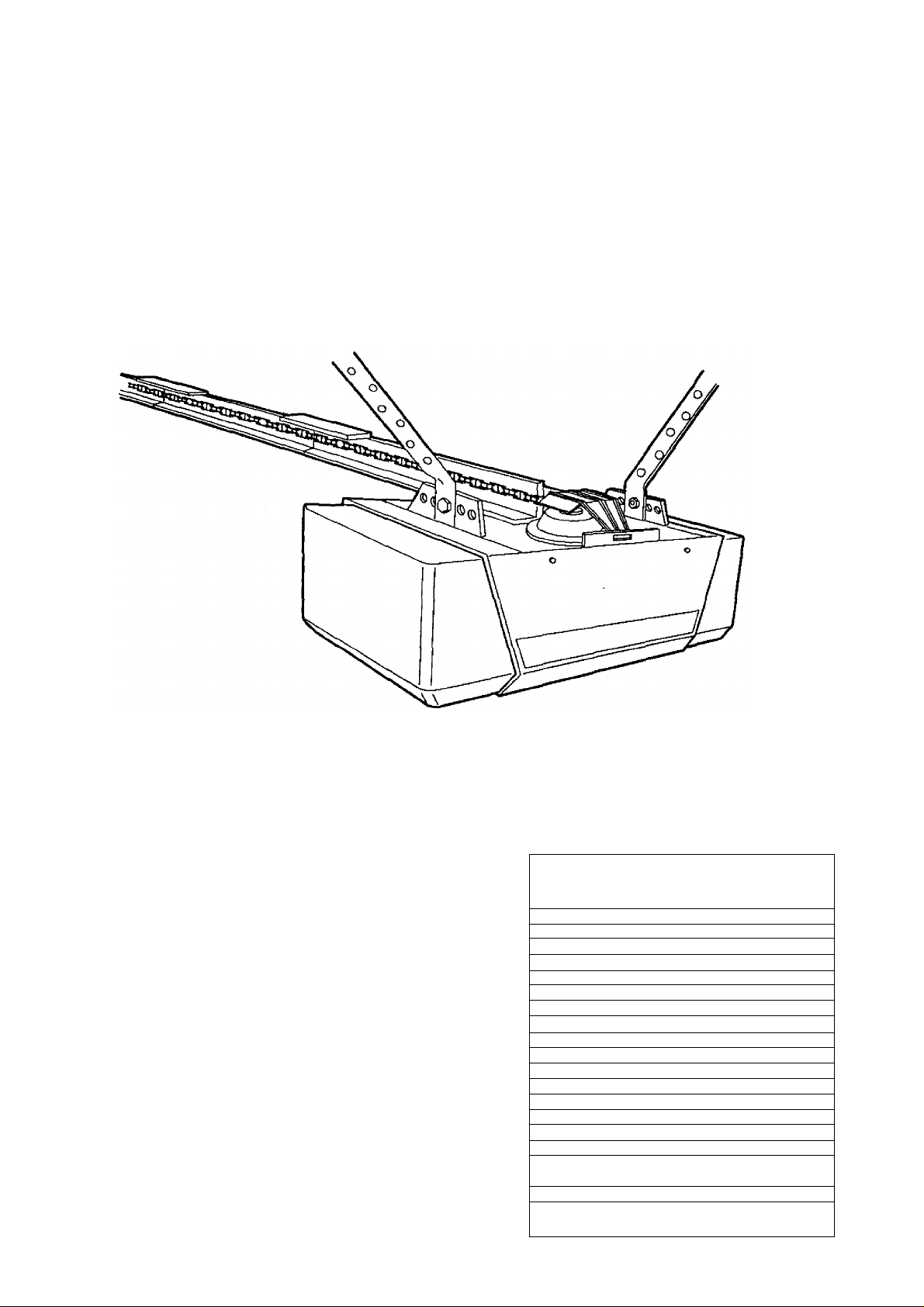

Craftsman 139.53515SR User Manual

Sears Bestl/ZnnmMm

Owners Manual

Garage Door Opener

Model 139.53626SR - 1/2HP

Model 139.53515SR - 1/2HP

FASTEN THIS MANUAL NEAR THE GARAGE DOOR AFTER

INSTALLATION. PERIODIC CHECKS OF THE OPENER ARE

REQUIRED TO INSURE SATISFACTORY OPERATION.

FOR RESIDENTIAL USE ONLY.

CAUTION

PLEASE READ THIS

MANUAL CAREFULLY

CONTENTS

Safety Rules

Operation of Hbur Opener............... .. 3

Maintenance Schedule

Features of \bur Opener

Specifications................................... .. 4

Accessories......................................

Carton Check List

Y}u’ll Need Tools

Assembly

Installation Information

installation........................................

Force & Limit Adjustjnent

Safety Reverse Test......................... .. 18

Setting/Changing Code

Having a Problem 7

Repair Parts, Rail Assembly ...

Repair Parts, Installation

Repair Parts, Chassis Assembly

How To Order Repair Parts

Maintenance Agreements

Sears Warranty

.....................................

....................

..................

............................

.............................

.........................................

...................

...............

...................

.........................

................

______

...............

................................

PAGE

. 2

.. 3

. 4

. 4

.. 5

.. 6

. 9

.. 17

.. 19

.. 20

.. 22

.. 22

.. 23

.. 24

.. 24

start By Reading These Important Safety Rules

THIS SAFETY ALERT SYMBOL MEANS CAUTION — PERSONAL SAFETY OR PROPERTY

DAMAGE INSTRUCTION. READ THESE INSTRUCTIONS CAREFULLY.

