Page 1

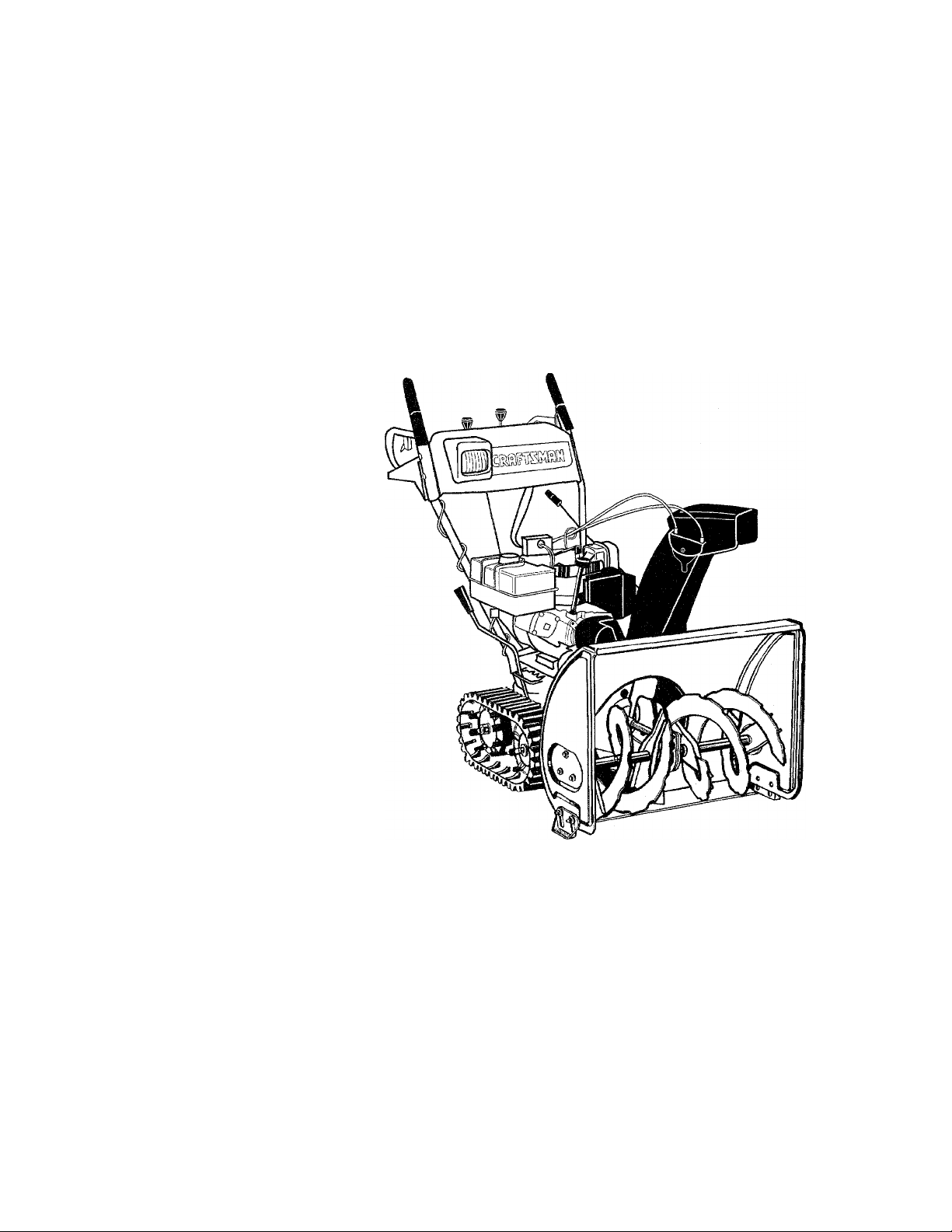

Owner’s Manual

CRRFTSMRN

8.5 Horse Power

26” Two-Stage Track Drive

Snow Thrower

Model No.

247.885500

CAUTION: Before using this product,

read this manual and follow all Safety

Rules and Operating Instructions.

Sears, Roebuck And Co., Hoffman Estates, IL 60179, U.S.A.

Printed in U.S.A.

770-0373A

Page 2

TABLE OF CONTENTS

Content

Warranty Information

Safe Operation Practices

Accessories

Assembly

Operation

Page

2

3

5 Off-Season Storage

7

12

Content

Maintenance

Service & Adjustment

Trouble-Shooting

Repair Parts

Page

17

20

24

25

26

WARRANTY INFORMATION

Two -Year Warranty on Craftsman Snow Thrower

For two years from the date of purchase, when this Craftsman Snow Thrower is maintained, lubricated and tuned

up according to the instructions in the owner’s manual, Sears will repair, free of charge, any defect in material

and workmanship.

If this Craftsman snow thrower is used for commercial or rental purposes, this warranty applies for only 30 days

from the date of purchase.

This warranty does not cover:

Expendable items which become worn during normal use, such as skid shoes, shave plate and spark

plugs.

Repairs necessary because of operator abuse or negligence, including bent crankshafts and the failure to

maintain the equipment according to the instructions contained in the owner’s manual.

WARRANTY SERVICE IS AVAILABLE BY RETURNING THE CRAFTSMAN SNOW THROWER TO THE NEAREST

SEARS SERVICE CENTER/DEPARTMENT IN THE UNITED STATES.

This warranty applies only while this product is in use in the United States.

This warranty gives you specific legal rights and you may also have other rights which may vary from state to state.

SEARS, ROEBUCK AND CO., D/817WA, HOFFMAN ESTATES, IL60179

PRODUCT SPECIFICATIONS

Horsepower; 8.5

Engine Oil SAE 5W30 oil

Fuel Capacity: 1 gallon

Spark Plug: RJ-19LM

Engine: 143.988501

MODEL NUMBER

247.885500Model Number

Serial Number.......

Date of Purchase

Record both serial number and date of purchase

and keep in a safe place for future reference.

Page 3

A

A

A

SAFE OPERATION PRACTICES

This symbol points out important safety instructions which, if not followed, could endanger the

personal safety and/or property of yourself and others. Read and follow all instructions in this manual

before attempting to operate your snow thrower. Failure to comply with these instructions may result in

personal injury. When you see this symbol—heed its warning.

Your snow thrower was built to be operated according to the rules for safe operation in this manual. As

DANGER:'''''^^ any type of power equipment, carelessness or error on the part of the operator can result in serious

injury. If you violate any of these rules, you may cause serious injury to yourself or others.

This unit is equipped with an internal combustion engine and should not be used on or near any unimproved

forest-covered, brush-covered or grass-covered land unless the engine’s exhaust system is equipped with a

spark arrester meeting applicable local or state laws (if any). If a spark arrester is used, it should be

maintained in effective working order by the operator.

In the State of California the above is required by law (Section 4442 of the California Public Resources

Code). Other states may have similar laws. Federal laws apply on federal lands. A spark arrester for the

muffler is available through your nearest Sears Authorized Service Center (See the REPAIR PARTS section

of this manual.)

TRAINING

• Read this owner’s guide carefully in its entirety before

attempting to assemble or operate this machine. Be

completely familiar with the controls and the proper

use of this machine before operating it. Keep this

manual In a safe place for future and regular

reference and for ordering replacement parts.

® Never allow children under 14 years old to operate a

snow thrower. Children 14 years old and over should

only operate a snow thrower under close parental

supervision. Only persons well acquainted with these

rules of safe operation should be allowed to use your

snow thrower.

• No one should operate this unit while intoxicated or

while taking medication that impairs the senses or

reactions.

• Keep the area of operation clear of all persons,

especially small children and pets.

• Exercise caution to avoid slipping or falling, especially

when operating in reverse.

PREPARATION

• Thoroughly inspect the area where the equipment is

to be used and remove all door mats, sleds, boards,

wires and other foreign objects.

• Do not operate equipment without wearing adequate

outer garments for winter. Do not wear jewelry, long

scarfs or other loose clothing which could become

entangled in moving parts. Wear footwear which will

improve footing on slippery surfaces.

• Before working with gasoline, extinguish all cigarettes

and other sources of ignition. Check the fuel before

starting the engine. Gasoline is an extremely

flammable fuel. Do not fill the gasoline tank indoors,

while the engine is running, or until engine has been

allowed to cool at least two minutes. Replace gasoline

cap securely and wipe off any spilled gasoline before

starting the engine as it may cause a fire or explosion.

® Use a grounded three wire plug-in for all units with

electric drive motors or electric starting motors.

« Adjust collector housing height to clear gravel or

crushed rock surface.

• Never attempt to make any adjustments while engine

is running (except where specifically recommended

by manufacturer).

® Let engine and machine adjust to outdoor

temperature before starting to clear snow.

® Always wear safety glasses or eye shields during

operation or while performing an adjustment or repair,

to protect eyes from foreign objects that may be

thrown from the machine in any direction.

OPERATION

“ Do not put hands or feet near or under rotating parts.

Keep clear of discharge opening and auger at all

times.

® Exercise extreme caution when operating on or

crossing gravel drives, walks, or roads. Stay alert for

hidden hazards or traffic.

« Do not carry passengers.

® After striking a foreign object, stop the engine, remove

wire from the spark plug and thoroughly inspect the

snow thrower for any damage. Repair the damage

before restarting and operating the snow thrower.

® If the snow thrower starts to vibrate abnormally, stop

the engine and check immediately for the cause.

Vibration is generally a warning of trouble.

» Stop the engine whenever you leave the operating

position, before unclogging the collector/impeller

housing or discharge guide and before making any

repairs, adjustments, or inspections. Never place your

Page 4

hand in the discharge or collector openings. Use a

stick or wooden broom handie to unclog the

discharge opening.

Take ail possible precautions when leaving the unit

unattended. Disengage the collector/impeller, stop

the engine and remove the key.

When cleaning, repairing, or inspecting, make

certain coiiector/impeilerand aii moving parts have

stopped. Disconnect spark piug wire and keep away

from plug to prevent accidental starting.

Do not run the engine indoors, except when starting it

and/or transporting the snow thrower in or out of

building. Open doors before starting the engine in that

case. Exhaust fumes are dangerous.

Do not clear snow across the face of slopes. Exercise

extreme caution when changing direction on slopes.

Do not attempt to clear steep slopes.

Never operate the snow thrower without guards,

piates or other safety protection devices in place.

Never operate the snow thrower near glass

enclosure, automobiles, window wells, drop off, etc.,

without proper adjustments of snow thrower

discharge angle. Keep children and pets away.

Do not overload machine capacity by attempting to

clear snow at too fast a rate. Never operate the

machine at high transport speeds on slippery

surfaces. Look behind and use care when backing.

Never direct discharge at bystanders or allow anyone

in front of unit while throwing snow.

Disengage power to collector/impeller of the snow

thrower when transporting it or when the unit is not in use.

Use only attachments and accessories (such as

wheel weights, counter weights, cabs, etc.) approved

by the snow thrower manufacturer.

• Never operate the snow thrower without good visibility

or light. Always be sure of your footing and keep a firm

hold on the handles. Walk, never run.

• Muffler and engine become hot and can cause severe

burn injury. Do not touch the muffler or the engine

while starting or operating the snow thrower.

MAINTENANCE AND STORAGE

• Check shear bolts, engine mounting bolts, etc., at

frequent intervals for proper tightness, thus ensuring

that the equipment is in safe working condition.

• Never store the machine with fuel in the fuel tank

inside a building where ignition sources are present,

such as hot water heaters, space heaters, clothes

dryers and the like. Allow engine to cool before storing

in any enclosure.

• Always refer to owner’s guide instructions for

important details if the snow thrower is to be stored for

an extended period.

• Run machine a few minutes after throwing snow to

prevent freeze-up of the collector/impeller.

• Check clutch controls periodically to verify that these

engage and disengage properly and readjust if

necessary. Refer to Service and Adjustments section

page 20 of this owner’s guide.

YOUR RESPONSIBILITY

• Restrict the use of this power machine to persons who

read, understand and follow the warnings and

instructions in this manual and on the machine.

Following are representations of some of the safety labels on your Craftsman snowthrower. Please follow the

instruction on these labels and maintain safety while using or servicing the equipment.

IadangerI

AWARNING

1. STOP ENGINE BEFORE REMOVING

DEBRIS AND SERVICING UNIT.

2. KEEP CLEAR OF IMPELLER WHILE

ENGINE IS RUNNING

3. NEVER DIRECT DISCHARGE AT

BYSTANDERS OR WINDOWS OR

ALLOW ANYONE IN FRONT OF

UNIT

4. THOROUGHLY INSPECT THE AREA

THE EQUIPMENT IS TO BE

USED AND REMOVE ALL DOOR

MATS, SLEDS, BOARDS, WIRES AND

OTHER FOREIGN OBJECTS

5. REFER TO OWNERS MANUAL FOR

FULL INSTRUCTIONS n7s<i

AVOID INJURY FROM

ROTATING AUGER KEEP HANDS, FEET

AND CLOTHING AWAY.

I A I

[ ' IdangerI

SHUTOFF ENGINE

BEFORE UNCLOG

GING DISCHARGE

CHUTE.

