Page 1

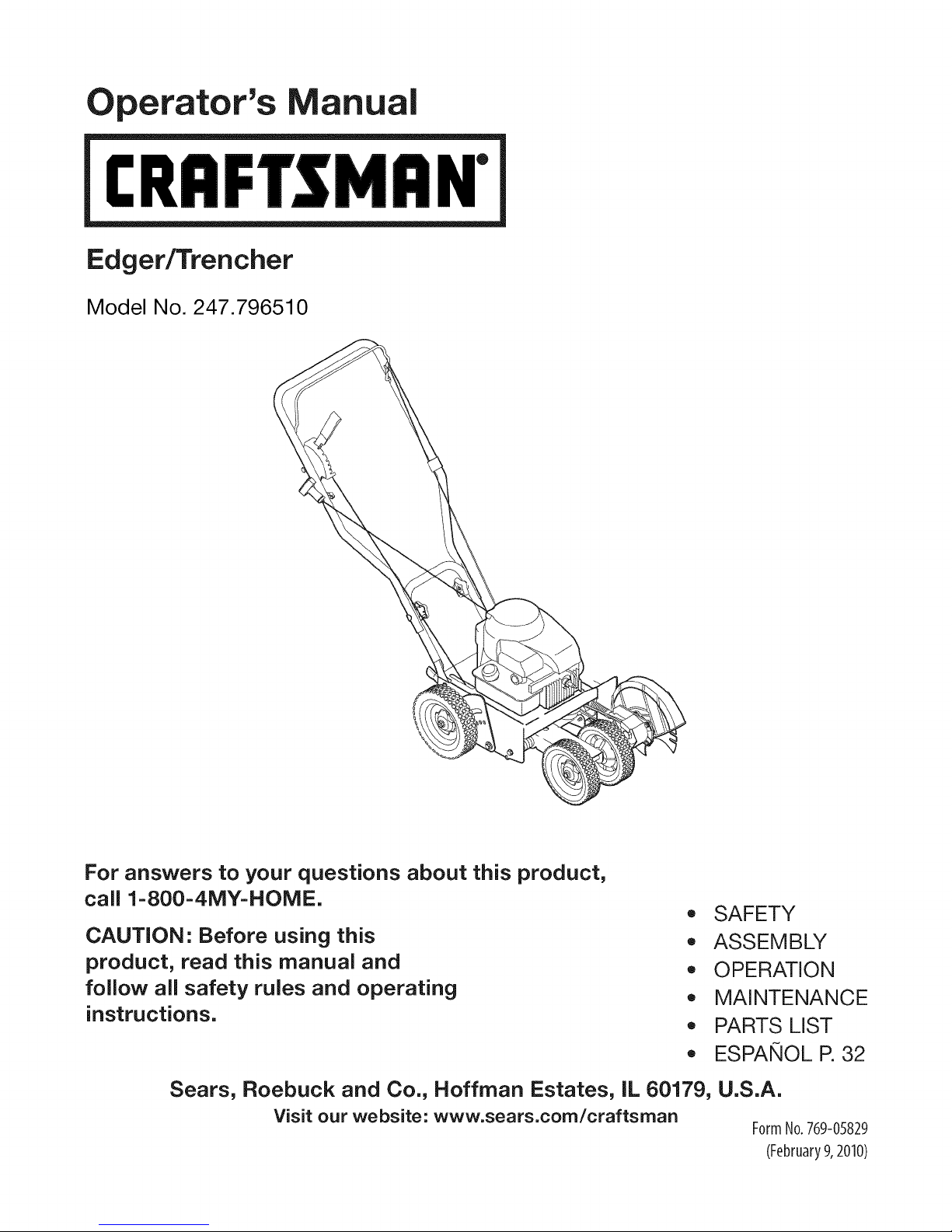

perator's nual

CRRFrsM N"

Edger/Trencher

Model No. 247.796510

For answers to your questions about this product,

call 1-800-4MY-HOME.

CAUTION: Before using this

product, read this manual and

follow all safety rules and operating

instructions.

Sears, Roebuck and Co., Hoffman Estates, IL 60179, U.S.A.

Visit our website: www.sears.com/craftsman

,, SAFETY

,, ASSEMBLY

,, OPERATION

,, MAINTENANCE

,, PARTS LIST

o ESPANOL R 32

FormNo.769-05829

(February9,2010)

Page 2

Warranty Statement .......................................................... 2

Safety Instructions ............................................................ 3

Assembly ........................................................................... 8

Operation ........................................................................ 11

Service and Maintenance .............................................. 14

Off-Season Storage ........................................................ 18

Troubleshooting .............................................................. 19

Parts List ......................................................................... 20

Espa_ol ............................................................................ 32

Service Numbers ............................................. Back Cover

CRAFTSMAN FULL WARRANTY

IfthisCraftsmanproductfailsduetoadefectin materialor workmanshipwithintwo yearsfromthedateof purchase,returnittoanySearsstore,

Parts&RepairServiceCenter,orotherCraftsmanoutletintheUnitedStatesforfreerepair(orreplacementif repairprovesimpossible).

Thiswarrantyappliesforonly90daysifthis productis everusedforcommercialor rentalpurposes.

ThiswarrantycoversONLYdefectsin materialandworkmanship.SearswillNOTpayfor:

• Expendableitemsthatcanwearoutfromnormalusewithinthewarrantyperiod,suchasbelts,filters,sparkplugsoredgingblades.

• Repairsnecessarybecauseof accident,suchas a bentcrankshaft,orfailuretooperateor maintaintheproductaccordingtoallsupplied

instructions.

• Preventivemaintenance,or repairsnecessaryduetoimproperfuelmixture,contaminatedor stalefuel.

Thiswarrantygivesyouspecificlegalrights,andyoumayalsohaveotherrightswhichvaryfromstatetostate.

Sears, Roebuck and Co.,Hoffman Estates, IL 60179

Fuel:

SparkPlug:

Engine:

UnleadedGasoline

ChampionRJ19LM

BriggsandStratton10T802-0711-B1

Model Number

Serial Number

Dateof Purchase

Recordthemodelnumber,serialnumber,

anddateof purchaseabove.

© SearsBrands,LLC 2

Page 3

Thissymbolpointsoutimportantsafetyinstructionswhich,if not

followed,couldendangerthepersonalsafetyand/orpropertyof

yourselfandothers. Readandfollowall instructionsin thismanual

beforeattemptingtooperatethismachine.Failuretocomplywith

theseinstructionsmayresultin personalinjury.Whenyou seethis

symbol,HEEDITSWARNING!

Thismachinewasbuilt to beoperatedaccordingto the safeopera-

tionpracticesin thismanual.Aswithanytypeof powerequipment,

carelessnessorerroronthe part of the operatorcan resultin

seriousinjury.Thismachineiscapableofamputatingfingers,hands,

toesandfeetandthrowingdebris.Failureto observethefollowing

safetyinstructionscouldresultin seriousinjuryordeath.

CALIFORNIA PROPOSITION 65

EngineExhaust,someof itsconstituents,andcertainvehicle

componentscontainoremitchemicalsknownto Stateof California

tocausecancerandbirthdefectsorotherreproductiveharm.

TRAINING

• Readthisoperator'smanualcarefullyin itsentiretybefore

attemptingtoassemblethis machine.Read,understand,and

followall instructionsonthemachineandinthemanual(s) before

operation.Keepthismanualina safeplacefor futureand regular

referenceandfororderingreplacementparts.

• Becompletelyfamiliarwiththecontrolsandtheproperuseof this

machinebeforeoperatingit.

• Thismachineisa precisionpieceofpowerequipment,nota

plaything.Therefore,exerciseextremecautionat alltimes.Your

machinehasbeendesignedto performonejob: to edgelawn.Do

notuseit for any otherpurpose.

• Neverallowchildrenunder14yearsofageto operatethis

machine.Children14andovershouldreadandunderstandthe

instructionsandsafeoperationpracticesinthismanualandon

themachineandbe trainedandsupervisedbyanadult.

• Only responsibleindividualswhoarefamiliarwiththeserulesof

safeoperationshouldbe allowedtousethis machine.

• Tohelpavoidbladecontactor athrownobjectinjury,stayin

operatorzonebehindhandlesandkeepchildren,bystanders,

helpersandpetsatleast75feetfromlawnedgerwhileitis in

operation.Stopmachineif anyoneentersarea.

Your Responsibility--Restrict theuseofthis powermachineto

personswhoread,understandandfollowthewarningsand instruc-

tionsin thismanualandon themachine.

SAVETHESEINSTRUCTIONS!

PREPARATION

• Thoroughlyinspecttheareawherethe equipmentistobeused.

Removeall stones,sticks,wire,bones,toysandotherforeign

objectswhichcould betrippedoveror pickedupandthrownby

theblade.Thrownobjectscancauseseriouspersonalinjury.

• Alwayswearsafetyglassesorsafetygogglesduringoperation

andwhileperformingan adjustmentorrepairto protectyoureyes.

Thrownobjectswhichricochetcancauseseriousinjurytothe

eyes.

• Wearsturdy,rough-soledworkshoesandclose-fittingslacks

and shirts.Shirtsand pantsthatcoverthearmsandlegsand

steel-toedshoesare recommended.Neveroperatethismachine

inbarefeet,sandals,slipperyorlightweight(e.g.canvas)shoes.

• Neverattempttomakeanyadjustmentswhiletheengineis

running,exceptwherespecificallyrecommendedintheoperator's

manual.

SAFE HANDLING OF GASOLINE:

Toavoidpersonalinjuryorpropertydamageuseextremecarein

handlinggasoline.Gasolineisextremelyflammableandthevaporsare

explosive.Seriouspersonalinjurycanoccurwhengasolineis spilled

on yourselforyourclotheswhichcanignite. Washyourskinand

changeclothesimmediately.

• Useonly anapprovedgasolinecontainer.

• Neverfillcontainersinsidea vehicleoron a truckortrailerbed

witha plasticliner.Alwaysplacecontainerson thegroundaway

fromyourvehiclebeforefilling.

• Removegas-poweredequipmentfromthetruckortrailerand

refuelit ontheground.Ifthisis notpossible,thenrefuelsuch

equipmenton atrailerwitha portablecontainer,ratherthanfrom

a gasolinedispensernozzle.

• Keepthe nozzleincontactwiththerimofthefueltankor

containeropeningatall timesuntilfuelingis complete.Donotuse

a nozzlelock-opendevice.

3

Page 4

• Extinguishallcigarettes,cigars,pipesandothersourcesof

ignition.

• Neverfuel machineindoorsbecauseflammablevaporswill

accumulatein the area.

• Neverremovegascapor addfuelwhileengineis hotor running.

Allowengineto coolat leasttwo minutesbeforerefueling.

• Neveroverfillfueltank.Filltankto nomorethan1/2inchbelow

bottomoffillerneckto provideforfuelexpansion.

• Replacegasolinecapandtightensecurely.

• Ifgasolineis spilled,wipe it off theengineandequipment.Move

machinetoanotherarea.Wait5 minutesbeforestarting engine.

• Neverstorethe machineorfuelcontainernearanopenflame,

sparkor pilotlightasona waterheater,spaceheater,furnace,

clothesdryeror othergasappliances.

• To reducefirehazard,keeplawnedgerfreeofgrass,leaves,or

otherdebrisbuild-up.Cleanupoil orfuelspillageandremoveany

fuelsoakeddebris.

• Allowa lawnedgertocoolatleastfive (5)minutesbeforestoring

OPERATION

• Do not puthandsorfeetnear rotatingparts.Contactwiththe

rotatingbladecanamputatehandsandfeet.

Thebladecontrolhandleisa safetydevice.Neverbypassits

operation.Doingso,makesthemachineunsafeand maycause

personalinjury.

Neveroperatewithoutbladeguard,debrisshieldandblade

controlhandlein placeandworking.

Neveroperatewithdamagedsafetydevices.Failuretodo so,can

resultinpersonalinjury.

Neverrunanengineindoorsorina poorlyventilatedarea. Engine

exhaustcontainscarbonmonoxide,anodorlessanddeadlygas.

Donotoperatemachinewhileundertheinfluenceofalcoholor

drugs.

Mufflerandenginebecomehotandcancausea burn.Donot

touch.

Neveroperatethismachinewithoutgoodvisibilityor light.Always

be sureofyourfootingandkeepa firmholdonthe handles.Walk,

neverrun.

Donotoperatethis machineif it has beendroppedor damaged.

Returnmachinetoyournearestauthorizedservicingdealerfor

examinationand repair.

Donotoperatethis machinewitha damagedorexcessivelyworn

cuttingblade.

Neverattempttoclearmaterialfromthe bladeguardwhilethe

engineis running.Shut theengineoff,disconnectthespark

plugwireandgroundagainsttheenginetopreventunintended

starting.

Donotoverloadmachinecapacitybyattemptingtoedgeat too

fastof a rate.

Stayalertforunevensidewalks,terrainetc.Alwayspushslowly

overroughsurfaces.Donotusethis machineon gravelsurfaces.

Donotoperatemachinein rainorwetsoil conditions.

• Alwaysoperatemachinefrombehindthe handlesandposition

yourselfwherethedirectlineof sightto cuttingbladeisblocked

byguards.

• Alwaysstopenginewhenedgingortrimmingisdelayedorwhen

transportingmachinefromonelocationtoanother.

• Neverleavea runningmachineunattended.Stoptheengine,

disconnectsparkplugwireandgroundagainsttheengineto

preventunintendedstarting.

• Only usepartsandaccessoriesmadeforthismachinebythe

manufacturer.Failuretodo so,canresultin personalinjury.

• Ifsituationsoccurwhichare notcoveredinthis manual,usecare

andgoodjudgment.ContactCustomerSupportforassistanceor

thenameof your nearestservicedealer.

CHILDREN

Tragicaccidentscanoccuriftheoperatorisnot alerttothepresence

ofchildren.Childrenareoftenattractedto powerequipmentsuchas

lawnedgers.Theydo notunderstandthedangers.Neverassumethat

childrenwill remainwhereyoulastsawthem.

Keepchildrenoutoftheedgingareaandunderwatchfulcareofa

responsibleadultotherthantheoperator.

Bealertandturnlawnedgeroff if achildentersthearea.

• Beforeandwhilemovingbackwards,look behindanddown for

smallchildren.

Useextremecarewhenapproachingblindcorners,doorways,

shrubs,trees,orotherobjectsthatmayobscureyourvisionof a

childwhomayrunintothelawnedger.

Keepchildrenawayfromhot or runningengines.Theycansuffer

burnsfroma hot muffler.

Neverallowchildrenunder14yearsof agetooperatethis

machine.Children14andovershouldreadand understandthe

instructionsandsafeoperationpracticesinthis manualandon

themachineand betrainedandsupervisedby an adult.

MAINTENANCE & STORAGE

• Neverrunanengineindoorsorin apoorlyventilatedarea.Engine

exhaustcontainscarbonmonoxide,an odorlessanddeadlygas.

Beforecleaning,repairing,or inspecting,makecertainthe

bladeandall movingpartshavestopped.Disconnectthespark

plugwireand groundagainsttheengineto preventunintended

starting.

