Page 1

Owner’s Manual

CRAFTSMAN

6.5 Horse Power

Self-Propelied

CHIPPER-SHREDDER VACUUM

Model No.

247.77763

CAUTION: Before using this product,

read this manual and follow all Safety

Rules and Operating Instructions.

Sears, Roebuck and Co., Hoffman Estates, IL 60179, U.S.A.

Printed in U.S.A.

i

i

I

E

770-i0034

(8/98)

Page 2

TABLE OF CONTENTS

Content

Warranty Information

Safe Operation Practices

Assembly

Operation

Maintenance

Page

2

3

5

8

13

Content

Sen/ice & Adjustment

Off-Season Storage

Trouble-Shooting

Parts List

Page

15

17

18

■ 19

WARRANTY INFORMATION

One-Year Warranty on Craftsman Chipper-Shredder Vacuum

For one year from the date of purchase, when this Craftsman chipper-shredder vacuum is maintained, lubricated,

and tuned up according to the operating and maintenance instructions in the owner’s manual, Sears will repair,

free of charge, any defect in material or workmanship.

This warranty excludes blades, chipper blades, flails, air cleaners, spark plugs, catcher bags and tires which are

expendable parts and become worn during normal use.

If this chipper-shredder vacuum is used for commercial or rental purposes, this warranty applies for only 30 days

from the date of purchase.

WARRANTY SERVICE IS AVAILABLE BY CONTACTING THE NEAREST SEARS SERVICE CENTER IN THE

UNITED STATES. THIS WARRANTY APPLIES ONLY WHILE THIS PRODUCT IS IN USE IN THE UNITED

STATES. '

This warranty gives you specific legal rights, and you may also have other rtghts'which vary^rom-state to state.

