Page 1

OPERATOR′S MANUAL

MANUAL DEL USUARIO

20V MAX* LITHIUM-ION

CORDLESS CIRCULAR SAW

20 V MÁX* DE IONES DE LITIO

SIERRA CIRCULAR INALÁMBRICA

Model No. 125.46569

Número de modelo. 125.46569

WARNING:

the Operator’s Manual before using this product.

ADVERTENCIA:

comprender el manual antes de utilizar este producto.

Sears Brands Management Corporation, Hoffman Estates, IL 60179 USA

Save this manual for future reference.

Conserve este manual para futura referencia.

* Maximum initial battery voltage (measured without workload) is 20 volts.

Nominal working voltage is 18 volts.

* La tensión inicial máxima de la batería (medida sin carga) es 20 voltios.

La tensión de trabajo nominal es 18 voltios.

To reduce the risk of injury, the user must read and understand

Para reducir el riesgo de lesiones, el usuario debe leer y

Page 2

TABLE OF CONTENTS / TABLA DE CONTENIDOS

ENGLISH

■ Warranty ................................................................ 2

■ Introduction ............................................................ 2

■ Safety Instructions .............................................. 3-6

■ Symbols .............................................................. 7-8

■ Features ................................................................ 9

■ Assembly ............................................................. 10

■ Operation For Circular Saw ..............................11-16

■ Care & Maintenance ............................................17

■ Troubleshooting ..............................................18

■ Illustrated Parts List...............................................19

■ Figure Numbers (Illustrations) ............................ i-v

CRAFTSMAN LIMITED WARRANTY

FOR ONE YEAR from the date of sale this power tool is warranted against defects in material or

workmanship.

WITH PROOF OF SALE a defective product will be replaced free of charge.

For warranty coverage details to obtain free replacement, visit the web page:

www.craftsman.com/warranty

This warranty does not cover the blade, which is an expendable part that can wear out from normal use within

the warranty period.

This warranty applies for only 90 days from the date of sale if this product is ever used while providing

commercial services or if rented to another person.

This warranty gives you specic legal rights, and you may also have other rights which vary from state to

state.

Sears Brands Management Corporation, Hoffman Estates, IL 60179

GARANTÍA LIMITADA CRAFTSMAN

DURANTE UN AÑO a contar de la fecha de venta, esta herramienta y la batería incluida con ella están

garantizadas contra defectos en sus materiales o fabricación.

Un producto defectuoso será reemplazado de manera gratuita contra presentación de una PRUEBA DE

VENTA.

Para conocer la cobertura de la garantía y obtener un reemplazo gratuito, visite el sitio Web:

www.craftsman.com/warranty

Esta garantía no cubre la broca, la cual es una pieza desechable que puede desgastarse debido al uso

normal dentro del periodo de garantía.

La garantía se aplica durante un periodo de solo 90 días si el producto se usa para proporcionar servicios

comerciales o si se le arrienda a otra persona.

Esta garantía le entrega derechos legales especícos que pueden variar según su estado (podría tener otros

derechos adicionales).

Sears Brands Management Corporation, Hoffman Estates, IL 60179

ESPAÑOL

■ Garantía ............................Sección de Inglés pág. 2

■ Introducción ......................Sección de Inglés pág. 2

■ Instrucciones de seguridad ................................ 3-7

■ Símbolos ............................................................ 8-9

■ Características ......................................................10

■ Armado ................................................................ 11

■ Funcionamiento De La Sierra Circular..............12-18

■ Cuidado Y Mantenimiento.................................19

■ Resolución de problemas.................................20

■ Lista de piezas, ilustrada..........................19

■ Números de las guras (ilustraciones)................ i-v

* * *

INTRODUCTION / INTRODUCCIÓN

This tool has many features for making its use more pleasant and enjoyable. Safety, performance, and

dependability have been given top priority in the design of this product making it easy to maintain and

operate.

* * *

Esta herramienta tiene muchas funciones para hacerla más agradable y cómoda de usar. Se ha dado

máxima prioridad a la seguridad, rendimiento y dependencia en las etapas de diseño de este producto

para que sea fácil de utilizar y mantener.

2 ― English

Page 3

SAFETY INSTRUCTIONS

WARNING

Read and understand all instructions. Failure to

follow all instructions listed below may result in

electric shock, re and/or serious personal injury.

Save all warnings and instructions for future

reference. The term “power tool” in the

warnings refers to your mains-operated

(corded) power tool or battery-operated

(cordless) power tool.

WORK AREA SAFETY

■ Keep work area clean and well lit. Cluttered

or dark areas invite accidents.

■ Do not operate power tools in explosive

atmospheres, such as in the presence of

ammable liquids, gases or dust. Power

tools create sparks which may ignite the dust

or fumes.

■ Keep children and bystanders away while

operating a power tool. Distractions can

cause you to lose control.

ELECTRICAL SAFETY

■ Power tool plugs must match the outlet.

Never modify the plug in any way. Do not

use any adaptor plugs with earthed

(grounded) power tools. Unmodied plugs

and matching outlets will reduce risk of

electric shock.

■ Avoid body contact with earthed or grounded

surfaces such as pipes, radiators, ranges

and refrigerators. There is an increased risk

of electric shock if your body is earthed or

grounded.

■ Do not expose power tools to rain or wet

conditions. Water entering a power tool will

increase the risk of electric shock.

■ Do not abuse the cord. Never use the cord

for carrying, pulling or unplugging the power

tool. Keep cord away from heat, oil, sharp

edges or moving parts. Damaged or

entangled cords increase the risk of electric

shock.

■ When operating a power tool outdoors,

use an extension cord suitable for outdoor

use. Use of a cord suitable for outdoor use

reduces the risk of electric shock.

■ If operating a power tool in a damp location

3 ― English

is unavoidable, use a ground fault circuit

interrupter (GFCI) protected supply. Use of

a GFCI reduces the risk of electric shock.

PERSONAL SAFETY

■ Stay alert, watch what you are doing and

use common sense when operating a

power tool. Do not use tool while tired or

under the inuence of drugs, alcohol, or

medication. A moment of inattention while

operating power tools may result in serious

personal injury.

