Craftsman 137224140 Owner’s Manual

CAUTION:

o Safety Instructions

Before using this band saw,

read this manual and follow

o nnstallation

o Operation

all its Safety Rules and

Operating Instructions.

o Maintenance

o Parts List

Customer Help Line

t °80@°843°1682

Sears, Roebuck and Co., Hoffman Estates, BL 60179 USA

Part No. 137224!40001

SECTION

PAGE

Warranty ................................................................ 2

Product Specifications ..................................................... 2

Safety Instructicms ........................................................ 3

Accessories and Attachments ............................................... 6

Carton Contents .......................................................... 6

Know Your Band Saw ...................................................... 8

Glossary of Terms ........................................................ 9

Assembly and Adjustments ................................................ 10

Operation .............................................................. 19

Maintenance ............................................................ 21

Troubleshooting guide .................................................... 22

Parts .................................................................. 24

GENERAL SAFETY _NSTRUCTIONS

BEFORE USING THE BAND SAW

Safety is a combination of common sense, staying alert

and knowing how to use your band saw.

To avoid mistakes that could cause serious injury, do not

plug the band saw in until you have read and understood

the following:

!. READ and become familiar with this entire instruction

manual. LEARN the tool's applications, limitations,

and possible hazards.

2, KEEP GUARDS mNPLACE and in working order.

11. WEAR PROPER APPAREL. DO NOT wear loose

clothing, gloves, neckties, rings, bracelets, or other

jewelry which may get caught in moving parts.

Non-slip footwear is recommended. Wear protective

hair covering to contain long hair.

12.

WEAR YOUR

ANSI safety standard Z87.1. Everyday eyeglasses

have only impact-resistant lenses. They ARE NOT

safety glasses. Safety Goggles are available at Sears.

NOTE: Glasses or goggles not in compliance with

ANSI Z87.1 could seriously hurt you when they break.

ALWAYS WEAR EYE

PROTECTION. Any band saw

can throw foreign objects into

the eyes which could cause

permanent eye damage.

ALWAYS wear Safety Goggles

(not glasses) that comply with

MOTOR

Power source ......

Horsepower .......

Speed ............

Type .............

DRIVE BELT .......... A 40

CUTTING CAPACITY

Throat ............ 13-5/8"

Height ............ 6"

BLADE

Width ............ 1/8", 1/4", 3/8", 1/2"

Length ........... 91-t/2" to 93-1/2"

TABLE

Size ............. 14" x 14"

Tilt .............. 0 - 15° Left, 0 - 450 Right

Some dust created by power sanding sawing, grinding, drilling, and other construction activities contains chemicals

known [to the State of California] to cause cancer, birth defects or other reproductive harm. Some examples of these

chemicals are:

® Lead from lead-based paints.

® Crystalline silica from bricks and cement and other masonry products, and

Q Arsenic and chromium from chemically4reated lumber.

Your risk from these exposures varies, depending on how often you do this type of work. To reduce your exposure to

these chemicals: work in awelt ventilated area, and work with approved safety equipment, such as those dust masks

that are specially designed to filter out microscopic particles.

t20 V AC, 60 HZ, 10 AMPS

1.5 HP (Max. Developed)

2700 Feet per minute (No load)

Induction

DUST COLLECTION ... Yes

NET WEIGHT ......... 194 LBS.

To avoid electrical hazards, fire hazards, or damage to

the toot, use proper circuit protection. Use a separate

electrical circuit for your tools,

Your band saw is wired at the factory for t20V operation.

Connect to a 120V, 15 AMP branch circuit and use a 15

AMP time delay fuse or circuit breaker. To avoid shock or

fire, replace power cord immediately if it is worn, cut or

damaged in any way.

REMOVE ADJUSTING KEYS AND WRENCHES.

Form the habit of checking to see that keys and

adjusting wrenches are removed from the tool before

turning ON.

4. KEEP WORK AREA CLEAN. Cluttered areas and

benches invite accidents.