Checkthe bladeandenginemountingboltsat frequentintervals

forpropertightness.Also,visuallyinspectbladefor damage(e.g.,

bent,cracked,worn)Replacebladewiththe originalequipment

rnanufacture's(O.E.M.)bladeonly,listedinthis manual."Useof

partswhichdonotmeettheoriginalequipmentspecificationsmay

leadtoimproperperformanceandcompromisesafety!"

Lawnedgerbladesare sharpandcancut.Wrapthebladeor

weargloves,and useextracautionwhenservicingthem.

Keepallnuts,bolts,andscrewstightto besurethe equipmentis

in safeworkingcondition.

Nevertamperwith safetydevices.Checktheirproperoperation

regularly.

4

Page 5

• Afterstrikingaforeignobject,stoptheengine,disconnectthe

sparkplugwireand groundagainsttheengine.Thoroughly

inspectthelawnedgerforanydamage.Repairthedamage

beforestartingandoperatingthelawnedger.

Neverattempttomakea wheeladjustmentwhiletheengineis

running.

Manycomponentson yournewedgercanwearwithcontinued

use. Forsafetyprotection,frequentlycheckall edgercomponents

andreplaceimmediatelywithoriginalequipmentmanufacturer's

(O.E.M.)partsonly,listedin thismanual."Useofpartswhich

donotmeettheoriginalequipmentspecificationsmayleadto

improperperformanceandcompromisesafety!"

Donotchangetheenginegovernorsettingor overspeedthe

engine.Thegovernorcontrolsthe maximumsafeoperatingspeed

oftheengine.

Maintainor replacesafetyandinstructionlabels,asnecessary.

Observeproperdisposallawsand regulationsfor usedgas,

oil,etc..Improperdisposaloffluidsandmaterialscanharmthe

environment.

AccordingtotheConsumerProductsSafetyCommission(CPSC)

andtheU.S.EnvironmentalProtectionAgency(EPA),thisproduct

hasan Average UsefulLifeof seven(7)years,or 70hoursof

operation.AttheendoftheAverage UsefulLifehavethe machine

inspectedannuallybyan authorizedservicedealerto ensurethat

allmechanicalandsafetysystemsareworkingproperlyandnot

wornexcessively.Failureto do socanresultinaccidents,injuries

ordeath.

DO NOT MODIFY ENGINE

Toavoidseriousinjuryordeath,donotmodifyenginein anyway.

Tamperingwiththegovernorsettingcanleadto a runawayengineand

causeittooperateat unsafespeeds.Nevertamperwithfactorysetting

ofenginegovernor.

NOTICE REGARDING EMISSIONS

EngineswhicharecertifiedtocomplywithCaliforniaandfederal

EPAemissionregulationsfor SORE(SmallOffRoadEquipment)are

certifiedto operateon regularunleadedgasoline,and mayinclude

thefollowingemissioncontrolsystems:EngineModification(EM),

OxidizingCatalyst(OC),SecondaryAirInjection(SAI)and ThreeWay

Catalyst(TWO)if so equipped.

SPARK ARRESTOR

Thismachineis equippedwithan internalcombustionengineand

shouldnotbe usedonor nearanyunimprovedforest-covered,

brushcoveredor grass-coveredlandunlesstheengine'sexhaust

systemisequippedwitha sparkarrestermeetingapplicablelocalor

statelaws(ifany)

Ifa sparkarresterisused,itshouldbemaintainedin effectiveworking

orderbytheoperator.Inthe StateofCaliforniatheaboveis required

bylaw (Section4442oftheCaliforniaPublicResourcesCode).Other

statesmayhavesimilarlaws. Federallawsapplyonfederallands.

A sparkarresterforthemuffleris availablethroughyournearestSears

PartsandRepairServiceCenter.

Page 6

SAFETY SYMBOLS

Thispagedepictsanddescribessafetysymbolsthatmayappearonthisproduct. Read,understand,andfollowall instructionson the machine

before attempting to assemble and operate.

READ THE OPERATOR'S MANUAL(S)

Read,understand,andfollowall instructionsinthe manual(s)beforeattemptingtoassembleand

1

operate

WARNING m ROTATING BLADES

Keephandsandfeetawayfrom rotatingblade.

• ®

BYSTANDERS

Keepbystanders,pets,andchildrenatleast75feetfromthemachinewhileitisin operation.Stop

machineifanyoneentersthearea.

WARNINGm HOT SURFACES

Donot touchmuffleroradjacentareas.

EYE PROTECTION

Alwayswearsafetyglassesorsafetygoggleswhenoperatingthismachine.

6

Page 7

Thispageleftintentionallyblank.

7

Page 8

NOTE:Thismachineis shippedWITHOUTGASOLINEor OIL.After

settinguptheedger,servicetheenginewithgasolineandoilas

instructed.

NOTE:Referenceto rightor lefthandsideoftheedgeris observed

fromtheoperatingposition.

ASSEMBLY

Handle

Removeanddiscardanypackagingcardboardthatmaybe present

betweentheupperhandleandthe lowerhandle.

1. Pivottheupperhandleupwarduntilit snapsinto place.See

Figure1.

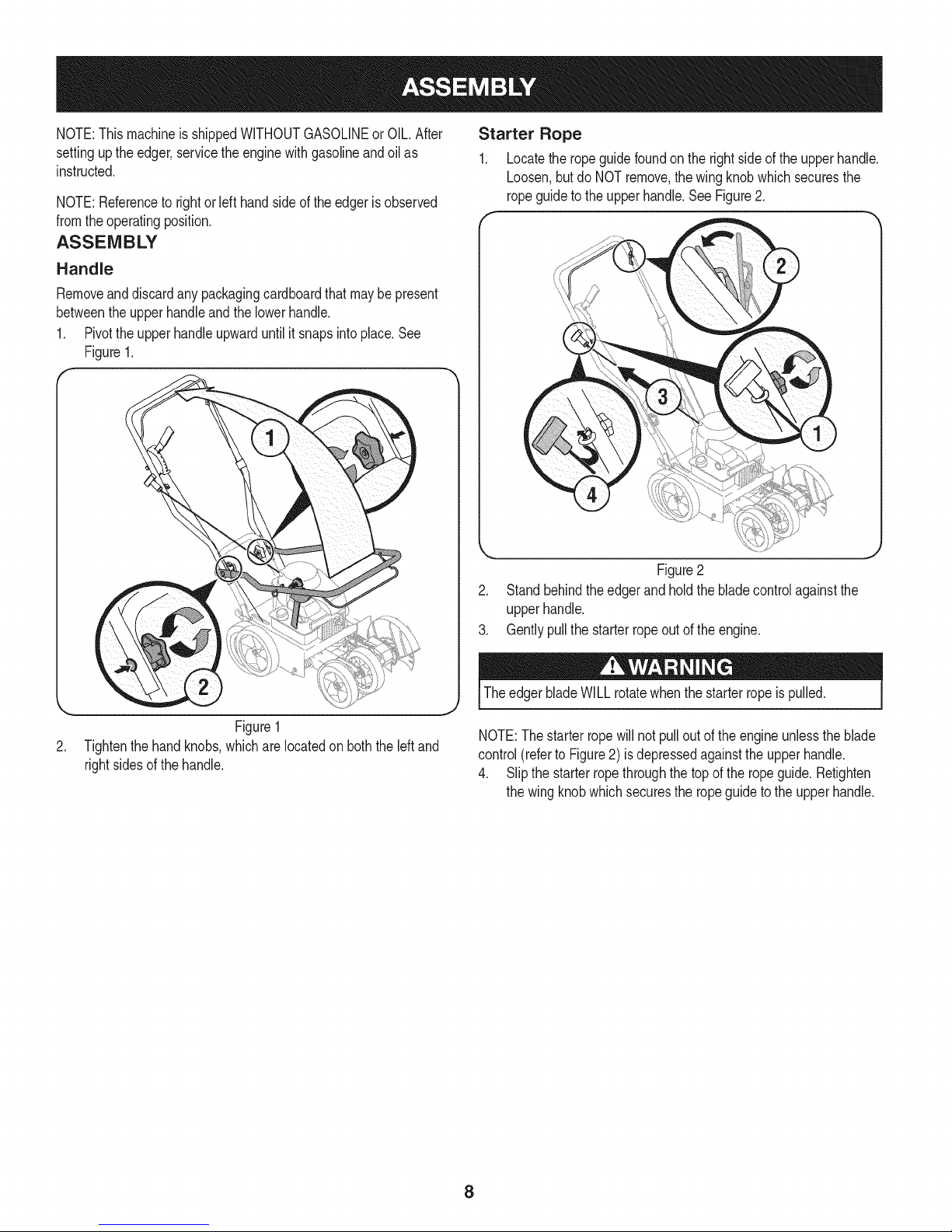

Starter Rope

1. Locatetheropeguidefoundontherightsideoftheupperhandle.

Loosen,butdo NOTremove,thewingknobwhichsecuresthe

ropeguidetotheupperhandle.SeeFigure2.

J

Figure2

2. Standbehindthe edgerandholdthebladecontrolagainstthe

upperhandle.

3. Gentlypullthe starterropeoutoftheengine.

Figure1

2. Tightenthehandknobs,whichare locatedon boththeleftand

rightsidesofthehandle.

TheedgerbladeWILLrotatewhenthestarterropeis pulled.

NOTE:Thestarterropewillnotpulloutoftheengineunlesstheblade

control(referto Figure2) isdepressedagainsttheupperhandle.

4. Slipthe starterropethroughthetopoftheropeguide.Retighten

thewingknobwhichsecuresthe ropeguidetotheupperhandle.

8

Page 9

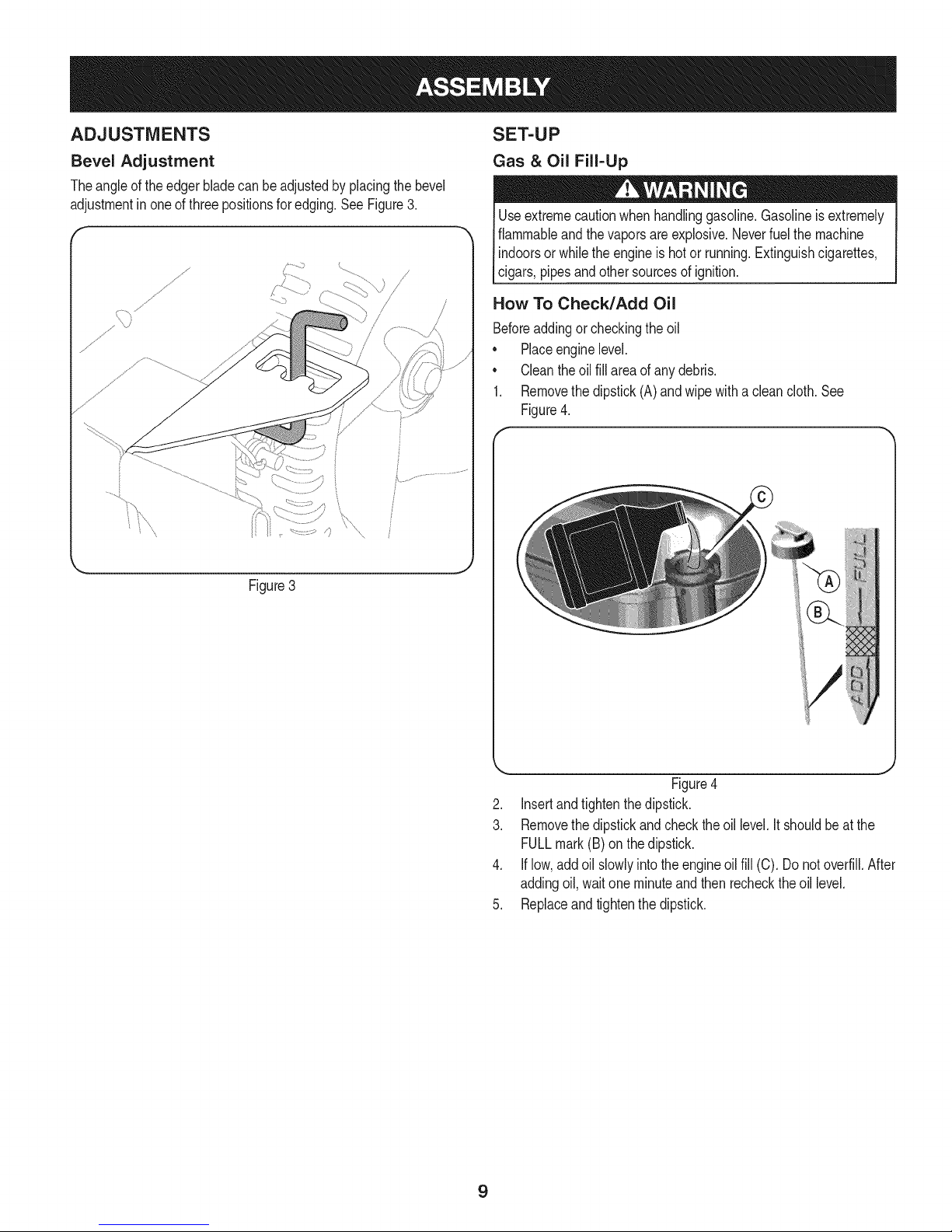

ADJUSTMENTS

SET-UP

Bevel Adjustment

Theangleoftheedgerbladecanbe adjustedbyplacingthebevel

adjustmentinoneof three positionsforedging.SeeFigure3.

f

j, ','.

' ,\\

,. J

Figure3

Gas & Oil Fill=Up

Useextremecautionwhenhandlinggasoline.Gasolineisextremely

flammableand thevaporsare explosive.Neverfuelthemachine

indoorsorwhilethe engineis hotor running.Extinguishcigarettes,

cigars,pipesandothersourcesof ignition.

How To Check/Add Oil

Beforeaddingorcheckingtheoil

• Placeenginelevel.

• Cleantheoilfillareaof any debris.

1. Removethedipstick(A)andwipewitha cleancloth.See

Figure4.

Figure4

.

Insertandtightenthedipstick.

3.

Removethe dipstickandcheckthe oillevel.It shouldbeat the

FULLmark(B)onthedipstick.

4.

Iflow,addoilslowlyintotheengineoil fill(C). Do notoverfill.After

addingoil,waitoneminuteandthenrechecktheoillevel.

5.

Replaceandtightenthedipstick.

9

Page 10

FUEL RECOMMENDATIONS

Fuelmustmeettheserequirements:

• Clean,fresh,unleadedgasoline.

• A minimumof 87 octane/87AKI(91RON). Highaltitudeuse,see

below.

• Gasolinewithupto 10%ethanol(gasohol)orupto 15%MTBE

(methyltertiarybutylether)isacceptable.

use

unapprovedgasolines,

gasolineormodifytheengineto runon alternatefuels.Thiswill

l Do not such E85.Do not mixoil in

damagetheenginecomponentsandvoidtheenginewarranty.

Toprotectthefuelsystemfromgumformation,mixa fuelstabilizer

intothe fuel.SeeStorage.Allfuel is notthesame.If startingor

performanceproblemsoccur,changefuel providersorchangebrands.

Thisengineiscertifiedtooperateongasoline.Theemissionscontrol

systemforthisengineis EM(EngineModifications).

