Craftsman 13026620 Owner’s Manual

Operator's Manual

P R 0 F E S S I 0 N A L _

Fixed Base/Plunge Base

Router Kit

Model No.

130.26620

• SAFETY

CAUTION: Read, understand and follow

all Safety Rules and Operating Instructions

in this manual before using this product.

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

• OPERATION

• MAINTENANCE

• ESPAI_IOL

Warranty ............Page 2

Safety Instructions.............................................................. . ............Pages 3 - 5

Safety Symbols.............. L..................................................... _ ............. Page 6

FunctionalDescriptionand Specf cat ons .......................... i.li

Assembly......

i._l............ Pages 7- 8

b

Pages

9- 11

Operating Instructions...L...................................................... ,.i ............Pages 12 - 19

Maintenance........................................................................... ............Page 20

ii ,

Accessodes.............................................................................. _.ii.............. Page 20

RepairParts................... _......................................................... .ii,. i............Pages 21 - 23

Service Numbers........... .......................................................... ii _.-f' /............Back Cover

ONE FULLYEAR WARRANTY ON C

IfthisCraftsman Toolfails tO

purchase,RETURN IT TO THE

Dyear from the date of

;& REPAIR

CENTER IN THE UNITED STATES, and Sears will repair it;

Thiswarranty givesyou _iflc legal rights, and you may

which vary from state tOstate.

Sears, Roebuck and Co. Dept. 817 WA, Hoffman

SAVE THESE INS_UCTIONS!

READ ALL INSTRUCTIONS!

-2-

rights

_Read and understand all instructions. Failure to follow all instructions listed

below, may resultin electric shock, fire and/or seriouspersonal injury.

SAVE THESE INSTRUCTIONS

Work Area

Keep your work area clean and well lit.

Cluttered benches and dark areas invite

accidents.

Do not operate power tools in explosive

atmospheres, such as in the presence of

flammable liquids, gases, or dust. Power

tools create sparks which may ignite the dust

or fumes.

Keep by-standers, children, and visitors

away while operating a power tool.

Distractions can cause you to lose control.

Double Insulated tools are sqmpped with a

polarized plug (one blade is wider than the

other.) This plug will fit in a polarized outlet

only one way. If the plug does not fit fully in

the outlet, reverse the plug. If It still does not

fIt, contact a qualified electrician to install a

polarized outlet. Do not cha.n_e the plug in

any way. Double Insulation LOJeliminates the

need for the three wire grounded power

cord and grounded power supply system.

Before plugging In the tool, be certain the

outlet voltage supplied is within the voltage

marked on the nameplate. Do not use "AC

only" rated tools with a DC power supply.

Avoid body contact with grounded surfaces

such as pipes, radiators, ranges and

refrigerators. There is an increased risk of

electric shock if your body is grounded. If

operating the power tool in damp locations is

unavoidable, a Ground Fault Circuit Interrupter

must be used to supply the power to your tool,

Electrician's rubber gloves and footwear will

further enhance your personal safety.

Don't expose power tools to rain or wet

conditions. Water entering a power tool will

increase the risk of electric shock,

Do not abuse the cord. Never use the cord

to carry the tools or pull the plug from an

outlet. Keep cord away from heat, oil, sharp

edges or moving parts. Replace damaged

cords Immediately. Damaged cords increase

the risk of electdc shock.

When operating a power tool outside, use an

outdoor extension cord marked "W-A" or

"W." These cords are rated for outdoor useand

Electrical Safet_

reduce the risk of electric shock. Refer to

"Recommended sizes of Extension Cords" In

the Accessory section of this manual.

Personal Safety

Stay alert, watch what you are doing and

use common sense when operating a power

tool. Do not use tool while tired or under the

influence of drugs, alcohol, or medication.

moment of inattention while operating power

tools may result inserious personal injury.

