Craftsman 139.53635SRT, 139.53637SRT, 139.53824SRT, 139.53425SRT, 139.53325SRT User Manual

...

Model No.

139.53225SRT

139.53325SRT

139.53425SRT

139.53628SRT

139.53629SRT

139.53635SRT

139°53637SRT

139.53824SRT

For Resldentla Use

Read and follow aH safety

rutes and operating

instructions _fore first

use of this product_

Fasten the manuat near

the garage door after

OP

E Safety Precautions

m Assembly

m Installation

H Adjustment

Care and Maintenance

Operation

s Troubleshooting

PaRs List

Complies with UL 325

_egulati_s effe_ve

January 1, 1_3

Sears, Roebuck and Co. Hoffman Estates, IL 60179 UoS.A.

Contents

A review of safety"a_e4symbols 2

Youll need tools 3

Safety information regarding garage deer k_ks

and ropes .............................................................. 3

Testing your garage door for sticking, binding

and balance .................................................................3

H_ustrationd _ion@ d_r instaIla_on .....................4

/l/usl_tio, n of one@i_e @_r inst_tation .................. 5

CP_on inventory ............... :......................................... 6

H_-dware inventory ................................................... 7

Assembly se_on opages 8 - 11

Assemble T--raii................................................... 8

A_ch c,_Ie pulley bracket ...................................... 8

Instil trolley ........................................................... g

P_ten T_r_l }o o_ner ............................................ 9

Inst_sl/cha_r{(_ble ................................................ 10

A_ach sprr_ket _ver ................................................10

_ghten fl_echainemd _e ..................................11

installation section - pages 11 --27

tns*alia_on sdety instr_adJons........................... 11

Detem_ine header bracket I_tion

Se_ionai @y_r...................................................12

One@i_e door.......................................................13

InsteJ/the header b_cket ........................................14

Attd_chf.heTorail to header bracket .........................15

PesitJon_e opener, ..............................................16

H_ng _e opener .....................................................17

Ins_JIthewall_ntro[.....................................18

Contents

hsta_I the _ightand lens ..............................................19

Attach emergency reles_sere;)e and h_dle ..............19

Eiectdoat requirememts ................................................20

Safety reversing _nsor infom_afon ..............................21

tn.sta_l_'_esdety reversing sensor ..........................._, 23

F_ten d_r bracket (se@ona_ d_O ..............................24

Fasten dear bracket (_e@i_ dc_0 ........................... 25

Conne_stdoor _q to #oHe¥ (sedJonat d<_O.................26

_nn¢_ d_r a_ to troliey (on_i_ d_aO .............. 27

Adjustment sc_ion -pages 28 - 30

Travellimitadjustments..........................................28

Force adjustments ...........................................................29

Test the _fe_, reve_ing sensor ......................................3,0

Test U_e_fety _eve_e _ystem ....................................._O

O_raflon _#etyinstm_ions...................................31

Care of your opene_ ...........................................................31

M@n_en_ce _hedule ......................................................3'I

O_ra,_on of your o_ner ................................................ 32

Re_eiver _d remote control pr_mming .................. 33

Ha_ng a premiere? ...................................................._, 35

Rep_r p_ta, rail as_mb_y ............................................... 36

Rep_r parts, instJation ......................................................_3

R_a_r pan.s, e_ner as_rnbly ..........................................37

A_ssor_es ........................................................................_S

Index ..................................................................................39

How to order repair pa_ ..................................................40

M_ntenance agreement ...................................................

Warranty ..........................................................................40

S_M by review!.ng these im_nt safeb_ aleM symbols

When you see th_s Safety Symbol on the following pages, it will aIeA you to the possibility of damage

to your garage door anNor the garage door opener if you do eot comply with the corresponding

instruct_onso Read the instpacdons carefu#y.

This garage door opener is designed and tested to offer safe service provided it Is Installed, operated_

mainta_ned and tested tn strict accordance with the safety Instructions contained tn this manual

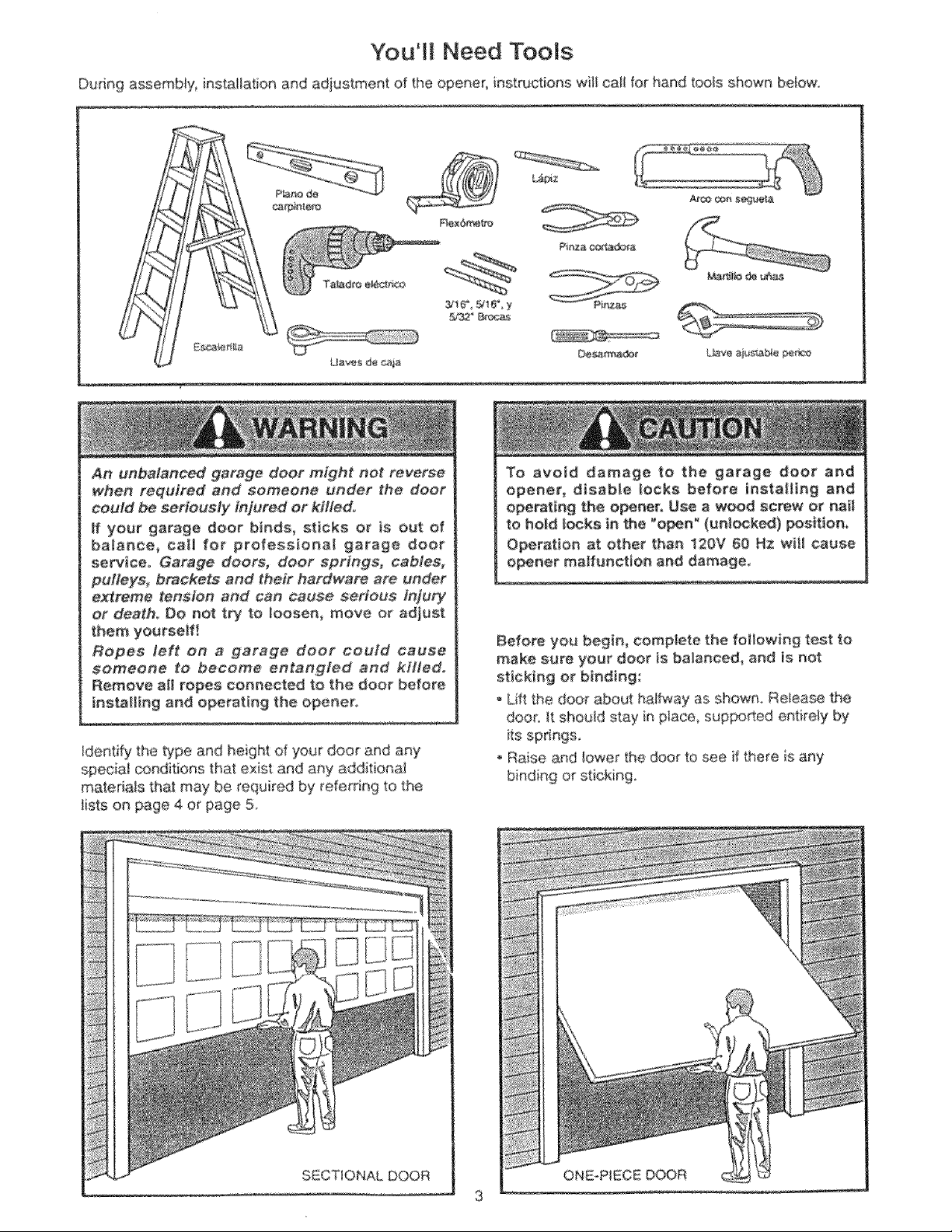

You'll Need Tools

Dudng assembly, installation and adjustment of the opener, instructions will call for hand too_sshown befowo

_16_ 9'16% y

Uaves de caja

An unbalanced garage door might not reverse

when required and someone under the door

could be seriously injured or killed,

If your garage door binds, sticks or ts oat of

balance, call for professional garage door

service, Garage doors, door springs, cablea,

pulleys, brackets and their hardware are under

extreme tension and can cause serious inJuc¢

or death, Do not try to loosen, move or adjust

them yourselft

Ropes left on a garage door could cause

someone to become entangled and killed.

Remove all ropes connected to the door before

installing and operating the opener.

Identify the type and height of your door and any

speeia_ conditions that exist and any additional

matedais that may be required by referring to the

lists on page 4 or page 5

To avoid damage to the garage door and

opener, disable locks before installing and

ope_ttng the opener, U_ a w_d screw or nail

to ho_d locke in _he "O_n" (unlike) _sttion,

Operation at other tha_ 120V 60 Ha wiil cause

o_eer maffunct_om and damage,

Before you begin, complete the following test to

make sure your door is balanced, and }s not

sticking or binding;