High Altitude

Ataltitudesover5,000feet(1524meters),a minimum85octane/85

AKI(89RON)gasolineisacceptable.Toremainemissionscompliant,

highaltitudeadjustmentisrequired.Operationwithoutthisadjustment

willcausedecreasedperformance,increasedfuelconsumption,and

increasedemissions.Seea Briggs&StrattonAuthorizedDealerfor

highaltitudeadjustmentinformation.

Operationof theengineataltitudesbelow2,500feet(762meters)with

thehighaltitudekitis not recommended.

as

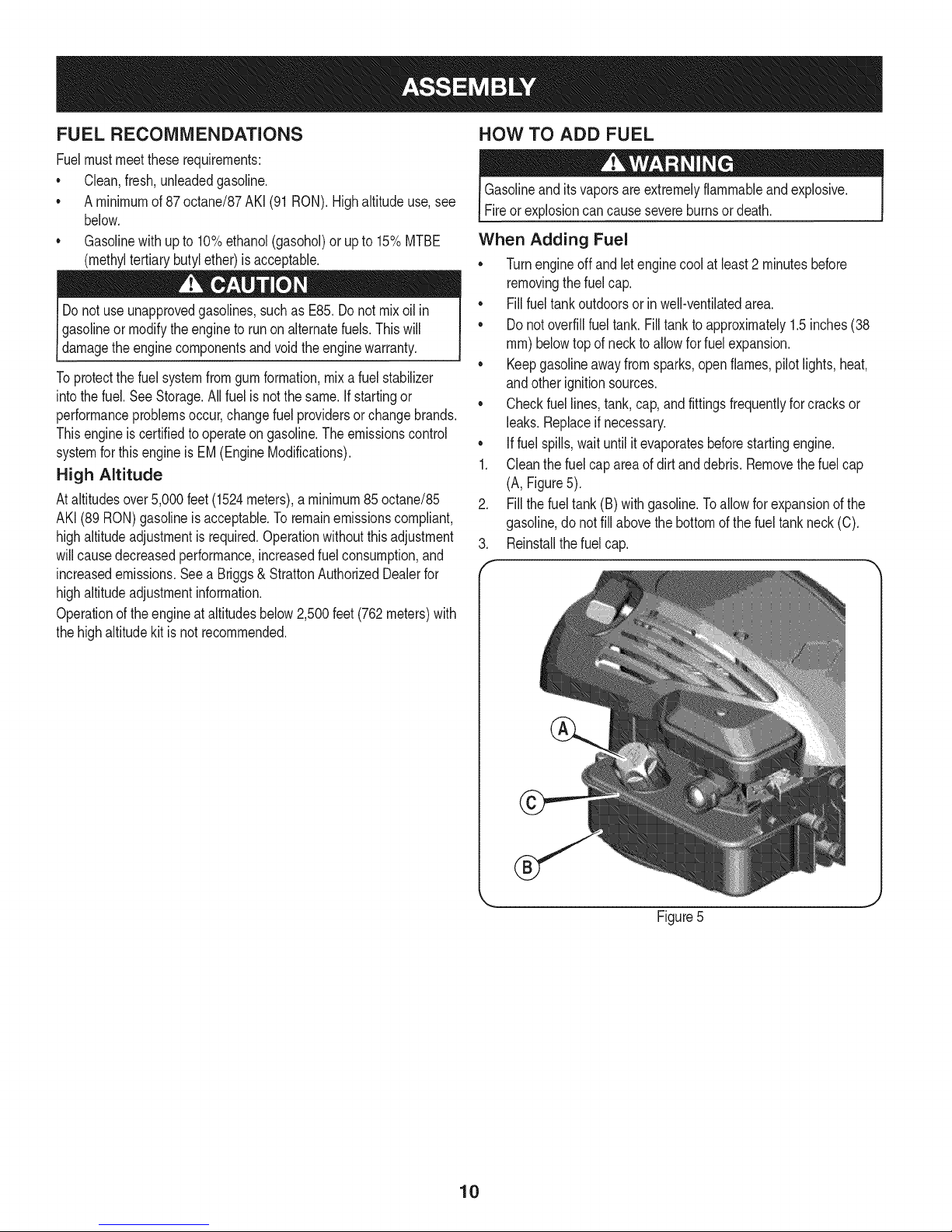

HOW TO ADD FUEL

Gasolineanditsvaporsareextremelyflammableandexplosive.

Fireorexplosioncancausesevereburnsordeath.

When Adding Fuel

• Turnengineoff andletenginecoolat least2 minutesbefore

removingthefuelcap.

• Fillfueltankoutdoorsorinwell-ventilatedarea.

• Donotoverfillfueltank.Filltankto approximately1.5inches(38

ram)belowtopofneckto allowforfuelexpansion.

• Keepgasolineawayfromsparks,openflames,pilotlights,heat,

andotherignitionsources.

• Checkfuellines,tank,cap,andfittingsfrequentlyfor cracksor

leaks.Replaceif necessary.

• Iffuelspills,waituntilit evaporatesbeforestartingengine.

1. Cleanthe fuelcap areaofdirtanddebris.Removethefuelcap

(A, Figure5).

2. Fillthefueltank (B)withgasoline.Toallowforexpansionofthe

gasoline,do not fill abovethebottomof the fueltankneck(C).

3. Reinstallthefuel cap.

f

J

Figure5

10

Page 11

f

BladeControl

Bail

BladeDepthControlLever

RecoilStarter

BevelAdjl

Lever

CurbHeight

AdjustmentLever

\

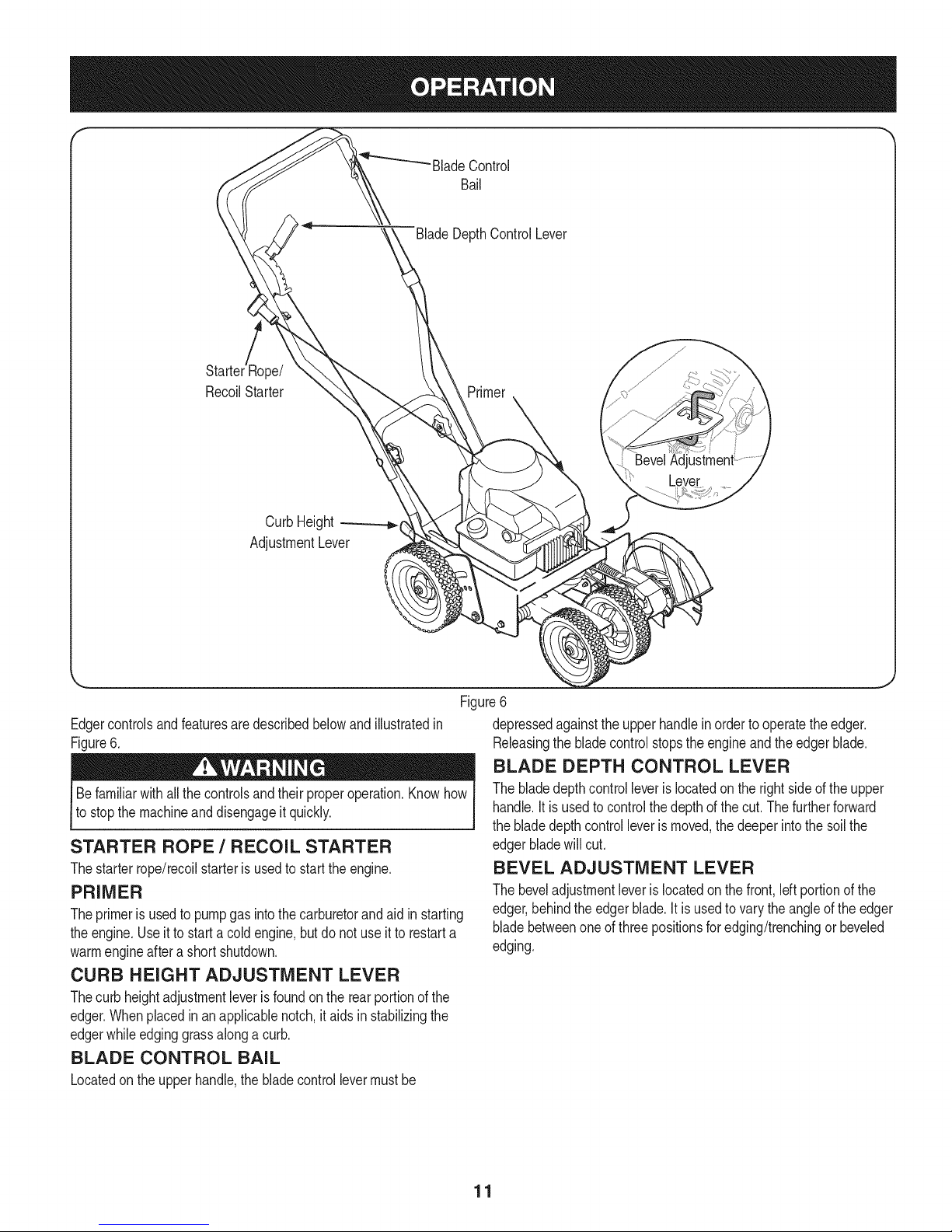

Edgercontrolsandfeaturesaredescribedbelowandillustratedin

Figure6.

Befamiliarwithallthecontrolsandtheir properoperation.Knowhow

to stopthe machineanddisengageitquickly.

STARTER ROPE / RECOIL STARTER

Thestarter rope/recoilstarterisusedto start the engine.

PRIMER

Theprimeris usedto pumpgasintothecarburetorandaid instarting

theengine.Useit to start a coldengine,butdo not useitto restarta

warmengineaftera shortshutdown.

CURB HEIGHT ADJUSTMENT LEVER

Thecurb heightadjustmentleveris foundon therearportionofthe

edger.Whenplacedinan applicablenotch,it aidsin stabilizingthe

edgerwhileedginggrassalongacurb.

BLADE CONTROL BAIL

Locatedon the upperhandle,thebladecontrollevermustbe

Figure6

depressedagainsttheupperhandleinordertooperatetheedger.

Releasingthebladecontrolstopstheengineandtheedgerblade.

BLADE DEPTH CONTROL LEVER

Thebladedepthcontrolleveris locatedontherightside of the upper

handle.Itisusedto controlthe depthofthecut.Thefurtherforward

thebladedepthcontrolleveris moved,thedeeperintothe soil the

edgerbladewillcut.

BEVEL ADJUSTMENT LEVER

Thebeveladjustmentleveris locatedon thefront,leftportionofthe

edger,behindthe edgerblade.It isusedtovarythe angleof the edger

bladebetweenoneofthreepositionsforedging/trenchingorbeveled

edging.

11

Page 12

STARTING THE ENGINE

Tostart theedger'sengine,proceedasfollows:

1. Attachthe sparkplugwireto the sparkplug.Makecertainthe

metalcapontheendof the sparkplugwireisfastenedsecurely

overthe metaltip on thesparkplug.

2. Movethebladedepthcontrolleverbackto the STARTpositionin

theadjacent(top) notch.

3. Depresstheprimerbulbthreetimes,pausingtwotothree

secondsbetweeneach push.Incold weather(below50°F/19°0),

itmaybe necessarytodepressthe primerbulbfouror fivetimes.

NOTE:Usingthe primerto restartawarmengineaftera short

shutdownis usuallynot necessary.Doingso mayresultina flooded

engine.

4. Standingbehindtheedger,depressthebladecontrolbailand

holditagainsttheupperhandlewithyour Idt hand.

_eration.

5. Withyourrighthand,grasptherecoilstarterhandleandslowly

pulltheropeoutwarduntilenginereachesthestartofits com-

pressioncycle(theropewillpullslightlyharderatthispoint).

6. Afterslowlyallowingtheropeto recoil,pullthe ropewitha rapid,

continuous,fullarmstroke.Keepa firmgripon starterhandle

throughouttheentirestroke.

7. Allowthestarterhandleto slowlyreturntothe eyebolt.

EDGING

Rotatingcuttingblademaythrowobjectscausingpersonalinjury.

Keepareaclearof bystandersanddo notoperatewithoutguardsin

)lace.

Donot lowerbladeif bladeisoverconcrete,asphalt,rocksorthe like.

Bade canstrke supportng surface,resut ng npersona njuryor |

propertydamage.

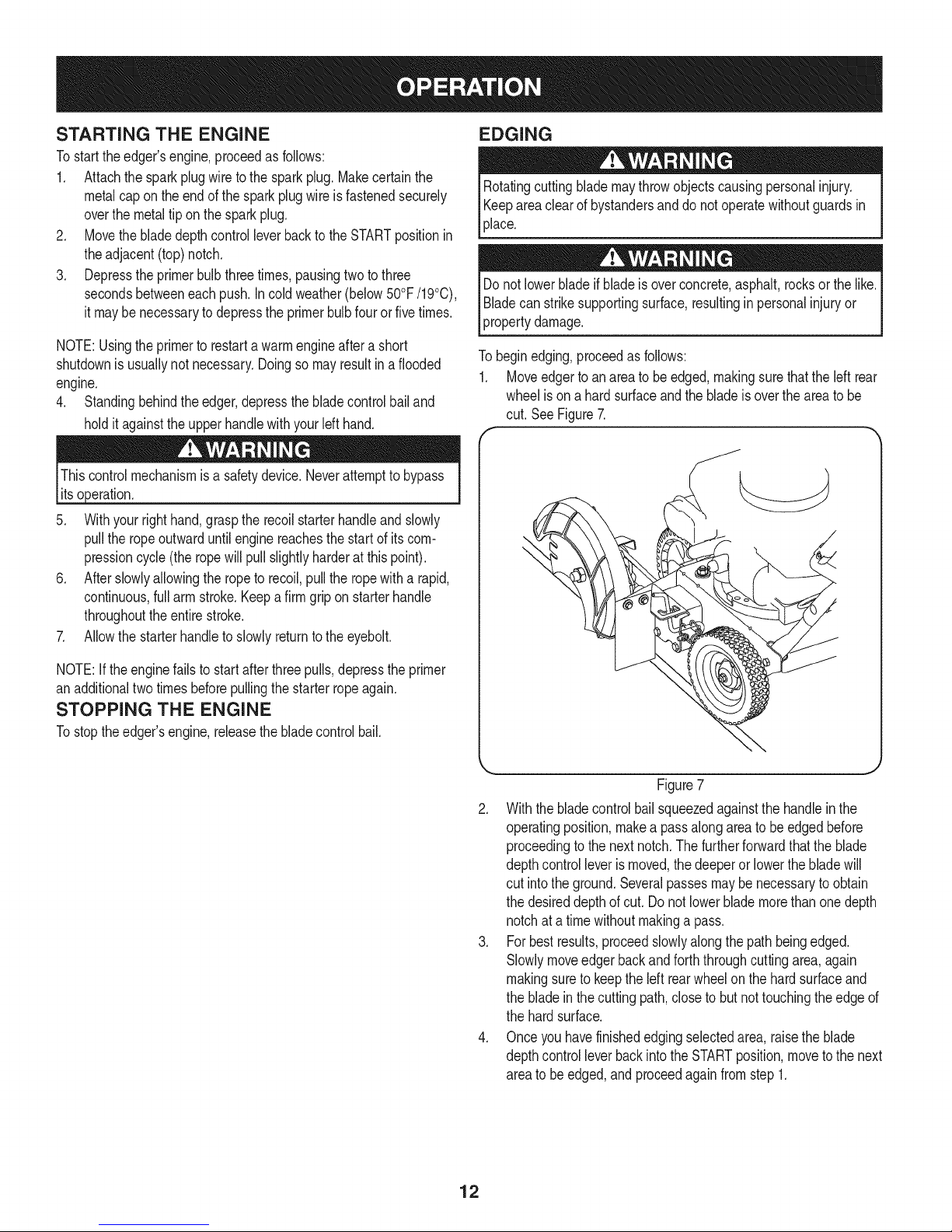

Tobeginedging,proceedasfollows:

1. Moveedgertoanareato beedged,makingsurethattheleftrear

wheelis on a hardsurfaceandthe bladeisovertheareato be

cut.SeeFigure7.

