Craftsman 127.28876 User Manual [en, es]

Operator’s Manual

m

CRRFTSMRN

¡professional!

Zero Turn Riding Mower

26HP B&S Engine / Sicfe Discharge / 52-inch Wide

iVlodel 127.28875

22HP B&S Engine / Side Discharge / 42-inch Wide

iVlodel 127.28876

22HP B&S Engine / Side Discharge / 36-inch Wide

iVlodel 127.28877

Espanol, p. 37

CAUTION: Before using this product,

read the manual and follow all its Safety

Rules and Operating Instructions

For answers to your questions

about this product call:

1-800-659-5917

Sears Craftsman Help Line

Sam - 5pm, Mon - Sat

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A

Visit the Craftsman website: www.sears.com/craftsman

MAN 4163202 Rev. B 11-2008 parts manual 4163201

CALIFORNIA

Proposition 65 Warning

À WARNING

Diesel engine exhaust and some

of its constituents are known to the

State of California to cause cancer,

birth defects and other reproductive

harm.

Californie Proposition 65 Avertissement

Les échappements des moteurs diesel et certains

de leurs composés sont reconnus par l’Etat de

Californie pour être cancérigènes, provoquer

des défauts congénitaux et d’autres dangers en

matière de reproduction.

California Advertencia

de la Proposición 65

The engine exhaust from this product

contains chemicals known to the State

of California to cause cancer, birth

defects or other reproductive harm.

A AVERTISSEMENT

L’émission du moteur de ce matériel con

tient des produits chimiques que l’Etat de

Californie considère être cancérigènes,

provoquer des défauts congénitaux et

d’autres dangers en matière de reproduc

tion.

El estado de California hace saber que

los gases de escape de los motores diesel

y algunos de sus componentes producen

cáncer, defectos de nacimiento y otros

daños en el proceso de reproducción

humana.

Proposition 65 Warning

Battery posts, terminals, wiring

insulation, and related accessories

contain lead and lead compounds,

chemicals known to the State of

California to cause cancer and birth

defects or other reproductive harm.

WASH HANDS AFTER HANDLING.

El estado de California hace saber que los

gases de escape de este producto contienen

productos químicos que producen cáncer,

defectos de nacimiento y otros daños en

el proceso de reproducción humana.

%

CALIFORNIA

TABLE OF CONTENTS PAGE

SAFETY..................................................................................................................................................................2-8

LABELS...................................................................................................................................................... 9-13

CONTROLS..............................................................................................................................................14-17

PRE-OPERATION CHECK LIST...................................................................................................................18

SETUP INSTRUCTIONS..........................................................................................................................19-20

OPERATION.............................................................................................................................................21-23

MAINTENANCE CHART............................................................................................................................... 24

MAINTENANCE RECORD............................................................................................................................25

MAINTENANCE........................................................................................................................................26-32

ADJUSTMENTS ...................................................................................................................................... 33-35

BELT REPLACEMENT..................................................................................................................................36

SERVICE INFORMATION.............................................................................................................BACK PAGE

WARRANTY

CRAFTSMAN PROFESSIONAL LIMITED WARRANTY

Two Years on Tractor

When operated and maintained according to all supplied instructions, if this tractor fails due to a defect in

material or workmanship within two years from the date of purchase, call 1-800-4-MY-HOME® to arrange for

free repair.

This warranty applies for only one year from the date of purchase if this tractor is ever used for commercial or

rental purposes.

During the first 30 days of purchase, there will be no charge to service the tractor in your home. For your con

venience, in-home warranty service will still be available after the first 30 days of purchase, but a trip charge

will apply. This charge will be waived if you transport the tractor to an authorized Craftsman drop-off iocation.

For the nearest authorized iocation, call 1-800-MY-HOME®.

90-Days on Battery

For ninety (90) days from the date of purchase, if the battery included with this tractor is defective in material

or workmanship (our testing proves it will not hold a charge), it will be replaced free of charge.

During the first 30 days of purchase, there will be no charge to replace the defective battery in your home.

For your convenience, in-home warranty service will still be available after the first 30 days of purchase, but a

trip charge will apply. This charge will be waived if you transport the tractor to an authorized Craftsman drop

off iocation. For the nearest authorized iocation, call 1-800-MY-HOME®.

This warranty covers ONLY defects in material and workmanship. Sears will NOT pay for:

• Expendable items that become worn during normal use, including but not iimited to blades,

spark plugs, air cleaners, belts, and oil filters.

• Standard maintenance servicing, oil changes, or tune-ups.

• Tire replacement or repair caused by punctures from outside objects, such as nails, thorns,

stumps, or glass.

• Tire or wheel replacement or repair resulting from normal wear, accident, or improper operation

or maintenance.

• Repairs necessary because of operator abuse, including but not iimited to damage caused by

towing objects beyond the capability of the tractor, impacting objects that bend the frame or

crankshaft, or over-speeding the engine.

• Repairs necessary because of operator negligence, including but not limited to, electrical and

mechanical damage caused by improper storage, failure to use the proper grade and amount

of engine oil, failure to keep the deck clear of flammable debris, or failure to maintain the

equipment according to the instructions contained in the operator's manual.

• Engine (fuel system) cleaning or repairs caused by fuel determined to be contaminated or

oxidized (stale). In general, fuel should be used within 30 days of its purchase date.

• Normal deterioration and wear of the exterior finishes, or product iabel replacement.

This warranty applies only while this product is within the United States.

This warranty gives you specific legal rights, and you may also have other rights, which vary, from state to

state.

Sears, Roebuck and Co., Hoffman Estates, IL 60179

11-2007

SAFETY

NOTICE If!

Unauthorized modifications may present extreme

safety hazards to operators and bystanders and

could also result in product damage.

Craftsman Professionalstrongly warns against,

rejects and disclaims any modifications, add-on

accessories or product alterations that are not

designed, developed, tested and approved by

Craftsman Professional Engineering Department.

Any Craftsman Professional product that is altered,

modified or changed in any manner not specifically

authorized after original manufacture-including the

addition of “aftermarket” accessories or component

parts not specifically approved by Craftsman

Profesional-will result in the Craftsman Professional

Warranty being voided.

Any and all liability for personal injury and/or property

damage caused by any unauthorized modifications,

add-on accessories or products not approved

by Craftsman Professional will be considered

the responsibility of the individual(s) or company

designing and/or making such changes. Craftsman

Professional will vigorously pursuefull indemnification

and costs from any party responsible for such

unauthorized post-manufacture modifications and/or

accessories should personal injury and/or property

damage result.

This symbol means:

ATTENTION!

A

Your safety and the safety of others is involved.

Signal word definitions;

The signal words below are used to identify levels

of hazard seriousness. These words appear in

this manual and on the safety labels attached

to Craftsman Professional machines. For your

safety and the safety of others, read and follow the

information given with these signal words and/or

the symbol shown above.

BECOME ALERT!

ik DANGER

DANGER indicates an imminently hazardous

situation which, if not avoided, WILL result in death

or serious injury.

^WARNING

WARNING indicates a potentially hazardous

situation which, if not avoided, COULD result in

death or serious injury.

ACAUTION

CAUTION indicates a potentially hazardous situation

which, if not avoided, MAY result in minor or moderate

injury. It may also be used to alert against unsafe

practices or property damage.

