Craftsman 247886510 Owner’s Manual

owner's

manual

MODEL NO.

247.886510

CAUTION:

Read

INSTRUCTIONS

carefully

Sold by Sears, Roebuck and Co., Chicago, IL 60684

Part No. 770-6870D

_/-___/_R,_/ CRRFT$MRN®

23" - 5 H.P. DUAL STAGE

SNOW THROWER

Optional Electric Starter Available

=Assembly

=Operation

=Maintenance

=Repair Parts

CRAFTSMAN WARRANTY'

LIMITED TWO YEAR WARRANTY ON CRAI_SMAN SNOW THROWER

For two years from the date of purchase, whet this Craftsman Snow Thrower is maintained, lubricated and tuned up

according to the instructions in the owner's manual, Sears will repair, free of charge, any defect in material and

workmanship.

If this Craftsman Snow Thrower is used for c<;mmercial or rental purposes, this warranty applies for only 90 days from

the date of purchase.

This warranty does not cover: Expendable terns which become worn during normal use, such as spark plugs, tire

chains and shear pins.

Repairs necessary because of operator aLuse or negligence, including bent cranksh_,ffs and the failure to maintain

the equipment according to the instructk ns contained in the owner's manual.

WARRANTY SERVICE IS AVAILABLE BY CO _ITACTING THE NEAREST SERVICE CENTER/DEPARTMENT IN THE

UNITED STATES. This warranty applies only while this product is in use in the United States.

This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

SEARS, ROEBUCK AND CO.

DEP' r. 698/731A SEARS TOWER

CHICAGO, IL 60684

OWNEF:'S INFORMATION

Record the following information about youl unit so that you will be able to provide it in case of loss or theft.

DATE PURCHASED:. MODEL NO./CODE: 247.886510L

STORE WHERE PURCHASED: ADDRES_

CITY: STATE: TELEPHONE:

MAINTENANCE AGREEMENT

A SEARS MAINTENANCE AGREEMENT IS AVAILABLE FOR THIS PRODUCT. CONTACT YOUR NEAREST

SEAR S STORE FOR DETAILS.

TABLF OF CONTENTS

Page

CRAFTSMAN WARRANTY ................. 2

OWNER'S INFORMATION .................. 2

MAINTENANCE AGREEMENT .............. 2

SAFE OPERATION PRACTICES ............. 3

ASSEMBLY INSTRUCTIONS .............. 4-9

OPERATING INSTRUCTIONS ........... 10-13

MAINTENANCE ..................... 13, 14

Page

STORAGE ........................... 14, 15

ADJUSTMENT/REPAIRS ............... 15-19

TROUBLE SHOOTING GUIDE ............. 20

SNOW THROWER REPAIR PARTS ...... 22-29

ENGINE REPAIR PARTS ............... 30-34

HOW TO ORDER REPAIR PARTS .. Back Cover

IMPOR ANT

SAFE OPERATION PRACTICES FOR WALK-BEHIND SNOW THROWERS

_lb THIS SYMBOL POINTS OUT IMPORTANT SAFETY INSTRUCTIONS WHICH, IF NOT FOLLOWED COULD

ENDANGER

FOLLOW ALL INSTRUCTIONS IN THIS MANUAL BEFORE ATTEMPTING TO OPERATE YOUR SNOW

THROWER.

To reduce the potential for any injury, comply with the following safety instructions. Failure to comp|y with

the instructions may result in personal injury.

TRAINING

1. Read this owner's guide carefully. Be thoroughly familiar with

the controls and proper use of the equipment. Know how to

stop the unit and disengage the controls quickly.

2. Never allow children to operate equipment. Never allow

adults to operate equipment without proper instructions.

3. No one should operate this unit while intoxicated or while

taking medication that impairs the senses or reactions.

4. Keep the area of operation clear of all persons, especialLy

small children and pets.

5. Exercise caution to avoid slipping or falling, especially when

operating in reverse.

PREPARATION

1. Thoroughly inspect the area where the equipment is to be

used and remove all door mats, sleds, boards, wires and

other foreign objects.

2. Disengage all clutches and shift into neutral before starting

engine.

3. Do not operate equipment without wearing adequate winter

outer garments. Wear footwear which will improve footing

on slippery surfaces.

4. Check the fuel before starting the engine. Gasoline is an ex-

tremely flammable fuel. Do not fill the gasoline tank indoors,

while the engine is running, or while the engine is still hot.

Replace gasoline cap securely and wipe off any spilled

gasoline before starting the engine as it may cause_a fire or

explosion.

5. Use a grounded three wire plug-in for all units with electric

drive motors or etectric starting motors.

6. Adjust auger housing height to clear gravel or crushed rock

surface.

7. Never attempt to make any adjustments while engine is run-

ning (except where specifically recommended by

manufacturer).

8. Let engine and machine adjust to outdoor temperature before

starting to clear snow.

9. Always wear safety glasses or eye shields during operation

or while performing an adjustment or repair, to protect eyes

from foreign objects that may be thrown from the machine

in any direction.

OPERATION

1, Do not put hands or feet near rotating parts. Keep clear of

discharge opening at all times.

2. Exercise extreme caution when operating on or crossing

gravel drives, walks, or roads. Stay alert for hidden hazards

or traffic. Do not carry passengers.

3. After striking a foreign object, stop the engine, remove wire

from spark plug, and thoroughly inspect the snow thrower

for any damage. Repair the damage before restarting and

operating the snow thrower.

4. If the snow thrower should start to vibrate abnormally, stop

the engine and check immediately for the cause. Vibration

is generally a warning of trouble.

THE PERSONAL SAFETY AND/OR PROPERTY OF YOURSELF AND OTHERS. READ AND

5_ Stop engine whenever you leave the operating position,

before unclogging the augerlimpel_,r housing or discharge

guide, and making any repairs, adjustments, or inspections.

6. Take all possible precautions when leaving the unit un-

attended. Disengage the auger/impeller, shift into neutral,

stop the engine, and remove the key.

7. When cleaning, repairing, or inspecting, make certain

auger/impeller and all moving parts have stopped. Discon-

nect spark plug wire and keep away from plag to prevent

accidental starting.

8. Do not run engine indoors, except when starting engine and

transporting snow thrower in or out of building. Open doors.

Exhaust fumes are dangerous.

9. Do not clear snow across the face of slopes. Exercise ex-

treme caution when changing direction on slopes. Do not at-

tempt to clear steep slopes.

10. Never operate snow thrower without guards, plates, or other

safety protection devices in place.

11. Never operate snow thrower near glass enclosures,

automobiles, windows wells, drop offs, etc., without proper

adjustment of snow thrower discharge angle. Keep children

and pets away.

12.

Do not overload machine capacity by attempting to clear

snow at too fast a rate.

13.

Never operate the machine at high transport speeds on slip-

pery surfaces. Look behind and use care when backing.

14.

Never direct discharge at bystanders or allow anyone in front

of unit.

15.