5. DON'T USE iN A DANGEROUS ENVIRONMENT.

Don't use power tools in damp or wet locations, or

expose them to rain. Keep work area well lighted.

6, KEEP CHILDREN AWAY. All visitors should be kept

at a safe distance from the work area.

7. MAKE WORKSHOP KID-PROOF with padlocks,

master switches, or by removing starter keys.

8. DON'T FORCE THE TOOL. It will do the job better

and safer at the rate for which it was designed.

9. USE THE RIGHT TOOL. Don't force tool or the

attachment to do a job for which it was not designed.

10, USE PROPER EXTENSION CORD. Make sure your

extension cord is in good condition. When using an

extension cord, be sure to use one heavy enough to

carry the current your product will draw.

An undersized cord will result in a drop in line voltage

and loss of power which will cause the tool to overheat,

The table on page 5 shows the correct size to use

depending on cord length and nameplate ampere

rating. If in doubt, use the next heavier gauge. The

smaller the gauge number, the heavier the cord.

13. WEAR A FACE MASK OR DUST MASK. Sawing

operation produces dust.

14, SECURE WORK, Use clamps or a vise to hold work

when practical. It's safer than using your hand and it

frees both hands to operate tool.

15, DlSCONNECTTOOLS before servicing, and when

changing accessories, such as blades, bits, cutters,

and the like.

16. REDUCE THE RISK OF UNINTENTIONAL

STARTING. Make sure the switch is in OFF position

before plugging in.

USE RECOMMENDED ACCESSORIES. Consult the

17.

owner's manual for the recommended accessories.

The use of improper accessories may cause risk of

injury to persons.

18. NEVER STAND ON TOOL. Serious injury could occur

if the toot is tipped or if the cutting blade is unintentionally

contacted.

19. CHECK FOR DAMAGED PARTS. Before further use

of the tool, a guard or other part that is damaged

should be carefully checked to determine that it wilt

operate properly and perform its intended function.

Check for alignment of moving parts, binding of moving

parts, breakage of parts, mounting, and any other

conditions that may affect its operation. A guard or

other part that is damaged should be properly repaired

or replaced.

SAVE THESE iNSTRUCTIONS

2

3

20.NEVERLEAVE TOOL RUNNING UNATTENDED.

TURN THE POWER OFF. Don't leave the tool until it

comes to a complete stop.

21. DON'T OVERREACH. Keep proper footing and

balance at all times.

22. MAINTAIN TOOLS WITH CARE. Keep tools sharp

and clean for best and safest performance. Follow

instructions for lubricating and changing acoessories.

23. DO NOT use power tools in the presence of

flammable liquids or gases.

24. DO NOT operate the toot if you are under the

influence of any drugs, alcohol or medication that

could affect your ability to use the tool properly.

25. Dust generated from certain materials can be

hazardous to your health. Always operate the band

saw in a well-ventilated area and provide for proper

dust removal. Use dust collection systems whenever

possible.

SPECiFiC SAFETY INSTRUCTaONS

. TO AVOID INJURY from unexpected movement, make

sure the saw is on a firm, level surface, properly

secured to prevent rocking. Make sure there is

adequate space for operating. Bolt the saw to a support

surface to prevent it from slipping, walking, or sliding

during operation.

2. TURN the saw OFF and unplug the saw before

moving it.

3. USE THE CORRECT size and style of blade.

4. USE blades rated at 2700 FPM or greater.

5. MAKE SURE the blade teeth point down and

towards the table.

6, BLADE GUIDES, SUPPORT BEARINGS, AND

BLADE TENSION must be properly adjusted to avoid

accidental blade contact and to minimize blade

breakage. To maximize blade support, afways adjust

the upper blade guide and blade guard so that it is

1/8 inch above the workpiece.

