Page 1

,';o’"" - rTT) ‘ -/T^,,1

- —- - -'-

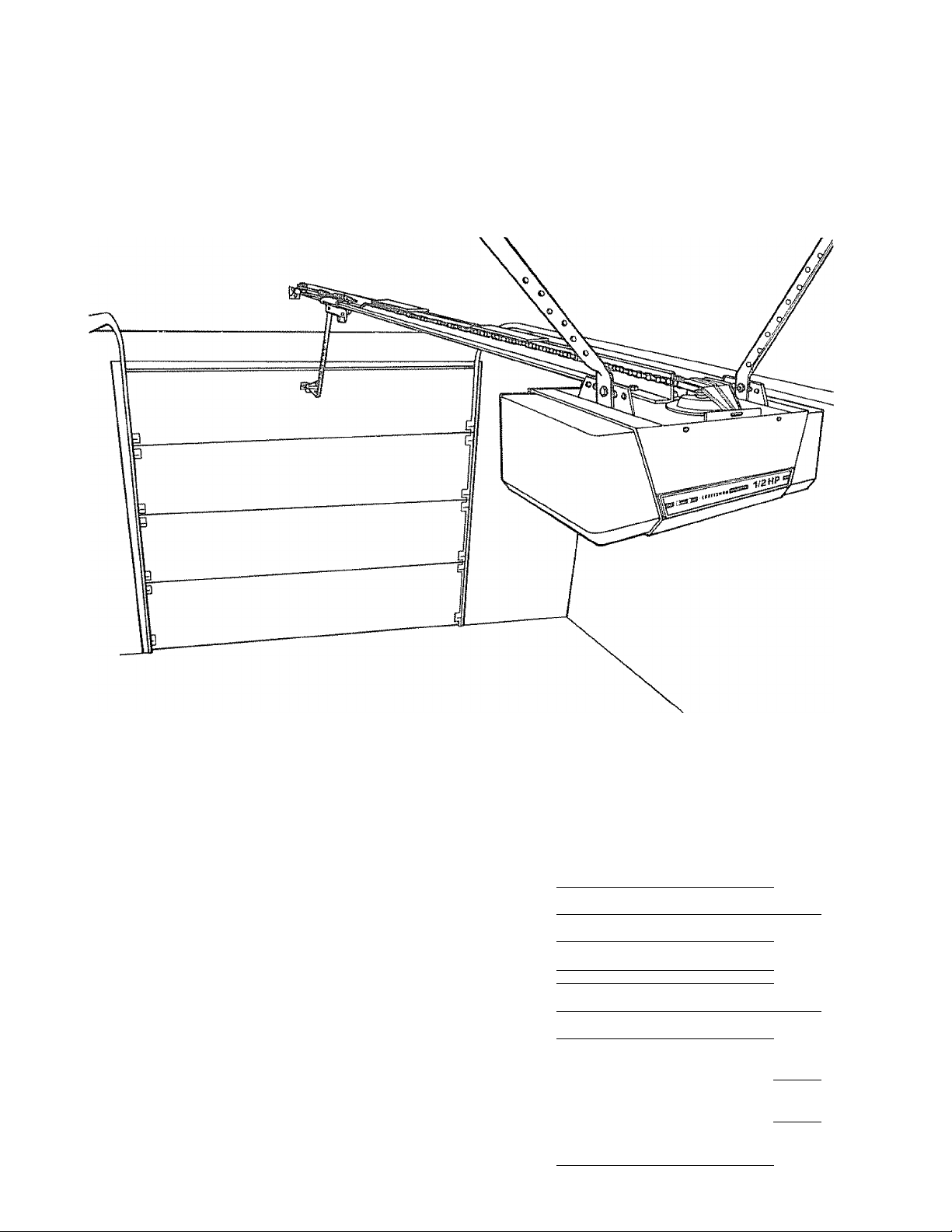

Owners Manual

Garage Door Opener

Model 139.535006

CAUTION: READ INSTRUCTIONS AND RULES

FOR SAFE OPERATION CAREFULLY.

FASTEN THIS MANUAL NEAR THE GARAGE

DOOR AFTER INSTALLATION. PERIODIC

CHECKS OF OPENER ARE REQUIRED

TO INSURE SATISFACTORY OPERATION.

IWDEX

Features of Your Opener

Specifications

You’ll Need Tools

Safety Rules —...........

Carton Check List

Accessories

Identify Your Door Type

Assembly

Installation

Adjustment................................

Operation of Your Opener

Radio Controls

Having a Problem?......

Transmitter Schematic

Wiring Diagram

Receiver Schematic

Repair Parts, Rail Assembly ....

Repair Parts, installation

Repair Parts, Chassis Assembly

How to Order Repair Parts......

Maintenance Agreements

Sears Warranty

.................

.....................................

....................................

.................

..............

................................

_________

_____

......................

.

..................

_____

_

________

.......................

..........

.....................

_________

..............

.............

..................28

____

_______

....

.

.......

___

........

.......

„

_

.

Page

....

2

... 2

... 2

....

3

.

...

4

... 5

... 5

.,. 6

....

10

... 18

... 21

... 22

...24

...24

...25

....

25

....

26

...26

....

27

... 28

... 28

Page 2

FEATURES OF YOUR OPENER

, Opener Lights: Turn on and off automatically,

with 4-1/2 minute illumination for your safety and

convenience. Provide constant light when Work

Light control button is pressed,,

, Safety System: Independent up and down force

adjustment Door reversesautomatically when ob

structed in DOWN direction Door STOPS when

obstructed in UP direction.

Emergency Disconnect: Pull cord disconnect

permits rnanuai door operation.

Automatic Reconnect: Trolley halves reconnect

for automatic operation when opener is energized

after emergency disconnect

SPECIFICATIONS

MOTOR

Type .

Speed

Volts .,

Current

Gear reduction

Drive

Lubrication

Length of Travel

Travel rate

Lamp

Door linkage

1/2 horsepower permanent split capacitor

, 1500 rpm

120 Volts AC - 60 Hz Only

4,5 amperes

DRIVE MECHANISM

16:1

Chain & cable with two-piece trolley on

steel Tee rail

Motor is seif-lubricated. Drive shaft bronze

oil-life bearings

Adjustable to 7-1/2 feet

6 to 8 inches per second

On when door starts in travel, off 4-1/2

minutes after stop. Also separate Work

Light push button

Adjustabie door arm Pull cord trolley

release

5. Motor Power: 1/2 horsepower permanently lubri

cated motor with automatic reset

6. Digital Radio Controls: 19,683 codes from which

to choose Can be changed easily by the owner.

7. Easy Limit Adjustment: Limits of door opening

and closing adjusted by turning screws without r e

moving chassis cover,

8. Vacation Push Button: When the Vacation Push

Button is ON, the opener wil! not operate from the

transmitter. The door will operate in the UP direc

tion ONLY from the Wali Control (or optional Key

Switch accessory, Page 5)

SAFETY

Personaf

Electronic

Electrical

Limit device. ...

Limit adjustment

Start circuit

Length (overall) . .

Headroom required

Shipping Weight

Push button S automatic reversal in down

rlirection. Push button S automatic stop

in up direction

Independent up a down force adjustment

screws

Motor overload protector and tow voltage

push button wiring

Circuit actuated by limit nut

Screwdriver adjustment on side panel

Low voltage push button or radio control

DIMENSIONS

122-1/2 inches

2 inches

43 pounds

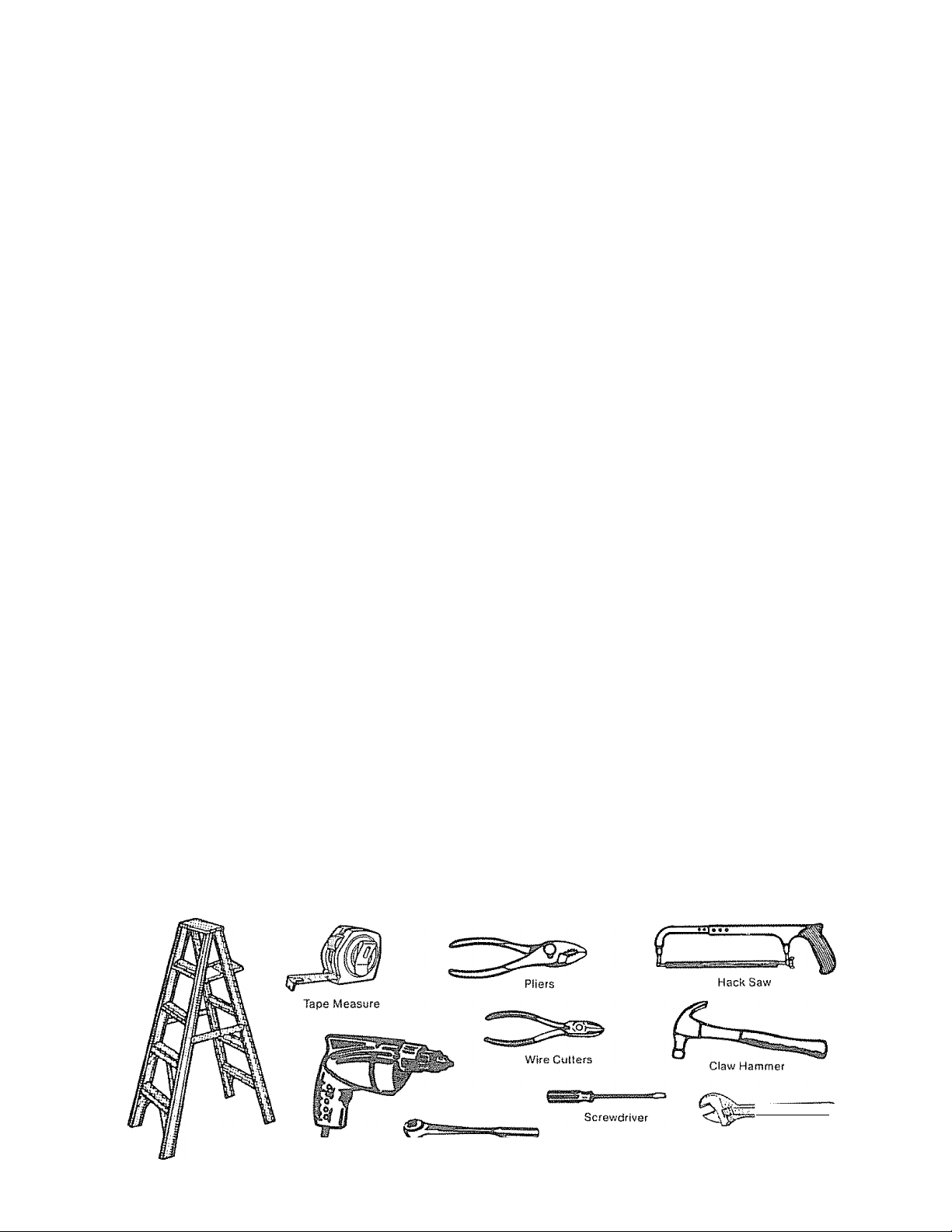

YOU’LL NEED TOOLS

During assembly and instaliaflon of your opener, the instruction will call for use of various hand tools. Have a

stepladder handy, and those tools illustraled below: Hammer, electric drill (also 3/16" and 5/16" drill bits), screw

driver, adjustable end wrench or socket wrench kit, wire cutters, tape measure, pliers and hack saw.

