Craftsman 143995007 Owner’s Manual

operator's

manual

MODEL NO. 143.995007

SOLID STATE IGNITION_

ENGIN

CAUTION:!

Read RULES for

Safe OPERATION

and INSTRUCTIONS

Carefully

_ CaliforniaProposition65WARNING: The engine exhaust from this product contains chemicals [

Printed in U.S.A. 2-1-99 181-1175-11

known to the State of California to cause cancer, birth defects or other reproductive harm.

Sold by SEARS, ROEBUCK AND CO., CHICAGO, IL 60684 U.S.A.

and SEARS CANADA, INC., TORONTO, ONTARIO, CANADA

• Operating

• Maintenance

• Repair Parts

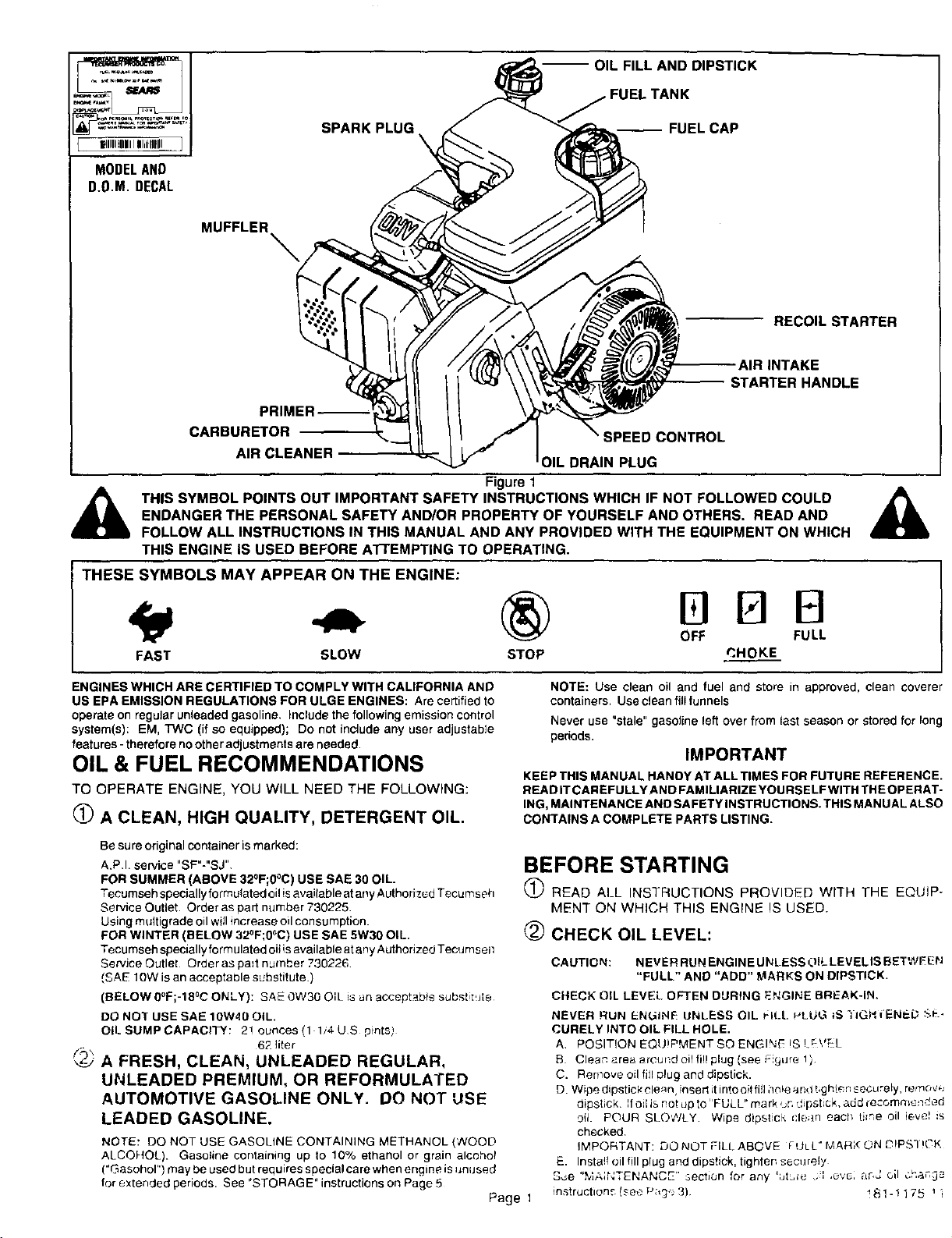

I OIL FILL AND DIPSTICK

FUEL TANK

SPARK PLUG

IIIIIllllll IIllllllllll

\

MODELAND

D.O.M. DECAL

MUFFLER

\

PRIMER--'

