Page 1

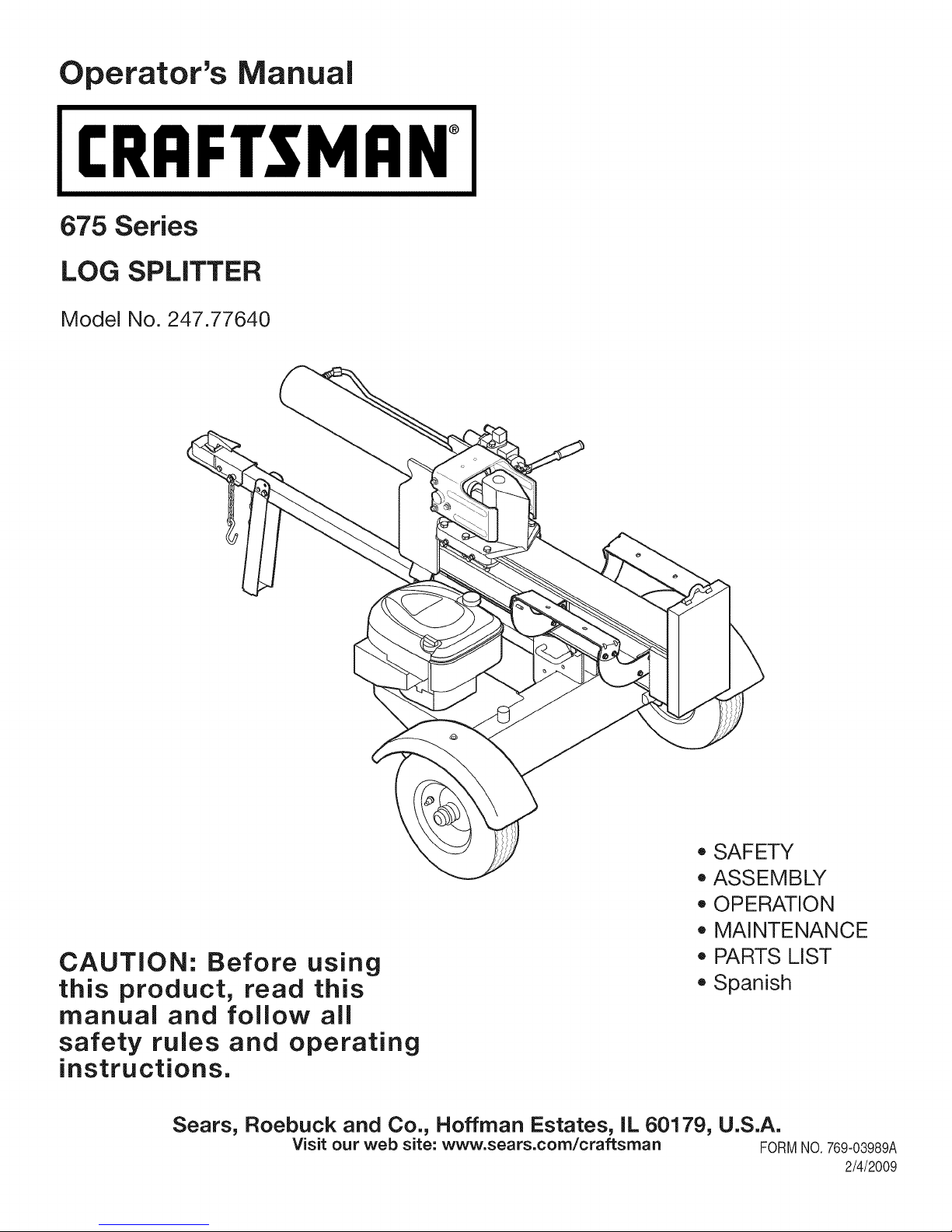

Operator's Manual

CRRFrSM ®

675 Series

LOG SPLITTER

Model No. 247.77640

CAUTION: Before using

this product, read this

manual and follow all

safety rules and operating

instructions.

Sears, Roebuck and Co., Hoffman Estates, IL 60179, U.S.A.

Visit our web site: www.sears.com/craftsman FORMNO.769-03989A

o SAFETY

ASSEMBLY

OPERATION

MAINTENANCE

PARTS LIST

Spanish

2/4/2009

Page 2

WarrantyStatement..................................Pac

RepairProtectionAgreement...................Pac

SafeOperationPractices..........................Pac

SafetyLabels............................................Pac

Assembly..................................................Pac

Operation..................................................Pac

Service&Adjustments.............................Pac

Limited Warranty on Craftsman Log Splitter

Forone(1)yearfromthedateofpurchase,ifthisCraftsmanEquipmentismaintained,lubricated,andtuned upaccordingto theinstructionsto

theoperator'smanual,Searswillrepairor replacefreeof chargeany partsfoundto bedefectiveinmaterMor workmanship.Warrantyserviceis

availablefreeofchargebyreturningCraftsmanequipmenttoyournearestSearsServiceCenter.In-homewarrantyserviceisavailablebuta trip

chargewillapply.ThisWarrantyappliesonly whilethisproductisintheUnitedStates.

This warranty does not cover:

• Expendableitemswhichbecomewornduringnormaluse,suchassparkplugs,aircleaners,belts,andoilfilters.

• Tire replacementor repaircausedbypuncturesfromoutsideobjects,suchasnails,thorns,stumps,orglass.

• Repairsnecessarybecauseof operatorabuse,includingbutnot limitedto,damagecausedbyobjects,suchasstonesor metaldebris,

oversizedstock,impactingobjectsthatbendthe frameor crankshaft,orover-speedingtheengine.

• Repairsnecessarybecauseof operatornegligence,includingbutnotlimitedto,electricalandmechanicaldamagecausedbyimproper

storage,failureto usethe propergradeandamountofengineoil, or failureto maintaintheequipmentaccordingtotheinstructionscontained

intheoperator'smanual.

• Engine(fuelsystem)cleaningorrepairscausedbyfueldeterminetobecontaminatedor oxidized(stale).Ingeneral,fuelshouldbeused

within30 daysof itspurchasedate.

• Equipmentusedforcommercialorrentalpurposes.

WARRANTYSERVICEISAVAILABLEBYRETURNINGTHECRAFTSMANSNOWTHROWERTOTHENEAREST

SEARSPARTS& REPAIRCENTERINTHEUNITEDSTATES.

Thiswarrantyappliesonlywhilethisproductisin use intheUnitedStates.

TOLOCATETHENEARESTSEARSPARTS&REPAIRCENTERORTOSCHEDULESERVICE,

SIMPLYCONTACTSEARSAT1-800-4-MY-HOME®.

Thiswarrantygivesyouspecificlegalrightsand youmayalso haveotherrightswhichmayvaryfromstateto state.

SEARS,ROEBUCKANDCO.,D/817WA,HOFFMANESTATES,IL60179

e2

e3

es4-6

e7

es8-9

es10-13

es14-15

Maintenance.............................................Pages16-18

OffSeasonStorage..................................Page19

Troubleshooting........................................Page20-22

PartsList...................................................Page24-31

Espa_ol.....................................................Page34

ServiceNumbers......................................BackCover

Engine Series: 126T02-0523

Engine Oil: SAE 30

Engine Oil Capacity: 20 Ounces

Fuel Capacity: 1.5 Quarts

Spark Plug (.030" Gap): Champion® RJ19LM

Hydraulic Fluid/Capacity: Dexron® Ill/3.0 gal.

Model Number .............................................................

Serial Number ..............................................................

Date of Purchase ..........................................................

Record the model number, serial number

and date of purchase above

2

Page 3

Congratulationson makingasmartpurchase.YournewCraftsman@

productisdesignedandmanufacturedforyearsofdependableopera-

tion.Butlikeall products,itmayrequirerepairfromtimeto time.That's

whenhavinga RepairProtectionAgreementcansaveyoumoneyand

aggravation.

Here'swhattheRepairProtectionAgreement*includes:

* Expert service byour 10,000professionalrepairspecialists

o Unlimitedserviceandno chargeforpartsand laboron all

coveredrepairs

o Product replacementupto$1500if yourcoveredproductcan'tbe

fixed

• Discountof 10%from regularpriceofserviceandrelatedinstalled

partsnotcoveredby theagreement;also,10%off regularpriceof

preventivemaintenancecheck

• Fast help byphone- wecall itRapidResolution- phonesupport

froma Searsrepresentative.Thinkof usasa"talkingowner's

manual."

Onceyoupurchasethe Agreement,a simplephonecall isall thatit

takesfor youto scheduleservice.Youcan callanytimedayor night,or

schedulea serviceappointmentonline.

TheRepairProtectionAgreementisa risk-freepurchase.Ifyoucancel

forany reasonduringtheproductwarrantyperiod,wewill provideafull

refund.Or,a proratedrefundanytimeafterthe productwarrantyperiod

expires.PurchaseyourRepairProtectionAgreementtoday!

Somelimitationsandexclusionsapply. Forpricesand additional

informationin the U.S.A.call 1-800-827-6655.

*CoverageinCanadavaries on some items.Forfull details call

SearsCanadaat 1-800-361-6665.

SearsInstallation Service

ForSearsprofessionalinstallationofhomeappliances,garagedoor

openers,waterheaters,andothermajorhomeitems,in theU.S.A.or

Canadacall1-800-4-MY-HOME®.

3

Page 4

instructions which, if not followed, could

This symbol points out important safety

endanger the personal safety and/or property of

yourself and others. Read and follow all

instructions in this manual before attempting to

operate this machine. Failure to comply with

these instructions may result in personal injury.

When you see this symbol, HEED ITS WARNING!

This machine was built to be operated according to the

safe operation practices in this manual. As with any type of

power equipment, carelessness or error on the part of the

operator can result in serious injury. This machine is capable

of amputating fingers, hands, toes and feet and throwing

debris. Failure to observe the following safety instructions

could result in serious injury or death.

CALIFORNIA PROPOSITION 65

Engine Exhaust, some of its constituents, and certain vehicle

components contain or emit chemicals known to State

Your Responsibility--Restrict the use of this power

machine to persons who read, understand and follow

the warnings and instructions in this manual and on the

machine.

of California to cause cancer and birth defects or other

reproductive harm.

Training lO.

1. Read, understand, and follow all instructions on the machine

and in the manual before attempting to assemble and

operate. Keep this manual in a safe place for future and regular

reference and for ordering replacement parts.

2. Read the Operator's Manual and follow all warnings and safety

instructions. Failure to do so can result in serious injury to the

operator and/or bystanders. For questions call, 1-800-659-5917.

3. Be familiar with all controls and their proper operation. Know

how to stop the machine and disengage them quickly.

4. Never allow children under 16 years of age to operate this

machine. Children 16 and over should read and understand the

instructions and safe operation practices in this manual and on

the machine and be trained and supervised by an adult.

5. Never allow adults to operate this machine without proper

instruction.

6.

Many accidents occur when more than one person operates

the machine. Ira helper is assisting in stacking logs, never

activate the control until the helper is a minimum of 10 feet

from the machine.

7. Keep bystanders, pets, and child ren at least 20 feet from the

machine while it is in operation.

8. Never allow anyone to ride on this machine.

9. Never transport cargo on this machine.

10. Leaks can be detected by passing cardboard or wood,

11. If injured by escaping fluid, see a doctor immediately. Serious

12. Keep the operator zone and adjacent area clear for safe, secure

13. If your machine is equipped with an internal combustion

14. This machine should be used for splitting wood only, do not

15. Follow the instructions in the manual(s) provided with any

SAVETHESEINSTRUCTIONS!

Hydraulic log splitters develop high fluid pressures during

operation. Fluid escaping through a pin hole opening can

penetrate your skin and cause blood poisoning, gangrene, or

death. Give attention to the following instructions at all times:

a. Do not check for leaks with your hand.

b. Do not operate machine with frayed, kinked, cracked, or

damaged hoses, fittings, or tubing.

c. Stop the engine and relieve hydraulic system pressure

before changing or adjusting fittings, hoses, tubing, or

other system components.

d. Do not adjust the pressure settings of the pump or

valve.

while wearing protective gloves and safety glasses, over the

suspected area. Look for discoloration of cardboard or wood.

infection or reaction can develop if proper medical treatment

is not administered immediately.

footing.

engine and is intended for use near any unimproved forest,

brush, or grass covered land, the engine exhaust should be

equipped with a spark arrester. Make sure you comply with

applicable local, state, and federal codes. Take appropriate

firefighting equipment with you.

use it for any other purpose.

attachment(s) for this machine.

4

Page 5

Preparation Operation

1. Always wear safety shoes or heavy boots.

2. Always wear safety glasses or safety goggles when operating

this machine.

3. Never wear jewelry or loose clothing that might become

entangled in moving or rotating parts of the machine.

4. Make sure machine is on a level surface before operating.

5. Always block wheels to prevent unintended movement, and

lock beam in either the horizontal or vertical position.

6. Always operate this machine from the operator zone(s)

specified in the manual.

7. Logs should be cut with square ends prior to splitting.

8. Use log splitter in daylight or under good artificial light.

SafeHandling ofGasoline

To avoid personal injury or property damage use extreme care in

handling gasoline. Gasoline is extremely flammable and the vapors

are explosive. Serious personal injury can occur when gasoline is

spilled on yourself or your clothes which can ignite. Wash your skin

and change clothes immediately.

a. Use only an approved gasoline container.

b. Extinguish all cigarettes, cigars, pipes, and other sources

of ignition.

c. Never fuel machine indoors.

d. Never remove gas cap or add fuel while the engine is

hot or running.

e. Allow engine to cool at least two minutes before

refueling.

fl Never overfill the fuel tank. Fill tank to no more than 1/2

inch below bottom of filler neck to provide space for

fuel expansion.

g. Replace gasoline cap and tighten securely.

h. If gasoline is spilled, wipe it off the engine and

equipment and move machine to another area. Wait five

(5) minutes before starting the engine.

i. Never store the machine or fuel container inside where

there is an open flame, spark or pilot light as on a water

heater, space heater, furnace, clothes dryer or other gas

appliances.

j. Allow machine to cool at least five (5) minutes before

storing.

1. Before starting this machine, review the "Safety Instructions".

Failure to follow these rules may result in serious injury to the

operator or bystanders.

2. Never leave this machine unattended with the engine running.

3. Do not operate machine while under the influence of alcohol,

drugs, or medication.

4. Never allow anyone to operate this machine without proper

instruction.

5.

Always operate this machine with all safety equipment in place

and working. Make sure all controls are properly adjusted for

safe operation.

