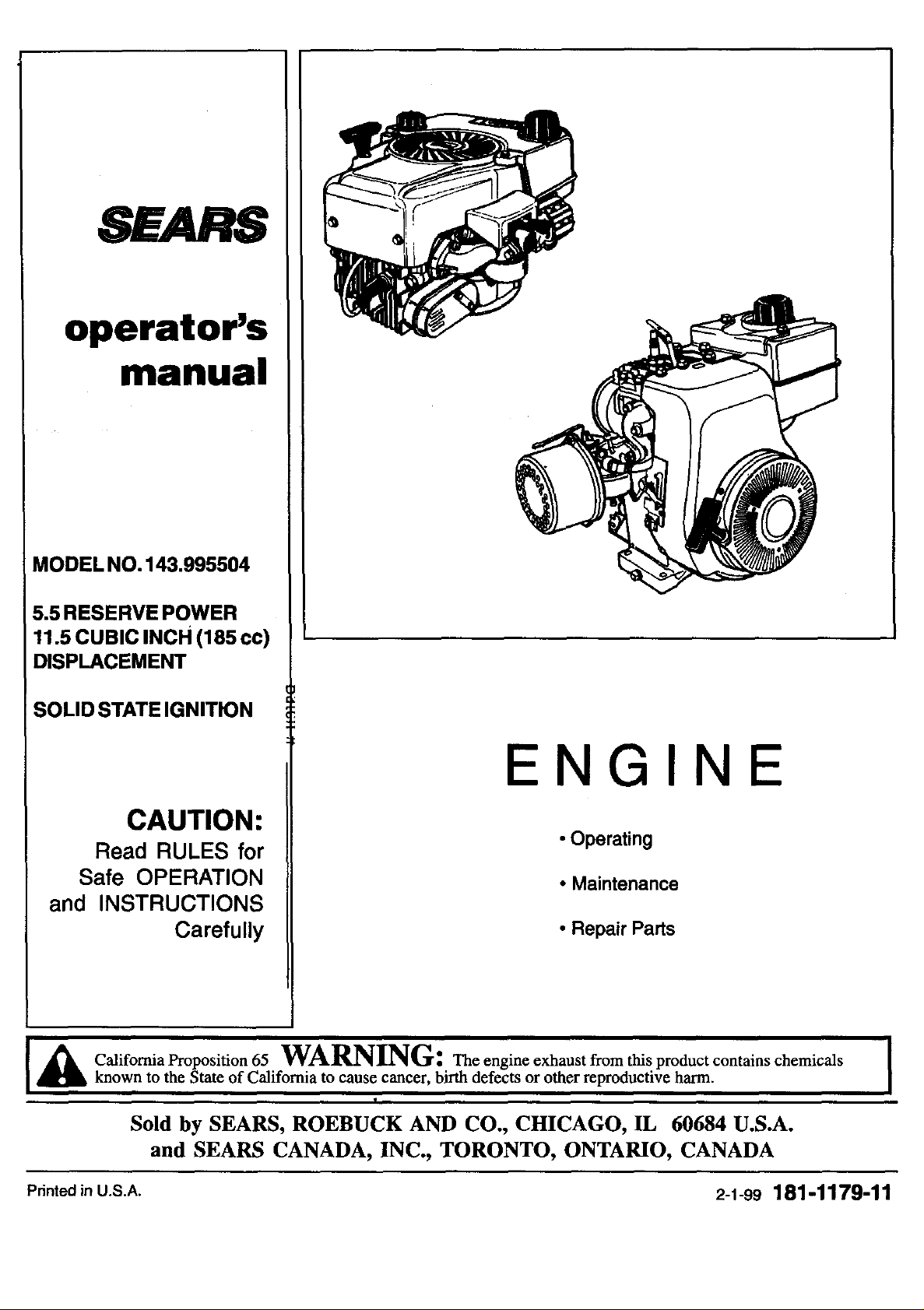

Craftsman 143995504 Owner’s Manual

operator's

manual

MODEL NO. 143.995504

5.5 RESERVE POWER

11.5 CUBIC INCH (185 cc)

DISPLACEMENT

SOLID STATE IGNITION

ENGIN

CAUTION:

Read RULES for

Safe OPERATION

and INSTRUCTIONS

Carefully

California Proposition 65 WARNING: me engine exhaust from this product contains chemicals

known to the State of California to cause cancer, birth defects or other reproductive harm.

