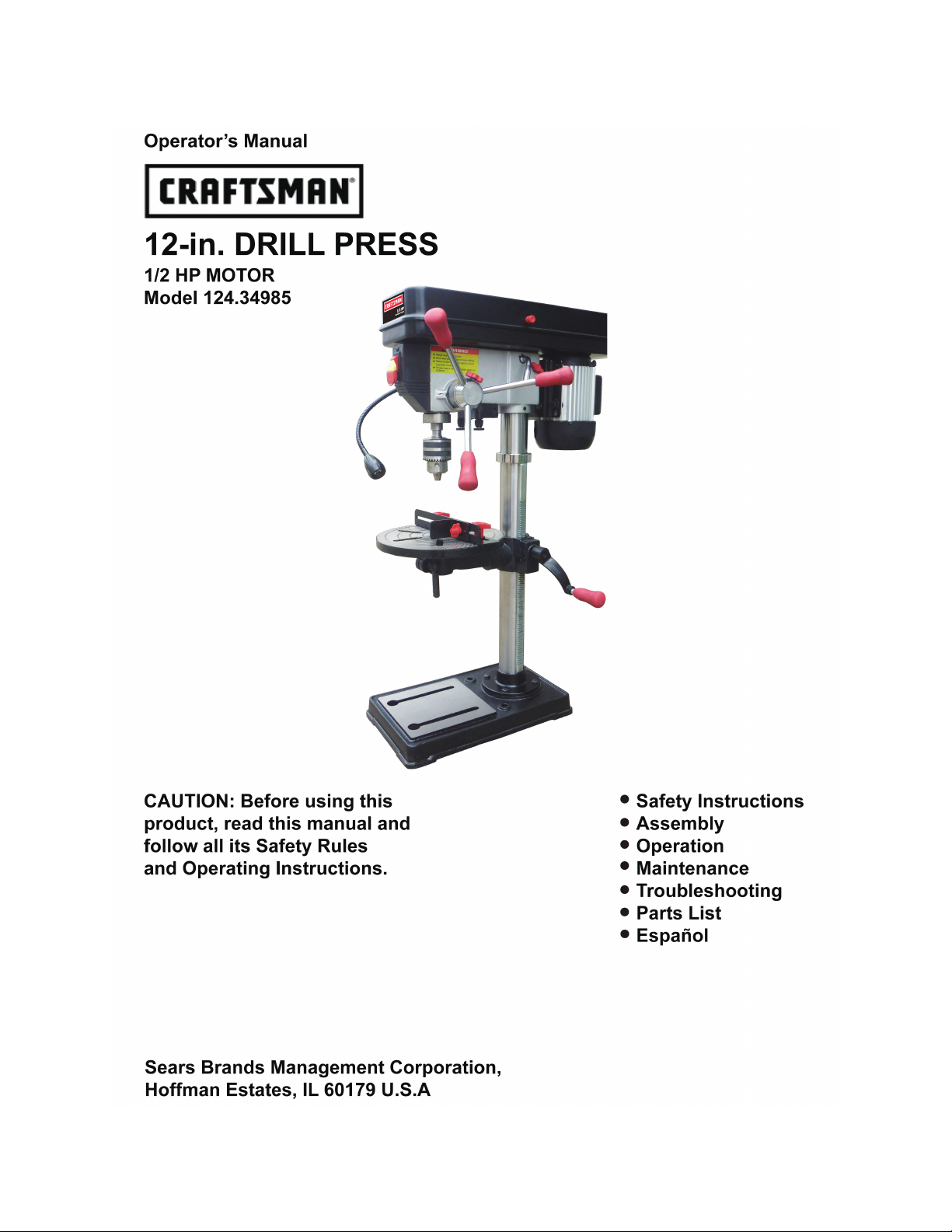

Craftsman 124.34985 Owner's Manual

TABLE OF CONTENTS

For Questions/Comments or Technical Assistance - Please Call Customer Service at: 1-877-866-8392 (M-F 8:30AM-5PM EST.)