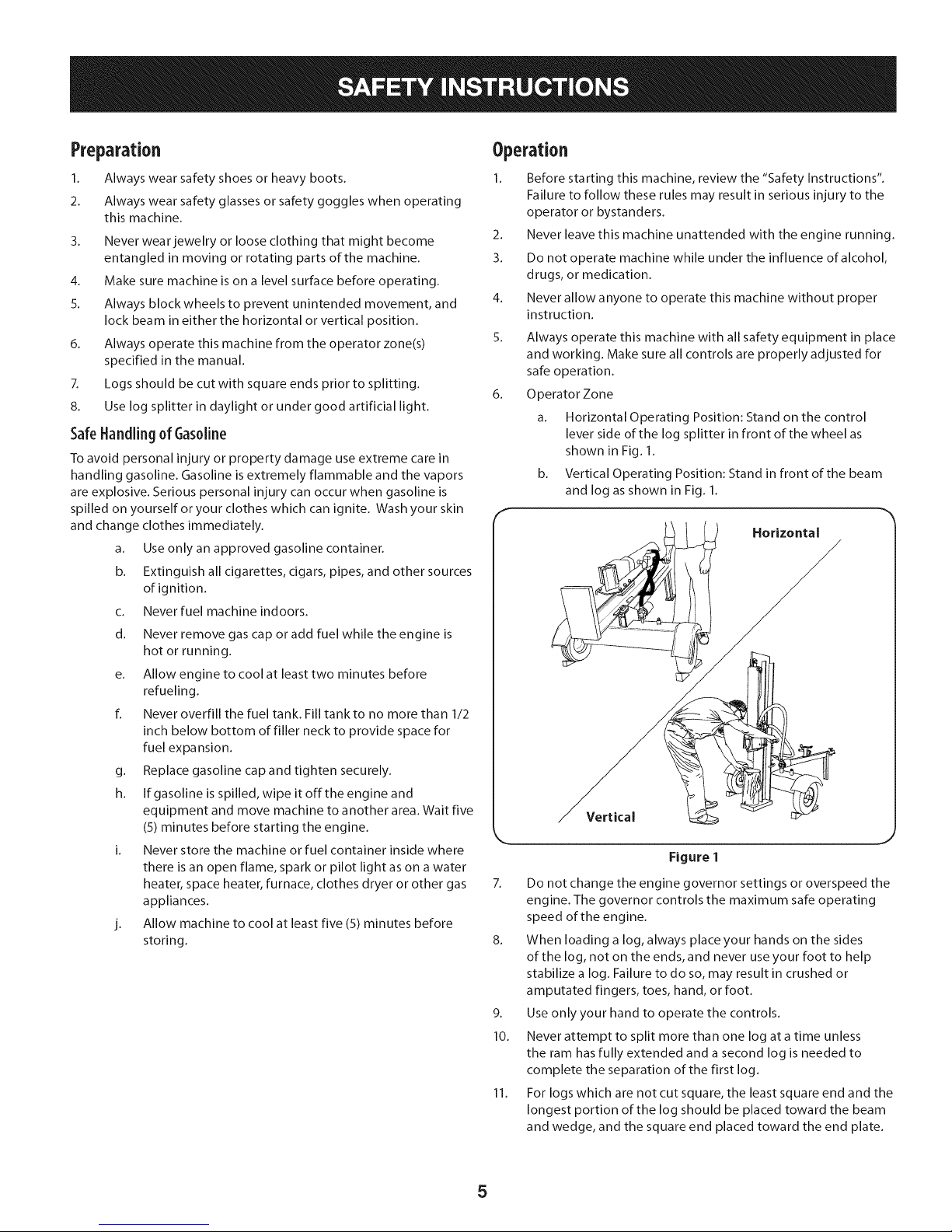

Operator Zone

a. Horizontal Operating Position: Stand on the control

b. Vertical Operating Position: Stand in front of the beam

7. Do not change the engine governor settings or overspeed the

engine. The governor controls the maximum safe operating

speed of the engine.

8. When loading a log, always place your hands on the sides

of the log, not on the ends, and never use your foot to help

stabilize a log. Failure to do so, may result in crushed or

amputated fingers, toes, hand, or foot.

9. Use only your hand to operate the controls.

10. Never attempt to split more than one log at a time unless

the ram has fully extended and a second log is needed to

complete the separation of the first log.

11. For logs which are not cut square, the least square end and the

longest portion of the log should be placed toward the beam

and wedge, and the square end placed toward the end plate.

lever side of the log splitter in front of the wheel as

shown in Fig. 1.

and log as shown in Fig. 1.

Horizontal

Vertical

Figure 1

Page 6

12.

Whensplittingintheverticalposition,stabilizethelogbefore

movingthecontrol.Splitasfollows:

a. Placelogontheendplateandturnuntilitleansagainst

thebeamandisstable.

b. Whensplittingextralargeorunevenlogs,thelogmust

bestabilizedwithwoodenshimsorsplitwoodbetween

thelogandendplateorground.

12. Alwayskeepfingersawayfromanycracksthatopeninthelog

whilesplitting.Theycanquicklycloseandpinchoramputate

yourfingers.

13. Keepyourworkareaclean.Immediatelyremovesplitwood

aroundthemachinesoyoudonotstumbleoverit.

14. Nevermovethismachinewhiletheengineisrunning.

15. Thismachineshouldnotbetowedonanystreet,highwayor

publicroadwithoutcheckingtheexistingfederal,state,or

localvehiclerequirements.Anylicensingormodificationssuch

astaillights,etc.,neededtocomply,isthesoleresponsibility

ofthepurchaser.Ifa"StatementofOrigin"isrequiredinyour

state,seeyourlocaldealer.

16. Donottowmachineover45mph.

17. SeeTransportingtheLogSplittersectioninthismanualfor

propertowinginstructionsonceallfederal,local,orstate

requirementsaremet.

MaintenanceandStorage

This machine is equipped with an internal combustion engine and

should not be used on or near any unimproved forest-covered,

brush-covered or grass-covered land unless the engine's exhaust

system is equipped with a spark arrester meeting applicable local

or state laws (if any)

1. Stop the engine, disconnect the spark plug and ground it

against the engine before cleaning, or inspecting the machine.

2. Stop the engine and relieve hydraulic system pressure before

repairing or adjusting fittings, hoses, tubing, or other system

components.

3. To prevent fires, clean debris and chaff from the engine

and muffler areas. If the engine is equipped with a spark

attester muffler, clean and inspect it regularly according to

manufacturers instructions. Replace if damaged.

4. Periodically check that all nuts and bolts, hose clamps, and

hydraulic fittings are tight to be sure equipment is in safe

working condition.

5. Check all safety guards and shields to be sure they are in the

proper position. Never operate with safety guards, shields, or

other protective features removed.

6_

The pressure relief valve is preset at the factory. Do not adjust

the valve.

7.

Never attempt to move this machine over hilly or uneven

terrain without atow vehicle or adequate help.

8.

For your safety, replace all damaged or worn parts immediately

with original equipment manufacturer's (O.E.M.) parts only.

"Use of parts which do not meet the original equipment

specifications may lead to improper performance and

compromise safety!"

9_

Do not alter this machine in any manner, alterations such as

attaching a rope or extension to the control handle, or adding

to the width or height of the wedge may result in personal

injury.

10.

According to the Consumer Products Safety Commission

(CPSC) and the U.S. Environmental Protection Agency (EPA),

this product has an Average Useful Life of seven (7) years, or

130 hours of operation. At the end of the Average Useful Life

have the machine inspected annually by an authorized service

dealer to ensure that all mechanical and safety systems are

working properly and not worn excessively. Failure to do so

can result in accidents, injuries or death.

SparkArrestor

Ira spark arrester is used, it should be maintained in effective

working order by the operator. In the State of California the above

is required by law (Section 4442 of the California Public Resources

Code). Other states may have similar laws. Federal laws apply on

federal lands.

A spark attester for the muffler is available through your nearest

Sears Parts and Repair Service Center.

6

Page 7

SafetySymbols

This page depicts and describes safety symbols that may appear on this product. Read, understand, and follow all instructions on the

machine before attempting to assemble and operate.

A

READ THE OPERATOR'S MANUAL(S)

Read, understand, and follow all instructions in the manual(s) before attempting to assemble and

operate

WARNING-- CRUSHING HAZARD

Keep hands away from wedge, end plate, partly split wood and moving parts.

BYSTANDARDS

Keep bystanders, helpers and children at least 10feet away.

SINGLE OPERATOR

Only one person should operate the machine at a time. The adult who loads and holds log must be

the one who operates control handle.

WARNING-- PRESSURIZED FLUID

Never check for hose leaks with your hands. High pressure fluid can escape through a pin hole leak

and cause serious injury by puncturing the skin and causing blood poisoning.

EYEPROTECTION

Always wear safety glasses or safety goggles when operating this machine.

WARNING-- MOVING WEDGE

Keep hands away from wedge and moving parts.

7

Page 8

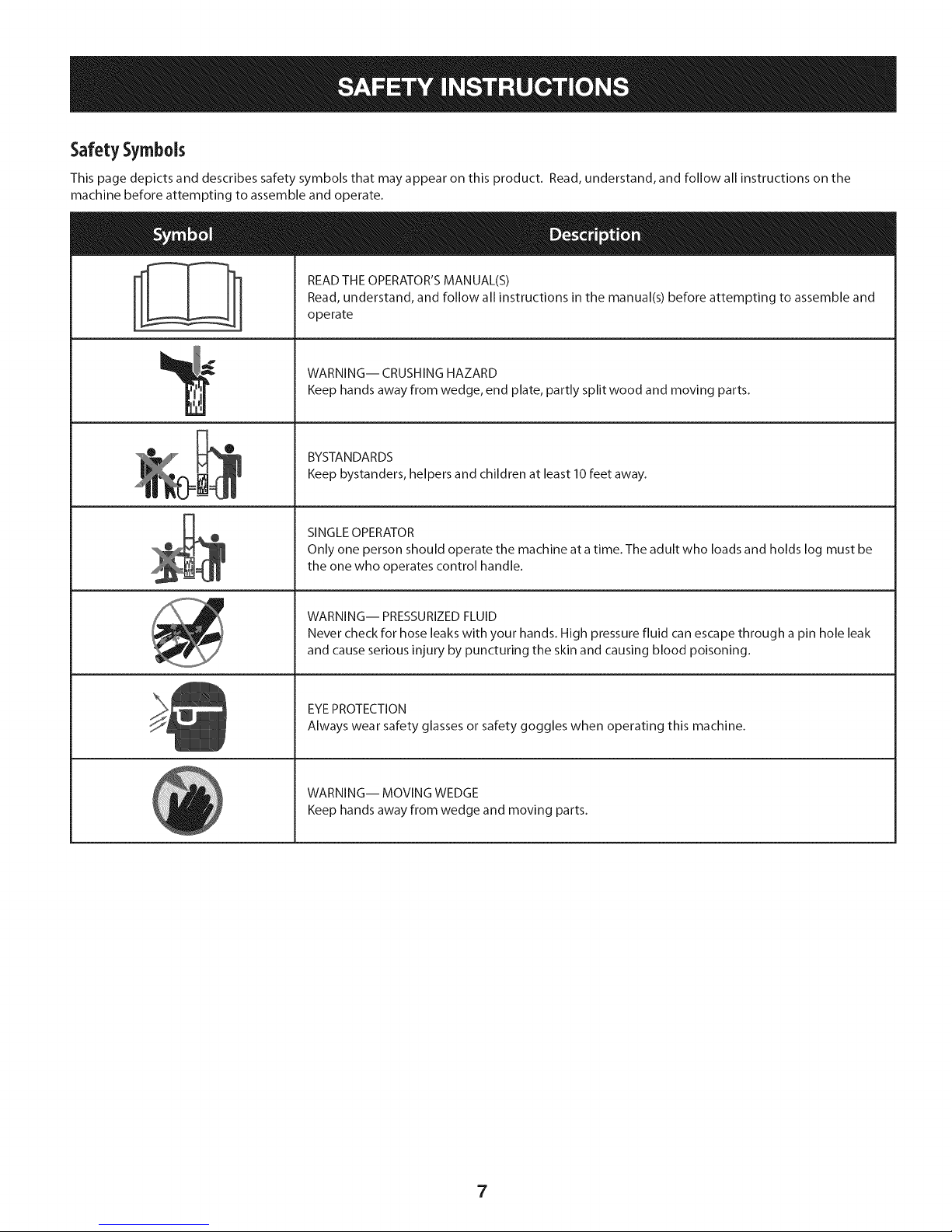

Figure 3=1

IMPORTANT:Yourlogsplitterisshippedwithmotoroil intheengine.

However,you MUSTchecktheoil levelbeforeoperating.Becareful

notto overfill.

NOTE:All referencesinthis manualtotheleftor rightsideof thelog

splitterarefromthe operatingpositiononly.

REMOVING THE LOG SPLITTER FROM THE

CARTON

1. Prythe top,sidesandendsoffofthecrate.

2. Setthe panelsasidetoavoidtirepuncturesorpersonalinjury.

3. Removeanddiscardtheplasticbagthatcoversthelogsplitter.

4. Removeanyloosepartsincludedwithwiththelogsplitter(i.e.,

operator'smanual,etc.)

_J

5. Cutand removethestrapswhichsecurethepartsto thebottomof

thecrate.Unboltanyremainingpartswhichmaybe boltedtothe

bottomof thecrate.

Useextremecautionunpackingthismachine.Somecomponentsare

veryheavyandwill requireadditionalpeopleor mechanicalhandling

equipment.

LOOSE PARTS IN CARTON

\

... j

Figure 3=2

1. TongueAssembly

Disconnectthe sparkplugwireandgroundit againsttheengineto

preventunintendedstarting.

ASSEMBLING THE TONGUE

Attaching the Jack Stand

Thejackstandisshippedinthetransportposition.

1. Removethespringclipandclevispinandpivotthejackstand

towardsthegroundtothe operatingposition.

2. Securethejackstandinpositionwiththeclevispinandspringclip.

See Figure3-1.

Attaching the Tongue

1. Withthelogsplitterstill standingupright,removethe twohexbolts

and hexnutsfromthe tankbracket.SeeFigure3-2.

2. Aligntheholesinthetonguewiththeholesinthetankbracketand

securewiththehardwarejustremoved.See Figure3-2.

NOTE:Thehighpressurehosemustbe abovethetongueassembly.

CONNECTING CYLINDER TO BEAM

Figure 3=3

Thelogsplitterisshippedwiththebeamin theverticalposition.

1. Pulloutthe verticalbeamlock,rotateit backandpivotthebeamto

thehorizontalpositionuntilitlocks.SeeFigure3-3.

2. Disconnectthedislodgerfromthebeamweldbracketby removing

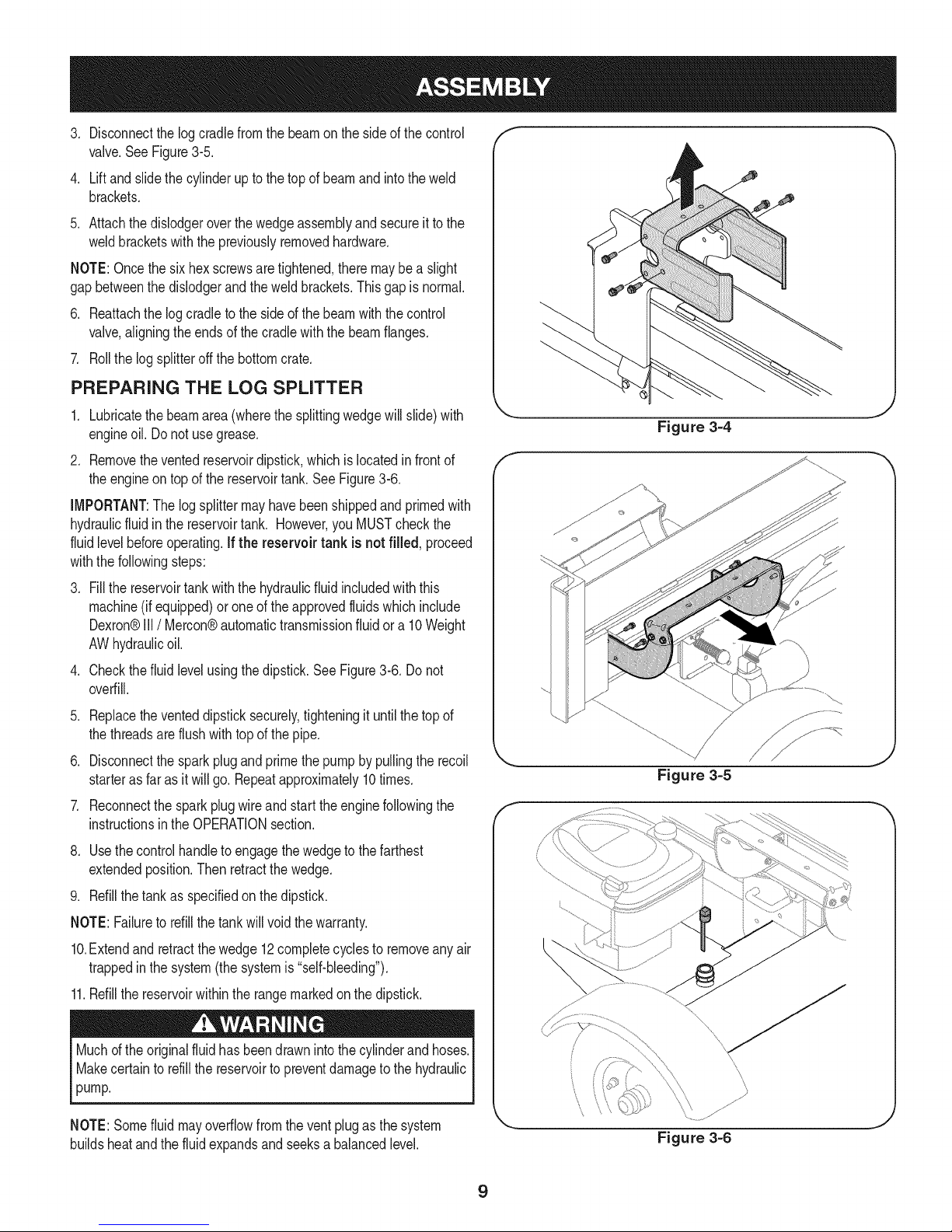

thesix hexscrews.SeeFigure3-4.

