Operator's Manual

JCRHFTSMIIN°J

10 in. COMPOUND MITER SAW

WITH LASER TRAC _

Model No..137.212360

CAUTION:

Before using this Miter Saw,

read this manual and follow

all its Safety Rules and

Operating Instructions

For Technical Support

Customer Help Line

1-800-843-1682

Sears, Roebuck and Co., Hoffman Estates, IL60179 USA

Visit our Craftsman website: www.sears.com/craftsman

Part No. 13721236001

• Parts List

Sears Parts &

Repair Center

1-800-469-4663

Safety Instructions

Installation

Operation

Maintenance

Printed in China

SECTION PAGE

warranty ............................................... 2

Product Specifications .......................... 2

Symbols ................................................ 3

Power Tool Safety ................................. 4

Compound Miter Saw Safety ................. 6

Electrical Requirements and Safety ...... 7

Accessories and Attachments ............... 8

Tools Needed for Assembly .................. 8

Carton Contents .................................... 9

SECTION PAGE

Know Your Compound Miter Saw .......... 10

Glossary of Terms ................................. 11

Assembly and Adjustments ................... 12

Operation ............................................... 18

Maintenance .......................................... 23

Troubleshooting Guide .......................... 24

Parts List ................................................ 25

Repair Protection Agreement .................. 28

CRAFTSMAN ONE YEAR FULL WARRANTY

If this Craftsman tool failsdue to a defect in material or workmanshipwithinone year from the

date of purchase, call 1-800-4-MY-HOME®to arrange for free repair(or replacement if repair

proves impossible).

This warranty appliesfor only90 daysfrom the date of purchaseifthis productisever used for

commercialor rentalpurposes.

This warranty does notincludeexpendable parts, suchas lamps, batteries,bitsor blades.

This warrantygives you specificlegal dghts, and you may also have other rightswhich vary from

state to state.

Sears, Roebuck and Co., Hoffman Estates, IL 60179

_i, WARNING J

Some dust created by using power tools contains chemicals known to the state of California to cause

cancer and birth defects or other reproductive harm. Some examples of these chemicals are:

Your risk from these exposures varies, depending on how often you do this type of work. To reduce

your exposure to these chemicals, work in a well ventilated area and work with approved safety

• Lead from lead-based paints

• Crystalline silica from bricks, cement and other masonry products

• Arsenic and chromium from chemically treated lumber

masks that are

MOTOR

Power Source................ 120V AC, 60Hz, 15 Amp

Arbor Shaft Size............ 5/8 in.

Speed ........................... 4800 RPM (No load)

Brake ............................ Electric

Cutting Capacity:

Crosscut ........................... 2-5/8 in. x 5-1/2 in.

Miter 450 R & L ................. 2-5/8 in. x 3-7/8 in.

Bevel 45 ° L ....................... 1-1/2 in. x 5-1/2 in.

45 ° Miter and 45 ° Bevel .... 1-1/2 in. x 3-7/8 in.

Double Insulated .......... No

MITER SAW

Rotating Table:

Miter Detent Stops ....... 0 °, 15 °, 22.5 °, 31.6 °, 45 ° R & L Arbor ................................. 5/8 in.

Bevel Positive Stops .... 0°, 45 ° L

BLADE

Diameter ........................... 10 in.

IA WARNING J

To avoid electrical hazards, fire hazards or damage to the tool, use proper circuit protection,

This tool is wired at the factory for 110-120 Volt operation. It must be connected to a 110-120

Volt / 15 Ampere time delay fuse or circuit breaker, To avoid shock or fire, replace power cord

immediately if it is worn, cut or damaged in any way.

Before using your tool, it is critical that you read and understand these safety rules. Failure to

follow these rules could result in serious injury to--damage to the tool.

