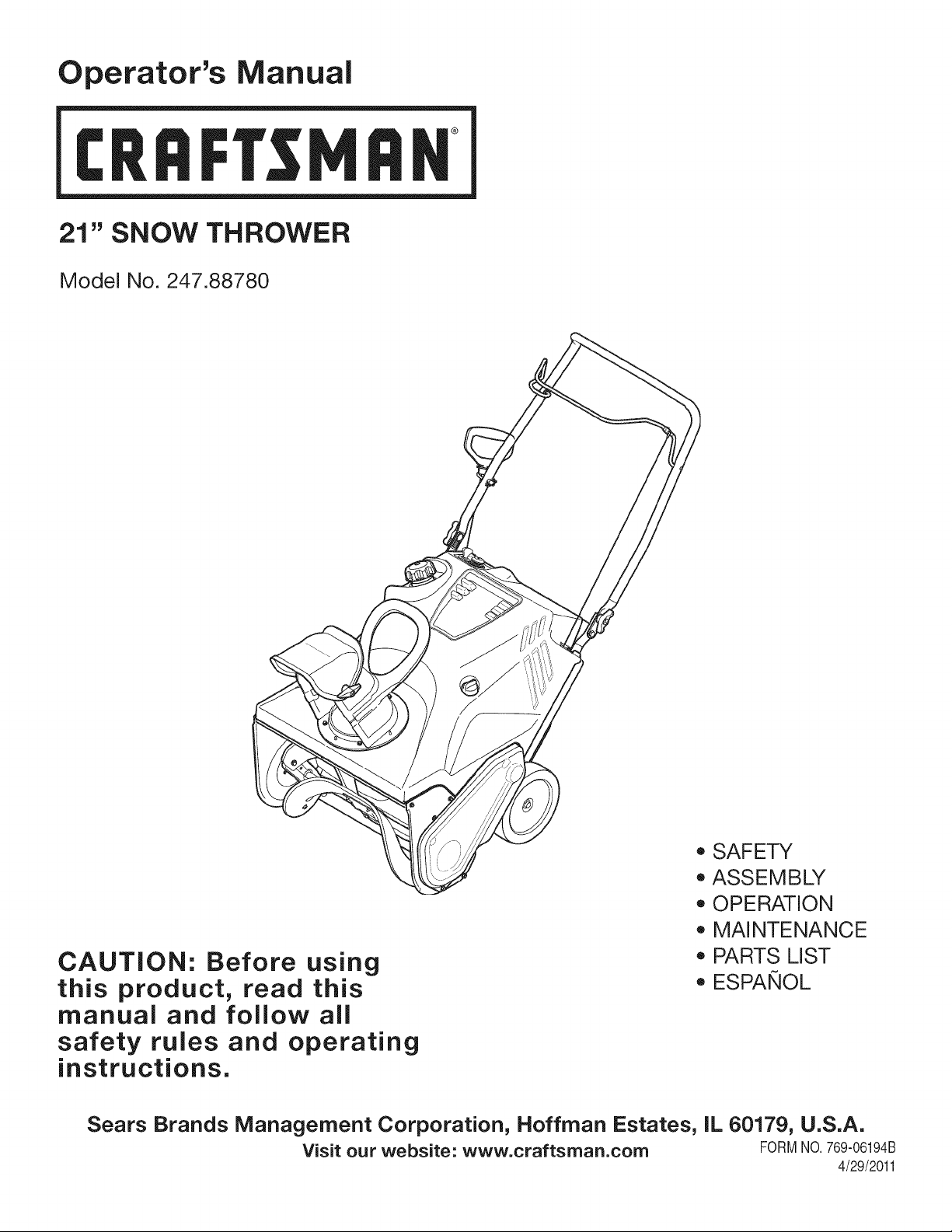

Craftsman 247887800 Owner’s Manual

Operator's Manual

CRRFr MRN

21" SNOW THROWER

Model No. 247.88780

o SAFETY

ASSEMBLY

OPERATION

MAINTENANCE

CAUTION: Before using

this product, read this

PARTS LIST

o ESPANOL

manual and follow all

safety rules and operating

instructions.

Sears Brands Management Corporation, Hoffman Estates, IL 60179, U.S.A.

Visit our website: www.craftsman.com FORM1/O.769-06194B

4/29/2011

WarrantyStatement..................................Pac

SafeOperationPractices..........................Pac

SafetyLabels............................................Pac

Assembly..................................................Pac

Operation..................................................Pac

ServiceandMaintenance.........................Pac

Off-SeasonStorage..................................Pac

e2

es3-6

e7

es8-10

es11-13

es14-18

e19

TroubleShooting.......................................Page20

PartsList...................................................Pages24-27

EnginePartsList.......................................Pages28-31

Labels.......................................................Page32

RepairProtectionAgreement...................Page36

Espa_ol.....................................................Page37

ServiceNumbers......................................BackCover

CRAFTSMANTWOYEAR FULL WARRANTY

FORTWOYEARSfromthe dateof purchase,this productiswarrantedagainstanydefectsin materialorworkmanship.Defectiveproductwill

receivefreerepairorfree replacementifrepairisunavailable.

Thiswarrantyisvoidif thisproductiseverusedwhile providingcommercialservicesorifrentedtoanotherperson.

Forwarranty coverage details to obtain repairor replacement,visit the website: www.craftsman.com

This warranty covers ONLYdefects in material andworkmanship. Warrantycoverage does NOTinclude:

• Expendableitemsthatcanwearoutfromnormalusewithinthewarrantyperiod,includingbutnotlimitedto augers,augerpaddles,drift

cutters,skidshoes,shaveplate,shearpins,sparkplug,air cleaner,belts,andoil filter.

• Standardmaintenanceservicing,oilchanges,ortune-ups.

• Tire replacementor repaircausedby puncturesfromoutsideobjects,suchasnails,thorns,stumps,orglass.

• Tireor wheelreplacementor repairresultingfromnormalwear,accident,orimproperoperationormaintenance.

• Repairsnecessarybecauseof operatorabuse,includingbutnotlimitedtodamagecausedbyover-speedingtheengine,or fromimpacting

objectsthatbendthe frame,augershaft,etc.

• Repairsnecessarybecauseof operatornegligence,includingbutnotlimitedto,electricalandmechanicaldamagecausedbyimproper

storage,failureto usethe propergradeandamountofengineoil, or failureto maintaintheequipmentaccordingto theinstructionscontained

intheoperator'smanual.

• Engine(fuelsystem)cleaningor repairscausedbyfuel determinedto becontaminatedoroxidized(stale).Ingeneral,fuelshouldbeused

within30 daysof itspurchasedate.

• Normaldeteriorationandwearof theexteriorfinishes,orproductlabelreplacement.

Thiswarrantygivesyouspecificlegalrights,andyou mayalsohaveotherrightswhichvaryfromstatetostate.

Sears Brands Management Corporation, Hoffman Estates, IL 60179

EngineOilType: SAE5W-30

EngineOilCapacity: 20ounces

FuelCapacity: 2 Quarts

SparkPlug: F6RTC

SparkPlugGap: .020"-.030"

©SearsBrands,LLC

Model Number.................................................................

Serial Number .................................................................

Dateof Purchase.............................................................

Recordthemodelnumber,serialnumber

anddateof purchaseabove

2

Thissymbolpointsout importantsafetyinstructionswhich,if not

followed,couldendangerthepersonalsafetyand/orpropertyof

yourselfandothers. Readandfollowall instructionsin thismanual

beforeattemptingtooperatethismachine.Failuretocomplywith

theseinstructionsmayresultin personalinjury.Whenyouseethis

symbol,HEEDITSWARNING!

Thismachinewasbuiltto beoperatedaccordingtothesafeopera-

tionpracticesinthis manual.Aswithanytypeof powerequipment,

carelessnessorerroron thepartoftheoperatorcanresultin serious

injury.Thismachineiscapableofamputatingfingers,hands,toes

andfeetandthrowingdebris.Failuretoobservethefollowingsafety

instructionscouldresultin seriousinjuryor death.

CALIFORNIA PROPOSITION 65

EngineExhaust,someof itsconstituents,andcertainvehicle

componentscontainoremitchemicalsknowntoStateofCalifornia

tocausecancerandbirthdefectsorotherreproductiveharm,

TRAiNiNG

• Read,understand,andfollowall instructionsonthemachineand

in themanual(s)beforeattemptingto assembleandoperate.

Failuretodo socan resultinseriousinjurytotheoperatorand/

orbystanders.Keepthismanualin a safeplaceforfutureand

regularreferenceandfor orderingreplacementparts. Forques-

tionscall,1-800-4MY-HOME.

• Befamiliarwithall controlsandtheirproperoperation.Knowhow

tostopthe machineanddisengagethemquickly.

Neverallowchildrenunder14yearsofageto operatethis

machine.Children14andover shouldreadandunderstandthe

instructionsandsafeoperationpracticesin thismanualandon

themachineandbe trainedandsupervisedbyanadult.

Neverallowadultsto operatethismachinewithoutproper

instruction.

• Thrownobjectscancauseseriouspersonalinjury.Planyour

snow-throwingpatterntoavoiddischargeof materialtoward

roads,bystandersandthe like.

Keepbystanders,petsandchildrenat least75feetfromthe

machinewhileitisinoperation.Stopmachineifanyoneenters

thearea.

Exercisecautiontoavoidslippingor falling,especiallywhen

operatinginreverse.

Your Responsibility--Restrict the useof thispowermachineto

personswhoread,understandandfollowthewarningsandinstruc-

tionsin thismanualandon the machine,

SAVE THESE INSTRUCTIONS!

PREPARATION

Thoroughlyinspecttheareawheretheequipmentistobeused.

Removeall doormats,newspapers,sleds,boards,wiresandother

foreignobjects,whichcouldbe trippedoverorthrownbythe auger/

impeller.

Alwayswearsafetyglassesoreyeshieldsduringoperationand

whileperformingan adjustmentor repairto protectyoureyes.

Thrownobjectswhichricochetcancauseseriousinjurytothe

eyes.

Donot operatewithoutwearingadequatewinteroutergarments.

Donot wearjewelry,longscarvesorotherlooseclothing,which

couldbecomeentangledinmovingparts.Wearfootwearwhich

willimprovefootingonslipperysurfaces.

Usea groundedthree-wireextensioncordand receptaclefor all

machineswithelectricstartengines.

Disengageallcontrolleversbeforestartingtheengine.

Neverattempttomakeanyadjustmentswhileengineis running,

exceptwherespecificallyrecommendedintheoperator'smanual.

Letengineandmachineadjustto outdoortemperaturebefore

startingtoclearsnow.

3

SafeHandling of Gasoline

Toavoidpersonalinjuryor propertydamageuseextremecarein

handlinggasoline.Gasolineisextremelyflammableandthevaporsare

explosive.Seriouspersonalinjurycan occurwhengasolineisspilled

onyourselforyourclotheswhichcan ignite. Washyourskinand

changeclothesimmediately.

• Useonlyan approvedgasolinecontainer.

• Extinguishallcigarettes,cigars,pipesandothersourcesof

ignition.

• Neverfuel machineindoors.

• Neverremovegascapor addfuel whilethe engineishotor

running.

• Allowenginetocoolat leasttwo minutesbeforerefueling.

• Neveroverfillfueltank.Fill tankto nomorethan1/2inchbelow

bottomoffillerneckto providespaceforfuelexpansion.

• Replacegasolinecapandtightensecurely.

• Ifgasolineisspilled,wipe itoff theengineandequipment.Move

machinetoanotherarea.Wait5 minutesbeforestartingthe

engine.

• Neverstorethe machineorfuelcontainerinsidewherethereisan

openflame,sparkor pilotlight(e.g.furnace,waterheater,space

heater,clothesdryeretc.).

• Allowmachineto coolat least5 minutesbeforestoring.

