Craftsman 247887550 Owner’s Manual

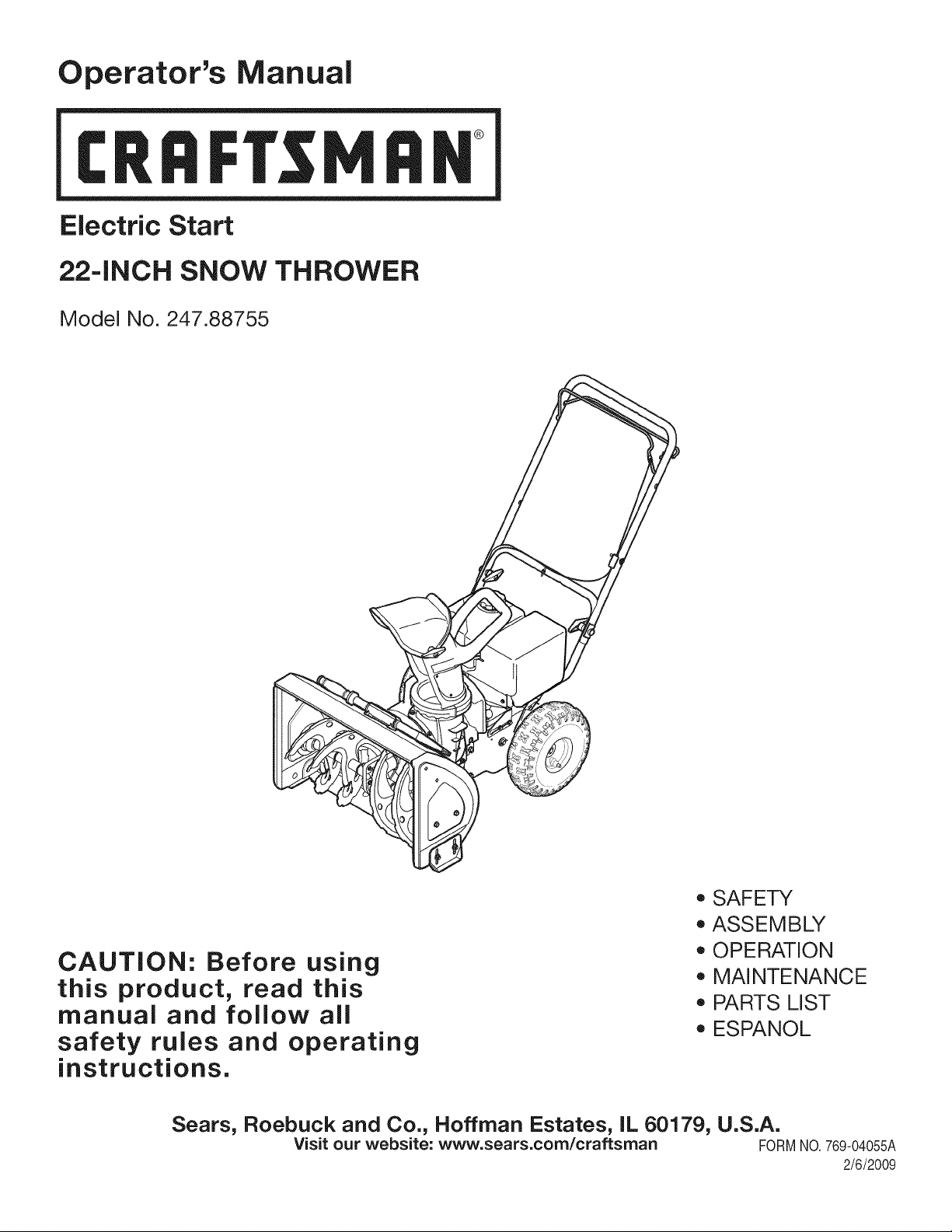

Operator's Manual

I:RRFI'$1 1RN

Electric Start

22=INCH SNOW THROWER

Model No. 247.88755

CAUTION: Before using

this product, read this

manual and follow all

safety rules and operating

instructions.

Sears, Roebuck and Co., Hoffman Estates, IL 60179, U.S.A.

Visit our website: www.sears.com/craftsman FORMNO.769-04055A

o SAFETY

ASSEMBLY

OPERATION

MAINTENANCE

PARTS LIST

ESPANOL

2/6/2009

WarrantyStatement.................... Page2

SafeOperationPractices................ Page3

SafetyLabels......................... Page7

Setup&Adjustment.................... Page8

Operation........................... Page12

Maintenance&Service................. Page16

Off-SeasonStorage................... Page21

Troubleshooting...................... Page22

PartsList............................ Page23

RepairProtectionAgreement............ Page32

Espa_ol............................. Page35

ContactNumbers.................. BackCover

CRAFTSMAN LiMiTED WARRANTY

Two Years on Snow Thrower

Whenoperatedandmaintainedaccordingto allsuppliedinstructions,ifthissnowthrowerfailsdueto adefectin materialorworkmanshipwithintwoyearsfromthe

dateor purchase,returnitto anyauthorizedCraftsmandrop-offlocationforfree repair. Forthe nearestauthorizedlocation,call 1-800-4MYHOME.

Thiswarrantyappliesfor only90 daysfromthe dateof purchaseifthis snowthroweriseverusedfor commercialor rentalpurposes.

ThiswarrantycoversONLYdefectsinmaterialandworkmanship.Searswill NOTpayfor:

• Expendableitemsthatbecomewornduringnormaluse,includingbutnotlimitedto skidshoes,shaveplate,shearpins,sparkplug,aircleaner,belts,

andoilfilter.

• Standardmaintenanceservicing,oil changes,ortune-ups.

• Tirereplacementor repaircausedbypuncturesfromoutsideobjects,suchas nails,thorns,stumps,orglass.

• Tireorwheel replacementor repairresultingfrom normalwear,accident,orimproperoperationormaintenance.

• Repairsnecessarybecauseofoperatorabuse,includingbutnotlimitedto damagecausedbyimpactingobjectsthatbendtheframeor crankshaft,or

over-speedingtheengine.

• Repairsnecessarybecauseofoperatornegligence,includingbutnotlimitedto,electricalandmechanicaldamagecausedbyimproperstorage,failure

tousethe propergradeandamountof engineoil,or failureto maintaintheequipmentaccordingtothe instructionscontainedinthe operator'smanual.

• Engine(fuelsystem)cleaningor repairscausedbyfueldeterminedto becontaminatedor oxidized(stale).In general,fuelshouldbe usedwithin30

daysof itspurchasedate.

• Normaldeteriorationandwearof the exteriorfinishes,orproductlabelreplacement.

Thiswarrantyappliesonly whilethisproductis withinthe UnitedStates.

Thiswarrantygivesyouspecificlegalrights,andyoumayalsohaveotherrightswhichvaryfromstatetostate.

Sears, Roebuck and Co., Hoffman Estates, IL 60179

EngineOilType: 5W-30

EngineOilCapacity: 20ounces

FuelCapacity: 2.3Quarts

SparkPlug: TorchF6RTC(F6TC)

SparkPlugGap: .020"to.030"

ModelNumber.................................................................

Serial Number .................................................................

Dateof Purchase.............................................................

Recordthemodelnumber,serialnumber

anddateof purchaseabove

©SearsBrands,LLC

2

Thissymbolpointsoutimportantsafetyinstructionswhich,if not

followed,couldendangerthepersonalsafetyand/orpropertyof

yourselfandothers. Readandfollowall instructionsin thismanual

beforeattemptingto operatethismachine.Failuretocomplywith

theseinstructionsmayresultin personalinjury.Whenyou seethis

symbol,HEEDITSWARNING!

Thismachinewasbuilttobeoperatedaccordingtothe safeopera-

tionpracticesinthis manual.Aswithanytypeof powerequipment,

carelessnessorerroron the partoftheoperatorcanresultinserious

injury.Thismachineiscapableofamputatingfingers,hands,toes

andfeetandthrowingdebris.Failureto observethefollowingsafety

instructionscouldresultin seriousinjuryor death.

CALIFORNIA PROPOSITION 65

EngineExhaust,someof itsconstituents,andcertainvehicle

componentscontainoremitchemicalsknowntoStateof California

tocausecancerandbirthdefectsorotherreproductiveharm,

TRAiNiNG

• Read,understand,andfollowallinstructionson themachineand

in themanual(s)beforeattemptingto assembleandoperate.

Failuretodo socan resultinseriousinjurytotheoperatorand/

orbystanders.Keepthismanualinasafeplaceforfutureand

regularreferenceandfor orderingreplacementparts.Forques-

tionscall,1-800-659-5917.

• Befamiliarwithall controlsandtheir properoperation.Knowhow

tostopthemachineanddisengagethemquickly.

• Neverallowchildrenunder14yearsof ageto operatethis

machine.Children14andover shouldreadandunderstandthe

instructionsandsafeoperationpracticesin thismanualandon

themachineandbe trainedandsupervisedbyanadult.

• Neverallowadultsto operatethismachinewithoutproper

instruction.

• Thrownobjectscancauseseriouspersonalinjury.Planyour

snow-throwingpatterntoavoiddischargeof materialtoward

roads,bystandersandthe like.

• Keepbystanders,petsandchildrenat least75feetfromthe

machinewhileitisinoperation.Stopmachineifanyoneenters

thearea.

• Exercisecautiontoavoidslippingorfalling,especiallywhen

operatinginreverse.

Your Responsibility--Restrict theuseofthis powermachineto

personswhoread,understandandfollowthewarningsandinstruc-

tionsin thismanualandon themachine,

SAVE THESE INSTRUCTIONS!

PREPARATION

Thoroughlyinspecttheareawheretheequipmentis tobeused.

Removeall doormats,newspapers,sleds,boards,wiresandother

foreignobjects,whichcouldbe trippedoverorthrownbytheauger/

impeller.

Alwayswearsafetyglassesoreyeshieldsduringoperationand

whileperforminganadjustmentor repairto protectyoureyes.

Thrownobjectswhichricochetcancauseseriousinjurytothe

eyes.

Donot operatewithoutwearingadequatewinteroutergarments.

Donot wearjewelry,longscarvesorotherlooseclothing,which

couldbecomeentangledinmovingparts.Wearfootwearwhich

willimprovefootingonslipperysurfaces.

Usea groundedthree-wireextensioncordand receptacleforall

machineswithelectricstartengines.

Disengageall controlleversbeforestartingtheengine.

Adjustcollectorhousingheighttocleargravelorcrushedrock

surfaces.

Neverattempttomakeanyadjustmentswhileengineis running,

exceptwherespecificallyrecommendedinthe operator'smanual.

Letengineandmachineadjusttooutdoortemperaturebefore

startingtoclearsnow.

3

SafeHandlingof Gasoline

Toavoidpersonalinjuryor propertydamageuseextremecarein

handlinggasoline.Gasolineisextremelyflammableandthevaporsare

explosive.Seriouspersonalinjurycanoccurwhengasolineisspilled

onyourselforyourclotheswhichcanignite.Washyourskinand

changeclothesimmediately.

• Useonlyanapprovedgasolinecontainer.

• Extinguishall cigarettes,cigars,pipesandother sources

ofignition.

• Neverfuelmachineindoors.

• Neverremovegas capor addfuel whiletheengineishot

or running.

• Allowenginetocoolat leasttwo minutesbeforerefueling.

• Neveroverfillfueltank.Filltanktono morethan1/2inch

belowbottomoffillerneckto providespaceforfuel

expansion.

• Replacegasolinecapandtightensecurely.

• Ifgasolineisspilled,wipeit offtheengineandequipment.

Movemachinetoanotherarea.Wait5 minutesbefore

startingtheengine.

• Neverstorethemachineor fuel containerinsidewhere

thereis anopenflame,sparkor pilotlight (e.g.furnace,

waterheater,spaceheater,clothesdryeretc.).

• Allowmachinetocoolatleast5 minutesbeforestoring.

• Neverfillcontainersinsidea vehicleor ona truckor trailer

bedwitha plasticliner.Alwaysplacecontainersonthe

groundawayfromyourvehiclebeforefilling.

• If possible,removegas-poweredequipmentfromthetruck

ortrailerand refueliton theground.Ifthisisnotpossible,

thenrefuelsuchequipmentona trailerwitha portable

container,ratherthanfromagasolinedispensernozzle.

• Keepthenozzleincontactwiththe rimofthefueltankor

containeropeningatalltimesuntilfuelingis complete.Do

notuse a nozzlelock-opendevice.

OPERATION

• Donotputhandsorfeetnear rotatingparts,in the auger/impeller

housingorchuteassembly.Contactwiththe rotatingpartscan

amputatehandsandfeet.

• Theauger/impellercontrolleverisa safetydevice.Neverbypass

itsoperation.Doingsomakesthemachineunsafeandmaycause

personalinjury.

• Thecontrolleversmustoperateeasilyinbothdirectionsand

automaticallyreturntothedisengagedpositionwhenreleased.

• Neveroperatewitha missingordamagedchuteassembly.Keep

all safetydevicesinplaceandworking.

• Neverrunanengineindoorsor ina poorlyventilatedarea.Engine

exhaustcontainscarbonmonoxide,anodorlessanddeadlygas.

• Donotoperatemachinewhileundertheinfluenceof alcoholor

drugs.

• Mufflerandenginebecomehotandcan causea burn.Do not

touch.Keepchildrenaway.