7. TABLE LOCK HANDLE should be tight.

8: USE EXTRA CAUTION with large, very small or

awkward workpieces.

g_ USE EXTRA SUPPORTS to prevent workpieces

from sliding off the table top. Never use another person

in place of a table extension, or to provide additional

support for the workpiece,

10. WORKPIECES must be secured so they don't twisL

rock, or slip while being cut.

SAVE THESE mNSTRUCTIONS

1t.

PLAN intricate and small work carefully to avoid

pinching the blade, Avoid awkward operation and

hand positions to prevent accidental contact with the

bJade.

12. SMALL PIECES should be secured with jigs or

fixtures. Do not hand hold pieces that are so small

your fingers are under the blade guard.

13. SUPPORT round work properly (with a V-block or

clamped to the miter gauge) to prevent it from rolling

and the blade from biting.

14. CUT only one workpiece at a time. Make sure the

table is clear of everything except the workpiece and

its guides before you turn the saw on.

ALWAYS WATCH the saw run before each use. If

15.

there is excessive vibration or unusual noise, stop

immediately. Turn the saw off. Unplug it immediately.

Do not start the saw again until the problem has

been located and corrected.

16. TO FREE any jammed material, turn the switch OFR

Remove the switch key and unplug the saw. Wait for

all moving parts to stop before removing jammed

material.

17. DON'T LEAVE the work area until all moving parts

are stopped. To childproof the workshop, shut off the

power to master switches and remove the switch key

from the band saw. Store it in a safe place, away

from children.

For your own safety, read the entire instruction manual

before operating the band saw.

1. Wear eye protection.

2. Do not wear gtoves, necktie, or loose clothing.

3. Make sure the saw is on a firm level surface and

properly secured.

4. USE ONLY THE RECOMMENDED ACCESSORIES.

5. Use extra caution with very large, very small, or

awkward workpieces.

6. Keep hands away from the blade at all times to

prevent accidental injury.

ELECTRnCAL REQUBREMENTS

POWER SUPPLY AND MOTOR SPECIFICATIONS

To avoid electrical hazards, fire hazards, or damage to the

tool, use proper circuit protection. Use a separate electrical

circuit for your tools.Your saw is wired at the factory for

120V operation. Connect to a 120V, t5 Amp circuit and use

a 15 Amp time delay fuse or circuit breaker. To avoid shock or

fire, if power cord is worn or cut, or damaged in any way,

have it replaced immediately.

GROUNDING INSTRUCTIONS

This tool must be grounded while in use to protect the

operator from electrical shock,

tN THE EVENT OF A MALFUNCTION OR BREAKDOWN,

grounding provides a path of least resistance for electric

current and reduces the risk of electric shock. This tool is

equipped with an electric cord that has an equipment

grounding conductor and a grounding plug. The plug

MUST be plugged into a matching receptacle that is

properly installed and grounded in accordance with ALL

local codes and ordinances.

DO NOT MODIFY'THE PLUG PROVIDED. If it wilt not fit the

receptacle, have the proper receptacle installed by a

qualified electrician.

IMPROPER CONNECTION of the equipment grounding

conductor can result in risk of electric shock. The

conductor with the green insulation (with or without yellow

stripes) is the equipment grounding conductor. If repair or

replacement of the electric cord or plug is necessary, DO

NOT connect the equipment grounding conductor to a live

terminal.

CHECK with a qualified electrician or service person if you

do not completely understand the grounding instructions, or if

you are not sure the tool is properly grounded.

USE ONLY 3-wire extension cords that have 3-prong

grounding plugs and 3-pole receptacles that accept the

tool's plug. Repair or replace damaged or worn cord

immediately.

Use a separate electrical circuit for your tools. This circuit

must not be less than #12 wire and should be protected

with a 15 Amp time lag fuse. Before connecting the motor to

the power fine, make sure the switch is in the OFF

position and the electric current is rated the same as the

current stamped on the motor nameplate. Running at a

lower voltage will damage the motor.

