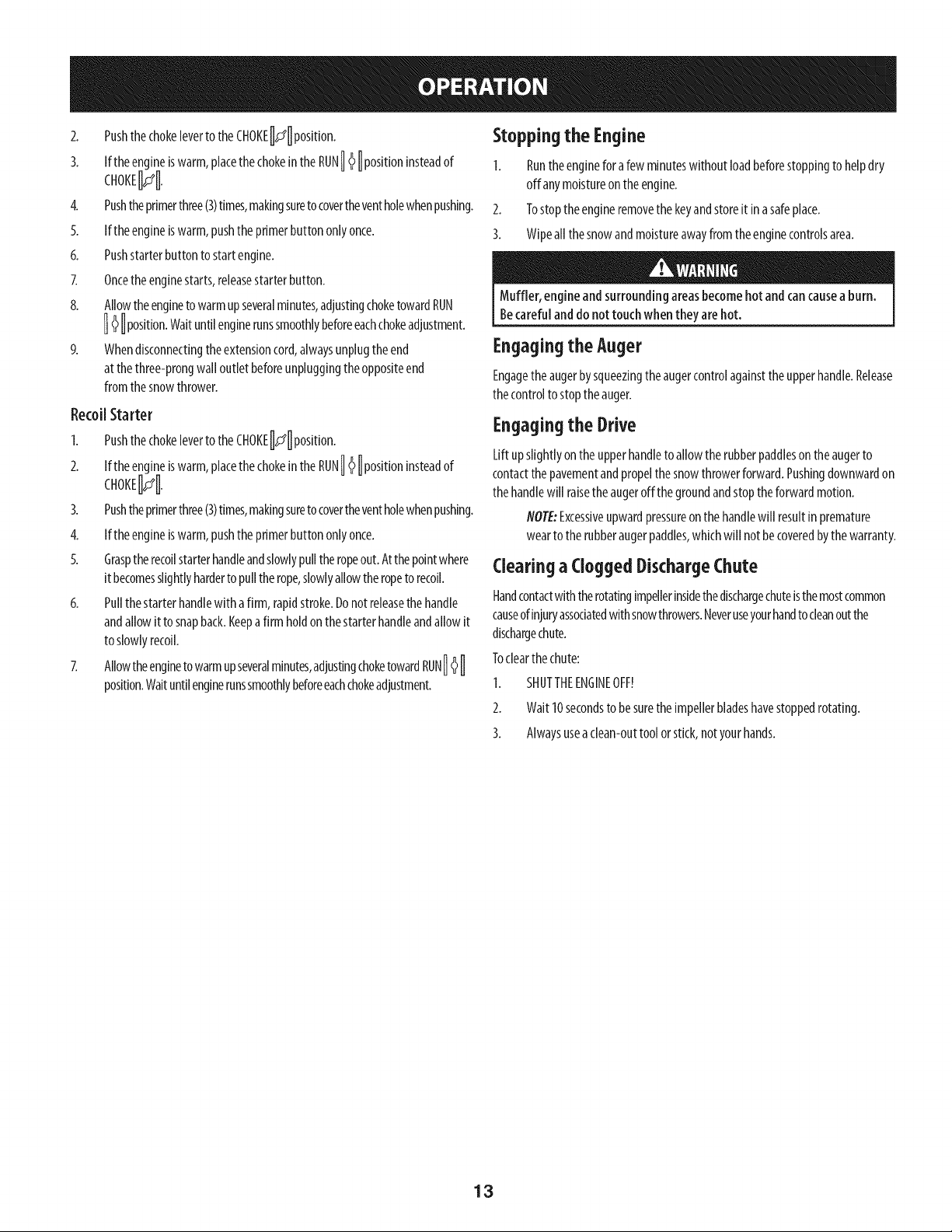

Theextensioncordcanbeanylength, but must beratedfor 15ampsat

125volts,groundedand ratedfor outdoor use.

Plugtheextensioncordintotheoutletlocatedontheengine'ssurface.Plugthe

otherendofextensioncordintoathree-prong120-volt,grounded,ACoutletina

well-ventilatedareaSeeFigure14.

Figure14

12

2. PushthechokelevertotheCHOKE_ position.

3. Iftheengineiswarm,placethechokeinthe RUN1_ I positioninsteadof

CHOKE_J0

4. Pushtheprimerthree(3)times,makingsuretocovertheventholewhenpushing.

S. Iftheengineiswarm,pushtheprimerbuttononlyonce.

6. Pushstarterbuttontostartengine.

7. Oncetheenginestarts,releasestarterbutton.

8. Allowtheengineto warmupseveralminutes,adjustingchoketowardRUN

1_ _position.Waituntilenginerunssmoothlybeforeeachchokeadjustment.

9. Whendisconnectingtheextensioncord,alwaysunplugtheend

atthethree-prongwalloutletbeforeunpluggingtheoppositeend

fromthesnowthrower.

RecoilStarter

1. PushthechokelevertotheCHOKE_J_ position.

2. Iftheengineiswarm,placethechokeinthe RUN1_ I positioninsteadof

CHOKE_B

3. Pushtheprimerthree(3)times,makingsuretocovertheventholewhenpushing.

4. Iftheengineiswarm,pushtheprimerbuttononlyonce.

S. Grasptherecoilstarterhandleandslowlypulltheropeout.Atthepointwhere

it becomesslightlyharderto pulltherope,slowlyallowtheropetorecoil.

6. Pullthestarterhandlewith afirm,rapidstroke.Donotreleasethehandle

andallowit tosnapback.Keepa firm holdonthestarterhandleandallowit

toslowlyrecoil.

7. Allowtheengineto warmupseveralminutes,adjustingchoketowardRUN1_ _

position.Waituntilenginerunssmoothlybeforeeachchokeadjustment.

Stoppingthe Engine

1. Runtheengineforafewminuteswithoutloadbeforestoppingtohelpdry

offanymoistureontheengine.

2. Tostoptheengineremovethekeyandstoreit in asafeplace.

3. Wipeallthesnowandmoistureawayfromtheenginecontrolsarea.

Muffler,engineand surroundingareasbecomehotandcancauseaburn.

Becarefulanddonottouchwhen theyarehot.

Engagingthe Auger

Engagetheaugerbysqueezingtheaugercontrolagainsttheupperhandle.Release

thecontroltostoptheauger.

Engagingthe Drive

Liftupslightlyontheupperhandleto allowtherubberpaddlesontheaugerto

contactthepavementandpropelthesnowthrowerforward.Pushingdownwardon

thehandlewill raisetheaugeroffthe groundandstoptheforwardmotion.

