Craftsman 137212140 Owner’s Manual

Operator's Manual

2.5 HP (Max. Developed)

10" Blade

4800 R.P.M.

COMPOUND MITER SAW

With Laser Trac®

Model 137.212140

CAUTION;

Before using this Miter Saw,

read this manual and follow

all its Safety Rules and

Operating Instructions

Customer Neip Line

t=800=843=t682

!

Sears, Roebuck and Co., Hoffman Estates,. 1L60179 U.S.A.

Visit our Craftsman website: _w_w,sears.comlcraftsman

Part No.:137212140001

e Safety Instructions

e Installation

• Operation

e Maintenance

e Pads List

SECTION PAGE

Warranty ................................................ 2

Product Specifications ........................... 2

-Power ToolSafety o............................. 3

Compound Miter Saw Safety ................. 4

Electrical Requirements and Safety ....... 4-5

Accessories and Attachments ............... 6

Tools Needed For Assembly ................... 6

Carton Contents ...................................... 7

i i i iiii, _,,i...... i .........ii, -i i ,:,,ii - ..... i"': .............. ii

SECTION PAGE

Know Your Compound Miter Saw .......... B

Glossary of Terms................................ 9

Assembly and Adjustments:; _._.,, ......... 10

Operation ......... _.................................... 15

Maintenance ............................................ 22

Troubleshooting Guide ............................ 23

Parts List,,,........................................... 24

FULL ONE YEAR WARRANTY

if this tool fails due to a defect in material or workmanship within one year ol date of purchase, Sears will

at !ts opt!on repair or replace it free of charge.

Return this tool to a Sears Service Center for repair, or to place of purchase for replacement.

This warranty gives you specific legal dghts, and YOUmay also have other rights which may vary from

state to slate,

Sears, Roebuck an d Co., Dept, 817 WA, Hoffman Estates, IL 60179

.................... '..... lUU i ii iiin,llli .................. i, 1,1,,11,

Some dust created by power sanding, sawing, grinding, drilling and other construction activities contains

chemicals known (to the State of California) to cause cancer, birth defects or other reproductive harm. Some

examples of these chemicals are:

Your risk from these exposures varies, depending on how often you do this type of work. To reduce your

exposure to these chemicals, work ina well ventilated area and work with approved Safety equipment such as

dust masks that are specially des}gnarl to filter out microscopic particles.

= Lead from lead-based paints

• Crystalline silica from bricks, cement and other masonry products

o Arsenic and chromiumfrom chemically treated lumber

: MOTOR : Rotating Table;

iPower source.......................... 120V AC; 6OHZIi5 Amp Diamatero_o,,::.,. ........................ t2.S/B"

Horsep0wer.;.L_...........i,... :;. 2,SHP (Max,Devet0ped} MtterDetentStops, ..................... 0, 15, 22o1.,'2,31.6,

ArborShaft Size 5./B" .... .... 45= R. & L

Speed.; ........_.o..o.;......... .,,,_. 4800 RPM(Noload) BeveiP0sitiveStaps_..:,.,,.:o,.,,,;, 0, 45= :

Brake.:.;.;; .............................. Electric Base Dirnensions,.o,i..i.,.;.i=_.... 20-112,x 16..1t4"

: Double Insulated................,:;.... Yes DustCollection........ :L,.;......... Yes

MITER SAW ExlensionWings....................... Yes

:Cutting Capacity: NetWeight................................. 33 Lbs

: :Crosscut......;.,-,, ... ............. 2-5/8' X5-1t2"

:: Miler45 '_R&L ..................... 2_/8' x 3-1/2"

: Bevel 45=L................. :........ t-t/2" x 5_1t2=

450Miler and45" Bevel.............. 1-1/2"X3-1/2"

To avoid electrical hazards, fire hazards Ordamage to the tool, u_e proper¢.Ircuit protection.

This to01 is wired at the factory for 110.120 Volt operation. It must be connected to a 110-120 Volt t 15 Ampere time

delay fuse or circuit breaker. To avoid shock or fire, replace power cord immediately If It is worn, cut or damaged

In any way.

Before using your tool, it is critical that you read and understand these safety rules. Failure to follow these rules

could result In serious injury to you or damage to the tool.