8

Page 9

.

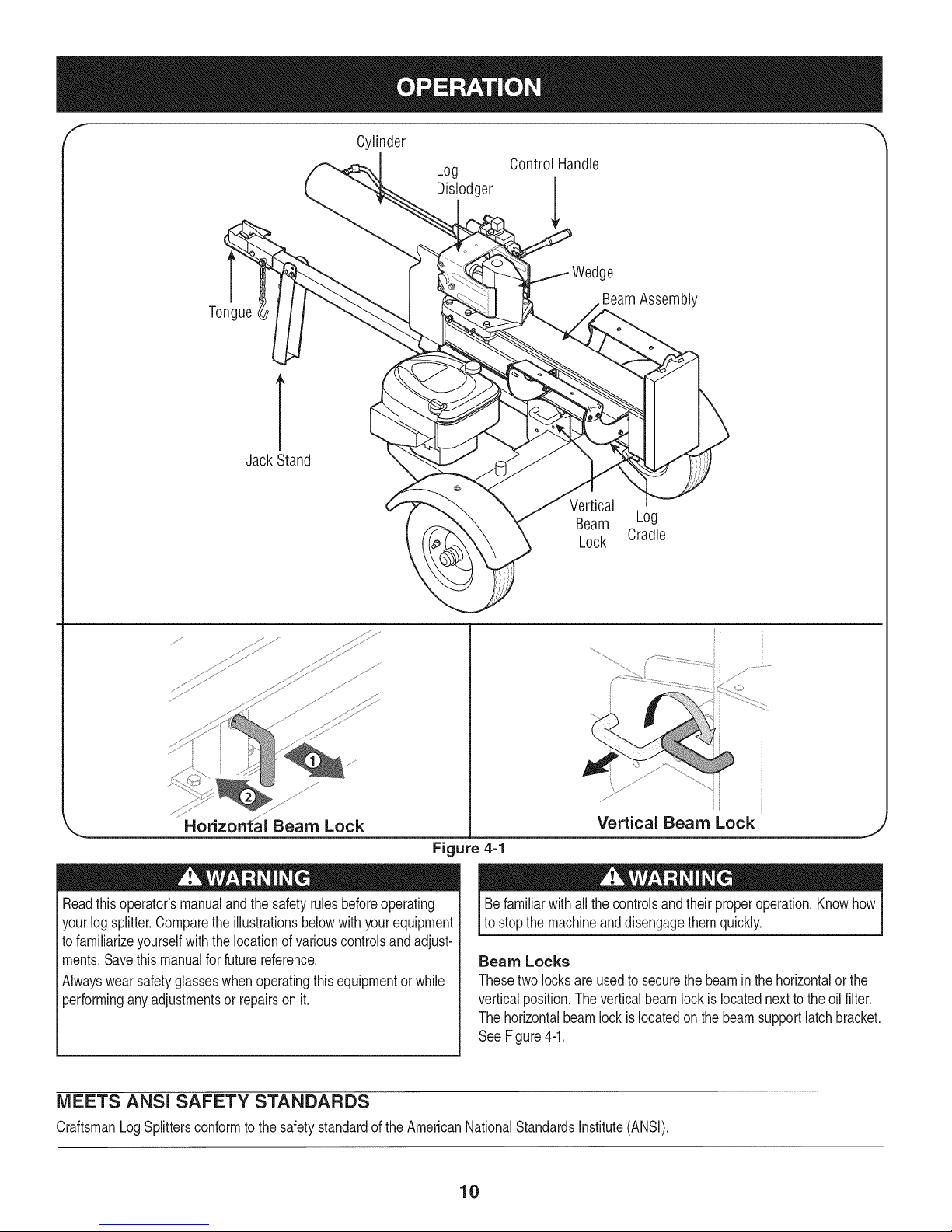

Disconnectthelogcradlefromthebeamonthesideofthe control

valve.SeeFigure3-5.

.

Liftand slidethe cylinderup tothe topof beamandintotheweld

brackets.

5. Attachthedislodgeroverthewedgeassemblyandsecureit to the

weldbracketswiththe previouslyremovedhardware.

NOTE:Oncethesixhex screwsaretightened,theremaybeaslight

gapbetweenthe dislodgerandtheweldbrackets.Thisgapisnormal.

6. Reattachthelogcradletothe sideof thebeamwiththecontrol

valve,aligningtheendsof thecradlewiththebeamflanges.

7. Rollthelog splitteroffthebottomcrate.

PREPARING THE LOG SPLITTER

1. Lubricatethebeamarea(wherethesplittingwedgewillslide)with

engineoil.Do notuse grease.

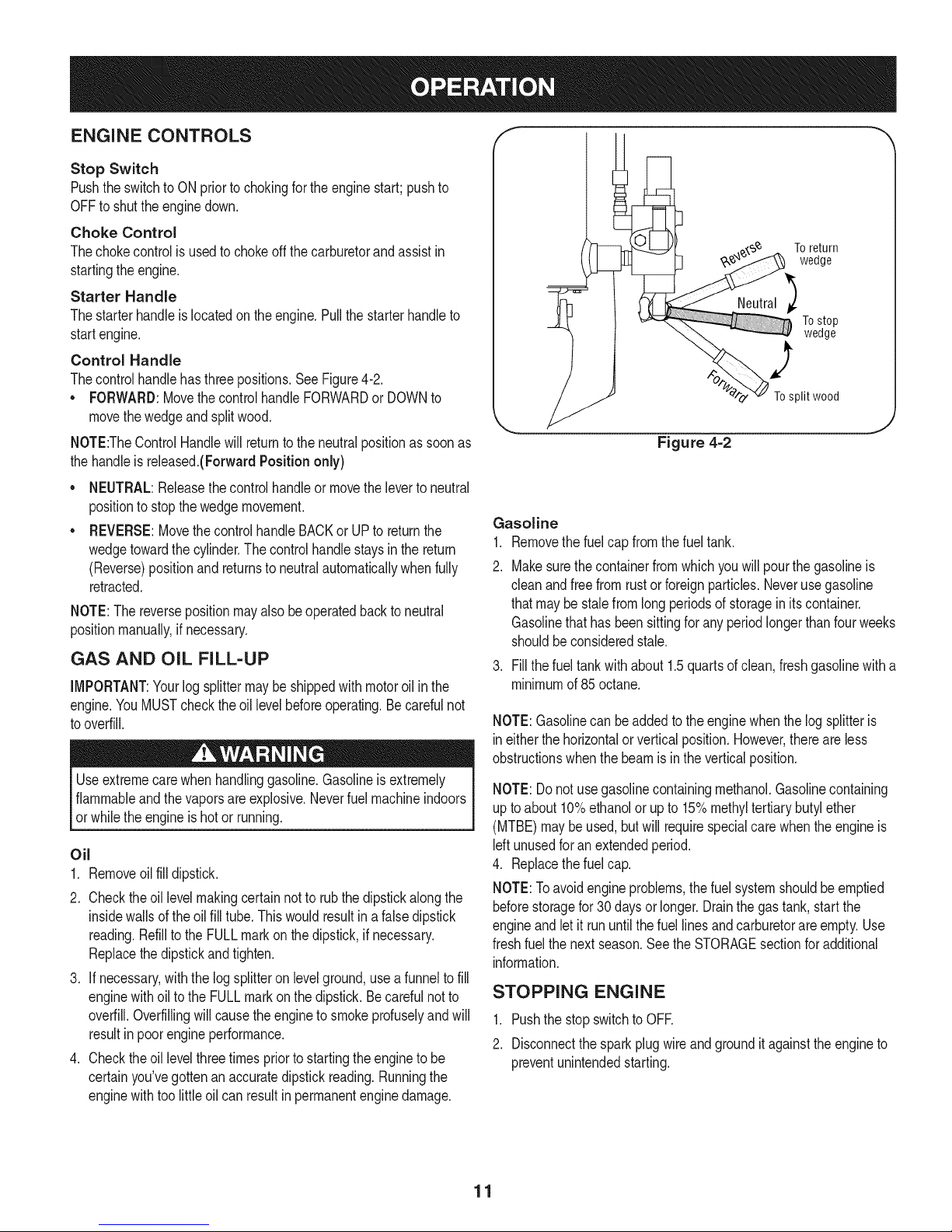

2. Removetheventedreservoirdipstick,whichis locatedinfrontof

theengineontop ofthe reservoirtank.SeeFigure3-6.

IMPORTANT:Thelogsplittermayhavebeenshippedandprimedwith

hydraulicfluidin the reservoirtank. However,youMUSTcheckthe

fluidlevelbeforeoperating.Ifthe reservoir tank is not filled, proceed

withthefollowingsteps:

.

Fillthe reservoirtankwiththehydraulicfluidincludedwiththis

machine(if equipped)oroneof theapprovedfluidswhichinclude

Dexron®III/ Mercon®automatictransmissionfluidora 10Weight

AWhydraulicoil.

.

Checkthefluidlevelusingthedipstick.SeeFigure3-6.Do not

overfill.

.

Replacetheventeddipsticksecurely,tighteningit untilthetopof

thethreadsareflushwithtop ofthe pipe.

6. Disconnectthesparkplugandprimethepumpby pullingthe recoil

starteras faras itwill go.Repeatapproximately10times.

7. Reconnectthesparkplugwireandstartthe enginefollowingthe

instructionsin theOPERATIONsection.

8. Usethecontrolhandleto engagethewedgetothe farthest

extendedposition.Thenretractthewedge.

9. Refillthetankas specifiedonthedipstick.

NOTE:Failuretorefillthetankwill voidthe warranty.

10.Extendand retractthewedge12completecyclesto removeanyair

trappedinthe system(thesystemis"self-bleeding").

11.Refillthereservoirwithintherangemarkedonthedipstick.

Muchd theoriginalfluidhasbeendrawnintothecylinderandhoses.

Makecertainto refillthereservoirtopreventdamageto thehydraulic

pump.

Figure 3=4

Figure 3=5

\\\

"x

,J

\

\

NOTE:Somefluidmayoverflowfromtheventplugasthesystem

buildsheatandthefluidexpandsandseeksa balancedlevel.

Figure 3=6

9

Page 10

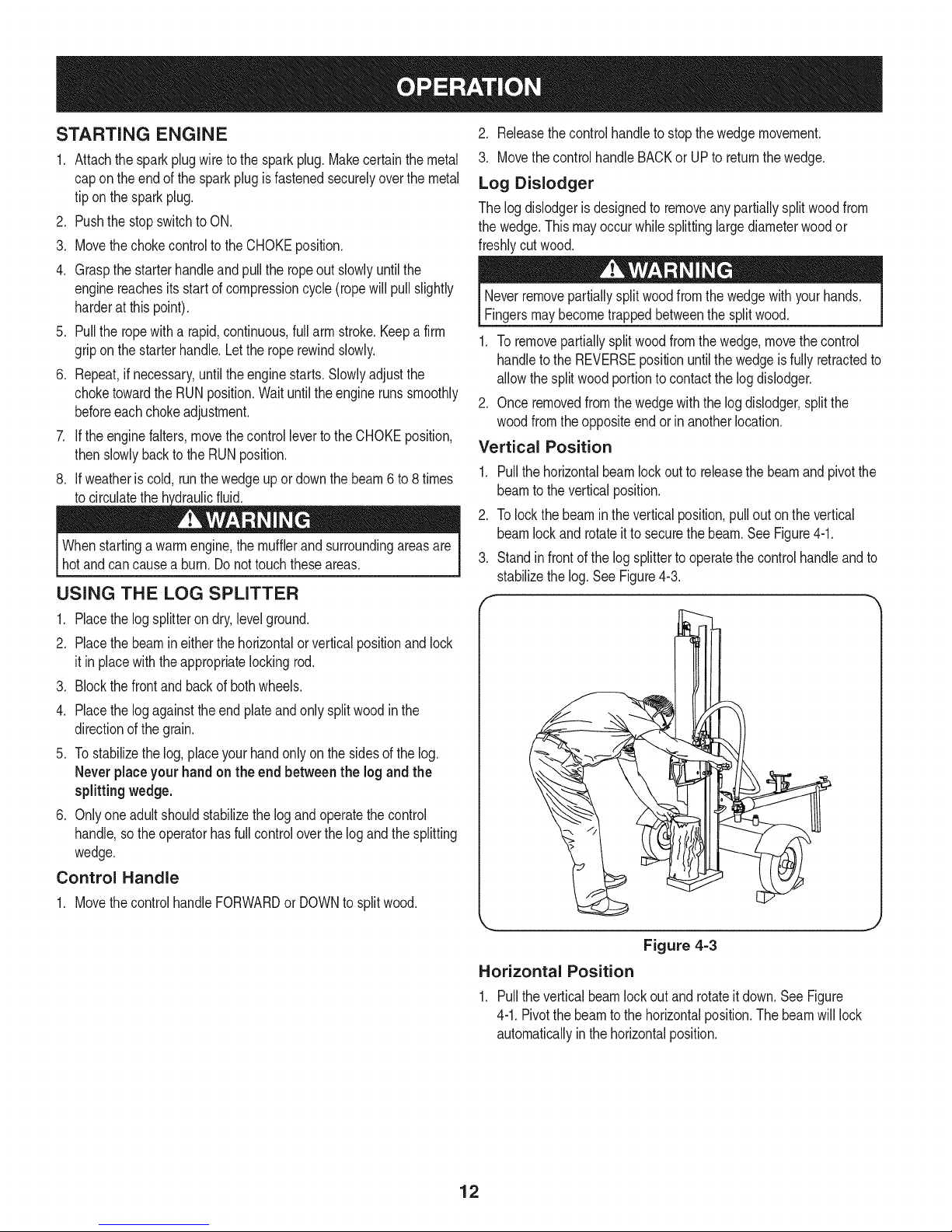

Cylinder

Log

Dislodger

Control Handle

e

Tongue

BeamAssembly

1

JackStand

Vertical

Beam Log

Lock Cradle

,_ Horizontai Beam Lock

Readthisoperator'smanualandthesafetyrulesbeforeoperating

yourlogsplitter.Comparetheillustrationsbelowwithyourequipment

tofamiliarizeyourselfwiththelocationofvariouscontrolsandadjust-

ments.Savethismanualforfuturereference.

