Craftsman 247887040 Owner’s Manual

Operator's Manual

CRRFr MRN

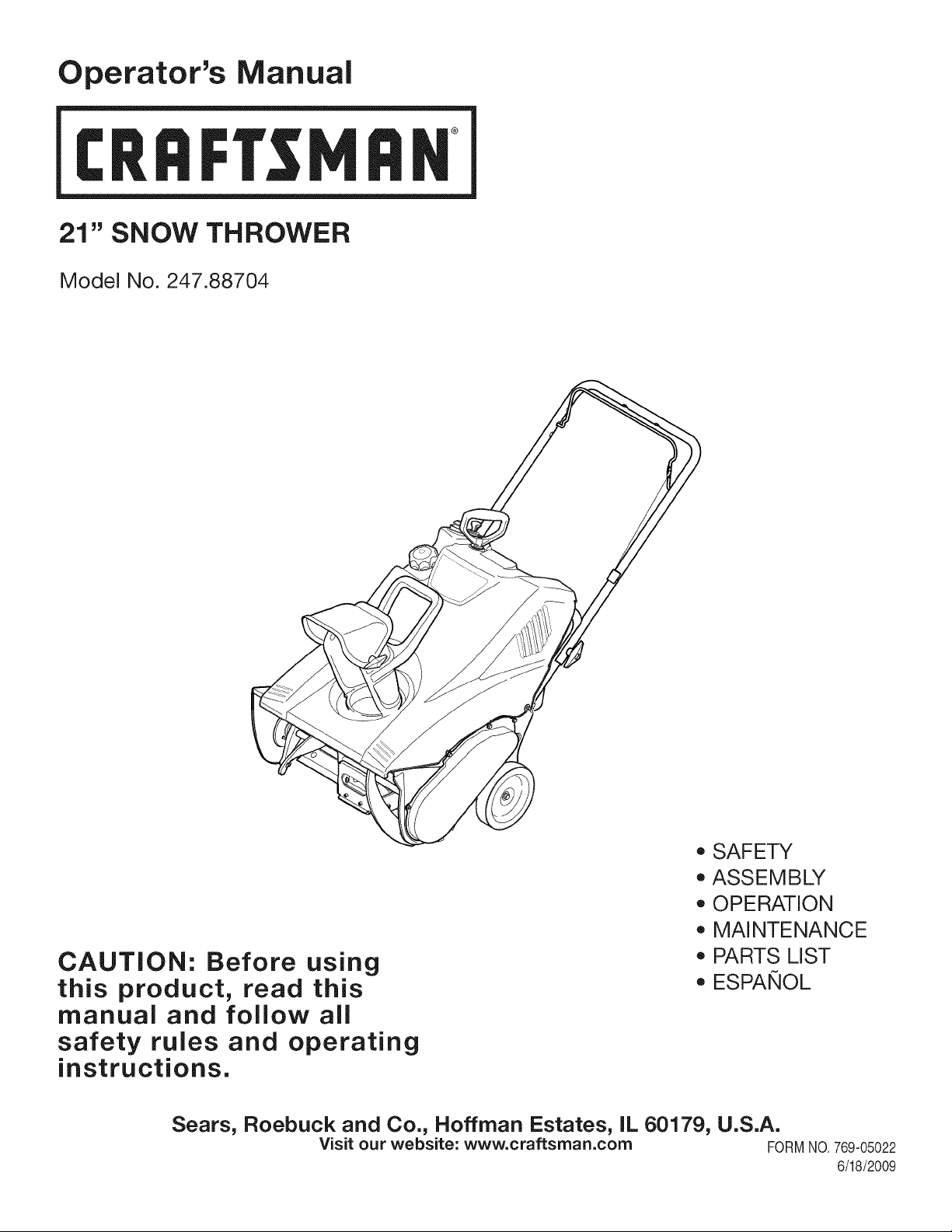

21" SNOW THROWER

Model No. 247.88704

CAUTION: Before using

this product, read this

manual and follow all

safety rules and operating

instructions.

Sears, Roebuck and Co., Hoffman Estates, IL 60179, U.S.A.

Visit our website: www.craftsman.com FORM1/0.769-05022

o SAFETY

ASSEMBLY

OPERATION

MAINTENANCE

PARTS LIST

o ESPANOL

6/18/2009

WarrantyStatement..................................Page2

SafeOperation Practices .......................... Pages 3-6

Safety Symbols ......................................... Page 6

Assembly .................................................. Pages 7-9

Operation .................................................. Pages 10-12

Service and Maintenance ......................... Pages 13-17

CRAFTSMAN FULL WARRANTY

When operated and maintained according to all supplied instructions, if this Craftsman snow thrower fails due to a

defect in material or workmanship within two years from the date of purchase, return it to any Sears store, Sears Parts

& Repair Service Center, or other Craftsman outlet in the United States for free repair (or replacement if repair proves

impossible).

This warranty applies for only 90 days from the date of purchase if this chipper-shredder is ever used for commercial or

rental purposes.

This warranty covers ONLY defects in material and workmanship. Sears will NOT pay for:

• Expendable items that become worn during normal use, including but not limited to

auger blades, skid shoes, shave plate, shear pins, spark plug, air cleaner, belts, and oil filter.

Standard maintenance servicing, oil changes, or tune-ups.

Tire replacement or repair caused by punctures from outside objects, such as nails, thorns, stumps, or glass.

Tire or wheel replacement or repair resulting from normal wear, accident, or improper operation or maintenance.

Repairs necessary because of operator abuse, including but not limited to damage caused by over-speeding the

engine, or from impacting objects that bend the auger, frame or crankshaft.

Repairs necessary because of operator negligence, including but not limited to, electrical and mechanical damage

caused by improper storage, failure to use the proper grade and amount of engine oil, or failure to maintain the

equipment according to the instructions contained in the operator's manual.

Engine (fuel system) cleaning or repairs caused by fuel determined to be contaminated or oxidized (stale). In

general, fuel should be used within 30 days of its purchase date.

Normal deterioration and wear of the exterior finishes, or product label replacement.

Off-Season Storage .................................. Page 18

Trouble Shooting ....................................... Page 19

Parts List ................................................... Page 20-27

Repair Protection Agreement ................... Page 31

Espa_ol ..................................................... Page 32

Service Numbers ...................................... Back Cover

This warranty applies only while this product is within the United States.

This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

Sears, Roebuck and Co., Hoffman Estates, IL 60179

EngineOilType: SAE5W-30

EngineOilCapacity: 20ounces

FuelCapacity: 2 Quarts

SparkPlug: TorchF6RTC

SparkPlugGap: .020"-.030"

©SearsBrands,LLC

Model Number.................................................................

Serial Number .................................................................

Dateof Purchase.............................................................

Recordthemodelnumber,serialnumber

anddateof purchaseabove

2

Thissymbolpointsoutimportantsafetyinstructionswhich,if not

followed,couldendangerthepersonalsafetyand/orpropertyof

yourselfandothers. Readandfollowall instructionsin thismanual

beforeattemptingtooperatethismachine.Failuretocomplywith

theseinstructionsmayresultin personalinjury.Whenyou seethis

symbol,HEEDITSWARNING!

Thismachinewasbuilttobeoperatedaccordingtothesafeopera-

tionpracticesinthis manual.As withanytypeof powerequipment,

carelessnessorerroron the partoftheoperatorcanresultin serious

injury.Thismachineiscapableofamputatingfingers,hands,toes

andfeetandthrowingdebris.Failuretoobservethefollowingsafety

instructionscouldresultin seriousinjuryor death.

CALIFORNIA PROPOSITION 65

EngineExhaust,someof itsconstituents,andcertainvehicle

componentscontainoremitchemicalsknownto StateofCalifornia

tocausecancerandbirthdefectsorotherreproductiveharm,

TRAiNiNG

• Read,understand,andfollowall instructionson the machineand

in themanual(s)beforeattemptingto assembleandoperate.

Failuretodo socan resultinseriousinjurytothe operatorand/

orbystanders.Keepthismanualina safeplaceforfutureand

regularreferenceandfororderingreplacementparts. Forques-

tionscall,1-800-4MY-HOME.

• Befamiliarwithallcontrolsandtheirproperoperation.Knowhow

tostopthemachineanddisengagethemquickly.

Neverallowchildrenunder14yearsof agetooperatethis

machine.Children14andovershouldreadandunderstandthe

instructionsandsafeoperationpracticesin thismanualandon

themachineandbe trainedandsupervisedbyanadult.

Neverallowadultsto operatethis machinewithoutproper

instruction.

• Thrownobjectscan causeseriouspersonalinjury.Planyour

snow-throwingpatterntoavoiddischargeof materialtoward

roads,bystandersandthelike.

Keepbystanders,petsandchildrenatleast75feetfromthe

machinewhileitisinoperation.Stopmachineifanyoneenters

thearea.

Exercisecautiontoavoidslippingorfalling,especiallywhen

operatinginreverse.

Your Responsibility--Restrict the useofthis powermachineto

personswhoread,understandandfollowthewarningsandinstruc-

tionsin thismanualandon themachine,

SAVE THESE INSTRUCTIONS!

PREPARATION

Thoroughlyinspecttheareawheretheequipmentistobeused.

Removeall doormats,newspapers,sleds,boards,wiresandother

foreignobjects,whichcouldbe trippedoverorthrownbytheauger/

impeller.

Alwayswearsafetyglassesoreyeshieldsduringoperationand

whileperforminganadjustmentor repairtoprotectyoureyes.

Thrownobjectswhichricochetcancauseseriousinjurytothe

eyes.

Donot operatewithoutwearingadequatewinteroutergarments.

Donot wearjewelry,longscarvesorotherlooseclothing,which

couldbecomeentangledinmovingparts.Wearfootwearwhich

willimprovefootingonslipperysurfaces.

Usea groundedthree-wireextensioncordand receptacleforall

machineswithelectricstartengines.

Disengageallcontrolleversbeforestartingtheengine.

Neverattempttomakeanyadjustmentswhileengineis running,

exceptwherespecificallyrecommendedinthe operator'smanual.

Letengineandmachineadjusttooutdoortemperaturebefore

startingtoclearsnow.