THIS GARAGE DOOR OPENER IS DESIGNED AND TESTED TO OFFER REASONABLY

A

CAUTION: IF YOUR GARAGE HAS NO SERVICE ENTRANCE DOOR, INSTALL MODEL S3702 EMERGENCY RELEASE

KEYLOCK (PAGE 4). THIS ACCESSORY ALLOWS MANUAL OPERATION OF GARAGE DOOR FROM OUTSIDE IN CASE

OF POWER FAILURE,

SAFE SERVICE PROVIDED IT IS INSTALLED AND OPERATED IN STRICT ACCORDANCE

WITH THE FOLLOWING SAFETY INSTRUCTIONS.

FAILURE TO COMPLY WITH THE FOLLOWING INSTRUCTIONS MAY RESULT IN SERIOUS

PERSONAL INJURY OR PROPERTY DAMAGE.

A

A

A

A

KEEP GARAGE DOOR BALANCED. Sticking or

binding doors must be repaired. Garage doors,

door springs, cables, pulleys, brackets and their

hardware are under extreme tension and can

cause serious personal injury. DO NOT

ATTEMPT TO LOOSEN, MOVE OR ADJUST

THEM. Call a garage door serviceman.

DO NOT WEAR RINGS, WATCHES OR LOOSE

CLOTHING while installing or servicing a garage

door opener.

To avoid serious personal injury from entangle-

menL REMOVE ALL ROPES CONNECTED TO

THE GARAGE DOOR before installing the

garage door opener.

DISENGAGE ALL EXISTING GARAGE DOOR

LOCKS to avoid damage to garage door.

Installation and wiring must be in compliance

with your local building and electrical codes.

CONNECT THE POWER CORD ONLY TO A

PROPERLY GROUNDED OUTLET.

A

A

A

A

THE SAFETY REVERSE SYSTEM TEST IS VERY

IMPORTANT (page 18). Ysur garage door MUST

reverse on contact with a 1' obstacle placed on

the floor. Failure to properly adjust the opener

may result in serious personal injury from a

closing garage door. REPEAT THE TEST AT

LEAST ONCE EVERY THREE MONTHS AND

MAKE NEEDED ADJUSTMENTS.

Fasten the CAUTION LABEL alongside the Wall

Control as a reminder of safe operating

procedures.

Install the Wall Control (or any additional push

buttons) IN A LOCATION WHERE THE GARAGE

DOOR IS VISIBLE, BUT OUT OF THE REACH OF

CHILDREN. DO NOT ALLOW CHILDREN TO

OPERATE THE WALL PUSH BUTTON(S) OR

TRANSMITTER. Serious personal injury from a

closing garage door may result from misuse of

the opener.

CAUTION: Activate opener only when the door

is in tuli view, free of obstructions and opener

is properly adjusted. NO ONE SHOULD ENTER

OR LEAVE THE GARAGE WHILE DOOR IS IN

MOTION. DO NOT ALLOW CHILDREN TO PLAY

NEAR THE DOOR.

A

A

LIGHTWEIGHT FIBERGLASS, ALUMINUM AND

STEEL DOORS MUST BE SUBSTANTIALLY

REINFORCED TO AVOID DOOR DAMAGE. (See

page 15.) The best solution is to check with your

garage door manufacturer for an opener

installation reinforcement kit.

DO NOT USE THE FORCE ADJUSTMENTS TO

COMPENSATE FOR A BINDING OR STICKING

GARAGE DOOR. Excessive force will interfere

with the proper operation of the safety reverse

system or damage the garage door (page 17).

A

A

Use the emergency release ONLY to disengage

the trolley and, if possible, ONLY when the door

is closed. DO NOT USE EMERGENCY HANDLE

TO PULL DOOR OPEN OR CLOSED.

DISCONNECT ELECTRIC POWER TO GARAGE

DOOR OPENER BEFORE MAKING REPAIRS OR

REMOVING COVERS.

Operation of Your Opener

CAUTION

BEFORE YOU PROCEED, PLEASE READ THE

SAFETY RULES ON PAGE 2 AND OPERATING

INSTRUCTIONS ON THIS PAGE CAREFULLY.

TO AVOID DIFFICULTY DURING INSTALLATION, DO

NOT RUN OPENER UNTIL INSTRUCTED TO DO SO.

USING THE OPENER

Your opener can be activated by any of the following devices:

1. The 3-Function Transmitter. Hold LARGE push button

down until the door starts to move.

2. The Wall Control. Hold push bar down until the door starts

to move.

3. The Key Switch or Touch Code Transmitter accessories.

Descried on page 4.

OPENING THE DOOR MANUALLY

THE DOOR SHOULD BE FULLY CLOSED IF POSSIBLE. WEAK OR

BROKEN SPRINGS COULD ALLOW AN OPEN DOOR TO FALL

RAPIDLY. PROPERTY DAMAGE OR SERIOUS PERSONAL INJURY

COULD RESULT. DO NOT USE EMERGENCY HANDLE TO PULL

DOOR OPEN OR CLOSED.

The door can be operated manually by disconnecting it from

the opener. Pull down sharply on the red emergency release

handle and lift the door manually. To automatically reconnect

the door to the opener, press the Wall Control push bar.

LOCKOUT FEATURE: prevents trolley from reconnecting

automatically. If you need to use this feature, pull emergen^

handle down and back (toward the opener). Trolley will remain

"Locked-Out" and door can be raised and lowered manually.

