Craftsman 247887820 Owner’s Manual

Operator's Manual

CRRFr MRN

21" SNOW THROWER

Model No. 247.887820

o SAFETY

ASSEMBLY

OPERATION

MAINTENANCE

CAUTION: Before using

this product, read this

PARTS LIST

o ESPANOL

manual and follow all

safety rules and operating

instructions.

Sears Brands Management Corporation, Hoffman Estates, IL 60179, U.S.A.

Visit our website: www.craftsman.com FORM1/O.769-07096B

6/13/2012

Warranty Statement .................................. Page 2

Safe Operation Practices .......................... Pages 3-6

Assembly .................................................. Pages 7-10

Operation .................................................. Pages 11-13

Service and Maintenance ......................... Pages 14-18

Off-Season Storage .................................. Page 19

CRAFTSMAN TWO YEAR FULL WARRANTY

FORTWOYEARSfromthe dateof purchase,this productiswarrantedagainstanydefectsin materialor workmanship.Defectiveproductwill

receivefreerepairorfree replacementifrepairis unavailable,

Thiswarrantyisvoidif thisproductiseverusedwhile providingcommercialservicesor if rentedtoanotherperson,

Forwarrantycoverage details to obtain repairor replacement,visit the website: www.craftsman.com

This warranty covers ONLYdefects in material andworkmanship. Warrantycoverage does NOTinclude:

• Expendableitemsthatcan wearoutfromnormalusewithinthewarrantyperiod,includingbutnot limitedtoaugers,augerpaddles,drift

cutters,skidshoes,shaveplate,shearpins,sparkplug,aircleaner,belts,andoilfilter.

• Standardmaintenanceservicing,oilchanges,ortune-ups.

• Tire replacementor repaircausedbypuncturesfromoutsideobjects,suchasnails,thorns,stumps,orglass.

• Tireor wheelreplacementor repairresultingfromnormalwear,accident,orimproperoperationor maintenance.

• Repairsnecessarybecauseof operatorabuse,includingbutnotlimitedtodamagecausedbyover-speedingtheengine,orfromimpacting

objectsthatbendthe frame,augershaft,etc.

• Repairsnecessarybecauseof operatornegligence,includingbutnotlimitedto,electricalandmechanicaldamagecausedbyimproper

storage,failureto usethepropergradeandamountofengineoil,or failureto maintaintheequipmentaccordingtothe instructionscontained

intheoperator'smanual.

• Engine(fuelsystem)cleaningor repairscausedbyfueldeterminedto becontaminatedoroxidized(stale).Ingeneral,fuelshouldbeused

within30 daysof itspurchasedate.

• Normaldeteriorationandwearof theexteriorfinishes,orproductlabelreplacement.

Troubleshooting ........................................ Page 20

Parts List ..................................................... Pages 22-33

Labels ....................................................... Page 34

Repair Protection Agreement ................... Page 39

Espa_ol ..................................................... Page 40

Service Numbers ...................................... Back Cover

Thiswarrantygivesyouspecificlegalrights,andyou mayalsohaveotherrightswhichvaryfromstatetostate.

Sears Brands Management Corporation, Hoffman Estates, IL 60179

EngineOilType: SAE5W-30

EngineOilCapacity: 20ounces

FuelCapacity: 2 Quarts

SparkPlug: F6RTC

SparkPlugGap: .020"-.030"

©SearsBrands,LLC

ModelNumber.................................................................

Serial Number .................................................................

Dateof Purchase.............................................................

Recordthe modelnumber,serialnumber

anddateof purchaseabove

2

Thissymbolpointsout importantsafetyinstructionswhich,if not

followed,couldendangerthepersonalsafetyand/orpropertyof

yourselfandothers. Readandfollowall instructionsin thismanual

beforeattemptingtooperatethismachine.Failureto complywith

theseinstructionsmayresultin personalinjury.Whenyouseethis

symbol,HEEDITSWARNING!

Thismachinewasbuiltto beoperatedaccordingtothesafeopera-

tionpracticesinthis manual.Aswithanytypeof powerequipment,

carelessnessorerroron thepartofthe operatorcanresultin serious

injury.Thismachineiscapableofamputatingfingers,hands,toes

andfeetandthrowingdebris.Failuretoobservethefollowingsafety

instructionscouldresultin seriousinjuryor death.

CALIFORNIA PROPOSITION 65

EngineExhaust,someof itsconstituents,andcertainvehicle

componentscontainoremitchemicalsknownto StateofCalifornia

tocausecancerandbirthdefectsorotherreproductiveharm,

TRAiNiNG

• Read,understand,andfollowall instructionson themachineand

in themanual(s)beforeattemptingto assembleandoperate.

Failuretodo socan resultinseriousinjurytotheoperatorand/

orbystanders.Keepthismanualin a safeplaceforfutureand

regularreferenceandfor orderingreplacementparts.Toorder

replacementpartscall,1-800-4MY-HOME.

• Befamiliarwithall controlsandtheirproperoperation.Knowhow

tostopthe machineanddisengagethemquickly.

• Neverallowchildrenunder14yearsofagetooperatethis

machine.Children14andover shouldreadandunderstandthe

instructionsandsafeoperationpracticesin thismanualandon

themachineandbe trainedandsupervisedbyanadult.

Neverallowadultsto operatethismachinewithoutproper

instruction.

• Thrownobjectscancauseseriouspersonalinjury.Planyour

snow-throwingpatterntoavoiddischargeof materialtoward

roads,bystandersandthe like.

Keepbystanders,petsandchildrenat least75feetfromthe

machinewhile itis in operation.Stopmachineifanyoneenters

thearea.

• Exercisecautiontoavoidslippingorfalling,especiallywhen

operatinginreverse.

Your Responsibility--Restrict theuseofthispowermachineto

personswhoread,understandandfollowthewarningsand instruc-

tionsin thismanualandon the machine,

SAVE THESE INSTRUCTIONS!

PREPARATION

Thoroughlyinspecttheareawherethe equipmentistobeused.

Removeall doormats,newspapers,sleds,boards,wiresandother

foreignobjects,whichcouldbe trippedoverorthrownbythe auger/

impeller.

• Alwayswearsafetyglassesoreyeshieldsduringoperationand

whileperformingan adjustmentor repairto protectyoureyes.

Thrownobjectswhichricochetcancauseseriousinjurytothe

eyes.

Donot operatewithoutwearingadequatewinteroutergarments.

Donot wearjewelry,longscarvesorotherlooseclothing,which

couldbecomeentangledin movingparts.Wearfootwearwhich

willimprovefootingonslipperysurfaces.

Usea groundedthree-wireextensioncordand receptacleforall

machineswithelectricstartengines.

Disengageall controlleversbeforestartingtheengine.

• Neverattempttomakeanyadjustmentswhileengineis running,

exceptwherespecificallyrecommendedintheoperator'smanual.

Letengineandmachineadjustto outdoortemperaturebefore

startingtoclearsnow.

3

SafeHandling of Gasoline

Toavoidpersonalinjuryor propertydamageuseextremecarein

handlinggasoline.Gasolineisextremelyflammableandthe vaporsare

explosive.Seriouspersonalinjurycanoccurwhengasolineis spilled

onyourselforyourclotheswhichcan ignite. Washyourskinand

changeclothesimmediately.

• Useonlyan approvedgasolinecontainer.

• Extinguishallcigarettes,cigars,pipesandothersourcesof

ignition.

• Neverfuel machineindoors.

• Neverremovegascapor addfuelwhilethe engineishotor

running.

• Allowenginetocoolat leasttwo minutesbeforerefueling.

• Neveroverfillfuel tank.Filltankto nomorethan1/2inchbelow

bottomoffillerneckto providespaceforfuelexpansion.

• Replacegasolinecapandtightensecurely.

• Ifgasolineisspilled,wipeitoff theengineandequipment.Move

machineto anotherarea.Wait5 minutesbeforestartingthe

engine.

• Neverstorethe machineorfuelcontainerinsidewherethereisan

openflame,sparkor pilotlight(e.g.furnace,waterheater,space

heater,clothesdryeretc.).

• Allowmachineto coolat least5 minutesbeforestoring.

• Neverfill containersinsidea vehicleor ona truckor trailerbed

witha plasticliner.Alwaysplacecontainersonthe groundaway

fromyourvehiclebeforefilling.

• If possible,removegas-poweredequipmentfromthe truckor

trailerandrefuelitonthe ground.Ifthis is notpossible,then refuel

suchequipmenton a trailerwitha portablecontainer,ratherthan

froma gasolinedispensernozzle.

• Keepthe nozzlein contactwiththerimofthefueltankor

containeropeningat alltimesuntilfuelingis complete.Do notuse

a nozzlelock-opendevice.

OPERATION

• Do notputhandsorfeetnear rotatingparts,intheauger/impeller

housingorchuteassembly.Contactwiththe rotatingpartscan

amputatehandsandfeet.

• Theauger/impellercontrolleverisa safetydevice.Neverbypass

itsoperation.Doingsomakesthe machineunsafeandmaycause

personalinjury.

• Thecontrolleversmustoperateeasilyinbothdirectionsand

automaticallyreturntothedisengagedpositionwhenreleased.

• Neveroperatewithamissingordamagedchuteassembly.Keep

all safetydevicesinplaceandworking.

• Neverrunanengineindoorsorina poorlyventilatedarea.Engine

exhaustcontainscarbonmonoxide,anodorlessanddeadlygas.

• Do notoperatemachinewhileundertheinfluenceofalcoholor

drugs.

• Mufflerandenginebecomehotandcancauseaburn.Donot

touch.Keepchildrenaway.

• Exerciseextremecautionwhenoperatingonorcrossinggravel

surfaces.Stayalertforhiddenhazardsortraffic.

Exercisecautionwhenchangingdirectionandwhileoperatingon

slopes.

Planyoursnow-throwingpatternto avoiddischargetowards

windows,walls,carsetc.Thus,avoidingpossibleproperty

damageorpersonalinjurycausedby a ricochet.

Preventpossiblepropertydamageorpersonalinjuryfrom

objectricochetbyplanningyoursnowthrowingpatterntoavoid

dischargetowardswindows,walls,cars,etc.

• Donotoverloadmachinecapacitybyattemptingtoclearsnowat

toofastof a rate.

• Neveroperatethismachinewithoutgoodvisibilityorlight.Always

be sureof yourfootingand keepa firmholdon thehandles.Walk,

neverrun.

• Disengagepowertotheauger/impellerwhentransportingor not

in use.

• Neveroperatemachineathightransportspeedsonslippery

surfaces.Lookdownand behindandusecarewhenbackingup.

• Ifthemachineshouldstarttovibrateabnormally,stoptheengine,

disconnectthe sparkplugwireandgroundit againsttheengine.

Inspectthoroughlyfordamage.Repairanydamagebefore

startingandoperating.

• Disengageallcontrolleversandstopenginebeforeyouleave

theoperatingposition(behindthehandles).Waituntiltheauger/

impellercomestoa completestopbeforeuncloggingthechute

assembly,makinganyadjustments,or inspections.

• Neverputyourhandinthedischargeorcollectoropenings.Do

notunclogchuteassemblywhileengineis running.Shutoff

engineand remainbehindhandlesuntilall movingpartshave

stoppedbeforeunclogging.

• Useonlyattachmentsandaccessoriesapprovedbythemanufac-

turer(e.g.wheelweights,tire chains,cabsetc.).

• Whenstartingengine,pullcordslowlyuntilresistanceisfelt,then

pull rapidly.Rapidretractionof startercord(kickback)willpull

handandarmtowardenginefasterthanyoucanletgo.Broken

bones,fractures,bruisesorsprainscouldresult.

• Call 1-800-4MY-HOMEforthe locationofthe nearestSearsParts

& RepairServiceCenter.

CLEARING A CLOGGED DISCHARGE CHUTE

Handcontactwiththe rotatingimpellerinsidethedischargechute

is the mostcommoncauseofinjuryassociatedwithsnowthrowers.

Neveruse yourhandto cleanout thedischargechute.

Toclear thechute:

1. SHUTTHEENGINEOFF!

2. Wait 10secondstobe surethe impellerbladeshavestopped

rotating.

3. Alwaysusea clean-outtool,notyourhands.

4

MAINTENANCE & STORAGE

• Nevertamperwithsafetydevices.Checktheirproperoperation

regularly.Referto themaintenanceandadjustmentsectionsof

thismanual.

• Beforecleaning,repairing,or inspectingmachinedisengageall

controlleversandstoptheengine.Waituntiltheauger/impeller

cometoa completestop.Disconnectthe sparkplugwireand

groundagainsttheengineto preventunintendedstarting.

Checkboltsand screwsforpropertightnessatfrequentintervals

tokeepthemachineinsafeworkingcondition.Also,visually

inspectmachineforanydamage.

