Page 1

FR Manuel d'utUisation, pp. 23-44 I 2SEx_sERIES

EN Operator's manual, pp, 2-22 .125B Q

ES Manual de instrucciones, pp. 45-66

EN FR ES

Page 2

CONTENTS

Contents

Introduction ................... 2

Key to symbols .................. 3

Safety instructions ............... 4

Description ..................... 6

Fuel handling .................... 11

Starting and stopping ............ 12

Using the blower ................. 13

Maintenance .................... 18

Technical data ................... 19

Maintenance, replacement, or repair of the

emission control devices and system may

be performed by any nonroad engine re-

pair establishment or individual

WARNING

Theengine exhaust from this product

containschemicalsknown to theState

ofCaliforniatocausecancer,birth

defectsorotherreproductiveharm.

Note the following before

starting:

Husqvama AB has a policy of continuous

product development and therefore

reserves the right to modify the design and

appearance of products without prior

noede. Long-term exposure to noise can

result in permanent hearing impairment.

Always use approved hearing protection.

This operator's manual describes in detaJ+

how to use and service the blower and

how to carry out regular maintenance. It

also descdbes which measures should be

taken to achieve maximum safety while

operating the blower, how the safety de-

vices work and how they should be ser-

viced.

Note[ The section of the manual that deals

with safety, must be read and understood

by all persons who come in contact with

the blower.

This operator's manual has been wdnen

for those who need guidance when it

comes to fault tracing, thorough servicing

and carrying out corrective maintenance of

the blower.

There are warning symbols on the blower.

Should any of the warning symbols on the

blower become disfigured or worn, new ones

should be ordered and fitted to the blower as

soon as possible. Note that some of the

warning symbols may be molded in certdln

components of the blower.

The blower is used for blowing away leaves

and other debris on the ground. When op-

erating the blower, the operator must stand

with both feet firmly on the ground.

The Emissions Compliance Period referred

to on the Emissions Compliance label indi-

cates the number of operating hours for

which the engine has been shown to meet

Federal emissions requirements.

Category C 50 hours, B 125 hours, and

A 300 hours.

For reference, please fill out the following

information that will be needed for future

servicing of your blower:

Model Number:

Serial Number:

Purchase Date:

Purchased From:

WARNING: Under no circum-

stances may the design of the

machine be modified without the

permission of the manufacturer.

Always use genuine accessories.

Non-authorized modifications

and/or accessories can result

in serious personal injury or the

death of the operator or others.

Your warranty may not cover

damage or liabiIRy caused by the

use of non-authorized accesso-

ries or replacement parts.

For customer assistance, calI:

1-800-487-5951

Contact us at our website:

www.husqvarna.com

English-2545154658 Rev. 5 7/15/08

Page 3

KEY TO SYMBOLS

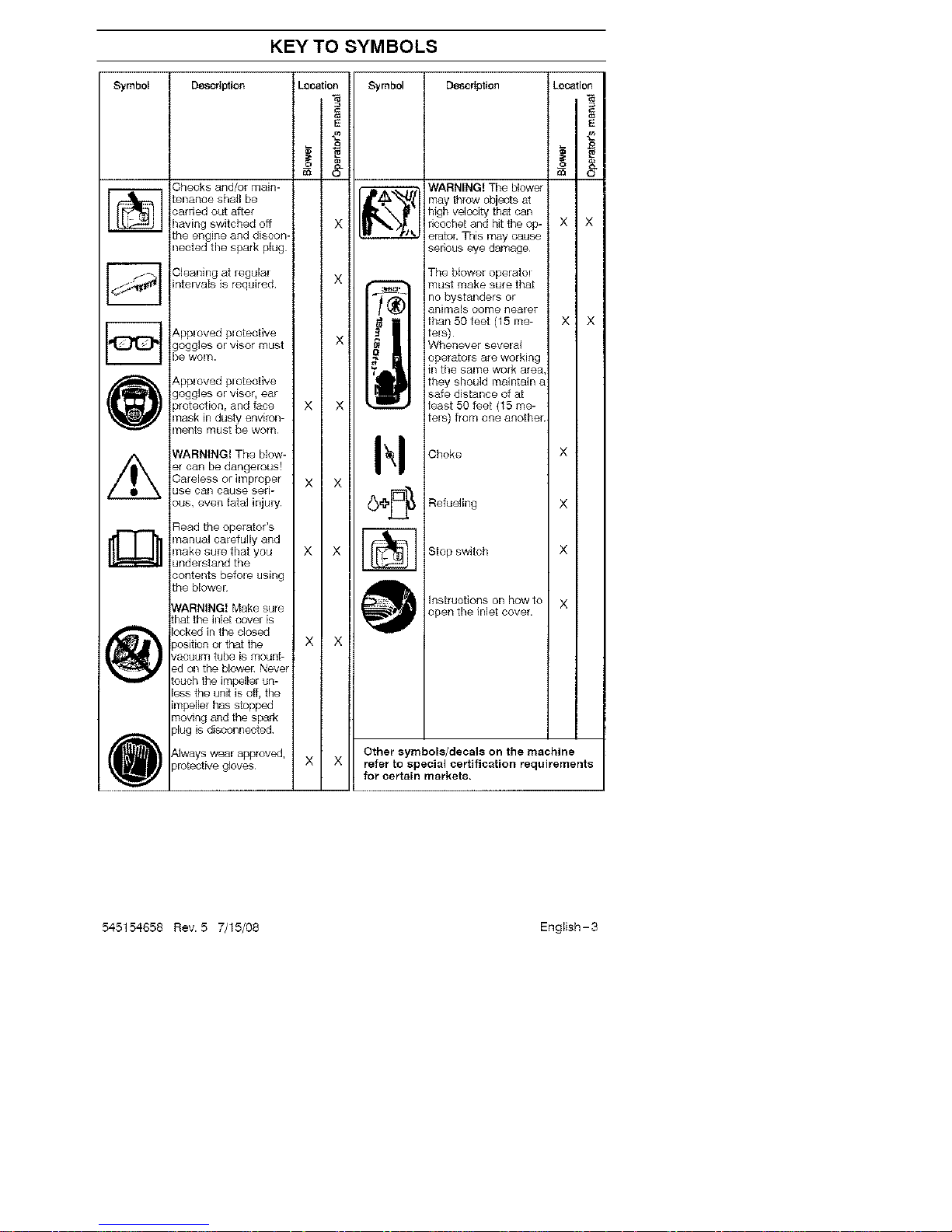

o_ _ el Descrtpt{on LocationSymbol Descrlptien Locatio_ ;yml _ _"_.

lllmaythr°wohi tsatI I

II_ f II high veJocity that can { I

carried out after

ricochet and hit the op- × ×

_ eratoL This may causethe engine and discon-

nected tile spark plug sedous eye damage

_ Cleaning at regulal X _ The btower oparatol

i. must make sure that

intervals is required _ - no bystanders or

( animals oome nealer

I_ I i {than50feet(15n_e- X X

Applovedplotecfive II !tels) I I

goggles el visor must X Whenever sevelal

be WOrn. ope[ators are working

_'! ill the same work area,

{_ Apploved plotective they should maiatahl a

safe distance of atgoggles el visor, ear

protection, and face X X ' _ least 50 feet (15 me-

_F'J Imask in dusty environ- I I II I _ I tels) from one another

ments must be worn

WARNING! The blow- Choke X

er can he dangerous!

