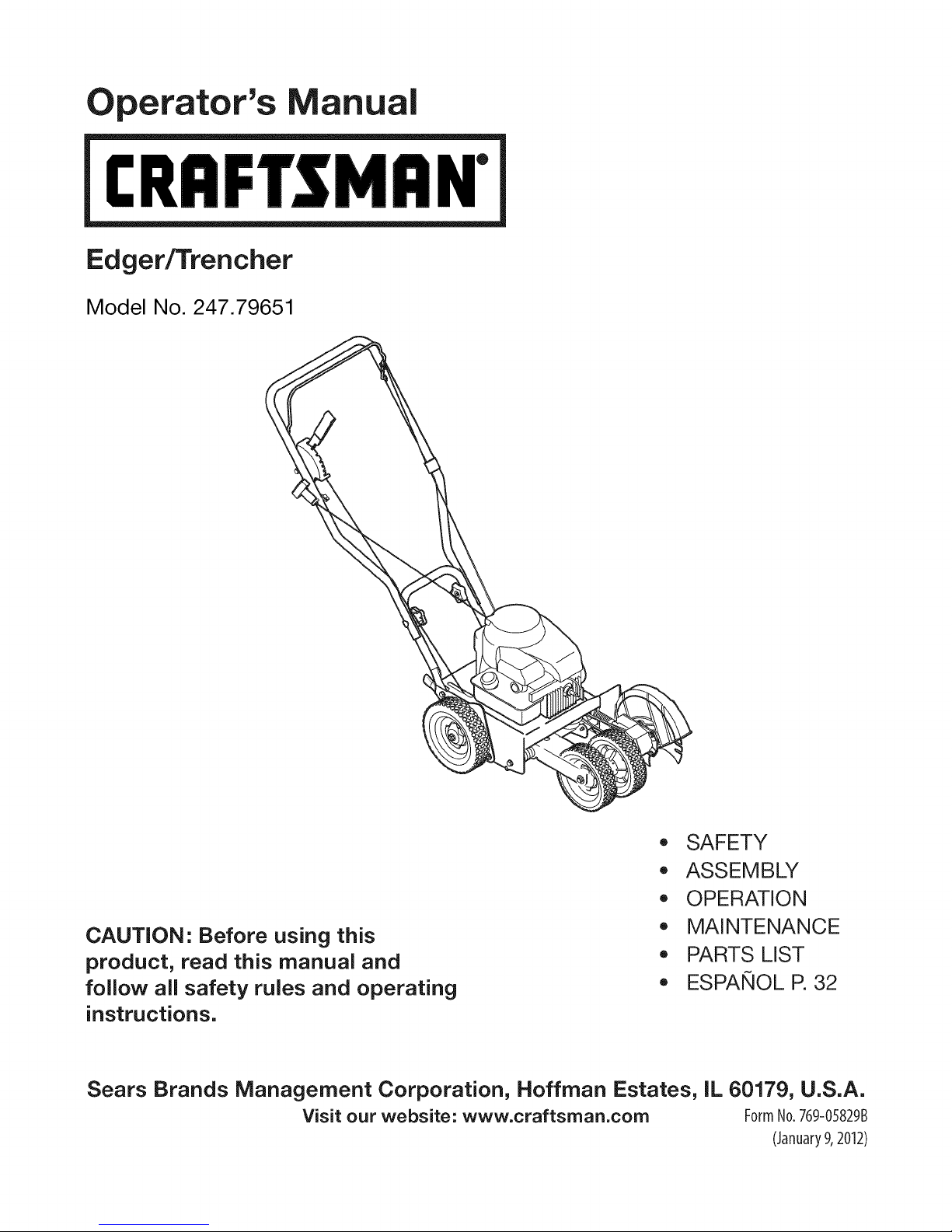

Page 1

perator's nual

CRFiFrSM N"

Edger/Trencher

Model No. 247.79651

CAUTION: Before using this

product, read this manual and

follow aJl safety ruJes and operating

instructions.

Sears Brands Management Corporation, Hoffman Estates, IL 60179, U.S.A.

Visit our website: www.craftsman.com FormNo.769-05829B

o SAFETY

ASSEMBLY

OPERATION

MAINTENANCE

PARTS LIST

o ESPANOL R 32

(January9,2012)

Page 2

Warranty Statement .......................................................... 2

Safety instructions ........................................................ 3-6

Assembly ........................................................................ 7-8

Operation ..................................................................... 9-11

Service and Maintenance ......................................... 12-16

Off-Season Storage ........................................................ 17

Troubleshooting .............................................................. 18

Parts List .................................................................... 20-28

Espa_oi ............................................................................ 32

Service Numbers ............................................. Back Cover

Craftsman Two Year Full Warranty

FORTWOYEARSfromthedated purchase,this productiswarrantedagainstanydefectsinmaterialor workmanship.Defectiveproductwill

receivefreerepairor freereplacementifrepairisunavailable.

Forwarranty coveragedetails to obtain repairor replacement,visit the website: www.craftsman.com.

This warranty covers ONLYdefects in material andworkmanship. Warranty coverage does NOTinclude:

• Expendableitemswhichcan wearoutfromnormalusewithinthewarrantyperiod,suchas belts,filters,sparkplugsoredgingblades.

• Productdamageresultingfromuserattemptsat productmodificationor repairorcausedbyproductaccessories.

• Repairsnecessarybecauseof accidentorfailureto operateor maintaintheproductaccordingtoall suppliedinstructions.

• Preventativemaintenanceor repairsnecessarydueto improperfuelmixture,contaminatedorstalefuel.

Thiswarrantyisvoid if thisproductiseverusedwhileprovidingcommercialservicesor if rentedtoanotherperson.

Thiswarrantygivesyouspecificlegalrights,andyou mayalso haveotherrightswhichvaryfromstatetostate.

Sears BrandsManagementCorporation, Hoffman Estates,IL 60179

EngineOilType: SAE30

EngineOilCapacity: 18ounces

Fuel: UnleadedGasoline

SparkPlug: Champion®RJ19LM

Engine: Briggs& Stratton

Model Number

Serial Number

Dateof Purchase

Recordthe modelnumber,serialnumber,

anddateof purchaseabove.

© SearsBrands,LLC 2

Page 3

Thissymbolpointsoutimportantsafetyinstructionswhich,if not

followed,couldendangerthe personalsafetyand/orpropertyof

yourselfandothers. Readandfollowall instructionsin thismanual

beforeattemptingtooperatethismachine.Failureto complywith

theseinstructionsmayresultin personalinjury.Whenyouseethis

symbol,HEEDITSWARNING!

Thismachinewasbuilttobeoperatedaccordingto the safeopera-

tionpracticesin thismanual.Aswithany typeofpowerequipment,

carelessnessorerroronthepartoftheoperatorcan resultin

seriousinjury.Thismachineiscapableof amputatingfingers,hands,

toesandfeetandthrowingdebris.Failureto observethefollowing

safetyinstructionscouldresultin seriousinjuryordeath.

CALIFORNIA PROPOSITION 65

EngineExhaust,someof itsconstituents,andcertainvehicle

componentscontainoremitchemicalsknowntoStateofCalifornia

tocausecancerandbirthdefectsorother reproductiveharm.

TRAINING

• Readthisoperator'smanualcarefullyin itsentiretybefore

attemptingto assemblethis machine.Read,understand,and

followall instructionsonthemachineandinthe manual(s) before

operation.Keepthismanualina safeplacefor futureand regular

referenceandfororderingreplacementparts.

• Becompletelyfamiliarwiththecontrolsandthe properuseofthis

machinebeforeoperatingit.

• Thismachineis a precisionpieceofpowerequipment,nota

plaything.Therefore,exerciseextremecautionat alltimes.Your

machinehas beendesignedto performonejob:to edgelawn.Do

notuseit for any otherpurpose.

• Neverallowchildrenunder14yearsofagetooperatethis

machine.Children14andovershouldreadandunderstandthe

instructionsandsafeoperationpracticesin thismanualandon

themachineandbe trainedandsupervisedbyanadult.

• Only responsibleindividualswhoarefamiliarwiththeserulesof

safeoperationshouldbe allowedtousethis machine.

• Tohelpavoidbladecontactor athrownobjectinjury,stayin

operatorzonebehindhandlesandkeepchildren,bystanders,

helpersandpetsatleast75feetfromlawnedgerwhile it is in

operation.Stopmachineifanyoneentersarea.

Your Responsibility--Restrict theuseofthispowermachineto

personswhoread,understandandfollowthewarningsand instruc-

tionsin thismanualandonthemachine.

SAVETHESEINSTRUCTIONS!

PREPARATION

• Thoroughlyinspecttheareawherethe equipmentistobeused.

Removeall stones,sticks,wire,bones,toys andother foreign

objectswhichcould betrippedoveror pickedupandthrownby

theblade.Thrownobjectscancauseseriouspersonalinjury.

• Alwayswearsafetyglassesorsafetygogglesduringoperation

andwhileperformingan adjustmentor repairto protectyoureyes.

Thrownobjectswhichricochetcancauseseriousinjurytothe

eyes.

• Wearsturdy,rough-soledworkshoesandclose-fittingslacks

and shirts.Shirtsand pantsthatcoverthe armsandlegsand

steel-toedshoesare recommended.Neveroperatethis machine

inbarefeet,sandals,slipperyorlightweight(e.g.canvas)shoes.

• Neverattempttomakeanyadjustmentswhilethe engineis

running,exceptwherespecificallyrecommendedinthe operator's

manual.

SAFE HANDLING OF GASOLINE:

Toavoidpersonalinjuryorpropertydamageuseextremecarein

handlinggasoline.Gasolineis extremelyflammableandthevaporsare

explosive.Seriouspersonalinjurycanoccurwhengasolineis spilled

on yourselforyourclotheswhichcanignite. Washyourskinand

changeclothesimmediately.

• Useonlyanapprovedgasolinecontainer.

• Neverfillcontainersinsidea vehicleoron a truckortrailerbed

witha plasticliner.Alwaysplacecontainerson thegroundaway

fromyourvehiclebeforefilling.

• Removegas-poweredequipmentfromthetruckortrailerand

refuelit ontheground.Ifthisis notpossible,thenrefuelsuch

equipmenton atrailerwitha portablecontainer,ratherthanfrom

a gasolinedispensernozzle.

• Keepthenozzleincontactwiththerimofthefueltankor

containeropeningat all timesuntilfuelingiscomplete.Donotuse

a nozzlelock-opendevice.

3

Page 4

• Extinguishallcigarettes,cigars,pipesandothersourcesof

ignition.

• Neverfuel machineindoorsbecauseflammablevaporswill

accumulatein thearea.

• Neverremovegascapor addfuelwhileengineis hotor running.

Allowengineto coolat leasttwo minutesbeforerefueling.

• Neveroverfillfueltank.Filltankto nomorethan1/2inchbelow

bottomoffillerneckto provideforfuelexpansion.

• Replacegasolinecapandtightensecurely.

• Ifgasolineis spilled,wipe it off theengineandequipment.Move

machineto anotherarea.Wait5 minutesbeforestarting engine.

• Neverstorethe machineorfuelcontainernearanopenflame,

sparkor pilotlightasona waterheater,spaceheater,furnace,

clothesdryeror othergasappliances.

• To reducefirehazard,keeplawnedgerfreeofgrass,leaves,or

otherdebrisbuild-up.Cleanupoil orfuelspillageandremoveany

fuelsoakeddebris.

• Allowa lawnedgerto cool at leastfive (5) minutesbeforestoring

OPERATION

• Do not puthandsorfeetnear rotatingparts.Contactwiththe

rotatingbladecanamputatehandsandfeet.

Thebladecontrolhandleisa safetydevice.Neverbypassits

operation.Doingso,makesthemachineunsafeand maycause

personalinjury.

Neveroperatewithoutbladeguard,debrisshieldandblade

controlhandlein placeandworking.

Neveroperatewithdamagedsafetydevices.Failuretodo so,can

resultinpersonalinjury.

Neverrunanengineindoorsorina poorlyventilatedarea.Engine

exhaustcontainscarbonmonoxide,anodorlessanddeadlygas.

Donotoperatemachinewhileundertheinfluenceof alcoholor

drugs.

Mufflerandenginebecomehotandcancausea burn.Donot

touch.

Neveroperatethismachinewithoutgoodvisibilityor light.Always

be sureofyourfootingandkeepa firmholdonthehandles.Walk,

neverrun.

Donotoperatethis machineif it has beendroppedor damaged.

Returnmachineto your nearestauthorizedservicingdealerfor

examinationand repair.

Donotoperatethis machinewitha damagedorexcessivelyworn

cuttingblade.

Neverattempttoclearmaterialfromthe bladeguardwhilethe

engineis running.Shuttheengineoff,disconnectthe spark

plugwireandgroundagainsttheenginetopreventunintended

starting.

Donotoverloadmachinecapacitybyattemptingtoedgeattoo

fastof a rate.

Stayalertforunevensidewalks,terrainetc.Alwayspushslowly

overroughsurfaces.Donotusethis machineon gravelsurfaces.

Donotoperatemachinein rainorwetsoil conditions.

• Alwaysoperatemachinefrombehindthe handlesandposition

yourselfwherethedirectlineof sighttocuttingbladeis blocked

byguards.

• Alwaysstopenginewhenedgingortrimmingisdelayedor when

transportingmachinefromonelocationto another.

• Neverleavearunningmachineunattended.Stopthe engine,

disconnectsparkplugwireandgroundagainsttheengineto

preventunintendedstarting.

• Only usepartsandaccessoriesmadefor thismachinebythe

manufacturer.Failuretodo so,canresultin personalinjury.

• Ifsituationsoccurwhichare notcoveredinthis manual,use care

andgoodjudgment.ContactCustomerSupportforassistanceor

thenameof your nearestservicedealer.

CHILDREN

Tragicaccidentscan occuriftheoperatorisnotalerttothepresence

ofchildren.Childrenareoftenattractedto powerequipmentsuchas

lawnedgers.Theydo notunderstandthedangers.Neverassumethat

childrenwill remainwhereyoulastsawthem.

Keepchildrenoutoftheedgingareaandunderwatchfulcareofa

responsibleadultotherthan theoperator.

Bealertandturnlawnedgeroffif achildentersthearea.

• Beforeandwhilemovingbackwards,look behindanddown for

smallchildren.

Useextremecarewhenapproachingblindcorners,doorways,

shrubs,trees,orotherobjectsthatmayobscureyourvisionofa

childwhomayrunintothelawnedger.

Keepchildrenawayfromhot or runningengines.Theycansuffer

burnsfroma hot muffler.

Neverallowchildrenunder14yearsofageto operatethis

machine.Children14andovershouldreadand understandthe

instructionsandsafeoperationpracticesinthis manualandon

themachineand betrainedandsupervisedby an adult.

MAINTENANCE & STORAGE

• Neverrunanengineindoorsorin a poorlyventilatedarea.Engine

exhaustcontainscarbonmonoxide,an odorlessanddeadlygas.

Beforecleaning,repairing,or inspecting,makecertainthe

bladeandall movingpartshavestopped.Disconnectthespark

plugwireand groundagainsttheengineto preventunintended

starting.

Checkthe bladeandenginemountingboltsat frequentintervals

forpropertightness.Also,visuallyinspectbladefor damage(e.g.,

bent,cracked,worn)Replacebladewiththeoriginalequipment

rnanufacture's(O.E.M.)bladeonly,listedinthis manual."Useof

partswhichdonotmeettheoriginalequipmentspecificationsmay

leadtoimproperperformanceandcompromisesafety!"