Disengage power to auger/impeller when transporting or not

in use.

16.

Use only attachments and accessories approved by the

manufacturer of snow thrower (such as wheel weights,

counterweights, cabs, etc.).

17.

Never operate the snow thrower without good visibility or light.

Always be sure of your footing and keep a firm hold on the

handles. Walk, never run.

MAINTENANCE AND STORAGE

1. Check shear bolts, engine mounting bolts, etc., at frequent

intervals for proper tightness to be sure equipment is in safe

working condition.

2. Never store the machine with fuel in the fuel tank inside a

building where ignition sources are present, such as hot water

and space heaters, clothes dryers, and the like. Allow engine

to cool before storing in any enclosure.

3. Always refer to owner's manual instructions for important

details if snow thrower is to be stored for an extended period.

4. Maintain or replace safety and instruction labels, as

necessary.

5. Run machine a few minutes after throwing snow to prevent

freeze up of auger/impeller.

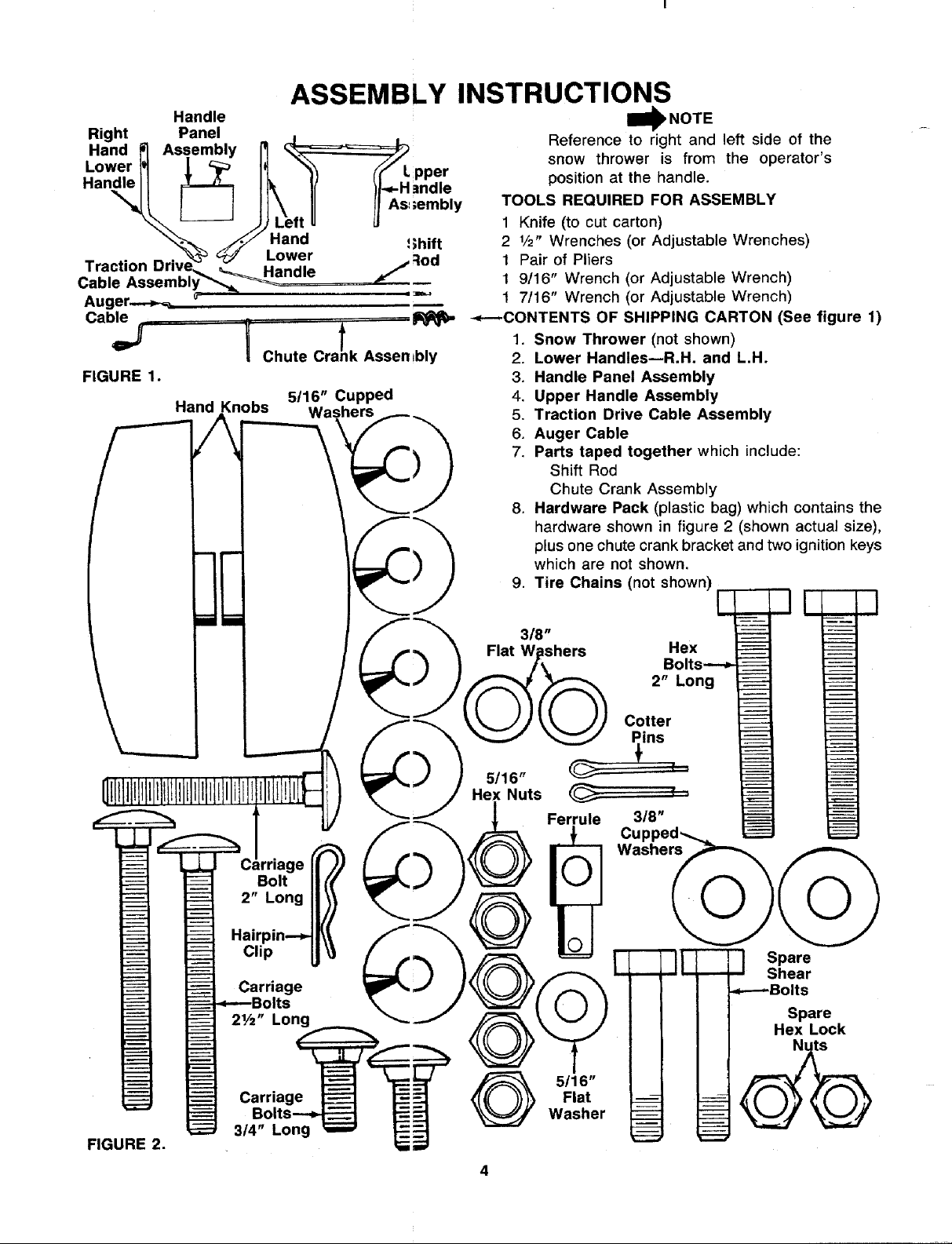

ASSEMBLY INSTRUCTIONS

Handle

Right Panel , .

Hand P] Assembly _ _-====_==,_1_

Lower

Han_dleI1 [L_ I_ "_ _'HL PPd_r

\\t_s JJ e,,

"_.'_ ._',F Hand !;hift

Traction Driv__'_ _ h_nw_ /:iod

Cable Assembly__ _ L _=_

Augers,

Cable

I Chute Cra!k Assembly

FIGURE 1.

Hand Knobs

5/16" Cupped

Wa _ers

I1_ NOT E

Reference to right and left side of the

snow thrower is from the operator's

position at the handle.

TOOLS REQUIRED FOR ASSEMBLY

1 Knife (to cut carton)

2 1/2" Wrenches (or Adjustable Wrenches)

1 Pair of Pliers

1 9/16" Wrench (or Adjustable Wrench)

1 7/16" Wrench (or Adjustable Wrench)

--_---CONTENTS OF SHIPPING CARTON (See figure 1)

1. Snow Thrower (not shown)

2. Lower Handles--R.H. and L.H.

3. Handle Panel Assembly

4. Upper Handle Assembly

5. Traction Drive Cable Assembly

6. Auger Cable

7. Parts taped together which include:

Shift Rod

Chute Crank Assembly

8. Hardware Pack (plastic bag) which contains the

hardware shown in figure 2 (shown actual size),

plus one chute crank bracket and two ignition keys

which are not shown.

9. Tire Chains (not shown)

E q q

FIGURE 2.

rriage

Bolt

2" Long

Clip

Carriage

Its

21/2" Long

Carriage

3/4" Long

Flat

5/16"

Washer

2" Long

Cotter

ins

3/8"

Bolts----_

I

--LJ Spare

Shear

_---Bolts

Spare

Hex Lock

I

Upper

Chute

FIGURE 3.

Upper

Hand

Knob

5/16"

Carria

Bolt 2"

Long

FIGURE 4.

washer_ k_-..-Hand

5/16" Hex_.\ Lower

Ri

Hand

Lower

Handle

Hex Bolt 2" Long

318" d Washer

Nut _

Carriage

Bolts 21/2"

Long

Knob

5/16" Cupped

Washer

Left

Loosen

Screw

UNPACKING

1. Cut the four corners of the carton from top to bot-

tom. Lay the panels flat on the ground.