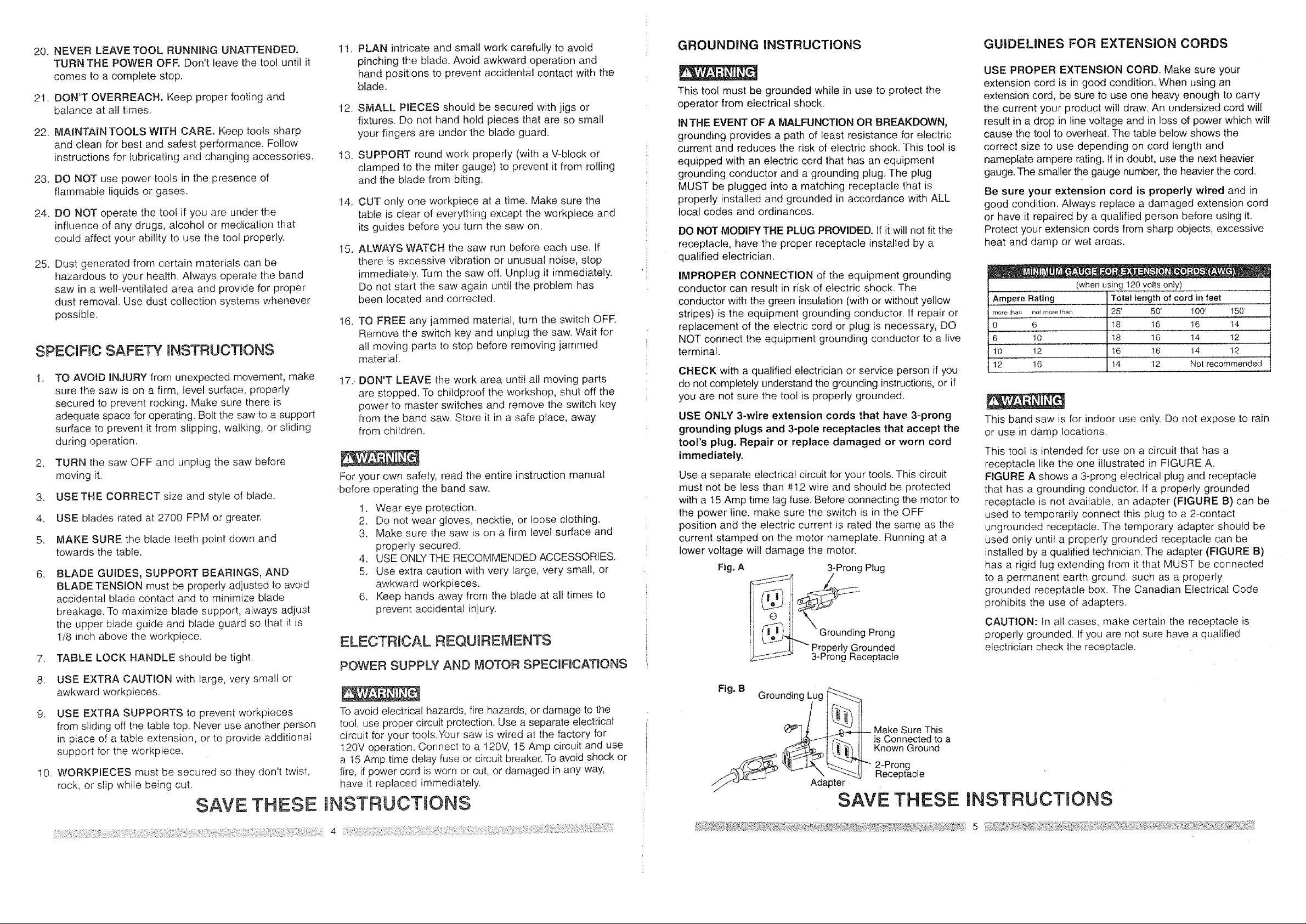

Fig. A

I__ Grounding Prong

3-Prong Plug

Properly Grounded

3-Prong Receptacle

Fig. 13 Grounding Lug _-_

(_-_ / _L Make Sure This

_[_-_F_.-T-_ i is Connected to a

_',_,- _" "_"t,_ Known Ground

_-4_ _t_l_ _---.- I]_" 2-Prong

j% 'f_-'_y_ - _N '_--._ Receptacle

_<-"_-- Adapter

SAVE THESE iNSTRUCTiONS

GUIDEUNES FOR EXTENSION CORDS

USE PROPER EXTENSION CORD. Make sure your

extension cord is in good condition, When using an

extension cord, be sure to use one heavy enough to carry

the current your product will draw. An undersized cord will

result in a drop in line voltage and in loss of power which will

cause the tool to overheat. The table below shows the

correct size to use depending on cord length and

nameplate ampere rating. If in doubt, use the next heavier

gauge. The smaller the gauge number, the heavier the cord,

Be sure your extension cord is properly wired and in

good condition. Always replace a damaged extension cord

or have it repaired by a qualified person before using it.

Protect your extension cords from sharp objects, excessive

heat and damp or wet areas.

(when using 120 volts only)

Ampere Rating

mo_e tha¢_ not more thaf_

0 6

6 10

10 12

12 16

This band saw is for indoor use only. Do not expose to rain

or use in damp locations.

This tool is intended for use on a circuit that has a

receptacle like the one illustrated in FIGURE A.

FIGURE A shows a 3-prong electrical plug and receptacle