Lawnedgerbladesare sharpandcancut.Wrapthebladeor

weargloves,and useextracautionwhenservicingthem.

Keepallnuts,bolts,andscrewstightto besurethe equipmentis

in safeworkingcondition.

Nevertamperwith safetydevices.Checktheir properoperation

regularly.

4

Page 5

• Afterstrikingaforeignobject,stoptheengine,disconnectthe

sparkplugwireand groundagainsttheengine.Thoroughly

inspectthelawnedgerforanydamage.Repairthedamage

beforestartingandoperatingthelawnedger.

Neverattempttomakea wheeladjustmentwhiletheengineis

running.

Manycomponentson yournew edgercan wearwithcontinued

use. Forsafetyprotection,frequentlycheckall edgercomponents

andreplaceimmediatelywithoriginalequipmentmanufacturer's

(O.E.M.)partsonly,listedin thismanual."Useofpartswhich

donotmeettheoriginalequipmentspecificationsmayleadto

improperperformanceandcompromisesafety!"

Donotchangetheenginegovernorsettingor overspeedthe

engine.Thegovernorcontrolsthe maximumsafeoperatingspeed

oftheengine.

Maintainor replacesafetyandinstructionlabels,asnecessary.

Observeproperdisposallawsand regulationsforusedgas,

oil,etc..Improperdisposalof fluidsandmaterialscanharmthe

environment.

Accordingto the ConsumerProductsSafetyCommission(CPSC)

andtheU.S.EnvironmentalProtectionAgency(EPA),thisproduct

hasan Average UsefulLifeofseven(7)years,or 70hoursof

operation.At the endoftheAverageUsefulLifehavethemachine

inspectedannuallybyan authorizedservicedealertoensurethat

allmechanicalandsafetysystemsareworkingproperlyandnot

wornexcessively.Failureto do socanresultinaccidents,injuries

ordeath.

DO NOT MODIFY ENGINE

Toavoidseriousinjuryordeath,donot modifyenginein anyway.

Tamperingwiththe governorsettingcanleadto a runawayengineand

causeittooperateat unsafespeeds.Nevertamperwithfactorysetting

ofenginegovernor.

NOTICE REGARDING EMISSIONS

EngineswhicharecertifiedtocomplywithCaliforniaandfederal

EPAemissionregulationsfor SORE(SmallOffRoadEquipment)are

certifiedto operateon regularunleadedgasoline,and mayinclude

thefollowingemissioncontrolsystems:EngineModification(EM),

OxidizingCatalyst(CO),SecondaryAirInjection(SAI)and ThreeWay

Catalyst(TWO)if soequipped.

SPARK ARRESTOR

Thismachineis equippedwithan internalcombustionengineand

shouldnotbe usedonor nearanyunimprovedforest-covered,

brushcoveredor grass-coveredlandunlessthe engine'sexhaust

systemisequippedwitha sparkarrestermeetingapplicablelocalor

statelaws(ifany)

Ifa sparkarresterisused,itshouldbemaintainedin effectiveworking

orderbytheoperator.Inthe Stateof Californiatheaboveis required

bylaw (Section4442oftheCaliforniaPublicResourcesCode).Other

statesmayhavesimilarlaws. Federallawsapplyonfederallands.

A sparkarresterfor the mufflerisavailablethroughyournearestSears

PartsandRepairServiceCenter.

Page 6

SAFETY SYMBOLS

Thispagedepictsanddescribessafetysymbolsthatmayappearonthisproduct. Read,understand,andfollowall instructionson themachine

before attempting toassemble and operate.

READ THE OPERATOR'S MANUAL(S)

Read,understand,andfollowall instructionsinthe manual(s)beforeattemptingtoassembleand

1

operate

WARNING m ROTATING BLADES

Keephandsandfeetawayfrom rotatingblade.

• ®

BYSTANDERS

Keepbystanders,pets,andchildrenatleast75feetfromthemachinewhileitisin operation.Stop

machineif anyoneentersthearea.

WARNINGm HOT SURFACES

Donot touchmuffleroradjacentareas.

EYE PROTECTION

Alwayswearsafetyglassesorsafetygoggleswhenoperatingthismachine.

6

Page 7

NOTE:Thismachineis shippedWITHOUTGASOLINEor OIL.After

settinguptheedger,servicetheenginewithgasolineandoil as

instructed.

NOTE:Referenceto rightor lefthandsideoftheedgeris observed

fromtheoperatingposition.

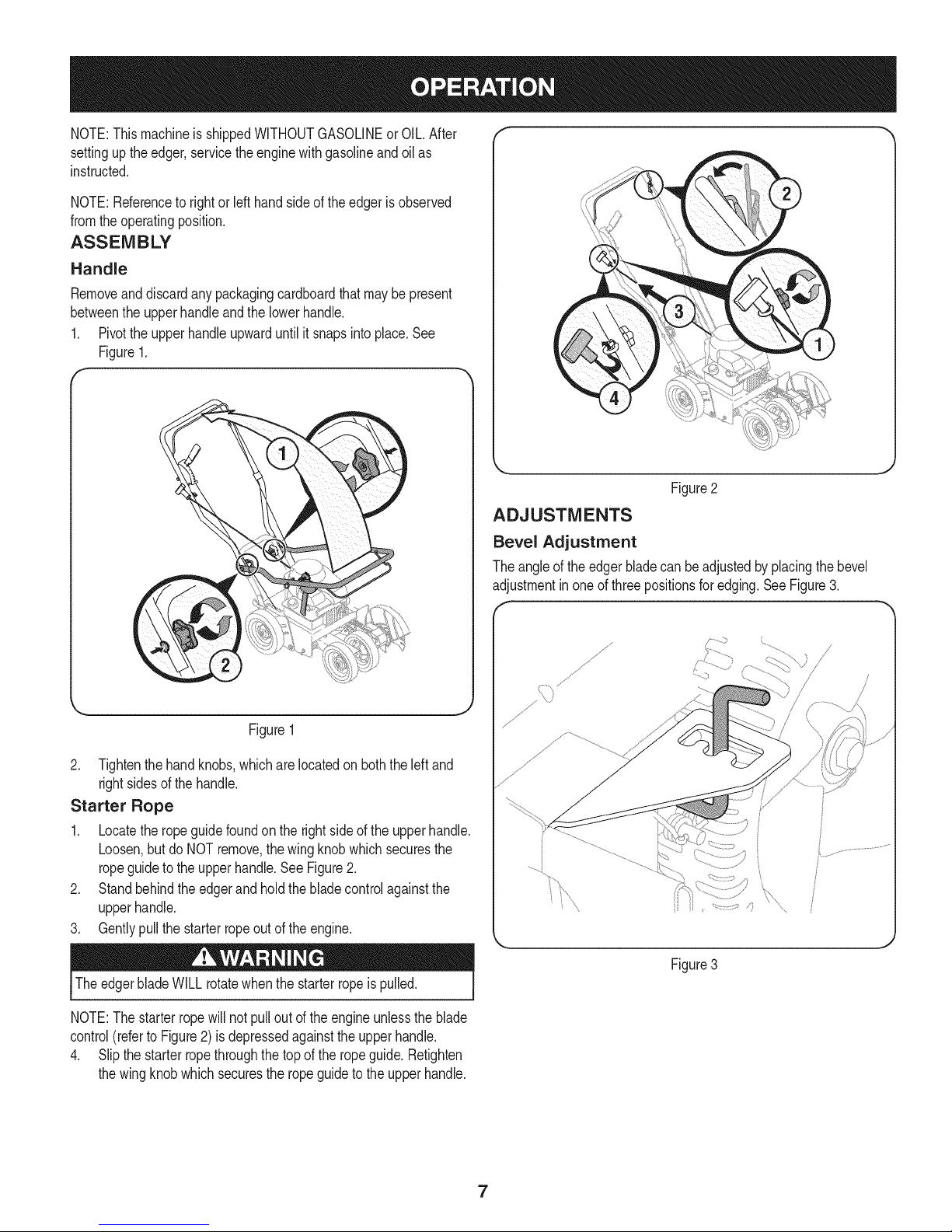

ASSEMBLY

Handle

Removeanddiscardanypackagingcardboardthatmaybepresent

betweenthe upperhandleandthelowerhandle.

1. Pivotthe upperhandleupwarduntilit snapsintoplace.See

Figure1.

Figure2

ADJUSTMENTS

Bevel Adjustment

Theangleoftheedgerbladecanbeadjustedbyplacingthebevel

adjustmentin oneof threepositionsforedging.SeeFigure3.

Figure1

2. Tightenthehandknobs,whichare locatedonboththeleftand

rightsidesofthehandle.

Starter Rope

1. Locatethe ropeguidefoundonthe rightsideoftheupperhandle.

Loosen,butdo NOTremove,the wingknobwhichsecuresthe

ropeguidetotheupperhandle.SeeFigure2.

2. Standbehindthe edgerandholdthebladecontrolagainstthe

upperhandle.

3. Gentlypullthestarterropeoutoftheengine.

TheedgerbladeWILLrotatewhenthestarterropeis pulled.

NOTE:Thestarterropewillnotpulloutd theengineunlessthe blade

control(referto Figure2)is depressedagainstthe upperhandle.

4. Slipthestarterropethroughthetopoftheropeguide.Retighten

thewingknobwhichsecurestheropeguidetotheupperhandle.

/"

.......3

Figure3

/

7

Page 8

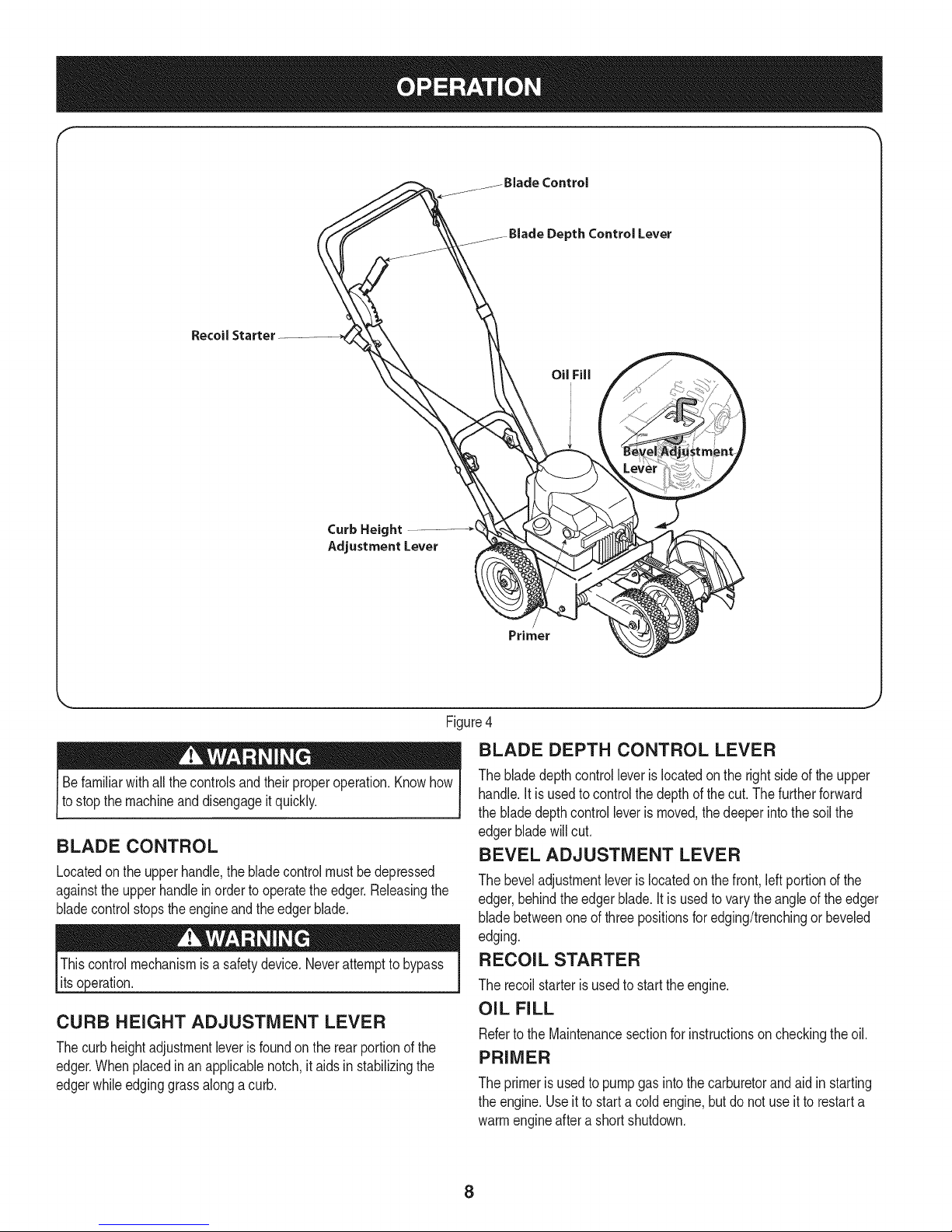

Recoil Starter

Curb Height

Adjustment Lever

Befamiliarwithallthecontrolsandtheir properoperation.Knowhow

tostopthemachineanddisengageitquickly.

BLADE CONTROL

Locatedon theupperhandle,thebladecontrolmustbedepressed

againsttheupperhandlein orderto operatetheedger.Releasingthe

bladecontrolstopstheengineandthe edgerblade.

_eration.

CURB HEIGHT ADJUSTMENT LEVER

Thecurb heightadjustmentleverisfoundon the rearportionofthe

edger.Whenplacedinan applicablenotch,it aidsin stabilizingthe

edgerwhileedginggrassalongacurb.

Primer

Figure4

BLADE DEPTH CONTROL LEVER

Thebladedepthcontrolleveris locatedontherightsideof the upper

handle.It isusedtocontrolthedepthofthecut.Thefurtherforward

thebladedepthcontrolleveris moved,thedeeperintothesoilthe

edgerbladewillcut.

BEVEL ADJUSTMENT LEVER

Thebeveladjustmentleveris locatedon thefront,leftportionofthe

edger,behindtheedgerblade.It is usedtovarythe angleof the edger

bladebetweenoneof threepositionsforedging/trenchingor beveled

edging.

RECOIL STARTER

Therecoilstarterisusedtostarttheengine.

OIL FILL

RefertotheMaintenancesectionforinstructionsoncheckingtheoil.

PRIMER

Theprimeris usedtopumpgasintothe carburetorandaidin starting

theengine.Useit tostarta cold engine,butdonotuseitto restarta

warmengineaftera shortshutdown.

