Craftsman 139.53610, 139.53413, 139.53606 Owner's Manual

00000

OD

139

1

139°53606

139.5361 0

- 1/3HP

- 1/2 HP

= 1/2 HP

° 1/3 HP

Owners Manual

CAUTION

READ INSTRUCTIONS AND RULES

FOR SAFE OPERATION CAREFULLY

CONTENTS PAGE

Features of Your Opener ............. 2

Specifications .......................... 2

Accessories ............................... 2

Carton Check List ...................... 3

You'll Need Tools .................... 3

Safety Rules .............................. 4

Operation of Your Opener ............ 5

Maintenance Schedule ............... 5

Assembly .................................. 6

Installation Information ................. 9

Installation ........................... 9

Force& Limit Adjustment ............ 17

Safety Reverse Test ...................... 18

Setting/Changing Code ................ 19

Having a Problem? ..................... 20

Repair Parts, Rail Assembly ........... 22

Repair Parts, Installation .............. 22

Repair Parts, Chassis Assembly ..... 23

How to Order Repair Parts ........... 24

Maintenance Agreements ........... 24

Sears Warranty ......................... 24

FASTEN OWNERS MANUAL NEAR GARAGE DOOR AFTER INSTALLATION IS COMPLETE.

PERIODIC CHECKS OF THE OPENER ARE REQUIRED TO INSURE SATISFACTORY OPERATION.

