Page 1

OWNER’S

MANUAL

MODEL NO.

247.795940

CRAFTSMAN

5 HORSEPOWER

3 CUTTING STAGE

Caution:

Read and Follow

All Safety Rules

and Instructions

Before Operating

This Equipment

SEARS, ROEBUCK AND CO., Hoffman Estates, IL 60179 U.S.A.

MULCHING AND BAGGING

CHIPPER-SHREDDER

Assembly

Oper atio n

Customer Responsibilities

Service and Adjustment

Repair Parts

Printed in U.S.A.

77O-0474H 3/93

Page 2

A

SAFETY RULES

WARNING: TO REDUCE THE POTENTIAL FOR ANY INJURY, COMPLY WITH THE FOLLOWING

SAFETY INSTRUCTIONS. FAILURE TO COMPLY WITH THE INSTRUCTIONS MAY RESULT IN

PERSONAL INJURY.

TRAINING

• Read this owner’s manual carefully in its entirety before

attempting to assemble or operate this machine. Be com

pletely familiar with the controls and the proper use of this

machine before operating it. Keep this manual in a safe

place for future and regular reference and for ordering

replacement parts.

• Children must never be allowed to operate this equipment.

• No one should operate this unit while intoxicated or while

taking medication that impairs the senses or reactions.

• This equipment should never be operated in the vicinity

of children, pets or other persons.

• Never run your machine in an enclosed area as the

exhaust from the engine contains carbon monoxide, which

is an odorless, tasteless and deadly poisonous gas.

• Never place your hands or any part of your body or cloth

ing inside the feeding chamber, discharge chute, or near

any moving part while the machine or engine is running.

• If it is necessary for any reason to Inspect or repair the

feeding chamber or any part of the machine where a mov

ing part can come in contact with your body or clothing,

stop the machine, allow it to cool, disconnect the spark

plug wire from the spark plug and move it away from the

spark plug before attempting such inspection or repair.

PREPARATION

• Wear safety glasses provided with your unit while operat

ing the chipper-shredder to prevent injury from any mate

rial which may be ejected out of the openings.

• Wear proper apparel. Avoid wearing loose fitting clothing.

Wear gloves when handling material.

• HANDLE GASOLINE WITH CARE as it is an extremely

flammable fuel.

• Check the fuel before starting the engine. Do not fill the

fuel tank indoors, while the engine is running, or while the

engine is still hot. Turn the unit off and let the engine cool

before refueling.

• Fuel your chipper-shredder in a clean area. Do not

smoke while refueling.

• Fuel tank cap must be secure at all times except during

refueling.

• Avoid spilling gasoline or oil. Wipe the unit clean of any

spilled fuel or oil.

• Store fuel and oil in approved containers, away from heat

or open flame, and out of reach of children.

• This machine should be operated only upon a level surface.

• Assure that all screws, nuts and bolts and other fasteners

are properly secured.

OPERATION

• When feeding shreddable material into this equipment,

be extremely careful that pieces of metal, rocks, bottles,

cans or other foreign objects are not included. Personal

injury or damage to the machine could result.

• If the cutting mechanism strikes any foreign object or if

your machine should start making an unusual noise or

vibration, immediately stop the engine, disconnect the

spark plug wire from the spark plug and move it away

from the spark plug. Allow the machine to stop and take

the following steps:

Inspect for damage.

Replace or repair any damaged parts.

Check for any loose parts and tighten to assure contin

ued safe operation.

• The engine must be kept clean of debris and other accu

mulations.

• Do not allow an accumulation of processed material to

build up in the discharge area as this will prevent proper

discharge and can result in kick-back from feed opening.

• Never place your hands or any other part of your body or

clothing inside the feeding chamber, discharge chute or

near any moving part while the engine is running.

• Keep all guards and deflectors in place and in good work

ing condition to assure continued safe operation.

• Always stand clear of the discharge area when operating

this machine.

• Keep your face and body back from the feed opening to

avoid accidental bounce back of any material.

• Do not over-reach. Keep proper balance and footing at all

times.

• The engine governor settings on your machine must not

be altered, changed, or tampered with. The governor

controls the maximum safe operating speeds and pro

tects the engine and all moving parts from damage

caused by overspeed.

• Do not transport machine while engine is running.

• Do not operate engine if air cleaner or cover directly over

carburetor air intake is removed, except for adjustment.

Removal of such parts could create a fire hazard.

MAINTENANCE AND STORAGE

• When this equipment is stopped for servicing, inspection,

storage or to change an accessory, make sure the spark

plug wire is disconnected from the spark plug and moved

away from the spark plug. The machine should be

allowed to cool down before making such inspection,

adjustments, service, etc. Maintain your machine with

care and keep it clean for the best and continued safe

operation.

• Do not use flammable solutions to clean the air filter.

• When not in use, your machine should be stored out of

the reach of children. Keep where gasoline fumes will not

reach an open flame or spark. For long periods of stor

age, refer to the “Storage" section of this manual.

A

LOOK FOR THIS SYMBOL TO POINT OUT

IMPORTANT SAFETY PRECAUTIONS. IT

MEANS—AHENTION!!! BECOME ALERT!!!

YOUR SAFETY IS INVOLVED.

Page 3

CONGRATULATIONS on your purchase of a Sears

Craftsman Chipper-Shredder. It has been designed, engi

neered and manufactured to give you the best possible

dependability and performance.

Should you experience any problem you cannot easily rem

edy, please contact your nearest Sears Service Center/

Department in the United States. We have competent, welltrained technicians and the proper tools to service or repair

this unit.

Please read and retain this manual. The instructions will

enable you to assemble and maintain your chipper-shredder

properly. Always observe the “SAFETY RULES.”

MODEL

NUMBER 247.795940

SERIAL

NUMBER_

PRODUCT SPECIFICATIONS

Horsepower: 5.0

Displacement:

Fuel Capacity:

Spark Plug (Gap .030 in.):

Ignition Air Gap: .0125 in.

12.00 cu. in.

1-7/8 Quarts

(Unleaded)

Champion

J-8C (or

Equivalent)

DATE OF

PURCHASE.

THE MODEL AND SERIAL NUMBERS WILL BE FOUND

ON A LABEL ATTACHED TO THE FRAME OF THE

CHIPPER-SHREDDER.

YOU SHOULD RECORD BOTH SERIAL NUMBER AND

DATE OF PURCHASE AND KEEP IN A SAFE PLACE

FOR FUTURE REFERENCE.

CUSTOMER RESPONSIBILITIES

Read and observe the safety rules.

Follow a regular schedule in maintaining, caring for

and using your chipper-shredder.

Follow the instructions under “Customer Respon

sibilities” and “Storage” sections of this Owner’s

Manual.

A Sears Maintenance Agreement is available on this

product. Contact your nearest Sears store for details.

WARNING: This unit is equipped with an internal combus

tion engine and should not be used on or near any unim

proved forest-covered, brush-covered or grass-covered land

unless the engine’s exhaust system is equipped with a

spark arrester meeting applicable local or state laws (if any).

If a spark arrester is used, it should be maintained in effec

tive working order by the operator.

In the State of California the above is required by law

(Section 4442 of the California Public Resources Code).

Other states may have similar laws. Federal laws apply on

federal lands. A spark arrester for the muffler is available

through your nearest Sears Authorized Service Center (See

the REPAIR PARTS section of this manual.)

MAINTENANCE AGREEMENT

WARRANTY

ONE YEAR LIMITED WARRANTY ON CRAFTSMAN GAS CHIPPER-SHREDDER

For one year from the date of purchase, when this Craftsman Chipper-Shredder is maintained, lubricated and

tuned up according to the instructions in the owner’s manual. Sears will repair, free of charge, any defect in

material and workmanship.

If this Craftsman Chipper-Shredder is used for commercial or rental purposes, this warranty applies for only 30

days from the date of purchase.

This warranty does not cover;

• Expendable items which become worn during normal use, such as blades, chipper blades, flails, air cleaners,

spark plugs and catcher bags.

• Repairs necessary because of operator abuse or negligence, including bent crankshafts and the failure to

maintain the equipment according to the instructions contained in the owner's manual.

WARRANTY SERVICE IS AVAILABLE BY RETURNING THE CRAFTSMAN CHIPPER-SHREDDER TO THE

NEAREST SEARS SERVICE CENTER/DEPARTMENT IN THE UNITED STATES. THIS WARRANTY

APPLIES ONLY WHILE THIS PRODUCT IS IN USE IN THE UNITED STATES.

This warranty gives you specific legal rights, and you may also have other rights which may vary from state to

state.

SEARS, ROEBUCK AND CO., D/817WA, Hoffman Estates, IL 60179

Page 4

TABLE OF CONTENTS

SAFETY RULES

PRODUCT SPECIFICATIONS.............

MAINTENANCE AGREEMENT

CUSTOMER RESPONSIBILITIES.

WARRANTY

INDEX...................................................

ASSEMBLY

OPERATION

Accessories

Adjustments:

Carburetor

Engine Speed

Assembly Instructions:

Catcher Bag....................

Chute Deflector

Catcher Bag

Controls...............................

Customer Responsibilities

Engine:

Lubrication

Maintenance

Starting

Stopping

Storage

Fuel......................................

Lubrication..........................

Maintenance:

Agreement

Schedule

Engine.............................

Chipper-Shredder

..................................

...........

.........................................

..........................................

........................................

A

........................

......................

.................

..............

C

........................

...................

E

.....................

...................

...........................

.........................

...........................

F

1

L

M

......................

.........................

.........

...2 CUSTOMER RESPONSIBILITIES

...3 STORAGE..........................................................................12

...3 SERVICE AND ADJUSTMENT

...3 TROUBLESHOOTING.......................................................15

...3 PARTS ORDERING/SERVICE

...4 REPAIR PARTS—CHIPPER-SHREDDER

...5 REPAIR PARTS—ENGINE

-10

INDEX

............................4

..........................

..........................14

............................

............................

............................

............................

..............

..........................10

...................

............................

............................

..........................

............................

..........................10

............................

..........................10

...................

..........................10

14

3, 10, 11

10, 11

12

10, 11

......................................

....................................

..........................................

..................

..........................................

0

Oil

.................................

Operating Tips

Repair/Replacement Parts

Responsibilities, Customer

5

5

5

6

9

7

8

3

Safety Rules

Sharpening...................

Spark Plug

Specifications

Storage

Table of Contents

Trouble Shooting

Unclogging...................

Unpacking

Warranty

.........................

.............

R

....................

..................

S

.................

...................

..............

T

........

.........

u

....................

w

......................

............................

.......................

....................

...............3, 10, 11

............................

...................

..........................11

............................

..........................12

............................

..........................15

..........................

............................

............................

10, 11

12-14

15

16, 17

17-20

8

7, 8

16-20

2

13, 14

3

4

12

5

3

CHIPPER-SHREDDER ACCESSORIES

These accessories were available when the chipper-shredder was purchased. They are also available at most

Sears retail outlets, catalog and service centers. Most Sears stores can order repair parts for you, when you pro

vide the model number of your chipper-shredder.

ENGINE CHIPPER-SHREDDER

Spark

Plug

Muffler

Engine

Oil

Gas Can Stabilizer

Page 5

ASSEMBLY INSTRUCTIONS

IMPORTANT: This unit is shipped WITHOUT GASO

LINE or OIL. After assembly, see operation section of

this manual for proper fuel and engine oil recommen

dations.

NOTE: To determine right and left hand sides of your

chipper-shredder, stand behind and face the hopper

(engine is at the front of the unit).

Your chipper-shredder has been completely assem

bled at the factory, except for the chute deflector and

the catcher bag. A pair of safety glasses are also

included in the carton.

Spacers

(Inside

Hinge)

FIGURE 1.

Hex Bolt

Chute

Deflector

TO REMOVE CHIPPER-SHREDDER FROM CARTON

Cut the corners of the carton. Remove all packing

inserts. Roll chipper-shredder out of the carton. Make

certain all parts, literature and the safety glasses have

been removed before the carton is discarded.