2009/03

n 2 - I

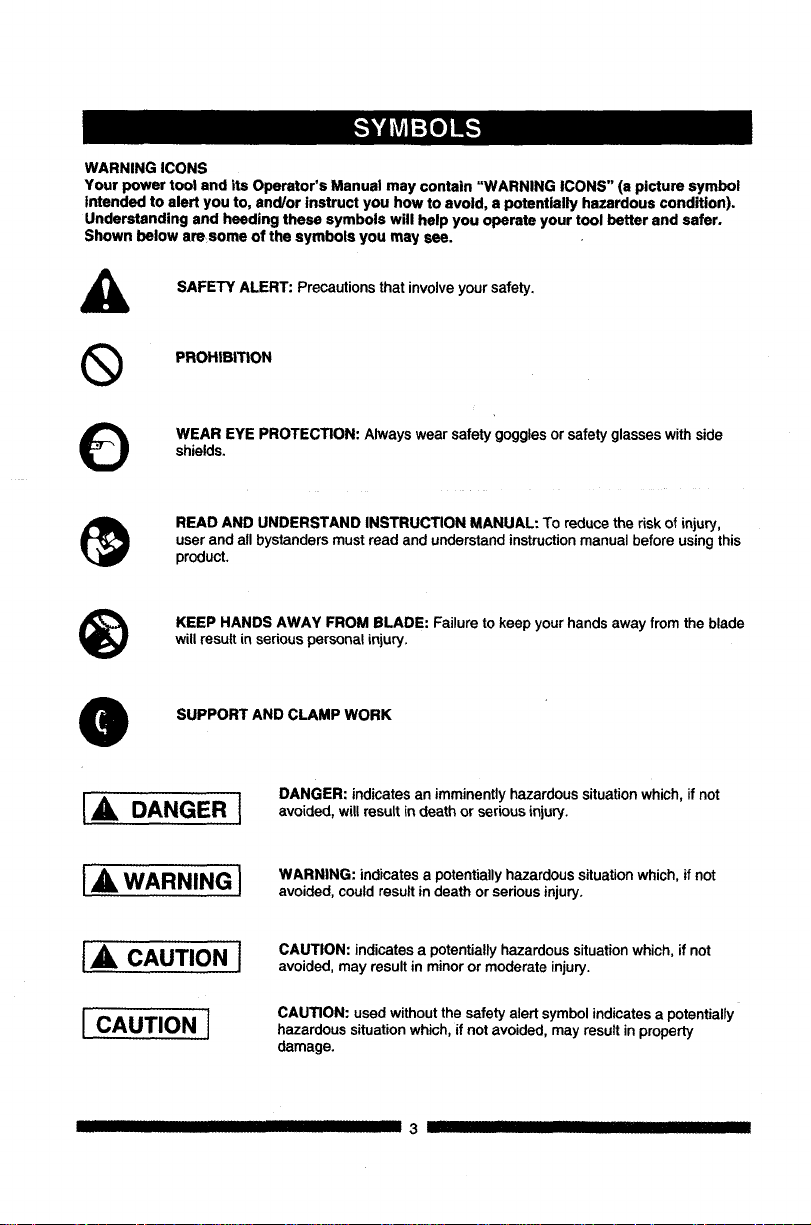

WARNING ICONS

Your power tool and its Operator's Manual may contain "WARNING ICONS" (a picture symbol

intended to alert you to, and/or instruct you how to avoid, a potentially hazardous condition).

Understanding and heeding these symbols will help you operate your tool better and safer.

Shown below amsome of the symbols you may see.

SAFETY ALERT: Precautions that involve your safety.

®

PROHIBITION

WEAR EYE PROTECTION: Always wear safety goggles orsafety glasseswithside

shields.

READ AND UNDERSTAND INSTRUCTION MANUAL: To reduce the risk of injury,

user and all bystanders must read and understand instruction manual before using this

product,

KEEP HANDS AWAY FROM BLADE: Failure to keep your hands away from the blade

®

I,A DANGER I

IA WARNING]

will result in serious personal injury.

SUPPORT AND CLAMP WORK

DANGER: indicates an imminentlyhazardoussituationwhich,if not

avoided, willresult indeathor seriousinjury.

WARNING: indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

I,& CAUTIONI

I CAUTIONI

IIIIIIIII IIIIIIIIII IIII I 3 III III III

CAUTION: indicates a potentially hazardous situation which, if not

avoided, may result in minor or moderate injury.

CAUTION: used without the safety alert symbol indicates a potentially

hazardous situation which, if not avoided, may result in property

damage.

GENERALSAFETYINSTRUCTIONS

BEFOREUSINGTHISPOWERTOOL

Safetyisacombinationofcommonsense,

stayingalertandknowinghowtouseyourpower

tool.

[_IL WARNING]

To avoid mistakes that could cause serious

Injury, do not plug the tool in until you have

read and understood the following.

1. _ READ and become familiar withthe

2. KEEP GUARDS IN PLACE and in working

order.