• Neverfill containersinsidea vehicleor ona truckor trailerbed

witha plasticliner.Alwaysplacecontainersonthe groundaway

fromyourvehiclebeforefilling.

• If possible,removegas-poweredequipmentfromthetruckor

trailerandrefuelitonthe ground.Ifthis is notpossible,thenrefuel

suchequipmentonatrailerwitha portablecontainer,ratherthan

froma gasolinedispensernozzle.

• Keepthe nozzleincontactwiththerimofthe fueltankor

containeropeningatalltimesuntilfuelingis complete.Donotuse

a nozzlelock-opendevice.

OPERATION

• Do notputhandsorfeetnear rotatingparts,in theauger/impeller

housingorchuteassembly.Contactwiththe rotatingpartscan

amputatehandsandfeet.

• Theauger/impellercontrolleverisa safetydevice.Neverbypass

itsoperation.Doingsomakesthe machineunsafeandmaycause

personalinjury.

• Thecontrolleversmustoperateeasilyin bothdirectionsand

automaticallyreturntothedisengagedpositionwhenreleased.

• Neveroperatewitha missingordamagedchuteassembly.Keep

all safetydevicesinplaceandworking.

• Neverrunanengineindoorsor ina poorlyventilatedarea.Engine

exhaustcontainscarbonmonoxide,anodorlessanddeadlygas.

• Do notoperatemachinewhileundertheinfluenceofalcoholor

drugs.

• Mufflerandenginebecomehotandcancauseaburn.Donot

touch.Keepchildrenaway.

• Exerciseextremecautionwhenoperatingonorcrossinggravel

surfaces.Stayalertforhiddenhazardsortraffic.

Exercisecautionwhenchangingdirectionandwhileoperatingon

slopes.

Planyoursnow-throwingpatternto avoiddischargetowards

windows,walls,carsetc.Thus,avoidingpossibleproperty

damageorpersonalinjurycausedby a ricochet.

Neverdirectdischargeatchildren,bystandersandpetsorallow

anyoneinfrontof themachine.

Donot overloadmachinecapacitybyattemptingtoclearsnowat

toofastof a rate.

Neveroperatethismachinewithoutgoodvisibilityorlight.Always

be sureof yourfootingand keepa firmholdon thehandles.Walk,

neverrun.

Disengagepowertotheauger/impellerwhentransportingor not

in use.

Neveroperatemachineathightransportspeedsonslippery

surfaces.Lookdownand behindandusecarewhenbackingup.

Ifthemachineshouldstartto vibrateabnormally,stopthe engine,

disconnectthe sparkplugwireandgroundit againsttheengine.

Inspectthoroughlyfordamage.Repairanydamagebefore

startingandoperating.

Disengageallcontrolleversandstopenginebeforeyouleave

theoperatingposition(behindthehandles).Waituntiltheauger/

impellercomestoa completestopbeforeuncloggingthechute

assembly,makinganyadjustments,or inspections.

Neverputyourhandinthedischargeorcollectoropenings.Do

notunclogchuteassemblywhileengineis running.Shutoff

engineand remainbehindhandlesuntilall movingpartshave

stoppedbeforeunclogging.

Useonlyattachmentsandaccessoriesapprovedbythemanufac-

turer(e.g.wheelweights,tirechains,cabsetc.).

Whenstartingengine,pullcord slowlyuntilresistanceis felt,then

pull rapidly.Rapidretractionof startercord(kickback)willpull

handandarmtowardenginefasterthanyoucanlet go.Broken

bones,fractures,bruisesorsprainscouldresult.

Ifsituationsoccurwhichare notcoveredinthis manual,usecare

andgoodjudgment.ContactCustomerSupportforassistance

andthenameofyour nearestservicingdealer.

CLEARING A CLOGGED DISCHARGE CHUTE

Handcontactwiththe rotatingimpellerinsidethe dischargechute

is the mostcommoncauseofinjuryassociatedwithsnowthrowers.

Neveruseyourhandtocleanoutthedischargechute.

Toclear thechute:

1. SHUTTHEENGINEOFF!

2. Wait 10secondstobe surethe impellerbladeshavestopped

rotating.

3. Alwaysusea clean-outtool,notyourhands.

4

MAINTENANCE & STORAGE

• Nevertamperwithsafetydevices.Checktheirproperoperation

regularly.Refertothemaintenanceandadjustmentsectionsof

thismanual.

• Beforecleaning,repairing,or inspectingmachinedisengageall

controlleversandstoptheengine.Waituntilthe auger/impeller

cometoa completestop.Disconnectthe sparkplugwireand

groundagainsttheengineto preventunintendedstarting.

Checkboltsand screwsforpropertightnessatfrequentintervals

tokeepthemachineinsafeworkingcondition.Also,visually

inspectmachineforanydamage.

Donotchangetheenginegovernorsettingor over-speedthe

engine.Thegovernorcontrolsthe maximumsafeoperatingspeed

ofthe engine.

Snowthrowershaveplatesandskidshoesaresubjecttowear

anddamage.Foryoursafetyprotection,frequentlycheckall

componentsandreplacewithoriginalequipmentmanufacturer's

(OEM)partsonly.Useof partswhichdo notmeetthe original

equipmentspecificationsmayleadto improperperformanceand

compromisesafety!

Checkcontrolleversperiodicallytoverifytheyengageanddisen-

gageproperlyandadjust,ifnecessary.Refertotheadjustment

sectioninthisoperator'smanualforinstructions.

Maintainorreplacesafetyandinstructionlabels,asnecessary.

• Observeproperdisposallawsand regulationsforgas,oil,etc.to

protecttheenvironment.

Priorto storing,runmachineafewminutestoclear snowfrom

machineandpreventfreezeupof auger/impeller.

Neverstorethemachineorfuel containerinsidewherethereisan

openflame,sparkorpilot lightsuchas a waterheater,furnace,

clothesdryeretc.

Alwaysrefertothe operator'smanualforproperinstructionson

off-seasonstorage.

Checkfuelline,tank, cap,andfittingsfrequentlyforcracksor

leaks.Replaceif necessary.

Donotcrankenginewithsparkplugremoved.

AccordingtotheConsumerProductsSafetyCommission(CPSC)

andtheU.S.EnvironmentalProtectionAgency(EPA),thisproduct

hasan AverageUsefulLifeof seven(7)years,or 60 hoursof

operation.At theendof theAverageUsefulLifehavethe machine

inspectedannuallybyan authorizedservicedealertoensurethat

allmechanicalandsafetysystemsareworkingproperlyand not

wornexcessively.Failuretodo socanresultinaccidents,injuries

ordeath.

DO NOT MODIFY ENGINE

Toavoidseriousinjuryor death,do not modifyengineinany way.

Tamperingwiththegovernorsettingcanleadto a runawayengineand

causeitto operateat unsafespeeds.Nevertamperwithfactorysetting

ofenginegovernor.

NOTICE REGARDING EMISSIONS

EngineswhicharecertifiedtocomplywithCaliforniaandfederal

EPAemissionregulationsforSORE(SmallOffRoadEquipment)are

certifiedto operateonregularunleadedgasoline,and mayinclude

thefollowingemissioncontrolsystems:EngineModification(EM),

OxidizingCatalyst(OC),SecondaryAirInjection(SAI)and ThreeWay

Catalyst(TWO)if soequipped.

SPARK ARRESTOR

Thismachineisequippedwithaninternalcombustionengineand

shouldnotbe usedonor nearany unimprovedforest-covered,

brush-coveredorgrass-coveredlandunlesstheengine'sexhaust

systemisequippedwitha sparkarrestormeetingapplicablelocalor

statelaws(if any)

Ifa sparkarrestorisused,it shouldbe maintainedin effectiveworking

orderbytheoperator.Inthe StateofCaliforniatheaboveis required

bylaw (Section4442ofthe CaliforniaPublicResourcesCode).Other

statesmayhavesimilarlaws. Federallawsapplyonfederallands.

A sparkarrestorforthemufflerisavailablethroughyournearestSears

PartsandRepairServiceCenter.

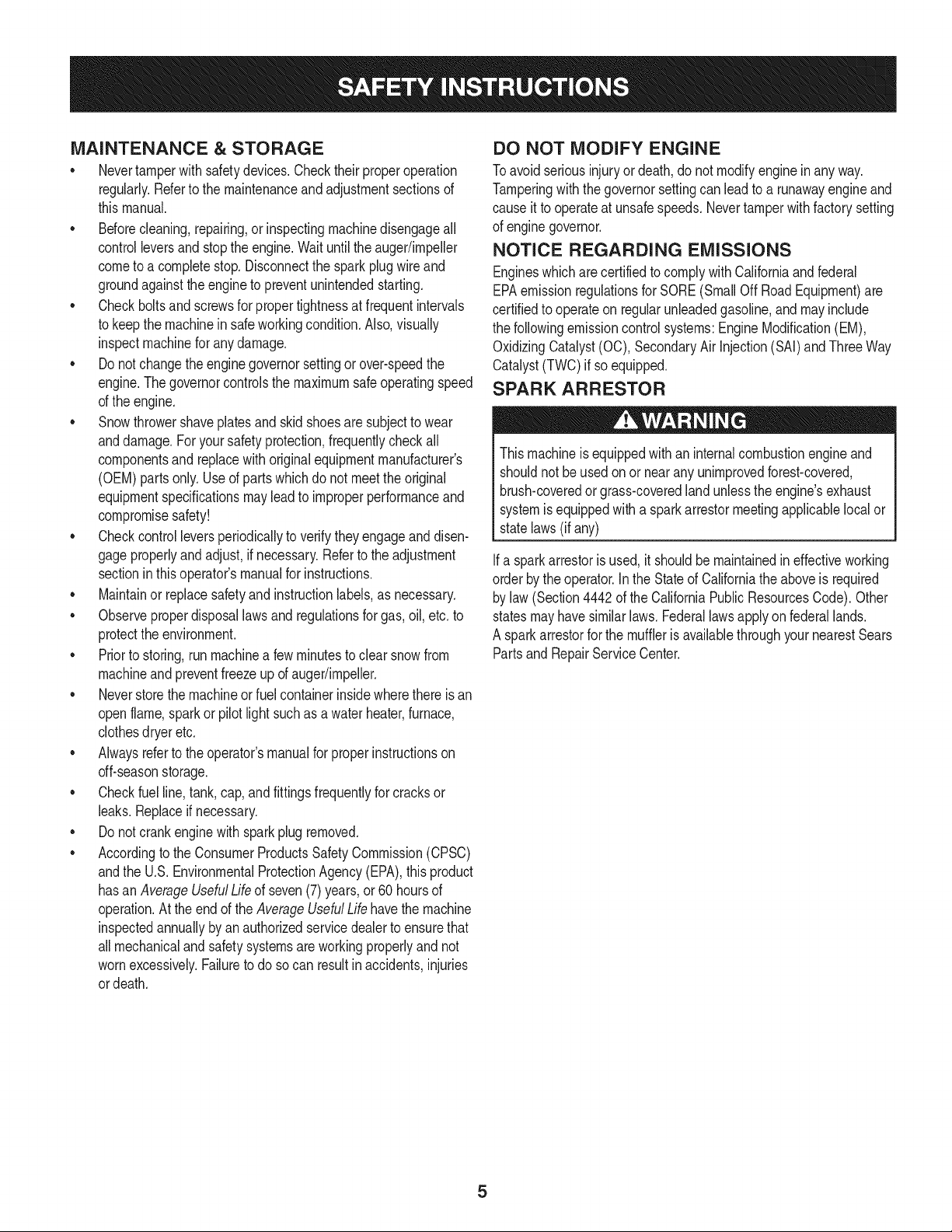

SAFETY SYMBOLS

Thispagedepictsanddescribessafetysymbolsthatmayappearonthisproduct. Read,understand,andfollowall instructionsonthemachine

beforeattemptingtoassembleandoperate.