Warranty..........................................................................................................................................................................................2

Safety Instructions.....................................................................................................................................................................................2-3

Sp ecifications... ....... ....... ....... ...................... ....... ....... ...................... ....... ....... ............................. ....... ....... ...........3

Gloss a r y o f Terms.................. . . . . ........................ . . . . ........................ . . . . ....................... . . . . . ....................... . . . . .......4

Safety...........................................................................................................................................................................5

Accessories and Attachments.....................................................................................................................................6

Carto n Co nt e nt s .. . .. .. . .. . .. . .. . .. . .. . .. .. . .. . .. . .. . .. . .. .. . .. . .. . .. . .. . .. . .. .. . .. . .. . .. . .. . .. .. . .. . .. . .. . .. . .. . .. .. . .. . .. . .. . .. . .. .. . .. . .. . .. . .. . .. . .. 7

Ass e mbly. .... . .... . .. .... . .... . .... . .. .... . .... . .. .... . .... . .. .... . .... . .. .... . .... . .... . .. .... . .... . .. .... . .... . .. .... . .... . .. .... . .... . .... . .. ...8 - 9

Adju s tm en ts .. . .. .. .. .. . .. .. .. .. . .. .. .. .. .. . .. .. .. .. . .. .. .. .. .. . .. .. .. .. . .. .. .. .. . .. .. .. .. .. . .. .. .. .. . .. .. .. .. . .. .. .. .. .. . .. .. .. .. . .. .. .. .. . .. .. .. 10 -1 2

Ope r at io n.... . ..... . ..... .. .. .. .. .. .. ..... . ..... .. .. .. .. .. .. ..... . ..... .. .. .. .. .. .. ..... . ..... .. .. .. .. .. .. ..... . ..... .. .. .. .. .. .. ..... . ..... .. .. .1 3- 14

Maintenance & Troubleshooting..................................................................................................................................15

Parts Diagram.................................................................................................................................................................................16

Parts Lists. . . . .. . . . ... . . ... . . . .. . . . ... . . ... . . ... . . . .. . . . ... . . ... . . . .. . . . ... . . ... . . ... . . . .. . . . ... . . ... . . . .. . . . ... . . ... . . ... . . . .. . . . ... . . ... . . . .. . . . ... . 1 7- 1 8

Repair Protection Agreement......................................................................................................................................19

Español..........................................................................................................................................................................................20

CRAFTSMAN ONE YEAR FULL WARRANTY

FOR ONE YEAR from the date of purchase, this product is warranted against any defects in material or workmanship. A defective

product will receive free repair or replacement if repair is unavailable.

For warranty coverage details to obtain free repair or replacement, visit the web site: www.craftsman.com

This warranty is void if this product is ever used while providing commercial services or if rented to another person.

This warranty gives you specic legal rights, and you may also have other rights which vary from state to state.

Sears Brands Management Corporation, Hoffman Estates, IL 60179

Proposition 65 Warning:

WARNING: Some dust created by power sanding, sawing, grinding, drilling, and other construction activities contains

chemicals known to the State of California to cause cancer and birth defects or other reproductive harm.

SAFETY INSTRUCTIONS

GENERAL SAFETY INSTRUCTIONS

BEFORE USING THE DRILL PRESS

Safety is a combination of common sense, staying alert and

knowing how to use this Drill Press.

WARNING: To avoid mistakes that could cause serious injury,

do not plug the Drill Press in until you have read and

understood the following:

1. READ and become familiar with the entire Operator’s Manual.

LEARN the tool’s application, limitations and possible hazards.

2. KEEP GUARDS IN PLACE and in working order.

3. REMOVE ADJUSTING KEYS AND WRENCHES. Form a

habit of checking to see that keys and adjusting wrenches are

removed from the tool before turning ON.

4. KEEP WORK AREA CLEAN. Cluttered areas and benches

invite accidents.

5. DON’T USE IN DANGEROUS ENVIRONMENT. Don’t use

power tools in damp or wet locations, or expose them to rain.

Keep work area well lighted.

6. KEEP CHILDREN AWAY. All visitors should be kept at a safe

distance from work area.

7. MAKE WORKSHOP CHILDPROOF with padlocks.

8. DON’T FORCE THE TOOL. It will do the job better and safer

at the rate for which it was designed.

9. USE THE RIGHT TOOL. Do not force tool or attachment to do

a job for which it was not designed.

10. USE PROPER EXTENSION CORD. Make sure your

extension cord is in good condition. When using an extension

cord, be sure to use one heavy enough to carry the current

your product will draw. An undersized cord will result in a drop

in line voltage and in loss of power that will cause the tool to

overheat.

11. WEAR PROPER APPAREL. Do not wear loose clothing,

gloves, neckties, rings, bracelets, or other jewelry that may

get caught in moving parts. Nonslip footwear is

recommended. Wear protective hair covering to contain long

hair.

12. ALWAYS WEAR EYE PROTECTION. Any Drill Press can

throw foreign objects into the eyes that could cause

permanent eye damage. ALWAYS wear Safety Goggles

(not glasses). Everyday eyeglasses have only impact-

resistance lenses. They ARE NOT safety glasses.