3

SafeHandlingof Gasoline

Toavoidpersonalinjuryor propertydamageuseextremecarein

handlinggasoline.Gasolineisextremelyflammableandthe vaporsare

explosive.Seriouspersonalinjurycan occurwhengasolineisspilled

onyourselforyourclotheswhichcan ignite.Washyourskinand

changeclothesimmediately.

• Useonlyanapprovedgasolinecontainer.

• Extinguishall cigarettes,cigars,pipesandother sources

ofignition.

• Neverfuelmachineindoors.

• Neverremovegascapor addfuelwhilethe engineis hot

or running.

• Allowenginetocoolat leasttwo minutesbeforerefueling.

• Neveroverfillfueltank. Filltankto no morethan1/2inch

belowbottomoffillerneckto providespaceforfuel

expansion.

• Replacegasolinecapandtightensecurely.

• Ifgasolineisspilled,wipeit offtheengineandequipment.

Movemachinetoanotherarea.Wait5 minutesbefore

startingtheengine.

• Neverstorethemachineor fuelcontainerinsidewhere

thereis anopenflame,sparkor pilotlight(e.g.furnace,

waterheater,spaceheater,clothesdryeretc.).

• Allowmachineto cool at least5 minutesbeforestoring.

• Neverfillcontainersinsidea vehicleor ona truckor trailer

bedwitha plasticliner.Alwaysplacecontainersonthe

groundawayfromyourvehiclebeforefilling.

• If possible,removegas-poweredequipmentfromthetruck

ortrailerand refueliton the ground.If thisisnotpossible,

thenrefuelsuchequipmentona trailerwitha portable

container,ratherthanfromagasolinedispensernozzle.

• Keepthenozzleincontactwiththe rimof the fueltankor

containeropeningatalltimesuntilfuelingis complete.Do

notuse a nozzlelock-opendevice.

OPERATION

• Donotputhandsorfeetnear rotatingparts,in the auger/impeller

housingorchuteassembly.Contactwiththe rotatingpartscan

amputatehandsandfeet.

• Theauger/impellercontrolleverisa safetydevice.Neverbypass

itsoperation.Doingsomakesthemachineunsafeandmaycause

personalinjury.

• Thecontrolleversmustoperateeasilyin bothdirectionsand

automaticallyreturntothe disengagedpositionwhenreleased.

• Neveroperatewitha missingordamagedchuteassembly.Keep

all safetydevicesin placeandworking.

• Neverrunanengineindoorsorina poorlyventilatedarea.Engine

exhaustcontainscarbonmonoxide,anodorlessanddeadlygas.

• Donotoperatemachinewhileundertheinfluenceofalcoholor

drugs.

• Mufflerandenginebecomehotandcancausea burn.Donot

touch.Keepchildrenaway.

• Exerciseextremecautionwhenoperatingonorcrossinggravel

surfaces.Stayalertforhiddenhazardsortraffic.

• Exercisecautionwhenchangingdirectionandwhileoperatingon

slopes.

• Planyoursnow-throwingpatternto avoiddischargetowards

windows,walls,carsetc.Thus,avoidingpossibleproperty

damageorpersonalinjurycausedbya ricochet.

• Neverdirectdischargeatchildren,bystandersandpetsor allow

anyoneinfrontofthemachine.

• Donotoverloadmachinecapacitybyattemptingtoclearsnowat

toofastof a rate.

• Neveroperatethismachinewithoutgoodvisibilityorlight.Always

be sureofyourfootingand keepa firmholdon thehandles.Walk,

neverrun.

• Disengagepowertotheauger/impellerwhentransportingor not

in use.

• Neveroperatemachineat hightransportspeedsonslippery

surfaces.Lookdownand behindand usecarewhenbackingup.

• Ifthe machineshouldstarttovibrateabnormally,stoptheengine,

disconnectthe sparkplugwireandgroundit againsttheengine.

Inspectthoroughlyfor damage.Repairanydamagebefore

startingandoperating.

• Disengageallcontrolleversandstopenginebeforeyouleave

theoperatingposition(behindthehandles).Waituntiltheauger/

impellercomestoa completestopbeforeuncloggingthechute

assembly,makinganyadjustments,orinspections.

• Neverputyourhandinthe dischargeorcollectoropenings.Do

notunclogchuteassemblywhileengineisrunning.Shutoff

engineand remainbehindhandlesuntilall movingpartshave

stoppedbeforeunclogging.

• Useonlyattachmentsandaccessoriesapprovedbythe manufac-

turer(e.g.wheelweights,tirechains,cabsetc.).

• Whenstartingengine,pullcordslowlyuntilresistanceisfelt,then

pull rapidly.Rapidretractionofstartercord(kickback)willpull

handandarmtowardenginefasterthanyoucan let go. Broken

bones,fractures,bruisesorsprainscould result.

• Ifsituationsoccurwhichare notcoveredinthis manual,usecare

andgoodjudgment.ContactCustomerSupportforassistance

andthenameofyournearestservicingdealer.

CLEARING A CLOGGED DISCHARGE CHUTE

Handcontactwiththe rotatingimpellerinsidethe dischargechute

is themostcommoncauseofinjuryassociatedwithsnowthrowers.

Neveruseyourhandtocleanout thedischargechute.

Toclear thechute:

1. SHUTTHEENGINEOFF!

2. Wait 10secondstobe suretheimpellerbladeshavestopped

rotating.

3. Alwaysusea clean-outtool,notyourhands.

4

MAINTENANCE & STORAGE

• Nevertamperwithsafetydevices.Checktheirproperoperation

regularly.Refertothemaintenanceandadjustmentsectionsof

thismanual.

• Beforecleaning,repairing,orinspectingmachinedisengageall

controlleversandstopthe engine.Waituntiltheauger/impeller

cometoa completestop.Disconnectthe sparkplugwireand

groundagainsttheenginetopreventunintendedstarting.

Checkboltsand screwsforpropertightnessatfrequentintervals

tokeepthe machineinsafeworkingcondition.Also,visually

inspectmachineforanydamage.

Donotchangetheenginegovernorsettingor over-speedthe

engine.Thegovernorcontrolsthe maximumsafeoperatingspeed

oftheengine.

Snowthrowershaveplatesandskidshoesaresubjecttowear

anddamage.Foryoursafetyprotection,frequentlycheckall

componentsandreplacewithoriginalequipmentmanufacturer's

(OEM)partsonly.Useofpartswhichdo notmeettheoriginal

equipmentspecificationsmayleadto improperperformanceand

compromisesafety!

Checkcontrolleversperiodicallytoverifytheyengageanddisen-

gageproperlyandadjust,if necessary.Refertotheadjustment

sectioninthisoperator'smanualforinstructions.

Maintainor replacesafetyandinstructionlabels,asnecessary.

• Observeproperdisposallawsand regulationsforgas,oil,etc.to

protecttheenvironment.

Priorto storing,runmachineafew minutestoclear snowfrom

machineand preventfreezeupof auger/impeller.

Neverstorethemachineorfuelcontainerinsidewherethereisan

openflame,sparkorpilotlightsuchasa waterheater,furnace,

clothesdryeretc.

Alwaysrefertotheoperator'smanualforproperinstructionson

off-seasonstorage.

Checkfuelline,tank,cap,andfittingsfrequentlyforcracksor

leaks.Replaceif necessary.

Donotcrankenginewithsparkplugremoved.

AccordingtotheConsumerProductsSafetyCommission(CPSC)

andtheU.S.EnvironmentalProtectionAgency(EPA),thisproduct

hasan AverageUsefulLifeof seven(7)years,or60 hoursof

operation.At the endoftheAverageUsefulLifehavethemachine

inspectedannuallybyan authorizedservicedealertoensurethat

allmechanicalandsafetysystemsareworkingproperlyandnot

wornexcessively.Failuretodo socan resultinaccidents,injuries

ordeath.

DO NOT MODIFY ENGINE

Toavoidseriousinjuryor death,do notmodifyengineinanyway.

Tamperingwiththegovernorsettingcanleadtoa runawayengineand

causeittooperateat unsafespeeds.Nevertamperwithfactorysetting

ofenginegovernor.

NOTICE REGARDING EMiSSiONS

EngineswhicharecertifiedtocomplywithCaliforniaandfederal

EPAemissionregulationsforSORE(SmallOff RoadEquipment)are

certifiedto operateon regularunleadedgasoline,and mayinclude

thefollowingemissioncontrolsystems:EngineModification(EM),

OxidizingCatalyst(OC),SecondaryAirInjection(SAI)and ThreeWay

Catalyst(TWO)if soequipped.

SPARK ARRESTOR

Thismachineisequippedwithaninternalcombustionengineand

shouldnotbe usedonor nearanyunimprovedforest-covered,

brush-coveredorgrass-coveredlandunlesstheengine'sexhaust

systemisequippedwitha sparkarrestermeetingapplicablelocalor

statelaws(ifany)

Ifa sparkattesterisused,itshouldbemaintainedineffectiveworking

orderbytheoperator.Inthe StateofCaliforniatheaboveis required

bylaw (Section4442oftheCaliforniaPublicResourcesCode).Other

statesmayhavesimilarlaws. Federallawsapplyonfederallands.

A sparkarresterforthemuffleris availablethroughyournearestSears

PartsandRepairServiceCenter.

SAFETY SYMBOLS

Thispagedepictsanddescribessafetysymbolsthatmayappearonthisproduct. Read,understand,andfollowall instructionson themachine

beforeattemptingtoassembleandoperate.

READ THE OPERATOR'S MANUAL(S)

i

i

Read, understand, and follow all instructions in the manual(s) before attempting to assemble and

operate

WARNING-- ROTATING BLADES

Keep hands out of inlet and discharge openings while machine is running. There are rotating blades

inside

WARNING-- ROTATING BLADES

Keep hands out of inlet and discharge openings while machine is running. There are rotating blades

inside

WARNING-- ROTATING AUGER

Do not put hands or feet near rotating parts, in the auger/impeller housing or chute assembly.

Contact with the rotating parts can amputate hands and feet.

WARNING--THROWN OBJECTS

This machine may pick up and throw and objects which can cause serious personal injury.

WARNING--GASOLINE ISFLAMMABLE

Allow the engine to cool at least two minutes before refueling.

