Page 1

Owner's

Manual

Model No.

139.53661SRT1

139.53671SRT1

139.53672SRT1

139.53673SRT1

139.53674SRT

139.53677SRT1

For Residential Use

Only

/

CRAFTSMRN®

GARAGE DOOR OPENER

Caution:

Read and follow all

safety rules and

operating instructions

before first use of this

product.

Fasten the manual

near the garage door

after installation.

Complies wib_UL 325

regulations effective

January 1, 199:3

• Safety Precautions

• Assembly

• Installation

• Adjustment

• Care and Maintenance

• Operation

• Troubleshooting

• Parts List

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

Page 2

Contents Page

A review of safety alert symbols ................................. 2

You'll need tools.......................................................... 3

Safety informationregarding garage door locks

and ropes .................................................................. 3

Testing your garage door for sticking,binding

and balance............................................................... 3

Illustretionof sectionaldoor installaUon.....................4

Illustration of one-piece door installation...................5

Carton inventory.......................................................... 6

Hardware inventory.:................................................... 7

Assembly section - pages 8 - 11

Assemble T-rail ......................................................... 8

Attach cable pulleybracket....................................... 8

Instail trolley...?......................................................... 9

Fasten T-reJltoopener ............................................. g

Install chin/cable ................................................... 10

Attach sprocketcover ............................................. 10

Tighten b_echain and cable ................................... 11

Installation section - pages 11 - 27

Installationsafety inetmctions................................. 11

Determine header bracket location

Sectional door....................................................... 12

One-piece door..................................................... 13

Installthe header bracket ....................................... 14

Attach the T-raJ1toheader bracket ......................... 15

Positionthe opener................................................. 16

Hang the opener..................................................... 17

Installthe doorcontrol............................................ 18

Contents Page

Install the lightand lens................................................. 19

Attach emergency release rope and handle ................. 19

Electrical requirememts................................................. 20

Safety reversing sensor information.............................. 21

Installthe safety reversing sensor........................... 22, 23

Fasten door bracket (sectional door) ............................ 24

F:asten door bracket (one-piece door)........................... 25

Connect door arm to trolley (sectional door)................. 26

Connect door arm to trolley (one-piece door) ...............27

Adjustment section - pages 28- 30

Travel limitadjustments................................................. 28

Force adjustments ......................................................... 29

Test the safety reversingsensor................................... 30

Test the safety reverse system .................................... 30

Operation safety instructions............................. ;.............31

Care ofyour opener......................................................... 31

Maintenance schedule .................................................... 31

Operation of your opener ................................................ 32

Receiver and remote control programming .................... 33

Having a problem? .................................................... 34, 35

Repair parts, rail assembly.............................................. 36

Repair parts, installat_t .................................................. 36

Repair parts, opener assembly ....................................... 37

Accessories......................................................................38

Index ................................................................................ 39

How to order repair parts................................................. 40

Maintenance agreement.................................................. 40

Warranty .......................................................................... 40

Start by reviewing these important safety alert symbols

Mechanical

When you see this Safety Symbol on the following pages, It will alert you to the possibility of damage

to your garage door and/or the garage door opener If you do not comply with the corresponding

instructions. Read the instructions carefully.

This garage door opener is designed and tested to offer safe service provided it Is Installed, operated,

maintained and tested in strict accordance with the safety instructions contained in this manual.

Electrical

2

Page 3

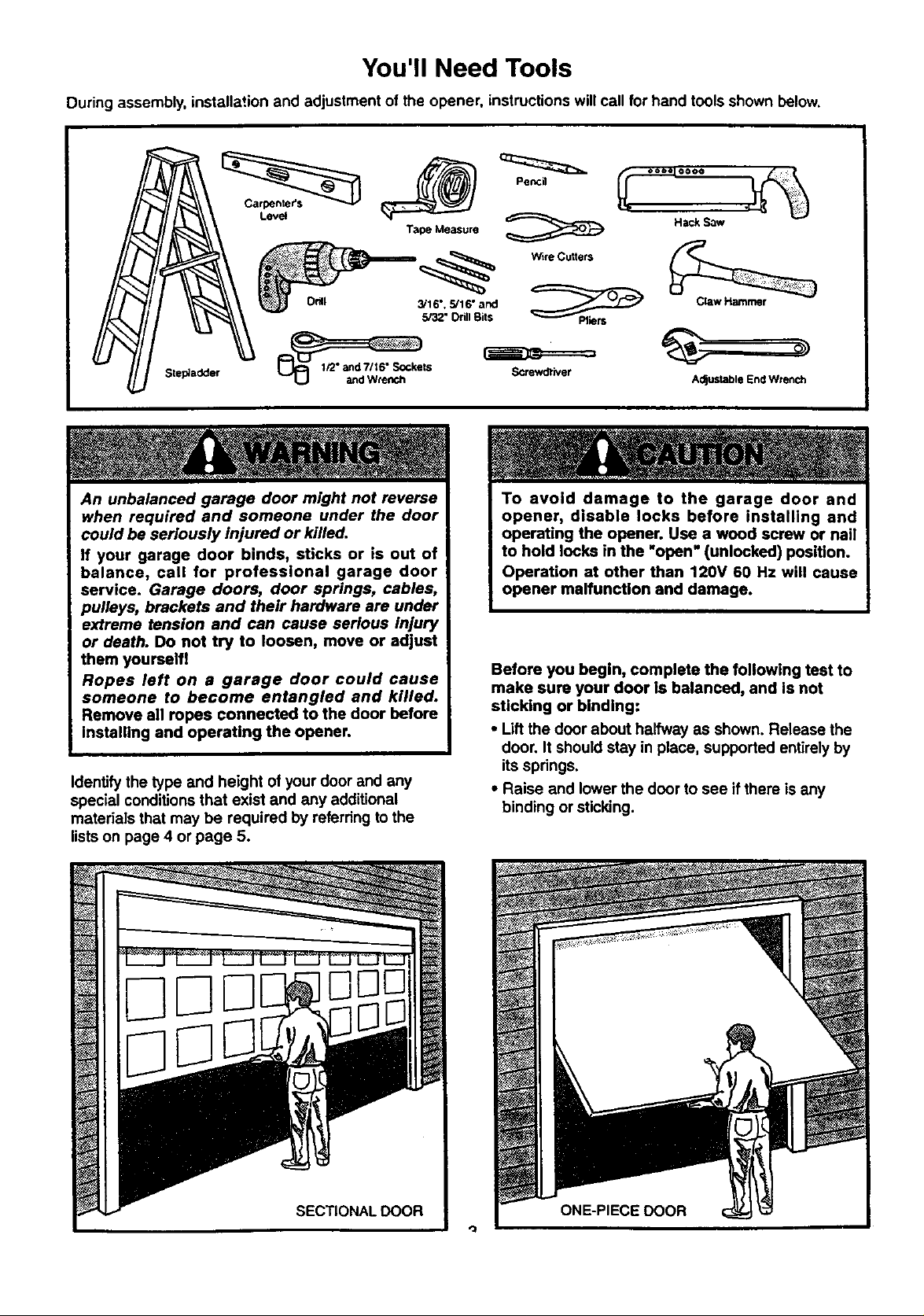

You'll Need Tools

During assembly, installation and adjustment of the opener, instructions willcall for hand tools shown below.

Pencil

Lev_

Ta_e Measure

W3re Cutters

Oooel OOO O

Hack Saw

Step_adder

An unbalanced garage door might not reverse

when required and someone under the door

could be seriously injured or killed.

If your garage door binds, sticks or is out of

balance, call for professional garage door

service. Garage doors, door springs, cables,

pulleys, brackets and their hardware are under

extreme tension and can cause serious Injury

or death. Do not try to loosen, move or adjust

them yourself!

Ropes left on a garage door could cause

someone to become entangled and killed.

Remove all ropes connected to the door before

installing and operating the opener.

Identify the type and height of your door and any

special conditions that exist and any additional

materials that may be required by referring to the

lists on page 4 or page 5.

3116", 5116" awJ

5/32" Drill Bits

ClawHammer

_rewdl'iver

Adjustable End Wrench

To avoid damage to the garage door and

opener, disable locks before installing and

operating the opener. Use a wood screw or nail

to hold locks in the "open" (unlocked) position.

Operation at other than 120V 60 Hz will cause

opener malfunction and damage.

Before you begin, complete the following test to

make sure your door is balanced, and is not

sticking or binding:

• Lift the door about halfway as shown. Release the

door. It should stay in place, supported entirely by

its springs.

• Raise and lower the door to see if there is any

binding or sticking.