■ Use personal protective equipment. Always

wear eye protection. Protective equipment

such as dust mask, non-skid safety shoes,

hard hat, or hearing protection used for

appropriate conditions will reduce personal

injuries.

■ Prevent unintentional starting. Ensure the

switch is in the off-position before

connecting to power source and/or battery

pack, picking up or carrying the tool.

Carrying power tools with your nger on the

switch or energizing power tools that have

the switch on invites accidents.

■ Remove any adjusting key or wrench

before turning the power tool on. A wrench

or a key left attached to a rotating part of

the power tool may result in personal injury.

■ Do not overreach. Keep proper footing

and balance at all times. This enables

better control of the power tool in

unexpected situations.

■ Dress properly. Do not wear loose clothing

or jewelry. Keep your hair, clothing and

gloves away from moving parts. Loose

clothes, jewelry or long hair can be caught

in moving parts.

■ If devices are provided for the connection

of dust extraction and collection facilities,

ensure these are connected and properly

used. Use of these devices can reduce dust

related hazards.

POWER TOOL USE AND CARE

■ Use only with compatible Craftsman 20V

Max powered by DieHard slide-type lithiumion battery packs.

■ Do not use the power tool if the switch

Page 4

SAFETY INSTRUCTIONS

does not turn it on and off. Any power tool

that cannot be controlled with the switch is

dangerous and must be repaired.

■ Disconnect the plug from the power source

and/or the battery pack from the power tool

before making any adjustments, changing

accessories, or storing power tools. Such

preventive safety measures reduce the risk

of starting the power tool accidentally.

■ Store idle power tools out of the reach of

children and do not allow persons unfamiliar

with the power tool or these instructions

to operate the power tool. Power tools are

dangerous in the hands of untrained users.

■ Maintain power tools. Check for

misalignment or binding of moving parts,

breakage of parts and any other condition

that may affect the power tool’s operation.

If damaged, have the power tool repaired

before use. Many accidents are caused by

poorly maintained power tools.

■ Keep cutting tools sharp and clean.

Properly maintained cutting tools with sharp

cutting edges are less likely to bind and are

easier to control.

■ Use the power tool, accessories and

tool bits etc. in accordance with these

instructions, taking into account the working

conditions and the work to be performed.

Use of the power tool for operations

different from those intended could result in

a hazardous situation.

■ Hold the power tool by the insulated

gripping surfaces when performing an

operation where the saw blade may come

into contact with hidden wiring. If the blade

contacts a "live" wire, it may activate the

exposed metal parts of the power tool and

could give the operator an electric shock.

■ Know your power tool. Read the Operator's

Manual carefully. Learn its applications

and limitations, as well as the specic

potential hazards related to this power tool.

Following this rule will reduce the risk of

electric shock, re, or serious injury.

■ Always wear eye protection with side

shields marked to comply with ANSI Z87.1

when assembling parts, operating the tool,

or performing maintenance. Following

this rule will reduce the risk of serious

personal injury.

■ Protect your lungs. Wear a face or dust

mask if the operation is dusty. Following

this rule will reduce the risk of serious

personal injury.

■ Protect your hearing. Wear hearing

protection during extended periods of

operation. Following this rule will reduce

the risk of serious personal injury.

■ Battery tools do not have to be plugged

into an electrical outlet; therefore, they

are always in operating condition. Be

aware of possible hazards when not

using your battery tool or when changing

accessories. Following this rule will

reduce the risk of electric shock, re, or

serious personal injury.

■ Do not use on an unstable support. Stable

footing on a solid surface enables better

control of the power tool in unexpected

situations.

■ Do not force the power tool. Use the

correct power tool for your application.

The correct power tool will do the job

better and safer at the rate for which it

was designed.

CIRCULAR SAW USE AND CARE

CUTTING PROCEDURES

DANGER

Keep hands away from cutting area and the

blade. Keep your second hand on auxiliary

handle, or motor housing. If both hands are

holding the saw, they cannot be cut by the

blade.

■ Do not reach underneath the workpiece.

The guard cannot protect you from the

blade below the workpiece.

■ Adjust the cutting depth to the thickness

of the workpiece. Less than a full tooth of

the blade teeth should be visible below

the workpiece.

■ Never hold the piece being cut in your

hands or across your leg. Secure

4 ― English

Page 5

SAFETY INSTRUCTIONS

the workpiece to a stable platform. It is

important to support the workpiece properly

to minimize body exposure, blade binding,

or loss of control.

■ When ripping, always use a rip fence or

straight edge guide. This improves the

accuracy of cut and reduces the chance of

blade binding.

■ Always use blades with correct size and

shape (diamond versus round) of arbour

holes. Blades that do not match the

mounting hardware of the saw will run

eccentrically, causing loss of control.

■ Never use damaged or incorrect blade

washers or bolt. The blade washers and

bolt were specially designed for your saw,

for optimum performance and safety of

operation.

KICKBACK CAUSES AND RELATED

WARNING

■ Kickback is a sudden reaction to a pinched,

bound or misaligned saw blade, causing

an uncontrolled saw to lift up and out of the

workpiece toward the operator;

■ When the blade is pinched or bound tightly

by the kerf closing down, the blade stalls

and the motor reaction drives the unit

rapidly back toward the operator;

■ If the blade becomes twisted or misaligned

in the cut, the teeth at the back edge of the

blade can dig into the top surface of the

wood causing the blade to climb out of the

kerf and jump back toward the operator.

Kickback is the result of saw misuse and/or

incorrect operating procedures or conditions

and can be avoided by taking proper

precautions as given below:

■ Maintain a rm grip with both hands on

the saw and position your arms to resist

kickback forces. Position your body to

either side of the blade, but not in line with

the blade. Kickback could cause the saw

to jump backwards, but kickback forces

can be controlled by the operator, if proper

precautions are taken.

■ When blade is binding, or when interrupting

a cut for any reason, release the trigger and

hold the saw motionless in the material until

the blade comes to a complete stop. Never

attempt to remove the saw from the work or

pull the saw backward while the blade is in

motion or kickback may occur. Investigate

and take corrective actions to eliminate the

cause of blade binding.

