Page 1

Operator's Manual

CRA

P R 0 F E S I 0 N A L

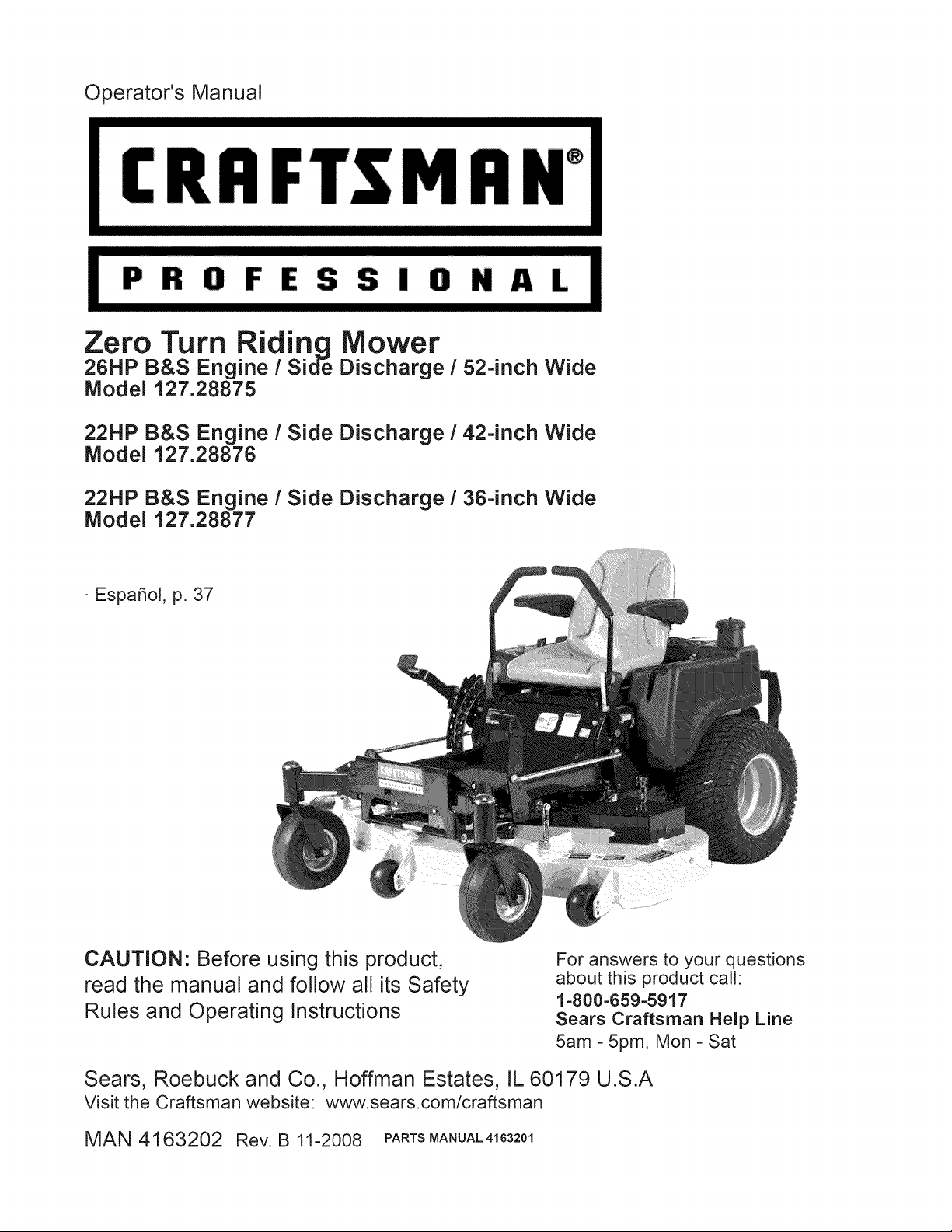

Zero Turn Ridinq Mower

26HP B&S Engine / Sid'_ Discharge / 52-inch Wide

Model 127.28875

22HP B&S Engine / Side Discharge / 42-inch Wide

Model 127.28876

22HP B&S Engine / Side Discharge / 36=inch Wide

Model 127.28877

• EspaSol, p. 37

CAUTION" Before using this product,

read the manual and follow all its Safety

Rules and Operating Instructions

For answers to your questions

about this product call:

1-800=659=5917

Sears Craftsman Help Line

5am - 5pm, Mon- Sat

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A

Visit the Craftsman website: www.sears.com/craftsman

MAN 4163202 Rev. B 11-2008 PARTSMANUAL4163201

Page 2

CALiFORNiA

Proposition 65 Warning

A WARNING

Diesel engine exhaust and some

of its constituents are known to the

State of California to cause cancer,

birth defects and other reproductive

harm.

Californie Proposition 65 Avertissemenl

Les 6chappements des moteurs diesel et certains

de leurs compos6s sont reconnus par l'Etat de

Califomie pour 6tre canc6rigbnes, provoquer

des d6fauts cong6nitaux et d'autres dangers en

matibre de reproduction.

California Advertencia

de la Proposicion 65

E1 estado de California hace saber que

los gases de escape de los motores diesel

y algunos de sus componentes producen

cfincer, defectos de nacimiento y otros

dafios en el proceso de reproducci6n

humana.

The engine exhaust from this product

contains chemicals known to the State

of California to cause cancer, birth

defects or other reproductive harm.

A AVERTISSEMENT

L'6mission du moteur de ce mat6riel con-

tient des produits chimiques que l'Etat de

Californie considbre 6tre canc6rigbnes,

provoquer des d6fauts cong6nitaux et

d'autres dangers en matibre de reproduc-

tion.

A ADVERTENCIA

E1estado de California hace saber que los

gases deescape de este producto contienen

productos qulmicos que producen cfincer,

defectos de nacimiento y otros dafios en

el proceso de reproducci6n humana.

CALIFORNIA

Proposition 65 Warning

Battery posts, terminals, wiring

insulation, and related accessories

contain lead and lead compounds,

chemicals known to the State of

California to cause cancer and birth

defects or other reproductive harm.

WASH HANDS AFTER HANDLING.

Page 3

TABLE OF CONTENTS PAGE

SAFETY ......................................................................................................................................................... 2-8

LABELS ....................................................................................................................................................... 9-13

CONTROLS ............................................................................................................................................... 14-17

PRE-OPERATION CHECK LIST .................................................................................................................... 18

SET UP INSTRUCTIONS .......................................................................................................................... 19-20

OPERATION .............................................................................................................................................. 21-23

MAINTENANCE CHART ................................................................................................................................ 24

MAINTENANCE RECORD ............................................................................................................................ 25

MAINTENANCE ........................................................................................................................................ 26-32

ADJUSTMENTS ....................................................................................................................................... 33-35

BELT REPLACEMENT ................................................................................................................................... 36

SERVICE INFORMATION ............................................................................................................. BACK PAGE

WARRANTY

CRAFTSMAN PROFESSIONAL LIMITED WARRANTY

Two Years on Tractor

When operated and maintained according to all supplied instructions, if this tractor fails due to a defect in

material or workmanship within two years from the date of purchase, call 1-800-4-MY-HOME® to arrange for

free repair.

This warranty applies for only one year from the date of purchase if this tractor is ever used for commercial or

rental purposes.

During the first 30 days of purchase, there will be no charge to service the tractor in your home. For your con-

venience, in-home warranty service will still be available after the first 30 days of purchase, but a trip charge

will apply. This charge will be waived if you transport the tractor to an authorized Craftsman drop-off location.

For the nearest authorized location, call 1-800-MY-HOME®.

90-Days on Battery

For ninety (90) days from the date of purchase, if the battery included with this tractor is defective in material

or workmanship (our testing proves it will not hold a charge), it will be replaced free of charge.

During the first 30 days of purchase, there will be no charge to replace the defective battery in your home.

For your convenience, in-home warranty service will still be available after the first 30 days of purchase, but a

trip charge will apply. This charge will be waived if you transport the tractor to an authorized Craftsman drop-

offlocation. For the nearest authorized location, call 1-800-MY-HOME®.

This warranty covers ONLY defects in material and workmanship. Sears will NOT pay for:

• Expendable items that become worn during normal use, including but not limited to blades,

spark plugs, air cleaners, belts, and oil filters.

• Standard maintenance servicing, oil changes, or tune-ups.

• Tire replacement or repair caused by punctures from outside objects, such as nails, thorns,

stumps, or glass.

• Tire or wheel replacement or repair resulting from normal wear, accident, or improper operation

or maintenance.

• Repairs necessary because of operator abuse, including but not limited to damage caused by

towing objects beyond the capability of the tractor, impacting objects that bend the frame or

crankshaft, or over-speeding the engine.

• Repairs necessary because of operator negligence, including but not limited to, electrical and

mechanical damage caused by improper storage, failure to use the proper grade and amount

of engine oil, failure to keep the deck clear of flammable debris, or failure to maintain the

equipment according to the instructions contained in the operator's manual.

• Engine (fuel system) cleaning or repairs caused by fuel determined to be contaminated or

oxidized (stale). In general, fuel should be used within 30 days of its purchase date.

• Normal deterioration and wear of the exterior finishes, or product label replacement.

This warranty applies only while this product is within the United States.

This warranty gives you specific legal rights, and you may also have other rights, which vary, from state to

state.

Sears, Roebuck and Co., Hoffman Estates, IL 60179

11-2007 1

Page 4

SAFETY

NOTICE !!!

Unauthorized modifications may present extreme

safety hazards to operators and bystanders and

could also result in product damage.

Craftsman Professionalstrongly warns against,

rejects and disclaims any modifications, add-on

accessories or product alterations that are not

designed, developed, tested and approved by

Craftsman Professional Engineering Department.

Any Craftsman Professional product that is altered,

modified or changed in any manner not specifically

authorized after original manufacture-including the

addition of "aftermarket" accessories or component

parts not specifically approved by Craftsman

Profesional-will result inthe Craftsman Professional

Warranty being voided.

Any and all liability for personal injury and/or property

damage caused by any unauthorized modifications,

add-on accessories or products not approved

by Craftsman Professional will be considered

the responsibility of the individual(s) or company

designing and/or making such changes. Craftsman

Professional will vigorously pursue full indemnification

and costs from any party responsible for such

unauthorized post-manufacture modifications and/or

accessories should personal injury and/or property

damage result.

This symbol means:

ATTENTION!

BECOME ALERT!

Your safety and the safety of others is involved.

Signal word definitions:

The signal words below are used to identify levels

of hazard seriousness. These words appear in

this manual and on the safety labels attached

to Craftsman Professional machines. For your

safety and the safety of others, read and follow the

information given with these signal words and/or

the symbol shown above.

DANGER indicates an imminently hazardous

situation which, if not avoided, WILL result in death

or serious injury.

WARNING indicates a potentially hazardous

situation which, if not avoided, COULD result in

death or serious injury.

A CAUTION

CAUTION indicates a potentially hazardous situation

which, ifnot avoided, MAY result in minor or moderate

injury. It may also be used to alert against unsafe

practices or property damage.

CAUTION

CAUTION used without the safety alert symbol

indicates a potentially hazardous situation which, if

not avoided, MAY result in property damage

MODEL NUMBER: This number appears on sales literature, technical manuals and

price lists.

SERIAL NUMBER: This number appears only on your mower. It contains the model

number followed consecutively by the serial number. Use this number when ordering

parts or seeking warranty information.

Serial Number Tag is located under seat; on the far back wall of the frame; left of battery

from operators point of view.

2

Page 5

PREPARING FOR SAFE OPERATION

Operator preparation and training

Read the Operation & Safety

Manual

If an operator or mechanic

cannot read English, it is

the owner's responsibility

to explain this material to

them. If any portion of this

material is unclear, contact

your factory representative for

clarification.

Become familiar with the safe operation of the

equipment, operator controls and safety signs.

Know how to stop the engine and attachments

quickly in an emergency. Do not operate or allow

another person to operate this machine if there

are any questions about safety.

All operators and mechanics should be trained.

The owner is responsible for training the users.

Wear appropriate clothing, including long

trousers and safety goggles or safety glasses

with side shields when operating mower. Do not

operate barefoot or wearing open sandals. Long

hair, loose clothing or jewelry may get tangled in

moving parts.

Wear hearing protection.

Never allow underage children, unskilled

or improperly trained people operate this

equipment. Local regulations can restrict the age

of the operator.

Data indicates that those operators age 60 years

and above are involved in a large percentage of

riding mower-related injuries. Those operators

should evaluate their ability to operate the riding

mower safely enough to protect themselves and

others from injury.

Do not carry passengers, especially small

children. They may fall off and be seriously

injured.

Keep warning labels and this operator's manual

legible and intact. Replacement labels and

manuals are available from the factory.

Do not operate machine while under the

influence of drugs or alcohol.

The owner/user can prevent and is responsible

for accidents or injuries occurring to themselves,

other people or property.

