Craftsman 137242760 Owner’s Manual

Operator's Manual

CRRFTSMRN°

3 HP (Max. Developed)

10" Blade

4800 R.P.M.

MULTI-MITER TM

COMPOUND

MITER SAW

Model No.

137.242760

CAUTION:

Before using this Miter Saw,

read this manual and follow

all its Safety Rules and

Operating Instructions

Customer Help Line

1-800-843-1682

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

Visit our Craftsman webslte: www.sears.comlcraftsman

PaN No. 137242760001

• Safety Instructions

• Installation

• Operation

• Maintenance

• Parts List

SECTION PAGE

Warranty ........................................ 2

Product Specifications ....................... 2

Power Tool Safety ............................ 3

Compound Miter Saw Safety............... 4

Electrical Requirements and Safety...... 4-5

Accassodes and Attachments .............. 6

Tools Needed For Assembly................ 6

Carton Contents .............................. 7

SECTION PAGE

KnowYour Miter Saw........ 8

Glossary of Terms ............................ 9

Assembly and Adjustments................. 10

Operation....................................... 17

Maintenance ................................... 24

Troubleshooting Guide....................... 25

Parts List......................................... 26

FULL ONE YEAR WARRANTY

If this tool fails due to a defect in material or workmanship within one year of date of purchase, Sears will

at its option repair or replace it free of charge.

Return this tool to a Sears Service Center for repair, or to place of purchase for replacement.

This warranty gives you specific legal rights, and you may also have other rights which may vary from

state to state.

Seam, Roebuck and Co., Dept. 817 WA, Hoffman Estates, IL 60179

UA WARNING ]

Some dust created by power sanding, sawing, grinding, dHIlinQ and other construction activities contains

chemicals known (to the State of Ca.fornie) to cause cancer, bnrthdefects or other reproductive harm. Some

examples of these chemicals are:

• Lead from lead-based paints

• Crystalline silica from bricks, cement and other masonry products

• Arsenic and chromium from chemically treated lumber

Your Hak from these exposures varies depending on how often you do this type of work. To reduce your

exposure to these chemicals work in a well ventilated area and work with approved safety aquipmantsuch as dust

masks that are specially des gned to fi tar out microscop c part ces.

MOTOR

Pov_r Source.....................

Horsepower........................

Speed.................................

Brake.................................

DoubleInsulated....................

MITER SAW

Cutting Capacity:

Crosscut............................

Miter45°R.&L.....................

Bevel45=L........................

45° Miterand45° Bevel.........

120VAC, 60HZ, 15 Amp

3HP (Max. Developed)

4800 RPM (No load)

Electric

Yes

2-5/8"x 5-1/2"

2-5/8"x 3-1/2"

1-1/2"x 5-1/2"

1-1/2"x 3-1/2"

Rotating Table:

Diameter .............................. 12-5/8"

Miter Detent Stops.................. 0, 15,22-1/2, 31.6,

450 R. & L.

Bevel Positive Stops............... 0, 450

Base Dimensions................... 19-7/8" x 16-3/8"

Dust Collection...................... Yes

Extension Table ..................... Yes

Net Weight ........................... 51.25 Lbs

IA WARNONGI

To avoid electrical hazards, fire hazards or damage to the tool, use proper circuit protection.

This tool Is wired st the factory for 110-120 Volt operation. It must be connected to a 110-120 Volt 1 15 Ampere time

delay fuse or circuit breaker. To avoid shock or firs, replace power cord Immediately if it is worn, cut or damaged

in any way.

Before using your tool, it is cdtlcal that you read and understand these safety rules. Failure to follow these rules

could result in serious injury to you or damage to the tool.

2

GENERAL SAFETY INSTRUCTIONS

BEFOREUSINGTHISPOWERTOOL

Safety is a combination of common sense, staying alert

and knowing how to use your power tool.

A WARNING I

To avoid mistakes that could cause serious injury, do not

plug the tool in untilyou have read and understood the

following.

1. READ and become familiar with the entire Operators

Manual. LEARN the tool'sapplication,limitations and

possible hazards.

2. KEEP GUARDS IN PLACE and in working order.

3. REMOVE ADJUSTING KEYS AND WRENCHES.

Form the habit of checking tosee that keys and

adjusting wrenches are removed from the tool before

turning ON.

4. KEEP WORK AREA CLEAN. Cluttered areas and

benches inviteaccidents.

5. DON'T USE IN DANGEROUS ENVIRONMENTS.

Don't use power tools in damp locations, or expose

them to rain or snow. Keep work area well lighted.

6. KEEP CHILDREN AWAY.All visitorsand bystanders

shouldbe kept a safe distance from work area,

7. MAKE WORKSHOP CHILD PROOF with padlocks,

master switches, or by removing starter keys.

8. DON'T FORCE THE TOOL. It will do thejob better

and safer at the rate for which itwas designed.

9. USE THE RIGHT TOOL. Do not force the tool or an

attachment to do a job for which itwas not designed.

10.USE PROPER EXTENSION CORDS. Make sure

yourextension cord is in good condition. When using

an extension cord, be sure to use one heavy enough

to carry the current your productwilldraw.An

undersized cord will result in a drop in line voltage

and in loss of power which will cause the toolto

overheat. The table on page 5 shows the correct size

to use depending on cord lengthand nameplate

ampere rating. If in doubt, use the next heavier gauge.

The smaller the gauge number,the heavier the cord.

12.ALWAYS WEAR EYE PROTECTION. Any power tool

can throwforeign objects into the eyes and

,,,*,,_ could cause permanent eye damage.

ALWAYS wear Safety Goggles (not

glasses) that comply with ANSI Safety

standard Z87.1 Everyday eyeglasses

have only impact -resistance lenses.

TheyARE NOT safety glasses. Safety Goggles are

available at Sears. NOTE: Glasses or goggles not in

compliance with ANSI Z87.1 could seriously injure

you when they break.

13.WEAR A FACE MASK OR DUST MASK. Sawing

operation produces dust.

14.SECURE WORK. Use clamps or a vise to holdwork

when practical. It's safer than using your hand and it

frees both hands to operate the tool.

15.DISCONNECT TOOLS FROM POWER SOURCE

before servicing, and when changing accessories

such as blades, bits and cutters.

16.REDUCE THE RISK OF UNINTENTIONAL

STARTING. Make sure switch is in the OFF position

before pluggingthe toolin.

17.USE RECOMMENDED ACCESSORIES. Consult this

Operators Manual for recommended accessories.

The use of improper accessories may cause risk of

injuryto yourself or others.

18.NEVER STAND ON THE TOOL. Serious injury could

occur if the tool is tipped or ifthe cuttingtool is

unintentionallycontacted.

19.CHECK FOR DAMAGED PARTS. Before further use

of the tool, a guard or other part that is damaged

should be carefully checked to determine that it will

operate properlyand perform its intended function-

check for alignment of movingparts, bindingof

moving parts, breakage of parts, mounting, and any

other conditions that may affect its operation.A guard

or other part that is damaged should be propedy

repaired or replaced.

20.NEVER LEAVETHE TOOL RUNNING UNAI-rENDED.