8

Page 9

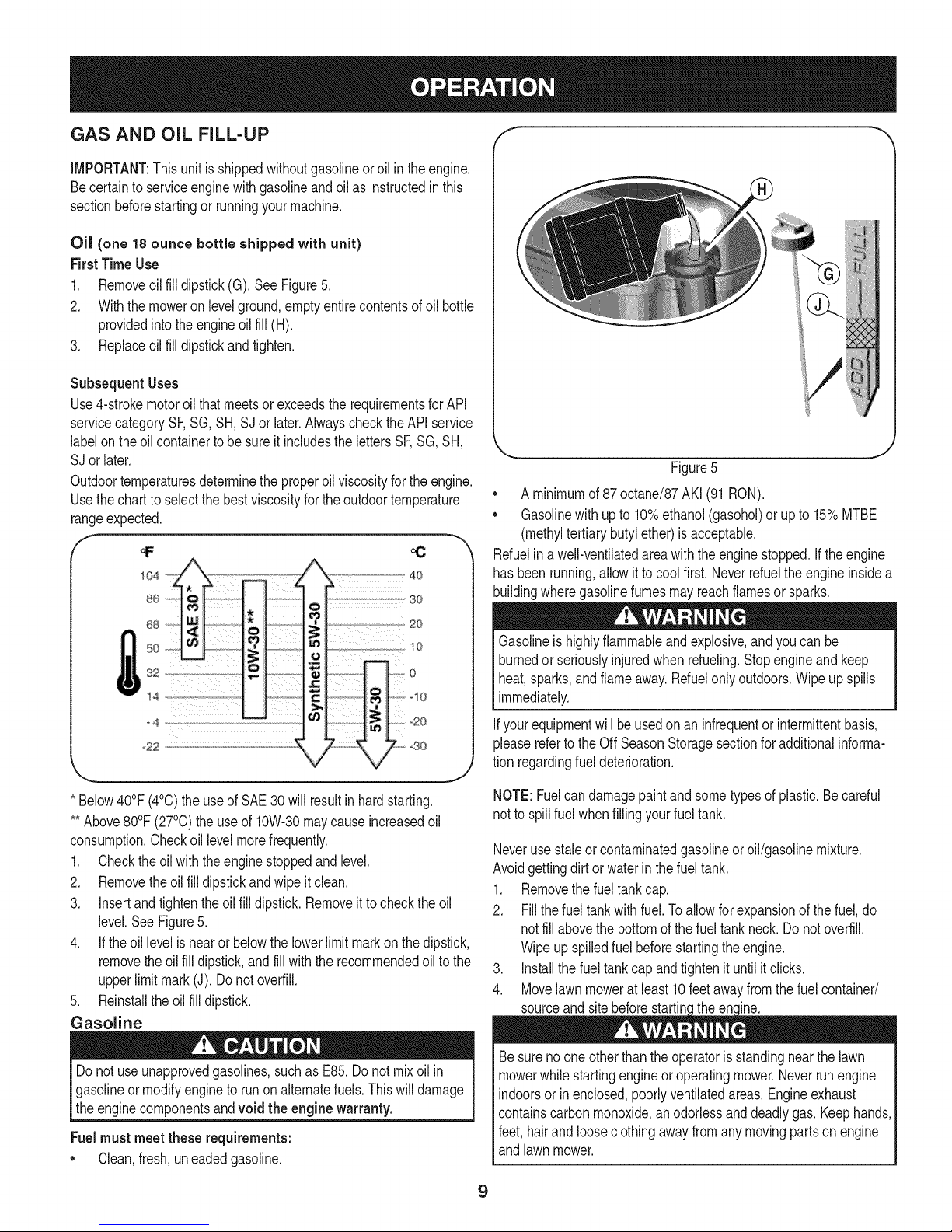

GAS AND OIL FILL-UP f

IMPORTANT:Thisunitisshippedwithoutgasolineoroil intheengine.

Becertainto serviceenginewithgasolineandoilas instructedinthis

sectionbeforestartingor runningyourmachine.

Oil (one 18ounce bottle shipped with unit)

FirstTime Use

1. Removeoilfilldipstick(G).See Figure5.

2. Withthemoweronlevelground,emptyentirecontentsof oil bottle

providedintotheengineoil fill (H).

3. Replaceoilfilldipstickandtighten.

Subsequent Uses

Use4-strokemotoroilthatmeetsor exceedstherequirementsfor API

servicecategorySF,SG,SH,SJor later.Alwayscheckthe APIservice

labelonthe oilcontainertobesureitincludesthelettersSF,SG,SH,

SJorlater.

Outdoortemperaturesdeterminetheproperoilviscosityfor theengine.

Usethechartto selectthe bestviscosityfortheoutdoortemperature

rangeexpected.

4o

N 2o

5o ,

32 _ t 0

!4

o4 ........................L _

¢t_ _ _20

.so

• Aminimumof87octane/87AKI(91RON).

• Gasolinewith upto 10%ethanol(gasohol)orupto 15%MTBE

Figure5

(methyltertiarybutylether)isacceptable.

Refuelina well-ventilatedareawiththeenginestopped.Iftheengine

hasbeenrunning,allowitto cool first.Neverrefuelthe engineinsidea

buildingwheregasolinefumesmayreachflamesorsparks.

o

Gasolineis highlyflammableandexplosive,andyoucanbe

burnedor seriouslyinjuredwhenrdueling. Stopengineandkeep

heat,sparks,andflameaway.Refuelonlyoutdoors.Wipeupspills

immediately.

Ifyourequipmentwill be usedonan infrequentorintermittentbasis,

pleaserefertotheOff SeasonStoragesectionforadditionalinforma-

tionregardingfueldeterioration.

* Below40°F(4°C)the use of SAE30willresultinhardstarting.

** Above80°F(27°C)theuseof 10W-30maycauseincreasedoil

consumption.Checkoil levelmorefrequently.

1. Checktheoil withtheenginestoppedandlevel.

2. Removetheoil fill dipstickandwipeitclean.

3. Insertandtightentheoilfilldipstick.Removeittochecktheoil

level.See Figure5.

4. If theoil levelis nearor belowthelowerlimitmarkon the dipstick,

removethe oil filldipstick,andfillwiththerecommendedoil to the

upperlimitmark(J). Donotoverfill.

5. Reinstalltheoilfill dipstick.

Gasoline

Donotuse unapprovedgasolines,suchasE85.Do not mixoilin

gasolineormodifyengineto runonalternatefuels.Thiswill damage

theenginecomponentsandvoid the engine warranty.

Fuelmustmeet these requirements:

• Clean,fresh,unleadedgasoline.

NOTE:Fuelcandamagepaintand sometypesof plastic.Becareful

notto spillfuelwhenfillingyourfueltank.

Neverusestaleorcontaminatedgasolineor oil/gasolinemixture.

Avoidgettingdirtor waterin the fueltank.

1. Removethefueltankcap.

2. Fillthefuel tankwith fuel.Toallowforexpansionofthefuel,do

notfill abovethebottomofthe fuel tankneck.Donotoverfill.

Wipeupspilledfuel beforestartingtheengine.

3. Installthefueltankcapandtightenituntilitclicks.

4. Movelawnmowerat least10feetawayfromthe fuel container/

sourceandsitebeforestartin( me.

Besurenooneotherthantheoperatorisstandingnearthelawn

mowerwhilestartingengineoroperatingmower.Neverrunengine

indoorsor inenclosed,poorlyventilatedareas.Engineexhaust

containscarbonmonoxide,anodorlessanddeadlygas.Keephands,

feet,hairand looseclothingawayfromanymovingpartson engine

andlawnmower.

9

Page 10

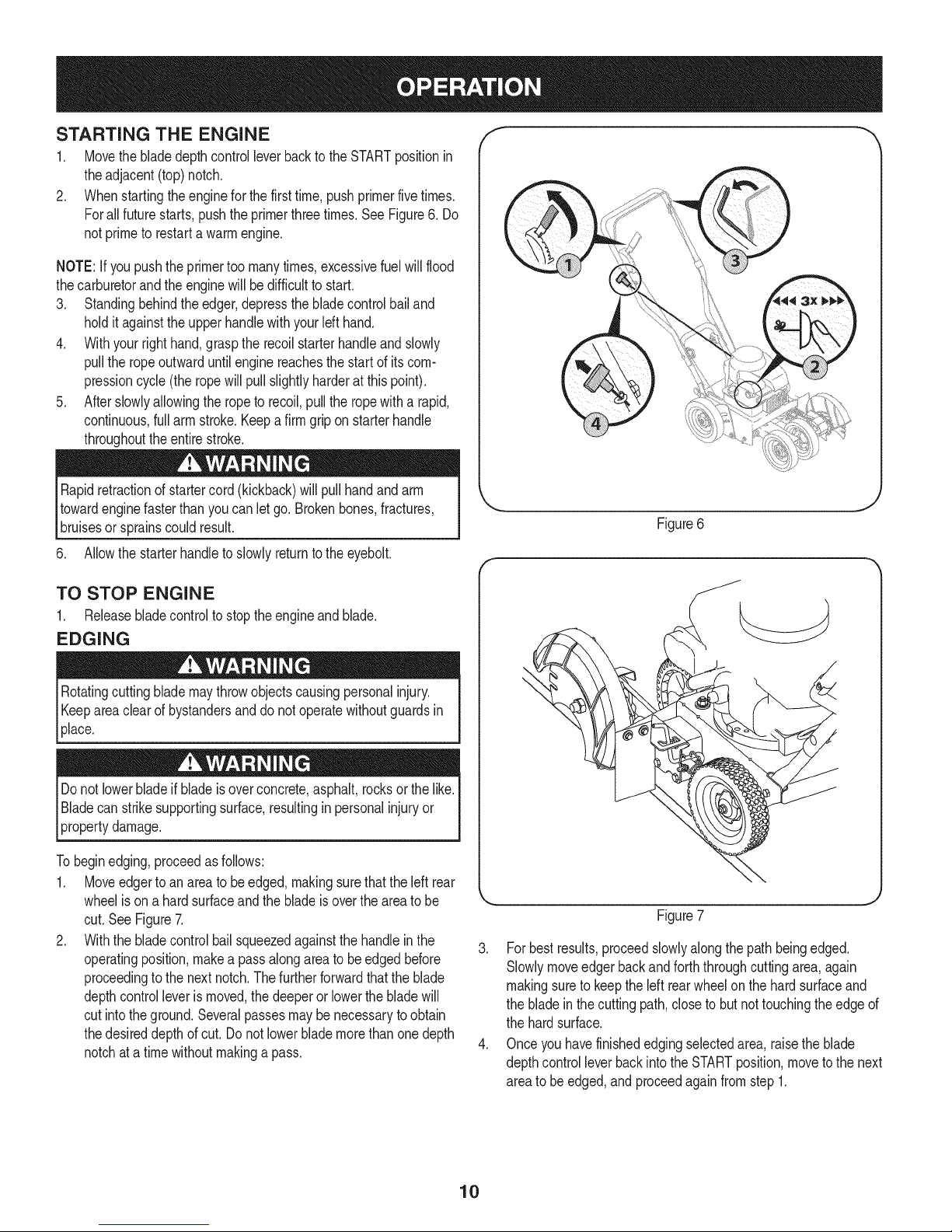

STARTING THE ENGINE

1. Movethebladedepthcontrolleverbackto the STARTpositionin

theadjacent(top) notch.

2. Whenstartingtheengineforthefirsttime, pushprimerfivetimes.

Forall futurestarts,pushthe primerthreetimes.SeeFigure6.Do

notprimeto restartawarmengine.

NOTE:If youpushthe primertoo manytimes,excessivefuelwillflood

thecarburetorandthe enginewill be difficulttostart.

3. Standingbehindtheedger,depressthebladecontrolbailand

holditagainsttheupperhandlewithyour lefthand.

4. Withyourrighthand,grasptherecoilstarterhandleandslowly

pulltheropeoutwarduntilenginereachesthestart of its com-

pressioncycle (the ropewill pullslightlyharderat thispoint).

5. Afterslowlyallowingtheropeto recoil,pullthe ropewitha rapid,

continuous,fullarmstroke.Keepa firmgripon starterhandle

throughouttheentirestroke.

Rapidretractionof startercord(kickback)willpull handandarm

towardenginefasterthanyoucanletgo. Brokenbones,fractures,

bruisesor sprainscouldresult.

6. Allowthestarterhandletoslowlyreturntotheeyebolt.

f

Figure6

TO STOP ENGINE

1. Releasebladecontroltostoptheengineandblade.

EDGING

Rotatingcuttingblademaythrowobjectscausingpersonalinjury.

Keepareaclearofbystandersanddo notoperatewithoutguardsin

.pace.

Donotlowerbladeif bladeisoverconcrete,asphalt,rocksorthelike.

IBladecan strikesupportingsurface,resultingin personalinjuryor

[propertydamage.

Tobeginedging,proceedasfollows:

1. Moveedgertoan areatobeedged,makingsurethattheleft rear

wheelis ona hardsurfaceandthe bladeisovertheareatobe

cut.SeeFigure7.

2. Withthe bladecontrolbailsqueezedagainstthehandlein the

operatingposition,makea passalongareatobeedgedbefore

proceedingtothenextnotch.Thefurtherforwardthattheblade

depthcontrolleverismoved,thedeeperor lowerthebladewill

cutintotheground.Severalpassesmaybe necessarytoobtain

thedesireddepthofcut. Do notlowerblademorethanonedepth

notchata timewithoutmakingapass.

Figure7

3. Forbestresults,proceedslowlyalongthepathbeingedged.

Slowlymoveedgerbackandforththroughcuttingarea,again

makingsureto keeptheleftrearwheelon the hardsurfaceand

thebladeinthe cuttingpath,closetobutnottouchingtheedgeof

thehardsurface.

4. Onceyouhavefinishededgingselectedarea,raisetheblade

depthcontrolleverbackinto theSTARTposition,movetothenext

areatobe edged,andproceedagainfromstep1.

10

Page 11

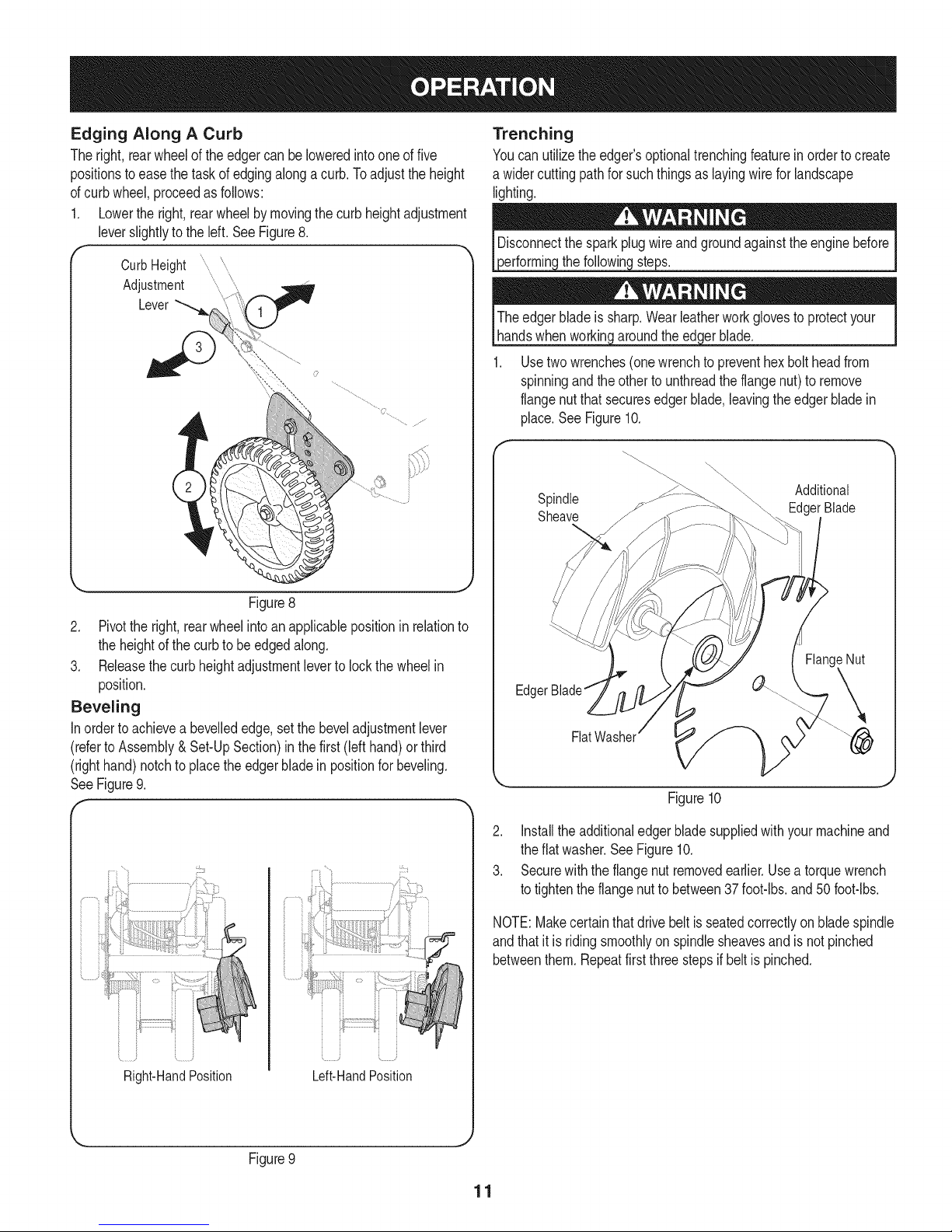

Edging Along A Curb

Theright,rearwheeloftheedgercanbe loweredintooneoffive

positionstoeasethetaskof edgingalonga curb.Toadjusttheheight

ofcurbwheel,proceedasfollows:

1. Lowerthe right,rearwheelbymovingthecurbheightadjustment

leverslightlytotheleft.SeeFigure8.

f CurbHeight ............'.....