GENERAL SAFETY INSTRUCTIONS

BEFORE USING THIS POWER TOOL

Safety is a combinatio_ of common sense, staying ale_

and knowing how to use your power tool

To avoid mistakes that could cause sedous injury,do not

plug the tool in until you have read and _mderstood the

following

1. READ and become familiar with the entire Operators

Manual. LEARN the tool's application, limitations and

possible hazards.

2. KEEP GUARDS IN PLACE and in working order,

3. REMOVE ADJUSTING KEYS AND WRENCHES.

Form the habit of checking to see that keys and

adjusting wrenches are removed from the tool before

turning ONe

4. KEEP WORK AREA CLEAN. Cluttered areas and

benches invite accidents.

5. DON'T USE IN DANGEROUS ENVIRONMENTS.

Don't use power tools in damp locations, or expose

them to rain or snow. Keep work area well lighted.

6. KEEP CHILDREN AWAY. All visilors and bystanders

should be kept a safe distance from work area

7. MAKE WORKSHOP CHILD PROOF with padlocks,

master switches, or by removing starter keys

8. DON'T FORCE THE TOOL. {t wilt do the job better

and safer at the rate for which it was designed.

9. USE THE R1Gt'rr TOOL. Do not force the tool or an

attachment to do a job for which it was not designed,

10,USE PROPER EXTENSION CORDS. Make sure

your extension cord is in good condition. When using

an extension cord, be sure to use one heavy enough

to carry the current your product will draw, An

undersized cord will result in a drop in line voltage

and in loss of power which will cause the tool to

overheat. The table on page 5 shows the correct size

to use depending on cord length and nameplate

ampere rating_ If in doubt, use the next heavier gauge.

The smaller the gauge number,the heavier the cord.

11,WEAR PROPER APPAREL. Do not wear loose

¢10thihg,gloves, neckties, dngs, bracelets, c rother

jewelry which may get caught in moving parts

Nonslip footwear is recommended Wear Drotective

hair covedng to contain long hair.

12.ALWAYS WEAR EYE PROTECTION. Any power tool

can throw foreign objecl_sinto the eyes and

could cause permanent eye damage.

ALWAYS wear Safety Goggias (not

glasses) that comply with ANSI Safety

standard Z87.t Everyday eyeglasses

have onfyimpact -resistance lenses

They ARE NOT safety glasses. Safety Goggles ere

available at Sears, NOTE: Glasses or goggles not in

complianCE with ANS! Z87ol could seriously injure

you wllen they break.

13.WEAR A FACE MASK OR DUST MASK, Sawing

operation produces dust.

14oSECURE WORK. Use clamps or a vise to hold work

when practical. It's safer than using your hand and it

free_ both hands to operate the tool

15.DISCONNECT TOOLS FROM POWER SOURCE

beIore sewicing, and when changing accessories

sucl_ as blades, bits and cutters,

16.REDUCE THE RISK OF UNINTENTIONAL

STARTING. Make sure switch is in the OFF position

before plugging the tool in,

17,USE RECOMMENDED ACCESSORIES. Consult this

Operators Manual for recommended accessories

The use of improper accessories may cause risk ol

injury to yourself or others

1B_NEVER STAND ON THE TOOL. Serious injury could

occur if ]h_ Iool is tipp@dor il the culling tool is

uninlentfona]ly contacted

19oCHECK FOR DAMAGED PARTS. Before further usa

of the tool, a guard or other part that ]sdamaged

should be carefully checked to determine th_t it will

operate properly and perform its intended funclion -

check for alignment of moving parts, binding of

moving parts, breakage of pans. mounting, and any

other conditions that may affect itsoperalion A guard

orother part that isdamaged should be properly

repaired or replaced

20°NEVER LEAVE THE TOOL RUNNING UNATTEt._DED.

TURN THE POWER "OFF". Don't wa]k away from a

running toot until the blade comes to a complete stop

& unplug Ihe unit

21.DON'T OVERREACH. Keep proper ioo_ing and

balance at all times,

22.MAINTAIN TOOLS WITH CARE. Keep tools sharp

and clean for bes[ and safest par[ormanceoFoIIow

instrucUonsfor lubricating and changing accessories.

