Craftsman 13953678SRT Owner’s Manual

Owner's

Manual

Model No.

139.53678SRT

For Residential Use

Only

CRRFTSHRN®

GARAGE DOOR OPENER

Caution:

Read and foPow a,,

safety rules and

operating Instructions

before first use of this

product.

Fasten the manual

near the garage door

after installation.

1/2 HP

• Safety Precautions

• Assembly

• Installation

• Adjustment

• Care and Maintenance

• Operation

• Troubleshooting

• "Parts List

regulalonseffective

CO_ withUL 325 (_

Jar_ary 1, lSe3

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

Content= Page

A review of safety alert symbols................................ .2

You'll need tools.......................................................... 3

Salety informmJonregarding garage door

locks and ropes ......................................................... 3

Tes_ng your garage door for s_cking,

bindingand balance.................................................. 3

Illustralicnof sec'donaldoor instahlJon ..................... 4

IllustralJonof one-piece door installation....................5

Carton inventory.......................................................... 6

Hardware inventory..................................................... 7

Assernbly ssntion - pages 8 -11

Assemble T-rail ......................................................... 8

Attach cable pulley bracket....................................... 8

Installtrolley ......................................................... ,...9

Fasten T-rail to opener ............................................. 9

Installchain/cabla .................................................. "10

Attach sprocket cover ............................................. 10

T_'den the chain and cable ................................... 11

Installation section - pages 11 - 27

Installationsafety i_s ................................. 11

Determine header bracket location

Sectional door ...................................................... 12

One-piece door .................................................... 13

Installthe header bracket ....................................... 14

Attach the T-rail to header bracket ......................... 15

Positionthe opener ................................................. 16

Hang the opener ..................................................... 17

Installthe door control............................................ 18

Contents Page

Installthe lightsand lenses...................................... 19

Attach emergency relaasa rope and handle ........... 19

Electrical requirements............................................. 20

Safety reversing sensor information ....................... .21

Installthe safety reversingsensor.....................22, 23

Fasten door bracket (sectionaldoor) .......................24

Fasten door bracket (one-piece door) ..................... 25

Connect door arm totrolley (sectionaldoor) ..........26

Connect door arm to trolley (one-piece door).........27

Adjustment section - pages 28 - 30

Travel limitadjustments ........................................... 28

Force adjustments.................................................... 29

Test the safety reversingsensor.............................. 30

Test the safety reverse system ............................... 30

Operation safety insVuctJons..................................... 31

Care of youropener ................................................... 31

Maintenance schedule ............................................... 31

Operation ofyour opener ........................................... 32

and remote conlrol programming............... 33

Having a problem?............................................... 34, 35

Repair parts, railassembly......................................... 36

Repair parts, installation............................................. 36

Repayparts,openerassarrt ..................................37

_ .° ..=o .i ..oo.o ..o= H.°n=o.o=o *H. _*.=°, .ooo=o n..*.=.*°=. *°.= .._8

Index........................................................................... 39

How to order repair parts ........................................... 40

Maintenance agreement ........................................... 40

Warranty ..................................................................... 40

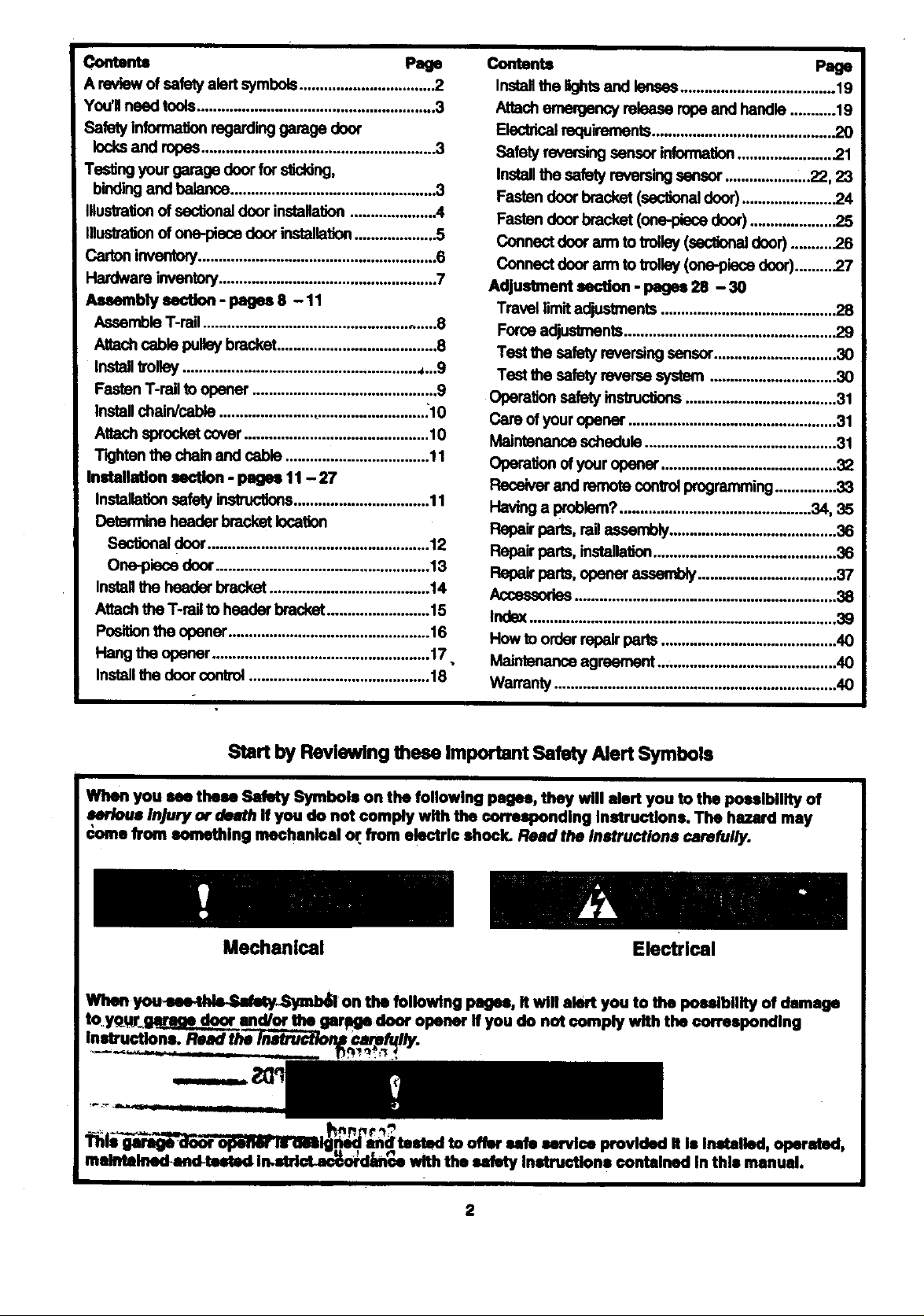

Start by Reviewing these Important Safety Alert Symbols

When you m these Safety Symbols on the following pages, they will alert you to the possibility of

awrloue Injury or death if you do not comply with the corresponding instructions. The hazard may

&=me from something mechanical oT.from electric shock. Read the Instructions carefully.

Mechanical

When you_thk_/_n:_ on the following pages, It will alert you to the possibility of damage

Instructions.

..... h, r_.

This

malMll_tsstod i_kn_e with the safety Inntruotlons contained In this manual.

you do not comply with the corresponding

2

Electrical

You'll Need Tools

During assembly, installation and adjustment of the opener, instructionswillcall for hand tools shown below.

Tape Measure

(_ Wire Cutters

Drill

Stepladder

3/16",

5/32' Drill Bits

An unbalanced garage door might not reverse

when required and someone under the door

could be seriously Injured or killed.