TURN THE POWER "OFF". Don't walk away from a

runningtool untilthe blade comes to a complete stop

& unplugthe unit.

2t .DON'T OVERREACH. Keep proper footing and

balance at all times.

11.WEAR PROPER APPAREL. Do not wear loose

clothing,gloves, neckties, rings,bracelets, or other

jewelry which may get caught in moving parts.

Nonslip footwear is recommended. Wear protective

hair covering to contain long hair.

22.MAINTAIN TOOLS WITH CARE. Keep tools sharp

and clean for best and safest performance. Follow

instructionsfor lubricating and changing accessodes.

23. WARNING: Dust generated from certain materials

can be hazardous toyour health. Always operate

saw in well-ventilated area and providefor proper

dust removal.

3

SPECIFIC SAFETY INSTRUCTIONS FOR

THIS COMPOUND MITER SAW

1. USE ONLY CROSS-CUTTING SAW BLADES. When

using carbide tipped blades, make sure they have a

negative hook angle.

IMPORTANT: DO NOT USE THIN KERF BLADES-

they can deflect and contact guard and can cause

possibleinjuryto the operator.

2. DO NOT operate the miter saw untilit is completely

assembled and installedaccording to these

instructions.

3. IF YOU ARE NOT thoroughlyfamiliarwith the

operation of miter sews, seek guidance from your

supervisor, instructor,or other qualified person.

4. ALWAYS hold the work firmly against the fence and

table. DO NOT perform any operation free hand (use

clamp wherever possible).

5. KEEP HANDS out of the path of the saw blade. Ifthe

workpiece you are cuttingwould cause your handsto

be within6-1/2" inches of the saw blade, the

workpiece should be clamped in place before making

the cut.

6. BE SURE the blade is sharp, runs freely, and isfree of

vibration.

7. ALLOW the motor to come up to full speed before

starting a cut.

8. KEEP THE MOTOR AIR SLOTS CLEAN and free of

chips or dust.

9. ALWAYS MAKE SURE allhandles are tight before

cutting, even if the table is positionedin one of the

positivestops,

tO.BE SURE boththe blade and the coUarare clean and

the arbor bolt is tightened securely.

11.USE only blade collars specifiedfor yoursaw.

17.NEVER reach around the sew blade.

18.MAKE SURE the blade is not contactingthe

workpiece before the switchis turned ON.

19.IMPORTANT: Aftercompleting the cut, release the

power switchand wait for the blade to stopbefore

returningthe saw to the raised position.

20.MAKE SURE the blade has come to a complete stop

before removing or securingthe workpiece, changing

the workpiece angle, or changingthe angle of the

blade.

21.NEVER cut ferrous metals or masonry with thistool.

22.NEVER cut small pieces..If the workpiece being cut

would cause your hand or fingers to be within7-1/4

inchesof the saw blade the workpiece is too small.

23.PROVIDE adequate support to the sides of the saw

table for longworkpieces.

24.NEVER use the mitersaw in an area with flammable

liquidsorgases.

25.NEVER use solvents to clean plastic parts. Solvents

could possiblydissolve or otherwise damage the

matedaL

26,SHUT OFF the power before servicing or adjustingthe

tool.

27,DISCONNECT the saw from the power source and

clean the machine when finished using.

28.MAKE SURE the work area is clean before leaving

the machine.

29.SHOULD any part of your miter saw be missing,

damaged, or fail in any way, or any electrical

component fail to perform propedy, shut off the switch

and remove the plugfrom the power supplyoutlet.

Replace missing, damaged, or failed parts before

resumingoperation.

12. NEVER use blades'larger or smaller in diameter than

10oinches.

13. NEVER apply lubricants to the blade when itis

running.

t4. ALWAYS check the blade for cracks or damage

before operation. Replace a cracked or damaged

blade immediately.

15. NEVER use blades recommended for operationat

less than 4800 RPM

16.ALWAYS keep the blade guards inplace and use at

all times.

POWER SUPPLY AND MOTOR SPECIFICATIONS

The AC motor used in this sew is a universal,

nonreversible type. See "MOTOR" in the "PRODUCT

SPECIFICATIONS" section on page 2.

To avoid electdcal hazards, fire hazards, or damage to

the tool, use proper circuitprotection.Your saw is wired at

the factory for 120V operation. Connect to a 120V, 15

Amp circuit and use a 15 amp. time delay fuse or circuit

breaker. To avoid shock or fire, if power cord is worn or

cut, or damaged in any way, have it replaced

immediately.

4

ELECTRICAL REQUIREMENTS - cont'd

DOUBLE INSULATED []

The power tool is double insulated to providea double

thickness of insulationbetween you and tool'selectricel

system. All exposed metal parts are isolated from the

internalmetat motor componentswith protecting insulation.

Replacement parts - When servicinguse only identical

replacement parts.