CARBURETOR SPEED CONTROL

AIR CLEANER

THIS SYMBOL POINTS OUT IMPORTANT SAFETY INSTRUCTIONS WHICH IF NOT FOLLOWED COULD

ENDANGER THE PERSONAL SAFETY AND/OR PROPERTY OF YOURSELF AND OTHERS, READ AND

FOLLOW ALL INSTRUCTIONS IN THIS MANUAL AND ANY PROVIDED WITH THE EQUIPMENT ON WHICH

THIS ENGINE IS USED BEFORE A'rrEMPTING TO OPERATING.

THESE SYMBOLS MAY APPEAR ON THE ENGINE:

_FUEL CAP

RECOIL STARTER

--AIRINTAKE

STARTER HANDLE

OIL DRAIN PLUG

Figure 1

FAST SLOW STOP P,HOKE

ENGINES WHICH ARE CERTIFIED TO COMPLY WITH CALIFORNIA AND

US EPA EMISSION REGULATIONS FOR ULGE ENGINES: Are certified to

operate on regular unleaded gasoline. Include the following emission control

system(s): EM, TWC (if so equipped); Do not include any user adjustable

features - therefore no other adjustments are needed.

OIL & FUEL RECOMMENDATIONS

TO OPERATE ENGINE, YOU WILL NEED THE FOLLOWING:

(_ A CLEAN, HIGH QUALITY, DETERGENT OIL.

Be sure original container is marked:

A.P.I. service "SF"-"SJ"

FOR SUMMER (ABOVE 32°F;0°C) USE SAE 30 OIL.

Tecumseh speciallyformutated oil isavaitable atany Authorized Tecumseh

Service Outlet. Order as part number 730225.

Using muitigrade oil will increase oil consumption.

FOR WINTER (BELOW 32°F;0°C) USE SAE 5W30 OIL.

Tecumseh specially formulated oiiis available at any Authorized Tecumsen

Service Outlet Order as pa_t number 730226

!SAE 10W is an acceptable substitute.)

(BELOW O_F;-18aC ONLY): SAE 0W30 OIL is an acceptab!e substitute

DO NOT USE SAE 10W40 OIL.

OIL SUMP CAPACITY: 2! ounces (1 1/4 US pints)

62 liter

(2) A FRESH, CLEAN, UNLEADED REGULAR,

UNLEADED PREMIUM, OR REFORMULATED

AUTOMOTIVE GASOLINE ONLY. DO NOT USE

LEADED GASOLINE.

NOTE: DO NOT USE GASOLINE CONTAINING METHANOL (WOOD

ALCOHOL). Gasoline containing up to 10% ethanol or grain alcohol

("Gasohor') may be used but requires special care when engine is unused

for extended periods. See "STORAGE" instructions on Page 5

OFF FULL

NOTE: Use clean oil and fuel and store in approved, clean coverer

containers. Use clean fill funnels

Never use "stale" gasoline left over from last season or stored for long

pedods.

IMPORTANT

KEEP THIS MANUAL HANDY AT ALL TIMES FOR FUTURE REFERENCE.

READ IT CAREFULLY AND FAMILIARIZE YOURSELF WITH THE OPERAT-

ING, MAINTENANCE AND SAFETYINSTRUCTIONS. THIS MANUAL ALSO

CONTAINS A COMPLETE PARTS LISTING.

BEFORE STARTING

(_) READ ALL INSTRUCTIONS PROVIDED WITH THE EQUiP-

MENT ON WHICH THIS ENGINE IS USED.

CHECK OIL LEVEL:

Page 1

CAUTION: NEVER RUN ENGINE UNLESS OIL LEVELIS BETWEEN

CHECK OIL LEVEL OFTEN DURING ENGINE BREAK-IN.

NEVER RUN ENL_iNE UNLESS OIL _lt_t. =-,LUG _STIGHi'ENED S_.-

CURELY INTO OIL FILL HOLE,

A. POSITION EQU!PMENT SO ENGI'S_ !S ! _\'EL

B Clean area around oil fill plug (see eeure 1 )

C. Remove oil fill plug and dipstick.

D Wipe dipstick ele_n, insert it into oil fill ho!e and t_gh!en securely, remove

dips{Jck. Ifoil is not up to IIFULL" mark un dipstick, add rec.omme=ided

oit. POUR SLOWLY Wipe dipstick clean eacl_ time oil ieve! is

checked

IMPORTANT: DO NOT FILL ABOVE FtJL{." MAR;< ON D!PSI !CK

E. Insta!l oil fill plug arid dipstick, tighter, sec_lrely

See "MAINTENANCE" _ection for any ';Jtb_c .] ,evG: ar,_ oil Ch,_¢_

instructions (see P;,g, 3) ! 81 - ! 175 _i

"FULL" AND "ADD" MARKS ON DIPSTICK.