3. REMOVE ADJUSTING KEYS AND

WRENCHES. Form the habit of checking to

see that keys and adjusting wrenches are

4. KEEP WORK AREA CLEAN, Cluttered areas

and benches inviteaccidents.

5. DO NOT USE IN DANGEROUS

ENVIRONMENTS. Do not usepower tools

in damp locations,or expose them to rain or

snow. Keep workarea well lit.

6. KEEP CHILDREN AWAY. All visitorsand

bystandersshould be kept a safe distance

from work area.

7. MAKE WORKSHOP CHILD PROOF with

padlocks,master switchesorby removing

starterkeys.

8. DO NOT FORCE THE TOOL. Itwill do thejob

better and saferat the rate for which it was

designed.

9. USE THE RIGHT TOOL. Do not force the tool

or an attachment to do a job for which it was

not designed.

10.USE PROPER EXTENSION CORDS. Make

sureyourextension cordis ingood condition.

When using an extensioncord, be sureto use

one heavy enoughto carrythe currentyour

productwilldraw. An undersizedcord will

resultina dropin line voltageand inlossof

power whichwill cause the toolto overheat.

III IIIIIIII III I

entire Operator'sManual. LEARN

the tool's application,limitationsand

possiblehazards.

removed from the tool before turning ON.

The table on page 7 shows the correct

size to usedepending on cord length and

nameplate ampere rating.If indoubt, use the

next heavier gauge. The smallerthe gauge

number,the heavier the cord.

11.WEAR PROPER APPAREL. Do notwear

loose clothing,gloves, neckties, rings,

braceletsor otherjewelry which mayget

caught in movingparts.Nonslip footwear is

recommended.Wear protectivehaircovering

to contain long hair.

12.ALWAYS WEAR EYE PROTECTION. Any

intothe eyes and could cause

O ower tool canthrow foreignobjects

permanenteye damage. ALWAYS

wear Safety Goggles (not glasses)

that complywithANSI Safety standard Z87.1.

Everydayeyeglasses have only impact-

resistantlenses.They ARE NOT safety

glasses.Safety Goggles are available at

Sears. NOTE: Glasses orgoggles not in

compliance with ANSI 7.87.1 could seriously

injureyou"when they break.

13.WEAR A FACE MASK OR DUST MASK.

Sawing operationproducesdust.

14.SECURE WORK, Use clamps or a vise to

than using your hand and it frees

O old work when practical. It is safer

both hands to operate the tool.

15.DISCONNECT TOOLS FROM POWER

SOURCE before servicing,and when

changingaccessories such as blades, bits

and cutters.

16.REDUCE THE RISK OF UNINTENTIONAL

STARTING, Make sure switch is in the OFF

position before plugging the tool in.

17.USE RECOMMENDED ACCESSORIES.

Consult this Operator's Manual for

recommended accessories. The use of

improper accessories may cause risk of injury

to yourself or others.

18.NEVER STAND ON THE TOOL. Serious

injury could occur if the tool is tipped or if the

cutting tool is unintentionally contacted.

19.CHECK FOR DAMAGED PARTS, Before

further use of the tool, a guard orother part

thatis damaged shouldbe carefully checked

4 ---_ III

todetermine thatit willoperate properly and

perform its intended function - check for

alignmentof movingpads, binding of moving

parts, breakage of pads, mountingand any

other conditionsthat may affect itsoperation.

A guard or other part that is damaged should

be properlyrepaired or replaced.

20,NEVER LEAVE THE TOOL RUNNING

UNATTENDED. TURN THE POWER "OFF".

Do not walk away from a running tool untilthe

blade comes to a complete stopand the tool

is unpluggedfrom the powersoume.

21,DO NOT OVERREACH. Keep properfooting

and balance at all times.

22,MAINTAIN TOOLS WITH CARE. Keep

toolssharp and clean_forbest_

performance,Follow instructionsfor

lubricatingand changing accessories,

23,WARNING: Dustgenerated from certain

materialscan be hazardous to your health.

Alwaysoperate saw in well-ventilatedarea

and providefor proper dustremoval.

24.1A DANGER I

People with electronic devices, such as

pacemakers, should consult their physician(s)

before using this product. Operation of

electrical equipment in close proximity to a

heart pacemaker could cause interferenceor

failureof the pacemaker.