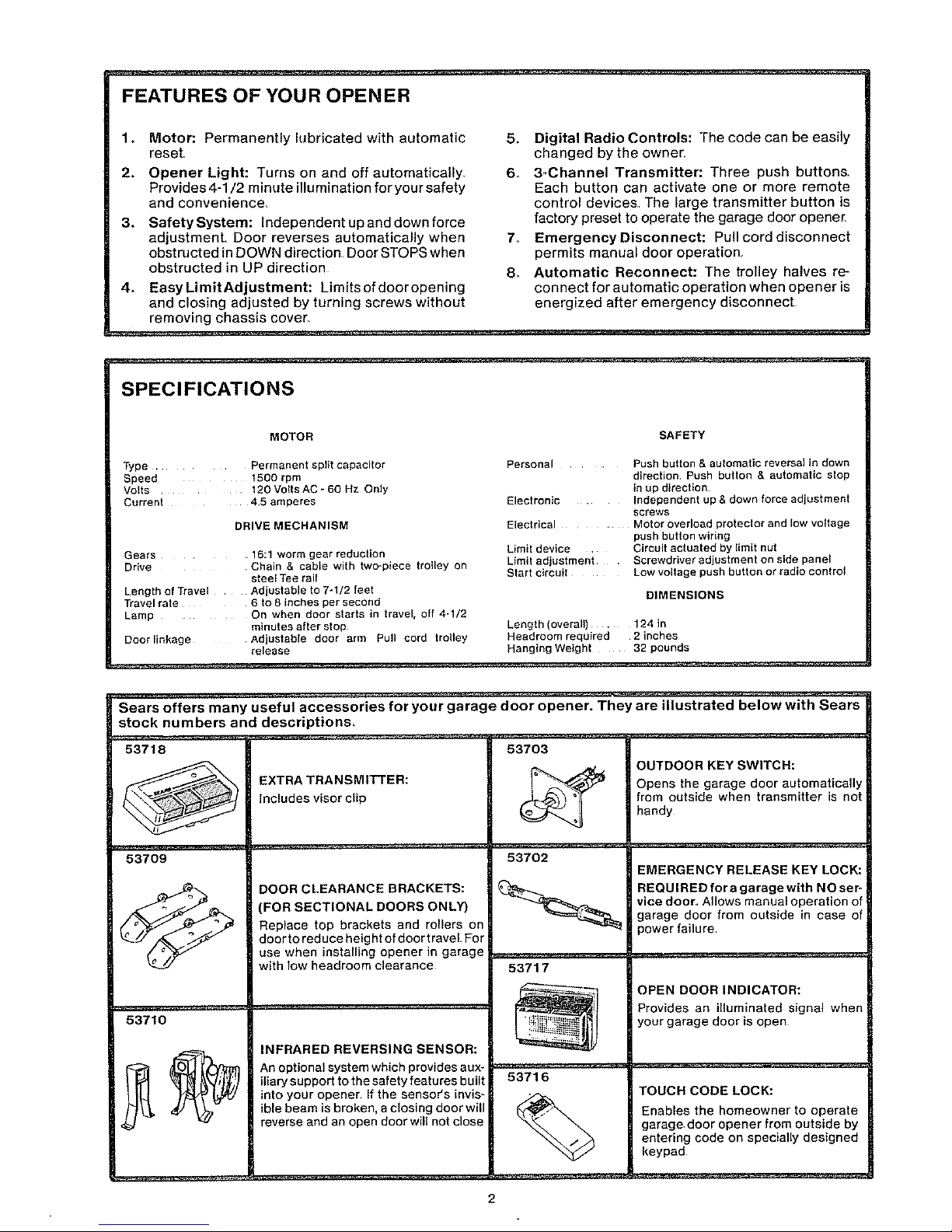

FEATURES OF YOUR OPENER

1. Motor: Permanently lubricated with automatic

reset,

2. Opener Light: Turns on and off automatically.

Provides 4-1/2 minute illumination for your safety

and convenience,

3. Safety System: Independent up and down force

adjustment. Door reverses automatically when

obstructed in DOWN direction Door STOPS when

obstructed in UP direction

4. EasyLimitAdjustment: Limitsofdooropening

and closing adjusted by turning screws without

removing chassis cover

5. Digital Radio Controls: The code can be easily

changed by the owner

6. 3_Channel Transmitter: Three push buttons,

Each button can activate one or more remote

control devices The large transmitter button is

factory preset to operate the garage door opene_

7. Emergency Disconnect: Pullcord disconnect

permits manual door operation,

8. Automatic Reconnect: The trolley halves re-

connect for automatic operation when opener is

energized after emergency disconnect

SPECIFICATIONS

MOTOR SAFETY

Type . Permanent split capacitor

Speed 1500 rpm

Vofts .... 120 Volts AC - 60 Hz Only

Current 45 amperes

DRIVE MECHANISM

Gears ..... 16:1 worm gear reduction

Drive Chain & cable with two*piece trolley on

steel Tee rail

Length of Travel Adjustable to 7-1/2 feet

Travel rate 6 to 8 inches per second

Lamp .... On when door starts in travel, off 4-1/2

minutes after stop

Door linkage Adjustable door arm Pug cord troUey

release

Personal .... Push button & automatic reversal in down

direction Push button & automatic stop

tn up direction

Electronic Independent up & down force adjustment

screws

Electrical Motor overload protector and low voltage

push button wiring

Limit device . Circuit actuated by limit nut

Limit adjustment Screwdriver adjustment on side panel

Start circuil Low voltage push button or radio control

DIMENSIONS

Length (overall) . 124 in

Headroom required 2 inches

Hanging Weight 32 pounds

Sears offers many useful accessories for your garage door opener. They are illustrated below with Sears

stock numbers and descriptions,

53718 53703

OUTDOOR KEY SWITCH:

EXTRA TRANSMITTER: Opens he garage doer automat ca ly

Includes visor clip from outside when transmitter is not

handy

53709 53702

EMERGENCY RELEASE KEY LOCK:

_/_ DOOR CLEARANCE BRACKETS: REQUIRED fora garage with NO set-

(FOR SECTIONAL DOORS ONLY} vice door° Allows manual operation of

garage door from outside in ease of

Replace top brackets and rollers on power failure

doorto reduce height of door travel For

use when installing opener in garage ......................................................................................

with low headroom clearance 53717

......_-7 OPEN DOOR INDICATOR:

Provides an illuminated signal when i

• !_ your garage door is open

53710 . ._ii_E_.._

INFRARED REVERSING SENSOR:

"_ t_'. I_l'Ybzm An optional system which provides aux ...........................................................................................

iliary support to the safety features built 53716

into your opener If the sensor's invis- _ TOUCH CODE LOCK:

ible beam is broken, a closing door will _ Enables the homeowner to operate

reverse and an open door will not close garage door opener from outside by

entering code on specially designed

keypad

2

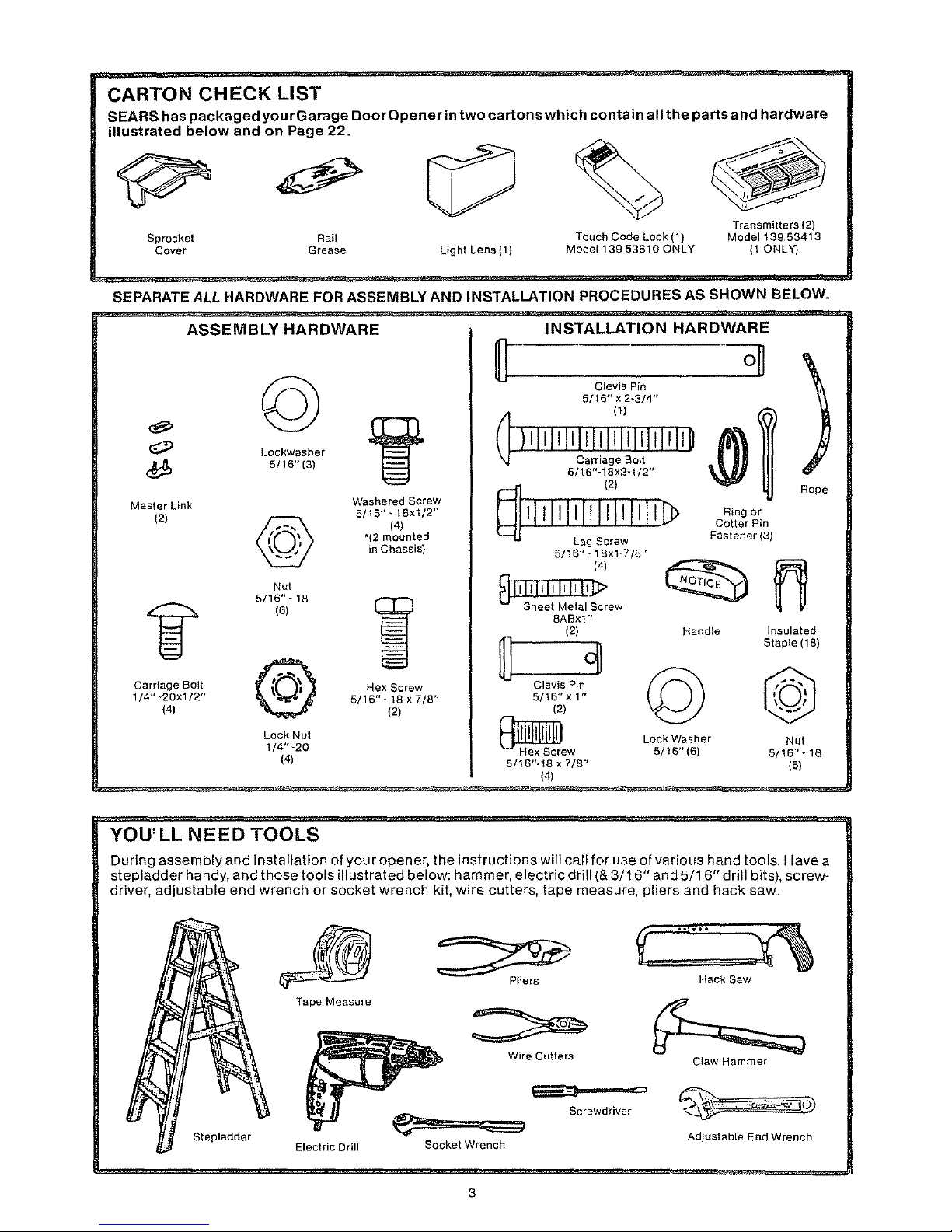

CARTON CHECK LIST

SEARS has packaged yourGarage Door Opener in two cartons which contain all the parts and hardware

illustrated below and on Page 22.

Light Lens (1)

Transmitters {2)

Sprocket Rail Touch Code Lock (1) Model 13953413

Cover Grease Model 139 53610 ONLY (1 ONLY)

SEPARATE ALL HARDWARE FOR ASSEMBLY AND INSTALLATION PROCEDURES AS SHOWN BELOW.

ASSEMBLY HARDWARE INSTALLATION HARDWARE

Lockwasher

(_ 5116"(3)

Master Link

(2)

Washered Screw

5/16"- 18xl/2'"

(41

*(2 mounted

in Chassis)

Nut

5/16 "_ 18

(B)

Carriage Bolt _f _ Hex Screw

1/4''_20xl/2" _ 5/16"-18x7/8"

(4) (2)

Lock Nut

1/4" -20

(4)

Clevis Pin

5/16" x 2-3/4"

5116"-18x2-1/2"

5!16" - 18xl-7/8"'

(4)

8ABxl '

(2) Handle

Clevis Pin

5/16" x 1"

(2)

_re Lock Washer

w 5/15"(6)

5/16"-18 × 7/8"

(4)

Ring or

Cotter Pin

Fastener(3)

Insulated

Staple (18)

©

Nut

5/16"-18

(6)

YOU'LL NEED TOOLS

During assembly and installation of you ropener, the instructions willcall for use of various hand tools,Have a

stepladder handy, and those tools illustrated below: hammer, electric drill (& 3/1 6" and 5/1 6" drill bits), screw-

driver, adjustable end wrench or socket wrench kit, wire cutters, tape measure, pliers and hack saw

Stepladder

Tape Measure

Electric Drill

Pliers

Hack Saw

Wire Cutters

Screwdriver

Socket Wrench

Claw Hammer

Adiustable End Wrench

3

Start By Reading These Impo ant Safety Rules

THIS SAFETY ALERT SYMBOL MEANS CAUTION -- PERSONAL SAFETY OR PROPERTY

DAMAGE INSTRUCTION. READ THESE INSTRUCTIONS CAREFULLY°

THIS GARAGE DOOR OPENER IS DESIGNED AND TESTED TO OFFER REASONABLY

SAFE SERVICE PROVIDED IT IS INSTALLED AND OPERATED IN STRICT ACCORDANCE

WITH TH E FOLLOWING SAFETY INSTRUCTIONS.

FAILURE TO COMPLYWITH THE FOLLOWING INSTRUCTIONS MAY RESULTIN SERIOUS

PERSONAL INJURY OR PROPERTY DAMAGE,

CAUTION: IF YOUR GARAGE HAS NO SERVICE ENTRANCE DOOR, INSTALL MODEL 53702 EMERGENCY RELEASE

KEYLOCK (PAGE 2). THIS ACCESSORY ALLOWS MANUAL OPERATION OF GARAGE DOOR FROM OUTSIDE IN CASE OF

POWER FAILURE.

KEEP GARAGE DOOR BALANCED° Sticking or

binding doors must be repaired.. Garage doors,

door springs, cables, pulleys, brackets and their

hardware may be under extreme tension and can

cause serious personal injury. DO NOT ATTEMPT

ADJUSTMENTS. Call a garage door seP_iceman

to move or adjust door springs or hardware_

DO NOT USE FORCE ADJUSTMENTS TO COM-

PENSATE FOR A BINDING OR STICKING

GARAGE DOOR. Excessive force will Interfere

with the proper operation of the safety reverse

system or damage the garage door° (Page 17)..