Adjustment

Lever

Trenching

Youcanutilizetheedger'soptionaltrenchingfeaturein orderto create

a widercuttingpathfor suchthingsaslayingwireforlandscape

lighting.

thefollowinc _s.

Usetwowrenches(onewrenchtopreventhexbolt headfrom

spinningand theotherto unthreadtheflangenut)to remove

flangenut thatsecuresedgerblade,leavingtheedgerbladein

place.SeeFigure10.

Spindle Additional

Sheave EdgerBlade

Figure8

2. Pivottheright,rearwheelintoanapplicablepositioninrelationto

theheightofthecurbtobeedgedalong.

3. Releasethecurbheightadjustmentleverto lockthewheelin

position.

Beveling

Inordertoachievea bevellededge,setthebeveladjustmentlever

(referto Assembly&Set-UpSection)inthefirst(lefthand)orthird

(righthand)notchtoplacethe edgerbladein positionfor beveling.

SeeFigure9.

Edc

Flat \\_

Figure10

2. Installtheadditionaledgerbladesuppliedwithyourmachineand

theflatwasher.SeeFigure10.

3. Securewiththe flangenutremovedearlier.Usea torquewrench

totightentheflangenut to between37foot-lbs,and50 foot-lbs.

NOTE:Makecertainthatdrive beltis seatedcorrectlyonbladespindle

andthatit isridingsmoothlyonspindlesheavesandis not pinched

betweenthem.Repeatfirstthreesteps if beltis pinched.

Right-HandPosition

Left-HandPosition

Figure9

J

11

Page 12

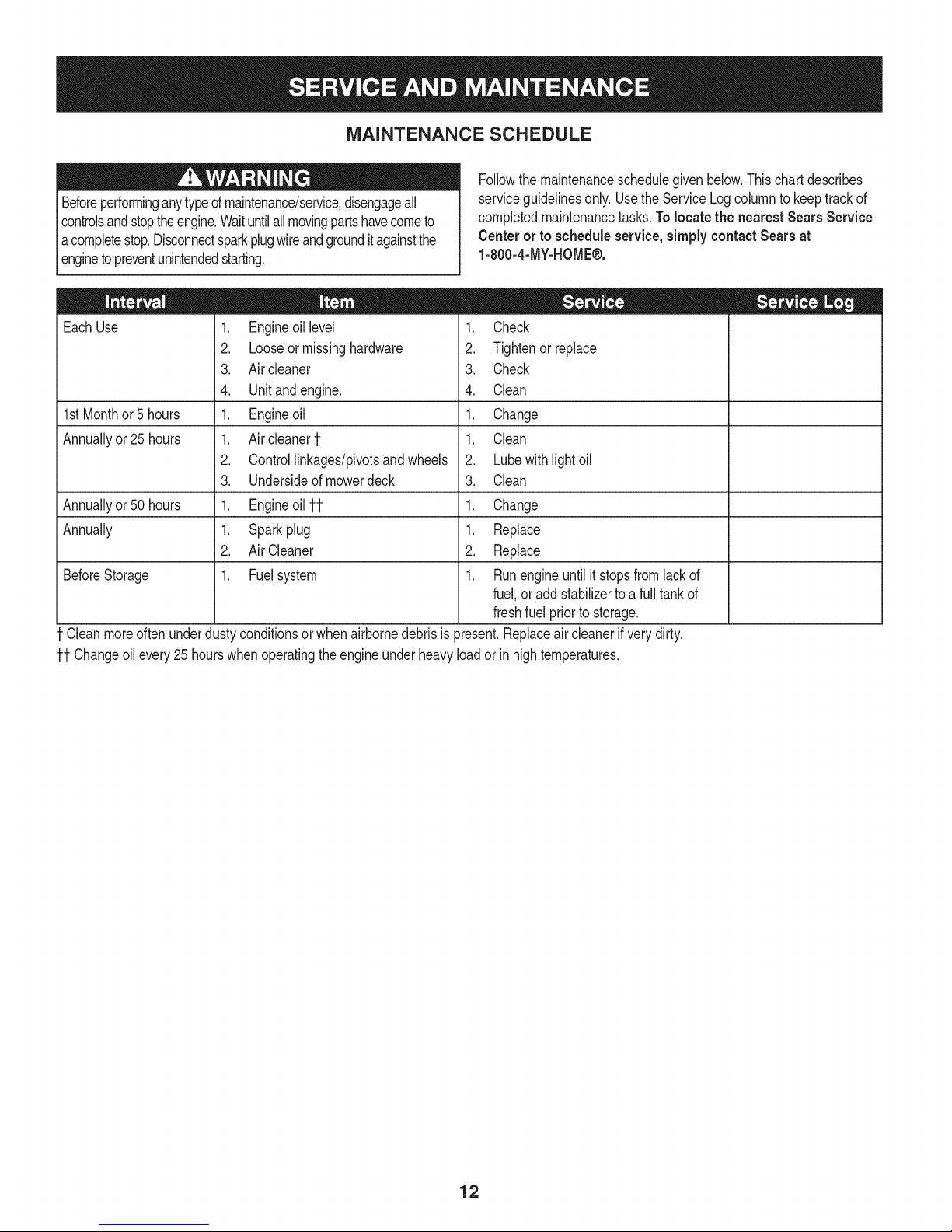

MAINTENANCE SCHEDULE

Beforeperforminganytypeofmaintenance/service,disengageall

controlsandstoptheengine.Waituntilallmovingpartshavecometo

acompletestop.Disconnectsparkplugwireandgroundit againstthe

enginetopreventunintendedstarting.

Followthe maintenanceschedulegivenbelow.Thischartdescribes

serviceguidelinesonly.UsetheServiceLogcolumnto keeptrackof

completedmaintenancetasks.To locate the nearest SearsService

Centeror toscheduleservice,simplycontactSearsat

1-800-4-MY-HOME®.

EachUse

1stMonthor 5 hours

Annuallyor25hours

Annuallyor50hours

Annually

BeforeStorage

.

Engineoillevel

2.

Looseormissinghardware

3.

Aircleaner

4.

Unitandengine.

1.

Engineoil

1.

Aircleaner1

2.

Controllinkages/pivotsandwheels

3.

Undersideof mowerdeck

1.

Engineoilff

1.

Sparkplug

2.

AirCleaner

1.

Fuelsystem

1. Check

2. Tightenor replace

3. Check

4. Clean

1. Change

1. Clean

2. Lubewithlightoil

3. Clean

1. Change

1. Replace

2. Replace

1. Runengineuntilitstopsfromlackof

fuel,oraddstabilizertoa fulltankof

freshfuelpriortostorage.

Cleanmoreoftenunderdustyconditionsor whenairbornedebrisis

_resent.Replaceaircleanerif verydirty.

11 Changeoil every25 hourswhenoperatingtheengineunderheavyloador in hightemperatures.

12

Page 13

Alwaysstopengine,disconnectsparkplugwire,andgroundagainst

enginebeforeperforminganytypeofmaintenanceon yourmachine.

GENERAL RECOMMENDATIONS

• Alwaysobservesafetyruleswhenperforminganymaintenance.

• Thewarrantyonthisedger/trencherdoesnotcoveritemsthat

havebeensubjectedtooperatorabuseor negligence.Toreceive

fullvaluefromwarranty,operatormustmaintaintheequipmentas

instructedhere.

• Changingof engine-governedspeedwillvoidenginewarranty.

• Alladjustmentsshouldbecheckedat leastonceeachseason.

• Periodicallycheckall fastenersandmakesurethesearetight.

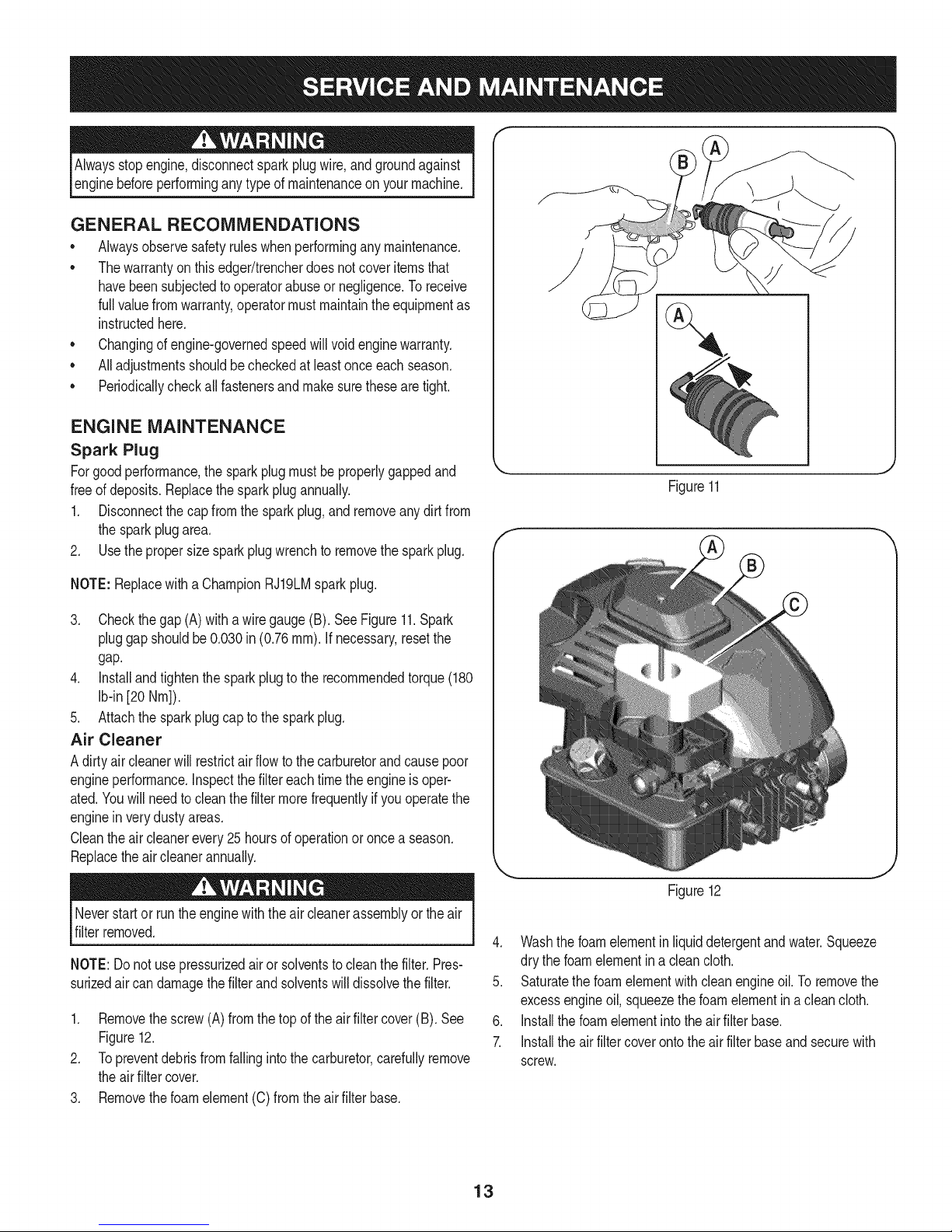

ENGINE MAINTENANCE

Spark Plug

Forgoodperformance,thesparkplugmustbeproperlygappedand

freeof deposits.Replacethesparkplugannually.

1. Disconnectthe cap fromthe sparkplug,andremoveanydirt from

thesparkplugarea.

2. Usethepropersizesparkplugwrenchtoremovethe sparkplug.

NOTE:Replacewitha ChampionRJ19LMsparkplug.

Figure11

3. Checkthegap (A)witha wiregauge(B). SeeFigure11.Spark

pluggapshouldbe0.030in (0.76ram).if necessary,resetthe

gap.

4. installandtightenthe sparkplugtotherecommendedtorque(180

Ib-in[20 Nm]).

5. Attachthe sparkplugcapto thesparkplug.

Air Cleaner

A dirtyaircleanerwillrestrictairflowto the carburetorandcausepoor

engineperformance,inspectthefiltereachtimetheengineisoper-

ated.Youwillneedtocleanthefiltermorefrequentlyifyouoperatethe

enginein verydusty areas.

Cleantheair cleanerevery25hoursof operationoroncea season.

Replacetheaircleanerannually.

Neverstartor runthe enginewiththeaircleanerassemblyor theair

filterremoved.

NOTE:Do notusepressurizedairor solventstocleanthe filter.Pres-

surizedair candamagethefilterandsolventswilldissolvethefilter.

1. Removethescrew(A)fromthetopoftheairfiltercover(B). See

Figure12.

2. Topreventdebrisfromfallingintothe carburetor,carefullyremove

theairfiltercover.

3. Removethefoamelement(C)fromtheairfilter base.

Figure12

4. Washthefoamelementinliquiddetergentandwater.Squeeze

drythefoamelementin a cleancloth.

5. Saturatethe foamelementwithcleanengineoil.To removethe

excessengineoil,squeezethe foamelementina cleancloth.

6. installthefoamelementintotheair filterbase.

7. installtheairfiltercoveronto theair filterbaseandsecurewith

screw.