Care_easSc°_hs_P_°f_er X X

x

Read the operator's

i_ manual carefully and [

make sure that you X X Stop switch X

understand thecovel "._ _ _lf_t

contents befole using

the blowel

that the inter is _._

lockedintheclosed

position or that the X X

vaouum tub@ is mount-

ed on the bloweE Never

touch the impaIler un-

less the unit is off, the /

impaller has stopped

!

moving and the spark

plug is disoonneated

I Always wear approved, Other symbols/decals on the machine

protective gloves X X refer to special certification requirements

for certain markets.

545154658 Rev. 5 7/15/08 English-3

Page 4

SAFETY INSTRUCTIONS

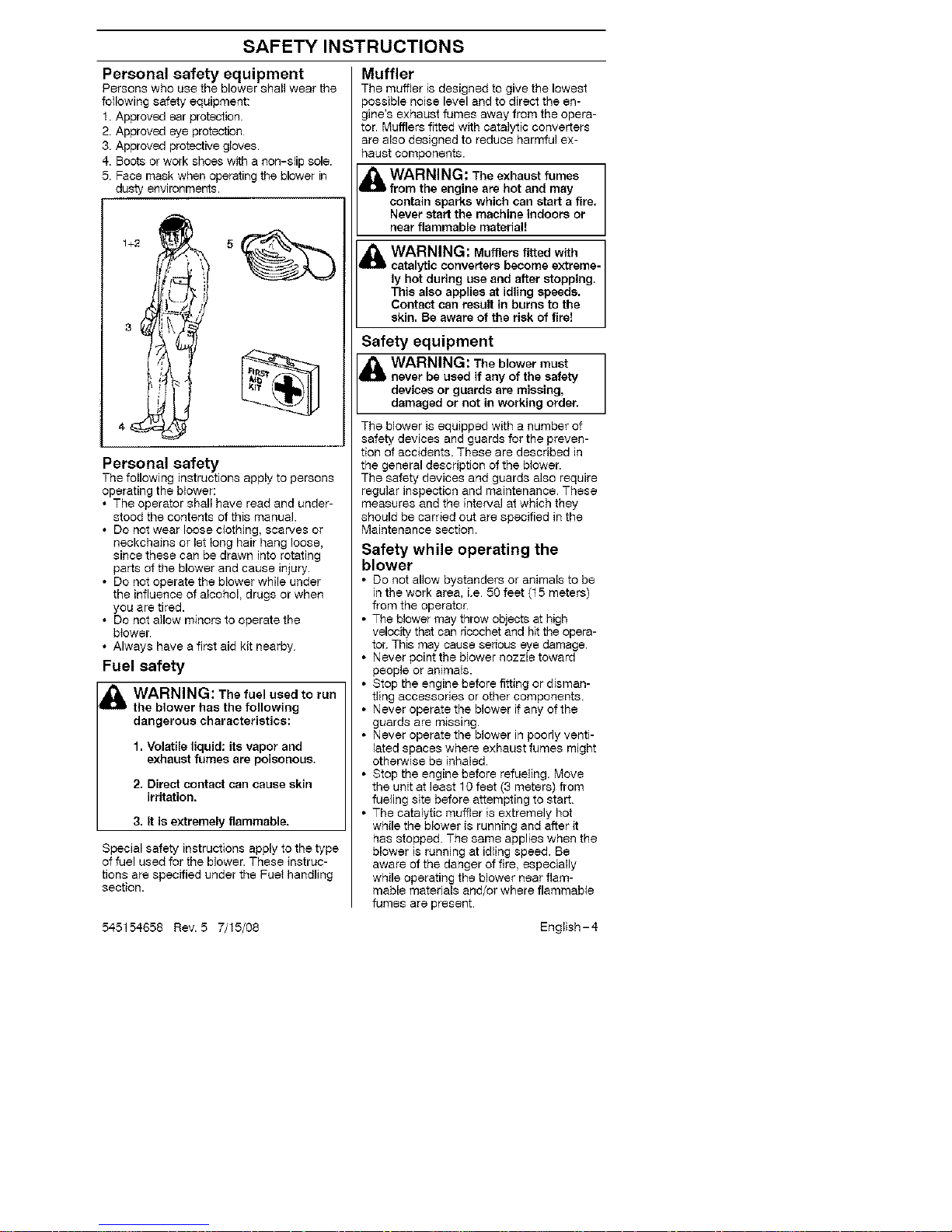

Personal safety equipment

Persons who use the blower shall wear the

following safety equipment:

1. Approved ear protection.

2. Approved eye protection

3. Approved protective gloves.

4. Boots or work shoes with a non-slip sole.

5. Face mask when operating the blower in

dusty environments.

Personal safety

The following instructions apply to persons

operating the blower:

• The operator shall have read and under-

stood the contents of this manual.

• Do not wear loose clothing, scarves or

neckchains or let long hair hang loose,

since these can be drawn into rotating

parts of the blower and cause injury.

• Do not operate the blower while under

the influence of alcohol, drugs or when

you are tired.

• Do not allow minors to operate the

blower.

• Always have a first aid kit nearby

Fuel safety

_ WARNING: The fuel used to run

the blower has the following

dangerous characteristics:

1. Volatile liquid: its vapor and

exhaust fumes are poisonous.

2, Direct contact can cause skin

irritation.

3. It is extremely flammable.

Special safety instructions apply to the type

of fuel used for the blower. These instruc-

tions are specified under the Fuet handling

section.

545154658 Rev. 5 7/15/08

Muffler

The muffler is designed to give the lowest

possible noise level and to direct the en-

gine's exhaust fumes away from the opera-

tor. Mufflers fitted with catalytic converters

are also designed to reduce harmful ex-

haust components.

WARNING: The exhaust fumes

from the engine are hot and may

contain sparks which can start a fire.

Never start the machine indoors or

near flammable material!

WARNING: Mufflers fitted with

catalytic converters become extreme-

ly hot during use and after stopping.

This also applies at idling speeds.

Contact can result in burns to the

skin. Be aware of the risk of fire!

Safety equipment

WARNING: The blower must

never be used if any of the safety

devices or guards are missing,

damaged or not in working order.

The blower is equipped with a number of

safety devices and guards for the preven-

tion of accidents. These are described in

the general description of the b_ower.

The safety devices and guards also require

regular inspection and maintenance. These

measures and the interval at which they

should be carried out are specified in the

Maintenance section.

Safety while operating the

blower

• Do not allow bystanders or animals to be

in the work area, i.e 50 feet (15 meters)

from the operator.

• The blower may throw objects at high

velocity that can ricochet and hit the opera-

tor. This may cause serious eye damage.

• Never point the blower nozzle toward

people or animals.

• Stop the engine before fitting or disman-

tling accessories or other components.

• Never operate the blower if any of the

guards are missing.

• Never operate the blower in poorly venti-

lated spaces where exhaust fumes might

otherwise be inhaled.

• Stop the engine before refueling. Move

the unit at least 10 feet (3 meters) from

fueling site before attempting to start.

• The catalytic muffler is extremely hot

while the blower is running and after it

has stopped. The same applies when the

blower is running at idling speed. Be

aware of the danger of fire, especially

while operating the blower near flam-

mable materials and/or where flammable

fumes are present

English-4

Page 5

SAFETY INSTRUCTIONS

• Be careful, particularly if _ett hand opera-

tion is applied. Avoid any direct body con-

tact with inlet cover area. Keep jewelry,

loose clothing, or clothing with loosely

hanging straps, ties, tassels, etc., away

from inlet cover area.