WARNING-- CARBON MONOXIDE

Never run an engine indoors or in a poorly ventilated area. Engine exhaust contains carbon

monoxide, an odorless and deadly gas.

WARNING-- ELECTRICAL SHOCK

Do not use the engine's electric starter in the rain

6

NOTE:Referencesto rightorleft sideofthesnowthrowerare

determinedfrombehindthe unit intheoperatingposition(standing

directlybehindthesnowthrower,facingthe handlepanel).

REMOVING FROM CARTON

1. Cutthe cornersof thecartonandlaythesidesflaton theground.

Removeanddiscardallpackinginserts.

2. Movethesnowthroweroutofthecarton.

3. Makecertainthecartonhas beencompletelyemptiedbefore

discardingit.

ASSEMBLY

Positioning the Upper Handle

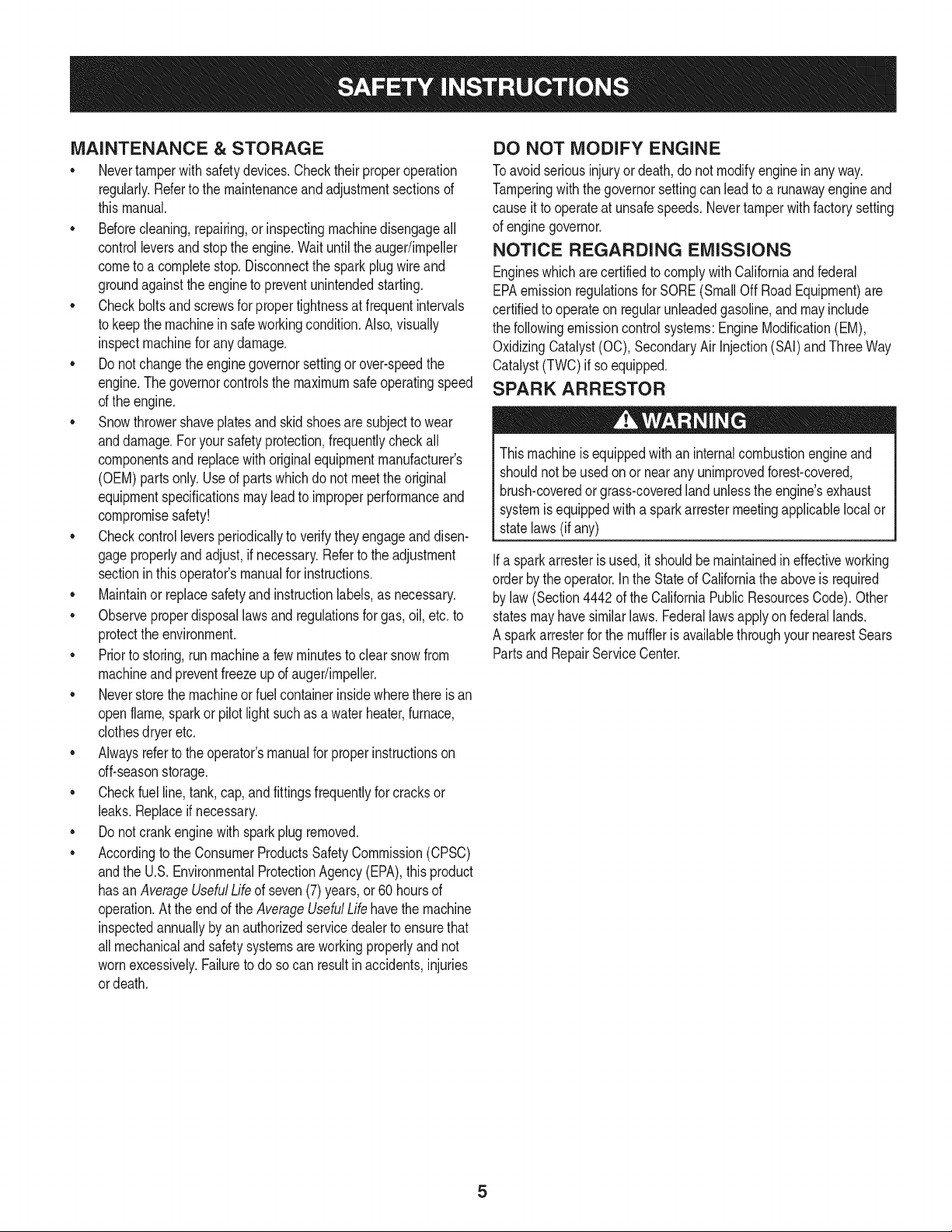

1. Pivottheupperhandleintothe operatingpositionmakingsurenot

topinchthe cablein theprocess,asillustratedinFigure1,untilit

clicksintoplace.

J

Figure1

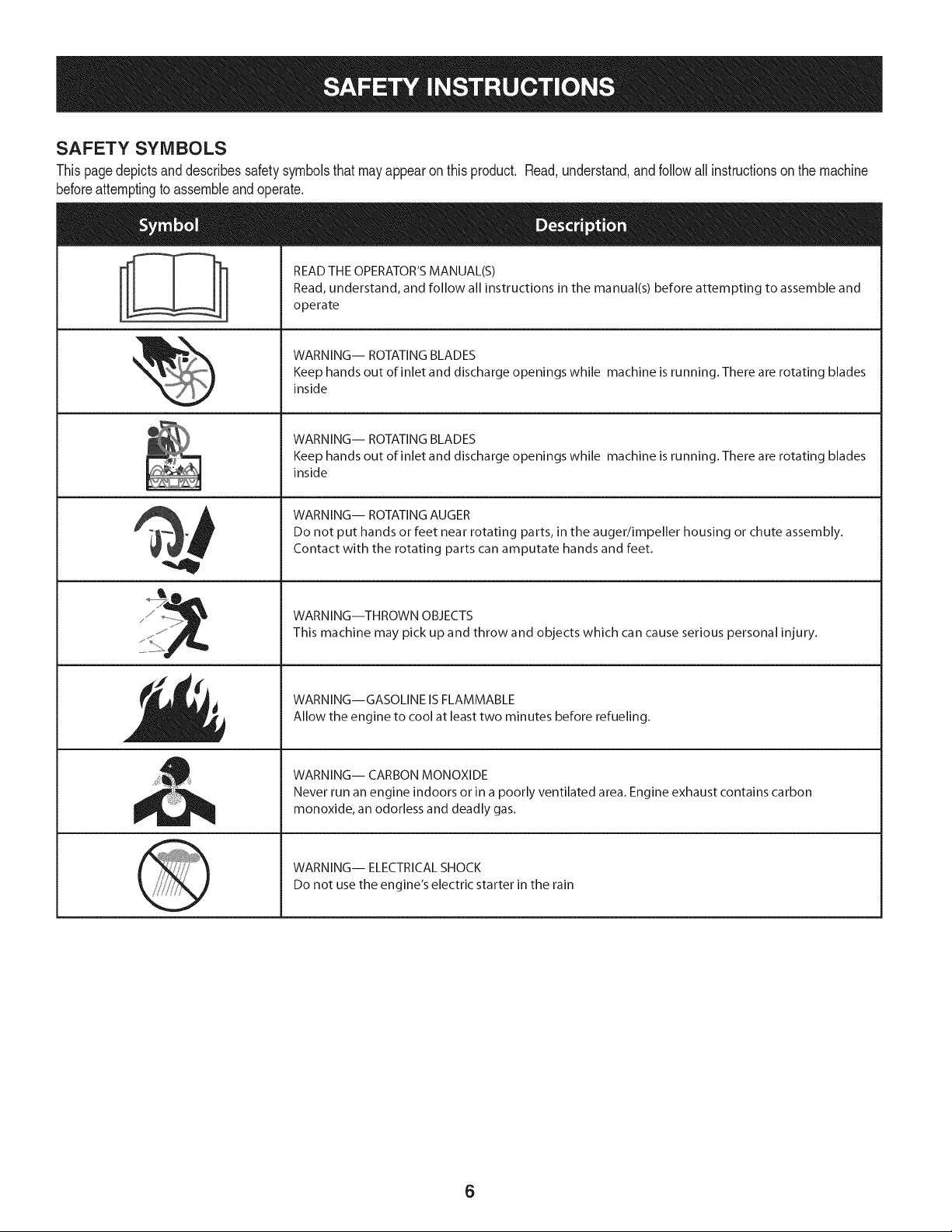

2. Tightenthewingknobstosecurethehandleinplace.

See Figure2.

f,

J

Figure2

SETUP

Fuel Recommendations

Useautomotivegasoline(unleadedor lowleadedtominimizecombus-

tionchamberdeposits)witha minimumof87 octane.Gasolinewith

up to 10%ethanolor 15%MTBE(MethylTertiaryButylEther)canbe

used.Neverusean oil/gasolinemixtureordirty gasoline.Avoidgetting

dirt, dust,or waterinthefueltank.DO NOTuse E85gasoline.

• Refuelina well-ventilatedareawiththe enginestopped.Donot

smokeorallowflamesor sparksin theareawheretheengineis

refueledor wheregasolineisstored.

• Donotoverfillthefueltank.After refueling,makesurethetank

capisclosedproperlyandsecurely.

• Becarefulnotto spillfuelwhenrefueling.Spilledfuelorfuel vapor

mayignite.Ifanyfuelis spilled,makesuretheareais dry before

startingthe engine.

• Avoidrepeatedorprolongedcontactwithskinor breathingof

vapor.

Adding Fuel

Useextremecarewhenhandlinggasoline.Gasolineisextremely

flammableandthe vaporsareexplosive.Neverfuelthe machine

indoorsorwhilethe engineis hot or running.Extinguishcigarettes,

cigars,pipesandothersourcesofignition.

Alwayskeephandsandfeetclearofequipmentmovingparts.Donot

usea pressurizedstartingfluid.Vaporsareflammable.

1. Removethegascap,checkthefuellevelandaddfuel if neces-

sary.

7

Adding Oil

Theengineis shippedwithoutoilintheengine.Youmustfillthe

enginewithoilbeforeoperating.Runningtheenginewithinsufficient

oilcancauseseriousenginedamageandvoidtheproductwarranty.

.