Page 5

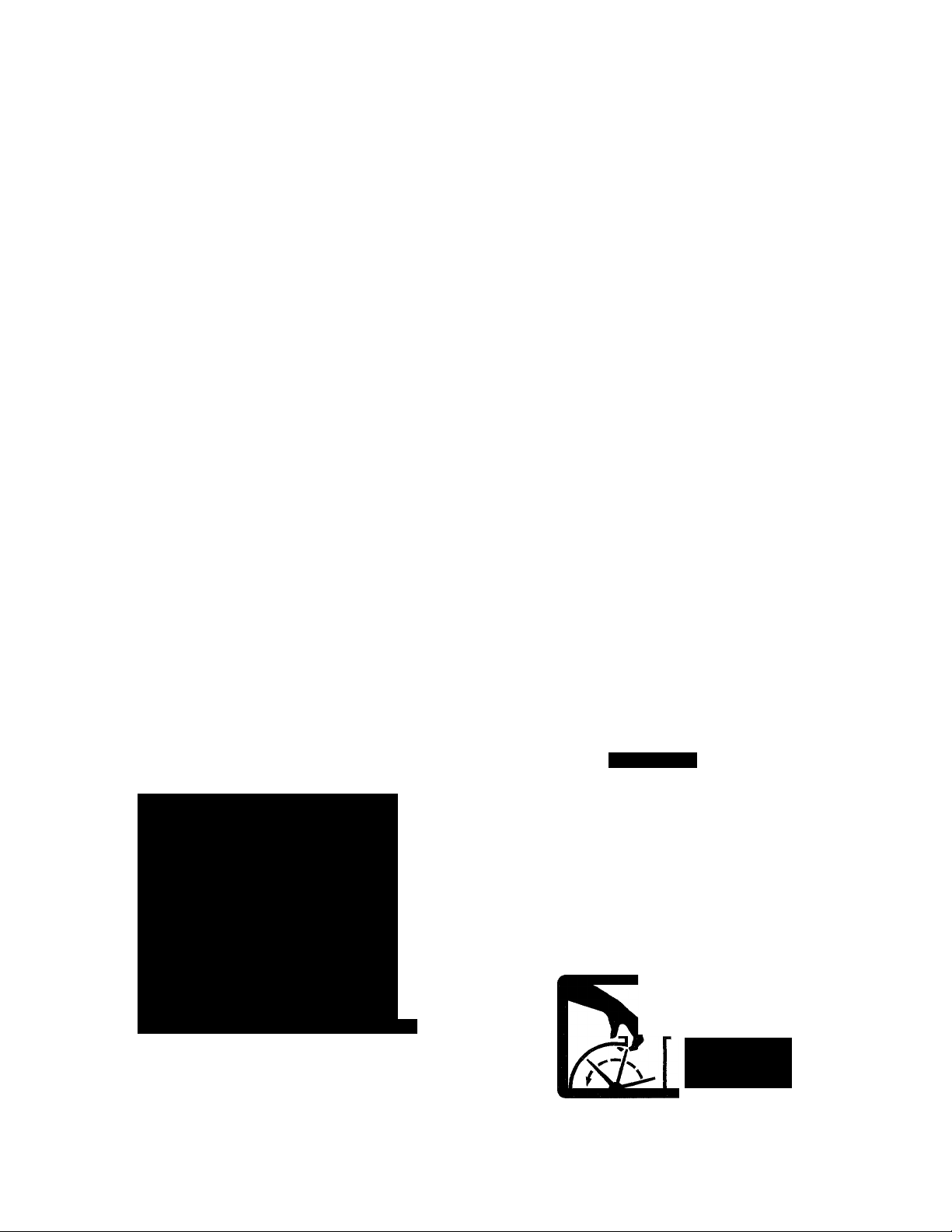

ACCESSORIES

These accessories were available when the snow thrower was purchased. They are also

available at most Sears retail outlets, catalog and service centers. Most Sears stores can

order repair parts for you when you provide the model number of your snow thrower.

Belt

Spark Plug

Page 6

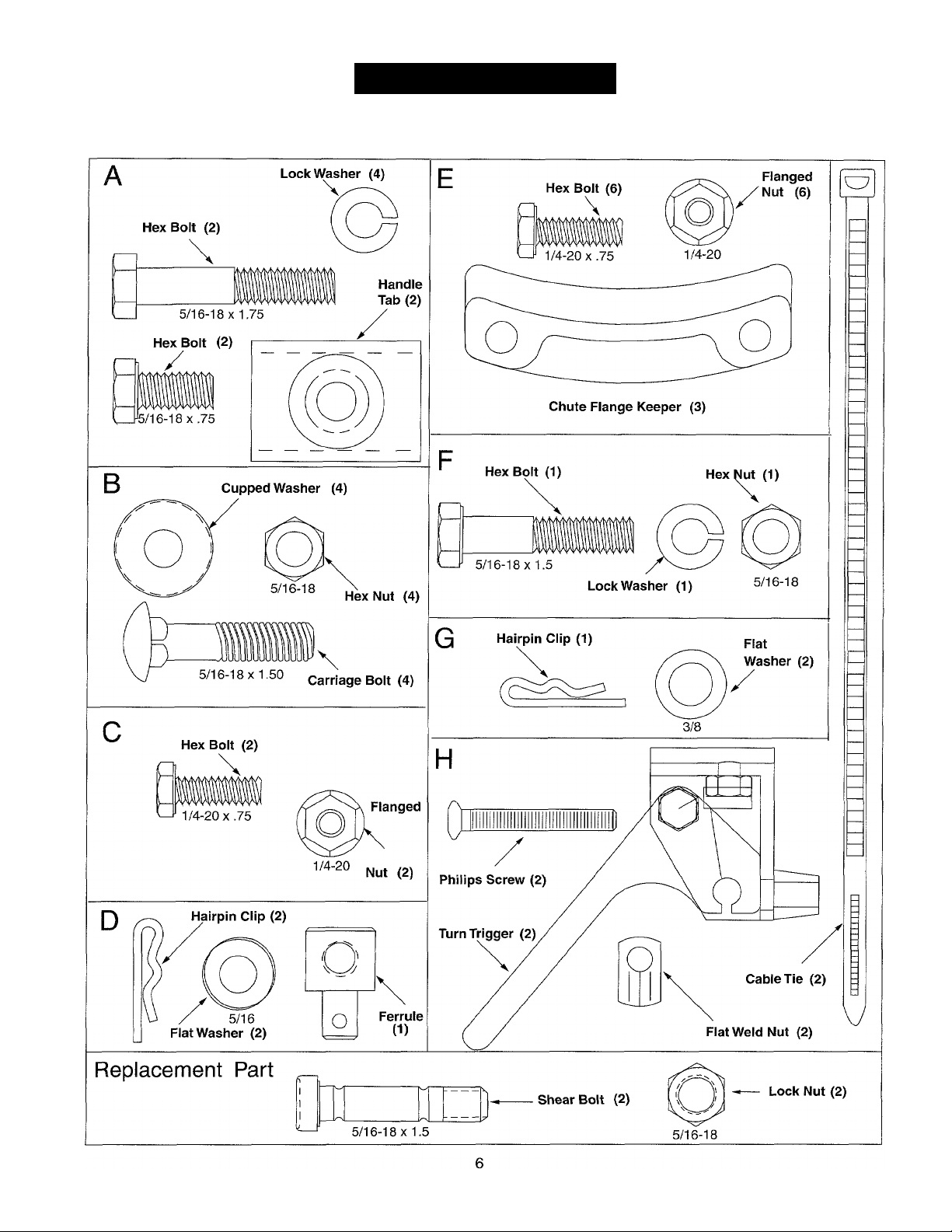

HARDWARE PACK

Lay the hardware pieces from the hardware pack on the figure here and you will have automatically sorted these

according to the steps of the assembly procedure described later. (Only one unit of each hardware has been shown per group.

The number in parenthesis indicates the total number of the hardware needed in that group.)

Page 7

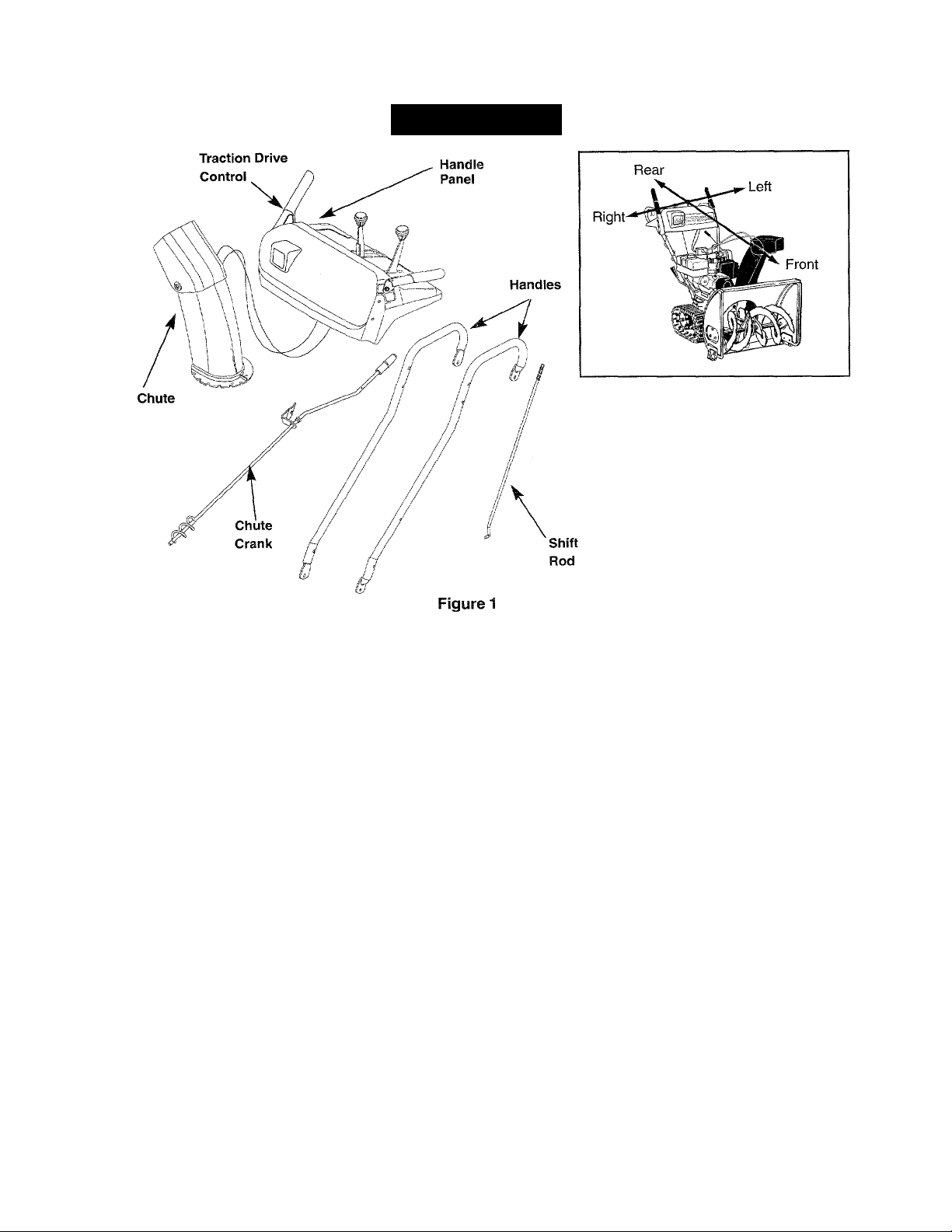

ASSEMBLY

IMPORTANT: This unit is shipped with engine oil, but

without gasoline, in the engine. After assembly, see

OPERATION section of this manual for fuel selection

and fill-up.

NOTE: To determine right and left hand sides of your

snow thrower, stand behind the unit with the engine

farthest away from you. See Figure 1 inset.

Your snow thrower has been completely assembled

at the factory, except the handle and the handle

panel, the discharge chute assembly, the chute crank

assembly and the shift rod. These parts are shipped

loose in the carton.

Removing From Carton

® Cut the corners of the carton and lay the sides

flat on the ground. Remove all packing inserts.

• Remove all loose parts. For a complete list of

the loose parts, refer to the following section,

• Move the snow thrower out of the carton.

• Make certain all parts and literature have been

removed before discarding the carton.

Loose Parts

(See Figure 1.)

a. Handle Panel and Chute Assembly

b. Right Hand Handle

c. Left Hand Handle

d. Chute Crank Assembly

e. Shift Rod

f. Hardware Pack

Assembly Tips: For easier assembly purposes,

remove the chute from the carton and lay it on top of

the engine. Do not unwrap the chute till you have

installed the handle panel and the clutch cables.

Tools Required

1. 1/2", 7/16”, 3/8” wrenches or a set of adjustable

wrenches

2. Set of standard head screw drivers

3. Set of philips head screw drivers

4. Funnel

WARNING: Make certain the spark plug

A

wire is disconnected and moved away from

the spark plug before assembling the snow

thrower.

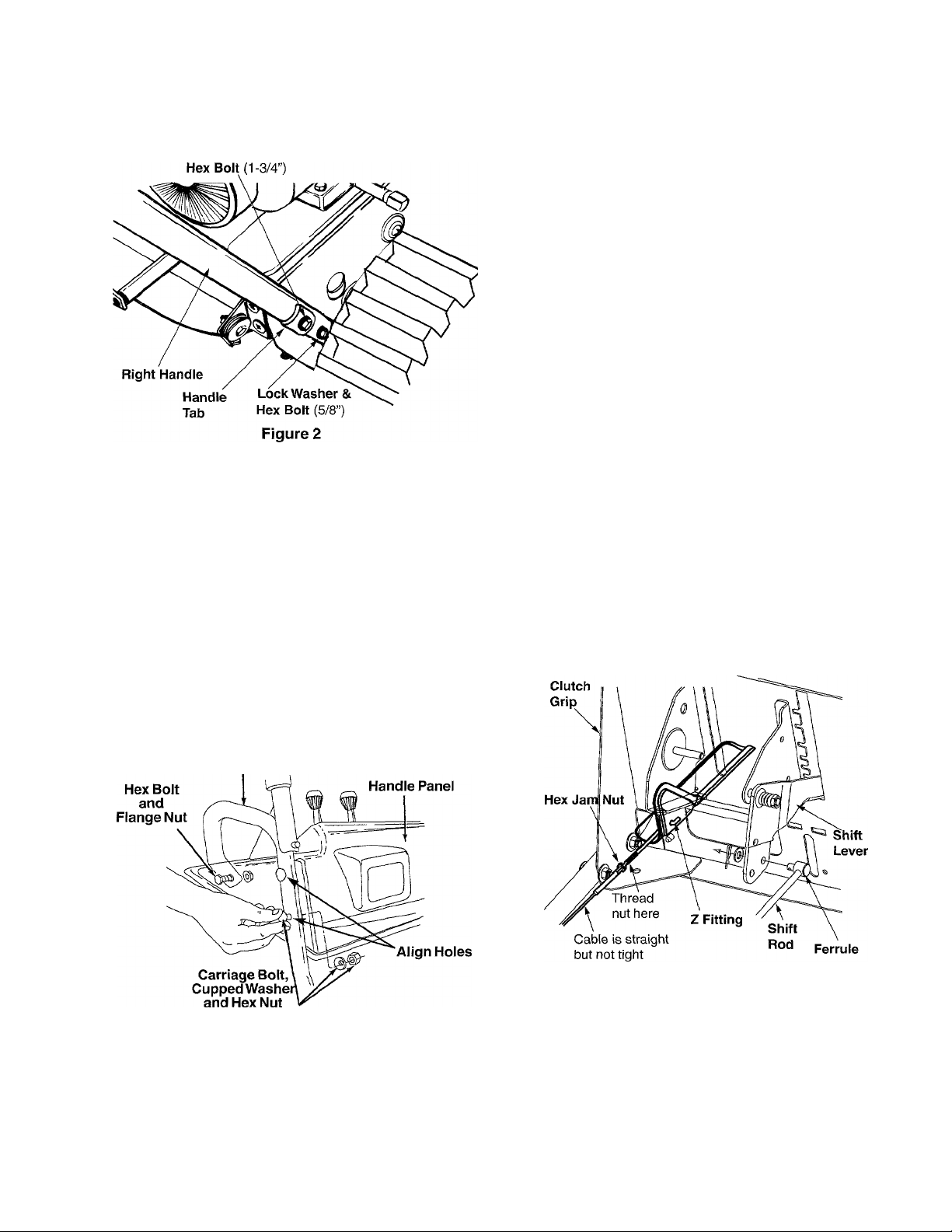

Attaching Handle Assembly

® Stretch out control cables and place on the floor.