• Exerciseextremecautionwhenoperatingonorcrossinggravel

surfaces.Stayalertforhiddenhazardsor traffic.

• Exercisecautionwhenchangingdirectionandwhileoperatingon

slopes.

• Planyoursnow-throwingpatternto avoiddischargetowards

windows,walls,carsetc.Thus,avoidingpossibleproperty

damageorpersonalinjurycausedbya ricochet.

• Neverdirectdischargeatchildren,bystandersand petsor allow

anyoneinfrontofthemachine.

• Donotoverloadmachinecapacityby attemptingto clearsnowat

toofastof a rate.

• Neveroperatethis machinewithoutgoodvisibilityorlight.Always

be sureofyourfootingand keepafirmholdon the handles.Walk,

neverrun.

• Disengagepowertotheauger/impellerwhentransportingor not

in use.

• Neveroperatemachineat hightransportspeedson slippery

surfaces.Lookdownand behindand usecare whenbackingup.

• Ifthe machineshouldstartto vibrateabnormally,stoptheengine,

disconnectthesparkplugwireandgrounditagainsttheengine.

Inspectthoroughlyfor damage.Repairanydamagebefore

startingandoperating.

• Disengageall controlleversandstopenginebeforeyouleave

theoperatingposition(behindthe handles).Waituntiltheauger/

impellercomestoacompletestopbeforeuncloggingthechute

assembly,makingany adjustments,or inspections.

• Neverput yourhandinthe dischargeorcollectoropenings.Do

notunclogchuteassemblywhileengineisrunning.Shutoff

engineand remainbehindhandlesuntilall movingpartshave

stoppedbeforeunclogging.

• Useonlyattachmentsandaccessoriesapprovedbythemanufac-

turer(e.g.wheelweights,tire chains,cabsetc.).

• Whenstartingengine,pullcordslowlyuntilresistanceisfelt,then

pull rapidly.Rapidretractionof startercord(kickback)willpull

handandarmtowardenginefasterthan youcanletgo.Broken

bones,fractures,bruisesorsprainscouldresult.

• Ifsituationsoccurwhichare notcoveredinthismanual,use care

andgoodjudgment.ContactCustomerSupportforassistance

andthenameof yournearestservicingdealer.

CLEARING A CLOGGED DISCHARGE CHUTE

Handcontactwiththe rotatingimpellerinsidethedischargechute

is themostcommoncauseofinjuryassociatedwithsnowthrowers.

Neveruseyourhandtocleanoutthedischargechute.

Toclear thechute:

1. SHUTTHEENGINEOFF!

2. Wait 10secondstobe suretheimpellerbladeshavestopped

rotating.

3. Alwaysusea clean-outtool,not yourhands.

4

MAINTENANCE & STORAGE

• Nevertamperwithsafetydevices.Checktheirproperoperation

regularly.Refertothemaintenanceandadjustmentsectionsof

thismanual.

• Beforecleaning,repairing,or inspectingmachinedisengageall

controlleversandstopthe engine.Waituntilthe auger/impeller

cometoacompletestop.Disconnectthe sparkplugwireand

groundagainsttheenginetopreventunintendedstarting.

Checkboltsand screwsfor propertightnessatfrequentintervals

tokeepthemachineinsafeworkingcondition.Also,visually

inspectmachineforanydamage.

Donotchangetheenginegovernorsettingor over-speedthe

engine.Thegovernorcontrolsthe maximumsafeoperatingspeed

oftheengine.

Snowthrowershaveplatesandskidshoesaresubjecttowear

anddamage.Foryoursafetyprotection,frequentlycheckall

componentsand replacewithoriginalequipmentmanufacturer's

(OEM)partsonly."Useof partswhichdonotmeettheoriginal

equipmentspecificationsmayleadto improperperformanceand

compromisesafety!"

Checkcontrolleversperiodicallytoverifytheyengageanddisen-

gageproperlyandadjust,if necessary.Refertotheadjustment

sectioninthisoperator'smanualforinstructions.

Maintainor replacesafetyandinstructionlabels,asnecessary.

• Observeproperdisposallawsand regulationsforgas,oil,etc.to

protecttheenvironment.

Priorto storing,runmachineafew minutestoclearsnowfrom

machineand preventfreezeupof auger/impeller.

Neverstorethemachineorfuelcontainerinsidewherethereisan

openflame,sparkorpilotlightsuchasa waterheater,furnace,

clothesdryeretc.

Alwaysrefertotheoperator'smanualfor properinstructionson

off-seasonstorage.

Checkfuelline,tank,cap,andfittingsfrequentlyforcracksor

leaks.Replaceif necessary.

Donotcrankenginewithsparkplugremoved.

AccordingtotheConsumerProductsSafetyCommission(CPSC)

andtheU.S.EnvironmentalProtectionAgency(EPA),thisproduct

hasan AverageUsefulLifeof seven(7)years,or 60 hoursof

operation.AttheendoftheAverageUsefulLifehavethemachine

inspectedannuallybyan authorizedservicedealertoensurethat

allmechanicalandsafetysystemsareworkingproperlyand not

wornexcessively.Failuretodo socanresultinaccidents,injuries

ordeath.

DO NOT MODIFY ENGINE

Toavoidseriousinjuryor death,do not modifyengineinanyway.

Tamperingwiththegovernorsettingcanleadtoa runawayengineand

causeittooperateatunsafespeeds.Nevertamperwithfactorysetting

ofenginegovernor.

NOTICE REGARDING EMISSIONS

EngineswhicharecertifiedtocomplywithCaliforniaandfederal

EPAemissionregulationsforSORE(SmallOffRoadEquipment)are

certifiedto operateonregularunleadedgasoline,andmayinclude

thefollowingemissioncontrolsystems:EngineModification(EM),

OxidizingCatalyst(OC),SecondaryAirInjection(SAI)and ThreeWay

Catalyst(TWO)if so equipped.

SPARK ARRESTOR

Thismachineisequippedwithaninternalcombustionengineand

shouldnotbe usedonor nearanyunimprovedforest-covered,

brush-coveredorgrass-coveredlandunlesstheengine'sexhaust

systemisequippedwitha sparkarrestermeetingapplicablelocalor

statelaws(ifany)

Ifa sparkattesterisused,itshouldbemaintainedineffectiveworking

orderbytheoperator.IntheStateofCaliforniathe aboveis required

bylaw (Section4442of theCaliforniaPublicResourcesCode).Other

statesmayhavesimilarlaws. Federallawsapplyonfederallands.

A sparkarresterforthemuffleris availablethroughyournearestSears

PartsandRepairServiceCenter.

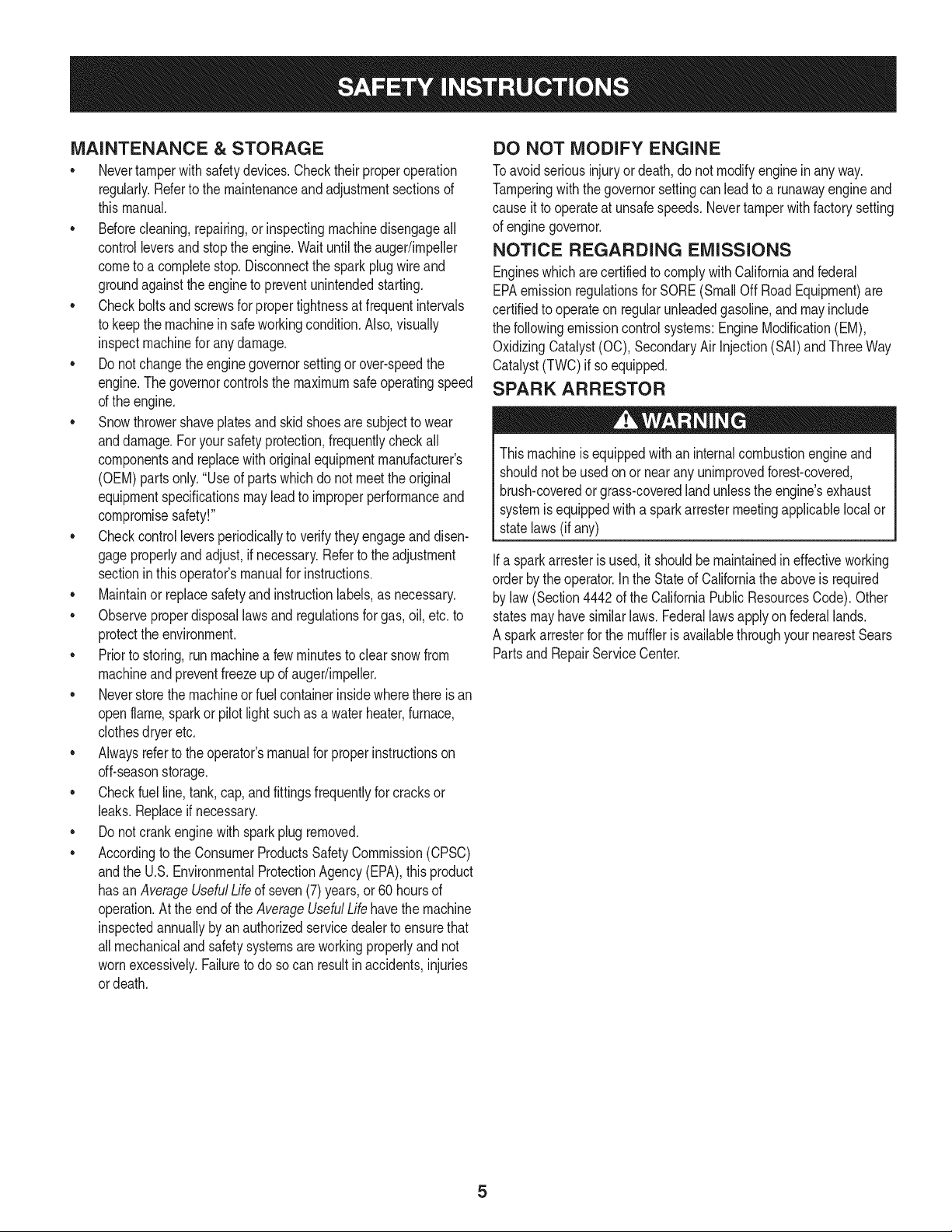

SAFETY SYMBOLS

Thispagedepictsanddescribessafetysymbolsthatmayappearonthisproduct. Read,understand,andfollowall instructionson themachine

beforeattemptingto assembleandoperate.

READ THE OPERATOR'S MANUAL(S)

i

i

Read, understand, and follow all instructions in the manual(s) before attempting to assemble and

operate

WARNING-- ROTATING BLADES

Keep hands out of inlet and discharge openings while machine is running. There are rotating blades

inside

WARNING-- ROTATING BLADES

Keep hands out of inlet and discharge openings while machine is running. There are rotating blades

inside

WARNING-- ROTATING AUGER

Do not put hands or feet near rotating parts, in the auger/impeller housing or chute assembly.

Contact with the rotating parts can amputate hands and feet.

WARNING--THROWN OBJECTS

This machine may pick up and throw and objects which can cause serious personal injury.

WARNING--GASOLINE IS FLAMMABLE

Allow the engine to cool at least two minutes before refueling.

WARNING-- CARBON MONOXIDE

Never run an engine indoors or in a poorly ventilated area. Engine exhaust contains carbon

monoxide, an odorless and deadly gas.

WARNING-- ELECTRICAL SHOCK

Do not use the engine's electric starter in the rain

6

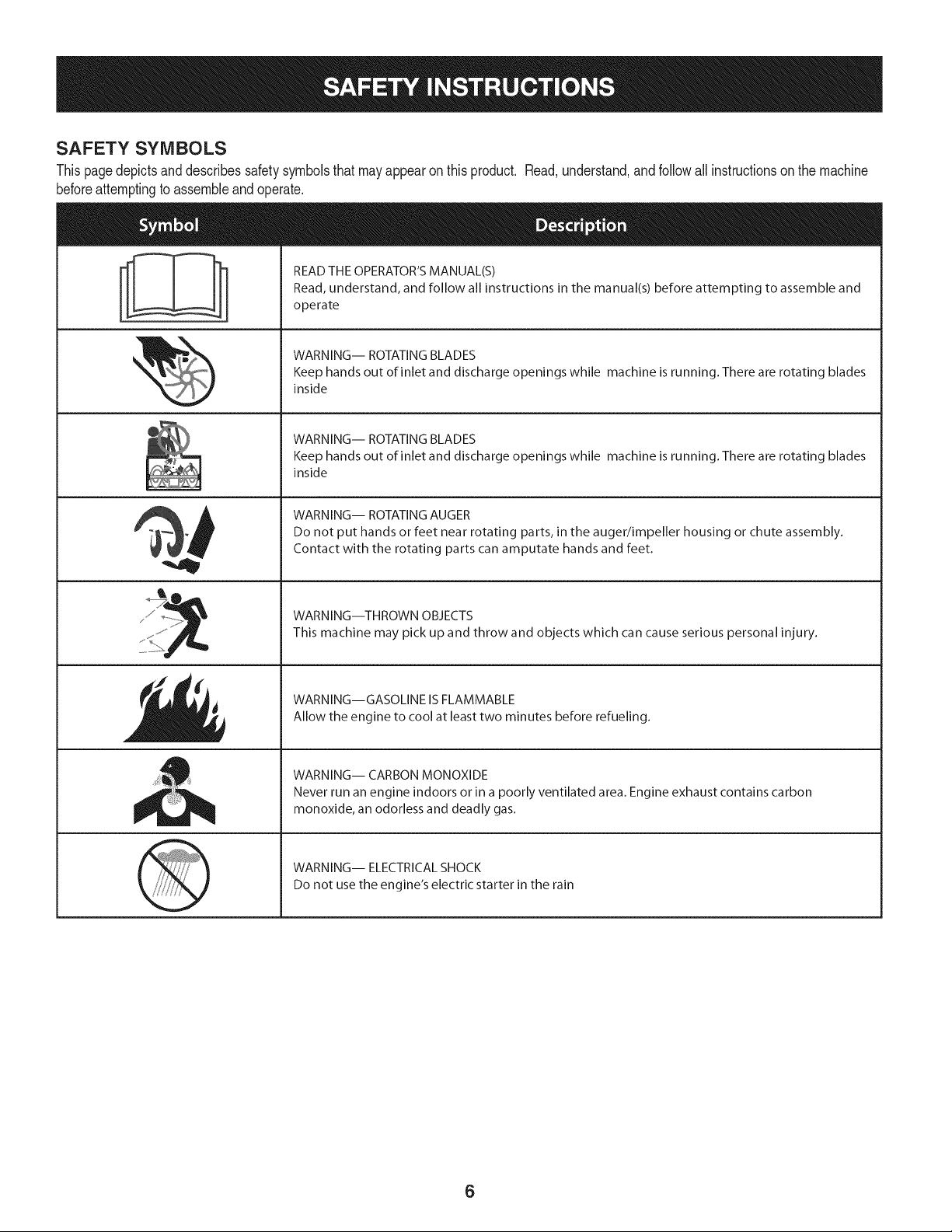

1.KEEPAWAYFROMROTATINGiMPELLER

ANDAUGER,CONTACTWiTHiMPELLEROR

AUGERCANAMPUTATEHANDSANDFEET.