13. SECURE WORK. Use clamps or a vise to hold work when

practical. It’s safer than using your hand and it frees both

hands to operate tool.

14. DISCONNECT TOOLS before servicing; when changing

accessories such as blades, bits, cutters, and the like.

15. REDUCE THE RISK OF UNINTENTIONAL STARTING.

Make sure switch is in OFF position before plugging in.

16. USE RECOMMENDED ACCESSORIES. Consult the

Operator’s Manual for recommended accessories. The use of

improper accessories may cause serious injury.

2

17. NEVER STAND ON TOOL. Serious injury could occur if the

tool is tipped or if the cutting tool is unintentionally contacted.

18. CHECK FOR DAMAGED PARTS. Before further use of the

tool, a guard or other part that is damaged should be carefully

checked to determine that it will operate properly and perform

its intended function – check for alignment of moving parts,

binding of moving parts, breakage of parts, mounting, and any

other conditions that may affect its operation. A guard or other

part that is damaged should be properly repaired or replaced.

19. NEVER LEAVE TOOL RUNNING UNATTENDED. TURN

POWER “OFF”. Don’t leave tool until it comes to a complete

stop.

20. DON’T OVERREACH. Keep proper footing and balance at all

times.

SPECIFIC SAFETY INSTRUCTIONS FOR DRILL PRESS

21. MAINTAIN TOOLS WITH CARE. Keep tools sharp and clean

for best and safest performance. Follow instructions for

lubricating and changing accessories.

22. DO NOT use power tools in the presence of ammable liquids

or gases.

23. DO NOT OPERATE the tool if you are under the inuence of

any drugs, alcohol or medication that could affect your ability to

use the tool properly.

24. ALWAYS operate the Drill Press in a well-ventilated area and

provide for proper dust removal. Use dust collection systems

whenever possible. Dust generated from certain materials can

be hazardous to your health.

WARNING: For your own safety, do not try to use your drill press

or plug it in until it is completely assembled and installed

according to the instructions, and until you have read and

understood this instruction manual.

1. THIS DRILL PRESS is intended for use in dry conditions, indoor

use only.

2. WEAR EYE PROTECTION. USE a face or dust mask along

with safety goggles if drilling operation is dusty. USE ear

protectors, especially during extended periods of operation.

3. DO NOT wear gloves, neckties, or loose clothing.

4. DO NOT try to drill material too small to be securely held.

5. ALWAYS keep hands out of the path of a drill bit. Avoid

awkward hand positions where a sudden slip could cause your

hand to move into the drill bit.

6. DO NOT install or use any drill bit that exceeds 175mm

in length or extends 150mm below the chuck jaws. They can

suddenly bend outward or break.

7. DO NOT USE wire wheels, router bits, shaper cutters, circle (y)

cutters, or rotary planers on this drill press.

8. WHEN cutting a large piece of material, make sure it is fully

supported at the table height.

9. DO NOT perform any operation freehand. ALWAYS hold the

workpiece rmly against the table so it will not rock or twist.

Use clamps or a vise for unstable workpieces.

10. MAKE SURE there are no nails or foreign objects in the part of

the workpiece to be drilled.

11. CLAMP THE WORKPIECE OR BRACE IT against the left

side of the column to prevent rotation. If it is too short or the

table is tilted, clamp it solidly to the table.

12. IF THE WORKPIECE overhangs the table such that it will fall

or tip if not held, clamp it to the table or provide auxiliary

support.

13. SECURE THE WORK. Use clamps or a vise to hold the work

when practical. It’s safer than using your hand and it frees both

hands to operate tool.

14. MAKE SURE all clamps and locks are rmly tightened before

drilling.

15. SECURELY LOCK THE HEAD and table support to the

column, and the table to the table support before operating the

drill press.

16. NEVER turn your drill press ON before clearing the table of all

objects (tools, scraps of wood, etc.).

17. BEFORE STARTING the operation, jog the motor switch to

make sure the frill bit does not wobble or vibrate.

18. LET THE SPINDLE REACH FULL SPEED before starting to

drill. If your drill press makes an unfamiliar noise or if it vibrates

excessively, stop immediately, turn the drill press OFF and

unplug. Do not restart the unit until the problem is corrected.

19. DO NOT perform layout assembly or set up work on the table

while the drill press is in operation.

20. USE THE RECOMMENDED SPEED for any drill press

accessory and for different workpiece material.

21. WHEN DRILLING large diameter holes, clamp the workpiece

rmly to the table. Otherwise, the bit may grab and spin the

workpiece at high speeds. DO NOT USE y cutters or multiple

part hold cutters, as they can come apart or become un-

balanced in use.