If your garage door binds, sticks or is out of

balance, call for professional garage door

sorvice. Garage doors, door springs, cables,

pulleys, brackets and their hardware are under

extreme tension and can cause serious injury

or death. Do not by to loosen, move or adjust

them youreelfl

Ropes left on a garage door could cause

someone to become entangled and killed.

Remove all ropes connected to the door before

installing and operstlng the opener.

Identify the type and height of your door and any

special conditions that exist and any additional

materials that may be required by referring to the lists

on page 4 or page 5.

HackSaw

5/16" _nd _ _..._ Claw Hammer

Screwdriver

AdjustableEndWrench

To avoid damage to the garage door and

opener, disable locks before installing and

operating the opener. Use a wood screw or nail

to hold locks in the "open" (unlocked)

position.

Operation at other than 120V 60 Hz will cause

opener malfunction and damage.

Before you begin, complete the following teat to

make sure your door is balanced, and is not

sticking or binding:

• Lift the door about halfway as shown. Release the

door. Itshould stay in place, supported entirely by

its springs.

• Raise and lower the door to see ifthere is any

bindingor sucking.

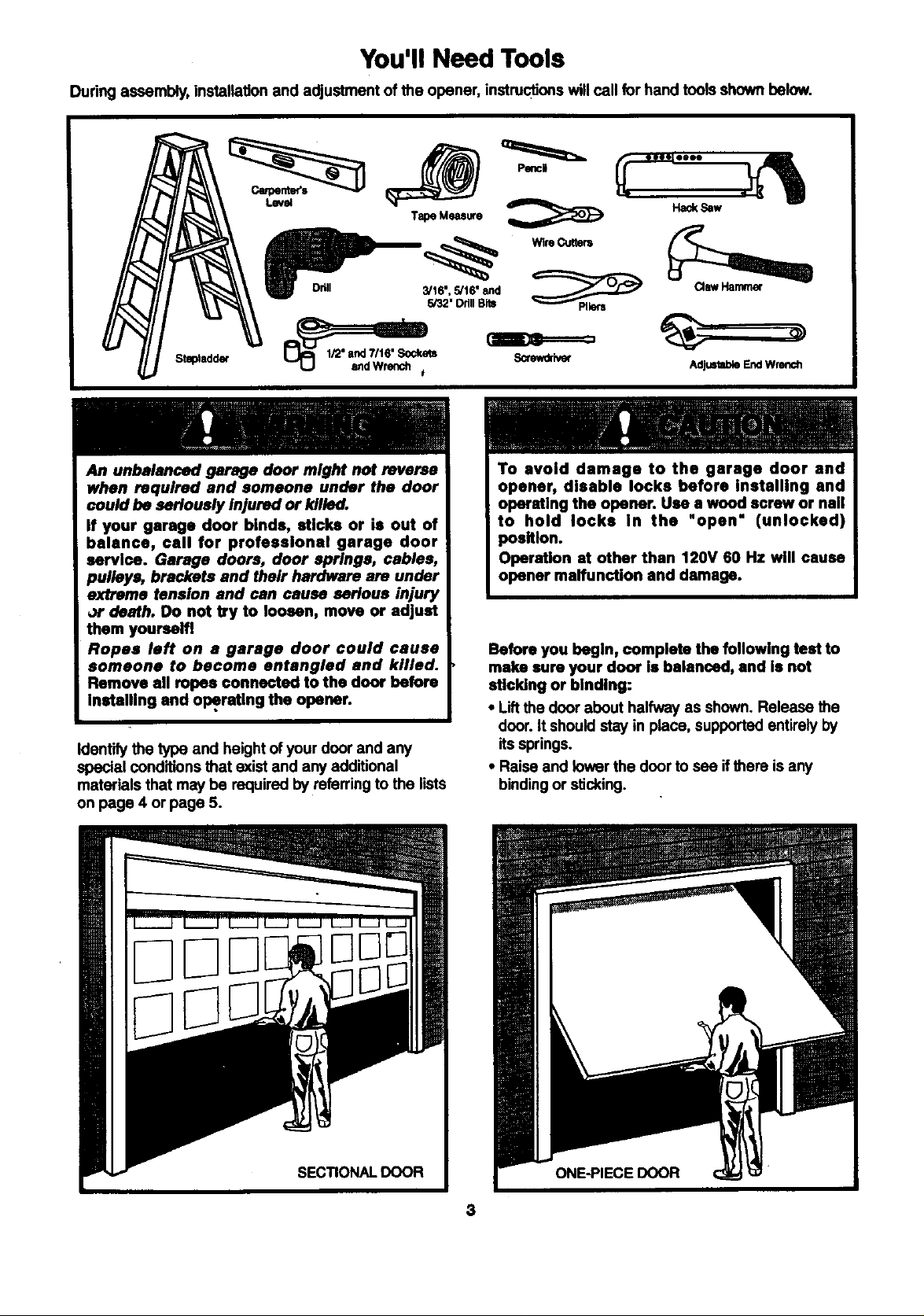

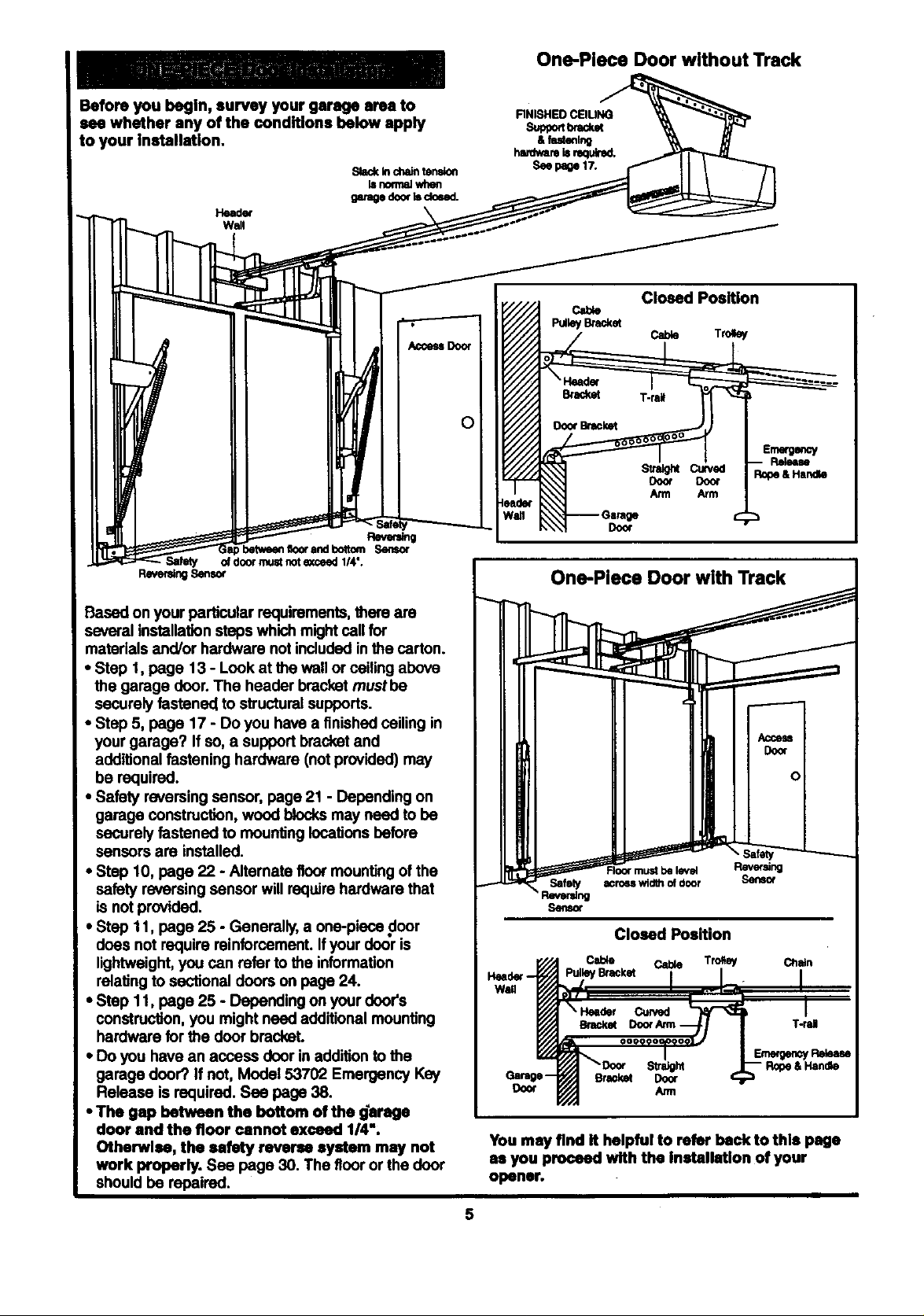

Before you begin, survey your garage urea to

see whether any of the conditions below apply

to your Installation.