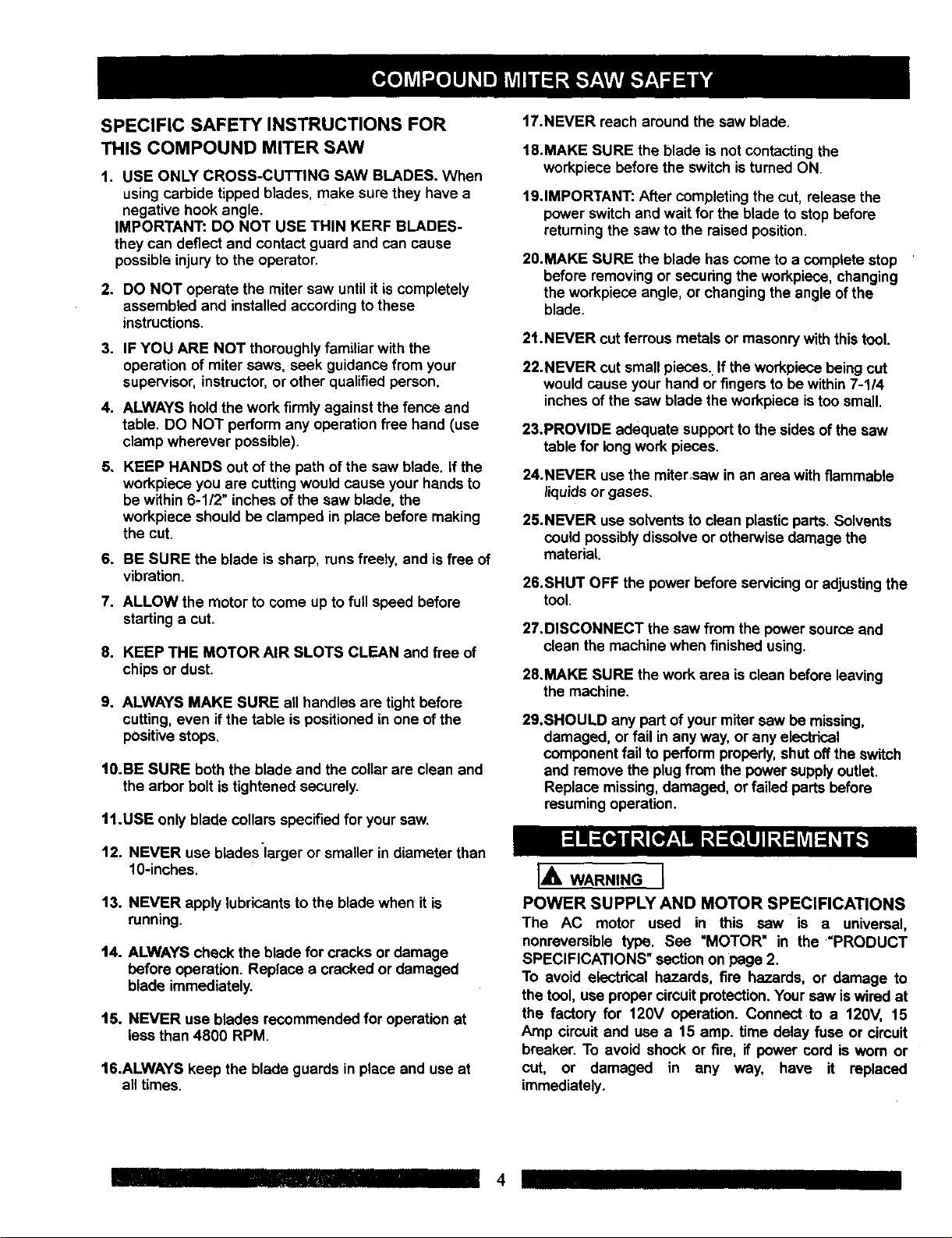

Polarized plugs - This saw has a plugthat lookslike the

one shown below:

-i;222

To reduca the risk of electrical shock, this saw has a

polarized plug (one blade iswider than the other). This

plug will fit in a polarized outlet only one way. If the plug

does not fit fully in the outlet, reverse the plug. If it still

does not fit, contact a qualified electrician to install the

proper outlet. Do not change the plug in any way.

[AWARN,NG]

Double insulationdoes nottake the place of normal safety

precautions when operating this tool.

To avoid electrocution:

1. Use only identical replacement parts when servicinga

toolwith double insulation.Servicing should be performed

by a qualified technician.

2. Do not use power tools inwet or damp locationsor

expose them to rain or snow.

MOTOR SAFETY PROTECTION

IMPORTANT:

To avoid motor damage, the motor shouldbe blownout or

vacuumed frequently to keep sawdust from interfering with

the motor ventilation.

1.CONNECT this saw to a 120V, 15 amp. circuitwitha 15

amp. time delay fuse or circuit breaker. Using the wrong

size fuse can damage the motor.

2. If the motor won't start, release the trigger switch

immediately.UNPLUG THE SAW. Check the saw blade

to make sure it turns freely. If the blade is free, try to

start the sew again. Ifthe motor still does not start, refer

to the "TROUBLESHOOTING GUIDE"

3. If the tool suddenlystalls whilecutting wood, release the

trigger switch, unplugthe tool, and free the blade from

the wood. The saw may now be started and the cut

finished.

4.FUSES may "blow" or circuit breakers may tdp

frequently if:

a. MOTOR is overloaded - overloading can occur if

you feed too rapidly or make too many start/stops

in a short time.

b. LINE VOLTAGE is morethan 10% above or below

the nameplate voltage rating. For heavy loads, the

voltage at motor terminals mustequal the voltage

specified on the nameplate.

c. IMPROPER or dull saw blades are used.

5. Most motor troublesmay be traced to loose or incorrect

connections, overload, lowvoltage or inadequate power

supplywiring.Always check the connections,the load

and supplycircuitif the motor doesn't runwell. Check

minimum gauge for the lengthof cord you are usingon

the chart below.

/

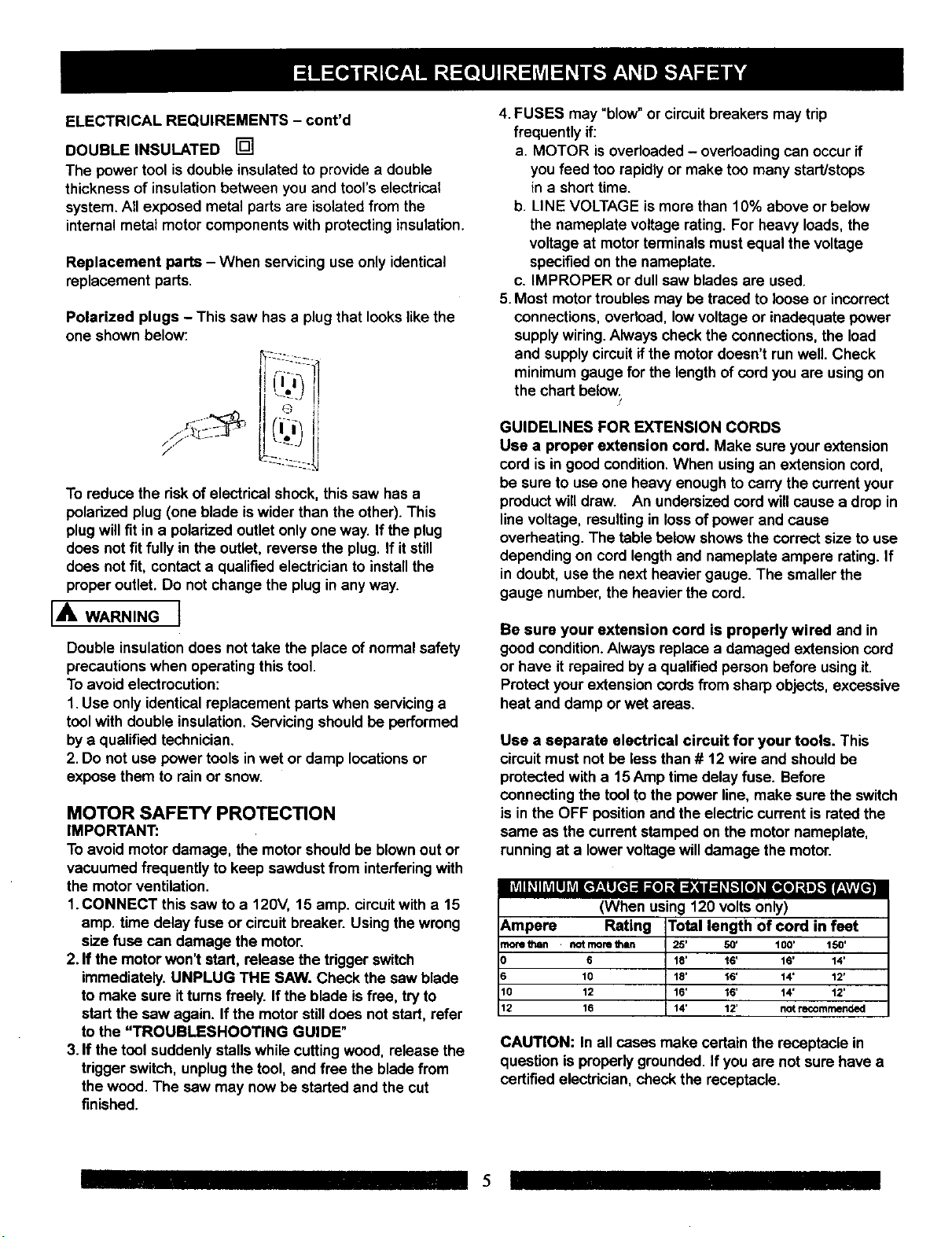

GUIDELINES FOR EXTENSION CORDS

Use a proper extension cord. Make sure yourextension

cord is in good condition.When using an extension cord,

be sure to use one heavy enough to carry the current your

productwill draw. An undersized cord will cause a drop in

linevoltage, resulting in lossof power and cause

overheating. The table below shows the correct sizeto use

depending on cord length and nameplate ampere rating. If

in doubt, use the next heavier gauge. The smaller the

gauge number,the heavier the cord.