DO NOT WEAR RINGS, WATCHES OR LOOSE

CLOTH ING while installing or servicing a garage

door opener.

Fasten the CAUTION LABEL on the wall nearthe

lighted wall control as a reminderof safe operating

procedures.

To avoid serious personal injury from entangle-

ment, REMOVE ALL ROPES CONNECTED TO

THE GARAGE DOOR before installing the garage

door opener.

DISENGAGE ALL EXISTING GARAGE DOOR

LOCKS to avoid damage to garage door,,

Installwallcontrol(or additional push buttons) IN

A LOCATION WHERE GARAGE DOOR ISVISIBLE,

BUT OUT OF THE REACH OF CHILDREN. DO

NOTALLOWCHILDREN TOOPERATETHEWALL

PUSH BUTTON(S) OR TRANSMITTER. Serious

personal injury from a closing garage door may

result from misuse of opener..

Installation and wiring must be in compliance

with your local building and electrical codes.

CONNECT POWER CORD ONLYTO A PROPERLY

GROUNDED OUTLET.

CAUTION: Activate opener onlywhen the door is in

fu IIview, free of obstm ctio n an d opener is properly

adjusted° NO ONE SHOULD ENTER OR LEAVE

THE GARAGE WHILE DOOR IS IN MOTION° DO

NOT ALLOW CHILDREN TO PLAY NEAR DOOR°

LIGHTWEIGHT FIBERGLASS, ALUMINUM AND

STEEL DOORS MUST BE SUBSTANTIALLY RE-

INFORCED TO AVOID DOOR DAMAGE. (See

page 15.) The best solution is to check with you r

garage door manufacturer for an opener installa o

tion reinforcement kit_

Use emergency release ONLY to disengage trolley

and, if possible, ON LY when the door is closed.

DO NOT USE RED EMERGENCY RELEASE ROPE

AND HANDLE TO PULL DOOR OPEN OR CLOSED

THE SAFETY REVERSE SYSTEM TEST IS IM*

PORTANT. (See Pg.18). Your garage door MUST

reverse on contact with a one*inch obstacle placed

on the floor_ Failure to properly adjust the opener

may result in serious personal injury from a closing

garage door., REPEAT TEST AT LEAST ONCE

EVERY THREE MONTHS AND MAKE NEEDED

ADJ USTMENTS_

_ DISCONNECT ELECTRIC POWER TO GARAGE

DOOR OPENER BEFORE MAKING REPAIRS OR

REMOVING COVERS..

Operation of Your Opener

CAUTION

e BEFORE YOU PROCEED, PLEASE READ THE SAFETY

RULES ON PAGE 4 AND OPERATING INSTRUCTIONS

ON THIS PAGE CAREFULLY.

e TO AVOID DIFFICULTY DURING INSTALLATION, DO

NOT RUN OPENER UNTIL INSTRUCTED TO DO SO.

• DO NOT PERMIT CHILDREN TO PLAY IN DOOR AREA.

• OPERATEONLYWHENTHEOPENERISPROPERLYAD-

JUSTED AND DOOR IS WSIBLE AND UNOBSTRUCTED.

IJSING THE OPENER

Your opener can be activated by any of the following devices

(wait one-second between commands):

1 The transmitter. (The TOP (large) push button has been

factory preset to operate door) Hold push button down

until door starts to move

2 The lighted wall control, Hold button down until door

starts to move

3 The KeySwitch orTouch Code Lock(if you have installed

either of these accessories)

OPENING THE DOOR MANUALLY

The door can be operated manually by disconnecting it from

the opener THE DOOR SHOULD BE FULLY CLOSED IF

POSSIBLE, WEAK OR BROKEN SPRINGS COULD ALLOW

AN OPEN DOOR TO FALL RAPIDLY. PROPERTY DAMAGE

OR SERIOUS PERSONAL INJURY COULD RESULT.

Simply pull down sharply on red emergency release handle

and lift the door manually To automatically reconnect the

door to the opener, press the wall control push button

DO NOT USE THE EMERGENCY HANDLE TO PULLTHE

DOOR OPEN OR CLOSED

WHEN OPENER IS ACTIVATED:

I If open, door will close if closed, door will open

2 If closing, the door will reverse

3 If opening, the door will stop (allowing space for entry and

exit of pets and for fresh air)

4 If the door has been stopped in a partially open position, it

will close

5 If an obstruction is encountered while closing, the door

will reverse

6 If an obstruction is encountered while opening, the door

will stop

7 [f the optional Infrared Reversing Sensor is installed, the

garage door will reverse in the closing cycle when the

invisible beam is broke n An open doorwill not close when

the beam is broken The sensor has no effect in the open-

ing cycle

THE OPENER LIGHT will turn on under the following con-

ditions: when the opener is initially plugged in; when power is

interrupted; when the opener is activated. It will turn off auto-

matically after 4-1/2 minutes. Bulb size-75 Watts maximum

CARE OF THE OPENER

When properly installed, the opener will provide high perfor-

mance with a minimum of maintenance Opener does not

require additional lubrication

Most complaints of unsatisfactory opener operation can be

traced to problems with the door itself....OPENER IS NOT

INTENDEDTOCORRECT PROBLEMSTHATARECAUSED

BYAN UNBALANCED OR BINDING DOOR, BROKEN DOOR

SPRINGS OR BY FAULTY DOOR HARDWARE.