Sears, Roebuokand Co., D/817WA, Hoffman Estates, II60179

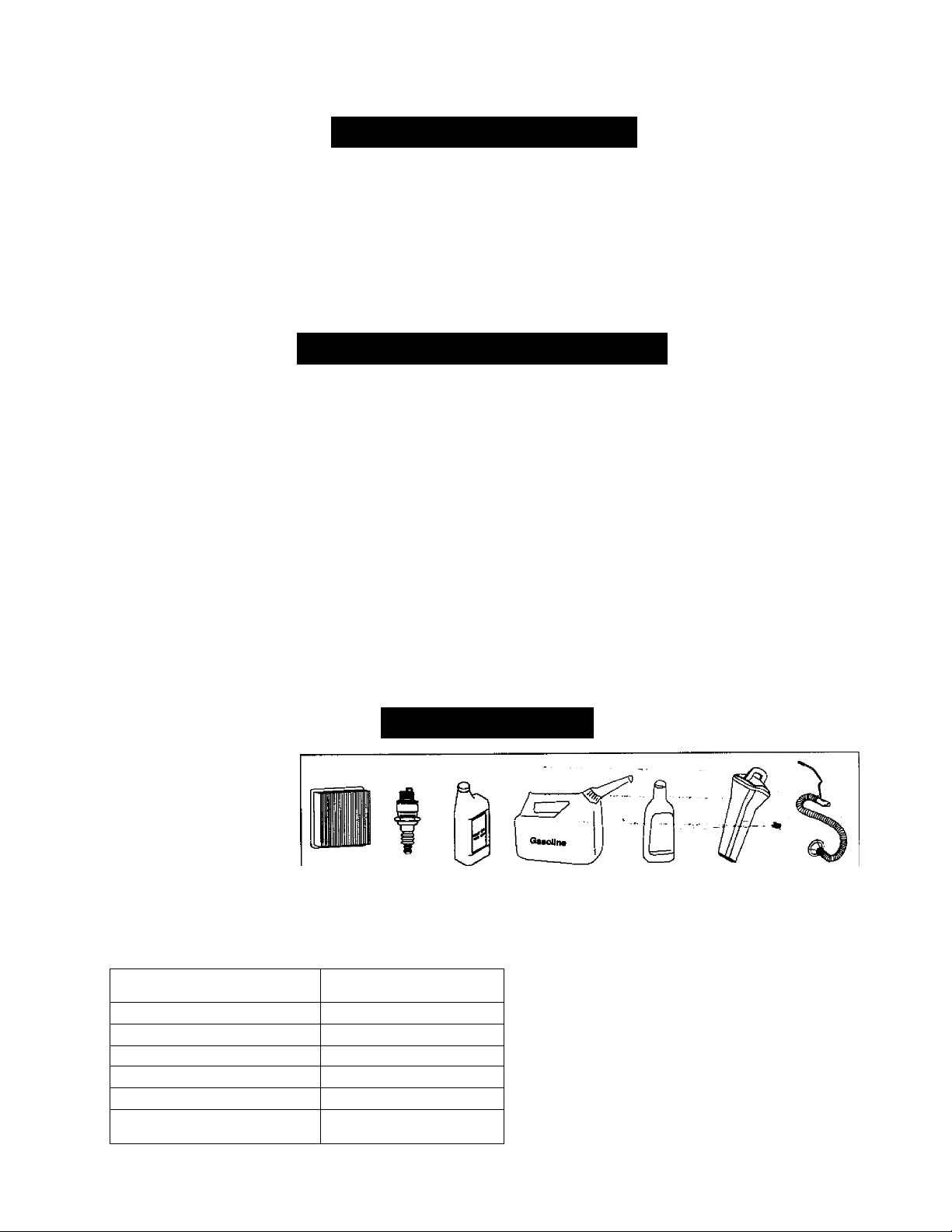

ACCESSORIES

These accessories are

available where the unit was

purchased. They are also

available at most Sears retail

outlets, and service centers.

Most Sears stores can order

repair parts tor you when you

provide the model number of

your Craftsman chipper

shredder vacuum.

Horsepower;

Engine Oil Type

Engine Oil Capacity

Fuel Capacity:

Spark Plug

Spark Plug Gap

Tire Pressure

Air

Filter

Spark Engine Gas

Plug Oil Can

PRODUCT SPECIFICATION

6.5 Horse Power

SAE30

20 Ounces

Approx. 3 Quarts

Champion RN4C

.030"

24 P.S.l.

Model Number

Serial Number.............................

Date of Purchase

Record both serial number and date of purchase and

keep in a safe place for future reference.

Fuel Tamper

Stabilizer Plug

.....

.247.7.7763,

.......................

10-foot

Hose Kit

Page 3

A

A

A

SAFE OPERATION PRACTICES

This symbol points out important safety instructions wtiicti, if not followed, could endanger the per

sonal safety and/or property of yourself and others. Read and follow all instructions in this manual before

attempting to operate your chipper-shredder vacuum. Failure to comply with these Instructions may result in

personal injury. When you see this symbol—heed its warning.

Your chipper-shredder vacuum was built to be operated according to the rules for safe opera-

DANGFR- manual. As with any type of power equipment, carelessness or error on the part of

UANutn. operator can result in serious injury. If you violate any of these rules, you may cause seri

ous injury to yourself or others.

This unit is equipped with an internal combustion engine and should not be used on or near any unimproved

forest-covered, brush-covered or grass-covered land unless the engine's exhaust system is equipped with a

spark arrester meeting applicable local or state laws (if any), if a spark arrester is used, it should be

maintained in effective working order by the operator.

in the State of Caiifornia the above is required by law (Section 4442 of the California Public Resources

Code). Other states may have similar laws. Federal laws apply on federal lands. A spark arrester for the

muffler is available through your nearest Sears Authorized Service Center (See the REPAIR PARTS section

of this manual.)

General Operation

• Read this owner's guide carefully in its entirety before

attempting to assemble this machine. Read,

understand, and follow all instructions on the machine

and in the manual(s) before operation. Be completely

familiar with the controls and the proper use of the

machine before operating it. Keep this manual in a

safe place for future and regular reference and for

ordering replacement parts.

• Your chipper-shredder vacuum is a powerful tool, not a

plaything. Therefore, exercise extreme caution at all

times. Your unit has been designed to perform two

jobs: to chip and vacuum vegetation found in a normal

yard. Do not use it tor any other purpose.

• Never allow children under 16 to operate the unit.

Children 16 years and older should only operate under

close parental supervision. Only responsible

individuals who are familiar with these rules of safe

operation should be allowed to use your unit.

• Keep the area of operation clear of all persons,

particularly small children and pets. Stop the engine

when they are in the vicinity of the unit.

• When feeing material into this equipment, be

extremely careful that pieces of metal, rocks, bottles,

cans or other foreign objects are not included.

Personal injury or damage to the machine could result.

• Always wear safety glasses or safety goggles, during

operation and while performing an adjustment or

repair, to protect eyes from foreign objects that may be

thrown from the machine.