SPECIFICSAFETYINSTRUCTIONSFORTHIS

COMPOUNDMITERSAW

1. DO NOT USE THIN KERF BLADES they

can deflect and contact guard and can cause

possible injury to the operator.

2. DO NOT operate the miter saw until it

is completely assembled and installed

according to these instructions.

3. IF YOU ARE NOT thoroughly familiar with

the operation of miter saws, seek guidance

from your supervisor, instructor or other

qualified person.

4. ALWAYS hold the work firmly against the

fence end table. DO NOT perform any

operation free hand (use clamp wherever

possible).

5, KEEP HANDS out of the path of the saw

blade. If the workpiece you are cutting would

cause your hands to be within 6-3/4 in. of the

saw blade, the workpiece should be clamped

in place before making the cut.

6. BE SURE the blade is sharp, runs freely and

is free of vibration.

7. ALLOW the motor to come up to full speed

before starting a cut.

8. KEEP THE MOTOR AIR SLOTS CLEAN

and free of chips or dust.

9. ALWAYS MAKE SURE all handles are tight

before cutting, even if the table is positioned

in one of the positive stops.

10. BE SURE both the blade and the collar are

clean and the arbor bolt is tightened securely.

11. USE only blade collars specified for your saw.

12. NEVER use blades larger in diameter than

10 inches.

13. NEVER apply lubricants to the blade when it

is running,

14. ALWAYS check the blade for cracks or

damage before operation. Replace a cracked

or damaged blade immediately.

15. NEVER use blades recommended for

operation at less than 4800 RPM.

16. ALWAYS keep the blade guards in place and

use at all times.

17. NEVER reach around the saw blade.

18. MAKE SURE the blade is not contacting the

workpiece before the switch is turned ON.

19. IMPORTANT: After completing the cut,

release the trigger and wait for the blade to

stopbefore returningthe saw to the raised

position.

20. MAKE SURE the blade has cometo a

completestop before removingor secudng

the workpiece,changingthe workpieceangle

orchangingthe angle ofthe blade.

21. NEVER cutmetalsor masonryproductswith

thistool. This miter saw is designedfor use

on wood and wood-like products.

22. NEVER cutsmall pieces. Ifthe workpiece

beingcut wouldcause your handorfingers

to be within6-3/4 in. of the saw bladethe

workpieceistoo small.

23. PROVIDE adequate supportto the sides of

the saw table for longwork pieces.

24. NEVER usethe mitersaw inan area with

flammableliquidsor gases.

25. NEVER usesolvents to clean plasticparts.

Solventscouldpossiblydissolveor otherwise

damage the material.

26. SHUT OFF the power before servicingor

adjustingthe tool.

27. DISCONNECT the saw from the power

sourceand clean the machinewhen finished

using.

28. MAKE SURE the work area isclean before

leavingthe machine.

29. SHOULD anypart ofyour mitersaw be

missing,damaged, or fail in any way, orany

electricalcomponent fail to perform properly,

lockthe switchand removethe plugfrom

the powersupply outlet. Replacemissing,

damaged, orfailed parts before resuming

operation.

POWER SUPPLY AND MOTOR

SPECIFICATIONS

The AC motor used in this saw is a universal,

nonreversible type. See "MOTOR" in the

"PRODUCT SPECIFICATIONS" section on

page 2.

IA WARNINGI

To avoid electrical hazards, fire hazards,

or damage to the tool, use proper circuit

protection. Your saw is wired at the factory

for 120 V operation. Connect to a 120 V, 15

A circuit and use a 15 A time delay fuse or

circuit breaker. To avoid shock or fire, If

power cord is worn or cut, or damaged in any

way, have it replaced immediately.

6 ...... [....

GROUNDING INSTRUCTIONS

IN THE EVENT OF A MALFUNCTION OR

BREAKDOWN, grounding provides a path of

least resistance for electric currents and reduces

the risk of electric shock. This tool is equipped

with an electrical cord that has an equipment-

grounding conductor and a grounding plug. The

plug must be plugged into a matching receptacle

that is properly installed and grounded in

accordance with all local codes and ordinances.

DO NOT MODIFY THE PLUG PROVIDED.

If it will not fit the receptacle, have the proper

receptacle installed by a qualified electrician,

IMPROPER CONNECTION of the equipment

groundingconductorcan result in riskof electric

shock. The conductorwiththe green insulation

(with or withoutyellowstripes)is the equipment

groundingconductor. If repairor replacementof grounded receptaclebox.

oorv_'t theequipment groundingconductortoa

liveterminal.