Place the right handle in position with the flat

side against the snow thrower. You can identify

the right handle by the traction drive control label

on it and the left handle by the auger dutch

control label on it.

® Secure bottom hole in the handle to the snow

Page 8

thrower using 5/16 x3/4" hex bolt and lock

washer from the hardware pack (group A on

page 6). Do not tighten at this time. See Figure 2.

Lock Washer &

Place a handle tab, included in the hardware

pack (group A on Page 6), over the upper hole in

handle so that the contour of the handle tab

matches that of the handle. See Figure 2.

Secure handle tab to the snow thrower using

hex bolt (5/16 X 1 -3/4" long) and lock washer

from the same group in the hardware pack. Do

not tighten at this time.

Attach the left handle in the same manner. Do

not tighten at this time.

Place the handle panel in position between the

handles so the ends of the curved part of the

handles go through the slots in the handle panel.

Align the holes in the handle with the holes on

the two sides of the handle panel. See Figure 3.

the contour of the carriage bolt head with the

handle.

• Attach each side of rear of handle panel with one

1 /4-20 hex bolt and flange nut from the hardware

pack (group C on page 6). See Figure 3. Do not

tighten at this time.

• Tighten all loose hardware on the handle

assembly in the following order — first the hex

bolts at the bottom of the handle, then the

carriage bolts and lastly the hex bolts on the rear

of the handle panel.

Attaching Clutch Cables

The Z ends of the clutch cables are hooked into the

clutch grips on each handle.

• Locate two .375” wide hex jam nuts which were

placed on the Z ends for shipping purposes.

Thread these nuts all the way up the threaded

portion of the Z ends of the clutch cables. See

Figure 4.

• Place the clutch grip in the raised (up) position.

• Thread the cable onto the threaded portion of

the Z fitting until there is no slack in the cable,

but the cable is NOT tight. See Figure 4. Do not

overtighten cable.

• When correct adjustment is reached, tighten the

hex nut against the bottom portion of the cable to

lock it in position. Use pliers and 3/8" wrench to

lock the hex nut.

• Tighten traction drive control cable in the same

manner.

Right Handle

Figure 3

Attach the handle panel to the handle with two

carriage bolts, cupped washers (cupped side

against the handle panel) and hex nuts on each

side. See Figure 3. You will find these fasteners

in the hardware pack (group B on page 6). Align

A

(Viewed from under the handle panel)

Figure 4

WARNING: If there is tension on the cable

when the clutch grip is released, the safety

features of the snow thrower may be

overridden.

Page 9

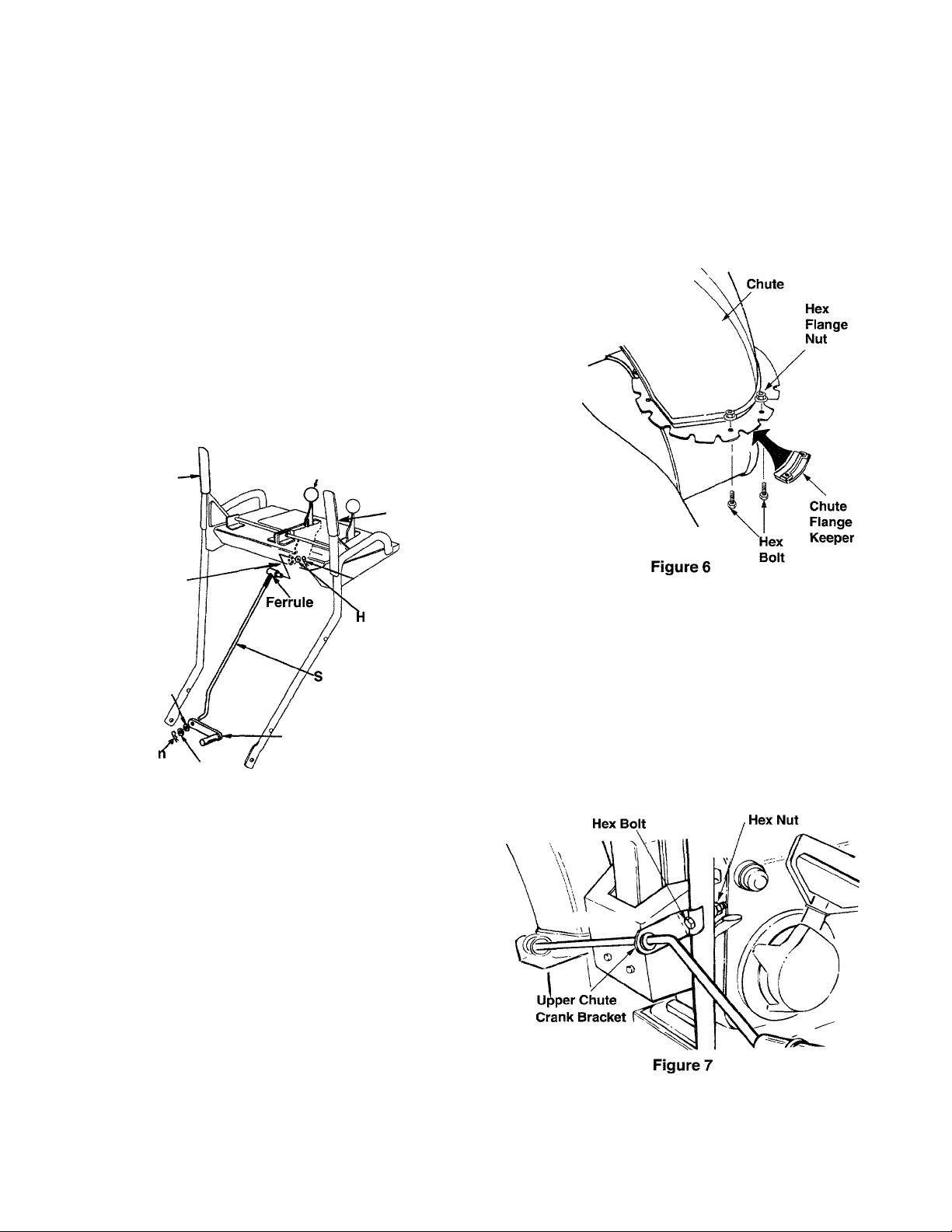

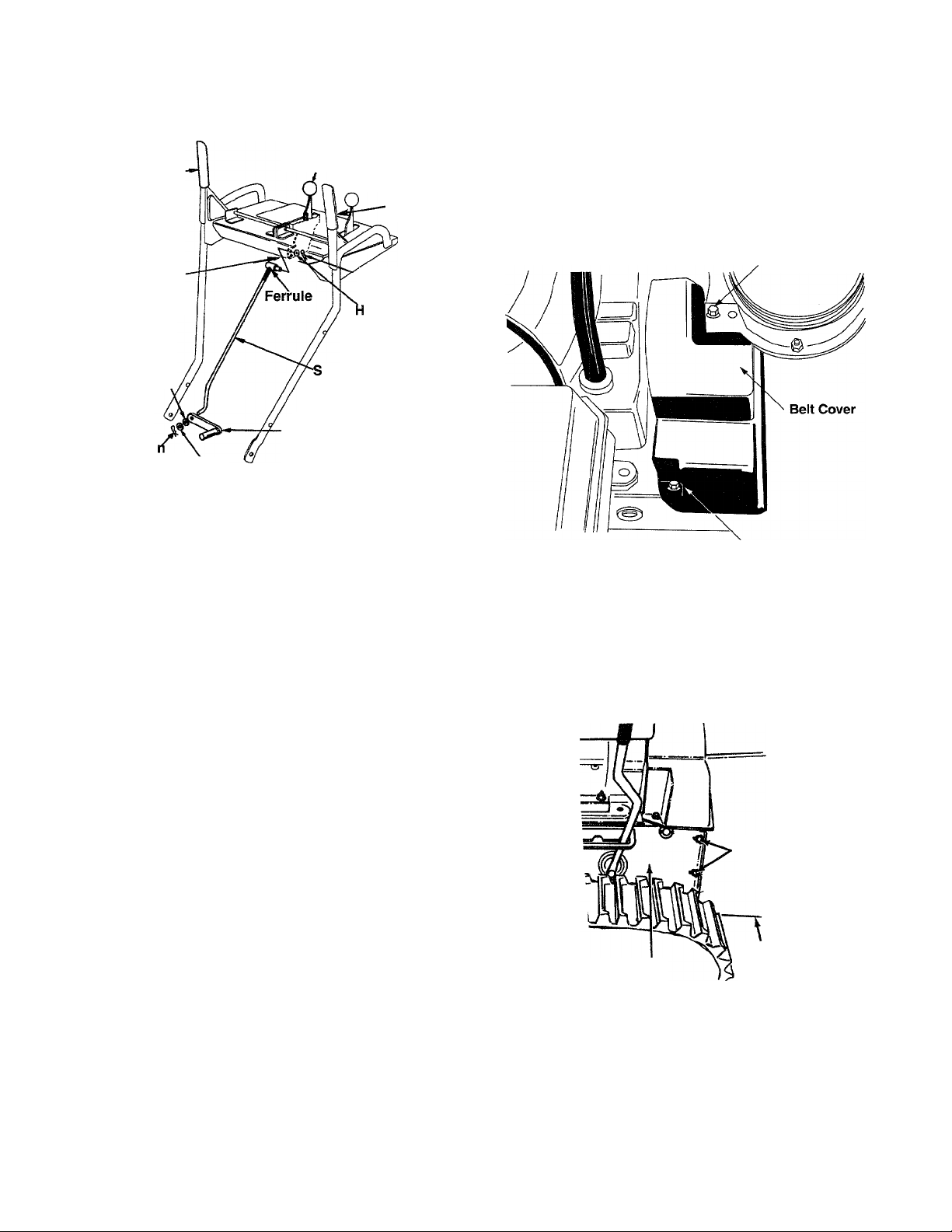

Attaching Shift Rod

• Place the shift lever in the sixth (6) speed

position.

• Place the bent end of the shift rod into the hole in

the shift arm assembly. See Figure 5. Secure with

5/16 flat washer and hairpin clip from the hardware

pack (group D on page 6).

• Start threading the ferrule (included in the same

group in the hardware pack) onto the other end

of the shift rod. It has to line up with the upper

hole in the shift lever (beneath the handle

panel). While aligning the ferrule, push down on

the shift rod and the shift arm assembly as far as

it will go.

• Once the ferrule slides into the hole, turn it

counter-clockwise one more full turn and insert it

in the hole in the shift lever.

Place the chute flange keeper (flat side down)

beneath lip of chute assembly as shown in

Figure 6.You will find the chute flange keepers in

group E of the hardware pack,

insert 1/4-20 hex bolt from group E of the

hardware pack (on page 6) up through chute

flange keeper and chute assembly as shown in

Figure 6. Do not tighten at this time. Rotate

chute to install all the flange keepers.

Traction

Drive

Clutch

Shift

Lever

Chute Distance

Control

/

Auger

Control

Upper

Hole in

Shift

Lever

Flat

Washer

airpin

Clip

Spring

Washer

hift

Rod

Shift Arm

Hairpi

Clip

Flat

Assembly

Washer

Figure 5

NOTE: It may be necessary to pull the shift lever out

of the sixth speed position and move it towards the

fifth speed position until the ferrule slides into the hole

without force.

• After assembling all three chute flange keepers,

tighten, then back off 1/4 turn to allow easier

movement of the chute. Use (2) 7/16" wrenches.

Attaching Chute Crank

• Insert 5/16x1.5" hex bolt (from group F of the

hardware pack on page 6) through the upper

chute crank bracket. This bracket is already

assembled on the chute crank. See Figure 7 for

the position of the chute crank on the snow

thrower.

Lock Washer,

• Secure the ferrule to the shift lever with another

5/16 flat washer and hairpin clip from group D of

the hardware pack. See Figure 5.

• Make certain to check for correct adjustment of

the shift rod as instructed in the Adjustment

section before operating the snow thrower.

Attaching Chute

• Place the chute assembly over the chute

opening with the latter facing the front of the unit.

NOTE: Make sure that the chute cables are

straightened while assembling the chute.

Place the hex bolt into the hole provided in the

left handle. Fasten with lock washer and 5/16

hex nut from the same group of the hardware

pack. Do not tighten until after attaching the

other end of the chute crank.

Page 10

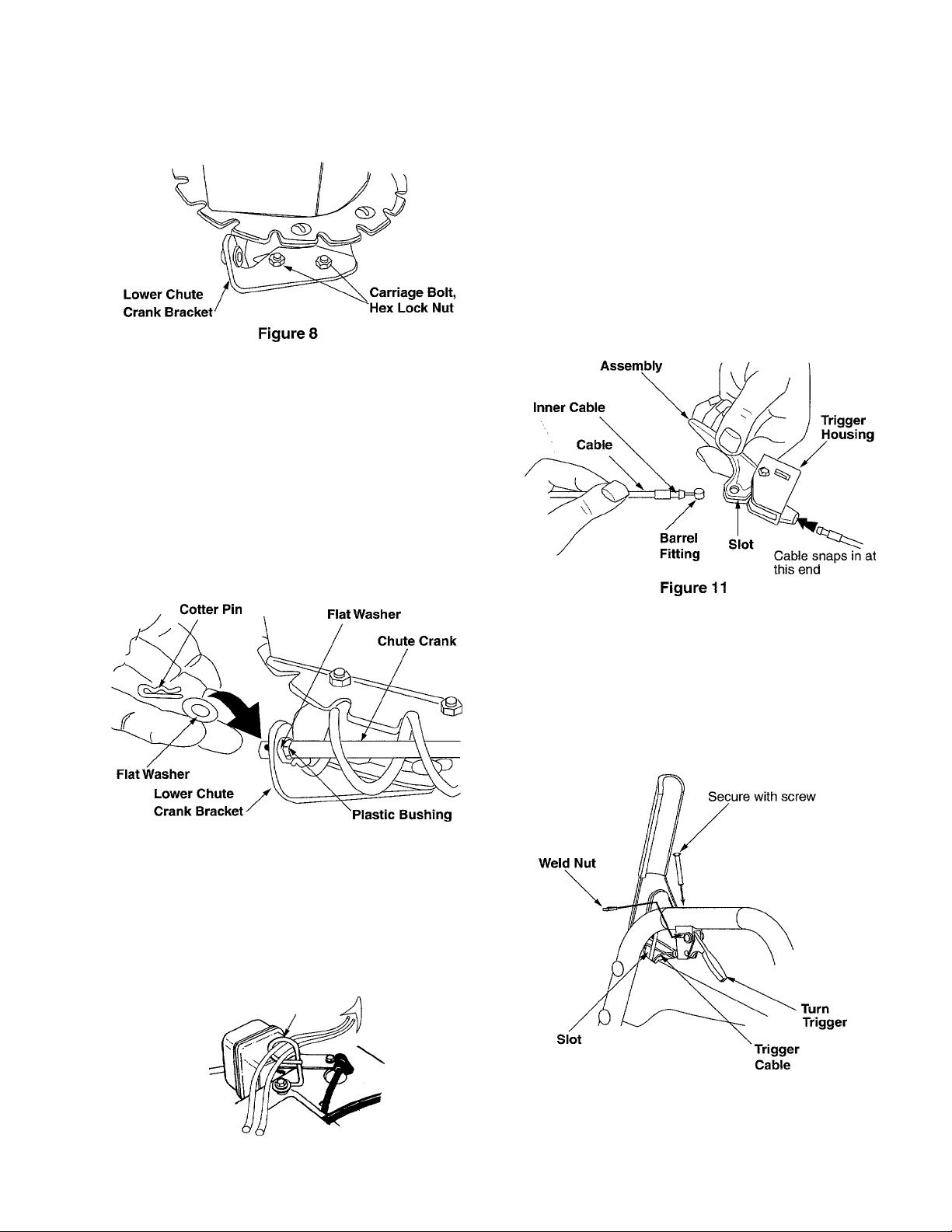

You may have to loosen the carriage bolts and

hex lock nuts which secure the lower chute

crank bracket to the extension on the left side of

the chute assembly. See Figure 8.