Donotchangetheenginegovernorsettingor over-speedthe

engine.Thegovernorcontrolsthe maximumsafeoperatingspeed

ofthe engine.

Snowthrowershaveplatesandskidshoesaresubjecttowear

anddamage.Foryoursafetyprotection,frequentlycheckall

componentsand replacewithoriginalequipmentmanufacturer's

(OEM)partsonlyaslistedinthe Partspagesof thisOperator's

Manual.Useofpartswhichdonot meettheoriginalequipment

specificationsmayleadto improperperformanceandcompro-

misesafety!

Checkcontrolleversperiodicallytoverifytheyengageanddisen-

gageproperlyandadjust,ifnecessary.Referto theadjustment

sectioninthisoperator'smanualforinstructions.

Maintainor replacesafetyandinstructionlabels,as necessary.

Observeproperdisposallawsand regulationsfor gas,oil,etc. to

protecttheenvironment.

Priorto storing,runmachinea few minutestoclear snowfrom

machineand preventfreezeupof auger/impeller.

Neverstorethemachineorfuel containerinsidewherethereisan

openflame,sparkorpilot lightsuchas a waterheater,furnace,

clothesdryeretc.

Alwaysrefertothe operator'smanualforproperinstructionson

off-seasonstorage.

Checkfuelline,tank, cap,andfittingsfrequentlyforcracksor

leaks.Replaceif necessary.

Donotcrankenginewithsparkplugremoved.

Accordingto theConsumerProductsSafetyCommission(CPSC)

andtheU.S.EnvironmentalProtectionAgency(EPA),thisproduct

hasan AverageUsefulLifeof seven(7)years,or 60 hoursof

operation.At theendof theAverageUsefulLifehavethe machine

inspectedannuallybyan authorizedservicedealertoensurethat

allmechanicalandsafetysystemsareworkingproperlyand not

wornexcessively.Failureto do socan resultinaccidents,injuries

ordeath.

DO NOT MODIFY ENGINE

Toavoidseriousinjuryor death,do not modifyengineinany way.

Tamperingwiththe governorsettingcanleadto a runawayengineand

causeitto operateat unsafespeeds.Nevertamperwithfactorysetting

ofenginegovernor.

NOTICE REGARDING EMiSSiONS

EngineswhicharecertifiedtocomplywithCaliforniaandfederal

EPAemissionregulationsfor SORE(SmallOff RoadEquipment)are

certifiedto operateonregularunleadedgasoline,and mayinclude

thefollowingemissioncontrolsystems:EngineModification(EM),

OxidizingCatalyst(OC),SecondaryAirInjection(SAI)and ThreeWay

Catalyst(TWO)if so equipped.

SPARK ARRESTOR

Thismachineisequippedwithaninternalcombustionengineand

shouldnotbe usedonor nearany unimprovedforest-covered,

brush-coveredorgrass-coveredlandunlessthe engine'sexhaust

systemisequippedwitha sparkarrestormeetingapplicablelocalor

statelaws(if any)

Ifa sparkarrestorisused,it shouldbe maintainedin effectiveworking

orderbytheoperator.Inthe StateofCaliforniatheaboveisrequired

bylaw (Section4442ofthe CaliforniaPublicResourcesCode).Other

statesmayhavesimilarlaws. Federallawsapplyonfederallands.

A sparkarrestorfor themufflerisavailablethroughyournearestSears

PartsandRepairServiceCenter.

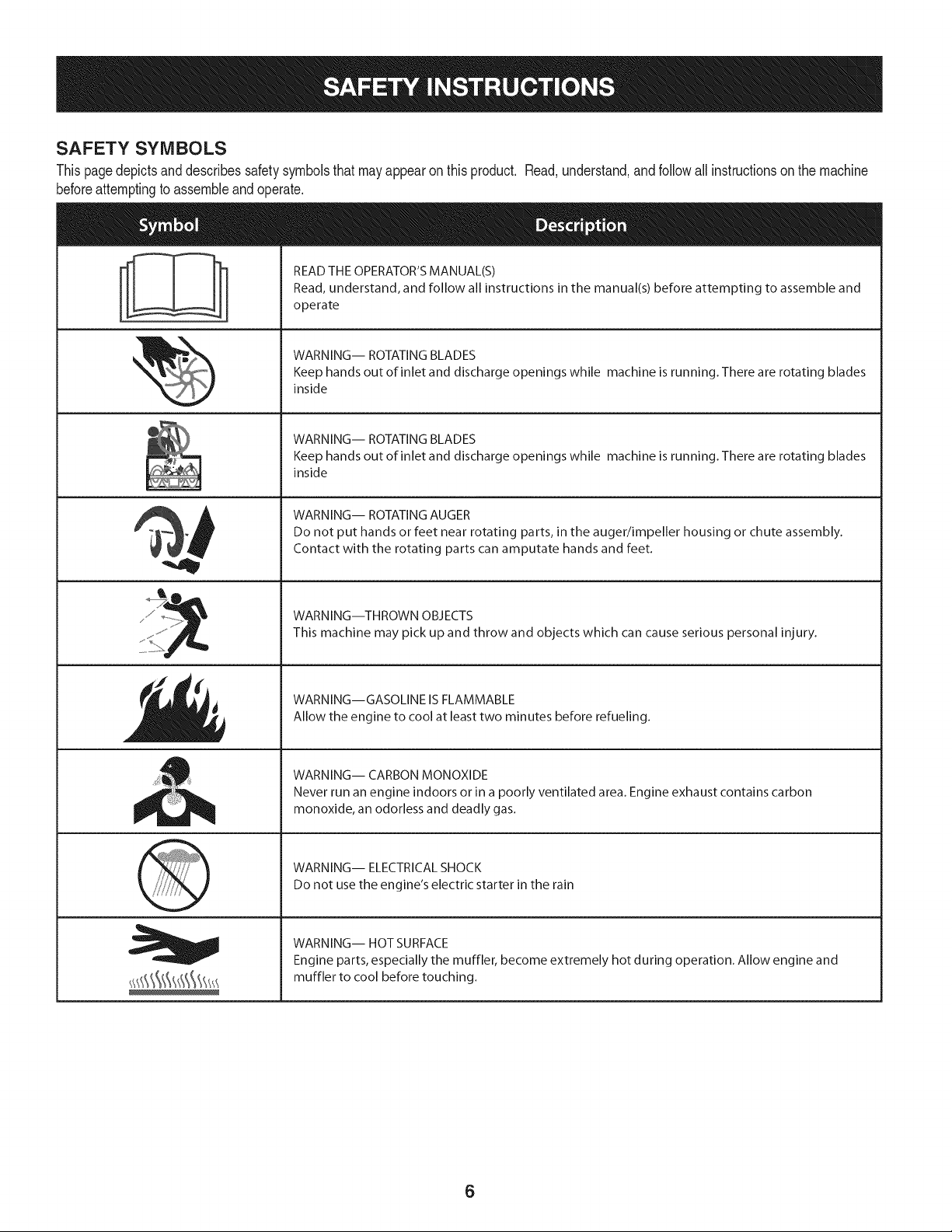

SAFETY SYMBOLS

Thispagedepictsanddescribessafetysymbolsthatmayappearonthisproduct. Read,understand,andfollowall instructionson themachine

beforeattemptingtoassembleandoperate.

READ THE OPERATOR'S MANUAL(S)

i

. +

i

Read, understand, and follow all instructions in the manual(s) before attempting to assemble and

operate

WARNING-- ROTATING BLADES

Keep hands out of inlet and discharge openings while machine is running. There are rotating blades

inside

WARNING-- ROTATING BLADES

Keep hands out of inlet and discharge openings while machine is running. There are rotating blades

inside

WARNING-- ROTATING AUGER

Do not put hands or feet near rotating parts, in the auger/impeller housing or chute assembly.

Contact with the rotating parts can amputate hands and feet.

"JIp

WARNING--THROWN OBJECTS

This machine may pick up and throw and objects which can cause serious personal injury.

WARNING--GASOLINE ISFLAMMABLE

Allow the engine to cool at least two minutes before refueling.

WARNING-- CARBON MONOXIDE

Never run an engine indoors or in a poorly ventilated area. Engine exhaust contains carbon

monoxide, an odorless and deadly gas+

WARNING-- ELECTRICAL SHOCK

Do not use the engine's electric starter in the rain

WARNING-- HOT SURFACE

Engine parts, especially the muffler, become extremely hot during operation. Allow engine and

muffler to cool before touching.

6

NOTE:All referencesto theleftor rightsideof thesnowthrowerare

fromtheoperator'sposition.Anyexceptionswillbe noted.

UNPACKING THE SNOW THROWER

1. Openthetop ofthe carton.

2. Cutdownthe cornersonthefrontofthecartonandfolddownthe

frontside.

3. Pullthesnowthroweroutofthe carton.Besure notto damage

thechute,chuterotationcontrolassemblyorany cablesattached

tothe chute.Someofthesepartsareshippedundertheshroud

onthebacksideofthe carton.Checkforany cabletiessecuring

thechuteand removeifnecessary.

ASSEMBLY

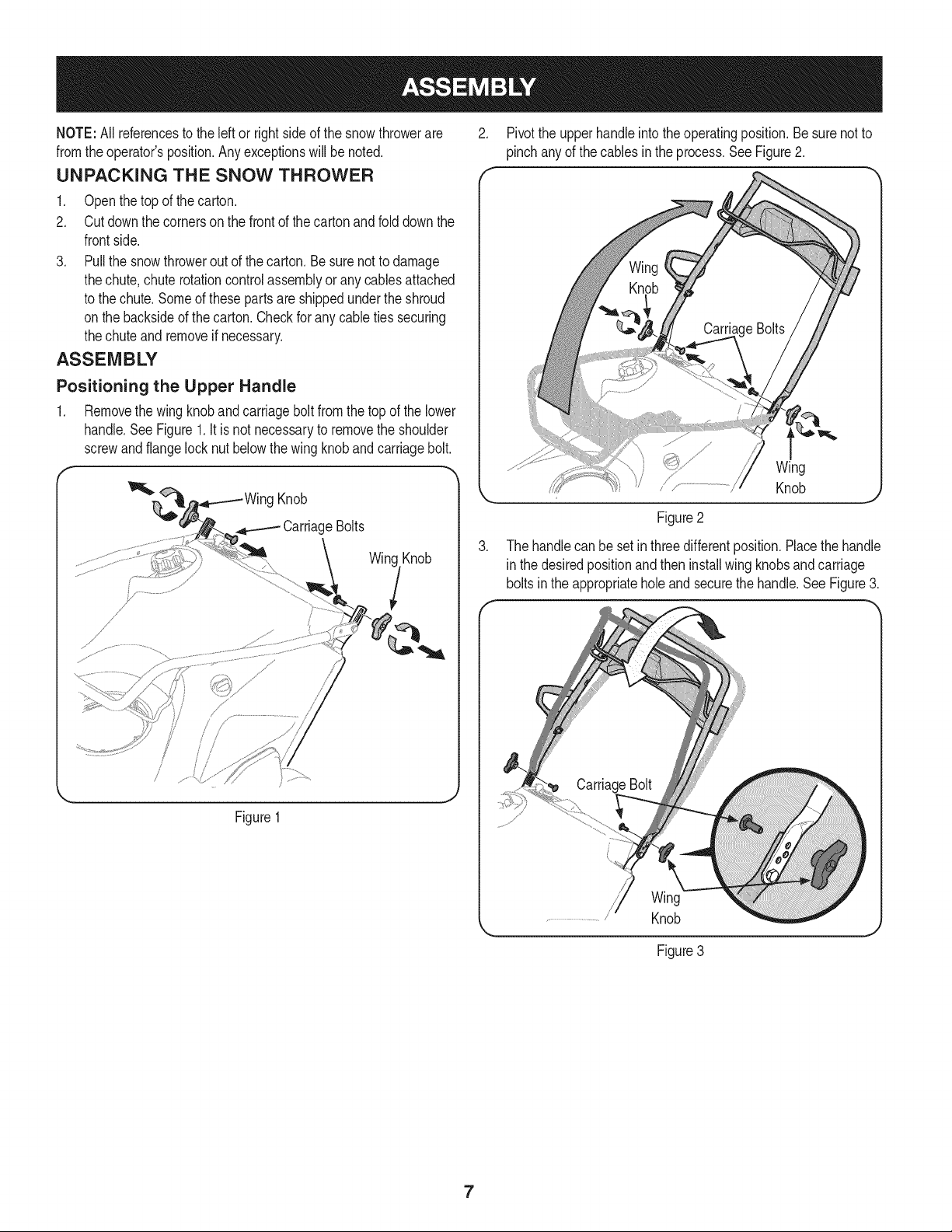

Positioning the Upper Handle

1. Removethewingknobandcarriageboltfromthe topof thelower

handle.SeeFigure1.Itis notnecessarytoremovetheshoulder

screwandflangelocknutbelowthewingknobandcarriagebolt.

g Knob

CarriageBolts

Win(

2. Pivottheupperhandleintotheoperatingposition.Besurenotto

pinchanyofthe cablesin theprocess.SeeFigure2.