- Lift the door about hatfway as shown, Re_ease the

door, _tsho@d stay in place, sup_ded entire_y by

its spdngs,

, Raise and _ower the door to see if there is any

SECTIONAL DOOR

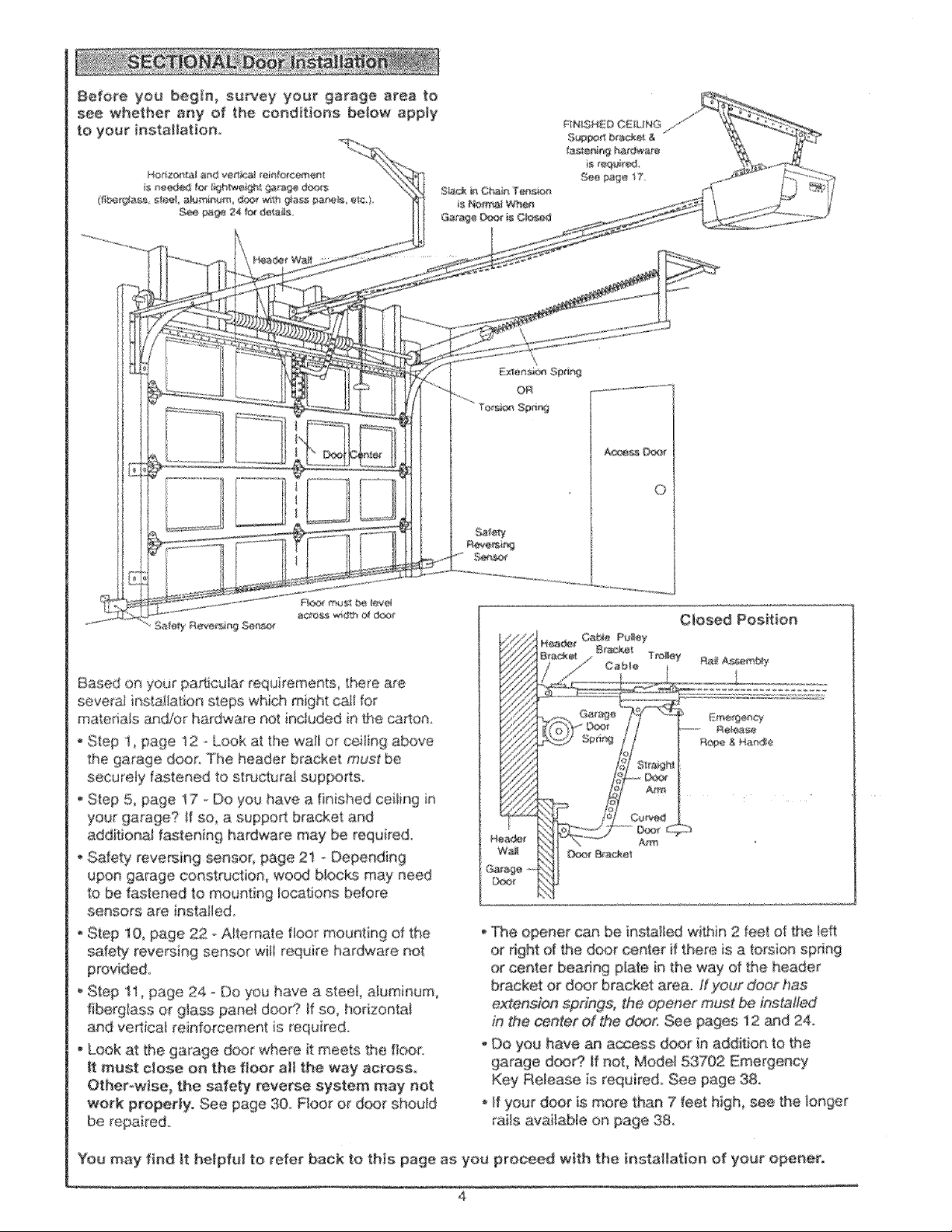

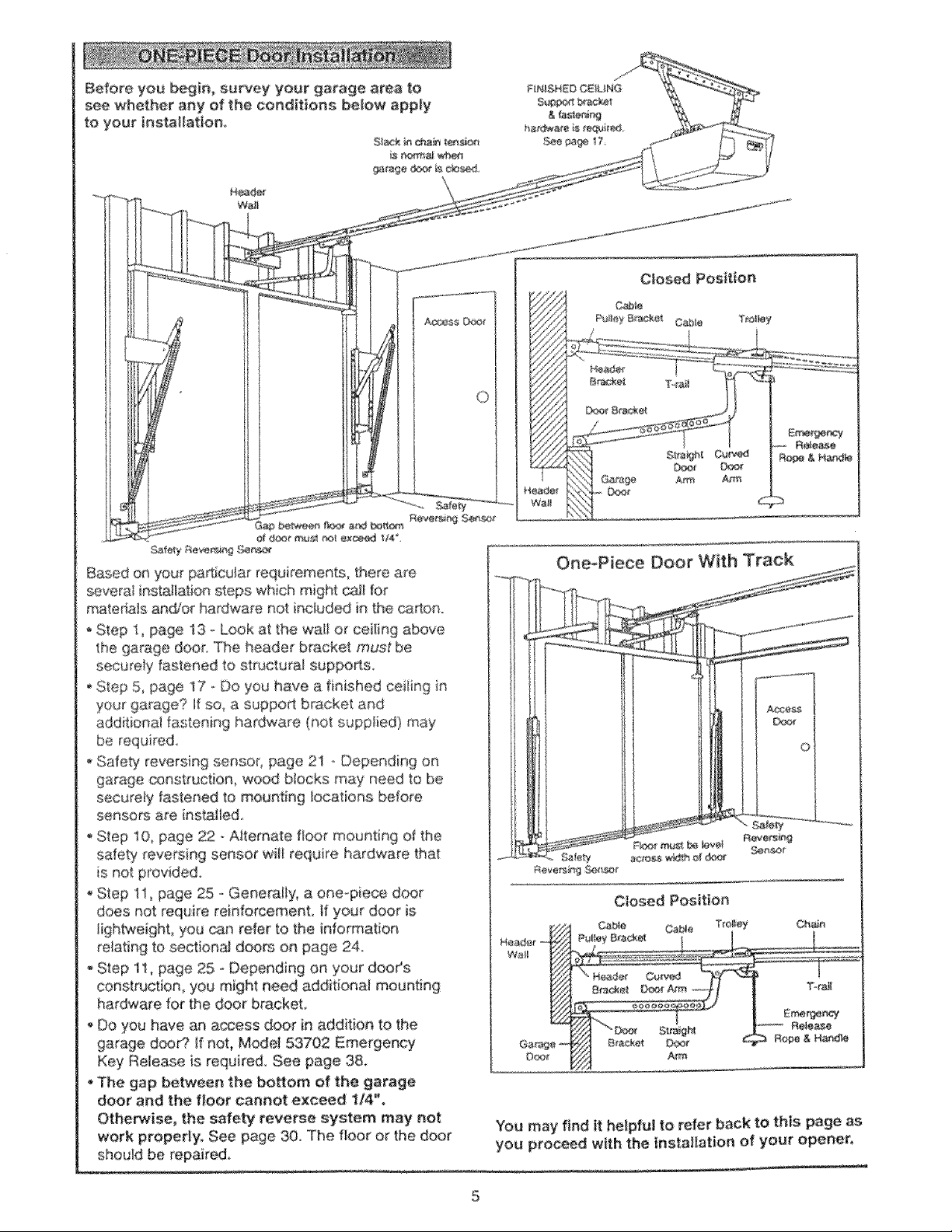

Before you begin, su_ey your garage area to

see whether any of the conditions below apply

O

Based on your particular requirements, there are

severaI installation steps which might call for

materials and!or hardware not included in the carton.

,_Step 1 page ! 2 - Look at the wail or ceiling above

the garage door. The header bracket must be

securety fastened to stn3ctura_sup_rts.

,, Step 5, page 17 - Do you have a finished ceiling in

your garage? if so, a suppo_ bracket and

additional fastening hardware may be required.

Safety* reve_ing sensor, page 21 _Depending

upon gauge constructioe, wo¢_ blocks may need

to be fastened to mounting locations before

sensors are installed.

, Step 10, page 22 _Alternate floor mounting of the

safety reversing sensor will require hardware not

, Step 11, page 24 oDo you have a steel, aluminum,

fiberglass or g!_ss panel dood* if so, hodzontai

and recital reinforcement is required.

, Look at the garage door where it meets the fioor.

it must close o# the floor sit the way across.

Other_wlse, the safety reverse system may _ot

work properlyo See page 30. Floor or d_r should

be repaired.

oThe opener c_ be installed within 2 feet of the ieR

or dght of the door _e_er if there is a torsion spnng

or center bearing plate in the way d the header

bracket or d_r bracket area_ if.your door has

the opener must be insta#ed

in the center of the d_ See pages 12 &qd 24.

• Do you have _q a_ess door in addition to the

garage d_ if not, Model 53702 Emergency

Key Re_ease is required, See page 38.

, If your door is more than 7 feet high, see the longer

raiis available on page 38,

You may find it helpful to refer back to this page as you proceed with the _nstaitatton of your opener:

4

0

Based on your particular requirements, there are

several insIailation steps which might _l br

materials @qS_orhardware not included in _e _&£on

Step I, page 13 oLook at the wafl o{ ceiiing above

the garage door. 'The header bracket must be

securely fastened to structural suppo_ls

* Step 5_page t7 oDo you have a finished ceiling in

your garage? If so, a suppo£ bracket and

add tiona! fastening hardware (riot supplied) may

be required.

, Safety reversing sensor, page 21 Depending on

garage construction, wood blocks may need to be

securety fastened to mounting Iocations before

senso_ are installed.

Step 10, page 22 - Alternate floor mounting of the

safety reversing sensor will require hardware that

is not provided.

Step 11, page 25 _Generally, a one pie_ door

does not require reinforcemenL tf your door is

lightweight, you _e refer to the information

relating to section_ doors on page 24.

,,Step 11, page 25 _Depending on your dooCs

construction, you might need additional mounting

hardware for the door brackeL

oDo you have an a_ess door in addition to the

garage dc_r? if not, Model 53702 Emergency

Key Release is required. See page 38

, The gap between the bo_om of the garage

door and the floor cannot exceed 1/4".

Otherwise, the safety reverse system may not

work properly. See page 30. The floor or the door

should be repaired

One-Piece Door With Track

You may find it helpful to refer back to this page as

you proceed with the installation of your o_ner.

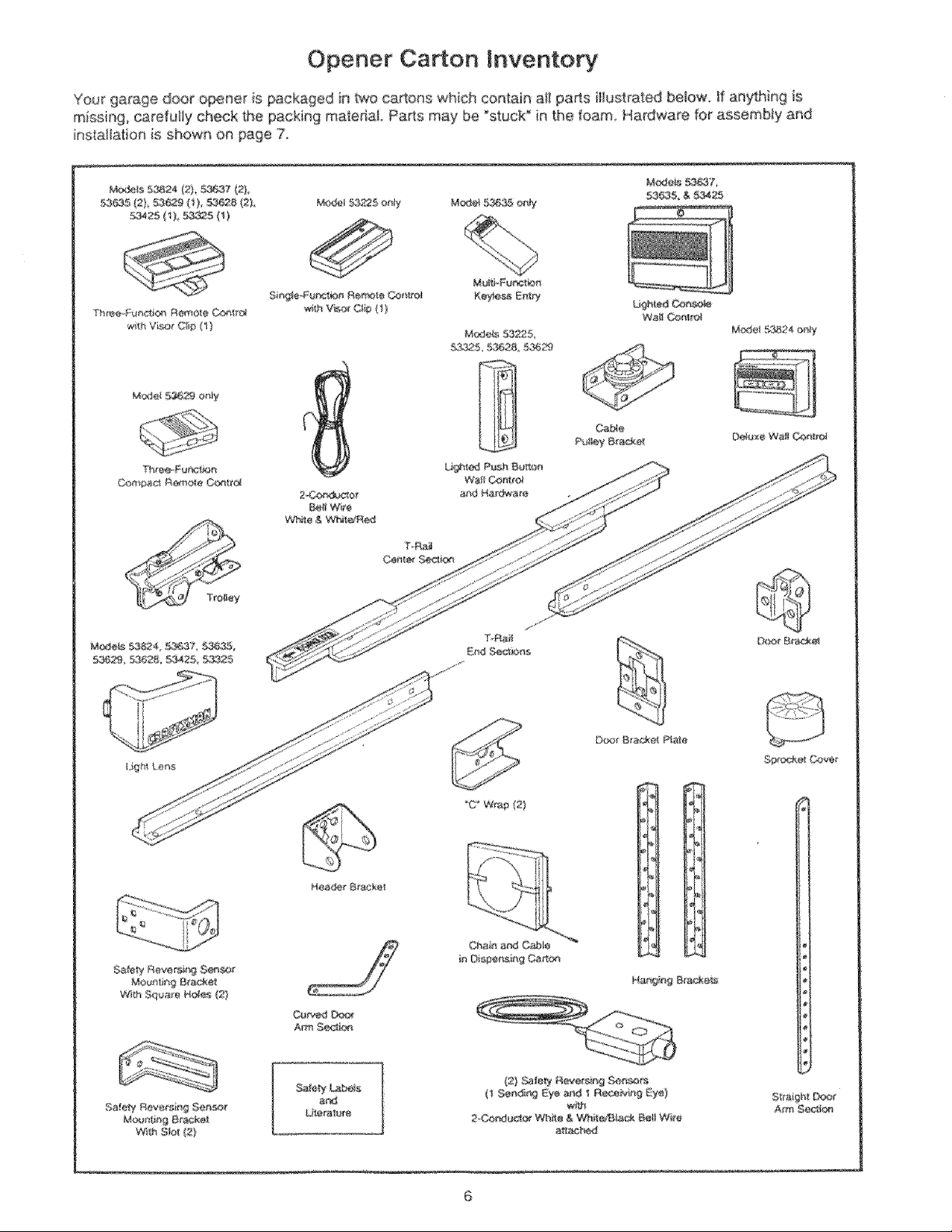

Opener CaAon Inventory

Your garage door o2_ner is packaged in two ca_ons which contain at_pa_s illustrated b@[ow,_fanylhing is

missing_ carefu!!y check the packing matedaL PaAs may be "stuck" in Me foam_ Hardware for assembly and

installation is shown on page 7

5_25 ('9, 5_5 (1)

Ugh_ed C4_

M_x_ieb 93225

Model 5_ e¢_y

Compa_ R_o{e C_tt_

M_¢_ S[_24 or'4y

S4sfe_yRevergr_ £s_50{

_@ua_ng Bta_

V_4_hSquare H_@_ (2}

Safety Revers_g Sen_

Wth S_ (2)

_4ea_r Bt_ke_

C_'_aimar_8 C@lm

Arm _

6

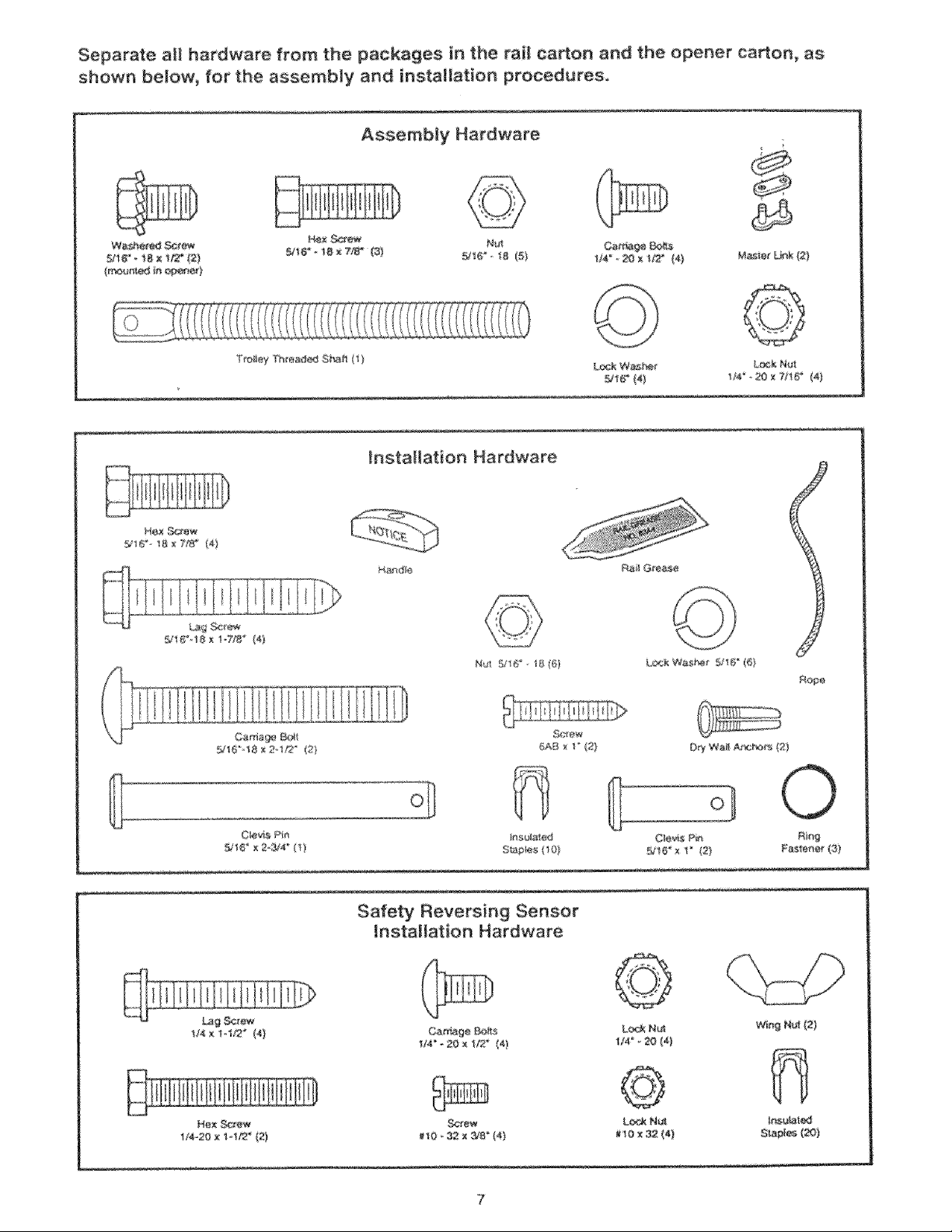

Separate all hardware from the packages in the rail carton and the opener carton, as

shown below, for the assembly and installation procedures.