23,WARNING: Dust g_nerated from certain mater;als

can be hazardous to your heaith, Always opera[e saw

in well-ventilated area ant provide for _roper dust

removal

SPECIFIC SAFETY INSTRUCTIONS FOR workpiece before the switch is turned ON

18.MAKE SURE the blade is notcontacting the

THIS COMPOUND MITER SAW

I. USE ONLY CROSS-CUTTING SAW BLADES. When ....... power switch and wait for the blade to stop before

using carbide tipped blades, make sure they have a

negative hook angle.

IMPORTANT: DO NOT USE THtN KERF BLADES-

they can deflecl and conlacl guard and can cause

possible injuryto the operator.

2. DO NOT operate the miter saw until it iscompletely

assembled and installed according to these

instructions,

3. IF YOU ARE NOT thoroughly familiar with the

operation o! miter saws, seek guidance from your

supervisor instructor, or other qualified person would cause your hand or fingers to be within 7-t/4"

4. ALWAYS held the work firmly against the fence and

table. DO NOT pedorm any operalion free hand (use

clamp wherever possible)

5. KEEP HANDS out of the path ot the saw b]ade, Ifthe

werkpiece you are cutting would cause your hands to

be within 7-1/4" inches of the saw blade, the

workpieca should be ciamped in place before making

the cut.

6. BE SURE the blade is sharp, runs freely, and is free

of vibration

7. ALLOW the motor Io come up to fu_lspeed before

starting a cut.

8. KEEP THE MOTOR AIR SLOTS CLEAN and #eeoI

chips or dust, 28.MAKE SURE the work area is clean before leaving

9. ALWAYS MAKE SURE all handles are tight before

cutting, even if the table is positioned in one of the

positbe stops,,

10,BE SURE both the blade and the collar are clean and

the arbor bolt istightened securely.

11.USE only blade collars specified for your sew.

19JMPORTANT: After completing the cut, release the

returning the saw to the raised position..

2&MAKE SURE the blade has come to a compfete stop

before removing or securing the workpiece, changing

the workpiece angle, or changing the angle of the

blade.

21.NEVER cut metals or masonry products with this tool,

This miter saw is designed for use on wood and

wood-like products,

22.NEVER cut small pieces If the workpiece being cut

inches of the saw blade the workpiece is too small

?_3.PROVIDE adequate support to the sldes of the saw

table far long work pieces.

24,NEVER use the miter saw in an area with fiammabb

liq_Jidsor gases

2&NEVER use solvents to clean plastic parts. Solvents

could possibly dissolve or other,,4se damage the

material.

26.SHUT OFF the power belore servicing or adjusting

the too].

27,DISCONNECT the saw from the power source and

clean the machine when finished using

the machine.

29.SHOULD any pan of your miter saw be missing,

damaged, or fail in any way, or any electrical

component fail te pedorm properly, shut off the switch

and remove the plug from thepower supply oullet.

Replace missing, damaged, or falled parts before

resuming operation.

12. NEVER use blades Iarger or smaller in diameter

than 10-inches.

13. NEVER apply lubricants tc the blade when it is

running,

14. ALWAYS check the blade for cracks or damage

before operation. Replace a cracked or damaged

blade immediately.

15. NEVERuseblades recommendedbr operalional

less than4800RPM.

16.ALWAYS keep the blade guards in place and use at

all times

17.NEVER reach around the saw blade

POWER SUPPLY AND MOTOR SPECIFICATIONS

The AC motor used _n this saw is a uriiverse[.

nonreversible type. See "MOTOR _ in the "PRODUCT

SPECIFICATIONS" seciion on page 2.

To avoid electrical hazards, fire hazard_ or damage 1o

the tool, use proper ,circuit protection. Your saw is wired

at the factory for 120V operatbn Connect to a 120V, 15

Amp circuit and use a I5 amp, time delay lose or circuit

breaker, To avoid shock or fire, if power cord is worn or

cut, or damaged in any way, have it replaced

immediately.