,.,j

Page 4

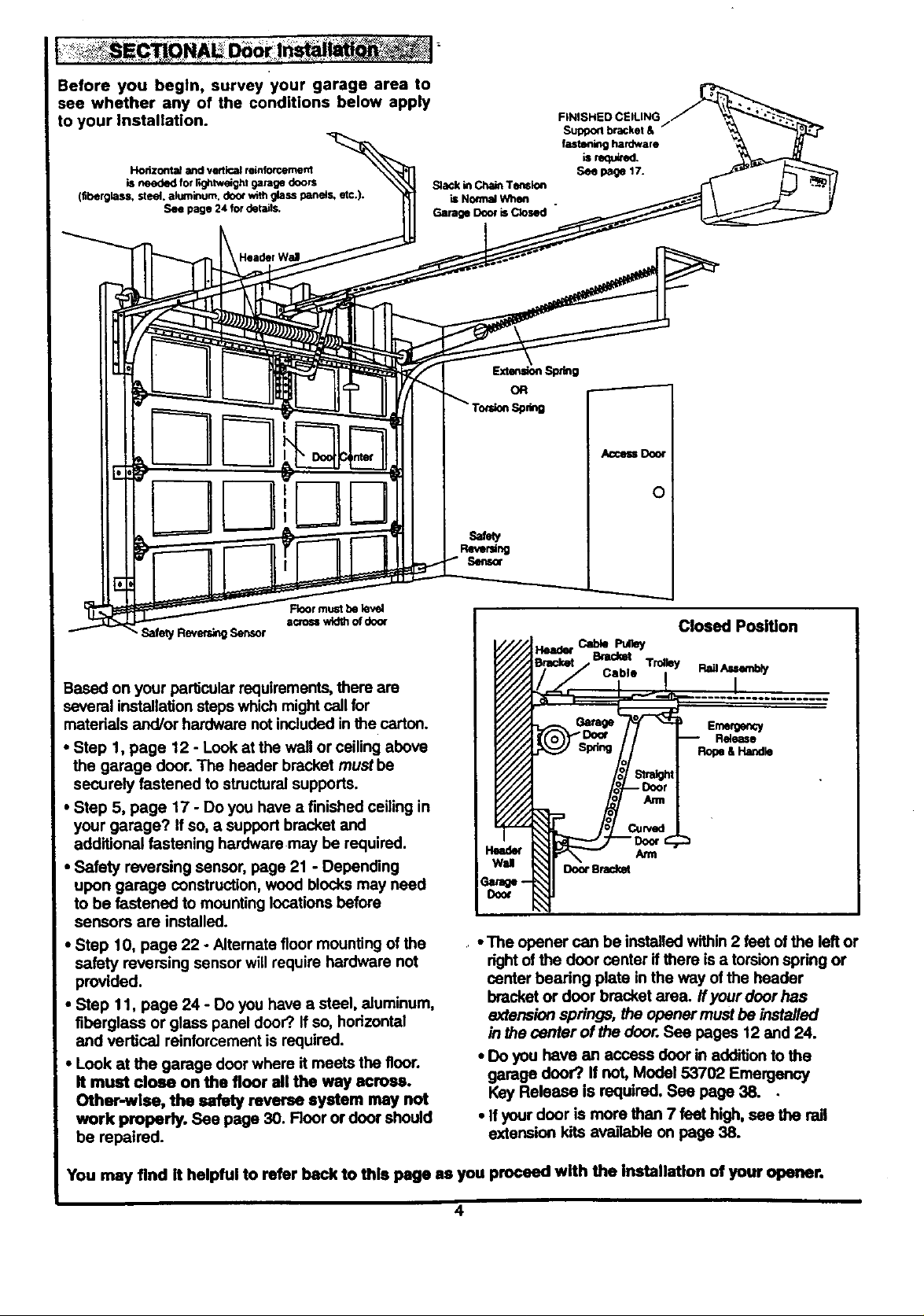

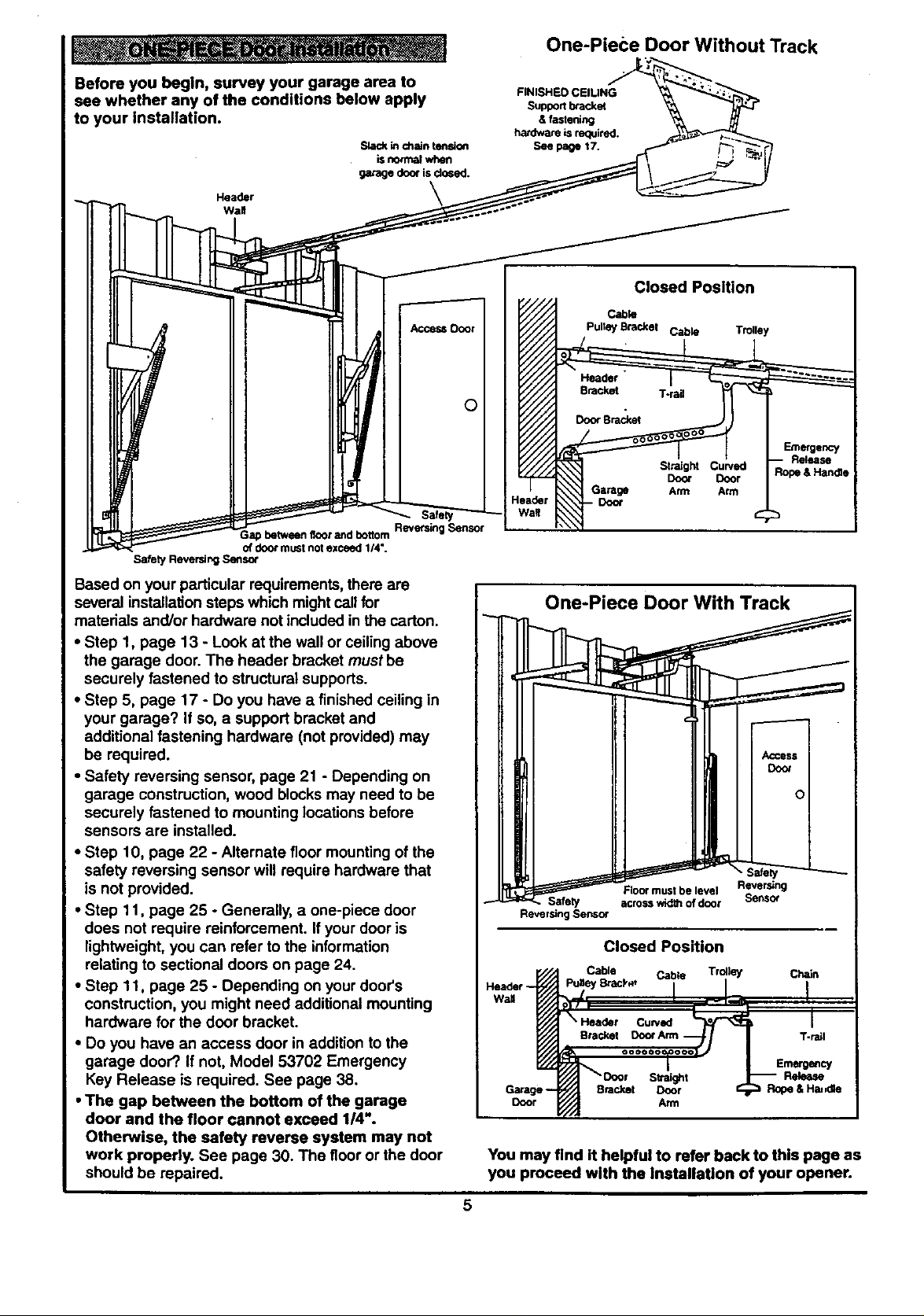

Before you begln, survey your garage area to

see whether any of the conditions below apply

to your installation.

Horizontal and vertical reinforcement

iS needed to_'llghtw_ght _ doors

(fiberglass. steel, akJminum, door v_th glass panels, etc.).

See page 24 for details.

FINISHED CEILING

SuI_ bracket &

fastlminghardware

Seg page 17.

Slackin ChainTen6ion

isNormalWhen

Garage DoorisClosed "

AccellDoor

o

Based on your particular requirements, there are

several installation steps which mightcall for

matedals and/or hardware not included in the carton.

• Step 1, page 12 - Look at the wall or ceiling above

the garage door. The header bracket must be

securely fastened to structural supports.

• Step 5, page 17 - Do you have a finished ceiling in

your garage? If so, a support bracket and

additional fastening hardware may be required.

• Safety reversing sensor, page 21 - Depending

upon garage construction,wood blocks may need

to be fastened to mounting locations before

sensors are installed.

• Step 10, page 22 - Alternate floor mounting of the

safety reversing sensor will require hardware not

provided.

• Step 11, page 24 - Do you have a steel, aluminum,

fiberglass or glass panel deer?.If so, horizontal

and vertical reinforcement is required.

• Look at the garage door where it meets the floor.

It must close on the floor all the way across.

Other-wise, the safety reveree system may not

work properly. See page 30. Floor or door should

be repaired.

Closed PeeWon

Cab_ Puny

Bracket Troaey

Cable RailAssembly

I

Emergency

Release

Roge&Hand_

, • The opener can be installed within 2 feet of the left or

rightof the door center if there is a torsion spdng or

center bearing plate in the way of the header

bracket or door bracket area. If your door has

extension springs, the opener must be installed

in the center of the door.See pages 12 and 24.

• Do you have an access door in addition to the

garage door? If not, Model 53702 Emergency

Key Release is required. See page 38.

• If your door is more than 7 feet high, see the rail

extension kits avaJlable on page 38.

You may find It helpful to refer back to this page as you proceed with the Installation of your opener.

4

Page 5

One-Piece Door Without Track

Before you begin, survey your garage ares to

see whether any of the conditions below apply

to your installation.

in chain thns_on

is normal when

garage door is dosed.

Header

Wa!l

) betweenfloorand bottomReversingSensor

of doormustnot exceed I/4".

Safety Reversir_ Sensor

Based on your particular requirements, there are

several installation steps which mightcall for

materials and/or hardware not included in the carton.

• Step 1, page 13 - Look at the wall or ceiling above

the garage door. The header bracket must be

securely fastened to structural supports.

• Step 5, page 17 - Do you have a finished ceiling in

your garage? If so, a support bracket and

additional fastening hardware (not provided) may

be required.

• Safety reversing sensor, page 21 - Depending on

garage construction, wood blocks may need to be

securely fastened to mounting locations before

sensors are installed.

• Step 10, page 22 - Alternate floor mounting of the

safety reversing sensor will require hardware that

is not provided.

• Step 11, page 25 - Generally, a one-piece door

does not require reinforcement. Ifyour door is

lightweight, you can refer to the information

relating to sectional doors on page 24.

• Step 11, page 25 - Depending on yourdoor's

construction, you might need additional mounting

hardware for the door bracket.

• Do you have an access door in addition to the

garage door?. If not, Model 53702 Emergency

Key Release is required. See page 38.

• The gap between the bottom of the garage

door and the floor cannot exceed 1/4".

Otherwise, the safety reverse system may not

work properly. See page 30. The floor or the door

should be repaired.

FINISHED CEILING

Support bracket

& faslening

hardware is required.

See page t7.

Closed Position

Cable

Pultey Bracket Cable Trolley

/

O

Bracket T-rail

DoorSrac_xet

Coot

Release

Door

Arm

One-Piece Door With Track

Safety acrosswidthof door

Floormust be level

ReversingSensor

Closed Position

Cable Cable Trolley Chain

Revering

I mL"

Garage--

Door

You may find it helpful to refer back to this page as

you proceed with the Installation of your opener.

_'//.I "saor s_ig_t _ P,ele=se

5

Page 6

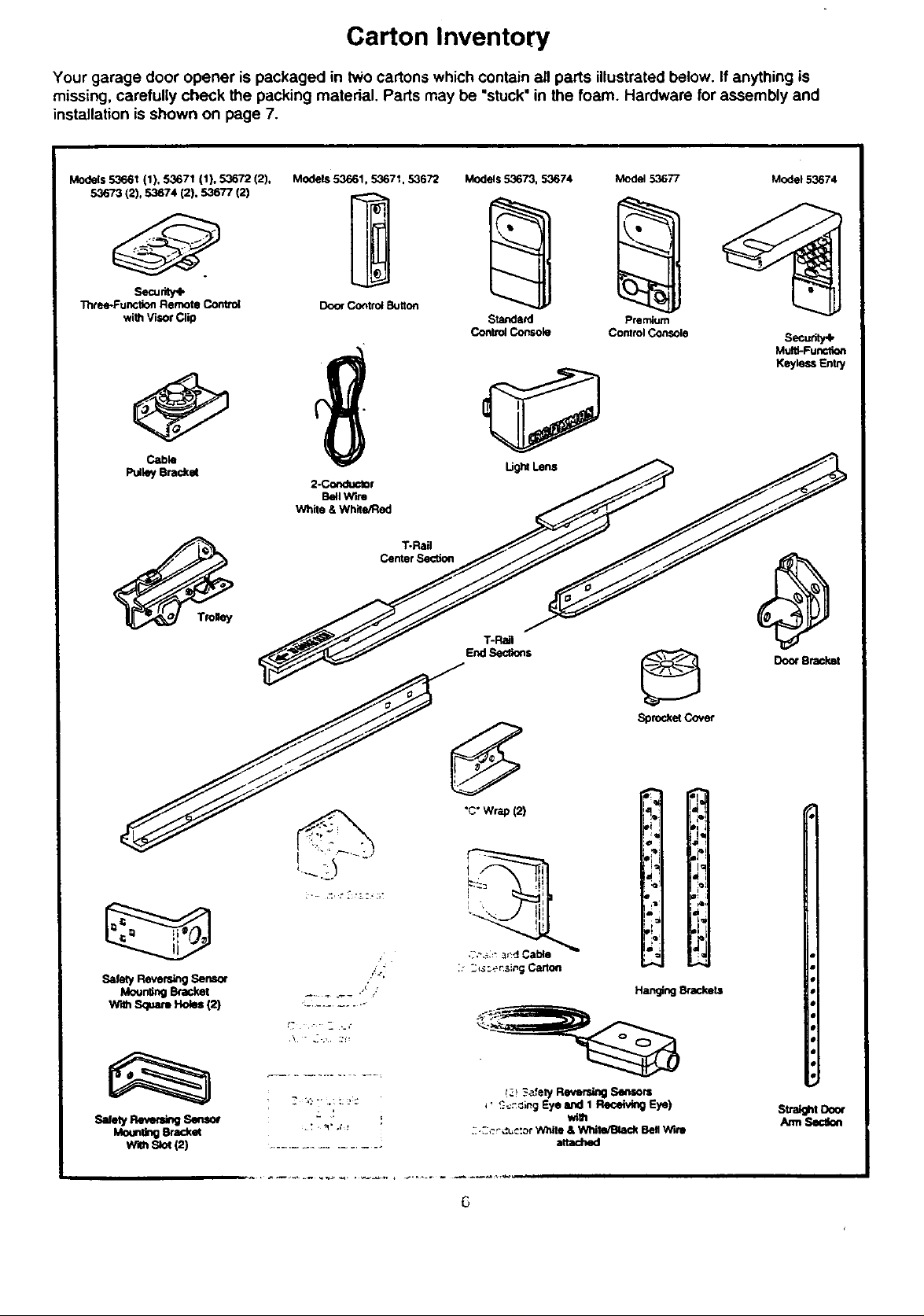

Carton Inventory

Your garage door opener is packaged in two cartons which contain all pads illustrated below. If anything is

missing, carefully check the packing material. Parts may be "stuck" in the foam. Hardware for assembly and

installation is shown on page 7.

Models 5366t (1), 53671 (1), 53672 (2).