• Do not operate the blower while standing

on a ladder or a stand.

Other safety measures

Operate the blower only at reasonable

hours, i.e. not early in the morning or late

at night when people might be disturbed

Comply with times listed in local ordi-

nances. Usual recommendations are 9:00

a.m to 5:00 p.m., Monday through Satur-

day.

• Operate the blower at the lowest possible

throttle setting to do the job.

• Check the condition of the blower before

operation, especially the muffler, air intake

and air filter.

• Use a rake or a broom to loosen ground

debris before blowing

• Under dusty conditions, slightly spray the

work area with a hose.

• Conserve water by using blowers instead

of hoses for many lawn and garden

applications, including areas such as roof

gutters, screens, patios and gardens etc.

• Watch out for children, pets, open windows

or vehicles, and blow debris safely away.

• Use the full nozzle extension so the air

stream can work close to the ground.

• After using the blower, clean up and

dispose of debris in trash receptacles.

545154658 Rev. 5 7/15/08 English-5

Page 6

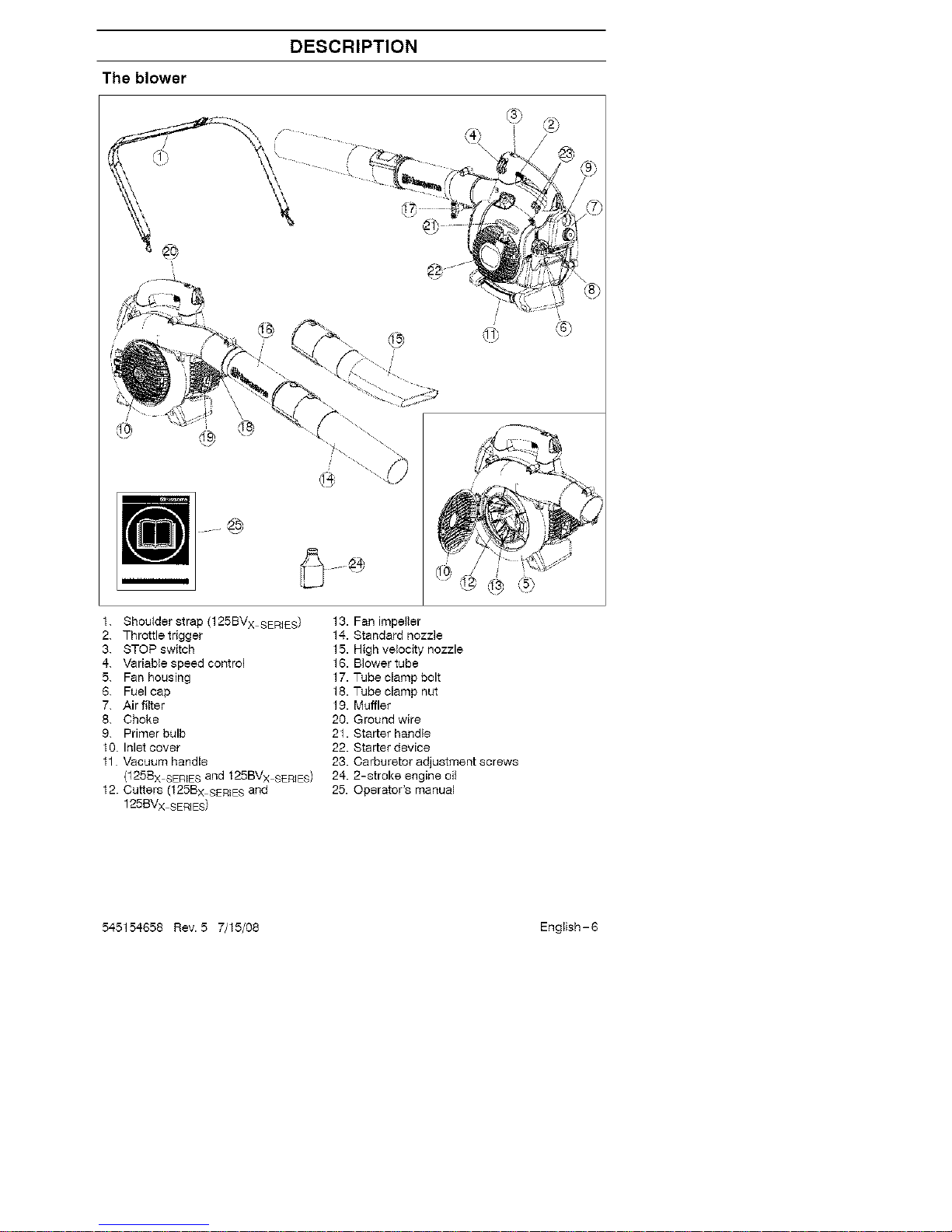

DESCRIPTION

The blower

1. Shoulder strap (125BV x SERIES) 13. Fan impeller

2. Throttle trigger 14. Standard nozzle

3. STOPswitch 15. High ve{ocity nozzle

4. Variab{espeed control 16. BIowertube

5. Fan housing 17. Tube clamp bolt

6. Fuel cap 18. Tube clamp nut

7. Airfilter 19. Muffler

8. Choke 20. Ground wire

9. Primer bulb 21. Starter handle

10. Inlet cover 22. Starter device

11 Vacuum handle 23. Carburetor adjustment screws

(125Bx SERIESand 125BV x SERES) 24. 2-stroke engine oil

12. Cutters (125B x SEREESand 25. Operator's manual

125BVx SERIES)