2. USECLEAN-OUTTOOLTOUNCLOG

DISCHARGECHUTE.

3.DISENGAGECLUTCHLEVERS,STOPENGINE,

AND REMAINBEHINDHANDLESUNTILALL

MOVING PARTSHAVE STOPPEDBEFORE

UNCLOGGING OR SERViCiNGMACHINE.

TO AVOIDTHROWN OBJECTSiNJURiES,

NEVERDIRECTDISCHARGEATBYSTANDERS.

USEEXTRACAUTIONWHEN OPERATINGON

GRAVELSURFACES.

5.BEAD OPERATOR'S MANUAL.

CLEAN-OUT TOOL

7

IMPORTANT:Thisunitis shippedwiththeenginefullof oil. After

assembly,see page10for fuelandoildetails.

Removing From Carton

1. Cutthecornersofthecartonandlaythesidesflaton theground.

Removeall packinginserts.

2. Movethesnowthroweroutofthecarton.

3. Makecertainthecartonhasbeencompletelyemptiedbefore

discardingit.

DO NOTliftthe snowthrower bythechutehandle.

Before Assembly

NOTE:Referenceto right,left, frontor rearoftheunitisfromthe

operatingpositionunlessotherwisestated.

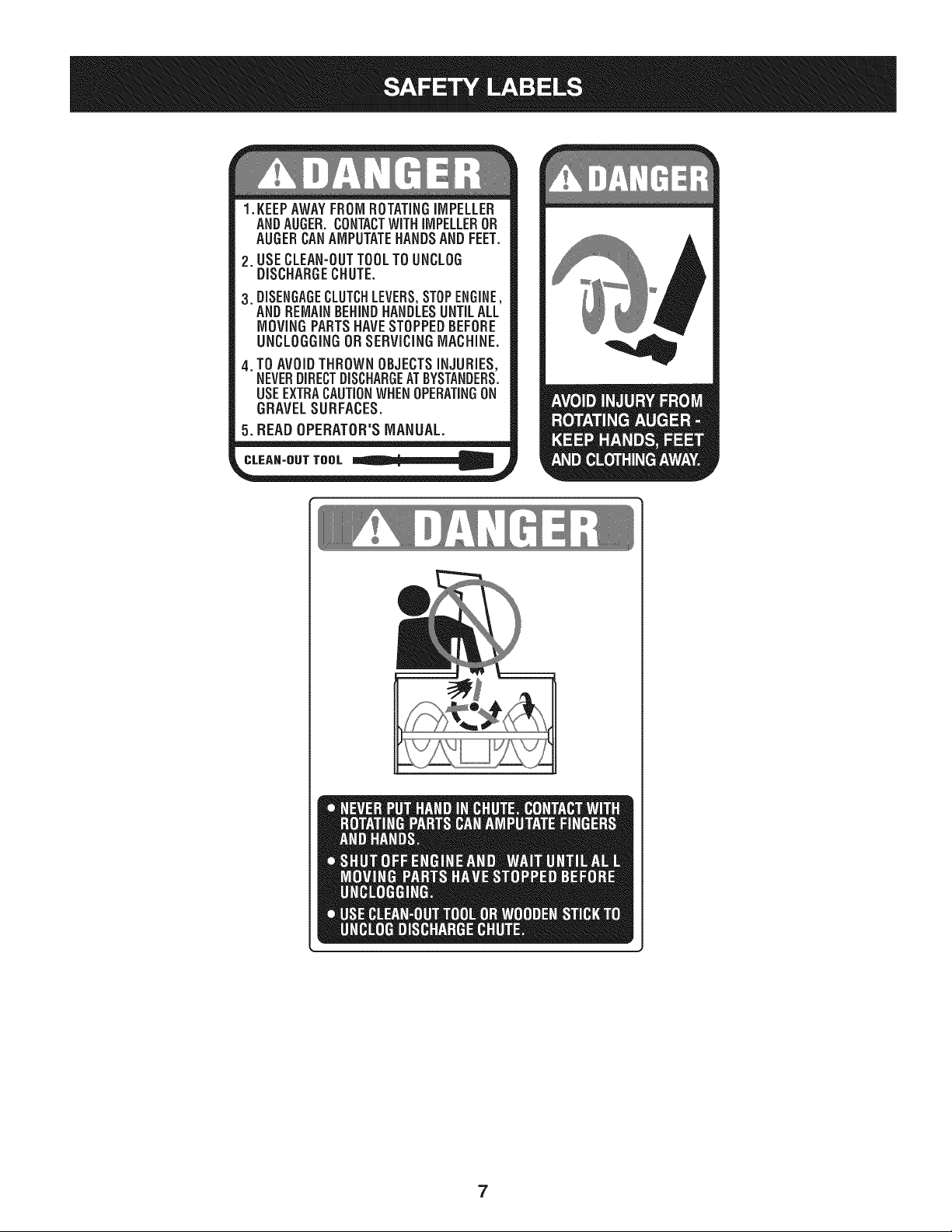

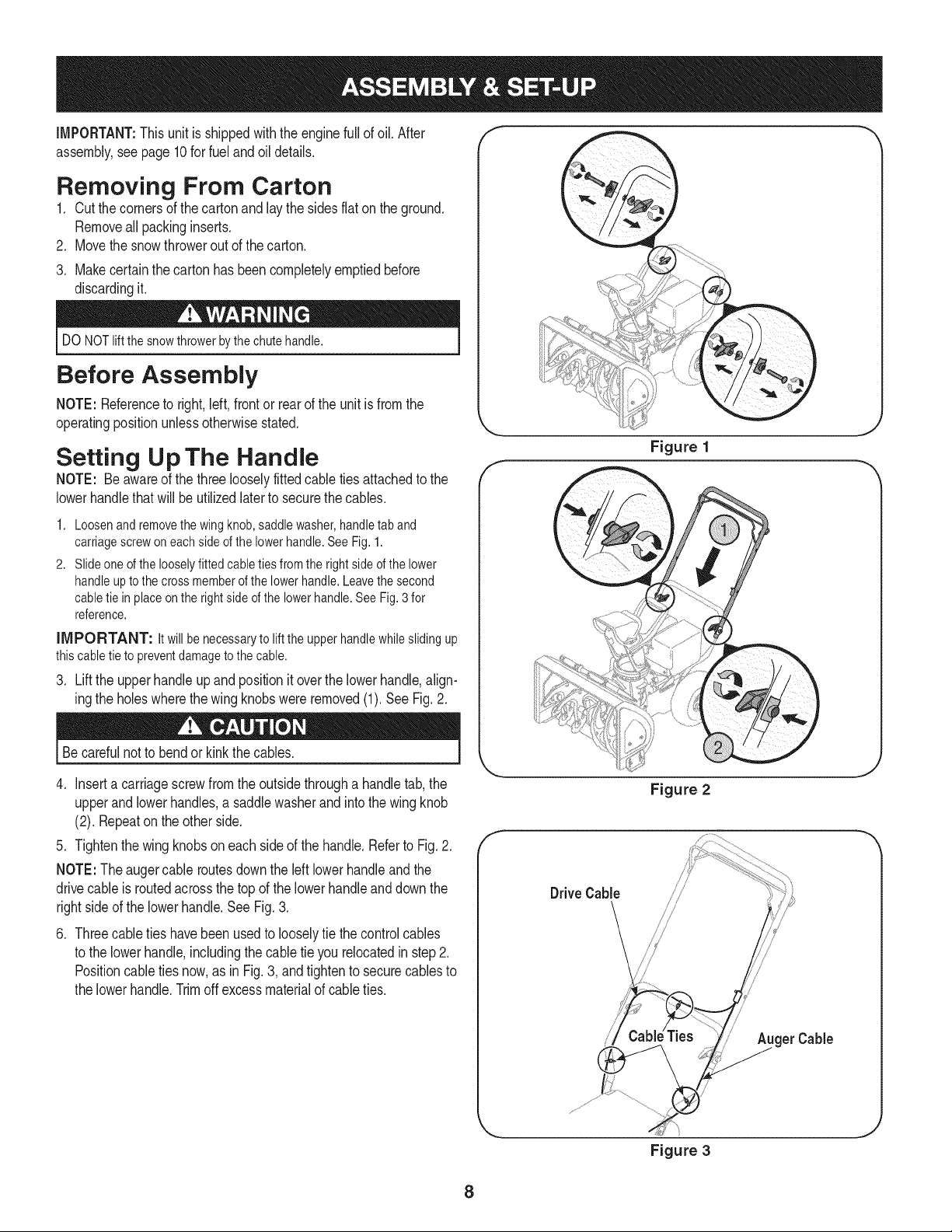

Setting Up The Handle

NOTE: Beawareofthethreelooselyfittedcabletiesattachedto the

lowerhandlethatwillbeutilizedlatertosecurethecables.

1. Loosenandremovethe wingknob,saddlewasher,handletab and

carriagescrewoneachside ofthe lowerhandle.See Fig.1.

2. Slideone ofthe looselyfitted cabletiesfromthe right side ofthe lower

handleupto thecross memberofthe lowerhandle.Leavethe second

cabletiein placeonthe rightside ofthe lowerhandle.See Fig.3for

reference.

iMPORTANT: Itwillbenecessarytolifttheupperhandlewhileslidingup

thiscabletieto preventdamagetothecable.

3. Lifttheupperhandleupandpositionitoverthelowerhandle,align-

ingtheholeswherethewingknobswereremoved(1).SeeFig.2.

f

Figure 1

Becarefulnottobendorkinkthe cables.

4. Inserta carriagescrewfromtheoutsidethrougha handletab,the

upperand lowerhandles,asaddlewasherandintothewingknob

(2). Repeatonthe otherside.

5. Tightenthewing knobsoneachsideofthehandle.RefertoFig.2.

NOTE:The augercableroutesdowntheleft lowerhandleandthe

drivecableisroutedacrossthetopofthelowerhandleanddownthe

rightside ofthelowerhandle.SeeFig.3.

.

Threecabletieshavebeenusedtolooselytiethecontrolcables

tothelowerhandle,includingthe cabletieyourelocatedinstep2.

Positioncabletiesnow,asinFig.3,andtightentosecurecablesto

thelowerhandle.Trimoffexcessmaterialofcableties.