53673 (2), 53674 (2). 53677 (2)

Three-Function Remote Control

Security+

with Visor Clip

Cable

PulleyBmc_

Models 53661, 53671, 53672

2-Conductor

BellWire

White &Whi_e/l:_ed

T.P.ail

CenterSection

Models 53673, 53674 Model 53677 Model 53674

Standard

ContmlConsole

Premium

Control Console

Safety Reversing Sensor

MountingBcacket

w_ Squa_Ho_ t2)

T-Rail

EndSec.ons

Do<_Bracket

Sprod_etCover

"C"Wrap (2)

i: ::_s_si,_g Carton

Hanging Brackets

¸7¸'¸ -- __

Sa_etyRe_n¢_ Seesor

Mount_gBraCka

W_ Sk_(2)

_' _¢;ng Eyeand 1 ReceivingEye)

::.3*_r=_c:or',_nitO& WhJle/t_ackBellWhl

attad'md

6

Stra_ Door

Am_Set,on

Page 7

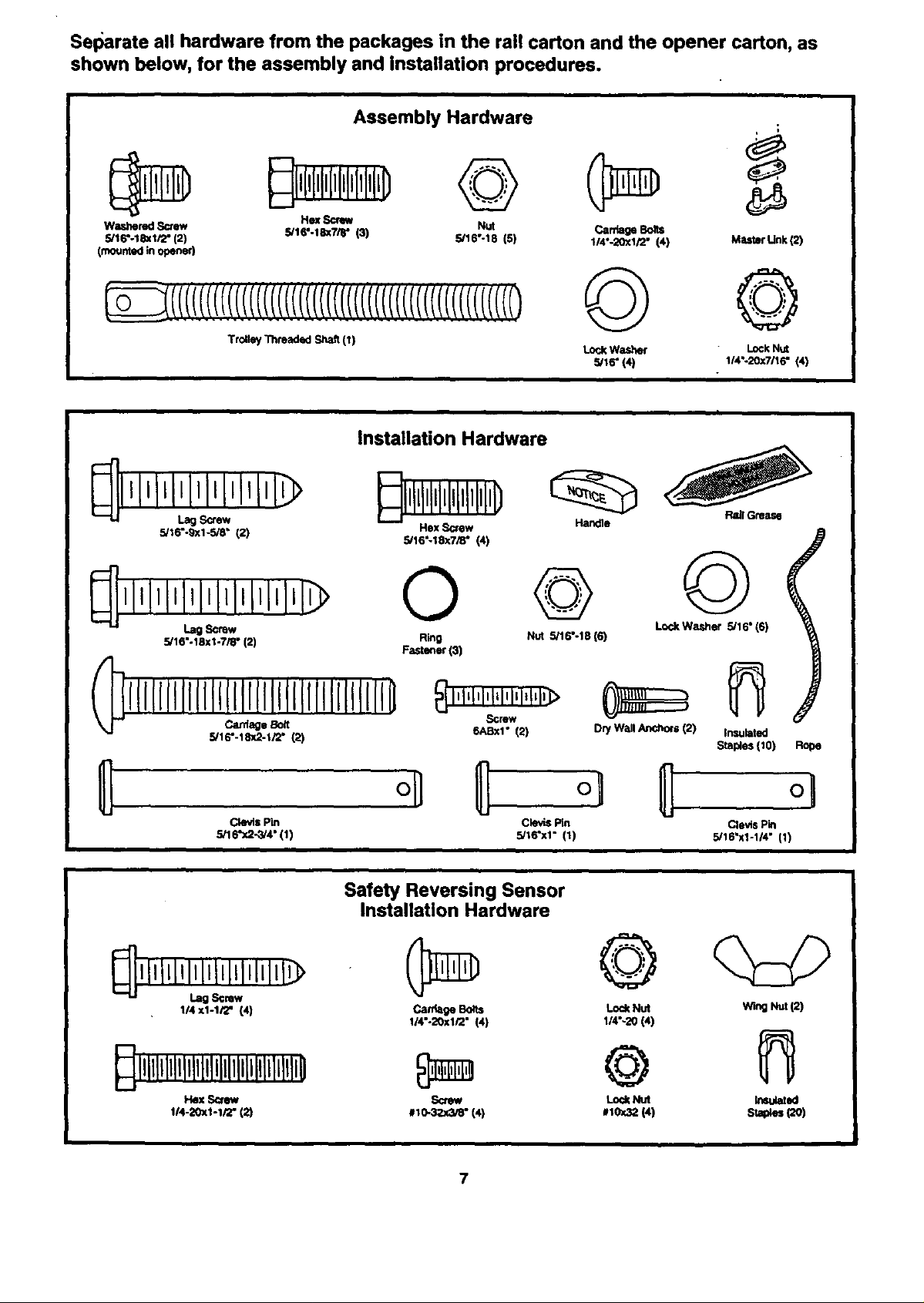

Sel_arate all hardware from the packages in the rail carton and the opener carton, as

shown below, for the assembly and installation procedures.

Assembly Hardware

Washered Screw Hex Sorew Nut Carriage Bolts

5/16"-183(1/2"(2) 5/16".18xTir (3) 5/16".18 (5) 114--20xl/2" (4) Master Unk (2)

(mounted in opener)

Trolley'i_maded Shaft II1

installation Hardware

Hex Screw

5/16"-18x7/8" (4)

0

5/16"-18xi-7/8" (2) Ring

IIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIII0

Carriage Boit

5/16"-18x2-1FZ' 121

Fastener (3)

6ABxl" (2) Dry Wall Anchors (2) Insulated

Nut 5/16"-18(6) L_JcWa_,her 5/16"(6)

Lock Washer Lock NUt

5/16" (4) 1/4"-20_7/16" (4)

Handle

_ Gma_

Staples (I0) Rope

Clevis Fm Clevis Pin

5/16"x2-3/4" (1) 5/16°xl" (1)

Safety Reversing Sensor

installation Hardware

1/4xl-lt2" (4)

_llllllllllllllltllllllllllllllllllliO

114-20x1-1/2" (2)

Carr_ge Bo_ts

1/4"-20xl/2" (4)

#10-3_(3/_" (4I

7

o,

©

Lock Nut

1/4"-20 (4)

@

Cle_s Pin

5/16"x1-114"(1)

WingNut(2)

Page 8

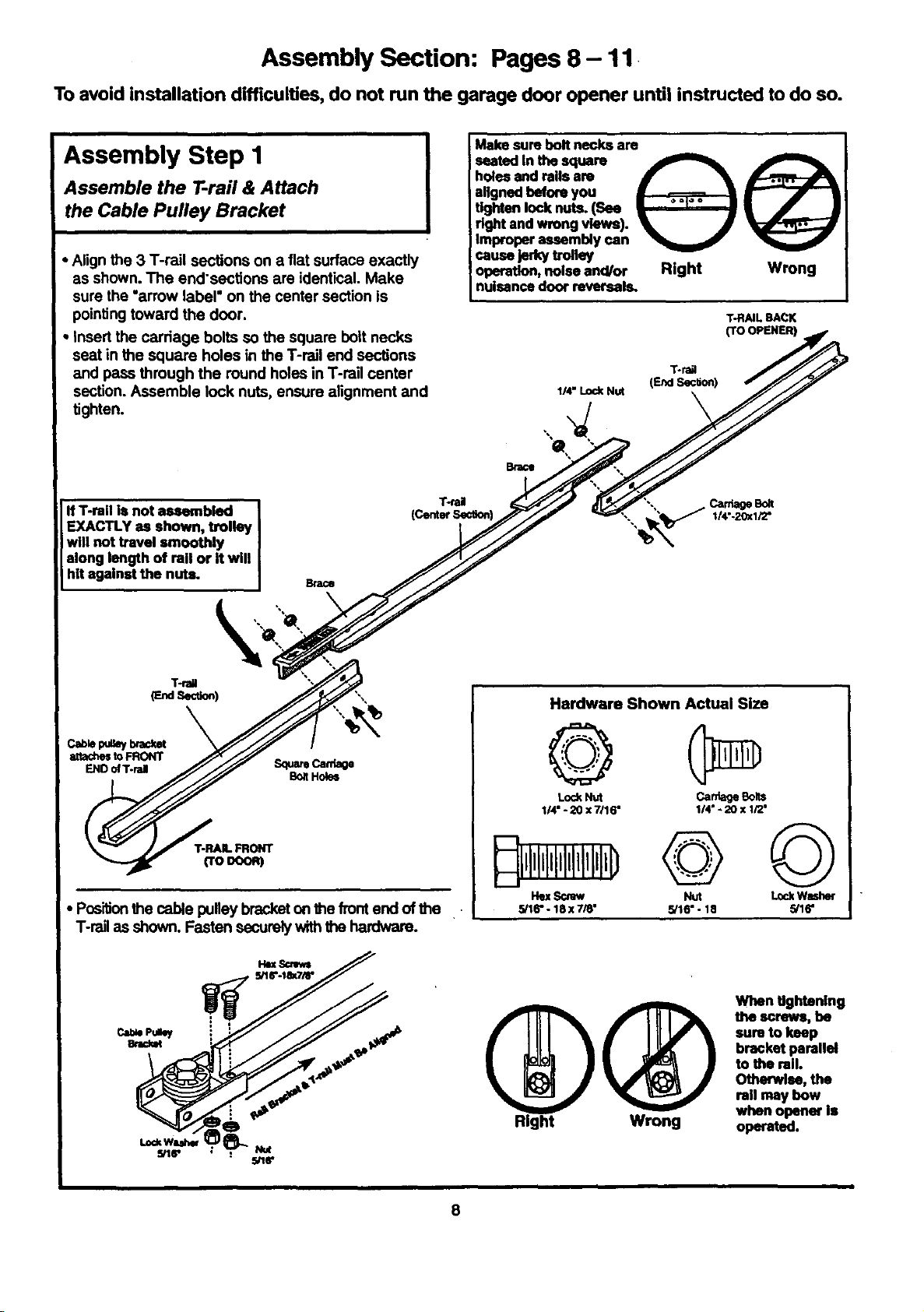

Assembly Section: Pages 8- 11

To avoid installation difficulties, do not run the garage door opener until instructed to do so.

Makesure boltnecks are

Assembly Step I

Assemble the T.rail & Attach

the Cable Pulley Bracket

• Align the 3 T-rail sections on a fiat surface exactly

as shown. The end'sections are identical. Make

sure the "arrow label" on the center section is

pointingtoward the door.

• Insert the carriage bolts so the square bolt necks

seat in the square holes in the T-rail end sections

end pass through the round holes in T-rail center

section. Assemble lock nuts, ensure alignment and

tighten.

If T-rail is not assembled

EXACTLY as shown, trolley I

will not travel smoothly ]

along length of rail or it will

hit againstthe nuts. I Brace

seatedIn thesquare _

holesend railsare _ _k A_P'-"-"-'_I'--_

alignedbeforeyou _ _ t

.omenlo (Sas __ . | / •

iright and wrong views). '_k J '_

iImproper assembly can _

cause]edo/trolley

operation,noise and/or Right Wrong

nuisancedoor reversals.

1/4"LockNut

Brace

• • I •

TRAIL BACK

(TO OPENER)

T.rail

(End Sec_on)

T-raU

Cab_p._/brackst

attachestoFRONT

ENDofT-ral SquareCarthage

(TOsoon)

• Positionthe cable pufley bracketon the front end of the . •

T-r_qas shown. Fasten sscurely with_e hardware.

cab*,Pamy

Brad_

L=_Wuhw

5/16"

s

B_tHole=

Hardware Shown Actual Size

©

Lod_Nut CardageSob

114"* 20 x 7116" 1/4" -20 x 1/2"

HexScrow Nut L_:k W_ner

5/16"- 18 x 7/8" 5/16" - 18 5/16"

sure to keep

bracket parallel

to the mllo

Q hen tightening

Right Wrong operated.