AssembLy Hardware

T_o_ey ThCe_d_ Sh_ (1}

_16 _ {4} I/4 _ 20 _ 7/16 _ (4}

Installation Hardware

,,.-'_1¢*_8 _ _o;b__ (4)

H_,_d_ R_t Gte_

NL4 _ _8i6t

Ro?e

Safety Reversing Sensor

Installation Hardware

Hex _¢_w

i/_-20 _ 11_" (2)

Ca_ge _Rs Lo_ N_ _,/i#gN_ (2)

_/4"- 20× 1_" (4) _/4" _ (4)

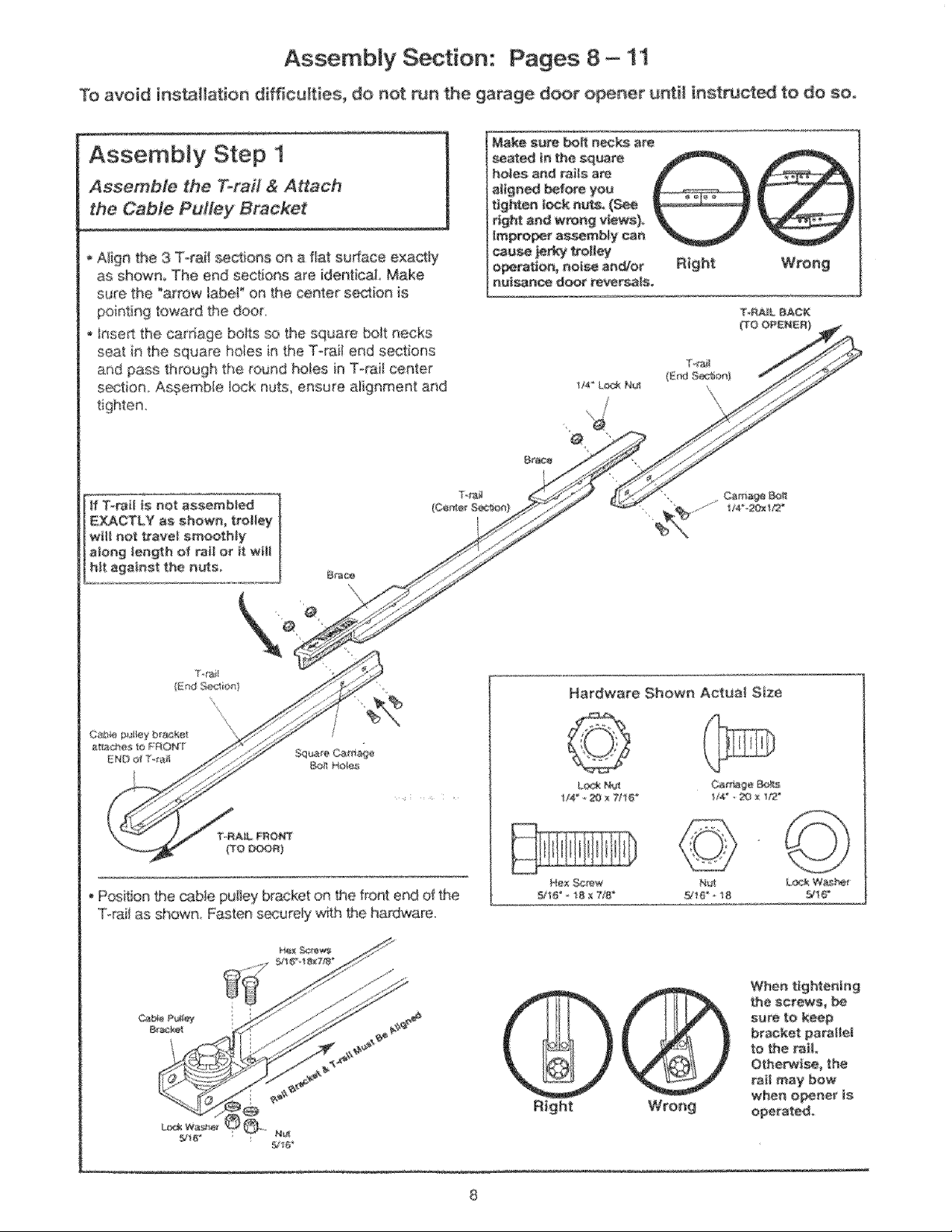

Assembly Section: Pages 8- 11

To avoid installation d:mcu[ties, do not run the gauge d_r opener until :nst_ to do so.

Ma_ sure _ n_ks are

tig_en i_k nuts {_

, Align _e 3 Torai_se_ons on a fiat suRace exactty

as shown° The end sections are identical Make

sure the "arrow labet° on the center se_ion is

pointing toward the door..

, Inse_ the carnage bolts so the square bolt necks

seat in the square holes in the T-rai! end sections

and pass through the round holes in T_rait center

section. Assemble lock nuts, ensure alignment and

%

o_ratJon, nef_ anddOr

aa_n_ d_ re_r_lm

Hardware Shown Actual S:ze

END of "T _a_l

, Pos_on #_e_ble putiey bracket on #_efront end:of the

T_raiias shown Fasten s_cure_yv_4th_e hardware,

_16 _ 18×;7/8" Sd!6_ 18 _1_

Whe_ t_ghte_ing

_e sorews_

tO t_herail

Otherwise, the

whe_ o_aer _s

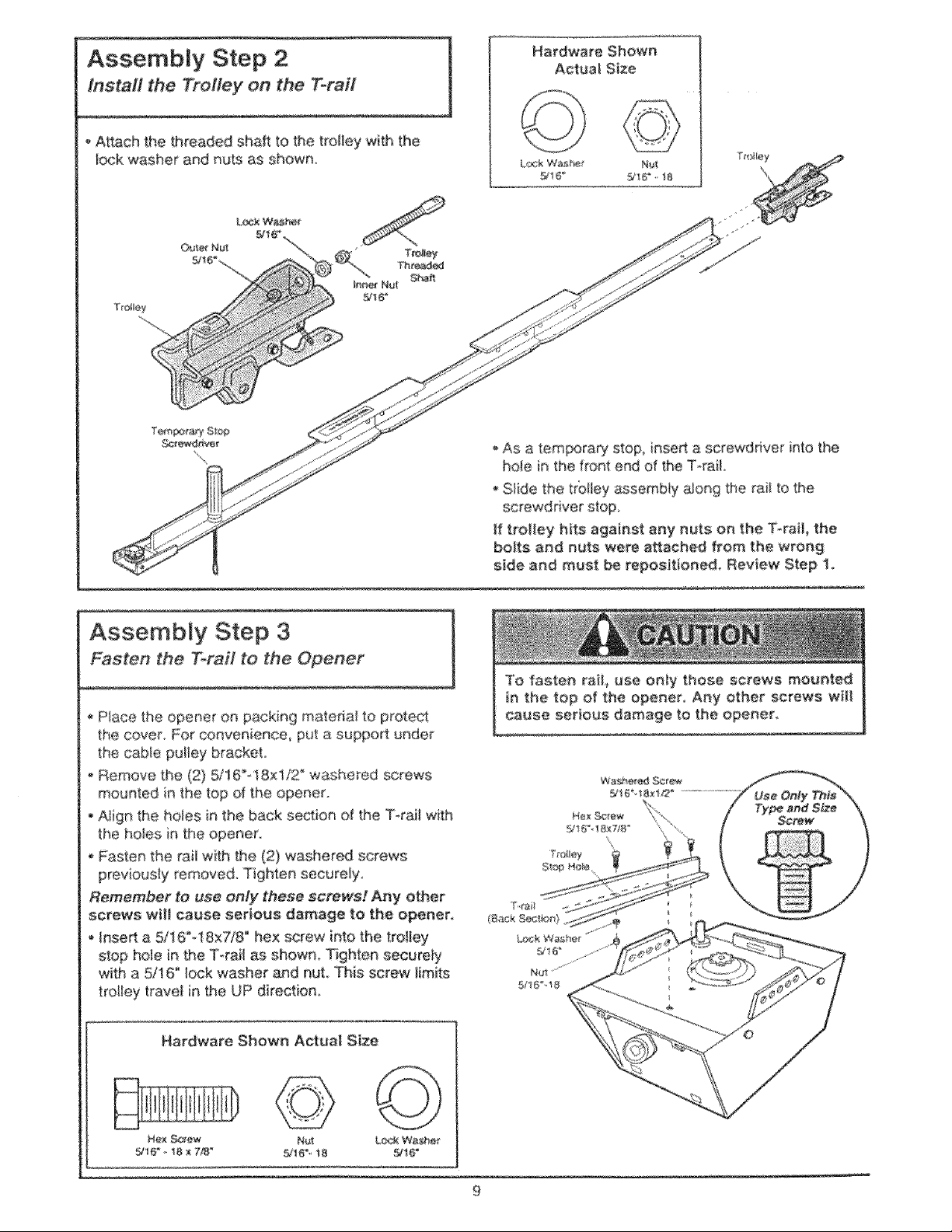

Assembly Step 2

Install the Trolley on the T_ra#

Hardware Shown

Actua_ Size

- Attach the threaded sha_ to the trotley wi_ the

I_xckwasher and nuts as shown

L¢_k W_;_t Nut

_'16" _1_ _ ,, 18

Trolley

As a tem_rary stop. insed a screwdnver into the

hole in the front end d the %rait.

Slide the trolley assembly _ong the rail to the

screwdriver stop

if trolley hits against any nuts on the T_rai_,the

bolts and Ruts were attached from the wrong

side and must _ reposittoned. Review Step 1.

Assembly Step 3

Fasten the T-rail to the Opener

Place the opener on packing material to protect

the cover. For coevenience, pat a support under

the came pui_ey brackeL

Remove the (2) 5/I6_18×1/2 _ washered _rews

mounted in the top d the opener_

- Atign the holes in the back seGion of the %r'ai_with

the holes in the opener.

* Fasten the rail with _e (2) washer_J screws

previously remove& Tighten securely.

Remember to use only these screwsf Any other

screws wil! cause serious damage to the opener.

lnse_ a 5/16"-18x7/8" hex screw

stop hole in the T.-rail as shown. Tighten securely

with a 5116_lock washer and nuL This screw limits

trolley travel in the UP direction.

Hardware Shown Actual Size

To fasten rail, use only those screws mounted

in the top of the opener. Any other screws will

cause serious damage to the opener.