SAFETY

I G

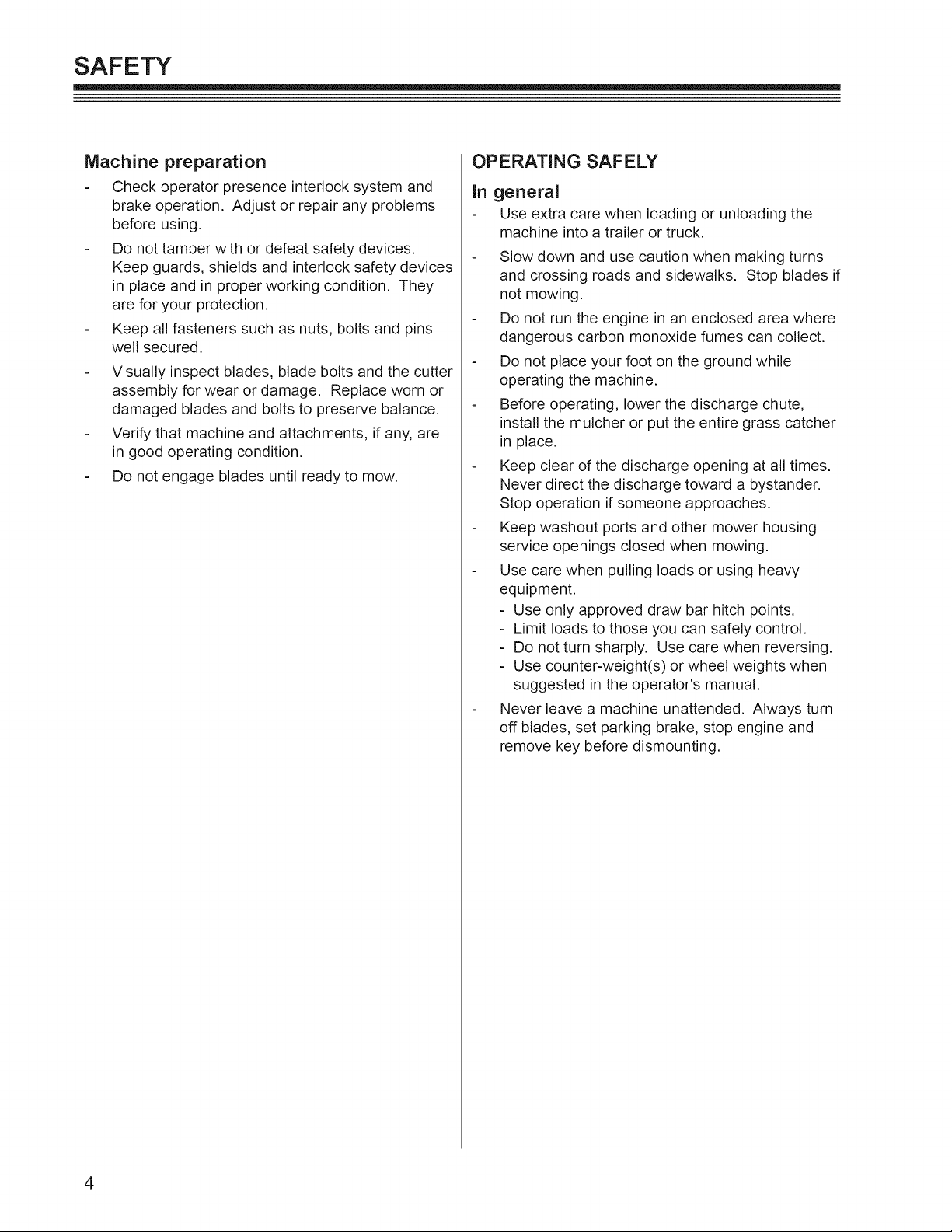

All rotary lawnmowers are potentially

dangerous. They can amputate hands and

feet and throw objects, Failure to follow

these safety and operating instructions

could result in serious injury or death.

Site preparation and circumstances

Evaluate the terrain to determine what

accessories and attachments are needed to

properly and safely perform the job. Only use

accessories and attachments approved by the

manufacturer,

Clear the area to be mowed of objects such as

rocks, toys, wire or other debris that may be

picked up or thrown by the mower.

Be sure the area is clear of pets and people,

especially young children. Never assume they

will remain where you last saw them. Stop the

machine if any enter the area.

Mow only in daylight or in good artificial light.

Do not mow wet grass as tires may lose traction.

3

Page 6

SAFETY

Machine preparation

Check operator presence interlock system and

brake operation. Adjust or repair any problems

before using.

Do not tamper with or defeat safety devices.

Keep guards, shields and interlock safety devices

in place and in proper working condition. They

are for your protection.

Keep all fasteners such as nuts, bolts and pins

well secured.

Visually inspect blades, blade bolts and the cutter

assembly for wear or damage. Replace worn or

damaged blades and bolts to preserve balance.

Verify that machine and attachments, if any, are

in good operating condition.

Do not engage blades until ready to mow.

OPERATING SAFELY

in general

Use extra care when loading or unloading the

machine into a trailer or truck.

Slow down and use caution when making turns

and crossing roads and sidewalks. Stop blades if

not mowing.

Do not run the engine in an enclosed area where

dangerous carbon monoxide fumes can collect.

Do not place your foot on the ground while

operating the machine.

Before operating, lower the discharge chute,

install the mulcher or put the entire grass catcher

in place.

Keep clear of the discharge opening at all times.

Never direct the discharge toward a bystander.

Stop operation if someone approaches.

Keep washout ports and other mower housing

service openings closed when mowing.

Use care when pulling loads or using heavy

equipment.

Use only approved draw bar hitch points.

Limit loads to those you can safely control.

Do not turn sharply. Use care when reversing.

Use counter-weight(s) or wheel weights when

suggested in the operator's manual.

Never leave a machine unattended. Always turn

off blades, set parking brake, stop engine and

remove key before dismounting.

4

Page 7

SAFETY

Starting

Start only according to instructions in this manual

or on the machine.

Before attempting to start the engine, make sure:

- the parking brake is on;

- the PTO is disengaged;

- the traction drive is in NEUTRAL.

When starting the engine, make sure hands and

feet are clear of the blades.

Do not start the machine while standing in front

of the discharge chute or with the chute directed

at someone.

Do not engage PTO at full throttle. Throttle to

idle or lowest possible engine speed.

Do not change engine governor settings or

over-speed the engine. Operating the engine

at excessive speed can increase the hazard of

personal injury.

interrupting operation

Before leaving the operator's position:

- Park on level ground.

- Disengage the PTO.

- Set the parking brake.

- Shut off the engine and remove the key.

Disengage the PTO and wait until the blades quit

rotating:

- before raising cutterdeck;

- when not mowing;

- for transport;

- when crossing surfaces other than grass.

Stop the engine, disengage the PTO, set parking

brake and wait until the blades quit rotating and

lower cutting unit:

- before refueling;

- before removing grass catcher;

- before making height adjustment unless the

adjustment can be made from the operator's

position.

Stop the engine, disengage the PTO, set parking

brake and disconnect the spark plug wire(s) or

remove the key:

- before clearing blockages or unclogging chute;

- before checking, cleaning or working on the

machine;

- after striking a foreign object. Inspect the

machine for damage and make repairs before

restarting;

- if the machine begins to vibrate abnormally:

shut off machine immediately. Inspect and

make repairs as needed before restarting;

- except for repairs or adjustments as specifically

noted, such as for carburetor adjustment,

where the engine must be running. Keep

hands and feet clear of moving parts in these

circumstances.

Allow the blades to come to a complete stop

when stopping operation to clear blockages,

unclog, inspect the machine, do maintenance or

repair.

Reduce the throttle setting during engine shut-

down and, if the engine is provided with a shut-

off valve, turn the fuel off at the conclusion of

mowing.

5

Page 8

SAFETY

MANEUVERING SAFELY

in general

Slow down before turning•

Do not mow in reverse unless absolutely

necessary. Always look behind and down

for small children and pets before and during

backing.

Be aware when approaching blind corners,

shrubs, trees, tall grass or other objects that may

obscure vision.

If tires lose traction, disengage the blades• If on

a slope, head downhill.

Mowing slopes

Slopes are a major factor in

loss-of-control and tip over

accidents that sometimes lead

to severe injury or death. All

slopes require extra caution.

Do not mow on slopes if uneasy or uncertain.

Ultimate responsibility for safe operation on

slopes rests with the operator.

Do not mow excessively steep slopes.

A slope is too steep if:

• The machine will not back up the slope.

• The machine must be crabbed (turned

partially sideways uphill) to drive across

the slope.

• The machine turns downhill going across slope.

• You are uneasy about being on the slope.

On zero turn machines, mow across slopes, not

up and down.

Avoid starting or stopping on a slope. If tires

lose traction, disengage the blades and proceed

slowly straight down the slope.

With a zero turn machine, if tires lose traction

going down a slope, steering control may be

regained by speeding up.

Mid-mount zero turns (belly mounted deck) have

much greater traction pointed up slope than

down slope. Be aware that traction may be lost

going down a slope. Do not operate a mid-mount

zero turn on slopes it cannot back up.

Keep all movement on the slopes slow and

_lb WARNING

gradual. Do not make sudden changes in speed

or direction.

Do not turn on slopes unless necessary, and then

turn slowly and downhill when possible.

Stay away from slopes if the ground is loose or if

caught in the rain during mowing.

Use lower speeds on a slope to avoid stopping or

shifting.

Use extra care with grass catchers or other

attachments. These can change the stability of

the machine.

Remove obstacles such as rocks, tree limbs etc.

Avoid driving over obstacles such as ruts, holes,

rocks and roots whenever possible. Be alert to

dips and rises. Uneven terrain can overturn a

mower or cause it to slide. Tall grasses can hide

obstacles.

Do not mow drop=offs, ditches or embankments.

The machine could suddenly turn over if a wheel

runs over the edge or an edge caves in•

Follow the manufacturer's recommendations

for wheel weights or counterweights to improve

stability.

Do not mow slopes when grass is wet• Reduced

traction could cause sliding.

6

Page 9

MAINTENANCE SAFETY

in general

Maintain machine according to manufacturer's

schedule and instructions for maximum safety

and best mowing results.

Park machine on level ground.

Never allow untrained personnel to service ma-

chine.

Adjust or repair only after the engine has been

stopped and the blades have quit rotating.

Inspect grass catcher components regularly. If

worn, damaged or deteriorated, they may expose

moving parts or allow objects to be thrown.

Replace parts if worn, damaged or faulty.

For best results, always replace with parts

recommended by the manufacturer.

Disconnect battery or remove spark plug wire(s)

before making any repairs. Disconnect the

negative terminal first and the positive last. Re-

connect positive first and negative last.

Do not dismantle the machine without releasing

or restraining forces which may cause parts to

move suddenly.

Provide adequate support, e.g. jackstands for

lifted machine or parts if working beneath.

Do not put hands or feet near or under rotating

parts.

Clean up spilled oil or fuel thoroughly.

Replace faulty mufflers.

To reduce fire hazards, keep the engine, muffler,

battery compartment and fuel storage area free

of grass, leaves, debris buildup or grease.

Hydraulic fluid can penetrate skin, use paper

to check for leaks. Relieve hydraulic pressure

before disconnecting hoses. Make sure

connections are tight and hoses are in good

condition.

SAFETY

WARNING

Blades

Mower blades are sharp and

can cut. Use extra caution

when handling. Remove ob-

structions with care. Wrap the

blade(s) or wear gloves.

Be aware that rotating one

blade on multi-blade mowers can cause other

blades to rotate.

Only replace blades. Never straighten or weld

them.

Keep other persons away from blades.

WARNING

Fuel

Gasoline and diesel fuels are

flammable; gasoline vapors

are explosive. Use extra care

when handling.

Store only in containers spe-

cifically designed for fuel.

When refueling or checking fuel level:

- Stop the engine and allow to cool;

- Do not smoke;

- Refuel outdoors only;

- Use a funnel;

- Do not overfill;

- If fuel is spilled, do not attempt to start the

engine until the spill is cleaned up and vapors

have cleared.

Sparks from static electricity can start fires or cause

explosions. Flowing fuel can generate static

electricity. To prevent static electricity sparks:

Keep containers electrically grounded. Do not fill

containers in a vehicle or on a truck or trailer bed

with a plastic liner. Fill containers on the ground

away from the vehicle.

When practical, remove gas powered equip-

ment from the truck or trailer and refuel it on the

ground. If equipment must be refueled on the

truck or trailer, refuel from a portable container

rather than a dispenser nozzle.

Keep the dispenser nozzle in contact with the rim

of the fuel tank or container opening until fueling

is complete. Do not use a nozzle lock-open

device.

Replace caps on fuel cans and tanks securely.

7

Page 10

SAFETY

BATTERY

Battery acid is caustic and fumes

are explosive and can cause

serious injury or death.

To reduce the risk of personal

injury when working near a bat-

tery:

When working with battery -=

acid, use protective equipment

such as, but not limited to, goggles, face shield,

rubber gloves and apron.

Avoid leaning over a battery.

Do not expose a battery to open flames or

sparks.

Be sure batteries with filler caps are properly

filled with fluid.

Do not allow battery acid to contact eyes or skin.

Flush any contacted area with water immediately

and get medical help.

Charge batteries in an open, well ventilated area,

away from sparks and flames. Unplug charger

before connecting or disconnecting from battery.

Stop the engine and allow to cool before storing.

Drain the fuel tank outdoors only.

Store fuel in an approved container in a cool, dry

place.

Keep the machine and fuel containers in a locked

storage place to prevent tampering and to keep

children from playing with them.

When the machine is to be parked, stored or left

unattended, lower the cutterdeck unless a posi-

tive mechanical lock is used.

Do not store the machine or fuel container near

heating appliances with an open flame such as a

water heater or an appliance with a pilot light.

Keep gasoline storage area free of grass, leaves

and excessive grease to reduce fire hazard.

Clean grass and debris from cutting units, drives,

mufflers and engine to help prevent fires.

WARNING

,

Be sure the jumper cables are in good condition.