Dress properly. Do not wear loose clothing

or jewelry. Contain long hair. Keep your hair,

clothing, and gloves away from moving

parts. Loose clothes, jewelry, or long haircan

be caught in moving parts. Keep handles dry,

clean and free from oil and grease.

Avoid accidental starting. Be sure switch is

"OFF" before plugging in. Carrying tools with

your finger on the switch or plugging in tools

that havethe switch "ON" invitesaccidents.

Remove adjusting keys or wrenches before

turning the tool "ON". A wrench or a key that

isleftattached to a rotating part of the tool may

resultin personal injury.Do not overreach.

Keep proper footing and balance at all

times. Proper footing and balance enables

better control of the tool in unexpected

situations,

Use safety equipment. Always wear eye

protection. Dust mask, non-skid safety

shoes, hard hat, or hearing protection must be

used for appropdate conditions.

Tool Use and Care

use clamps or other practical way to secure

and support the workpiece to a stable

platform. Holding the work by hand or against

your body Is unstable and may lead to loss of

control.

Do not force tool. Use the correct tool for

your applicstlon. The correct tool will do the

job better and safer at the rate for which it is

designed.

Do not use tool if switch does not turn it

"ON" or "OFF". Any tool that cannot be

controlled with the switch is dangerous and

must be repaired.

-3-

Disconnect the plug/tom the power source

before making any adjustments, changing

accessories, or storing the tool. Such

preventive safety measures reduce the Hsk of

startingthe tool accidentally.

Store Idle tools out of reach of children and

other untrained persons. Tools are dangerous

inthe hands of untrained users.

Maintain tools with cere_ Keep cutting tools

sharp and clean. Prope_ maintained tools,

with sharp cutting edges are less likelyto bind

and are easier to control. Any alteration or

modification Is a misuse and may result in a

dangerous condition.

Check for misalignment or binding of

moving parts, breakage of parts, and any

other condition that m_ affect the toolJs

operation, if damaged, have the tool

serviced before using. Many accidents are

caused by poorly maintained tools. Develop a

pedodic maintenance schedule for your tool.

for your

suitable

when used on ;

Tool service

qualified

maintenance

example:

pinched,

improperly

When

replacement _ Follow l_ns in the

Maintenance_of this manual.

unauthorized I_rtb or failure to follow

Maintenance Ii_ions may create a risk of

elsctdc shock €_lll_ry. Certain cleaning agents

such as gas@il_e, carbon tetrachlcride,

ammonia etc. I_damage plastic parts.

that are sold at Sears

may become hazardous

be performed only by

|ersonnel. Service or

3rmed by unqualified

dt in a risk of injury. For

may be misplaced or

return springs may be

that may be

use only identical

Hold tool by insulated gripping surfaces

when performing an operation where the

cutting tool may contsct hidden wiring or its

own cord. Contact with a "live' wire will make

exposed metal parts of the tool "live" and

shock the operator, ff _ into existing walls

or other blind areas where electrical wiringmay

exist is unavoidable, disconnect all fuses or

circuitbreakers feeding this worksite.

Always make sure the work mwface is free

from nails and other toreign objects. Cutting

into a nail can cause the bit and the tool to

Jumpand damage the bit.

Never hold the workpfeGe in one hand and

the tool in the other hand when in use.

Never place hands near or below cutting

surface. Clamping the mstedai and guiding the

tool with both hands is safer.

Never lay workplace on top of hard

surfaces, like concrete, stone, etc...

Protrudingcutting bit may cause tool to jump.

Always wear safety goggles end dust mask.

Use only in well ventilated area. Using

personal safety devices and working in safe

environment reduces risk of injury.