Was_e_e_J _¢ew

Hex _tew Nut L¢_ Wa#_e_

9

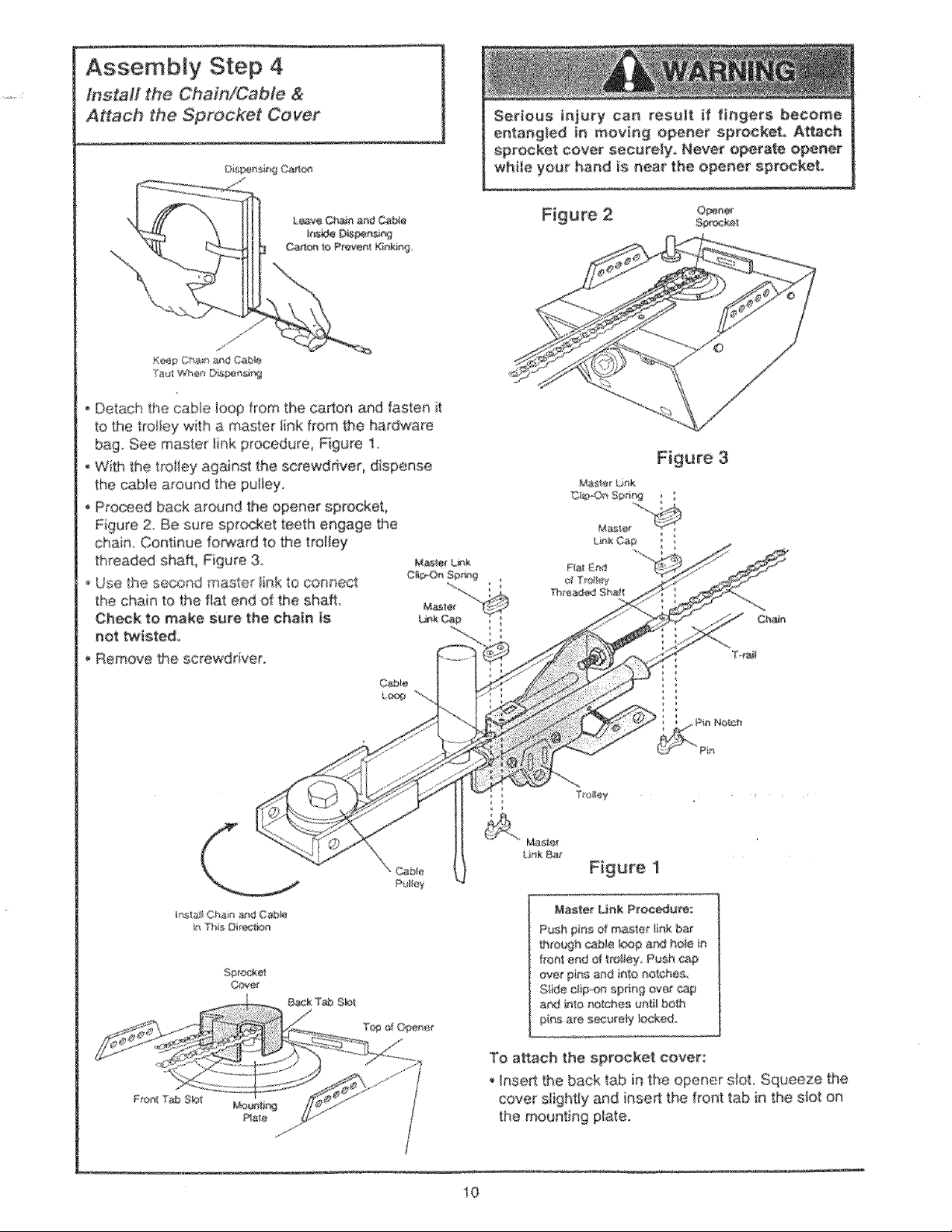

Assembly Step 4

Install the Chain/Cab@ &

Attach the Sprocket Cover

Detach the came loop from the capon and fasten it

to the tro!fey with a master link from #Behardware

bag See master link procedure, Figure 'I,

WiShthe trolley against the serewdnvec dispense

the c_>_e around the pu_tey,

, Pro@_edback around the opener sprockeL

Figure 2. Be sure sprocket teeth engage t}he

chain, Continue forward to the trolley

thresd_ shaft, Figure 3.

Use the se_:md master _nk to connect

the chain to the flat end of the shaft.

Check to make sure the chain is

not twtsted,

, Remove the screwdriver

Figure 2 o_

_OCkef

F_gure 3

Ma$_er Unk

n The Oit_a

Master LJ_k Pr_r_;

P_sh pins of r_3_stet link bar

through _b_e k_p a_ hole in

#on_ end d t_liey, Push _p

over pins_nd into risk;hoe

Stag c_po_ spdng over_ep

a_ into _yotchee unti_ _t_h

pins are s_ure_y i_kedo

To a_ach the sprocket cover:

InseA the back t_ inthe opener sbt. Squeeze the

cover slightly and inseA the front tab in the s/st on

the mounting plate,

10

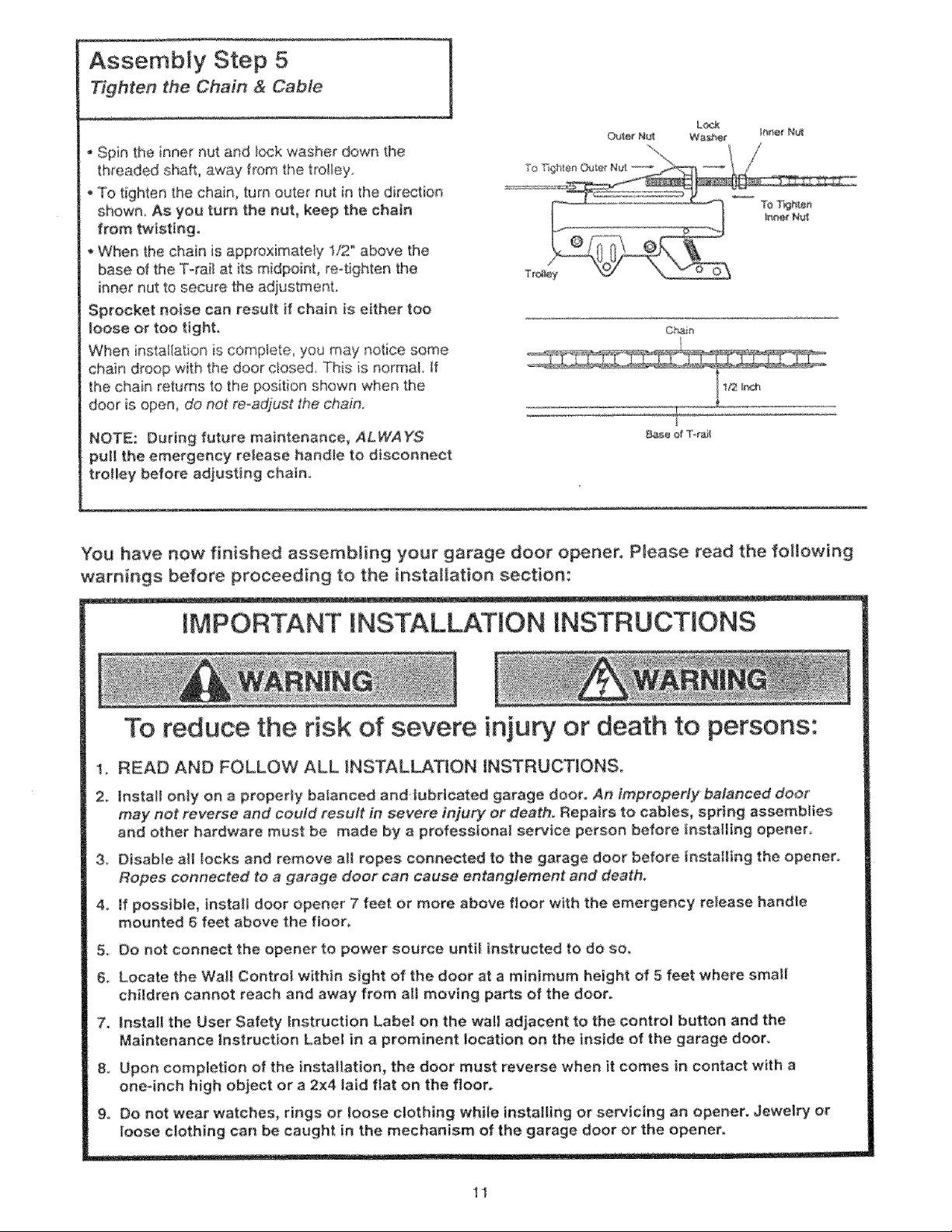

C_Jte_Nu_

}e_tN_

Spir_theinnernutandiockwasherdownthe

threadedshaftawayfromthetrolley

Totightenthechain,turnouternutinthed#ection

shown.As you turn the nut, keep the chain

from Misting.

- When the chain is appm×imate_y 1/2" above the

base of the T-rail at its midpoint, re-tighten the

inner nut to secure the adjustment.

Sprocket noise can result if chain is either too

Ch_

When installation }s compete, you may notice some

chain droop with the door ciosed This is normal if

the chain returns to the position shown when the

door is open, do not re-adjust the chain.

NOTE: During future maintenance, ALWAYS

pulI the emergency reiease handle to disconnect

trolley before adiusting chain.

You have now finished assembling your garage door opener. Please read the following

warnings before proceeding to the installation section:

I

IMPORTANT INSTALLATION INSTRUCTIONS

To reduce the risk of severe or death to persons:

1. READ AND FOLLOW ALL INSTALLA_ON INSTRUCTIONS.

2. install only on a properly balanced and lubricated garage door. An improperly balanced door

may not reverse and could reautt in severe tnju_ or death. Repairs to cables, .spring assemblies

and other hardware must be made by a professional service person before installing opener_

3. Disable aii iocks and remove all ropes connected to the garage door before ins:tailing the opener._

Ropes connected to a garage doer can cause entanglement and death.

4. _fpossible, install door opener 7 feet or more above floor with the emergency release handle

mounted 6 feet above the floor_

5_ Do not connect the opener to power source until instructed to do so,

6. Locate the Wall Control within sight of the door at a minimum height of 5 feet where small

children cannot reach and away from all moving pa_s of the door.

7. Install the User Safe_ instruction Label on the wall adjacent to the control bu_on and the

Maintenance instruction Labei in a prominent location on the inside of the garage door.

8. Upon completion of the installation, the door must reverse when it comes in contact with a

oneqnch high object or a 2x4 laid fiat on the floor,

i "U

9. Do not wear watches, rings or loose clothing whRe installing or servicing an opener. Jewelq or

loose clothing can be caught in the mechanism of the garage door or the opener.

11

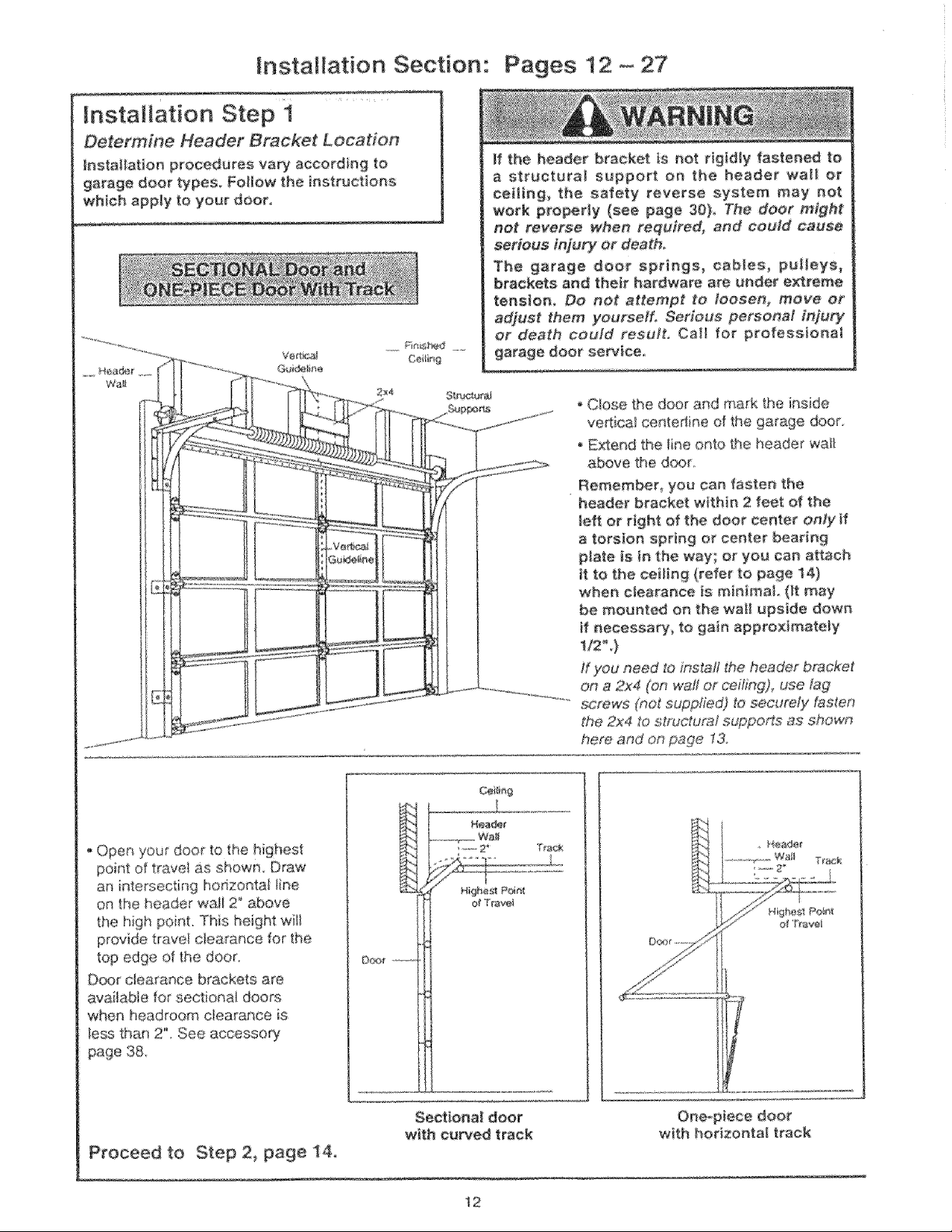

installation Section:

installation Step 1

Determine Header Bracket Location

installation procedures van/according to

garage door bjpes_ Follow the instructions

which appty to your door,

Pages 12- 27

if the header bracket ts not rigtdiy fasten_ to

a structural support on the header watt or

cet[tng_ the safety reverse system may not

work property (see page 30) The door might

not reverse when required, and could cause

The garage door springs, cables, putteys,

brackets and theft hardware are under extreme

tension, Do not attempt to loosen_ move or

adjust them yoursef£ Serious personal inju_

or death could result, Call for protessior_aI

garage door servfceo

Str#_utal

_(y_p_.s ............ _Ciose the door and mark the inside

...... _.............. veAieal centertine of the garage door

_ilt * E£end the line onto the header wall

_:_ above the de_:)r

_ Remember, you can fasten the

header bracket within 2 feet of the

left or right of the door center only tf

a torsion spring or center bearing

p_ate is in the way; or' you can a_ach

it to the ceiling (refer to page 14)

when clearance ts m_nimaL (It may

be mounted on the wall upstde down

if necessary, to gain appro×imate_y

1/2 j

If you need to install the header b_acket

o,_a 2x4 (on wall or ceiling), use lag

......... screws (not supplied) to securely @sten

the 2x4 to structu£d sqppof_s as shown

here and on page t&

Open your door to the highest

point of travel as shown Draw

an intersecting hodzanta_ line

on the header wat/2 above

the high point. This height wi_/

provide traw_t clearance for the

top edge of the door.