that has a grounding conductor. If a properly grounded

receptacle is not available, an adapter (FIGURE B) can be

used to temporariIy connect this plug to a 2-contact

ungrounded receptacle. The temporary adapter shoutd be

used only until a properly grounded receptacle can be

installed by a qualified technician. The adapter (FIGURE B)

has a rigid lug extending from it that MUST be connected

to a permanent earth ground, such as a properly

grounded receptacle box. The Canadian Electrical Code

prohibits the use of adapters.

CAUTION: In all cases, make certain the receptacle is

properly grounded, If you are not sure have a qualified

electrician check the receptacle.

Totallength of cord in feet

25' 50' 100' 150'

18 16 16 14

18 16 14 12

16 16 14 12

14 12 Not recommended

5

UNPACKING YOUR BAND SAW

AVAILABLE ACCESSORIES

Do not attempt to modify this tool or create accessories not

recommended for use with this tool. Any such alteration or

modification is misuse and could result in a hazardous

condition leading to possible serious injury.

Visit your Sears Hardware Department or see the Sears

Power and Hand Toot Catalog for the following accessories:

ITEM

Miter gauge

Blade width: 1/8", 1/4", 3/8", 1/2"

Blade length: 91-1/2" to 93-1/2"

Follow instructions that accompany accessories. Use of

improper accessories may cause hazards.

Do not use any accessory unless you have completely

read the instruction or owner's manual for that accessory.