22. MAKE SURE the spindle has come to a complete stop before

touching the workpiece.

23. TO AVOID INJURY from accidental starting, always turn the

switch OFF and unplug the drill press before installing or

removing any accessory or attachment or making any

adjustment.

SPECIFICATIONS

Motor.............................................................1/2 HP

Chuck...............................................0.63" / 16mm

Spindle Travel...................................2.44" / 62mm

Spindle Taper....................................................MT2

Speed Changes...................................................12

Speeds............................................355 / 3065 rpm

SAVE THESE INSTRUCTIONS.

Refer to them often.

Base Size.................16.54" x 9.84" / 420 X 250mm

Column..............................................2.28" / 58mm

Swing..............................................11.81" / 300mm

Total Height.....................................35.43" / 900mm

Weight........................................80.47LBS / 36.5kg

Box Dimensions...................30.31"X17.72"X10.63"

3

GLOSSARY OF TERMS

BASE – Supports drill press. For additional stability, holes

are provided in base to bolt drill press to bench.

BACKUP MATERIAL – A piece of scrap wood placed

between the workpiece and table. The backup board

prevents wood in the workpiece from splintering when the

drill passes through the backside of the workpiece. It also

prevents drilling into the table top.

HEAD ASSEMBLY – Covers the pulleys and belt during

operation of the drill press.

BELT TENSION – Refer to the Assembly Section, “In-

stalling and Tensioning Belt”.

BELT TENSION LOCK KNOBS – Tightening the

knobs locks the motor bracket support and the belt tension handle, maintaining correct belt distance and tension.

BEVEL SCALE – Shows degree of table tilt for bevel

operations. The scale is mounted on the side of the table

bracket.

CHUCK – Holds a drill bit or other recommended acces-

sory to perform desired operations.

CHUCK KEY – A self-ejecting chuck key which will pop

out of the chuck when you let go of it. This action is designed to help prevent throwing of the chuck key from the

chuck when the power is turned ON. Do not use any other

key as a substitute; order a new one if Damaged or Lost.

COLUMN – Connects the head, table, and base on a

one piece tube for easy alignment and movement.

COLUMN COLLAR – Holds the rack to the column. The

rack remains movable in the collar to permit table support

movements.

COLUMN SUPPORT – Supports the column, guides

the rack and provides mounting holes for the column to

the base.

DEPTH SCALE STOP NUTS – Lock the spindle to a

selected depth.

DEPTH SCALE – Indicates depth of hole being drilled.

DRILL BIT – The cutting tool used in the drill press to

make holes in a workpiece.

DRILL ON/OFF SWITCH – Has a locking feature. This

feature is intended to help prevent unauthorized and possible hazardous use by children and others. Insert the key

into the switch to turn the drill press on.

DRILLING SPEED – Changed by placing the belt in

any of the steps (grooves) in the pulleys. See the Spindle

Speed Chart inside belt guard or in the manual.

FEED HANDLE – Moves the chuck up or down. If

necessary, one or two of the handles may be removed

whenever the workpiece is of such unusual shape that it

interferes with the handles.

RACK – Combines with gear mechanism to provide easy

elevation of the table by the hand operated table crank.

RPM – Revolutions per minute. The number of turns com-

pleted by a spinning object in one minute.

SPINDLE SPEED – The RPM of the spindle.

SPRING CAP – Adjusts the spindle return spring tension.

TABLE BRACKET LOCKING HANDLE – Tighten-

ing locks the table support tot he column. Always have it

locked in place while operating the drill press.

TABLE – Provides a working surface to support the work-

piece.

TABLE ARM – Extends beyond the table support for

mounting and aligning the table.

TABLE TILT LOCK BOLT – Locks the table in any posi-

tion from 0° to 45°.

TABLE CRANK – Elevates and lowers the table. Turn

clockwise to elevate the table. Support lock must be released before operating the crank.

TABLE LOCK – Locks the table after it is rotated to vari-

ous positions.

TABLE BRACKET – Rides on the column to support the

table arm and table.

WORKPIECE – Material being drilled.

4

SAFETY

ELECTRICAL REQUIREMENTS

POWER SUPPLY AND MOTOR SPECIFICATIONS

WARNING: To avoid electrical hazards, re hazards, or damage to the

tool, use proper circuit protection. Use a separate electrical circuit for

your tools. To avoid shock or re, if power cord is worn or cut, or damaged in any way, have it replaced immediately.

GROUNDING INSTRUCTIONS

WARNING: This tool must be grounded while in use to protect the op-

erator from electrical shock.