(_) FILL FUEL TANK

with gasoline as specified in the preceding "OIL & FUEL

RECOMMENDATIONS" item 2.

NEVER MIX OIL WITH GASOLINE

Never use "stale" gasoline left over from last season or stored for long

periods.

,_ NEVER FILL FUEL TANK INDOORS, NEVER FILL FUEL TANK WHEN

ENGINE IS RUNNING OR HOT, DO NOTSMOKE WHEN FILLING FUEL

TANK.

_ NEVER FILL FUEL TANK COMPLETELY. FILL TANK TO 1/2" BELOW

BOTrOM OF F LLER NECK TO PROV DE SPACE FOR FUEL EXPAN-

I SION. WIPE ANY FUEL SPILLAGE FROM ENGINE AND EQUIPMENT

l BEFORE STARTING ENGINE.

_ANY LIQUEFIED pETROLEUM (LPG) OR NATURAL GAS FUEL SYS-

TEM MUST BE LEAKPROOF AND MEET ALL APPLICABLE CODES

L AND REGULATIONS.

(_ CHECK THE FOLLOWING:

STOPPING

(_ Moveequipmentcontroloranyignitionstopswitehonengineto

STOP or OFF (see equipment manufacturer's instructions).

_) AFTER ENGINE IS STOPPED:

DISCONNECT SPARK PLUG WIRE FROM SPARK PLUG AND

KEEP IT AWAY FROM SPARK PLUG.

TURN IGNITION SWITCH KEY (IF SO EQUIPPED) TO "OFF" POSI-

TION AND REMOVE KEY FROM SWITCH. THIS WILL REDUCE THE

POSSIBILITY OF UNAUTHORIZED STARTING OF ENGINE WHILE

EQUIPMENT IS NOT IN USE.

NEVER STORE ENGINE WITH FUEL IN TANK INDOORS OR IN

ENCLOSED, POORLY VENTILATED AREAS, WHERE FUEL FUMES

MAY R EACH AN OPEN FLAME, SPA RKOR PILOT LIGHT AS ON A

FURNACE, WATER HEATER, CLOTHES DRYER OR OTHER GAS

APPLIANCE

,_A. BE SURE EQUIPMENT IS IN NEUTRAL GEAR WITH CLUTCHES,

BELTS, CHAINS AND SAFETY SWITCHES DISENGAGED. (FUL-

SHOULD PLACE ANY SAFETY SWITCHES IN SAFE STARTING

l LOW EQUIPMENT MANUFACTURER'S INSTRUCTIONS.) THIS

POSITION.

S. Be sure spark plug wire isattached to spark plug (see Figure 1).

C. SesureanyignitionswitchonengineorequipmentisinON, RUNor-

START position.

STARTING

,_ NEVER RUN ENGINE INDOORS OR IN ENCLOSED, POORLY VENTI-

LATED AREAS ENG NE EXHAUST CONTA NS CARBON MONOX-

IDE, AN ODORLESS AND DEADLY GAS (CARBON MONOXIDE IS

ALSO PRESENT IN ENGINE EXHAUST FROM LIQUID PETROLEUM

(LPG'JAND NATURAL GAS FUEL SYSTEMS).

_k KEEP HANDS, FEET, HAIR AND LOOSE CLOTHING AWAY FROM

ANY MOVING PARTS ON ENGINE AND EQUIPMENT.

,_WARNING: TEMPERATURE OF MUFFLER AND NEARBY AREAS

MAY EXCEED 150°F (65aC). AVOID THESE AREAS.

