Page 1

OWNERS

MANUAL

MODEL NO.

247.796890

A

Carefully read and

follow Safety

Rules, Precautions

and Operating

Instructions. Failure

to do so can result

in serious personal

injury.

WARNING

5 H.P.

CHIPPER-SHREDDER

• Assembly

• Operation

Always wear eye protection during

operation

• Maintenance

• Repair Parts

Soid by Sears. Roebuck and Co., Chicago it! 60684 US.A.

Part No. 770-58758 8/87

Page 2

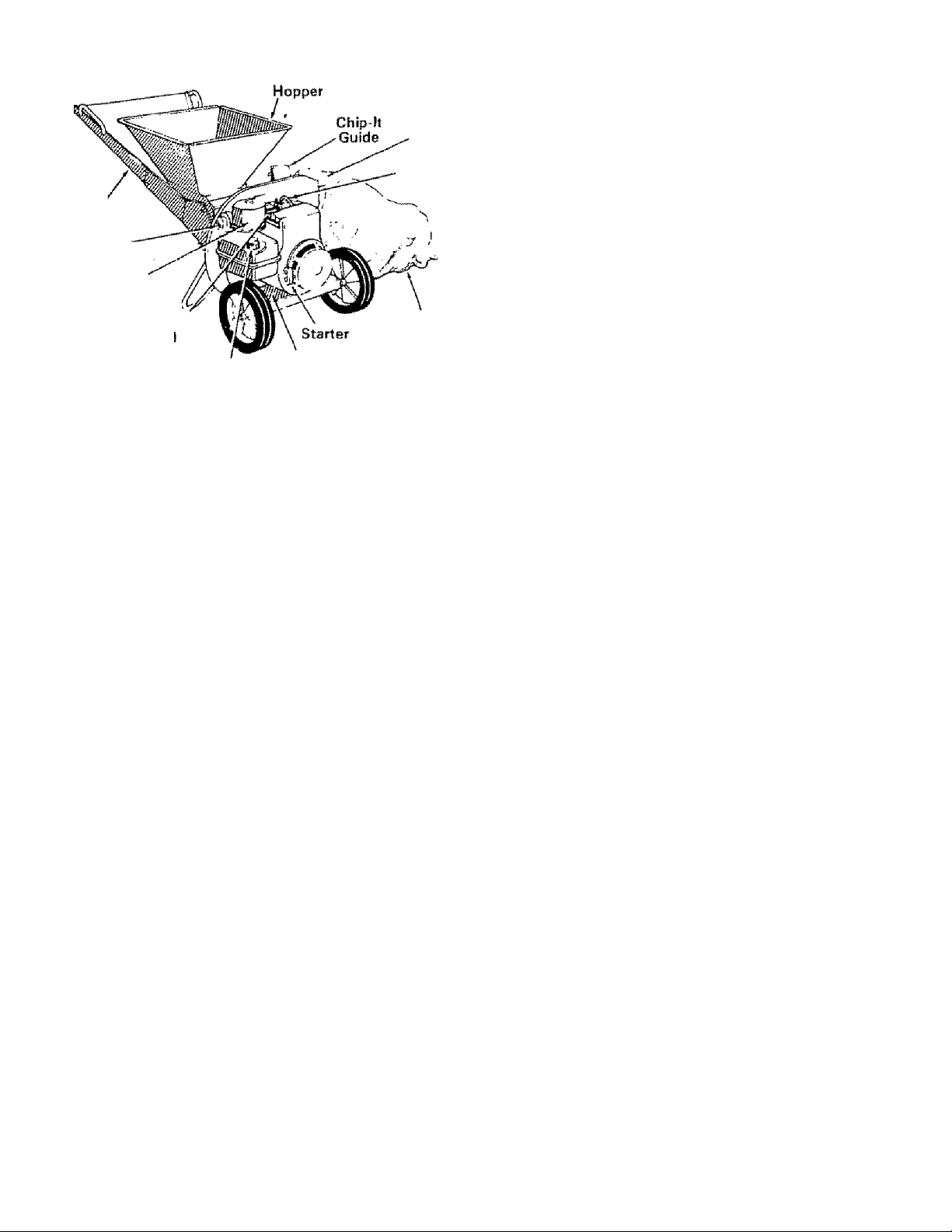

REAR

Leaf

Ramp

Muffler

Air

Cleaner

Chute

Deflector

Spark Plug,

Wire and Elbow

MODEL

NUMBER

SERIAL

NUMBER

THE MODEL AND SERIAL NUMBERS

WILL BE FOUND ON THE MODEL PLATE

ATTACHED TO THE FRAME. SEE ILLUSTRA

TION AT LEFT

YOU SHOULD RECORD BOTH MODEL AND

SERIAL NUMBERS AND KEEP IN A SAFE

PLACE FOR FUTURE REFERENCE

____________________________

Throttle ^

Contro

Fuel

Tank

Model

Plate

FRONT

f^atcher

Bag

A

Instructions given with this sym

bol are for personal safety. Be

sure to follow them.

INDEX

Warranty .

Rules for Safe Operation

Assembly . - Operation

How to Use Your Chipper-Shredder

Adjustments

MAINTENANCE AGREEMENT

A Sears Maintenance Agreement is available on this product Contact your nearest Sears store for details.

UMITED ONE YEAR WARRANTY ON CRAFTSMAN GAS CHiPPER-SHREDDER

For one year from the date of purchase, when this Craftsman Chipper-Shredder is maintained, lubricated

and tuned up according to the instructions in the owner's manual, Sears will repair, free of charge, any defect

in material and workmanship.

If this Craftsman Chipper-Shredder is used for commercial or rental purpose, this warranty applies for only

30 days from the date of purchase.

This warranty does not cover:

— Expendable items which become worn during normal use, such as blades, blade guides, blade adapters,

air cleaners, spark plugs and catcher bags;

— Repairs necessary because of operator abuse or negligence, including bent crankshafts

WARRANTY SERVICE IS AVAILABLE BY RETURNING THE CRAFTSMAN CHIPPER-SHREDDER TO THE

NEAREST SERVICE CENTER/DEPARTMENT IN THE UNITED STATES

This warranty gives you specific legal rights, and you may also have other rights which vary from state to state

SEARS, ROEBUCK AND CO , Dept 698/731 A, Sears Tower, Chicago, IL 60684

2

3

4

6

7

9

Maintenance Off-Season Storage

Maintenance Check List

Trouble Shooting Chart

Repair Parts , , -

9

n

12

12

13-19

-►

NOTE

This unit is equipped with an internal combustion engine and should not be used on or near any unimproved forestcovered, brush-covered or grass-covered land unless the engine's exhaust system is equipped with a spark arrester

meeting appiicable local or state laws ilf any) If a spark arrester is used, it should be maintained in effective work

ing order by the operator

In the State of California the above is required by law (Section 4442 ot ihe California Public Resources Code) Other

states may have similar laws. Federal law apply on federal lands A spark arrester muffler is available at your Sears