Turn off the ignition and all electrical accessories

on both machines.

2. Position the machine with a good (charged) bat-

tery next to but not touching the machine with the

dead battery so jumper cables will reach.

3. When making cable connections:

make sure the clamps do not touch anywhere

except to intended metal parts,

Never connect a positive ("+" or red) terminal

to a negative ("-" or black) terminal.

Make sure the cables won't get caught in any

parts after the engines are started.

4. Connect one end of the first jumper cable to the

positive terminal on one battery. Connect the

other end to the positive terminal on the other

battery.

5. Connect one end of the other cable to the

negative terminal of the machine with a good

(charged) battery. Make the final connection on

the engine of the machine to be started, away

from the battery.

6. Start the vehicle with the good battery, then the

machine with the discharged battery.

7. Remove the cables in the exact reverse order of

installation. When removing each clamp, take

care it does not touch any other metal parts while

the other end remains attached.

8

Page 11

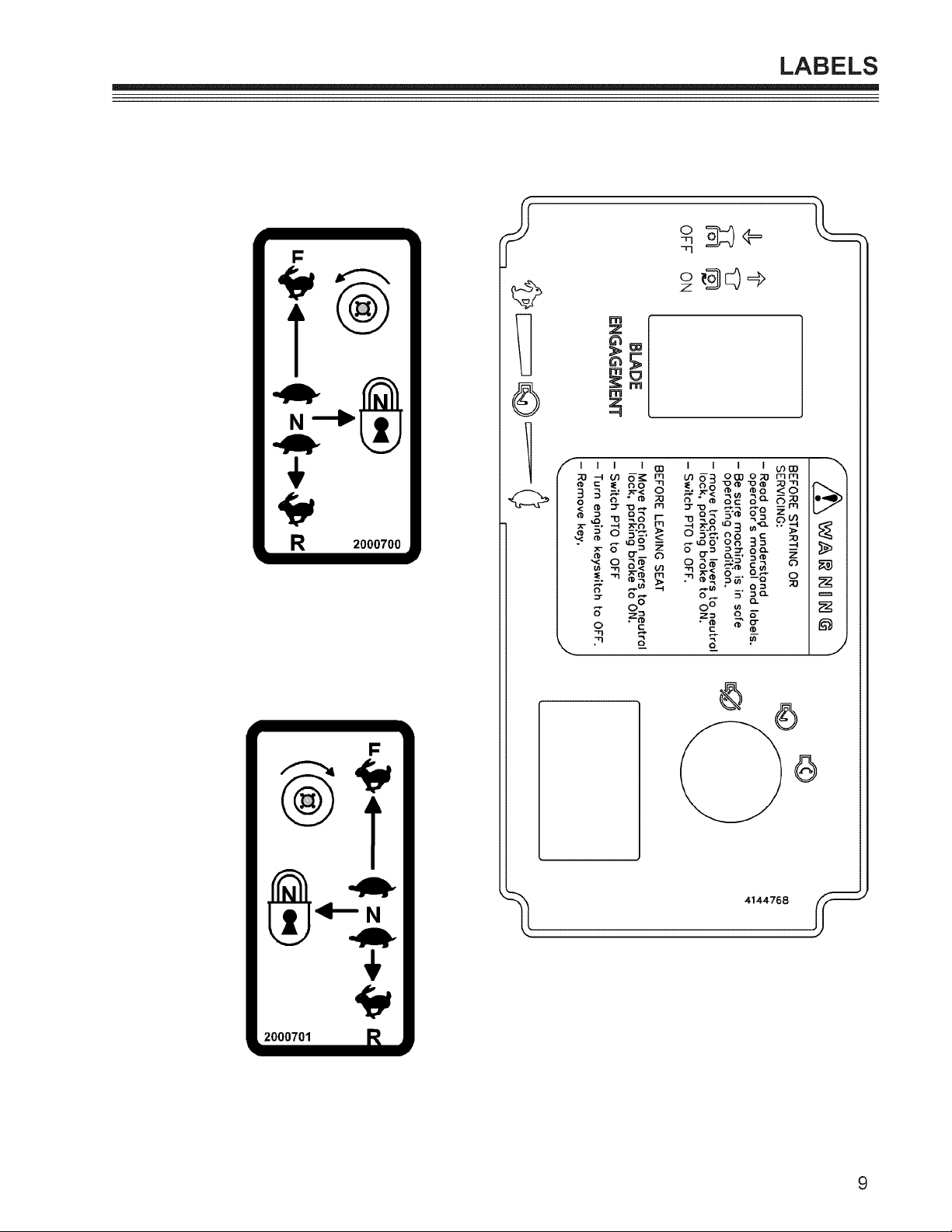

T

©

LABELS

rN

Z

R 2000700

6

!

tt3

f-I I I I oo

0 • :::r -0_ P7

_- 5"8 _-=<>

O"__ C)

0 o

o _

-t1

-n 8

_ -

2000701

9

Page 12

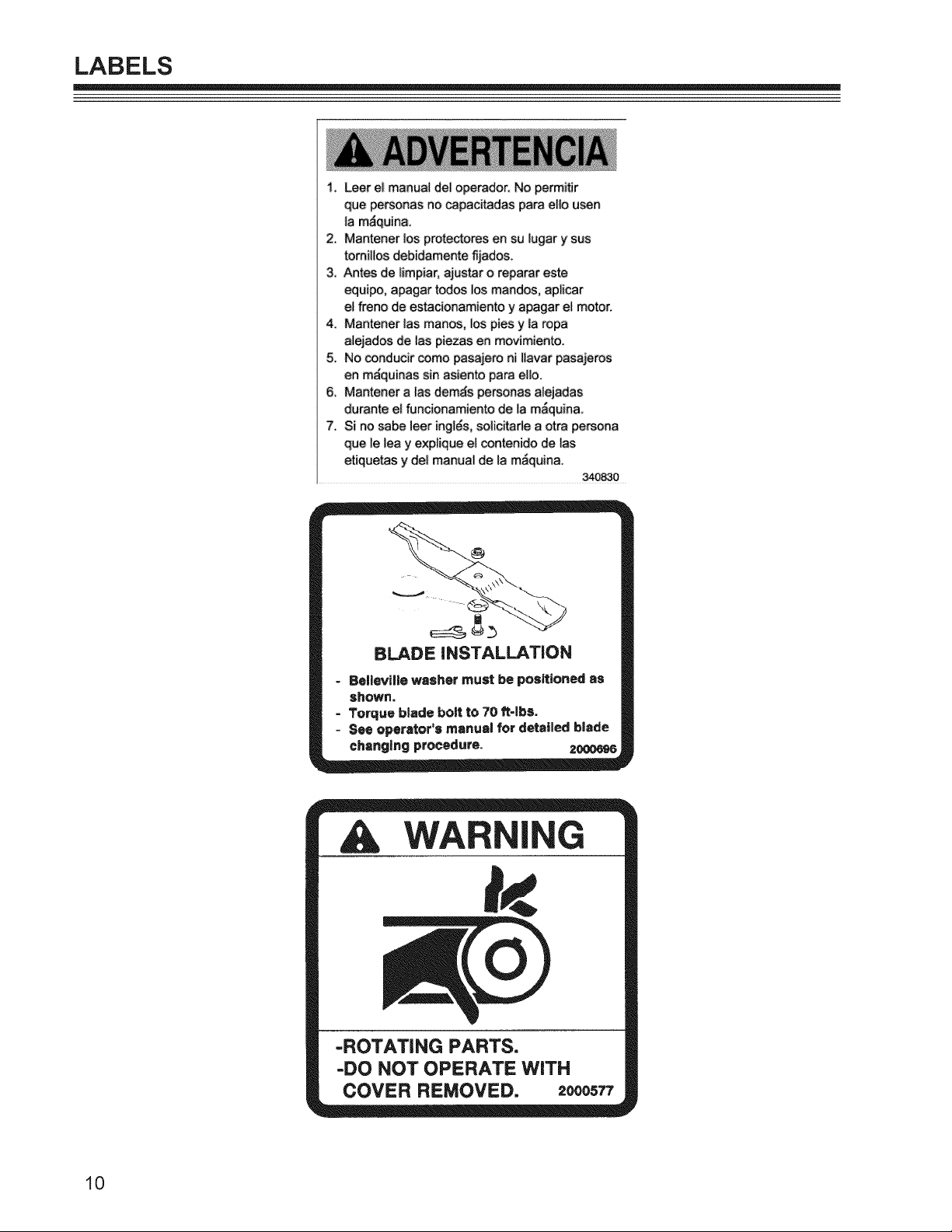

LABELS

1, L_r el manual del o_::_rador.No permitir

que personas no _pacitadas pa_ e_o usen

la m_quina,

2. Mantener los protectores en su lugar y sus

tomil{os debidamente _ados.

3. Antes de iimpiar, ajustar o reparar este

equipo, apagar todos los mandos, aplicar

e{ freno de es_cionamiento y apagar el motor.

4_ Mantener {as manos, los pies y la ropa

a{ejados de las piezas en movimiento,

5. No _nducir _mo pasajeroni liavar pasajeros

en m_quinas sin as_ento pan ello.

6 Mantener aias demos personas aiejadas

durante el funcionamiento de la m_quina.

7. Si no sabe I_r ing|_s, solici_de a otra _rsona

que le lea y expiique e! contenido de las

etiquetas y del manual de la m_quina.

340830

BLADE iNSTALLATiON

=ROTATING PARTS.