TOOLS REQUIRED FOR ASSEMBLY

(2) 7/16" or Adjustable Wrenches

HOW TO SET-UP YOUR CHIPPER-SHREDDER

MAKE CERTAIN THE SPARK PLUG

WIRE IS DISCONNECTED AND MOVED

AWAY FROM THE SPARK PLUG

A

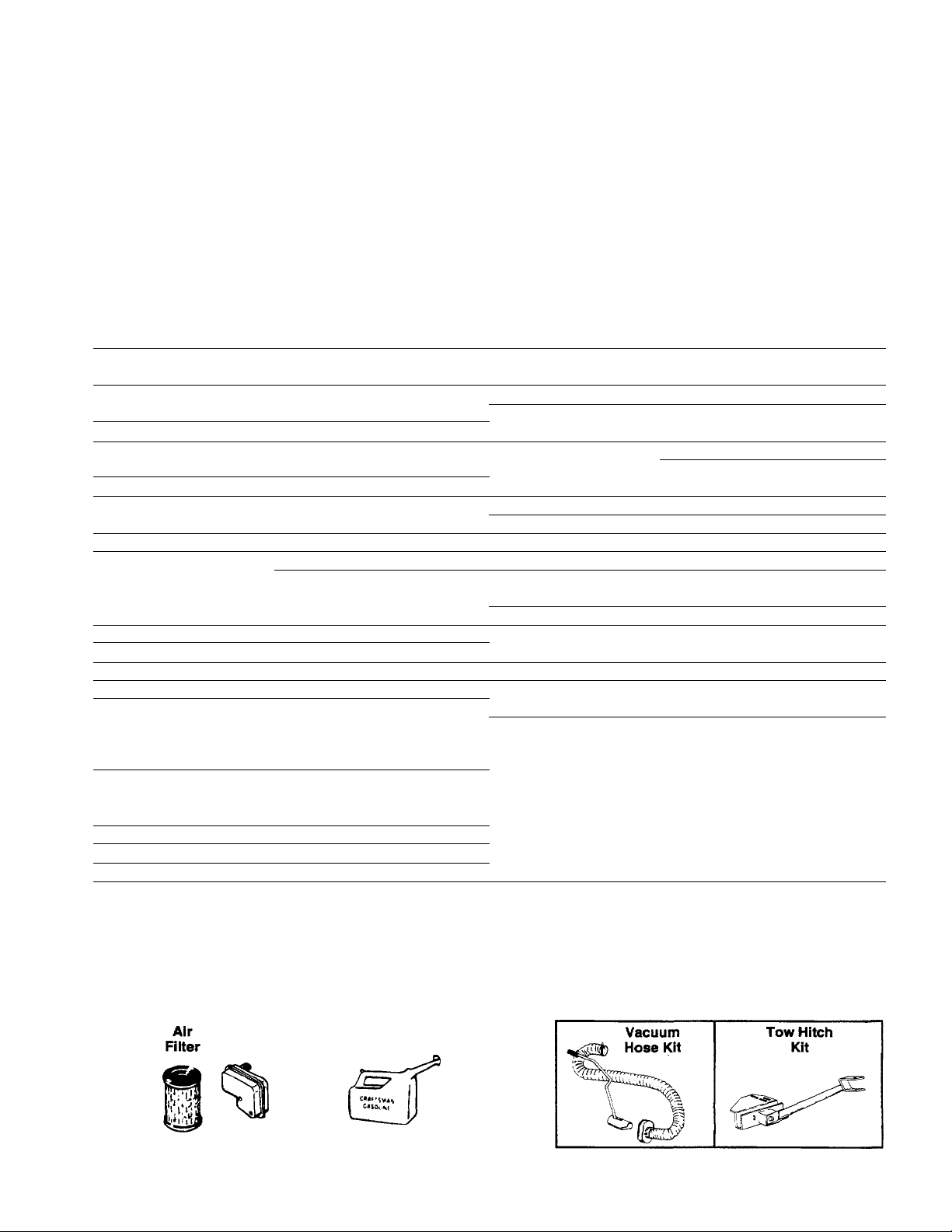

ATTACHING THE CHUTE DEFLECTOR

• Remove the hand knobs and cupped washers from

each side of the discharge opening on the left side

of the shredder.

• Remove the hex lock nut, two spacers and hex bolt

from inside the hinge on top of the discharge open

ing. Do not remove one spacer from the hex bolt.

• Place the chute deflector in position on the dis

charge opening. Insert bolt through hinge on chute

deflector and housing (spacer fits inside hinge).

• Place second spacer over the hex bolt, inside the

other part of hinge. Secure with hex lock nut.

Tighten securely.

• Secure both sides of the chute deflector to the

housing using hand knobs and cupped washers

(cupped side of washers go against chute deflec

tor).

BEFORE ASSEMBLING THE CHIPPERSHREDDER.

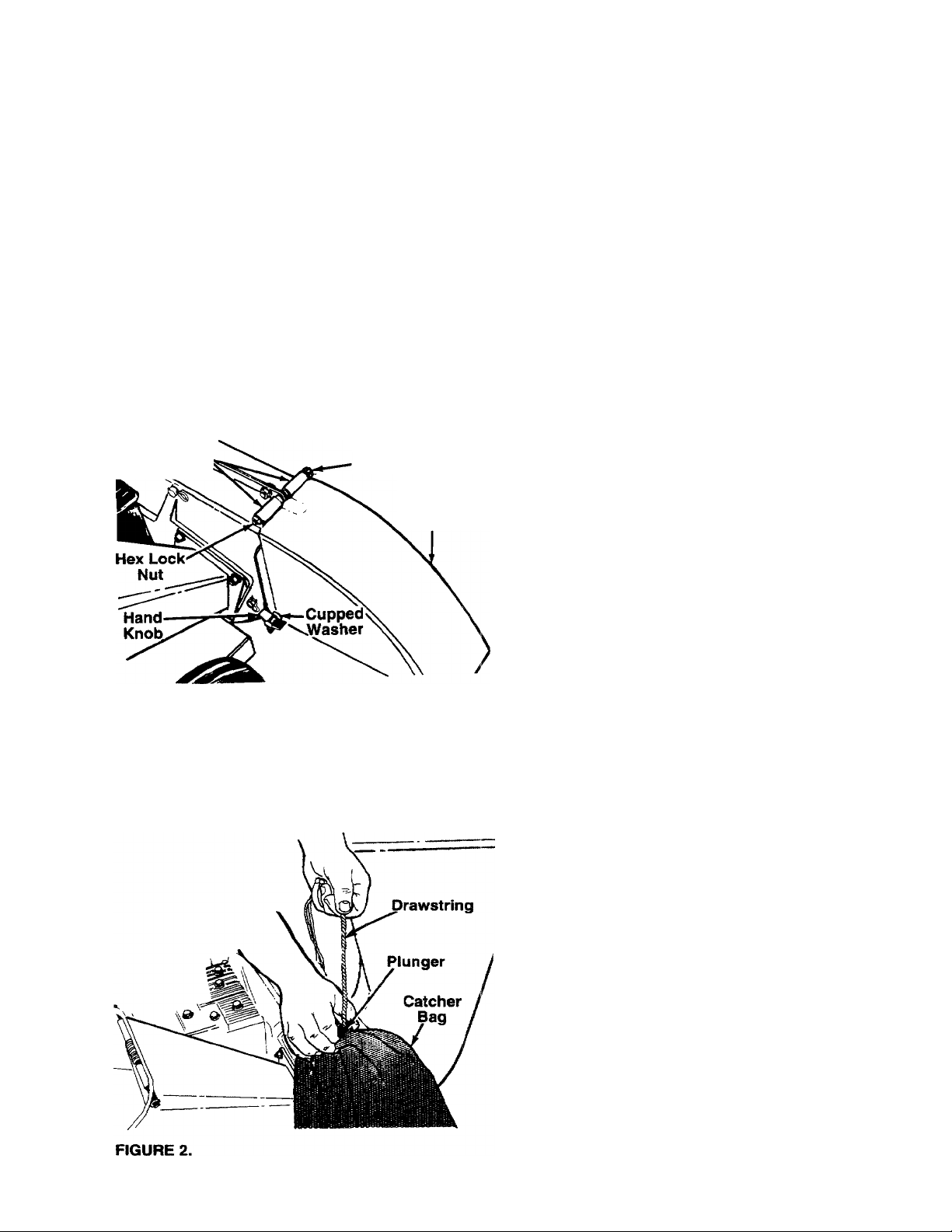

ATTACHING THE CATCHER BAG

Your chipper-shredder is equipped with a catcher bag

to catch the shredded material.

• To attach bag, place bag opening over the chute

deflector so it completely covers chute opening.

Depress plunger on drawstring, pull on drawstring

until bag is tight around chute opening. Release

plunger to lock it into position. See figure 2.

Page 6

OPERATION

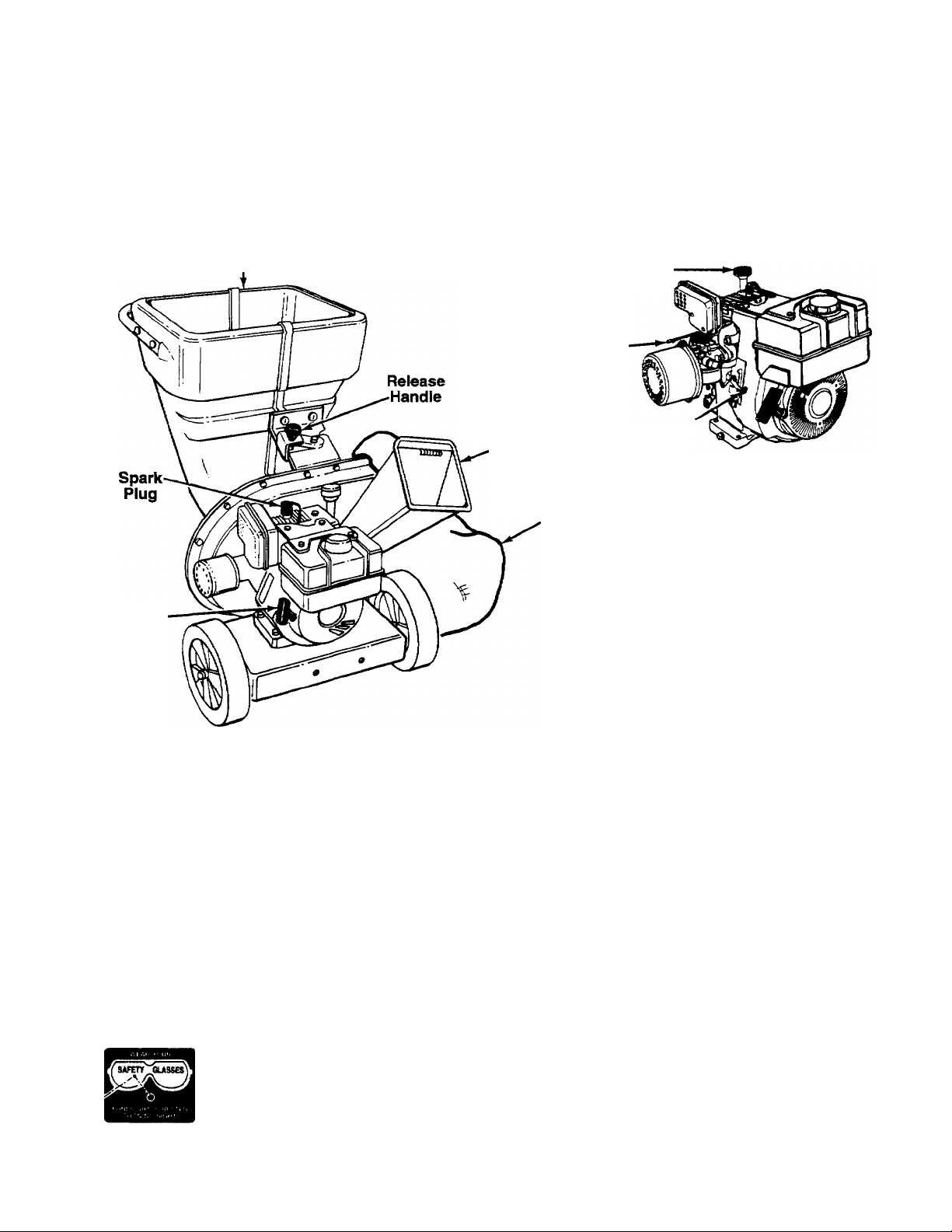

KNOW YOUR CHIPPER-SHREDDER

READ THIS OWNER’S MANUAL AND SAFETY RULES BEFORE OPERATING YOUR CHIPPER-SHREDDER.

Compare the illustrations with your chipper-shredder to famiiiarize yourself with the location of various controls

and adjustments. Save this manual for future reference.

Hopper

Assembly

Oil Fill-

Dipstick

Choke

Lever

Chipper

Chute

Catcher

Bag

Starter

Handle

FIGURE 3.

Throttle

Control

MEETS ANSI SAFETY STANDARDS

Sears chipper-shredders conform to the safety standards of the American National Standards Institute.

OPERATING CONTROLS (See figures 3 and 4)

CHOKE LEVER—Used to enrich the fuel mixture in

the carburetor when starting a cold engine.

STARTER HANDLE—Used to manually start the

engine.

THROTTLE CONTROL—Controls engine speed and

stops the engine.

RELEASE HANDLE—Used to release the hopper

when lowering to the ground.

FIGURE 4.

BEFORE USING YOUR CHIPPER-SHREDDER, AGAIN REFER TO THE “SAFETY RULES”

PAGE 2 OF THIS MANUAL. ALWAYS BE CAREFUL.

The operation of any chipper-shredder can result in foreign objects being thrown into

the eyes, which can result in severe eye damage. Always wear the safety glasses pro

vided with the chipper-shredder or eye shields before chipping or shredding, or while

performing any adjustments or repairs. We recommend Wide Vision Safety Mask for

over spectacles or standard glasses available at Sears Retail or Catalog Stores.