Otherwlas, the

the scraws, be

railmay bow

when opener is

8

Page 9

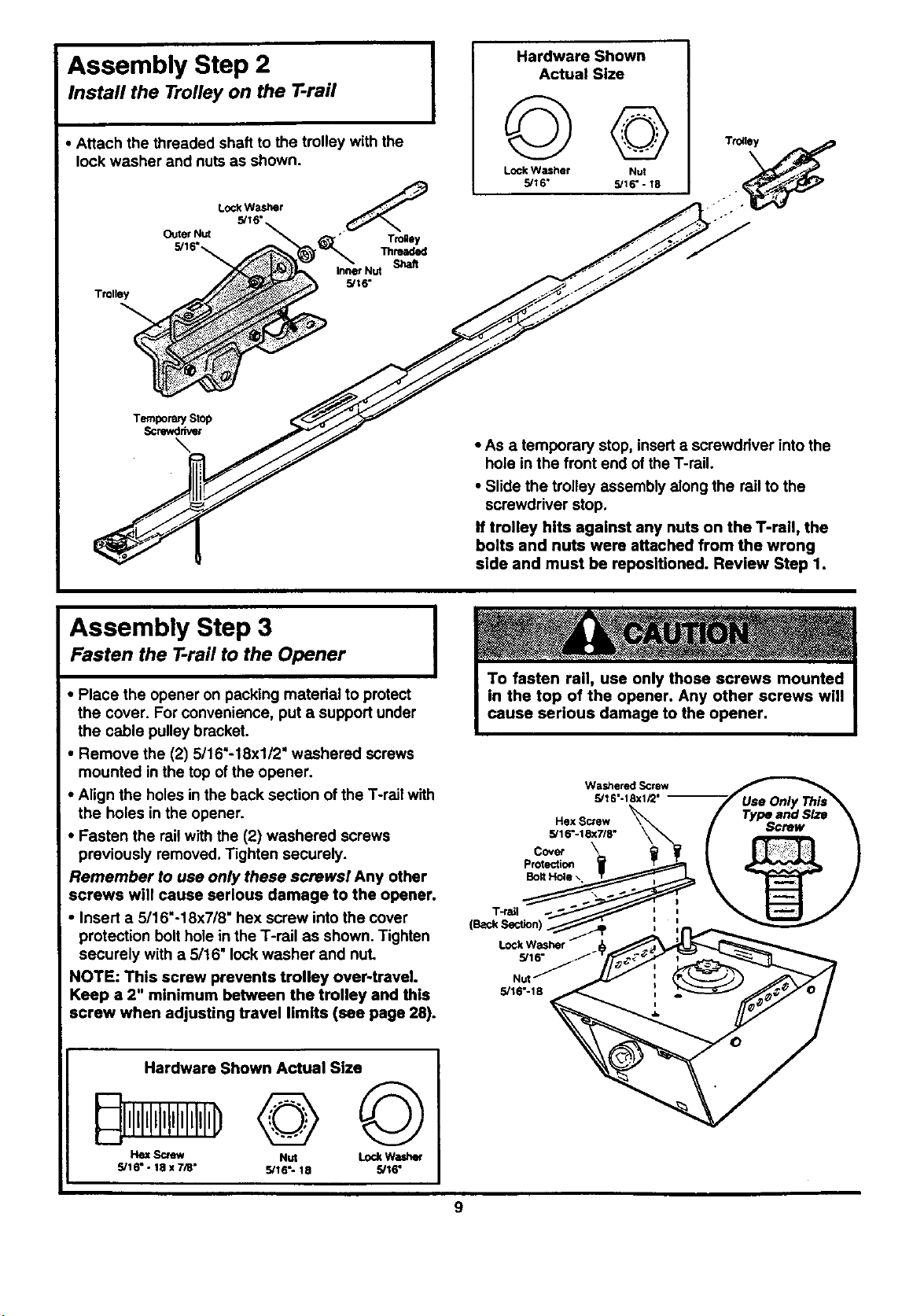

Assembly Step 2

Install the Trolley on the T-rail

Hardware Shown

Actual Size

• Attach the threaded shaft to the trolley with the

lock washer and nuts as shown.

LockWasher

5/16"

InnerNut

5/16"

Tro!ley

Threaded

Trolley

OuterNut

5/16"_

TemporarySlop

Screwdriver

©©

Lock Washer Nut

5/16" 5/16" - 18

Shaft

• As a temporary stop, insert a screwdriver into the

hole in the front end of the T-rail.

• Slide the trolley assembly along the rail to the

screwdriver stop.

If trolley hits against any nuts on the T-rail, the

bolts and nuts were attached from the wrong

side and must be reposltioned. Review Step 1.

Assembly Step 3 I

Fasten the T-rail to the Opener

• Place the opener on packing material to protect

the cover. For convenience, put a support under

the cable pulley bracket.

• Remove the (2) 5/16"-18xl/2 =washered screws

mounted in the top of the opener.

• Align the holes in the back section of the T-rail with

the holes in the opener.

• Fasten the rail with the (2) washered screws

previously removed. Tighten securely.

Remember to use only these screws! Any other

screws will cause serious damage to the opener.

• Insert a 5/16"-18x7/8" hex screw into the cover

protection bolt hole in the T-rail as shown. Tighten

securely with a 5/16" lock washer and nuL

NOTE: This screw prevents trolley over-travel.

Keep a 2" minimum between the trolley and this

screw when adjusting travel limits (see page 28).

Hardware Shown Actual Size

I

WasheredScrew

5/16".18xl/2"

Hex Screw

5/16"-18x7/8"

Cover \

Protection

Bolt Hole \,

T..raJl

(B=ckSection).

5/16"

NUt"

5/16"-18

5/16" - 18 x 7/8" 5/16; 18 5/16"

9

Page 10

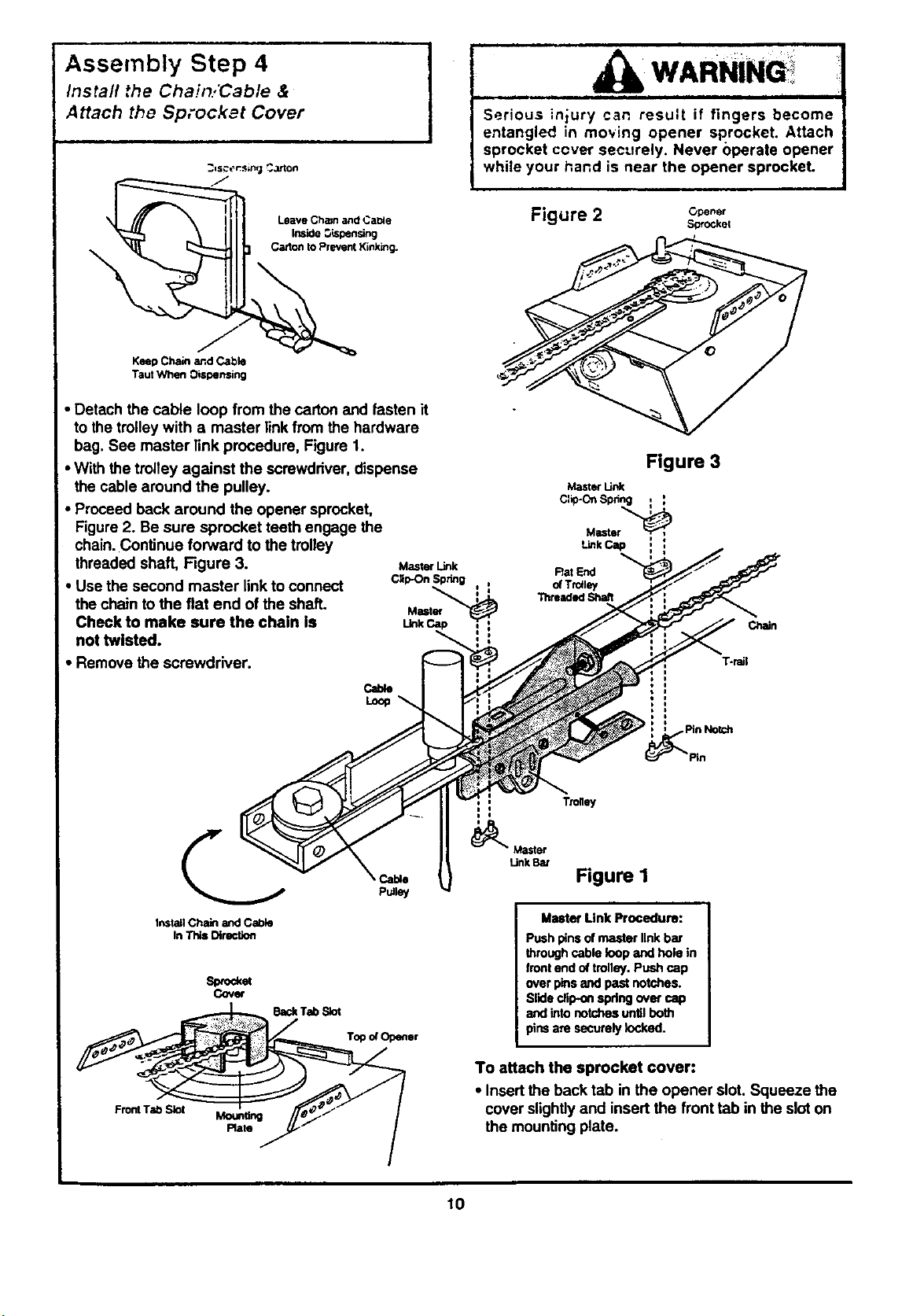

Assembly Step 4

Install the Chain/Cable &

Attach the Sprocket Cover

u

WARNINQi

i i i i i • i

Serious injury can result if fingers become

entangled in moving opener sprocket. Attach

sprocket cover securely. Never operate opener

while your hand is near the opener sprocket.

KeepChain andCable

TautWhen Dispensing

• Detach the cable loop from the carton and fasten it

to the trolley with a master link from the hardware

bag. See master link procedure, Figure 1.

• With the trolley against the screwdriver, dispense

the cable around the pulley.

• Proceed back around the opener sprocket,

Figure 2. Be sure sprocket teeth engage the

chain. Continue forward to the trolley

threaded shaft, Figure 3.

• Use the second master link to connect

the chain to the flat end of the shaft.

Check to make sure the chain Is

Master Link

C_p-On Spring , ,

Master

Link

not twisted.

• Remove the screwdriver.

Figure 2 c._.,.

Sprockel

Figure 3

Rat End

of Trolley

ThreadedShaft

Chain

T-rail

Install Chain and Cadle

In This Direction

Spmckat

Cov_

Front Tab Slot Mortaring

Plate

Cable

PuJley

m

t

_ Master

LinkBat

Trolley

Figure I

M_ Unk Procedure:

Pushpinsofmasterlink bar

throughcableloopand holein

frontendoftrolley.Pushcap

overpinsandpastnotches.

Slidedip-onspdngover cap

and intonotchesunUIboth

pinsare securelyIo_ked.

To attach the sprocket cover:

• Insert the back tab in the opener slot. Squeeze the

cover slightly and insert the front tab in the slot on

the mounting plate.

lO

Page 11

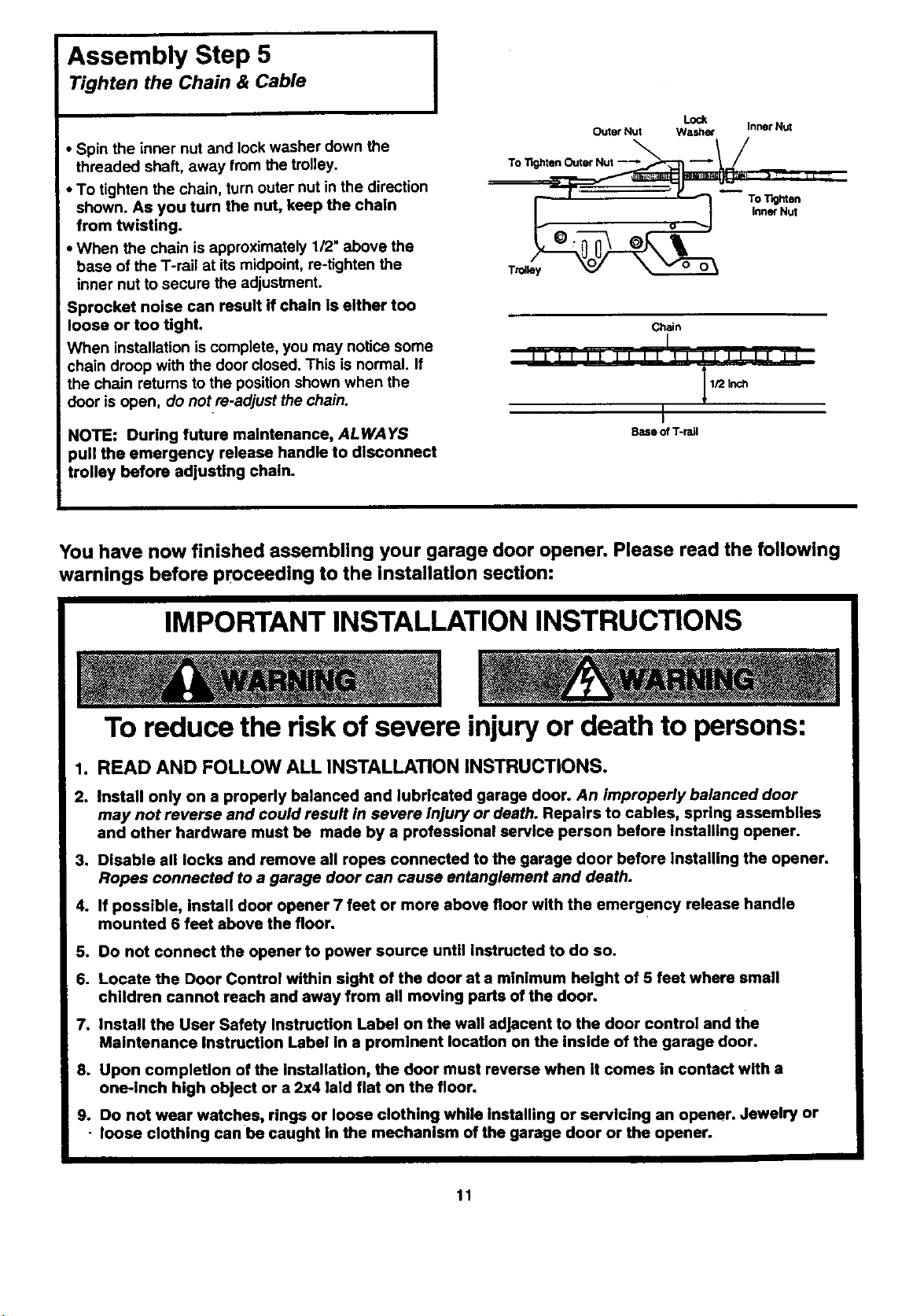

Assembly Step 5

Tighten the Chain & Cable

I

Lock

Chin

1/2 Inch

• Spin the inner nut and lock washer down the

threaded shaft, away from the trolley.