To reconnect trolley, pull emergency handle straight down.

• DO NOT PERMIT CHILDREN TO PLAY IN DOOR

AREA.

• OPERATE ONLY WHEN OPENER IS PROPERLY

ADJUSTED AND THE DOOR IS VISIBLE AND

UNOBSTRUCTED.

WHEN OPENER IS ACTIVATED:

1. If open, the door will close. If closed, the door will open.

2. If closing, the door will reverse.

3. If opening, the door will stop (allowing space for entry and

exit of pets and for fresh air),

4. If the door has been stopped in a partially open position,

it will close.

5. If an obstruction is encountered while closing, the door will

reverse.

6. if an obstruction is encountered while opening, the door

will stop.

7. If the optional ‘Infrared Sensor’ is installed, the garage door

will reverse in the closing cycle when the invisible beam

is broken. An open door will not close when beam is broken.

The sensor has no effect in the opening cycle.

OPENER LIGHTS will turn on under the following conditions:

when the opener is initially plugged in; when the power is

interrupted; when the opener is activated. They will turn off

automatically after 4’/i minutes or provide constant light when

Light Feature is activated. Bulb size 75 watts maximum.

CARE OF THE OPENER

When properly instiled, opener will provide high performance

with a minimum of maintenance. The opener does not require

additional lubrication.

Most complaints of unsatisfactory opener operation can be

traced to problems with the door itself. When operated

manually, a properly balanced door will stay in any point of

travel while being supported entirely by its springs.

THE OPENER IS NOT INTENDED TO CORRECT ANY

PROBLEMS THAT ARE CAUSED BY AN UNBALANCED OR

BINDING DOOR, BROKEN DOOR SPRINGS OR BY FAULTY

DOOR HARDWARE.

LIMIT AND FORCE ADJUSTMENTS: These a(fjustments

must be checked and properly set when opener is installed.

Only a screwdriver is required. Page 17 refers to the limit and

force adjustments. Follow instructions carefully.

REPEAT SAFETY REVERSE TEST AFTER ANY ADJUST

MENT OF FORCE AND/OR LIMITS. Weather conditions

may cause some minor changes in door operation requir

ing some readjustments, particularly during the first year

of operation.

THE SAFETY REVERSE SYSTEM IS IMPORTANT (See

pg. 18). GARAGE DOOR MUST REVERSE ON CONTACT

WITH A ONE-INCH OBSTACLE PLACED ON THE FLOOR.

FAILURE TO PROPERLY ADJUST OPENER MAY RESULT

IN SERIOUS PERSONAL INJURY FROM A CLOSING

GAR.<\GE DOOR.

CHAIN TENSION ADJUSTMENT; After installation of the

opener and adjustment of forces and limits, the chain may

appear loose. This is normal. To check the chain tension:

disconnect the trolley by pulling the red emergency handle.

If the chain returns to the position described and illustrated

in Step 5 page 9, DO NCT make ANY further adjustments.

TRANSMITTER; The 3-function transmitter will operate more

than one garage door opener, if desired. The other push but

tons may also be used to operate 53000 and 53000SR Series

light controls. Transmitter may be secured to car sun visor

with clip provided. Additional transmitters can be purchased

at any time. Refer to Accessories on page 4.

Any new transmitters must be set to the same code as the

original transmitter. Page 19 explains how to change your

existing code and use the transmitter(s) with other 53000 and

53000 SR receivers. Self service of your radio controls is rwt

recommended. If service is needed, contact your nearest

Sears Service Center.

TRANSMITTER BATTERY: The 12 Vblt battery should

produce power for at least one year. As long as the battery

power is adequate, the transmitter test light will glow when

the push button is pressed (and the opener will operate).

When the light does not come on, replace the battery. If trartsmission range lessens, check battery test light.

TO CHANGE BATTERY Slide №e battery compartment cover

down. Position new 12 Volt battery as directed.

MAINTENANCE OF YOUR OPENER

AT LEAST 4 TIMES A YEAR

MANUALLY OPERATE DOOR. If it is unbalanced or birfoing,

call for professional garage door service.

CHECK TO BE SURE DOOR OPENS & CLOSES FULLY.

Adjust Limits and/or Force if necessary.

REPEAT SAFETY REVERSE TEST. Make any necessary

adjustments (see page 18).

TWICE A YEAR

CHECK CHAIN TENSION. Adjust if necessary.

ONCE A YEAR

OIL DOOR ROLLERS, BEARINGS AND HINGES.

FEATURES OF YOUR OPENER

1. Motor: Permanently lubricated with automatic reset.

2. Opener Lights: Turn on and off automatically with ЛУг

minute illumination for your safety and convenience.

Provide constant fight when Light Feature is activated.

3. Safety System: Independent up and down force

adjustment. The door reverses automatically when

obstructed in DOVVN direction. The door STOPS when

obstructed in UP position

4. Easy Limit Adjustment: Limits of door opening and

closing adjust^ by turning screws without removing

chassis cover.

5. Digital Radio Controls: The code can be easily

changed by the owner,

6. Emergency Disconnect: Pull cord disconnect permits

manual door operation.

7. 3-Function Transmitter: Has three push buttons. Each

button can activate one or more remote control devices.

Opener is factory preset to activate when LARGE push

button on transmitter is pressed.

8. Automatic Reconnect: The trolley halves reconnect

for automatic operation when the opener is energized

after emergency disconnect.

9. Lock Push Button: When Lock Feature is activated,

opener will not operate from portable transmitters. Door

will OPEN from Wall Control push bar, Key Switch and

Touch Code Transmitter accessories, described below.