AS SHOWN ON

Page 7

TO STOP ENGINE

• Move throttle control lever to OFF position. See fig

ure 4.

• Disconnect spark plug wire and move away from

spark plug to prevent accidental starting while

equipment is unattended.

HOW TO USE YOUR CHIPPER-SHREDDER

Do not attempt to shred or chip any material other

than vegetation found in a normal yard (i.e., branches,

leaves, twigs, etc,).

FIGURE 5.

WARNING: THE CHIPPER-SHREDDER

DISCHARGES MATERIALS WITH CON

A

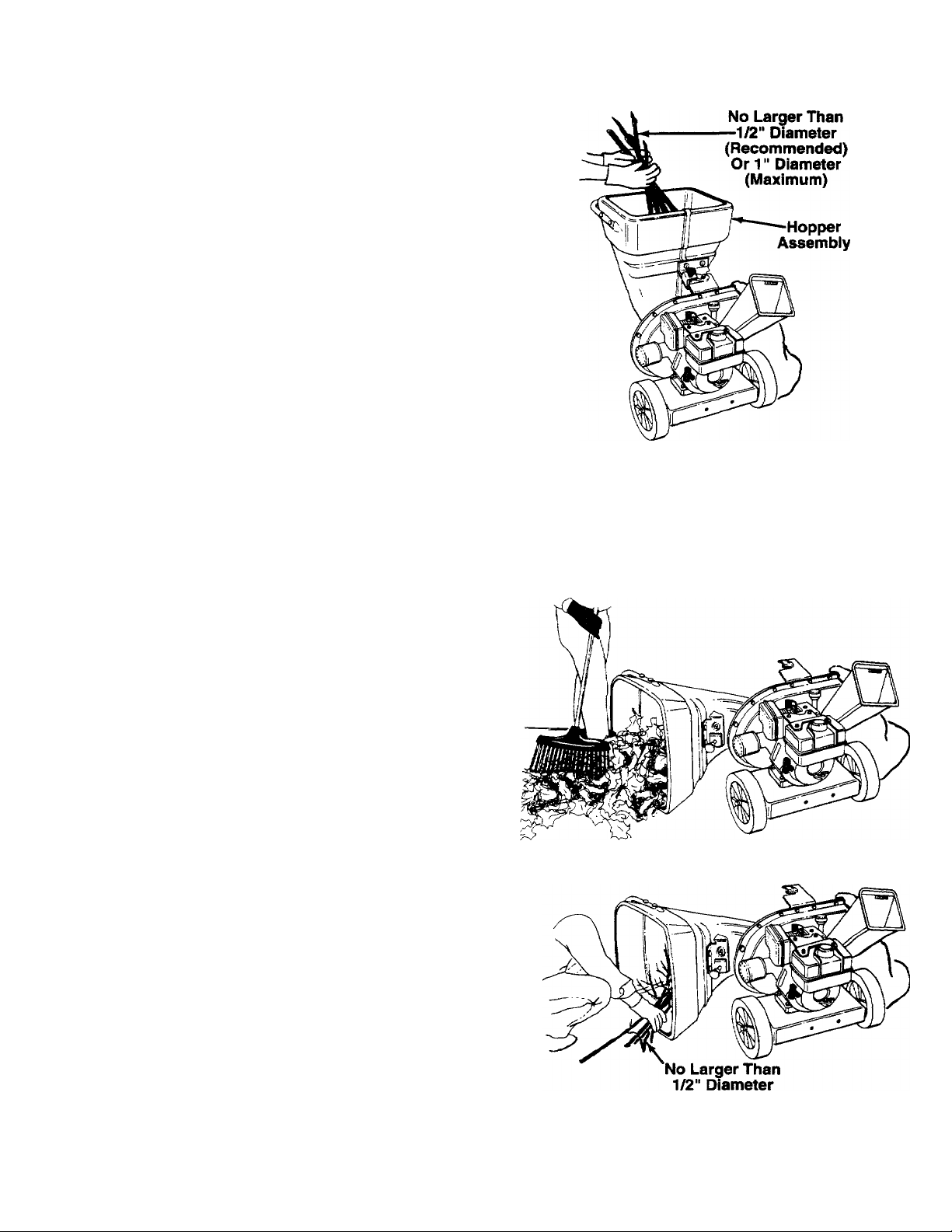

The chipper-shredder is designed for three different

methods of operation.

• Leaves and small branches up to 1/2" diameter

(recommended) or 1“ diameter (maximum) can be

fed into the hopper assembly when it is in the

raised position. See figure 5. If it becomes neces

sary to push material into the chipper-shredder,

use a small diameter stick—NOT YOUR HANDS.

The stick should be small enough that it will be

ground up if gets into the impeller assembly.

SIDERABLE VELOCITY. KEEP AWAY

FROM THE AREA AROUND THE CHUTE

DEFLECTOR. ALWAYS STOP THE

ENGINE AND DISCONNECT THE SPARK

PLUG WIRE WHEN REMOVING OR

ATTACHING THE BAG WHEN CHANGING

CONTAINERS OR WHEN REMOVING THE

SHREDDED MATERIAL. WEAR SAFETY

GLASSES AND GLOVES WHENEVER

USING YOUR CHIPPER-SHREDDER.

• Leaves and small twigs can be raked into the hop

per assembly when the hopper assembly is low

ered to the ground. See figure 6. Small branches

up to 1/2" diameter (recommended) or 1" diam

eter (maximum) can also be fed into the hopper

assembly in this position. See figure 7.

FIGURE 6.

A

WARNING: DO NOT PUT MATERIAL

LARGER THAN 1/2" IN DIAMETER (REC

OMMENDED) or 1" DIAMETER (MAXI

MUM) INTO THE HOPPER ASSEMBLY.

MATERIAL UP TO A MAXIMUM OF 3" IN

DIAMETER MATERIAL MAY BE FED

INTO THE CHIPPER CHUTE. DO NOT

ATTEMPT TO SHRED OR CHIP ANY

MATERIAL LARGER THAN 3" IN DIAME

TER. PERSONAL INJURY OR DAMAGE

TO THE MACHINE COULD RESULT.

(Recommended)

Or 1" Diameter

(Maximum)

FIGURE 7.

Page 8

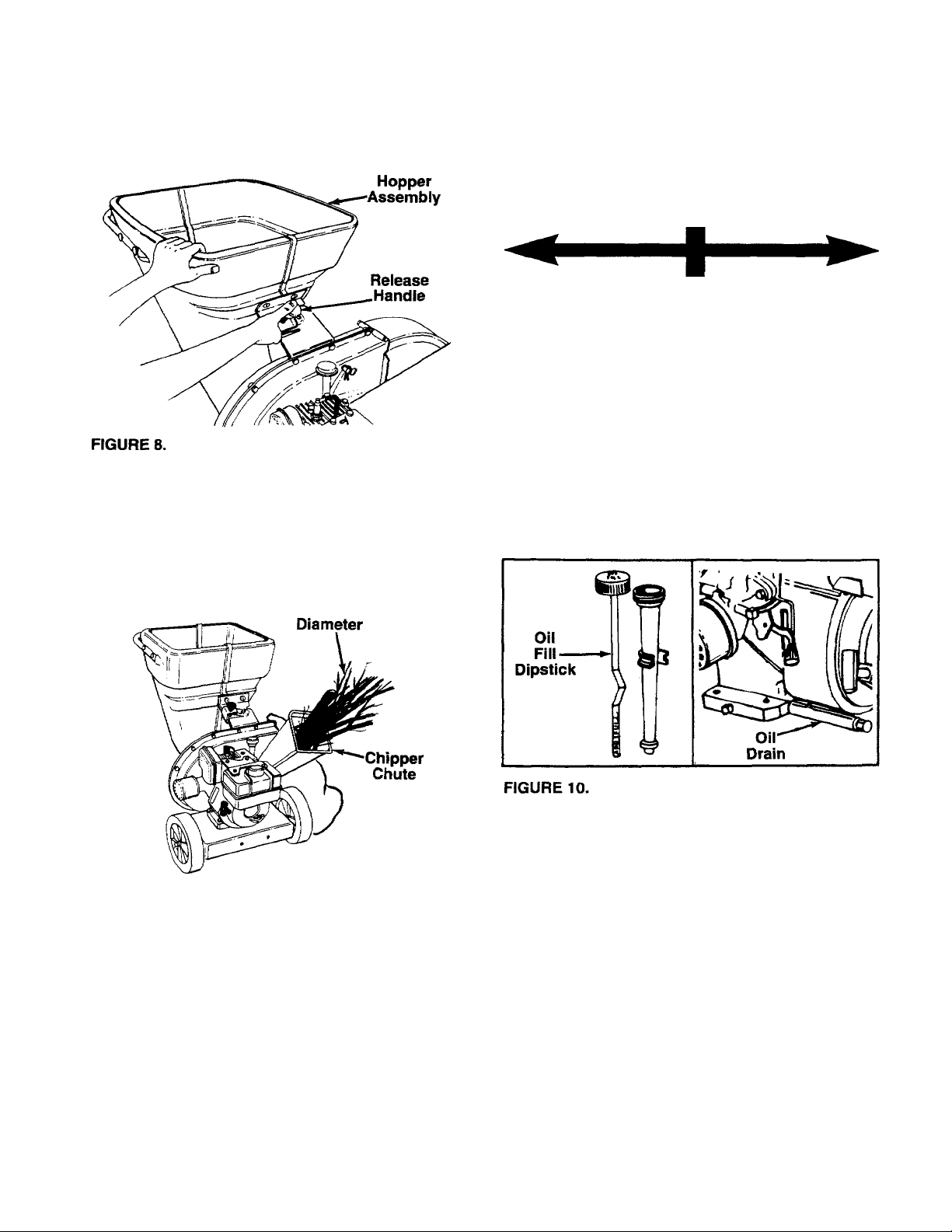

To lower the hopper assembly to the ground, use

one hand to grasp the top of the hopper assembly.

Push down on the release handle, and pivot the

hopper assembly to the right. See figure 8.

GAS AND OIL FILL-UP

OIL

Only use high quality detergent oil rated with API ser

vice classification SG. Select the oil’s viscosity grade

according to your expected operating temperature.

Colder

------------------------

32°F

-----------------

► Warmer

• Bulky material, such as stalks or heavy branches,

up to 3" in diameter, should be fed into the chipper

chute. See figure 9.

WARNING: MAKE CERTAIN THE CHIP

PER CHUTE DOOR IS CLOSED WHEN

A

NOT IN USE.

3" Maximum

5W30

NOTE: Although multi-viscosity oils (5W30, 10W30,

etc.) improve starting in cold weather, these multi

viscosity oils will result in increased oil consumption

when used above 32°F. Check your oil level more fre

quently to avoid possible engine damage from run

ning low on oil.

• Fill engine with oil as follows. Remove oil fill dip

stick. See figure 10. With chipper-shredder level,

use a funnel to fill engine with oil to FULL mark on

dipstick. Capacity is approximately 1-1/4 pints. Be

careful not to overfill. Tilt chipper-shredder toward

the left (from behind the hopper), then re-level.

Check oil level. Refill to FULL mark on dipstick if

necessary. Replace dipstick and tighten.

SAE30

FIGURE 9.

IMPORTANT: There is a flail screen located inside

the housing in the discharge area. If the flail screen

becomes clogged, remove and clean as instructed in

the Service and Adjustments section. For best per

formance, it is important to keep the shredding blade

and the chipper blades sharp. If the composition of

the material being discharged changes (becomes

stringy, etc.) or if the rate at which the material is dis

charged slows down considerably, it is likely that the

shredding blade and/or chipper blades are dull and

need to be sharpened or replaced. Refer to Service

and Adjustments section.

GAS

• Remove fuel cap and fill fuel tank with about 1-7/8

quarts of clean, fresh, lead-free grade automotive

gasoline. DO NOT use Ethyl or high octane gaso

line. Be certain container is clean and free from

rust or foreign particles. Never use gasoline that

may be stale from long periods of storage in the

container. Replace fuel cap.

WARNING: DO NOT FILL CLOSER THAN

1/2 INCH OF TOP OF FUEL TANK TO

A

PREVENT SPILLS AND TO ALLOW FOR

FUEL EXPANSION. IF GASOLINE IS

ACCIDENTLY SPILLED, MOVE CHIPPERSHREDDER AWAY FROM AREA OF

SPILL. AVOID CREATING ANY SOURCE

OF IGNITION UNTIL GASOLINE VAPORS

HAVE DISAPPEARED.

Page 9

Check the fuel level periodically to avoid running out

of gasoline while operating the chipper-shredder. If

the unit runs out of gas as it is shredding or chipping,

it may be necessary to unclog the unit before it can be

restarted. Refer to “Removing the Flail Screen" in

SERVICE AND ADJUSTMENT section.

WARNING: EXPERIENCE INDICATES THAT ALCO

HOL BLENDED FUELS (CALLED GASOHOL OR

USING ETHANOL OR METHANOL) CAN ATTRACT

MOISTURE WHICH LEADS TO SEPARATION AND

FORMATION OF ACIDS DURING STORAGE.