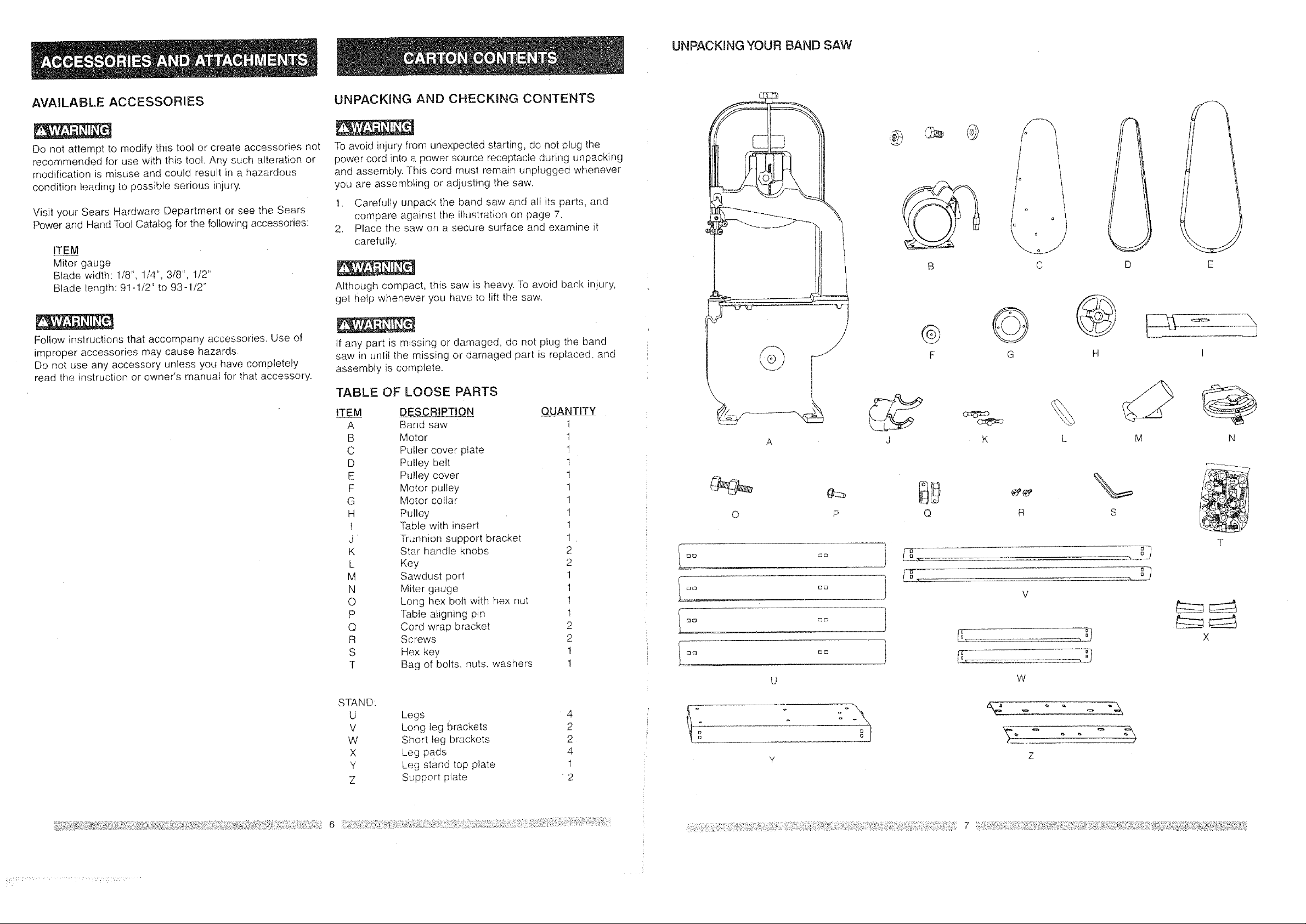

UNPACKING AND CHECKgNG CONTENTS

To avoid injury from unexpected starting, do not plug the

power cord into a power source receptacle during unpacking

and assembly. This cord must remain unplugged whenever

you are assembting or adjusting the saw.

!. Carefully unpack the band saw and all its parts, and

compare against the i!_ustration on page 7,

2, Place the saw on a secure surface and examine it

carefully.

Although compact, this saw is heavy. 3b avoid bank injury,

get l_etp whenever you have to lift the saw.

If any part is missing or damaged_ do not plug the band

saw in until the missing or damaged part is replaced, and

assembly is complete.

TABLE OF LOOSE PARTS

iTEM DESCRIPTION QUANTITY

A Band saw 1

B Motor 1

C Puller cover plate 1

D Pulley belt t

E Pulley cover 1

F Motor pulley 1

G Motor collar 1

H Pulley 1

1 "table with insert 1

J Trunnion support bracket 1

K Star handle knobs 2

L Key 2

M Sawdust port 1

N Miter gauge 1

O Long hex bolt with hex nut I

P Table aligning pin 1

Q Cord wrap bracket 2

R Screws 2

S Hex key 1

T Bag of bolts, nuts, washers !