When operated manually, a properly balanced door will stay

in any point of travel while being supported entirely by its

springs

LIMIT AND FORCE ADJUSTMENTS: These adjustments

must be checked and properly set when opener is installed,

Only a screwdriver is required Weather conditions may

cause minor changes in door operation requiring some

re-adjustments, particularly during the first year of opera-

tion. Page 17 refers to limit and force adjustments. Follow

instructions carefully and repeat SAFETY REVERSE TEST

after any adjustment

THE SAFETY REVERSE SYSTEM IS IMPORTANT (SEE

PG.18)., GARAGE DOOR MUSTREVERSE ON CONTACT

WITH A ONE-INCH OBSTACLE PLACED ON THE FLOOR.

FAILURE TO PROPERLYADJUSTOPEN ER MAY RESULT

IN SERIOUS PERSONAL INJURY FROM A CLOSING GAR-

AGE DOOR.

CHAIN TENSION ADJUSTMENT: After installation of the

opener and adjustment of forces and limits, chain may appear

loose This is normal

TO CHECK THE CHAIN TENSION: disconnect the trolley

by pulling the red emergency handle If the chain returns to

the position described and illustrated in Step 5 Page 9, DO

NOT make ANY further adjustments.

THE TRANSMITTER: The 3-channel transmitter will operate

more than one garage door opener, if desired. The additional

push buttons may also be used to operate other remote con-

trol devices. Transmitter(s) may be secured to a car sun visor

with clip(s) provided. Additional transmitters can be purchased

at any time (Refer to Accessories, Pg_ 2)

Any new transmitters must be set to the same code as original

transmitter and receive_ Page 19 explains how to change

your existing code and how to use the transmitter(s) with

other remote control devices Self service of your radio con-

trois is not recommended If service is needed, contact your

nearest Sears Service Center

TRANSMITTER BATTERY: The 9-Volt battery should pre-

d_ce power for approximately one year As long as there is

adequate power, the transmitter battery test light will glow

when a push button is pressed (and the opener will operate)

When the light does not come on, replace battery If transmis-

sion range lessens, check battery light

Avoid the inconvenience of unexpected failure by replacing

battery annually, preferably before winter Use a general

purpose, 9 volt battery

TO CHANGE BATTERY: Remove visor clip and connecting

screw in transmitter case Set aside top of case and discard

old battery Snap connector onto new battery Replace top of

case and connecting screw Replace visor clip,

MAINTENANCE OF YOUR OPENER

AT LEAST4 TIMES A YEAR

MANUALLY OPERATE DOOR. If it is unbalanced or bind-

ing, call for professional garage door service

CHECK TO MAKE SURE DOOR OPENS AND CLOSES

FULLY. Adjust Limits and/or Force if necessary

REPEAT SAFETY REVERSE TEST. Make any necessary

adjustments (see page 18)

TWICE A YEAR

CHECK CHAIN TENSION. Adjust if necessary

ONCE A YEAR

OIL DOOR ROLLERS, BEARINGS AND HINGES,

REPLACE THE TRANSMITTER BATTERY, preferably be-

fore winter

Assembly

TO AVOID INSTALLATION DIFFICULTIES, DO NOT RUN THE GARAGE DOOR OPENER UNTIL YOU ARE

INSTRUCTED TO DO SO.