CAUTION

CAUTION used without the safety alert symbol

indicates a potentially hazardous situation which, if

not avoided, MAY result in property damage

MODEL NUMBER: This number appears on sales literature, technical manuals and

price lists.

SERIAL NUMBER; This number appears only on your mower. It contains the model

number followed consecutively by the serial number. Use this number when ordering

parts or seeking warranty information.

Serial Number Tag is located under seat; on the far back wall of the frame; left of battery

from operators point of view.

PREPARING FOR SAFE OPERATION

Operator preparation and training

Read the Operation & Safety

Manual

- If an operator or mechanic

cannot read English, it is

the owner's responsibility

to explain this material to

them. If any portion of this

material is unclear, contact

your factory representative for

clarification.

- Become familiar with the safe operation of the

equipment, operator controls and safety signs.

Know how to stop the engine and attachments

quickly in an emergency. Do not operate or allow

another person to operate this machine if there

are any questions about safety.

- All operators and mechanics should be trained.

The owner is responsible for training the users.

- Wear appropriate clothing, including long

trousers and safety goggles or safety glasses

with side shields when operating mower. Do not

operate barefoot or wearing open sandals. Long

hair, ioose clothing or jewelry may get tangled in

moving parts.

- Wear hearing protection.

- Never allow underage children, unskilled

or improperly trained people operate this

equipment. Local regulations can restrict the age

of the operator.

- Data indicates that those operators age 60 years

and above are involved in a large percentage of

riding mower-related injuries. Those operators

should evaluate their ability to operate the riding

mower safely enough to protect themselves and

others from injury.

- Do not carry passengers, especially small

children. They may fall off and be seriously

injured.

- Keep warning labels and this operator's manual

legible and intact. Replacement labels and

manuals are available from the factory.

- Do not operate machine while under the

influence of drugs or alcohol.

- The owner/user can prevent and is responsible

for accidents or injuries occurring to themselves,

other people or property.

SAFETY

A WARNING

All rotary lawnmowers are potentially

dangerous. They can amputate hands and

feet and throw objects. Failure to follow

these safety and operating instructions

could result in serious injury or death.

Site preparation and circumstances

- Evaluate the terrain to determine what

accessories and attachments are needed to

properly and safely perform the job. Only use

accessories and attachments approved by the

manufacturer.

- Clear the area to be mowed of objects such as

rocks, toys, wire or other debris that may be

picked up or thrown by the mower.

- Be sure the area is clear of pets and people,

especially young children. Never assume they

will remain where you last saw them. Stop the

machine if any enter the area.

- Mow only in daylight or in good artificial light.

- Do not mow wet grass as tires may iose traction.

SAFETY

Machine preparation

- Check operator presence interlock system and

brake operation. Adjust or repair any problems

before using.

- Do not tamper with or defeat safety devices.

Keep guards, shields and interlock safety devices

in place and in proper working condition. They

are for your protection.

- Keep all fasteners such as nuts, bolts and pins

well secured.

- Visually inspect blades, blade bolts and the cutter

assembly for wear or damage. Replace worn or

damaged blades and bolts to preserve balance.

- Verify that machine and attachments, if any, are

in good operating condition.

- Do not engage blades until ready to mow.

OPERATING SAFELY In general

- Use extra care when loading or unloading the

machine into a trailer or truck.

- Slow down and use caution when making turns

and crossing roads and sidewalks. Stop blades if

not mowing.

- Do not run the engine in an enclosed area where

dangerous carbon monoxide fumes can collect.

- Do not place your foot on the ground while

operating the machine.

- Before operating, lower the discharge chute,

install the mulcher or put the entire grass catcher

in place.

- Keep clear of the discharge opening at all times.

Never direct the discharge toward a bystander.

Stop operation if someone approaches.

- Keep washout ports and other mower housing

service openings closed when mowing.

- Use care when pulling loads or using heavy

equipment.

- Use only approved draw bar hitch points.

- Limit loads to those you can safely control.

- Do not turn sharply. Use care when reversing.

- Use counter-weight(s) or wheel weights when

suggested in the operator's manual.

- Never leave a machine unattended. Always turn

off blades, set parking brake, stop engine and

remove key before dismounting.

SAFETY

starting

start only according to instructions in this manual

or on the machine.

Before attempting to start the engine, make sure:

- the parking brake is on;

- the PTO is disengaged;

- the traction drive is in NEUTRAL.

When starting the engine, make sure hands and

feet are clear of the blades.

Do not start the machine while standing in front

of the discharge chute or with the chute directed

at someone.

Do not engage PTO at full throttle. Throttle to

idle or lowest possible engine speed.

Do not change engine governor settings or

over-speed the engine. Operating the engine

at excessive speed can increase the hazard of

personal injury.

Interrupting operation

- Before leaving the operator's position:

- Park on level ground.

- Disengage the PTO.

- Set the parking brake.

- Shut off the engine and remove the key.

- Disengage the PTO and wait until the blades quit

rotating:

- before raising cutterdeck;

- when not mowing;

- for transport;

- when crossing surfaces other than grass.

- Stop the engine, disengage the PTO, set parking

brake and wait until the blades quit rotating and

lower cutting unit:

- before refueling;

- before removing grass catcher;

- before making height adjustment unless the

adjustment can be made from the operator's

position.

- Stop the engine, disengage the PTO, set parking

brake and disconnect the spark plug wire(s) or

remove the key:

- before clearing blockages or unclogging chute;

- before checking, cleaning or working on the

machine;

- after striking a foreign object. Inspect the

machine for damage and make repairs before

restarting;

- if the machine begins to vibrate abnormally:

shut off machine immediately. Inspect and

make repairs as needed before restarting;

- except for repairs or adjustments as specifically

noted, such as for carburetor adjustment,

where the engine must be running. Keep

hands and feet clear of moving parts in these

circumstances.

- Allow the blades to come to a complete stop

when stopping operation to clear blockages,

unclog, inspect the machine, do maintenance or

repair.

- Reduce the throttle setting during engine shut

down and, if the engine is provided with a shut

off valve, turn the fuel off at the conclusion of

mowing.

SAFETY

MANEUVERING SAFELY

In general

- Slow down before turning.

- Do not mow in reverse unless absolutely

necessary. Always look behind and down

for small children and pets before and during

backing.

- Be aware when approaching blind corners,

shrubs, trees, tall grass or other objects that may

obscure vision.

- If tires lose traction, disengage the blades. If on

a slope, head downhill.