2. Remove all packing inserts. Make certain all loose

parts and literature have been removed before

discarding the inserts or carton.

3. Pull the snow thrower out of the carton.

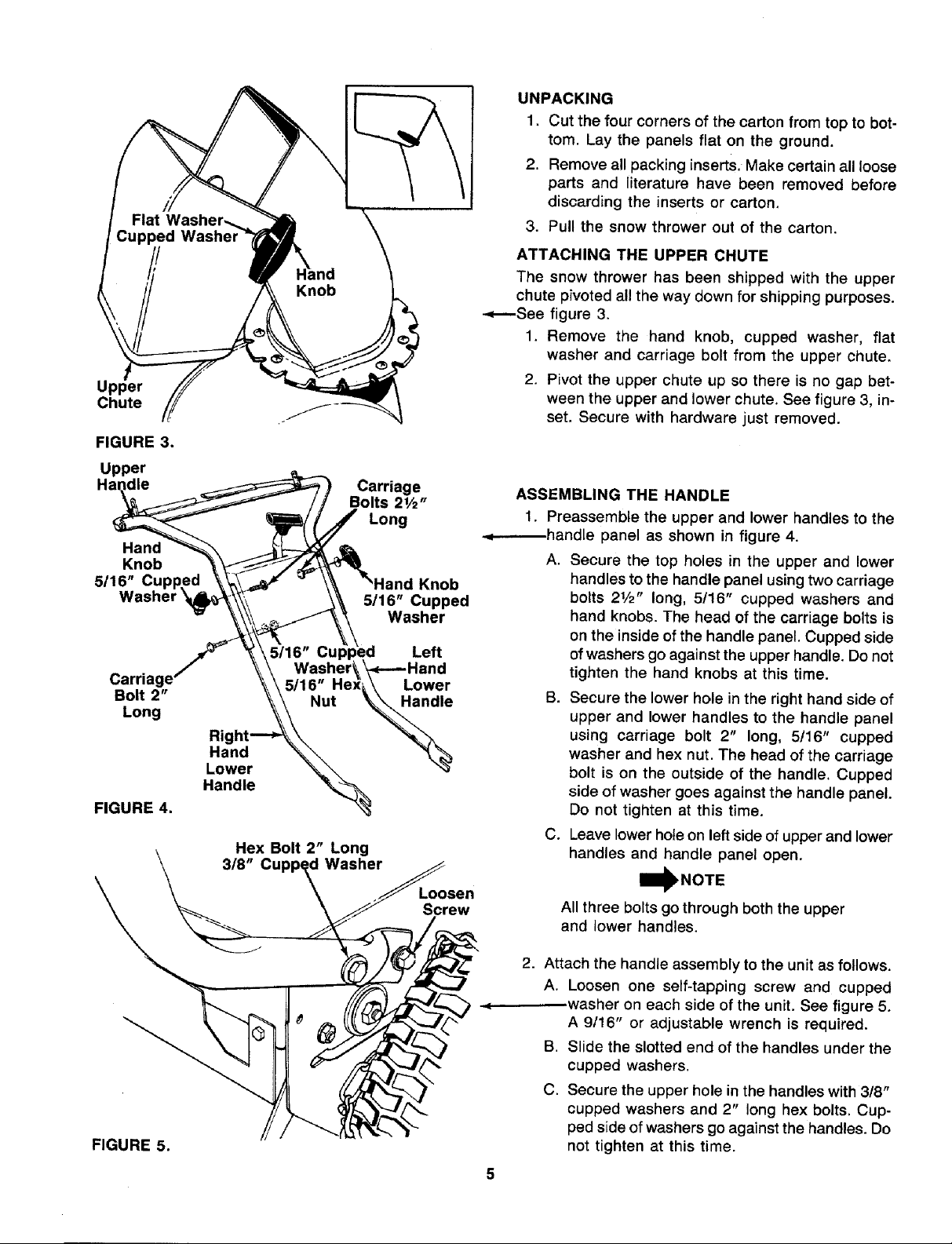

ATTACHING THE UPPER CHUTE

The snow thrower has been shipped with the upper

chute pivoted all the way down for shipping purposes.

-.,_----See figure 3.

1, Remove the hand knob, cupped washer, fiat

washer and carriage bolt from the upper chute.

2. Pivot the upper chute up so there is no gap bet-

ween the upper and lower chute. See figure 3, in-

set. Secure with hardware just removed.

ASSEMBLING THE HANDLE

1. Preassemble the upper and lower handles to the

.d------handle panel as shown in figure 4.

A. Secure the top holes in the upper and lower

handles to the handle panel using two carriage

bolts 21/2" long, 5!16" cupped washers and

hand knobs. The head of the carriage bolts is

on the inside of the handle panel. Cupped side

of washers go against the upper handle. Do not

tighten the hand knobs at this time.

B. Secure the lower hole in the right hand side of

upper and lower handles to the handle panel

using carriage bolt 2" long, 5/16" cupped

washer and hex nut. The head of the carriage

bolt is on the outside of the handle. Cupped

side of washer goes against the handle panel.

Do not tighten at this time.

C. Leave lower hole on left side of upper and lower

handles and handle panel open.

I_NOTE

All three bolts go through both the upper

and lower handles.

FIGURE 5.

2. Attach the handle assembly to the unit as follows.

A. Loosen one self-tapping screw and cupped

.washer on each side of the unit. See figure 5.

A 9/16" or adjustable wrench is required.

B. Slide the slotted end of the handles under the

cupped washers.

C. Secure the upper hole in the handles with 318"

cupped washers and 2" long hex bolts. Cup-

ped side of washers go against the handles. Do

not tighten at this time.

FIGURE 6.

EyeboIt

Crank

Assembly

5116"