Authorized Service Center isee page 19)

Page 3

♦

WARNING

A>;

To reduce the potential for any injury, comply with the foilowirtg safety instruc

♦

tions Failure to comply with the instructions may result in personal injury

RULES FOR SAFE OPERATION

TRAINING

1. Read this ov\/ner's manual carefully in its entirety

before attempting to assemble or operate this

machine Be completeiy familiaf with the controls

and the proper use of this machine before operating

it, Keep this manual in a safe place for future and

regular reference and for ordering replacement

parts,

2. Children must never be allowed to operate this

equipment,

3. No one should operate this unit while intoxicated or

while taking medication that impairs the senses or

reactions

4. This equipment should never be operated in the

vicinity of chiidren, pets or other persons

5- Never run your machine in an enclosed area as the

exhaust from the engine contains carbon monox

ide, which is an odorless, tasteless and deadly

poisonous gas

6.. Never allow your hands or any part of your body or

clothing inside the feeding chamber, discharge

chute, or near any moving part while the machine

or engine is running

7 If it is necessary for any reason to inspect or repair

the feeding chamber or any part of the machine

where a moving part can come in contact with your

body or clothing, stop the machine, allow it to cool,

and disconnect the spark plug wire from the spark

plug before attempting such inspection or repair

PREPARATION

1, Wear safety glasses provided with your unit

while operating the chipper-shredder to prevent in

jury from any chips which may be ejected out of

the openings

2 Wear proper apparel Avoid wearing loose fitting

clothing. Wear gloves when handling material

3 HANDLE FUEL WITH CARE as gasoline is an

extremely flammable fuel

A Check the fuel before starting the engine. Do

not fill the fuel tank indoors, while the engine

is running, or while the engine is stiil hot. Turn

the unit off and let the engine cool before

refueiing.

B, Fuel your chipper-shredder in a clean area Do

not smoke while refueling.

C Fuel tank cap must be secure at all times

except during refueling

D Avoid spilling gasoline or oil. Wipe the unit

clean of any spilled fuel or oil,

E Store fuel and oil in approved containers, away

from heat or open flame, and out of reach of

children.

4, This machine should be operated only upon an

level earthen surface

5.. Assure that all screws, rsuts and bolts and other

fasteners are properly secured

OPERATION

1, When feeding shreddable material into this equip

ment, be extemely careful that pieces of metal,

rocks, bottles, cans or other foreign objects are not

included

2 If the cutting mechanism strikes any foreign object

or if your machine should start making an unusual

noise or vibration, immediately stop the engine and

disconnect the spark plug wire from the spark plug

Allow the machine to stop and take the following

steps:

A Inspect for damage

B Replace or repair any damaged parts

C, Check for any loose parts and lighten to assure

continued safe operation.

3 The engine must be kept clean of debris and other

accumulations.

4 Do not altowr an accumulation of processed material

to build up in the discharge area as this will pre

vent proper discharge and can result in kick-back

from feed opening

5 Never allow your hands or any other part of your

body or clothing inside the feeding chamber,

discharge chute or near any moving part while the

engine is running

6 Keep all guards and deflectors in place and in

good working condition to assure continued safe

operation

7 Always stand clear of the discharge area when

operating this machine

8 Keep your face and body back from the feed

opening to avoid accidental bounce back of any

material,

9 Do not over-reach Keep proper balance and

footing at ail times

10 The engine governor settings on your machine

must not be altered, changed, or tampered with

The governor controls the maximum safe operating

speeds and protects the engine and all moving

parts from damage caused by overspeed.