. SOI

stepladder

Electric Drill

Socket Wrench

Adjustable End Wrench

Page 3

Start By

Reading

THIS SAFETY ALERT SYMBOL MEANS CAUTION - PERSONAL SAFETY OR PROPERTY DAMAGE IN

STRUCTION, READ THESE INSTRUCTIONS CAREFULLY.

THIS GARAGE DOOR OPENER IS DESIGNED AND TESTED TO OFFER REASONABLY SAFE SERVICE

PROVIDED IT IS INSTALLED AND OPERATED IN STRICT ACCORDANCE WITH THE FOLLOWING

SAFETY INSTRUCTIONS,

FAILURE TO COMPLY WITH THE FOLLOWING INSTRUCTIONS MAY RESULT IN SERIOUS PERSONAL

INJURY OR PROPERTY DAMAGE,

These Important Safety Rules

KEEP GARAGE DOOR BALANCED, STICKING

OR BINDING DOORS MUST BE REPAIRED

GARAGE DOORS, DOOR SPRINGS, CABLES,

PULLEYS, BRACKETS ANDTHEIR HARDWARE

MAY BE UNDER EXTREME TENSION ANDCAN

CAUSE SERIOUS PERSONAL INJURY. DO NOT

ATTEMPT ADJUSTMENTS. CALL A GARAGE

DOOR SERVICEMAN TO MOVE, LOOSEN OR

ADJUST DOOR SPRINGS OR HARDWARE.

DO NOT WEAR RINGS, WATCHES OR LOOSE

CLOTHING WHILE INSTALLING OR SERVICING

A GARAGE DOOR OPENER,

TO AVOID SERIOUS PERSONAL INJURY FROM

ENTANGLEMENT, REMOVE ALL ROPES CON

NECTED TO THE GARAGE DOOR BEFORE IN

STALLING THE GARAGE DOOR OPENER

DISENGAGE ALL EXISTING GARAGE DOOR

LOCKS TO AVOID DAMAGE TO GARAGE DOOR-

DO NOT USE FORCE ADJUSTMENTSTOCOMPENSATE FOR A BINDING OR STICKING

GARAGE DOOR. EXCESSIVE FORCE WILL IN

TERFERE WITH THE PROPER OPERATION OF

THE SAFETY REVERSE SYSTEM OR DAMAGE

THE GARAGE DOOR (SEE PAGE 19).

FASTEN THE CAUTION LABEL ON THE WALL

NEAR THE WALL CONTROL AS A REMINDER

OF SAFE OPERATING PROCEDURES.

INSTALL THE WALLCONTROLjOR ADDITION

AL PUSH BUTTONS) OUT OF THE REACH OF

CHILDREN, DO NOT ALLOW CHILDREN TO

OPERATE WALL CONTROL OR TRANSMITTER.

SERIOUS PERSONAL INJURY FROM A CLOS

ING GARAGE DOOR MAY RESULT FROM ANY

MISUSE OF THE OPENER.

INSTALLATION AND WIRING MUST BE IN COM

PLIANCE WITH LOCAL BUILDING AND ELEC

TRICAL CODES

LIGHTWEIGHT DOORS REQUIRE SUBSTAN

TIAL REINFORCEMENT TO AVOID DOOR

DAMAGE. (SEE PAGE 10).

THE SAFETY REVERSE SYSTEM TEST IS IM

PORTANT (SEE PAGE 20), THE GARAGE DOOR

MUST REVERSE ON CONTACT WITH A ONE-

INCH OBSTACLE PLACED ON THE FLOOR

FAILURE TO PROPERLY ADJUST THE OPENER

MAY RESULT IN SERIOUS PERSONAL INJURY

FROM A CLOSING GARAGE DOOR. REPEAT

THE TEST AT LEAST ONCE A YEAR AND MAKE

ANY NEEDED ADJUSTMENTS,

CAUTION; ACTIVATE OPENER ONLY WHEN

THE DOOR IS IN FULL VIEW, FREE OF OB

STRUCTION AND OPENER IS PROPERLY AD

JUSTED. NO ONE SHOULD ENTER OR LEAVE

THE GARAGE WHILE DOOR IS IN MOTION,

DO NOT ALLOW CHILDREN TO PLAY NEAR

DOOR.

USE EMERGENCY RELEASE ONLY TO DIS

ENGAGE TROLLEY.. DO NOT USE RED EMER

GENCY RELEASE ROPE AND HANDLE TO PULL

DOOR OPEN OR CLOSED.

DISCONNECT ELECTRIC POWER TO GARAGE

DOOR OPENER BEFORE MAKING REPAIRS

OR REMOVING COVERS.

Page 4

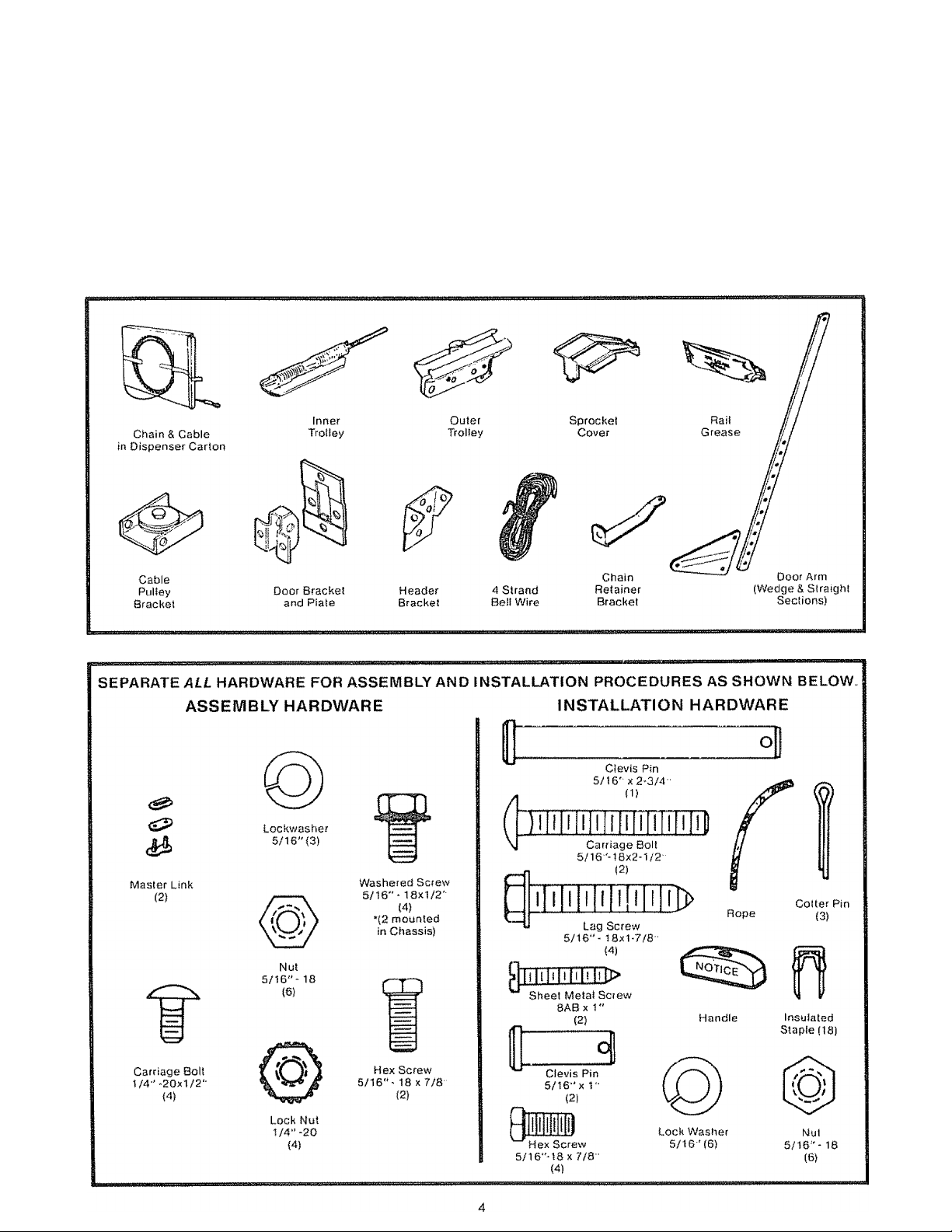

CARTON CHECK LIST

SEARS has packaged your Garage Door Opener in two cartons THE RAIL ASSEMBLY CARTON CONTAINS; a

three-piece rail, two hanging straps, straight door arm section* and rail assembly hardware.

THE OPENER CARTON CONTAINS:

Opener Chassis Wall Control Header Bracket*

Plastic Light Lenses (2) Sprocket Cover* 4-Strand Bell Wire*

Transmitter and Clip (1) Cable Pully Bracket* Owners Manual

Chain & Cable (in dispenser carton)* Door Bracket & Plate* Hardware Bag

2-Piece Trolley* Wedge Door Arm Section* (includes Caution Label)