Be sure your extension cord is properly wired and in

good condition.Always replace a damaged extension cord

or have it repaired by a qualified person before usingit.

Protect your extension cords from sharp objects, excessive

heat and damp or wet areas.

Use a separate electrical circuit for your tools. This

circuit must not be less than # 12 wire and should be

protected with a 15 Amp time delay fuse. Before

connecting the tool to the power line,make sure the switch

is in the OFF positionand the electric current israted the

same as the current stamped on the motor nameplate,

runningat a lower voltagewilldamage the motor.

lltd I _I liVdlllvJ1¢f_,_1[€t =1 :re] _.i =);,4111:1_k.'f[e] _I[o(I] :| J_l f:VlvL_!

(When using 120 voltsonly)

_mpere Rating Total length of cord in feet

_ore fJlen notmore I_n 25' 50' t00' 150'

6 18' 16' 16' 14'

10 18' 16' 14' 12'

I0 12 16' 16' 14' 12'

12 16 14' 12' not recommended

CAUTION: Inall cases make certain the receptacle in

question is properly grounded. If you are not sure have a

certified electrician, check the receptacle.

5

RECOMMENDED ACCESSORIES

IA, WARNING]

• Use only accessories recommended for this miter saw.

Follow instructions that accompany accessories. Use

of improper accessories may cause hazards.

• The use of any cutting tool except 10 inch saw blades

which meet the requirements under recommended

accessories is prohibited. Do not use accessobes such

as shaper cutters or dado sets. Ferrous metal cutting

and the use of abrasive wheels is prohibited.

• Do not attempt to modify this tool or create

accessories not recommended for use with this tool.

Any such alteration or modification is misuse and could

result in a hazardous condition leading to possible

serious injury.

ACCESSORIES

Visit your Sears Hardware Department or see the Sears

Power and Hand Tool Catalog to purchase recommendec

accessories for this power tool.

[A WARNINGI

To avoid the risk of personal injury, do not modifythis

power tool or use accessories not recommended by Sear

I,A WARNING]

Read warnings and conditionson your CARBIDE TIPPEr

SAW BLADE. Do not operate the saw without the proper

saw blade guard in place. Carbide is a very hard but brittle

material. Care should be taken while mounting, using, and

storingcarbide tipped blades to prevent accidental

damage. Slight shocks, such as striking the tip while

handling, can seriously damage the blade. Foreign objects

in the workpiece, such as wire or nails, can also cause tips

to crack or break off. Before using, always visually

examine the blade and tips for bent teeth, cracks,

breakage, missing or loose tips, or other damage. Do not

use if damage is suspected. Failure to heed safety

instructionsand warnings can result in serious bodily

injury.