• Wear sturdy, rough-soled work shoes and close fitting

slacks and shirt. Shirt and slacks that cover the arms

and tegs and steel-toed shoes are recommended. Do

not wear loose fitting clothes or jewelry, and secure

hair above shoulder length. They can be caught in

moving parts. Never operate a unit in bare feet,

sandals or sneakers. Wear gloves when feeding

material in the chipper chute.

Do not operate the unit while under the influence of

alcohol or drugs.

Do not over-reach. Keep proper footing and balance at

all times.

Never place your hands or any part of your body or

clothing near or under rotating parts. Keep clear of the

discharge opening at all times Never insert your

hands or any part of your body or clothing into the

nozzle, chipper chute or discharge opening as the

rotating impeller can cause serious injury.

If it is necessary for any reason to unclog the feed

intake or discharge openings or to inspect or repair any

part of the machine where a moving part can come in

contact with your body or cipthintg- sUiP the machine,

allow it to cool, disconnect the spark plug wire from the

spark plug and move it away from the spark plug

before attempting to unclog, inspect or repair.

Never operate unit without vacuum bag and discharge

chute properly affixed to unit. Large zippered end of

bag must be closed to prevent objects from being

blown out.

Never operate unit without either the inlet nozzle or

optional hose attachment properly affixed to unit.

These devices shield the operator from accidental

contact with the rotating impeller. Never attempt to

convert the unit from nozzle to hose mode or vice versa

with the engine running.

Never attempt to remove or empty vacuum bag when

engine is running. Shut the engine off and wait for the

impeller to come to a complete stop before removing

the bag. The impeller continues to rotate for a tew

Page 4

• seconds after the engine is shut off. Never piece any

part of the body In the impelier area until you are sure

the impeller has stopped rotating.

• Keep all guards and safety devices in place and

operating properly.

• Do not allow an accumulation of processed material

to build up in the discharge area as this will prevent

proper discharge and can result in kick-back from the

chipper chute.

• - Keep your face and body back from chipper chute to

avoid accidental bounce back of any material.

• If the cutting mechanism strikes a foreign object or if

your machine should start making an unusual noise

or vibration, immediately stop the engine, disconnect

the spark plug wire and move the wire away from the

spark plug. Allow the machine to stop and take the

following steps:

a. I nspect for damage

b. Repair or replace any damaged parts.

c. . Check for any loose parts and tighten to assure

continued safe operation.

• Muffler and engine become hot and can cause a burn.

Do not touch.

• Do not allow leaves or other debris to build up on

engine's muffler. The debris could ignite and cause a

fire.

• Do not ope rate engine if aircleaneror cover over

carburetor air-intake is removed, except for

adjustment. Removal of such parts could create a fire

hazard.

Children

Tragic accidents can occur if the operator is not alert to the

presence of small children. Children are often attracted to

the chipping and vacuuming activity. Never assume that

children will remain where you last saw them.

• Keep children out of the work area and under the

watchful eye of a responsible adult other than the

operator.

• Be alert and turn the unit off if a child enters the area.

• Never allow children under the age of 16 to operate

the chipper-shredder vacuum.

• Che<^ and add fuel before starting the engine. Never

remove gas cap or add fuel while the engine is

running. Allow engine to cool at least two minutes

before refueling,

• Replace gasoline cap securely and wipe off any

spilled gasoline before starting the engine as It may

cause a fire or explosion.

• Extinguish all cigarettes, cigars, pipes and other

sources of ignition.

• Never refuel unit indoors because flacnrnable vapors

will accumulate in the area.

• Never store the machine or fuel container inside

where there is an open flame or spark such as a gas

hot water heater, clothes dryer or furnace.

• Never run your machine in an enclosed area as the

exhaust from the engine contains carbon monoxide,

which Is a odorless, tasteless and deadly poisonous

gas.

• To reduce fire hazard, keep engine and muffler free of

leaves, grass, and other debris build-up. Clean up

fuel and oil spillage. Allow unit to cool at least 5

minutes before storing.

• Before cleaning, repairing, or inspecting, make certain

the impeller and all moving parts have stopped.

Disconnect the spark plug wire and keep wire away

from spark plug to prevent accidental starting. Do not

use flammable solutions to clean air filter.

• Keep all nuts, bolts, and screws tight to be sure the

equipment is in safe working condition.

• Never tamper with safety devices. Check their proper

operation regularly.

• After striking a foreign object, immediately stop the

engine, disconnect the spark plug wire from the spark

plug, and thoroughly inspect the unit for any damage.