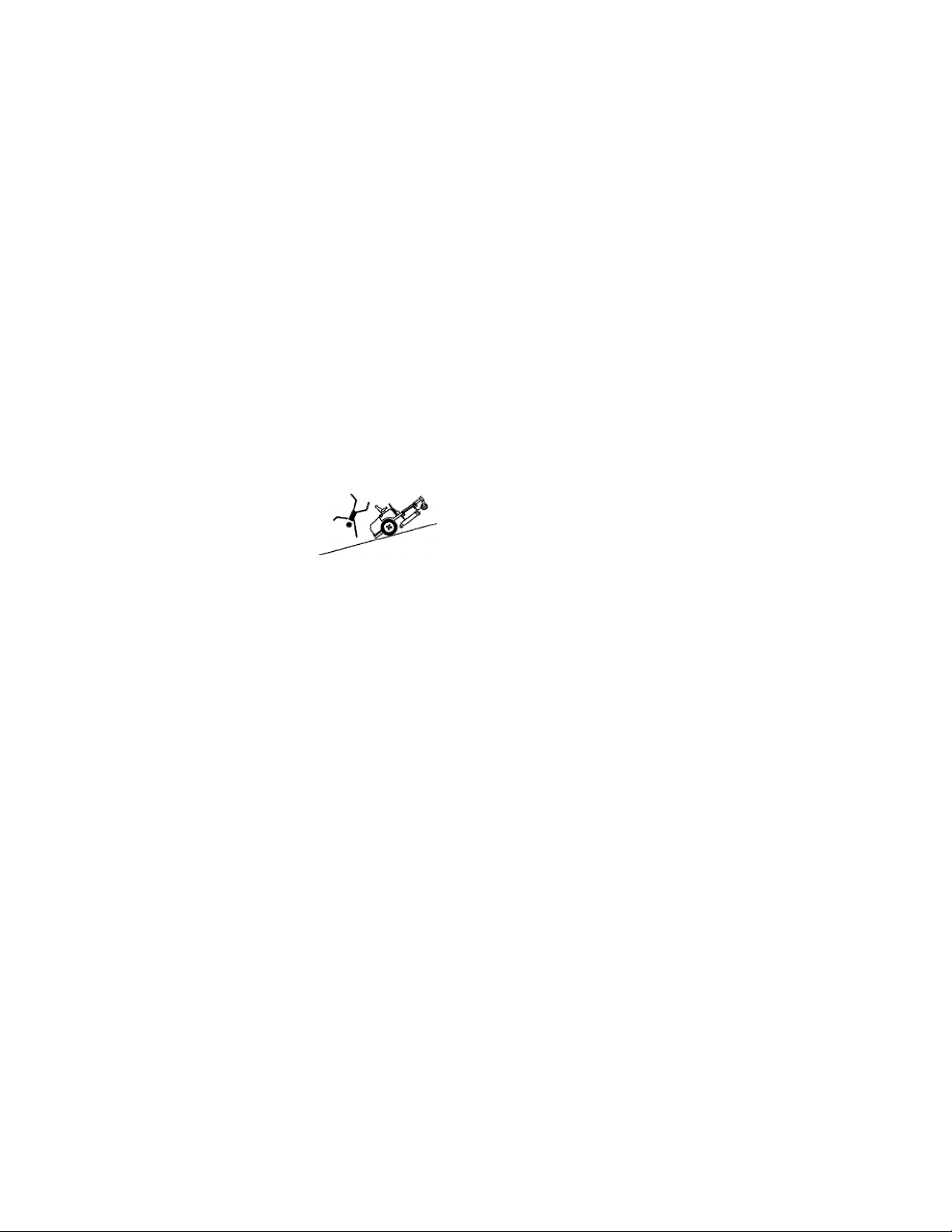

Mowing slopes A warning

Slopes are a major factor in

loss-of-control and tip over

accidents that sometimes lead

to severe injury or death. All

slopes require extra caution.

- Do not mow on slopes if uneasy or uncertain.

Ultimate responsibility for safe operation on

slopes rests with the operator.

- Do not mow excessively steep slopes.

A slope is too steep if:

■ The machine will not back up the slope.

■ The machine must be crabbed (turned

partially sideways uphill) to drive across

the slope.

■ The machine turns downhill going across slope.

■ You are uneasy about being on the slope.

- On zero turn machines, mow across slopes, not

up and down.

- Avoid starting or stopping on a slope. If tires

lose traction, disengage the blades and proceed

slowly straight down the slope.

- With a zero turn machine, if tires lose traction

going down a slope, steering control may be

regained by speeding up.

- Mid-mount zero turns (belly mounted deck) have

much greater traction pointed up slope than

down slope. Be aware that traction may be lost

going down a slope. Do not operate a mid-mount

zero turn on slopes it cannot back up.

- Keep all movement on the slopes slow and

gradual. Do not make sudden changes in speed

or direction.

Do not turn on slopes unless necessary, and then

turn slowly and downhill when possible.

Stay away from slopes if the ground is loose or if

caught in the rain during mowing.

Use lower speeds on a slope to avoid stopping or

shifting.

Use extra care with grass catchers or other

attachments. These can change the stability of

the machine.

Remove obstacles such as rocks, tree limbs etc.

Avoid driving over obstacles such as ruts, holes,

rocks and roots whenever possible. Be alert to

dips and rises. Uneven terrain can overturn a

mower or cause it to slide. Tall grasses can hide

obstacles.

Do not mow drop-offs, ditches or embankments.

The machine could suddenly turn over if a wheel

runs over the edge or an edge caves in.

Follow the manufacturer's recommendations

for wheel weights or counterweights to improve

stability.

Do not mow slopes when grass is wet. Reduced

traction could cause sliding.

MAINTENANCE SAFETY

In general

- Maintain machine according to manufacturer's

schedule and instructions for maximum safety

and best mowing results.

- Park machine on level ground.

- Never allow untrained personnel to service ma

chine.

- Adjust or repair only after the engine has been

stopped and the blades have quit rotating.

- Inspect grass catcher components regularly. If

worn, damaged or deteriorated, they may expose

moving parts or allow objects to be thrown.

- Replace parts if worn, damaged or faulty.

For best results, always replace with parts

recommended by the manufacturer.

- Disconnect battery or remove spark plug wire(s)

before making any repairs. Disconnect the

negative terminal first and the positive last. Re

connect positive first and negative last.

- Do not dismantle the machine without releasing

or restraining forces which may cause parts to

move suddenly.

- Provide adequate support, e.g. jackstands for

lifted machine or parts if working beneath.

- Do not put hands or feet near or under rotating

parts.

- Clean up spilled oil or fuel thoroughly.

- Replace faulty mufflers.

- To reduce fire hazards, keep the engine, muffler,

battery compartment and fuel storage area free

of grass, leaves, debris buildup or grease.

- Hydraulic fluid can penetrate skin, use paper

to check for leaks. Relieve hydraulic pressure

before disconnecting hoses. Make sure

connections are tight and hoses are in good

condition.

SAFETY

Blades

Mower blades are sharp and

can cut. Use extra caution

when handling. Remove ob

structions with care. Wrap the

blade(s) or wear gloves.

Be aware that rotating one

blade on multi-blade mowers can cause other

blades to rotate.

Only replace blades. Never straighten or weld

them.

Keep other persons away from blades.

Fuel

- Gasoline and diesel fuels are

flammable; gasoline vapors

are explosive. Use extra care

when handling.

- Store only in containers spe

cifically designed for fuel.

- When refueling or checking fuel level:

- Stop the engine and allow to cool;

- Do not smoke;

- Refuel outdoors only;

- Use a funnel;

- Do not overfill;

- If fuel is spilled, do not attempt to start the

engine until the spill is cleaned up and vapors

have cleared.

Sparks from static electricity can start fires or cause

explosions. Flowing fuel can generate static

electricity. To prevent static electricity sparks:

- Keep containers electrically grounded. Do not fill

containers in a vehicle or on a truck or trailer bed

with a plastic liner. Fill containers on the ground

away from the vehicle.

- When practical, remove gas powered equip

ment from the truck or trailer and refuel it on the

ground. If equipment must be refueled on the

truck or trailer, refuel from a portable container

rather than a dispenser nozzle.