READ THE OPERATOR'S MANUAL(S)

i

i

Read, understand, and follow all instructions in the manual(s) before attempting to assemble and

operate

WARNING-- ROTATING BLADES

Keep hands out of inlet and discharge openings while machine is running. There are rotating blades

inside

WARNING-- ROTATING BLADES

Keep hands out of inlet and discharge openings while machine is running. There are rotating blades

inside

WARNING-- ROTATING AUGER

Do not put hands or feet near rotating parts, in the auger/impeller housing or chute assembly.

Contact with the rotating parts can amputate hands and feet.

WARNING--THROWN OBJECTS

This machine may pick up and throw and objects which can cause serious personal injury.

WARNING--GASOLINE ISFLAMMABLE

Allow the engine to cool at least two minutes before refueling.

WARNING-- CARBON MONOXIDE

Never run an engine indoors or in a poorly ventilated area. Engine exhaust contains carbon

monoxide, an odorless and deadly gas.

WARNING-- ELECTRICAL SHOCK

Do not use the engine's electric starter in the rain

WARNING-- HOT SURFACE

Engine parts, especially the muffler, become extremely hot during operation. Allow engine and

muffler to cool before touching.

6

NOTE:All referencesto theleftorrightsideof thesnowthrowerare

fromtheoperator'sposition.Anyexceptionswillbe noted.

UNPACKING THE SNOW THROWER

1. Openthetop ofthe carton.

2. Cutdownthecornersonthefrontofthecartonandfolddownthe

frontside.

3. Pullthesnowthroweroutofthe carton.Besure notto damage

thechute,or anycablesattachedtothe chute,whichis shipped

undertheshroudonthebacksideofthe carton.

ASSEMBLY

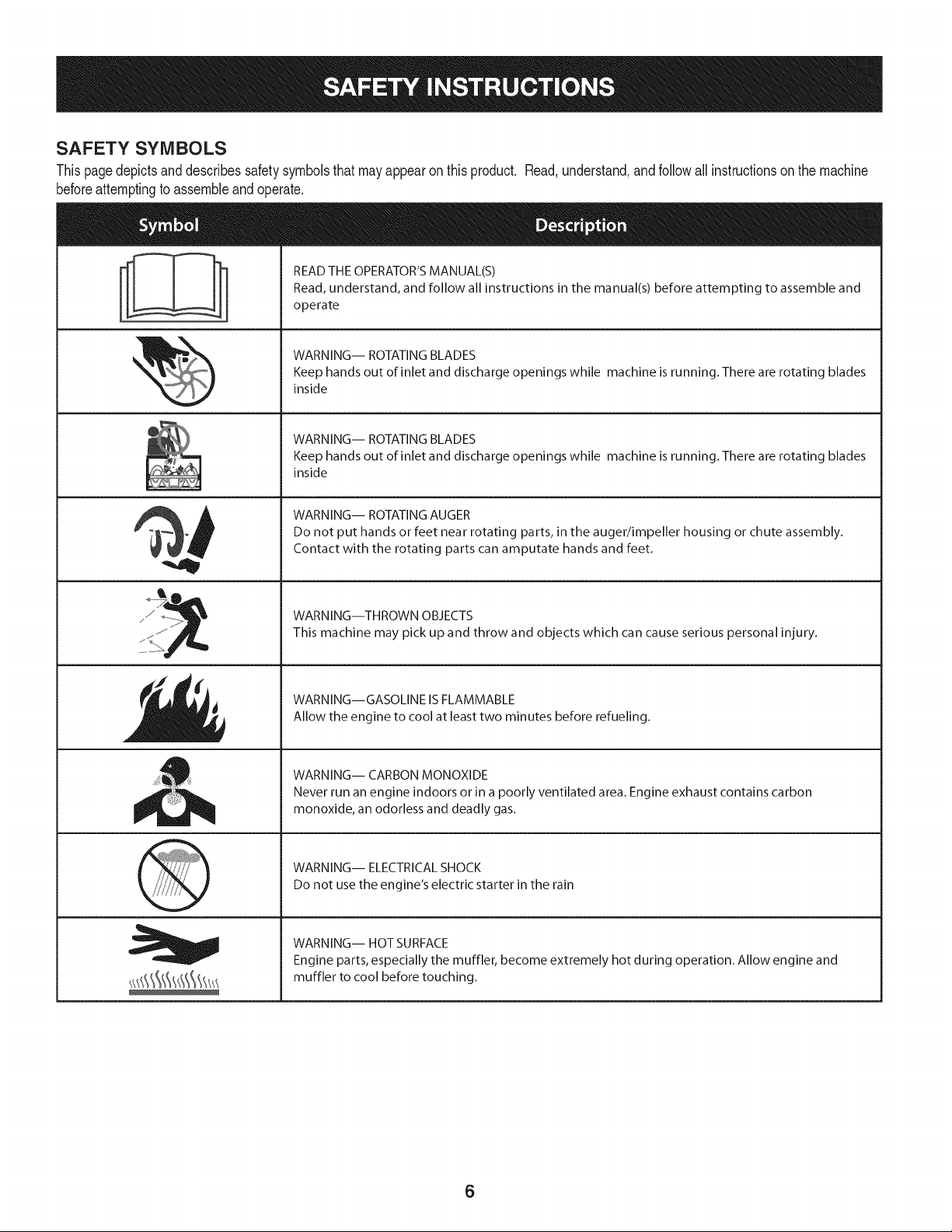

Positioning the Upper Handle

1. Removethewingknobsandcarriageboltsfromthetopofthelower

handle.SeeFigure1.Itisnotnecessaryto removetheshoulder

screwandflangelocknutbelowthewingknobandcarriagebolt.

3. Tightenthepreviouslyremovedhardwaretosecurethe handlein

place.SeeFigure2.

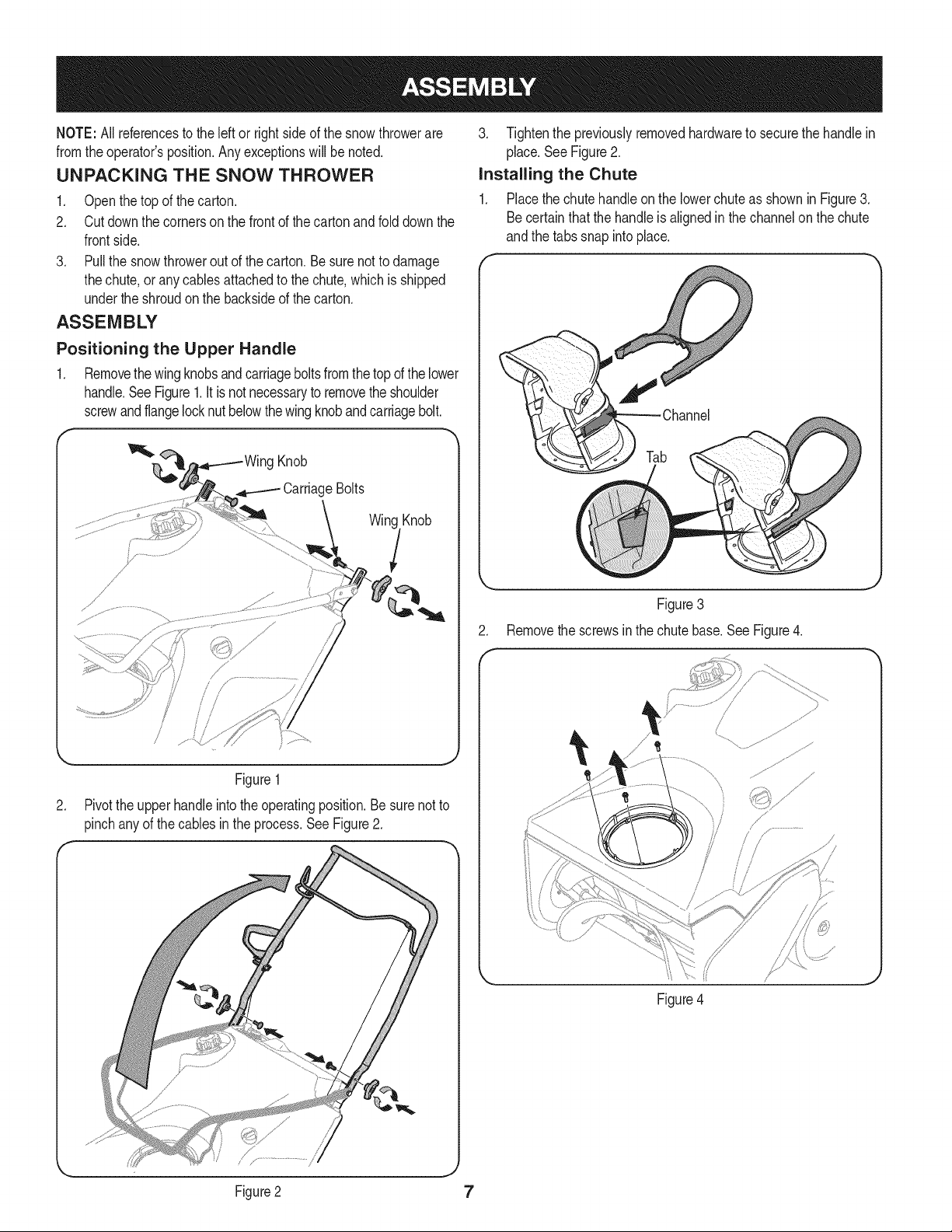

installing the Chute

1. PlacethechutehandleonthelowerchuteasshowninFigure3.

Becertainthatthehandleis alignedinthechannelonthechute

andthetabssnap intoplace.

f

g Knob

CarriageBolts

Win(

i

i

/

Figure1

.

Pivottheupperhandleintotheoperatingposition.Besurenotto

pinchanyof thecablesintheprocess.SeeFigure2.

Tab

Figure3

2. Removethe screwsinthechutebase.SeeFigure4.

/ _

/ /, .......

Figure2

Figure4

7

.

Aligntheholes inthechutebasewiththe holesinthelowerchute

andsecurewiththepreviouslyremovedscrews.SeeFigure5.

f

SET-UP

Fuel Recommendations

Useautomotivegasoline(unleadedorlowleadedto minimizecombus-

tionchamberdeposits)withaminimumof87 octane.Gasolinewith

upto10%ethanolor 15%MTBE(MethylTertiaryButylEther)canbe

used.Neverusean oil/gasolinemixtureordirty gasoline.Avoidgetting

dirt, dust,orwaterinthe fueltank.DONOTuse E85gasoline.

• Refuelinawell-ventilatedareawiththeenginestopped.Donot

smokeorallowflamesor sparksin theareawheretheengineis

refueledor wheregasolineisstored.

• Donotoverfillthefueltank.Afterrefueling,makesurethetank

capis closedproperlyandsecurely.

• Becarefulnotto spillfuelwhenrefueling.Spilledfuelorfuelvapor

mayignite.Ifanyfuelisspilled,makesuretheareaisdrybefore

startingtheengine.

• Avoidrepeatedor prolongedcontactwithskinorbreathingofvapor.