11 Do not transport machine while engine is running

12 Do not operate engine if air cleaner or cover

directly over carburetor air intake is removed,

except for adjustment Removal of such parts

could create a fire hazard,

MAINTENANCE AND STORAGE

1 When this equipment is stopped for servicing,

inspection, storage or to change an accessory,

make sure the spark plug wire is disconnected from

the spark plug The machine should be allowed to

cool down before making such Inspection, ad

justments, service, etc Maintain your machine with

care and keep it dean for the best and continued

safe operation

2. Do not use flammable solutions to clean the air

filter

3 When not in use, your machine should be stored out

of the reach of children Keep where gasoline fumes

will not reach an open flame or spark, For long

periods of storage, the gasoline should be drained

and disposed in a safe manner. Always allow the

machine to coo! before storing in any enclosure

Page 4

NOTE

This unit Is shipped WITHOUT GASOLINE

Or OIL, After assembly, see operation

section of this manual for proper fuel and

engine oil recommendations

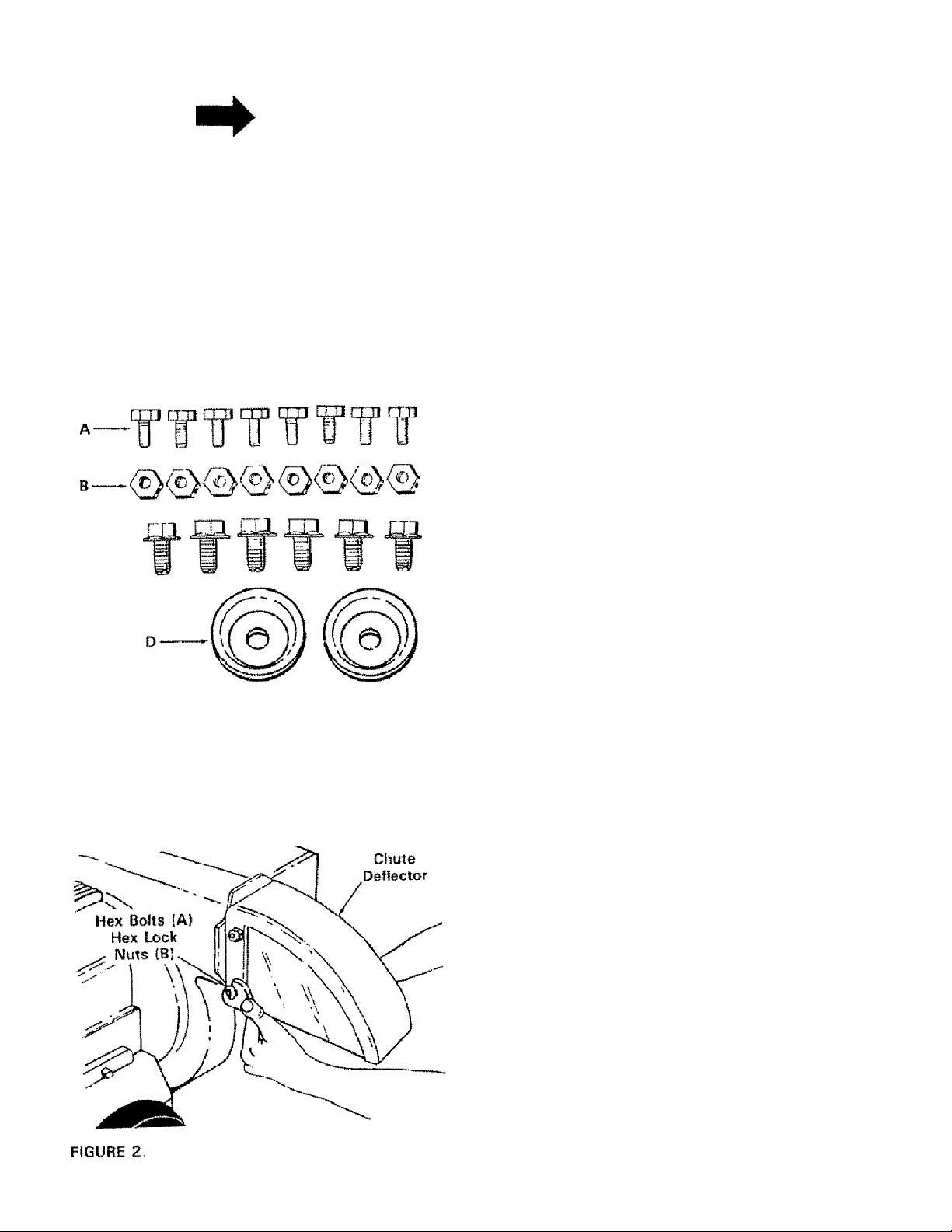

ASSEMBLY INSTRUCTIONS

Tools Required for Assembly:

¡2) 7/16" Open End or Box Wrenches’

ill 1/2" Socket Wrench

‘ An Adjustable Wrench may be used in place of one

of the wrenches

NOTE

The right and feft side of your chipper

shredder is determined from behind the

unit.

FIGURE 1

UNPACKING

Remove the chipper-shredder and loose parts from the

carton. Make certain all parts and literature have been

removed before the carton is discarded.

Parts in Carton:

Chipper-Shredder

Chute Deflector

Hopper

Upper Leaf Ramp Section

Catcher Bag

Hardware Pack

Safety Glasses

-Contents of Hardware Pack (See Figure 1):

A 181

B (81

c (6)