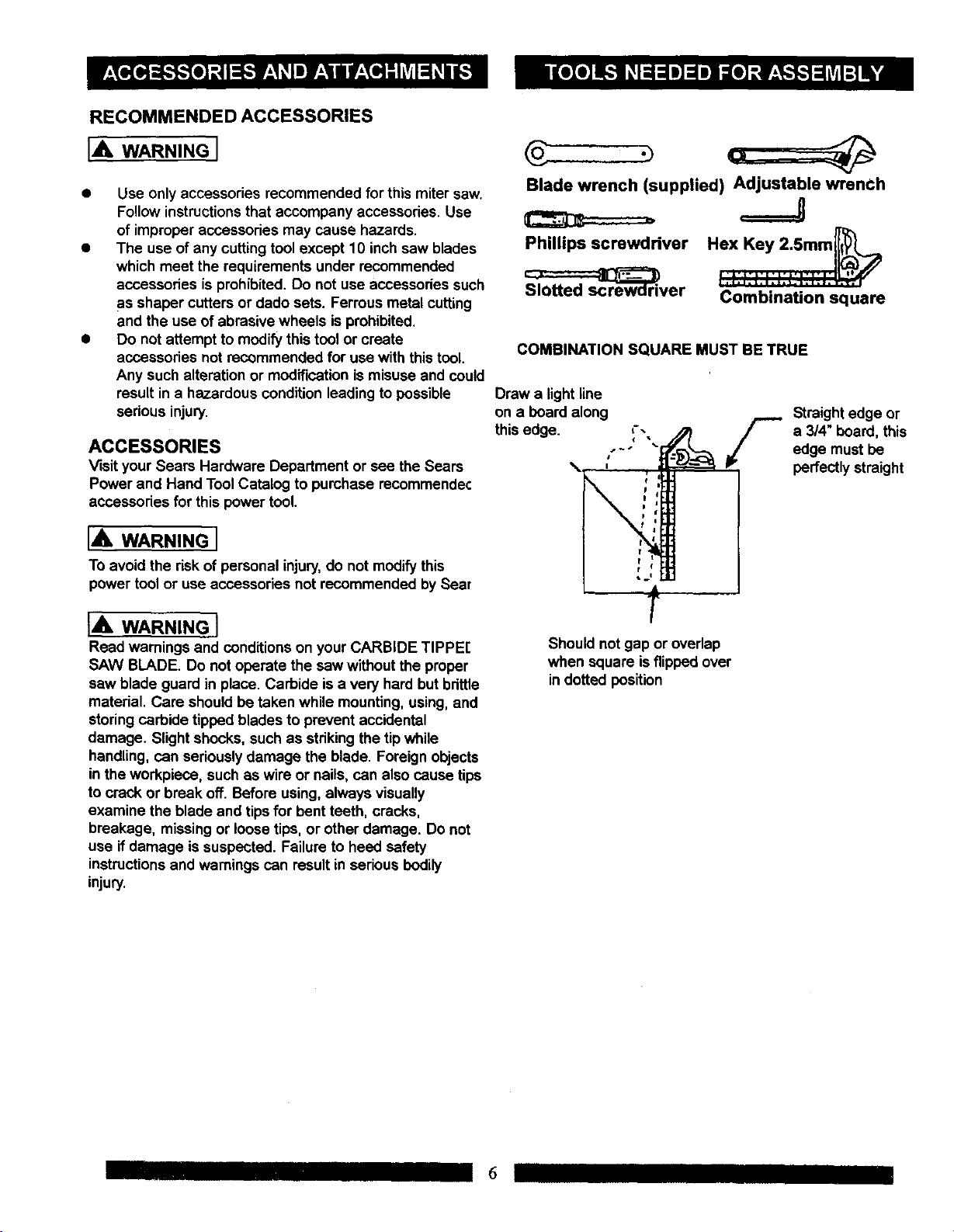

Blade wrench (supplied) Adjustable wrenCh

===J

Phillips screwdriver

_ver

COMBINATION SQUARE MUST BE TRUE

Draw a light line

on a board along

this edge. ,--

s_J

Should not gap or overlap

when square is flipped over

in dotted position

Combination square

Straight edge or

a 3/4" board, this

edge must be

perfectlystraight

I 6

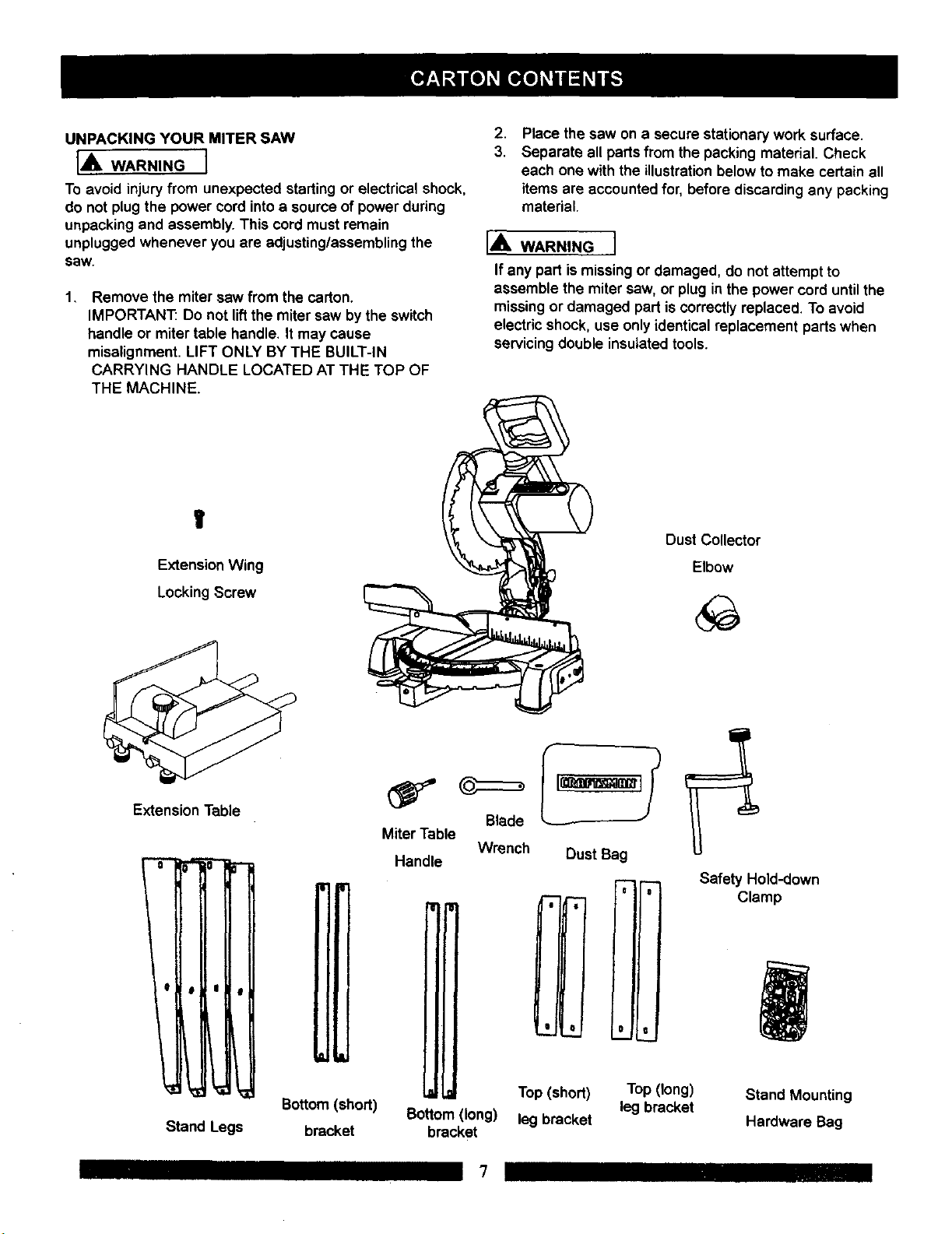

UNPACKING YOUR MITER SAW

IA WARNINGI

To avoid injury from unexpected starting or electrical shock,

do not plugthe power cord intoa sourceof power during

unpacking and assembly. This cord must remain

unplugged whenever you are adjusting/assemblingthe

saw.

1, Remove the miter saw from the carton.

IMPORTANT: Do not liftthe miter saw bythe switch

handle or miter table handle. It may cause

misalignment. LIFT ONLY BY THE BUILT-IN

CARRYING HANDLE LOCATED AT THE TOP OF

THE MACHINE.

V

Extension Wing

.

Place the saw on a secure stationary work surface.

3.

Separate all parts from the packing material. Check

each one with the illustration below to make certain all

items are accountedfor, before discardingany packing

material.

I,_b. WARNING I

If any part is missingor damaged, do not attempt to

assemble the miter saw, or plug in the power cord untilthe

missingor damaged part is correctlyreplaced. To avoid

electricshock, use only identical replacement parts when

servicingdouble insulated tools.

Dust Collector

Elbow

LockingScrew

Extension Table

I

Miter Table

Blade

Handle Wrench Dust Bag

Safety Hold-down

Clamp

,I

Stand Legs

Bottom(short)

bracket

Bottom(long)

bracket

7

Top (short)

leg bracket

Top (long)