=DO NOT OPERATE WiTH

COVER REMOVED. 2ooos77

10

Page 13

LABELS

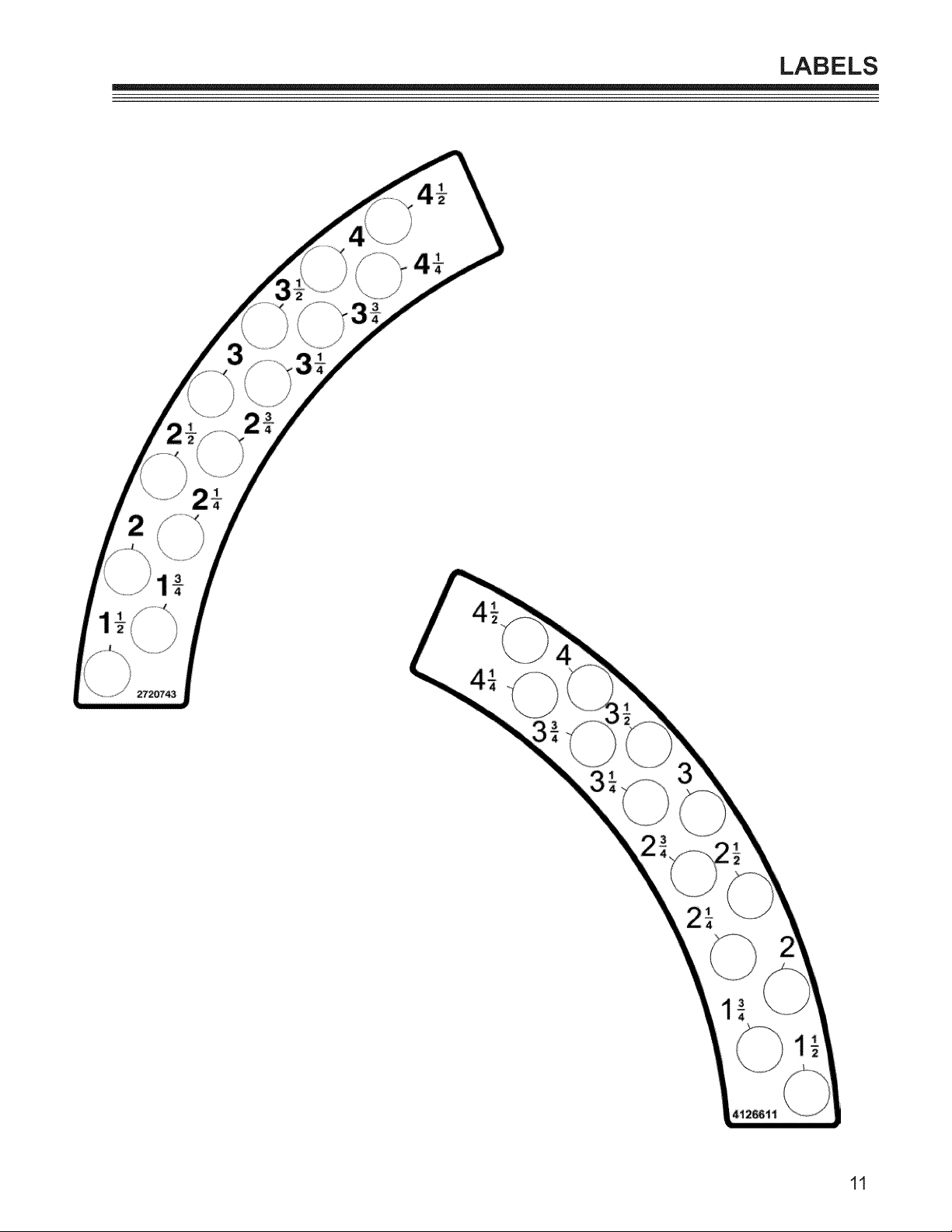

1

2720743

1

3

4126611

11

Page 14

LABELS

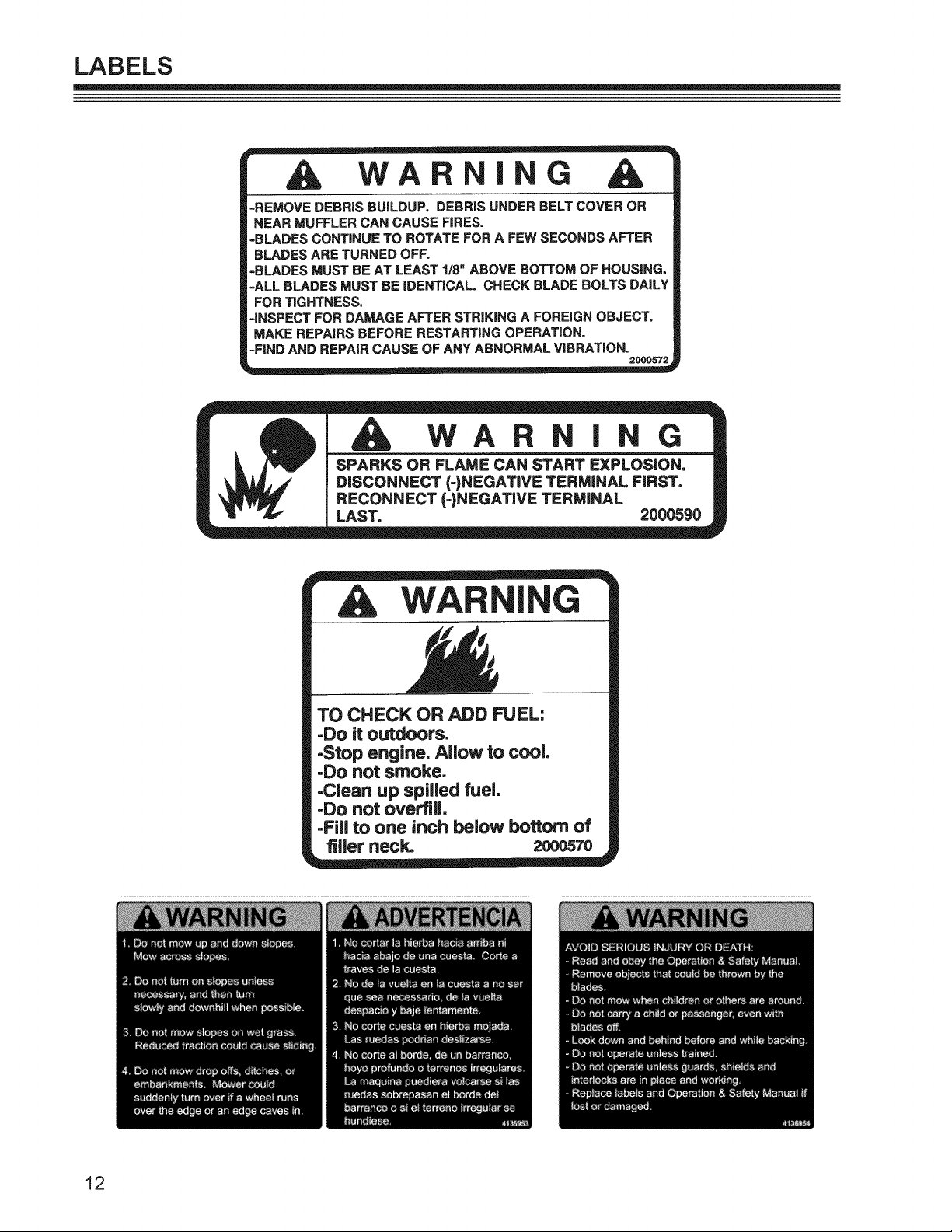

,A WARNING ,A

=REMOVE DEBRIS BUILDUP. DEBRIS UNDER BELT COVER OR

NEAR MUFFLER CAN CAUSE FIRES.

=BLADES CONTINUE TO ROTATE FOR A FEW SECONDS AFTER

BLADES ARE TURNED OFF.

=BLADES MUST BE AT LEAST 1/8" ABOVE BOTTOM OF HOUSING,

-ALL BLADES MUST BE iDENTICAL. CHECK BLADE BOLTS DAILY

FOR TIGHTNESS,

=iNSPECT FOR DAMAGE AFTER STRiKiNG A FOREIGN OBJECT,

MAKE REPAIRS BEFORE RESTARTING OPERATION.

=FINDAND REPAIR CAUSE OF ANY ABNORMAL ViBRATiON.

2000572

WARNING

SPARKS OR FLAME CAN START EXPLOSION,

DISCONNECT (=)NEGATIVE TERMINAL FIRST.

RECONNECT (=)NEGATIVE TERMINAL

LAST. 2000590

TO CHECK OR ADD FUEL:

=Do it outdoors.

-Stop engine. Allow to cool,

-Do not smoke.

-Clean up spilled fuel.

=Donot overfill.

-Fill to one inch below bottom of

filler neck. 2000570

12

Page 15

LABELS

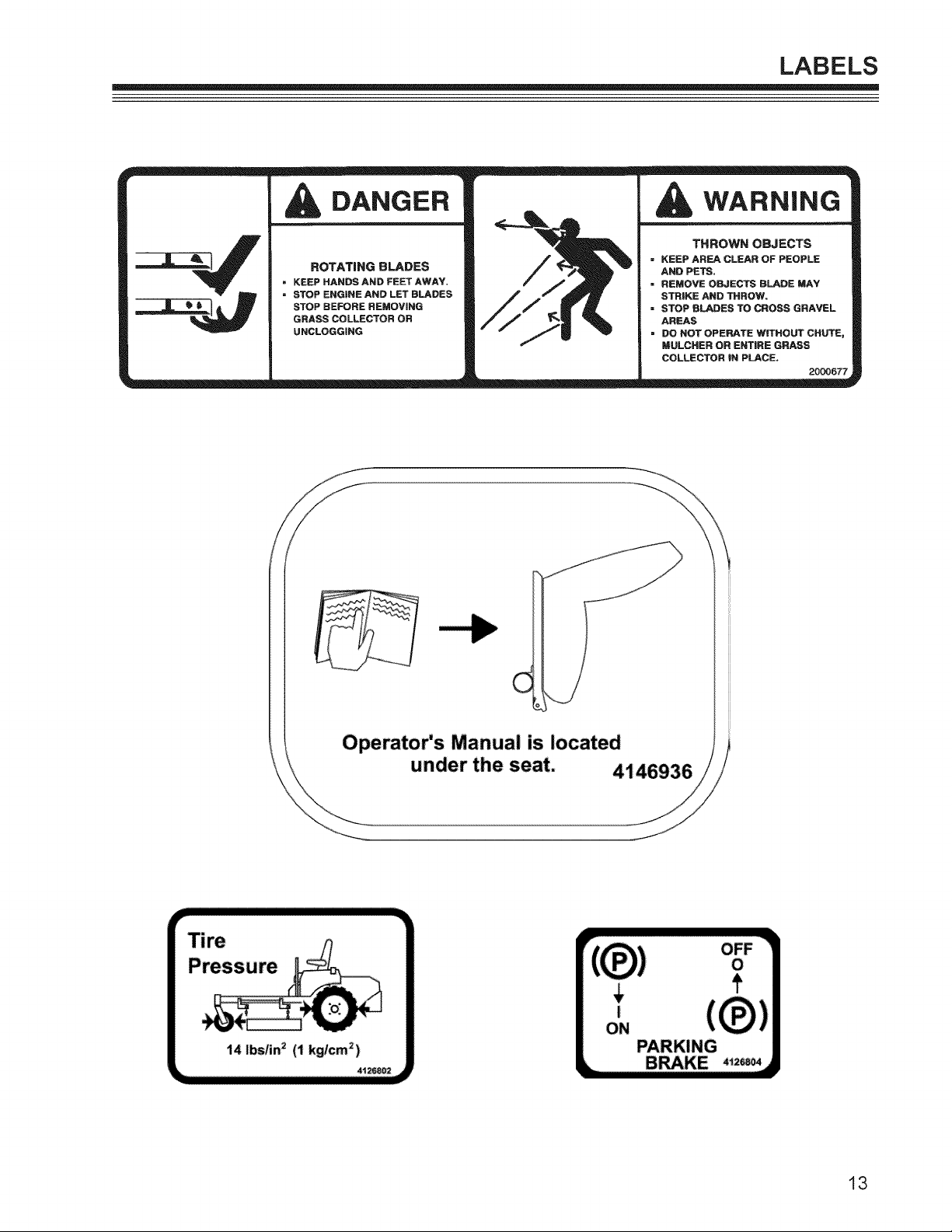

DANGER

ROTATING BLADES

= KEEP HANDS AND FEET AWAY.

= STOP ENGINE AND LET BLADES

STOP BEFORE REMOVING

GRASS COLLECTOR OR

UNCLOGGING

WARNING

THROWN OBJECTS

= KEEP AREA CLEAR OF PEOPLE

AND PETS,

= REMOVE OBJECTS BLADE MAY

STRIKE AND THROW.

= STOP BLADES TO CROSS GRAVEL

AREAS

• DO NOT OPERATE WITHOUT CHUTE,

MULCHER OR ENTIRE GRASS

COLLECTOR iN PLACE.

2000677

Operator's Manual is located

14 |bs/in 2 (1 kglcm z)

•!2e80__i

13

Page 16

CONTROLS

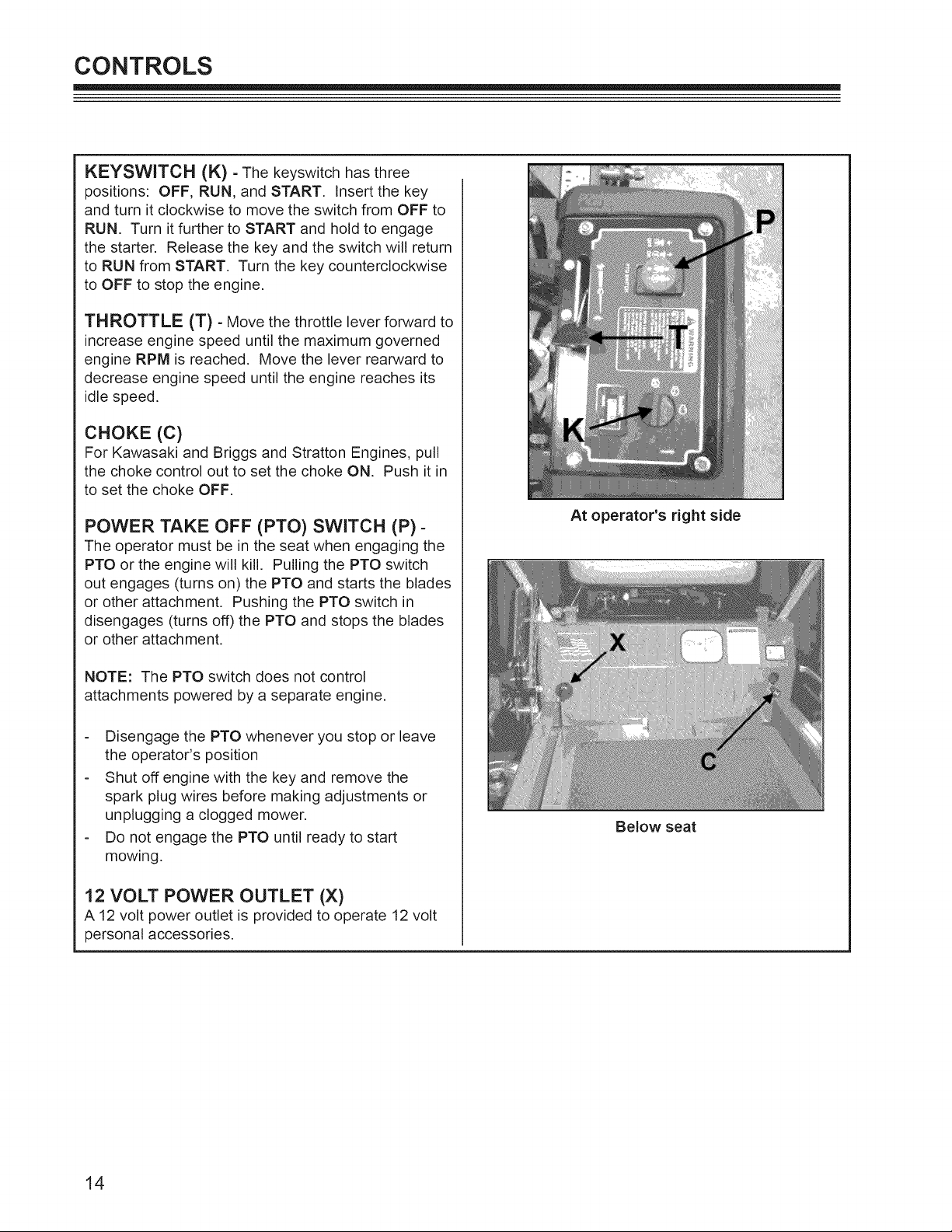

KEYSWITCH (K) - The keyswitch has three

positions: OFF, RUN, and START. Insert the key

and turn it clockwise to move the switch from OFF to

RUN. Turn it further to START and hold to engage

the starter. Release the key and the switch will return

to RUN from START. Turn the key counterclockwise

to OFF to stop the engine.

THROTTLE (T) - Move the throttle lever forward to

increase engine speed until the maximum governed

engine RPM is reached. Move the lever rearward to

decrease engine speed until the engine reaches its

idle speed,

CHOKE (C)

For Kawasaki and Briggs and Stratton Engines, pull

the choke control out to set the choke ON. Push it in

to set the choke OFF.