Attaching Turn Triggers

• Check and make sure that the right hand trigger

cable is routed in front of the traction drive cable.

• Feed the trigger cable up through the outer side of

the slot in the handle panel. Do noffeed the cable

through the same side of the slot as the Z fitting.

• Place the cable barrel fitting into the hole in the

trigger. You can find the triggers and associated

hardware in group H of the hardware pack (on

page 6). Pull on the cable and rotate it around the

bottom of the trigger, with the inner cable in the

slot, until the cable end can be pushed into the

trigger housing and snapped tight. See Figure 11.

Place one 3/8 ID flat washer (from group G of

the hardware pack) on the end of the chute

crank, then insert the end of the crank into the

eye hole in the plastic bushing in the chute crank

bracket. See Figure 9.

Place the other 3/8 ID flat washer (from the

same group of hardware) on the end of the

chute crank and insert hairpin clip into eye hole

at the end of the chute crank. See Figure 9.

Adjust the chute bracket so that the spiral on the

chute crank fully engages the teeth on the chute

assembly. Tighten the nuts on the lower chute

crank bracket securely.

Trigger

Note: When the cable is installed correctly, you should

not be able to pull the cable out of the trigger housing.

• Place the right turn trigger in position

underneath the right handle. Secure with screw

and weld nut from group H of the hardware pack.

See Figure 12. You will need a phlllips

screwdriver for tightening the screw.

Figure 9

Using a wrench, tighten the hex bolt and the hex

nut on the upper chute crank bracket.

Fully rotate the chute, using the chute crank, to

make sure that it moves freely.

Slip the cables that run from the handle panel to

the chute into the cable guide located on top of

the engine. See Figure 10.

Cable Guide

Figure 10

10

Figure 12

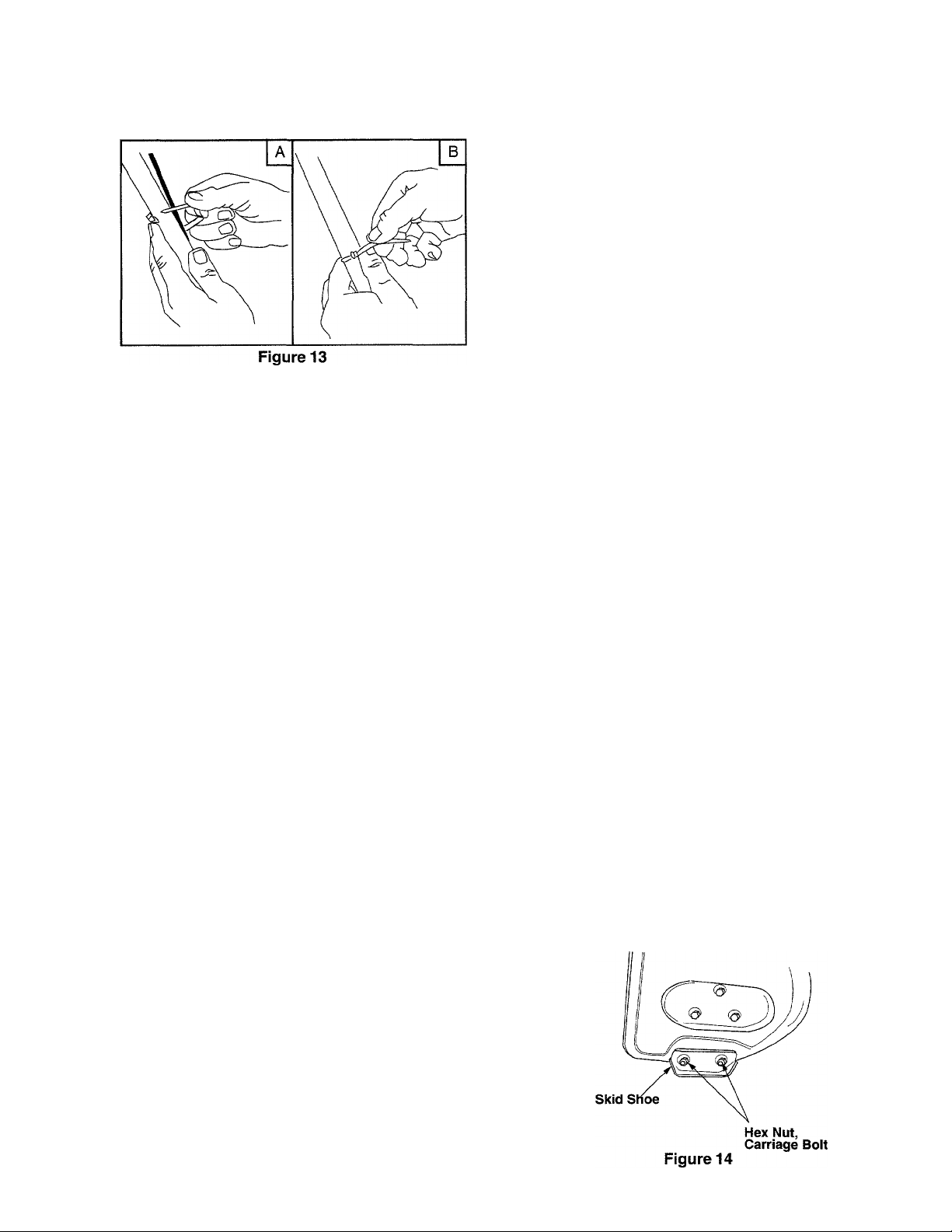

Secure the right turn trigger cable to the right

lower handle, using cable tie provided in the

Page 11

hardware pack. Make sure to route the cable tie

over the drive cable. See Figure 13.

• Secure the left turn trigger cable to the lower

handle using the other cable tie. Make sure to

route the cable tie below the auger drive cable

so that when the trigger cable is secured by the

cable tie, the auger drive cable is left outside the

cable tie.

• Trim excess ends from each cable tie.

Adjusting Traction Drive Control

• To check the adjustment of the traction drive

control and shift lever, move the weight transfer

lever to the transport position (shown in Figure

16 on page 13) and the shift lever all the way

forward to sixth (6) position.

• With the traction drive controi released, pull the

triggers up to the handle and then push the snow

thrower forward to check that the tracks turn.

• Squeeze traction drive control against the handle

and pull the starter. The tracks should turn.

• Now release the traction drive control and pull

the starter again. The unit should not move.

• Before proceeding with adjustment, check to

make sure that the spark plug is

disconnected.

• If the traction drive control needs adjustment,

loosen the jam nut on the traction drive cable

and thread the cable one turn. Recheck

adjustment and repeat as necessary.

• Tighten the jam nut to secure the cable when

correct adjustment is reached.

NOTE: The right side cable tie must be used to keep

cable from coming in contact with the moving shift

arm from the transmission.

Lamp Wiring

• Wrap the wire from the lamp down the right

handle. Plug wire into the alternator lead wire

under the fuel tank.

IMPORTANT: Assemble your snow thrower, then

check the adjustments as instructed and make any

final adjustments necessary before operating the unit.

Failure to follow the instructions may cause damage

to the snow thrower.

Final Adjustments

Adjusting Auger Control

• To check the adjustment of the auger control,

squeeze the left hand clutch grip until the rubber

bumper is compressed. There should be slack in

the clutch cable.

• Release the clutch grip. The cable should be

straight. Make certain you can depress the

auger control grip against the left handle

completely.

• If adjustment is necessary, loosen the hex jam

nut and thread the cable in (for less slack) or out

(for more slack).

• Recheck the adjustment. Tighten the jam nut

against the cable when correct adjustment is

reached.

NOTE: For more details, refer to the Service and

Adjustment section.

Adjusting Skid Shoe

The space between the shave plate and the ground

can be changed by adjusting the skid shoe.

® Return weight transfer lever (shown in Figure

16) to normal position before adjusting skid

shoes.

• For close snow removal, adjust skid shoes

higher to minimize gap between the shave plate

and the ground.

• For snow removal from uneven ground like

gravel, adjust skid shoes downward to create

sufficient clearance between the bottom edge of

shave plate and the ground.

• Adjust the skid shoes by loosening the four hex

nuts and carriage bolts and moving skid shoes

to desired position. Make certain the entire

bottom surface of skid shoe is against the

ground to avoid uneven wear on the skid

shoes. See Figure 14.

• Retighten nuts and bolts securely.

11

Page 12

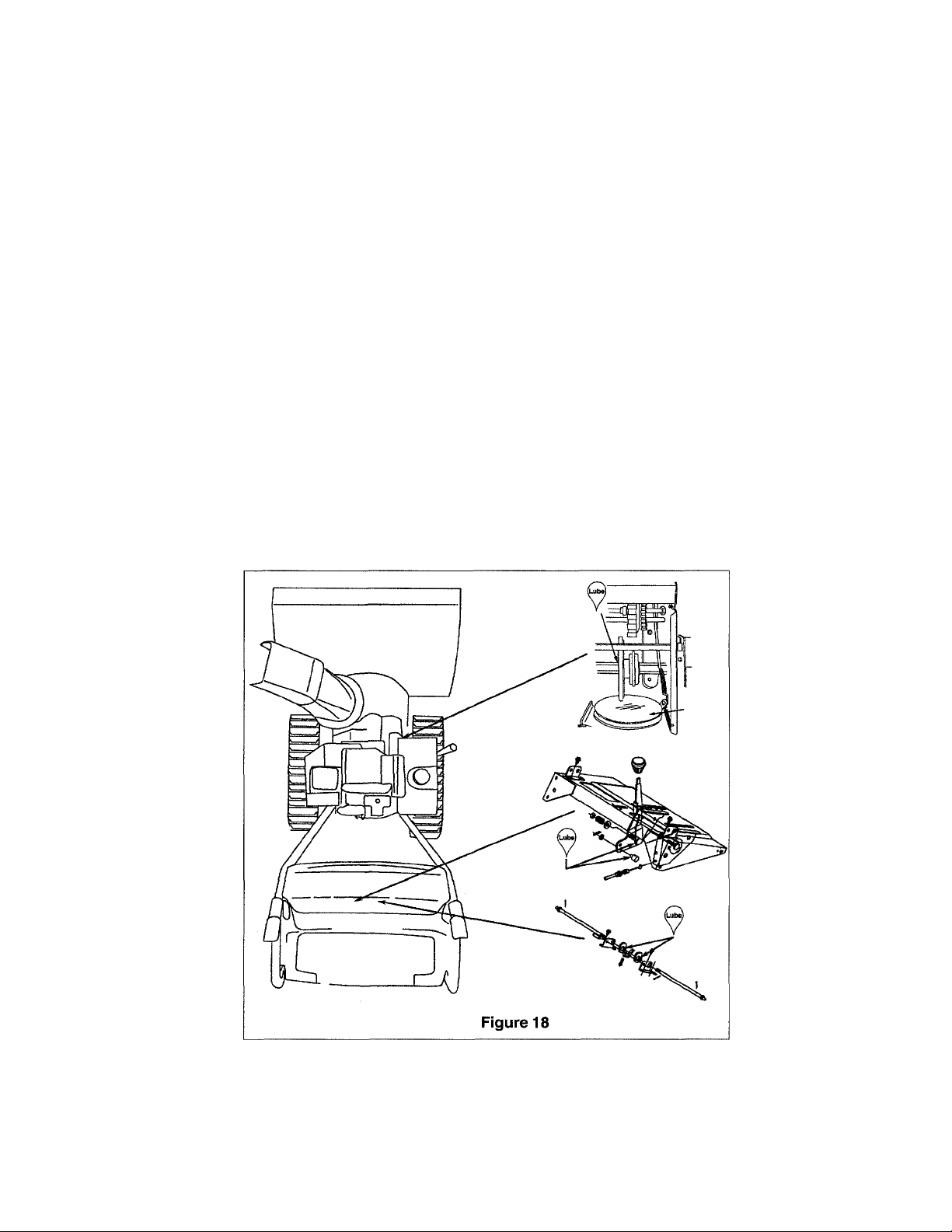

IMPORTANT: Keep all grease and oil off of the

friction wheel and the drive plate.

Shifting Mechanism

• Lubricate the shifting mechanism and pivot

points on the shift rod with engine oil at least

once a season or after every 25 hours of

operation.

Traction Drive Control

• Lubricate cams on the ends of the control rods

which interlock the traction drive and auger

controls at least once a season or every 25

hours of operation with grease. The cams can be

accessed beneath the handle panel.

Gear Case

• The gear case is lubricated with grease at the

factory and does not require checking. If

disassembled for any reason, lubricate with two

ounces of Shell Alvania grease.

Bearings

• Once a season lubricate the auger bearings and

the bearings on the side of the frame with light

oil. See lube chart below.

Check V-belts

Follow the instructions below to check the condition

of the drive belts every 50 hours of operation.

• Remove the plastic belt cover on the front of the

engine by removing two self-tapping screws.

• Visually inspect for frayed, cracked, or

excessively worn out belts.

Check Friction Wheel

Follow the instructions below to check the condition of

the friction wheel rubber every 25 hours of operation.

• Remove the four self-tapping screws from the

frame cover underneath the snow thrower.

• Visually inspect the friction wheel rubber for

excessive wear, cracks, or loose fit on the

friction wheel drive hub.