Door clearance brackets are

available for sectional doors

when headroom clearance is

_essthan 2°_See accessory

page 38

Proceed to Step 2_ page 14o

ocH,) f ...........

Sectiona! door

wtth curved track

Ce_r_g

He_der

Tr_:k

of Trav_

One,_p_ece door

with horizontal track

12

Read the Safety instructions on page 12. They also apply to doors without tracks.

,Ciose #_e d_r and ma_'kthe

inside veRicai centerline of

your garage door. E_end the

line onto the header wall

above door

tf headr_m c{earance {s

minimal, you can instai_ the

header bracket on the ceiling.

See page 14.

header bMcket on a 2x4 (on

wall or ceiling), use lag _rews

(not suppti_) to secure_J

fasten the 2x# to structural

On.piece door without track

, Open your door to the highest _int of trave_ as

shown Measure the distance from the top d the

door to the floor° Subtract t,he actual height d the

door. Add 8_to the remainder. (See Example).

- Close the door and draw an inte_ectJng horizontal

line on the header w_l at the dete_ined height..

if the total number of inches exceeds the height

available in your garage, use the maximum

height possible, or refer to page 14 for ceiling

ins_llatfon.

Proceed to Step 2, page 14.

One-pi_e door without track

pivot hardware

EXAMPLE

Distance from top of door

(at highest point of travel) to fk_r .................... 92"

Actua_ height of dc@r............................................88"

Remainder ..................................................................

Add .........................................................................8

Bracket height on header wali .............................. =12"

(Measure UP from top of CLOSED door.)

13

Youcanat_ch theheaderbracketeithertothe

wail above the garage door, or to the ceiling.

Follow the tnstr_Jctions which will work _st for

your pa_leuJar requirements.

Fasten the Header Bracket to the Wall

o Center the bracket on the veAical guideline with

the bo_om edge of the bracket on the hodzonta[

tine as shown (with the arrow pointing toward the

* Mark either set of bracket holes (do not use _e

holes designated for ce#ing mount), Ddl{ _16" pilot

holes and fasten the bracket securely to a stm_u_

suppo_ with the hardware provided.

W_

Hardware Shown Actua_ S_ze

Fasten the Header Bracket to the Ceiling

, Extend the ve_icat guide{ine onto the ceiling as

shown,

- Center the bracket on the ve_ica_ maP_ no more

than 6" from the wall, Make sure the arrew is

pointing toward the wall The bracket can be

mounted flush against the ceiling when clearance

is minima_

Mark h@es designated for ceiling mount only Drill

3/16 _pilot holes and fasten bracket securely to a

stru_ura_ suppo_ with the hardware pro,tided

r_i_g M_r_Sng Ho_es

The n_ how is for _'6_n 9 ®_y,

Yo,J must _se _ag _r_s lo _T_un_

_h@header b_'_ck_{

14

installation Step 3

Attach the Torafl to the Header Bracket

o Position the o_ner on the garage fl_r below the

header bracket, Use packing material as a

If the door spring Is in the way you'l! need help,

Have someone hold the opener securely on a

tem_ra_ suppoA to allow the T-rail to clear the

oPosition the _b_e puiley bracket against the header

bracket

Align the bracket holes and ioin with a clevis p_n as

shewn,

hse_ a r_ngfastener to secure,

Hardware Shown Actual Size

Clevis P_

15

O

Installation Step 4

Position the Opener

Folow instructions wMch apply to your door

type as l_ustrated.

A 2×4 [aid fiat is convenient for setting an ideal

door4o-T-ra/distance°

Raise the opener onto a stepladder,

You will ne_ help at this point it the ladder _a

+Open the door a/the way and place a 2×4 _aidflat

on the top section beneath the T-ra/

If the top panel hits the trolley when you raise

the door, puff down on the troltey release arm lo

disconnect the inner and outer sections. The

trolley can remain disconnected until S_ep 12 is

With the door fu/y open and paratel to the floor,

measure the distance from the floor to the top of

the door

Using a stepladder as a sup_)£, raise the opener

to the same distance as the d_r from the floor (it

will be at a stght angle as shown).

The top of the door should be level with the top of

the opener Do not position the opener more than

2'_above this point

16

installation Step 5

Hang the Opener

Two represen_gve installations are showo.

Yours may be different, Hanging brackets should

be &qgted, Figure 1, to provide rigid support On

finished ceilings, Figure 2, a_ach a sturdy metat

bracket to st_Jctural supports before installing the

opener. The bracket and fastening hardware are not

supplied. See accessory page 38.

Measure the distance from each side of the opener

to the strdctura! support°

Cut both pieces of the hanging bracket to requ red

DdH3/16" pilot h@es in the structural supports

Attach one end of each bracket to a support with

5/16"xl _.7/8_lag screws.

,, Fasten the opener to _hehanging brackets with

5/t 6_18x7/8" screws, _ockwashers and nuts.

Check to make sure the Torai/is centered over the

door (or in _inewith the header bracket if the

bracket is not centered above the doo0_

Remove the 2x4 Operate the d(x_r manuaHyo _fthe

door hits the rai_,raise the header bracket

Figure 1

_'I 6%18x7/8 __e'w

Hardware Shown Actua_ Size

Lag Screw

Hex Screw

@'16 18×778 _ Nut _#16"_18 t,.6_kWAshef _i6"

17

Installation Step 6

InstMt the Wall Control

, Stdp 1/4° of [ns@ation from one end of the be{{

wre; connect the wire to the two screw terminals

on the back of the Wail Centre/: white to 2 and

white!red to 1

Locate the Wall Control within sight of the door

at a minimum height of 5 feet where small

children cannot reach_ and away from all

moving parts of the door and door hardware.

Fasten the Lighted Push Button Wa_l Contro_

securely with 6ABxl 1,'2"screws The consote

style uses 6AB×I" screws _finstalling into d_waIL

dri!_5/32" hoes and use the anchors provided

Run the be/[ wire up the wall and across the ceiling

to the opener_ Use insulated staples to secure the

wre in severa_ @aces. Be cater@ not to pieree the

wire with a stapIe, thereby resulting in a sho_.

Receiver terminal _rews and the antenr@ are

_ocated on the back pane_of the opener. Position

the antenna wire as shown.

Then connect the bell wire to Ihe opener terminal

screws: white to 2; whitdred to I.

Remember to affix the User Safety Instruction

tube[ to the walf near the Wall Control, and the

Maintenance _nstruetion [abe_ in a prominent

_oeat_on oe the {aside of the garage d_r.

ff the label adhesive will not adhere to your garage

wail surface (or becomes bose with time) use _acks

to secure the [abe_alongs de the wa_lcontrol

Page 32 explains bow to operate the opener using

the lighted push bar or button as w@/as the L.._k

and L.ight features on the Deiuxe Wail CorstroL

Children operath_g or p_ay_n9 w_th a garage

door opener can injure themselves or others_

The garage door could dose and cause serious

injury or death

Install the Wall Control (or any additionat push

buttons) out of the reach of chHdrer_ and away

from aH moving parts of the door and door

hardware, but where the door is visJbleo

Do not allow children to operate the p_eh

buYeR(s) or the remote contro{(s)o

A moving garbage door could injure someone

under it Activate the opener on_y when the

door is pro_r[y adjusted, you can s_ it e_ear_y,

and there are no obstructions to door travel

Do NOT connect the power and operate the

opener at this dine. The trolley wH[ trave_ to the

f@! open position but will not return to the

c_oee posft_on until the sensor beam is

connected and proper_y aligned.

See Safety Reversing Sensor _nstructions

begirming on page 2t.

Outdoor Key Switch Accessory Connections

To opener termin_ screws: white to 2; whitdr¢_d to I

Deluxe Waft Control

Lighted Console Waif Control

Hardware Shown Actual Size

6AB x ¢* 8_tew

Lghed Co_tsole Wail r;on tel D0' Wa;i Ar_chocs

Deh_A_ W_# O_vt_'@

[ igh[_ Con_ole Ugh_t

Wt_ Con_to_ P_sh auAe#

wa_ Coa{_ea

18

Installation Step 7

Instafl the Light and the Lens

Instal| the lights

- Install a 75 watt me_imum light bulb in the stoker.

The light will turn ON and remain lit for

approximately 4q/2 minutes when _wer is

connected. Then the light will turn OFF.

, If the bulb bums out prematurely due to vibration,

replace it with a standard neck "Garage Door

Install the lens (except for Modef 53225)

Apply slight pressure on IJsesides of the _ens and

slide _e tabs into the slots in the end p_ef

, Reverse the procedure to remove the fens°

Ught

lnstalJation Step 8

Attach the Emergency Release

R®e

Do not use the red handle to pull the door

open or closed, The rope knot couid become

untied and you could Carl. Use the emergency

release only to d_sengage the trolley and:, if

possible, only when the door ts etosed.

Garage doors are heavy. If the door is open

when the handle is pulled, the door could

close inadvertently if ft is not properly

balanced, Sedous injury may result to persons

under the door, Make sure the doorway ts clear

of persons and obstructions before pulling

handle when door is open,

- Thread one end of the rope through the hole in the

top of the red handle so "NOTICE" reads dght side

up as shown Secure with an overh_d keel

The knot should be at least 1" from the end of the

rope to prevent slipping,

, Thread the other end of the rope through the hole in

the release arm of the outer trolley

* Adjust rope length so the handie is 6 feet above the

floor. Secure with an overhand knoL

If it is necessary to cut the rope, heat seal the cut

end with a match or lighter to prevent unraveling.

t9

t

ins aliat on Step 9

Electrical Requirements

"Toreduce the dsk of eleetdc shock, your garage

door opener has a grounding type plug with a third

grounding pin. This pbg will only fit into a grounding

If the plug doesnt fit into the outlet you have,

conta_ a qu_ifi_d el6_Cia_ to install the pro_r

outlet.

"Toavoid inataflatlOn difficulties,

{

If permanent wiring is required by your local code, refer to the following procedure:

do not run the opener at this time,

j

]

To prevent eiectrocufion, remove power from

the garage door opener and from the circuit

you plan to use for the permanent connection,

To make a permanent oannection through the

718_diameter hole in the top of the opener

(according to I_l code):

Remove the opener cover screws and set the

cover aside_

Remove the attached 3 prong cord

, Connect the black (line) wire to the screw on the

b_ass terminal;: the white (neutral) wire to the

screw on the shyer terminal7 and td-_eground wire

to the green ground screw. The opener must be

o Reinstall the cover.

To avoid insfatlation dtfficutties_

do not run the opener at this time.

2O

Safety Reversing System

Information you1] need before you begin the installation of the safety reversing sensor.

The safety reversing sensor must _ connected

and aligned correctly before the garage door

opener wlil move in the down direction. This is a

required _fety device and cannot be disabled,

Instalia#on pr_edures are the same for sedionat

Without a properly working safety reversing

sensor, persona (particularly children) could

be in]u_ or killed by a closing garage door.

Read and follow all instructions.

To protect small children, Install the safety

reversing sensor so that the beam wi[[ be no

higher than 4"4" above the garage fi_ro

Disconnect power to the garage door opener

before installing the safety reversing sensor.

Be sure po'#er to the opener is disconnected.