Sold by SEARS, ROEBUCK AND CO., CHICAGO, IL 60684 U.S.A.

and SEARS CANADA, INC., TORONTO, ONTARIO, CANADA

Printedin U.S.A. 2-1-99 181-1179-11

• Operating

• Maintenance

• Repair Parts

ISlI_IIIIII|IIIISll 1

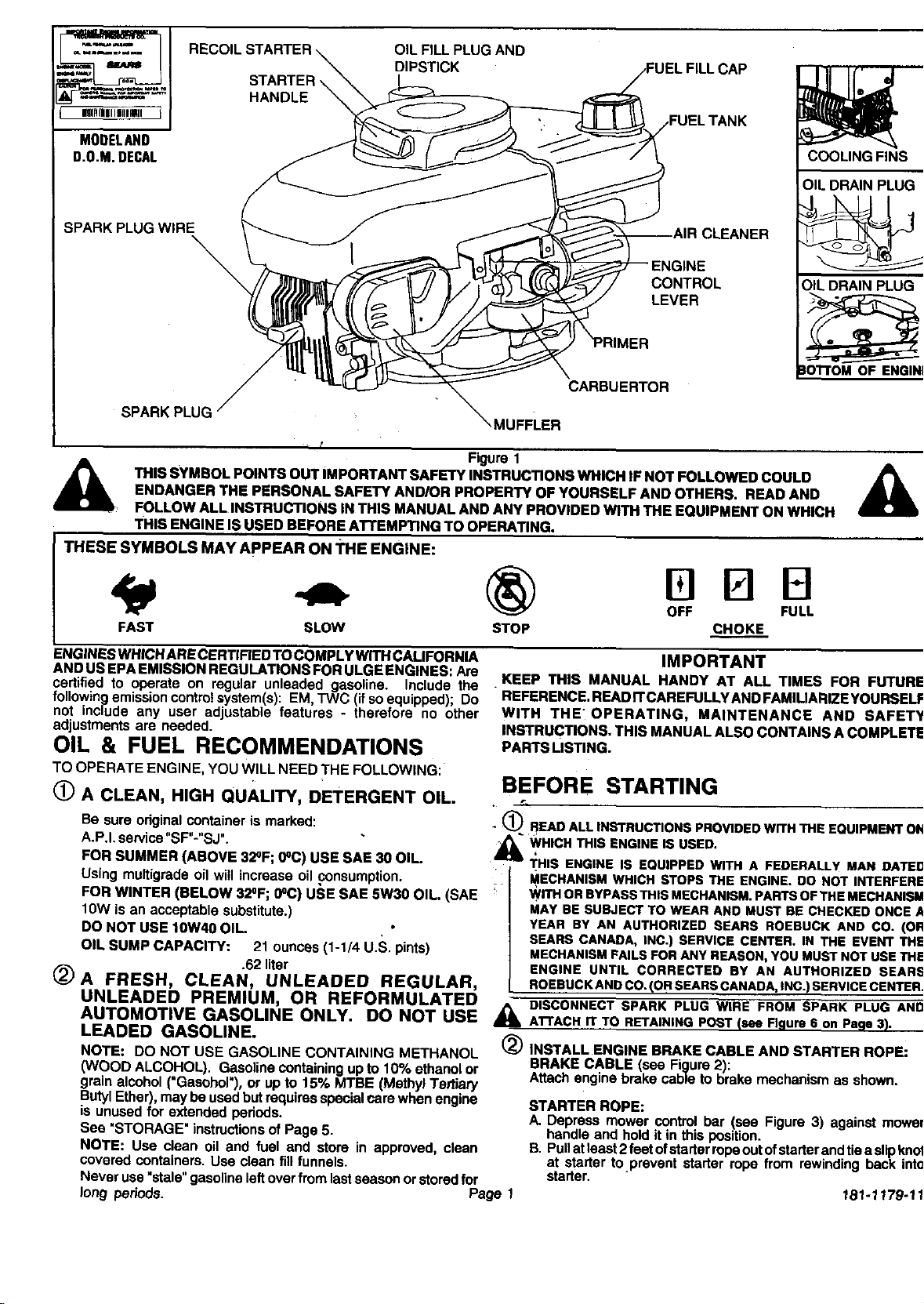

MODELAND

D.O.M.DECAL

RECOILSTARTEF

STARTER\

HANDLE

OIL FILL PLUG AND

DIPSTICK

FILL CAP

COOLING FINS

OIL DRAIN PLUG

SPARK PLUG WIRE

\

SPARK PLUG

!