■ When restarting a saw in the workpiece,

center the saw blade in the kerf and check

that saw teeth are not engaged into the

material. If the saw blade is binding, it may

walk up or kickback from the workpiece as

the saw is restarted.

■ Support large panels to minimize the risk

of blade pinching and kickback. Large

panels tend to sag under their own weight.

Supports must be placed under the panel

on both sides, near the line of cut and near

the edge of the panel.

■ Do not use dull or damaged blades.

Unsharpened or improperly set blades

produce narrow kerf causing excessive

friction, blade binding and kickback.

■ Blade depth and bevel adjusting locking

levers must be tight and secure before

making cut. If blade adjustment shifts while

cutting, it may cause binding and kickback.

■ Use extra caution when sawing into existing

walls or other blind areas. The protruding

blade may cut objects that can cause

kickback.

LOWER GUARD FUNCTION

■ Check the lower guard for proper closing

before each use. Do not operate the saw if

the lower guard does not move freely and

close instantly. Never clamp or tie the lower

guard into the open position. If the saw is

accidentally dropped, the lower guard may

be bent. Raise the lower guard with the

retracting handle and make sure it moves

freely and does not touch the blade or any

other part, in all angles and depths of cut.

■ Check the operation of the lower guard

spring. If the guard and the spring are not

operating properly, they must be serviced

before use. Lower guard may operate

sluggishly due to damaged parts, gummy

5 ― English

Page 6

SAFETY INSTRUCTIONS

deposits, or a build-up of debris.

■ Lower guard should be retracted manually

only for special cuts such as “plunge cuts”

and “compound cuts”. Raise lower guard

by retracting handle and as soon as blade

enters the material, the lower guard must

be released. For all other sawing, the lower

guard should operate automatically.

■ Always observe that the lower guard is

covering the blade before placing saw

down on bench or oor. An unprotected,

coasting blade will cause the saw to walk

backwards, cutting whatever is in its path.

Be aware of the time it takes for the blade

to stop after the switch is released.

ADDITIONAL SAFETY WARNINGS

■ Use clamps or other practical ways to

secure and support the workpiece to a

stable platform. Holding the workpiece by

hand or against your body is unstable and

may lead to loss of control.

■ Do not place battery tools or their batteries

near re or heat. This will reduce the risk of

explosion and possibly injury.

■ Do not crush, drop or damage a battery

pack. Do not use a battery pack or charger

that has been dropped or received a sharp

blow. A damaged battery is subject to

explosion. Properly dispose of a dropped or

damaged battery immediately.

■ Batteries can explode in the presence of

a source of ignition, such as a pilot light.

To reduce the risk of serious personal

injury, never use any cordless product in

the presence of open ame. An exploded

battery can propel debris and chemicals. If

exposed, ush with water immediately.

■ Do not charge battery tool in a damp or wet

location. Following this rule will reduce the

risk of electric shock.

■ For best results, your battery tool should

be charged in a location where the

temperature is between 40°F (4°C) and

100°F (38°C). To reduce the risk of serious

personal injury, do not store outside or in

vehicles.

■ Under extreme usage or temperature

conditions, battery leakage may occur. If

liquid comes in contact with your skin, wash

immediately with soap and water. If liquid

gets into your eyes, ush them with clean

water for at least 10 minutes, then seek

immediate medical attention. Following this

rule will reduce the risk of serious personal

injury.

Save these instructions.

Refer to them frequently and use them to

instruct others who may use this product.

If you loan someone this product, loan them

these instructions also.

CALIFORNIA PROPOSITION 65

WARNING

Drilling, sawing, sanding or machining wood

products can expose you to wood dust, a

substance known to the State of California

to cause cancer. Avoid inhaling wood dust

or use a dust mask or other safeguards for

personal protection.

For more information go to:

www.P65Warnings.ca.gov/wood

Wash hands after handling.