‘ILLUSTRATED BELOW

Page 5

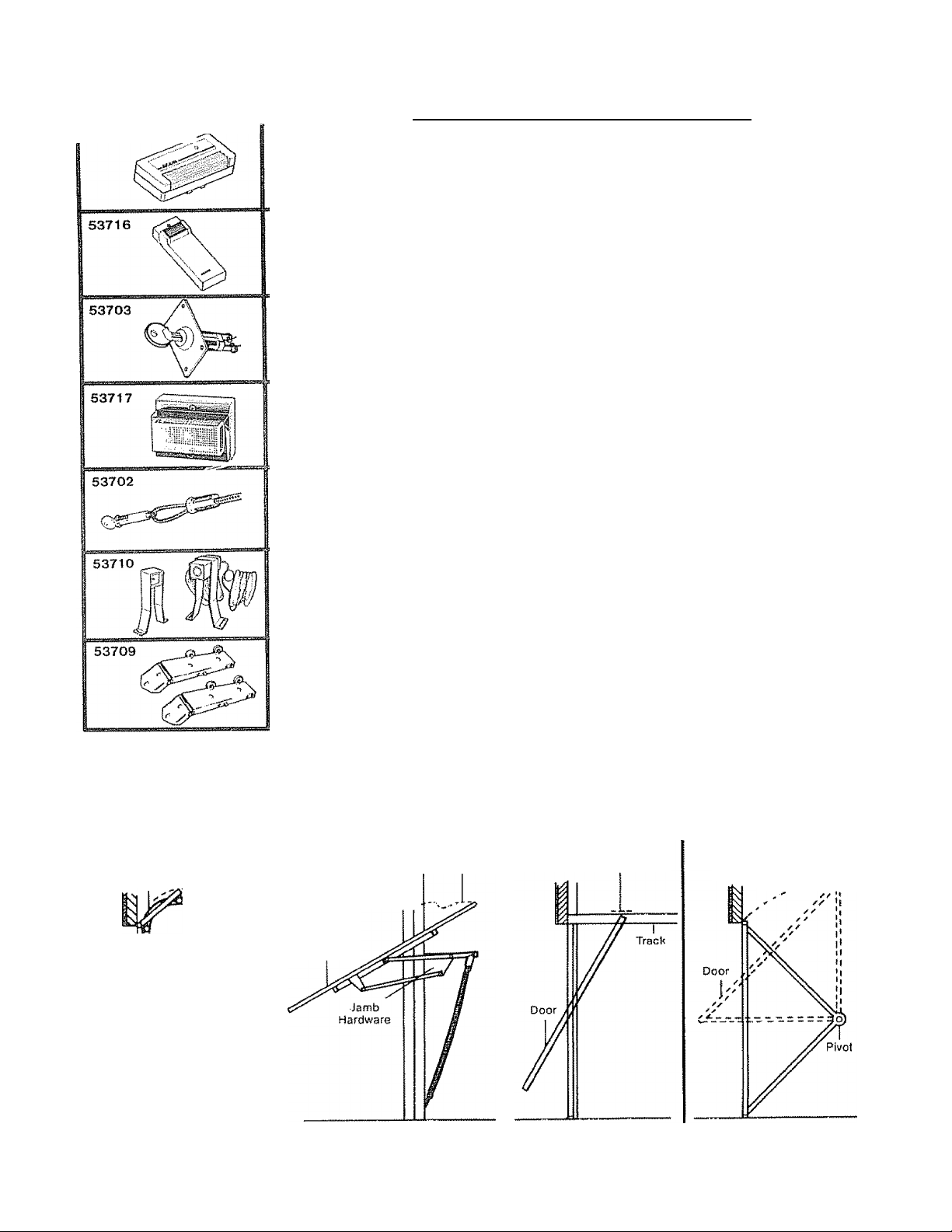

Accessories

Sears offers many useful accessories foryour garage door opener. They are illustrated below with Sears stock num

bers and descriptions.

" EXTRA TRANSMITTER: Includes visor clip.

.............................

TOUCH CODE LOCK: Enables homeowner to open the garage door opener from the

...............................................................................

....................

outside by entering code on specially designed keypad

OUTDOOR KEY SWITCH: Opens the garage door automatically from outside when

transmitter is not handy

OPEN DOOR INDICATOR: Provides an illuminated signal when your garage door

Is open

QUICK RELEASE KEY LOCK: Allows manual operation of yourgaragedoorfrom the

outside in case of power failure or where there is no service entrance For wood or

metal doors only

SECTIONAL DOOR

CURVED TRACK

Highest Point of Travel

---

1—

Track

INFRARED REVERSING SENSOR: An optional system which provides auxiliary

support to the safety features built into your opener. Sensors detect any obstruction

to your door while in the down cycle and transmit a signal to the opener. The opener

will cause a closing door to reverse and prevent an open door from closing.

FOR SECTIONAL DOORS ONLY

QUICK TURN BRACKETS: Replace top brackets and rollers on door to reduce

height of door travel For use when installing opener in garage with low head

room clearance

IDENTIFY YOUR DOOR TYPE FROM THESE ILLUSTRATIONS

ONE PIECE DOOR

NO TRACK

JAMB HARDWARE

Highest PoinI of Travel

^ -

Door

ONE PIECE DOOR

HORIZONTAL TRACK

JAMB HARDWARE

Highest Point ot Travel

ONE PIECE DOOR

NO TRACK

PIVOT HARDWARE

Highest Point of Travel

)

---------

Door

CERTAIN INSTALLATION PROCEDURES VARY ACCORDING TO GARAGE DOOR TYPES. WHERE DIFFERENCES

OCCUR. BE SURE TO FOLLOW ONLY THOSE INSTRUCTIONS WHICH APPLY TO YOUR DOOR

CONSTRUCTION

Page 6

Assembly

TO AVOID INSTALLATION DIFFICULTIES, DO NOT RUN THE GARAGE DOOR OPENER UNTIL YOU HAVE

COMPLETED STEPS, PAGE 15.

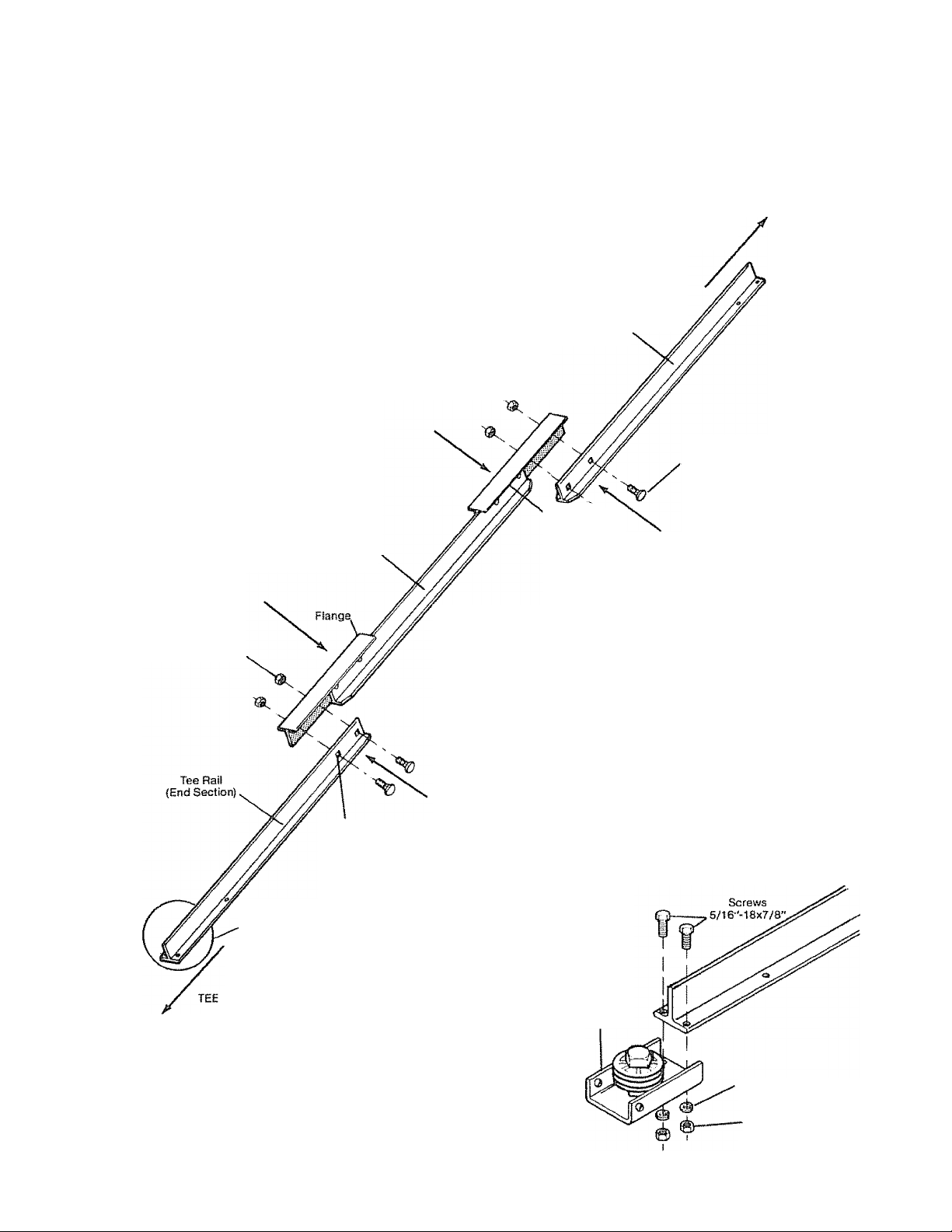

SXE P 1 Assemble Tee Rail & Attach Cable Pulley Bracket

TEE RAIL BACK

CTO CHASSIS)

CAUTION: Do not tighten the lock nuts until bolt

necks are seated in square holes.

Tee Rail

(End Seciiors)

Carriage Bolt

1/4"-20x1/2"

Flange

Tee Rail

(Center Section)

1 /4" Lock Nut

; RAIL FRONT

(TO DOOR)

Cable pulley bracket

. attaches to FRONT

END of Tee Rail

Square Carriage

Bolt Hole

PROCEDURE: Place the 3 Tee rail sections on a fiat

surface for assembly. THIS IS IM PORTANT. The center

section has two connection flanges The end sections

are identical.

Refer to illustration. BE SURE CENTER SECTION IS

POSITIONED ON THE CORRECT SIDE OF TEE

RAIL. (When assembled, Tee rail has a front-to-back

position as shown).

Bolt center rail section to end sections with the hard

ware illustrated.

SQUARE NECKS ON CARRIAGE BOLTS MUST BE

SEATED IN SQUARE HOLES IN TEE RAILS.

Cable Pulley

Bracket

Align front end of tee rail with cable pulley bracket and

connect as shown. Tighten screws and nuts securely.