Hex Nui s

5/16" Cupped

Washer

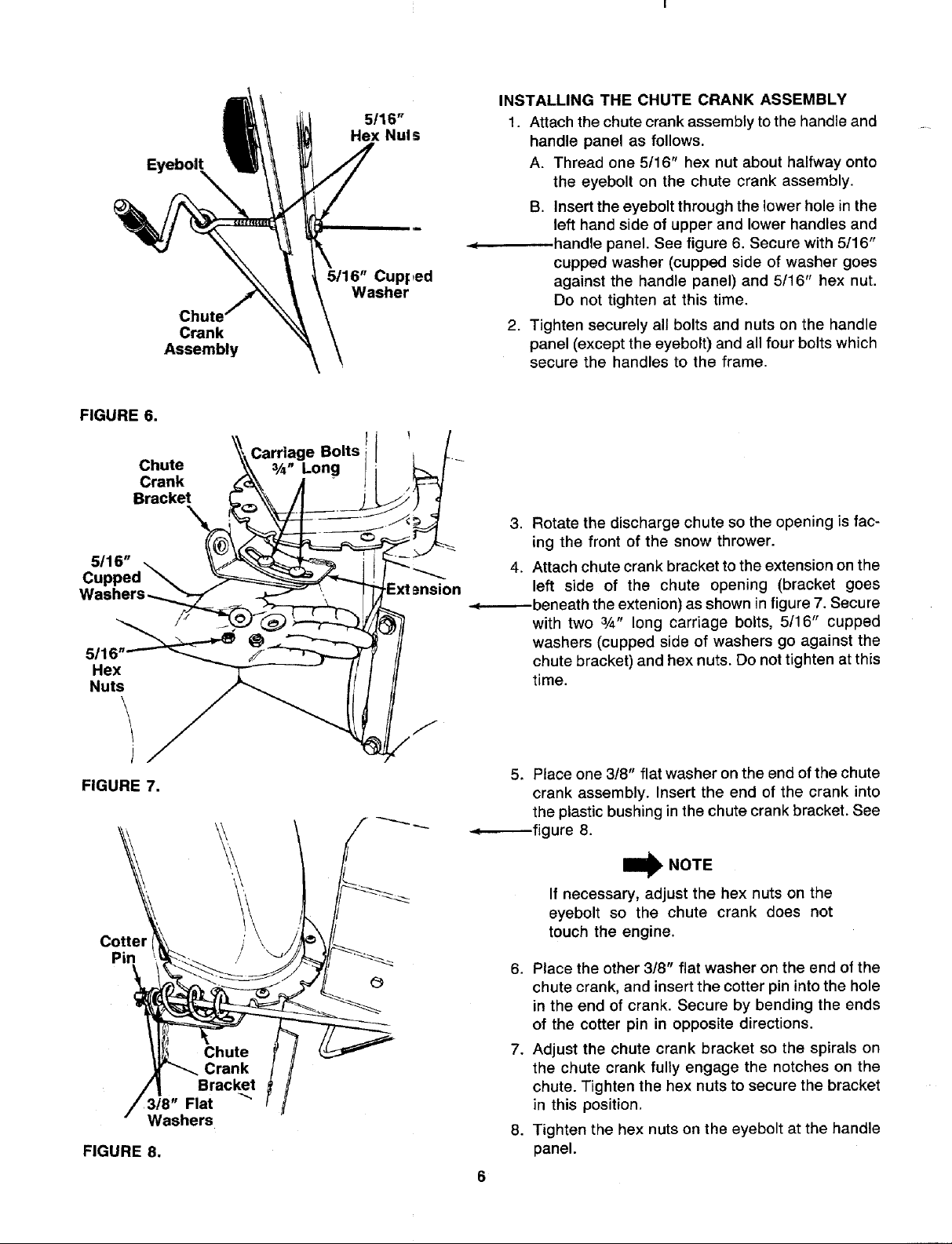

INSTALLING THE CHUTE CRANK ASSEMBLY

1. Attach the chute crank assembly to the handle and

handle panel as follows.

A. Thread one 5/16" hex nut about halfway onto

the eyebolt on the chute crank assembly.

B. Insert the eyebolt through the lower hole in the

left hand side of upper and lower handles and

handle panel. See figure 6. Secure with 5/16"

cupped washer (cupped side of washer goes

against the handle panel) and 5/16" hex nut.

Do not tighten at this time.

2. Tighten securely all bolts and nuts on the handle

panel (except the eyebolt) and all four bolts which

secure the handles to the frame.

Chute

Crank

Bracket

5116"

Cur

5116

Hex

Nuts

Carriage Bolts

3/_" Long

\

J

FIGURE 7.

Cotter _\ /' \ _/j_'_/_

• Washers

FIGURE 8.

3. Rotate the discharge chute so the opening is fac-

ing the front of the snow thrower.

4. Attach chute crank bracket to the extension on the

left side of the chute opening (bracket goes

-.(---_--beneath the extenion) as shown in figure 7. Secure

with two 3/4" long carriage bolts, 5116" cupped

washers (cupped side of washers go against the

chute bracket) and hex nuts. Do not tighten at this

time.

5. Place one 318" flat washer on the end of the chute

crank assembly. Insert the end of the crank into

the plastic bushing in the chute crank bracket. See

-.,_-----fig ure 8.

W NOTE

If necessary, adjust the hex nuts on the

eyebolt so the chute crank does not

touch the engine.

6. Place the other 3/8" flat washer on the end of the

chute crank, and insert the cotter pin into the hole

in the end of crank. Secure by bending the ends

of the cotter pin in opposite directions.

7. Adjust the chute crank bracket so the spirals on

the chute crank fully engage the notches on the

chute. Tighten the hex nuts to secure the bracket

in this position.

8. Tighten the hex nuts on the eyebolt at the handle

panel.

FIGURE 9.