• Also engage traction drive control and check if

the friction wheel is making contact with the

friction plate.

• If it does not make contact, adjust the traction

drive cable following instructions page 11 and

page 20. Recheck the friction wheel.

• Replace friction wheel rubber if necessary.

Refer to instructions on page 22.

18

Page 13

Engine Maintenance

Engine Oil

Only use high quality detergent oil rated with API

service classification SF, SG or SH. Select the oil’s

SAE viscosity grade according to the expected

operating temperature.

colder

5W30-^

-32°

Viscosity Chart

NOTE: Although multi-viscosity oils (5W30, 10W30

etc.) improve starting in cold weather, these multi

viscosity oils will result in increased oil consumption

when used above 32° F. Check your snow thrower’s

engine oii level more frequently to avoid possible

engine damage from running low on oil.

Refer to the viscosity chart for proper selection of

engine oil.

Checking Oil Level

Before operating the snow thrower, check the oil

level.

• With engine on level ground, the oil must be to

FULL mark on dipstick.

• Stop engine and wait several minutes before

checking oil level. Remove oil fill cap and

dipstick.

• Wipe dipstick clean, insert it into oil fill hole and

tighten securely.

• Remove dipstick and check. If oil is not up to the

FULL mark on dipstick, add 5W30 oil.

warmer

► SAE30

Changing Oi!

Change engine oil after the first two hours of

operation and every 25 hours thereafter.

In order to do that you will have to first drain the spent

engine oii from the engine and then refill with fresh oil.

• Drain oil while engine is warm. Remove oil drain

cap located at the bottom of the recoil starter of

the engine. Catch oil in a suitable container.

• When engine is drained of all oil, replace drain

plug securely.

• Remove the dipstick from the oil fill plug. For

location of the oil fill plug, see Figure 17. Pour

fresh oil slowly through the plug. Replace

dipstick.

• Check and make sure that the level of oil is up to

the FULL mark on the dipstick.

WARNING: Temperature of muffler and

A

nearby areas may exceed 150° F(65°C).

Avoid these areas.

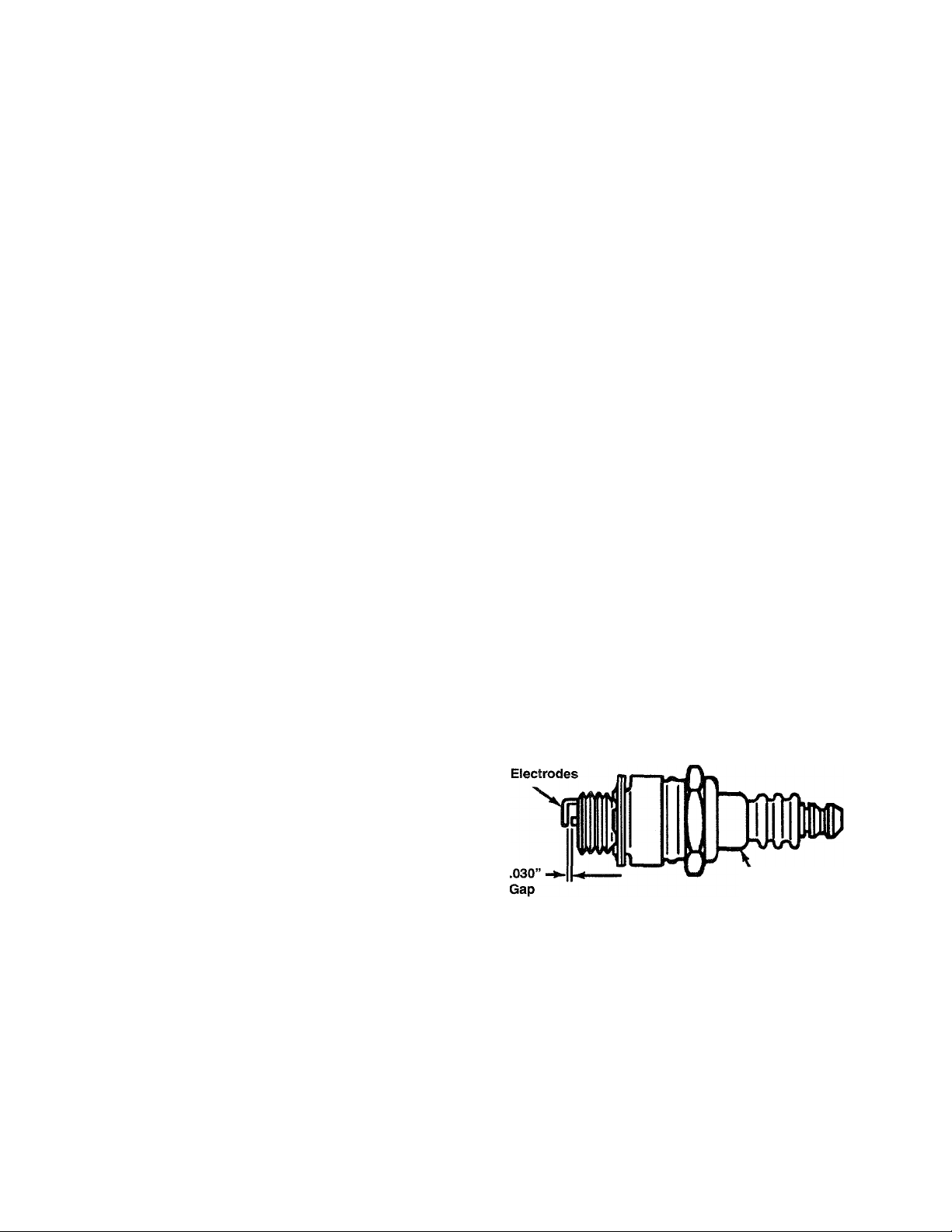

Spark Plug

• Clean area around the spark plug base.

• Remove and inspect the spark plug.

• Replace the spark plug if electrodes are pitted,

burned, or the porcelain is cracked. See Figure 19.

• Clean the spark plug and reset the gap to 0.030"

at least once a season or every 50 hours of

operation. See Figure 19.

• Spark plug replacement is recommended at the

start of each season. Refer to engine parts list

for correct spark plug type.

NOTE: Do not sandblast spark plug. Sparkplug

should be cleaned by scraping or wire brushing and

washing with a commercial solvent.

19

Porcelain

Figure 19

Page 14

SERVICE & ADJUSTMENTS

WARNING: Always stop the engine, dis

A

connect spark plug wire and move it away

from the spark plug before performing any

adjustments or repairs.

Never attempt to clean the chute or make

any adjustments while the engine is running.

Adjustments

Traction Drive Control

Refer to the Final Adjustment section of the Set-Up

Instructions to adjust the traction drive control. If you

are not sure of proper adjustment, check as follows.

• Drain the gasoline or place plastic film under the

gas cap if the snow thrower has already been

operated.

• Tip the snow thrower forward and remove the

four self-tapping screws that hold the frame

cover underneath the snow thrower.

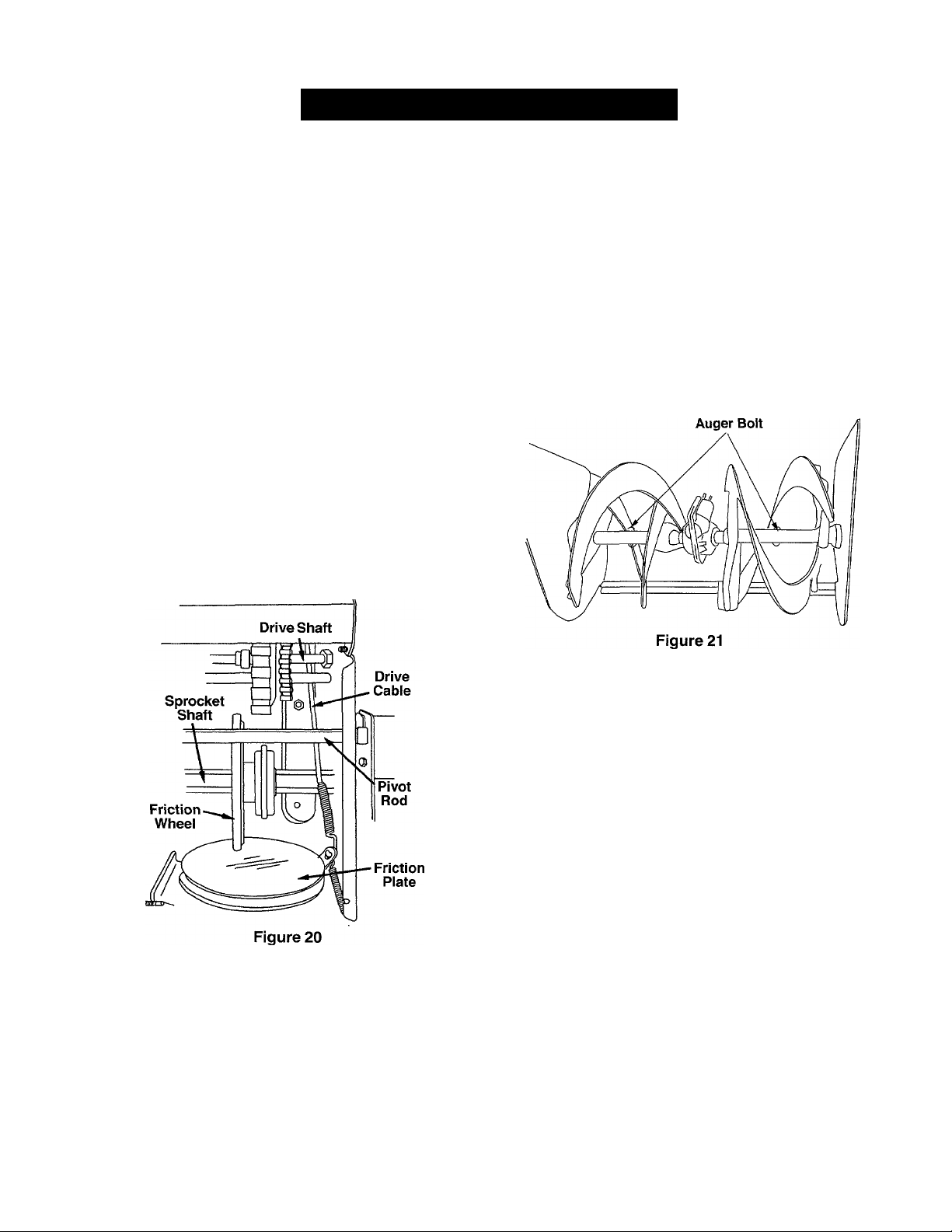

• With the traction drive control released, make

sure that there is clearance between the friction

wheel and the friction plate in all positions of the

shift lever. See Figure 20.

NOTE: If you placed plastic under the gas cap, be

certain to remove it.

Augers

The augers are secured to the spiral shaft with two

shear bolts and hex lock nuts. If you hit a foreign

object or ice jam, the snow thrower is designed so

that the bolts will shear.

• If the augers will not turn, check to see if the

bolts have sheared. Replace if necessary. See

Figure 21. Two replacement shear bolts and hex

lock nuts have been provided in the hardware

pack with the snow thrower. See page 6.

With the traction drive control engaged, make

sure that the friction wheel is making contact

with the friction plate. Also make sure that the

overtravel spring is stretched.

If adjustment is necessary, loosen the jam nut

on the traction drive cable and thread the cable

in or out as necessary.

Tighten the jam nut to secure the cable when

correct adjustment is reached. Reassemble the

frame cover.

Auger Clutch

To adjust the auger clutch, refer to Final Adjustment

section of Assembly Instructions.

Chute Assembly

The distance snow is thrown can be adjusted by

adjusting the angle of the chute assembly. Refer to

page 13.

Skid Shoe

The space between the shave plate and the ground

can be adjusted by adjusting the skid shoe. Refer to

page 11 of this manual.

Shift Rod

To adjust the shift rod, proceed as follows.

• Remove the hairpin clip and flat washer from the

ferrule underneath the shift panel. Remove the

ferrule from the hole in the shift lever.

• Place the shift lever on the handle panel in the

sixth (6) speed position (all the way forward).

• Push down on the shift rod (and shift arm

assembly) as far as it will go. Hold it in this

position. See Figure 22.

• Thread the ferrule up or down the shift rod as

necessary until the ferrule lines up with the

20

Page 15

upper hole in the shift iever.

Traction

Drive

Clutch

Upper

Hole in

Shift

Lever

Shift

Lever

Chute Distance

Control

^ Auger

Control

Flat

Washer

airpin

Clip

Auger Drive Belts

• Disconnect the chute crank at the chute

assembly by removing the cotter pin and the flat

washer.

• Remove the plastic belt cover on the front of the

engine by removing two self-tapping screws.

See Figure 23.

Self-Tapping

Screw

Spring

Washer

Hairpi

Clip

Flat

Washer

Figure 22

hift

Rod

Shift Arm

Assembly

• Insert the ferrule into the upper hole in the shift

lever from the right side when adjustment is

correct. Secure with the flat washer and the

hairpin clip that you had earlier removed. See

Figure 22.

• Check for correct adjustment of the traction

drive control as instructed in the Final

Adjustment section.

Service

Shave Plate And Skid Shoes

The shave plate and skid shoes on the bottom of the

snow thrower are subject to wear. They should be

checked periodically and replaced when necessary.

• To remove skid shoes, remove the two carriage

bolts, belleville washers and hex nuts (on each

side) which attach them to the snow thrower.

See Figure 14.

• Reassemble new skid shoes with the hardware

earlier removed. Make sure to insert the cupped

side of the washer against the skid shoe so that the

skid shoe is adjusted to be level.

• To remove shave plate, remove the carriage

bolts, belleville washers and hex nuts which

attach it to the snow thrower housing.

Reassemble new shave plate, making sure

heads of the carriage bolts are to the inside of

the housing. Tighten securely.

Belt Removal And Replacement

WARNING: Disconnect the spark plug wire

from the spark plug and ground it.

A

Self-Tapping Screw

Figure 23

Unthread the bottom of the auger cable from the

top of the cable, leaving the hex nut in place.

Remove the six lock washers and hex nuts which

attach the auger housing assembly to the frame.

See Figure 24. (Only two pairs of lock washers and

hex nuts are shown in the figure.)

Lock Washer

and Hex Nut

Track

Frame

Figure 24

Separate the housing from the frame assembly

by standing in the operating position and lifting

up on the handles. The frame and housing will

separate and the rear auger drive belt will come

21

Page 16

off the pulleys. See Figure 25.