Lock Washer

5/16"

Nut

5/16"

Page 7

Assembly

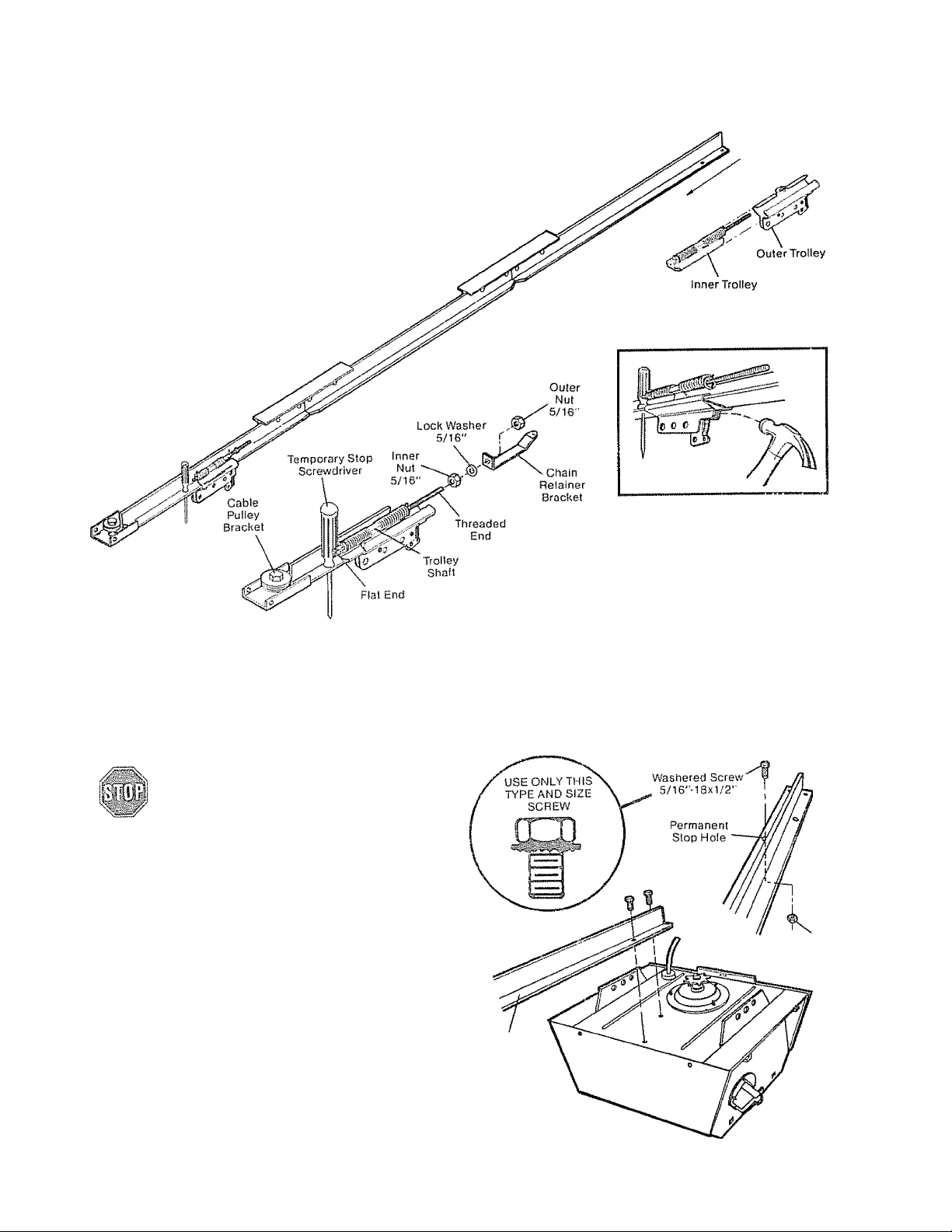

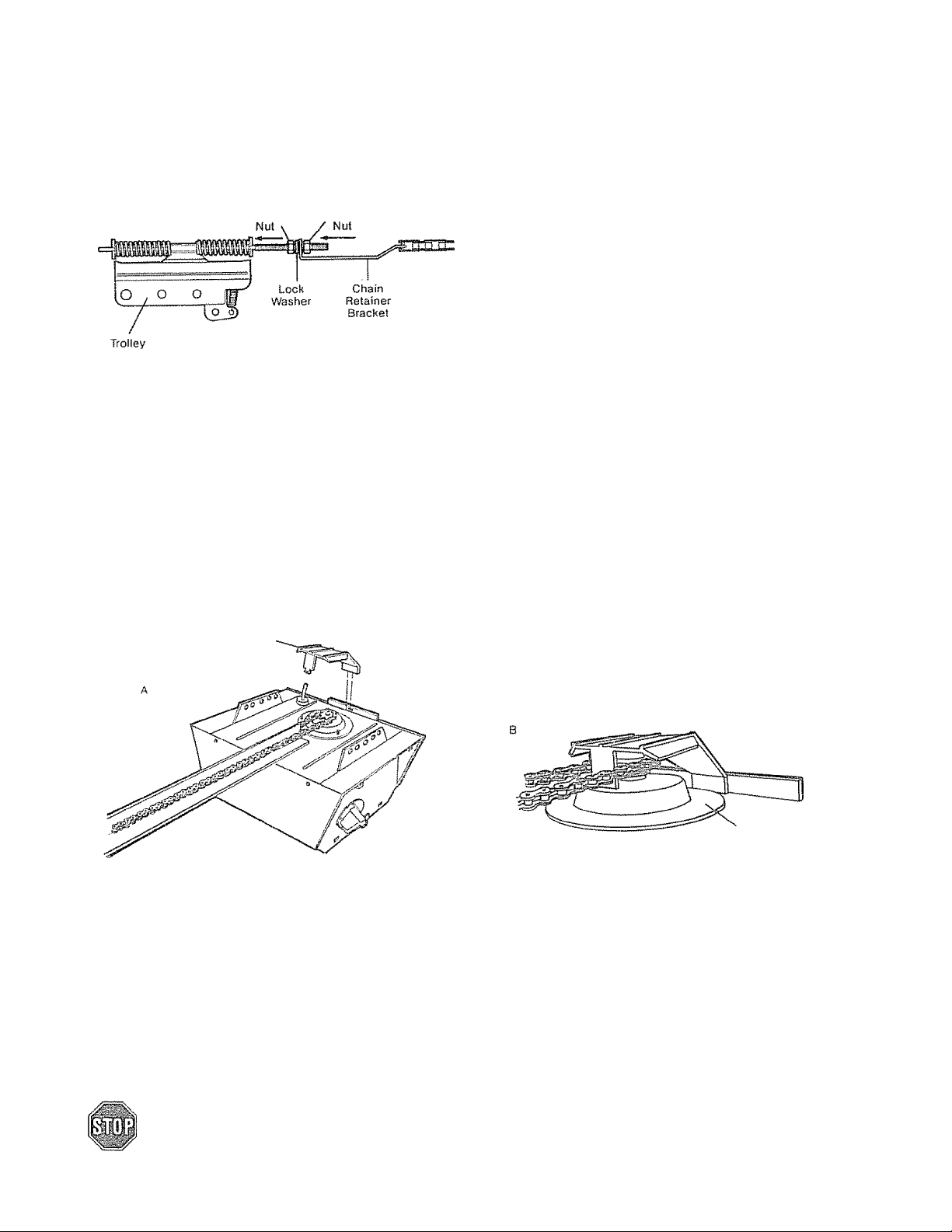

STEP 2 Connect Trolley & Attach Chain Retainer Bracket

Asa temporary stop, inserta screwdriver into Tee

rail as shown. Slide the inner trolley onto the Tee

rail, as shovi/n, until it is firmly against the screw

driver. Slide the outer trolley onto the Tee rail until it

partially engages the inner trolley and stops,

TO FULLY ENQAGE TROLLEY: With a hammer,

firmly tap the back end of outer trolley just below the

rail guide. Outer trolley must move forward to fully

engage inner trolley, Be careful to avoid damaging

trolley spring.

STEPS

USE ONLY THOSE SCREWS MOUNTED

INTOPOFOPENERCHASSIS. FAILURE

TO DO SO WILL CAUSE SERIOUS DAM

AGE TO THE DOOR OPENER,

PROCEDURE: Place opener chassis on packing

ma terial to protect cover. For convenience, place a

support under the cable pulley bracket.

Remove 5/16"-18x1/2" washered screws mounted

in top of opener chassis. Align holes in back end of

Tee rail with holes in opener chassis. Fasten the rail

to the chassis with washered screws previously

removed. CAUTION: USEONLYTHESESCRBWS!

Use of any other screws will cause serious dam

age to door opener. Tighten screws securely

Insert a 5/16”-18x1/2" washered screw into the per

manent stop hoie in the Tee rail back section as

shown. Tighten securely with a 5/16" nut

Attach Tee Rail to Opener Chassis

Attach inner nut, lock washer, chain retainer bracket

and outer nut to trolley shaft in the order shown. The

retainer bracket should be kept in the illustrated

position DO NOT TIGHTEN NUTS UNTIL STEP 5,

PAGE 9

5/16"-18

Tee Rail

(Back Section)

Nut

Page 8

Assembly

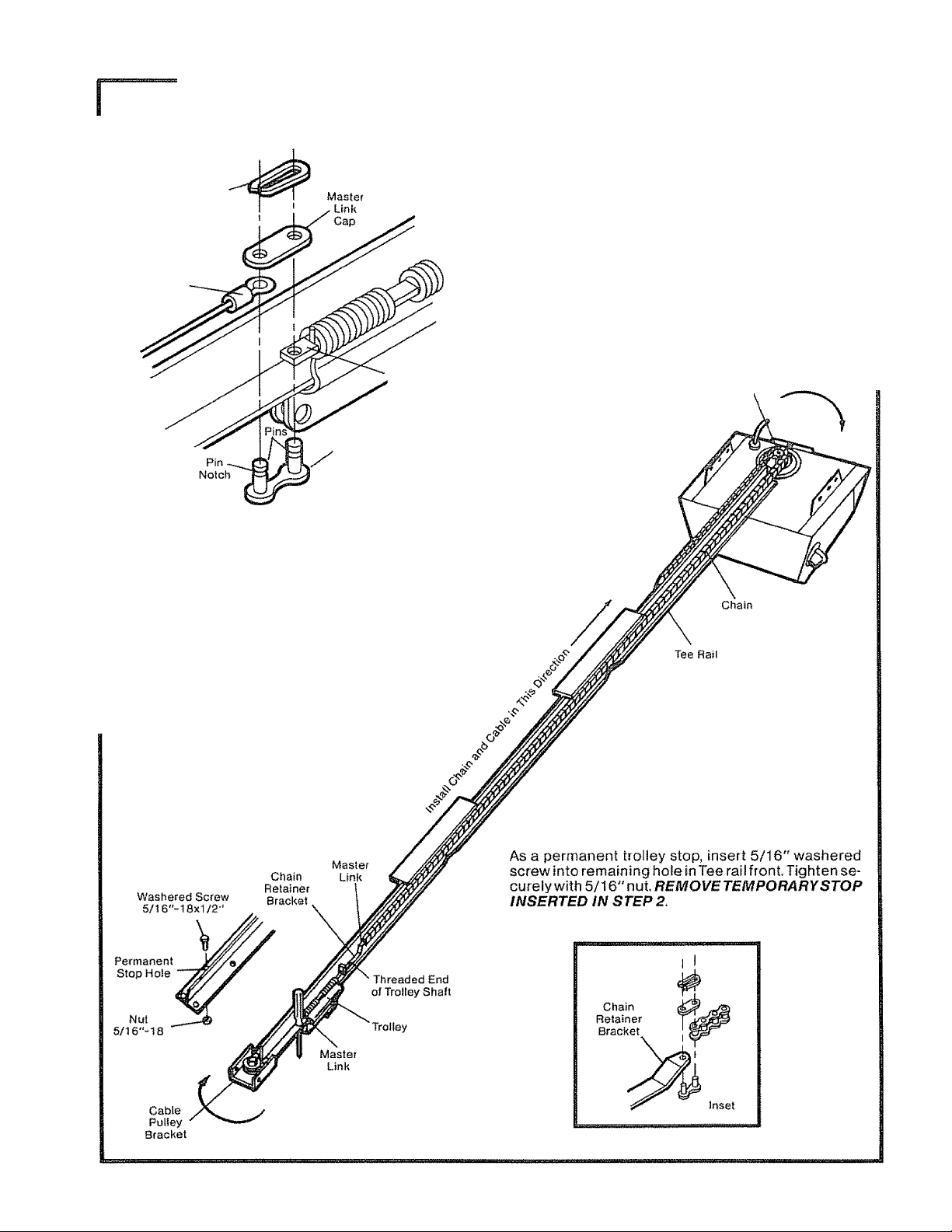

STEP 4 Install Chain and Cable

Master

Link

Clip-On

Spring

Cable

Loop

Flat End

Trolley

Shall

Ivl aster

Link

Outside

Bar

CAUTION: Keep chain taut while dispensing from

carton to help prevent kinking.