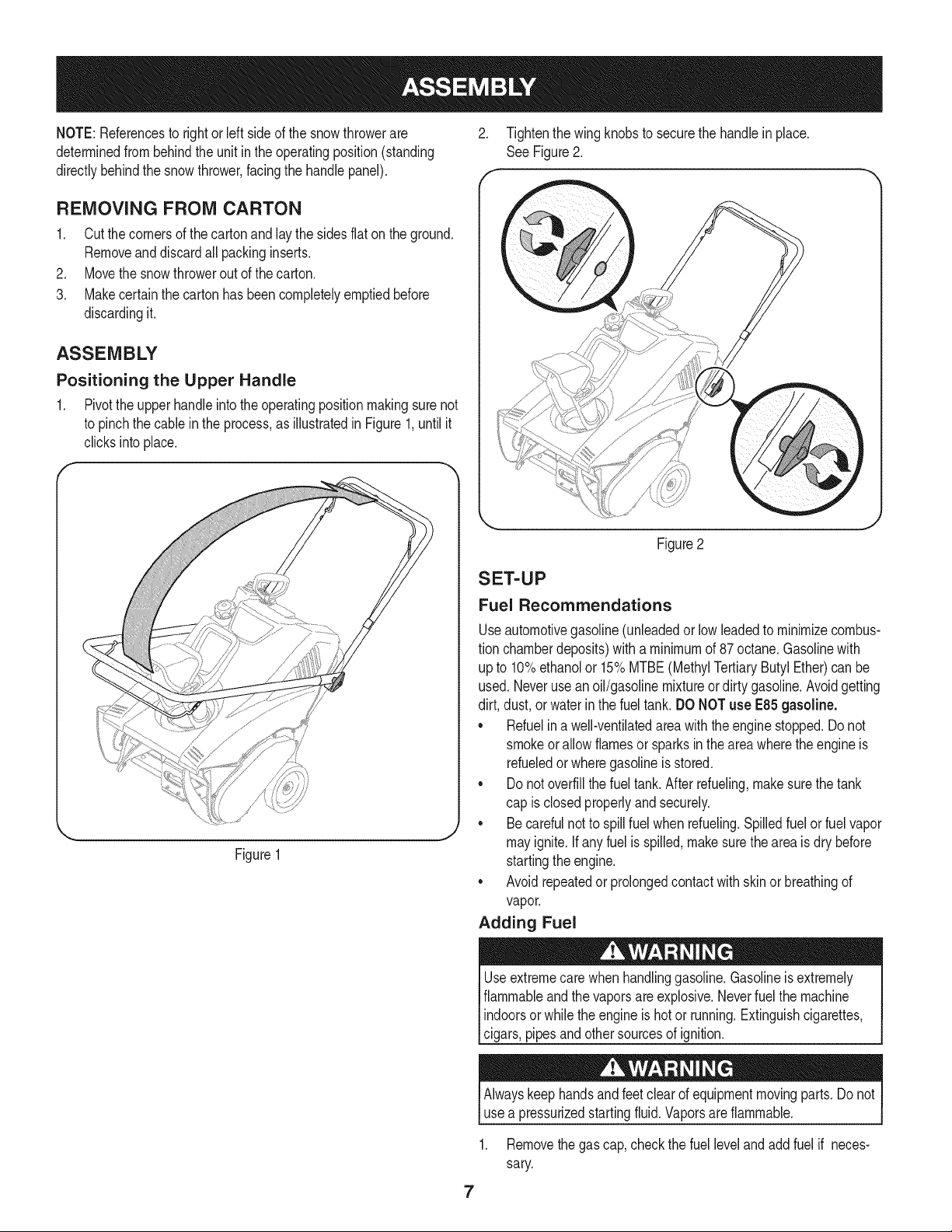

Placethe snowthrowerona flat, levelsurface.

2.

Removetheoil fillercap/dipstickandwipethedipstickclean.See

Figure3.

f.-

NOTE:Donotoverfill.Overfillingtheenginewithoilmayresultinthe

enginesmoking,hardstartingor sparkplugfouling.

ADJUSTMENTS

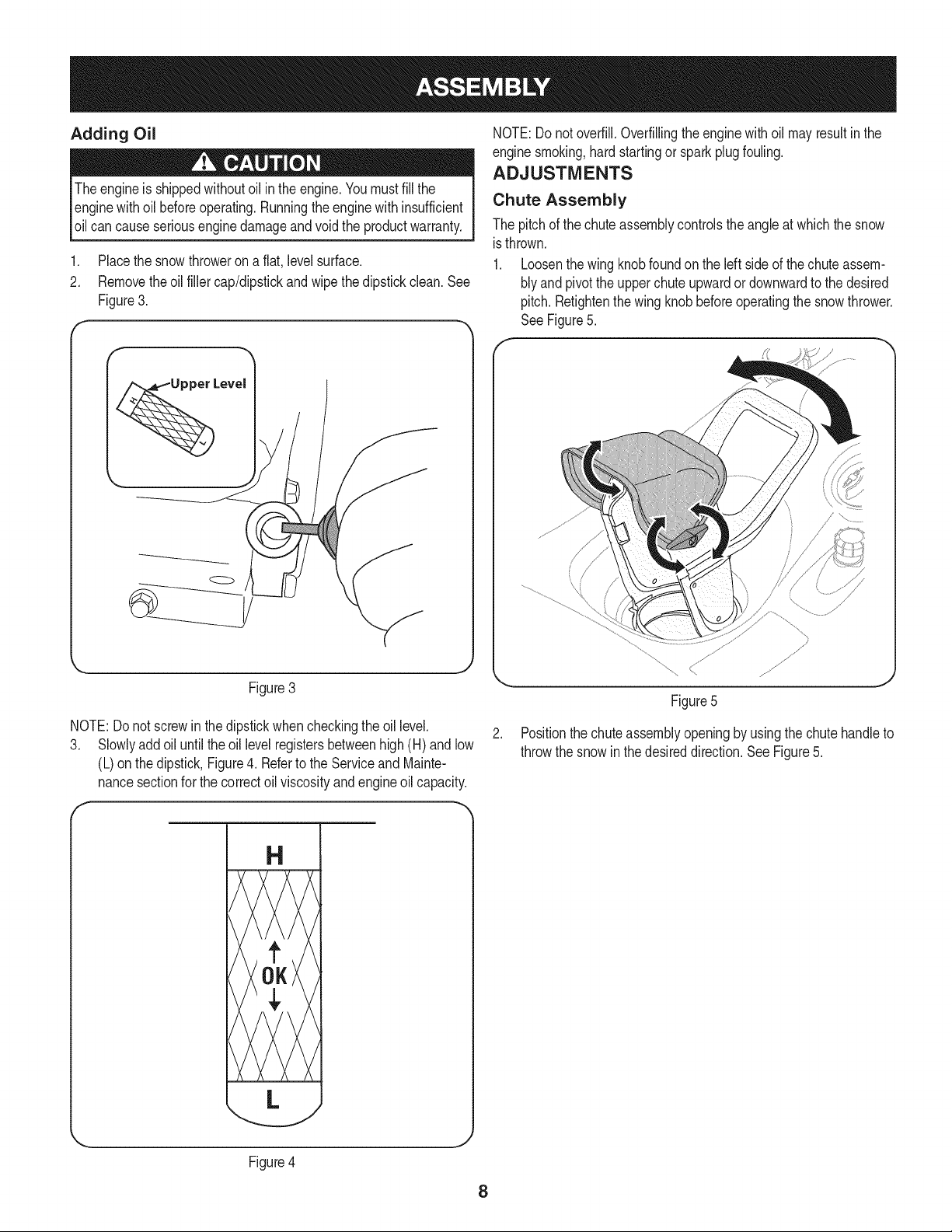

Chute Assembly

Thepitchofthechuteassemblycontrolstheangleatwhichthesnow

isthrown.

1. Loosenthewingknobfoundontheleftsideofthechuteassem-

blyandpivottheupperchuteupwardordownwardtothedesired

pitch.Retightenthe wingknobbeforeoperatingthesnowthrower.

SeeFigure5.

Figure3

NOTE:Donotscrewinthedipstickwhencheckingtheoil level.

3. Slowlyaddoil untilthe oillevelregistersbetweenhigh(H) andlow

(L)on thedipstick,Figure4. Referto the ServiceandMainte-

nancesectionforthecorrectoilviscosityandengineoil capacity.

f

H

J

Figure5

Positionthechuteassemblyopeningby usingthechutehandleto

throwthesnowinthedesireddirection.SeeFigure5.

Figure4

8

This pageleft intentionallyblank.