13

Page 14

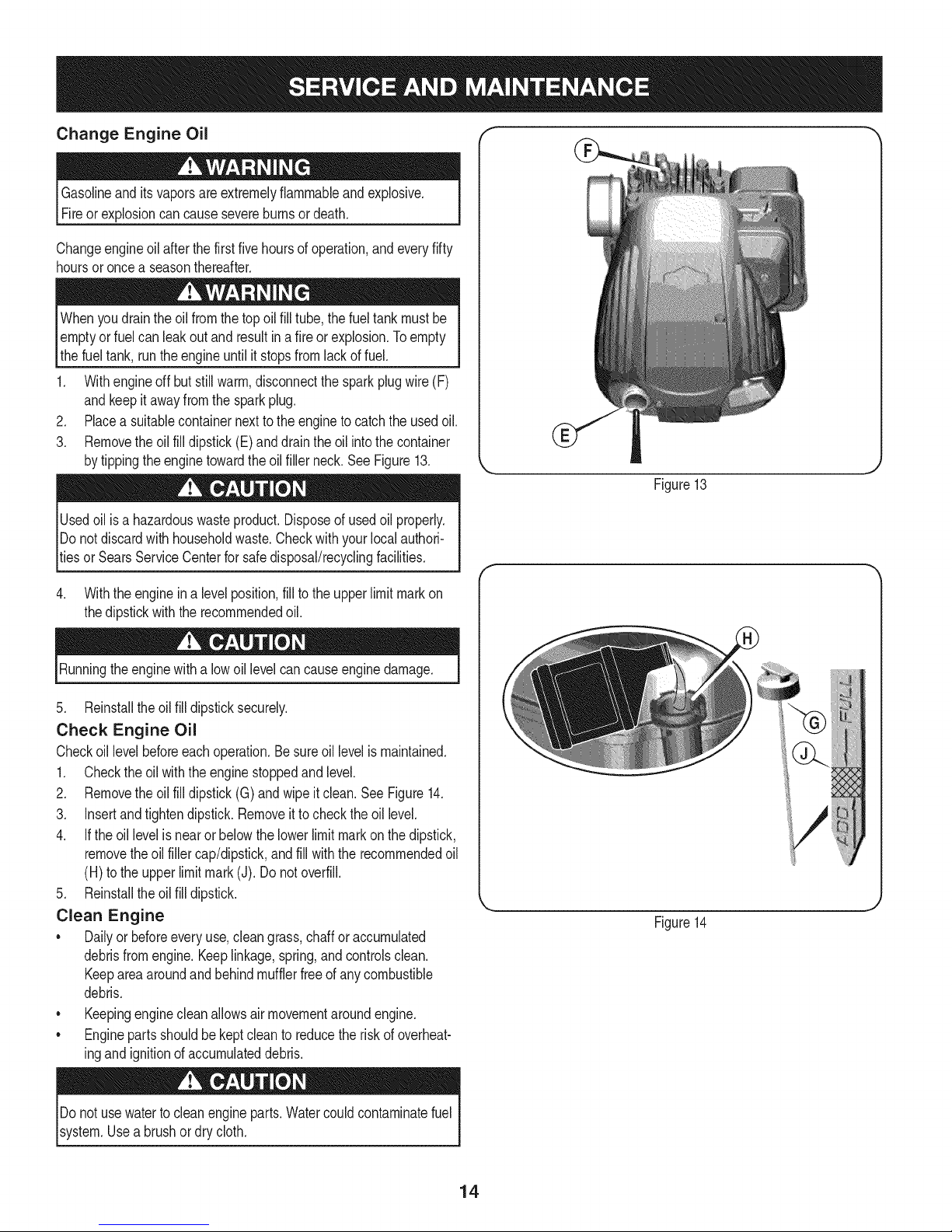

Change Engine Oil "" "

Gasolineanditsvaporsare extremelyflammableandexplosive.

Fireor explosioncancausesevereburnsordeath.

Changeengineoilafterthefirstfivehoursof operation,andeveryfifty

hoursoroncea seasonthereafter.

you

emptyor fuelcanleakoutand resultin afireor explosion.Toempty

lWhen drainthe oil fromthe oil fill thefueltankmustbe

thefueltank,runtheengineuntilitstopsfromlackoffuel.

1. Withengineoff butstillwarm,disconnectthesparkplugwire (F)

andkeepitawayfromthesparkplug.

2. Placea suitablecontainernexttotheenginetocatchtheusedoil.

3. Removetheoil filldipstick(E)anddrainthe oil intothecontainer

bytippingtheenginetowardtheoilfiller neck.SeeFigure13.

Usedoilis a hazardouswasteproduct.Disposeofusedoil properly.

IDonotdiscardwithhouseholdwaste.Checkwithyourlocalauthori-

_tiesor SearsServiceCenterfor safedisposal/recyclingfacilities.

4. Withtheengineina levelposition,filltotheupperlimitmarkon

thedipstickwiththerecommendedoil.

Runningtheenginewitha lowoil levelcancauseenginedamage.

5. Reinstalltheoilfill dipsticksecurely.

Check Engine Oil

Checkoillevelbeforeeachoperation.Besureoil levelismaintained.

1. Checktheoil withtheenginestoppedand level.

2. Removetheoil filldipstick(G) andwipeit clean.SeeFigure14.

3. Insertandtightendipstick.Removeitto checktheoillevel.

4. Iftheoil levelisnearor belowthelowerlimitmarkonthedipstick,

removethe oil fillercap/dipstick,andfill withtherecommendedoil

(H)totheupperlimitmark(J). Donotoverfill.

5. Reinstalltheoilfill dipstick.

Clean Engine

• Dailyor beforeeveryuse,cleangrass,chaffor accumulated

debrisfromengine.Keeplinkage,spring,andcontrolsclean.

Keepareaaroundandbehindmufflerfreeof any combustible

debris.

• Keepingenginecleanallowsairmovementaroundengine.

• Enginepartsshouldbekeptcleanto reducethe riskofoverheat-

ingandignitionofaccumulateddebris.

top tube,

Figure13

Figure14

Donotusewaterto cleanengineparts.Watercouldcontaminatefuel

system.Usea brushor drycloth.

14

Page 15

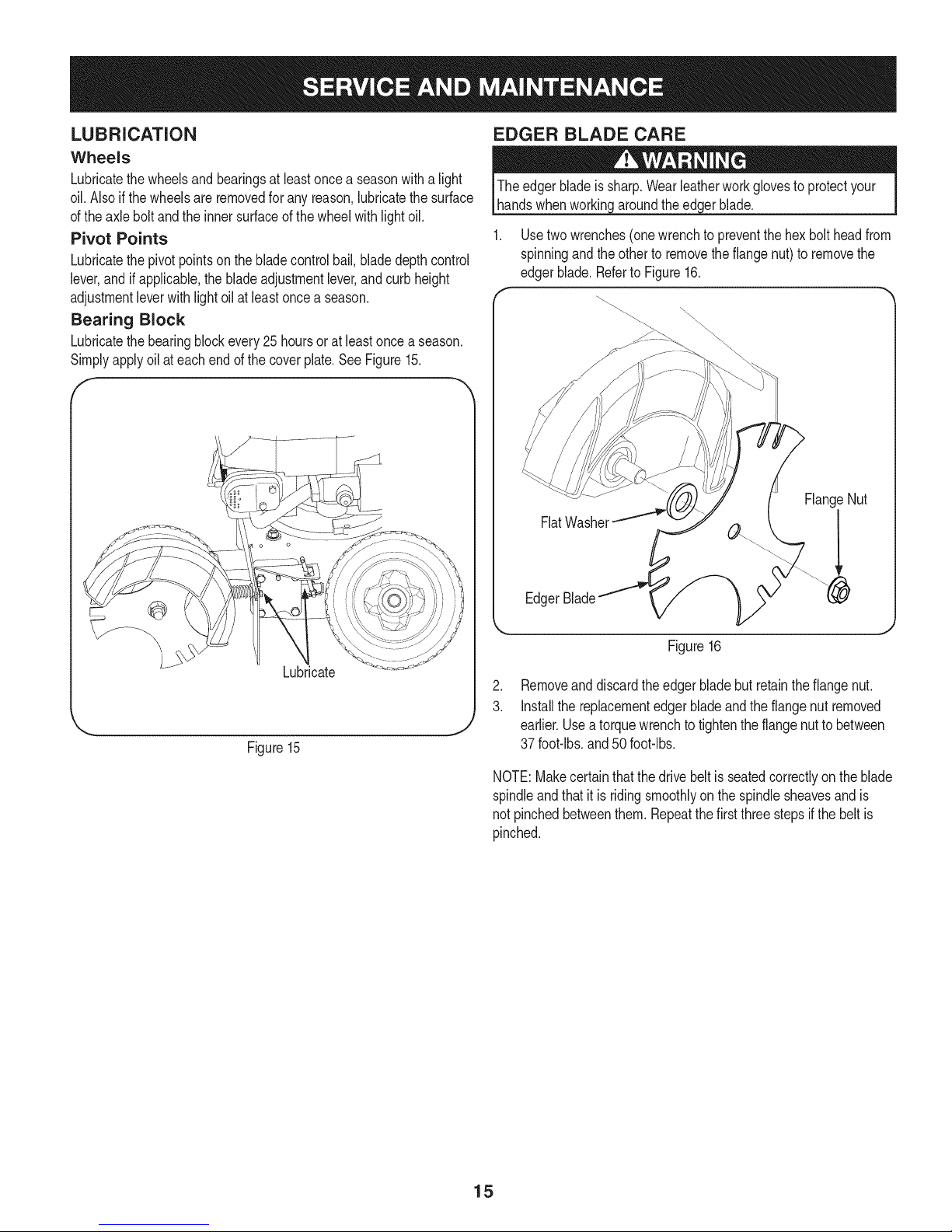

LUBRiCATiON

Wheels

Lubricatethe wheelsandbearingsatleastoncea seasonwitha light

oil.Alsoif the wheelsare removedfor any reason,lubricatethesurface

oftheaxlebolt andtheinnersurfaceofthe wheelwithlightoil.

Pivot Points

Lubricatethe pivotpointsonthebladecontrolbail,bladedepthcontrol

lever,and ifapplicable,thebladeadjustmentlever,andcurbheight

adjustmentleverwith lightoilat leastoncea season.

Bearing Block

Lubricatethe bearingblockevery25hoursor at leastonce a season.

Simplyapplyoil ateachendofthecoverplate.See Figure15.

f -

EDGER BLADE CARE

Usetwowrenches(onewrenchtopreventthehex boltheadfrom

spinningand theotherto removetheflangenut)to removethe

edgerblade.RefertoFigure16.

FlangeNut

FlatWasher \!

Edg

Lubricate

Figure15

Figure16

.

Removeanddiscardtheedgerbladebut retaintheflangenut.

3.

Installthereplacementedgerbladeandtheflangenut removed

J

earlier.Usea torquewrenchtotightentheflangenuttobetween

37 foot-lbs,and50 foot-lbs.

NOTE:Makecertainthatthe drive beltis seatedcorrectlyontheblade

spindleandthatit isridingsmoothlyonthe spindlesheavesandis

notpinchedbetweenthem.Repeatthefirstthreestepsif the beltis

pinched.

15

Page 16

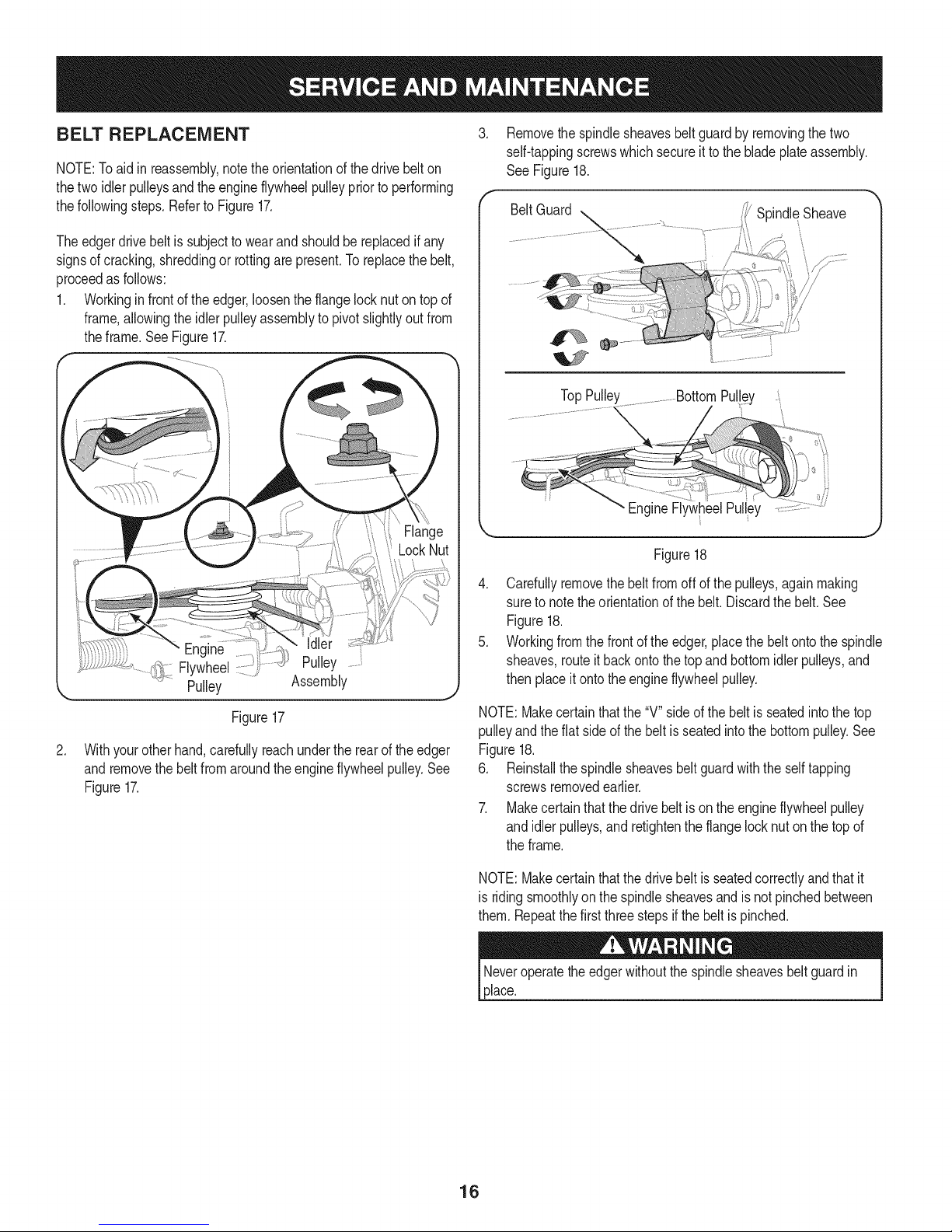

BELT REPLACEMENT

NOTE:Toaid inreassembly,notetheorientationofthedrivebelton

thetwo idlerpulleysandtheengineflywheelpulleypriorto performing

thefollowingsteps.Referto Figure17.

Theedgerdrivebelt issubjecttowearand shouldbe replacedifany

signsofcracking,shreddingorrottingarepresent.Toreplacethebelt,

proceedasfollows:

1. Workingin frontoftheedger,loosenthe flangelock nuton topof

frame,allowingthe idlerpulleyassemblytopivotslightlyoutfrom

theframe.SeeFigure17.

Flange

LockNut

Engine ..........., Idler

Flywheel........... Pulley .......!_

'_.....Pulley Assembly

Figure17

.

Withyourotherhand,carefullyreachundertherearoftheedger

andremovethebeltfromaroundtheengineflywheelpulley.See

Figure17.

.

Removethespindlesheavesbelt guardby removingthe two

self-tappingscrewswhichsecureittothebladeplateassembly.

See Figure18.

/ii Spindle Sheave

TopPulley Pul!ey

EngineFlywheelPulley

Figure18

4. Carefullyremovethebeltfromoffof the pulleys,againmaking

sureto notetheorientationof the belt.Discardthebelt.See

Figure18.