Slide trolley tight against screwdriver stop Dispense

cable around pulley bracket. Proceed back around

the opener sprocket and forward to chain retainer

bracket. Be sure teeth on chassis sprocket engage

chain.

Connect chain to chain retainer bracket, as shown in

inset, using second master link from coin envelope,

NOTE: Check to make sure chain is not twisted.

DO NOT REMOVE CHAIN AND CABLE FROM DIS-^

PENSER CARTON.

Detach cable from side of car ton and fasten to tr olley

with a master link from coin envelope,

MASTER LINK PROCEDURE: Push pins of master

link bar through loop of cable and hole in flat end of

trolley shaft Push cap onto pins and into notches

Slide clip-on spring over cap and into pin notches

until both pins are locked in place.

opener Chassis

Sprocket'

Page 9

Assembly

STEPS

Tighten the Chain and Cable

dAUTIONt Keep chain from twisting as nuts are

turned.

Loosen Tighten

Inner Outer

Chain

1/2 Inch

Base ot Tee Rail

PROCEDURE: Connect chain and cable to threaded

shaft of trolley in the order itiustrated: inner nut, lockwasher, chain retainer bracket and outer nut

Tighten the chain and cable by threading outer nut

toward trolley.

Chain is properly tightened when it is approximately

1/2" above the base of Tee rail midway between

cable pulley bracket and chassis.

When chain tension is correct, turn inner nut toward

chain retainer bracket untii tight

Sprocket noise can result if chain is either too

loose or too tight.

CAUTION: Do not overtighten chain and cable.

Refer to Page 21.

STEP® Attach Sprocket Cover to Opener Chassis

Sprocket

Cover '

ASSEMBLY OF YOUR GARAGE DOOR OPENER IS NOW COMPLETE.

CERTAIN INSTALLATION PROCEDURES VARY ACCORDING TO GARAGE DOOR TYPES. WHERE DIFFER

ENCES OCCUR, BE SURE TO FOLLOW ONLY THOSE INSTRUCTIONS WHICH APPLY TO YOUR DOOR

CONSTRUCTION.

PROCEDURE: Attach sprocket cover to chassis as

shown in Illustrations (A) and (B). insert back tab in

chassis slot. Then bend cover forward and insert

front tab in slot provided on mounting plate.

Mounting

Plate

DO NOT WEAR WATCHES, RINGS OR LOOSE CLOTHING WHILE INSTALLING OR SERVICING A DOOR OPENER.

KEEP GARAGE DOOR BALANCED. STICKING OR BINDING DOORS MUST SE REPAIRED. GARAGE DOORS,

DOOR SPRINGS, CABLES, PULLEYS, BRACKETS AND THEIR HARDWARE MAY BE UNDER EXTREME TEN

SION AND CAN CAUSE SERIOUS PERSONAL INJURY. DO NOT ATTEMPT ADJUSTMENTS. CALL A GARAGE

DOOR SERVICEMAN TO MOVE, LOOSEN OR ADJUST DOOR SPRINGS OR HARDWARE.

Page 10

Installation

Completed installations of header bracket, door bracket with plate and door arm (depending on door type) are shown

below,. The header bracket supports the front end of the Tee rail, The door bracket connects door arm to trolley,

IT IS RECOMMENDED THATTHE OPENER BE INSTALLED 7 FEETOR MORE ABOVE THE FLOOR WHERE SPACE

PERMITS. Follow only those instructions which apply to your door type as shown on Page 5.

STEP1

TO PREVENT DAMAGETO LIGHTWEIGHT GARAGE DOORS, ALWAYS REINFORCE THE INSIDEOFDOORBOTH VERTICALLY AND HORiZONTALLY-WITH 2x4 BOARDS OR ANGLE IRON.

Horizontal brace should be a! least 6 feet long Vertical brace should cover height of top panel. Reinforcement

hardware is not supplied (See No 1 Below.) FASTEN SECURELY AS SHOWN BEFORE INSTALLING DOOR

BRACKET AND PLATE

install Door Bracket and Plate

Sectional Door Installation Procedure

With door closed, locate and mark the vertical center

line of garage door. Extend line onto header wall

above door.

SECTIONAL DOOR

Door

Arm

Reinforcement

Board for

Lightweight Doors

1. Assemble door bracket and plate as shown Cen

ter bracket on vertical guideline (or up to one foot left

or right of center if necessary)

2. Position bracket assembly on face of door within

the following limits: A. Top edge of bracket 2" to 4"

below the top edge of door, B. Directly below any

structural support across top of door.

Placement depends on your particular needs

3. Mark and drill 5/16"TOP and BOTTOM fastening

holes. Secure bracket as shown

Carriage Bolt

5/i6'*-18x2-t/2

------------

Inside Edge

of Door or

Reinlofcement Board

Nut

5/16'-1S

Door Bracket

Plale

Lock

Washer

All One-Piece Door Installation Procedure

With door closed, locate and mark vertical center line

of door. Extend line onto header wall above door,

NOTE: The door bracket has left and right side

fastening holes. Assemble door bracket and plate

If your installation requires top and bottom fas

tening holes. (Refer to illustration).

Center bracket (with or without plate as required) on

top edge of door as shown Mark and drill two 5/16"

fastening holes and secure door bracket, NOTE; If

door has no exposed framing, drill 3/16" pilot

holes and substitute 5/16" x 1-1/2" lag screws

(not supplied) to fasten bracket to top of door.

Lock Washer

5/16"

NOTE: Door bracket may be installed on face of

door if required for your installation. (Refer to

dotted line drawing). HOWEVER, drill 3/16"pilot

holes and substitute 5/16" x 1-1/2" lag screws

(not supplied) to fasten bracket to door.

10

Header

Wall

Door Bracket

Plate

(Optional)

Page 11

Installation

THE HEADER BRACKET MUST BE RfGIDLY FASTENED TO THE HEADER WALL OR CElLtNG. REINFORCE

WALL OR CEILING WITH 2x4 IF NECESSARY.

STEP 2 Position & Install Header Bracket

Locate height for header bracket by opening door to

highest point of travel as shown. Draw a horizontal

line on header wall 2" above high point This height

provides travel clearance for top edge of door

When headroom is not sufficient for 2" clearance,

bottom edge of bracket may be placed parallel to the

high point of travel, or bracket may be attached to

ceiling

Optional Quick Turn Brackets are designed for low

headroom installations They replace top brackets

and rollers on the garage door, thereby lowering the

high point of door travel Installation instructions are

contained in the accessory carton

Position bracket as shown (bottom edge of bracket

on horizontal line), Mark either top and bottom or left

and right bracket holes Drill 3/16" pilot holes and

fasten bracket

Lag Screws

INSTALLATION

SECTIONAL DOOR AND

1-PIECE DOOR WITH TRACK

SECTIONAL DOOR

CURVED TRACK

^ Header

'( Bracket

Highest Point

of Travel

Door

Ceiling

Track

t

ONE-PIECE DOOR

HORIZONTAL TRACK

JAMB HARDWARE

INSTALLATION

1-PIECE DOOR WITHOUT TRACK

ONE-PIECE DOOR

NO TRACK

PIVOT HARDWARE

Header

k-l / Bracket

ONE-PIECE DOOR

NO TRACK

•JAMB HARDWARE

Highest Point

ol Travel

Locate height for header bracket by opening door to

highest point of travel as shown. Measure distance

from top of door to floor. Subtract actual height of

door Add 8" to the remainder See example below.

If the total number of inches exceeds the height

available in your garage, use the maximum height

possible On finished ceilings, do not position the

bracket closer than 1/2" from ceiling.

Measuring from top of door, draw a horizontal line on

the header wall at the determined height Position

bottom edge of header bracket on horizontal line,

centering bracket on vertical line. Mark either top

and bottom or left and right holes. Drill 3/16" pilot

holes and fasten with 5/16" x 1-7/8" lag screws as

shown above

EXAMPLE

0>

c

w Actual height of door -88"

Q

Distance from top of door (at

highest point of travel) to floor

Remainder

92"

Add + 8"

Bracket height on header wail =12"

''

4"

11

Page 12

Installation

STEPS

Attach Tee Rail to Header Bracket

PROCEDURE: Position opener chassis on garage

floor below door and header brackets. Use packing

material base to protect cover, iSiOTE: To enable

Tee rail to clear sectional door springs, it may be

necessary to lift the chassis onto a temporary

support.

CAUTION: Chassis must either be secured to sup

port or held firmly in place by another person.

Raise Tee rail until cable pulley and header brackets

come together, Align bracket holes and join with

clevis pin as shown. Insert and spread cotter pin to

secure.

STEP 4 Position Opener Chassis

TO PREVENT DAMAGE TO ALL LIGHTWEIGHT DOORS, AND DOORS WITH WINDOWS, DO NOT RESTTHE

OPENER ON THE DOOR.

SECTIONAL and ONE-PIECE

DOOR WITH TRACK

INSTALLATION

NOTE: A 2x4 Is convenient for setting an ideal

door-tO'Tee rail distance. It is not necessary

where headroom is insufficient.

PROCEDURE: Raise the opener chassis onto a

stepladder. Open the garage door. Place a 2x4 on

edge on top section of door directly above door

bracket. Rest Tee rail on 2x4,

ONE-PIECE DOOR

WITH NO - TRACK

INSTALLATION

PROCEDURE: Measure the distance from floor to

top of door (in fully open position and parallel to

floor).