POWER TAKE OFF (PTO) SWITCH (P)-

The operator must be in the seat when engaging the

PTO or the engine will kill. Pulling the PTO switch

out engages (turns on) the PTO and starts the blades

or other attachment. Pushing the PTO switch in

disengages (turns off) the PTO and stops the blades

or other attachment.

NOTE: The PTO switch does not control

attachments powered by a separate engine.

Disengage the PTO whenever you stop or leave

the operator's position

Shut off engine with the key and remove the

spark plug wires before making adjustments or

unplugging a clogged mower.

Do not engage the PTO until ready to start

mowing,

12 VOLT POWER OUTLET (X)

A 12 volt power outlet is provided to operate 12 volt

personal accessories.

At operator's right side

Below seat

14

Page 17

FUEL SELECTOR VALVE (U)

The fuel tank selector valve is located behind the

seat,

The fuel tank selector valve has three positions:

Off: The tank selector is off when the lever points

down. The selector should be off whenever the

machine is transported or stands unused for any

length of time. Shutting off the fuel supply avoids the

possibility of flooding should any dirt get under the

carburetor float needle. Leaving the tank selector in

either tank position can allow severe flooding, which

may ruin the engine by diluting the oil.

Right Tank: Fuel flows from the right tank when the

selector is turned 1/4 turn toward the right.

Left Tank: Fuel flows from the left tank when the

selector is turned 1/4 turn toward the left.

CONTROLS

15

Page 18

CONTROLS

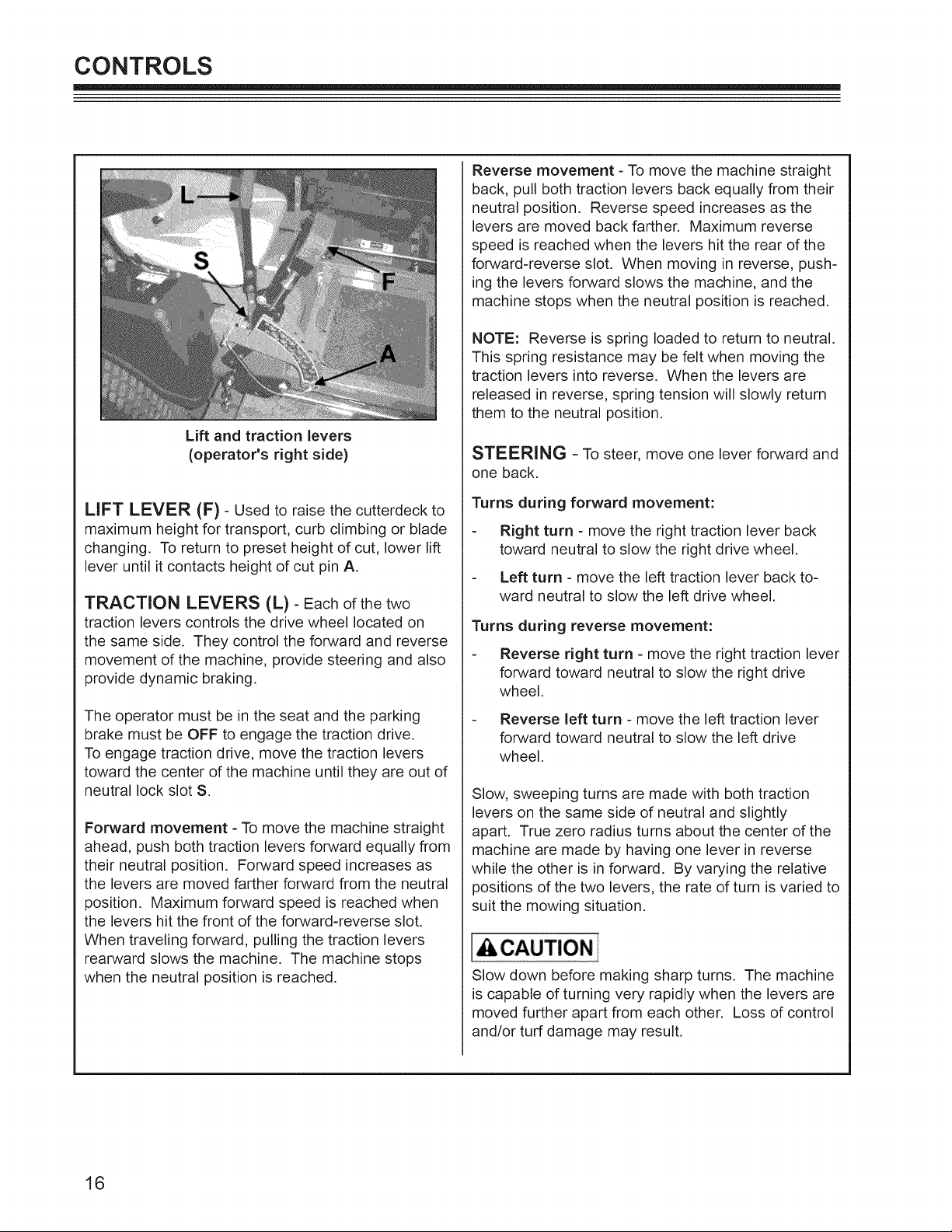

Lift and traction levers

(operator's right side)

Reverse movement - To move the machine straight

back, pull both traction levers back equally from their

neutral position. Reverse speed increases as the

levers are moved back farther. Maximum reverse

speed is reached when the levers hit the rear of the

forward-reverse slot. When moving in reverse, push-

ing the levers forward slows the machine, and the

machine stops when the neutral position is reached.

NOTE: Reverse is spring loaded to return to neutral.

This spring resistance may be felt when moving the

traction levers into reverse. When the levers are

released in reverse, spring tension will slowly return

them to the neutral position.

STEERING - To steer, move one lever forward and

one back.

LIFT LEVER (F) - Used to raise the cutterdeck to

maximum height for transport, curb climbing or blade

changing. To return to preset height of cut, lower lift

lever until it contacts height of cut pin A.

TRACTION LEVERS (L)- Each of the two

traction levers controls the drive wheel located on

the same side. They control the forward and reverse

movement of the machine, provide steering and also

provide dynamic braking.

The operator must be in the seat and the parking

brake must be OFF to engage the traction drive.

To engage traction drive, move the traction levers

toward the center of the machine until they are out of

neutral lock slot S.

Forward movement - To move the machine straight

ahead, push both traction levers forward equally from

their neutral position. Forward speed increases as

the levers are moved farther forward from the neutral

position. Maximum forward speed is reached when

the levers hit the front of the forward-reverse slot.

When traveling forward, pulling the traction levers

rearward slows the machine. The machine stops

when the neutral position is reached.

Turns during forward movement:

Right turn - move the right traction lever back

toward neutral to slow the right drive wheel,

Left turn - move the left traction lever back to-

ward neutral to slow the left drive wheel.

Turns during reverse movement:

Reverse right turn - move the right traction lever

forward toward neutral to slow the right drive

wheel.

Reverse left turn - move the left traction lever

forward toward neutral to slow the left drive

wheel.

Slow, sweeping turns are made with both traction

levers on the same side of neutral and slightly

apart. True zero radius turns about the center of the

machine are made by having one lever in reverse

while the other is in forward. By varying the relative

positions of the two levers, the rate of turn is varied to

suit the mowing situation.

Slow down before making sharp turns. The machine

is capable of turning very rapidly when the levers are

moved further apart from each other. Loss of control

and/or turf damage may result.

16

Page 19

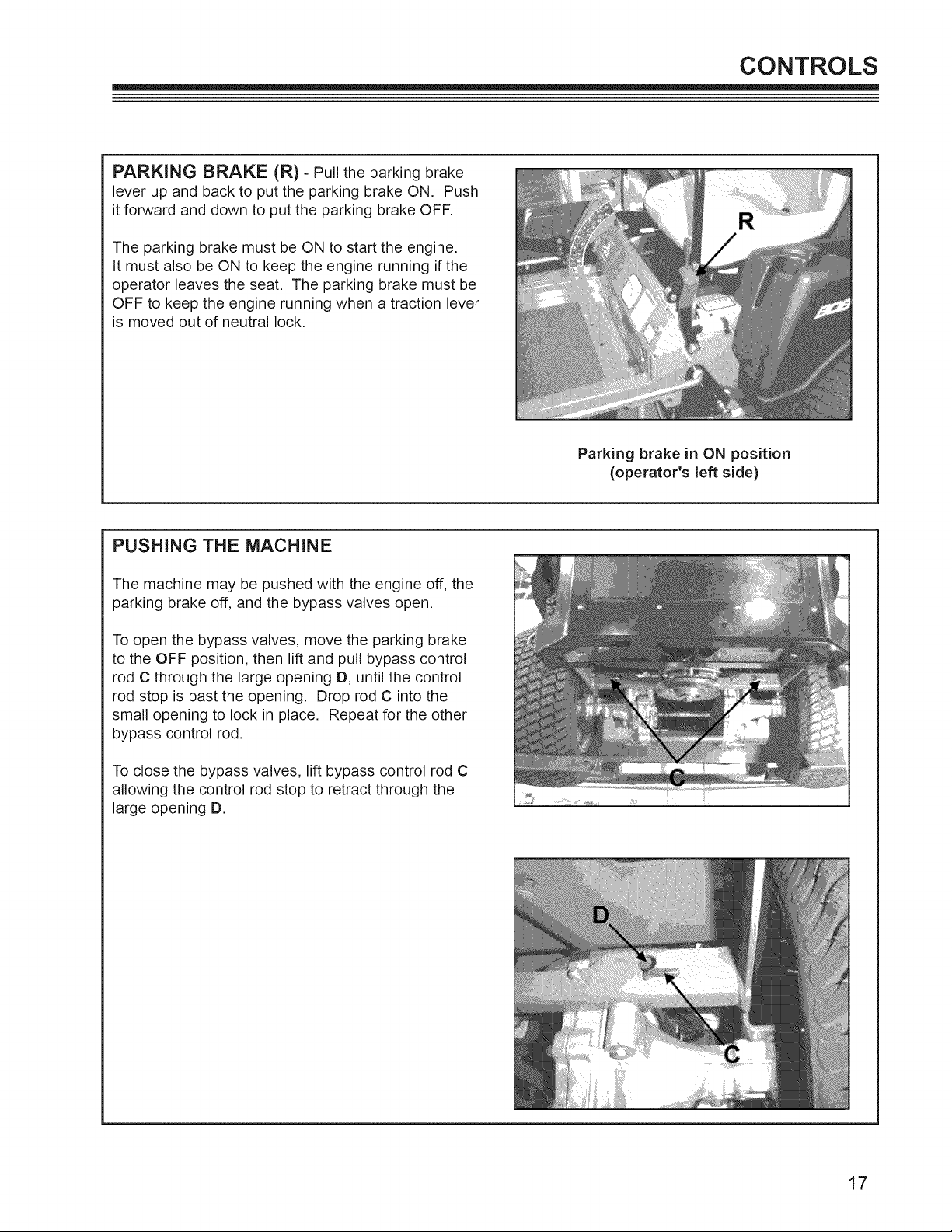

PARKING BRAKE (R) - Pull the parking brake

lever up and back to put the parking brake ON. Push

it forward and down to put the parking brake OFF.

The parking brake must be ON to start the engine.

It must also be ON to keep the engine running if the

operator leaves the seat. The parking brake must be

OFF to keep the engine running when a traction lever

is moved out of neutral lock.

CONTROLS

Parking brake in ON position

(operator's left side)

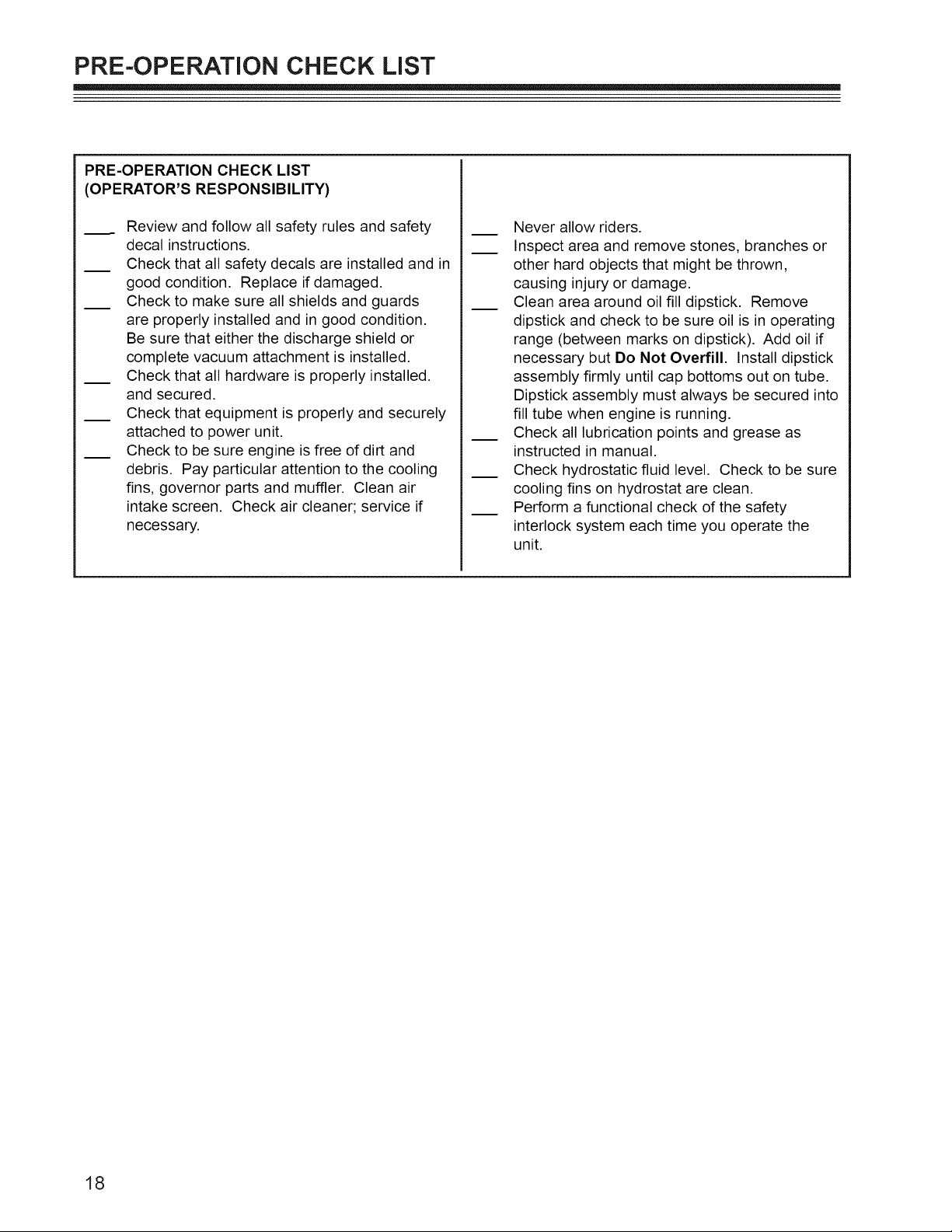

PUSHING THE MACHINE

The machine may be pushed with the engine off, the

parking brake off, and the bypass valves open.