54-5154658 Rev. 5 7/15/08 English-8

Page 7

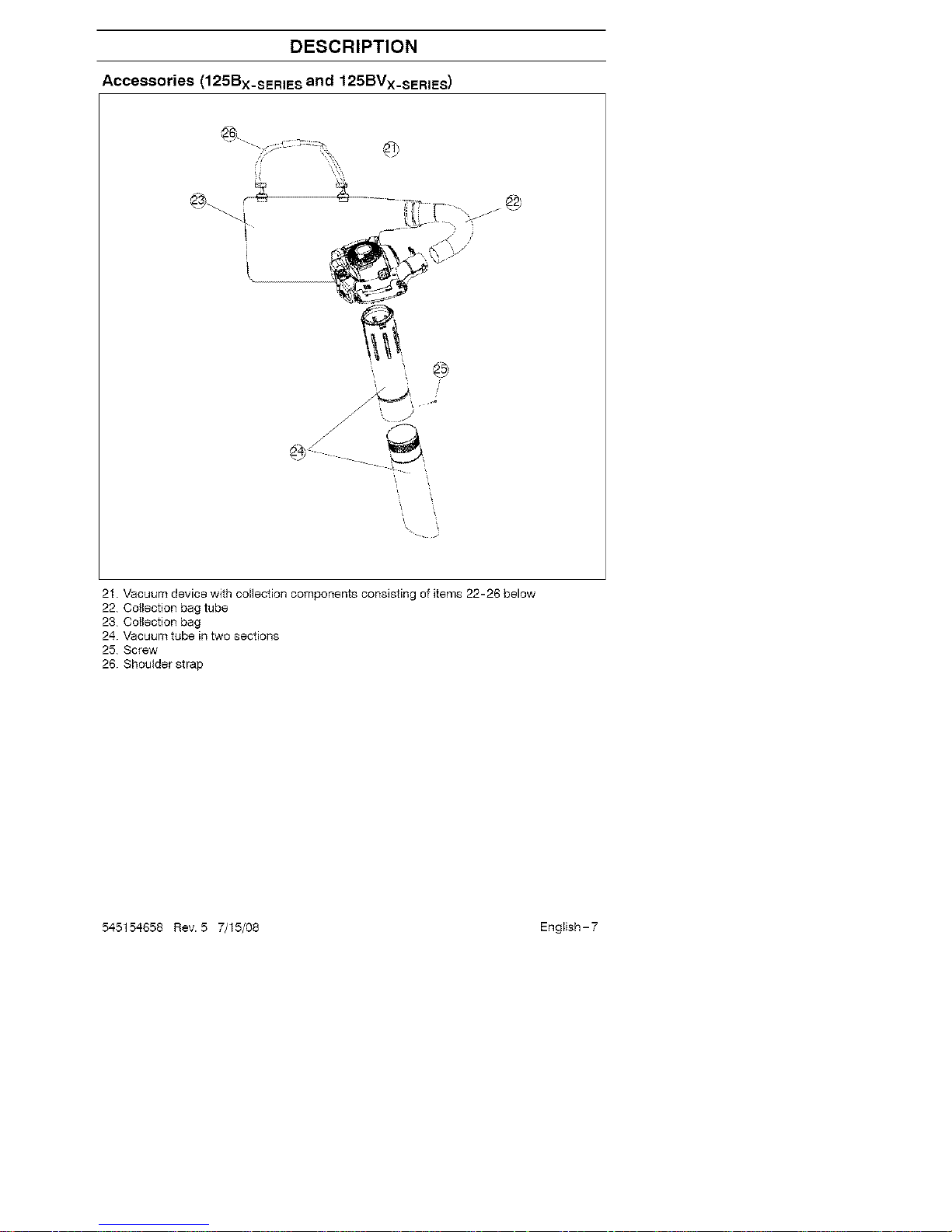

DESCRIPTION

Accessories (125Bx_sERIESand 125BVx_sERIES)

©

. @

21. Vacuum device with collection components consisting of items 22-26 below

22. Collection bag tube

23. Collection bag

24. Vacuum tube in two sections

25. Screw

26. Shoulder strap

545154658 Rev. 5 7/15/08 English-7

Page 8

DESCRIPTION

Safety equipment

The following equipment on the blower is

designed for protecting personnel and

materials. These components should

receive special attention whenever you

operate, inspect and service the blower.

Stop switch

• The stop switch (A) is used to stop tile

engine.

j_ A

.J

/

Muffler

• The muffler is designed to give the low-

est possible noise level and to direct the

engine's exhaust fumes away from the

operator. Mufflers fitted with catalytic

converters are also designed to reduce

harmful exhaust components.

• The engine exhaust fumes are hot and

can contain sparks, which may cause

fire if they come in contact with dry or

flammable material

• Some blower models, especially those

sold in countries where the climate is

dry, are equipped with a spark arresting

screen (B). This screen must be cleaned

or replaced at specific intervals See the

Maintenance section

B

WARNING: The muffler is ex-

tremely hot while the engine is run-

ning and after it has stopped. DO

NOT TOUCH THE MUFFLER IF IT IS

HOT! This can cause severe burns.

545154658 Rev. 5 7/15/08

Other equipment

Throttle trigger

• The speed and the output of the engine

are regulated by the throttle trigger (C).

/

C

Variable speed control

• The variable speed control (D) is de-

signed to allow setting engine speed as

necessary during blower use only.

/

• To avoid causing damage to the unit, DO

NOT attempt to use the variable speed

control during starting or during vacuum

use.

Fan housing

• The blower fan housing (E) and the fan

impeller (F) provide high performance air

discharge.

+

F /

E

English-8

Page 9

DESCRIPTION

Ground wire

• The ground wire (G) reduces static

beNd-up during operation indry condb

tions.

!

Inlet cover

• An inlet cover (H) is located on the side

of the fan housing• Opening this cover

allows access for cleaning and inspect-

ing the impe,er (125Bx SERIES and

125BVx SERES only). If the vacuum tube

is used. it must be fitted to the opening in

the inlet cover• To open the inlet cover.

use a tool to lift the edge of the cover

opposite the hinge (indicated by arrow

on inlet cover).

H

j•

WARNING: Never start the blower

if the inlet cover is not closed, is

damaged or cannot be closed

(except if the vacuum tube is fitted).

Cutter8

(125BX_SERIES and 125BVx_sERIES)

• Two cutters (J) are fastened to the impeF

lee The cutters are there to mulch leaves

and other debris that have been vacuumed

before they enter the collection bag.

Blower tube and nozzle

NOTE: The tube clamp bolt and nut must

be insta,ed prior to initial use (see the gen-

eral description of the blower on page 6)

• The blower tube (K) has a begged slot

mounting system to the unit To install or

remove the bbwer tube (or co,ecf_3n bag

tube for the 125BVx SERIES).the tube

clamp bolt must be removed• Align slot in

the bbwer air outlet with the raised rib on

the tube and insert tube until the holes in

the tube and housing align. Re-insert the

tube clamp bolt and tk:jhten.

• The nozzles (L) have a bayonet mount

for connection to the blower tube• Air is

channeled through the blower tube to the

nozzles, where the air discharge velocity

increases and the air stream discharge

pattern is formed to prov{de best perfor-

mance. The length of the blower tube

can be adjusted by twisting the nozzle to

the left to disengage the bayonet mount

and sliding the nozzle to the appropriate

position. Twist the nozzle to the right until

a click is fed to resecure the nozzle

K

Starter device and 8tarter handle

• The starter device (M) is located on the

side of the engine shrouding and en-

gages the crankshaft only when the

starter handle (N) is pulled.

_%... jrt" '2

Fuel cap

• The fuel cap (O) is located at the rear of

the engine shrouding on the fuel tank

and has a seal to prevent fuel from leak-

ing out.

j' L%

Air filter

• The air filter (P) consists of a fiber filter

medium in a resilient frame. The air filter

should be cleaned at specific intervals

(see Maintenance section). Otherwise,

the blower will consume too much fuel.

the performance win be reduced and an

oily deposit may form on the spark plug

electrodes•

545154658 Rev. 5 7/15/08 English-g

Page 10

DESCRIPTION

Choke

• The choke (Q) is located below the air

filter cover and should be used every

time the engine is cold-started

'S%,-, j_ '2

Adjusting the carburetor

NOT FOR ALL MODELS

• There are three adjusting screws (R)for

adiusting the carburetor:

• Low speed jet

• High speed jet

• Adjustment screw for idling

• Adjusting the carburetor involves adapt-

ingthe engine to local operating condi-

tions, e.g. climate, altitude, gesoline and

type of two-stroke engine oil used For

details about carburetor adjustment, see

the Maintenence section.

545154658 Rev. 5 7/15/08 English-10

Page 11

FUELHANDLING

Fuel mixture

CAUTION! The machine is equipped with

a two-stroke engine and must always be

run using a mixture of gasoline and two-

stroke engine oil. It is important to accu-

rately measure the amount of oil to be

mixed to ensure that the correct mixture is

obtained. When mixing sinai+ amounts of

fuel, even smelt inaccuracies can drasticaF

ty effect the ratio of the mixture

&WARNING: Always ensure

there is adequate ventilation when

handling fuel.

Gasoline

CAUTION! Always use high quality

unleaded gasoline

• This engine is certified to operate on

unleaded gasoline.