Using a stepladder as a support, raise the opener

chassis to the same distance from the floor (chassis

will have a slight angle as shown)

The top of the door should be level with the top of the

opener For maximum efficiency, do not position the

opener chassis more than 2 inches above this point,

Top of Opener

12

Page 13

Installation

STEPS

Hang Opener Chassis

THE OPENER CHASSIS MUST BE ATTACHED TO A

STRUCTURAL SUPPORT OF THE GARAGE, Three

representative installations are shown. Yours may be

different Hanging brackets should be angled to pro

vide rigid support

PROCEDURE: On EACH side of opener measure

the distance from chassis to structural support

Cut both pieces of the hanging bracket to required

lengths. Flatten one end of each bracket and bend or

twist to fit fastening angles, DO NOT BEND AT BRAC

KET HOLES Drill 3/16" pilot holes in structural sup

port Fasten flattened ends of brackets to support

as shown.

Lift opener and fasten to hanging bracket as shown.

Checkto make sureTee rail is centered overdoor

bracket. Close the garage door. If door hits rail,

raise header bracket. REMOVE 2x4.

Grease rail surfaces on which trolley slides. A tube of

grease is supplied.

Bracket

(Not Supplied)

Finished

Ceiling

(Not Suppiied)

5/16'’-tax7/8" Screw

5/16" Lock Washer

5/16"-18 Nut

STEP 6

USE EMERGENCY RELEASE ONLY TO DIS

ENGAGE TROLLEY. DO NOT USE RED

EMERGENCY RELEASE ROPE AND HAN

DLE TO PULL DOOR OPEN OR CLOSED.

Attach Emergency Release Rope ^ Handle

PROCEDURE: Thread one end of rope through hole

in top of red handle so 'NOTICE' reads right side up

as shown. Secure with an overhand knot NOTE: Knot

should be at least 1 inch from end of rope to pre

vent slipping. Thread other end of rope through

hole in release arm of outer trolley. Adjust rope length

so that handle is 6 feet above the floor. Secure with

an overhand knot as above.

NOTE: If it is necessary to cut rope, heat seal cut

end with a match or lighter to prevent fraying

and/or raveling.

13

Emergency

Release Handle

Overhand

Knot

Page 14

Installation

Top

(astaliaHon

Flange

STEP?

Instali Wall Control

PROCEDURE: There are 4 screw terminals on the

back of the Wail Control, Connect the bell wire by

color; yellow to yellow, white to white, red to red and

black to black.

Fasten Wall Control to an Inside garage wall, as shown,

with the 8ABx1" sheet metal screws provided. A con

venient place is beside the service door and OUT OF

THE REACH OF CHILDREN,

Run the bell wire up the wall and across the ceiling to

the garage door opener. Use insulated staples.

Opener

Terminals

The receiver terminals as well as the antenna are

located on the right side pane! of the opener. Bend

antenna wire down until it is parallel to chassis panel.

Then connect the wire by color to the red, white,

black and yellow opener terminal screws.

INSTALL WALL CONTROL (OR ADDITIONAL

PUSH BUTTONS) OUTOFTHE REACH OFCHILDREN, DO NOT ALLOW CHILDREN TO OPER

ATE WALL CONTROL OR TRANSMITTER.

SERIOUS PERSONAL INJURY FROM A CLOS

ING GARAGE DOOR MAY RESULT FROM ANY

MISUSE OF OPENER.

FASTEN THE CAUTION LABEL ON THE WALL

NEAR THE WALL CONTROL AS A REMINDER

OF SAFE OPERATING PROCEDURES.

Flight Side

Panel

of

Opener

Wall Control

Push Button

Work Light

Push Button

WIRING INSTRUCTIONS FOR ACCESSORIES

Iftfrared Reversing System:

To white & black opener terminals

Open Door Indicator;

To white & orange opener terminals

Key Switch;

To red S white opener terminals

OPERATION OF WALL CONTROL

WALLCONTROLPUSH BUTTON

Press and release So open or close door

Press and release again So REVERSE door during CLOSING cycle

or to STOP door during OPENING cycle

VACATION PUSH BUTTON

Activate Vacation feature only when door is in ciosed position,

Press and release, Push button light will turn ON The Vacation fea

ture was designed to prevent operation of door Irom the transmitter

and allow door to travel in the UP direction ONLY Irom the Wall Con

trol push button (press and release) and Key Switch accessory

Press and release again. Push button light will turn OFF Opener will

return to normal operation

A power failure of more than 30 seconds will cause the vacation

feature to turn OFF

WORK LIGHT PUSH BUTTON

Press and release Opener light will turn on and remain on

Press and release again Opener light wilt return to normal operation.

14

Page 15

Installation

STEPS

TO AVOID SERIOUS PERSONAL INJURY FROM ENTANGLEMENT, REMOVE ALL ROPES CONNECTEDTO THE

GARAGE DOOR BEFORE OPERATING DOOR OPENER.

REMOVE EXISTING GARAGE DOOR LOCKS OR USE A WOOD SCREW OR NAIL TO MAKE THEM INOPERATIVE,

INSTALLATION AND WIRING MUST BE IN COMPLIANCE WITH LOCAL BUILDING AND ELECTRICAL CODES.

OPERATION AT OTHER THAN 120V 60Hz WILL CAUSE OPENER MALFUNCTION AND DAMAGE,

IF LOCAL ELECTRICAL CODES DO NOT REQUIRE

PERMANENT WIRING: Insert the 3-prong plug into a

3-hole receptacle. UNIT MUST BE GROUNDED, DO

NOT USE A 2-WIRE ADAPTER,

IF LOCAL CODES REQUIRE PERMANENT WIRING:

Refer to illustration,,

PROCEDURE: Make connection through 7/8 inch

diameter hole in top of opener chassis,

1. Remove opener chassis cover by removing the 4

cover screws,

2. Remove attached 3-prong cord,

3. Connect black (line) wire to black wire on terminal

block; white (neutral) wire to white terminal wire; green

(ground) wire to green ground screw

Coimect Eiectric Power

CAUTION: BE SURE UNIT IS GROUNDED

ACCORDING TO LOCAL CODE

STEPS

PROCEDURE; Install a 75 watt maximum light bulb

in each socket as shown. The lights turn on automati

cally when opener starts. After 4-1/2 minutes they

will turn off. Lights will REMAIN ON when Work Light

push button on Wall Control is pressed,

Install Lights and Lenses

IMPORTANT NOTE: If the lights in your garage

door opener do not work, it may NOT be the fault of

the opener. Some shorPneck bulbs, because of

their shape, do not make contact with the socket

base tab. Use standard-neck bulbs.

INSTALLING LENSES; Slide lenses into the lens

guides as shown. Snap bottom tabs into lens slots.

(The force and limit adjustment settings are located

on side panels behind lenses),

NOTE: FOR CONVENIENCE, LENSES MAYBE IN

STALLED AFTER ADJUSTMENT, STEPS, PAGE20.

15

Lens

Slot

Page 16

Installation

STEP 10

Connect Door Arm to Trolley

SECTIONAL DOOR INSTALLATION ONLY

PROCEDURE: Fasten straight door arm section to

trolley and wedge door arm section to door bracket,

as shown (A). Insert and spread a cotter pin to secur e

each connection,.

B

Bring the door arm sections together. Find a pair of

holes that line up and join sections as shown (B).

INSTALLATION FOR SECTIONAL DOOR IS COMPLETE. PROCEED TO ADJUSTMENT STEP 1, PAGE 18.

ALL ONE-PIECE DOOR INSTALLATIONS

ASSEMBLE DOOR ARM PROCEDURE: Fasten

straight and wedge door arm sections together to

their longest possible length. With dootclosed, con-,

nect straight door arm section to door bracket as

shown. Insert and spread cotter pin to secure.

16

Page 17

Installation

STEP 11

Adjust Limits (Ail One-Piece Doors Only}

CAUTION; To prevent damage to garage doors,

the opener limits must be adjusted on ALL ONEPIECE DOORS,

Limit Adjustment settings regulate the points at

which door will stop when moving up or down.

Repeated operation of theopenerduring adjustment

may cause the motor to overheat and shut off. Simply

wait 15 minutes and continue adjustments.

Limit adjustment screws are located on the left side

panel of the openeras shown. Increase limits by turn

ing screws in direction shown on label. Decrease

limits by turning screws in opposite direction.

Left Side

Panel UimiS

Adjustment

Screws

imii

iKßgwaosäL.si

iii®L?ilil '~r'. ‘ tifj>

■,

---

- -T- i J-

Adjustment Label

The following illustration shows the position of the door arm and trolley when the door is open (solid line drawing),

and when the door is closed (dotted line drawing)

PROCEDURE - OPEN DOOR ADJUSTMENT

DECREASE the UP limit by turning the UP limit adjust

ment screw counterclockwise 8 complete turns.

Press Wall Control push button. Trolley will travel to

full open position.

Manually raise garage door to open position (paral

lel to floor) and lift door arm to trolley. The arm should

touch trolley Just in back of door arm connector hole

as shown In solid line drawing If the arm does not

extend far enough, make further DECREASED limit

adjustment. One full turn equals 2 inches of door

PROCEDURE - CLOSED DOOR ADJUSTMENT

DECREASE the DOWN limit by turning the DOWN

limit adjustment screw clockwise 4 complete turns

Press Wall Control push button. Trolley will travel to

full closed position,

Manually close garage door and lift door arrh to the

trolley Arm should touch trolley just ahead of door

arm connector hole as shown in dotted line drawing.

If arm is behind the connector hole, make further

DECREASED limit adjustment. One full turn equals 2

inches of door travel.

travel,

CONNECT DOOR ARM TO TROLLEY PROCEDURE: With door closed,Join wedge door arm to connector hole in

trolley with the remaining clevis pin Secure with a cotter pin. NOTE: It may be necessary to lift door slightly to

make connection.

Run the opener through a complete travel cycle, If door has a slight ‘downward' slant in full open position, turn the

UP limit adjustment screw counterclockwise to decrease travel until door is parallel to floor.

17

Page 18

Adjustment

STEP1

The limit adjustment screws are located on the left side panel of the opener chassis as shown LI MIT ADJUSTMENT

settings regulate the points at which the door will stop when moving up or down

Adjust UP and DOWN Limits

NOTE: Door STOPS in UP direction if anything interferes with door travel. Door REVERSES in DOWN direc

tion if anything interferes with door travel (including binding or unbalanced doors).

PROCEDURE: To operate opener, press Wall Con

trol Push Button or transmitter push button. Run the

opener through a COMPLETE TRAVEL CYCLE. No

adjustments are needed when the door opens and

closes completely and does not reverse uninten

tionally in down direction.

The following char t outlines adjustment procedures.