ACIDIC GAS CAN DAMAGE THE FUEL SYSTEM

OF AN ENGINE WHILE IN STORAGE. TO AVOID

ENGINE PROBLEMS, THE FUEL SYSTEM

SHOULD BE EMPTIED OR TREATED WITH FUEL

STABILIZER BEFORE STORAGE FOR 30 DAYS

OR LONGER. USE FRESH FUEL NEXT SEASON.

SEE “STORAGE” SECTION FOR ADDITIONAL

INFORMATION.

NEVER USE ENGINE OR CARBURETOR CLEAN

ER PRODUCTS IN THE FUEL TANK OR PERMA

NENT DAMAGE MAY OCCUR.

Spark Plug,

Wire and

Rubber Boot

Throttle Control

FIGURE 12.

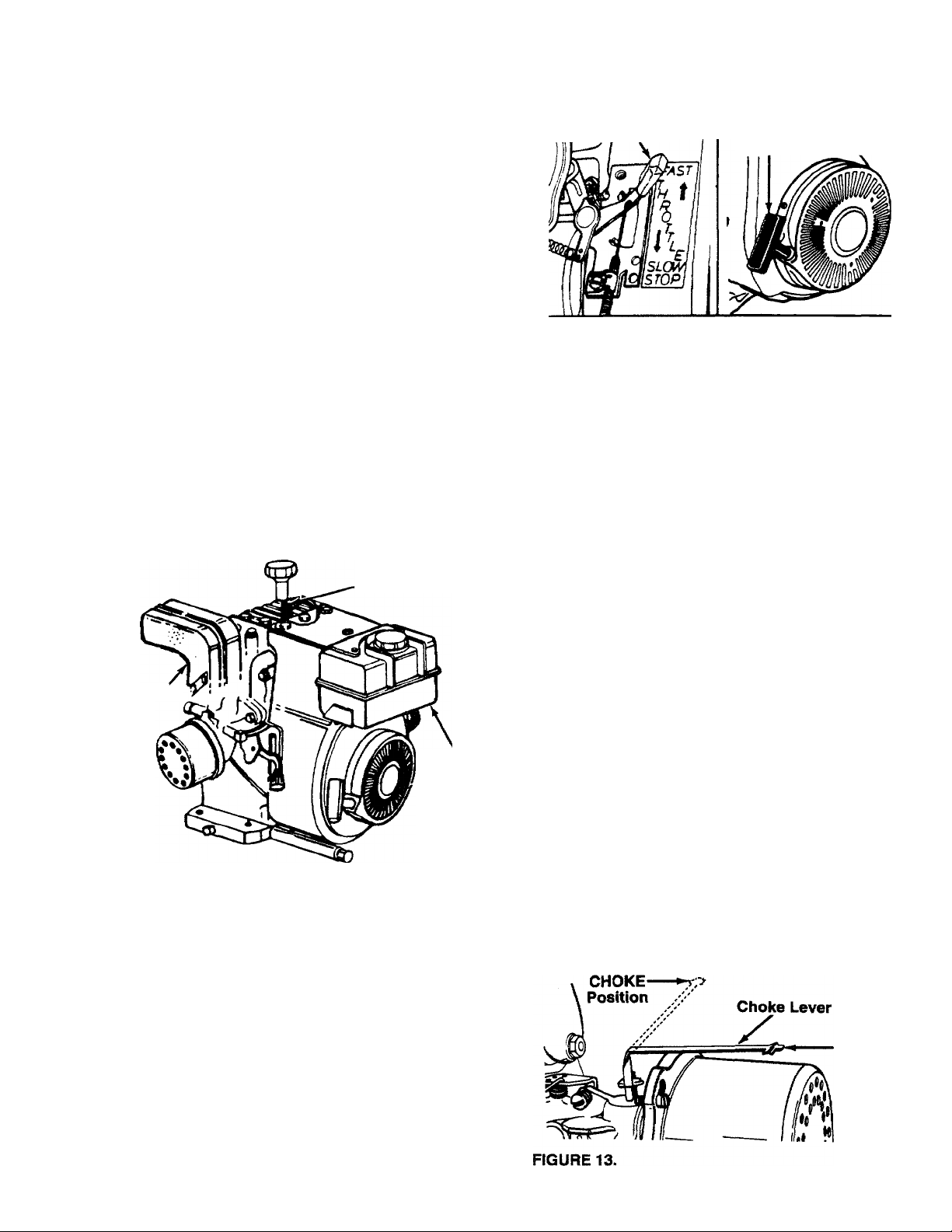

• Move choke lever to CHOKE position (See figure

13.).

• Grasp starter handle (see figure 12) and pull rope

out slowly until engine reaches start of compres

sion cycle (rope will pull slightly harder at this

point). Let the rope rewind slowly.

NOTE: A noise will be heard when finding the start of

the compression cycle. This noise is caused by the

flails and fingers which are part of the shredding mech

anism falling into place, and should be expected. In

addition, the flails and fingers will be noisy after the

engine is started, until the impeller reaches full speed.

Starter

Handle

Muffler

FIGURE 11.

TO START ENGINE

WARNING: BE SURE NO ONE OTHER

THAN THE OPERATOR IS STANDING

A

NEAR THE CHIPPER-SHREDDER WHILE

STARTING OR OPERATING. DO NOT

OPERATE THIS CHIPPER-SHREDDER

UNLESS THE CHUTE DEFLECTOR HAS

BEEN PROPERLY INSTALLED AND IS

SECURED WITH THE HAND KNOBS.

Fuel

Tank

• Pull rope with a rapid, continuous, full arm stroke.

Keep a firm grip on start handle. Let rope rewind

slowly. Do not let starter handle snap back against

starter.

• Repeat preceding two instructions until engine

fires. When engine starts, move choke lever on

engine halfway between CHOKE and RUN.

NOTE: If engine does not fire after three attempts,

move choke lever halfway between CHOKE and RUN

position and try again. See figure 13.

• Move throttle control to IDLE position for a few min

utes warm-up. Move choke lever to RUN position

as engine warms up.

NOTE: In order to idle smoothly, a new engine may

require 3 to 5 minutes running above slow idle speed.

Idle speed has been adjusted to be correct after this

break-in period.

OFF

Position

• Attach spark plug wire and rubber boot to spark

plug if necessary. See figure 11.

• Place the throttle control lever in FAST position.

See figure 12.

Page 10

TO STOP ENGINE

• Move throttle control lever to OFF position. See fig

ure 13.

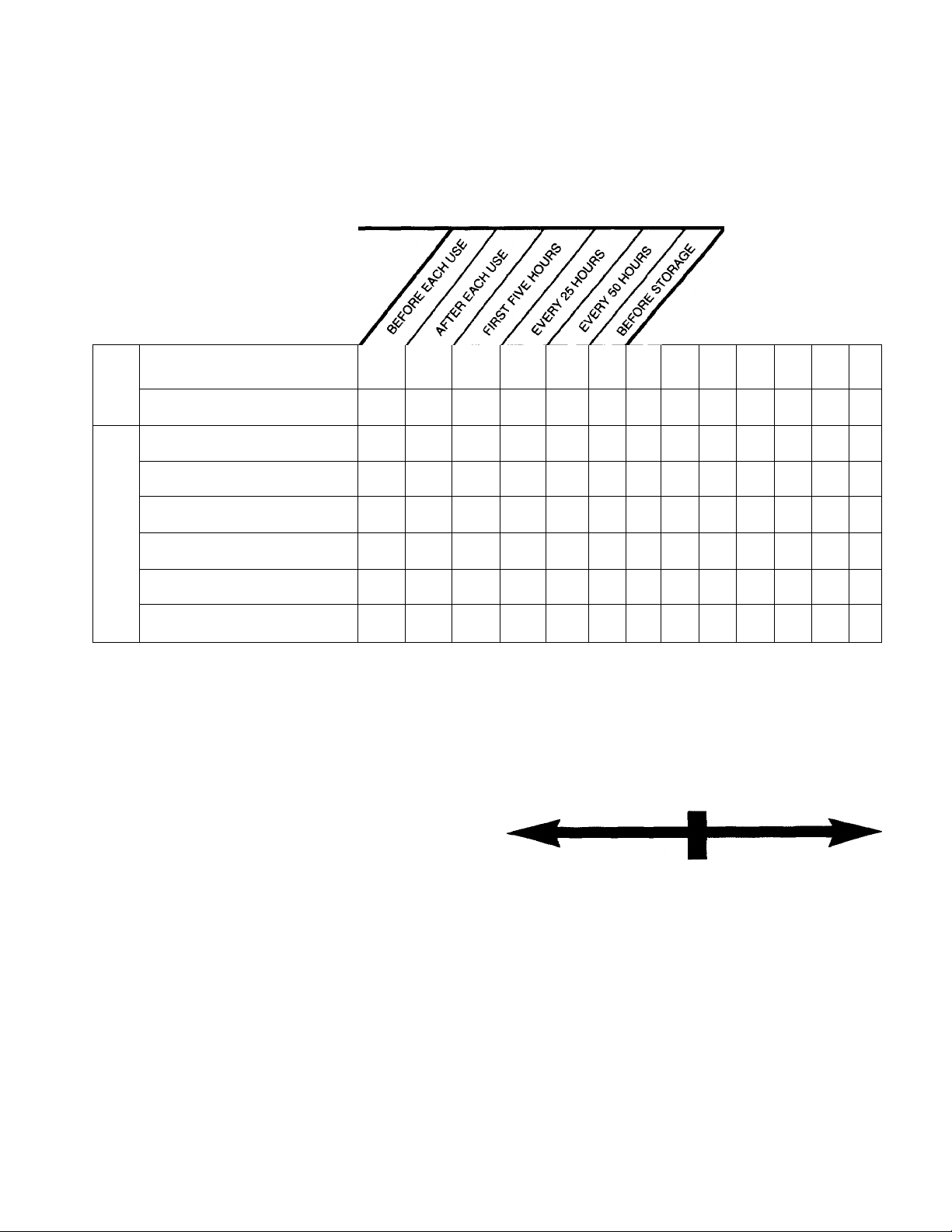

CUSTOMER RESPONSIBILITIES

MAINTENANCE SCHEDULE

FILL IN DATES

AS YOU COMPLETE

REGULAR SERVICE

h—

o

Oil Pivot Points

=)

o

o

tc

Clean Shredder

a.

Check Engine Oil

Change Engine Oil

V

t

Disconnect spark plug wire and move away from

spark plug to prevent accidental starting while

equipment is unattended.

SERVICE DATES

V

V

V

UJ

Service Air Cleaner

z

o

z

Clean Engine Cylinder

ai

Spark Plug

Muffler

V CHECK

GENERAL RECOMMENDATIONS

WARNING: ALWAYS STOP THE ENGINE

AND DISCONNECT THE SPARK PLUG

A

• Periodically check all fasteners and be sure they

are tight.

• Follow the Maintenance Schedule above.

WIRE BEFORE PERFORMING ANY

MAINTENANCE OR ADJUSTMENTS.

CHIPPER-SHREDDER

LUBRICATION

Lubricate the pivot points on the release handle, hop

per assembly, chute deflector and chipper chute once

a season using a light oil.

CLEANING

• The chipper-shredder may be cleaned by running

water from a hose through the hopper assembly

and chipper chute with the engine running. Allow

the chipper-shredder to dry thoroughly.

• Wash the bag periodically with water. Allow to dry

thoroughly in the shade. Do not use heat.

V

V

V

V

V

ENGINE

ENGINE OIL

Only use high quality detergent oil rated with API ser

vice classification SG. Select the oil’s viscosity grade

according to your expected operating temperature.

Colder ------------------------ 32°F

5W30

NOTE: Although multi-viscosity oils (SE30, 10W30,

etc.) improve starting in cold weather, these multi- vis

cosity oils will result in increased oil consumption

when used above 32°F. Check your oil level more fre

quently to avoid possible engine damage from run

ning low on oil.

Your four-cycle engine will normally consume some

oil—therefore, check engine oil level regularly approx

imately every five hours of operation and before each

usage. Stop engine and wait several minutes before

checking oil level. With engine level, the oil must be to

FULL mark on dipstick (refer to figure 10). Change

engine oil after the first five hours of operation, and

every twenty-five hours thereafter.

-----------------

SAE30

► Wanner

10

Page 11

To Drain Oil:

• Drain oil while engine is warm.

a. Remove oil drain cap. Refer to figure 10. Catch

oil in a suitable container.

b. When engine is drained of all oil, replace drain

cap securely.

• Refill with fresh oil. Refer to GAS AND OIL FILL

UP section.

• Replace dipstick.