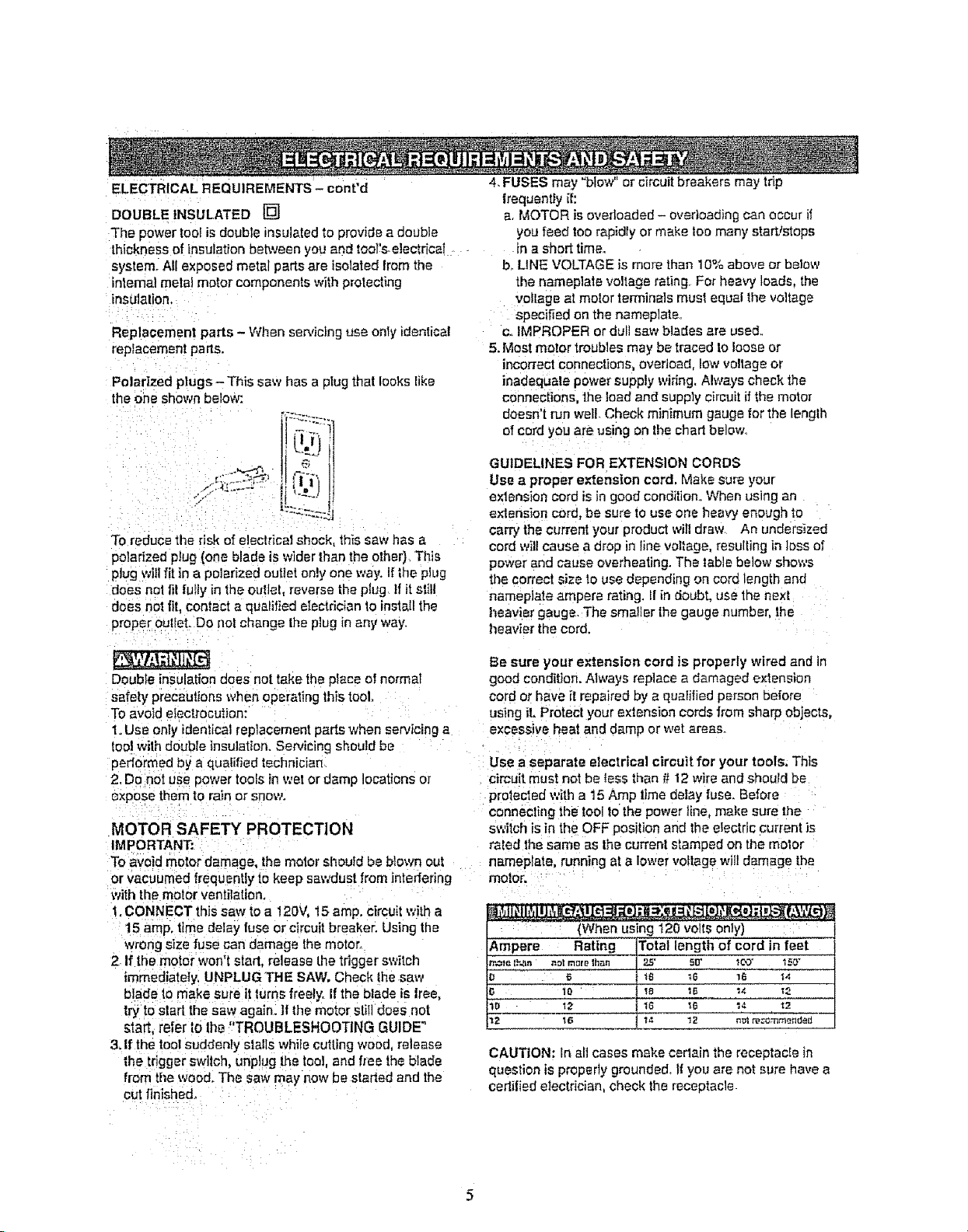

ELECTRICAL REQUIREMENTS - cont'd

DOUBLE INSULATED []

The power tool is double insulated to provide a double

thickness of insulation beb.veen you and tool,s-electrical

system. All exposed metal parts are isolated from the

internal metal motor components with protecting

insulation,

Replacement parts - When servicing use only identical

replacement parts.

Polarized plugs-This saw has a plug that looks like

the one shown below:

To reduce the risk of eleclricat shock, this saw has a

polarized plug (one blade is wider than the other] Tllis

plug willfit in a polarized outlet only one way. If|he plug

does not fit fully in the curie! reverse the plug tf it st;tl

does not fit, contact a qualified electrician to install the

proper outlet. DOriot change the plug in any way.