Figure 2

DriveCable

getCable

Figure 3

8

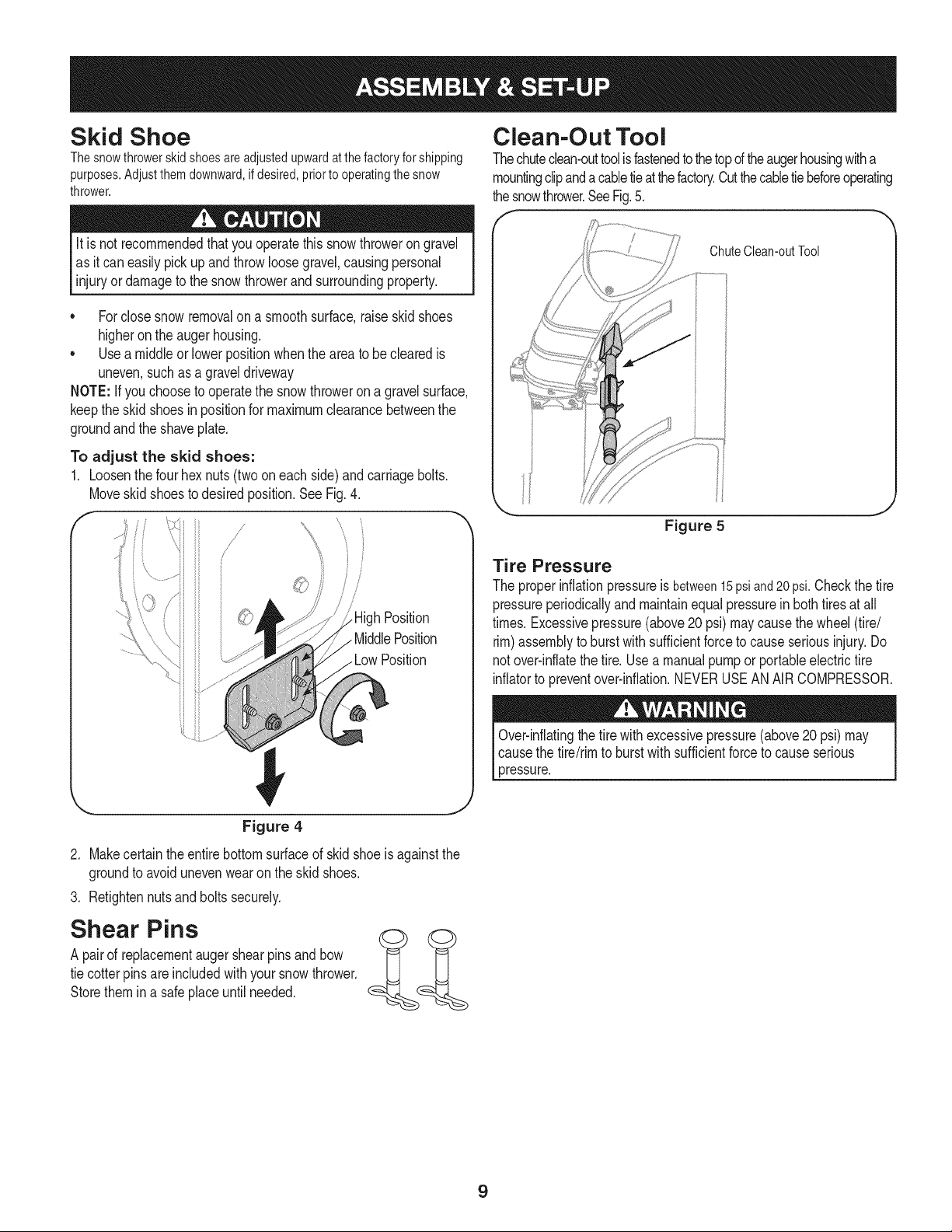

Skid Shoe

Thesnowthrowerskidshoesareadjustedupwardatthefactoryforshipping

purposes.Adjustthemdownward,ifdesired,priortooperatingthesnow

thrower.

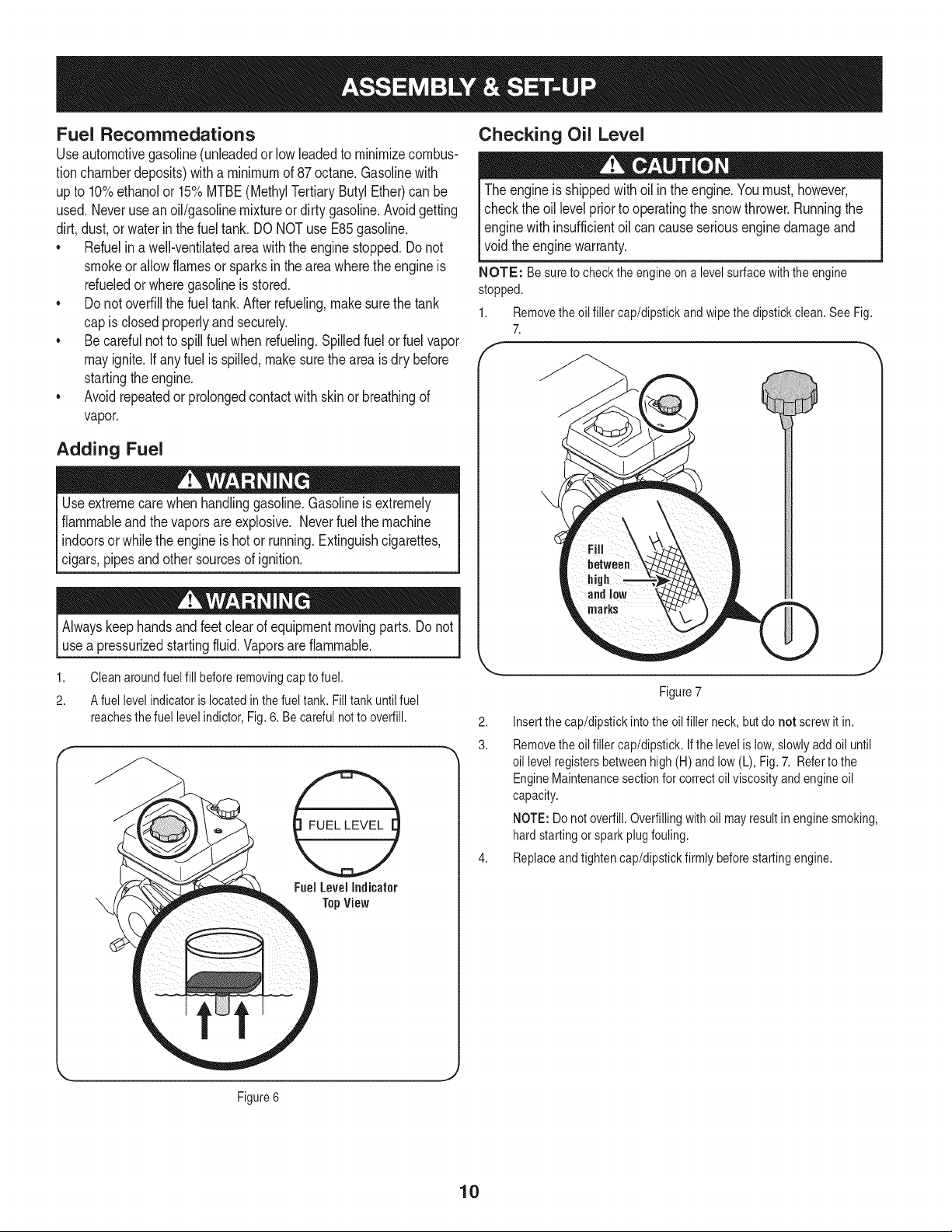

Clean-Out Tool

Thechuteclean-outtoolisfastenedto thetopd theaugerhousingwitha

mountingclipandacabletieatthefactory.Cutthecabletiebeforeoperating

thesnowthrower.SeeFig.5.

It isnotrecommendedthatyouoperatethissnowthrowerongravel

as itcaneasilypickup andthrowloosegravel,causingpersonal

injuryordamagetothesnowthrowerand surroundingproperty.

• Forclosesnowremovalona smoothsurface,raiseskidshoes

higherontheaugerhousing.

• Usea middleor lowerpositionwhentheareato be clearedis

uneven,suchas a graveldriveway

NOTE:Ifyouchoosetooperatethesnowthrowerona gravelsurface,

keepthe skidshoesin positionformaximumclearancebetweenthe

groundandtheshaveplate.

To adjust the skid shoes:

1. Loosenthefourhexnuts(twooneachside)andcarriagebolts.

Moveskidshoestodesiredposition.See Fig.4.

/-

!,/ \

1 i i

/i

h Position

. MiddlePosition

ChuteClean-outTool

!

Figure 5

Tire Pressure

Theproperinflationpressureisbetween15psiand20psi.Checkthe tire

pressureperiodicallyandmaintainequalpressureinbothtiresat all

times.Excessivepressure(above20psi)maycausethe wheel(tire/

rim)assemblytoburstwithsufficientforcetocauseseriousinjury.Do

notover-inflatethetire.Usea manualpumpor portableelectrictire

inflatorto preventover-inflation.NEVERUSEANAIRCOMPRESSOR.

_J

Figure 4

2. Makecertaintheentirebottomsurfaceof skidshoeisagainstthe

groundtoavoidunevenwearonthe skidshoes.

3. Retightennutsandboltssecurely.

Shear Pins

A pairof replacementaugershearpinsandbow

tiecotterpinsare includedwithyoursnowthrower.

Storetheminasafeplaceuntilneeded.

Over-inflatingthe tirewithexcessivepressure(above20psi)may

causethetire/rimto burstwithsufficientforcetocauseserious

pressure.

9

Fuel Recommedations

Useautomotivegasoline(unleadedor lowleadedtominimizecombus-

tionchamberdeposits)witha minimumof87octane.Gasolinewith

upto 10%ethanolor 15%MTBE(MethylTertiaryButylEther)canbe

used.Neveruseanoil/gasolinemixtureordirtygasoline.Avoidgetting

dirt,dust,or waterinthefueltank.DONOTuseE85gasoline.

• Refuelin awell-ventilatedareawiththeenginestopped.Donot

smokeorallowflamesorsparksintheareawheretheengineis

refueledorwheregasolineisstored.

• Donotoverfillthefueltank.Afterrefueling,makesurethe tank

capisclosedproperlyandsecurely.

• Becarefulnottospillfuelwhenrefueling.Spilledfuelor fuelvapor

mayignite.Ifanyfuelisspilled,makesuretheareaisdry before

startingtheengine.

• Avoidrepeatedor prolongedcontactwithskinor breathingof

vapor.

Adding Fuel

Useextremecarewhenhandlinggasoline.Gasolineisextremely

flammableandthe vaporsareexplosive.Neverfuelthe machine

indoorsorwhiletheengineishotor running.Extinguishcigarettes,

cigars,pipesandother sourcesofignition.

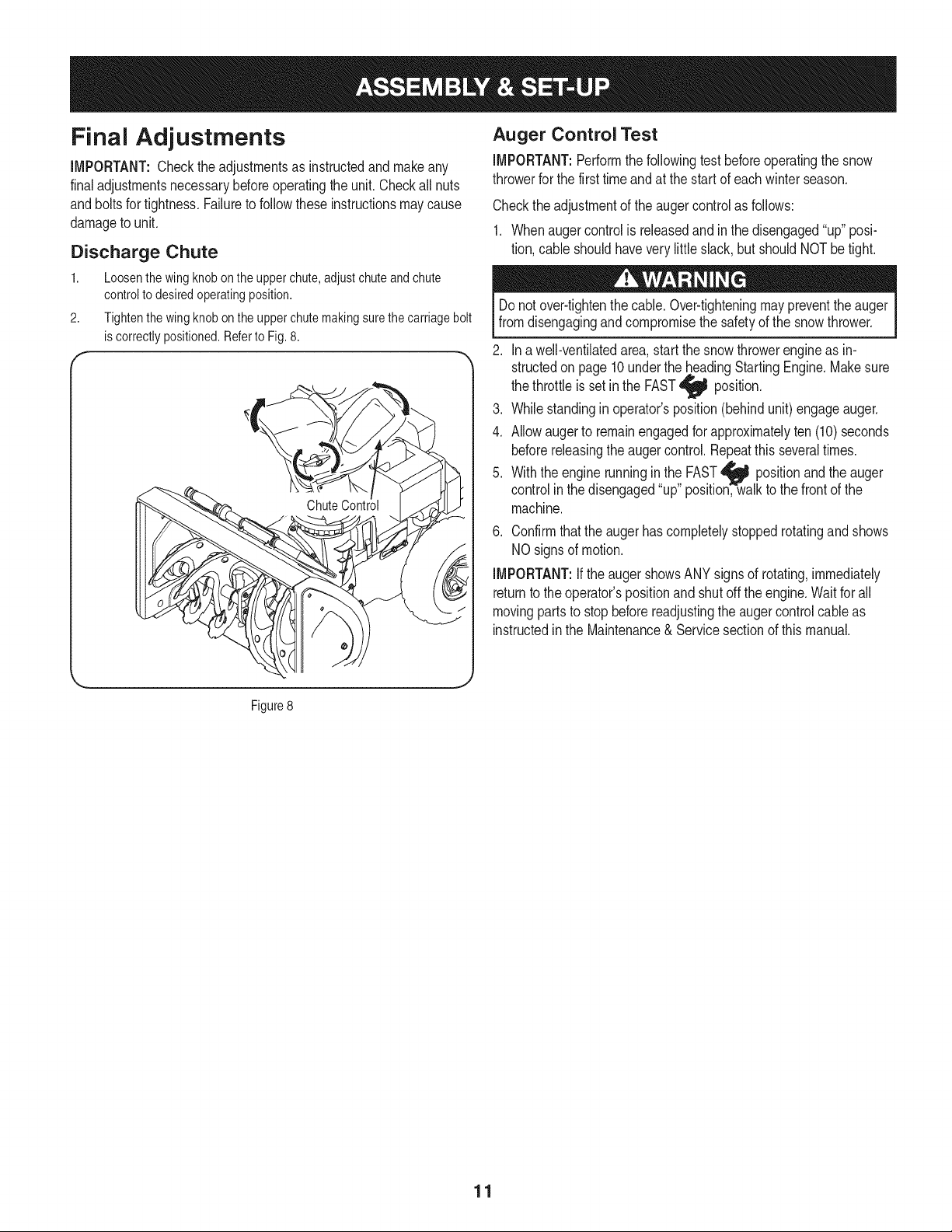

Checking Oil Level

Theengineisshippedwithoil in theengine.Youmust,however,

checkthe oil levelpriortooperatingthesnowthrower.Runningthe

enginewithinsufficientoilcancauseseriousenginedamageand

voidtheenginewarranty.