Wing

/ J'................... Knob

Figure2

.

Thehandlecan besetin threedifferentposition.Placethehandle

in thedesiredpositionandtheninstallwing knobsandcarriage

boltsin theappropriateholeandsecurethe handle.SeeFigure3.

Figure1

.J

ing

Knob

Figure3

7

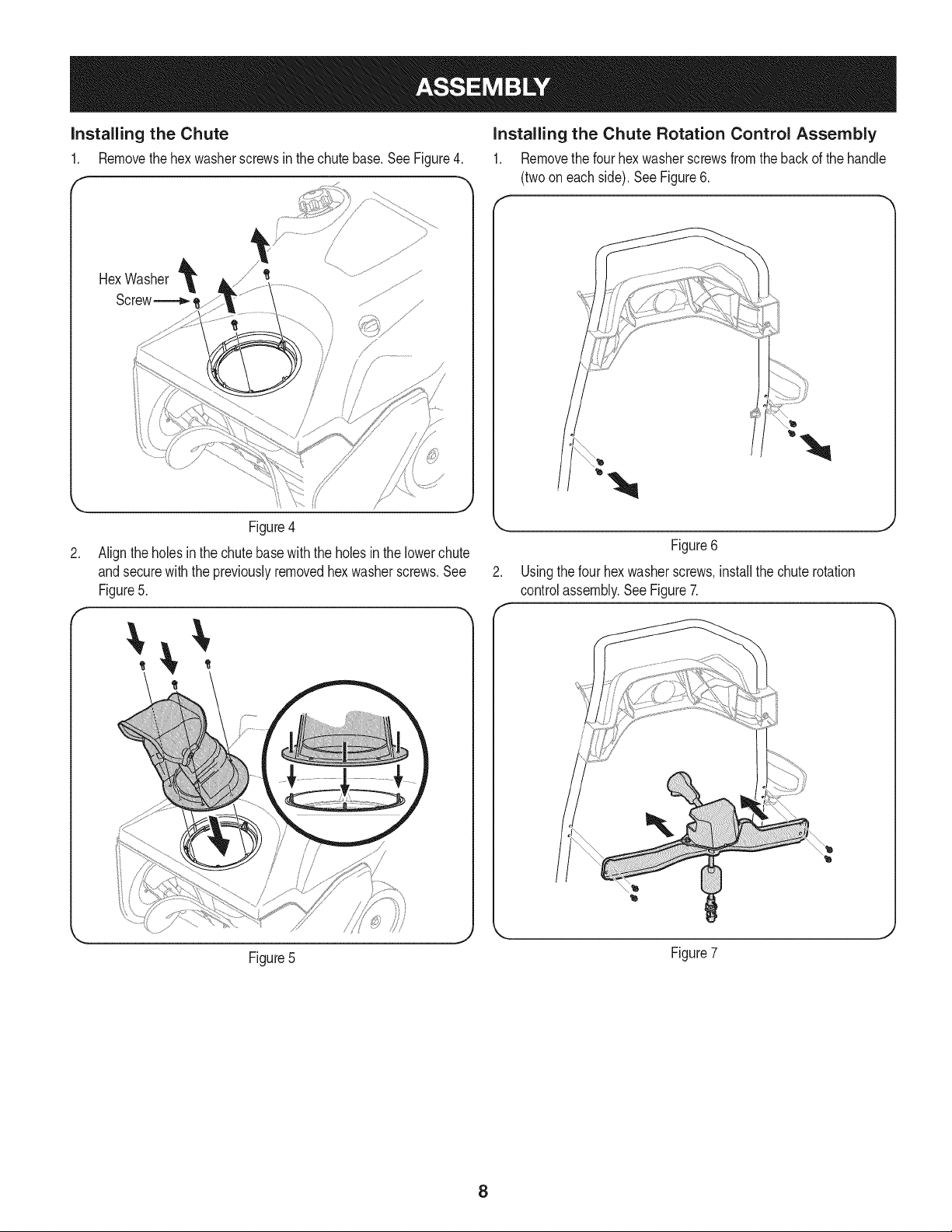

installing the Chute

1. Removethehexwasherscrewsinthechutebase.SeeFigure4.

HexWasher

Screw_,

/

/

Figure4

.

Aligntheholes inthechutebasewiththe holesinthelowerchute

andsecurewiththepreviouslyremovedhexwasherscrews.See

Figure5.

Installing the Chute Rotation Control Assembly

1. Removethefourhexwasherscrewsfromthebackofthehandle

(twoon eachside).SeeFigure6.

Figure6

Usingthefour hexwasherscrews,installthechuterotation

controlassembly.SeeFigure7.

Figure5

Figure7

8

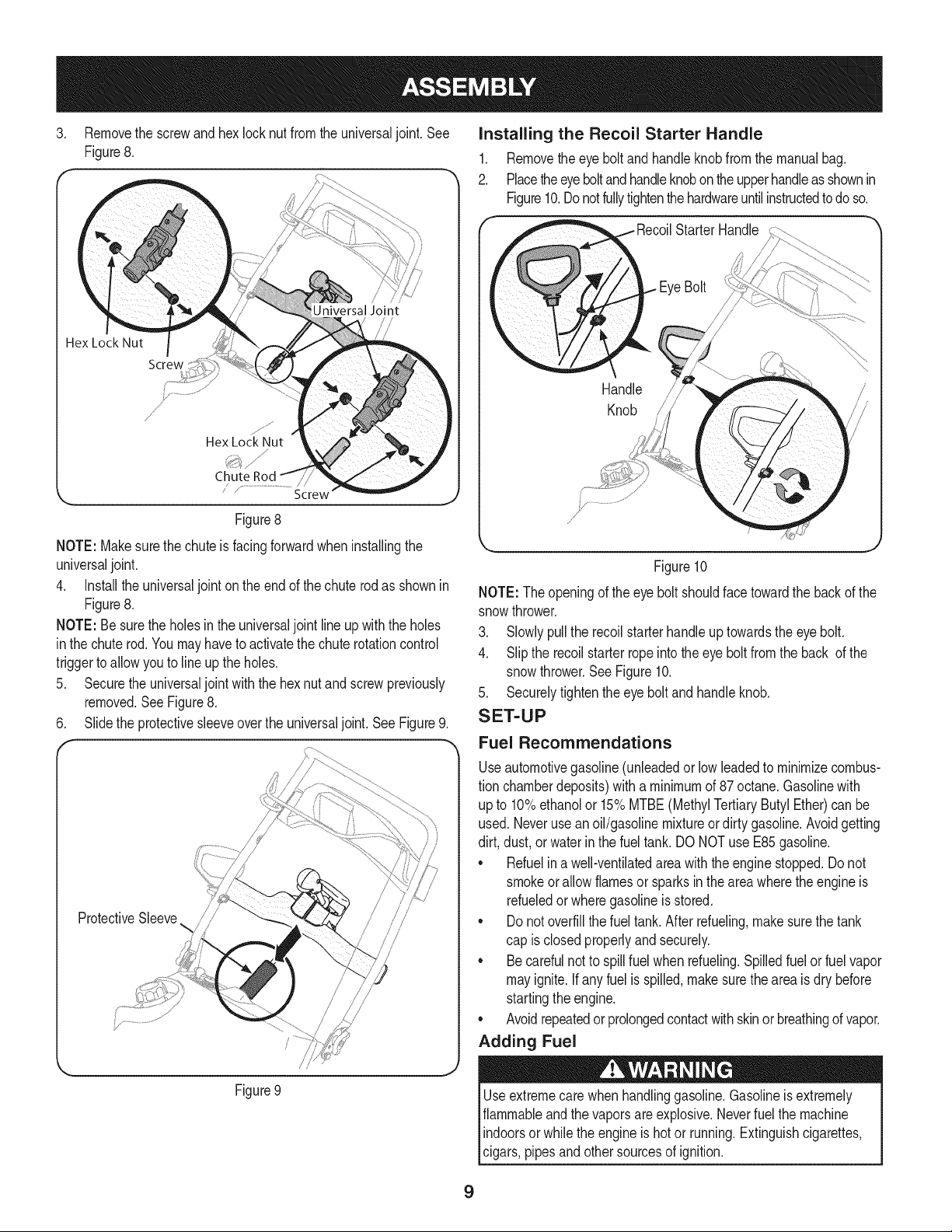

3. Removethe screwandhex locknutfromthe universaljoint.See

Figure8.

Universal Join{

Hex Lock Nut

Screw

f

/

//

Hex Lock Nut

Chute

/ "..............................................Screw

Figure8

NOTE:Makesurethechuteis facingforwardwheninstallingthe

universaljoint.

4. Installthe universaljointon theendof thechuterodas shownin

Figure8.

NOTE:Besuretheholesintheuniversaljointlineupwiththe holes

inthechuterod.Youmayhaveto activatethechuterotationcontrol

triggerto allowyoutoline upthe holes.

5. Securetheuniversaljoint withthehexnutandscrewpreviously

removed.See Figure8.

6. Slidethe protectivesleeveovertheuniversaljoint.See Figure9.

/

ProtectiveSleeve%/ ,

/

Installing the Recoil Starter Handle

1. Removetheeyeboltandhandleknobfromthemanualbag.

2. Placetheeyeboltandhandleknobontheupperhandleas shownin

Figure10.Donotfullytightenthehardwareuntilinstructedtodoso.

Handle /

Knob

J

j

Figure10

NOTE:Theopeningofthe eyebolt shouldfacetowardthe backofthe

snowthrower.

3. Slowlypullthe recoilstarterhandleuptowardstheeyebolt.

4. Slipthe recoilstarterropeintotheeyeboltfromtheback ofthe

snowthrower.See Figure10.

5. Securelytightentheeyeboltandhandleknob.

SET-UP

Fuel Recommendations

Useautomotivegasoline(unleadedor lowleadedtominimizecombus-

tionchamberdeposits)witha minimumof87 octane.Gasolinewith

up to 10%ethanolor 15%MTBE(MethylTertiaryButylEther)canbe

used.Neverusean oil/gasolinemixtureordirty gasoline.Avoidgetting

dirt, dust,or waterinthe fueltank.DONOTuse E85gasoline.

• Refuelina well-ventilatedareawiththeenginestopped.Donot

smokeorallowflamesor sparksin theareawheretheengineis

refueledor wheregasolineisstored.

• Donotoverfillthefueltank.After refueling,makesurethetank

capis closedproperlyandsecurely.

• Becarefulnotto spillfuelwhenrefueling.Spilledfuel orfuelvapor

mayignite.Ifanyfuelis spilled,makesuretheareais drybefore

startingthe engine.

• Avoidrepeatedor prolongedcontactwithskinorbreathingofvapor.

Adding Fuel

Figure9

Useextremecarewhenhandlinggasoline.Gasolineisextremely

flammableandthevaporsareexplosive.Neverfuelthemachine

indoorsorwhiletheengineis hotor running.Extinguishcigarettes,

cigars,pipesandothersourcesof ignition.

9

Alwayskeephandsandfeetclearofequipmentmovingparts.Donot

usea pressurizedstartingfluid.Vaporsareflammable.

1. Removethegascap,checkthefuellevelandaddfuelifnecessary.

Fillthetankuntilthefuelreaches1/2"belowthebottomofthefiller

necktoallowforfuelexpansion.Becarefulnottooverfill.