• The _owest recommended octane rating

is 87. If you run the engine on lower oc-

tane rating than 87, "knock{ng" can oc-

cur. This leads to an increased engine

temperature, which can resutt in a serb

ous engine breakdown.

• When working at continuous high rays a

higher octane rating is recommended.

Two-stroke oil

• For great resutts and performance use

HUSQVARNA two-stroke oil, which is

special+y formutated for our two-stroke

engines. Mixture 1:50 (2%).

• To maximize the life of your blower, you

may choose to use a high quality syn-

thetic oil formulated for two-stroke

engines. Mixture 1:50 (2%).

• Never use two-stroke oi+ intended for

water-cooled outboard engines,

sometimes referred to as outboard oil.

• Never use oit intended for four-stroke

engines.

Two-stroke oil

Gasoline 2% (1:50)

U.S. gallon U.S. fl. oz.

1 2 1/2

2 1/2 6 1/2

5 12 7/8

Mixing

• Always mix the gasoline and oit in a

clean container intended for fuel.

• Always start by filling haft the amount of

the gasoline to be used. Then add the

entire amount of oil. Mix (shake) the fuel

mixture. Add the remaining amount of

gasoline.

• Mix (shake) the fuei mixture thoroughly

before fi+ling the machine's fuet tank.

• Do not mix more than one month's sup-

ply of fuel at a time.

• if the machine is not used for some time,

the fuel tank should be emptied and

cleaned.

WARNING: The catalytic con-

verter muffler gets very hot during

and after use. This also applies

during idling. Be aware of the fire

hazard, especially when working

near flammable substances and/or

vapors.

Fueling

WARNING: Taking the following

precautions, will lessen the risk of

fire:

Do not smoke or place hot objects

near fuel.

Always shut oft the engine before

refueling.

Always stop the engine and let it

cool for a few minutes before

refueling.

When refueling, open the fuel cap

slowly so that any excess pressure

is released gently.

Tighten the fuel cap carefully after

refueling.

Always move the machine away

from the refueling area before

starting.

545154658 Rev. 5 7/15/08 English - 11

Page 12

STARTING AND STOPPING

• Clean the area around the fue{ cap.

Contamination {n the tank can cause

operating problems.

• Ensure that the fuel is well mixed by shak-

ing the container before filling the tank.

Starting and stopping

WARNING: Never start the blower

if the inlet cover is not closed, is

damaged or cannot be closed

(except if the vacuum tube is fitted).

Cold engine

Primer bulb: Press the primer bulb 10

times until fuel begins to fill the bulb. The

primer bulb need not be completely filled.

Choke: Move the blue engine choke ]ever

over to the FULL CHOKE (closed) besitJon.

Starting: Hold the body of the machine on

the ground using your ]eft hand

CAUTION! Not with your foot0.

Firmly grip the starter rope handle with

your right hand. DO NOT squeeze

throttle trigger, Slowly pull out the cord

until you feel some resistance (the starter

paw_s grip); then quicMy and powerfully

)u_lthe cord.

_1 WARNING: Never wrap the starter ]

cord around your hand. J

Pull starter handle unti_ engine attempts to

run, but no more than 3 pulis. Move choke

to 'J, position and pull the cord until the en-

gine starts and runs. Allow the engine to

warm up for approximately 10 seconds:

then, move the choke to the OFF CHOKE

(opened) position.

NOTE: If engine dies, return blue engine

choke lever to the closed position and

repeat starting steps.

CAUTION! Do not pull the starter cord all

the way out and do not let go of the starter

handle when the cord is fully extended

This can damage the machine.

Warm engine

With a warm engine, squeeze and hold the

throttle trigger. Move choke to 1/zposition.

Pull starter rope sharply while squeezing

throttle trigger until engine runs. Move the

choke to the OFF CHOKE (opened)

3osition.

I

Stopping

To stop the engine, push and release the

engine STOP switch (S). The switch will

automatically return to the ON position.

Wait 7 seconds before attempting to restart

unit to allow switch to reset.

!

545154658 Rev. 5 7/15/08 English-12

Page 13

USING THE BLOWER

To blow away debris on the

ground

Fitting the blower tube and nozzle

on the blower

&WARNING: When fitting the blow-

er tube and nozzle, the engine must

be switched off.

The blower tube (T) has a begged slot

mounting system to the unit. To install or

remove the blower tube (or collection bag

tube for 125BV X SERIES), the tube clamp

bolt must be removed Align slot in the

blower air oubet with the raised rib on the

tube and insert tube until the holes in the

tube and housing align Re-insert the tube

clamp bolt and tighten•

!,½ :

°i

T

The nozzles (U) have a bayonet mount for

connection to the blower tube• Air is chan-

neled through the blower tube to the

nozzles, where the air discharge velocity

increases and the air stream discharge pat-

tern is formed to provide best performance.

The length of the blower tube can be ad-

justed by twisting the nozzle to the left to

disengage the bayonet mount and sliding

the nozzle to the appropriate position.

Twist the nozzle to the right until a click is

fe{t to re-secure the nozzle

Blowing

Before you begin blowing, put on tile re-

quired safety equipment•

WARNING: When working with

the blower, wear the required per-

sonal safety equipment:

1. Hearing protection.

2. Eye protection.

g. Protective gloves.

4. Face mask in dusty environments.

125BVx SERIEScan be used with a shoul-

der strap for extra comfort. The strap

should be worn over the sbeulder as

shown

&

WARNING: Never point the blower

nozzle at people or animals. The

high-velocity air stream can contain

particles that may cause serious

injury, especially if the blower has

previously been used for vacuuming.

Be careful, particularly if left hand

operation is applied. Avoid any di-

rect body contact with inlet cover

area. Keep jewelry, loose clothing,

or clothing with loosely hanging

straps, ties, tassels, etc., away from

inlet cover area.

54-5154658 Rev. 5 7/15/08 English-13

Page 14

USING THE BLOWER

&WARNING: Never start the blower

if the inlet cover is not closed, is

damaged or cannot be closed

(except if the vacuum tube is fitted).

&WARNING: Do not operate the

blower while standing on a ladder or

a stand.

Start the bbwer as described in the Starting

and Stopping section. Work according to the

following instructions:

1. Never blow air toward fixed objects such

as wails, large rocks, automobiles and

fences.

2. When working inside corners, blow from

the corner and inward toward the center of

the work area. Otherwise, debris can fly

up in your face and cause eye injury.

3. Never point the blower nozzle at delicate

plants.

Standard nozzle

The standard nozzle (V) is included with

the 125B, 125Bx SERESand 125BVx SE

RIES.When greater accuracy and high air

stream concentration is desired, use the

standard nozzle.

V

High-velocity nozzle

The high-velocity nozzle (W) is an acces-

sory of the blower (included with the

125Bx SERIES and 125BV x SERIES)-

When a wider air stream and greater air

velocity is desired, use the high-velocity

nozzle.

To vacuum debris from the

ground (125Bx.sERIES and

125BVx_sERIES )

Fitting the collection bag with the

various vacuum tube8

The vacuuming device is an accessory (in-

cluded with the 125BV x SERIES).

_ WARNING: When the

fitting

tubes to the blower, the engine

must be switched off.

1. Open the collection bag. Insert the

collection bag tube from inside the bag to

fit in the vacuum inlet opening of the bag

as shown. Ensure elastic is seated in

groove. Close the zipper on the bag.

2. Remove the blower tube and install the

collection bag tube. Install and tighten

tube clamp bolt. Attach the carrying strap

to the collection bag loops.