NOTE: Besuretochecktheengineonalevelsurfacewiththeengine

stopped.

1. Removetheoilfillercap/dipstickandwipethedipstickclean.SeeFig.

7.

f

Alwayskeephandsandfeetclearof equipmentmovingparts.Donot

usea pressurizedstartingfluid.Vaporsareflammable.

1. Cleanaroundfuel fill beforeremovingcaptofuel.

2. A fuellevelindicatoris locatedinthefuel tank. Filltankuntil fuel

reachesthefuel levelindictor,Fig.6. Becarefulnotto overfill.

FuelLevelIndicator

TopView

Figure7

2. Insertthe cap/dipstickintothe oilfillerneck,butdo not screwit in.

3. Removetheoil fillercap/dipstick.Ifthe levelis low,slowlyaddoiluntil

oil levelregistersbetweenhigh(H) andlow(L), Fig.7. Refertothe

EngineMaintenancesectionfor correctoil viscosityandengineoil

capacity.

NOTE:Do notoverfill.Overfillingwithoil mayresultin enginesmoking,

hardstartingor sparkplugfouling.

4. Replaceandtightencap/dipstickfirmly beforestartingengine.

Figure6

10

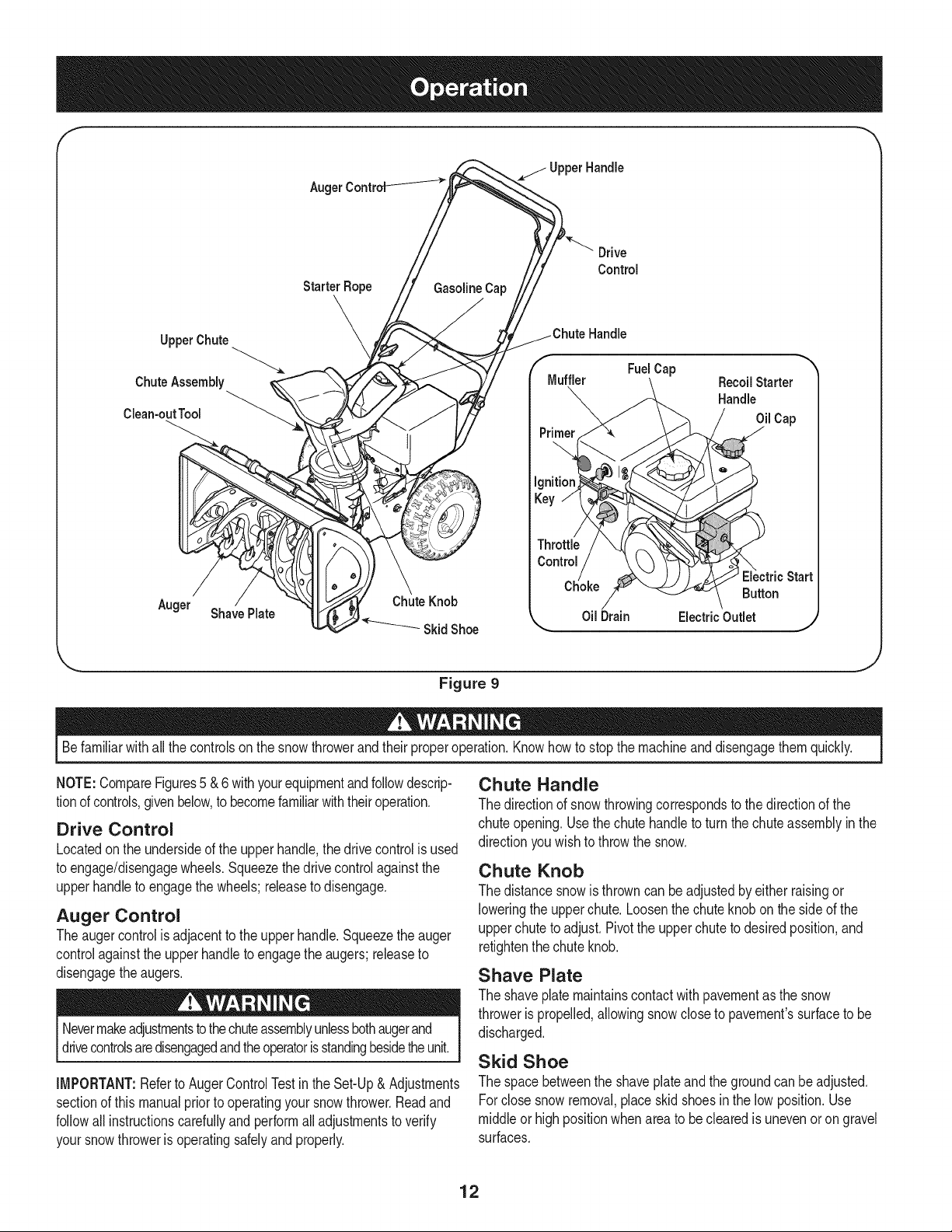

Final Adjustments

IMPORTANT:Checktheadjustmentsasinstructedand makeany

finaladjustmentsnecessarybeforeoperatingthe unit.Checkall nuts

andboltsfortightness.Failureto followtheseinstructionsmaycause

damagetounit.

Discharge Chute

1. Loosenthewingknobontheupperchute,adjustchuteandchute

controltodesiredoperatingposition.

2. Tightenthewingknobontheupperchutemakingsurethecarriagebolt

iscorrectlypositioned.RefertoFig.8.

( "

Auger Control Test

IMPORTANT:Performthefollowingtestbeforeoperatingthesnow

throwerforthefirsttimeandatthe startof eachwinterseason.

Checktheadjustmentof theaugercontrolasfollows:

1. Whenaugercontrolisreleasedandinthe disengaged"up"posi-

tion,cableshouldhaveverylittleslack,butshouldNOTbetight.

Donot over-tightenthecable.Over-tighteningmaypreventtheauger

fromdisengagingandcompromisethesafetyofthesnowthrower.

2. Ina well-ventilatedarea,startthesnowthrowerengineasin-

structedon page10underthe,,.headingStartingEngine.Makesure

thethrottleissetin theFAST,_ position.

3. Whilestandingin operator'sposition(behindunit) engageauger.

4. Allowaugerto remainengagedforapproximatelyten(10)seconds

beforereleasingtheaugercontrol.Repeatthisseveraltimes.

5. Withtheenginerunninginthe FAST_ positionand theauger

controlinthe disengaged"up"position,w-alk to thefrontofthe

machine.

6. Confirmthattheaugerhascompletelystoppedrotatingandshows

NOsignsofmotion.

IMPORTANT:IftheaugershowsANYsignsof rotating,immediately

returntotheoperator'spositionandshutofftheengine.Waitforall

movingpartsto stopbeforereadjustingtheaugercontrolcableas

instructedinthe Maintenance& Servicesectionofthismanual.

\

Figure8

11

f

j UpperHandle

Drive

Control

StarterRope GasolineCap

\

UpperChute _ Handle

ChuteAssembly

Clean-outTool

Auger Shave Plate i._.........._...._

Fuel Cap

ChuteKnob

Skid Shoe

RecoilStarter

Handle

Figure 9

Befamiliarwithall the controlsonthesnowthrowerand theirproperoperation.Knowhowto stopthe machineanddisengagethemquickly.

NOTE:CompareFigures5 &6 withyourequipmentandfollowdescrip-

tionof controls,givenbelow,tobecomefamiliarwiththeiroperation.

Drive Control

Locatedon the undersideofthe upperhandle,thedrivecontrolisused

toengage/disengagewheels.Squeezethedrivecontrolagainstthe

upperhandleto engagethewheels;releasetodisengage.

Auger Control

Theaugercontrolisadjacentto theupperhandle.Squeezethe auger

controlagainsttheupperhandletoengagethe augers;releaseto

disengagethe augers.

Chute Handle

Thedirectionof snowthrowingcorrespondsto thedirectionofthe

chuteopening.Usethechutehandleto turn thechuteassemblyin the

directionyouwishtothrowthesnow.

Chute Knob

Thedistancesnowisthrowncanbeadjustedbyeitherraisingor

loweringtheupperchute.Loosenthechuteknobonthesideofthe

upperchutetoadjust.Pivotthe upperchuteto desiredposition,and

retightenthechuteknob.

Shave Plate

Theshaveplatemaintainscontactwithpavementasthesnow

throwerispropelled,allowingsnowclosetopavement'ssurfacetobe

Nevermakeadjustmentstothechuteassemblyunlessbothaugerand

discharged.

drivecontrolsaredisengagedandtheoperatorisstandingbesidetheunit.

Skid Shoe

IMPORTANT:Referto AugerControlTestintheSet-Up& Adjustments

sectionofthis manualpriortooperatingyoursnowthrower.Readand

followall instructionscarefullyandperformalladjustmentsto verify

yoursnowthroweris operatingsafelyandproperly.

Thespacebetweentheshaveplateand thegroundcanbeadjusted.

Forclosesnowremoval,placeskidshoesin thelowposition.Use

middleor highpositionwhenareato beclearedis unevenorongravel

surfaces.

,J

12

Augers

Whenengaged,theaugersrotateanddrawsnowintothe auger

housing.

Chute Assembly

Snowdrawnintotheaugerhousingisdischargedoutthechute

assembly.

Choke Control

Activatingchokecontrolbyturningitall theway

totheleftclosesthechokeplateoncarburetor

andaidsin startingtheengine.Forinformationon

chokeusage,seeStartingTheEnginelaterin this

section.

Recoil Starter & Starter Handle

Thismotorisfittedwith a recoilactionpullstartanda mittengrip

handleforeasyaccesswhilewearingglovesormittens.

Ignition Key

Theignitionkeyisa safetydevice.It mustbefully _ ,,,,._

insertedinorderfor theenginetostart.Remove

theignitionkeywhenthesnowthrowerisnotin

use.

NOTE:Do notturntheignitionkeyin anattemptto

startthe engine.Doingso maycauseit to break.

Fe

|

Electric Starter Button

Pressingtheelectricstarterbuttonengagestheengine'selectric

starterwhenpluggedintoa 120Vpowersource.

Electric Starter Outlet

Requirestheuseof athree-prongoutdoorextensioncord(included)

anda 120Vpowersource/walloutlet.

Thethrottlecontrolislocatedontheengine.It regulatesthespeedof

theengineandwillshutofftheenginewhenpusheddowncompletely.

Theimagetotherightrepresentsthespeedsofthethrottlecontroland

correspondswiththelabelontheengine.Theimagesbelowillustrate

theddinition of eachsymbol.

Clean=Out Tool

Neveruseyour handstoclear acloggedchuteassembly.Shutoff

engineandremainbehindhandlesuntilall movingpartshavestopped

[before usngtheccan-outtoo toc earthechuteassemby.

Thechuteclean-outtoolis convenientlyfastenedtothe rearof the

augerhousingwitha mountingclip.Shouldsnowandicebecome

lodgedinthechuteassemblyduringoperation,proceedasfollowsto

safelycleanthechuteassemblyandchuteopening:

1. ReleaseboththeAugerControlandtheDriveControl.

2. Stoptheenginebyremovingthe ignitionkey.

3. Removetheclean-outtool fromthe clipwhichsecuresitto the

rearoftheaugerhousing.

4. Usethe shovel-shapedendoftheclean-outtooltodislodgeand

scoopanysnowandicewhichhasformedinand nearthechute

assembly.

5. Refastenthe clean-outtooltothemountingclipon the rearof

theaugerhousing,reinserttheignitionkeyand startthesnow

thrower'sengine.

6. Whilestandingin theoperator'sposition(behindthe snow

thrower),engagetheaugercontrolfora fewsecondstoclearany

remainingsnowand icefromthechuteassembly.

Before Starting Engine

Primer

Depressingprimerforcesfuel directlyintoengine's

carburetorto aidin cold-weatherstarting.Referto qk_P,_.__L__

thestartinginstructionsintheOperationsection I

ofthismanualforproperprimerusage.Theimage |

belowleft,correspondswiththelabelonthe

engineidentifyingtheprimer.

Oil Fill

Removeoilcap toaddoil. Refertothe Maintenance&Servicesection

forcheckingandaddingoil instructions.

Gasoline Cap

Removegascaptoaddfuel.Unitrunson regulargas.

NOTE:Thisunitmayincludea fuel plug,whichisonly usedduring

assemblytokeepdirt anddebrisoutoffueltank. Discardthefuel plug

beforefillingthefueltank.

Throttle Control

Read,understand,andfollowallinstructionsandwarningsonthe

machineandinthis manualbeforeoperating.

Engine Oil

Theunitwas shippedwith oilin the engine.Checkoillevelbeforeeach

operationtoensureadequateoil intheengine.Forfurtherinstructions,

refertothe Maintenance&Servicesectionofthis manual.

NOTE:Besuretocheckthe engineonalevelsurfacewiththeengine

stopped.

1. Removetheoilfillercap/dipstickandwipe thedipstickclean.

2. Insertthecap/dipstickintotheoilfillerneck,butdonotscrewit in.

3. Removetheoilfillercap/dipstick.Ifthe levelis low,slowlyadd

oil (5W-30,witha minimumclassificationofSF/SG)untiloil level

registersbetweenhigh(H)andlow(L).