6 ― English

Page 7

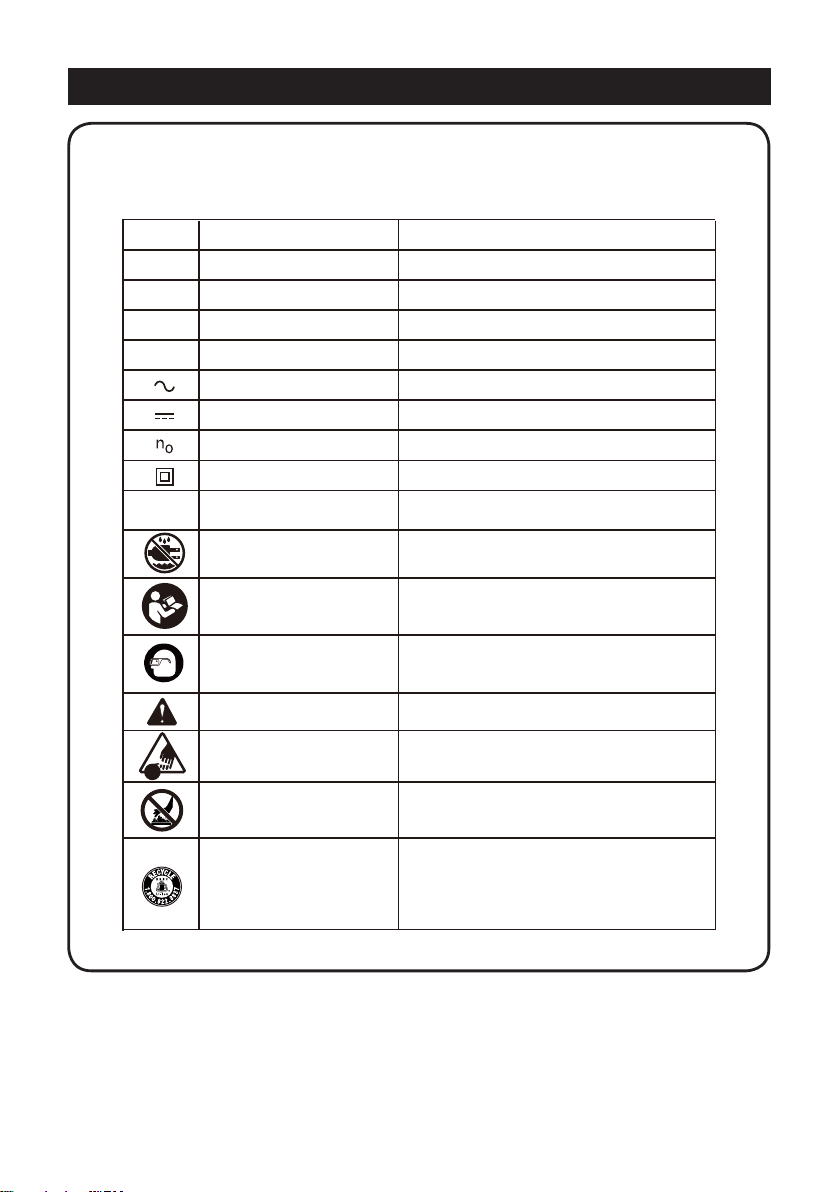

SYMBOLS

Some of the following symbols may be used on this product. Please study them and

learn their meaning. Proper interpretation of these symbols will allow you to operate

the product better and safer.

SYMBOL NAME DESIG NATION/EXP LANATION

V Volts Voltage

A Amperes Current

Hz Hertz Frequency (cycles per second)

W Watt Power

min Minutes Time

Alternating Current Type of current

Direct Current Type or a c haracteristic of c urrent

Rotational speed, at no load

Revolutions, s trokes, surface speed,

orbits, etc., per minute

Do not expose to rain or use in damp

locations.

To reduce the risk of injur

ad and understand operator’s manual

re

before using this product.

y, user must

.../mi n

No-load Speed

Class II C onstruction Double-insulated construction

Per Minute

Wet Conditions Alert

Read The O perator’s Manual

Eye protection

Safety Alert Prec autions that involve your safety.

No-Hands Symbol

Hot Surface

Recycle Symbol

Always wear eye protection with side

shields marked to comply with ANSI Z87.1.

Failure to keep your hands away from the

blade will result in serious personal injury.

To reduce the risk of injury or damage,

avoid contact with any hot surface.

This product uses lithium-ion batteries. Local,

state, or federal laws may prohibit disposal of

batteries in ordinary trash. Consult your local

waste authority for information regarding

available recycling and/or disposal options.

7 ― English

Page 8

SYMBOLS

The following signal words and meanings are intended to explain the levels of risk

associated with this product.

SYMBOL SIGNAL MEANING

DANGER

Indicates an imminently hazardous situation, which, if not

avoided, will result in death or serious injury.

WARNING

CAUTION

NOTICE

Indicates a potentially hazardous situation, which, if not

avoided, could result in death or serious injury.

Indicates a potentially hazardous situation, which, if not

avoided, may result in minor or moderate injury.

(Without Safety Alert Symbol) Indicates a situation that may

result in property damage.

8 ― English

Page 9

FEATURES

PRODUCT SPECIFICATIONS

Circular Saw

Model No. .................................................................................................................

Type...................................................................................................Cordless, battery-powered

Motor.................................................................................................................... 20 V max* d.c.

Blade Diameter...............................................................................................................6-1/2 in.

Blade Arbor........................................................................................................................5/8 in.

Maximum Cutting Depth at 0°.............................................................................................. 2 in.

Maximum Cutting Depth at 45°......................................................................................1-1/3 in.

No Load Speed............................................................................................................3300 rpm

Weight (with included battery)...........................................................................................6.8 lbs

125.46569

KNOW YOUR CIRCULAR SAW

See Figure 1, page i

The safe use of this product requires an

understanding of the information on the

product labeling and in this Operator's Manual

as well as a knowledge of the project you

are attempting. Before use of this product,

familiarize yourself with all operating features

and safety rules.

BEVEL ADJUSTMENT

The bevel adjustment allows you to set the

circular saw for bevel cuts from 0° to 45°.

BLADE WRENCH STORAGE

Convenient wrench storage for quick blade

changes.

DEPTH ADJUSTMENT KNOB

The depth adjustment knob adjusts the depth

of cut from 0 in. to 2 in.

SAFETY SWITCH

The safety switch reduces the possibility of

accidental starting.

SPINDLE LOCK BUTTON

The spindle lock button allows you to secure

the blade when turning the blade screw.

WIDTH OF CUT GUIDE

When making straight cross cuts or rip cuts,

the guide can be used to measure up to 4 in.

on the right side of the blade, and up to 1 in.

on the left side of the blade.

TRIGGER SWITCH

Depress the safety switch, and then squeeze

the trigger switch to start the saw. To stop it,

release the trigger switch.

LOWER BLADE GUARD

The lower blade guard attached to the circular

saw is covering the blade for your protection

and safety.

9 ― English

Page 10

ASSEMBLY

UNPACKING

This product requires assembly.

■ Carefully remove the product and any

accessories from the box. Make sure

that all items listed in the packing list are

included.

WARNING:

if any parts on the Packing List are already

assembled to your product when you unpack

it. Parts on this list are not assembled to the

product by the manufacturer and require

customer installation. Use of a product that

may have been improperly assembled could

result in serious personal injury.

■ Inspect the product carefully to make sure

no breakage or damage occurred during

shipping.

■ Do not discard the packing material until

you have carefully inspected and

satisfactorily operated the product.

■ If any parts are damaged or missing, do not

operate the product. Return it for

replacement to the retailer from which it

was purchased.

Do not use this product

PACKING LIST

(1) 20V Cordless Circular Saw

(1) Circular Saw Blade

(1) Rip Fence

(1) Blade Wrench

(1) Operator's Manual

WARNING:

missing, do not attempt to attach the battery

pack or operate the tool until the broken or

missing parts are replaced. Failure to do so

could result in possible serious injury.

If any parts are broken or

WARNING:

modify this tool or create accessories not

recommended for use with this tool. Any such

alteration or modication is misuse and could

result in a hazardous condition leading to

possible serious injury.