• To tighten the chain, turn outer nut in the direction

shown. As you turn the nut, keep the chain

from twisting.

• When the chain is approximately 1/2" above the

base of the T-rail at its midpoint, re-tighten the

inner nut to secure the adjustment.

Sprocket noise can result if chain is either too

loose or too tight.

When installation is complete, you may notice some

chain droop with the door closed. This is normal. If

the chain returns to the position shown when the

door is open, do not re-adjust the chain.

NOTE: During future maintenance, ALWAYS

)ull the emergency release handle to disconnect

trolley before adjusting chain.

Outer Nut Washer Inner Nut

TO "ilghten Outer Nut --'_"_ -- lJ __

T_olle_ InnerNut

Baseof T-rail

You have now finished assembling your garage door opener. Please read the following

warnings before proceeding to the installation section:

IMPORTANT INSTALLATION INSTRUCTIONS

To reduce the risk of severe injuryor death to persons:

1. READ AND FOLLOW ALL INSTALLATION INSTRUCTIONS,

2. Install only on a properly balanced and lubricated garage door. An improperly balanced door

may not reverse and could result in severe Injury or death. Repairs to cables, spring assemblies

and other hardware must be made by a professional service person before Installing opener.

3. Disable all locks and remove all ropes connected to the garage door before Installing the opener.

Ropes connected to a garage door can cause entanglement and death.

4. If possible, Install door opener 7 feet or more above floor with the emergency release handle

mounted 6 feet above the floor.

5. Do not connect the opener to power source until Instructed to do so.

6. Locate the Door Control within sight of the door at a mlnlmum height of 5 feet where small

children cannot reach and away from all moving parts of the door.

7. Install the User Safety Instruction Label on the wall adjacent to the door control and the

Maintenance Instruction Label in a prominent location on the inside of the garage door.

8. Upon compleUon of the Installation, the door must reverse when it comes in contact with a

one-inch high object or a 2x4 laid flat on the floor.

9. Do not wear watches, rings or loose clothing while installing or servlclng an opener. Jewelry or

• loose clothing can be caught in the mechanism of the garage door or the opener.

11

Page 12

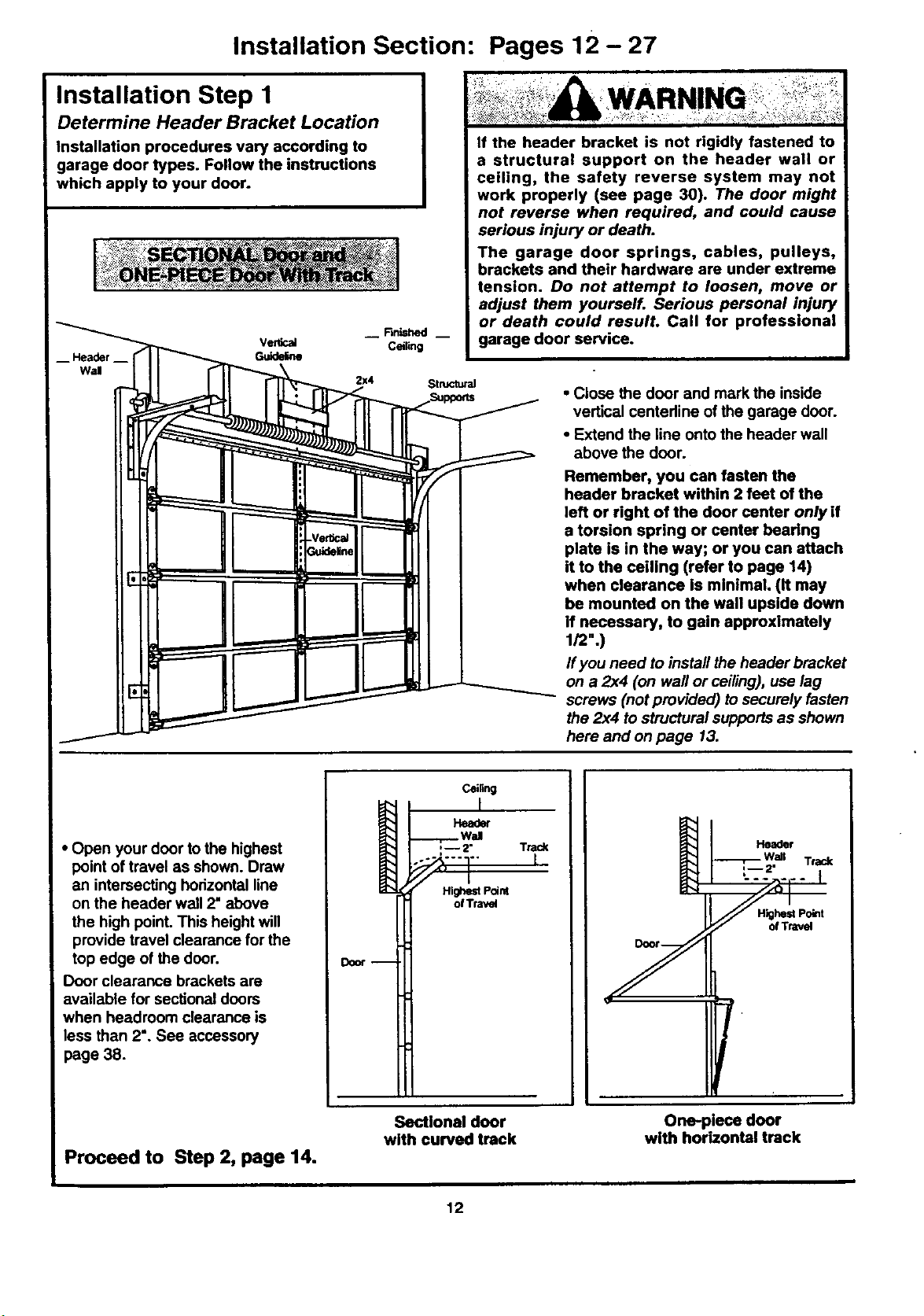

Installation Section: Pages 12- 27

Installation Step I

Determine Header Bracket Location

Installation procedures vary according to

garage door types. Follow the instructions

which apply to your door.

Verlical

-- Header --

Wal

Guideline

2X4

Structural

WARN

If the header bracket is not rigidly fastened to

a structural support on the header wall or

ceiling, the safety reverse system may not

work properly (see page 30). The door might

not reverse when required, and could cause

serious injury or death.

The garage door springs, cables, pulleys,

brackets and their hardware are under extreme

tension. Do not attempt to loosen, move or

adjust them yourself. Serious personal injury

or death could result. Call for professional

garage door service.

• Close the door and mark the inside

vertical centedine of the garage door.

• Extend the line onto the header wall

above the door.

Remember, you can fasten the

header bracket within 2 feet of the

left or right of the door center onlyif

a torsion spring or center bearing

plate is in the way; or you can attach

it to the ceiling (refer to page 14)

when clearance is minimal. (It may

be mounted on the wall upside down

if necessary, to gain approximately

1/2".)

Ifyou need to install the header bracket

on a 2x4 (on wall or ceiling), use lag

screws (not provided) tosecurely fasten

the 2x4 to structural supports as shown

here and on page 13.

• Open your door to the highest

point of travel as shown. Draw

an intersecting horizontal line

on the header wall 2" above

the high point. This height will

provide travel clearance for the

top edge of the door.

Door clearance brackets are

available for sectional doors

when headroom clearance is

less than 2". See accessory

page 38.

Proceed to Step 2, page 14.

Ceiling

Wal

N_ Point

Sectional door

with curved track

12

Tra_

Header

I

Track

HighestPoint

olTravel

One-piece door

with horizontal track

Page 13

Read the Safety instructions on page 12. They also apply to doors without tracks.

Header Wall

2x4

• Close the door and mark the

inside vertical centedine of

your garage door. Extend the

line onto the header wall

above door.

If headroom clearance is

minimal, you can install the

header bracket on the ceiling.

See page 14.

• If you need to install the

header bracket on a 2x4 (on

wall or ceiling), use lag screws

(not provided) tosecurely

fasten the 2x4 tostructural

supports as shown.

Header Wall

_,_1 I _ Highest point

of Trawd

1 Wall of Travel

OPTIONAL CEIUNG MOUNT

FORHEADER BRACKET

Door

Jamb

Hardware

One-piece door without track

jamb hardware

• Open your door to the highest point of travel as

shown. Measure the distance from the top of the

door to the floor. Subtract the actual height of the

door. Add 8" to the remainder. (See Example),

• Close the door and draw an intersecting horizontal

line on the header wall at the determined height.

If the total number of inches exceeds the height

available in your garage, use the maximum

height possible, or refer to page 14 for ceiling

installation.

Header Highestioint

ii

One-piece door without track

pivot hardware

EXAMPLE

Distance from top of door

(at highest point of travel) to floor ........................... 92"

Actual height of door ............................................. -88.____."

Remainder ................................................................ 4"

Add ......................................................................... +8"

Bracket height on header wall............................... 12"

(Measure UP from top of CLOSED door.)

Proceed to Step 2, page 14.

13

Page 14

Install the Header Bracket

Installation Step 2 I

Fasten the Header Bracket to the Wall

i

You can attach the header bracket either to the

wall above the garage door, or to the ceiling.

Follow the Instructions which will work best for

your particular requirements,

• Center the bracket on the vertical guideline with

the bottom edge of the bracket on the horizontal

line as shown (with the arrow pointing toward the

ceiling).

Vertical

Center

Line

• Mark either set of bracket holes (do not use the

holes designated for ceiling mount). Drill 3/16" pilot

holes and fasten the bracket securely to a structural

support with the hardware provided.

"" "*Lag Screws f

Spring " The nailho_ is for posilioning \ //

only. y_J must use lag scrk=e_ts 1o V

mounithe header b'acket.

Wall Mounting

le_

Door

Hardware Shown Actual Size

Wall

Mount_ Holes

opt_lal

Ho_es

Fasten the Header Bracket to the Ceiling

• Extend the vertical guideline onto the ceiling as

shown.

• Center the bracket on the vertical mark, no more

than 6" from the wall. Make sure the arrow is

pointing toward the wall. The bracket can be

mounted flush against the ceiling when clearance

is minimal.

• Mark holes designated for ceiling mount only• Drill

3/16" pilot holes and fasten bracket securely to a

structural support with the hardware provided.

Ceil!rigMountingHoles

"n_naJho_L_forpo=_k_ngonly.

You rnust use kRgscrews to motml_

the header btackel.

_16"-9XI-_"

Door

Spdng

14

Page 15

ii

Attach the T-rail to the Header Bracket

Installation Step 3 [

Header

BW

//

//

//

//

//

• Position the opener on the garage floor below the

header bracket. Use packing material as a

protective base.

If the door spring is In the way you'll need help.

Have someone hold the opener securely on a

temporary support to allow the T-rail to clear the

spring.

• Position the cable pulley bracket against the header

bracket.

• Align the bracket holes and join with a clevis pin as

shown.

• Insert a ring fastener to secure.

Garage

Door

Ring Fastener

Header Bracket

Clevis Pin

5/I 6"x2-3/4 • Cable

Pulley

Bracket

Temporary

i

Support

Hardware Shown Actual Size

0

Ckr_s P_

5/16" x 2-3/4"

15

©

Ring Fastener

Page 16

Installation Step 4

Position the Opener

Follow instructions which apply to your door

type as Illustrated.

A 2x4 laid flat is convenient for setting an Ideal

door-toT-rail distance.

• Raise the opener onto a stepladder.

You will need help at this point ff the ladder is

not tall enough.

• Open the door all the way and place a 2x4 laid flat

on the top section beneath the T-rail.

ff the top panel hits the trolley when you raise

the door, pull down on the trolley release arm to

disconnect the Inner and outer sections. The

trolley can remain disconnected until Step 12 Is

completed.

Door

i

T-ra_

2x4

I

ReleaseAnn

T_ley

• With the door fully open and parallel tothe floor,

measure the distance from the floor to the top of

the door.