- Keep the dispenser nozzle in contact with the rim

of the fuel tank or container opening until fueling

is complete. Do not use a nozzle lock-open

device.

- Replace caps on fuel cans and tanks securely.

■ WARNING

¥

^WARNING

M

SAFETY

BATTERY

Battery acid is caustic and fumes

are explosive and can cause

serious injury or death.

To reduce the risk of personal

injury when working near a bat

tery:

- When working with battery

acid, use protective equipment

such as, but not limited to, goggles, face shield,

rubber gloves and apron.

- Avoid leaning over a battery.

- Do not expose a battery to open flames or

sparks.

- Be sure batteries with filler caps are properly

filled with fluid.

- Do not allow battery acid to contact eyes or skin.

Flush any contacted area with water immediately

and get medical help.

- Charge batteries in an open, well ventilated area,

away from sparks and flames. Unplug charger

before connecting or disconnecting from battery.

Stop the engine and allow to cool before storing.

Drain the fuel tank outdoors only.

Store fuel in an approved container in a cool, dry

place.

Keep the machine and fuel containers in a locked

storage place to prevent tampering and to keep

children from playing with them.

When the machine is to be parked, stored or ieft

unattended, iower the cutterdeck unless a posi

tive mechanical lock is used.

Do not store the machine or fuel container near

heating appliances with an open flame such as a

water heater or an appliance with a pilot light.

Keep gasoline storage area free of grass, leaves

and excessive grease to reduce fire hazard.

Clean grass and debris from cutting units, drives,

mufflers and engine to help prevent fires.

WARNING

1. Be sure the jumper cables are in good condition.

Turn off the ignition and all electrical accessories

on both machines.

2. Position the machine with a good (charged) bat

tery next to but not touching the machine with the

dead battery so jumper cables will reach.

3. When making cable connections:

- make sure the clamps do not touch anywhere

except to intended metal parts,

- Never connect a positive ("+" or red) terminal

to a negative or black) terminal.

- Make sure the cables won't get caught in any

parts after the engines are started.

4. Connect one end of the first jumper cable to the

positive terminal on one battery. Connect the

other end to the positive terminal on the other

battery.

5. Connect one end of the other cable to the

negative terminal of the machine with a good

(charged) battery. Make the final connection on

the engine of the machine to be started, away

from the battery.

6. Start the vehicle with the good battery, then the

machine with the discharged battery.

7. Remove the cables in the exact reverse order of

installation. When removing each clamp, take

care it does not touch any other metal parts while

the other end remains attached.

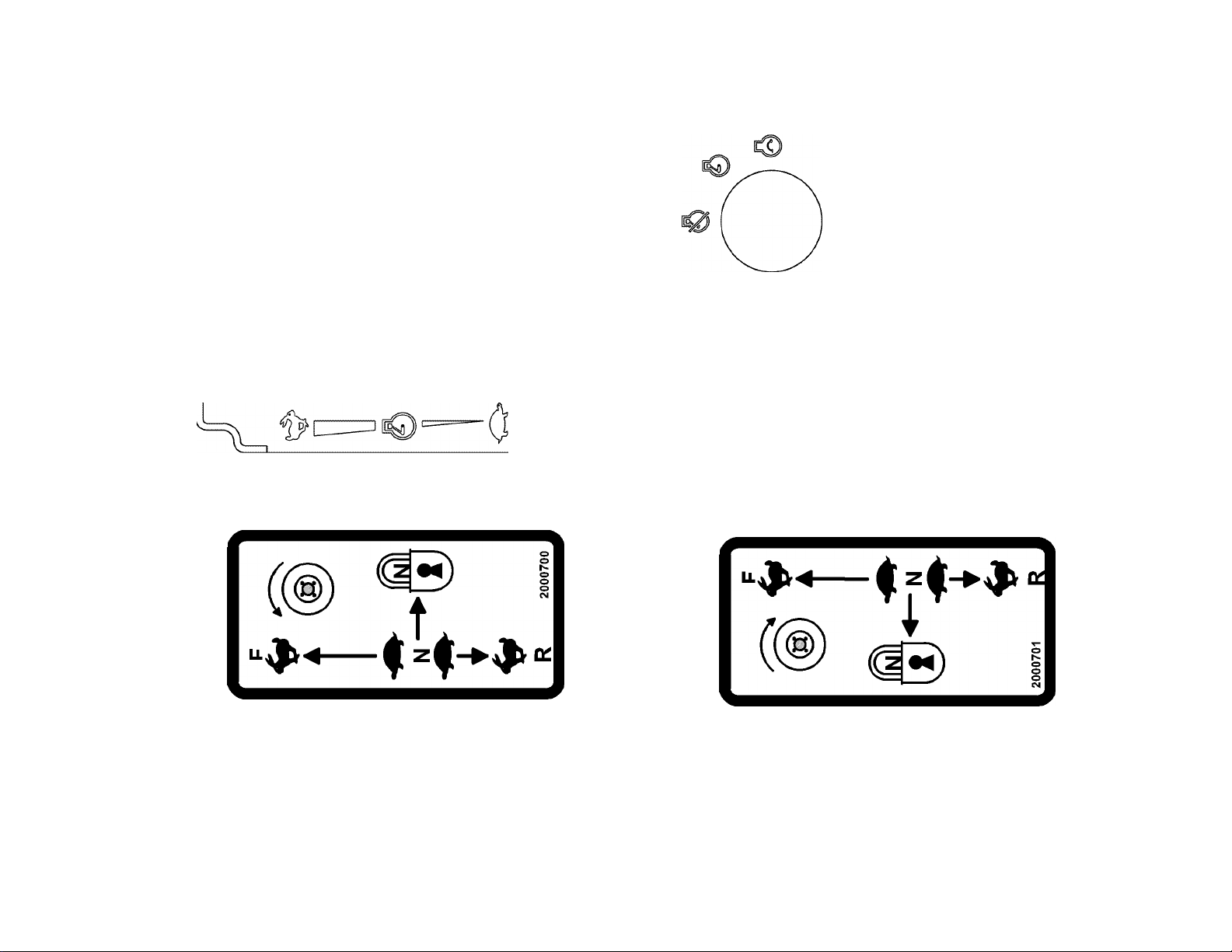

m

LU

m

5

4 t

=r? t?

ICT igi

OFF ON

BLADE

ENGAGEMEMT

BEFORE STARTING OR

SERVICING;

- Read on;l understand

operotor s monuol ond labels.

- Be sure machine Is in sofe

operoting condition.

- move troction levers to neutral

lock, porking brake to ON.

- Switch PTO to OFF.

BEFORE LEAVING SEAT

- Move troction levers to neutral

lock, parking broke to ON.

- Switch PTO to OFF

- Turn engine keyswitch to OFF.

- Remove key,

N

LABELS

A ADVERTENCIA

1. Leer el manual del operador. No permitir

que personas no capacitarJas para ello usen

la máquina.

2. Mantener los protectores en su lugar y sus

tornillos debidamente ijados.

3. Antes de limpiar, ajustar o reparar este

equipo, apagar toóos los mandos, aplicar

el freno de estacionamiento y apagar el motor.

4. Mantener fas manos, los pies y la ropa

alejados de las piezas en movimiento.

5. No conducir como pasajero ni llavar pasajeros

en máquinas sin asiento para ello.