Adding Fuel

Figure5

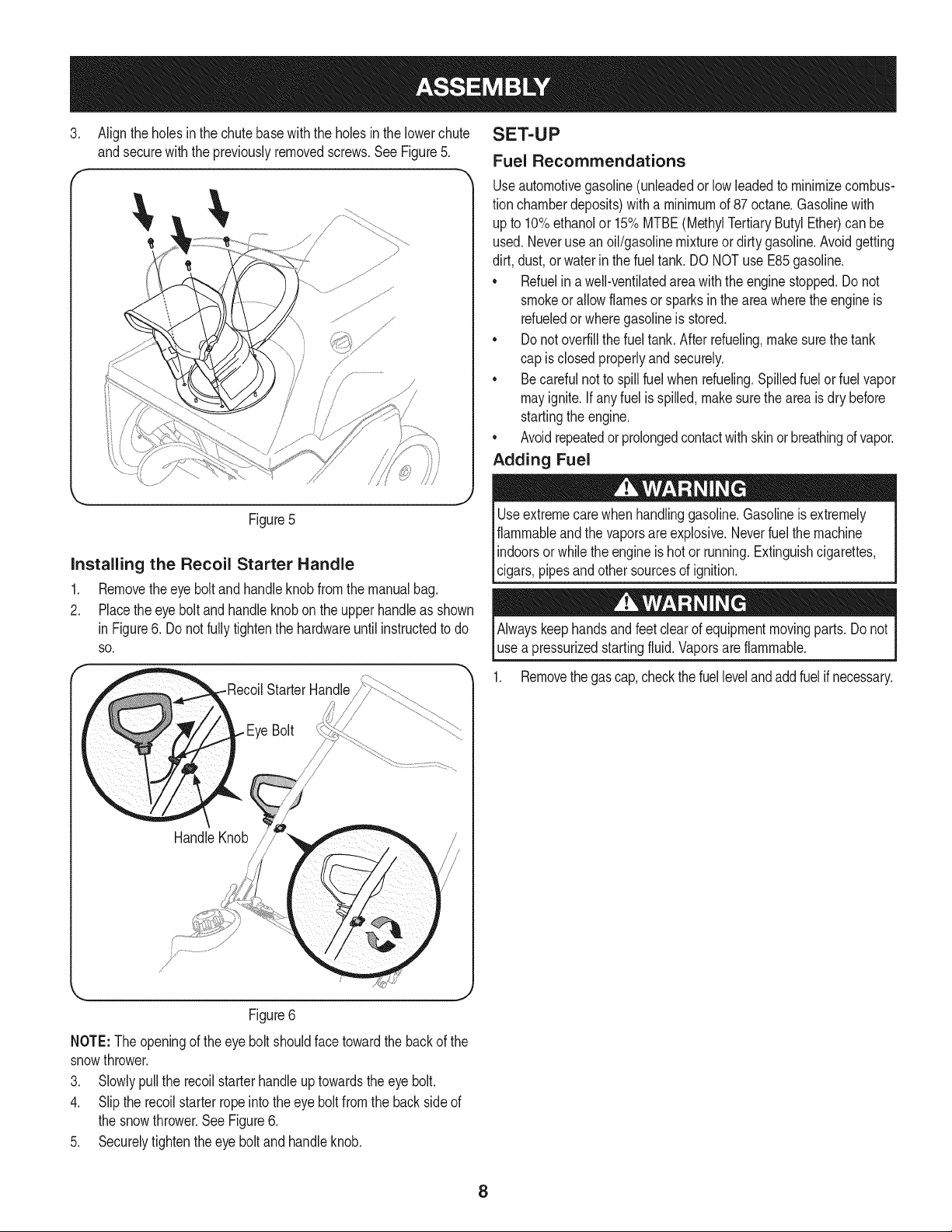

Installing the Recoil Starter Handle

1. Removetheeyeboltandhandleknobfromthemanualbag.

2. Placetheeyeboltand handleknobonthe upperhandleasshown

inFigure6. Donot fullytightenthehardwareuntil instructedtodo

SO.

HandleKnob

Useextremecarewhenhandlinggasoline.Gasolineis extremely

flammableandthe vaporsare explosive.Neverfuelthemachine

indoorsorwhilethe engineishotor running.Extinguishcigarettes,

lc gars,p pesandothersourcesof gnt on.

Alwayskeephandsandfeetclearofequipmentmovingparts.Donot

usea pressurizedstartingfluid.Vaporsareflammable.

1. Removethegascap,checkthefuellevelandaddfuelifnecessary.

Figure6

NOTE:The openingof theeye boltshouldfacetowardthebackof the

snowthrower.

3. Slowlypulltherecoilstarterhandleuptowardstheeye bolt.

4. Sliptherecoilstarterropeintotheeyeboltfromthebacksideof

thesnowthrower.SeeFigure6.

5. Securelytightentheeyeboltandhandleknob.

8

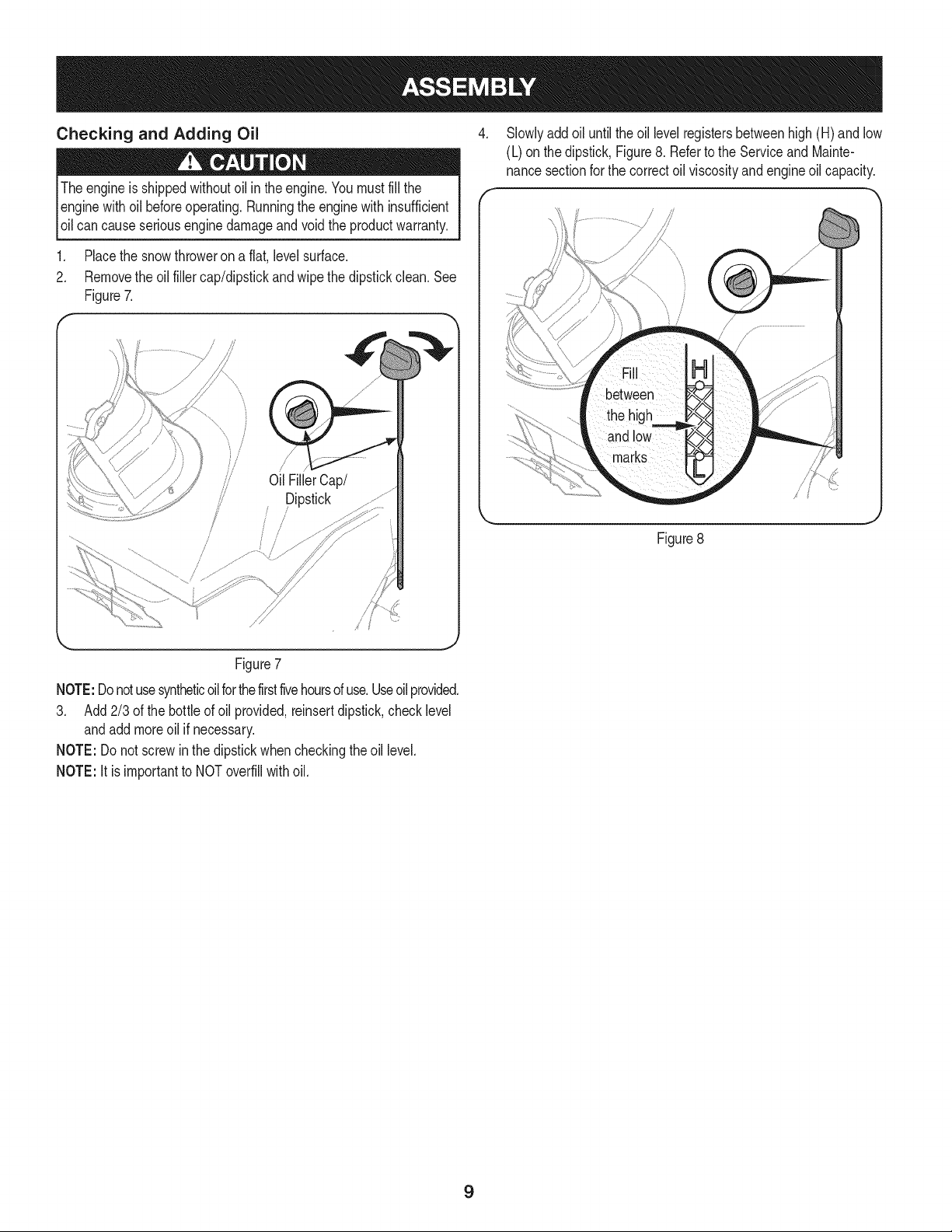

Checking and Adding Oil

Theengineis shippedwithoutoil intheengine.Youmustfillthe

enginewithoil beforeoperating.Runningtheenginewithinsufficient

_o cancauseserous engnedamageandvod the productwarranty.

1. Placethe snowthroweronaflat,levelsurface.

2. Removetheoilfillercap/dipstickandwipethedipstickclean.See

Figure7.

...._J

ii

/

Oil FillerCap/

Dipstick

/

/

/

/

//

/

.

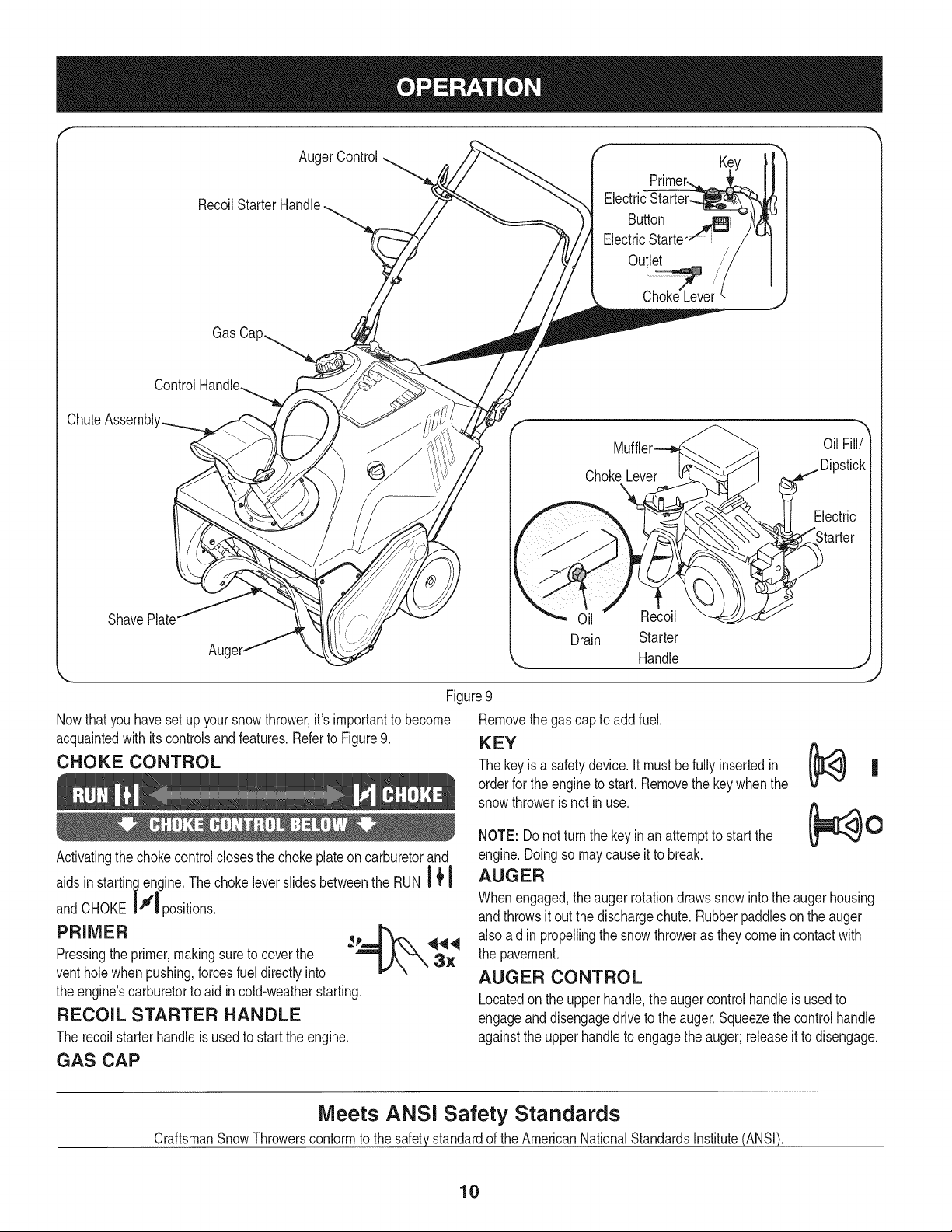

Slowlyaddoil untilthe oil levelregistersbetweenhigh(H) and low

(L) onthedipstick,Figure8. RefertotheServiceandMainte-

nancesectionforthe correctoil viscosityandengineoilcapacity.