Do not attempt to

10 ― English

Page 11

OPERATION FOR CIRCULAR SAW

This product will accept compatible Craftsman

20V Max powered by DieHard slide-type

lithium-ion battery packs. For complete charging

instructions, refer to the Operator's Manual for

your battery pack and charger models.

WARNING:

starting that could cause serious personal

injury, always remove the battery pack from

the tool when assembling parts, making

adjustments, installing or removing saw

blade, cleaning, or when it is not in use.

TO ATTACH BATTERY PACK

See Figure 2, page ii

To install the battery pack, align the tongue

on the battery pack with the groove in the

housing and slide it into place. Insert it all the

way until it locks in place with a click.

NOTICE:

battery pack snaps into place and the battery

pack is secured to the tool before beginning

operation. Improper assembly of the

battery pack can cause damage to internal

components.

TO DETACH BATTERY PACK

See Figure 2, page ii

To remove the battery pack, slide it from the

tool while pressing the button on the front of

the pack.

WARNING:

operating condition. To prevent accidental

starting, always ensure the safety switch is

not depressed when the tool is not in use or

when carrying the tool at your side. Always

carry the tool by its handgrip.

ATTACHING THE BLADE

See Figure 3, page ii

WARNING:

maximum blade capacity of the saw. Never

use a blade that is too thick to allow outer

blade washer to engage with the ats on the

spindle. Larger blades will come in contact

To prevent accidental

Make sure that the latch on the

Battery tools are always in

A 6-1/2 in. blade is the

11 ― English

with the blade guard, while thicker blades will

prevent blade screw from securing blade on

spindle. Either of these situations could result

in a serious accident.

■ Remove the battery pack from the saw.

■ Obtain the blade wrench (5mm hex key)

from storage area. See Figure 1, page i.

■ Depress and hold the spindle lock button.

■ Insert blade wrench into blade screw head

and turn clockwise to loosen and remove

screw.

NOTE:

mechanism pin engages.

■ Remove the outer blade washer.

■ Use the lower blade guard lever to rotate

■ Carefully remove the old blade (if present)

WARNING

can cut ngers if touched.

■ Release the lower blade guard to allow

NOTICE:

or spindle lock, always allow motor to come

to a complete stop before engaging spindle

lock.

NOTE:

spindle lock engaged.

■ Wipe a drop of oil onto the inner blade

WARNING:

has been removed, replace it before placing

the blade on the spindle. The larger diameter

of the inner blade washer should be placed

against the blade. Failure to do so could

cause an accident as the blade will not

tighten properly.

■ Use the lower blade guard lever to rotate

■ Carefully t the saw blade onto the spindle

The spindle may turn until lock

and hold the guard all the way to the left.

from saw.

: Blade teeth are sharp and

guard to swing back into place.

To prevent damage to the spindle

Do not run the circular saw with the

washer and outer blade washer where they

contact the blade.

If the inner blade washer

guard all the way to the left.

and under the lower blade guard. Insert the

blade so that the teeth point upward at the

front of the saw as shown in Figure 3, E.

Page 12

OPERATION FOR CIRCULAR SAW

WARNING

can cut ngers if touched.

■ Release the lower blade guard lever to

allow guard to swing back into place.

■ Replace the outer blade washer onto

spindle.

■ Thread the blade screw counterclockwise

into spindle. Depress and hold the spindle

lock button.

■ Use the blade wrench to tighten blade

screw securely.

: The spindle may turn until lock

NOTE

mechanism pin engages.

■ Return the blade wrench to the storage

area.

: Never use a blade that is too thick to

NOTE

allow the outer blade washer to engage with

the ats on the spindle.

: Blade teeth are sharp and

REMOVING THE BLADE

See Figure 4, page ii.

■ Remove the battery pack from the saw.

■ Obtain the blade wrench (5mm hex key)

from storage area. See Figure 1, page i.

■ Depress and hold the spindle lock button.

■ Insert the blade wrench into blade screw

head and turn clockwise to loosen and

remove screw.

: The spindle may turn until lock

NOTE

mechanism pin engages.

■ Remove the outer blade washer.

■ Use the lower blade guard lever to rotate

and hold the guard all the way to the left.

■ Carefully remove blade from the saw.

WARNING

can cut ngers if touched.

■ Release the lower blade guard to allow

guard to swing back into place.

: Blade teeth are sharp and

KICKBACK

See Figures 5 - 8, pages ii - iii

Kickback occurs when the blade stalls rapidly

and the saw is driven back towards you.

Blade stalling is caused by any action which

pinches the blade in the wood.

DANGER:

if blade binds or saw stalls. Kickback could

cause you to lose control of the saw. Loss of

control can lead to serious injury.

Release switch immediately

To guard against kickback, avoid

dangerous practices such as the

following:

■ Setting blade depth incorrectly.

■ Sawing into knots or nails in the workpiece.

■ Twisting the blade while making a cut.

■ Making a cut with a dull, gummed up, or

improperly set blade.

■ Supporting the workpiece incorrectly.

■ Forcing a cut.

■ Cutting warped or wet lumber.

■ Operating the tool incorrectly or misusing

the tool.

To lessen the chance of kickback,

follow these safety practices:

■ Keep blade at the correct depth setting.

The depth setting should not exceed 1/4 in.

below the material being cut.

■ Inspect the workpiece for knots or nails

before cutting. Never saw into a knot or

nail.

■ Make straight cuts. Always use the rip

fence when rip cutting. This helps prevent

twisting the blade.

■ Use clean, sharp, and properly set blades.

Never make cuts with dull blades.

■ Support the workpiece properly before

beginning a cut.

■ Use steady, even pressure when making a

cut. Never force a cut.

■ Do not cut warped or wet lumber.

■ Hold the saw rmly with both hands and

keep your body in a balanced position so

as to resist the forces if kickback should

occur.

WARNING:

always stay alert and exercise control. Do not

remove the saw from the workpiece while the

blade is moving.

When using the saw,

SAW BLADES

The best of saw blades will not cut efciently

12 ― English

Page 13

OPERATION FOR CIRCULAR SAW

if they are not kept clean, sharp, and properly

set. Using a dull blade will place a heavy

load on the saw and increase the danger of

kickback. Keep extra blades on hand, so that

sharp blades are always available.