IN THE EVENT OF A MALFUNCTION OR BREAKDOWN, grounding

provides a path of least resistance for electric current and reduces the

risk of electric shock. This tool is equipped with an electric power cord

that contains an equipment-grounding conductor wire and a 3-prong

plug with a grounding pin. The plug MUST be plugged into a matching

receptacle that is properly installed and grounded in accordance with

ALL local codes and ordinances.

DO NOT MODIFY THE PLUG PROVIDED. If it will not t the recep-

tacle, have the proper receptacle installed by a qualied electrician.

IMPROPER CONNECTION of the power cord can result in risk of electric shock. If repair or replacement of the electric cord or plug is necessary, DO NOT plug it into an electrical outlet.

CHECK with a qualied electrician or service person if you do not completely understand the grounding instructions, or if you are not sure the

tool is properly grounded.

WARNING: Improper connection of equipment grounding conductor

can result in the risk of electrical shock. Equipment should be grounded

while in use to protect operator from electrical shock.

- Check with a qualied electrician if you do not understand grounding

instructions or if you are in doubt as to whether the tool is properly

grounded.

- This tool is equipped with an approved cord and a 3-prong grounding

type plug for your protection against shock hazards.

- Grounding plug should be plugged directly into a properly installed

and grounded 3-prong grounding-type receptacle, as shown.

- Do not remove or alter grounding pin in any manner. In the event

of a malfunction or breakdown, grounding provides a path of least

resistance for electrical shock.

WARNING: This Drill Press is for indoor use only. Do not expose to rain

or use in damp locations.

GUIDELINES FOR EXTENSION CORDS

USE PROPER EXTENSION CORD. Make sure your extension cord is

in good condition. When using an extension cord, be sure to use one

heavy enough to carry the current your product will draw. An undersized

cord will cause a drop in line voltage, resulting in loss of power and

cause overheating.

Be sure your extension cord is properly wired and in good condition. Always replace a damaged extension cord or have it repaired by a qualied person before using it. Protect your extension cords from sharp

objects, excessive heat and damp or wet areas.

5

ACCESSORIES AND ATTACHMENTS

CARTON CONTENTS

UNPACKING AND CHECKING CONTENTS

Carefully unpack the Drill Press and all its parts, and compare against the

illustration following.

WARNING:

• To avoid injury from unexpected starting, do not plug the power cord into a

power source receptacle during unpacking and assembly. This cord must

remain unplugged whenever you are assembling or adjusting the drill press.

• If any part is missing or damaged, do not plug the drill press in until the miss-

ing or damaged part is replaced, and assembly is complete.

• To protect the drill press from moisture, a protective coating has been applied

to the machined surfaces.

Remove this coating with a soft cloth moistened with kerosene .

WARNING: To avoid re or toxic reaction, never use gasoline, naphtha, acetone,

lacquer thinner or similar highly volatile solvents to clean the drill press.