THIS SYMBOL POINTS OUT IMPORTANT SAFETY INSTRUCTIONS WHICH IF NOT FOLLOWED COULD

_lb Figure 1

THESE SYMBOLS MAY APPEAR ON THE ENGINE:

ENGINES WNICH ARE C_-HHt-I_:u TO COMPLY WrrH CALIFORNIA

AND US EPA EMISSION REGULATIONS FOR ULGE ENGINES: Are

certified to operate on regular unleaded gasoline. Include the

following emission control system(s): EM, TWC (if so equipped) Do

not include any user ad ustab e features - therefore no other

adjustments are needed.

ENDANGER THE PERSONAL SAFETY AND/OR PROPERTY OF YOURSELF AND OTHERS. READ AND

FOLLOW ALL INSTRUCTIONS N TH S MANUAL AND ANY PROVIDED WITH THE EQUIPMENT ON WHICH

THIS ENGINE IS USED BEFORE A'n'EMPTING TO OPERATING.

FAST SLOW STOP CHOKE

OIL & FUEL RECOMMENDATIONS

TO OPERATE ENGINE, YOU WILL NEED THE FOLLOWING:

(_ A CLEAN, HIGH QUALITY, DETERGENT OIL.

Be sure original container is marked:

A.P.I. service "SF"-"SJ".

FOR SUMMER (ABOVE 32°F; 0°C) USE SAE 30 OIL.

Using multigrade oil will increase oil consumption.

FOR WINTER (BELOW 32OF;0°C) USE SAE 5W30 OIL. (SAE "

10W is an acceptable substitute.)

DO NOT USE 1OW4O OIL. °

OIL SUMP CAPACITY: 21 ounces (1-114 U.S. pints)

.62 liter

(_) A FRESH, CLEAN, UNLEADED REGULAR,

UNLEADED PREMIUM, OR REFORMULATED

AUTOMOTIVE GASOLINE ONLY. DO NOT USE _I_

LEADED GASOLINE.

NOTE: DO NOT USE GASOLINE CONTAINING METHANOL (_

(WOOD ALCOHOL). Gasoline containing up to 10% ethanol or

grain alcohol ("Gasohol"), or up to 15% MTBE (Methyl Tertiary

Butyl Ether), may be used but requires special care when engine

is unused for extended periods.

See "STORAGE" instructions of Page 5.

NOTE: Use clean oil and fuel and store in approved, clean

covered containers. Usa clean fill tunnels.

Never use "stale" gasoline left over from last season or stored for

long periods. Page f

,MUFFLER

KEEP THIS MANUAL HANDY AT ALL TIMES FOR FUTURE

REFERENCE. READ IT CAREFULLY AND FAMIUARIZE YOURSELF

WITH THE OPERATING, MAINTENANCE AND SAFETY

INSTRUCTIONS, THIS MANUAL ALSO CONTAINS A COMPLETE

PARTS LISTING.

BEFORE STARTING

_ I_IEADALL INSTRUCTIONS PROVIDED WITH THE EQUIPMENT ON

_ WHICH THIS ENGINE IS USED.d

3LEANER

CONTROL

LEVER

CARBUERTOR

EI88

OFF FULL

IMPORTANT

"I_HISENGINE IS EQUIPPED WITH A FEDERALLY MAN DATED

MECHANISM WHICH STOPS THE ENGINE. DO NOT INTERFERE

WITHOR BYPASSTHIS MECHANISM.PARTS OFTHE MECHANISM

MAY BE SUBJECT TO WEAR AND MUST BE CHECKED ONCE A

YEAR BY AN AUTHORIZED SEARS ROEBUCK AND CO. (OR

SEARS CANADA, INC.) SERVICE CENTER. IN THE EVENT THE

MECHANISM FAILS FORANY REASON,YOU MUST NOT USE THE

ENGINE UNTIL CORRECTED BY AN AUTHORIZED SEARS

ROEBUCKANDCO. (OR SEARSCANADA,INC.) SERVICECENTER.

DISCONNECT SPARK PLUG WIRE FROM SPARK PLUG AND

ATTACH IT TO RETAINING POST (see Figure 6 on Page 3).