FrontAuger

Drive Belt

Figure 25

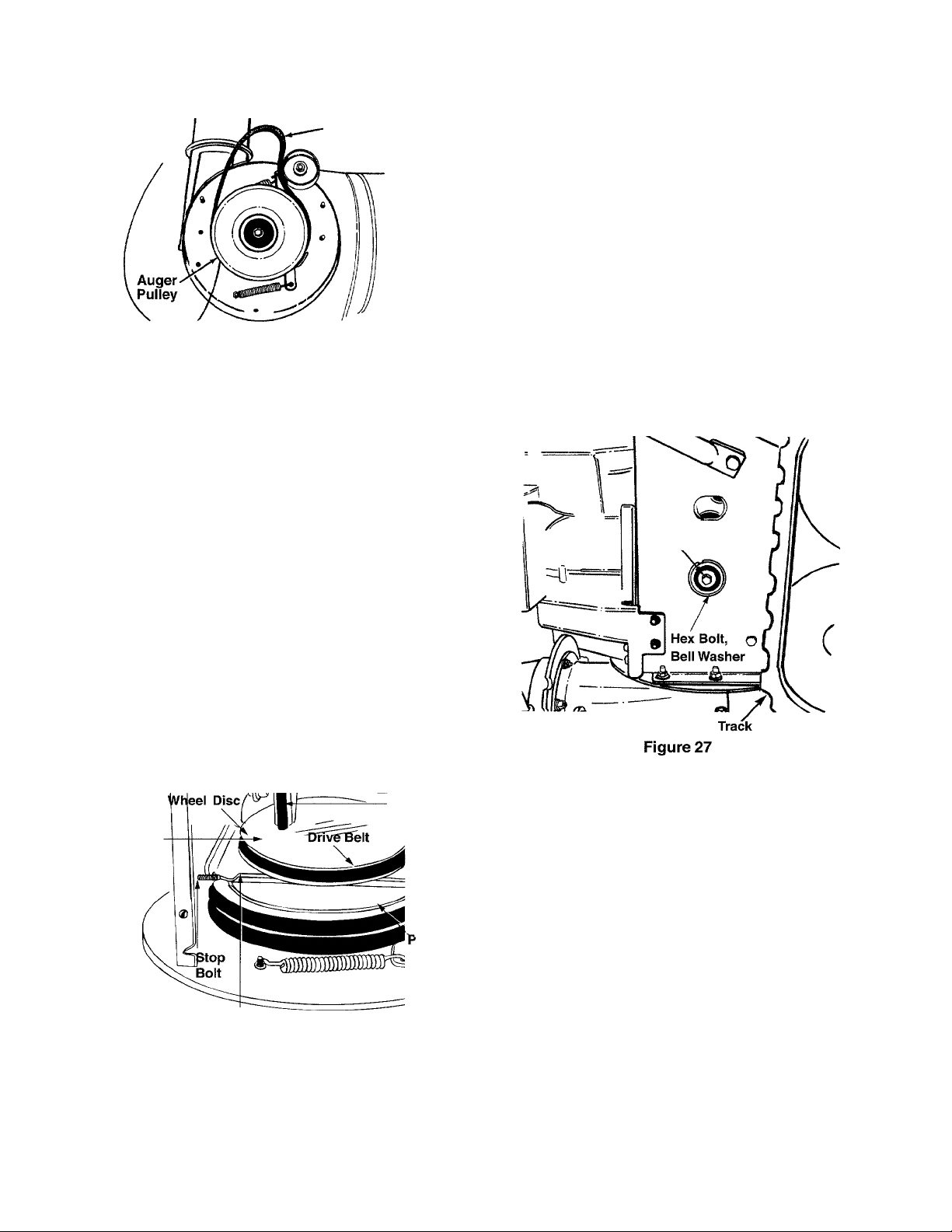

• To remove the front auger drive belt, push the

idler pulley to the left and lift front auger drive

belt from the front auger pulley. See Figure 25.

Replace both auger drive belts by following the

preceding instructions.

NOTE: When reassembling the two halves of the unit,

make sure that the auger drive cabie is routed

through the cabie roiier guide.

Drive Belt

NOTE: The support bracket must rest on the stop boit

after the new belt has been assembled. See Figure 26.

Friction Wheel Rubber

The rubber on the friction wheel is subject to wear and

should be checked after the first 25 hours of operation

and periodically thereafter. Replace the friction wheel

rubber if any signs of wear or cracking are found.

• Drain the gasoline from the snow thrower, or

place a piece of plastic under the gas cap.

• Tip the snow thrower up and forward, so that it

rests on the housing.

• Remove four self-tapping screws from the

frame cover underneath the snow thrower.

• Using a 7/8" wrench to hold the shaft, loosen,

but do not completely remove, the hex bolt and

bell washer from the left end of the shaft. See

Figure 27.

• Remove the plastic belt cover on the front of the

engine by removing the two self-tapping screws.

See Figure 23.

• Drain the gasoline from the snow thrower, or

place a piece of plastic under the gas cap.

• Tip the snow thrower up and forward so that it

rests on the auger housing.

• Remove four self-tapping screws from the frame

cover underneath the snow thrower.

• Pulling the idler pulley upward, roll the belt off

the idler pulley and the engine pulley and lift belt

off friction wheel disc. See Figure 26.

=riction

Friction

Removeold

V№eei

belt from

here

Auger

uiiey

Support

Bracket

Figure 26

Back out the stop bolt until the support bracket

drops on the auger pulley. See Figure 26.

Slip belt between friction wheel and friction disc

plate and remove the belt. See Figure 26.

Reassemble with new drive belt.

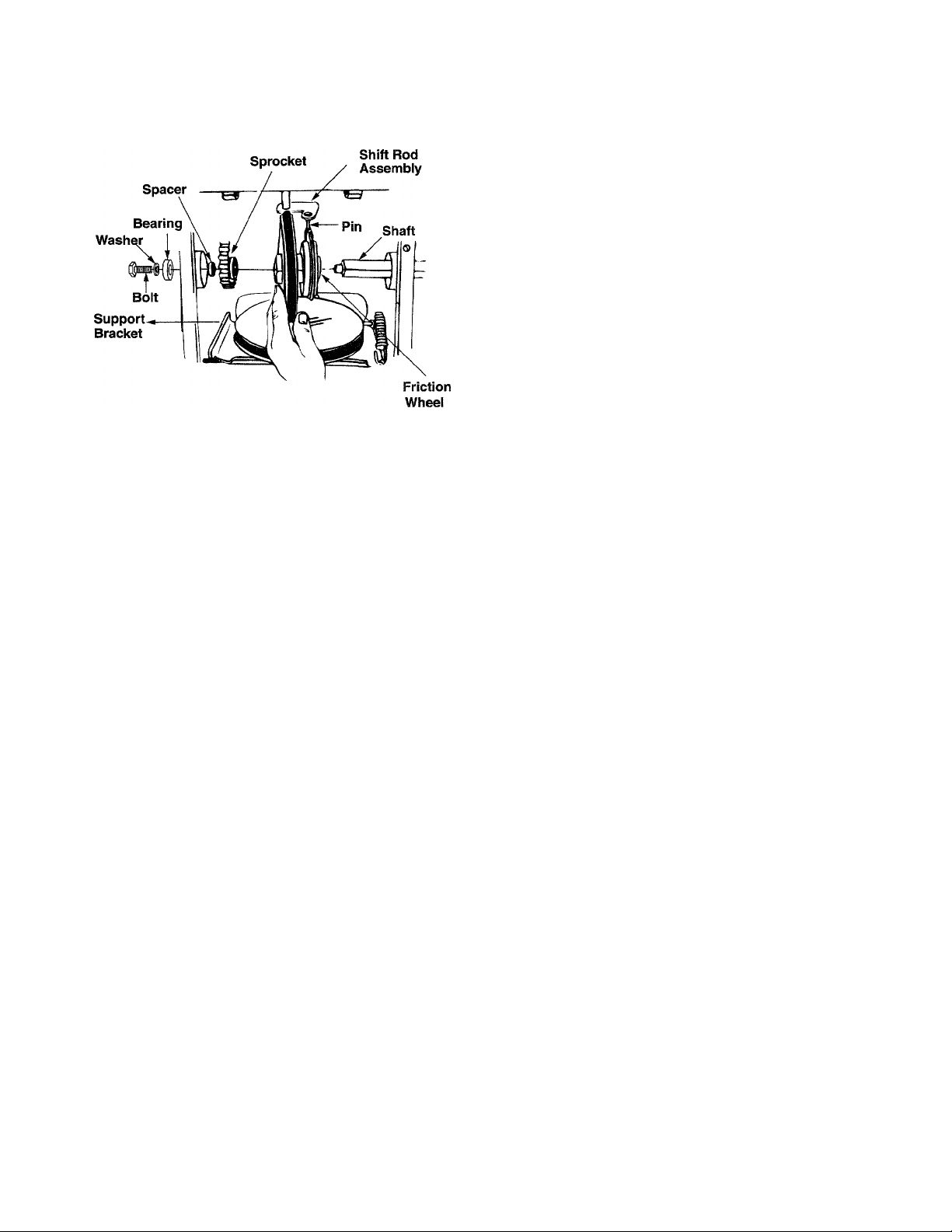

Move the weight transfer lever to the packed

snow position. Refer to Figure 16.

Lightly tap the head of the bolt to dislodge the

ball bearing from the right side of the frame; then

remove the hex bolt and the bell washer from left

end of the shaft.

Sliding the shaft to the right, remove the spacer,

the sprocket and the friction wheel assembly

from the shaft. See Figure 28.

Remove the six screws from the friction wheel

assembly (three from each side). Remove the

friction wheel rubber from between the friction

wheel plate.

Reassemble the new friction wheel rubber to the

friction wheel assembly tightening the six screws

in rotation and with equal force.

Position the friction wheel assembly up onto the

pin of the shift rod assembly and slide the shaft

through the friction wheel. See Figure 28.

Slide the shaft into the hex I.D. of the sprocket,

the spacer and the left ball bearing and secure

22

Page 17

with the bell washer and hex bolt. See Figure 28.

Figure 28

Carburetor

WARNING: If any adjustments are made to

A

If you think the carburetor needs to be adjusted, see

your nearest authorized Tecumseh Service Outlet.

the engine while the engine is running (e.g.

carburetor), keep clear of all moving parts.

Be careful of heated surfaces and muffler.

23

Page 18

OFF-SEASON STORAGE

If your snow thrower is left unused for 30 days or

longer, It needs to be prepared for storage. Also, at

the end of the snow season, you should follow the

same set of instructions and store the snow thrower

properly for the off-season. Proper storage ensures

longer life of the snow thrower.

Preparing Engine

WARNING; Never store snow thrower with

fuel in tank indoors or in poorly ventilated

A

To avoid engine problems, the fuel system should be

empf/edbefore storage for 30 days or longer. Follow

these instructions to prepare your snow thrower for

storage:

• Remove all gasoline from the carburetor and the

areas, where fuel fumes may reach an open

flame, spark or pilot light as on a furnace,

water heater, clothes dryer or gas

appliance.

It is important to prevent gum deposits from

forming in essential fuel system parts of the

engine such as the carburetor, fuel filter,

fuel hose or tank during storage.

Also experience indicates that alcohol

blended fuels (called gasohol or using

ethanol or methanol) can attract moisture

which leads to separation and formation of

acids during storage. Acidic gas can

damage the fuel system of an engine while

in storage.

fuel tank to prevent gum deposits from forming

on these parts and causing possible malfunction

of the engine.

WARNING: Drain fuel into approved

A

A

NOTE: Fuel stabilizer (such as STA-BIL) is an

acceptable alternative in minimizing the formation of

fuel gum deposits during storage. Add stabiiizer to

gasoiine in fuel tank or storage container. Always

follow mix ratio found on stabilizer container. Run

engine at least 10 minutes after adding stabilizer to

allow it to reach the carburetor. Do not drain

carburetor if using fuel stabilizer.

• Remove the spark plug and pour one (1) ounce

container outdoors, away from any open

flame. Be certain engine is cool. Do not

smoke.

Fuel left in engine during warm weather

deteriorates and will cause serious starting

problems.

Run the engine until the fuel tank is empty and it

stops due to lack of fuel.

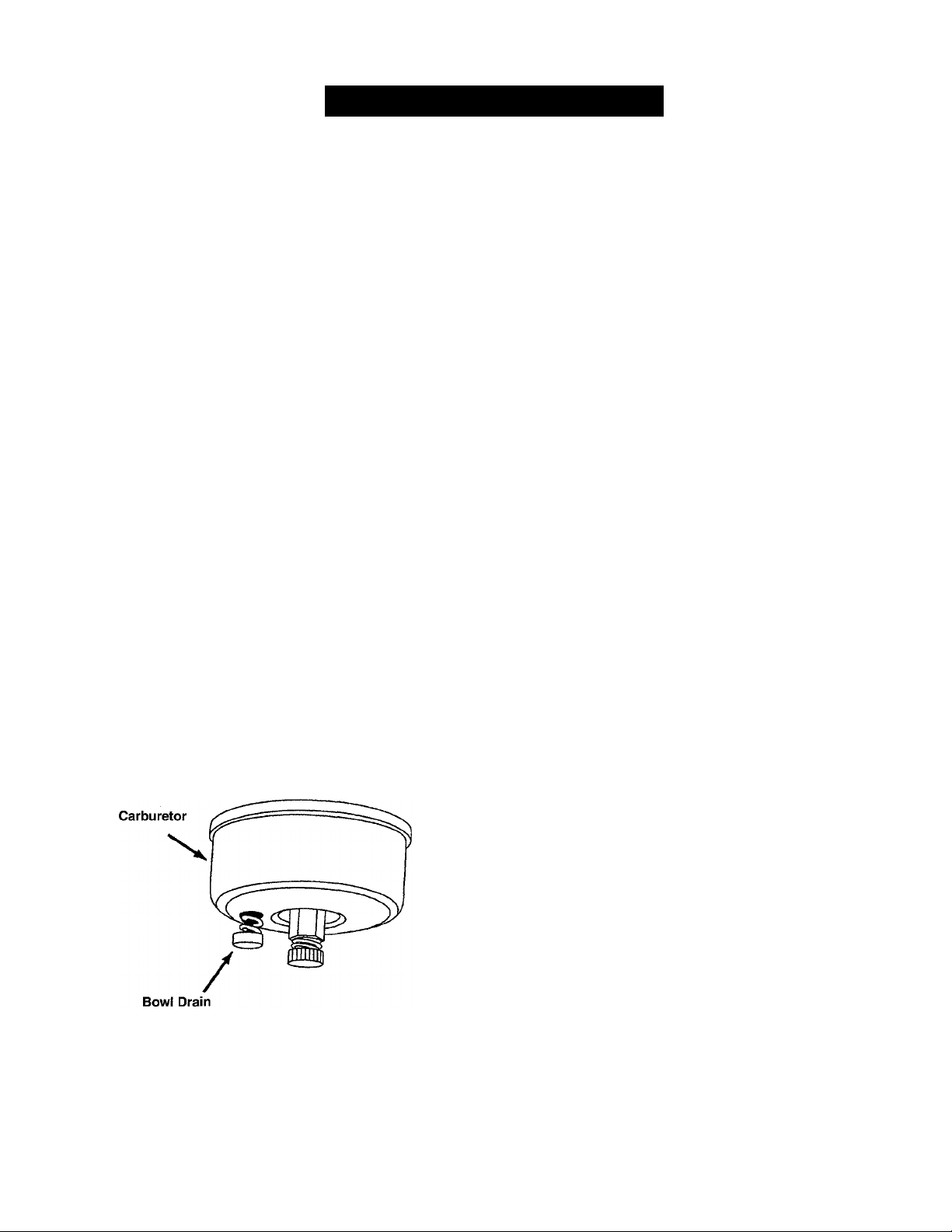

Drain carburetor by pressing upward on bowl

drain, located below the carburetor cover. See

Figure 29.