Door will CLOSE if Wall Control push bar is pressed

and held through a complete down cycle. If push bar

is released before travel Is completed, door will reverse.

SPECIFICATIONS

MOTOR

Type

................................

Speed............................. 1500 rpm

\folts

...............................

Current

..........................

Gears

..............................

Drive

..............................

Length of travel

Travel rate

Lamps

Door linkage..................Adjustable door arm. Pull cord trolley

......................

............................

Permanent split capacitor

120 Volts AC - 60 Hz. Only

45 amperes

DRIVE MECHANISM

16:1 worm gear reduction

Chain & cable with two-piece trolley on

steel Tee-rail

............

Adjustable to Th leet

6 to 8 inches per second

On when door starts in travel, off 4’A

minutes after stop. Constant light when

Light Control is ON.

release.

Personal........................Push button and automatic reversal in

Electronic......................Independent UP and DOWN force

Electrical

Limit device

Limit adjustment

Start circuit

Length (overall)

Headroom required .. 2 inches

Hanging weight

.......................

.................

...................

SAFETY

down direction. Push button and

Automatic stop in UP direction

adjustment screws

Motor overload protector & low voltage

push button wiring

Circuit actuated by limit nut

..........

Screwdriver adjustment on side panel

Low voltage push button or radio

control

DIMENSIONS

............

124 inches

............

32 pounds

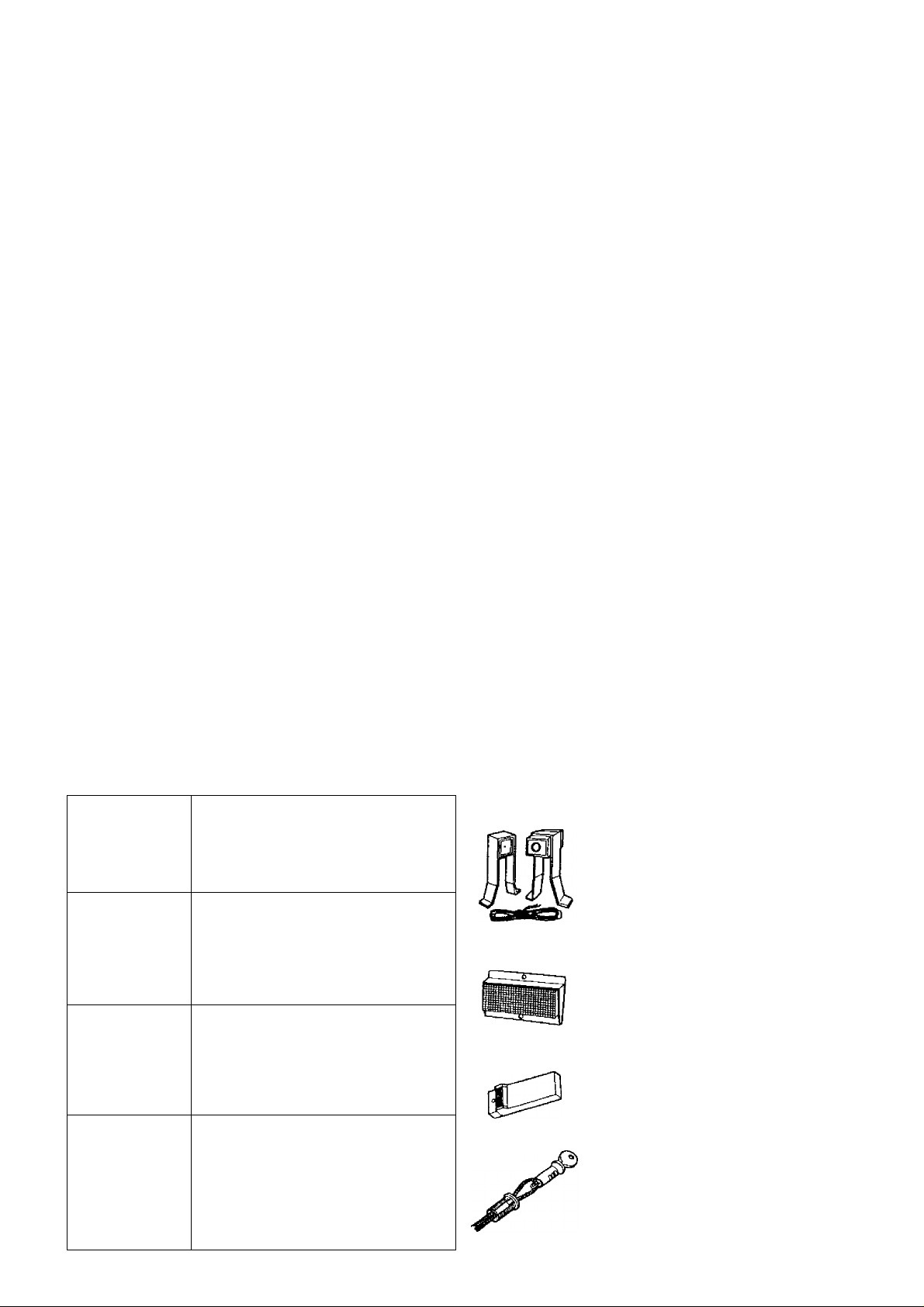

ACCESSORIES

Sears offers many useful accessories for your garage door opener. They are illustrated below with sears stock

numbers and descriptions.

53778 _^^

53758

EXTRA TRANSMITTER:

Standard size. Includes visor clip.