leg bracket

Stand Mounting

Hardware Bag

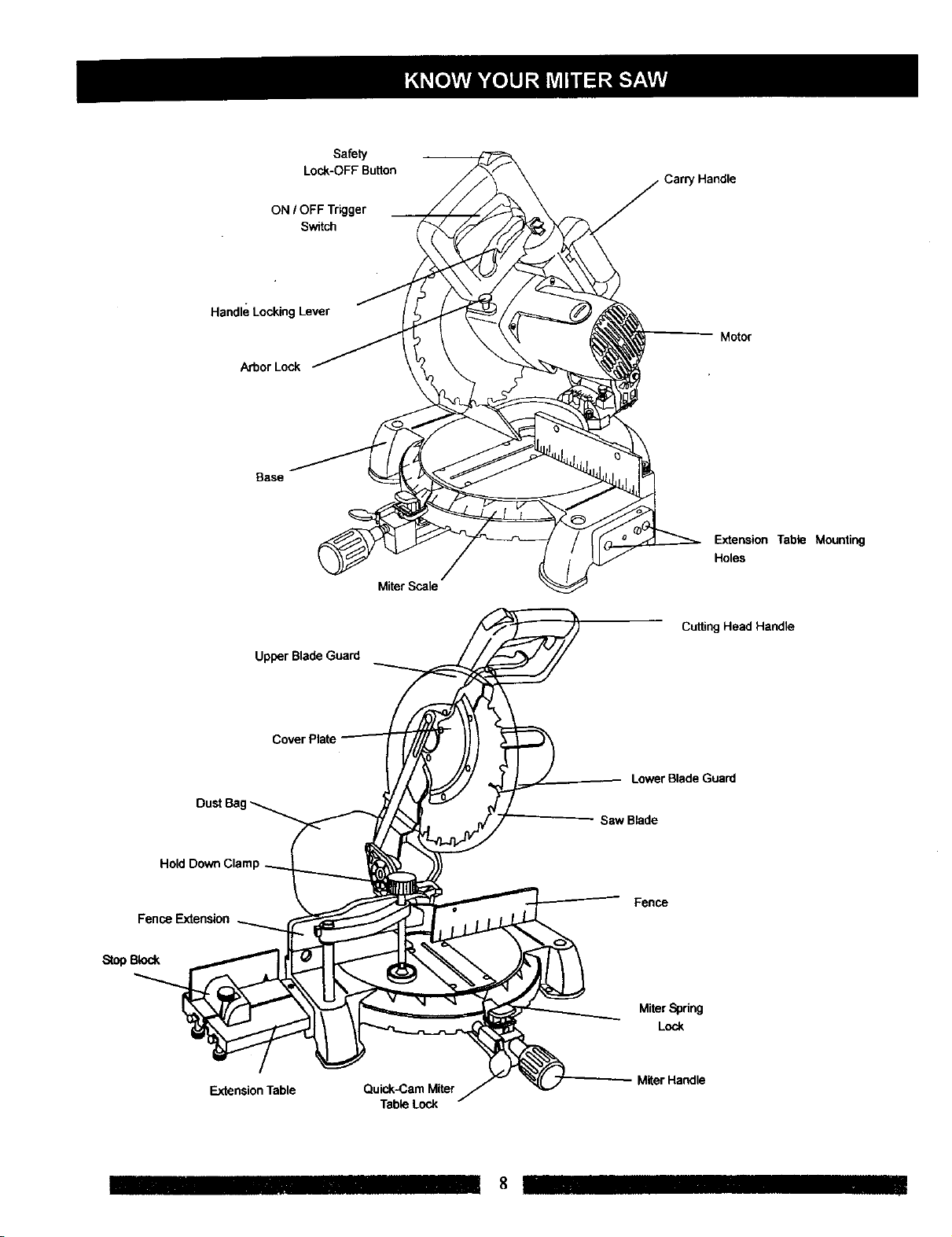

Lock-OFFButton

ON I OFF Trigger

Switch

Handle Locking Lever

Arbor Lock

Base

Safety

' Handle

Motor

ExtensionTable Mounting

Holes

Miter Scale

Fence Extension

StopBlock

Upper Blade Guard

Extension Table

Quick-Cam Miter

Table Lock

Cutting Head Handle

Lower Blade Guard

Saw Blade

Fence

MiferSpdng

Lock

M_rHa_le

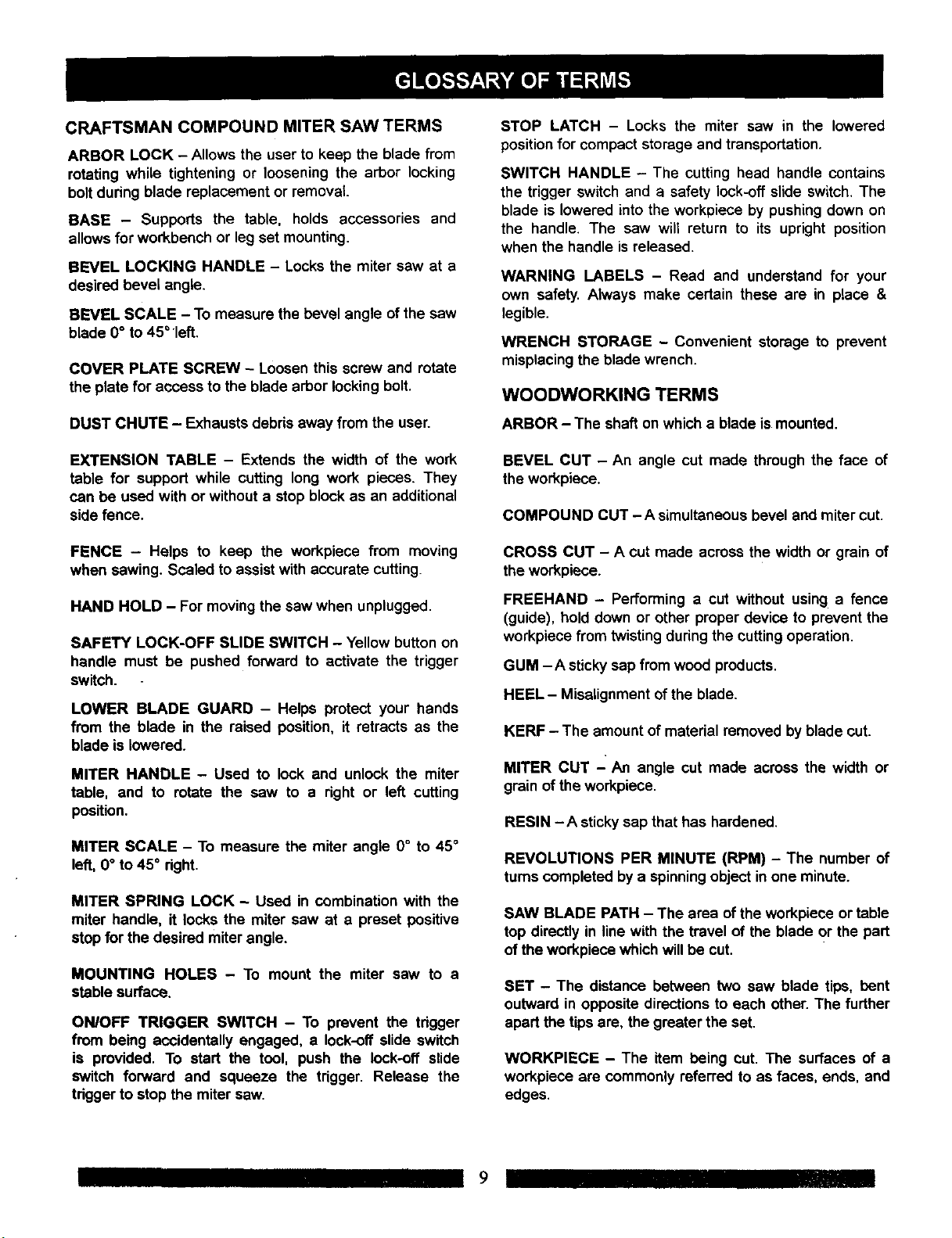

CRAFTSMAN COMPOUND MITER SAW TERMS

ARBOR LOCK - Allows the user to keep the blade from

rotating while tightening or loosening the arbor locking

boltduring blade replacement or removal.

BASE - Supports the table, holds accessories and

allows for workbench or leg set mounting.

BEVEL LOCKING HANDLE - Locks the miter saw at a

desired bevel angle.

BEVEL SCALE - To measure the bevel angle of the saw

blade 0° to 45°left.