Gum and wood pitch hardened on blades will

slow the saw down. Remove saw blade from

the saw and use gum and pitch remover, hot

water, or other non-ammable cleaners to

remove these accumulations.

GASOLINE

.

DO NOT USE

BLADE GUARD SYSTEM

See Figure 9, page iii

The lower blade guard attached to the circular

saw is there for your protection and safety.

Do not alter it for any reason. If it becomes

damaged, do not operate the saw until you

have the guard repaired or replaced. Always

leave guard in operating position when using

the saw.

DANGER:

workpiece, the lower blade guard does not

cover the blade on the underside of the

workpiece. Since the blade is exposed on

the underside of the workpiece, keep hands

and ngers away from cutting area. Any part

of your body coming in contact with moving

blade will result in serious injury.

CAUTION:

is not operating correctly. Check the guard for

correct operation before each use. The guard

is operating correctly when it moves freely

and readily returns to the closed position.

If you drop the saw, check the lower blade

guard and bumper for damage at all depth

settings before reuse.

If at any time the lower blade guard does not

snap closed, remove the battery from the

saw. Exercise the lower guard by moving

it rapidly back and forth from the full open

position to the closed position several times.

Normally this will restore the guard to its

When sawing through the

Never use saw when guard

normal operating condition. If it does not

correct a slow or sluggish closing lower

guard, do not use the saw. Take it to an

authorized factory service center for repair.

STARTING/STOPPING THE SAW

See Figure 10, page iii

To start the saw:

■ Depress the safety switch.

■ Squeeze the trigger switch.

Always let the blade reach full speed, and

then guide the saw into the workpiece.

WARNING:

contact with the workpiece before it reaches

full speed could cause the saw to “kickback”

toward you resulting in serious injury.

To stop the saw:

After you release the trigger switch, allow the

blade to come to a complete stop. Do not

remove the saw from the workpiece while the

blade is moving.

The blade coming in

Release the trigger switch.

SAFETY SWITCH

See Figure 10, page iii

The safety switch reduces the possibility

of accidental starting. The safety switch

is located on the handle above the trigger

switch. The safety switch must be depressed

before you pull the trigger switch. The lock

resets each time the trigger is released.

You can depress the safety switch

NOTE:

from either the left or right side.

ADJUSTING BLADE DEPTH

See Figure 11, page iii

Always keep correct blade depth setting.

The correct blade depth setting for all cuts

should not exceed 1/4 in. below the material

being cut. More blade depth will increase

the chance of kickback and cause the cut to

be rough. For more depth of cut accuracy,

a guide is located on the back of the upper

blade guard.

■ Remove the battery pack from the saw.

13 ― English

Page 14

OPERATION FOR CIRCULAR SAW

■ Loosen the depth adjustment knob.

■ Determine the desired depth of cut.

■ Locate the depth of cut guide on back of

upper blade guard.

■ Hold base at against the workpiece and

raise or lower saw until the indicator mark

on bracket aligns with pointer on blade

guard.

■ Tighten the depth adjustment knob

securely.

OPERATING THE SAW

See Figures 12 - 14, page iii - iv

It is important to understand the correct

method for operating the saw. Refer to the

gures in this section to learn the correct and

incorrect ways for handling the saw.

DANGER:

the workpiece, the blade is exposed on the

underside of the saw until the lower blade

guard closes. Make sure the lower blade

guard is closed before setting the saw down.

WARNING:

safer, always maintain proper control of the

saw. Loss of control could cause an accident

resulting in possible serious injury.

To make the best possible cut, follow these

helpful hints:

■ Hold the saw rmly with both hands.

■ Avoid placing your hand on the workpiece

while making a cut.

■ Support the workpiece so that the cut (kerf)

is always to your side.

■ Support the workpiece near the cut.

■ Clamp the workpiece securely so that the

workpiece will not move during the cut.

■ Always place the saw on the workpiece that

is supported, not the “cut off” piece.

■ Place the workpiece with the “good” side

down.

■ Draw a guideline along the desired line of

cut before beginning your cut.

When lifting the saw from

To make sawing easier and

CROSS CUTTING/RIP CUTTING

See Figure 15, page iv

When making a cross cut or rip cut, align the

line of cut with the outer blade guide notch on

the base.

Since blade thicknesses vary, always make a

trial cut in scrap material along a guideline to

determine how much, if any, you must offset

the guideline to produce an accurate cut.

The distance from the line of cut to

NOTE:

the guideline is the amount you should offset

the guide.

RIP CUTTING

See Figure 16, page iv

Use a guide when making long or wide rip

cuts with the saw.

■ Secure the workpiece.

■ Clamp a straight edge to the workpiece

using C-clamps.

■ Saw along the straight edge to achieve a

straight rip cut.

Do not bind the blade in the cut.

NOTE:

WIDTH OF CUT GUIDE

See Figure 17, page iv

A width of cut guide has been provided on

the base of your saw. When making straight

cross cuts or rip cuts, the guide can be used

to measure up to four inches to the right side

of the blade. It can be used to measure up to

one inch to the left side of the blade.

ADJUSTING THE RIP FENCE

See Figure 18, page iv.

The supplied rip fence can be used for rip

cutting or bevel cutting.

■ Loosen the rip fence locking knob.

■ Slide the rip fence into the slot and set it

to the desired length. Tighten the locking

knob.

For sawing with the blade totally

NOTE:

vertical, i.e. at 90°, read the guide from notch

C. For sawing at a bevel angle of 45°, read

the guide from notch B.

14 ― English

Page 15

OPERATION FOR CIRCULAR SAW

BEVEL CUTTING

See Figures 19 - 20, page v

■ Align the line of cut with the inner blade

guide notch on the base when making 45°

bevel cuts.

■ Make a trial cut in scrap material along

a guideline to determine how much you

should offset the guideline on the cutting

material.

■ Adjust the angle of the cut to any desired

setting between 0° to 45°. Refer to

Adjusting the Bevel Setting

next.