5. Workingfromthefrontoftheedger,placethebeltontothespindle

sheaves,routeit backontothetopandbottomidlerpulleys,and

thenplaceit ontotheengineflywheelpulley.

NOTE:Makecertainthatthe "V" sideof thebeltisseatedintothetop

pulleyandtheflatsideofthebeltisseatedintothe bottompulley.See

Figure18.

6. Reinstallthespindlesheavesbeltguardwiththeselftapping

screwsremovedearlier.

7. Makecertainthatthedrivebeltisontheengineflywheelpulley

and idlerpulleys,and retightentheflangelocknuton thetopof

theframe.

NOTE:Makecertainthatthe drivebeltisseatedcorrectlyandthatit

is ridingsmoothlyon the spindlesheavesandis notpinchedbetween

them.Repeatthe firstthreestepsifthebeltispinched.

Neveroperatetheedgerwithoutthespindlesheavesbeltguardin

place.

16

Page 17

Neverstoreedgerwithfuelin tankindoorsorin poorlyventilated

areaswherefuelfumesmayreachanopenflame,spark,orpilot

lightas ona furnace,waterheater,clothesdryer,orgasappliance.

PREPARING THE ENGINE

Forenginesstoredover30days:

1. Topreventgum fromforminginfuelsystemoron carburetor

parts,runengineuntilitstopsfromlackoffueloradda gasoline

additiveto thegasin thetank.If youuse agasadditive,runthe

engineforseveralminutesto circulatetheadditivethroughthe

carburetor--afterwhichtheengineandfuelcanbestoredupto

24months.

2. Whileengineisstillwarm,changetheoil.

3. Cleanengineof surfacedebris.

PREPARING THE EDGER

• Cleanandlubricateedgerthoroughlyasdescribedinthelubrica-

tioninstructions.

• Donotusea pressurewasherorgardenhosetocleanyourunit.

• Coatedgerbladewithchassisgreaseto preventrusting.

• RefertoPREPARINGTHE ENGINEforcorrectenginestorage

instructions.

• Storeedgerina dry,cleanarea. Donotstorenexttocorrosive

materials,suchasfertilizer.

Whenstoringany typeofpowerequipmentina poorlyventilatedor

metalstorageshed,careshouldbetakentorust-prooftheequipment.

Usinga lightoil orsilicone,coattheequipment,especiallycablesand

all movingpartsof youredgerbeforestorage.

17

Page 18

Beforeperforminganytypeofmaintenance/service,disengageallcontrolsandstopthe engine.Waituntilall

movingpartshavecometoacompletestop.Disconnectsparkplugwireandgrounditagainsttheengineto

Ipreventunintendedstarting.Alwayswearsafetyglassesduringoperationorwhileperforminganyadjustmentsor

[repairs.

Enginefailstostart

Enginerunserratic

Engineoverheats 1. Engineoil levellow.

Occasionalskips(hesitates) 1, Sparkpluggaptoo close.

Idlespoorly 1, Sparkplugfouled,faulty,or gaptoowide.

Excessivevibration 1, Edgerbladebentordamaged.

Drive-beltSlips 1. Beltwornor stretched

1. Bladecontroldisengaged.

2. Sparkplugbootdisconnected.

3. Fueltankemptyorstalefuel.

4. Faultysparkplug.

5, Engineflooded.

6. Blockedfuelline.

1. Sparkplugbootloose.

2. Stalefuel.

3. Ventingascapplugged.

4. Wateror dirt in fuelsystem.

5. Dirtyair cleaner.

6. Blockedfuelline.

2. Air flowrestricted.

2, Dirtyair cleaner.

2. Bladespindlebentor damaged.

1. Engagebladecontrol.

2. Connectwiretosparkboot.

3. Filltankwithclean,freshgasoline.

4. Clean,adjustgap,or replace.

5, Waita fewminutestorestart.

6. ContactyourSearsParts& RepairCenterto have

fuellinecleaned.

1, Connectandtightensparkplugboot.

2. Filltankwithclean,freshgasoline.

3. Clearvent.

4. Runengineuntilit stopsfromlackoffuel. Refillwith

freshfuel.

5, RefertoAirCleanerin EngineMaintenancesection.

6. ContactyourSearsParts& RepairCenterto have

fuellinecleaned.

1. Fillcrankcasewithproperoil.

2. Cleanareaaroundandontopofengine.

1. Adjustgapto.030".

1. Resetgapto ,030"or replacesparkplug.

7. RefertoAirCleanerin EngineMaintenancesection.

1, Replaceedgerblade.

2, ContactyourSearsParts& RepairCenterto have

unitinspected.

1. Replacedrivebelt.

NEED MORE HELP?

You'll find the answe_ _and more on s_a_agemylifeocem _ for free_

Find this and aLLyour other product manuals online.

Get answers from our team of home experts.

Get a personalized maintenance plan for your home.

o Find information and tools to help with home projects.

managemylife

18

Page 19

19

Page 20

Craftsman Edger/Trencher B IViodel No. 247.79651

66

49

58

F/z2_9_

4_L

A_/_ 4_ 32

55 _. 51`` _

``_ 57`` _

_11 _``7

62

39

2O

Page 21

Craftsman Edger/Trencher B IViodel No. 247.79651

35

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

2O

21

22

23

24

25

26

27

28

29

30

31

32

33

34

687-02022

687-02585

687-02126

710-0191

710-0411

710-04389

710-0599

710-0654A

710-0726

710-0870

710-1143A

710-1174

710-1205

710-3180

711-05696

711-04440

712-04063

712-04065

712-0417A

714-3010

718-04012

720-0142

720-0279

720-04072A

726-0299

931-04207

731-05063

731-05064

732-0188A

932-0369

732-04045

932-04169

734-1264

734-1268

736-04019

CurbHeightAdjustmentLever

CurbHeightAdjusterPlate

BladePlateAssembly

Screw3/8-24

Screw3/8-16

HexScrew,5/16-18

Self-tappingScrew,1/4-20

Screw,3/8-16

HexScrew,5/16-12

HexScrew5/16-18

HexScrew,5/8-18

CarriageBolt,5/16-18

RopeGuide(EyeBolt)

HexScrew,5/16-18

AxleShaft.50x6.65

FrameSpacer.50x9.25

LockFlangeNut,5/16-18

FlangeNut3/8-16

FlangeNut,5/8-18

ClevisPin3/32x .625

BearingCup

Grip

WingNut

StarKnob

PushCap1/2"rod

BearingBlock

DebrisGuard

BladeGuard

DoubleTorsionSpring

CompressionSpring

TorsionSpring

CompressionSpring

Wheel7 x 1.75T-Tread

Wheel8 x 1.75T-Tread

Flat Washer, .531 x 125 x .181

m

36

936-0232

37

736-0234

38

736-0258

39

936-04088

4O

936-0452

41

738-04149

42

738-0706C

43

738-0929

44

941-0524A

45

746-04035

46

946-04036

47

747-04110A

48

747-0976A-0637

49

749-04183-0637

5O

749-04234-0637

51

950-04105

52

750-04129

53

950-04142

54

750-0547

55

954-04032B

56

756-04148

57

956-0449

58

756-1150A

59

781-0427-0637

60

781-0741A

61

781-0742-0637

62

781-0748-0637

63

787-01081A-4044

64

787-01240-4044

65

787-01304o4044

66

10L802-5547-F2

67

712-04217

68

750-05548

69

750-0664

D = O O

WaveWasher.531x .781x .013

FiatWasher,.385x 1.5x .075

FiatWasher.385x 1.0x .135t

FiatWasher.635xl.24x.181

BellWasher,.396x 1.140

ShoulderScrew,3/8-16

ShoulderScrew

ShoulderScrew,3/8-16

Bearing,.625IDx 1.57OD

ControlCable(Briggs&Stratton)

WheelAdjustmentCable

BladeAdjustmentRod

BailHandle

UpperHandle

LowerHandle

Spacer,.63 x 1.12x 1.06

Spacer

PulleyMountSpacer

Spacer,.64 x.88x .50

Belt

FiatIdlerPulley,2.50D

Sheave

CombinationFlywheelPulley

BeltGuard

DepthindexBracket

DepthindexLever

Tri-StarBlade

BracketPlate

WheelBracket

Frame

Engine

FlangeLockNut,3/8-16

Spcr.,.525x .775x.93

Spcr.,.5051Dx .880Dx .440

21

Page 22

Craftsman Engine Model No. 10L802-5547-F2 For Craftsman Edger/Trencher Model No. 247.79651

48 SHORTB LOCK ] I 1058 OPERATOR'S MANUAL I [ 1329 REPLACEMENTE NGINE ] [ 1330R EPAIRM ANUAL ]

}_ 842O

523

@

287

525

524 O

@

7180

E

2[_zJ _o5 ®

562

615

404 @

lO_

358 ENGINE GASKET SET

@

g

616 _

1095 VALVEG ASKET SET

524 O

22

Page 23

Craftsman Engine IViodel No. 10L802=5547=F2 For Craftsman Edger/Trencher IViodel No. 247.79651

24[_

_j

12

15_ 22

23

Page 24

Craftsman Engine Model No. 10L802=5547=F2 For Craftsman Edger/Trencher Model No. 247.79651

o%

612

390

190A (_

222

202_ 209_

300

729

334

534

635

535

745

745A

163

24

Page 25

Craftsman Engine IViodel No. 10L802=5547=F2 For Craftsman Edger/Trencher IViodel No. 247.79651

969

73

%

I 1036E MISSIONS LABEL ]

78

55

592

1211

1210 _

6O

689

456 @

597 _

%

37A

455

332

@

3O4

78

305 (_

37

25

Page 26

Craftsman Engine Model No. 10L802=5547=F2 For Craftsman Edger/Trencher Model No. 247.79651

590770 CylinderAssembly

2 796961 Kit-Bushing/Seal(MagnetoSide)

3 299819s Seal-Oil(MagnetoSide)

4 590569 Sump-Engine

5 790169 Head-Cylinder

7 _ 698747 Gasket-CylinderHead

8 791781 BreatherAssembly

9 695890 Gasket-Breather

10 691666 Screw(BreatherAssembly

11 691245 Tube-Breather

12 692218 Gasket-Crankcase

13 691640 Screw(CylinderHead)

15 691680 Plug-OilDrain

16 796217 Crankshaft

20 391483s SeaI-Oil(PTOSide)

22 692551 Screw(CrankcaseCover/Sump),1/4-20x 1.19

22A 590763 Screw(CrankcaseCover/Sump),1/4-20x .78

23 799682 Flywheel

24 222698s Key-Flywheel

25 795691 PistonAssembly(Standard)

795689 PistonAssembly(.020"Oversize)

26 795690 RingSet(Standard)

795688 RingSet(.020"Oversize)

27 691588 Lock-PistonPin

28 699659 Pin-Piston

29 699654 Rod-Connecting

32 691664 Screw(ConnectingRod)

33 296676 Valve-Exhaust

34 296677 Valve-Intake

35 690520 Spring-Valve(Intake)

36 690520 Spring-Valve(Exhaust)

37 793478 Guard-Flywheel(MufflerSide)

37A 697403 Guard-Flywheel(CarburetorSide)

40 692194 Retainer-Valve

43 697799 Slinger-Governor/Oil

45 690762 Tappet-Valve

46 691998 Camshaft

48 N/A ShortBlock(Notavailableatthis printing)

50 699644 Manifold-Intake

50 792388A Manifold-Intake

792389 Gasket-Intake

54 691111 Screw(IntakeManifold)

55 692144 Housing-RewindStarter

58 697316 Rope-Starter

60 691915 Grip-StarterRope

65 690837 Screw(RewindStarter)

73 699850 Screen-Rotating

78 692198 Screw(FlywheelGuard)

90 795476 Carburetor

97 697414 Shaft-Throttle

106 690901 Seat-Net

130 691190 Valve-Throttle

163 271139s Gasket-AirCleaner

180 795473 Tank-Fuel

188 692198 Screw(ControlBracket)

190 691640 Screw(FuelTank)(13A"Long)

190A 691108 Screw(FuelTank)(9/16"Long)

202 698835 Link-MechanicalGovernor

209 698719 Spring-Governor(LightBlue)

222 798686 Bracket-Control

227 697402 Lever-GovernorControl

287 691002 Screw(DipstickTube)

300 394569s Muffler

304 697411 Housing-Blower

305 692198 Screw(BlowerHousing)

332 690662 Nut(Flywheel)

333 799471 Armature-Magneto

334 691061 Screw(MagnetoArmature)

337 802592s Plug-Spark

356 692390 Wire-Stop

358 590777 GasketSet-Engine

365 790029 Screw(Carburetor)

390 691839 Spring-ChokeDiaphragm

393 691837 Screen-Carburetor

394 795478 Diaphragm-Carburetor

404 690272 Washer(GovernorCrank)

455 691236 Cup-Flywheel

456 692299 Plate-PawlFriction

459 281505s PawI-Ratchet

505 691251 Nut(GovernorControlLever)

26

Page 27

Craftsman Engine IViodel No. 10L802=5547=F2 For Craftsman Edger/Trencher IViodel No. 247.79651

692040 Dipstick

524 691876 Seal-DipstickTube

525 691320 Tube-Dipstick

529 692189 Grommet

534 691417 Screw(AirCleaner)

535 698369 Filter-AirCleanerFoam

536 698472 Cleaner-Air

562 691119 Bolt(GovernorControlLever)

592 690800 Nut(RewindStarter)

597 691696 Screw(PawlFrictionPlate)

608 499706 Starter-Rewind

612 496046s Tube-PickUp

615 690340 Retainer-GovernorShaft

616 697405 Crank-Governor

617 270344s Seal-ORing(IntakeManifold)

621 692310 Switch-Stop(Brake)

633 691321 SeaI-Choke/ThrtleShft (ThrtleShft)

635 66538s Boot-SparkPlug

670 691633 Spacer-FuelTank

689 691855 Spring-Friction

718 690959 Pin-Locating

724 697478 Retainer-Seal

694394 Primer-Carburetor

1036 EmissionsLabel

1058 277038 Operator'sManual

1095 498526

1210 499901

1211 499901

1218 695866

1329 N/A

1330 270962

GasketSet-Valve

Pulley/SpringAssembly(Pulley)

Pulley/SpringAssembly(Spring)

Seal-ORing(Carburetor)

ReplacementEngine(Notavailableatprinting)

RepairManual

EngineGasketSet Key.No.358

ValveGasketSet Key.No.1095

729 690586 Clip-Wire

741 796210 Gear-Timing

745 691146 Screw(Brake)(7/8"Long)

745A 690859 Screw(Brake)(1/2"Long)

842 691870 Seal-ORing(DipstickTube)

847 691440 Dipstick/TubeAssembly

851 493880s Terminal-SparkPlug

868 697338 Seal-Valve

869 699641 Seat-Valve(Intake)

870 699642 Seat-Valve(Exhaust)

871 699643 Bushing-ValveGuide(ExhaustValve)

63709 Bushing-ValveGuide(IntakeValve)

913 494409 Seat-CheckValve

921 793973 Cover-BlowerHousing

922 692135 Spring-Brake

923 691487 Brake

957 795472 Cap-Fuel

969 799014 Screw(BlowerHousingCover)

27

Page 28

1171_t40

_ TTIEIMI_

17712_4

TnIJ1TI51

777_

28

Page 29

(Thispageapplicableinthe U.S.A.and Canadaonly.)