COVER PLATE SCREW - Loosen this screw and rotate

the plate for access to the blade arbor lockingbolt.

STOP LATCH - Locks the miter saw in the lowered

positionfor compact storageand transportation.

SWITCH HANDLE - The cutting head handle contains

the trigger switch and a safety lock-off slide switch. The

blade is lowered into the workpiece by pushing down on

the handle. The saw will return to its upright position

when the handle is released.

WARNING LABELS - Read and understand for your

own safety. Always make certain these are in place &

legible.

WRENCH STORAGE - Convenient storage to prevent

misplacing the blade wrench.

WOODWORKING TERMS

DUST CHUTE - Exhausts debds away from the user.

EXTENSION TABLE - Extends the width of the work

table for support while cutting long work pieces. They

can be used with or without a stop block as an additional

side fence.

FENCE - Helps to keep the workpiece from moving

when sawing. Scaled to assist with accurate cutting.

HAND HOLD - For movingthe saw when unplugged.

SAFETY LOCK-OFF SLIDE SWITCH - Yellow buttonon

handle must be pushed forward to activate the trigger

switch.

LOWER BLADE GUARD - Helps protect your hands

from the blade in the raised position, it retracts as the

blade is lowered.

MITER HANDLE - Used to lock and unlock the miter

table, and to rotate the saw to a right or left cutting

position.

MITER SCALE - To measure the miter angle 0° to 45°

left, 0° to 45° dght.

MITER SPRING LOCK - Used in combination with the

miter handle, it locks the miter saw at a preset positive

stop for the desired miter angle.

MOUNTING HOLES - To mount the miter saw to a

stable surface.

ON/OFF TRIGGER SWITCH - To prevent the tdgger

from being accidentally engaged, a lock-off slide switch

is provided. To start the tool, push the lock-off slide

switch forward and squeeze the trigger. Release the

tdgger to stop the miter saw.

ARBOR - The shaft on which a blade is mounted,

BEVEL CUT - An angle cut made through the face of

the workpiece.

COMPOUND CUT -A simultaneous bevel and miter cut.

CROSS CUT - A cut made across the width or grain of

the workpiece.

FREEHAND - Performing a cut without using a fence

(guide), hold down or other proper device to prevent the

workpiece from twistingduringthe cuttingoperation.

GUM -A stickysap from wood products.

HEEL- Misalignmentof the blade.

KERF - The amount of material removed by blade cut.

MITER CUT - An angle cut made across the width or

grain of the workpiece.

RESIN -A stickysap that has hardened.

REVOLUTIONS PER MINUTE (RPM) - The number of

turns completed by a spinningobject in one minute.

SAW BLADE PATH - The area of the workpiece or table

top directly in line with the travel of the blade Or the part

of the workpiece which will be cut.

SET - The distance between two saw blade tips, bent

outward in opposite directions to each other. The further

apart the tips are, the greater the set.

WORKPIECE - The item being cut. The surfaces of a

workpiece are commonly referred to as faces, ends, and

edges.

9

ASSEMBLY INSTRUCTIONS

IA WARNINGI

To avoid injury,do not connect this miter saw to the power

source untilit is completely assembled and adjusted, and

you have read and understood this Operators Manual.

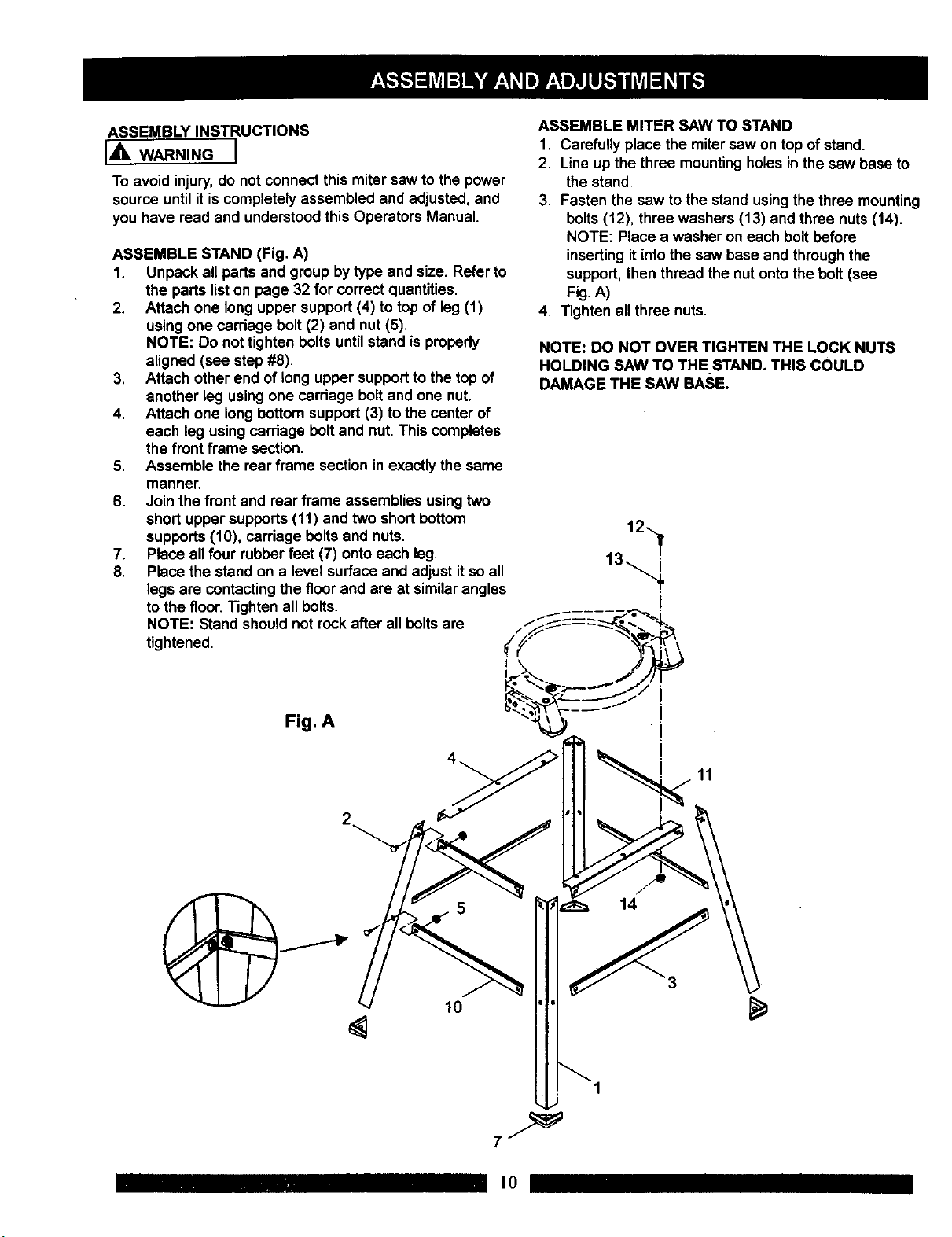

ASSEMBLE STAND (Fig. A)

1. Unpack all parts and group by type andsize. Refer to

the parts list on page 32 for correct quantities.