0

Based on your particular requirements, there are

several installation steps which might call for

materials and/or he.ware not includedin the carton.

• Step 1, page 12 - Look at the wall orceiling above

the garage door. The header bracket mustbe

securely fastened to structural supports.

t Step 5, page 17 - Do you have a finished ceiling in

your garage? If so, a support bracket and

additional fastening hardware may be required.

• Safety reversing sensor, page 21 - Depending

upon garage construction, wood blocks may need

to be fastened to mounting locations before

sensors are installed.

• Stop 10, page 22 - Alternate floor mounting, of the

sefaty reversing sensor will require hardware not

provided.

• Step 11, page 24 - Do you have a steel, aluminum,

fiberglass or glass panel door? If so, horizontal

and vertical reinforcement is required.

• Lcok ai the garage door where it meets the floor.

It must clom on tbe floor all the way acroea.

OtluMm4se,the _ _ eystem nHy n,_t

work propedy. See page 30. Floor or dpor should

be repaired.

DoorBracket

Ann

• The opener can be installed within 2 feet to the left

or rigM of the door center if there is a torsion spring

or center beadng plate in the way of the header

bracket or door bracket area. ff your door has

extension springs, the opener must be installed

in the center of the dooa:.Sea pages 12 and 24.

• Do you have an access door In addition to the

garage door? If not, Model 53702 E_ncy

Key Release is required. See page 38.

• If your door Is more than 7 feet high, see the rail

e_enslon kits listed on page 38.

You may find it helpful to retbr back to thfa page H you proceed with the thstallation of your opeear.

I

4

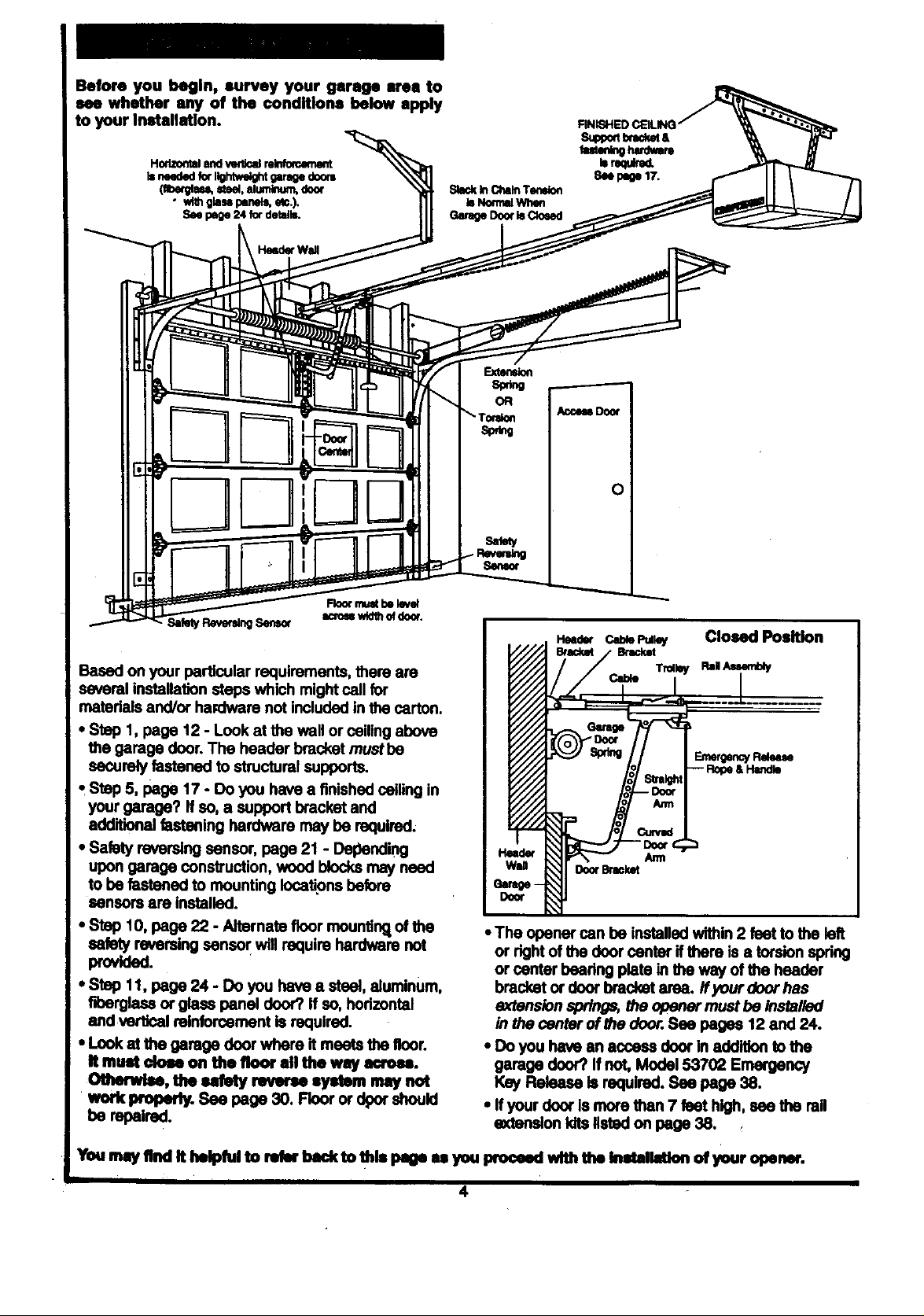

Before you begin, survey your garage area to

see whether any of the conditions below apply

to your inetallation.

Slack k_chaintension

_ nom_ when

garagedoorIs closed.

Walt

One-Place Door without Track

AccessDoor

Salely ofdoormustnote_Jed 1/4".

betweenfloorandboltom Sensor

Pawer_ngSensor

Rever_

Based on your particular requirements,there are

several installation steps which might cell for

materials and/or hardware not included in the carton.

• Step 1, page 13 - Look at the wall or ceiling above

the garage door. The header bracket must be

securely fastened to structuralsupports.

• Step 5, page 17 - Do you have a finished ceiling in

your garage? If so, a support bracket and

additional fastening hardware (not provided) may

be required.

• Safety reversing sensor, page 21 - Depending on

garage construction, wood blocksmay need to be

securely fastened to mounting locations before

sensors are installed.

• Step 10, page 22 - Alternate floor mounting of the

safety reversing sensor will require hardware that

is not provided.

• Step 11, page 25 - Generally, a one-piece door

does not require reinforcement. Ifyour door is

lightweight, you can refer to the information

relating to sectional doors on page 24.

• Step 11, page 25 - Depending on your door's

construction, you might need additional mounting

hardware for the door bracket.