9

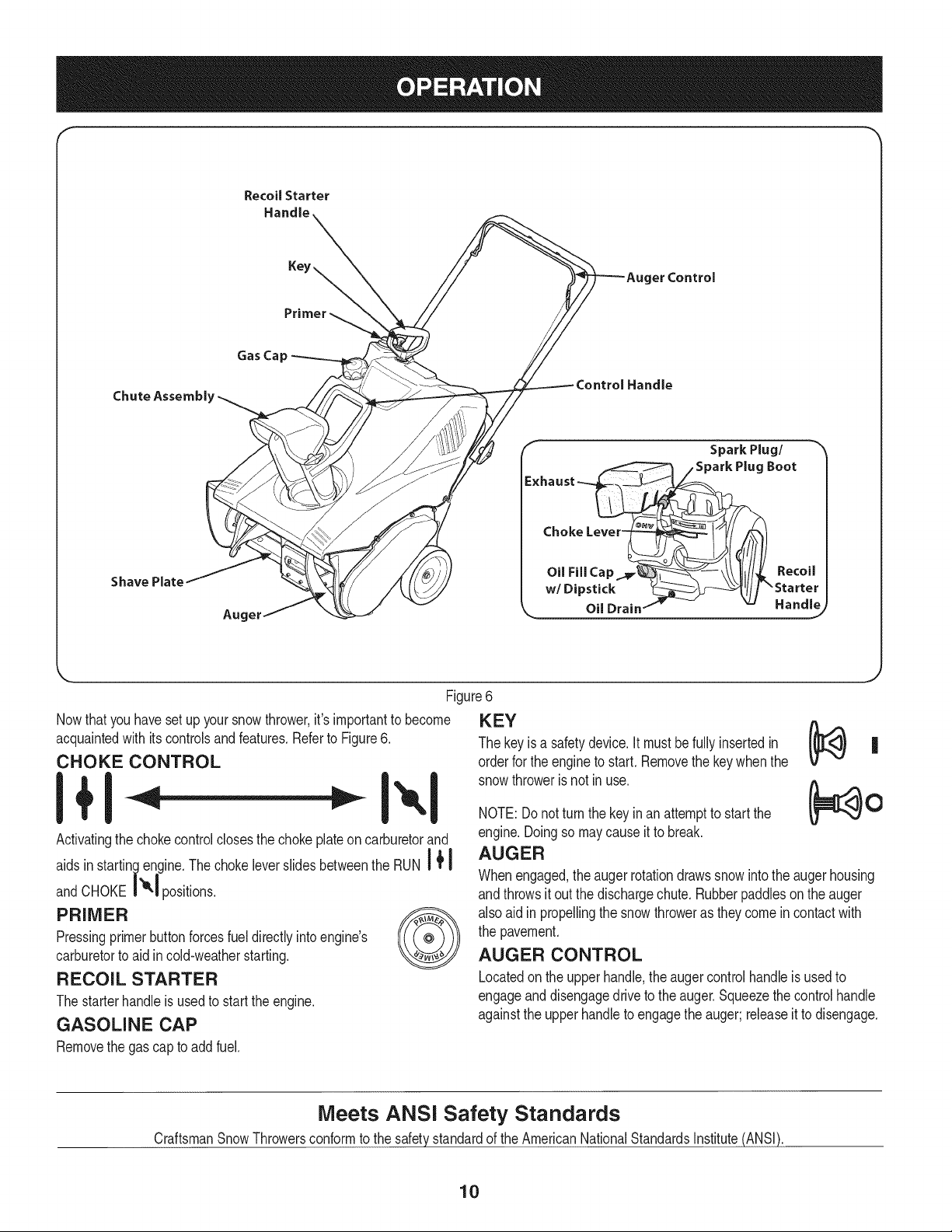

Recoil Starter

Primer

Gas Ca

er Control

Handle

Shave Plate

Auger

Figure6

Nowthat youhavesetup yoursnowthrower,it'simportanttobecome

acquaintedwithitscontrolsandfeatures.RefertoFigure6.

CHOKE CONTROL

t+ t'.,I

Activatingthechokecontrolclosesthe chokeplateoncarburetorand

aidsinstartingengine.ThechokeleverslidesbetweentheRUNI _1

andCHOKEI'°'_ positions.

Pressingprimerbuttonforcesfueldirectlyintoengine's

PRIMER

carburetortoaidin cold-weatherstarting.

l

RECOIL STARTER

Thestarterhandleis usedtostarttheengine.

GASOLINE CAP

Removethegascaptoaddfuel.

! / I

f

Chok

Exhaust

Oil FillCap..w_

w/Dipstick

k,_ Oil Drain t

SparkPlug/ "_

Boot

_\/\_l//_ Recoil

pStart+r

Hand_

KEY

Thekeyisa safetydevice.It mustbefullyinsertedin

orderfortheenginetostart.Removethekeywhenthe

snowthrowerisnotinuse.

NOTE:Donotturnthekeyinanattemptto startthe

engine.Doingsomaycauseit to break.

AUGER

Whenengaged,theaugerrotationdrawssnowintotheaugerhousing

andthrowsitoutthedischargechute.Rubberpaddlesontheauger

alsoaidin propellingthe snowthroweras theycomein contactwith

thepavement.

AUGER CONTROL

Locatedontheupperhandle,theaugercontrolhandleisusedto

engageanddisengagedrivetotheauger.SqueezethecontrolhandJe

againsttheupperhandletoengagetheauger;releaseitto disengage.

Meets ANSi Safety Standards

CraftsmanSnowThrowersconformto the safetystandardoftheAmericanNationalStandardsInstitute(ANSI).

10

CHUTE ASSEMBLY

Rotatethedischargechuteto the leftor rightusingthechutehandle.

Thepitchofthedischargechutecontrolstheangleatwhichthesnow

isthrown.Loosenthewing knobonthe side of the dischargechute

beforepivotingthedischargechuteupwardordownward.Retighten

theknoboncethedesiredpositionhasbeenachieved.

SHAVE PLATE

Theshaveplate maintainscontactwiththepavementasthesnow

throwerispropelled,allowingsnowclosetothe pavement'ssurfaceto

bedischarged.

BEFORE STARTING THE ENGINE

machineandin thismanualbeforeo

1. Thesparkplugwirewasdisconnectedforsafety.Attachthespark

plugwiretothesparkplugbeforestarting.

STARTING THE ENGINE

)ressurizedstartin( flammable.

Toavoidcarbonmonoxidepoisoning,makesuretheengineis

outdoorsina well-ventilatedarea.

4. Pushintheprimerbuttonfivetoseven(5-7)times,makingsureto

covertheventholewhenpushing.

5. Ifthe engineis warm,pushtheprimerbuttononlyonce.

NOTE:Alwayscovertheventholeintheprimerbuttonwhenpushing.

Additionalprimingmaybe necessaryforthefirststartifthetempera-

tureisbelow15° E

6. Graspthestarterhandleandpulltheropeoutslowly,untilitpulls

slightlyharder.Letthe roperewindslowly.

7. Pullthestarterhandlerapidly.Do notallowthehandletosnap

back.Allowit torewindslowlywhilekeepinga firmholdon the

handle.

8. Astheenginewarmsupandbeginstooperateevenly,slidethe

chokeleverslowlytothe 1/2-chokeposition(mid-waybetween

RUNandOFF).Whentheenginebeginsto runsmoothly,move

thechoketothe RUN_ _position.Iftheenginefails,returnto

theCHOKEI_1 position,thenslowlymoveto 1/2-chokethenthe

RUNI _ i position.

|t,I

STOPPING THE ENGINE

1. Runthe enginefora fewminutesbeforestoppingto helpdry

CHOKEanymoistureon theengine.

2. Tostoptheengineremovethekeyand storeitin a safeplace.

3. Wipeall the snowandmoistureawayfromthe enginecontrols

area.

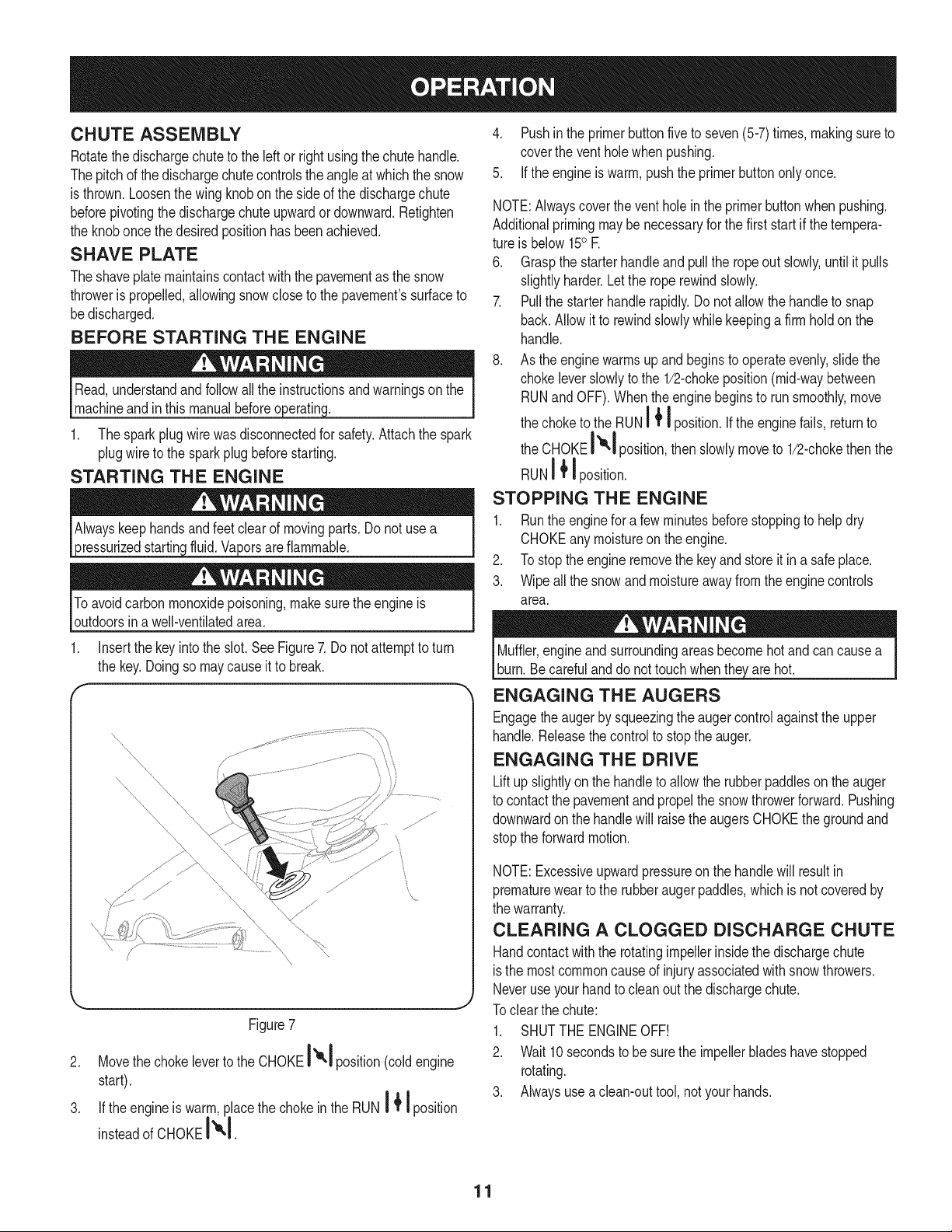

1. Insertthe keyintothe slot. SeeFigure7.Donotattempttoturn

thekey.Doingsomaycauseitto break.

r

,%

Figure7

2. Movethechokeleverto the CHOKEI",1 os t on(co dengine

start).