D (21

Hex Bolts 1/4-20 x 1/2" Long

Hex Lock Nuts 1/4-20 Thread

Hex Washer Head Self-Tapping Screws

5/16-18 X 3/4" Long

Keepers

CHUTE DEFLECTOR INSTALLATION

1. Place the chute deflector in position on the

discharge opening (on the left side of the chipper-

—~ shredder) See figure 2

2 Secure chute deflector to discharge opening with

hex bolts |A) and hex lock nuts (B) Heads of the

hex bolts are inside the discharge opening Hex nuts

go on the outside

3 Tighten al! four nuts and bolts securely

Page 5

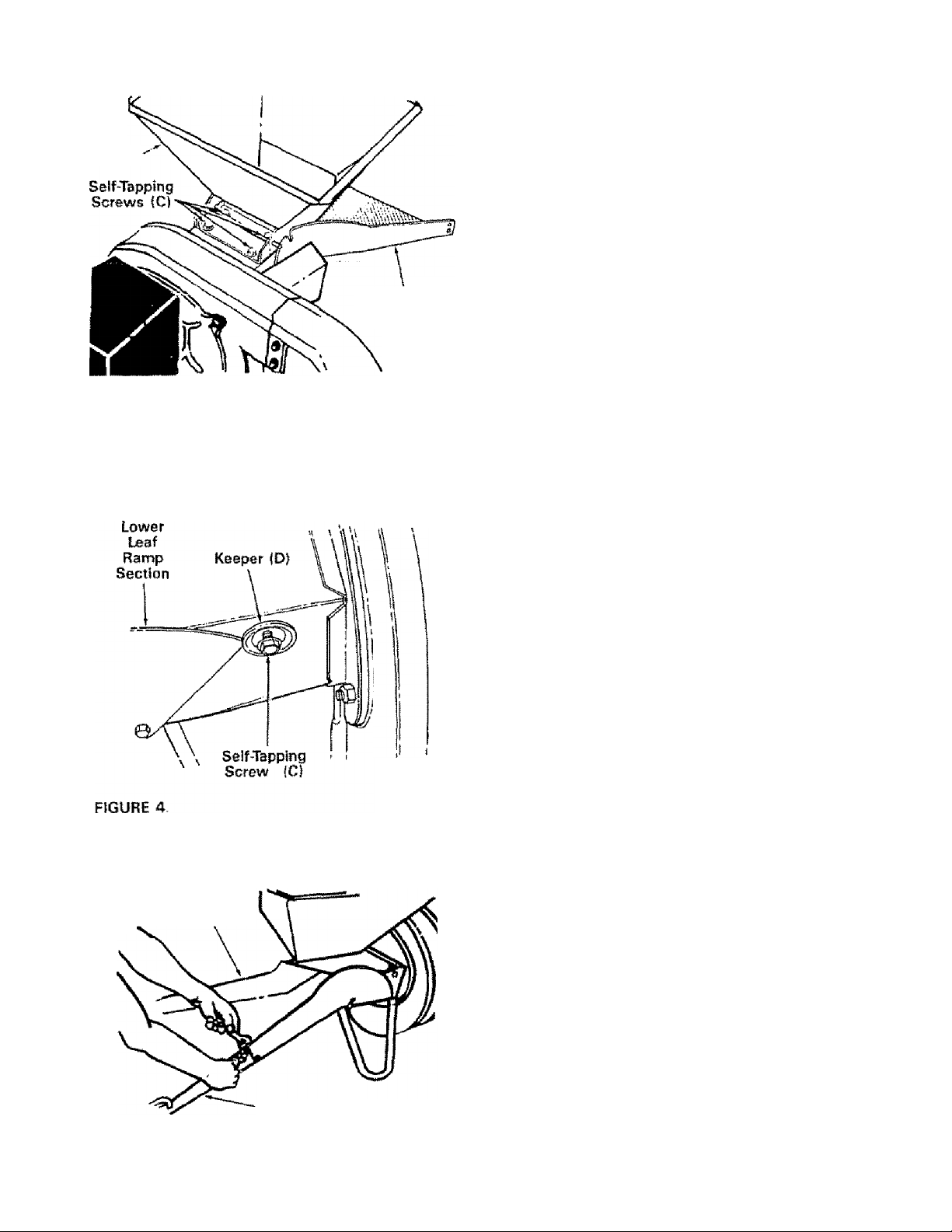

Happer

FIGURE 3

Lower Leef

Rarnp Section

INSTALLATION OF HOPPER AND UPPER GUtlDE EXTENSION

T The lower leaf ramp section on the chipper-shred

der is placed in an upright position for shipping

purposes Lower this section-

2

----

Place the hopper in position on the shredder

-----

See figure 3. Start all four hex washer head seif

tapping screws fCi. 'then tighten securely using a

1/2" socket wrench

Lower Leaf

Ramp Section

Assemble the keepers (Dl to the sides of the unit

with two hex washer head self-tapping screws (Ci,

using a 1/2" socket wrench. Tighten securely

Place upper leaf ramp section inside the lower ieaf

ramp section Secure with four hex bolts iA! and

hex lock nuts IBI- Tighten securely See figure 5,

FIGURE S,

" Upper Leaf

Ramp Section

Page 6

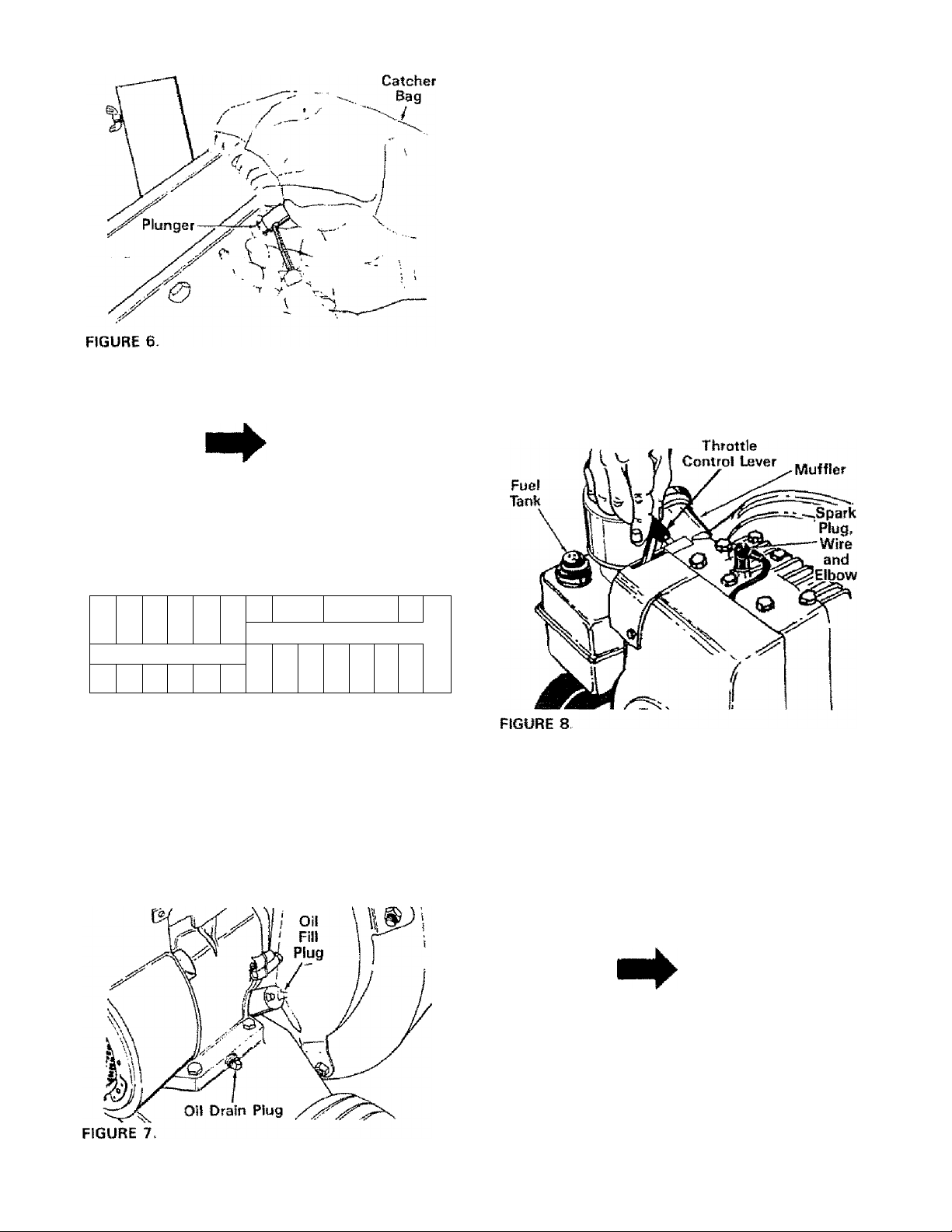

ATTACHING THE CATCHER BAG

Your unit is equipped with a nylon bag which attaches

to the discharge opening. If desired, place the end of

the bag over the chute deflector. Depress plunger, pull

on the drawstring, and release plunger to lock it in

■ position. See figure 6

OPERATION

GAS AND OIL FILL UP

NOTE

ENGINE IS SHIPPED WITHOUT OIL. FILL

CRANKCASE WITH OIL BEFORE STAR

TING. BE VERY CAREFUL NOT TO

ALLOW DIRT TO ENTER THE ENGINE

WHEN CHECKING OR ADDING OIL OR

FUEL

Recommended SAE Viscosity Grades

30 or 10W30

c 5W20

-20“ 0“

TEMPERATURE RANGE EXPECTED BEFORE NEXT OIL

CHANGE, ALL OILS MUST A.P.I SERVICE CLASSIFICA

TION SD. SE OR SR

1, Fill engine with oil,

a Remove engine oil fit! plug- See figure 7.

b With chipper-shredder level, fill engine with oil

to point of overflowing. Capacity is 1-1/4 pints

c Tilt chipper-shredder forward on its wheels,

then re-level

d Check oil level. Refill to point of over-flowing

if necessary. Replace oil ft'K plug,,

32“

60“ 80“ 100“

Fill fuel tank. See figure 8, Use fresh, dean,

unleaded automotive gasolirte Capacity is 3 quarts.

WARNING

Ac

Fill to within 1/2 inch of top of fuel tank

to prevent spills and to allow for fuel

expansion If gasoline is accidently spill

ed, move chipper-shredder away from

area of spill. Avoid creating any source of

ignition until gasoline vapors have

disappeared.

NOTE

DO NOT USE GASOHOL OR

METHANOL. These type fuels react with

water content in the fuel and tend to form

strong acids which can corrode metal

parts and harm rubber plastics.

USE CLEAN OIL AND FUEL. STORE IN

APPROVED, CLEAN, COVERED CON

TAINERS, USE CLEAN FILL FUNNELS.

Page 7

то START ENGINE

1

Attach spark plug wire and boot to spark plug

Place the throttle control lever in START position.

2.

See figure 8

Grasp starter handle (see figure 9i and pull rope

3.

out slowly until engine reaches start of compres

sion cycle (rope will pull slightly harder at this

point). Let the rope rewind slowly

NOTE: A noise will be heard when finding the

start of the compression cycle This notice is

caused by the flails and fingers which are part

of the shredding mechanism falling into place,

and should be expected.

Puli rope with a rapid, continuous, full arm stroke.