• Do you have an access door inaddition to the

garage door? If not, Model 53702 Emergency Key

Release is required. See page 38.

• The gap between the bottom of the _arage

door and the floor cannot exceed 1/4",

Otherwlea, the safety reverse system may not

work properly. Sea page 30. The floor or the door

should be repaired.

Cable

P_W/Bmck_

Closed Position

Cable Trolley

O

Emergency

Door Doo¢

Arm Arm

Door

Rope&Handle

One-Piece Door with Track

Floor must be level Revef_ng

Safety

Reverldng

acroe,s widthof door Sef_ot

Closed Position

Cable Cable Tromey Chain

i Bracket

Garage- Br_ket Door

Door Arm

S_ht

You may find it helpful to refer back to this page

as you proceed with the Installation of your

opener.

ifmy

I:lek_u

5

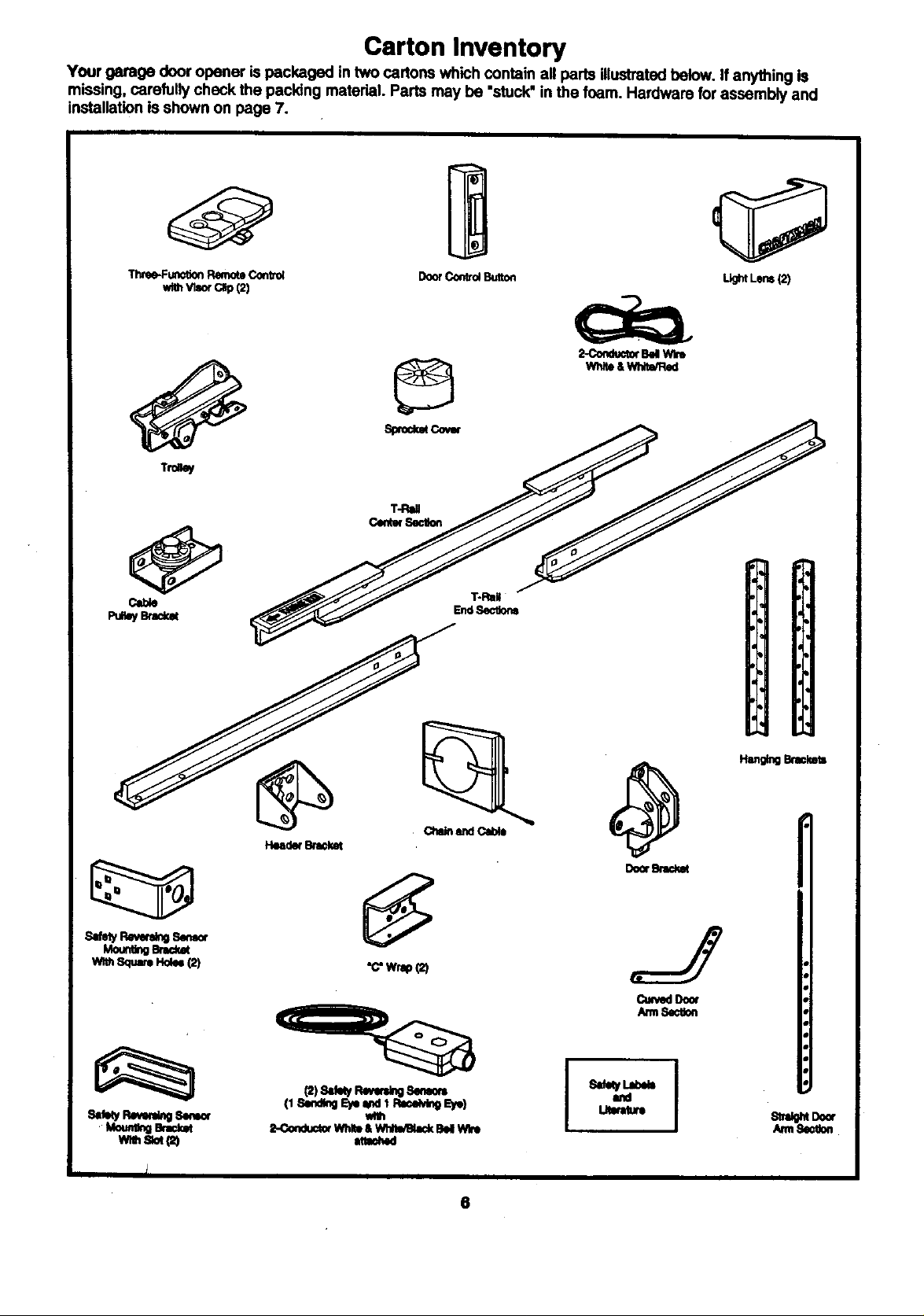

Carton Inventory

Your garage door opener is packaged in two cartons which contain all parts illustrated below. If anything is

missing, carefully check the packing material. Parts may be "stuck"in the foam. Hardware for assembly and

installation is shown on page 7.

Three-Fu_tionRemoteConvo_

v_thVt_ C_ (2)

DoorConed Button _ Lens(2)

s,_y Rev_ S.n_

Mo_nOem,:_

w_ Sq.m HO_ (2)

Sal_yR_,_CngS,m_

MounUnOerac_

YalhSlot_)

,, I

•c"wrap(2)