ADJUSTING THE BEVEL SETTING

See Figure 19, page v

■ Remove the battery pack from the saw.

■ Loosen the bevel adjustment knob.

■ Raise the motor housing end of the saw

until you reach the desired angle setting on

the bevel guide.

■ Tighten the bevel adjustment knob securely.

WARNING:

without having the bevel adjustment knob

securely tightened can result in serious injury.

Attempting a bevel cut

MAKING A BEVEL CUT

See Figure 20, page v

■ Hold the saw rmly with both hands as

shown.

■ Rest the front edge of the base on the

workpiece.

■ Start the saw and let the blade reach full

speed.

■ Guide the saw into the workpiece and make

the cut.

■ Release the trigger and allow the blade to

come to a complete stop.

■ Lift the saw from the workpiece.

POCKET CUTTING

See Figure 21, page v

WARNING:

setting to zero before making a pocket cut.

Attempting a pocket cut at any other setting

Always adjust bevel

can result in loss of control of the saw

possibly causing serious injury.

■ Remove the battery pack from the saw.

■ Adjust the bevel setting to zero.

■ Set the blade to the correct blade depth

setting.

■ Reinsert the battery pack.

■ Swing the lower blade guard up using the

lower blade guard lever.

NOTE:

with the lever to avoid serious injury.

■ Hold the lower blade guard by the lever

WARNING:

while holding the lower blade guard lever.

Extending your ngers could result in contact

with the blade, causing serious injury.

■ Rest the front of the base at against the

■ Start the saw and let the blade reach full

■ Guide the saw into workpiece, release

WARNING:

direction when pocket cutting. Cutting in the

reverse direction could cause the saw to

climb up on the workpiece and back toward

you.

■ Release the trigger and allow the blade to

■ Lift the saw from the workpiece.

■ Clear corners out with a hand saw or saber

WARNING:

blade guard in a raised position. Leaving the

blade exposed could lead to serious injury.

Always raise the lower blade guard

while holding the saw rmly with both

hands as shown.

Never extend your ngers

workpiece with the rear of the handle raised

so the blade does not touch the workpiece.

speed.

lower blade guard lever, and make the cut.

Always cut in a forward

come to a complete stop.

saw.

Never tie or retain the lower

15 ― English

Page 16

OPERATION FOR CIRCULAR SAW

ADJUSTING POSITIVE 0° BEVEL STOP

WARNING:

adjustment, make sure the battery pack

is removed from tool. Failure to heed this

warning could result in serious personal

injury.

Before performing any

POSITIVE 0° BEVEL STOP

See Figure 22, page v

The saw has a positive 0° bevel stop that

has been factory adjusted to assure 0° angle

of the saw blade when making 0° (right

angle) cuts.

To check positive 0° bevel stop:

■ Remove the battery pack from the saw.

■ Place the saw in an upside down position

on a work-bench.

■ Check the squareness of the saw blade

to the base of the saw using a carpenter′s

square.

To adjust positive 0° bevel stop:

■ Remove the battery pack from the saw.

■ Loosen the bevel adjustment knob.

■ Loosen the hex nut securing the adjustment

screw.

■ Turn the adjustment screw and adjust the

base until square with the saw blade.

■ Tighten the hex nut and the bevel

adjustment knob securely.

WARNING:

without having the bevel adjustment knob

securely tightened can result in serious injury.

Attempting a bevel cut

16 ― English

Page 17

CARE & MAINTENANCE

WARNING:

identical replacement parts as listed in this

manual. Use of any other parts may create a

hazard or cause product damage.

WARNING:

injury, always remove the battery pack from

the tool when cleaning or performing any

maintenance.

When servicing, use only

To avoid serious personal

GENERAL MAINTENANCE

Avoid using solvents when cleaning plastic

parts. Most plastics are susceptible to damage

from various types of commercial solvents

and may be damaged by their use. Use clean

cloth to remove dirt, dust, oil, grease, etc.

WARNING:

uids, gasoline, petroleum-based products,

penetrating oils, etc. come in contact with

plastic parts. Chemicals can damage, weaken

or destroy plastic which may result in serious

personal injury.

Only the parts shown on the parts list are

intended to be repaired or replaced by the

customer. All other parts should be replaced

at the Sears Service Center.

WARNING:

identical replacement parts as listed in this

manual. Use of any other parts may create a

hazard or cause product damage. To ensure

Do not at any time let brake

When servicing, use only

safety and reliability, all repairs should be

performed by a qualied service technician.

STORAGE

■ Remove the battery pack from the tool

before storing.

■ Clean all foreign material from the tools.

■ Store the tools and its accessories in a dry,

frost free place.

■ Always store the tools in a place that is

inaccessible to children. The ideal storage

temperature is between 40°F (4°C) and

100°F (38°C).

■ Keep tools away from corrosive agents

such as garden chemicals and de-icing

salts.

■ We recommend using the original package

for storage or covering the product with a

suitable cloth to protect it against dust.

TRANSPORTATION

■ Set the rotation selector to OFF and

remove battery pack before transporting

tool anywhere.

■ Ordinarily, always carry the tool by its

handgrip. If the tool is tted with a belt

hook, it may be hung from your belt.

■ Protect the tool from any heavy impact or

strong vibrations which may occur during

transportation in vehicles.

17 ― English

Page 18

TROUBLESHOOTING

PROBLEM CAUSE SOLUTION

The battery is defective. Replace with a new, charged battery.

Tool will not turn on.

The saw is sluggish and/or

cuts out.

Motor overheats.

The switch is dead. Tool must be replaced.

Brushes are worn out. Tool must be replaced.

Worn/damaged saw blade.

Too much force applied. Decrease the applied force.

Cooling vents are clogged with saw

dust or debris, or are being covered

by hand during operation.

Check the blade and replace with a

new blade if necessary.

Clear vents with compressed air.

Do not cover vents with hand during

operation.

18 ― English

Page 19

CRAFTSMAN 20V MAX* LITHIUM-ION CORDLESS CIRCULAR SAW-MODEL NUMBER 125.46569

4

The model number will be found on a label attached to the motor housing.