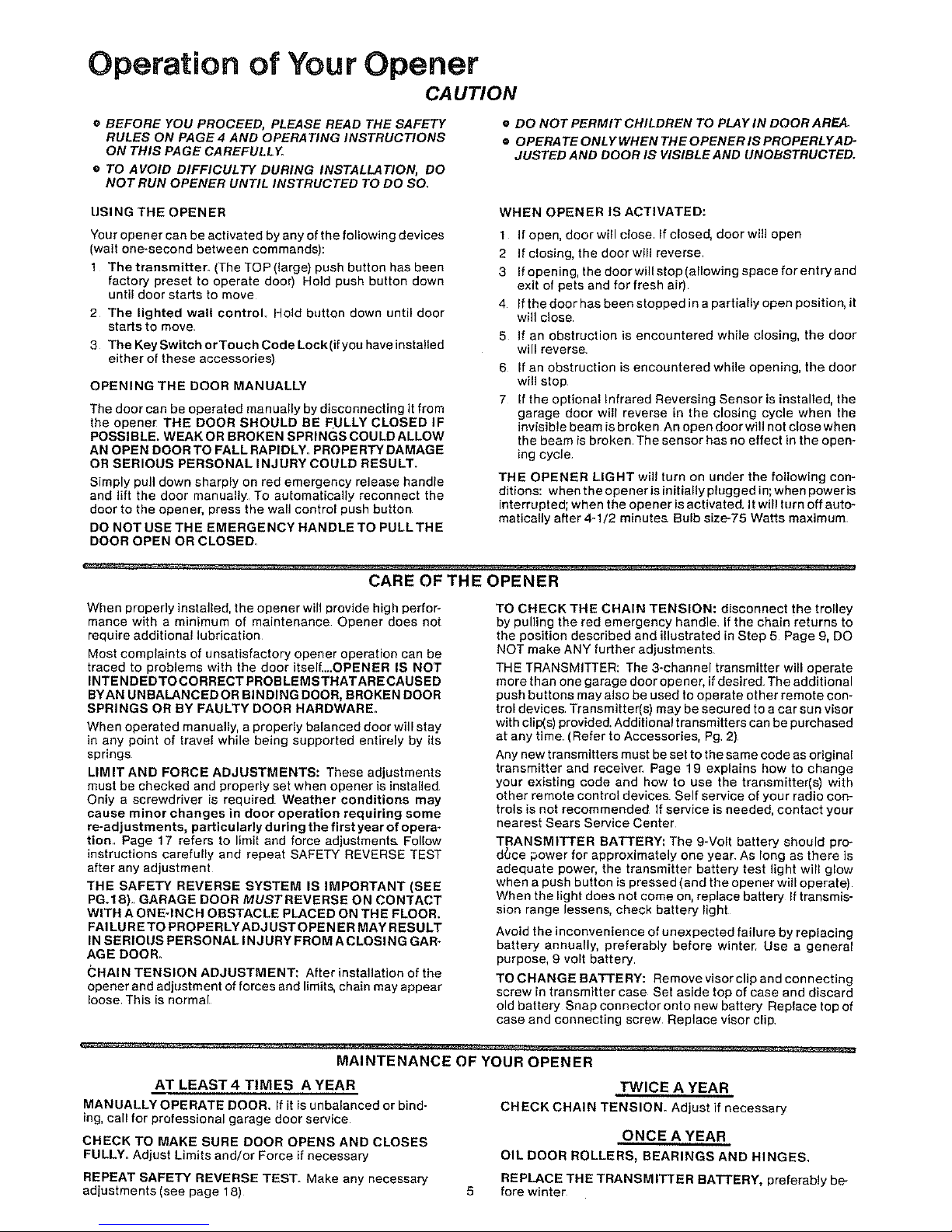

ST _: P "1 Assemble Tee Rail & Attach Cable Pulley Bracket

TEE RAIL BACK

(TO CHASSIS)

CAUTION: Do not tighten the lock nuts until bolt

necks are seated in square holes.

Tee Rail

(End Section)

t/4' Lock Nut

Tee Rail

The center rail section MUST be

positioned on the LEFTSIDE of end

rails as shown,

Otherwise, trolley will hit against nut

when installed (Pg. 7).

Brace

Tee Rail

(End Section)

Square Carriage

Bolt Hole

Cable pulley bracket

attaches to FRONT

END of Tee Rail

TEE RAIL FRONT

(TO DOOR)

Carriage Bolt

/2"

Brace _

PROCEDURE: Place the 3 Tee rail sections on a flat

surface for assembly. THIS IS IMPORTANT. The end

sections are identical. THE CENTER SECTION MUST BE

POSITIONED WITH THE BRACES ON THE LEFT SIDE OF

END SECTIONS. If there is a label attached to the cen-

ter section, make sure that the "directional arrow" is

pointing toward the front (to door) Otherwise, study

the illustration CAREFULLY

(When assembled, Tee rail has a front-to-back posi-

tion as shown).

Bolt rail sections together with the hardware illus-

trated and from the direction indicated

SQUARE NECKS ON CARRIAGE BOLTS MUST BE

SEATED IN SQUARE HOLES IN RAIL SECTIONS,

Screws

_ _5/16"_18x7/8""

Cable Pulley _ _,_';

k°ckW_s--_her_l _ Nut

5/16"

5/16"

Position cable pulley bracket on front end of tee rail as

shown. Fasten securely with the hardware provided

IMPORTANT: Whentighteningscrews, besureto

keep bracket parallel to rail, Otherwise, rail may

bow when opener is operated.