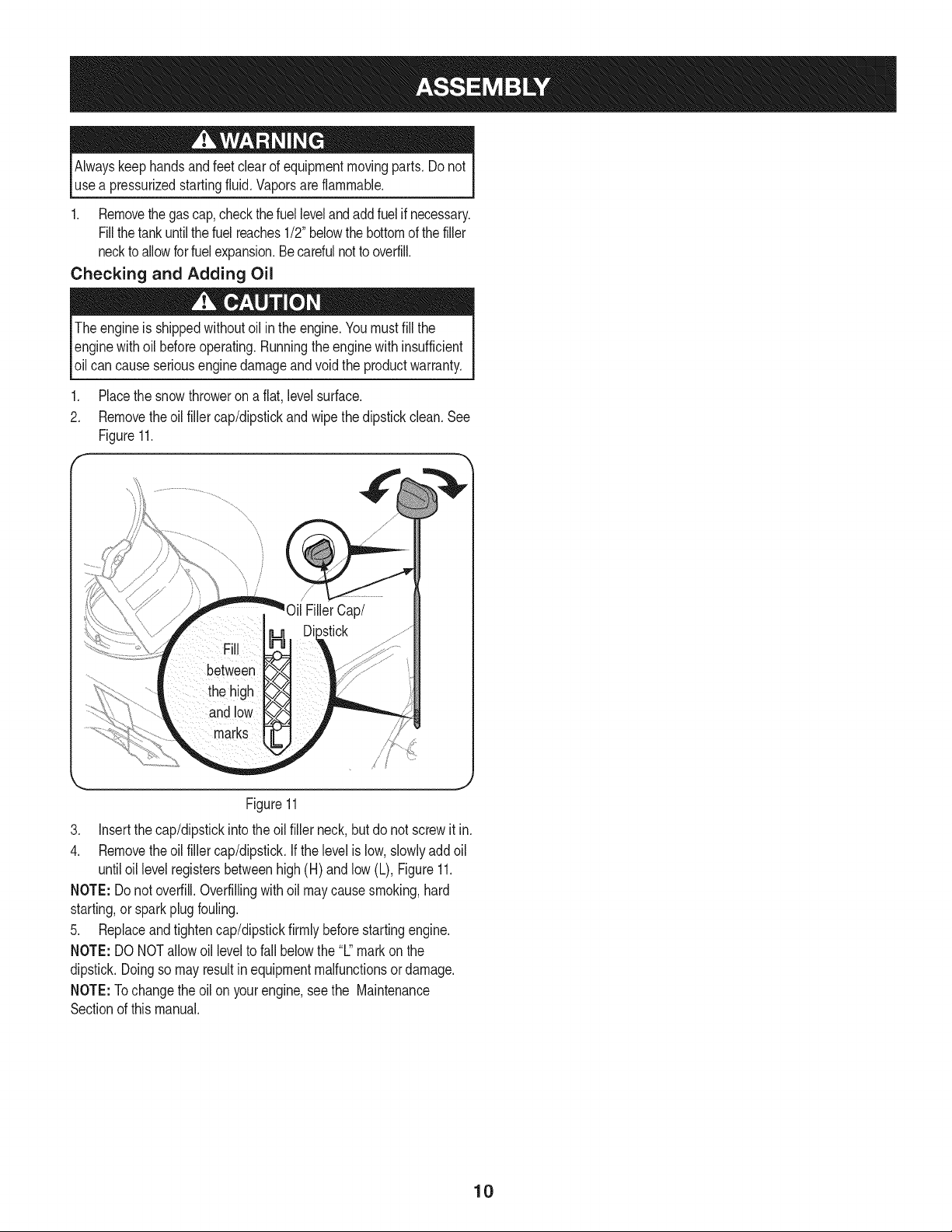

Checking and Adding Oil

Theengineis shippedwithoutoil in theengine.Youmustfill the

enginewithoilbeforeoperating.Runningthe enginewithinsufficient

oilcancauseseriousenginedamageandvoidtheproductwarranty.

Placethe snowthroweron a flat, levelsurface.

2. Removetheoil fillercap/dipstickandwipethedipstickclean.See

Figure11.

\

Figure11

.

Insertthe cap/dipstickinto theoil filler neck,butdo notscrewit in.

4.

Removetheoil fillercap/dipstick.Ifthelevelislow,slowlyaddoil

untiloil levelregistersbetweenhigh(H) andlow(L), Figure11.

NOTE:Donotoverfill.Overfillingwithoil maycausesmoking,hard

starting,or sparkplugfouling.

5. Replaceandtightencap/dipstickfirmlybeforestartingengine.

NOTE:DONOTallowoil leveltofall belowthe"L"markonthe

dipstick.Doingsomayresultin equipmentmalfunctionsordamage.

NOTE:Tochangethe oilon yourengine,seethe Maintenance

Sectionofthismanual.

10

f Auger

ChuteAssembl'

Shave

RecoilStarterHandle

ChuteRotation

GasCap

Key

ElectricStarterButton

ElectricStarterOutlet

Aug

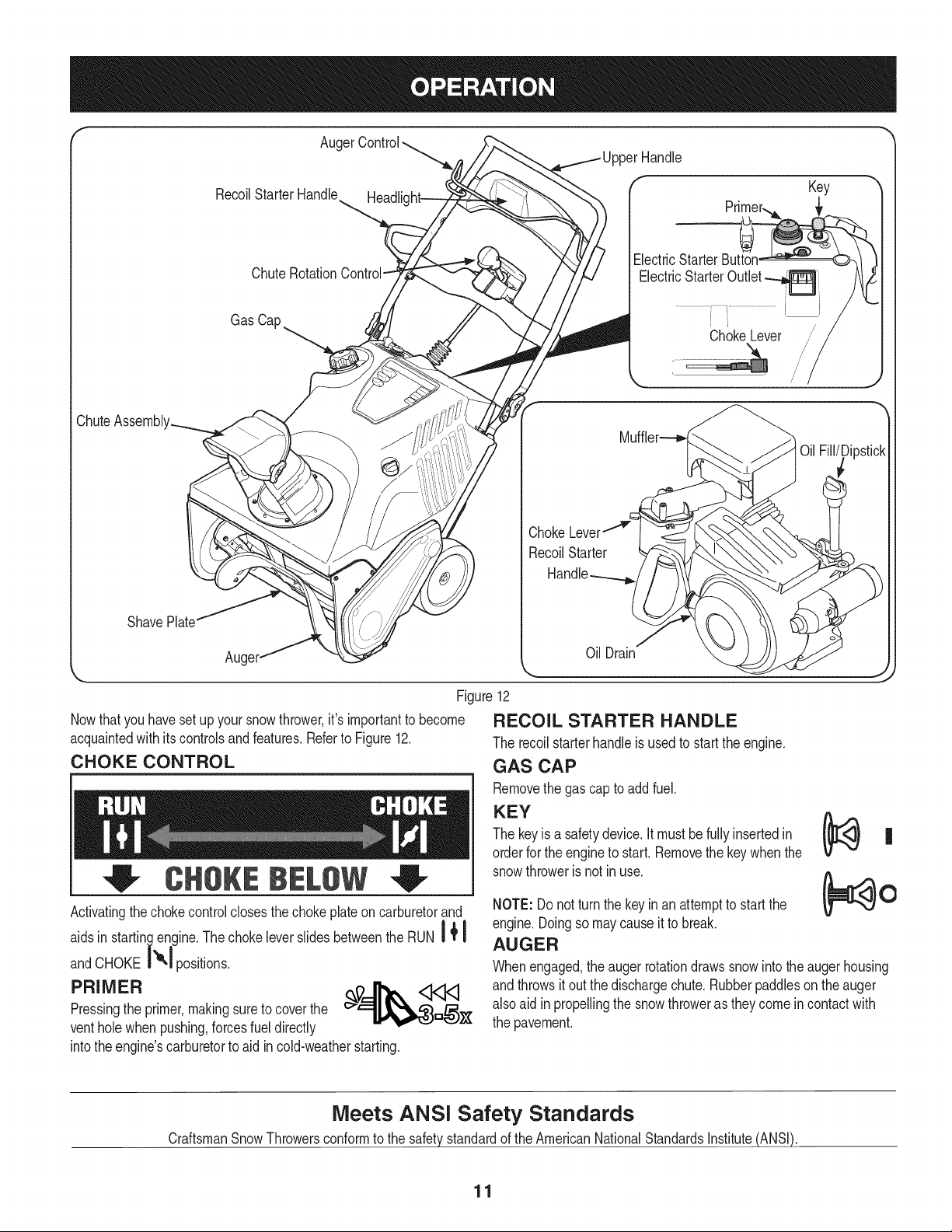

Nowthatyouhavesetupyoursnowthrower,it'simportanttobecome

acquaintedwith itscontrolsandfeatures.RefertoFigure12.

CHOKE CONTROL

CHO BELOW

Activatingthechokecontrolclosesthechokeplateoncarburetorand

aidsin startin_,,.lengine.ThechokeleverslidesbetweentheRUN I + !

andCHOKEi",1 positions.

Pressingthe primer,makingsureto coverthe

PRIMER __%_

ventholewhenpushing,forcesfueldirectly

intothe engine'scarburetorto aidin cold-weatherstarting.

Oil Drain

12

Figure

RECOIL STARTER HANDLE

Therecoilstarterhandleis usedto starttheengine.

GAS CAP

Removethegascapto addfuel.

KEY

Thekeyis a safetydevice.Itmust befullyinsertedin

orderfortheengineto start.Removethe keywhenthe

snowthrowerisnot inuse.

NOTE:Do notturn thekeyinan attemptto startthe

engine.Doingsomaycauseit tobreak.

AUGER

Whenengaged,theaugerrotationdrawssnowintotheaugerhousing

andthrowsit outthe dischargechute.Rubberpaddleson theauger

alsoaidin propellingthesnowthrowerastheycomein contactwith

thepavement.

Meets ANSI Safety Standards

CraftsmanSnowThrowersconformtothesafetystandardoftheAmericanNationalStandardsInstitute(ANSI).

11

AUGER CONTROL

Locatedon the upperhandle,theaugercontrolhandleisusedto

engageanddisengagedriveto theauger.Squeezethecontrolhandle

againsttheupperhandleto engagetheauger;releaseittodisengage.

MUFFLER

Engineexhaustexitstheenginevia themuffler.

CHUTE ROTATION CONTROL

Thechuterotatecontrolis locatedin thecenterof thecontrolpanel

andcontrolsthedirectionsnowisthrown.Depressthe buttonand

rotatethechuterotationcontroltotherightto turnthechutetothe right

androtatetothe lefttoturn thechuteto theleft.

CHUTE ASSEMBLY

Thepitchof thedischargechutecontrolstheangleat whichthesnow

isthrown.Loosenthewing knobonthe sideof thedischargechute

beforepivotingthedischargechuteupwardordownward.Retighten

theknoboncethe desiredpositionhasbeenachieved.

SHAVE PLATE

Theshaveplatemaintainscontactwiththe pavementasthe snow

throwerispropelled,allowingsnowcloseto thepavement'ssurfaceto

bedischarged.

OIL FILL/DIPSTICK

Engineoillevelcan becheckedandoil addedthroughtheoil fill.

OIL DRAIN

Engineoilcanbedrainedthroughtheoil drain.

HEADLIGHT

Theheadlightis locatedon theuppercenterof thecontrolpanelandis

onwhenthe snowthroweris running.

ELECTRIC STARTER OUTLET

Requiresthe useof a three-prongoutdoorextensioncordanda 120V

powersource/walloutlet.

ELECTRIC STARTER BUTTON

Pressingthe electricstarterbuttonengagestheengine'selectric

starterwhenpluggedintoa 120Vpowersource.

BEFORE STARTING THE ENGINE

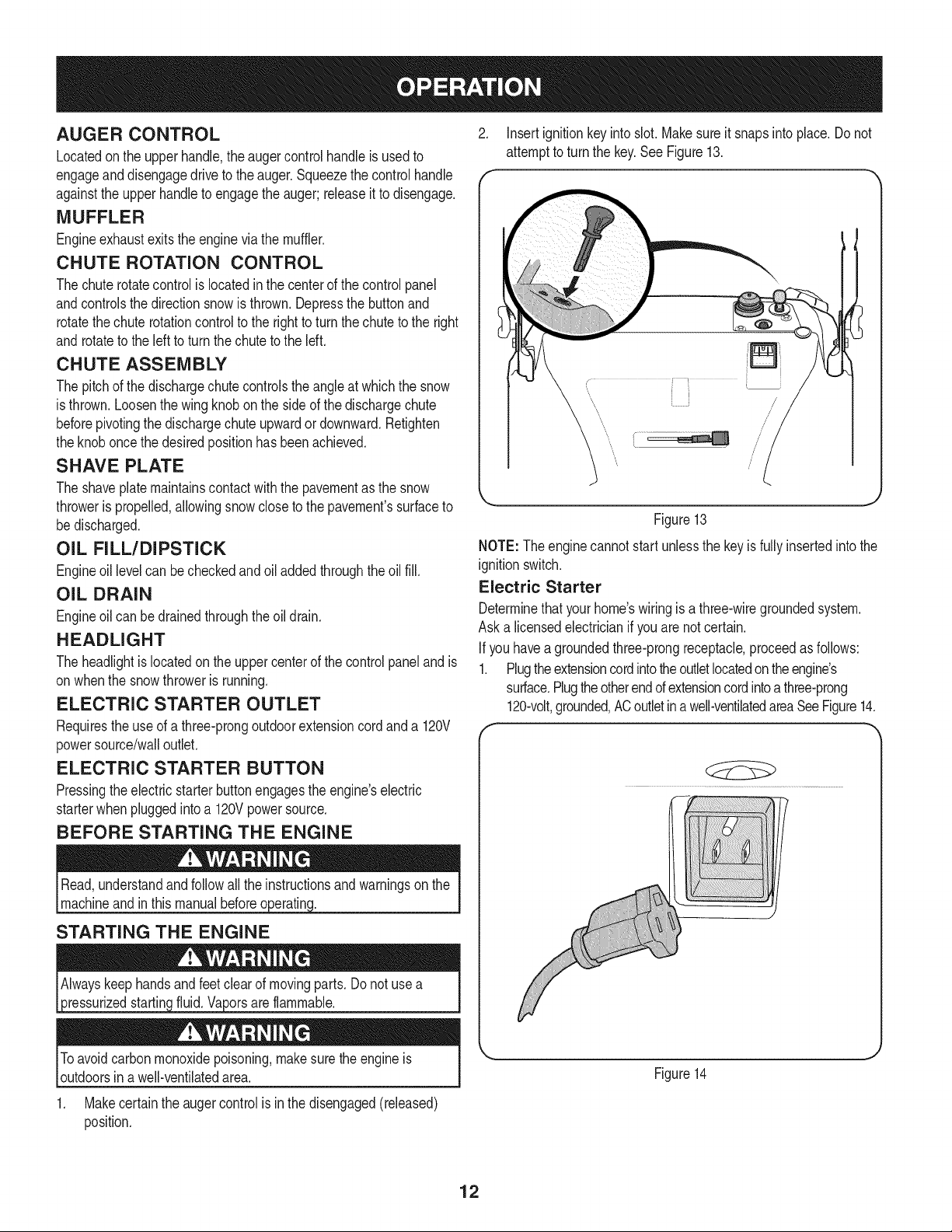

2. Insertignitionkeyintoslot.Makesureit snapsintoplace.Do not

attempttoturn thekey.See Figure13.