The sending eye transmits an invisible tight _am to

the receiving eye The units can be installed on

eider side of the garage door as long as the sun

never shines directly into the receiving eye lens,

Lc_k at the label on the eonneGor end of each use

to identiPy the sensors.

The brackets must be connected and fastened so

that the sending and receiving eyes face each other

as shown in Figure I.

If an obstruct on breaks the light beam while the

garage door is c_osing_the door wilt stop and

reverse to fuil open position and the opener lights

will flash for 5 seconds

The bracket_ must be securely fastened to a solid

sudar_ such as the studs on either side of the door,

or add a piece of wood at each location if installing in

The invisible Hght beam path must be unobstnJcted.

No pad of ttie garage door (or door tracks, spdngs,

hinges_ roIIers or other hardware} can interrupt the

beam whiie the d_3r is closing If it does, use a pie_

of wr_d te build out each sensor mounting iocation to

the minimum depth required for Ight beam c_earance

f_rot_::_n Area

Figure 1 : Facing the door from inside the garage

21

a_3ve f;c_

Figures2and3 showassemblyofbracke_and

°C" wrap based on the recommended instafiation of

the sensors as shown on page 21

However, Figures 4 and 5 are variations which may

ins_i_ation requirements baser Make sure

the wraps and brackets are align_ so the

sensors will face each other across _e garage

door,

Fasten the "C_ wraps to the mounting brackets

having square holes, using the hardware shown

n Figure 2

Connect each assembly to a slo_ed bracket, using

the hardware shown in Figure 3_

Note the alignment of the brackets for left and

right stdes of the door_

, Finger tighten the lock nuts

o Use bracket mounting holes as a template to

locate and drill (2) 3/16 _diameter pilot holes on

both sides d the g_age door, 4%6` above the

floor but not exceeding 6t (See warning on

AEach bracket assemblies with 1/4"xl-1/2 __ag

_crews as shown in Figure 3.

Adiust dght and le_ side bracket assemblies to the

same distance out from the mounting sudace.

Make sure all door hardware obstructions are

cleared Tighten the nuts securely.

Figure 2

Me#_tk_ Br_k_t

Figure 3

Hardware Shown Actual Size

#10 32 _ :_8" #10 x 32 1/4 x 1_1_ 1/4" -

_o_& Nut

Figure 5

A_ternate Wall Mount

_i_h Sq_e Ho e8

f f:_ A,¢> &/ wlb_te

: r :i ' ,o

"Z_:....

A_temate FIoo_ Mount

22

'_Centereachsensorunitina"C_wrapwithlenses

pointingtowardeachotheracrossthed_r (see

SecuresensorswiththehardwareshownFinger

tightenthewingnutonthereceMng eye to allow

for final adjustmenL Securely tighten the sending

eye wing nut,

, Run the wires from _th sen_rs to _e opener_

Use insulated stapJes to secure wire to walt and

Step 1/4 _of insulation from each set of wires.

Separate white and whit_lblack wires sufficien#y to

cermet to the opener terminal screws: white to 2

and white,_lack to 3.

Plug in the opener.. Make sure the Lock Feature is

off, Green indicator !ights in both the sending and

receiving eyes wi/i gtow steadily [f widng

connections and aIignment are correct.

if the indicator light is offin the receiviog eye (and

the invisible light beam path is not obstru_ed)_

alignment is required

Loosen the receiving eye wing nut to alfow slight

rotatiGq of unit. Adjust sensor vertically newer

hodzontaily until the green indicator light glows

When indicator lights are glowing steadily in bo_h

units, tighten the wing nut in the receiving eye uniL

Figure 6

1 If the sending eye indicator light does r_ot glow

steadily after !nstJlation, check for:

- Kle_tdc power to the opener.

A short in the white or white,_l_k wres These

can _cur under staples or at screw tem_in_

connections,

* Incorrect widng between senso_s and opener,

, An open wke (wre break}.

2. if the sen#ing eye indicator light clews stead@ but

the receiving eye indi@.tor light doesn't:

o Check alignment

, Check for an open wire to the receiving eye.

Hardware Shown Actual Size

Figure 7

O_;_r_et 7 ermi_9t,_;

_#z4Wre

i

OPffN_R TERMINAL _R[WS

Pro_P_ A_-ea

23

Installation Step 11

Fasten Door Bracket

Foliow instructions which apply to your door

type as illustrated beiow or on page 25°

To prevent damage to steel, aluminum_

fiberglass or glass pane_ doors, always

reinforce the inside of the door _th veAicaily

and horizontally with an angle Iron.

Figure i

Center the door bracket on the previously marked

vertical guideline used for the header bracket

installation

- Position the bracket on lhe face ot the door within

the following limits:

A) The top edge of the bracket 2°4 '`below the top

edge of the door.

B) The top edge d the bracket directly below any

structural suppoM across the top of the door.

Mark and ddti &ll 6" _eftand right fastening holes

Secure the bracket as shown in Figure I if there is

ve_'ticaI reinforcemenL

if your installation doesn't require vertical reinforce

meat but does need top and bottom fastening holes

_or the door brackeL position the door p_ate over the

door b_acket as shown in Figure 2 Fasten securely

with hardware shown in Figure 1

Hardware Shown Actual Size

24

P_ease read and comply with the warnings and reinforcement instructions on page 24.

They apply to oneopieoe doors also,

* Center the bracket on the top of the doer, in fine

with the header bracket as shown. Mark hotes.

Drill 5/16_ pilot holes and fasten _e door bracket

with hardware supplied_

_fthe door has no exposed framing, drill 3/16" pilot

holes &nd fasten the bracket with 5/16_xl _1/2" lag

screws (not supplied) to the top of the door.

The door bracket may be installed on the top

edge of the door ff required for your installation.

(Rder to the dotted line optional placement

drawing.) Drill 3/16" pilot holes and substitute

5/16"x1_1_" lag screws (not supplied) to fasten

the bracket to the door.

Hardware Shown Actual Size

25

Installation Step !2

Connect Door Arm to TrMley

Fotlow _nstructtons which appy to your door

type as illustrated below and on page 27,

Make sure garage door ts fully c_o_d. Pull the emergency release handle to disco#nect _e outer trollley

from the inner trolley, Slide the outer trolley back (away from the door) about 2" as shown _n

Figures I, 2 and 3.

F_gare 1:

Fasten straight door arm section to outer trol[ey

with a cevis pin_ Secure the connection with a ring

fastener

Fasten cawed door arm to the doer bracket in the

same way as shown.

[n_r Toffy

F_gure 2:

Bdng arm s6stJons together, Find two pairs of holes

that _ineup and join se_ions Select ho_es as far

apart as possible to increase door arm rigidib:,o

Hole Affgnment Alternative

Figure 3:

_,if holes in catered arm are above bores in straight

arm, disconnect straight am'L Cut about 6" from

the solid end, Reconnect to trolley with cut end

down as shown_

Bring arm sections together.

Find two pairs of hoies that line up and join with

screws, lock washers and r_uts,

Hardware Shown Actual Size

Nui 5f16" _18 L_k Washer _l_'J" e#_# F_slene¢

He_: _;_ew CI_s Pi_

Proc_d @

to Adjustment otep t, page 28, Troiiey wH[ re_ngage automatically when the opener ts operated_

Figure 3

26

AssembletheDoorArm:

,, Fasten the straight and curved door am_ secl,ions

toge_er to lhe longest possible length (with a 2 or

. With the door closed, connect the straight door

am s_tion to the door bracket with a c_evis pin

, Secure with a ring fastener.

On one-pie_e doo_, before connedJng _e d_r a_ to the trolby the t_.¢el limits must _ a_usted. Um_ adiustment

screws are I<%atedon the/eft side panei as shown on page 28. Follow adiustment pnx:edures below

J ........ C_

E#_ck_a_d S_&nt

Adiustment Proc_ures for One-Pi_e Doors

Ope_ Door Adjustment:

Decrease UP limit

- Turn the UP t_mitadiustment screw counter,-

Turn the DOWN Iim}t adiustment screw cbckwise 5

Closed Door Adjustment:

D_rease DOWN limit

cl_kwise 5-1/2 turns

• Press the Wai_Controt push bar or button. The

troliey witl travel to the fully open _sition.

- Manu_ly raise the door to the open position

(paralle_ to the floor), and _iflthe door arm to the

trolley_ The a_m shouid touch the trolley lust in

back of the door arm connecter hole. Refer to the

fully open trolley/door am positio_ in the

illustratiom If the arm does not extend far enough,

• Press _he Wa{_Cont_)I push bar or button. The

troliey wiIt trave_to the fully ctosed position.

. Manually etose the door and iiff _e d_r arm to the

troltey. The arm should touch the trolley just ahead

of the door arm connector hob. Refer _othe fufty

c_osed trolley/door arm positions in the iliustratiom if

_he am is beh}nd the connector ho_e,adiust the iimit

further. One ftJl_turn equals 2" of troliey travei

adjust the _imitfu_her. One full turn equals 2" of

Connect the door arm to the trolley

. Close the door and ioin the eu_ed arm to the connector hole in [he trot_ey with the remaining clevis pin. It may

be necessa_ to lift the door slightly to make the connection,

- Secure with a nng fastener.

. Run the opener through a comptete travel cycled if the door has a slight "backward" slant in fu_l open position

as shown in the illustration, decrease the UP limit until the d_r is paraItel to the floor.

27

Adjustment Section:

Adjustment Step 1

Pages 28- 30

Adjust the UP and DOWN Limits

Do not make any i{mit adjustments until the

safety reversing sensors are completely

installed°

Limit adjustment settings regu{ate the points at

which Lhe doer will stop when moving up o_down,

The door will stQo in the up direc_on # anything

intederes with door t_avel The door wil_reverse in

the down direction if anything intederes with the

door trave_ (including binding or unbalanced doors)_

To operate the opener, press the Wa_ Centre! push

bar, Run the opener through a complete trave_

o Does the door open and close @mpletely?

Does the door stay closed and not reverse

unintentionally when tulty closed?

/f your door passes beth of these tests, no limit

adjustments are necessaPy unless the reversing test

Adjustment procedures are outlined below° Run

the opener through a complete travel cycle afler

}mproper adjustment of the trave! Hmits will

inte_ere w}th the proper operation of the safety

reverse system_ The door m_ght not reverse

properly when required and could seriously

injure or kill someone under it, Test the safety

reverse system following aH adjustments to the

trave| HInes, See page 30.

A_us_men_

f

Le_ _ Pa_i

Repeated operat}on of the opener dur}eg

adjustment procedures may cause the motor to

overheat and shot off, Stmp}y wait 15 minutes

and t_ again°

Read the pr,_edures carefuNy before proceeding to

Adjustment Step 2 Use a screwdriver to make limit

How and When to Adjust the Limits

}f the door does not open completely

but opens at least f}ve feet

hcrease up travel Turn the UP limit adjustment

screw ciockwise. One turn equals 2" of travel

}f door d_s not open at }east 5 feet: Adjust the

UP (open) force as e×plained in Adjustment Step 2,

if the door does not close completely

hcrease obwn travel Turn the DOWN limit

adiustment screw counterclockwise One turn

equals 2" of travel

ff dc8r sfli_ won't c_ose compiete_y, try lengthening

the door arm, (Page 26,)

if you have adjusted the door a_ to the m_imum

length and the door still wil_not dose completely,

Iower the header bracket, See _nstaHatJonStep 1,

pages 1211&

If the opener reverses in folly c}os_ pos}tton

Decrease down travel Turn the DOWN _imit

adiustment screw c_ockwise One turn equals 2_of

travel

]ifthe door reverses when dosing and

there is no vistb}e _ntederence to trave_ cycle

if the opener _ights are flashing_ the Safety Reversing

Sensor is obstru_ed Remove the obstrue_en

Test the door for binding: Pull the emergency re}ea_

handle Manually open and c_ose the door, If the door

is binding, call fer garage door service ff the dr_r is

not binding or unbalanced, adjust the DOWN (close)

force. See Adjustment Step 2.

28

Forceadiustmentcontrolsareiocatedontheback

paneloftheopener.Forceadiustmentee_ings

regulatetheamountofpowerrequiredtoopenand

dosethedoor

Thedoorwillstop in the up direction if &%_hing

intederes with its travel The door will reverse in the

down direction if an_hing intederes with its travel

(including binding or unbalanced doors).

if the fercJesare set too light, door travel may be

interrupted by nu,_sancereversats in the down

dire<:tion and stops in the up direclion. Weather

cond}tions can affect the door movement so

occasional adiustment may be needed.

The maximum force ad}ustment r_ge is 260 d_rees,

about 3,/4d a complete turn Do not force controls

beyond that _xsinLTurn force adjustment controts

with a screwdr ver.