6. Mantener a las demás personas alejadas

durante el funcionamiento de la máquina.

7. Si no sabe leer inglés, solicitarle a otra persona

que le lea y explique el conterrido de las

etiquetas y del manual de la máquina.

340830

10

LABELS

11

LABELS

A WARNING A

-REMOVE DEBRIS BUILDUP. DEBRIS UNDER BELT COVER OR

NEAR MUFFLER CAN CAUSE FIRES.

-BLADES CONTINUE TO ROTATE FOR A FEW SECONDS AFTER

BLADES ARE TURNED OFF.

-BLADES MUST BE AT LEAST 1/8" ABOVE BOTTOM OF HOUSING.

-ALL BLADES MUST BE IDENTICAL. CHECK BLADE BOLTS DAILY

FOR TIGHTNESS.

-INSPECT FOR DAMAGE AFTER STRIKING A FOREIGN OBJECT.

MAKE REPAIRS BEFORE RESTARTING OPERATION.

-FIND AND REPAIR CAUSE OF ANY ABNORMAL VIBRATION.

A WARNING

SPARKS OR FLAME CAN START EXPLOSION.

DISCONNECT {-)NEGATIVE TERMINAL FIRST.

RECONNECT (-)NEGATIVE TERMINAL

LAST. 2000590

2000572

A WARNING

TO CHECK OR ADD FUEL:

-Do It outdoors.

-Stop engine. Allow to cool.

-Do not smoke.

-Clean up spilled fuel.

-Do not overfill.

-Fill to one inch below bottom of

filler neck. 2000570

À WARNING A advertencia

A WARNING

12

LABELS

^ DANGER

ROTATING BLADES

■ KEEP HANDS AND FEET AWAY.

■ STOP ENGINE AND LET BLADES

STOP BEFORE REMOVING

GRASS COLLECTOR OR

UNCLOGGING

A WARNING

THROWN OBJECTS

■ KEEP AREA CLEAR OF PEOPLE

AND PETS.

■ REMOVE OBJECTS BLADE MAY

STRIKE AND THROW.

■ STOP BLADES TO CROSS GRAVEL

Jr

AREAS

■ DO NOT OPERATE WITHOUT CHUTE,

MULCHER OR ENTIRE GRASS

COLLECTOR IN PLACE.

2000677

13

CONTROLS

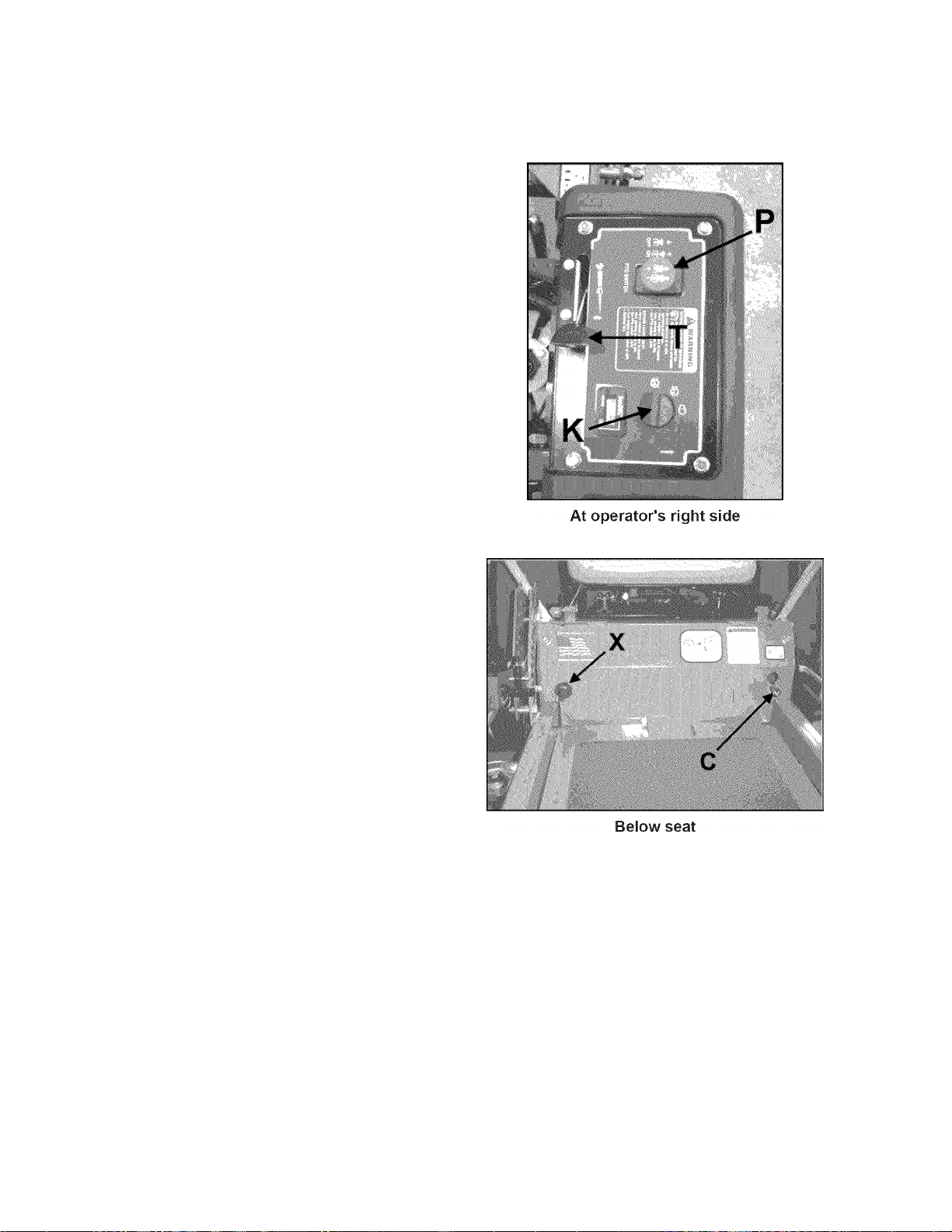

KEYSWITCH (K) - The keyswitch has three

positions: OFF, RUN, and START. Insert the key

and turn it clockwise to move the switch from OFF to

RUN. Turn it further to START and hold to engage

the starter. Release the key and the switch will return

to RUN from START. Turn the key counterclockwise

to OFF to stop the engine.

THROTTLE (T) - Move the throttle lever forward to

increase engine speed until the maximum governed

engine RPM is reached. Move the iever rearward to

decrease engine speed until the engine reaches its

idle speed.

CHOKE (C)

For Kawasaki and Briggs and Stratton Engines, pull

the choke control out to set the choke ON. Push it in

to set the choke OFF.

POWER TAKE OFF (PTO) SWITCH (P) -

The operator must be in the seat when engaging the

PTO or the engine will kill. Pulling the PTO switch

out engages (turns on) the PTO and starts the blades

or other attachment. Pushing the PTO switch in

disengages (turns off) the PTO and stops the blades

or other attachment.

NOTE: The PTO switch does not control

attachments powered by a separate engine.

- Disengage the PTO whenever you stop or ieave

the operator’s position

- Shut off engine with the key and remove the

spark plug wires before making adjustments or

unplugging a clogged mower.

- Do not engage the PTO until ready to start

mowing.

12 VOLT POWER OUTLET (X)

A 12 volt power outlet is provided to operate 12 volt

personal accessories.