To open the bypass valves, move the parking brake

to the OFF position, then lift and pull bypass control

rod C through the large opening D, until the control

rod stop is past the opening. Drop rod C into the

small opening to lock in place. Repeat for the other

bypass control rod.

To close the bypass valves, lift bypass control rod C

allowing the control rod stop to retract through the

large opening D.

17

Page 20

PRE-OPERATION CHECK LiST

PRE-OPERATION CHECK LIST

(OPERATOR'S RESPONSIBILITY)

Review and follow all safety rules and safety

decal instructions.

Check that all safety decals are installed and in

good condition. Replace if damaged.

Check to make sure all shields and guards

are properly installed and in good condition.

Be sure that either the discharge shield or

complete vacuum attachment is installed.

Check that all hardware is properly installed.

and secured.

Check that equipment is properly and securely

attached to power unit.

Check to be sure engine is free of dirt and

debris. Pay particular attention to the cooling

fins, governor parts and muffler. Clean air

intake screen. Check air cleaner; service if

necessary.

Never allow riders.

Inspect area and remove stones, branches or

other hard objects that might be thrown,

causing injury or damage.

Clean area around oil fill dipstick. Remove

dipstick and check to be sure oil is in operating

range (between marks on dipstick). Add oil if

necessary but Do Not Overfill. Install dipstick

assembly firmly until cap bottoms out on tube.

Dipstick assembly must always be secured into

fill tube when engine is running.

Check all lubrication points and grease as

instructed in manual.

Check hydrostatic fluid level. Check to be sure

cooling fins on hydrostat are clean.

Perform a functional check of the safety

interlock system each time you operate the

unit.

18

Page 21

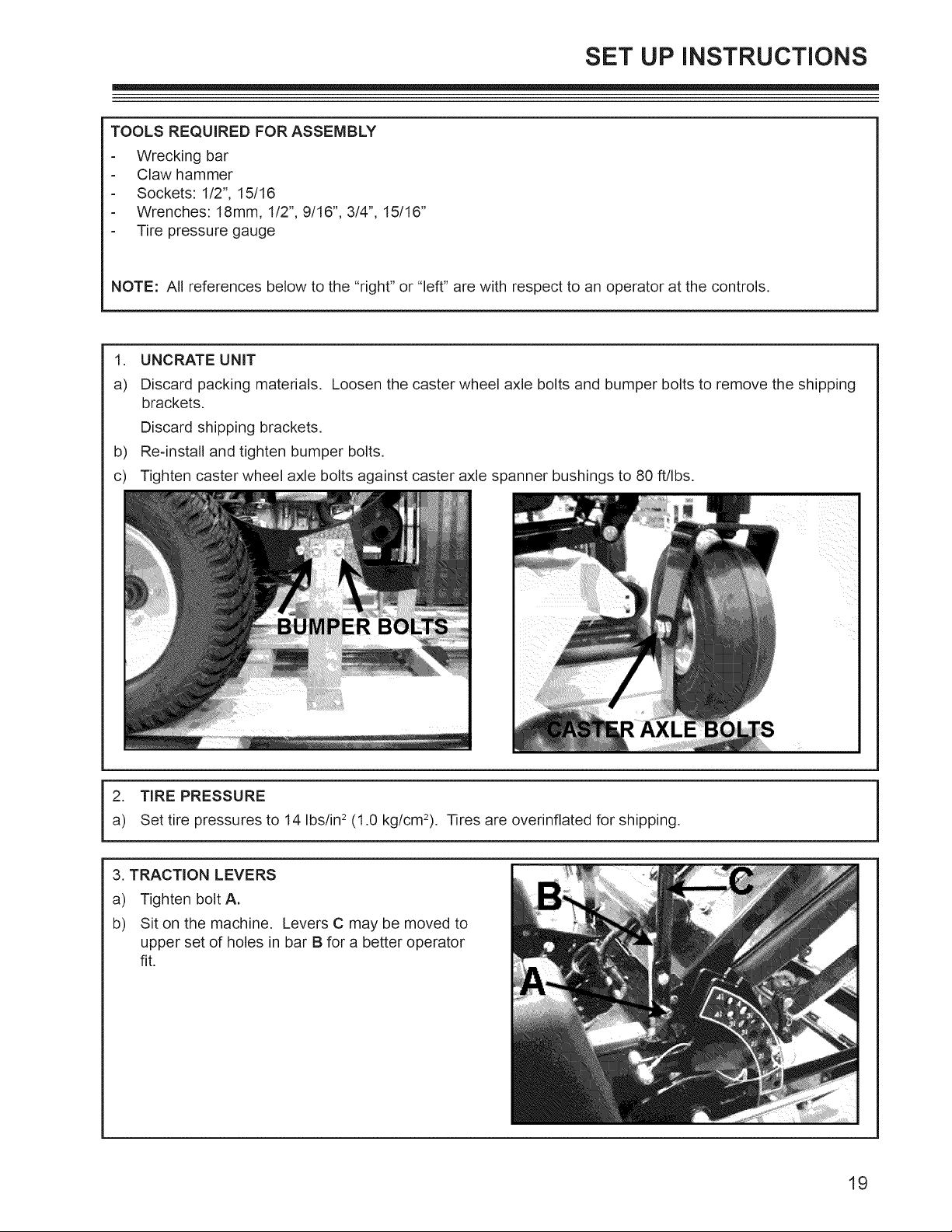

SET UP iNSTRUCTIONS

TOOLS REQUIRED FOR ASSEMBLY

Wrecking bar

Claw hammer

Sockets: 1/2", 15/16

Wrenches: 18mm, 1/2", 9/16", 3/4", 15/16"

Tire pressure gauge

NOTE: All references below to the "right" or "left" are with respect to an operator at the controls.

1. UNCRATE UNIT

a) Discard packing materials, Loosen the caster wheel axle bolts and bumper bolts to remove the shipping

brackets.

Discard shipping brackets.

b) Re-install and tighten bumper bolts.

c) Tighten caster wheel axle bolts against caster axle spanner bushings to 80 ft/Ibs.

2. TIRE PRESSURE

a) Set tire pressures to 14 Ibs/in 2 (1.0 kg/cm2). Tires are overinflated for shipping.

3, TRACTION LEVERS

a) Tighten bolt A.

b) Sit on the machine. Levers C may be moved to

upper set of holes in bar B for a better operator

fit.

19

Page 22

SETUP iNSTRUCTiONS

4. FINAL PREPARATIONS

Check the engine and hydraulic oil levels. Top offwith the correct oil if necessary. Use 10W30 motor oil

for the engine. Use fresh, clean 20W50 motor oil for the hydraulic system.

Insure Battery cables are connected properly.

'--IAWARNING Battery acid is caustic. Fumes are explosive and can cause serious injury or death.

Use insulated tools, wear protective glasses or goggles and protective clothing when working with batteries.

Read and obey the battery manufacturer's instructions.

Be certain the ignition switch is OFF and the key has been removed before servicing the battery.

a) Verify battery polarity before connecting or disconnecting the battery cables.

b) When installing the battery, always assemble the RED, positive ( + ) battery cable first and the

ground, BLACK, negative ( - ) cable last.

c) Tighten cables securely to battery terminals and apply a light coat of silicone dielectric grease to

terminals and cable ends to prevent corrosion. Keep terminal covers in place.

Read Operation and Safety Manual before starting. Operator Manual is located under the seat. Tilt seat

forward to access manual.

--Ii,

OperatoCs Manual is located

If deck does not cut level, see deck leveling procedure in the Operator's Manual

Run engine at full RPM for 5 minutes before engaging blades to allow the engine to be fully lubricated

before load is applied.

Check the hydrostat neutral adjustment. Neutral is set at the factory but may require readjustment. See

adjustments section in the operator's manual.

Do not use the machine without an approved grass collector, the grass discharge chute or mulching

plates correctly fitted.

20

Page 23

OPERATION

FUELING

Fill fuel tank with good quality, clean, unleaded

regular gasoline. Do not use hi-test fuel.

Use a funnel to avoid spilling.

WARNING

TO CHECK ORADD FUEL:

- Do it outdoors

- Do not smoke

- Stop engine; allow to cool

- Fill to one inch below bottom

of filler neck

- Do not overfill

- Clean up spilledfuel

BEFORE STARTING THE ENGINE

Be familiar with all controls, how each functions

and what each operates.

Check the engine oil level and add if necessary.

Using the fuel selector valve, select which tank

will supply fuel

Choke: For cold starts, set the throttle lever to the

half-open position and pull the choke out to the

ON position. For warm starts set the throttle to

the half-open position and the choke to the OFF

position.

OPERATOR PRESENCE

iNTERLOCK SYSTEM

To

start the engine:

The PTO switch must be OFF.

Both traction levers must be in the neutral lock

position,

The parking brake must be ON.

To operate the machine:

1. The operator must be in the seat or engaging the

PTO will kill the engine.

2. The parking brake must be OFF and the opera-

tor must be in the seat, or moving a traction lever

from the neutral lock position will kill the engine.

STARTING THE ENGINE

,

Turn the key to operate the electric starter to start

the engine. Release the key when the engine

starts.

2. If the engine does not start immediately, do not

crank for more than 10 seconds at a time. Allow

60 seconds for the starter motor to cool down

between starting attempts to prevent the starter

motor from burning out.

3. If the choke is ON when the engine starts,

gradually back it off until the engine runs with no

choke at all.

21

Page 24

OPERATION

OPERATING NOTES

Practice at slow engine and travel speeds with the

PTO off until fully familiar with the controls.

For normal cutting the throttle should be set at the

full open position. By using the traction levers to

speed up or slow down the machine during use,

maximum control and cutting efficiency can be

maintained.

Using the machine at less than full throttle in

heavy conditions will cause the engine to labor

and result in excessive wear.

DRIVING

,

With the PTO disengaged, move the parking

brake to OFF.

2.

3.

4. Steering - Move one lever forward and one back.

Turns during forward movement:

Turns during reverse movement:

Move both traction levers out of neutral lock.

Push both traction levers forward evenly to

drive forward in a straight line. Pull both traction

levers back evenly to drive backward in a straight

line.

Right turn - move the right traction lever back

toward neutral to slow the right drive wheel,

Left turn - move the left traction lever back to-

ward neutral to slow the left drive wheel,

Reverse right turn - move the right traction lever

forward toward neutral to slow the right drive

wheel.

Reverse left turn - move the left traction lever

forward toward neutral to slow the left drive

wheel.

Use caution when making turns. Slow down before

making sharp turns to help maintain control and to

prevent torn turf from skidding or spinning tires. To

help prevent turf damage, keep both drive tires mov-

ing whenever a turn is made.

TIP: The best way to make a sharp "zero" turn is to

come to a stop, get the machine moving in reverse

with both drive wheels and then power the machine

around with the outside wheel. This technique keeps

the drive tires turning and results in less turf damage.

22

Page 25

CUTTING

OPERATION

1. Place the discharge chute in the down position or

correctly fit a grass collector or mulcher plate.

2. Sit in the seat.

3. Start the engine.

4. Turn the blades on by pulling up on the PTO

switch. Do not start the blades at full throttle.

Instead, use the slowest throttle setting that will al-

low the engine to pick up the blade load to reduce

the wear on the belts and electric clutch.

5. After the blades are rotating, set the throttle to

maximum. Use the traction levers to obtain the

required cutting speed, to steer around obstacles

and to turn at the end of a cut.

CUTTING TiPS

When mowing large areas, start by turning to the

right so that clippings will be discharged away

from shrubs, fences, driveways, etc. After two or

three rounds, mow in the opposite direction, left

hand turns, until finished.

If grass is extremely tall, it should be mowed

twice, the first cut relatively high, the second cut to

the desired height.

Use the left side of the mower for trimming.