6

Assernbiy

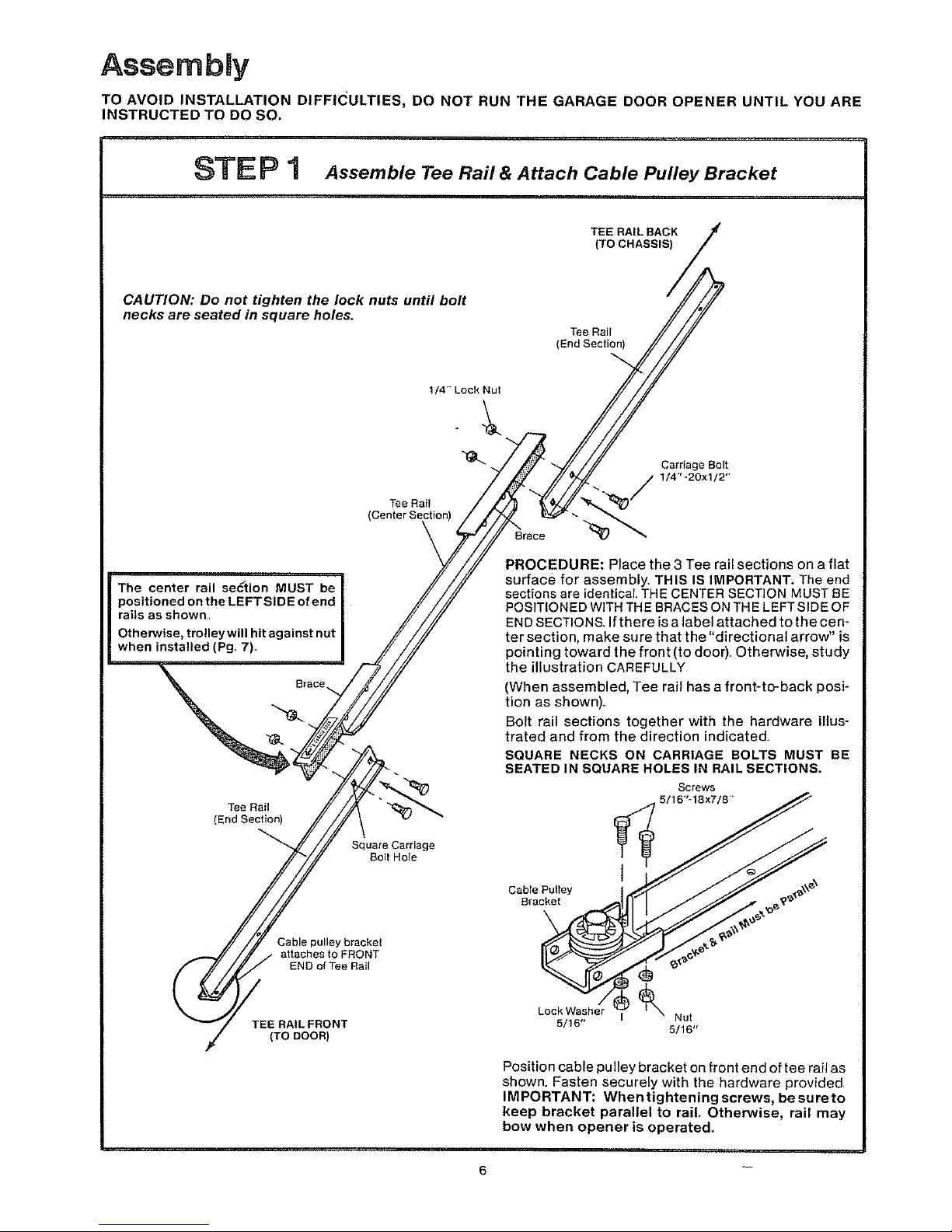

STE P 2 Install Trolley & Attach Chain Retainer Bracket

As a temporary stop, insert a screwdriver into

hole in front end of Tee rail as shown. Slide the

inner trolley onto the Tee rail until it is firmly against

the screwdriver

NOTE: If trolley hits against nut on Tee rail, center

section was attached from wrong side and must

be repositioned. Review Step 1.

Slide the outer trolley onto the Tee rail until it partially

engages the inner trolley and stops

TO FULLY ENGAGE TROLLEY: With a hammer,

firmly tap the back end of outer trolley just below the

rail guide Outer trolley must move forward to fully

engage inner trolley Be careful to avoid damaging

trolley spring,

Outer Trolley

Inner Trolley

Cable

Pulley

Bracket

\

Temporary Stop

Screwdriver

Flat End

Lock Washer

5/16"

Inner

Nut

Threaded

End

Outer

Nut

._5/16"

r

Chain

Retainer

Bracket

Trolley

Shaft

Attach inner nut, lock washer, chain retainer bracket

and outer nut to trolley shaft in the order shown_ DO

NOT TIGHTEN NUTS UNTIL STEP 5, PAGE 9,

STE P 3 Attach Tee Rail to Opener Chassis

USE ONLYTHOSE SCREWS MOUNTED

IN TOPOFOPEN ER CHASSIS. FAILURE

TO DO SO WILL CAUSE SERIOUS DAM-

AGE TO THE DOOR OPENER°

PROCEDURE: Place opener chassis on packing

ma terial to protect cover For convenience, place a

support under the cable pulley bracket

Re move 5/16"-18xl/2" washered screws mounted

in top of opener chassis Align holes in back end of

Tee ran with holes in opener chassis. Fasten the rail

to the chassis with washered screws previously

removed. CAUTION: USEONLYTHESESCREWS!