After chang

adjustments,

any uther adj

tightened.

unexpectedly i

loose rotating

thrown, i

Never start thll

in the mat_

the material di_

cutter. I

Always hold

start-up.

cause the tool

The

material Is

the

the tool

cuts will rac

-4-

the bits or making any

_sure the conct nut and

_ devices are securely

ladjustment device can

t,_ausing loss of control,

_tponents will be violently

[

when the bit is engaged

bit cutting edge may grab

_|_g loss of control of the

d with two hands during

torque of the motor can

the bit into the

and it relates to

When viewing

top, the bit rotates

of cutting must be

feed direction, refer to

Feeding the tool

causes the cutting edge

1of this feed.

and pull the

Never use dull or damaged bits. Sharp bits

must be handled with care. Damaged bits can

snap during use. Dull bits require more force to

push the tool, possibly causing the bit to break.

Never touch the bit during or immediately

after the use. After use the bit is too hot to be

touched by bare hands.

Never lay the tool down until the motor has

come to a complete standstill. The spinning

bit can grab the surface end pull the tool out of

your control.

Never use bits that have a cutting diameter

greeter than the opening in the base.

8ome dust created by power

drilling, and other construction activities

contains chemicals known to cause cancer,

birth defects or other reproductive harm.

Some examples of these chemicals are:

• Lead from lead-based paints,

• Crystalline silica from bricks and cement and

other masonry products, and

• Arsenic and chromium from chemically-

treated lumber.

Your risk from these exposures varies,

depending on how often you do this type of

work. To reduce your exposure to these

chemicals: work in a well ventilated area, and

work with approved safety equipment, such as

those dust masks that are specially designed to

filter out microscopic particles.