€

O P Q

i 1

u w

B

G

F

J

©

G

cu_=o

R S

@

D

H

M

N

X

STAND:

U Legs 4

V Long leg brackets 2

W Short leg brackets 2

X Leg Pads 4

Y Leg stand top plate I

Z Support plate 2

°.... ° ° °

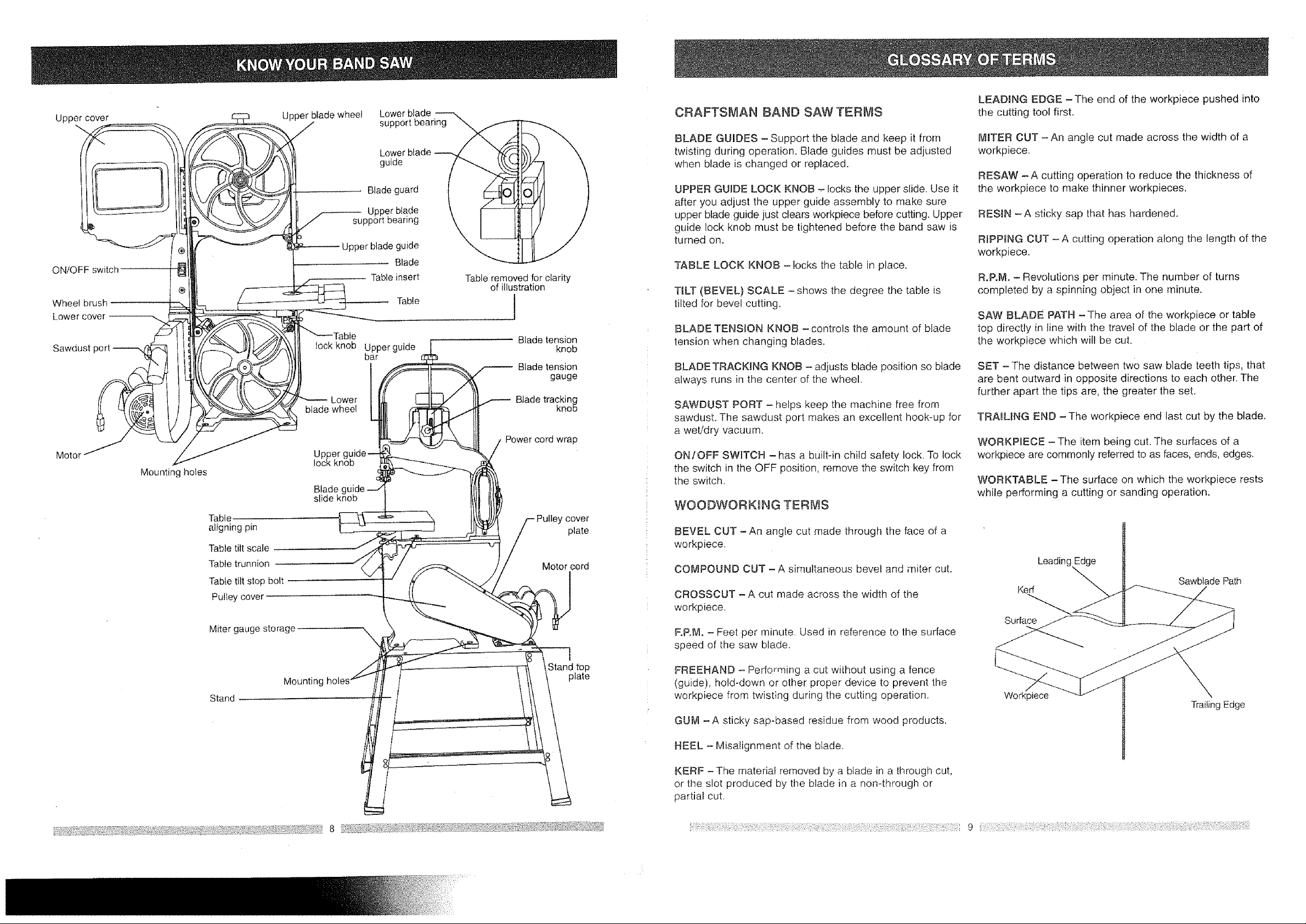

Upper cover

ON/OFF switch

Wheel brush

Lower cover

Sawdust port

Motor

Mounting holes

Upper blade wheel Lower blade

Table

aligning pin

Table tilt scale

Table trunnion

Table tilt stop bolt

Pulley cover

Miter gauge storage.

support bearing

Lowe

guide

Blade guard

Upper blade

support bearing

Upper blade guide

Blade

Table insert

Table

lock knob Upper guide

Blade guide

slide knob

bar

Tableremoved forclarity

of illustration

1

Blade tension

Blade tension

Biade tracking

Power cord wrap

knob

gauge

knob

,cover

Motor cord

plate

CRAFTSMAN BAND SAW TERMS

BLADE GUIDES - Support the blade and keep it from

twisting during operation. Blade guides must be adjusted

when blade is changed or replaced.

UPPER GUIDE LOCK KNOB -,-locks the upper slide. Use it

after you adjust the upper guide assembly to make sure

upper blade guide just clears workpiece before cutting. Upper

guide lock knob must be tightened before the band saw is

turned on.

TABLE LOCK KNOB - locks the table in place.

TILT (BEVEL) SCALE -shows the degree the table is

tilted for bevel cutting.

BLADE TENSION KNOB - controls the amount of blade

tension when changing blades.

BLADETRACKING KNOB -adjusts blade position so blade

always runs in the center of the wheel.

SAWDUST PORT - helps keep the machine free from

sawdust_ The sawdust port makes an excellent hook-up for

a webJdry vacuum.

ONIOFF SWITCH -has a built-in child safety lock. To lock

the switch in the OFF position, remove the switch key from

the switch.

WOODWORKING TERMS

BEVEL CUT - An angle cut made through the face of a