14

FUEL SELECTOR VALVE (U)

The fuel tank selector valve is located behind the

seat.

The fuel tank selector valve has three positions:

Off: The tank selector is off when the lever points

down. The selector should be off whenever the

machine is transported or stands unused for any

length of time. Shutting off the fuel supply avoids the

possibility of flooding should any dirt get under the

carburetor float needle. Leaving the tank selector in

either tank position can allow severe flooding, which

may ruin the engine by diluting the oil.

Right Tank: Fuel flows from the right tank when the

selector is turned 1/4 turn toward the right.

Left Tank: Fuel flows from the left tank when the

selector is turned 1/4 turn toward the left.

CONTROLS

15

CONTROLS

Reverse movement - To move the machine straight

back, pull both traction levers back equally from their

neutral position. Reverse speed increases as the

levers are moved back farther. Maximum reverse

speed is reached when the levers hit the rear of the

forward-reverse slot. When moving in reverse, push

ing the levers forward slows the machine, and the

machine stops when the neutral position is reached.

NOTE: Reverse is spring loaded to return to neutral.

This spring resistance may be felt when moving the

traction levers into reverse. When the levers are

released in reverse, spring tension will slowly return

them to the neutral position.

STEERING - To steer, move one lever forward and

one back.

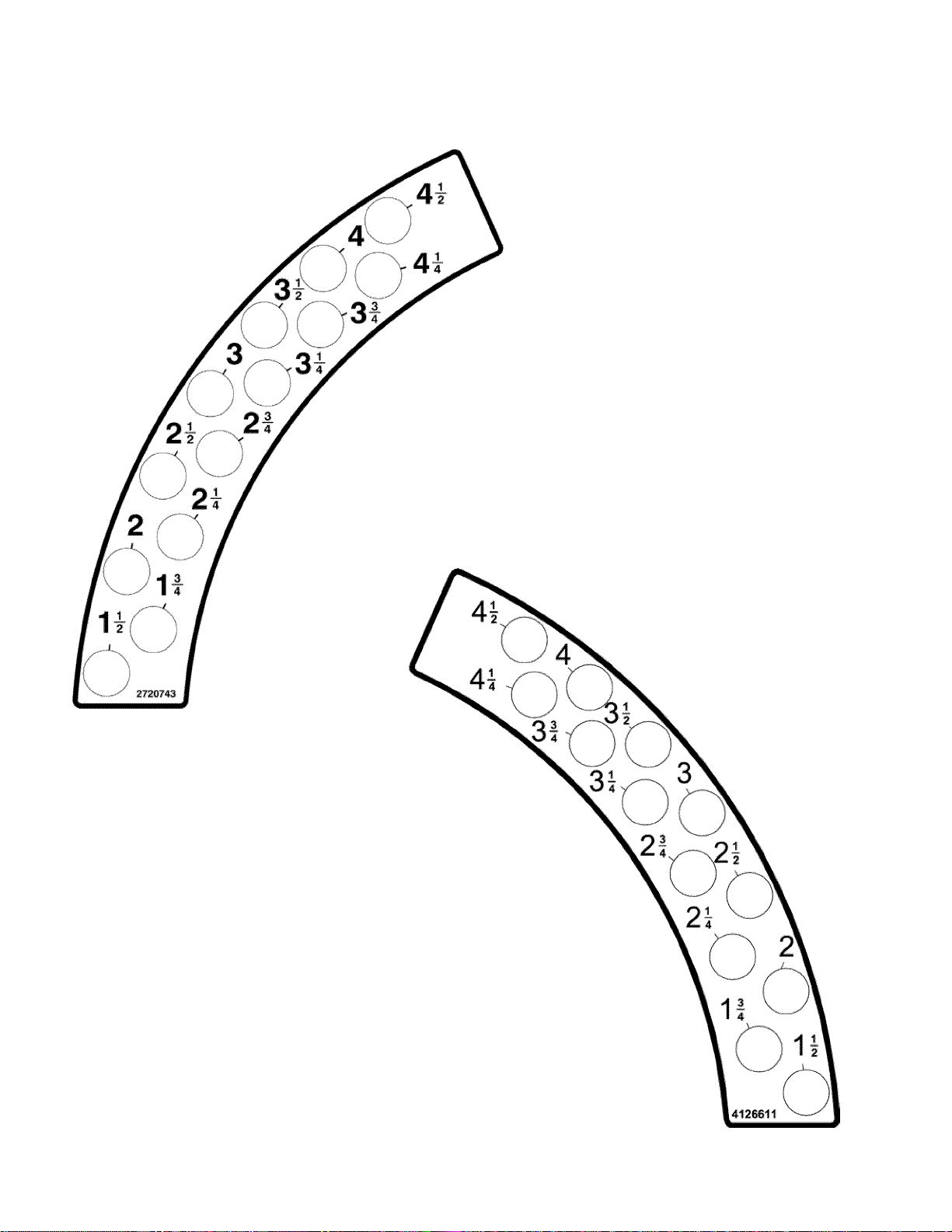

LIFT LEVER (F) - Used to raise the cutterdeck to

maximum height for transport, curb climbing or blade

changing. To return to preset height of cut, lower lift

lever until it contacts height of cut pin A.

TRACTION LEVERS (L) - Each of the two

traction levers controls the drive wheel located on

the same side. They control the forward and reverse

movement of the machine, provide steering and also

provide dynamic braking.

The operator must be in the seat and the parking

brake must be OFF to engage the traction drive.

To engage traction drive, move the traction levers

toward the center of the machine until they are out of

neutral lock slot S.

Forward movement - To move the machine straight

ahead, push both traction levers forward equally from

their neutral position. Forward speed increases as

the levers are moved farther forward from the neutral

position. Maximum forward speed is reached when

the levers hit the front of the forward-reverse slot.

When traveling forward, pulling the traction levers

rearward slows the machine. The machine stops

when the neutral position is reached.

Turns during forward movement:

- Right turn - move the right traction lever back

toward neutral to slow the right drive wheel.

- Left turn - move the left traction lever back to

ward neutral to slow the left drive wheel.

Turns during reverse movement:

- Reverse right turn - move the right traction lever

forward toward neutral to slow the right drive

wheel.

- Reverse left turn - move the left traction lever

forward toward neutral to slow the left drive

wheel.

Slow, sweeping turns are made with both traction

levers on the same side of neutral and slightly

apart. True zero radius turns about the center of the

machine are made by having one lever in reverse

while the other is in forward. By varying the relative

positions of the two levers, the rate of turn is varied to

suit the mowing situation.

A CAUTION

Slow down before making sharp turns. The machine

is capable of turning very rapidly when the levers are

moved further apart from each other. Loss of control

and/or turf damage may result.

16

PARKING BRAKE (R) - Pull the parking brake

lever up and back to put the parking brake ON. Push

it forward and down to put the parking brake OFF.

The parking brake must be ON to start the engine.

It must also be ON to keep the engine running if the

operator leaves the seat. The parking brake must be

OFF to keep the engine running when a traction lever

is moved out of neutral lock.