Figure13

NOTE:Theenginecannotstartunlessthe keyisfullyinsertedintothe

ignitionswitch.

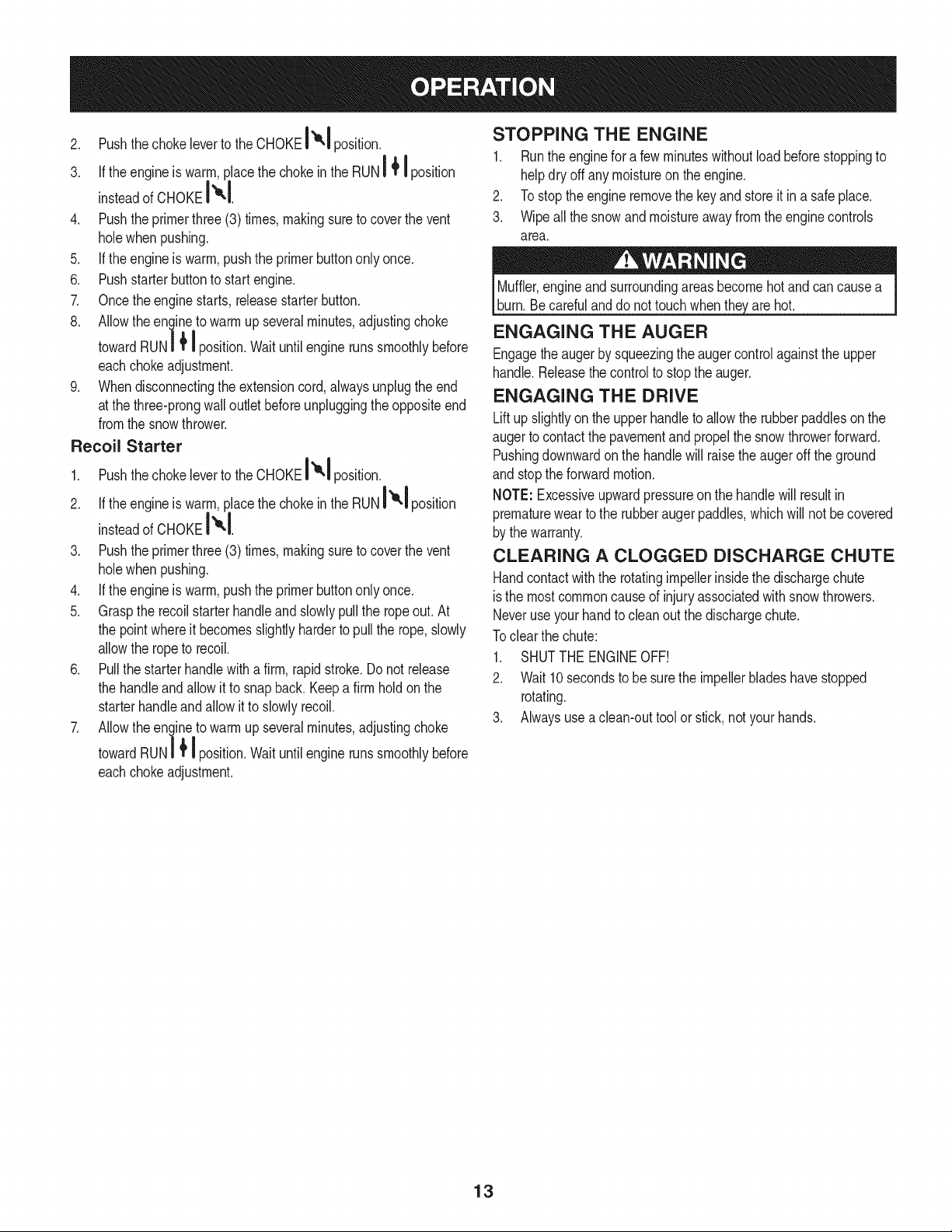

Electric Starter

Determinethatyourhome'swiringisathree-wiregroundedsystem.

Aska licensedelectricianifyouarenotcertain.

Ifyouhavea groundedthree-prongreceptacle,proceedasfollows:

1. Plugtheextensioncordintotheoutletlocatedontheengine's

surface.Plugtheotherendofextensioncordintoa three-prong

120-volt,grounded,ACoutletinawell-ventilatedareaSeeFigure14.

f

machineand inthismanualbefore

STARTING THE ENGINE

3ressurizedstartinc areflammable.

Toavoidcarbonmonoxidepoisoning,makesuretheengineis

outdoorsin awell-ventilatedarea.

1. Makecertaintheaugercontrolis in thedisengaged(released)

position.

Figure14

12

2. Pushthechokeleverto theCHOKEI'e,I position.

a

3. If theengineis warm,placethechokeintheRUNi ! position

insteadof CHOKEI_1.

4. Pushthe primerthree(3) times,makingsureto coverthevent

holewhenpushing.

5. If theengineis warm,pushthe primerbuttononlyonce.

6. Pushstarterbuttontostart engine.

7. Oncethe enginestarts,releasestarterbutton.

8. Allowtheenginetowarmup severalminutes,adjustingchoke

| |

towardRUN| _position.Waituntilenginerunssmoothlybefore

eachchokeadjustment.

9. Whendisconnectingtheextensioncord,alwaysunplugtheend

atthe three-prongwalloutletbeforeunpluggingthe oppositeend

fromthesnowthrower.

Recoil Starter

1. PushthechokelevertotheCHOKEI_1 position.

2. If theengineis warm,placethechokeintheRUNI_1 position

insteadof CHOKEI"_1.

3. Pushthe primerthree(3) times,makingsureto coverthevent

holewhenpushing.

4. If theengineis warm,pushthe primerbuttononlyonce.

5. Graspthe recoilstarterhandleand slowlypullthe ropeout.At

thepointwhereit becomesslightlyhardertopullthe rope,slowly

allowthe ropeto recoil.

6. Pullthestarterhandlewitha firm, rapidstroke.Donot release

thehandleandallowitto snapback.Keepafirmholdonthe

starterhandleandallowitto slowlyrecoil.

7. Allowtheenginetowarmup severalminutes,adjustingchoke

| |

towardRUN| _position.Waituntilenginerunssmoothlybefore

eachchokeadjustment.

STOPPING THE ENGINE

1. Runthe enginefora fewminuteswithoutloadbeforestoppingto

helpdryoff anymoistureontheengine.

2. Tostopthe engineremovethe keyand storeitin a safeplace.

3. Wipeallthe snowandmoistureawayfromthe enginecontrols

area.

Muffler,engineandsurroundingareasbecomehotandcan causea

burn.Becarefulanddonot touchwhentheyare hot.

ENGAGING THE AUGER

Engagethe augerbysqueezingtheaugercontrolagainsttheupper

handle.Releasethecontrolto stoptheauger.

ENGAGING THE DRIVE

Liftup slightlyonthe upperhandletoallowtherubberpaddlesonthe

augertocontactthe pavementandpropelthesnowthrowerforward.

Pushingdownwardonthe handlewill raisetheaugeroff the ground

and stoptheforwardmotion.

NOTE:Excessiveupwardpressureonthe handlewillresultin

prematureweartothe rubberaugerpaddles,whichwill notbecovered

bythe warranty.

CLEARING A CLOGGED DISCHARGE CHUTE

Handcontactwiththe rotatingimpellerinsidethedischargechute

isthe mostcommoncauseofinjuryassociatedwithsnowthrowers.

Neveruseyourhandtocleanoutthe dischargechute.

Toclear thechute:

1. SHUTTHEENGINEOFF!

2. Wait 10secondstobe surethe impellerbladeshavestopped

rotating.

3. Alwaysusea clean-outtoolor stick,notyourhands.

13

MAINTENANCE SCHEDULE

Beforeperforminganytypeof maintenance/service,disengageall

controlsandstopthe engine.Waituntilall movingpartshavecome

toa completestop.Disconnectsparkplugwireandgroundit against

theengineto preventunintendedstarting.Alwayswearsafetyglasses

duringoperationorwhileperforminganyadjustmentsor repairs.

Eachuse .

Engineoillevel.

2.

Snowthrowerandexhaust

1. Check

2. Clean

Followthemaintenanceschedulegivenbelow.Thischartdescribes

serviceguidelinesonly.Usethe ServiceLogcolumntokeeptrackof

completedmaintenancetasks.Tolocate the nearest SearsService

Centeror to scheduleservice,simplycontactSearsat

1-800-4-MY-HOME®.

= =

area.

1st5 hours 1. 1. Change.

Every5hours 1. 1. Check.

25 hours 1. 2. Check.

Everyseason/50hours 1. 1. Change

Everyseason/100hours 1. 1. Clean,replace,re-gap

Everyseason/Before 1. 1. Lubricate

storage 2. 2. Lubricate

ENGINE MAINTENANCE

Engineoil.

Engineoil.

Exhaustarea.

2. 2. Clean.

Sparkplug.

Engineoil

Sparkplug

Pivotpoints

Controlhandle

3. 3. Lubricate

Extensionspring

Engineoil capacityis 600ml(approx.20oz.). Donotover-fill.Usea

4-stroke,oran equivalenthighdetergent,premiumqualitymotoroil

certifiedto meetor exceedU.S.automobilemanufacturer'srequire-

mentsfor serviceclassificationSG,SE Motoroils classifiedSG, SF

usedoil.