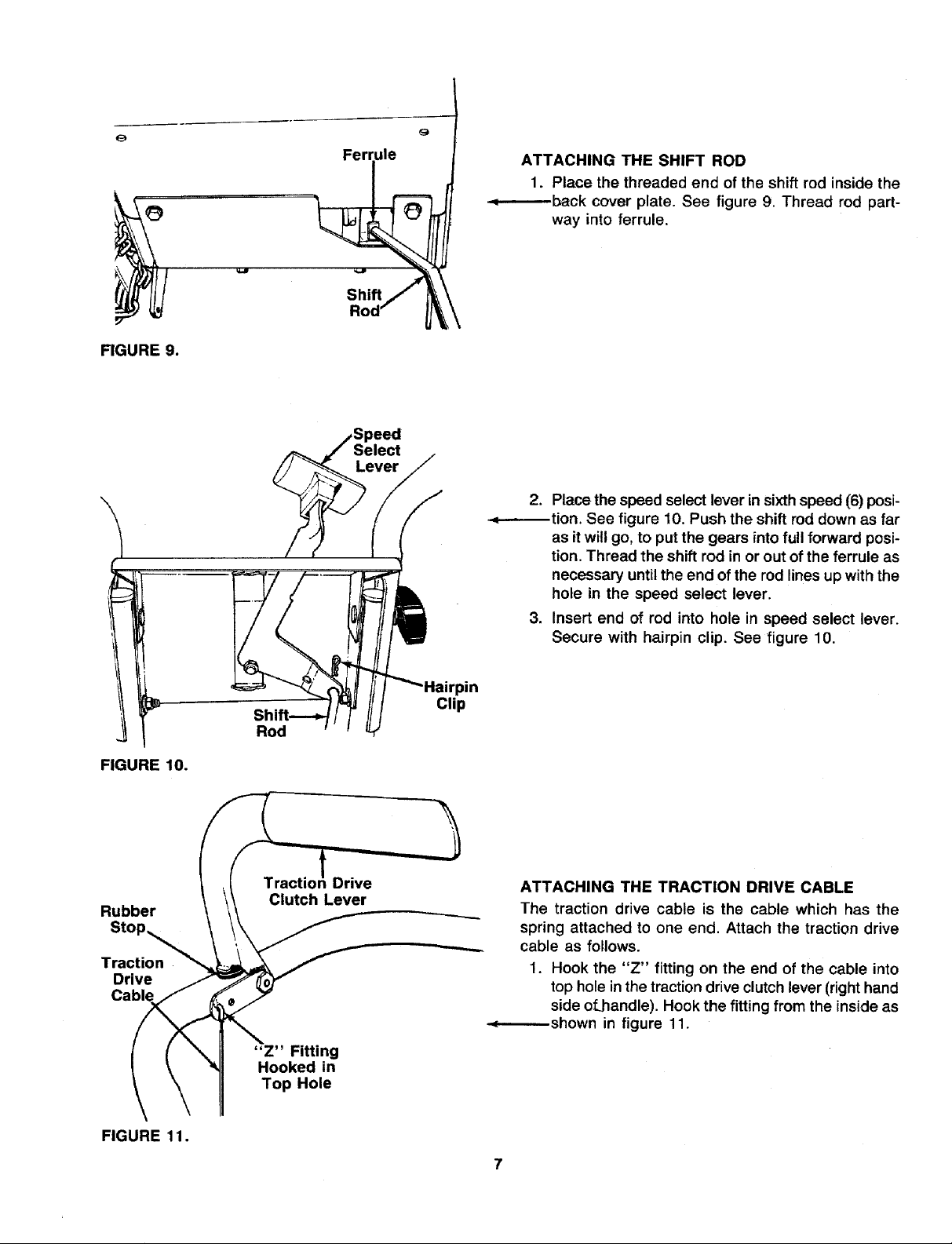

ATTACHING THE SHIFT ROD

1. Place the threaded end of the shift rod inside the

-.q-------.-back cover plate. See figure 9. Thread rod part-

way into ferrule.

Shift

2. Place the speed select lever Lnsixthspeed (6) posi-

_tion. See figure 10. Push the shift rod down as far

as it will go, to put the gears intofull forward posi-

tion. Thread the shift rod in or out of the ferrule as

necessary until the end ofthe rod lines up with the

hole in the speed select lever.

3. Insert end of rod into hole in speed select lever.

Secure with hairpin clip. See figure 10.

FIGURE 10.

Rubber

Stop_

Traction

Drive

Cable

FIGURE 11.

Rod

Clutch Lever

"Z" Fitting

Hooked in

Top Hole

Drive

pin

Clip

ATTACHING THE TRACTION DRIVE CABLE

The traction drive cable is the cable which has the

spring attached to one end. Attach the traction drive

cable as follows.

1. Hook the "Z" fitting on the end of the cable into

top hole inthe traction drive clutch lever (righthand

side of.handle). Hook the fitting from the inside as

•._-..-----shown in figure 11.

LineUpCenter

of HookWith

Centerof Hole

FIGURE12.

Lengthl

Drive Brack _=t

Traction

Dri_!e

Cal0te

Hooke _ in

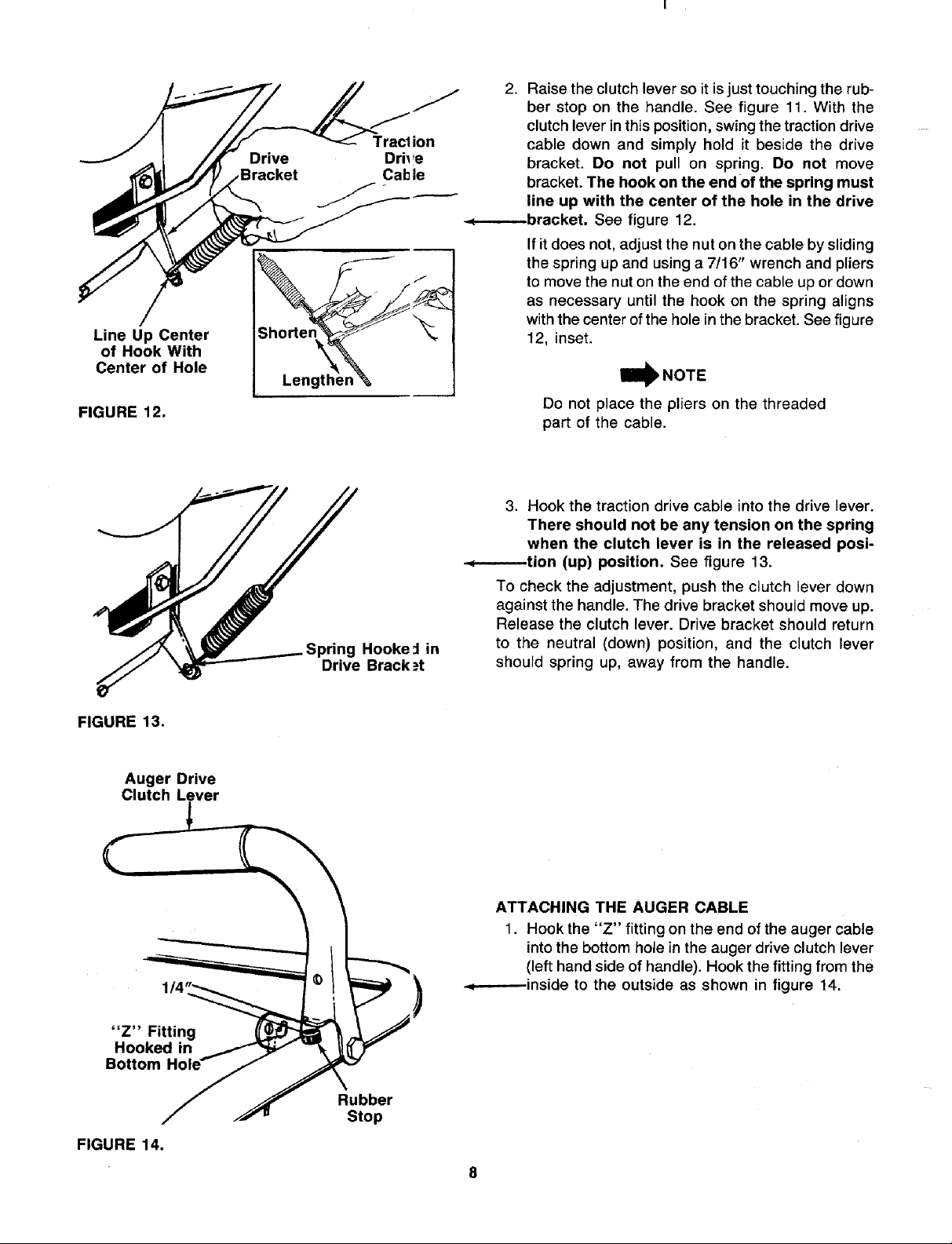

2. Raise the clutch lever so it is just touching the rub-

ber stop on the handle. See figure 11. With the

clutch lever in this position, swing the traction drive

cable down and simply hold it beside the drive

bracket. Do not pull on spring. Do not move

bracket. The hook on the end of the spring must

line up with the center of the hole in the drive

-._--.------bracket. See figure 12.