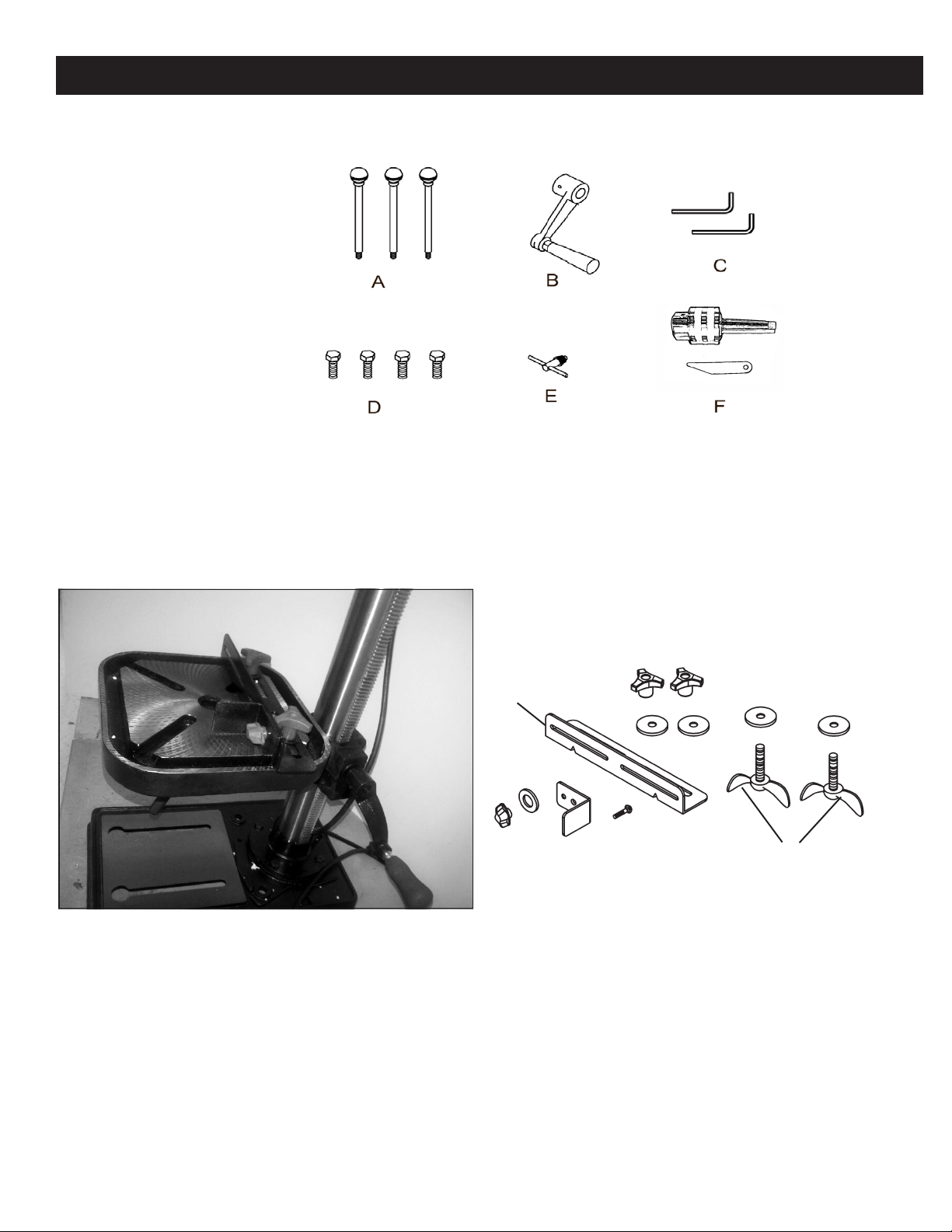

TABLE OF LOOSE PARTS

Unpack carton; check the machine to see parts listed below:

1

A. Main parts :

See Fig. 1

1. Head assembly

2. Column Assembly

3. Table

4. Base

5. ON/OFF Switch

6. Flexible Lamp

To turn on drill press, lift paddle switch from bottom.

To turn off drill press, push paddle switch down.

To prevent unauthorized use, remove the center key from the

switch. Figure 1B and 1C

Drill press cannot be turned ON if key is not inserted.

FIGURE 1B FIGURE 1C

5

6

2

3

4

FIGURE 1

6

CARTON CONTENTS

B. Accessories (in one separate box)

See Fig.2

A. Feed handles

B. Crank handle

C. Hex wrenches

D. Hex bolts

E. Chuck key

F. 5/8-inch Chuck and

chuck removal tool

G Table fence set

Table Fence

Use the supplied hardware to attach the fence to the table as shown in the picture below.

Use the fence to align the workpiece and provide a backstop for secure drilling.

NOTE: Table pictured is different shape than equipped with product. Fence attaches through

slots in the same manner.