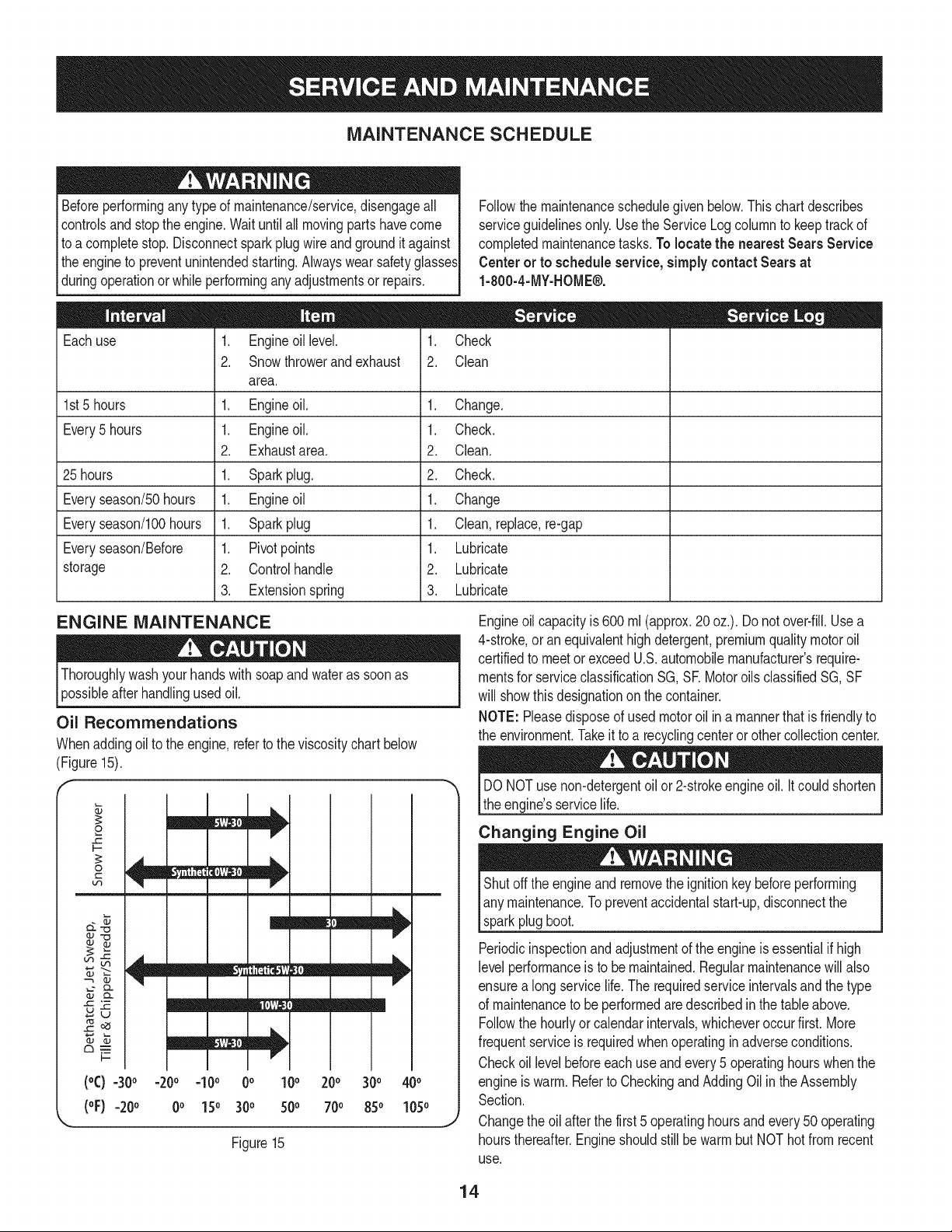

Oil Recommendations

Whenaddingoilto theengine,referto theviscositychartbelow

willshowthis designationon thecontainer.

NOTE:Pleasedisposeofused motoroilin a mannerthatisfriendlyto

theenvironment.Takeitto a recyclingcenteror othercollectioncenter.

(Figure15).

DONOTusenon-detergentoil or2-strokeengineoil.It couldshorten

I

£

F-

O

Lf_

- r I ] [

theengine'sservicelife.

Changing Engine Oil

Shutoffthe engineand removethe ignitionkeybeforeperforming

anymaintenance.Topreventaccidentalstart-up,disconnectthe

mW/==b,

Iv

sparkplugboot.

Periodicinspectionandadjustmentoftheengineisessentialifhigh

levelperformanceis tobemaintained.Regularmaintenancewillalso

oJ t'_

CL

mm /m!

V

ensurea longservicelife.Therequiredserviceintervalsandthe type

of maintenanceto be performedaredescribedinthe tableabove.

Followthe hourlyorcalendarintervals,whicheveroccurfirst.More

mm mlb,

I-=

(°C) =30° -20o =10o 0o 100 200 300 400

(oF)-20 o 0o 150 300 500 700 850 1050

frequentserviceis requiredwhenoperatinginadverseconditions.

Checkoil levelbeforeeachuseandevery5 operatinghourswhenthe

engineiswarm.RefertoCheckingandAddingOilintheAssembly

Section.

Changetheoil afterthefirst5 operatinghoursandevery50 operating

Figure15

hoursthereafter.EngineshouldstillbewarmbutNOThotfromrecent

use.

14

.

Drainfuelfromthetankby runningtheengineuntilthefueltankis

empty.Besurethe fuelfill capis secure.

2.

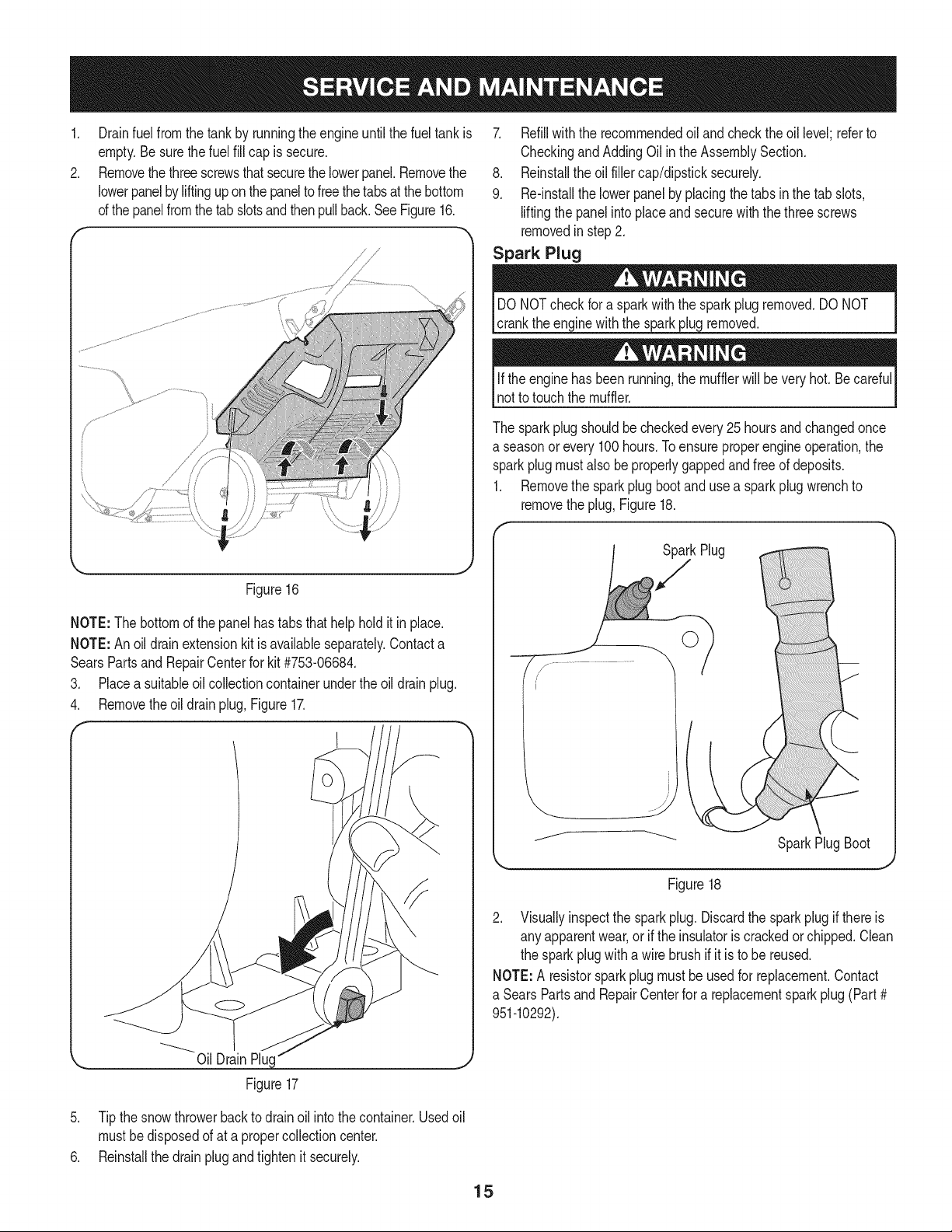

Removethethreescrewsthatsecurethelowerpanel.Removethe

lowerpanelbyliftinguponthepaneltofreethetabsatthebottom

d thepanelfromthetab slotsandthenpullback.SeeFigure16.

f

7. Refillwiththerecommendedoiland checktheoil level;referto

CheckingandAddingOil intheAssemblySection.

8. Reinstalltheoilfillercap/dipsticksecurely.

9. Re-installthelowerpanelbyplacingthetabsinthetabslots,

liftingthepanelintoplaceandsecurewiththethreescrews

removedinstep2.

Spark Plug

DONOTcheck fora sparkwiththe sparkplugremoved.DONOT

cranktheenginewiththe sparkplugremoved.

Iftheenginehas beenrunning,the mufflerwillbeveryhot. Becareful

notto touchthemuffler.

/

k. j

Figure16

NOTE:The bottomofthepanelhastabsthathelpholdit in place.

NOTE:An oildrainextensionkitisavailableseparately.Contacta

SearsPartsand RepairCenterforkit#753-06684.

3. Placea suitableoil collectioncontainerundertheoildrainplug.

4. Removetheoil drainplug,Figure17.

F 1

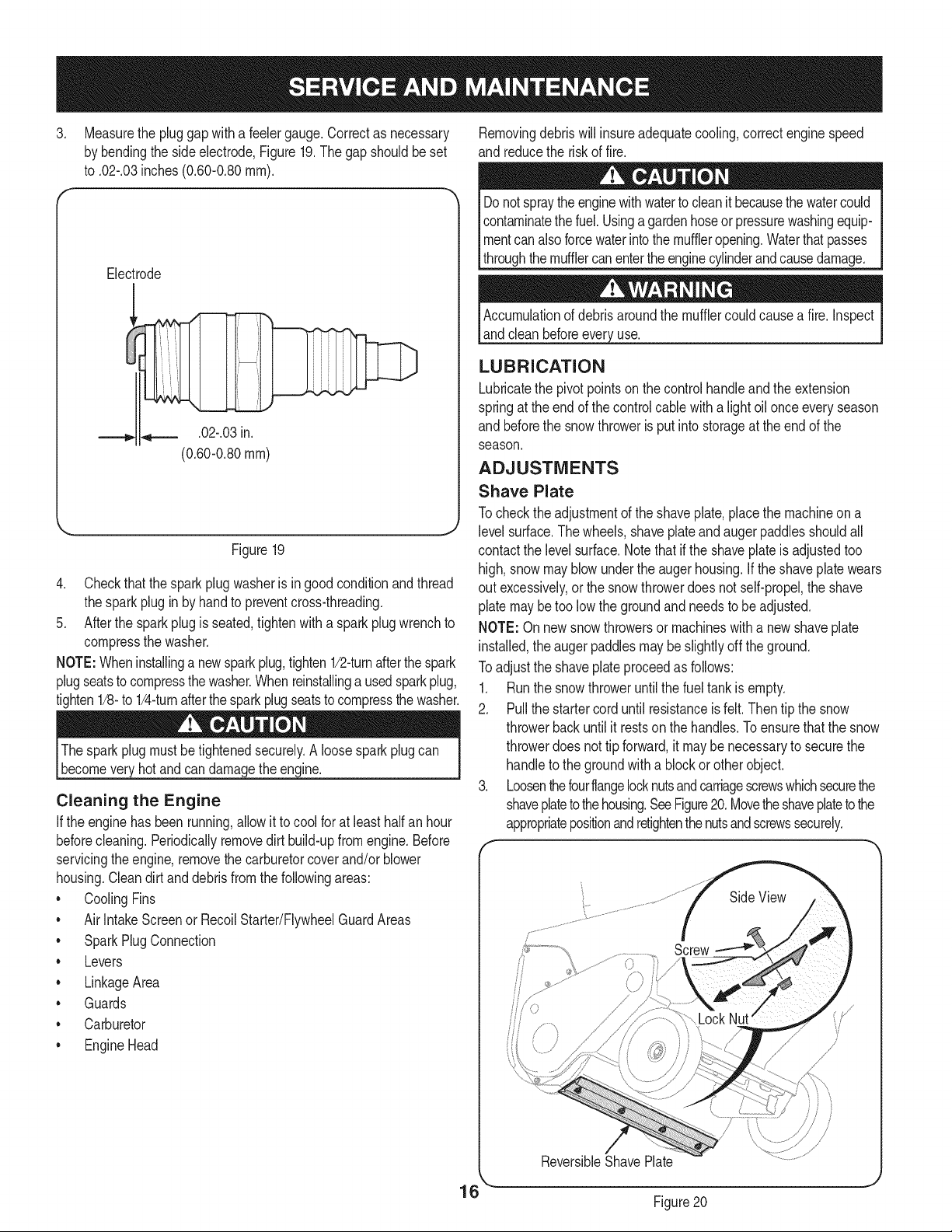

Thesparkplugshouldbecheckedevery25hoursandchangedonce

a seasonor every100hours.Toensureproperengineoperation,the

sparkplugmustalso beproperlygappedandfreeof deposits.

1. Removethesparkplugbootand usea sparkplugwrenchto

removethe plug,Figure18.

SparkPlugBoot

k_ Oil DrainPlug

Figure17

5. Tipthesnowthrowerbacktodrainoil intothecontainer.Usedoil

mustbedisposedof ata propercollectioncenter.