sanding, sawing, grinding,

-5-

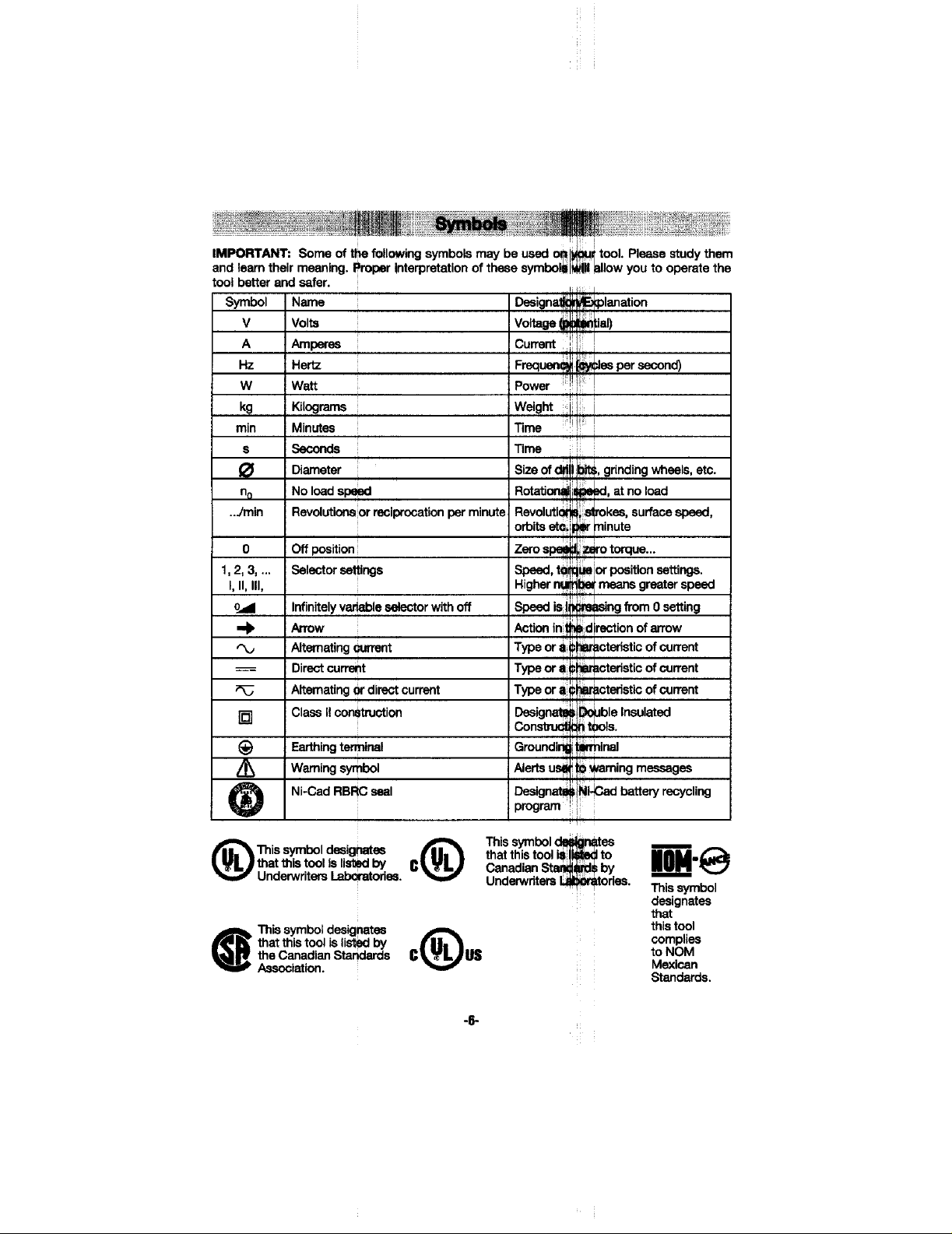

IMPORTANT: Some of the following symbols may be used on _=T tool. Please study them

and earn the r mean ng. Prober Interpretat on of these symbolmll_l!i alow you to operate the

toolbetterand safer.

Symbol

V

A

Hz

W

kg

min

s

0

no

.../rain

Name

Volts

Amperes

Hertz

Watt

Kilograms

Minutes

Seconds

Diameter

No load speed

Revolutions or reciprocation per minute

Time

I wheels, etc.

0

1,2,3,...

I, II, III,

Offposition

Selectorsettings

Infinitelyvariableselectorwithoff

..e

Arrow

Altemating _mant

Directcu_t

Altematingordirectcurrent

[]

e This symbol designates

ClassIIconstruction

Earthing terminal

Warning symbol

Ni-Cad RBRC seal

This symbol designates

that this tool is listed by

Underwriters Laboratories.

that this tool is listed by

the Canadian Standards

Association.

rection of arrow

I

, ,, "_'_=ff,,tedstic

Design '= _ble Insulated

Con_ i tbois.

:i

Groond,. in,

Alerts u_ i,iWarningmessages

I_sign_ I1_:11_ttsry recycling

program j

(_) This symbol dlNt_nates

G Canadian Stal_,_Uld$by

that this tool is i!_ to

Underwriters U_l:m_todes.

C_US

, ,i,p

of current

This symbol

designates

that

this tool

complies

to NOM

Mexican

Standards.