Too much force on the d_r wil! interfere with

the proper operation of the safety reverse

system, The door might not reverse properly

when require_ and could seriously injure or kill

someone under it. Do not increase the force

_yond the minimum amount required to dose

the d_r. Do not use the force adjustments to

compensate for a binding or sticking garage

door, Test the safety reverse system fol|owing

aH adju_ments to force levets, See page 30,

_ot_

Adtu_l_n_

A_iir_ L_L_

How and When to Adjust the Forces

Test the DOWN (close) force

Grasp the door bo_om when the door is about

haffway through DOWN (ctose) travel. The door

should reverse Reversal halfway through down

travel does not guarantee reversal on a two4nch

obstruction. See page 3& If the doer is hard to

hold or doesnt reverse, decrease the DOWN (close)

force by turning the control counterc!oekwise

Make 10 degree turn adiustments unti_ the door

reve_%esnormally After each adiustment, run the

opener through a complete cycle.

Test the UP (open) force

Grasp the door bottom when the door is about

halfway through UP (open) travel The door shouid

stop If the door is hard to hotd or doesn_ stop,

decrease UP (open) force by turning the control

counterclockwise.

Make 10 degree turn adjustments unti_the door stops

easily. After each adiustment, run the opener through

a Gsmp_etetravel cycle,

ff the door doesn't open at least 5 feet

increase UP (Open) force by turning the control

clockwise Make 10 degree turn adiustments untii

door opens completely. Re-adjust the UP limit if

neeessa_. After each adjustment, run the opener

through a complete travel cycle.

if the door reverses during the down (ciose) cycle

and the opener lights aren't flashing

increase DOWN (dose) force by turning the control

c!oskwise. Make 10 degree turn adjustments until the

door completes a close cycle. After each adjustment,

run the opener through a cornplete travel cycle. Do

not increase the force beyond the minimum

amount required to close the door,

29

Test The Safety" Reversing Sense

Press the remote control push button to open the

door.

. Place the opener ca4on in the path of the door.

Press the remote control push bu_on to close the

door The deer will not move more than an

and the opener f@ht will flash.

Prdessional se_Jce is required if the opener

ctoses the door when the safe_y reversing

sensor is obstructed. I

The garage door opener wH! not ctose from a

remote control if the indicator light in either

sensor is off(aleAing you to the fact that the

sensor is misaligned or obstructed).

The garage door can be closed by pressing and

holding the Wa}_ Control push bar or bu_on unti_

down travel is completed, sa_,wRew_.ts_gse_4__ Sa_et

Adjustment Step 4

Test the Safety Reverse System

Test.:

Place a on@inch board (or a 2x4 _mdflat} on the

floor centered under the garage door.

Operate the door in the down direction. The doer

must reverse on s#lking the obstruction,

_fthe door steps on the obstruetion_ it isnot traveling

far"enough in the down direction.

o hcrease the DOWN limit by turning the DOWN

Hmitadiustment screw countercJc_wise 1/4 turn.

Repeat the test

On a sectional door, make sure Ilmff adjustments

do not force the door arm beyond a straight up

and down positiom _ _e }liasfmatlon on page 26

, When the door reverses on the onednch t_ard,

remove the obstruction and mn the opener througt_

3 or 4 complete travel _ie_es to test a_diustment.

|f the door wH! not reverse after repeated

adiustment atIempts, call Sears Service Center

for garage door opener service.

Failure to test and adjust the safety reverse

system may result in serious injury or death to

persons trapped by a closing garage dean

Repeat this test once a month and adjust as

nc_ded_

Important safety check

Repeat Adjustment Steps 1, 2 and 4 after:

o Each adiustment of door arm Ienggq, force controls

or _imRcontrols

oAny repair to or adjustment of the garage door

(including spdngs and hardware},

oAny repair to or buckling of the garage floor.

Any repair to or ad:iustment of the opener

30

iMPORTANT SAFETY iNSTRUCTiONS

To reduce the risk of severe injury or death to persons:

t READ AND FOLLOW ALL |NSTRUCT!ONS,

2. Do not permit children either to operate or to play with the opener_ K_p remote contro! in a

locagon inaccess_Me to chiidren.

3. Operate opener only when the door ts _nfull view and free from any obstruction. K_p the door tn

sight until it is completely closed. NO ONE SHOULD CROSS THE PATH OF THE MOVING DOOR.

4. Check safety reversal system monthty_ See page 30. The garage door MUST reverse on contact

with a oneqnch (or a 2x4 board iatd fiat) object placed on the floor. If an adjustment Is made to

either the force or the limit of travet, both adiustments may be needed and the safety rever_l

system must be checked. Failure to property adjust the opener may result in severe injutTy or death.

5. if possible, use the emergency retease Only when the door is in a c!os_ position. Caution should

be taken whenever the disconnect cord is actuated with the door open. Weak or broken springs

may cause the door to fail rapidly, causing injury or death to persons.

6. KEEP GARAGE DOORS PROPERLY BALANCED. S_ page 3. An improperly balanced door may not

reverse when required and could result in severe injury or deat,5. Repairs to _bles, spring

assemblies and other hardware must be made by a professional garage door _rson.

7. Discoenect the e{ectric power to the garage door opener before making any repairs or removing the

covers.

s.SAVE THESE INSTRUCTIONS°

Care of Your Opener

Limit and force adjustment controls _e remote control

Limit Controls Force Controls

Ad!ustmer_ L_bga

Weather conditions may cause some minor

changes in door operation requiring some re,*

adjustments, paAicularly dudng the first year of

Pages 28 and 29 refer to the limit and force

adiustments Only a screwdriver s required_ FoIIow

the instructions carefu{_y

Repeat the safety revers_ test (page 30) after any

adjustment of limits or force.

Maintenance Schedule

Once a Month

Manually operate door. If it is unbalanced or

binding, call for professional garage door sePvice,

Check to be sure door opens & closes fully.

Adiust iimits and/or force if necessary.

(See pages 28 and 29.)

Repeat the safety reverse test. Make any

necessary adjustments (See page 30)

1%e opener must learn the code oNany new remote

control Page 33 explains how to program your

receiver and how to erase a!l codes if required Self

ser,4ce of you_'reseiver is not recommended If

seP4ce is r-_eeded contact your nearest Sears

Service Center

_he remote control ba_e_

The green test light should glow and the opener

should operate when the remote contr@ is activated

If the green test light is dim or does not eeme on,

The 12 Voit bakery should produce power for at least

a year

Dispose of your old battery propedy_

Check chain tenstom Disconnect trolley first.

Adiust if necessary (See page 11),

Oil door toilers, bearings and hinges

The opener does not require additional

lubrication.

Do not grease the door tracks_

Twice a Year

Once a Year

31

Operation of Your Opener

A_ivate the o_ner with ar_yof the fo_lowing_

l. T_heRemote Control

3-Funetion and Compacb Hold large push

button down until the door starls to move,

Sing,_ function Hoid push button unti! the door

starts to move,

2. The Wall Control Hold push bar or button down

until the door sta_s to move.

3. _e Key Switch or Key!ess Entry.

Weak or broken springs could allow an open

door to fail (either rapidly or unexpectedly),

resulting in serious injury, death or property

damage, _f possible, use the emergency

re_ease rope and handle only when the door _s

fully ciosed,

When the opener is activated with the safe_

reversing sensor installed and correctly aiigned:

I /f open, the door wil_ dose.. If closed, it wiil open.

2. If closin% the door will reverse.

3. If openingsthe door will stop (allowing space for

entry and exit of pets and for fresh air)_

4 If the door has been stopped in a pa_ial_y open

_>sition, it will c_ose_

5 _fobstructed while closin% the door will reverse

6 If obstructed while opening, the dc_orw_l_stop,

7. The garage do/or wi/_revere in the dosing cTde when

_e invisible _am is broken, ff fully c_en, the d<_r wi_

not dose When the beam is broken, "gee sensor has

no effe_ in _e opening _yde.

If the sensor is not installed or r_otat gned correctly,

the door won't close from any remote control You can

c{ose the d_or with the Wall Control, hheKey Switch,

or Key_ess Entry, however', if you activate them until

down travet is complete, if you release them too soon,

the door wili reverse.

The opener lights will brink for 5 seconds when the

safety revers ng sensor causes the door to reverse.

The O_ner Ughts will turn on under the following

conditions: When the opener is init aIly p!ugged in; when

the power is intemJpted; when #_eopener is activated. It

will turn off autamati_ly after 4-112minutes or provide

constant light when the Light feature is activated. Bulb

size is 75 wa_s maximum

Bme_ger_

Re_ HarcJ_

Manual d_sconnect

The toeko_ feature

prevents the troliey

from reconnecting

aatomat;caIty_ Pull the

down and back (toward

the opener} The door

can then be raised and

lowered manually as

often as necessary, To

disengage the _ockout

feature, pull the

emergency handle

troiley will reconnect on

the next UP or DOWN

To open the door

The doo_ shouid be

fully dosed if possiMe_

Puli down on the red

emergency reIease

handle and lift the door

manually To

re_nnect the d@r to

the opener, press 1_he

Wal! Control push bar

or button.

Re}ease H _'_Se

Lockout position

Operation of the

Press the _ighted push bar or button to open or

c_ose the d_r

Press again to reverse the deer dudng the c_osing

cyc}e or to stop the door while it's opening..

Deluxe Lighted Console (model 53824 on_y)

Light feature: Press the Light button, If the opener

light is off. it w_l turn on

_fthe opener _ightis on, (even in the 4ol,/2 minute

automat c cycle} it will turn off.

But it you use the Ught button to turn the !ight or'}

and then activate the opener, the light will turn off

after 4_l/2 minutes_

The Light button will not coet_ol the opener light

when the door is in motion,

Wall Contro_

Lock feature: The Lock feature is designed to

prevent operation d the door from portable remote

controls. However, the door w_I open and close

from the Detuxe Wa_t Control push bar the Key

Switch and the Multi*Function Key[ess Entry.

To activate: Press and ho_d_e Lock button for

2 seconds The push bar _[ght will flash as _ongas

the Lock feature is on.

To turn o#: Pre_s and hoid the Lock bu_on again

for 2 seconds,The push bar _ightw_Hstop flashing.

No_a_ operation witl resume The Lock feature wi!l

also turn off whenever the SRT bu_on on the opener

end pand is activated.

32

Receiver and Remote Control Programming

To comply wt_ F'CC Pates adiustmenl or modifications of _his

receiver _n(_/or _rar_smi_er ere prohibited e×cepl k)_' changing

the code $et_ ng or _eplacieg _he bsttery_ THERE ARE NO

OTHER USER SERVICEABLE PARTS,

Models with 3-function remote controls: The

remote contro!(s) has been factory set to operate

with the large push button. However, you can use

either of the two smart bu_ons, if you prefen And,

the 34unction remote @ntroi(s) _n a_ activate

additional garage door openers andtor _ightcontrols,

Below are instru_ions for programming your opener

to match the other buttons on your remote controls

and any additional remote controls you may

}urchase_ See availaMe accessories on page 38.

Models with a single4unction remote control:

The garage door wilt operate when you press the

remote control push button. Refer to the information

betow if you _;,antto add a 3 funclion remote cmntrol

or erase ysur programmed code.

53000SRT Series Garage Door Openers

(With "SRT" Bu_on)

Your "SRT ° garage door opener will operate with as

many as four "SRT" po_le remote controis and

one Mufti_Function Key_ess Ent_

To Add A Remote Control

1 Se/e_ a remote contro_ push button to operate

the receiver

2. Press and hold the selected remote control push

button, Figure t.

3 Then press and release the "SR7_' button on the

back panel of the opener, Figure 2 The opener

light will flash once.

Now the opener will operate when the remote

control push bu_on is pressed.

If you re_ease the remote control push butlon

before the opener Hght flashes, the opener wHI

To Change the Selected Push Button

On the Same Remote Control

if you decide to use a different remote control button

than originally programmed into the opener, you

need to erase aNthe Iearn_ c_es and reprogram

each remote _ntrol used to operate the garage

Children operating or p_aylng with a garage

door opener can injure themse|ves or others.

The garage door could cfose and cause

serious injury or death. Do not allow children

tO operate the wat| push button(s) or remote

A moving garage doer could injure or kill

someone under it_ Activate the opener only

when you can see the door c|ear|y, it is free of

obstructions, and is properly adjusted.

Figure 1

S|ngle Function

M|R_3-Fan.ion Remote Control

Remote_Control

_o# to _te O_er

Standard 3.oFunction Remote Control

Figure 2

Garage Door Opener

(With "SmaW' Bu_on)

7

To Erase All Remote Control Codes

, Press and ho[d the °SRT° button on the opener

panel until the indicator light turns off (about 6

seconds). All the codes the opener has learned

will be erased.

To repro]ram, repeat Steps 1,2 and 3 for each

remote centre[ in use

Code programming instructions are also located

_ND _AN_L

33

Having a ProbJem?