3. if theengineiswarm,placethechokeintheRUNI _ Iposition

insteadofCHOKEI'I

Muffler,engineandsurroundingareasbecomehotandcancausea

burn.Becarefulanddonottouchwhenthe,/are hot.

ENGAGING THE AUGERS

Engagethe augerby squeezingtheaugercontrolagainsttheupper

handle.Releasethecontroltostoptheauger.

ENGAGING THE DRIVE

Liftup slightlyonthe handleto allowthe rubberpaddlesontheauger

tocontactthepavementand propelthe snowthrowerforward.Pushing

downwardonthehandlewill raisetheaugersCHOKEthegroundand

stoptheforwardmotion.

NOTE:Excessiveupwardpressureonthe handlewill resultin

prematureweartotherubberaugerpaddles,whichisnotcoveredby

thewarranty.

CLEARING A CLOGGED DISCHARGE CHUTE

Handcontactwiththe rotatingimpellerinsidethe dischargechute

isthe mostcommoncauseofinjuryassociatedwithsnowthrowers.

Neveruseyourhandto cleanoutthedischargechute.

Toclear thechute:

1. SHUTTHEENGINEOFF!

2. Wait 10secondstobe suretheimpellerbladeshavestopped

rotating.

3. Alwaysusea clean-outtool,notyourhands.

11

Thispageleftintentionallyblank.

12

MAINTENANCE SCHEDULE

Beforeperforminganytypeofmaintenance/service,disengageall

controlsandstoptheengine.Waituntilallmovingpartshavecometo

acompletestop.Disconnectsparkplugwireandgrounditagainstthe

enginetopreventunintendedstarting.Alwayswearsafetyglassesduring

operationorwhileperforminganyadjustmentsorrepairs.

Eachuse 1. Engineoillevel.

2. Snowthrowerandexhaust

1. Check

2. Clean

Followthemaintenanceschedulegivenbelow.Thischartdescribes

serviceguidelinesonly.UsetheServiceLogcolumnto keeptrackof

completedmaintenancetasks.To locate the nearest Sears Service

Centeror to scheduleservice,simplycontactSearsat

1-800-4-MY-HOME@.

= =

area.

1st5 hours 1. Engineoil. 1. Change.

Every5hours 1. Engineoil. 1. Check.

2. Exhaustarea. 2. Clean.

25 hours 1. Sparkplug. 2. Check.

Everyseason/50hours 1. Engineoil 1. Change

Everyseason/lO0hours 1. Sparkplug 1. Clean,replace,re-gap

Everyseason/Before 1. Pivotpoints 1. Lubricate

storage 2. Controlhandle 2. Lubricate

3. Extensionspring 3. Lubricate

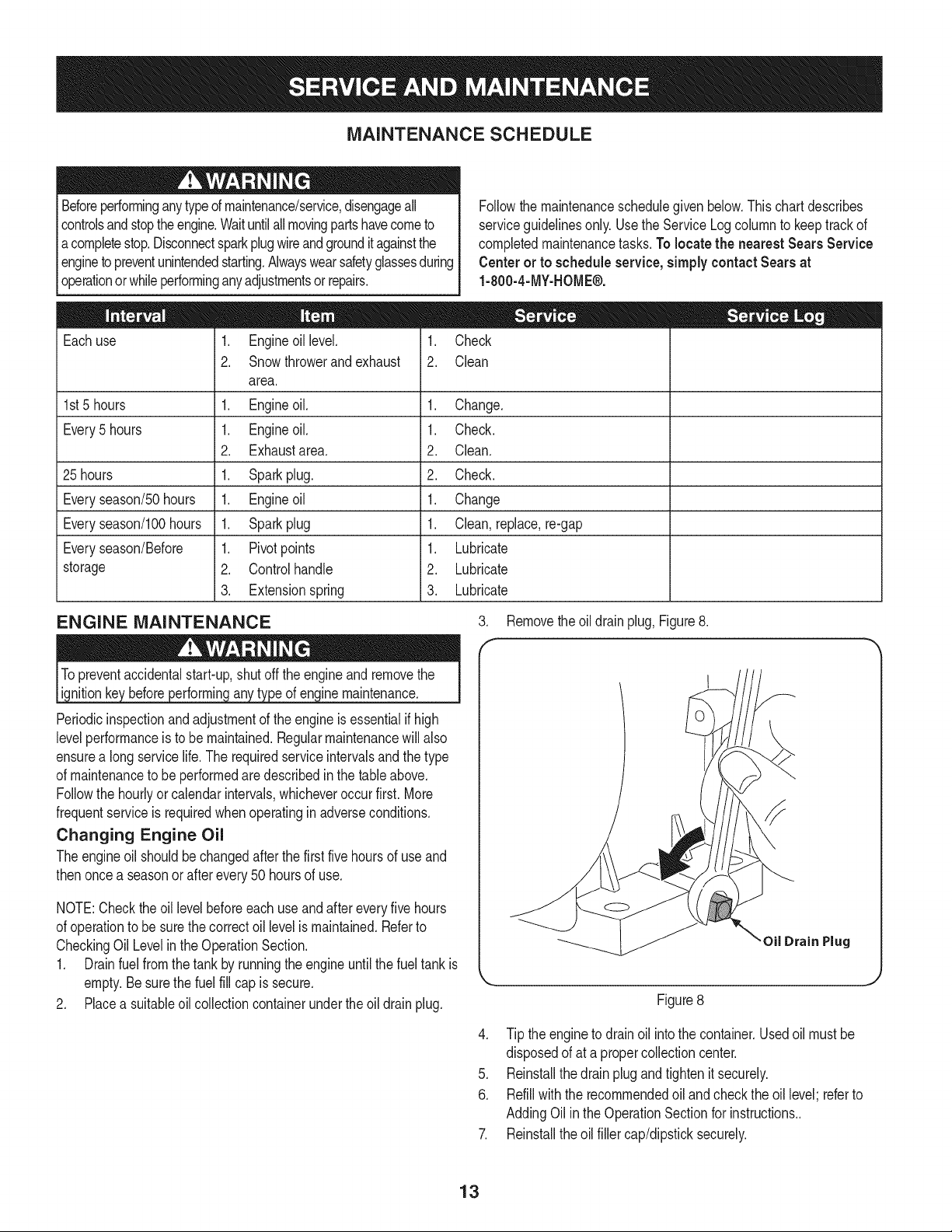

ENGINE MAINTENANCE

.

Removetheoildrainplug,Figure8.

f

ine maintenance.

Periodicinspectionandadjustmentoftheengineisessentialifhigh

levelperformanceisto be maintained.Regularmaintenancewillalso

ensurealongservicelife.Therequiredserviceintervalsandthetype

ofmaintenanceto beperformedaredescribedinthe tableabove.

Followthehourlyorcalendarintervals,whicheveroccurfirst. More

frequentserviceis requiredwhenoperatinginadverseconditions.

Changing Engine Oil

Theengineoil shouldbechangedafterthe firstfive hoursof useand

thenoncea seasonor afterevery50 hoursof use.

NOTE:Checktheoil levelbeforeeachuseandaftereveryfivehours

ofoperationtobesurethecorrectoil levelismaintained.Referto

CheckingOilLevelintheOperationSection.

1. Drainfuelfromthetankbyrunningtheengineuntilthefueltankis

empty.Besurethefuelfillcapissecure.

2. Placea suitableoil collectioncontainerundertheoil drainplug.

Figure8

4. Tiptheenginetodrainoilintothecontainer.Usedoil mustbe

disposedofata propercollectioncenter.

5. Reinstallthe drainplugandtightenitsecurely.

6. Refillwiththe recommendedoilandchecktheoil level;referto

AddingOilinthe OperationSectionforinstructions..

7. Reinstallthe oil fillercap/dipsticksecurely.

13

Thoroughlywashyourhandswithsoapandwateras soon as

possibleafterhandlingusedoil.

NOTE:Pleasedisposeofusedmotoroil ina mannerthatis friendlyto

theenvironment.Takeit toa recyclingcenteror othercollectioncenter.