Use of any other screws will cause serious dam-

age to door opener. Tighten screws securely,

insert a 5/16"-18xl/2" washered screw into trolley

stop hole in the Tee rail as shown, Tighten securely

with a 5/16" nut

Washered Screw

5/16"-1Sxl/2"

Stop Hole

Tee Rall

(Back Sectior

5/16"-18

7

Assembly

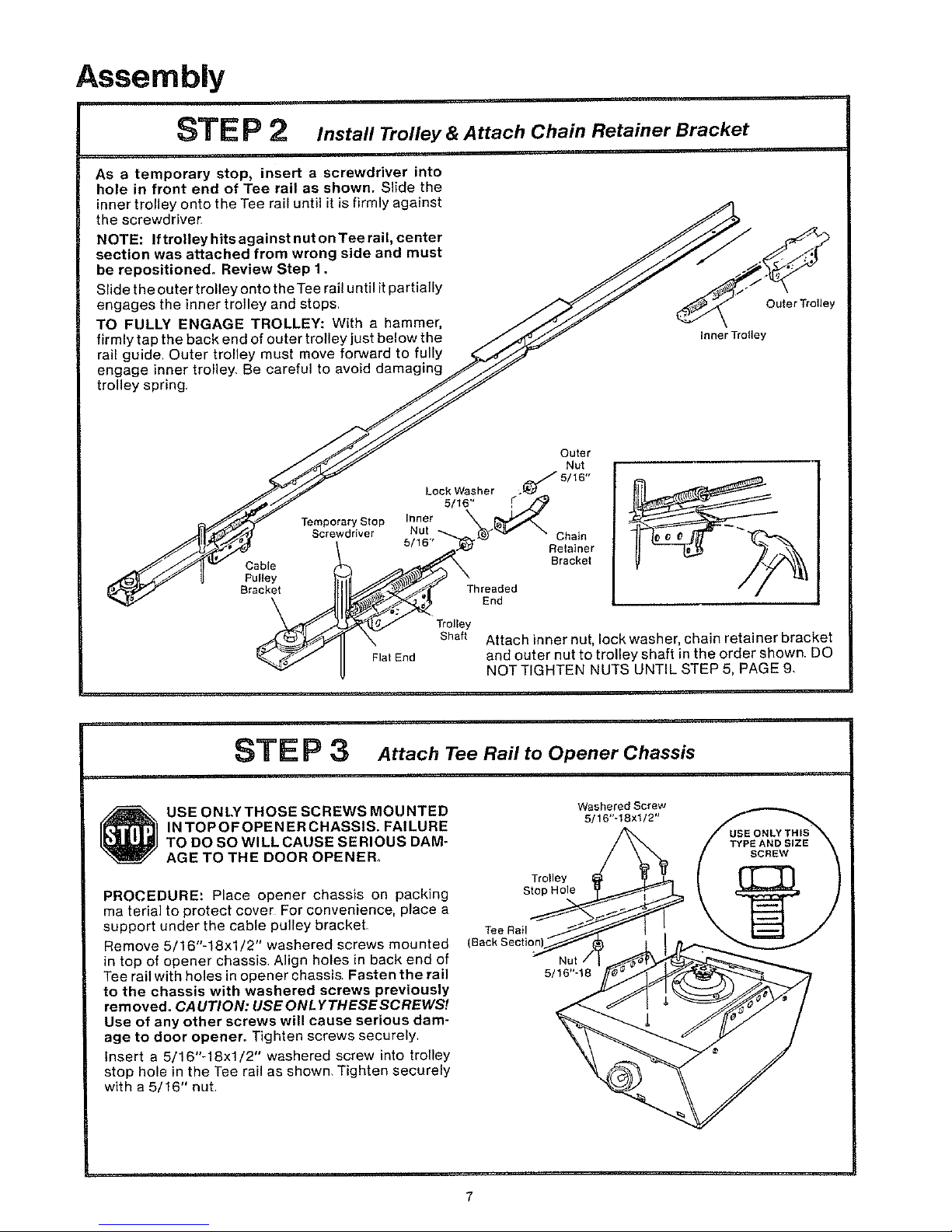

STE P 4 I.stallChainandCable

DO NOT REMOVE CHAIN AND CABLE FROM CARTON

Detach cable from side of carton and fasten to trolley

with a master link from coin envelope

MASTER LINK PROCEDURE: Push pins of master

link bar through loop of cable and hole in flat end of

trolley shaft (A) Push cap over pins and onto notches.

Slide clip-on spring over cap and onto pin notches

until both pins are locked in place,

I=!

installChainandCable

inThisDirection

Opener Chassis

Sprocket /

Caution: Keep chain taut while installing to help

prevent kinking,

With trolley against the screwdriver, dispense cable

around pulley Proceed back around opener sprocket

(B) - be sure sprocket teeth engage chain - and forward

to chain retainer bracket (C).

Use second master link to connect chain to retainer

bracket. Check to make sure chain is not twisted.

A

Pulley

Install Chain and Cable

in This D{recl[on

Master

Link

Clip-On

Spring

Master

Link

Outside

Bar

As a permanent trolley stop, insert 5/16" washered

screw and nut into remaining hole in Tee rail front

Tighten securely REMOVE SCREWDRIVER.

Tab Plate

Slot

C

Th_reo_rde_dsEhndTee Rail _ j Chain

Retaai_eetr ear

End Trolley

Trolley

St°P_H¢_ 5S/'Cr6ewWaan'h_ruetd

\

Remove

Screwdriver

Attach sprocket cover to chassis as shown, Insert

back tab in chassis slot Then bend cover forward and

insert front tab in slot provided on mounting plate

Loading...

Loading...