Sears Brands Management Corporation (Sears), the California Air Resources Board (CARD)

and the United States Environmental Protection Agency (U.S. EPA)

Emission Control System Warranty Statement (Owner's Defect Warranty Rights and Obligations)

EMISSIONCONTROLWARRANTYCOVERAGEISAPPLICABLETOCERTI-

FIEDENGINESPURCHASEDINCALIFORNIAIN1995ANDTHEREAF-

TER,WHICHAREUSEDINCALIFORNIA,ANDTOCERTIFIEDMODEL

California and United States Emission

TheCaliforniaAirResourcesBoard(CARD),U.S.EPAandSearsare pleased

toexplainthe EmissionControlSystemWarrantyonyour modelyear2000and

latersmalloff-roadengine(SORE).InCalifornia,newsmall off-roadengines

mustbe designed,builtandequippedto meettheState'sstringentanti-smog

standards.Elsewherein theUnitedStates,newnon-road,spark-ignition

enginescertifiedformodelyear1997and latermustmeetsimilarstandardsset

forthbythe U.S.EPA.Searsmustwarranttheemissioncontrolsystemonyour

YEAR1997AND LATERENGINESWHICHARE PURCHASEDANDUSED

ELSEWHEREINTHEUNITEDSTATES(ANDAFTERJANUARY1,2001 IN

CANADA).

Control Defects Warranty Statement

enginefortheperiodsoftime listedbelow,providedtherehasbeennoabuse,

neglector impropermaintenanceof your smalloff-roadengine.Youremis-

sioncontrolsystemincludespartssuchasthecarburetor,aircleaner,ignition

system,mufflerandcatalyticconverter.Alsoincludedmaybeconnectorsand

otheremissionrelatedassemblies.Wherea warrantableconditionexists,Sears

will repairyoursmalloff-roadengineat nocostto youincludingdiagnosis,parts

andlabor.

Sears Emission Control Defects Warranty Coverage

Smalloff-roadenginesarewarrantedrelativeto emissioncontrolpartsdefects

fora periodofone year,subjectto provisionssetforthbelow.Ifanycovered

Owner's Warranty

Asthe smalloff-roadengineowner,youare responsiblefor theperformanceof

therequiredmaintenancelistedin yourOperatingand MaintenanceInstruc-

tions.Searsrecommendsthatyouretainallyourreceiptscoveringmaintenance

onyoursmalloff-roadengine,butSears cannotdenywarrantysolelyfor the

lackofreceiptsorforyourfailuretoensuretheperformanceof allscheduled

maintenance.Asthe smalloff-roadengineowner,youshouldhoweverbe

awarethat Searsmaydenyyouwarrantycoverageifyour smalloff-roadengine

ora parthasfaileddueto abuse,neglect,impropermaintenanceor unap-

parton yourengineis defective,the partwillbe repairedorreplacedbySears.

Responsibilities

provedmodifications.Youareresponsiblefor presentingyoursmalloff-road

engineto anAuthorizedSearsServiceDealerassoonasaproblemexists.The

undisputedwarrantyrepairsshouldbecompletedina reasonableamountof

time,notto exceed30days.Ifyouhaveanyquestionsregardingyourwarranty

rightsandresponsibilities,you shouldcontacta SearsServiceRepresentative

at 1-800-469-4663.The emissionwarrantyis a defectswarranty.Defectsare

judgedonnormalengineperformance.Thewarrantyis notrelatedtoan in-use

emissiontest.

Sears Emission Control Defects Warranty Provisions

ThefollowingarespecificprovisionsrelativetoyourEmissionControlDefectsWarrantyCoverage.ItisinadditiontotheSearsenginewarrantyfornon-regulated

enginesfoundin theOperatingand MaintenanceInstructions.

1. WarrantedParts

Coverageunderthiswarrantyextendsonlytothe partslistedbelow(the

emissioncontrolsystemsparts)tothe extentthese partswerepresenton

theenginepurchased.

a. FuelMeteringSystem

• Coldstartenrichmentsystem

• Carburetorandinternalparts

• FuelPump

b. AirlnductionSystem

• Aircleaner

• Intakemanifold

c. IgnitionSystem

• Sparkplug(s)

• Magnetoignitionsystem

d. CatalystSystem

• Catalyticconverter

• Exhaustmanifold

• Air injectionsystemor pulsevalve

e. MiscellaneousItemsUsedin AboveSystems

• Vacuum,temperature,position,timesensitivevalves

andswitches

• Connectorsandassemblies

2. Lengthof Coverage

Searswarrantsto the initialownerand eachsubsequentpurchaserthat

theWarrantedPartsshallbefreefromdefectsin materialsandworkman-

shipwhich causedthefailureof the WarrantedPartsfor aperiodofone

yearfromthe datethe engineis deliveredtoa retailpurchaser.

Inthe USAandCanada,a 24hourhotline,1-800-469-4663,hasamenuofpre-recordedmessagesofferingyouenginemaintenanceinformation.

3. NoCharge

Repairorreplacementof anyWarrantedPartwill beperformedat no

chargeto the owner,includingdiagnosticlaborwhichleadstothe

determinationthata WarrantedPartisdefective,ifthe diagnosticworkis

performedatanAuthorizedSearsServiceDealer.Foremissionswarranty

servicecontact yournearestAuthorizedSearsServiceDealeras listed in

the "YellowPages"under"Engines,Gasoline,""GasolineEngines,""Lawn

Mowers,"orsimilarcategory.

4. Claimsand CoverageExclusions

Warrantyclaimsshallbefiled in accordancewiththe provisionsof the

SearsEngineWarrantyPolicy.Warrantycoverageshall beexcludedfor

failuresof WarrantedPartswhicharenotoriginalSearspartsor because

ofabuse,neglector impropermaintenanceassetforth inthe Sears

EngineWarrantyPolicy.Searsisnotliableto coverfailuresof Warranted

Partscausedby theuseof add-on,non-original,ormodifiedparts.

5. Maintenance

AnyWarrantedPartwhichis notscheduledfor replacementasrequired

maintenanceor whichis scheduledonlyforregularinspectiontothe effect

of"repairor replaceas necessary"shallbe warrantedasto defectsfor the

warrantyperiod.AnyWarrantedPartwhich is scheduledfor replacement

asrequiredmaintenanceshallbewarrantedas to defectsonlyforthe

periodoftime uptothe firstscheduledreplacementfor that part.Any

replacementpart that isequivalentinperformanceand durabilitymay

beusedin the performanceofany maintenanceorrepairs.Theowneris

responsibleforthe performanceof all requiredmaintenance,asdefinedin

the SearsOperatingand MaintenanceInstructions.

6. ConsequentialCoverage

Coveragehereundershallextendto thefailure ofanyenginecomponents

causedbythe failureofany WarrantedPartstill underwarranty.

GDOC-100188Rev.B

29

Page 30

Look For Relevant Emissions Durability Period and

Air index information On Your Engine Emissions Label

Engines that are certified to meet the California Air Resources Board (CARB) Tier 2 Emission Standards must

display information regarding the Emissions Durability Period and the Air Index. Sears Brands Management

Corporation makes this information available to the consumer on our emission labels.

The Emissions Durability Period describes the number of hours of actual running time for which the engine is

certified to be emissions compliant, assuming proper maintenance in accordance with the Operating & Mainte-

nance Instructions. The following categories are used:

Moderate: Engine is certified to be emission compliant for 125 hours of actual engine running time.

Intermediate: Engine is certified to be emission compliant for 250 hours of actual engine running time.

Extended: Engine is certified to be emission compliant for 500 hours of actual engine running time.

For example, a typical walk-behind lawn mower is used 20 to 25 hours per year. Therefore, the Emissions

Durability Period of an engine with an intermediate rating would equate to 10 to 12 years.

The Air index is a calculated number describing the relative level of emissions for a specific engine family. The

lower the Air Index, the cleaner the engine. This information is displayed in graphical form on the emissions label.

After July 1,2000, Look For Emissions Compliance Period

On Engine Emissions Compliance Label

After July 1, 2000 certain Sears Brands Management Corporation engines will be certified to meet the United

States Environmental Protection Agency (USEPA) Phase 2 emission standards. For Phase 2 certified engines, the

Emissions Compliance Period referred to on the Emissions Compliance label indicates the number of operating

hours for which the engine has been shown to meet Federal emission requirements.

For engines less than 225 cc displacement, Category C = 125 hours, B = 250 hours and A = 500 hours.

For engines of 225 cc or more, Category C = 250 hours, B = 500 hours and A = 1000 hours.

This is a generic representation of the emission label typically found on a certified engine.

FAMILYYBSXS.3192VA 274812

GDOC-100182Rev.B

30

Page 31

Congratulations on making a smart purchase. Your new Craftsman® product is designed and

manufactured for years of dependable operation. But like all products, it may require repair

from time to time. That's when having a Repair Protection Agreement can save you money and

aggravation.

Here's what the Repair Protection Agreement* includes:

[] Expert service by our 10,000 professional repair specialists

[] Unlimited service and no charge for parts and labor on all covered repairs

[] Product replacement up to $1500 if your covered product can't be fixed

[] Discount of 25% from regular price of service and related installed parts not covered by the

agreement; also, 25% off regular price of preventive maintenance check

[] Fast help by phone - we call it Rapid Resolution - phone support from a Sears representative.

Think of us as a "talking owner's manual."

Once you purchase the Repair Protection Agreement, a simple phone call is all that it takes for you

to schedule service. You can call anytime day or night, or schedule a service appointment online.

The Repair Protection Agreement is a risk-free purchase. If you cancel for any reason during the

product warranty period, we will provide a full refund. Or, a prorated refund anytime after the

product warranty period expires. Purchase your Repair Protection Agreement today!

Some limitations and exclusions apply. For prices and additional information in the U.S.A.

call 1=800=827=6655.

*Coverage in Canada varies on some items. For full details call Sears Canada at 1=800=361=

6665.

Sears Installation Service

For Sears professional installation of home appliances, garage door openers, water heaters, and

other major home items, in the U.S.A. or Canada call 1=800=4=MY=HOME®.

31

Page 32

Declaraci6n de garantia .................................................. 32

Medidas importantes de seguridad .......................... 33-36

Montaje ...................................................................... 37-38

Funcionamiento .......................................................... 39-41

Servicio y Mantenimiento ........................................... 42-46

Aimacenamiento fuera de temporada ............................ 47

Soluci6n de problemas ................................................... 48

NOmero de servicio ............................................... Cubierta

posterior

GARANTiA COMPLETA CRAFTSMAN POR DOS AltOS

PORDOSANOSapartirdela fechade lacompra,esteproductoest,.garantizadopordefectosen los materialesy la manodeobra.

Losproductosdefectuososser_.nreparadossin costoo reemplazadossin costosi la reparaci6nnoest,.disponiNe.

Paraobtener informaci6nsobre el alcancede la garantiay solicitar la reparaci6no el reemplazo,visiteel sitio Web:www.craftsman.com.

Esta garantiacubre 0NICAMENTElosdefectos en los materiales y enla manode obra. EstagarantiaNOcubre:

• Articulosde duraci6nlirnitadaquepuedendesgastarsebajocondicionesnormalesdeuso duranteel periododegarantia,talescomo,

correas,filtrosdeaire,bujiasdeencendido,ylascuchillasdela bordeadora.

• ProductodaSosresultantesde los intentosdelusuariodemodificaci6ndelproducto,reparaci6no causadosporaccesoriosdeproductos.

• Reparacionesnecesariasdebidoalaccidenteo por nooperaro mantenerelproductoseg_nlasinstruccionesprovistas.

• Mantenimientoprevenfivoo reparacionesnecesariasdebidoa mezcladecombustibleimpropia,combustiblecontaminadoo aSejo.

La presentegaranfiase anulasiseutilizaesteproductoalgunavezparaprestarservicioscomercialeso siseIoalquilaa otra persona.

Estagarantiale otorgaderechoslegalesespedficos,peroustedpodriagozardeotrosderechosenraz6ndesu lugarde residencia.

Sears BrandsManagementCorporation, Hoffman Estates,IL 60179

Aceitedelmotor: SAE30

Capacidaddeaceitedel motor: 18onzas

Combustible: Gasolinasin plomo

Bujia: Champion®RJ19LM

Motor: Briggs& Stratton

©SearsBrands,LLC 32

N_mero de modelo.........................................................

N_mero de serie ............................................................

Fecha de compra.........................................................................

RegistreelnQmerodemodelo,nQmerode serie

y fechade compram_.sarriba

Page 33

Lapresenciade estesirnboloindicaquesetratade instrucciones

irnportantesde seguridadque sedebenrespetarparaevitar

ponerenpeligrosu seguridadpersonaly/o materialy la deotras

personas.Leay sigatodaslas instruccionesde estemanualantes

de poneren funcionarnientoestarnAquina.Sino respetaestas

instruccionespodriaprovocarlesionespersonales.Cuandoveaeste

sirnbolo,ipresteatenci6na laadvertencia!

EstarnAquinarueconstruidaparaseroperadadeacuerdocon

lasreglasdeseguridadcontenidasenestemanual.AIigualque

concualquiertipode equipornotorizado,undescuidoo errorpor

partedeloperadorpuedeproducirlesionesgraves.EstarnAquina

escapazde arnputarrnanosy piesy dearrojarobjetoscon gran

fuerza.De norespetarlasinstruccionesde seguridadsiguientesse

puedenproducirlesionesgravesolarnuerte.

PROPOSICION 65 DE CALIFORNIA

Elescapedel motordeesteproducto,algunosdesuscornponentes

y algunoscornponentesdelvehiculocontienenoliberansustancias

quirnicasqueelestadodeCaliforniaconsideraque puedenproducir

cancer,defectosdenacirnientouotrosproblernasreproductivos.

CAPACITACION

• Leaconatenci6ntodaslas instruccionescontenidasen esteman-

ualantesde intentarensarnblaresta rnAquina.Lea,cornprenday

respetetodaslasinstruccionesquefiguranenla rnAquinayen el

o los rnanualesantesde hacerlafuncionar.Guardeestemanual

enun lugarseguroparaconsultasfuturasy peri6dicas,asicorno

parasolicitarrepuestos.

• Antesdeoperaresteequipo,farniliaricesetotalrnentecon los

controlesyel usocorrectodelrnisrno.

• EstarnAquinaes unaunidaddeequipornotorizadode precisi6n,

nounjuguete.PotIo tanto,tengarnuchocuidadoentodo

rnornento.EstarnAquinaruedise_adapararealizarunatarea:

bordearelc_sped.NolautiliceparaningOnotrofin.

• No perrnitanuncaquelosni_osrnenoresde 14a_osutilicen

estarnAquina.Losni_osde 14a_osen adelantedebenleery

entenderlasinstruccionesdeoperaci6ny norrnasdeseguridad

contenidaseneste manual,yen la rnAquinay debenser

entrenadosy supervisadospor unadulto.

• S61osedebeperrnitirusarestarnAquinaa individuosrespons-

ablesy farniliarizadosconsusreglasde seguridad.

• Paraayudaraevitarel contactoconlacuchillao unalesi6npor

unobjetoarrojado,rnant_ngaseen lazonadeloperadordetrAs

delasrnanijasy rnantengaa losni_os,observadores,ayudantes

yrnascotasapartadosalrnenos25metrosdelabordeadora

decespedrnientrasestaen operaci6n.DetengalarnAquinasi

alguienentraen lazona.