Figure8

/

ij .....

Figure7

NOTE:Donotusesyntheticoilforthefirstfivehoursofuse.Useoilprovided.

3. Add2/3ofthebottleof oil provided,reinsertdipstick,checklevel

andaddmoreoil if necessary.

NOTE:Donotscrewinthedipstickwhencheckingtheoil level.

NOTE:Itisimportantto NOToverfillwithoil.

9

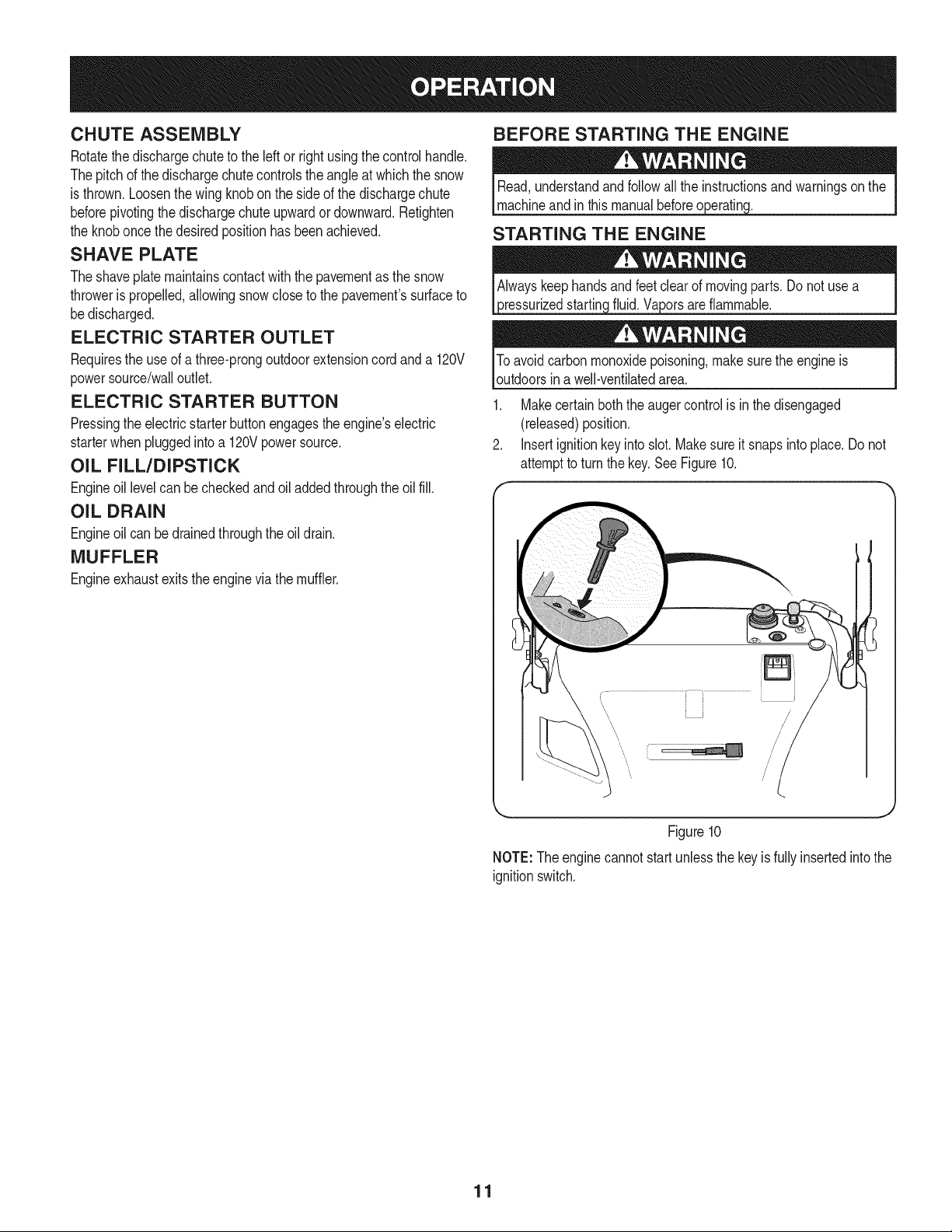

ChuteAssembl'

AugerControl

Recoil

GasCa

Control

Oil

ShavePlate

Aug{

Figure9

Nowthat youhavesetup yoursnowthrower,it'simportanttobecome

acquaintedwithitscontrolsandfeatures.RefertoFigure9.

CHOKE CONTROL

Activatingthechokecontrolclosesthe chokeplateoncarburetorand

aidsinstartingengine.Thechokeleverslidesbetweenthe RUNI { I

I

andCHOKE|f_ positions.

PRIMER __ ,q_,q

Pressingtheprimer,makingsureto coverthe

ventholewhenpushing,forcesfueldirectlyinto _-'X 3X

theengine'scarburetortoaid incold-weatherstarting.

RECOIL STARTER HANDLE

Therecoilstarterhandleisusedto starttheengine.

GAS CAP

Handle

Removethegascaptoaddfuel.

KEY

Thekeyis a safetydevice.It mustbefullyinsertedin

orderfortheenginetostart.Removethekeywhenthe

snowthrowerisnot inuse.

NOTE:Do notturn thekeyinanattemptto startthe

engine.Doingsomaycauseit tobreak.

AUGER

Whenengaged,theaugerrotationdrawssnowintotheaugerhousing

andthrowsit outthe dischargechute.Rubberpaddlesontheauger

alsoaidin propellingthesnowthrowerastheycomein contactwith

thepavement.

AUGER CONTROL

Locatedontheupperhandle,theaugercontrolhandleisusedto

engageanddisengagedrivetothe auger.Squeezethecontrolhandle

againsttheupperhandleto engagethe auger;releaseitto disengage.

Meets ANSI Safety Standards

CraftsmanSnowThrowersconformtothesafetystandardofthe AmericanNationalStandardsInstitute(ANSI).

10

CHUTE ASSEMBLY

Rotatethedischargechuteto theleftorrightusingthe controlhandle.

Thepitchof thedischargechutecontrolstheangleat whichthesnow

isthrown.Loosenthewingknobontheside ofthe dischargechute

beforepivotingthedischargechuteupwardordownward.Retighten

theknoboncethe desiredpositionhasbeenachieved.

SHAVE PLATE

Theshaveplate maintainscontactwiththepavementasthesnow

throwerispropelled,allowingsnowclosetothe pavement'ssurfaceto

bedischarged.

ELECTRIC STARTER OUTLET

Requirestheuseof athree-prongoutdoorextensioncordanda 120V

powersource/walloutlet.

ELECTRIC STARTER BUTTON

Pressingtheelectricstarterbuttonengagestheengine'selectric

starterwhenpluggedintoa 120Vpowersource.

OIL FILL/DiPSTICK

Engineoil levelcanbecheckedandoiladdedthroughtheoil fill.

OIL DRAIN

Engineoilcanbedrainedthroughtheoil drain.

MUFFLER

Engineexhaustexitstheenginevia themuffler.

BEFORE STARTING THE ENGINE

machineandin thismanualbefore

STARTING THE ENGINE

3ressurizedstartinc areflammable.

Toavoidcarbonmonoxidepoisoning,makesurethe engineis

outdoorsina well-ventilatedarea.

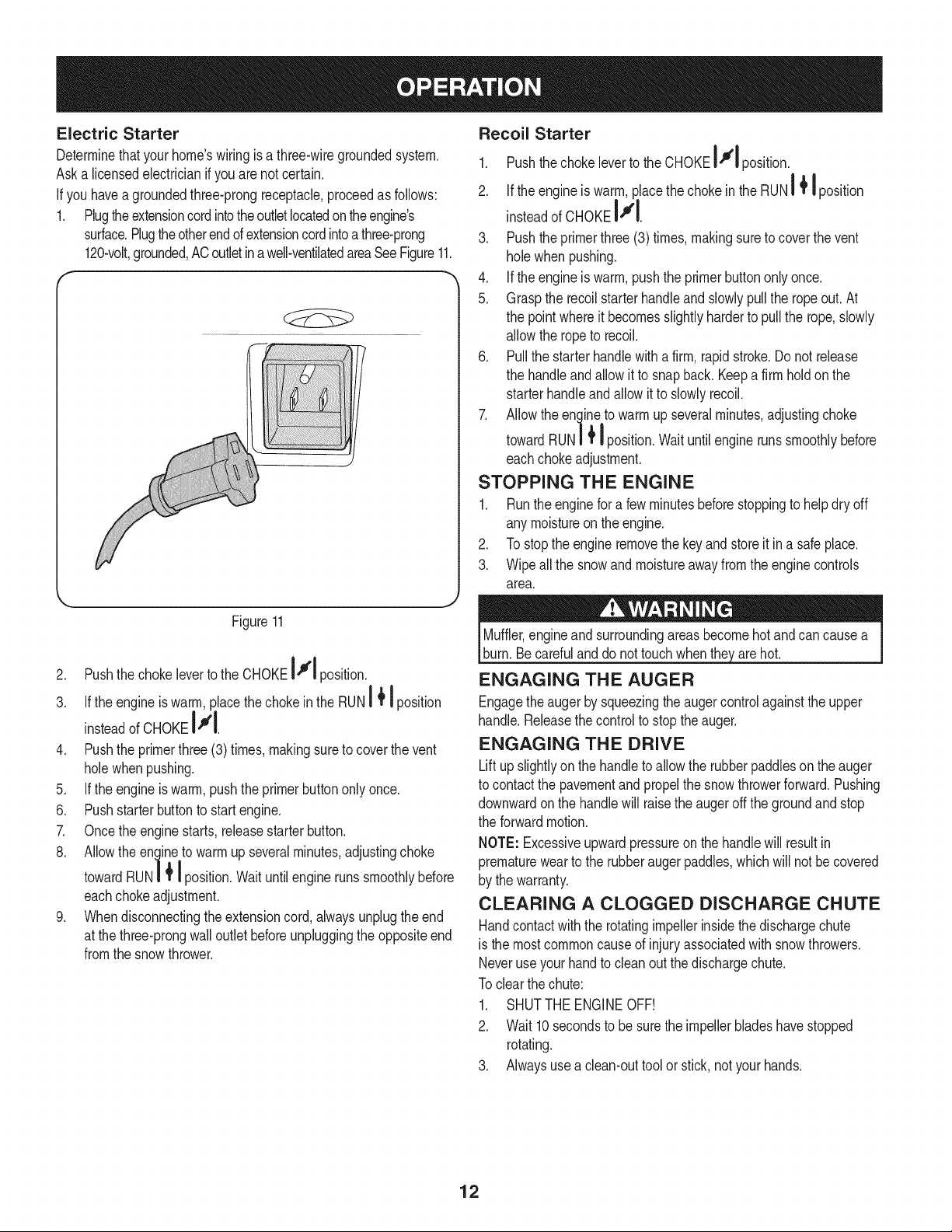

1. Makecertainboththe augercontrolisin thedisengaged

(released)position.

2. Insertignitionkeyintoslot.Makesureit snapsintoplace.Do not

attempttoturn thekey.See Figure10.

\

\ /

NOTE:Theenginecannotstartunlessthe keyisfullyinsertedintothe

ignitionswitch.

I J /

Figure10

11

Electric Starter

Determinethatyourhome'swiringis a three-wiregroundedsystem.

Aska licensedelectricianifyouarenotcertain.