CHECK witha qualifiedelectricianorservice

person if youdo notcompletely understandthe

groundinginstructions,orifyou are not certain

the tool isproperlygrounded.

USE onlythree-wire extensioncords that have

three-prongedgroundingplugswith three-pole

receptacles thataccept the tool'splug. Repair or

replace damaged orworn cords immediately.

or IAWARNiNGI

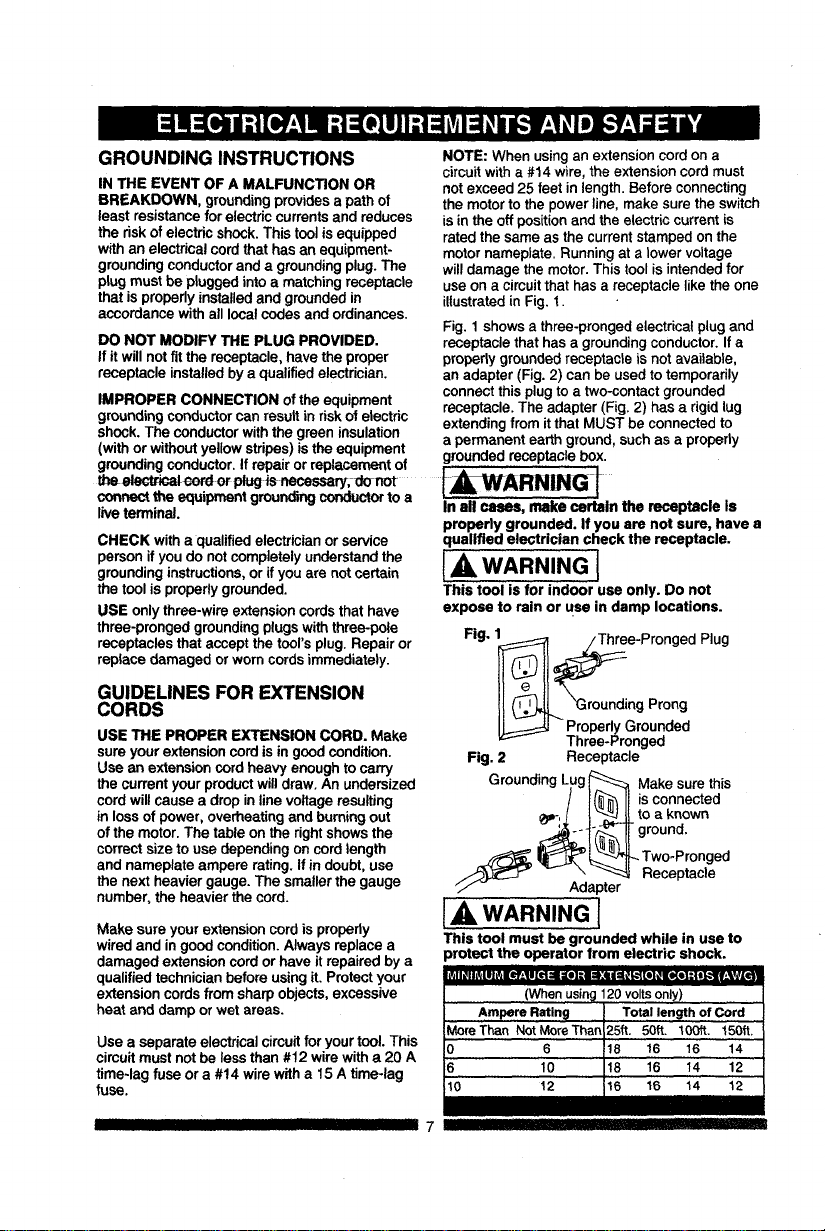

NOTE: When using an extension cord on a

circuit with a #14 wire, the extension cord must

not exceed 25 feet in length. Before connecting

the motor to the power line, make sure the switch

is in the off position and the electric current is

rated the same as the current stamped on the

motor nameplate. Running at a lower voltage

will damage the motor. This tool is intended for

use on a circuit that has a receptacle like the one

illustrated in Fig. 1.