4. FUSES may "blow" or circuit breakers may trip

frequently if:

a. MOTOR is overloaded - ovedoading can occur if

you feed too rapidly or make too many startJstops

in a shod time.

b. LINE VOLTAGE is more than 10% above or below

the nameplate voltage rating For heavy loads, the

voltage at motor terminals must equal the voltage

specified on the nameplate.

c,,IMPROPER or dull saw blades are used,

5.Most motor troubles may be traced to loose or

incorrect connections, overload, low voltage or

inadequate power supply widng, Always check the

connections, the load and supply circuit ifthe motor

doesn't run well. Check minimum gauge for the lenglh

of cord you are using on the chad below,

GUIDELINES FOR EXTENSION CORDS

Use a proper extension cord. Make sure your

exlension cord is in good condition. When using an

ex'lension cord, be sure to use one heavy enough to

carry the current your product will draw, An undersized

cord will cause a drop in line voltage, resulling in loss of

power and cause overheating. The table below shows

the correct size to use depending on cord length and

nameplate ampere rating. II in doubt, use the nexl

heavier gauge The smaller lhe gauge number, the

heavier the cord.

Double insulation does not take the place o! normal

safety precautions when operating this tool

To avoid electrocution:

1.Use only identical replacement parts when servicing a

toolwith double Insulation. Servicing should be

performed by a qualified technician

2, Do not use power tools tn wet or damp locations or

expose them to ra'=nor snow.

MOTOR SAFETY PROTECTION

IMPORTANT:

Toavoid motor damage, the motor sl_outd be blown out

or vacuumed frequently to keep sawdust from intedefing

with the motor ventilation,

t. CONNECT this saw to a 120V, 15 amp. circuitwith a

15 amp, time delay fuse or circuit breaker. Using the

wrong size fuse can damage the motor..

2 If the motor won't start, release the tdgger swilch

immediately, UNPLUG "THE SAW, Check the saw

blade t.omake sure it turns freely<If the blade is Iree,

try to sled the saw again. If the motor still does not

start, refer to lhe "TROUBLESHOOTING GUIDE"

3. If the tool suddenly stalls while cuttingwood, release

the tdgger swltch, unplug the tool, and free the blade

from tile wood. The saw may now be started and the

cut flnisha&

Be sure your extension cord is property wired and in

good condition. Always replace a damaged extension

cord or have it repaired by a qualified person before

using iL Protect your extension cords from sharp objects,

excessive heat and damp or wet areas.

Use a separate electrical circuit for your tools. This

circuit must not be less than # 12 wire and should be

protected with a 15 Amp lime delay fuse. Before

connecting the to01to the power line, make sure the

switch isin the OFF position and the electric current is

raled the same as the current stamped on ti_e motor

nameplate, running at a lower voltage will damage the

motor.

......... (When using 120 volts only)

Amper_e Rating Totat lengt_ of cord in feet

i"r,,_ie l_n n_l more lhan 25' 5[t' Ic_3* t50 +

o _ 18 _6 16 _4

l0 18 15 14 ;_

10 12 16 IS '14 12

1i'_"_ 1S 14 12 n_l re_--'_mm-.nded --

CAUTION: In all cases make cedain the receptacle in

question is properly grounded. I{ you are not sure have a

certified electrician, check the receptacle

RECOMMENDED ACCESSORIES

o Use only sccessories recommended for thismiter

saw. Followinstructions that accompany aocessodes_

Use ot improper accessories may cause hazards

• The use el any cutting toot e×cept 10 inch saw

blades thai meet the requirements under

recommended accessories isprohibited. Do not use

accessories such as shaper cutters or dude sets.

Ferrous metal cutting, the use of abrasive wheels

and the cutting of masonry producL_are prohibited

e Do not attempt to modify this tool or create

accessories not recommended for use with this tool.

Any such alteration or modification is m}suse and

could result in a hazardous condition leading tO

possibleseriousinjury,

ACCESSORIES

Visit your Sears HardwareDepartmentOrsee [heSears

Powerand HandTootCatalogto purchase

recommendedaccessories forthis powertool.

To avoid the risk el personal injury,do not modify this

power tool or use accessories not recommended by

Sears.

Phillips screwdriver

Read warnings and conditions on your CARBIDE

TIPPED SAW BLADE. Do not operate the saw without

tile proper saw blade guard in place. Carbide is a very

hard but brittle material Care should be taken while

mounting, using, and storing carbide tipped btades to

prevent accidental damage. Slight shocks, such as

striking the tip while handling, can seriously damage the

bladeo Foreign objects in the workpiece, such as wire or

nails, can also cause tipsto crack or break off. Bo!ero

using, always visually examine the blade and tips tor

bent teeth, cracks, breakage, missing or loose t_ps,or

other damage. Do not use if damage is suspected,

Failure to heed safety instructions and warningscan

resull in serious bodily injury.