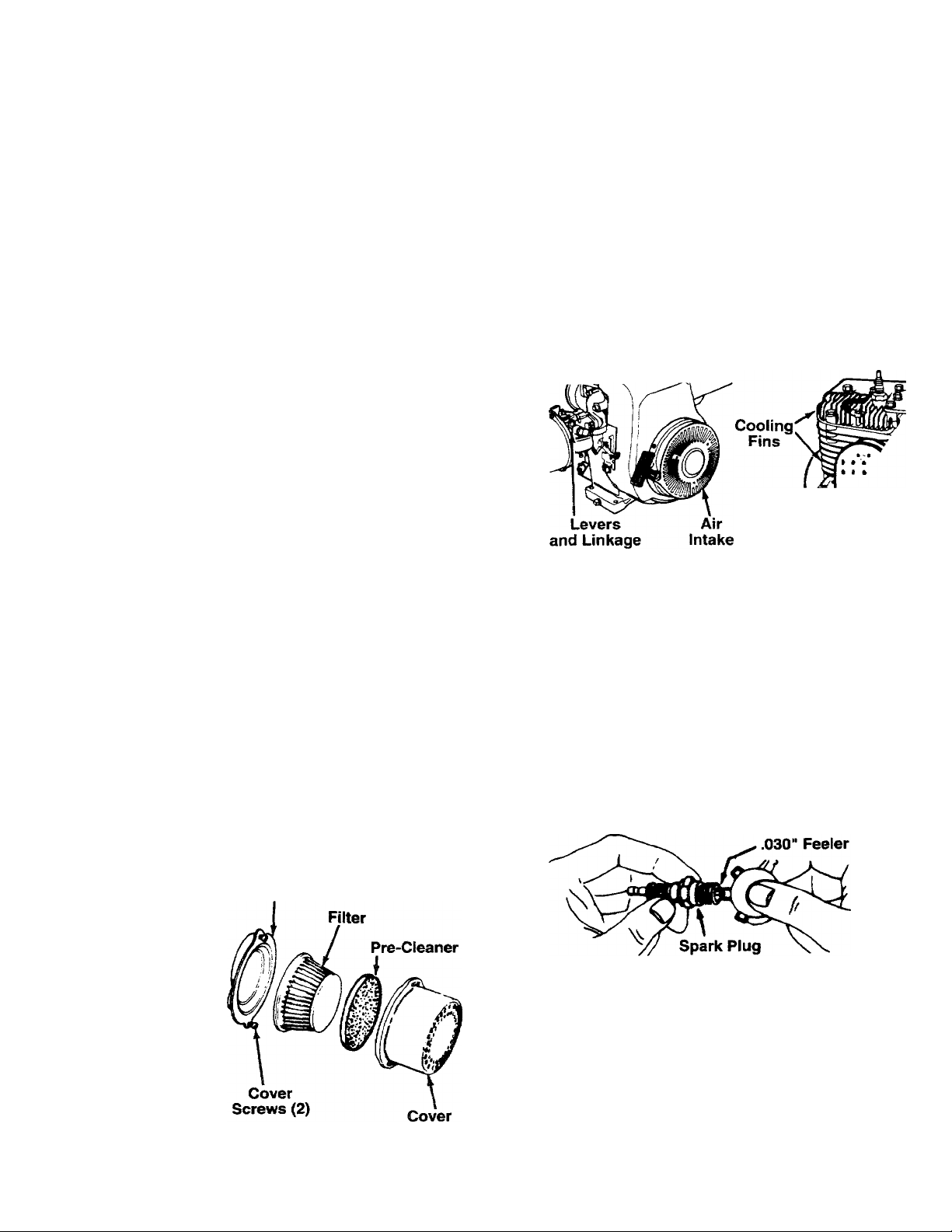

AIR CLEANER

The air cleaner prevents damaging dirt, dust, etc.,

from entering the carburetor and being forced into the

engine and is important to engine life and per

formance.

Never run your engine without air cleaner com

pletely assembled.

To Service Air Cleaner:

Service pre-cleaner after every 25 hours of use, or at

least once a season. Service cartridge every 100 hours

of use, or at least once a season. Sen/ice pre-cleaner

and cartridge more often under dusty conditions.

• Loosen (do not remove) the two screws which

secure the cover.

• Turn the cover counterclockwise and remove it

from the base.

• Carefully remove pre-cleaner and cartridge.

• Clean the inside of base and cover thoroughly.

• Clean cartridge by tapping gently on a flat surface.

If very dirty, replace cartridge and pre-cleaner or

clean as follows;

Wash in a low or non-sudsing detergent and warm

water solution. CAUTION: Do not use petroleum

solvents such as kerosene to clean cartridge.

Rinse thoroughly with flowing water from inside out

until water is clear.

Allow cartridge to stand and air dry thoroughly

before using. DO NOT OIL CARTRIDGE OR PRE

CLEANER. DO NOT USE PRESSURIZED AIR TO

CLEAN OR DRY CARTRIDGE.

• Reassemble cover to engine. Tighten the two

screws securely.

CLEAN ENGINE

Clean engine periodically, Remove dirt and debris

with a cloth or brush. Cleaning with a forceful spray of

water is not recommended as water could contami

nate the fuel system.

Yearly or every 25 hours, whichever occurs first,

remove the blower housing and clean the areas

shown in figure 15 to avoid overspeeding, overheating

and engine damage, Clean more often if necessary.

WARNING: PERIODICALLY CLEAN MUF

FLER AREA TO REMOVE ALL GRASS,

A

DIRT AND COMBUSTIBLE DEBRIS.

FIGURE 15.

SPARK PLUG

The spark plug should be cleaned and the gap reset

to .030" at least once a season or every 50 hours of

operation. See figure 16. Spark plug replacement is

recommended at the start of each season. Refer to

engine parts list for correct spark plug type.

NOTE: Do not sandblast spark plug. Spark plug

should be cleaned by scraping or wire brushing and

washing with a commercial solvent.

FIGURE 14.

Base

FIGURE 16.

MUFFLER

Do not operate the chipper-shredder without a muffler

or tamper with the exhaust system. Damaged mufflers

or spark arresters could create a fire hazard. Inspect

periodically, and replace if necessary. If your engine

is equipped with a spark arrester screen assembly,

remove every 50 hours for cleaning and inspection.

Replace if damaged.

11

Page 12

STORAGE

Prepare your chipper-shredder for storage at the end

of the season or if the unit will not be used for 30 days

or more.

WARNING; NEVER STORE MACHINE

WITH FUEL IN THE FUEL TANK INSIDE

A

NOTE: A yearly check-up by your local Sears Service

Center is a good way to make certain your chippershredder will provide maximum performance for the

next season.

OF BUILDING WHERE FUMES MAY

REACH AN OPEN FLAME OR SPARK, OR

WHERE IGNITION SOURCES ARE

PRESENT SUCH AS HOT WATER AND

SPACE HEATERS, FURNACES, CLOTHES

DRYERS, STOVES, ELECTRIC MOTORS,

ETC.

CHIPPER-SHREDDER

• Clean the chipper-shredder thoroughly.

• Wipe unit with an oiled rag to prevent rust (use a

light oil or silicone).

ENGINE

IMPORTANT: IT IS IMPORTANT TO PREVENT

GUM DEPOSITS FROM FORMING IN ESSENTIAL

FUEL SYSTEM PARTS SUCH AS CARBURETOR,

FUEL FILTER, FUEL HOSE, OR TANK DURING

STORAGE. ALSO, EXPERIENCE INDICATES THAT

ALCOHOL BLENDED FUELS (CALLED GASOHOL

OR USING ETHANOL OR METHANOL) CAN

ATTRACT MOISTURE WHICH LEADS TO SEPARA

TION AND FORMATION OF ACIDS DURING STOR

AGE. ACIDIC GAS CAN DAMAGE THE FUEL SYS

TEM OF AN ENGINE WHILE IN STORAGE.

• Drain the fuel tank.

• Start the engine and let it run until the fuel lines and

carburetor are empty.

• Never use engine or carburetor cleaner products in

the fuel tank or permanent damage may occur.

• Use fresh fuel next season.

NOTE: Fuel stabilizer is an acceptable alternative in

minimizing the formation of fuel gum deposits during

storage. Add stabilizer to gasoline in fuel tank or stor

age container. Always follow the mix ratio found on

stabilizer container. Run engine at least 10 minutes

after adding stabilizer to allow the stabilizer to reach

the carburetor. Do not drain the gas tank and carbure

tor if using fuel stabilizer.

• Drain all the oil from the crankcase (this should be

done after the engine has been operated and is still

warm) and refill the crankcase with fresh oil.

• If you have drained the fuel tank, protect the inside

of the engine as follows. Remove spark plug, pour

approximately 1/2 ounce (approximately one table

spoon) of engine oil into cylinder and crank slowly

to distribute oil. Replace spark plug.

OTHER

• Do not store gasoline from one season to another.

• Replace your gasoline can if your can starts to rust.

Rust and/or dirt in your gasoline will cause problems.

• Store unit in a clean, dry area. Do not store next to

corrosive materials, such as fertilizer.

NOTE: If storing in an unventilated or metal storage

shed, be certain to rustproof the equipment by coating

with a light oil or silicone.

SERVICE & ADJUSTMENT

WARNING; ALWAYS STOP ENGINE AND

DISCONNECT SPARK PLUG WIRE AND

A

REMOVING THE FLAIL SCREEN

If the discharge area becomes clogged, remove the

flail screen and clean area as follows.

• Stop the engine, make certain the chipper-shredder

has come to a complete stop and disconnect spark

plug wire from the spark plug before unclogging the

chute.

MOVE IT AWAY FROM SPARK PLUG

BEFORE PERFORMING ANY ADJUST

MENTS OR REPAIRS.

• Loosen the two hand knobs on each side of the

chute deflector. Lift the chute deflector up, and tie it

out of the way.

• Remove two hairpin clips from the clevis pins which

extend through the housing. Remove the clevis

pins. Lift the flail screen from inside the housing.

See figure 17.

• Clean the screen by scraping or washing with

water. Reinstall the screen.

NOTE: Be certain to reassemble the flail screen with

the curved side down as shown in figure 17.

12

Page 13

Chute Deflector

Hand Knobs

FIGURE 17.

SHARPENING OR REPLACING THE BLADES

CHIPPER BLADES

• Disconnect spark plug wire and move it away from

spark plug.

• Remove the flail screen as instructed in previous

section.

• Remove the chipper chute by removing three hex

nuts and washers. A 1/2" wrench is required. See

figure 17.

NOTE: When reassembling, the cupped washer goes

on the bottom of the chipper chute with the cupped

side against the chute.

• Rotate the impelier assembly by hand until you

locate one of the chipper blades in the chipper

chute opening. Remove the blade, using a 3/16"

alien wrench on the outside of the blade and 1/2"

wrench on the impeller assembly (inside the hous

ing). See figure 18.

• Remove the other blade in the same manner.

Replace or sharpen blades. If sharpening, make cer

tain to remove an equal amount from each blade.

Reassemble in reverse order.

Make certain blades are reassembled with the sharp

edge facing the direction shown in figure 18 (sharp

edge is assembled toward the slotted opening in the

impeller assembly).

SHREDDING BLADE

The shredding blade may be removed for sharpening

or replacement as follows.

• Disconnect spark plug wire and move it away from

spark plug.

• Lower the hopper assembly. Block up the housing.

See figure 19.

• Remove the six hex lock nuts and lock washers

from the housing weld bolts using a 1/2“ wrench.

Separate the chipper-shredder into two halves.

• Remove the back-up plate.

NOTE: When reassembling, make certain the open

ing on the back-up plate is toward the bottom of the

unit. The back-up plate may be reversed to provide a

new cutting edge.

Allen

Screws

FIGURE 18.

Torque

Wrench

FIGURE 19.

Loosen the two hand knobs and cupped washers

which secure the chute deflector, and raise the

chute deflector.

Insert a 1/2" or 3/4" diameter pipe through the flail

screen into the impeller to keep it from turning, or

remove the flail screen and insert a piece of wood

(2 X 4) into the chute opening.

Remove the two outside screws on the blade,

using a 3/16" alien wrench and a 1/2" wrench.

Remove the blade by removing the center bolt, lock

washer and flat washer.

13

Page 14

NOTE: Use caution when removing the blade to avoid

contacting the weld bolts on the housing.

• When sharpening the blade, follow the original

angle of grind as a guide. It is extremely important

that each cutting edge receives an equal amount of

grinding to prevent an unbalanced blade. An unbal

anced blade will cause excessive vibration when

rotating at high speeds and may cause damage to

the unit.

• The blade can be tested for balance by balancing it

on a round shaft screwdriver or nail. Remove metal

from the heavy side until it is balanced evenly. See

figure 20.

CARBURETOR ADJUSTMENT

WARNING: IF ANY ADJUSTMENTS ARE

MADE TO THE ENGINE WHILE THE

A

The carburetor has been pre-set at the factory and

should not require adjustment. However, if your

engine does not operate properly due to suspected

carburetor problems, take your shredder to your near

est SEARS Service Center.

ENGINE IS RUNNING (E.G. CARBURE

TOR), KEEP CLEAR OF ALL MOVING

PARTS. BE CAREFUL OF HEATED SUR

FACES AND MUFFLER.