J

NOTE:Iftheenginefailstostartafterthreepulls,depresstheprimer

anadditionaltwotimesbeforepullingthestarterropeagain.

STOPPING THE ENGINE

Tostoptheedger'sengine,releasethebladecontrolbail.

Figure7

2. Withthe bladecontrolbailsqueezedagainstthe handleinthe

operatingposition,makea passalongareato beedgedbefore

proceedingtothenextnotch.Thefurtherforwardthattheblade

depthcontrolleveris moved,thedeeperor lowerthe bladewill

cut intotheground.Severalpassesmaybe necessarytoobtain

thedesireddepthof cut.Donot lowerblademorethanonedepth

notchata timewithoutmakingapass.

3. Forbestresults,proceedslowlyalongthepathbeingedged.

Slowlymoveedgerbackandforththroughcuttingarea,again

makingsureto keeptheleftrearwheelonthehardsurfaceand

thebladeinthe cuttingpath,closeto but not touchingtheedgeof

thehardsurface.

4. Onceyouhavefinishededgingselectedarea,raisetheblade

depthcontrolleverbackinto theSTARTposition,movetothenext

areatobe edged,andproceedagainfromstep1.

12

Page 13

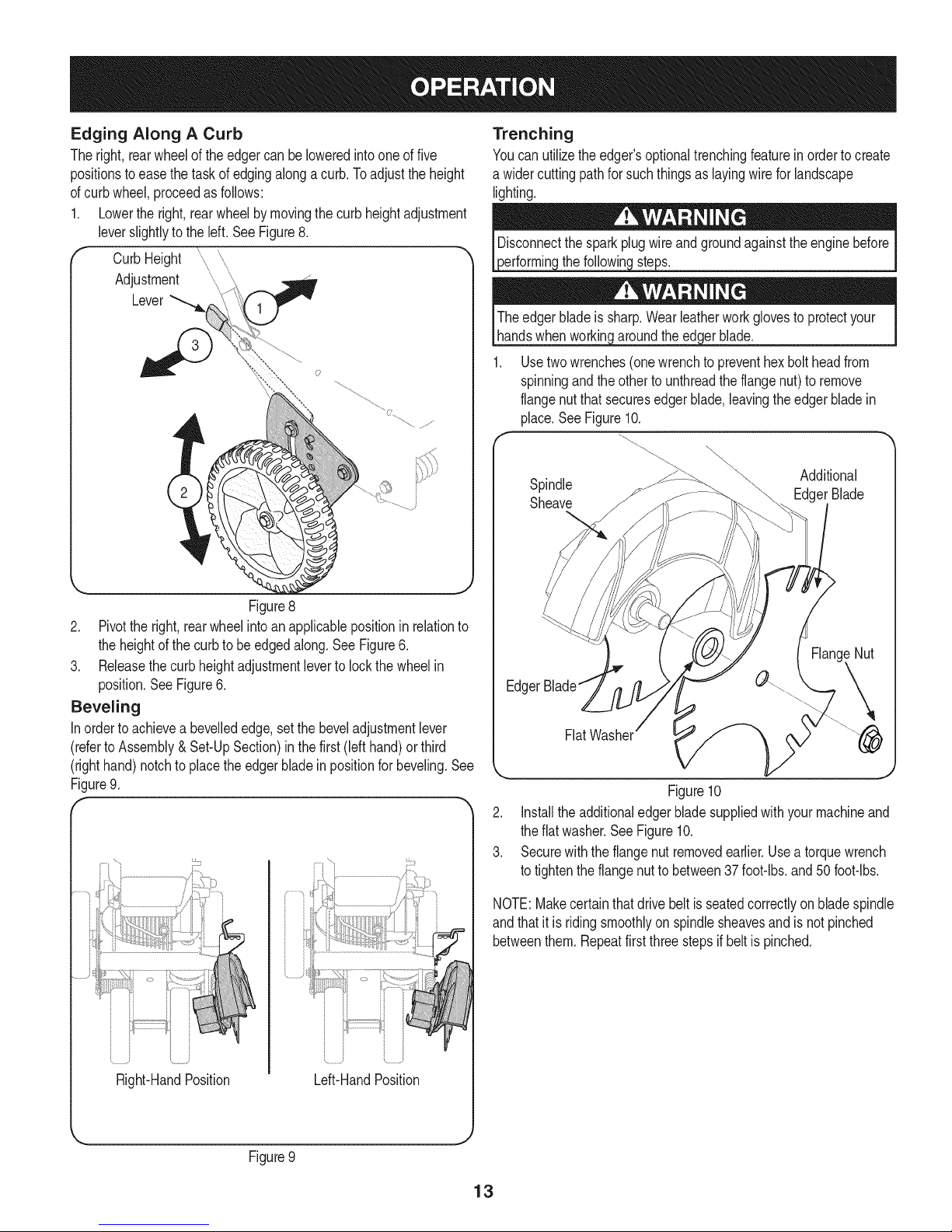

Edging Along A Curb

Theright,rearwheeloftheedgercanbe loweredintooneoffive

positionstoeasethetaskof edgingalonga curb.Toadjusttheheight

ofcurbwheel,proceedasfollows:

1. Lowerthe right,rearwheelby movingthecurb heightadjustment

leverslightlytotheleft.SeeFigure8.

"" CurbHeight

Adjustment

Lever

Trenching

Youcanutilizetheedger'soptionaltrenchingfeaturein ordertocreate

a widercuttingpathfor suchthingsaslayingwireforlandscape

lighting.

thefollowinc _s.

Usetwowrenches(onewrenchtopreventhexbolt headfrom

spinningand theotherto unthreadtheflangenut)to remove

flangenut thatsecuresedgerblade,leavingtheedgerbladein

place.SeeFigure10.

(

Figure8

2. Pivottheright,rearwheelintoanapplicablepositionin relationto

theheightofthecurbtobeedgedalong.SeeFigure6.

3. Releasethecurbheightadjustmentlevertolockthewheelin

position.SeeFigure6.

Beveling

Inordertoachievea bevellededge,setthebeveladjustmentlever

(referto Assembly&Set-UpSection)inthefirst(lefthand)orthird

(righthand)notchtoplacethe edgerbladein positionfor beveling.See

Figure9.

Spindle Additional

Sheave EdgerBlade

Edger

J

Figure10

.

Installtheadditionaledgerbladesuppliedwithyourmachineand

theflatwasher.SeeFigure10.

3.

Securewiththe flangenutremovedearlier.Usea torquewrench

totightentheflangenut to between37foot-lbs,and50 foot-lbs.

NOTE:Makecertainthatdrive beltisseatedcorrectlyon bladespindle

andthatit isridingsmoothlyonspindlesheavesandisnotpinched

betweenthem.Repeatfirstthreestepsifbeltispinched.

Figure9

13

Page 14

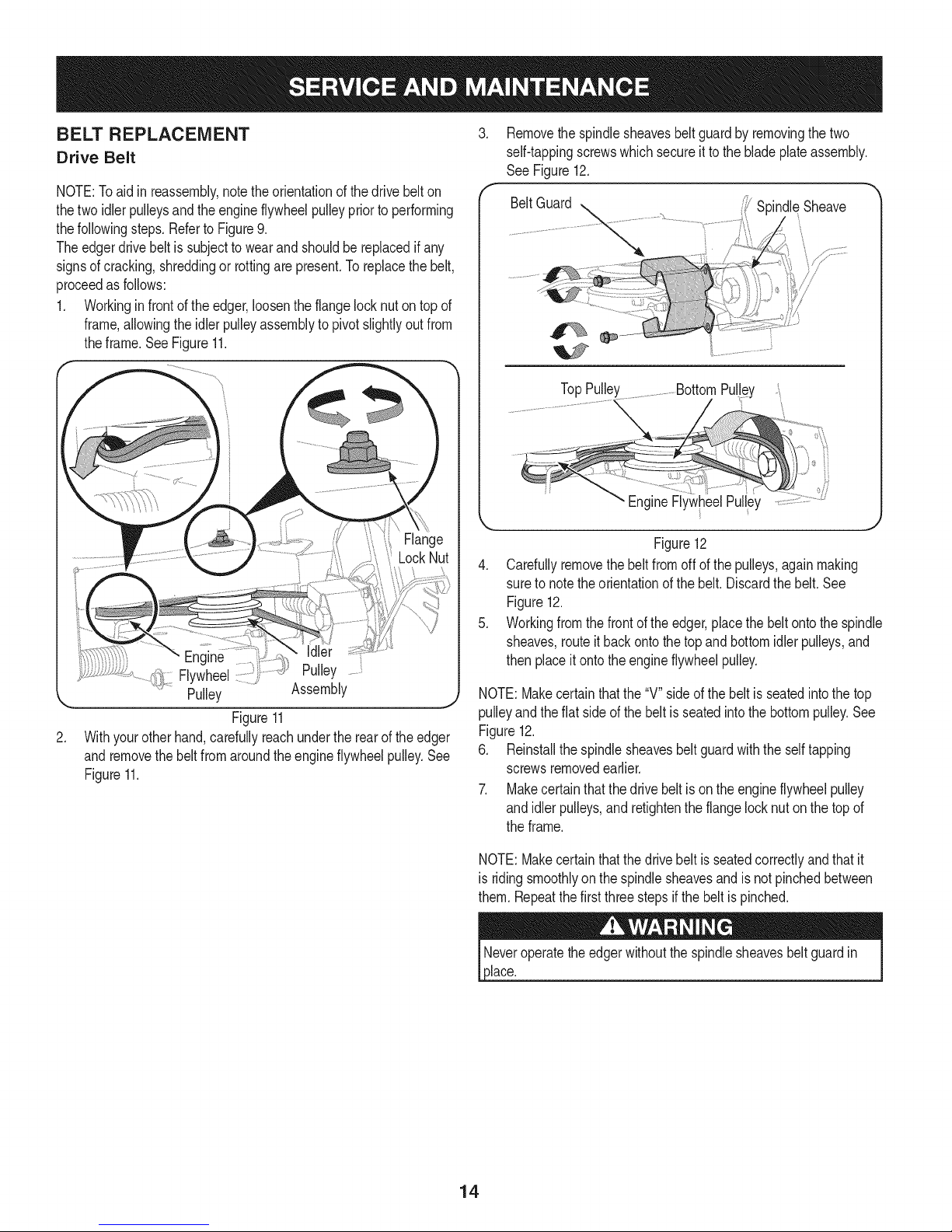

BELT REPLACEMENT

Drive Belt

NOTE:Toaid in reassembly,notetheorientationofthedrivebelton

thetwo idlerpulleysandtheengineflywheelpulleypriorto performing

thefollowingsteps.Referto Figure9.

Theedgerdrivebelt is subjecttowearand shouldbereplacedifany

signsofcracking,shreddingorrottingarepresent.Toreplacethebelt,

proceedasfollows:

1. Workinginfrontoftheedger,loosentheflangelock nuton topof

frame,allowingtheidlerpulleyassemblytopivotslightlyoutfrom

theframe.SeeFigure11.

.

Removethe spindlesheavesbeltguardby removingthe two

self-tappingscrewswhichsecureitto the bladeplateassembly.

See Figure12.

BeltGuard ._ _indleSheave

--,..

TopPulley ............BottomPul!ey

EngineFlywheelPulley

Figure12

4. Carefullyremovethebeltfromoffofthepulleys,againmaking

sureto notetheorientationofthebelt.Discardthebelt.See

Figure12.

5. Workingfromthefrontof the edger,placethebeltontothespindle

sheaves,routeit backontothetopandbottomidlerpulleys,and

thenplaceit ontotheengineflywheelpulley.

Assembly

Figure11

.

Withyourotherhand,carefullyreachundertherearof the edger

andremovethebeltfromaroundtheengineflywheelpulley.See

Figure11.

NOTE:Makecertainthatthe "V" sideof thebeltisseatedintothetop

pulleyandtheflatsideofthebeltisseatedintothe bottompulley.See

Figure12.

6. Reinstallthespindlesheavesbeltguardwiththe selftapping

screwsremovedearlier.

7. Makecertainthatthe drivebeltisonthe engineflywheelpulley

and idlerpulleys,and retightentheflangelocknuton thetopof

theframe.

NOTE:Makecertainthatthe drivebeltisseatedcorrectlyandthatit

isridingsmoothlyon the spindlesheavesandisnotpinchedbetween

them.Repeatthefirstthree stepsifthebeltispinched.

14

Page 15

MAINTENANCE

ustment,re

Edger Blade

Theedgerbladeis sharp.Wearleatherworkglovesto protectyour

handswhenworkingaroundtheedgerblade.

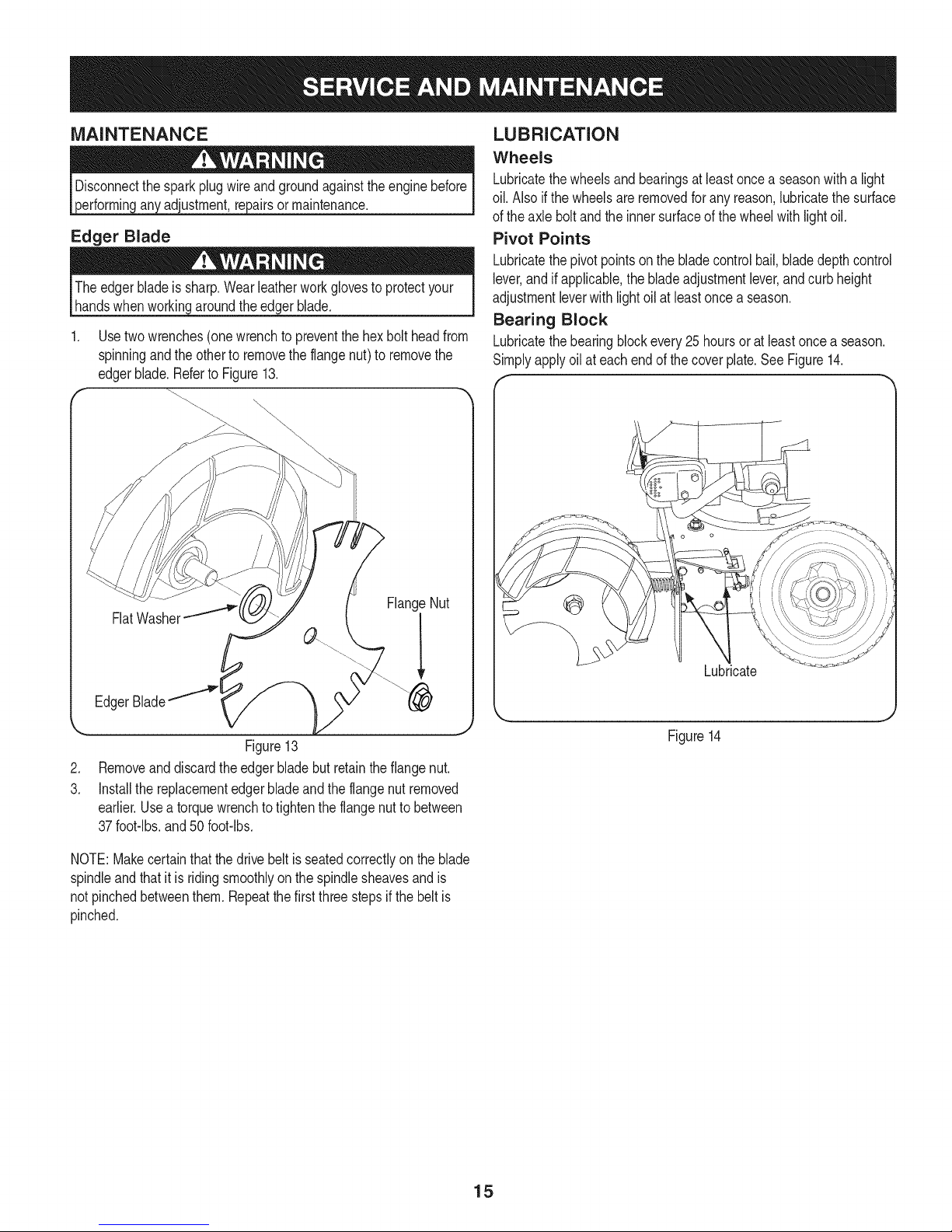

Usetwowrenches(onewrenchto preventthehexbolt headfrom

spinningandthe othertoremovetheflangenut)to removethe

edgerblade.Referto Figure13.