Su responsabilidad--Restrinja el usode estarnAquina

rnotorizadaalas personasquelean,cornprendany respetenlas

advertenciase instruccionesque aparecenen estemanualyen la

rnAquina.

iGUARI)E ESTASINSTRUCCIONES!

PR E PARATIVO S

• InspeccionerninuciosarnenteelAreadondeutilizarAelequipo.

Retiretodaslaspiedras,palos,Ilantas,huesos,juguetesy

otrosobjetosextra_osquepodrianhacertropezarycaero ser

recogidosy arrojadosporla acci6nde lascuchillas.Losobjetos

arrojadosporla rnAquinapuedenproducirlesionesgraves.

• Paraprotegerselosojosutilicesiernpreanteojosoantiparras

de seguridadrnientrasoperala rnAquinao rnientrasla ajusta

o repara.Losobjetosarrojadosquerebotanpuedenproducir

lesionesocularesgraves.

• Utilicezapatosdetrabajoresistentes,desuelafuerte,asicorno

pantalonesycarnisasajustados.Se recorniendavestircarnisay

pantal6nparacubrirbrazosy piernasy usarzapatosconpuntera

de acero.Nuncaopereesta rnAquinadescalzo,consandalias,

zapatosresbalososo livianos(porej. deIona).

• Nuncaintenterealizarajustesrnientrasel motorestAenrnarcha

exceptoenloscasosespedficarnenterecornendadosen el

manualdeloperador.

Manejosegurode la gasolina

Paraevitarlesionespersonalesoda_osrnaterialesseasurnarnente

cuidadosoal rnanipularlagasolina.Lagasolinaes surnarnente

inflarnabley susvaporespuedencausarexplosiones.Sisederrarna

gasolinaencirnao sobrela ropasepuedelesionargravernenteya que

sepuedeincendiar.LAvesela pielycArnbiesede ropade inrnediato.

• Utilices61orecipientesparagasolinaautorizados.

• NuncaIlenelos recipientesen el interiordeunvehiculoo carni6n

o caja de rernolquecon recubrirnientoplAstico.Coloquesiernpre

losrecipientesenel pisoy lejosdelvehiculoantesde realizarla

carga.

• Retireelequipoa gasolinadelcarni6norernolquey II_neloen

el piso.Siestono esposible,Ileneelequipoenun rernolque

conuncontenedorportAtil,envezde hacerloconunaboquilla

dispensadorade gasolina.

33

Page 34

• Mantengalaboquillade Ilenadoencontactoconelhordedel

dep6sitode combustibleo conla aberturadelrecipienteentodo

rnornento,hastaterrninarlacarga.Noutiliceundispositivode

boquilladeapertura/cierre.

• Apaguetodoslos cigarrillos,cigarros,pipasyotrasfuentesde

cornbusti6n.

• Nuncacarguecombustibleen larn_.quinaen interioresporquelos

vaporesinfiarnablespodrianacurnularseenel _.rea.

• Nuncasaquela tapade lagasolinaniagreguecombustible

rnientrasel motorest,.calienteoen rnarcha. Dejequeel motor

seenfrieporIornenosdosrninutosantesdevolvera cargar

combustible.

• NuncaIleneenexcesoel dep6sitodecombustible.Lleneel

tanqueano rn_.sde1/2pulgadapot debajode la basedelcuello

deltap6nde carga,paraperrnitirlaexpansi6ndelcombustible.

• Vuelvaa colocarla tapade lagasolinayajQstelabien.

• Lirnpieelcombustiblequesehayaderrarnadosobreel motoryel

equip&Trasladela rn_.quinaa otrazona.Espere5 rninutosantes

deencenderelmotor.

• Nuncaalrnacenela rn_.quinao el recipientedecombustible

cercade llamaexpuesta,chispasoaparatoscon pilotocornopor

ejernplo,calentadoresdeagua,calefactores,hornos,secadores

de ropau otrosaparatosagas.

• Parareducirelriesgodeincendiornantengala bordeadorade

cespedlirnpiade pasto,hojasy de laacurnulaci6nde otros

desechos.Lirnpielosderrarnesdeaceiteo combustibleysaque

todoslosresiduosernbebidosdecombustible.

• Dejequela bordeadorade c_spedseenfriecinco(5) rninutospor

Iornenosantesdealrnacenarla.

FUNCIONAIVIIENTO

• Nocoloquelasrnanosnilospiescercade laspiezasgiratorias.

Elcontactoconlacuchillagiratoriapuedeproducirlaarnputaci6n

de rnanosy pies.

• El mecanisrnodecontrolde la cuchillaes undispositivode

seguridad.Nuncaevitesufuncionarniento.Si Iohace,la rn_.quina

setornapeligrosaypuedecausarlesionespersonales.

• Nuncahagafuncionarla bordeadorasinusarelprotectordela

cuchilla,elescudocontraescornbrosy larnanijadecontrolde la

cuchillaenel lugarcorrespondienteyen funcionarniento.

• Nuncaoperelabordeadorasilosdispositivosde seguridadest_.n

daSados.Si noIohace,puedenproducirselesionespersonales.

• Nuncaenciendael motorenespacioscerradosoenunazona

conpocaventilaci6n.Elescapedel motorcontienernon6xidode

carbono,un gasinodoroy letal.

• No utilicela rn_.quinabajola influenciadelalcoholo lasdrogas.

• El silenciadory elmotorsecalientany puedencausarquernadu-

ras.Nolostoque.

• Nuncaopereesta rn_.quinasinbuenavisibilidado ilurninaci6n.

Siernpredebeestarsegurodequeest,.bienafirrnadoy su-

jetandofirrnernentelasrnanijas.Carnine,nuncacorra.

• Noopereestarn_.quinasiseha caidoo est,.daSada.Regrese

la rn_.quinaal serviciot_cnicodesudistfibuidorautorizadorn_.s

cercanoparaquela examiney larepare.

• No hagafuncionarlarn_.quinasi lacuchillade corteest,.daSada

oexcesivarnentedesgastada.

• Nuncaintentesacarmaterialdelprotectorde la cuchillasiel

motorest,.en funcionarniento.Apagueel motor,desconecteel

cabledela bujiayp6ngalode rnaneraquehagarnasacontrael

motorparaevitarqueseenciendaaccidentalrnente.

• Nosobrecarguelacapacidadde la rn_.quinatratandode bordear

a unavelocidaddernasiador_.pida.

• Mant_ngasealertaparaadvertirla existenciade aceraso terreno

desparejos,etc.Siernpreernpujelentarnentesobrelassuperficies

_.speras.Noutiliceestarn_.quinasobrepedregullo.

• Nooperelarn_.quinabajola Iluviao encondicionesde suelo

hQrnedo.

• Siernprehagafuncionarlarn_.quinadesdedetr_.sde lasrnanijas

y col6quesede rnodoquelalineadevistadirectahaciala

cuchillade cortequedebloqueadaporlosprotectores.

• Siernpredetengael motorcuandoel bordeadoorecortesevean

dernoradoso cuandoest_trasladandola rn_.quinade unlugara

otto.

• Nuncadejelarn_.quinaen funcionarnientosinvigilancia.Detenga

el motor,desconecteel cabledela bujiayp6ngalode rnanera

que hagarnasacontrael motorparaevitarqueseencienda

accidentalrnente.

• Utilicesolarnentepiezasy accesoriosrnanufacturadosparaesta

rn_.quinaporel fabricante.Si noIohace,puedenproducirse

lesionespersonales.

• Si sepresentansituacionesquenoest_.nprevistaseneste

manual,seacuidadosoy useel sentidocornQn.P6ngaseen

contactoconAsistenciaal Clienteparasolicitarayudao el

nornbredel distribuidorde serviciorn_.scercanoa sudornicilio.

NINOS

Puedenocurriraccidentestr_.gicossiel operadornoest,.atentoa

la presenciadeni_os.PorIogeneral,losni_ossesientenatraidos

por equiposrnotofizadostalescornolasbordeadorasde c_sped.No

entiendenlosriesgosni lospeligros.Nuncaasurnaquelosni_os

perrnanecer_.nenel rnisrnolugardondelosvio porQltirnavez.

• Mantengaa los ni_osfueradel_.reade bordeadoy bajoestricta

vigilanciadeun adultoresponsableadern_.sdeloperador.

• Est_alertayapaguelabordeadoradecespedsiunni_oingresa

al _.rea.

• Antesde rnoversehaciaatr_.sy rnientrasIoest_haciendo,mire

haciaatr_.sy cuideque nohayani_os.

• Tengaextrernaprecauci6ncuandoseaproxirnea esquinas

ciegas,entradasdepuertas,arbustos,_.rbolesu otrosobjetos

que puedanobstaculizaflela vistade unni_oquepudiese

toparseconla bordeadorade c_sped.

• Mantengaa los ni_osalejadosdelosrnotoresen rnarchao

calientes.Puedensufrirquernadurascon unsilenciadorcaliente.

• Noperrnitanuncaquelosni_osrnenoresde 14a_osutilicen

estarn_.quina.Losni_osde 14a_osenadelantedebenleery

entenderlasinstruccionesdeoperaci6nynorrnasdeseguridad

contenidasenestemanualyen larn_.quinay debenserentrena-

dosy supervisadosporunadulto.

34

Page 35

MANTENIMIENTO Y ALMACENAMIENTO

• Nuncaenciendael motorenespacioscerradosoen unazona

conpocaventilacidn.Elescapedelmotorcontienernondxidode

carbono,un gasinodoroy letal.

• Antesde lirnpiar,repararo inspeccionarla rn_.quina,cornpruebe

quela cuchillaytodaslaspartesrn6vilessehayandetenido.

Desconecteel cabledela bujiay p6ngalohaciendornasacontra

el motorparaevitarqueseenciendaaccidentalrnente.

Reviselospernosdernontajedelacuchillaydel motora

intervalosfrecuentesparaverificarqueest_nbienapretados.

Inspeccioneadern_.svisualrnentelacuchillaen buscadeda_os

(abolladuras,desgaste,roturas,etc).Reernplacelacuchilla

Onicarnenteconequipooriginaldelfabricante(OEM)listadoen

estemanual."Elusode piezasquenocurnplenconlasespe-

cificacionesdelequipooriginalpodriatenercornoresultadoun

rendirnientoincorrectoyadern_.sponeren riesgola seguridad".

Lascuchillasdelas bordeadorasdec_spedsonrnuyafiladasy

puedenproducircortaduras.Envuelvalacuchillao utiliceguantes

yextremelasprecaucionescuandoefectOernantenirniento.

Mantengatodoslospernos,tuercasy tornillosbienajustados

paraasegurarsede quela rn_.quinaseencuentraen condiciones

segurasde operaci6n.

Nuncaalterelos dispositivosde seguridad.Controleperiddica-

rnentequefuncionencorrectarnente.

Despu_sdegolpearcon algQnobjetoextra_o,detengaelmotor,

desconecteelcablede la bujfay conecteel motora rnasa.

Inspeccionerninuciosarnentela bordeadorade cespedparaver

siest,.da_ada.Repareel da_oantesde arrancaryoperarla

bordeadora.

Nuncaintenteajustarunaruedarnientrasel motorest,.en

rnarcha.

Muchoscornponentesde la nuevabordeadorasedesgastanen

raz6ndelusocontinuo.Paraprotegersuseguridad,verifique

frecuenternentetodosloscornponentesdela bordeadoray

reernpl_.celosinrnediatarnentes61ocon piezasdelosfabricantes

deequiposoriginales(O.E.M.)listadasenestemanual."Eluso

depiezasque nocurnplenconlasespecificacionesdel equipo

originalpodriatenetcornoresultadounrendirnientoincorrectoy

adern_.sponeren riesgola seguridad".

Nocarnbielaconfiguracidndel reguladordelmotorni acelere

dernasiadoelrnisrno.Elreguladordelmotorcontrolala velocidad

rn_.xirnaseguradefuncionarnientodelmotor.

Mantengao reernplacelasetiquetasdeseguridade instrucciones

segQnseanecesario.

Respetelasleyesy regulacionesdeelirninaci6ncorrespondientes

paradesecharlagasolina,el aceite,etc.,usados.La elirninaci6n

inapropiadade liquidosornaterialespuededa_arel medic

arnbiente.

NO MODIFIQUE EL MOTOR

Paraevitarlesionesgraveso larnuerte,nornodifiqueel motorbajo

ningunacircunstancia.Si carnbiala configuraci6ndel reguladorel

motorpuededescontrolarsey operara velocidadesinseguras.Nunca

carnbielaconfiguracidndef_.bricadel reguladordelmotor.

AVISO REFERIDO A EMISIONES

Losrnotoresqueest&ncertificadosy curnplenconlasregulaciones

de ernisionesfederalesEPAyde CaliforniaparaSORE(Equipos

peque_ostodoterreno)est_.ncertificadosparaoperarcongasolina

cornQnsinplornoy puedenincluirlossiguientessisternasde control

de ernisiones:Modificaci6ndemotor(EM) y catalizadorde tresvias

(TWO)si est_.nequipadosde esa rnanera.

AMORTIGUADOR DE CHISPAS

Estarn&quinaest&equipadaconunmotorde cornbusti6ninternay

nodebeser utilizadaeno cercade unterrenoagrestecubiertopor

bosque,rnalezaso hierbaexceptosiel sisternade escapedelmotor

est,.equipadoconunarnortiguadordechispasquecurnplaconlas

leyeslocaleso estatalescorrespondientes,encasode haberlas.

Siseutilizaun arnortiguadordechispasel operadorIodebernantener

en condicionesde usoadecuadas.Enel Estadode Californialas

rnedidasanteriorrnenternencionadassonexigidasporley(Arficulo

4442del C6digodeRecursosPOblicosde California).Esposible

queexistanleyessirnilaresenotrosestados.Lasleyesfederalesse

aplicanenterritoriosfedexrales.

Puedeconseguirelarnortiguadorde chispasparael silenciadora

travesde sudistribuidorautorizadodernotoreso poni_ndoseen

contactoconeldepartarnentodeservicios.

35

Page 36

SilVIBOLOS DE SEGURIDAD

Estap_ginarepresentay describelaseguridadlossimbolosquepuedenpareceren esteproducto.Lea,comprenda,ysigatodasinstrucciones

en iamfiquinaantes procurar para reunir y operar.

LEA EL MANUAL(S) DEL OPERADOR

Lea, comprenda, y siga todas instrucciones en el manual (manuales) antes procurar para

1

reunir y operar

ADVERTENCIA-- CUCHILLAS ROTATIVAS

Mantegna manos y pies lejos de girar hoja.

• ®

ESPECTADORES

Mantenga a espectadores, los animales favoritos, y los ni_os pot Io menos 75 pies de la

m_iquina mientras est.1 en la operaci6n. Pare m_iquina si cualquiera entra el _irea.

ADVERTENClA-- SUPERFICIES CALIENTES

No toque el silenciador o zonas adyacentes.

PROTECCION DE OJO

Siempre Ileve gafas de seguridad o gafas de seguridad al operar esta m_iquina.

36

Page 37

NOTA:Estaunidadse entregaSIN GASOLINAniACEITE.Despuesdearmar

la unidad,realicelacargade gasolinadelmotorsegQnlas instrucciones.

NOTA:Lasreferenciasalladoderechooizquierdodelabordeadorase

observandesdelaposici6ndeloperador.

MONTAJE

Barra

Retireydesechecualquiercart6ndeempaqueque pudierehaber

entrela barrasuperiory la barrainferior.