NOTE:Donotoverfill.Overfillingwithoil mayresultin enginesmoking,

hardstartingor sparkplugfouling.

4. Replaceandtightencap/dipstickfirmlybeforestartingengine.

13

Gasoline

Useautomotivegasoline(unleadedor lowleadedtominimizecombus-

tionchamberdeposits)witha minimumof87octane.Gasolinewith

upto 10%ethanolor 15%MTBE(MethylTertiaryButylEther)canbe

used.Neveruseanoil/gasolinemixtureordirtygasoline.Avoidgetting

dirt,dust,or waterinthefueltank.DONOTuseE85gasoline.

• Refuelin awell-ventilatedareawiththeenginestopped.Donot

smokeorallowflamesorsparksintheareawheretheengineis

refueledorwheregasolineisstored.

• Donotoverfillthefueltank.Afterrefueling,makesurethe tank

capisclosedproperlyandsecurely.

• Becarefulnottospillfuelwhenrefueling.Spilledfuelor fuelvapor

mayignite.Ifanyfuelisspilled,makesuretheareaisdry before

startingtheengine.

• Avoidrepeatedor prolongedcontactwithskinor breathingof

vapor.

Useextremecarewhenhandlinggasoline.Gasolineisextremely

flammableandthevaporsareexplosive.Neverfuelthemachine

indoorsorwhilethe engineishotorrunning.Extinguishcigarettes,

cigars,pipesandothersourcesofignition.

.

Cleanaroundfuelfill beforeremovingcaptofuel.

2.

Afuellevelindicatorislocatedinthefueltank.Filltankuntilfuel

reachesthefuellevelindictor.SeeFigure10inset.Becarefulnot

tooverfill.

Starting The Engine

Determinethatyourhome'swiringisa three-wiregroundedsystem.

Aska licensedelectricianifyouarenotcertain.

Ifyou haveagroundedthree-prongreceptacle,proceedasfollows.

Ifyou donot havetheproperhousewiring,DONOTusetheelectric

starterunderanyconditions.

1. Plugtheextensioncord intotheoutletlocatedon theengine's

surface.Plugtheotherendof extensioncord intoa three-prong

120-volt,grounded,ACoutletina well-ventilatedarea.

2. Movethrottlecontrolto FAST(rabbit)_ position.

3. Movechoketo theONpositionI,,i(I (coldenginestart).Ifengine

iswarm,placechokeinOFFposition.

4. Pushprimerthreetofive(3-5) times,makingsuretocovervent

holewhenpushing.If engineiswarm,pushprimeronlyonce.

Alwayscoverventholewhenpushing.Coolweathermayrequire

primingto be repeated.

5. Pushstarterbuttonto startengine.Oncetheenginestarts,im-

mediatelyreleasestarterbutton.Electricstarteris equippedwith

thermaloverloadprotection;systemwilltemporarilyshut-downto

allowstarterto cool ifelectricstarterbecomesoverloaded.

6. Astheenginewarms,slowlyrotatethechokecontroltoOFF

position,iftheenginefalters,restartengineandrunwith choke

at half-chokepositionfor a shortperiodoftime,andthenslowly

rotatethechokeintoOFFposition.

7. Afterengineis running,disconnectpowercordfromelectric

starter.Whendisconnecting,alwaysunplugtheendat thewall

outletbeforeunpluggingtheoppositeend fromthe engine.

Recoil Starter

Alwayskeephandsandfeetclearof movingparts.Donotusea

pressurizedstartingfluid.Vaporsareflammable.

NOTE:Forlocationofalltheenginecontrolsreferredto inthis section,

referto Fig.9 onpage 12.

NOTE:Allowtheengineto warmupfora fewminutesafterstarting.

Theenginewill notdevelopfullpoweruntilit reachesoperating

temperatures.

1. Makecertainboththeaugercontrolanddrivecontrolare inthe

disengaged(released)position.

2. Insertignitionkeyinto slot.Makesureit snapsintoplace.Donot

attempttoturnthekey.

NOTE:The enginecannotstartwithoutthekeyfullyinsertedintothe

ignitionswitch.

Electric Starter

Theoptionalelectricstarterisequippedwitha groundedthree-wire

powercordandplug,andisdesignedtooperateon 120voltAC

householdcurrent.Itmustbeusedwitha properlygroundedthree-

prongreceptacleatalltimesto avoidthepossibilityofelectricshock.

Followall instructionscarefullypriortooperatingtheelectricstarter.

DONOTuseelectricstarterintherain.

Donot pullthe starterhandlewhiletheenginerunning.

1. Movethrottlecontrolto FAST(rabbit)_ position.

2. MovechoketotheONpositionI,,,_1(coldenginestart).Ifengineis

warm,placechokeinOFFposition.

3. Pushprimerthreeto five(3-5) times,makingsuretocovervent

holewhenpushing.If engineiswarm,pushprimeronlyonce.

Alwayscoverventholewhenpushing.Coolweathermayrequire

primingto be repeated.

4. Pullgentlyonthe starterhandleuntilitbeginsto resist,thenpull

quicklyandforcefullytoovercomethecompression.Donot release

thehandleandallowit to snapback.ReturnropeSLOWLYto

originalposition.If required,repeatthisstep.

5. Astheenginewarms,slowlyrotatethechokecontroltoOFF

position.Iftheenginefalters,restartengineandrunwith chokeat

half-chokepositionfora shortperiodoftime,andthenslowlyrotate

thechokeintoOFFposition.

Toavoidunsupervisedengineoperation,neverleavethemachine

unattendedwiththe enginerunning.Turnthe engineoff afteruseand

removeignitionkey.

14

Stopping The Engine

Runenginefor a fewminutesbeforestoppingtohelpdryoff any

moistureonthe engine.

1. Movethrottlecontrolto STOP position.

2. Removetheignitionkey.Removingthekeywill reducethepos-

sibilityof unauthorizedstartingof theenginewhileequipmentis

notinuse.Keepthekeyin a safeplace.Theenginecannotstart

withouttheignitionkey.

Positioning Discharge Chute

Loosenthechuteknobandpivotupperchuteto desiredposition.Tighten

thechuteknobmakingsurethecarriageboltiscorrectlypositioned.

Rotatechutehandletodesiredoperatingposition.

Donot liftthe snowthroweratanytimebythe chutehandle.

3. Wipeanymoistureawayfromthe controlsontheengine.

Before Stopping

1. Runenginefor afewminutestohelpdryoffanymoistureonengine.

2. Toavoidpossiblefreeze-upof therecoilstarter,followthisstep:

Recoil Starter

a. Withtheenginerunning,pullthestarterropewitha rapid,

continuousfull armstrokethreeor fourtimes.

To Stop The Snow Thrower

1. Tostopthewheels,releasethe drivecontrol.

2. Tostopthrowingsnow,releasetheaugercontrol.

3. Tostopengine,pushthrottlecontrollevertoOFF I_ and pullout

thekey.Donotturnkey.

Thetemperatureofmufflerandthesurroundingareasmayexceed

1500F.Avoidtheseareas.

Clearing The Snow

CAUTION:Checktheareato be clearedforforeignobjects.Remove

foreignobjects,if any.

1. Starttheenginefollowingstartinginstructions.

2. Allowtheengineto warmupfora fewminutesasthe enginewill not

developfullpoweruntilit reachesoperatingtemperature.

3. Rotatethechuteassemblytothedesireddirection,awayfrom

bystandersand/orbuildings.

4. Makingcertainno bystandersor obstaclesareinfrontd theunit,

squeezetheaugercontrolcompletelyagainsttheupperhandleto

fullyengagetheaugers.

5. Whiletheaugercontrolisengaged,squeezethedrivecontrol

completelyagainstthe upperhandletoengagethewheels.Donot

"feather"thedrivecontrol.

6. Asthesnowthrowerstartsto move,maintaina firmholdon the

handle,andguidethesnowthroweralongthe pathtobecleared.

7. Releasethe augerand drivecontrolsto stopthe snowthrowing

actionandforwardmotion.

NOTE:Yourunit isequippedwitha clutchinthetransmission.If the

wheelsstopturningwhiletryingto dischargelargevolumesofsnow,

immediatelydisengagethedrivecontroland allowthe rotatingaugers

todischargesnowfromthehousing.Reducethe clearingwidthand

continueoperation.

8. Oneachsucceedingpass,readjustthechuteassemblytothe

desiredpositionandslightlyoverlapthepreviouslyclearedpath.

Operating Tips

1. Formostdficientsnowremoval,removesnowimmediatelyafteritfalls.

2. Dischargesnowdownwindwheneverpossible.Slightlyoverlap

eachpreviouspath.

3. Setthe skidshoes1/4"belowtheshaveplatefornormalusage.

Theskidshoesmaybeadjustedupwardforhard-packedsnow.

NOTE:It isnot recommendedthatyouoperatethis snowthroweron

gravelas loosegravelcanbe easilypickedupand thrownbytheauger

causingpersonalinjuryand/ordamageto the snowthrower.

4. Ifforsomereason,you haveto operatethesnowthrowerongravel,

keeptheskidshoe inthe highestpositionformaximumclearance

betweenthegroundandtheshaveplate.

5. Cleanthesnowthrowerthoroughlyaftereachuse.

REPLACING SHEAR PINS

Theaugersare securedto thespiralshaftwithtwoshearpinsand

bow-tieclips.Iftheaugershouldstrikea foreignobjector icejam,the

snowthrowerisdesignedso thatthe shearpinsmayshear.Ifaugers

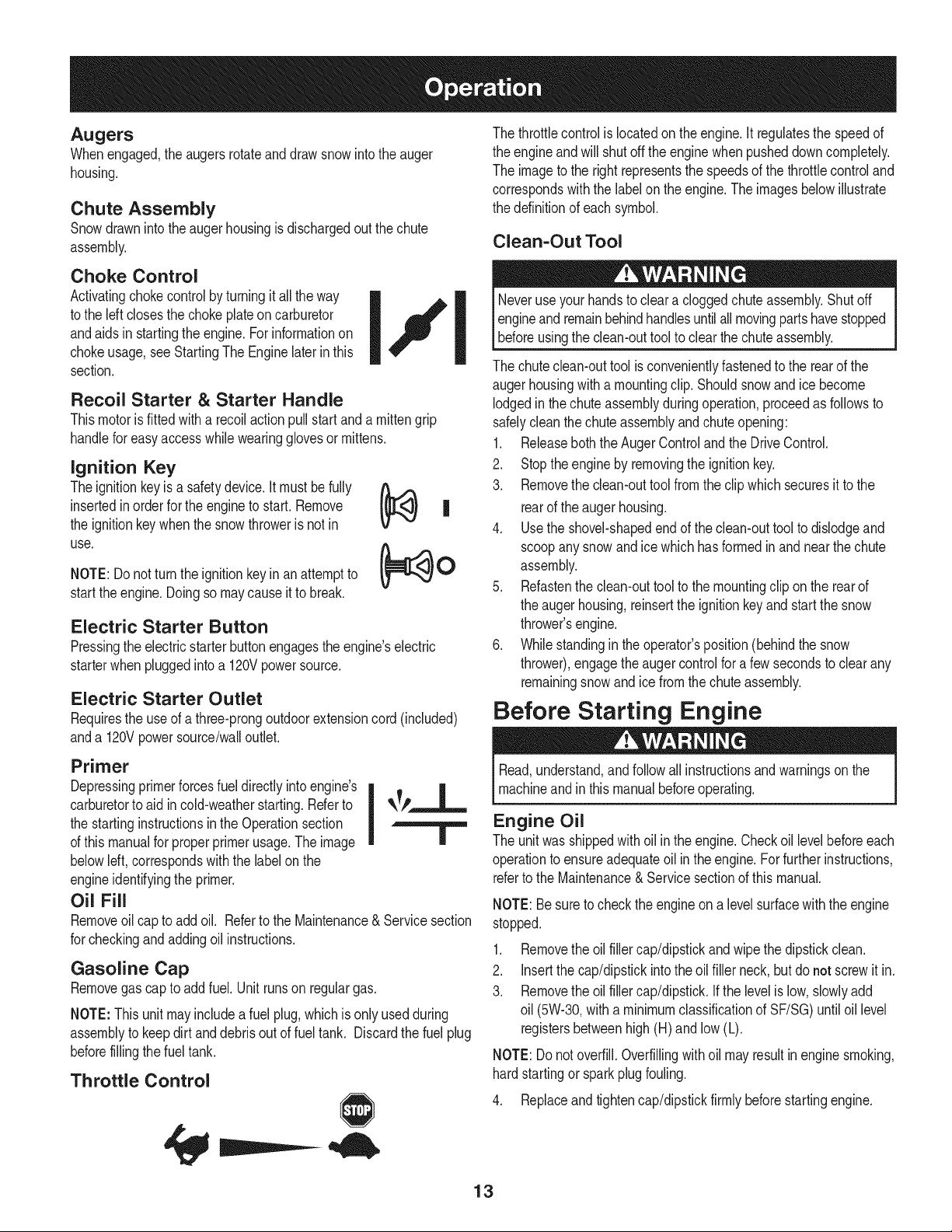

willnotturn,checkto seeifthepinshavesheared.SeeFig. 10.

NEVERreplacetheaugershearpinswithanythingotherthanOEM I

PartNo.0EM-738-04124replacementshearpins.Anydamageto theI

augergearboxorothercomponentsas,aresultoffailingtodo sowill I

NOTbecoveredbyyoursnowthrowerswarranty.