CONTROLS

i R '

Parking brake in ON position

(operator's left side)

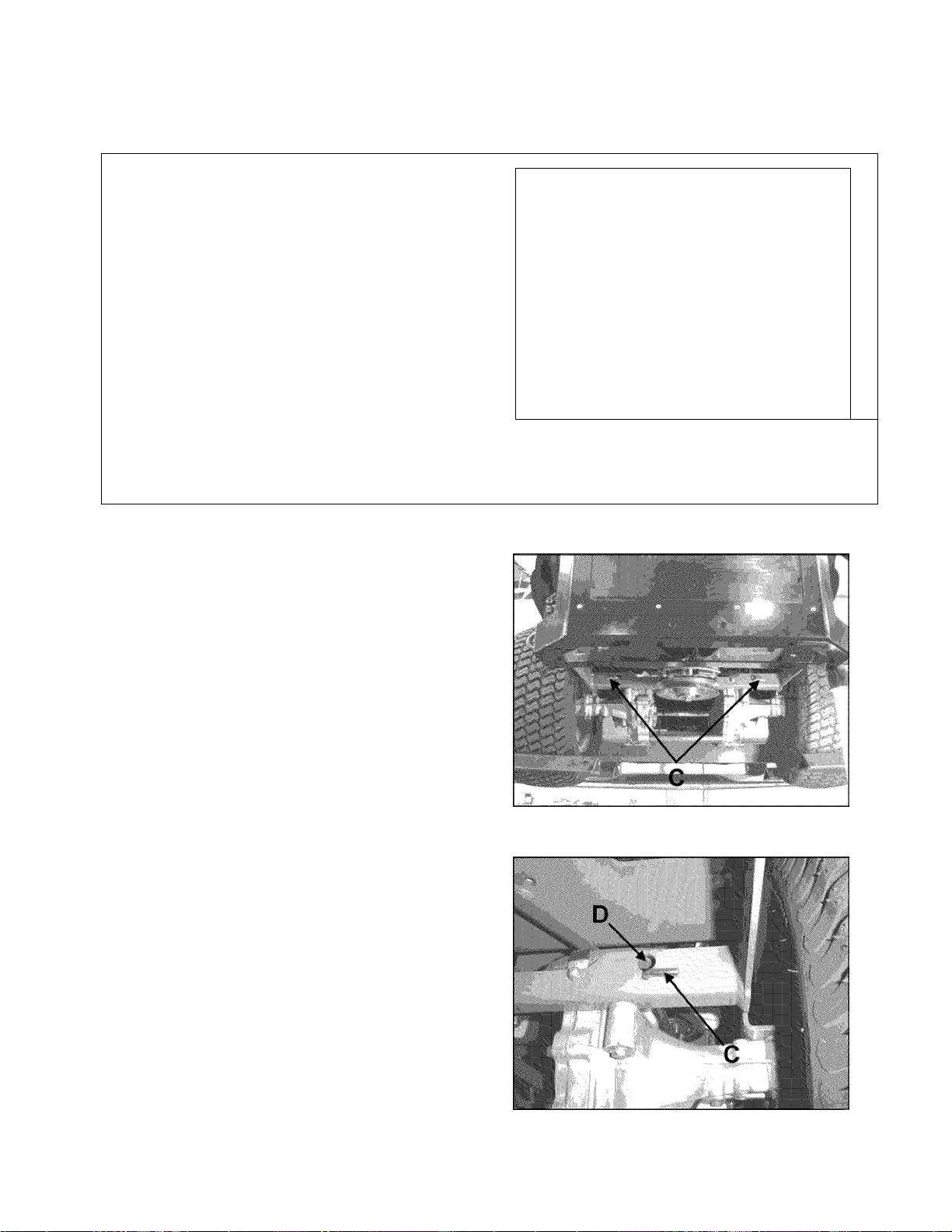

PUSHING THE MACHINE

The machine may be pushed with the engine off, the

parking brake off, and the bypass valves open.

To open the bypass valves, move the parking brake

to the OFF position, then lift and pull bypass control

rod C through the large opening D, until the control

rod stop is past the opening. Drop rod C into the

small opening to lock in place. Repeat for the other

bypass control rod.

To close the bypass valves, lift bypass control rod C

allowing the control rod stop to retract through the

large opening D.

17

PRE-^OPERATION CHECK LIST

PRE-OPERATION CHECK LIST

(OPERATOR’S RESPONSIBILITY)

Review and follow all safety rules and safety

decal instructions.

Check that all safety decals are installed and in

good condition. Replace if damaged.

Check to make sure all shields and guards

are properly installed and in good condition.

Be sure that either the discharge shield or

complete vacuum attachment is installed.

Check that all hardware is properly installed,

and secured.

Check that equipment is properly and securely

attached to power unit.

Check to be sure engine is free of dirt and

debris. Pay particular attention to the cooling

fins, governor parts and muffler. Clean air

intake screen. Check air cleaner; service if

necessary.

Never allow riders.

Inspect area and remove stones, branches or

other hard objects that might be thrown,

causing injury or damage.

Clean area around oil fill dipstick. Remove

dipstick and check to be sure oil is in operating

range (between marks on dipstick). Add oil if

necessary but Do Not Overfill. Install dipstick

assembly firmly until cap bottoms out on tube.

Dipstick assembly must always be secured into

fiil tube when engine is running.

Check all lubrication points and grease as

instructed in manual.

Check hydrostatic fluid level. Check to be sure

cooling fins on hydrostat are clean.

Perform a functional check of the safety

interlock system each time you operate the

unit.

18

SET UP INSTRUCTIONS

TOOLS REQUIRED FOR ASSEMBLY

- Wrecking bar

- Claw hammer

- Sockets: 1/2”, 15/16

- Wrenches: 18mm, 1/2”, 9/16”, 3/4”, 15/16”

- Tire pressure gauge

NOTE: All references below to the “right” or “left” are with respect to an operator at the controls.

1. UNCRATE UNIT

a) Discard packing materials. Loosen the caster wheel axle bolts and bumper bolts to remove the shipping

brackets.

Discard shipping brackets.

b) Re-install and tighten bumper bolts.

c) Tighten caster wheel axle bolts against caster axle spanner bushings to 80 ft/lbs.