WARNING: Do not drain carburetor if using

fuel stabilizer. Never use engine or

carburetor cleaning products in the fuel tank

or permanent damage may occur.

of engine oil through the spark plug hole into the

cylinder. Crank the engine several times to

distribute the oil. Replace spark plug.

Preparing Snow Thrower

• When storing the snow thrower in an

unventilated or metal storage shed, care should

be taken to rustproof the equipment. Using a

light oil or silicone, coat the equipment,

especially any chains, springs, bearings and

cables.

• Remove all dirt from exterior of engine and

equipment.

• Follow lubrication recommendations on

page 17.

• Store in a clean, dry area.

Figure 29

24

Page 19

TROUBLE-SHOOTING

PROBLEM

Shift lever not locking

into the sixth speed

Engine fails to start

Engine runs erratic. 1. Unit running on choke.

Loss of power 1. Spark plug wire loose.

Engine overheats 1. Engine oil level low.

Excessive vibration 1. Loose parts or auger damaged.

Hard to shift speed, or

will not shift

Unit fails to propel

itself

Unit fails to discharge 1. Auger shear bolt broken.

snow

Track does not turn 1. Track control cable not inserted.

1. Shift rod out of adjustment

1. Fuel tank empty, or stale fuel.

2. Fuel shut-off valve closed.

3. Ignition key not in switch or engine.

4. Spark plug wire disconnected.

5. Blocked fuel line.

6. Faulty spark plug.

2. Blocked fuel line or stale fuel.

3. Water or dirt in fuel system.

4. Carburetor out of adjustment.

2. Gas cap vent hole plugged.

2. Carburetor not adjusted properly.

1. Shift rod not adjusted

1. Incorrect adjustment of drive clutch

2. Drive belt loose or damaged.

2. Discharge chute clogged.

3. Foreign object lodged in auger.

4. Auger drive clutch not adjusted.

5. Auger drive belt loose or damaged.

POSSIBLE CAUSE

2. Lower cable bracket not fully positioned against

gear box.

CORRECTIVE ACTION

1. Remove washer and pin. Turn ferrule

clockwise one turn and reinstall.

1. Fill tank with clean, fresh gasoline.

2. Open valve.

3. Insert key.

4. Connect spark plug wire.

5. Clean fuel line.

6. Clean, adjust gap or replace.

1. Turn choke to off position.

2. Clean fuel line, fill tank with fresh fuel.

3. Drain carburetor following instructions on

page 24. Refill with fresh fuel.

4. Contact Sears service center.

1. Connect and tighten spark plug wire.

2. Remove ice and snow from cap. Make sure

that the vent hole is clear.

1. Fill crankcase with proper engine oil.

2. Contact Sears service center.

1. Stop engine immediately and disconnect

spark plug wire. Tighten all nuts and bolts.

Check for the source of vibration. Make all

necessary repairs. If vibration persists,

contact Sears service center.

1. Readjust shift rod. Follow instructions on

page 20.

1. Adjust drive clutch. Refer to page 11 of this

manual.

2. Replace drive belt following instructions on

page 21.

1. Replace shear bolt.

2. Stop engine, disconnect spark plug wire and

clean discharge chute and inside of auger

housing.

3. Stop engine, disconnect spark plug wire and

remove object from auger.

4. Adjust properly. See page 20.

5. Replace belt. See page 21.

1. Insert the cable completely into the trigger

assembly.

2. Loosen two self-tapping screws on each slot

of bracket. Retighten making sure that the

bolt is completely at the bottom of the slot.

For repairs beyond the minor adjustments listed above,

please contact your nearest SEARS service center.

25

Page 20

PARTS LIST

SEARS CRAFTSMAN 8.5 H.P. SNOW THROWER MODEL 247.885500

26

Page 21

Key

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14 710-1003

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

' Includes references 58 through 75

Part No.

629-0058

684-0008A-

0637

684-0022

684-0066

684-0102

684-0111

684-0112

710-0262

710-0442

710-0451

710-0459

710-0599

710-0896

711-0653

712-0116

712-0415

712-0429

712-3010

714-0507

715-0138

720-0201A

720-0300

725-1300

726-0100

731-1300A

731-1313B

731-1317

731-1320

731-1773A

732-0145

732-0193

732-0705

732-0746

735-0199A

736-0105

736-0119

Harness for Headlight

Shift Arm Assembly

Chute Crank Assembly

Hardware Pack*

Handle Panel Assembly w/

Tilt

Handle Assembly

Engagement (L.H.)

Handle Assembly

Engagement (R.H.)

Carriage Bolt 5/16-18 x 1.50

Hex Bolt 5/16-18x1.5

Carriage Bolt 5/16-18 x.75

Hex Screw 3/8-24 x 1.5

Hex Washer Hd. TT Screw

1/4-20x0.5"

Hex AB Tap Screw 1/4 x .62

Hex B-Tapp Screw # 10-16 x .62

Clevis Pin

Hex Ins. Lock Nut 3/8-24

Self Threading Nut

Lock Nut 5/16-18

Hex Nut

Cotter Pin

Roll Pin

Chute Crank Knob

Shift Knob

Headlight

Push Cap

Lower Chute

Cable Guide

Headlight Bezel

Upper Chute

Handle Panel

Compression Spring

Compression Spring

Cable Control Wire

Torsion Spring

Rubber Bumper

Bell Washer .380 X .880 x.062

Lock Washer 5/16 I.D.

Description Qty.

2

2

1

9

2

2

3

3

1

1

2

1

1

1

2

1

1

1

1

1

1

1

2

2

Key

No.

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

1

75

Part No.

736-0159

736-0506

736- 0509

737- 0133

741-0475

746-0896

746-0901

747-

0798A

747-

0877

748-

0362

748-

0363

0908A

749749-

0909

784-

5594

5604

784784-

5619A

784-

5679

784-

5680

784-

5681

784-

5682

712-

•3010

712-

■3027

710-

•0442

736-

■0119

784-

•5599

710-

-3180

710-

-3008

736-

■0275

736-

-0185

714-

-0104

-0851A

731710-

-3015

711-

-0677

710-

-0262

-0778

746712

-0121

784

-5678

736-0242

Washer 5/6 I.D. 2

Special Washer 1

Special Washer 2

Grease 1

Plastic Bushing 1

Chute Deflector Control Cable 1

Chute Deflector Cable 1

w/ Clip

Shift Rod 1

Cam Rod 2

Cam Handle Lock 2

Pawl Handle lock 1

Right Handle 1

Left Handle 1

Cable Bracket 1

Chute Tilt Handle 1

Shift Handle 1

Handle Support Bracket (LH.) 5/8 1

Handle Support Bracket (R.H.) 5/8 1

Handle Support Bracket (LH.) 3/8 1

Handle Support Bracket (R.H.) 3/8 1

Hex Nut 5/16-18 Thd. 5

Hex Flange Locked Nut 1 /4-20 Thd. 8

Hex Bolt 5/16-18x1.5 1

Lock Washer 5/16 5

Handle Tab 2

Hex Bolt 5/16-18x1.75 Gr.5 2

Hex Bolt 2

Flat Washer 5/16 2

Flat Washer 3/8 x .738 x .063 2

Hairpin Clip 3

Chute Flange Keeper 3

Hex Bolt 5/16-18x1.50 8

Ferrule 1

Carriage Bolt 5/16-18x1.50 4

Z Fitting 2

Hex Nut #10-24 2

Chute Crank Reinforcement 1

Bracket

Cupped Washer .340 I.D. X 4

.872 O.D.

Description Qty.

27

Page 22

28

Page 23

Key

No.

1

2

3

4 618-0169

7

9

10

12

14

17

18

19

20

21

22

23

24 710-0875

25

27

28

29

30

33

36

37

38

39

40

Part No.

611-0053

618-0043

618-0044

683-0024

684-0014B

684-0021

684-0031

684-0042B

710-0538

710-0599

710-0602

710-0604

710-0654A

710-0788

710-0809

710-0896

710-1233

711-0911

711-1042

712-0127

712-0324

712-0711

713-0233

713-0413

713-0437

714-0474

Description Qty.

Axle Assembly

Dogg Assembly: R.H.

Dogg Assembly; LH.

Shift Assembly; Track Drive

Hub Assembly: Track Drive

Shift Rod Assembly

Friction Wheel Support

Bracket Assembly

Frame Assembly

Friction Wheel Bearing

Assembly

Hex Lock Screw 5/16-18 x

.625 Grade 5

Hex Washer Hd. TT Screw

Hex Washer Hd. TT Screw

Hex Washer Hd. TT Screw

Hex Washer Hd. TT Screw

Hex Washer Screw

Hex Washer Screw

TT Screw

Hex Washer Head AB Screw

Oval C-Sunk Screw

Actuator Shaft

Hex Shaft: Track Drive

Flanged Weld Nut #10-24

Top Lock Nut 1/4-20

Jam Nut 3/8-24

Chain Links

Sprocket: 10T

Chain

Cotter Pin

2

8

6

4

2

2

1

1

10

1

1

2

1

1

1

1

2

1

Key

No.

41

43

46

47

48

49

50

51

52

54

58

59

60

61

62

63

64

65

66

67

70

71

74

75

76

77

80

81

82

83

84

Part No.

719-0295A

725-0157

732-0209

732-0264

736-0105

736-0160

736-0176

736-0242

736-0270

736-0287

738-0924

741-0339

741-0563

741-0597

746-0897

746-0898

746-0948

746-0950

748-0190

748-0234

750-0903

750-0904

750-0997

756-0625

784-5590

784-5609

784-5648

784-5687

784-5688

784-5689A

710-0371

Description Qty.

Track Housing 1

Cable Tie 2

Extension Spring 2

Extension Spring 1

Bell Washer 1

Flat Washer 1

Flat Washer 2

Bell Washer 5

Bell Washer 2

Flat Washer 2

Shoulder Screw 3

Flange Bearing 4

Ball Bearing 2

Hex Flange Bearing 2

Auger Clutch Cable 1

Drive Clutch Cable 1

Track Steering Cable 2

Trigger Control 2

Spacer 1

Shoulder Spacer 2

Split Spacer 2

Split Spacer 1

Spacer 1

Roller Cable 3

Shift Bracket 1

Steering Cable Bracket 1

Frame Cover 1

Auger Clutch Cable Bracket 1

Drive cable Bracket 1

Front Support Bracket 1

Hex Screw 2

29

Page 24

30

i®

© \(fi

Page 25

Key

No.

1

11

12

13

14

15

17

18

19

20

21

22

Part No.

631-0032

684-0009

2

684-0024

3

684-0038

4

710-0157

5

710-0459

6

710-0604

7

710-1231

8

712-0214

9

712-0346

712-0429

720-0223

731-1292 Track

731-1538A

736-0242

736-0272

736-0406

737-0170

738-0140

748-0353A

Description

Wheel Assembly idler

Rod Track Pivot

Axle Assembly

Handle Assembly

Screw

Screw

Screw

Screw

Lock Nut

Jam Nut

Hex Nut

Grip

Wheel-Track Drive

Bell Washer

Flat Washer

Flat Washer

Lubricant

Shoulder Screw

Lift-Shaft Drive

Qty.

2

1

1

1

1

1

2

2

1

4

6

1

2

2

1

4

4

1

4

1

Key

Part No.

No.

750-0547

23

24 750-0909

750-0995

25

784-5639-0483

26

784-5642

27

717-1211

28

717-1209

29

717-1210

30

741-0542

31

32 718-0188

618-0046

33

711-0912

34

713-0414 Sprocket—13 Tooth

35

36 715-0120

736-0502

37

736-0336

38

716-0115

39

716-0114 Snap Ring .56" Shaft

40

Description Qty.

Spacer

Spacer

Spacer 2

Plate-Track Side 2

Plate-Track Lockout

Gear Ring

Gear 12-Tooth 6

Gear 18-Tooth 2

Pin Dowei 6

Carrier

Carrier Assembly

Shaft—Track Drive

Spring Pin

Flat Washer 6

Flat Washer 2

Snap Ring .625" Shaft

2

2

1

2

2

2

1

1

1

2

1

LABELS

Key

No .

1

2

3

4

5

6

7

8

Part

No.

777-4865

777-4866

777-4867 Chute Tilt

777-4958

777-4959

777-4965

777-3396

777-8088B

Description

Traction Control R.H.

Traction Control L.H.

Auger Control

Traction Drive

Transport

Danger Warning

Danger, Top of Chute

Qty.

1

1

1

1

1

1

1

1

31

Page 26

32

Page 27

Key

No.

1 05931

2

3

4

5

6

7

8

9

10

Part No.

605-5192

605-5193

618-0121

684-0040A

684-0065

705-5226

710-0134

710-0451

710-0459

710-0604

11

710-0890A

12

712-0116

13

712-0324

14

712-0429

15

712-0798

16

712-3010

17

715-0114 Spiral Pin

18

Description

Bearing Housing

Spiral Assembly

Spiral Assembly

Auger Gear Assembly

Spiral Housing Assembly

Impeller Assembly

Chute Reinforcement

Carriage Screw 1/4-20 X .62

Carriage Bolt 5/16-18 X .75

Hex Screw3/8-24 X1.5 Grade 5

Hex Washer Head TT-Screw

5/16-18 X.62

Shear Bolt 5/16-18 X 1.5

Jam Lock Nut

Toplock Nut 1/4-20

Hex Lock Nut 5/16-18

Hex Nut 3/8-16

Hex Nut 5/16-18

Qty.

1

1

1

1

1

1

1

5

10

1

6

2

1

5

2

1

19

2

Key

No.

19

20 732-0611

21

22

23

24 736-0188

25

26

27 738-0281

28

29

30

31

32 756-0178

33

34 784-5580

35

36

37

Part No.