Fig. 1 shows a three-pronged electrical plug and

receptacle that has a grounding conductor. If a

properly grounded receptacle is not available,

an adapter (Fig. 2) can be used to temporarily

connect this plug to a two-contact grounded

receptacle. The adapter (Fig. 2) has a rigid lug

extending from it that MUST be connected to

a permanent earth ground, such as a properly

In all cases, make certain the receptacle is

properly grounded. If you are not sure, have a

qualified electrician check the receptacle.

[A WARNING l

This tool is for indoor use only. Do not

expose to rain or use in damp locations.

Fig. 1 _i1 _:_:ee-Pronged Plug

GUIDELINES FOR EXTENSION

CORDS

USE THE PROPER EXTENSION CORD. Make

sureyour extensioncord is in goodcondition.

Use an extensioncordheavy enoughto carry

the currentyour productwilldraw. An undersized

cordwill cause a dropin line voltage resulting

in lossof power, overheating and burningout

of the motor.The table on the rightshows the

correctsize touse dependingoncord length

and nameplate ampere rating.If in doubt,use

the next heaviergauge. The smallerthe gauge

number,the heavier the cord.

Make sureyour extension cordis properly

wiredand in goodcondition.Always replace a

damaged extensioncord or have it repaired by a

qualifiedtechnician beforeusingit. Protectyour

extensioncordsfrom sharpobjects, excessive

heat and damp or wet areas.

Use a separate electrical circuit for your tool. This

circuit must not be less than #12 wire with a 20 A

time-lag fuse or a #14 wire with a 15 A time-lag

fuse.

II'-0AJ L roundingProng

ProperlyGrounded

Fig. 2 Receptacle

GroundingLug_ Make sure this

...-_ _ Receptacle

U/" - Adapter

Three-Pronged

! I(_"l II iSconnected

_i-!.L ! "_'_l_lJ_to a known

IAWARNING[

This tool must be grounded while in use to

irotect the operator from electric shock.

(When usin_l120 volts only)

IIground

Two-Pronged

iil,e] =-illi_ll r,_,_.vll

III II III III II 7

_e,][e,]:k'.,5.-,[e]-i i :[..,fzl _i elz| ii IVzTI,];i_v_i:1_| i

RECOMMENDED ACCESSORIES

I,_ WARNING I

• Use only accessories recommended for

this miter saw. Follow instructions that

accompany accessories. Use of Improper

acceseorles may cause hazards.

• The use of any cutting tool except 10 in.

saw blades which meet the requirements

under recommended accessories is

prohibited. Do not use accessories such

as shaper cutters or dado sets. Ferrous

metal cutting and the use of abrasive

wheels is prohibited.

• Do not attempt to modify this tool or

create accessories not recommended for

use with this tool. Any such alteration or

modification is misuse and could result in

a hazardous condition leading to possible

serious injury.

ACCESSORIES

Visit your Sears Hardware Department or see the

Sears Power and Hand Tool Catalog to purchase

recommended accessories for this power tool.

[A, WARNING]

• To avoid the risk of personal injury, do not

modify this power tool or use accessories

not recommended by Sears.

• Read warnings and conditions on your

CARBIDE TIPPED SAW BLADE. Do not

operate the saw without the proper saw

blade guard in place. Carbide is a very

hard but brittle material. Care should be

taken while mounting, using, and storing

carbide Upped blades to prevent accidental

damage. Slight shocks, such as striking

the tip while handling, can seriously

damage the blade. Foreign objects in the

workpiece, such as wire or nails, can also

cause tips to crack or break off. Before

using, always visually examine the blade

and tips for bent blade, cracks, breakage,

missing or loose tips, or other damage. Do

not use if damage is suspected. Failure to

heed safety instructions and warnings can

result in serious bodily injury.

munro_o]nk,'ln+l=1:lm:lntl=+o]:ir;1.-,_-_:lmi=]m¥_

SUPPLIED NOT SUPPLIED

Blade Wrench Adjustable Wrench

=====J :::::::::::::::::::::

Hex Key Combination Square

Philips Screwdriver

Slotted Screwdriver

COMBINATION SQUARE MUST BE TRUE

Shouldnot gap or overlapwhen square is flipped

over (see dotted figure).

Draw light lineon a 3/4 in. board,

board along this this edge must be

edge. perfectly straight.

Straight edge or

ji

i !

f I

//

I I

L

Gap from untrue square when

. flipped over.