Keep a firm grip on start handle Let rope rewind

slowly. Do not let starter handle snap back against

starter

Repeat preceding instructions 3 and 4 until engine

fires.

After engine starts, move throttle control lever on

engine to slow position for a few minutes warm up.

Then move throttle control lever to RUN position

for shredding-chipping operations.

A

Ì WARNING }

The chipper-shredder discharges material

with considerable velocity Keep away

from the area around the discharge chute

Always stop the engine and disconnect

the spark plug wire when renioving or

attaching the bag when changing

containers or when removing the

shredded material ,

If if becomes necessary to push materials into the

chipper-shredder, use a small diameter stick, NOT

YOUR HANDS The stick should be small enough that

it will be ground up if it gets into the impeller assembly.

WARNING

A(

Do not deposit material larger then 12"

diameter in the hopper or upper guide

exterrsion Any materia! heavier then 1/2”

should be fed into the chip-it guide

Leaves and smaller branches can be fed into the

hopper with the leaf ramp raised as shown in figures

10 and 11

FIGURE a

TO STOP ENGINE

1 Move throttle control lever to STOP position See

figure 8.

2„ Disconnect spark plug wire from spark plug and

ground against the engine to prevent accidental

starting while equipment is unattended

HOW TO USE YOUR CHIPPER-SHREDDER

Your shredder is designed for safe, efficient operation.

KEEP HANDS AND FEET AWAY FROM ALL OPENINGS

WARNING

Wear the safety glasses provided with

your unit while operating the chipper

shredder to prevent injury from any chips

which may be ejected out of the

openings Make certain chip-it guide is

closed when not in use.

Wear gloves when handling material Feed material

into the chipper-shredder at a steady rate it is

possible to feed too fast. Experiment with feeding rates

to determine what rate provides the best results

without stalling the engine or plugging the discharge

chute.

The discharge chute will direct the shredded materia!

into a pile, a container or the bag provided with your

shredder

Hopper

Chip-lt

Guide

leaf

Ramp

FIGURE 10

No larger than

1/2 Inch diameter

Hopper

Chip-lt

Guide

Leaf

Ramp

FIGURE 11

Page 8

Lower the leaf ramp by holding the handle and pulling

up on the release bar See figure 12 Leaves and small

twigs can be raked into the chipper-shredder with the

leaf ramp In this position. See figure 13

NOTE

Bulky material, such as stalks or heavy

branches (anything over 1/2" diameter},

should be fed into the chip-it guide,, See

figure 15. Do not force or jam material in

to the cNp-it guide Make certain leaf

ramp is raised as shown in figure 15 when

using the chip-it guide.

FIGURE 13.

Small branches can also be fed into the leaf ramp See

figure 14.

I WARNING {

'Ф"0 Ф

Make certain chip-it guide door is closed

when not in use

Keep Leaf Ramp Raised

When Using Chip-It Guide

v/iiip-ii Guide

FIGURE 15,

Page 9

ADJUSTMEIMTS

CARBURETOR ADJUSTMENT

WARNING

If any adjustments are made to the engine while the engine if running {eg- car

buretor), keep clear of al! moving parts

Be careful of heated surfaces and muffler.

Minor carburetor adjustment may be required to com

pensate for differences in fuel, temperature, altitude or

load

NOTE

A DIRTY AIR CLEANER WILL CAUSE

ENGINE TO RUN ROUGH. BE CERTAIN

AIR CLEANER IS CLEAN AND ATTACH

ED TO THE carburetor before

ADJUSTING CARBURETOR DO NOT

MAKE UNNECESSARY ADJUSTMENTS

FACTORY SETTINGS ARE SATISFAC

TORY FOR MOST APPLICATIONS AND

CONDITIONS.

Never attempt to change maximum engine speed It is

pre-set at the factory and should be changed only by

a qualified service technician who has the necessary

equipment,

The carburetor may need re-adjusting if engine lacks

power or does not idle properly If adjustments are

needed, proceed as follows.

To Adjust Carburetor:

1. Close needle valve (See figure 16} clockwise

(Oi' finger tight only Forcing may cause damage.

Then open 1-1/2 turns counterclockwise ik~h)

2. Start engine and allow to warm for five minutes.

3 With throttle in RUN position, close needle valve

clockwise until engine starts to lose speed

{lean mixture) Then slowly open needle valve

counterclockwise ik~N) until engine JUST BEGINS

to run unevenly This mixture should be rich enough

for best performance under load.

4 Place throttle control in IDLE position:

a If engine idles, no further adjustment is

necessary.

b. If engine idles too fast, turn idle speed

adjusting screw counterclockwise until

slower speed is obtained

c If engine dies, turn idle speed adjusting screw

1/4 turn clockwise l/^i Place throttle

control in FAST position arid restart engine,

d Move throttle control to IDLE position If

engine does not idle, repeat step c

Test the engine by operating the chipper-shredder,

If engine lends to stall or die out, it usually

indicates that the mixture is slightly lean and it may

be necessary to open iX">) the needle valve slightly

to provide a richer mixture This richer

mixture may cause a slight unevenness in idling.

Idle Speed

Adjusting Screw Throttle

Needle Valve

FIGURE 16.

Stop

MAINTENAIMCE

Ac

WARNING

Disconnect spark plug wire and ground

it against the engine before performing

any repairs or maintenance-

ENGINE LUBRICATION

Your four cycle engine will normally consume some oil;

therefore check engine oii level regularly - approxiniateiv

every five hours of operation and before each usage

Stop engine and wait several minutes before checking

oii level, With engine level, the oil must be even with

the oil fill (refer to figure 7) Change engine oil after the

first two hours of operation, and every twenty five

hours thereafter

1. Drain oil while engine is warm

a. Remove oil drain plug Refer to figure 7

b. Tip the chipper-shredder forward, and catch oil

in a suitable container

c. When engine is drained of all oil. replace drain

plug securely.

2 Refill with fresh oil Above 32°, use oil labeled

SAE 30W or 10W30 Below 32°, use oil labeled

5W20 Capacity is 1-1/4 pints Refer to "Gas and

Oil Fill-Up" on page 6

3- Replace oil fill plug.

Page 10

AIR CLEANER

The air cleaner prevents damaging dirt, dust, etc, from

entering the carburetor and being forced into the engine

and Is important to engine life and performance

Never run your engine without air cteaner completely

assembled

To Service Air Cleaner:

Clean and re-oil foam pre-cleaner at three month

intervals or every 25 hours, whichever occurs first:

See figure 17 Service more often under dusty

conditions

1. Remove knob and cover.

2. Remove foam pre-cleaner by sliding it off the

paper cartridge.

a. Wash foam pre-cleaner in liquid detergent

and water.

b Wrap foam pre-cleaner in cloth and squeeze

dry.

c Saturate foam pre-cleaner in clean engine

oil, Sqeeze to remove excess oil.