Ifyouhavea groundedthree-prongreceptacle,proceedas follows:

1. Plugtheextensioncordintotheoutletlocatedontheengine's

surface.Plugtheotherendofextensioncordintoathree-prong

120-volt,grounded,ACoutletinawell-ventilatedareaSeeFigure11.

Recoil Starter

1. Pushthechokeleverto theCHOKEIll position.

A

2. Iftheengineiswarm,placethechokeintheRUN_ I position

|+l

insteadofCHOKEI"rl.

3. Pushtheprimerthree(3) times,makingsuretocoverthevent

holewhenpushing.

4. Iftheengineiswarm,pushtheprimerbuttononlyonce.

5. Graspthe recoilstarterhandleandslowlypullthe ropeout.At

thepointwhereit becomesslightlyharderto pullthe rope,slowly

allowthe ropeto recoil.

6. Pullthestarterhandlewitha firm,rapidstroke.Donotrelease

thehandleandallowit to snapback. Keepa firm holdon the

starterhandleandallow itto slowlyrecoil.

7. Allowtheenginetowarmupseveralminutes,adjustingchoke

towardRUN| _position.Waituntilenginerunssmoothlybefore

eachchokeadjustment.

STOPPING THE ENGINE

1. Runtheenginefora fewminutesbeforestoppingtohelpdry off

anymoistureontheengine.

2. Tostoptheengineremovethekeyand storeit inasafeplace.

3. Wipeallthesnowandmoistureawayfromtheenginecontrols

area.

|+I

Figure11

2. Pushthe chokeleverto theCHOKEI"#1 position.

a ii

3. Iftheengineis warm,placethechokeintheRUN_ I position

insteadofCHOKEIII.

4. Pushthe primerthree(3)times,makingsuretocoverthevent

holewhenpushing.

5. Iftheengineis warm,pushtheprimerbuttononlyonce.

6. Pushstarterbuttontostart engine.

7. Oncethe enginestarts,releasestarterbutton.

8. Allowtheenginetowarmupseveralminutes,adjustingchoke

towardRUN| _position.Waituntilenginerunssmoothlybefore

eachchokeadjustment.

9. Whendisconnectingtheextensioncord,alwaysunplugtheend

atthe three-prongwalloutletbeforeunpluggingthe oppositeend

fromthesnowthrower.

|+I

Muffler,engineandsurroundingareasbecomehotandcancausea

burn.Becarefulanddonot touchwhenthe_arehot.

ENGAGING THE AUGER

Engagethe augerbysqueezingtheaugercontrolagainsttheupper

handle.Releasethecontroltostopthe auger.

ENGAGING THE DRIVE

Liftupslightlyonthe handletoallowtherubberpaddiesontheauger

tocontactthe pavementand propelthe snowthrowerforward.Pushing

downwardonthe handlewill raisetheaugeroff the groundandstop

theforwardmotion.

NOTE:Excessiveupwardpressureonthehandlewillresultin

prematureweartothe rubberaugerpaddies,whichwillnotbecovered

bythe warranty.

CLEARING A CLOGGED DISCHARGE CHUTE

Handcontactwiththe rotatingimpellerinsidethedischargechute

isthe mostcommoncauseofinjuryassociatedwithsnowthrowers.

Neveruseyourhandtocleanoutthedischargechute.

Toclear thechute:

1. SHUTTHEENGINEOFF!

2. Wait 10secondstobe surethe impellerbladeshavestopped

rotating.

3. Alwaysusea clean-outtoolor stick,notyourhands.

12

MAINTENANCE SCHEDULE

Beforeperforminganytypeof maintenance/service,disengageall

controlsandstopthe engine.Waituntilall movingpartshavecome

toa completestop.Disconnectsparkplugwireandgroundit against

theengineto preventunintendedstarting.Alwayswearsafetyglasses

duringoperationorwhileperforminganyadjustmentsor repairs.

Eachuse .

1st5 hours 1. 1. Change.

Every5hours 1. 1. Check.

25 hours 1. 2. Check.

Everyseason/50hours 1. 1. Change

Everyseason/100hours 1. 1. Clean,replace,re-gap

Everyseason/Before 1. 1. Lubricate

storage 2. 2. Lubricate

Engineoillevel.

2.

Snowthrowerandexhaust

area.

Engineoil.

Engineoil.

Exhaustarea.

2. 2. Clean.

Sparkplug.

Engineoil

Sparkplug

Pivotpoints

Controlhandle

3. 3. Lubricate

Extensionspring

1. Check

2. Clean

ENGINE MAINTENANCE

usedoil.

Oil Recommendations

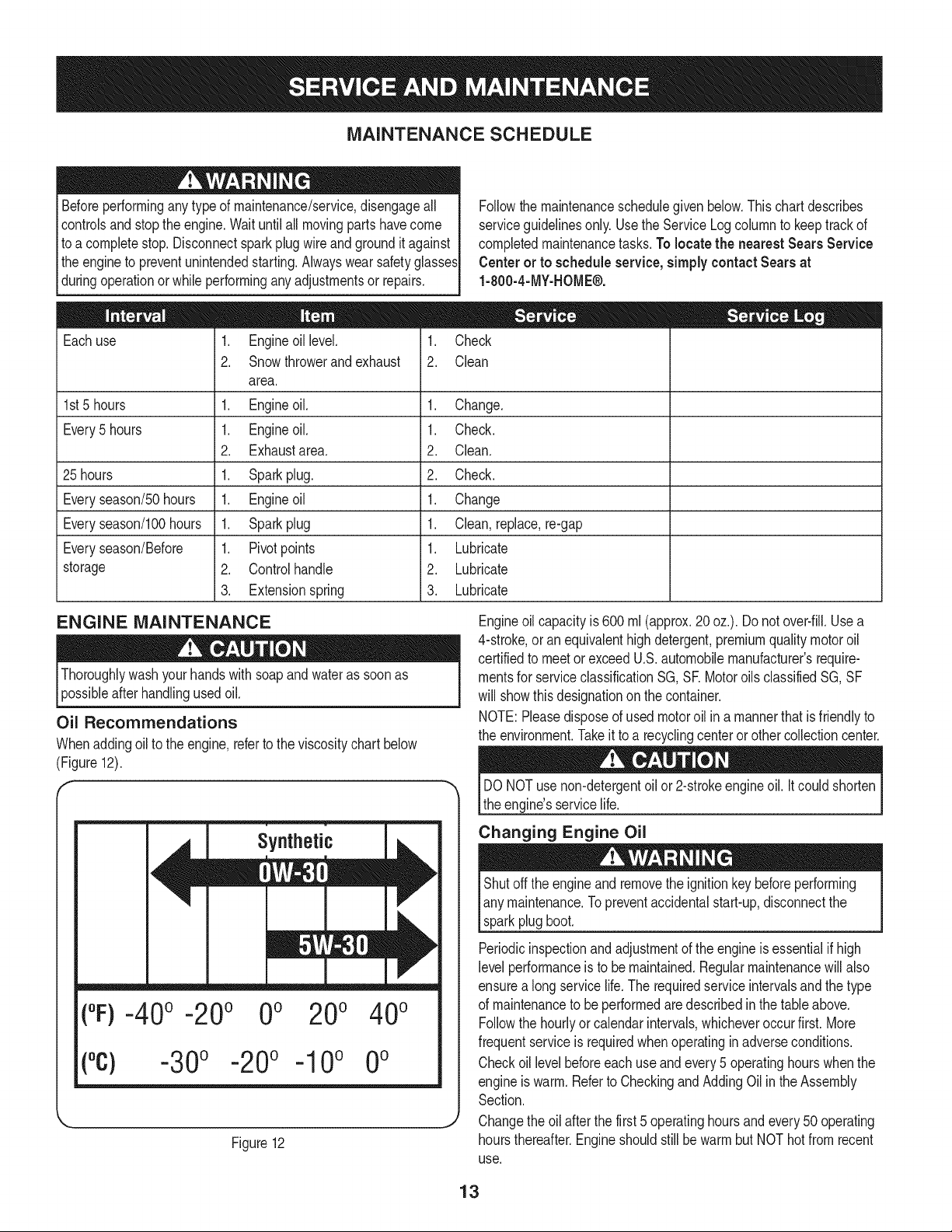

Whenaddingoilto theengine,referto theviscositychartbelow

(Figure12).

Followthemaintenanceschedulegivenbelow.Thischartdescribes

serviceguidelinesonly.UsetheServiceLogcolumntokeeptrackof

completedmaintenancetasks.To locate the nearest Sears Service

Centeror to scheduleservice,simplycontactSearsat

1-800-4-MY-HOME®.

= =

Engineoilcapacityis600ml(approx.20oz.). Donotover-fill.Usea

4-stroke,oran equivalenthighdetergent,premiumqualitymotoroil

certifiedto meetor exceedU.S.automobilemanufacturer'srequire-

mentsfor serviceclassificationSG,SEMotoroils classifiedSG,SF

willshowthis designationon thecontainer.

NOTE:Pleasedisposeofusedmotoroilina mannerthatisfriendlyto

theenvironment.Takeittoa recyclingcenteror othercollectioncenter.

DONOTusenon-detergentoilor2-strokeengineoil.It couldshorten

theengine'sservicelife.

Synthetic

("F)-40o-20o 0o 200 400

(°c) -30° -20° -10° 0°

Figure12

Changing Engine Oil

Shutoffthe engineand removethe ignitionkeybeforeperforming

anymaintenance.Topreventaccidentalstart-up,disconnectthe

sparkplugboot.

Periodicinspectionandadjustmentoftheengineis essentialif high

levelperformanceis tobemaintained.Regularmaintenancewillalso

ensurea longservicelife.Therequiredserviceintervalsandthe type

of maintenancetobe performedaredescribedin the tableabove.

Followthehourlyorcalendarintervals,whicheveroccurfirst.More

frequentserviceis requiredwhenoperatinginadverseconditions.

Checkoil levelbeforeeachuseandevery5 operatinghourswhenthe

engineiswarm.RefertoCheckingandAddingOilintheAssembly

Section.

Changetheoil afterthefirst5 operatinghoursandevery50 operating

hoursthereafter.EngineshouldstillbewarmbutNOThotfrom recent

use.

13

.

Drainfuelfromthetankby runningtheengineuntilthefueltankis

empty.Besurethe fuelfill capis secure.

2.