• Using a stepladder as a support, raise the opener

to the same distance as the door from the floor (it

will be at a slight angle as shown).

• The top of the door should be level with the top of

the opener. Do not position the opener more than

2' above this point.

Header

16

Page 17

Installation Step 5

Hang the Opener

Two representative Installations are shown.

Yours may be different. Hanging brackets should

be angled, Figure 1, to provide dgid support. On

finished ceilings, Figure 2, attach a sturdy metal

bracket to structuralsupports before installing the

opener. The bracket and fastening hardware are not

provided. See accessory page 38.

• Measure the distance from each side of the opener

to the structural support.

• Cut both pieces of the hanging bracket to required

lengths.

• Drill 3/16" pilotholes in the structural supports.

• Attach one end of each bracket to a support with

5/16"-18xl -7/8" lag screws.

• Fasten the opener to the hanging brackets with

5/16"-18x7/8" screws, lock washers and nuts.

• Check to make sure the T-rail is centered over the

door (or in line with the header bracket if the

bracket is not centered above the door).

• Remove the 2x4. Operate the door manually. If the

door hits the rail, raise the header bracket.

I

Figure I

_ StructuraJ

5/16 -18xl -7/8"

Measure .__,

5/16"-18x7/8" Screw

5/16" Lock Washer

5/16".18 Nut

Figure 2

Grease the top and underside of the

rail surface where the trolley __,_

slides. A tube of grease is _-__

supplied.

SupportSra_dxet_ _ _'" 5/ (Not Prodded)

Not Provided) _.\_, ..°-:.°- _ 16"-18x7/8 Screw

5/I 6"-I 8X7/8" Scte_ _ _---_..-

Hardware Shown Actual Size

5/16"18xl-7/8"

11111111111111111,llD

5/16"- 18X7/8" Nut 5/16"-18

LockWasher 5/16"

Hidden . o....° o-"" "'"

SupDort .

o,..- ...;-:::-

..... "" _ ..;-;'.;;"'°"--_.0SH=OCSlU,G--

"" ° - "".'.. - °"" Lag Screws •

..-'_ 5/16"-18X1-?/8 ..-"

17

Page 18

Installation Step 6

Install the Door Control

Locate the door control within sight of the door

at a minimum height of 5 feet where small

children cannot reach, and away from all moving

)arts of the door and door hardware.

The door control is typically attached directly to the

wail. If installing into drywall, drill 5/32" holes and

use the anchors provided. For pre-wired installations

(as in new home construction), Console models

may be mounted to a.standard single gang box

(Figure 2).

1. Strip 1/4" of insulation from one end of the bell

wire and connect it to the two screw terminals on

the back of the door control: white to 2 and

white/red to 1.

2. Door Control Button: Fasten securely with

6ABx1-1/2" screws.

Console Model: Pry off cover along one side

with a screwdriver blade (Figure 1). Fasten with

6ABx1-1/4" self-tapping screws (standard

installation) or 6-32x1" machine screws (pre-wired

installation) as follows:

• Install bottom screw, allowing 1/8" to protrude

above wall surface.

• Position bottom of door control on screw head

and slide down to secure. Adjust screw for snug

fit.

• Install top screw with care to avoid cracking

plastichousing. Do not overtighten.

• Insert top tabs and snap on cover.

3. (For standard insta/lation only) Run the bellwire

up the wall and across the ceiling to the opener.

Use insulated staples to secure the wire in

several places. Be careful not to pierce the wire

with a staple, creating a short.

4. Connect the bell wire to the terminal screws on

the opener panel: white to 2; white/red to 1.

5. Positionthe antenna wire as shown.

I Do not connect to live electrical widng. Connect

only to 24 Volt low voltage wires. Connection to

live wires or higher voltage may cause serious

injury from shock, burn or electrocution.

Children operating or playing with a garage

door opener can injure themselves or others.

The garage door could close and cause

serious injury or death.

Install the door control (or any additional push

buttons) out of the reach of children and away

from all moving parts of the door and door

hardware, but where the garage door is visible.

Do not allow children to operate the push

button(s) or the remote control(s).

A moving garage door could injure someone

under it. Activate the opener only when the

door is properly adjusted, you can see It clearly,

and the.re are no obstructions to door travel.

Hardware Shown

6ABx 1-1/2"Screw

DoorControlButton

Contxo4Console(stdinstaltadon) Staples

Actual Size

ControlConsoleLore-wired) DryWa_Anchom

Figure 1

REMOVE & REPLACECOVER

Figure 2

PRE-WIRED

INSTALLA'RON

STANDARD CONTROL

(BACKVIEW)

24Volt

2-Conducto¢

BellWire

Top

DOOR

CONTROL

BuTroN

STANDARO

CONTROL

CONSOLE

PREMIUM

CONTROL

CONSOLE

BackPanel

orOpener

18

DOOR CONTROL

BUTTON (BACK)

Wire

TerminalScrews

T_nal

PREMIUM CONTROL

(BACKVIEW)

_ Te_Nnal

Top

_1 ''_=_ >scfewt

Be.. [.__ .Mou_ng

W'ffm _.

HO_

Page 19

6. Attach the User Safety Instruction label to the wall

neat the door control, and the Maintenance

Instruction label in a prominent location on the

inside of the garage door.

Page 32 explains how to use the door control.

Installation Step 7

Install the Light and the Lens

Install the light:

• Install a 75 watt maximum light bulb in each

socket. The lights will turn ON and remain lit for

approximately 4-1/2 minutes when power is

connected. Then the lights will turn OFF.

• If the bulbs bum out prematurely due to vibration,

replace them with standard neck "Garage Door

Opener =bulbs.

, r

Do NOT connect the power and operate the

openerat this time. The trolley will travel to the

full open position but wilt not return to the

close position until the sensor beam is

connected and properly aligned.

See Safety Reversing Sensor instructions

beginning on page 21.

Install the lens:

• Apply slight pressure on the sides of each lens

and slide the tabs into the slots in the side panels.

', For convenience, the lens may be Installed

after Adjustment Step 4 on page 30.

• Reverse the procedure to remove the lenses.

Installation Step 8

Attach the Emergency

Release Rope and Handle

• Thread one end of the rope through the hole in release only to disengage the trolley and, if

the top of the red handle so "NOTICE" reads dght possible, only when the door Is closed.

side-up a_shown. Secme with an overhand knot. Garage doors are heavy. _t the door is open

The knot should be at least 1" from the end of

the rope to prevent slipping.

:• Thread the other end of the rope through the hole

in the release arm of the outer trolley.

• Adjust rope length so the handle is 6 feet above

the floor. Secure with an overhand knot.

If it is necessary to cut the rope, heat seal the

cut end with a ma_ch or lighter to prevent

unraveling.

I Do not use the red handle to pull the door

open or closed. The rope knot could become

untied and you could fall. Use the emergency

when the handle is pulled, the door could

close inadvertently if it Is not properly

balanced. Serious Injury may result to persons

under the door. Make sure the doorway is clear

of persons and obstructions before pulling

handle when door is open.

r

19

P.ekmseAnn

Rem Handle

Page 20

Installation Step 9

Electrical Requirements

To prevent electrocution or fire, installation

and wiring must be In compliance with local

To reduce the risk of electric shock, your garage

door opener has a grounding type plug with a third

grounding pin. This plug will onlyfit into a grounding

type outlet.

If the plug doesn't fit into the outlet you have,

contact a qualified electrician to install the proper

outlet.

To avoid installation difficulties,

do not run the opener at this time.

electrical and building codes.

Do NOT use an extension cord, 2-wire adapter,

or change the plug In any way to make it fit

your outleL

OQ

Right Wrong

If permanent wiring Is required by your local code, refer to the following procedure:

To prevent e/ecfrocut/on, remove power from

the garage door opener and from the circuit

To make a permanent connection through the

7/8" diameter hole in the top of the opener

(according to local code):

• Remove the opener cover screws and set the

cover aside.

• Remove the attached 3-pmag cord.

• Connect the black (line) wire to the screw on the

brass terminal; the white (neutral) wire to the

screw on the silver terminal; andthe ground wire

to the green ground screw. The opener must be

grounded.

• Reinstall the cover.

i,

To avoid installation difficulties,

do not run the opener at this time.

GroundTab

Gresn

S_ew

Wire

Permanent

Wiring

Connections

Back

Winl

Wh.e W_I

Wire

2O

Page 21

The Safety Reversing System

Information you'll need before you begin the installation of the safety reversing sensor,

The safety reversing sensor must be connected

and aligned correctly before the garage door

opener will move In the down direction. This is a

required safety device and cannot be disabled.

Installation procedures are the same for sectional

and one-piece doors.

Read and follow all Instructions.

To protect small children, install the safety

reversing sensor so that the beam will be no

higher than 4"-6" above the garage floor.

Disconnect power to the garage door opener

before Installing the safety reversing sensor.

Be sure power to the opener is disconnected.

The sending eye transmits an invisible light beam to

the receiving eye. The units can be Installed on

either slde-of the'garage door as long as the sun

never shines directly into the receiving eye lens.

Look at the label on the connector end of each case

to identify the sensors.

The brackets must be connected and fastened so

that the sending and receiving eyes face each other

as shown in Rgure 1.

If an obstruction breaks the light beam while the

garage door is closing, the door will stop and

reverse to full open position and the opener lights

will,flash for 5 seconds.

[

The brackets mustbe securely fastened to a solid

surlace such as the studs on either side of the door,

or add a piece of wood at each location if installing in

masonry construction.

The invisible light beam path must be unobstructe(_l.

No part of the garage door (or door tracks, spdngs,

hinges, rollers or other hardware) can interrupt the

beam while the door is closing. If it does, use a piece

of wood to build out each sensor mounting location to

the minimum depth required for light beam clearance.

SensorBeam

=bore n_x

Figure 1: Facing the door from inside the garage

21

Page 22

Installation Step 10

Install the Safety Reversing Sensor

I

' Figures 2 and 3 show assembly of brackets and

i "C" wrap based on the recommended installation of

the sensors as shown on page 21.

However, Figures 4 and 5 are vadetions which may

fityour installation requirements better. Make sure

the wraps end brackets are aligned so the

sensors will face each other across the garage

door,

• Fasten the "C" wraps to the mounting brackets

having square holes, using the hardware shown

in Figure 2.

• Connect each assembly to a slotted bracket, using

the hardware shown in Figure 3.

Note the alignment of the brackets for left and

right aides of the door.

• Finger tighten the lock nuts.

• Use bracket mounting holes as a template to

locate and ddll (2) 3/16' diameter pilot holes on

both sides of the garage door, 4"-6" above the

floor but not exceeding 6: (See warning on

page 21.)

• Attach bracket assemblies with 1/4"x1-1/2" lag

screws as shown in Figure 3.

• Adjust dght and left side bracket assemblies to the

same distance out from the mounting surface.

Make sure all door hardware obstructions are

dealed. Tighten the nuts securely.

Figure 2

Mo_ Brac_l

W'dhSquareHoles

#10-32

Lo<:kNuts

Figure 3

#10 o_12x :_gS" #10x32

SOtew LockNut

Figure 4

Alternate Wall Mount

©

withSlot

Hardware Shown Actual Size

Lag_ St=paB

Figure 5

114"- 20 x 1i'Z'

Alternate Floor Mount

--Floor--

©

114"-20

LockNut

_2

Page 23

• Center each sensor unit in a "C" wrap with lenses

pointing toward each other across the door (see

Figure 6).

• Secure sensors with the hardware shown. Finger

tighten the wing nut on the receiving eye to allow

for final adjustment. Securely tighten the sending

eye wing nut.

• Hun the wires from both sensors to the opener.

Use insulated staples to secure wire to wall and

ceiling.

• Strip 1/4" of insulation from each set of wires.

Separate white and white/black wires sufficiently to

connect to the opener terminal screws: white to 2

and white/black to 3.

Aligning the Safety Sensors

• Plug in the opener. Green indicator lights in both

the sending and receiving eyes will glow steadily if

wiring connections and alignment are correct.

The sending eye indicator lightwill glow regardless

of alignment or obstruction. If the indicator light is

off dim or flickering in the receiving eye (and the

invisible light beam path is not obstructed),

alignment is required.

• Loosen the sending eye wing nut and re-adjust,

aiming directly at the receiving eye. Look in place.

• Loosen the receiving eye wing nut and adjust

sensor vertically and/or horizontally until it receives

the sender's beam. When the green indicator light

glows steadily, tighten the wing nut.

Figure 6

114-20x 1-1/2°

FlexBoat

Trouble Shooting

1. If the sending eye indicator light does not glow

steadily after installation, check for:.