3. Install faorn pre-cleaner over paper cartridge.

Reassemble cover and screw down tight.

Replace and clean cartridge included with dual

element air cleaner yearly or every 100 hours.

Service more often if necessary.

Clean cartridge by tapping gently on a flat surface

If very dirty, replace cartridge or clean as follows;

a Wash in a iow or non-sudsing detergetji and

warm water solution CAUTION; Do not use

petroleum solvents such as kerosene, to clean

cartridge,

b. Rinse thoroughly with flowing water from

inside Out until water is clear,

c Allow cartridge to stand and air dry thoroughly

before using, DO NOT Oil CARTRIDGE, DO

NOT USE PRESSURIZED AIR TO CLEAN OR

DRY CARTRIDGE

4. Install cartridge and pre-cleaner then the cover

Screw knob down securely.

-Knob

MUFFLER

Do not operate the chipper-shredder without a muffler

or tamper with the exhaust system. Damaged mufflers

or spark arresters could create a fire hazard. Inspect

periodically, and replace if necessary If your engine is

equipped with a spark arrester screen assembly, remove

every 50 hours for cleaning and inspection. Replace if

damaged

CLEAN ENGINE

Clean engine periodically Remove dirt and debris with

a doth or brush Cleaning with a forceful spray of water

is not recommended as water could contaminate the

fue! system.

Yearly or every 50 hours, whichever occurs first, remove

the blower housing and clean the areas shown in figure

18 to avoid overspeeding, overheating and engine

damage Clean more often if necessary.

WARNING

Periodically clean muffler area to remove

ail grass, dirt and combustible debris.

Clean Out

Chaff and

Dirt

FIGURE 18

SPARK PLUG

The spark plug should be cleaned and the gap reset

to 030" at least once a season or every 50 hours of

operation Spark plug replacement is recommended at

the start of each season. Refer to engine parts list for

correct spark plug type

NOTE; Do not blast dean spark plug Spark plug should

be cieaned by scraping or wire brushing and washing

with a commercial solvent

FIGURE 17.

030 Feeler Guage

10

Page 11

LUBRICATION

Wheels ^ The wheels require no lubrication.

Flails and Fingers - if the unit is disassembled for any

reason, lubricate the flails and fingers with a light oil

(engine oil may be usedi

CUTTING BLADE

The cutting blade may be removed for grinding or

replacement as follows

1

Lower the upper guide extension

2,

Block up the housing. See figure 20,

3,

Remove the four elastic lock nuts from the back

of the housing using a 1/2" wrench Refer to figure

14, Separate the shredder into two halves

4,

Remove the back-up plate, See figure 20

NOTE

When reassembling, make certain the

opening on the back up plate is toward

the bottom of the unit The back up plate

may be reversed to provide a new cutting

edge.

When sharpening the blade, follow the original angle

of grind as a guide It is extremely important that each

cutting edge receives an equal amount of grinding to

prevent an unbalanced blade An unbalanced blade will

cause excessive vibration when rotating at high speeds

and may cause damage to the unit

The blade can be tested by balancing it on a round shaft

screwdriver or nail Remove metal from the heavy side

until it balanced evenly See figure 21

When reassembling the blade, tighten to between 375

and 450 inch pounds, or lacking torque wrench, tighten

securely

FLAILS AND FINGERS

The flails and fingers may be reversed when they

become dull It is suggested that thts procedure be

performed by your nearest Sears Service Department

Hold the blade retainer on the impeller assembly

with an adjustable wrench to keep the blade from

turning as shown in figure 20

Remove the blade by removing the center bolt, lock

6.

washer and flat washer.

NOTÉ

Use caution when removing the blade to

avoid contacting the weld bolts

protrudirig from the housing.

WARNING {

At

The blade is reversible and can be

assembled to the crankshaft with either

side showing

OFF-SEASON STORAGE

If the chipper-shredder is to be inoperative fora period

longer than 30 days, the following precautions are

recommended,

1, Working outdoors, drain all fuel from the fuel tank.

Run the engirte until it stops from lack of fuel

WARNING

DO NOT DRAIN FUEL WHILE SMOKING,

OR IF NEAR AN OPEN FIRE

2.

Drain all the oil from the crankcase {this should be

done after the engine has been operated and is still

warm) and refill crankcase with fresh oil

Protect the inside of the engine for storage as

follows.

Remove spark plug, pour approximately 1/2 ounce

(approximately one tablespoon) of engine oil into

cylinder and crank slowly to distribute oil. Replace

spark plug

Clean the engine and the entire chipper-shredder

thoroughly

NOTE

When storing any type of power

equipment in an unventilated or metal

storage shed, care should be taken to

rustproof the equipment. Using a light oil

or silicone, coat the equipment, especially

ail moving parts

5 Store in a clean, dry area

11

Page 12

SERVICE RECORD

FILL IN DATES

AS YOU COMPLETE

REGULAR SERVICE

Check Engine Oil Level

MAIIMTENANCE CHECK LIST

/ ^ / ¡2 / ¡2 /

/ ^ / ■

/ 1^1'

/ o j S! J

/ 5 / Jr / «

/ I I

/ c? /

9

^ 1 ° ^ ^ 1 SERVICE DATES

iii Uj LU f

Change Engine Oil

Clean Engine

Service Air Cleaner

Clean Engine Cylinder Fins

Clean or Replace Spark Plug

9

10

10

10

10

TROUBLE SHOOTING CHART

SYMPTON POSSIBLE CAUSE(S)

Engine fails to start 1. Check fuel tank for gas.

2 Spark plug lead wire

disconnected

3 Faulty spark plug

Hard starting or loss of

power

1 Spark plug wire loose.

2 Dirty air cleaner

SOLUTION 1

1. Fill tank if empty !p. 6).

2 Connect lead wire {p. 6!

3 Clean, adjust gap or replace ip. 10)

1 Connect and tighten spark plug

wire {p. 6).

2 Clean air cleaner as described in

maintenance section (p. 10).

Engine overheats 1 Carburetor not adjusted

properly

2 Air flow restricted.

3 Engine oil level low

Material not shredding

Engine bogs down or

stalls

NOTE: For repairs beyond the minor adjustments listed above, please contact your Sears Authorized Service Center

Blade and/or flails not sharp

1 No fuel in fuel tank

2. Feeding material into the

machine too quickly

\2

1 Adjust carburetor. See adjustment

section (p, 9)

2. Remove blower housing and clean

as described in the maintenance

section ip. 10).

3. Fill crankcase with the proper oil ip. 6)

Sharpen or reverse blade and flails (p, 11)

1. Fill tank if empty !p. 6).

2. Do not force material into the opening.

Feed gradually (p. 7)

Page 13

Repair Parts

5 H.P. Chipper-Shredder—Model 247.796890

Page 14

Repair Parts

5.HP. Chipper-Shredder--Model 247.796890

Key

No.