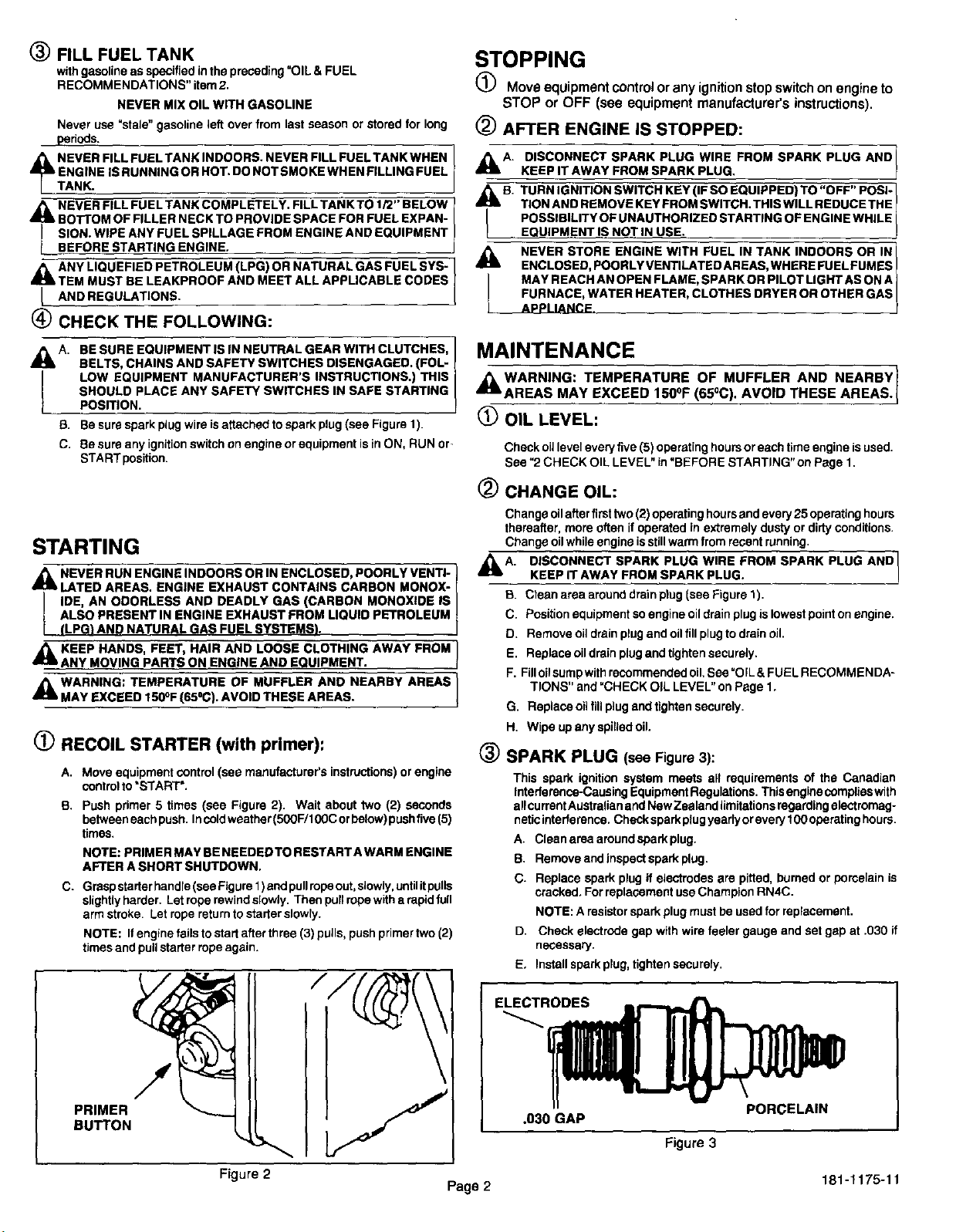

(_ RECOIL STARTER (with primer):

A.

Move equipment control (see manufacturer's instructions) or engine

controlto "START'.

B.

Push primer 5 times (see Figure 2). Wait about two (2) seconds

between each push. Incold weather (500F/100C or below) push five (5)

times.

NOTE: PRIMER MAY BE NEEDEDTO RESTARTA WARM ENGINE

AFTER A SHORT SHUTDOWN.

C.

Grasp starter handre(see Figure 1)and pullrope out,slowly, untilitpulls

slightly harder. Let rope rewind slowly. Then pull rope with a rapid full

arm stroke. Let rope return to starter slowry.

NOTE: If engine fails to start after three (3) pulis, push primer two (2)

times and pull starter rope again.

MAINTENANCE

,_WARNING: TEMPERATURE OF MUFFLER AND NEARBY_

AREAS MAY EXCEED 150°F (65°C). AVOID THESE AREAS._

OIL LEVEL:

Check oiJlevel every five (5) operating hours or each time engine is used.

See "2 CHECK OIL LEVEL" in "BEFORE STARTING" on Page 1.

_) CHANGE OIL:

Change oil after firsttwo (2) operating hours and every 25 operating hours

thereafter, more often if operated in extremely dusty or dirty conditions.

Change oilwhile engine isstill warm from recent running,

,_A. DISCONNECT SPARK PLUG WIRE FROM SPARK PLUG AND[

KEEP iT AWAY FROM SPARK PLUG.