ENGINE SPEED

Your engine speed has been factory set. Do not

attempt to increase engine speed or it may result in

personal injury. If you believe the engine is running

too fast or too slow, take your chipper-shredder to the

nearest SEARS Service Center for repair and adjust

ment.

• When reassembling the blade, tighten to between

550 and 650 inch pounds, or lacking torque

wrench, tighten securely.

FLAILS

The flails, located inside the housing, may be

reversed when they become dull. It is suggested that

this procedure be performed by your nearest Sears

Service Department.

14

Page 15

TROUBLE SHOOTING

PROBLEM

Engine fails to start • Fuel tank empty, or stale fuel.

Loss of power;

operation erratic

Engine overheats • Carburetor not adjusted

Too much vibration

Unit does not

discharge

Rate of discharge

slows considerably or

composition of

discharged material

changes

POSSIBLE CAUSE(S)

• Spark plug wire disconnected.

• Faulty spark plug.

• Spark plug wire loose.

• Unit running on CHOKE.

• Blocked fuel line or stale fuel.

• Water or dirt in fuel system.

• Carburetor out of adjustment.

• Dirty air cleaner.

properly.

• Engine oil level low.

• Loose parts or damaged

impeller.

• Discharge chute clogged.

• Foreign object lodged in impeller.

• Shredding blade and/or chipper

blades dull.

CORRECTIVE ACTION

• Fill tank with clean, fresh fuel.

• Connect wire to spark plug.

• Clean, adjust gap or replace.

• Connect and tighten spark plug wire.

• Move choke lever to OFF position.

• Clean fuel line; fill tank with clean

fresh gasoline.

• Disconnect fuel line at carburetor to drain fuel

tank. Refill with fresh fuel.

• Adjust carburetor or contact your SEARS

Senrice Center.

• Service air cleaner. See Customer Responsibilities

section of this manual.

• Contact your SEARS Service Center.

• Fill crankcase with proper oil.

• Stop engine immediately and disconnect

spark plug wire. Tighten all bolts and nuts.

Make all necessary repairs. If vibration continues,

have unit serviced by a SEARS Sevice Center.

• Stop engine immediately and disconnect

spark plug wire. Clean flail screen and inside

of blower housing. See Service/Adjustments

section of this manual.

• Stop engine immediately and disconnect

spark plug wire. Remove lodged object.

• Sharpen or replace shredding and chipper

blades.

NOTE; For repairs beyond the minor adjustments listed above, please contact your nearest SEARS Service Center.

HOW TO ORDER REPLACEMENT PARTS

Each chipper-shredder has its own model number.

Each engine has its own model number.

The model number for your chipper-shredder will be

found on a label attached to the frame.

The model number for the engine will be found on !he

blower housing of the engine.

All parts listed herein may be ordered through Sears,

Roebuck and Co. Service Centers and most Retail

Stores.

WHEN ORDERING REPAIR PARTS, ALWAYS GIVE

THE FOLLOWING INFORMATION:

‘PRODUCT - “5 H.P. Chipper-Shredder”

‘MODEL NUMBER - 247.795940

‘ENGINE MODEL NO. - HS50-67344G

‘PART NUMBER

‘PART DESCRIPTION

Your Sears merchandise has added value when you

consider that Sears has service units nationwide

staffed with Sears trained technicians...professional

technicians specifically trained on Sears products,

having the parts, tools and the equipment to insure

that we meet our pledge to you...“we service what we

sell.”

15

Page 16

SEARS CRAFTSMAN 5 H.P. CHIPPER-SHREDDER MODEL NO. 247.795940

Repair Parts

16

Page 17

SEARS CRAFTSMAN 5 H.R CHIPPER-SHREDDER MODEL NO. 247.795940

Repair Parts

KEY

NO.

PART

NO.

1 742-0571

710-1254

2

DESCRIPTION

KEY

NO.

Blade 36 781-051OA

Hex Patch Bolt 3/8-24 x 37 710-0157

2.25" Lg.

4 736-0217 L-Wash. 3/8" I.D. H.D.

736-0247

5

FI-Wash. .406" I.D. X 1.25" (Gr. 5)

O.D. Hdn.

11459B Flail 41

6

7 711-0564

711-0833A

8

711-0834

9

715-0249 Spring Roll Pin 1.12" Lg.

10

Flail Spacer 42 781-0474A Flail Housing Ass’y.—R.H.

Clevis Pin .496" Dia. 43

Flail Spacer w/. 160” Dia. Hole

11 736-0192 FI-Wash. .531” I.D. x .94" O.D. 47

681-0030

12

781-0490

13

710-1054

14

712-0411 Hex Top L-Nut 5/16-24 (Gr. 5)

15

736-0119

16

17 710-0825

736-0142

18

750-0793 Ohute Hinge Spacer 1.66" Lg. 57

19

20 711-0835

21 731-1427

712-0291 Hex Ctr. L-Nut 1/4-20 Thd.

22

23 714-3010

781-0457

24

714-0149B

25

781-0480

26

27 712-3010

736-0242

28

29 720-0170

747-0744A Chipper Door Rod

30

732-0542

31

Impeller Ass’y- Comp.f

Chipper Blade

Flat Hd. Scr. 5/16-24 x .75" Lg.

L-Wash. 5/16" I.D.*

Hex Bolt 1/4-20 x 3.75" Lg.* 55 749-0932

FI-Wash. .281" I.D. x .50" O.D. 56 781-0574

Clevis Pin .5" Dia. x 4.62" Lg. 58 781-0561

Rotating Hopper

Cotter Pin

Shredder Screen

Internal Cotter Pin 3/8" Dia. 64 720-0232

Chute Deflector Ass’y. 65

Hex Nut 5/16-18 Thd. (Gr. 5)

Bell-Wash. .345" I.D. x .88"

Hand Knob 67

Torsion Spring 1.14" Lg.

32 781-0489 Chipper Door

781-0475

33

Chipper Chute Ass'y.

34 736-0170 Spec. L-Wash. 5/16" I.D.

35

712-3010

Hex Nut 5/16-18 Thd. (Gr. 5)

tincl. Ref. 1, 6, 7, 8, 9, 10, 11, 12, 13, 14

‘Common Hardware—May Be Purchased Locally.

PART

NO.

DESCRIPTION

Shredder Frame

Hex Bolt 5/16-24 X.75" Lg.

38 736-0119

L-Wash. 5/16" I.D.*

39 710-3008 Hex Bolt 5/16-18 X .75" Lg.

40 710-0442 Hex Bolt 5/16-18 X 1.5" Lg.*

681-0004

735-0639

44

HS50-67344G

Flail Housing Ass’y.—L.H.

Spark Plug Boot

Engine—^Tecumseh

HS50-67344G

712-0429 Elastic Lock Nut 5/16-18 Thd.

48

731-1428 Hopper Mtg. Collar

49 781-0568

736-0264

50

Locking Pin

Fl-Wash. 5/16" I.D.

53 732-0730 Spring 1.5" Lg.

54

736-0117 Fl-Wash. .385" I.D. x .62" O.D.

Handle

Back-Up Plate

781-0562

Lower Locking Brkt.

Upper Locking Brkt.

726-0214

59

Push Cap 5/8" Dia. Rod

61 750-0786 Spacer .64" I.D. x .38“ Lg.

62

738-0814 Shredder Axle

63

734-1600 Wheel Ass’y. Comp.

Knob

710-0376 Hex Bolt 5/16-18 x 1“ Lg. (Gr. 5)

66 710-1267

Curved Carr. Bolt 5/16-18 x

1.25" Lg.

736-0451 Saddle Wash. .32" I.D.

68

710-0451

69

781-0515 Front Support Brkt.

—

764-0199A

—

723-0400 Safety Glasses (Not Shown)

—

770-8474H

Carr. Bolt 5/16-18 x .75" Lg.

Bag (Not Shown)

Owner’s Manual

NOTE: Specifications subject to change without

notice or obligation.

TECUMSEH 5 H.P. ENGINE MODEL NO. HS50-67344G

Repair Parts

KEY

NO.

1

2

3 590615

4

5

6

7 590617

8

9

10 590620 Cover, Spring

11

12

13 590452

—

17

PARTS LIST FOR REWIND STARTER

PART

NO.

590599A

590600

Pin, Spring (Incl. No. 4)

Washer

DESCRIPTION

Retainer

590601

590598

Washer

Spring, Brake

590616 Dog, Starter

Spring, Dog

590618 Pulley

590619 Spring, Rewind

590687 Housing Ass’y., Starter (40° Grommet)

590535 Rope, Starter (Length 98“ & 9/64" Dia.)

Handle, Starter

590688

Starter, Rewind

Page 18

TECUMSEH 5 H.P. ENGINE MODEL NO. HS50-67344G

Repair Parts

MODEL and SERIAL

NUMBERS HERE

18

Page 19

TECUMSEH 5 Н.Р. ENGINE MODEL NO. HS50-67344G

Repair Parts

KEY

NO.

1 33674B

2

4

5

14

15

16

17 31335

18

19

20 32600 Seal, Oil

25

26

30

40

40

40

41 33562B

41

41

42

42

42

43 20381

45 32875

46

48

49

50

60

64

64A 8345

65

69

70

75

80

81

82

83

86

89

90

92

93

100

101

PART

NO.

Cylinder Ass’y. (Incl. Nos. 2 & 20)

26727 Pin, Dowel

34171 Oil Drain Extension

30969

28277 Washer, Flat

31334

31510

650548

31426

t33342

650561

36421

34535

34536

34537 Piston, Pin & Ring Ass’y.

33563B

33564B

33567 Ring Set, Piston (Std.)

33568

33569 Ring Set, Piston (.020 Oversize)

3261OA

27241 Lifter, Valve

32654

33158

29745

30063

650128

*27677A

34674C

27897 Seal, Oil

30574A

30590A

30591

30588A Spool. Governor

650488

610961 Key, Flywheel

611080

650815

650816

34443A Solid State Ass’y.

610118

Oil Drain Cap

Rod, Governor

Lever, Governor

Clamp, Governor Lever

Screw, Hex Washer Hd. 8-32 x 5/16

Spring, Extension

Baffle, Blower Housing

Screw, Hex Washer Hd. Duriok,

Crankshaft Ass’yPiston, Pin & Ring Ass’y. (Std.)

Piston, Pin & Ring Ass’y.

Piston & Pin Ass’y. (Std.) (Incl.

Piston & Pin Ass’y. (.010 Oversize)

Piston & Pin Ass’y. (.020 Oversize)

Ring Set, Piston (.010 Oversize)

Ring, Piston Pin Retaining

Rod Ass’y., Connecting (Incl. Nos.

Bolt, Connecting Rod

Dipper, Oil

Camshaft (Compression Release)

Extension, Blower Housing

Screw, Torx T-30 Hex Washer. Hd.

Washer, Flat

Screw, Hex Hd. Sems, 10-24 x 1/2

Gasket, Cylinder Cover

Cover, Cylinder (Incl. Nos. 75, 80,

Shaft, Mechanical Governor

Washer, Flat

Gear, Governor (Incl. No. 81)

Screw, Hex Hd. Sems, 1/4-20 x 1-1/4

Flywheel

Washer, Belleville

Nut, Flywheel

Cover, Spark Plug

DESCRIPTION

1/4-20x5/8

(Incl. Nos. 41,42 & 43)

(.010 Oversize) (Incl. Nos. 41,

42 & 43)

(.020 Oversize) (Incl. Nos. 41,

42 & 43)

No. 43)

(Incl. No. 43)

(Incl. No. 43)

46 & 49)

Sems, 1/4-20 X 1/2

311 &312)

KEY

NO.

102 650872

103

110

118 35515

119

120 33016A

125

125 29315C

126 32644A

126

127 650691

129

130 6021A

131

135 33636

137 29752

150 31672

151 31673

169

170 27666 Body, Valve Cover

171

172 34146

173 35350

174

178 29752

181

182

184

185 33666

186 32698

200 t33858A

203 31342

204

206

209

209A

215 32410 Control Knob

223

224

238

239 *27272A Gasket, Air Cleaner

242

243 28820

245 30727

246 35974

250 31715

260

261

267

268 30200 Screw, Hex Washer Hd. Self-Tap

274 *33670A Gasket, Exhaust

275

PART

NO.

Stud, Solid State Mounting

650814

35182

*33554A Gasket, Cylinder Head

29313C

32645A Valve, Intake (1/32" Oversize)

650818

650694A

*27234A Gasket, Breather

31410

650128

6201

650870

*26756

650549

610973

1650139

t30322

30646

*33673A

650152 Screw, Fil. Hd., 8-32 x 3/8

31914 Bracket, Air Cleaner

35657 Housing, Blower

29212

34212 Bracket, Hold Down

35771 Muffler

Screw, Torx T-15 Hex Washer Hd.