_) sd_y RGv_ Ser_om

wire

L_Corr_ WI_ & W','Vil,'l_a:k8M WI_

6

Fhu_g _

Cu*'ve¢lDoor

Am1S*,_Uon

ArmS_

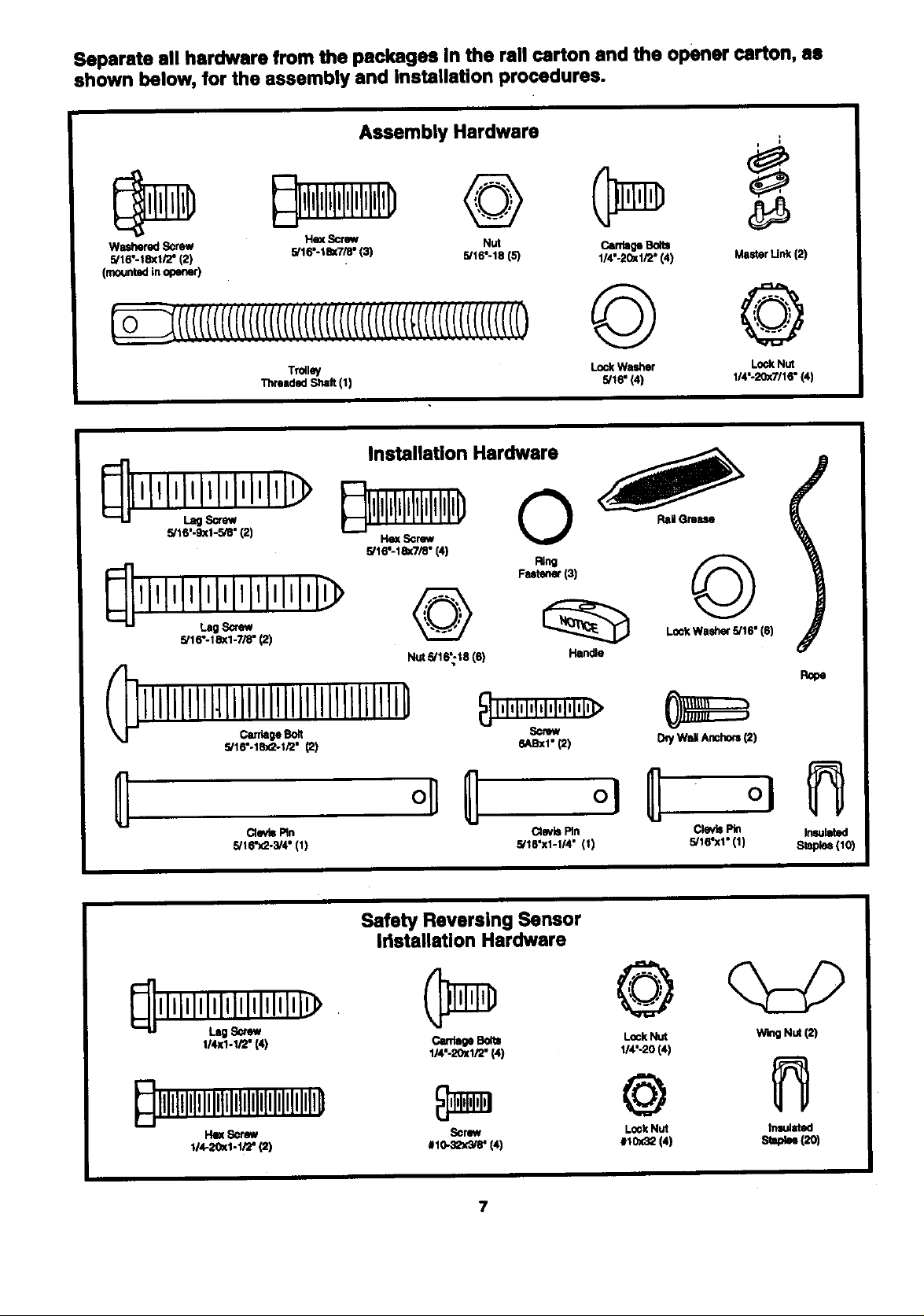

Separate all hardware from the packages in the rail carton and the opener carton, as

shown below, for the assembly and installation procedures.

Assembly Hardware

Washerecl Screw He_( Screw Nut Carriage Bolts

5/f 6"-f 8xf/2" (2) 5/16"-%_7/8" (3) 5/16:18 (5) 1/4"-2C_1/2" (4) Master Unk (2}

(mounted in opener)

@

Trdlley Lock Washer Lock Nut

11_oadsd Shaft (1) 5/18" (4) 1/4'-20x9'/16" {41

Installation Hardware

_llllllll,;,lllll,lllll,_

Lag ,Screw

Stl 6"-I 83(I -7/8" (2)

5/16".18x2-t,'2" (2)

ClevisPin

5/16"x2.3/4"(I)

_HGmase

Fa_u_ (3)

©

Handle Lock Washer S/16" 16)

_oe

6ABXl" (2) D_yWag Anchors (2)

Pin Clevis Pin /nsukKed

5/18'X1-1/4" (t) 5/16"x1" (1) _taple_ (10)

Safety Reversing Sensor

Iflstallatlon Hardware

1/4x1-1/2" (4)

_,llllllllllllllllllllllllllllll[llllll]

114-20x1-1/2" _1

Cardage Bolts Lock Nut Wing Nut (2)

1/4"-20x1/2" (4) 114"-20 (4)

@

#I0-32x3/8' (4) #I0X32 (4) Slapkm 120)

7

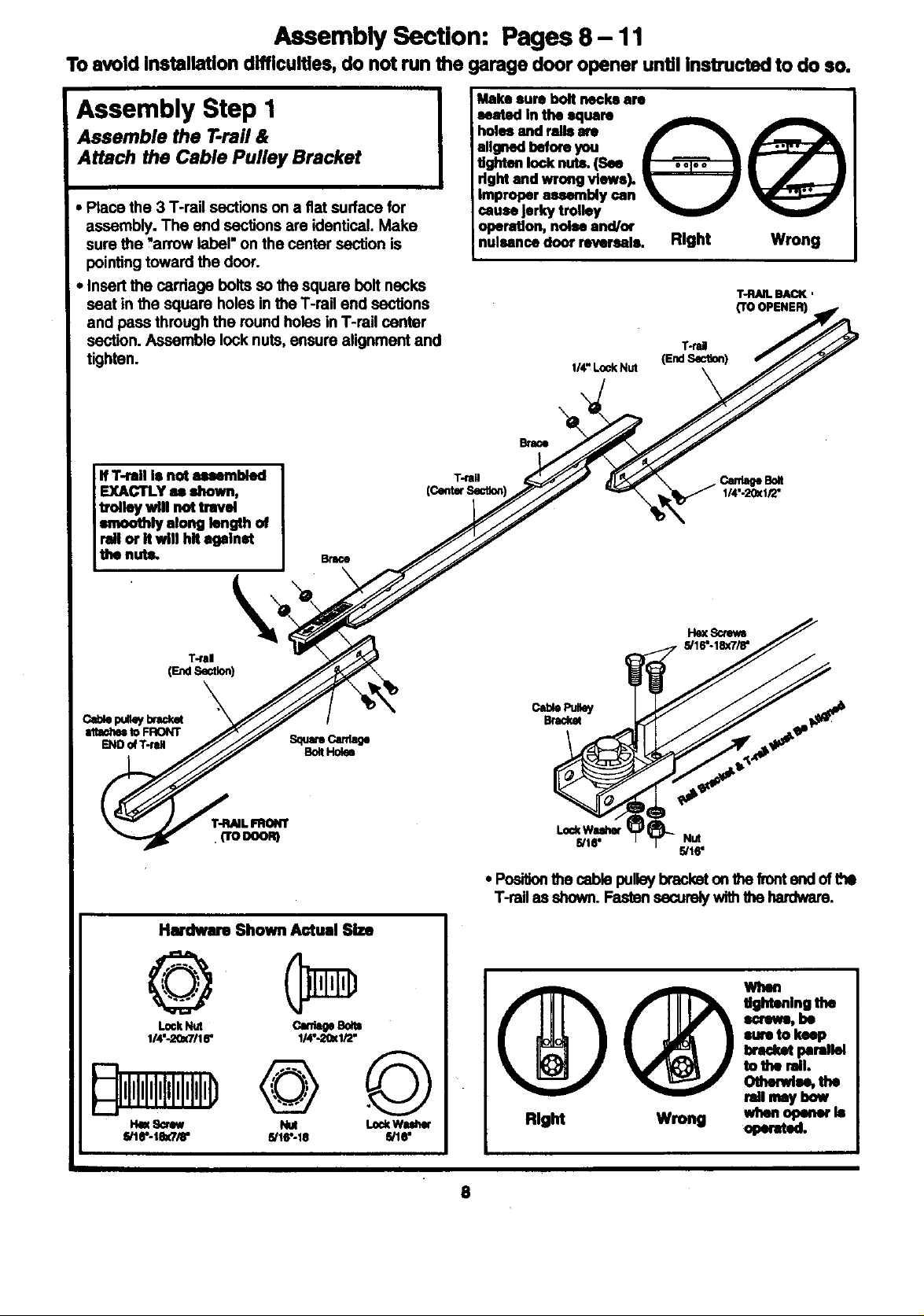

Assembly Section: Pages 8 - 11

To avoid Installation difficulties, do not run the garage door opener until insb,uctad to do so.

Assembly Step I

Assemble the T-rail &

Attach the Cable Pulley Bracket

Place the 3 T-rail sections on a fiat surface for

assembly. The end sections are identical. Make

sure the "arrow label" on the center section is

pointingtoward the door.

,Insert the cardage bolts so the square bolt necks

seat inthe square holes in the T-rail end sections

and pass through the round holes in T-rail center

section. Assemble locknuts, ensure alignment and

tighten.

EXACTLY as shown,

trolley will not travel

smoothly along length of

I IfT-rail Is not assembled I

rail or Itwill hltagainst

the nuts.