EXTRA TRANSMITTER:

Mini.

53710

53717

INFRARED REVERSING SENSOR:

An optional system which provides

auxiliary support to the safety features

built into your opener. If the sensor's

invisible beam is broken, a closing

door will reverse and an open door will

not close.

OPEN DOOR INDICATOR:

Provides an illuminated signal when

your garage door is open.

53703

53709

OUTDOOR KEY SWITCH:

Opens the garage door automatically

from outside when transmitter is not

handy.

DOOR CLEARANCE BRACKETS:

(For Sectional Doors Only)

Replace top brackets and rollers on

door to reduce height of door travel.

For use when installing opener in

garage with low headroom clearance.

53776

53702

TOUCH CODE TRANSMITTER:

Enables homeowner to operate garage

door opener from outside by entering

code on specially designed keyboard.

EMERGENCY RELEASE KEYLOCK

REQUIRED for a garage with NO

service door.

Allows manual operation of garage

door from outside in case of power

failure.

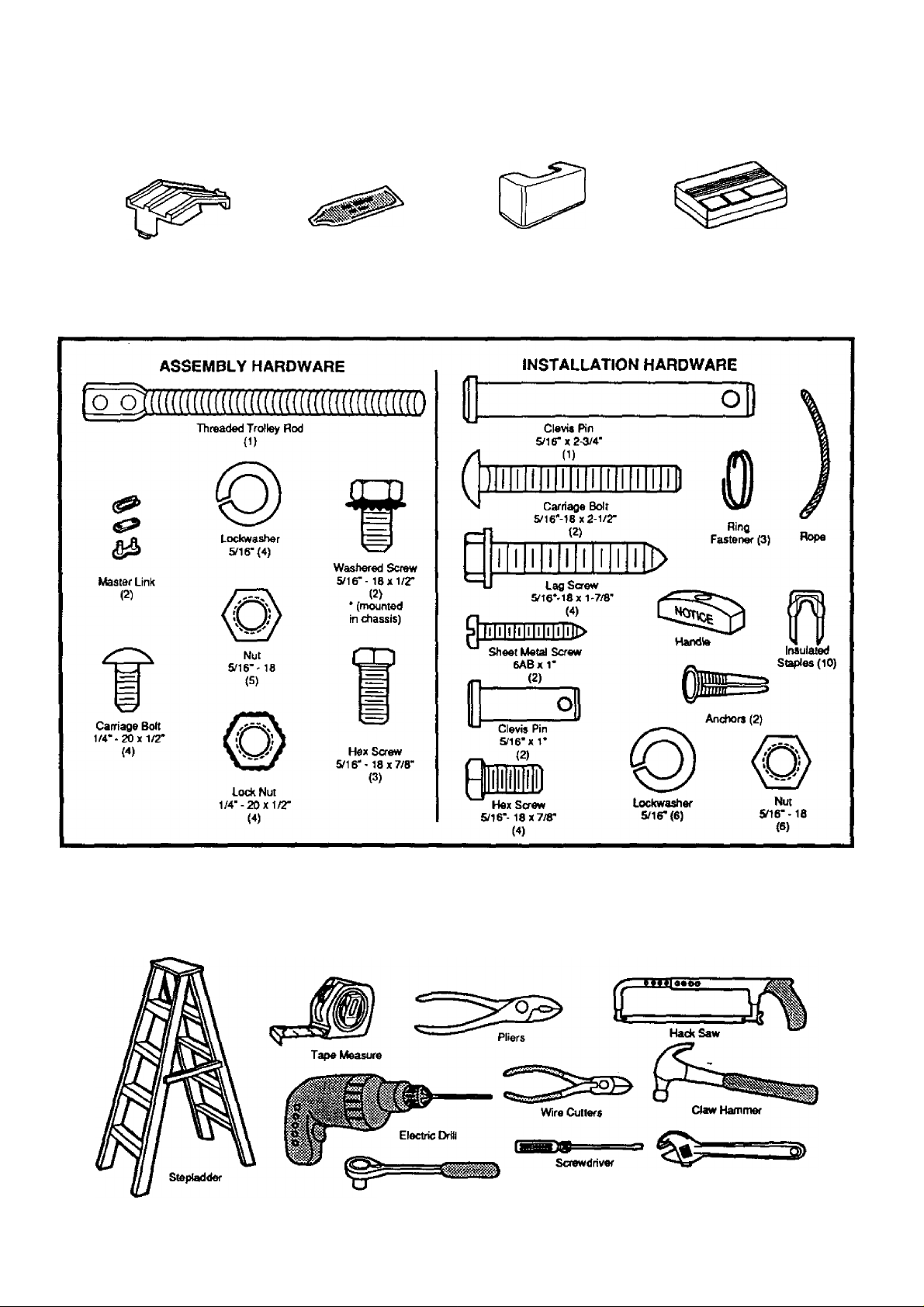

CARTON CHECK LIST

SEARS has packaged your GARAGE DOOR OPENER in two cartons which contain all the parts and hardware

Illustrated below and on Page 22.

Sprockel

Cower

Rail

Grease

Light

Lees (2)

3 Function Tiaosmitter

Model 139.53626 (1)

Model 139.53515 (2)

SEPARATE ALL HARDWARE FOR ASSEMBLY AND INSTALLATION PROCEDURES AS SHOWN BELOW.