Choose cutting directions so that clippings are

thrown onto areas that already have been cut.

This method results in the most even distribution

of clippings and more uniform, better appearing

cuts.

Use a different mowing pattern each time where

possible. This helps prevent rutting and leads

to a more uniform cut by keeping the grass from

always laying the same way.

DANGER

ROTATING BLADES

- KEEP HANDS AND FEET AWAY.

- STOP ENGINE AND LET BLADES STOP

BEFORE REMOVING GRASS COLLEC-

TOR OR UNCLOGGING.

WARNING

THROWN OBJECTS

- KEEP AREA CLEAR OF PEOPLE

AND PETS.

- REMOVE OBJECTS BLADE MAY

STRIKE AND THROW.

- STOP BLADES TO CROSS GRAVEL

AREAS

- DO NOT OPERATE WITHOUT CHUTE,

MULCHER OR ENTIRE GRASS

CATCHER IN PLACE.

23

Page 26

MAINTENANCE CHART

X

X

X

X

X

X

X *X X

X X X

X

X

X

X

X

X

X

X X

X

*Change oil after first 5 to 8 hours of use, then every 50 hours. Change oil every 25 hours when

operating the engine under heavy load or in high temperatures,

24

Page 27

MAINTENANCE RECORD

I

I

I

I

Repair Protection Agreements

Congratulations on making a smart purchase. Your new Craftsman@ Professional product is designed

and manufactured for years of dependable operation. But like all products, it may require repair from

time to time. That's when having a Repair Protection Agreement can save you money and aggravation.

Here's what the Repair Protection Agreement* includes:

Expert Service by our 10,000 professional repair specialists

Unlimited service and no charge for parts and labor on all covered repairs

_ Product replacement up to $1500 if your covered product can't be fixed

_ Discount of 10% from regular price of service and related installed parts not covered by the

agreement; also, 10% off regular price of preventative maintenance check

_Fast help by phone - we call it Rapid Resolution - phone support from a Sears representative.

Think of us as a "talking owner's manual."

Once you purchase the Repair Protection Agreement, a simple phone call is all that it takes for you to

schedule service. You can call anytime day or night, or schedule a service appointment online.

The Repair Protection Agreement is a risk-free purchase. If you cancel for any reason during the product

warranty period, we will provide a full refund. Or, a prorated refund anytime after the product warranty

period expires. Purchase your Repair Protection Agreement today!

Some limitations and exclusions apply.

For prices and additional information in the U.S.A. call 1=800=827-6655

*Coverage in Canada varies on some items. Full full details call Sears Canada 1=800=361=6665

Sears installation Service

For Sears professional installation of home appliances, garage door openers, water heaters, and other

major home items, in the U.S.A. or Canada call 1-800-4-MY-HOME®.

25

Page 28

MAINTENANCE

CHECK DAILY

Operator Presence interlock System =Start Operation

For the engine to crank, the parking brake must be on, the PTO (blades) off and traction levers in the neutral

lock position. Sit in the seat and check, one by one, if the engine will crank with the parking brake off, the

blades on, and either traction lever out of neutral lock.

Operator Presence interlock System - Run Operation

The operator must be in the seat for the engine to run with the parking brake off, the traction levers moved out

of the neutral lock )osition, or the blades on. To check:

1. Start the engine and run at 1/2 throttle with the operator on the machine but raised off the seat.

2. One by one: move the parking brake to the OFF position, traction levers out of the neutral lock position

(check each independently), and turn the blades on. Each check should kill the engine after 1/2 second.

(A 1/2 second delay is built into the system to prevent engine cutout when traversing rough terrain.)

Repair machine before using if the Operator Presence Interlock System does not operate correctly in start or

run.

Hardware

Tighten any nuts and bolts found loose. Replace any broken or missing cotter pins. Repair any other prob-

lems before operating.

Tire pressure

Tires should be kept inflated to 14 Ibs/in2 (1.0 kg/cm2). Improper tire inflation can cause rapid tire wear and

poor traction. Uneven inflation can cause uneven cutting. Overinflation of caster tires can cause casters to

"wobble" on hard surfaces.

BATTERY

r L.,,.WARNING Battery acid is caustic and fumes

are explosive and can cause serious injury or death.

Use insulated tools, wear protective glasses or

goggles and protective clothing when working with

batteries, Read and obey the battery manufacturer's

instructions.

Be certain the ignition switch is OFF and the key has

been removed before servicing the battery.

1. Verify battery polarity before connecting or dis-

connecting the battery cables.

2. When installing the battery, always assemble

the RED, positive ( + ) battery cable first and the

BLACK ground, negative ( - ) cable last.

4. Check the electrolyte level every 100 hours of

operation or yearly, whichever comes first. Top

off with distilled water if necessary.

NOTE: Sealed batteries cannot be checked or

topped off.

,

Clean the cable ends and battery posts with steel

wool. Use a solution of baking soda and water

to clean the battery. Do not allow the solution to

enter into the battery cells.

,

Tighten cables securely to battery terminals and

apply a light coat of silicone dielectric grease to

terminals and cable ends to prevent corrosion.

Keep terminal covers in place.

3. When removing the battery, always remove the

BLACK ground, negative ( - ) cable first and the

red, positive ( + ) cable last.

26

Page 29

4 $1

, r-i

II,

III

,j L.............

2

MAINTENANCE

, r .............

[-i

4

LUBRICATION

Every 50 hours of operation, lubricate the following points (1-3) with grease:

1. Deck lift lever (1 point)

2. Deck lift pivots (4 points)

3. Pull arms (2 points located at the front of the cutterdeck)

4. Caster wheel pivots (2 points)

(Lubricate every 500 hours or once a year)

NOTE ON BLADE SPINDLES =The blade spindles on these machines use a

superior sealed bearing that does not require relubrication.

27

Page 30

MAINTENANCE

ENGINE OIL

Perform engine maintenance with the engine off,

spark plug wires disconnected and PTO disengaged.

AFTER FIRST FIVE (5) HOURS

While the engine is warm:

1. Remove drain cap at location D and drain the

crankcase. Dispose of used oil in accordance

with local requirements.

2. Clean and replace the cap.

3. Change oil filter.

4. Fill the crankcase with fresh oil to the full mark.

Do not overfill. See engine manual for oil

specifications.

DAILY

1. Check oil level with the dipstick.

2. If oil is needed, add fresh oil of proper

viscosity and grade. See engine manual for oil

specifications. Do not overfill.

3. Replace dipstick before starting engine.

PERIODIC OIL CHANGES

1. See Page 22 maintenance chart for oil and filter

change intervals after the break-in period.

2. Follow instructions for first oil change, above.

OIL CAPACITY

Engine without oil filter holds approximately 1-7/8

quarts (60 ounces; 1.8 liters).

Engine equipped with oil filter holds approximately 2

quarts (64 ounces; 1.9 liters).

Use a high quality detergent oil classifed "For Service

SF, SG, SH, SJ" or higher.

Use recommended SAE viscosity grade oil per start-

ing temperature according to Figure 1.

SAE Viscosity Grades

Figure 1

F -20 0 20 32 40 60 80 100

SPARK PLUGS

Remove each plug and check condition.

- Good operating conditions are indicated if the plug has a light coating of grey or tan deposit.

- A white blistered coating indicates overheating. A black coating indicates an "over rich" fuel mixture.

Both may be caused by a clogged air cleaner or improper carburetor adjustment.

- Do not sandblast, wire brush or otherwise attempt to repair a plug in poor condition. Best results are

obtained with a new plug.

- Set plug gap as specified in engine manual..

28

Page 31

FUEL FILTER

An in-line fuel filter is located in the fuel supply line.

Inspect at every oil change to make sure it is clean

and unobstructed. Replace if dirty.

DUAL ELEMENT AIR CLEANER

Engines equipped with dual element air cleaners

have a paper air cleaner element with an oiled, foam

precleaner element on the dirty side of the paper

element. Both should be inspected regularly and

maintained.

Clean and re-oil precleaner element every 25 hours

(more often under dusty conditions).

1. Disassemble air cleaner cover.

2. Remove precleaner.

3. Wash precleaner in kerosene or liquid detergent

and water.

4. Wrap precleaner in cloth and squeeze to remove

cleaner.

5. Saturate precleaner in engine oil. Squeeze to

remove excess oil.

6. Re-install precleaner. Reassemble air cleaner

components and screw assembly down tight.

MAINTENANCE

KNOB

COVER

BASE

Every 100 hours (more often under very dusty or dirty

conditions), check the paper cartridge.

- Clean by tapping gently.

- Do not wash the cartridge or use compressed air

which can cause damage.

- Replace when cartridge is dirty, bent or

damaged.

29

Page 32

MAINTENANCE

ENGINE COOLING

Continued operation with a clogged cooling system

will cause severe overheating and can result in en-

gine damage.

Daily: Clean air intake screen V.

Every 100 hours: Clean cooling fins beneath

blower housing H with reference to information in

the engine manufacturer's manual.

SPECIFIC TORQUES

PURGING TRANSAXLES

Due to the effects air has on efficiency in hydrostatic

drive applications, it is critical that it be purged from

the system.

These purge procedures should be implemented any

time a hydrostatic system has been opened to fa-

cilitate maintenance or any additional fluid has been

added to the system.

Purging may be required if the unit shows any of the

following symptoms:

- Noisy operation.

- Lack of power or drive after short term use.

- High operation temperature, excessive oil

expansion.

BLADE BOLTS

iWHEEL HUB NUTS

ENGINE CRANKSHAFT BOLT

TRANSAXLE PULLEY NUT

TRANSAXLE DRAmN PLUG

TRANSAXLE FILTER

70 FT-LBS (95 Nm)

150 FT-LBS (203 Nm)

50 FT-LBS (68 Nrn)

28.3 - 41.6 FT-LBS (38 - 56 Nrn)

15- 20 FT-LBS (20- 27 Nrn)

130 - 150 in-robs(14.6 - 16.9 Nm)

1. Check the transaxle fluid, fill to proper level, if

required.

2. Raise the drive wheels off the ground. Support

unit with jackstands or other suitable means.

3. With the bypass valves open, and the engine

running, slowly move the control levers in both

forward and reverse directions 5 to 6 times. As

air is purged from the unit, the oil level will drop.

4. With the bypass valve closed, and the engine

running, slowly move the control levers in both

forward and reverse directions 5 to 6 times.

5. Stop engine. Check the transaxle fluid level, add

fluid as required.

6. It may be necessary to repeat steps 3-5 until all

the air is completely purged from the system.

When the transaxle moves forward and reverse

at normal speed, purging is complete.

30

Page 33

TRANSAXLES

Inattention to proper safety, operation, or

maintenance procedures could result in personal

injury, or damage to the equipment. Jacobsen

recommends returning the machine to your

authorized CGC, Inc. dealer for service or repair.

Perform transaxle maintenance with the engine off,

spark plug wires disconnected and PTO disengaged.

TRANSAXLE FLUID CHANGE

Change the transaxle fluid every 200 hours of

operation. It is essential that the exterior of the

transaxle be free of debris, prior to fluid maintenance.

1. Remove the three 1/4" filter guard screws and

filter guard A. Remove the oil filter B from the

transaxle and discard. Dispose of used oil in ac-

cordance with local requirements.

2. Wipe the filter base surface off and apply a film

of new oil to the gasket of the new replacement

filter. Install the new filter by hand, turn 3/4 to

one full turn after the filter gasket contacts the

filter base surface.

3. Re-install the filter guard and torque the three

screws to 65 in. Ibs. each.

4. Remove cap C, fill the transaxles through the

expansion tank D with approximately 2 quarts of

SAE 20W-50 engine oil PER TRANSAXLE.

MAINTENANCE

Do not overfill! If you overfill the transaxle while the unit

is "cold", it may overflow as it reaches normal operating

temperatures. The oil level should not be above the

manufacturer's suggestions. This will allow the space

needed for the oil to expand as it warms up.

5. After starting engine, check the fluid level and

continue to add oil to overflow tank D to fill line

on tank.

6. Purge the transaxles, following the purging pro-

cedures on Page 29.

31

Page 34

MAINTENANCE

BLADE REMOVAL

Follow these instructions to prevent injury during

blade removal:

1. Loosen with a box wrench or a socket and long

breaker bar. To gain additional leverage, slip a

long pipe or thick-walled tube over breaker bar or

wrench.

2. Insert wood block A as shown, with grain

perpendicular to blade, to prevent blade from

turning when loosening.

3. Wear thickly padded gloves. Keep hands clear

of blade path. Blades may rotate when bolt

releases.

SHARPENING

BLADE BALANCE

Blade balance must be maintained at 5/8 oz-in (19.4

g-cm) or less. Failure to keep blades balanced

causes excess vibration, wear, and shortened life of

most components of the machine.

To balance a blade:

1. Sharpen blade first.

2. Balance the blade at the center.

3. Attach a 1/8 oz (3.9 g) weight at a distance 5"

(127 mm) from center on the light end. This

should make the light end the heavy end:

If it does, the blade is balanced.

If does not, file or grind the heavy end until

the addition of the weight makes the light end

the heavy end.

BLADE INSTALLATION

1. Wear thickly padded gloves to prevent cuts from

the sharp blade.

2. Insert the blade bolt, in order, through the conical

washer (cup side toward the blade, as shown),

the blade, and the blade spacer.

3. Install assembly on the blade spindle.

4. Torque the blade bolt to 70 ft-lbs.

Blades may be sharpened by filing or grinding.

Inspect blades before sharpening.

Replace bent or cracked blades.