-6-

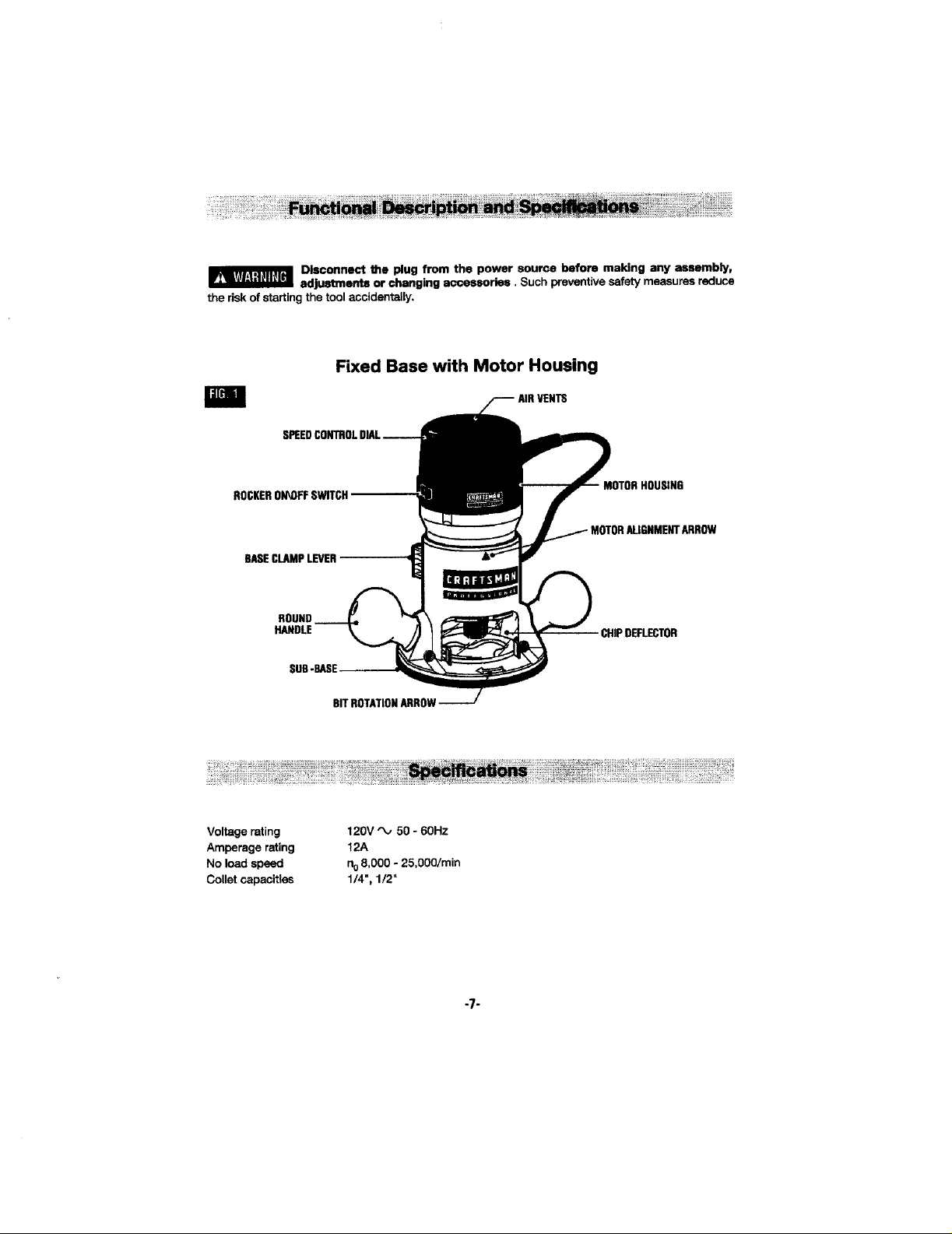

_ Disconnect the plug from the power source before making any assembly,

the risk of starting the tool accidentally,

adjustments or changing accessories. Such preventive safety measures reduce

Fixed Base with Motor Housing

_[_

ROCKERON'OFFSWITCH-

B_EC_MPL_ER

ROUND

HANDLE _HIPDEFLECTOR

Voltage rating

Amperage rating

No loadspeed

Collet capacities

MOTORHOUSING

RAUGNMENTARROW

SUB-BASE

BIT ROTATIONARROW

120V "_, 50 - 60Hz

12A

no8,000 - 25,000/min

1/4", 1/2"