6. Reinstallthedrainplugandtightenit securely.

Figure18

2. Visuallyinspectthe sparkplug.Discardthe sparkplugif thereis

anyapparentwear,or if theinsulatoris crackedorchipped.Clean

thesparkplugwitha wire brushif it is tobe reused.

NOTE:A resistorsparkplugmustbeusedforreplacement.Contact

a SearsPartsandRepairCenterfora replacementsparkplug(Part#

951-10292).

15

.

Measurethe pluggapwitha feelergauge.Correctas necessary

bybendingthesideelectrode,Figure19.Thegapshouldbeset

to.02-.03inches(0.60-0.80ram).

Electrode

.02-.03in.

(0.60-0.80ram)

Figure19

4. Checkthatthesparkplugwasherisingoodconditionandthread

thesparkplugin by handtopreventcross-threading.

5. Afterthe sparkplugisseated,tightenwitha sparkplugwrenchto

compressthe washer.

NOTE:Wheninstallinga newsparkplug,tighten1/2-turnafterthespark

plugseatstocompressthe washer.Whenreinstallingausedsparkplug,

tighten1/8-to1/4-turnafterthe sparkplugseatstocompressthe washer.

Thesparkplugmustbetightenedsecurely.A loosesparkplugcan

becomeveryhotandcan damagetheengine.

Cleaning the Engine

Iftheenginehasbeenrunning,allowittocoolforatleasthalfanhour

beforecleaning.Periodicallyremovedirt build-upfromengine.Before

servicingtheengine,removethecarburetorcoverand/orblower

housing.Cleandirtanddebrisfromthefollowingareas:

• CoolingFins

• AirIntakeScreenorRecoilStarter/FlywheelGuardAreas

• SparkPlugConnection

• Levers

• LinkageArea

• Guards

• Carburetor

• EngineHead

Removingdebriswillinsureadequatecooling,correctenginespeed

and reducetheriskoffire.

Donotspraytheenginewithwatertocleanit becausethewatercould

contaminatethe fuel.Usingagardenhoseorpressurewashingequip-

mentcan alsoforcewaterintothemuffleropening.Waterthatpasses

throughthemufflercanentertheenginecylinderandcausedamage.

Accumulationof debrisaroundthe mufflercouldcausea fire.Inspect

andcleanbeforeevery_use.

LUBRICATION

Lubricatethe pivotpointson thecontrolhandleandtheextension

springat theendof thecontrolcablewitha lightoilonceeveryseason

and beforethesnowthrowerisput intostorageat theendof the

season.

ADJUSTMENTS

Shave Plate

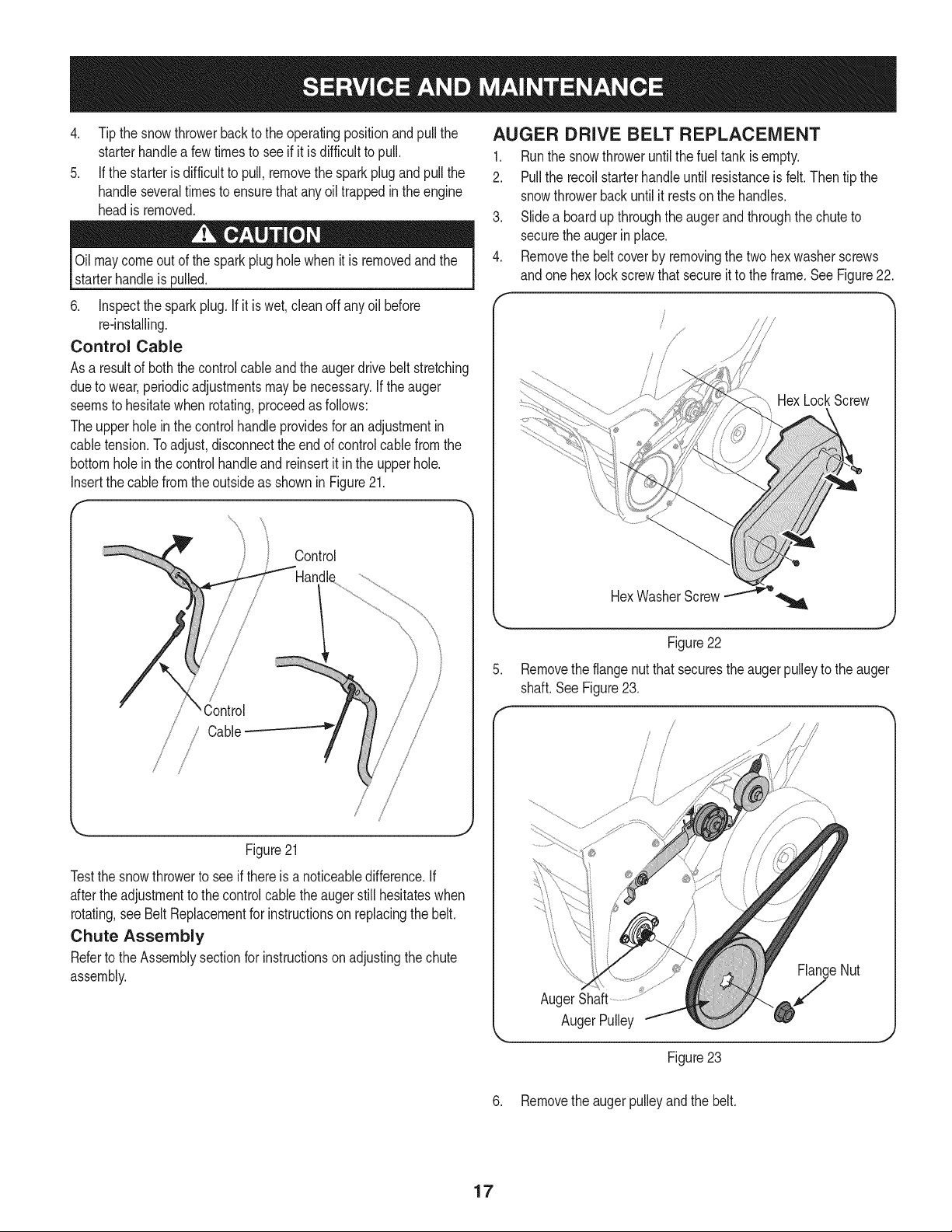

Tochecktheadjustmentoftheshaveplate,placethemachineona

levelsurface.Thewheels,shaveplateandaugerpaddlesshouldall

contactthelevelsurface.Notethat ifthe shaveplateis adjustedtoo

high,snowmayblowundertheaugerhousing.Iftheshaveplatewears

outexcessively,or the snowthrowerdoesnot self-propel,theshave

platemaybetoo lowthe groundand needstobeadjusted.

NOTE:Onnewsnowthrowersormachineswitha newshaveplate

installed,theaugerpaddlesmaybeslightlyoff theground.

Toadjustthe shaveplateproceedasfollows:

1. Runthe snowthroweruntilthe fueltankis empty.

2. Pullthestartercorduntilresistanceisfelt.Thentip thesnow

throwerbackuntilit restsonthehandles.Toensurethatthesnow

throwerdoesnot tipforward,it maybe necessarytosecurethe

handletothe groundwitha blockorotherobject.

3. Loosenthefourflangelocknutsandcarriagescrewswhichsecurethe

shaveplatetothehousing.SeeFigure20.Movetheshaveplatetothe

appropriatepositionandretightenthenutsandscrewssecurely.

16 ``.¸

ReversibleShavePlate

J

Figure20

4. Tipthesnowthrowerbacktotheoperatingpositionandpullthe

starterhandleafewtimestoseeifitisdifficulttopull.

5. Ifthestarterisdifficulttopull,removethesparkplugandpullthe

handleseveraltimestoensurethatanyoiltrappedintheengine

headisremoved.

Oilmaycomeoutofthesparkplugholewhenitisremovedandthe

starterhandleispulled.

6. Inspectthesparkplug.Ifitiswet,cleanoffanyoilbefore

re-installing.

Control Cable

Asaresultofboththecontrolcableandtheaugerdrivebeltstretching

duetowear,periodicadjustmentsmaybenecessary.Iftheauger

seemstohesitatewhenrotating,proceedasfollows:

Theupperholeinthecontrolhandleprovidesforanadjustmentin

cabletension.Toadjust,disconnecttheendofcontrolcablefromthe

bottomholeinthecontrolhandleandreinsertitintheupperhole.

InsertthecablefromtheoutsideasshowninFigure21.

f

Control

AUGER DRIVE BELT REPLACEMENT

1. Runthe snowthroweruntilthe fueltankis empty.

2. Pullthe recoilstarterhandleuntilresistanceisfelt.Thentipthe

snowthrowerbackuntilit restson thehandles.

3. Slidea boardup throughtheaugerandthroughthechuteto

securethe augerinplace.

4. Removethebeltcoverbyremovingthetwohexwasherscrews

andone hexlockscrewthatsecureitto theframe.SeeFigure22.

HexLockScrew

/

Cable

Figure21

Testthesnowthrowerto seeifthereisa noticeabledifference.If

aftertheadjustmenttothecontrolcabletheaugerstill hesitateswhen

rotating,seeBeltReplacementforinstructionson replacingthebelt.

Chute Assembly

Refertothe Assemblysectionforinstructionsonadjustingthechute

assembly.

j

/

/

/

Figure22

.

Removetheflangenutthat securestheaugerpulleytothe auger

shaft.SeeFigure23.

/

FlangeNut

AugerShaft

AugerPulley

Figure23

J

J

6. Removetheaugerpulleyandthebelt.

17

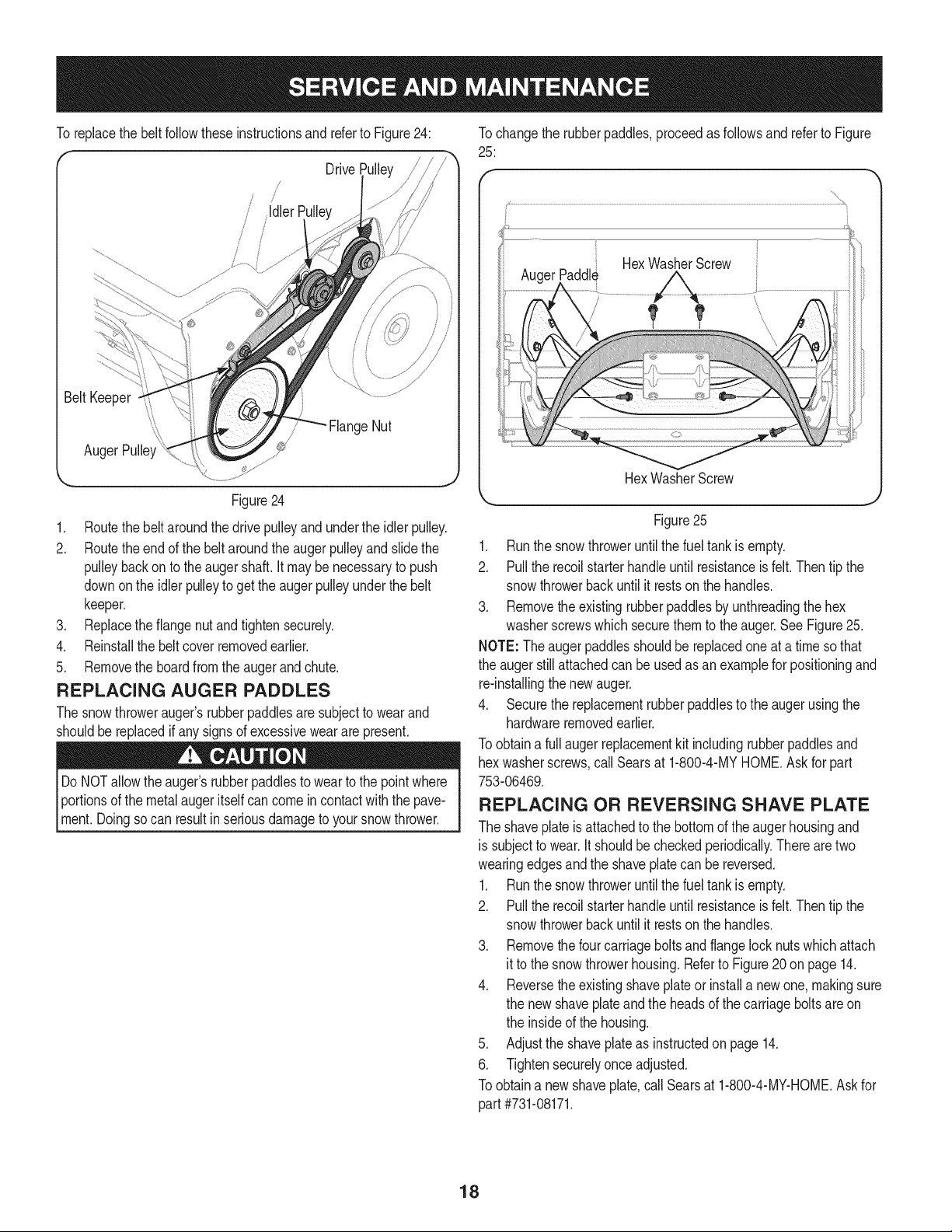

Toreplacethe beltfollowtheseinstructionsandrefertoFigure24:

Drive

js

Figure24

1. Routethebeltaroundthedrivepulleyandunderthe idlerpulley.

2. Routetheendof thebeltaroundtheaugerpulleyand slidethe

pulleybackon to theaugershaft.It maybe necessarytopush

downonthe idlerpulleyto gettheaugerpulleyunderthe belt

keeper.