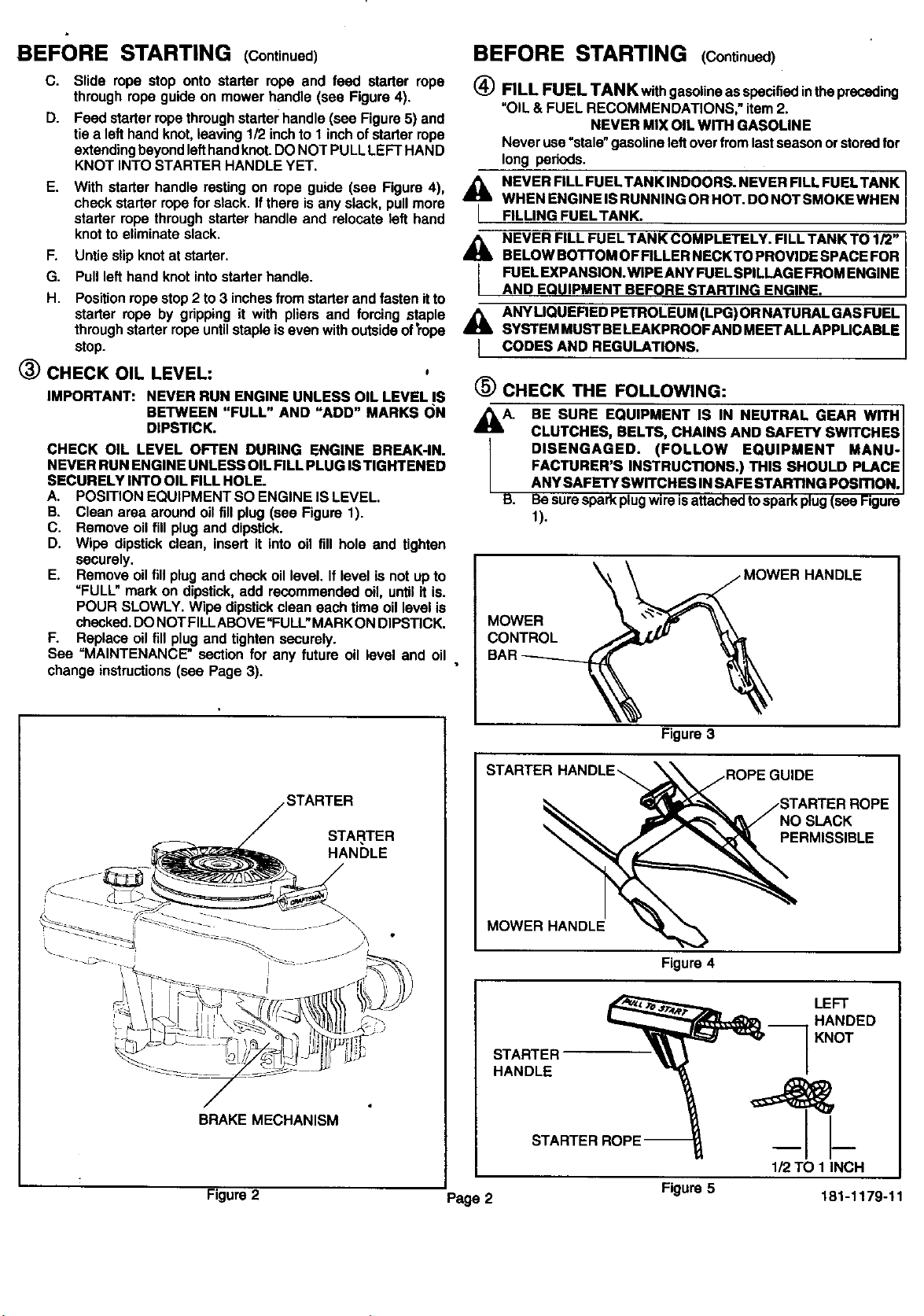

INSTALL ENGINE BRAKE CABLE AND STARTER ROPE:

BRAKE CABLE (see Figure 2):

Attach engine brake cable to brake mechanism as shown.

STARTER ROPE:

A. Depress mower control bar (sea Figure 3) against mower

handle and hold it in this position.

E. Pullat least 2 feet of starter rope out ofstarter and tie aslip knot

at starter to.prevent starter rope from rewinding back into

starter.