TO PURCHASE REPLACEMENT PARTS, CALL 1-888-331-4569

1

3

2

ITEM NO. PART NO. DESCRIPTION QTY

1 125.CC20A-B

2 411006102

3 411006103

4 411006104

Circular Saw Tool Body

Flange Set

Saw Blade

Rip Fence

19 ― English

1

1

1

1

Page 20

See this section for all of the gures referenced in the

Operator's Manual.

(Consulte esta sección para ver todas las guras mencionadas

en el manual del usuario.)

Fig. 1

D

B

C

A

A. Bevel Adjustment Knob (Perilla de ajuste de bisel)

B. Spindle Lock Button (Botón de bloqueo del husillo)

C. Width of Cut Guide (Anchura de la guía de corte)

D. Safety Switch (Interruptor de seguridad)

E. Trigger Switch (Gatillo interruptor)

F. Lower Blade Guard (Protección de la hoja inferior)

G. Rip Fence (Guía de rasgado)

H. Blade Wrench Storage (Almacenamiento de la llave de la hoja)

I. Depth Adjustment Knob (Perilla de ajuste de profundidad)

E

H

F

G

I

i

Page 21

Fig. 2

Fig. 3

A

C

B

A. Battery Pack (not included) (Paquete de baterías (no incluido))

B. To install (Para instalación)

C. Depress Battery Release Button to remove

(Presione el botón de liberación de la batería para quitarlas)

A. Spindle Lock Button (Botón de bloqueo del husillo)

B. Lower Blade Guard (Protección de la hoja inferior)

C. Spindle (Eje rotor)

D. Inner Blade Washer (Arandela de la hoja interior)

E. Blade (Hoja)

F. Outer Blade Washer (Arandela de la hoja exterior)

G. Blade Screw (Tornillo de la hoja)

H. Lower Blade Guard Lever

(Palanca de la protección de la hoja inferior)

Fig. 4 Fig. 6

A

F

B

E

C

A

C

H

INCORRECT SUPPORT

SOPORTE INCORRECTO

(

B

D

E

F

G

)

D

A. Spindle Lock Button (Botón de bloqueo del husillo)

B. Blade Screw (Tornillo de la hoja)

C. Lower Blade Guard (Protección de la hoja inferior)

D. To tighten (Para apretar)

E. To loosen (Para aflojar)

F. Lower Blade Guard Lever

(Palanca de la protección de la hoja inferior)

Fig. 5

(CONTRAGOLPE - HOJA AJUSTADA DEMASIADO PROFUNDAMENTE)

KICKBACK - BLADE SET TOO DEEP

WRONG

INCORRECTO

(

)

ii

Page 22

CORRECT BLADE DEPTH SETTING = BLADE EXPOSED 1/4 in.

(6.35MM) OR LESS ON UNDERSIDE OF WORKPIECE

CONFIGURACIÓN DE PROFUNDIDAD DE LA HOJA CORRECTA

= HOJA EXPUESTA DE 1/4 pulg. (6,35 MM) O MENOS EN EL

EXTERIOR DE LA PIEZA DE TRABAJO

Fig. 8Fig. 7

CORRECT SUPPORT

SOPORTE CORRECTO

Fig. 9

A

B

A.

Lower blade guard is in up position when making a cut

(El protector inferior de la hoja está en posición elevada al hacer

un corte)

B. Blade exposed on underside of workpiece

(Hoja expuesta en la parte inferior de la pieza de trabajo)

Fig. 11

C

A

B

Fig. 10

B

A. Safety Switch (Interruptor de seguridad)

B. Trigger Switch (Gatillo interruptor)

Fig. 12

A

A. Depth Adjustment Knob (Perilla de ajuste de profundidad)

B. Depth of Cut Guide (Profundidad de la guía de corte)

C. Guide Pointer (Puntero de la guía)

WRONG

INCORRECTO

iii

Page 23

Fig. 13 Fig. 14

Fig. 15

TOP VIEW OF SAW

VISTA SUPERIOR DE LA SIERRA

Fig. 16

A

B

C

A. Blade Guide Notch (Muesca de la guía de la hoja de sierra)

B. Guideline (Línea de la guía)

C. Front of Saw (Hoja frontal)

A. Straight Edge (Borde recto)

B. Cut Line (Línea de corte)

C. C-Clamp (Abrazadera en C)

Fig. 17 Fig. 18

A

WRONG

(INCORRECTO)

C

A

C

B

C

B

A

A. Width of Cut Guide (Anchura de la guía de corte)

A. Rip Fence Locking Knob

(Muesca de bloqueo de la guía de rasgado)

B. Notch for sawing at a bevel angle of 45°

(Muesca para cortar en un ángulo de bisel de 45°)

C. Notch for sawing at a vertical angle of 90°

(Muesca para cortar en un ángulo vertical de 90°)

iv

Page 24

Fig. 19

Fig. 20

E

A. Bevel Adjustment Knob

(Perilla de ajuste de bisel)

B. Bevel Guide

(Guía del bisel)

C. Blade Guide Notch

(Muesca de la guía de

D

A

la hoja de sierra)

D. Guideline

(Línea de la guía)

E. Motor Housing

(Carcasa del motor)

A

B

C

B

C

A. Bevel Guide (Guía del bisel)

B. Bevel Adjustment Knob (Perilla de ajuste de bisel)

C. Blade Guide Notch (Muesca de la guía de la hoja de sierra)

Fig. 22Fig. 21

D

C

A

B

C

B

A

A. Lower Blade Guard Lever

(Palanca de la protección de la hoja inferior)

B. Pocket Cut (Corte de bolsillo)

C. Lower Blade Guard (Protección de la hoja inferior)

F

A. Adjustment Screw (Tornillo de ajuste)

B. Hex Nut (Tuerca hexagonal)

C. 0° Bevel Guide Position (Posición de la guía del bisel de 0°)

D. Bevel Adjustment Knob (Perilla de ajuste de bisel)

E. Blade (Hoja)

F. Carpenter's Square (not included)

(Escuadra de carpintero (no incluida))

v

E

Loading...

Loading...