NOTE:Excessiveupwardpressureonthehandlewill resultinpremature

weartotherubberaugerpaddles,whichwill notbecoveredbythewarranty.

ClearingaCloggedDischargeChute

Handcontactwiththerotatingimpellerinsidethedischargechuteisthemostcommon

causeofinjuryassociatedwithsnowthrowers.Neveruseyourhandtocleanoutthe

dischargechute.

Toclearthechute:

1. SHUTTHEENGINEOFF!

2. Wait10secondstobesuretheimpellerbladeshavestoppedrotating.

3. Alwaysuseaclean-outtoolorstkk, notyourhands.

13

MAINTENANCESCHEDULE

Followthemaintenanceschedulegivenbelow.Thischartdescribesserviceguidelines

only.UsetheServiceLogcolumntokeeptrackofcompletedmaintenancetasks.To

Beforeperforminganytype of maintenance/service,disengageall controls scheduleservicefrom SearsParts& Repair,call 1-800-659-5917.

andstop theengine.Wait untilall movingpartshavecometo acomplete

stop.Disconnectspark plugwire and grounditagainsttheengineto

preventunintendedstarting. Alwayswearsafety glassesduring operation

orwhile performing anyadjustmentsor repairs.

Eachuse

1st5hours

Every5hours

25hours

Everyseason/50hours

Everyseason/lO0hours

Everyseason/Beforestorage

1. Engineoil level.

2. Snowthrowerandexhaustarea.

1. Engineoil.

1. Engineoil.

2. Exhaustarea.

1. Sparkplug.

1. Engineoil

1. Sparkplug

1. Pivotpoints

2. Controlhandle

3. Extensionspring

EngineMaintenance

Thoroughlywashyour handswith soapandwater assoonaspossibleafter

handlingusedoil.

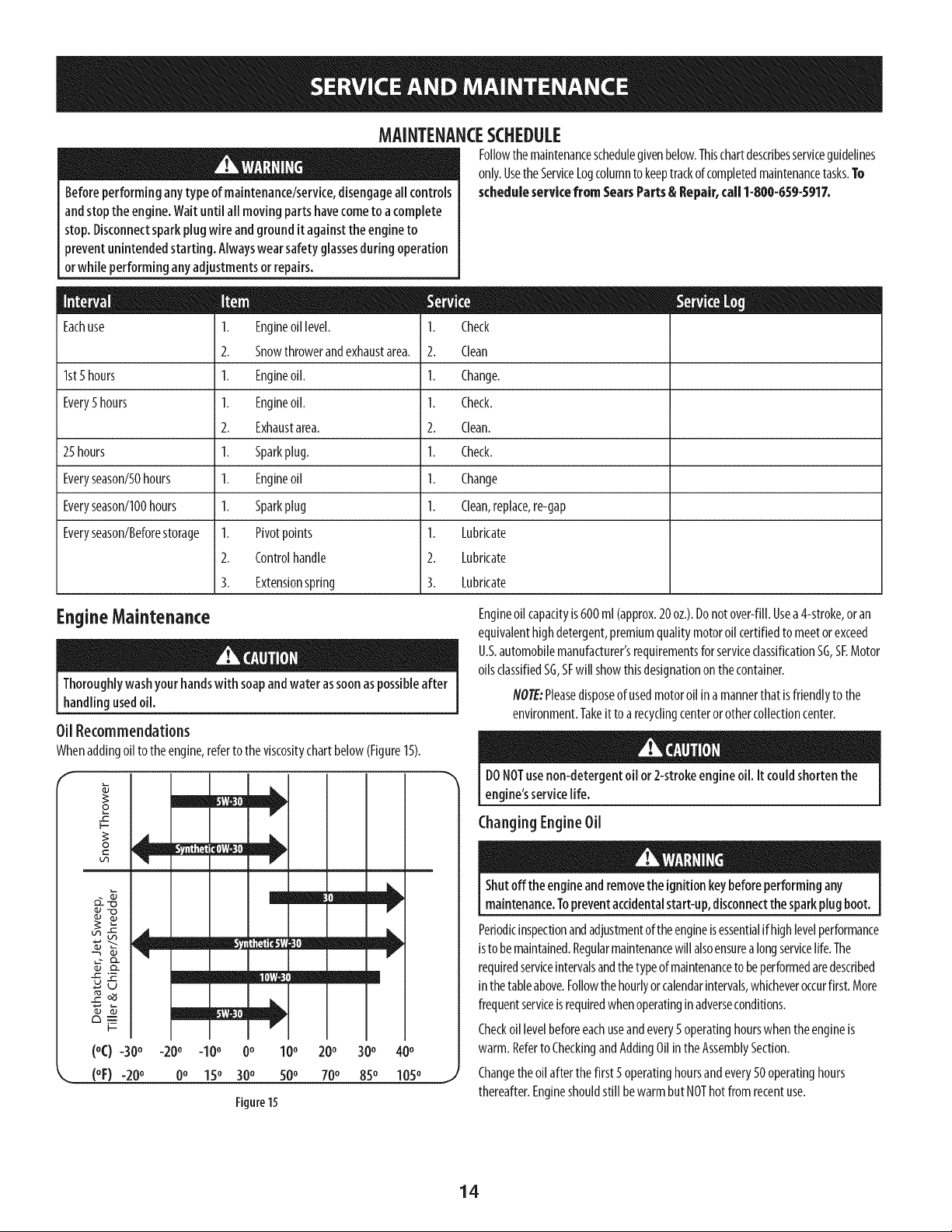

Oil Recommendations

Whenaddingoiltotheengine,refertotheviscositychartbelow(Figure15).

o

_c:

m mlb

iv

1. Check

2. Clean

1. Change.

1. Check.

2. Clean.

1. Check.

1. Change

1. Clean,replace,re-gap

1. Lubricate

2. Lubricate

3. Lubricate

Engineoilcapacityis600ml(approx.20oz.).Donotover-fill.Usea4-stroke,oran

equivalenthighdetergent,premiumqualitymotoroilcertifiedtomeetorexceed

U.S.automobilemanufacturer'srequirementsforserviceclassificationSG,SEMotor

oilsclassifiedSG,SFwill showthisdesignationonthecontainer.

NOTE:Pleasedisposeof usedmotoroilinamannerthat isfriendlytothe

environment.Takeittoarecyclingcenterorothercollectioncenter.

DONOTusenon-detergentoil or2-strokeengineoil. It couldshorten the

engine'sservicelife.