LUBRICATION

Wheels

Lubricatethewheelsand bearingsat leastoncea seasonwitha light

oil.Alsoifthewheelsareremovedforanyreason,lubricatethesurface

oftheaxleboltand theinnersurfaceof thewheelwithlightoil.

Pivot Points

Lubricatethepivotpointson the bladecontrolbail,bladedepthcontrol

lever,andifapplicable,thebladeadjustmentlever,andcurbheight

adjustmentleverwithlightoil atleastoncea season.

Bearing Block

Lubricatethebearingblockevery25 hoursorat leastoncea season.

Simplyapplyoilateachendof thecoverplate.SeeFigure14.

f

FlangeNut

!

Figure13

.

Removeanddiscardtheedgerbladebutretaintheflangenut.

3.

Installthe replacementedgerbladeandthe flangenutremoved

earlier.Usea torquewrenchtotightentheflangenuttobetween

37foot-lbs,and50foot-lbs.

NOTE:Makecertainthatthedrivebelt is seatedcorrectlyontheblade

spindleandthatitisridingsmoothlyonthespindlesheavesandis

notpinchedbetweenthem. Repeatthefirstthreestepsif the belt is

pinched.

Figure14

15

Page 16

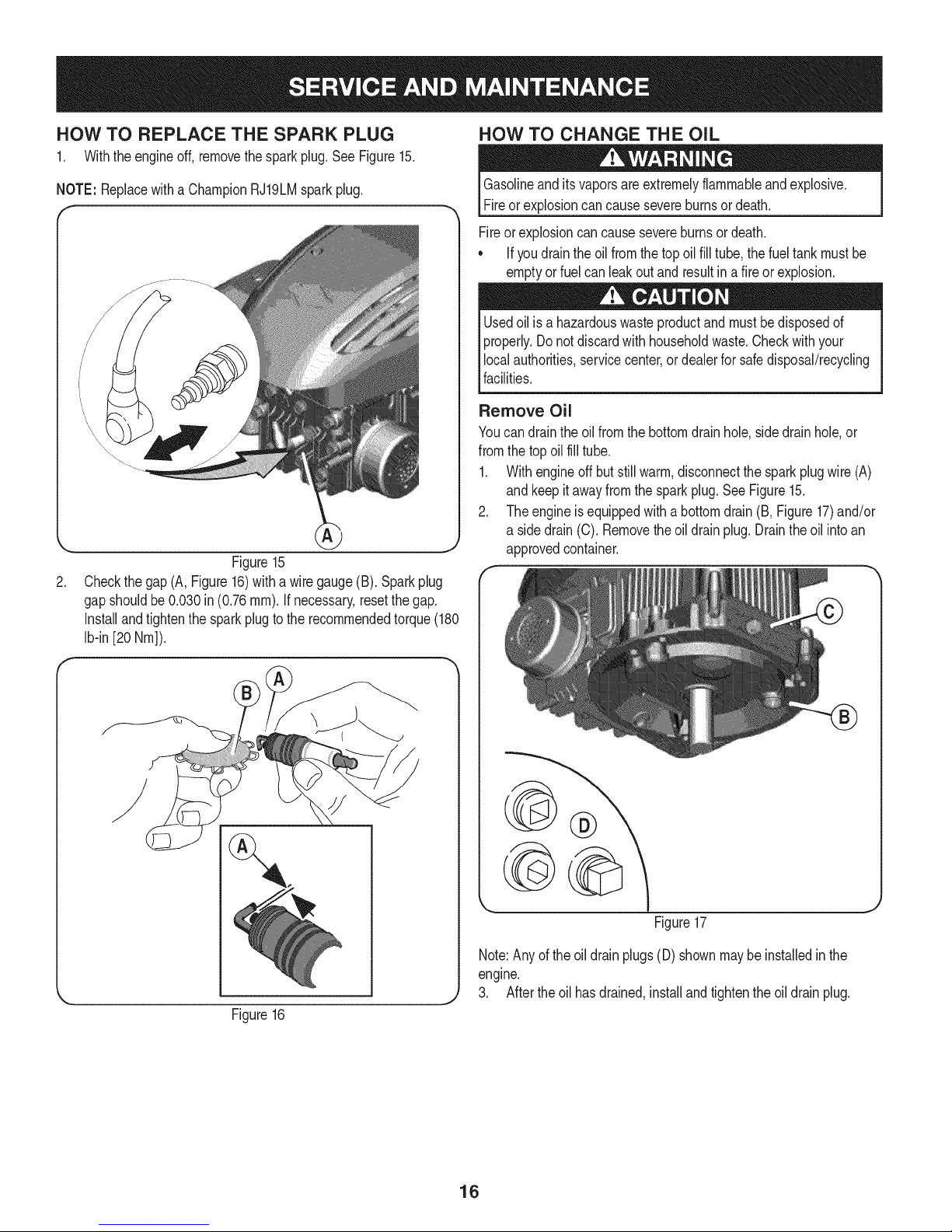

1. Withtheengineoff, removethesparkplug.See Figure15.

HOW TO CHANGE THE OILHOW TO REPLACE THE SPARK PLUG

NOTE:Replacewitha ChampionRJ19LMsparkplug.

Figure15

.

Checkthegap (A,Figure16)witha wiregauge(B).Sparkplug

gapshouldbe0.030in(0.76ram).If necessary,resetthegap.

Installandtightenthesparkplugtotherecommendedtorque(180

Ib-in[20 Nm]).

Gasolineandits vaporsareextremelyflammableandexplosive.

Fireorexplosioncancausesevereburnsor death.

Fireorexplosioncancausesevereburnsor death.

• Ifyoudraintheoil fromthe top oilfilltube,thefueltank mustbe

emptyor fuelcan leakoutand resultina fire orexplosion.

Usedoilis a hazardouswasteproductandmust bedisposedof

properly.Donot discardwithhouseholdwaste.Checkwithyour

localauthorities,servicecenter,ordealerforsafedisposal/recycling

facilities.

Remove Oil

Youcandraintheoilfromthebottomdrainhole,sidedrainhole,or

fromthetopoilfill tube.

1. Withengineoff butstillwarm,disconnectthesparkplugwire(A)

and keepitawayfromthe sparkplug.SeeFigure15.

2. Theengineisequippedwitha bottomdrain(B, Figure17)and/or

a side drain(C).Removetheoil drainplug.Draintheoilinto an

approvedcontainer.

f

Figure16

©

J

Figure17

Note:Anyoftheoildrainplugs(D) shownmaybe installedinthe

engine.

3. Afterthe oil hasdrained,installandtightenthe oildrainplug.

16

Page 17

.

If youdrainthe oilfromthetopoil fill tube (E), keepthespark

plugendof the engine(F) up. SeeFigure18.Draintheoil intoan

approvedcontainer.

f

Figure18

2. Pourtheoil slowlyintothe engineoil fill(H). Do notoverfill.After

addingoil,waitoneminuteandthenchecktheoil level.

3. Installandtightenthe dipstick.

4. Removethedipstickandcheckthe oillevel.It shouldbeat the

FULLmark(J)on the dipstick.

5. Installandtightenthe dipstick.

HOW TO SERVICE THE AIR FILTER

Gasolineanditsvaporsareextremelyflammableandexplosive.

Fireorexplosioncancausesevereburnsor death.

• Neverstartor runtheenginewiththeair cleanerassemblyor the

air filterremoved.

Donot use pressurizedair orsolventstocleanthefilter.Pressurized

air candamagethefilterandsolventswilldissolvethefilter.

1. Removethescrew(A)fromthetop of the airfilterassembly(B).

SeeFigure20.

Ifyoudraintheoil fromthetopoil filltube,thefueltankmustbe

emptyorfuelcanleakout andresultin a fireor explosion.To empty

thefuel tank, runtheengineuntilit stopsfromlackof fuel.

Add Oil

• Placeenginelevel.

• Cleantheoil fill areaofanydebris.

• SeetheSpecificationssectionforoil capacity.

1. Removethedipstick(G)andwipewitha cleancloth.See

Figure19.

f

Figure20

2. Topreventdebrisfromfallingintothe carburetor,carefullyremove

theair filterassembly.

3. Removethefoamelement(C) fromtheairfilterbase.

4. Washthefoamelementinliquiddetergentandwater.Squeeze

drythefoamelementin acleancloth.

5. Saturatethefoamelementwithcleanengineoil.Toremovethe

excessengineoil,squeezethefoamelementina cleancloth.

6. Installthefoamelementinto theair filterbase.

7. Installtheairfilterassemblyontothecarburetorand securewith

screw.

_k

Figure19

J

17

Page 18

Iftheedgerwill not beusedfor 30daysor longer,theequipmentneedstobe storedproperly.Followstorageinstructionsbelowto ensuretop

performancefromthe edgerformanymoreyears.

PREPARING THE ENGINE

Enginesstoredover30daysneedtobedrainedoffueltoprevent

deteriorationandgumfromforminginthe fuel systemor onessential

carburetorparts.If thegasolineinyourenginedeterioratesduring

storage,youmayneedto havethecarburetor,andotherfuelsystem

components,servicedor replaced.

1. Removeallfuelfromthetankby runningtheengineuntilit stops.

2. Changetheengineoil.

3. Removethe sparkplugandpourapproximately1oz.(30ml)of

cleanengineoil intothe cylinder.Pullthe recoilstarterseveral

timesto distributetheoil,and reinstallthesparkplug.

4. Cleandebrisfromaroundthe engine,andunder,around,and

behindthemuffler.Applya lightfilmofoilon anyareasthatare

susceptibletorust.

5. Storeina clean,dry andwellventilatedareaawayfromany

appliancethatoperateswitha flameor pilot light,suchasa

furnace,waterheateror clothesdryer.Avoidanyareawitha spark

producingelectricmotor,orwherepowertoolsareoperated.

6. if possible,avoidstorageareaswithhighhumidity.

7. Keeptheenginelevelin storage.Tiltingtheengine cancause

fuelor oil leakage.

PREPARING EDGER

iftheedgerwillnotbeusedfor30 daysor longer,followtheinstruc-

tionsbelow.

1. Storethe edgerina dry,cleanarea.Do not storenexttoany

corrosivematerials,suchaslawnfertilizer.

2. Coatthe edgerbladewithchassisgreasetopreventrustingand

corrosion.

3. Coatthe edger,especiallyanyspringsandbearingswitha light

oil or siliconespray.

4. Cleanthe exteriorof the engineandtheedger.

NOTE:Whenstoringanytypeofpowerequipmentinan poorly

ventilatedormetalstorageshed,careshouldbetakentorustproofthe

equipment.

18

Page 19

Beforeperforminganytypeofmaintenance/service,disengageallcontrolsandstoptheengine.Waituntilall

movingpartshavecometo acompletestop.Disconnectsparkplugwireandgrounditagainsttheengineto

Ipreventunintendedstarting.Alwayswearsafetyglassesduringoperationorwhileperforminganyadjustmentsor

[repairs.

Thissectionaddressesminorserviceissues.Tolocate the nearestSearsService Centeror to scheduleservice,simplycontactSears

at 1-800-4-MY-HOME®.

Enginefailsto start

Enginerunserratically

Engineoverheats

Excessivevibration

Drive-beltSlips

1. Dirtyaircleaner

2. Engineneedsto be primed

3. Fueltankempty

4. Stalefuel in gasolinetank

5. Sparkplugwiredisconnected.

6. Sparkplugfouled

1. Sparkplugwireloose

2. Stalefuel in gasolinetank

3. Ventin gascapplugged

4. Wateror dirtinfuelsystem

5. Dirtyaircleaner

6. Carburetoroutof adjustment

1. Engineoil levellow

2. Airflow restricted

3. Dirtyairfilter

4. Carburetoroutof adjustment

1. Edgerbladebentor damaged

2. Bladespindlebentor damaged

1. Beltwornor stretched

1. RefertotheServiceAnd MaintenanceSection.

2. Pushprimerbulbthreetimes.

3. Filltankwithclean,freshgasoline.

4. Draingasolineand refilltankwithclean,fresh

gasoline.

5. Connectthesparkplugwiretothesparkplug.

6. Clean,adjustgap or replacesparkplug.

1. Connectandtightensparkplugwire.

2. Draingasolineand refilltankwithclean,fresh

gasoline.

3. Clearventofanydebris.

4. Drainfueltank.Refillwithfreshfuel.

5. RefertotheServiceAnd MaintenanceSection.

6. Contacta Searsorotherqualifieddealer.

1. Fillcrankcasewithproperoil.

2. Cleanthe areaaroundthe engine'scoolingfins.

3. Replacetheengine'sair filter.

4. Contacta Searsorotherqualifieddealer.

1. Replaceedgerblade.

2. Contacta Searsorotherauthorizedservicedealer.

1. Replacedrivebelt.

NEED MORE HELP?

You'H f_nd the answer 4_nd mov'e or_ managemyBome corn - Io_ Iree

Find this and all your other product manuals online.

Get answers from our team of home experts.

Get a personalized maintenance plan for your home.