Probable Cause and Solution

1 Does the opener have electdc power? Plug a _ampinto the outlet. _tit doesn't light,

operate from either check the fuse box or Me @rcuitbreaker (Some outlets are centre/ted by aw@Iswitdq,)

the Waft Cent,rot or 2. Have you d sabred all d_×_rk_ks? Review installation instnsction w_onings on Page 11.

the remote control: 3. is there a buiid_up of Joeor snow under the door? The door may be frozen to the

ground Remove any restriction

4. The garage door spring may be broken. Have it repkaced.

5. Repeated opera£ion may have tdpped the ovedoad prote_tor in the motor. Wait

15 minutes. Try again_

! _sthe Wail Centre//it? If not, remove the bell wire from the opener terminal screws.

from the remote Short the red and whte terminals by touching both terminals at the _sme time with a

control_ but not from piece of wire _fthe opener runs, cheek for a faulty wire connection at the Wall

the Wall Controh Centre!, a short under the staples, or a broken wire.

2 Are the wiring connections correct? Review Step 6, page 18.

1. If your model has the Lock feature, make sure the lock is Off.

from the Wail Control,

but net from the

remote centre#

2. Is any wall push button flashing? Your opener needs to redeam a remote controi

cede Refer to InstnJctions on the opener p_neL

3. Does the battery test light glow when the remote control push button is pressed? _f

not, replace the bakery.

4. Program the r(xseiver to match the remote control code.

5 Repeat the receiver programming procedure with aft remote controls.

_ee remote control 1. Check the battery test light, if the light is d{m, replace the bakery

2_ Change the Iocation of the remote centre{ {r_yourcar_

3. Check to be sure. the antenna on the side or back panel of opener extends fully

downward

4. Some instailations may have sho_er range due to a meta_ door, toil backed

insulation, or metal garage siding

If operational n_se is a problem because of proximity of the opene_ to the _iving

disturbing in tiring quarters, the Vibration iselator Kit 41A3263 can be installed. This kit was designed to

quatt_,rs of homo: minimize vibration to the house and is easy to install

The garage door 1. Be sure that a{I remote control push bu_ons and battery indi_'_tor !ights are off,

2 Remove the bell wire from the Wall Control terminals and operate from the remote

control on_y_If this so!yes the problem, the Wall Contrei is faulty (replace), or there is

an intermittent sho_ on the wire beb_een the Wall Control and the opener

The door doesn't 1. If the door has been woAing propedy but now doesn't open a_ithe way, increase t_he

open completely: up force. See page 29.

2. Is something obstructing the door? Remove the obstruction or repair the door_

3, if door opens at least 5 feet, the trove! limits may need to be increased One turn

equats 2 inches of travel See page 28.

Repeat the safety reverse test after the adjustment is complete.

Review the travel iimits adiustment procedures on page 28.

doesn't close Repeat the aafo_ reverse test after any adjustment of door arm length, close

force or down limit.

34

Having a Problem? (continued)

Probable Cause & Solution

I. tf the opener lights blink, check the safety reversing sensor, See page 23,

won't close: 2. It the opener _ights do not b_inkand: it is a new installation check the down force.

See Adjustment Step 2, page 29. For an existing installation, see below,

Repeat the safety reverse test after the adjustment ,is complete;

me door reveres for 1 Is something obstructing timed@or?Puli the red emergency retease handle. Operate

the door manua{ly. It it is unbalanced or binding, cali for professional garage doer

sewice

don't blink:- 2, Clear armyJoe or snow from the garage floor area where the door closes.

3. Review the force adjustment procedures on page 29.

4. _fdoor reverses in the tufty ctosed posit on, decrease the travel limits (page 28),

Repeat safety reverse test a£ter a_iustments to force or travel limits. The nc_d

for occasional adjustment of the force and limff ,settings is normal Weather

conditions in particular can affect door travel.

_e door rever_s for Check the safety reversing sensor_ Remove any obstruction or a_ign_he receiving eye

See page 23.

biiek for S_ds

.... don't turn on:

Replace the light bulbs (75 watts m_imum) Use a standard neck garage door opener

bulb it regular bu{b bums out

, , don't turn off:

/s the Light feature on? Turn it off.

The opener strains or The door may be out of bal&_'_;eor the spdngs are broken C_ose the d_r art_ u_>the

maximum force is emergen@, televise to di_;onne_ the trolley, Open and cio_ _e d_r m_-_ual/y. A property

beJan_d d_r will stay in _y p®intof _ave_while _ing sup_d6<l entireb/by its spdr_s. If it

door: d_s not_disconnect _e o_ner _nd c_/I a professional ga_@e de_r _eviceman, Do not

increase the force to o_te t,5e o_nero

The opener motor 1 The garage door spdngs are broken, See above.

hums briefly, then 2, It the prob_ern_rs on the first operation of the opener, dc_r may be k_kc_£ DL_sbte

won't work: the door/_k: If the chain was removed and reinstaIl_J, the motor may be out of phase.

Remove t_hechain; cycte the motor to the down _aition Obsewe the drive spr_Ket.

When _ turns in a citY, vise direction e_d stops in _nedown _s_ion, reins_!_ the ehan,

Repeat the safety reverse test after the adjustment is complete,

1, U99the emerger>_y re}e_e to dis@nne_ iXe trolley. _r_e_@r _ _ o[_en_ a_.t cbs_S

operate due to manually W_en lf_e r_wer is restore, pre_ __eW_[ _ntrot pash _ &qd troliey wilt

power failure: automaticJy r_nned (unle_ trolley is in _;ko_ posi_on.) See _ge 32,

2 The Emergency Key Re_ease accessory (for use on garages with no service d_r)

disconnects the trolley from outside the garage in case of power failure.

The chain droops It is norma_ for the chain to droop slightly in the c!osed d_r position° Use the

or sags: emergency release to disconnect the trolley, It the chain returns to norma_ height when

the trolley is disengaged and the door reverses on a one@_ch board, no adjustments

are needed (see page 11)

35

Rail AssemMy Pa£s

Repair PaNs

3

3

4

5

6

7

installation PaNs

3

KEY PART

NO. NO_ DESCRIPTION

1 4!A4086,,i Lighted _nsole wai controt

2 41A4t66 Lighted push bu_on wail control

3 41A4086A Deiuxe lighted wa_l control

4 41A_8i Singie,otune_ oh remote contro_ hous ng & screw

5 41A3888 3,°functiOr_remote cont_o_ housing & screw only

6 41A3592 34unction compact remote cofltrel

7 10A14

8 29C!28

g 41 f,2828

!0 217A238

11 12B380

12 12B374

13 41A4353

4 t A4373A

I5

'i78B35

I6

178B_

12B350

12_84

18 Square hole bracket

12_83

19 °C_wrap bracket

12£%_85

20 S_ot_edbracket

4iA3535 k_staHation ha_'dware bag (_ncludes hardware

4tA4116 Safe_[y sensor hardware

114A1903 Ownees manua_

enly(nockcu_t[_ard)

housing & screw onty

Remote control visor c!ip

Emergency _ope & handle assy:

2_onductor bell wire _,,white & white/red

Door bracket

Header bracket w/Clev s pin & fastener

(r_eh4ng and sending eyes)

w_th3' 2o_nductor bei/wire attache4

Cuw_ door arm sectioe

NOT SHOWN

illustratedon page 7)

tAgg5

41 A3489

1B3117

183B110

83A4

4 t A3473

41B2616

4! A3594

4

Master link kR

Compiete t_ei/ey assembly

Torai_ center section

Lrai/_ end sect on (each)

Chain _d cabte

Cabie pulley bracket assembly

NOT BROWN

Rai} assembly hardware kit (in<;_udes

hardware i_lustrat_ on page 7)

7 8

12

|

18

19

36

Opener Assembly Pa_s

Repair Parts

18 17

3

11

13

12

PART KEY PART

KEY

NO DESCRiPTiON NO. NO, DESCRIPTION

NO.

1

310380 Spr_Pket cove_

2

41C4220A Gear and sptc_:ket a,ssy.

Complete with:

Spdng washer

_rust washer

Ro# pins (2}

Ohve gear and wom_ gear

Hei_a! gear wlretainer and grease

Ddv¢_worm gear kit w!grease

Line cerd

Ught s(_ket

Lens

Capacitor 1/2 hp

Capacitor - !/3 hp

Capac}tor 1/4 h@

Terminal b!_k w/screws

4

5

8

7

8

9

10

41A2817

41B4245

41A4352

175B88

108048

30B363

30B387

30B366

1_373

41A3150

tl 4t03058

12 41A3,474-1

41A3474_2

41A_74o5

13 41A2818

14 4103452

15 41C4898A

16 41C4246

!7 41A2826

18 414JZ822A

!9 41A4315-'7C

2O 4tA3691

41A2825

Ung_e_31 replacement motor and

bracket assemNy

Complete with: Motoc worm° bracket,

bearing assembly, RPM sensor

Cover - 1/2 h,p

Cover _ 1/3 h,po

Cover o 1/4 h,p,

HeI_! gear and retainer w/grease

RPMsensor assembly

Wire hamess assy. w/p_ug

Iniermpter cup assy

Reviver logic board assy

Complete with:

End panel w/NI labels

End panel w/ail labels

NOT SHOWN

Opener assembly hardware kit (includes

screws not de_gnat_ by a number in illus )

37

Searsmode_numbersanddescriptions_

53702

53703

537_

53705

Requ£ed for a garage with NO

access door,

Opens the garage d_sr automaScal}y

from outside when remote control is

8 F®t Rail E_ension

To_/ow an 8 fc>ot_x_r to c_n _dHy.

i0 F_t Rail Exttension:

_Tb_low a 10fc_t _r to c_en fusty,

53759

53773

53774

53_5

3-Function Compact Remote

Control:

With key dr_g& Velcro faster in9

W_re4n Light Contro_:

Controls intedor or extedor Iights.

Wires into the electrica_ box like a

dimmer switch_

Pfugqn Light Control:

Controls interior Iights Piugs into a

wall receptacle

Mu_ti Function Key_ess EntPj:

Enables homeowner to operate

garage door opener from outside

by enter eg code on speeialIy

designed keyboard.

53709

53714

Door Clearance Brackets:

{For Sectional Doors Om_4

Replace top brackets and rollers on

door to reduce height of door travel

For use when insta_iing opener in

garage with iow headroom

clearance,

For finished ceilings or where you require additional support based on garage constnJction.

Includes bracket and fastening hardware

53779

3-Function Standard Size

Remote Controi:

includes visor clip.

38

index

Access DoodOutstde Key Release Aecesso_ 4, 5

Chain Tension 4, 5_ 11

Electrical Safety Warnings 2, 20, 3t

Garage Door

Testing for balance, binding and sticking 3, 28, 31

Determining high point of travel:

Secflo_l door 12

On@piece door 13

Disabling existing locks 3, 11

Door cbaranee brackets (for garages with low headroom) 12, 38

Force controls

Adiustment proe_ures 4, 29

Problems that might require force adjustments _ 35

Safety warP_ngs 29, 3l

Door hardware 3, 9, 11, 12, 18, 31,32

Mainten_ce instruction iabel 11 28

Reinforcement requirements 4, 24

Removing of aHropes 3, 11

Possibie door damage : 16, 24

Travel Iimits

Adiustment prc_edures 28

Problems that might requk_ limit adiustments 34, 35

Safety warnings 28, 31

Manual} (Emergency) Release Rope & Handle

Lc.skout feature 32

Manual di_onnect 32

Safety warnings 1I, 19, 31,32

Wall contro_ connections 18

Safety reversing sensor connections 23

O_;tdoor key switch a_essoPj connections 18

Sprocket noise 11

Vibration noise (isolator kit) 34

Receiver and Remote Control

Programming the receiver 33

Erasing a[[ codes 33

Activating other openers 33

Safe_ warning 33

Problems with remote control operation

Safety Reverse Test Procedure 30

Testing required t t, 30, %4,35

Safety reverse system problems

Secunng header bracket to wall 12

Applying excessive force on the door 29

Buckling or uneven floor 4, 5

Safety' Warnings 2, 3, 9, I1.12, 16, 18, !9, 20, 21, 24, 28, 29, 30, 31, 32, 33

User Instruction Label for garage wall 11, I8

39

i:1•

OWNER'S

MANUAL

Model No.

139°53824SRT

GARAGE DOOR OPENER

For the repair or replacement pa_s you need

Cati 7 am - 7 pm 7 days a week

1 oaooo366oPART

For {mhome maior brand repair service

Cali 24 hours a day, 7 days a week

t _800-4_REPAIR

For the location of a

Sears Repair Service Center in your area

Caii 24 hours a day, 7 days a week

t o8OOo488-1222

For information on purchasing a Sears

Maintenance Agreement or to inquire

about an existing Agreement

CaR9 am - 5 pm, Monday Saturday

The model numbe_

iabe! is located under

the _ight lens on the

front end panel of

your opener.

When requesting

service or ordering

pa_s, always provide

the following

s Product Type

Model Number

n Part Number

Pa_t Description

Sears, RoebL_ck and Co, Hoffmar_ Estates I_. 60179 USA_

114A1903 @1995, All Rights Reserved Printed in Mexico

Loading...

Loading...