6

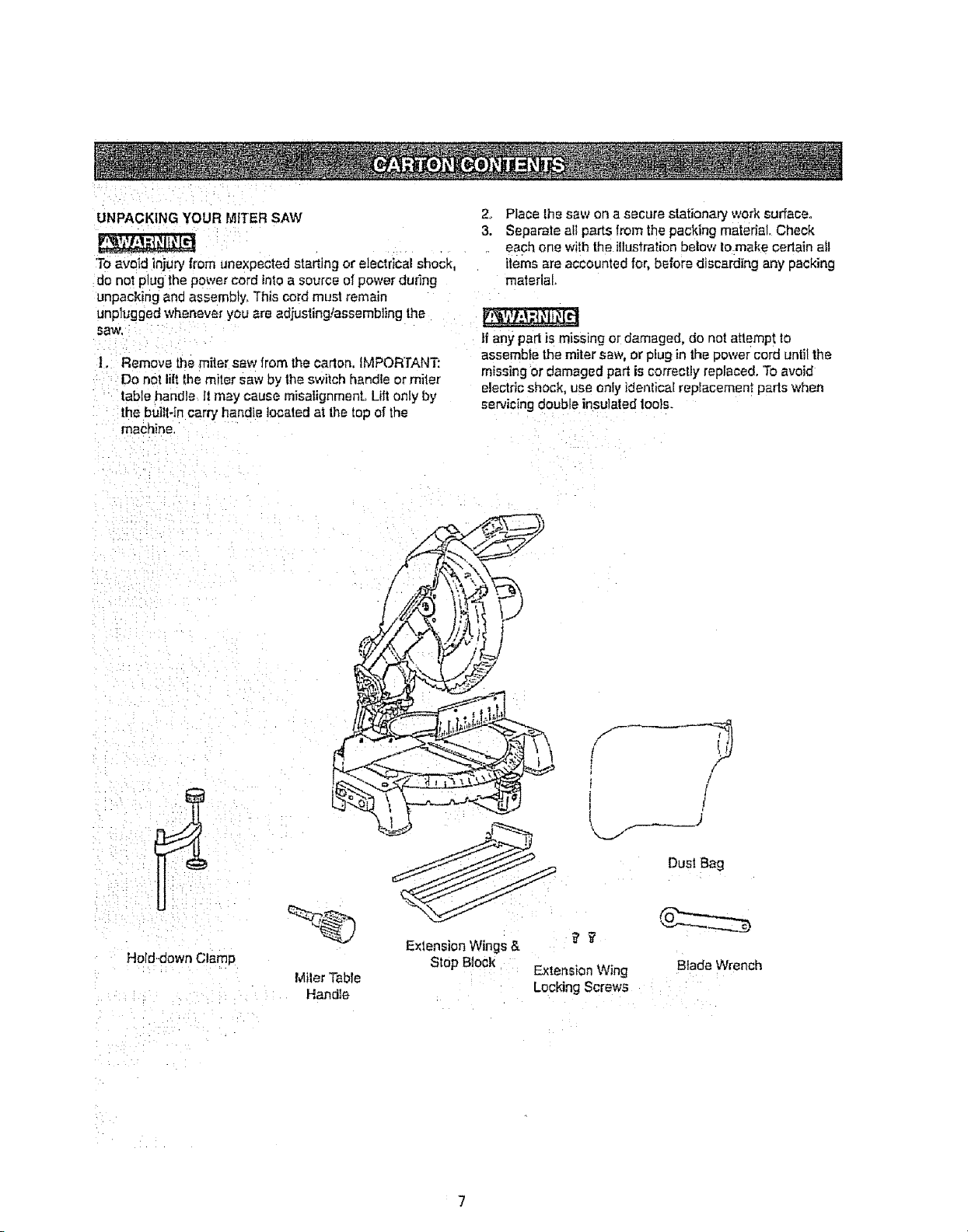

UNPACKING YOUR MITER SAW

'Toavoid injury from unexpected sta_ing or electrical shock,

do not plug the power cord into a source of power dur}ng

unpacking and assembly, This cord must remain

unplugged whenever you are adjusting!assembling the

saw,

1. Remove the miter saw from the Carton. IMPORTANT:

Do not lilt the miter saw by the switch handle or miter

table handle.. It may cause misatignmenL Lift only by

the buill-In carry handle located at the topof the

machine.