3. Align arrows on lower vacuum tube and

upper vacuum tube. Push bwer vacuum

tube into upper vacuum tube until the lower

tube is securely seated in the upper tube

(about 3 inches/7 cm). Permanently as-

semble the two tubes together with the

supplied screw.

0

rk Open the cover on the s_de of the blower

by using a screwdriver to pry up under the

edge of the cover on the side opposite the

hinge (indicated by arrow on inlet cover).

5. Press the vacuum tubes in the large

opening at the underside of the blower

and align the tabs with the slots in the

tube. Turn it until the bayonet mount

locks (_ock symbols _, align).

545154658 Rev. 5 7/15/08 English-14

Page 15

USING THE BLOWER

Vacuuming

Before vacuuming, put on tile required

safety equipment.

_1 WARNING: When working with

the blower, wear the required per-

sonal safety equipment:

1. Hearing protection.

2. Eye protection.

3. Protective gloves.

4. Face mask in dusty environments.

When operating the blower, the collection

bag must be supported by the shoulder

strap. The strap should be worn over the

shoulder as shown.

_1 WARNING: check that

Always

tbe collection bag is intact and the

zipper is closed before starting tbe

blower. Never use a damaged bag.

There is risk of injury due to flying

debris. Be careful, particularly if left

band operation is applied. Avoid any

direct body contact with the ex-

haust outlet area.

_1 WARNING: Never start the blower ]

if the inlet cover is not closed, is

damaged or cannot be closed

(except if the vacuum tube is fitted),

WARNING: Do not the

operate

blower while standing on a ladderor

a stand.

Start the blower as described in the Starting

and Stopping section. Work according to the

following instructions:

1. Do not vacuum large solid objects that

can damage the fan, such as wood, cans

(tins) or lengths of string or ribbon.

2. Do not let the vacuum tube strike the

ground.

3. The collection bag can be emptied by first

stopping the unit and then opening the zip-

per on the side.

54-5154658 Rev. 5 7/15/08 English-15

Page 16

MAINTENANCE

Maintenance Safety

The owner is responsible for the perfor-

mance of all required maintenance as

defined in the operator's manual.

Disconnect the spark plug before perform-

ing maintenance, except carburetor adjust-

ments.

&WARNING: tmproper mainte-

nance could result in serious engine

damage or in serious injury.

Carburetor

Your Husqvama product has been designed

and manufactured to specifications that re-

duce harmful emissions. After the engine

has used 8-10 tanks of fuel, the engine witt

be run-in. To ensure that it continues to run

at peak performance and to minimize harm-

ful exhaust emissions after the run-in peri-

od, ask your servicing dealer to adjust your

carburetor.

Function

• The carburetor governs the engine's

speed vie the throttle control Air and fuel

are mixed in the carburetor.

• The T-screw (BB) regulates the throttle

setting at idle speed. If the T-screw is

turned clockwise this gives a higher idle

speed; turning it counterclockwise gives a

lower idle speed.

Basic setting

• The basic carburetor settings are ad-

justed during testing at the factory. Fine

adjustment should be carried out by a

skirled technician.

Recommended idle speed:

See "Technical data" section.

Recommended max. speed:

See "Technical data" section

Fine adjustment of the idle speed-T

Adjust the idlespeed using the idle adjust-

ment T-screw if itis necessary to readjust.

The idlespeed iscorrectly adjusted when

the engine wilt run smoothly inevery posi-

tion.

BB

Muffler

Some mufflers are fitted with catalytic con-

verters. See the Technical data section to

find out if your machine is equipped with a

catalytic converter.

The muffler is designed to dampen the

noise level and to direct the exhaust fumes

away from the use£ The exhaust fumes

are hot and can contain sparks, which can

result in fire if the exhaust fumes are

directed towards a dry and flammable

material.

Some mufflers are equipped with a special

spark arresting screen (CC). If your ma-

chine is fitted with this type of screen, it

should be cieaned regulady. To access the

screen, remove the outlet cover on the

front of the muffler. Use a wire brush to

clean the screen On mufflers without a

catalytic converter the screen should be

cieaned weekly, or replaced if necessary.

On mufflers fitted with a catalytic converter

the screen should be checked and cleaned

monthly. If the screen is damaged it

should be replaced. If the screen is fre-

quently blocked, this can be a sign that the

function of the catalytic converter is im-

paired Contact your dealer to inspect the

muffler. A blocked screen wiil cause the

engine to overheat resulting in damage to

the cyiinder and piston

CAUTION! Never use a machine that has

a faulty or loose muffler. Ensure the muffler

bolts are tight.

545154658 Rev. 5 7/15/08 English-16

Page 17

MAINTENANCE

/CC

_1 WARNING: Mufflersfitted with

catalytic converters get very hot

during use and remain so for some

time after stopping. This also ap-

plies at idle speed. Contact can re-

sult in burns to the skin. Remember

the risk of fire!

WARNING: Bear in mind that:

Engine exhaust fumes contain car-

bon monoxide, which can cause

carbon monoxide poisoning. For

this reason you should not start or

run the machine indoors, or any-

where that is poorly ventilated.

The exhaust fumes from the engine

are hot and may contain sparks

which can start a fire. Never start

the machine indoors or near flam-

mable material!

_1_ WARNING: The inside of the

muffler contain chemicals that may

be carcinogenic. Avoid contact with

these elements in the event of a

damaged muffler.

Cooling system

The engine is equipped with a coefing

system for maintaining the right operating

temperature•

The cooling system consists of the follow-

ing components:

1.Air intake on the starter device (DD).

2. Fan blades on the flywheel (EE).

3. Cooling fins on the cylinder (FF).

4. Cylinder cowling (guides cooling a{r f_ow

aga{nst cylinder surfaces).

Ctean the coefing system by brushing once

a week, or more often, if necessary.

A dirty or b_ocked coefing system will

cause the b_ower to overheat and this will

damage the cytinder and piston

EE

Air filter

The air filter (GG) must be regulady cleaned

to remove dust and dirt in order to avoid:

• Carburetor mallunctions

• Starting problems

• Loss of engine power

• Unnecessary wear to engine parts

• Excessivefuef consumption

• Elevated content of harmful exhaust

fumes•

Clean the filter every 25 hours, or more

regularly if conditions are exceptionally

dusty.

Cleaning the air filter

Remove the air fiEter cover (HH) and take out

the filter. Wash it clean in warm, soapy water•

Rinse thoroughly. Ensure that the _ter is dry

before reinstalling it

An air filter that has been in use for a long

time cannot be cleaned completely. The

filter must therefore be replaced with a new

one at regular intervals.

CAUTION! A damaged air filter must

always be replaced.

545154658 Rev. 5 7/15/08 English-17

Page 18

MAINTENANCE

Spark plug

The spark plug condition is influenced by:

• Incorrect carburetor adjustment.

• An incorrect fuel mixture (too much or in-

correct type of oil).

• Poor quality gasoline and/or oil

• A dirty air fitter.

These factors cause deposits on the spark

plug electrodes, which may result in operat-

ing problems and starting difficulties.

If the machine is low on power, difficult to

start or runs poorly at idle speed: always

check the spark plug first before taking

any further action, if the spark plug is dirty,

clean it and check that the electrode gap is

0.024" (0.6 mm) The spark plug should be

replaced after about a month in operation or

earlier if necessary.

0.024" (0.6 ram)

CAUTION! Always use the recommended

spark p_ug typet Use of the wrong spark

plug can damage the piston/cylinder.