If it does not, adjust the nut on the cable by sliding

the spring up and using a 7116" wrench and pliers

to move the nut on the end of the cable up or down

as necessary until the hook on the spring aligns

with the center of the hole in the bracket. See figure

12, inset.

Do not place the pliers on the threaded

part of the cable.

3. Hook the traction drive cable into the drive lever.

There should not be any tension on the spring

when the clutch lever is in the released posi-

-.,_-_--tion (up) position. See figure 13.

To check the adjustment, push the clutch lever down

against the handle. The drive bracket should move up.

Release the clutch lever. Drive bracket should return

to the neutral (down) position, and the clutch lever

should spring up, away from the handle.

FIGURE 13.

Auger Drive

Clutch Lever

"Z" Fitting

Hooked in

Bottom

FIGURE 14.

1/4

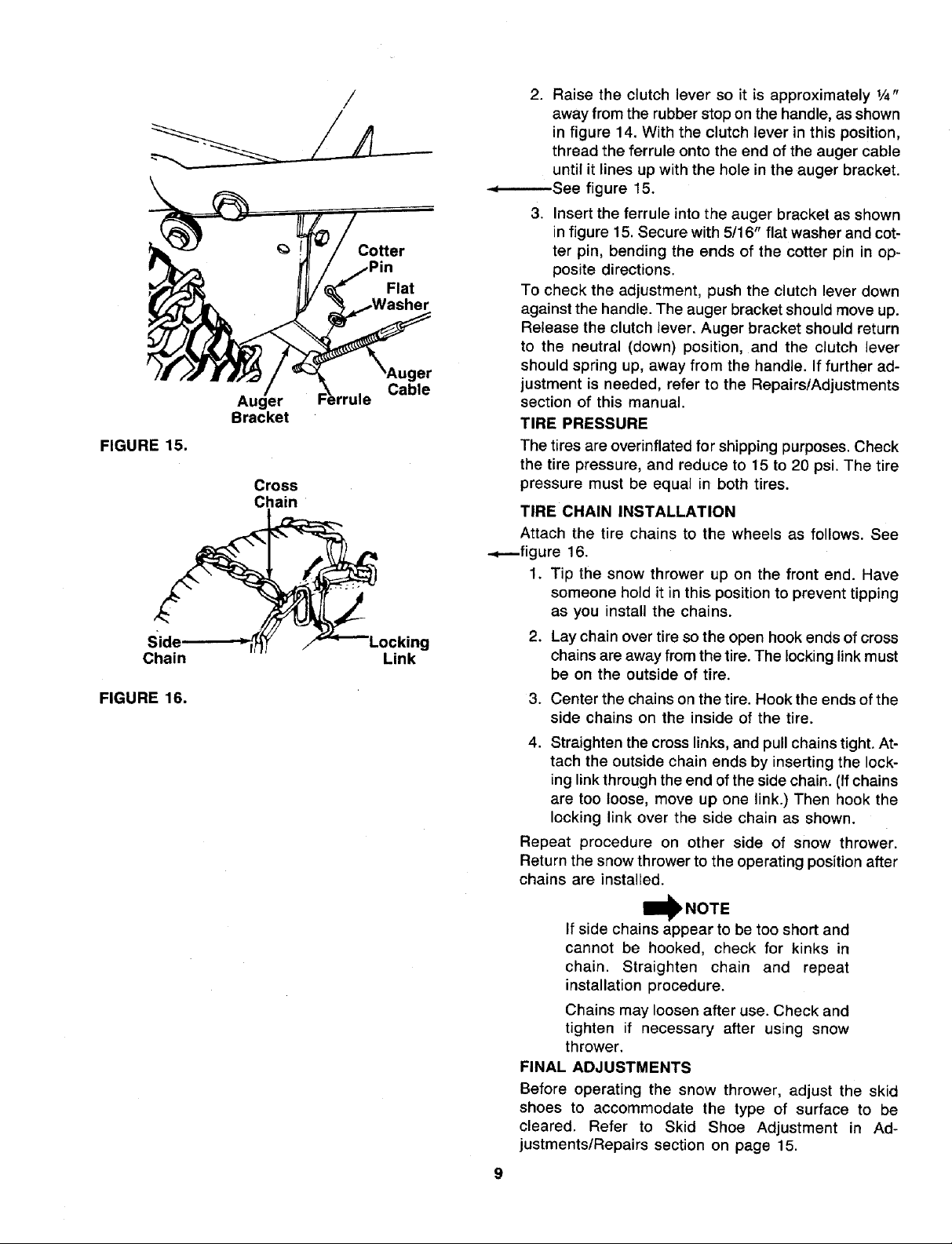

ATTACHING THE AUGER CABLE

1. Hook the "Z" fitting on the end of the auger cable

intothe bottom hole in the auger drive clutch lever

(left hand side of handle). Hook the fitting from the

.,=----.---inside to the outside as shown in figure 14.

Rubber

Stop

FIGURE 15.

Chain

FIGURE 16.

Auger

Bracket

Cross

Chain

/

Cotter

Flat

Link

Cable

2. Raise the clutch lever so it is approximately 1/4"

away from the rubber stop on the handle, as shown

in figure 14. With the clutch lever in this position,

thread the ferrule onto the end of the auger cable

until it lines up with the hole in the auger bracket.

-.,--..------See figure 15.

3. Insert the ferrule into the auger bracket as shown

in figure 15. Secure with 5/16" flat washer and cot-

ter pin, bending the ends of the cotter pin in op-

posite directions.

To check the adjustment, push the clutch lever down

against the handle. The auger bracket should move up.

Release the clutch lever. Auger bracket should return

to the neutral (down) position, and the clutch lever

st

should spring up, away from the handle. If further ad-

justment is needed, refer to the Repairs/Adjustments

section of this manual.

TIRE PRESSURE

The tires are overinflated for shipping purposes. Check

the tire pressure, and reduce to 15 to 20 psi. The tire

pressure must be equal in both tires.