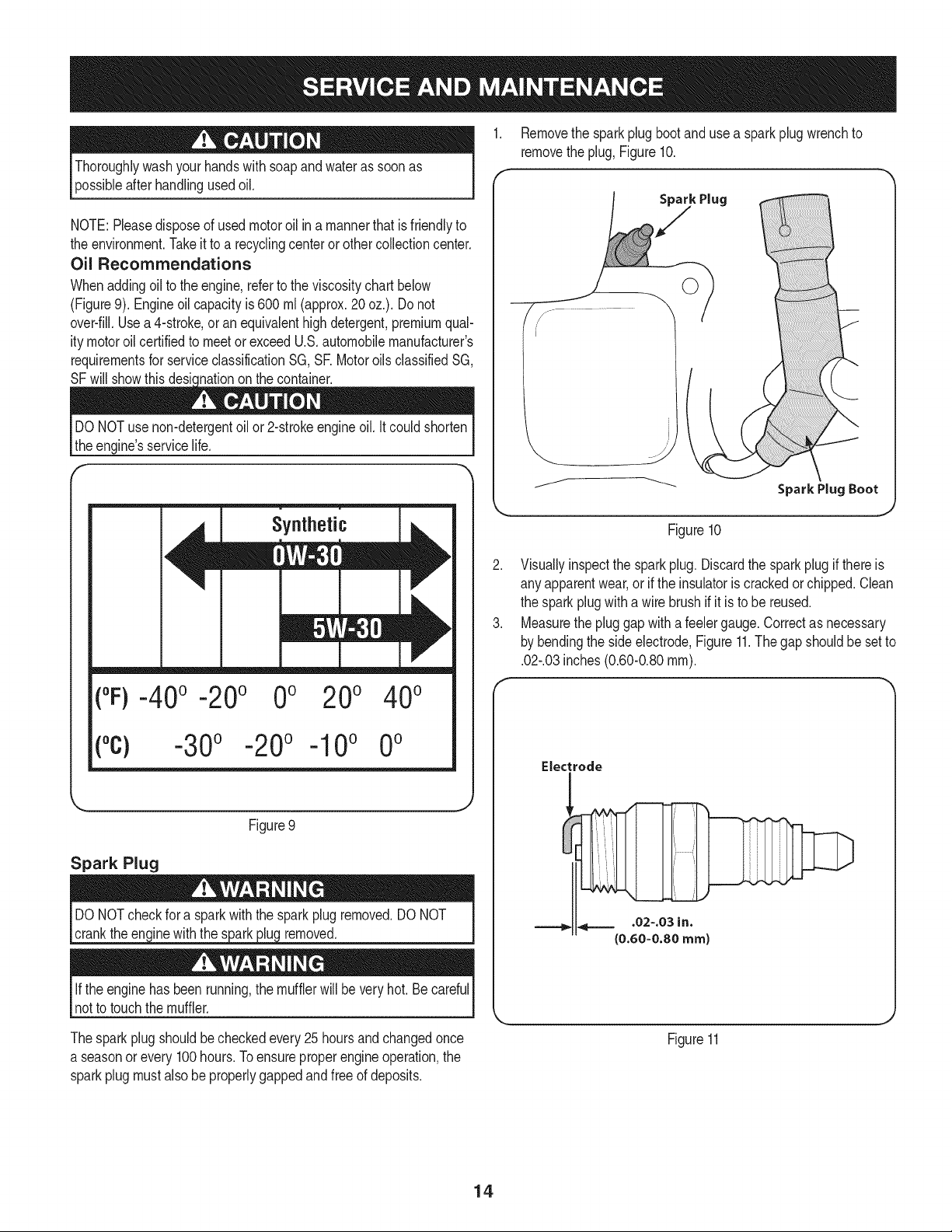

Oil Recommendations

Whenaddingoiltotheengine,refertotheviscositychartbelow

(Figure9). Engineoilcapacityis600 ml (approx.20oz.).Donot

over-fill.Usea4-stroke,or anequivalenthighdetergent,premiumqual-

ity motoroilcertifiedto meetor exceedU.S.automobilemanufacturer's

requirementsfor serviceclassificationSG,SRMotoroilsclassifiedSG,

SFwillshowthisdesicnationonthecontainer.

DONOTusenon-detergentoil or 2-strokeengineoil.itcouldshorten

theengine'sservicelife.

f,

_ Im&lmmwNiwl _ I_L_ _

Removethesparkplugbootand usea sparkplugwrenchto

removetheplug,Figure10.

Spar Plug

©

Spark Plug Boot

Figure10

Visuallyinspectthe sparkplug. Discardthe sparkplugifthereis

anyapparentwear,or if theinsulatoris crackedorchipped.Clean

thesparkplugwitha wirebrushif it isto be reused.

Measurethepluggapwitha feelergauge.Correctasnecessary

bybendingthe sideelectrode,Figure11.Thegap shouldbe setto

.02-.03inches(0.60-0.80ram).

(%-400 -200 0o 200 400

(°c) -30° -20° -10° 0°

Figure9

Spark Plug

cranktheen(inewiththesark__ removed.

Iftheenginehasbeenrunning,themufflerwillbe veryhot.Becareful

notto touchthe muffler.

Thesparkplugshouldbecheckedevery25hoursandchangedonce

a seasonorevery100hours.Toensureproperengineoperation,the

sparkplugmustalsobeproperlygappedandfreeofdeposits.

Electrode

_t===== .02=.03 in.

(0.60-0.80 rnm)

Figure11

14

4. Checkthatthesparkplugwasheris ingoodconditionandthread 3.

thesparkplugin byhandto preventcross-threading.

5. Afterthe sparkplugis seated,tightenwitha sparkplugwrenchto

compressthewasher, f

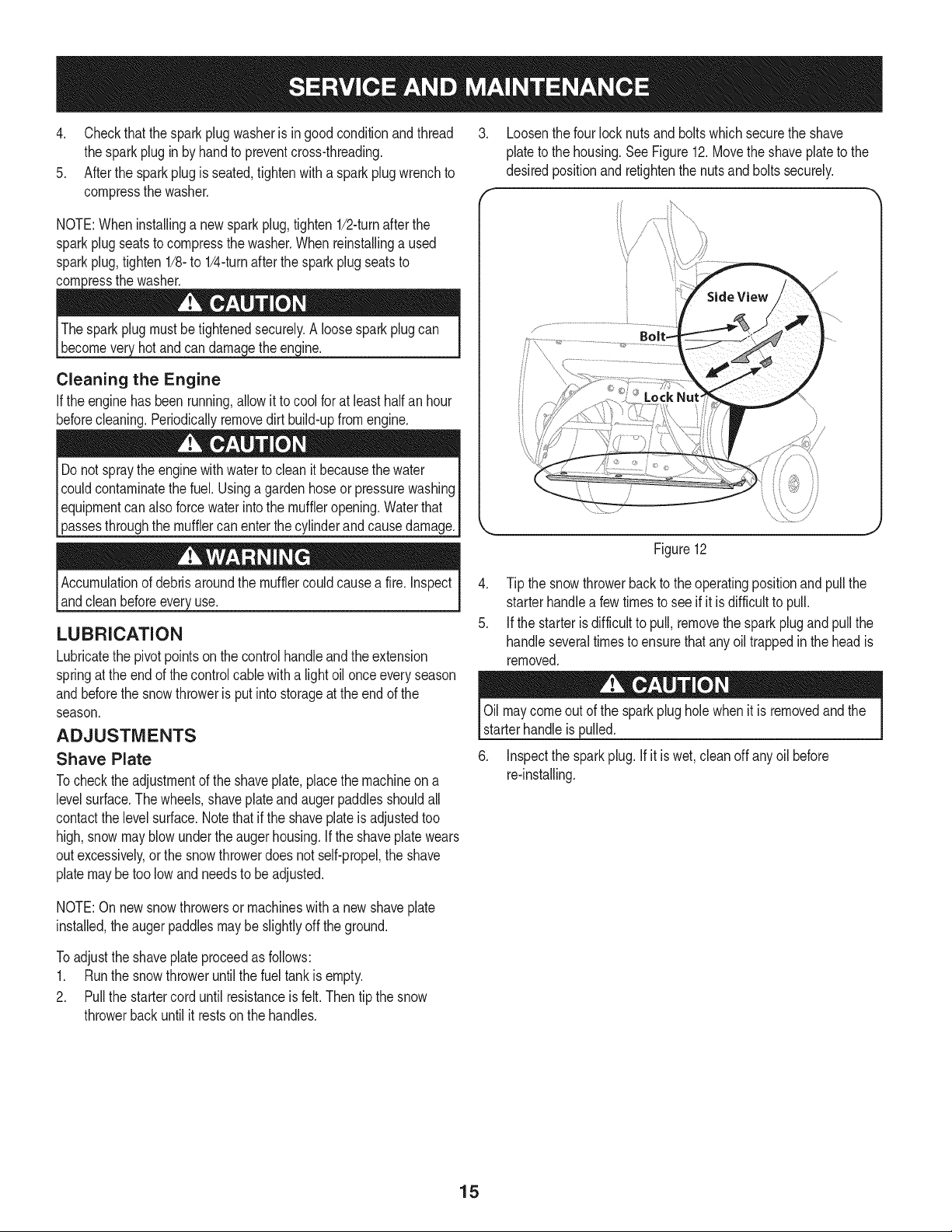

Loosenthefourlocknutsandboltswhichsecuretheshave

plateto the housing.SeeFigure12.Movetheshaveplatetothe

desiredpositionandretightenthe nutsandboltssecurely.

NOTE:Wheninstallinga newsparkplug,tighten1/2-turnafterthe

sparkplugseatstocompressthewasher.Whenreinstallinga used

sparkplug,tighten1/8-to 1/4-turnafterthe sparkplugseatsto

corn_ressthewasher.

becomever hotandcandamac ine.

Cleaning the Engine

Iftheenginehasbeenrunning,allowit to cool for at leasthalfan hour

beforecleaning.Periodicallyremovedirtbuild-upfromengine.

Donotspraytheenginewithwatertocleanitbecausethewater

couldcontaminatethefuel.Usinga gardenhoseor pressurewashing

Iequipmentcanalsoforcewaterintothemuffleropening.Waterthat

[passesthroughthe muffer can enterthecy nderandcausedamage,j

Accumulationofdebrisaroundthemufflercouldcausea fire.Inspect

andcleanbeforeeveryuse.

LUBRICATION

Lubricatethepivotpointsonthe controlhandleandtheextension

springat the endofthecontrolcablewitha lightoil onceeveryseason

andbeforethesnowthroweris putinto storageattheendof the

season.

ADJUSTMENTS

Shave Plate

Tochecktheadjustmentof theshaveplate,placethe machineona

levelsurface.Thewheels,shaveplateandaugerpaddlesshouldall

contactthelevelsurface.Notethatifthe shaveplateis adjustedtoo

high,snowmayblowundertheaugerhousing.Iftheshaveplatewears

outexcessively,orthesnowthrowerdoesnotself-propel,theshave

platemaybetoolowand needstobe adjusted.

\

\\

Figure12

4. Tipthesnowthrowerbackto theoperatingpositionandpullthe

starterhandlea fewtimestoseeifit isdifficulttopull.

5. Ifthe starterisdifficultto pull,removethesparkplugand pullthe

handleseveraltimestoensurethatanyoil trappedintheheadis

removed.

Oilmaycomeout of the sparkplugholewhenitis removedandthe

starterhandleis pulled.

6. Inspectthesparkplug.If itiswet,cleanoffanyoil before

re-installing.

NOTE:Onnewsnowthrowersor machineswitha newshaveplate

installed,theaugerpaddlesmaybeslightlyoff theground.

Toadjustthe shaveplateproceedasfollows:

1. Runthe snowthroweruntilthe fuel tankisempty.

2. Pullthe startercorduntilresistanceisfelt.Thentipthesnow

throwerbackuntilitrestson thehandles.