Brace

Make sure bolt necks are

seated in the sqcam

wignedbeforeyou f _k

Ughtantooknuts.(See

right and wrong views).

holes and ralla are _

Improper aesembiy can _t_ _'

cause Jerkytrolley

operation, noise8ncl/(x

nuisance door reversals. Right Wrong

T-RAIL BACK,

(TO OPENER)

T-rd

1/4"LockNut

(End Section)

Canlege Bolt

1/4".20_1/2"

Hudwm Shown Actual Size

©

L_ckN_I

114"-2_lallr

lqqq@lqllll)

ll4t-L_Klr2"

Itex Scmws

5/16"-18X7/8"

Nut

5/16"

* Positionthe cable pulleybracketon the fronterKIof thO

T-rail ss shown. Fasten sscuroly withthe hardware.

tighteningthe

imrewo,be

eureto keep

bracket parallel

tothe roll.

Othendes, the

rail may bow

fd16"-18 E_I8"

I

8

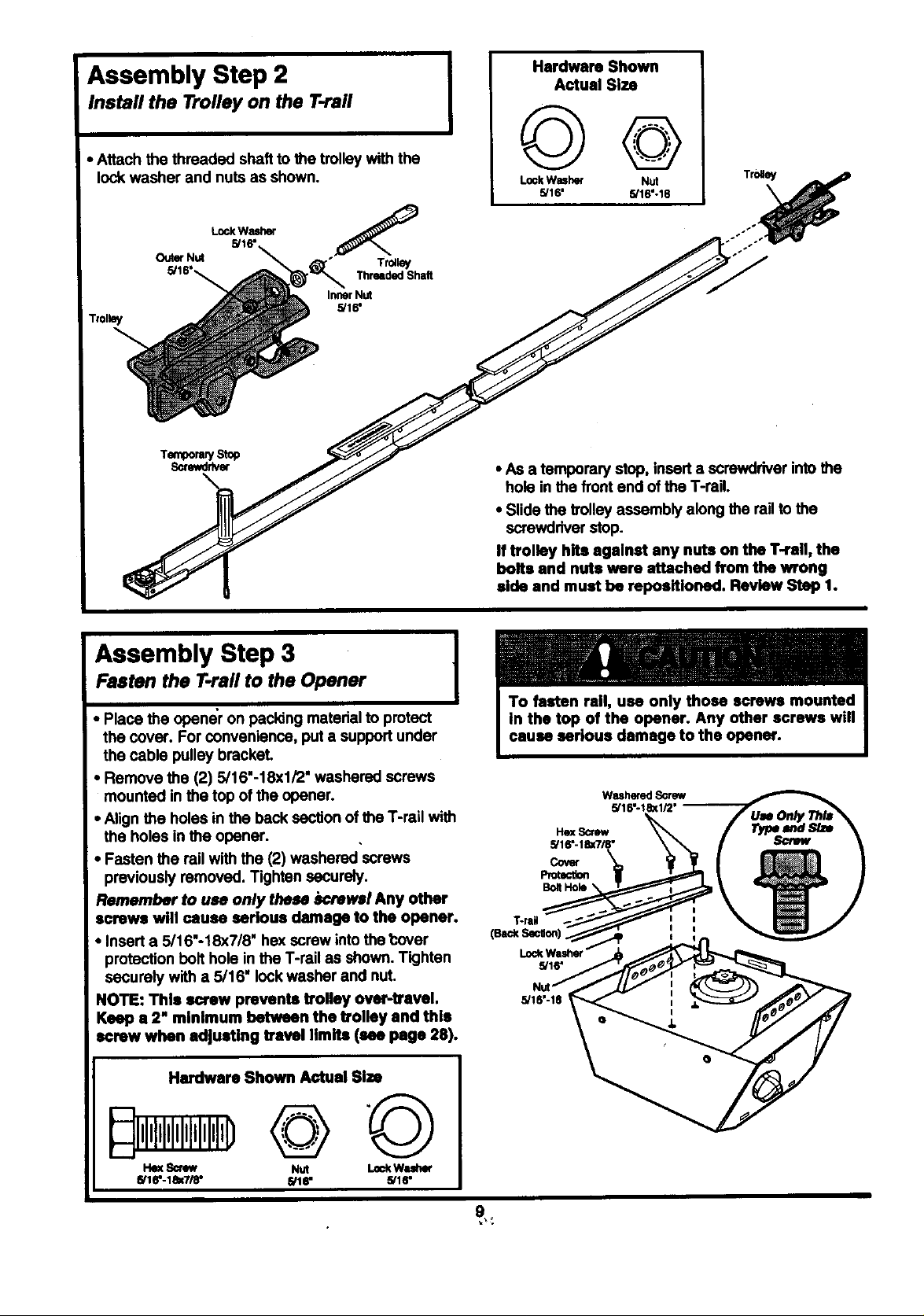

Assembly Step 2

Install the Trolley on the T-raft

• Attach the threaded shaft to the trolley with the

lock washer and nuts as shown,

LockWasher

OuterNut

Trolley

5/16"

ThreadedShalt

InnerNut

5/16"

Trolley

Hardware Shown

Actual Size

I

LookWasher Nut

5/16' 5/16--18

• As a temporary stop, insert a screwdriver into the

hole in the front end of the T-reil,

• Slide the trolley assembly along the rail to the

screwdriver stop.

If trolley hits against any nuts on the T-rail, the

bolts and nuts were attached from the wrong

side and must be repoeitioned. Review Step 1.

Assembly Step 3 1

Fasten the T.rail to the Opener

• Place the opener on packing material to protect

the cover. For convenience, put a support under

the cable pulley bracket.

• Remove the (2) 5/16"-18xl/2" washered screws

mounted in the top of the opener.

• Align the holes in the back section of the T-rail with

the holes in the opener.

• Fasten the rail with the (2) washered screws

previously removed. Tighten securely.

Remember to use only these screwsl Any other

screws will cause serious damage to the opener.

• Insert a 5/16"o18X7/8' he)(screw into the t:over

protection bolt hole in the T-rail as shown. Tighten

securely with a 5/16" lock washer and nuL

NOTE: This screw prevents trolley over-travel.

Keep a 2" minimum between the trolley and this

screw when adjusting travel limits (see page 28).

Hardware Shown Actual Size

I

WasheredScrew

5/16--180(1/2'