2. Attach one long upper support(4) to topof leg (1)

usingone carriage bolt (2) and nut (5).

NOTE: Do not tighten bolts untilstand is propedy

aligned (see step#8).

3. Attach other end of long upper support to the top of

another leg usingone carriage bolt and one nut.

4. Attach one long bottom support (3) to the center of

each leg using carriage bolt and nut. This completes

the front frame section.

5. Assemble the rear frame sectionin exactly the same

manner.

6. Join the front and rear frame assemblies usingtwo

short upper supports (11) and two shortbottom

supports (10), carriage bolts and nuts.

7. Place all four rubber feet (7) onto each leg.

8. Place the stand on a level surface and adjust it soall

legs are contactingthe floor and are at similarangles

to the floor.Tighten all bolts.

NOTE: Stand should not rock after all bolts are

tightened.

ASSEMBLE MITER SAW TO STAND

1. Carefully place the miter saw on top ofstand.

2. Line up the three mountingholes inthe saw base to

the stand.

3. Fasten the saw tothe stand using the three mounting

bolts(12), three washers (13) and three nuts (14).

NOTE: Place a washer on each bolt before

insertingit into the saw base and throughthe

support, then thread the nut onto the bolt(see

Fig. A)

4. Tighten all three nuts.

NOTE: DO NOT OVER TIGHTEN THE LOCK NUTS

HOLDING SAW TO THE STAND. THIS COULD

DAMAGE THE SAW BASE.

12

Fig. A

10

11

5

14

1

]0

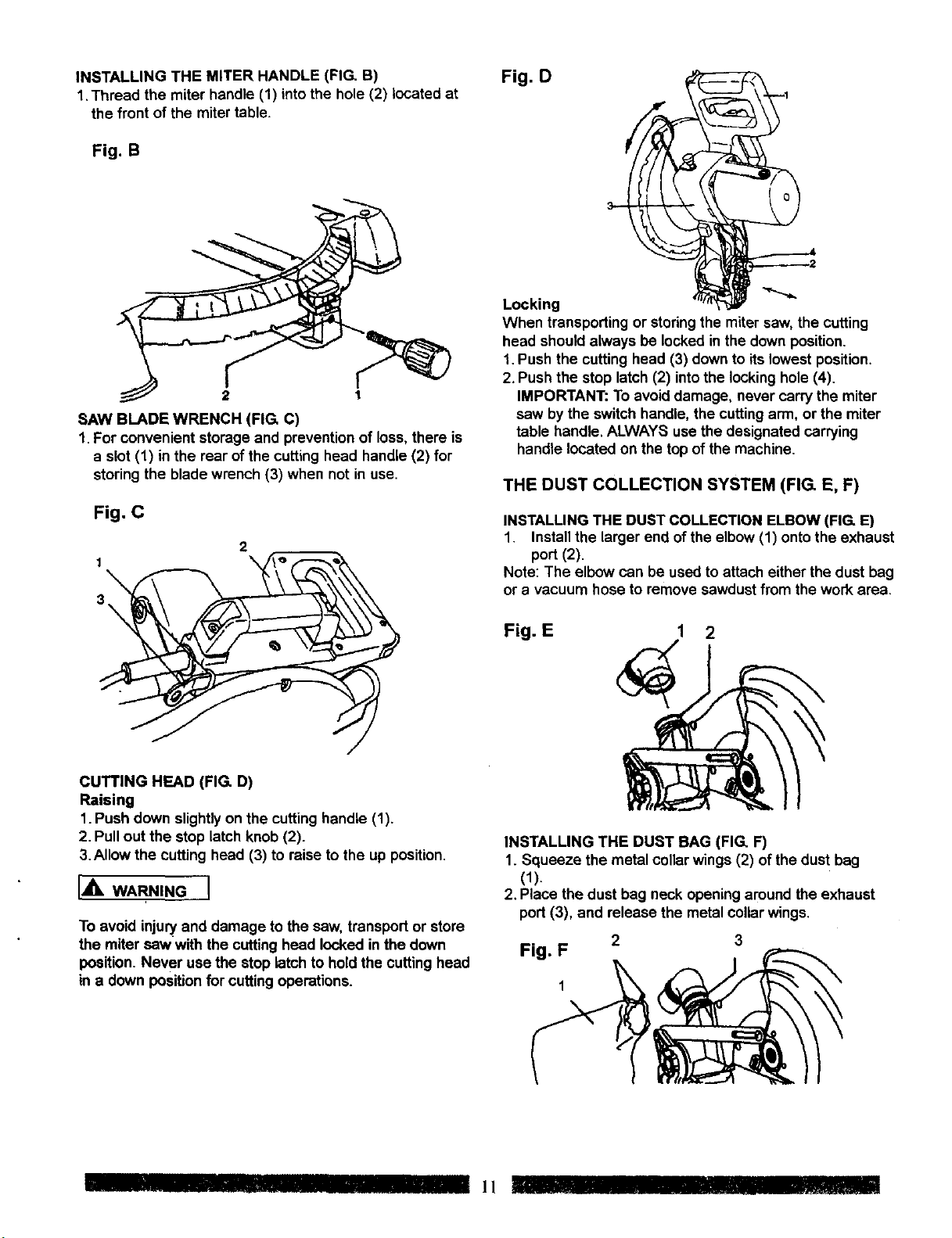

INSTALLING THE MITER HANDLE (FIG. B)

1,Thread the miter handle (1) into the hole (2) located at

the front of the mitertable.

Fig. B

2 1

SAW BLADE WRENCH (FIG. C)

1.For convenient storage and prevention of loss, there is

a slot (1) inthe rear of the cutting head handle (2) for

storing the blade wrench (3) when not in use.

Fig. D

Locking

When transporting or storing the miter saw, the cutting

head shouldalways be locked inthe downposition.

1.Push the cuttinghead (3) downto its lowest position,

2,Push the stop latch(2) intothe locking hole (4).

IMPORTANT: To avoiddamage, never carry the miter

saw by the switch handle, the cuttingarm, or the miter

table handle, ALWAYS use the designated carrying

handle located on the top ofthe machine.

THE DUST COLLECTION SYSTEM (FIG. E, F)

Fig. C

2

1

3

CUTTING HEAD (FIG. D)

Raising

1.Push down slightlyon the cutting handle (1).

2. Pull out the stop latch knob (2).

3.Allow the cutting head (3) to raise to the up position.

IA WA ,NGI

To avoid injuryand damage to the saw, transport or store

the miter saw with the cutting head locked in the down

position. Never use the stop latch to hold the cutting head

in a down position for cutting operations.

INSTALLING THE DUST COLLECTION ELBOW (FIG. E)

1. Install the larger end of the elbow (1) onto the exhaust

port (2).

Note: The elbow can be used to attach either the dust bag

or a vacuum hose to remove sawdust from the work area.

Fig. E 1 2

INSTALLING THE DUST BAG (FIG. F)

1. Squeeze the metal collar wings (2) of the dust bag

(1).

2, Place the dust bag neck opening around the exhaust

port (3), and release the metal collarwings,

2 3

Fig. F

IIIIIlllllll !_

Loading...

Loading...