Find information and tools to help with home projects.

b_ou@/d: t:o ye_ by gears

19

Page 20

EdgedTrencher B Model No. 247.772460

14,

13

38

5

19

62

26"

2O

Page 21

Edger/Trencher -- Model No. 247.772460

I

Ref,

I Part No,

1 687-02022

2 687-02125A

3 687-02126

4 710-0191

5 710-0411

6 710-04389

7 710-0599

8 710-0654A

9 710-0726

10 710-0870

II 710-1143A

12 710-1174

13 710-1205

14 710-3180

15 711-04361

16 711-04440

17 712-04063

18 712-04065

19 712-0417A

20 714-3010

21 718-04012

22 720-0142

23 720-0279

24 720-04072A

25 726-0299

26 931-04207

27 731-05063

28 731-05064

29 732-0188A

30 932-0369

31 732-04045

32 932-04169

33 734-1264

Description

Curb Height Adjustment Lever

Curb Height Adjuster Plate

Blade Plate Assembly

Screw 3/8-24

Screw 3/8-16

Hex Screw, %o-18

Self-tapping Screw, I/4-20

Screw, 3/8-16

Hex Screw, %o-12

Hex Screw %o-18

Hex Screw, %-18

Carriage Bolt, %0-18

Rope Guide (Eye Bolt)

Hex Screw, %o-18

Axle Shaft .50x6.65

Frame Spacer .50x9.25

Lock Flange Nut, %0-I 8

Flange Nut %-16

Flange Nut,%-18

Clevis Pin 3/32x .625

Bearing Cup

Grip

Wing Nut

Star Knob

Push Cap 1/2"rod

Bearing Block

Debris Guard

Blade Guard

Double Torsion Spring

Compression Spring

Torsion Spring

Compression Spring

Wheel 7 x 1.75 T-Tread

|

Ref,

I Part No,

34 734-1268

35 936-0179

36 936-0232

37 736-0234

38 736-0258

39 936-04088

40 936-0452

41 738-04149

42 738-0706C

43 738-0929

44 941-0524

45 746-04035

46 946-04036

47 747-04110

48 747-0976A-0637

49 749-04183-0637

50 749-04234-0637

51 950-04105

52 750-04129

53 950-04142

54 750-0547

55 954-04032B

56 756-04148

57 956-0449

58 756-1150A

59 781-0427-0637

60 781-0741A

61 781-0742-0637

62 781-0748-0637

63 787-01081A-0721

64 787-01239-0721

65 787-01304-0721

Description

Wheel 8 x 1.75 T-Tread

Flat Washer 1/2x 1.25 x .10

Wave Washer .531 x .781 x .013

Flat Washer, .385 x 1.5 x .075

Flat Washer .385 x 1.0 x .135 ±

Flat Washer .635xl.24x.181

Bell Washer,.396 x 1.140

Shoulder Screw, 3/8-16

Shoulder Screw

Shoulder Screw, 3/8-16

Bearing, .625 ID x 1.57 OD

Control Cable (Briggs & Stratton)

Wheel Adjustment Cable

Blade Adjustment Rod

Bail Handle

Upper Handle

Lower Handle

Spacer, .63 x 1.12 x 1.06

Spacer

Pulley Mount Spacer

Spacer, .64 x.88 x .50

Belt

Flat Idler Pulley, 2.50D

Sheave

Combination Flywheel Pulley

Belt Guard

Depth Index Bracket

Depth Index Lever

Tri-Star Blade

Bracket Plate

Dual Wheel Bracket

Frame

21

Page 22

Briggs and Stratton lOL802=O713-F1

11

523

287

842 ,_ ,_

525

11

_z

89

524 <}_?

/

_ol

.........718

51

18'70II869II-b_

635

616

22

Page 23

Briggs and Stratton lOL802-O713-F1

358 ENGINE GASKET SET

51

20 163 _ =_z_'

524 *_)

4o_,

4o_;_

27

45_,X

z /5)

35

868

1095 VALVE GASKET SET

7 9

842 _ ,_

868 _

868 -_'_

24_

46

74

41

43

12

22

15_

23

Page 24

Briggs and Stratton lOL802=O713-F1

J

13941 _:_ . __.

,- __%::-....

393

163

612

390

97

633 _ _

724

0_

529

L3

222

300

729

635

745

745A _

334 @'

0

356 .... :__.

s_,__. ....._

_ 621

<',J ?,_ )

L( _229 _

534

535

163

24

Page 25

Briggs and Stratton lOL802=O713=F1

921

969

37A

[ 1036 EMISSIONS LABEL ]

3O4

55

1211

1210

/--- ....... -

459 L._ _

dr ..=

689 '_' _?)

456

78

37

455

332

597 _,#

73

23 r__ _ _i_{ 'Y'_":_

25

Page 26

Briggs and Stratton lOL802=O713=F1

m = 0 O

699650 CylinderAssembly

2 399269 Kit-Bushing/Seal(MagnetoSide)

3 299819s Seal-Oil(MagnetoSide)•

4 798264 Sump-Engine

5 790169 Head-Cylinder

7 698747 Gasket-CylinderHead,+

8 791781 BreatherAssembly

9 695890 Gasket-Breather

10 691666 Screw(BreatherAssembly

11 691245 Tube-Breather

12 692218 Gasket-Crankcase•

13 691640 Screw(CylinderHead)

15 691680 Plug-OilDrain

16 796217 Crankshaft

20 391483s Seal-Oil(PTOSide)

22 692551 Screw(CrankcaseCover/Sump)

23 795549 Flywheel

24 222698s Key-Flywheel

25 795691 PistonAssembly(Standard)

795689 PistonAssembly(.020"Oversize)

26 795690 RingSet(Standard)

795688 RingSet(.020"Oversize)

27 691588 Lock-PistonPin

28 699659 Pin-Piston

29 699654 Rod-Connecting

32 1691664 Screw(ConnectingRod)

33 296676 Valve-Exhaust

34 1296677 Valve-Intake

35 690520 Spring-Valve(Intake)

36 690520 Spring-Valve(Exhaust)

37 793478 Guard-Flywheel(MufflerSide)

37A 697403 Guard-Flywheel(CarburetorSide)

[40 _692194 Retainer-Valve

i43 697799 Slinger-Governor/Oil

i45 690762 Tappet-Valve

i46 691998 Camshaft

i48 793347 ShortBlock

i50 792388 Manifold-Intake

i 51 792389 Gasket-intake_+

54 691111 Screw(IntakeManifold)

692144 Housing-RewindStarter

58 697316 Rope-Starter

60 691915 Grip-StarterRope

65 690837 Screw(RewindStarter)

73 699850 Screen-Rotating

78 692198 Screw(FlywheelGuard)

89 692348 Plug(Cylinder)

90 795476 Carburetor

97 697414 Shaft-Throttle

106 690901 Seat-Inlet

130 794060 Valve-Throttle

163 271139s Gasket-AirCleaner

180 795473 Tank-Fuel

188 692198 Screw(ControlBracket)

190 691640 Screw(FuelTank)(13A"Long)

190A 691108 Screw(FuelTank)(9/16"Long)

202 698835 Link-MechanicalGovernor

209 698719 Spring-Governor(Light Blue)

222 698725 Bracket-Control

227 697402 Lever-GovernorControl

287 691002 Screw(DipstickTube)

300 394569s Muffler

304 697411 Housing-Blower

305 692198 Screw(BlowerHousing)

332 690662 Nut(Flywheel)

333 793281 Armature-Magneto

334 691061 Screw(MagnetoArmature)

337 802592s Plug-Spark

356 692390 Wire-Stop

358 794209 GasketSet-Engine

365 790029 Screw(Carburetor)

390 691839 Spring-ChokeDiaphragm

393 691837 Screen-Carburetor

394 795478 Diaphragm-Carburetor

404 690272 Washer(GovernorCrank)

455 691236 Cup-Flywheel

456 692299 Plate-PawlFriction

459 281505s PawI-Ratchet

505 691251 Nut(GovernorControlLever)

523 692040 Dipstick

26

Page 27

Briggs and Stratton lOL802=O713-F1

691876 Seal-DipstickTube

525 691320 Tube-Dipstick

529 692189 Grommet

534 691417 Screw(AirCleaner)

535 698369 Filter-AirCleanerFoam

536 698472 Cleaner-Air

562 691119 Bolt(GovernorControlLever)

592 690800 Nut(RewindStarter)

597 691696 Screw(PawlFrictionPlate)

608 499706 Starter-Rewind

612 .496046s JTube-P!ckUp

615 690340 Retainer-GovernorShaft

616 697405 Crank-Governor

617 270344s Seal-ORing(IntakeManifold)

621 692310 Switch-Stop(Brake)

633 691321 SeaI-Choke/ThrtleShft (ThrtleShft)

635 66538s Boot-SparkPlug

670 691633 Spacer-FuelTank

689 691855 Spring-Friction

718 690959 Pin-Locating

724 697478 Retainer-Seal

729 690586 Clip-Wire

741 796210 Gear-Timing

745 691146 Screw(Brake)(7/8"Long)

745A 690859 Screw(Brake)(1/2" Long)

842 691870 Seal-ORing(DipstickTube)

847 691440 Dipstick/TubeAssembly

851 493880s Terminal-SparkPlug

868 697338 Seal-Valveo+

869 699641 Seat-Valve(Intake)

870 699642 Seat-Valve(Exhaust)

871 699643 Bushing-ValveGuide(ExhaustValve)

63709 Bushing-ValveGuide(IntakeValve)

913 494409 Seat-CheckValve

1058 277038

1095 498526

1210 499901

1211 499901

1218 695866

1329 10L802-OO15-F1

1330 270962

o

+

Includedin EngineGasketSet,Key.No.358

Includedin ValveGasketSet,Key.No.1095

D= I O O

EmissionsLabel

Operator'sManual

GasketSet-Valve

Pulley/SpringAssembly(Pulley)

Pulley/SpringAssembly(Spring)

Seal-ORing(Carburetor)

ReplacementEngine

RepairManual

921 L795397 LCover-B!owerHous!ng

922 692135 Spring-Brake

923 691487 Brake

957 795472 Cap-Fuel

969 694046 Screw(BlowerHousingCover)

976 694394 Primer-Carburetor

27

Page 28

Congratulationson makingasmartpurchase.YournewCraftsman@

productisdesignedandmanufacturedfor yearsof dependableopera-

tion.Butlikeall products,itmayrequirerepairfromtimetotime.That's

whenhavinga RepairProtectionAgreementcansaveyoumoneyand

aggravation.

Here'swhatthe RepairProtectionAgreement*includes:

* Expert service byour 10,000professionalrepairspecialists

o Unlimitedserviceand no chargefor partsand laboron all

coveredrepairs

o Product replacementupto$1500if yourcoveredproductcan'tbe

fixed

• Discountof 10%from regularpriceofserviceandrelatedinstalled

partsnotcoveredbytheagreement;also,10%off regularpriceof

preventivemaintenancecheck

• Fasthelp byphone- wecallitRapidResolution- phonesupport

froma Searsrepresentative.Thinkof usasa "talkingowner's

manual."

OnceyoupurchasetheAgreement,asimplephonecallisall thatit

takesfor youto scheduleservice.Youcancallanytimedayor night,or

schedulea serviceappointmentonline.

TheRepairProtectionAgreementisa risk-freepurchase.Ifyoucancel

foranyreasonduringtheproductwarrantyperiod,wewillprovideafull

refund.Or,a proratedrefundanytimeafterthe productwarrantyperiod

expires.Purchaseyour RepairProtectionAgreementtoday!

Somelimitationsandexclusionsapply. Forpricesand additional

informationin the U.S.A.call 1-800-827-6655.

*CoverageinCanadavaries on someitems.Forfull details call

SearsCanadaat 1-800-361-6665.

SearsInstallation Service

ForSearsprofessionalinstallationofhomeappliances,garagedoor

openers,waterheaters,andothermajorhomeitems,in theU.S.A.or

Canadacall1-800-4-MY-HOME®.

28

Page 29

29

Page 30

30

Page 31

31

Page 32

Declaracion de garantia .................................................. 32

Medidas importantes de seguridad ................................ 33

Montaje ........................................................................... 38

Funcionamiento ............................................................... 41

Servicio y Mantenimiento ................................................ 44

Almacenamiento fuera de temporada ............................ 48

Solucion de problemas ................................................... 49

NL_merode servicio ............................................... Cubierta

posterior

GARANTiA LLENA CRAFTSMAN

SiesteCraftsmanproductofalladebidoa undefectoenmaterialo habilidaddentrodedosaSosdelafechaocompra,vu_lvaloa cualquier

Sears,iasPartes& Centrode reparacionesde Reparaci6n,uotrasalidade Craftsmanen EstadosUnidoshacerlosarregiosparareparaci6n

libre(oel reemplazosi reparaci6ndemuestraimposible).

Estagaranfias61otendr_,validezdurante90diassiesteproductoseutilizaen cualquiermomentoparafinescomercialeso dealquiler.

Esta garantia cubreSOLOdefectos enmaterialyhabilidad.Searsno pagar_para:

• Losarficuiosprescindiblesquesehaceniievadospuestosduranteeiusonormal,inciuso,perono iimitadosparabujia,fiitros,cinturones,y

filtro.

• Reparacionesnecesariasdebidoanegligenciadeloperador,incluyendoentreotros,da_osmecanicoyeBctricoocasionadoporunalmace-

namientonoapropiadoo pornodarmantenimientoal equipodeacuerdoconlas instruccionescontenidasenel manualdeloperador.

• Mantenimientopreventivo,iimpiezao reparacionesai motor(sistemadecombustible)provocadaspor uncombustiblecontaminadou

oxidado.

Estagaranfialeotorgaderechoslegalesespecificos,peroustedpodriagozarde otrosderechosen raz6nde su lugarde residencia.

Sears, Roebuck and Co.,Hoffman Estates, IL 60179

N_mero de modelo.........................................................

Combustible GasolinasinPlomo

Bujiadeencendido TorchF6RTC

Motor BriggsandStratton10T802-0711-B1

N_rnero de serie ............................................................

Fecha de cornpra.........................................................................

RegistreelnQmerodemodelo,nQmerode serie

y fechade compram_sarriba

©SearsBrands,LLC 32

Page 33

Lapresenciade estesirnboloindicaquesetratade instrucciones

irnportantesde seguridadque sedebenrespetarparaevitar

ponerenpeligrosu seguridadpersonaly/omaterialy la deotras

personas.Leay sigatodaslas instruccionesde estemanualantes

de poneren funcionarnientoestarn_.quina.Sino respetaestas

instruccionespodriaprovocarlesionespersonales.Cuandoveaeste

sirnbolo,ipresteatenci6na laadvertencia!

Estarn_.quinarueconstruidaparaseroperadadeacuerdocon

lasreglasdeseguridadcontenidasenestemanual.AI igualque

concualquiertipode equipornotorizado,undescuidoo errorpor

partedeloperadorpuedeproducirlesionesgraves.Estarn_.quina

escapazde arnputarrnanosy piesy dearrojarobjetoscon gran

fuerza.De norespetarlasinstruccionesde seguridadsiguientesse

puedenproducirlesionesgravesolarnuerte.

PROPOSICION 65 DE CALIFORNIA

Elescapedel motordeesteproducto,algunosde suscornponentes

y algunoscornponentesdelvehiculocontieneno liberansustancias

quirnicasqueelestadodeCaliforniaconsideraque puedenproducir

cancer,defectosdenacirnientouotrosproblernasreproductivos.

CAPACITACION

• Leaconatenci6ntodaslas instruccionescontenidasen esteman-

ualantesde intentarensarnblaresta rn_.quina.Lea,cornprenday

respetetodaslasinstruccionesquefiguranenla rn_.quinayen el

o los rnanualesantesde hacerlafuncionar.Guardeestemanual

enun lugarseguroparaconsultasfuturasy peri6dicas,asi corno

parasolicitarrepuestos.