ChangingEngineOil

L/3

OJ (u

V"

mm_mll

m ==lib

F-

(°C) -30° -20° -I0 ° 0° 100 20o 300 400

(°F)-20o 0o 150 300 500 700 850 105o j

Figure15

Shutoffthe engineandremovethe ignitionkeybeforeperformingany

maintenance.Topreventaccidentalstart-up,disconnectthe sparkplugboot.

Periodicinspectionandadjustmentof theengineisessentialifhighlevelperformance

istobemaintained.Regularmaintenancewill alsoensurealongservicelife.The

requiredserviceintervalsandthetypeofmaintenanceto beperformedaredescribed

inthetableabove.Followthehourlyorcalendarintervals,whicheveroccurfirst.More

frequentserviceisrequiredwhenoperatinginadverseconditions.

Checkoillevelbeforeeachuseandevery5 operatinghourswhentheengineis

warm.RefertoCheckingandAddingOilintheAssemblySection.

Changetheoilafterthefirst5operatinghoursandevery50operatinghours

thereafter.EngineshouldstillbewarmbutNOThotfromrecentuse.

14

Drainfuelfromthetankbyrunningtheengineuntilthefueltankisempty.

Besurethefuelfill capissecure.

2.

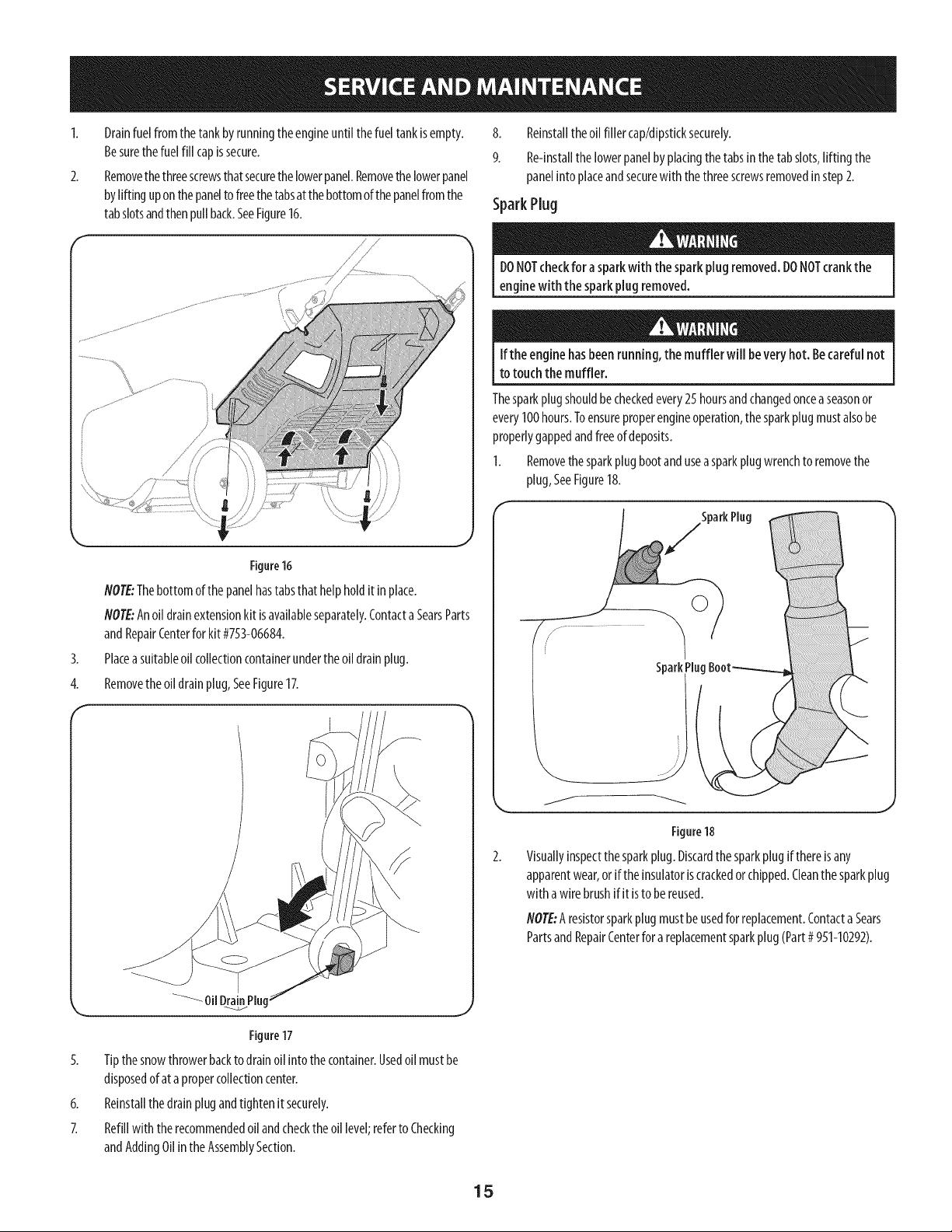

Removethethreescrewsthatsecurethelowerpanel.Removethelowerpanel

bylifting uponthepaneltofreethetabsatthebottomofthepanelfromthe

tabslotsandthenpullback.SeeFigure16.

/,

/!/

Figure16

NOTE:Thebottomofthepanelhastabsthathelpholditinplace.

NOTE:Anoil drainextensionkit isavailableseparately.ContactaSearsParts

andRepairCenterfor kit#753-06684.

3.

Placeasuitableoilcollectioncontainerundertheoildrainplug.

4.

Removetheoildrainplug,SeeFigure17.

8. Reinstalltheoil filler cap/dipsticksecurely.

9. Re-installthelowerpanelbyplacingthetabsinthetabslots,liftingthe

panelintoplaceandsecurewith thethreescrewsremovedinstep2.

SparkPlug

DONOTcheckfor a sparkwith the sparkplug removed.DONOTcrankthe

enginewith the sparkplug removed.

Ifthe enginehasbeenrunning, the muffler willbeveryhot.Becarefulnot

totouch the muffler.

Thesparkplugshouldbecheckedevery25hoursandchangedonceaseasonor

every100hours.Toensureproperengineoperation,thesparkplugmustalsobe

properlygappedandfreeofdeposits.