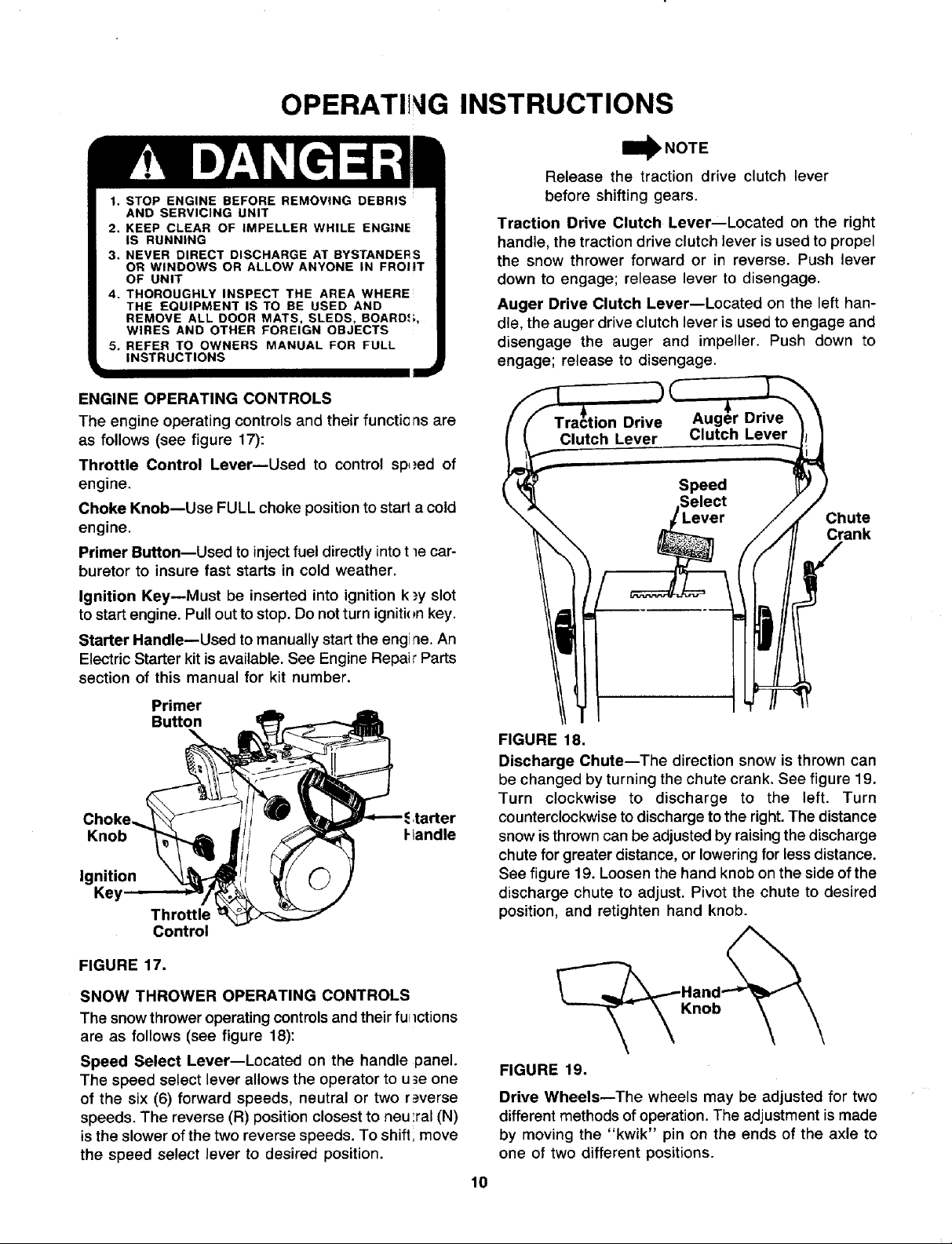

TIRE CHAIN INSTALLATION

Attach the tire chains to the wheels as follows. See

-+--figure 16.

1. Tip the snow thrower up on the front end. Have

someone hold it in this position to prevent tipping

as you install the chains.

2. Lay chain over tire so the open hook ends of cross

chains are away from the tire. The locking link must

be on the outside of tire.

3. Center the chains on the tire. Hook the ends of the

side chains on the inside of the tire.

4. Straighten the cross links, and pull chains tight. At-

tach the outside chain ends by inserting the lock-

ing link through the end of the side chain. (If chains

are too loose, move up one link.) Then hook the

locking link over the side chain as shown.

Repeat procedure on other side of snow thrower.

Return the snow thrower to the operating position after

chains are installed.

If side chains appear to be too short and

cannot be hooked, check for kinks in

chain. Straighten chain and repeat

installation procedure.

Chains may loosen after use. Check and

tighten if necessary after using snow

thrower.

FINAL ADJUSTMENTS

Before operating the snow thrower, adjust the skid

shoes to accommodate the type of surface to be

cleared. Refer to Skid Shoe Adjustment in Ad-

justments/Repairs section on page 15.