B. Ctean area around drain ptug (see Figure 1).

C. Position equipment so engine oildrain plug is lowest point on engine.

D. Remove oil drain plug and oilfill plug to drain oil.

E. Replace oil drain plug and tighten securely.

F. Filloilsump with recommended oil. See "OIL & FUEL RECOMMENDA-

TIONS" and "CHECK OIL LEVEL" on Page 1.

G. Replace oil fill plug and tighten securely.

H. Wipe up any spilled oil.

(_) SPARK PLUG (see Figure 3):

This spark ignition system meets all requirements of the Canadian

Interference-Causing Equipment Regulations. Thisengine complies with

allcurrantAustralian andNew Zealand limitations regarding electromag-

netic interference. Check spark plugyearly or every 100 operating hours.

A. Clean area around spark plug.

B. Remove and inspect spark plug.

C. Replace spark plug if electrodes are pitted, burned or pomelain is

cracked. For replacement use Champion RN4C.

NOTE: A resistor spark plug must be used for replacement.

D. Check electrode gap with wire feeler gauge and set gap at .030 if

necessary.

E, Install spark plug, tighten securely,

_J

PRIMER

BUTTON

Figure 3

Figure 2 181-1175-11

Page 2

MAINTENANCE (Continued)

@ AIR CLEANER:

IMPORTANT: NEVER RUN ENGINE WITHOUT COMPLETE AIR

A. TO REMOVE AND INSTALL FILTER(S) (see Figure 6):

1. Remove wing nut and cover. Remove paper element.

2. Remove and inspect foam filter(if so equipped) for discolorationor

dirt accumulation. If either is present, service per following "TO

SERVICE FILTER(S)" instructions.

3. Clean inside of base and cover thoroughly.

4. Replacefoamfilter(ifsoequipped),makingsurethescreenside

istowards the paper element. Then tighten wing nut securely,

B.

TO SERVICE FILTER(S) (see Figure 6):

1. FOAM FILTER:

2, PAPER FILTER:

C.

ANTHCING RAFFLE

Some engines may be equipped with an anti-icing air cleaner feature

to enable the engine to runat temperatures below 32OF(0°C), without

ice forming in the carburetor.

Ifso equipped, the air cleaner base will have an opening which draws

warm air from the muffler into the air cleaner housing. To work

effectively, it is necessary to block cold air from entering the air

cleaner.

IN TEMPERATURES 32°F (0°C) AND BELOW: (See figure 6)

1. Remove wing nut from air cleaner cover.

2. Remove aircleaner cover from base.

3. Remove red baffle from inside of air cleaner cover,

4. insert red baffle in "winter" position shown.

5. Reinstall air cleaner cover onto base.

6 Reinstall wing nut;tighten securely.

IN TEMPERATURES ABOVE 32OF(0oC):

Fellow above directions, removing baffle from "winter" position and

reinstalling in "summer" position.

CLEANER INSTALLED ON ENGINE.

Clean and re-oil every three (3) months or every 25 operating

hours. Clean and re-oildaily ifused inextremelydustyconditions.

a. Wash in water and detergent solution and squeeze (don't

twist) untilalldirt is removed.

b. Rinse thoroughly in clear water.

c. Wrap ina cleanclothand squeeze (don'ttwist)untilccmpletely

dry.

d. Saturatewithengineoilandsqueeze(don'ttwist)todistribute

oil and remove excess oil

Replace once a year or every 1O0ope rating hours, more offen if

used in extremely dusty conditions.

Replacement filters are available at any Authorized Tecumseh

Service Outlet.

MAINTENANCE (Continued)

BASE

PAPER ELEMENT

/ FOAM FILTER (IF SO EQUIPPED)

•_'<'i>\ W,NGNUT

I

RED BAFFLE SHOWN IN

"WINTER" POSITION

COVER

-- RED BAFFLE "SUMMER" POSITION

" " 0 I

ANTI-ICING FEATURE

Figure 4

(_ COOLING SYSTEM: (see Figure 1and 5):

IMPORTANT: Frequently remove grass clippings, dirt and debris from

coolingfins, air intake screen and levers and linkage. This willhelp ensure

adequate cooling andcorrect engine speed.

COOLING FINS

LEVERS AND

RECOIL

LINKAGE COVER

NOTE: RECOIL COVER CUTAWAY TO SHOWCOOLING FINS

Figure 5

OLd) CHECK ENGINE AND EQUIPMENT OFTEN FOR LOOSE

_IL NUTS, BOLTS AND ATTACHMENTS, AND KEEP THESE

ITEMS TIGHTENED.

L

Page 3 181-1175-11

Loading...

Loading...