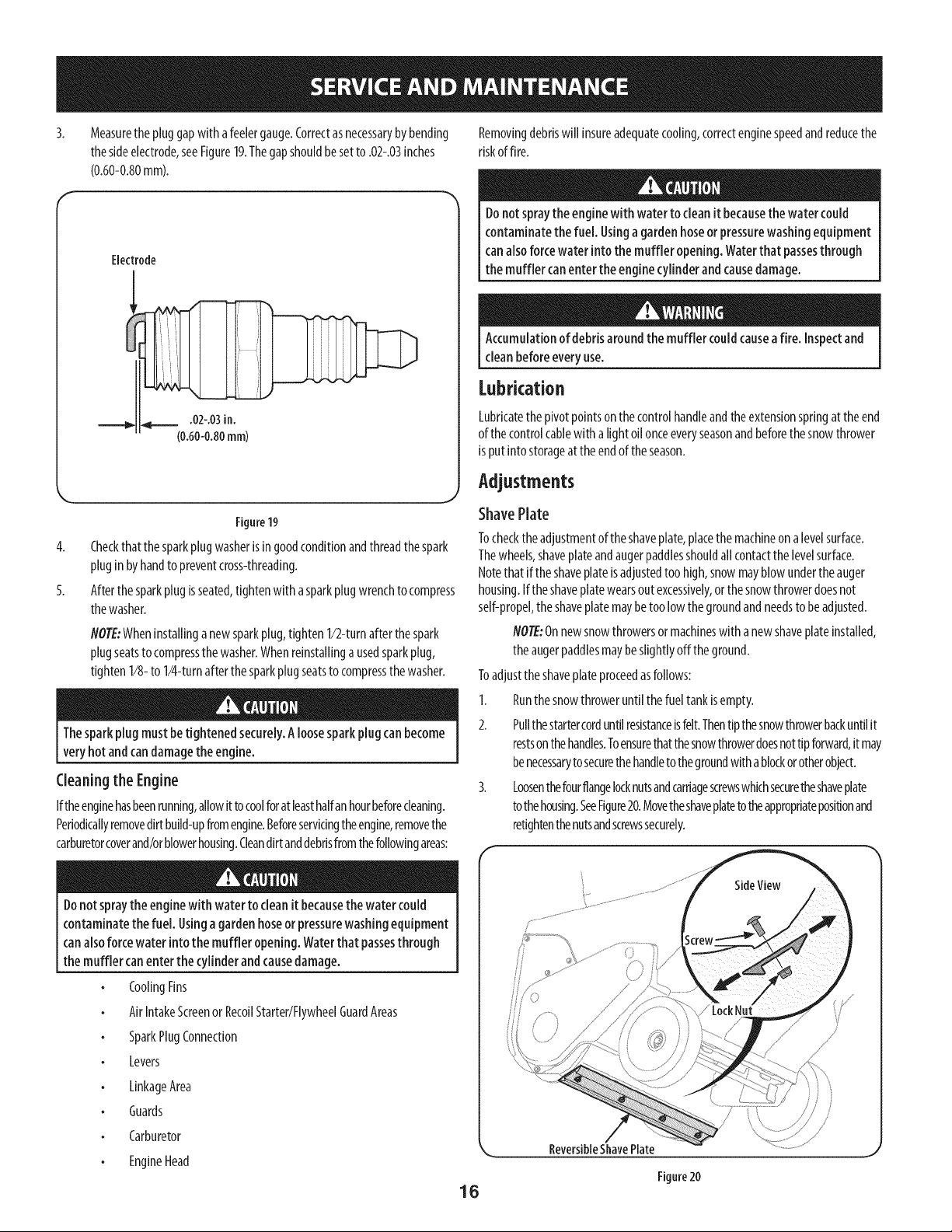

I. Removethesparkplugbootanduseasparkplugwrenchtoremovethe

plug,SeeFigure18.

SparkPlug

©

SparkPlug

OilDrainnPlug

Figure17

5. Tipthesnowthrowerbacktodrainoilintothecontainer.Usedoilmustbe

disposedofatapropercollectioncenter.

6. Reinstallthedrainplugandtightenit securely.

7. Refillwith therecommendedoilandchecktheoil level;refertoChecking

andAddingOilintheAssemblySecUon.

Figure18

Visuallyinspectthesparkplug.Discardthesparkplugifthereisany

apparentwear,oriftheinsulatoriscrackedorchipped.Cleanthesparkplug

with awirebrushif it istobereused.

NOTE:Aresistorsparkplugmustbeusedforreplacement.Contacta Sears

PartsandRepairCenterfora replacementsparkplug(Part#951-10292).

J

15

Measurethepluggapwithafeelergauge.Correctasnecessarybybending

thesideelectrode,seeFigure19.Thegapshouldbesetto .02-.03inches

(0.60-0.80mm).

Electrode

Removingdebriswillinsureadequatecooling,correctenginespeedandreducethe

riskoffire.

Donotspraytheenginewith water to cleanit becausethe watercould

contaminatethe fuel.Usingagardenhoseor pressurewashingequipment

canalsoforcewater into the muffler opening.Waterthat passesthrough

the muffler canenter theenginecylinderandcausedamage.

Accumulationofdebris aroundthe muffler couldcauseafire. Inspectand

cleanbeforeeveryuse.

Lubrication

.02-.03in.

(0.60-0.80ram)

Figure19

4. Checkthatthesparkplugwasherisin goodconditionandthreadthespark

pluginbyhandtopreventcross-threading.

5. Afterthesparkplugisseated,tightenwithasparkplugwrenchtocompress

thewasher.

NOTE:Wheninstallinganewsparkplug,tighten1/2-turnafterthespark

plugseatsto compressthewasher.Whenreinstallingausedsparkplug,

tighten1/8-to 1/4-turnafterthesparkplugseatstocompressthewasher.

Thesparkplug mustbetightened securely.Aloosesparkplugcanbecome

veryhot and candamagetheengine.

Cleaningthe Engine

Iftheenginehasbeenrunning,allowittocoolforatleasthalfanhourbeforecleaning.

Periodicallyremovedirtbuild-upfromengine.Beforeservicingtheengine,removethe

carburetorcoverand/orblowerhousing.Cleandirtanddebrisfromthefollowingareas:

Lubricatethepivotpointsonthecontrolhandleandtheextensionspringattheend

ofthecontrolcablewithalightoilonceeveryseasonandbeforethesnowthrower

isputinto storageattheendoftheseason.