Alwayswearsafetyglasseswhenoperatingthisequipmentorwhile

performinganyadjustmentsor repairson it.

MEETS ANSI SAFETY STANDARDS

CraftsmanLogSplittersconformtothesafetystandardoftheAmericanNationalStandardsInstitute(ANSI).

Vertical Beam Lock

Figure 4=1

Befamiliarwithallthecontrolsandtheirproperoperation.Knowhow

tostopthe machineanddisengagethemquickly.

Beam Locks

Thesetwo locksareusedto securethebeamin thehorizontalor the

verticalposition.Theverticalbeamlockis locatednexttotheoil filter.

Thehorizontalbeamlockislocatedonthe beamsupportlatchbracket.

See Figure4-1.

10

J

Page 11

ENGINE CONTROLS

Stop Switch

Pushthe switchtoON priortochokingfor theenginestart;pushto

OFFto shutthe enginedown.

Choke Control

Thechokecontrolis usedto chokeoff thecarburetorandassistin

startingtheengine.

Starter Handle

Thestarterhandleis locatedonthe engine.Pullthe starterhandleto

startengine.

Control Handle

Thecontrolhandlehasthreepositions.SeeFigure4-2.

• FORWARD:MovethecontrolhandleFORWARDor DOWNto

movethewedgeand splitwood.

NOTE:TheControlHandlewillreturntotheneutralpositionassoonas

thehandleisreleased.(ForwardPosition only)

NEUTRAL:Releasethecontrolhandleor movethelevertoneutral

positiontostopthewedgemovement.

REVERSE:MovethecontrolhandleBACKorUPto returnthe

wedgetowardthecylinder.Thecontrolhandlestaysinthe return

(Reverse)positionand returnsto neutralautomaticallywhenfully

retracted.

NOTE:The reversepositionmayalsobeoperatedbacktoneutral

positionmanually,ifnecessary.

GAS AND OiL FILL-UP

iMPORTANT:Yourlog splittermaybeshippedwithmotoroil inthe

engine.YouMUSTcheckthe oillevelbeforeoperating.Becarefulnot

tooverfill.

Useextremecarewhenhandlinggasoline.Gasolineisextremely

flammableandthe vaporsareexplosive.Neverfuelmachineindoors

or whilethe engineishotor running.

Oil

1. Removeoilfill dipstick.

2. Checktheoil levelmakingcertainnottorubthedipstickalongthe

insidewallsoftheoil fill tube.Thiswouldresultina falsedipstick

reading.Refillto theFULLmarkon thedipstick,if necessary.

Replacethedipstickandtighten.

3. If necessary,withthelogsplitteronlevelground,usea funnelto fill

enginewithoiltothe FULLmarkonthedipstick.Becarefulnotto

overfill.Overfillingwillcausetheenginetosmokeprofuselyandwill

resultinpoorengineperformance.

4. Checktheoil levelthreetimespriortostartingtheengineto be

certainyou'vegottenan accuratedipstickreading.Runningthe

enginewithtoolittleoilcan resultinpermanentenginedamage.

To return

wedge

Tostop

wedge

2

To split wood

Figure 4=2

Gasoline

1. Removethefuelcapfromthefuel tank.

2. Makesurethe containerfromwhichyouwill pourthegasolineis

cleanandfree fromrustorforeignparticles.Neverusegasoline

thatmaybe stalefromlongperiodsof storageinitscontainer.

Gasolinethathasbeensittingforany periodlongerthanfourweeks

shouldbeconsideredstale.

3. Fillthe fueltankwithabout 1.5quartsof clean,freshgasolinewitha

minimumof85octane.

NOTE:Gasolinecan beaddedtotheenginewhenthelog splitteris

ineitherthe horizontalorverticalposition.However,thereareless

obstructionswhenthe beamisintheverticalposition.

NOTE:Donotusegasolinecontainingmethanol.Gasolinecontaining

uptoabout10%ethanolor upto 15%methyltertiarybutylether

(MTBE)maybe used,butwill requirespecialcarewhentheengineis

Idt unusedforanextendedperiod.

4. Replacethefuelcap.

NOTE:Toavoidengineproblems,thefuel systemshouldbe emptied

beforestoragefor30 daysor longer.Drainthegas tank,startthe

engineand letit rununtilthe fuellinesandcarburetorareempty.Use

freshfuelthe nextseason.Seethe STORAGEsectionforadditional

information.

STOPPING ENGINE

1. PushthestopswitchtoOFE

2. Disconnectthesparkplugwireandgroundit againsttheengineto

preventunintendedstarting.

11

Page 12

STARTING ENGINE

1. Attachthe sparkplugwiretothesparkplug.Makecertainthemetal

capon the endofthe sparkplugisfastenedsecurelyoverthemetal

tiponthe sparkplug.

2. Pushthe stopswitchtoON.

3. Movethechokecontrolto theCHOKEposition.

4. Graspthe starterhandleandpullthe ropeoutslowlyuntilthe

enginereachesitsstartof compressioncycle (ropewillpullslightly

harderatthispoint).

5. Pulltheropewitha rapid,continuous,fullarmstroke.Keepafirm

griponthestarterhandle.Lettheroperewindslowly.

6. Repeat,if necessary,untiltheenginestarts.Slowlyadjustthe

choketowardtheRUNposition.Waituntiltheenginerunssmoothly

beforeeachchokeadjustment.

7. Iftheenginefalters,movethecontrolleverto theCHOKEposition,

thenslowlybacktothe RUNposition.

8. Ifweatheriscold, runthewedgeupor downthebeam6 to8 times

tocirculatethe

Whenstartinga warmengine,the mufflerandsurroundingareasare

hotandcan causea burn.Donottouchtheseareas.

USING THE LOG SPLITTER

.

Placethe logsplitterondry,levelground.

2.

Placethe beamineitherthehorizontalorverticalpositionandlock

itin placewiththeappropriatelockingrod.

.

Blockthefrontandbackof bothwheels.

4.

Placethe logagainsttheend plateandonlysplitwoodin the

directionofthegrain.

5. Tostabilizethelog,placeyour handonlyonthesidesofthelog.

Neverplaceyour handon the endbetweenthe logandthe

splittingwedge.

6. Onlyoneadultshouldstabilizethelogandoperatethecontrol

handle,sotheoperatorhasfull controloverthe logand thesplitting

wedge.

Control Handle

1. MovethecontrolhandleFORWARDor DOWNtosplitwood.

2. Releasethecontrolhandletostopthewedgemovement.

3. MovethecontrolhandleBACKor UPto returnthewedge.

Log Dislodger

Thelogdislodgerisdesignedto removeanypartiallysplitwoodfrom

thewedge.Thismayoccurwhilesplittinglargediameterwoodor

freshlycutwood.

Neverremovepartiallysplitwoodfromthewedgewithyourhands.

Fingersmaybecometrappedbetweenthesplitwood.

1. Toremovepartiallysplitwoodfromthewedge,movethecontrol

handletothe REVERSEpositionuntilthewedgeisfullyretractedto

allowthe splitwoodportiontocontactthe logdislodger.

2. Onceremovedfromthewedgewiththe logdislodger,splitthe

woodfromthe oppositeendorin anotherlocation.

Vertical Position

1. Pullthehorizontalbeamlockoutto releasethebeamandpivotthe

beamto theverticalposition.

2. Tolockthebeamintheverticalposition,pulloutonthe vertical

beamlockand rotateit tosecurethe beam.See Figure4-1.

3. Standin frontof thelogsplittertooperatethecontrolhandleandto

stabilizethelog.SeeFigure4-3.

Figure 4=3

Horizontal Position

1. Pulltheverticalbeamlockout androtateitdown.SeeFigure

4-1.Pivotthe beamto thehorizontalposition.Thebeamwilllock

automaticallyinthehorizontalposition.

12

Page 13

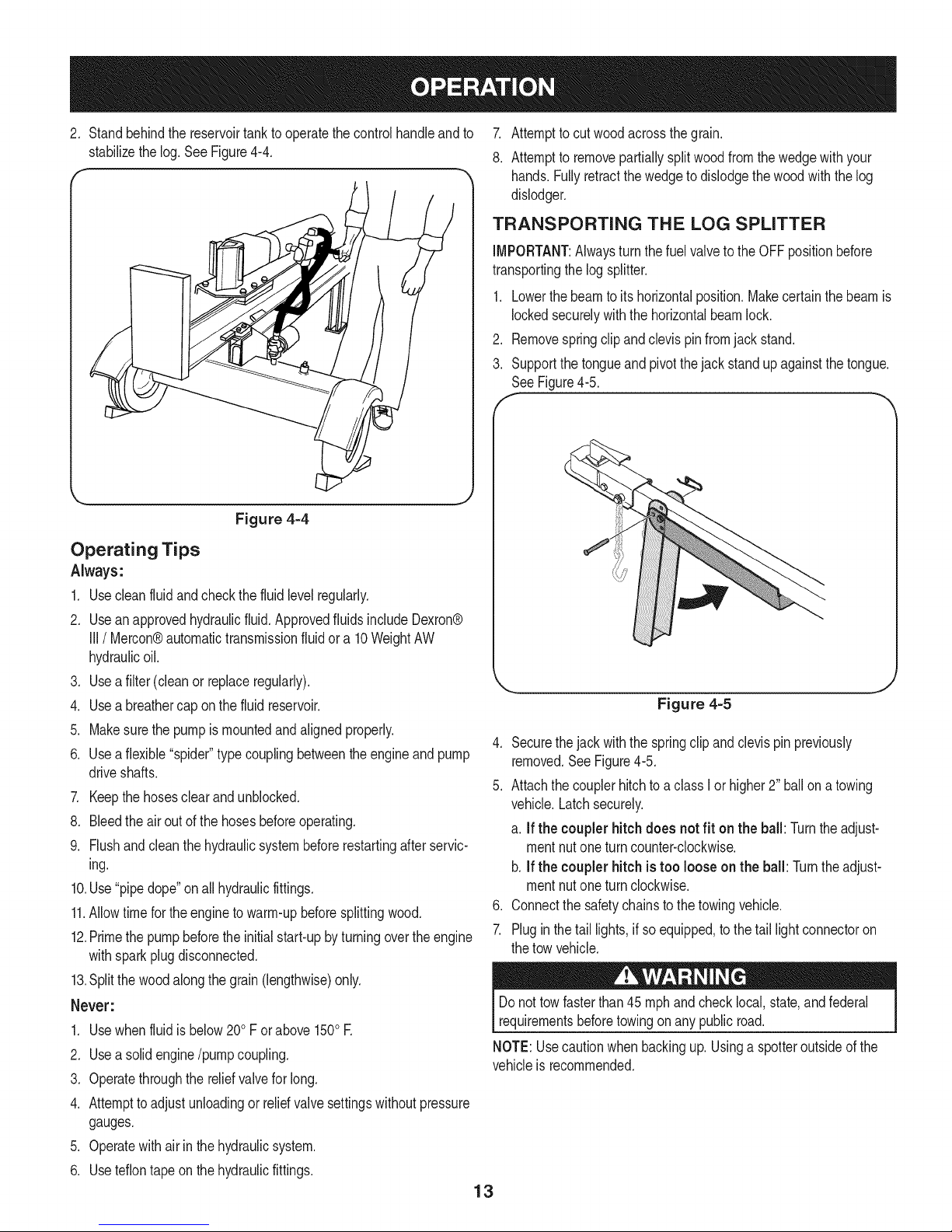

2, Standbehindthe reservoirtanktooperatethecontrolhandleandto 7.

stabilizethelog,See Figure4-4, 8,

TRANSPORTING THE LOG SPLITTER

transportingthelogsplitter.

2. Removespringclipandclevispinfromjackstand.

3. Supportthetongueandpivotthejack standup againstthetongue.

Figure 4=4

Operating Tips

Always:

1. Usecleanfluidandcheckthefluidlevelregularly.

2. Useanapprovedhydraulicfluid.ApprovedfluidsincludeDexron®

III/ Mercon®automatictransmissionfluidora 10WeightAW

hydraulicoil.

3. Useafilter(cleanor replaceregularly).

4. Usea breathercaponthefluid reservoir.

5. Makesurethe pumpis mountedandalignedproperly.

6. Useaflexible"spider"typecouplingbetweentheengineandpump

driveshafts.

7. Keepthehosesclear andunblocked.

8. Bleedtheairout ofthehosesbeforeoperating.

9. Flushandcleanthe hydraulicsystembeforerestartingafterservic-

ing.

10.Use"pipedope"onallhydraulicfittings.

11.Allowtimefortheenginetowarm-upbeforesplittingwood.

12.Primethe pumpbeforetheinitialstart-upbyturningovertheengine

withsparkplugdisconnected.

13.Splitthewoodalongthe grain(lengthwise)only.

Never:

1. Usewhenfluidis below200Forabove1500E

2. Usea solidengine/pumpcoupling.

3. Operatethroughthereliefvalveforlong.

4. Attempttoadjustunloadingorrelid valvesettingswithoutpressure

gauges.

5. Operatewithairin thehydraulicsystem.

6. Useteflontapeon thehydraulicfittings.

4. Securethejack withthe springclipandclevispinpreviously

5. Attachthe couplerhitchtoa classIor higher2" ballona towing

6. Connectthe safetychainstothetowingvehicle.

vehicleis recommended.

13

Attempttocutwoodacrossthe grain.

Attemptto removepartiallysplitwoodfromthewedgewithyour

hands.Fullyretractthewedgeto dislodgethewoodwiththe log

dislodger.