Sems, 10-24 x 1

Ground Wire

Rope Guard

Head, Cylinder (Incl. No. 131)

Valve, Exhaust (Std.) (Incl. No. 151)

Valve, Exhaust (1/32" Oversize)

(Incl. No. 151)

Valve, Intake (Std.) (Incl. No. 151)

(Incl. No. 151)

Washer, Flat

Screw, Special Hex Hd., 5/16-18 x

1-1/2

Screw, Hex Flange Hd., 5/16-18 x

1-1/2

Screw, Hex Flange Hd., 5/16-18 x 2

Resistor Spark Plug

Nut & Lock Washer, 1/4-28

Spring, Valve

Cap, Valve Spring

Element, Breather

Cover, Breather

Tube, Breather

Screw, Hex Hd. Sems, 10-24 x 1/2

Nut & Lock Washer, 1/4-28

Screw, Hex Hd., 1/4-28 x 7/8

Screw, Hex Hd., 1/4-28 x 1-11/16

Gasket, Carburetor

Pipe, Intake

Link, Governor to Throttle

Control Ass’y., Bracket (Incl. Nos. 203

& 204, 206, 209 & 209A)

Spring, Compression

Screw, Fil. Hd., 5-40 x 7/16

Terminal Ass’y.

Screw, Fil. Hd. Sems, 8-32 x 1/2

Lock Nut, Hex ‘‘Keps,’’ 8-32

Screw, Fil. Hd. Sems, 1/4-20 x 1-3/8

Gasket, Intake to Cylinder

Screw, Fil. Hd. Sems, 10-32 x 1/2

Filter, Air Cleaner (Paper)

Pre-Air Filter

Cover, Air Cleaner

Screw, Hex Hd. Sems, 1/4-28 x 7/16

Sems, 10-24x9/16

DESCRIPTION

19

Page 20

TECUMSEH 5 H.P. ENGINE MODEL NO. HS50-67344G

Repair Parts

KEY

NO.

277

PART

NO.

650327

DESCRIPTION

Screw, Hex Hd., 1/4-20 x 2-3/8

285 34694 Cup, Starter

287

650926 Screw, Hex Washer Hd., 8-32 x

21/64"

290

292 26460

30962

Line, Fuel

Clamp, Fuel Line

298 650665 Screw, Hex Washer Hd. Thread

Cutting, 1/4-15 X 7/8

300 35591

Tank Ass’y.. Fuel (Incl. Nos. 292 &

301)

301

305

307

308

35355

35554

35499

Cap Ass’y., Fuel

Oil Fill Tube

“0”-Ring

35539 Fill Tube Clip

* Indicates Parts Included in Gasket Set, Ref. No. 400.

t In original production the speed control assembly is rivet

ed to the blower housing baffle. Replacement speed con

trol assembly includes screws and nuts for mounting.

Replacement baffle has threaded holes.

26

24

11

25

O

12

13

KEY

NO.

310 35556

PART

NO.

DESCRIPTION

Dipstick

313 34080 Spacer, Flywheel Key

327 35392

Plug, Starter

340 35230 Plate, Fuel Tank Mounting

342

650751 Screw, Hex Washer Hd. Durlok,

1/4-20x7/16

352 35883 Extension, Baffle

353

370 36261

370A 35344

650926 Screw, Hex Washer Hd., 8-32 x 21/64"

Decal, Instruction

Decal, Throttle

380 631923 Carburetor (Incl. No. 184)

390 590688

400

33683B Gasket Set (Incl. Items Marked*)

420 730225

Starter, Rewind

Oil, 4-Cycle SAE 30 (Quart)

In original production, the starter is riveted to the blower

housing. Replacement housing has threaded studs.

Order four nuts (29752) when remounting starter.

MUFFLER SPARK ARRESTER KIT

Part No. 35983 (Optional Equipment)

PARTS LIST FOR CARBURETOR

KEY

NO.

1

PART

NO.

631615

2 631767

3

4

5

631036 Shutter, Throttle

650506 Screw, Throttle & Choke Shutter

630766 Spring, Idle Regulating Screw

—

DESCRIPTION

Shaft & Lever Ass’y., Throttle

Spring, Throttle Return

6 650417 Screw, Idle Regulating

7

8

9 31837

631919

Shaft & Lever Ass’y., Choke

630735 Spring, Choke Stop

Shutter, Choke

10 *630748 Plug, Welch

11

12 *631021

16

13

14

*631027 Plug, Welch

Inlet Needle, Seat & Clip Ass’y.

(Incl. No. 13)

631022 Clip, Inlet Needle

632019

Float, Carburetor

15 *631024 Shaft, Float

16 631867 Bowl, Float

17

18

21

22

632042 Spring

631183 Washer, Felt

27110

*31839 Adjustment Screw Ass’y., Main

Gasket, Bowl-to-Body

(Incl. Nos. 21,23, 30&31)

23 *630740

24

25

*631078 Screw, Idle Adjustment

*631028 Gasket, Bowl-to-Body

26 631807

27

631184

O-Ring, Adjustment Screw

Fitting, Fuel Inlet

Washer

29 631971 Seal, Dust

30

31

32

—

630738

630739

31840

Spring, Main Adjustment Screw

Washer, Flat

Repair Kit (Incl. Items Marked *)

631923 Carburetor Comp.

20

Page 21

mmi DEL

ROPIETARIO

NUMERO DE

MODELO

247.795940

CRflFTSMRN®

5 CABALLOS DE FUERZA

3 ETAPAS DE CORTE

Precaución:

Lea y observe

todas las reglas

e instrucciones

de seguridad antes

de operar este

equipo

SEARS, ROEBUCK AND CO., Hoffman Estates, IL 60195 U.S.A.

CUBRIDOR DE PAJA Y EMBOLSADOR

PICADORA-DESMENUZADORA

Armado

Operación

Responsabilidades del Cliente

Servicio y Ajuste

Piezas de Reparación

preso en U.S.A.

770-8474H 3/93

Page 22

A

REGLAS DE SEGURIDAD

ADVERTENCIA: PARA REDUCIR EL POTENCIAL DE CUALQUIER LESION CUMPLA CON LAS

INSTRUCCIONES DE SEGURIDAD SIGUIENTES. LA FALLA EN CUMPLIR CON LAS INSTRUC

CIONES PUEDE RESULTAR EN LESIONES PERSONALES.

ENTRENAMIENTO

• Lea este manual del propietario cuidadosamente por completo

antes de tratar de armar u operar esta máquina. Esté

completamente familiarizado con los controles y el uso adecua

do de esta máquina antes de operarla. Guarde este manual en

un lugar seguro para referencia futura y regular y para ordenar

piezas de reemplazo.

• Nunca se debe permitir que los niños operen este equipo.

• Nadie debería operar esta unidad mientras esté intoxicado o

esté tomando medicamentos que menoscaban los sentidos o

reacciones.

• Nunca debería operarse este equipo en la vecindad de niños,

cachorros u otras personas.

• Nunca haga funcionar su máquina en un área cerrada ya que el

escape del motor contiene monóxido de carbono, el cual es un

gas inodoro, insípido y mortalmente venenoso.

• Nunca coloque sus manos o cualquier parte de su cuerpo o

ropas dentro de la cámara de alimentación, canaleta de descar

ga, o cerca de cualquier pieza móvil mientras la máquina o

motor esté funcionando.

• Si por cualquier razón es necesario inspeccionar o reparar la

cámara de alimentación o cualquier parte de la máquina donde

una parte móvil puede entrar en contacto con su cuerpo o ropas,

apague la máquina, permita que se enfríe, desconecte el cable

de la bujía de la bujía y aléjelo de la misma antes de intentar tal

inspección o reparación.

PREPARACION

• Use los lentes de seguridad provistos con su unidad mientras

opere la picadora-desmenuzadora para evitar lesiones por

cualquier material que pueda ser expelido por las aberturas.

• Use ropas apropiadas. Evite usar ropas sueltas. Use guantes

cuando maneje el material.

• MANEJE CON CUIDADO LA GASOLINA ya que es un com

bustible extremadamente inflamable.

• Revise el combustible antes de encender el motor. No llene el

tanque de combustible bajo techo, mientras el motor esté

funcionando, o mientras el motor esté todavía caliente. Apague

la unidad y permita que el motor se enfríe antes de cargar

combustible.

• Cargue combustible a su picadora-desmenuzadora en un área

limpia. No fume mientras carga combustible.

• La tapa del tanque de nafta debe estar asegurada en todo

momento excepto durante la carga de combustible.

• Evite derramar gasolina o aceite. Limpie la unidad de cualquier

combustible o aceite derramado.

• Almacene combustible y aceite en contenedores aprobados,

lejos del calor o llamas, y fuera del alcance de los niños.

• Esta máquina debería operarse sólo al nivel de la superficie

• Asegúrese de que todos los tomillos, tuercas y pernos y otros

sujetadores estén adecuadamente asegurados.

OPERACION

• Cuando alimente material desmenuzadle dentro de este equipo,

sea extremadamente cuidadoso de que no incluya piezas de

metal, rocas, botellas, latas u otras objetos extraños. Podría

resultar en lesiones personales o daños a la máquina.

• Si el mecanismo de corte entra en contacto con cualquier objeto

extraño o si su máquina comenzara a emitir un ruido inusual o

vibración, apague inmediatamente el motor, desconecte el cable

de la bujía y aléjelo de la misma. Permita que la máquina se

detenga y efectúe las siguientes etapas:

Inspeccione por daño.

Reemplace o repare cualquier pieza dañada.

Revise por piezas sueltas y ajuste para asegurar una operación

continuada segura.

• Debe mantenerse a la máquina libre de desechos y otras

acumulaciones.

• No permita que se acumule una acumulación de material proce

sado en el área de descarga ya que esto evitará la descarga

adecuada y puede resultar en una reacción de la abertura de ali

mentación.

• Nunca coloque sus manos o cualquier parte de su cuerpo o

ropas dentro de la cámara de alimentación, canaleta de descar

ga, o cerca de cualquier pieza móvil mientras la máquina o

motor esté funcionando.

• Mantenga todas las guardas y deflectores en su lugar y en bue

nas condiciones de trabajo para asegurar una operación contin

uada segura.

• Cuando opere esta máquina manténgase siempre alejado del

área de descarga.

• Mantenga su cara y cuerpo detrás de la abertura de ali

mentación para evitar el rebote accidental de cualquier material.

• No se incline. Mantenga el equilibrio y posición de los pies

adecuadamente en todo momento.

• Los ajustes del regulador del motor en su máquina no deben

alterarse, cambiarse, o manipularse. El regulador controla las

velocidades máximas seguras y protege al motor y a todas las

piezas móviles contra el daño causado por la sobrevelocidad.

• No transporte la máquina mientras el motor esté funcionando.

• No opere el motor si se ha quitado el filtro de aire o la cubierta

directamente sobre la toma de aire del carburador, excepto para

ajustar. La extracción de tales piezas podría causar un riesgo de

incendio.

MANTENIMIENTO Y ALMACENAMIENTO

• Cuando este equipo se detiene para servicio, inspección,

almacenamiento o para cambiar un accesorio, asegúrese de

que el cable de la bujía esté desconectado de la bujía y alejado

de la misma. Se debería permitir que la máquina se enfríe antes

de efectuar tal inspección, ajustes, servicio, etc. Mantenga su

máquina con cuidado y manténgala limpia para la operación

mejor y más continuada.

• No use soluciones inflamables para limpiar el filtro de aire.

• Cuando no está en uso, su máquina debería almacenarse fuera

del alcance de los niños. Guárdela donde los vapores de la

gasolina no puedan alcanzar una llama o chispa. Refiérase a la

sección de “Almacenamiento” de este manual para períodos lar

gos de almacenamiento.

A

¡¡¡BUSQUE ESTE SIMBOLO PARA INDICAR

PRECAUCIONES IMPORTANTES DE SEGURI

DAD. SIGNIFICA-ATENCION!!! ¡¡¡ESTE

ALERTA!!!SU SEGURIDAD ESTA INVOLU

CRADA.

Page 23

FELICITACIONES por su compra de una Picadora-

Desmenuzadora Craftsman de Sears. Ha sido diseñada,

planeada y fabricada par proporcionarle la confiabllidad y

rendimiento mejor posible. Si tuviera algún problema que

no se pudiera remediar fácilmente, llame a su Centro/

Departamento de Servicio Sears más cercano en los

Estados Unidos. Tenemos técnicos competentes, bien

entrenados y las herramientas adecuadas para servir o

reparar esta unidad. Por favor lea y guarde este manual.

Las instrucciones le permitirán armar y mantener su picadora-desmenuzadora adecuadamente. Siempre observe las

“REGLAS DE SEGURIDAD”

NUMERO DE

MODELO

NUMERO DE

SERIE

______

FECHA DE

COMPRA

LOS NUMEROS DE MODELO Y SERIE SE HAL

LARAN EN UN ROTULO PEGADO AL MARCO DE

LA PICADORA-DESMENUZADORA

USTED DEBERIA REGISTRAR AMBOS, EL NUMERO

DE SERIE Y LA FECHA DE COMPRA Y GUARDAR EN

UN LUGAR SEGURO PARA REFERENCIA FUTURA.