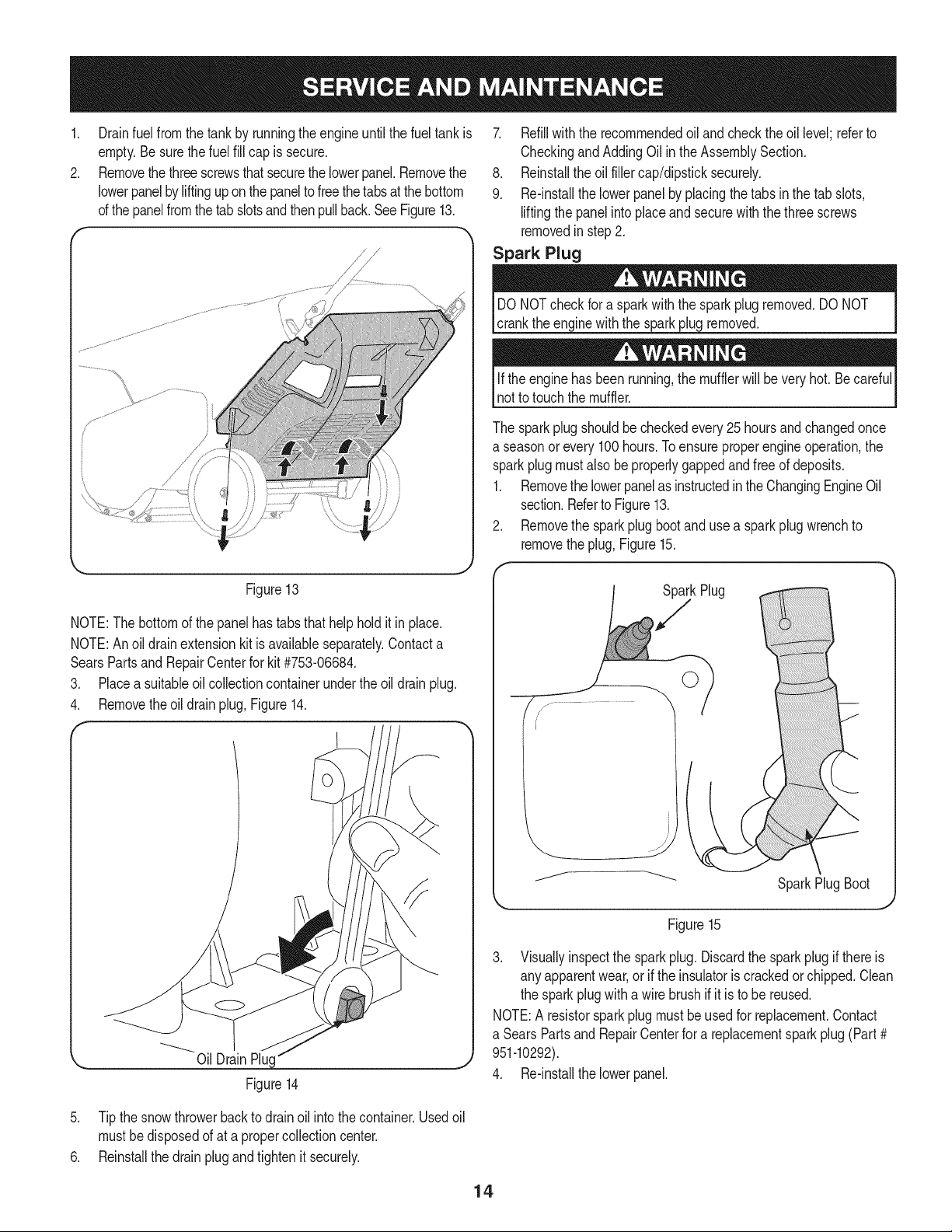

Removethethreescrewsthatsecurethelowerpanel.Removethe

lowerpanelbyliftinguponthepaneltofreethetabsatthe bottom

ofthepanelfromthetab slotsandthenpullback.SeeFigure13.

7. Refillwiththe recommendedoiland checktheoil level;referto

CheckingandAddingOil intheAssemblySection.

8. Reinstallthe oil fillercap/dipsticksecurely.

9. Re-installthe lowerpanelbyplacingthetabs inthetab slots,

liftingthepanelintoplaceandsecurewiththe threescrews

removedinstep2.

Spark Plug

DONOTcheck fora sparkwiththe sparkplugremoved.DONOT

cranktheenginewiththe sparkplugremoved.

Iftheenginehas beenrunning,the mufflerwillbeveryhot. Becareful

notto touchthemuffler.

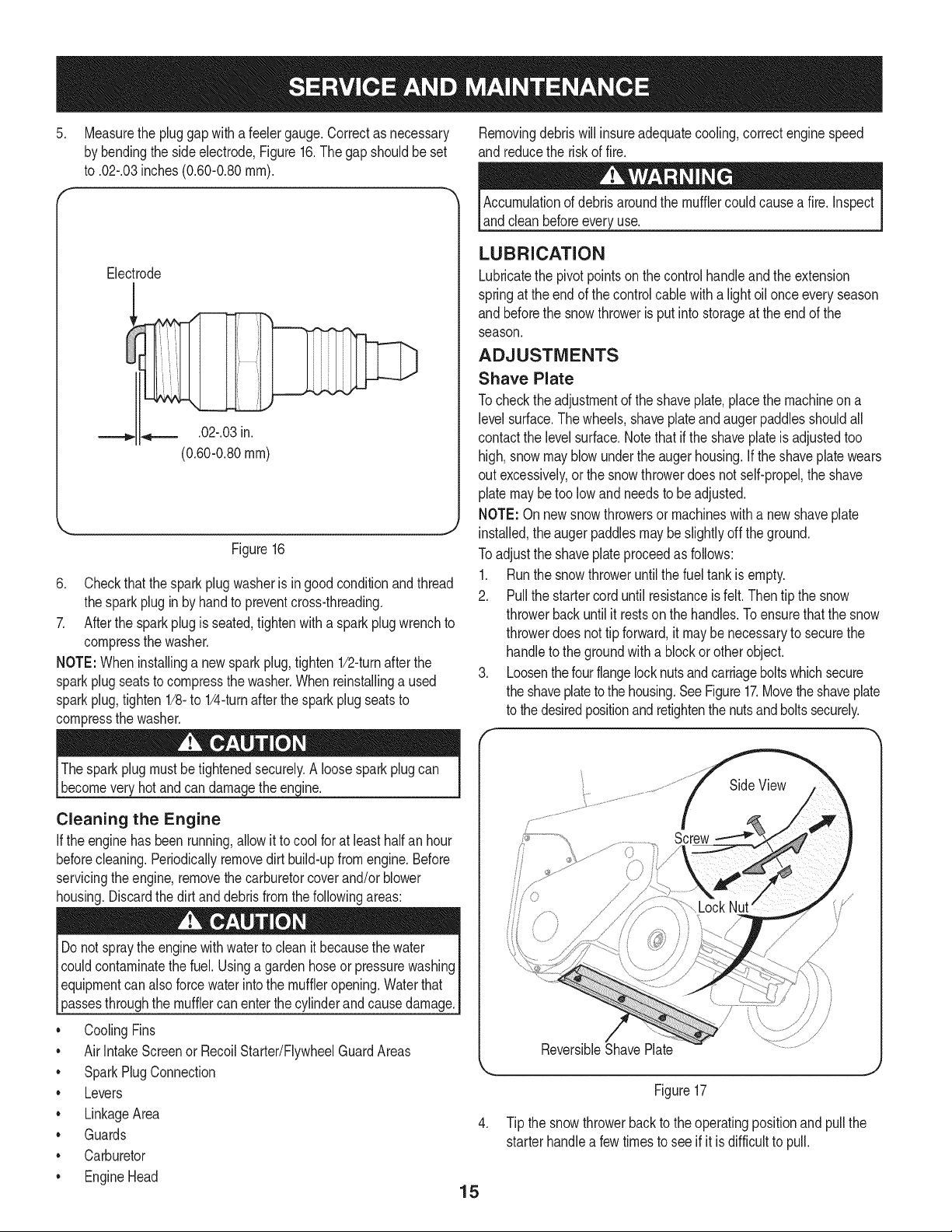

Thesparkplugshouldbecheckedevery25hoursandchangedonce

a seasonor every100hours.Toensureproperengineoperation,the

sparkplugmustalso beproperlygappedandfreeof deposits.

1. RemovethelowerpanelasinstructedintheChangingEngineOil

section.RefertoFigure13.

2. Removethe sparkplugbootand usea sparkplugwrenchto

removetheplug,Figure15.

Figure13

NOTE:Thebottomof thepanelhastabsthathelpholdit in place.

NOTE:Anoil drainextensionkitisavailableseparately.Contacta

SearsPartsand RepairCenterforkit#753-06684.

3. Placea suitableoilcollectioncontainerundertheoildrainplug.

4. Removetheoil drainplug,Figure14.

F 1

k,_ Oil DrainPlug" .,,

Figure14

SparkPlug

,J

SparkPlugBoot

Figure15

3. Visuallyinspectthe sparkplug.Discardthe sparkplugifthereis

anyapparentwear,oriftheinsulatoriscrackedorchipped.Clean

thesparkplugwitha wire brushif it is tobe reused.

NOTE:Aresistorsparkplugmustbeusedforreplacement.Contact

a SearsPartsandRepairCenterfora replacementsparkplug(Part#

951-10292).

4. Re-installthe lowerpanel.

5. Tipthesnowthrowerbacktodrainoilintothecontainer.Usedoil

mustbedisposedof ata propercollectioncenter.

6. Reinstallthedrainplugandtightenit securely.

14

.

Measurethepluggapwitha feelergauge.Correctasnecessary

bybendingthesideelectrode,Figure16.Thegapshouldbeset

to.02-.03inches(0.60-0.80turn).

Electrode

.02-.03in.

(0.60-0.80ram)

_J

Figure16

6. Checkthatthesparkplugwasherisingoodconditionandthread

thesparkplugin by handtopreventcross-threading.

7. Afterthe sparkplugis seated,tightenwitha sparkplugwrenchto

compressthewasher.

NOTE:Wheninstallinga newsparkplug,tighten1/2-turnafterthe

sparkplugseatsto compressthe washer.Whenreinstallinga used

sparkplug,tighten1/8-to 1/4-turnafterthesparkplugseatsto

compressthewasher.

Removingdebriswillinsureadequatecooling,correctenginespeed

and reducetheriskoffire.

Accumulationofdebrisaroundthemufflercouldcausea fire.Inspect

andcleanbeforeeveryuse.

LUBRICATION

Lubricatethe pivotpointson thecontrolhandleandthe extension

springat theendof thecontrolcablewitha lightoilonceeveryseason

and beforethesnowthrowerisput intostorageat theendof the

season.

ADJUSTMENTS

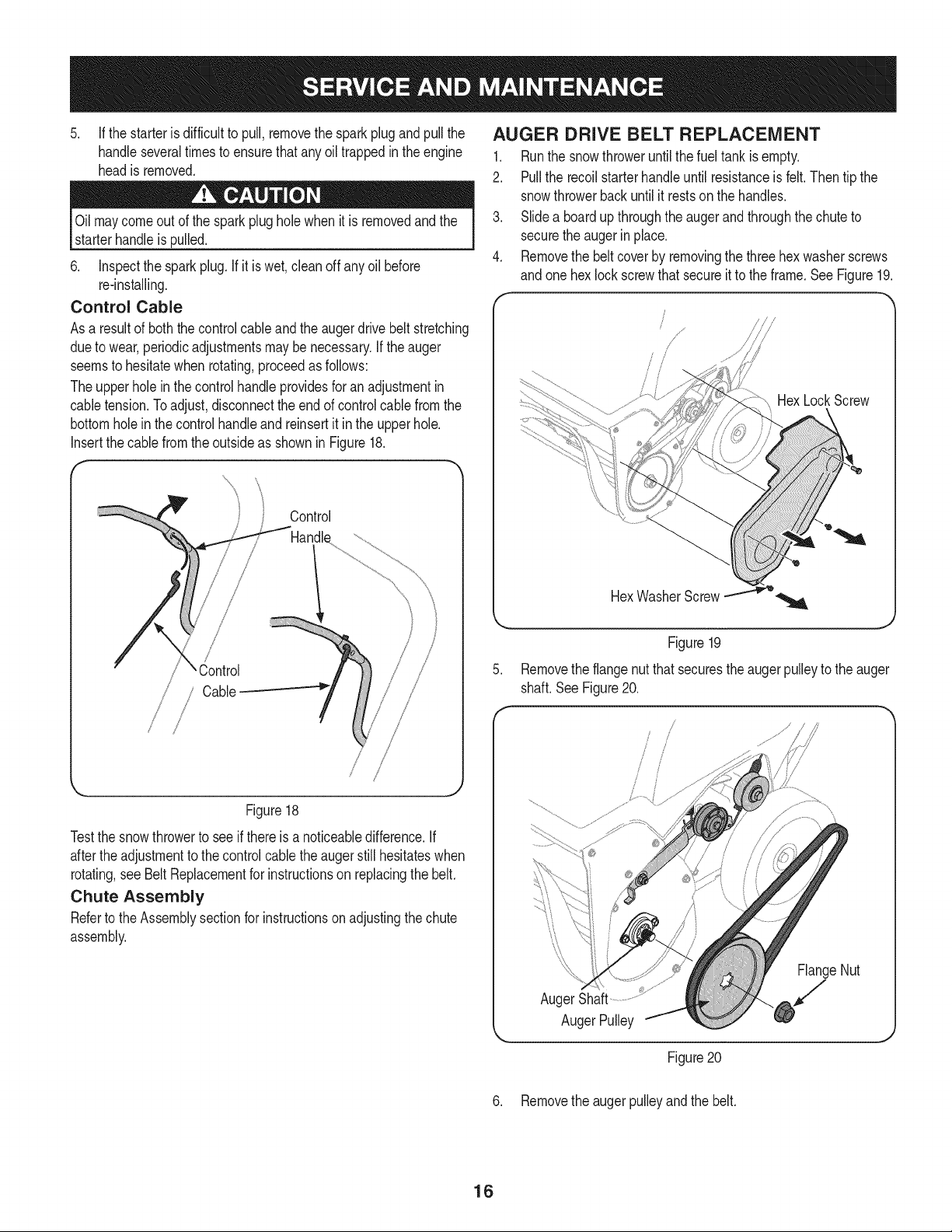

Shave Plate

Tochecktheadjustmentoftheshaveplate,placethemachineona

levelsurface.Thewheels,shaveplateandaugerpaddlesshouldall

contactthelevelsurface.Notethat ifthe shaveplateis adjustedtoo

high,snowmayblowundertheaugerhousing.Ifthe shaveplatewears

outexcessively,orthesnowthrowerdoesnot self-propel,theshave

platemaybetoo lowandneedstobeadjusted.