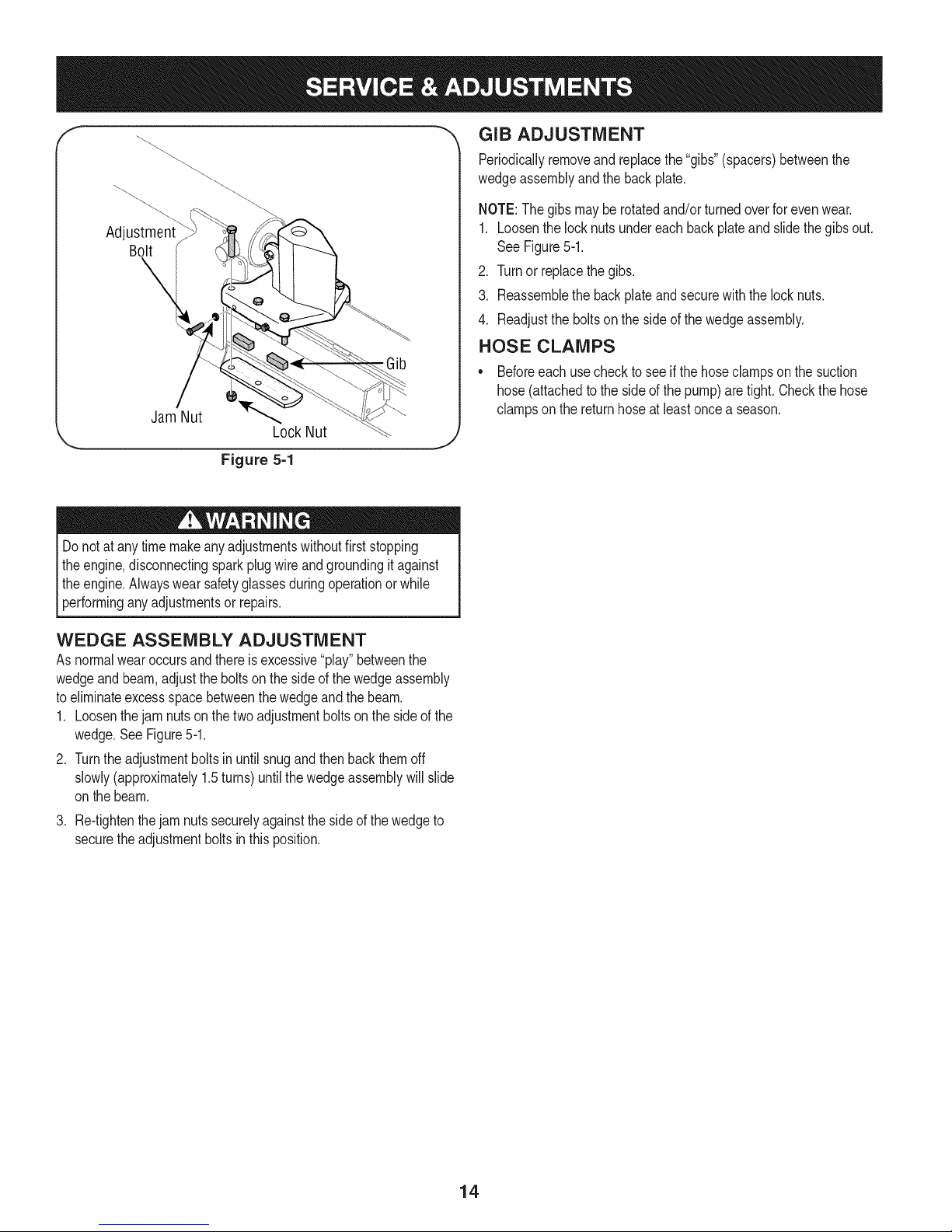

IMPORTANT:Alwaysturnthe fuelvalveto theOFFpositionbefore

1. Lowerthebeamto itshorizontalposition.Makecertainthe beamis

lockedsecurelywiththe horizontalbeamlock.

SeeFigure4-5.

Figure 4=5

removed.SeeFigure4-5.

vehicle.Latchsecurely.

a. If the couplerhitchdoes notfit on the ball: Turntheadjust-

mentnutone turncounter-clockwise.

b.If thecouplerhitch is too loose onthe ball: Turntheadjust-

mentnutone turnclockwise.

7. Plugin thetail lights,if soequipped,tothe taillight connectoron

thetowvehicle.

Donot towfasterthan45mphandchecklocal,state,andfederal

requirementsbeforetowingonanypublicroad.

NOTE:Usecautionwhenbackingup.Usinga spotteroutsideofthe

Page 14

f

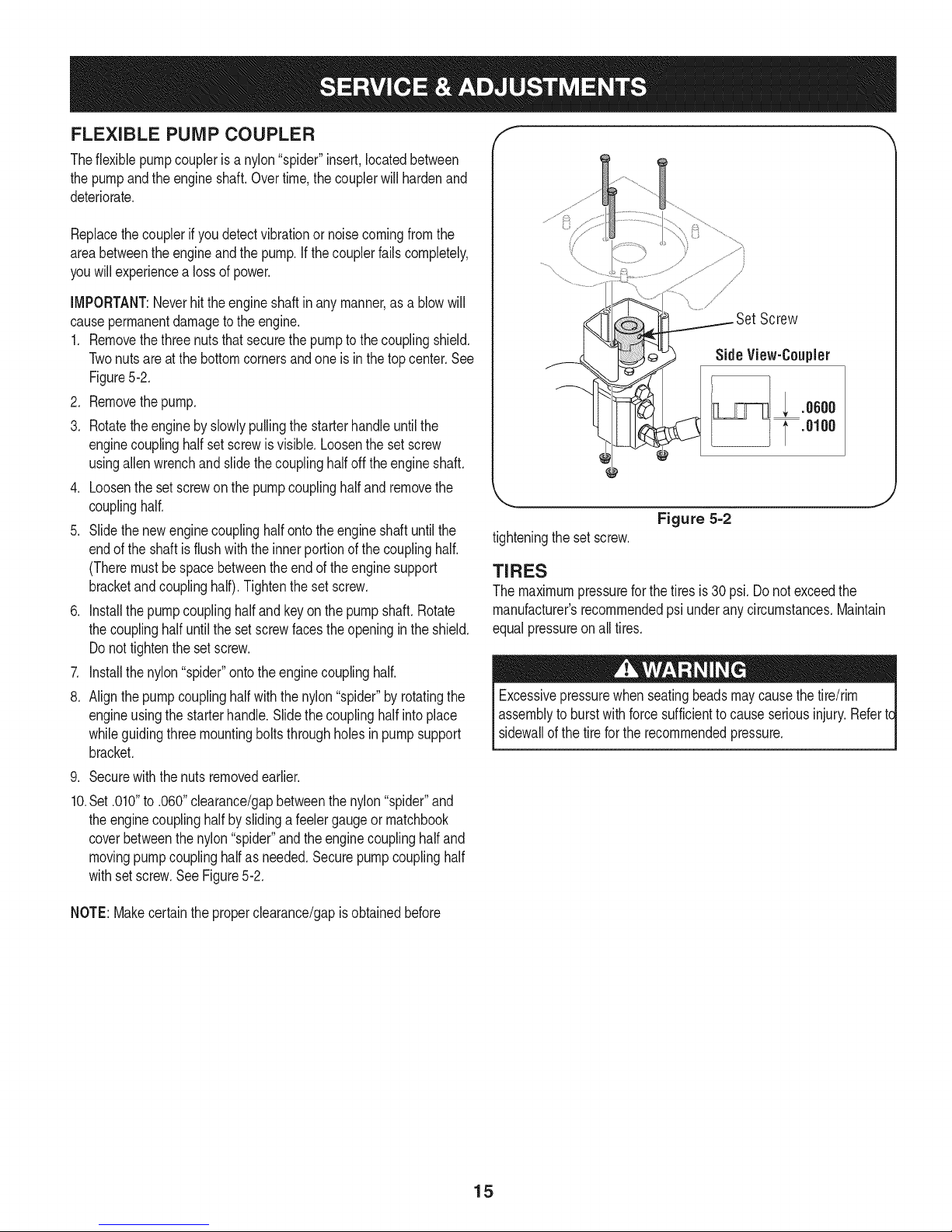

Adjustment

Bolt

.Gib

Jam Nut

Lock Nut

Figure 5=1

Donotatany timemakeanyadjustmentswithoutfirststopping

theengine,disconnectingsparkplugwireandgroundingit against

theengine.Alwayswearsafetyglassesduringoperationor while

[performng anyadjustmentsor repars.

"_ GIB ADJUSTMENT

Periodicallyremoveandreplacethe"gibs"(spacers)betweenthe

wedgeassemblyandthe backplate,

NOTE:The gibsmaybe rotatedand/orturnedoverforevenwear.

1. Loosenthelocknutsundereachbackplateandslidethe gibsout.

See Figure5-1.

2. Turnor replacethegibs.

3. Reassemblethe backplateandsecurewiththelocknuts.

4. Readjusttheboltsonthe sideofthewedgeassembly.

HOSE CLAMPS

• Beforeeachusechecktoseeif thehoseclampsonthe suction

hose(attachedtothe sideof thepump)aretight.Checkthehose

clampsonthe returnhoseatleastoncea season.

WEDGE ASSEMBLY ADJUSTMENT

Asnormalwearoccursandthereis excessive"play"betweenthe

wedgeandbeam,adjustthe boltsonthesideofthe wedgeassembly

toeliminateexcessspacebetweenthewedgeandthebeam.

1. Loosenthejam nutsonthe twoadjustmentboltson thesideofthe

wedge.SeeFigure5-1.

2. Turntheadjustmentboltsinuntilsnugandthenbackthemoff

slowly(approximately1.5turns)untilthewedgeassemblywillslide

onthebeam.

.

Re-tightenthejam nutssecurelyagainstthesideofthewedgeto

securetheadjustmentboltsinthisposition.

14

Page 15

FLEXIBLE PUMP COUPLER

Theflexiblepumpcoupleris a nylon"spider"insert,locatedbetween

thepumpandtheengineshaft.Overtime,the couplerwillhardenand

deteriorate.

Replacethecouplerifyou detectvibrationornoisecomingfromthe

areabetweenthe engineandthepump.Ifthecouplerfailscompletely,

youwill experiencea lossofpower.

]i!ill

iMPORTANT:Neverhittheengineshaftin anymanner,asa blowwill

causepermanentdamagetothe engine.

1. Removethethreenutsthatsecurethepumptothecouplingshield.

Twonutsareatthe bottomcornersandoneis inthetop center.See

Figure5-2.

2. Removethepump.

3. Rotatetheenginebyslowlypullingthestarterhandleuntilthe

enginecouplinghalfsetscrewis visible.Loosenthesetscrew

usingallenwrenchandslidethecouplinghalfoff the engineshaft.

4. Loosenthesetscrewonthe pumpcouplinghalfandremovethe

couplinghalf.

5. Slidethenewenginecouplinghalfontotheengineshaftuntil the

endofthe shaftis flushwiththeinnerportionofthe couplinghalf.

(Theremustbespacebetweenthe endoftheenginesupport

bracketandcouplinghalf).Tightenthesetscrew.

6. Installthe pumpcouplinghalfandkeyonthepumpshaft.Rotate

thecouplinghalfuntilthesetscrewfacestheopeningin theshield.

Donottightentheset screw.

7. Installthe nylon"spider"ontotheenginecouplinghalf.

8. Alignthepumpcouplinghalfwiththenylon"spider"byrotatingthe

engineusingthe starterhandle.Slidethecouplinghalfinto place

whileguidingthreemountingboltsthroughholesinpumpsupport

bracket.

9. Securewiththe nutsremovedearlier.

10.Set.010"to .060"clearance/gapbetweenthenylon"spider"and

theenginecouplinghalfbyslidinga feelergaugeor matchbook

coverbetweenthenylon"spider"andtheenginecouplinghalfand

movingpumpcouplinghalfas needed.Securepumpcouplinghalf

withsetscrew.SeeFigure5-2.

/

Screw

Side View-Coupler

; .oooo

.0100

J

Figure 5=2

tighteningthe set screw.

TIRES

Themaximumpressureforthetiresis30psi.Donotexceedthe

manufacturer'srecommendedpsiunderany circumstances.Maintain

equalpressureonall tires.

Excessivepressurewhenseatingbeadsmaycausethetire/rim

assemblyto burstwithforcesufficienttocauseseriousinjury.Refertc

sidewallofthe tirefor therecommendedpressure.

NOTE:Makecertainthe properclearance/gapisobtainedbefore

15

Page 16

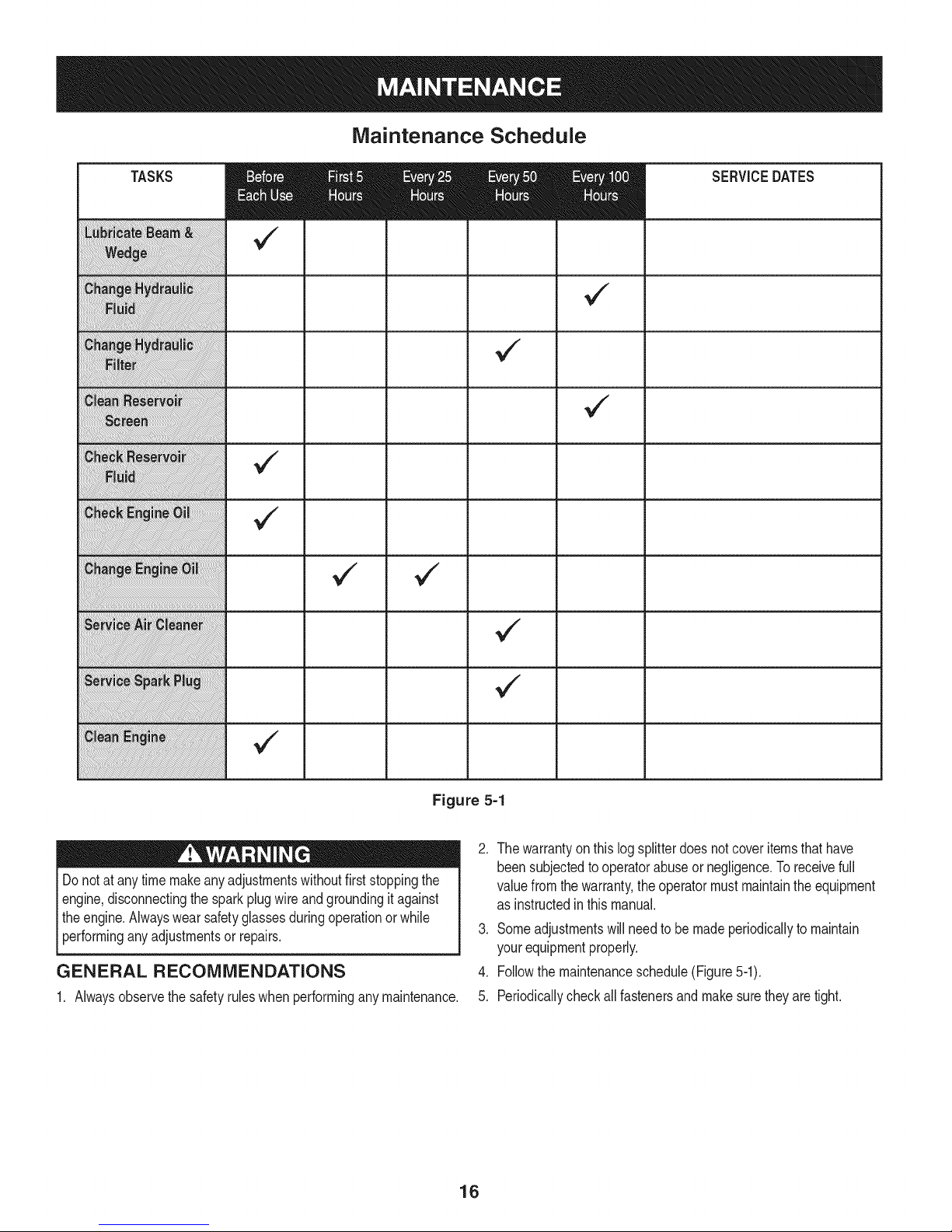

Maintenance Schedule

TASKS

SERVICEDATES

v

Figure 5=1

Donotatany timemakeanyadjustmentswithoutfirststoppingthe

engine,disconnectingthesparkplugwireandgroundingit against

theengine.Alwayswearsafetyglassesduringoperationor while

performinganyadjustmentsor repairs.

GENERAL RECOMMENDATIONS

1. Alwaysobservethesafetyruleswhenperforminganymaintenance.

.

Thewarrantyonthis logsplitterdoesnotcoveritemsthathave

beensubjectedtooperatorabuseor negligence.Toreceivefull

valuefromthe warranty,the operatormustmaintaintheequipment

asinstructedinthis manual.

3. Someadjustmentswillneedto bemadeperiodicallytomaintain

yourequipmentproperly.

4. Followthemaintenanceschedule(Figure5-1).

5. Periodicallycheckallfastenersandmakesuretheyaretight.

16

Page 17

HYDRAULIC FLUID AND iNLET FILTER

Checkthehydraulicfluid levelinthelogsplitterreservoirtank

beforeeachuse.Maintainthe fluidlevelwithintherangespecified

onthedipstickat all times.