10 16568

11

12 710-0289

13

14 13430

15

16

17

19

21

22

24

25

27 736-0100

28

29

Part No.

1 11476

2 710-0465 Hex Bolt 1/2-20 X 4 50" Lg *

3 711-0580 Clevis Pin 32

711-0579

5 11455

6 736-0921

7

726-0111

8 712-0922

714-0507 Cotter Pin 3/32" Dia. x 3/4"

9

712-0107

714-0114 Sq Key 1/4" x 2.00" Lg,

710-0157 Hex Bolt 5/16-24 x 3/4" Lg * 42 11478

736-0119

14573

5 H P.

IB

11464

20

712-0123

736-0119

738-0521

23 736-0170

726-0221

711-0494 Spacer 52

734-1173

26

710-0624

712-0429

30 710-023?

Door Chip it

Flail Spacer 7/32" Lg,

Cutting Finger

L-Wash 1/2" I.D.*

Palnut 3/16" Dia.

Hex Jam Nut 1/2-20 Thd * 36

Lg,*

Chute Deflector

L,.-Nut 1/4-20 Thd,

Hex Bolt 1/4-20 x 50" Lg * 40

Impeller Assembly 41

L-Wash. 5/16" l,D.‘ 43

Hopper to Engine Mtg, Plate 44 712-0109

Engine - B & S 130212-1731-01 45

Engine Mounting Plate

Hex Nut 5/16-24 Thd*

L.-Wash. 5/16" 1..D* 48

Shaft 49

Special L-Wash 5/16" I D

Push Cap

Wheel Ass'y-Comp.

FL-Wash, 50" i D

Hex Bolt 5/16-24 x 1 50" Lg.‘ 56

Elastic Lock Nut 5/16-18 Thd ’

Hex Bolt 5/16-24 x 62" Lg,* 764-0199

Description

Key

No,

31

33

34

35

37 736-0217

38

39

48

47

50

53

55 11480

57

—

Part No-

714-0144

736-0192

11459 Flail

711-0564 Flail Spacer 23/32" Lg

711-0578

736-0247 Fl-Wash. 406" I D X 125"

710-01SI Hex Bolt 3/8-24 x 2 0" Lg HT

14575-629

732-0546

11477

747-0531

13431

11460-629

16624-629

736-0264

11481-629

710-0601

11454

16522

710-0542

735-0639

723-0400

Cotter Pin 1/8" Dia x 100"

Lg * ¡Special)

Fl.-Wash .531" 1 D x 937

O D X .09 ■

Clevis Pin 50" Dia x 3 0" Lg.

O.D. Hdn.

L.-Wash. 3/8" I D, H D,

Flail Housing Ass'y.-Comp.

Torsion Spring 062 Día. x 1 06

LgChip-lt Guide Ass'y

Hinge Pin

Release Bar

Wing Nut Elastic 1/4-20 Thd

Blade

Upper Leaf Ramp Section

Lower Leaf Ramp Section

Fl.-Wash. 5/16" I D.

Hopper Assembly

Hex Wash.. Hd, Self-Tap Scr,

5/16-18 X 75" Lg

Back-Up Plate

Inlet Guide Assembly

Stop Washer

Hex Bolt 5/16-18 X 8,38" Lg

Spark Plug Elbow

Bag (Not Shown)

Safety Glasses {Not Shown)

Description

'Common Hardware - May be purchased locally.

NOTE: Specifications subject to change without notice or obligation

14

Page 15

Repair Parts

5 H.R Chipper Shredder—Model 247*796890

Engine-Model 130212 Type 1731-01

6

25

26

(/8a

13i

14

,337

33

S41

34

*870

208 201

15

299

Page 16

Repair Parts

5'H.P. Chipper-Shredder—Model 247.796890

Engine-Mode! 130212 Type 1731-01

♦REQUIRES

special tools

IQ install

SEE REPAIR

INSTRUCTION

MANUAL,

363

333

851 ^

7

si

335

i

16

Page 17

Repair Parts

5 HP. Chipper-Shredder—IVIodel 247.796890

Engine-"Model 130212 Type 1731-01

17

Page 18

Repair Parts

S'H P. Chipper-Shredder—Model 247.796890

Engine-Model 130212 Type 1731-01

KEY

NO NO

1

2 297565

PART

395990

Note;

DESCRIPTION

Cylinder Assembly

Bushing - Cylinder

Requires special tools for

installation

3 299819

5 211542

7 *270383

294178

B

9 * 27549

10

93394

11 6657S

12

*270080

Seal-Oil

Head— Cylinder

Gasket-Cylinder Head

Breather—Valve Chamber

Gasket-Valve Cover

Screw-Breather Mig, Sem

Grommet-Breather Tube

Gasket--Crankcase - 015 thick

(Standard!

Gasket—Crankcase- 005" thick

Gasket—Crankcase— 009" thick

Screw—Cylinder Head

13

*270125

* 270126

93368

{2-3/32" long)

14 93369

Screw—Cylinder Head

(2-15/32" long)

15 912*^9

Plug-Pipe, 1/4" Std

Square Head

To Replace Crankshaft Gear Pin,

Order Part No. 230978

16

18

19

398098

298517

297603

Crankshaft

Cover Assy—Crankcase

Bushing—Crankcase Cover

NotetRequires special tools for

installation

20

21

22

298504

66768

93032

Oil Seal and Spacer

Plug-Oil Filler

Screw— Crankcase Cover

Mounting Sem

23

24

25

297229

222698

298904

298905

298906

298907

Fly wheel — Magneto

Key—Flywheel

Piston Assy — Standard

Piston Assy.-.010" OS,

Piston Assy — 020" OSPiston Assy— 030" O D

PISTON RING SETS:

Note:For Chrome Piston

Ring Set — Standard Size Order Part No. 299742.

26

27

28

29

298982

298983

298984

296985

26026

298909

298908

299430

fling Set —Standard Piston

Ring Set-,010" OS, Piston

fling Set-.020" O.S, Piston

Ring Set-030" OS. Piston

Lock—Piston Pin

Pin Assy—Piston— Standard

Pin Assy—Piston —-005" OS,

Rod Assy “Connecting

Note: For Connecting Rod with

,020" undersize Crankpin Bore —

Order No, 390459.