3. Replacetheflangenutandtightensecurely.

4. Reinstallthebeltcoverremovedearlier.

5. Removethe boardfromtheaugerandchute.

REPLACING AUGER PADDLES

Thesnowthrowerauger'srubberpaddlesaresubjecttowearand

shouldbereplacedifany signsof excessiveweararepresent.

DoNOTallowtheauger'srubberpaddlesto wearto thepointwhere

Iportionsof themetalaugeritselfcancomein contactwiththe pave-

_ment.Doingsocan resultin seriousdamageto yoursnowthrower.

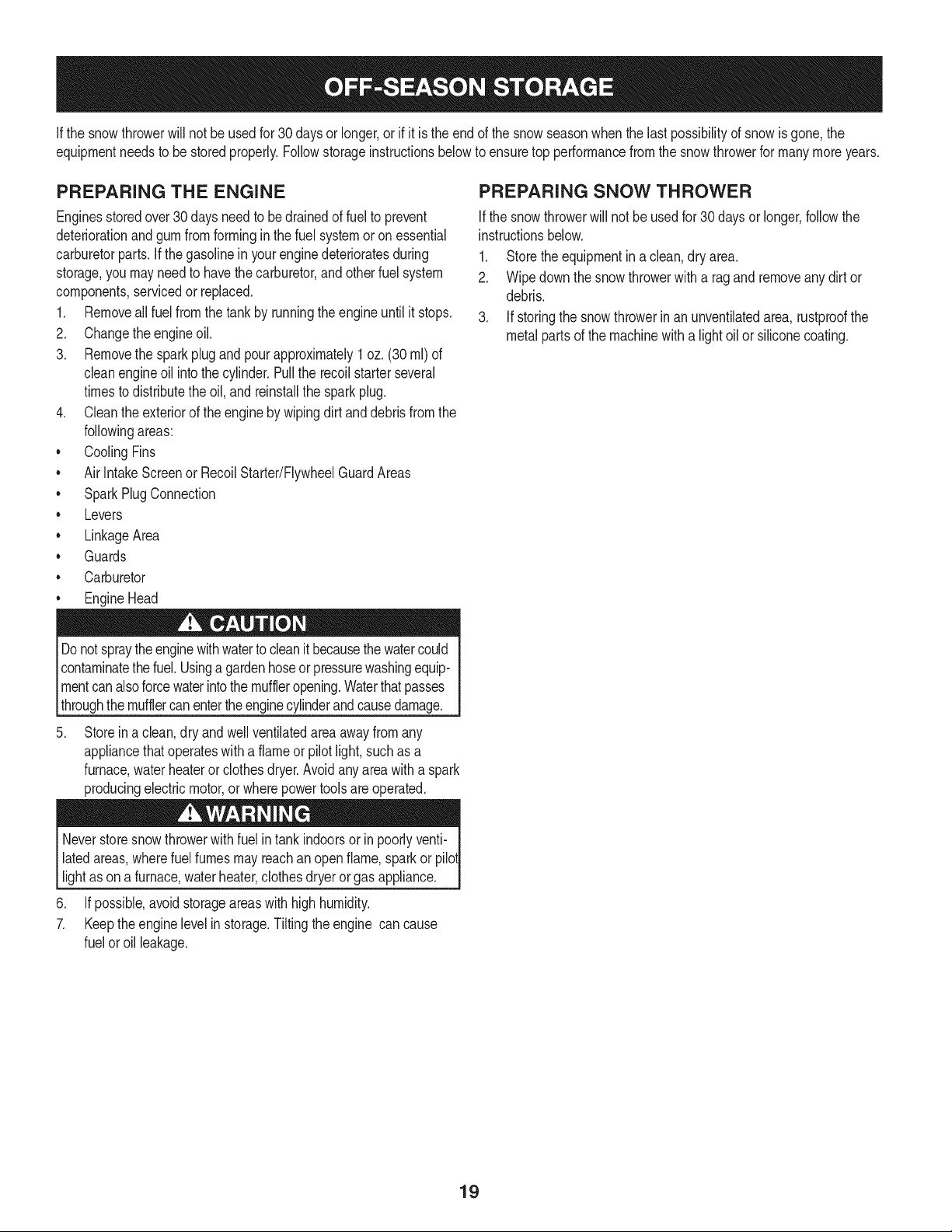

Tochangetherubberpaddles,proceedasfollowsandrefertoFigure

25:

HexWasherScrew

HexWasherScrew

Figure25

1. Runthe snowthroweruntilthe fueltankis empty.

2. Pulltherecoilstarterhandleuntilresistanceisfelt.Thentip the

snowthrowerbackuntilit restson the handles.

3. Removetheexistingrubberpaddlesby unthreadingthehex

washerscrewswhichsecurethemto theauger.See Figure25.

NOTE:Theaugerpaddlesshouldbereplacedoneatatimesothat

theaugerstillattachedcanbeusedasanexampleforpositioningand

re-installingthe newauger.

4. Securethe replacementrubberpaddlestotheaugerusingthe

hardwareremovedearlier.

Toobtaina fullaugerreplacementkit includingrubberpaddlesand

hexwasherscrews,callSearsat 1-800-4-MYHOME.Askforpart

753-06469.

REPLACING OR REVERSING SHAVE PLATE

Theshaveplateisattachedtothe bottomof theaugerhousingand

is subjecttowear.Itshouldbecheckedperiodically.Therearetwo

wearingedgesandtheshaveplatecanbe reversed.

1. Runthe snowthroweruntilthe fueltankis empty.

2. Pulltherecoilstarterhandleuntilresistanceisfelt.Thentip the

snowthrowerbackuntilit restson the handles.

3. Removethefourcarriageboltsandflangelocknutswhichattach

it to thesnowthrowerhousing.Referto Figure20on page14.

4. Reversetheexistingshaveplateor installa newone,makingsure

thenew shaveplateandthe headsofthecarriageboltsareon

theinsideofthe housing.

5. Adjustthe shaveplateas instructedon page14.

6. Tightensecurelyonceadjusted.

Toobtaina newshaveplate,call Searsat 1-800-4-MY-HOME.Askfor

part#731-08171.

18

Ifthe snowthrowerwillnotbe usedfor30 daysor longer,or ifit istheendofthesnowseasonwhenthelastpossibilityof snowis gone,the

equipmentneedstobestoredproperly.Followstorageinstructionsbelowtoensuretopperformancefromthesnowthrowerformanymoreyears.

PREPARING THE ENGINE

Enginesstoredover30daysneedtobedrainedoffueltoprevent

deteriorationandgumfromforminginthefuel systemoronessential

carburetorparts.If thegasolineinyourenginedeterioratesduring

storage,youmayneedto havethecarburetor,andotherfuelsystem

components,servicedorreplaced.

1. Removeall fuelfromthetankbyrunningtheengineuntilit stops.

2. Changetheengineoil.

3. Removethe sparkplugandpourapproximately1oz.(30 ml)of

cleanengineoil intothecylinder.Pullthe recoilstarterseveral

timesto distributetheoil,and reinstallthesparkplug.

4. Cleantheexteriorofthe enginebywipingdirtanddebrisfromthe

followingareas:

• CoolingFins

• AirIntakeScreenorRecoilStarter/FlywheelGuardAreas

• SparkPlugConnection

• Levers

LinkageArea

Guards

Carburetor

EngineHead

!

PREPARING SNOW THROWER

Ifthesnowthrowerwill notbeusedfor30daysor longer,followthe

instructionsbelow.

1. Storetheequipmentinaclean,dryarea.

2. Wipedownthesnowthrowerwitha ragand removeanydirtor

debris.

3. Ifstoringthesnowthrowerinanunventilatedarea,rustproofthe

metalpartsofthe machinewitha lightoil or siliconecoating.

Donotspraythe enginewithwatertocleanit becausethe watercould

contaminatethefuel.Usinga gardenhoseorpressurewashingequip-

Imentcanalsoforcewaterintothemuffleropening.Waterthatpasses

[throughthe mufflercanentertheenginecylinderandcausedamage.

5. Storeina clean,dry andwellventilatedareaawayfromany

appliancethatoperateswitha flameor pilot light,suchasa

furnace,waterheateror clothesdryer.Avoidanyareawitha spark

producingelectricmotor,or wherepowertoolsareoperated.

Neverstoresnowthrowerwithfuel intank indoorsorinpoorlyventi-

latedareas,wherefuelfumesmayreachanopenflame,sparkorpilol

lightas ona furnace,waterheater,clothesdryer orgasappliance.

6. If possible,avoidstorageareaswithhighhumidity.

7. Keeptheenginelevelin storage.Tiltingtheengine cancause

fuelor oil leakage.

19

Beforeperforminganytypeofmaintenance/service,disengageallcontrolsandstoptheengine.Waituntilall

movingpartshavecometo acompletestop.Disconnectsparkplugwireandgrounditagainstthe engineto

Ipreventunintendedstarting.Alwayswearsafetyglassesduringoperationorwhileperforminganyadjustmentsor

[repairs.

This section addresses minor service issues.Tolocate the nearest SearsService Centeror to schedule service, simply contact Sears

at 1-800-4-MY-HOME®.

Enginefailsto start 1. Fueltankempty,or stalefuel.

2. Blockedfuelline.

3. Keynotinsertedalltheway.

4. Sparkplugwiredisconnected.

5. Faultysparkplug.

6. Enginenotprimed.

7. Enginefloodedfromexcessivepriming.

Enginerunningerratically/

inconsistentRPM(huntingor

surging)

1. Enginerunningonchoke.

2. Fuellineblocked,orstalefuel.

3. Wateror dirtinfuelsystem.

1. Filltankwithcleanfreshgasoline.

2. Contacta SearsServiceCenter.

3. Insertkeyalltheway.

4. Connectwireto sparkplug.

5. Cleansparkplug,readjustgap,or replace.

6. Pushtheengineprimerbuttonfivetoseventimes.

7. Waitatleastten minutesbeforestarting.

1. MovechokecontroltoRUNposition.

2. Contacta SearsServiceCenter.

3. Runengineuntilthefueltank isempty.Rdillwith

freshfuel.

4. Carburetoroutofadjustment.

5. Over-governedengine

Engineoverheats Contacta SearsServiceCenter.

Lossof power Firmlyconnectsparkplugwire.

1. Carburetoroutofadjustment.

1. Sparkplugwireloose.

2. Ventin gascap plugged.

Excessivevibration Stopengineimmediatelyandremovekey.Checkfor

1. Loosepartsordamagedauger.

4. Contacta SearsServiceCenter.

5. Contacta SearsServiceCenter.

1.

1.

2.

Clearvent.

1.

possibledamage.Tightenall boltsand nuts.Repair

asneeded.Ifproblempersists,takesnowthrowerto

a SearsServiceCenter.

Snowthrowerfailsto self- 1. Augercontrolcableoutofadjustment. 1. Adjustaugercontrolcableasshownin Serviceand

propel Maintenancesection.

2. Augerdrivebeltlooseor damaged. 2. Replaceaugerdrivebelt.

Augercontinuesto rotate 1. Augercontrolcableoutof adjustment. 1. Adjustaugercontrolcableasshownin Serviceand

Maintenancesection.

Unitfailstodischargesnow 1. Chuteassemblyclogged. 1.

Stopengineanddisconnectsparkplugwire.Clean

chuteand insideof augerhousingwithclean-outtool

or stick.

2. Foreignobjectlodgedin auger.

2. Stopengineimmediatelyanddisconnectthe spark

plugwire.Removeobjectfromauger.

3. Augercontrolcableoutofadjustment.

4. Augerbeltlooseor damaged.

3. Adjustaugercontrolcable.

4. Replaceaugerbelt.

lqg_/1 find the a_swez a[_d z[_or{÷on maztagemy[£e,,,_om - [0[ [ree!

Find this and all your other product manual.sonl.ine.

Get answers from our team of home experts.

Get a personaLized maintenance pl.an for your home.

Find information and tools to hel.pwith home projects.

_ managemylife

b_g_t t_ ye_ By S_a_'s

2O

Loading...

Loading...