Changethehydraulicfluid inthereservoirevery100hoursof

operation.Followthe stepsbelow:

Disconnectthesuctionhosefromthe bottomofthereservoirtank.

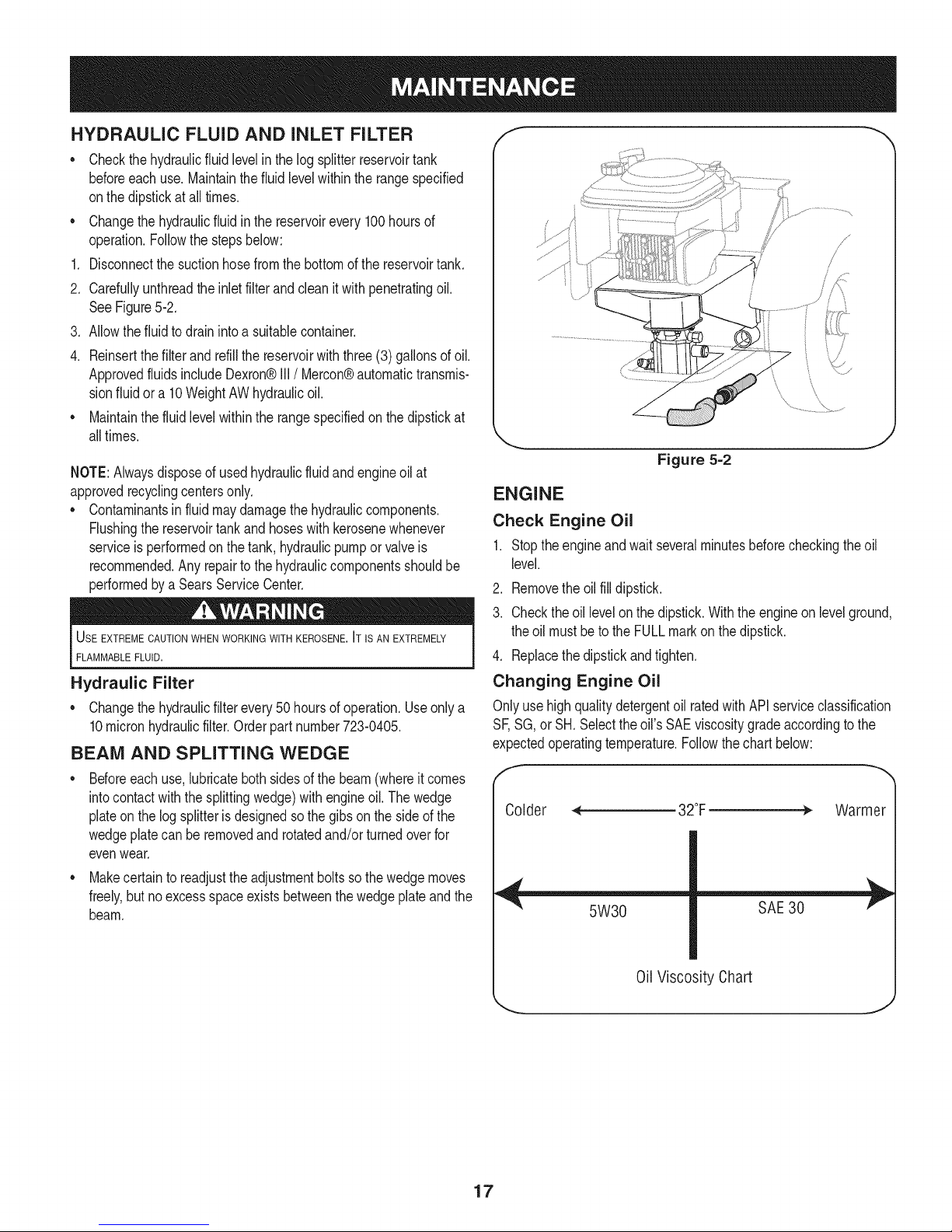

2. Carefullyunthreadthe inletfilterandclean itwithpenetratingoil.

SeeFigure5-2.

3. Allowthefluidto drainintoa suitablecontainer.

4. Reinsertthefilterandrefillthe reservoirwiththree(3) gallonsofoil.

ApprovedfluidsincludeDexron®III/Mercon® automatictransmis-

sionfluid ora 10WeightAWhydraulicoil.

• Maintainthefluidlevelwithintherangespecifiedon thedipstickat

alltimes.

NOTE:Alwaysdisposeofusedhydraulicfluidandengineoilat

approvedrecyclingcentersonly.

• Contaminantsinfluidmaydamagethehydrauliccomponents.

Flushingthereservoirtankand hoseswithkerosenewhenever

serviceisperformedonthe tank,hydraulicpumporvalveis

recommended.Anyrepairtothehydrauliccomponentsshouldbe

performedbya SearsServiceCenter.

USE EXTREME CAUTIONWHEN WORKING WITH KEROSENE. IT IS AN EXTREMELY

FLAMMABLEFLUID.

Hydraulic Filter

• Changethehydraulicfilterevery50 hoursof operation.Useonlya

10micronhydraulicfilter.Orderpartnumber723-0405.

BEAM AND SPLITTING WEDGE

Beforeeachuse,lubricatebothsidesof thebeam(whereit comes

intocontactwiththesplittingwedge)withengineoil.Thewedge

plateonthe log splitterisdesignedsothegibs onthesideof the

wedgeplatecanbe removedandrotatedand/orturnedoverfor

evenwear.

• Makecertainto readjusttheadjustmentboltssothewedgemoves

freely,butnoexcessspaceexistsbetweenthe wedgeplateandthe

beam.

/

Figure 5=2

ENGINE

Check Engine Oil

1. Stoptheengineandwait severalminutesbeforecheckingtheoil

level.

2. Removetheoilfilldipstick.

3. Checktheoillevelon the dipstick.Withthe engineon levelground,

theoil mustbetothe FULLmarkon thedipstick.

4. Replacethedipstickandtighten.

Changing Engine Oil

Onlyusehighqualitydetergentoil ratedwithAPIserviceclassification

SF,SG,or SH.Selecttheoil'sSAEviscositygradeaccordingto the

expectedoperatingtemperature.Followthechartbelow:

Warmer

5W30

SAE 30

0il Viscosity Chart

17

Page 18

NOTE:Althoughmulti-viscosityoils(5W30,10W30,etc.)improve

startingincold weather,theywillresultinincreasedoilconsumption

whenusedabove32°RCheckyourengineoillevelmorefrequentlyto

avoidpossibleenginedamagefromrunninglow onoil.

Changetheengineoilafterthefirst fivehoursof operation,andevery

50 hoursthereafter.Changetheoilevery25hoursofoperationifthe

engineisoperatedunderheavyloadorin highambienttemperatures.

To Drain Oil

Drainthe oilwhilethe engineiswarm.Followtheinstructionsgiven

below.

.

Removethedrainplugontheengineanddraintheoilintoa

suitablecontainer.

2.

Whentheengineisdrainedof alloil, replacethedrainplugand

refillwithapproximately20oz.offreshoil. RefertoGasAnd Oil

Fill-upinthe OPERATIONsection.

Service Air Cleaner

Theair cleanerpreventsdamagingdirt, dust,etc.,fromenteringthe

carburetorandbeingforcedintotheengineandisimportanttoengine

lifeand performance.

Neverruntheenginewithoutan aircleanercompletelyassembled.

Servicethecartridgeevery25operatinghoursor everyseason.

Servicethecartridgemoreoftenunderdustyconditions.

To Service Air Filter

.

Loosentheaircleanercoverscrew,butdo notremovethescrew

fromthecover.Swingthecoverdownto removefromthehinge.

2.

Inspectthefilterfor discolorationor dirtaccumulation.Ifeitheris

present,proceedas follows:

a. Cleantheinsideof bodyandcoverthoroughlyand removethe

cartridge.

b. Reassemblethenewcartridgein thebody.Swingthecover

downandtightenthe screwloosenedearlier.

Temperatureof mufflerandnearbyareasmayexceed150°F(65°C).

Avoidtheseareas.

seasonor every50 hoursof operation.

• Cleantheareaaroundthe sparkplug.Removeandinspectthe

sparkplug.

• Replacethesparkplugif theelectrodesarepitted,burnedorthe

porcelainiscracked.

• Checktheelectrodegapwitha wire feelergaugeandresetthe gap

to .030inches.SeeFigure5-3.

NOTE:Donotsandthesparkplug.Thesparkplugshouldbecleaned

witha wirebrushanda commercialsolvent.

f

1..030 (.76 mm) Gap

2. Electrodes

3. Porcelain

J

Figure 5=3

Clean Engine

• Cleantheengineperiodically,byremovingdirtanddebriswitha

clothor brush.

NOTE:Cleaningwitha forcefulsprayof waterisnot recommendedas

watercouldcontaminatethefuelsystem.

• Toensuresmoothoperationoftheengine,keepthe governor

linkage,springsandcontrolsfreeofdebris.

• Every100hoursofoperation,removecombustiondepositsfrom

topof cylinder,head,topof pistonandaroundvalves.

Service Spark Plug

* Cleanthesparkplugandresetthegapto .030"atleastoncea

18

Page 19

Prepareyourlogsplitterforstorageattheendoftheseasonor if the

logsplitterwill notbeusedfor30daysor more.

WARNING:Neverstorethemachinewithfuel inthefueltank inside

ofbuildingwherefumesmayreachanopenflameor sparkor where

ignitionsourcesarepresentsuchashot waterandspaceheaters,

furnaces,clothesdyers,stoves,electricmotors,etc.

NOTE:Ayearlycheck-upbyyour localSearsservicecenteris a good

waytoensureyourlog splitterwillprovidethemaximumperformance

nextseason.

LOG SPLITTER

1. Cleanthe logsplitterthoroughly.

2. Wipethe logsplitterwithanoiledragtopreventrust,especiallyon

thewedgeandthebeam.

ENGINE

IMPORTANT:Itisimportanttopreventgumdepositsfromforming

intheessentialfuelsystempartssuchasthecarburetor,fuelfilter,

fuelhoseortankduringstorage.Also,alcoholblendedfuels(called

gasoholorusingethanolormethanol)canattractmoisturewhichleads

toseparationandformationof acidsduringstorage.Acidicgascan

damagethefuelsystemofanenginewhilein storage.

1. Drainthe fueltank.Alwaysdrainthefuelintoanapprovedcontainer

outdoorsawayfromopenflame.Besurethe engineiscool.Donot

smokewhilehandlingthe fuel.

2. Starttheengineandlet it rununtilthefuel linesandcarburetorare

empty.

IMPORTANT:Neveruseengineorcarburetorcleanerproductsinthe

fueltankor permanentdamagemayoccur.Usefreshfuelnextseason.

3. Removethesparkplug,pourapproximately1/2oz.of engineoilinto

cylinderandcrankitslowlytodistributetheoil.

4. Replacethesparkplug.

NOTE:Fuelstabilizerisanacceptablealternativeinminimizingthe

formationoffuelgumdepositsduringstorage.

Pleasefollowtheinstructionsbelowfor storingyourlogsplitterwith

fuelandstabilizerintheengine:

1. Addstabilizertothe gasolineinthe fueltankor storagecontainer.

Alwaysfollowthe mixratiofoundonthestabilizercontainer.

2. Runtheengineatleast10minutesafteraddingstabilizertoallow

thestabilizertoreachthecarburetor.

IMPORTANT:Donotdrainthegas tankandcarburetorifusingfuel

stabilizer.Drainalltheoil fromthecrankcase(thisshouldbedone

aftertheenginehas beenoperatedandis still warm)andrefillthe

crankcasewithfreshoil.

OTHER

• Donotstorethegasolinefromoneseasontoanother.

• Replaceyourgasolinecanif itstartsto rust.

Storethe logsplitterin a clean,dryarea.Do notstoreit nextto

anycorrosivematerials,suchasfertilizer.

• Wipetheequipmentwithan oiledragto preventrust.

19

Page 20

Problem Cause

I I section.

Remedy

Engineruns erratic

1. UnitrunningwithCHOKEapplied,ifso

equipped.

2. Sparkplugwire loose.

3. Blockedfuellineor stalefuel.

4. Waterordirtinfuelsystem.

5. Dirtyaircleaner.

6. Carburetornot adjustedproperly.

3. Carburetornotadjustedproperly.

1. Movechokeleverto RUNposition.

.

Connectandtightenspark

plugwire.

3.

Cleanfuel line;fill tankwithclean,

fresh(lessthan30daysold)

gasoline.

.

Drainfueltank.Refillwith

freshfuel.

5.

Cleanor replaceaircleaner.

6.

ContactSearsservicecenter.

3. ContactSearsservce center.

NEED MORE HELP?

Youll find d_e answer and moe or_mar_agemyl_ome corn -k'_r Iree!

Find this and all your other product manuals online.

,, Get answers from our team of home experts.

Get a personalized maintenance plan for your home.

,, Find information and tools to help with home projects.

manage _ home

NOTE:This section addressesminorservice issues.Forfurther details,contact Searsserwce informationline bycalling

1-800-4-MY-HOME

bro'_gl_t to yes by Sea_

2O

Page 21

Problem

Cylinderrod willnot

move

1. Brokendriveshaft.

2. Shippingplugsleft in hydraulichoses.

Cause

Remedy

1. Returnunitto Searsservicecenter.

2. Disconnecthydraulichoses,

removeshippingplugs,reconnect

hoses.

,

,

Setscrewsin couplingnotadjusted

properly.

4.

Looseshaftcoupling.

5. Gearsectionsdamaged.

6. Damagedreliefvalve.

7. Hydrauliclinesblocked.

8. Incorrectoil level.

Seeoperator'smanualforcorrect

adjustment.

4.

Correctengine/pumpalignmentas

necessary.

5. Returnunitto Searsservicecenter.

6. Returnunitto Searsservicecenter.

7. Flushandcleanhydraulicsystem.

8. Checkoillevel.Refillif necessary.

9. Damagedor blockeddirectionalvalve. 9. Returnunitto Searsservicecenter.

Slowcylindershaft I 1. Gearsectionsdamaged. 1.ReturnunittoSearsservicecenter.

speedwhile extendng 2 Excessivepumpinletvacuum. 2. Makecertainpumpinlethosesare

and retractng cearandunblocked.Useshort

" largediameternlethoses.

3 Returnunt to Searsservcecenter

3. Slowenginespeed.

4 Returnunt to Searsservcecenter

4. Damagedreliefvalve

5. ncorrecto' eve. 5.Checkoillevel.Ref l ifnecessary.

6. Contaminatedoil.

6 Dran o ceanreservor andref

I 7 Returnuntto Searsservcecenter

7, Directionalvalveleaking nternally.

8 Returnunitto Searsservicecenter.

8. nternay damagedcy nder.

LeakingCylinder 1. Brokenseals. 1. Returnunitto Searsservicecenter.

2. Scoredcylinder. 2. Returnunitto Searsservicecenter.

NEED MORE HELP?

You'll lind the _n wel ahd more or_ m4_r_4_()emyhome corn - Io[ IFee

o Find this and all your other product manuals online.

o Get answers from our team of home experts.

Get a personalized maintenance plan for your home.

o Find information and tools to help with home projects.