II 8 !11 _ I IIII flllllllll

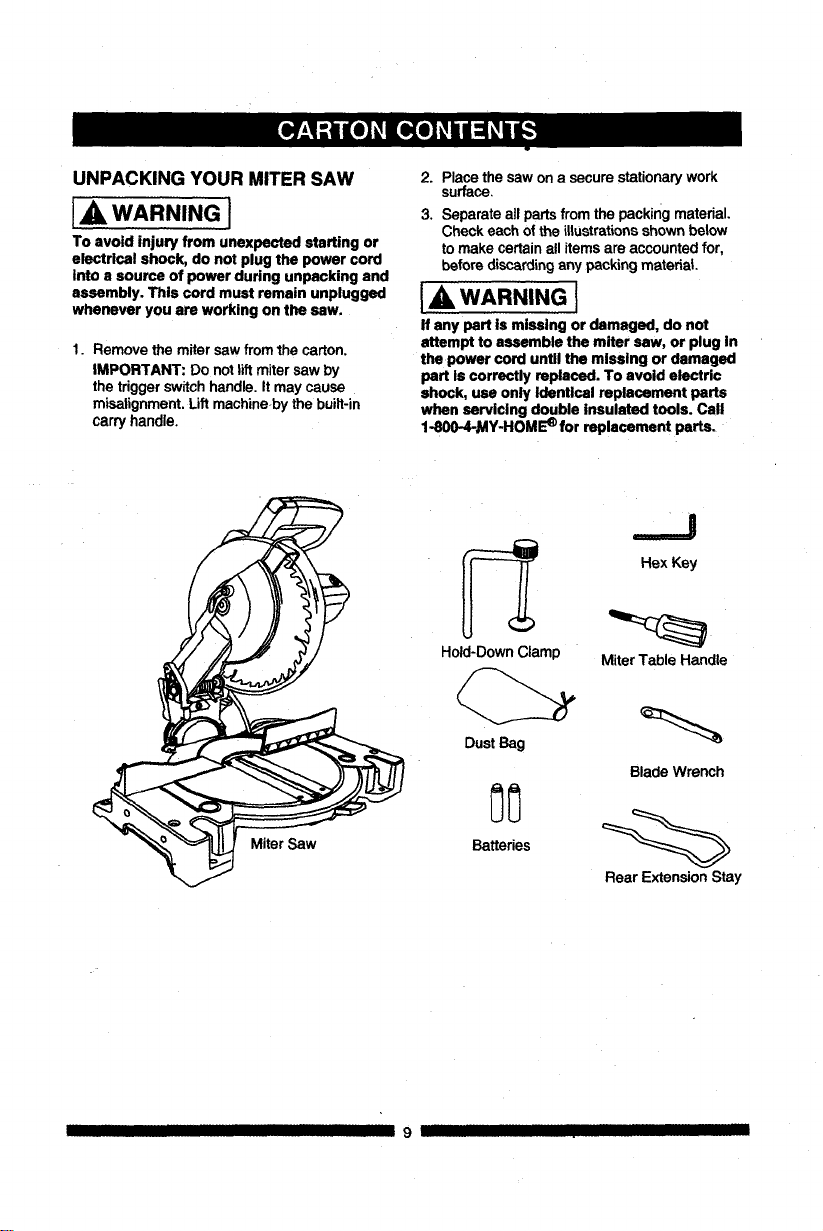

UNPACKINGYOURMITERSAW

IA WARNING I

To avoid injury from unexpected starting or

electrical shock, do not plug the power cord

into a source of power during unpacking and

assembly. This cord must remain unplugged

whenever you are working on the saw.

1. Remove the miter sawfrom the carton.

iMPORTANT: Do not lift mitersaw by

the triggerswitchhandle. It maycause

misalignment. Liftmachine bythe built-in

carry handle.

2. Placethe saw ona secure stationarywork

surface.

3. Separate all partsfrom the packingmaterial.

Check each of the illustrationsshownbelow

to make certain all itemsare accounted for,

before discardingany packing material

I,A WARNING I

If any part is missing or damaged, do not

attempt to assemble the miter saw, or plug In

the power cord untll the mlssing or damaged

part Is correctly replaced. To avoid electric

shock, usa only Identical replacement parts

when servicing double insulated tools. Call

1-800-4-_AY-HOM_ for replacement parts.

.._J

Hex Key

Miter Saw

Hold-DownClamp

Dust Bag

Batteries

MiterTable Handle

Blade Wrench

Rear Extension Stay

II III 9 IJ IIIII

Loading...

Loading...