Run opener through a COMPLETE TRAVEL CYCLE

AFTER EACH ADJUSTMENT. NOTE: REPEATED

OPERATION OFTHE OPEN ER DURING ADJUST

MENT PROCEDURES MAY CAUSE THE MOTOR

TO OVERHEATANDSHUTOFF. SIMPLYWA1T15

MINUTES AND TRY AGAIN. Read the chart care

fully before proceeding to Step 2, Pg. 19 Use a screw

driver to make limit adjustments

Adjustmen! Label

IF DOOR DOES NOT

OPEN COMPLETELY

BUT OPENS AT

LEAST FIVE FEET

IF DOOR DOES NOT

CLOSE COMPLETELY

IF DOOR REVERSES

WHEN CLOSING AND

THERE IS NO INTER-

FERENCETO

TRAVEL CYCLE

LliVilT ADJUSTMENT CHART

Increase UP travel by turning UP LIMIT adjustment screw in

clockwise direction as shown on label One turn equals 2

Inches of travel

If door doesn't open at least 5 feet, adjust OPEN FORCE as

explained in Step 2, Page 19

1. ON SECTIONAL DOORS:

Lengthen the door arm (See Step 10, Page 16).

If door arm is at maximum length, increase the DOWN travel

by turning the down limit adjustment screw in a counter

clockwise direction as shown on label. One turn equals 2

inches of travel.

If door still will not close completely, the header bracket is

positioned too high. Repeat Step 2, Page 11

2. ON ONE-PIECE DOORS:

Increase DOWN travel by turning the down limit adjustment

screw in a counterclockwise direction as shown on label. One

turn equals 2 inches of travel.

TEST DOOR FOR BINDING

Pull emergency release handle and manually open and close

the door. If door is binding, call a door ser viceman

1 . IF OPENER REVERSES BEFORE DOOR CLOSES FULLY:

Adjust the CLOSE FORCE as explained in Step 2, Page 19

2. IF OPENER REVERSES IN FULLY CLOSED POSITION;

Decrease DOWN travel. Tur n the down limit adjustment screw

in clockwise direction. One turn equals 2 Inches of travel

.............

.....................................................................................-

18

Page 19

Adjustment

STEP 2 Adjust Force

nn wrjT force ADJUSTMENTS TO COMPENSATE FOR A BINDING OR STICKING GARAGE DOOR.

iJcE^lil fStcE wfLUOTM OPERATION OFTHE SAFETY REVERSE SYSTEM

OR DAMAGE THE GARAGE DOOR.

Force Adjustment Controls are located on right side

panel of the opener chassis FORCE ADJUSTMENT

settings regulate the amount of power required to

open and close the door.

NOTE: Door STOPS In UP direction if anything

interferes with door travel. Door REVERSES in

DOWN direction if anything interferes with door

travel (including binding or unbalanced doors).

If force adjustments are set too light, door travel may

be interrupted by nuisance reversals in the DOWN

direction and stops in the UP direction As weather

conditions can affect door movement, occasional

adjustment may be needed

The maximum force adjustment range is 260 degrees,

about 3/4 of a complete turn. Do not force controls

beyond that point Turn force adjustment controls

with a screwdriver.

FORCE ADJUSTMENT CHART

Adjustment

Label

Force

■Adiustment

Controls

IF DOOR DOESN’T

OPEN AT LEAST 5 FT:

IF DOOR REVERSES

DURING THE DOWN

(CLOSE) CYCLE:

TEST DOWN

(CLOSE) FORCE:

Increase UP (OPEN) FORCE by turning control in a clock

wise direction as shown on label . Make 10 degree turn adjust

ments until door opens completely. Readjust UP LIMIT if

necessary. After each adjustment, run the opener through a

complete travel cycle.

Increase DOWN (CLOSE) FORCE by turning control in a

clockwise direction as shown on label, Make 10 degree turn

adjustments until door completes the close cycle. After each

adjustment, run opener through a complete travel cycle.

Grasp the door handle or door bottom when door is about

halfway through DOWN (CLOSE) TRAVEL. The door should

reverse If the door is hard to hold or doesn’t reverse, de

crease the DOWN (CLOSE) FORCE by turning the control in a

counter clockwise direction Make 10 degree turn adjust

ments until the door reverses normally. After each adjust

ment, run the opener through a complete travel cycle.

19

Page 20

Adjustment

STEFS

THE SAFETY REVERSE SYSTEM TEST IS IMPORTANT. THE GARAGE DOOR MUSTREVERSE ON CONTACT

WITH AONE INCH OBSTACLE PLACEDON THE FLOOR. FAILURETO PROPERLY ADJUSTTHE OPENER MAY

RESULT IN SERIOUS PERSONAL INJURY FROM ACLOSING GARAGE DOOR. REPEATTHE TEST AT LEAST

ONCE A YEAR AND MAKE ANY NEEDED ADJUSTMENTS,

PROCEDURE: Place a 1-inch obsiacle on the floor under the garage door. Operate the door in the DOWN

direction. The door must reverse on the obstruction.

If a SECTIONAL door STOPS on the obstruction,

lenghthen door arm (Step 10, Page 16) until the door

reverses in DOWN direction,.

If a ONE-PIECE door stops on obstruction, door is

not traveling far enough in DOWN direction. Increase

the DOWN limit by turning the DOWN limit adjust

ment screw counter-clockwise 1/4 turn REPEATTEST.

When the door reverses on the 1-inch obstruction,

remove obstruction and run opener through a com

plete travel cycle, Door must not reverse in closed

position, if it does, repeat Adjustment Steps 2 and 3.

Test Safety Reverse System

SECTIONAL DOOR

REPEAT ADJUSTMENT STEP 3 AFTER:

1. EACH ADJUSTMENT OF DOOR ARM LENGTH, CLOSE FORCE OR DOWN LIMIT

2. ANY REPAIR OR ADJUSTMENT OF THE GARAGE DOOR (INCLUDING SPRINGS AND HARDWARE)

3. ANY REPAIR OR BUCKLING OF THE GARAGE FLOOR

;

4,. ANY REPAIR OR ADJUSTMENT OF THE GARAGE DOOR OPENER

(Optional)

The INFRARED REVERSING SENSOR provides an

ADDITIONAL measure of safety against small child

ren being caughtunderagarage door, It uses an invis

ible beam which, when broken by an obstruction,

causes a closing door to open or prevents an open

door from closing

After the garage door opener has been completely

installed and adjusted, the INFRARED REVERSING

SENSOR accessory can be installed. Instructions are

included with this optional device

STEP 4

CAUTION: The Infrared Reversing Sensor will not

be in effect when Vacation Light is ON.

Install Infrared Reversing System

1/ ^'i'/ '^// "m ''^/Z ^^z

20

Page 21

Operation

CAUTION:

® START BY READING THE SAFETY RULES ON PAGE 3.

® READ THE OPERATING INSTRUCTIONS ON THIS PAGE CAREFULLY.

© DO NOT PERMIT CHILDREN TO PLA Y IN AREA OF DOOR.

© OPERATE ONLY WHEN OPENER IS PROPERLY ADJUSTED AND DOOR IS IN SIGHT AND FREE OF OBSTRUCTION.

THE SAFETY REVERSE SYSTEM IS IMPORTANT (SEE PAGE 20). GARAGE DOOR MUST REVERSE ON CON-

TACTWITHAONE-INCH OBSTACLE PLACEDONTHEFLOOR.FAILURETO PROPERLY ADJUSTOPENERMAY

RESULT IN SERIOUS PERSONAL INJURY FROM A CLOSING GARAGE DOOR. REPEATTHE TEST AT LEAST

ONCE A YEAR AND MAKE NEEDED ADJUSTMENTS.

USING THE OPENER

Your garage door opener can be activated by any of the following methods:

1. Pressing the transmitter push button, Hold the button down until door starts to move,

2. Pressing the Wall Control push buttons.

3. By turning the Key Switch (if you have installed this accessory).

WHEN EITHER THE WALL CONTROL OR TRANSWMTTER PUSH BUTTONS ARE PRESSED, ONE OF THE

FOLLOWING WILL OCCUR (Vacation Light OFF):

1. If open, the door wilt close. If closed, the door will open,

2. if closing, the door will reverse.

3. If opening, the door will stop (allowing space for entry and exit of pets and for fresh air).

4. If the door has been stopped in a partially open position (refer to 3. above), it will close.

5. If an obstruction is encountered while closing, the door wilt reverse.

6. If an obstruction is encountered while opening, the door will stop.

7. The optional Infrared Reversing Sensor, if instalied, will signal the opener to reverse the door in the closing cycle

when the IR beam is obstructed and prevent an open door from closing. It has no effect in the opening cycle.

of

Your Opener

THE LIGHTS

When the opener is activated, lights will turn on. They will turn off automatically after4-l/2 minutes. BULB SlZE-75

watts maximum. When Work Light is ON, the lights will remain on.

OPENING THE DOOR MANUALLY

The door can be operated manually by disconnecting it from the opener. Simply pul! down sharply on the red

emergency release handle. The door may now be lifted manually DO NOTUSE EMERGENCY ROPE AND HANDLE

TO PULL THE DOOR OPEN OR CLOSED. To automatically reconnect the door to the opener, press the Wall Control

push button

CARE OF THE OPENER

When properly installed, your opener will perform efficiently with a minimum of maintenance. You will be required to

replace a light bulb or change a transmitter battery from time to time. A 9-Volt Alkaline battery is the most reliable, and

is available at Sears.

The opener does not require additional lubrication - HOWEVER - the door rollers, bearings and hinges should be

oiled yearly.

Most complaints of unsatisfactory opener operation can be traced to problems with the door itself. The opener is not

intended to correct problems caused by an unbalanced or binding door, broken door springs orfaulty door hardware.

When operating the door manually, a properly balanced door will stay in any point of travel while being supported

soley by its springs, if you encounter any difficulty when operating door manually, call a garage door serviceman,

RADIO CONTROLS

Refer to pages 22 and 23 for complete details.

LIMIT AND FORCE ADJUSTMENTS

Refer to pages 18 and 19 for limit and force adjustments These adjustments must be checked and properly set when opener

is installed Weather conditions may cause minor changes in door operation requiring some change in adjustments,

particularly during the first year of operation. Only a screwdriver is required. Follow instructions carefully.

CHAIN TENSION ADJUSTMENT

After installation of opener and adjustment of forces and limits, chain may appear loose. This is normal. TO CHECK

CHAIN TENSION: disconnect the trolley by pulling red emergency handle. If chain returns to position described in

Step 5. Page 9, DO NOT make further adjustments.

21

Page 22

Radio Controls

RECEIVER

Right Side

Panel

Terminais

. Code

Swiich

Block

RADIO CONTROLS consist of a transmitter and a

receiver. The transmitter sends a coded signal from

outside the garage. The receiver is fastened to the

right side panel of the door opener, it receives the

transmitted signal and starts the door opener.

The signal code is set at the factory Page 23 des

cribes code changing procedures, if required.

Self service of radio controls is not recommended, if

service is needed, contact your nearest Sears Ser

vice Center.