------------

■

>

/

CASTER AXLE BOLTS

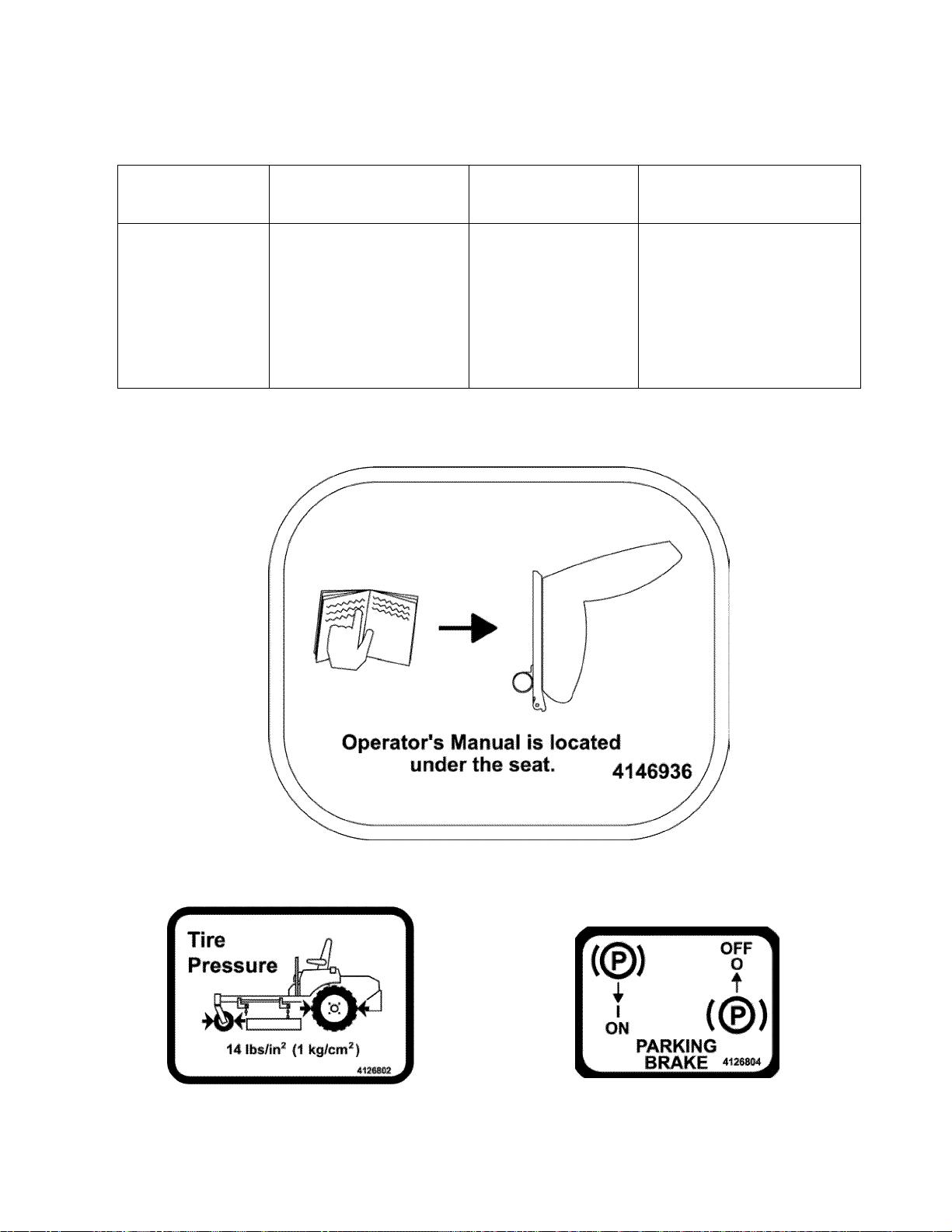

2. TIRE PRESSURE

a) Set tire pressures to 14 Ibs/in^ (1.0 kg/cm^). Tires are overinflated for shipping.

3. TRACTION LEVERS

a) Tighten bolt A.

b) Sit on the machine. Levers C may be moved to

upper set of holes in bar B for a better operator

fit.

#

19

SETUP INSTRUCTIONS

4. FINAL PREPARATIONS

- Check the engine and hydraulic oil levels. Top off with the correct oil if necessary. Use 10W30 motor oil

for the engine. Use fresh, clean 20W50 motor oil for the hydraulic system.

- Insure Battery cables are connected properly.

^WARNING

Use insulated tools, wear protective glasses or goggles and protective clothing when working with batteries.

Read and obey the battery manufacturer’s instructions.

Be certain the ignition switch is OFF and the key has been removed before servicing the battery.

a) Verify battery polarity before connecting or disconnecting the battery cables.

b) When installing the battery, always assemble the RED, positive ( + ) battery cable first and the

ground, BLACK, negative (-) cable last.

c) Tighten cables securely to battery terminals and apply a light coat of silicone dielectric grease to

terminals and cable ends to prevent corrosion. Keep terminal covers in place.

- Read Operation and Safety Manual before starting. Operator Manual is iocated under the seat. Tilt seat

forward to access manual.

Battery acid is caustic. Fumes are explosive and can cause serious injury or death.

If deck does not cut level, see deck leveling procedure in the Operator’s Manual

Run engine at full RPM for 5 minutes before engaging blades to allow the engine to be fully lubricated

before ioad is applied.

Check the hydrostat neutral adjustment. Neutral is set at the factory but may require readjustment. See

adjustments section in the operator’s manual.

Do not use the machine without an approved grass collector, the grass discharge chute or mulching

plates correctly fitted.

20

OPERATION

FUELING

- Fill fuel tank with good quality, clean, unleaded

regular gasoline. Do not use hi-test fuel.

- Use a funnel to avoid spilling.

TO CHECK OR ADD FUEL:

- Do it outdoors

- Do not smoke

- Stop engine; allow to cool

- Fill to one inch below bottom

of filler neck

- Do not overfill

- Clean up spilled fuel

BEFORE STARTING THE ENGINE

- Be familiar with all controls, how each functions

and what each operates.

- Check the engine oil level and add if necessary.

Using the fuel selector valve, select which tank

will supply fuel

- Choke: For cold starts, set the throttle lever to the

half-open position and pull the choke out to the

ON position. For warm starts set the throttle to

the half-open position and the choke to the OFF

position.

OPERATOR PRESENCE

INTERLOCK SYSTEM

To start the engine:

- The PTO switch must be OFF.

- Both traction levers must be in the neutral lock

position.

- The parking brake must be ON.

To operate the machine:

1. The operator must be in the seat or engaging the

PTO will kill the engine.

2. The parking brake must be OFF and the opera

tor must be in the seat, or moving a traction lever

from the neutral lock position will kill the engine.

STARTING THE ENGINE

1. Turn the key to operate the electric starter to start

the engine. Release the key when the engine

starts.

2. If the engine does not start immediately, do not

crank for more than 10 seconds at a time. Allow

60 seconds for the starter motor to cool down

between starting attempts to prevent the starter

motor from burning out.

3. If the choke is ON when the engine starts,

gradually back it off until the engine runs with no

choke at all.

21

OPERATION

OPERATING NOTES

- Practice at slow engine and travel speeds with the

PTO off until fully familiar with the controls.

- For normal cutting the throttle should be set at the

full open position. By using the traction levers to

speed up or slow down the machine during use,

maximum control and cutting efficiency can be

maintained.

- Using the machine at less than full throttle in

heavy conditions will cause the engine to labor

and result in excessive wear.

DRIVING

1. With the PTO disengaged, move the parking

brake to OFF.

2. Move both traction levers out of neutral lock.

3. Push both traction levers forward evenly to

drive forward in a straight line. Pull both traction

levers back evenly to drive backward in a straight

line.

4. Steering - Move one lever forward and one back.

Turns during forward movement:

- Right turn - move the right traction lever back

toward neutral to slow the right drive wheel.

- Left turn - move the left traction lever back to

ward neutral to slow the left drive wheel.

Turns during reverse movement:

- Reverse right turn - move the right traction lever

forward toward neutral to slow the right drive

wheel.

- Reverse left turn - move the left traction lever

forward toward neutral to slow the left drive

wheel.

A CAUTION

Use caution when making turns. Slow down before

making sharp turns to help maintain control and to

prevent torn turf from skidding or spinning tires. To

help prevent turf damage, keep both drive tires mov

ing whenever a turn is made.

TIP: The best way to make a sharp "zero" turn is to

come to a stop, get the machine moving in reverse

with both drive wheels and then power the machine

around with the outside wheel. This technique keeps

the drive tires turning and results in less turf damage.

22

Loading...

Loading...