Alwaysturnoffthe snowthrower'sengineand removethe keypriorto

replacingshearpins.

f- _,,

\\

J

Figure10

15

ENGINE MAINTENANCE

Beforelubricating,repairing,or inspecting,disengageall controls

Iandstopengine.Waituntilall movingpartshavecometo a complete

[stop.

Checking Engine Oil

NOTE: Checktheoil levelbeforeeachuseandaftereveryfivehours

ofoperationto besurecorrectoil levelismaintained.

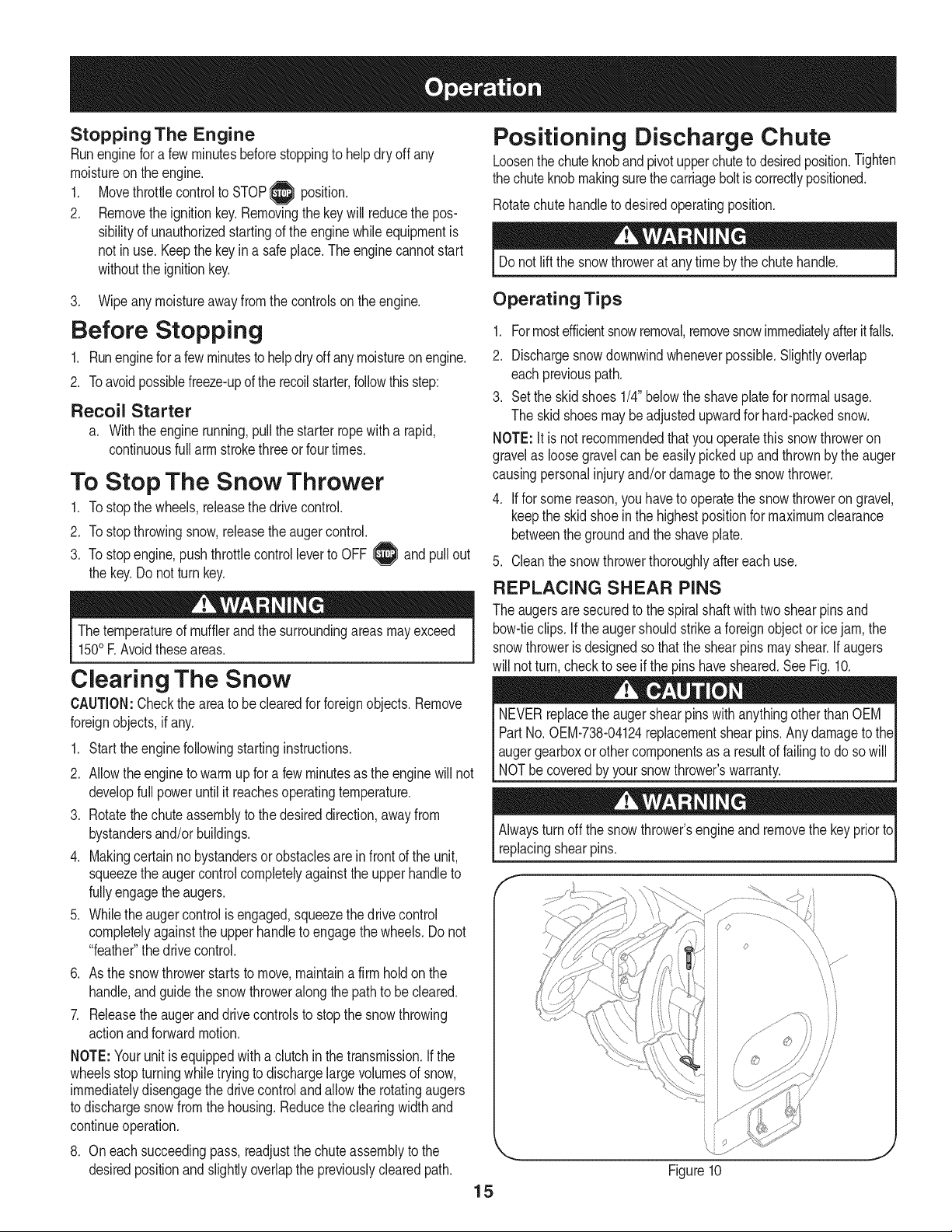

Whenaddingoiltothe engine,referto viscositychartbelow.Engine

oilcapacityis 600ml (approx.20oz.). Donotover-fill.Usea4-stroke,

oran equivalenthighdetergent,premiumqualitymotoroilcertified

tomeetorexceedU.S.automobilemanufacturer'srequirementsfor

serviceclassificationSG, SE MotoroilsclassifiedSG, SFwillshow

thisdesignationonthecontainer.

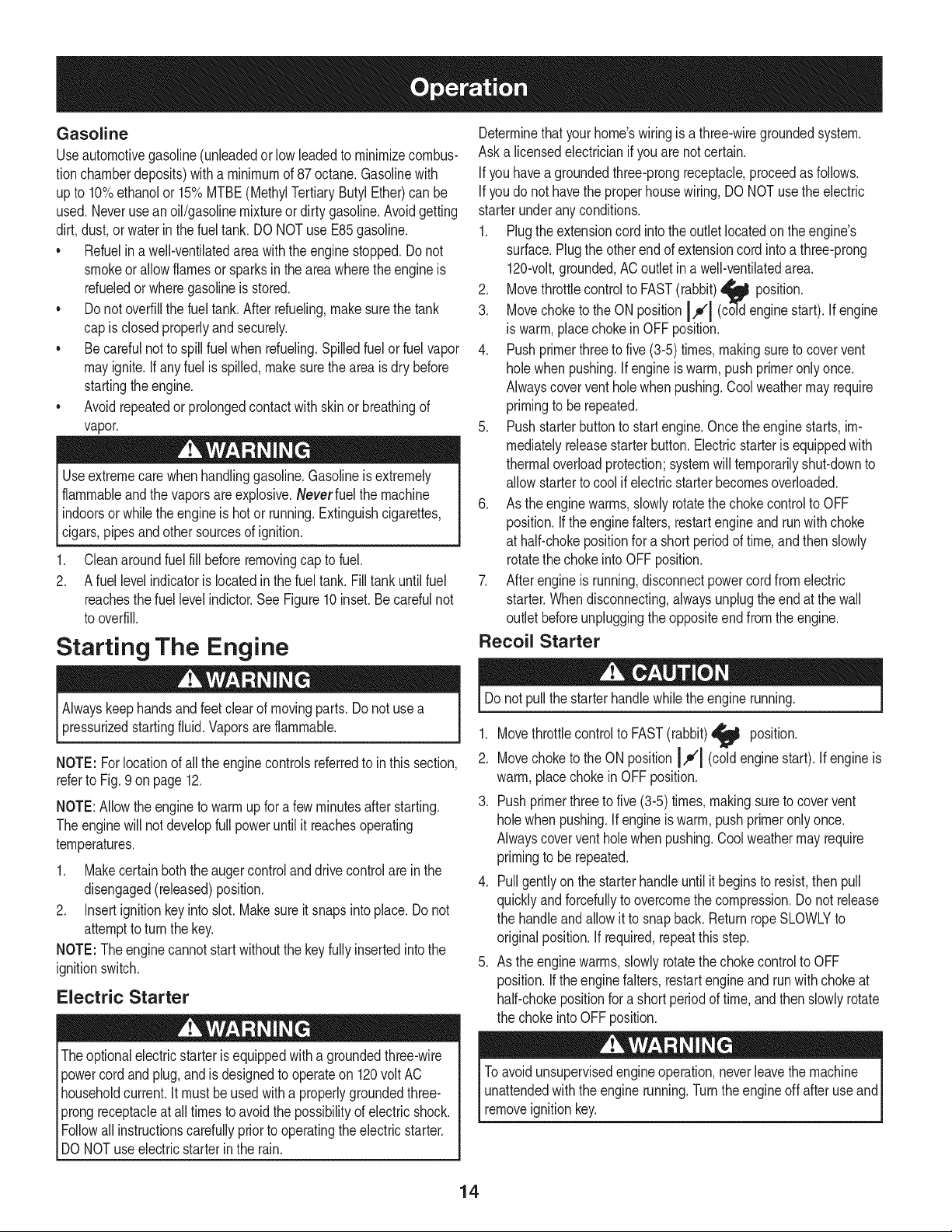

1. Removetheoilfillercap/dipstickandwipethedipstickclean.

2. Insertthecap/dipstickintotheoilfillerneck,butdo notscrewitin.

3. Removetheoilfillercap/dipstick.Iflevelislow,slowlyaddoiluntil

oil levelregistersbetweenhigh(H)andlow(L).SeeFigure11.

4. Replaceandtightencap/dipstickfirmlybeforestartingengine.

Changing Engine Oil

f

J

Figure11

NOTE:Changetheengineoilafterthefirst5 hoursof operationand

oncea seasonorevery50 hoursthereafter.

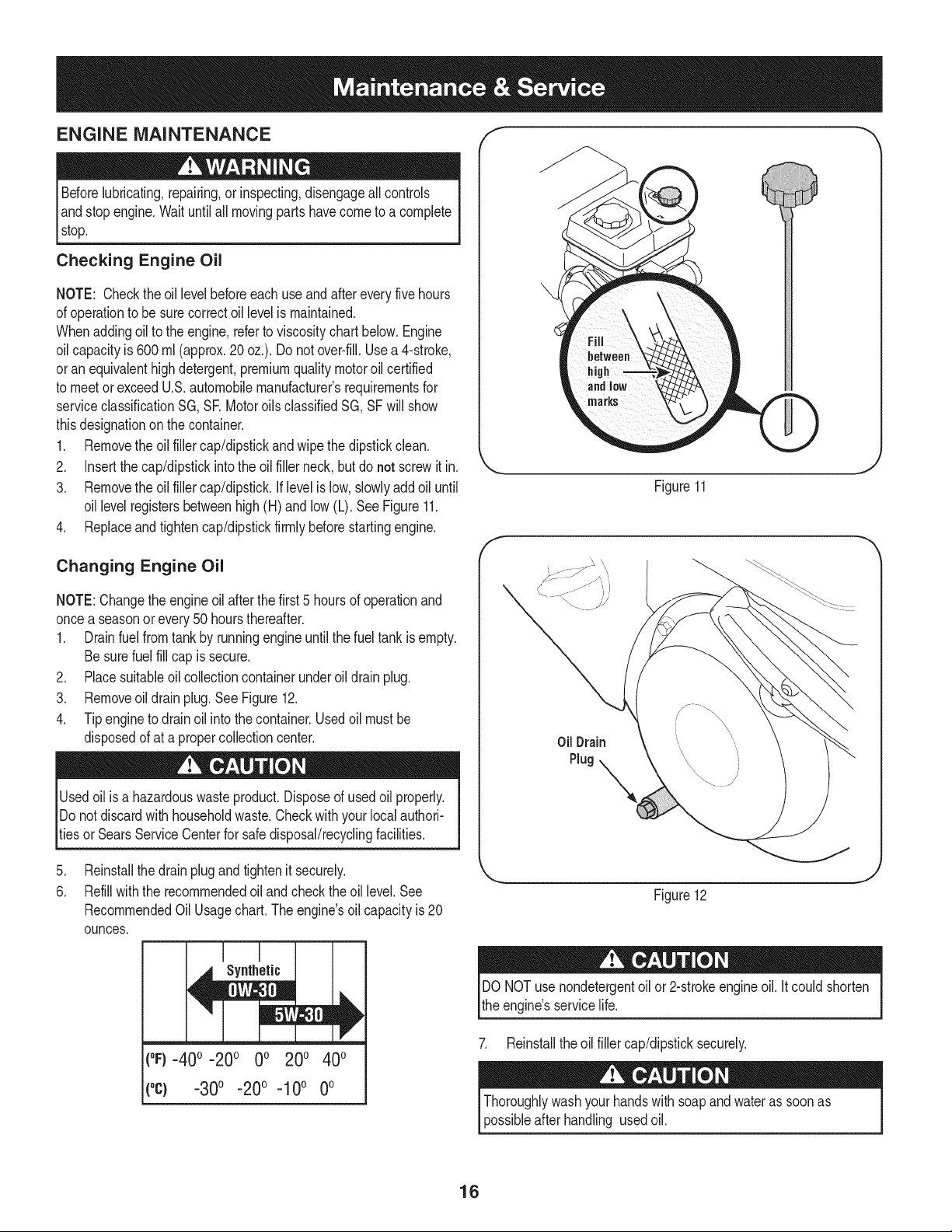

1. Drainfuelfromtankbyrunningengineuntilthefueltankisempty.

Besurefuelfillcap issecure.

2. Placesuitableoilcollectioncontainerunderoildrainplug.

3. Removeoil drainplug.SeeFigure12.

4. Tipenginetodrainoil intothecontainer.Usedoilmustbe

disposedofat apropercollectioncenter.

Donotdiscardwith householdwaste.Checkwithyourlocalauthori-

tUsedoil isa hazardouswasteproduct.Disposeof usedoilproperly.

iesorSearsServiceCenterforsafedisposal/recyclingfacilities.

.

Reinstallthedrainplugandtightenit securely.

6.

Refillwiththe recommendedoil andchecktheoillevel.See

RecommendedOilUsage chart. The engine's oilcapacity is 20

ounces.