_i!!!:!i!i!!!!i!i!!i!i!!i!i!!i!i!!i!i!!i!i!!i!i!!i!i!!i!i!!i!i!!i!i!!i!i!!i!i!!i!i!!i!i!!i!i!!i!i!!i!i!!i!i!!i!i!!i!i!!i!i!!i!i!!i!i!!i!i!!i!i!!i!i!!i!i!!i!i!!i!i!!i!i!!i!i!!i!i!!i!i!!i!i!!i!i!!i!i!!i!i!!i!i!!i!i!!i!i!!i!i!!i!i!!i!i!!i!i!!i!i!!i!i!!i!i!!i!i!!i!i!!i!i!!i!i!!i!i!!i!i!!i!i!!i!i!!i!i!!i!i!!i!i!!i!i!!i!i!!i!i!!i!i!!i!i!!i!i!!i!i!_i!iiii!;¸

NOTE:This sectionaddressesminorservice issues.Forfurther details,contact Sears service informationline bycalling

1-800-4-MY-HOME.

brought to yo-g_'by Se_rs .....

_HHH_

21

Page 22

Problem

Engineruns but wood

will not split or wood

splits too slowly

1. Smallgearsectiondamaged.

2. Pumpcheckvalveleaking.

3. Excessivepumpinletvacuum.

Csuse

Remedy

1. Returnunitto Searsservicecenter.

2. Returnunitto Searsservicecenter.

3. Makecertainpumpinlethosesare

clearandunblocked.Useshort,

largediameterinlethoses.

4. Incorrectoillevel.

5. Contaminatedoil.

4. Checkoillevel.Refillif necessary.

5. Drainoil, cleanreservoir,and refill.

6. Returnunitto Searsservicecenter.

6. Directionalvalveleakinginternally.

7. Donotattemptto splitwood

againstthegrain.

8. Returnunitto Searsservicecenter.

.

Returnunitto Searsservicecenter.

2.

Donotattempttosplitwood

Enginestalls during

splitting

7. Overloadedcylinder.

8. Internallydamagedcylinder.

1. Lowhorsepower/weakengine.

2. Overloadedcylinder.

againstthegrain. Ifenginestalls

repeatedly,contactSearsservice

center.

Engine Willnotturn or Engine/pumPmisalignment. I 1: Coirect alignmentasnecessaryl

stalls under lowload Frozenorseizedpump Returnunitto Seaisservicecenter.

condtons LowhorSepOwer/weakengne J 3 Returnunt t0 searsservCecenter

Hydrauliclinesb!ocked, 4, Flushandcleanhydraulicsysteml

. 5: Blockeddirectionalvalvel. 5: Returnunitto Searsservicecenter.

Leakingpumpshaft

seal

.... Will not split logs ' 1. Reservorfud eve ow. 1. Ref WthDexron automatc

1. Brokendriveshaft.

2. Engine/pumpmisalignment.

3. Gearsectionsdamaged.

4. Poorlypositionedshaftseal.

5. Pluggedoil breather.

, . transmissionfluid.

' i 1

1. Returnunitto Searsservicecenter.

2. Correctalignmentasnecessary.

3. Returnunitto Searsservicecenter.

4. Returnunitto Searsservicecenter.

5. Makecertainreservoirisproperly

vented.

NEED MORE HELP?

Yo_/II fired tt_e answe,_" a_d more o__mar_afjemyl_ome corn -Io_ Iree!

,, Find this and all your other product manuals online.

" Get answers from our team of home experts.

,, Get a personalized maintenance plan for your home.

Find information and tools to help with home projects.

maHage _ home

NOTE:This section addressesminorservice issues.Forfurther details,contact Searsservice informationline bycalling

1-800-4-MY-HOME.

b_e_t to ye_._by Sea_s

22

Page 23

23

Page 24

A

24

Page 25

Craftsman Log Splitter Model 247.77641

718-0769A HydraulicCylinder

2. 727-04166 HydraulicTube

3. 710-1018 HexCapScrew1/2-20x2.75

4. 737-0192 90 DegreeSolidAdapter

5. 718-0481A ControlValve

6. 737-0153 ReturnElbow

7. 737-0238 NipplePipe1/2-14

8. 710-1806 HexCapScrew1/2-13x3.25

9. 719-0550A WedgeAssembly

10. 712-3058 HexLockNut,1/2-20

11. 712-0711 HexJam Nut3/8-24

12. 710-0459A HexCapScrew3/8-24x 1.5

13. 781-0351 AdjustableGib

14. 736-0116 FiatWasher.635x.93x.06

15. 712-3022 HexLockNut1/2-13

16. 681-04071A-0637 BeamAssembly

17. 710-3056 HexScrew,5/16-18x3.25

18. 710-0654A HexWasherScrew3/8-16x 1.0

19. 781-1048A-0637 DislodgerBracket

20. 781-0790-0637 BackPlate

21. 737-04093 inletFilter

22. 727-0443 ReturnHose3/4" IDx 44" Lg.

23. 726-0132 HoseClamp5/8"

24. 737-0316 FilterHousing

25. 723-0405 OilFilter

26. 734-0873 HubCap

27. 714-0162 CotterPin

28. 712-0359 SlottedNut3/4-16

29. 634-0186 WheelAssembly

30. 736-0351 FiatWasher.760IDx.500OD

31. 737-0312 Adapter3/4-14

32. 781-0526A HoseGuard

33. 737-0348A VentedDipstick

34. 711-1587 ClevisPin

35. 781-0690 LockRod

36. 714-0470 CotterPin

37. 726-0214 PushCap

38. 732-0583 CompressionSpring

39. 781-04180-0637 LogTrayBracket

40. 710-0484 HexWasherScrew,5/16-18x .750

712-04065 FlangeLockNut,3/8-16

42. 781-04179-0637 LogTray

43. 681-04040A-0637 FrameAssembly

44. 710-0521 HexBolt3/8-16x 3"

45. 719-0353 CouplingShield

46. 714-0122 SquareKey3/16"x.75

47. 710-1842 Screw,1/4-20x .38

-- 718-04392 Coupling,.500

-- 718-04395 Coupling,.875

-- 735-04103 SpiderCoupling

48. 712-04063 FlangeLockNut,5/16-18

49. 781-0097-0637 RearCouplingSupportBracket

50. 781-1024-0637 FenderMountingBracket

51. 727-04130 Hose

52. 718-04127 GearPump

53. 737-0329 45DegreeElbowFitting

54. 727-0502 HighPressureHydraulicHose

55. 781-0788-0637 TongueAssembly

56. 747-1261 LatchRod

57. 781-1045-0637 Latch

58. 732-3127 CompressionSpring

59. 736-0371 FiatWasher

60. 781-0538At HoseGuard

61. 710-3085 HexCapScrew,3/8-16x3.50

62. 736-0185 FiatWasher,.375x.738x.063

63. 747-04539 HydraulicValveControl

64. 681-04030 HitchCouplingAssembly

65. 713-0433A Chain

66. 731-2496A Fender

67. 711-0813 ClevisPin

68. 720-04088 Grip

69. 732-0194 SpringPin

70. 781-0789-0721 Jack Stand

71. 715-0120 SpiralPin

72. 710-0650 TTScrew,5/16-18x 0.875"

73. 710-0602 TTScrew,5/16-18x 1.00

74. 711-04585 ClevisPin

75. 713-04036 ValveHandleLink

76. 714-0111 CotterPin

77. 710-0376 HexScrew,5/16-18x 1.00

t NotShown

25

Page 26

5O

383_

m

51

525 i

524 _

718_

11

741

1330 REPAIR MANUAL I

306

26

Page 27

Craftsman Engine Model No. 126L02

For Log Splitter Model 247.77641

836

968

445

m

29_ 97o%

81

613

977 CARBURETOR

GASKET SET

633A ®

633 G

276

121 CARBURETOR OVERHAUL KIT

633A @

633G

365

692 I

633A®

163_

108

104

137_

276 Q

276 O

127 _

(5

°33

130 _ O

95

617

@

m

276

@

]

27

Page 28

627

930

78

304

55

347

332

497 4

455

363

23

1OO5

6s_'

58

592

601

1036 EMiSSiONS LABEL i

i

"° S 9

ssg O

456 _

597 _

J

28

i

6O

Page 29

Craftsman Engine Model No. 126L02

For Log Splitter Model 247.77641

i1329 REPLACEMENT ENGINEJ

i

615

404

616

m

505 _

29

Page 30

Ref.No. PartNo. Description

1. 697322 CylinderAssembly

2. 399269 Kit-Bushing/Seal

3. 299819S1- Seal-Oil(MagnetoSide)

4. 493279 Sump-Engine

5. 691160 Head-Cylinder

7. 6922491- Gasket-CylinderHead

8. 695250 BreatherAssembly

9. 696125 Gasket-Breather

10. 691125 Screw(BreatherAssembly)

11. 691781 Tube-Breather

12. 6922321- Gasket-Crankcase

13. 690912 Screw(CylinderHead)

15. 691680 Plug-OilDrain

16. 691455 Crankshaft

Ref.No. PartNo. Description

58. 697316 Rope-Starter(Cut toRequiredLength)

60. 281434S Grip-StarterRope

65. 690837 Screw(RewindStarter)

78. 691108 Screw(FlywheelGuard)

81. 691740 Lock-MufflerScrew

95. 691636 Screw(ThrottleValve)

97. 696565 Shaft-Throttle

104. 6912421-1- Pin-FloatHinge

108. 691182 Valve-Choke

109. 498593 Shaft-Choke

117. 498981 Jet-Main(Standard)

118. 498978 Jet-Main(HighAltitude)

121. 498260 Kit-CarburetorOverhaul

125. 792253 Carburetor

20. 3997811- Seal-Oil(PTOSide)

22. 691092 Screw(EngineSump)

23. 691992 Flywheel

24. 222698 Key-Flywheel

25. 791097 PistonAssembly(Standard)

791326 PistonAssembly(.020"Oversize)

26. 791098 RingSet-Piston(Standard)

791324 RingSet-Piston(.020"Oversize)

27. 691866 Lock-PistonPin

28. 499423 Pin-Piston

29. 499424 Rod-Connecting

32. 691664 Screw(ConnectingRod)

32A. 695759 Screw(ConnectingRod)

33. 262651S Valve-Exhaust

34. 262652S Valve-Intake

35. 691270 Spring-Valve(Intake)

36. 691270 Spring-Valve(Exhaust)

37. 694086 Guard-Flywheel

40. 692194 Retainer-Valve

43. 691997 Slinger-Governor/Oil

45. 690548 Tappet-Valve

46. 691449 Camshaft

48. 792740 Short Block

50. 794305 Manifold-Intake

51. 7943061- Gasket-intake

54. 691650 Screw(IntakeManifold)

55. 691421 Housing-RewindStarter

127. 6944681-1- Plug-Welch

130. 696564 Valve-Throttle

133. 398187 Float-Carburetor

134. 3981881-1- Valve-Needle/Seat

137. 6939811-1-* Gasket-FloatBowl

159. 691753 Bracket-AirCleanerPrimer

163. 272653St*it Gasket-AirCleaner

187. 791766 Line-Fuel(CuttoRequiredLength)

188. 693399 Screw(ControlBracket)

190. 690940 Screw(FuelTank)

202. 691829 Link-MechanicalGovernor

209. 790944 Spring-Governor

222. 692982 Bracket-Control

227. 690783 ControlLever-Governor

276. 2717161-1-* SealingWasher

287. 690940 Screw(DipstickTube)

300. 692038 Muffler

304. 493294 Housing-Blower

305. 691108 Screw(BlowerHousing)

306. 690450 Shield-Cylinder

307. 690345 Screw(CylinderShield)

332. 690662 Nut(Flywheel)

333. 802574 Armature-Magneto

334. 691061 Screw(ArmatureMagneto)

337. 802592S Plug-Spark

347. 691396 Switch-Rocker

356. 693010 Wire-Stop

30

Page 31

Craftsman Engine Model No. 126L02

For Log Splitter Model 247.77641

Ref.No. Part No. Description

358. 497316 EngineGasketSet

363. 19069 FlywheelPuller

365. 692524 Screw(Carburetor)

383. 89838S Wrench-SparkPlug

404. 690272 Washer(GovernorCrank)

425. 690670 Screw(AirCleanerCover)

443. 692523 Screw(AirCleanerPrimerBase)

445. 491588S Filter-AirCleanerCartridge

455. 791960 FlywheelCup

456. 692299 Plate-PawlFriction

459. 281505S PawI-Ratchet

497. 690664 Screw(Stopswitch)

505. 691251 Nut(GovernorControlLever)

523. 499621 Dipstick

524. 6922961- Seal-DipstickTube

525. 495265 Tube-Dipstick

529. 691923 Grommet

562. 92613 Bolt(GovernorControlLever)

584. 697734 Cover-BreatherPassage

585. 6918791- Gasket-BreatherPassage

592. 690800 Nut(RewindStarter)

597. 691696 Screw(PawlFrictionPlate)

601. 791850 Clamp-Hose

608. 497680 Starter-Rewind

613. 691340 Screw(Muffler)

615. 690340 Retainer-GovernorShaft

616. 698801 Crank-Governor

617. 2703441-'1-1- SeaI-ORing(intakeManifold)

627. 792565 Bracket-Stopswitch

633. 6913211-1-* Seal-Choke/ThrottleShaft

633A. 6938671-1-* Seal-Choke/ThrottleShaft

635. 66538 Boot-SparkPlug

668. 493823 Spacer

670. 692294 Spacer-FuelTank

Ref.No. PartNo. Description

684. 690345 Screw(BreatherPassageCover)

689. 691855 Spring-Friction

692. 690579 Spring-Detent

718. 690959 Pin-Locating

741. 790345 Gear-Timing

832. 499034 Guard-Muffler

836. 690664 Screw(MufflerGuard)

842. 6910311- SeaI-ORing(DipstickTube)

843. 691895 Sleeve-Lever

847. 692047 Assembly-Dipstick/Tube

851. 493880S Terminal-SparkPlug

868. 697338 Seal-Valve

869. _691155 Seat-Valve (intake)

870. 690380 Seat-Valve(Exhaust)

871. 262001 Bushing-Guide(Exhaust)

63709 Bushing-Guide(intake)

930. 691919 Guard-Rewind

957. 699985 Cap-FuelTank

966. 792040 Base-AirCleanerPrimer

968. 692298 Cover-AirCleaner

970. 691669 Screw(AirCleanerPrimerBracket)

972. 699374 Tank-Fuel

975. 493640 Bowl-Float

976. 694395 Primer-Carburetor

977. 498261 Set-CarburetorGasket

1005. 691346 Fan-Flywheel

1036. 697457 Label-Emission

1058. MS3260 Owner'sManual

1059. 692311 Kit-Screw/Washer

1210. 498144 Assembly-Pulley/Spring(Pulley)

1211. 498144 Assembly-Pulley/Spring(Spring)

1329. 126T02-0005 ReplacementEngine(Transfer

GovernorSpringand Flywheel)

1330. 272147 RepairManual

1-Includedin EngineGasketSet,Key.No.358

1-1-IncludedinCarburetorOverhaulKit,Key.No.121

*includedinCarburetorGasketSet,Key.No.977

31

Page 32

(Thispageapplicableinthe U.S.A.and Canadaonly.)