NOTE:Onnewsnowthrowersormachineswithanewshaveplate

installed,theaugerpaddlesmaybeslightlyoff theground.

Toadjustthe shaveplateproceedasfollows:

1. Runthe snowthroweruntilthe fueltankis empty.

2. Pullthestartercorduntilresistanceisfelt.Thentip thesnow

throwerbackuntilit restsonthe handles.To ensurethatthe snow

throwerdoesnot tipforward,it maybe necessarytosecurethe

handletothe groundwitha blockorotherobject.

3. Loosenthefourflangelocknutsandcarriageboltswhichsecure

theshaveplatetothe housing.SeeFigure17.Movetheshaveplate

tothe desiredpositionandretightenthenutsandboltssecurely.

Thesparkplugmustbetightenedsecurely.Aloosesparkplugcan

becomeveryhotandcan damagetheengine.

Cleaning the Engine

Iftheenginehasbeenrunning,allowitto coolfor atleasthalfan hour

beforecleaning.Periodicallyremovedirtbuild-upfromengine.Before

servicingtheengine,removethecarburetorcoverand/orblower

housing.Discardthedirtand debrisfromthefollowingareas:

Donot spraytheenginewithwaterto cleanit becausethewater

couldcontaminatethefuel.Usinga gardenhoseor pressurewashing

Iequipmentcanalsoforcewaterintothemuffleropening.Waterthat

[passesthroughthe muffercan enterthecy nderandcausedamage.]

* CoolingFins

* AirIntakeScreenor RecoilStarter/FlywheelGuardAreas

* SparkPlugConnection

* Levers

* LinkageArea

* Guards

* Carburetor

* EngineHead

SideView

y

/

i\

Ji

ReversibleShavePlate

J

Figure17

4. Tipthesnowthrowerbacktotheoperatingpositionandpullthe

starterhandlea fewtimestosee ifit isdifficultto pull.

15

5, If thestarterisdifficulttopull,removethesparkplugandpullthe

handleseveraltimesto ensurethatany oiltrappedinthe engine

headisremoved,

Oilmaycomeoutof thesparkplugholewhen itis removedandthe

starterhandleis pulled.

6. Inspectthesparkplug. Ifit is wet,cleanoff anyoil before

re-installing.

Control Cable

Asa resultof boththecontrolcableandthe augerdrivebelt stretching

duetowear,periodicadjustmentsmaybenecessary.Iftheauger

seemsto hesitatewhenrotating,proceedas follows:

Theupperholeinthe controlhandleprovidesforanadjustmentin

cabletension.Toadjust,disconnectthe endofcontrolcablefromthe

bottomholein the controlhandleand reinsertit intheupperhole.

Insertthe cablefromtheoutsideas shownin Figure18.

Control

AUGER DRIVE BELT REPLACEMENT

1. Runthe snowthroweruntilthe fueltankisempty.

2. Pullthe recoilstarterhandleuntilresistanceisfelt.Thentipthe

snowthrowerbackuntilitrestson thehandles.

3. Slidea boardup throughtheaugerandthroughthechuteto

securetheaugerinplace.

4. Removethe beltcoverby removingthe threehexwasherscrews

andone hexlockscrewthatsecureitto theframe.SeeFigure19.

HexLockScrew

/ Cable

/ /

Figure18

Testthesnowthrowerto seeif thereisa noticeabledifference.If

aftertheadjustmenttothecontrolcabletheaugerstill hesitateswhen

rotating,seeBeltReplacementforinstructionsonreplacingthebelt.

Chute Assembly

Refertothe Assemblysectionforinstructionsonadjustingthechute

assembly.

HexWasherScrew.............:._o

Figure19

,

Removetheflangenutthat securestheaugerpulleytothe auger

shaft.SeeFigure20.

/

/

FlangeNut

AugerShaft

/

AugerPulley

Figure20

J

6. Removethe augerpulleyandthe belt.

16

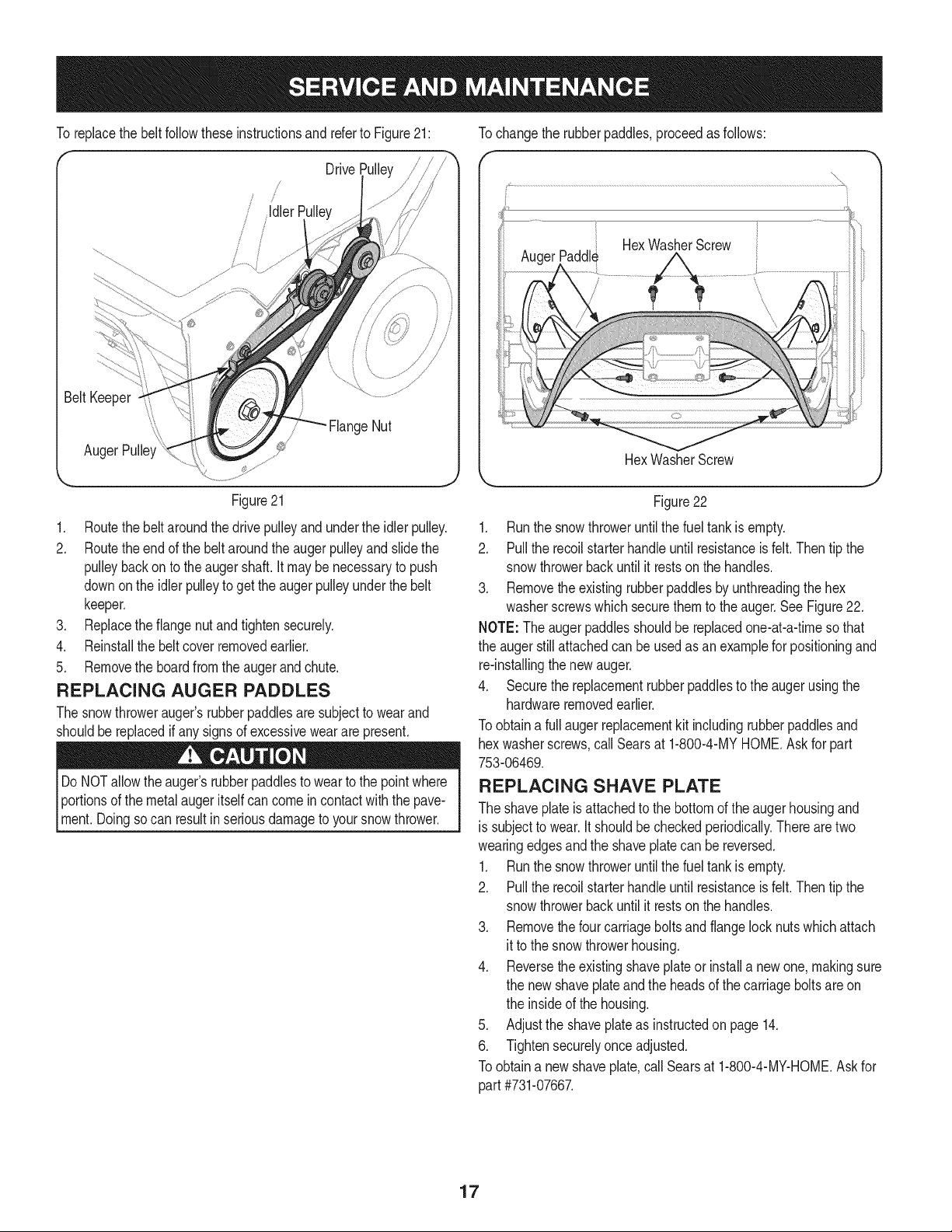

ToreplacethebeltfollowtheseinstructionsandrefertoFigure21: Tochangetherubberpaddles,proceedasfollows:

Drive

HexWasherScrew

Paddl_

HexWasherScrew

Figure21

1. Routethebeltaroundthedrivepulleyandundertheidlerpulley.

2. Routetheendofthebeltaroundtheaugerpulleyand slidethe

pulleybackon to theaugershaft.It maybe necessarytopush

downonthe idlerpulleyto gettheaugerpulleyunderthe belt

keeper.

3. Replacetheflangenutandtightensecurely.

4. Reinstallthebeltcoverremovedearlier.

5. Removethe boardfromtheaugerandchute.

REPLACING AUGER PADDLES

Thesnowthrowerauger'srubberpaddlesaresubjecttowearand

shouldbereplacedifany signsof excessiveweararepresent.

DoNOTallowtheauger'srubberpaddlesto wearto thepointwhere

Iportionsof themetalaugeritselfcancomein contactwiththe pave-

[ment.Doingsocan resultin seriousdamageto yoursnowthrower.

Figure22

1. Runthe snowthroweruntilthe fueltankis empty.

2. Pulltherecoilstarterhandleuntilresistanceisfelt.Thentip the

snowthrowerbackuntilit restson the handles.

3. Removethe existingrubberpaddlesbyunthreadingthehex

washerscrewswhichsecurethemto theauger.See Figure22.

NOTE:Theaugerpaddlesshouldbereplacedone-at-a-timesothat

theaugerstillattachedcanbeusedasanexamplefor positioningand

re-installingthenewauger.

4. Securethe replacementrubberpaddlestotheaugerusingthe

hardwareremovedearlier.

Toobtaina fullaugerreplacementkitincludingrubberpaddlesand

hexwasherscrews,callSearsat 1-800-4-MYHOME.Askforpart

753-06469.

REPLACING SHAVE PLATE

Theshaveplateisattachedtothe bottomof theaugerhousingand

is subjecttowear.Itshouldbecheckedperiodically.Therearetwo

wearingedgesandtheshaveplatecanbe reversed.

1. Runthe snowthroweruntilthe fueltankis empty.

2. Pulltherecoilstarterhandleuntilresistanceisfelt.Thentip the

snowthrowerbackuntilit restson the handles.

3. Removethe fourcarriageboltsandflangelocknutswhichattach

it to thesnowthrowerhousing.

4. Reversethe existingshaveplateorinstallanewone,makingsure

thenew shaveplateandthe headsofthecarriageboltsareon

theinsideofthe housing.

5. Adjustthe shaveplateas instructedon page14.

6. Tightensecurelyonceadjusted.

Toobtaina newshaveplate,call Searsat 1-800-4-MY-HOME.Askfor

part#731-07667.

17

Loading...

Loading...