Synthetic

1

(oF)-40o-20 o 0o 200 400

Oil Drain

Plug

J

Figure12

DONOTusenondetergentoilor 2-strokeengineoil.It couldshorten

theengine'sservicelife.

7. Reinstalltheoil fillercap/dipsticksecurely.

("c) -30° -20° -10° 0°

Thoroughlywashyourhandswithsoapandwateras soonas

possibleafterhandling usedoil.

16

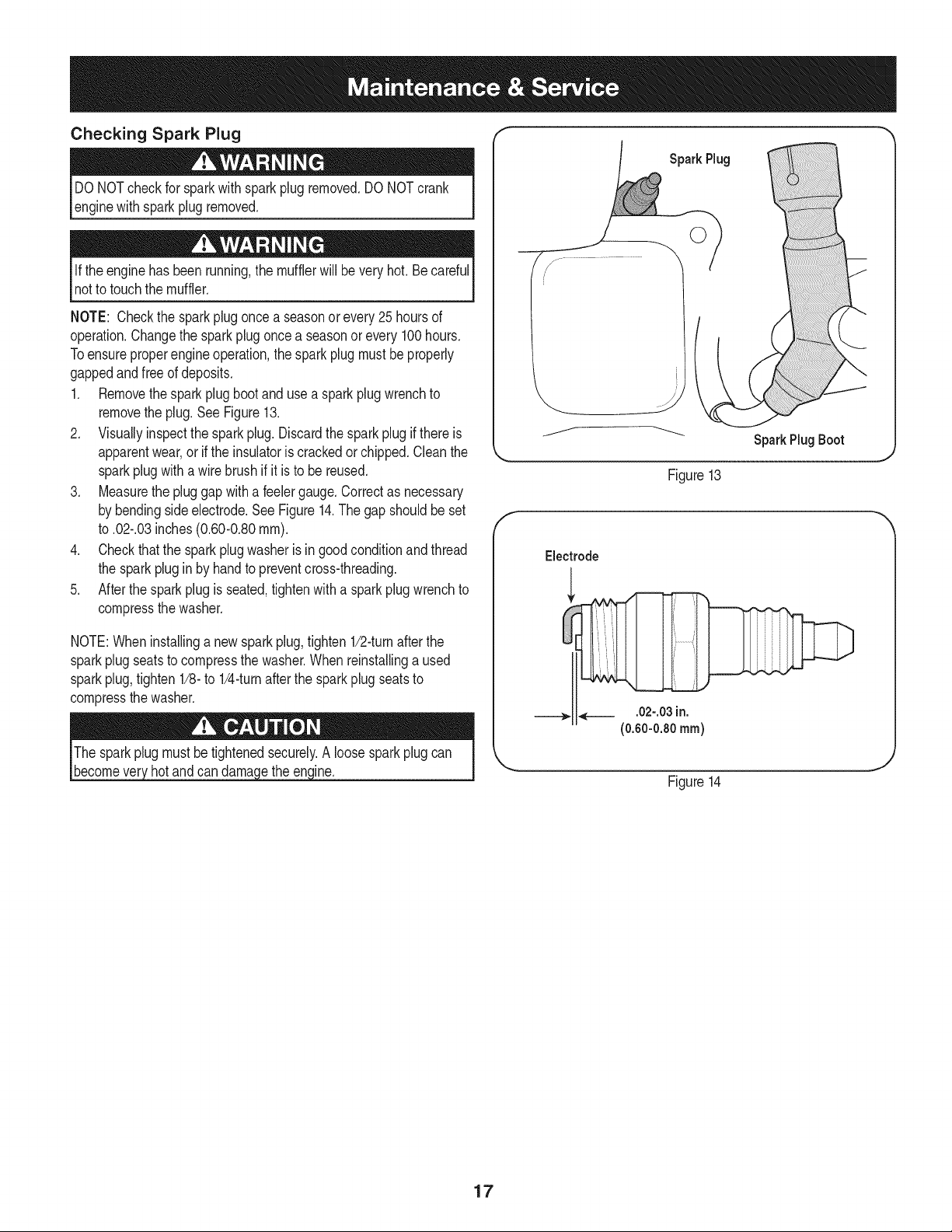

Checking Spark Plug

DONOTcheckforsparkwithsparkplugremoved.DO NOTcrank

enginewithsparkplugremoved.

Iftheenginehasbeenrunning,themufflerwillbevery hot.Becareful

notto touchthe muffler.

NOTE: Checkthe sparkplugoncea seasonorevery25hoursof

operation.Changethesparkplugoncea seasonor every100hours.

Toensureproperengineoperation,thesparkplugmustbe properly

gappedandfreeofdeposits.

1. Removethesparkplugbootanduse a sparkplugwrenchto

removetheplug.See Figure13.

2. Visuallyinspectthesparkplug.Discardthesparkplugifthereis

apparentwear,orif the insulatoriscrackedorchipped.Cleanthe

sparkplugwitha wirebrush if itisto be reused.

3. Measurethe pluggapwitha feelergauge.Correctas necessary

bybendingsideelectrode.SeeFigure14.Thegapshouldbeset

to.02-.03inches(0.60-0.80ram).

4. Checkthatthe sparkplugwasherisingoodconditionandthread

thesparkplugin byhandtopreventcross-threading.

5. Afterthesparkplugisseated,tightenwitha sparkplugwrenchto

compressthewasher.

Spark Rug

SparkPlugBoot

Figure13

Electrode

NOTE:Wheninstallinga newsparkplug,tighten1/2-turnafterthe

sparkplugseatstocompressthewasher.Whenreinstallinga used

sparkplug,tighten1/8-to 1/4-turnafterthe sparkplugseatsto

compressthewasher.

Thesparkplugmustbe tightenedsecurely.Aloosesparkplugcan

becomevet hotandcan dama ethe enine.

Figure14

17

General Recommendations

.

Alwaysobservesafetyruleswhenperforminganymaintenance.

2.

Thewarrantyon thissnowthrowerdoesnotcoveritemsthathave

beensubjectedtooperatorabuseornegligence.Toreceivefull

valuefromthe warranty,operatormustmaintainthe snowthrower

asinstructedinthismanual.

3. Periodicallycheckall fastenersand hardwaretomakesurethese

aretight.

Beforeservicing,repairing,lubricatingorinspecting,disengageallcontrols

andstopengine.Waituntilallmovingpartshavecometoacompletestop.

Disconnectsparkplugwireandgroundit againsttheenginetoprevent

unintendedstarting.Alwayswearsafetyglassesduringoperationorwhile

performinganyadjustmentsor repairs.

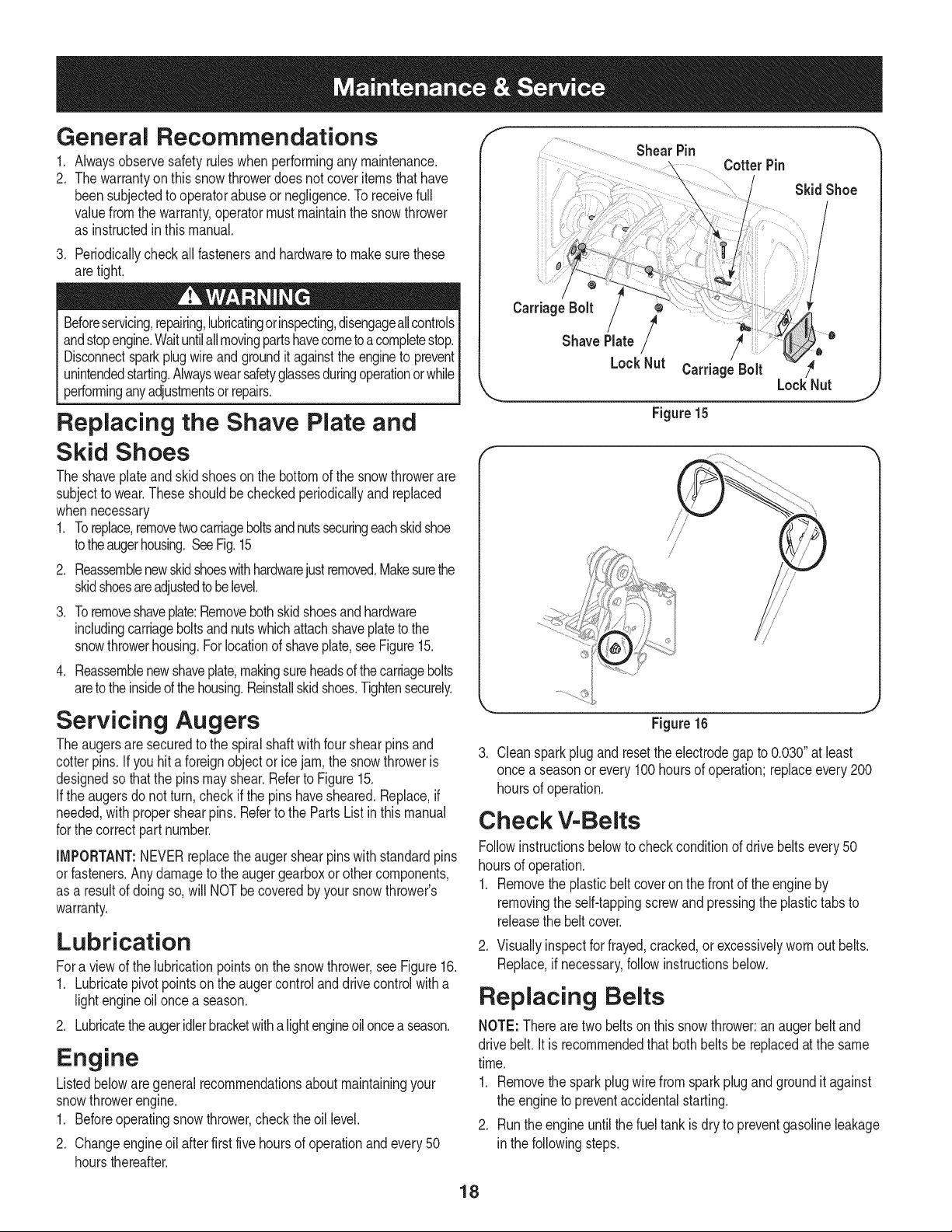

Replacing the Shave Plate and

Skid Shoes

Theshaveplateand skidshoesonthebottomofthesnowthrowerare

subjecttowear.Theseshouldbe checkedperiodicallyandreplaced

whennecessary

1. Toreplace,removetwocarriageboltsandnutssecuringeachskidshoe

totheaugerhousing.SeeFig.15

.

Reassemblenewskidshoeswithhardwarejustremoved.Makesurethe

skidshoesareadjustedtobelevel.

3.

Toremoveshaveplate:Removebothskidshoesandhardware

includingcarriageboltsandnutswhichattachshaveplatetothe

snowthrowerhousing.Forlocationofshaveplate,see Figure15.

.

Reassemblenewshaveplate,makingsureheadsofthecarriagebolts

aretotheinsideofthehousing.Reinstallskidshoes.Tightensecurely.

f Shear Pin

CotterPin

Skid Shoe

_iiiii

CarriageBolt

ShaveP,ate/ /

LockNut CarriageBolt /4

,_ LockNut j

Figure 15

i/

/ /

/

/

Servicing Augers

Theaugersaresecuredto thespiralshaftwithfourshearpinsand

cotterpins.Ifyouhita foreignobjectoricejam,thesnowthroweris

designedsothatthe pinsmayshear.RefertoFigure15.

Iftheaugersdo notturn,checkif thepinshavesheared.Replace,if

needed,withpropershearpins.Referto thePartsListinthismanual

forthecorrectpartnumber.

IMPORTANT:NEVERreplacetheaugershearpinswithstandardpins

orfasteners.Anydamagetothe augergearboxor othercomponents,

asaresultofdoingso,will NOTbe coveredbyyoursnowthrower's

warranty.

Lubrication

Fora viewofthelubricationpointson the snowthrower,seeFigure16.

1. Lubricatepivotpointsontheaugercontrolanddrivecontrolwitha

lightengineoil oncea season.

2. Lubricatetheaugeridlerbracketwithalightengineoilonceaseason.

Engine

Listedbelowaregeneralrecommendationsaboutmaintainingyour

snowthrowerengine.

1. Beforeoperatingsnowthrower,checkthe oillevel.

2. Changeengineoilafterfirstfivehoursofoperationandevery50

hoursthereafter.

Figure16

3. Cleansparkplugandresetthe electrodegapto 0.030"at least

onceaseasonor every100hoursofoperation;replaceevery200

hoursof operation.

Check V-Belts

Followinstructionsbelowto checkconditionofdrivebeltsevery50

hoursof operation.

1. Removetheplasticbeltcoveron thefrontof theengineby

removingtheself-tappingscrewandpressingtheplastictabsto

releasethebeltcover.

2. Visuallyinspectforfrayed,cracked,or excessivelywornout belts.

Replace,if necessary,followinstructionsbelow.

Replacing Belts

NOTE:Therearetwobeltsonthis snowthrower:anaugerbeltand

drivebelt.Itis recommendedthatbothbeltsbereplacedatthe same

time.

1. Removethesparkplugwirefrom sparkplugandgrounditagainst

theenginetopreventaccidentalstarting.

2. Runtheengineuntilthefueltank isdryto preventgasolineleakage

inthefollowingsteps.

18

Loading...

Loading...