2., Place the saw on a secure siafionary work surface.

3. Separate all parts from the packing material. Check

. each one with the illustration below lo make certain aJl

items are accounted for, before discarding any packing

material,

If any parl is missing or damaged, do not atlempt to

assemble the miler saw, or plug in the power cord until the

missing or damaged par_is correctly replaced, To avoid

electric shock, use only identical replacement pads when

servicing double insulated lools.

Hold-down Cla_

MilerTable

Handle

Extension Wings &

Stop Block

ExlensionWing

LockingScrews

/

/

/

]

Dust Bag

BladeWrench

Dust Bag

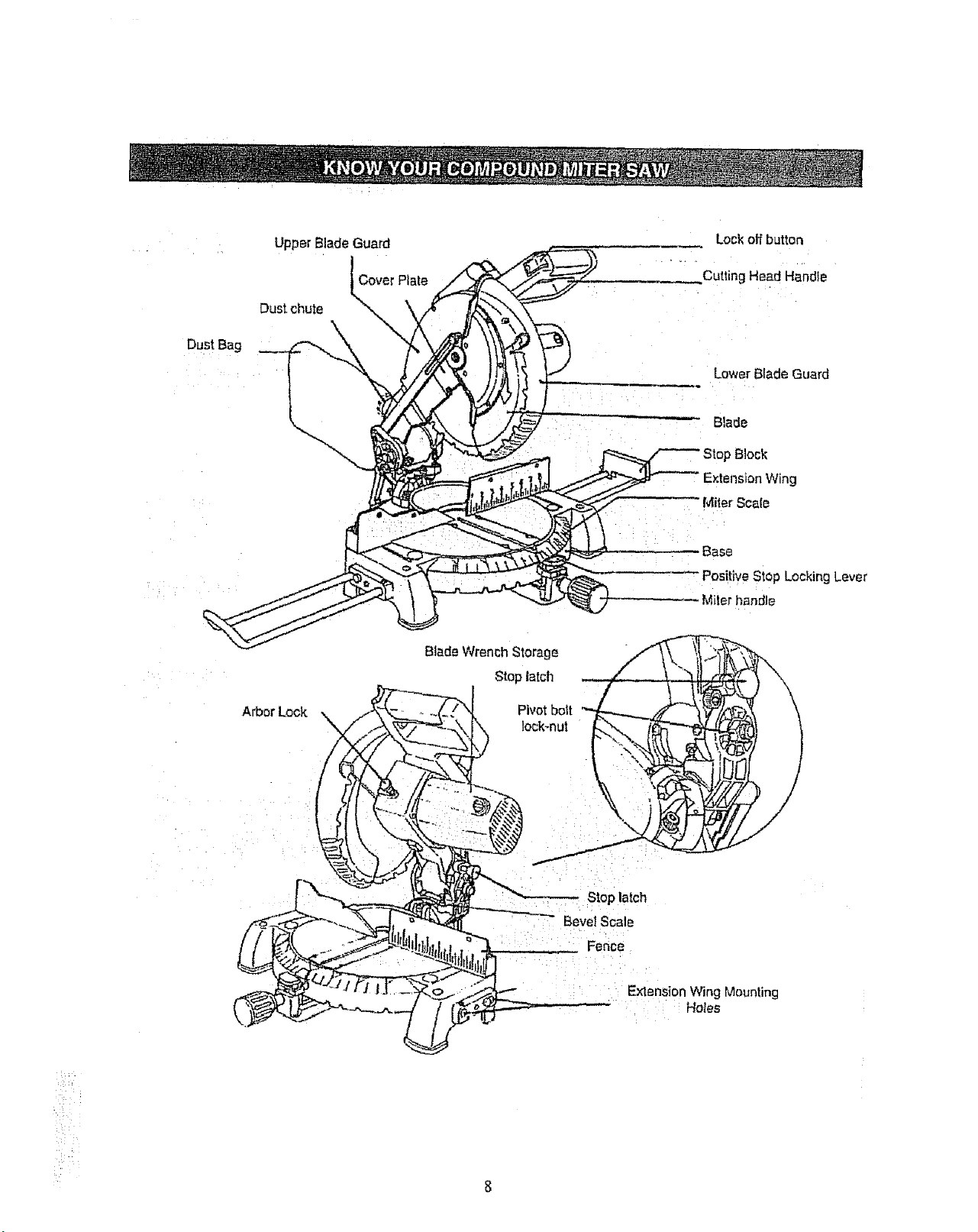

Upper Blade Guard

Dust chute

Lock off button

Cutting Head Handte

Lower Blade Guard

Blade

g

Miter Scale

Base

" Positive Stop Locking Lever

i;ler handle

Stop lalch

Arbor Lock ,_

Pivot boll

Bevel Scale

: : : Fence

i Ex-lension Wing Mounting

Hotes

CRAFTSMAN COMPOUND MITER SAW TERMS

ARBOR LOCK - Allows the user to keep the btade lmm

rotating while tightening or loosening the arbor locking

bolt during blade replacement or removal.

BASE - Supports the fable, holds accessories and

allows for workbench or leg set mounting

BEVEL LOCKING HANDLE - Locks the miter saw at a

desired bevel angle,

BEVEL SCALE - To measure the bevel angle of the saw

blade O"to 45 ° left

COVER PLATE SCREW - Loosen this screw and rotate

the plata for access to the blade arbor locking boil

DUST CHUTE - Exhausts debds away Item the user,

STOP LATCH - Locks the miler saw in the lowered

position for compact sloraga and ttarLsportation.

SWITCH HANDLE - The cutting head handle contains

the tr_gger switchand a safety lock-off Slide switch. The

_lade is lowered into the workpiece by pushing down on

the handle, 'The saw will return to its upright position

when the handle is released,

WARNING LABELS .- Read and understand for your

own safely. Aiways make certain the_e are in place &

legible.

WRENCH STORAGE - Convenient storage to prevent

misplacing the blade wrench

WOODWORKING TERMS

ARBOR - The shaft on which a blade is mounted

EXTENSION WING - Exlends the width of the work

table for support while cutting long work pieces, They