Cover

Protection

I'kmSorew Nut LockWuher

5/16--18X7/6- 5/18" 5/1r

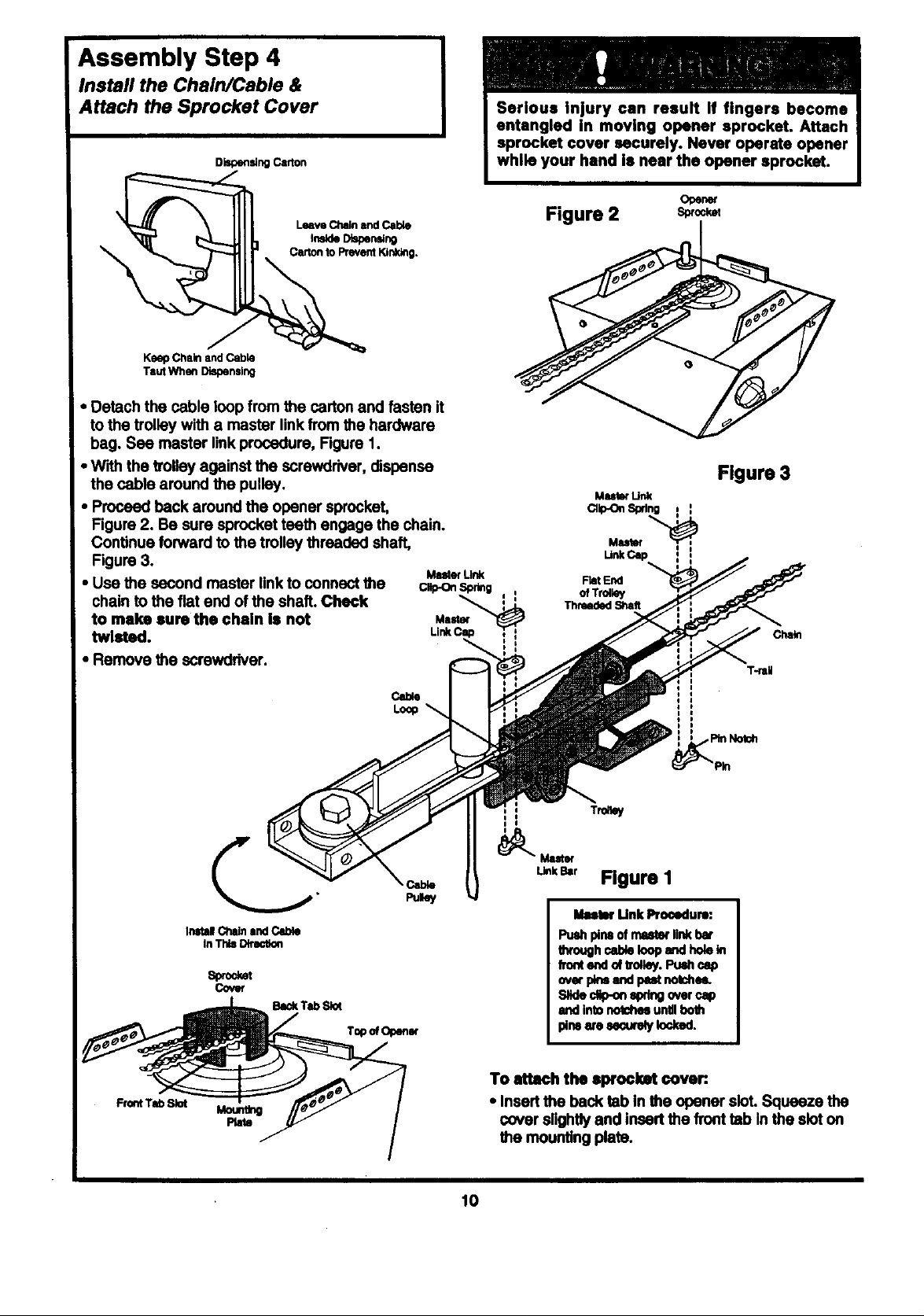

Assembly Step 4

Install the Chain/Cable &

Attach the Sprocket Cover

DispensingCarton

LeaveChainand _

tnsldeDiapering

Ce;lon to PreventKJnl_g.

KeepChain andCable

TautWhen Dispensing

• Detach the cable loop from the carton and fasten it

to the trolley with a master linkfrom the hardware

bag. Sea master link procedure, Figure 1.

• W'_h the volley against the screwdriver, dispense

the cable around the pulley.

• Proceed back around the opener sprocket,

Figure 2. Be sure sprocket teath engage the chain.

Continue forward to the trolley threaded shaft,

Figure 3.

• Use the second master link to connect the

chain to the fiat end of the shaft. Chock

to maim suro the chain Is not

twlatod.

• Remove the screwdriver.

sprocket cover securely. Never operate opener

Opener

Figure 2 s_o_

Figure 3

Muler Unk

Master

UnkCap

FlatEnd

Master

Chain

Inltal Chlln Ind Cable

In This Dltlmtion

s_et

cover

Moundng

Plato

Ikmtw Unk Pro(_lum:

Puedlplrm of mlwto( link bot

lhroughcableloopandholekt

frontendoftrolley.Pu_ c_o

ovorpN andpestnotoheL

Slideclip-onq)dng overcap

andintonotchesuntilboth

pl_ wo _MJ_:uro_jIodcod.

To attach tho 8prockat cover:.

• Insert the back tab In the opener sloL Squeeze the

cover slightlyand insert the front tab In the slot co

the mounting plate.

10

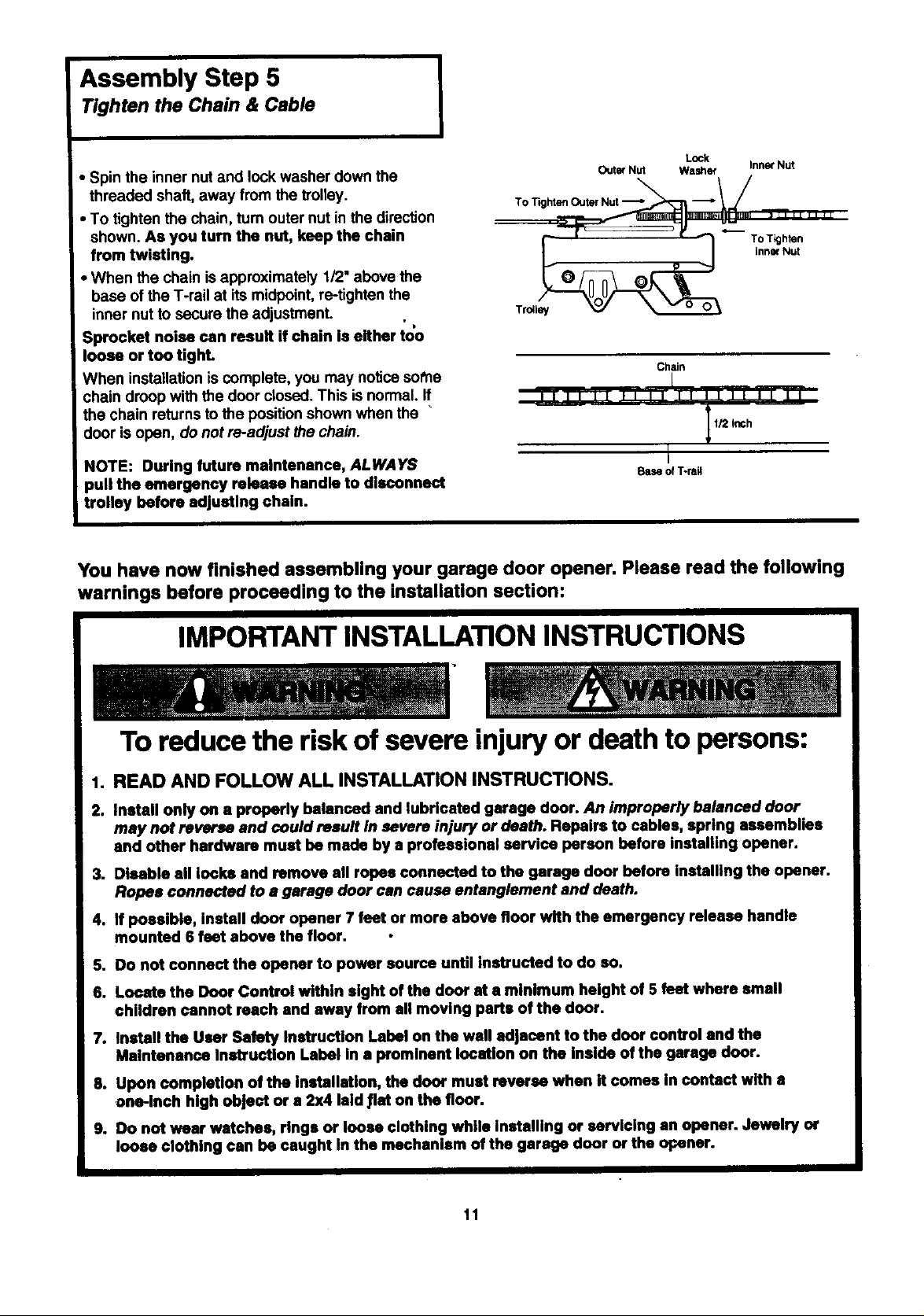

Assembly Step 5

Tighten the Chain & Cable

I

• Spin the inner nutand lock washer down the

threaded shaft, away from the trolley.

• To tighten the chain, turn outer nut in the direction

shown. As you turn the nut, keep the chain

from twisting.