• Electric power to the opener.

• A short in the white or white/black wires. These

can occur under staples or at screw terminal

connections.

• Incorrect wiring between sensors and opener.

• An open wire (wire break).

2. If the sending eye indicator light glows steadily but

the receiving eye indicator light doesn't:

• Check alignment.

• Check for an open wire to the receiving eye.

3. If the receiving eye indicator light is dim, realign

either sensor.

NOTE: When the invisible beam path is obstructed or

miseligned while the door is closing, the door will

reverse. If the door is already open, it will not close.

The opener lights will flash 10 times. (If bulbs are not

installed, 10 clicks are audible.) See page 21.

Hardware Shown Actual Slze

1/4-20 x 1-I/2"

HI,II,l,l,I;liiI,%II,I,I,I,D

Bel Wire __ Rn_'md --

Ceiling

Figure 7

BellWire

ConnectWire to

OpenerTerminals

DoorControl Sensor

Connectloes_ Con_ections

(dottedline) .-.

[]

OPENER TERMINAL SCREWS

InvisibleLightBum

ProtectionArea

Sensor

23

Page 24

Installation Step 11

Fasten Door Bracket

Follow instructions which apply to your door

type as illustrated below or on page 25.

A horizontal brace should be long enough to be secured to 2 vertical supports. A vertical brace should

cover the height of the top panel.

The illustration shows one piece of angle iron as the horizontal brace. For the vertical brace, 2 pieces of

angle iron are used to create a "U"-shaped support. The best solution is to check with your garage door

manufacturer for an opener installation door reinforcement kit.

I I! _-_---tTIJ"___.etc)-_,Pr°_) t-igure 1

r

To prevent damage to steel, aluminum,

fiberglass or glass panel doors, always

reinforce the inside of the door both vertically

and horizontally with an angle iron.

II\H =*

• Center the door bracket on the previously marked

vertical guideline used for the header bracket

installation. Note the correct UP placement, as

stamped inside the bracket.

• Position the bracket on the face of the door within

the following limits:

A) The top edge of the bracket 2'-4" below the top

edge of the door.

S) The top edge of the bracket directly below any

structural support across the top of the door.

• Mark and ddll 5/16" left and right fastening holes.

Secure the bracket as shown in Figure I if there is

vertical reinforcement.

Ifyour installation doesn't require vertical reinforce-

ment but does need top and bottom fastening holes

for the door bracket, fasten as shown in Figure 2.

""---- Carriage Bolt. UP

_.=deEd_ Figure 2

of Door ot

Reinforcement Board

!i_ .P.-i=_

Door Bracket

Hardware Shown Actual Size

©

Nut 5/16--18 l.ockWasher 5/16"

IIIIIIIIIIIII11IIIllll111111111111

5/16--18 x 2-1/2"

24

Page 25

Please read and comply with the warnings and reinforcement instructions on page 24.

They apply to one-piece doors also.

• Center the bracket on the top of the door, in line

with the header bracket as shown. Mark holes

• Ddl! 5/16" pilot holes and fasten the door bracket

with hardware supplied,

If the door has no exposed framing, drill 3/16" pilot

holes and fasten the bracket with 5/16=x1-I/2" lag

screws (not provided) to the top of the door.

The door bracket may be installed on the top

edge of the door if required for your installation.

(Refer to the dotted line optional placement

drawing.) Drill 3/16" pilot holes and substitute

5/16"x1-1/2" lag screws (not provided) to fasten

the bracket to the door.

Hardware Shown Actual Size

©

I_.< _16"-18 LockWashe_ 5/_6"

5/1_'-1_t X2-1/2 =

k

25

Page 26

Installation Step 12

Connect Door Arm to Trolley

Follow Instructions which apply to your door

type as illustrated below and on page 27.

Make sure garage door is fully closed. Pull the emergency release handle to disconnect the outer trolley

from the inner trolley. Slide the outer trolley back (away from the door) about 2" as shown in

Figures 1, 2 and 3.

Figure 1:

Fasten straight door arm section to outer trolley

with the 5/16"x1" clevis pin. Secure the connection

with a ring fastener.

Fasten curved door arm to the door bracket in the

same way, using the 5/16 "xI -1/4" clevis pin.

Inner Trolley

Figure 2:

• Bring arm sections together. Find two pairs of holes

that line up and join sections. Select holes as far

apart as possible to increase door arm rigidity.

Ring

Fastener

5/16"x1"

/

/

0 Ooor

', BPac_et

5/16"x1-1/4" v Door Arm

Figure 3:

• If holes in curved arm are above holes in straight

arm, disconnect straight arm. Cut about 6" from

the solid end. Reconnect to trolley with cut end

down as shown.

Bring arm sections togeg_er.

Find two pairs of holes that line up and join with

screws, lock washers and nuts.

Hardware Shown Actual Size

Do_ Am1

Figure I ooo,e._t Figure 2

Hole Alignment Alternative

"_ S116"-18xTi8"

• 5/16"

Nut 5/16" - 18 Lock Washer 5/16" r

_Pg'l C_Nn

sit6"x1"(Tfot_ey)

Proceed to Adjustment Step 1, page 28. Trolley will re-engage automatically when the opener is operated.

5/16"x1-114" (Door B_lcket) 5/16"- 18 x 7/_"

He_ Screw

26

Figure 3

Page 27

AssembletheDoorArm:

• Fasten the straight and curved door arm sections ooor

together to the longest possible length (with a 2 or

3 hole ovedap).

• With the door closed, connect the straight door arm

section to the door bracket with the 5/16"xl -1/4" cle_sF_n

clevis pin. _ls'xl.t/4"

• Secure with a ring fastener.

On one-piece doors, before connectingthe door arm to _ trolleythe travel limitsmust be adjusted. Limitadjustment

screws are located on the left side panel as shown on page 28. Follow adjustment procedure s below.

FuUyClosed

Trolley

SctN

5/16"-18X7/8

PJ_

.......... .....

....... •-_ o o ° . Do(x Ann

.._ _,.,A' _ Conne_of Hole

................ .:22222JJI

....... t .....--'°l......

I

Adjustment Procedures for One-Piece Doors

Open Door Adjustment:

Decrease UP limit

• Turn the UP limit adjustment screw counter-

clockwise 5-1/2 turns.

• Press the Door Control push bar or button. The

trolley will travel to the fully open position.

• Manually raise the door to the open position

(parallel to the floor), and lift the door arm to the

trolley. The arm should touch the trolley just in

back of the door arm connector hole. Refer to the

fully open trolley/door arm positions in the

illustration. If the arm does not extend far enough,

adjust the limit further. One full tum equals 2" of

trolley travel.

• Turn the DOWN limit adjustment screw clockwise 5

complete turns.

• Press the Door Control push bar or button. The

trolley will travel to the fully closed position.

• Manually close the door and liftthe door arm to the

trolley. The arm should touch the trolley just ahead

of the door arm connector hole. Refer to the fully

closed trolley/door arm positions in the illustration. If

the arm is behind the connector hole, adjust the limit

further. One full turn equals 2" of trolley travel.

Closed Door Adjustment:

Decrease DOWN limit

Connect the door arm to the trolley,

• Close the door and join the curved arm to the connector hole in the trolley with the remaining clevis pin. It may

be necessary to lift the door slightly to make the connection.

• Secure with a dng fastener.

• Run the opener through a complete travel cycle. If the door has a slight "backward" slant in full open position

as shown inthe illustration, decrease the UP limit until the door is parallel to the floor.

27

Page 28

Adjustment Section: Pages 28 - 30

Adjustment Step 1

Adjust the UP and DOWN Limits

Do not make any limit adjustments until the

safety reversing sensors are completely

installed.

Limit adjustment settings regulate the points at

which the door wilt stopwhen moving up or down.

The door will stop i6the up direction if anything

interferes with door travel. The door will reverse in

the down direction if anything interferes with the

door travel (including binding or unbalanced doors).

To operate the opener, press the Door Control push

button. Run the opener through a complete tra,_el

cycle.

• Does the door open and close completely?

Does the door stay closed and not reverse

unintentionally when fully closed?

f your door passes both of these tests, no limit

adjustments are necessary unless the reversing test

fails (See page 30).

Cover /

Protection

Bo_t

LeftSidePanel

Umit

Adju=lr_.mt

Screws

Adjustment procedures are outlined below. Run the

opener through a complete travel cycle after

each adjustment.

Repeated operation of the opener during adjustment

)rocedures may cause the motor to overheat and

shut off. Simp/y wait 15 minutes and try again.

Read the procedures carefully before continuing on

to Adjustment Step 2. Use a screwdriver to make

limit adjustments.

How and When to Adjust the Limits

• If the door does not open completely

but opens at least five feet:

Increase up travel. Turn the UP limit adjustment

screw clockwise. One turn equals 2" of travel.

NOTE: To prevent the trolley from hitting the

cover protection bolt, keep a minimum distance

of 2-4" between the trolley and the bolt.

• If door does not open at least 5 feet:

Adjust the UP (open) force as explained in

Adjustment Step 2.

• If the door does not close completely:

Increase down travel. Turn the DOWN limit

adjustment screw counterclockwise. One turn

equals 2" of travel.

If door still won't close completely and the trolley

bumps into the pulley bracket (see page 4 or 5), try

lengthening the door arm. (see page 26).

Adjustment Label

If you have adjusted the door arm to the maximum

length and the door stillwill not close completely,

lower the header bracket. See Installation Step 1,

pages 12 and 13.

• If the opener reverses In fully closed position:

Decrease down travel. Turn the DOWN limit

adjustment screw clockwise. One turn equals 2" of

travel.

• If the door reverses when closing and

there is no visible Interference to travel cycle:

If the opener lights are flashing, the Safety Reversing

Sensors are either not installed, misaligned, or

obstructed. See Troubleshooting, page 23.

Test the door for binding: Pull the emergency release

handle. Manually open and close the door. If the door

is binding, call for garage door service. If the door is

not binding or unbalanced, adjust the DOWN (close)

force. See Adjustment Step 2.

28

Page 29

Adjustment Step 2

Adjust the Force

Force adjustment controls are located on the back

_anel of the opener. Force adjustment settings

regulate the amount of power required to open and

close the door.

The door will stop in the up direction if anything

interferes with its travel The door will reverse in the

down direction if anything interferes with its travel

(including binding or unbalanced doors).

If the forces are set too light, door travel may be

interrupted by nuisance reversals in the down

direction and stops in the up direction. Weather

conditions can affect the door movement, so

occasional adjustment may be needed.

The maximum force adjustment range is 260 degrees,

about 3/4 of a complete turn. Do not force controls

beyond that point. Turn force adjustment controls

with a screwdriver.

WARNING

I

Too much force on the door will interfere with

the proper operation of the safety reverse

system. The door might not reverse properly

when required and could seriously injure or kill

someone under iL Do not increase the force

beyond the minimum amount required to close

the door. Do not use the force adjustments to

compensate for a binding or sticking garage

door. Test the safety reverse system following

all adjustments to force levels. See page 30.

Backpanel of

dooropener " Force

\ Ad|uslmlmt

AdjusUnentLabel

How and When to Adjust the Forces

Test the DOWN (close) force

Grasp the door bottom when the door is about

halfway through DOWN (close) travel. The door

should reverse. Reversal halfway through down

travel does not guarantee reversal on a one-inch

obstruction. See page 30. If the door is hard to

hold or doesn't reverse, decrease the DOWN (close)

force by turning the control counterclockwise.

Make 10 degree turn adjustments until the door

reverses normally. After each adjustment, run the

opener through acomplete cycle.

Test the UP (open) force

Grasp the door bottom when the door is about

halfway through UP (open) travel. The door should

stop. If the door is hard to hold or doesn't stop,

decrease UP (open) force by tuming the control

counterclockwise.

Make 10 degree turn adjustments untilthe door stops

easily. After each adjustment, run the opener through

a complete travel cycle.

If the door doesn't open at least 5 feet

Increase UP (Open) force by turningthe control

clockwise. Make 10 degree turn adjustments until

door opens completely. Re-adjust the UP limit if

necessary. After each adjustment, run the opener

through a complete travel cycle.

If the door reverses during the down (close) cycle

and the opener lights aren't flashing

Increase DOWN (close) force by turning the control

clockwise. Make 10 degree turn adjustments until the

door completes a close cycle. After each adjustment,

run the opener through a complete travel cycle. Do

not increase the force beyond the minimum

amount required to close the door.

29

Page 30

Adjustment Step 3

Test The Safety Reversing Sensor

• Press the remote control push buttonto open the

door.

• Place the opener carton in the path of the door.

• Press the remote control push button to close the

door. The door will not move more than an inch,

and the opener light will flash.