Sears, Roebuck and Co., U.S.A. (Sears), the California Air Resources Board (CARD)

and the United States Environmental Protection Agency (U.S. EPA)

Emission Control System Warranty Statement (Owner's Defect Warranty Rights and Obligations)

EMISSIONCONTROLWARRANTYCOVERAGEISAPPLICABLETOCERTI-

FIEDENGINESPURCHASEDINCALIFORNIAIN1995ANDTHEREAF-

TER,WHICHAREUSEDINCALIFORNIA,ANDTOCERTIFIEDMODEL

California and United States Emission

TheCaliforniaAirResourcesBoard(CARD),U.S.EPAandSearsare pleased

toexplainthe EmissionControlSystemWarrantyonyour modelyear2000and

latersmalloff-roadengine(SORE).InCalifornia,newsmall off-roadengines

mustbe designed,builtand equippedto meettheState'sstringentanti-smog

standards.ElsewhereintheUnitedStates,newnon-road,spark-ignition

enginescertifiedformodelyear1997and latermustmeetsimilarstandardsset

forthbythe U.S.EPA.Searsmustwarranttheemissioncontrolsystemonyour

YEAR1997ANDLATERENGINESWHICHAREPURCHASEDANDUSED

ELSEWHEREINTHEUNITEDSTATES(ANDAFTERJANUARY1,2001 IN

CANADA).

Control Defects Warranty Statement

enginefortheperiodsoftime listedbelow,providedtherehasbeennoabuse,

neglector impropermaintenanceofyour smalloff-roadengine.Youremis-

sioncontrolsystemincludespartssuchasthecarburetor,aircleaner,ignition

system,mufflerandcatalyticconverter.Also includedmaybeconnectorsand

otheremissionrelatedassemblies.Wherea warrantableconditionexists,Sears

will repairyoursmalloff-roadengineatnocostto youincludingdiagnosis,parts

andlabor.

Sears Emission Control Defects Warranty Coverage

Smalloff-roadenginesarewarrantedrelativeto emissioncontrolpartsdefects

fora periodofone year,subjecttoprovisionssetforthbelow.Ifanycovered

Owner's Warranty

Asthe smalloff-roadengineowner,youare responsiblefor theperformanceof

therequiredmaintenancelistedinyourOperatingand MaintenanceInstruc-

tions.Searsrecommendsthatyouretainallyourreceiptscoveringmaintenance

onyoursmalloff-roadengine,butSearscannotdenywarrantysolelyforthe

lackofreceiptsorforyourfailuretoensuretheperformanceof allscheduled

maintenance.As the smalloff-roadengineowner,youshouldhoweverbe

awarethat Searsmaydenyyouwarrantycoverageifyoursmalloff-roadengine

ora part hasfaileddueto abuse,neglect,impropermaintenanceor unap-

parton yourengineis defective,the partwillbe repairedorreplacedbySears.

Responsibilities

provedmodifications.Youareresponsiblefor presentingyour smalloff-road

engineto anAuthorizedSearsServiceDealerassoonas aproblemexists.The

undisputedwarrantyrepairsshouldbecompletedina reasonableamountof

time,notto exceed30days.Ifyouhaveanyquestionsregardingyourwarranty

rightsandresponsibilities,youshouldcontacta SearsServiceRepresentative

at 1-800-469-4663.Theemissionwarrantyisa defectswarranty.Defectsare

judgedonnormalengineperformance.Thewarrantyis notrelatedtoan in-use

emissiontest.

Sears Emission Control Defects Warranty Provisions

ThefollowingarespecificprovisionsrelativetoyourEmissionControlDefectsWarrantyCoverage.ItisinadditiontotheSearsenginewarrantyfornon-regulated

enginesfoundintheOperatingandMaintenanceInstructions.

1. WarrantedParts

Coverageunderthiswarrantyextendsonly tothe partslistedbelow(the

emissioncontrolsystemsparts)to the extentthesepartswerepresenton

the enginepurchased.

a. FuelMeteringSystem

• Cold startenrichmentsystem

• Carburetorand internalparts

• FuelPump

b. AirlnductionSystem

• Aircleaner

• Intakemanifold

c. IgnitionSystem

• Sparkplug(s)

• Magnetoignitionsystem

d. CatalystSystem

• Catalyticconverter

• Exhaustmanifold

• Air injectionsystemor pulsevalve

e. MiscellaneousItemsUsedin AboveSystems

• Vacuum,temperature,position,timesensitivevalves

andswitches

• Connectorsandassemblies

2. Lengthof Coverage

Searswarrantsto the initialownerandeachsubsequentpurchaserthat

the WarrantedPartsshallbefree fromdefectsin materialsandworkman-

shipwhich causedthefailureofthe WarrantedPartsfor a periodofone

yearfromthe datethe engineis deliveredtoa retailpurchaser.

Inthe USAandCanada,a 24hourhotline,1-800-469-4663,hasa menuofpre-recordedmessagesofferingyouenginemaintenanceinformation.

3. NoCharge

Repairorreplacementof anyWarrantedPartwillbe performedat no

chargeto the owner,includingdiagnosticlaborwhichleadstothe

determinationthata WarrantedPartisdefective,ifthediagnosticworkis

performedatanAuthorizedSearsServiceDealer.Foremissionswarranty

servicecontact yournearestAuthorizedSearsServiceDealeras listedin

the "YellowPages"under"Engines,Gasoline,""GasolineEngines,""Lawn

Mowers,"orsimilarcategory.

4. Claimsand CoverageExclusions

Warrantyclaimsshallbefiled in accordancewiththe provisionsofthe

SearsEngineWarrantyPolicy.Warrantycoverageshallbeexcludedfor

failuresof WarrantedPartswhicharenotoriginal Searspartsor because

ofabuse,neglector impropermaintenanceassetforth intheSears

EngineWarrantyPolicy.Searsisnotliableto coverfailuresof Warranted

Partscausedby theuseof add-on,non-original,ormodifiedparts.

5. Maintenance

AnyWarrantedPartwhichis notscheduledforreplacementasrequired

maintenanceor whichis scheduledonlyfor regularinspectiontothe effect

of"repairor replaceasnecessary"shallbe warrantedasto defectsforthe

warrantyperiod.AnyWarrantedPartwhichis scheduledfor replacement

asrequiredmaintenanceshallbewarrantedasto defectsonlyforthe

periodoftime uptothe firstscheduledreplacementforthat part.Any

replacementpartthat isequivalentinperformanceanddurabilitymay

beusedinthe performanceofanymaintenanceor repairs.Theowneris

responsibleforthe performanceof allrequiredmaintenance,as definedin

the SearsOperatingandMaintenanceInstructions.

6. ConsequentialCoverage

Coveragehereundershallextendto thefailureofanyenginecomponents

causedbythefailureofanyWarrantedPartstill underwarranty.

GDOC-100188Rev.A

32

Page 33

Look For Relevant Emissions Durability Period and

Air index information On Your Engine Emissions Label

Engines that are certified to meet the California Air Resources Board (CARB) Tier 2 Emission Standards must

display information regarding the Emissions Durability Period and the Air Index. Sears, Roebuck and Co., U.S.A.

makes this information available to the consumer on our emission labels.

The Emissions Durability Period describes the number of hours of actual running time for which the engine is

certified to be emissions compliant, assuming proper maintenance in accordance with the Operating & Mainte-

nance Instructions. The following categories are used:

Moderate: Engine is certified to be emission compliant for 125 hours of actual engine running time.

Intermediate: Engine is certified to be emission compliant for 250 hours of actual engine running time.

Extended: Engine is certified to be emission compliant for 500 hours of actual engine running time.

For example, a typical walk-behind lawn mower is used 20 to 25 hours per year. Therefore, the Emissions

Durability Period of an engine with an intermediate rating would equate to 10 to 12 years.

The Air Index is a calculated number describing the relative level of emissions for a specific engine family. The

lower the Air Index, the cleaner the engine. This information is displayed in graphical form on the emissions label.

After July 1,2000, Look For Emissions Compliance Period

On Engine Emissions Compliance Label

After July 1, 2000 certain Sears, Roebuck and Co., U.S.A. engines will be certified to meet the United States

Environmental Protection Agency (USEPA) Phase 2 emission standards. For Phase 2 certified engines, the Emis-

sions Compliance Period referred to on the Emissions Compliance label indicates the number of operating hours

for which the engine has been shown to meet Federal emission requirements.

For engines less than 225 cc displacement, Category C = 125 hours, B = 250 hours and A = 500 hours.

For engines of 225 cc or more, Category C = 250 hours, B = 500 hours and A = 1000 hours.

This isa generic representation of the emission label typically found on acertified engine.

FAMILYYBSXS.3192VA 274812

GDOC-100182Rev.A

33

Page 34

Garantia....................................................Page34

Protecci6n.................................................Page35

Ensamble..................................................Page40-41

Funcionamiento........................................Page42-45

Mantenimiento..........................................Page48-50

Almacenamiento.......................................Page51

GuiDeLocalizaci6ndefallas...................Page52-54

ControldeEmisi6n...................................Page55

Servicioyajustes......................................Page46-47

Garantfa limitada de la cortadora de troncos Craftsman

Searsreparar_,o reemplazar_,gratistodapiezaquese determinedefectuosaenmaterialo manode obra,a partirde un(1)a_ode lafecha

decompra,si esteequipoCraftsmansemantiene,lubricayafinadeacuerdoconlasinstruccionesenel manualdeloperador.El serviciode

garanfiaest,.disponiblegratisdevolviendoelequipoCraftsmanal centrode servicioSearsm_.scercano.Estadisponiblela garantiaen el sitio

peroseaplicauncargoporviaje.EstaGarantiaseaplica mientrasesteproductoseencuentreen losEstadosUnidossolamente.

Esta Garantia no cubre:

• Articulosconsumiblesquesedesgastanduranteel usonormal,talescomobujias,filtros,correasy filtrosparaaceite.

• Reemplazoo reparacionesde neum_.ticoscausadospotperforacionesde objetosexternostalescomoclavos,espinas,toconeso vidrio.

• Reparacionesnecesariascausadasporabusodel operador,incluyendo,perosinestarlimitadas,adaSoscausadosporobjetostalescomo

piedrasodesechosmet_Jicos,materialesdegrantamaSo,objetosimpactantesquedoblanel bastidoro el cig(JeSal,o velocidadexcesivadel

motor.

• Reparacionesnecesariascausadaspor negligenciadeloperador,incluyendo,perosin estarlimitadas,a da5osel_ctricosomec_.nicoscausa-

dospot almacenamientoinadecuado,fallaen usarel gradoycantidadcorrectosdeaceitede motor,ofallaen mantenerel equipode acuerdo

conlas instruccionescontenidasen el manualdeloperador.

• Limpiezaoreparacionesdel sistemade combustibledel motorcausadosporelcombustiblequese determineestarcontaminadouoxidado

(rancio).Engeneralel combustibledebeusarsedentrodelos30 dias desufechade compra.

• Equipousadoparafinescomercialesodealquiler.

LLAMARAL1-800-4-MY-HOMEPARALOCALIZARELCENTRODESERVICIOSEARSMASCERCANO0 PARA PROGRAMARELSERVl-

ClO.

Lagarantialeotorgaciertosderechoslegalesespecificosyustedpuedetenettambi_notrosderechos,quevariandeestadoa estado.

Serie de motor

Tipo del aceite de motor

Cap. de aceite del motor

Capacidad de combustible

Bujfa (separaci6n de .030")

Lfquido hidr,_ulico

126T02

SAE 30

20 Onzas

1.5 Cuartos

Champion RJ-19LM

Dexron III/3.0 gal

NOmero de modelo ....................................................

N0mero de serie ........................................................

Fecha de compra ......................................................

Para referencia futura registrar el nOmero de serie y la

fecha de compra y guardar en un lugar seguro.

34

Page 35

Felicitacionesporhaberrealizadounaadquisici6ninteligente.El

productoCraftsman@queha adquiridoest_dise_adoyfabricado

parabrindarrnuchosa_osde funcionarnientoconfiable.Perocorno

todoslosproductosa vecespuederequerirdereparaciones.Esen

esernornentocuandoel disponerdeunAcuerdode protecci6npara

reparacionesle puedeahorrardineroy problernas.

A continuaci6nsedetallanlospuntosincluidosenel Acuerdo:

• Servicio experto prestadopornuestros10,000especialistasen

reparacionesprofesionales

• Servicio ilirnitadosincargoparalaspiezasyla rnanodeobraen

todaslas reparacionescubiertas

• Reernplazodel productohasta1500d61aressinoesposible

repararel productocubierto

• Descuentode10%del precionormaldelservicioy delas piezas

relacionadasconel rnisrnoqueno est_ncubiertasporelacuerdo;

adern&s,10%del precionormaldelaverificaci6ndernanten-

irnientopreventivo

• Ayudar_pidapottel_fono- IoIlarnarnosResoluci6nR_pida- el

apoyotelef6nicode unCharnuscaal representante.Pienseen

nosotroscornoel manual"deundue_ohablador."

Unavezadquiridoel Acuerdo,puedeprograrnarel serviciocon

tans61orealizarunaIlarnadatelef6nica.PuedeIlarnarencualquier

mornentodeldia o dela nocheo prograrnarun servicioen linea.

ElAcuerdodeProtecci6nde Reparaci6nesunacornprasinriesgo.

Siustedanulaporalgunaraz6nduranteel periododegarantiade

producto,proporcionarernosun reernbolsoIleno.O,unreernbolso

prorrateadoencualquiermornentodespu_sdelperiodode garantia

de productoexpira,iAdquieraboysu acuerdodeprotecci6npara

reparaciones!

Seaplican deterrninadaslimitaciones y exclusiones.Paraobtener

inforrnaci6nadicional ypreciosenlos Estados UnidosIlarneal

1-800-827-6655.

El*Coverageen Canad_variaenalgunosarticulos. Paradetalles

IlenoslaIlarnadaCharnuscaCanad_en 1-800-361-6665.

Servicio de instalaci6ndeSears

Sideseasolicitarla instalaci6nprofesionalde Searsdeaparatos

dorn_sticos,dispositivosparaabrirportones,calentadoresde agua

y otrosarficulosdorn_sticosirnportantes,en losEstadosUnidoso

Canad_Ilarneal 1-800-4-MY-HOME®.

35

Page 36

_ DVERTENCIA: La presencia de este s[mbolo indica que se trata de instrucciones importantes

de seguridad que se deben respetar para evitar poner en peligro su seguridad personal y/o

material y la de otras personas. Lea y siga todas las instrucciones de este manual antes de poner

en funcionamiento esta m_quina. Si no respeta estas instrucciones puede provocar lesiones

personales. Cuando vea este s[mbolo, iTENGA EN CUENTA LAS ADVERTENCIAS!

PROPOSICION 65 de California "_

_ DVERTENCIA: El escape del motor de este producto, algunos de sus componentes y

algunos componentes del veh[culo contienen o liberan sustancias qu[micas que el estado de

California considera que pueden producir c_ncer, defectos de nacimiento u otros problemas

reproductivos.

PEUGRO: Esta m_quina est_ diser_ada para set utilizada respetando las normas de seguridad

_ ontenidas en este manual. AI igual que con cualquier tipo de equipo motorizado, un descuido o

error pot parte del operador puede producir lesiones graves. Esta m_quina es capaz de amputar

manos y pies y de arrojar objetos con gran fuerza. De no respetar las instrucciones de seguridad

siguientes se pueden producir lesiones graves o la muerte.

Capa¢itaci6n 9.

1. Lea, entienda y cumpla todas las instrucciones incluidas en la

m_quina yen el(los) manual(es) antes de intentar realizar el

montaje de la unidad y utilizarla. Guarde este manual en un

lugar seguro para consultas futuras y peri6dicas, asi como para

solicitar repuestos.

2. Familiaricese con todos los controles y con el uso adecuado

de los mismos. Sepa c6mo detener la m_quina y desactivar los

controles r_pidamente.

3. No permita nunca que los niEos menores de 16 ahos utilicen

esta m_quina. Los niEos de 16 aEos en adelante deben