YOU'LL NEED TOOLS

During assembly and installation of your opener, the Instructions will call for the use of various hand tools. Have a

stepladder handy, and those tools Illustrated below; hammer, electric drill (& 3/l6"and S/I6"drlll bits), screwdriver,

adjustable end wrench or socket wrench kit, wire cutters, tape measure, pliers and hack saw.

Socket Wrench

At^etable End Wrench

Assembly

TO AVOID INSTALLATION DIFFICULTIES, DO NOT RUN THE GARAGE DOOR OPENER UNTIL INSTRUCTED TO DO SO.

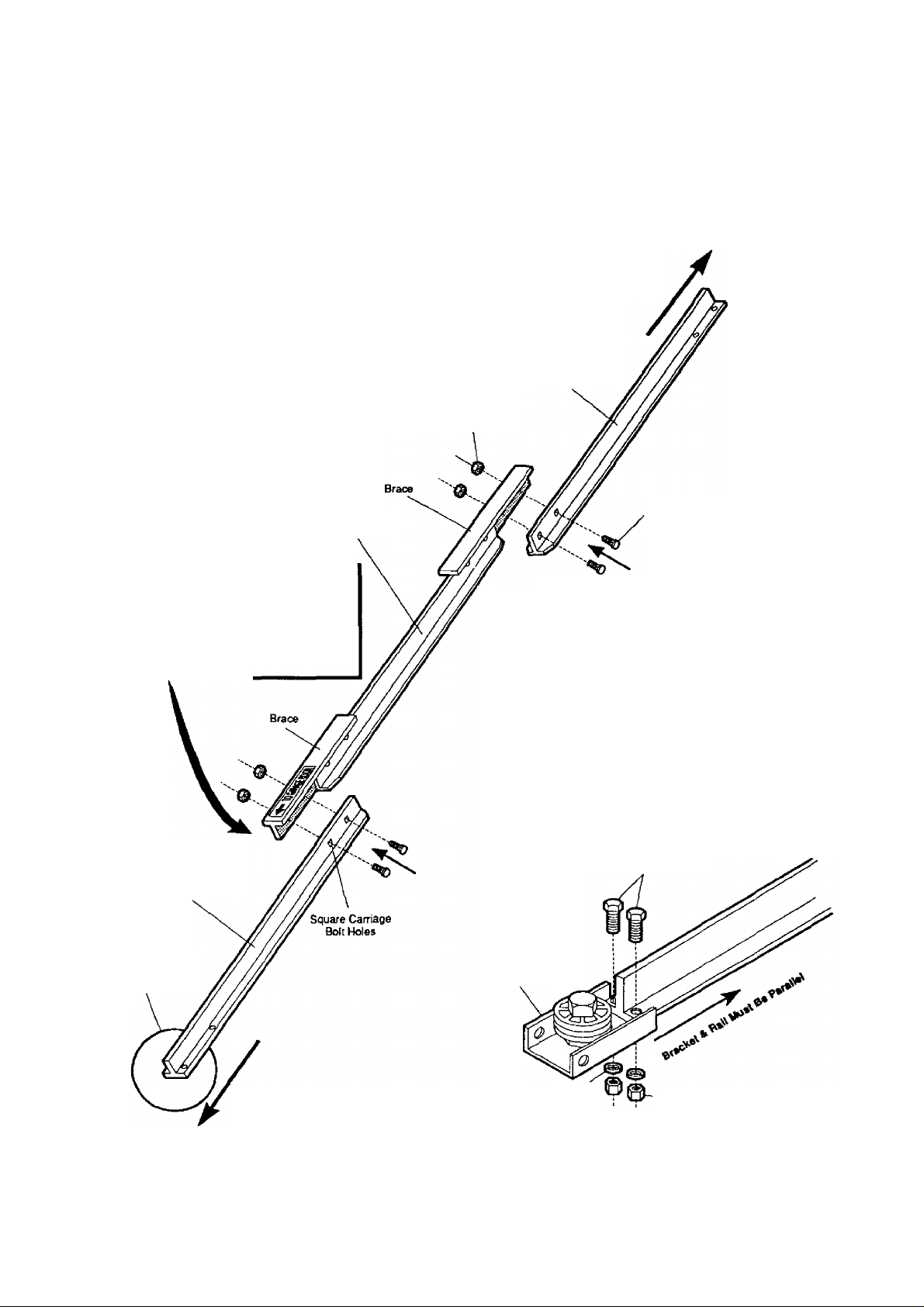

STEP 1 Assemble Tee Rail & Attach Cable Pulley Bracket

TEE RAIL BACK

(TO CHASSIS)

Tee Rail

CAUTION: Do not tighten the lock nuts until bolt necks

sre seated in square holes.

Tee Rail

(Center Section)

1/4“ Lock Nut

(End Section)

Carriage Bolt

1/4--20X1/2*

The end sections of the rsil MUST be

connected to the center section from

the direction shown in the illustration.

Otherwise, the trolley will hit against

the nut when installed (Pg. 7).

Tee Ral

(End Section)

Cable pulley bracket

attaches to FRONT

END of tee rail

PROCEDURE: Place the 3 Tee rail sections on a flat

surface for assembly. THIS IS IMPORTANT. The end

sections are identical. THE CENTER SECTION BRACES

MUST BE POSITIONED AGAINST THE END SECTIONS

AS SHOWN. Make sure that the “directional arrow’’is

pointing toward the front (to door). Study the illustration

CAREFULLY.

(When assembled. Tee rail has a front-to-back position as

shown.)

Bolt rail sections together with the hardware illustrated arxl

from the direction indicated.