Repair damage before starting and operating unit.

• Do not alter or tamper with the engine’s governor

setting. The governor controls the maximum safe

operating speed of the engine. Over-speeding the

engine is dangerous and will cause damage to the

engine and to other moving parts of the machine.

• Check the vacuum bag frequently for wear. Replace if

worn or damaged.

• Keep vacuum bag free of debris when njt in use.

Service

• Use extreme care in handling gasoline and other

fuels. They are extremely flammable and the vapors

are explosive.

• Store fuel and oil in approved containers, away from

heat and open flame, and out of the reach of children.

SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE.

Your Responsibility

Restrict the use of this power machine to

persons who read, understand and follow the

A

warnings and instructions in this manual and on

the machine.

Page 5

ASSEMBLY

iMPORTANT: This unit is shipped without gasoiine

or oii in the engine. After assembly, see

OPERATION section of this manual for proper fuel

and engine oil fill-up.

NOTE: To determine right ar)d left hand sides of your

chipper-shredder vacuum, stand behin^the unit with

the engine farthest away from you.

Your chipper-shredder vacuum has been completely ’

assembled at the factory, except for the nozzle, the

chipper chute with support bracket and the catcher bag.

These parts are shipped loose in the carton. A pair of

safety glasses and a 20-oz. bottle of engine oil are also

included in the carton.

I

m

1

Removing From Carton

• Cut the corners of the carton.

• Remove all packing inserts.

• Remove all loose parts. See Figure 1.

• Push down on handle to lift front of chipper

shredder vacuum and roll unit out of the carton.

• Make certain all parts and literature have been

removed before the carton is discarded.

Loose Parts

with Support Bracket

N

(See Figure 1.)

1. Nozzle

2. Chipper Chute with Support Bracket

3. Catcher Bag

4. Safety Glasses (Not Shown in Figure 1 }

5. A 20-oz. Bottle of Engine Oil

20-oz. Bottle

of Engine Oii

Figure 1

Tools Required

1. 1 /2" or adjustable wrenches

2. 7/16" or adjustable wrenches

3. Funnel (Recommended)

4. Pliers ' ,

___

..7 - *

Disconnecting Spark Plug

(See Figure 2.)

• Before proceeding with assembly of your new

chipper-shredder vacuum unit, disconnect the

spark plug wire from the spark plug on the

engine and move it away. This will prevent

accidental starting of the engine in any way.

Page 6

Attaching the Nozzle

(See Figure 3.)

• Remove the three plastic wing nuts from the

front of the chipper-shredder vacuum.

• Place the nozzle over the three weld studs.

• Secure with the plastic wing nuts just removed.

Attaching the Chipper Chute

• Loosen, but do NOT remove, the two hex bolts,

Plastic

Wing Nuts

Plastic

Wing Nuts

Figure 4

flat washers, and flange nuts which are secured

to the support bracket. See Figure 5,

Tighten

Securely

Figure 3

NOTE: The metal tab in the nozzle must depress the

safety switch on the front of the chipper-shredder

vacuum or the engine will not start. See Figure 4.

Figure 5

Remove the two flange nuts, hex bolts and

saddle washers which secure the right side of

the upper handle to the right side of the lower

handle. See Figure 6.

Next, remove the three hex nuts and bell

washers from the weld studs found beside the

opening on the right side of the chipper-shredder

vacuum. See Figure 6.

Page 7

• Align the support bracket with the holes in the

• Replace the hex bolts, saddle washers and

• Follow by tighten! ng al I hardware'securely fi rst

Attaching the Catcher Bag

• Place the catcher bag inside of handle

Place the chipper chute over the weld studs

keeping the slotted side towards the bottom.

Loosely secure with the three hex nuts and bell

washers that were removed earlier. Do not fuliy

tighten the hex nuts at this point in the assembly.

See Figure 7.

• Place the four straps on the top of the bag over

• Squeeze the clamp on the drawstring and pull

right side of the upper and lower handles where

the hex bolts were just removed. Push up

slightly on the chipper chute in order to better

align the holes in the support bracket with the

holes in the handles.

flange nuts.to affix the support bracket to the

handle assemblies. See Figure 7.

on the chipper chute, then on the support

bracket, and finally on the handle.

assembly. Slip the opening on the bag over the

discharge chute, making certain it is over the rib

on the discharge chute.

the upper handle, hooking them on the studs.

the drawstring tight. Release the clamp. See

Figure 8.