• Antesdeoperaresteequipo,farniliaricesetotalrnenteconlos

controlesyel usocorrectodelrnisrno.

• Estarn_.quinaes unaunidaddeequipornotorizadode precisi6n,

nounjuguete.PotIo tanto,tengarnuchocuidadoentodo

rnornento.Estarn_.quinaruedise_adapararealizarunatarea:

bordearelc_sped.NolautiliceparaningOnotrofin.

• No perrnitanuncaquelosni_osrnenoresde 14a_osutilicen

estarn_.quina.Losni_osde 14a_osen adelantedebenleery

entenderlasinstruccionesde operaci6ny norrnasdeseguridad

contenidaseneste manual,yen larn_.quinay debenser

entrenadosy supervisadospor unadulto.

• S61ose debeperrnitirusarestarn_.quinaa individuosrespons-

ablesy farniliarizadosconsusreglasdeseguridad.

• Paraayudaraevitarel contactoconlacuchillao unalesi6npor

unobjetoarrojado,rnant_ngaseen lazonadeloperadordetr_.s

delasrnanijasy rnantengaa losni_os,observadores,ayudantes

yrnascotasapartadosal rnenos25 metrosde labordeadora

decespedrnientrasest,.en operaci6n.Detengala rn_.quinasi

alguienentraen lazona.

Su responsabilidad--Restrinja el usode estarn_.quina

rnotorizadaalas personasquelean,cornprendany respetenlas

advertenciase instruccionesque aparecenen estemanualyen la

rn_.quina.

iGUARDEESTASINSTRUCCIONES!

PR E PARATIVO S

• Inspeccionerninuciosarnenteel_.readondeutilizar_,el equipo.

Retiretodaslaspiedras,palos,Ilantas,huesos,juguetesy

otrosobjetosextraSosquepodrianhacertropezary caero ser

recogidosyarrojadosporla acci6nde lascuchillas.Losobjetos

arrojadosporla rn_.quinapuedenproducirlesionesgraves.

• Paraprotegerselosojosutilicesiernpreanteojosoantiparras

de seguridadrnientrasoperala rn_.quinao rnientrasla ajusta

o repara.Losobjetosarrojadosquerebotanpuedenproducir

lesionesocularesgraves.

• Utilicezapatosdetrabajoresistentes,desuelafuerte,asicorno

pantalonesycarnisasajustados.Se recorniendavestircarnisay

pantal6nparacubrirbrazosy piernasy usarzapatosconpuntera

de acero.Nuncaopereesta rn_.quinadescalzo,consandalias,

zapatosresbalososo livianos(porej.deIona).

• Nuncaintenterealizarajustesrnientrasel motorest,.enrnarcha

exceptoenloscasosespecificarnenterecornendadosen el

manualdeloperador.

Manejoseguro de lagasolina

ParaevitarlesionespersonalesodaSosrnaterialesseasurnarnente

cuidadosoal rnanipularlagasolina.Lagasolinaes surnarnente

inflarnabley susvaporespuedencausarexplosiones.Sisederrarna

gasolinaencirnao sobrela ropasepuedelesionargravernenteya que

sepuedeincendiar.L_.veselapiely c_.rnbiesede ropade inrnediato.

• Utilices61orecipientesparagasolinaautorizados.

• NuncaIlenelos recipientesen el interiorde unvehiculoo carni6n

o caja de rernolqueconrecubrirnientopl_.stico.Coloquesiernpre

losrecipientesenel pisoy lejosdelvehiculoantesde realizarla

carga.

• Retireelequipoa gasolinadel carni6no rernolquey II_neloen

el piso.Siestono esposible,Ileneelequipoenun rernolque

conuncontenedorport_.til,envezde hacerloconunaboquilla

dispensadorade gasolina.

33

Page 34

• Mantengalaboquillade Ilenadoencontactoconelhordedel

dep6sitode combustibleo conla aberturadel recipienteentodo

rnornento,hastaterrninarlacarga.Noutiliceundispositivode

boquilladeapertura/cierre.

• Apaguetodoslos cigarrillos,cigarros,pipasyotrasfuentesde

cornbusti6n.

• Nuncacarguecombustibleen larn_.quinaen interioresporquelos

vaporesinfiarnablespodrianacurnularseenel _.rea.

• Nuncasaquela tapade lagasolinaniagreguecombustible

rnientrasel motorest,.calienteo en rnarcha. Dejequeel motor

seenfrieporIornenosdosrninutosantesdevolvera cargar

combustible.

• NuncaIleneenexcesoel dep6sitodecombustible.Lleneel

tanqueano rn_.sde1/2pulgadapot debajode la basedelcuello

deltap6nde carga,paraperrnitirlaexpansi6ndelcombustible.

• Vuelvaa colocarlatapadelagasolinayajQstelabien.

• Lirnpieelcombustiblequesehayaderrarnadosobreel motoryel

equip&Trasladela rn_.quinaa otra zona.Espere5rninutosantes

deencenderelmotor.

• Nuncaalrnacenela rn_.quinao el recipientedecombustible

cercade llamaexpuesta,chispasoaparatosconpilotocornopor

ejernplo,calentadoresdeagua,calefactores,hornos,secadores

de ropau otrosaparatosa gas.

• Parareducirelriesgodeincendiornantengala bordeadorade

cespedlirnpiade pasto,hojasy de laacurnulaci6nde otros

desechos.Lirnpielosderrarnesdeaceiteo combustibleysaque

todoslosresiduosernbebidosdecombustible.

• Dejequela bordeadorade c_spedse enfriecinco(5) rninutospor

Iornenosantesdealrnacenarla.

FUNCIONAIVIIENTO

• Nocoloquelasrnanosnilospiescercade laspiezasgiratorias.

Elcontactoconlacuchillagiratoriapuedeproducirlaarnputaci6n

de rnanosy pies.

• El mecanisrnodecontrolde la cuchillaesundispositivode

seguridad.Nuncaevitesufuncionarniento.Si Io hace,la rn_.quina

setornapeligrosaypuedecausarlesionespersonales.

• Nuncahagafuncionarla bordeadorasinusarelprotectordela

cuchilla,elescudocontraescornbrosy larnanijadecontrolde la

cuchillaenel lugarcorrespondienteyen funcionarniento.

• Nuncaoperelabordeadorasilosdispositivosdeseguridadest_.n

daSados.Si noIohace,puedenproducirselesionespersonales.

• Nuncaenciendael motorenespacioscerradosoenunazona

conpocaventilaci6n.Elescapedel motorcontienernon6xidode

carbono,un gasinodoroy letal.

• No utilicela rn_.quinabajola influenciadelalcoholo lasdrogas.

• El silenciadory elmotorse calientany puedencausarquernadu-

ras.Nolostoque.

• Nuncaopereestarn_.quinasinbuenavisibilidado ilurninaci6n.

Siernpredebeestarsegurodequeest,.bienafirrnadoy su-

jetandofirrnernentelas rnanijas.Carnine,nuncacorra.

• Noopereestarn_.quinasi se ha caidoo est,.daSada.Regrese

la rn_.quinaal serviciot_cnicodesudistfibuidorautorizadorn_.s

cercanoparaquela examiney larepare.

• No hagafuncionarlarn_.quinasi lacuchillade corteest,.daSada

oexcesivarnentedesgastada.

• Nuncaintentesacarmaterialdelprotectorde la cuchillasi el

motorest,.en funcionarniento.Apagueel motor,desconecteel

cabledela bujiayp6ngalode rnaneraquehagarnasacontrael

motorparaevitarqueseenciendaaccidentalrnente.

• Nosobrecarguelacapacidaddela rn_.quinatratandode bordear

a unavelocidaddernasiador_.pida.

• Mant_ngasealertaparaadvertirla existenciade aceraso terreno

desparejos,etc. Siernpreernpujelentarnentesobrelassuperficies

_.speras.Noutiliceestarn_.quinasobrepedregullo.

• Nooperelarn_.quinabajola Iluviao encondicionesdesuelo

hQrnedo.

• Siernprehagafuncionarlarn_.quinadesdedetr_.sdelasrnanijas

y col6quesede rnodoquelalineadevistadirectahaciala

cuchillade cortequedebloqueadaporlosprotectores.

• Siernpredetengael motorcuandoel bordeadoorecortesevean

dernoradoso cuandoest_trasladandolarn_.quinade unlugara

otto.

• Nuncadejelarn_.quinaenfuncionarnientosinvigilancia.Detenga

el motor,desconecteel cabledela bujiayp6ngalode rnanera

que hagarnasacontrael motorparaevitarqueseencienda

accidentalrnente.

• Utilicesolarnentepiezasyaccesoriosrnanufacturadosparaesta

rn_.quinaporel fabricante.Si noIohace,puedenproducirse

lesionespersonales.

• Si sepresentansituacionesquenoest_.nprevistaseneste

manual,seacuidadosoy useel sentidocornQn.P6ngaseen

contactoconAsistenciaal Clienteparasolicitarayudao el

nornbredel distribuidordeserviciorn_.scercanoa sudornicilio.

NINOS

Puedenocurriraccidentestr_.gicossi el operadornoest,.atentoa

la presenciadeni_os.PorIogeneral,losni_ossesientenatraidos

por equiposrnotofizadostalescornolasbordeadorasde c_sped.No

entiendenlosriesgosni lospeligros.Nuncaasurnaquelosni_os

perrnanecer_.nenel rnisrnolugardondelosvio porQltirnavez.

• Mantengaa losni_osfueradel_.reade bordeadoy bajoestricta

vigilanciadeun adultoresponsableadern_.sdeloperador.

• Est_alertayapaguelabordeadoradecespedsi unni_oingresa

al _.rea.

• Antesde rnoversehaciaatr_.sy rnientrasIoest_haciendo,mire

haciaatr_.sycuideque nohayani_os.

• Tengaextrernaprecauci6ncuandose aproxirnea esquinas

ciegas,entradasdepuertas,arbustos,_.rbolesu otrosobjetos

que puedanobstaculizaflela vistade unni_oquepudiese

toparseconla bordeadorade c_sped.

• Mantengaa losni_osalejadosde los rnotoresen rnarchao

calientes.Puedensufrirquernadurasconunsilenciadorcaliente.

• Noperrnitanuncaquelos ni_osrnenoresde14a_osutilicen

estarn_.quina.Losni_osde 14a_osenadelantedebenleery

entenderlasinstruccionesdeoperaci6nynorrnasdeseguridad

contenidasenestemanualyen larn_.quinay debenserentrena-

dosy supervisadosporunadulto.

34

Page 35

MANTENIMIENTO Y ALMACENAMIENTO

• Nuncaenciendael motorenespacioscerradosoen unazona

conpocaventilacidn.Elescapedelmotorcontienernondxidode

carbono,un gas inodoroy letal.

• Antesde lirnpiar,repararo inspeccionarla rn_.quina,cornpruebe

quela cuchillaytodaslaspartesrn6vilessehayandetenido.

Desconecteel cabledela bujiayp6ngalohaciendornasacontra

el motorparaevitarqueseenciendaaccidentalrnente.

Reviselospernosdernontajedelacuchillay del motora

intervalosfrecuentesparaverificarqueest_nbienapretados.

Inspeccioneadern_.svisualrnentelacuchillaen buscadeda_os

(abolladuras,desgaste,roturas,etc).Reernplacela cuchilla

Onicarnenteconequipooriginaldelfabricante(OEM)listadoen

estemanual."El usode piezasquenocurnplenconlasespe-

cificacionesdelequipooriginalpodriatenercornoresultadoun

rendirnientoincorrectoyadern_.sponeren riesgola seguridad".

Lascuchillasdelas bordeadorasdec_spedsonrnuyafiladasy

puedenproducircortaduras.Envuelvalacuchillao utiliceguantes

yextremelasprecaucionescuandoefectOernantenirniento.

Mantengatodoslospernos,tuercasy tornillosbienajustados

paraasegurarsede quela rn_.quinaseencuentraencondiciones

segurasde operaci6n.

Nuncaalterelos dispositivosde seguridad.Controleperiddica-

rnentequefuncionencorrectarnente.

Despu_sdegolpearcon algQnobjetoextra_o,detengael motor,

desconecteelcablede la bujfay conecteel motora rnasa.

Inspeccionerninuciosarnentela bordeadoradecespedparaver

siest,.da_ada.Repareel da_oantesde arrancaryoperarla

bordeadora.

Nuncaintenteajustarunaruedarnientrasel motorest,.en

rnarcha.

Muchoscornponentesde la nuevabordeadorasedesgastanen

raz6ndelusocontinuo.Paraprotegersuseguridad,verifique

frecuenternentetodosloscornponentesdela bordeadoray

reernpl_.celosinrnediatarnentes61oconpiezasde los fabricantes

deequiposoriginales(O.E.M.)listadasen estemanual."Eluso

depiezasque nocurnplenconlasespecificacionesdel equipo

originalpodriatenetcornoresultadounrendirnientoincorrectoy

adern_.sponeren riesgola seguridad".

Nocarnbielaconfiguracidndel reguladordelmotorni acelere

dernasiadoelrnisrno.Elreguladordelmotorcontrolala velocidad

rn_.xirnaseguradefuncionarnientodelmotor.

Mantengao reernplacelasetiquetasde seguridade instrucciones

segQnseanecesario.

Respetelasleyesy regulacionesdeelirninaci6ncorrespondientes

paradesecharlagasolina,el aceite,etc.,usados.La elirninaci6n

inapropiadade liquidoso rnaterialespuededa_arelmedic

arnbiente.

NO MODIFIQUE EL MOTOR

Paraevitarlesionesgraveso larnuerte,nornodifiqueelmotorbajo

ningunacircunstancia.Si carnbiala configuraci6ndel reguladorel

motorpuededescontrolarsey operara velocidadesinseguras.Nunca

carnbielaconfiguracidndef_.bricadel reguladordel motor.

AVISO REFERIDO A EMISIONES

Losrnotoresqueest&ncertificadosycurnplenconlasregulaciones

de ernisionesfederalesEPAy de CaliforniaparaSORE(Equipos

peque_ostodoterreno)est_.ncertificadosparaoperarcongasolina

cornQnsinplornoy puedenincluirlossiguientessisternasde control

de ernisiones:Modificaci6ndemotor(EM)ycatalizadordetresvias

(TWO)si est_.nequipadosde esa rnanera.

AMORTIGUADOR DE CHISPAS

Estarn&quinaest&equipadaconunmotorde cornbusti6ninternay

nodebeser utilizadaeno cercade unterrenoagrestecubiertopor

bosque,rnalezaso hierbaexceptosiel sisternade escapedelmotor

est,.equipadoconunarnortiguadordechispasquecurnplaconlas

leyeslocaleso estatalescorrespondientes,encasode haberlas.

Siseutilizaun arnortiguadordechispasel operadorIodebernantener

en condicionesde usoadecuadas.Enel Estadode Californialas

rnedidasanteriorrnenternencionadassonexigidasporley (Arficulo

4442del C6digode RecursosPOblicosdeCalifornia).Esposible

queexistanleyessirnilaresenotrosestados.Lasleyesfederalesse

aplicanenterritoriosfedexrales.

Puedeconseguirelarnortiguadordechispasparael silenciadora

travesde sudistribuidorautorizadode rnotoreso poni_ndoseen

contactoconeldepartarnentodeservicios.