30 2219SO Dipper-Connecting Rod

KEY

NO

31

32

33

PART

NO

221876

92296

211119

34 261044

260552

35

36

37

40

45

46

26478

222443

93312

260642

212733

52

299431

55

295871

56

294,303

57

58

59

60

65

66

67

68

70

71

73

74

75

90

95

96

97

108

114

116

117

118

124

66884

230228

393152

93105

399671

394897

63770

298436

394606

221923

93490

220865

397940

93499

211203

299212

397134

66594

65978

230590

23433

93357

127 22831

147 230591

148

149

152

154

163

166

180

181

190

22233

26336

260575

93527

271139

231332

397137

394B18

93440

DESCRIPTION

Lock —Screw Head

Screw —Connecting Rod

Valve —Exhaust ■

Valve-Intake

Spring—Intake Valve

Spring - Exhaust Valve

Guard-Flywheel

Retainer—Valve Spring

Tappet—Valve

Gear—Cam

Gasket—Carburetor Mounting (2)

Housing—Rewind Starter

Pulley—Rewind Starter

{Includes 63” long rope)

Spring —Rewind Starter

Rope —Rewind Starter — 63" lone

Pin —Starter Grip

Grip —Starter Rope

Screw—Standard Steel Housing

Mig Sem

Clutch Assy—Rewind Starter

Housing-Starter Clutch

Ball-Clutch

Ratchet—Rewind Starter

Washer—Clutch Retainer

Screen —Starter Pulley

Screw—Sem

Washer—Spring

Carb. A,ssy

Screw—Throttle Valve to Shaft

Sem

Throttle — Carburetor

Shaft and Lever— Throttle

Valve Group—Choke

Gasket—Needle Valve Nut

Packing-Needle Valve

Nut —Needle Valve

Valve —Needle

Screw—Hex Head

Plug—Welch

Seat—Needle Valve

Washer—Needle Valve (2)

Spring —Needle Valve

Spring-Throttle Adjustment

Screw-Machine, Rd„ Hd.—

5-40 X 5/8“

Gasket-Air Cleaner Mounting

Stud—Air Cleaner

Tank Assembly—Fuel

Cap —Fuel Tank

Screw—Fuel Tank Mounting

Sem (2|

Note; 84094 Screw-Fuel Tank

Mounting lì)

18

Page 19

Repair Parts

5 H.P. Chipper-Shredder--Model 247*796890

Engine—Model 130212 Type 1731-01

KEY

NO.

191

200

201

202 260678

203

204 222962

205

206

208

209 260695

216

21?

219

220

223

224

227 393920

230

256

238

ooo

304

305

306

307

308

333

335

337 298809

346

356

358

363

373

383

392

394

409

432

433

434 210959

PART

NO.

*271592 Gasket —Fuel Tank Mounting 435

221480

261558

393919

93838

280012 Nut—Control Rod

230946

397709

261951

391737

221561

221517 Lever—Governor Control

93491

222450

397709

261409

393368

299410

93158

221511

93042

221512

397358

93414

Q370^

Zf f \J

QQQOriQ

Lsyoouo

397145

19069

93987

89838

260455

270026

29983?

221377

93265

DESCRiPTlON

Guide —Air 445 396424

Link — Governor

Link-Throttle ■ - (not shown)

Crank— Bell

Bushing-Governor Lever (Flat)

Screw —Shoulder

Rod —Control

Spring —Governor 527 221514 Clamp Breather Tube

Link “Choke (includes Beil Crank)

Spring —Choke

Gear- Governor

Washer “Thrust

Rivet —Governor Control Lever

Mounting

Lever Assy - Governor

Washer—Governor Lever

Crank—Bell (Includes Choke link)

Locknut—Muffler

Muffler- Exhaust

Housing —Blower

Screw—Blower Housing Mounting

Shield — Cylinder

Screw—Cylinder Shield Mounting

Sem

Cover-Cylinder Head

Armature Assembly

Screw—Armature Mtg- Sem

plug —Spark 1-1/2" High —

37-42 M M

Screw—Sem

Wire—Ground

Gasket Set

Flywheel Puller (Optional

Accessory

Nut — Hex

Wrench—Spark Plug

Spring— Fuel Pump Diaphragm

Diaphragm

Lever-Trot-Speed Control

Cap— Spring

Pin-Diaphragm Cover

Cover- Diaphragm

KEY

NO,

446

467 212706

473 93612

526 933-3 3

528 231386

529 67838

541

542 94025

552 231079

562

592 231082 Nut Hex 10 24

608 390463

609

6H

612

614

615

616

621

634

634A 270382

642 223306

655 222598

676

581

725

741 261696

851 221798

852

869

870

871

987

988

PART

NO

93141 Screw—Diaphragm Cover

Cartridge—Air Cleaner

271466

222844

22398

92613

260294

391813 Fuel pipe and Clip Assembly

296811

93306

93307 Retainer E-Ring

231077 Crank Governor (1/4" Dia 1

297472 Switch -Stop

2 *1 ^ g

395700

239060 Needle Valve Kit

223334

396397

211787

211172

231348

398970

735-0639

Foam Pre-Cleaner Element

cj.iSK -Air Cleaner

Knob Air Cleaner

Screw Sem

St.^ew Tank Bracket Mounting

Sent

Tube Breather

Grommet Broathcrr Tube

Wasirer

Screw

Sushing GiivCfiior Crank

n,-4"I D)

Bolt Governor Lever

Starter Assy Rewind

Spring Throttle Link

Pipe - Fuel

Cotter ■ Hair Pin

Washer-Throttle Shaft (Foam)

Washer Choke Shaft

Cover Air Cleaner

Anchor Spring

Deflector Exhaust (Direct

Outlet)

Shield - Heat

Gear Timing

Cable Terminal--Ignition

Cleanet Group - Air

Seat - Intake Valve (Standard)

Seat -Exhaust Valve (Standard)

Note: For Options see Repair

Manua)

Guide Exhaust Valve

Note: 63709 Guide Intake Valve

See Repair Instruction Manual

Seal Throttle Shaft

Spark Plug Elbow

DESCRIPTION

' Included in Gasket Set

Dart h\n

ran iNu- f ino*.

SPARK ARRESTING MUFFLER ASSEMBLY 392390 (Optional Equipment)

Consists of the following:

392154 Screen (1 required)

223372 Deflector (1 required)

93705 Screw (4 required)

_______________________

19

Page 20

me/CRRFTSMRN.

OWNERS

MANUAL

MODEL NO.

247.796890

1 I

5

H.r.

CHIPPER-SHREDDER

The model number will be found on the mode! plate, attached to the

frame Always mention the mode! number when requesting service

or repair parts for your chipper-shredder

Ai! parts listed herein may be ordered from any Sears Service Center

^

WHEN ORDERING REPAIR PARTS, ALWAYS GIVE THE FOLLOW

ING INFORMATION;

• THE PART NUMBER

e THE PART DESCRIPTION

• THE MODEL NUMBER 247 796890

• THE NAME OF MERCHANDiSE-CHiPPER-SHREODER

HOW TO ORDER REPAIR PARTS

PRINTED IN U S A

If the parts you need are not stocked locally, your order will be elec

tronically transmitted to a Sears Repair Parts Distribution Center for

handling.

Sears, Roebuck and Co , Chicago, III 60684 USA

PART NO. 770-5875B

{248-650-099) 6/87

Loading...

Loading...