workpiece.

COMPOUND CUT - A simultaneous bevel and miter cut.

CROSSCUT - A cut made across the width of the

workpiece,

F.RM, - Feet per minute. Used in reference to the surface

speed of the saw blade.

LEADING EDGE - The end of the workpiece pushed into

the cutting tool first.

MITER CUT - An angle cut made across the width of a

workpiece.

RESAW -A cutting operation to reduce the thickness of

the workpiece to make thinner workpieces.

RESgN - A sticky sap that has hardened.

RiPPiNG CUT - A cutting operation along the length of the

workpiece_

R.P.M. - Revolutions per minute. The number of turns

completed by a spinning object in one minute.

SAW BLADE PATH -The area of the workpiece or table

top directly in line with the travel of the blade or the part of

the workpiece which will be cut.

SET -The distance between two saw Made teeth tips, that

are bent outward in opposite directions to each other. The

further apart the tips are, the greater the set.

TRABUNG END - The workpiece end last cut by the blade.

WORKPIECE -The item being cut. The surfaces of a

workpiece are commonly referred to as faces, ends, edges.

WORKTABLE -The surface on which the workpiece rests

while performing a cutting or sanding operation.

Leading Edge

Sawblade Path

Kerr

Surface

Stand

Mounting

I top

)late

FREEHAND - Performing a cut without using a fence

(guide), hold-down or other proper device to prevent the

workpiece from twisting during the cutting operation.

Workpiece

Trailing Edge

GUM - A sticky sap-based residue from wood products.

HEEL - Misatignment of the blade.

KERF - The material removed by a blade in a through cut,

or the slot produced by the blade in a non-through or

partial cut.

8 :. : :. : :: :: : :=:=: : , 9 : ,=: = : : : : = : =

Loading...

Loading...