Adjustments

ShavePlate

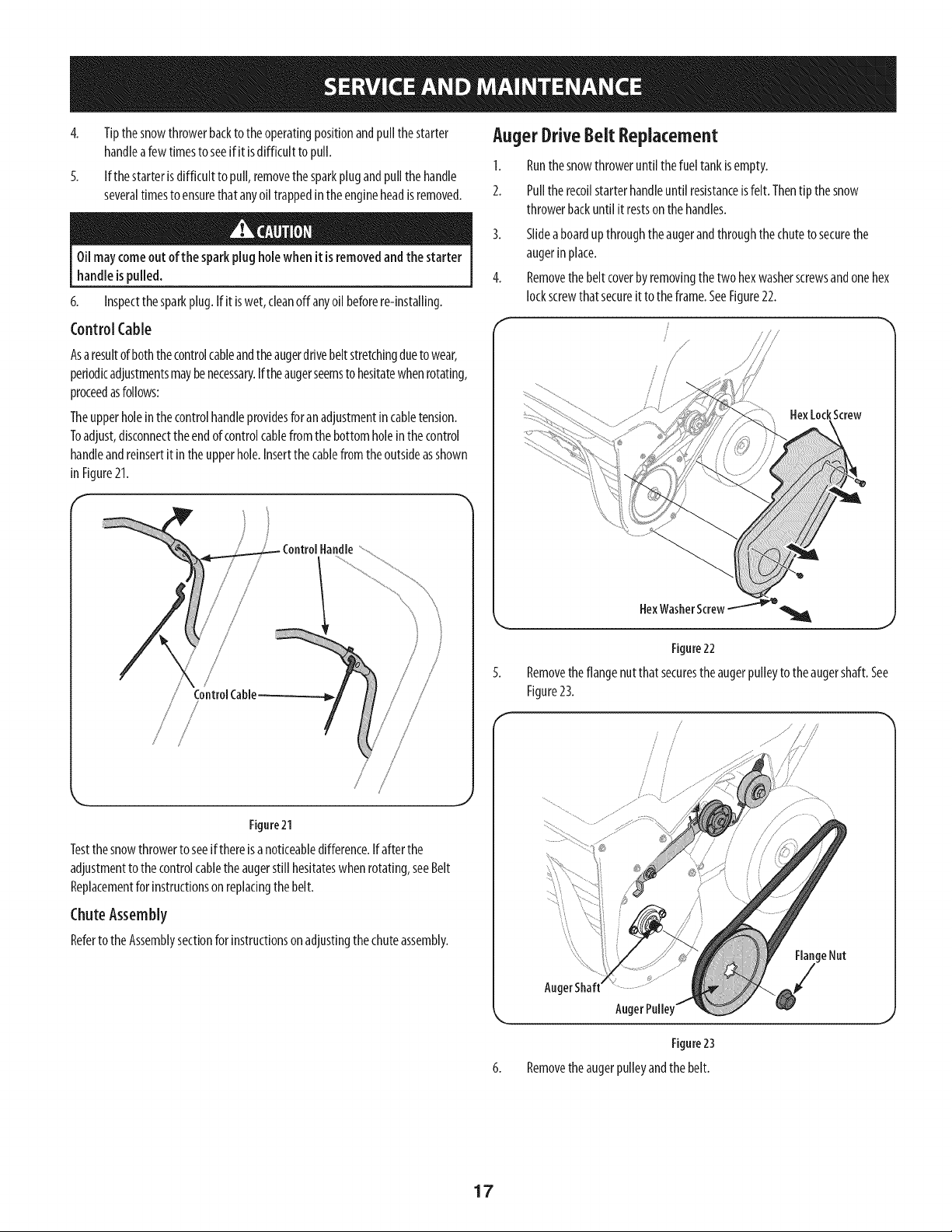

Tochecktheadjustmentof theshaveplate,placethemachineonalevelsurface.

Thewheels,shaveplateandaugerpaddlesshouldallcontactthelevelsurface.

Notethatif theshaveplateisadjustedtoohigh,snowmayblowundertheauger

housing.Iftheshaveplatewearsoutexcessively,orthesnowthrowerdoesnot

self-propel,theshaveplatemaybetoolowthegroundandneedsto beadjusted.

NOTE:Onnewsnowthrowersormachineswithanewshaveplateinstalled,

theaugerpaddlesmaybeslightlyofftheground.

Toadjusttheshaveplateproceedasfollows:

1. Runthesnowthroweruntilthefueltankisempty.

2. Pullthestartercorduntilresistanceisfelt.Thentipthesnowthrowerbackuntilit

restsonthehandles.Toensurethatthesnowthrowerdoesnottipforward,it may

benecessarytosecurethehandletothegroundwithablockorotherobject.

3. Loosenthefourflangelocknutsandcarriagescrewswhichsecuretheshaveplate

tothehousing.SeeFigure20.Movetheshaveplatetotheappropriatepositionand

retightenthenutsandscrewssecurely.

Donotspraythe enginewith waterto cleanit becausethewater could

contaminatethe fuel.Usingagardenhoseorpressurewashingequipment

canalsoforcewaterintothe muffler opening.Waterthat passesthrough

the muffler canenterthe cylinder andcausedamage.

CoolingFins

AirIntakeScreenor RecoilStarter/FlywheelGuardAreas

SparkPlugConnection

Levers

LinkageArea

Guards

Carburetor

EngineHead

16

ReversibleShavePlate

Figure20

......./ /

/

4. Tipthesnowthrowerbacktotheoperatingpositionandpullthestarter

handleafewtimestoseeif itisdifficulttopull.

5. Ifthestarterisdifficultto pull,removethesparkplugandpullthehandle

severaltimestoensurethat anyoil trappedintheengineheadisremoved.

Oilmaycomeout of the sparkplug holewhen it isremovedand the starter

handleispulled.

6. Inspectthesparkplug.If it iswet,cleanoffanyo11beforere-installing.

ControlCable

Asaresultofboththecontrolcableandtheaugerdrivebeltstretchingduetowear,

periodicadjustmentsmaybenecessary.Iftheaugerseemstohesitatewhenrotating,

proceedasfollows:

Theupperholeinthecontrolhandleprovidesforan adjustmentin cabletension.

Toadjust,disconnecttheendofcontrolcablefromthebottomholeinthecontrol

handleandreinsertit intheupperhole.Insertthecablefromtheoutsideasshown

in Figure21.

F

AugerDriveBelt Replacement

1. Runthesnowthroweruntilthefueltankisempty.

2. Pulltherecoilstarterhandleuntil resistanceisfelt.Thentip thesnow

throwerbackuntilit restsonthehandles.

3. Slideaboardupthroughtheaugerandthroughthechutetosecurethe

augerinplace.

4. Removethebeltcoverbyremovingthetwohexwasherscrewsandonehex

lockscrewthatsecureit totheframe.SeeFigure22.

HexLockScrew

/

/

ControlCable

Figure21

Testthesnowthrowertoseeif thereisanoticeabledifference.Ifafterthe

adjustmenttothecontrolcabletheaugerstillhesitateswhenrotating,seeBelt

Replacementforinstructionsonreplacingthebelt.

ChuteAssembly

Referto theAssemblysectionforinstructionsonadjustingthechuteassembly.

HexWasherScre_

Figure22

Removetheflangenutthat securestheaugerpulleyto theaugershaft.See

Figure23.