Professional serv.lce is required if the opener

closes the door when the safety reversing

sensor is obstructed.

The garage door opener will not close from a

remote control if the Indicator light In either

sensor is off(alerting you to the fact that the

sensor is mlseligned or obstructed).

The garage door can be dosed by pressingand

holding the Door Control push button untildown

travel is completed.

Adjustment Step 4

Test the Safety Reverse System

I

I

Test:

• Place a one-inch board (or a 2x4 laid flat) on the

floor, centered under the garage door.

• Operate the door in the down direction. The door

must reverse on striking the obstruction.

Adjustment:

If the door stops on the obstruction, it is not traveling

far enough in the down direction.

• Increase the DOWN limit by turningthe DOWN

limitadjustment screw counterclockwise 1/4 turn.

• Repeat the test.

On a sectional door, make sure limit adjustments

do not force the door arm beyond a straight up

and down position. See the illustration on page 26.

• When the door reverses on the one-inch board,

remove the obstruction and run the opener through

3 or 4 complete travel cycles to test adjustment.

If the door will not reverse after repeated

adjustment attempts, call Sears Service Center

for garage door opener service.

L_

-

Important safety check

Repeat Adjustment Steps 1, 2 and 4 after:

• Each adjustment of door arm length, force controls

or limitcontrols.

• Any repair to or adjustment of the garage door

(including springsand hardware).

• Any repair to or buckling of the garage floor.

• Any repair to or adjustment of the opener.

3O

Page 31

IMPORTANT SAFETY INSTRUCTIONS

' ':-, ;,.i ! WARNING

f.. , , , , , i i

To reduce the risk of severe injury or death to persons:

1. READ AND FOLLOW ALL INSTRUCTIONS.

2. Do not permit children either to operate or to

play with the opener. Keep remote control In a

location inaccessible to children.

3. Operate opener only when the door is in full

view and free from any obstruction. Keep the

door in sight until it is completely closed. NO

ONE SHOULD CROSS THE PATH OF THE

MOVING DOOR.

4. Check safety reversal system monthly. See

page 30. The garage door MUST reverse on

contact with a one-inch (or a 2x4 board I.ald

flat) object placed on the floor. If an adjustment

is made to either the force or the limit of travel,

both adjustments may be needed and the

safety reversal system must be checked.

Failure to properly adjust the opener may

result in severe injury or death.

5. If possible, use the emergency release only

when the deer is in a closed position. Caution

should be taken whenever the disconnect cord

is actuated with the door open. Weak or broken

springs may cause the door to fall rapidly,

causing injury or death to persons.

6. KEEP GARAGE DOORS PROPERLY

BALANCED. See page 3. An improperly

balanced door may not reverse when required

and could result in severe injury or death.

Repairs to cables, spring assemblies and other

hardware must be made by a professional

garage door person.

7. Disconnect the electric power to the garage

door opener before making any repairs or

removing the covers.

s.SAVE THESE INSTRUCTIONS.

Care of Your Opener

Limit and force adjustment controls

Limit Controls Force Controls

AdjustmentLabel AdJu_at_mtLabe/

(Locatedon the le/tsidepanel] (Locatedon therightside panel)

Weather conditions may cause some minor

changes In door operation requiring some re-

adjustments, particularly during the first year of

operation.

Pages 28 and 29 refer to the limitand force

adjustments. Only a screwdriver is required. Follow

the instructions carefully.

Repeat the safety reverse test (page 30) after any

adjustment of limits or force.

Maintenance Schedule

Once a Month

Manually operate door. if it is unbalanced or

binding, call for professional garage door service.

Check to be sure door opens & closes fully.

Adjust limits and/or force it necessary.

(See pages 28 and 29.)

Repeat the safety reverse test. Make any

necessary adjustments (See page 30).

The remote control

The lithium batteries should

produce power for up to

5 years. To replace batteries,

use the visor clip or screwdriver

blade to pry open the case, as

shown. (UOpen"location is

stamped on back of remote

control case.) Insert batteries positive side down.

Replace cover as follows. 3-Function remote: insert

the 3 tabs at the opposite end and snap shut. Compact

3-Function remote: Snap shut along bothsides.

Dispose of old batteries properly.

Twice a Year

Check chain tension. Disconnect trolley first.

Adjust if necessary (See page 11).

Once a Year

Oil door rollers, bearings and hinges. The opener

does not require additional lubrication. Do not

grease the door tracks.

3-FUNCTION

Openthls end

Twist hem

COMPAC

to oden

31

Page 32

Operation of Your Opener

Activate the opener with any of the following:

• The Remote Control: Hold push button down until

the door starts to move.

• The Door Control: Hold push button down until the

door starts to move.

• The Outdoor Key Switch or Keyless Entry.

(See Accessories)

When the opener is activated with the safety

reversing sensor installed and correcUy aligned:

1. If open, the door will close. If closed, the door will

open.

2. If closing, the door will reverse.

3. If opening, the door willstop (allowing space for

entry and exit of pets and for fresh air).

4. If the door has been stopped in a partially open

position, itwill close.

5. If obstructed while closing, the door will reverse.

6. if obstructed while opening, the door will stop.

7. The garage door will reverse in the closingcycle when

the invisiblebeam is broken,if fullyopen, the door will

notclose when the beam is broken. The sensor has

no effect in the opening cycle.

If the sensor is not installed or not aligned correctly,

the door won't close from any remote control. You can

close the door with the Door Control, the Outdoor Key

Switch, or Keyless Entry, however, ifyou activate

them until down travel is complete. If you release them

too soon, the door will reverse.

The opener lights will blink for 5 seconds when the

safety reversing sensor causes the door to reverse.

The Opener Lights will turnon under the following

conditions:When the opener is initiallyplugged in; when

the power is interrupted;whenthe opener is activated.

They will turn offautomatically after 4-1/2 minutes or

provide constant light when the Light feature on the

Premium Control Console is activated. SECURITY,I,

models: Lights will also turn on when someone walks

through the open garage door. Bulb size is 75 watts

maximum.

Weak or broken springs could allow an open

door to fall (either rapidly or unexpectedly),

resulting in serious injury, death or property

damage. If possible, use the emergency

release rope and handle only when the door is

fully closed.

To open the door

manually:

The door should be

fully closed if possible.

Pulldown on the red

emergency release

handle and liftthe door

manually. To

Emergency

Release Handle

(Pull Down)

Manual disconnect

position

reconnect the door to

the opener, press the

Door Control push

button.

The lockout feature

prevents the trolley

from reconnecting

automatically. Pull the

O _ . Trolley

Release Arm

emergency handle

down and back (toward

the opener). The door

can then be raised and

lowered manually as

often as necessary. To

disengage the lookout

feature, pull the

emergency handle

Lockout position

Emergency

Release Handle

(PullDoom& Back

Towards Opener)

straight down. The

trolley will reconnect on

the next UP or DOWN

operation.

Operation of the Door Controls (see page 18)

(SECURITY.I, models: See additional programming features, next page.)

Press the lighted push button to open or close the

door.

Press again to reverse the door during the closing

cycle or to stop the door while it's opening.

Premium Console:

Light feature: Press the large round Light button, if

the opener light is off, itwill tum on. If the opener

light is on, (even in the 4-1/2 minute automatic

cycle) itwill turn off.

But if you use the Light button to turn the lights on

and then activate the opener, the lights will turn off

after 4-1/2 minutes.

The Light button will not control the opener lights

when the door is in motion.

Premium Console (cont.):

Lock feature: The Lock feature is designed to

prevent operation of the door from remote controls.

However, the door will open and close from the

Door Control, the Outdoor Key Switch and the

Keyless Entry Accessories.

To activate: Press and hold the small round Lock

button for 2 seconds. The push button light will

flash as long as the Lock feature is on.

To turn off: Press and hold the Lock button again

for 2 seconds.The push button light will stop

flashing. The Lock feature willalso turn off

whenever the SRT button on the opener panel is

activated.

32

Page 33

Receiver and Remote Control Programming

SECURITY

Your garage door opener receiver and remote control

have been pre-set at the factory. The door will open

when you press the LARGE remote control push

button. The code between the remote control and the

receiver changes with each use, randomly accessing

over 100 billion new codes.

The 3-function remote control can also activate

additional SECURITY+ garage door openers and/or

light controls.

Your SECURITY+ opener will operate with:

• several SECURITY+ remote controls (with blue

push buttons) utilizing up to 8 functions.

• one SECURITY+ Keyless Entry System

(Model 139.53684).

Follow the instmctionsbelow to program your opener

to match any additional remotes you may purchase.

See Accessories on page 38.

To Add A Remote Control

If you have a Premium Control Console:

1. With the door closed, press and hold a remote

control push button. See Figure 1.

2. Press and hold the Light button on the door

control.

3. Press and hold the door control push button.

4. After the opener lightflashes, release all buttons.

Test by pressing the remote push button.

ff you do not have a Premium Control Console:

1. Press and holdthe selected remote control push

button. See Figure 1.

2.Then press and release the SRT (leam) button on

the back panel of the opener, Figure 2. The

indicator light on the panel will begin to blink and

the opener lightwill flash once.

3. Release the remote push button.

Test by pressing the remote push button.

To Erase All Remote Control Codes

Press and hold the SRT button on the opener panel

until the indicator light turns off (about 6 seconds). All

remote control codes are now erased. Then follow

the steps above to re-program each remote control.

To comply with FCO roles, adjustment or modifications of _s receiver and/or

I_ilter are ptohlbited, except for changing the code setling or ,_placing

Ihe battery. THERE ARE NO OTHER USER SERVICEABLE PARTS.

Children operating or playing with a garage

door opener can injure themselves or others.

The garage door could close and cause serious

injury or death. Do not allow children to operate

the door push button(s) or remote control(s).

A moving garage door could injure or kill

someone under it. Activate the opener only

when you can sea the door clearly, it is free of

obstructions, and is properly adjusted.

Rgure I

Select= remotecontrolpush

buttonto o_emlo opener

Figure 2

SECURITY,I,

SECURITY'I"

Remote Control

3-Function

.,._O0000tl_ • SRT(leam) Indicator BACK

To Control the Opener Light (Premium Consoles)

With SECURITY.Ik remote controls, a push button can

be programmed to operate the opener lightwithout

opening the door.

1. With the door closed, press and hold the remote

button that you want to control the light.

2. Press and hold the Light button on the door

control.

3. Press and hold the Lock button on the door control.

4. After the opener light flashes, release all buttons.

Test by pressing the remote push button. The opener

lightshouldturn on or offbut the door shouldnotmove.

Garage Door Opener

Button Ught PANEL

IISO tocatod OIt the opllner _

33

Page 34

Having a Problem?

Situation

The opener doesn't

operate from either

the Door Control or

the remote control:

Opener operates

from the remote

control, but not from

the Door Control:

The door operates

from the Door

Control, but not from

the remote control:

Probable Cause and Solution

1. Does the opener have electric power?.Plug a lamp into the outlet, ffit doesn'tlight,

check the fuse box or the cimuit breaker. (Some outlets are controlled by a wail switch.)

2. Have you disabled all door locks? Review installation instructionwamings on Page 11.

3. Is there a build-up of ice or snow under the door?.The door may be frozen to the

ground. Remove any restriction.

4. The garage door spring may be broken. Have it replaced.

5. Repeated operation may have tripped the overload protector in the motor. Wait

15 minutes. Try again.

1. Is the Door Control lit? If not, remove the bell wire from the opener terminal screws.

Short the red and white terminals by touching both terminals at the same time with a

piece of wire. If the opener runs, check for a faulty wire connection at the Door

Control, a short under the staples, or a broken wire.

2. Are the wiring connections correct? Review Step 6, page 18.

1. Is any door push button flashing? If your model has the Lock feature, make sure the

lock is Off.

2. Your opener needs to re-learn a remote control code. Refer to instructions on the

opener panel.

3. Program the receiver to match the remote control code.

4. Repeat the receiver programming procedure with all remote controls.

The remote control

has short range:

Opener noise Is

disturbing in living

quarters of home:

The garage door

opens and closes

by Itself:

The door doesn't

open completely:

1. Change the location of the remote control in your car.

2. Check to be sure the antenna on the side or back panel of opener extends fully

downward.

3. Some installations may have shorter range due to a metal door, foil backed

insulation, or metal garage siding. (Antenna Extender Kit 41A3504)

If operational noise is a problem because of proximity of the opener to the living

quarters, the Vibration Isolator Kit 41A3263 can be installed. This kit was designed to

minimize vibration to the house and is easy to install

1. Be sure that all remote control push buttons are off.

2. Remove the bell wire from the Door Control terminals and operate from the remote