247,795940

RESPONSABILIDADES DEL CLIENTE

• Lea y observe las reglas de seguridad.

• Siga un programa regular en mantener, cuidar y

usar su picadora-desmenuzadora.

• Siga las instrucciones en las secciones de

“Responsabilidades del Cliente” y “Almacena

miento” de este Manual del Propietario.

ESPECIFICACIONES DEL PRODUCTO

Caballos de fuerza:

Desplazamiento:

Capacidad de combustible:

Bujías (Distancia: .030 pul.): Champion

Distancia de aire del encendido

12.00 pul.cub

1 -7/8 Cuartos

(Sin plomo)

equivalente)

5.0

J-8C (o

.0125 pul.

ACUERDO DE MANTENIMIENTO

Un Acuerdo de Mantenimiento de Sears está

disponible para este producto. Llame a su tienda más

cercana de Sears para detalles.

ADVERTENCIA: Esta unidad está equipada con un motor

de combustión intema y no debería usarse en o cerca de

cualquier terreno cubierto por bosques no mejorados,

cubierto por matorrales o grama a menos que el sistema de

escape del motor esté equipado con un retenedor de chis

pas que cumpla con las leyes aplicables locales o del

Estado {de haberlas). Si se usa un retenedor de chispas,

debería mantenerse en una condición efectiva de trabajo

por el operador.

El Estado de California lo anterior se requiere por ley

(Sección 4442 del Código de Recursos Públicos de

California). Otros Estados pueden tener leyes similares. Las

leyes federales se aplican en los terrenos federales. Un

retenedor de chispas para el silenciador está disponible a

través de su Centro de Servicio Autorizado de Sears (Vea

la sección de PIEZAS DE REPARACION de este manual.)

GARANTIA

UN ANO DE GARANTIA LIMITADA PARA LA PICADORA-DESMENUZADORA A GASOLINA CRAFTSMAN

A partir de un año de la fecha de compra, cuando esta Picadora-Desmenuzadora Craftsman sea mantenida,

lubricada y puesta a punto de acuerdo con las instrucciones en el manual del propietario, Sears reparará,

gratis, cualquier defecto en materiales y confección.

Si esta Picadora-Desmenuzadora Craftsman se usa para fines comerciales o de alquiler, esta garantía se apli

ca por sólo 30 días desde la fecha de compra.

Esta garantía no cubre:

• Artículos descartables que se desgastan durante el uso normal, tales como cuchillas, cuchillas picadoras,

desgranadoras, filtros de aire, bujías y bolsas colectoras.

• Reparaciones necesarias a causa de abuso o negligencia del operador, incluyendo cigüeñales doblados y la

falla de mantener el equipo de acuerdo con las instrucciones contenidas en el manual del propietario.

EL SERVICIO DE GARANTIA ESTA DISPONIBLE RETORNANDO LA PICADORA-DESMENUZADORA

CRAFTSMAN AL CENTRO/DEPARTAMENTO DE SERVICIO MAS CERCANO DE SEARS EN LOS ESTA

DOS UNIDOS. ESTA GARANTIA SE APLICA SOLAMENTE MIENTRAS EL PRODUCTO ESTA EN USO EN

LOS ESTADOS UNIDOS.

Esta garantía le proporciona derechos legales específicos, y usted puede tener también otros derechos que

pueden variar de Estado a Estado.

SEARS, ROEBUCK AND CO., D/817WA, Hoffman Estates, IL 60195

Page 24

TABLA DE MATERIAS

REGLAS DE SEGURIDAD................................................2

ESPECIFICACIONES DEL PRODUCTO

ACUERDO DE MANTENIMIENTO

RESPONABILIDADES DEL CLIENTE..............................3

GARANTIA.........................................................................3

ACCESORIOS....................................................................4

INSTRUCCIONES DE ARMADO

..........................

....................................

......................................

3

3

5

OPERACION.................................................................6-10

RESPONABILIDADES DEL CUENTE

ALMACENAMIENTO..................................................12, 13

SERVICIO Y AJUSTE.................................................13-15

LOCALIZACION DE FALLAS

COMO ORDENAR PIEZAS DE REPUESTO

.........................................

.......................

....................

10-12

16

16

ACCESORIOS PARA LA PICADORA-DESMUNEZADORA

Estos accesorios estaban disponibles cuando se compró la picadora. También están a su disposición en la

mayoría de las tiendas al detalle y los centros de catálogo y de servicio de Sears. La mayoría de las tiendas

Sears pueden hacer sus pedidos por piezas de repuesto, cuando usted les indique el número del modelo de su

picadora-desmenuzadora.

Bujía

Filtro de

aire

Silen

ciador

MOTOR

Aceite

para

motor

Recipiente para

gasolina

Esta

bilizador

PICADORA-DESMENUZADORA

:

i

Page 25

INSTRUCCIONES DE ARMADO

IMPORTANTE: Esta unidad se envía SIN GASOLINA

O ACEITE. Después del armado, vea la sección de

operación de este manual para las recomendaciones

del combustible y aceite del motor adecuados.

NOTA: Para determinar los lados de mano derecha e

izquierda de su picadora-desmenuzadora, párese

detrás y enfrente la tolva (ei motor está al frente de la

unidad).

Su picadora-desmenuzadora ha sido completamente

armada en la fábrica, excepto por deflector de la

canaleta y la bolsa colectora. Se incluyen también en

la caja los lentes de seguridad.

Separadores

(Bisagra,

interior)’

Contratuerca'

hexagonal

Perilla de mano

FIGURAI.

Perno hexagonai

Deflector

de ia tolva

PARA EXTRAER LA PICADORA-DESMENUZADORA DE LA CAJA

Corte las esquinas de la caja. Extraiga todos las

inserciones de empaque. Ruede la picadora-des

menuzadora fuera de la caja. Asegúrese de que

todas las piezas y literatura se hayan sacado antes

de disponer de la caja.

HERRAMIENTAS REQUERIDAS PARA EL ARMADO

(2) Llaves de 7/16" o ajustables

COMO PREPARAR SU PICADORADESMENUZADORA

ASEGURESE DE QUE EL CABLE DE LA

BUJIA ESTE DESCONECTADO Y ALEJA

A

-SUJETANDO EL DEFLECTOR DE LA CANALETA

• Quite las perillas de mano y arandela acopadas de

cada lado de la abertura de descarga en el lado

izquierdo de la picadora-desmenuzadora.

• Quite la contratuerca hexagonal, dos separadores

y perno hexagonal de adentro de la bisagra en la

parte superior de la abertura de descarga. No

extraiga un separador del perno hexagonal.

• Coloque el deflector de la canaleta en posición en

la abertura de descarga. Inserte el perno hexago

nal y separador en la bisagra en el deflector y

cubierta de la canaleta (el separador calza dentro

de la bisagra). Vea la figura 1.

• Coloque el segundo separador sobre el perno

hexagonal, dentro de otra parte de la bisagra.

Asegure con la contratuerca hexagonal. Ajuste

firmemente.

• Asegure ambos lados del deflector de la canaleta a

la cubierta usando las perillas de mano y arandelas

acopadas (el lado acopado de las arandelas está

ubicado contra el deflector de la canaleta).

SUJETANDO LA BOLSA COLECTORA

Su picadora-desmenuzadora está equipada con una

bolsa colectora para colectar el material desmenuza

do.

-• Para sujetar ia bolsa, coloque la abertura de la

misma sobre el deflector de la canaleta de tal

manera de cubrir completamente la abertura de la

misma. Oprima el vástago sobre la cuerda de

extracción, y tire de la misma hasta que la bolsa

esté ajustada alrededor de la abertura de la

canaleta. Libere el vástago para fijarlo en posición.

Vea la figura 2.

DO DE LA MISMA ANTES DE ARMAR LA

PICADORA-DESMENUZADORA

Page 26

OPERACION

CONOZCA SU PiCADORA-DESMENUZADORA

LEA ESTE MANUAL DEL PROPIETARIO Y LAS REGLAS DE SEGURIDAD ANTES DE OPERAR SU PICADO

RA-DESMENUZADORA Compare las ilustraciones con su picadora-desmenuzadora para familiarizarse con la

ubicación de varios controles y ajustes. Guarde este manual para referencia futura.

Conjunto de

ia tolva

Palanca de

desenganche

Varilla para

medir la

profundidad

de llenado

de aceite

Palanca del

regulador

de aire

Canaleta de la

picadora

Control del

acelerador

FIGURA 4.

Bolsa

colectora

Manija del

encendido

FIGURA 3.

CUMPLE CON LAS NORMAS DE SEGURIDAD ANSI

Las picadoras-desmenuzadoras de Sears están en conformidad con la norma de seguridad B71.6-1982 del

instituto Americano de Normas Nacionales.

CONTROLES DE OPERACION

(Vea la figura 3 y 4)

PALANCA DEL REGULADOR DE AIRE - Usada

para enriquecer la mezcla de combustible en el car

burador cuando se arranque un motor en frío.

MANIJA DEL ENCENDIDO-Usada para encender

manualmente el motor.

ANTES DE USAR SU PICADORA-DESMENUZADORA, REFIERASE NUEVAMENTE A LAS “REGLAS DE

SEGURIDAD” INDICADAS EN LA PAGINA 2 DE ESTE MANUAL. SIEMPRE SEA CUIDADOSO,

CONTROL DEL ACELERADOR - Controla la veloci

dad del motor y detiene el motor.

PALANCA DE DESENGANCHE - Usada para desen

ganchar la tolva cuando se baje al suelo.

La operación de cualquier picadora-desmenuzadora puede resultar en que haya objetos

extraños proyectados contra los ojos, lo que puede resultar en daños graves a los ojos.

Siempre use los lentes de seguridad que están provistos con la picadora-desmenuzadora o

protectores de los ojos antes de picar o desmenuzar, o mientras efectuando cualquier ajuste o

reparación. Recomendamos la máscara de seguridad Wide Vision para usar sobre los anteojos

o lentes normales, disponible en las tiendas al por menor o de catálogo de Sears.

Page 27

PARA APAGAR EL MOTOR

• Mueva la palanca de control del acelerador a la

posición OFF (APAGADO). Vea la figura 4.

• Desconecte el cable de la bujía y aléjelo de la

misma para evitar un arranque accidental mientras

el equipo no esté atendido.

COMO USAR SU PICADORA-

DESMENUZADORA

No trate de picar o desmenuzar cualquier material

diferente de vegetación que se encuentra en

cualquier patio normal (por ej., ramas, hojas, ramitas,

etc.).

ADVERTENCIA: LA PICADORA-DES*

MENUZADORA DESCARGA MATERI

A

ALES A UNA VELOCIDAD CONSIDER

ABLE. MANTENGASE ALEJADO DEL

AREA ALREDEDOR DEL DEFLECTOR

DE LA CANALETA. SIEMPRE APAGUE

EL MOTOR Y DESCONECTE EL CABLE

DE LA BUJIA CUANDO ESTE EN PRO

CESO DE SACAR O SUJETAR LA

BOLSA CUANDO CAMBIE LOS CON

TENEDORES O CUANDO EXTRAIGA EL

MATERIAL DESMENUZADO. USE

LENTES DE SEGURIDAD Y GUANTES

SIEMPRE QUE USE SU PiCADORA-DESMENUZADORA.

Más pequeño que 1/2“

de diámetro

(Recomendado)

o 1" de diámetro

(Máximo)

Conjunto de

ia tolva

FIGURA 5.

• Pueden rastrillarse hojas y ramitas pequeñas cuan

do el conjunto de la tolva se baja al nivel del suelo.

Vea la figura 6. Ramas pequeñas de hasta 1/2“ de

diámetro (recomendado) o de 1" de diámetro (máx

imo) pueden también alimentarse al conjunto de la

tolva en esta posición. Vea la figura 7.

La picadora-desmenuzadora está diseñada para tres

métodos diferentes de operación.

• Hojas y ramas pequeñas de hasta 1/2" de diámetro

(recomendado) o 1" de diámetro (máximo) pueden

alimentarse en el conjunto de la tolva cuando está

en la posición elevada. Vea la figura 5. Si fuera

necesario empujar el material dentro de la

picadora-desmenuzadora use un palo de diámetro

pequeño - NO SUS MANOS. El palo debería ser

suficientemente pequeño para ser molido si

quedara atrapado en el conjunto propulsor.

ADVERTENCIA: NO PONGA MATERIAL

MAS GRANDE QUE 1/2" DE DIAMETRO

A

(RECOMENDADO) O 1" DE DIAMETRO

(MAXIMO) DENTRO DEL CONJUNTO DE

LA TOLVA. PUEDE ALIMENTARSE A LA

CANALETA DE PICADO CON MATERI

ALES DE HASTA UN MAXIMO DE 3" DE

DIAMETRO. NO TRATE DE PICAR O

DESMENUZAR CUALQUIER MATERIAL

MAS GRANDE QUE 3" DE DIAMETRO.

PODRIA RESULTAR EN LESIONES PER