Fence

Wingnuts

G

7

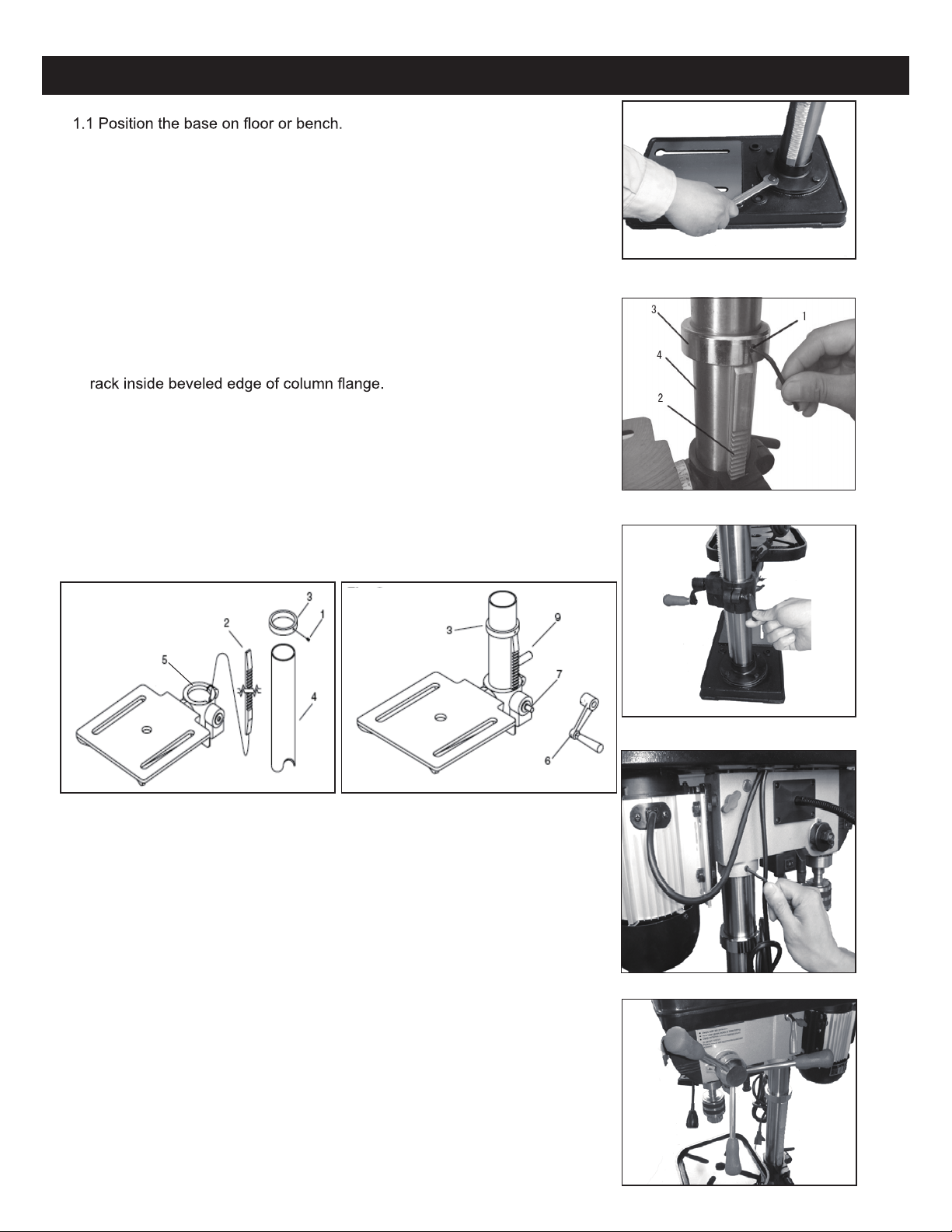

ASSEMBLY

1. Column support to base

1.2 Place the column on the base, aligning the holes in the column

support with the holes in the base.

1.3 Locate the four long hex bolts from the loose parts bag.

1.4 Place a bolt in each hole through the column support and the

base. Tighten with an adjustable wrench. See Fig. 1

2. Installing the Table

2.1 Loosen set screw (1). Remove rack (2) and retaining ring (3) from

column (4). Fig. 2A

2.2 Place rack inside table assembly bracket (5) with large, unma-

chined portion of rack to the top. Slide rack into slot in bracket so

that teeth of rack engage pinion gear in bracket. Fig. 2A

2.3 Slide table assembly with rack over column. Place bottom end of

2.4 Slide rack retaining ring (3) over column with beveled edge down.

Position ring against top of rack so that rack is in beveled edge of

ring. Fig. 2B Secure ring with hex wrench (1). Fig. 2C

2.5 Rotate table assembly around column. Adjust rack retaining ring

as necessary to prevent binding of rack.

2.6 Attach crank handle (6) to shaft (7), rotate to remove slack, and

shoulder crank handle against table bracket. Secure handle with

screw. Fig. 2B

2.7 Tighten table bracket locking handle (9) to secure table assembly.

Fig. 3

Figure 1

Figure 2C

Figure 2A Figure 2B

3. Installing head assembly

3.1. Carefully lift the head above the column and slide it onto the

column.

Make sure the head slides down over the column as far as

possible.

Align the head with the base.

3.2. Using the hex wrench, tighten the head lock set screws.

See Fig. 4

4. Installing feed handles

4.1. Locate the three feed handles in the loose parts box.

4.2. Screw the feed handles into the threaded holes in the hub.

Tighten.

Figure 3

Figure 4

See Fig. 5.

8

Figure 5

ASSEMBLY

5. Installing the chuck

WARNING: Before any assembly of the chuck and arbor to the drill

press head, clean all mating surfaces with a non-petroleum based

product; such as alcohol or lacquer thinner. Any oil or grease used

in the packing of these parts must be removed; otherwise the chuck

may come loose during operation.

5.1 Open the jaws of the chuck by rotating the chuck sleeve clockwise.

To prevent damage, make sure the jaws are completely receded into

the chuck.

5.2 Push the chuck shaft into the spindle.

5.3.Use a wooden mallet to rmly tap the chuck securely into place in the

spindle. See Fig. 6.