Page 8

OPERATION

Know Your Chipper-Shredder Vacuum

Read this owner’s manual and safety rules before operating your chipper-shredder vacuum. Compare the

illustrations below with your equipment to familiarize yourself with the location of various controls and

adjustments. Save this manual for future reference.

The operation of any chipper-shredder vacuum can result in foreign objects being thrown into

FET^^sEsm gygg vvhich can result in severe eye damage. Always wear safety glasises, provided with

file Craftsman chipper-shredder vacuum, for operating this equipment or while performing any

adjustments or repairs on it.

Drive Clutch Control

Chipper

Chute

Nozzle Door Height

Adjustment Levers

Catcher Bag

Air Filter

Front Caster Wheel

Nozzle Door

Figure 9

Operating Controls

Front Caster Wheels

Allows for a choice in the manueverability of the

Chipper Chute

Allows twigs and small branches up to three inches in

diameter to be fed into the impeller for shredding.

Nozzle

Yard waste such as leaves and pine needles can be

vacuumed up through the nozzle.

Catcher Bag

Collects shredded material fed in through the chipper

chute or vacuumed in through the noiizie.

Drive Clutch Control

Squeezing the drive clutch control causes the

chipper-shredder vacuum to self-propel.

Nozzle Door

Nozzle ground clearance can be adjusted with the

chipper-shredder vacuum.

Primer

The primer is u^ed to assist in starting a cold engine

or restarting of a engine after a'short sttErtdown.

Starter Handle

This is used to start the engine.

Throttle Control

Controls the engine speed and stops the engine.

Stopping the Engine

• Move throttle control lever to STOP position.

• Disconnect spark plug wire and move away from

the spark plug to prevent accidental starting while

the equipment is unattended.

nozzle door.

Starter

Handle

Primer

View from rear of

chipper-shredder vacuum

Meets ANSI safety standards

Craftsman chipper-shredder vacuums conform to the safety standard of the American National Standards Institute (Af

Page 9

Gas And Oil Fill-up

Oil (one 20-oz. bottle shipped with unit)

Only use high quality detergent oil rated with API

service classification SF, SG or SH. Select the oil’s

viscosity grade according to the expected operating

temperature. Follow the chart below.

NOTE: Although multi-viscosity oils (5W30, 10W30,

etc.) improve starting in cold weather, these

multiviscosity oils will result in increased oil

consumption when used above 32°F. Check engine

oil level more frequently to avoid possible engine

damage from running low on oil.

Colder

32°F

Warmer

A

A

A

WARNING: Never fill the fuel tank indoors.

Gasoline produces noxious fumes. Always

be certain to fill the fuel tank in a welt

ventilated area to avoid inhalation of

gasoline fumes.

WARNING: Never smoke while fueling

your chipper-shredder vacuum. Gasoline

produces cumbustable fumes which can

ignite and cause personal injury.

WARNING: Do not fill closer than 1/2 inchfrom the top of the fuel tank to prevent

spills and to allow for fuel expansion. If

gasoline is accidently spilled, move

chipper-shredder vacuum away from area

of spill. Avoid creating any source of

ignition until gasoline vapors have

disappeared.

5W30 SAE30

Oil Viscosity Chart

• Check the fuel level periodically to avoid running

• Remove oil fill dipstick.

• With the chipper-shredder vacuum on level

ground, use a funnel to fill engine with oil to

FULL mark on dipstick. Capacity is

approximately 20 oz. Be careful not to overfill.

Overfilling will cause the engine to smoke

profusely and will result in poor engine

performance. The oil bottle packaged with your

Starting The Engine

IMPORTANT: If your unit shows any sign of motion

with the drive dutch control in the disengaged

position, shut the engine off immediately. Readjust

following the instructions on page 16.

chipper-shredder vacuum contains 20 oz. of oil.

• Tilt chipper-shredder vacuum toward the left,

then re-level. Check the oil level making certain

A

■ not to rub the dipstick along the inside walls of

the oil fill tube. This would result in a false

dipstick reading. Refill to FULL mark on dipstick,

if necessary. Replace dipstick and tighten.

• Check oil level three times prior to starting

A

engine to be certain you’ve gotten an accurate

dipstick reading. Running the engine with too

little oil can result in permanent engine damage.

Gasoline

• Remove fuel cap from the fuel tank.

• Make sure the container from which you will

pour the gasoline is clean and free from rust or

foreign particles. Never use gasoline that may

be stale from long periods of storage in its

container. Gasoline that has been sitting for any

period longer than four weeks should be

considered stale.