• When the chain is approximately 1/2" above the

base of the T-rail at its midpoint, re-tighten the

inner nut to secure the adjustment.

Sprocket noise can result if chain is either too

loose or too tighL

When installationis complete, you may notice sot'he

chain droop with the door closed. This is normal. If

the chain returns to the position shown when the "

door is open, do not re-adjust the chain.

NOTE: During future maintenance, ALWAYS

pull the emergency release handle to disconnect

i trolley before adjusting chain.

You have now finished assembling your garage door opener. Please read the following

warnings before proceeding to the installation section:

• D

To Tighten Outer Nut "_"

Tr_ley

fill II II li II II II II il

Outer Nut

Base of T-rsA

Lock

Washer InnerNut

Chain

I

1/2Inch

L

To Tighten

inner Nut

IMPORTANT INSTALLATION INSTRUCTIONS

To reduce the risk of severe injury or death to persons:

1. READ AND FOLLOW ALL INSTALLATION INSTRUCTIONS.

2. Install only on a properly balanced and lubricated garage door. An improperly balanced door

may not reverse and could result In severe injury or death. Repairs to cables, spring assemblies

and other hardware must be made by a professional service parson before installing opener.

3. Disable all looks and remove all ropes connected to the garage door before installing the opener.

Ropes connected to a garage door can cause entanglement and death.

4. If possible, install door opener 7 feet or more above floor with the emergency release handle

mounted 6 feet above the floor.

5. Do not connect the opener to power source until Instructed to do so.

6. Locate the Door Control within sight of the door st a minimum height of 5 feet where small

children cannot reach and away from all moving parts of the door.

7. Install the User Safety Instruction Label on the wall adjacent to the door control and the

Maintenance Instruction Label in a prominent location on the Inside of the garage door.

8. Upon completion of the Installation, the door must reverse when it comes In contact with a

one-inch high object or a 2x4 laid 11ston the floor.

9. Do not wear watches, rings or loose clothing while installing or servicing an opener. Jewelry or

loose clothing can be caught in the mechanism of the garage door or the opener.

11

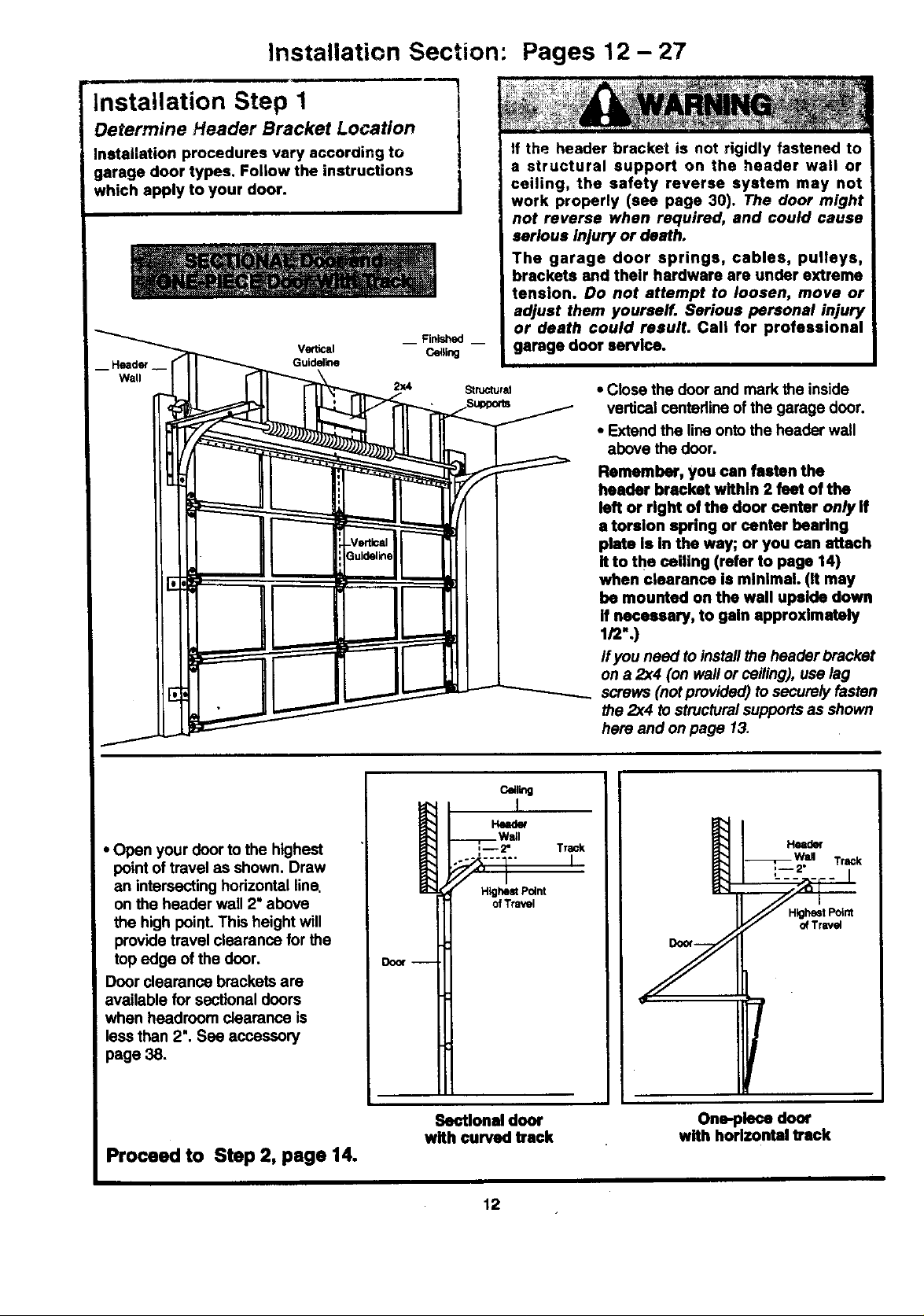

Installation Section: Pages 12- 27

Installation Step 1

Determine Header Bracket Location

Installation procedures vary according to

garage door types. Follow the instructions

which apply to your door.

Vertical Ce_ling

Guidal_e

__ Finished __

2x4

l

1

l

StruotursJ

tf the header bracket is not rigidly fastened to

a structural support on the header wall or

ceiling, the safety reverse system may not

work properly (see page 30). The door might

not reverse when required, and could cause

serious injury or death.

The garage door springs, cables, pulleys,

brackets and their hardware are under extreme

tension. Do not attempt to loosen, move or

adjust them yourself. Serious personal injury

or death could result. Call for professional

garage door service.

• Close the door and mark the inside

vertical centedine of the garage door.

• Extend the line onto the header wall

above the door.

Remember, you can fasten the

header bracket within 2 feet of the

left or right of the door center onlylf

a torsion spring or center hearing

plate Is In the way; or you can attach

It to the ceiling (refer to page 14)

when clearance is minimal. (it may

be mounted on the wall upside down

If necessary, to gain approximately

1/2".)

Ifyou need to install the header bracket

on a 2x4 (on wall or ceiling), use lag

screws (not provided) to secure_/ fasten

the 2x4 to structuralsupports as shown

here and on page 13.

• Open your door to the highest

point of travel as shown. Draw

an intersecting horizontal line,

on the header wall 2" above

the high point. This height will

provide travel clearance for the

top edge of the door.

Door clearance brackets are

available for sectional doors

when headroom clearance is

less than 2". Sea accessory

page 38.

Proceed to Step 2, page 14.

Door --

Sectional door

with curved track

c_l_g

HNder

Wall

-- 2" Track

F1 '

Hig_ Point

ofTravel

12

Head<)(

HighestPotrd

of Travel

One-piece door

with horizontal track

Track

Loading...

Loading...