/

\\

FlangeNut

Ang_

An

J

Figure23

6. Removetheaugerpulleyandthebelt.

17

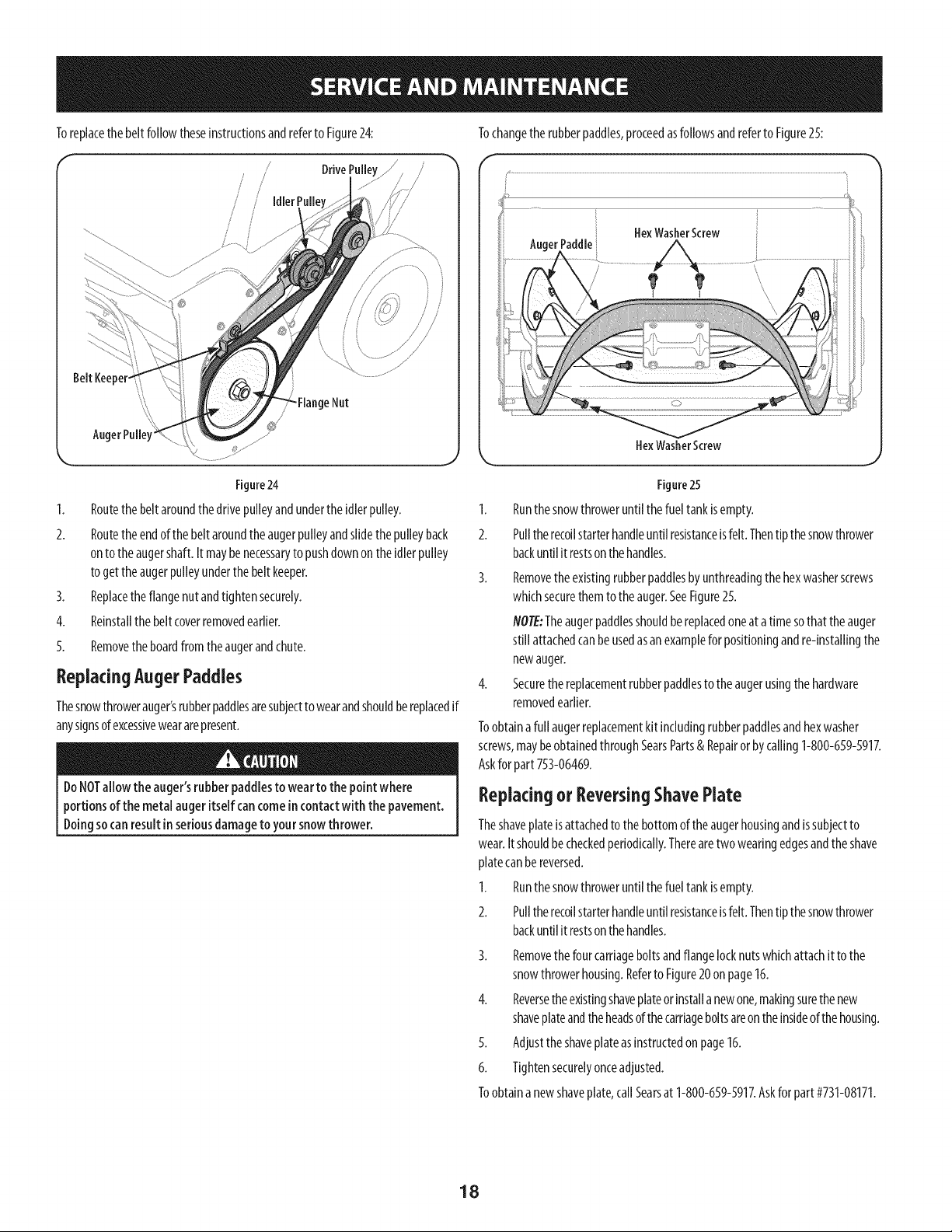

ToreplacethebeltfollowtheseinstructionsandrefertoFigure24:

/

s /

/ i/

/ IdlerPulle

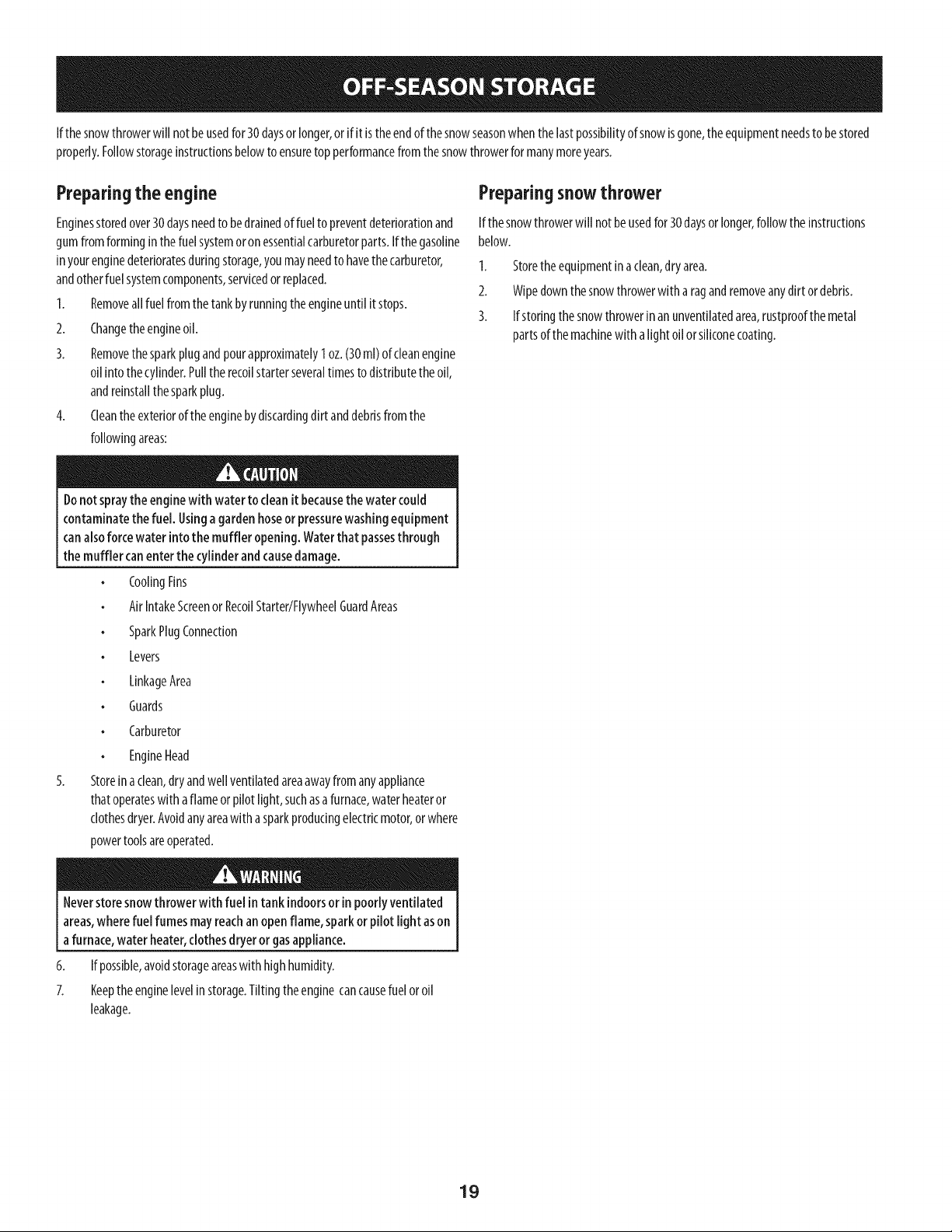

Tochangetherubberpaddles,proceedasfollowsandreferto Figure25:

/

/

erPaddle

HexWasherScrew

HexWasherScrew

Figure24

1. Routethebeltaroundthedrivepulleyandundertheidlerpulley.

2. Routetheendofthe beltaroundtheaugerpulleyandslidethepulleyback

ontotheaugershaft.Itmaybenecessaryto pushdownontheidlerpulley

togettheaugerpulleyunderthe beltkeeper.

3. Replacetheflangenutandtightensecurely.

4. Reinstallthebeltcoverremovedearlier.

5. Removetheboardfromtheaugerandchute.

ReplacingAugerPaddies

Thesnowthrowerauger'srubberpaddlesaresubjectto wearandshouldbereplacedif

anysignsofexcessiveweararepresent.

DoNOTallowthe auger'srubber paddlesto weartothe pointwhere

portionsof the metal augeritselfcancomeincontactwith the pavement.

Doingsocanresultinseriousdamagetoyoursnowthrower.

Figure25

1. Runthesnowthroweruntilthefueltankisempty.

2. Pulltherecoilstarterhandleuntilresistanceisfelt.Thentipthesnowthrower

backuntilitrestsonthehandles.

3. Removetheexistingrubberpaddlesbyunthreadingthehexwasherscrews

whichsecurethemtotheauger.SeeFigure25.

NOTE:Theaugerpaddlesshouldbereplacedoneatatimesothattheauger

stillattachedcanbeusedasanexampleforpositioningandre-installingthe

newauger.

4. Securethereplacementrubberpaddlesto theaugerusingthehardware

removedearlier.

Toobtainafullaugerreplacementkitincludingrubberpaddlesandhexwasher

screws,maybeobtainedthroughSearsParts& Repairor bycalling1-800-659-5917.

Askfor part753-06469.

Replacing or ReversingShavePlate

Theshaveplateisattachedtothebottomoftheaugerhousingandissubjectto

wear.Itshouldbecheckedperiodically.Therearetwowearingedgesandtheshave

platecanbereversed.

1. Runthesnowthroweruntilthefueltankisempty.

2. Pulltherecoilstarterhandleuntilresistanceisfelt.Thentipthesnowthrower

backuntilitrestsonthehandles.

3. Removethefourcarriageboltsandflangelocknutswhichattachittothe

snowthrowerhousing.RefertoFigure20onpage16.

4. Reversetheexistingshaveplateorinstallanewone,makingsurethenew

shaveplateandtheheadsofthecarriageboltsareontheinsideof thehousing.

5. Adjusttheshaveplateasinstructedon page16.

6. Tightensecurelyonceadjusted.

Toobtainanewshaveplate,callSearsat 1-800-659-5917.Askforpart#731-08171.

18

Ifthesnowthrowerwill notbeusedfor30daysorlonger,orifit istheendofthesnowseasonwhenthelastpossibilityof snowisgone,theequipmentneedstobestored

properly.Followstorageinstructionsbelowtoensuretopperformancefromthesnowthrowerformanymoreyears.

Preparingthe engine

Enginesstoredover30daysneedtobedrainedoffueltopreventdeteriorationand

gumfromforminginthefuelsystemoron essentialcarburetorparts.Ifthegasoline

inyourenginedeterioratesduringstorage,youmayneedto havethecarburetor,

andotherfuelsystemcomponents,servicedorreplaced.

1. Removeallfuelfromthetankbyrunningtheengineuntilit stops.

2. Changetheengineoil.

3. Removethesparkplugandpourapproximately1oz.(30ml)ofdeanengine

oilintothecylinder.Pulltherecoilstarterseveraltimestodistributetheoil,

andreinstallthesparkplug.

4. Cleantheexterioroftheenginebydiscardingdirt anddebrisfromthe

followingareas:

Donotspraytheenginewith water to cleanit becausethewater could

contaminatethe fuel.Usingagardenhoseorpressurewashingequipment

canalsoforcewaterintothe muffler opening.Waterthat passesthrough

the muffler canenterthe cylinder andcausedamage.

CoolingFins

AirIntakeScreenor RecoilStarter/FlywheelGuardAreas

SparkPlugConnection

Levers

LinkageArea

Guards

Carburetor

EngineHead

5. Storeinaclean,dryandwellventilatedareaawayfromanyappliance

thatoperateswith aflameorpilotlight,suchasafurnace,waterheateror

clothesdryer.Avoidanyareawitha sparkproducingelectricmotor,orwhere

powertoolsareoperated.

Preparingsnow thrower

Ifthesnowthrowerwill notbeusedfor30daysorlonger,followtheinstructions

below.

1. Storetheequipmentinaclean,dryarea.

2. Wipedownthesnowthrowerwith a ragandremoveanydirt ordebris.

3. Ifstoringthesnowthrowerinanunventilatedarea,rustproofthemetal

partsofthemachinewith alightoilorsiliconecoating.

Neverstore snowthrowerwith fuel in tank indoorsor inpoorlyventilated

areas,wherefuelfumes mayreachanopenflame,sparkor pilotlight ason

afurnace,waterheater,clothesdryeror gasappliance.

6. Ifpossible,avoidstorageareaswith highhumidity.

7. Keeptheenginelevelinstorage.Tiltingtheenginecancausefueloroil

leakage.

19

Disconnectthesparkplugwireandgrounditagainsttheengineto prevent

unintendedstarting.Beforeperforminganytypeofmaintenance/service,

disengageallcontrolsandstoptheengine.Waituntilall movingparts

havecometoacompletestop.Alwayswearsafetyglassesduringoperation

orwhileperforminganyadjustmentsorrepairs.