SQUARE NECKS ON THE CARRIAGE BOLTS MUST BE

SEATED IN THE SQUARE HOLES IN RAIL SECTIONS.

Screws

8x7/8"

Cable Pulley

Bracket

TEE RAIL FRONT

(TOEXXJR)

Lock Washer

5/16"

Nut

-5/16"

Position the cable pulley bracket on front end of tee rail

as shown. Fasten securely with the hardware provided.

IMPORTANT: When tightening screws, be sure to keep

bracket parallel to rail. Otherwise, rail may bow when

opener is operated.

Assembly

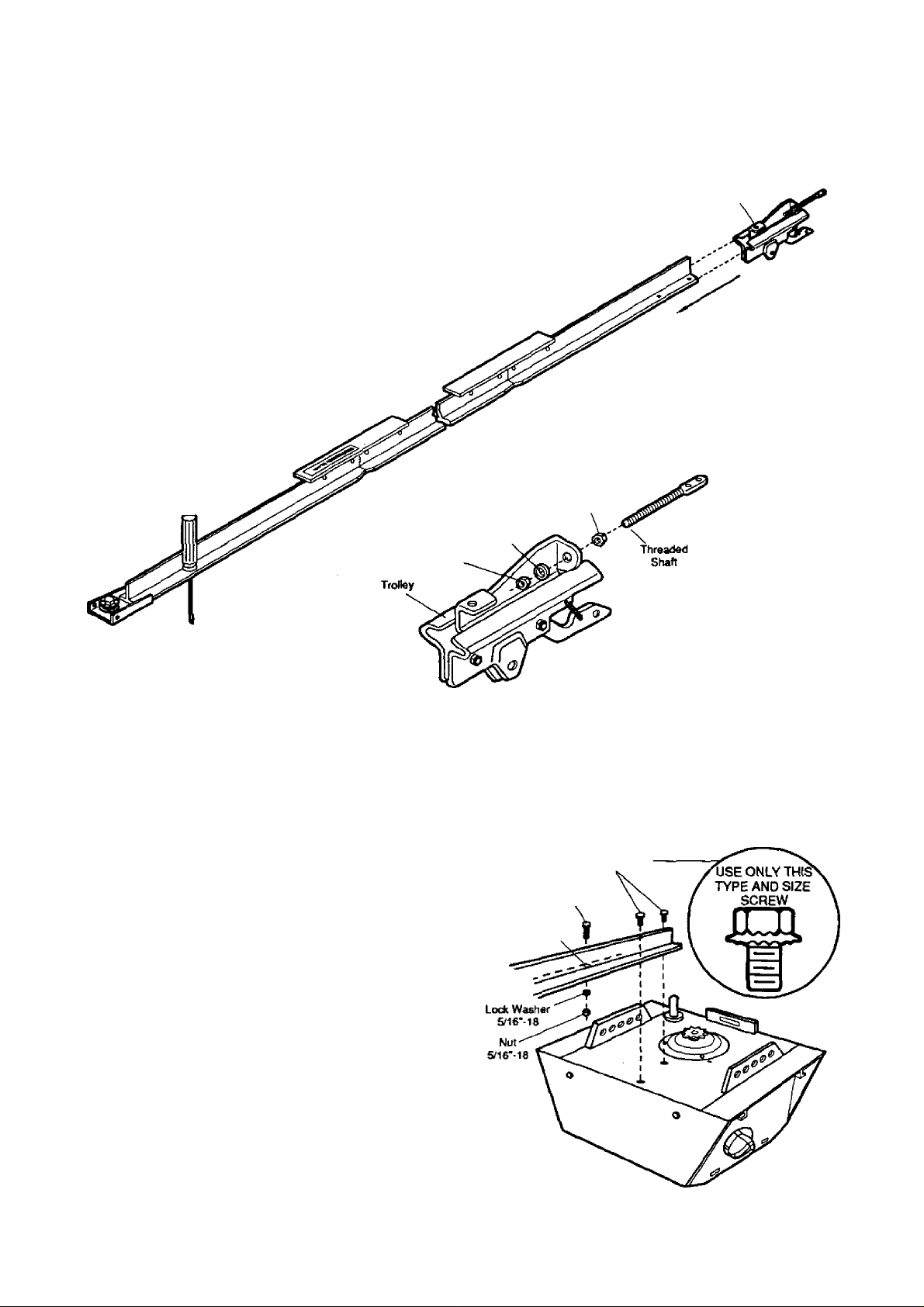

STEP 2 Install Trolley

AS A TEMPORARY STOP, INSERT A SCREWDRIVER

INTO HOLE IN FRONT END OF TEE RAIL AS SHOWN.

1. Attach threaded shaft to trolley with lockwasher and n uts

as shown.

2. Slide trolley assembly along rail to screwdriver stop.

NOTE: If trolley hits against the nut on Tee rail, center

section was attached from wrong side and must be

repositioned. Review Step 1.

Temporary Stop

Screwdriver

Inner Nut

5/16*

Trolley

Outer Nut

5/16'

Lock Waalner

5/16*

STEP 3 Attach Tee Rail To Opener Chassis

USE ONLY THOSE SCREWS MOUNTED IN

TOP OF OPENER CHASSIS. FAILURE TO DO

A

PROCEDURE: Place the opener chassis on packing

material to protect the cover. For convenience, place a

support under the cable pulley bracket.