Replace blades when the lift portion has worn

thin.

Maintain cut angle at 30°.

Do not overheat blades when sharpening.

Always use Craftsman Professeional blades.

Use of another manufacturer's blades may be

dangerous.

@

32

Page 35

DECK LEVELING

1. Park the machine on a smooth, level surface.

Raise the deck to the transport position.

2. Lower the deck onto a set of equal height blocks

under the rear corners of the deck. Place an-

other set of blocks under the front of the deck so

that the deck top is pitched forward 1/8".

NOTE: The front and rear of the deck are at different

heights.

3. Measure the height of the blade cutting edge

above the ground. Remove pin B and set the

height of cut lever E to that height

4. Loosen nuts on bolts G. Move bolts in slot to

remove slack in chain. Tighten nuts on bolts G.

HEIGHT OF CUT

ADJUSTMENTS

The height of cut is set by moving height of cut pin B

to the hole designated for the height of cut desired.

To change the height of cut:

1. Lift the deck to the highest position.

2. Move pin B to the selected hole.

3. Lower the deck until the lift lever is stopped by

the pin.

NOTES:

Height of cut may vary due to the amount of

tread on the tires, tire diameter or inflation pres-

sure.

DECK ROLLERS

The deck rollers are adjustable up and down to

provide improved deck flotation and scalping protec-

tion at various heights of cut. They are not intended

to ride continuously on the ground. Adjust no closer

than 3/8" (10mm) to the ground.

2-1/2" -3-1/2"

i l _:_ 1-1/2" - 2-1/2"

Height of cut ranges for roller adjustment

3-1/2" &

Higher

33

Page 36

ADJUSTMENTS

PARKING BRAKE

NOTE: There are 2 brakes, 1 on each transaxle.

The parking brake should keep the machine from

moving. To check the parking brake, park the ma-

chine on a level surface, open the bypass valves and

set the parking brake to ON. Attempt to move the

machine forward and backward by pushing it. If the

machine moves, adjust the parking brake linkage as

follows:

1. Move the machine to a flat horizontal surface.

2. Grip the flats on the brake rod A. Tighten nut

B on the brake rod until you run out of threads.

See Figure 1 for detailed view.

3. Move the parking brake handle to the OFF

position.

4. Loosen nut X.

5. Hold brake arm in the OFF position as shown in

Figure 2.

TIGHTEN UNTIL YOU

RUN OUT OF THREADS

FIGURE 1

6. Adjust swivel U until swivel stud meets brake arm

hole in the OFF position.

7. Insert cotter pin into swivel U.

8. Tighten nut X.

9. Repeat Steps 1-8 on the opposite side.

34

FIGURE 2

Page 37

HYDROSTATIC TRANSA×LE ADJUST=

MENTS

A turnbuckle style hydrostat neutral adjustment is

provided,

Neutral:

1. Support the machine with the rear wheels off

the ground. Use jackstands or equivalent sup=

port. Do not rely only on mechanical or hydraulic

jacks.

2. Move the traction levers out into the neutral lock

position and raise the seat.

3. Disconnect the seat switch wire and temporarily

connect the two terminals with jumper wire J as

shown.

4. Start the engine and run at low speed.

5. Move parking brake to the OFF position.

6. Loosen jam nuts K at both ends of the control

rod L.

7. Rotate the control rod until the corresponding

wheel stops turning. Lock the control rod jam

nuts. Run the engine up to high idle and stroke

the traction levers forward and back to check the

adjustment. Move traction levers back to neutral

and readjust if necessary.

8. Repeat steps 6 and 7 for the opposite side.

9. Remove the jumper wire and reconnect the seat

switch,

ADJUSTMENTS

35

Page 38

BELT REPLACEMENT

NOTE: Always use Craftsman Professional replacement belts, not general purpose belts.

Craftsman Professional belts are specially designed for use on this mower and will nor-

mally last longer.

CUTTERDECK BELT

1. Remove floorplate.

2. Set the cutterdeck in a middle height-of-cut posi-

tion.

. Use a 3/8" ratchet and extension to back

tensioning idler off to remove belt from idler.

Remove belt from cutterdeck pulleys.

A

NOTE: Use the 3/8" ratchet in the square hole A on

the idler.

4. Remove belt from clutch pulley.

5. Install the new belt by performing these steps in

reverse order.

2 SPINDLE DECK 3 SPINDLE DECK

HYDRO TRANSAXLE DRIVE BELT

1. Remove cutterdeck belt (see cutterdeck belt

replacement).

2. Disconnect wire I at clutch M. Remove bolts J

and remove torque restraint.

3. Using a ratchet with a 9/16" socket, place over

nut at location P. Use the ratchet to rotate it

enough to remove the transaxle drive belt.

4. Install a new transaxle drive belt by performing

these steps in reverse order.

5. Inspect the fans. Replace if worn or damaged.

Torque transaxle pulley nut to 28.3-41.6 ft-lbs

(38-56 Nm).

6. Reinstall cutterdeck belt (see cutterdeck belt

replacement).

BELT TENSION

All belts are tensioned by spring loaded idlers and do not require any adjustment.

36

Page 39

Manual del operador

P R 0 F E S 0 N A L

Podadora tipo tractor con radio de giro cero

Motor B&S de 26HP / descarga lateral / 52 pulg. (132 cm) de ancho

Modelo 127.28875

Motor B&S de 22HP / descarga lateral / 42 pulg. (132 cm) de ancho

Modelo 127.28876

Motor B&S de 22HP / descarga lateral / 36 pulg. (132 cm) de ancho

Modelo 127.28877

PRECAUCION: Antes de usar este

producto, lea el manual y siga todas las

instrucciones de seguridad y operacion

que contiene

Llame al siguiente numero para

obtener respuesta alas preguntas

que tenga sobre este producto:

1-800-659-5917

Linea de ayuda de Sears Craftsman

Lunes a sabado de 5 am a 5 pm

Sears, Roebuck and Co., Hoffman Estates, IL 60179 EE.UU.

Visite el sitio Web de Craftsman: www.sears.com/craftsman

MAN 4163202 Rev. B 11-2008 MANUALDEPIEZAS4163201

37

Page 40

CALIFORNIA

Proposition 65 Warning

Diesel engine exhaust and some of its

constituents are known to the State of

California to cause cancer, birth defects and

other reproductive harm.

WARNING

The engine exhaust from this product

contains chemicals known to the State of

California to cause cancer, birth defects

or other reproductive harm.

Ca lifornie

Avertissement Proposition 65

L'echappement d'un moteur diesel et

certains de ses constituants sont declares

par I'Etat de la Californie responsables de

cancer, malformations congenitales et autres

anomalies de la reproduction,

California

Advertencia sobre la Proposicion 65

Los gases de escape de los motores diesel

y sus constituyentes son considerados en el

estado de California como sustancias que

causan cancer, defectos congenitos y danos

en el sistema reproductivo,

CALIFORNIA

Proposition 65 Warning

A AVERTISSEMENT

L'echappement du moteur de ce produit

contient des produits chimiques declares

par rEtat de la Californie responsables de

cancer, malformations congenitales ou

autres anomalies de la reproduction.

ADVERTENClA

El escape del humo emanado pot este

producto es considerado en el estado

de California como una mezcla de

sustancias qulmicas que causan cancer,

defectos congenitos y dahos en el sistema

reproductivo.de reproducci0n humana.

CALIFORNIE

Avertissement Proposition 65

Battery posts, terminals, wiring insulation, and

related accessories contain lead and lead

compounds, chemicals known to the State of

California to cause cancer and birth defects

or other reproductive harm. WASH HANDS

AFTER HANDLING.

Advertencia sobre la Proposicion 65

Los bornes, terminales, material de aislamiento de los

cables de las baterias y los accesorios relacionados

contienen plomo y compuestos del plomo, que son

sustancias quimicas que el estado de California

considera que causan cancer, defectos congenitos u

otros dahos en el sistema reproductivo. LAVESE LAS

MANOS DESPUES DE MANE JAR EL PRODUCTO.

Les bornes de batterie, raccords, gaines de

ills et accessoires associ6s contiennent du

plomb et des composes de plomb declares

par rEtat de la Californie responsables de

cancer, malformations congenitales ou autres

anomalies de la reproduction. SE LAVER

LES MAINS APRES MANIPULATION.

CALIFORNIA

38

Page 41

CONTENIDO PAGINA

SEGURIDAD ............................................................................................................................................. 40-46

ETIQUETAS .............................................................................................................................................. 47-51

CONTROLES ............................................................................................................................................ 52-55

LISTA DE VERIFICACION ANTES DE LA OPERACION ............................................................................... 56

ESTABLEZCA INSTRUCTIONES ............................................................................................................. 57-58

OPERACION ............................................................................................................................................. 59-61

TABLA DE MANTENIMIENTO ....................................................................................................................... 62

REGISTRO DE MANTENIMIENTO ............................................................................................................... 63

MANTE NIMIENTO .................................................................................................................................... 64-70

AJUSTES ................................................................................................................................................. 71-73

REEMPLAZO DE LA CORREA ...................................................................................................................... 74

INFORMACION SOBRE EL SERVICIO ......................................................................... PAGINA POSTERIOR

GARANTiA

GARANTiA LIMITADA DE CRAFTSMAN PROFESSIONAL

Dos anos en el tractor

Si este tractor falla debido a defectos en el material y la mano de obra en un lapso de dos ahos a partir de la

fecha de la compra, y se ha usadoy mantenido de acuerdo con las instrucciones del manual del operador,

Ilame al telefono 1-800-4-MY-HOME para coordinar que se le repare sin costo.

Si este tractor alguna vez se usa con propositos comerciales o de arrendamientos, esta garantia aplica solo

pot un aho a partir de la fecha de la compra.

Durante los primeros 30 dias de la compra el servicio al producto en su hogar ser_i gratuito. Para su

conveniencia, aun podr_i recibir el servicio de la garantia en su hogar despues de los primeros 30 dias de

la compra, pero se le aplicar_fi un cargo pot el viaje. Si Ileva el producto a un centro de entrega autorizado

por Craftsman, no se le har_i este cargo. Llame al 1-800-MY-HOME para saber la ubicacion del centro de

entrega autorizado m_is cercano.

90 Dias erl la Bateria

Si la bateria que se incluye con este tractor presenta defectos en el material o la mano de obra (se determina

mediante nuestras pruebas que no almacena carga) en el periodo de noventa (90) dias a partir de la fecha

de compra, se reemplazar_i sm costo alguno.

Durante los primeros 30 dias de la compra no se le har_i cargo alguno por reemplazar la bateria en su hogar.

Para su conveniencia, aun podr_i recibir el servicio de la garantia en su hogar despues de los primeros

30 dfas de la compra, pero se le aplicar_i un cargo pot el viaje. Si Ileva la tractor a un centro de entrega

autorizado por Craftsman, no se le har_i este cargo. Llame al 1-800-MY-HOME para saber la ubicacion del

centro autorizado m_is cercano.

Esta garantia cubre solo defectos en la materia y la habilidad. Sears no pagar,i por:

• Arficulos fungibles que se desgasten durante el uso normal, inclusive pero sin limitarse a cuchillas, bujias,

filtros de aire, correas y filtros de aceite.

• Servicio de mantenimiento est&ndar, cambios de aceite o afinaciones.

• Reemplazo o reparaci6n de los neum_ticos requerida por perforaciones con objetos extrados tales como

clavos, espinas, tocones o vidrio.

• El reemplazo de la Ilanta o la rueda o repara reulting de uso normal, del accidente, o de la operaci6n o la

conservacion impropias.

• Reparaciones necesarias causadas pot abuso del operador, inclusive pero sin limitarse a da_os causado

por remolcar objetos que excedan la capacidad del tractor, golpear objetos que doblen la armadura o el

cigQehal u operacion del motor a una velocidad excesiva.

• Reparaciones necesarias debido a negligencia del operador, inclusive pero sin limitarse a da_os elOctricos

ydmec_inicos causados pot almacenamiento inadecuado, uso de una cantidad y calidad inadecuadas

el aceite para motor, acumulaci6n de residuos inflamables en la coraza o negligencia para mantener el

equipo de acuerdo con las instrucciones del manual del operador.

• Limpieza o reparaci6n del motor (sistema de combustible) requerida debido a la contaminaci6n u

oxidacion (rancidez) del combustible. En general, el combustible se debe usar en un lapso de 30 dias a

partir de la fecha de su compra.

• Deterioro y desgaste norma/del acabado exterior, o reemplazo de las etiquetas del producto.

Toda cobertura bajo la garantia aplica solamente cuando el producto se encuentra en Estados Unidos.

Esta garanfia le otorga derechos legales especificos, y usted puede tener otros que vadan entreestados.

Sears, Roebuck and Co., Hoffman Estates, IL 60179 EE.UU.

11-2008 39

Page 42

SEGURIDAD

iAVISO!

Las modificaciones no autorizadas pueden causar

riesgos extremos a la seguridad de operadores y

espectadores, y tambien podrian causar dahos al

producto.

Craftsman Professional se opone, rechaza y se libera

de toda responsabilidad por cualquier modificaci6n,

adicion de accesorios o alteraciones del producto

que no esten disehados, desarrollados, probados

y aprobados por el Departamento de Ingenieria

de Crafstman Professional. Cualquier alteracion,

modificaci6n o cambio realizado a un producto

de Craftsman Professional de una manera que

no sea especificamente autorizada despuOs de

la manufactura original,inclusive la adicion de

accesorios o piezas de posventa especiflcamente