can be used with or without a stop block as an additional

side fence,

FENCE - Helps to keep the workpieca trom moving

when sav4ng Scaled to assist with accurate cutting

HAND HOLD -Location of hands for transportation.

SAFETY LOCK-OFF BUTTON -YeIlow button on

handle must be pushed lorward to activate the trigger

switch,

LOWER BLADE GUARD - Helps protect your hands

from the blade in the raised position, it refracts as file

blade is lowered,

MITER HANDLE -Used to rotate Ihe sew to the fight or

[eft cuttingposition,

MITER SCALE - To measure the 'niter angle 0_ to 45°

left, 0=to 45° fight.

MITER SPRING LOCK - Used in combination with the

miter handle, it locks the miler saw at a preset positive

stop for the desired miter angle,

MOUNTING HOLES - To mount the miter saw to a

stable surface,

ON/OFF TRIGGER SWITCH - To prevent tile trigger

|rom being accidentally engaged, a lock-off slide switch

is provided. To start the fool, push the lock-off slide

switch Ion,yard and squeeze the thgger Release the

trigger to stop the miter saw.

BEVEL CUT - An angle cut made through the face of

Lheworkp|ece,

COMPOUND CUT-A simultaneous bevel and miter cuL

CROSS CUT - A cut made across the widthor grain of

the workpiece,

FREEHAND - Performing a cut without using a fence

(guide), hold down or other proper device to prevent the

workpiece from twisting during the cutting operation.

GUM - A sticky sap from wood products,

HEEL - MisaIignmenf of the blade.

KERF-The amount of mater;el removed by blade CUL

MITER CUT - An angle cut made across the width or

grain of the workpiece,

RESIN - A sticky sap that has hardened.

REVOLUTIONS PER MINUTE (RPM} - The r'=umberot

turns completed by a spinning objecl in one minute,

SAW BLADE PATH - The area of the workplace or table

top directly in line with the travel of the blade or the parl

of the workpiece which wil! be cm,

SE'r - The distance between two saw blade tips, bent

oub,,,,ardin opposite directions to each other. The further

apart the tipsare, the greater the set.

WORKPIECE - The item being cut. The surfaces o! a

workpiece are commonly referred to as faces, ends, and

edges°

Loading...

Loading...