Maintenance schedule

Below you will find some general mainte-

nance instructions.

Daily maintenance

• Clean the exterior surfaces of the blower.

• Check that the variable speed control and

the throttle trigger function in a safe man-

ner. Replace damaged parts.

• Check that the stop switch works proper-

ly. Replace if necessary.

• Clean the air filter Replace if necessary

• 125Bx SER+ESand 125BV x SERIES:

Check that the inlet cover can be locked

in the closed position. Carefully check

that the fan impeller is clean, especially if

the blower has been used for collecting

debris (vacuuming).

• Check that all nuts and screws are prop-

edy tightened.

• Check that a_l the housings are free of

cracks Replace damaged parts.

• 125Bx SER]ESand 125BV x SERIES:

Check that the collection bag is intact and

that the zipper works Replace it if neces-

sary.

Weekly maintenance

• Check the condition of the starter device,

the starter cord and the tensioning spring.

Replace damaged parts.

• Check the condition of the air intake at

the starter device. Remove debris if it is

clogged.

• Clean the outside of the spark plug. Re-

move it and check the electrode gap Ad-

just the gap to 0.024" (0.6 mm), or

replace the spark plug Use resistor spark

plug Champion RCJ-8Y or equivalent.

• Clean the fan blades on the flywheel

• Clean or replace the spark arresting

screen (not on mufflers with a catalytic

converter).

• Clean the carburetor area.

• Clean the air filter.

Monthly maintenance

• Clean the fue_ tank.

• Clean the outside of the carburetor and

the area around it.

• Clean the fan blades on the flywheel and

the area around it.

• Check fuel lines for cracks or other dam-

age. Change if necessary.

• Change the fuel fitter in fuel tank.

• Check all cables and connections. Re-

place damaged parts.

• Replace the spark plug Use spark plug

Champion RCJ-8Y or equivalent.

• Change the air fitter.

54-5154658 Rev. 5 7/15/08 English-18

Page 19

TECHNICAL DATA

Technical data

Engine

Cylinder volume, cu.Jn./cm3

Cylinder bore, inch/mm

Stroke, inch/mm

Idle speed, rpm

Max. speed - bbwing, rpm:

Max. speed - vacuuming, rpm:

Max. engine output, acc. to ISO 8893,

hp/kW

Catalytic converter muffler

Speed-regulated ignition system

Ignition system

Manufacturer/type of ignition system

Spark plug

E_ectrode gap, inch/mm

Fuel and lubrication system

Manufacturer/type of carburetor

Fuet tank capacity, US pint/liter

Weight

Weight, without fuel but with blower tube

and standard nozz{e fitted, Ibs/kg

Sound levels

Equivatent sound pressure ]eve_, measured

according to ANSI 8175.2-2000, dB(A)

Vibration levels

Vibration levels at handtes, measured

according to ANSI S175.3-1997, m/s 2

At idle:

At max. speed:

125B 125Bx_sERIES 125BVx_sERIES

1.7/28 1.7/28 1.7/28

1.4/35 1.4/35 1.4/35

1.130/28.7 1.130/28.7 1.130/28.7

2,800-3,200 2,800-3,200 2,800-3,200

8,600 8,600 8,600

-- 7,500 7,500

1.1/0.8 1.1/08 1.1/0.8

Yes Yes Yes

No No No

Phelon/CD Phelon/CD Phelon/CD

Champion Champion Champion

RCJ-6Y RCJ-6Y RCJ-6Y

0.024/0.6 0.024/0.8 0.024/0.6

Zama Zam8 Zama

1.05_.5 1.05_.5 1.05/0.5

9.4/4.3 9.6/44 9.6/44

70 70 71

5.0 5.0 5.0

11.8 11.8 11.8

Fan 125B 125Bx_sER+ES 125BVx_sERIES

Type Radial fan Radial fan Radial fan

Max. air velocity, m/s (kin/h), standard nozzle 60 (217) 80 (217) 60 (217)

Max. air velocity, m/s (kin/h), high velocity

nozzle* 76 (273) 76 (273) 76 (273)

Air volume - blowing, m3/h (cfm) 722 (425) 722 (425) 722 (425)

Air volume - vacuuming, m3/h (cfm) -- 756 (445) 756 (445)

*optional accessory for some models

Model 125B, 125BX_SERIES, 125BVx_sERIES

Approved accessories t Part. no.

9 TS-g18

Model 125Bx_sERIES, 125BVx_sERIES

Approved accessories _ Part. no.

545154658 Rev. 5 7/15/08 English-19

Page 20

WARRANTY STATEMENT

SECTION 1: UMITED WARRANTY

Husqvarna warrants Huegvamaproduct to

theoriginal purchaser to befree from defects

in materialand workmanship fromthe date of

purchasefor the _VarraofyPeriod" of the

products asset forth below:

Lifetime Warranty: Ignition coifs and mo-

dules.

2 Year NON-COMMERCIAL Warranty:

Blowers for non-commercial, non-prefessbn-

aJ,nondns_rtutionalor non-income producing

use, except as herein stated.

Emissbn controlsystem components neces-

sary to comply with CARB and EPA regula-

tions.

1 Year Warranty: All blowers usedfor com-

mercial, institutional,professional,or income

producingpurposes or use.

SECTION 2: HUSQVARNA'S OB-

MGATIONS UNDER THE WARRANTY

Husqvama will repair or replace defective

components without charge for parts or tabor

if a component fails because of a defect in

matarial or workmanship during the warranty

period

SECTION 3: ITEMS NOT COVERED

BY THIS WARRANTY

The following items are not covered by this

warranty:

(1) Normal customer maintenance items

which become worn through normal regu-

lar use, including, but not limited to, filters,

lubricants, rewind springs, spark plugs,

and starter ropes.

(2) Natural discoloration of material due to

uifraviolet _ight.

SECTION 4: EXCEPTIONS AND

LIMITATIONS

This warranty shall be inapplicable to de-

fects resulting from the following:

(1) Accident, abuse, misuse, negligence and

neglect, including stale fuel, dirt, abra-

sives, moisture, rust, corrosion, or any

adverse reaction due to incorrect storage

or use habits.

(2) Failure to operate or mdtntain the unit in

accordance with the operator's manual or

instruction sheet furnished by Husqvama

(3) Alterations or modifications that change

the intended use of the product or affects

the product's performance, operation,

safety, or durability, or causes the product

to fail to comply with any applicable laws.

(4) Additional damage to parts or compo-

nents due to continued use occurring af-

ter any of the above.

REPAIR OR REPLACEMENT AS PRO-

VIDED UNDER THIS WARRANTY IS THE

EXCLUSIVE REMEDY OF THE PURCHAS-

ER HUSQVARNA SHALL NOT BE LIABLE

FOR ANY INCIDENTAL OR CONSEQUEN-

TIAL DAMAGES FOR BREACH OF ANY

EXPRESS OR IMPLIED WARRANTY ON

545154658 Rev. 5 7/15/08

THESE PRODUCTS EXCEPT TO THE EX-

TENT PROHIBITED BY APPLICABLE CaW.

ANY IMPLIED WARRANTY OR MER-

CHANTABIUTY OR FITNESS FOR A PAR-

TICUCaR PURPOSE ON THESE PROD-

UCTS IS LIMITED IN DURATION TO THE

WARRANTY PERIOD AS DEFINED iN THE

LIMITED WARRANTY STATEMENT HUSQ-

VARNA RESERVES THE RIGHT TO

CHANGE OR IMPROVE THE DESIGN OF

THE PRODUCT WITHOUT NOTICE, AND

DOES NOT ASSUME OBLIGATION TO UP-

DATE PREVIOUSLY MANUFACTURED

PRODUCTS.