35

Page 36

SilVIBOLOS DE SEGURIDAD

Estap_ginarepresentay describelaseguridadlossimbolosquepuedenpareceren esteproducto.Lea,comprenda,y sigatodasinstrucciones

en iamfiquina antes procurar para reunir y operar.

LEA EL MANUAL(S) DEL OPERADOR

Lea, comprenda, y siga todas instrucciones en el manual (manuales) antes procurar para

1

reunir y operar

ADVERTENCIA-- CUCHILLAS ROTATIVAS

Mantegna manos y pies lejos de girar hoja.

• ®

ESPECTADORES

Mantenga a espectadores, los animales favoritos, y los ni_os por Io menos 75 pies de la

m_iquina mientras est,1 en la operaci6n. Pare m_iquina si cualquiera entra el _irea.

ADVERTENCIA-- SUPERFICIESCALIENTES

No toque el silenciador o zonas adyacentes.

PROTECCION DE OJO

Siempre Ileve gafas de seguridad o gafas de seguridad al operar esta m_iquina.

36

Page 37

Estapgtginasemarch6intencionadamenteenblanco.

37

Page 38

NOTA:Estaunidadse entregaSIN GASOLINAniACEITE.Despuesdearmar

la unidad,realicelacargade gasolinadelmotorsegQnlasinstrucciones.

NOTA:Lasreferenciasal ladoderechooizquierdodelabordeadorase

observandesdelaposici6ndeloperador.

MONTAJE

Barra

Retireydesechecualquiercart6ndeempaquequepudierehaber

entrela barrasuperiory la barrainferior.

1. Pivotela barrasuperiorhaciearribahastaquecalceensu lugar.

V6aselaFigura1.

Cuerda de Arranque

1. Ubiquelaguia dela cuerdadelladoderechodelabarrasuperior.

Afioje,peroNOretire,la perilladealetasqueaseguralaguiade

la cuerdaa labarrasuperior.V6aselaFigura2.

Figura1

.

Aprietelasperillasdemano,ubicadasa derechae izquierdade

la barra.

Figura2

2. P_.resedetr_.sdela unidady sostengael controlde lacuchilla

contrala barrasuperior.

3. Jalesuavementedela cuerdadearranquefueradel motor.

!ue.

NOTA:Lacuerdadearranquenoseseparadelmotoramenosqueelcontrol

delacuchilla(consultelaFigura2)estepresionadocontralabarrasuperior.

4. Deslicelacuerdadearranquea travesdela partesuperiorde

la guiade lacuerda.Vuelvaaajustarla perillade aletasque

aseguralaguiaa labarrasuperior.

38

Page 39

AJUSTE

CONFIGURACI6N

Ajuste Bisel

El_.ngulodela cuchilladela bordeadorasepuedeajustarcolocando

el ajustedelbiseladoenunadetresposicionesderecorte.Veala

Figura3.

f --.,

...... ;.................., /

......... 7<

/7

J

Figura3

Gasolina y Aceite llene

Nuncacargueeltanquedecombustibleenespacioscerradosconel [

motorenrnarchaohastaquehayadejadoqueel rnisrnoseenfrfepor[

[ o rnenosdosrnnutosdespu_sdehaberestadoen rnarcha. 1

C6mo verificar/Afiadir aceite

Antesdeaprovisionarcon aceiteo decornprobarelnivelde aceite

• Coloqueel motora nivel.

• Lirnpieel_.reade Ilenadodeaceitedetododesecho.

1. RernuevalavariNaindicadoradenivelde aceite(A)y Ifrnpielacon

untrapolirnpio(Figura4).

39

Figura4

,

InserteyaprietelavariNaindicadoradenivelde aceite.

3.

Rernuevalavarillaindicadoradenivelde aceiteycornpruebeel

niveldeaceite.ElaceitedebealcanzarlarnarcaFULL(B)en la

varillaindicadoradenivelde aceite.

Siel niveldeaceiteesbajo,aSadaaceitelentarnentepordentro

del tubode Nenadodeaceite(C). NoNeneexcesivarnente.

Despu_sde aprovisionarconaceite,espereunrninutoydespu_s

vuelvaa cornprobarel niveldeaceite.

Coloquey aprietelavarillaindicadoradeniveldeaceite.

Page 40

RECOMENDACIONESPARA EL COMBUSTIBLE C6MO AGREGAR COMBUSTIBLE

Elcombustibledebecurnplirconestos requerirnientos:

• Gasolinalirnpia,frescaylibrede plorno.

• Un rnfnirnode87 octanos/87AKI(91RON).Parausoa alta

altitudveaacontinuaci6n.

• El usodegasolinahastacon el 10%deethanol(gasohol)ohasta

el 15%de MTBE(methyltertiarybutylether),esaceptable.

NousegasolinaquenohayasidoaprobadatalcornoE85.No

rnezcleel aceitecon la gasolina,nirnodifiqueelmotorparaoperarlo I

concombustiblesalternos.Estoda_ar_,los cornponentesdelmotoreI

[nva dar_.a garanfiade motor. 1

Paraprotegerelsisternadecombustibledelaforrnaci6ndedep6sitos

degorna,rn_zcleleunestabiNzadordecombustiblecuandole a_ada

combustible.Consulteelaparte:Bodegaje.Todosloscombustibles

no sonlosrnisrnos.Sisepresentanproblernasdearranqueo de

rendirnientocarnbiede proveedorde combustibleo de rnarca.Este

motorest,.certificadoparaoperarcongasolina.Elsisternadecontrol

deernisionesparaestemotoresEM(ModificacionesdelMotor).

Alta Altitud

Paraaltitudessuperioresa 5.000pies(1.524metros),esaceptable

el usode gasoNnaconun rnfnirnode85 octanos/85AKI(89RON).

Paracurnplirconlasernisiones,serequierehacerun ajustepara

altaaltitud.Si laoperaci6nse realizarsinhaberhecho_steajustese

causar_,unadisrninuci6nenel rendirniento,unaurnentodelconsurno

decombustibley unaurnentoen lasernisiones.Consulteconun

distribuidorautorizadode Briggs& Strattonparaobtenerinforrnaci6n

relacionadaconel ajusteparaaltaaltitud.No se recorniendaoperar

el motora altitudesinferioresa 2.500pies (762metros)conel kit para

altaaltitud.

Lagasolinay susvaporessonextrernadarnenteinfiarnablesy

explosivos.

Unincendioounaexplosi6npuedencausargravesquernaduraso la

rnuerte.

Cuando Aprovisione con Combustible

• Apagueel motorydejequeel motorseenfrfeporIornenos2

rninutosantesde removerlatapadecombustible.

• Lleneeltanquede combustibleen exterioreso en un_.reabien

ventilada.

• NoIlenedernasiadoeltanquedecombustible.Lleneeltanque

hastaaproximadarnente1,5pulgadas(38rnrn)pordebajode la

partesuperiordelcueNoparaperrnitirlaexpansi6ndelcombus-

tible.

• MantengalagasoNnay susvaporesa distanciade chispas,

Narnasabiertas,testigospiloto,calor,o decualquierotrafuente

de encendido.

• Cornpruebeconfrecuenciasiexistengrietaso fugasen las

rnanguerasdecombustible,el tanque,latapayen losacceso-

rios.C_.rnbielossi es necesario.

• Si sederrarn6combustible,esperehastaquese hayaevaporado

antesdedarlearranqueal motor.

1. Lirnpieel _.reade la tapadecombustiblede polvoydesechos.

Retirelatapadecombustible(A).(Figura5).

Figura5

2. Lleneeltanquede combustible(B)congasolina.A finde perrnitir

la expansi6ndelagasolina,noNeneporencirnadelrondodel

cuellodel tanquedecombustible(C).

3. Relinstalelatapa de combustible.

4O

Page 41

Cuerdade

arranque/

Arrancadorde

retroceso

Palancade controlde

lascuchillas

Palancade controldela

cuchilla

Cebador

Palancadeajuste

de alturadelbordillo

Figura4

Edgercontrolaylascaracteristicassondescritasabajoe ilustradosen

Figura4.

Familiaricesecontodosloscontrolesyconel usoadecuadodelos

mismos.Sepac6modetenerla m_.quinay desactivarloscontroles

r_.pidamente.

CUERDA DE ARRANQUE/ARRANCADOR DE

RETROCESO

Lacuerdadearranque/arrancadorde retrocesoseusaparaarrancar

el motor.

CEBADOR

Eicebadordeusa,parabombeargasoiinaalcarburadory ayudara

arrancarelmotor.Useloparaarrancarunmotorfrio,peronoIo use

paravolveraarrancarunmotorcalienteluegodeapagarseporcorto

tiempo.

PALANCA DE AJUSTE DE ALTURA DEL

BORDILLO

La palancadeajustede alturadelbordillose encuentraenlaparte

posteriorde la bordeadora.Cuandoselacolocaenla muesca

indicada,ayudaa estabilizarlabordeadoramientrasrecortapastoa Io

largodeun bordillo.

PALANCA DE CONTROL DE LAS CUCHILLAS

Elcontrolde lacuchilla,ubicadoen labarradecontrolsuperior,se

debepresionarcontralabarrasuperiorparapoderoperarla unidad

AIsoltarel controlde lacuchillasedetieneel motory la cuchillade la

bordeadora.

PALANCA DE CONTROL DE LA CUCHILLA

Lapalancadecontroldeprofundidadde lacuchillaseencuentradel

ladoderechodela barrasuperior.Seusaparacontrolarlaprofundidad

del corte.Cuantom_.shaciaadelantesemuevala palancadecontrol

de profundidaddela cuchilla,m_.sprofundoser_.el cortede lacuchilla

de la bordeadora.

PALANCA DE AJUSTE DEL BISELADO

Lapalancadeajustedelbiseladoseencuentraen elfrenteizquierdo

de la bordeadora,detr_.sdela cuchilladelabordeadora.Se usapara

variarel _.ngulode lacuchillade labordeadoraentretresposiciones

pararecorte/zanjadoo recortebiselado.

41

Page 42

ENCENDIDO DEL MOTOR

NOTA:Consulteel manualdelmotorentregadoconsubordeadora

paraobtenerunadescripci6ndetalladadetodoslos controlesy

cornponentesrelacionadoscon el motor.Paraencenderel motorde la

bordeadora,procedade lasiguienteforrna:

1. Conecteelcablede labujfaa larnisrna.AsegQresede queel

capuch6nrnet_.licosobreel extrernodelcable dela bujiade

encendidoest,. biensujetosobrelapuntarnet_.licade la bujia.

2. Muevala palancadecontrolde profundidaddela cuchillapara

atr_.sa la posici6nINICIOde larnuescaadyacente(superior).

3. Presionelabornbilladelcebadortresveces,haciendounapausa

dedosa tressegundosentrecadapresi6n.Cuandohacefrio

(debajode50°F/19°C),puedesernecesariopresionarel bulbodel

cebadorcuatroocincoveces.

NOTA:Generalrnentenohacefaltausarel cebadorparavolvera

arrancarunmotorcaliente.Hacerlopuedeprovocarqueel motorse

ahogue.

4. Paradodetr_.sdelaunidad,presionelapalancadecontrolde

lacuchillay sost_ngalocontralabarrasuperiorconlarnano

izquierda.

Esternecanisrnode controlesundispositivode seguridad.Nunca

intenteevitarsufuncionarniento.

BORDEADO

Lacuchilladecortegiratoriapuedelanzarobjetosycausarlesiones

personales.Mantengael _.realibredeobservadoresynooperesin

tenettodoslos protectores.

Nobajelacuchillasi lacuchillaseencuentrasobreconcreto,asfalto,

rocaso similar.Lacuchillapuedegolpearcontralasuperficiede

apoyoy provocarlesionespersonaleso perjuiciosrnateriales.

Paracornenzara bordear,procedadelasiguienteforrna:

1. Mueva[aunidada[_.reaquevaa recortar,asegur_.ndosedeque

[a ruedaposteriorizquierdaest_sobreuna superficieduray que

la cuchillaest,.sobreel _.reaa cortar.Veala Figura5.

5. Conlarnanoderecha,tomela rnanijadel arrancadorde retroceso

ylentarnentetirede lacuerdahaciaafuerahastaqueel motor

Ileguealprincipiodesuciclodecornpresi6n(la cuerdaestar_,un

pocorn_.stensaen estepunto).

6. Despu_sdeperrnitirquela cuerdavuelvalentarnente,tirede la

cuerdaconun rnovirnientodebrazor_.pidoy continuo.Durante

todoel rnovirnientornantengafirrnernentesujetala rnanijadel

arrancador.

7. Perrnitaquelarnanijadelarrancadorvuelvalentarnentealperno

deanilla.

NOTA:Si el motornoIograarrancarluegode tresintentos,preslone

elcebadordosvecesrn_.santesdejalar nuevarnentede lacuerdade

arranque.

DETENCION DEL MOTOR

Paradetenerelmotorde la bordeadora,sueltela palancadecontrol

de lacuchilla.

Figura5

2. Conla palancadecontrolde la cuchillaenla posici6nde

funcionarniento,hagaunapasadaporel _.reaa recortarantesde

procedera[asiguienternuesca.Cuantorn_.sadelantesernueva

la palancade controlde profundidadde la cuchilla,rn_.sprofundo

o rn_.sabajoser_.elcortede lacuchillaen elsuelo.Puedehacer

faitahacervariaspasadasparaobtenerlaprofundidaddecorte

deseada.Nobajelacuchillarn_.sde unarnuescadeprofundidad

porvezsin hacerunapasada.

3. Pararnejoresresuitados,procedalentarnenteporel sendero

queest,. recortando,rnoviendo[abordeadoraparaatr_.sy

paraadelanteporel _.readecorte,siernpreasegur_.ndosede

rnantener[a ruedaposteriorizquierdasobre[a superficieduray [a

cuchillaen el senderodecorte,cercaperosintocarel hordede

la superficiedura.

4. Unavezquehaterrninadode recortarel_.reaseleccionada,

vuelvaa co[ocarlapalancade controlde lacuchillaen laposici6n

INICIO,rnu_vasea [a siguiente_.reaa recortar,y proceda

nuevarnentedesdeel paso1.

42

Page 43

RECORTEA LO LARGO DE UN BORDILLO

La ruedaposteriorderechade la bordeadorasepuedebajara una

decincoposicionesparafacilitarlatareade recorteaIolargodeun

bordillo.

Paraajustarla alturade laruedadelbordillo,hagaIosiguiente:

1. Bajela ruedaposteriorderecharnoviendola palancadeajustede

la alturadel bordilloligerarnentea la izquierda.Veala Figura6.

f Palancade \.

ajustede ....

altura

del bordillo

ZANJADO (Sl EST.&. EQUIPADO)

Sepuedeutilizarla caracteristicadezanjadoopcionalde labordea-

dora,paracrearunsenderodecortern_.sanchoparacosastales

cornotendidode cablesparala ilurninaci6npaisajista

Desconecteel cablede labujiade encendidoy hagarnasacontrael

motorantesde realizarlossi_asos.

Elbordede labordeadoraesfiloso.P6ngaseguantesdetrabajode

cueroparaprotegerselasrnanoscuandotrabajacercade lacuchilla

de la bordeadora..