15

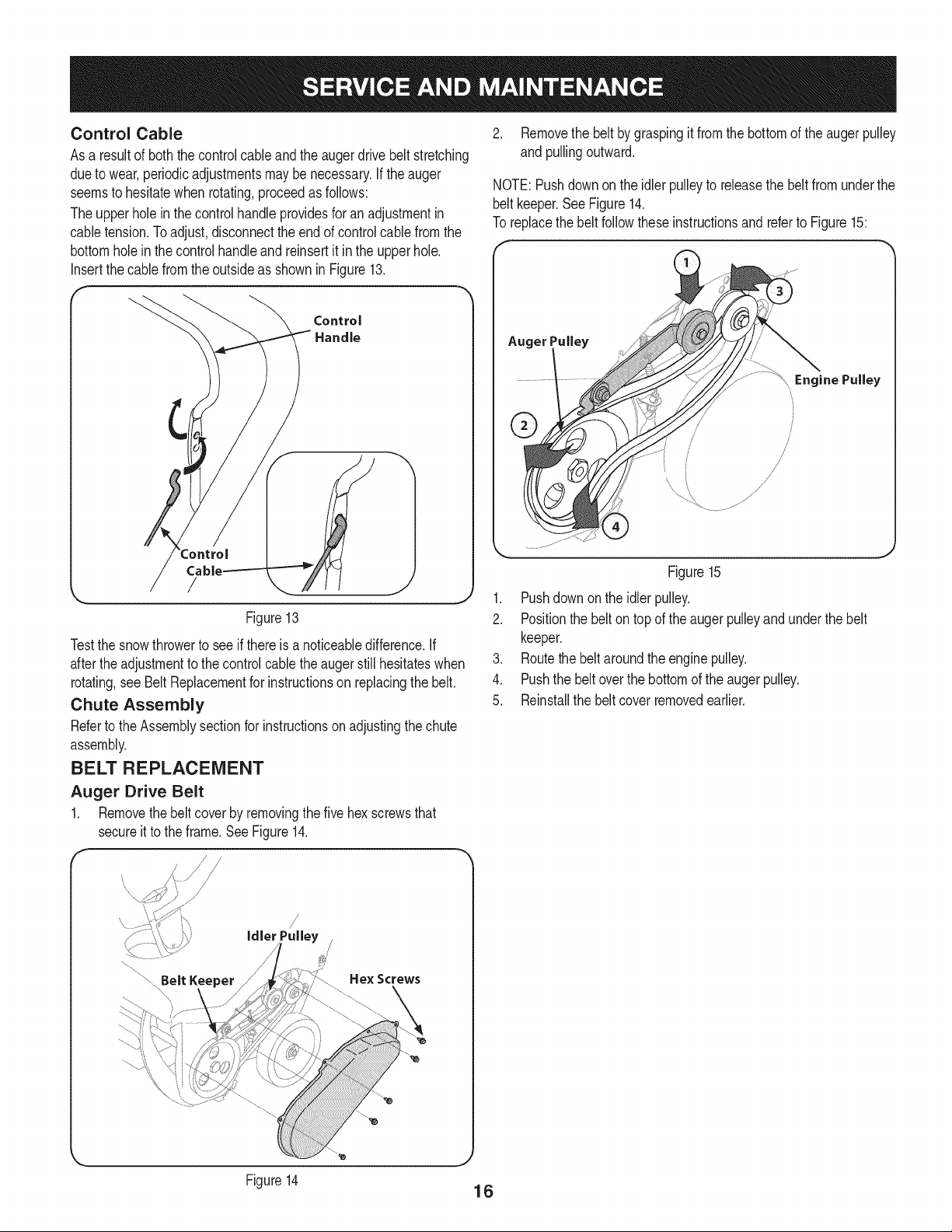

Control Cable

Asa resultof both thecontrolcableandtheaugerdrivebeltstretching

duetowear,periodicadjustmentsmaybenecessary.Iftheauger

seemsto hesitatewhenrotating,proceedasfollows:

Theupperholeinthe controlhandleprovidesforanadjustmentin

cabletension.Toadjust,disconnecttheendof controlcablefromthe

bottomholein thecontrolhandleand reinsertit intheupperhole.

Insertthe cablefromtheoutsideas shownin Figure13.

Control

Handle

2. Removethe belt bygraspingitfromthebottomof the augerpulley

and pullingoutward.

NOTE:Pushdownontheidlerpulleytoreleasethebeltfromunderthe

beltkeeper.SeeFigure14.

Toreplacethebeltfollowtheseinstructionsand referto Figure15:

/

/

/

/

J

Figure13

Testthesnowthrowerto seeifthereisa noticeabledifference.If

aftertheadjustmenttothecontrolcablethe augerstill hesitateswhen

rotating,seeBeltReplacementforinstructionson replacingthebelt.

Chute Assembly

RefertotheAssemblysectionfor instructionsonadjustingthechute

assembly.

BELT REPLACEMENT

Auger Drive Belt

1. Removethebeltcoverbyremovingthefivehex screwsthat

secureittotheframe.SeeFigure14.

................Belt Keeper

Figure15

1. Pushdownon the idlerpulley.

2. Positionthebelton topof theaugerpulleyandunderthebelt

keeper.

3. Routethebeltaroundtheenginepulley.

4. Pushthebelt overthebottomofthe augerpulley.

5. Reinstallthe belt coverremovedearlier.

Figure14

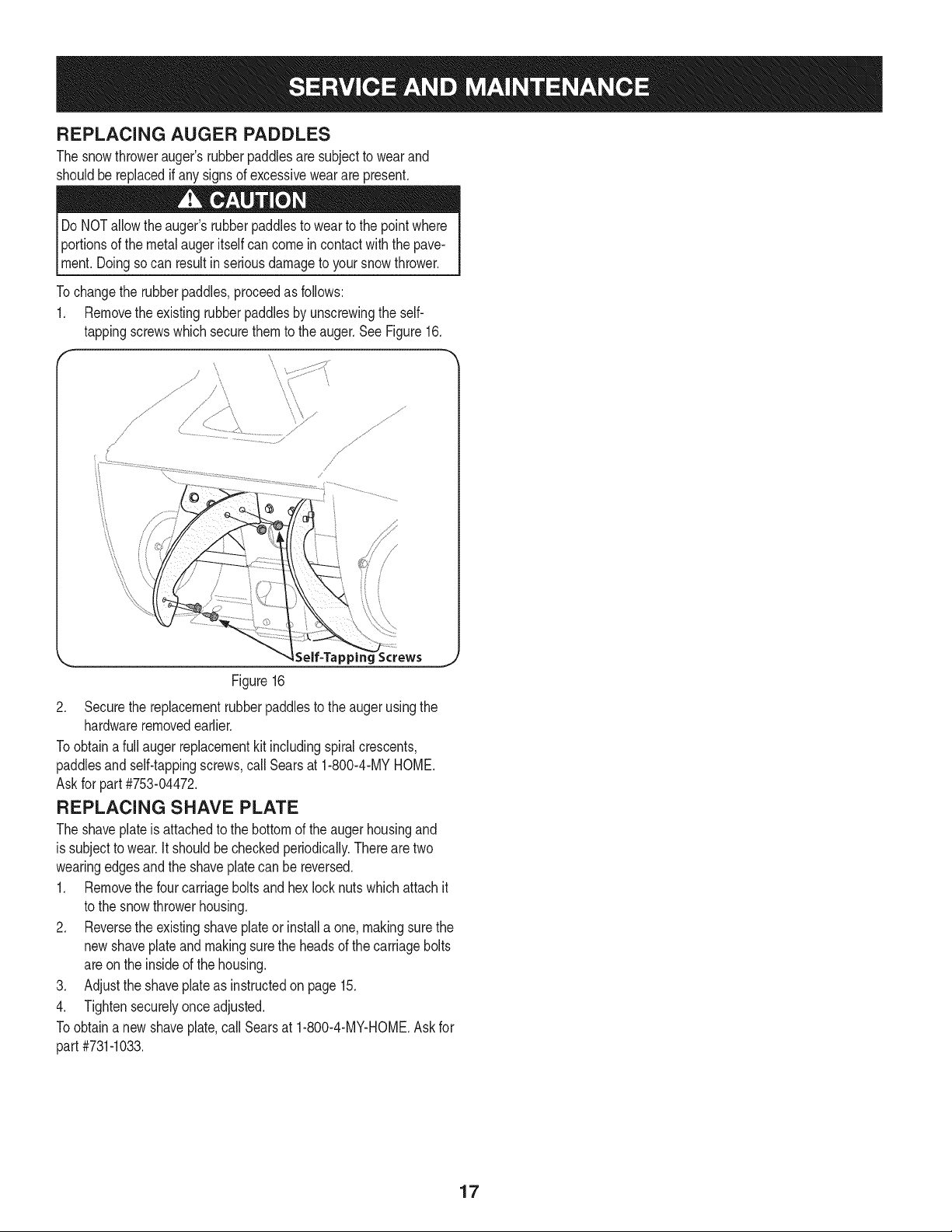

REPLACING AUGER PADDLES

Thesnowthrowerauger'srubberpaddlesaresubjecttowearand

shouldbereplacedifanysignsof excessiveweararepresent.

DoNOTallowthe auger'srubberpaddlesto wearto the pointwhere

Iportionsof the metalaugeritselfcancomein contactwiththepave-

lment.Doingsocan resultin seriousdamageto yoursnowthrower.

Tochangethe rubberpaddles,proceedasfollows:

1. Removetheexistingrubberpaddlesbyunscrewingthe self-

tappingscrewswhichsecurethemto theauger.SeeFigure16.

/

......." / +,

............i/." k _\I.........

f

Self-Tappir

Figure16

2. Securethereplacementrubberpaddlestotheaugerusingthe

hardwareremovedearlier.

Toobtainafull augerreplacementkitincludingspiralcrescents,

paddlesandself-tappingscrews,callSearsat 1-800-4-MYHOME.

Askforpart#753-04472.

REPLACING SHAVE PLATE

Theshaveplateisattachedtothe bottomoftheaugerhousingand

issubjecttowear.It shouldbe checkedperiodically.Therearetwo

wearingedgesandtheshaveplatecanbe reversed.

1.

Removethefourcarriageboltsandhexlocknutswhichattachit

tothesnowthrowerhousing.

.

Reversetheexistingshaveplateor installa one,makingsurethe

newshaveplateand makingsuretheheadsofthecarriagebolts

areonthe insideofthehousing.

3. Adjusttheshaveplateas instructedonpage15.

4. Tightensecurelyonceadjusted.

Toobtaina newshaveplate,callSearsat 1-800-4-MY-HOME.Askfor

part#731-1033.

17

Loading...

Loading...