Remove 5/16'-18 x 1/2' washered screws mounted in top

of opener chassis. Align hoies in back end of Tee rail with

holes in opener chassis. Fasten the raii to the chassis

with washered screws previously removed. CAUTION:

USE ONLY THESE SCREWS! Use of any other screws

will cause serious damage to door opener. Tighten

screws secureiy.

insert a 5/16'-16 X 7/8' hex screw into trolley stop hole in

the Tee rail as shown. Tighten securely with a 5/16* lockwasher and nut.

SO WILL CAUSE SERIOUS DAMAGE TO THE

OPENER.

Hex Screw

5/16*-18x7/8'

Trolley

Stop Hole

Tee Rail

(Back Section)

Washered Screw

5/16"-18x1/2*

Assembly

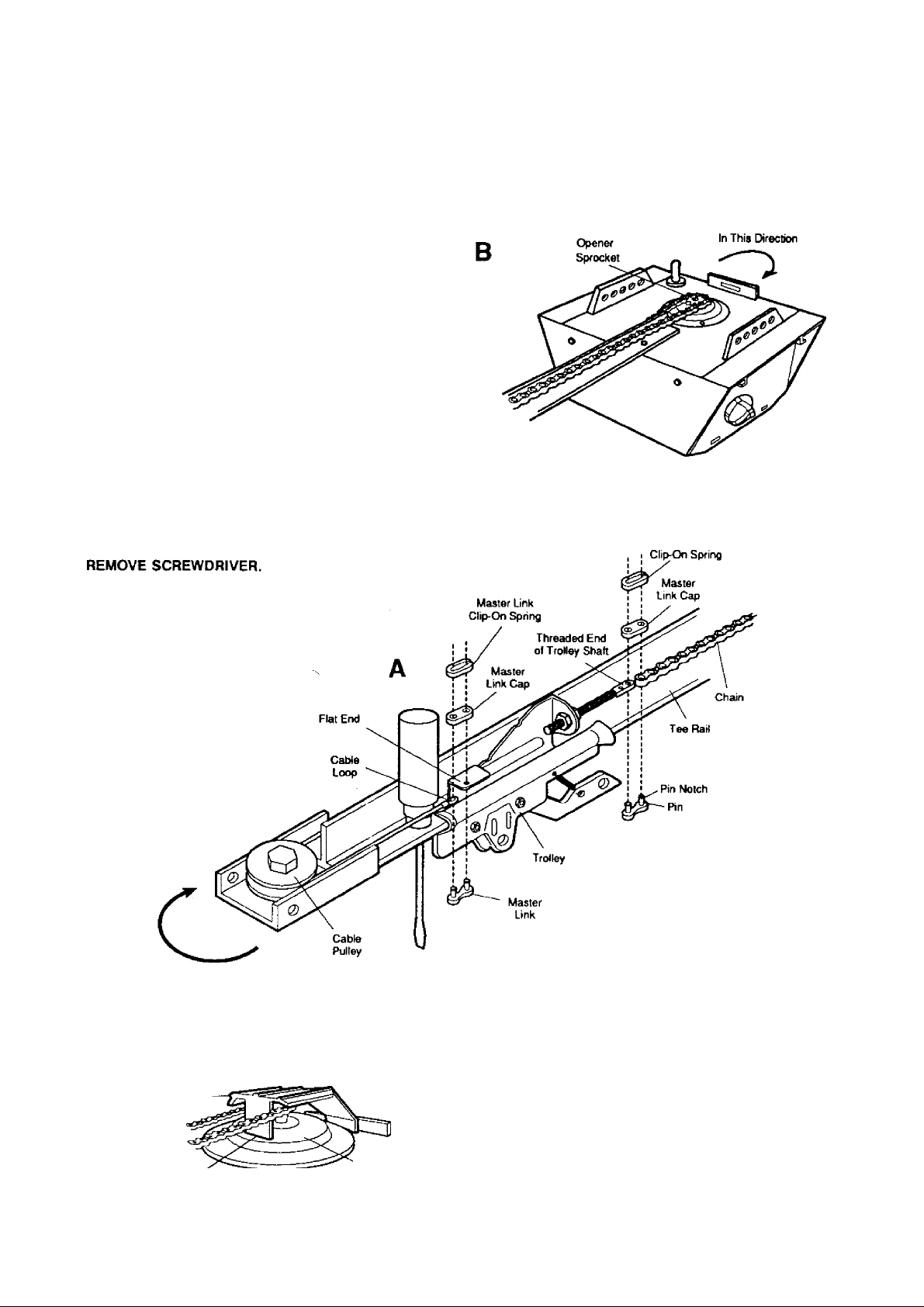

STEP 4 Install Chain and Cable

DO NOT REMOVE CHAIN AND CABLE FROM CARTON.

Detach cable from side of carton. Remove master links

from coin envelope. .

MASTER LINK PROCEDURE: Insert pins of master link

bar through cable loop and hole in front end of trolley (A)

as shown. Push cap over pins and onto notches. Slide clipon spring over cap and onto pin notches until pins are

locked in place.

Caution: Keep the chain taut while installing to help

prevent kinking.

With trolley against the screwdriver, dispense cable around

pulley. Proceed back around opener sprocket (B)- be sure

sprocket teeth engage chain- and forward to the threaded

trolley shaft (C).

Use second master link to connect the chain to the flat

end of shaft as shown. Check to make sure chain is not

twisted.

Install Chain

Master Link

instaJI Chain and Cable

In This Direction

Sprocket

Cover

Tab Slot

Mounting

Plate

ATTACH SPROCKET COVER TO CHASSIS:

insert back tab in chassis slot. Then bend cover forward

and insert front tab in slot provided on mounting plate.

Loading...

Loading...