Some states do not allow the exclusion of in-

cidental or consequential damages, or limita-

tions on how long an implied warranty lasts,

so the above limitations or exclusions may not

apply to you. This warranty gives you specific

lega_ rights, and you may also have other

rights which vary from state to state

SECTION 5: CUSTOMER RE-

SPONSIBILITIES

The product must exhibit reasonable care,

maintenance, operation, storage and gener-

al upkeep as written ts the maintenance

section ofthe operataCs manual. Should an

operational problem or failure occur, the

product should not be used, but detivered

as is to an authorized Huegvarna dealer for

evaluation. Proof of purchase, as explained

in Section 6, rests so_ely with the custame£

SECTION 6: PROCEDURE TO OB-

TAIN WARRANTY CONSIDERATION

It is the Owner's and Dealer's responsibility to

make certain that the Warranty Registration

Card is properly filled out and mailed to

Husqvarna This card should be mailed within

ten (10) days from the date of purchase in

order to confirm the warranty and to facilitate

3ost-saie service.Proof of purchase must be

3resented to the authorized Husqvama dealer

in order to obtain warranty service. This proof

must include date purchased, model number,

serial number, and complete name and ad-

dress of the selling dealer To obtain the benefit

of this warranty, the product believed to be

defective must be delivered to an authorized

Husqvama dearer in a timely manner, no later

than thirty (30) days from date of the opera-

tional problem or failure. The product must be

delivered at the owner's expense. P_ck-eg

and delivery charges are not covered by this

warranty An authorized Husqvarna dealer

can be normally located through the "Yellow

Pages" of the local telephone directory or by

calling 1-800-438-7297 for a dealer in your

area.

Husqvarna

7349 Statesville Road

CHARLOTTE, NC 28269

English-2O

Page 21

U.S. EPA / CALIFORNIA / ENVIRONMENT CANADA

EMISSION CONTROL WARRANTY STATEMENT

YOUR WARRANTY RIGHTS AND

OBLIGATIONS:

The U.S. Environmental Protection Agency,

California Air Resources Board, Environment

Canada and HUSQVARNA are pleased to

explain the emissions control system warranty

on your year 2007 and later small off-toed

engine. In California, all smai_ off-roed en-

gines must be designed, built, and equipped

to meet the State's stringent anti-smog stan-

dards. HUSQVARNA must warrant the emis-

sion control system on your small off-toed

engine for the periods of time listed below pro-

vided there has been no abuse, neglect, or

improper maintenance of your small off-toed

engine. Your emission control system includes

parts such as the carburetor, the ignition sys-

tem and the fuel tank (California only). Where

a warrantable condition exists, HUSQVARNA

will repair your small off-road engine at no

cost to you. Expenses covered under warran-

ty include diagnosis, parts and labor.

MANUFACTURER'S WARRANTY

COVERAGE:

If any emissions related part on your engine

(as listed under Emissions Control Warran-

ty Parts List) is defective or a defect in the

materials or workmanship of the engine

causes the failure of such an emission re-

lated part, the part will be repaired or re-

placed by HUSQVARNA.

OWNER'S WARRANTY RESPONSI-

BILITIES:

As the small off-road engine owner, you are

responsible for the performance of the re-

quired maintenance listed in your operator's

manual. HUSQVARNA recommends that

you retain all receipts covering maintenance

on your small off-road engine, but HUSQ-

VARNA cannot deny warranty solely for the

lack of receipts or for your failure to ensure

the performance of all scheduled mainte-

nance. As the small off-road engine owner,

you should be aware that HUSQVARNA

may deny you warranty coverage if your

small off-road engine or a part of it has

failed due to abuse, neglect, improper main-

tenance, unapproved modifications, or the

use of parts not made or approved by the

original equipment manufacturer You are

responsible for presenting your small off-

road engine to a HUSQVARNA authorized

repair center as soon as a problem exists.

Warranty repairs should be completed in a

reasonable amount of time, not to exceed

38 days. If you have any questions regard-

ing your warranty rights and responsibilities,

you should contact your nearest authorized

service center or ca_l HUSQVARNA at

1-800-438-7297

WARRANTY COMMENCEMENT

DATE:

The warranty period begins on the date the

small off-road engine is purchased

LENGTH OF COVERAGE:

This warranty shall be for a period of two

years from the initial date of purchase.

WHAT IS COVERED: REPAIR OR

REPLACEMENT OF PARTS.

Repair or replacement of any warranted

part will be performed at no charge to the

owner at an approved HUSQVARNA ser-

vicing center. If you have any questions re-

garding your warranty rights and responsi-

bilities, you should contact your nearest au-

thorized service center or call HUSQVAR-

NA at 1-800-4-38-7287.

WARRANTY PERIOD:

Any warranted part which is not scheduled

for replacement as required maintenance,

or which is scheduled only for regular in-

spection to the effect of "repair or replace

as necessary" shall be warranted for 2

years. Any warranted part which is sched-

uled for replacement as required mainte-

nance shall be warranted for the period of

time up to the first scheduled replacement

point for that part.

DIAGNOSIS:

The owner shall not be charged for diag-

nostic labor which leads to the determina-

tion that a warranted part is defective if the

diagnostic work is performed at an ap-

proved HUSQVARNA servicing center.

CONSEQUENTIAL DAMAGES:

HUSQVARNA may be _iablefor damages to

other engine components caused by the fail-

ure of a warranted part still under warranty.

WHAT IS NOT COVERED:

Aft failures caused by abuse, neglect, or

improper maintenance are not covered.

ADD-ON OR MODIFIED PARTS:

The use of add-on or modified parts can be

grounds for disallowing a warranty claim.

HUSQVARNA is not liable to cover failures

of warranted parts caused by the use of

edd-on or modified parts.

HOW TO FILE A CLAIM:

if you have any questions regarding your

warranty rights and responsibilities, you

should contact your nearest authorized ser-

vice center or call HUSQVARNA at

1-800-4-38-7287.

WHERE TO GET WARRANTY SER-

VICE:

Warranty services or repairs sha_l be pro-

vided at all HUSQVARNA service centers.

Call 1-808-438-7287.

545154658 Rev. 5 7/15/08 English-21

Page 22

U.S. EPA / CALIFORNIA / ENVIRONMENT CANADA

EMISSION CONTROL WARRANTY STATEMENT

MAINTENANCE, REPLACEMENT

AND REPAIR OF EMISSION RE-

LATED PARTS:

Any HUSQVARNA approved replacement

part used in the performance of any warran-

ty maintenance or repair on emission re-

lated parts wilJ be provided without charge

to the owner if the part is under warranty.

EMISSION CONTROL WARRANTY

PARTS LIST:

Carburetor, Ignition System: Spark Plug

(covered up to maintenance schedule), Igni-

tion Module, Muffler including Catalyst, Fuel

Tank (California only).

MAINTENANCE STATEMENT:

The owner is responsible for the perfor-

mance of all required maintenance as de-

fined in the operator's manual.

This engine is certified to be emissions compliant for the following use:

[] Moderate (50 hours)

[] intermediate (125 hours)

[] Extended (300 hours)

54-5154658 Rev. 5 7/15/08 English-22

Loading...

Loading...