-7-

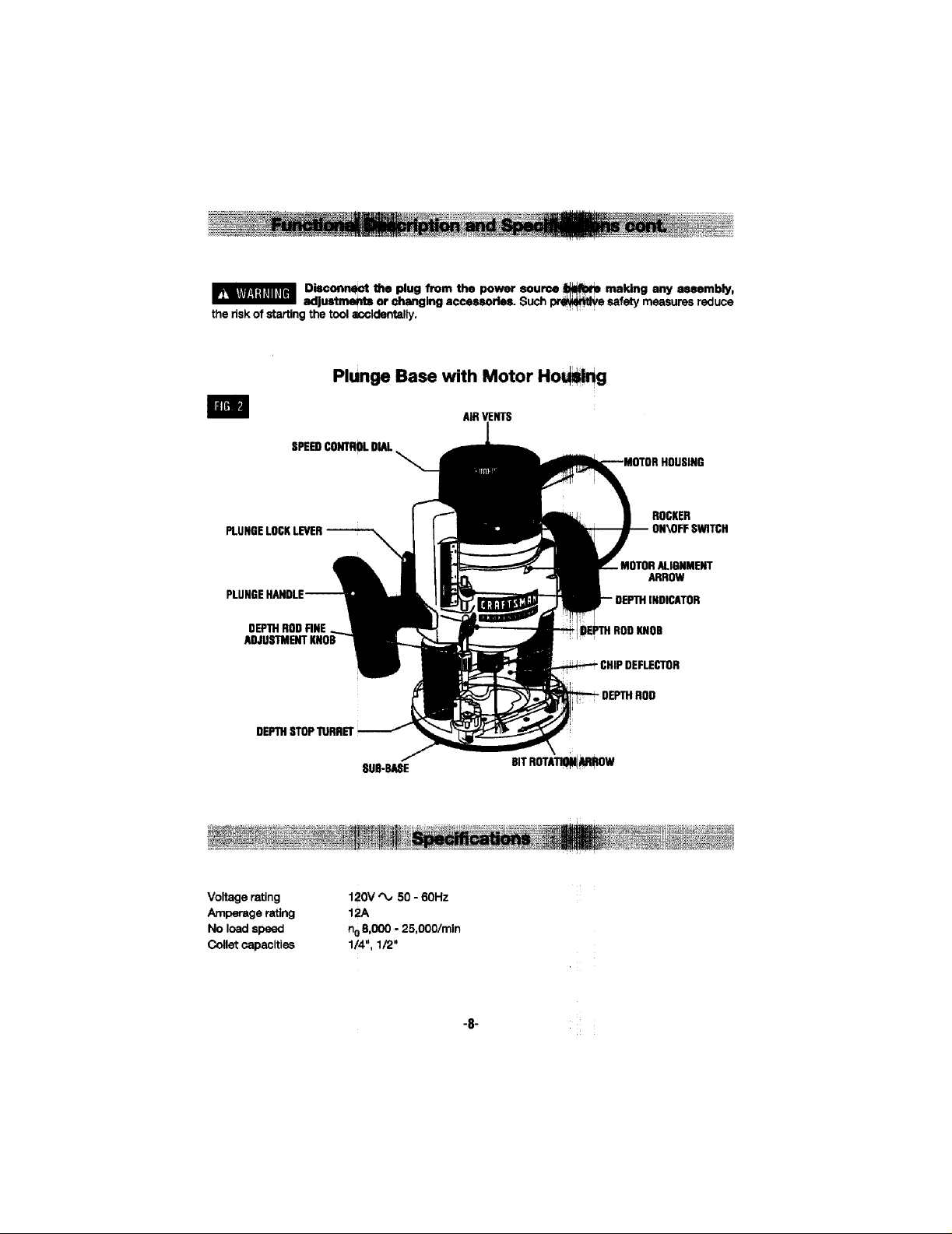

_r_ Discon_ the plug from the power souroe _ making any membly,

the risk of starting the toolaooldentally.

adjustments or ehanglng acoassodes. Such _ safety measures reduce

Plunge Base with Motor Ho_lng

AIRVENTS

SPEEDCONTROLDIAL

ROCKER

ARROW

DEPTHRODFINE

Voltage rating

Amperage rating

No loadspeed

Collet capacities

SUB-BASE

120V '%, 50 - 60Hz

12A

no8,000 - 25,000/rain

1/4", 1,,2'

RODKNOB

- DEPTHROD

BITROTATI_ _ROW

-8-

Loading...

Loading...