• Fill fuel tank with approximately 3 quarts of

clean, fresh, lead-free grade automotive

gasoline. DO NOT use Ethyl or high octane

gasoline. Replace fuel cap.

out of gasoline while operating the chipper

shredder vacuum. If the unit runs out of gas as it

is chipping, it may be necessary to unclog the

unit before it can be restarted. Refer to

Removing the Flail Screen on page 15.

WARNING: Make sure that no one other

than the operator is standing near the

chipper-shredder vacuum unit while starting

or operating.

Do not operate this unit unless the nozzle,

discharge chute, and the bag have been

propqrly installed.

Attach spark plug wire and rubber boot to spark

plug if not already attached.

Place the throttle control lever in FAST position.

Depress the primer three to four times slowly.

Wait about two seconds between each push.

When temperature is at or below 50“F/10“C, it

may be necessary to depress the primer five to

six times. You may have to use the primer to

restart a warm engine after a short shutdown.

Place one foot on the left rear wheel to prevent

the unit from skidding while starting.

Grasp starter handle and pull rope out slowly

until engine reaches start of compression cycle.

The rope will pull slightly harder at this point. Let

the rope rewind slowly.

Page 10

NOTE: V\fi}ile the engine is reaching №te compressk>n

cycle, you may hear a “clanking“ ncHse. Thisnaseis

caus^ by the impeller flails («voting and falling into

place and IS normal. This noise will continue untill the

impeller reaches full speed.

• Pull the rope with a rapid, continuous, full arm

stroke while keeping a firm grip on the starter

handle.

•' Continuing to keep a firm grip on the starter

handle, let the rope rewind slowly. Do not let the

starter handle snap back against the eye bolt on

the handle. Repeat, if necessary, until engine

starts. Additional priming may be necessary.

• Move throttle control to IDLE position for a few

minutes to warm up the engine. Move it back to

fast when running.

• ALWAYS keep the throttle control in the Fast

postion when operating the chipper-shredder

vacuum.

NOTE: Engine may run very slowly for the first five to

ten seconds after it has been started until the impeller

gains momentum and allows the engine to reach its

top RPM.

NOTE: To idle smoothly, a new engine may require 3

to 5 minutes of running at above the slow idle speed.

The idle speed has been adjusted for proper running

after this break-in period.

Stopping the Engine

• Move throttle control lever to STOP position.

• Disconnect spark plug wire and move away from

the spark plug to prevent accidental starting while

the equipment is unattended.

NOTE: Raise the nozzle height to vacuum a thick

layer of leaves; lower the nozzle height for smoother

lawns.

Operation of your Chipper-Shredder Vacuum

Your chipper-shredder vacuum is designed to chip

small tree branches and twigs, shred leaves and

vacuum foliage and other lawn debris. For

convenience in operation, your Craftsman chipper

shredder vacuum is equipped with a drive clutch

control allowing it to "self-propel."

A

A

Adjusting Nozzle Height

• The nozzle door height adjustment levers have

five position settings and are found each side of

the nozzle door. See Figure 10. The nozzle door

height should be adjusted according to the

conditions.

• Slide the height adjustment lever forward or

backward for adjusting the nozzle door upwards

or downwards. See Figure 10.

WARNING: Keep your hands, feet and

any loose clothing clear of the nozzle any

A

A

time the engine is running. When the

engine Is running, a vacuum Is being

created in the nozzle which can draw in

loose clothing.

WARNING: Never make any adjustments

on the nozzle while the engine is running.

IMPORTANT: Your chipper-shredder vacuum is

equipped with a safety switch at the front left portion

of the impeller housing. The metal fab bn'the nozzle

must depress this switch for the engine to start. Be

certain the nozzle is properly in place before

attempting to start the unit. See Figure 4 on page 6.

A

WARNING: The impeller (chipping/

shredding mechanism) is rotating at all

times when the engine is running.

WARNING: Keep your hands away from

the nozzle opening and NEVER place your

hands or arms inside Of the chipper chute

when the engine is running. Doing so could

result in serious personal injury.

WARNING: Always survey the area to be

vacuumed thoroughly before operating the

chipper-shredder vacuum. Clear the area

of any obstructions such as toys, dog

chains, etc. Running over such an

obstruction can result in personal injury as

well as damage to the chipper-shredder

vacuum.

Do not vacuum up anything other than normal

yard waste such as leaves or pine needles.

10

Loading...

Loading...