OPERATII G INSTRUCTIONS

1. STOP ENGINE BEFORE REMOVING DEBRIS

AND SERVICING UNIT

2. KEEP CLEAR OF IMPELLER WHILE ENGINE

IS RUNNING

3. NEVER DIRECT DISCHARGE AT BYSTANDERS

OR WINDOWS OR ALLOW ANYONE IN FROliT

OF UNIT

4. THOROUGHLY INSPECT THE AREA WHERE

THE EQUIPMENT IS TO BE USED AND

REMOVE ALL DOOR MATS, SLEDS, BOARD,*;,

WIRES AND OTHER FOREIGN OBJECTS

5. REFER TO OWNERS MANUAL FOR FULL

INSTRUCTIONS

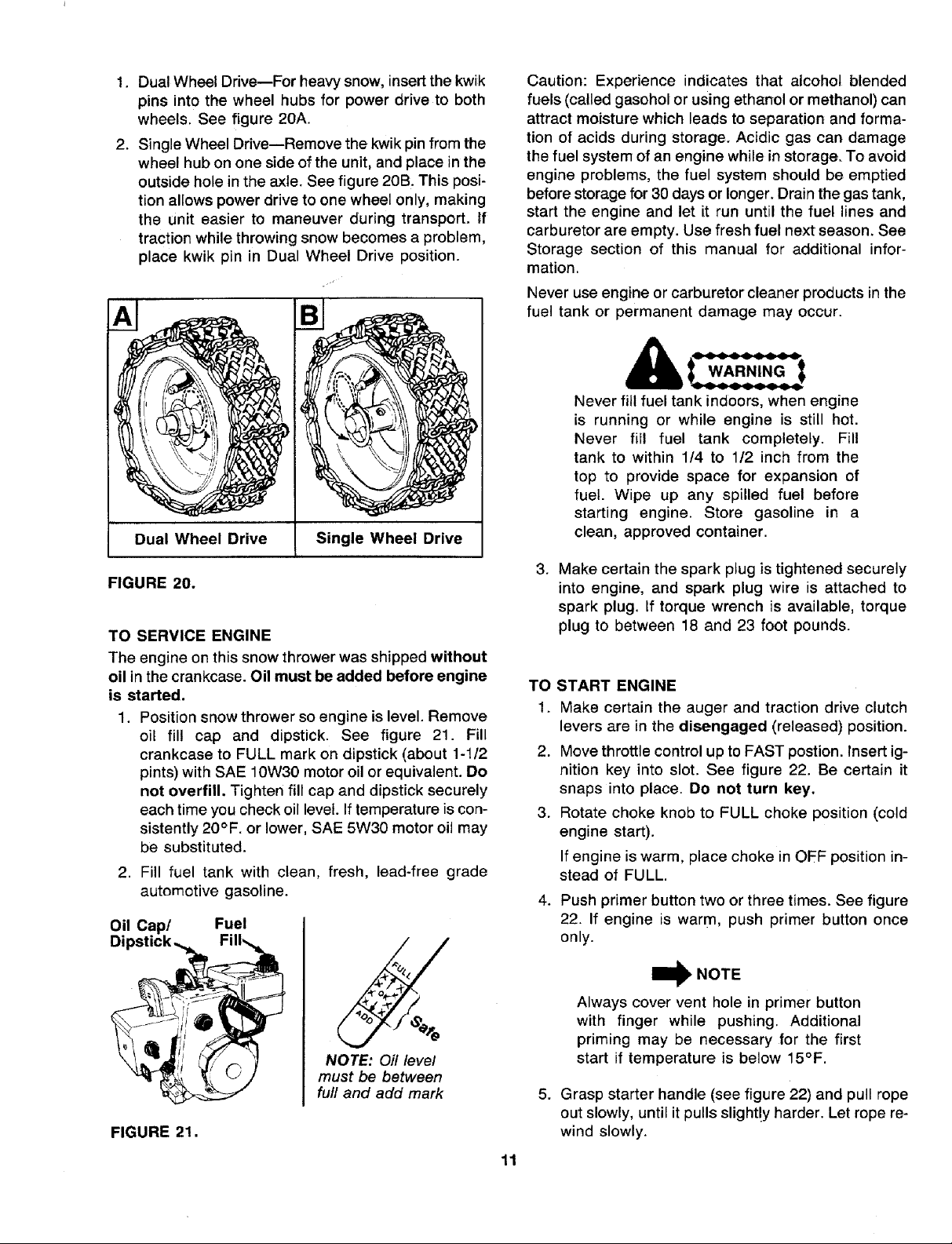

ENGINE OPERATING CONTROLS

The engine operating controls and their functions are

as follows (see figure 17):

Throttle Control LevermUsed to control sp,_ed of

engine.

Choke Knob--Use FULL choke position to start a cold

engine.

Primer Button--Used to injectfuel directly intot le car-

buretor to insure fast starts in cold weather.

Ignition Key--Must be inserted into ignition k,_yslot

to startengine. Pullout tostop. Do notturn igniti<_nkey.

Starter Handle--Used to manually start the engine. An

Electric Starter kit is available. See Engine Repair Parts

section of this manual for kit number.

W NOTE

Release the traction drive clutch lever

before shifting gears.

Traction Drive Clutch Lever--Located on the right

handle, the traction drive clutch lever is used to propel

the snow thrower forward or in reverse. Push lever

down to engage; release lever to disengage.

Auger Drive Clutch Lever--Located on the left han-

dle, the auger drive clutch lever is used to engage and

disengage the auger and impeller. Push down to

engage; release to disengage.

Chute

Crank

Primer

Button

Knob I-tandle

Ignition

Key

Throttle

Control

FIGURE 17.

SNOW THROWER OPERATING CONTROLS

The snow thrower operating controls and their furlctions

are as follows (see figure 18):

Speed Select Lever--Located on the handle panel.

The speed select lever allows the operator to u3e one

of the six (6) forward speeds, neutral or two r_=verse

speeds. The reverse (R) position closest to neu ;ral (N)

is the slower ofthe two reverse speeds. To shift; move

the speed select lever to desired position.

FIGURE 18.

Discharge Chute--The direction snow is thrown can

be changed by turning the chute crank. See figure 19.

Turn clockwise to discharge to the left. Turn

counterclockwise to discharge to the right. The distance

snow isthrowncan be adjusted by raising the discharge

chute for greater distance, or lowering for less distance.

See figure 19. Loosen the hand knob on the side of the

discharge chute to adjust. Pivot the chute to desired

position, and retighten hand knob.

Knob

FIGURE 19.

Drive Wheels--The wheels may be adjusted for two

different methods of operation. The adjustment ismade

by moving the "kwik" pin on the ends of the axle to

one of two different positions.

10

1. Dual Wheel Drive--For heavy snow, insert the kwik

pins into the wheel hubs for power drive to both

wheels. See figure 20A.

2. Single Wheel Drive--Remove the kwik pin from the

wheel hub on one side of the unit, and place in the

outside hole in the axle. See figure 20B. This posi-

tion allows power drive to one wheel only, making

the unit easier to maneuver during transport. If

traction while throwing snow becomes a problem,

place kwik pin in Dual Wheel Drive position.

Dual Wheel Drive Single Wheel Drive

Caution: Experience indicates that alcohol blended

fuels (called gasohol or using ethanol or methanol) can

attract moisture which leads to separation and forma-

tion of acids during storage. Acidic gas can damage

the fuel system of an engine while in storage. To avoid

engine problems, the fuel system should be emptied

before storage for 30 days or longer. Drain the gas tank,

start the engine and let it run until the fuel lines and

carburetor are empty. Use fresh fuel next season. See

Storage section of this manual for additional infor-

mation.

Never use engine or carburetor cleaner products in the

fuel tank or permanent damage may occur.

Never fill fuel tank indoors, when engine

is running or while engine is still hot.

Never fill fuel tank completely. Fill

tank to within 1/4 to 1/2 inch from the

top to provide space for expansion of

fuel. Wipe up any spilled fuel before

starting engine. Store gasoline in a

clean, approved container.

FIGURE 20.

TO SERVICE ENGINE

The engine on this snow thrower was shipped without

oil in the crankcase. Oil must be added before engine

is started.

1. Position snow thrower so engine is level. Remove

oil fill cap and dipstick. See figure 21. Fill

crankcase to FULL mark on dipstick (about 1-1/2

pints) with SAE 10W30 motor oil or equivalent. Do

not overfill. Tighten fill cap and dipstick securely

each time you check oil level. If temperature iscon-

sistently 20°F. or lower, SAE 5W30 motor oil may

be substituted.

2. Fill fuel tank with clean, fresh, lead-free grade

automotive gasoline.

Oil Cap/ Fuel

Dipstick._ Fill_

_rliili O (_ _

NOTE: Oil level

must be between

full and add mark

FIGURE 21.

.

Make certain the spark plug is tightened securely

into engine, and spark plug wire is attached to

spark plug. If torque wrench is available, torque

plug to between 18 and 23 foot pounds.

TO START ENGINE

1. Make certain the auger and traction drive clutch

levers are in the disengaged (released) position.

2. Move throttle control up to FAST postion. Insert ig-

nition key into slot. See figure 22. Be certain it

snaps into place. Do not turn key,

3. Rotate choke knob to FULL choke position (cold

engine start).

If engine is warm, place choke in OFF position in-

stead of FULL.

4. Push primer button two or three times. See figure

22. If engine is warm, push primer button once

only.

_)_ NOTE

Always cover vent hole in primer button

with finger while pushing. Additional

priming may be necessary for the first

start if temperature is below 15°F.

5. Grasp starter handle (see figure 22) and pull rope

out slowly, until it pulls slight!y harder. Let rope re-

wind slowly.

11

Loading...

Loading...