OIL DRAIN PLUG

So'FrOM OF ENGINI

181-1179-1f

BEFORE STARTING (Continued)

C, Slide rope stop onto starter rope and feed starter rope

throughropeguideon mower handle(see Figure4).

D. Feed starterropethroughstarterhandle(see Figure5) and

tiea lefthandknot,leaving1/2 inchto1 inchofstarterrope

extendingbeyondlefthandknot.DONOT PULLLEFTHAND

KNOT INTO STARTER HANDLEYET.

E.

With starter handle resting on rope guide (see Figure 4),

check starter rope for slack. If there is any slack, pull more

starter rope through starter handle and relocate left hand

knot to eliminate slack.

F. Untie slip knot at starter.

G. Pull left hand knot into starter handle.

H. Positionropestop2 to 3 inchesfromstarterand fasten itto

starter rope by grippingit with pliers and forcing staple

throughstarterropeuntilstapleis evenwithoutsideof'rope

stop.

(_) CHECK OIL LEVEL:

IMPORTANT: NEVER RUN ENGINE UNLESS OIL LEVEL IS

BETWEEN "FULL" AND "ADD" MARKS ON

DIPSTICK.

CHECK OIL LEVEL OFTEN DURING ENGINE BREAK-IN.

NEVER RUN ENGINE UNLESS OIL FILL PLUG IS TIGHTENED

SECURELY INTO OIL FILL HOLE.

A. POSITION EQUIPMENT SO ENGINE IS LEVEL.

B. Clean area around oil fill plug (sea Figure 1).

C. Remove oil fill plug and dipstick.

D. Wipe dipstick clean, insert it into oil fill hole and tighten

securely.

E. Remove oil fill plug and check oil level. If level is not up to

=FULL" mark on dipstick, add recommended oil, until it is.

POUR SLOWLY. Wipe dipstick clean each time oil level is

checked. DO NOT FILLABOVE "FULL" MARK ON DIPSTICK.

F. Replace oil fill plug and tighten securely.

See =MAINTENANCE" section for any future oil level and oil •

change instructions (see Page 3).

BEFORE STARTING (Continued)

(_) FILL FUEL TAN K with gasoline as specified inthe preceding

"OIL & FUEL RECOMMENDATIONS," item 2.

NEVER MIX OIL WITH GASOLINE

Never use =stale" gasoline left over from lastseason orstored for

long periods.

WHEN ENGINE IS RUNNING OR HOT. DO NOT SMOKE WHEN

i_ NEVER FILLFUELTANK INDOORS. NEVER FILL FUEL TANK

FILLING FUELTANK.

_IL NEVER FILL FUEL TANK COMPLETELY. FILL TANK TO 1/2"

BELOW BOTTOM OF FILLER NECK TO PROVIDE SPACE FOR

I FUEL EXPANSION.WIPEANY FUEL SPILLAGE FROM ENGINE

AND EQUIPMENT BEFORE STARTING ENGINE.

,_ ANY UQUERED PETROLEUM (LPG) OR NATURAL GAS FUEL

SYSTEM MUST BE LEAKPROOFAND MEETALLAPPUCABLE

I CODES AND REGULATIONS.

_) CHECK THE FOLLOWING:

i_iA BE SURE EQUIPMENT IS IN NEUTRAL GEAR WITH I

CLUTCHES, BELTS, CHAINS AND SAFETY SWITCHES J

DISENGAGED. (FOLLOW EQUIPMENT MANU- I

FACTURER'S INSTRUCTIONS.) THIS SHOULD PLACE

ANY SAFETY SWITCHES N SAFE STARTING PosmoN.

B. Be sure spark plugwire is attached to spark plug (see Figure

1).

_ __ ._ MOWER HANDLE

STARTER

BRAKE MECHANISM

STARTER

HANDLE

STARTER HANDLE_

MOWER HANDLE

STARTER

HANDLE

STARTER

Figure 3

GUIDE

NO SLACK

PERMISSIBLE

Figure 4

LEFT

HANDED

KNOT

1/2 TO 1 INCH

Figure 2 Page 2 Figure 5 181-1179-11

STARTING

MAINTENANCE

_k NEVER RUN ENGINE INDOORS OR IN ENCLOSED, POORLY

VENTILATED AREAS. ENGINE EXHAUST CONTAINS

CARBON MONOXIDE, AN ODORLESS AND DEADLY GAS

(CARBON MONOXIDE IS ALSO PRESENT IN ENGINE

EXHAUST FROM LIQUID PETROLEUM (LPG)AND NATURAL

GAS FUEL SYSTEMS).