THE TRANSMITTER

The portable transmitter may be secur ed to a car sun

visor with the clip provided Additional transmitters

can be purchased at any time for use in ali vehicles

using the garage, (Refer to Accessories, Page 5)„

New transmitters must be set to the same code as

original transmitter and receiver Foilow code set

ting procedures described on Page 23.

A 9-volt battery supplies the power The transmitter is

equipped with a battery check light When the trans

mitter push button is pressed, light will glow if battery

has power (and the opener will operate). When light

does not come on, replace battery. If transmission

range lessens, check battery light,

THE BATTERY

The battery should produce adequate po\«er for

approximately one year. Avoid the inconvenience of

unexpected battery failure by replacing it annualiy,

preferably before winter. Alkaline batteries are the

most reliable and are available at Sears.

TO REPLACE BATTERY: Remove visor dip and un

fasten connecting screw. Remove top of transmitter

case and discard old battery. Snap connector onto

new battery. Replace top of case and connecting

screw,. Replace visor clip

TRANSMITTER

Battery Tes

Light ■

22

Page 23

Radio Controls

Sears Trinary Radio Control

Manulactured under 1 or more oi Ure following li S. patents: 3 445 848: 3 906.348; and 4 037 201

The coded signal in Sears Trinary RadioControls can be changed easily without the aid of aserviceman.The only tool

needed Is a flat blade screwdriver Choose your own code by changing position of switches numbered 1 through 9 on

the receiver code switch block. Changing the position of only one switch makes an entirely different code.

MATCHING YOUR CODE IN A NEW TRANSMITTER

The original transmitter is preset at the factory to the same coded signal as the receiver. The code in any

NEW transmitters must be set to match the code In the original transmitter and the receiver.

PROCEDURE: With visor clip off, remove screw in

the original and new transmitter{s) as illustrated in

Figure 1. Carefully turn cades over (push button

sides up). Remove case tops as shown in Figure 2.

CAUTION: Be careful not to move circuit board

components.

Place transmitter circuit boards side by side as shown

in Figure 3, Set the code switches in the new trans

mitter to match those in the original transmitter. Use

a fingernail or screwdriver to slide the switches,.

Figure 3

E

-----------------

CHANGING YOUR CODE IN RECEIVER AND TRANSMITTER(S}

DISCONNECT POWER TO OPENER BEFORE CHANGING THE CODE IN THE RECEIVER.

The receiver is fastened to the right side panel of the

opener chassis. Code switches are shown in Figure 4.

IF YOUCHANGETHE CODE IN YOUR RECEIVER, ALSO

CHANGE THE CODE IN YOUR TRANSMITTER(S}.

PROCEDURE: Hold transmitter circuit board along

side recelvercode switches as shown To change the

code, use a fingernail or screwdriver. Slide one or

more receiver switches to a plus, minus or center

(0) position.

Set code switches in the transmitter(s) to match thé

new receiver code settings.

Code

Switch

Figure 1

-----------------------

5!||И1В!В r

-

V

Transmitter Circuit Board

RED WHT BLK

Hill HI Ü!@

:;i

Code Switches

Figure rt

1

c~~~n

•BiBiiîlîs c

Figure 2

щмицнитмццмшиии

ORN YEL

IMPORTANT NOTE: Code settings must be ex

actly the same in the receiver, transmitter and all

additional transmitters used to operate the door.

Please keep this instruction manual handy for

future reference.

23

h a 14 ъ:. 1 D 9

шеввееее

i-tf

Page 24

Having a Problem?

OPENER DOESN’T ACTIVATE

T Have you removed all door locks and bolts?

2 Does the opener have electric power? Check wall

switch, fuse, etc.

3. Is there a broken wire between Wall Control and

opener? Check under staples (A positive check

can be made by temporarily installing another wire)

4. Are wiring connections correct? Refer to Step 7,

Page 14.

5. Repeated operation may have tripped the over load

protector in the motor. Wait 15 minutes. Try again,

TRANSMITTER RANGE INSUFFICIENT

1. Check battery.

2 Change transmitter location in car

3. Metal garage door, foil-backed insulation or metal

siding will reduce range

4 Antenna on side panel of opener must be fully

extended downward.

DOOR DOESN’T OPEN OR CLOSE COMPLETELY

1, Is something obstructing the door?

2, Limits may need adjustment. See Pg. 18.

3., Force may need adjustment See Pg. 19

4 Door will not close while in Vacation mode.

DOOR OPENS AND CLOSES BY ITSELF

1 Neighbor with a Sears opener using the same code?

Change your code.

LIGHTS

1 Won’t turn OFF? Check Work Light Is it ON?

2. Won’t turn ON? Check light bulbs.

DOOR OPERATES FROM PUSH BUTTON BUT NOT

FROM TRANSMITTER

1. Replace the battery.

2 New transmitter? Have you set the code? Referto

Page 23..

3 Vacation light is ON.

DOOR REVERSES FOR NO APPARENT REASON

1 Pull red emergency release handle Operate the

door manually. Is it balanced? Binding? If service is

needed call a garage door serviceman

2 Force adjustment may be needed. See Pg 19

3 Check for proper alignment of Infrared Reversing

Sensor (if you have installed this accessory)..

4 Cleat ice and snow from gar age floor area where gar

age door closes.

THE NEED FOR OCCASIONAL ADJUSTMENT OF FORCE AND LIMIT CONTROLS IS NORMAL. WEATHER

CONDITIONS IN PARTICULAR CAN AFFECT DOOR MOVEMENT.

Transmitter

Schematic

24

Page 25

Wiring Diagram and Receiver Schematic

25

Page 26

INSTALLATION PARTS LIST

KEY

NO

1

2

3

4

5

6

7

8

9

10

11

PART

NO.

4102736

10A13

41A2830

29C121-2

41A2828

219A319

41A2829

12B374

12B3B0

178B32

178B33

NOT

41A2815

Wall control assy

9 volt battery (available at Sears!

Transmitter case, cover and screw assy

Transmitter visor dip

Emergency rope and handle assy

4-Strand bell wire

Header bracket plus colter pin and clevis

Door bracket

Door bracket piate

Wedge door arm section

Straight door arm section

SHOWN

Installation hardware bag (includes hardware illus

trated on Page 4)

-11

J

26

Page 27

Repair Parts

Chassis Assembly Parts List

KEY

PART

NO.

NO.

1 31C290

2 41A2827

3 41A2817

4

41B2S91

5 41C2725

41A3063

6

7 41A3073

KEY

DESCRIPTION

Sprockel cover

Gear and sprocket assy 9 108D30-1 Lens (each)

Complete with: 10 30B363

Spring washer 11 12A3T3

Thrust washer 12 1A2510

Retaining ring 13 41A2821 Motor assy, w/roli pin

Bearing plate

Roll pins (2)

Drive gear

Worm gear

Helical gear w/retainer 18 41A3027 Motor bracket and bearing assy.

Grease

Drive/worm gear kit w/grease

Roll pins(2i 21 41A3074 End panel

Line cord

Wire harness assy w/p!ug

Receiver logic board assy

Logic board

fcna pane! w/an lapeis

Light socket (1)

End pane! w/aii labels

PART

NO.

NO. DESCRIPTION

6 175888 Light socket (each)

Capacitor

Capacitor bracket

Terminal block w/screws

14

41C2740

15

41A2818

16

41D3013

17

41C3005

19

41A2826

41A2822 Interrupter cup assy

20

Cover w/ail labeis

Helicai gear and retainer w/grsase

Limit switch assy

RPM sensor assembly

Shaft bearing Kit

22 12B350 Hanging brackets

114AB95 Owners manual

41A2825 Chassis assy hardware kit (inctudes screws

not designated by number in illustration)

27

Page 28

Owners Manual

Al

ii VJ®

Garage

Door

Opener

Model

139.535006

V -r 3)-r’-y

i/ éü u\x ltJ Li ^

HOW TO ORDER REPAIR PARTS

Now that you have purchased your Sears Garage Door Opener, should a

need ever exist for repair parts or service, simply contact any Sears Service

Center and most Sears, Roebuck and Co, stores. Be sure to provide all

pertinent facts when you call or visit

The MODEL NUMBER of your garage door opener is printed on a label

located on the right side panel of the opener chassis.

Ail parts listed may be ordered from any service center and most Sears

stores.

WHEN ORDERING REPAIR PARTS, ALWAYS GIVE THE FOLLOWING

INFORMATION;

® PART NUMBER ® PART DESCRIPTION

® MODEL NUMBER ® NAME OF ITEM

If thé parts you need are not stocked locally, your order will be electroni

cally transmitted to a Sears Repair Parts Distribution Center for handling

IMPORTANT NOTE: If you suspect radio malfunction, contact your near

est SEARS Service Center

JMJtJlJ

MAINTENANCE AGREEMENTS ...YOUR WAY TO BUY TOMORROW’S SERVICE

TODAY’S PRICE ... With nationwide service and the benefits of a Sears warranty plus a Sears Mainte

nance Agreement, you don't have to worry about costly repairs resulting from normal use

The Maintenance Agreement does not cover installation or re-installation of the product or damage resulting from

external causes such as: acts of abuse, fire, flood, wind, lightning, freezing, etc.

To Purchase a Sears Maintenance Agreement - Ask Any Salesperson or Call Sears Service Today.

mIpHkSZÌSéIiiZ

SEARS WARRANTY

GARAGE DOOR OPENER MODEL 139.535006

FULL 90 DAY WARRANTY ON GARAGE DOOR OPENER

For 90 days from the date of purchase. Sears will repair this Garage Door Opener, free of charge, if defective in

material or workmanship.

From the 91st day until one year from the date of purchase, Sears will furnish replacement parts for any defective parts,

free of charge,. You pay for iabo

LIMITED WARRANTY ON MOTOR

After 1 year and through 5 years, if the motor on this Garage Door Opener is defective, Sears will furnish a replacement

motor, free of charge. You pay for labor.

Sears will not be liable for loss or damage to property or any incidental or consequential loss or

expense from property damage due directly or indirectly from the use of this product.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation or

exclusion may not apply to you

This warranty does not cover repairs necessary because of operator abuse or negligence, including the failure to install,

adjust and operate this garage door opener according to the instructions contained in the owner’s manual,

WARRANTY SERVICE iS AVAILABLE BY SIMPLY CONTACTING THE NEAREST SEARS SERVICE CENTER/DEPABTMENT IN THE UNITED STATES. This warranty applies only while the product is in use in the United States.

This warranty gives you specific legal rights, and you may also have other rights which vary from state to state

LIMITED WARRANTY

LIMITATION ON LIABILITY

114A895

SEARS ROEBUCK AND COMPANY, Dept 698/731 A, Sears Tower, Chicago, IL 60684

ÖSZ

zsz 'ZSDSZ

■Z3XZ

Printed in Mexico

Loading...

Loading...