731-1379

736-0119

736-0169

736-0174

736-0242

736-0463

741-0245

741-0309

741-0475

741-0493A

784-5579A Shave Plate

784-5618

784-5632

784-5647

Description

Chute Adapter

Extension Spring

Lock Washer 5/16 9

Lock Washer 3/8

Wave Washer

Flat Washer .761.D. x 1.49 O.D. 6

Bell Washer.345 I.D.x.88 16

Flat Washer 1/4 X.630

Shoulder Screw

Hex Flange Bearing

Ball Bearing

Plastic Bushing

Flange Bushing

Flat Idler

Slide Shoe

Bearing Assembly

Auger Idler Arm

Chute Crank Bracket

Qty.

1

1

1

1

5

1

2

1

1

4

1

1

2

2

1

1

Key

No

1

Part No.

618-0123

2 618-0124

710-0642

3

4 711-0909

714-0161

5

715-0143

6

7 717-0526

8 717-0528

9 718-0186

721-0325

10

Description Qty

Housing—R.H.

Housing—L.H.

Screw

Axle, Spiral

Key, Hi-Pro

Pin, Spiral

Worm, Shaft

Gear, Worm

Collar, Thrust

Plug

Key

No.

1

5

1

1

1

1

1

1

1

11

12 721-0328

13

14 736-0369

15

16

17

18

Part No.

721-0327 Seal, Oil

736-0351

736-0445

737-0168

741-0662

741-0663

Description Qty

Loctite 5699, Ultra

Washer

Washer 4

Washer

Grease

Bearing Flange 1

Bearing Flange 1

1

2

1

1

1

33

Page 28

Ref.

No. Part No. Description

1

2 629-0071

3

4

5 710-0230

6 710-0342

7 710-0696

8 710-0888

9 710-0896

10 712-0181

11 731-1324

12

13 736-0119

14 736-0242 Washer—Bell 1

15

16 736-0329

05896A

710-0117 Screw

710-0157 Screw 1

732-0710 Spring

736-0247 Washer—Flat

Bracket

Cord, Extension 1

Screw

Screw 1

Screw 1

Screw

Screw

Nut, Hex

Belt Cover

Washer—Flat

Washer—Lock 1

Qty.

Ref.

No.

1

1

1

1

2

1

1

1

1

1

17 736-0331

18

19

20

21 754-0346

22 754-0430

23 756-0313

24 756-0569

25

26

27

28 390-985

29

30

Part No. Description

Washer—Bell 1

736-0505

748-0234 Shoulder Spacer

748-0360

756-0967

756-0986

756-0987

390-987

143.988501

770-0373A

Washer—Flat

Pulley, Adapter 1

V-Belt

V-Belt Matched

Idler, Flat 1

Pulley, Half

Pulley—Auger

Pulley Half

Pulley Half

Starter 1

Starter

Engine 1

Owner's Manual

(Not Shown)

Qty.

1

1

1

2

4

2

1

1

1

1

34

Page 29

Craftsman Engine Model No. 143.988501 for Craftsman

Snow Thrower Model 247.885500

CARBURETOR

Key

No.

0

1 631776A

2

6

7 650506

10

14

15 630735

16

17

18 630766

20

20A

25 631951

27

28

29 631028

30

31

32 27136A

33

36

37

40

44 27110

47 630748

48

Part

No.

640052

631970

631778

632112 Choke Shaft & Lever Ass’y632174

632164

650417

640016

640053

631024 Float Shaft

632019

631021

631022

27554

640005

632547

640055

631027

Description Qty.

Carburetor (Incl. 184 of

Engine Parts List)

Throttle Shaft & Lever Ass’y-

Throttle Return Spring

Throttle Shutter

Shutter Screw

Choke Shutter

Choke Positioning Spring

Fuel Fitting

Throttle Crack Screw/ldle

Speed Screw

Tension Spring

Idle Restrictor Screw

Idle Restrictor Screw Cap

Float Bowl Ass’y. (Incl. 32 &

33)

Float

Float Bowl “0” Ring

Inlet Needle, Seat & Clip

(Incl. 31)

Spring Clip

Bowl Drain Ass’y.

Drain Plunger Gasket

Main Nozzle Tube

0 Ring

High Speed Bowl Nut

Bowl Nut Washer

Welch Plug, Idle Mixture We

Welch Plug, Atmospheric

Vent

1 1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1

35

Page 30

Craftsman Engine Model No. 143.988501 for Craftsman

Snow Thrower Model 247.885500

298\|

£^^328

370G

36

Page 31

Craftsman Engine Model No. 143.988501 for Craftsman

Snow Thrower Model 247.885500

Key

No.

1

2

3

4

5

15

15A

15B

16

17

18

19

20

25

26

28

30

35

36

37

38

40

40

41

41

42

42

43

45

47

48

49

50

60

65

69

70

71

75

76

80

81

82

83

84

86 650833

87 650832

89

Part

No.

35385

27652 Dowel Pin

650820

—

30969

30699C

30700

650494 Screw

33454

29916

651028 Screw, Torx

34663

35319 Oil Seal

36460

650561 Screw

30322 Lock Nut

35980A

29826 Screw

29918

29216

29642

40011

40012

40009

40010

40013

40014 Ring Set (.010” OS)

27888

36897

651033

34034

36896

36655

33273A

650128

35262A

35445A

35377 Crankshaft Bushing

35319 Oil seal

28926

31845

30590A

35378 Governor Gear Asss’y30588A

29193

32589 Flywheel Key

Description

Cylinder

Screw

Oil Drain Extension

Extension Cap

Governor Rod

Governor Yoke

Governor Lever

Governor Lever Clamp

Speed Control Spring

Blower Housing Baffle

Crankshaft

Lock Washer

Lock Nut

Retaining Ring

Piston, Pin & Ring Set (Std.)

Piston, Pin & Ring Set (.010” OS

Piston, & Pin Ass’y (Std.)

Piston, & Pin Ass’y (.010” OS)

Ring Set (Std.)

Piston Pin Retaining Ring

Connecting Rod Ass’y

Connecting Rod Bolt

Valve Lifter

Oil Dipper

Camshaft (MCR)

Blower Housing Extension

Screw

Cylinder Cover Gasket

Cylinder Cover

Camshaft Seal

Governor Shaft

Washer

Governor Spool

Retaining Ring

Screw

Screw

Qty.

5) 1

Key

No.

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

90

92

2

93

2

100 35135

101

102

103

110

110A

119

120

125

125

126

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

126

127

130

130A

130B 650713

135

139

149

149A

150

2

2

2

7

1

140 650836

151

169

170

171

172

173

174 650128

178

182

183

184 33263

185

186

186B

200

203

204

206 610973

207

209

215

219

Part

No.

611093

650880 Belleville Washer

650881

610118

651024 Solid State Mounting Stud

651007 Screw, Torx

35187

37047 Ground Wire

36448 Cylinder Head Gasket

36449

27878A

27880A

34035

34036

650691 Washer

650727 Screw

6021A Screw

35395

33369

27882

35862 Valve Spring Cap

27881

32581

27896A

28423

28424 Breather Element

28425 Valve Cover

35350

29752 Nut & Lock Washer

30088A Screw

34587A

33877 Intake Pipe

34667 Governor Link

36652 Choke Spring

34677

31342 Compression Spring

651029

33878 Throttle Link

650821 Screw

35440

34586

Description

Flywheel (W/ Ring Gear)

Flywheel Nut

Solid State Ignition

Spark Plug Cover

Ground Wire

Cylinder Head

Exhaust Valve (Std.)

Exhaust Valve (1/32” Os)

Intake Valve(Std.)

Intake Valve (1/32” Os)

Screw

Resistor Spark Plug

Governor Gear Bracket

Screw

Valve Spring Cap

Valve Spring

Valve Spring Keeper

Valve Cover Gasket

Breather Body

Breather Tube

Screw

Choke Bracket

Carburetor to intake

pipe gasket

Control Bracket

Torx. Screw

Terminal

Control Knob

Choke Rod

Qty.

1

1

1

1

1

2

2

1

1

1

1

1

1

1

1

2

2

7

2

1

1

2

1

1

2

2

1

1

1

1

1

2

2

2

1

1

1

1

1

1

1

1

1

1

2

1

1

37

Table continued on next page

Page 32

Craftsman Engine Model No. 143.988501 for Craftsman

Snow Thrower Model 247.885500

Table continued from previous page

Key

No.

Part

No. Description

220 35438

222

223

224

260

261

262

264A

265

275

276

277

281

282

285

287

290

292

298

300

301

305

28820

650378

27915A Intake Pipe Gasket

35447A Blower Housing

650788

29747B Screw, Torx

650802 Screw

33272B

35056

31588

651002 Screw

33013

650760

35985B Starter Cup

29752 Nut & Lock Washer

30705

26460

650665 Screw

34156A Fuel Tank

35355

35554 Oil Fill Tube

307 35499

308

310

35540 Fill Tube Clip

36205

314 650873

Choke Knob

Screw

Screw, Torx

Screw

Cylinder Head Cover

Muffler

Locking Plate

Starter Bubble Cover

Screw

Fuel Line

Fuel Line Clamp

Fuel Cap

“O” Ring

Dipstick

Screw

Qty.

2

2

Key

No.

315

323B 611118

1 325

1

1

2

2

1

327

328

329

335

336

1 338

1

340

1 341

2

342 650561

1 350

1 351

1

4

355

364 33377

1 365

Part

No.

611111

29443

35392 Starter Plug

35593

610973 Terminal

35057A Carburetor Cover

650765

28942

34154

34155

570682

32180C

590574 Starter Handle

650767

4 370 36261

2

1 370G

1 370H

1

1

1 396

1

1

370C

380

390

400

900

36501

35077 Instruction Decal

35878

640052 Carburetor

590733

37000 Electric Starter Motor

36450A

Description

Alternator Coil

Terminal

Wire Clip

Ignition Key

Screw

Screw 2

Fuel Tank Bracket

Fuel Tank Bracket

Screw

Primer Bulb

Primer Line

Carburetor Cover Bracket 1

Screw

Identification Decal

Primer Decal

Warning Decal

Rewind Starter

Gasket Set

Replacement Engine—none

Qty.

1

1

1

1

2

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

0

38

Page 33

Craftsman Engine Model No. 143.988501 for Craftsman

Snow Thrower Model 247.885500

Recoil Starter

Key

Part

No.

No.

0 590733

590599A

1

590600

2

590696

3

4 590601

590697

5

590698

6

7 590699

590709 Pulley & Rewind Spring Ass’y-

8

590734 Starter Housing Ass’y-

11

12 590535

590574

13

O

o —

---------

-6

-4

2

Description

Rewind Starter

Spring Pin (Incl. 4)

Washer

Retainer

Washer

Brake Spring

Starter Dog

Dog Spring

Starter Rope (Length 98" x

9/64" Dia.)

Mitten Grip Handle (Not

Included With Starter)

Qty.

1

1

1

1

1

1

2

2

1

1

1

1

Recoil Starter (Optional)

-----

1

Part

Key

No.

No.

0 590749

590599A

1

590600

2

590679

3

4 590601

590678

5

590680

6

590412 Dog Spring

7

590682

8

590750

11

590535

12

590574

13

Description

Rewind Starter

Spring Pin (Incl. 4)

Washer

Retainer

Washer

Brake Spring

Starter Dog

Pulley & Rewind Spring Ass’y

Starter Housing Ass’y.

Starter Rope (Length 98" x

9/64" Dia.)

Mitten Grip Handle (Not

Included With Starter)

Qty

1

1

1

1

1

1

2

2

1

1

1

1

O

-------------2

39

Page 34

For the repair or repfacement parts you need

delivered directly to your home

Call 7 am - 7 pm, 7 days a week

1-800-366-PART

(1-800-366-7278)

For in-home major brand repair service

Call 24 hours a day, 7 days a week

1-800-4-REPAIR

(1-800-473-7247)

For the location of a

Sears Parts and Repair Center In your area

Call 24 hours a day, 7 days a week

1-800-488-1222

For information on purchasing a Sears

Maintenance Agreement or to inquire

about an existing Agreement

call 9 am - 5 pm, Monday-Saturday

1 -800-827-6655

REPAIR SERVICES

America's Repair Specialists

Page 35

Manual Del Propietario

CRRFTSMflr

EXPULSOR DE NIEVE

8.5 CABALLOS DE FUERZA

PROPULSION DE ORUGA DE DOS ETAPAS DE 26"

No. De Modelo

247.885500

Precaución: Lea y siga todas

las reglas e instrucciones de

seguridad antes de operar este

equipo.

Sears, Roebuck And Co., Hoffman Estates, IL 60179 USA

Form No. 770-0373A

Page 36

TABLA DE CONTENIDO

Garantía

Operación Segura

Paquete de Ferretería

Ensambiado

Operación..................................................................12

...................................................................

.....................................................

...............................................

..............................................................

2

3

6

7

Mantenimiento..........................................................17

Ajuste

.......................................................................

Almacenamiento fuera de temporada

Locaiización de Faiias..............................................23

......................

19

22

GARANTIA DE INFORMACION

Por un año desde la fecha de compra cuando este expuisor de nieve Craftsman sea mantenido, iubricado y puesto a punto de

acuerdo con las instrucciones de operación y mantenimiento en el manual del proprietario, Sears reparará libre de costo

cualquier defecto de material o de mano de obra.

Esta garantía se aplica por 30 dias solamente a partir de la fecha de compra, si el expulsor de nieve se usa para fines

comerciales o de alquiler.

Esta garantía no cubre:

..................................................................................Artículos desechables que se desgastan durante el uso normal, tales

como zapatas deslizantes, placa raspodara y bujías,

..................................................................................Reparaciones necesarias a causa de abuso o negligencia por parte del

operador, incluyendo cigüeñies doblados y la falla en mantener el equipo de acuerdo con las instrucciones contenidas en el

manual del proprietario.

El servició de garantía esta disponible si se devuelve el expulsor de nieve Craftsman ai centro/departamento de servicio de Sears

mas cercano en ios estados unidos.

Esta garantiá se aplica solamente mientras este producto esté en uso en los Estados Unidos.

Esta garantiá le otorga derechos legales específicos y usted ouede también tener otros derechos que varián de Estado a Estado.

Sears, Roebuck and Co., D817/WA, Floffman Estates, IL 60179

Especificaciones Del Producto

Caballos de Fuerza:

Desplazamiento.........................................................

19.43 pies.cub.

Capacidad de Combustible

cuartos

Bujía..........................................................................RJ-

19LM

Motor

.........................................................................

Modelo 143.978501

.................................................

.......................................

8.5

4

Numero De Modelo

Numero De Serie............................................................

Fecha De Compra.....................................................

Los números de modelo y de serie se encuentran en el

rotulo pegado al armazón del expulsor de nieve.

Usted debería registrar el numero de serie y la fecha de

compra y guardarlos en un lugar seguro para referencia

futura.

........

..............................................