_ KEEP HANDS, FEET, HAIR AND LOOSE CLOTHING AWAY

FROM ANY MOVING PARTS ON ENGINE AND EQUIPMENT.

_ ARNING -- TEMPERATURE OF MUFFLER AND NEARBY

AREAS MAY EXCEED 150°F (65°C). AVOID THESE AREAS.

(_ Move engine control (see Figure 1)to HI Position.

(_) START ENGINE:

A.

The carburetor on yourengine has been completely a_tjusted

at the factory. When startinga cold engine, push redprimer B.

bulb firmly with your thumb 5 tlmee, allowing primer bulb

to return completely to odginal position between p_shes. C.

Repeat the above for each starter operation as necessary.

NOTE: DO NOT USE PRIMER "IF,O RESTART A WARM D.

ENGINE AFTER A SHORT SHUTDOWN.

B. Operate mowercontrolto releaseengine brake.

C. Graspstarterhandle(seeFigure4) andpullropeout,slowly,

untilitpullsslightlyharder.Let roperewindslowly.Then pull

ropewitha rapidfull arm stroke.Let roperewindSLOWLY.

Donotletstarterhandlesnapbackagainstropeguide(sea

Figure4).

D. RepeatinstructionsBandC ifnecessary,untilenginestarts.

NOTE: Ifenginedoesnotstart,repeatinstructionsA, B, C

andD untilitstarts.

STOPPING

(_) See mower manufacturer's instructions.

(_) AFTER ENGINE IS STOPPED:

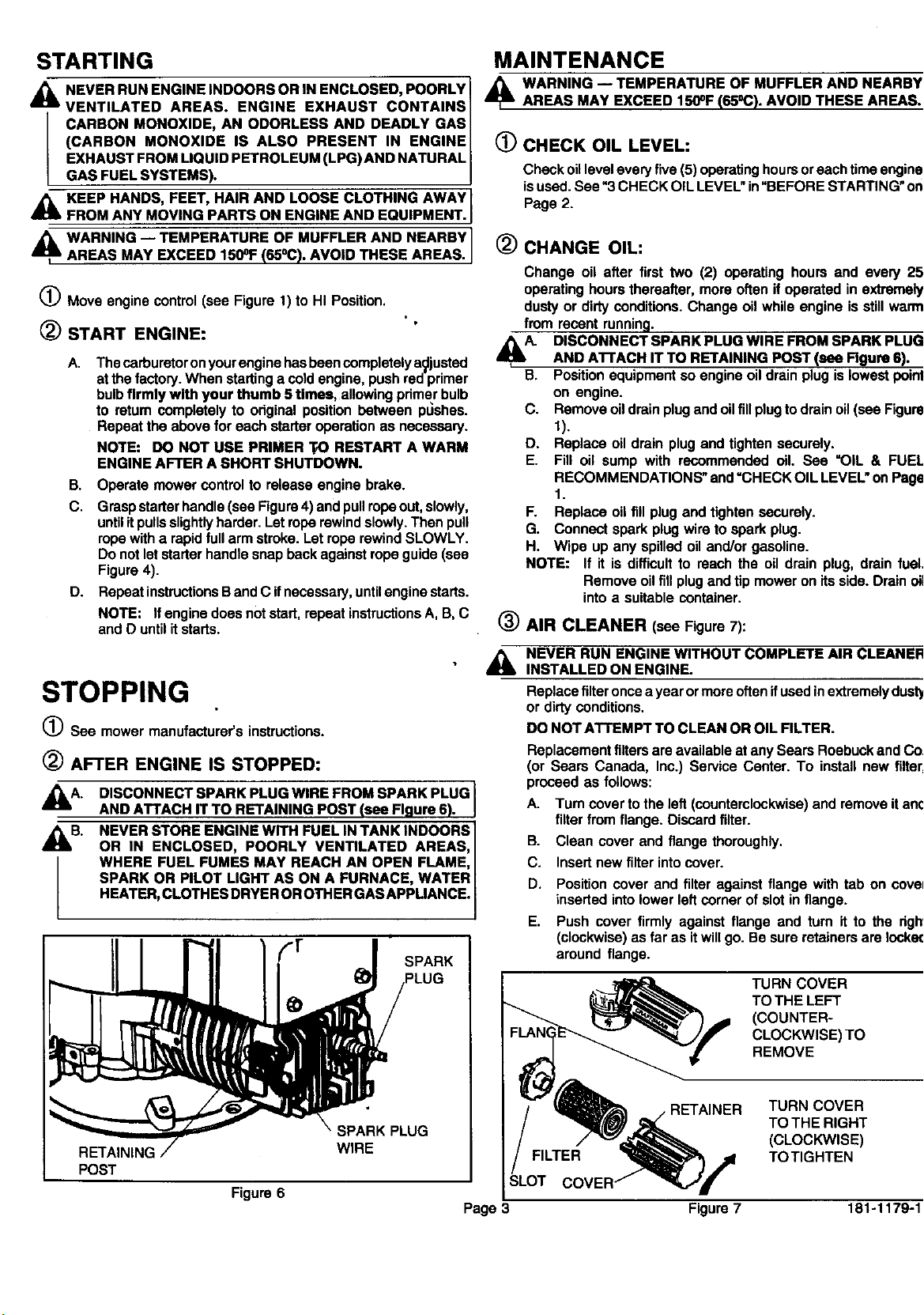

_IIA. DISCONNECT SPARK PLUG WIRE FROM SPARK PLUG

,_kB. NEVER STORE ENGINE WITH FUEL IN TANK INDOORS

AND ATTACH IT TO RETAINING POST (see Figure 6).

OR IN ENCLOSED, POORLY VENTILATED AREAS,

WHERE FUEL FUMES MAY REACH AN OPEN FLAME,

SPARK OR PILOT LIGHT AS ON A FURNACE, WATER

HEATER,CLOTHES DRYER OR OTHER GASAPPLIANCE.

fF

SPARK

PLUG

_ ARNING -- TEMPERATURE OF MUFFLER AND NEARBY

AREAS MAY EXCEED 150°F (65°C). AVOID THESE AREAS.

CHECK OIL LEVEL:

Checkoillevelevery five(5)operatinghoursoreachtimeengine

isused.See"3 CHECK OILLEVEL"in"BEFORESTARTING"on

Page2.

(_ CHANGE OIL:

Change oil after first two (2) operating hours and every 25

operating hours thereafter, more often if operated in extremely

dusty or dirty conditions. Change oil while engine is still warm

from recent running.

DISCONNECT SPARK PLUG WIRE FROM SPARK PLUG

AND ATTACH IT TO RETAINING POST (see Rgure 6).

Position equipment so engine oil drain plug is lowest point

on engine.

Remove oil drain plug and oil fill plug to drain oil (see Figure

1).

Replace oil drain plug and tighten securely.

E. Fill oil sump with recommended oil. See "OIL & FUEL

RECOMMENDATIONS" and =CHECK OIL LEVEL" on Page

1.

F. Replace oil fill plug and tighten securely.

G. Connect spark plug wire to spark plug.

H. Wipe up any spilled oil and/or gasoline.

NOTE: If it is difficult to reach the oil drain plug, drain fuel.

Remove oil fill plug and tip mower on its side. Drain oil

into a suitable container,

®

AIR CLEANER (see Figure 7):

NEVER RUN ENGINE WITHOUT COMPLETE AIR CLEANER

A

INSTALLED ON ENGINE.

Replace filter once a year or more often ifused in extremely dusty

or dirty conditions.

DO NOT ATTEMPT TO CLEAN OR OIL FILTER.

Replacement filters are available at any Sears Roebuck and Co.

(or Sears Canada, Inc.) Service Center. To install new filter,

proceed as follows:

A. Tum cover to the left (counterclockwise) and remove it and

filter from flange. Discard filter.

a.

Clean cover and flange thoroughly.

C.

Insert new filter into cover.

D,

Position cover and filter against flange with tab on cover

inserted into lower left corner of slot in flange.

E,

Push cover firmly against flange and turn it to the right

(clockwise) as far as it will go. Be sure retainers are locked

around flange.

TURN COVER

TOTHELEFT

(COUNTER-

CLOCKWISE)TO

REMOVE

I

RETAINING

POST

Figure 6

SPARKPLUG

WIRE

S_A_INELoT COVER' "_/

Page

Figure 7

TURN COVER

TOTHE RIGHT

(CLOCKWISE)

TOTIGHTEN

181-1179-11

Loading...

Loading...