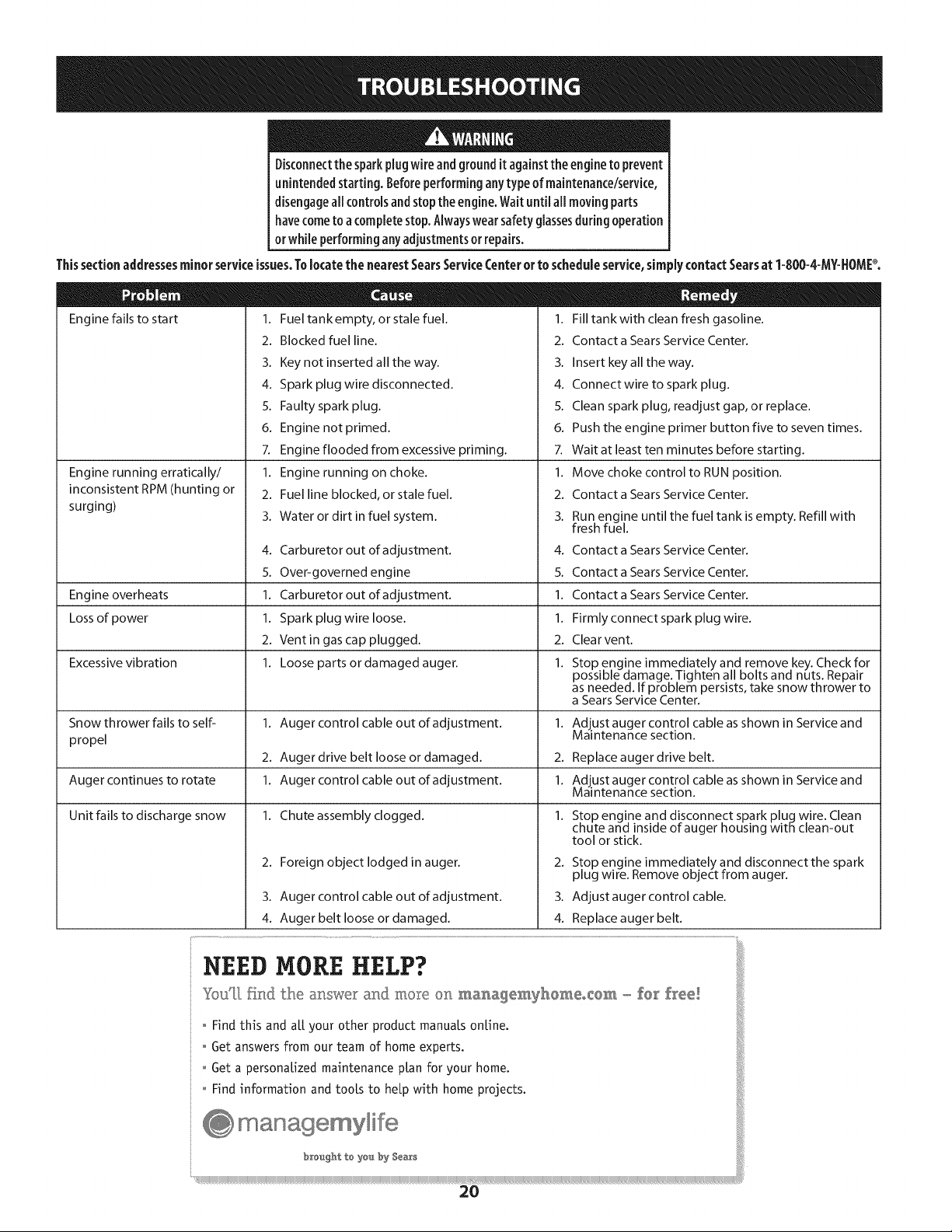

Thissectionaddressesminorserviceissues.Tolocatethe nearestSearsServiceCenterortoscheduleservice,simplycontactSearsat1-800-4-MY-HOM[_.

Engine fails to start 1. Fuel tank empty, or stale fuel 1. Fill tank with dean fresh gasoline.

2. Blocked fuel line.

3. Keynot inserted all the way.

4. Spark plug wire disconnected.

5. Faulty spark plug.

6. Engine not primed. 6.

7. Engine flooded from excessive priming. 7.

Engine running erratically/

inconsistent RPM (hunting or

surging)

Engine overheats 1. Carburetor out of adjustment. 1.

Loss of power 1. Spark plug wire loose. 1.

Excessive vibration 1. Loose parts or damaged auger. 1.

Snow thrower fails to self- 1. Auger control cable out of adjustment. 1.

propel

Auger continues to rotate 1. Auger control cable out of adjustment. 1.

Unit fails to discharge snow 1. Chute assembly clogged. 1.

1. Engine running on choke. 1.

2. Fuel line blocked, or stale fuel. 2.

3. Water or dirt in fuel system. 3.

4. Carburetor out of adjustment. 4.

5. Over-governed engine 5.

2. Ventin gas cap plugged. 2.

2. Auger drive belt loose or damaged. 2.

2. Foreign object lodged in auger. 2. Stop engine immediately and disconnect the spark

3. Auger control cable out of adjustment. 3. Adjust auger control cable.

4. Auger belt loose or damaged. 4. Replace auger belt.

2. Contact a Sears Service Center.

3. Insert key all the way.

4. Connectwire to spark plug.

5. Clean spark plug, readjust gap, or replace.

Push the engine primer button five to seven times.

Wait at least ten minutes before starting.

Move choke control to RUN position.

Contact a Sears Service Center.

Run engine until the fuel tank is empty. Refill with

fresh fuel.

Contact a Sears Service Center.

Contact a Sears Service Center.

Contact a Sears Service Center.

Firmly connect spark plug wire.

Clear vent.

Stop engine immediately and remove key. Check for

possible damage. Tighten all bolts and nuts. Repair

as needed. If problem persists, take snow thrower to

a Sears Service Center.

Adjust auger control cable asshown in Service and

Maintenance section.

Replace auger drive belt.

Adjust auger control cable asshown in Service and

Maintenance section.

Stop engine and disconnect spark plug wire. Clean

chute and inside of auger housing with clean-out

tool or stick.

plug wire. Remove object from auger.

NEED MORE HELP? !

You'll. f:ind the a_swe:_" ar_d_more on mas_agemy_OmeoCem - £er £ree!

o Find this and a[[ your other product manuals online.

: ° Get answers from our team of home

i

experts.

202122

Loading...

Loading...