NOTE: To remove chuck perform the following:

- Rotate the chuck sleeve clockwise until the jaws recede completely into

the chuck.

- Lower the spindle as far as it will go to reveal the spindle slot. See Fig.6A

- Raise the table to a position just below the the chuck.

- Insert the tip of the chuck removal tool into the spindle slot above the tip

of the chuck shaft.

- Tap on the blunt end of the wedge tool until the chuck releases from the

spindle.

Figure 6

Figure 6A

Knob

6. Install knob for the head assembly lid. Fig. 7

7. Flexible lamp

Install the exible lamp

7.1. Connect the lamp plug contact to the power source plug contact in

the drill head as shown.

7.2. Use four pan head screws to install the lamp assembly to the drill

head as shown.

7.3. Turn on the exible lamp switch to check the lighting. Fig. 8

Figure 7

Pan head

screw

Plug

contact

Flex lamp

switch

Figure 8

9

ADJUSTMENT

1. Table adjustment

A. Tilting adjustment:

- On underside of table support bracket, loosen the nut (right-handed rotation)

with an open end wrench and back out the threaded pin. Loosen large hex

head bolt.

- Rotate table to desired angle right or left. Use bevel scale for precise setting.

See Fig.10

See Fig.9

- Tighten hex head bolt to secure table tilt. Threaded pin should not come into

the hole when table is tilted.

- To return table to level, loosen large hex head bolt. Rotate table to level

position. Make nut and thread pin end at the same level position, then push

the thread pin into the hole. Securely tighten large hex head bolt.

B. Height adjustment

Loosen the clamp bolt then adjust the table to your desired position by

turning the table bracket crank handle. See Fig. 11

C. Swing Adjustment 360°

Loosen the table swing locking handle, then swing table to desired

position and retighten the handle. See Fig. 12

Crank

handle

Figure 9

Figure 10

Clamp bolt

Figure 11

10

Table Swing Locking

Handle

Figure 12

ADJUSTMENT

WARNING: To prevent personal injury, always disconnect the plug from the

power source when making any adjustment.

2. Feed Depth Adjustment

The depth gauge is located on the feed handle hub. Use the depth

gauge to accurately and consistently set the required drilling depth.

Loosen the depth stop xing screw, set the depth stop as required and

subsequently re-tighten the xing screw.

3. Speed Adjustment

This drill press has 12 speeds shown in the speed label located on the un derside of the head assembly lid. To change the speed, loosen the belt

tension lock knob on each side of the head. Then use the adjustment lever

to draw the motor mounting plate toward the front end of the drill head.

Next, change the belt locations on the pulleys.

Tighten the belts by pushing the adjustment lever towards the rear of the

drill head and locking the belt tension knobs. See Fig.13 and Fig.13A

4. Spindle Spring Adjustment

The spindle return spring may need adjustment if the tension causes the

spindle to return too rapidly or too slowly.

4.1 Lower the table for additional clearance.

4.2 Place a screwdriver in the lower front notch (1) of the spring cap (2).

Hold it in place while loosening and removing only the outer lock nut (3).

4.3 With the screwdriver still engaged in the notch loosen the inner

nut (4) just until the notch (5) disengages from the boss (6) on the drill

press head.

CAUTION: DO NOT REMOVE THIS INNER NUT, because the spring will

forcibly unwind.

4.4 Carefully turn the spring cap (2) counterclockwise with the screwdriver,

engaging the next notch.

4.5 Lower the spindle to the lowest position by rotating the feed handle in a

counterclockwise direction while holding the spring cap (2) in position.

4.6 If the spindle moves up and down as easily as you desire, tighten the

inner nut (4) with the adjustable wrench. If too loose, repeat steps 2

through 4 to tighten. If too tight, reverse steps 3 and 4. DO NOT OVER-

TIGHTEN and restrict spindle movement.

4.7 Replace the lock nut (3) and tighten against the inner nut (4) to prevent

the inner nut from reversing. See Fig.14 and Fig. 14A

5. SPINDLE

Rotate the feed handles counterclockwise to lower spindle to its lowest

position. Grasp the spindle and attempt to move it back and forth. If there is

play, do the following:

5.1 Loosen the spring cap lock nut (1).

5.2 Turn the screw (2) clockwise to eliminate the play, but without

obstructing the upward movement of the spindle.

5.3 Tighten the lock nut (1). See Fig. 15

Figure 12

Figure 13

Adjustment Lever

Lock Knob

Figure 13A

Figure 14

Spring Cap

Figure 14A

11

1

2

Figure 15

Loading...

Loading...